Page 1

DSA8300

xx

ZZZ

Digital Serial Analyzer and Modules

Service Manual

*P077057200*

077-0572-00

Page 2

Page 3

xx

DSA8300

ZZZ

Digital Serial Analyzer and Modules

Service Manual

www.tektronix.com

077-0572-00

Page 4

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O. B o x 5 0 0

Beaverto

USA

For product information, sales, service, and technical support:

n, OR 97077

In North America, call 1-800-833-9200.

Worl dwid e, visi t www.tektronix.com to find contacts in your area.

Page 5

Warranty

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1)

year from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its

option, either will repair the defective product without charge for parts and labor, or will provide a replacement

in exchange for the defective product. Parts, modules and replacement products used by Tektronix for warranty

work may be n

the property of Tektronix.

ew or reconditioned to like new performance. All replaced parts, modules and products become

In order to o

the warranty period and make suitable arrangements for the performance of service. Customer shall be responsible

for packaging and shipping the defective product to the service center designated by Tektronix, with shipping

charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a location within

the country in which the Tektronix service center is located. Customer shall be responsible for paying all shipping

charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

result

b) to repair damage resulting from improper use or connection t o incompatible equipment; c) to repair any damage

or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been modified or

integrated with other products when the effect of such modification or integration increases the time or difficulty

of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TRONIX' RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE

TEK

AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

[W2 – 15AUG04]

btain service under this warranty, Customer must notify Tektronix of the defect before the expiration of

ing from attempts by personnel other than Tektronix representatives to install, repair or service the product;

Page 6

Page 7

Table of Contents

General Safety Summary ......................................................................................... vi

Service Safety Summary.............. .................................. ................................ ......... viii

Preface .............................................................................................................. ix

Related Documentation ....................................................................................... x

Operating Information

Operating Information ........................................................................................... 1-1

Windows Safe Mode ........... .................................. ................................ ........... 1-1

Where to Find User Information ........................................................................... 1-1

Theory of Operation

Theory of Operation............................... ................................ ............................... 2-1

Mainframe Overview........................................................................................ 2-2

Electrical Sampling Modules .............................. ................................ ................. 2-4

Optical Sampling Modules ...... ................................ .................................. ......... 2-6

80A01 Trigger Prescale Preamplifier Module .......................................................... 2-13

80A02 EOS/ESD Protection Module.................................................................... 2-14

80A05 Electrical Clock Recovery Module.............................................................. 2-14

82A04 Phase Reference Module......................................................................... 2-15

Adjustment Procedures

Adjustment Procedures .......................................................................................... 3-1

Required Equipment.............................. ................................ ........................... 3-1

Equipment Hookup............. ................................ ................................ ............. 3-2

Main Instrument Adjustments ........................... .................................. ................. 3-2

DC Calibrator Adjust ................................................................................... 3-2

DC Calibrator Adjust Verification..................................................................... 3-3

Internal 10 MHz Adjust ................... .................................. ........................... 3-4

Maintenance

Maintenance....................................................................................................... 4-1

Preventing ESD .............................................................................................. 4-1

Inspection and Cleaning........................ ................................ ............................. 4-1

Removal and Installation ............... ................................ .................................. ....... 4-5

Required Equipment.............................. ................................ ........................... 4-5

External Assemblies......................................................................................... 4-6

Line Fuses and AC Power Cord....................................................................... 4-7

DSA8300 Digital Serial Analyzer and Modules Service Manual i

Page 8

Table of Contents

Front-Panel Kn

Trim and Carrying Handle ............................................................................. 4-9

Bottom Cover............................... ................................ ........................... 4-10

Left and Right Covers ................................................................................ 4-10

Internal Assemblies................... ................................ .................................. ... 4-11

Front-Panel Assembly................. ................................ ............................... 4-12

Front Panel Board..................................................................................... 4-13

Front Panel Keypad............................................ ................................ ....... 4-14

Display Assembly.................................. ................................ ................... 4-14

Display Adapter Board ............................................................................... 4-16

Standby/On Switch Flex Circuit .................................................................... 4-18

USB Assembly........................................................................................ 4-19

Hard Disk Drive....................................................................................... 4-20

CD-RW/DVD Drive Assembly...................................................................... 4-22

CD-RW/DVD and Hard Disk Drive Mounting Frame............................................ 4-24

ATX Assembly ........................................................................................ 4-25

Power PC Board............................ ................................ ........................... 4-28

Power Side Board ........................ ................................ ............................. 4-30

Bridge Board ................. ................................ .................................. ....... 4-30

Fan Assembly ......................................................................................... 4-31

Low-Voltage Power Supply....................... .................................. ................. 4-33

Module Slot Doors................................... ................................ ................. 4-40

Electrical Sampling Modules .............................. ................................ ............... 4-45

Optical Sampling Modules ...... ................................ .................................. ....... 4-48

80A00 and 82A00 Series Modules ............... ................................ ....................... 4-48

Troubleshooting................................................................................................. 4-50

Required Equipment....................................................................................... 4-50

Check for Common Problems............................................................................ 4-50

Isolating Failures to the 80E0X/80C0X Modules or the Mainframe................ ................. 4-53

Isolating to a Board If Power Will Not Come Up................... .................................. . 4-54

Checking the Power Supply Voltages ................................................................... 4-55

PPC and ATX PC Diagnostics................. .................................. ......................... 4-56

BIOS Beep Codes................................. .................................. ....................... 4-57

Firmware Updates ......................................................................................... 4-58

After Repair ................... ................................ ................................ ............. 4-58

Installing the Instrument Model and Serial Number .... . ..... . ..... ..... . ..... . ..... . .... . ..... . ..... . 4-59

Repackaging Instructions ...................................................................................... 4-60

obs..... ................................ ................................ ................. 4-8

Replaceable Parts L ist

Replaceable Parts List............................................................................................ 5-1

ii DSA8300 Digital Serial Analyzer and Modules Service Manual

Page 9

List of Figures

Figure 2-1: DSA8300 block diagram .......................................................................... 2-2

Figure 4-1: External assemblies ............. ................................ .................................. . 4-6

Figure 4-2: Knob removal........ ................................ .................................. ............. 4-8

Figure 4-3: Internal assemblies ............................................................................... 4-11

Figure 4-4: J1 flex cable connector removal ................................................................ 4-13

Figure 4-5: Display assembly removal........................ ................................ ............... 4-16

Figure 4-6: Display adaptor board removal ................................................................. 4-17

Figure 4-7: Display adaptor board replacement............................ ................................ . 4-18

Figure 4-8: USB assembly removal .......................................................................... 4-19

Figure 4-9: Hard disk drive removal ......................................................................... 4-21

Figure 4-10: CD-RW/DVD assembly removal............... ................................ ............... 4-22

Figure 4-11: CD-RW/DVD drive removal................................................................... 4-23

Figure 4-12: Hard drive and CD-RW/DVD drive mounting frame removal............................. 4-25

Figure 4-13: ATX assembly removal.................................... ................................ ..... 4-27

Figure 4-14: Power PC board removal....................................................................... 4-29

Figure 4-15: Fan assembly removal ................... ................................ ....................... 4-32

Figure 4-16: Acquisition System ............................................................................. 4-35

Figure 4-17: T-10 screws and threaded posts....................... .................................. ....... 4-36

Figure 4-18: Module slot door removal......................................... ............................. 4-41

Figure 4-19: Module ejector handles removal .............................................................. 4-43

Figure 4-20: Spring arm position ..... . ..... . ..... . ..... . ..... . ... . . . .... . . .... . ..... . ..... . ..... . ..... . ..... . 4-44

Figure 4-21: Sample of electrical module hardware removal ............................................. 4-46

Figure 4-22: 80A00 and 82A00 series parts removal (80A01 shown) ................................... 4-49

Figure 4-23: Location of debug pins ...... ................................ .................................. . 4-54

Figure 5-1: External parts ............ ................................ .................................. ......... 5-5

Figure 5-2: Drives... ................................ ................................ ............................. 5-7

Figure 5-3: Front panel and processors ........................................................................ 5-9

Figure 5-4: ATX assembly ......... ................................ ................................ ........... 5-11

Figure 5-5: Power supply...................................................................................... 5-13

Figure 5-6: Acquisition system ... . . . .... . ..... . ..... . ..... . ..... . ..... ..... . ..... . ..... . ..... . ..... . ... . . . ... 5-15

Figure 5-7: Time base delay cables........................................................................... 5-16

Figure 5-8: Electrical front end cables....................................................................... 5-17

Figure 5-9: Optical front end cables............................. .................................. ........... 5-18

Figure 5-10: 80E01, 80E02, 80E03, and 80E04 modules................................... ............... 5-20

Figure 5-11: 80E05 module (Option 10G shown) .......................................................... 5-21

Figure 5-12: 80E06 module ................ .................................. ................................ . 5-22

Figure 5-13: 80E07, 80E08, 80E09, and 80E10 modules................................... ............... 5-23

Figure 5-14: Optical modules................................................................................. 5-24

Figure 5-15: 80A01 module................................................................................... 5-25

DSA8300 Digital Serial Analyzer and Modules Service Manual iii

Page 10

Table of Contents

Figure 5-16: 82

Figure 5-17: 80A06 module................................................................................... 5-28

A04 module................................................................................... 5-26

iv DSA8300 Digital Serial Analyzer and Modules Service Manual

Page 11

List of Tables

Table 4-1: Required equipment for Removal and Replacement............................................. 4-5

Table 4 -2: P

Table 4-3: BIOS beep codes................................................................................... 4-57

Table 4-4: Action required for assembly replaced ............................... ........................... 4-58

Table 5-1: Mainframe cable connections ...................................................................... 5-3

Table 5-2: External replaceable parts ......... ................................ ................................. 5-4

Table 5-3: Drives replaceable parts...................... ................................ ....................... 5-6

Table 5 -4

Table 5-5: ATX assembly replaceable parts list............................................................. 5-10

Table 5-6: Power supply replaceable parts list ....................... .................................. ..... 5-12

Table 5-7: Acquisition system replaceable parts list..... . ..... . ... . . ..... . ..... . .... . ..... . ..... . ... . . ..... 5-14

Table 5-8: Time Base delay cables replaceable parts list ................... ............................... 5-16

Table 5-9: Electrical Front End cables replaceable parts list ......... ................................ ..... 5-17

Table

Table 5-11: 80E01, 80E02, 80E03, and 80E04 modules replaceable parts list ................... ....... 5-19

Table 5-12: 80E05 module replaceable parts list ........................................................... 5-21

Table 5-13: 80E06 module replaceable parts list ........................................................... 5-22

Table 5-14: 80E07, 80E08, 80E09, and 80E10 modules replaceable parts list .......................... 5-23

Table 5-15: Optical modules replaceable parts list ......................................................... 5-24

ble 5-16: 80A01 module replaceable parts list ........................................................... 5-25

Ta

Table 5-17: 80A04 module replaceable parts list ........................................................... 5-26

Table 5-18: 80A06 module parts list ......................................................................... 5-27

ossible causes of instrument failure............................................................ 4-50

: Front panel and processors replaceable parts list................................................. 5-8

5-10: Optical Front End cables replaceable parts list ............................................... 5-18

Table of Contents

DSA8300 Digital Serial Analyzer and Modules Service Manual v

Page 12

General Safety Summary

General Safet

To Avoid Fire or Personal

Injury

ySummary

Review the fo

this product or any products connected to it.

To avoid pot

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of a larger system.

Read the safety sections of the other component manuals for warnings and

cautions r

Use proper power cord. Use only the power cord specified for this product and

certified for the country of use.

Connect and disconnect properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

llowing safety precautions to avoid injury and prevent damage to

ential hazards, use this product only as specified.

elated to operating the system.

Observe all terminal ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

The inputs are not rated for connection to mains or Category II, III, or IV circuits.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating o f that terminal.

Power disconnect. The power switch disconnects the product from the power

source. See instructions for the location. Do not block the power switch; it must

remain accessible to the user at all times.

Do not operate without covers. Do not operate this product with covers or panels

removed.

Do not operate with suspected failures. If you suspect that there is damage to this

product, have it inspected by qualified service personnel.

Avoid exposed circuitry. Do not touch exposed connections and components when

power is present.

Use proper fuse. Use only the fuse type and rating specified for this product.

Wear eye protection. Wear eye protection if exposure to high-intensity rays or

laser radiation exists.

vi DSA8300 Digital Serial Analyzer and Modules Service Manual

Page 13

General Safety Summary

TermsinThisManual

Symbols and Terms on the

Product

Do not operate i

Do not operate in an explosive atmosphere.

Keep product surfaces clean and dry.

Provide prop

on installing the product so it has proper ventilation.

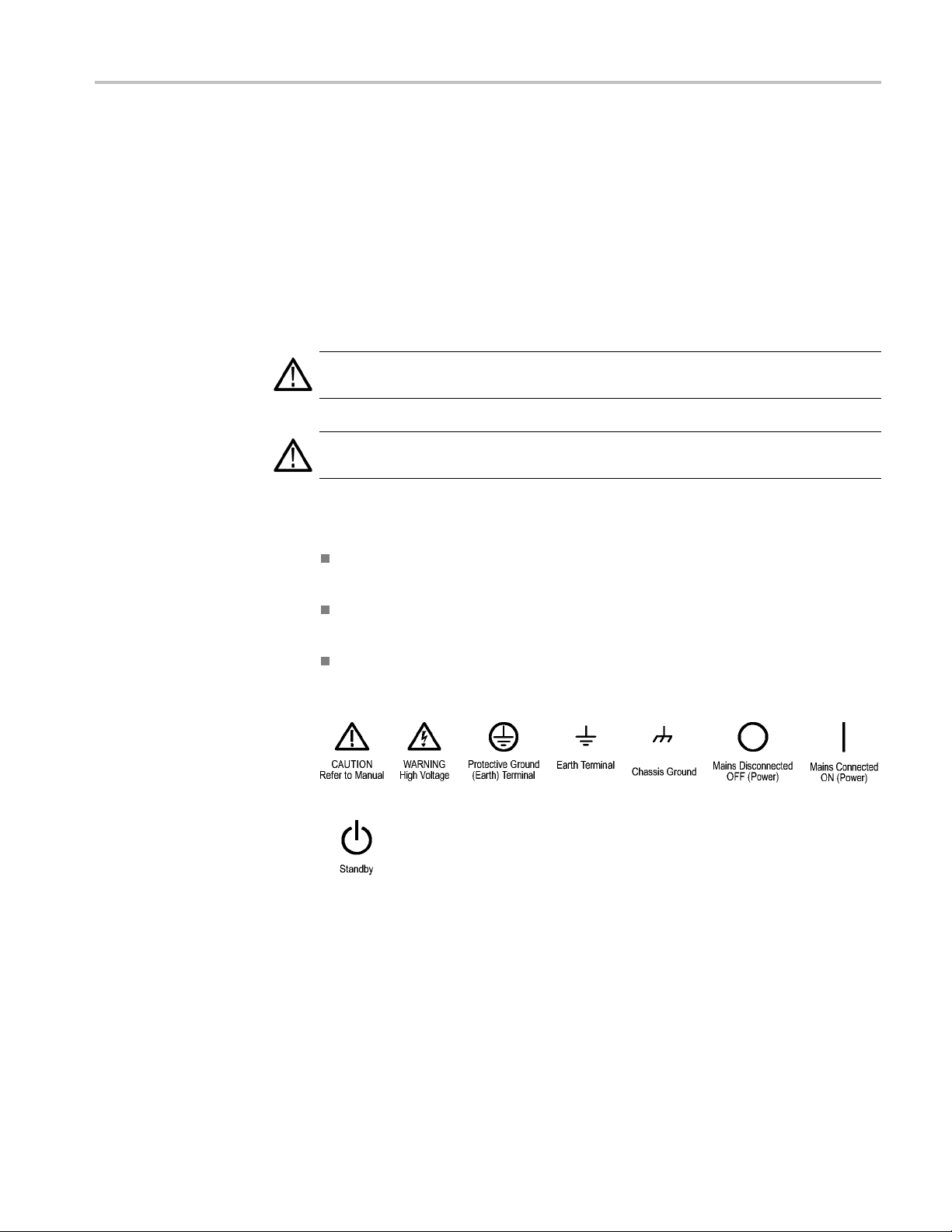

These terms may appear in this manual:

WAR NI NG .

in injury or loss of life.

CAUTION

damage to this product or other property.

These t

erms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read

the ma

n wet/damp conditions.

er ventilation. Refer to the manual's installation instructions for details

Warning statements identify conditions or practices that could result

. Caution statements identify conditions or practices that could result in

rking.

WARNING indicates an injury hazard not immediately accessible as you

the marking.

read

CAUTION indicates a hazard to property including the product.

The following symbol(s) may appear on the product:

DSA8300 Digital Serial Analyzer and Modules Service Manual vii

Page 14

Service Safety Summary

Service Safet

y Summary

Only qualifie

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

d personnel should perform service procedures. Read this Service

this product. Disconnect power, remove battery (if applicable), and

viii DSA8300 Digital Serial Analyzer and Modules Se rvice Manual

Page 15

Preface

This is the service manual for the DSA8300 Digital Serial Analyzer and the

modules that install in the instrument (except for the 80A03 module).

Manual Structure

Manua

l Conventions

NOTE. The 80

servicing information.

Read this p

andwhereyoucanfind other information related to servicing this product. Read

the Introduction following this preface for safety and other important background

information needed before servicing this product.

This manual is divided into sections, whic h are made up of related subordinate

topics. These topics can be cross referenced as sections.

Be sure to read the introductions to all procedures. These introductions provide

important information needed to do the service correctly, safely, and efficiently.

This manual uses certain conventions that you should become familiar with

before beginning service.

A03 instruction manual contains its own specifications and

reface to learn how this manual is structured, what conventions it uses,

emblies and Modules

Ass

Replaceable Parts

Safety

DSA8300 Digital Serial Analyzer and Modules Service Manual ix

Throughout this manual, the term assembly appears. An assembly is composed

of electrical and mechanical assemblies, circuit c ards, interconnecting cables,

and a user-accessible front panel. References to an assembly are different

an references to a module such as “Sampling modules,” “Phase Reference

th

modules,” or “Accessory modules,” which are products installed in the instrument

compartments.

This manual refers to any field-replaceable assembly or mechanical part by its

name or generically as a replaceable part. In general, a replaceable part is any

circuit board or assembly, such as a hard disk drive, or a mechanical part, such as

I/O port connectors, that is listed in the replaceable parts list.

Symbols and terms related to safety appear in the General Safety Summary and

the Service Safety Summary found at the beginning of this manual.

Page 16

Preface

Related Documentation

The following documents relate to the instruments this service manual supports:

DSA8300 Quick Start User manual. Tektronix part number 071-2897-XX.

This document also contains specification changes when using the 82A04

Phase Reference module.

DSA8300 Specifi cations and Performance Verification manual. Tektronix

part number 077-0571-XX.

DSA8300 Online Help. An online document accessed from the instrument

Help menu.

DSA8300 Programmer Guide. An online document accessed from the

instrument Help menu.

80E01, 80E02, 80E03, 80E04, and 80E06 Electrical Sampling Modules User

manual. Tektronix part number 071-0434-XX.

80E07, 80E08, 80E09, and 80E10 Electrical Sampling Remote Modules User

manual. Tektronix part number 071-2038-XX.

80C00 Series Optical Sampling Modules User manual. Tektronix part number

071-0435-XX.

80A01 Trigger Prescale Limiting Preamplifier Module User manual.

Tektronix part number 071-0873-XX.

80A02 EOS/ESD Protection Module Instructions. Tektronix part number

071-1317-XX.

80A03 TekConnect Probe Interface Module Instructions. Tektronix part

number 071-1298-XX.

80A05 Electrical Clock Recove ry Module User manual. Tektronix part

number 071-1467-XX.

82A04 Phase Reference Module User manual. Tektronix part number

077-0345-XX.

Rackmount Kit Instructions. Te ktronix part number 071-0696-XX.

TDR Z-Meas Application Online Help. Ships with this product on a separate

disc. Provides information about this TDR Impedance Measuring application

that implements the TDR calibration procedures specified by the IPC TM-650

test method.

Fast NRZ Application Online Help. Ships with this product on a separate

disc. Provides information about this application that improves throughput

for optical eye-pattern mask testing.

x DSA8300 Digital Serial Analyzer and Modules Service Manual

Page 17

Operating Information

Page 18

Page 19

Operating Information

CAUTION. Keep the bottom of the instrument clear of obstructions to allow proper

cooling.

Windows Safe Mode

If the instrument is turned off before the operating system boots, or if you’ve

installed a third-party product with a driver that is not compatible with the

instrument start-up, Windows will open in Safe mode. The touch screen will not

operate; you must install the standard-accessory keyboard and mouse. Information

about ins

Tektronix part number 071-2897-00.

talling these accessories is in the DSA8300 Quick Start User Manual,

When you

have removed any barrier to Windows start-up, you can reboot. If

the instrument no longer boots to Safe mode, you can remove the keyboard and

mouse if desired.

WheretoFindUserInformation

CAUTION. Be sure to read all safety information, warnings, and cautions in the

manuals that relate to the information you use there.

user

Some topics of interest when servicing the product are listed in the following

le. The manuals are available at www.tektronix.com/manuals.

tab

Location of user topics

Manual Topic

DSA8300 Quick Start User Manual, Tektronix

part number 071-2897-00

Your sample-module user manual. (Module

manual part numbers are provided in the

preface o f this manual.)

Environmental requirements (site

considerations, operating requirements,

ckmount requirements)

ra

aximum configuration

M

onnecting peripherals such as monitor,

C

printer, keyboard, and mouse

Powering the instrument on and off

System hard drive rebuild

Diagram of rear-panel connectors

Installing sampling modules

Installing probes and other accessories to

the sampling modules

DSA8300 Digital Serial Analyzer and Modules Service Manual 1–1

Page 20

Operating Information

Location of user topics

Manual Topic

DSA8300 Speci

Verification manual, Tektronix part number

077-0571-00

Product software install instructions,

Tektronix p

with the product software disc.

fications and Performance

art number 071-2050-02. Shipped

System diagno

System hard drive rebuild procedure

Software r elease notes

Software installation

Operating system reinstallation

stics procedure

1–2 DSA8300 Digital Serial Analyzer and Modules Service Manual

Page 21

Theory of Operation

Page 22

Page 23

Theory of Operation

This chapter describes the electrical operation of the instrument and sampling

modules.

The instrument contains many digital logic circuits. This manual refers to these

circuits with standard logic s ymbols and terms. Unless otherwise stated, all logic

functions a

the two logic levels is the high (1) state, and the more negative level is the low (0)

state. Signal states may also be described as "true", meaning their active state,

or "false", meaning their nonactive state. The specific voltages that constitute a

high or low state vary among the electronic devices.

The instrument control system is a dual Wintel/PowerPC based processor board.

The platform features XGA resolution flat-panel display, transparent touch screen

and user front-panel with direct access to commonly used oscilloscope functions.

The inst

advanced functions.

re described using the positive-logic convention: the more positive of

rument is also equipped with a mous e and keyboard for access to more

DSA8300 Digital Serial Analyzer and Modules Service Manual 2–1

Page 24

Theory of Operation

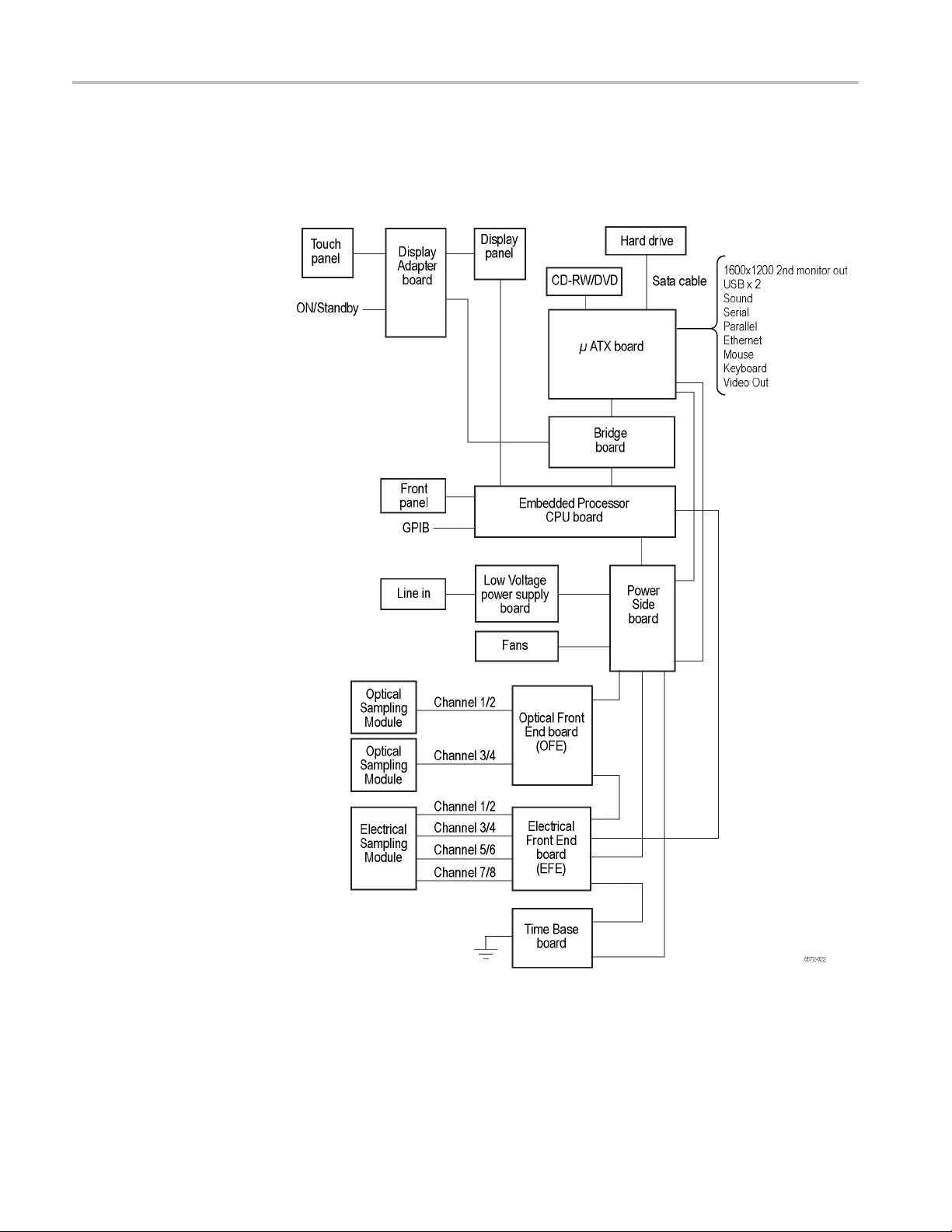

Mainframe Ove

rview

This mainframe overview describes the basic operation o f each functional circuit

block as shown in the following figure:

Figure 2-1: DSA8300 block diagram

2–2 DSA8300 Digital Serial Analyzer and Modules Service Manual

Page 25

Theory of Operation

Input Signal Path

Asignalenters

connector on a sampling module, or a real time probe connected to the sampling

module channel.

Acquisition system. The acquisition system conditions the input signals, samples

them, converts them to digital signals, and controls the acquisition process under

direction of the processor system.

The acquisition system includes the multi-source trigger, acquisition time base,

and acquisition mode generation and control circuitry. The acquisition boards

are located in the bottom compartment of the instrument and can accommodate

four small slot sampling plug-ins, two large slot plug-ins and a trigger/holdoff

subsystem. Up to eight vertical channels are accommodated simultaneously.

Channels 1, 2, 3, and 4 can be either large or small slots. The presence of an

assembly in one or both large slots displaces the small slot functionality in

the corresponding small slots. The external trigger and all small slot channels

feature a Tekprobe Level 2 probe power connector for a dditional front end signal

conditioning functions like high input-impedance real-time probes, if equipped on

the sampling module.

Processor system. The processor system contains a dual Wintel/PowerPC

The basic instrument configuration supports up to eight channels labeled Ch 1

through Ch 8, provides two external trigger inputs for direct and prescaled/clock

triggering through built-in prescaler and is able to support four optional internal

trigger sources associated with the large slot channels.

the instrument through a direct coaxial connection to the input

Display Panel

Front Panel

Color LCD display Active-matrix touch panel.

Display system. The display system sends the text and waveform information to

the display panel

Touch panel. The touch panel sends information to the processor. Any changes in

their settings are reported to the processor system.

The front panel board reads the front-panel switches and knob sensors. Any

changes in their settings are reported to the Windows system. The front panel

board also turns the LEDs on. One USB port is also accessible from the front

panel.

Front-panel menu switches are also read by the front-panel microcontroller. The

microcontroller sends any changes in menu selections to the Windows system. The

ON/STBY switch is one of the menu switches. However, it is not read by the front

panel board, but passes through the front panel board to the Wintel motherboard.

The CD-RW/DVD drive enables you to load software to customize your

instrument for your measurement needs and to save data to a writable CD.

DSA8300 Digital Serial Analyzer and Modules Service Manual 2–3

Page 26

Theory of Operation

Rear Panel

Low Voltage Power Supply

Fans

The removable h

ard drive contains the product software and operating system

software. It also provides capability to store and access waveform data. The GPIB

allows for external control of the instrument.

You can make hard copies on the GPIB and RS-232 ports. Other ports are

outputs from the ATX board: DVI-I, USB (4), sound, serial, Ethernet, mouse,

and keyboard.

The low voltage power supply is a switching power converter with active power

factor control. It supplies power to all of the circuitry in the instrument.

The principal POWER switch, located on the rear panel, controls all power to the

instrument including the Low Voltage Power Supply. The ON/STBY switch,

located on the front panel, also controls all of the power to the instrument except

for part of the circuitry in the Low Voltage Power Supply and stand-by power on

the motherboard.

The power supply sends a power fail (~PF) warning to the proces sor system if the

power is going down.

The fan assembly provides forced air cooling for the instrument.

The fans are controlled by the PPC processor.

Electrical Sampling Modules

80E01, 80E02, 80E03,

80E06, 80E07, and 80E09

Sampling Modules

The electrical sampling m odules (non-TDR capable) are one- and two-channel

sampling modules. Their basic features are listed in the following table. (The

TDR capable sampling modules are describe later.)

Electrical sampling module features

ature

Fe

Number

f

o

independent

channels

Bandwidth

Selectable

bandwidths

Signal

connectors

Remote

sampler

E01

80

122122

50 GHz 12.5 GHz 20 GHz 70 GHz 30 GHz 60 GHz

N.A. N.A. N.A. N.A.

2.4 mm

female

N.A. N.A. N.A. N.A. 2 meter

E02

80

3.5 mm

female

E03

80

3.5 mm

female

E06

80

1.85 mm

(V)

female

E07

80

20 GHz,

30 GHz

2.92 mm

(K)

female

cable

E09

80

40 GHz,

30 GHz,

60 GHz

1.85 mm

(V)

female

2 meter

cable

2–4 DSA8300 Digital Serial Analyzer and Modules Service Manual

Page 27

Theory of Operation

80E04, 80E08, and 80E10

TDR/Sampling Modules

For the two-cha

nnel modules, a single strobe delivered from the instrument

mainframe to both acquisition channels controls the timing of the strobe assertion

to both channels. If channel-to-channel deskew is zero and the channel delays (if

equipped) are matched, the sampling coincidence between channels is very close.

Acquisition deskew function is carried out either by making separate acquisitions

over individual acquisition windows or by adjusting Channel Delay (if equipped).

For the one-channel modules, an individual strobe delivered from the instrument

mainframe to the acquisition channel controls the timing of the strobe assertion

to the chan

nel. Acquisition deskew function is carried out by moving the strobe

timing for the channel to a unique acquisition window or by adjusting Channel

Delay (if equipped).

Most electrical channels feature a Tekprobe Level 2 probe power connector for

attachment of a real time probe. The control of this probe is a mainframe function.

All module calibration signals are derived from a 2.5 V precision voltage reference

internal to the sampling module. Settings derived from this reference are stored in

a nonvolatile EEPROM in the sampling module, although the responsibility for

the execution of these settings is with the mainframe.

The TDR/Sampling modules are low noise samplers, with each channel capable

of generating its own Time Domain Reflectometry (TDR) step. The basic features

of these modules are listed in the following table.

TDR sampling module features

ture

Fea

ber of

Num

independent

channels

Number of TDR

annels

ch

Bandwidth

Selectable

bandwidths

Signal connectors 3.5 mm female 2.92 mm (K) female 1.85 mm (V) female

Remote sampler N.A. 2 meter cable 2 meter cable

04

80E

222

222

0GHz

2

N.A.

08

80E

0GHz

3

20 GHz, 30 G Hz 40 GHz, 30 GHz,

10

80E

0GHz

5

50 GHz

For these modules, a single strobe d elivered from the instrument mainframe to

both acquisition channels controls the timing of the strobe assertion to both

channels. If channel-to-channel deskew is zero and the channel delays (if

equipped) are matched, the sampling coincidence between channels is very close.

Acquisition deskew function is carried out by making separate acquisitions over

acquisition windows or by adjusting Channel Delay (if equipped).

Each electrical channel features a Tekprobe Level 2 probe power connector for

attachment of a real time probe. The control of this probe is a mainframe function.

DSA8300 Digital Serial Analyzer and Modules Service Manual 2–5

Page 28

Theory of Operation

All module cali

internal to the sampling module. Settings derived from this reference are stored in

a nonvolatile EEPROM in the sampling module, although the responsibility for

the execution of these settings is with the mainframe.

When used in the acquisition mode (that is, with the TDR step generator turned

off) each channel functions as a normal sampling input. In the TDR mode, a fast

rise time step is generated internally for each channel and applied to the input

signal path for that channel. The acquisition part of the TDR/sampling module

remains functional for monitoring the primary step and its reflected components.

The sampling module provides two self-contained TDR channels. The polarity

of the output step can be selected independently for each channel. This allows

differential or common mode testing of two coupled lines as well as independent

testing of isolated lines.

Optical Sampling Modules

80CXX and 80CXX-CR optical modules share the same mechanical package and

are built with a common circuit board. D ifferent functionality within the m odules

(current and future modules) is achieved by installing different O/E modules,

filters and clock recovery boards along with setting the sampler bandwidth as

demanded. The key features supported in the module are:

bration signals are derived from a 2.5 V precision voltage reference

A one channel, low noise, adjustable bandwidth sampler allowing multiple

bandwidth settings for optimizing noise versus bandwidth demands.

An amplified or nonamplified O/E converter.

Support for internal RF switches in the signal path with a straight-through

path and three hardware-filtered reference receiver paths between the O/E

converter and the sampler.

An average optical power meter.

Integral clock recovery option with internal coaxial connection to the

mainframe trigge

Communication with the mainframe for identification, control and

calibration/compensation storage.

The "system response" depends on all of the c omponents in the signal path from

the front panel to the sampler. Bandwidth and reference receiver responses are

calibrated at the factory with a sub-picosecond optical impulse applied to the

front panel connector or with an optical heterodyne system. This ensures that all

components are included, but also means that components cannot be replaced

without performing calibration.

Compensation performs a DC transfer curve characterization for each

bandwidth/reference receiver setting. The curve data is stored in the module

EEPROM and used to generate a look-up table in the mainframe. This data

corrects for linearity, gain and offset errors in the sampler.

r, front panel clock and data output (not all have data).

2–6 DSA8300 Digital Serial Analyzer and Modules Service Manual

Page 29

Theory of Operation

Reference rece

ivers can be created in any of the following ways:

Ahardwarefilter inserted between the O/E and the sampler and dominates

the res ponse.

No filter is used, but the bandwidth of the sampler is adjusted.

The O/E bandwidth is adjusted and dominates the response.

Information about the available bandwidth and reference receiver selections, and

the method used to set the bandwidth for the optical modules is in the Optical

Sampling Module section. (See page 2-8.)

The power monitor is a second measure of the photo-diode current that is

independent of the sampler signal path. Analog circuitry continuously senses the

current flowing into the bias side of the photo diode. The signal is amplified

by a programmable gain amplifier and input to an 8-bit AD converter. The AD

2

converter and amplifier are controlled through the I

C interface. Compensation

performs two functions in the power meter: First, two offset inputs are adjusted in

the amplifier so that the signal stays in range for all of the gain settings. Next,

offset is measured for all gain s ettings and stored so it can be subtracted from the

raw measured current. Because the m easurements are made through independent

paths the power monitor is useful in debugging module/mainframe problems.

The main board of the module only provides power and control bits to the clock

recovery board. A small fraction of the input signal is split off and applied to

the clock recovery components. The type of splitter for each module is shown

in the foll

owing table.

Module optical/electrical split

Module Optical Split Electrical Split

C01

C02

C03

C04

C07

C07B

C08

C08B

C08C

C09

C11

C12

n

n

n

n

n

n

n

n

n

n

n

n

The recovered clock is routed in coaxial cable through the rear connector of the

module to the Optical Front End board in the mainframe. The Optical Front End

board has a switch that selects which modules clock is applied to the trigger. The

control signal for that switch comes from the optical module.

DSA8300 Digital Serial Analyzer and Modules Service Manual 2–7

Page 30

Theory of Operation

80C01 Optical Sampling

Module

The 80C01 modul

(1100-1650 nm) signals at 622, 2488, and 9953 Mb/s a s well as general purpose

testing up to 20 GHz optical bandwidth. Bandwidth and reference receiver

calibration is performed with a sub-picosecond optical impulse and a Fourier

transform method.

OC12: The electrical sampler is adjusted to approximately 7.5 GHz (-3 dB)

bandwidth and signal is routed through a hardware filter designed to result in

the combined system having an OC12 (STM-4) Reference Receiver response.

OC48: The electrical sampler is adjusted to 7.5 GHz (-3 dB) bandwidth and

signal is routed through a hardware filter designed to result in the combined

system having an OC48 (STM-16) Reference Receiver response. These

adjustmentsmustbemadeatthefactory.

OC192: The electric al sampler is adjusted to give the desired response,

and s ignal is not routed through any filter (signal is sent through the

straight-through path). The sampler bandwidth and response is optimized

during the calibration such that the combined system will have an OC192

(STM-64) Reference Receiver response.

12.5 GHz: The sampler bandwidth and response is set during the calibration

such that the combined system will have an Optical Bandwidth (-6 dB)

>12.5 GHz.

20 GHz: The sampler bandwidth and response is set during the calibration

such that the combined system will have an Optical Bandwidth (-6 dB)

>20 GHz.

e supports conformance testing of long wavelength

80C02 Optical Sampling

Module

The 80C02 module is optimized for testing of long-wavelength (1100-1650 nm)

signals at (9.953 Gb/s) SONET OC-192 / SDH STM-64 standards. With its

high optical bandwidth (>30 GHz) it is also well suited to general purpose

high-performance optical component testing.

OC192: The electric al sampler is adjusted to give the desired response,

and s ignal is not routed through any filter (signal is sent through the

straight-through path). The sampler bandwidth and response is optimized

during the calibration such that the combined system will have an OC192

(STM-64) Reference Receiver response.

12.5 GHz: The sampler bandwidth and response is set during the calibration

such that the combined system will have an Optical Bandwidth (-6 dB)

>12.5 GHz.

20 GHz: The sampler bandwidth and response is set during the calibration

such that the combined system will have an Optical Bandwidth (-6 dB)

>20 GHz.

30 GHz: The sampler bandwidth and response is set during the calibration

such that the combined system will have an Optical Bandwidth (-6 dB)

>30 GHz.

2–8 DSA8300 Digital Serial Analyzer and Modules Service Manual

Page 31

Theory of Operation

80C03 Optical Sampling

Module

The 80C03 modul

(700-1650 nm) signals at 1.063, 1.250, and 2.488 Mb/s as well as general purpose

testing with >2.3 GHz optical bandwidth. Its amplified optical to electrical

converter design enables the user to examine very low-level optic al signals.

OC48: The electrical sampler is adjusted to approximately 12.5 GHz (-3 dB)

bandwidth and signal is not routed through any filter (signal is sent through

the straight-through path). The O/E converter is designed by the vendor to

match the OC48 reference receiver response curve. The span adjustment

provides l

factory so that the combined system will have an OC48 (STM-64) Reference

Receiver response. This mode is synonymous with the 2.3 GHz maximum

bandwidth setting.

FC1063: The electrical sampler is adjusted and O/E converter span volta ge

are the same values as in the OC48 mode. The signal is routed through a

hardware filter designed to result in the combined system having an FC1063

(1.0625 Gb/s Fibre Channel) Reference Receiver response.

GBE: The electrical sampler is adjusted and O/E converter span voltage are

the same values as in the OC48 mode. The signal is routed through a hardware

designed to result in the combined system having an GBE (1.25 Gb/s

filter

Gigabit Ethernet) Reference Receiver response.

0C03 module can be configured with clock recovery that supports Fibre

The 8

Channel 1063 (1.063 Gb/s) and OC-48 / STM-16 (2.488 Gb/s) standards.

e supports conformance testing of both short and long bandwidth

imited adjustment of the frequency response. It is adjusted at the

80C04 Optical Sampling

ule

Mod

The 80C04 module is optimized for testing of long wavelength (1100-1650 nm)

nals at either 9.953 Gb/s or 10.664 Gb/s. With its high optical bandwidth

sig

>28 GHz, it is also well suited to general-purpose, high-performance optical

component testing.

OC192 or 10.664 Gb/s: The electrical sampler is adjusted to give the desired

response, and signal is not routed through any filter (signal is sent through

the straight-through path). The sampler bandwidth and response is optimized

during the calibration such that the combined system will have an OC192

(STM-64) or 10.66 Gb Reference Receiver response.

20 GHz: The sampler bandwidth and response is set during the calibration

such that the combined system will have an Optical Bandwidth (-6 dB)

>20 GHz.

30 GHz: The sampler bandwidth and response is set during the calibration

such that the combined system will have an Optical Bandwidth (-6 dB)

>28 GHz.

The 80C04 can be optionally configured with clock recovery (Opt. CR-1) that

supports 9.953 Gb/s telecom standards.

DSA8300 Digital Serial Analyzer and Modules Service Manual 2–9

Page 32

Theory of Operation

80C05 Optical Sampling

Module

80C06 Optical Sampling

Module

80C07 Optical Sampling

Module

The 80C05 modul

Thismoduleisintendedtobeusedasatestandmeasurementtoolforhigh

bandwidth telecommunications with its high optical bandwidth >40 GHz.

OC192: There is one Reference Receiver setup selectable for 9.95328 Gb/s

SONET/SDH standard.

There is no clock recovery option available.

The 80C06 module is designed to test long wavelength (1520-1580 nm) signals.

Thismoduleisintendedtobeusedasatestandmeasurementtoolforhigh

bandwidth telecommunications with its high optical bandwidth >55 GHz.

55 GHz: There is only a single bandwidth selection available, no Reference

Receiver setups selectable.

There is no clock recovery option available.

The 80C07 module is designed to test both long and short wavelength

(700-1650 nm) signals. This module is intended to be used as a test and

measurement tool for high bandwidth telecommunications with its high optical

bandwidth >2.3 GHz.

e is designed to test long wavelength (1520-1580 nm) signals.

80C07B Optical Sampling

Module

80C08 Optical Sampling

Module

Filtered rates are OC-3, OC-12; unfiltered rate is OC-48.

There is clock recovery option available (155/622/2488 Multi-rate).

The 80C07B module is designed to test both long and short wavelength

(700-1650 nm) signals. This module is intended to be used as a test and

measurement tool for high bandwidth telecommunications with its high optical

bandwidth >2.3 GHz.

Supported standards or data filtering rates include OC-3, OC-12, OC-48,

ENET2500/2GBE, GBE, FC1063, FC2125, and Infiniband.

Clock recovery options are available

(155/622/1063/1250/2125/2488/2500/2666).

The 80C08 module is designed to test both long and short wavelength

(700-1650 nm) signals. This module is intended to be used as a test and

measurement tool for high bandwidth telecommunications with its high optical

bandwidth >9.0 GHz.

10.0 GHz: No filter is used and the sampler bandwidth is adjusted; the O/E

bandwidth is adjusted and dominates the response (9.953/10.3125 Gb/s

Multi-rate).

There is clock recovery option available (9.953/10.3125 Gb/s Multi-rate).

2–10 DSA8300 Digital Serial Analyzer and Modules Service Manual

Page 33

Theory of Operation

80C08B Optical Sampling

Module

80C08C Optical Sampling

Module

The 80C08B modu

(700-1650 nm) signals. This module is intended to be used as a test and

measurement tool for high bandwidth telecommunications with its high optical

bandwidth >9.5 GHz.

10.0 GHz: No filter is used and the sampler bandwidth is adjusted; the O/E

bandwidth is adjusted and dominates the response (9.953/10.3125 Gb/s

Multi-rate).

Clock recovery options are available (9.953/10.3125/10.51875 Gb/s

Multi-rate).

The 80C08C module is designed to test both long and short wavelength

(700-1650 nm) signals. This module is intended to be used as a test and

measurement tool for high bandwidth telecommunications with its high optical

bandwidth >10 GHz.

10.0 GHz: No filter is used and the sampler bandwidth is adjusted;

the O/E bandwidth is adjusted and dominates the response

/10.3125/10.518/10.66/10.709/11.1/11.317 Gb/s).

(9.953

Clock recovery options are available (9.953/10.3125/10.518 Gb/s and

nuous-rate from 9.8 Gb/s to 12.6 Gb/s).

Conti

le is designed to test both long and short wavelength

80C09 Optical Sampling

Module

80C10 Optical Sampling

Module

The 80C09 module is d esigned to test long wavelength (1100-1650 nm) signals.

This module is intended to be used as a test and measurement tool for high

dwidth telecommunications with its high optical bandwidth >30 GHz.

ban

Supported standards or data filtering rates include OC-192 and FEC10.709.

Clock recovery options are available (OC-192 and FEC10.709).

The 80C10 module is designed to test long wavelength (1310 and 1550 nm)

signals. This module is intended to be used as a test and measurement tool for

high bandwidth telecommunications with its high optical bandwidth >65 GHz.

Supported standards or data filtering rates include OC-768 and FEC43.02

(G.709).

30 GHz: The sampler bandwidth and response is set during the calibration

such that the combined system will have an Optical Bandwidth (-6 dB)

>30 GHz.

65 GHz: The sampler bandwidth and response is set during the calibration

such that the combined system will have an Optical Bandwidth (-6 dB)

>65 GHz.

There is no clock recovery option available.

DSA8300 Digital Serial Analyzer and Modules Service Manual 2–11

Page 34

Theory of Operation

80C10B Optical Sampling

Module

80C11 Optical Sampling

Module

The 80C10B modu

signals. This module is intended to be used as a test and measurement tool for

high bandwidth telecommunications with its high optical bandwidth >80 GHz.

Supported standards or data filtering rates include OC-768 and FEC43.02

(G.709).

30 GHz: The sampler bandwidth and response is set during the calibration

such that the combined system will have an Optical Bandwidth (-6 dB)

>30 GHz.

65 GHz: The sampler bandwidth and response is set during the calibration

such that the combined system will have an Optical Bandwidth (-6 dB)

>65 GHz.

80 GHz: The sampler bandwidth and response is set during the calibration

such that the combined system will have an Optical Bandwidth (-6 dB)

>80 GHz.

There is no clock recovery option available.

The 80C11 module is designed to test long wavelength (1100-1650 nm) signals.

Thismoduleisintendedtobeusedasatestandmeasurementtoolforhigh

bandwidth telecommunications with its high optical bandwidth >20 GHz.

le is designed to test long wavelength (1310 and 1550 nm)

80C12 Optical Sampling

Module

Supported standards or data filtering rates include

9.953/10.31/10.518/10.66/10.71/11.1 Gb/s.

Clock recovery options are available (9.953/10.66/10.71 Gb/s and

Continuous-rate from 9.8 Gb/s to 12.6 Gb/s).

The 80C12 module is designed to test both long and short wavelength

(700-1650 nm) signals. This module is intended to be used as a test and

measurement tool for high bandwidth telecommunications with its high optical

bandwidth >10 GHz.

There are three Reference Receiver filters selectable that are customer

specified from the following list of five rates: 1FC (FC1063) for 1.0625 Gb/s

Fibre Channel, 2FC (FC2125) for 2.125 Gb/s Fibre Channel, 10GBase-X4

for 3.125 Gb/s, VSR-5 for 3.31776 Gb/s, and 4FC (FC4250) for 4.25 Gb/s

Fibre Channel. Filterless, full-bandwidth settings (8.5 GHz and 9 GHz) are

also ava ilable.

In addition, this module offers the option to support 10 Gb/s optical standards

as well. This option is mutually exclusive with the sub-10 Gb/s filter options.

The standard reference receiver filter rates offered with the Option 10G are

SONET/SDH OC-192/STM-64, 10GBase-W, 10 Gb Ethernet (9.95338 Gb/s),

10GBase-R (10.3125 Gb/s), 10G Fibre Channel (10.51875 Gb/s), G.975

FEC (10.66 Gb/s), G.709 FEC (10.71 Gb/s), 10GBE FEC (11.0957 Gb/s),

2–12 DSA8300 Digital Serial Analyzer and Modules Service Manual

Page 35

Theory of Operation

80C14 Optical Sampling

Module

80C25GBE Optical

Sampling Module

8G FibreChanne

filter settings require no hardware filters.

An electrical

the Tektronix 80A05 or 80A07 for clock recovery.

The 80C14 Series Optical Sampling Module is a high-performance optical module

that suppor

Fibre Channel and 14.063 Gb/s Infiniband.

The 80C14 s

(8.500 Gb/s), OC-192/STM-64 (9.953 Gb/s), 10GBase-W (9.953 Gb/s),

10GBase-R (10.31 Gb/s), 40GBase-R4 (10.31 Gb/s), 100GBase-SR10

(10.31 Gb/s), 10GFC (10.52 Gb/s), ITU-T G.975 FEC (10.664 Gb/s), ITU-T

G.709 (10.709 Gb/s), 10 GbE FEC (11.1 Gb/s), 10GFC FEC (11.3 Gb/s),

Super FEC (12.5 Gb/s), 16GFC (14.025 Gb/s), 14G Infiniband FDR

(14.062

Clock recovery is supported with the use of the CR175A or CR286A Clock

Recove

The 80C25GBE module is designed to test long wavelength (1310 and 1550 nm)

signals. This module is intended to be used as a test and measurement tool for

high

ts high bandwidth telecom and datacom standards, including 16 GFC

5Gb/s).

ry instrument (purchased separately).

bandwidth telecommunications with its high optical bandwidth >65 GHz.

l (8.5 Gb/s), 10G FibreChannel FEC (11.317 Gb/s). These

clock recovery output signal is provided that can be routed to

upports the following standards and data filtering rates: 8GFC

Supported standards or data filtering rates include 25.781 Gb/s 100GBase-xR4

27.739 Gb/s 100GBase-xR4 FEC.

and

65 GHz: The sampler bandwidth and response is set during the calibration

ch that the combined system will have an Optical Bandwidth (-6 dB)

su

>65 GHz.

ere is no clock recovery option available.

Th

80A01 Trigger Prescale Preamplifier Module

The 80A01 module is designed to increase the sensitivity of the prescale trigger

input of the DSA8300 to ≤200 mV

The major function block of the module is a high sensitivity, high gain RF

amplifier. The input and output to this a mplifier are routed to two identical SMA,

female connectors, labeled Input and Output at the module front panel.

The module receives power from the main instrument through a single connector

at the rear of the module. The power LED indicates the module is receiving power

through the interface connector.

p-p

.

DSA8300 Digital Serial Analyzer and Modules Service Manual 2–13

Page 36

Theory of Operation

80A02 EOS/ESD

Protection Module

The 80A02 EOS/ESD (Electrical Over Stress/Electro-Static Discharge) protection

module works with any DSA8300 instrument and provides static electricity

damage prote

elements.

The 80A02 EO

to provide static protection to a sensitive single input channel of a sampling

oscilloscope with very minimal speed degradation.

The 80A02 EOS/ESD module is designed to work with either the Tektronix P8018

probe for manual test station static protection as well as automated test stations.

ction to vulnerable sampling head input stages and/or other sensitive

S/ESD module has a 26 GHz bandwidth, making it possible

80A05 Electrical Clock Recovery M odule

The electrical clock recovery module is capable of performing clock recovery on

the input signal (signal input must meet data rate and format requirements), and

provides this signal as a trigger source to the DSA8300.

Front panel connectors provide a replica of the recovered clock signal.

Themoduleusesoneoftwoseparateclock recovery circuits dependant on the

specified data rate. The single-ended or complementary input signals are split

with a 1:2 divider and routed to the two circuits.

The low bandwidth circuit recovers clock and data from input data in the 50 Mb/s

to 2.7 Gb/s range. The recovered clock from this circuit is routed directly to the

front panel and internal trigger.

The high bandwidth circuit recovers clock a nd data from input data in the 2.7 Gb/s

to 12.6 Gb/s range. The recovered clock to the front panel and internal trigger

gnals are always clock/16.

si

With option 10G, the 10G recovered clock is also routed to the front panel.

There is one front panel indicator LED - Clock Recovery Enable. It indicates the

clock recovery circuitry is on and programmed to the requested bit rate.

2–14 DSA8300 Digital Serial Analyzer and Modules Service Manual

Page 37

Theory of Operation

82A04 Phase Re

ference Module

The 82A04 Phase Reference Module is designed to decrease horizontal position

uncertainty with data signals, when a r eference clock signal synchronized to the

data signal,

both channels in that slot.

The Phase Co

unit circle location information for the phase of the data sample, and triggered,

where the module, in conjunction with the trigger signal, provides both base

positioning, and refined positioning, for the data sample.

The input is precision 1.85 mm. Phase correction works over the range of 2.5 GHz

- 25 GHz (82A04), or 2.5 GHz - 60 GHz (82A04-60G). The LED indicates the

module is being utilized for phase correction.

is available. It consumes a small slot, and displaces operation of

rrection modes available are free run, where the module provides

DSA8300 Digital Serial Analyzer and Modules Service Manual 2–15

Page 38

Theory of Operation

2–16 DSA8300 Digital Serial Analyzer and Modules Service Manual

Page 39

Adjustment Procedures

Page 40

Page 41

Adjustment Procedures

This section contains an adjustment procedure for your instrument. The purpose

of this procedure is to return the instrument conformance to its specifications.

Adjustment interval. The voltage and timing references inside the instrument

are very sta

time you should perform the Adjustment Procedures is if the instrument fails

any of the mainframe performance verification checks provided in the DSA8300

Specifications and Performance Verification manual.

Adjustment environment. The instrument must be adjusted in a 20°C to 30 °C

ambient t

up at least 20 minutes in this environment b efore you begin the adjustment

procedure.

Required Equipment

The adjustment procedure requires the specific test equipment and materials listed

in the following table.

ble over time and should not need routine adjustment. The only

emperature environment. The instrument and signal source must warm

Category Specific equipment required Quantity

Signal source Signal generator 50 MHz to 1 GHz,≤ 1 ppm frequency accuracy

Frequency counter Frequency resolution 12 digits 1 ea

Meter Digital Multimeter, with 6.5 plus digits 1 ea

Instrument controller (only

one of these configurations

required)

Divider

Adapter

Adapter

Adapter

Coaxial cables 50Ω, male-to-male SMA connectors

GPIB cables GPIB cable, 1 m min length, Tektronix part number 002-0991-01

1

Depending on other USB devices attached to the instrument, a USB hub may also be required. Consult your National

Instruments documentation for more information.

PC-compatible computer with National Instruments GPIB Controller card and

software, running Windows 95/98 or NT

National Instruments USB GPIB Controller card for Windows 98 and National

Instruments NI-488.2 for Windows software (to install in the instrument)

Power, 50Ω, SMA "T" male Tektronix 015-0565-00

SMA "T", male to 2 SMA female Tektronix part number 015-1016-00

SMA male to BNC female, Tektronix part number 015-0554-00

BNC to dual banana plug, Tektronix part number 103-0095-00

1ea

1ea

1ea

1ea

1ea

1ea

1ea

3ea

1ea

DSA8300 Digital Serial Analyzer and Modules Service Manual 3–1

Page 42

Adjustment Procedures

Equipment Hookup

1. Connect the equipment as shown in the following figure:

2. Set the National Instruments GPIB Interface command software to allow

GPIB communications between the PC controller and DSA8300, device

under test (DUT).

3. Allow the test equipment and DUT to warm up for at least 20 minutes before

starting the adjustment procedures.

Main Instrument Adjustments

DC Calibrator Adjust

1. Use the equipment connection shown in the preceding figure. Make sure that

the equipment has warmed up for at least 20 minutes.

2. Run the compensation routine.

3. Verify communication between the controller and DUT by entering the

following GPIB command:

The instrument should respond with Tektronix and Firmware Version.

4. Turn off the instrument cal constant protection by entering the following

GPIB command:

5. Set the instrument DC calibrator offset cal constant to 0 by entering the

following GPIB command:

6. Wait 8 seconds, and then set the instrument DC calibrator Lsb cal constan

to 1.0 by entering the following GPIB command:

"DcCalLsbAdj",1.0

*IDN

SYST:PROT OFF

CALCOMP:DOUBLE "DcCalOffsetAdj",0.0

t

CALCOMP:DOUBLE

7. Wait 8 seconds, and then set the instrument DC calibrator output to 0 Volts by

entering the following GPIB command:

8. Record the DMM reading.

3–2 DSA8300 Digital Serial Analyzer and Modules Service Manual

CALIBRATE:DCCALIBRATOR 0.0

Page 43

Adjustment Procedures

9. Set the instrum

reading by entering the following GPIB command:

"DcCalOffsetAdj",(-1.0 * the DMM reading)

ent DC calibrator o ffset cal constant to -1 * DMM

CALCOMP:DOUBLE

Example: CALCOMP:DOUBLE "DcCalOffsetAdj", 3.2e-4

10. Set the inst

command:

11. Record the D

rument calibrator to 1.0 V by entering the following GPIB

CALIBRATE:DCCALIBRATOR 1.0

MM reading (reading1).

12. Set the instrument calibrator to -1.0 V by entering the following GPIB

ALIBRATE:DCCALIBRATOR -1.0

command:

C

13. Record the DMM reading (reading2).

14. Calculate the cal constant using the following equation: (–1.0 * Reading2

+ Reading1) ÷ 2.

15. Set the instrument calibrator Lsb cal constant by entering the following

GPIB command:

calcul

ated in previous step)

CALCOMP:DOUBLE "DcCalLsbAdj", (cal constant

16. Wait 8 seconds, and then save the DC adjustments by entering the following

GPIB c

ommand:

CAL:SAVE:FACT:MAIN

17. Update the mainframe calibration time/date/temperature stamp by entering

ollowing GPIB command:

the f

CAL:UPDATEINFO:MAIN

DC Calibrator Adjust

Verification

18. Turn on the instrument cal constant protection by entering the following

com

mand:

SYST:PROT ON

To verify that the DC calibration adjustment was successful, complete the

lowing:

fol

1. Set the instrument DC calibrator to -1.0 V by entering the following GPIB

mmand:

co

CALIBRATE:DCCALIBRATOR -1.0

2. Verify that the DMM reads -1.0 V ±1 mV

3. Set the instrument DC calibrator to 1.0 V by entering the following GPIB

command:

CALIBRATE:DCCALIBRATOR 1.0

4. Verify that the DMM reads 1.0 V ±1 mV

5. Set the instrument DC calibrator to 0.0 V by entering the following GPIB

command:

CALIBRATE:DCCALIBRATOR 0.0

6. Verify that the DMM reads 0.0 V ±0.1 mV

DSA8300 Digital Serial Analyzer and Modules Service Manual 3–3

Page 44

Adjustment Procedures

Internal 10 MHz Adju st

Connect the DSA

8300 to a signal generator and frequency counter as shown

in the following figure:

1. Set the signal generator as follows

Frequency to 1 GHz

Amplitude to 1.0 V peak to peak

Output to on

2. Set the frequency counter as follows:

Frequency to 200 kHz

Number of digit

sto9

3. Set the DSA8300 as follows:

Trigger source to TDR

Clock rate to 200 kHz

TDR Trigger mode to External (select Advance Trigger mode, and then

select External Trigger for TDR mode)

4. Enter the following GPIB command to turn the instrument cal constant

protection off:

“SYST:PROT OFF”

5. Set the calibration value to the default by entering the following GPIB

command:

“CALCOMP:DOUBLE "Internal10MHzRefFreq",

10e6

6. Measure the TDR Clock Out frequency (Reading 1).

7. Set the DSA8300 trigger mode to Internal.

8. Measure the TDR Clock Out frequency (Reading 2).

9. Enter the following GPIB command:

“Internal10MHzRefFreq”,

(Reading2/Reading1 * 10M)

“CALComp:DOUBLE

3–4 DSA8300 Digital Serial Analyzer and Modules Service Manual

Page 45

Adjustment Procedures

10. Measure the TDR

Clock Out frequency. (Recheck)

11. Verify that the 10 MHz measurement is within 2 kHz.

12. Save the mainframe factory calibration constants by entering the following

GPIB command:

“CAL:SAV:FACTORY:MAIN”

13. Update the mainframe calibration time/date/temperature stamp by entering

the following GPIB command:

“CAL”UPDATEINFO:MAIN”

14. Enter the following GPIB command to turn the instrument cal constant

protection on:

SYST:PROT ON

End of Procedure

DSA8300 Digital Serial Analyzer and Modules Service Manual 3–5

Page 46

Adjustment Procedures

3–6 DSA8300 Digital Serial Analyzer and Modules Service Manual

Page 47

Maintenance

Page 48

Page 49

Maintenance

This section contains the information needed to do periodic and corrective

maintenance on the mainframe, electrical modules, and optical modules, as well

as repackaging instructions for returning the products to Tektronix for service.

Preventing

ESD

Before servicing this product, read the General Safety Summary and Service

Safety Summary at the front of the manual, and familiarize yourself with the

following

CAUTION. Electrostatic discharge can damage any semiconductor component

in this instrument.

When performing any service that requires internal access to the instrument,

adhere to the fol

their components due to electrostatic discharge:

1. Minimize handl

2. Transport and store static-sensitive assemblies in their static protected

3. Discharge th

4. Do not place anything capable of generating or holding a static charge on the

electrostatic discharge (ESD) information.

lowing precautions to avoid damaging internal assemblies and

ing of static-sensitive circuit boards and components.

containers or

boards.

wrist strap while handling these assemblies. Service static-sensitive

assemblies only at a static-free w ork station.

work station surface.

on a metal rail. Label any package that contains static-sensitive

e static voltage from your body by wearing a grounded antistatic

5. Handle circuit boards by the edges when possible.

6. Do not sli

7. Avoid handling circuit boards in areas that have a floor or work-surface

coverin

de the circuit boards over any surface.

g capable of generating a static charge.

Inspection and Cleaning

tion and cleaning are done as preventive maintenance. Preventive

Inspec

maintenance, when done regularly, may prevent instrument malfunction and

enhance its reliability.

Preventive maintenance consists of visually inspecting and cleaning the

instrument and using general care when operating it.

DSA8300 Digital Serial Analyzer and Modules Service Manual 4–1

Page 50

Maintenance

General Care

Flat Panel Display Cleaning

How often to do m

the instrument is used. A proper time to perform preventive maintenance is just

before instrument adjustment.

The cabinet h

place when operating the instrument.

WARNING. To avoid personal injury due to electric shock, power off the instrument

and disconnect it from line voltage before performing any procedure that follows.

The mainframe display is a soft plastic display and must be treated with care

during cleaning.

CAUTION. Improper cleaning agents or methods can damage the flat panel

display.

To avoi

to clean the display surface.

Do not s

Do not scrub the display with excessive force.

d damage, do not use abrasive cleaners or commercial glass cleaners

pray liquids directly on the display surface.

aintenance depends on the severity of the environment in which

elps keep dust out of the instrument and should normally be in

Exterior Cleaning

Clean the flat-panel display surface by gently rubbing the display with a

clean-room wipe (such as WypAll Medium Duty Wipes, #05701, available from

erly-Clark Corporation).

Kimb

If the display is very dirty, moisten the wipe with distilled water or a 75%

propyl alcohol solution and gently rub the display surface. Avoid using excess

iso

force or you may damage the plastic display surface.

CAUTION. To prevent getting moisture inside the instrument during external

cleaning, use only enough liquid to dampen the cloth or applicator.

Do not use chemical cleaning agents that might damage the plastics used in

his instrument. Use only deionized water when cleaning the menu buttons or

t

front-panel buttons. Use a 75% isopropyl alcohol solution as a cleaner and

rinse with deionized water. Before using any other type of cleaner, consult your

Tektronix Service Center or representative.

4–2 DSA8300 Digital Serial Analyzer and Modules Service Manual

Page 51

Maintenance

Exterior Inspection

Clean the exter

ior surfaces of the chassis with a dry lint-free cloth or a soft-bristle

brush. If any dirt remains, use a cloth or swab dipped in a 75% isopropyl alcohol

solution. Use a swab to clean narrow spaces around controls and c onnectors. Do