Page 1

Application Note

HDMI Compliance and Sink Characterization Using the

DTG5000 Series Data Timing Generator

Introduction

The High Definition Multimedia Interface (HDMI) is

an emerging consumer electronics standard that is

fast gaining acceptance by manufacturers of digital

tainment pr

enter

one-cable inter

and audio content between receiver/playback

devices and display devices.

ypical r

T

boxes, DVD players, satellite r

Definition tuners as well as personal computers.

Display devices connected via HDMI include LCD

eceiver/playback devices include cable

oducts. HDMI offers an efficient

face for High Definition (HD) video

eceivers, and High

displays, plasma displays, and pr

Thanks to the simplicity of setup and the resulting

quality of the presentation, consumers are accepting

HDMI as a “must-have” item for the full HD experience.

HDMI uses the existing Digital Video Interface (DVI)

architecture and adds capability for High Definition

Audio and High-Bandwidth Digital Content Protection

(HDCP). The latter technology enables tr

protection of high-quality digital movie content.

HDCP is r

entertainment industry, which is advocating its use in

all HD consumer products.

eceiving an enthusiastic response from the

ojection units.

ue copy

Page 2

DMI Compliance & Sink Characterization Using DTG5000 Series Data Timing Generator

H

Application Note

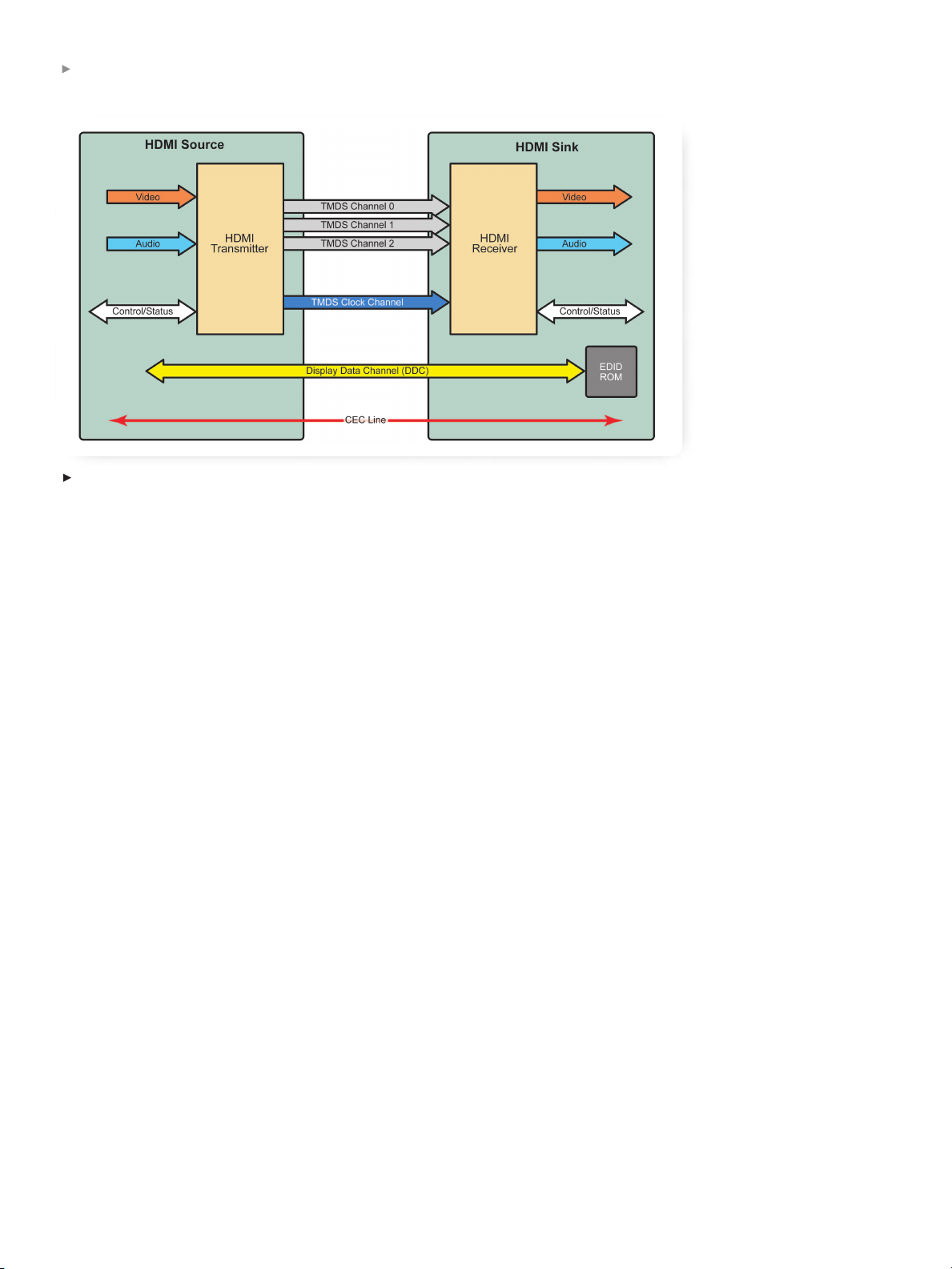

Figure 1.

HDMI pixel data flow and organization from Source to Sink.

HDMI supports standard, enhanced, or HD video as

well as standard or multi-channel surround audio. The

interface offers uncompressed digital video and a

bandwidth of up to 5 gigabytes per second through

one small connector instead of several cables and

connectors as in the past. In addition, HDMI enables

communication between the video source and the

digital television (DTV). HDMI development is overseen by HDMI Founders including Sony, Hitachi,

Panasonic (Matsushita Electric Industrial), Silicon

Image, Philips, Thomson (RCA) and T

oshiba.

The HDMI Founders have stipulated that all HDMI

products must pass a battery of required compliance

tests to qualify to use the HDMI logo. This compliance

testing will ensure true interoperability and accordingly,

customer satisfaction. Today, these tests can only be

performed at an HDMI Authorized Testing Centers

TC). Pr

(A

e-compliance testing during the design and

manufacturing stages greatly increases the likelihood

of successfully passing the final compliance tests at

the ATC. Pre-compliance testing can save valuable

time and resources.

This technical brief discusses the equipment required

for pre-compliance and compliance testing to the HDMI

physical layer Compliance Test Specifications (CTS).

HDMI Technical Characteristics

HDMI uses a high-speed serial interface that is based

on transition-minimized differential signaling (TMDS)

to send data to the r

eceiver

. TMDS signals transition

between “on” and “off” states using an algorithm that

minimizes the number of transitions to avoid excessive

levels of electr

omagnetic inter

ference (EMI) on the

cable. The differential signal amplitude is +3.3 volts,

terminated in 50 Ω with 500 mV nominal amplitude

transitions (from +2.8 V to +3.3 V).

2

2

2

www.tektronix.com/signal_sources

Page 3

DMI Compliance & Sink Characterization Using DTG5000 Series Data Timing Generator

H

Application Note

Standard Resolution Data Rate Frequency

VGA 640 x 480 252 Mb/s 25.2 MHz

SVGA 800 x 600 400 Mb/s 40 MHz

XGA 1024 x 768 650 Mb/s 65 MHz

SXGA 1280 x 1024 1080 Mb/s 108 MHz

UXGA 1600 x 1200 1620 Mb/s 162 MHz

640 x 480p 640 x 480 252 Mb/s 25.2 MHz

720 x 480p 720 x 480 270.27 Mb/s 27.027 MHz

576p 768 x 576 270 Mb/s 27 MHz

720p 1280 x 720 742.5 Mb/s 74.25 MHz

1

080i 1920 x 1080 742.5 Mb/s 74.25 MHz

Table 1.

Display Clock

Standards and respective data rates.

The basic TMDS transmission line is made up of three

data channels and a clock channel. Data consists of

8-bit pixels (256 discrete levels) in each of three

channels (R/G/B). These are encoded into ten-bits

words using 8B/10B encoding to minimize transitions

and to remove the DC component. The signals have

rise times on the order of 100 picoseconds. A pair of

TMDS lines is used when higher data rates are needed.

Figure 1 shows the flow of pixel data from the

graphics controller or Source device to the digital

Sink receiver.

TMDS data rates range fr

om 22.5 megapixels per

second (Mpps) to 165 Mpps, equivalent to or up to

1.65 G bits per second at the maximum clock rate

of 165 MHz. The data rate depends on the display

resolution. The relationships of display resolution, bit

rate and clock frequency are shown in the Table 1.

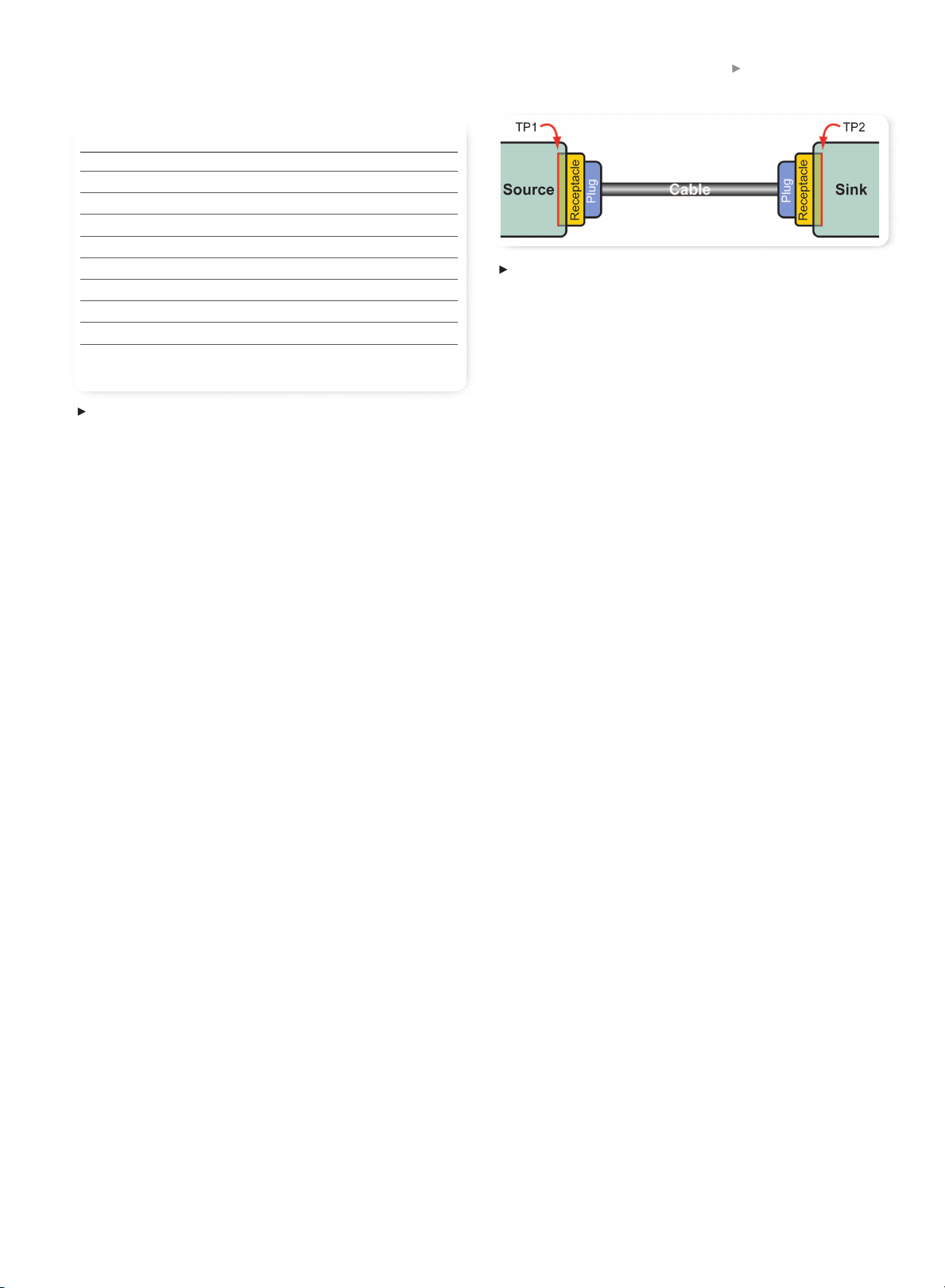

Figure 2.

Test points for HDMI measurements.

Compliance Testing Tools and Solutions DTG5000 Series

The goal of compliance testing is to ensur

e interoperability among the many hundreds of different HDMI

devices from as many manufacturers. By conforming

to published HDMI specifications, a device manufactur

can pave the way for a new product's acceptance in

the marketplace.

esting should also ensure that the designs are robust

T

enough to withstand the harsh treatment they can

expect to receive in the real world. As new displays

become more rugged, the devices that use them will

find their way into less sheltered environments than in

the past. Therefore, new devices should be tested to

comply with standards under a variety of operating

conditions, not just “nominal” or best-case conditions.

est parameters should r

T

each out beyond the basic

limits defined in the specifications.

Figure 2 illustrates the major elements of the HDMI

transmission system: Source, Cable and Sink. The

ce signals ar

Sour

e tested at TP1 while the Sink

devices are tested at TP2. For testing cables, meas-

ements must be performed at both TP1 and TP2.

ur

er

www.tektronix.com/signal_sources

3

Page 4

DMI Compliance & Sink Characterization Using DTG5000 Series Data Timing Generator

H

Application Note

Electrical Signals Test CTS Test ID Test Point

Source Clock and/or Data Data Eye Diagram 7-10 TP1

Clock Jitter 7-9 TP1

Clock Duty Cycle 7-8 TP1

Overshoot/Undershoot 7-5 TP1

Rise/Fall Time 7-4 TP1

I

nter-pair Skew 7-6 TP1

Data-Data Inter-pair Skew 7-6 TP1

S

ingle-ended Intra-pair Skew 7-7 TP1

Low Level Output Voltage (VL) 7-2 TP1

S

ink Jitter Tolerance 8-7 TP2

Minimum Differential Sensitivity 8-5 TP2

Intra-pair Skew 8-6 TP2

Differential Impedance 8-8 TP2

Cable Data Eye Diagram 5-3 TP1, TP2

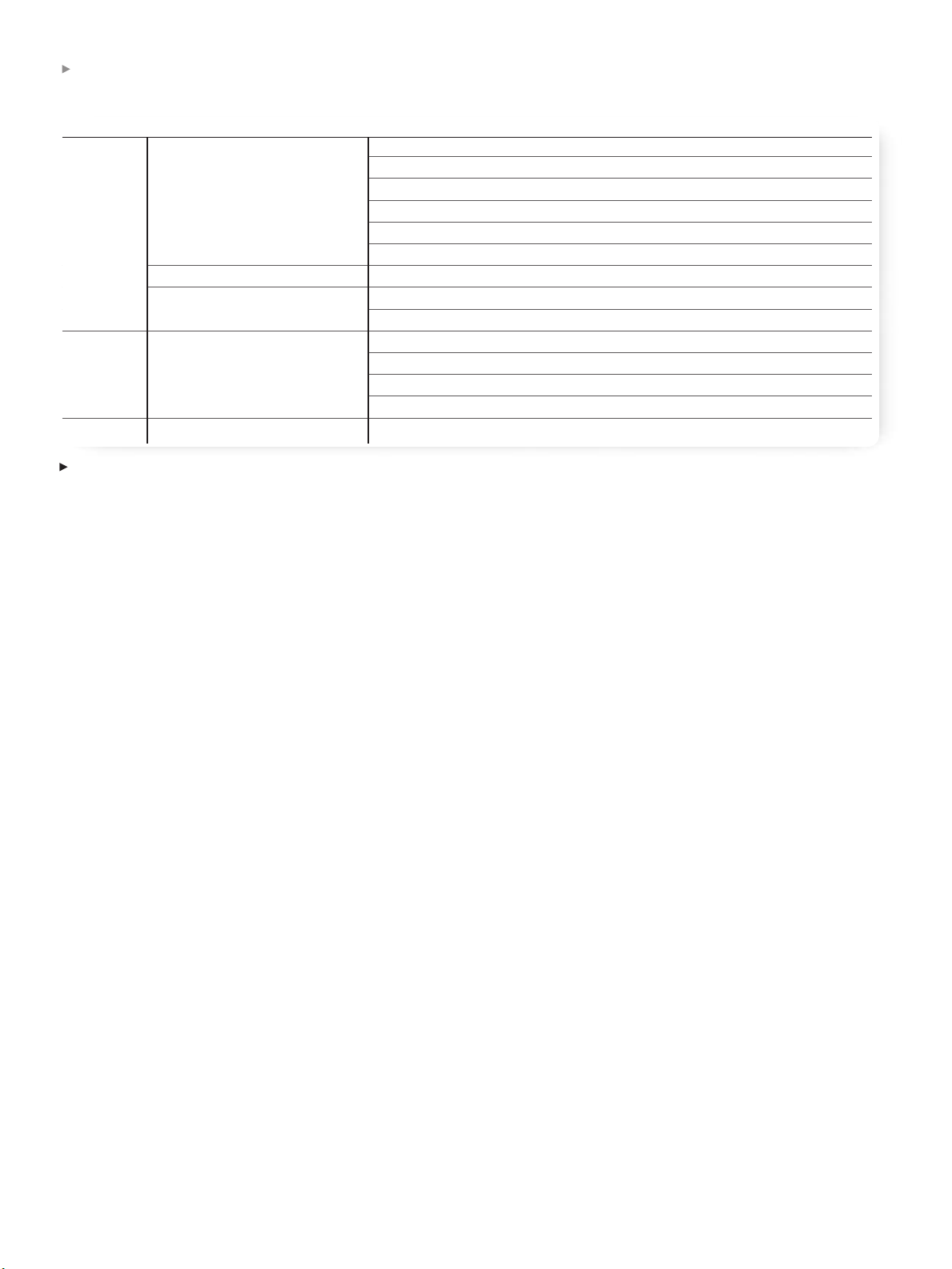

Table 2.

Core HDMI tests.

Most HDMI product developers want to perform

pre-compliance testing; they have a clear incentive to

ensure interoperability and compatibility. While it is

recommended to perform as many tests as possible,

certain core tests are an essential part of compliance.

able 2 summarizes some of the above core tests.

T

Transmitter or Source signal characteristics can be

effectively characterized by measuring signals at test

point TP1 to ensure that they are within standard

timing, jitter and voltage margins.

The oscilloscope is of course the key platform for

observing signals at these test points. The digital

storage oscilloscopes (DSO) and digital phosphor

oscilloscopes (DPO) in the Tektronix TDS family

can be pair

ed with the TDSHT3 application softwar

e

package for HDMI work. TDSHT3 provides accurate

automated Sour

ce measur

ements for HDMI compliance,

including those summarized in Table 2. For more

information about this subject, refer to the Tektronix

application note titled Physical Layer Compliance

Testing for HDMI Using TDSHT3 HDMI Compliance

Test Software (available at wwww.tektronix.com).

This balance of this technical brief will concentrate on

the equipment and procedures for compliance and

characterization measurements on HDMI Sink devices

and cables.

HDMI Sink T

ests

Jitter Tolerance

One of the most critical characteristics of a Sink

device is its tolerance to jitter in the incoming signal.

The HDMI standard defines the limit as 0.3 x T

ter

m T

is HDMI syntax for “unit inter

BIT

val.” The test

BIT

; the

approach is straightforward: specified amounts of jitter are injected in steps into the transmitted TMDS

signal. Each step increases the jitter amount from low

to high until the sink device fails to r

ecover the signal.

The amount of jitter at which this failure occurs is

compar

ed against the published limits for compliance.

4

4

www.tektronix.com/signal_sources

Page 5

DMI Compliance & Sink Characterization Using DTG5000 Series Data Timing Generator

H

Application Note

The jitter tolerance testing is performed in the following broad steps:

Determining Worst-case Clock-Data skew:

1.

The skew in data is varied until the worst point is

determined. This test is performed over several

bit

b

it

iterations as illustrated in Figure 3. The signal

generator providing the TMDS is then set to

produce this worst-case level of skew.

Measuring Jitter Margins: several measurements

2.

involve injecting a specified amount of jitter to the

clock signal path. Three measurements are

Figure 3.

Determining worst-case jitter tolerance.

performed over two test cases. Again, these

Data and Clock components are injected only into

the system clock path. The measurements and test

bit

cases are as follows:

– Data Jitter amplitude (D

)

jw

– Data Jitter Frequency at 500 KHz and

Clock Jitter Frequency at 10 MHz

– Data Jitter Frequency at 1 MHz and Clock Jitter

Frequency at 7 MHz.

– Worst Data Jitter Amplitude

– Data Jitter Frequency at 500 KHz and Clock

Jitter Frequency at 10 MHz

Data Jitter Frequency at 1 MHz and Clock

–

Jitter Frequency at 7 MHz.

– Worst Clock Jitter Amplitude

– Data Jitter Frequency at 500 KHz and Clock

Jitter Fr

equency at 10 MHz

– Data Jitter Frequency at 1 MHz and Clock

Jitter Fr

equency at 7 MHz.

Figure 4 explains the measurement criteria for

D_JITTER and C_JITTER mar

gins. The tests need to

be performed at all pixel clock rates supported by the

device under test. Because of the many parameters to

be adjusted and the tight mar

gins, this test can be

rather complex and time-consuming.

Minimum Differential Sensitivity

The minimum differential sensitivity test is common to

many serial standar

ds. The test confirms that the Sink

meets interoperability requirements even when it

bit

Figure 4.

Measurement criteria for jitter margins.

experiences attenuated differential voltage swings.

A TMDS signal generator with the ability to change

amplitude is the proper tool for this test. The source

is used to generate a Sink-suppor

ted 27 MHz video

format that repeats the RGB gray ramp signal from

0 to 255 during each video period. The test starts at

170 mV V

amplitude is r

device reports an error. If the minimum V

on all pairs, then the differential signal

DIFF

educed in steps of 20 mV until the Sink

DIFF

to which

the Sink responds without error is less than 150 mV,

the device passes the test. The test stops when

minimum V

reaches 70 mV. Another important

DIFF

element of this test is that it is performed at two

different V

(common-mode voltage) settings,

ICM

namely 3.0 V and 3.13 V. The DTG5000 Series offers

a specific termination voltage capability that allows

the generation of the TMDS signals at the appr

opriate

levels without the requirement for external adapters

such as Bias T

ees.

www.tektronix.com/signal_sources

5

Page 6

DMI Compliance & Sink Characterization Using DTG5000 Series Data Timing Generator

H

Application Note

Sink Test Instrument Jitter Min. Diff.

Requirements Tolerance Sensitivity Intra-Pair Skew Remarks

Digital Storage Oscilloscope • • • 16M record length

Differential Probes • • • > 2 ea

TPA-R Test Adapter Set • • • 013-A012-50

TPA-P Test Adapter Set • • • 013-A013-50

12 SMA Cables • • • 174-1428-00

JAE Cable Emulator • 74.25, 27MHz

DC Power Supply • • • +5V

GPIB USB Controller • • • NI GPIB-USB-B

GPIB Cable • • •

Characterization Solution

Data Timing Generator • • • DTG5274 w/ 3 DTGM30 (Note1)

Arbitrary Waveform Generator • AWG710/B (Note1)

1) SMA-BNC adaptor • 015-1018-00

Cable from DTG DC O/P Pin-to-SMA • 012-1506-00 + 015-0671-00 +

at Bias Tee (2 nos.) 015-1018-00 (Note1)

SMA(m) - SMA(f) Cables (2) • (Note1)

Mini-Circuits Bias Tee (2 nos.) • ZFBT-4R2GW (Note1)

C

ompliance Solution

Data Timing Generator • • • DTG5274 w/ 3 DTGM30/ 1

DTGM32

Function Generator up to 10MHz • 2 channel AFG3022, 3102 or 3252

2) SMA-BNC adaptor • 015-1018-00

2) SMA Cables • 174-1428-00

Table 3.

Intra-P

The Sink device also must tolerate a certain amount of

intra-pair skew, that is, timing skew (misalignment)

within respective differential TMDS pairs. The CTS

standar

skew tolerance.

The test starts by setting the clock and data pairs to

zero skew and then increasing the intra-pair skew in

steps of 0.1 x T

Equipment for sink jitter tolerance tests.

air Ske

w

d defines a limit of 0.4 x T

until the Sink device displays an

BIT

for intra-pair

BIT

. The maximum skew setting that still pr

or

r

er

ovides

error-free Sink operation is defined as the intra-pair

skew; this r

esult is compar

limit. If the skew tolerance is greater than 0.4 x T

ed against the published

BIT

the device is considered compliant with the standard.

The DTG5000 Series uses its unique differential timing

fset capability in conjunction with 2 channels of a

of

differential DTGM30 module to fulfill this specific

test requirement.

,

1

There are two recommended solutions for the Jitter Tolerance test; one for characterization and one for compliance. Using the AWG710B as the jitter generator allows for jitter profiles beyond compliance standards, which is

te for characterizia

ppropria

a

6

6

www.tektronix.com/signal_sources

Using the DTGM32 as the jitter genera

tion work.

tor will enable testing up to the compliance specifica

tions.

Page 7

DMI Compliance & Sink Characterization Using DTG5000 Series Data Timing Generator

H

Application Note

Hardware Requirements: Test Equipment and

Peripherals For Sink Tests

Table 3 summarizes the measurement equipment and

accessories (probes, cables, etc.) required for the

sink tests just described. The list includes many

products recommended in the current version of the

HDMI compliance test specifications. Note that the

requirements for characterization and compliance

testing dif

of tools contingent on the task at hand

fer somewhat, necessitating a selection

1

.

In addition to the items in Table 3, instruments such

as digital multimeters, protocol analyzers and LCR

meters are required for certain HDMI compliance tests

beyond the scope of this document.

The high bandwidths, differential signaling, and

complex stimulus requirements of the HDMI architecture place rigorous demands on the instrumentation

used in compliance and characterization testing. The

following headings summarize some essential points

to consider when choosing test equipment for HDMI

test applications.

Digital Storage Oscilloscope/Digital

Phosphor Oscilloscope

HDMI jitter tolerance tests r

e a minimum r

equir

ecord

length of 16 megapoints (16M) in the oscilloscope.

In addition, the instrument must offer a means for

recovering the embedded clock (the HDMI specification

escribes softwar

pr

e-based clock r

ecover

y) for eye

diagram measurements. The Tektronix TDS family

of digital storage oscilloscopes (DSO) and digital

phosphor oscilloscopes (DPO) can be equipped with

integrated TDSHT3 application software for automated

HDMI clock recovery, eye diagram measurements,

and more. The TDS7404B, with its four input channels,

4 GHz bandwidth, and 20 megasample-per-second

sample rate, is a good match for HDMI measurements.

Data Timing Generator

The stimulus source (generator) that provides the

TMDS signal plays a pivotal role in HDMI Sink tests.

The key challenge for a TMDS signal generator is

to provide the needed range of highly accurate

signals, and to provide precise control of the signal

parameters. For example, differential sensitivity tests

require an amplitude resolution of 20 mV. Intra-pair

skew tests require precise delay settings with

sub-picosecond resolution.

Historically, TMDS data signals have been generated

by aggregations of custom devices designed for

narrow output ranges and/or test conditions.

The Tektronix DTG5000 Series Data Timing Generator

offers a complete stimulus solution for HDMI sink

testing. The DTG5000 Series combines the power

of a data generator with the capabilities of a pulse

generator to provide a wide range and variety of

accurate test signals on multiple output channels

simultaneously. The user operates a set of simple

graphic controls to set the signal parameters

and variables.

Every DTG5000 Series instrument is configured from a

mainframe and plug-in output modules to provide the

desired number and type of signals. Channels may be

ential, depending on the test

single-ended or dif

fer

requirement. Output terminals of the plug-in channel

modules are SMA connectors that can easily be

converted to HDMI connectors using optional TPA test

adapter accessories.

The DTG5274 Data Timing Generator with its maximum

sample rate of 2.7 Gb/s or the DTG5334 with its

sample rate of 3.35 Gb/s maximum rate ar

e the

mainframes of choice for HDMI applications. Both

can support the maximum resolution of a UXGA

device with the required data rate of 1.62 Gb/s; both

fer contr

of

ollable voltage levels that suppor

t all TMDS,

timing, and jitter parameters.

www.tektronix.com/signal_sources

7

Page 8

DMI Compliance & Sink Characterization Using DTG5000 Series Data Timing Generator

H

Application Note

Figure 5.

Sink jitter tolerance test setup using an AWG as the jitter source.

Jitter tolerance tests require a variable amount of jitter

to be imposed on signals being sent to the device

under test. The DTG5000 Series instruments are fully

compatible with either of two recommended jitter

solutions. One solution pairs the DTG5000 Series with

an arbitrary waveform generator for either compliance

or characterization work; the other, lower-cost solution

involves a jitter generator module plugged into the

DTG5000 Series mainframe and driven by an external

function generator. Both approaches provide the

necessar

y modulated jitter pr

ofiles for the generated

clock signal as follows:

orm Generator (AWG) Method:

vef

–

Arbitrar

a

W

y

This solution taps the full power of the DSO and

its TDSHT3 application softwar

Series instr

The TDSHT3 softwar

ument, and the AWG.

e generates the specific jitter

e, the DTG5000

modulation waveform and sends it to the AWG710B,

which in turn acts as the clock source for the jitter

tolerance test. The jitter is steadily increased by the

softwar

e until the device fails. The data lines ar

e

then verified by the oscilloscope for compliance.

WG has two digital “Marker” outputs that can

The A

be used for synchronization, among other purposes.

In HDMI sink testing, one marker connects to the

DTG5000 Series exter

nal clock input while the second

marker connects to the DTG5000 Series trigger

input, both providing synchronization. Data signals

for the device under test are sourced by the

DTG5000 Series. Bias Tees are required to bring the

AWG710B out put's clock signals up to the required

TMDS levels. Conveniently

, these Bias T

ees can be

powered by the built-in DC output on the DTG5000

Series. The A

WG method is able to str

ess the

device beyond the compliance specification levels,

making it suitable for characterization work. Figure 5

illustrates the layout of a test configuration using the

WG method.

A

8

8

www.tektronix.com/signal_sources

Page 9

DMI Compliance & Sink Characterization Using DTG5000 Series Data Timing Generator

H

Application Note

Figure 6.

Figure 7.

DTGM32 module.

DTGM32 Jitter Generation Module.

Sink jitter tolerance test setup using a function generator to the jitter modulation source for the

Figure 8.

Spectral display of jitter at 1 MHz and 7 MHz.

– DTGM32 and Function Generator Method: This

oach is ideal for quick verification and cost-

appr

effective pre-compliance testing. The method uses

a DTGM32 module (Figure 6) plugged into the

DTG5000 Series mainframe, in conjunction with a 2

channel function generator to add the required jitter

content. Figur

e 7 depicts this scheme. The DTGM32

module allows jitter components to be added to its

output. The jitter amplitude is contr

olled by the

input amplitude of the jitter source, in this case a

Tektronix AFG3102. An input level of 1 volt produces

e 8 illustrates a

up to 2 ns peak-to-peak jitter

. Figur

jitter spectrum produced using this method with

1 MHz and 7 MHz added.

www.tektronix.com/signal_sources

9

Page 10

DMI Compliance & Sink Characterization Using DTG5000 Series Data Timing Generator

H

Application Note

Test Adapters

The approach using the DTGM32 and the AFG allows

for thorough compliance and pre compliance testing

with a much simpler setup than the AWG method.

This method was designed for pre/compliance testing

only since the maximum available jitter just meets

specification requirement. If testing is required above

the specification (as in characterization), then the

AWG method would be the recommended solution.

Reliable connections are key to maintaining precision

and signal integrity for all HDMI tests. There are two

igure 9.

TPA-P-TDR (013-A013-50) adapter.

F

types of test adapter sets available. For most of the

Sink tests devices, the plug-type adapters (TPA-P) set

eceptacle-type adapters (TPA-R) set are well

and r

suited for making the primary connection to the

Device-under-test (DUT). Figure 9 shows a TPA-P

plug-type test adapter.

DTG5000 Series Files Used in HDMI Compliance Test by TDSHT3

Test Pix Clock 861B ID Filename Type Image Description

Sink Minimum 25.2 MHz 480 p@60 Hz 640x480 p 60 Hz.dtg

8-5 Diff. Sensitivity

27.027 MHz

27.027 MHz 480 p@60 Hz 720x480 p 60 Hz.dtg US

27.0 MHz

27.0 MHz 576 p@50 Hz 720x576 p 50 Hz.dtg EU Normal

74.25 MHz 1080 i@60 Hz 1920x1080 i 60 Hz.dtg US

74.25 MHz 720 p@50 Hz 1280x720 p 50 Hz.dtg EU

148.5 MHz 1080 p@60 Hz 1920x1080 p 60 Hz.dtg

Sink Intra-Pair Skew 25.2 MHz 480 p@60 Hz 640x480 p 60 Hz IP.dtg

8-6

27.027 MHz

27.027 MHz 480 p@60 Hz 720x480 p 60 Hz IP.dtg US

27.0 MHz

27.0 MHz 576 p@50 Hz 720x576 p 50 Hz IP.dtg EU Diff. Timing Offset

74.25 MHz

74.25 MHz 1080 i@60 Hz 1920x1080 i 60 Hz IP.dtg US

74.25 MHz

74.25 MHz 720 p@50 Hz 1280x720 p 50 Hz IP.dtg EU

148.5 MHz

148.5 MHz 1080 p@60 Hz 1920x1080 p 60 Hz IP.dtg Gray RGB

olerance 25.2 MHz 480 p@60 Hz 640x480 p 60 Hz.dtg

T

Sink

8-7

Cable

5-3 Eye Diagram

Jitter

Cable Da

27.027 MHz

27.027 MHz 480 p@60 Hz 720x480 p 60 Hz.dtg US

27.0 MHz

27.0 MHz 576 p@50 Hz 720x576 p 50 Hz.dtg EU

74.25 MHz

74.25 MHz 1080 i@60 Hz 1920x1080 i 60 Hz.dtg US Normal

74.25 MHz

74.25 MHz 720 p@50 Hz 1280x720 p 50 Hz.dtg EU

148.5 MHz

148.5 MHz 1080 p@60 Hz 1920x1080 p 60 Hz.dtg

ta 27.027 MHz 480 p@60 Hz 720x480 p 60 Hz CT.dtg US

27.027 MHz

27.0 MHz

27.0 MHz

74.25 MHz

74.25 MHz

74.25 MHz

74.25 MHz

148.5 MHz

148.5 MHz 1080 p@60 Hz 1920x1080 p 60 Hz CT.dtg

576 p@50 Hz

1080 i@60 Hz

720 p@50 Hz

Most Likely Test Condition

Optional

The Maximum Is 27MHz

Only If

720x576 p 50 Hz CT

1920x1080 i 60 Hz CT

1280x720 p 50 Hz CT.dtg EU

.dtg

.dtg

EU

US

VH=3.3

VL=2.9

V

V

Table 4.

10

10

www.tektronix.com/signal_sources

DTG5000 Series files used by TDSHT3 in HDMI compliance tests.

Page 11

DMI Compliance & Sink Characterization Using DTG5000 Series Data Timing Generator

H

Application Note

Software Tools For Sink Tests

Sink tests, like Source tests, can take a lot of time. In

case of Sink tests, there is the complexity of controlling

several tools to conclude a measurement, as well as

the challenge of precisely setting jitter parameters.

All this makes automation an implicit requirement.

The TDSHT3 application package described earlier

is optimized to speed HDMI testing and compliance

work. TDSHT3 makes uses the GPIB interface to

remotely control various parameters. The oscilloscope

connects to the DTG5000 Series using a GPIB cable

and to the AWG or arbitrary function generator using

a GPIB-USB-B cable or E-Net to GPIB converter

(available from National Instruments).

F

igure 10.

HDMI eye diagram captured with TDSHT3 application software.

Many HDMI test setups and measurements reside

within the TDSHT3 application; others can be downloaded at www.tek.com. Table 4 lists the standard

setups, and the CTS tests to which they apply.

Testing HDMI Cables

HDMI cables can be characterized in either or both of

two ways: time-domain reflectometry (TDR) and eye

diagram testing. The TDR technique uses a digital

sampling oscilloscope to measur

characteristics of a cable with gr

e the impedance

ecision, but

eat pr

cannot verify waveform quality.

Eye diagram testing involves displaying a waveform

that consists of rising and falling edges superimposed

in such a way that there is an “eye” opening bounded

on all sides by positive-going and negative-going

transitions. T

ypically there is a region within this

opening that must not be violated by any waveform

data point. To do so would indicate insufficient

signal amplitude, slow rise or fall times, jitter

, or a

cable and eye mask testing performed with the

TDSHT3 package at the end. If jitter violates the

eye mask, the cable has insufficient bandwidth. If

the signals have insufficient level, the cable loss is

too high. Figure 10 is an eye diagram captured by

the TDSHT3 application software package.

Conclusion

Compliance testing of HDMI Sink devices is no longer

limited to the use of custom data sour

ces and tedious

manual methods. The DTG5000 Series high performance data generators solve the problem by providing

a full complement of highly accurate data signals with

precise control over the signal parameters. Testing to

DVI/HDMI standards receiver products over a wide

range of operating conditions can now be automated

using simple, graphical controls and a set of industrystandar

d adapter accessories.

combination of these aberrations.

The DTG5000 Series can produce standard HDMI

signals for use as test data in eye diagram mask

testing to reveal the true waveform performance of

References

1. HDMI Specifications Version 1.0

2. Compliance Test Specifications (CTS) Version 1.0a

the cable. First, transmitter performance can be

verified by inserting the test data signals ahead of the

ming the eye mask test at the

transmitter and per

for

transmitter output. Once this is confirmed, the test

data signals can be inser

ted at the beginning of the

3. Physical Layer Compliance Testing for HDMI

Using TDSHT3 HDMI Compliance T

est Softwar

(Tektronix Application Note 61W-17974-1)

e

www.tektronix.com/signal_sources

11

Page 12

C

SEAN / Australasia / Pakistan (65) 6356 3900

A

alkan, Israel, South Africa and other ISE Countries+41 52 675 3777

B

razil & South America55 (11) 3741-8360

B

entral East Europe, Ukraine and Baltics+41 52 675 3777

C

entral Europe & Greece+41 52 675 3777

C

rance & North Africa+33 (0) 1 69 86 81 81

F

ontact Tektronix:

ustria +41 52 675 3777

A

elgium07 81 60166

B

anada1(800) 661-5625

C

enmark+45 80 88 1401

D

inland+41 52 675 3777

F

Germany +49 (221) 94 77 400

Hong Kong (852) 2585-6688

India (91) 80-22275577

Italy +39 (02) 25086 1

Japan 81 (3) 6714-3010

uxembourg+44 (0) 1344 392400

exico, Central America & Caribbean52 (55) 56666-333

M

L

Middle East, Asia and North Africa +41 52 675 3777

he Netherlands090 02 021797

T

eople’s Republic of China86 (10) 6235 1230

P

epublic of Korea82 (2) 528-5299

R

R

outh Africa+27 11 254 8360

S

orway800 16098

N

oland+41 52 675 3777

P

ortugal80 08 12370

P

ussia & CIS7095 775 1064

pain (+34) 901 988 054

S

Sweden 020 08 80371

Switzerland +41 52 675 3777

Taiwan 886 (2) 2722-9622

United Kingdom & Eire +44 (0) 1344 392400

USA 1 (800) 426-2200

For other areas contact Tektronix, I

nc. at: 1 (503) 627-7111

Last Updated June 15 2005

For Further Information

Tektronix maintains a comprehensive, constantly expanding collection

of application notes, technical briefs and other resources to help engineers

working on the cutting edge of technology

Copyright © 2005, Tektronix. All rights reserved. Tektronix products are covered by U.S. and foreign

patents, issued and pending. Infor

published material. Specification and price change privileges reserved. TEKTRONIX and TEK are

registered trademarks of Tektronix, Inc. All other trade names referenced are the service marks,

trademarks or r

10/05 FLG/WOW 86W-16884-2

ed trademarks of their r

egister

mation in this publication supersedes that in all previously

. Please visit

espective companies.

www

.tektr

onix.com

Loading...

Loading...