Page 1

Service Manual

DG2040

Data Generator

071-0259-50

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Page 2

Copyright © T ektronix, Inc. All rights reserved.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

T ektronix, Inc., P.O. Box 500, Beaverton, OR 97077

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects in materials and workmanship

for a period of one (1) year from the date of shipment. If a product proves defective during this warranty period, T ektronix,

at its option, either will repair the defective product without charge for parts and labor, or will provide a replacement in

exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by T ektronix, with shipping charges prepaid.

T ektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

T ektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than T ektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or malfunction

caused by the use of non-T ektronix supplies; or d) to service a product that has been modified or integrated with other

products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO

REP AIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO

THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE

LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE

OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 4

Page 5

Table of Contents

Specifications

Operating Information

General Safety Summary vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Safety Summary ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contacting Tektronix xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction xv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Overview 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Characteristics 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Certification and Compliances 1-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Information 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Cord Information 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Environment 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuse T ype and Rating 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Panel Controls 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Applying and Interrupting Power 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repackaging Instructions 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Instructions 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How to Power On 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Internal Diagnostics Routines 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

User Interface 2-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Elements 2-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menus 2-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pattern Storage and I/O 2-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loading Files 2-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signal Output 2-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Theory of Operation

Module Overview 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification

Before Running the Performance Tests 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T est Procedure Notes 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self Tests 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance T ests 4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T est Record 4-43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment Procedures

Adjustment Procedures 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DG2040 Service Manual

i

Page 6

Table of Contents

Maintenance

Maintenance 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Cleaning 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Installation Procedures 6-7. . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation 6-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Access Procedure 6-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedures for External Modules 6-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedures for Internal Modules 6-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 6-45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Procedures 6-45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DG2040 Data Generator Diagnostics 6-45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options and Accessories

Options 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Electrical Parts

Replaceable Electrical Parts 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagrams

Diagrams 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Mechanical Parts

Replaceable Mechanical Parts 10-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Ordering Information 10-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Parts List 10-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

DG2040 Service Manual

Page 7

List of Figures

Table of Contents

Figure 1-1: Timing definition in edge control input 1-10. . . . . . . . . . . . . . .

Figure 1-2: Transfer function for edge control input 1-11. . . . . . . . . . . . . .

Figure 1-3: Signal timing 1-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-1: Rear panel power switch, fuse holder,

and connector 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-2: Location of the ON/STBY switch 2-6. . . . . . . . . . . . . . . . . . . .

Figure 2-3: Rear panel controls 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-4: Display elements 2-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-5: Load Data and Parameters menu 2-16. . . . . . . . . . . . . . . . . . .

Figure 2-6: Operating buttons and menu layout 2-17. . . . . . . . . . . . . . . . .

Figure 2-7: Output voltage level and delay time display 2-19. . . . . . . . . . .

Figure 4-1: Operating buttons and menu layout 4-4. . . . . . . . . . . . . . . . .

Figure 4-2: Diagnostics menu 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-3: Frequency measurement connections 4-8. . . . . . . . . . . . . . . .

Figure 4-4: Sequence & data output connections 4-11. . . . . . . . . . . . . . . . .

Figure 4-5: Sequence & data output timing chart 4-13. . . . . . . . . . . . . . . .

Figure 4-6: External reference input connections 4-15. . . . . . . . . . . . . . . .

Figure 4-7: Maximum operating frequency connections 4-18. . . . . . . . . . .

Figure 4-8: Maximum operating frequency (1) 4-20. . . . . . . . . . . . . . . . . .

Figure 4-9: Maximum operating frequency (2) 4-20. . . . . . . . . . . . . . . . . .

Figure 4-10: Maximum operating frequency (3) 4-21. . . . . . . . . . . . . . . . .

Figure 4-11: Maximum operating frequency connections 4-23. . . . . . . . . .

Figure 4-12: Maximum operating frequency (4) 4-25. . . . . . . . . . . . . . . . .

Figure 4-13: Maximum operating frequency (5) 4-25. . . . . . . . . . . . . . . . .

Figure 4-14: Internal trigger generator & external trigger input

connection 4-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-15: Edge control mode operation connection 4-30. . . . . . . . . . . .

Figure 4-16: Edge control mode 4-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-17: Output level measurement connections 4-32. . . . . . . . . . . . . .

Figure 4-18: Clock output amplitude measurement connection 4-35. . . . .

Figure 4-19: Delay time measurement connection 4-39. . . . . . . . . . . . . . . .

Figure 4-20: Rise time and fall time measurement connection 4-42. . . . . .

DG2040 Service Manual

Figure 6-1: DG2040 Data Generator orientation 6-9. . . . . . . . . . . . . . . . .

iii

Page 8

Table of Contents

Figure 6-2: Guide to removal procedures 6-10. . . . . . . . . . . . . . . . . . . . . . .

Figure 6-3: External modules 6-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-4: Internal modules 6-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-5: Front-panel knob removal 6-14. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-6: Line fuse and line cord removal 6-15. . . . . . . . . . . . . . . . . . . . .

Figure 6-7: Rear cover and cabinet removal 6-17. . . . . . . . . . . . . . . . . . . .

Figure 6-8: Front cover, trim ring, and menu button

removal (front cover not shown) 6-19. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-9: Front-panel module removal 6-21. . . . . . . . . . . . . . . . . . . . . . .

Figure 6-10: A12 keyboard removal 6-22. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-11: Front-panel module disassembly 6-23. . . . . . . . . . . . . . . . . . .

Figure 6-12: Connector module removal 6-26. . . . . . . . . . . . . . . . . . . . . . .

Figure 6-13: Fan and fan frame removal 6-27. . . . . . . . . . . . . . . . . . . . . . .

Figure 6-14: Rear shield cover removal 6-29. . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-15: Power supply module removal 6-30. . . . . . . . . . . . . . . . . . . . .

Figure 6-16: AUX power board and AC inlet removal 6-32. . . . . . . . . . . .

Figure 6-17: Monitor module removal 6-34. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-18: CRT frame removal 6-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-19: A6 CPU board, A30 CPU Interface board

and A40 Clock board removal 6-37. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-20: A50 PG & Output board removal 6-39. . . . . . . . . . . . . . . . . .

Figure 6-21: A16 Back plane board removal 6-41. . . . . . . . . . . . . . . . . . . .

Figure 6-22: Battery location on the A16 Back plane board 6-43. . . . . . . .

Figure 6-23: Floppy-disk drive module removal 6-44. . . . . . . . . . . . . . . . .

Figure 6-24: A6 CPU Board 6-46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-25: Primary troubleshooting procedure 1 6-47. . . . . . . . . . . . . . .

Figure 6-26: Primary troubleshooting procedure 2 6-48. . . . . . . . . . . . . . .

Figure 6-27: Power Supply module troubleshooting procedure 6-49. . . .

Figure 6-28: AUX Power board 6-50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-29: Power Supply module 6-50. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-30: A6 CPU Board or front-panel module

troubleshooting procedure 6-51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-31: Key board 6-52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-32: Monitor module troubleshooting procedure 6-53. . . . . . . . . .

Figure 6-33: Monitor module 6-54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-34: Horizontal and vertical sync signals 6-54. . . . . . . . . . . . . . . .

Figure 6-35: A video signal with white and black levels 6-55. . . . . . . . . . .

Figure 6-36: A30 CPU Interface board, A40 Clock board

or A50 PG & Output board troubleshooting procedure 6-56. . . . . . . .

iv

DG2040 Service Manual

Page 9

Table of Contents

Figure 6-37: Module isolation troubleshooting procedure 6-57. . . . . . . . .

Figure 9-1: DG2040 block diagram 9–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9-2: DG2040 interconnect diagram 9–4. . . . . . . . . . . . . . . . . . . . . .

Figure 10-1: Cabinet 10-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10-2: Main chassis and CRT 10-7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10-3: Main chassis and circuit boards 10-9. . . . . . . . . . . . . . . . . . . .

Figure 10-4: Circuit boards 10-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10-5: Front panel assembly 10-13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DG2040 Service Manual

v

Page 10

Table of Contents

List of Tables

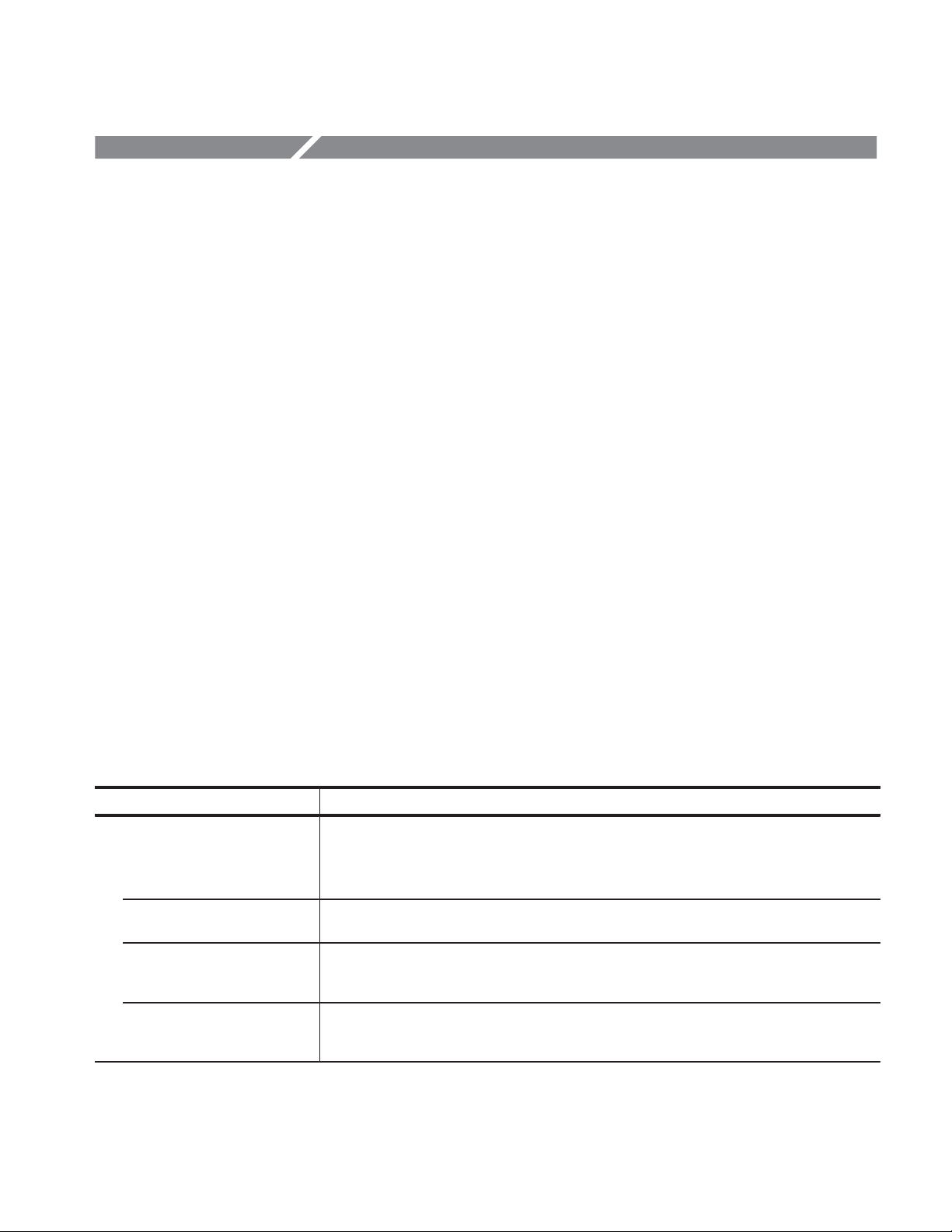

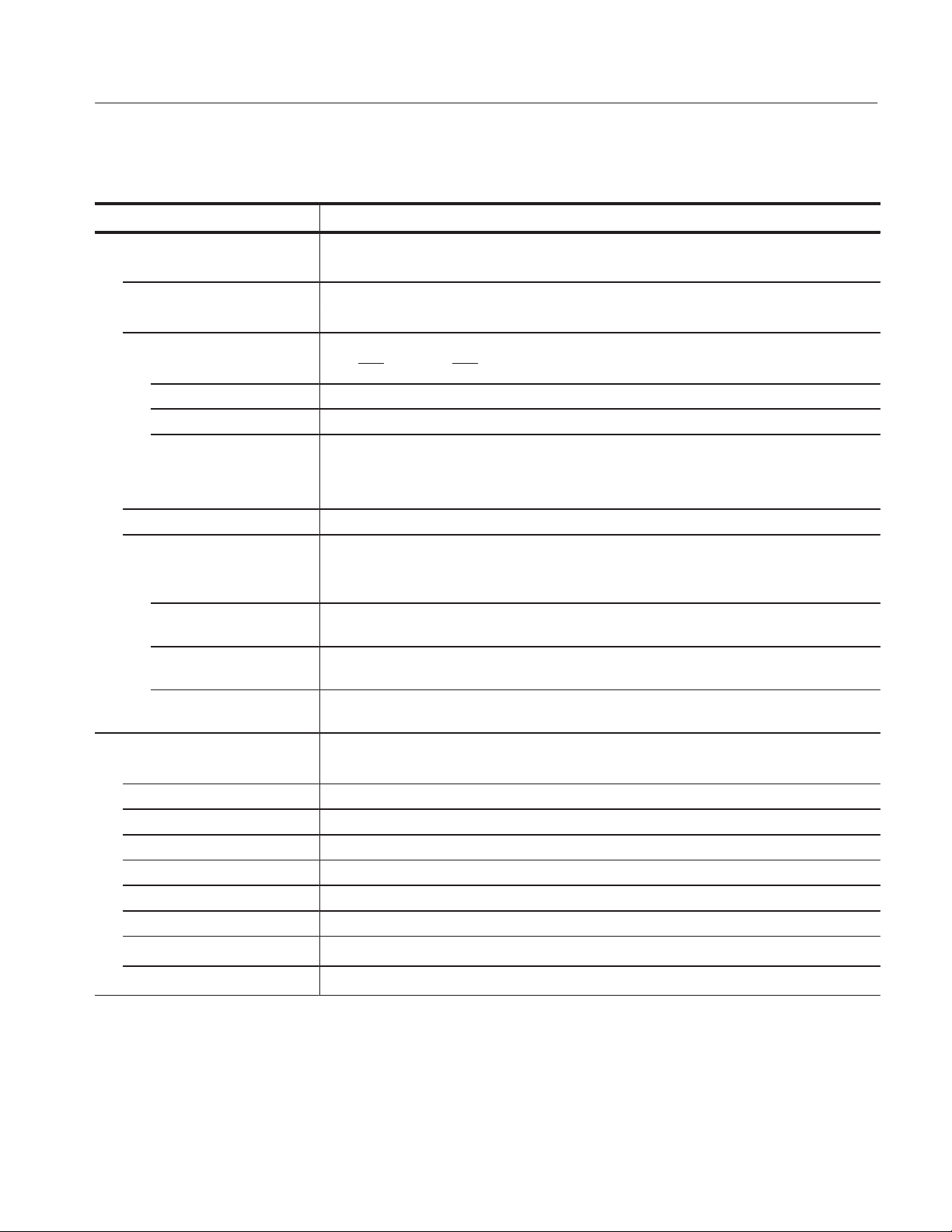

Table 1-1: Electrical characteristics 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . .

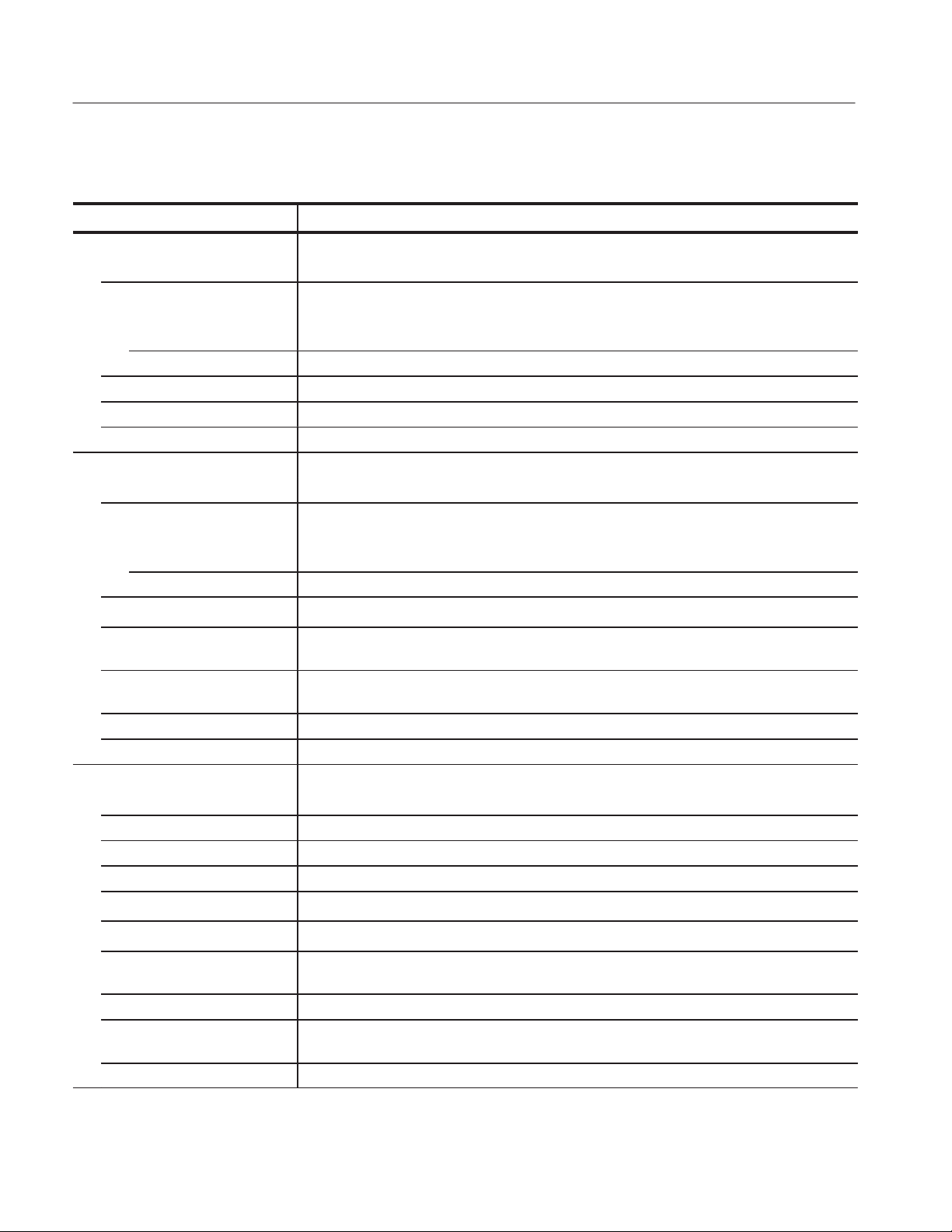

Table 1-2: Period JItter 1-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1-3: Cycle to Cycle JItter 1-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1-4: Mechanical characteristics 1-8. . . . . . . . . . . . . . . . . . . . . . . . .

Table 1-5: Environmental characteristics 1-8. . . . . . . . . . . . . . . . . . . . . .

Table 1-6: Certifications and compliances 1-12. . . . . . . . . . . . . . . . . . . . . .

Table 2-1: Power-cord conductor identification 2-2. . . . . . . . . . . . . . . . .

Table 2-2: Power cord identification 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-3: Fuse and fuse cap part numbers 2-4. . . . . . . . . . . . . . . . . . . . .

Table 2-4: AC line power requirements 2-4. . . . . . . . . . . . . . . . . . . . . . . .

Table 2-5: DG2040 Data Generator display elements 2-14. . . . . . . . . . . . .

Table 4-1: Performance check disk files 4-2. . . . . . . . . . . . . . . . . . . . . . . .

Table 4-2: Required equipment 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-3: Error codes 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-4: Internal clock frequency accuracy 4-10. . . . . . . . . . . . . . . . . . .

Table 4-5: High level output voltage accuracy 4-34. . . . . . . . . . . . . . . . . .

Table 4-6: Low level output voltage accuracy 4-34. . . . . . . . . . . . . . . . . . .

Table 4-7: Clock output voltage accuracy 4-37. . . . . . . . . . . . . . . . . . . . . .

Table 4-8: Rise and fall time accuracies 4-43. . . . . . . . . . . . . . . . . . . . . . .

Table 4-9: DG2040 test record 4-44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-1: Relative susceptibility to static-discharge damage 6-3. . . . . .

Table 6-2: External Inspection Check List 6-4. . . . . . . . . . . . . . . . . . . . . .

Table 6-3: Internal inspection check list 6-5. . . . . . . . . . . . . . . . . . . . . . . .

Table 6-4: Equipment required 6-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 7-1: International Power Cords 7-1. . . . . . . . . . . . . . . . . . . . . . . . .

Table 7-2: Standard accessories 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 7-3: Optional accessories 7-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

DG2040 Service Manual

Page 11

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Connect and Disconnect Properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

DG2040 Service Manual

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

vii

Page 12

General Safety Summary

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

WARNING

High Voltage

Protective Ground

(Earth) Terminal

CAUTION

Refer to Manual

Double

Insulated

viii

DG2040 Service Manual

Page 13

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, disconnect the mains power by means

of the power cord or, if provided, the power switch.

Use Caution When Servicing the CRT. To avoid electric shock or injury, use

extreme caution when handling the CRT. Only qualified personnel familiar with

CRT servicing procedures and precautions should remove or install the CRT.

CRTs retain hazardous voltages for long periods of time after power is turned off.

Before attempting any servicing, discharge the CRT by shorting the anode to

chassis ground. When discharging the CRT, connect the discharge path to ground

and then the anode. Rough handling may cause the CRT to implode. Do not nick

or scratch the glass or subject it to undue pressure when removing or installing it.

When handling the CRT, wear safety goggles and heavy gloves for protection.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

XĆRadiation. To avoid x-radiation exposure, do not modify or otherwise alter the

high-voltage circuitry or the CRT enclosure. X-ray emissions generated within

this product have been sufficiently shielded.

DG2040 Service Manual

ix

Page 14

Service Safety Summary

x

DG2040 Service Manual

Page 15

Introduction

This manual contains information needed to properly service the DG2040 Data

Generator, as well as general information critical to safe and effective servicing.

To prevent personal injury or damage to the DG2040 Data Generator, consider

the following before attempting service:

H The procedures in this manual should be performed only by a qualified

service person

H Read the General Safety Summary and the Service Safety Summary,

beginning on page vii

H Read the Operating Information section beginning on page 2-1

When using this manual for servicing be sure to follow all warnings, cautions,

and notes.

Performance Verification Interval

Generally, the performance verification should be done every 12 months and is

recommended after the replacement of a module.

Strategy for Servicing

If the DG2040 Data Generator does not meet performance criteria, repair is

necessary.

This manual contains all the information needed for periodic maintenance of the

DG2040 Data Generator. (Examples of such information are procedures for

checking performance.)

Further, the manual contains all information for corrective maintenance at the

module level. To isolate a failure to a module, use the troubleshooting procedures found in Maintenance:Troubleshooting section, beginning on page 6-1. To

remove and replace any failed module, follow the instructions in the Mainte-

nance:Removal and Installation Procedures beginning on page 6-15. After

isolating a faulty module, replace it with a fully-tested module obtained from

your local Tektronix distributor or sales office. The Replaceable Mechanical

Parts section, beginning on page 10-1, contains part number and ordering

information for all replaceable modules.

DG2040 Service Manual

xi

Page 16

Introduction

Tektronix Service Offerings

Tektronix provides service to cover repair under warranty as well as other

services that may provide a cost-effective answer to your service needs.

Whether providing warranty repair service or any of the other services listed

below, Tektronix service technicians are well trained to service the DG2040 Data

Generator. They have access to the latest information on improvements to the

DG2040 Data Generator as well as the latest new options.

Warranty Repair Service

Self Service

Tektronix warrants this product for one year from date of purchase. The warranty

appears on the back of the title page in this manual. Tektronix technicians

provide warranty service at most Tektronix service locations. The Tektronix

product catalog lists all worldwide service locations.

Tektronix supports repair to the module level by providing Module Exchange.

Module Exchange. This service reduces down-time for repair by allowing you to

exchange most modules for remanufactured ones. Each module comes with a

90-day service warranty.

For More Information. Contact your local Tektronix service center or sales

engineer for more information on any of the repair or adjustment services just

described.

xii

DG2040 Service Manual

Page 17

Preface

Manual Structure

This is the service manual for the DG2040 Data Generator. The manual contains

information needed to service the data generator to the module level.

This manual is divided into sections, such as the Specification and Theory of

Operation. Some sections are divided into subsections, such as Product

Description and Removal and Installation Procedures.

Sections containing procedures also contain introductions to those procedures.

Be sure to read these introductions because they provide information needed to

do the service correctly and efficiently. Following is a brief description of each

manual section.

H The Specification section contains a description of the DG2040 Data

Generator and the characteristics that apply to it.

H The Operating Information section includes general information and

operating instructions.

H The Theory of Operation section contains circuit descriptions that support

service to the module level.

H The Performance Verification section contains procedures to verify that the

DG2040 Data Generator functions properly and meets warranted limits.

H The Adjustment Procedure section contains a statement explaining that no

adjustment is needed for the DG2040 Data Generator.

H The Maintenance section contains information and procedures to perform

preventive and corrective maintenance of the DG2040 Data Generator. These

instructions include cleaning, module removal and installation, and fault

isolation to the module.

H The Options section contains information for servicing factory-installed

options.

H The Replaceable Electrical Parts section contains a statement that refers you

to the Replaceable Mechanical Parts. Both the electrical and mechanical

replaceable parts are listed in the mechanical section.

H The Diagrams section contains block diagrams and an interconnect diagram.

H The Replaceable Mechanical Parts. section includes a table of all replace-

able modules, their descriptions, and their Tektronix part numbers.

DG2040 Service Manual

xiii

Page 18

Preface

Manual Conventions

This manual uses certain conventions that you should become familiar with.

Some sections of the manual contain procedures for you to perform. To keep

those instructions clear and consistent, this manual uses the following

conventions:

H Names of front panel controls and menus appear in the same case (initial

capitals, all uppercase, etc.) in the manual as is used on the DG2040 Data

Generator front panel and menus. Front panel names are all upper-case

letters; for example, SETUP MENU, HARDCOPY, etc.

H Instruction steps are numbered unless there is only one step.

Modules

Safety

Throughout this manual, any replaceable component, assembly, or part of the

DG2040 Data Generator is referred to generically as a module. In general, a

module is an assembly (like a circuit board), rather than a component (like a

resistor or an integrated circuit). Sometimes a single component is a module. For

example, the chassis of the DG2040 Data Generator is a module.

Symbols and terms related to safety appear in the Safety Summary near the

beginning of this manual.

Finding Other Information

Other documentation for the DG2040 Data Generator includes:

H The DG2040 Data Generator User Manual contains a tutorial that explains

H The DG2040 Data Generator Programmer Manual explains how to use a

how to operate the DG2040 Data Generator. Also included is instructions

explaining how to use other DG2040 Data Generator features.

GPIB or RS-232 interface to remotely control the DG2040 Data Generator.

xiv

DG2040 Service Manual

Page 19

Contacting Tektronix

Preface

Phone 1Ć800Ć833Ć9200*

Address Tektronix, Inc.

Department or name (if known)

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

Web site www.tektronix.com

Sales support 1Ć800Ć833Ć9200, select option 1*

Service support 1Ć800Ć833Ć9200, select option 2*

Technical support Email: techsupport@tektronix.com

1Ć800Ć833Ć9200, select option 3*

6:00 a.m. - 5:00 p.m. Pacific time

* This phone number is toll free in North America. After office hours, please leave a

voice mail message.

Outside North America, contact a Tektronix sales office or distributor; see the

Tektronix web site for a list of offices.

DG2040 Service Manual

xv

Page 20

Preface

xvi

DG2040 Service Manual

Page 21

Product Overview

The DG2040 Data Generator is a portable digital data generator designed for

high performance and ease of use. The DG2040 Data Generator is easy to use for

testing and evaluating semiconductors and logic circuits, which are continually

becoming faster and more complex. The DG2040 Data Generator provides high

performance and a wide range of functions in a compact package.

Main Features

Following are the main features of the DG2040 Data Generator :

H Maximum data rate of 1.1 GHz

H 256 K word pattern memory

H Flexible sequence looping (which does the equivalent of over a billion word

H Two channels (Complementary)

H For each output channel:

patterns)

H Variable output levels (from –1.125 to +3.5 V, into 50 W)

H Edge Control function (CH0 only)

H Delay setting (–1.0 ns to +2.0 ns, 10 ps resolution)

H Serial/Parallel pattern editing

Any memory size from 360 words to 256 K words can be used easily with no

restrictions within that range. Either of the two bit data channels can be assigned

to any output channel. The output channels support setting of high and low

output voltage levels, and delay time. CH0 supports edge position.

The DG2040 Data Generator also provides a 4000-step sequence controller,

which enables the generation of not only a data pattern longer than the pattern

memory but also dynamic pattern change triggered by external events.

The DG2040 Data Generator provides flexible data editing functions, including

word and line unit input and extended data creation functions. The DG2040 Data

Generator also provides functions that are required for system construction, such

as a sequencing function which is a jump function using external input.

DG2040 Service Manual

1Ć1

Page 22

Product Overview

Applications

Following are some of the DG2040 Data Generator applications:

H Supports subassembly and system testing by simulating the digital signals

from incomplete sections of a product

H Performs margin tests by using the DG2040 Data Generator to generate

patterns that have a low probability of occurrence or are difficult to generate

H Constructs interactive digital simulation systems by using the sequence

output, external jump, and tristate control functions

H Uses flexible data output functions to make the DG2040 Data Generator an

ideal data generator for simulation of semiconductor devices and drivers

specific to serial data communication and all types of digital circuits

H Performs various timing analysis and jitter/wander tests by using the edge

control function to generate jitter on all the edges or selected edge(s)

1Ć2

DG2040 Service Manual

Page 23

Specifications

General Characteristics

This section describes the general characteristics of the DG2040 Data Generator.

All specifications are guaranteed unless labeled “typical”. Typical specifications

are provided for your convenience but are not guaranteed. Specifications marked

with the √ symbol are checked in the performance verification procedure

beginning on page 4-1.

The certification and compliances for the DG2040 Data Generator are found at

the end of this appendix.

Performance Conditions

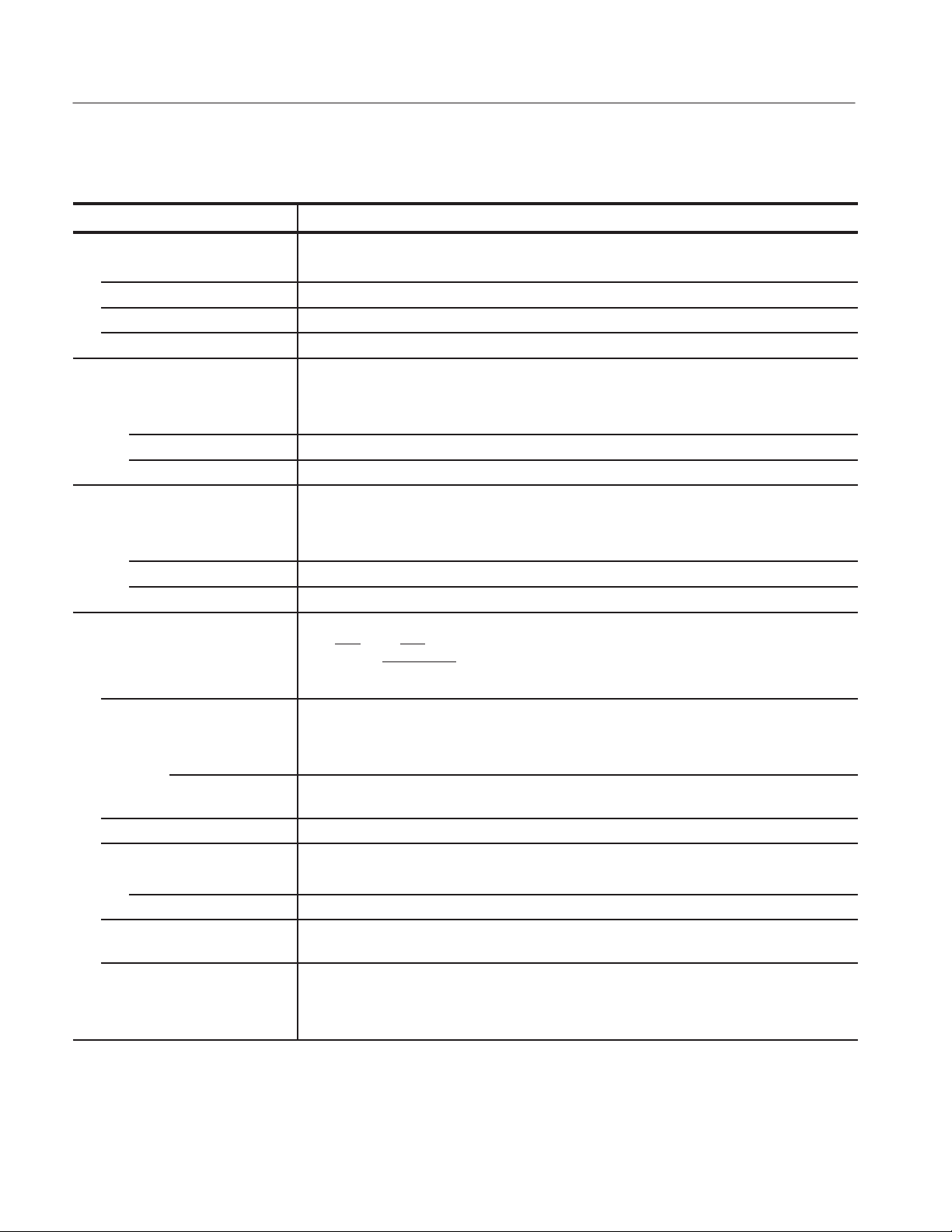

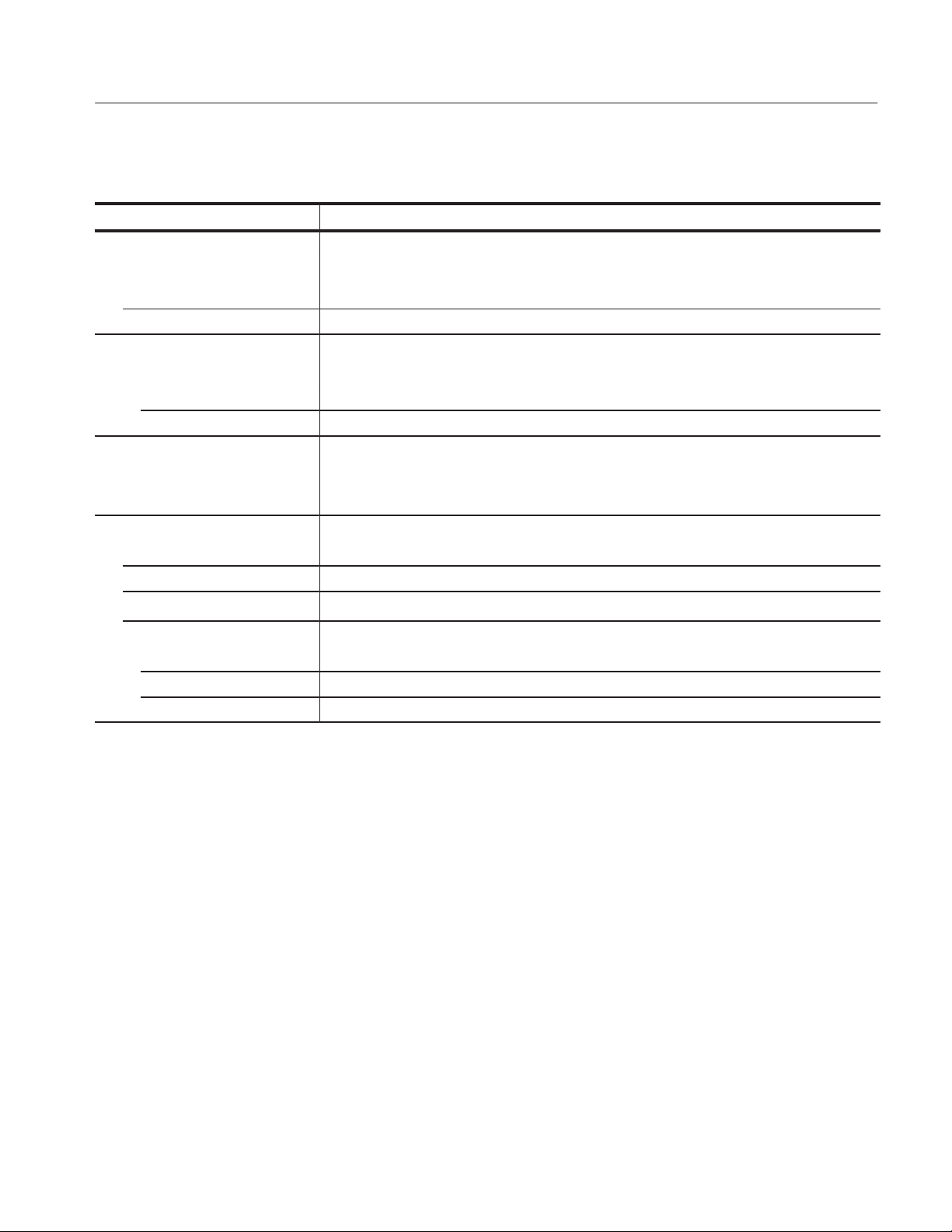

Table 1Ć1: Electrical characteristics

Characteristics Description

Operation mode

Repeat Pattern data is repeatedly output. When a sequence is specified, patterns are repeated

Single Pattern data is output only once. When a sequence is specified, a trigger signal outputs

Step Pattern data is output based on the clock, not specified by the clock source, but generated by

Enhanced Pattern data is output completely according to a sequence. All extended sequence functions,

1

The electrical characteristics are valid under the following conditions:

H The instrument must be in an environment with temperature, altitude,

humidity, and vibration within the operating limits described in these

specifications.

H The instrument must have had a warm-up period of at least 20 minutes.

H The instrument must have been calibrated and adjusted at an ambient

temperature between +20

H The instrument must be operating at an ambient temperature between

+10_ C to +40_ C, unless otherwise noted.

according to the sequence order. The extended sequence functions such as trigger wait, event

jump, and so on are ignored in this mode.

according to the sequence order.

pressing the STEP/EVENT button on the front panel. This mode is the same as the Repeat

mode except for the clock.

such as trigger wait, and event jump, are valid in this mode. This mode is the same as the

Repeat mode except for the extended sequence functions.

_ C and +30_ C.

DG2040 Service Manual

1Ć3

Page 24

Appendix A: Specifications

Table 1Ć1: Electrical characteristics (Cont.)

Characteristics Description

Output pattern

Pattern length 360 to 262144 points

Number of channels 2 Channels, Complementary

Sequence Maximum 4000 steps

Number of blocks Maximum 256

Internal trigger generator

Internal trigger rate

Range 1.0 ms to 10.0 s

Resolution 3 digits, 0.1 ms min.

Accuracy ± 0.01 %

Clock generator

√ Internal clock

Frequency 0.1 Hz to 1.1 GHz

Resolution 7 digits

Accuracy ± 0.0001 %, 1 year after shipment from factory

Data and clock out

Connectors CH0, CH0, CH1, CH1. (SMA connectors at front panel)

√ Output voltage

Accuracy

Maximum Output Current ± 100 mA

Aberration

Overshoot

Undershoot

√ Rise/fall time (20% to 80%)

√ Channel skew

1, 2

CLOCK OUT, CLOCK OUT

(SMA connector at rear panel)

All outputs are complementary.

DC (data out) (± 3 % of setting) ± 50 mV (into 50 W)

Amplitude (clock

(± 5 % of setting) ± 50 mV (into 50 W)at1MHz

out)

t 5%at1.5V

t 5%at1.5V

t 150 ps at 1 V

at 10 MHz

pĆp

at 10 MHz

pĆp

at 10 MHz, measured with a 0.5 m (20 inches), 50 W cable. See Optional

pĆp

Accessories on page 7Ć3 for details.

t ± ( | 25° C-Ta| × 15 ps ± 100 ps), where Tais the ambient temperature °C.

1Ć4

At 10 MHz, 1.0 V high, 0 V low, in Repeat Mode, the pattern is Clock except when using the

Edge Control function.

DG2040 Service Manual

Page 25

Appendix A: Specifications

Table 1Ć1: Electrical characteristics (Cont.)

Characteristics Description

Period jitter Measured by TDS694C-1MHD with TDSJIT1

(typical) Refer to Table 1Ć2.

Cycle to cycle jitter Measured by TDS694C-1MHD with TDSJIT1

(typical) Refer to Table 1Ć3.

√ Delay function

Delay channel CH0 (CH0), and CH1 (CH1),

Delay time -1.0 ns to +2.0 ns

Resolution 10 ps

Accuracy

Output impedance (typical) 50 W

Output voltage

High level (VOH) -1.75 V to +7.00 V (into 1 MW)

Low level (VOL) -2.25 V to +6.50 V (into 1 MW)

Resolution 10 mV (into 1 MW)

Voltage swing (VOH-VOL) 0.5 V to 5 V (into 1 MW)

Event input

Connector BNC at rear panel

Threshold level -5.0 V to +5.0 V, +1.4 V at default

Resolution 0.1 V

Input impedance (typical) 1kW

Turning point for event jump 230.5 to 254.5 clocks before the next block. Refer to Tacin Figure 1Ć3 on page 1Ć11.

Maximum input voltage ± 5V

Polarity Positive (rising edge)

Minimum pulse width

Sensitivity

t(± 3 % of setting) ± |25° C-Ta| × 15 ps ± 100 ps, where Tais the ambient temperature °C.

At 10 MHz, 1.0 V high, 0 V low, in Repeat Mode, the pattern is Clock except when using the

Edge Control function.

-0.875ĂV to +3.5 V (into 50 W)

-1.125 V to +3.25 V (into 50 W)

5 mV (into 50 W)

0.25 V

pĆp

to 2.5 V

(into 50 W)

pĆp

y 100 ns

y 1.0 V

pĆp

DG2040 Service Manual

1Ć5

Page 26

Appendix A: Specifications

Table 1Ć1: Electrical characteristics (Cont.)

Characteristics Description

Event output

Connector BNC at rear panel

Level

High level (Vhi) Approximately5Vinto1MW

Approximately 2.5 V into 50 W

Low level (Vlo) Approximately 0 V into both 1 MW and 50 W

Delay time 194.5 to 214.5 clocks before data output change. Refer to Td5in Figure 1Ć3 on page 1Ć11.

Pulse width 180 to 200 clocks. Refer to PW2in Figure 1Ć3 on page 1Ć11.

Impedance 50 W

Sync output

Connector BNC at rear panel

Level (typical)

High level (VOH) Approximately 5 V (into 1 MW)

Approximately 2.5 V (into 50 W)

Low level (VOL) Approximately 0 V (into both 1 MW and 50 W)

Trigger Input (typical)

Delay time from external trigger

input signal (typical)

Delay time to clock out and

data out (typical)

Pulse width (typical) 32 or 36 clocks. Refer to PW1in Figure 1Ć3 on page 1Ć11.

Impedance (typical) 50 W

Trigger input

Connector BNC at front panel

Threshold level -5.0 V to +5.0 V, +1.4 V at default

Resolution 0.1 V

Threshold accuracy (± 5 % of setting) ± 0.1 V

Minimum pulse width

Sensitivity

Impedance 50 W ± 2 W

Polarity Positive or Negative

Maximum input ± 10Vinto1kW

Trigger holdoff Minimum 100 ns

55 ns + 8/F

x Td1x 55 ns + 12/F

clk (GHz)

clk (GHz)

(Typical)

Internal Reference. Refer to Td1in Figure 1Ć3 on page 1Ć11.

1.5 Clocks, Refer to Td2in Figure 1Ć3 on page 1Ć11.

y 10 ns

y 0.5 V

pĆp

1kW ± 100 W

± 5 V into 50 W

1Ć6

DG2040 Service Manual

Page 27

Table 1Ć1: Electrical characteristics (Cont.)

Characteristics Description

Reference 10 MHz clock input

Connector BNC at front panel

Input voltage range 0.2 V to 3.0 V

Input voltage level

"Ă10 V Max

Impedance 50 W, AC Coupling

FrequencyĂRange 10ĂMHzñĂ0.1ĂMHz

Edge control input

Connector BNC at front panel

Voltage Range (typical) -Ă1Vto+1V

Input Impedance (typical) 50ĂW

Frequency Range (typical) DC to less than 500 MHz (-3 dB)

Transfer Function (typical) See Figure 1Ć2 on page 1Ć11.

Display

Display area Width: 13.2 cm (5.2 inches)

Height: 9.9 cm (3.9 inches)

Resolution Horizontal: 640 pixels

Vertical: 480 pixels

AC line power

Rating Voltage 100Ć240 V AC

Voltage Range and

Frequency Range

90Ć250 V AC, Input voltage frequency range is 48 Hz to 63 Hz

90Ć127 V AC, Input voltage frequency range is 48 Hz to 440 Hz

Maximum power 300 W

Maximum current 4A

Fuse rating 6A FAST, 250 V, UL 198G ( 3AG )

pĆp

Appendix A: Specifications

5A(T),250V,IEC127

1

Clock outputs continuously regardless of the operation mode.

2

The data output duty cycle varies from 3:7 to 7:3 at 1.0 V

pĆp

clock continuously outputs regardless of the run mode or sequence.

DG2040 Service Manual

during the 10 ms just after the output has been started. The

1Ć7

Page 28

Appendix A: Specifications

Table 1Ć2: Period JItter

Clock frequency 1.1 GHz 800 MHz

Measurement StdDev Pk-Pk StdDev Pk-Pk

Clock output 3.0 ps 16 ps 3.0 ps 13 ps

CH0 output 3.5 ps 20 ps 3.5 ps 20 ps

Table 1Ć3: Cycle to Cycle JItter

Clock frequency 1.1 GHz 800 MHz

Measurement StdDev Pk-Pk StdDev Pk-Pk

Clock output 5.0 ps 28 ps 4.0 ps 22 ps

CH0 output 5.5 ps 32 ps 5.5 ps 32 ps

Table 1Ć4: Mechanical characteristics

Characteristics Description

Net weight

Standard 10.3 kg (22.7 lb)

Dimensions

Height 164 mm (6.4 inches) including feet

Width 362 mm (14.3 inches) including handle

Length 491 mm (19.25 inches) including front cover

576 mm (22.2 inches) with handle extended

Table 1Ć5: Environmental characteristics

Characteristics Description

Temperature

Operating +10_ Cto+40_ C

Nonoperating -20_ Cto+60_ C

Relative humidity

Operating 20% to 80% (No condensation)

Maximum wetĆbulb temperature 29.4_ C

Nonoperating 5% to 90% (No condensation)

Maximum wetĆbulb temperature 40.0_ C

1Ć8

DG2040 Service Manual

Page 29

Table 1Ć5: Environmental characteristics (Cont.)

Characteristics Description

Altitude

Operating To 4.5 km (15,000 feet).

Maximum operating temperature decreases 1 _C each 300 m above 1.5 km.

Nonoperating To 15 km (50,000 feet).

Dynamics

Vibration

Operating 0.27 G

Nonoperating 2.28 G

Shock

Nonoperating 294 m/s2(30 G), halfĆsine, 11 ms duration.

Three shocks per axis in each direction (18 shocks total)

Installation requirements

Power consumption 300 watts maximum. Maximum line current is 4 A

Dissipation (fully loaded) 90 V line, with 5% clipping

Surge current

x 9 A peak for less than 5 line cycles at 25_ C after product has been off for at least 30 s.

Cooling clearance

Top clearance 2.5 cm (1 inch)

Side clearance 15 cm (6 inches)

Rear clearance 7.5 cm (3 inches)

, 5 to 500 Hz

rms

, 5 to 500 Hz

rms

rms

Appendix A: Specifications

at 50 Hz

DG2040 Service Manual

1Ć9

Page 30

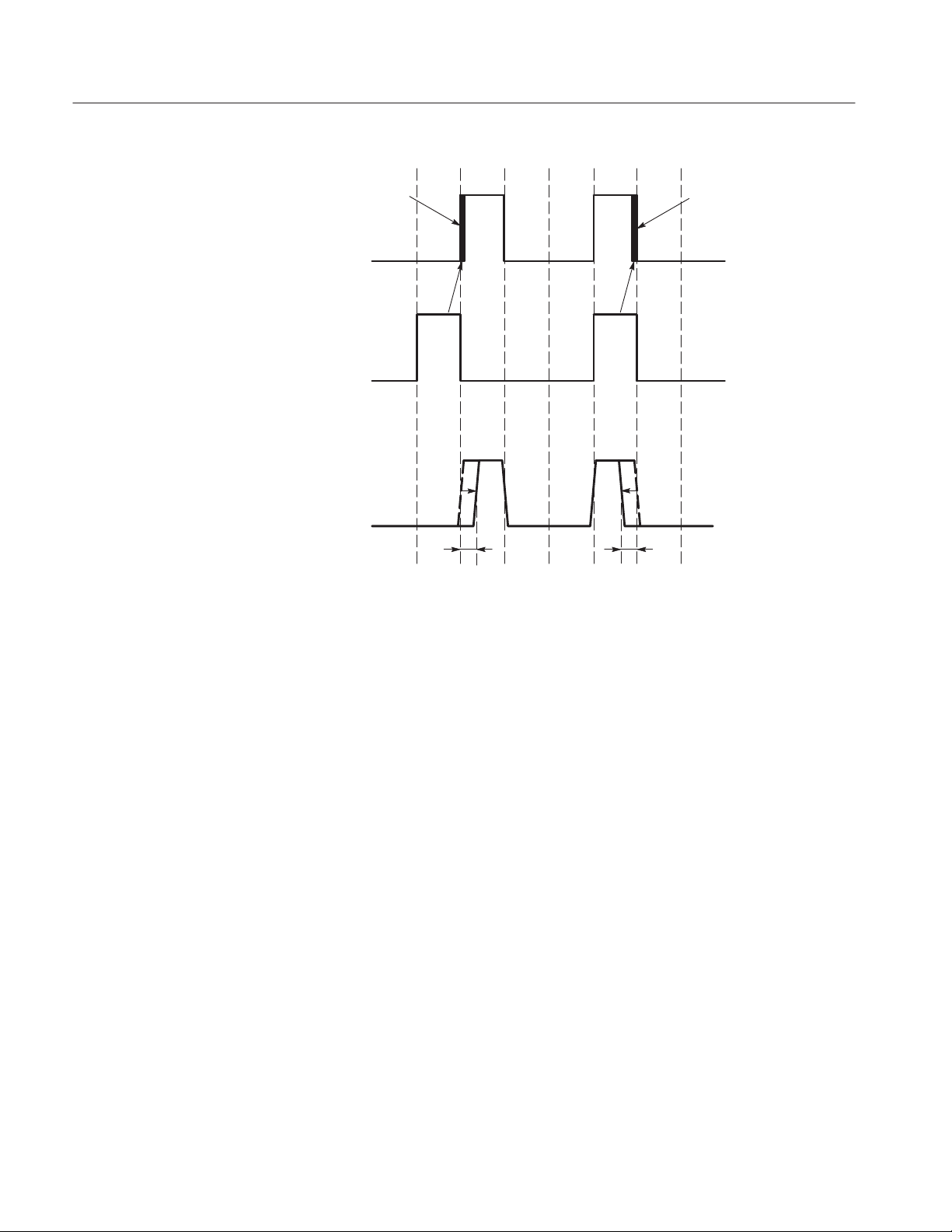

Appendix A: Specifications

Controlled Edge

CH0 Pattern

CH1 Pattern

CH0 Output

11

00 00

11

000000

ntr

The rising edge moves to the right and falling edge moves to the left, when the

position offset is set to more than 0 ps or when the edge control input is more

than 0V.

Controlled Edge

00

ntf

Figure 1Ć1: Timing definition in edge control input

1Ć10

DG2040 Service Manual

Page 31

Appendix A: Specifications

300

Rising Edge

Falling Edge

200

100

0

-100

Position Offset [ps]

-200

-300

-1.5

-1 -0.5 0 0.5 1 1.5

Edge Control Input [V]

Figure 1Ć2: Transfer function for edge control input

External

trigger input

Clock output

Data output

Sync output

Data output

Event input

Event input

Event output

Start

D1N D20 D10 D22 D23 D24 D25 D26 D27 D28

T

d1

Current block Next block

P

w2

T

ac

(Td5)

T

Stop

D2NĆ3 D2NĆ2 D2NĆ1

P

w1

d2

(Typical) 55 ns + 8/F

x Td1x 55 ns + 12/F

clk (GHz)

Td2= 1.5 clocks (typical)

= 32 to 36 clocks

P

w1

T

) = 194.5 to 214.5 clocks

ac(Td5

= 180 to 200 clocks

P

w2

Jump to the specified block after the current block

Jump to the specified block after the next block

D2NĆ2

clk (GHz)

Figure 1Ć3: Signal timing

DG2040 Service Manual

1Ć11

Page 32

Appendix A: Specifications

Certification and Compliances

The certification and compliances for the DG2040 Data Generator are listed in

Table 1-6.

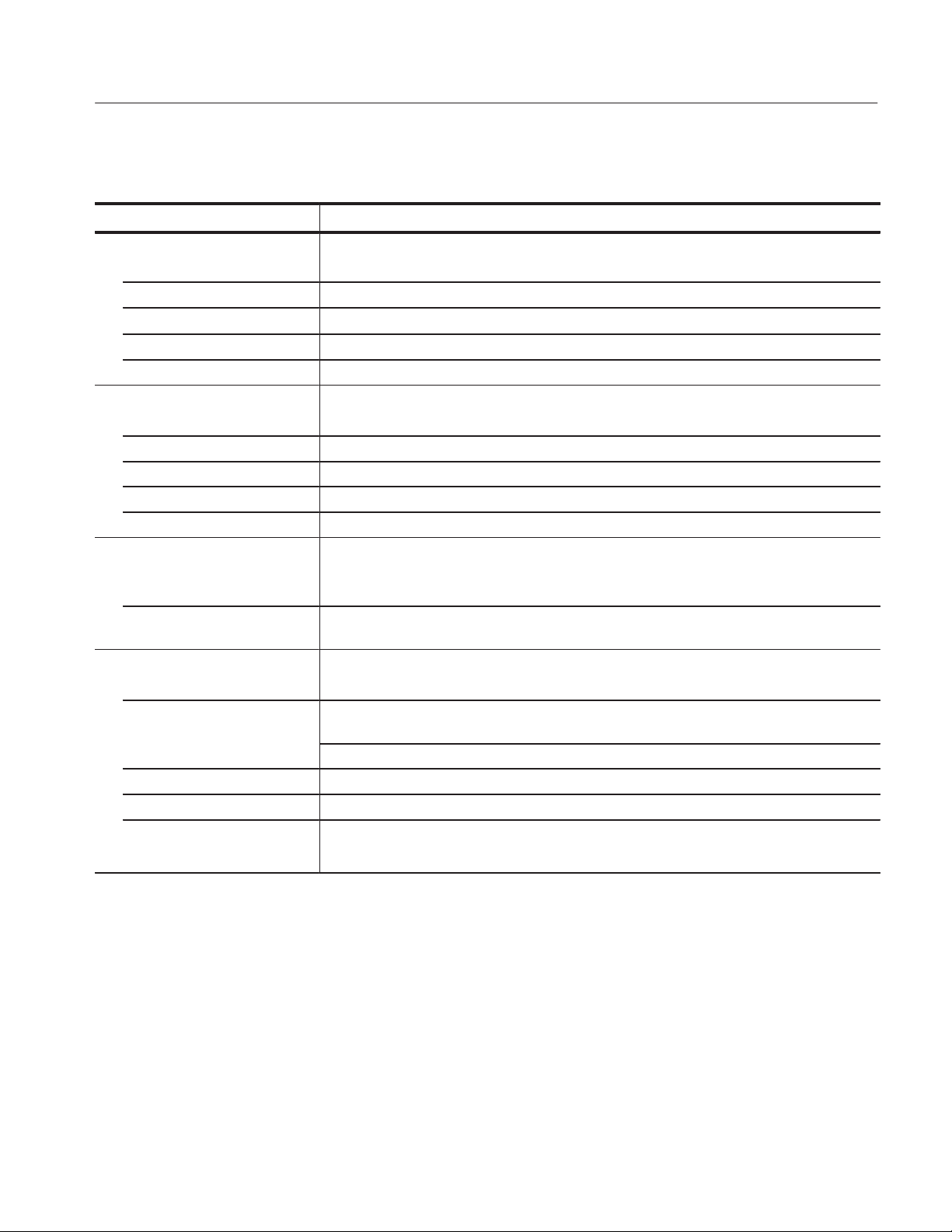

Table 1Ć6: Certifications and compliances

Category Standards or description

EC Declaration of Conformity EMC

Australian/New Zealand

declaration of Conformity Ć EMC

EC Declaration of Conformity Low Voltage

Meets intent of Directive 89/336/EEC for Electromagnetic Compatibility. Compliance was

demonstrated to the following specifications as listed in the Official Journal of the European

Communities:

EMC Directive 89/336/EEC:

EN 55011

Class A Radiated and Conducted Emissions

EN 50081Ć1 Emissions:

EN61000Ć3Ć2

AC Power Line Harmonic Emissions

EN 50082Ć1 Immunity:

EN61000Ć4Ć2

Electrostatic Discharge Immunity

EN61000Ć4Ć3

RF Electromagnetic Field Immunity

EN61000Ć4Ć4

Electrical Fast Transient/Burst Immunity

EN61000Ć4Ć6

Conducted Disturbance Induced by Radio-frequency Field

EN61000Ć4Ć8

Power Frequency Electromagnetic Field Immunity

EN61000Ć4Ć11

Voltage Dips and Interruptions Immunity

Complies with EMC provision of Radio-communications Act per the following standard:

AS/NZS 2064.1/2 Industrial, Scientific, and Medical Equipment: 1992

Compliance was demonstrated to the following specification as listed in the Official Journal of the

European Communities:

Low Voltage Directive 73/23/EEC, amended by 93/68/EEC

EN 61010Ć1/A1:1992

Safety requirements for electrical equipment for

measurement, control and laboratory use.

Approvals Complies with the following safety standards:

UL3111-1, First Edition Standard for electrical measuring and test equipment.

CAN/CSA C22.2 No.1010.1Ć92

Safety requirements for electrical equipment for

measurement, control and laboratory use.

1Ć12

DG2040 Service Manual

Page 33

Appendix A: Specifications

Table 1Ć6: Certifications and compliances (cont.)

Category Standards or description

Installation Category Description Terminals on this product may have different installation (over-voltage) category designations. The

installation categories are:

Category Examples of products in this category

CAT III DistributionĆlevel mains (usually permanently connected). Equipment at this

level is typically in a fixed industrial location.

CAT II LocalĆlevel mains (wall sockets). Equipment at this level includes appliances,

portable tools, and similar products. Equipment is usually cordĆconnected.

CAT I Secondary (signal level) or battery operated circuits of electronic equipment.

Pollution Degree A measure of the contaminates that could occur in the environment around and within a product.

Typically the internal environment inside a product is considered to be the same as the external.

Products should be used only in the environment for which they are rated.

Pollution Degree 2 Normally only dry, nonconductive pollution occurs. Occasionally a

temporary conductivity that is caused by condensation must be

expected. This location is a typical office/home environment.

Temporary condensation occurs only when the product is out of

service.

Conditions of Approval Safety Certifications/Compliances are made for the following conditions:

Altitude (maximum operation): 2000 meters

IEC Characteristics Equipment type:

Test and Measuring

Installation Category II (as defined in IEC 61010-1, Annex J)

Pollution Degree 2 (as defined in IEC 61010-1)

Safety Class I (as defined in IEC 61010-1, Annex H)

DG2040 Service Manual

1Ć13

Page 34

Appendix A: Specifications

1Ć14

DG2040 Service Manual

Page 35

Operating Information

Page 36

Page 37

Operating Information

This subsection provides the following information:

H Operating environment

H Supplying operating power

H Applying and interrupting power

H Checking the fuse

NOTE. Read all information and heed all warnings in this subsection before

connecting the DG2040 Data Generator to a power source.

Refer to the Specification section of this manual for line voltage and frequency

ranges.

WARNING. To avoid equipment failure and potential fire or personal shock

hazards, do not exceed the maximum rated operating voltage of 250 V between

the voltage-to-ground (earth) and either pole of the power source. The DG2040

Data Generator operates from a single-phase power source and has a three-wire

power cord with a two-pole, three-terminal grounding plug. Also, before making

connection to the power source, be sure the DG2040 Data Generator has a

suitable two-pole, three-terminal grounding-type plug.

DG2040 Service Manual

To avoid personal shock hazard, do not touch conductive parts. All accessible

conductive parts are directly connected through the grounding conductor of the

power cord to the grounded (earth) contact of the power plug. The DG2040

Data Generator is safety Class 1 equipment (IEC designation).

WARNING. To avoid personal shock hazard, do not defeat the grounding

connection. Insert the power input plug only in a mating receptacle with a

grounding contact where earth ground has been verified by a qualified service

person. Also, for electrical shock protection, make the grounding connection

before making connection to the DG2040 Data Generator input or output

terminals.

2Ć1

Page 38

Operating Information

Power Cord Information

The DG2040 Data Generator is shipped with the required power cord as ordered

by the customer. Table 2-1 gives the color-coding of the conductors in the power

cord. Table 2-2 shows information on the available power cords.

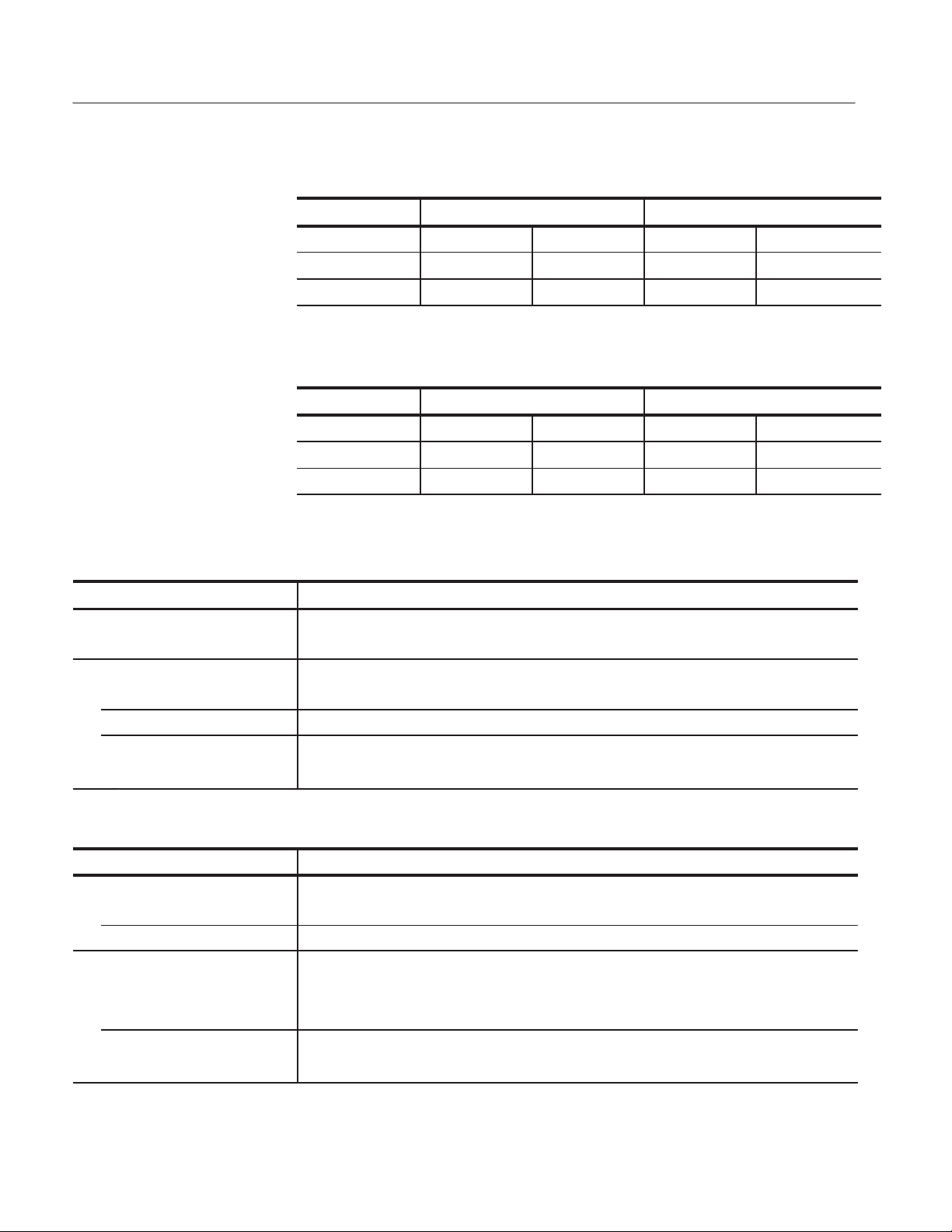

Table 2Ć1: PowerĆcord conductor identification

Conductor Color Alternate color

Ungrounded (Line) Brown Black

Grounded (Neutral) Light Blue White

Grounded (Earthing) Green/Yellow Green

Table 2Ć2: Power cord identification

Plug configuration Normal usage Option number

North America

125 V

Europe

230 V

United Kingdom

230 V

Australia

230 V

North America

230 V

Switzerland

230 V

Standard

A1

A2

A3

A4

A5

2Ć2

DG2040 Service Manual

Page 39

Operating Environment

Operating Information

To ensure proper DG2040 Data Generator operation and long life, note the

following environmental requirements.

CAUTION. Damage to the instrument can occur if this instrument is powered on

at temperatures outside the specified temperature range.

NOTE. If you are installing the instrument in a dedicated rack, refer to the

instruction sheet that comes with the rack mounting kit for proper installation

procedures.

Operating Temperature

Ventilation Requirements

Fuse Type and Rating

The DG2040 Data Generator operates correctly in ambient temperatures from

+10_ C to +40_ C and in relative humidity from 20% to 80%.

Verify that there is at least 2.5 cm (1 inch) of clearance on top and bottom, 15.0

cm (6 inches) on the left and right sides, and 7.5 cm (3 inches) at the rear of the

instrument to allow for heat dissipation. Verify that the air intake holes on the

sides and bottom of the cabinet are not obstructed.

The feet on the bottom of the DG2040 Data Generator cabinet provide the

required clearance when it is set on a flat surface.

CAUTION. To prevent temporary shutdown of the DG2040 Data Generator, do

not restrict air flow through the chassis. If the DG2040 Data Generator shuts

down unexpectedly, improve ventilation around the DG2040 Data Generator and

wait a few minutes to allow it to cool down; then switch the power on again.

The DG2040 Data Generator uses the same fuse for all operating line voltage

ranges. One of two fuse types is installed in the instrument, depending upon the

power cord option. Table 2-3 provides the available types and ratings.

DG2040 Service Manual

WARNING. To avoid electrical shock, always unplug the power cord from the

socket before checking the line fuse.

2Ć3

Page 40

Operating Information

Check Fuse

Check the fuse to be sure it is the proper type and rating.

To check the fuse, remove the fuse holder on the rear panel. Refer to Figure 2-3

for the location of the fuse holder. To remove the fuse holder, turn it counterclockwise with a screwdriver while pushing it in.

WARNING. To avoid electrical shock, be sure that the power cord is disconnected

before checking the fuse.

Use a slotted screwdriver to remove the fuse. Push in and turn the fuse holder

cap counterclockwise. See Figure 2-1 for the fuse location.

The instrument order specified either a UL approved or an IEC approved fuse.

Each fuse requires its own cap. See Table 2-3.

Table 2Ć3: Fuse and fuse cap part numbers

Tektronix fuse

Fuse

0.25 inch × 1.25 inch (UL 198.6, 3 AG):

6 A fast, 250

5mm× 20 mm (IEC 127): 5 A (T), 250 V 159Ć0210Ć00 200Ć2265Ć00

part number

159Ć0239Ć00 200Ć2264Ć00

Tektronix fuse cap

part number

Check Voltage Settings

Connect Power Cable

NOTE. The second fuse listed in Table 2-3 is approved under the IEC standards.

This fuse is used in equipment sold in the European market.

Check that you have the proper electrical connections. Refer to Table 2-4 for

power requirements.

Table 2Ć4: AC line power requirements

Name Description

Line voltage range 90 V - 250 V

Line frequency 48 Hz - 440 Hz ( 90 V - 127 V)

48 Hz - 63 Hz (127 V - 250 V)

Maximum power 300 W

Connect the proper power cord from the rear panel power connector to the power

system. Refer to Table 2-2 for power cord identification.

2Ć4

DG2040 Service Manual

Page 41

Operating Information

CAUTION. The instrument is shipped with a power cord appropriate for use with

your power systems (normal 115 V power system or 230 V power system). If the

instrument is to be used with a power system other than what the order specified,

the power cord must be replaced with one appropriate for the power source

used.

Standby Power

Apply power to the standby circuit of the instrument by pushing the

PRINCIPAL POWER SWITCH on the rear panel of the instrument. Refer to

Figure 2-1.

NOTE. After the instrument is installed, leave the PRINCIPAL POWER

SWITCH on and use the ON/STBY switch as the power switch.

Power Connector

Power On

DG2040 Service Manual

Fuse PRINCIPAL POWER

SWITCH

Figure 2Ć1: Rear panel power switch, fuse holder, and connector

Press the ON/STBY switch on the lower left side of the front panel to power on

the instrument. Refer to Figure 2-2.

Verify that the fan is operating.

2Ć5

Page 42

Operating Information

NOTE. Allow a 20 minute warm-up period prior to calibrating the clock for the

instrument to operate at its optimum precision.

StartĆUp Diagnostics

Power Off

ON/STBY Switch

Figure 2Ć2: Location of the ON/STBY switch

The DG2040 Data Generator automatically runs diagnostics when the instrument

is powered on from the ON/STBY switch. These diagnostics check whether the

instrument is performing within its defined operating characteristics. If all the

diagnostic items have been completed without error, the instrument displays the

EDIT menu.

NOTE. If the instrument chassis temperature is outside the specified operating

range, an error will occur during the power-up diagnostics. If this happens,

power off the instrument, wait until the chassis temperature is within normal

operating range, and then power on the instrument again.

If an error is displayed, contact your Tektronix Field Office or representative.

To power off the DG2040 Data Generator, press the ON/STBY switch.

2Ć6

DG2040 Service Manual

Page 43

Rear Panel Controls

Operating Information

NOTE. The ON/STBY switch disables the outputs of the power supply. The

PRINCIPAL POWER SWITCH on the rear panel disconnects the instrument

from the primary voltage source.

Figure 2-3 shows the rear panel controls for the DG2040 Data Generator.

Power Connector

Figure 2Ć3: Rear panel controls

Applying and Interrupting Power

Consider the following information when you power on or power off the

DG2040 Data Generator, or when external power loss occurs.

PowerĆon Cycle

DG2040 Service Manual

At power-on, the start-up diagnostics check the DG2040 Data Generator

operation. If all diagnostic items complete without error, the DG2040 Data

Generator displays the EDIT menu.

Fuse PRINCIPAL POWER

SWITCH

2Ć7

Page 44

Operating Information

If the diagnostics detect an error, the DG2040 Data Generator displays the error

code. To exit the diagnostics menu, press any key; then the system displays the

EDIT menu. See the Maintenance:Troubleshooting section, beginning on page

6-1 for information on diagnostics and fault isolation.

NOTE. If the ambient temperature goes outside the specified operating temperature range, an error occurs during the diagnostics at power-on. If this happens,

power off the DG2040 Data Generator and wait until the chassis temperature is

appropriate; then switch the power on again.

PowerĆoff Cycle

Memory Backup Power

Wait for the DG2040 Data Generator to finish the operation when saving data

files. Improper power-off or unexpected loss of power to the DG2040 Data

Generator can result in the corruption of data stored in nonvolatile memory.

A lithium battery maintains internal nonvolatile memory, allowing the DG2040

Data Generator to retain data files if AC power is lost. This battery has a shelf

life of about three years. Partial or total loss of stored information at power-on

may indicate that the battery needs to be replaced.

WARNING. To avoid risk of fire or explosion, replace the DG2040 Data

Generator battery with a lithium battery having the part number listed in the

Replaceable Mechanical Parts section beginning on page 10-10.

To avoid risk of fire or explosion, do not recharge, rapidly discharge, or

disassemble the battery; and do not incinerate the battery or heat it above

100° C. Also, dispose of used batteries promptly. Small quantities of used

batteries can be disposed of in normal refuse. Keep lithium batteries away from

children.

Repackaging Instructions

If this instrument is shipped by commercial transportation, use the original

packaging material. If the original packaging is unfit for use or is not available,

repackage the instrument as follows:

1. Obtain a corrugated cardboard shipping carton having inside dimensions at

2Ć8

least six inches greater than the instrument dimensions and having a carton

test strength of at least 124.74 kg (275 pounds).

DG2040 Service Manual

Page 45

Operating Information

2. If the instrument is being shipped to a Tektronix Service Center for repair or

calibration, attach a tag to the instrument showing the following: owner of

the instrument (with address), the name of a person at your firm who may be

contacted if additional information is needed, complete instrument type and

serial number, and a description of the service required.

3. Wrap the instrument with polyethylene sheeting or equivalent to protect the

outside finish and prevent entry of packing materials into the instrument.

4. Cushion the instrument on all sides by tightly packing dunnage or urethane

foam between the carton and the instrument, allowing for three inches of

padding on each side (including top and bottom).

5. Seal the carton with shipping tape or with an industrial stapler.

DG2040 Service Manual

2Ć9

Page 46

Operating Information

2Ć10

DG2040 Service Manual

Page 47

Operating Instructions

Before servicing the DG2040 Data Generator, read the following operating

instructions. These instructions are at the level appropriate for servicing the

DG2040 Data Generator. The user manual contains complete operator instructions.

How to Power On

The Performance Verification section, begining on page **

instructions for making the front-panel settings required to check DG2040 Data

Generator characteristics.

To power-on the DG2040 Data Generator, follow these steps:

1. Set the PRINCIPAL POWER SWITCH (on the rear of the DG2040 Data

Generator) to the ON position. This switch is the main power switch; it

routes power to the standby circuit in the DG2040 Data Generator.

2. Press the ON/STBY (standby) switch on the front (lower-left corner) of the

DG2040 Data Generator. This switch applies power to the remaining circuits

of the DG2040 Data Generator. Allow at least 20 minutes for the DG2040

Data Generator to warm up.

WARNING. To avoid personal shock hazard, turn off both the ON/STBY switch

and the PRINCIPAL POWER SWITCH before servicing. The PRINCIPAL

POWER SWITCH on the rear panel is the true power disconnect switch. The

ON/STBY (standby) switch simply toggles operation on and off. When connected

to a power source and when the PRINCIPAL POWER SWITCH is on, the

internal power supplies and much of the other circuitry of the DG2040 Data

Generator remain energized regardless of the setting of the ON/STBY switch.

**, includes

To avoid personal shock hazard, set the PRINCIPAL POWER SWITCH off

before connecting or disconnecting the line cord to or from the power source.

Internal Diagnostics Routines

At power-on, the DG2040 Data Generator performs internal start-up diagnostics.

These diagnostics check the internal circuit function and report any failures. In

addition, you can initiate internal diagnostics using the Diag item in the

UTILITY menu; these diagnostics differ from the start-up diagnostics in that

they do more extensive memory checking.

DG2040 Service Manual

2Ć11

Page 48

Operating Instructions

User Interface

The DG2040 Data Generator uses a combination of front-panel buttons, keys, a

knob, and on-screen menus to control generator functions. Some front-panel

controls select menus and manipulate menu items. Others enter values and units,

allow manual triggering, start/stop DG2040 Data Generator output, advance the

pattern data, generate an event pulse, and make a hard copy. On-screen graphics

show various aspects of the current DG2040 Data Generator configuration.

On-screen menus set most DG2040 Data Generator functions. Main menus

provide access to lower-level submenus. Buttons in the center of the front panel

select the main menus.

When you select a menu, the display shows the items controlled by that menu

and numeric values currently in effect. Buttons around the display select

lower-level menus, change menu selections, modify numeric values and units,

and execute functions.

2Ć12

DG2040 Service Manual

Page 49

Operating Instructions

Display Elements

Figure 2-4 shows the display elements, including bottom and side menus, work

area, status lines, and so on. Also shown are a pop-up menu and message box.

Table 2-5 describes each element in detail.

1 2

6

3

5

Figure 2Ć4: Display elements

4

7

8

DG2040 Service Manual

2Ć13

Page 50

Operating Instructions

Table 2Ć5: DG2040 Data Generator display elements

Figure

number

1 Status area

Label Description

Displays the current status of the instrument. This status

line is always displayed, whichever menu is displayed.

The status line displays the following two items.

MODE: Displays the run mode in which pattern data will

be output.

UPDATE: Displays the update method for pattern data

output when data is updated.

In addition, there is also a disk icon that indicates

whether or not a floppy disk is inserted in the disk drive.

A clock icon may also be displayed at the left end of the

status line. When this icon is displayed, the instrument is

busy with internal processing and cannot accept other

inputs.

2 Date and Time

display area

3 Side menu Related side menu items are displayed here when a

4 Bottom menu When one of the buttons in the menu section is pressed,

5 Button function

description

area

6 Message disĆ

play area

7 PopĆup mesĆ

sage box

8 PopĆup menu The instrument sometimes displays a popĆup menu

The date and time display can be turned on or off using

the UTILITY menu.

bottom menu item is selected. The topmost entry in the

side menu displays either a label representing the side

menu or the operation name for the confirmed item.

the corresponding bottom menu is displayed. When a

bottom menu item is selected the corresponding side

menu is displayed. Selecting the same bottom menu

item again closes the side menu.

Displays descriptions of the functions of the front panel

buttons.

Displays messages that report on the current processing

state. This area can be also used by remote commands

to display user messages.

When required, the instrument temporarily displays a

window at the center of the screen to display a warning

or question for the user.

when a bottom menu or side menu item is selected.

Enter a numeric value or select an item using either the

general purpose knob or the front panel buttons.

2Ć14

DG2040 Service Manual

Page 51

Menus

Operating Instructions

The DG2040 Data Generator operation is primarily controlled by means of

menus that correspond to the EDIT, SETUP, APPLICATION and UTILITY

buttons in the MENU column. To display one of these main menus on the

screen, push the corresponding button. The button LED indicates which menu is

currently selected. Refer to the DG2040 Data Generator User Manual for more

details concerning these menus.

H EDIT Menu

Provides functions for editing pattern data and creating sequences.

H SETUP Menu

Provides functions for defining groups, setting up channels, and setting

output channel voltages, the operating mode, and triggers.

H APPLICATION Menu

The current version of the firmware provides edge control functions under

the APPLICATION menu.

Pattern Storage and I/O

Loading Files

H UTILITY Menu

This menu provides functions for manipulating the basic instrument settings.

The DG2040 Data Generator has internal nonvolatile memory (NVRAM) for

pattern file storage. The DG2040 Data Generator generates patterns from files

residing in internal nonvolatile memory.

The DG2040 Data Generator also has a floppy-disk drive for loading files from a

floppy disk into internal nonvolatile memory, and for saving files from memory

to a floppy disk. The disk drive accepts 3.5-inch floppy disks in the MS-DOS

format.

The following steps explain how to load files from a floppy disk into internal

memory.

1. Turn the disk so the side with the arrow is on top; insert the disk into the

DG2040 Data Generator floppy disk drive.

DG2040 Service Manual

2. Press the EDIT button on the front panel.

2Ć15

Page 52

Operating Instructions

3. Select File from the bottom menu.

4. Select Load Data & Setup from the side menu. The menu in Figure 2-5

appears.

5. Turn the general purpose knob to highlight the file you want to load and

select OK from the sub menu.

6. Push the floppy drive button and remove the disk from the floppy drive.

Signal Output

2Ć16

Figure 2Ć5: Load Data and Parameters menu

The procedure assumes that data has already been loaded as explained in the

previous section.

The following example first groups the data bits from the pattern data already

created and allocates each data bit to output channels. Next, this procedure sets

all the settings required for signal output and actually outputs the signals.

DG2040 Service Manual

Page 53

Operating Instructions

H Tables such as the one below shows the sequence of the operating procedure.

Execute the action on the left side of the top row first. Then execute actions

from left to right across the row. When one row has been completed, move to

the left side of the next row down. For pop-up menus, use the general

purpose knob to select items from the menu list. Operations such as

Operation 6 (below) do not involve pressing the buttons shown in the row

above, but rather are descriptions of operations to be performed. Figure 2-6

shows the buttons used and the menu layout.

Front panel

Menu button Bottom button PopĆup menu Side button

Operation 1 Operation 2 Operation 3 Operation 4 Operation 5

Operation 6 (For example, set to xx with general purpose knob.)

Operation 7

button

Setting Sampling Clock

Frequency

PopĆup Menu

Bottom Menu

Side Menu

Bottom Button

General Purpose Knob

Menu Button

Side Button

Figure 2Ć6: Operating buttons and menu layout

1. Set the sampling clock frequency to 800 MHz.

Menu button Bottom button PopĆup menu Side button

Clock Source

(Select Int)

Front Panel Button

Front panel

button

DG2040 Service Manual

Int FREQ 800

MHz

2Ć17

Page 54

Operating Instructions

Setting Signal Generation

Mode

Setting Output Level

2. Set the signal generation mode to continuous mode.

Front panel

Menu button Bottom button PopĆup menu Side button

Run Mode Repeat

button

The output level is always at the TTL level.

3. Set the output channel CH0 and CH1 output levels to 2 V for the high level

and –1 V for the low level.

Front panel

Menu button Bottom button PopĆup menu Side button

Level Condition

Select channel CH0 using the front panel up and down arrow buttons.

High Level 2

Low Level -1

button

ENTER

ENTER

Setting Delay Timing

Set the output levels for channels CH1 to CH7 in the same manner.

The delay time for each channel can be set.

4. Set the delays for the output channel CH0 and CH1 to 2 ns.

Front panel

Menu button Bottom button PopĆup menu Side button

Select channel CH1 by pressing the front panel up and down arrow buttons.

Delay 10

Set the delays for channels CH5 to CH7 in the same manner.

button

ENTER

2Ć18

DG2040 Service Manual

Page 55

Delay Time Setting

Output Voltage Level Settings

Figure 2Ć7: Output voltage level and delay time display

Operating Instructions

Signal Output

This step actually outputs the signals.

5. Press the START/STOP button on the front panel.

DG2040 Service Manual

2Ć19

Page 56

Operating Instructions

2Ć20

DG2040 Service Manual

Page 57

Theory of Operation

This section describes the basic operation of the major circuit blocks or modules

in the DG2040 Data Generator. The Diagrams section, beginning on page 9-1,

includes a block diagram and an interconnect diagram. Figure 9-1 shows the

modules and functional blocks of the DG2040 Data Generator. Figure 9-2 shows

how the modules interconnect.

Module Overview

The module overview describes the basic operation of each functional circuit

block.

The DG2040 Data Generator consists of two major electrical sections; the Main

Frame section and the PG (Pulse Generator) & Output section. The Main Frame

section consists of Clock Board, CPU Board, Back Plane, Bezel Switch, Display

Monitor, Power Supply, Auxiliary Power Supply, FDD (Floppy Disk Drive), and

Fan. The PG & Output section consists of PG circuitry and Output circuitry.

Main Frame Section

The Main Frame section consists of the following modules and components.

Clock Board (A30). The clock board contains the clock generator, trigger circuit,

and miscellaneous control circuit for the PG and Output board. This trigger

signal is provided from the connector on the front panel.

CPU BoardĂ(A6). The CPU board receives commands from the front panel or the

GPIB/RS-232-C interface and controls the PG section through the Back Plane

board. It also sends the video signal to the display monitor for displaying various

graphical menus, data pattern figures, message texts, etc. The CPU board

contains MPU, ROM, RAM, video display, bus timing circuitry, and the

interfaces to GPIB, RS-232-C, FDD, and the front panel.

CAUTION. To avoid losing pattern data files stored in NVRam, save the files to a

floppy disk before removing the A6 CPU board or A16 Back plane board. Then

restore the files from floppy disk to the DG2040 Data Generator nonvolatile

memory after installing the new board(s).

Back Plane Board (A16). The DG2040 Data Generator back plane has five slots

which accommodate the CPU board and Clock board. This board receives

DG2040 Service Manual

3Ć1

Page 58

Theory of Operation

power from the Power Supply module and distributes the power to the boards in