Page 1

DriverLINX Programming

Tutorial Manual

A GREATER MEASURE OF CONFIDENCE

Page 2

Page 3

DriverLINX Programming

Tutorial Manual

©2001, Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

First Printing, October 2001

Document Number: KPCI-904-01 Rev. A

Page 4

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created

for this manual. The Revision Level letter increases alphabetically as the manual undergoes subsequent updates. Addenda, which are released between Revisions, contain important change information that the user should incorporate immediately into the manual. Addenda are numbered

sequentially. When a new Revision is created, all Addenda associated with the previous Revision

of the manual are incorporated into the new Revision of the manual. Each new Revision includes

a revised copy of this print history page.

Revision A (Document Number KPCI-904-01A)........................................................October 2001

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

DriverLINX is a registered trademark of Scientific Software Tools, Inc.

Portions of the material are copyright 1990-2001 by Scientific Software Tools, Inc. and used with permission.

Other brand names are trademarks or registered trademarks of their respective holders.

Page 5

Safety Precautions

The following safety precautions should be observed before using this product and any associated instrumentation. Although some instruments and accessories would normally be used with non-hazardous

voltages, there are situations where hazardous conditions may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar

with the safety precautions required to avoid possible injury. Read the operating information carefully

before using the product.

The types of product users are:

Responsible body

ensuring that the equipment is operated within its specifications and operating limits, and for ensuring

that operators are adequately trained.

Operators

and proper use of the instrument. They must be protected from electric shock and contact with hazardous

live circuits.

Maintenance personnel

setting the line voltage or replacing consumable materials. Maintenance procedures are described in the

manual. The procedures explicitly state if the operator may perform them. Otherwise, they should be

performed only by service personnel.

Service personnel

ucts. Only properly trained service personnel may perform installation and service procedures.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than 30V RMS, 42.4V peak, or 60VDC are present.

practice is to expect that hazardous voltage is present in any unknown circuit before measuring.

Users of this product must be protected from electric shock at all times. The responsible body must ensure that users are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential human contact. Product users in these circumstances must be

trained to protect themselves from the risk of electric shock. If the circuit is capable of operating at or

above 1000 volts,

As described in the International Electrotechnical Commission (IEC) Standard IEC 664, this instrument

is Installation Category I, and signal lines must not be directly connected to AC mains.

For rack mounted equipment in which the power cord is not accessible, in the event of fire or other catastrophic failure, the user must provide a separate power disconnect switch.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with

impedance limited sources. NEVER connect switching cards directly to AC mains. When connecting

sources to switching cards, install protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under test. ALWAYS remove power from the entire test system and discharge any

capacitors before: connecting or disconnecting cables or jumpers, installing or removing switching

cards, or making internal changes, such as installing or removing jumpers.

is the individual or group responsible for the use and maintenance of equipment, for

use the product for its intended function. They must be trained in electrical safety procedures

are trained to work on live circuits, and perform safe installations and repairs of prod-

no conductive part of the circuit may be exposed.

perform routine procedures on the product to keep it operating, for example,

A good safety

Page 6

Do not touch any object that could provide a current path to the common side of the circuit under test or power

line (earth) ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the voltage being measured.

The instrument and accessories must be used in accordance with its specifications and operating instructions

or the safety of the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications

and operating information, and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as safety earth

ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation

requires the use of a lid interlock.

If a screw is present, connect it to safety earth ground using the wire recommended in the user

documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in

the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of normal and common mode voltages. Use standard safety precautions to avoid personal contact

with these voltages.

The

WARNING

read the associated information very carefully before performing the indicated procedure.

heading in a manual explains dangers that might result in personal injury or death. Always

The

CAUTION

invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits, including the

power transformer, test leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses,

with applicable national safety approvals, may be used if the rating and type are the same. Other components

that are not safety related may be purchased from other suppliers as long as they are equivalent to the original

component. (Note that selected parts should be purchased only through Keithley Instruments to maintain accuracy and functionality of the product.) If you are unsure about the applicability of a replacement component,

call a Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based cleaner. Clean the exterior of the instrument

only. Do not apply cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist of a circuit board with no case or chassis (e.g., data acquisition board for installation into a

computer) should never require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the factory for proper cleaning/servicing.

heading in a manual explains hazards that could damage the instrument. Such damage may

Rev. 2/01

Page 7

Table of Contents

1 Introduction

About this manual ................................................................................ 1-2

Manual conventions ............................................................................. 1-2

2 Using the DriverLINX Manual Set

Manuals supplied with DriverLINX .................................................... 2-2

Using the DriverLINX manuals ........................................................... 2-4

3 Accessing the DriverLINX Tools

Introduction .......................................................................................... 3-2

Microsoft Visual Basic 6.0 ................................................................... 3-3

Microsoft Visual C++ 5.0 ..................................................................... 3-4

Creating the application ................................................................. 3-5

Building the dialog box ............................................................... 3-10

Adding code ................................................................................. 3-15

Running the application ............................................................... 3-18

Sample code fragments ................................................................ 3-19

Borland Delphi ................................................................................... 3-24

4 Learning DriverLINX

DriverLINX design philosophy ............................................................ 4-2

Devices, subsystems, and channels ...................................................... 4-3

Logical devices .............................................................................. 4-3

Logical subsystems ........................................................................ 4-3

Logical channels ............................................................................ 4-4

Understanding the Service Request ..................................................... 4-4

Overview ........................................................................................ 4-4

Control Group ................................................................................ 4-6

Request Group ............................................................................... 4-6

Events Group ................................................................................. 4-6

Select Group .................................................................................. 4-7

Page 8

Results Group ................................................................................ 4-8

Auditing the Service Request ........................................................ 4-8

Learning to use the Service Request .............................................. 4-9

Displaying the Edit Service Request dialog

with LearnDL ........................................................................ 4-10

Displaying the Edit Service Request dialog from

within an application ............................................................. 4-14

Visual Basic ........................................................................... 4-14

C/C++ .................................................................................... 4-15

DriverLINX source file examples ...................................................... 4-15

Analog input subsystem ............................................................... 4-16

Analog output subsystem ............................................................. 4-17

Analog I/O subsystems ................................................................ 4-17

Digital input subsystem ............................................................... 4-17

Digital output subsystem ............................................................. 4-18

Digital input/output subsystems .................................................. 4-19

Counter/timer subsystem ............................................................. 4-19

5 Common DriverLINX Tasks

Introduction .......................................................................................... 5-2

Basic sequence of operations ............................................................... 5-2

Opening the DriverLINX driver ........................................................... 5-3

Visual Basic ............................................................................. 5-3

C/C++ ...................................................................................... 5-4

Initialzing a device ............................................................................... 5-4

Visual Basic ............................................................................. 5-5

C/C++ ...................................................................................... 5-5

Initializing a subsystem ........................................................................ 5-6

Visual Basic ............................................................................. 5-6

C/C++ ...................................................................................... 5-6

Closing the DriverLINX driver ............................................................ 5-7

Visual Basic ............................................................................. 5-7

C/C++ ...................................................................................... 5-7

Using more than one subsystem on a board ......................................... 5-8

Using more than one data acquisition board ........................................ 5-8

Visual Basic ............................................................................. 5-8

C/C++ ...................................................................................... 5-9

Page 9

C/C++ special considerations ............................................................... 5-9

Variable declarations and include files ........................................ 5-10

Clearing buffers ........................................................................... 5-10

Error Check ................................................................................. 5-11

Allocate Buffers ........................................................................... 5-11

Channel Gain List ........................................................................ 5-12

Clearing a Channel/Gain List ...................................................... 5-12

6 Analog and Digital I/O Programming

Introduction .......................................................................................... 6-2

Basic steps for data acquisition ............................................................ 6-2

Windows messaging ............................................................................. 6-4

Using events ......................................................................................... 6-5

Software command events ............................................................. 6-5

Visual Basic ............................................................................. 6-6

C/C++ ...................................................................................... 6-6

Terminal count events .................................................................... 6-7

Visual Basic ............................................................................. 6-7

C/C++ ...................................................................................... 6-7

Rate events ..................................................................................... 6-8

Visual Basic ............................................................................. 6-8

C/C++ ...................................................................................... 6-8

Analog events ................................................................................ 6-9

Visual Basic ........................................................................... 6-10

C/C++ .................................................................................... 6-10

Digital events ............................................................................... 6-11

Visual Basic ........................................................................... 6-11

C/C++ .................................................................................... 6-11

Event delays ................................................................................. 6-12

Visual Basic ........................................................................... 6-12

C/C++ .................................................................................... 6-13

Reading a single digital value ............................................................ 6-13

Visual Basic ........................................................................... 6-14

C/C++ .................................................................................... 6-15

Reading a single analog value ............................................................ 6-15

Visual Basic ........................................................................... 6-16

C/C++ .................................................................................... 6-17

Page 10

Reading a series of digital values ....................................................... 6-17

Visual Basic ........................................................................... 6-18

C/C++ .................................................................................... 6-19

Writing a single digital value ............................................................. 6-20

Visual Basic ........................................................................... 6-21

C/C++ .................................................................................... 6-22

Writing a series of digital values ........................................................ 6-23

Visual Basic ........................................................................... 6-23

C/C++ .................................................................................... 6-25

Reading analog values on several channels ........................................ 6-26

Visual Basic ........................................................................... 6-27

C/C++ .................................................................................... 6-28

Using messages in a background task ................................................ 6-30

Visual Basic ........................................................................... 6-31

C/C++ .................................................................................... 6-32

Writing a single analog value ............................................................. 6-35

Visual Basic ........................................................................... 6-35

C/C++ .................................................................................... 6-36

Writing a series of analog values ....................................................... 6-36

Visual Basic ........................................................................... 6-37

C/C++ .................................................................................... 6-38

Writing analog values on several channels ........................................ 6-40

Visual Basic ........................................................................... 6-41

C/C++ .................................................................................... 6-42

Foreground and background operation .............................................. 6-43

Visual Basic ........................................................................... 6-44

C/C++ .................................................................................... 6-45

Using an external digital trigger ......................................................... 6-47

Visual Basic ........................................................................... 6-48

C/C++ .................................................................................... 6-50

Analog Input Events ........................................................................... 6-52

VB ......................................................................................... 6-53

C/C++ .................................................................................... 6-55

Page 11

7 Alternate API for Digital I/O Boards

Introduction .......................................................................................... 7-2

Configuration ....................................................................................... 7-3

Direct I/O using Visual Basic ............................................................... 7-5

Direct I/O using C/C++ ........................................................................ 7-5

Sample console application ........................................................... 7-5

GUI applications ............................................................................ 7-8

8 Counter/Timer Programming

Introduction .......................................................................................... 8-2

Task vs. group mode ............................................................................ 8-2

Task mode ...................................................................................... 8-2

Group mode ................................................................................... 8-3

Brief Hardware Review ................................................................. 8-3

Event counting ..................................................................................... 8-5

Visual Basic ............................................................................. 8-6

C/C++ ...................................................................................... 8-6

Frequency measurement ....................................................................... 8-7

Visual Basic ............................................................................. 8-9

C/C++ ...................................................................................... 8-9

Pulse width measurement ................................................................... 8-10

Visual Basic ........................................................................... 8-11

C/C++ .................................................................................... 8-12

Square wave generator ....................................................................... 8-13

Visual Basic ........................................................................... 8-13

C/C++ .................................................................................... 8-14

One shot pulse generator .................................................................... 8-15

Visual Basic ........................................................................... 8-15

C/C++ .................................................................................... 8-16

Time interval measurement ................................................................ 8-16

Visual Basic ........................................................................... 8-17

C/C++ .................................................................................... 8-23

Page 12

9 Troubleshooting

Introduction .......................................................................................... 9-2

LearnDL application ............................................................................ 9-2

About LearnDL .............................................................................. 9-2

Using LearnDL .............................................................................. 9-3

Preparing LearnDL ........................................................................ 9-4

Acquiring data with LearnDL ........................................................ 9-7

Error messages ..................................................................................... 9-8

Displaying error messages ............................................................. 9-9

Visual Basic ........................................................................... 9-10

C/C++ .................................................................................... 9-10

Common error messages ............................................................. 9-10

Interpreting error messages ................................................................ 9-12

Decoding error messages ............................................................. 9-12

Visual Basic ........................................................................... 9-12

C/C++ .................................................................................... 9-12

Responding to error messages ..................................................... 9-13

Visual Basic ........................................................................... 9-13

C/C++ .................................................................................... 9-14

Errors with Windows messaging ................................................. 9-14

Page 13

List of Illustrations

3 Accessing the DriverLINX Tools

Figure 3-1 Components dialog ........................................................ 3-3

Figure 3-2 Visual Basic tool box ..................................................... 3-4

Figure 3-3 New projects dialog ....................................................... 3-5

Figure 3-4 MFC AppWizard - step 1 ............................................... 3-6

Figure 3-5 MFC AppWizard - step 2 ............................................... 3-7

Figure 3-6 New project information dialog ..................................... 3-8

Figure 3-7 Microsoft Development Studio File tab ......................... 3-9

Figure 3-8 Starting the dialog box ................................................. 3-10

Figure 3-9 Adding the buttons ....................................................... 3-11

Figure 3-10 Setting button properties .............................................. 3-12

Figure 3-11 Edit properties dialog ................................................... 3-13

Figure 3-12 Adding button functions .............................................. 3-14

Figure 3-13 aioDlg.cpp file cope addition points ............................ 3-16

Figure 3-14 aioDlg.h file code addition points ................................ 3-17

Figure 3-15 Running the application ............................................... 3-18

Figure 3-16 Borland Delphi 5 Import ActiveX dialog ..................... 3-25

4 Learning DriverLINX

Figure 4-1 Edit Service Request dialog ........................................... 4-5

Figure 4-2 Edit Service Request dialog ........................................... 4-9

Figure 4-3 LearnDL Device menu ................................................. 4-10

Figure 4-4 Select Device window .................................................. 4-11

Figure 4-5 Edit Service Request dialog ......................................... 4-12

Figure 4-6 Completed Edit Service Request dialog ...................... 4-12

Figure 4-7 Oscilloscope display .................................................... 4-13

5 Common DriverLINX Tasks

Figure 5-1 Open DriverLINX dialog ............................................... 5-3

6 Analog and Digital I/O Programming

Figure 6-1 Burst generator ............................................................. 6-41

Page 14

8 Counter/Timer Programming

Figure 8-1 Basic counter elements .................................................. 8-4

Figure 8-2 16-bit frequency measurement ....................................... 8-7

9 Troubleshooting

Figure 9-1 OpenDriverLINX dialog ................................................ 9-4

Figure 9-2 LearnDL main window .................................................. 9-5

Figure 9-3 Select device dialog ....................................................... 9-6

Figure 9-4 Edit Service Request dialog ........................................... 9-7

Figure 9-5 DriverLINX modal dialog .............................................. 9-9

Page 15

1

Introduction

Introduction

1-1

Page 16

Introduction DriverLINX Programming Tutorial Manual

About this manual

This manual is provided as an introduction to programming with DriverLINX. This

manual focuses mainly on programming DriverLINX for the KPCI series boards

using the 32-bit driver, such as the KPCI and PIO series, and the DAS 800, 1700, and

1800 series. Some modification of the examples and lessons provided may be necessary when using other data acquisition boards such as the DAS-8, DAS-16, or DAS1600, and these products are not specifically addressed in this manual.

Programming languages covered in this manual include Visual Basic, Delphi, and

C/C++. Examples in the tutorials are provided for Microsoft Visual Basic 6 and for

Microsoft Visual C++ 6.0. With the exception of minor syntactical differences, the

programming examples provided for Visual Basic may also be used with the Delphi

programming language. The C++ source code examples will work with both the C and

C++ programming languages.

This manual assumes a basic familiarity with the chosen programming language. This

manual does not provide instruction on the selected programming language. It provides DriverLINX programming instruction, with examples and source code in various programming languages. There are many good instructional manuals and courses

available for basic programming instruction.

Manual conventions

This manual uses the following conventions when presenting material.

•

This Courier font denotes sample code that is presented as it would

appear in your program.

•

Manual titles, such as the

italics.

The following icons are used to denote the programming language to which the

description or sample code applies.

VB

C/C++

Visual Basic/Delphi

C/C++

Analog I/O Programming Guide

1-2

, are presented in

Page 17

2

Using the DriverLINX

Manual Set

Using Manual Set

2-1

Page 18

Using the DriverLINX Manual Set DriverLINX Programming Tutorial Manual

Manuals supplied with DriverLINX

There are several manuals supplied with the data acquisition board and DriverLINX.

Knowing how to use the manuals is a key step in learning to program DriverLINX

applications. The DriverLINX installation program provides an option to install these

manuals on your computer. If the manuals are installed, they can be viewed using

Adobe Acrobat Reader by selecting the On-line Manuals icon in the DriverLINX program group. A copy of the free Acrobat Reader is located on the DriverLINX installation CD-ROM.

The following manuals are provided with DriverLINX:

• Analog I/O Programming Guide —

the analog input and output functions of DriverLINX. Some information

regarding basic digital I/O and counter/timer operations is also provided. This

manual is a good starting point for new DriverLINX programmers.

• Digital I/O Programming Guide —

gramming the digital input and output functions of DriverLINX. Information is

also provided for configuring the digital I/O hardware.

• Counter/Timer Programming Guide —

programming the counter/timer functions of DriverLINX.

• DriverLINX Technical Reference Manual —

is a reference manual for the DriverLINX API. This manual focuses on the C/

C++ programming language. The manual contains a complete description of

the service request, logical device descriptor, and DriverLINX support and messaging functions. This manual is intended for the more experienced DriverLINX programmer. Users new to DriverLINX should refer to the Analog I/O

Programming Guide.

This manual contains information regarding

This manual contains information on pro-

This manual provides information for

The Technical Reference Manual

2-2

Page 19

DriverLINX Programming Tutorial Manual Using the DriverLINX Manual Set

• DriverLINX/VB Technical Reference Manual —

This manual is the reference

manual that describes the DriverLINX ActiveX control that is used when programming with VB or Delphi. The manual contains a complete description of

the service request, logical device descriptor, and DriverLINX support and

event functions. This manual is intended for the more experienced DriverLINX

programmer. Users new to DriverLINX should refer to the Analog I/O Programming Guide.

• Using DriverLINX With Your Hardware —

Unlike other DriverLINX manuals,

this manual is written specifically to apply to the data acquisition board with

which DriverLINX has been supplied. This manual contains information on

configuring the features of your board, and the support for those features provided by DriverLINX.

• Data Acquisition Board User’s Manual —

Keithley Instruments supplies a

user’s manual written specifically for each data acquisition board. This manual

focuses on the board itself, and not on DriverLINX. Information provided in

this manual includes hardware and software installation, capabilities of the

card, calibration, troubleshooting, and specifications.

Using Manual Set

2-3

Page 20

Using the DriverLINX Manual Set DriverLINX Programming Tutorial Manual

Using the DriverLINX manuals

The DriverLINX manuals are written to support the hardware independent nature of

DriverLINX. To accomplish this, the software manuals contain no hardware-specific

information. All hardware-specific information has been placed in the

LINX With Your Hardware

data acquisition board with which they are supplied.

Due to the hardware independent nature of the manuals, they contain information

which may not be applicable to the data acquisition board you are using. To be sure

that any individual function is supported by your data acquisition board, check the

Using DriverLINX With Your Hardware

When writing new DriverLINX applications, the best manual for new users to reference is the

on how DriverLINX functions, as well as basic steps for programming simple analog

I/O functions. In additional to information on programming analog I/O tasks, this

manual contains information on basic digital I/O and counter/timer functions.

For more in-depth information about programming digital I/O functions, refer to the

Digital I/O Programming Guide

hardware and logical channels for the digital I/O device, how to perform digital I/O

tasks, and contains some programming examples. This manual also contains information regarding hardware configuration.

Analog I/O Programming Guide

manuals. These manuals are written specifically for the

manual.

. This manual contains basic information

. This manual describes how DriverLINX maps the

Using Driver-

The

Counter/Timer Programming Guide

ent counter/timer chips, channel configuration, and task programming. This manual

also provides a description of the operating modes for the AMD Am9513 and Intel

8254 timing chips.

provides in-depth descriptions of the differ-

2-4

Page 21

3

Accessing the

DriverLINX Tools

Accessing Tools

3-1

Page 22

Accessing the DriverLINX Tools DriverLINX Programming Tutorial Manual

Introduction

After the DriverLINX drivers are installed on the computer they must be added to the

application programming environment before they can be used. There are two components which need to be added: the Service Request control and the Logical Device

Descriptor control. For Visual Basic or Delphi, these are separate ActiveX controls.

For C/C++, the controls are DLLs.

The following sections detail the procedures necessary to use the DriverLINX controls

in your application programming environment.

3-2

Page 23

DriverLINX Programming Tutorial Manual Accessing the DriverLINX Tools

Microsoft Visual Basic 6.0

Adding the DriverLINX ActiveX controls to the Visual Basic tool box is a simple task.

Perform the following procedure to add the ActiveX controls.

1. Start Visual Basic and select a project type of Standard Executable.

2. Open the Components dialog, shown in Figure 3-1, using one of the following

methods:

• Right click on the toolbox and select Components from the pop-up menu.

• From the Project menu, select Components.

• Use the keyboard shortcut CTRL+T.

3. In the Controls tab of the Components dialog, scroll down the components list

to find the DriverLINX ActiveX Controls item. Place a check mark in the box to

the left of this item and click the OK button.

Figure 3-1

Components dialog

3-3

Accessing Tools

Page 24

Accessing the DriverLINX Tools DriverLINX Programming Tutorial Manual

4. Two new controls are added to the tool box. These are the Service Request Control and the LDD Control, as shown in Figure 3-2.

Figure 3-2

Visual Basic tool box

Service

Request

Control

LDD Control

Microsoft Visual C++ 5.0

C and C++ use the DLL API of DriverLINX. It is possible to use the ActiveX control

with C/C++, but this is not covered in this manual. For an example, see the source

code provided in the drvlinx4\source\cpp\AIBuffX directory.

This sample program uses the DLL API to create a C++ dialog based application

using the MFC Application Wizard. This application demonstrates analog input and

analog output functions using a KPCI-3108 data acquisition card. This card has a D/A

memory buffer to store the wave form data for the analog output function. The

3-4

Page 25

DriverLINX Programming Tutorial Manual Accessing the DriverLINX Tools

KPCI-3108 oscillator will clock the D/A system at speed. Due to the latency of Windows from sample to sample, it would not be possible to achieve waveform generation

while storing the data in a Windows environment. While Windows can burst large

amounts of data at speed, the bursting operation can be 20 mS or longer between

bursts if there is no plug-in memory card to receive the data. That translates to 50 or

less updates per second.

Creating the application

Begin building the application by starting Microsoft Visual C++ 5.0 and select New

from the File menu. Perform the following procedure:

1. From the Projects Tab, select MFC AppWizard (exe). Use the Location: box to

specify the path for the new application build, and give the project a name. For

this example we will use “aio”. These selections are shown in Figure 3-3. The

Platforms: is Win32 and should already be checked. After completing all selections, click OK.

Figure 3-3

New projects dialog

3-5

Accessing Tools

Page 26

Accessing the DriverLINX Tools DriverLINX Programming Tutorial Manual

2. The MFC AppWizard, shown in Figure 3-4, provides a choice of application

types: Single Document, Multiple Document, or Dialog Based. The sample

application code provided with DriverLINX is written using the default Single

Document Model. For this tutorial, we will develop an application using the

Dialog based model. This will reduce the overall complexity of the application

development. Choose Dialog Based, then select Next.

Figure 3-4

MFC AppWizard - step 1

3-6

Page 27

DriverLINX Programming Tutorial Manual Accessing the DriverLINX Tools

3. For the Analog I/O example developed here does not include an About Box,

keeping the code simpler. This requires that the About Box be unchecked. In the

MFC AppWizard step 2, shown in Figure 3-5, uncheck the About box check

box and click Finish. Although additional options are available in steps 3 and 4,

they are not related to this DriverLINX application, and can be left at their

default.

Figure 3-5

MFC AppWizard - step 2

Note:

If your project uses

the alternate API for

digital I/O as described in Section 7,

you must check the

Automation check

box. However, this is

not used in this example program, and

this box should be

left unchecked.

3-7

Accessing Tools

Page 28

Accessing the DriverLINX Tools DriverLINX Programming Tutorial Manual

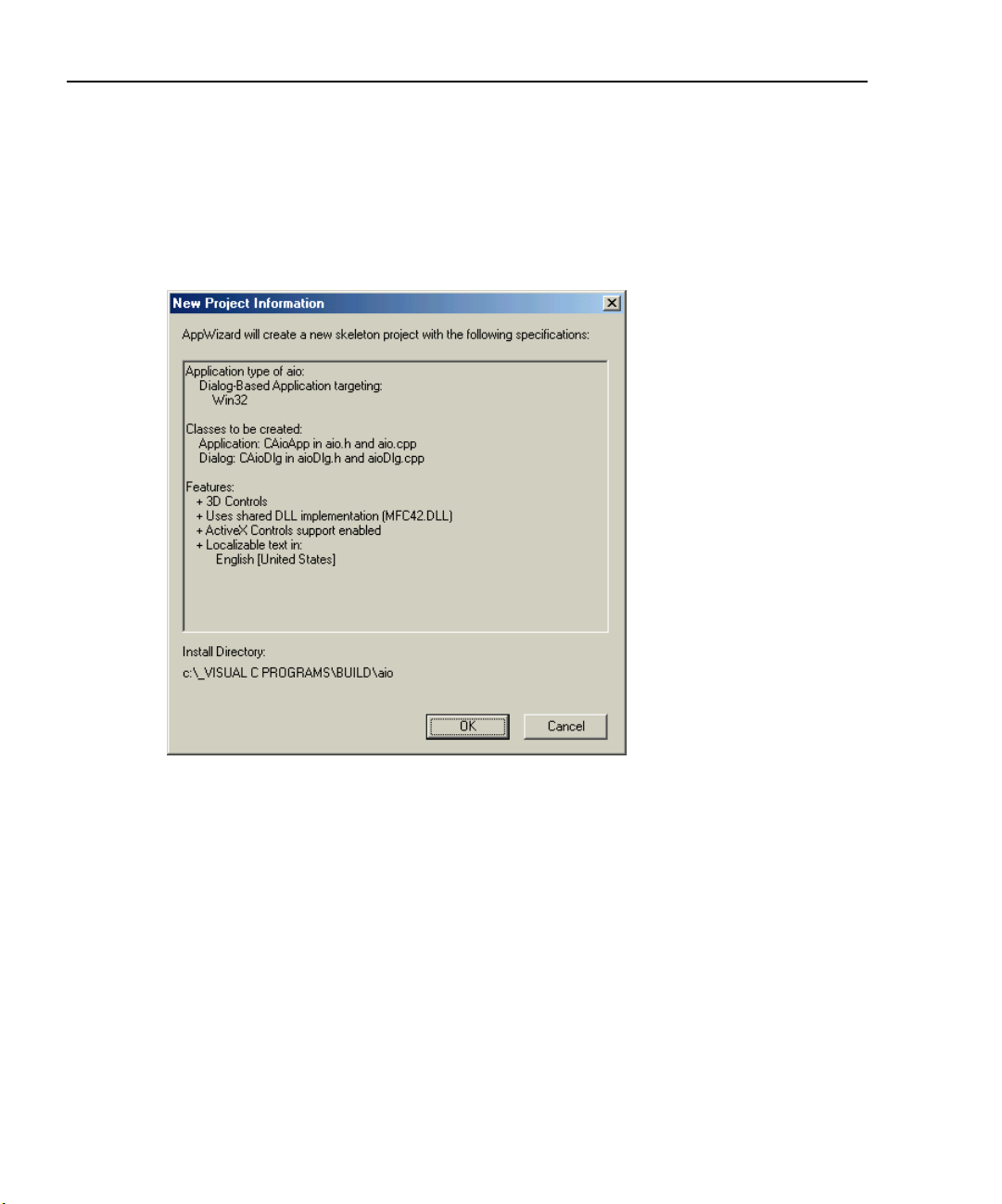

4. The MFC AppWizard will generate a dialog as shown in Figure 3-6. This box

lists a summary of the project that will be created. Click OK. The MFC AppWizard will build the foundation code.

Figure 3-6

New project information dialog

3-8

Page 29

DriverLINX Programming Tutorial Manual Accessing the DriverLINX Tools

5. Figure 3-7 shows the Visual C++ Development Studio project for the aio program with the File tab selected. Note the Source, Header and Resource files,

these will be edited to build the application.

Figure 3-7

Microsoft Development Studio File tab

3-9

Accessing Tools

Page 30

Accessing the DriverLINX Tools DriverLINX Programming Tutorial Manual

Building the dialog box

The first step of code development is building the visual panel, the 3-D controls that

will initiate and report program activity.

1. Choose Resource View.

2. If the dialog is not already visible, open the folders and double click the

IDD_AIO_DIALOG icon. The (TODO:Place dialog controls here) panel will

display along with the controls pallet, as shown in Figure 3-8.

Figure 3-8

Starting the dialog box

3-10

Page 31

DriverLINX Programming Tutorial Manual Accessing the DriverLINX Tools

3. Highlight the OK Button in the aio dialog box and choose delete. Do the same

for the Cancel Button and the Static Text so we have a clean dialog box to start

from.

4. Expand the dialog box to make it larger. From the Controls pallet, add five Push

Buttons, one Edit Box, and the Group Box as shown in Figure 3-9.

Figure 3-9

Adding the buttons

3-11

Accessing Tools

Page 32

Accessing the DriverLINX Tools DriverLINX Programming Tutorial Manual

5. Right Click on Button1. Choose Properties and edit the PushButton Properties

ID and Caption options as shown in Figure 3-10.

Figure 3-10

Setting button properties

3-12

Page 33

DriverLINX Programming Tutorial Manual Accessing the DriverLINX Tools

6. Repeat step 5 for PushButtons 2 through 5, using the properties shown below:

Initial Caption ID New Caption

Button1

IDC_Button1_StartAtoD Start A/D

Button2 IDC_Button2_ClearEditBox Clear

Button3 IDC_Button3_StartDtoA Start D/A

Button4 IDC_Button4_StopDtoA Stop D/A

Button5 IDC_Button5_Quit Quit

Static Text IDC_STATIC aio

7. For the Edit Box properties, check the Multiline and Vertical scroll check boxes

so multiple values can be displayed in the edit box, as shown in Figure 3-11.

Figure 3-11

Edit properties dialog

Accessing Tools

3-13

Page 34

Accessing the DriverLINX Tools DriverLINX Programming Tutorial Manual

8. Next, use the ClassWizard to place code for these controls in the program. The

ClassWizard is also used to set up Windows Messaging and assign a variable

name to the edit box. Refer to Figure 3-12 and perform steps 9 to 11.

Figure 3-12

Adding button functions

3-14

Page 35

DriverLINX Programming Tutorial Manual Accessing the DriverLINX Tools

Adding windows messaging

9. From the View Tab, Select ClassWizard, note that we are in the Message Maps

TAB of the ClassWizard. The CaioDlg Object ID should be highlighted. In the

Messages window, scroll down and select WindowProc. Choose Add Function.

WindowProc will appear in the Member Functions window. Choose OK. This

added function dispatches messages through the message map, an extremely

important part of the program.

Adding code blocks for the push buttons

10. From the View Tab, select ClassWizard and highlight the

IDC_Button1_StartAtoD selection in the Object ID’s box. Highlight

BN_Clicked in the Messages Box and choose Add Function, then OK. Repeat

this for each of the Push Buttons listed in the Object ID’s box.

Adding a variable for the edit box

11. Before closing the MFC ClassWizard, choose the Member Variables Tab.

Highlite IDC_Edit2 in the Controls ID window and select Add Variable. Assign

a member variable name of m_editBox, and choose OK. Choose OK once more

to close the MFC ClassWizard.

Adding code

Figure 3-13 and Figure 3-14 show the aioDlg.cpp and aioDlg.h files as they exist in

the application at this time. These are the only files that need to be edited to add all

required code for the Service Request. The code to be added is broken into 13 parts.

This demonstrates how to build an application after the AppWizard portion is

complete.

The 13 code fragments are provided at the end of this example in “Sample code

fragments.”

Code part 14 is not a code fragment that must be added, but is simply a reminder to

add the DriverLINX library file, DRVLNX32.lib, to the project. This file is normally

located in C:\DrvLINX4\DLApi\DRVLNX32.lib. To add this file, select Project > Add

to Project > Files from the menu bar.

Refer to Figure 3-13 and Figure 3-14 and place the 13 code parts in the appropriate

locations in the AIODgl.cpp and AIODlg.h files.

3-15

Accessing Tools

Page 36

Accessing the DriverLINX Tools DriverLINX Programming Tutorial Manual

Figure 3-13

aioDlg.cpp file cope addition points

3-16

Page 37

DriverLINX Programming Tutorial Manual Accessing the DriverLINX Tools

Figure 3-14

aioDlg.h file code addition points

Note that the DRVLNX32.lib file has been placed in the project. Once the project has

been compiled, there is an additional folder, External Dependencies, in the aio files.

For the data to report vertically in the Edit Box, you must edit the properties: Multiline

and Vertical scroll bars.

3-17

Accessing Tools

Page 38

Accessing the DriverLINX Tools DriverLINX Programming Tutorial Manual

Running the application

Figure 3-15 shows the final application running.

Figure 3-15

Running the application

3-18

Page 39

DriverLINX Programming Tutorial Manual Accessing the DriverLINX Tools

Sample code fragments

Listed below are the program code parts that must be added to the locations shown in

Figure 3-13 and Figure 3-14.

//AIODLG.cpp//

//Start Step 1 Code: adding the math functions //

#include<math.h> /*math functions must be included*/

//End Step 1 Code: adding the math functions //

//Start Step 2 Code: initialization//

m_logicalDevice=0;

m_samples=1000;

m_driverInstance=OpenDriverLINX(m_hWnd,"KPCI3108");

m_AOsr=(DL_ServiceRequest*) new DL_ServiceRequest;

m_AIsr=(DL_ServiceRequest*) new DL_ServiceRequest;

memset(m_AIsr,0,sizeof(DL_ServiceRequest));

DL_SetServiceRequestSize(*m_AIsr);

memset(m_AOsr,0,sizeof(DL_ServiceRequest));

DL_SetServiceRequestSize(*m_AOsr);

m_AOsr->operation=INITIALIZE;

m_AOsr->device=m_logicalDevice;

m_AOsr->mode=OTHER;

m_AOsr->hWnd=m_hWnd;

DriverLINX(m_AOsr);

showMessage(m_AOsr);

m_DLmsg=RegisterWindowMessage(DL_MESSAGE);

//End Step 2 Code: initialization//

Accessing Tools

//Start Step 3 Code://

void CAioDlg::showMessage(DL_ServiceRequest *SR)

{

SR->operation=MESSAGEBOX;

DriverLINX(SR);

}

//End Step 3 Code://

//Start Step 4 Code://

void CAioDlg::clearBuffers(DL_ServiceRequest *SR)

3-19

Page 40

Accessing the DriverLINX Tools DriverLINX Programming Tutorial Manual

{

if(SR!=NULL)

{

if(SR->lpBuffers!=NULL)

{

if(SR->lpBuffers->BufferAddr[0]!=NULL)

{

BufFree(SR->lpBuffers->BufferAddr[0]);

SR->lpBuffers->BufferAddr[0]=NULL;

}

delete SR->lpBuffers;

SR->lpBuffers=NULL;

}

}

}

//End Step 4 Code://

//Start Step 5 code://

void CAioDlg::done()

{

float *readings;

readings = new float[m_samples];

CString temp,fullstr;

int index;

m_AIsr->operation=CONVERT;

m_AIsr->mode=OTHER;

m_AIsr->start.typeEvent=DATACONVERT;

m_AIsr->start.u.dataConvert.startIndex=0;

m_AIsr->start.u.dataConvert.nSamples=m_samples;

m_AIsr->start.u.dataConvert.numberFormat=tSINGLE;

m_AIsr->start.u.dataConvert.offset=0.0f;

m_AIsr->start.u.dataConvert.scaling=0.0f;

m_AIsr->start.u.dataConvert.wBuffer=0;

m_AIsr->start.u.dataConvert.lpBuffer=readings;

DriverLINX(m_AIsr);

showMessage(m_AIsr);

m_editBox="";

fullstr="";

for(index=0;index<m_samples;index++)

3-20

Page 41

DriverLINX Programming Tutorial Manual Accessing the DriverLINX Tools

{

temp.Format("%f %d\r\n",readings[index],index);

fullstr+=temp;

}

m_editBox=fullstr;

UpdateData(FALSE);

delete [] readings;

}

//End Step 5 Code://

//Start Step 6 Code://

if(message==m_DLmsg)

{

switch(wParam)

{

case DL_BUFFERFILLED:

done();

break;

}

}

//End Step 6 Code://

//Start Step 7 Code: Start the Analog Acquisitiion//

clearBuffers(m_AIsr);

m_AIsr->operation=START;

m_AIsr->subsystem=AI;

m_AIsr->mode=INTERRUPT;

m_AIsr->start.typeEvent=COMMAND;

m_AIsr->timing.typeEvent=RATEEVENT;

m_AIsr->stop.typeEvent=TCEVENT;

m_AIsr->channels.nChannels=1;

m_AIsr->channels.chanGain[0].channel=0;

m_AIsr->channels.chanGain[0].gainOrRange=Gain2Code(m_logicalDevice,AI,-1.0);

m_AIsr->channels.numberFormat=tNATIVE;

m_AIsr->lpBuffers=(DL_BUFFERLIST*) new BYTE[DL_BufferListBytes(1)];

m_AIsr->lpBuffers->notify=NOTIFY;

m_AIsr->lpBuffers->nBuffers=1;

m_AIsr->lpBuffers->bufferSize=Samples2Bytes(m_logicalDevice,AI,0,m_samples);

3-21

Accessing Tools

Page 42

Accessing the DriverLINX Tools DriverLINX Programming Tutorial Manual

m_AIsr->lpBuffers->BufferAddr[0]=BufAlloc(GBUF_INT,m_AIsr->lpBuffers->bufferSize);

m_AIsr->timing.u.rateEvent.channel=DEFAULTTIMER;

m_AIsr->timing.u.rateEvent.mode=RATEGEN;

m_AIsr->timing.u.rateEvent.clock=INTERNAL1;

m_AIsr->timing.u.rateEvent.gate=DISABLED;

m_AIsr->timing.u.rateEvent.period=Sec2Tics(m_logicalDevice,AI,INTERNAL1,0.00001f);

m_AIsr->timing.u.rateEvent.pulses=0;

m_AIsr->hWnd=m_hWnd;

DriverLINX(m_AIsr);

showMessage(m_AIsr);

//End Step 7 Code: Start the Analog Acquisitiion//

//Start Step 8 Code: Clear the Edit Box//

m_editBox="";

UpdateData(FALSE);

MessageBeep((WORD)-1);

//End Step 8 Code: Clear the Edit Box //

//Start Step 9 Code:Start the Analog Output//

clearBuffers(m_AOsr);

float *sinebuf;

sinebuf=new float[m_samples];

int i;

for(i=0;i<m_samples;i++)

{

sinebuf[i]=(float) sin(i*2*3.14159/m_samples);

}

m_AOsr->operation=CONVERT;

m_AOsr->device=m_logicalDevice;

m_AOsr->subsystem=AO;

m_AOsr->mode=OTHER;

m_AOsr->start.typeEvent=DATACONVERT;

m_AOsr->lpBuffers=(DL_BUFFERLIST*) new BYTE[DL_BufferListBytes(1)];

m_AOsr->lpBuffers->nBuffers=1;

m_AOsr->lpBuffers->bufferSize=Samples2Bytes(m_logicalDevice,AO,0,m_samples);

m_AOsr->lpBuffers->BufferAddr[0]=BufAlloc(GBUF_INT,m_AOsr->lpBuffers->bufferSize);

m_AOsr->lpBuffers->notify=NULL;

m_AOsr->channels.nChannels=2;//1;

m_AOsr->channels.chanGain[0].channel=0;

m_AOsr->channels.numberFormat=tNATIVE;

3-22

Page 43

DriverLINX Programming Tutorial Manual Accessing the DriverLINX Tools

m_AOsr->start.u.dataConvert.startIndex=0;

m_AOsr->start.u.dataConvert.nSamples=m_samples;

m_AOsr->start.u.dataConvert.numberFormat=tSINGLE;

m_AOsr->start.u.dataConvert.scaling=0.0f;

m_AOsr->start.u.dataConvert.offset=0.0f;

m_AOsr->start.u.dataConvert.wBuffer=0;

m_AOsr->start.u.dataConvert.lpBuffer=sinebuf;

DriverLINX(m_AOsr);

showMessage(m_AOsr);

m_AOsr->operation=START;

m_AOsr->device=m_logicalDevice;

m_AOsr->subsystem=AO;

m_AOsr->mode=INTERRUPT;

m_AOsr->start.typeEvent=COMMAND;

m_AOsr->timing.typeEvent=RATEEVENT;

m_AOsr->timing.u.rateEvent.channel=DEFAULTTIMER;

m_AOsr->timing.u.rateEvent.mode=RATEGEN;

m_AOsr->timing.u.rateEvent.clock=INTERNAL1;

m_AOsr->timing.u.rateEvent.gate=DISABLED;

m_AOsr->timing.u.rateEvent.period=Sec2Tics(m_logicalDevice,AO,INTERNAL1,0.00001f);

m_AOsr->timing.u.rateEvent.pulses=0;

m_AOsr->stop.typeEvent=COMMAND;

DriverLINX(m_AOsr);

showMessage(m_AOsr);

//End Step 9 Code:Start the Analog Output//

Accessing Tools

//Start Step 10 Code: Stop the Analog Output//

m_AOsr->operation=STOP;

DriverLINX(m_AOsr);

showMessage(m_AOsr);

//End Step 10 Code: Stop the Analog Output//

//Start Step 11 Code: Code block for the QUIT Button//

clearBuffers(m_AOsr);

clearBuffers(m_AIsr);

delete m_AOsr;

m_AOsr=NULL;

delete m_AIsr;

m_AIsr=NULL;

CloseDriverLINX(m_driverInstance);

3-23

Page 44

Accessing the DriverLINX Tools DriverLINX Programming Tutorial Manual

m_driverInstance=NULL;

OnOK();

//End Step 11 Code: Code block for the QUIT Button//

//AIODlg.h://

//Step 12 Code://

#include"c:\drvlinx4\dlapi\drvlinx.h"

#include"c:\drvlinx4\dlapi\dlcodes.h"

//Step 13 Code://

private:

int m_samples;

void done();

WORD m_DLmsg;

void clearBuffers(DL_ServiceRequest* SR);

int m_logicalDevice;

void showMessage(DL_ServiceRequest* SR);

DL_ServiceRequest* m_AIsr; //Declare SS Structure

DL_ServiceRequest* m_AOsr;

HINSTANCE m_driverInstance; //To contain Instance Handle

//Step 14 Code://

//Add the DriverLINX library file to the project, C:\DrvLINX4/DLApi/DRVLNX32.lib

Borland Delphi

Borland programming environments interact with DriverLINX through an ActiveX

control. Sample programs written in Delphi are installed when the DriverLINX driver

is installed. These are located in the C:\DrvLINX4\Source directory by default.

3-24

Page 45

DriverLINX Programming Tutorial Manual Accessing the DriverLINX Tools

Adding the ActiveX controls is very similar to the procedure for Visual Basic, but

there are some differences. Perform the following procedure to install the ActiveX

controls.

1. Start the Borland Delphi program.

2. From the Component menu select Import ActiveX. The Import ActiveX dialog

shown in Figure 3-16 will appear.

3. In the alphabetical list of controls, select the DriverLINX ActiveX Controls.

4. Note the names listed in the Class names box. Delphi 5.0 will typically use the

names TDriverLINXSR and TDriverLINXLDD. Any class name can be used.

However, when moving applications to another computer, the class names must

be the same between the two computers to share the application. The sample

programs provided on the Keithley Instruments web site are created with the

class names TDriverLINXSR and TDriverLINXLDD. To change the name of

an installed control, it must be removed and reinstalled with the new name.

5. Click the Install button to close the Import ActiveX dialog.

6. Click the OK button to close the Install Components dialog.

Figure 3-16

Borland Delphi 5 Import ActiveX dialog

Accessing Tools

3-25

Page 46

Accessing the DriverLINX Tools DriverLINX Programming Tutorial Manual

3-26

Page 47

4

Learning DriverLINX

4-1

Learning DriverLINX

Page 48

Learning DriverLINX DriverLINX Programming Tutorial Manual

DriverLINX design philosophy

DriverLINX is designed as a high-performance data acquisition device driver for 32bit version of Microsoft Windows. The DriverLINX API is device independent, lending to the development of device independent portable code. DriverLINX is multi-user

and multi-tasking, allowing both foreground and background tasks. It allows for multiple programs to access the data acquisition boards simultaneously, if supported by

the board.

Due to the device independent nature of DriverLINX, it implements more functions

than are available in any single data acquisition board. As a result, any individual

board can only use a subset of the DriverLINX full function set. To find the specific

functions of DriverLINX supported by an individual data acquisition board, refer to

the Using DriverLINX with Your Hardware manual for that board.

To aid in developing device independent code, DriverLINX provides a control called

the Logical Device Descriptor (LDD). The LDD contains information regarding the

physical capabilities of the hardware, including the number and type of channels,

operating modes, and others. Applications written with DriverLINX can dynamically

obtain information about the data acquisition hardware from the LDD, rather than

hard coding for a specific board. The application can then be moved to a different

environment with different hardware and still function, provided that the installed

board meets the minimum requirements of your application.

DriverLINX does not require the use of the Logical Device Descriptor when creating

applications. It is provided as an aide for developing portable applications. When

learning to program DriverLINX applications, it is a good idea to avoid the LDD. As

you learn more about DriverLINX and grow more comfortable with the DriverLINX

API, you can add the LDD capabilities to create more flexible, robust applications.

The sample programs provided with DriverLINX are created using the LDD to take

advantage of the full capabilities of whatever data acquisition hardware is installed on

the system.

4-2

Page 49

DriverLINX Programming Tutorial Manual Learning DriverLINX

Devices, subsystems, and channels

There are three logical levels used to control data acquisition boards when programming with DriverLINX. These are the logical device, subsystem, and channel. When

performing any task with DriverLINX, all three of these must be specified.

For information on how DriverLINX assigns logical devices, subsystems, and channels for a particular data acquisition board, refer to the Using DriverLINX with Your

Hardware manual specific to that board. This manual will list all logical subsystems

and channels defined for that board, along with the corresponding physical channels,

connectors, and signals.

Logical devices

The logical device corresponds to the physical data acquisition board itself. Systems

with more than one data acquisition board will have more than one logical device. The

logical device is used to tell DriverLINX which data acquisition board will be used.

There is a maximum of six devices per family, indicated by the driver name, installed

at one time. The device numbers should start at zero and increment by one. It is legal

to have more than one device numbered zero as long as they correspond to boards

from different board families (driver names).

Logical subsystems

The logical subsystem refers to the general function that will be performed. For example, when performing analog input operations, the analog input subsystem is used.

DriverLINX considers each data acquisition board to have the following subsystems:

• System – Refers to the actual data acquisition board itself.

• Analog input – Refers to the A/D converters, multiplexers, and associated

hardware.

• Analog output – Refers to the D/A converters and associated hardware.

• Digital input – Refers to the digital input ports and associated hardware.

• Digital output – Refers to the digital output ports and associated hardware.

• Counter/timer – Refers to the counter/timer channels and associated hardware.

4-3

Learning DriverLINX

Page 50

Learning DriverLINX DriverLINX Programming Tutorial Manual

Logical channels

Logical channels refer to the addressable hardware channels of each subsystem. For

most analog and digital subsystems, the logical channel assignment is very straightforward. Logical channel assignments usually match the physical channel assignments. For example, physical analog input channel 0 is assigned to logical channel 0.

DriverLINX may assign a logical channel to items which are not normally thought of

as channels. This is most noticeable with counter/timer functions. For example, DriverLINX may assign a 1-bit digital logical channel to external hardware trigger input

lines.

For counter/timer subsystems, the logical channel assignments can be more complex.

In some cases, multiple logical channels may be assigned to a single physical channel.

This may occur when a hardware channel has multiple operating modes. A logical

channel may be assigned to each individual counter/timer when operating independently, and another logical channel may be assigned when two counters are used in a

cascaded mode. (KPCI-3108 series boards implement this for the counter/timer subsystem.)

In some cases, DriverLINX may assign multiple physical channels to a single logical

channel. This occurs when the physical channels cannot be operated independently. In

this case, DriverLINX will assign all such physical channels to a single logical channel for ease of operation.

Understanding the Service Request

Overview

A Service Request is a data structure or control created by an application that provides

DriverLINX with all the information it needs to perform a task.

DriverLINX uses a data, or table, oriented approach to tasks, as opposed to a procedural approach. Using DriverLINX, it is not necessary to specify all the steps to be

performed to complete a task. Rather, all the required data needed by the task is

assigned to the table or control. The data is then sent to DriverLINX all at once.

Depending on the programming language, this is done either with a single function

call or using the control’s refresh method. DriverLINX takes care of the rest.

4-4

Page 51

DriverLINX Programming Tutorial Manual Learning DriverLINX

Not all DriverLINX tasks will use all properties of the Service Request. The properties

used are determined by the individual task being performed. Detailed information on

the Service Request can be found in the DriverLINX Technical Reference Manual in

Section 6 - Service Requests, and in the DriverLINX/VB Technical Reference Manual

in Section 6 - Service Request Control. All unused properties should be initialized to a

defined value, such as zero. This will prevent problems in case updated version of the

DriverLINX drivers use previously undefined properties.

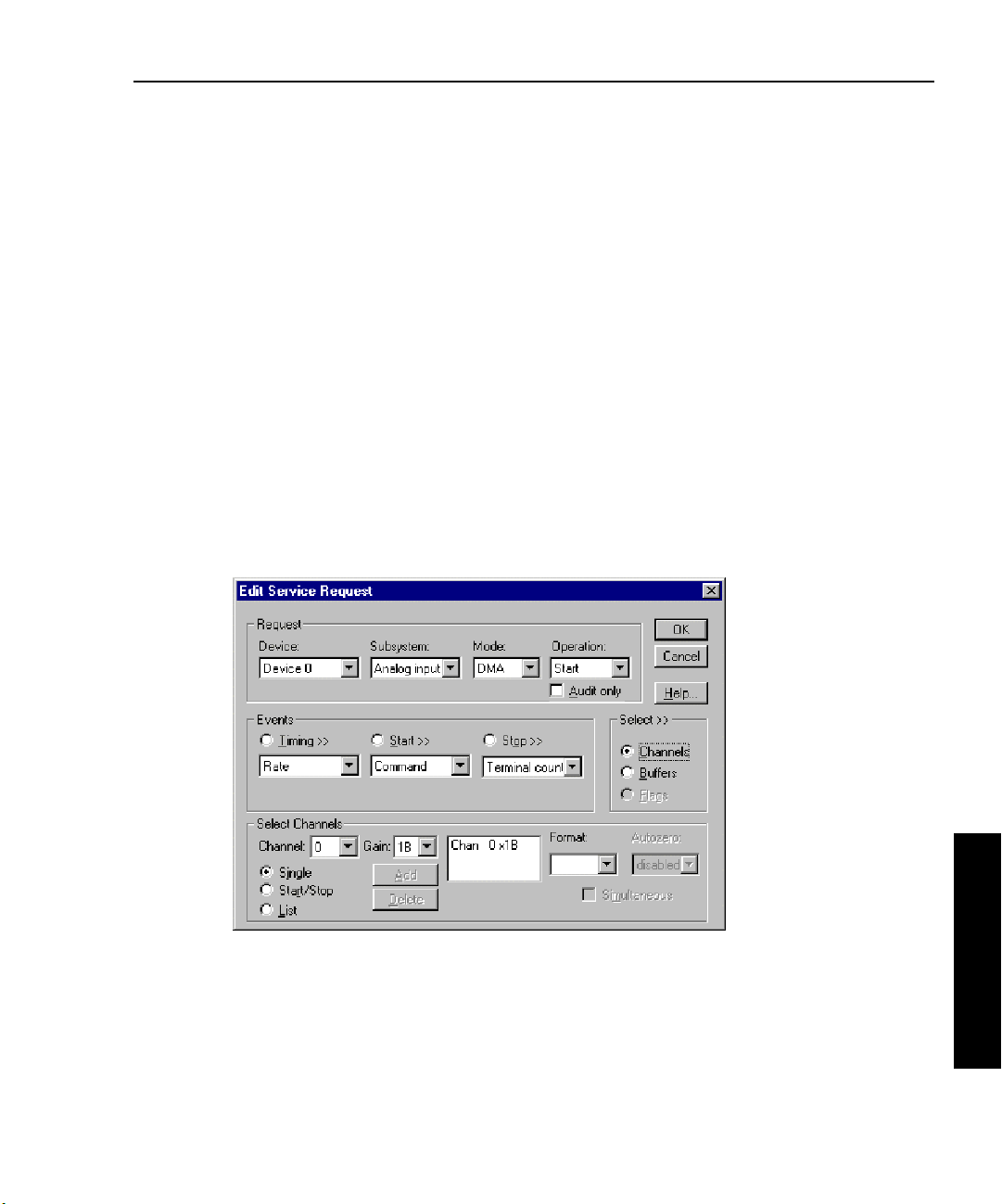

The Service Request is depicted graphically by DriverLINX using the Edit Service

Request dialog, shown in Figure 4-1. Not all properties of the Service Request dialog

are displayed in the Edit Service Request dialog. The properties that are not displayed

are assigned dynamically at run-time.

Two ways to display the Edit Service Request dialog are by using the LearnDL application, and by calling it directly from an application. Both of these methods are discussed later in this section.

Figure 4-1

Edit Service Request dialog

The properties of the Service Request are broken into five separate groups. These

groups are the Control, Request, Events, Select, and Results groups. The following is

a brief description of these groups.

4-5

Learning DriverLINX

Page 52

Learning DriverLINX DriverLINX Programming Tutorial Manual

Control Group

VB

The Control group is only used when using the ActiveX controls of the DriverLINX.

This group contains standard control properties, such as the control name, window

handle, and control design-time coordinates. These properties do not directly affect

data acquisition tasks. The Control group is not displayed in the Edit Service Request

dialog.

Request Group

The Request group contains data specifying the device and subsystem being used, the

data acquisition mode, and the operation being performed. When programming in C/

C++ the Request group also contains the window handle, since C/C++ does not use

the Control group. The Request group is displayed at the top of the Edit Service

Request dialog.

Of all the groups in a Service Request, only the Request group is required for all services. The fields of the Events and Select groups are used selectively depending on the

particular task requested of DriverLINX.

Events Group

The Events group contains properties controlling the timing of the data acquisition,

and the start and stop events for the task. This group is displayed in the center portion

of the Edit Service Request dialog. There are several classes of events that can be

assigned to the timing, start, and stop properties. These classes are simple, analog,

digital, rate, and setup.

The simple events are events that do not require additional properties. These include

null events, command events, and terminal count events. Command events are software generated start and stop events. Terminal count events are used when the task

should automatically stop after one trip through the data buffers.

Analog events perform real-time (board level hardware/firmware) monitoring of an

analog input channel for the occurrence of the specified signal condition. Depending

on the features of your hardware, analog events can be used as start and stop events,

and may use a delay.

4-6

Page 53

DriverLINX Programming Tutorial Manual Learning DriverLINX

Digital events perform real-time monitoring of a digital input channel and signal when

the channel meets the specified condition. Digital events use a mask to specify which

bits to monitor, and a pattern to which they are compared. The comparison can be an

equals or not equals condition. The mask and pattern properties control rising and falling edge sensitivities.

Rate events can be used as timing events or counter/timer setup events. Timing events

pace or clock the data acquisition task. Counter/timer setup events can specify frequency and time interval measurements and event counters.

Setup events configure digital I/O ports. Configuration events are hardware specific.

Refer to the Using DriverLINX with Your Hardware manual for information on config-

uration events supported by a specific data acquisition board.

DriverLINX supports many start and stop events. To determine which events are supported by a particular data acquisition board, refer to the Using DriverLINX with Your

Hardware manual.

Select Group

The Select group defines the channels and data buffers to be used for the task. In addition, a flag property is provided to allow the disabling of some DriverLINX message

notifications in specific circumstances.

The channel properties of the Select group specify the logical channel to be used, the

gain for the channel, and the number format of the data. Depending on the hardware

capabilities, it may be possible to specify a single channel, a range of channels or a

channel-gain list. If the hardware does not directly support a channel-gain list, this

feature may not be used.

The data buffers properties of the Select group specify the number and size of the data

buffers to be used for the data acquisition task. The actual number of buffers supported

by DriverLINX varies with the specific version. The exact number may be obtained

from the Logical Device Descriptor (LDD). For information on the LDD, refer to the

DriverLINX Technical Reference Manual in Section 7 - Logical Device Descriptors, or

the DriverLINX/VB Technical Reference Manual in Section 7 - Logic Device Descrip-

tor Control.

The flags properties of the Select group allow the disabling of event flags. These flags

can be enabled to improve performance of DriverLINX in certain circumstances. This

4-7

Learning DriverLINX

Page 54

Learning DriverLINX DriverLINX Programming Tutorial Manual

may be helpful when repeatedly polling for a small number of samples. For more

information on these flags, refer to the DriverLINX/VB Technical Reference Manual.

The Select group is represented in the Service Request dialog, shown in Figure 4-1, in

a different manner than the other groups. The right side of the center of the window

contains the first portion of the Select group, labeled Select>>. This series of three

radio buttons controls which properties are displayed in the bottom of the Edit Service

Request dialog. Selecting the Channels, Buffers, or Flags radio button displays the

respective properties in the bottom of the dialog. To display a different set of properties, select the appropriate radio button.

Results Group

The Results group contains the results of the task returned by DriverLINX. Using the

Results group, DriverLINX returns the status of the task and various information

regarding the buffers and the data in the buffers. The actual information returned

depends on the type of task performed. The Results group is not displayed in the Edit

Service Request dialog.

Auditing the Service Request

DriverLINX automatically performs an audit, or error checking process, on all Service

Requests. This process verifies that all the values passed to DriverLINX are valid. The

values are verified against the device information stored in the Logical Device

Descriptor. The audit process helps prevent problems resulting from executing Service

Requests with invalid data.

Service Requests can be audited without being executed. Setting the property

Req_op_auditOnly to DL_True when calling a Service Request will audit, but not execute, the Service Request. If the audit process detects any problems with the Service

Request, DriverLINX returns an error code. For information on displaying and interpreting error codes, refer to Section 9, Troubleshooting, of this manual.

4-8

Page 55

DriverLINX Programming Tutorial Manual Learning DriverLINX

Learning to use the Service Request

DriverLINX provides some tools to help learn to use the Service Request. These tools

include the Edit Service Request dialog and the LearnDL application.

The Edit Service Request dialog, shown in Figure 4-2, is an interactive method of filling out a Service Request. As choices are made, the dialog changes to show the appropriate controls available for the current selections. Controls are added and removed in

response to selections. The Edit Service Request dialog will only show controls and

choices valid for the selected device. If a given set of selections can be made in the

Edit Service Request dialog, then the same configuration may achieved when

programming.

Figure 4-2

Edit Service Request dialog

4-9

Learning DriverLINX

Page 56

Learning DriverLINX DriverLINX Programming Tutorial Manual

Displaying the Edit Service Request dialog with LearnDL

The easiest way to display and learn to use the DriverLINX Edit Service Request dialog is through the LearnDL application. LearnDL is installed when the DriverLINX

driver itself is installed. A shortcut to LearnDL is created in the DriverLINX program

group. The LearnDL application is designed to step you through all the actions

required to acquire data using DriverLINX.

The LearnDL application can be very useful for a new DriverLINX programmer.

LearnDL provides access to almost all of DriverLINX’s features. This allows you to

test the data acquisition hardware and ensure DriverLINX is installed and functioning

properly. In some cases LearnDL may be used by technical support to assist in setting

up and troubleshooting the data acquisition hardware and DriverLINX. More information regarding the LearnDL application can be found in Section 9, Troubleshooting, of

this manual.

The following procedure demonstrates using LearnDL to perform a simple analog

input operation using the Edit Service Request dialog.

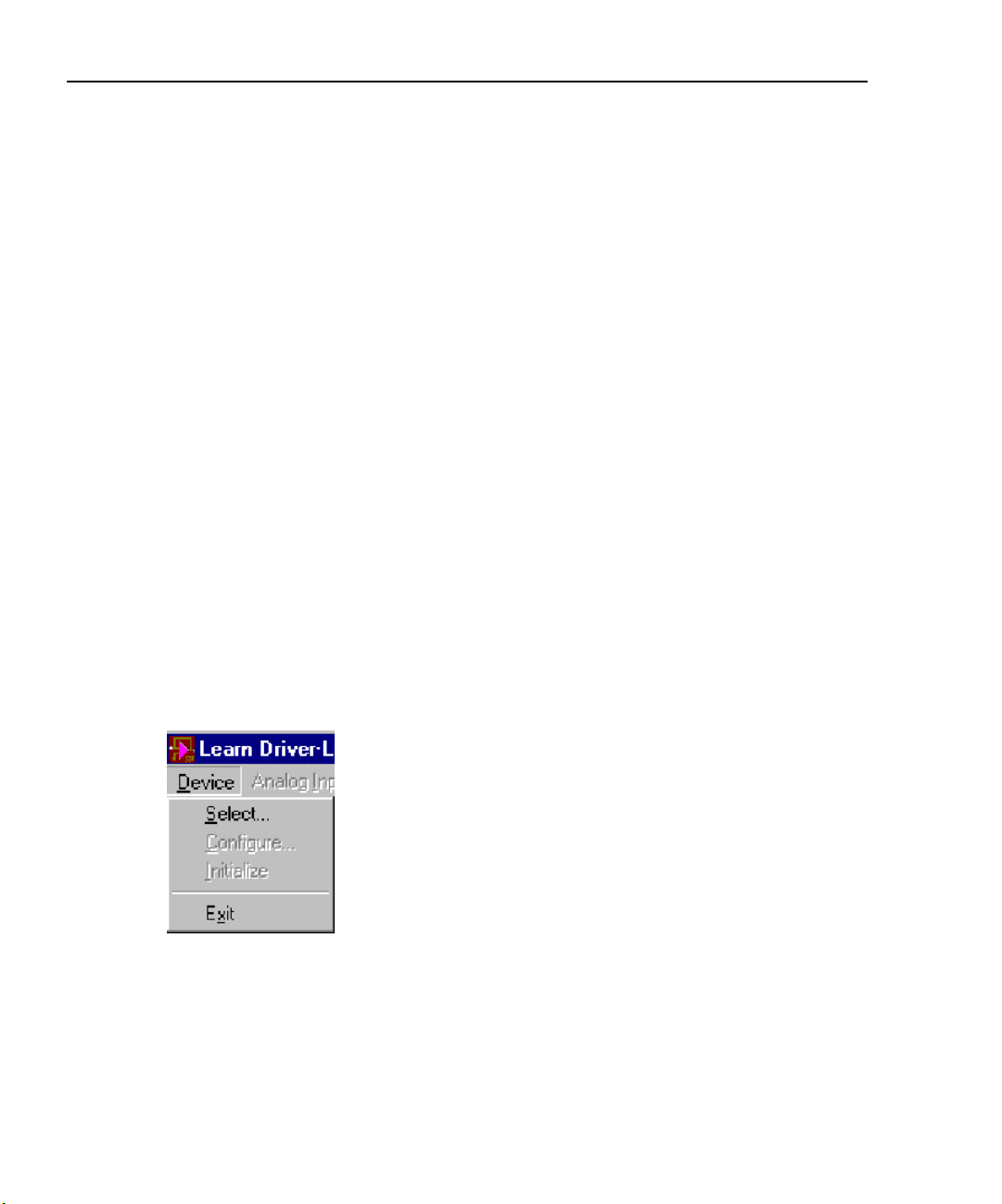

1. From the LearnDL main window, click the Device menu. The menu shown in

Figure 4-3 appears. Notice that the only menu choice enabled is Select. You

must first tell DriverLINX what device you will be using before you can do

anything with the device. Click the Select option.

Figure 4-3

LearnDL Device menu

4-10

Page 57

DriverLINX Programming Tutorial Manual Learning DriverLINX

2. When the Select Device window appears, as shown in Figure 4-4, select the

desired logical device. Unless more than one data acquisition board is installed,

the logical device should be zero. Click the OK button to select the device and

close the window.

Figure 4-4

Select Device window

3. From the LearnDL main window, click the Device menu. Notice that the Configure and Initialize choices are now available. It is not necessary to configure

the device before using it unless the data acquisition task requires a new configuration. Click the Initialize option to set the device to a known state. The Initialize option of the Device menu can also be used to abort any current task.

4. From the Analog Input menu, select Initialize. This will perform a software

reset of the subsystem on the selected device. Notice that before the Initialize

option is selected, all other options for that subsystem are disabled.

4-11

Learning DriverLINX

Page 58

Learning DriverLINX DriverLINX Programming Tutorial Manual

5. From the Analog Input menu, select Edit/execute. This will open the Edit Service Request dialog shown in Figure 4-5. Note that there are very few selections

available when the dialog opens. As choices are made, additional options will

become enabled as appropriate.

Figure 4-5

Edit Service Request dialog

6. Fill out the Edit Service Request dialog as shown in Figure 4-6. These settings

instruct DriverLINX to take an analog reading on channel 0.

Figure 4-6

Completed Edit Service Request dialog

4-12

Page 59

DriverLINX Programming Tutorial Manual Learning DriverLINX

7. To instruct DriverLINX to execute the Service Request, click the OK button.

This will close the Edit Service Request dialog and execute the Service

Request. When the Service Request is complete, the LearnDL window will

update to show the results of the Service Request. This specific Service Request

performs a task that acquires 500 data points from analog input channel 0. The

data points are graphed on a digital oscilloscope display, as shown in

Figure 4-7.

Figure 4-7

Oscilloscope display

8. The Service Request can be executed again by selecting Start from the Analog

Input menu, or clicking the Acquire button.

9. If the Service Request takes an extended period of time to execute, it can be

stopped by clicking the Stop button, or selecting Stop from the Analog Input

menu. If a task is not currently running when the Stop button is clicked, a

DriverLINX error will be displayed.

4-13

Learning DriverLINX

Page 60