Tektronix DPO77002SX, DPO75902SX, DPO75002SX, DPO73304SX, DPO72304SX Performance Verification

...Page 1

DPO70000SX

Series Oscilloscopes

Technical Reference

*P077104305*

077-1043-05

Page 2

Page 3

DPO70000SX

Series Oscilloscopes

Technical Reference

Warning

The servicing instructions are for use by qualified personnel only. To avoid

personal injury, do not perform any servicing unless you are qualified to do

so. Refer to all safety summaries prior to performing service.

Supports Product Firmware V10.0 and above.

www.tek.com

077-1043-05

Page 4

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions. Tektronix products

are covered by U.S. and foreign patents, issued and pending. Information in this publication supersedes that in all

previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

■

In North America, call 1-800-833-9200.

■

Worldwide, visit www.tek.com to find contacts in your area.

Page 5

Warranty

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one

(1) year from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at

its option, either will repair the defective product without charge for parts and labor, or will provide a replacement

in exchange for the defective product. Parts, modules and replacement products used by Tektronix for warranty

work may be new or reconditioned to like new performance. All replaced parts, modules and products become the

property of Tektronix.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period and make suitable arrangements for the performance of service. Customer shall be

responsible for packaging and shipping the defective product to the service center designated by Tektronix, with

shipping charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a

location within the country in which the Tektronix service center is located. Customer shall be responsible for

paying all shipping charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

resulting from attempts by personnel other than Tektronix representatives to install, repair or service the product;

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any

damage or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been

modified or integrated with other products when the effect of such modification or integration increases the time

or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TEKTRONIX' RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE

VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

[W2 – 15AUG04]

Page 6

Page 7

Table of Contents

Contacting Tektronix ......................................................................................................................... 0

Important safety information .............................................................................................................. iii

General safety summary ................................................................................................................ iii

Terms in the manual ...................................................................................................................... vi

Terms on the product ..................................................................................................................... vi

Symbols on the product ................................................................................................................. vi

Specifications

Vertical system analog channels ..................................................................................................... 1

Horizontal and acquisition system ................................................................................................ 15

Trigger specifications ................................................................................................................... 18

Serial trigger specifications .......................................................................................................... 25

Input-output port specifications .................................................................................................... 25

Data storage specifications ........................................................................................................... 28

Power source specification ........................................................................................................... 28

Mechanical specifications ............................................................................................................. 29

Environmental specifications ....................................................................................................... 30

Performance verification

Performance verification .............................................................................................................. 31

Conventions .................................................................................................................................. 32

Brief procedures ........................................................................................................................... 34

Self tests ........................................................................................................................................ 34

Functional tests ............................................................................................................................. 35

Verify all analog input channels ................................................................................................... 36

Verify the time base ...................................................................................................................... 38

Verify the A (Main) and B (Delayed) trigger systems ................................................................. 40

Verify the file system ................................................................................................................... 41

Performance tests .......................................................................................................................... 42

Prerequisites .................................................................................................................................. 43

Equipment required ...................................................................................................................... 43

Test record .................................................................................................................................... 48

Signal acquisition system checks ................................................................................................. 79

Check DC voltage measurement accuracy, ATI channel ............................................................. 80

Check DC voltage measurement accuracy, TekConnect channels ............................................... 83

Check DC gain accuracy, ATI channel ........................................................................................ 90

DPO70000SX Series i

Page 8

Table of Contents

Check DC gain accuracy, TekConnect channels .......................................................................... 93

Check offset accuracy, ATI channel ........................................................................................... 109

Check offset accuracy, TekConnect channels ............................................................................ 112

Check analog bandwidth, ATI channel ...................................................................................... 117

Check channel bandwidth, TekConnect channels ...................................................................... 120

Check Input Resistance, ATI channel ........................................................................................ 125

Check input resistance, TekConnect channels ........................................................................... 126

Time base system checks ............................................................................................................ 128

Check timebase and delay time accuracy and reference ............................................................ 128

Check delta time measurement accuracy .................................................................................... 132

Trigger system checks ................................................................................................................ 137

Check time qualified trigger accuracy ........................................................................................ 137

Check sensitivity edge trigger DC coupled ................................................................................ 141

Output signal checks ................................................................................................................... 148

Check fast edge output ............................................................................................................... 148

Sine wave generator leveling procedure ..................................................................................... 153

Method 1 ................................................................................................................................ 153

Method 2 ................................................................................................................................ 155

ii DPO70000SX Series

Page 9

Important safety information

This manual contains information and warnings that must be followed by the user

for safe operation and to keep the product in a safe condition.

General safety summary

Use the product only as specified. Review the following safety precautions to

avoid injury and prevent damage to this product or any products connected to it.

Carefully read all instructions. Retain these instructions for future reference.

This product shall be used in accordance with local and national codes.

For correct and safe operation of the product, it is essential that you follow

generally accepted safety procedures in addition to the safety precautions

specified in this manual.

The product is designed to be used by trained personnel only.

Only qualified personnel who are aware of the hazards involved should remove

the cover for repair, maintenance, or adjustment.

Before use, always check the product with a known source to be sure it is

operating correctly.

This product is not intended for detection of hazardous voltages.

Use personal protective equipment to prevent shock and arc blast injury where

hazardous live conductors are exposed.

DPO70000SX Series iii

Page 10

Important safety information

To avoid fire or personal

injury

Use proper power cord. Use only the power cord specified for this product and

certified for the country of use. Do not use the provided power cord for other

products.

Ground the product. This product is grounded through the grounding conductor of

the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded. Do not

disable the power cord grounding connection.

Power disconnect. The power cord disconnects the product from the power

source. See instructions for the location. Do not position the equipment so that it

is difficult to operate the power cord; it must remain accessible to the user at all

times to allow for quick disconnection if needed.

Connect and disconnect properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source. Use only insulated voltage

probes, test leads, and adapters supplied with the product, or indicated by

Tektronix to be suitable for the product.

Observe all terminal ratings. To avoid fire or shock hazard, observe all rating and

markings on the product. Consult the product manual for further ratings

information before making connections to the product. Do not exceed the

Measurement Category (CAT) rating and voltage or current rating of the lowest

rated individual component of a product, probe, or accessory. Use caution when

using 1:1 test leads because the probe tip voltage is directly transmitted to the

product.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do not operate without covers. Do not operate this product with covers or panels

removed, or with the case open. Hazardous voltage exposure is possible.

Avoid exposed circuitry. Do not touch exposed connections and components when

power is present.

Do not operate with suspected failures. If you suspect that there is damage to this

product, have it inspected by qualified service personnel.

Disable the product if it is damaged. Do not use the product if it is damaged or

operates incorrectly. If in doubt about safety of the product, turn it off and

disconnect the power cord. Clearly mark the product to prevent its further

operation.

Before use, inspect voltage probes, test leads, and accessories for mechanical

damage and replace when damaged. Do not use probes or test leads if they are

damaged, if there is exposed metal, or if a wear indicator shows.

Examine the exterior of the product before you use it. Look for cracks or missing

pieces.

Use only specified replacement parts.

Do not operate in wet/damp conditions. Be aware that condensation may occur if a

unit is moved from a cold to a warm environment.

Do not operate in an explosive atmosphere.

iv DPO70000SX Series

Page 11

Important safety information

Keep product surfaces clean and dry. Remove the input signals before you clean

the product.

Provide proper ventilation. Refer to the installation instructions in the manual for

details on installing the product so it has proper ventilation.

Slots and openings are provided for ventilation and should never be covered or

otherwise obstructed. Do not push objects into any of the openings.

Provide a safe working environment. Always place the product in a location

convenient for viewing the display and indicators.

Avoid improper or prolonged use of keyboards, pointers, and button pads.

Improper or prolonged keyboard or pointer use may result in serious injury.

Be sure your work area meets applicable ergonomic standards. Consult with an

ergonomics professional to avoid stress injuries.

Use care when lifting and carrying the product. This product is provided with a

handle or handles for lifting and carrying.

WARNING. The product is heavy. To reduce the risk of personal injury or damage

to the device get help when lifting or carrying the product.

Probes and test leads

Use only the Tektronix rackmount hardware specified for this product.

Before connecting probes or test leads, connect the power cord from the power

connector to a properly grounded power outlet.

Keep fingers behind the protective barrier, protective finger guard, or tactile

indicator on the probes.

Remove all probes, test leads and accessories that are not in use.

Use only correct Measurement Category (CAT), voltage, temperature, altitude,

and amperage rated probes, test leads, and adapters for any measurement.

DPO70000SX Series v

Page 12

Important safety information

Terms in the manual

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the product

These terms may appear on the product:

■

DANGER indicates an injury hazard immediately accessible as you read the

marking.

Symbols on the product

■

WARNING indicates an injury hazard not immediately accessible as you

read the marking.

■

CAUTION indicates a hazard to property including the product.

When this symbol is marked on the product, be sure to consult the

manual to find out the nature of the potential hazards and any actions

which have to be taken to avoid them. (This symbol may also be used

to refer the user to ratings in the manual.)

The following symbols may appear on the product:

vi DPO70000SX Series

Page 13

Specifications

This chapter contains specifications for the instrument. All specifications are

guaranteed unless noted as "typical." Typical specifications are provided for your

convenience but are not guaranteed. Specifications that are marked with the

symbol are checked in Performance Verification.

All specifications apply to all models unless noted otherwise. To meet

specifications, the following conditions must first be met:

■

The instrument must have been adjusted in an ambient temperature range

between 18 °C and 28 °C.

■

The instrument must be powered from a source that meets the specifications.

■

The instrument must have been operating continuously for twenty minutes

within the specified operating temperature range. (60 minutes continuous

operation required if the ambient relative humidity is greater than 60%.)

■

You must perform the Signal Path Compensation (SPC) operation described

in the user manual and the online help. If the operating temperature changes

by more than 5 °C, you must perform the SPC operation again.

Vertical system analog channels

Number of channels ≥50 GHz models: 2+1,

<50 GHz models: Four channels, all identical

Input connector

TekConnect channels: TekConnect. Power supply compatible with VPI.

ATI channel: Male 1.85 mm coax.

Input coupling

TekConnect channels: Two modes: DC, 50 ohms to a programmable termination voltage; Ground.

The termination can be connected to a DC voltage:

≤ 1.2 VFS settings: -3.5 V to 3.5 V,

> 1.2 VFS settings: 0.0 V

ATI channel: DC, 50 Ω.

DPO70000SX Series 1

Page 14

Specifications Vertical system analog channels (cont.)

Input resistance

≤1.2 VFS settings 50 Ω ±3% at 18 to 28 ºC (64 to 82 ºF)

50 Ω ±4% over 5 to 45 ºC (45 to 113 ºF)

>1.2 VFS settings 50 Ω ±4.4% over 5 to 45 ºC (45 to 113 ºF)

ATI channel 50 Ω ±3% from 18 °C to 28 °C

50 Ω ±4% from 5 °C to 45 °C

Maximum input voltage

TekConnect channels: ≤1.2 VFS settings:

±1.5 V relative to the termination bias (30 mA maximum)

±5 V absolute maximum input

>1.2 VFS settings:

±8 V. Limited by maximum Vterm current and the attenuator power rating at maximum

temperature.

ATI channel: ±0.75 V

Aux channel: ±5.0 V

pk

pk

Input termination voltage (VTerm)

range, TekConnect channels

≤1.2 VFS settings: -3.5 V to +3.5 V

>1.2 VFS settings: 0 V

Input VSWR, typical Measured with a TekConnect TCA-292D adaptor and a network analyzer.

≤1.2 VFS settings: 0 – 17 GHz: 1.4:1

17 – 20 GHz: 1.6:1

20 – 33 GHz: 2.0:1

>1.2 VFS settings: 0 – 17 GHz: 1.4:1

17 – 33 GHz: 2.0:1

ATI channel: 0-20GHz: 1.7:1

>20-33 GHz: 2.0:1

> 33-70 GHz: 3.0:1

Number of digitized bits 8 bits

Digitizer nonlinearity (typical) < 1.0 DL (digitization level), differential; < 1 DL integral, independently based

Sensitivity range

TekConnect channels 62.5 mVFS to 6 V

FS

ATI channel 100 mVFS to 300 mVFS.

DC gain accuracy ± 2%

2 DPO70000SX Series

Page 15

Vertical system analog channels (cont.) Specifications

DC voltage measurement

Net offset = offset - (position × volts/division).

accuracy, Sample, Average, and

Hi-Res modes

Full scale setting DC measurement accuracy

62.5 mVFS – 6 V

1

FS

Delta voltage reading

62.5 mVFS – 6 V

FS

Position range ± 5 divisions

Offset range

TekConnect channels

ATI channel

Full Scale voltage range Offset range

62.5 mVFS – 1.2 V

>1.2 VFS – 6 V

FS

FS

Full Scale voltage range Offset range

100 mVFS – 300 mV

FS

Offset accuracy Net offset = offset - (position × volts/division).

Full scale voltage range Offset accuracy

62.5 mVFS to 1.2 VFS (TekConnect channels) ±(0.4% | net offset | + 0.2% | net offset – Vterm

>1.2 VFS to 6 VFS (TekConnect channels) ±(0.6% | net offset | + 13.4 mV + 1% FS)

100 mVFS to 300 mVFS (ATI channel) ±(0.35% | net offset | + 2 mV + 1% FS)

±(Gain accuracy x | vertical value - net offset |) +

offset accuracy + 0.4% x FS

±(Gain accuracy x | Delta voltage measured | +

0.008 x FS

±3.4 V

±6 V

±300 mV - (10 div × Volts/div)

setting | + 2.5 mV + 1% FS)

Analog bandwidth Bandwidth with a TCA292D adapter on TekConnect channels or directly into ATI channel.

Ambient temperature 18ºC to 28ºC assumed for all guaranteed bandwidth specifications.

Enhanced bandwidth is guaranteed at the following full scale (FS) stepped gain settings:

TekConnect channels: 62.5 mV, 100 mV, 200 mV, 500 mV, 1 V, 2 V, and 5 V.

ATI channel: All settings from 100 mV through 300 mV.

1

For ATI channels, the full scale settings range is 100 mVFS to 300 mVFS.

DPO70000SX Series 3

Page 16

Specifications Vertical system analog channels (cont.)

Instrument Channel BW settings Bandwidth

DPO77002SX ATI, 1 Ch 70 GHz BWE >67 GHz

70 GHz typical

DPO77002SX

TekConnect, 2 Ch No BWE >33 GHz All

DPO73304SX

DPO77002SX

TekConnect, 2 Ch 33 GHz BWE >33 GHz 100 GS/s

DPO73304SX

DPO77002SX

DPO73304SX

TekConnect, 2 Ch

TekConnect, 4 Ch

23 GHz BWE >23 GHz 50 GS/s

DPO75902SX ATI, 1 Ch 59 GHz BWE >59 GHz 200 GS

DPO75902SX

ATI, 1 Ch 50 GHz BWE >50 GHz 200 GS

DPO75002SX

DPO75902SX TekConnect No BWE >33 GHz All

DPO75002SX TekConnect No BWE >25 GHz All

DPO75002SX TekConnect 25 GHz BWE >25 GHz 100 GS/s

DPO75002SX TekConnect 23 GHz BWE >23 GHz 50 GS/s

DPO72304SX TekConnect No BWE >23 GHz 50 GS/s, 100 GS/s

DPO72304SX TekConnect 23 GHz BWE >23 GHz 50 GS/s, 100 GS/s

DPO71604SX TekConnect 16 GHz BWE >16 GHz 50 GS/s, 100 GS/s

DPO71304SX TekConnect 13 GHz BWE >13 GHz 50 GS/s, 100 GS/s

2

Sample rate

200 GS

3

TekConnect channel

ATI channel

Typical temperature derating

Frequency TC, (dB/°C) 5 °C 45 °C

DC - 5 GHz 0.005 dB/°C 0.07 -0.09

10 GHz 0.010 dB/°C 0.13 -0.17

15 GHz 0.025 dB/°C 0.33 -0.43

20 GHz 0.045 dB/°C 0.59 -0.77

23 GHz 0.10 dB/°C 1.30 -1.70

25 GHz 0.10 dB/°C 1.30 -1.70

30 GHz 0.115 dB/°C 1.50 -1.96

33 GHz 0.160 dB/°C 2.08 -2.72

Typical temperature derating

Frequency TC, (dB/°C)

DC - 10 GHz 0.002 dB/°C

15 GHz 0.005 dB/°C

20 GHz 0.01 dB/°C

30 GHz 0.05 dB/°C

40 GHz 0.07 dB/°C

2

To determine the amount of performance derating above the temperature limit, use the Typical Temperature Variation table.

3

200 GS/s is the only sample rate available on the ATI channel.

4 DPO70000SX Series

Page 17

Vertical system analog channels (cont.) Specifications

Typical temperature derating

Frequency TC, (dB/°C)

50 GHz 0.05 dB/°C

60 GHz 0.05 dB/°C

67 GHz 0.05 dB/°C

Frequency response tolerance

All modes, BWE on, 18 ºC to

28 ºC (typical)

TekConnect channel: Step settings TekConnect channels: 77.5 mVFS, 151 mVFS, 302 mVFS, 605 mVFS, 1210 mVFS.,

ATI channel: All volts/div settings

To determine the amount of performance derating above the temperature limit, use the Typical

Temperature Variation table

1620 mV

3240 mV

FS,

FS

±0.5 dB from DC to 50% of nominal BW

±1.5 dB from 50% to 80% of nominal BW

All other gain settings:

±1.0 dB from DC to 50% of nominal BW

±2.0 dB from 50% to 80% of nominal BW

±0.5 dB from DC to 20 GHz

±0.75 dB from >20 GHz to 30 GHz

±1.25 dB from >30 GHz to 68.5 GHz

±2 dB from >68.5 GHz to 69.5 GHz

+2 / -3 dB at 70 GHz

DPO70000SX Series 5

Page 18

Specifications Vertical system analog channels (cont.)

TekConnect channel

ATI channel

Typical temperature derating

Frequency TC, (dB/°C) 5 °C 45 °C

DC - 5 GHz 0.005 dB/°C 0.07 -0.09

10 GHz 0.010 dB/°C 0.13 -0.17

15 GHz 0.025 dB/°C 0.33 -0.43

20 GHz 0.045 dB/°C 0.59 -0.77

23 GHz 0.10 dB/°C 1.30 -1.70

25 GHz 0.10 dB/°C 1.30 -1.70

30 GHz 0.115 dB/°C 1.50 -1.96

33 GHz 0.160 dB/°C 2.08 -2.72

Typical temperature derating

Frequency TC, (dB/°C)

DC - 5 GHz 0.005 dB/°C

DC - 10 GHz 0.002 dB/°C

15 GHz 0.005 dB/°C

20 GHz 0.01 dB/°C

30 GHz 0.05 dB/°C

40 GHz 0.07 dB/°C

50 GHz 0.05 dB/°C

60 GHz 0.05 dB/°C

Calculated rise time (typical)

Calculated risetimes for specified instrument bandwidths

Instrument bandwidth BWE On BWE Off

10% - 90% 20% - 80% 10% - 90% 20% - 80%

70 GHz 5.6 ps 4.3 ps n/a n/a

50 GHz 7.8 ps 6 ps n/a n/a

33 GHz 13 ps 9 ps 21 ps 14 ps

25 GHz 16 ps 12 ps 22 ps 15 ps

23 GHZ 17 ps 13 ps 24 ps 16 ps

6 DPO70000SX Series

Page 19

Vertical system analog channels (cont.) Specifications

Step response settling time

(typical)

BWE off

BWE on (fastest BWE setting)

(typical)

The time by which the step response enters and stays below the indicated % error. Step transition

occurs at the 50% amplitude point of the step leading edge.

Instrument Gain setting (FS) Settling Error

Amount Time

DPO77002SX

TekConnect

channels

DPO75902SX

TekConnect

channels

DPO75002SX

TekConnect

channels

DPO73304SX 62.5 mV, 100 mV, 200 mV,

DPO72304SX 62.5 mV, 100 mV, 200 mV,

BWE on (fastest BWE setting) Instrument Gain setting (FS) Settling

Instrument Gain setting (FS) Settling Error

DPO77002SX,

DPO75902SX,

DPO75002SX ATI

channel

DPO77002SX,

DPO75902SX,

DPO75002SX

TekConnect

channels

DPO73304SX,

DPO72304SX

62.5 mV, 100 mV, 200 mV,

500 mV, 1.0 V, 1.2 V, 1.4 V,

2 V, 4 V

62.5 mV, 100 mV, 200 mV,

500 mV, 1.0 V, 1.2 V, 1.4 V,

2 V, 4 V

62.5 mV, 100 mV, 200 mV,

500 mV, 1.0 V, 1.2 V, 1.4 V,

2 V, 4 V

500 mV, 1.0 V, 1.2 V, 1.4 V,

2 V, 4 V

500 mV, 1.0 V, 1.2 V, 1.4 V,

2 V, 4 V

100 mV, 200 mV, 300 mV <3.5%

62.5 mV, 100 mV, 200 mV, 500 mV,

1.0 V, 1.2 V, 1.4 V, 2 V, 4 V

62.5 mV, 100 mV, 200 mV, 500 mV,

1.0 V, 1.2 V, 1.4 V, 2 V, 4 V

<6%

<5.5%

<3%

<6%

<5.5%

<3%

<6%

<5.5%

<3%

<6%

<5.5%

<3%

<6%

<5%

<3%

150 ps – 400 ps

400 ps – 3 ns

3 ns – 1 ms

150 ps – 400 ps

400 ps – 3 ns

3 ns – 1 ms

150 ps – 400 ps

400 ps – 3 ns

3 ns – 1 ms

150 ps – 400 ps

400 ps – 3 ns

3 ns – 1 ms

150 ps – 400 ps

400 ps – 3 ns

3 ns – 1 ms

Amount Time

150 ps – 400 ps

<2.5%

<1.5%

<3.5%

<2.5%

<1.5%

<3.5%

<2.5%

<1.5%

400 ps – 3 ns

3 ns – 1 ms

150 ps – 400 ps

400 ps – 3 ns

3 ns – 1 ms

150 ps – 400 ps

400 ps – 3 ns

3 ns – 1 ms

DPO70000SX Series 7

Page 20

Specifications Vertical system analog channels (cont.)

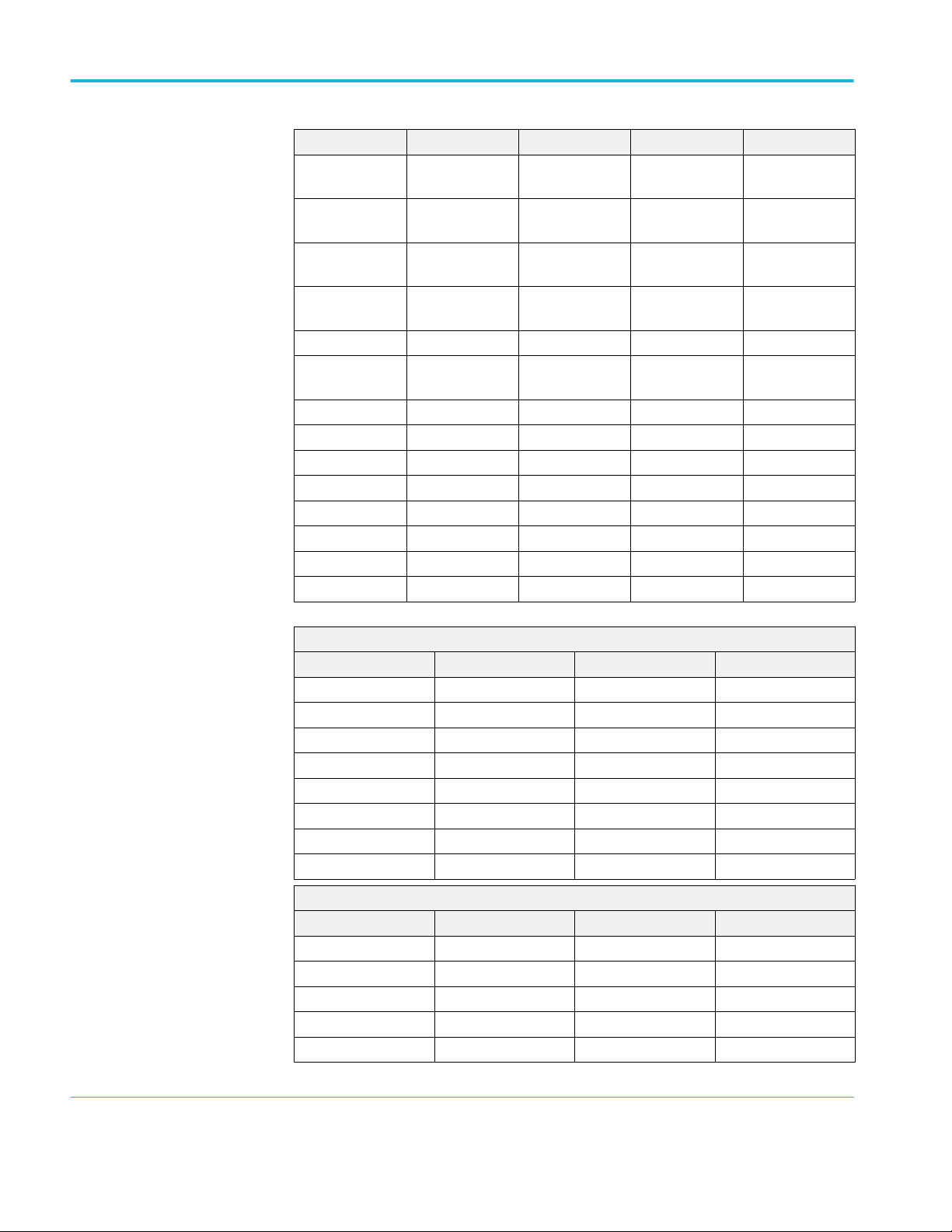

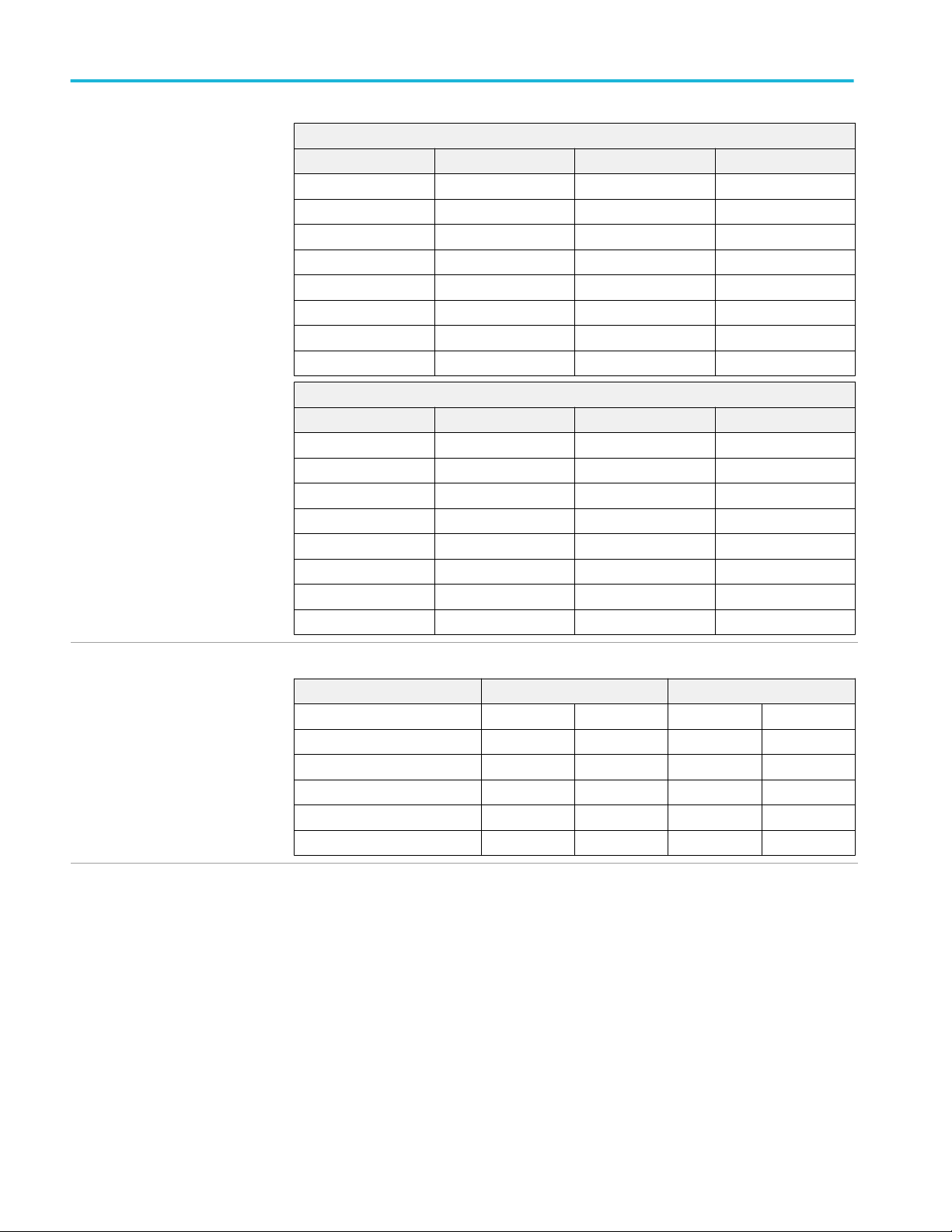

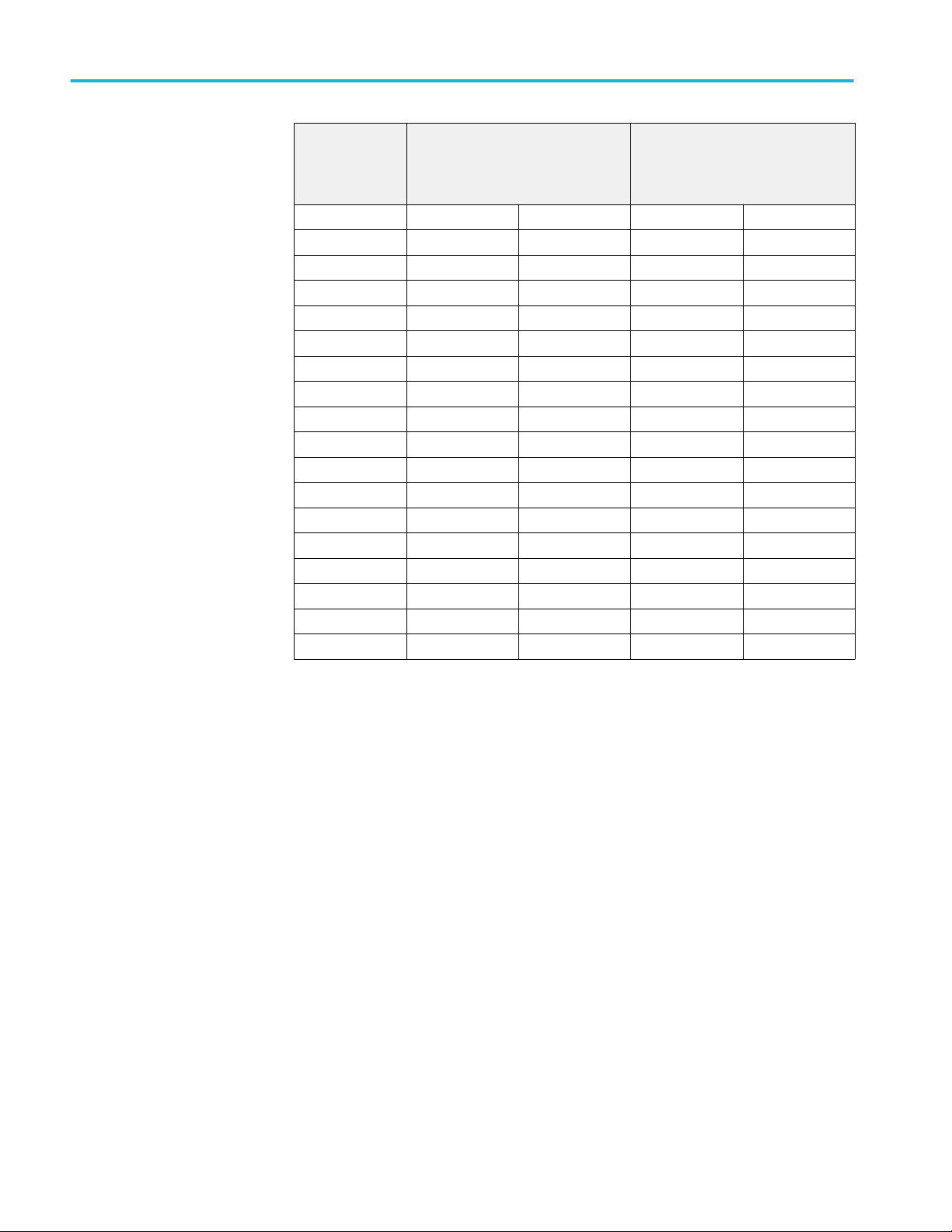

Effective bits, typical. The following charts give the typical effective bits for a 225 mV p-p sine-wave input sampled at

250 mVFS and maximum sample rate.

DPO77002SX DPO75902SX DPO75002SX

Input Frequency 200 GS/s 70 GHz 200 GS/s 59 GHz 200 GS/s 50 GHz

10 MHz 5.0 bits 5.13 bits 5.22 bits

0.92 GHz 5.0 bits 5.13 bits 5.21 bits

1.92 GHz 5.0 bits 5.13 bits 5.21 bits

2.92 GHz 5.0 bits 5.14 bits 5.21 bits

3.92 GHz 5.0 bits 5.13 bits 5.21 bits

4.92 GHz 4.9 bits 5.02 bits 5.10 bits

5.92 GHz 4.9 bits 5.03 bits 5.10 bits

6.92 GHz 4.9 bits 5.02 bits 5.09 bits

7.92 GHz 4.9 bits 5.02 bits 5.08 bits

8.92 GHz 4.9 bits 5.02 bits 5.09 bits

9.92 GHz 4.9 bits 5.03 bits 5.10 bits

10.92 GHz 4.9 bits 5.03 bits 5.10 bits

11.92 GHz 4.9 bits 5.07 bits 5.14 bits

12.92 GHz 4.9 bits 5.06 bits 5.18 bits

13.92 GHz 4.9 bits 5.08 bits 5.20 bits

14.92 GHz 4.9 bits 5.11 bits 5.22 bits

15.92 GHz 4.8 bits 4.98 bits 5.11 bits

16.92 GHz 4.8 bits 4.88 bits 5.05 bits

17.92 GHz 4.7 bits 4.75 bits 4.90 bits

18.92 GHz 4.7 bits 4.76 bits 4.92 bits

19.92 GHz 4.7 bits 4.80 bits 4.93 bits

20.92 GHz 4.7 bits 4.81 bits 4.93 bits

21.92 GHz 4.6 bits 4.76 bits 4.85 bits

22.92 GHz 4.6 bits 4.81 bits 4.89 bits

23.92 GHz 4.8 bits 4.87 bits 4.94 bits

24.92 GHz 4.7 bits 4.83 bits 4.89 bits

25.92 GHz 4.7 bits 4.84 bits 4.92 bits

26.92 GHz 4.6 bits 4.86 bits 4.93 bits

27.92 GHz 4.6 bits 4.82 bits 4.90 bits

28.92 GHz 4.6 bits 4.85 bits 4.94 bits

29.92 GHz 4.6 bits 4.85 bits 4.95 bits

30.92 GHz 4.6 bits 4.74 bits 4.90 bits

31.92 GHz 4.5 bits 4.70 bits 4.80 bits

32.92 GHz 4.5 bits 4.58 bits 4.74 bits

33.92 GHz 4.5 bits 4.67 bits 4.76 bits

35.92 GHz 4.5 bits 4.60 bits 4.67 bits

8 DPO70000SX Series

Page 21

Vertical system analog channels (cont.) Specifications

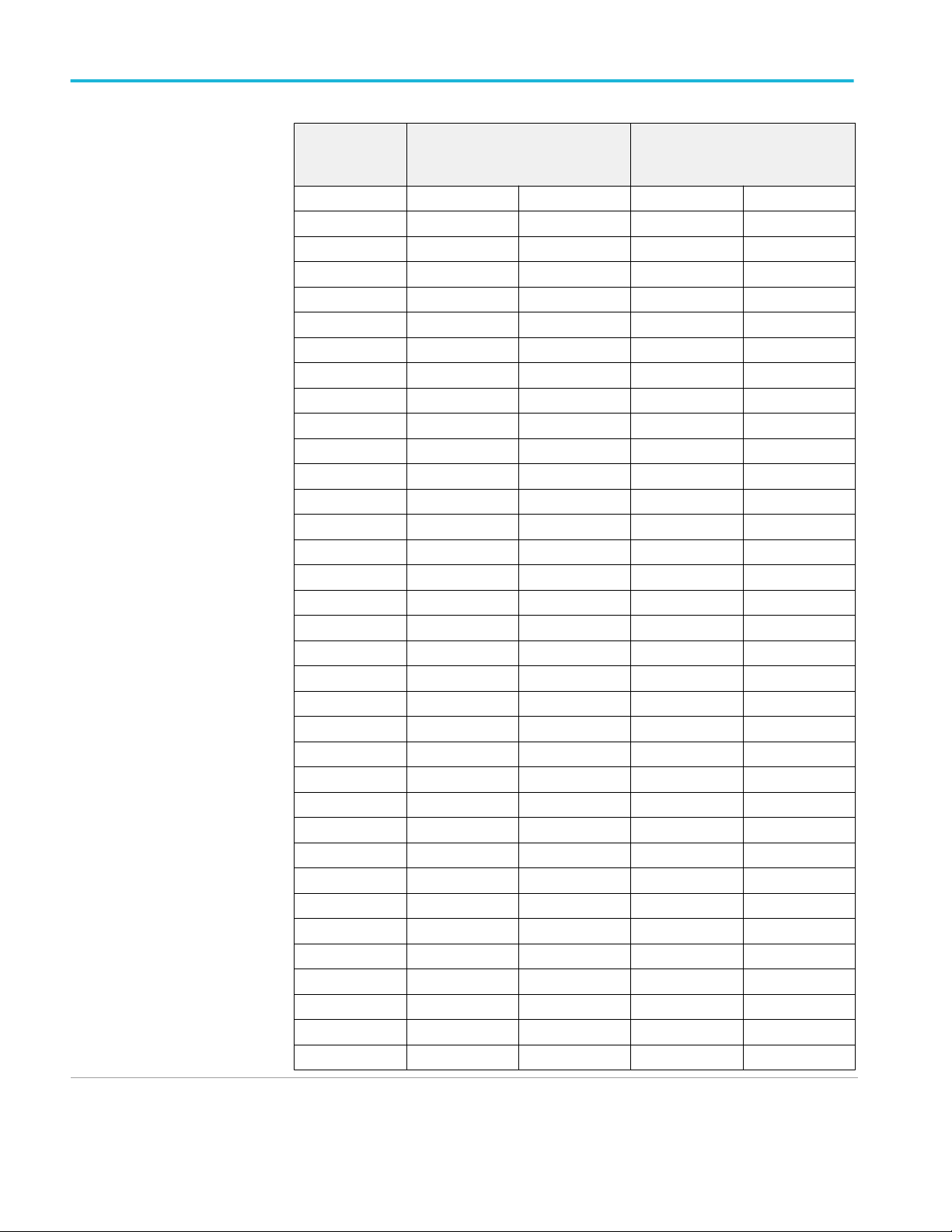

DPO77002SX DPO75902SX DPO75002SX

37.92 GHz 4.3 bits 4.41 bits 4.47 bits

39.92 GHz 4.3 bits 4.57 bits 4.65 bits

41.92 GHz 4.4 bits 4.49 bits 4.62 bits

43.92 GHz 4.6 bits 4.71 bits 4.87 bits

45.92 GHz 4.4 bits 4.54 bits 4.71 bits

47.92 GHz 4.4 bits 4.53 bits 4.64 bits

49.92 GHz 4.4 bits 4.60 bits 4.68 bits

51.92 GHz 4.5 bits 4.72 bits

53.92 GHz 4.6 bits 4.63 bits

55.92 GHz 4.5 bits 4.57 bits

57.92 GHz 4.5 bits 4.43 bits

59.92 GHz 4.8 bits 4.90 bits

61.92 GHz 4.8 bits

63.92 GHz 4.9 bits

65.92 GHz 4.9 bits

67.92 GHz 4.9 bits

69.92 GHz 4.7 bits

BWE on, Enhanced MIMO

filter, full bandwidth

DPO70002SX, DPO75902SX,

DPO75002SX,

DPO73304SX

TekConnect channels

Input frequency 100 GS/s, 33 GHz 50 GS/s, 23 GHz 100 GS/s, 23 GHz 50 GS/s, 23 GHz

10 MHz 5.4 bits 5.4 bits 5.9 bits 5.3 bits

1 GHz 5.2 bits 5.3 bits 5.8 bits 5.2 bits

2 GHz 5.2 bits 5.2 bits 5.7 bits 5.2 bits

3 GHz 5.1 bits 5.1 bits 5.6 bits 5.1 bits

4 GHz 5.1 bits 5.2 bits 5.6 bits 5.2 bits

5 GHz 5.2 bits 5.1 bits 5.6 bits 5.1 bits

6 GHz 5.0 bits 5.1 bits 5.6 bits 5.0 bits

7 GHz 5.0 bits 5.1 bits 5.5 bits 5.1 bits

8 GHz 5.1 bits 5.1 bits 5.6 bits 5.1 bits

9 GHz 5.1 bits 5.0 bits 5.6 bits 5.0 bits

10 GHz 5.2 bits 5.1 bits 5.5 bits 5.0 bits

11 GHz 5.1 bits 4.9 bits 5.4 bits 4.9 bits

12 GHz 5.2 bits 5.0 bits 5.5 bits 5.0 bits

13 GHz 5.1 bits 4.9 bits 5.4 bits 4.9 bits

14 GHz 5.1 bits 4.9 bits 5.3 bits 4.8 bits

15 GHz 4.9 bits 4.8 bits 5.1 bits 4.8 bits

DPO72304SX

DPO70000SX Series 9

Page 22

Specifications Vertical system analog channels (cont.)

DPO70002SX, DPO75902SX,

DPO75002SX,

DPO73304SX

TekConnect channels

16 GHz 4.8 bits 4.8 bits 5.2 bits 4.7 bits

17 GHz 4.9 bits 4.8 bits 5.2 bits 4.7 bits

18 GHz 4.9 bits 4.8 bits 5.3 bits 4.8 bits

19 GHz 4.8 bits 4.8 bits 5.2 bits 4.7 bits

20 GHz 4.7 bits 4.6 bits 5.1 bits 4.7 bits

21 GHz 4.8 bits 4.8 bits 5.3 bits 4.8 bits

22 GHz 4.8 bits 4.9 bits 5.3 bits 4.8 bits

23 GHz 4.9 bits 5.2 bits

24 GHz 5.0 bits

25 GHz 4.8 bits

26 GHz 4.9 bits

27 GHz 4.8 bits

28 GHz 4.7 bits

29 GHz 4.9 bits

30 GHz 4.9 bits

31 GHz 4.8 bits

32 GHz 4.8 bits

33 GHz 4.8 bits

DPO72304SX

10 DPO70000SX Series

Page 23

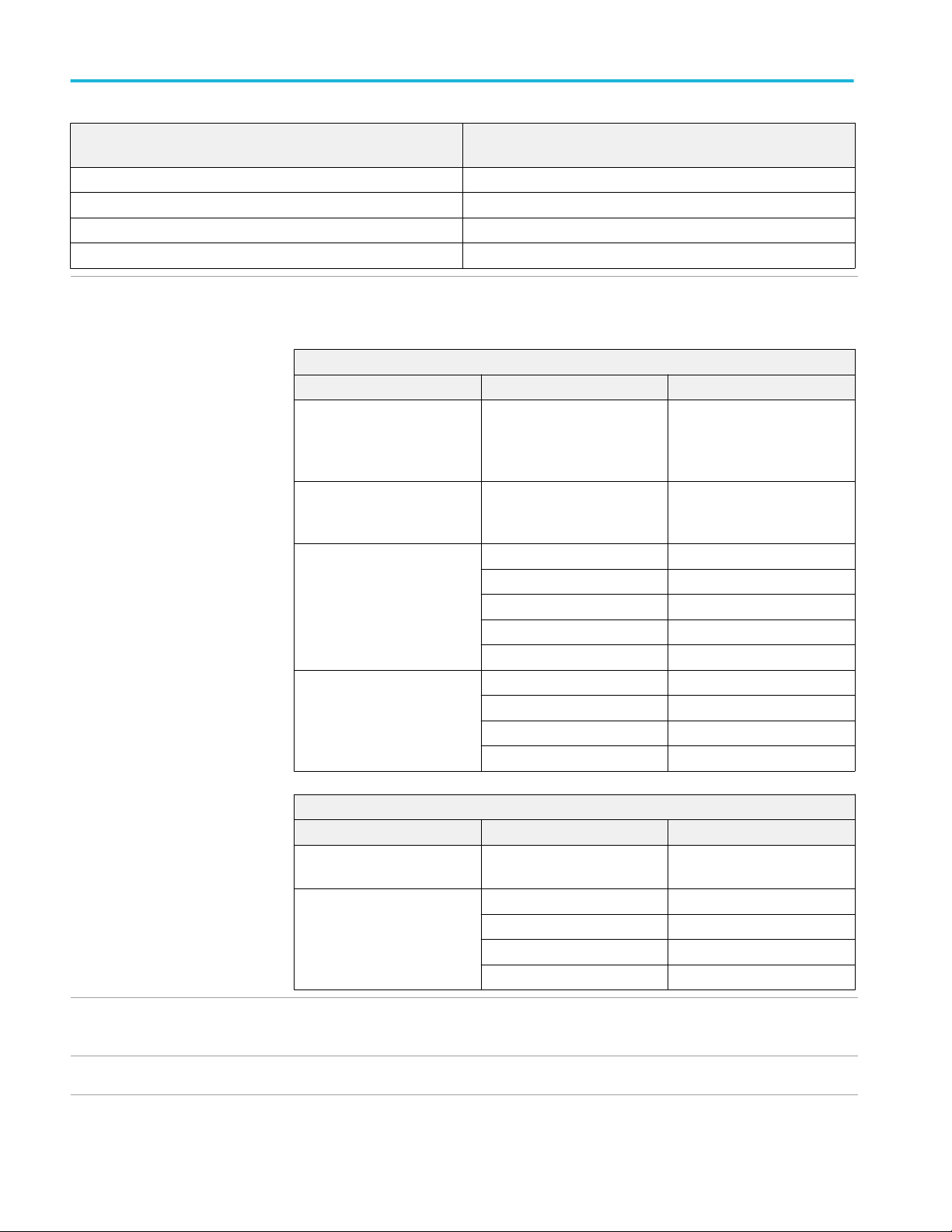

Vertical system analog channels (cont.) Specifications

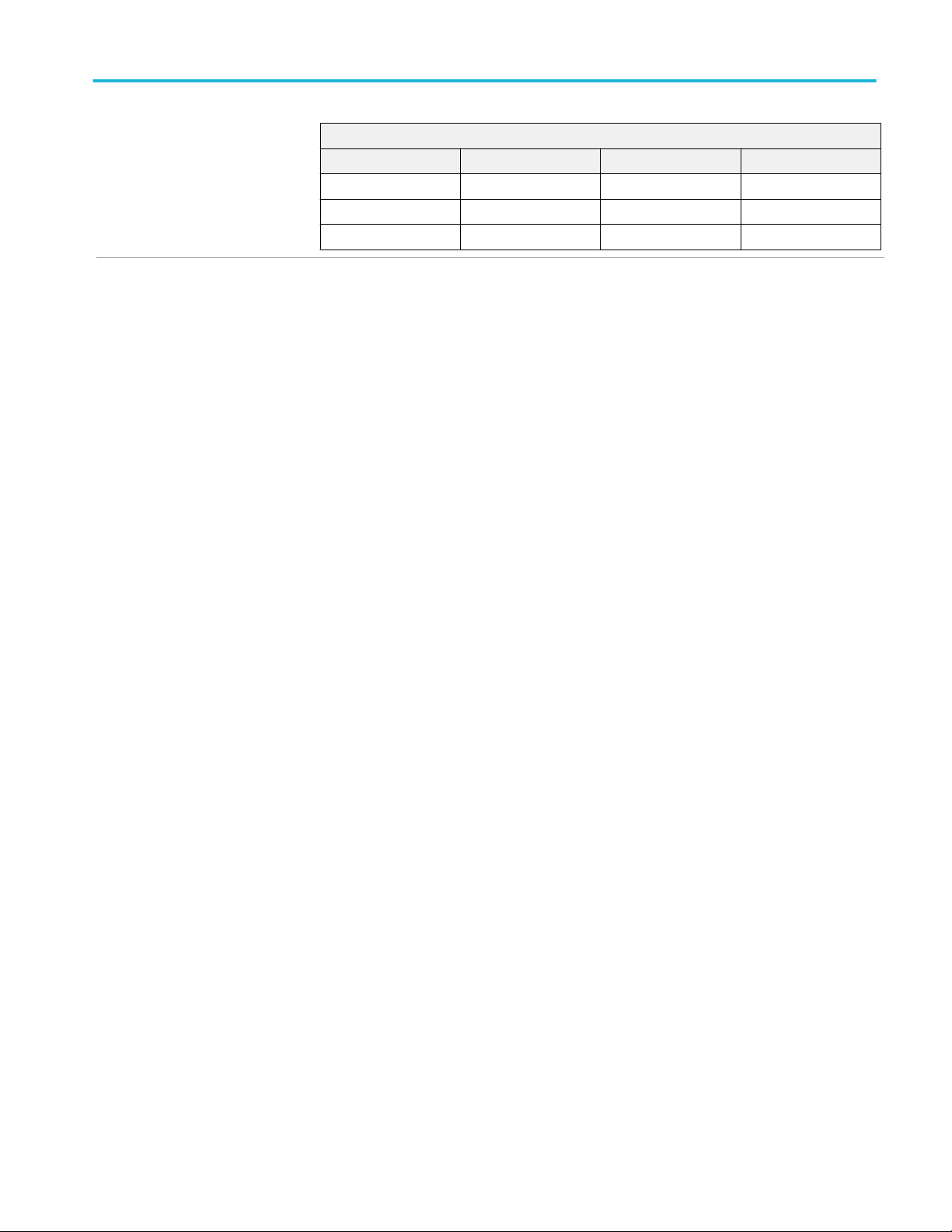

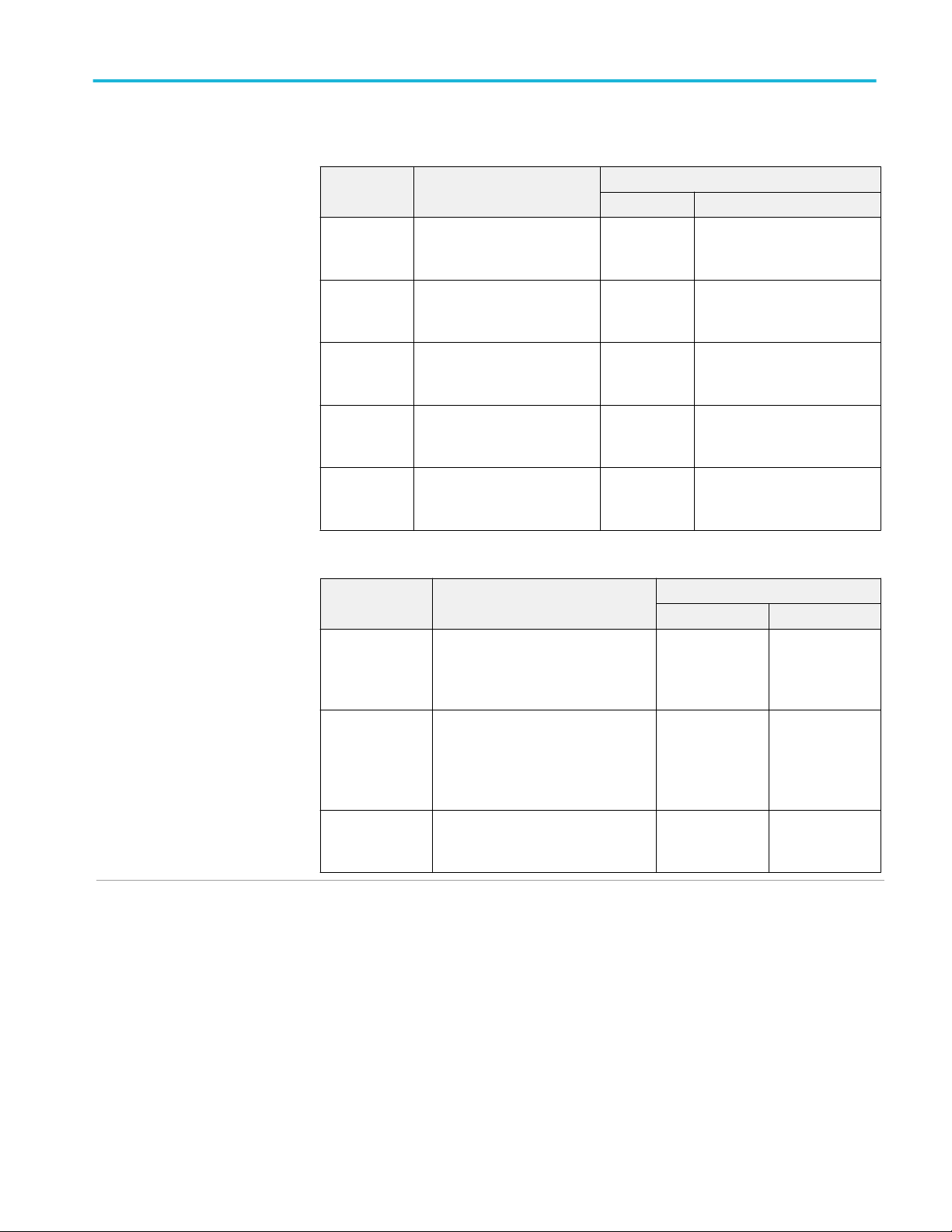

BWE on, full bandwidth Nine division sine wave input at the indicated frequency, sampled at 500 mVFS vertical sensitivity

and maximum sample rate

DPO73304SX,

DPO77002SX, DPO75902SX,

DPO75002SX TekConnect channels

Input frequency 100 GS/s, 33 GHz 50 GS/s, 23 GHz 100 GS/s, 23 GHz 50 GS/s, 23 GHz

10 MHz 5.4 bits 5.2 bits 6.0 bits 5.2 bits

1 GHz 4.9 bits 5.0 bits 5.5 bits 5.0 bits

2 GHz 4.9 bits 5.0 bits 5.3 bits 5.0 bits

3 GHz 5.0 bits 4.9 bits 5.4 bits 4.9 bits

4 GHz 4.5 bits 4.8 bits 4.8 bits 4.5 bits

5 GHz 4.7 bits 4.7 bits 5.3 bits 4.7 bits

6 GHz 4.8 bits 4.7 bits 5.2 bits 4.7 bits

7 GHz 4.9 bits 4.8 bits 5.3 bits 4.8 bits

8 GHz 5.0 bits 4.8 bits 5.4 bits 4.8 bits

9 GHz 5.0 bits 4.7 bits 5.3 bits 4.7 bits

10 GHz 5.0 bits 4.7 bits 5.4 bits 4.7 bits

11 GHz 5.0 bits 4.7 bits 5.2 bits 4.7 bits

12 GHz 5.1 bits 4.7 bits 5.3 bits 4.7 bits

13 GHz 4.7 bits 4.7 bits 5.2 bits 4.7 bits

14 GHz 5.0 bits 4.8 bits 5.2 bits 4.8 bits

15 GHz 4.8 bits 4.6 bits 5.1 bits 4.6 bits

16 GHz 4.6 bits 4.6 bits 5.2 bits 4.6 bits

17 GHz 4.8 bits 4.6 bits 5.1 bits 4.6 bits

18 GHz 4.7 bits 4.6 bits 5.1 bits 4.6 bits

19 GHz 4.5 bits 4.6 bits 5.0 bits 4.6 bits

20 GHz 4.4 bits 4.5 bits 5.0 bits 4.6 bits

21 GHz 4.4 bits 4.6 bits 5.1 bits 4.6 bits

22 GHz 4.6 bits 4.6 bits 5.1 bits 4.6 bits

23 GHz 4.6 bits 5.1 bits

24 GHz 4.7 bits

25 GHz 4.7 bits

26 GHz 4.6 bits

27 GHz 4.6 bits

28 GHz 4.6 bits

29 GHz 4.6 bits

30 GHz 4.6 bits

31 GHz 4.5 bits

32 GHz 4.5 bits

33 GHz 4.5 bits

DPO72304SX

DPO70000SX Series 11

Page 24

Specifications Vertical system analog channels (cont.)

Full analog bandwidth

DPO73304SX,

DPO77002SX, DPO75902SX,

DPO75002SX TekConnect channels

Input frequency 100 GS/s 50 GS/s 100 GS/s 50 GS/s

10 MHz 5.2 bits 5.2 bits 5.4 bits 5.2 bits

1 GHz 4.8 bits 4.8 bits 5.0 bits 5.0 bits

2 GHz 4.9 bits 4.9 bits 5.1 bits 5.0 bits

3 GHz 4.8 bits 4.8 bits 5.1 bits 4.9 bits

4 GHz 4.7 bits 4.7 bits 4.7 bits 4.7 bits

5 GHz 4.7 bits 4.7 bits 4.8 bits 4.7 bits

6 GHz 4.7 bits 4.7 bits 4.8 bits 4.7 bits

7 GHz 4.7 bits 4.7 bits 4.9 bits 4.7 bits

8 GHz 4.6 bits 4.6 bits 4.9 bits 4.8 bits

9 GHz 4.6 bits 4.7 bits 4.9 bits 4.7 bits

10 GHz 4.7 bits 4.7 bits 4.9 bits 4.7 bits

11 GHz 4.7 bits 4.7 bits 4.9 bits 4.7 bits

12 GHz 4.7 bits 4.7 bits 4.9 bits 4.7 bits

13 GHz 4.5 bits 4.5 bits 4.8 bits 4.5 bits

14 GHz 4.7 bits 4.7 bits 4.9 bits 4.7 bits

15 GHz 4.6 bits 4.6 bits 4.7 bits 4.6 bits

16 GHz 4.4 bits 4.5 bits 4.7 bits 4.5 bits

17 GHz 4.4 bits 4.5 bits 4.7 bits 4.5 bits

18 GHz 4.4 bits 4.5 bits 4.6 bits 4.5 bits

19 GHz 4.1 bits 4.2 bits 4.5 bits 4.5 bits

20 GHz 4.2 bits 4.3 bits 4.5 bits 4.5 bits

21 GHz 4.5 bits 4.5 bits 4.6 bits 4.5 bits

22 GHz 4.4 bits 4.5 bits 4.8 bits 4.5 bits

23 GHz 4.4 bits 4.5 bits 4.8 bits 4.3 bits

24 GHz 4.5 bits 4.4 bits

25 GHz 4.4 bits 4.5 bits

26GHz 4.3 bits 4.4 bits

27 GHz 4.3 bits 4.1 bits

28 GHz 4.1 bits 4.1 bits

29 GHz 3.8 bits 4.2 bits

30 GHz 4.2 bits 4.2 bits

31 GHz 4.2 bits 4.4 bits

32 GHz 4.1 bits 4.1 bits

33 GHz 4.2 bits 4.3 bits

DPO72304SX

12 DPO70000SX Series

Page 25

Vertical system analog channels (cont.) Specifications

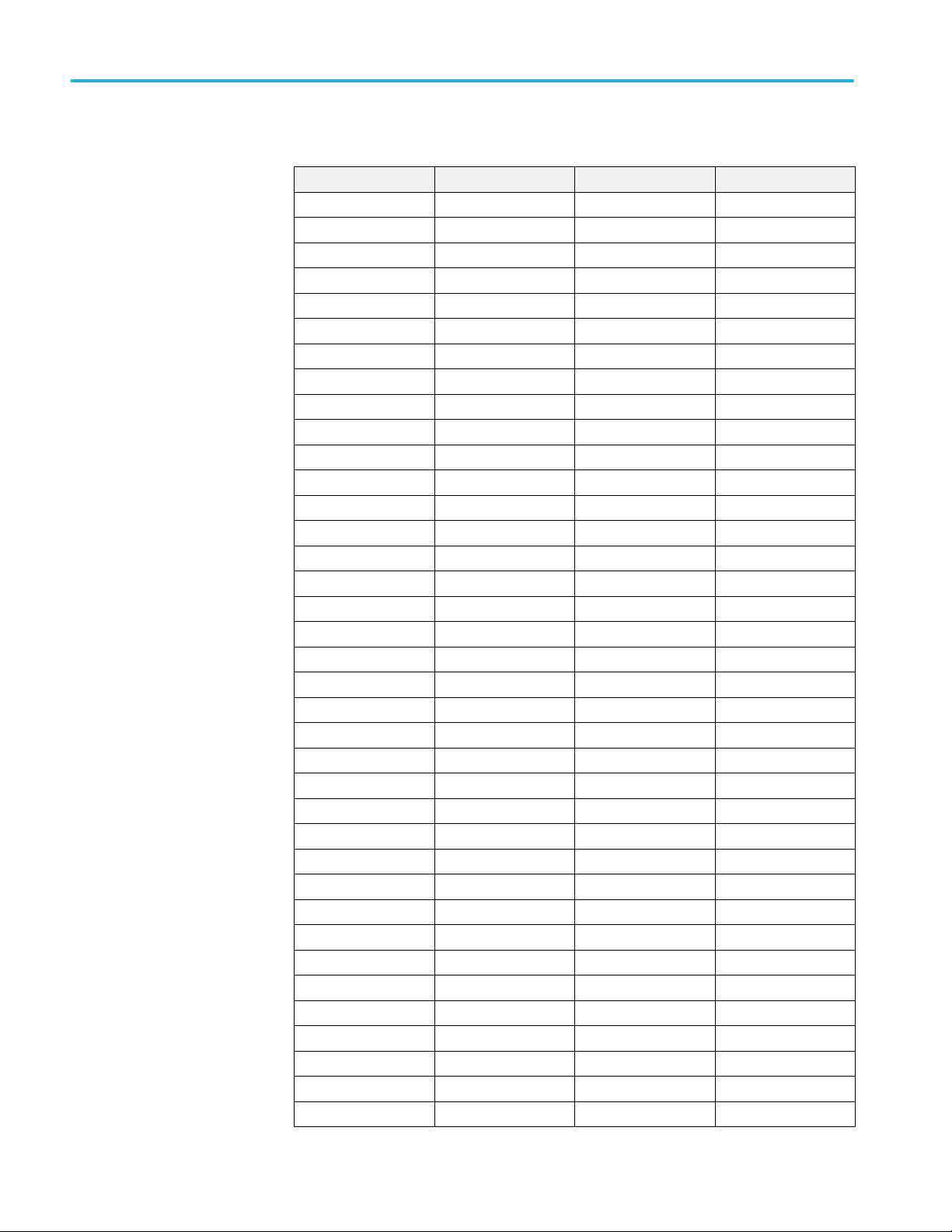

Noise (typical)

Gain setting, full scale,

BWE off

62.5 mV 0.88 mV 0.79 mV 0.74 mV 0.70 mV

100 mV 0.96 mV 0.86 mV 0.82 mV 0.79 mV

200 mV 1.53 mV 1.41 mV 1.30 mV 1.32 mV

500 mV 4.19 mV 3.14 mV 3.00 mV 3.05 mV

1 V 8.30 mV 6.10 mV 5.90 mV 6.08 mV

2.0 V 18.84 mV 14.19 mV 13.07 mV 13.09 mV

3.0 V 24.64 mV 19.09 mV 18.37 mV 18.37 mV

4.0 V 37.91 mV 26.01 mV 25.35 mV 25.55 mV

5.0 V 43.36 mV 31.84 mV 30.52 mV 30.62 mV

6.0 V 47.93 mV 36.97 mV 35.91 mV 36.33 mV

Gain setting,

full scale,

BWE on

62.5 mV 0.84 mV 0.84 mV 0.75 mV 0.72 mV 0.78 mV 0.77 mV 0.71 mV 0.69 mV

100 mV 0.93 mV 0.93 mV 0.78 mV 0.82 mV 0.77 mV 0.81 mV 0.68 mV 0.73 mV

150 mV 1.31 mV 1.29 mV 1.08 mV 1.19 mV 0.94 mV 1.01 mV 0.88 mV 0.95 mV

200 mV 1.52 mV 1.60 mV 1.14 mV 1.43 mV 1.04 mV 1.18 mV 0.99 mV 1.14 mV

300 mV 2.49 mV 2.52 mV 2.10 mV 2.29 mV 1.58 mV 1.8 mV 1.57 mV 1.79 mV

400 mV 2.92 mV 3.12 mV 2.58 mV 2.29 mV 1.82 mV 2.20 mV 1.82 mV 2.21 mV

500 mV 3.55 mV 3.80 mV 2.65 mV 3.38 mV 2.17 mV 2.66 mV 2.2 mV 2.69 mV

600 mV 4.86 mV 4.86 mV 4.14 mV 4.42 mV 3.02 mV 3.46 mV 3.01 mV 3.43 mV

700 mV 5.25 mV 5.39 mV 4.64 mV 4.96 mV 3.28 mV 3.85 mV 3.25 mV 3.80 mV

800 mV 5.76 mV 6.08 mV 5.08 mV 5.52 mV 3.61 mV 4.37 mV 3.56 mV 4.29 mV

900 mV 6.30 mV 6.66 mV 5.63 mV 6.13 mV 3.96 mV 4.81 mV 3.89 mV 4.69 mV

1 V 6.80 mV 7.30 mV 5.09 mV 6.54 mV 4.29 mV 5.29 mV 4.2 mV 5.14 mV

1.1 V 8.69 mV 9.02 mV 7.79 mV 8.20 mV 5.48 mV 6.94 mV 5.45 mV 6.74 mV

1.2 V 9.12 mV 9.60 mV 8.28 mV 8.72 mV 5.75 mV 7.50 mV 5.73 mV 7.28 mV

2.0 V 15.40 mV 14.53 mV 11.66 mV 14.65 mV 9.70 mV 12.23 mV 9.88 mV 11.87 mV

3.0 V 19.91 mV 19.82 mV 15.31 mV 20.51 mV 12.98 mV 16.55 mV 13.19 mV 16.81 mV

4.0 V 28.83 mV 27.85 mV 21.61 mV 27.84 mV 19.56 mV 23.17 mV 18.64 mV 21.32 mV

5.0 V 34.32 mV 32.80 mV 25.69 mV 34.07 mV 22.82 mV 27.79 mV 21.82 mV 26.03 mV

6.0 V 39.82 mV 38.96 mV 29.65 mV 39.18 mV 26.65 mV 32.42 mV 25.74 mV 31.45 mV

DPO77002SX,

DPO75902SX,

DPO75002SX,

DPO73304SX

TekConnect channels

100 GS/s 50 GS/s 100 GS/s 50 GS/s 100 GS/s 50 GS/s 100 GS/s 50 GS/s

DPO77002SX,

DPO75902SX,

DPO75002SX,

DPO73304SX

TekConnect channels

DPO72304SX DPO71604SX DPO71304SX

DPO72304SX DPO71604SX DPO71304SX

DPO70000SX Series 13

Page 26

Specifications Vertical system analog channels (cont.)

Gain setting, full scale, ATI channel DPO77002SX

DPO75902SX, DPO75002SX

100 mV 1.19 mV

200 mV 1.76 mV

250 mV 2.10 mV

300 mV 2.49 mV

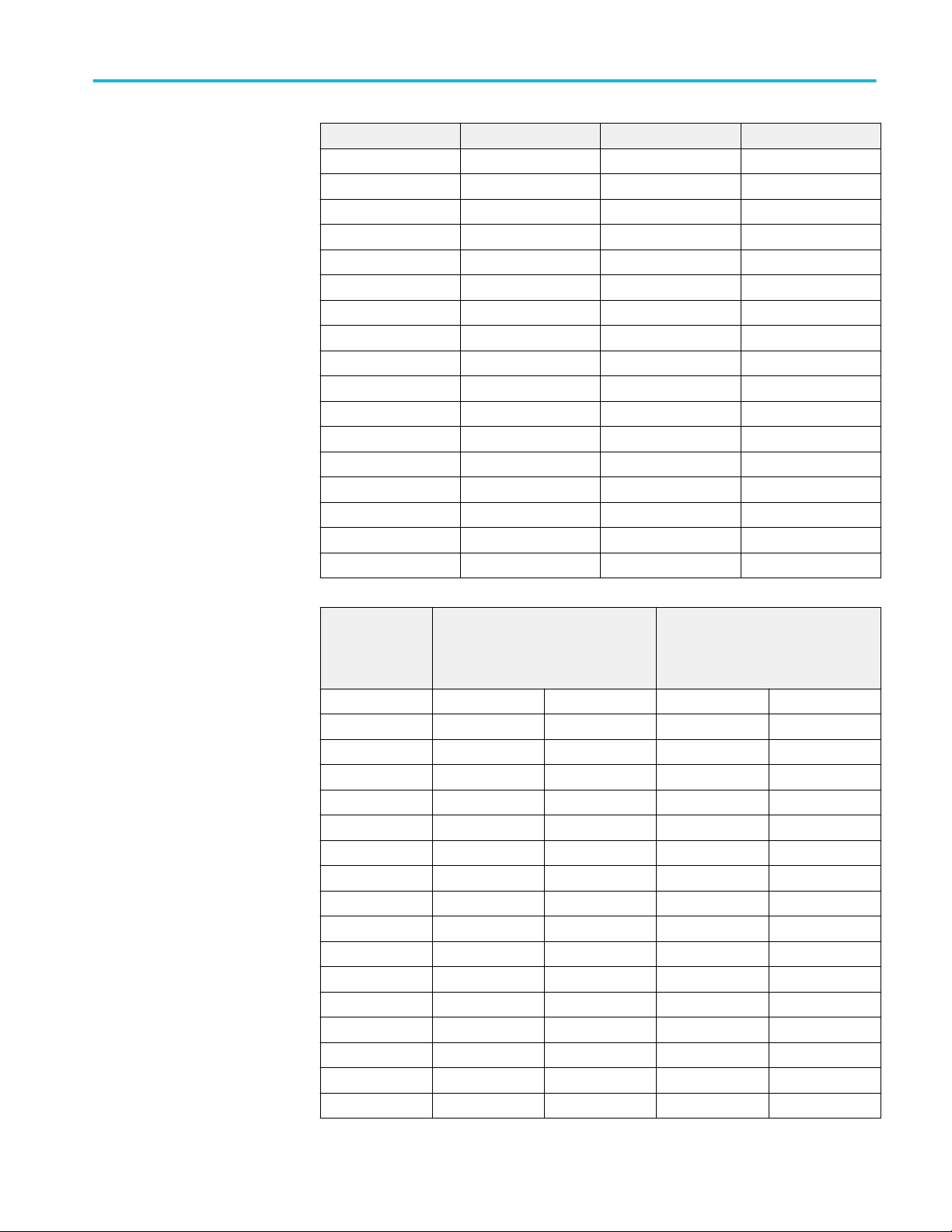

Channel-to-channel crosstalk

(channel isolation), typical

Input frequency range (up to the rated bandwidth). Assumes two channels with the same scale and

bandwidth settings. The limits apply up to the bandwidth of the particular instrument.

ATI models

Specified channels Instrument frequency range Isolation

ATI channels (isolation between

any two [or more] ATI channels

in separate units), requires

UltraSync

TekConnect channels in an ATI

unit (isolation between channels

1 and 3)

TekConnect channels to ATI

channel (isolation between

channels 1 and 3 to channel 2)

ATI channel to TekConnect

(non-ATI) channels (isolation

between channel 2 and

channels 1 or 3)

DC to 70 GHz 70 dB

DC to 33 GHz 60 dB

DC to 4 GHz 55 dB

>4 GHz to 10 GHz 45 dB

>10 GHz to 20 GHz 35 dB

>20 GHz to 30 GHz 30 dB

>30 GHz to 33 GHz 27 dB

DC to 3 GHz 55 dB

>3 GHz to 12 GHz 40 dB

>12 GHz to 33 GHz 30 dB

>33 to 70 GHz 60 dB

TekConnect models (non-ATI)

Specified channels Instrument frequency range Isolation

Isolation between channels 1 or

2 and channels 3 or 4

Isolation between channels

1 and 2, or channels 3 and 4

Measurement category The measuring terminals on this product are not rated for connection to mains or Measurement

Category II, III or IV circuits.

TekConnect interface The instrument TekConnect channels support the TekConnect interface.

DC to 33 GHz 60 dB

DC to 2 GHz 60 dB

>2 to 10 GHz 42 dB

>10 to 20 GHz 35 dB

>20 to 33 GHz 30 dB

14 DPO70000SX Series

Page 27

Horizontal and acquisition system

Specifications

Delay between channels, full

bandwidth, equivalent time, BWE

off, without deskew (typical)

Delay between channels, BWE

(typical)

Channel skew stability, UltraSync

(typical)

Real-time sample rate range

Equivalent-time sample rate or

interpolated waveform rate range

Maximum record length, sample

mode

≤ 1 ps between any two channels at any gain setting at 25 °C ±5 °C.

Derate linearly to ≤3 ps at 5 °C and 45 °C

≤ 500 fs between any two channels within the same box at any gain setting at 25 °C ±5 °C prior to

any user adjustment. Manual adjustment available with 10 fs minimum resolution. Derate linearly to

≤ 1.5 ps at 5 °C and 45 °C.

≤ 250 fs

Derate linearly to ≤ 3 ps at 5 °C and 45 °C.

Channels Sample rate, maximum

TekConnect channels Up to 100 GS/s

ATI channels 200 GS/s only

Equivalent-time acquisition can be enabled or disabled. When disabled, waveforms are interpolated

at the fastest time base settings.

Up to 5 TS/s (waveform interval down to 0.2 ps) in E.T. and 0.2 ps resolution in trigger placement.

The maximum record length depends on the installed record length options. Maximum record

length is less in serial trigger mode, hi-res mode, or when using the FIR filter.

between any two channels between instruments at any gain setting at 25 °C ±5 °C.

RMS

(Standard)

500,000,000 points (all channels), 1 G samples on 1–2 channels at 50 GS/s and 100 GS/s sample

rates or greater (interpolated or equivalent time)

Maximum record length, HiRes

mode

Record length limits

Seconds division range Fastest sweep speed is 10 ps per division

Internal time-base reference

frequency

Half the record length of sample mode

Operation 4 X 50 GS/s

Acquisition

Display acquired

waveform

Waveform data

CURVE? output any PI

Math1 = Ch1 - Ch3 250 Msamples 250 Msamples 250 Msamples

Arbfilt (Ch1, "filter")

FFTmag(Ch1)

Reference Waveforms

(Rn)

10 MHz

Electronically adjustable over about ±10 ppm.

500 Msamples 1 Gsamples 1 Gsamples

500 Msamples 1 Gsamples 1 Gsamples

1 Gsamples 1 Gsamples 1 Gsamples

2 x 100 GS/s

Acquisition

1 x 200 GS/s

Acquisition

DPO70000SX Series 15

Page 28

Specifications Horizontal and acquisition system (cont.)

Time base accuracy ±0.8 x 10-6 (within 1st year), ±0.3 x 10-6 aging/year after first year when operated within 23° C ±5°

C after 30 minute warm-up.

Typical: ±0.1 x 10-6 initial accuracy after adjustment.

Timing jitter (aperture uncertainty),

(typical)

Measured at the maximum sample rate.

External Reference Low with ~0 dBm input drive at 10 MHz

TekConnect:

<100 fs rms for record durations less than 10 μs

<120 fs rms for record durations less than 100 μs

<140 fs rms for record durations less than 10 ms

<300 fs rms for record durations less than 10 s

ATI:

<65 fs rms for record durations less than 10 μs

External Reference Hi with ~0 dBm input drive at 10 MHz

TekConnect:

<100 fs rms for record durations less than 2 μs

<500 fs rms for record durations less than 10 s

ATI:

<65 fs rms for record durations less than 10 μs

For external reference in high (tracking) mode, the input reference must be low noise and the edge

slew rate must exceed 1.5 V/ns to achieve the typical jitter results.

Internal Reference

TekConnect:

<100 fs rms for record durations less than 10 μs

<120 fs rms for record durations less than 100 μs

<140 fs rms for record durations less than 5 ms

ATI:

<65 fs rms for record durations less than 10 μs

For internal reference, specification assumes no signal attached to the external reference input.

Jitter noise floor (typical) Applies to time periods as long as 10.0 ns. Typical jitter noise floor is measured at the maximum,

BWE enabled bandwidth:

DPO77002SX <250 fs

DPO75902SX <250 fs

DPO75002SX <250 fs

DPO73304SX <250 fs

DPO72304SX <250 fs

Calculate the jitter noise floor (JNF) for a given instrument setting using the following formula:

16 DPO70000SX Series

Page 29

Horizontal and acquisition system (cont.) Specifications

N

= typical input-referred noise spec (volts rms)

typ

FN = 1.3 for instrument bandwidth ≤9 GHz; 1.5 for instrument bandwidth ≥10 GHz

SR = slew rate around the measurement

FI = (1.7 x 10–2)/sqrt(2) = 1.2 x 10–2

tr = rise time of the measurement edge

tj = timebase jitter or aperture uncertainty

TBA = timebase accuracy (2 ppm)

2

JNF

The interpolated sample rate of the waveform must be at least 25 times the bandwidth of the signal

being measured.

Acquisition update rate (typical)

DPO models 300,000 waveforms per second maximum

RMS

= (N

typ

× FN)2×

(

SR

1

2

2

× t

r

+ t

2

seconds

j

RMS

+ F

)

I

Delta time measurement

accuracy

The formula to calculate the maximum delta-time measurement accuracy (DTAmax) for a given

instrument setting and input signal is given below (assumes insignificant signal content above

Nyquist and insignificant error due to aliasing, overdrive recovery and overdrive interpolation):

N

= typical input-referred noise spec (volts rms)

typ

FN = 1.3 for instrument bandwidth ≤9 GHz; 1.5 for instrument bandwidth ≥10 GHz

SR1 = slew rate around 1st point in measurement (1st edge)

SR2 = slew rate around 2nd point in measurement (2nd edge)

FI = 1.2 × 10–2

tr1 = rise time of first edge

tr2 = rise time of second edge

tj = sample jitter/aperture uncertainty (about 100 fs for time durations less than 10 μs)

Peak-peak based on statistical accumulation of 500 waveforms.

(

2

)

rms

pk-pk

+

(

SR

(

seconds

seconds

1

DTA

MAX

1

=10 × (N

RMS is guaranteed regardless of data-gathering duration.

typ

× FN)

2

DTA

(

SR

1

MAX

)

2

2

2

+ F

)

2

×(t

I

)

2

+ t

)

r1

r2

+ (2 × t

2

)

j

= (N

typ

The term under the square-root sign is the stability and is due to time interval error (TIE).

× FN)

2

(

SR

+

)

1

2

1

2

1

(

SR

2

2

2

×(t

2

+ t

)

r1

r2

+ F

)

I

+ (2 × t

2

)

j

DPO70000SX Series 17

Page 30

Specifications

Trigger specifications

Trigger jitter DC coupled A edge

(typical)

Edge trigger sensitivity DC

coupled (typical)

10 fs using enhanced trigger placement.

1 ps rms for low frequency, fast rise time signal, A edge, holdoff time = 30 μs

All sources, positive or negative edge.

Trigger Source Sensitivity

A-Event trigger ≤ 5%FS from DC to 50 MHz

≤ 7.5%FS at 5 GHz

≤ 10%FS at 10 GHz

≤ 15%FS at 15 GHz

≤ 35%FS at 20 GHz

≤ 50%FS at 25 GHz

B-Event trigger ≤ 5%FS from DC to 50 MHz

≤ 7.5%FS at 5 GHz

≤ 10%FS at 10 GHz

≤ 15%FS at 15 GHz

≤ 35%FS at 20GHz

≤ 50%FS at 25 GHz

Auxiliary input 100 mVpp from DC to 1 GHz

175 mVpp at 4 GHz

225 mVpp at 8 GHz

450 mVpp at 10 GHz

800 mVpp at 11 GHz

Trigger sensitivity TPC (typical) The minimum signal levels required for stable triggering of a waveform when the hardware is

incapable of doing so (excessive frequency, small input).

Trigger Source Sensitivity

A Event trigger, Ch1 – Ch4 20%×FS from DC to instrument bandwidth

B Event trigger, Ch1 – Ch4 20%×FS from DC to instrument bandwidth

18 DPO70000SX Series

Page 31

Trigger specifications (cont.) Specifications

Edge trigger sensitivity, non-DCcoupled modes (typical)

All sources, positive or negative edge, for vertical scale settings ≥10 mV/div and ≤1 V/div

Trigger Coupling Sensitivity

NOISE REJ 15%FS from DC to 50 MHz

22.5% at 5 GHz

30%FS at 10 GHz

45%FS at 15 GHz

100%FS at 20 GHz

AC Same as DC-coupled limits for frequencies >

100 Hz, attenuates signals <100 Hz

HF REJ Same as DC-coupled limits for frequencies <

20 kHz, attenuates signals > 20 kHz

LF REJ Same as DC-coupled limits for frequencies >

200 kHz, attenuates signals < 200 kHz

RF Minimum hysteresis / High sensitivity

A TRIG TekConnect

2.5% FS from DC to 50 MHz

2.5% FS at 5 GHz

2.5% FS at 10 GHz

5% FS at 15 GHz

7.5% FS at 20 GHz

12.5% FS at 25 GHz

B TRIG TekConnect

2.5% FS from DC to 50 MHz

2.5% FS at 5 GHz

2.5% FS at 10 GHz

5% FS at 15 GHz

7.5% FS at 20 GHz

20% FS at 25 GHz

A TRIG ATI

2.5% FS from DC to 50 MHz

2.5% FS at 5 GHz

2.5% FS at 10 GHz

5% FS at 15 GHz

10% FS at 20 GHz

22.5% FS at 25 GHz

B TRIG ATI

2.5% FS from DC to 50 MHz

2.5% FS at 5 GHz

2.5% FS at 10 GHz

5% FS at 15 GHz

10% FS at 20 GHz

22.5% FS at 25 GHz

DPO70000SX Series 19

Page 32

Specifications Trigger specifications (cont.)

Trigger level or threshold range

Trigger Source Range

Ch1, 2, 3, or 4 Full scale

Auxiliary input ±3.65 V

Line 0 V, Not settable

Trigger level or threshold accuracy

Edge trigger, DC coupled

(typical)

Trigger Source Accuracy

Channel 1, 2, 3, or 4 ± [(2% | trigger level - net offset | ) + (3.5% FS)

+ offset accuracy]

Auxiliary Not specified

Trigger position error (typical) Edge trigger, DC coupling, for a 5 division peak to peak 1 GHz sine wave signal.

Acquisition mode Trigger Position Error

Sample, Average ± (1 waveform sample interval + 50 ps)

Peak Detect, Envelope ± (2 waveform sample intervals + 50 ps)

Time range for time-qualified

triggers

Setup/Hold Violation

Setup time

Hold time

Setup + hold time

-100 ns to +100 ns

-1 ns to +100 ns

500 ps minimum

Time qualified pattern 300 ps to 1 s

Timeout 40 ps to 1 s

Time qualified window, outside >t 40 ps to 1 s

All other types 40 ps to 1 s

Time-qualified trigger timer

accuracy

For glitch, width, time qualified runt, transition, or window and timeout triggering (40 ps to 1.0 ns

typical):

Time range Accuracy

40 ps to ≤50 ns ±(3% of setting + 15 ps)

40 ps to ≤1 ns ±(3% of setting + 15 ps) (typical)

1 ns to ≤50 ns ±(3% of setting + 15 ps)

500 ns to 1 s ±(150 ppm x setting + 500 ps)

Setup/hold violation and time qualified pattern (40 ps to 1.0 ns typical):

300 ps to 1.01 μs ±(5% of setting + 200 ps)

1.02 μs to 1 s ±(TB

1

TB Accuracy is the Time Base Accuracy expressed as a percentage of setting

1

accuracy + 20 ns)

20 DPO70000SX Series

Page 33

Trigger specifications (cont.) Specifications

Advanced trigger sensitivity

(typical)

15% x FS from DC to 10 GHz (pattern and state trigger DC to 1 GHz), not violating the minimum

timing requirements for each type (for vertical settings from 6.5 mV/div to 600 mV/div at the

TekConnect connector)

DPO70000SX Series 21

Page 34

Specifications Trigger specifications (cont.)

Advanced trigger types minimum

timing requirements (typical)

Minimum duration of the

pattern includes delay

mismatch between channels.

Trigger Minimum

Minimum rearm time Setup

pulse

width

Width 40 ps 50 ps for time < 5 ns,

75 ps above 5 ns.

Logic-Qualified Width 40 ps 50 ps for time < 5 ns,

75 ps above 5 ns.

Glitch 40 ps 50 ps for time < 5 ns,

75 ps above 5 ns.

Logic-Qualified Glitch 40 ps 50 ps for time < 5 ns,

75 ps above 5 ns.

Timeout n/a 50 ps for time < 5 ns,

75 ps above 5 ns.

Logic-Qualified Timeout

2

n/a 50 ps for time < 5 ns,

75 ps above 5 ns.

Window

3

Enters 50 ps

Inside

75 ps rearm outside

window

window

0 ps

transition

through

window

Exits 50 ps

Outside

75 ps rearm inside

window

window

Time-Qualified

Window

Inside > t 50 ps

Inside

75 ps rearm outside

window

window

0 ps

transition

through

window

Outside > t 50 ps

Outside

75 ps rearm inside

window

window

Hold time

time

n/a n/a

0 ps 100 ps

n/a n/a

15 ps 85 ps

n/a n/a

10 ps 90 ps

n/a n/a

55 ps 145 ps

2

Hold Time for logic qualified Timeout is measured from the expiration of the timer that causes the trigger.

3

Window trigger for A trigger implemented with both triple masters basically performing edge trigger with the outputs or'ed together so it could have

much better specs for minimum pulse width and rearm time (40ps/40ps) than the Time Qualified Window trigger which uses the actual window trigger

circuitry and time qualifiers in the Tek46. However the B trigger also may have to use the window trigger circuitry if triple master not available so we've

used the reduced specs for all window trigger modes. If you adjust the trigger levels you can get more performance out of window trigger.

22 DPO70000SX Series

Page 35

Trigger specifications (cont.) Specifications

Trigger Minimum

pulse

Minimum rearm time Setup

time

Hold time

width

Logic Qualified Window 50 ps

Inside

75 ps rearm outside

window

70 ps 30 ps

window

0 ps

transition

through

window

50 ps

Outside

75 ps rearm inside

window

window

Runt 40 ps 50 ps n/a n/a

Time Qualified Runt 40 ps 50 ps for time < 5 ns,

n/a n/a

75 ps above 5 ns.

Logic-Qualified Runt 40 ps 50 ps 15 ps 85 ps

Transition

4

0 ps.

Triggers

50 ps for time < 5 ns,

75 ps above 5 ns.

n/a n/a

with equal

threshold

settings

Logic-Qualified Transition 0 ps.

Triggers

50 ps for time < 5 ns,

75 ps above 5 ns.

0 ps 100 ps

with equal

threshold

settings

Pattern 150 ps 200 ps N.A. N.A.

Time qualified pattern 150 ps 300 ps N.A. N.A.

State 1.7 GHz

5

N.A. 25 ps 100 ps

Setup and hold times refer to the amount of time before and after a triggering "event" that the

qualifying signal must be true. In some cases (like Glitch) the "event" is the trailing edge of the

glitch.

Setup/hold violation Clock active

6

Clock inactive

(Hold times ≥ 0) Hold time setting + 550 ps 500 ps

(Hold times < 0) Hold time setting + 1.6 ns 500 ps

4

Rearm time for transition trigger is time below lower threshold and time above upper threshold. Neither rearm time may be violated.

5

Maximum frequency for clock signal in state trigger type

6

Clock Active time refers to the minimum time from active to inactive edge. Clock Inactive refers to the minimum time from inactive to active clock

edge. Active edge is the edge that does the clocking, inactive edge is the other edge. For example, for positive edge clock, clock active time refers to the

positive pulse width and clock inactive refers to the negative pulse width.

DPO70000SX Series 23

Page 36

Specifications Trigger specifications (cont.)

Envelope trigger (typical)

B trigger after events minimum

timing requirements (typical)

B trigger after events, event

counter range

B trigger after time, time delay

range

Variable A-Event trigger holdoff

range

Minimum frequency Maximum frequency

500 MHz 20 GHz

Minimum Burst Time Minimum Gap

< 20 ns < 20 ns

500 MHz - 10 GHz 40% x FS

15 GHz 80% x FS

20 GHz 100% x FS

Minimum pulse width Maximum counting frequency Minimum time between

channels

40 ps 3.5 GHz 1 ns

1 to 2,000,000,000

3.2 ns to 3 Ms

250 ns to 12 s + random holdoff

Lowest frequency for successful

set level to 50% (typical)

Low speed serial trigger

Number of bits 128 bits

Baud rate limits (typical) 10 Mbaud

50 Hz

24 DPO70000SX Series

Page 37

Serial trigger specifications

Specifications

High speed serial trigger number

of bits

Serial interface triggering

standards supported

Serial trigger baud rate limits 600 MBd to 14.1 GBd

Serial trigger decoding types 8b10b, NRZ

160 bits for 8b/10b and generic NRZ data rates between 600 MBd and 14.1 GBd

I2C, CAN, SPI, USB, PCIe, LIN, FlexRay, RS232/422/485/UART, MIL-STD-1553, 10/100BASE-T

Ethernet

Input-output port specifications

Auxiliary trigger input

characteristics and range

Auxiliary output logic polarity and

functionality

Auxiliary output logic levels

50 Ω, ±5 V (DC plus peak AC)

Default output is A trigger low true (a negative edge when the A trigger event occurs). You can also

program the output to A trigger high true, and B trigger low or high true.

V

high V

out

≥2.5 V into 1 MΩ load,

≥1.0 V into 50 Ω load to ground

low (true)

out

≤0.7 V into 1 MΩ load

≤0.25 V into 50 Ω load to ground

Fast Edge output step

amplitude and offset

Fast Edge output step frequency 1 kHz ± 20%

Fast Edge output step rise time

(typical)

Fast Edge output step aberrations

(typical)

Fast Edge output skew between

differential outputs.

Jitter of internal Fast Edge trigger

(typical)

External reference input frequency 10 MHz, 100 MHz, 12.5 GHz

External reference input frequency

variation tolerance (typical)

1200 mV differential into a 100 Ω load with a -300 mV common mode.

30 ps directly into an input channel. To deskew a probe, use a 50 Ω terminator in series with the

deskew fixture to minimize HF aberrations.

≤ ± 1% after the first 500 ns following the square wave transition. To deskew a probe, use a 50 Ω

terminator in series with the deskew fixture to minimize HF aberrations.

<0.8 ps skew between Positive and Negative Fast Edge Outputs.

2 ps rms

The instrument scans for either 10 MHz or 100 MHz. 12.5 GHz supported on separate SMA input.

Low (stable) jitter mode: ± 15 ppm

High (tracking) mode: ± 1%

DPO70000SX Series 25

Page 38

Specifications Input-output port specifications (cont.)

Run SPC whenever the external reference is more than 0.1% (1000 ppm) different from the

nominal reference frequency or the reference at which SPC was last run.

External reference input sensitivity

≥ 200 mV

(-10.0 dBm)

p-p

(typical)

External reference input voltage,

2.8 V

(+13 dBm)

p-p

maximum

External reference input

Rin = 50 Ω

impedance (typical)

12.5 GHz Clock In 1.3 V

B, C, D 12.5 GHz Clock Out

1.3 V

(6 dBm)

p-p

(6 dBm)

p-p

(UltraSync)

Timebase reference output

10 MHz and 12.5 GHz outputs

frequency

Internal reference output voltage

(typical)

10 MHz Vout pk-pk > 800 mV peak-peak into 50 Ω

> 1.6 V peak-peak into 1 MΩ (internally AC coupled).

Input and output ports

DVI-D Video port A female Digital Visual Interface (DVI-D) compatible port

VGA port A female Video Graphics Array (VGA) compatible port

DisplayPort Two connectors (primary, secondary) provide digital display interfaces

PCIe PCIe ports to configure multi-instrument systems

Trigger UltraSync trigger bus

Keyboard and Mouse ports PS-2 compatible, instrument must be powered down to make connection

LAN ports Two RJ-45 connectors (LAN1, LAN2), support 10BASE-T, 100BASE-TX, and Gigabit Ethernet

External audio ports External audio jacks for microphone input and line output

USB ports Four front panel USB 2.0 connectors

Four rear panel USB 3.0/USB 2.0 connectors

One rear panel USB device connector

USB 3.0 Device Port 5 GBit/sec Rx and Tx (USB Super Speed native)

480 Mbit/sec (High Speed compatible)

12 Mbit/sec (Full Speed compatible)

PCIe Device Port PCI Express x4 Gen 2

5 Gbits/s per lane, 4 lanes Rx, 4 lanes Tx per port

20 Gbits/s upstream, 20 Gbits/s downstream per port

26 DPO70000SX Series

Page 39

Input-output port specifications (cont.) Specifications

40 Gbits/s aggregate per port

UltraSync

Input/Output ports UltraSync Trigger, Data, Clock Input, and Clock Output Ports

Maximum number of

UltraSync connected

Instruments

Cable length 1 Meter or 2 Meters

Number of clock outputs 3 SMA clock output ports to extensions (ports B,C,D)

Number of clock inputs 1 SMA clock input port from master (port A)

Number of data ports 3 bidirectional PCIe Express data communication ports (ports B,C,D). Port D is referred to as Port

Data port bandwidth PCI Express x4 Gen2. 20 Gbits/s upstream, 20 Gbits/s downstream per port. 5 Gbits/s per lane,

Number of trigger connection

ports

Crosstalk (channel isolation) Channel isolation between any 2 channels in an Ultrasync configuration that do not reside within

4 synchronized Instruments

3 extensions per master

A when the instrument is operating as an extension and Port D when the instrument is operating as

the master. iPASS Mini-SAS x4 Connector.

4 lanes Rx, 4 lanes Tx per port. 40 Gbits/s aggregate per port.

3 bidirectional acquisition control and trigger synchronization ports (ports B,C,D). Port D is referred

to as Port A when the instrument is operating as an extension and Port D when the instrument is

operating as the master.

the same chassis.

Input frequency range (stay within BW of

instrument)

0-70 GHz 70 dB

Isolation

DPO70000SX Series 27

Page 40

Specifications

Data storage specifications

Nonvolatile memory retention time

(typical)

Solid state drive Waveforms and setups are stored on the solid state drive.

>20 years

Solid state drive is a ≥900 GB solid state drive (removable).

Power source specification

Power consumption

<980 W, single instrument, maximum

≤780 W, single unit (typical)

Source voltage and frequency 100 V to 240 V

115 V ±10%, 400 Hz

CAT II

, 50/60 Hz

RMS

28 DPO70000SX Series

Page 41

Specifications

Mechanical specifications

Weight

DPO70000SX models 19 kg (42 lbs) oscilloscope only

Dimensions

DPO70000SX models

157 mm (6.0 in) height

452 mm (17.8 in) width

553 mm (21.8 in) depth

DPO70000SX models,

Rackmount configuration

Cooling

Required clearances

Construction material Chassis parts are constructed of aluminum alloy, front panel is constructed of plastic laminate,

177 mm (7.0 in) height

440 mm (19.75 in) width

523 mm (20.6 in) depth (from rack mounting ear to back of instrument)

Fan-forced air circulation with no air filter

Top 0 mm (0 in)

Bottom 6.35 mm (0.25 in) minimum or 0 mm (0 in) when

standing on feet, flip stands down

Left side 76 mm (3 in)

Right side 76 mm (3 in)

Rear 0 mm (0 in) on rear feet

circuit boards are constructed of glass laminate

DPO70000SX Series 29

Page 42

Specifications

Environmental specifications

Temperature

Operating +5 °C to +45 °C (41 °F to +113 °F), with 11 °C per hour maximum gradient, noncondensing,

derated 1 °C per 300 meters (984.25 feet) above 1500 meters (4921.25 feet) altitude

Nonoperating -20 °C to +60 °C (-4 °F to +140 °F), with 20 °C/hour maximum gradient

Humidity

Operating 8% to 80% relative humidity at up to +32 °C (+90 °F)

5% to 45% relative humidity above +32 °C (+90 °F) up to +45 °C (+113 °F), noncondensing, and is

limited by a maximum wet-bulb temperature of +29.4 °C (+85 °F) (derates relative humidity to 32%

at +45 °C (+113 °F)

Nonoperating 5% to 95% relative humidity at up to +30 °C (+86 °F),

5% to 45% relative humidity above +30 °C (+86 °F), up to +60 °C (+140 °F), noncondensing, and

is limited by a maximum wet-bulb temperature of +29.4 °C (+85 °F) (derates relative humidity to

11% at +60 °C (+140 °F))

Altitude

Operating Up to 3,000 meters (9,843 feet), derate maximum operating temperature by 1 °C per 300 meters

(984.25 feet) above 1500 meters (4921.25 feet) altitude

Nonoperating Up to 12,000 meters (39,370 feet)

30 DPO70000SX Series

Page 43

Performance verification

Performance verification

Two types of Performance Verification procedures can be performed on these

products: Brief Procedures and Performance Tests. You may not need to perform

all of these procedures, depending on what you want to accomplish.

If you are not familiar with operating this instrument, read the instrument user

manual or explore the online help.

■

To rapidly confirm that the instrument functions and was adjusted properly,

perform only the brief procedures under Self Tests.

Advantages. These procedures are quick to do, require no external equipment

or signal sources, and perform extensive functional and accuracy testing to

provide high confidence that the instrument will perform properly. They can

be used as a quick check before making a series of important measurements.

■

To further check functionality, first do the Self Tests just mentioned; then do

the brief procedures under Functional Tests.

Advantages. These procedures require minimal additional time to perform,

require no additional equipment other than cables and adapters, and these

procedures more completely test the internal hardware of the instrument.

They can be used to quickly determine if the instrument is suitable for putting

into service, such as when it is first received.

■

If more extensive confirmation of performance is desired, perform the

Performance Tests after performing the Functional and SelfTests mentioned

above. Performance tests on page 42

Advantages. These procedures add direct checking of the warranted

specifications that are marked with the symbol. These procedures require

specific test equipment. Equipment required on page 43

DPO70000SX Series 31

Page 44

Performance verification

Conventions

Throughout these procedures the following conventions apply:

■

Each test procedure uses the following general format:

■

Title of Test

■

Equipment Required

■

Prerequisites

■

Procedure

■

Each procedure consists of as many steps, substeps, and subparts as required

to do the test. Steps, substeps, and subparts are sequenced as follows:

1. First Step

a. First Substep

■

First Subpart

■

Second Subpart

b. Second Substep

2. Second Step

■

In steps and substeps, the lead-in statement in italics instructs you what to do,

while the instructions that follow tell you how to do it, as in the example step

below:

Initialize the instrument: Pull down the File menu, select Recall Default

Setup.

32 DPO70000SX Series

Page 45

Performance verification

STOP. The STOP notation at the left is accompanied by information you must

read to do the procedure properly.

■

The term "toolbar" refers to a row of buttons at the top of the display. The

term "menu bar" refers to a row of menus at the top of the display. You can

switch between toolbar and menu bar operating modes by using the menu at

the top right of the toolbar or menu bar. (See Figure 1: Toolbar and menu

bar on page 33.)

■

Item numbers in the equipment required lists refer to the equipment. (See

Equipment required on page 43.)

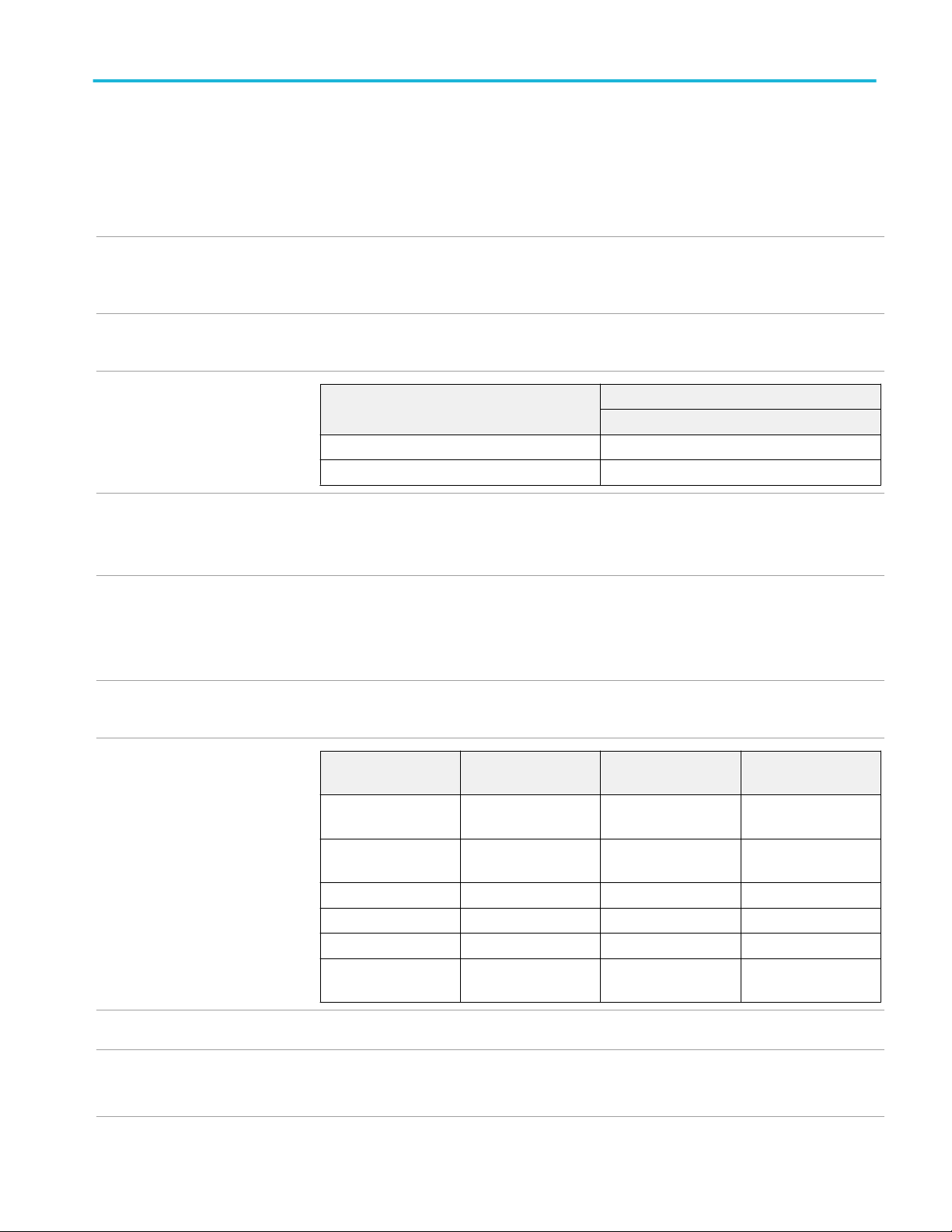

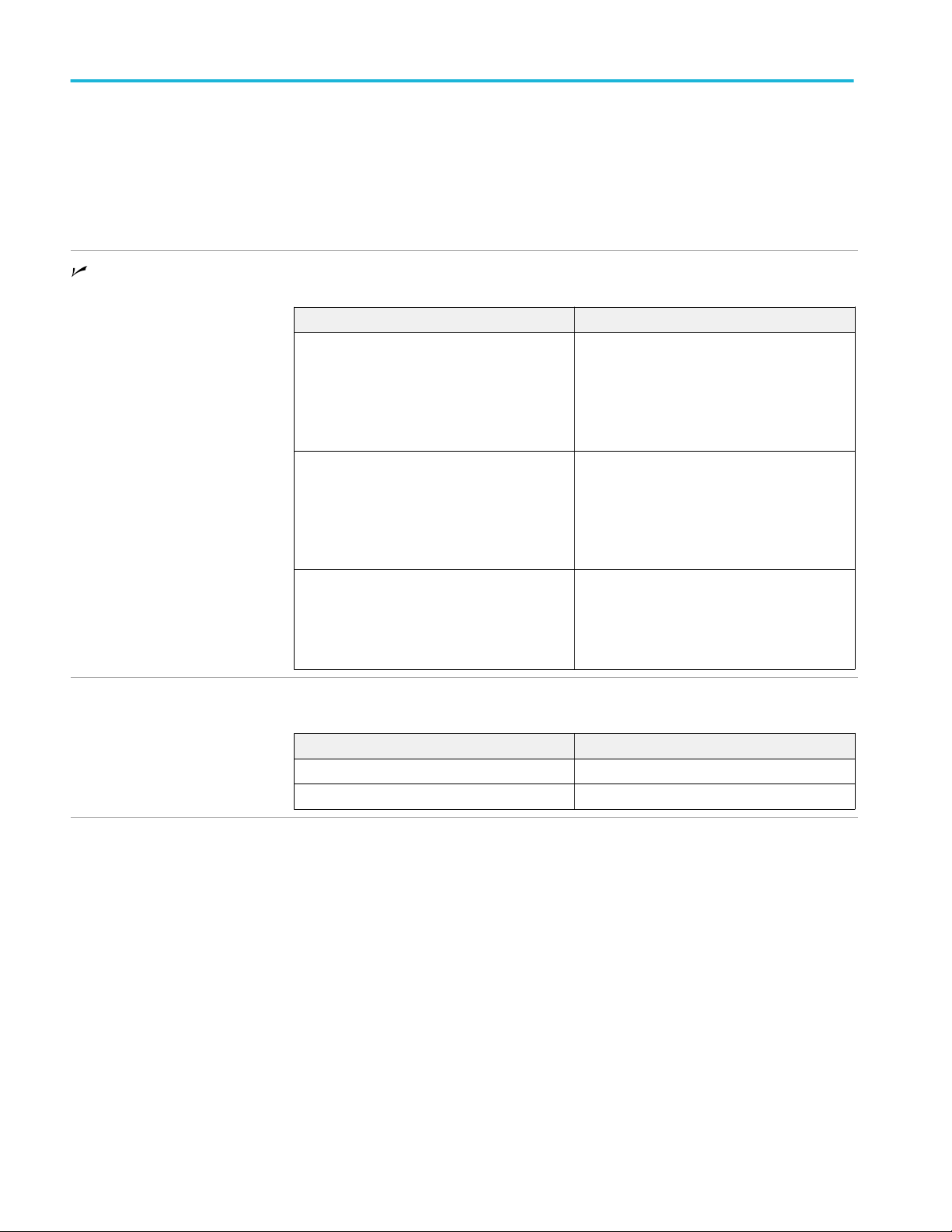

Figure 1: Toolbar and menu bar

■

The procedures assume you have connected a mouse to the instrument so you

can click on the screen controls. If you have not connected a mouse, you can

use the touch screen to operate the screen controls.

DPO70000SX Series 33

Page 46

Performance verification

Brief procedures

Self tests

The Self Tests use internal routines to confirm basic functionality and proper

adjustment. No test equipment is required to do these test procedures.

The Functional Tests utilize the probe-compensation output at the front panel as a

test-signal source for further verifying that the instrument functions properly. A

BNC cable and an adaptor or a probe, depending on your instrument model are

required to do these test procedures.

This procedure uses internal routines to verify that the instrument functions and

was adjusted properly. No test equipment or hookups are required.

Equipment required Prerequisites

None Power on the instrument and allow a 20 minute

warm-up before doing this procedure.

1. Verify that internal diagnostics pass: Do the following substeps to verify

passing of internal diagnostics.

a. Display the System diagnostics menu:

If the instrument is in toolbar mode, put the instrument into menu bar

mode.

Pull down the Utilities menu and select Instrument Diagnostics. . . .

This displays the diagnostics control window.

b. Run the System Diagnostics:

■

First disconnect any input signals from all channels.

■

Click the Run button in the diagnostics control window.

c. Wait: The internal diagnostics do an exhaustive verification of proper

instrument function. This verification may take several minutes. When

the verification is finished, the resulting status will appear in the

diagnostics control window.

d. Verify that no failures are found and reported on-screen. All tests should

pass.

e. Run the signal-path compensation routine:

Pull down the Utilities menu and select Instrument Calibration. . . .

This displays the instrument calibration control window.

If required because the instrument is in service mode, select the Signal

Path button under Calibration Area.

Click the Run SPC button to start the routine.

34 DPO70000SX Series

Page 47

Performance verification

f. Wait: Signal-path compensation may take five to fifteen minutes to run.

g. Confirm signal-path compensation returns passed status: Verify that the

word Pass appears in the instrument calibration control window.

2. Return to regular service: Click the X (close) button to exit the instrument

calibration control window.

Functional tests

The purpose of these procedures is to confirm that the instrument functions

properly. The only equipment required is a BNC or SMA cable and an adapter or

the instrument probe. If you need to store settings during these procedures, access

the local C: drive and store them in the TekScope > Setups directory.

STOP. These procedures verify functions; that is, they verify that the instrument

features operate. They do not verify that they operate within limits.

Therefore, when the instructions in the functional tests that follow call for you to

verify that a signal appears on-screen "that is about five divisions in amplitude"

or "has a period of about six horizontal divisions," etc., do NOT interpret the

quantities given as limits. Operation within limits is checked in Performance

Tests. (See Performance tests on page 42.)

STOP. DO NOT make changes to the front-panel settings that are not called out

in the procedures. Each verification procedure will require you to set the

instrument to certain default settings before verifying functions. If you make

changes to these settings, other than those called out in the procedure, you may

obtain invalid results. In this case, just redo the procedure from step 1.

When you are instructed to press a front-panel or screen button, the button may

already be selected (its label will be highlighted). If this is the case, it is not

necessary to press the button.

DPO70000SX Series 35

Page 48

Performance verification

Verify all analog input channels

Equipment required Prerequisites

One SMA cable (item 19)

One adapter (item 18)

One termination (item 4)

one attenuator (item 3)

1. Initialize the instrument: Pull down the File menu, select Recall Default

Setup.

2. Hook up the signal source: Connect the equipment as shown in the following

figure to the channel input you want to test (beginning with Ch 1). Terminate

the unused Fast Edge output.

None

Figure 2: Universal test hookup for functional tests - Ch 1 shown

3. Turn off all channels:

Pull down the Vertical menu, select Vertical Setup. Select each Channel tab

and verify that the Display is off.

4. Select the channel to test: Press the Display button for the channel you are

currently testing. The channel display comes on.

5. Set up the instrument:

NOTE. If the AutoSet Undo window appears, click the X.

■

Pull down the Horiz/Acq menu, select Autoset. This sets the horizontal

and vertical scale and vertical offset for a usable display and sets the

trigger source to the channel you are testing.

■

Pull down the Vertical menu, select Vertical Setup. Confirm that the

Ch1 Offset is about -300 mV.

6. Verify that the channel is operational: Confirm that the following statements

are true.

■

Verify that the vertical scale readout and the waveform amplitude for the

channel under test. (See Table 3: Vertical settings on page 37.)

36 DPO70000SX Series

Page 49

Performance verification

Table 3: Vertical settings

Setting Without probe ATI input with attenuator

Scale 100 mV 30 mV

Waveform amplitude about 4.5 to 6.5 divisions about 6 divisions

■

The vertical Position control (for the channel you are testing) moves

the signal up and down the screen.

■

Increasing the vertical Scale (for the channel you are testing)

decreases the amplitude of the waveform on-screen, decreasing the