Page 1

Service Manual

DTG5078 & DTG5274 & DTG5334

Data Timing Generators

071-1615-00

This document applies to firmware version 2.0.0

and above.

www.tektronix.com

Page 2

Copyright © Tektronix, Inc. All rights reserved.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supercedes that in all previously published material. Specifications and price change privileges reserved.

Tektronix, Inc., P.O. Box 500, Beaverton, OR 97077-0001

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Page 3

WARRANTY 2

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1)

year from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its

option, either will repair the defective product without charge for parts and labor, or will provide a replacement in

exchange for the defective product. Parts, modules and replacement products used by Tektronix for warranty work

may be new or reconditioned to like new performance. All replaced parts, modules and products become the property

of Tektronix.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of

the warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by Tektronix, with shipping charges

prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a location within the country

in which the Tektronix service center is located. Customer shall be responsible for paying all shipping charges, duties,

taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

resulting from attempts by personnel other than Tektronix representatives to install, repair or service the product; b) to

repair damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or

malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been modified or integrated

with other products when the effect of such modification or integration increases the time or difficulty of servicing the

product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TEKTRONIX' RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE

AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR

THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

Page 5

Table of Contents

Specifications

Operating Information

General Safety Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Service Safety Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Manual Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Finding Other Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Contacting Tektronix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Performance Verification Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Strategy for Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Tektronix Service Offerings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Key Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Mainframe and Output Module Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Product Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Supplying Operating Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Checking the Environment Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Output Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Powering On the Data Timing Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Shutting Down the Data Timing Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Creating an Emergency Rescue Disk. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Backing Up User Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Installing Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Operating Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Front Panel Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Front Panel Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Rear Panel Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

Display Area and Application Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

Using the Menu System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

Theory of Operation

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Interconnect Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual i

Page 6

Table of Contents

Performance Verification

Performance Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Adjustment Procedures

Adjustment Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Maintenance

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Related Maintenance Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Inspection and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Removal and Installation Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Preparation for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Access Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Procedures for External Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Procedures for Internal Modules (Lower). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

Procedures for Internal Modules (Upper) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-40

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-45

Troubleshooting tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-45

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-53

System Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-73

Requirements for System Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-73

Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-73

Service Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-77

Enable the Service mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-77

Serial number registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-78

Replaceable Electrical Parts

Electrical Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Diagrams

Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Replaceable Mechanical Parts

Replaceable Mechanical Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Parts Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Using the Replaceable Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

ii DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual

Page 7

List of Figures

Table of Contents

Figure 2-1: Principal power switch and AC power connector . . . . . . . . . . . . . . 2-12

Figure 2-2: On/Standby switch location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Figure 2-3: Front panel (DTG5078) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Figure 2-4: Front panel (DTG5274, DTG5334) . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Figure 2-5: Front panel controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Figure 2-6: Front panel connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Figure 2-7: Rear panel (DTG5078) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

Figure 2-8: Rear panel connectors (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Figure 2-9: Rear panel connectors (DTG5078) (2) . . . . . . . . . . . . . . . . . . . . . . . 2-29

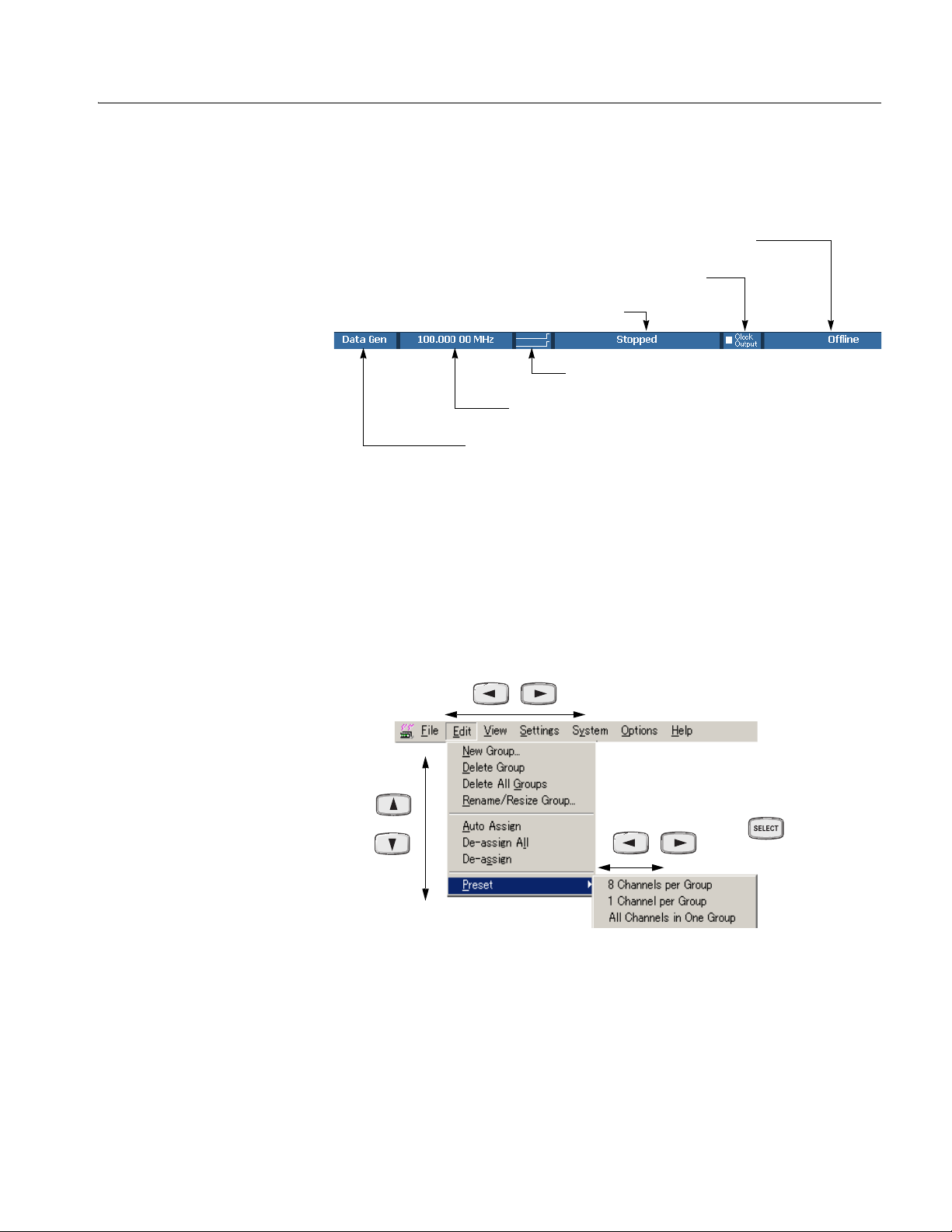

Figure 2-10: Screen elements just after the power on . . . . . . . . . . . . . . . . . . . . . 2-32

Figure 2-11: Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

Figure 2-12: Status bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

Figure 2-13: Menu selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

Figure 2-14: Window operation: Time Base window . . . . . . . . . . . . . . . . . . . . . 2-37

Figure 3-1: DTG5078 interconnection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Figure 3-2: DTG5274 interconnection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Figure 3-3: DTG5334 interconnection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Figure 3-4: DTG5078 block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Figure 3-5: DTG5274 block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Figure 3-6: DTG5334 block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Figure 6-1: Instrument orientation (DTG5078) . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Figure 6-2: External modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Figure 6-3: Front-Panel assembly & Display assembly . . . . . . . . . . . . . . . . . . . . 6-11

Figure 6-4: Internal modules (Lower) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Figure 6-5: Internal modules (Upper) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Figure 6-6: Output Module removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Figure 6-7: Modules on the rear panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Figure 6-8: Loosen the screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Figure 6-9: CD-ROM module removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

Figure 6-10: Loosen the screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

Figure 6-11: Hard Disk drive removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

Figure 6-12: Loosen the screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

Figure 6-13: Cabinet removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

Figure 6-14: Remove the screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Figure 6-15: Front-Panel assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Figure 6-16: Front-Panel assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

Figure 6-17: FD drive removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

Figure 6-18: Front-panel chassis removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

Figure 6-19: A20 Front Key & DC Output board removal . . . . . . . . . . . . . . . . 6-25

Figure 6-20: A22 Power Switch Board removal . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

Figure 6-21: Display assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

Figure 6-22: Inverter board removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

Figure 6-23: Fan removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29

Figure 6-24: Support bracket removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

Figure 6-25: Unplug the cables and connectors (DTG5078) . . . . . . . . . . . . . . . . 6-31

Figure 6-26: Unplug the cables and connectors (DTG5274) . . . . . . . . . . . . . . . . 6-32

DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual iii

Page 8

Table of Contents

Figure 6-27: Unplug the cables and connectors (DTG5334) . . . . . . . . . . . . . . . . 6-33

Figure 6-28: Plug-In Box removal (DTG5078 & DTG5274) . . . . . . . . . . . . . . . . 6-34

Figure 6-29: Plug-In Box removal (DTG5334) . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-35

Figure 6-30: Unplug the cables and connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-36

Figure 6-31: 16 screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-38

Figure 6-32: Power supply removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-40

Figure 6-33: A10 Connector & PCI Interface board removal . . . . . . . . . . . . . . . 6-41

Figure 6-34: A10 Connector & PCI Interface board removal . . . . . . . . . . . . . . . 6-42

Figure 6-35: Compact PCI Frame removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-43

Figure 6-36: A30 Compact PCI Backplane removal . . . . . . . . . . . . . . . . . . . . . . . 6-44

Figure 6-37: Primary troubleshooting procedure (1) . . . . . . . . . . . . . . . . . . . . . . 6-46

Figure 6-38: Primary troubleshooting procedure (2) . . . . . . . . . . . . . . . . . . . . . . 6-47

Figure 6-39: Primary troubleshooting procedure (3) . . . . . . . . . . . . . . . . . . . . . . 6-48

Figure 6-40: Troubleshooting procedure B - Display section . . . . . . . . . . . . . . . 6-48

Figure 6-41: Troubleshooting procedure A - Power Supply and

A10 board section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-49

Figure 6-42: Test point on the A10 Connector board . . . . . . . . . . . . . . . . . . . . . . 6-50

Figure 6-43: Diagnostics dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-54

Figure 6-44: Diagnostics error code format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-58

Figure 6-45: Service Password dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-77

Figure 6-46: Set Serial Number dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-78

Figure 9-1: Main Chassis (1) (DTG5078) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Figure 9-2: Main Chassis (1) (DTG5274) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

Figure 9-3: Main Chassis (1) (DTG5334) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Figure 9-4: Main Chassis (2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

Figure 9-5: Main Chassis & Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

Figure 9-6: A30 & Compact PCI Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

Figure 9-7: Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

Figure 9-8: Floppy Disk Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-16

Figure 9-9: A10 Connector & PCI Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

Figure 9-10: A32 CDROM Extender . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-18

Figure 9-11: CPU Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-19

Figure 9-12: Front Panel (DTG5078) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-21

Figure 9-13: Front Panel (DTG5274) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-23

Figure 9-14: Front Panel (DTG5334) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-25

Figure 9-15: Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-27

Figure 9-16: Plug-In Box (DTG5078) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-28

Figure 9-17: Plug-In Box (DTG5274) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-29

Figure 9-18: Plug-In Box (DTG5334) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-30

Figure 9-19: Blank Plug-In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-31

Figure 9-20: DTGM10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-33

Figure 9-21: DTGM20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-35

Figure 9-22: DTGM21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-37

Figure 9-23: DTGM30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-39

Figure 9-24: DTGM31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-41

Figure 9-25: DTGM32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-43

Figure 9-26: Op 1R (Rack Mount) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-44

iv DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual

Page 9

List of Tables

Table of Contents

Table 2-1: DTG5000 series key features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Table 2-2: DTG5000 series Output module key features . . . . . . . . . . . . . . . . . . . 2-3

Table 2-3: Current consumption coefficient . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Table 2-4: Power cord identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Table 2-5: Operating requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Table 2-6: Front panel controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Table 2-7: Front panel connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Table 2-8: Rear panel connector (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Table 2-9: Rear panel connectors (2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

Table 2-10: Menu selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

Table 2-11: Time Base Window operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

Table 2-12: Example of Numeric Keys input . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

Table 2-13: Example of Numeric Keys input . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

Table 2-14: Selecting a file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

Table 2-15: Key operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

Table 6-1: External inspection check list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Table 6-2: Internal inspection check list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Table 6-3: Tools required for module removal . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Table 6-4: Performance Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-51

Table 6-5: Diagnostics dialog box buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-54

Table 6-6: Information on Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-57

Table 6-7: Category of the Diagnostics Error Code . . . . . . . . . . . . . . . . . . . . . . 6-59

Table 6-8: Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-60

DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual v

Page 10

Table of Contents

vi DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual

Page 11

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to this

product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Ground the Product. This product is grounded through the grounding conductor of

the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings and

markings on the product. Consult the product manual for further ratings

information before making connections to the product.

The common terminal is at ground potential. Do not connect the common terminal

to elevated voltages.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Avoid Exposed Circuitry. Do not touch exposed connections and components when

power is present.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual vii

Page 12

General Safety Summary

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result in

injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

WAR NING

High Voltage

Protective Ground

(Earth) Terminal

CAUTION

Refer to Manual

Double

Insulated

viii DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual

Page 13

Service Safety Summary

DTG5000 Series only qualified personnel should perform service procedures.

Read this Service Safety Summary and the General Safety Summary before

performing any service procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, disconnect the mains power by means

of the power cord or, if provided, the power switch.

Use Care When Servicing With Power On. Dangerous voltages or currents may exist

in this product. Disconnect power, remove battery (if applicable), and disconnect

test leads before removing protective panels, soldering, or replacing components.

To avoid electric shock, do not touch exposed connections.

Calendar (date and time) Backup Battery. This product contains a

Lithium:poly-carbon mono fluoride battery for calendar backup purposes. This

battery is part of the CPU unit and is not replaceable.

DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual ix

Page 14

Service Safety Summary

x DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual

Page 15

Preface

Manual Structure

This manual provides information necessary for service technicians to service the

DTG5000 Series Data Timing Generator to the module level.

This manual is divided into sections, such as Specifications and Theory of

Operation. Further, some sections are divided into subsections, such as Product

Description and Removal and Installation Procedures.

Sections containing procedures also contain introductions to those procedures. Be

sure to read these introductions because they provide information needed to do the

service correctly and efficiently. The following contains a brief description of each

manual section.

Operating Information includes general information and operating

instructions.

Theory of Operation contains circuit descriptions that support service to the

module level.

Adjustment Procedures contains information that you need to manually adjust

the data timing generator so that it meets specifications.

Maintenance contains information and procedures for performing preventive

and corrective maintenance of the data timing generator. These instructions

include cleaning, module removal and installation, and fault isolation to the

module.

Replaceable Electrical Parts contains a statement referring you to Replaceable

Mechanical Parts, where both electrical and mechanical modules are listed.

Diagrams contains block diagrams and an interconnection diagram.

Replaceable Mechanical Parts includes a table of all replaceable modules,

their descriptions, and their Tektronix part numbers.

DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual xi

Page 16

Preface

Manual Conventions

This manual uses certain conventions that you should become familiar with.

Some sections of the manual contain procedures for you to perform. To keep those

instructions clear and consistent, this manual uses the following conventions:

Front-panel controls and menu names appear in the same case (initial capitals,

all uppercase, and so on) in the manual as is used on the data timing generator

front-panel and menus. Front-panel labels are all upper case letters (for

example, MENU, SELECT, PULSE GEN, and so on).

Instruction steps are numbered unless there is only one step.

Modules

Throughout this manual, any replaceable component, assembly, or part of the data

timing generator is referred to generically as a module. In general, a module is an

assembly (like a circuit board), rather than a component (like a resistor or an

integrated circuit). Sometimes a single component is a module; for example, the

chassis of the data timing generator is a module.

Safety

Symbols and terms related to safety appear in the Safety Summary near the

beginning of this manual.

Finding Other Information

This manual mainly focuses on the troubleshooting and maintenance of the data

timing generator. See the following list for other documents supporting the data

timing generator operation. All documents are on the DTG5000 Series Product

Documents CD-ROM that shipped with instrument.

Document name Description

DTG5000 Series Technical Reference for

Performance Verification & Specifications

DTG5000 Series User Manual 1 A quick reference to major features of the instrument and how they operate. It also provides

DTG5000 Series User Manual 2 A reference provides an encyclopedia of topics that describe the data timing generator

DTG5000 Series Programmer Manual Provides complete information on programming commands and remote control of the

DTG5000 Series Online Help An online help system, integrated with the User Interface application that ships with this

Describes how to verify the performance of the data timing generator and lists its

specifications. (Product Documents CD)

several tutorials to familiarize the user with basic instrument features. (Product Documents

CD)

interface and features, and gives background information on how to use them. (Product

Documents CD)

instrument. (Product Documents CD)

product. The help is preinstalled in the instrument.

xii DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual

Page 17

Contacting Tektronix

Preface

Phone 1-800-833-9200*

Address Tektronix, Inc.

Department or name (if known)

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

Web site www.tektronix.com

Sales support 1-800-833-9200, select option 1

Service support 1-800-833-9200, select option 2*

Technical support Email: techsupport@tektronix.com

1-800-833-9200, select option 3

6:00 a.m. - 5:00 p.m. Pacific time

* This phone number is toll free in North America. After office hours, please leave

a voice mail message.

Outside North America, contact a Tektronix sales office or distributor; see the

Tektronix web site for a list of offices.

*

*

DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual xiii

Page 18

Preface

xiv DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual

Page 19

Introduction

This manual contains information that is needed to properly service the DTG5000

Series Data Timing Generator as well as general information that is critical to safe

and effective servicing.

To prevent personal injury or damage to the data timing generator, consider the

following before attempting service:

The procedures in this manual should be performed only by a qualified service

person.

Read the General Safety Summary on page vii and the Service Safety Summary,

beginning on page ix.

Read Installation in Operating Information.

When using this manual for servicing, be sure to follow all warnings, cautions, and

notes.

Performance Verification Procedures

Strategy for Servicing

The performance check should be done every 12 months. In addition, a

performance check is recommended after module replacement. The performance

check procedures for this instrument are on the DTG5000 Series Product

Documents CD-ROM (Tektronix part number 063-3883-xx) that shipped with

your product. Look for the DTG5000 Series Technical Reference for Performance

Verification & Specifications PDF on this disk.

If the data timing generator does not meet performance criteria, repair is necessary.

Throughout this manual, the term, module, refers to any field-replaceable

component, assembly, or part of the data timing generator.

This manual contains the information needed for periodic maintenance of the data

timing generator. Further, it contains information for corrective maintenance down

to the module level. To isolate a failure to a module, use the troubleshooting

procedures found in the Maintenance section. To remove and replace any failed

module, follow the instructions in the Removal and Installation Procedures

subsection. After isolating a faulty module, replace it with a fully-tested module

obtained from the factory. The Replaceable Mechanical Parts section contains part

number and ordering information for all replaceable modules.

DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual xv

Page 20

Introduction

Tektronix Service Offerings

Tektronix provides service to cover repair under warranty as well as other services

that may provide a cost-effective answer to your service needs.

Whether providing warranty repair service or any of the other services listed

below, Tektronix service technicians are well trained to service the data timing

generator. They have access to the latest information on improvements to the

DTG5000 Series as well as new options.

Warranty Repair Service

Self Service

Tektronix warrants this product for one year from date of purchase. The warranty

appears at the front of this manual. Tektronix technicians provide warranty service

at most Tektronix service locations. The Tektronix product catalog lists all

worldwide service locations.

Tektronix supports repair to the module level by providing Module Exchange.

Module Exchange. This service reduces down-time for repair by allowing you to

exchange most modules for remanufactured ones. Each module comes with a

90-day service warranty.

For More Information. Contact your local Tektronix service center or sales engineer

for more information on any of the repair or adjustment services just described.

xvi DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual

Page 21

Specifications

Page 22

Page 23

Specifications

The specifications for this instrument are now available on the DTG5078 &

DTG5274 & DTG5334 Performance Verification & Specifications Technical

Reference (Tektronix part number 071-1611-xx). A PDF of this technical reference

is provided on the DTG5000 Series Product Documents CD-ROM (Tektronix part

number 063-3833-xx) that shipped with your product.

DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual 1-1

Page 24

Specifications

1-2 DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual

Page 25

Operating Information

Page 26

Page 27

Product Description

This section describes the key features of the DTG5000 Series Data Timing

Generators and their Output modules.

Models

This manual supports the following data timing generators:

DTG5078 Data Timing Generator

DTG5274 Data Timing Generator

DTG5334 Data Timing Generator

The differences between the data timing generators will be called out when

necessary; otherwise, the material applies to all data timing generators. The term

“data timing generator” refers to all of the products.

Key Features

The DTG5000 Series Data Timing Generator is a high-speed, multichannel signal

generator that creates a wide range of digital timing signals. The products are

designed to generate a data pattern for standard and nonstandard pulses necessary

for functional tests or characterization of legacy devices (TTL, CMOS, ECL) as

well as the latest devices (PECL, LVDS, GTL, CML).

Use the DTG5000 series to insert glitches and jitter as needed, and easily create

patterns for device stress testing. In addition, to shorten testing time, use the

sequence function to create signal sequences from combinations of various

patterns.

The DTG5000 Series Data Timing Generator supports six types of output modules

(DTGM10, DTGM20, DTGM21, DTGM30, DTGM31 and DTGM32). Table 2-1

lists the key features of the data timing generators, and Table 2-2 lists the key

features of the output modules.

DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual 2-1

Page 28

Product Description

Table 2-1: DTG5000 series key features

DTG5078 DTG5274 DTG5334

Maximum clock

frequency/Maximum data rate

Number of slots 8 (A, B, C, D, E, F, G, and H) 4 (A, B, C, and D) 4 (A, B, C, and D)

Pattern length 240 to 8,000,000 words/channel 960 to 32,000,000 words/channel 960 to 64,000,000 words/channel

Block size

granularity

Sequence steps 1 to 8,000 steps 1 to 8,000 steps 1 to 8,000 steps

Sequence

repeat counter

Master-Slave Up to three (one Master, two Slaves) Up to two (one Master, one Slave) Up to two (one Master, one Slave)

Data Generator

Mode

Data format

Slot A to D NRZ, RZ, and R1 NRZ, RZ, and R1 NRZ, RZ, and R1

Slot E to H NRZ

Data rate

RZ and R1 50 kb/s to 375 Mb/s 50 kb/s to 1.35 Gb/s 50 kb/s to 1.675 Gb/s

Channel addition Slot A, B, C, and D Slot A, B, C, and D Slot A, B, C, and D

Jitter generation Channel 1 of slot A Channel 1 of slot A Channel 1 of slot A

Lead delay

resolution

Trail delay

resolution

Pulse width

resolution

Pulse Generator

Mode

Clock frequency 50 kHz to 375 MHz 50 kHz to 1.35 GHz 50 kHz to 1.675 GHz

750 MHz/750 Mb/s 2.7 GHz /2.7 Gb/s 3.35 GHz /3.35 Gb/s

1 1 to 4 (depends on Vector Rate) 1 to 4 (depends on Vector Rate)

1 to 65,536 or Infinite 1 to 65,536 or Infinite 1 to 65,536 or Infinite

Slot A, B, C, D, E, F, G, and H Slot A, B, C, and D Slot A, B, C, and D

NRZ 50 kb/s to 750 Mb/s 50 kb/s to 2.7 Gb/s 50 kb/s to 3.35 Gb/s

1 ps 0.2 ps 0.2 ps

5 ps 5 ps 5 ps

5 ps (slot A, B, C, and D) 5 ps (slot A, B, C, and D) 5 ps (slot A, B, C, and D)

Slot A, B, C, and D Slot A, B, C, and D Slot A, B, C, and D

2-2 DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual

Page 29

Product Description

Table 2-2: DTG5000 series Output module key features

DTGM10 DTGM20 DTGM21 DTGM30 DTGM31 DTGM32

Number of channels 444211

Number of

available channels

DTG5078444211

DTG5274 2 (CH1, CH2) 2 (CH1, CH2) 2 (CH1, CH2) 2 1 1

DTG5334 2 (CH1, CH2) 2 (CH1, CH2) 2 (CH1, CH2) 2 1 1

Amplitude (50 Ω) 3.5 V

Amplitude

10 V

p-p

p-p

3.5 V

7 V

p-p

p-p

(1 MΩ)

Rise time/ fall

time at 1 V

p-p

into

<540 ps

(variable)

<340 ps

(variable)

50 Ω

(20% to 80%)

Hi Z Control yes

External Jitter

Input

3.90 V

5.35 V

7.81 V

p-p

p-p

p-p

(50 Ω)

(23 Ω)

1.25 V

2.5 V

p-p

p-p

1.25 V

2.5 V

p-p

p-p

1.25 V

2.5 V

p-p

<350 ps <110 ps <110 ps <110 ps

yes

one Input

yes

two Inputs

p-p

DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual 2-3

Page 30

Product Description

Mainframe and Output Module Configuration

The DTG5000 Series Data Timing Generator offers a modular card system. Six

types of the output modules can be combined in any combination. Each module can

be inserted into any slot. The functional restrictions are:

8 slots installed in the DTG5078 (A, B, C, D, E, F, G, and H)

4 slots installed in the DTG5274 and DTG5334 (A, B, C, and D)

When a DTGM10, DTGM20, or DTGM21 is installed in a DTG5274 or

DTG5334, CH3 and CH4 are unavailable. Only CH1 and CH2 can be used.

Slots E, F, G, and H are unavailable in the Pulse Generator mode.

Available data formats are different:

NRZ, RZ, R1 (Slot A, B, C, and D)

NRZ (Slot E, F, G, and H)

Due to power consumption constraints, the output modules used with the

DTG5078 are limited as follows:

Using the power consumption figures for each installed output module

[P(Mxx) in Table 2-3], the sum of all P(Mxx) values must not exceed 100.

Table 2-3: Current consumption coefficient

Module Current consumption coefficient

DTGM10 P(M10) = 9

DTGM20 P(M20) = 10

DTGM21 P(M21) = 10

DTGM30 P(M30) = 8

DTGM31 P(M31) = 33

DTGM32 P(M32) = 32

Example 1: DTGM31 1 each, DTGM30 7 each

P(M31) + P(M30) x 7 = 33 + 8 x 7 = 89 < 100; Acceptable

Example 2: DTGM32 3 each, DTGM30 5 each

P(M32) x 3 + P(M30) x 5 = 32 x 3 + 8 x 5 = 136 >100; Not Acceptable

2-4 DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual

Page 31

Product Software

Product Description

The data timing generator includes the following software:

The system software, which includes a specially configured version of

Windows 2000, comes preinstalled on the data timing generator. Windows

2000 is the operating system on which the user-interface application of this

product runs, and provides an open desktop for you to install other compatible

applications.

NOTE. Do not attempt to substitute any version of Windows that is not specifically

provided by Tektronix for use with this instrument.

The DTG5000 Software comes preinstalled on the data timing generator. This

software, which runs on Windows 2000, is the data timing generator

application. This software starts automatically when the data timing generator

is powered on, and provides the user interface (UI) and all other instrument

control functions. You can also minimize the data timing generator

application.

The product software runs not only on a data timing generator mainframe,

but also on a PC. When the software runs on the data timing generator

mainframe, it is called the Online mode. While running on the PC, it is

called the Offline mode. In the Offline mode, it is possible to create and edit

the pattern data and set the output parameters.

The DTG5000 Configuration Utility comes preinstalled on the data timing

generator. This software, running on Windows 2000, is used for setting up the

system configurations for the DTG5000 Software. This software controls the

Master operation, Master/Slave operation, Online/Offline operation, and so

forth.

NOTE. When you use the DTG5000 software in the offline mode, you must also

install the DTG5000 Configuration Utility into your PC.

The Readme file contains release notes and updates that could not be included

in other product documentation.

There are no limits on the number of PCs that can operate in the offline mode.

Occasionally new versions of software for your instrument may become available

on our Web site. See Contacting Tektronix on page xiii in the Preface section for

Web site information.

DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual 2-5

Page 32

Product Description

2-6 DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual

Page 33

Installation

This section covers installation of the data timing generator, addressing the

following topics:

Checking the Environment Requirements on page 2-10

Output Module on page 2-11

Powering On the Data Timing Generator on page 2-12

Shutting Down the Data Timing Generator on page 2-13

Creating an Emergency Rescue Disk on page 2-15

Backing Up User Files on page 2-17

Installing Software on page 2-17

CAUTION. Be sure to create your emergency rescue disk as described on

page 2-15. You may need that disk if you ever need to reinstall Windows 2000 from

the data timing generator hard drive.

DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual 2-7

Page 34

Installation

Supplying Operating Power

WARNING. To avoid equipment failure and potential fire or personal shock

hazards, do not exceed the maximum rated operating voltage of 250 V between the

voltage-to-ground (earth) and either pole of the power source. The DTG5000

Series operates from a single-phase power source and has a three-wire power cord

with a two-pole, three-terminal grounding plug. Before connecting to the power

source, be sure the DTG5000 Series has a suitable two-pole, three-terminal,

grounding-type plug.

To avoid personal shock hazard, do not touch conductive parts. All accessible

conductive parts are directly connected through the grounding conductor of the

power cord to the grounded (earth) contact of the power plug. The DTG5000 Series

is safety Class 1 equipment (IEC designation).

To prevent electrical shock, remove all power from the instrument, switch the

PRINCIPAL POWER SWITCH on the back panel to OFF, and disconnect the

power cord from the instrument. Some components in the DTG5000 Series are still

connected to line voltage after powering off the instrument from the front-panel

ON/STBY button.

Power Cord Information

A power cord with the appropriate plug configuration is supplied with each

DTG5000 Series Data Timing Generator. If you require a power cord other than

the one supplied, refer to Table 2-4

2-8 DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual

Page 35

Installation

Table 2-4: Power cord identification

Plug configuration Normal usage Option number

North America

125 V/15 A Plug

NEMA 5-15P

Standard

Europe

230 V

United Kingdom

230 V

Australia

230 V

Switzerland

230 V

Japan

100 V

A1

A2

A3

A5

A6

China

230 V

No power cord supplied. A99

A10

DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual 2-9

Page 36

Installation

Checking the Environment Requirements

Read this section before attempting any installation procedures. This section

describes site considerations and power requirements for your data timing

generator.

Site Considerations

Operating Requirements

The data timing generator is designed to operate on a bench in the normal position

(on the bottom feet). For proper cooling, at least three inches (7.62 cm) of clearance

is required on both sides of the data timing generator, and the bottom requires the

clearance provided by the bottom feet.

If you operate the data timing generator in the Master-Slave mode, you can stack

up to two mainframes.

CAUTION. To avoid damage to the mainframe, always close the bottom stands

when you stack the mainframes.

Using a cart is not recommended when you stack the mainframes. Doing so could

result in serious damage to the cart or mainframes.

Do not operate the mainframe while it rests on its left side feet. Always place the

mainframe in the normal position (on the bottom feet) while the mainframe

powered on.

Table 2-5 shows general operating requirements for the data timing generator. For

more information, refer to Specifications section in the DTG5078 & DTG5274 &

DTG5334 Performance Verification & Specifications Technical Reference. It

covers power source, temperature, humidity and altitude information.

Table 2-5: Operating requirements

Item Description

Operating temperature +10 °C to +40 °C

Operating relative humidity 20% to 80% (No condensation)

Operating altitude Up to 3 km (10,000 ft)

Power supply

Rating voltage 100 V to 240 V

Voltage range 90 V to 250 V

Frequency 47 Hz to 63 Hz

Maximum power 600 VA maximum

2-10 DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual

Page 37

Output Module

Installation

The DTG5000 Series Data Timing Generator mainframe and output module(s) are

shipped separately. At least one output module must be installed in the mainframe

slot to operate properly.

Six types of output modules can be combined in any combination. Each module

can be inserted in any slot. There are functional differences between slot A to D

and slot E to H. (Refer to Mainframe and Output Module Configuration on page

2-4.) It is recommended that slot A is used when only one output module is

installed in the mainframe slot.

Installing the Output

Module

To install the output module, first power off the mainframe using the front panel

On/Standby switch.

CAUTION. To prevent damage to the output module or mainframe, never install or

remove the output module when the mainframe is powered on.

To avoid damage from Electro Static Discharge, please do not touch the board

surface or connectors of the output module with your fingers when you handle the

module.

Attach the blank panel to the mainframe module slot(s) when the output module(s)

are not installed.

If the output module is not in use for a long time, attach the connector caps and

SMA terminations (DTGM30) to the output module and then store the output

module in the shipping carton. The connector caps and SMA terminations are

provided with your output module.

1. Verify that the data timing generator mainframe is not powered on.

2. Remove the blank panel from the mainframe slot.

3. Place the output module in a compartment.

4. Gently push the output module into the slot with firm pressure.

5. Once the module is seated, tighten the two screws with a screwdriver to secure

the module to the mainframe.

Removing the Output

Verify that the data timing generator mainframe is not powered on.

Module

1. Loosen the two screws.

2. Grasp the right and left screws and slowly pull the module out of the

mainframe slot.

3. Attach a blank panel to the slot.

DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual 2-11

Page 38

Installation

Powering On the Data Timing Generator

Follow these steps to power on the data timing generator.

1. Connect the proper power cord from the rear panel power connector to the

power system.

PRINCIPAL

Principal

power

Switch

AC power

connector

POWER SWITCH

1

AC INPUT

ONOFF

+

'44

*&&

470

.#0

8)#

+06456

5%5+

%1/

-';$1#4& /175'

CLOCK

153535

0.4Vpk-pk MIN

Vpk-

2

OUTEXTERNAL IN

-2V

TO 7

V

FROM 50˴

pk MAX

OUT

-2V

TO 7

V

FROM 50˴

MASTER/SLAVE CONNECTION

CLKIN CLK OUT 1JUMPIN JUMP OUT 2 CLKOUT 2 CLKOUT 3

CLKINJUMPOUT 1 JUMPOUT 3 CLKOUT 1 CLK OUT2 CLK OUT 3

FORMASTER/SLAVE OPERATION ONLY

PHASE LOCK

EXTERNAL

10MHz REF IN

0.2Vpk-pk MIN

Vpk-

pk MAX

3

10MHz REF OUT

2.4Vpk-pk

FROM 50˴

PHASE

LOCKIN

0.2Vpk-pk MIN

Vpk-

3

pk MAX

Figure 2-1: Principal power switch and AC power connector

NOTE. To set up Windows 2000, connect the keyboard and mouse before turning

the power on.

Connect the keyboard, mouse and other accessories before applying power to the

product.

2. Turn on the principal power switch at the rear panel. (See Figure 2-1 for switch

location.)

3. Push the front panel On/Standby switch to power on the data timing generator.

(See Figure 2-2 for the switch location.)

On/Standby

Switch

Figure 2-2: On/Standby switch location

2-12 DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual

Page 39

Shutting Down the Data Timing Generator

When you push the front-panel On/Standby switch, the data timing generator starts

a shutdown process (including a Windows shutdown) to preserve settings. This

action removes power from most circuitry in the data timing generator. Avoid

using the rear panel power switch or disconnecting the line cord to power off the

mainframe.

The DTG5000 Series Data Timing Generator runs on Windows 2000; the

shut-down process is similar to a PC.

There are three ways to shut down the mainframe:

Push the On/Standby switch

Select the Windows Start menu, and then select Shut Down...

Select the File menu from the DTG5000 software, then select Shutdown.

When the data timing generator settings were not changed. When the DTG5000

software is not running, or if the data timing generator settings have not changed

since the mainframe start-up, the shut-down process closes all the programs on

Windows, and then restores the settings. The power is automatically shut off.

Installation

When the data timing generator settings were changed. If the DTG5000 Series

Data Timing Generator settings were changed after the mainframe start-up, the

dialog box shown below appears on the screen and asks if you want to save the

current settings. Push any button within five seconds.

Select Yes to specify the file name and location, and then select OK to

continue the shut-down process.

Select No without saving the setup file and continue the shut-down process.

Select Cancel to abort the shut-down process and to return to the DTG5000

software.

DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual 2-13

Page 40

Installation

If you do not select the options within five seconds, Windows forces you to

terminate the DTG5000 software. The End Program dialog appears.

Select End Now to continue the shut-down process without saving the setup

file.

Without any action in ten seconds, the following dialog box appears.

The DTG5000 software is waiting for the information about whether the user wants

to save the setup information. In this case, Windows cannot terminate the

DTG5000 software.

Select End Now to continue the shut-down process without saving the setup

file.

Select Cancel to return to the DTG5000 software.

In all cases, select End Now to exit all the Windows programs while preserving the

current Windows settings. This shuts off the power to the mainframe.

2-14 DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual

Page 41

To completely remove the power from the data timing generator, shut off the

principal power switch at the rear panel, and then disconnect the power cord from

the mainframe.

NOTE. If you push the front panel On/Standby switch for more than four seconds,

the data timing generator power is forced to be shut off.

Do not attempt to push the rear panel principal power switch before shutting down

the mainframe properly.

Creating an Emergency Rescue Disk

Now that you have completed the basic installation process, you should create an

emergency rescue disk that you can use to restart your data timing generator in case

of a major hardware or software failure.

Installation

NOTE. Create the emergency rescue disk and store it in a safe place. It may allow

you to recover your Windows 2000 installation without rebuilding the entire data

timing generator hard disk.

The emergency rescue disk contains basic files to restart your data timing

generator. Follow these steps to create the emergency rescue disk:

1. Log on to the mainframe with the administrator name.

2. Click the Windows Start button, select Program ! Accessories ! System

Tools ! Backup. The following dialog box appears.

DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual 2-15

Page 42

Installation

3. Insert a formatted floppy disk into the floppy disk drive, and then click

Emergency Repair Disk.

4. The Emergency Repair Diskette dialog box appears.

5. Click Also backup the registry..., and then click OK.

6. Wait until the task completes. The following dialog appears.

7. Click OK, and then remove the floppy disk and store it in a safe place.

2-16 DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual

Page 43

Backing Up User Files

Installation

You should always back up your user files on a regular basis. Use the Back Up tool

to back up files stored on the hard disk. The Back Up tool is located in the System

Tools folder in the Accessories folder.

1. Log on to the mainframe with the administrator name.

2. Click the Windows Start button, select Program ! Accessories ! System

Tools ! Backup.

3. Click Backup Wizard.

4. Follow the on-screen instructions.

The backup tool allows you to select your backup media and to select the files and

folders that you want to back up. Use the Windows online help for information on

using the Backup tool. You can back up to the floppy drive or to a third-party

storage device.

Installing Software

System Diagnostics

The data timing generator mainframe ships with the product software installed, so

only perform the reinstallation if it becomes necessary. For more information on

the software reinstallation, refer to the User Manual, volume 2.

In case of instrument problems, you may want to run the system diagnostics. See

the DTG5078 & DTG5274 & DTG5334 Performance Verification and

Specifications Technical Reference manual for more information on self tests and

system diagnostics.

DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual 2-17

Page 44

Installation

2-18 DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual

Page 45

Operating Basics

Front Panel

This section contains information on the various interfaces for controlling the

DTG5000 Series Data Timing Generator and basic menu operation of the

instrument.

Front Panel Controls on page 2-21 provides a quick overview of front panel

controls such as the knob, buttons and keys.

Front Panel Connectors on page 2-24 subsection provides a quick overview of

front panel connectors.

Rear Panel Connectors on page 2-27 provides a quick overview of rear panel

connectors.

Display Area and Application Windows on page 2-32 provides an overview of

screen elements and the application windows.

Using the Menu System on page 2-35 provides an overview of the menu and

key operations of the data timing generator.

Figure 2-3: Front panel (DTG5078)

DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual 2-19

Page 46

Operating Basics

DTG 5274

DTG 5334

Data Timing Generator

A

Data Timing Generator

2.7 Gb/s

B

3.35 Gb/s

C

D

CAB D

Figure 2-4: Front panel (DTG5274, DTG5334)

2-20 DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual

Page 47

Front Panel Controls

Operating Basics

This section introduces you to the front panel controls of the data timing generator,

which provides a brief overview of how to use the front panel key controls.

In addition to the front panel controls, you can also control the data timing

generator from a keyboard and a mouse (provided with the instrument).

Navigation

keys

Digit Select

arrow keys

Figure 2-5: Front panel controls

Navigation Keys

The MENU and SELECT buttons, TAB, ESC, and the Up, Down, Left and Right

arrow keys are called navigation keys. These buttons and keys allow you to

perform the data timing generator basic windows operation without using a mouse

or a keyboard. Figure 2-5 shows the locations of the front-panel controls.

Table 2-6: Front panel controls

Key, Button Description

MENU button

Opens the pull-down menu items of the last menu bar that you opened, regardless of current

selection.

To cancel the pull-down menu, push the MENU button again. Pressing the ESC key also forces

the pull-down menu to disappear, however the menu bar is still active. If you press any arrow key

in this state, the key operates on the menu bar area. Pressing the ESC key twice moves the focus

to the lower window area.

DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual 2-21

Page 48

Operating Basics

Table 2-6: Front panel controls

Key, Button Description

SELECT button

TAB key

ESC key

Arrow keys

The SELECT button has the same capability as the Windows standard ENTER key. This button

is mainly used for the following actions:

Use to make a selection on the pull-down menu items

Use to open a pop-up menu in a tabular view

Use to select an item in a pop-up menu

Use to select OK or Cancel in the dialog box

The TAB key is used to move the focus within the window. By pressing the SHIFT and TA B keys

simultaneously, you can move the focus in the reverse direction.

The ESC key is used to cancel text input or dialog box appearance. To cancel the menu items

opened with the MENU button, press the ESC key twice.

The arrow keys are used for the following actions:

Use to open the pull-down menus on the menu bar and move to the desired items, after

pushing the MENU button (you can also use the knob).

Use to move the current cell (cursor position) in a tabular view

Use to select a radio button

The arrow keys have the capability of auto repeat.

Provide direct access to frequently used menus.

DATA button

The DATA button is used to display previously selected pattern data editing window (Data-Listing

window or Data-Waveform window). While one window is displayed, pushing this button switches

to the alternate window on the screen.

Provide direct access to frequently used menus.

LEVEL button

The LEVEL button is used to display the Level window and moves the focus to the previously

selected items.

Provide direct access to frequently used menus.

TIMING button

The TIMING button is used to display the Timing window and moves the focus to the Clock

Frequency or previously selected item.

Knob.

The knob is used to increment or decrement a set value or select an item from a pop-up or

pull-down menu. Use right or left arrow keys just under the knob to move the digit when you

increment or decrement the setup value.

Digit Select arrow keys

RUN button

RUN

The Digit Select arrow key is used to move the underbar to a field that contains an editable

number. This will allow you to change the digit.

The RUN button is used to control the start and stop of signal outputs.

If the signal is being output, the LED indicator lights up . To actually output the signal

through the output connectors, you must turn the Output on in the Level window or push the front

panel ALL OUTPUTS ON/OFF button.

2-22 DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual

Page 49

Table 2-6: Front panel controls

Key, Button Description

PULSE GEN button

PULSE

GEN

MANUAL TRIGGER button

MANUAL

TRIGGER

The PULSE GEN button is used to toggle between Pulse Generator and Data Generator modes.

The LED lights up when the instrument is in PG mode.

The MANUAL TRIGGER button is used to generate an internal trigger.

Operating Basics

MANUAL EVENT button

MANUAL

EVENT

Suffix buttons (p, G/n, M/µ, k/m)

SHIFT key

ALPHA key

SPACE key

ALPHA

SPACE

ENTER key

BKSP key

The MANUAL EVENT button is used to generate an event signal internally.

After you complete the input with numeric keys, you can determine the unit by pushing one of the

suffix buttons, without pressing the Enter key.

If you push a suffix button for a frequency, the unit is interpreted as G (giga-), M (mega-) or k (kilo-).

If you push it for a time or voltage, the unit is interpreted as p (pico-), n (nano-), µ (micro-) or m

(milli-).

The SHIFT key has the same capability as the Shift key on a Windows PC keyboard.

The ALPHA key is used to enter a character with a numeric key. Pressing the ALPHA key causes

the LED to light up.

While the LED is on, the data timing generator is in the text input mode and you can use numeric

keys to enter alphanumeric characters.

The SPACE key switches the On/Off state of a check box. Pressing the ALT and SPACE keys

simultaneously displays the Control menu. See DTG icons on page 2-32 for details on the Control

menu.

The ENTER key has the same capability as the Enter key on a Windows PC keyboard.

This also switches the On/Off state of a check box.

The BKSP key has the same capability as the Back Space key on a Windows PC keyboard.

DEL key

DEL

ALL OUTPUTS ON/OFF button

The DEL key has the same capability as the Delete key on a Windows PC keyboard.

This button is used to switch the on/off of channel output, DC output or clock output. To turn on or

off these outputs, use the Level window, DC Output window, or Time Base window, respectively.

You can turn on or off the channel (or DC or clock) outputs all together by using this button, instead

of switching them the on/off separately.

If you push this button while at least one active channel or DC output or clock output is on, all the

outputs turn off.

If you push this button while all the outputs are off, all the outputs turn on.

In the Data Generator mode, the physical channels that are not assigned to a logic channel do not

turn on.

DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual 2-23

Page 50

Operating Basics

Front Panel Connectors

Figure 2-6 shows the locations of the data timing generator front panel connectors.

DC OUTPUT

USB

SKEW CAL IN

TRIGGER IN

EVENT IN

Figure 2-6: Front panel connectors

CAUTION. To prevent damage to your data timing generator, do not apply a

voltage outside the specified input voltage range.

Do not apply a voltage to the output connector.

Table 2-7: Front panel connectors

Connector Description

TRIGGER IN

External trigger signal input connector. Use for Wait Trigger on Sequence operation and for

starting trigger of Burst mode on Pulse Generator operation.

Input Voltage Range.

–5 V to +5 V, 50 Ω

–10 V to 10 V, 1 kΩ

Connector: BNC

SYNC OUT

2-24 DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual

Page 51

Table 2-7: Front panel connectors (cont.)

Connector Description

EVENT IN

Event signal input connector. Use for Event Jump on Sequence operation.

Input Voltage Range.

–5 V to +5 V, 50 Ω

–10 V to 10 V, 1 kΩ

Connector: BNC

Synchronized signal output connector for CML level.

SYNC OUT

SYNC OUT

Data Generator Mode. A pulse is output at the head of each block of the output pattern. If the

block repeats, the pulse is output at each repeated block head.

CURRENT MODE LOGIC

-0.4V to 0V

Pulse Generator Mode. A single pulse is output at the timing of Burst. No signal is output in

Continuous operation.

Operating Basics

SKEW CAL IN

CLOCK

SKEW CAL IN

V

Connector: SMA

= 0 V, VOL = –0.4 V into 50 Ω to GND

OH

Signal input connector for adjusting channel-to-channel skews.

Input Voltage Level.

ECL into 50 Ω to –2 V

Connector: SMA

The following external clock input/output signal connectors are provided in the DTG5334.

EXTERNAL IN. Connect the external clock input signal.

Input Voltage Range: 0.4 V

Input Frequency Range:

p-p

to 2 V

into 50 Ω

p-p

DTG5334: 1 MHz to 3.35 GHz

OUT, OUT. Outputs the clock signal. Amplitude and Offset can be set in the Time Base window.

Output Voltage Range VOH: –1.00 V to 2.47 V into 50 Ω to GND

Output Voltage Range VOL: –2.00 V to 2.44 V into 50 Ω to GND

Output Voltage Amplitude: 0.03 Vp-p to 1.25 Vp-p

Resolution: 10 mV

Signal type: Complementary

Connector: SMA

NOTE.

A 50Ω SMA termination is provided with your data timing generator

mainframe. When you use the instrument with single end, attach the termination

to the unused connector.

DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual 2-25

Page 52

Operating Basics

Table 2-7: Front panel connectors (cont.)

Connector Description

DC OUTPUT

Outputs eight channel DC voltages. This signal is independent of the output module signal.

Output Voltage Range.

+30mA MAX

USB

– 3.0 V to 5.0 V

Connector: 2.54 mm 2 x 8 pin header (female)

Connect a USB device.

2-26 DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual

Page 53

Rear Panel Connectors

PRINCIPAL

POWER SWITCH

1

AC INPUT

Operating Basics

Figure 2-7, Figure 2-8, and Figure 2-9 show the locations of the data timing

generator rear panel connectors.

'44

*&&

ONOFF

+

470

.#0

+06456

8)#

5%5+

%1/

-';$1#4& /175'

CLOCK

OUTEXTERNAL IN

153535

0.4Vpk-pk MI N

2

Vpk-

-2V

TO 7

V

FROM 50˴

pk MAX

OUT

-2V

TO 7

V

FROM 50˴

Figure 2-7: Rear panel (DTG5078)

MASTER/SLAVE CONNECTION

CLK IN CLKOUT 1JUMP IN JUMP OUT 2 CLK OUT 2 CLK OUT 3

CLK INJUMPOUT 1 JUMP OUT 3 CLK OUT 1 CLK OUT 2 CLK OUT 3

FOR MASTER/SLAVE OPERATION ONLY

PHASE LOCK

EXTERNAL

10 MHz REF IN

0.2Vpk-pk MI N

3

Vpk-

pk MAX

10 MHz REF OUT

2.4Vpk-pk

FROM 50˴

PHASE

LOCK IN

0.2Vpk-pk MI N

3

Vpk-

pk MAX

DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual 2-27

Page 54

Operating Basics

CD-ROM drive COM Mouse

LAN VGA monitor

USB GPIB Keyboard

Figure 2-8: Rear panel connectors (1)

Table 2-8: Rear panel connector (1)

CD-ROM drive

COM

Mouse

Keyboard

GPIB

USB (2 each)

VGA

LAN

Description

The CD-ROM drive is used to reinstall the DTG5000 product software or to rebuild the operating

system.

COM port.

Connect a PS/2 mouse. A USB mouse must be connected to the USB port.

Connect a PS/2 keyboard. By connecting a keyboard and mouse to the connectors, you can

perform the Windows PC operations more easily. A USB keyboard must be connected to the USB

port.

The GPIB port. Used to control the data timing generator through the GPIB.

Connect a USB device. The keyboard and mouse of the data timing generator standard

accessories must be connected to the USB port.

If an external display is connected to this connector, the same image as the data timing generator

LCD screen is displayed on it.

Resolution Settings.

The 800 by 600 setting is recommended.

It is possible to set the data timing generator display off (from the Control Panel settings) and

to display the screen image with external display. In this condition, images can be displayed

at a higher resolution. If the external display is disconnected from the connector, images are

displayed on the data timing generator screen at a resolution of 800 by 600 pixels, regardless

of the resolution settings of the external display.

LAN is a port used to connect the data timing generator to a network. Connect a 10Base-T or

100BASE-T connector here. In the Master-Slave operation, the Master mainframe controls the

Slave machine by way of network.

2-28 DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual

Page 55

Operating Basics

Figure 2-9: Rear panel connectors (DTG5078) (2)

CAUTION. To prevent damage to your data timing generator, do not apply a

voltage outside the specified input voltage range.

Do not apply a voltage to the output connector.

Table 2-9: Rear panel connectors (2)

Connector Description

CLOCK

EXTERNAL IN

0.4Vpk-pk MIN

2

Vpk-

-2V

FROM 50˴

-2V

FROM 50˴

pk MAX

OUT

TO 7

OUT

TO 7

V

V

The following external clock input/output signal connectors are provided. (These are provided on

the front panel in the DTG5334)

EXTERNAL IN. Connect the external clock input signal.

Input Voltage Range: 0.4 V

Input Frequency Range:

DTG5078: 1 MHz to 750 MHz

DTG5274: 1 MHz to 2.7 GHz

OUT, OUT. Outputs the clock signal. Amplitude and Offset can be set in the Time Base window.

Output Voltage Range VOH: –1.00 V to 2.47 V into 50 Ω to GND

Output Voltage Range VOL: –2.00 V to 2.44 V into 50 Ω to GND

Output Voltage Amplitude: 0.03 Vp-p to 1.25 Vp-p

Resolution: 10 mV

Signal type: Complementary

Connector: SMA

NOTE.

A 50Ω SMA termination is provided with your data timing generator

mainframe. When you use the instrument single-ended, attach the termination to

the unused connector.

p-p

to 2 V

into 50 Ω

p-p

DTG5078 & DTG5274 & DTG5334 Data Timing Generators Service Manual 2-29

Page 56

Operating Basics