Tektronix DPO70000SX Series, DPO77002SX, DPO75002SX, DPO73304SX, DPO72304SX User Manual

...

DPO70000SX Series

Oscilloscopes

User

*P071335707*

071-3357-07

DPO70000SX Series

Oscilloscopes

User

Warning

The servicing instructions are for use by qualified personnel only. To avoid

personal injury, do not perform any servicing unless you are qualified to do

so. Refer to all safety summaries prior to performing service.

Supports DPO70000SX Series Product Firmware V10.0 and above

www.tek.com

071-3357-07

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or suppliers, and are

protected by national copyright laws and international treaty provisions. Tektronix products are covered by U.S. and foreign patents, issued

and pending. Information in this publication supersedes that in all previously published material. Specifications and price change privileges

reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

TekScope, TekConnect, and FastAcq are registered trademarks of Tektronix, Inc.

FastFrame, OpenChoice, MyScope, MultiView Zoom, SignalVu, TekExpress, TriMode, TekSecure, TekProbe, TekVPI, TekVISA,

UltraSync, and PinPoint are trademarks of Tektronix.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

■

In North America, call 1-800-833-9200.

■

Worldwide, visit www.tek.com to find contacts in your area.

Table of Contents

Important safety information ............................................................................................................................... vii

General safety summary ............................................................................................................................... vii

Service safety summary ................................................................................................................................ ix

Terms in the manual ...................................................................................................................................... ix

Terms on the product .................................................................................................................................... ix

Symbols on the product ................................................................................................................................. ix

Compliance Information ...................................................................................................................................... xi

EMC compliance ........................................................................................................................................... xi

Safety compliance ........................................................................................................................................ xii

Environmental compliance ........................................................................................................................... xiii

Preface ............................................................................................................................................................... xv

Install your instrument

Standard accessories ..................................................................................................................................... 1

Operating requirements ................................................................................................................................. 2

Power supply requirements ............................................................................................................................ 3

Preventing instrument damage ...................................................................................................................... 3

Preventing ESD ........................................................................................................................................ 3

Observe maximum input voltage .............................................................................................................. 5

Selecting the proper attenuator ................................................................................................................ 5

Connector cleaning .................................................................................................................................. 5

Proper connection technique .................................................................................................................... 6

Power on the instrument ................................................................................................................................ 9

Power off the instrument .............................................................................................................................. 10

Multi-instrument configuration ...................................................................................................................... 10

Instrument stacking ................................................................................................................................ 10

Before startup ......................................................................................................................................... 13

UltraSync™ bus cable ............................................................................................................................ 13

UltraSync™ bus cable connection order ................................................................................................ 13

Master and extension connection order ................................................................................................. 15

Multi-instrument power on ...................................................................................................................... 16

Switching between multi-instrument modes ........................................................................................... 20

ATI versus TekConnect channels .......................................................................................................... 21

Multi-instrument status displays ............................................................................................................. 22

Available features ................................................................................................................................... 22

DPO7AFP Auxiliary Front Panel (optional) .................................................................................................. 23

DPO70000SX Series User

i

Table of Contents

Inspect the instrument .................................................................................................................................. 23

Verify internal diagnostics pass .............................................................................................................. 23

Activating Windows 10 ........................................................................................................................... 24

Windows interface guidelines ................................................................................................................. 25

Signal path compensation ............................................................................................................................ 26

Connecting to a network .............................................................................................................................. 29

Adding a second monitor ............................................................................................................................. 30

Activating Windows 10 ................................................................................................................................. 30

Restoring instrument operating system and product software ..................................................................... 31

Operating system restore ............................................................................................................................. 31

Internal recovery utility ................................................................................................................................. 31

Product software installation ........................................................................................................................ 32

Getting acquainted with your instrument

Front-panel connectors ................................................................................................................................ 33

Rear-panel connectors ................................................................................................................................. 35

Interface and display .................................................................................................................................... 36

Control panel ................................................................................................................................................ 38

Accessing online help .................................................................................................................................. 39

Accessing menus and control windows ....................................................................................................... 40

Inspect your instrument

Verify internal diagnostics pass .................................................................................................................... 41

Acquisition

Signal path compensation ............................................................................................................................ 43

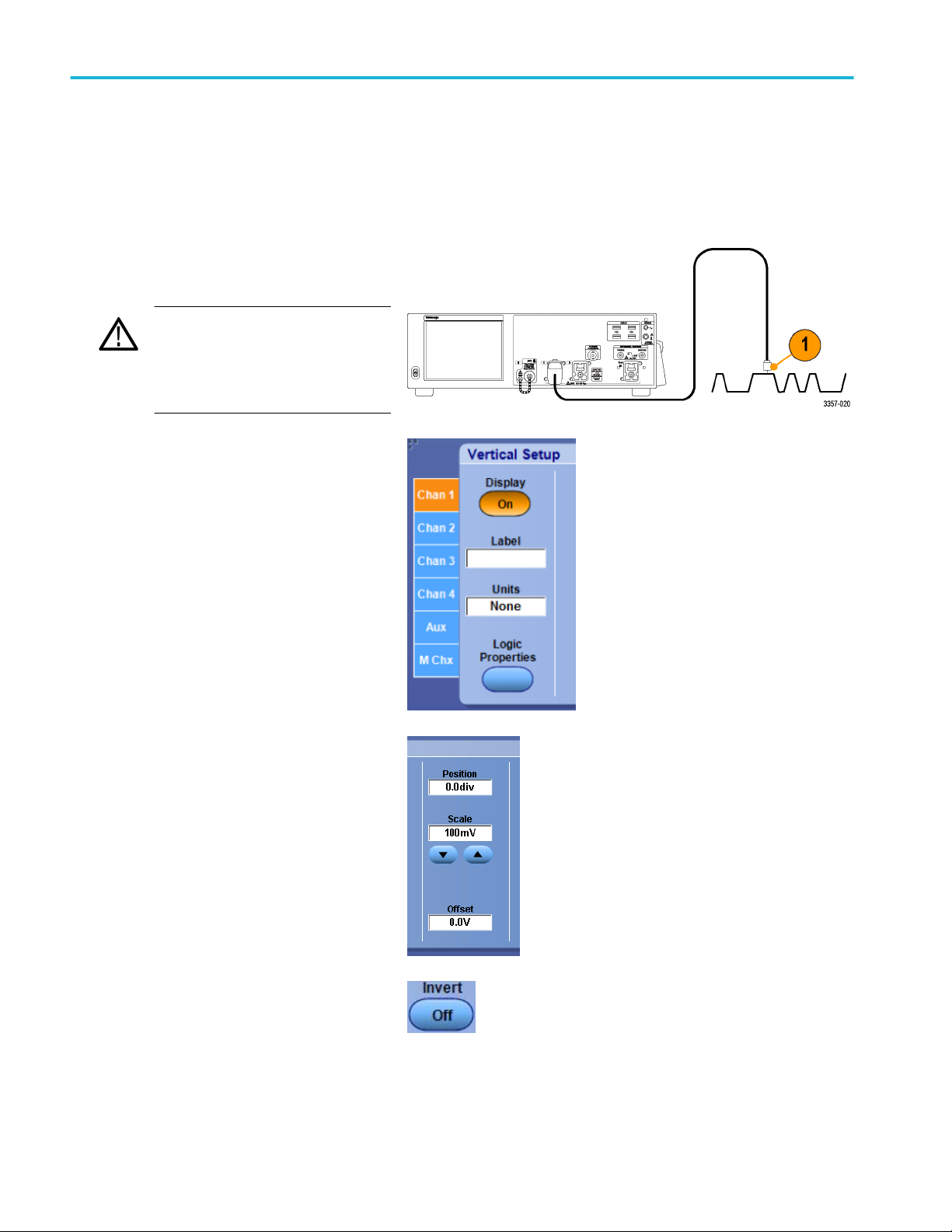

Setting up analog signal input ...................................................................................................................... 46

Using default setup ...................................................................................................................................... 48

Using autoset ............................................................................................................................................... 49

Probe compensation and deskew ................................................................................................................ 50

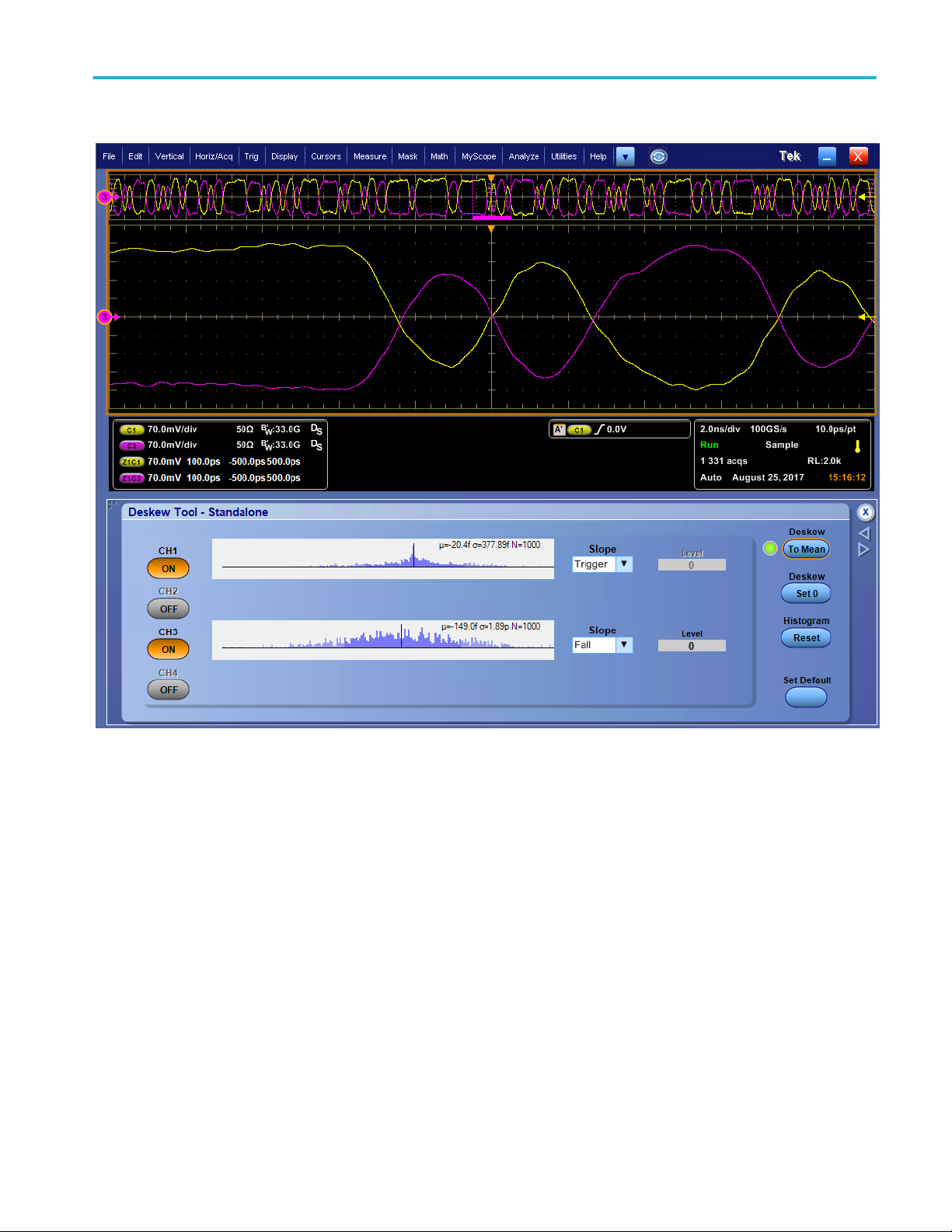

Deskew Tool ................................................................................................................................................ 50

Acquisition concepts .................................................................................................................................... 55

Acquisition hardware .............................................................................................................................. 55

Sampling process ................................................................................................................................... 56

Real-Time sampling ............................................................................................................................... 56

Interpolated Real-Time sampling ........................................................................................................... 56

Equivalent-Time sampling ...................................................................................................................... 56

Waveform record .................................................................................................................................... 57

ii DPO70000SX Series User

Table of Contents

Interpolation ............................................................................................................................................ 57

How the acquisition modes work ............................................................................................................ 57

Enable enhanced effective number of bits ................................................................................................... 58

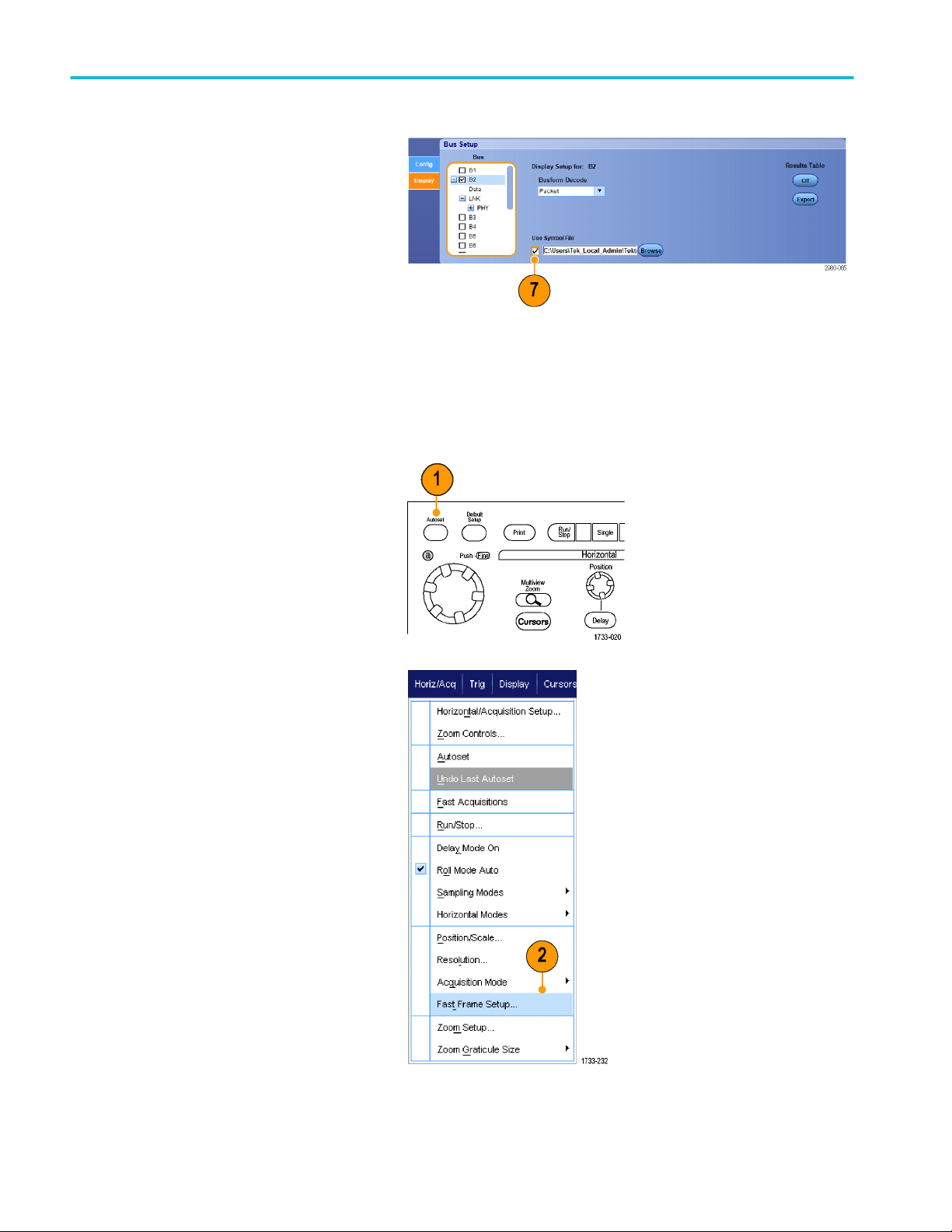

Changing the acquisition mode .................................................................................................................... 59

Starting and stopping an acquisition ............................................................................................................ 60

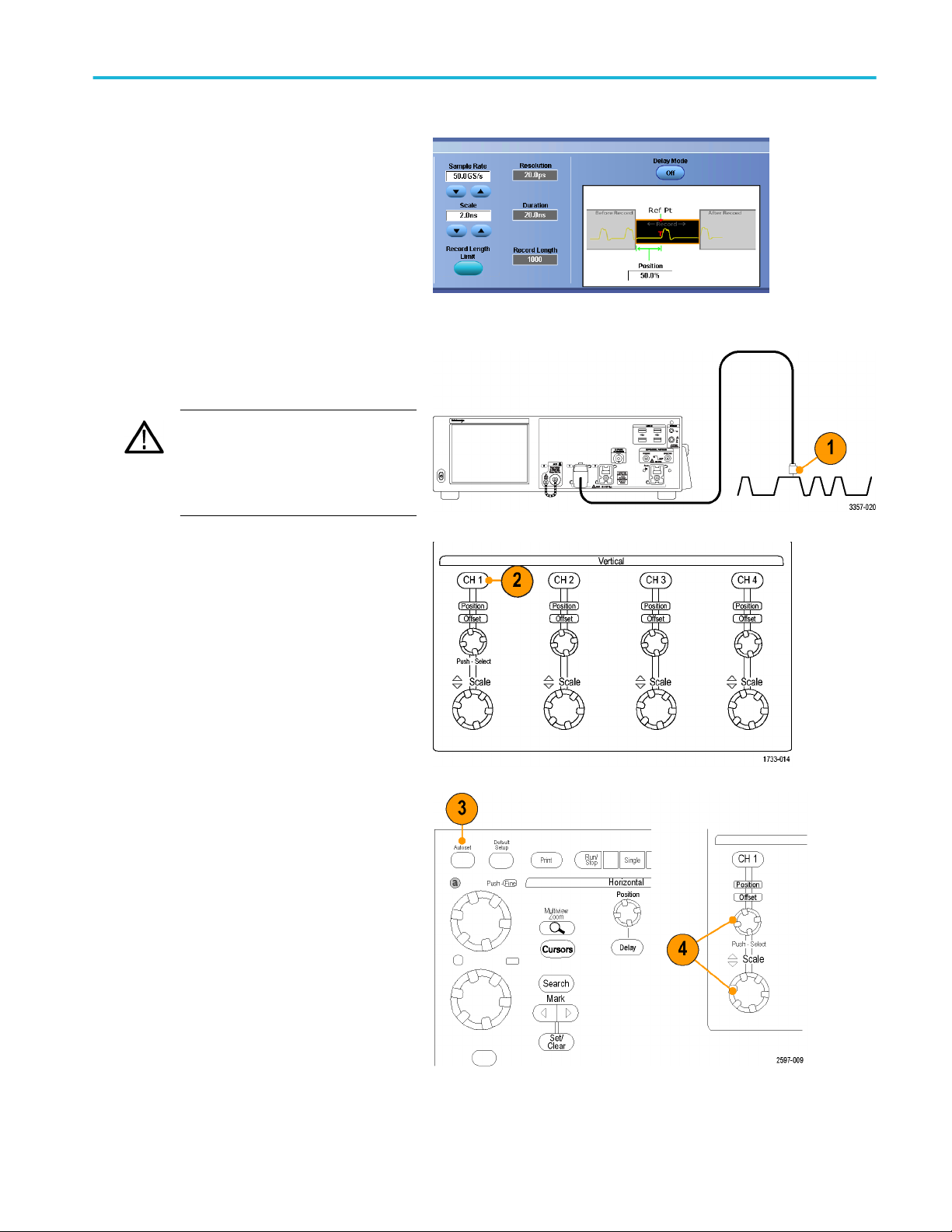

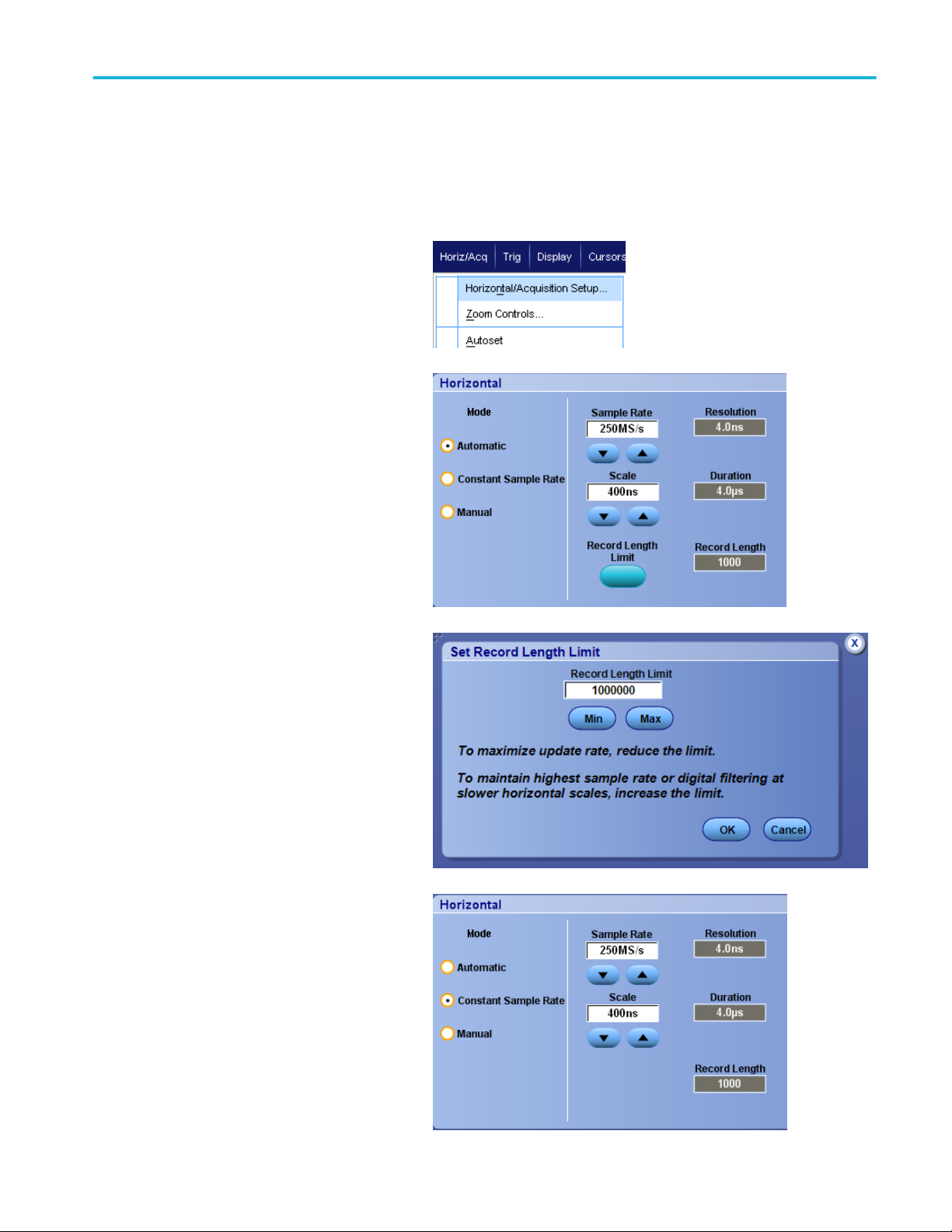

Selecting the horizontal mode ...................................................................................................................... 61

Using FastAcq .............................................................................................................................................. 63

Using DSP enhanced bandwidth ................................................................................................................. 64

Setting the termination voltage ..................................................................................................................... 66

Using roll mode ............................................................................................................................................ 67

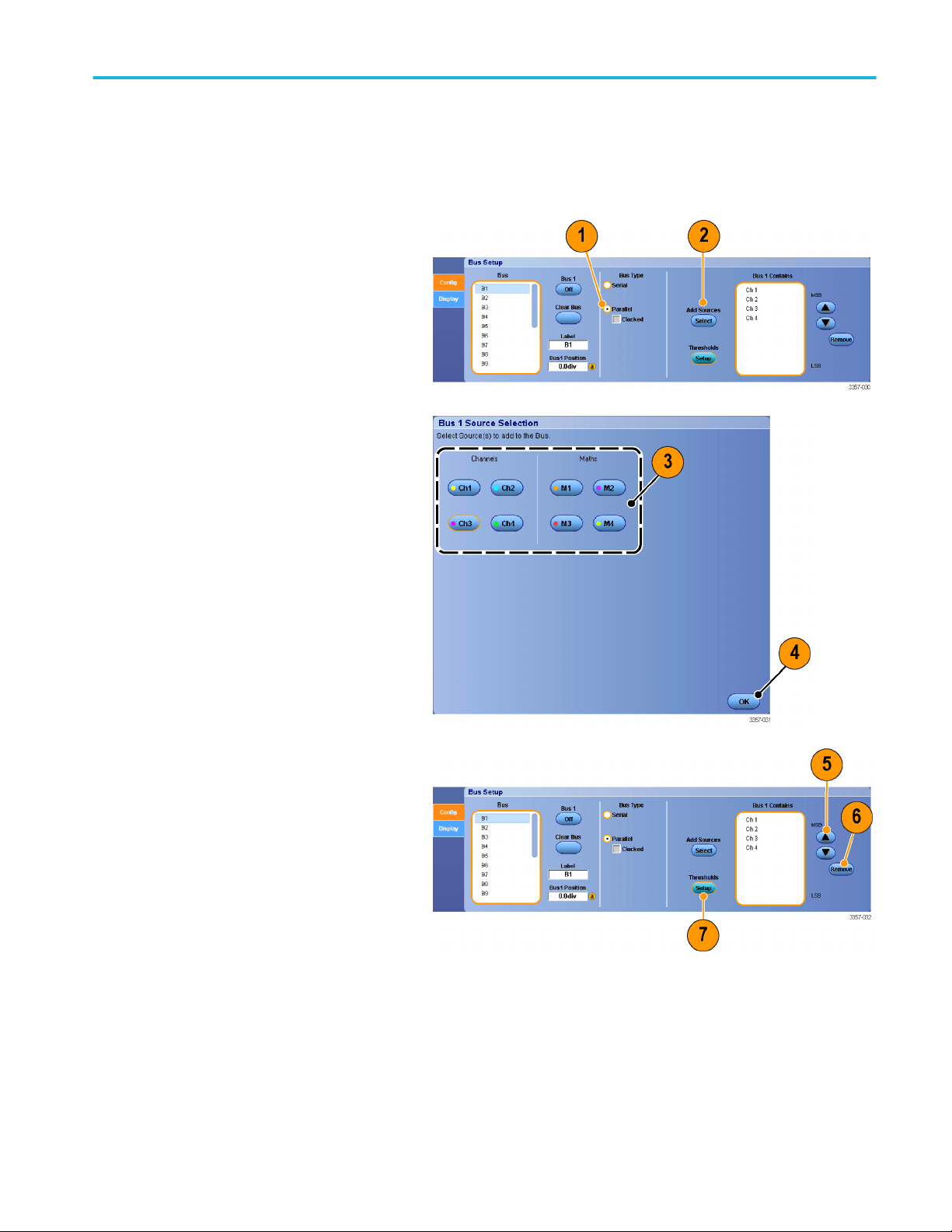

Setting up a bus ........................................................................................................................................... 68

Set up a serial bus ....................................................................................................................................... 70

Set up a parallel bus .................................................................................................................................... 71

Set up bus display ........................................................................................................................................ 73

Using FastFrame mode ................................................................................................................................ 74

Using FastFrame frame finder ..................................................................................................................... 76

Pinpoint triggers

Triggering concepts ...................................................................................................................................... 79

Trigger event .......................................................................................................................................... 79

Trigger modes ........................................................................................................................................ 79

Trigger holdoff ........................................................................................................................................ 79

Trigger coupling ...................................................................................................................................... 80

Horizontal position .................................................................................................................................. 80

Slope and level ....................................................................................................................................... 80

Delayed trigger system ........................................................................................................................... 80

Choosing a trigger type ................................................................................................................................ 81

Trigger selections ......................................................................................................................................... 83

Checking trigger status ................................................................................................................................ 84

Using A (Main) and B (Delayed) triggers ..................................................................................................... 85

Trigger on B event .................................................................................................................................. 86

B trigger after delay time ........................................................................................................................ 86

B triggers after arm on A ........................................................................................................................ 86

Arm-on-A then Trigger-on-B (Horizontal delay on) ................................................................................. 87

Vertical setup control window (M Chx tab) ............................................................................................. 88

Triggering with reset ............................................................................................................................... 89

Correcting trigger position ...................................................................................................................... 90

Triggering with B-Event scan ....................................................................................................................... 91

Triggering on a parallel bus .......................................................................................................................... 94

DPO70000SX Series User iii

Table of Contents

Triggering on a serial bus ............................................................................................................................. 96

Triggering using visual triggers (Visual triggering) ....................................................................................... 98

Setting up action on event .......................................................................................................................... 100

Sending E-Mail on trigger ........................................................................................................................... 101

Setting up E-Mail on event ......................................................................................................................... 102

Using horizontal delay ................................................................................................................................ 104

Display a waveform

Setting the display style ............................................................................................................................. 105

Setting the display persistence .................................................................................................................. 106

Setting the display format ........................................................................................................................... 107

Selecting the waveform interpolation ......................................................................................................... 108

Adding screen text ..................................................................................................................................... 109

Setting the graticule style ........................................................................................................................... 110

Setting the trigger level marker .................................................................................................................. 111

Displaying the date and time ...................................................................................................................... 111

Using the color palettes .............................................................................................................................. 112

Setting reference waveform colors ............................................................................................................. 113

Setting math waveform colors .................................................................................................................... 114

Using MultiView zoom ................................................................................................................................ 115

Zooming in multiple areas .......................................................................................................................... 116

Lock and scroll zoomed waveforms ........................................................................................................... 118

Hide waveforms in the zoomed window ..................................................................................................... 119

Searching and marking waveforms ............................................................................................................ 119

To manually set and clear (delete) marks: ................................................................................................. 120

To automatically set and clear (delete) search marks ................................................................................ 122

Using a visual search ................................................................................................................................. 127

Analyzing waveforms

Taking automatic measurements ............................................................................................................... 129

Automated measurement selections .......................................................................................................... 130

Customizing an automatic measurement ................................................................................................... 133

Gating ................................................................................................................................................... 134

Statistics ............................................................................................................................................... 134

Snapshot .............................................................................................................................................. 135

Annotate measurements ...................................................................................................................... 135

Reference levels ................................................................................................................................... 136

Taking cursor measurements ..................................................................................................................... 138

iv DPO70000SX Series User

Table of Contents

Setting up a histogram ............................................................................................................................... 140

Using math waveforms ............................................................................................................................... 142

Using spectral analysis .............................................................................................................................. 145

Using the error detector ............................................................................................................................. 148

Using mask testing ..................................................................................................................................... 152

Using limit testing ....................................................................................................................................... 155

MyScope

Creating a new MyScope control window .................................................................................................. 157

Using MyScope control windows ............................................................................................................... 161

Saving and recalling information

Saving screen captures .............................................................................................................................. 163

Saving waveforms ...................................................................................................................................... 165

Recalling waveforms .................................................................................................................................. 167

Saving instrument setups ........................................................................................................................... 168

Recalling instrument setups ....................................................................................................................... 169

Saving measurements ............................................................................................................................... 170

Saving user masks ..................................................................................................................................... 171

Saving histogram data ............................................................................................................................... 172

Saving timestamps ..................................................................................................................................... 173

Copying your results to the clipboard ......................................................................................................... 174

Printing a hard copy ................................................................................................................................... 176

Run application software

Application examples

Capturing intermittent anomalies ............................................................................................................... 179

Using the extended desktop and OpenChoice architecture for efficient documentation ............................ 182

Triggering on buses ................................................................................................................................... 184

Specifications

Vertical system analog channels ................................................................................................................ 187

Horizontal and acquisition system .............................................................................................................. 191

Trigger specifications ................................................................................................................................. 192

Input-output port specifications .................................................................................................................. 194

DPO70000SX Series User v

Table of Contents

Power source specification ........................................................................................................................ 194

Mechanical specifications .......................................................................................................................... 195

Environmental specifications ...................................................................................................................... 195

Appendix A, Maintenance

Maintenance ............................................................................................................................................... 197

Cleaning ..................................................................................................................................................... 197

Exterior cleaning ........................................................................................................................................ 197

Adjustment interval ..................................................................................................................................... 198

Adjustment ................................................................................................................................................. 198

Flat panel display cleaning ......................................................................................................................... 198

Returning the instrument for service .......................................................................................................... 199

TekScope recovery report utility ................................................................................................................. 199

Replaceable parts ...................................................................................................................................... 201

Parts ordering information .......................................................................................................................... 202

Appendix B, Version releases

Obtaining the latest advanced analysis application and version releases ................................................. 203

vi DPO70000SX Series User

Important safety information

This manual contains information and warnings that must be followed by the user for safe operation and to keep the product in a

safe condition.

To safely perform service on this product, see the Service safety summary that follows the General safety summary.

General safety summary

Use the product only as specified. Review the following safety precautions to avoid injury and prevent damage to this product or

any products connected to it. Carefully read all instructions. Retain these instructions for future reference.

This product shall be used in accordance with local and national codes.

For correct and safe operation of the product, it is essential that you follow generally accepted safety procedures in addition to

the safety precautions specified in this manual.

The product is designed to be used by trained personnel only.

Only qualified personnel who are aware of the hazards involved should remove the cover for repair, maintenance, or adjustment.

Before use, always check the product with a known source to be sure it is operating correctly.

This product is not intended for detection of hazardous voltages.

Use personal protective equipment to prevent shock and arc blast injury where hazardous live conductors are exposed.

While using this product, you may need to access other parts of a larger system. Read the safety sections of the other

component manuals for warnings and cautions related to operating the system.

When incorporating this equipment into a system, the safety of that system is the responsibility of the assembler of the system.

To avoid fire or personal injury

Use proper power cord. Use only the power cord specified for this product and certified for the country of use. Do not use the

provided power cord for other products.

Ground the product. This product is grounded through the grounding conductor of the power cord. To avoid electric shock, the

grounding conductor must be connected to earth ground. Before making connections to the input or output terminals of the

product, ensure that the product is properly grounded. Do not disable the power cord grounding connection.

Power disconnect. The power cord disconnects the product from the power source. See instructions for the location. Do not

position the equipment so that it is difficult to operate the power cord; it must remain accessible to the user at all times to allow for

quick disconnection if needed.

Connect and disconnect properly. Do not connect or disconnect probes or test leads while they are connected to a voltage

source. Use only insulated voltage probes, test leads, and adapters supplied with the product, or indicated by Tektronix to be

suitable for the product.

Observe all terminal ratings. To avoid fire or shock hazard, observe all rating and markings on the product. Consult the product

manual for further ratings information before making connections to the product.

Do not apply a potential to any terminal, including the common terminal, that exceeds the maximum rating of that terminal.

The measurement terminals on this product are not rated for connection to mains or Category II, III, or IV circuits.

Do not operate without covers. Do not operate this product with covers or panels removed, or with the case open. Hazardous

voltage exposure is possible.

Avoid exposed circuitry. Do not touch exposed connections and components when power is present.

DPO70000SX Series User

vii

Important safety information

Do not operate with suspected failures. If you suspect that there is damage to this product, have it inspected by qualified

service personnel.

Disable the product if it is damaged. Do not use the product if it is damaged or operates incorrectly. If in doubt about safety of the

product, turn it off and disconnect the power cord. Clearly mark the product to prevent its further operation.

Before use, inspect voltage probes, test leads, and accessories for mechanical damage and replace when damaged. Do not use

probes or test leads if they are damaged, if there is exposed metal, or if a wear indicator shows.

Examine the exterior of the product before you use it. Look for cracks or missing pieces.

Use only specified replacement parts.

Do not operate in wet/damp conditions. Be aware that condensation may occur if a unit is moved from a cold to a warm

environment.

Do not operate in an explosive atmosphere.

Keep product surfaces clean and dry. Remove the input signals before you clean the product.

Provide proper ventilation. Refer to the installation instructions in the manual for details on installing the product so it has

proper ventilation.

Slots and openings are provided for ventilation and should never be covered or otherwise obstructed. Do not push objects into

any of the openings.

Provide a safe working environment. Always place the product in a location convenient for viewing the display and indicators.

Avoid improper or prolonged use of keyboards, pointers, and button pads. Improper or prolonged keyboard or pointer use may

result in serious injury.

Be sure your work area meets applicable ergonomic standards. Consult with an ergonomics professional to avoid stress injuries.

Use care when lifting and carrying the product. This product is provided with a handle or handles for lifting and carrying.

WARNING. The product is heavy. To reduce the risk of personal injury or damage to the device get help when lifting or carrying

the product.

Use only the Tektronix rackmount hardware specified for this product.

viii DPO70000SX Series User

Important safety information

Service safety summary

The Service safety summary section contains additional information required to safely perform service on the product. Only

qualified personnel should perform service procedures. Read this Service safety summary and the General safety summary

before performing any service procedures.

To avoid electric shock. Do not touch exposed connections.

Do not service alone. Do not perform internal service or adjustments of this product unless another person capable of rendering

first aid and resuscitation is present.

Disconnect power. To avoid electric shock, switch off the product power and disconnect the power cord from the mains power

before removing any covers or panels, or opening the case for servicing.

Use care when servicing with power on. Dangerous voltages or currents may exist in this product. Disconnect power, remove

battery (if applicable), and disconnect test leads before removing protective panels, soldering, or replacing components.

Verify safety after repair. Always recheck ground continuity and mains dielectric strength after performing a repair.

Terms in the manual

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in damage to this product or other property.

Terms on the product

These terms may appear on the product:

■

DANGER indicates an injury hazard immediately accessible as you read the marking.

■

WARNING indicates an injury hazard not immediately accessible as you read the marking.

■

CAUTION indicates a hazard to property including the product.

Symbols on the product

When this symbol is marked on the product, be sure to consult the manual to find out the nature of the potential

hazards and any actions which have to be taken to avoid them. (This symbol may also be used to refer the user to

ratings in the manual.)

The following symbols may appear on the product:

DPO70000SX Series User ix

Important safety information

x DPO70000SX Series User

Compliance Information

This section lists the EMC (electromagnetic compliance), safety, and environmental standards with which the instrument

complies.

EMC compliance

EC Declaration of Conformity – EMC

Meets intent of Directive 2014/30/EU for Electromagnetic Compatibility. Compliance was demonstrated to the following

specifications as listed in the Official Journal of the European Communities:

EN 61326-1, EN 61326-2-1. EMC requirements for electrical equipment for measurement, control, and laboratory use.

■

CISPR 11. Radiated and conducted emissions, Group 1, Class A

■

IEC 61000-4-2. Electrostatic discharge immunity

■

IEC 61000-4-3. RF electromagnetic field immunity

■

IEC 61000-4-4. Electrical fast transient / burst immunity

■

IEC 61000-4-5. Power line surge immunity

■

IEC 61000-4-6. Conducted RF immunity

■

IEC 61000-4-11. Voltage dips and interruptions immunity

1 2 3

4

5

5

EN 61000-3-2. AC power line harmonic emissions

EN 61000-3-3. Voltage changes, fluctuations, and flicker

Australia / New Zealand Declaration of Conformity – EMC

Complies with the EMC provision of the Radiocommunications Act per the following standard, in accordance with ACMA:

■

EN 61326-1 and EN 61326-2-1. Radiated and conducted emissions, Group 1, Class A.

1

This product is intended for use in nonresidential areas only. Use in residential areas may cause electromagnetic interference.

2

Emissions which exceed the levels required by this standard may occur when this equipment is connected to a test object.

3

If interconnect cables are used, they must be high quality, low-EMI shielded cables.

4

Equipment may not meet the immunity requirements of this standard when test leads and/or test probes are connected due to coupling of electromagnetic interference

onto those leads/probes. To minimize the influence of electromagnetic interference, minimize the loop area between the unshielded portions of signal and associated

return leads, and keep leads as far away as possible from electromagnetic disturbance sources. Twisting unshielded test leads together is an effective way to reduce

loop area. For probes, keep the ground return lead as short as possible and close to the probe body. Some probes have accessory probe tip adapters to accomplish this

most effectively. In all cases, observe all safety instructions for the probes or leads used.

5

The performance criterion for when the oscilloscope is subjected to the continuously present electromagnetic phenomenon: 10 mV/division to 1 V/division: ≤0.4 division

waveform displacement or ≤0.8 division increase in peak–to–peak noise.

DPO70000SX Series User xi

Compliance Information

Safety compliance

This section lists the safety standards with which the product complies and other safety compliance information.

EU declaration of conformity – low voltage

Compliance was demonstrated to the following specification as listed in the Official Journal of the European Union:

Low Voltage Directive 2014/35/EU.

■

EN 61010-1. Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use – Part 1: General

Requirements.

U.S. nationally recognized testing laboratory listing

■

UL 61010-1. Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use – Part 1: General

Requirements.

Canadian certification

■

CAN/CSA-C22.2 No. 61010-1. Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use

– Part 1: General Requirements.

Additional compliances

■

IEC 61010-1. Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use – Part 1:

General Requirements.

Equipment type

Test and measuring equipment.

Safety class

Class 1 – grounded product.

Pollution degree description

A measure of the contaminants that could occur in the environment around and within a product. Typically the internal

environment inside a product is considered to be the same as the external. Products should be used only in the environment for

which they are rated.

■

Pollution Degree 1. No pollution or only dry, nonconductive pollution occurs. Products in this category are generally

encapsulated, hermetically sealed, or located in clean rooms.

■

Pollution Degree 2. Normally only dry, nonconductive pollution occurs. Occasionally a temporary conductivity that is caused

by condensation must be expected. This location is a typical office/home environment. Temporary condensation occurs only

when the product is out of service.

■

Pollution Degree 3. Conductive pollution, or dry, nonconductive pollution that becomes conductive due to condensation.

These are sheltered locations where neither temperature nor humidity is controlled. The area is protected from direct

sunshine, rain, or direct wind.

■

Pollution Degree 4. Pollution that generates persistent conductivity through conductive dust, rain, or snow. Typical outdoor

locations.

xii DPO70000SX Series User

Compliance Information

Pollution degree

Pollution Degree 2 (as defined in IEC 61010-1). Note: Rated for indoor, dry location use only.

IP rating

IP20 (as defined in IEC 60529).

Measurement and overvoltage category descriptions

Measurement terminals on this product may be rated for measuring mains voltages from one or more of the following categories

(see specific ratings marked on the product and in the manual).

■

Measurement Category II. For measurements performed on circuits directly connected to the low-voltage installation.

■

Measurement Category III. For measurements performed in the building installation.

■

Measurement Category IV. For measurements performed at the source of low-voltage installation.

NOTE. Only mains power supply circuits have an overvoltage category rating. Only measurement circuits have a measurement

category rating. Other circuits within the product do not have either rating.

Mains overvoltage category rating

Overvoltage Category II (as defined in IEC 61010-1)

Environmental compliance

This section provides information about the environmental impact of the product.

Product end-of-life handling

Observe the following guidelines when recycling an instrument or component:

Equipment recycling. Production of this equipment required the extraction and use of natural resources. The equipment may

contain substances that could be harmful to the environment or human health if improperly handled at the product’s end of life.

To avoid release of such substances into the environment and to reduce the use of natural resources, we encourage you to

recycle this product in an appropriate system that will ensure that most of the materials are reused or recycled appropriately.

This symbol indicates that this product complies with the applicable European Union requirements according to

Directives 2012/19/EU and 2006/66/EC on waste electrical and electronic equipment (WEEE) and batteries. For

information about recycling options, check the Tektronix Web site (www.tek.com/productrecycling).

Perchlorate materials. This product contains one or more type CR lithium batteries. According to the state of California, CR

lithium batteries are classified as perchlorate materials and require special handling. See www.dtsc.ca.gov/hazardouswaste/

perchlorate for additional information.

DPO70000SX Series User xiii

Compliance Information

xiv DPO70000SX Series User

Preface

This manual describes the installation and basic operation of DPO70000SX series instruments. For additional operating

information, refer to the instrument help on your instrument. The following instruments are supported by this document:

■

DPO77002SX

■

DPO75902SX

■

DPO75002SX

■

DPO73304SX

■

DPO72304SX

■

DPO71604SX

■

DPO71304SX

Key features

DPO70000SX Series instruments can help you verify, debug, and characterize electronic designs. Key features include:

■

70 GHz bandwidth and 200 GS/s on 1 analog channel and 33 GHz bandwidth and 100 GS/s on 2 analog channels,

DPO77002SX

■

59 GHz bandwidth and 200 GS/s on 1 analog channel and 33 GHz bandwidth and 100 GS/s on 2 analog channels,

DPO75902SX

■

50 GHz bandwidth and 200 GS/s on 1 analog channel and 33 GHz bandwidth and 100 GS/s on 2 analog channels,

DPO75002SX

■

33 GHz bandwidth and 100 GS/s on 2 analog channels or 4 channels at 50 GS/s, DPO73304SX

■

23 GHz bandwidth and 100 GS/s on 2 analog channels or 4 channels at 50 GS/s, DPO72304SX

■

16 GHz bandwidth and 100 GS/s on 2 analog channels or 4 channels at 50 GS/s, DPO71604SX

■

13 GHz bandwidth and 100 GS/s on 2 analog channels or 4 channels at 50 GS/s, DPO71304SX

■

Enhanced Bandwidth capability that, when enabled, applies Digital Signal Processing (DSP) filters that can extend the

bandwidth and flatten the passband. Enhanced Bandwidth provides a matched response across enabled channels when

they are at maximum sample rate. You can limit the bandwidth down to 500 MHz to optimize the signal to noise ratio.

Enhanced bandwidth is extended to the probe tip for some high performance probes and tips.

■

Record lengths up to 1,000,000,000 samples, depending on model and option

■

Up to 1.0% DC vertical gain accuracy, depending on model

■

Combine up to 4 instruments using UltraSync™ interface for increased channel count.

■

Display user interface on an optional external monitor

■

Up to 4 analog input channels, depending on model (each with 8-bit resolution when not in Hi-Res mode), auxiliary trigger

input and output

■

Full programmability, with an extensive command set and a message-based interface

■

PinPoint triggering with flexible A and B trigger events

■

Edge trigger >20 GHz, Aux trigger > 10 GHz.

■

Selectable trigger position correction to more accurately place the trigger and reduce jitter

DPO70000SX Series User

xv

Preface

■

Powerful built-in measurement capability, including histograms, automatic measurements, eye pattern measurements and

measurement statistics

■

Mathematically combine waveforms to create waveforms that support your data-analysis task. Use arbitrary filters in math

equations. Use spectral analysis to analyze waveforms in the frequency domain.

■

Ability to control sample rate and record length separately from horizontal scale

■

An intuitive, graphical user interface (UI), with online help that is built in and available on screen

■

Internal, removable disk storage

Documentation

Review the following table to locate more information about this product.

To read about Use these documents

Installation and operation (overviews) User manual.

Operation and user interface Instrument help from the Help menu.

Programmer commands Programmer manual. This manual is available on the Tektronix

Web site (www.tektronix.com/manuals).

Conventions used in this manual

The following icons are used throughout this manual.

Step Front panel

power

Connect power Network PS-2 SVGA USB

xvi DPO70000SX Series User

Install your instrument

Unpack the instrument and check that you received all items listed as Standard Accessories. Recommended accessories,

probes, instrument options, and upgrades are listed in the online help. Check the Tektronix Web site (www.tektronix.com) for the

most current information.

Standard accessories

Accessory Tektronix part number

User manual -- depends on language option 071-3357-xx

Front protective cover , TekConnect instruments

ATI instruments

PCIe Host Port protective plug 200-5344-00

2nd ethernet port plug 200-5389-00

50 Ω term on Fast Edge (2X) 015-1022-01

TCA-292D (5X) (3X on ATI instruments) 090-0044-00

Windows compatible keyboard 119-7275-xx

Windows compatible mouse 119-7054-xx

Static protection wrist strap 006-3415-05

Deskew cable (M2.92 to M2.92) 174-6793-00

Deskew adapter (1.85F to 2.92F), ATI instruments only 103-0483-00

Attenuator 2.92 mm female to 2.92 mm male, 50 Ω,10 DB 011-0221-00

ATI connector saver (1.85mm), ATI instruments only 103-0474-00

ATI protective cap, ATI instruments only 016-2101-00

Torque wrench, ATI instruments only 067-2787-00

Backing wrench, ATI instruments only 003-1942-00

Accessories pouch 016-2045-00

Best Practices manual 071-2989-04

ROHS info 071-2185-04

Calibration certification 001-1179-00

Cal cert envelope 006-8018-01

Power cord – one of the following:

200-5337-00

200-5358-00

DPO70000SX Series User 1

Install your instrument

Accessory Tektronix part number

North America (Option A0) 161-0213-00

Universal Euro (Option A1) 161-0209-00

United Kingdom (Option A2) 161-0210-00

Australia (Option A3) 161-0211-01

Switzerland (Option A5) 161-0212-01

Japan (Option A6) 161-0213-00

China (Option A10) 161-0320-00

India (Option A11) 161-0325-00

Brazil (Option A12) 161-0358-00

No power cord (Option A99)

Operating requirements

WARNING.

To prevent injury and instrument damage, do not operate the instrument while the instrument is resting on its rear feet.

1. Place the instrument on a cart or bench. The instrument should rest on its bottom feet. An optional rack mounting kit is

available. Observe the following clearance requirements and dimensions:

■

Top: 0 in (0 mm)

■

Left side: 3 in (76 mm)

■

Right side: 3 in (76 mm)

■

Rear: 3 in (76 cm) beyond the rear feet to protect any cables connected to the rear panel

■

Bottom: 0 in (0 mm) standing on feet, flip stands down

CAUTION. To ensure proper cooling, keep the bottom and sides of the instrument clear of obstructions.

To ensure proper cooling, if the instruments are stacked on top of each other, the bottom feet must remain on the

instruments.

2. Width: 19.0 inches (483 mm)

3. Height: 6.0 inches (152 mm)

4. Before operating the instrument, verify the ambient temperature: 5 °C to +45 °C (+41 °F to +113 °F)

5. Verify the operating humidity: 8% to 80% relative humidity at up to +32 °C (+90 °F)

5% to 45% relative humidity above +32 °C (+90 °F) up to +45 °C (+113 °F), noncondensing, and is limited by a maximum

wet-bulb temperature of +29.4 °C (+85 °F) (derate relative humidity to 32% at +45 °C (+113 °F))

6. Verify the operating altitude: 3,000 m (9,843 feet), derate maximum operating temperature by 1 °C per 300 meters

(984.25 feet) above 1500 meters (4921.25 feet) altitude.

7. Maximum input voltage:

TekConnect channels: ≤1.2 V/FS settings:

±1.5 V relative to the termination bias (30 mA maximum).

2 DPO70000SX Series User

Install your instrument

±5 V absolute maximum input.

>1.2 V/FS settings: ±8.0 V. Limited by maximum Vterm current and the attenuator power.

ATI Channel: ± 0.75 V

Aux channel: ±5.0 V

pk

pk

Power supply requirements

The power supply requirements for your instrument are listed in the following table.

Source Voltage and Frequency Power Consumption

100 VAC to 240 VAC, 50/60 Hz

or 115 VRMS, 400 Hz.

WARNING.

To reduce the risk of fire and shock, ensure that the mains supply voltage fluctuations do not exceed 10% of the operating

voltage range.

Preventing instrument damage

Preventing ESD

980 W

CAUTION. A direct electrostatic discharge can damage the instrument input. To learn how to avoid this damage, read the

following information.

Electrostatic discharge (ESD) is a concern when handling any electronic equipment. The instrument is designed with robust ESD

protection, however it is still possible that large discharges of static electricity directly into the signal input may damage the

instrument. To avoid damage to the instrument, use the following techniques to prevent electrostatic discharge to the instrument.

1. Discharge the static voltage from your

body by wearing a grounded antistatic

wrist strap while connecting and

disconnecting cables and TekConnect

adapters. The instrument provides a front

panel connection for this purpose.

DPO70000SX Series User 3

Install your instrument

2. A cable that is left unconnected on a

bench, or carried across a room, can

develop a large static charge. Discharge

the static voltage from all cables before

connecting them to the instrument or

device under test by momentarily

grounding the center conductor of the

cable, or by connecting a 50 Ω

termination to one end, before attaching

the cable to the instrument.

CAUTION. Do not use a tool (such as a

screwdriver, wrench end, etc) to short the

center conductor to the ground shell on

the connector, as any sort of scratch or

nick may damage the RF response of the

cable.

4 DPO70000SX Series User

Install your instrument

Observe maximum input voltage

WARNING. Observe all terminal ratings. To avoid damaging the instrument, observe all rating and markings on the product.

Consult the product manual for further ratings information before making connections to the product.

Do not apply a potential to any terminal, including the common terminal, that exceeds the maximum rating of that terminal.

The maximum input voltage for the ATI (Asynchronous Time-Interleaved) input is ±0.75 Vpk. This is the maximum voltage before

damage occurs.

The maximum input voltage for the TekConnect inputs is ±1.5 V relative to the termination bias (30 mA maximum) on ≤ 1.2 V full

scale settings and 8 V on >1.2 V full scale settings.

Selecting the proper attenuator

The ATI input has a maximum voltage range of 300 mVFS. Use of an attenuator can increase the maximum voltage range.

Table 4: Maximum ATI voltage range

Attenuator Maximum ATI voltage range

None 300 mV

3 dB 420 mV

6 dB 600 mV

10 dB 950 mV

16 dB (6 dB + 10 dB attenuators) 1.88 V

20 dB 3 V

FS

FS

FS

FS

FS

FS

Connector cleaning

All connectors must be kept clean. Dirt in connectors can damage the connector and any connectors the dirty connector is used

with. Dirt will also likely impair the RF performance. All cables, attenuators, and adapters should be stored with connector covers

to keep dust out.

Before each use do the following:

DPO70000SX Series User 5

Install your instrument

1. Verify that the connectors are free of dirt,

metal particles, scratches and

deformations.

2. Verify the connectors are the correct size.

WARNING. To avoid eye damage, ware

eye protection when using compressed

air.

3. With the connector pointed down, use low

pressure compressed air, at an angle to

the connector, to clean the connectors.

4. If the connector still needs cleaning, use

an appropriately sized swab moistened

with isopropyl alcohol to clean the

connector threads and mating surfaces.

Do not snag the center conductor.

CAUTION. Never put pressure on the

center pin of the connectors. Applying

pressure to the center pin could damage

the connector.

Proper connection technique

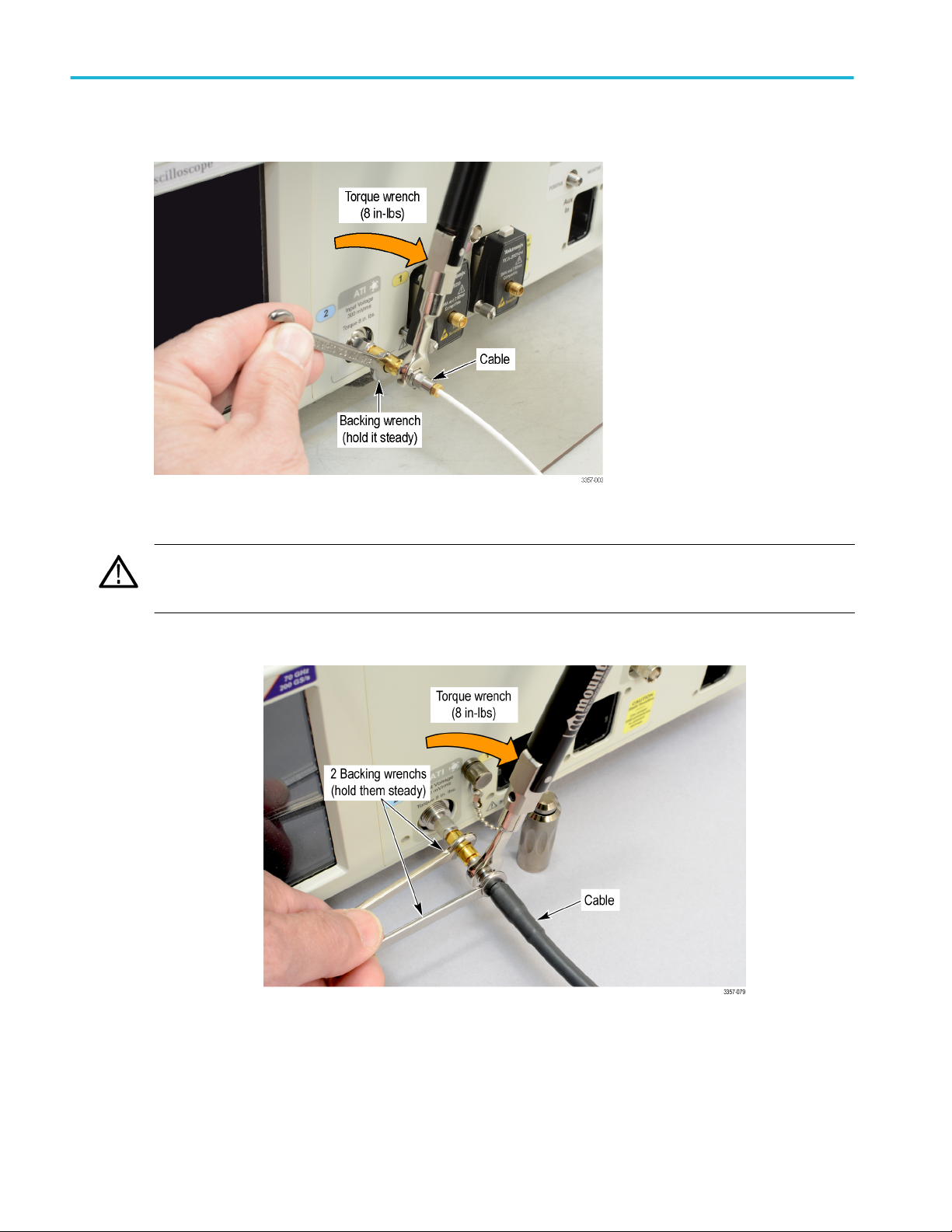

Use 8 inch-pounds of torque when making connections to the ATI 1.85 mm connector, SMA connectors, adapters, DC Blocks, or

cables. Using the improper torque or connection technique may degrade your signals and damage the connectors.

Use the following procedure to make connections to the ATI input:

CAUTION. Failure to use the supplied backing wrench and torque wrench when making connections to the ATI input may

damage your instrument.

6 DPO70000SX Series User

Install your instrument

1. Discharge the static voltage from your body by wearing a grounded antistatic wrist strap while connecting and disconnecting

cables and adapters. The instrument provides a front panel connection for this purpose. Use the ground connection with the

black plastic grommet, as this has a 1 MΩ series isolation resistance, so that there is no chance of shock, but the static

voltage can be discharged.

Figure 1: Wear an antistatic wrist strap

2. Use the supplied connector saver to protect the instrument connector. When not in use, protect against dirt and ESD

damage by installing the end cap. Alternate locations to store the ATI protective cover include the upper right corner of the

front panel and to the right of the audio connectors on the rear panel. When installing the connector saver tighten to 8 inchpounds.

CAUTION. The connector saver can appear to tighten/loosen opposite to expectations because the oscilloscope ATI input

connector is a male connector.

Figure 2: Installing a connector saver

3. Use the backing wrench on the connector saver to prevent damage caused by rotation of the connectors when installing a

connector.

DPO70000SX Series User 7

Install your instrument

4. Use the supplied torque wrench to tighten (8 inch-pounds) your cable connector to the connector saver.

Figure 3: Installing a cable

CAUTION. Failure to prevent rotation of the center conductors when making connections to the ATI input will damage your

instrument. If necessary use a second backing wrench on the cable, to prevent its rotation. Use the supplied torque wrench

to tighten (8 inch-pounds) all connectors.

5. If necessary use a second backing wrench on the cable, to prevent its rotation.

Figure 4: Use a second backing wrench

8 DPO70000SX Series User

Install your instrument

Power on the instrument

1. Connect the AC power cord to the rear of the instrument.

2. Use the front-panel power button to switch the instrument on.

The power button indicates instrument power states:

■

No light – no power applied

■

Green – powered on

DPO70000SX Series User 9

Install your instrument

Power off the instrument

1. Press the front-panel power button to shut down the instrument.

NOTE. If powering off a multi-instrument configuration, power off the master first.

The shutdown process takes approximately 30 seconds to complete, placing the instrument in standby mode. Alternatively,

use the Windows Shutdown menu.

NOTE. You can force an immediate shutdown by pressing and holding the power button for four seconds. Unsaved data is

lost.

2. To completely remove power to the instrument, perform the shutdown just described, and then remove the power cord from

the instrument.

Multi-instrument configuration

Connect instruments in a multi-instrument configuration to create an up to 4 channel, highest bandwidth, and highest sample rate

system with synchronized trigger and sample clock.

Instrument stacking

Multiple instruments may be stacked to save space and allow shorter cables and more convenient connections.

WARNING. When using an instrument upside down, be careful to avoid pinching your fingers.

10 DPO70000SX Series User

Install your instrument

DPO70000SX Series User 11

Install your instrument

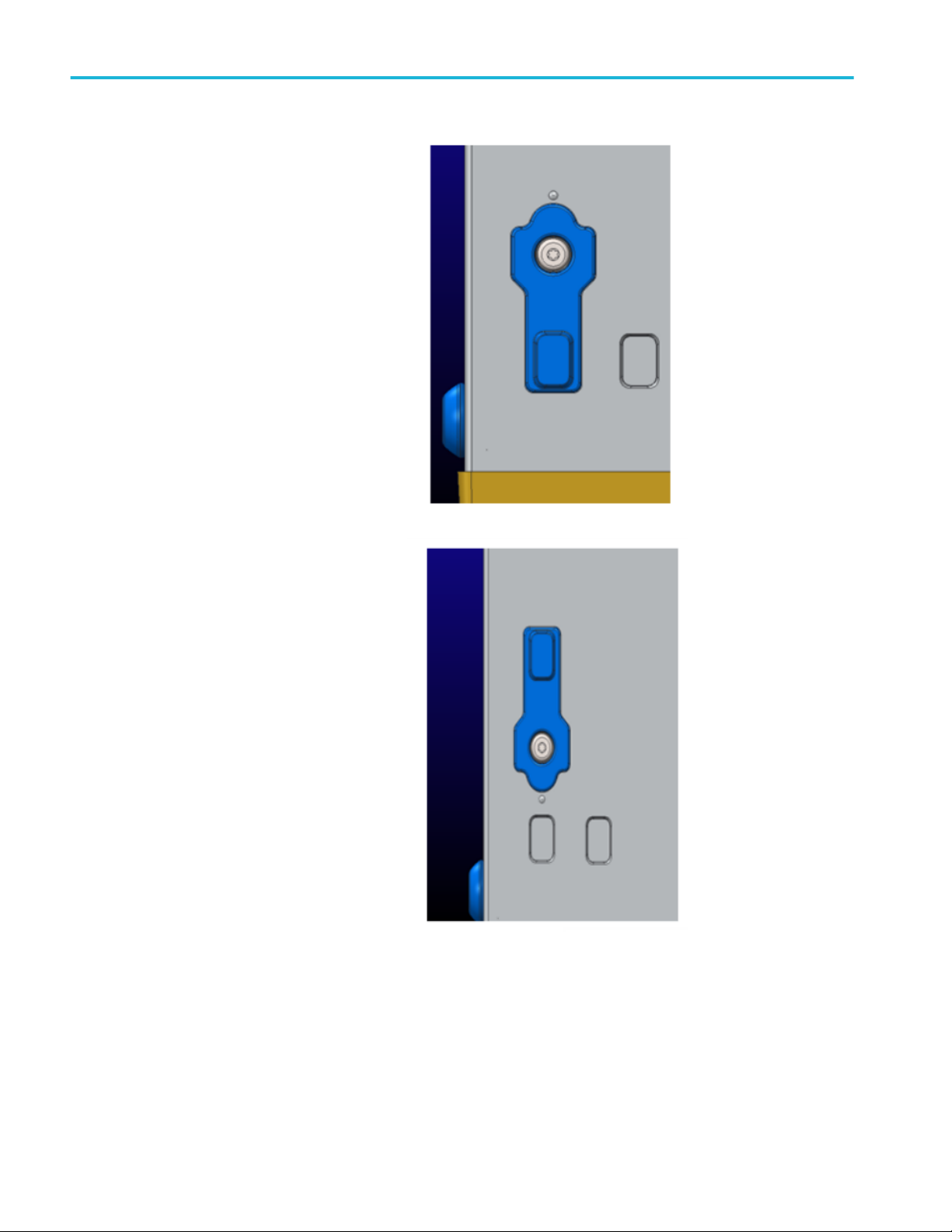

Standard orientation of the top feet is useful

when placing an instrument inverted on the

work bench. Standard orientation of the top

feet is also use when stacking an OM4000 on

the instrument.

Use the rotated orientation of the top feet to

stack two instruments on top of each other.

When stacking two instruments, the bottom feet sit in the holes exposed when the top feet are rotated.

12 DPO70000SX Series User

Install your instrument

Before startup

All instruments in a multi-Instrument configuration must be connected properly before powering on the instruments. If the

configuration is changed after the instruments are powered on, a system restart may be required.

If an instrument is not connected in a multi-instrument configuration, the instrument powers on in its stand alone mode, not multiinstrument mode.

UltraSync™ bus cable

An UltraSync bus cable will connect any multi-instrument configuration capable instrument.

All cables must be connected to the instruments prior to power up. A restart will be required if the instruments are turned on

before the cables are connected.

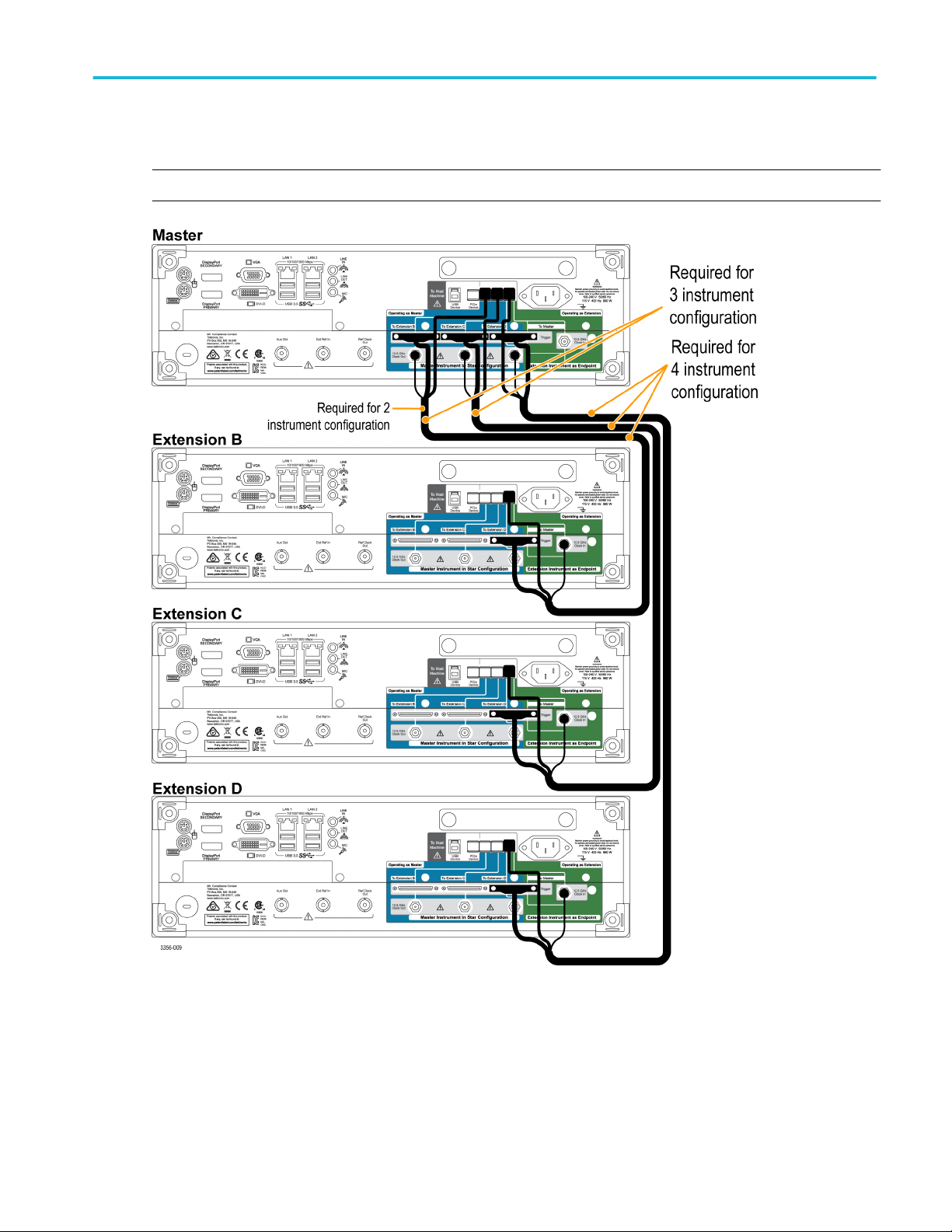

UltraSync™ bus cable connection order

Connect UltraSync bus cable bundles to the Master:

1. Select which instrument will be the Master instrument.

At the Master instrument connect each UltraSync cable bundle set to the designated ports (start with the To Extension B

ports; then if connecting a third instrument use the To Extension C ports, and then if connecting a fourth instrument use the

To Extension D ports):

2. Connect the clock cable to the 12.5 GHz Clock Out connector (8 in-lbs torque).

3. Connect the Trigger cable to the Trigger connector.

4. Connect the PCIe cable to the PCIe connector.

DPO70000SX Series User 13

Install your instrument

Connect UltraSync bus cable bundles to the Extension.

At the Extension, connect each UltraSync cable bundle set to the designated ports:

1. Connect the clock cable to the 12.5 GHz Clock In connector (8 in-lbs torque).

2. Connect the trigger cable to the To Master Trigger connector.

3. Connect the PCIe cable to the PCIe connector

14 DPO70000SX Series User

Install your instrument

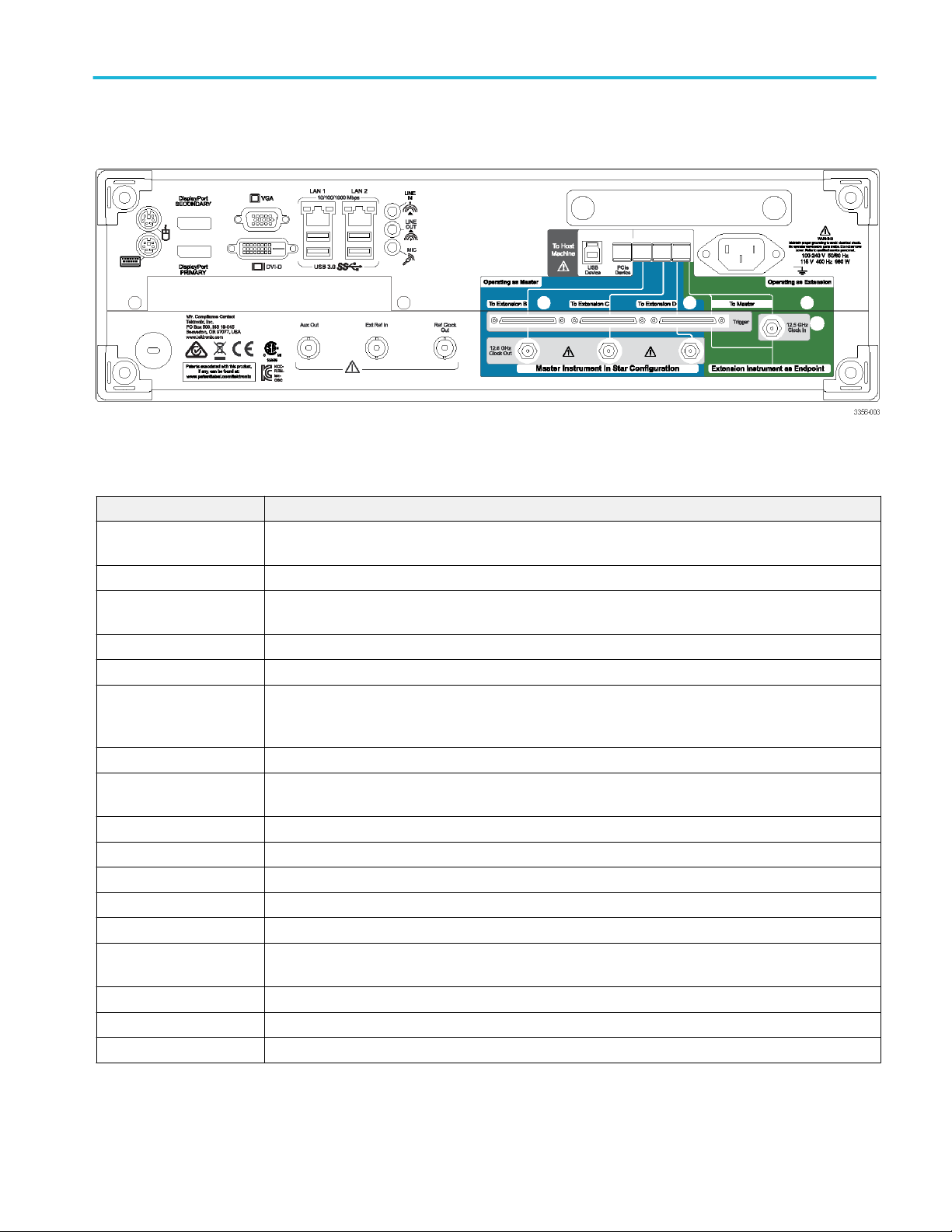

Master and extension connection order

Connect each extension instrument to the master instrument sequentially from left to right (Extension B, C, and then D).

NOTE. Connect the extensions to the master in a star pattern, do not daisy chain the instruments.

If powering off a multi-instrument system, power off the master first.

DPO70000SX Series User 15

Install your instrument

Multi-instrument power on

During the start-up process the instrument checks to see if instruments are connected in a Multi-instrument configuration. If

instruments are not connected, the instrument powers up in stand-alone mode. If instruments are connected, the configuration is

validated. If the configuration is not valid, guidance is provided to help you create a valid configuration.

NOTE. After successful power on of your multi-instrument system, wait for the warm-up time to complete, and then run Signal

Path Compensation.

The following image shows an extension with a connection that is invalid and provides guidance to correct the connection

(provide the missing connection to the master).

The following image shows a master connected incorrectly and provides guidance to fix the problem (provide the missing

connection to the extension).

16 DPO70000SX Series User

Install your instrument

The following images show the master and extension with valid connections.

DPO70000SX Series User 17

Install your instrument

After the multi-instrument connections are verified and the instruments display their operating status displays, the master displays

its status and timer display. Pause the timer if you have additional changes to make before the oscilloscope application starts.

Press Start Scope to bypass the timer. When the timer runs down, the oscilloscope application starts.

18 DPO70000SX Series User

Install your instrument

If your multi-instrument configuration includes ATI instruments, you have the opportunity to select either ATI Channels or non-ATI

(TekConnect) Channels. In this example ATI Channels are selected.

NOTE. You also have the option to select Time Synchronized mode of all TekConnect channels. In this mode acquisitions are

time synchronized and the Master controls the horizontal, record length, and trigger settings of all TekConnect channels. To

ensure all channels are synchronized, operate the multi-instrument configuration in single sequence mode. Retrieve all

TekConnect channel data using programmable interface commands. Waveform data is not sent to the Master. If you plan to use

Time Synchronized mode, contact your Tektronix representative for additional information.

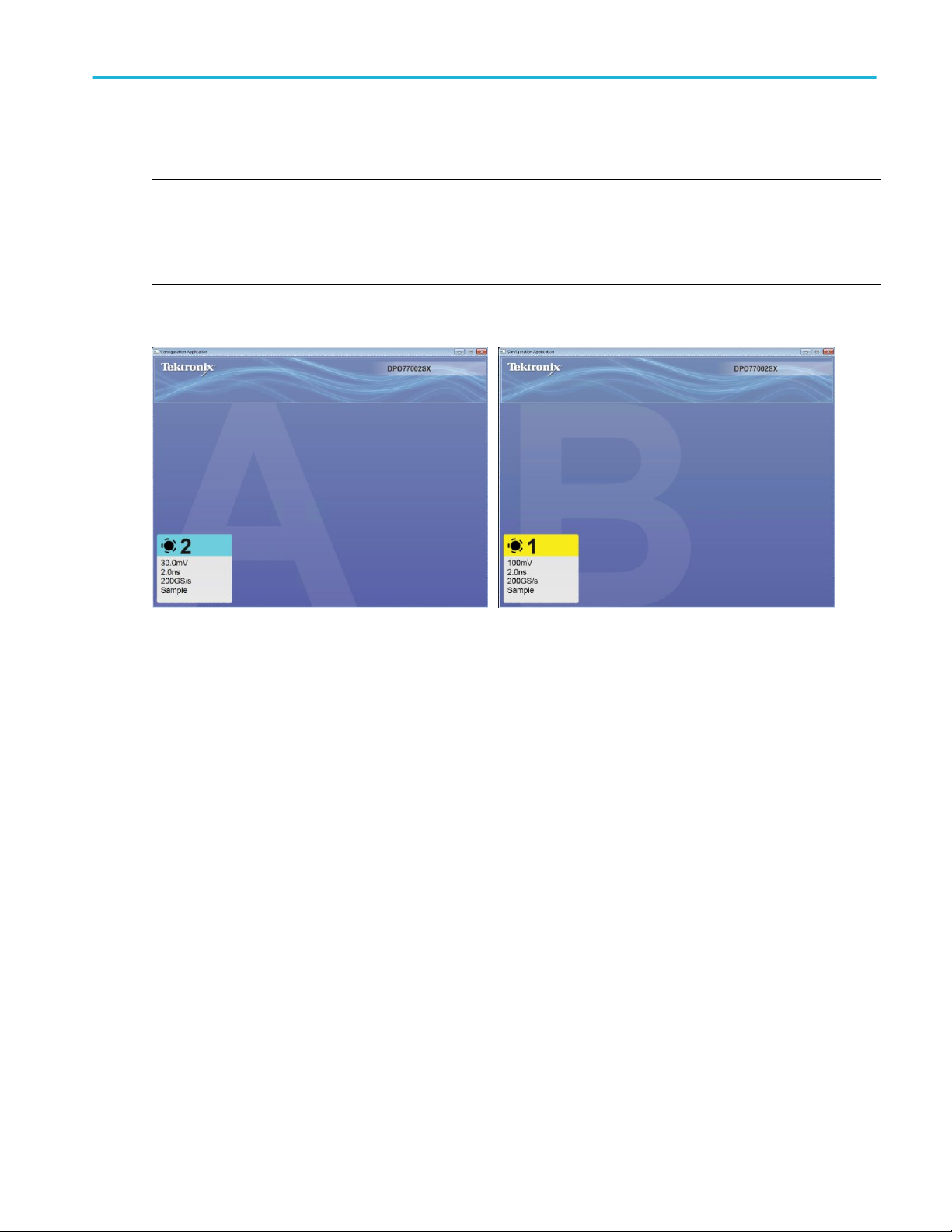

After the multi-instrument connections are verified, the instruments display their operating status displays. In this example the

Master (A) is acquiring on channel 2 (ATI). The Extension (B) is acquiring on channel 2 (ATI) and is displayed as channel 1.

The master display identifies itself as the Master and identifies the channels being acquired.

To switch between the Configuration Application and the oscilloscope display (on the oscilloscope), use Alt-Tab. To close the

Configuration Application, click the x. If the x is not visible, make the x visible by double clicking in the upper right hand corner of

the Configuration Application.

DPO70000SX Series User 19

Install your instrument

After the multi-instrument system powers on, perform a signal path compensation. See Signal path compensation on page 26.

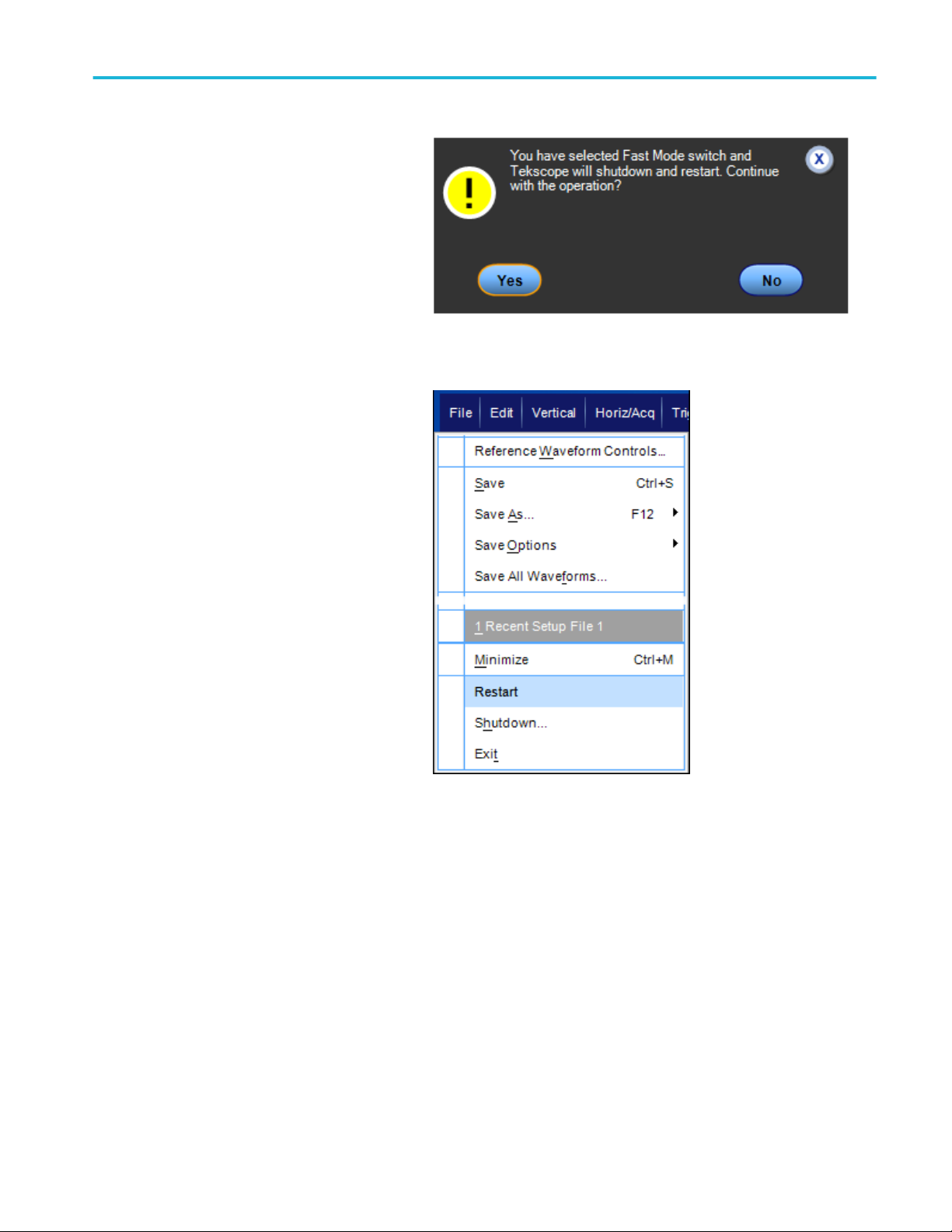

Switching between multi-instrument modes

To switch among ATI channels, TekConnect channels, and Time Synchronized modes, use the following procedure:

1. From the Vertical > Configuration menu

select either ATI, TekConnect, or

TimeSync.

20 DPO70000SX Series User

Install your instrument

2. Click Yes to continue.

Restart of a multi-instrument system. To restart your multi-instrument system without powering down the oscilloscopes, do the

following step:

1. To shut down the Configuration Manager

and all of the Scope applications and

then restart them without changing the

configuration mode, select File > Restart.

ATI versus TekConnect channels

ATI channels provide up to 70 GHz bandwidth and 200 GS/s sample rate and the lowest noise. When using the ATI channel, the

TekConnect channels are not available.

TekConnect channels have up to 33 GHz bandwidth and 100 GS/s sample rate. TekConnect channels offer multiple connection

options with TCA adapters, and are compatible with a wide range of performance probes.

DPO70000SX Series User 21

Install your instrument

Multi-instrument status displays

In a multi-instrument configuration, the display shows status information such as: channel numbers, on/off, run/stop, Arm/trig'd,

and UltraSync connectivity information. The master instrument also displays the trigger setup and the channels being acquired

and displayed.

Available features

Features discussed in this manual that are available on some instruments or configurations are noted in the tables.

Table 5: Stand-Alone instrument

Feature DPO77002SX

DPO75902SX

DPO75002SX

State (Clocked

Available on TekConnect channels Available

Pattern) trigger

XYZ mode Available on TekConnect channels Available

Equivalent time

Available on TekConnect channels Available

acquisitions

HiRes and peak

Available on TekConnect channels Available

detect

FastAcq Available on TekConnect channels Available

Roll mode Available on TekConnect channels Available

IRE and MV graticule

Available on TekConnect channels Available

modes

DPO73304SX

DPO72304SX

DPO71604SX

DPO71304SX

22 DPO70000SX Series User

Install your instrument

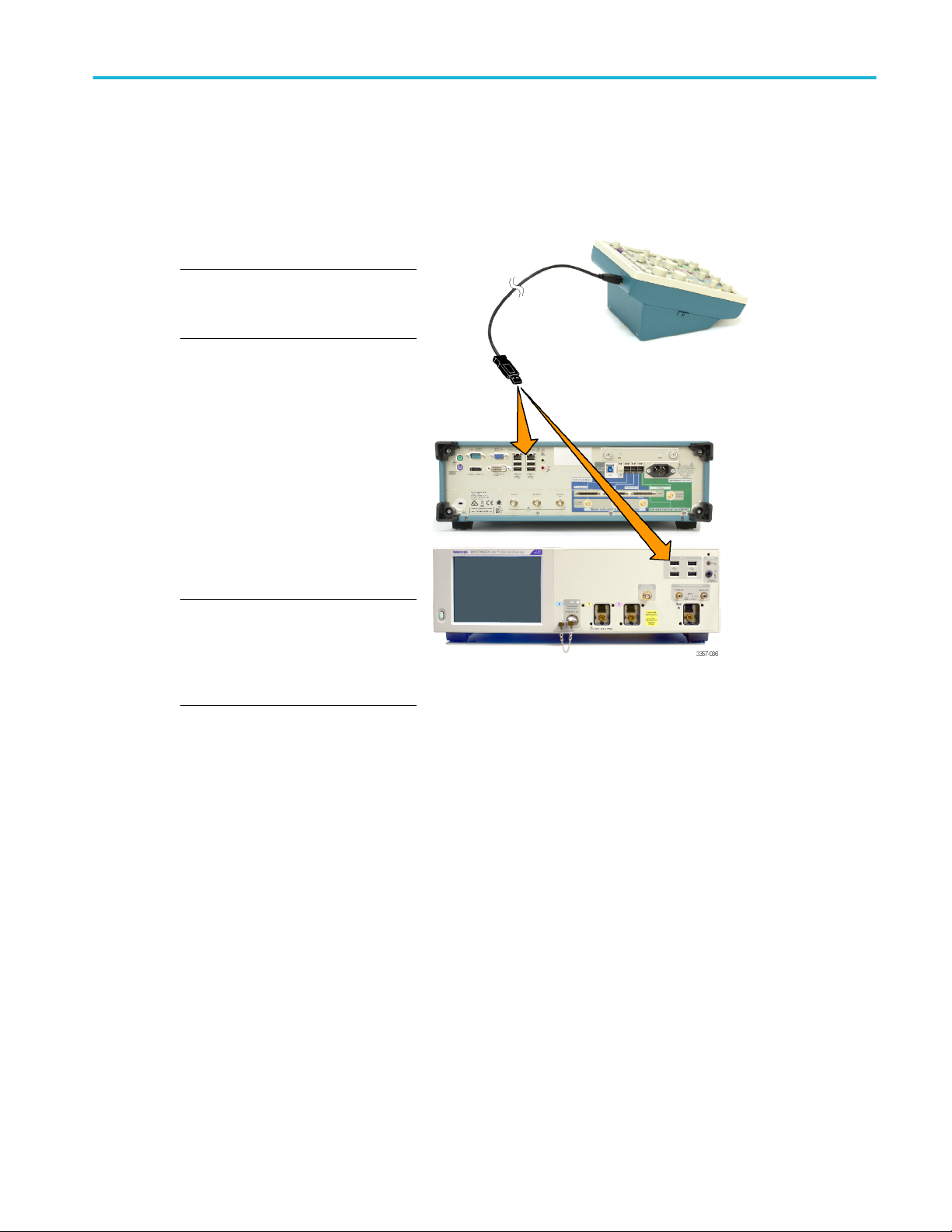

DPO7AFP Auxiliary Front Panel (optional)

The DPO7AFP is an optional plug-in panel that provides physical knobs and buttons to control the DPO70000SX series

oscilloscope. To connect the DPO7AFP:

1. Close the TekScope application.

NOTE. The TekScope application must

be closed before connecting the

DPO7AFP.

2. Plug the DPO7AFP into any USB port on

the DPO70000SX. Wait until the

Windows OS recognizes and loads the

required drivers.

3. Start the TekScope application. The

panel LEDs will light when TekScope

connects to the panel.

4. To verify that the DPO7AFP is working,

push any channel button and observe

that the TekScope application enables or

disables the selected channel

NOTE. If you unplug the DPO7AFP while

TekScope is running, you will need to

close TekScope, reconnect the

DPO7AFP, and restart TekScope to use

the DPO7AFP.

Inspect the instrument

Every time you power on the instrument, the instrument automatically performs the power-on self test diagnostics.

Verify internal diagnostics pass

Use the following procedures to verify the functionality of your instrument.

DPO70000SX Series User 23

Install your instrument

1. Power on the instrument.

2. Select Instrument Diagnostics....

3. Click Run. The test results appear in the

diagnostics control window.

4. Verify that all tests pass. If diagnostic

failures occur, contact your local

Tektronix service personnel.

Activating Windows 10

The copy of Microsoft Windows 10 that ships with this product is shipped in Deferred Activation mode. Microsoft has a default

activation method that requires a connection to the Internet. If you are not able to connect to the Internet, you can activate

Windows 10 by phone or you can continue to operate in Deferred Activation mode.

First time activation. You can activate Windows 10 either of the following ways.

1. Connect the instrument to the Internet. Windows will automatically activate. You can also go to System Properties to

connect and activate.

2. Call Microsoft and speak with a representative to activate Windows 10. Contact information and a unique activation code

(installation ID) will appear in a pop up window.

Activation with removable drives. If the SSD is removed from one instrument and inserted into another instrument, then the

activation process will need to run again on the second instrument. If the second instrument is not connected to the Internet, the

activation will fail and an Activate Windows watermark will display on the screen. To activate Windows and remove the

watermark, you must connect to the Internet or call Microsoft.

24 DPO70000SX Series User

Install your instrument

Windows interface guidelines

Because the instrument uses the Microsoft Windows interface, you have open access to the Windows operating system. You can

access the Windows desktop to load and run other Windows-based applications such as Microsoft Excel.

Follow these guidelines to avoid making operating system changes that might cause problems while using the instrument:

■

Be careful when making changes in the Control Panel. Avoid making changes to any controls with which you are unfamiliar.

■

Do not delete or change any system fonts; this can affect the quality of the display.

■

Be careful when making changes to the system Display properties. Changing settings such as resolution, text size, fonts,

and orientation affects the usability of the display and the touchscreen.

■

Do not change the contents of the Windows folder or the Program Files\Tektronix\AWG70000\ folder.

■

Do not change the BIOS settings; this can affect the overall operation of the instrument.

DPO70000SX Series User 25

Install your instrument

Signal path compensation

Perform the Signal Path Compensation (SPC) regularly to ensure that your measurements have the highest level of accuracy.

Tektronix considers it a best practice to run SPC when using the instrument to measure signals with higher sensitivity (10 mV/div

and lower) settings regardless of temperature shift or time since it was last run. Failure to perform SPC may result in the

instrument not meeting warranted performance levels.

SPC corrects for DC inaccuracies caused by temperature variation or by long-term drift. SPC optimizes the acquisition system,

corrects DC offset, and interleave calibration. SPC is adversely affected by input signals with AC components.

Use this procedure to optimize the acquisition system:

■

If the temperature has changed more than 5 °C (9 °F) since the last signal path compensation (SPC)

■

If using the instrument to measure signals with higher sensitivity (10 mV/div and lower) run SPC at least once a week

■

If the front panel SPC status icon is not green

■

If you replace or insert drive media

■

If you change the configuration of your multi-instrument system, such as changing which instrument is the master or an

extension.

1. Prerequisites:

■

Instrument must be powered on until

Utility > Instrument Calibration >

Temperature Status is Ready.

■

All channel input signals must be

removed.

■

If the timebase external reference

mode is selected, leave the external

reference signal connected and

active.

26 DPO70000SX Series User

Install your instrument

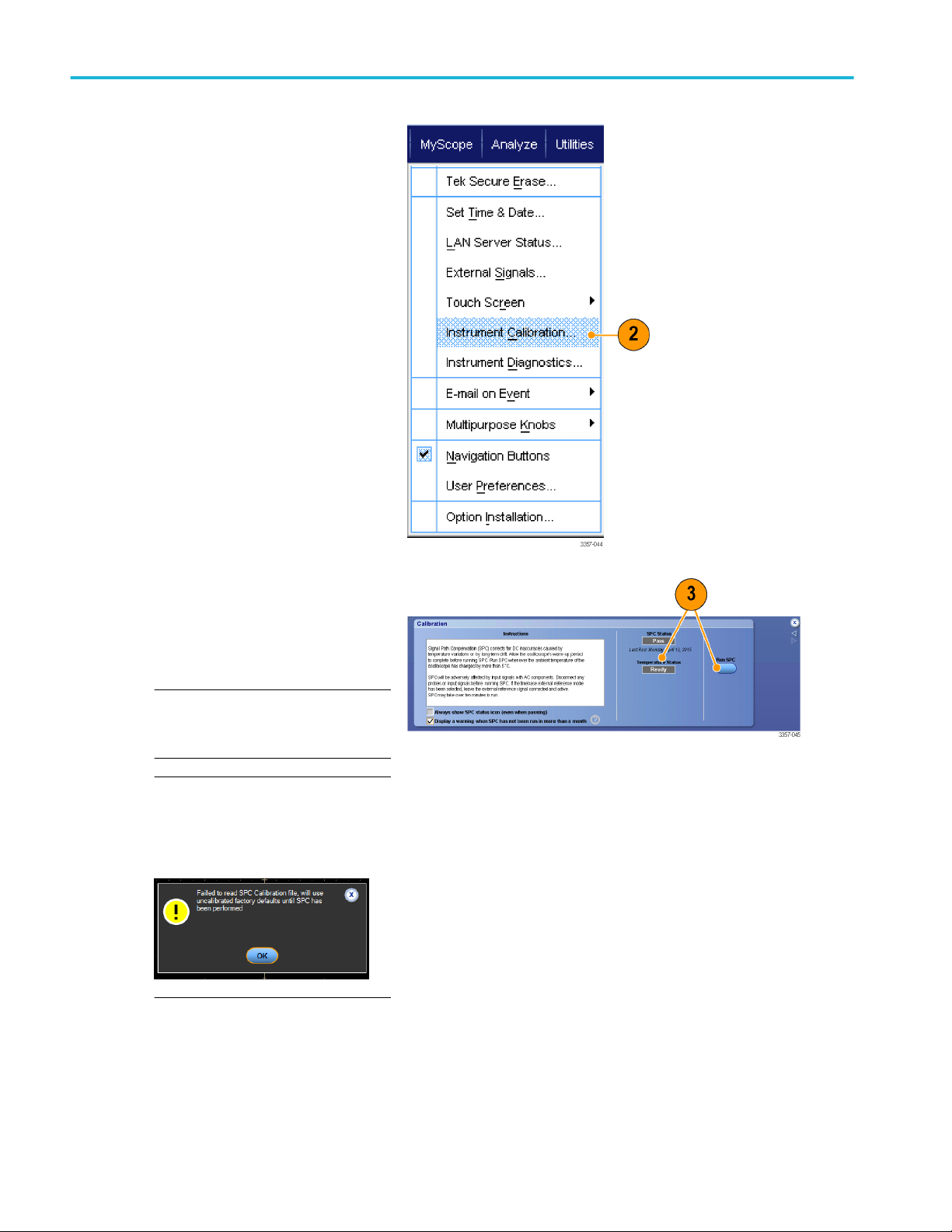

2. Select Instrument Calibration.

3. When the Temperature Status changes

to Ready, click Run SPC to start the

calibration. Calibration may take 10 to

15 minutes.

NOTE. Before running the SPC

calibration, remove all channel input

signals.

NOTE. If you use a drive that has not had

SPC run while in the current instrument,

you will see a no prior SPC warning

message. If you see this warning, run

SPC.

Utility menu on DPO70000SX

instruments

Calibration menu on DPO70000SX instruments

DPO70000SX Series User 27

Install your instrument

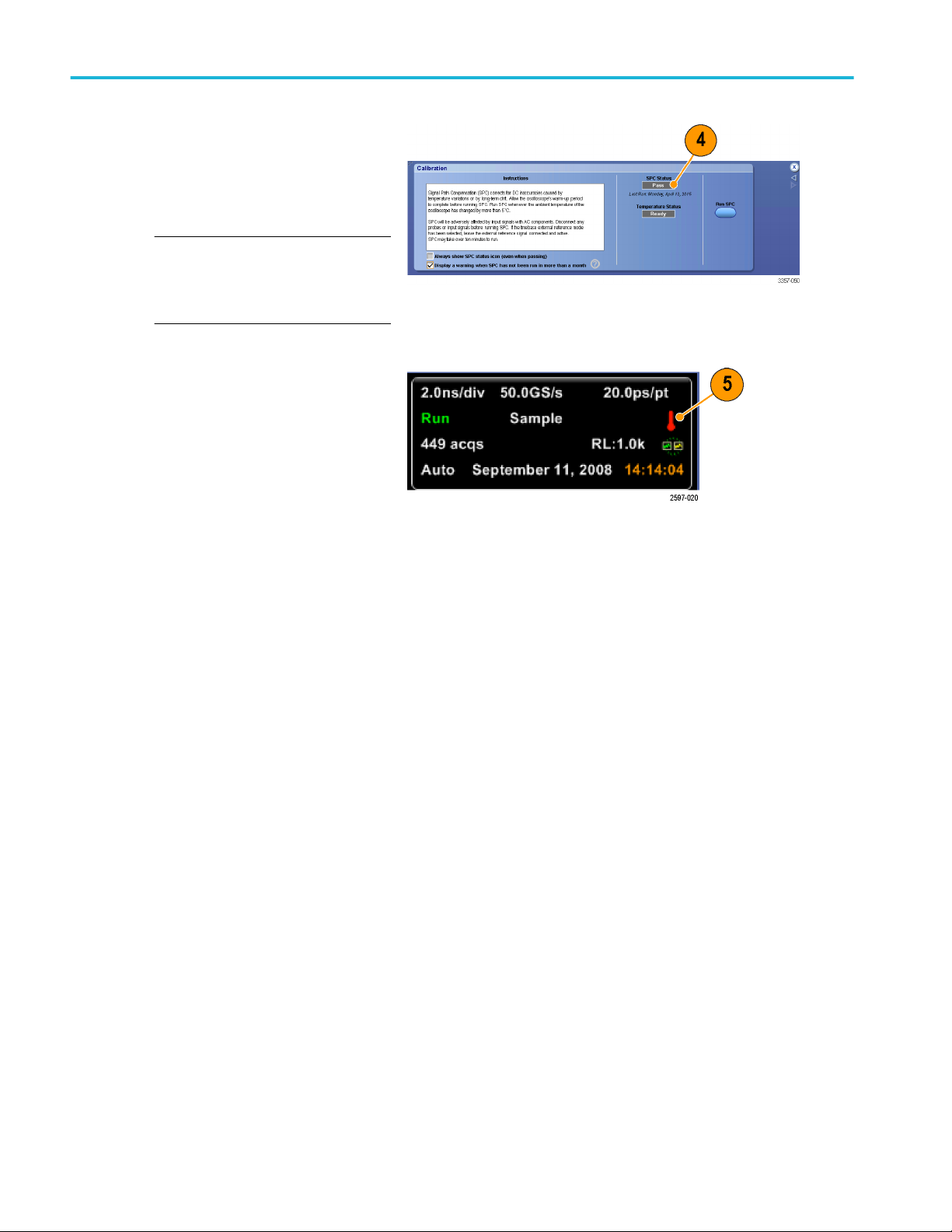

4. If the instrument does not pass,

recalibrate the instrument, or have the

instrument serviced by qualified service

personnel.

NOTE. To always show the SPC status

icon or display a warning when SPC has

not been run in more than a month, click

the corresponding check box.

Calibration menu on DPO70000SX instruments

5. If the SPC needed icon is red, perform a

signal path compensation.

Check the color of the SPC Status icon:

■

Green indicates that SPC

successfully passed and the

temperature is stable.

■

Yellow indicates that the instrument

is in the warm up state or that it has

been over 30 days since SPC was

last run.

■

Red indicates that SPC needs to be

run (the temperature has varied

more than 5 °C, SPC failed, or SPC

has not been run).

28 DPO70000SX Series User

Install your instrument

Connecting to a network

Connect your instrument to a network for

printing, file sharing, internet access, and other

functions. Consult with your network

administrator and use the standard Windows

utilities to configure the instrument for your

network.

Use the Remote Desktop Connection of

Windows to control and view the instrument

remotely.

DPO70000SX Series User 29

Install your instrument

Adding a second monitor

You can operate the instrument while using Windows and installed applications on an external monitor. Follow the procedure

below to set up a dual monitor configuration.

1. Turn power off.

2. Connect second monitor.

3. Connect keyboard.

4. Connect mouse.

5. Turn instrument power on.

6. Turn monitor power on.

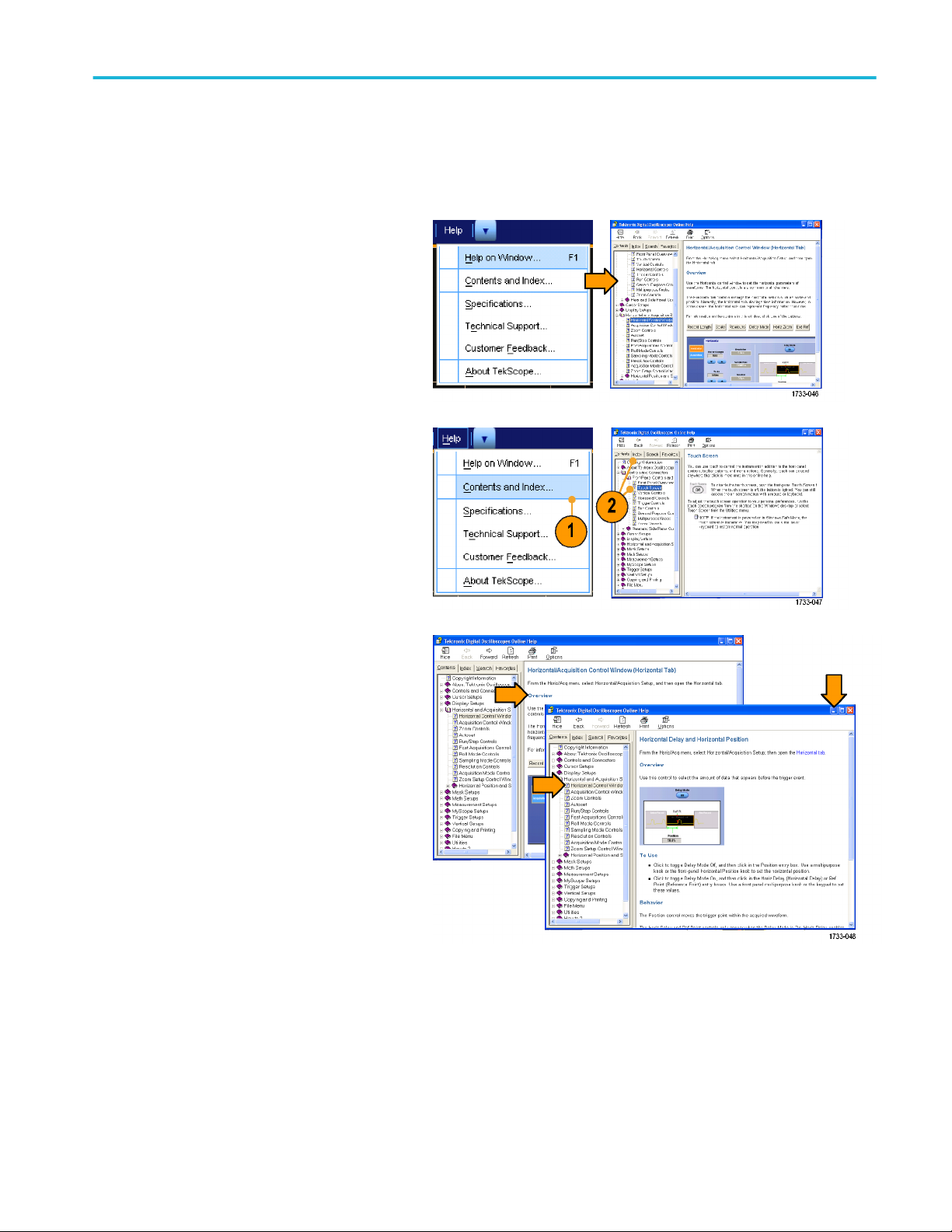

Activating Windows 10