Page 1

DlOl A

Digital Input/Output Module

The DIOlA Digital Input Output Module provides 32

digital input or output channels at TTL levels. These

channels are grouped into four &bit ports which can be

individually programmed for input or output by software commands. The inputs are read directly by the host

computer, and the outputs are latched. A power on reset

circuit automatically configures all ports as inputs when

the DIOlA module is powered up.

I/O connections are made to on-card quick disconnect

screw terminal blocks, which accept 16-24 gauge wire

stripped 3/W. In addition to the screw terminals, a

mass termination connector for ribbon cable is provided

on the forward edge of the module.

CAUTION

Always turn off the data acquisition system

power supply before installing or removing

modules. To avoid the possibility of EMI radiation, never operate the system with the

top cover open or removed.

module, and is functionally compatible with the older

module. The older DIOl module has hardware switches

for port configuration, while this function is performed

through software for the DIOlA.

User Connections

User connections can be made to either the quick disconnect terminal blocks at the top of the module, or to the

mass termination connector located at one end of the

board <through the supplied ribbon cable).

Table 1. User-configured Components

Component

Screw Terminals

I/O Connector

t

Designation

Jl-J14

J6

Function

Input/Output

connections

Quick Disconnect

Mass Termination

for Ribbon Cable

The DIOlA module can be installed in any available slot

in any Keithley/DAC Data Acquisition System. However, for best performance any analog modules should

be plugged into the lowest-numbered available slots,

leaving the higher slots for digital modules. To install the

module in a Model 500 or Model 556, remove the top

cover and insert the module in any available slot with the

component side of the module facing the power supply.

To install the module in a Model570 or a Model 575, open

the clamshell cover and insert the module into the option

slot with the component side of the module facing up.

See your data acquisition system manual for details on

opening the system and installing modules.

The DIOlA module can be identified by a Model 575,

5OOA, 5OOP, or 556 mainframe through the use of a Self-ID

resistor which is mounted on the module. The value of

this resistor is measured by the mainframe, and an JD

code is generated from the value. The DIOlA module

uses the same ID code 52 (4530 ohms) as the older DIOl

Documen~umbert 501-916-01 Rev. B

Copyright’ 1989 Keithky Instruments, Inc., Cleveland, OH 44139 (216)248-0400

Screw terminals for making input/output connections

are located on Jl, J2, J3, and J4 across the top edge of the

module board. The channelnumbers (0 to31) are marked

across the top edge of the board and are also shown in

Figure 1.

Two connections each for the module ground (GND) and

+5

volts (+5) are also included on the top edge of the

board. The terminals are intended to be used with 16 to

24

gauge wire stripped 3/W’, and the terminal blocks

can be pulled off of the strip to facilitate connections. A

typical input/output connection for the screw terminals

is shown in Figure 2.

In situations requiring rapid connection and disconnec-

tion of signal lines, J6 can be used as an alternate means of

signal connection. Figure 3 shows the pin diagram for J6,

which is designed for use with a matching optional rib-

DIOl A-l

Page 2

DIOIA

.Digital Input/Output Module

Mass Termination (J6) Screw Terminals (Jl J4)

I/

/

t

:

:

:

:

:

:

:

:

:

:

1

J6

Terminal Designations

Ground : Pins 1,36

+5 Volts :

PortA :

PortB :

PortC :

PortD :

Figure 1. DIOl AModule Configurafion

Pins 2,35

Pins3-10

Pins11 -18

Pins19-26

Pins 27 - 34

A

Strain Relief

-6 ’

\

Digital Device

p+

::

::

::

. .

::

::

::

::

::

. .

::

ir

CAUTION : Non-isolated lTL

Figure 2. Typical DIOl A Input Connecf ions

Connections only

bon cable available from Keithley. When connecting signals in this manner, the screw terminals should not be

used.

If FMI radiation becomes a problem, use shielded cables

for input and output connections. Connect the shield of

the cable to the baseboard ground ONLY (or one of the

GND terminals of the screw terminal connectors), and

leave the other end of the shield unconnected. Do not use

the shield of the cable as a signal carrying connection.

CAUTION

DIOlA inputs arid outputs are non-isoIated,

meaning that the circuit ground is connected

to power ground. Any circuits connected to

the module must also be referenced to power

ground and must not be floating, or themodule may be damaged.

DIOl A-2

Page 3

Pin 40

G:D CZ31

Ci30 c:29

Ci26 C:27

C:26 CZ25

C:24 0 i5v

Pin 39

Digital Input/Output Module

DIOlA

Input/Output Programming

The 32 digital I/O channels of the DIOlA are grouped

into four ports of 8 channels each. Port A consists of channels 0 to 7, Port B of channels 8 to 15, Port C of channels 16

to 23, and Port D of channels 24 to 31. The function of

each port (and thus, the 8 channels associated with that

port,) can be programmed individually for input or output through the use of software commands discussed below. The data written to or read from any port can be

handled as a byte of information, in which eight channels

are accessed at one time.

G:D C:23

CL A21

CZO CL9

Left edge

of Module

pin* I PinI

CL8 cE17

C&6

G:D

C&4 C&3

Ck2 &I

C&O

Ci6

GiiD c:7

C:6 CZ5

CZ4

Ci2 c&

0

+5v

c&

ci9

0

+5v

CZ3

Matching 3M Ribbon

Connector Part

No. 3417

TTL Levels and Loading Considerations

When configured for input, each channel of the DIOlA

represents one LS TT’L load to the external circuitry

(2Oj,tA high, 0.4mA low). Logic low should be between 0

volts and 0.5 volts, and logic high should be between 2

volts and 5 volts (standard TTL levels).

When configured as outputs, each channel is capable of

driving a maximum of 60 LS TI’L loads or 15 standard

TTL loads

(maximum

output is 1.2 mA high and 24 mA

low). Logic low will be in the range of 0 volts to 0.5 volts,

and logic high will be between 2.7 volts and 5 volts.

Commands

The DIOlA uses the slot dependent CMDA and CMDB

lines for setup and read/write operations. To select a

port for a read or write operation, or to configure the

ports for input or output, write to CMDA of the appropriate slot. In order to write or read data, write to or read

from CMDB for the appropriate slot. See Table 2 for a list

of the slots and memory locations corresponding to the

CMDA and CMDB lines. Figure 4 includes details on the

DIOlA register usage. Memory locations indicated for

these commands assume that the interface card in the

host PC is set for a base address of CPF80. Any other setting of the base address will require the appropriate offset of the supplied command locations.

Figure 3. Connecfor 16 Terminal Configurafion

DIOlA-3

Page 4

DIOZA

Channels

Digiid

input/Output Module

Select

Gonfigure

and

Port

Reg

setup

CMDA

(Write)

1

32

Input/Output

)

ReadMite Data

CMDB -

(Read/Write)

CMDA (write) Address - Select port, configure port

Must be issued in order to read or write data to a specified port.

b7 c

CMDB (read) Address - Digital input

Read data from specifkl port provided port is contigured as an input port.

CMDB (write) Address - Digital Output

Write data to specSed port provided port is configured as an ougxn port.

D5 D4 D3 D2 Dl DO

‘L

Beleot Port: O-Port 4 Ch O-7

Configure Port A: 1 -Output, O-Input

Contigure Port B : 1 -Output, 0 - Input

Configure Port C : I- Cutput, 0 - Input

Configure Port D: i-Output, O-Input

Enable Configuration Bits : 0 - Cff , 1 -On

1 -Port B. Ch 8-15

O-Port C, Ch16-23

3-Port D, Ch 24-31

Figure 4.

DIOlA-4

DIOIA Block Diagram and Command Register

Page 5

Digital Input/Output Module

DIOlA

Table2. Locations for Slot Dependent

Commands

Select/Configure

Slot

1

2

Port (CMDA)

XXX80

XXX82

xxx84 XXX85

:

5

6

7

8

9

10

xXx=1

xxx86

xxx88 XXX89

xxx8A

XXX8C

XXX8E

xxx90 x>o(91

xxx92 xxx93

;t 3 digits of IEUN addn

SELECT/CONFIGURE PORT

Location: Slot dependent CMDA write

The CODA write command is used to configure the ports

for input or output, and to select the port that data is to be

written to or read from. Refer to Figure 4 for the following discussion of the CMDA write data byte.

Digital I/O

OADB)

XXX81

XXX83

XXX87

xxx8B

xxx8D

xxx8F

s,

e.g.

“CFF

operations

NOTE

Upon power up, a random port will be selected; therefore, port selection should be accomplished prior to read or write operation

with CIvlDB.

NOTE

In

some

applications, you may find it useful

to read back the levels previously programmed to a DIOlA port configured for output. The value read back will be the last byte

value successfully programmed to the port.

This feature can be implemented using

BASIC’s PEEK command, or the equivalent

memory read function of other languages.

This WAS NOT a capability of the older DIOl

module, and should not be attempted using

the older module.

DIGITAL INPUT/OUTPUT operations

Location: Slot-dependent CMDB read or write

A CMDB read is used to access data from a selected port

when that port is configured as an input port. A CMDB

write is used to write data to the selected port when that

port is configured as an output port. Note that each of the

four ports can be individually programmed as either an

input or output port, as discussed above.

Bits D3 through D7 are used to configure the ports for input or output. Bit D7must be set to a logic 1 to enable bits

D3 through D6 to set their appropriate port to an input or

an output port. When bit D7 is set to a logic 0, bits D3

through D6 are ignored. Bits D3 through D6 are used for

PORT A through PORT D, respectively. Setting the appropriate bit to a logic 1 sets that port and

all associated

channels, to a digital output. Setting the appropriate bit

to a

logic 0

sets that

port, and

all associated channels, to a

digital input.

NOTE

Upon power up, all ports are set to be digital

inputs.

Bits DO and Dl are used to select a particular port for input or output. A value from 0 to 3 will select port A

through port D respectively. Port selection will always

occur with a CMDA write to the DIOlA module, regardless of the logic value of bit D7.

When a port is configured as an input port, the CMDB

command location is read to access the status of the channels associated with the port. Reading this location will

return an 8 bit binary number, with the DO thru D7 lines

representing the input lines for the selected port as indicated in Table 3. Since the inputs are not latched, the data

will reflect the condition of the input channels at the instant that the read operation is performed. Note that the

channels being read will depend on the port selected

with the CMDA write command discussed above.

If you need to know the status of a particular channel, a

logical AND instruction can be used to “mask oft?’ the unnecessary bit positions. The mask should contain zeros in

the irrelevant bit positions and logic ones in the bit positions representing the channels in question. The result of

ANDingthemaskwiththeinputdatawillthenbean8bit

binary number with each bit in an irrelevant position

equal to zero. The relevant channels will contain a 1 or a 0

depending on the status of the corresponding bit in the

masked byte (a 1 if the object bit is high, a 0 if the object bit

is low).

DIOlA-5

Page 6

DIOZA

Dig&z2 Input/Output Module

When reading a DIOlA port with the BASIC PEEK command, the returned value will be a decimal number be-

tween 0 and 255, depending on the status of the input

channels. The status of a particular channel can be determined by ANDing the returned value with the decimal

weighting for that particular channel.

sult is nonkero, the channel is high (logic 1).

EXAMPLE

telmlin~

100 POKE CMDA,O

110 STATUS6 = PEEK(CMDB) AND 64

If the value returned in variable STATUS6 is non-zero,

then channel 6 is high.

If a DIOl A port is configured as output, the value written

to CMDB should be the equivalent of an 8 bit binarynum-

ber, with the status of the 8 bits (1 or 0) representing the

status of the 8 channels of the selected port (high or low).

The channels affected will depend on the selected port, as

outied hi ‘I’abie 3.

into the outputs and will remain unchanged until the

port is written to again, or the port is configured as an input port.

the POKE command will be a decimal value in the range

from 0 to 255.

To change the status of one output channel while leaving

the others unchanged, you must know the status of all of

the channels. To accomplish this, a variable in the controiiing program could be assigned to the current status

of the port in question (and updated every time the port is

written to), or the output on the port could be read di-

The status of channel 6 on port A is to be de-

- Data wr&en to a port will be

From BASIC, the value written to the port using

If the ANDed re-

iatched

rectly from the port using the readback feature (and

stored in a variable).

channels on the particular port is known, the value of the

variable can be changed to correspond to the desired

status of the selected port, and this new value written to

the CMDB location.

In assembly language, this modification can be performed by using logical AND and logical OR instructions. When turning a single channel on (high) the vari-

able representing the current port status should should

be ORed with a number equivalent to an 8 bit binary

value with zeros in the bit positions to remain unchanged

and ones in the bit positions to be turned on. When turning a channel off, the port status variable should be

ANDed with an 8 bit binary value with ones in the bit positions to remain unchanged and zeros in the positions to

be turned off

From BASIC, the decimal weight of the bit to be turned on

or off should be added to (off to on) or subtracted from

(on to off) the decimal number that represents the current

er.d- r+-k.r

y”Lr 3LaLUJ. I‘“I GvuAyAc, I.” LULLI uLcul.LLtzL tt vu, IL W”l.uU

be necessary to subtract 8 from the decimal value representing the port status. To turn on channel 8, it would be

necessary to add 128 to the status.

It should be noted that the DIOlA module is command

compatible with the older DIOl module, with the added

programmability of the port configuration versus the

switch selectability of the older module. Programs written for the older module can be modified for use with the

new module by simply issuing a CMDA WRlTE to configure the ports before any input or output is accomplished.

Cr.” rwrm,rle Lrr Lr.... #.a.,.......-1 A -CL :r-..#...lA

When the current status of all the

DIOlA-6

Table 3.

Bit Position

Weighting

Port A ChanNos. 7 6

Port B Chan Nos. 15 14

Port CChanNos. 23 22

Port D Chan Nos.

Digital I/O Channels and Bit Values

1 D7 1 D6

128 64

31 30

D5 D4

32 16

5 4

13 12

21 20

29 28

I

D2

D3

8 4

3 2

11

10

19 18

27

26

Page 7

Digital Input/Output Module

DIOlA

Theory of Operation

A schematic drawing of the DIOlA module is located on

drawing number 501-206.

The DIOlA circuitry may be divided into six sections:

data bus buffering circuitry, port selection circuitry, port

configuration circuitry, channel input buffers, channel

output latches, and power up reset circuitry.

Data from the baseboard bus circuitry is applied to the

octal bus transceiver U13 (74LS245). Bus transmission direction of U13 is controlled by the baseboard Read/Write

line, while the CMDB line is used to enable the device

when reading or writing data to one of the 4 ports on the

module using the DIGITAL I/O command.

The two least significant bits of the data bus (DO and Dl)

are also applied to the port selection circuitry made up of

a dual D type flip flop U2 (74LS75) and a 3 to 8 line decoder U4 (74LS138).

select port mode, the values on the DO, Dl, and Read/

Write lines are latched into U4. When the CMDB line

next goes low, U4 decodes the input from U2 into an enabling signal to go to only 1 of the 4 ports (either the input

buffer or the output latch, depending upon the state of

the Read/Write line). For example, if 11 (binary) were

present at DO and Dl, and the Read/ Write line was active

(low), executing a CMDA write would latch the data into

U4; then the Y7 output of U4 would go low with the next

CMDB write, latching the data present on the bus at’that

time to the output of the port.

When a CMDA write is issued in the

Input/Output selection is performed by triple 3 input

nor gate Ul(74LS27) and quad latch U3 (74LS175). When

a CMDA write is issued (bit D7 high) the data on lines D3

to D6 is latched into the inverting outputs of U3. A low to

the output control of the output latches US, US, UlO, and

U12 (74LS374) allows the Read/Write line to clock the

data from the bus to the port. When D3 to D6 are low, the

output latches t&state and the select port registers of U4

enable the input buffer for the selected port.

The Self-ID resistor (R40) connected between pins 4 and

41 of the card edge connector allow the mainframe to

identify the module by reading the value of the resistor

with an A/D conversion circuit and generating a code

based on the value of the resistor. The ID resistor has a

value of 4.53 kilohms, with a tolerance of 0.1%.

The power up reset circuitry is used to ensure that all outputs power up in a high impedance state by holding the

clear line of U3 low until power up is complete, forcing all

inverting outputs of the quad latch high.

Troubleshooting Information

Troubleshoot the DIOlA by using the procedure out-

lined in Table 4. This process is fairly straightforward, as

signal tracing is simply a matter of checking for the correct digital logic level throughout the module.

If a defective part is found, a replacement can be ordered

from Keithley Data Acquisition and Control. Refer to the

Service Section of the hardware manual for ordering details. Part numbers for the module are located on the

component layout drawing (501-200).

DIOlA-7

Page 8

DIOIA

Digital

Input/Output Module

Table 4. DIOlA Troubleshooting Information

Step

1

I\Tote: Slot 10 locations

Component Required Condition Remarks

1

DIOlA module

2

channel O-31

3

computer

4

computer

5

ports B-D

channel O-31

6

7

computer

computer

8

9

ports ED

10

computer

11

computer

channelO-7

12

13

ports B-D

14

computer

15

computer

channelO-7

:;

ports ED

Install in slot 10

apply logic high (+Rr)

program ah ports as inputs and select port A

read back 255 from port A

repeat steps 4 and 5

apply logic low (WI

select port A

read back 0 from port A

repeat steps 8 and 9

program all ports as outputs and select port A

write 255 to port

all outputs high

repeat steps 13 and 14

select port A

write 0 to port

all outputs low

repeat steps 17 and 18

CMDAXXX92

CMDBXXX93

DlOl A Specifications

Channels: 32, software programmable in groups of 8 for

input or output

turn power on

apply to inputs

use CMDA write DATA 11111X00

use CMDB read

to test ports ED

apply to inputs

use CMDA write

use CMDB read

to test ports ED

use CMDA write

DATA 10000X00

use CMDB write

use logic probe/DMM

to test ports B-D

use CMDA write

use CMDB write

use logic probe/DMM to test ports B-D

General: AII inputs and outputs referenced to system

ground

AU inputs and outputs power up in high impedance state

as inputs for safety

Signal connection: Quick disconnect screw terminal

blocks, 40 pin receptacle for ribbon cable assembly

Input characteristics:

T&-compatible, high-true

High-level Input Current: 2OpA

Low-level Input Current: -0.4mA

Output characteristics:

TI’L-compatible, high true

Drive capacity: 60 IS-TIT, loads or 15 standard ‘ITL

loads; 24mA sink at 0.5V

Self-ID: resistor value - 4.53kQ zt.1 %. ID code 52

DIOlA-8

Accessories: Ribbon cable assembly, 6 foot, 40 conductor; one end mates with 40 pin receptacle on DIOIA,

other end is unterminated. KeithIey part number

5OO-cA3.

Cable ribbon plug, only - 3M part number 3417.

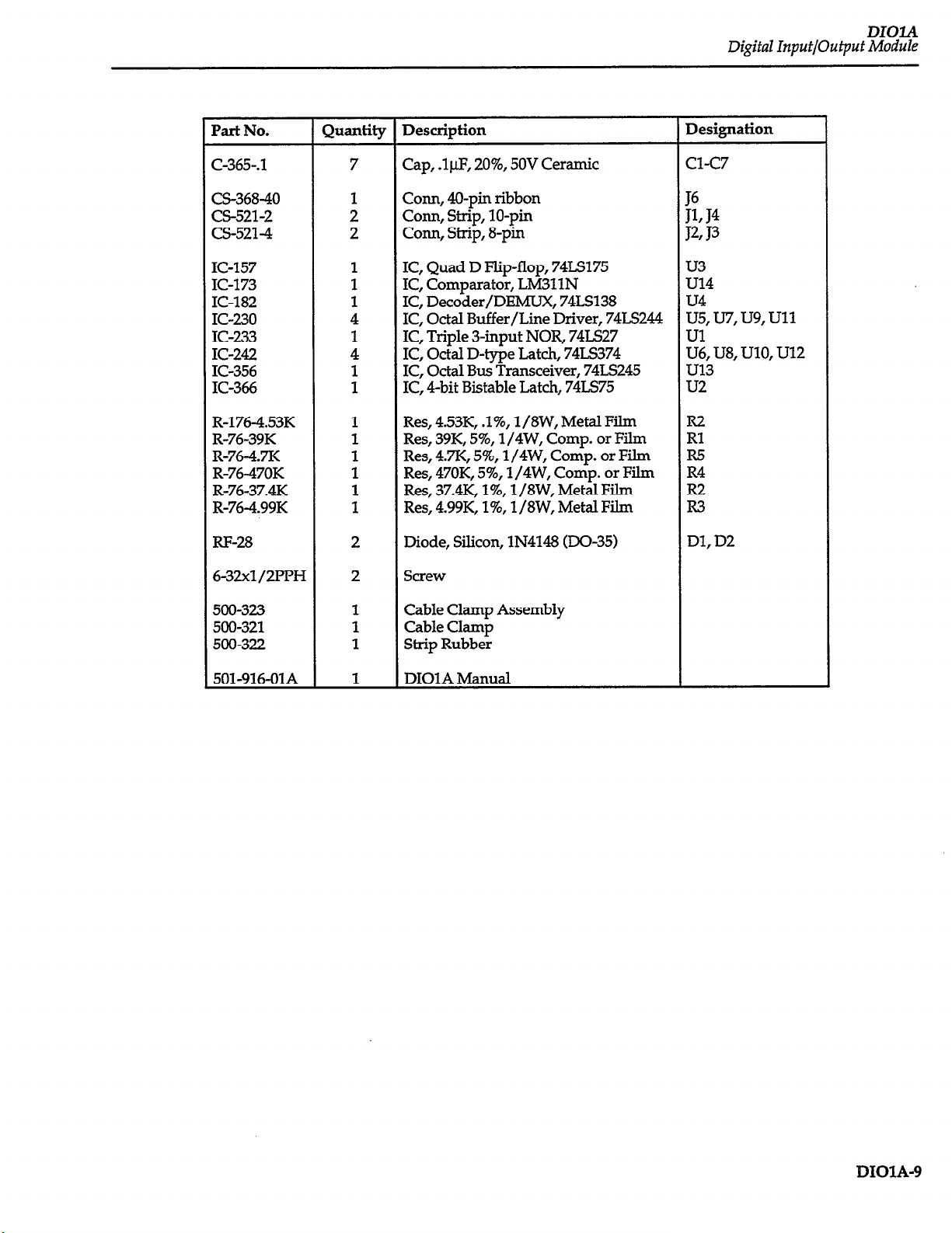

Parts List

The following components are used in the DIOlA module. Spares can be ordered from the repair department of

KeithIey Instruments, Inc., 28775 Aurora Road, UeveIand, OH 44139. Please supply the part number, description, and quantity when ordering.

Page 9

Digital Input/Output Module

DIOIA

Part No.

C-365-.1

Cs-368-40

(X-521-2

(X-521-4

IC-157

IC-173 1

IC-182 1

IC-230

IC-233

IC-242

IC-356

IC-366 1

R-176-4.53K

R-76-39K

R-76-4.7K :

R-76-47OK

R-76-37.4K

R-76-4.99K

W-28 2

6-32xl/2PPH 2

Quantity Description

7 Cap, .l@?, 20%, 50V Ceramic

1

2 corm, strip, IO-pin

2 Conn, Strip, 8-pin

1

4

1

4

1

1

1

1

1

Designation

Cl-C7

Corm, 40-pin ribbon

IC, Quad D Flip-flop, 74LS175 u3

IC, Comparator, LM311N

IC, Decoder/DEMUX, 74LS138

IC, Octal Buffer/Line Driver, 74LS244 us, u7, u9, Ull

IC, Triple 3-input NOR, 74LS27

IC, Octal D-type Latch, 74LS374

IC, Octal Bus Transceiver, 74LS245 u13

IC, 4-bit B&able Latch, 74LS75 u2

Res, 4.53K, .I%, 1/8W, Metal Film R2

Res, 39K, 5%, 1/4W, Comp. or Film

Res, 4.7K, 5%, 1/4W, Comp. or Film E

Res, 47OK, 5%, 1/4W, Comp. or Film

Res, 37.4K, I%, 1/8W, Metal Film R2

Res, 4.99K, I%, 1 /SW, Metal Film R3

Diode, Silicon, lN4148 0X-35)

Screw

J6

JL J4

JZ

J3

u14

u4

Ul

US, U8, UlO, U12

R4

Dl, D2

500-323

500-321

500-322

501-916-OlA

1

1

1

1

Cable Clamp Assembly

Cable Clamp

Strip Rubber

DIOlA Manual

DIOlA-9

Page 10

I-

Page 11

-

Page 12

Using the DIOlA

and

KDAC500 Software

The DIOlA digital I/O module

can be used in a variety of control

and monitoring applications to

source and sense digital logic levels.

The module’s 32 channels can be

configured for input or output in

groups of 8 channels. Each group of

8 channels is a called a “port”. Port

A consists of channels O-7, port B

consists of channels 8-15, and so on.

The DIOlA channels can be read or

written individually, or as ports.

The DIOlA channels are nonisolated, meaning that DIOlA digital

ground is connected to earth

ground. Therefore, the low side of

any circuitry connected to the

DIOlA must also be at ground potential or the circuitry, DIOlA, or

data acquisition system may be

damaged.

DIOlA inputs and outputs are

compatible with low-power

Schottky transistor-transistor logic

(IS-‘ITLJ. This defines the voltage

and current levels associated with

logical high and low. When configured for input, each DIOlA channel presents one IS-TTL load to an

external circuit. The external circuit

must be able to absorb (sink) at least

0.4mA at O-O.5 volts for the DIOlA

to recognize an input signal as a

logic low. The same input must be

capable of sourcing at least 20@ at

2-5 volts to drive a DIOlA input

high.

A DIOlA output can drive up to

60 IS-TTL inputs, or 15 standard

TTL inputs. This corresponds to a

current sink capability of 24mA at O-

0.5 volts. Drive current available

from a high output is approximately

1mA at 2-5 volts.

Do not connect signals of less than

OV or greater than 5V to the DIOlA

or you may damage the module.

Connection to Digital

Logic

The DIOlA can interface many

types of digital circuitry and logic

families. However, it is important

that any external voltages applied to

the DIOlA inputs or outputs be

within the range of 0-5V. Any input

signal connected to the DIOlA must

have sufficient sink and source capability to drive at least one IS-ITL

load. Any load connected to a

DIOlA output must not cause the

DIOlA output to sink more than

24mA. Review the input and output

specifications for the type of logic

connected to the DIOlA to determine what conditioning, if any, may

be required. This information is

readily available in IC

manufacturers’ data books.

Page 13

Using the DIOIA and

KDAC500

The DIOlA can usually be

connected to standard T-l-L logic

without concern for voltage levels.

However, the total current loading is

important where one lTL output is

connected to several DIOlA inputs,

or where several external loads are

connected to one DIOlA output. A

variety of TTL sub-families exist,

including low- medium- and high-

power types. Each sub-family has

different current sink and source

specifications associated with input

and output. Make sure that a DIOlA

channel and the external logic can

each sink and source sufficient

current to control each other.

Open-collector digital circuitry is

another type of TTL logic which

requires special consideration. As

with standard TI’L, an opencollector logic low sinks some

current at O-O.5 volts. However, a

logic high simply floats, and cannot

actively drive an input. In contrast, a

standard TTL gate contains internal

circuitry to actively set a high output

to at least 2V. To assure that an

open-collector output will reliably

control a DIOlA input, connect a 2k

pull-up resistor between the DIOlA

input and +5 volts.

CMOS and other low-power logic

families operate at extremely low

current levels, with logic high

Open Collector

Driver

Figure 1. Pull-up Resistor for Open

Connector Input

Software

2K

I

06c$

5V ]CHO

DlOlA

typically being 3-15 volts according

to the circuit supply voltage. These

devices usually require level translation or buffering to interface

DIOlA channels. Integrated circuits

such as the 4049 and 4050 buffer ICs

are available for CMOS-to-TTL

buffering; Buffering circuits based

on discrete components can also be

used.

Note: For reliable operation, a

DIOlA input must be actively

driven to 2-5 volts when the signal

is high. Hardware switches, opencollector logic, and

types of signals may allow a

DIOlA input to “float” then they

switch high. A floating DIOlA

input may be susceptible to false

triggering. A 2k pull-up resistor

should be connected between a

DIOlA input and +5V if the signal

does not actively drive the input

high.

some

other

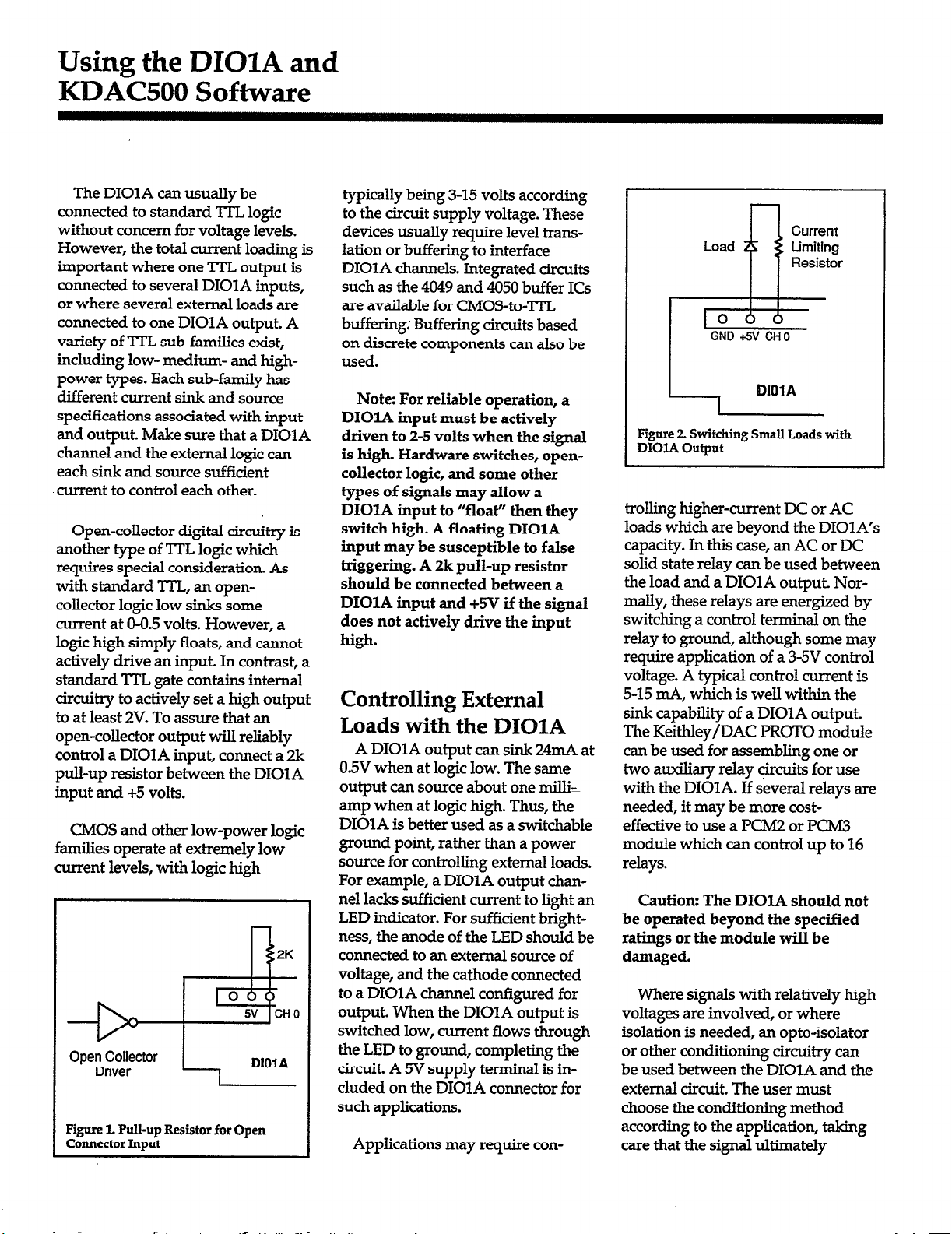

Controlling External

Loads with the DIOlA

A DIOlA output can sink 24mA at

05V when at logic low. The same

output can source about one mill&

amp when at logic high. Thus, the

DIOlA is better used as a switchable

ground point, rather than a power

source for controlling external loads.

For example, a DIOlA output channel lacks sufficient current to light an

LED indicator. For sufficient brightness, the anode of the LED should be

connected to an external source of

voltage, and the cathode connected

to a DIOlA channel configured for

output. When the DIOlA output is

switched low, current flows through

the LED to ground, completing the

circuit. A 5V supply terminal is included on the DIOlA connector for

such applications.

Applications may require con-

Load 2S :; Limiting

lo 0 b

GND +!3V CH 0

I L1

I

Figure 2. Switching Small Loads with

DIOlA Output

I

trolling higher-current DC or AC

loads which are beyond the DIOlA’s

capacity. In this case, an AC or DC

solid state relay can be used between

the load and a DIOlA output. Normally, these relays are energized by

switching a control terminal on the

relay to ground, although some may

require application of a 3-5V control

voltage. A typical control current is

5-15 mA, which is well within the

sink capability of a DIOlA output.

The Keithley/DAC PROTO module

can be used for assembling one or

two auxiliary relay circuits for use

with the DIOIA. If several relays are

needed, it may be more costeffective to use a PCM2 or PCM3

module which can control up to 16

relays.

Caution: The DIOlA should not

be operated beyond the specified

ratings or the module will be

damaged.

Where signals with relatively high

voltages are involved, or where

isolation is needed, an opto-isolator

or other conditioning circuitry can

be used between the DIOlA and the

external circuit. The user must

choose the conditioning method

according to the application, taking

care that the signal ultimately

I

, Current

Resistor

DIOlA

Page 14

Current Limiting

~~$g-~Lk+v

Figure 3. Opto-Isolator for Controlling Loads

applied to the DIOlA is within

acceptable limits. Where many

channels are involved, Keithley’s

DIM1 and DOMl digital I/O

modules offer 16 channels each, with

optical isolation and the ability to

interface voltages

up

to 2SV and

loads up to 50&L Both modules

maintain isolation of up to 500V

between channels, or from channel

to ground.

Monitoring the status of .

mechanical

switches presents two

problems. Where an application

must detect a contact closure, it is a

simple matter to connect the switch

+5v

1

^.,

Using the DIOlA and

KDAC500 Software

from

a DIOlA input to ground.

However, this method will allow the

DIOlA input to float when the

switch is opened. The channel may

be susceptible to noise or activity on

other channels. The solution is to

also connect a 2% pull-up resistor

between the DIOlA input channel

and +5V (Figure 4). When the switch

opens, the channel will be pulled to

+5V through the resistor, and be

immune to noise and false

triggering.

Second, mechanical switch

contacts usually exhibit ‘bounce”, in

which electrical continuity rapidly

makes and breaks several times at

the instant the contacts close. In

some digital applications, this

bounce may be unacceptable. The

solution is to use a “debouncing”

circuit between the switch and

DIOlA input. A flip-flop circuit

suitable for debouncing SPDT limit

switches is shown below. A second

Switoh at

position 2

Connection to

Mechanical Switches

2K

I

lo 6 0

GND +5V CHO

Figure 4. Mechanical SPST Switch with

Pull-up Resistor

Release

Figure 5. Debouncing Circuits

Page 15

Using the DIOAI and

KDAC500

remedy, ideal for debouncing

momentary push-button switches,

uses a circuit which generates a

single pulse when triggered by the

switch. The pulse must be longer

than the time it takes the contacts to

settle (typically a matter of milliseconds). A 555 timer integrated circuit or various types of one-shot ICs

can be used for this application. See

IC manufacturers’ data books for

more information.

Software

Reading BCD Outputs

Before IEEE488 and RS232-C

serial interfaces became the preferred method, binary-coded

decimal (BCD) outputs were included on some instruments to make

digitized data available to computers, calculators, or other digital

equipment. In principle, BCD uses

four lines to represent the numerals

O-9, but the actual encoding method

and number of digits varied among

manufacturers and instruments. A

multi-digit BCD readout might use

four separate lines for each digit,

resulting in many lines but relatively

simple decoding. Alternately, an

instrument might multiplex several

digits onto four lines plus a few

additional digit select lines, resulting

in fewer lines but more complicated

decoding.

With attention to signal levels and

the BCD encoding method, a DIOlA

can be used to read BCD lines. The

easiest method is to read the DIOlA

inputs as ports. This will return

eight data bits at one time. The

.

DIOlA’s 32 inputs can thus deal

with 6-8 BCD digits. If the digits are

multiplexed, the DIOlA can read an

unlimited number of digits, but the

requisite program will be more com-

plex. The decoding of the signals

must be done in software, and may

be based upon a look-up table or

some

calculation method.

Software Considerations

The DIOlA powers up with all

ports configured for input. Any

software used with the DIOlA must

be able to configure the module’s

ports for output if the application

requires digital output.

Keithley’s KDAC5OO software

provides complete control of all

DIOlA functions. The following

suggestions cover programming in a

BASIC or QuickBASIC environment,

but are equally useful in all

KDAC500 versions. Most applications of KDAC500 and the DIOlA

are simple in concept, and can be

summarized as follows:

1. Where one digital input reading

is required, a foreground read

(FGREAD) command can be used.

FGREAD will return the bit value

representing a single input channel,

or the byte value representing an

input port (8 channels).

Where a port is read, the values of

an individual bit within the byte can

be extracted by “ANDing” the byte

value with the weight of the bit’s

position. For example, the weight of

the most significant bit (MSB) in a

byte is 128. To test the value of the

MSB in the byte value “BV”, one

would execute the BASIC statement:

BT=BVAND128

If BT equals 0, the MSB value is 0,

otherwise the MSB value is 1.

Channel and bit values are covered

in more detail in the DIOlA manual.

2. Where values must be read

from a digital input channel at

regular intervals, a background read

(BGREAD) command should be

used. BGREAD will automatically

allocate and store the data in a

KDAC5OO memory array. If single

channels are being read, a KDAC500

bit array should be specified in the

BGREAD command. If ports are

being read, a KDACSOO byte array

should be specified in BGREAD.

The BGREAD command will

begin taking data when the

KDAC5OO INTON command is

executed. One data value will be

read when each interrupt fires. A

BGSTATUS command should be

used after the lNTON to determine

when all the data points have been

collected. Afterward, the individual

data values can be read from the

array by using an ARGET command

nested in a FOR-NEXT loop. If the

array is a byte array, the values of

individual bits in each byte can be

extracted by ANDing the byte

values with bit weights as described

above.

3. Where one digital value must be

programmed to a DIOlA output

channel or port, a foreground write

(FGWRITE) command is most convenient. FGWRITE can write a 0 or 1

to a single channel, or a byte value O255 to a port. The value of the byte

can be calculated by adding up the

weights of all the high bits in the

byte. For example, a port is to be

programmed with the bit values

11010011:

BYTE

WEIGHT

MSB

1:s d4 2 1’6 : 4 2 1

128+64+0+16+0+0 +2+ 1

TOTAL

LSB

0 1 1

-211

Page 16

Using the DIOAl and

KDAC500Software

The byte value 211 should be

written to the port.

4. Where several values must be

written to a digital output channel or

port, a background write

(BGWRITE) command should be

used.

Before BGWRlTE, a KDACSOO

array must be allocated with

ARMAKE to hold the output data. If

the data values are intended for a

single channel, the array must be a

bit array, and the data will consist ot

l’s and 0’s. If the data values are

intended for a port, the array should

be a byte array, and the data will

consist of values O-255. The array

must be long enough to hold the

desired number of data points.

The data values should be written

to the array using an AR??UT command. A FOR-NEXT loop around

ARPTJT may be helpful in reducing

the number of program lines need to

fill the array.

If the desired output is a simple

digital square wave, a single 1 and 0

can be written with ARPUT to a

two-deep, KDAC500 bit array.

If the output involves a more complex pattern of pulses, ARRJT can

be used to fill a longer KDAC500 bit

array with the necessary order of l’s

and 0’s.

If the output involves a digital

port, a KDAC500 byte array must be

used. The values of individual bytes

should be calculated as shown in the

weighting example above, and then

written to the array with ARMJT.

In all cases for BGWRlTE, output

will commence when interrupts are

turned on with INTON. One data

value will be written from the array

each time an interrupt fires. Note

that one complete cycle through an

array may require many interrupts,

so the period of square waves and

other pulses will probably not equal

the interrupt rate. BGWRITE’s

cycling parameter can be set for a

specific number of repeats, or for

continuous output of the array. If

cycling is not continuous, a

BGSTATUS command should be

used after INTON to determine

when all the data points have been

written.

Page 17

Data Acquisition and Control Division

Keithley Instrumegs, Inc. l 28775 Aurora Road l Cleveland, Ohio 44139 l (216) 2484400 l Fax: 349-4569

WEST GERMANY:

GREAT BRITAIN:

FRAXE Keithley Instruments SARL 03 All&z des Garays*B.P. 60 091124 Palaiseau/ZL l l-6-0115 155 l Telexz 600 933.F~ 1-6-0117726

NETHERLANDS:

SWITZERLAND:

AUSTRIA;

ITALYz Keithley Instruments SRL l Viale S. Giignano 4/A l 20146

Keithley Instruments GmbH l Heiglhofstr. 5 l Miinchen 70 l 089-71002-0 l Telex: 52-12160 l Fax: 089~7lOO25Q

Keithley Instruments, Ltd. l 1 Boulton Road l Reading, E&shire RG 2 ONL l 0734-861287 l Telex: 847 047 l Fax: 0734-863665

Keithley Instruments BV* Avelingen West 49 04202 MS GorincherwP.0. Box 559*42&l AN Gorinchan*OlS30-m*T& 24 684*Fax: 01830-30821

Keithley Instruments SA l Kriesbachstr. 4 l 86CO Diibendorf l 01-8219444 l Telex: 828 472 l Faxz 0222-315366

Keithley

Instruments

GesmbH l Rosenhiigelstrasse 12 0 A-1120 Vienna l (0222) 84 65 48 l Telex: 131677 l Fax: (0222) 84 35 97

Milan0 l

024120360 or 02-4156540 l Fax: 024121249

Loading...

Loading...