Page 1

User Manual

DG2040

Data Generator

071-0257-50

This document applies to firmware version 1.00

and above.

www.tektronix.com

Page 2

Copyright © T ektronix, Inc. All rights reserved.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

T ektronix, Inc., P.O. Box 500, Beaverton, OR 97077

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects in materials and workmanship

for a period of one (1) year from the date of shipment. If a product proves defective during this warranty period, T ektronix,

at its option, either will repair the defective product without charge for parts and labor, or will provide a replacement in

exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by T ektronix, with shipping charges prepaid.

T ektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

T ektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than T ektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or malfunction

caused by the use of non-T ektronix supplies; or d) to service a product that has been modified or integrated with other

products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO

REP AIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO

THE CUSTOMER FOR BREACH OF THIS WARRANTY . TEKTRONIX AND ITS VENDORS WILL NOT BE

LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE

OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 4

Page 5

TableĂofĂContents

Getting Started

Operating Basics

General Safety Summary ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contacting Tektronix xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Getting Started 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Description 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initial Inspection 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Cord Options 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options 1-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 1-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repackaging for Shipment 1-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Basics 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controls, Connectors, and Display 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Theory of Operation 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Structure Overview 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Modes Overview 2-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Menu Operations 2-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tutorials 2-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference

Reference 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Edit Menu Screen 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu Trees 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Edit Menu Functions 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

File Menu 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Settings Menu 3-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block Menu 3-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Execute Action Menu 3-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enhanced Action Menu 3-45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Make Sequence Menu 3-57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setup Menu 3-65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setup Display 3-66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Group Assign Menu 3-67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output Condition Menu 3-70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Level Condition Menu 3-72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timing Condition Menu 3-73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Run Mode Menu 3-74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trigger Menu 3-77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clock Menu 3-79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Application Menu 3-80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Utility Menu 3-84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DG2040 Data Generator

i

Page 6

Table of Contents

Appendices

Index

Appendix A: Specifications A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Characteristics A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Certification and Compliances A-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B: Performance Verification B-1. . . . . . . . . . . . . . . . . . . . . . . . .

Before Running the Performance Tests B-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self Tests B-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance T ests B-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T est Record B-43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C: Miscellaneous C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Factory Settings C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conversion T able Examples C-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Cleaning C-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

DG2040 Data Generator

Page 7

ListĂofĂFigures

Table of Contents

Figure 1-1: Rear panel power switch, fuse holder,

and connector 1-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1-2: Location of the ON/STBY switch 1-10. . . . . . . . . . . . . . . . . . . .

Figure 2-1: Front panel controls 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-2: Rear panel connectors 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-3: Floppy disk drive 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-4: Display elements 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-5: Hardware block diagram 2-8. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-6: Data structures 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-7: Menu and bezel buttons 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-8: DG2040 front-panel keypad 2-16. . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-9: Numeric entry in a menu item field 2-17. . . . . . . . . . . . . . . . . .

Figure 2-10: General-purpose knob and arrow buttons 2-18. . . . . . . . . . .

Figure 2-11: Menu element knob icon and underscore 2-18. . . . . . . . . . . .

Figure 2-12: Timing display format 2-19. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-13: Table display format 2-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-14: Binary display format 2-20. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-15: Numeric display format 2-21. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-16: Pattern data editing procedure 2-22. . . . . . . . . . . . . . . . . . . .

Figure 2-17: Serial/Parallel editing mechanism 2-22. . . . . . . . . . . . . . . . . .

Figure 2-18: Area and Point cursors 2-23. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-19: Text input menu 2-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-20: Pop-up message box 2-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-21: Operating buttons 2-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-22: Binary pattern creation 2-30. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-23: Pattern edited in Tutorial 2 2-33. . . . . . . . . . . . . . . . . . . . . . .

Figure 2-24: Output parameter settings 2-35. . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-25: DG2040 Data Generator

and oscilloscope connection 2-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-26: Tutorial 4 block sequence 2-37. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-27: Block separation 2-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-28: Creating a binary up-counter for block BK1 2-41. . . . . . . . .

Figure 2-29: Creating a binary down-counter for block BK3 2-42. . . . . . .

Figure 2-30: Sample subsequence 2-43. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-31: Sample sequence 2-44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DG2040 Data Generator

iii

Page 8

Table of Contents

Figure 2-32: Line pointer 2-45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-33: Sample sequence 2-48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-34: Pattern and edges to be controlled in the DATA0 2-49. . . . .

Figure 2-35: Created pattern and highlighted edges 2-51. . . . . . . . . . . . . .

Figure 2-36: DG2040 and oscilloscope connection 2-52. . . . . . . . . . . . . . . .

Figure 3-1: EDIT menu (timing display) 3-1. . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-2: Edit Menu tree 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-3: Setup Menu tree 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-4: Application Menu tree 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-5: Utility Menu tree 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-6: Import Configuration Menu (File format:

AWG2000 series waveform file) 3-11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-7: Data write in terms of point positions 3-12. . . . . . . . . . . . . . . .

Figure 3-8: Data write in terms of data bit positions 3-13. . . . . . . . . . . . . .

Figure 3-9: The Export Config menu 3-16. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-10: Settings pop-up menu 3-18. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-11: Reference mark “M” display 3-19. . . . . . . . . . . . . . . . . . . . . .

Figure 3-12: Arrow button action display (timing display) 3-20. . . . . . . . .

Figure 3-13: The Arrow button menu 3-21. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-14: Operation flow for pattern data output #1 3-25. . . . . . . . . . .

Figure 3-15: Operation flow for pattern data output #2 3-26. . . . . . . . . . .

Figure 3-16: Bit Width pop-up menu 3-27. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-17: Block pop-up menu 3-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-18: Block cursor movement 3-29. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-19: Dividing a block 3-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-20: Combine blocks 3-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-21: Change a block size 3-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-22: Pop-up action menu 3-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-23: Edit area 3-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-24: Cut 3-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-25: Paste-insert 3-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-26: Paste-replace 3-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-27: Set data to high 3-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-28: Set data to low 3-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-29: Insert high data 3-37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-30: Insert low data 3-37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-31: Invert data 3-37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-32: Mirror vertical 3-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv

DG2040 Data Generator

Page 9

Table of Contents

Figure 3-33: Mirror horizontal 3-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-34: Magnify 3-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-35: Shift left (add zero) 3-41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-36: Shift right (add zero) 3-41. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-37: Shift left 3-41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-38: Shift right 3-42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-39: Rotate left 3-43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-40: Rotate right 3-43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-41: Standard pattern data 3-44. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-42: Creating the clock pattern 3-45. . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-43: Clock Pattern pop-up menu 3-46. . . . . . . . . . . . . . . . . . . . . . .

Figure 3-44: Register value and tap setting example 3-47. . . . . . . . . . . . . .

Figure 3-45: Shift Register Generator pop-up menu 3-48. . . . . . . . . . . . . .

Figure 3-46: Logical AND Operation Example 3-50. . . . . . . . . . . . . . . . . .

Figure 3-47: Logical Operation pop-up menu 3-50. . . . . . . . . . . . . . . . . . .

Figure 3-48: Bit Operation pop-up menu 3-52. . . . . . . . . . . . . . . . . . . . . . .

Figure 3-49: Serial Code Converter menu 3-53. . . . . . . . . . . . . . . . . . . . . .

Figure 3-50: Edit Code Table menu 3-55. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-51: Make Sequence menu and a sequence example 3-57. . . . . . .

Figure 3-52: Make Subsequence menu and a subsequence

example 3-58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-53: Example of a sequence expanded into sequence

memory 3-62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-54: Event jump operation timing 3-63. . . . . . . . . . . . . . . . . . . . . .

Figure 3-55: SETUP menu display 3-66. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-56: Group Assign pop-up menu 3-67. . . . . . . . . . . . . . . . . . . . . . .

Figure 3-57: Bit structure assignment 3-68. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-58: Output channel assign pop-up menu 3-70. . . . . . . . . . . . . . . .

Figure 3-59: Example delay parameter 3-73. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-60: Repeat Mode pattern data output

(when no sequence is defined) 3-74. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-61: Repeat Mode pattern data output

(when a sequence is defined) 3-74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-62: Single Mode pattern data output

(when no sequence is defined) 3-75. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-63: Single Mode pattern data output

(when a sequence is defined) 3-75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-64: Enhanced Mode sequence output 3-76. . . . . . . . . . . . . . . . . .

Figure 3-65: Trigger slope and level control 3-77. . . . . . . . . . . . . . . . . . . . .

DG2040 Data Generator

v

Page 10

Table of Contents

Figure 3-66: Relation between incoming signal and

edge position shift 3-81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-67: Examples of the edge control bit 3-82. . . . . . . . . . . . . . . . . . .

Figure 3-68: Display/hardcopy menu 3-88. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-69: System menu 3-92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-70: Status display 3-96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-71: Diag menu 3-96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure A-1: Timing definition in edge control input A-8. . . . . . . . . . . . . .

Figure A-2: Transfer function for edge control input A-9. . . . . . . . . . . . .

Figure A-3: Signal timing A-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure B-1: Operating buttons and menu layout B-4. . . . . . . . . . . . . . . . .

Figure B-2: Diagnostics menu B-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure B-3: Frequency measurement connections B-8. . . . . . . . . . . . . . . .

Figure B-4: Sequence & data output connections B-11. . . . . . . . . . . . . . . .

Figure B-5: Sequence & data output timing chart B-13. . . . . . . . . . . . . . . .

Figure B-6: External reference input connections B-15. . . . . . . . . . . . . . . .

Figure B-7: Maximum operating frequency connections B-18. . . . . . . . . .

Figure B-8: Maximum operating frequency (1) B-20. . . . . . . . . . . . . . . . . .

Figure B-9: Maximum operating frequency (2) B-20. . . . . . . . . . . . . . . . . .

Figure B-10: Maximum operating frequency (3) B-21. . . . . . . . . . . . . . . . .

Figure B-11: Maximum operating frequency connections B-23. . . . . . . . .

Figure B-12: Maximum operating frequency (4) B-25. . . . . . . . . . . . . . . . .

Figure B-13: Maximum operating frequency (5) B-25. . . . . . . . . . . . . . . . .

Figure B-14: Internal trigger generator & external trigger input

connection B-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure B-15: Edge control mode operation connection B-30. . . . . . . . . . . .

Figure B-16: Edge control mode B-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure B-17: Output level measurement connections B-32. . . . . . . . . . . . .

Figure B-18: Clock output amplitude measurement connection B-35. . . .

Figure B-19: Delay time measurement connection B-39. . . . . . . . . . . . . . . .

Figure B-20: Rise time and fall time measurement connection B-42. . . . .

Figure C-1: Conversion image example C-3. . . . . . . . . . . . . . . . . . . . . . . .

vi

DG2040 Data Generator

Page 11

ListĂofĂTables

Table of Contents

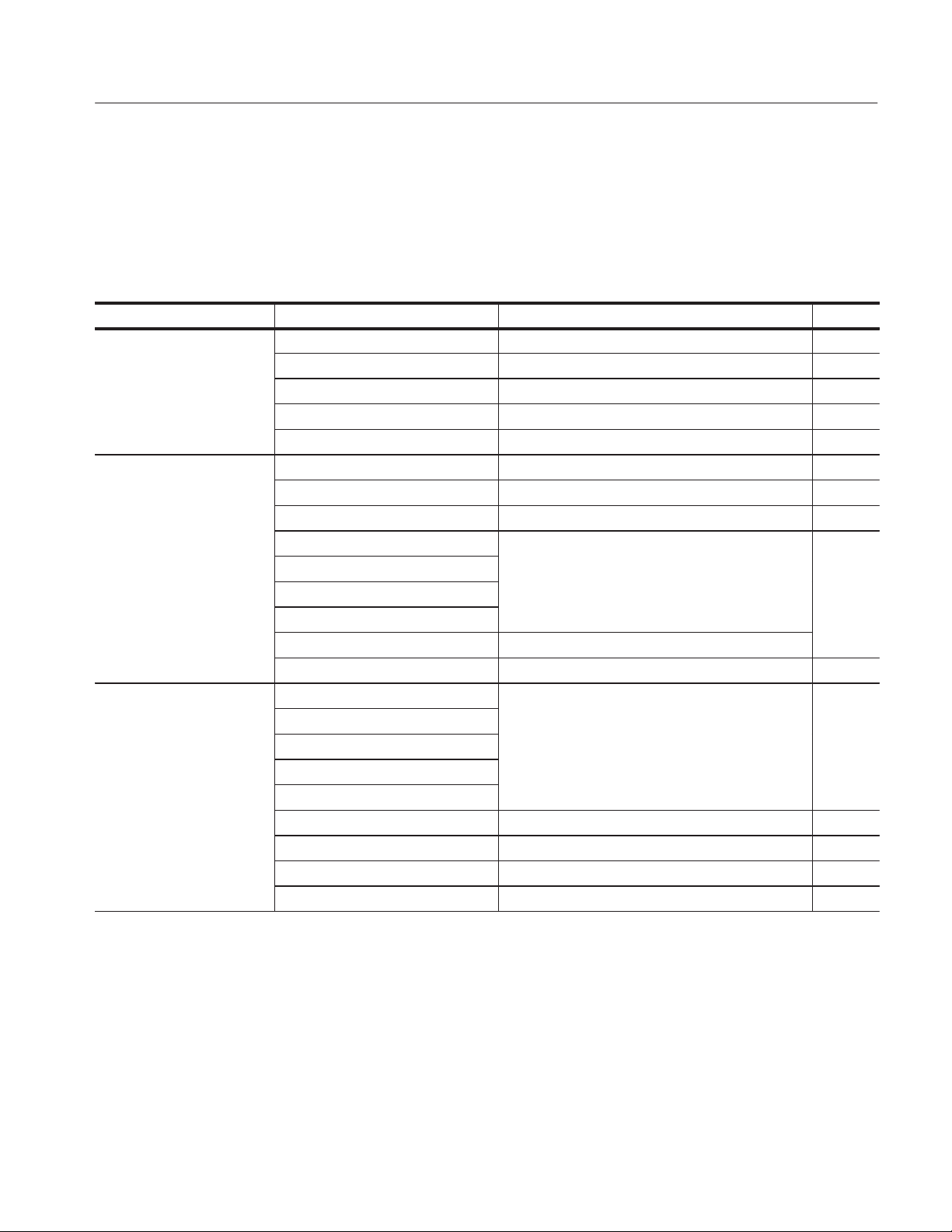

Table 1-1: Power cord options 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1-2: Power Cord Identification 1-4. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1-3: Standard accessories 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1-4: Optional accessories 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1-5: Fuse And Fuse Cap Part Numbers 1-8. . . . . . . . . . . . . . . . . . .

Table 1-6: AC Line Power Requirements 1-8. . . . . . . . . . . . . . . . . . . . . . .

Table 2-1: DG2040 display elements 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-2: Data structure terms 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-3: Run modes 2-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-4: Update modes 2-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-5: Bottom menu elements 2-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-6: Side and submenu elements 2-16. . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-7: Numeric input example 2-17. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-1: Edit menu display 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-2: EDIT menu functions 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-3: Import parameters 3-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-4: Export parameters 3-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-5: Arrow button functions 3-21. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-6: Pattern data display format 3-22. . . . . . . . . . . . . . . . . . . . . . . .

Table 3-7: Block cursor movement 3-28. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-8: Numeric input differences 3-40. . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-9: Standard pattern data descriptions 3-44. . . . . . . . . . . . . . . . . .

Table 3-10: Parameter Items 3-46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-11: Shift register generator parameters 3-48. . . . . . . . . . . . . . . . .

Table 3-12: Logical operation parameters 3-51. . . . . . . . . . . . . . . . . . . . . .

Table 3-13: Bit operation parameters 3-52. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-14: Serial code converter parameters 3-54. . . . . . . . . . . . . . . . . . .

Table 3-15: Edit Code Table parameters 3-55. . . . . . . . . . . . . . . . . . . . . . .

Table 3-16: Numeric key description 3-56. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-17: SETUP menu functions 3-65. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-18: Setup menu display 3-66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-19: APPLICATION menu functions 3-80. . . . . . . . . . . . . . . . . . .

Table 3-20: UTILITY menu functions 3-84. . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-21: Error Code 3-97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DG2040 Data Generator

vii

Page 12

Table of Contents

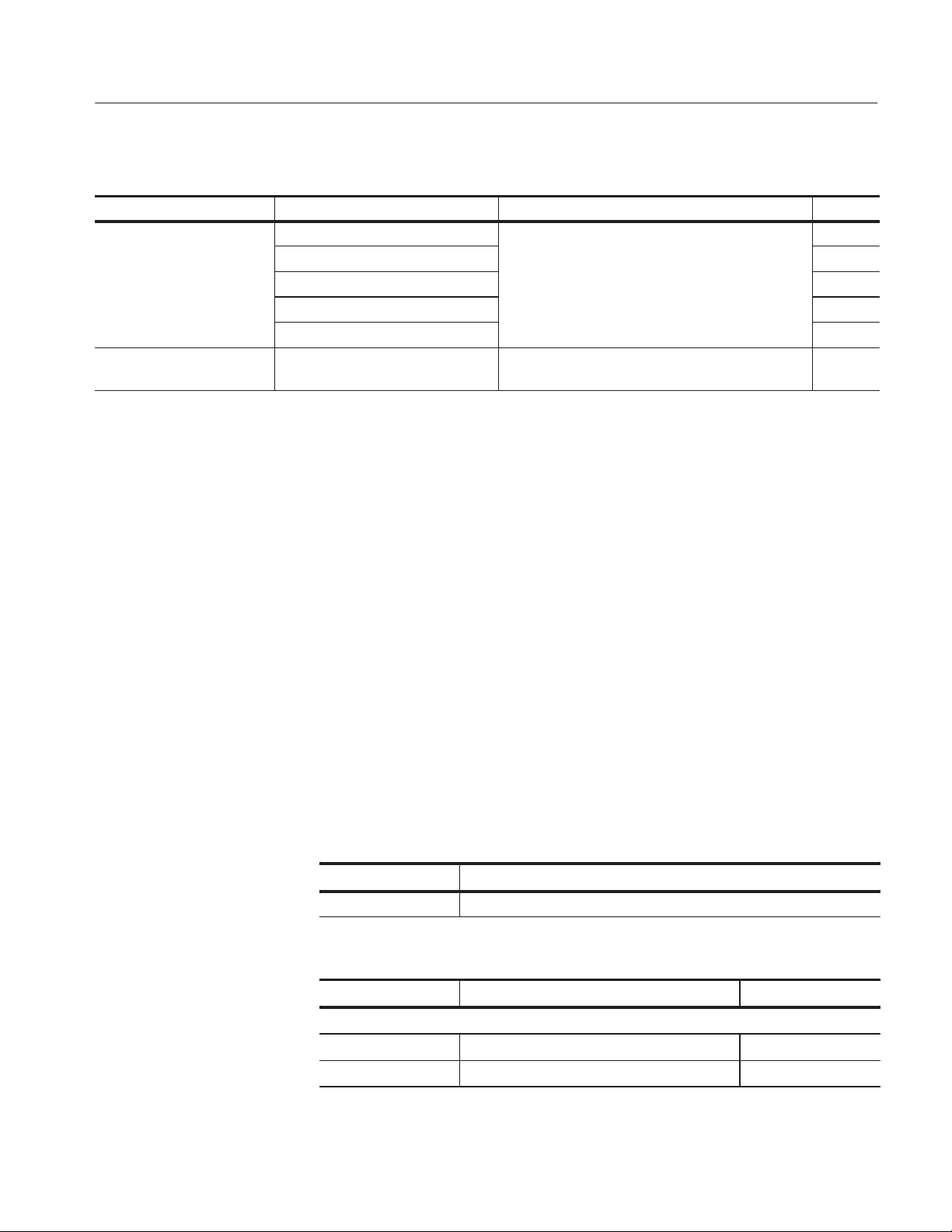

Table A-1: Electrical characteristics A-1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A-2: Period JItter A-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A-3: Cycle to Cycle JItter A-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A-4: Mechanical characteristics A-6. . . . . . . . . . . . . . . . . . . . . . . . .

Table A-5: Environmental characteristics A-6. . . . . . . . . . . . . . . . . . . . . .

Table A-6: Certifications and compliances A-10. . . . . . . . . . . . . . . . . . . . .

Table B-1: Performance check disk files B-2. . . . . . . . . . . . . . . . . . . . . . .

Table B-2: Required equipment B-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table B-3: Error codes B-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table B-4: Internal clock frequency accuracy B-10. . . . . . . . . . . . . . . . . .

Table B-5: High level output voltage accuracy B-34. . . . . . . . . . . . . . . . . .

Table B-6: Low level output voltage accuracy B-34. . . . . . . . . . . . . . . . . .

Table B-7: Clock output voltage accuracy B-37. . . . . . . . . . . . . . . . . . . . .

Table B-8: Rise and fall time accuracies B-43. . . . . . . . . . . . . . . . . . . . . . .

Table B-9: DG2040 test record B-44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table C-1: Factory settings C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table C-2: External Inspection Check List C-8. . . . . . . . . . . . . . . . . . . . .

viii

DG2040 Data Generator

Page 13

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Connect and Disconnect Properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Symbols and Terms

DG2040 Data Generator

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

ix

Page 14

General Safety Summary

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

CAUTION

Refer to Manual

WARNING

High Voltage

Double

Insulated

Protective Ground

(Earth) Terminal

Not suitable for

connection to

the public telecomĆ

munications network

x

DG2040 Data Generator

Page 15

Preface

Related Manuals

The user manual for the DG2040 Data Generator contains the following sections:

The Getting Started section briefly describes the DG2040 Data Generator and

provides installation instructions, options listing, accessories listing, repacking

instructions, and power on and off instructions.

The Operating Basics section introduces terminology specific to the DG2040

Data Generator and provides an overview of the internal structure of the

instrument, operating principles, basic operating procedures, and numeric input

methods. This section also provides examples of basic signal editing.

The Reference section provides detailed information about the functions and use

of the DG2040 Data Generator’s main menus.

The Appendices section provides product specifications, performance verification

instructions, factory settings, conversion table examples, and inspection and

cleaning instructions.

Other documentation for the instrument includes:

H The DG2040 Data Generator Programmer Manual explains how to control

the DG2040 Data Generator with a computer through the GPIB or RS-232-C

interface. This programmer manual is a standard accessory.

H The DG2040 Data Generator Service Manual describes how to maintain and

service the DG2040 Data Generator and provides a complete module-level

description of the operation of the instrument. This manual is an optional

accessory.

DG2040 Data Generator

xi

Page 16

Preface

Conventions

The following typographical conventions are used in this manual:

H Names of front-panel controls and menu item names are in bold with the

same case (initial capitals or all upper case) as they appear on the unit itself.

For example, SETUP, Sub-sequence.

H Sections 2, 3, and Appendix B describe the instrument functions by using a

table to list a sequence of steps. Each operating procedure is presented in

order, starting with step 1, and progresses until the end of the procedures.

Execute the action in the top-left table entry first. Then execute actions from

left to right along each row. When you are done executing the steps in one

row, move to the left end of the next row down, and continue executing the

listed steps until the end of the table.

H When steps require that you make a sequence of selections using menu

buttons, an arrow ( ! ) marks each transition between menu buttons. Refer

to Menu Notation on page 2-14 for further information.

For pop-up menus, use the general-purpose knob to select items from the

menu list. Operations, such as Operation 6 (below), do not involve pressing

the buttons shown in the row above, but rather are descriptions of operations

to be performed.

Front panel

Menu button Bottom button PopĆup menu Side button

Operation 1 Operation 2 Operation 3 Operation 4 Operation 5

Operation 6 (for example, Use the generalĆpurpose knob to set cursor field to 360.")

Operation 7

button

xii

DG2040 Data Generator

Page 17

Contacting Tektronix

Preface

Phone 1Ć800Ć833Ć9200*

Address Tektronix, Inc.

Department or name (if known)

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

Web site www.tektronix.com

Sales support 1Ć800Ć833Ć9200, select option 1*

Service support 1Ć800Ć833Ć9200, select option 2*

Technical support Email: techsupport@tektronix.com

1Ć800Ć833Ć9200, select option 3*

6:00 a.m. - 5:00 p.m. Pacific time

* This phone number is toll free in North America. After office hours, please leave a

voice mail message.

Outside North America, contact a Tektronix sales office or distributor; see the

Tektronix web site for a list of offices.

DG2040 Data Generator

xiii

Page 18

Preface

xiv

DG2040 Data Generator

Page 19

Getting Started

Product Description

This section provides the following information:

H Description and features of the DG2040 Data Generator

H Initial inspection procedure

H Standard and optional accessories listings

H Installation procedures

H Power on and off procedures

H Repackaging procedure for shipment

The DG2040 Data Generator is a programmable data generator with a 2-channel

data output pattern memory. It accommodates a 4k-step sequence controller,

which enables the generation of data patterns longer than the pattern memory and

also the dynamic change of the patterns due to the external events. The operating

parameters, the channel configuration, and the pattern data are displayed or set

using the graphic menu on the CRT monitor. The menu has a tree structure and

can be operated easily using the bottom and side bezel switches.

Main Features

The DG2040 can be manually controlled from the front panel or remotely

programmed via GPIB or RS-232-C.

The DG2040 Data Generator includes the following main features:

H Maximum data rate of 1.1 GHz

H 256 K word pattern memory

H Flexible sequence looping (which does the equivalent of over a billion word

patterns)

H Two channels (complementary) providing the following:

Variable output levels (from –1.125 V to +3.5 V into 50 W)

Edge Control function (CH0 only)

Delay setting (10 ps resolution)

H Parallel and serial pattern editing

DG2040 Data Generator

1Ć1

Page 20

Getting Started

Any memory size from 360 words to 256 K words can be used with no

restrictions within that range. Each of the two bit data channels can be assigned

to any output channel. The output channels support the setting of high and low

output voltage levels, delay time, and edge position.

The DG2040 Data Generator also provides a 4000-step sequence controller,

which enables the generation of a data pattern longer than the pattern memory

and dynamic pattern changes triggered by external events.

The DG2040 Data Generator provides flexible data editing functions, including

word and line unit input and extended data creation functions. Also, the DG2040

Data Generator provides a set of functions required for system construction, such

as a sequencing function and a jump function using external input.

Applications

Initial Inspection

The following lists some of the DG2040 Data Generator applications:

H Supports subassembly and system testing by simulating the digital signals

from incomplete sections of a product

H Performs margin tests by using the DG2040 Data Generator to generate

patterns that have a low probability of occurrence or are difficult to generate

H Constructs interactive digital simulation systems by using the sequence

output, external jump, and tristate control functions

H Uses flexible data output functions to make the DG2040 Data Generator an

ideal data generator for simulation of semiconductor devices and drivers

specific to serial data communication and all types of digital circuits.

H Performs various timing analysis and jitter/wander tests by using the edge

control function to generate jitter on all the edges or selected edge(s)

Inspect the DG2040 Data Generator shipping carton for external damage.

Remove the DG2040 Data Generator from its package and check that it has not

been damaged in transit. Verify that the carton contains the basic instrument and

its standard accessories. Refer to Accessories on page 1-5.

1Ć2

This instrument was thoroughly inspected for mechanical and electrical defects

before shipment. It should be free of scratches and meet or exceed all electrical

specifications. To confirm this, after inspecting the instrument for physical

damage incurred in transit, test the electrical performance by following the

procedures in Appendix B: Performance Verification. Contact your distributor if

you find a discrepancy.

DG2040 Data Generator

Page 21

Power Cord Options

Getting Started

NOTE. Save the shipping carton and packaging materials for repackaging in

case shipment becomes necessary.

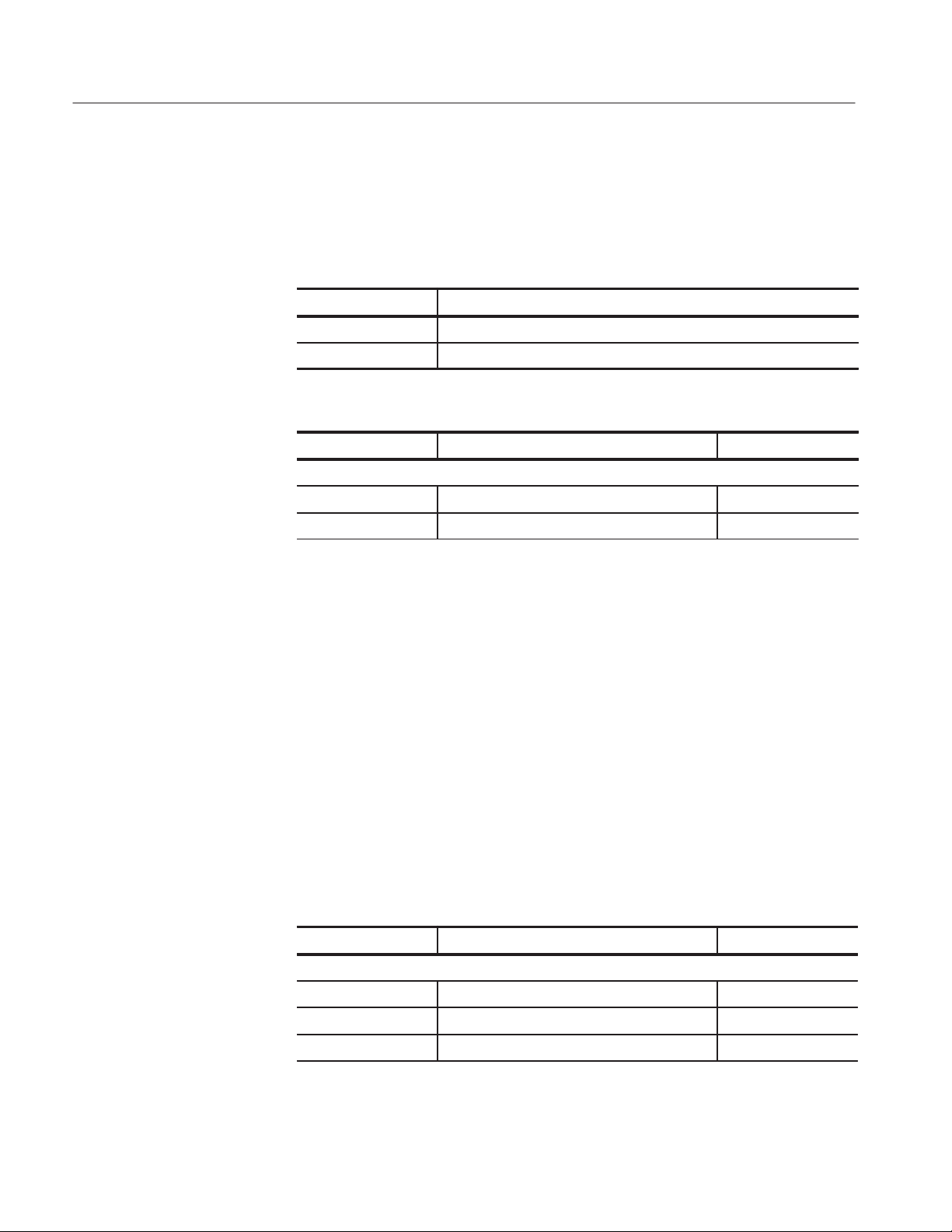

Table 1-1 lists the power cords available with the DG2040 Data Generator.

Table 1Ć1: Power cord options

Option Description Tektronix part number

A1 Europe 161Ć0104Ć06

A2 United Kingdom 161Ć0104Ć07

A3 Australia 161Ć0104Ć05

A4 North America 161Ć0104Ć08

A5 Switzerland 161Ć0167Ć00

DG2040 Data Generator

1Ć3

Page 22

Getting Started

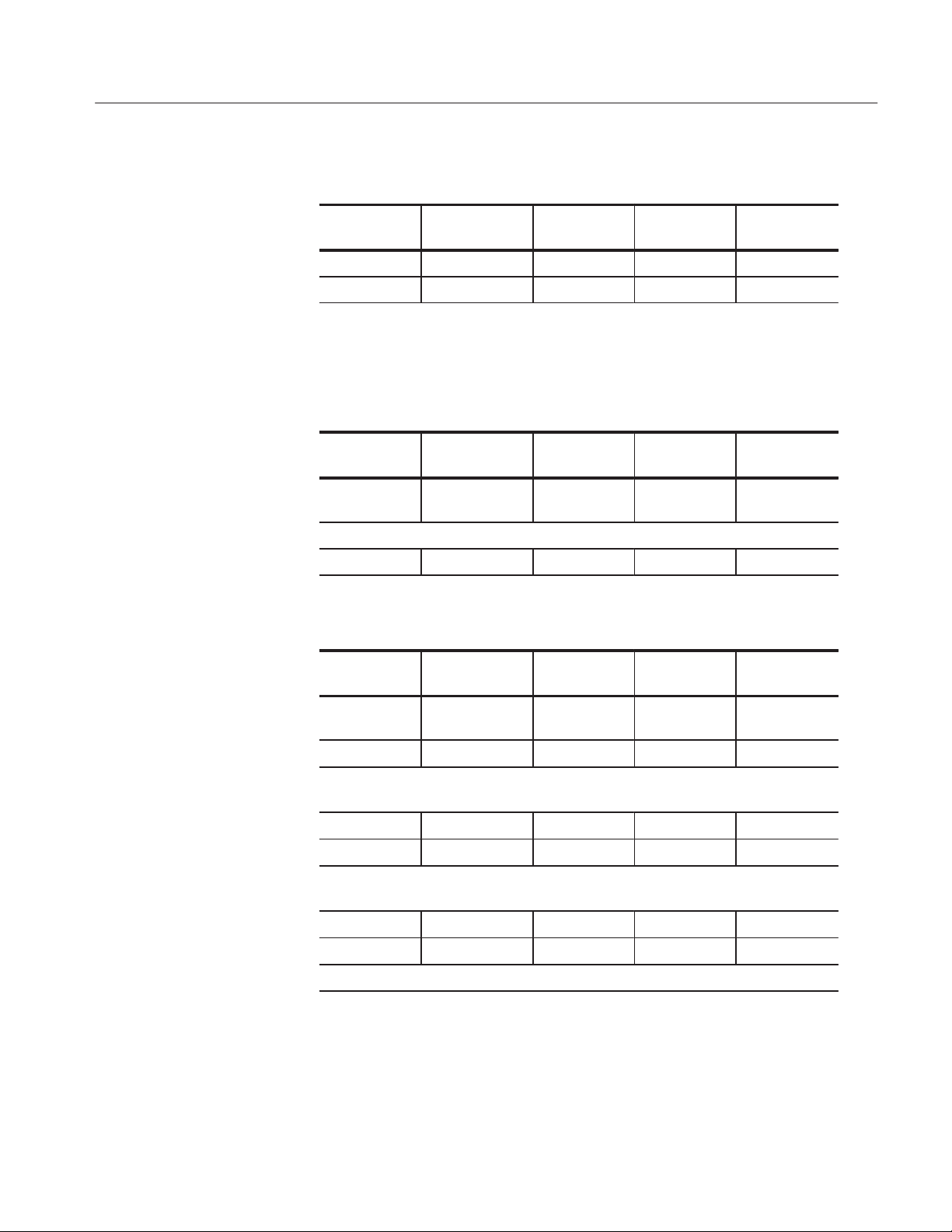

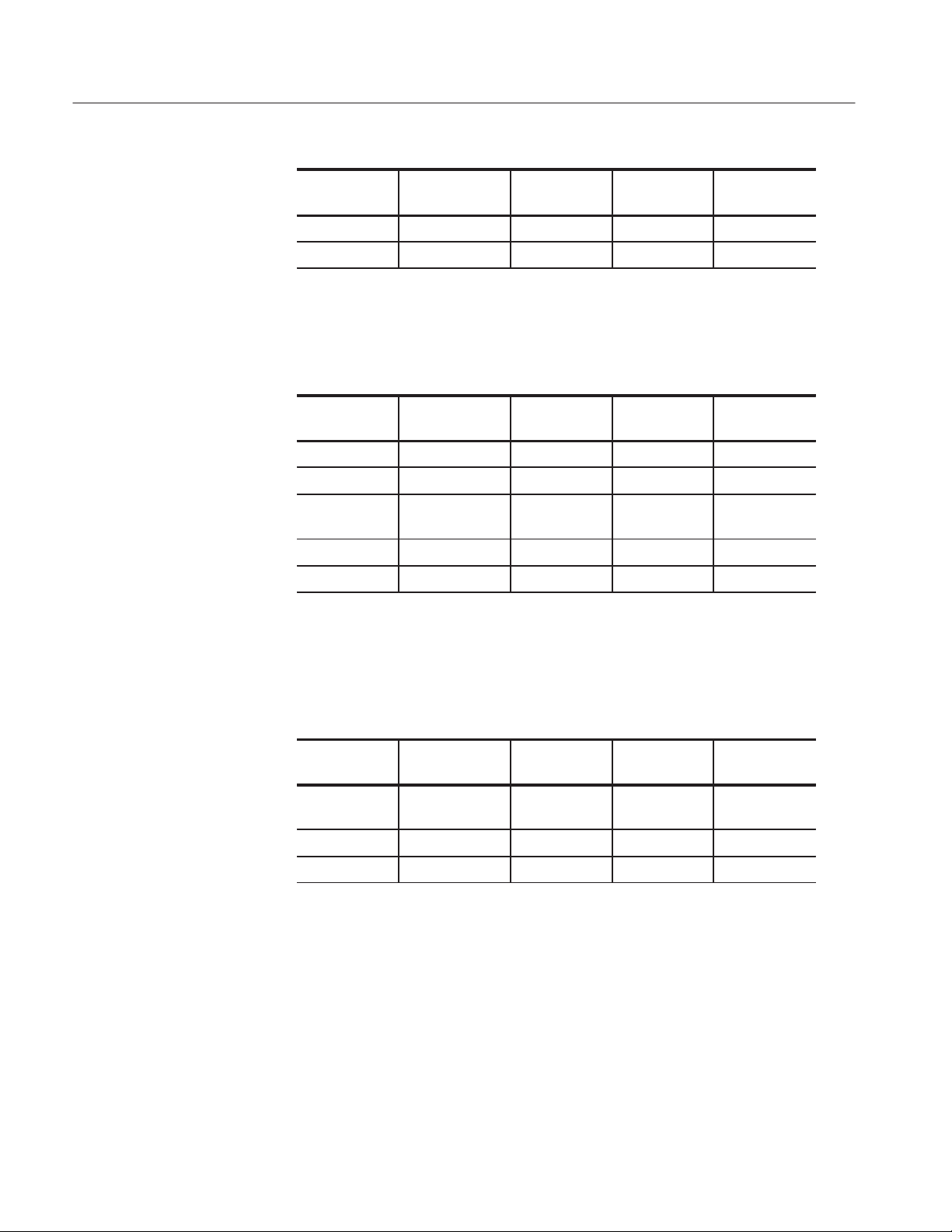

Table 1Ć2: Power Cord Identification

Plug Configuration Normal Usage Option Number

North America Standard

Europe A1

United Kingdom A2

Australia A3

North America A4

Switzerland A5

1Ć4

DG2040 Data Generator

Page 23

Accessories

Getting Started

Standard Accessories

Table 1-3 lists the standard accessories provided with the DG2040 Data

Generator.

Table 1Ć3: Standard accessories

Standard accessories Tektronix part number

DG2040 Data Generator User Manual

DG2040 Data Generator Programmer Manual 071Ć0258ĆXX

Performance Check Disk, 3.5Ćinch 063Ć3121ĆXX

GPIB Sample Program Disk, 3.5Ćinch 063Ć3122ĆXX

DGĆLINK Application Program Disk, 3.5Ćinch 063Ć2920ĆXX

Fuse 6A Fast 250 V (UL198G/3AG) 159Ć0239Ć00

Power cord 125 V/6A 161Ć0230Ć01

071Ć0257ĆXX

DG2040 Data Generator

1Ć5

Page 24

Getting Started

Optional Accessories

Table 1-4 lists the optional accessories that are recommended for use with the

DG2040 Data Generator.

Table 1Ć4: Optional accessories

Optional accessory Tektronix part number

DG2040 Data Generator Service Manual 071Ć0259ĆXX

Front Cover 200Ć3232Ć01

Accessory Pouch 016Ć1159Ć00

Rackmount kit 040Ć1444Ć00

Fuse 6A Fast 250 V (UL198G/3AG) 159Ć0239Ć00

Fuse cap 200Ć2264Ć00

Fuse 5A 250 V (T) (IEC127) 159Ć0210Ć00

Fuse cap 200Ć2265Ć00

GPIB Cable 012Ć0991Ć00

50 W SMA Cable, 1 m (39 inches), male 174Ć1341Ć00

50 W SMA Cable, 2 m (21 inches), male 174Ć0679Ć00

50 W SMA Cable, 0.5 m (20 inches), male 174Ć1427Ć00

SMA Precision Delay Cable, 1 ns, male 015Ć0562Ć00

SMA Precision Delay Cable, 2 ns, male 015Ć0560Ć00

SMA Precision Delay Cable, 4 ns, male 015Ć0561Ć00

50 W BNC Cable, 1 m (43 inches), male 012Ć0057Ć01

50 W BNC Cable, 0.6 m (24 inches), male 012Ć1342Ć00

50 W BNC Cable, double shield 2.5m (98 inches), male 012Ć1256Ć00

SMA T Connector, male to female, male 015Ć1016Ć00

50 W SMA termination, male 015Ć1022Ć00

50 W SMA Divider, male 015Ć1014Ć00

SMA Male to BNC Female Adapter, 015Ć0554Ć00

SMA Adapter Kit 020Ć1693Ć00

1Ć6

DG2040 Data Generator

Page 25

Options

Getting Started

This subsection describes the options available for the DG2040 Data Generator.

The following options are available:

Option 1R (Rack mounting)

Option D1 (Test result report)

Each of these options is discussed in detail in the following paragraphs.

Option 1R (Rack Mount)

Option D1 (Test Result

Report)

Installation

Environment

When ordered with option 1R, the DG2040 Data Generator is shipped configured

for mounting in a 19-inch rack. The floppy disk drive is moved so that it can be

accessed from the front panel in this instrument.

If you need to configure a standard DG2040 Data Generator for mounting in a

19-inch rack refer to Table 1-4 Optional accessories on page 1-6 for the

Tektronix part number for the rackmount kit.

A calibration data test result report will be provided with the DG2040 Data

Generator when this option is specified.

Before you begin the installation, refer to the General Safety Summary at the

front of this manual for power source, grounding, and other safety information.

Verify that you have the correct operating environment.

CAUTION. Damage to the instrument can occur if this instrument is powered on

at temperatures outside the specified temperature range.

DG2040 Data Generator

The DG2040 Data Generator operates correctly in ambient temperatures from

+10_ C to +40_ C and in relative humidity from 20% to 80%. For more

operating environment information, refer to Appendix A: Specifications.

NOTE. If you are installing the instrument in a dedicated rack, refer to the

instruction sheet that comes with the rack mounting kit for proper installation

procedures.

Verify that there is at least 2.5 cm (1 inch) of clearance on top and bottom, 15.0

cm (6 inches) on the left and right sides, and 7.5 cm (3 inches) at the rear of the

instrument to allow for heat dissipation. Verify that the air intake holes on the

sides and bottom of the cabinet are not obstructed.

1Ć7

Page 26

Getting Started

Check Fuse

Check the fuse to be sure it is the proper type and rating.

WARNING. To avoid electrical shock, be sure that the power cord is disconnected

before checking the fuse.

Use a slotted screwdriver to remove the fuse. Push in and turn the fuse holder

cap counterclockwise. See Figure 1-1 for the fuse location.

The instrument order specified either a UL approved or an IEC approved fuse.

Each fuse requires its own cap. See Table

1-5.

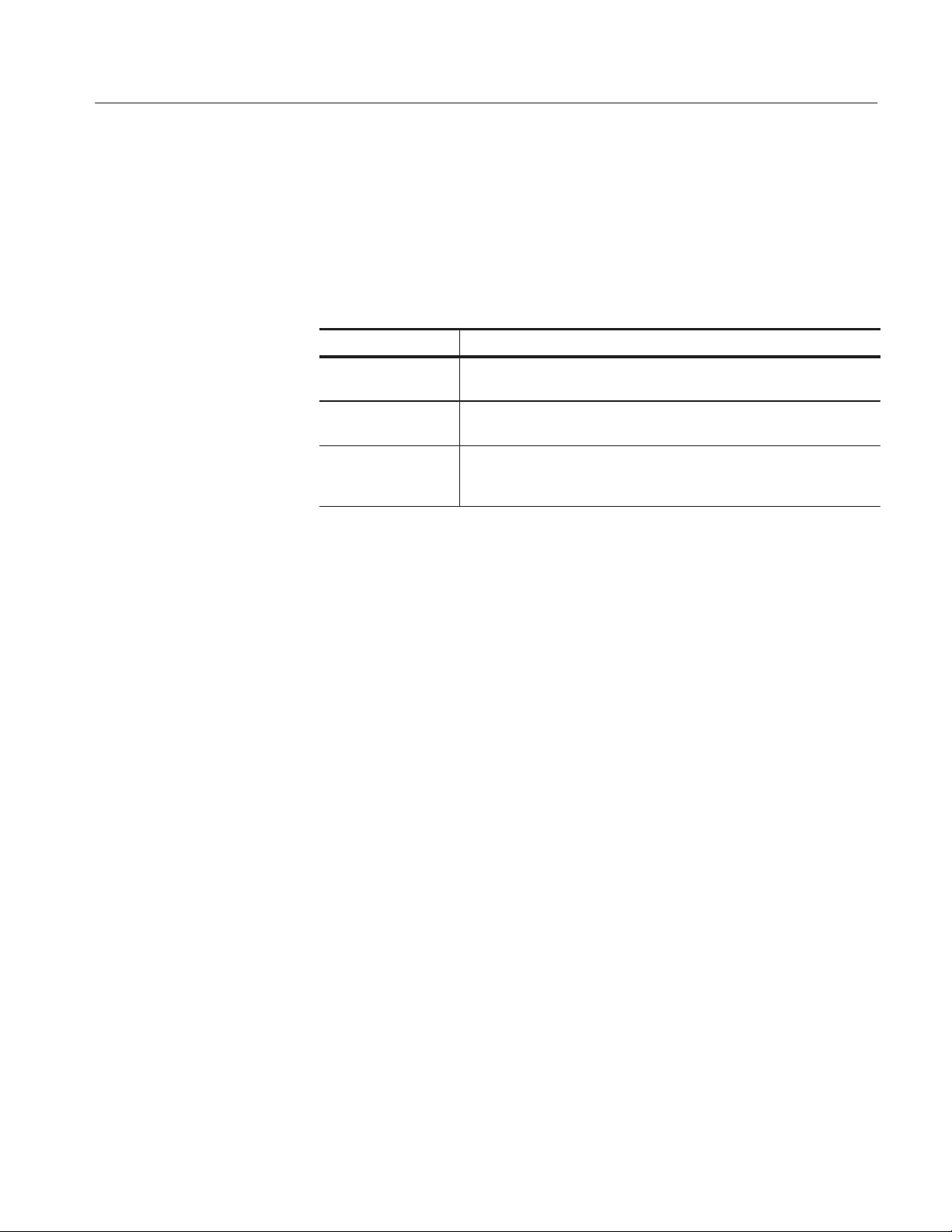

Table 1Ć5: Fuse And Fuse Cap Part Numbers

Tektronix Fuse

Fuse

0.25 inch × 1.25 inch (UL 198.6, 3 AG):

6 A fast, 250 V

5mm× 20 mm (IEC 127): 5 A (T), 250 V 159Ć0210Ć00 200Ć2265Ć00

Part Number

159Ć0239Ć00 200Ć2264Ć00

Tektronix Fuse Cap

Part Number

NOTE. The second fuse listed in the table above is approved under the IEC

standards. This fuse is used in equipment sold in the European market.

Check Voltage Settings

Connect Power Cable

Check that you have the proper electrical connections. Refer to Table 1-6 for

power requirements.

Table 1Ć6: AC Line Power Requirements

Name Description

Line Voltage Range 90 V - 250 V

Line frequency 48 Hz - 440 Hz ( 90 V - 127 V)

48 Hz - 63 Hz (127 V - 250 V)

Maximum power 300 W

Connect the proper power cord from the rear panel power connector to the power

system. Refer to Table 1-2 for power cord identification.

1Ć8

DG2040 Data Generator

Page 27

Getting Started

CAUTION. The instrument is shipped with a power cord appropriate for use with

your power systems (normal 115 V power system or 230 V power system). If the

instrument is to be used with a power system other than what the order specified,

the power cord must be replaced with one appropriate for the power source

used.

Standby Power

Apply power to the standby circuit of the instrument by pushing the

PRINCIPAL POWER SWITCH on the rear panel of the instrument. Refer to

Figure 1-1.

NOTE. After the instrument is installed, leave the PRINCIPAL POWER

SWITCH on and use the ON/STBY switch as the power switch.

Power Connector

Power On

DG2040 Data Generator

Fuse PRINCIPAL POWER

SWITCH

Figure 1Ć1: Rear panel power switch, fuse holder, and connector

Press the ON/STBY switch on the lower left side of the front panel to power on

the instrument. Refer to Figure 1-2.

After power on, verify that the fan is operating.

1Ć9

Page 28

Getting Started

NOTE. Allow a 20 minute warm-up period prior to calibrating the clock for the

instrument to operate at its optimum precision.

StartĆUp Diagnostics

Power Off

ON/STBY Switch

Figure 1Ć2: Location of the ON/STBY switch

The DG2040 automatically runs diagnostics when the instrument is powered on

from the ON/STBY switch. These diagnostics check whether the instrument is

performing within its defined operating characteristics. If all the diagnostic items

have been completed without error, the instrument displays the EDIT menu.

NOTE. If the instrument chassis temperature is outside the specified operating

range, an error will occur during the power-up diagnostics. If this happens,

power off the instrument, wait until the chassis temperature is within normal

operating range, and then power on the instrument again.

If an error is displayed, contact your Tektronix Field Office or representative.

To power off the DG2040 Data Generator, press the ON/STBY switch.

1Ć10

DG2040 Data Generator

Page 29

NOTE. The ON/STBY switch disables the outputs of the power supply. The

PRINCIPAL POWER SWITCH on the rear panel disconnects the instrument

from the primary voltage source.

Repackaging for Shipment

If this instrument is shipped by commercial transportation, use the original

packaging material. If the original packaging is unfit for use or is not available,

repackage the instrument as follows:

1. Obtain a corrugated cardboard shipping carton having inside dimensions at

2. If the instrument is being shipped to a Tektronix Service Center for repair or

Getting Started

least six inches greater than the instrument dimensions and having a carton

test strength of at least 125 kg (275 pounds).

calibration attach a tag to the instrument showing the following information:

H The owner of the instrument (with address).

H The name of a person at your firm who may be contacted if additional

information is needed.

H The complete instrument type and serial number.

H A description of the service required.

3. Wrap the instrument with polyethylene sheeting or equivalent to protect the

outside finish and prevent entry of packing materials into the instrument.

4. Cushion the instrument on all sides by tightly packing dunnage or urethane

foam between the carton and the instrument, allowing for three inches

(7.62 cm) of padding on each side (including top and bottom).

5. Seal the carton with shipping tape or with an industrial stapler.

6. Mark the address of the Tektronix Service Center and your return address on

the carton in one or more prominent locations.

DG2040 Data Generator

1Ć11

Page 30

Getting Started

1Ć12

DG2040 Data Generator

Page 31

Operating Basics

This section provides the following information:

H An overview of the instrument controls and their functions

H An overview of the DG2040 Data Generator hardware

H Information on operations commonly performed on the instrument and how

to enter numbers

H Tutorials showing how to edit, save, and recall pattern data

DG2040 Data Generator

2Ć1

Page 32

Operating Basics

Controls, Connectors, and Display

Front Panel

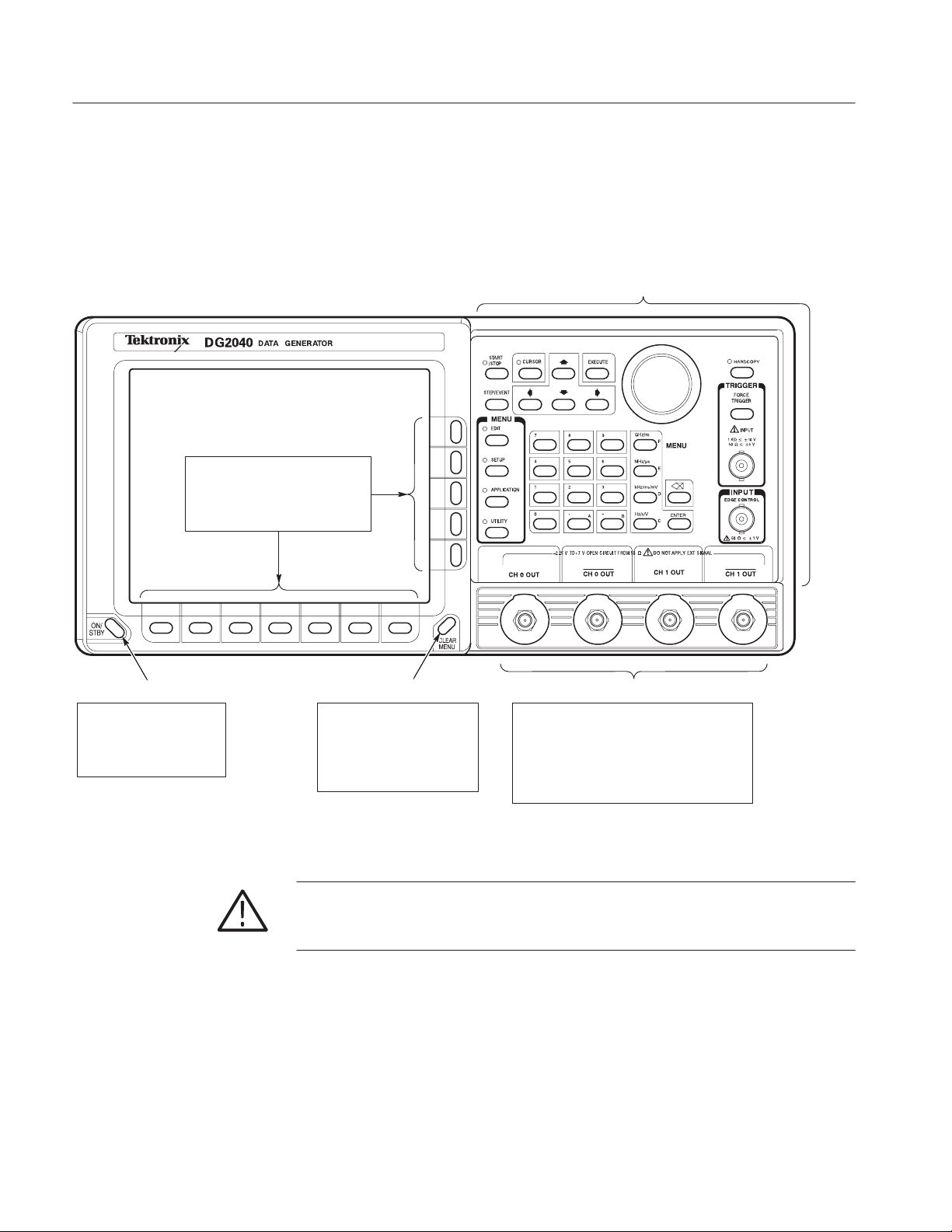

Figure 2-1 Shows the locations of the front panel controls and connectors.

Bottom and side

bezel buttons

The main use of the bottom buttons is

to call up sub menus, and the side

buttons are used to execute more

detailed operations within the sub

menus.

See Figure 2-1 on page 2Ć3

1.1 Gbps

ON/STBY Button CLEAR MENU Button

This button is used as the

power switch in normal

operation. The PRINCIPAL

POWER SWITCH on the rear

panel must be on.

Cancels the current operation

and closes side and submenus.

The display can be returned to

the top level by repeatedly

pressing on the CLEAR MENU

button.

Figure 2Ć1: Front panel controls

CAUTION. If external voltages are applied to the data output connectors, be sure

to set the high-impedance control correctly. Signal collisions may result in

output currents or voltages in excess of the rated values.

Output Connectors

The CH 0 to CH 1 SMA connectors output pattern

data with variable output level in the range

-1.125 V to +3.50 V into 50 W. The delay times

for each channel can be varied from -1.0 ns to

+1.0 ns. If you use only one output connector for

each channel, you must terminate the other

connector using an SMA termination.

2Ć2

DG2040 Data Generator

Page 33

Operating Basics

START/STOP Button

Starts or stops pattern data output. When automatic pattern data update is not used, the pattern data is updated before output is started.

The indicator lights in the output state. It will flash when there is a discrepancy between the output data and the displayed data due to pattern data not being updated.

When automatic pattern data update is specified, the indicator flashes rapidly during data update. It flashes slowly when automatic update is not performed and data

update is required.

Refer to Update on page 3Ć76 for update mode.

CURSOR Button Arrow Buttons EXECUTE Button GeneralĆpurpose knob

Activates or switches

the cursor. The LED

indicates that the

generalĆpurpose knob

will move the cursor.

The arrow buttons move the

cursor. They are also used for

special functions that are

described on the screen when

enabled.

STEP/EVENT Button

Advances the

pattern data by 1

step when in step

mode.

Generates an event

pulse when the run

mode is enhanced

mode.

MENU Buttons

These buttons are

the main menu

buttons. When

pressed, the menu

is displayed and the

corresponding LED

is on.

Numeric Keys, Units Buttons

The numeric keys enter values in numeric or character

input mode. The characters A to F are allocated to keys for

hexadecimal input. Instructions are displayed when used

for other operations.

When a units button appropriate for the input item is

pressed, the input value and unit are confirmed.

Executes the edit

operation set up with the

EDIT menu. Confirms

selection operations in

selection screens.

GHz/ns

ENTER Key

Confirms numeric and

character input.

Delete Key

Deletes previously input digits

during numeric input. Deletes the

character directly in front of the

cursor during character input.

Controls several functions

and adjusts numeric values.

The knob icon displayed on

the screen indicates that this

knob controls the item.

HARD COPY Button

Makes a hard copy of the

current screen. The LED

flashes while in progress.

FORCE TRIGGER Button

Generates a trigger event.

TRIGGER INPUT

BNC connector accepts an

external trigger signal.

EDGE CONTROL

BNCĂconnector accepts an external

signal to move the edge position on

CH0 data output.

Figure 2Ć1 : Front panel controls (cont.)

CAUTION. Only apply signals within the stipulated ranges to the TRIGGER

INPUT connector. Signals that exceed those ranges can damage the instrument.

DG2040 Data Generator

2Ć3

Page 34

Operating Basics

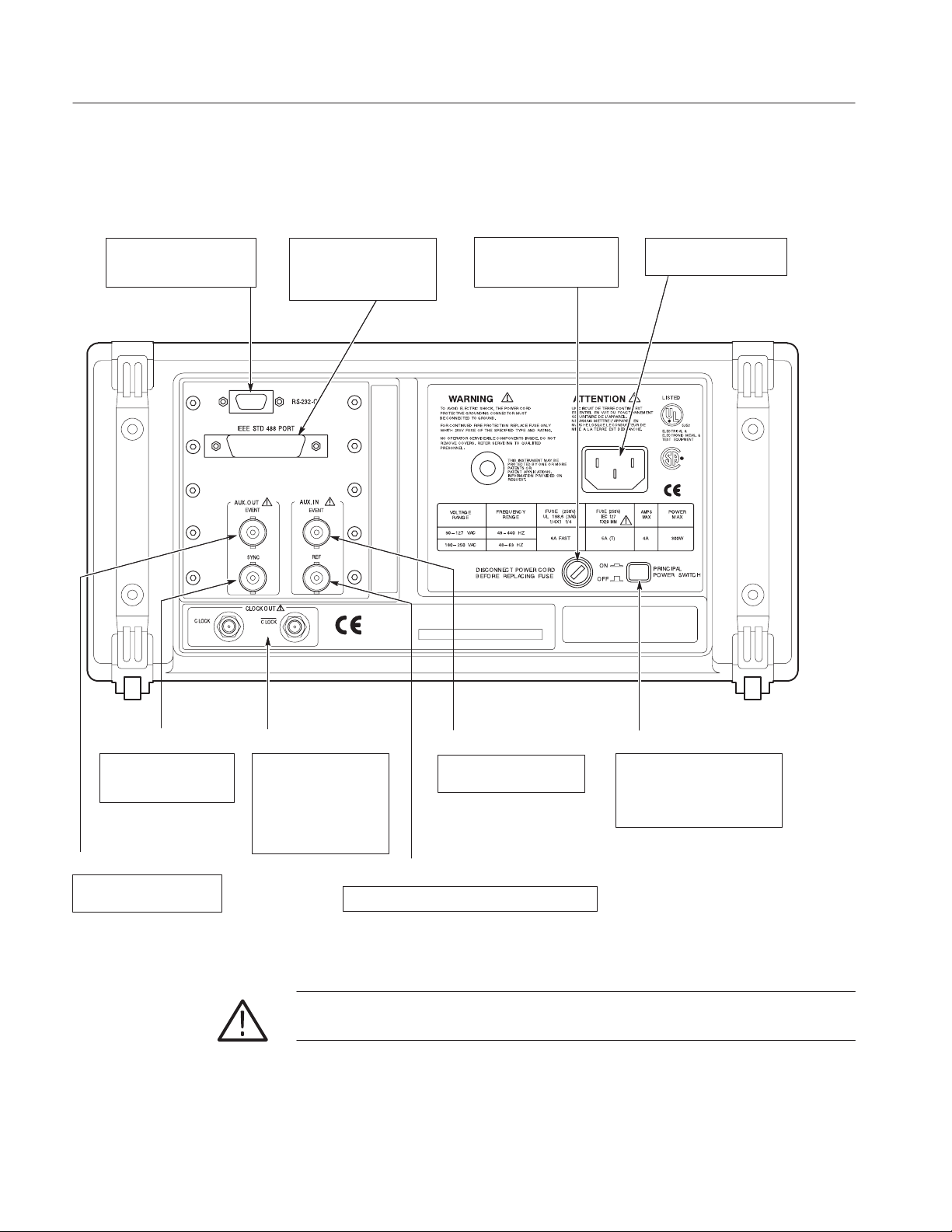

Rear Panel

RSĆ232 Connector

The RSĆ232 connector is

used for remote computer

control over a serial interface.

Figure 2-2 shows the rear panel signal and power connectors.

IEEE STD 488 Connector

This is a GPIB connector for

remote computer control

through an IEEE 488

standard parallel interface.

DIE IN DIESEM GERAT ENTSTEHENDE

RONTGENSTRAHLUNG IST AUSREICHEND ABGESCHIRMT

BESCHLEUNIGUNGSSPANNUNGKLEINER ALS

Power Supply Fuse Holder

The same 6A fastĆblow fuse

is used for both 115V and

230V systems.

20 KV

Power Connector

Connect the provided power

cable to this connector.

SYNC OUT Connector

BNC connector provides a

TTL level synchronization

output signal.

CLOCK OUT Connector

SMA connector provides

an internal clock output

signal. If you use only one

CLOCK OUT connector,

you must terminate the

other connector using an

SMA termination.

EVENT OUT Connector

BNC connector provides a

TTL level event output signal.

Figure 2Ć2: Rear panel connectors

2Ć4

EVENT IN Connector

BNC Connector accepts a

TTL level event input signal.

PRINCIPAL POWER SWITCH

This switch applies power to the

standby circuit. In addition to this

switch being on, the front panel

ON/STBY switch must also be

turned on.

EXT REF IN Connector

BNC connector accepts a external reference signal.

CAUTION. Voltages in excess of the stipulated range can damage the instrument.

Apply signals within the stipulated range to the AUX INPUT connector.

DG2040 Data Generator

Page 35

Operating Basics

Floppy Disk Drive

Figure 2-3 shows the floppy disk drive controls and indicators. The floppy disk

drive is located on the right side of the DG2040 Data Generator chassis. Use the

floppy disk drive to save and recall instrument patterns and for setting data.

CAUTION. Data corruption on the floppy disk may occur if the eject button is

pressed while the DG2040 Data Generator is writing to the floppy disk.

LED indicator Eject button

When the disk drive is in operation, the

LED indicator is on.

Remove a floppy disk by pressing the

eject button.

Figure 2Ć3: Floppy disk drive

DG2040 Data Generator

2Ć5

Page 36

Operating Basics

Display Elements

Figure 2-4 shows the display elements, including bottom and side menus, work

area, status lines, and so on. Also shown are a pop-up menu and message box.

Table 2-1 describes each element in detail.

1 2

6

5

3

Figure 2Ć4: Display elements

2Ć6

4

7

8

DG2040 Data Generator

Page 37

Table 2Ć1: DG2040 display elements

Reference

number

1 Status area

Label Description Page

Displays the current status of the instrument. This status

line is always displayed. The status line displays the

following two items:

MODE: Displays the run mode in which pattern

data will be output.

Operating Basics

3Ć74

UPDATE: Displays the update method for pattern

data output when data is updated.

In addition, there is also a disk icon that indicates if a

floppy disk is inserted in the disk drive. A clock icon may

also be displayed at the left end of the status line. When

this icon is displayed, the instrument is busy with internal

processing and cannot accept other inputs.

2 Date and Time

display area

3 Side menu Related side menu items are displayed here when a

4 Bottom menu When one of the buttons in the menu section is pressed,

5 Button function

description

area

6 Message for

display area

7 PopĆup for

message box

8 PopĆup menu The instrument sometimes displays a popĆup menu

The date and time display can be turned on or off using

the display function of the UTILITY menu.

bottom menu item is selected. The topmost entry in the

side menu displays either a label representing the side

menu or the operation name for the confirmed item.

the corresponding bottom menu is displayed. When a

bottom menu item is selected the corresponding side

menu is displayed. Selecting the same bottom menu

item again closes the side menu.

Displays descriptions of the functions of the frontĆpanel

buttons.

Displays messages regarding the current processing

state. This area can be also used by remote commands

to display user messages.

When required, the instrument temporarily displays a

window at the center of the screen to display a warning

or question for the user.

when a bottom menu or side menu item is selected.

Enter a numeric value or select an item using either the

generalĆpurpose knob or the frontĆpanel buttons.

3Ć76

3Ć89

2Ć15

2Ć15

2Ć2

and

2Ć3

2Ć6

2Ć25

2Ć6

DG2040 Data Generator

2Ć7

Page 38

Operating Basics

Theory of Operation

This section presents an overview of the DG2040 Data Generator hardware, data

structures, and operating modes to allow you to take full advantage of the

DG2040 Data Generator.

Reference

Input

Trigger Input

Block Diagram

Edge Control Input

Clock Unit

PLL

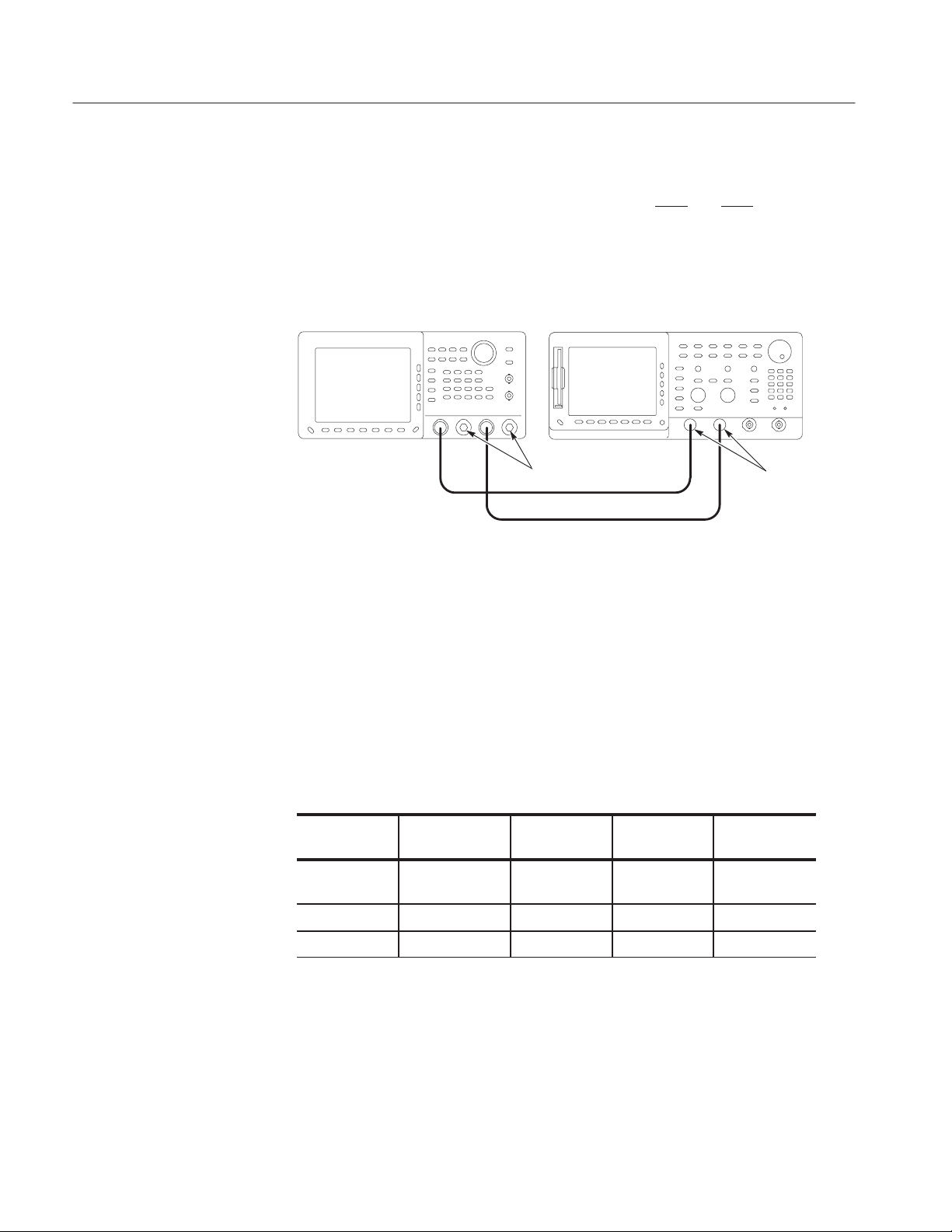

Figure 2-5 shows the main hardware blocks that make up the instrument. This

section describes these hardware blocks to provide the background knowledge

necessary to use the instrument effectively.

Event Input

Clock

Bus

Pattern Generation Unit

Pattern

Control

Circuit

CPU Unit

CPU

Pattern Memory

Sequence Memory

ROM

RAM

GPIB

Output Channels

RSĆ232ĆC

GPIB

RSĆ232ĆC

Data Output

(CH0 and CH1,

Complementary)

Clock Output

(Complementary)

Event Output

Sync Output

Front Panel

Figure 2Ć5: Hardware block diagram

2Ć8

Display

Floppy Disk Drive

DG2040 Data Generator

Page 39

Operating Basics

CPU Unit

Pattern Generation Unit

The CPU unit controls the instrument and includes read only memory (ROM),

random access memory (RAM), and an input/output (I/O) interface.

The ROM memory holds the program code that implements all the supported

functions. The ROM contents are loaded at the factory.

The RAM memory holds a variety of information required by the CPU. The

contents of RAM change according to the instrument’s operating state. The

contents of RAM are retained by a built-in battery even when the instrument is

turned off. The main instrument settings will still be in effect the next time the

instrument is turned on. The pattern data memory and the sequence data

memory, which are described later as a conceptual data model, are actually stored

in one section of this RAM.

External interfaces include GPIB and RS-232 interfaces for remote control, a

floppy disk drive controller, and a user interface consisting of the display and the

front panel.

The pattern generation unit generates digital pattern signals based on the pattern

data and sequence data specified by the user. This unit includes a pattern control

circuit, pattern memory, and sequence memory.

Pattern memory and sequence memory are high-speed memories that hold the

pattern data and sequence data, which are described later in this section. These

memories supply pattern data to the pattern control circuit.

Clock Unit

Output Channels

Display and Front Panel

The clock unit provides the clock signals that generate the data patterns and

detects and synchronizes external trigger signals.

The data generator uses the phase-lock-loop (PLL) circuit when generating the

clock signals. This provides an output with excellent frequency precision.

The output channels provide variable output levels and digital signals to the

device under test.

The output channels level-convert the pattern signals from the pattern generation

unit to output signals appropriate for the device under test. They also handle fine

adjustment of specific bit timing.

The user interface consists of the display and front panel.

The display is a 16-level monochrome 640 × 480 pixel CRT. The front panel

consists of menu buttons, numeric keys, bezel buttons, a general-purpose knob

for changing numeric values and item selection, and several signal output

connectors.

DG2040 Data Generator

2Ć9

Page 40

Operating Basics

Data Structure Overview

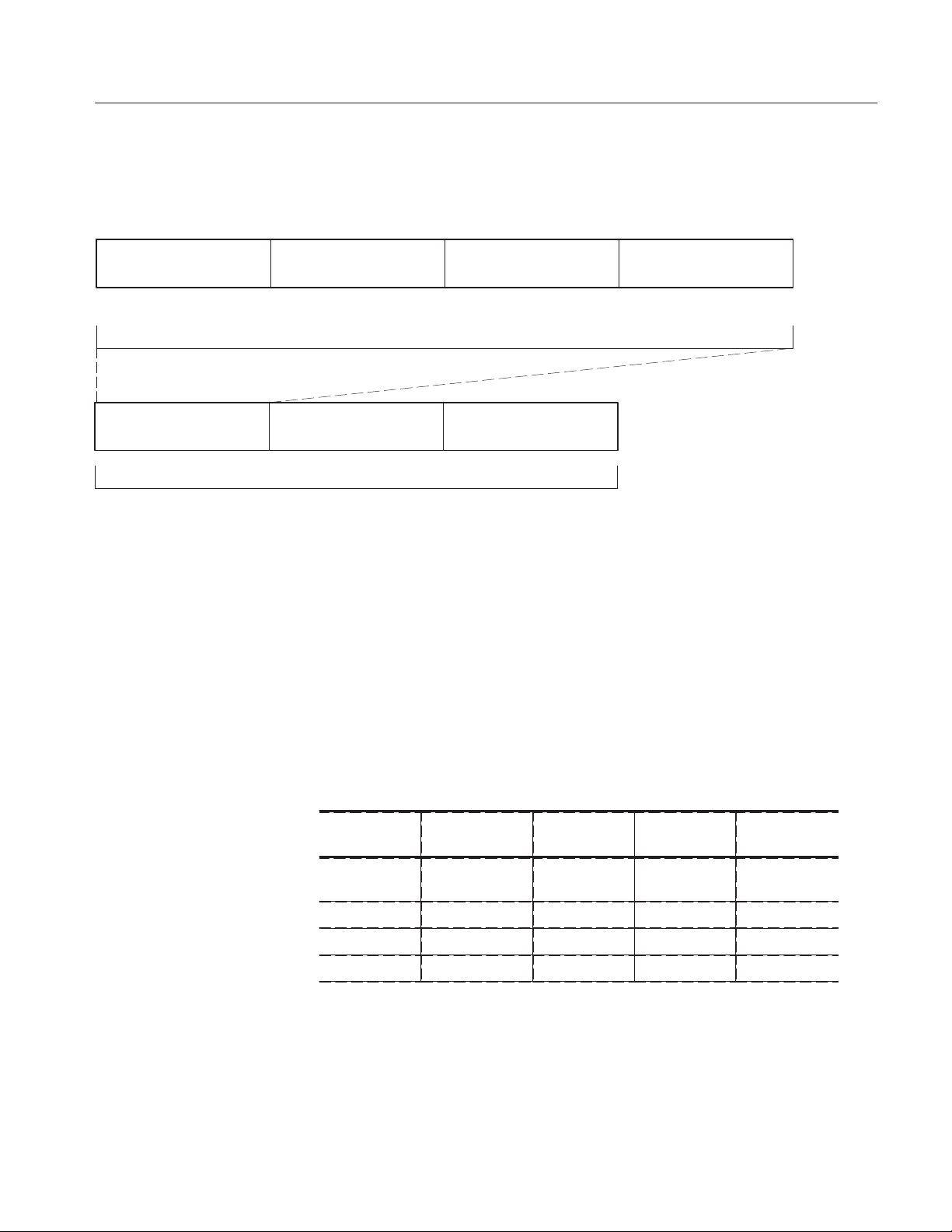

To make full and efficient use of the DG2040 Data Generator, you need to

understand the data structures of the DG2040 Data Generator. This section

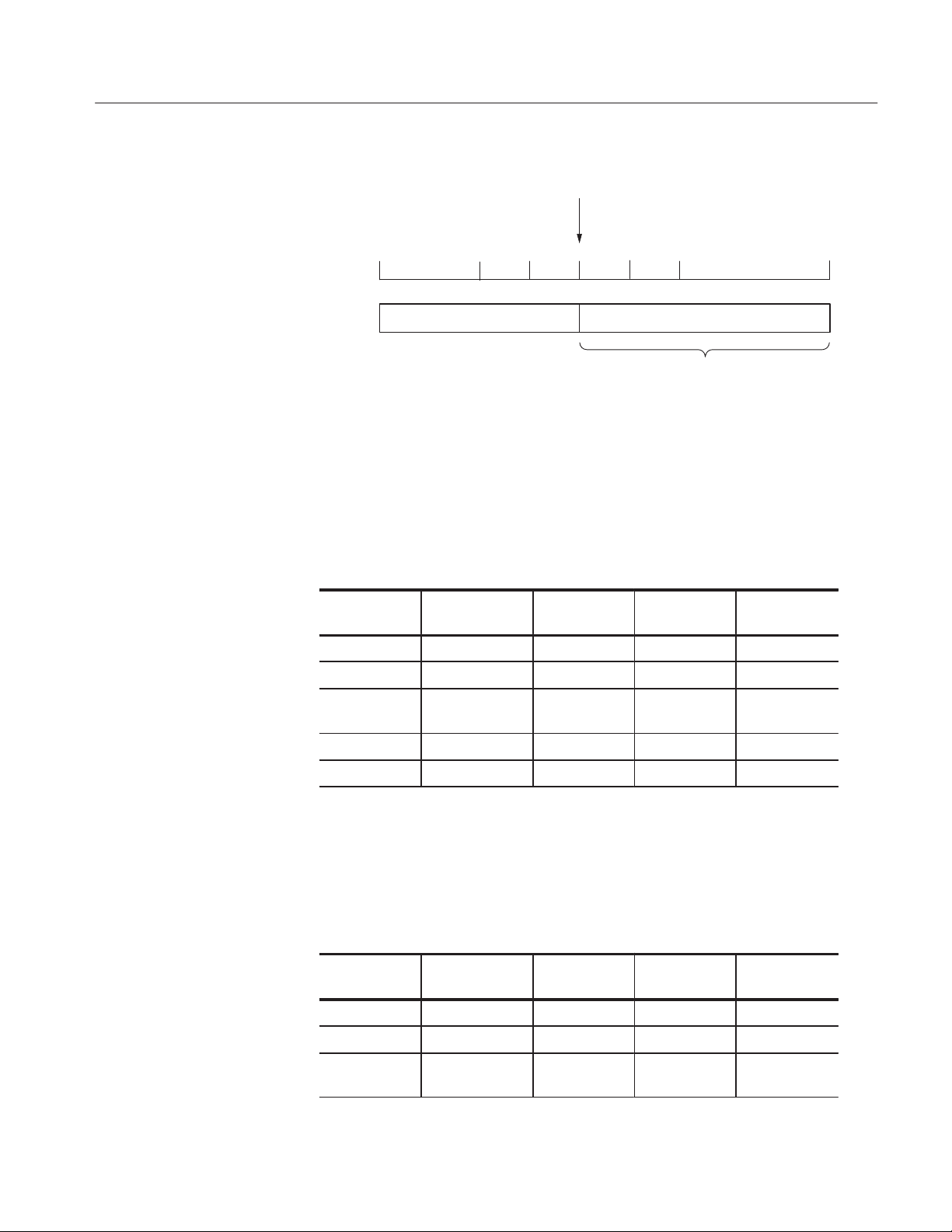

presents an overview of the pattern data, setup data, and sequence data. Figure

2-6 shows the data structures that are described in the following sections. Table

2-2 lists the data structure related technical terms that appear frequently in the

operating procedure descriptions.

Block Delimiter

BlockBlockBlockBlock

Group

Group

Allocation

D1

D0

Pattern Data

Output Channel

Allocation

Output

Channels

Figure 2Ć6: Data structures

Table 2Ć2: Data structure terms

Term Meaning

Pattern data Basic data for patterns, consisting of 2Ćbit words

Memory size The number of pattern data words (360 words to 256 K words)

Group allocation Definitions of pattern data bit combinations

Block delimiter Delimiter that defines pattern data start and stop points

Block division Pattern data division by block delimiters

Output channel allocation Definition of the corresponding relationship between pattern data

and output bits

2Ć10

Pattern Data

Setup data Settings for the above items

Sequence data Pattern output sequence program

Pattern data is the basic data that defines the digital signals to be output. The

pattern data is a collection of 2-bit words. The total number of words is called

the memory size. The memory size can be any value from a minimum of

360 words to a maximum of 256 K words (262,144).

DG2040 Data Generator

Page 41

Operating Basics

Pattern data that has been transferred to the pattern memory in the pattern

generation unit hardware can be output as digital signals. Pattern memory

consists of 2-bit words, with the 2 bits in a one-to-one correspondence with the 2

output channels. The definition of the relationship between pattern data bits and

pattern memory bits is called output channel allocation.

The pattern data to pattern memory transfer operation is performed automatically

each time the data is modified, or you can manually cause the transfer to occur.

This is called the data update mode, and it can be selected by user.

Setup Data

Groups

Blocks

There are numerous settings that define data structures and relationships between

data items and that specify output channel states and other parameters. These

settings are collectively referred to as the setup data. Since this data is associated

with the pattern data, it is handled together with the pattern data in operations,

such as saving instrument settings and data to a floppy disk.

The setup data includes a wide range of settings, including output voltage levels,

delay, and clock frequency settings in addition to the definitions described here.

Although each bit in the pattern data can be defined independently, it is easier to

edit and display data if multiple bits are collected and handled as a single group.

Any set of bits can be assigned as a group.

Pattern data can be divided into blocks. A block is a user-specified range of

pattern data identified with a unique label. Blocks are divided by setting

delimiters called block delimiters. Block delimiters are set in word units.

Sequences, which are described later, control data output in block units.

DG2040 Data Generator

2Ć11

Page 42

Operating Basics

Sequence Data

The sequence data is a program that specifies the order in which the pattern data

is output. The sequence data is used to set up operations, such as repeatedly

putting out blocks of pattern data for a specified number of times and jumping to

a specified block when an external event occurs. Sequences allow long patterns

to be set up without preparing large quantities of data.

Sequences can include subsequences so that you can make complex sequence

programming easier. Sequence data is transferred to the pattern generation unit

sequence memory, and controls the operation of the pattern control circuit.

When you use the run mode you can select whether all the sequence data is valid

or whether enhanced mode settings, such as event jumps in the sequence, are

ignored.

Operating Modes Overview

Run Modes

In the run modes, pattern output is controlled by the pattern generation units

pattern control circuit. The DG2040 Data Generator supports four run modes:

repeat, single, step, and enhanced. These run modes are specified with the

SETUP → Run Mode menu. Table 2-3 provides functional information for each

mode.

Table 2Ć3: Run modes

Run mode Function

Repeat Repeats the pattern data from the first to last data point indefinitely.

If a sequence is defined, it repeats the output according to that

sequence.

Single Outputs the pattern data once from the first to last data point in point

order. If a sequence is defined, outputs the pattern once according to

that sequence.

Step Operates identically to repeat mode, except that just one data point

is output each time the STEP/EVENT button is pressed.

Enhanced Same as Repeat with the addition that event jumps and trigger waits

are also effective.

NOTE. The Repeat, Single, and Step modes ignore the event jump and trigger

wait settings.

2Ć12

DG2040 Data Generator

Page 43

Operating Basics

Update Modes

When pattern data or sequence data is created or edited or the output channel

allocations are changed, the pattern that is actually output will not be updated

until the new settings are transferred to the pattern generation unit.

There are two update methods: auto and manual. The update modes are set up

with the Update item in the SETUP ! Run Mode menu. Table 2-4 provides

functional information for both modes.

Table 2Ć4: Update modes

Update mode Function

Auto Changes are reflected in the hardware as soon as they are entered.

Manual Changes are reflected in the hardware when specified by you.

NOTE. The response to edit operations while in Auto mode may be slow when

there is a large amount of data being edited. In such cases, it is more efficient to

perform a number of edit operations and then update the output data in manual

mode.

Basic Menu Operations

Menu System

This section describes the DG2040 Data Generator menu system and numeric

input methods.

The menu system is used for instrument settings, instrument operation, and

selection of the pattern data output parameter. Pressing one of the menu buttons

at the center of the front panel displays one of the menus that forms the basis of

DG2040 Data Generator operation. There are four menu buttons, EDIT, SETUP,

APPLICATION, and UTILITY, as shown in Figure 2-7.

The menu items displayed on the screen are selected by pressing the corresponding bottom or side bezel button. The bezel buttons consist of seven bottom

buttons and five side buttons, as shown in Figure 2-7.

DG2040 Data Generator

2Ć13

Page 44

Operating Basics

1.1 Gbps

Side Buttons

Bottom Buttons

Menu

Buttons

Figure 2Ć7: Menu and bezel buttons

When the target menu item is selected, the selection items and numeric input

entries controlled by that menu are displayed. Items can be selected or numeric

values changed using the numeric keys and the general-purpose knob.

Selecting a menu item causes one of the following operations:

H Invokes a lower level menu

H Selects an item:

H The selected item changes each time a bezel button is pressed.

2Ć14

Menu Notation

H A list is displayed and an item is selected from that list.

H Enables a numeric input

H Executes the function associated with the menu item as soon as the menu

item is selected.

The following notation is used in this manual to show the order to push

instrument buttons:

Front panel menu button ! Bottom menu button ! [Side menu button or

pop-up menu item]

The menu path starts with a front panel menu button, followed by an arrow (!),

and then a bottom menu. The item in parenthesis may be repeated more than

DG2040 Data Generator

Page 45

Operating Basics

once, as needed. For example, SETUP ! Output Condition ! Control

Condition is executed as follows:

1. Press the SETUP button on the front panel.

2. Press the Output Condition bottom button.

3. Press the Control Condition side button.

Menu Item Display

Starting with each main menu, the instrument displays bottom, side, and

submenu items according to fixed rules.

Bottom Menu. The bottom menu changes according to whether items are selected

or not, and whether an item is valid or not, as shown in Table 2-5.

Table 2Ć5: Bottom menu elements

Menu item Description

Menu item in the unselected state. The small box in the upper right

corner is black.

Menu item in the selected state. The small box in the upper right

corner is white.

Menu item that cannot be selected, since it is invalid in the current

state.

DG2040 Data Generator

Side and Submenus. The menu items that are manipulated with the side buttons,

can be classified according to the manipulations they support. These menu items

can be differentiated visually as shown in Table 2-6.

2Ć15

Page 46

Operating Basics

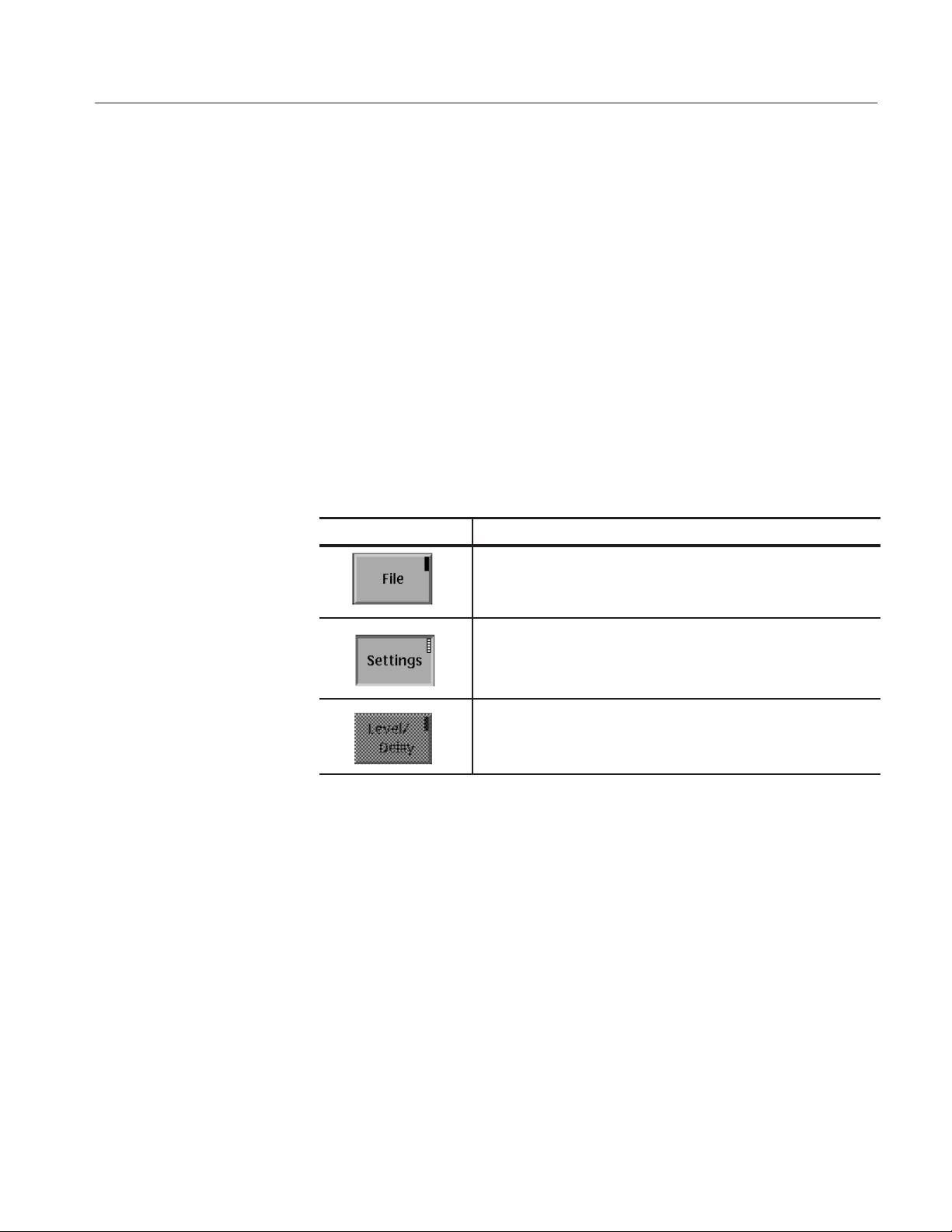

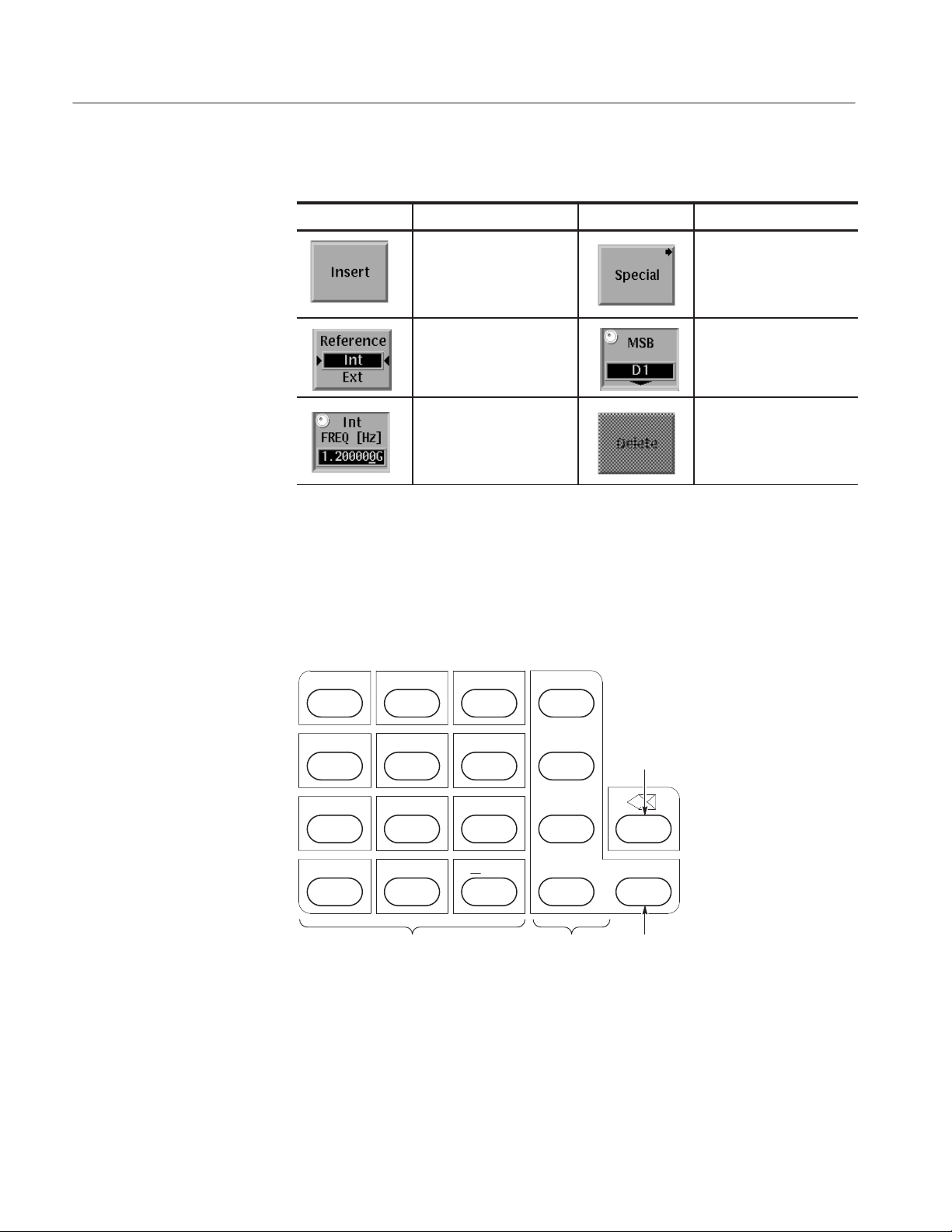

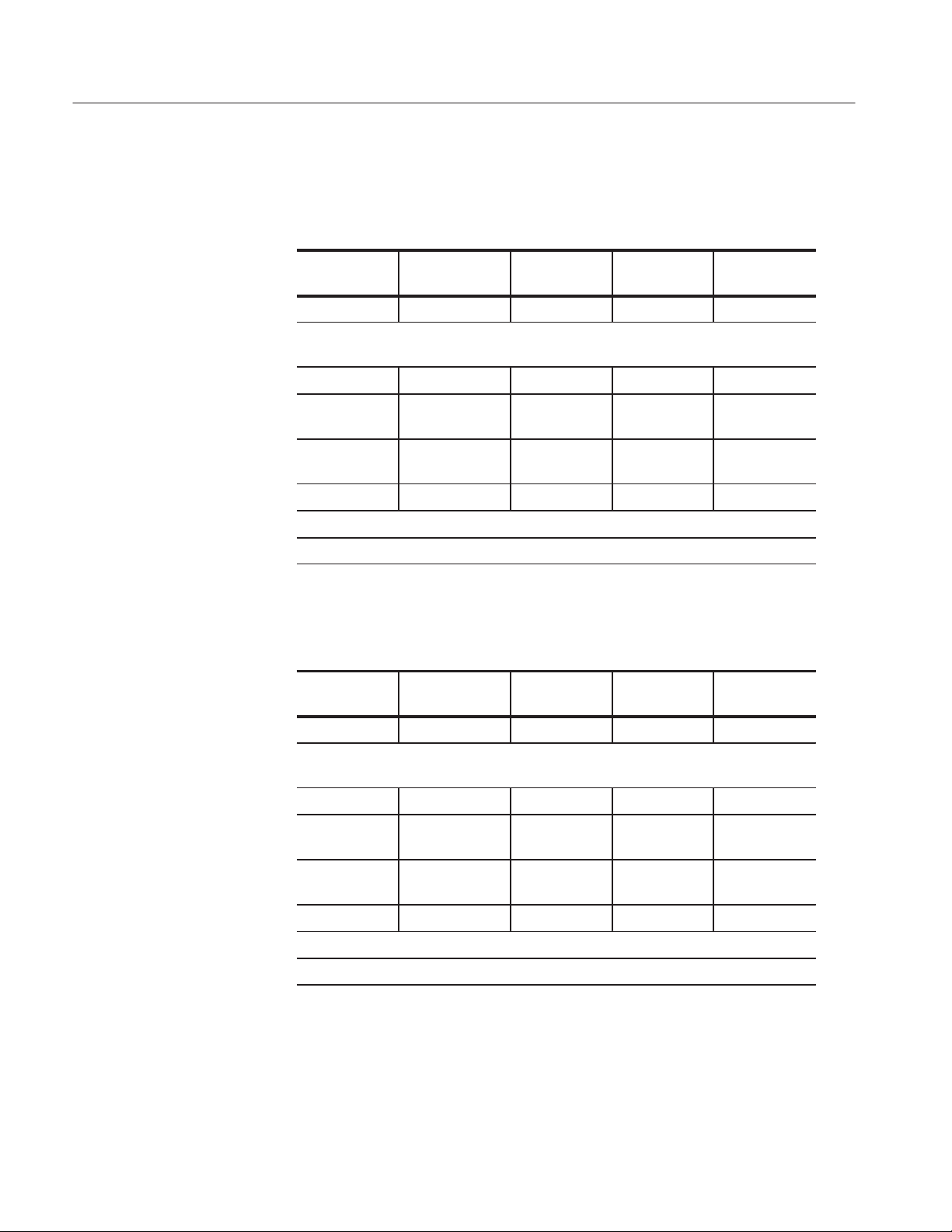

Table 2Ć6: Side and submenu elements

Menu Item Description Menu item Description

Menu items that execute a

function immediately

Menu items that call up

submenus

Numeric Input

Menu items that switch

between on and off each

time the side button is

pressed.

Menu items that allow

numeric values to be set

using the numeric keys or

Menu items that allow

selections to be made

with the generalĆpurpose

knob

Menu items that cannot

be used in the current

instrument state

the generalĆpurpose knob

Enter numeric values by using the front-panel keypad or the general-purpose

knob. This section describes these numeric input methods.

FrontĆPanel Keypad. The numeric keys, the units buttons, the delete key and the

ENTER key are used for entering numeric values. See Figure 2-8.

987

5

64

GHz/ns

MHz/ms

F

Delete

E

Key

2Ć16

1

0

.A

32

B

Numeric

Keys

Figure 2Ć8: DG2040 frontĆpanel keypad

kHz/ms/mV

D

Hz/s/V ENTER

C

Units

ENTER

Buttons

Key

DG2040 Data Generator

Page 47

Operating Basics

p

Use the following procedure to input numeric values with the numeric keys,

ENTER key, and units buttons on the front panel.

1. Press the button for the menu item to be changed.

2. Input the value using the numeric keys.

3. Press a units button or the ENTER key.

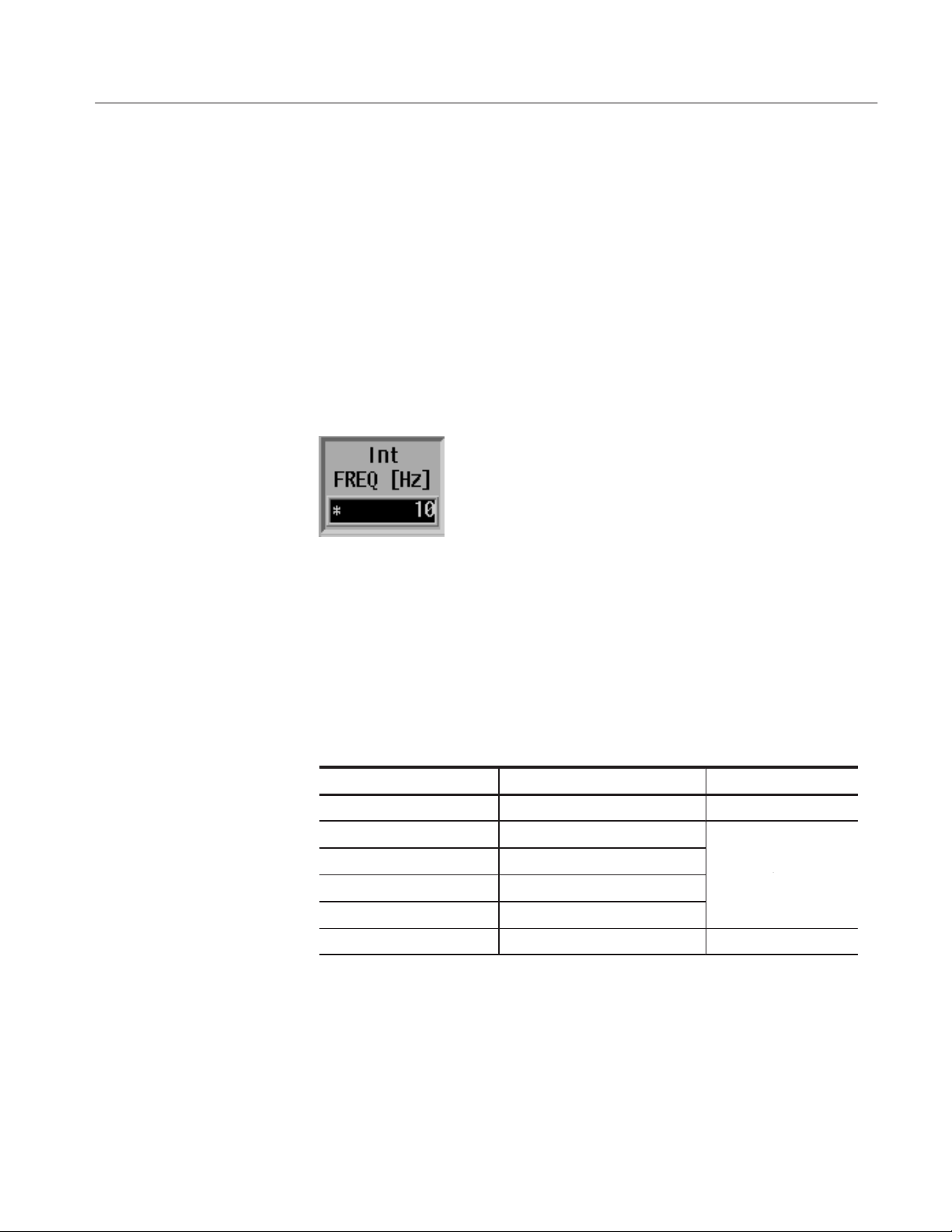

Figure 2-9 shows a menu display during numeric input. The asterisk to the left of

the menu items indicates that you are entering a value in that field. Press the

front panel ENTER key to confirm an entered value and to remove the asterisk

from the menu item field.

Figure 2Ć9: Numeric entry in a menu item field

Numeric Input Example. Table 2-7 shows how to change the clock frequency to

12.3 Hz when the value, before entering the input state, was 100.0 Hz. Press the

1, 2, ., 3, and ENTER keys in that order. The numeric input box changes as

shown in Table 2-7.

Table 2Ć7: Numeric input example

Press keys in this order Numeric input window display State of the value

100 Hz PreĆnumeric input

1 *1

2 *12

. * 12.

3 * 12.3

ENTER 12.30000 Hz Value confirmed

Numeric input

in progress

Press a units button after a value has been entered to confirm both the value and

the unit in a single operation. Pressing a units button before entering the input

state changes only the unit without changing the value.

DG2040 Data Generator

2Ć17

Page 48

Operating Basics

Failure to press the ENTER key or a units button after entering a value, prior to

switching menu items, will cause the entered value to be discarded. The value

returns to the previous value.

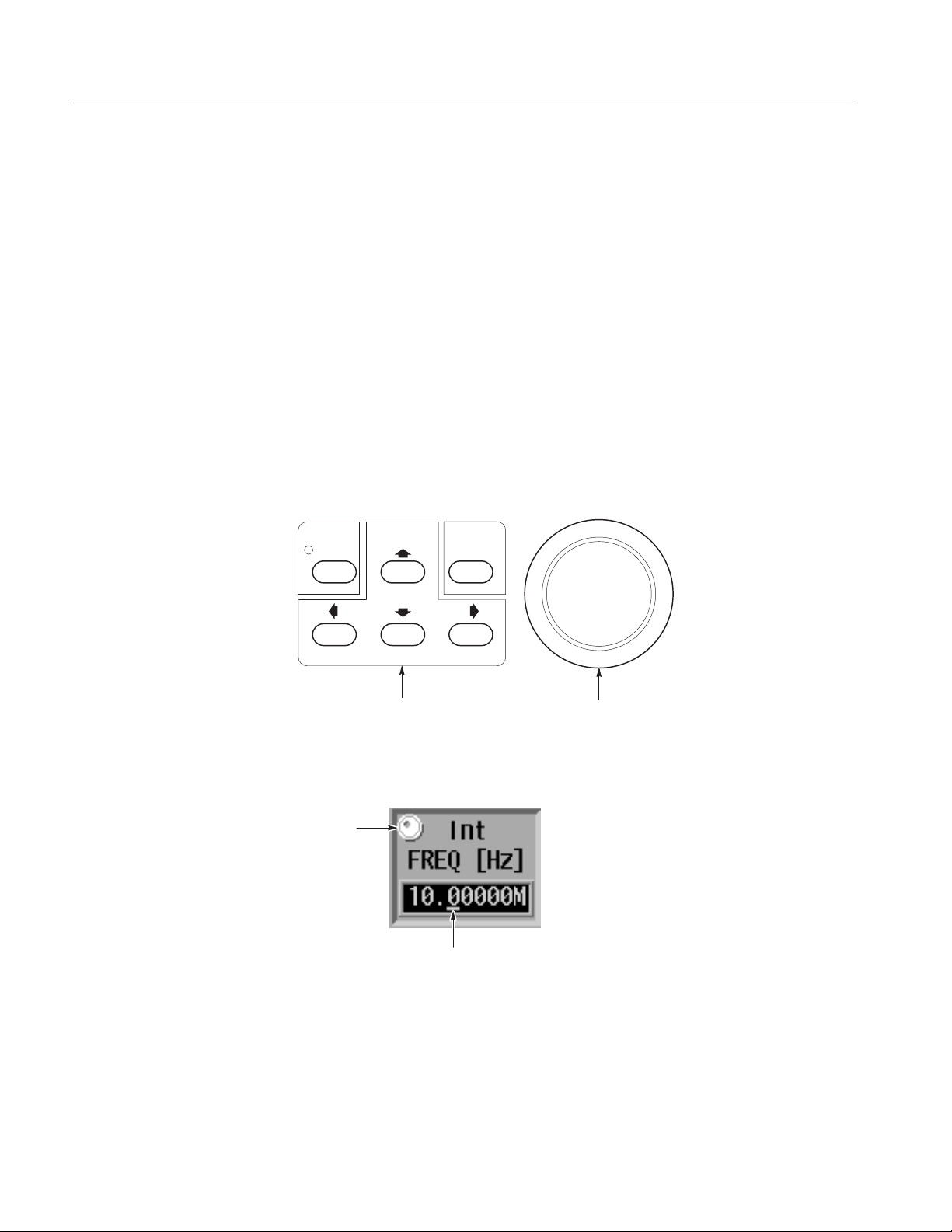

Setting Values with the GeneralĆPurpose Knob. The general-purpose knob and the

left and right arrow buttons can be used to set values in numeric input boxes.

The knob icon is displayed close to the box to show that you can use the

general-purpose knob to enter values. The general-purpose knob is used to

increase or decrease the value of the digit indicated by the underscore. Rotating

the knob to the left decreases the value and rotating it to the right increases the

value.

Figures 2-10 shows the arrow keys and the general-purpose knob.

Figure 2-11 shows a menu element that can use the general-purpose knob to

enter numeric values.

CURSOR EXECUTE

Arrow Buttons generalĆpurpose knob

Figure 2Ć10: GeneralĆpurpose knob and arrow buttons

Knob Icon

Underscore

2Ć18

Figure 2Ć11: Menu element knob icon and underscore

You do not need to use the front panel ENTER key to confirm a value when

using the general-purpose knob to change a value. The input value is confirmed

automatically without pressing the ENTER key.

DG2040 Data Generator

Page 49

Operating Basics

Follow the procedure below to change a value with the general-purpose knob.

1. Press the button for the menu item to be changed.

2. Use the left and right arrow buttons to move the underscore line to the digit

to be modified.

The front panel arrow buttons control the amount of change that can be

achieved with the general-purpose knob. Pressing the a button moves the

underscore one digit to the left and thus multiplies the effect of turning the

general-purpose knob by ten. Inversely, pressing the ' button moves the

underscore one digit to the right and reduces the effect of turning the

general-purpose knob by a factor of ten.

3. Change the value by turning the general-purpose knob.

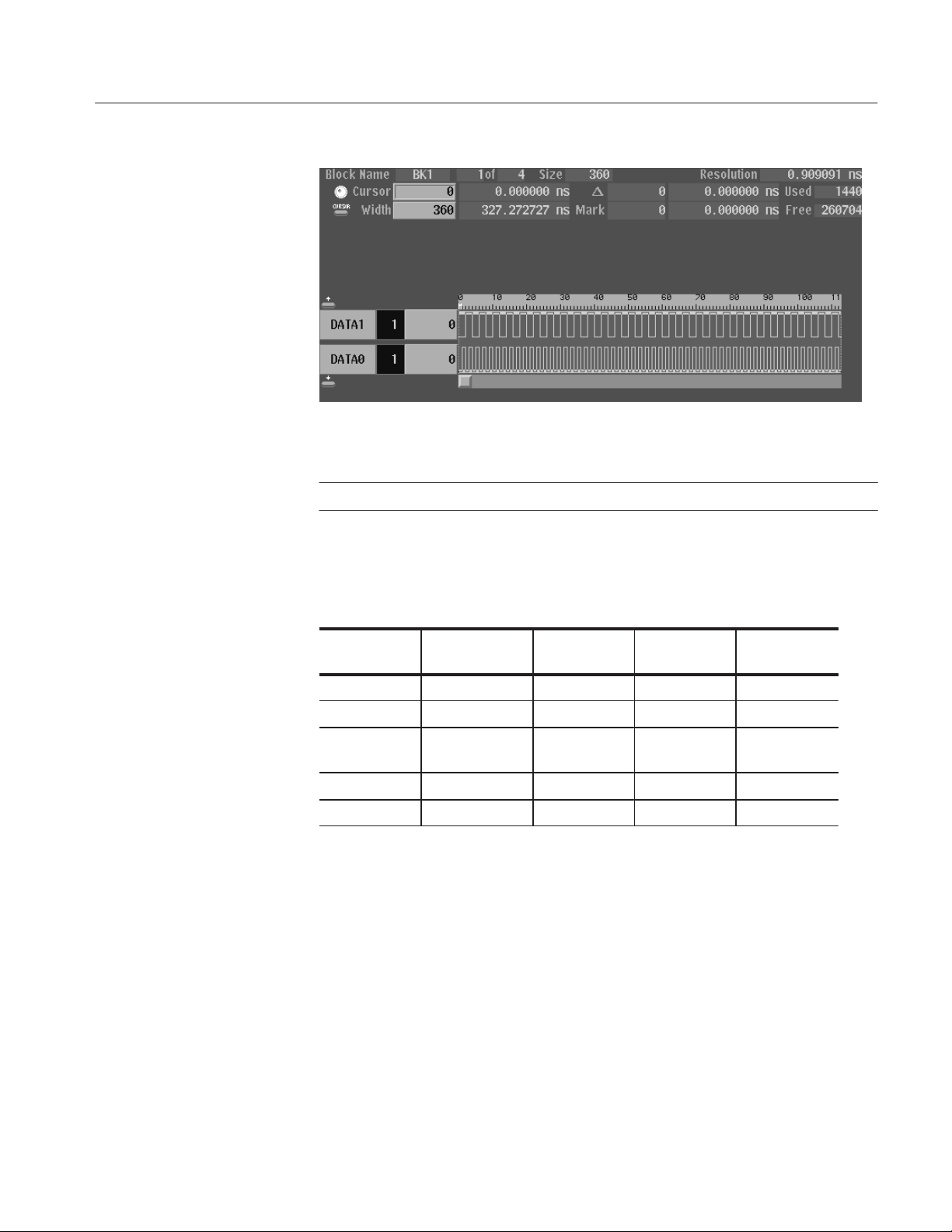

Pattern Data Display

Format