xx

DSA8300 Digital Serial Analyzer

80C00, 80E00 Sampling Modules

80A00 Accessory Modules

ZZZ

Performance Verification

Technical Reference

*P077068203*

077-0682-03

xx

DSA8300 Digital Serial Analyzer

80C00, 80E00 Sampling Modules

80A00 Accessory Modules

ZZZ

Performance Verification

Technical Reference

Warning

The servicing instructions ar

only. To avoid personal injury, do not perform any servicing

unless you are qualified to do s

prior to performing service.

www.tektronix.com

077-0682-03

e for use by qualified personnel

o. Refer to all safety summaries

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O . Bo x 50 0

Beaverto

USA

For product information, sales, service, and technical support:

n, OR 97077

In North America, call 1-800-833-9200.

World wide, visi t www.tektronix.com to find contacts in your area.

Warranty

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1)

year from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its

option, either will repair the defective product without charge for parts and labor, or will provide a replacement

in exchange for the defective product. Parts, modules and replacement products used by Tektronix for warranty

work may be n

the property of Tektronix.

ew or reconditioned to like new performance. All replaced parts, modules and products become

In order to o

the warranty period and make suitable arrangements for the performance of service. Customer shall be responsible

for packaging and shipping the defective product to the service center designated by Tektronix, with shipping

charges p repaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a location within

the country in which the Tektronix service center is located. Customer shall be responsible for paying all shipping

charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

result

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any damage

or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been modified or

integrated with other products when the effect of such modification or integration increases the time or difficulty

of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TRONIX' RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE

TEK

AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

[W2 – 15AUG04]

btain service under this warranty, Customer must notify Tektronix of the defect before the expiration of

ing from attempts by personnel other than Tektronix representatives to install, repair or service the product;

Table of Contents

Important safety information ....... ................................ ................................ .............. vi

General safety summary ..................................................................................... vi

Service safety summary .......................... .................................. ......................... viii

Terms in this manual ................. .................................. ................................ ...... ix

Symbols and terms on the product .......................................................................... ix

Preface .............................................................................................................. xi

Manual Structure.............................................................................................. xi

Manual Conventions.......................... .................................. .............................. xi

Related Documentation ..................................................................................... xii

Performance Verification Procedures............................................................................. 1

Functional Test Procedures ......... ................................ ................................ ............... 2

Instrument Diagnostics......................... ................................ ............................... 2

Instrument and Module Compensation........... ................................ ........................... 3

Instrument Functional Tests .................................................................................. 6

Performance Tests ................... ................................ ................................ .............. 15

Prerequisites ..................... ................................ .................................. ............ 16

Equipment Required.......................................................................................... 17

DSA8300 Digital Serial Analyzer Test Records .......................................................... 20

DSA8300 Main Instrument and 82A04 Module Test Record............................................ 21

80E00 Electrical Modules Test Record..................................................................... 23

80C00 Test Records .......................................................................................... 32

80A02 EOS/ESD Protection Module Test Record ........................ .............................. 148

80A05 Electrical Clock Recovery Module Test Record.............................. .................. 149

DSA8300 Performance Verification ........... ................................ ................................ 151

Prerequisites ..................... ................................ .................................. .......... 151

Time Interval Accuracy, Direct and Clock Trigger ..................................................... 151

External Trigger Direct Level Accuracy ................................................................. 154

External Direct Trigger Sensitivity .. . .. . ... ... . .. . ... ... . ... ... . .. . ... ... . ... ... . .. . ... ... . .. . ... ... . ... . 156

External Trigger Direct Input Connector Delay Jitter .. . ... ... . .. . ... ... . ... ... . ... ... . ... ... . ... ... . .. 158

Trigger Delay Jitter, Untriggered Phase Corrected Mode . ... ... . .. . ... ... ... ... . .. . ... ... ... ... . .. . ... 161

Trigger Delay Jitter, External Triggered Phase Corrected Mode - Clock Eye . ... ... . ... ... ... . ... .. 164

External Clock/Prescale Trigger Delay Jitter .. ... . ... ... . .. . ... ... . .. . ... ... . ... ... ... . ... ... . .. . ... ... . 167

External Clock/Prescale Trigger Sensitivity . . ... ... . .. . ... ... . .. . ... ... . ... ... ... . ... ... ... . ... ... ... . .. 170

DC Calibration Output . .................................. ................................ .................. 172

Electrical Sampling Modules................................................................................... 174

Prerequisites ..................... ................................ .................................. .......... 174

Input Impedance ............................................................................................ 175

DC Voltage Measurement Accuracy............................ ................................ .......... 177

Random Noise, Displayed ................................................................................. 182

DSA8300 Performance Verification i

Table of Contents

Analog Bandwid

80E11X1) ............................................................................................... 184

Analog Bandwidth above 50 GHz (80E06, 80E09B, 80E11, 80E11X1). ............................ 194

TDR-System Reflected Rise Time (80E04, 80E08B, 80E10B) ................... .................... 204

TDR-System Step Response Aberrations (80E04)............ ................................ .......... 206

TDR-System Step Response Aberrations (80E08B and 80E10B) .. .................................. 211

Optical Sam

Prerequisites ..................... ................................ .................................. .......... 219

Dark Level and Vertical Equivalent Optical Noise...................................................... 219

Minimum Optical Bandwidth and Reference Receiver Frequency Response ................. ...... 222

Integrated Rise Time and Aberrations Check............................................................ 235

Clock Recovery Optical Sensitivity Range and Recovered Clock Timing Jitter .. ... . .. . ... ... ... . . 241

80A02 EO

Prerequisites ..................... ................................ .................................. .......... 250

Logic Control Threshold......................... ................................ .......................... 250

80A05 Electrical Clock Recovery Module ................................................................... 253

Prerequisites ..................... ................................ .................................. .......... 253

Clock Recovery Sensitivity Range and Recovered Clock Timing Jitter. ... . ... ... . ... ... . ... ... . ... . 253

pling Modules ..................................................................................... 219

S/ESD Protection Module...... ................................ ................................ .... 250

th up to 50 GHz (80E01, 80E06, 80E07B, 80E08B, 80E09B, 80E10B, 80E11,

ii DSA8300 Performance Verification

List of Figures

Figure 1: Setup for electrical functional tests ................................................................... 6

Figure 2: Channel button location ......................... ................................ ....................... 7

Figure 3: Channel button location ......................... ................................ ...................... 10

Figure 4: Setup for the time base tests .............. ................................ ............................ 12

Figure5:Magtimebaseverification............................................................................ 14

Figure 6: Time interval accuracy test setup. ................................ ................................ .. 152

Figure 7: External direct trigger test setup.................................................................... 154

Figure 8: External direct trigger sensitivity test setup.. ... ... . ... ... . .. . ... ... . .. . ... ... . ... ... ... . ... ... . .. 157

Figure 9: External Trigger Direct Input jitter test setup . . ... ... . .. . ... ... . .. . ... ... . .. . ... ... . .. . ... ... . .. . . 159

Figure 10: Phase corrected untriggered jitter test setup .. ... . .. . ... ... . ... ... . .. . ... ... . .. . ... ... . ... ... ... . 162

Figure 11: Phase corrected, Clock Eye external triggered jitter test setup . . ... ... ... . ... ... ... . ... ... ... . 165

Figure 12: External Clock/Prescale trigger delay jitter test setup.......................................... 168

Figure 13: External prescaled trigger sensitivity test setup . .. . ... ... . .. . ... ... . .. . ... ... . .. . ... ... ... . .. . .. 170

Figure 14: DC calibration output test setup .................. ................................ ................ 173

Figure 15: Input impedance test setup ........................ ................................ ................ 175

Figure 16: Vertical DC accuracy test setup................................................................... 177

Figure 17: Power-reference setup ............................................................................. 185

Figure 18: Adapter characterization setup.................... ................................ ................ 187

Figure 19: Measure reference signals ......................................................................... 188

Figure 20: Reference signals setup ............................................................................ 191

Figure 21: Setup to measure Power-in .......... ................................ .............................. 195

Figure 22: Power-reference characterization setup ................................ .......................... 197

Figure 23: Adapter-loss setup.................. .................................. .............................. 199

Figure 24: HF response setup .................................................................................. 201

Figure 25: TDR reflected rise time setup ..................................................................... 204

Figure 26: TDR system step response aberrations setup .................................................... 206

Figure 27: TDR system step response aberrations setup .................................................... 211

Figure 28: Dark level and vertical equivalent optical noise test setup..................................... 219

Figure 29: Minimum optical bandwidth and reference receiver frequency response setup ............. 225

Figure 30: Proper positioning of the impulse for optimum curve download ... . ... ... ... . .. . ... ... ... . .. 228

Figure 31: Setup for heterodyne test .................. ................................ ........................ 231

Figure 32: Setup used for heterodyne sweep ....................... ................................ .......... 233

Figure 33: Integrated rise time and aberrations setup ..... ................................ .................. 236

Figure 34: Clock recovery optical sensitivity range and recovered clock timing jitter setup ... ... ... . . 242

Figure 35: Display example (clock signal not synchronized with the data rate input)................... 246

Figure 36: Display example (clock signal synchronized with the data rate input) ....................... 249

Figure 37: Display example (zoomed in at the crossing point)................. ............................ 249

Figure 38: 80A02 test setup .................... ................................ ................................ 251

Figure 39: Clock recovery sensitivity range and recovered clock timing jitter setup. . .. . ... ... ... . ... .. 254

DSA8300 Performance Verification iii

Table of Contents

Figure 40: Disp

Figure 41: Display example (zoomed in at the crossing point)..................................... ........ 259

lay example (clock signal synchronized with the data rate input) ....................... 257

iv DSA8300 Performance Verification

List of Tables

Table 1: Equipment required ..................................................................................... 17

Table 2: DC v

Table 3: Data for calculation of gain and linearity........................................................... 182

Table 4: Random noise limits ...................... ................................ ............................ 184

Table 5: Power reference ........... ................................ ................................ ............ 186

Table 6: DUT (device under test) reference response (80E01, 80E06, 80E07B)

Table 7: DUT (device under test) reference response (80E08B, 80E09B, 80E10B)

Table 8: D

Table 9: Bandwidth response (55 GHz - 65 GHz) ..................... .................................. .... 203

Table 10: Minimum limits .................................. ................................ .................... 239

Table 11: Aberrations ........................................................................................... 240

Table 12: Clock recovery settings . . .. . ... ... . .. . ... ... ... . ... ... ... . .. . ... ... . .. . ... ... . .. . ... ... . .. . ... ... . .. 245

Table 13: Clock recovery settings and jitter limits.. ... . ... ... ... . .. . ... ... . .. . ... ... . .. . ... ... . .. . ... ... . .. . 247

14: Clock recovery settings .. . ... ... . .. . ... ... . ... ... ... . ... ... ... . ... ... . .. . ... ... . .. . ... ... . .. . ... ... . 256

Table

Table 15: Clock recovery amplitude and jitter limits. . .. . ... ... . .. . ... ... . .. . ... ... ... . ... ... ... . .. . ... ... .. 258

oltage measurement accuracy ................................................................. 179

UT (device under test) reference response (80E11, 80E11X1)

Table of Contents

1

....................... 189

1

................... 190

1

............................... 191

DSA8300 Performance Verification v

Important safety information

Important saf

ety information

This manual c

for safe operation and to keep the product in a safe condition.

To safely perform service on this product, additional information is provided at

the end of this section. (See page viii, Service safety summary.)

General safety summary

Use the product only as specified. Review the following safety precautions to

avoid injury and prevent damage to this product or any products connected to it.

Carefully read all instructions. Retain these instructions for future reference.

Comply with local and national safety codes.

For correct and safe operation of the product, it is essential that you follow

generally accepted safety procedures in addition to the safety precautions specified

in this manual.

The product is designed to be used by trained personnel only.

Only qualified personnel who are aware of the hazards involved should remove

the cover for repair, maintenance, or adjustment.

ontains information and warnings that must be followed by the user

To avoid fire or personal

injury

Before use, always check the product with a known source to be sure it is

operating correctly.

This product is not intended for detection of hazardous voltages.

Use personal protective equipment to prevent shock and arc blast injury where

hazardous live conductors are exposed.

While using this product, you may need to access other parts of a larger system.

Read the safety sections of the other component manuals for warnings and

cautions related to operating the system.

When incorporating this equipment into a system, the safety of that system is the

responsibility of the assembler of the system.

Use proper power cord. Use only the power cord specified for this product and

certified for the country of use.

Do not use the provided power cord for other products.

Ground the product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, make sure that the product is properly grounded.

vi DSA8300 Performance Verification

Important safety information

Power disconne

source. See instructions for the location. Do not position the equipment so that

it is difficult to operate the power cord; it must remain accessible to the user at

all times to allow for quick disconnection if needed.

Connect and disconnect properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Use only insulated voltage probes, test leads, and adapters supplied with the

product, or indicated by Tektronix to be suitable for the product.

Observe all terminal ratings. To avoi d fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product. Do not exceed the

Measurement Category (CAT) rating and voltage or current rating of the lowest

rated individual component of a product, probe, or accessory. Use caution when

using 1:1 test leads because the probe tip voltage is directly transmitted to the

product.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

The measuring terminals on this pr

III, or IV circuits.

ct. The power cord disconnects the product from the power

oduct are not rated for mains or Category II,

Do not operate without covers. Do not operate this product with covers or panels

removed, or with the case open. Hazardous voltage exposure is possible.

Avoid exposed circuitry. Do not touch exposed connections and components

en power is present.

wh

Do not operate with suspected failures. If you suspect that there is damage to this

product, have it inspected by qualified service personnel.

Disable the product if it is damaged. Do not use the product if it is damaged

or operates incorrectly. If in doubt about safety of the product, turn it off and

disconnect the power cord. Clearly mark the product to prevent its further

operation.

Before use, inspect voltage probes, test leads, and accessories for m echanical

damage and replace when damaged. Do not use probes or test leads if they are

damaged, if there is exposed metal, or if a wear indicator shows.

Examine the exterior of the product before you use it. Look for cracks or missing

pieces.

Use only specified replacement parts.

Use proper fuse. Use only the fuse type and rating specified for this product.

Do not operate in wet/damp conditions. Be aware that condensation may occur if

a unit is moved from a cold to a warm environment.

DSA8300 Performance Verification vii

Important safety information

Do not operate i

Keep product surfaces clean and dry. Remove the input signals before you clean

the product.

Provide proper ventilation. Refer to the installation instructions in the manual for

details on installing the product so it has proper ventilation.

Slots and openings are provided for ventilation and should never be covered or

otherwise obstructed. Do not push objects into any of the openings.

Provide a safe working environment. Always place the product in a location

convenient for viewing the display and indicators.

Avoid improper or prolonged use of keyboards, pointers, and button pads.

Improper or prolonged keyboard or pointer use may result in serious injury.

Be sure your work area meets applicable ergonomic standards. Consult with an

ergonomics professional to avoid stress injuries.

Use care when lifting and carrying the product. This product is provided with

handles for lifting and carrying.

WARNING. The product is heavy. To reduce the risk of personal injury or damage

to the device, get he

n an explosive atmosphere.

lp when lifting or carrying the product.

Use only the Tektronix rackmount hardware specified for this product.

Servicesafetysummary

The Service safety summary section contains additional information required to

safely perform service on the product. Only qualified personnel should perform

service procedures. Read this Service safety summary and the General safety

summary before performing any service procedures.

To avoid electric shock. Do not touch exposed connections.

Do not service alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect power. To avoid electric shock, switch off the product power and

disconnect the power cord from the mains power before removing any covers or

panels, o r opening the case for servicing.

Use care when servicing with power on. Dangerous voltages or currents may exist

in this product. Disconnect power, remove battery (if applicable), and disconnect

test leads before removing protective panels, soldering, or replacing components.

viii DSA8300 Performance Verification

Important safety information

Verify safety a

strength after performing a repair.

fter repair. Always recheck ground continuity and mains dielectric

Terms in this manual

These t erms may appea r in this manual:

WAR N ING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Symbols and terms on the product

These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read

the marking.

WARNING indicates an injury hazard not immediately accessible as you

read the marking.

CAUTION indicates a hazard to property including the product.

this symbol is marked on the product, be sure to consult the manual

When

to find out the nature of the potential hazards and any actions which have to

be taken to avoid them. (This symbol may also be used to refer the user to

ngs in the manual.)

rati

The following symbol(s) may appear on the product:

DSA8300 Performance Verification ix

Important safety information

x DSA8300 Performance Verification

Preface

Manual Structure

This manual contains the specifications and performance verification procedures

for the DSA8300 Digital Serial Analyzer, the extender cables, and the modules

that can be in

NOTE. The 80A03 instruction manual contains its own specifications and

servicing information.

Read this preface to learn how this manual is structured, what conventions it uses,

and where you can find other information related to this product.

This manual is divided into chapters that are made up of related subordinate

topics. These topics can be cross referenced as sections.

Be sure to read the introductions to all procedures. These introductions provide

important information needed to do the service correctly, safely, and efficiently.

stalled in this instrument (except the 80A03 module).

Manual Conventions

Modules

Safety

This manual uses certain conventions that you should become familiar with

before attempting service.

Throughout this manual, the term module appears. A module is composed of

electrical and mechanical assemblies, circuit cards, interconnecting cables, and a

user-accessible front panel. References to a module are different than references to

products such as “Sampling modules”, “Phase Reference modules”, or “Accessory

dules”, which are products installed in the instrument compartments or on

mo

extender cables.

Symbols and terms related to safety appear in the General Safety Summary found

at the beginning of this manual.

DSA8300 Performance Verification xi

Preface

Related Documentation

The following documents relate to the instrument this manual supports:

DSA8300 Digital Serial Analyzer Quick Start User Manual. Tektronix part

number 071-2897-XX.

DSA8300 Digital Serial Analyzer Service Manual. Tektronix part number

071-2049-XX.

DSA8300 Digital Serial Analyzer Online Help. Installed with the application

software and accessed from the instrument Help menu.

DSA8300 Digital Serial Analyzer Programmer Guide. An online document

accessed from the instrument Help menu.

80C00 and 80E00 Series Optical and Electrical Sampling Modules User

Manual. Tektronix part number 071-3059-XX.

80A02 EOS/ESD Protection Module Instructions. Tektronix part number

071-1317-XX

80A03 TekConnect Probe Interface Module Instructions. Tektronix part

number 071-1298-XX.

80A05 Electrical Clock Recovery Module User Manual. Tektronix part

number 071-1467-XX.

DSA8300, DSA8200, CSA8200, CSA8000, CSA8000B, TDS8200, TDS8000,

and TDS8000B Rackmount Kit Instructions. Tektronix part number

071-0696-XX.

80N01 Extender Cable Instructions. Tektronix part number 071-2037-XX

80X01, 80X02 Extender Cable Instructions. Tektronix part number

071-3206-XX

xii DSA8300 Performance Verification

Performance Verification Procedures

Two types of Performance Verification procedures can be performed on this

product: Brief Procedures and the more extensive Performance Tests.Youmay

not need to pe

accomplish:

rform all of these procedures, d epending on what you want to

To rapidly c

just do the Perform the Diagnostics and Perform the Compensation

procedures. (See page 2, Functional Test Procedures.)

Advantages: These procedures are quick to do, require no external equipment

or signal sources, and perform extensive functional and accuracy testing to

provide high confidence that the instrument will perform properly. They can

be used as a quick check before making a series of i mportant measurements.

To further check functionality, first do the procedures just mentioned, and

then do the procedure Perform the Functional Tests,. (Seepage2,Functional

Test Procedures.)

Advantages: These procedures require minimal additional time to perform,

require no additional equipment other than connection hardware, and more

compl

quickly determine if the instrument is suitable for putting into service, such

as when it is first received.

If more extensive confirmation of performance is desired, do the Performance

Tests after doing the procedures just referenced. (See page 15, Performance

Tests.)

Advantages: These procedures add direct checking of warranted

specifications. They require more time to perform and suitable test equipment

is required. (See page 17, Equipment Required.)

onfirm that the instrument functions and was adjusted properly,

etely test the internal hardware of the instrument. They can be use d to

If you are not familiar with operating this instrument, refer to the online help or

the user information supplied with the instruments.

DSA8300 Performance Verification 1

Functional Test Procedures

Functional Test Procedures

There are three procedures in this section that provide a quick way to confirm

basic functionality and proper adjustment of the DSA8300:

(See page 2, Instrument Diagnostics.)

(See page 3, Instrument and Module Compensation.)

(See page 6, Instrument Functional Tests.)

These procedures require little or no test equipment. For information on when to

use these procedures, refer to Performance Verification Procedures. (See page 1,

Performance Verification Procedures.)

Instrument Diagnostics

The following steps run the internal routines that confirm basic functionality

and proper adjustment.

Equipm

Prerequisites Install all sampling modules to be diagnosed: see module user

ent required

None

for installation instructions.

manual

Power on the instrument and wait 20 minutes (warm-up period)

before doing this procedure.

2 DSA8300 Performance Verification

Functional Test Procedures

1. Set up the instr

dialog box.

2. Select a diagnostics suite:

a. Click the Subsystem Level tab.

b. Select all tests (click and hold the first entry (Control Proc) and drag down

to highlight all entries as shown above).

ument: Click Utilities > Diagnostics to open the Diagnostics

c. Leave Loop and Halt on Failure unchecked (Run area).

3. Verify that the diagnostic suite passes:

a. Click

b. Verify that Pass appears in the dialog box Status column when the

c. Click Close to exit.

End of Procedure

Run. The diagnostics may take several minutes to complete.

nostics complete. If an error number appears as Status, rerun the

diag

diagnostics. If Fail status continues after rerunning compensation and

you have allowed warm up to occur, the module or main instrument may

need service.

Instrument and Module Compensation

Performing a vertical compensation will maximize the accuracy of the automatic

measurements you take. This procedure uses internal routines to optimize the

vertical offset, gain, and linearity.

A complete compensation requires running separate compensations on the

mainframe and the modules.

DSA8300 Performance Verification 3

Functional Test Procedures

Equipment requ

Prerequisites

ired

For sampling mo

50 Ω terminati

part number 015-1022-xx).

Dust covers on all optical module channels.

The sampling modules ship from Tektronix with the proper

termination

Install all s

measurements: see module user manual for installation

instructions and ESD handling procedures.

Power on the

before doing this procedure.

dules:

ons on all electrical module channels (Tektronix

s and dust covers installed.

ampling modules you plan to use for your

instrument and wait 20 minutes (warm-up period)

CAUTION. Electrostatic discharge (ESD) can damage sampling module inputs

and output

s. Always store and transport modules in a static-free container, with

their supplied terminations installed. Do not transport or ship the instrument with

the modules installed in the instrument compartments.

Always use a safely-grounded wrist strap (provided with your instrument) when

installing modules in the mainframe, handling modules, or making connections.

Discharge cables to ground before attaching them to modules.

Compensate the

Mainframe

1. Select Utilities > Compensation.

The Compensation dialog box lists the main instrument and sampling

modules. The temperature change from the last compensation is also listed as

shown in the following figure.

ait until the Status for all items to compensate changes from Warm Up to

2.W

Pass, Fail, or Comp Req'd.

3. Click Compensate and Save (inSelectActionarea).

4 DSA8300 Performance Verification

Functional Test Procedures

Compensate the Modules

4. Click the Compe

Mainframe.

5. Click Execute to begi

6. Follow on-screen instructions to disconnect inputs and install terminations;

be sure to follow static pre

module) when following these instructions. The compensation may take

several minutes to complete.

7. Verify that Pass appears as Status for the main instrument when compensation

completes. If instead Fail appears as Status, rerun the compensation. If Fail

status continues after rerunning compensation and you have allowed warm-up

to occur, the main instrument may need service.

8. Click the Close button to exit, or continue to the next section to compensate

installed modules. (See page 5, Compensate the Modules.)

1. Wait until the Status for all items to compensate changes from Warm Up to

Pass, Fail, or Comp Req'd.

2. Click Compensate and Save (in Select Action area).

3. Click the Compensate Target button (below the Select Action area) and select

All Modules.

nsate Target button (below the Select Action area) and select

n the mainframe compensation.

cautions (see the user manual for your sampling

4. Click Execute to begin module compensation.

5. Follow on-screen instructions to disconnect inputs and install terminations,

while leaving trigger signals connected to the mainframe. Follow static

precautions (see the user manual for your sampling module) when connecting

or disconnecting termina tions and cables. The compensation may take several

minutes to complete.

CAUTION. Failing to install the 50 Ω terminations on

80EXX-Series sampling-module input connectors during compensation can cause

compensation failure messages or incorrect compensation settings.

NOTE. If you do not have typical trigger signals to apply to the instrument for

doing this performance verification, leave the CLOCK INPUT/PRESCALE

TRIGGER and TRIGGER DIRECT INPUT connectors unterminated.

6. Verify that Pass appears as Status for each module when compensation

completes. If instead Fail appears as Status, rerun the compensation. If Fail

status continues after rerunning compensation and you have allowed warm-up

to occur, move the m odule to another slot and run the compensation again (use

the Utilities > View/Change Module Config tool, available on TekScope

SW version 6.0.124 and greater to move the module while the instrument is

DSA8300 Performance Verification 5

Functional Test Procedures

powered on, or p

slot). If the module continues to fail, the indicated module may need service.

7. Click the Clos

End of Mainframe and Module Compensation Procedure

Instrument Functional Tests

These procedures use the DC CALIBRATION OUTPUT and the TDR CLOCK

OUTPUT con

SMA cable is required to do these test procedures. The equipment required is

intentionally kept to a minimum.

NOTE. These procedures verify that the instrument features operate. They do not

verify that they operate within limits; therefore, do not interpret any quantities

cited (such as "about five horizontal divisions") as limits.

NOTE. DO NOT make changes to the front-panel settings that are not called

out in the procedures. Each verification procedure will require you to set the

ument to default settings before verifying functions. If you make changes to

instr

these settings, other than those called out in the procedure, you m ay obtain invalid

results. In this case, go back to step 1 and repeat the procedure.

ower down the instrument and move the module to another

e button to exit.

nectors to further verify that the instrument functions properly. An

Verify Electrical Input

Channels

pment required

Equi

Prerequisites

One coaxial SMA cable, 50 Ω, 20 in (0.5 m), male-to-male (item

15)

One electrical sampling module (80E01, 80E02, 80E03, 80E04,

06, 80E07B, 80E08B, 80E09B, or 80E10B)

80E

Figure 1: Setup for electrical functional tests

6 DSA8300 Performance Verification

Functional Test Procedures

1. Initialize the

click Ye s in the confirmation dialog box.

2. Set the Trigger System: In the UI application toolbar, select Free Run from

the Trig menu.

3. Connect the SMA cable from the DC CALIBRATION output to the channel

input to test.

4. Set the DC CALIBRATOR OUTPUT:

a. Push the front-panel Vertical MENU button.

NOTE. When an optical module is installed, the optical setup dialog box

displays by default. Click the Basic button to display the basic dialog box.

b. Set the DC CAL value to 200 mV.

instrument: Push the front-panel DEFAULT SETUP button and

c. Push the front-panel Vertical MENU button again to dismiss the Vert

Setup dialog box.

5. Push the channel button for the channel to test. The button lights and the

screen shows the selected channel signal.

Figure 2: Channel button location

DSA8300 Performance Verification 7

Functional Test Procedures

6. Confirm that the

statements are true:

The vertical s

100 mV, and a DC level is at about 2 divisions above center screen.

The front-p

moves the DC offset level up and down the screen when rotated. Return

the DC level to 2 divisions (0.0 V offset) above center screen before

continuing.

Turning the vertical SCALE knob to 50 mV changes the amplitude of the

DC level to about 4 divisions above center screen, and returning the knob

to 100 mV returns the amplitude to about 2 divisions above center screen.

7. Confirm that the channel acquires in all acquisition modes: Push the

front-panel button ACQUISITION MENU to display the Acq Setup dialog

box. Click each of the three acquisition modes, and confirm that the following

ents are true:

statem

Sample mode displays an actively acquiring waveform on-screen. (Note

here is a small amount of noise present on the DC level).

that t

Average mode displays an actively acquiring waveform on-screen with

ise reduced.

the no

channel is operational: Confirm that the following

cale readout for the channel under test shows a setting of

anel Vertical OFFSET knob (for the channel you are testing)

Envelope mode displays an actively acquiring waveform on-screen with

pper and lower extremes of the noise displayed.

the u

8. Click the Sample acquisition mode.

9. Confirm the DC accuracy compensation: Do the following substeps:

a. Click the Meas tab in the Setups dialog box and set the following fields:

Select the source for the channel under test (lower half of the dialog

box). For example, select C3 on Main for channel 3.

Click the Signal Type Pulse button (lower half of the dialog box).

Click the Select Meas button ( top of dialog box) and select Pulse -

Amplitude > Mean.

b. Click the Vert tab in the Setups dialog box.

c. Set the Scale, Offset, and DC Calibration Output fields to the values shown

in the first row of the following table that applies to your module model.

d. Confirm that the Mean measurement readout value for the channel under

test is within the limits shown in the table.

e. Repeat steps c and d for each row in the table for your module.

8 DSA8300 Performance Verification

Functional Test Procedures

For the 80E01, 8

Vertical Scal

(mV/div)

100 –1000.0 –1000.0 –1.0090 –.9910

100 0.0 –450 –461.0 –439.0

100 0.0 0 –2.0 2.0

100 0.0 450 439.0 461.0

100 1000.0 1000.0 991.0 1009.0

For the 80E07B, 80E08B, 80E09B, and 80E10B

Vertical Scale

(mV/div)

100 –600.0 –600.0 –605.4 –594.6

100 0.0 –450 –461.0 –439.0

100 0.0 0 –2.0 2.0

100 0.0 450 439.0 461.0

100 600.0 600.0 594.6 605.4

0E02, 80E03, 80E04, and 80E06

e

Vertical Offs

(mV)

Vertical Offset

(mV)

et

DC CAL Output

(mV)

DC CAL Output

(mV)

Limits

Minimum (V) Maximum (V)

Limits

Minimum (mV) Maximum (mV)

10. Test all channels: Repeat steps 3 through 9 until a l l input channels are verified.

11. Remove

the test setup: Disconnect the SMA cable from the channel input

and the DC CALIBRATION output.

DSA8300 Performance Verification 9

Functional Test Procedures

Verify Optical Input

Channels

This verificati

Equipment required None

Prerequisites

on is done without an input signal.

At least one optical (80C00 series) sampling module must be

installed.

1. Initialize the instrument: Push the front-panel DEFAULT SETUP button.

2. Set the Trigger System: In the UI application toolbar, select Free Run from

the Trig menu.

3. Select the channel to test: Push the channel button for the channel to test. The

button lights and the screen shows the selected channel signal.

Figure 3: Channel button location

4. Verify that the channel is operational: Confirm that the following statements

are true.

A trace displays at about center screen.

The Waveform readout for the channel under test shows a value as follows:

80C01, 80C02, 80C04, 80C09, 80C11, and 80C11B: 1 mW

80C03: 100 μW

10 DSA8300 Performance Verification

Functional Test Procedures

80C05: 3 mW

80C06: 6 mW

80C07, and 80C07B: 100 μW

80C08, 80C08B, 80C08C, 80C08D, and 80C12: 200 μW

80C10, 80C10B, 80C10C: 3 mW

80C10B-F1, 80C10C-F1, 80C15, 80C25GBE: 2 mW

80C14: 200 μW

Rotating the front-panel Vertical POSITION knob (for the channel you

are testing) moves the signal up and down the screen when rotated. Return

the baseline trace to center screen before continuing.

Rotating the front-panel Vertical OFFSET knob counterclockwise offsets

the baseline towards the bottom of the screen; turning the knob clockwise

offsetsthebaselinetowardsthetopofthescreen.Return the offset value

to 0.0 (read the value in the Vertical Offset field along the bottom edge

of the graticule).

Verify that the Time Bases

Work

5. Verify that the channel acquires in all acquisition modes: Push the front-panel

Acquisition MENU button to display the Acq Setup dialog box. Click each of

the three acquisition modes and confirm that the following statements are true:

Sample mode displays an actively acquiring waveform on-screen. (Note

that there may be a small amount of noise present on the baseline level).

Average mode displays an actively acquiring waveform on-screen with

any noise present reduced.

Envelope mode displays an actively acquiring waveform on-screen with

the upper and lower extremes of the noise displayed.

Select Sample before continuing.

6. Test all channels: Repeat steps 3 through 5 to verify all optical input channels.

7. Close Acquisition setup dialog box: Push the Acquisition MENU button to

close the Acq setup dialog box.

After verifying the channels, you can now verify that the time bases function.

This verification is done using a front-panel signal.

Equipment required

Prerequisites None

One SMA cable, 50 Ω, 20 in (0.5 m), male-to-male connectors

(item 15)

One 10x SMA attenuator (item 56)

One electrical sampling module (80E01, 80E02, 80E03, 80E04,

80E06, 80E07B, 80E08B, 80E09B, or 80E10B)

DSA8300 Performance Verification 11

Functional Test Procedures

1. Initialize the

2. Hook up the signal source: Connect the SMA cable from the TDR Clock

output through a 10x attenuator to any 80E00 sampling module input channel

as shown in th

Figure 4: Setup for the time base tests

3. Set up the instrument:

a. Push the Trigger MENU front-panel button to display the Mode/Trigger

Setup dialog box.

instrument: Push the front-panel DEFAULT SETUP button.

e following figure.

b. Click TDR under Trigger Source in the Mode/Trigger Setup dialog box.

TheTDRClockrateshouldbesetto200 kHz.

c. Push the Trigger MENU front-panel button again to dismiss the

Mode/Trigger dialog box.

d. Push the Vertical channel button for the channel you connected to in step 2.

e. Turn the Vertical SCALE knob to set the vertical scale to 20 mV/div.

The channel scale readout is displayed in the Control bar at the bottom

of the graticule.

4. Set the time base: Set the Horizontal SCALE to 1 μs/div. The horizontal

scale readout is displayed in the Control bar at the bottom of the graticule.

a. Click Setup > Display in the main menu bar. In the Disp Setup dialog

box, set the display Style to Normal and enable (check) Show Vectors.

b. Close the Setups dialog box.

c. Rotate the vertical OFFSET knob counterclockwise so that the base of

the square wave is about 2 divisions below the center graticule. This is to

ensure that a vertical trace will be seen for rise and fall.

12 DSA8300 Performance Verification

Functional Test Procedures

5. Verify that the

are true:

One period of t

horizontal divisions on-screen.

Rotating th

waveform on-screen (more horizontal divisions per waveform period),

counterclockwise rotation contracts it, and returning the horizontal scale

to 1 μs/div returns the period to about five divisions. Leave the time

base set to 1 μs/div.

Rotating the horizontal POSITION knob moves the waveform left and

right on the screen.

NOTE. The signal will not move past the minimum position setting.

6. Set up the Mag1 time base:

a. Push the Horizontal View MAG1 front-panel button. The Mag1 time base

view displays below the Main time base v iew.

b. Set the Horizontal SCALE to 1 μs/div. The horizontal scale readout

is in the Control bar at the bottom of the graticule and now shows the

horizontal scale value of the Mag1 time base view.

Main time base operates: Confirm that the following statements

he TDR clock waveform (a square wave) is about five

e Horizontal SCALE knob clockwise expands the

7. Verify that the Mag1 time base operates: Confirm the following statements.

The Mag view brackets on the Main View waveform (top graticule) are a

full-screen width apart (10-divisions) as shown in the following figure.

One period of the internal clock signal (a square wave) in the Mag view

(bottom graticule) is about five horizontal divisions on-screen as shown in

the following figure. (Matches the waveform in the top graticule.)

Rotating the Horizontal SCALE knob clockwise to 500 ns/div expands

the waveform in the b ottom graticule to double the period (about 10

orizontal divisions per waveform period); rotating the Horizontal

h

SCALE knob counterclockwise returns the Horizontal scale setting to

1 μs/div returns the waveform period to about five divisions. Leave the

Horizontal Scale set to 1 μs/div.

DSA8300 Performance Verification 13

Functional Test Procedures

Figure 5: Mag time base verification

Checking the Cooling Fan

Operation

8. Verify that the Mag2 time base operates:

a. Push the Mag1 button to remove the display of the Mag1 time base.

b. Perform steps 6 and 7, but use the Mag2 button instead of the Mag1.

NOTE. The color of the Mag2 brackets in the main view are different than

those of the Mag1 brackets.

Equipment required None

Prerequisites The instrument must be powered on and running.

r on the instrument and verify that you can feel airflow from all six cooling

Powe

fans on the left side of the instrument.

End of Functional Test Procedures

14 DSA8300 Performance Verification

Performance Tests

Performance T

ests

This chapter

marked with the

suitable equi valent, is required to complete these procedures.

The procedures are arranged in sections:

Main Instr

Electrical Sampling Modules

Optical Sampling Modules

80A02 EOS/ESD Protection Module

80A05 Electrical Clock Recovery Module

They check all the characteristics that are designated as checked in Specifications.

To chec

Perform the performance test procedures for the main instrument and then

the in

To check a main instrument as an independent product:

contains performance verification procedures for the specifications

symbol. The equipment listed in the following table, or a

ument (includes 82A04 Phase Reference Module)

k a system consisting of a main instrument and its modules:

stalled modules.

Do the main instrument tests using a two-channel 80E02, 80E03, 80E04,

80E07B, 80E08B, 80E09B, or 80E10B module that has passed the tests in

0 Electrical Sampling Modules.(Seepage174,Electrical Sampling

80E0

Modules.) When performing the time interval accuracy and external direct

trigger delay jitter tests, check one channel of each small-module slot.

In addition, to confirm that a main instrument can properly compensate all

channels in all modules in all main instrument slots, do the DC Voltage

Measurement Accuracy using the tested two-channel 80E00-series module.

(See page 177, DC Voltage Measurement Accuracy.) Perform this check for

each channel of each small-module slot.

Be sure to run the instrument compensation routine with the tested module

installed each time you move the module to a new slot.

DSA8300 Performance Verification 15

Performance Tests

Prerequisites

To check a modul

using a main instrument that has passed the process just described for checking a

main instrument as an independent product.

NOTE. Checking the main instrument and modules as independent products

verifies each product independently for all measured specifications, except for DC

voltage accuracy of the main instrument and of 80E00 modules. The procedures

do check tha

that any combination of a main instrument and electrical module that passed

testing as independent products will meet the system DC voltage accuracy

specifications.

The Brief Procedures section of this manual includes a DC accuracy check to

support verification by users that their specific combination of main instrument

and electrical module meets system specifications. This test uses the main

instrument DC Calibration Output and does not require external test generators.

The tests in this section comprise an extensive, valid confirmation of performance

and functionality when the following requirements are met:

The cabinet must be installed on the instrument.

e as an independent product, do the tests for that module type

t DC compensation is functioning properly, so it is highly probable

ust have performed and passed the procedure Perform the Diagnostics,

You m

and the procedure Perform the Functional Tests. (Seepage2,Instrument

Diagnostics.) (See page 6, Instrument Functional Tests.)

A compensation must have been done within the recommended calibration

interval and at a temperature within ±2 °C of the present operating

temperature. (If, at the time you did the procedures Perform the Diagnostics

and Perform the Functional Tests, you also did the Perform the Compensation

procedure consider this prerequisite met). (See page 3, Instrument and

odule Compensation.)

M

The instrument must have been last adjusted at an ambient temperature

between +20 °C and +30 °C, must have been operating for a warm-up period

of at least 20 minutes, and must be operating at an ambient temperature.

Observe all safety rules, especially regarding voltage hazards.

These procedures cover all instrument models. Please ignore checks that do not

applytothespecific model you are testing.

16 DSA8300 Performance Verification

Equipment Required

Performance Tests

The procedures mentioned in Main Instruments section use external, traceable

signal sources to directly check warranted characteristics. (See page 151,

DSA8300 Performance Verification.) The following table lists the required

equipment.

WAR N ING. So

me of the generator equipment used to complete the performance

tests may be capable of producing dangerous output levels.

Optical generators may cause eye damage. Electrical generators may produce a

shock hazard.

Always turn generators to off or 0 before connecting and disconnecting from

the test setup.

Observe all the manufacturer's safety information provided with the test

equipment.

Table 1 : Equipment required

Item number and description Minimum requirements Part number or model

1.

2.

3.

4.

5.

6.

7.

8. Attenuator, optical

9.

10.

11.

12.

13.

14.

Adapter (80E01, 80E09B, 80E10B,

and 80E06 only)

Adapter (80E01, 80E09B, 80E10B,

and 80E06 only)

Adapter (Qty. 2) SMA female to BNC male connectors

Adapter (Qty. 2) BNC to dual banana plugs

Adapter

Attenuator (80E01 only) 10 dB, female to male SMA connectors

Attenuator

Airline (80E04 and 80E08B only) 50 Ω, airline, 3.5 mm connectors,

Airline (80E10B only) 50 Ω, precision airline, 2.4 mm

Cable, delay, coaxial Coaxial cable, 50 Ω, 500 ps, with

Cable, delay, coaxial Coaxial cable, 50 Ω, 2 ns delay, w ith

Cable, fiber-optic (Qty.2) Single-mode, 2 m, FC/PC to FC/PC

Cable, special (80E01 and 80E06

only)

2.4 mm, male-to-male connectors HP11900A

2.4 mm, female-to-female connectors

SMA"T"1maleto2SMAfemale

2X attenuator 50 Ω SMA connectors

30 mm, 10 dB, single-mode, FC to

FC, female to male

10 cm line

connectors

3.5 mm, male each end, 6.0 inch

length

SMA male each end

Phase and power stability

HP11900B

Tektronix part number 015-0572-00

Tektronix part number 103-0090-00

Tektronix part number 015-1016-00

HP8490D with option 10

Tektronix part number 015-1001-00

Tektronix part number 119-5118-00

Maury Microwave model number

8042D

Maury Microwave model number

7943G

Tektronix part number 015-0564-00

Tektronix part number 015-0560-00

Tektronix part number 174-1910-00

Gore-Tex FE0BM0BM025.0

DSA8300 Performance Verification 17

Performance Tests

Table 1: Equipment required (cont.)

Item number and description Minimum requirements Part number or model

15.

16.

17.

18. Digital multimeter

19.

20. Laser transmitter

21.

22.

23.

24.

25.

26. Power divider

27.

28. Terminator

29.

30.

31.

32.

33. Photodetector

34.

35.

36.

37.

Cable, coaxial (Qty. 2) 50 Ω,20in(0.5m),male-to-male

Cable, coaxial

Cable, Precision 50 Ω Coaxial (80E06

only)

DC power supply

Optical attenuator, variable Single-mode input and output, 0 to

Optical Impulser

Optical Wavelength Meter

Power meter (80E01, 80E06, 80E07B,

80E08B, 80E09B, and 80E10B only)

Power sensor (80E01, 80E06,

80E07B, 80E08B, 80E09B, and

80E10B only)

Short, coaxial Shorting, 34 GHz, precision 3.5 mm,

Terminator (80E10B only) 50 Ω coaxial terminator, V male

Short, coaxial Coaxial, short circuit 3.5 mm, SMA

Synthesized signal generator Signal generator 50 MHz to 50 GHz

Sampling module Tektronix 80C02 Sampling Module Tektronix 80C02 Sampling Module

Polarization-maintaining fiber coupler

Polarization-maintaining fiber coupler

PM fiber jumper cable F C/A PC and FC/PC connector Tempo-Camarillo part number

SMA fiber jumper cable FC/APC and FC/PC connector Fiber Instrument Sales, Inc., part

SMA connectors

50 Ω, 39.37 in (1.0 m), male-to-male

SMA connectors

50 Ω,60in(1.5m),male-to-male

SMA connectors

50 Ω, 36 in, male-to-male BNC

connectors

Four wire ohm meter. <0.25%

accuracy for volt and ohm

measurements

Variable amplitude to ±104 V;

accuracy to 0.1%

2.5 Gb/s SONET/SDH laser

transmitter

60 dB

1550 nm impulse

0.001 nm resolution

Power meter Anritsu-Wilton ML2437A

Power sensor w/attached cable

50 Ω, 3 SMA female connectors

female

50 Ω coaxial terminator, K male

male

>1 GHz bandwidth

Polarization Isolation <-24 dB

Polarization Isolation <-24 dB

Tektronix part number 174-1427-00

Tektronix part number 174-1341-00

Tektronix part number 174-1428-00

Tektronix part number 012-0482-00

Keithley 2000-20

Data Precision 8200

JDS Uniphase Model 420B

Tektronix part number OA5002

Calmar FPL-01 Optical Impulser

Advantest Q8326

Anritsu-Wilton ML2425A

Tektronix part number 015-0565-00

Tektronix part number 011-0150-00

Anritsu-Wiltron 28K50

Anritsu-Wiltron 28V50B

Tektronix part number 015-1020-00

Anritsu-Wiltron 69187B

Picometrix P-15B

CIRL Model 904P (50/50)

CIRL Model 904PS (5/95)

2M2L-1P5-1.5

number S3-77AS-1.5-FIS

18 DSA8300 Performance Verification

Performance Tests

Table 1: Equipment required (cont.)

Item number and description Minimum requirements Part number or model

38. Pulse pattern generator

39. Terminator, coaxial

40. Real-time oscilloscope 500 MHz bandwidth

41.

42.

43.

44.

45.

46.

47.

48.

49.

50.

51.

52.

53.

54.

55.

56.

Tunable ECL laser (Qty. 2) See Tunable Laser Requirements on

Scalar Network Analyzer (80E06,

80E07B, 80E08B, 80E09B, and

80E10B only)

SWR Autotester ( 80E06, 80E07B,

80E08B, 80E09B, and 80E10B only)

Reflectometer (80E06 and 80E09B

only)

Power meter (80E06, 80E07B,

80E08B, 80E09B, and 80E10B only)

Power sensor (80E06 and 80E09B

only)

RF Power Detector (80E06, 80E07B,

80E08B, 80E09B, and 80E10B only)

Power sensor (80E06 and 80E09B

only)

Open/Short (80E06, 80E07B, 80E08B,

80E09B, and 80E10B only)

Short (80E10B only) Short

Adapter (80E06 and 80E09B only) WR15 (Waveguide)-to-1.85 mm male

Adapter (80E06 and 80E09B only) WR15 (Waveguide)-to-1.85 mm

Waveguide section (80E06 and

80E09B only)

Attenuator (80E06, 80E07B, 80E08B,

80E09B, and 80E10B only) (Qty. 2)

Electrical sampling module extender

cable (2 meter)

Attenuator (80A05 only) (Q ty. 2) 10X (20 dB), female to male SMA

>12.5 Gb/s pulse pattern generator Advantest D3186 12 Gb/s Pulse

Pattern Generator

Coaxial terminator, 50 Ω 0.5 W, SMA

male

page 2-187

10 MHz to 50 GHz. Must use specified

equipment

10 MHz to 50 GHz. Must use specified

equipment

50 GHz to 65 GHz. Must use specified

equipment

Must use specified equipment

50 MHz to 50 GHz. Must use specified

equipment

10 MHz to 50 GHz. Must use specified

equipment

Waveguide Power Sensor. Must use

specified equipment

DC to 50 GHz. Must use specified

equipment

connectors, 50 GHz to 65 GHz. Must

use specified equipment

female connectors, 50 GHz to 65 G Hz.

Must use specified equipment

Straight section, 50 GHz to 75 GHz,

4 inch length, round flanged. Must

use specified equipment

6 dB attenuator, DC to 50 GHz,

2.4 mm connectors

Extender cable for use with certain

small compartment m odules

connectors

Tektronix part number 015-1022-01

Tektronix TDS 3052 or TDS3054

New Focus tunable ECL lasers (2),

Model 6528-HP or 6538-HP

Anritsu 54177A

Anritsu 560-98V5

Oleson R15RFT (specify OML DC

power cable to dual banana plug)

Agilent E4417A Power Meter

Agilent 8487A Power Sensor,

2002-07-31

Anritsu RF Detector, 560-7VA50

Agilent V8486A

Anritsu 22V50 Open and Short

Anritsu 23V50-5.1 V short

Anritsu 35WR15V

Anritsu 35WR15VF

Millitech SRW-15-RO400

Agilent 8490D, option 006

Tektronix 80N01 or 80X02 Module

Extender Cable

Tektronix part number 015-1003-00

DSA8300 Performance Verification 19

Performance Tests

Table 1: Equipment required (cont.)

Item number and description Minimum requirements Part number or model

57.

58. Adapter

Stereo mini phono plug (80A02 only) Stereo phono mine-plug with exposed

connections

SMA adapter, female to female

Common part, obtain by description

Tektronix part number 015-1012-00

DSA8300 Digital Serial Analyzer Test Records

This section contains test records that you can use to record the results of your

performance verification checks.

DSA8300 Main Instrument (includes 82A04 Phase Reference module)

80E00 El

ectrical Sampling Modules

80C00 Optical Sampling Modules

80A02 EOS/ESD Protection Module

80A05 Electrical Clock Recovery Module

Do not enter values into the records contained in this manual; rather, make copies

of the records and enter test results on the copies.

The test records provide entries for all checks found in the Performance Tests

procedures.

20 DSA8300 Performance Verification

Performance Tests

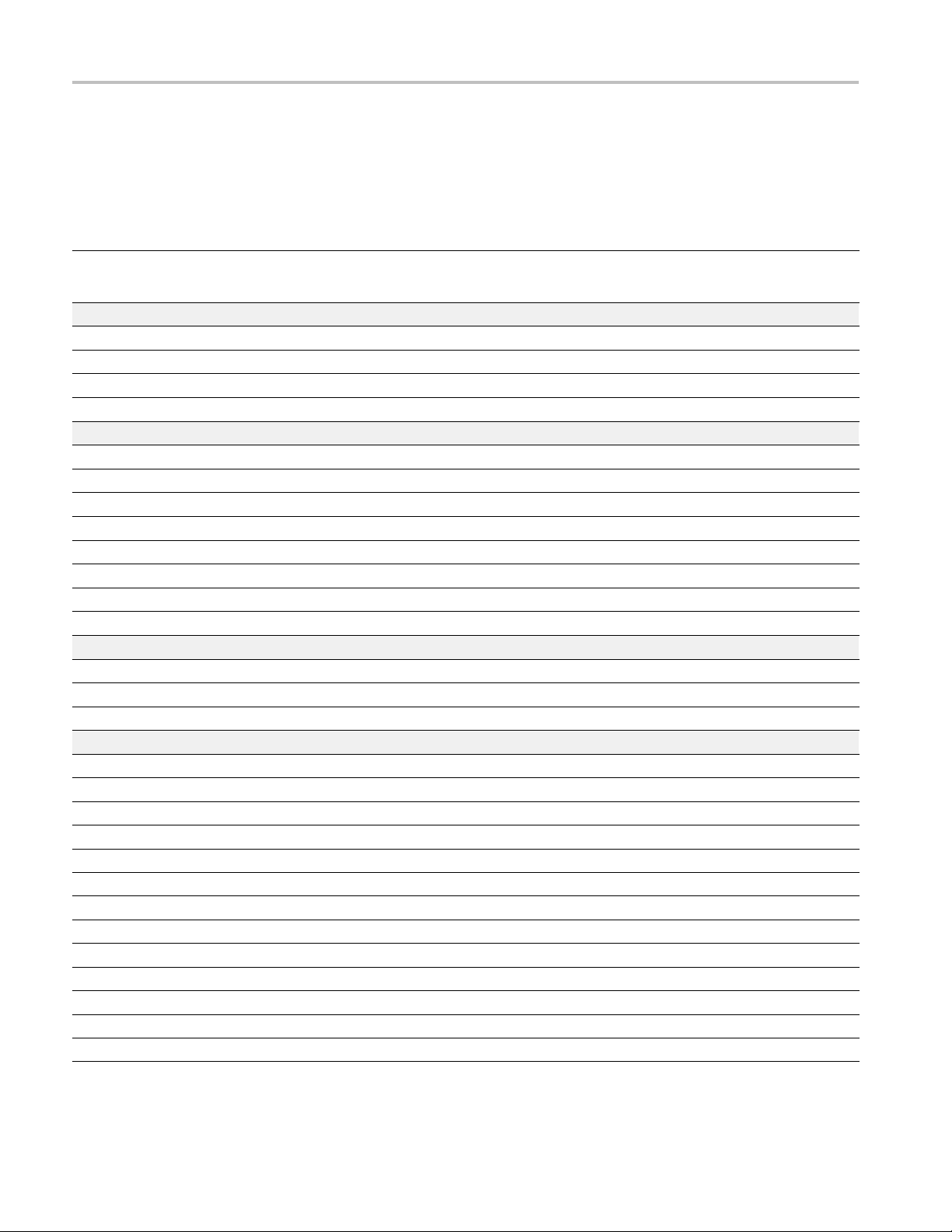

DSA8300 Main I

nstrument and 82A04 Module Test Record

For each channel tested, print this record and enter the performance test results

for your main-instrument test record.

DSA8300 and

Instrument Serial Number: Cal Certificate Number:

Date of Calibration:

82A04 Module Serial Number: Module Certificate Number:

Date of Calibration:

DSA8300 and 82A04 Performance Test

Time Interval Accuracy, Trigger Direct Input connector

Horizontal

Position

Time Interval Accuracy, Clock Input/Prescale Trigger connector; Eye mode

Horizontal

Position

Time Interval Accuracy, Clock Input/Prescale Trigger connector; Other mode

Horizontal

Position

External Trigger Direct Input connector delay jitter

Horizontal

Position

Trigger delay jitter, Untriggered phase corrected mode (with 82A04 m odule only)

Horizontal

Position

Trigger delay jitter, external triggered phase corrected mode- Clock Eye (with 82A04 modu le on ly)

Horizontal

Position

External Clock/Prescale trigger delay jitter

Horizontal

Position

Set to:

Set to:

Set to:

Set to:

Set to:

Set to:

Set to:

82A04 Test Record for Channel .

Technician:

Technician:

Minimum Incoming

1

19 ns

100 ns 0.991 ns 1.009 ns

1 μs 0.991 ns 1.009 ns

1

19 ns

100 ns 0.991 ns 1.009 ns

1 μs 0.991 ns 1.009 ns

1

19 ns

100 ns 0.991 ns 1.009 ns

1 μs 0.991 ns 1.009 ns

1

19 ns

100 ns

1 μs

1

20 ns

1

20 ns

1

20 ns

0.991 ns 1.009 ns

0.991 ns 1.009 ns

0.991 ns 1.009 ns

none

none

none

none

none

none

none

Outgoing

Maximum

<1.5 ps

<2.5 ps

<11.5 ps

≤200 fs,

typical

≤200 fs,

typical

<500 fs

<1.4 ps

DSA8300 Performance Verification 21

Performance Tests

DSA8300 and 82A04 Performance Test

DC Calibration Output

Set to:

1

29 ns for 80E07B, 80E08B, 80E09B, 80E10B

Minimum Incoming

Outgoing

Maximum

+1.0 V +0.9988 V +1.0012 V

0.0 V –0.2 mV +0.2 mV

–1.0 V –1.0012 V –0.9988 V

22 DSA8300 Performance Verification

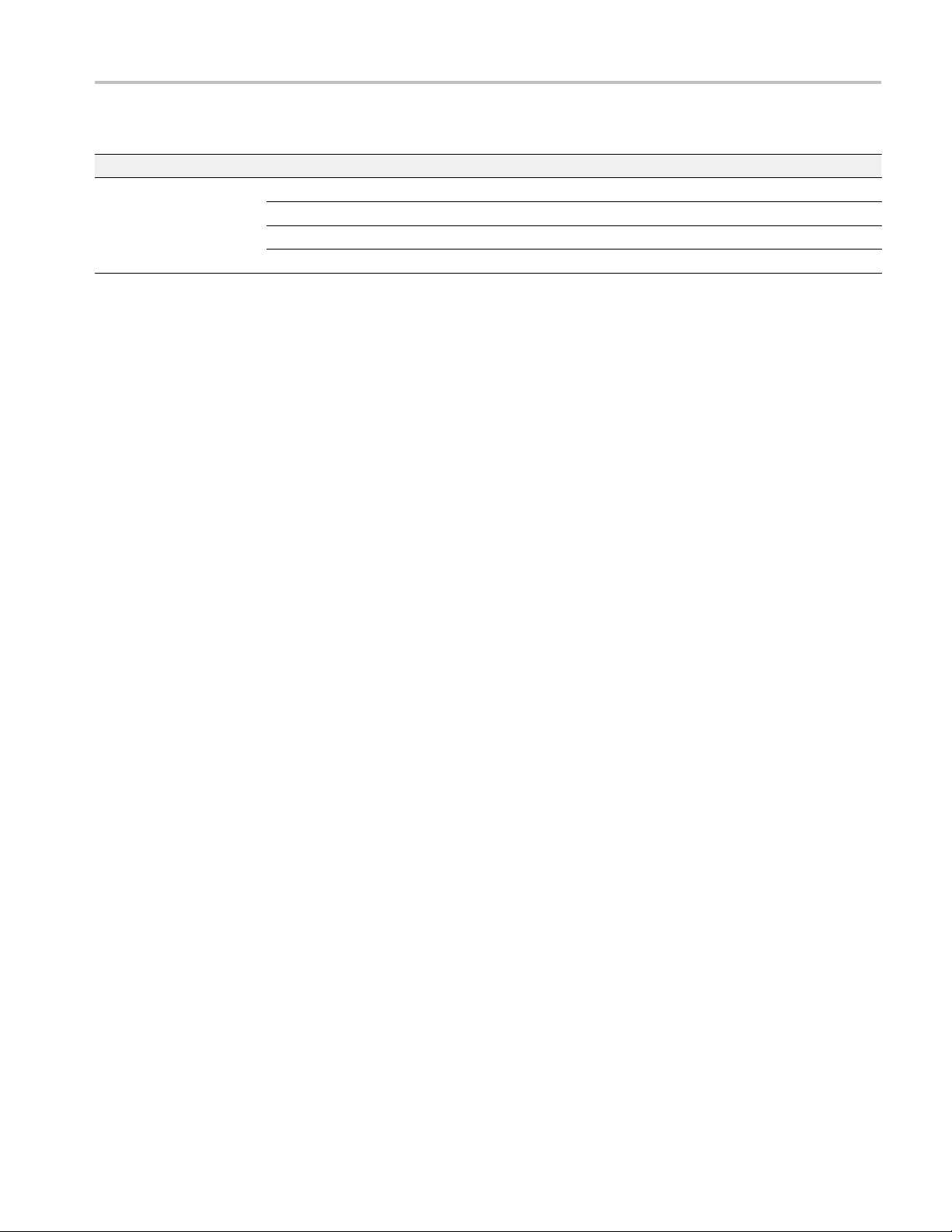

80E00 Electrical Modules Test Record

Print a the following table for each 80E00 module being tested. Use the copies to

record the performance test resultsforyourTestRecord.

NOTE. The C1 and C2 designations (channel 1/channel 2) in the test record may

be labeled as C3/C4, C5/C6, or C7/C8 in the instrument UI, depending on the

compartmen

80E00 Test Record.

Module Model:

Module Serial Number: Cal Certificate Number:

Date of Calibration:

80E00 Performance test

Input Impedance

80E01

80E02

80E03

80E04

80E06 Baseline (80E04 only)

80E07B

80E08B

80E09B

80E10B

C1

Baseline (80E04 only)

C2

C1

C2

t/slot in which the module is installed.

Technician:

Minimum Incoming

Impedance

Impedance

Impedance

Impedance

49.5 Ω 50.5 Ω

–1 mV 1 mV

49.5 Ω 50.5 Ω

–1 mV 1 mV

49 Ω 51 Ω

49 Ω 51 Ω

Performance Tests

Outgoing

Maximum

DSA8300 Performance Verification 23

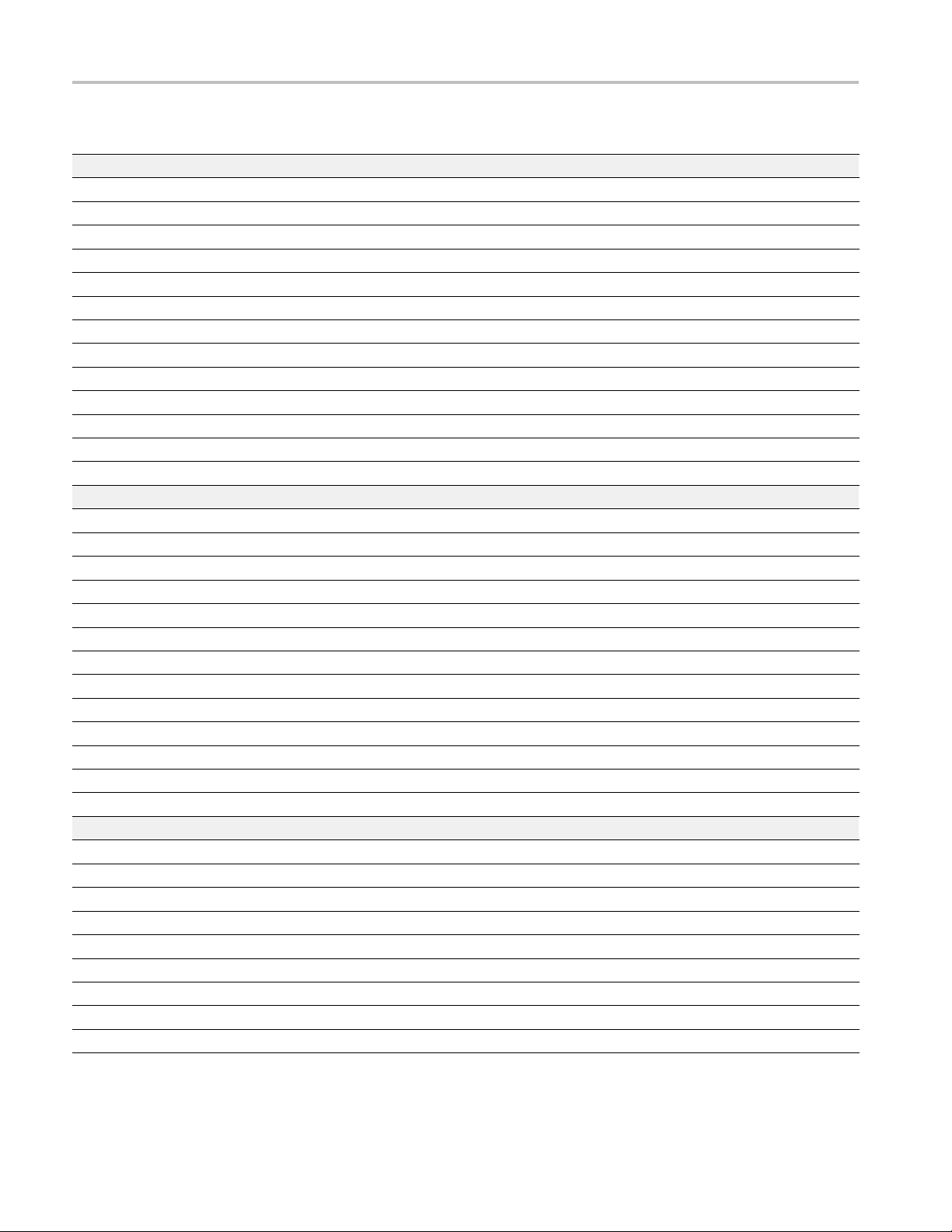

Performance Tests

80E00 Performance test

DC Voltage accuracy, single point, within ±5 °C of compensated temperature

80E01 ,

80E02,

80E03,

80E04,

80E06

C1 @

100 mV/div

C2 @ 100 mV/div

Input level:

-1550 mV -1100 mV -18.7 mV +18.7 mV

-1350 mV -1100 mV -14.7 mV +14.7 mV

-1100 mV -1100 mV -9.7 mV +9.7 mV

-850 mV -1100 mV -14.7 mV +14.7 mV

-650 mV -1100 mV -18.7 mV +18.7 mV

-450 mV 0 mV -11 mV +11 mV

-250mV 0mV -7mV +7mV

0 mV 0 mV -2 mV +2 mV

+250mV 0mV -7mV +7mV

+450 mV 0 mV -11 mV +11 mV

+650 mV +1100 mV -18.7 m V +18.7 m V

+850 mV +1100 mV -14.7 m V +14.7 m V

+1100 mV +1100 mV -9.7 mV +9.7 mV

+1350 m

+1550 mV +1100 mV -18.7 mV +18.7 m V

Input level:

-1550 mV -1100 mV -18.7 mV +18.7 mV

0mV

-135

-1100 mV -1100 mV -9.7 mV +9.7 mV

-850 mV -1100 mV -14.7 mV +14.7 mV

0mV

-65

-450 mV 0 mV -11 mV +11 mV

-250mV 0mV -7mV +7mV

V

0m

+250mV 0mV -7mV +7mV

+450 mV 0 mV -11 mV +11 mV

650 mV

+

+850 mV +1100 mV -14.7 m V +14.7 m V

+1100 mV +1100 mV -9.7 mV +9.7 mV

+1350 mV +1100 mV -14.7 mV +14.7 m V

+1550 mV +1100 mV -18.7 mV +18.7 m V

Offset:

V

+1100 m

Offset:

-110

-11

0m

+

V

0mV

00 mV

V

1100 mV

Minimum Incoming

-14.7 m

-14.

-18

-2

-

7mV

.7 mV

mV

18.7 mV

Outgoing

V

Maximum

+14.7 m

7mV

+14.

.7 mV

+18

mV

+2

18.7 mV

+

V

24 DSA8300 Performance Verification

Performance Tests

80E00 Performance test

80E07B

80E08B

80E09B

80E10B

C1 @ 100 mV/div

C2 @ 10

0 mV/div

Minimum Incoming

Input level:

-1050 mV -600 mV -15.2 mV +15.2 mV

-850 mV -600 mV -11.2 mV +11.2 mV

-600 mV -600 mV -6.2 mV +6.2 mV

-350 mV -600 mV -11.2 mV +11.2 mV

-150 mV -600 mV -15.2 mV +15.2 mV

-450 mV 0 mV -11 mV +11 mV

-250 mV 0 mV -7 mV +7 mV

0 mV 0 mV -2 mV +2 mV

+250 mV 0 mV -7 mV +7 mV

+450 mV 0 mV -11 mV +11 mV

+150 mV +600 mV -15.2 mV +15.2 mV

+350 mV +600 mV -11.2 mV +11.2 mV

+600 mV +600 mV -6.2 mV +6.2 mV

+850 mV +600 mV -11.2 mV +11.2 mV

+1050 m

Input level:

-1050 mV -600 mV -15.2 mV +15.2 mV

-850 mV -600 mV -11.2 mV +11.2 mV

mV

-600

-350 mV -600 mV -11.2 mV +11.2 mV

-150 mV -600 mV -15.2 mV +15.2 mV

0mV

-45

-250 mV 0 mV -7 mV +7 mV

0 mV 0 mV -2 mV +2 mV

50 mV

+2

+450 mV 0 mV -11 mV +11 mV

+150 mV +600 mV -15.2 mV +15.2 mV

350 mV

+

+600 mV +600 mV -6.2 mV +6.2 mV

+850 mV +600 mV -11.2 mV +11.2 mV

+1050 mV +600 mV -15.2 mV +15.2 mV

Offset:

V

+600 mV -15.2 m

t:

Offse

mV

-600

0mV -11

V

0m

600 mV

+

mV

-6.2

mV

mV

-7

11.2 mV

-

V

Outgoing

Maximum

+15.2 m

mV

+6.2

mV

+11

mV

+7

11. 2 mV

+

V

DSA8300 Performance Verification 25

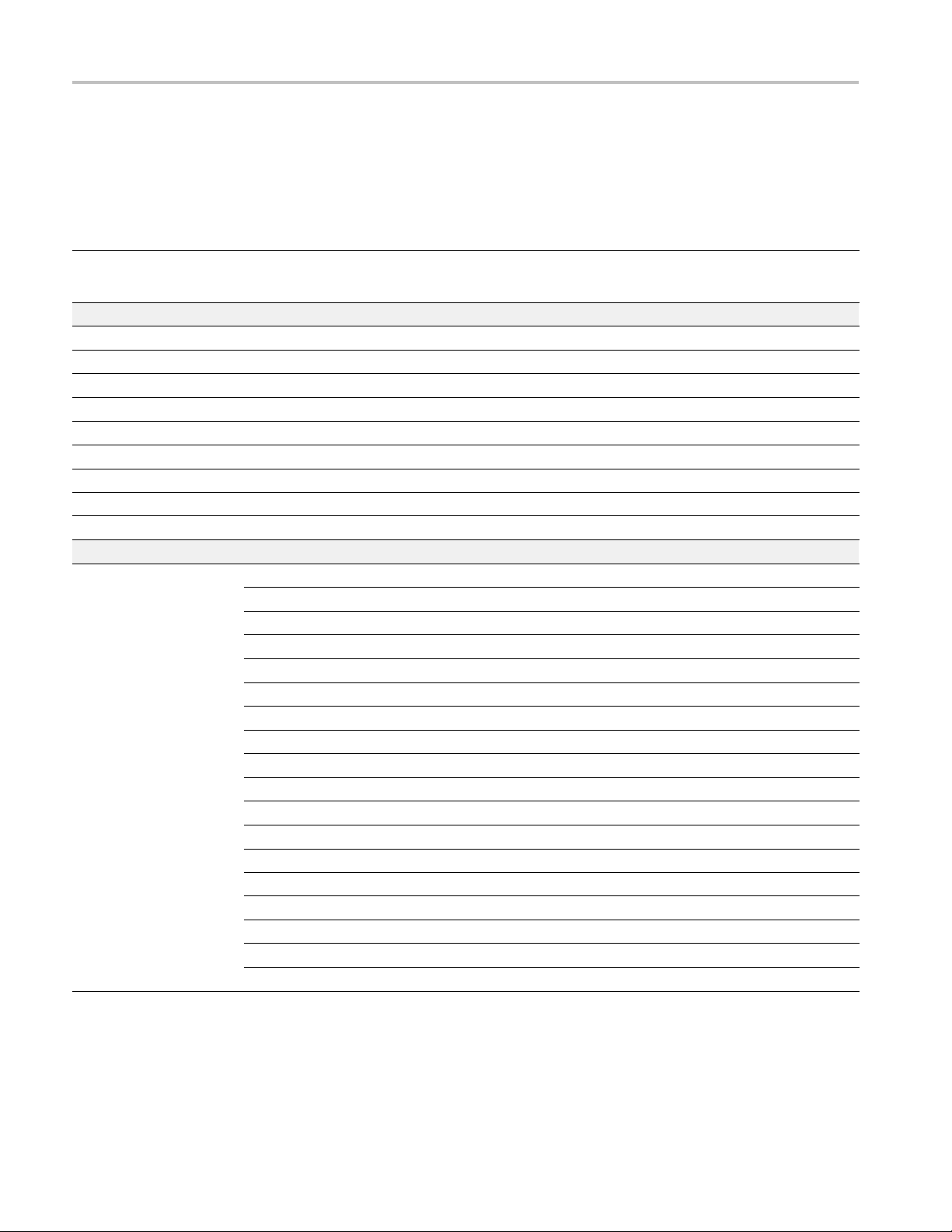

Performance Tests

80E00 Performance test

DC Vertical Voltage deviation from linear least squares fit

80E01,

80E02,

80E03,

80E04,

80E06,

80E07B,

80E08B,

80E09B,

C1 Set the Vin:

-450 mV -10 mV +10 mV

-350 mV -10 mV +10 mV

-250 mV -10 mV +10 mV

-150 mV -10 mV +10 mV

-50 mV -10 mV +10 mV

80E10B

+50 mV -10 mV +10 mV

+150 mV -10 mV +10 mV

+250 mV -10 mV +10 mV

+350 mV -10 mV +10 mV

+450 mV -10 mV +10 mV

C2 Set the V

:

in

-450 mV -10 mV +10 mV

-350 mV -10 mV +10 mV

-250 mV -10 mV +10 mV

-150 mV -10 mV +10 mV

-50 mV -10 mV +10 mV

+50 mV -10 mV +10 mV

+150 mV -10 mV +10 mV

+250 mV -10 mV +10 mV

mV

+350

+450 mV -10 mV +10 mV

Random Noise Displayed

01

80E

E02

80

0E03,

8

80E04

80E06

80E07B,

80E08B

C1

C1

C2

C1

C2

C1

C1 (BW 30 GHz)

C2 (BW 30 GHz)

C1 (BW 20 GHz)

C2 (BW 20 GHz)

Ver

Ve

Ve

ert scale: 1 mV

V

ert scale: 1 mV

V

Vert scale: 2 mV

Vert scale: 1 mV

Vert scale: 1 mV

Vert scale: 1 mV

Vert scale: 1 mV

tscale:2mV

rt scale: 1 mV

rt scale: 1 mV

Minimum Incoming

V

-10 m

e

non

ne

no

ne

no

one

n

one

n

none

none

none

none

none

Outgoing

Maximum

V

+10 m

mV

2.3

0 μV

80

0 μV

80

.2 mV

1

.2 mV

1

2.4 mV

410 μV

410 μV

380 μV

380 μV

26 DSA8300 Performance Verification

Performance Tests

80E00 Performance test

80E09B

80E10B

gBandwidth

Analo

80E01

80E06

80E07B,

E08B

80

80E09B

C1 (BW 60 GHz)

C2 (BW 60 GHz)

C1 (BW 40 GHz)

C2 (BW 40 GHz)

C1 (BW 30 GHz)

C2 (BW 30 GHz)

C1 (BW 50 GHz)

C2 (BW 50 GHz)

C1 (BW 40 GHz)

C2 (BW 40 GHz)

C1 (BW 30 GHz)

C2 (BW 30 GHz)

o50GHz)

C1 (t

to 65 GHz)

C1 (

(to30GHz)

C1

2(to30GHz)

C

C1(to60GHz)

C2(to60GHz)

Vert scale: 1 m

Vert scale: 1 m

Vert scale: 1

Vert scale:

Vert scale:

Vert scale

Vert scal

Vert scal

Vert sca

Vert sca

Vert sc

Vert s

Max power

(50 M

Min power

(50 M

Max power

(50

Min power

(50

Max power

0MHzref)

(5

Min power

0MHzref)

(5

Max power

50 MHz ref)

(

Min power

50 MHz ref)

(

Max power

(50 MHz ref)

Min power

(50 MHz ref)

Max power

(50 MHz ref)

Min power

(50 MHz ref)

1mV

1mV

:1mV

e: 1 mV

e: 1 mV

le: 1 mV

le: 1 mV

ale: 1 mV

cale: 1 mV

Hz ref)

Hz ref)

MHz ref)

MHz ref)

mV

Minimum Incoming

none

V

none

V

none

none

none

none

none

none

none

none

none

none

none

-3 dB

none

-3 dB

none

-3 dB

none

-3 dB

none

-3 dB

none

-3 dB

Outgoing

Maximum

600 μV

600 μV

480 μV

480 μV

410 μV

410 μV

700 μV

700 μV

480 μV

480 μV

410 μV

410 μV

+3 dB

+3 dB

+3 dB

+3 dB

+3 dB

+3 dB

DSA8300 Performance Verification 27

Performance Tests

80E00 Performance test

80E10B

C1 (to 50 GHz)

Max power

Minimum Incoming

none

(50 MHz ref)

Min power

-3 dB

(50 MHz ref)

C2 (to 50 GHz)

Max power

none

(50 MHz ref)

Min power

-3 dB

(50 MHz ref)

TDR system reflected rise time (80E04, 80E08B, 80E10B models only)

80E04

C1

TDR Polari

ty set

none

to +

TDR Polar

ity set

none

to -

C2

TDR Polar

ity set

none

to +

TDR Pola

rity set

none

to -

80E08B

C1

TDR Pola

rity set

none

to +

TDR Pol

arity set

none

to -

C2

TDR Pol

arity set

none

to +

TDR Po

larity set

none

to -

80E10

B

C1

TDR Po

larity set

none

to +

TDR P

olarity set

none

to -

C2

TDR P

olarity set

non

to +

TDR

Polarity set

non

to -

TDR system step response aberrations (80E04, 80E08B, 80E10B models only)

E04

80

C1 positive polarity zone: from

-10nsto-20ps