x

DSA8300

Digital Serial Analyzer

ZZZ

Quick Start User Manual

*P071289704*

071-2897-04

xx

DSA8300

Digital Serial Analyzer

ZZZ

Quick Start User Manual

www.tek.com

071-2897-04

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or suppliers, and are

protected by na

tional copyright laws and international treaty provisions.

Tektronix pro

previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

TEKPROBE and FrameScan are registered trademarks of Tektronix, Inc.

ducts are covered by U.S. and foreign patents, issued and pending. Information in this publication supersedes that in all

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

In North America, call 1-800-833-9200.

Worldwide, visit www.tek.com to find contacts in your area.

Warranty

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1) year from the date of

shipment. If any such product proves defective during this warranty period, Tektronix, at its option, either will repair the defective

product without charge for parts and labor, or will provide a replacement in exchange for the defective product. Parts, modules and

replacement products used by Tektronix for warranty work may be new or reconditioned to like new performance. All replaced

parts, modules and products become the property of Tektronix.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the warranty period

and make suitable arrangements for the performance of service. Customer shall be responsible for packaging and shipping the

defective product to the service center designated by Tektronix, with shipping charges prepaid. Tektronix shall pay for the return of the

product to Customer if the shipment is to a location within the country in which the Tektronix service center is located. Customer shall

be responsible for paying all shipping charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate maintenance and

care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting from a ttempts by personnel

other than Tektronix representatives to install, repair or service the product; b) to repair damage resulting from improper use or

connection to incompatible equipment; c) to repair any damage or malfunction caused by the use of non-Tektronix supplies; or

d) to service a product that has been modified or integrated with other products when the effect of such modification or integration

increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY OTHER WARRANTIES,

EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX' RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS

IS THE SOLE AND E XCLU S IVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX

AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES

IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

[W2 – 15AUG04]

Table of Contents

Important safety information .......................................................................................................... iii

General safety summary......................................................................................................... iii

Service safety summary ......................................................................................................... v

Terms in this manual .......................................................................... . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Symbols and terms on the product...................................................................................... . .. . . . . . vi

Compliance information .............................................................................................................. vii

EMC compliance ................................................................................................................ vii

Safety compliance.............................................................................................................. viii

Environmental considerations ................................................................................................... x

Preface................................................................................................................................. xi

Documentation ...................................................................................................................xi

Conventions used in this manual................................................................................................ xi

Key features ........................................................................................................................... 1

Install your instrument................................................................................................................. 3

Standard accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operating considerations ........................................................................................................ 4

Powering the instrument on and off ............................................................................................. 6

Adding a second monitor ........................................................................................................ 6

Installing modules .............................................................................................. . .. . . . . . . . . . . . . . ....... 9

Typical module installations......................................................................................................9

Install a module ...................................................... ... ... .. . .. . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Remove a module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . .............................................. . .. . . . . . . . . . . . .. . ........ 11

Powered-on module configuration.............................................................................................. 11

Getting acquainted with your instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Front panel . . . . . . . . . . . .............................................. . .. . . . . . . . . . . . . . . ............................................13

Control panel .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . ............................................................. . . ..14

Rear panel. . .. . . . . . . . . . . . . . . . . . ... .......................................................... . ....................................15

Computer I/O panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . ... .............................................................. 16

The user interface............................................................................................................... 17

Display - single waveform view................................................................................................. 18

lay - magnified waveform views ........................................................................................... 19

Disp

Accessing application help. ..................................................................................................... 20

Inspect your instrument .............................................................................................................. 21

Verify internal diagnostics pass. . . . . . . . . . . . . . . . . . . . ............................................................................. 21

Optimizing measurement accuracy.................................................................................................. 23

Signal path compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Dark-level and user wavelength gain compensations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . ........... 26

Align acquisition (and TDR steps) for two-channel modules ............................................ . . . . . . . . . . . . . . . . . . . . . . 28

Acquisition ............................................................................................................................ 29

Setting up signal input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . .. . ... ... ... .................................................. 29

Using factory default setup ..................................................................................................... 31

Using Autoset ................................................................................................................... 32

Table of Content

s

DSA8300 Q uick Start User Manual i

Table of Content

Triggers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . ... ... ................................................................................ 38

Waveform measurements............................................................................................................44

Skew and deskewing ................................................................................................................. 69

Cleaning the instrument ................................................................... . .......................................... 81

Restoring the operating system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 82

Index

s

Accessing the Setup dialog boxes ............................................................................................. 33

Changing the ac

Waveform databases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . ... .................................................................... 35

Setting the display style......................................................................................................... 36

Triggering concepts............................................................................................................. 38

Setting trigger controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Setting Patt

Checking trigger status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Taking auto

Turning off automatic measurements .......................................................................................... 48

Cursor measurements .......................................................................................................... 49

Math wavef

Display a communication signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Mask testing .....................................................................................................................55

FrameSca

To use TDR...................................................................................................................... 62

Phase reference............................................................................ . .................................... 64

Histogra

Document your results.......................................................................................................... 68

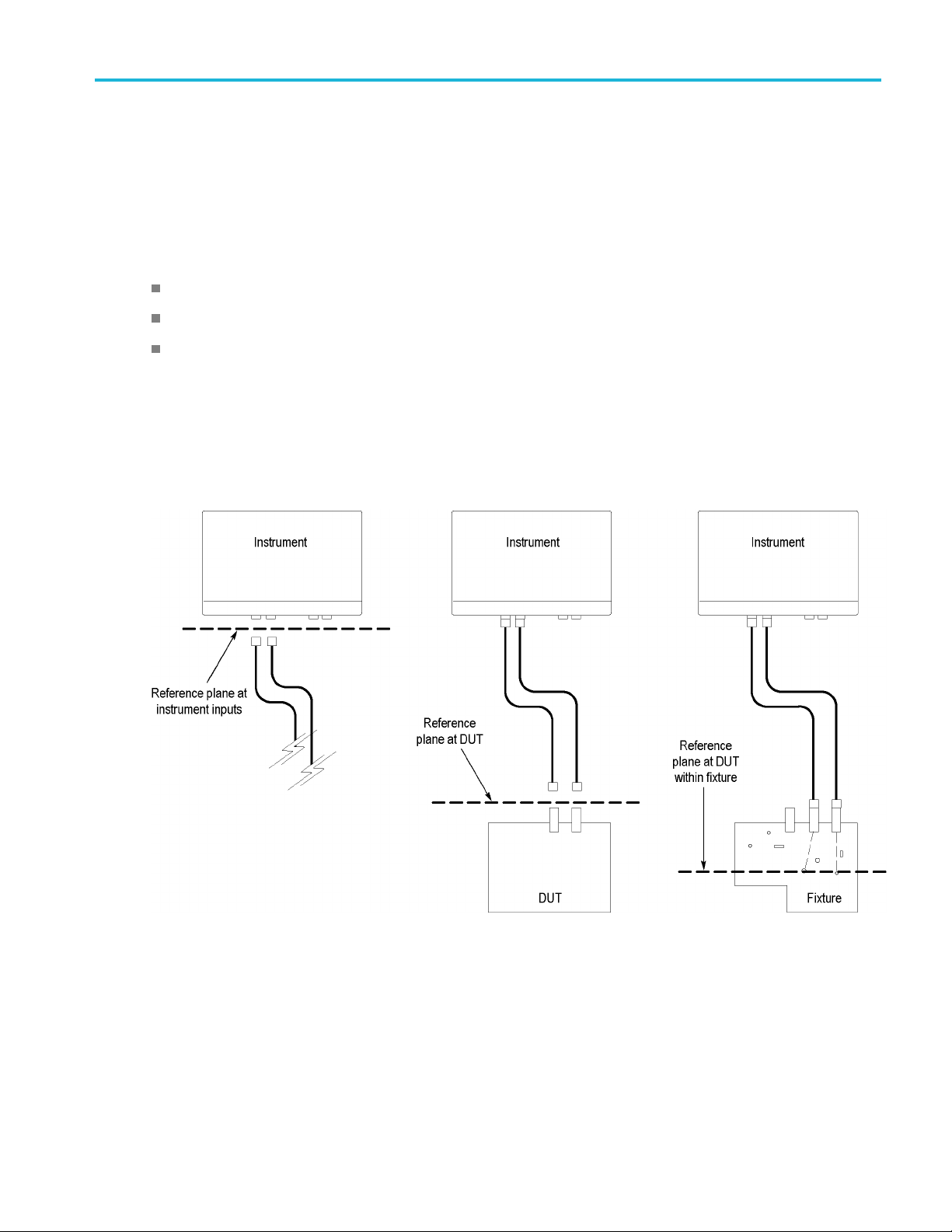

Methods

Setup considerations and procedures . ......................................................................................... 71

Acquisition deskew procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

TDR ste

Exterior cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . .. . .. . . .81

anel display cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Flat p

Optical connector cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . ... ..... 81

ring the operating system from the instrument hard disk drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Resto

quisition mode................................................................................................. 34

ern Sync and FrameScan controls ................................................................................ 42

matic measurements ............................................................................................... 44

orms................................................................................................................. 52

n ...................................................................................................................... 61

ms ...................................................................................................................... 67

to adjust skew......................................................................................................... 70

p deskew procedure .......................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . ............................. 77

ii DSA8300 Q uick Start User Manual

Important safet

y information

Important saf

This manual contains information and warnings that must be followed by the user for safe operation and to keep the

product in a safe condition.

To safely perform service on this product, additional information is provided at the end of this section. (See page v,

Service safety summary.)

ety information

General safety summary

Use the prod

or any products connected to it. Carefully read all instructions. Retain these instructions for future reference.

Comply with local and national safety codes.

For c orrect and safe operation of the product, it is essential that you follow generally accepted safety procedures in addition

to the safety precautions specified in this manual.

The product is designed to be used by trained personnel only.

Only qualified personnel who are aware of the hazards involved should remove the cover for repair, maintenance, or

adjustme

Before us

This pro

uct only as specified. Review the following safety precautions to avoid injury and prevent damage to this product

nt.

e, always check the product with a known s ource to be sure it is operating correctly.

duct is not intended for detection of hazardous voltages.

Use pers

While us

component manuals for warnings and cautions related to operating the system.

When incorporating this equipment into a system, the safety of that system is the responsibility of the assembler of the system.

onal protective equipment to prevent shock and arc blast injury where hazardous live conductors are exposed.

ing this product, you may need to access other parts of a larger system. Read the safety sections of the other

To avoid fire or personal injury

NG. To reduce the risk of fire and shock, ensure that the mains supply voltage fluctuations do not exceed 10% of the

WARNI

operating voltage range.

Use proper power cord. Use only the power cord specified for this product and certified for the country of use.

Do not use the provided power cord for other products.

Ground the product. This product is grounded through the grounding conductor of the power cord. To avoid electric

shock, the grounding conductor must be connected to earth ground. Before making connections to the input or output

terminals of the product, make sure that the product is properly grounded.

Power disconnect. The power cord disconnects the product from the power source. See instructions for the location. Do

not position the equipment so that it is difficult to disconnect the power cord; it must remain accessible to the user at all

times to a

llow for quick disconnection if needed.

DSA8300 Q uick Start User Manual iii

Important safet

Observe all terminal ratings. To avoid fire or shock hazard, observe all ratings and markings on the product. Consult

the product man

Do not apply a potential to any terminal, including the common terminal, that exceeds the maximum rating of that terminal.

The measuring terminals on this product are not rated for connection to mains or Category II, III, or IV circuits.

Do not operate without covers. Do not operate this product with covers or panels removed, or with the case open.

Hazardous voltage exposure is possible.

Avoid exposed circuitry. Do not touch exposed connections and components when power is present.

Do not operate with suspected failures. If you suspect that there is damage to this product, have it inspected by

qualified service personnel.

y information

ual for further ratings information before making connections to the product.

Disable the product if it is damaged. Do not use the product if it is damaged or operates

the product, turn it off and disconnect the power cord. Clearly mark the product to prevent its further operation.

Before use, inspect voltage probes, test leads, and accessories for mechanical damage and replace when damaged. Do not

use probes or test leads if they are damaged, if there is exposed metal, or if a w ear indicator shows.

Examine the exterior of the product before y ou use it. Look for cracks or missing pieces.

Use only specified replacement parts.

incorrectly. If in doubt about safety of

Use proper fuse. Use only the fuse type and rating specified for this product.

Do not operate in wet/damp conditions. Be aware that condensation may occur if a unit is moved from a cold to a

warm environment.

Do not operate in an explosive atmosphere.

Keep product surfaces clean and dry.

Remove the input signals before you clean the product.

Provide proper ventilation. Refer to the installation instructions in the manual for details on installing the product

so it has proper ventilation.

Slots and openings are provided for ventilation and should never be covered or otherwise obstructed. Do not push objects

into any of the openings.

Provide a safe working environment. Always place the product in a location convenient for viewing the display

and indicators.

Avoid improper or prolonged use of keyboards, pointers, and button pads. Improper or prolonged keyboard or pointer use

may result in serious injury.

Be sure your work area meets applicable ergonomic standards. Consult with an ergonomics professional to avoid stress

injuries.

Use care when lifting and carrying the product. This product is provided with handles for lifting and carrying.

WARNING. The product is heavy. To reduce the risk of personal injury or damage to

carrying the product.

Use only the Tektronix rackmount hardware specified for this product.

iv DSA8300 Q uick Start User Manual

the device get help when lifting or

Servicesafetysummary

The Service safety summary section contains additional information required to safely perform service on the product. Only

qualified personnel should perform service procedures. Read this Service safety summary and the General safety summary

before performing any service procedures.

To avoid electric shock. Do not touch exposed connections.

Do not service alone. Do not perform internal service or adjustments of this product unless another person capable of

rendering first aid and resuscitation is present.

Important safet

y information

Disconnect

power before removing any covers or panels, or opening the case for servicing.

power.

To avoid electric shock, switch off the product power and disconnect the power cord from the mains

Use care when servicing with power on. Dangerous voltages or currents may exist in this product. Disconnect

power, remove battery (if applicable), and disconnect test leads before removing protective panels, soldering, or replacing

components.

Verify sa

fety after repair.

Always recheck ground continuity and mains dielectric strength after performing a repair.

DSA8300 Q uick Start User Manual v

Important safet

y information

Terms in this manual

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in damage to this product or other property.

Symbols and terms on the product

These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the marking.

WARNING indicates an injury hazard not immediately accessible as you read the marking.

CAUTION indicates a hazard to property including the product.

When this symbol is marked on the product, be sure to consult the manual to find out the nature of the

potential hazards and any actions which have to be taken to avoid them. (This symbol may also be used to

refer the user to ratings

The following symbol(s) may appear on the product:

in the manual.)

vi DSA8300 Quick Start User Manual

Compliance info

rmation

Compliance in

This section lists the EMC (electromagnetic compliance), safety, and environmental standards with which the instrument

complies.

EMC compliance

EC declarati

Meets intent of Directive 2004/108/EC for Electromagnetic Compatibility. Compliance was demonstrated to the following

specifications as listed in the Official Journal of the European Communities:

EN 61326-1:2006, EN 61326-2-1:2006. EMC requirements for electrical equipment for measurement, control, and

laborator

CISPR 11:2

IEC 61000

IEC 61000

IEC 61000

IEC 6100

IEC 6100

IEC 6100

on of conformity – EMC

123

yuse.

003. Radiated and conducted emissions, Group 1, Class A

-4-2:2001. Electrostatic discharge immunity

-4-3:2002. RF electromagnetic field immunity

-4-4:2004. Electrical fast transient / burst immunity

0-4-5:2001. Power line surge immunity

0-4-6:2003. Conducted RF immunity

0-4-11:2004. Voltage dips and interruptions immunity

formation

46

6

5

EN 61000-3-2:2006. AC power line harmonic emissions

EN 6100

0-3-3:1995.

Voltage changes, fluctuations, and flicker

European contact.

Tektronix UK, Ltd.

Western Peninsula

Western Road

Bracknell, RG12 1RF

United Kingdom

1

2

3

4

product is intended for use in nonresidential areas only. Use in residential areas may cause electromagnetic interference.

This

Emissions which exceed the levels required by this standard may occur when this equipment is connected to a test object.

To ensure compliance with the EMC standards listed here, use high quality shielded interface cables.

Horizontal timing susceptibility of the optical sampling modules and their internal clock recovery trigger signals usually increases

the horizontal timing jitter when external electromagnetic fields are applied. For fields up to 3 V/m, the increase in the horizontal

high-frequency RMS jitter is typically less than 3 ps RMS of jitter, added using the square-root-of-the-sum-of-the-squares method.

xample, if an 80C01–CR operating in clock-recovery trigger mode exhibits 3.5 ps RMS of edge jitter, with no EMC field

For e

applied and for an ideal jitterless input, then for applied fields up to 3 V/m the edge jitter, degradation would typically result in

a total RMS jitter of:

DSA8300 Q uick Start User Manual vii

Compliance info

5

Performance Criterion C applied at the 70%/25 cycle Voltage-Dip and the 0%/250 cycle Voltage-Interruption test levels (IEC

61000-4-11). If the instrument powers down upon a voltage dip or interruption, it will take longer than ten seconds to reboot.

6

With an 80E01 Electrical Sampling module, up to 15 mV

signals as defined in the IEC 61000-4-3 and IEC 61000-4-6 tests.

Australia / New Zealand declaration of conformity – EMC

rmation

random noise is allowed when the instrument is subjected to fields and

RMS

Complies w it

CISPR 11:200

EN 61326-2-1:2006.

h the EMC provision of the Radiocommunications Act per the following standard, in accordance with ACMA:

3. Radiated and Conducted Emissions, Group 1, Class A, in accordance with EN 61326-1:2006 and

Safety compliance

This section lists the safety standards with which the product complies and other safety compliance information.

EU declaration of conformity – low voltage

Compliance was demonstrated to the following specification as listed in the Official Journal of the European Union:

Low Voltage Directive 2006/95/EC.

EN 61010-1. Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use – Part

1: Gener

U.S. nationally recognized testing laboratory listing

UL 61010-1. Safety R equirements for Electrical Equipment for Measurement, Control, and Laboratory Use – Part

1: General Requirements.

al Requirements.

Canadian certification

CAN/CSA-C22.2 No. 61010-1. Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory

Part 1: General Requirements.

Use –

Additional compliances

IEC 61010-1. Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use – Part

1: General Requirements.

Equipment type

Test and measuring equipment.

afety class

S

Class 1 – grounded product.

viii DSA8300 Q uick Start User Manual

Compliance info

rmation

Pollution degree descriptions

A measure of the contaminants that could occur in the environment around and within a product. Typically the internal

environment inside a product is considered to be the same as the external. Products should be used only in the environment

for which they are rated.

Pollution degree 1. No pollution or only dry, nonconductive pollution occurs. Products in this category are generally

encapsulated, hermetically sealed, or located in clean rooms.

Pollution degree 2. Normally only dry, nonconductive pollution occurs. Occasionally a temporary conductivity that is

caused by condensation m ust be expected. This location is a typical office/home environment. Temporary condensation

occurs only when the product is out of service.

Pollution degree 3. Conductive pollution, or dry, nonconductive pollution that becomes conductive due to condensation.

These are sheltered locations where neither temperature nor humidity is c ontrolled. The area is protected from direct

sunshine, rain, or direct wind.

Pollution degree 4. Pollution that generates persistent conductivity through conductive dust, rain, or snow. Typical

outdoor locations.

Pollution degree rating

Pollution degree 2 (as defined in IEC 61010-1). Rated for indoor, dry location use only.

IP rating

IP20 (as defined in IEC 60529).

Measurement and overvoltage category descriptions

Measurement terminals on this product may be rated for measuring mains voltages from one or more of the following

ories (see specific ratings marked on the product and in the manual).

categ

ory II. Circuits directly connected to the building wiring at utilization points (socket outlets and similar points).

Categ

gory III. In the building wiring and distribution system.

Cate

gory IV. At the source of the electrical supply to the building.

Cate

NOTE. Only mains power supply circuits have an overvoltage category rating. Only measurement circuits have a

measurement category rating. Other circuits within the product do not have either rating.

Mains overvoltage category rating

Overvoltage category II (as defined in IEC 61010-1).

DSA8300 Q uick Start User Manual ix

Compliance info

rmation

Environmental considerations

This section provides information about the environmental impact of the product.

Product end-of-life handling

Observe the following guidelines when recycling an instrument or component:

Equipment recycling. Production of this equipment required the extracti on and use of natural resources. The equipment

may contain substances that could be harmful to the environment or human health if improperly handled at the product’s

end of life. In order to avoid release o f such substances into the environment and to reduce the use of natural resources,

we encourage you to recycle this product i n an appropriate system that will ensure that most of the materials are reused

or recycled appropriately.

This symbol indicates that this product complies with the applicable European Union requirements according

to Directives 2002/96/EC and 2006/66/EC on waste ele ctrical and electronic equipment (WEEE) and

batteries. For information about recycling options, c heck the Support/Service section of the Tektronix Web

site (www.tektronix.com).

Perchlorate materials. This product contains one or more type CR lithium batteries. According to the s tate

of Califo

www.dtsc.ca.gov/hazardouswaste/perchlorate for additional information.

rnia, CR lithium batteries are classified as perchlorate materials and require special handling. See

Restriction of hazardous substances

This product is classified as an industrial monitoring and control instrument, and is not required to comply with the substance

restrictions of the recast RoHS Directive 2011/65/EU until July 22, 2017.

x DSA8300 Quick Start User Manual

Preface

Documentation

This manual describes the installation and operation of the DSA8300 Digital Serial Analyzer in cluding basic operation and

concepts. For more detailed information, see the application help on your instrument.

NOTE. The screen images in this manual may differ slightly from other versions of product software.

Additional information is available through a variety of sources. The following table points to the location of different types of

information available for this product.

Type of information Location

Unpacking, installation, operation and overviews

In-depth operation, UI help, programming help Instrument application help

Performance verification and specifications Product documentation CD

Product software Product software CD

Service Service manual

PDF files of instrument and modules manuals Product software CD

Preface

Quick Start User Manual

www.tektronix.com/software

www.tektronix.com/manuals

Conventions used in this manual

The following icons may be used in this manual.

Rear

power

panel

Fron

power

t panel

Connect power

Netw

ork

PS2 USB

DSA8300 Q uick Start User Manual xi

Preface

xii DSA8300 Q uick Start User Manual

Key features

The DSA8300 is a state-of-the-art equivalent time sampling oscilloscope that provides the highest fidelity measurement

and analysis capabilities for communications signal analysis, serial data network analysis, and serial data link analysis

applications.

Highest fidelity signal capture

Key features

Very Low Tim

425 fs typic

<100 fs typ

Best verti

Electrica

Optical r

full range) to <0.6 μW for the 80C10B (30 mW full range)

e-base Jitter:

al on up to 8 simultaneously acquired c hannels

ical on up to 6 channels with 82A04B phase reference module

cal resolution (16 bit A/D):

l resolution: <20 μV LSB (for 1 V full range)

esolution depends on the dynamic range of the optical module ranges from <20 nW for the 80C07B (1 mW

Flexible configurations

The DSA8300 supports up to 8 simultaneously acquired signals

A wide variety of optical, electrical, and accessory modules to support your specific testing requirements

Use the new Change/View Module Config function to install or remove modules without powering down the instrument

Optical modules

Fully i ntegrated optical modules that support all standard optical data rates from 155 Mb/s to 100 Gb/s

Certified optical reference receivers support specified requirements for standards-mandated compliance testing

Optical bandwidths to >80 GHz

High optical sensitivity and low noise as well as the wide dynamic range of the optical sampling modules allows accurate

ing and characterization of short-reach to long-haul optical communications standards

test

y calibrated clock recovery solutions; no need to manually calibrate for data pick-off losses

Full

ibrated extinction ratio measurements ensure repeatability of extinction ratio measurements to <0.5 dB among

Cal

systems with modules with this factory calibration option

Electrical modules

Electrical bandwidths to >70 GHz

Very low-noise electrical samplers (280 μV at 20 GHz, 450 μVat60GHz,typical)

Selectable bandwidths (module 80E07B, 80E08B, 80E09B, 80E10B, 80E11, 80E11X1) allow the user to trade-off

sampler bandwidth and noise for optimal data acquisition performance

DSA8300 Q uick Start User Manual 1

Key features

Remote samplers (module 80E07B, 80E08B, 80E09B, 80E10B, 80E11, 80E11X1) or compact sampling extender module

cables support

minimal signal degradation by locating the sampler in close proximity to the device under test

World’s highe

characterization and high dynamic range for S-parameter measurements to 50 GHz

st-performance integrated TDR (10 ps typical step rise time) supports exceptional impedance discontinuity

Analysis

Standard Analysis Capabilities:

Complete suite of over 120 automated measurements for NRZ, RZ, and Pulse signal types

Automated mask testing with over 80 industry-standard masks. New masks can be imported into the DSA8300 to

support new emerging standards. In addition, users can define their own masks for automated mask testing

Vertical and Horizontal histograms for statistical analysis of acquired waveforms

Vertical, Horizontal, and Waveform cursors (with measurements)

Jitter, Noise, BER, and Serial Data Link Analysis is provided through the 80SJNB Basic and Advanced software

application options

Advanced TDR Analysis, S-parameter measurements, Simulation Model Extraction, and Serial Link Simulation

capabilities are provided through the IConnect® Software application options

High test throughput

High Sample Acquisition Rate up to 300 kS/s per channel

Efficient Programmatic Interface (IEEE-488, Ethernet, or local processor access) enable High Test Throughput

2 DSA8300 Quick Start User Manual

Install your instrument

Unpack the instrument and check that you received all items listed as Standard Accessories. Recommended accessories

and probes, instrument options, and upgrades are listed in the application help. Check the Tektronix Web site

(www.tektronix.com) for the most current information.

Standard accessories

Accessory Tektronix part number

DSA8300 Digital Serial Analyzer Quick Start User Manual

Certificate of Traceable Calibration for p roduct at initial shipment

Business reply card Not orderable

Keyboard 119-7083-00

Mouse 119-7054-00

Instrument front cover

Accessory pouch 016-1441-00

Touch screen styluses (2)

ESD wrist strap with 6 foot coiled cord

DSA8300 Product Documentation CD

DSA8300 Application Help (part of application software)

DSA8300 Programmer Manual (part of application software)

DSA8300 Product Software Install Kit

Power cord Type dependent on selection

VGA female to DVI male adapter

Install your ins

071-2897-XX

Not orderable

200-4519-00

119-6107-00

006-3415-04

063-4356-XX

Not orderable

Not orderable

020-3088-XX

during order placement

013-0347-00

trument

DSA8300 Q uick Start User Manual 3

Install your ins

trument

Operating considerations

The following information lists the specifications related to the operation of the mainframe. Refer to the DSA8300 Digital

Serial A nalyzer Specifications and Performance Verification Manual for a complete list of speci fications.

Mechanical

Clearance requirements

Top, Front, and Rear: 0 mm (0 in)

Sides: 51 mm (2 in)

Bottom: 19 mm (0.75 in)

Weight

Orientation

Rack mounting

Dimensions

19.5 kg (43.0 lb.). This does not include any accessories or modules.

Place the instrument on a cart or bench. The instrument should rest on its

bottom or rear feet. The front feet fold down to angle the instrument.

An optional rack mounting kit (Option 1R) is available.

ronmental

Envi

erature

Temp

ative humidity

Rel

Altitude

4 DSA8300 Quick Start User Manual

10 °C to +40 °C

20% to 80%, with a maximum wet bulb temperature of 29 °C at or below

+40 °C

3,000 m (9,843 ft.)

Power supply

Install your ins

trument

Source voltag

Power Consump

e and Frequency

tion

100 - 240 V

600 watts maximum

Typically, 24

Fuses

3AG, 8 A, 250 V

159-0046-XX

or

6.3 A, 250 V,

Input connectors

Trigger Direct Input range

Trigger Prescaled Input absolute maximum

input (typical)

External 10 MHz Reference Input 500 mV

±1.5 V (DC + peak AC) maximum input voltage

±1.1 V

10%, 50 - 60 Hz or 115 V

±

RMS

±10%, 400 Hz

RMS

0 w atts (fully loaded); 160 watts (mainframe with no modules)

, 15 second, ceramic fuse, Tektronix part number

fast blow (European), Tektronix part number 159-0381-XX

p-p

p-p

to5V

AC coupled into 1 kΩ, ±5 V maximum

p-p

DSA8300 Q uick Start User Manual 5

Install your ins

trument

Powering the instrument on and off

1. Insert AC power cord.

2. Toggle the mains switch to on.

3. Use the front panel power button to

switch the instrument on and off.

CAUTION. To prevent damaging the modules, do not install or remove any modules while the instrument is powered on.

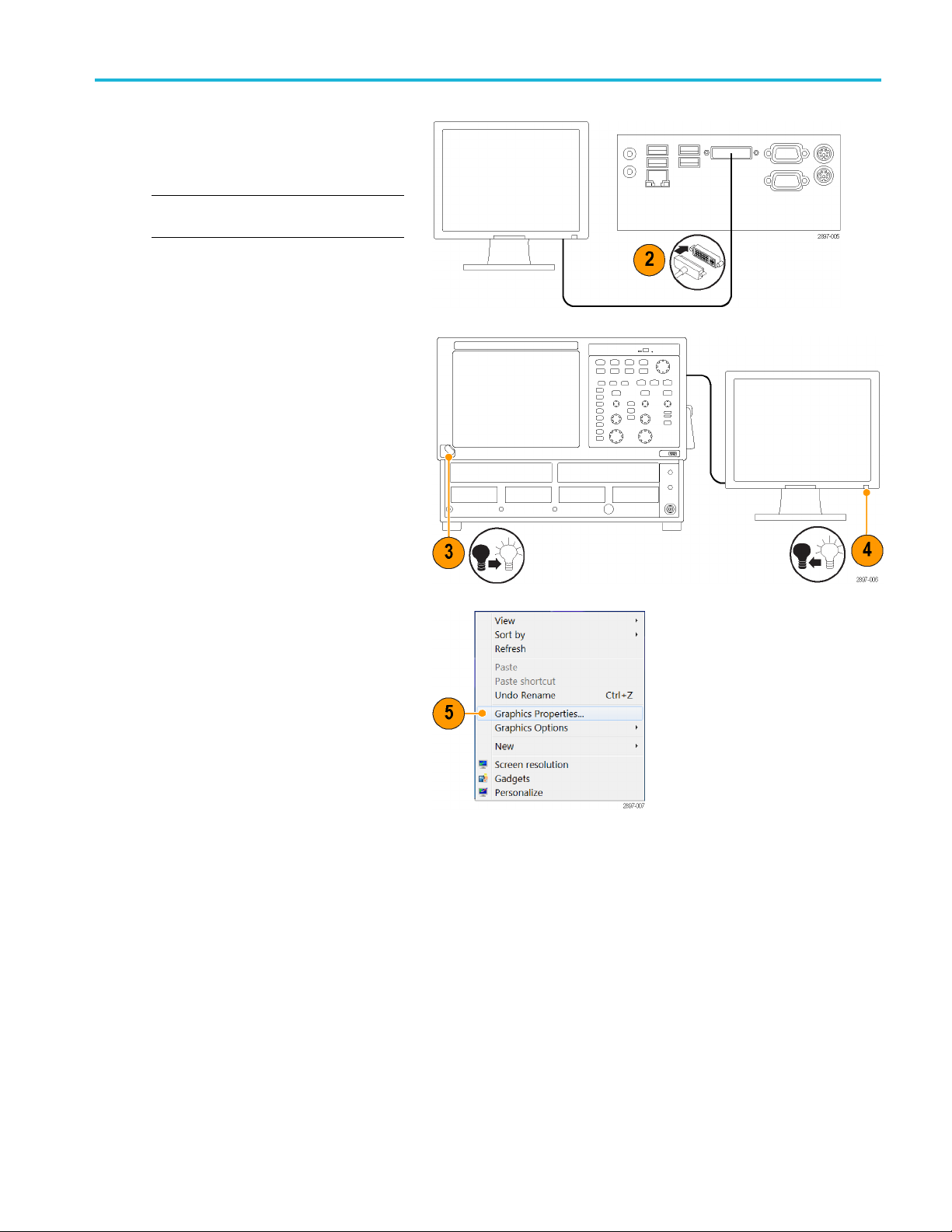

Adding a second monitor

You can add a second monitor to provide two screens for viewing instrument applications or readouts.

1. Power off the instrument.

6 DSA8300 Quick Start User Manual

2. Connect a video cable (not supplied)

from the D VI-I out video port on the back

of the instrum

external monitor.

NOTE. Use a DVI-I to SVGA adapter (not

supplied) to

3. Power on the instrument.

4. Power on the external monitor. The

instrument detects the external monitor

and displays the contents of the

instrument screen.

ent to the D VI-I port on the

connect to SVGA monitors.

Install your ins

trument

5. Move the cursor to a blank area of the

screen, right-click the mouse to open

the context menu, and select Graphics

Properties.

DSA8300 Q uick Start User Manual 7

Install your ins

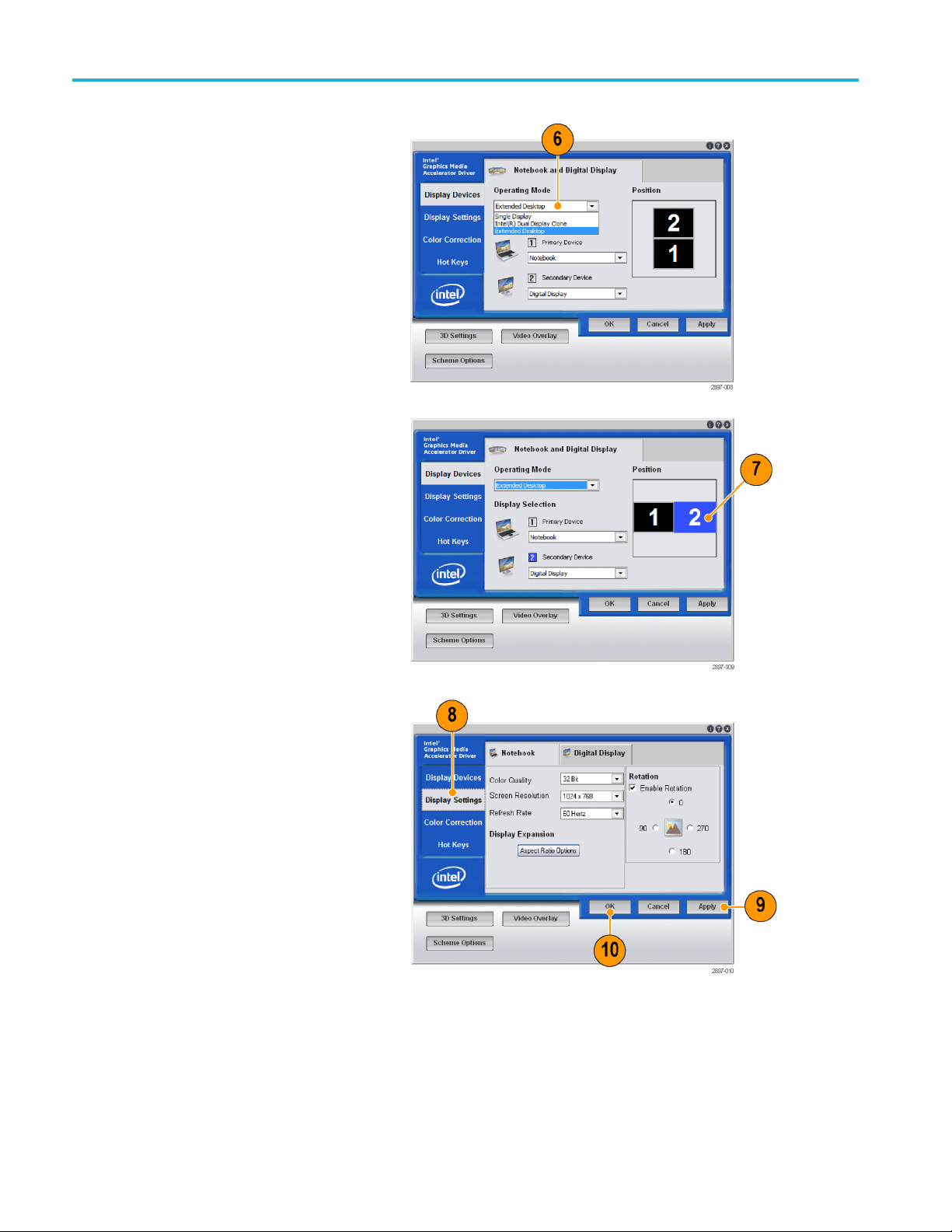

6. Select the display mode from the

7. If using an extended desktop, click the

trument

Operating Mode list.

external monitor 2 box in the Position

pane and drag the monitor to the position

that relates to the physical position of

monitor 2 in relation to monitor 1.

8. Click the Display Settings tab, click the

lDisplaytab, and use the fields to

Digita

set the monitor 2 screen characteristics.

9. Click Apply. The instrument makes the

selected changes and then prompts you

p the changes (if OK) or to Cancel

to kee

the settings and return to the prev ious

settings. If the new settings are correct,

k OK. You have about 15 seconds

clic

before the instrument automatically

returns to the previous display settings.

10. Click OK to close the Intel Graphics

ia Accelerator Driver window.

Med

8 DSA8300 Quick Start User Manual

Installing m odules

This section describes how to install and remove modules, as well as how to move modules while the instrument is

powered on.

Typical module installations

Installing modu

les

The followin

small compartment channels.

NOTE. A large compartment module that only derives power from the compartment does not use any small compartment

input chann

Eight channels: No large and four small

modules

Six channels: Two large modules and two

small mod

Seven c

in CH3 compartment, and three small

modules

Seven channels: One large module, installed

in CH1 compartment, and three small

modul

g are some typical module installations illustrating the interaction between large compartment channels and

els.

ules

hannels: One large module, installed

es

DSA8300 Q uick Start User Manual 9

Installing modu

les

Install a module

1. Connect an antistatic wrist strap to the instrument front-panel ground connection. Place the strap on your wrist.

2. For optical modules, turn the module lock screws counterclockwise to rotate the retaining tabs to a vertical position

before inserting the module.

3. Use the power cycle that is appropriate for your instrument:

DSA8300 instruments with TekScope application version 6.1.X and greater: Click Tools > View/Chang e Module

Config and follow the on-screen instructions. (See page 11, Powered-on module configuration.)

Legacy instruments and DSA8300 with TekScope application version 6.0.X: Power off the instrument using the

front-panel On/Standby button.

4. Push the module into a compartment, using firm pressure. When the module is seated, turn the lock screw(s) clockwise

to tighten the module in the slot.

5. Power on the instrument (legacy instruments or DSA8300 with 6.0.X software) or complete the View/Change Module

Config process (software version 6.1.X and later). Let the instrument warm up for 20 minutes.

NOTE. The warm-up cycle is not required if you installed the module using the View/Change Module Config function

(software version 6.1.X and later).

6. In the TekScope application, click Utilities > Compensate and run a compensation on the newly-installed module. You

must also run a compensation if a module is moved from one slot to another, or an extender is installed, changed, or

removed from a module.

10 DSA8300 Quick Start User Manual

Removeamodule

1. Connect an antistatic wrist strap to the instrument front-panel ground connection. Place the strap on your wrist.

2. Use the power cycle that is appropriate for your instrument:

DSA8300 instruments with TekScope application version 6.1.X and greater: Click Tools > View/Change Module

Config and follow the on-screen instructions. (See page 11, Powered-on module c onfiguration .)

Legacy instruments and DSA8300 with TekScope application version 6.0.X: Power off the instrument using the

front-panel On/Standby switch.

3. Turn lock screw(s) counterclockwise until loose or they stop turning.

4. Push the appropriate ejector lever (as indicated by the up or down arrow near each lever) to the right to disconnect

the module.

Installing modu

les

5. Pull the module out of the slot.

Powered-on module configuration

The View/Change Module Config function lets you remove, install, or move modules without powering down the mainframe.

CAUTION. Installing or changing modules when powered on requires DSA8300 TekScope software version 6.1.X or greater.

kScope software versions earlier than 6 .1.X , always power off the mainframe to remove or install modules. Failure to

For Te

do so may result in damage to the module or mainframe. Download the latest D SA8300 software from www.tek.com/software.

1. Select Utilities > View/Change Module

Config to open the module configuration

og box.

dial

DSA8300 Q uick Start User Manual 11

Installing modu

2. Click on all module slots that you want to

3. Click Start.

4. The instrument notifies you when you

5. Click Finish. The instrument notifies you

les

change. This includes slots from which

to remove a mod

to install a module.

can remove or install a module. Remove

or install modules only from the indicated

slots. Wear an antistatic strap when

handling modules.

when the s

use.

ule and slots in which

elected modules are ready to

6. Close the dialog box.

7. Select Utilities > Compensation and

run a compensation on each channel of

y installed m odules. All newly

all newl

installed modules require compensation,

even if they were moved from one slot

her.

to anot

12 DSA8300 Quick Start User Manual

Getting acquain

tedwithyourinstrument

Getting acqua

Front panel

The front panel of your instrument gives you access to the module c ompartments and the c ontrol panel.

inted with your instrument

1. Antistatic connection terminal (1 MΩ).

2. On/Off switch.

3. Clock Input/Prescale Trigger input.

4. Trigger direct input.

5. Trigger probe power.

6. External 10 MHz reference input.

7. DC calibration output.

8. TDR Clock Out signal.

9. USB port(s).

10. Control panel.

11. DVD-ROM/CD-RW drive.

DSA8300 Q uick Start User Manual 13

Getting acquain

ted with your instrument

Control panel

1. Access print dialog box for printing the display.

2. Optimize instrument settings for the selected channel to automatically display a waveform.

3. Quickly return the instrument to default control settings.

4. Display measurement cursors and assigns the knob and SELECT buttons to control them.

5. Menu buttons quickly access the setup dialog box for more detailed setup.

6. Clear all data and measurement results.

7. Adjust m ost control fields in setup dialogs. Push the SELECT button to select the active cursor (when cursors are

enabled). Push the FINE button to toggle between normal and fine adjustment.

8. Start and stop acquisition.

9. Display the Setup dialog box for c omprehensive setup of the instrument.

10. Toggle the touch screen on and off. Use the touch screen to control UI when you have not installed a mouse.

11. Select a waveform type (Channel, Reference, or Math) to display or adjust on screen (selected button lights).

12. Push a channel button to select and display a waveform for that channel. A lit button indicates selected and displayed

waveforms for that channel. An unlit button indicates that the channel is not selected.

14 DSA8300 Quick Start User Manual

Getting acquain

13. S e lect among displayed timebase views or display and select a magnified timebase view. Push the selected view to

turn it off (exc

ept main, which is always on).

tedwithyourinstrument

14. Vertically sc

15. Horizontally

16. Set trigger le

Rear panel

The rear panel of your instrument allows you access to input and output connectors and the AC input.

ale, position, and offset selected waveform.

scale, position, and set record length of selected waveform.

vel (applies only to Trigger Direct Input) and use lights to monitor trigger state.

1. Removable hard drive.

2. GPIB port. The instrument is factory set to be a talk/listen device, allowing you to control the instrument via the GPIB

port. You can change the instrument to be a GPIB controller, allowing you to control other devices via the GPIB port, or

set the instrument to be off bus. Refer to the Programmer Manual installed on the instrument.

3. Computer I/O panel. (See page 16, Computer I/O panel.)

4. AC input.

5. Fuses.

6. Mains power switch.

DSA8300 Q uick Start User Manual 15

Getting acquain

ted with your instrument

Computer I/O panel

1. Audio line

4. DVI-I video out for dual-monitor display 5. COM1 6. PS2 (keyboard)

7. PS2 (mouse) 8. COM2

out

2. Mic input

3. USB ports

9. LAN

16 DSA8300 Quick Start User Manual

The user interface

Getting acquain

tedwithyourinstrument

1. Measure

measure the selected waveform.

2. Tool Bar. Access to key features including printing, setup dialogs, m ath w aveform setup, waveform database, autoset,

clear data, acquisition mode, triggering, and applications.

3. Menu Bar. Access to data I/O, printing, application help system, and setup functions.

4. Status Bar. Waveform count and trigger/acquisition status.

5. System Time/Date and compensation status.

6. Readout Docking. Select to undock the readout area from the application.

7. Readout area. Displays waveform and measurement details. Use the arrow buttons at each end to scroll the contents.

8. Readout. Right click on a readout to display a context menu for additional settings for that readout category.

9. Readout Enable. Toggles the readout type (cursor, histogram, mask, measurement, and waveform) on or off.

10. Controls Bar. Click to select a waveform (channel, math, or reference), as well as quick access to scale, offset, and

posi

11. Dis

ments Bar. Access to automated measurements by signal type and category; click measurement buttons to

tion controls for adjustment.

play. Contains live, reference, and math waveforms, and histograms, cursors and test masks when enabled.

DSA8300 Q uick Start User Manual 17

Getting acquain

ted with your instrument

Display - single waveform view

1. Drag the Horizontal Reference to move the point around which the horizontal scaling expands and contracts the

waveforms.

2. Drag cursors to measure waveforms on screen.

3. Drag the waveform icon vertically to position waveform.

4. Right-click on a waveform or its icon to open the context menu with setup controls and properties.

5. Drag ground reference icon to add offset to a waveform.

6. Drag across the waveform area to horizontally zoom the boxed waveform segment to full screen width.

18 DSA8300 Quick Start User Manual

Display - magnified waveform views

Getting acquain

tedwithyourinstrument

1. MAIN View

2. Mag1 View

3. Mag2 Vie

4. Drag the

5. Drag the

6. Drag th

e border between graticules to vertically size Main, Mag1, and Mag2 Views.

.

.

w.

markers to enclose the portion of waveform to appear in Mag1 View.

markers to enclose the portion of waveform to appear in Mag2 View.

DSA8300 Q uick Start User Manual 19

Getting acquain

ted with your instrument

Accessing application help

In-depth information about all the features of your instrument is available in the application help.

Position the mouse cursor on a control,

such as a menu name, a menu item, toolbar

button, or toolbar readout. The help system

displays a short definition or description

(tooltips) of the control.

For in-depth, contextual overviews, most

dialog boxes have a Help button. Click

the button to open the help system for

information on that dialog box.

Select Help > Help Contents and Index to

open the overall help system.

20 DSA8300 Quick Start User Manual

Inspect your instrument

Use the following procedure to verify the functionality of your instrument. For a complete performance verification, see the

DSA8300 Digital Serial Analyzer Performance Verification and Specifications Manual, which can be downloaded from the

Tektronix Web site.

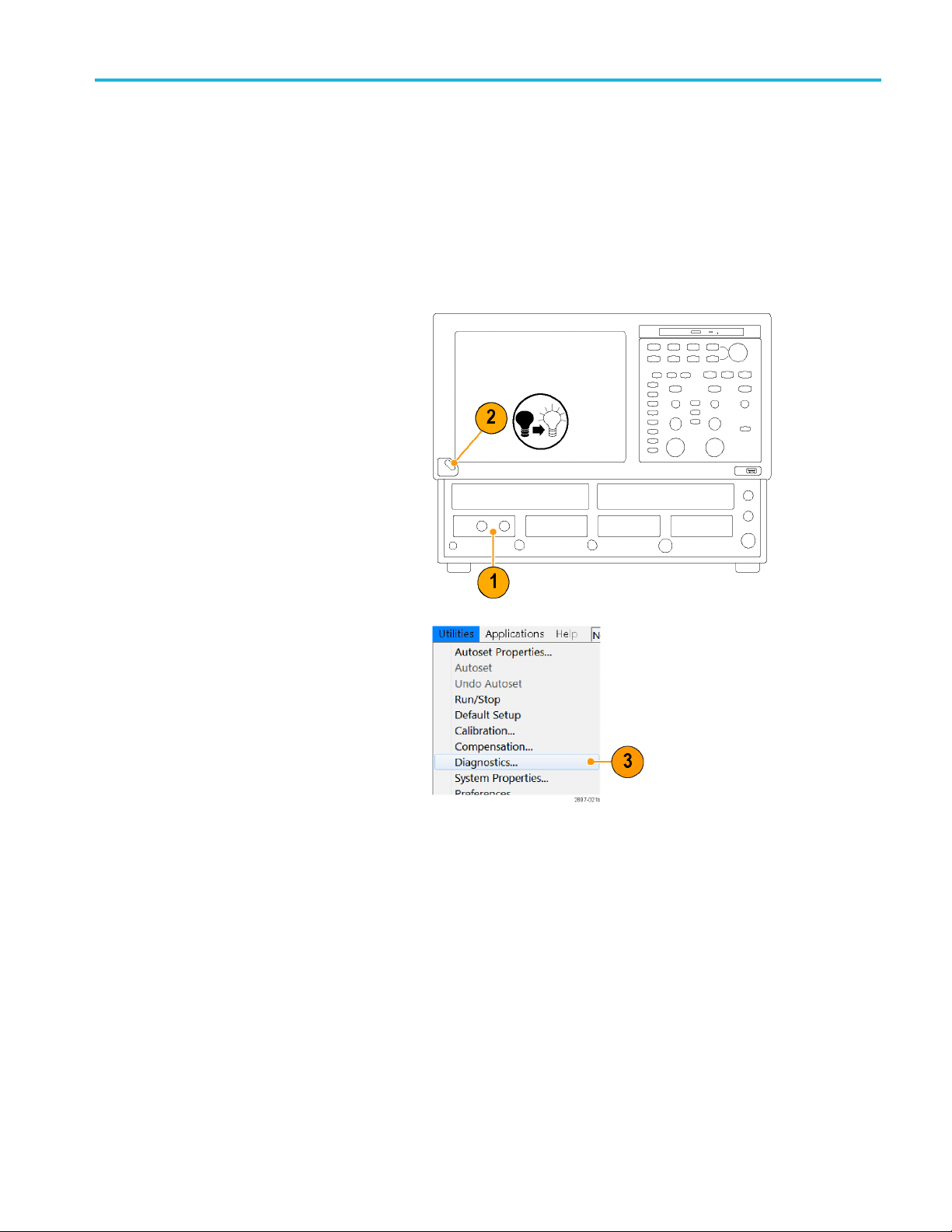

Verify internal diagnostics pass

1. Install all modules to be diagnosed.

2. Power on the instrument and wait

20 minutes for the warm-up period.

Inspect your ins

trument

3. Select U

tilities > Diagnostics.

DSA8300 Q uick Start User Manual 21

Inspect your ins

4. Select the Subsystem Level tab.

5. Select all the entries by clicking the first

6. Verify that the Loop and Halt on Failure

7. Click Ru n.

8. Verify that all tests display Pass in the

trument

entry Control Proc and dragging down

to select the r

est. All entries should be

highlighted.

boxes are unchecked.

Status colu

mn when the diagnostics

complete. If diagnostic failures occur,

contact your local Tektronix service

center.

22 DSA8300 Quick Start User Manual

Optimizing meas

urement accuracy

Optimizing me

The instrument provides several utilities that optimize measurement accuracy:

Signal path compensation (SPC) configures signal paths to improve measurement accuracy at the current ambient

temperature.

Dark-level compensation maximizes the accuracy of extinction ratio and other optical measurements

User Wavelength Gain c ompensation optimizes an optical channel for a custom input signal

Differential Channel Alignment application aligns input channels and TDR steps on supported electrical modules

asurement accuracy

Signal path compensation

Signal path compensation (SPC) configures the instrument and module signal paths to make accurate measurements at

the curren

You should

t ambient temperature.

run a SPC:

After add

After add

After mov

ing a module to the instrument

ing or removing an extender cable from a module.

ing a m odule to another slot.

The ambi

When mak

compensation once a week under these c onditions. Failure to do so may result in the instrument not meeting warranted

performance levels at these volts/div settings.

NOTE. Y

1. Install all modules to be compensated.

(See p

2. Insta

Failure to ins tal l the 50 Ω terminations

on electrical inputs can cause erroneous

comp

3. If yo

change module configuration, power on

the instrument and wait 20 minutes for

the w

ent temperature has changed more than 5 °C since the last signal path compensation.

ing measurements at vertical scale settings less than or equal to 5 mV/div. Perform the signal path

ou must save the compensation results or they will be lost when the instrument is powered down.

age 9, Installing modules.)

ll all terminations and dust covers.

ensation failures or results.

u powered off the instrument to

arm-up period.

DSA8300 Q uick Start User Manual 23

Optimizing meas

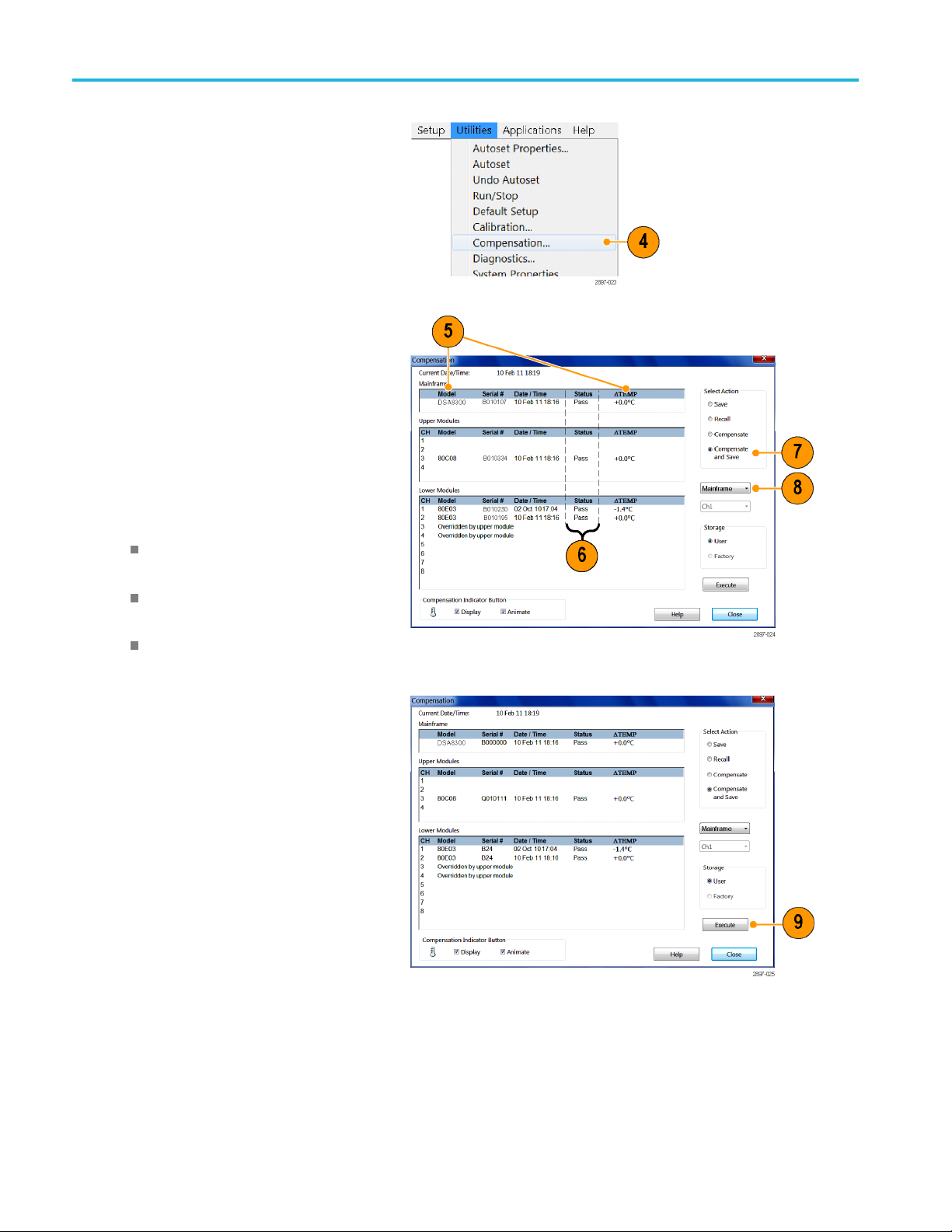

4. Select Utilities > Compensation

5. Verify that the main instrument

(mainframe) and all installed modules

are listed.

the last compensation is also listed.

6. Check that the Status for all items to

compensate changes from Warm Up to

Pass, Fail

urement accuracy

The temperature change from

,orComp Req'd.

7. Select Co

8. Select th

compensation:

Mainframe (default selection) to

compensate just the main instrument

All modules to compensate all installed

module c

Module

channels of the selected module

9. Click Execute.

Follow the on-screen instructions

regar

and terminations; be sure to follow

electrostatic handling precautions

(see

sampling module) when following these

instructions.

mpensate and Save (default).

eitemonwhichtorun

hannels

to compensate specified

ding signal and trigger inputs

the user information for your

24 DSA8300 Quick Start User Manual

10. Verify that the compensation routines

pass.

If the status i

again. If Fail status continues, the

module or main instrument may need

service.

s Fail, run the compensation

Optimizing meas

urement accuracy

11. Use the Compe

to display or h ide the compensation

indicator on the main display. Green

means that a

successfully compensated. Yellow

means that the instrument has not

competed it

Red means that one or more modules

require compensation.

nsation Indicator Button

ll modules have been

s 20 minute warm-up period.

DSA8300 Q uick Start User Manual 25

Optimizing meas

urement accuracy

Dark-level and user wavelength gain compensations

NOTE. You should run the Signal Path Compensation procedure before running dark-level or user wavelength gain

compensation

. (See page 23, Signal path compensation.)

These procedu

Dark-level compensation maximizes the accuracy of the extinction ratio and other optical automatic measurements.

Dark-level compensation performs a subset of the module compensation process. It is designed to be fast so it can be

performed f

selected bandwidth or filter path and the internal optical power meter.

User Wavelength Gain compensation optimizes an optical channel for your custom input signal.

1. Install one or two optical sampling

modules in the instrument. Set the

acquisiti

2. Select the channel to compensate.

res apply only to optical modules.

requently, just before measurements are taken. Dark-level compensation is not saved and is only valid for the

on system to run continuously.

3. Select Setup > Vertical.

26 DSA8300 Quick Start User Manual

Optimizing meas

urement accuracy

To run the Dark-

4. In Vert Setup d

Level button under Compensation.

Follow the instructions on screen.

NOTE. You need

dialog to the Optical dialog to access the

Dark Level Calibration button.

Repeat steps 2 and 4 for any

additional optical channels you want to

compensate

To run the U

compensation (for signals at wavelengths

other than the factory calibrated values;

typically

5. Use an independently-calibrated average

850, 1310 and/or 1550 nm):

optical p

power of an optical signal source.

Then connect the signal to the optical

module u

Level compensation:

ialog box, click the Dark

to switch from the Basic

.

ser Wavelength Gain

ower meter to measure the

sing the same fiber cable.

6. Click the User Wavelength Gain button

in the Vert Setup dialog box.

7. Enter the w avelength and measured

power of the signal applied to the

channel In the User Wavelength Gain

Compensation dialog box.

8. Click OK to execute the compensation.

DSA8300 Q uick Start User Manual 27

Optimizing meas

urement accuracy

Align acquisition (and TDR steps) for two-channel modules

Small signal misalignments on dual-channel electrical sampling modules can significantly impact differential and

common-mode signal measurements. The D ifferential Channel Alignment application provides a guided procedure to align

both the acquisition and (where applicable) the TDR steps of supported electrical sampling modules. This application is

available on DSA8300 instruments with TekScope firm ware ver sion 6.2.x and later.

You should run the Differential Channel Alignment application whenever you change the instrument module configuration,

such as when installing a new supported module, installing or moving supported modules from one slot to another,

or installing a module on an extender cable.

Click Applications > DiffChAlign to open the application. Open the help in the Differential Channel Alignment application

for more information.

28 DSA8300 Quick Start User Manual

Acquisition

This section contains concepts of and procedures for using the acquisition system. Detailed information is available in

the application help.

Setting up signal input

Acquisition

Use front-pa

CAUTION. Sampling modules are inherently vulnerable to static damage. Always observe static-safe procedures and

cautions as outlined in your sampling-module user manual.

1. Connect the instrument to the device or

signal under test u

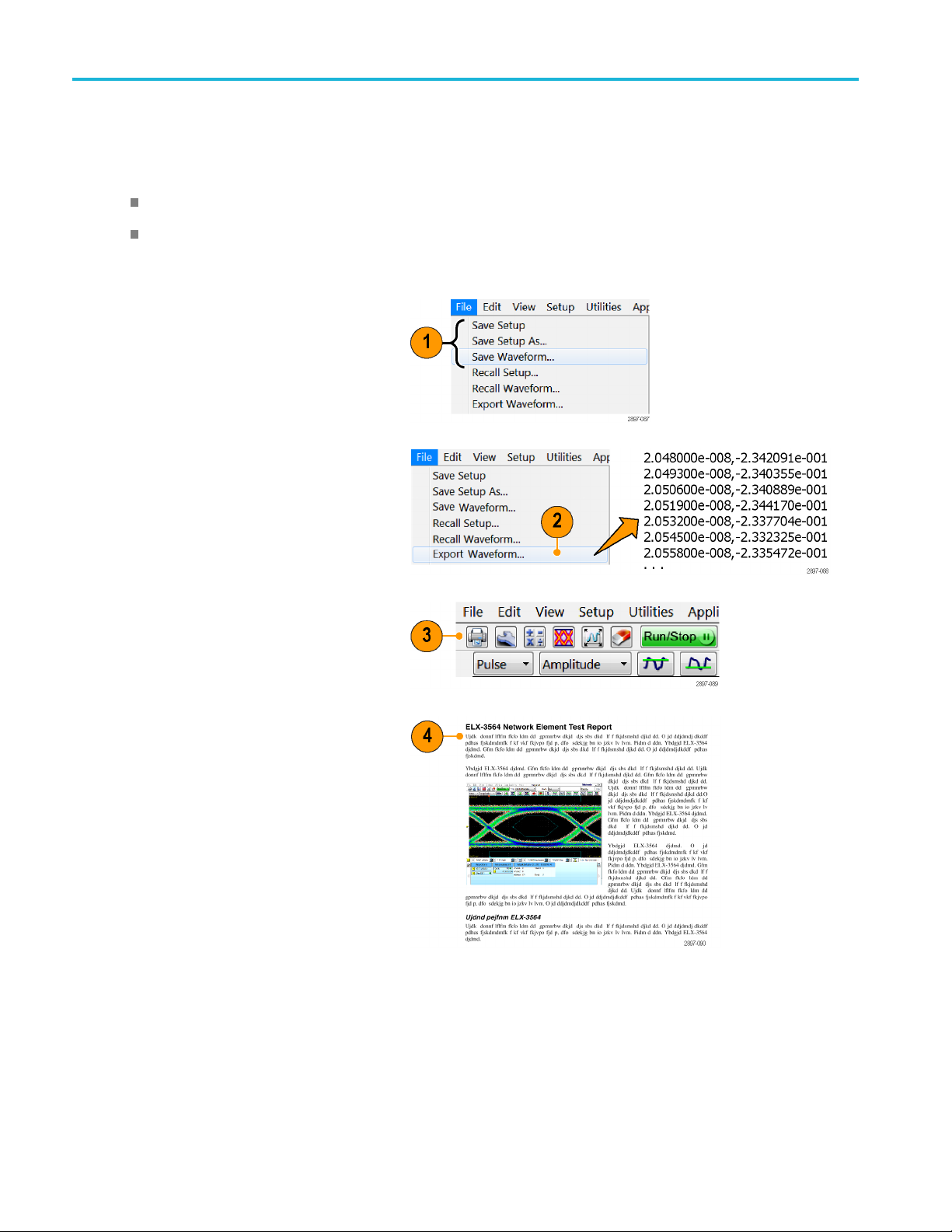

or connecting techniques. See the user

manual for the installed sampling module

for connection re

CAUTION. Discharge electrical cables to

ground before connecting them to a module.

2. Connect an appropriate t

the instrument. (See page 38, Triggers.)

nel buttons to set up your instrument to acquire the signal.

sing proper probing

quirements.

rigger signal to

DSA8300 Q uick Start User Manual 29

Acquisition

3. Push the CH button (turns amber) to

assign the waveform buttons (1–8)to

operate on cha

select the proper waveform button.

A waveform button lights when its

channel is on

the button is green; when on and

selected, the button is amber.

Push the MATH

waveform buttons to math waveforms.

If the selected math waveform is not

defined, the

Math dialog box.

Push the REF buttontoassign

the w avefo

waveforms. If no reference waveforms

are loaded into the channels, the Recall

Waveform d

nnel waveforms. Then

; w hen on but not selected,

button to assign the

instrument opens the Define

rm buttons to reference

ialog box appears.

4. Use the Ve

and Scale knobs to adjust the vertical

parameters o f the selected waveform.

rtical Position, Offset,

30 DSA8300 Quick Start User Manual

Acquisition

5. Push the View Ma

that the main time base view is selected.

Use the horizontal Position, Resolution,

and Scale knob

the waveform on the screen and to set

the sample resolution.

in buttontomakesure

s to scale and position

Quick tips

You can click a waveform trace or its reference indicator with the mouse pointer (or touch screen) to select it.

Push AUTOSET to quickly set up instrument parameters and display a waveform based on the input signal.

Push Set to 50% in the Trigger controls, if required, to stabilize the display when using the Trigger Direct Input connector.

Using fa

1. To quickly return to the factory default

2. Click Yes to restore the settings.

ctory default setup

settings, push DEFAULT SETUP.

DSA8300 Q uick Start User Manual 31

Acquisition

Using Autoset

Use Autoset to automatically set the instrument vertical, horizontal, and trigger parameters and display a waveform based on

the characteristics of the input signal.

NOTE. Make sure that the input channel(s) for the signal are on and selected before doing an autoset.

1. Push the AUTOSET button to execute

an Autoset.

If you use Autoset when one or more

channels are displayed, the instrument

uses the selected channel for horizontal

scaling. Vertically, all channels in use are

individually scaled.

Quick tips

If the ins

select the signal type. Then push the Autoset button again.

Select Utilities > Define Autoset to change the Autoset properties.

trument does not autoset to your signal, select Setup > Horizontal,clicktheComm Standard button, and

32 DSA8300 Quick Start User Manual

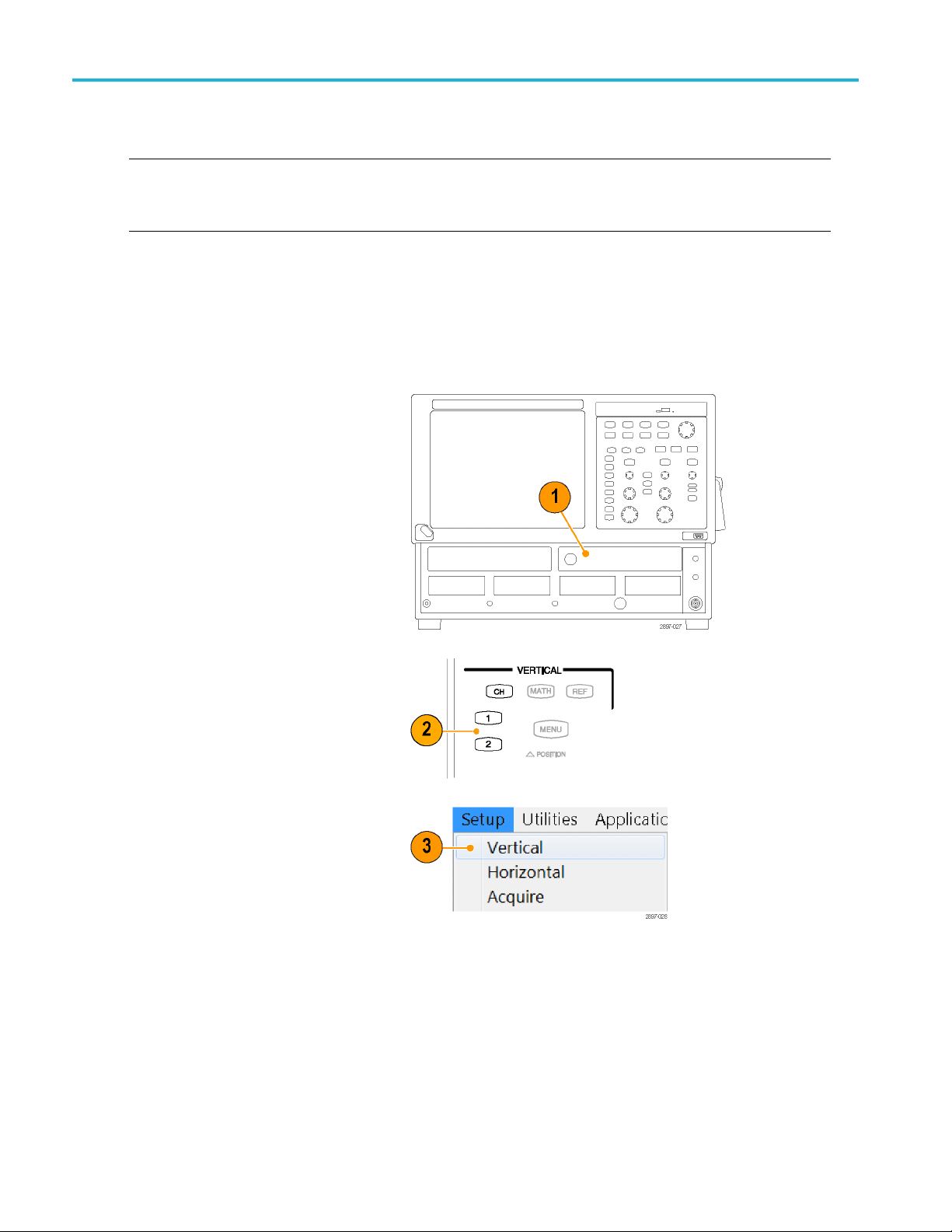

Accessing the Setup dialog boxes

The Setup dialog boxes are the key controls for setting instrument parameters such as Mode/Trigger, horizontal, vertical,

acquisition, cursors, hist ogram, display, and mask.

1. Access the Setup dialog boxes by using

the front panel buttons, the Setup menu

item, or the Setup button.

Acquisition

2. Click

DSA8300 Q uick Start User Manual 33

on the tabs to select among the

setup dialog boxes.

Acquisition

Changing the acquisition mode

Use the procedure that follows to set the data-acquisition mode and specify acquisition start and stop methods.

1. Push the Acquisition MENU button to

display the Acq Setup dialog box.

2. Select the acquisition mode.

3. For Average mode, enter the number of

samples to average.

4. Set the Stop After mode and action by

selecting Run/Stop Button Only or

Condition.

5. If you selected Condition, choose a

condition on which to stop from the

drop-down list. If the condition requires a

count, enter a count.

6. Enter a filename if you selected Print to

File or Save all Waveforms.

7. Select Ring Bell if you want the

instrument to produce an audio tone

when the acquisition stops.

NOTE. You must connect an external

speaker to the instrument to hear a tone on

a stop condition.

8. Push RUN/STOP to start the acquisition.

9. Push RUN/STOP again to stop the

acquisition.

Quick tips

Run/Stop is available on both the front panel and the touch screen.

If Stop After is set to Condition, pressing RUN/STOP causes only one acquisition to run if the original condition has been

met. You need to push CLEAR DATA so that the c ondition must be met again.

34 DSA8300 Quick Start User Manual

Waveform databases

Acquisition

NOTE. Certain

system to use a waveform database i f one is available.

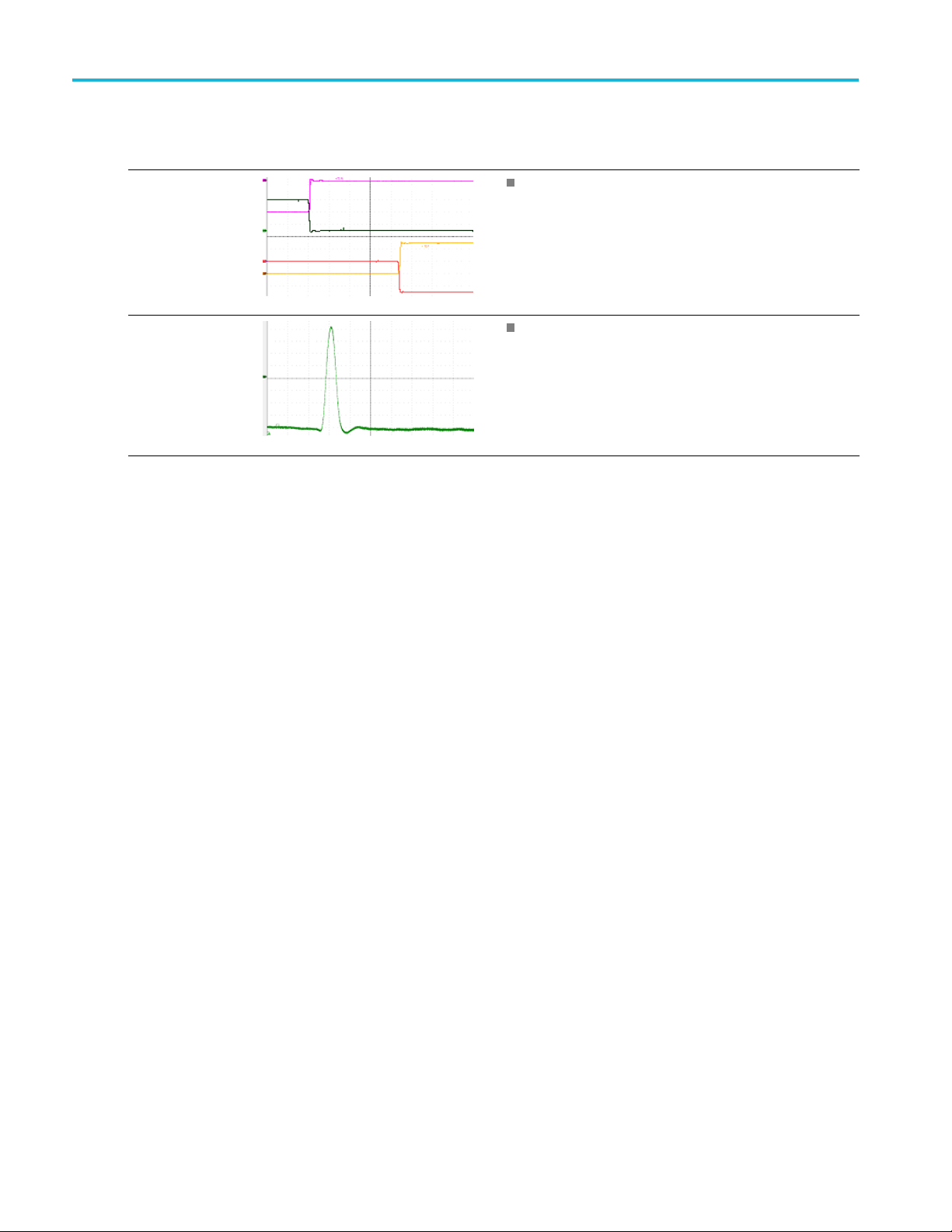

The four available waveform databases can be used for measurements, histogram calculations, mask testing, and generating

a density-st

mask testing.

1. Select Setu

main menu.

2. From the pu

Database, select one of the four

available databases.

3. Click the Source button to select the

waveform

4. Click On t

the selected source.

5. Click Display to turn on the display of

the waveform database.

6. Select the Persistence mode for the

select

measurements require the use of a waveform database. The instrument automatically sets the measurement

yle, graded display. Waveform databases may be automatically allocated for measurements, histograms, and

p > Wfm Database from the

lldown menu under

source.

o start accumulating data from

ed waveform.

7. If you s

NOTE. The following Display Options affect

all w aveform databases that you display.

8. Click a grading display option.

9. Click Invert to emphasize the least

10. Select one of the four grading methods.

11. If you selected one of the two

elected Variable persistence, you

can specify the number of waveforms

that are included in the waveform

ase.

datab

urring pixels by reversing the

occ

intensity/color assignments to each

grading partition.

phasized grading methods, slide the

Em

Emphasize Counts percentage control

to specify the range of counts you want

phasized.

em

DSA8300 Q uick Start User Manual 35

Acquisition

Setting the display style

1. Click the Setu

tab.

2. Select a waveform display style.

Normal selects a display with no

acquisit

are displayed with the new data from

ongoing acquisitions replacing data

acquire

Show Vectors turns on display lines

between waveform dots; deselect to

display only dots.

p button and click the Disp

ion data persistence. Waveforms

d from previous acquisitions.

Sin(x)/x interpolation computes

record points using a curve fit

between the acquired samples.

Linear interpolation computes

record points between actual

acquired samples by using a straight

line fit.

3. Variable Persistence makes data

persist for a specified time. New

waveform displays accumulate data as

new waveform records acquire, but with

continuous replacement of the oldest

data.

Set a time at which the oldest data is

removed.

36 DSA8300 Quick Start User Manual

Infinite Persistence makes data

persist until you change some control

or explicitly

clear the data. Waveform

displays accumulate data as the

instrument acquires new data, resulting

in a buildup o

f data in all time slots.

Acquisition

4. Use the Grat

icule settings to select the

graticule style and the g raticule color and

screen background.

DSA8300 Q uick Start User Manual 37

Triggers

Triggers

This section contains concepts and procedures for using the trigger system. Detailed information is available in the

application help.

Triggering concepts

Trigger event

A trigger event occurs when the trigger source (the signal that the trigger circuit monitors) passes through a specified voltage

level in a specified direction (the trigger slope). The trigger event sets the time-zero point in the waveform record and all

sampled waveforms on all inputs are measured with respect to that event.

When a trigger event occurs, the instrument acquires one sample of all active (selected) signals. When the next trigger

event occurs, the instrument acquires the next s ample. This process continues until the entire record is filled with acquired

samples. Without a trigger, the instrument does not acquire any samples. Sampling oscilloscope behavior differs from that of

real-time acquisition systems, which can acquire a complete waveform record from a single trigger event.

Trigger sources

ger source sets the source that the trigger system monitors for a trigger event. The source can be:

The trig

Aclocks

external to the instrument:

NOTE. Signals greater than 1 V

The instrument TDR clock, with selectable TDR Step repetition rates. The TDR CLOCK OUT connector on the

inst

Alo

used to acquire serial data signals at rates up to 3 Gb/s, its primary use is for low repetition rate (<150 MHz) signals or for

signals w here you need additional conditioning of the input trigger signal (such as trigger level, slope, and so on). This

flex

An i

this trigger source is useful primarily for locating a signal or clock and applying the appropriate offset to the data or

trigger for proper synchronous waveform acquisition.)

ignal used for acquiring optical or electrical serial data streams. The source of the clock can be internal or

External Clock Input/Prescale Trigger. Connect the trigger signal to the front panel connector. Triggering is

guaranteed for clocks from 800 MHz to 15 GHz (200 mV

(150 mV

Internal Clock-recovery trigger. This trigger source can be an optical sampling module that is equipped with a

clock

depend on the sampling module. For example, the 80C08C Optical Sampling Module with option CR4 provides

internal clock-recovered triggers for any data rate (standard or custom) from 8.5 Gb/s to 12.5 Gb/s.

rument front panel supplies a replica of the TDR clock,

w-repetition rate signal (DC to 3 GHz) connected to the External Trigger Direct input. While this trigger source can be

ibility comes at the cost of increased instrumentation jitter.

nternal clock for Free Run acquisition of signals. (Since the acquired signals are not synchronous with the trigger,

-1VPP).

PP

may cause the unit to stop triggering.

PP

-recovery option, or a dedicated electrical c lock recovery module. Available clock recovery triggering rates

-1VPP), and will typically work from 150 MHz to 20 GHz

PP

38 DSA8300 Quick Start User Manual

Trigger modes

When a Clock source is selected (whether Internal Clock recovery or external Clock Input/Prescale Trigger input) as the

trigger source, you must select the Trigger M ode. Available trigger modes are Eye, Pattern, and O ther:

Select Eye mode if the signal you are acquiring is synchronous with the selected clock source and you w ant to display

the acquired data as an "eye diagram" overlaying all of the acquired data bits with minimal clock to data jitter.

Select Pattern mode if the signal you are acquiring is synchronous with the selected clock source and you want to

display the individual bits as a "bit stream", with minimal clock to data jitter.

NOTE. Pattern mode is only available if Option ADVTRIG is installed on the instrument.

Select Other mode if the signal you are acquiring is synchronous with the s elected clock source and you want to display

the acquired data showing the effects of any clock modulation (such as Spread Spectrum Clocking).

Table 1: Application-based trigger modes

Triggers

Application

Optical or

Electrical Serial

Data (NRZ) Mask

and Parametric

Testi n g ( m i nimum

jitter)

Optical or

Electrical Serial

Data Pattern

Analysis (including

JNB analysis)

Optical or

Electrical Serial

Data (NRZ) Mask

and Parametric

Testi n g (w/ clock

modulation effects

– SSC)

Clock Signal

Analysis

Waveform display Trigger Source/Mode

Trigger Source: Clock Input/Prescale Trigger input or

Internal Clock Recovery

Clock Trigger Mode: Eye

Trigger Source: Clock Input/Prescale Trigger input or

Internal Clock Recovery

Clock Trigger Mode: Pattern (this mode of operation

requires the Advanced Trigger Option ADVTRIG).

Maximum supported pattern length= 2

Trigger Source: Clock Input/Prescale Trigger input or

Internal Clock Recovery

Clock Trigger Mode: Other

Trigger Source: Clock Input/Prescale Trigger input or

Internal Clock Recovery

Clock Trigger Mode: Eye

23

.

DSA8300 Q uick Start User Manual 39

Triggers

Table 1: Application-based trigger modes (cont.)

Application

TDR/TDT and

S-Parameter

Analysis

Low Repetition

Rate Signals

Waveform d isplay Trigger Source/Mode

Trigger Source: TDR

Trigger Source: External Direct Trigger input

40 DSA8300 Quick Start User Manual

Setting trigger controls

Nearly all trigger parameters a re set in the Mode/Trig Setup dialog box.

1. Push the Trigger MENU buttontodisplay

the Mode/Trig Setup dialog box.

2. Select a trigger source.

3. If the trigger source is Clock, select the