Page 1

Service Manual

DG2020A

Data Generator

071-0055-52

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Page 2

Copyright © Tektronix, Inc. All ri ghts reserved.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Tektronix, Inc., P.O. Box 500, Beaverton, OR 97077

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

H In North America, call 1--800--833--9200.

H Worldwide, visit www.tektronix.com to find contacts in your area.In North America, call 1--800--833--9200.

Page 3

WARRANTY

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1) year

from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its option, ei ther

will repair the defective product without charge for parts and labor, or will provide a replacement in exchange for the

defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suita ble arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center de signated by Tektronix, with shipping charges prepaid.

Tektronix shall pay for the re turn of the product to Customer if the shipment is to a location within the country in which the

Tektronix service center i s located. Customer shall be responsible for paying a ll shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than Tektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; or c) to service a product that has been

modified or integrated with other products when the effect of such modification or integration increases the time or

difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THIS PRODUCT IN LIEU OF ANY

OTHER W ARRANTIES, EXPRESSED OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED W ARRANTIES OF MERCHANT ABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX

AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

Page 5

Table of Contents

Specifications

Operating Information

General Safety Summary vii...................................

Service Safety Summary ix....................................

Preface xi...................................................

Introduction xiii..............................................

Product Description 1-1........................................

Features 1-1........................................................

Performance Characteristics 1-3................................

Warranted Characteristics 1-4..........................................

Typical Characteristics 1-9............................................

Nominal Traits 1-11..................................................

Certification and Compiances 1-16......................................

Preparation for Use 2-1........................................

Supplying Power 2-1.................................................

Power Cord Information 2-2...........................................

Operating Environment 2-3...........................................

Rear Panel Controls 2-3..............................................

Fuse Type and Rating 2-4.............................................

Applying and Interrupting Power 2-5....................................

Repackaging Instructions 2-6..........................................

Installed Options 2-6.................................................

Operating Instructions 2-7.....................................

How to Make Connection to Pods 2-7...................................

How to Power On 2-9................................................

Internal Diagnostics Routines 2-9......................................

User Interface 2-9...................................................

Display 2-11........................................................

Menus 2-13.........................................................

Pattern Storage and I/O 2-13...........................................

Loading Files 2-14...................................................

Signal Output 2-15...................................................

Theory of Operation

Theory of Operation 3-1.......................................

Module Overview 3-1................................................

Options 3-3........................................................

Performance Verification

Performance Verification 4-1...................................

Introduction 4-1....................................................

DG2020A Service Manual

i

Page 6

Table of Contents

Adjustment Procedure

Maintenance

Before Running the Operation Tests 4-2.................................

Test Procedure Notes 4-4.............................................

Self Tests 4-5.......................................................

Performance Tests for the DG2020A/Pod Combination 4-6..................

P3410 Pod Performance Test 4-17.......................................

P3420 Pod Performance Test 4-24.......................................

Adjustment Procedures 5-1.....................................

Maintenance 6-1..............................................

Preparation 6-1.....................................................

Inspection and Cleaning 6-4...........................................

Removal and Installation Procedures 6-9.........................

Preparation 6-9.....................................................

Access Procedure 6-12................................................

Procedures for External Modules 6-15....................................

Procedures for Internal Modules 6-26....................................

Repackaging 6-45..............................................

Repackaging Instructions 6-45..........................................

Troubleshooting 6-47...........................................

Troubleshooting Procedures 6-47........................................

DG2020A Diagnostics 6-47............................................

Options

Electrical Parts List

Diagrams

Mechanical Parts List

Options and Accessories 7-1....................................

Options A1--A5 7-1..................................................

Option 01 Description 7-2............................................

Option 02 Description 7-2............................................

Option 1R Description 7-2............................................

Option 95 Description 7-2............................................

P3410 Option 95 Description 7-3.......................................

P3420 Option 95 Description 7-3.......................................

Accessories 7-4.....................................................

Electrical Parts List 8-1........................................

Diagrams 9-1.................................................

Replaceable Mechanical Parts 10-1...............................

Parts Ordering Information 10-1.........................................

Using the Replaceable Parts List 10-2....................................

ii

DG2020A Service Manual

Page 7

List of Figures

Table of Contents

Figure 1-1: Trigger delay 1-7....................................

Figure 2-1: Rear panel controls 2-4..............................

Figure 2-2: Pod connection 2-7..................................

Figure 2-3: Yellow index mark and yellow wire for cable connection 2-8

Figure 2-4: CRT display 2-11....................................

Figure 2-5: Load data & setup menu 2-14..........................

Figure 2-6: Operating buttons and menu layout 2-15................

Figure 2-7: Pod channel data bit allocation 2-19....................

Figure 2-8: Output voltage level and delay time display

for the P3420 pod 2-21......................................

Figure 4-1: Operating buttons and menu layout 4-4................

Figure 4-2: Diagnostics menu 4-5................................

Figure 4-3: Frequency measurement connections 4-6...............

Figure 4-4: External clock input connection 4-8....................

Figure 4-5: Pod connection 4-10..................................

Figure 4-6: P3410 data output connectors 4-11......................

Figure 4-7: P3420 data output connectors 4-11......................

Figure 4-8: External trigger operation connections 4-13..............

Figure 4-9: P3410 event input connections 4-15.....................

Figure 4-10: P3420 event input connections 4-15....................

Figure 4-11: DG2020A event output connections 4-16................

Figure 4-12: Pod connection 4-17.................................

Figure 4-13: P3410 voltage level display 4-18.......................

Figure 4-14: P3410 output pi ns 4-18..............................

Figure 4-15: Pin header cable types 4-18...........................

Figure 4-16: Ou tput voltage test connections 4-19...................

Figure 4-17: Variable delay test connections 4-20....................

Figure 4-18: Event input operation confirmation connections 4-22.....

Figure 4-19: Inhibit operation confirmation connections 4-23.........

Figure 4-20: Pod connection 4-24.................................

Figure 4-21: P3420 voltage level display 4-25.......................

Figure 4-22: P3420 output connectors 4-25.........................

Figure 4-23: Ou tput voltage level measurement connections 4-26......

Figure 4-24: Variable delay precision check 4-29....................

Figure 4-25: Event input operation confirmation connections 4-31.....

DG2020A Service Manual

iii

Page 8

Table of Contents

Figure 4-26: Inhibit input operation confirmation connections 4-32....

Figure 6-1: DG2020A orientation 6-11.............................

Figure 6-2: Gu ide to removal procedures 6-12......................

Figure 6-3: External modules 6-13...............................

Figure 6-4: Internal modules 6-14................................

Figure 6-5: Front-panel knob removal 6-16........................

Figure 6-6: L ine fuse and line cord removal 6-17....................

Figure 6-7: Rear cover and cabinet removal 6-19....................

Figure 6-8: Front cover, trim ring, and menu button removal

(front cover not shown) 6-21..................................

Figure 6-9: Front-panel module removal 6-23......................

Figure 6-10: A12 keyboard removal 6-24...........................

Figure 6-11: Disassembly of front-panel module 6-25................

Figure 6-12: Connector module removal 6-28.......................

Figure 6-13: Fan and fan frame removal 6-29.......................

Figure 6-14: Rear shield cover removal 6-30........................

Figure 6-15: Power supply module removal 6-31....................

Figure 6-16: AUX power board and AC inlet removal 6-33...........

Figure 6-17: Monitor module removal 6-35.........................

Figure 6-18: CRT frame removal 6-36.............................

Figure 6-19: Circuit boards removal 6-39..........................

Figure 6-20: A17 backplane board removal 6-41....................

Figure 6-21: Battery location on the A17 backplan e board 6-43.......

Figure 6-22: Floppy-disk drive module removal 6-44................

Figure 6-23: A6 CPU board 6-48.................................

Figure 6-24: Primary troubleshooting procedure--(1) 6-49............

Figure 6-25: Primary troubleshooting procedure--(2) 6-50............

Figure 6-26: POD connector troubleshooting procedure 6-51..........

Figure 6-27: Troubleshooting procedure 1 — power supply module 6-52

Figure 6-28: AUX power board 6-53..............................

Figure 6-29: Power supply module 6-53...........................

Figure 6-30: Troubleshooting procedure 2 —

A6 CPU board or front-panel module 6-54.....................

Figure 6-31: Key board 6-55.....................................

Figure 6-32: Troubleshooting procedure 3 — monitor module 6-56....

Figure 6-33: Moni tor module 6-57................................

Figure 6-34: Horizontal and vertical syn c signals 6-57...............

Figure 6-35: A video signal with white and b lack levels 6-58..........

Figure 6-36: Troubleshooting procedure 4 — module Isolation 6-59...

iv

DG2020A Service Manual

Page 9

Table of Contents

Figure 9-1: Block diagram of DG2020A with options 01 and 02 9--3...

Figure 9-2: Interconnect diagram of DG2020A

with options 01 and 02 9--4..................................

Figure 10-1: Cabinet 10-5.......................................

Figure 10-2: Main chassis and CRT 10-7...........................

Figure 10-3: Main chassis and circuit boards 10-9...................

Figure 10-4: Circuit boards 10-11.................................

Figure 10-5: Front pan el assembly 10-13............................

Figure 10-6: Option 01 10-14.....................................

Figure 10-7: Option 02 10-15.....................................

DG2020A Service Manual

v

Page 10

Table of Contents

List of Tables

Table 1-1: Warranted electrical characteristics 1-4.................

Table 1-2: Warranted environmental characteristics 1-8............

Table 1-3: Electrical characteristics (typical) 1-9...................

Table 1-4: Nominal traits -- electrical characteristics 1-11............

Table 1-5: Nominal traits -- mechanical characteristics 1-15..........

Table 1-6: Certifications and compliances 1-16.....................

Table 2-1: Power-cord conductor identification 2-2................

Table 2-2: Power cord identification 2-2..........................

Table 2-3: Fuse type and rating 2-4..............................

Table 2-4: DG2030 display elements 2-12..........................

Table 4-1: Performance check disk’s file list 4-2...................

Table 4-2: Required equipment 4-3..............................

Table 4-3: Error Codes 4-5.....................................

Table 4-4: Internal clock frequency precision (PLL off) 4-8..........

Table 4-5: Delay precision 4-21..................................

Table 4-6: High level outpu t voltage ranges for a 1 MW load 4-27.....

Table 4-7: Low level output voltage ranges for a 1 MW load 4-28.....

Table 4-8: Delay precision 4-30..................................

Table 6-1: Relative susceptibility to static-discharge damage 6-3.....

Table 6-2: External inspection check list 6-5......................

Table 6-3: Internal inspection check list 6-6.......................

Table 6-4: Equipment required 6-10..............................

Table 7-1: International power cords 7-1.........................

Table 7-2: Standard accessories 7-4.............................

Table 7-3: Standard accessories for pods 7-4......................

Table 7-4: Optional accessories 7-5..............................

Table 7-5: Maintenance kit contents 7-6..........................

vi

DG2020A Service Manual

Page 11

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Connect and Disconnect Properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

DG2020A Service Manual

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

vii

Page 12

General Safety Summary

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

WARNING

High Voltage

Protective Ground

(Earth) Terminal

CAUTION

Refer to Manual

Double

Insulated

viii

DG2020A Service Manual

Page 13

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, disconnect the mains power by means

of the power cord or, if provided, the power switch.

Use Caution When Servicing the CRT. To avoid electric shock or injury, use

extreme caution when handling the CRT. Only qualified personnel familiar with

CRT servicing procedures and precautions should remove or install the CRT.

CRTs retain hazardous voltages for long periods of time after power is turned off.

Before attempting any servicing, discharge the CRT by shorting the anode to

chassis ground. When discharging the CRT, connect the discharge path to ground

and then the anode. Rough handling may cause the CRT to implode. Do not nick

or scratch the glass or subject it to undue pressure when removing or installing it.

When handling the CRT, wear safety goggles and heavy gloves for protection.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

X-Radiation. To avoid x-radiation exposure, do not modify or otherwise alter the

high-voltage circuitry or the CRT enclosure. X-ray emissions generated within

this product have been sufficiently shielded.

DG2020A Service Manual

ix

Page 14

Service Safety Summary

x

DG2020A Service Manual

Page 15

Preface

Manual Structure

This is the service manual for the DG2020A Data Generator. The manual

contains information needed to service the DG2020A to the module level.

This manual is divided into sections, such as Specifications and Theory of

Operation. Further, some sections are divided into subsections, such as Product

Description and Removal and Installation Procedures.

Sections containing procedures also contain i ntroductions to those procedures.

Be sure to read these introductions because they provide information needed to

do the service correctly and efficiently. The following contains a brief description

of each manual section.

H Specifications contains a description of t he DG2020A and the characteristics

that apply to it.

H Operating Information includes general information and operating instruc-

tions at the level needed to safely power on and service the DG2020A.

H Theory of Operation contains circuit descriptions that support general service

to the module level.

H Performance Verification contains a collection of procedures for confirming

that the DG2020A functions properly and meets warranted limits.

H Adjustment Procedures contains a statement explaining that adjustment is

unnecessary for the DG2020A.

H Maintenance contains information and procedures for performing preventive

and corrective maintenance of the DG2020A. These instructions include

cleaning, module removal and installation, and fault isolation to the module.

H Options contains information on servicing any of the factory-installed

options that your DG2020A includes.

H Electrical Parts List contains a statement referring you to Mechanical Parts

List, where both electrical and mechanical modules are listed. See below.

H Diagrams contains block diagrams and an interconnection diagram useful in

isolating failed modules.

H Mechanical Parts List includes a table of all replaceable modules, their

descriptions, and their Tektronix part numbers.

DG2020A Service Manual

xi

Page 16

Preface

Manual Conventions

This manual uses certain conventions that you should become familiar with.

Some sections of the manual contain procedures for you to perform. To keep

those instructions clear and consistent, this manual uses the following

conventions:

H Names of front panel controls and menus appear in the same case (initial

capitals, all uppercase, etc.) in t he manual as is used on the DG2020A front

panel and menus. Front panel names are all upper-case letters; for example,

SETUP MENU, HARDCOPY,etc.

H Instruction steps are numbered unless there is only one step.

Modules

Safety

Throughout this manual, any replaceable component, assembly, or part of the

DG2020A is referred to generically as a module. In general, a module is an

assembly (like a circuit board), rather than a component (like a resistor or an

integrated circuit). Sometimes a single component is a module; for example, the

chassis of the DG2020A is a module.

Symbols and terms related to safety appear in the Safety Summary near the

beginning of this manual.

Finding Other Information

Other documentation for the DG2020A Data Generator includes:

H The DG2020A User Manual contains a tutorial to quickly describe how to

H The DG2020A Programmer Manual explains how to control the DG2020A

operate the DG2020A. It also includes an in-depth discussion on how to

more completely use DG2020A features.

with a computer through the GPIB or RS-232-C interface.

xii

DG2020A Service Manual

Page 17

Introduction

This manual contains information needed to properly service the DG2020A Data

Generator, as well as general i nformation critical to safe and effective servicing.

To prevent personal injury or damage to the DG2020A, consider the following

before attempting service:

H The procedures in this manual should be performed only by a qualified

service person

H Read the General Safety Summary and the Service Safety Summary,

beginning on page vii near the beginning of this manual

H Read Preparation for Use in section 2, Operating Information

When using this manual for servicing, be sure to follow all warnings, cautions,

and notes.

Performance Check Interval

Generally, the performance check described in section 4, Performance Verification, should be done every 12 m onths. In addition, performance check is

recommended after module replacement.

Strategy for Servicing

If the DG2020A does not meet performance criteria, repair is necessary.

Throughout this manual, the term, module, refers to any field-replaceable

component, assembly, or part of the DG2020A.

This manual contains all the information needed for periodic maintenance of the

DG2020A. (Examples of such information are procedures for checking performance.)

Further, it contains all information for corrective maintenance down to the

module level. To isolate a failure to a module, use t he fault isolation procedures

found in Troubleshooting, part of section 6, Maintenance. To remove and replace

any failed module, follow the instructions in Removal and Installation Proce-

dures, also part of section 6. After isolating a faulty module, replace it with a

fully-tested module obtained from the factory. Section 10, Mechanical Parts

List, contains part number and ordering information for all replaceable modules.

DG2020A Service Manual

xiii

Page 18

Introduction

Tektronix Service Offerings

Tektronix provides service to cover repair under warranty as well as other

services that may provide a cost-effective answer to your service needs.

Whether providing warranty repair service or any of the other services listed

below, Tektronix service technicians are well equipped to service the DG2020A.

Tektronix technicians train on Tektronix products; they have access to the latest

information on improvements to the DG2020A as well as the latest new options.

Warranty Repair Service

Self Service

Tektronix warrants this product for one year from date of purchase. (The

warranty appears on the back of the title page in this manual.) Tektronix

technicians provide warranty service at most Tektronix service locations

worldwide. The Tektronix product catalog lists all service locations worldwide.

Tektronix supports repair to the module level by providing Module Exchange.

Module Exchange. This service reduces down-time for repair by allowing you to

exchange most modules for remanufactured ones. Tektronix ships an updated and

tested exchange module from the Beaverton, Oregon service center, typically

within 24 hours. Each module comes with a 90-day service warranty.

For More Information. Contact your local Tektronix service center or sales

engineer for more information on any of the repair or adjustment services just

described.

xiv

DG2020A Service Manual

Page 19

Product Description

The DG2020A is a digital data generator designed for high performance and ease

of use. The DG2020A is easy to use for testing and evaluating semiconductors

and logic circuits, which are continually becoming faster and more complex.

The DG2020A provides, in a compact package, high performance and a wide

range of functions. Features include a maximum data rate of 200 MHz, a 64K

word pattern memory, 12 channels (with support for up to 36 channels by adding

optional modules), a 100 ps timing skew adjustment function, and variable

output levels (from --3 to +7V).

Any memory size from 64 words to 64K words can be used easily, with no

restrictions within that range. TTL output level and variable output level pods

can be selected as the data output pods. Both pod types support setting of their

output stages to a high-impedance state. Each module supports delays in 4 of its

12 channels with a 100-ps-resolution variable delay time.

The DG2020A provides flexible data editing functions, including word and line

unit input and extended data creation functions. Furthermore, the DG2020A

provides a rich set of functions required for system construction, such as a

sequencing function, a jump function using external input, and an inhibit

function.

Features

H The DG2020A supports smooth and rapid product development by

simulating the digital signals from incomplete sections of a product.

H Logic function test systems can be constructed by combining this instrument

with a logic analyzer.

H Margin tests can be easily performed by using this instrument to generate

patterns that have a low probability of occurrence or are difficult to generate.

This can increase end-product reliability.

H Interactive digital simulation systems can be constructed using the sequence

output, external jump, and tristate control functions.

H Flexible data output functions make the DG2020A an ideal data generator

for simulation of LCD display units, CCD line and area sensors, and all

types of digital circuits.

DG2020A Service Manual

1-1

Page 20

Product Description

1-2

DG2020A Service Manual

Page 21

Performance Characteristics

The performance characteristics on the DG2020A can be divided into three

categories:

H Nominal Traits. General characteristics are described not by equipment

performance and limits but by such things as memory capacity.

H Warranted Characteristics. Warranted characteristics are described in terms of

quantifiable performance limits which are guaranteed.

H Typical Characteristics. Typical characteristics are described in terms of

typical or average performance for the DG2020A. The characteristics

described herein are not absolutely guaranteed.

Items marked with * are tested in the Performance Verification (Section 4).

The certification and compliances for the DG2020A are also found at the end of

this appendix.

DG2020A Service Manual

1-3

Page 22

Performance Characteristics

k

f

pag

page4-1

9

Warranted Characteristics

This section will describe the warranted characteristics of the DG2020A. These

can be divided into two main categories: electrical characteristics and environmental characteristics.

Performance Conditions

The electrical characteristics are valid under the following conditions:

1. The instrument must be in an environment whose limits are described in

Environmental Characteristics.

2. All tolerance limits apply after a 20 minute warm up.

3. The instrument is operating at an ambient temperature between +10 _Cto

+40 _C, unless otherwise noted.

Items marked with * are tested in the Performance Verification (Appendix B)

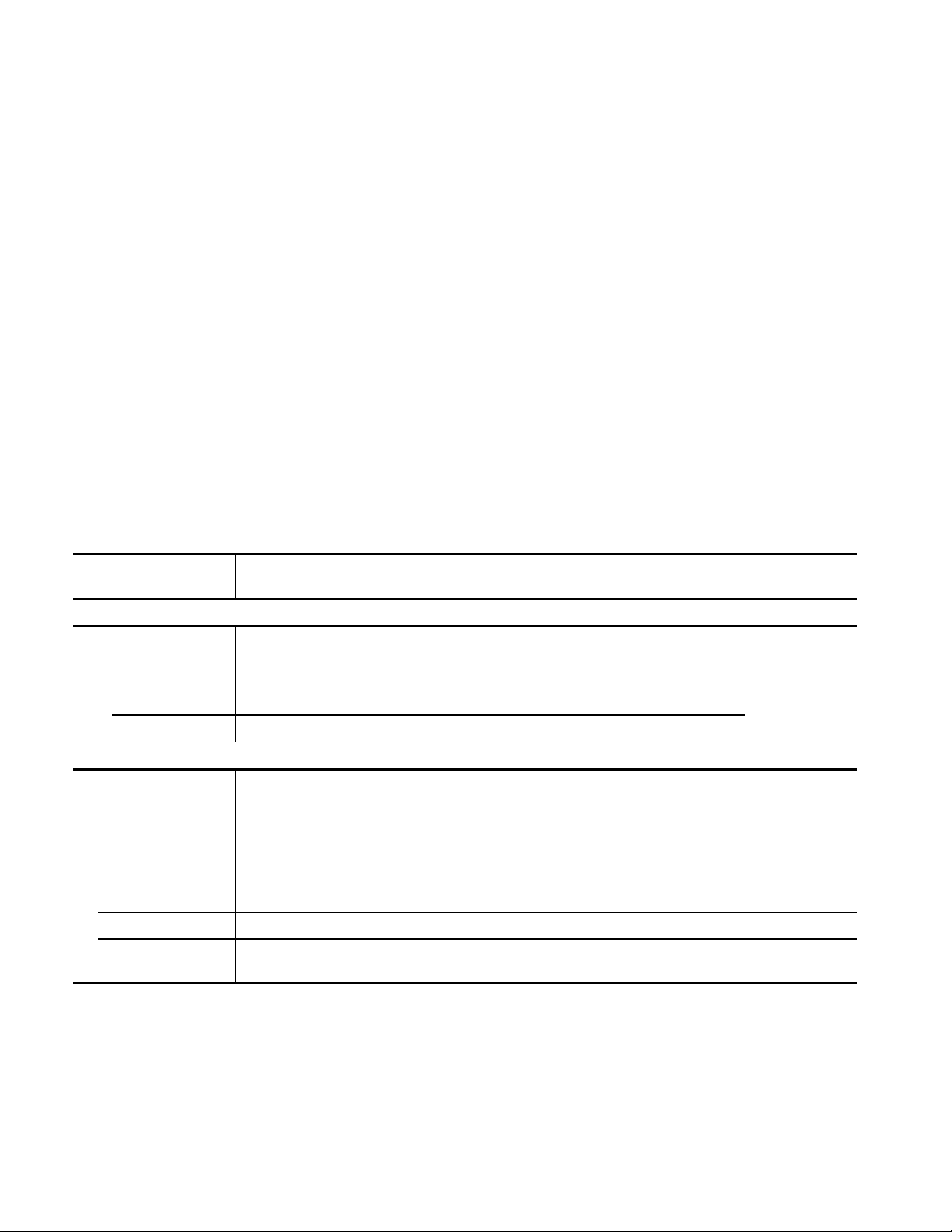

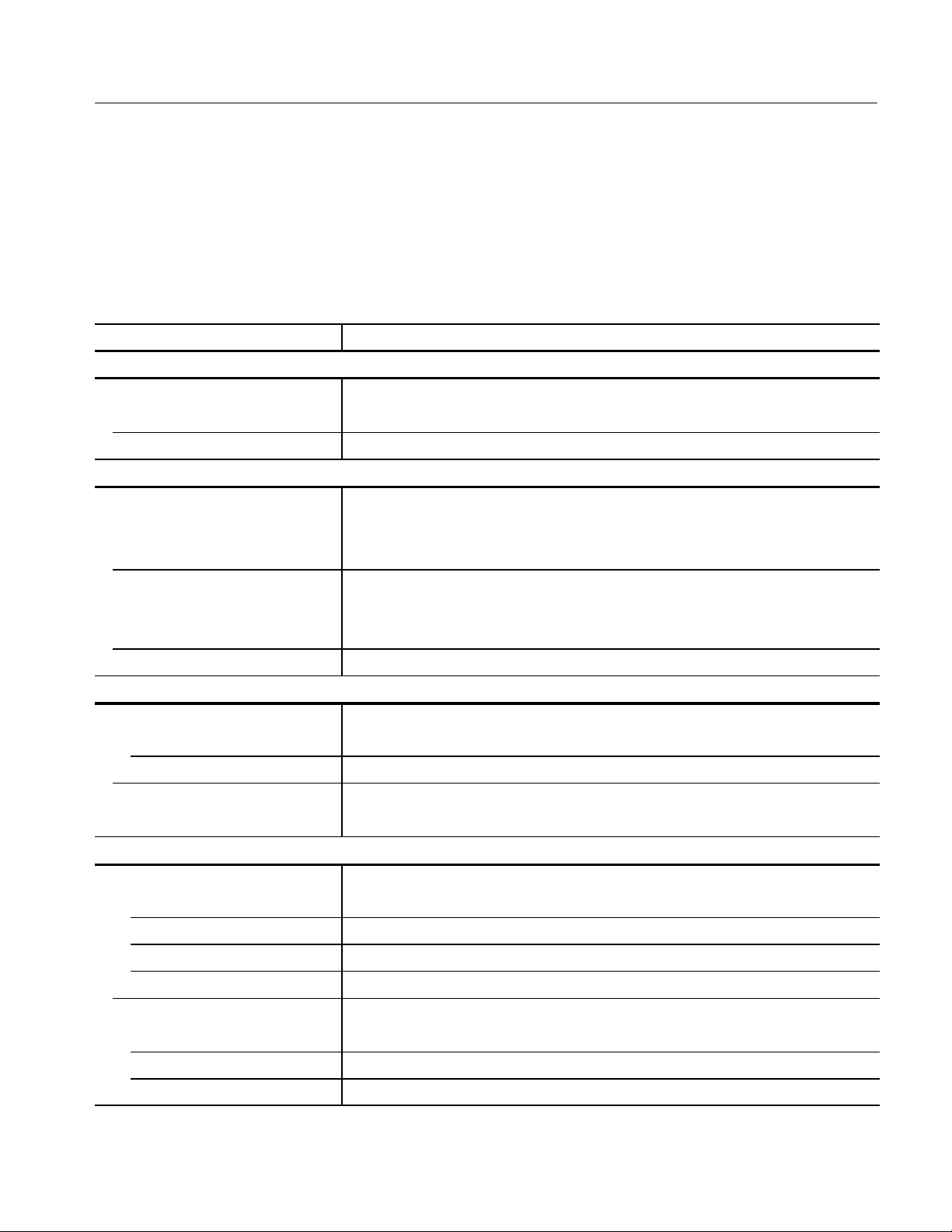

Table 1 -1: Warranted electrical characteristics

Characteristics Description Performance

T est

Clock generator

*Internal clock Check internal

cloc

Frequency accuracy

PLL on ¦50 ppm (0.005%)

PLL off ¦3%

P3410 ( TTL output pod )

requency,

page 4-6.

Data output Check output

*Output voltage

V

OH

V

OL

Rise / fall time < 5 ns ( 20% to 80%, into 1 MΩ 10 pF )

*Delay accuracy ¦2.0 ns ( CH0 reference ) Check variable

1-4

> 4.4Vinto1MΩ

> 3.5 V at 10 mA

< 0.1Vinto1MΩ

< 0.8 V at 10 mA

DG2020A Service Manual

voltage levels,

e 4-19.

.

delay, page 4-20.

Page 23

Table 1 -1: Warranted electrical characteristics (Cont.)

Performance Characteristics

Characteristics Performance

P3420 ( Variable output pod )

Data output Check output

*Output voltage

accuracy

*Delay accuracy ¦ 3% ¦ 0.8 ns ( CH0 reference )

Rise / fall time < 4ns ( 20% to 80%, into 1 MΩ 10pF,0to5VSwing)

Auxiliary outputs

Sync output

Delay from external

trigger input

Description

¦ 3% ¦ 0.1V(into1MΩ )

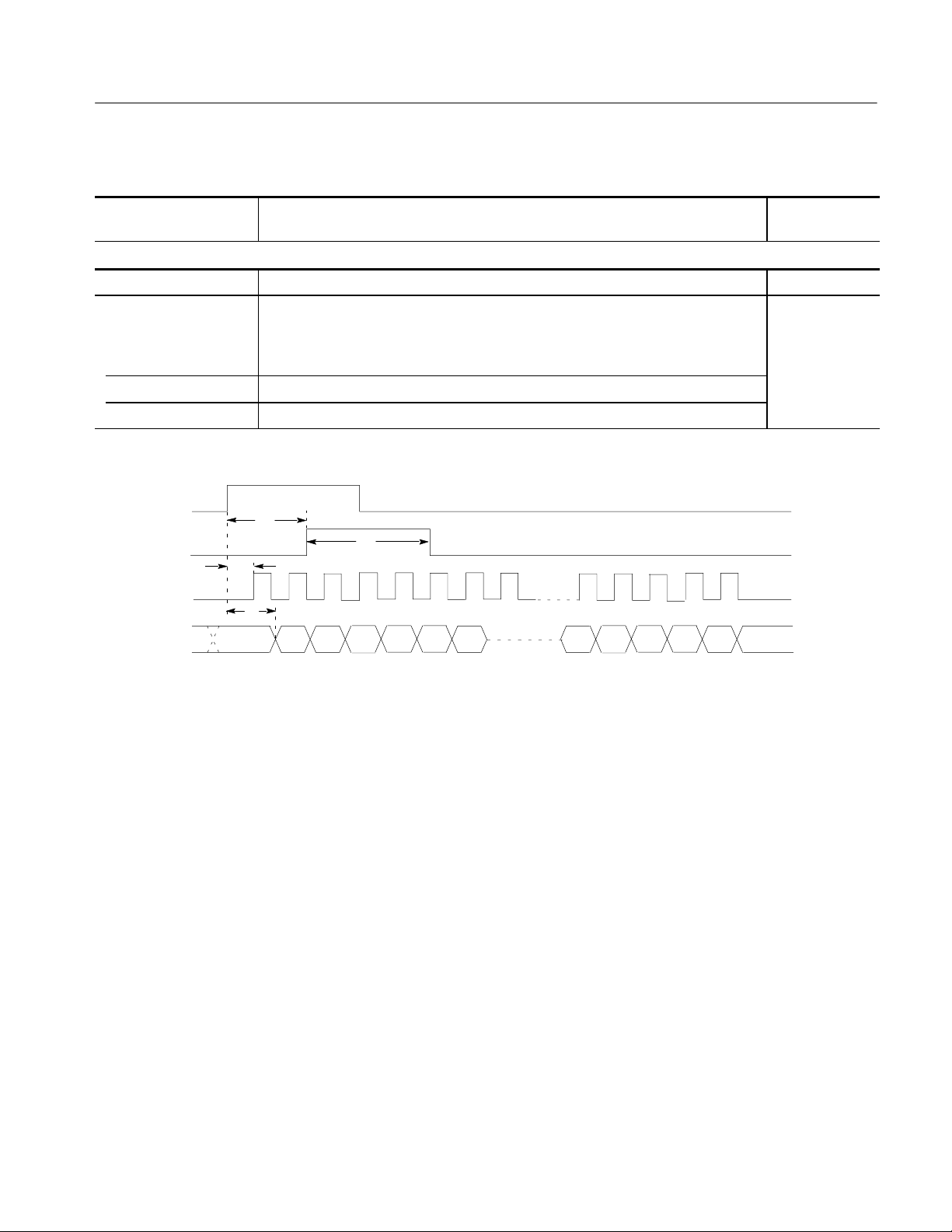

(Td1in Figure 1-1 )

Clock Setting Delay

Internal Clock, PLL ON, >6.25 MHz

Internal Clock, PLL ON, ≦6.25 MHz

Internal Clock, PLL OFF, >6.25 MHz

Internal Clock, PLL OFF, ≦6.25 MHz

18 ns to 55 ns

30 ns to 70 ns

20 ns to 50 ns

35 ns to 70 ns

T est

voltage levels,

page 4-25.

Check variable

delay, page 4-29.

External Clock

Delay from external

clock input

Clock output

Level VOH> 0.8 V ( typ. 1.0 V )

Delay from external

trigger input

Delay from external

clock input

16 ns to 30 ns

V

< 0.2V(typ.0.0V)(into50Ω )

OL

(Td2in Figure 1-1 )

Clock Setting Delay

Internal Clock, PLL ON, >6.25 MHz

Internal Clock, PLL ON, ≦6.25 MHz

Internal Clock, PLL OFF, >6.25 MHz

Internal Clock, PLL OFF, ≦6.25 MHz

External Clock

8nsto15ns

(15ns+0.5clock)to(30ns+1.5clock)

15 ns to 40 ns

25 ns to 60 ns

15 ns to 45 ns

25 ns to 60 ns

(7 ns + 0.5 clock) to (20 ns + 1.5 clock)

DG2020A Service Manual

1-5

Page 24

Performance Characteristics

ppg

Table 1 -1: Warranted electrical characteristics (Cont.)

Characteristics Performance

Auxiliary inputs

Trigger input

Threshold

Accuracy ¦ 5% ¦ 0.1 V

Pulse width >5 ns ( at 0.2 V amplitude )

Sensitivity >0.2 V ( at 1 MHz square wave )

Maximum input ¦ 10 V ( 1 kΩ )

Delay to P3410 data

output

Delay to P3420 data

output

Description

¦ 5V(50Ω )

(Td3in Figure 1-1 )

Clock Setting Delay

Internal Clock, >6.25 MHz

Internal Clock, ≦6.25 MHz

External Clock

(Td3in Figure 1-1 )

30 ns to 65 ns

45 ns to 80 ns

(25ns+0.5clock)to(45ns+1.5clock)

T est

Clock Setting Delay

Internal Clock, >6.25 MHz

Internal Clock, ≦6.25 MHz

External Clock

Trigger hold off <500 ns

*External clock

input

Threshold level VIH> 0.7 V, VIL< 0.3 V

Maximum input

voltage

Frequency DC to 200 MHz

Delay to P3410 data

output

Delay to P3420 data

output

¦ 2V

25 ns to 45 ns

20 ns to 40 ns

30 ns to 60 ns

40 ns to 70 ns

(20ns+0.5clock)to(40ns+1.5clock)

Check external

clock input, page

4-8.

1-6

DG2020A Service Manual

Page 25

Table 1 -1: Warranted electrical characteristics (Cont.)

Performance Characteristics

Characteristics Performance

Description

T est

AC line power

Rating voltage 100 to 240 V AC

Voltage range

90 μ 250 V AC 48.0 to 63.0 Hz

90 μ 127 V AC 48.0 to 440 Hz

Maximum power 300 W

Maximum current 4A

External

Trigger

Sync Out

Clock Out

Data Out

T

d1

T

w1

T

d2

T

d3

D

0

D

1

D

D

3

2

D

0

D

n

Figure 1-1: Trigger delay

DG2020A Service Manual

1-7

Page 26

Performance Characteristics

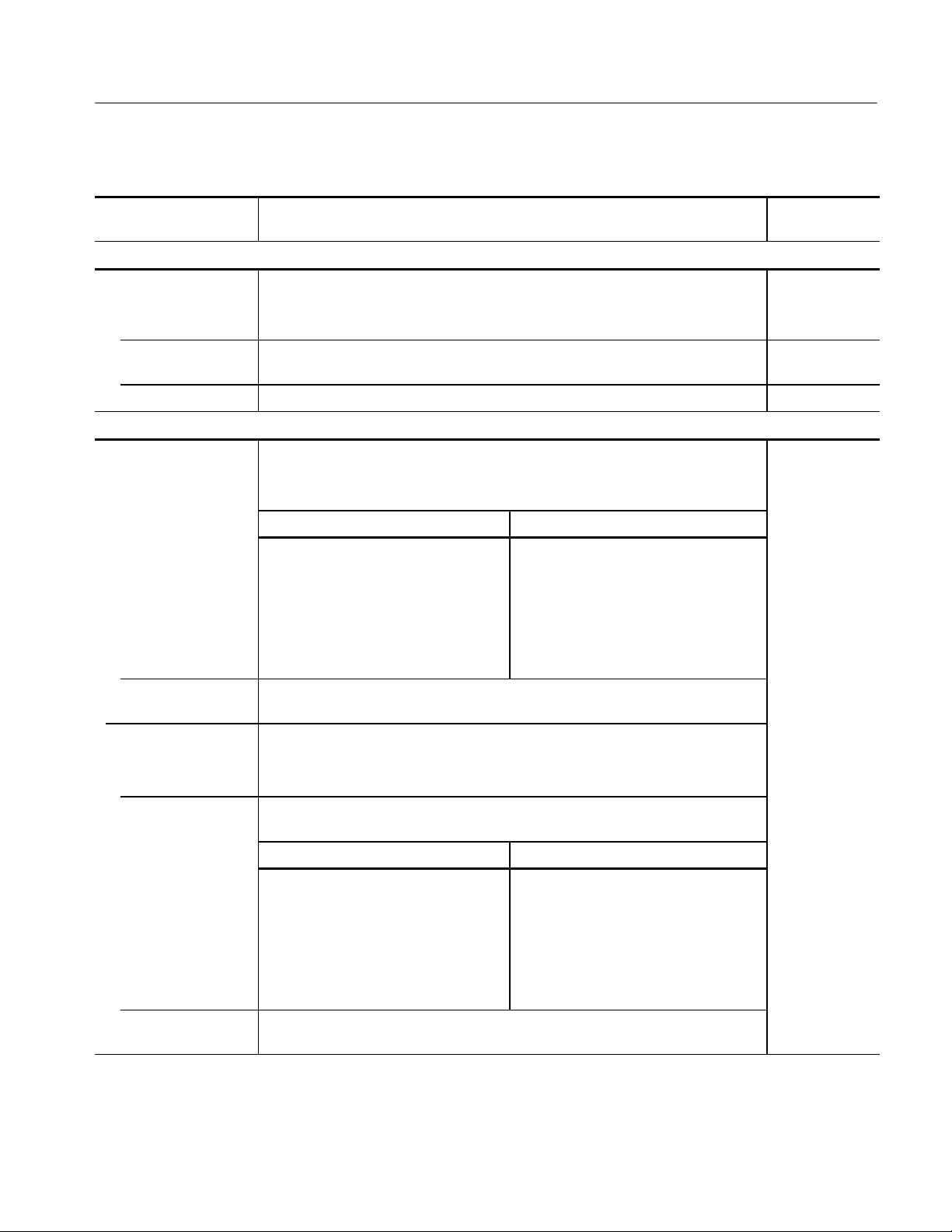

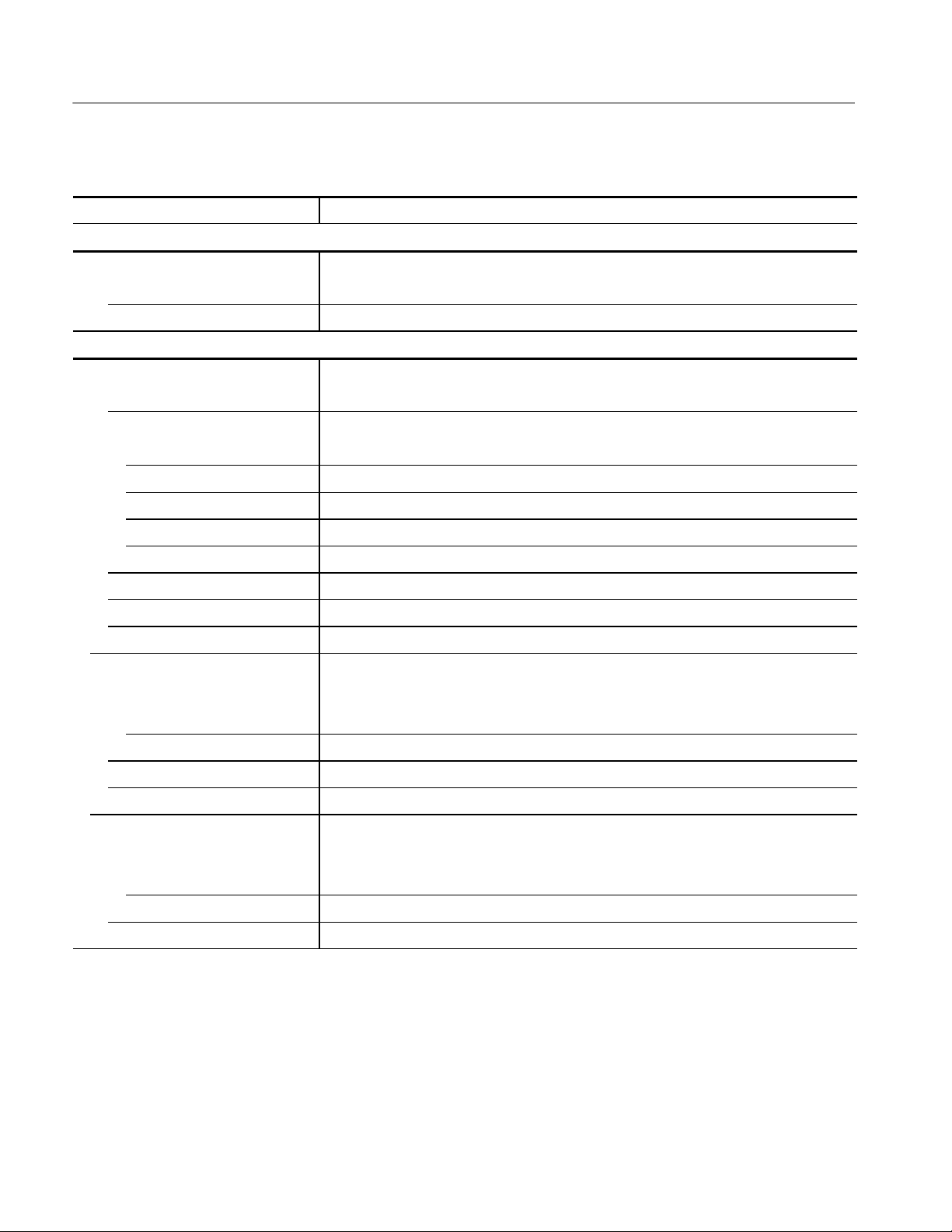

Table 1-2: Warranted environmental characteristics

Characteristics Description

Temperature

Operating +10 _Cto+40_C

Non operating -- 2 0 _Cto+60_C

Relative humidity

Operating 20% to 80% (No condensation)

Maximum wet-bulb temperature 29.4 _C

Non operating 5% to 90% (No condensation)

Maximum wet-bulb temperature 40.0 _C

Altitude

Operating To 4.5 km (15,000 feet).

Maximum operating temperature decreases 1_C each 300 m above

1.5 km.

Non operating To 15 km (50,000 feet).

Dynamics

Vibration

Operating 0.33 mm

Shock

Non operating 294 m/s2(30 G), half-sine, 11 ms duration.

Installation requirements

Power consumption

(Fully loaded)

Surge current 30 A peak for < 5 line cycles, after product has been off for at least 30 s.

Cooling clearance

Top clearance 1 inch

Side clearance 6 inches

Rear clearance 3 inches

300 watts max. Maximum line current is 4 A rms at 50 Hz, 90 V line.

, 10 to 55 Hz, 15 minutes

p-p

1-8

DG2020A Service Manual

Page 27

Typical Characteristics

This section will describe the typical characteristics for the DG2020A. These

values represent typical or average performance and are not absolutely guaranteed.

Table 1 -3: Electrical characteristics (typical)

Characteristics Description

Clock generator

Internal clock

Period jitter Measured by TDS694C--1MHD with TDSJIT1

RefertoTable1-4.

Cycle to cycle jitter Measured by TDS694C--1MHD with TDSJIT1

RefertoTable1-5.

P3410 ( TTL output pod )

Performance Characteristics

Data output

Over / under shoot < 0.5V(into1MΩ 10 pF )

Rise / fall time 2 ns ( 20% to 80%, into 1 MΩ 10 pF )

Channel skew < 3 ns ( CH0 and other channels, same pod )

< 2 ns ( CH0 and CH0, two pods of same type )

Internal inhibit delay -- 5 n s

Inhibit input

Delay to data output 18 ns

P3420 ( Variable output pod )

Data output

Output current Total output current < 500 mA

< --30 mA ( Sink )

> +30 mA ( Source )

Over / under shoot < ¦(5%ofSwing)¦ 0.1V(into1MΩ 10 pF )

Rise / fall time 2 ns ( 20% to 80%, into 1 MΩ 10pF,0to5Vswing)

Channel skew < 3 ns ( CH0 and other channels, same pod )

< 2 ns ( CH0 and CH0, two pods of same type )

Internal inhibit delay -- 2 n s

Inhibit input

Delay to data output 16 ns

DG2020A Service Manual

1-9

Page 28

Performance Characteristics

Table 1 -3: Electrical characteristics (typical) (Cont.)

Characteristics Description

P3420 ( Variable output pod )

Period jitter Measured by TDS694C--1MHD with TDSJIT1

RefertoTable1-4.

Cycle to cycle jitter Measured by TDS694C--1MHD with TDSJIT1

RefertoTable1-5.

Auxiliary outputs

Sync output

Duration 6 clocks ( Tw1in Figure 1-1 )

Clock output

Delay to data output 24 ns ( P3410 )

20 ns ( P3420 )

Auxiliary inputs

External clock input

Delay to P3410 data output 36 ns

Delay to P3420 data output 33 ns

Table 1-4: Period JItter

Clock frequency 200 MHz (When PLL to On.) 100 MHz (When PLL to On.)

Measurement StdDev Pk--Pk StdDev Pk--Pk

Clock output 13.0 ps 70.0 ps 10.0 ps 60.0 ps

Data output (CH0 output) 6.0 ps 35.0 ps 5.5 ps 34.0 ps

Table 1 -5: Cycle to Cycle JItter

Clock frequency 200 MHz (When PLL to On.) 100 MHz (When PLL to On.)

Measurement StdDev Pk--Pk StdDev Pk--Pk

Clock output 20.0 ps 115.0 ps 17.0 ps 110.0 ps

Data output (CH0 output) 9.0 ps 52.0 ps 8.5 ps 50.0 ps

1-10

DG2020A Service Manual

Page 29

Nominal Traits

This section describes general characteristics of the DG2020A. These can be

divided into two main categories: electrical characteristics and mechanical

characteristics.

Table 1 -6: Nominal traits - electrical characteristics

Characteristics Description

Output pattern

Pattern length 64 word to 64 K word ( non sequenced operation )

64 word to unlimited ( sequenced operation )

Number of channels Up to 12, 24 ( Option 01 ), 36 ( Option 02 )

Memory capacity

Pattern memory 64 K word ¢ 12 bits

64 K word ¢ 24 bits ( Option 01 )

Performance Characteristics

64 K word ¢ 36 bits ( Option 02 )

Sequence memory 2048 steps

NOTE: More than 2,048 lines can be input in the Sequence table. However, only first 2,048

steps expanded in the sequence memory are effective when executed.

NV RAM 0.5 M bytes

Clock generator

Internal clock

Frequency 0.1 Hz to 200 MHz

Resolution 4 digits

Reference oscillator

Frequency 10 MHz

P3410 ( TTL output pod )

Data output

Impedance 50 Ω

Delay channel CH8, CH9, CH10 and CH11

Delay time 0to20ns

Delay resolution 0.1 ns

Event input

Level TTL

Impedance 1 kΩ

Setup time to next block 47 clock to 54 clock

DG2020A Service Manual

1-11

Page 30

Performance Characteristics

Table 1 -6: Nominal traits - electrical characteristics (Cont.)

Characteristics Description

P3410 ( TTL output pod )

Inhibit input

Level TTL

Impedance 1 kΩ

P3420 ( Variable output pod )

Data output

Output impedance 50 Ω

Output voltage

V

OH

V

OL

--2.0Vto+7.0Vinto1MΩ

--3.0Vto+6.0Vinto1MΩ

Resolution 0.1 V

Maximum swing 9.0 V

Minimum swing 0.5 V

p-p

p-p

Delay channel CH8, CH9, CH10 and CH11

Delay time 0to20ns

Delay resolution 0.1 ns

Event input

Threshold

Level --5.0 V to +5.0 V

Resolution 0.1 V

Impedance 1 kΩ

Setup time to next block 47 clock to 54 clock

Inhibit input

Threshold

Level --5.0 V to +5.0 V

Resolution 0.1 V

Impedance 1 kΩ

1-12

DG2020A Service Manual

Page 31

Table 1 -6: Nominal traits - electrical characteristics (Cont.)

Characteristics Description

Auxiliary outputs

SYNC output

Level Positive TTL pulse

Performance Characteristics

2.4 V < V

0V<V

< 5.0 V ( into 1 MΩ )

OH

< 0.5 V ( into 1 MΩ )

OL

Output resistance 50 Ω

Connector BNC ( at front panel )

EVENT output

Level Positive TTL pulse

2.4 V < V

0V<V

< 5.0 V ( into 1 MΩ )

OH

< 0.5 V ( into 1 MΩ )

OL

Delay time 22 clocks before Data Output change

Duration 8 clocks

Output resistance 50 Ω

Connector BNC ( at front panel )

CLOCK output

Output resistance 50 Ω

Connector SMB ( at rear panel )

Auxiliary inputs

TRIGGER input

Threshold

Level --5.0 V to +5.0 V

Resolution 0.1 V

Impedance 1kΩ or 50 Ω ( selectable )

Connector BNC ( at front panel )

Data output delay uncertainty Clock Setting Delay Uncertainty

Internal Clock, PLL:ON

Internal Clock, PLL:OFF

External Clock

5nsto10ns

None

1 clock period

External clock input

Impedance 50 Ω, terminated to +0.5 V

Connector SMB ( at rear panel )

DG2020A Service Manual

1-13

Page 32

Performance Characteristics

Table 1 -6: Nominal traits - electrical characteristics (Cont.)

Characteristics Description

Display

Display area 5.2 inches ( width ) ¢ 3.9 inches ( height )

Resolution 640 ( H ) ¢ 480 ( V ) pixels

Power source

AC line power

Fuse Rating 6A FAST, 250 V, UL 198G ( 3AG )

5A ( T ), 250 V, IEC 127

Battery

Type Li3 V, 650 mAH

1-14

DG2020A Service Manual

Page 33

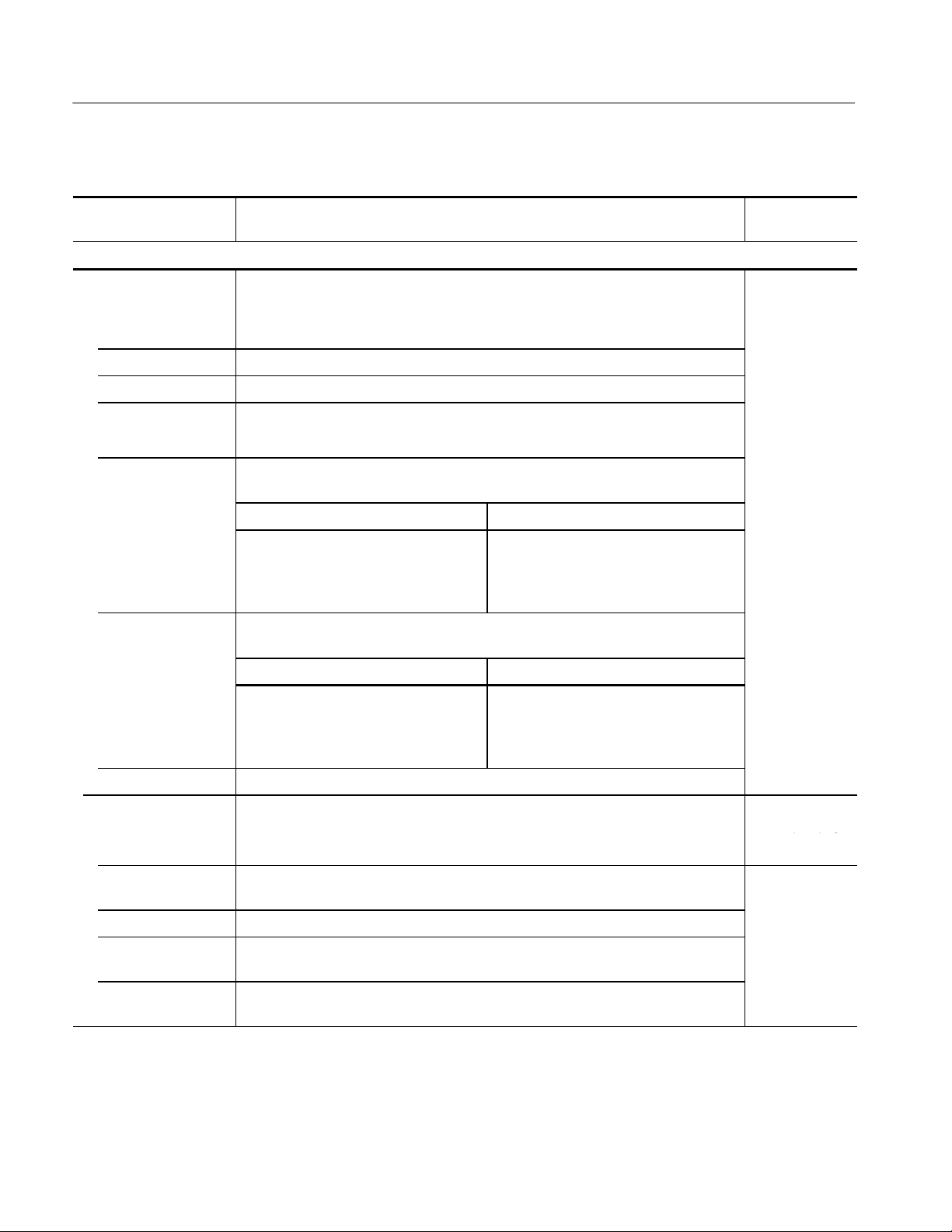

Table 1 -7: Nominal traits - m echanical characteristics

Characteristics Description

DG2020A

Net weight

Standard 9.7 kg

Dimensions

Height 6.4 inches including feet

Width 14.3 inches including handle

Length 19.25 inches including front cover

22.2 inches with handle extended

P3410 ( TTL output pod )

Net weight 0.5 kg ( excluding cables )

Dimensions

Height 2.0 inches including feet

Performance Characteristics

Width 5.9 inches

Length 4.0 inches

P3420 ( Variable output pod )

Net weight 1.0 kg ( excluding cables )

Dimensions

Height 2.0 inches including feet

Width 10.0 inches

Length 6.3 inches

Pod cable

Length 1.2 m

DG2020A Service Manual

1-15

Page 34

Performance Characteristics

Certification and Compliances

The certification and compliances for the DG2020A are listed in Table 1-8.

Table 1-8: Certifications and compliances

Category St andards or description

EC Declaration of Conformity -EMC

Australian/New Zealand

declaration of Conformity - EMC

EC Declaration of Conformity -Low Voltage

Approvals Complies with the following safety standards:

Installation Category Description Terminals on this product may have different installation (over--voltage) category designations. The

Meets intent of Directive 89/336/EEC for Electromagnetic Compatibility. Compliance was

demonstrated to the following specifications as listed in the Official Journal of the European

Communities:

EMC Directive 89/336/EEC:

EN 55011 Class A Radiated and Conducted Emissions

EN 50081-1 Emissions:

EN61000-3-2 AC Power Line Harmonic Emissions

EN 50082-1 Immunity:

EN61000-4-2 Electrostatic Discharge Immunity

EN61000-4-3 RF Electromagnetic Field Immunity

EN61000-4-4 Electrical Fast Transient/Burst Immunity

EN61000-4-6 Conducted Disturbance Induced by Radio--frequency Field

EN61000-4-8 Power Frequency Electromagnetic Field Immunity

EN61000-4-11 Voltage Dips and Interruptions Immunity

Complies with EMC provision of Radio--communications Act per the following standard:

AS/NZS 2064.1/2 Industrial, Scientific, and Medical Equipment: 1992

Compliance was demonstrated to the following specification as listed in the Official Journal of the

European Communities:

Low Voltage Directive 73/23/EEC, amended by 93/68/EEC

EN 61010-1/A1:1992 Safety requirements for electrical equipment for

measurement, control and laboratory use.

UL3 111 --11, First Edition Standard for electrical measuring and test equipment.

CAN/CSA C22.2 No.1010.1-921Safety requirements for electrical equipment for

measurement, control and laboratory use.

installation categories are:

Category Examples of products in this category

CAT III Distribution-level mains (usually permanently connected). Equipment at this

level is typically in a fixed industrial location.

CAT II Local-level mains (wall sockets). Equipment at this level includes appliances,

portable tools, and similar products. Equipment is usually cord-connected.

CAT I Secondary (signal level) or battery operated circuits of electronic equipment.

1-16

DG2020A Service Manual

Page 35

Performance Characteristics

Table 1-8: Certifications and compliances (cont.)

Category Standards or description

Pollution Degree A measure of the contaminates that could occur in the environment around and within a product.

Typically the internal environment inside a product is considered to be the same as the external.

Products should be used only in the environment for which they are rated.

Pollution Degree 2 Normally only dry , nonconductive pollution occurs. Occasionally a

temporary conductivity that is caused by condensation must be

expected. This location is a typical office/home environment.

Temporary condensation occurs only when the product is out of

service.

Conditions of Approval Safety Certifications/Compliances are made for the following conditions:

Altitude (maximum operation): 2000 meters

IEC Characteristics Equipment type:

Test and Measuring

Installation Category II (as defined in IEC 61010--1, Annex J)

Pollution Degree 2 (as defined in IEC 61010--1)

Safety Class I (as defined in IEC 61010--1, Annex H)

1

CSA-C22.2 No.1010.1, UL3111-1, IEC61010-1 Safety Certification Compliance:

Altitude (maximum operating): 2000 meters

DG2020A Service Manual

1-17

Page 36

Performance Characteristics

1-18

DG2020A Service Manual

Page 37

Preparation for Use

This section describes how to prepare the DG2020A Data Generator for use. The

information describes these items:

H Proper operating environment

H Checking power cord and line voltage configurations

H Checking the fuse

H Power-on and power-off cycles

Supplying Power

Before installing the DG2020A, note these precautions:

WARNING. To avoid equipment failure and potential fire or personal shock

hazards, do not exceed the maximum rated operating voltage of 250 V between

the voltage-to-ground (earth) and either pole of the power source. The DG2020A

operates from a single-phase power source and has a three-wire power cord with

a two-pole, three-terminal grounding plug. Also, before making connection to the

power source, be sure the DG2020A has a suitable two-pole, three-terminal

grounding-type plug.

DG2020A Service Manual

To avoid personal shock hazard, do not contact conductive parts. All accessible

conductive parts are directly connected through the grounding conductor of the

power cord to the grounded (earthing) contact of the power plug. The DG2020A

is safety Class 1 equipment (IEC designation).

To avoid personal shock hazard, do not defeat the grounding connection. Insert

the power input plug only in a mating receptacle with a grounding contact where

earth ground has been verified by a qualified service person. Also, for electrical

shock protection, make the grounding connection before making connection to

the DG2020A input or output terminals.

2-1

Page 38

Preparation for Use

Power Cord Information

The DG2020A ships with the required power cord as ordered by the customer.

Table 2-1 gives the color-coding of the conductors in the power cord. Table 2-2

shows information on the available power cords.

Table 2-1: Power-cord conductor identification

Conductor Color Alternate color

Ungrounded (Line) Brown Black

Grounded (Neutral) Light Blue White

Grounded (Earthing) Green/Yellow Green

Table 2-2: Power cord identification

Plug configuration Normal usage Option number

North America

125 V

Europe

230 V

United Kingdom

230 V

Australia

230 V

North America

230 V

Switzerland

230 V

Standard

A1

A2

A3

A4

A5

2-2

DG2020A Service Manual

Page 39

Operating Environment

Preparation for Use

To ensure proper DG2020A operation and long life, note the following environmental requirements.

Operating Temperature

Ventilation Requirements

The DG2020A operates in an environment with an ambient air temperature

between +10_ C and +40_ C. The DG2020A storage temperature ranges from

-- 2 0 _ Cto+60_ C. After storage at temperatures outside the operating limits,

allow the DG2020A chassis to stabilize at a safe operating temperature before

applying power.

Air drawn in and exhausted through the cabinet side and bottom panels cools

DG2020A internal circuits. To ensure proper cooling, allow the following

clearances:

Top 2.5 cm (1 in.)

Back 7.5 cm (3 in.)

Left and right 15 cm (6 in.)

The feet on the bottom of the DG2020A cabinet provide the required clearance

when it is set on a flat surface. The top of the DG2020A does not require

ventilation clearance.

CAUTION. To prevent temporary shutdown of the DG2020A, do not restrict air

flow through the chassis. If the DG2020A shuts down unexpectedly, improve

ventilation around the DG2020A and wait a few minutes to allow it to cool

down; then switch the power on again.

Rear Panel Controls

DG2020A Service Manual

Section 1, Specifications, lists the line voltage and frequency ranges over which

the DG2020A operates.

Figure 2-1 shows the rear panel controls for the DG2020A.

2-3

Page 40

Preparation for Use

Power Connector

Fuse Type and Rating

WARNING

Fuse

ATTENTION

!

!

PRINCIPAL POWER SWITCH

Figure 2-1: Rear panel controls

The DG2020A uses the same fuse for all operating line voltage ranges. One of

two fuse types is installed in the instrument, depending upon the power cord

option. Table 2-3 provides the available types and ratings.

Table 2-3: Fuse type and rating

Power cord option Fuse Fuse part number Fuse cap part number

Standard, Option A4 0.25 inch × 1.25 inch

159-0239-00 200-2264-00

(UL 198G,3AG):6A FAST,250V

Option A1, A2, A3, A5 5mm× 20 mm (IEC 127): 5A(T),250V 159-0210-00 200-2265-00

WARNING. To avoid electrical shock, always unplug the power cord from the

socket before checking the line fuse.

To check the fuse, remove the fuse holder on the rear panel. Refer to Figure 2-1

for the location of the fuse holder. To remove the fuse holder, turn it counterclockwise with a screwdriver while pushing it in. Then remove the fuse from the

fuse holder.

2-4

DG2020A Service Manual

Page 41

Applying and Interrupting Power

Consider the following information when you power on or power off the

DG2020A, or when external power loss occurs.

CAUTION. When connecting the DG2020A to a pod with a pod connection cable,

turn off the DG2020A power before connecting the cable. Connecting the cable

with the power in the on state can damage the DG2020A and the pod.

Preparation for Use

Power-on Cycle

Power-off Cycle

Memory Backup Power

At power-on, the start-up diagnostics check the DG2020A operation. If all

diagnostic items complete without error, the DG2020A displays the EDIT menu.

If the diagnostics detect an error, the DG2020A displays the error code. To exit

the diagnostics menu, press any key; then the system displays the EDIT menu.

See section 6, Maintenance, for information on diagnostics and fault isolation.

NOTE. If the ambient temperature goes outside the specified operating tempera-

ture range, an error occurs during the diagnostics at power-on. If this happens,

power off the DG2020A and wait until the chassis temperature is appropriate;

then switch the power on again.

Wait for the DG2020A to finish the operation when saving data files. Improper

power-off or unexpected loss of power to the DG2020A can result in the

corruption of data stored in nonvolatile memory.

A lithium battery maintains internal nonvolatile memory, allowing the DG2020A

to retain data files if AC power is lost. This battery has a shelf life of about three

years. Partial or total loss of stored information at power-on may indicate that the

battery needs to be replaced.

DG2020A Service Manual

WARNING. To avoid risk of fire or explosion, replace the DG2020A battery with a

lithium battery having the part number listed in section 10, Mechanical Parts

List. This battery is a safety-controlled part.

To avoid risk of fire or explosion, do not recharge, rapidly discharge, or

disassemble the battery; and do not incinerate the battery or heat it above

100° C. Also, dispose of used batteries promptly. Small quantities of used

batteries can be disposed of in normal refuse. Keep lithium batteries away from

children.

2-5

Page 42

Preparation for Use

Repackaging Instructions

Use a corrugated cardboard shipping carton having a test strength of at least

275 pounds and with an inside dimension at least six inches greater than the

DG2020A dimensions. (If available, use the original shipping carton, which

meets these requirements.)

If the DG2020A is shipped to a Tektronix Service Center, enclose the following

information:

H The owner’ s address

H Name and phone number of a contact person

H Type and serial number of the DG2020A

H Reason for returning

H A complete description of the service required

Seal the shipping carton with an industrial stapler or strapping tape.

Installed Options

Mark the address of the Tektronix Service Center and your own return address on

the shipping carton in two prominent locations.

Your DG2020A may include one or more options. To determine which options

are installed, look at the instrument option configuration listed on the rear panel.

Table 2-2 on page 2-2 gives information about line cord options. Section 7,

Options, lists other options and optional accessories. For further information and

prices of options, see your Tektronix Products catalog or contact a Tektronix

Field Office.

2-6

DG2020A Service Manual

Page 43

Operating Instructions

Before servicing the DG2020A, read the following operating instructions. These

instructions are at the level appropriate for s ervicing the DG2020A. The user

manual contains complete operator instructions.

In addition, Section 4, Performance Verification, includes instructions for

making the front-panel settings required to check DG2020A characteristics.

How to Make Connection to Pods

Connect the DG2020A connector to the pod using a pod connection cable as

shown in Figure 2-2 while paying attention to following points:

DG2020A (Rear)

P3410 or P3420 Pod (Rear)

DG2020A Service Manual

Pod Connection Cable

Figure 2-2: Pod connection

Note that the connectors on the DG2020A rear panel are installed with the tab

slot down, and the connector on the pod rear panel is installed with the tab slot

up (see Figure 2-3).

To connect a cable between the DG2020A and a pod, align the yellow wire end

of the cable connector with the triangular yellow index mark on the DG2020A or

pod connector. Doing this also correctly aligns the connector alignment tab. See

Figure 2-3. Then carefully but firmly insert the cable connector into the

DG2020A or pod connector.

2-7

Page 44

Operating Instructions

Pod Rear Panel

Tab S lot

Yellow Index

Mark

Yellow Index

Mark

To connect a cable between the DG2020A and a pod, align

the yellow wire end of the cable connector with the triangular

yellow index mark on the DG2020A or pod connector. Doing

this also correctly aligns the connector alignment tab. Then

carefully but firmly insert the cable connector into the

DG2020A or pod connector.

Tab

DG2020A Rear Panel

Yellow Wire

Cable

Tab S lots

Figure 2-3: Yellow index mark and yellow wire for cable connection

CAUTION. Turn off the instrument before connecting it to the pod. Connecting the

instrument to the pod with the power on could damage the instrument itself and

the pod. When attaching the pod cable, ensure that the plug and socket are

aligned correctly.

Make sure that you have correctly inserted the cable plug in the DG2020A and

the pod before turning on power. The yellow wire end of the connector must be

aligned with the triangular yellow index mark on the DG2020A or pod.

Incorrectly connected cables will damage the DG2020A and the pod.

The cable and the pod are coupled very tightly. Hold the connector housing to

avoid stress applied to the cable when attaching or removing the cable.

Electrostatic discharge can permanently damage the delicate ICs used in the

pod. Do not touch connector pins with bare hands, and do not bring conductive

materials, other than the DG2020A connection cable, close to the pod.

2-8

DG2020A Service Manual

Page 45

How to Power On

Operating Instructions

To power-on the DG2020A, follow these steps:

1. Set the PRINCIPAL POWER SWITCH (on the back of the DG2020A) to

the ON position. This switch is the main power switch; it routes power to the

standby circuit in the DG2020A.

2. Then, press the ON/STBY (standby) switch on the front (lower-left corner)

of the DG2020A. This switch applies power to the remaining circuits of the

DG2020A. Allow at least 20 minutes for the DG2020A to warm up.

WARNING. To avoid personal shock hazard, turn off both the ON/STBY sw itch

and the PRINCIPAL POWER SWITCH before servicing. The PRINCIPAL

POWER SWITCH on the rear panel is the true power disconnect switch. The

ON/STBY (standby) switch simply toggles operation on and off. When connected

to a power source and when the PRINCIPAL POWER SWITCH is on, the

internal power supplies and much of the other circuitry of the DG2020A remain

energized regardless of the setting of the ON/STBY switch.

To avoid personal shock hazard, set the PRINCIPAL POWER SWITCH off before

connecting or disconnecting the line cord to or from the power source.

Internal Diagnostics Routines

At power-on, the DG2020A performs internal start-up diagnostics. These

diagnostics check internal circuit function and report any failures. In addition,

you can initiate internal diagnostics using the Diag item in the UTILITY menu;

these diagnostics differ from the start-up diagnostics in that they do more

extensive memory checking.

User Interface

The DG2020A uses a combination of front-panel buttons, keys, a knob, and

on-screen menus to control generator functions. Some front-panel controls select

Menus and manipulate menu items. Others enter values and units, allow manual

triggering, start/stop DG2020A output, advance the pattern data, generate an

event pulse, and make a hard copy. On-screen graphics show various aspects of

the current DG2020A configuration.

DG2020A Service Manual

On-screen menus set most DG2020A functions. Main menus provide access to

lower-level nested submenus. Buttons in the center of the front panel select the

main menus.

2-9

Page 46

Operating Instructions

When you select a menu, the display shows t he items controlled by that menu

and numeric values currently in effect. Buttons around the display select

lower-level menus, change menu selections, modify numeric values and units,

and execute functions.

2-10

DG2020A Service Manual

Page 47

Operating Instructions

Display

1 2

6

3

5

4

7

8

Figure 2-4: CRT display

DG2020A Service Manual

2-11

Page 48

Operating Instructions

Table 2-4: DG2030 display elements

Figure

number

1 Status area Displays the current status of the instrument. This status line is

2 Date and Time

3 Side menu Related side menu items are displayed here when a bottom menu

Label

display area

Description

page

always displayed, whichever menu is displayed. The status line

displays the following four items.

MODE: Displays the run mode in which pattern data will be

output.

UPDATE: Displays the update method for pattern data output

when data is updated.

PLL: Displays whether or not the PLL circuit is used as the internal

oscillator circuit.

POD: Displays the configuration of pods attached to the

instrument.

In addition, there is also a disk icon that indicates whether or not a

floppy disk is inserted in the disk drive. A clock icon may also be

displayed at the left end of the status line. When this icon is

displayed, the instrument is busy with internal processing and

cannot accept other inputs.

The date and time display can be turned on or off using the

UTILITY menu.

item is selected. The topmost entry in the side menu displays

either a label representing the side menu or the operation name

for the confirmed item.

4 Bottom menu When one of the buttons in the menu section is pressed, the

corresponding bottom menu is displayed. When a bottom menu

item is selected the corresponding side menu is displayed.

Selecting the same bottom menu item again closes the side

menu.

5 Button function

description

area

6 Message dis-

play area

7 Popup mes-

sage box

8 Popup menu The instrument sometimes displays a pop-up menu when a

Displays descriptions of the functions of the front panel buttons.

Displays messages that report on the current processing state.

This area can be also used by remote commands to display user

messages.

When required, the instrument temporarily displays a window at

the center of the screen to display a warning or question for the

user.

bottom menu or side menu item is selected. Enter a numeric value

or select an item using either the general purpose knob or the

front panel buttons.

2-12

DG2020A Service Manual

Page 49

Menus

Operating Instructions

The DG2020A operation is primarily controlled by means of menus that

correspond to the SETUP, EDIT, APPLICATION and UTILITY buttons in

the MENU column. To display one of these main menus on the screen, push the

corresponding button. The button LED indicates which menu i s currently

selected. Refer to the User Manual for more details concerning these menus.

H EDIT Menu

Provides functions for editing pattern data and creating sequences.

H SETUP Menu

Provides functions for defining groups, setting up channels, and setting pod

voltages, the operating mode, and triggers.

H APPLICATION Menu

Although the current version of the firmware does not provide any functions

under the APPLICATION menu, Tektronix plans to provide functions that

support various application areas under this menu in future upgrades to the

firmware.

Pattern Storage and I/O

H UTILITY Menu

This menu provides functions for manipulating the basic instrument settings.

The DG2020A has internal nonvolatile memory (NVRAM) for pattern file

storage. The DG2020A generates patterns from file residing in internal nonvolatile memory.

The DG2020A also has a floppy-disk drive for loading files from floppy disk

into internal nonvolatile memory, and for saving files from memory to floppy

disk. The disk drive accepts 3.5-inch floppy disks in the MS-DOS format.

DG2020A Service Manual

2-13

Page 50

Operating Instructions

Loading Files

The following steps explain how to load files from a floppy disk into internal

memory.

1. Turn the disk so the side with the arrow is on top; insert the disk into the

DG2020A floppy disk drive.

2. Push the EDIT button in the MENU column.

3. Select File from the bottom menu.

4. Select Load Data & Setup from the side menu. The menu in Figure 2-5

appears.

5. Turn the general purpose knob to highlight the file you want to load and

select OK from the sub menu.

6. Push the floppy drive button and remove the disk from the floppy drive.

2-14

Figure 2-5: Load data & setup menu

DG2020A Service Manual

Page 51

Signal Output

Operating Instructions

The procedure assumes that data has already been loaded as explained in the

previous section.

The following example first groups the data bits from the pattern data already

created and allocates each data bit to pod pins. Next, this procedure sets all the

settings required for signal output and actually outputs the signals.

H Tables such as the one below show in the operating procedure. Execute the

action in left end of the top row first. Then execute actions from left to right

along the row. When one row has been completed, move to the left end of

the next row down, and repeat. For pop up menus, use the general purpose

knob to select items from the menu list. Operations such as operation 6

(below) do not involve pressing the buttons shown in the row above, but

rather are descriptions of operations to be performed. Figure 2-6 shows the

buttons used and the menu layout.

Front panel

Menu button Bottom button Popup menu Side button

Operation 1 Operation 2 Operation 3 Operation 4 Operation 5

button

Operation 6 (For example, set to xx with general purpose knob.)

Operation 7

Popup Menu

Bottom Menu

Side Menu

Bottom Button

General Purpose Knob

Side Button

Figure 2-6: Operating buttons and menu layout

Front Panel Button

Menu Button

DG2020A Service Manual

2-15

Page 52

Operating Instructions

Grouping the dat a bits

1. Assign DATA00 to DATA03 to a group called IC1.

a. Reset all bit allocations.

Menu button Bottom button Popup menu Side button

SETUP Group Assign Reset All bits

Assign

OK

b. Set the MSB and LSB to D03 and D00, respectively.

Menu button Bottom button Popup menu Side button

Select

32 DATA03.

Group Bit(s)

Config

Front panel

button

Front panel

button

MSB

(Set D03.)

LSB

(Set D00.)

OK

NOTE. The MSB setting may change depending on the direction the general

purpose knob is turned. If that happens, the MSB setting must be set again.

c. Attach the name IC1 to the newly created group.

Front panel

Menu button Bottom button Popup menu Side button

Rename

Clear String

I, C, 1 OK

button

2. Assign DATA04 to DATA07 to a group called IC2.

2-16

a. Set the MSB and LSB.

DG2020A Service Manual

Page 53

Operating Instructions

Front panel

Menu button Bottom button Popup menu Side button

Select

28 DATA07.

NOTE. The MSB setting may change depending on the direction the general

Group Bit(s)

Config

MSB

(Set D07.)

LSB

(Set D04.)

OK

button

purpose knob is turned. If that happens, the MSB setting must be set again.

b. Attach the name IC2 to the group.

Allocating Data Bits to the

Pod Channels

Front panel

Menu button Bottom button Popup menu Side button

Rename

Clear String

I, C, 2 OK

button

3. Allocate data bits to pod channels A-00 to A-11.

a. Clear the pod channel for channels A-00 to A-03.

Front panel

Menu button Bottom button Popup menu Side button

Pod Assign

Press the front panel up arrow button to select channel A-00 from the POD assign list.

Release

Clear the A-01 to A-03 allocations in the same manner.

button

DG2020A Service Manual

b. Allocate the IC1 group data to the pod channels A-04 to A-07 and turn

off the output impedance control for each channel.

2-17

Page 54

Operating Instructions

Front panel

Menu button Bottom button Popup menu Side button

Press the front panel down arrow button to select channel A-04 from the POD assign

list.

Select data D03 (IC1:03) from the Data bits list using the general purpose knob.

Assign

Change Inhibit

Control

Select OFF. OK

Allocate D02 to D00 to A-05 to A-07 using the same procedure and turn off the output

impedance control for each channel.

OK

NOTE.PresstheOK button when done to activate the allocations. Note that the

button

allocations will not become valid unless the OK button is pressed.

c. Allocate the IC2 group data to the pod channels A-08 to A-11 and turn

off the output impedance control for each channel.

Front panel

Menu button Bottom button Popup menu Side button

Pod Assign

Press the front panel down arrow button to select channel A-08 from the POD assign

list.

Select data D07 (IC2:03) from the Data bits list using the general purpose knob.

Assign

Change Inhibit

Control

Select OFF. OK

Allocate D06 to D04 to A-09 to A-11 using the same procedure and turn off the output

impedance control for each channel.

OK

NOTE.PresstheOK button when done to activate the allocations. Note that the

button

allocations will not become valid unless the OK button is pressed.

2-18

DG2020A Service Manual

Page 55

Operating Instructions

To summarize, the above has allocated data bits to the pods as shown in Figure

2-7.

POD assign

Channel Name Data Inhibit

Setting the Sampling

Clock Frequency

A-00

Allocations cleared

Data bits D03 to

D00 allocated

Data bits D07 to

D04 allocated

A-01

A-02

A-03

A-04

A-05

A-06

A-07

A-08

A-09

A-10

A-11

Pod Channel

IC1:03

IC1:02

IC1:01

IC1:00

IC2:03

IC2:02

IC2:01

IC2:00

Group Name Data bit

D03

D02

D01

D00

D07

D06

D05

D04 OFF

Figure 2-7: Pod channel data bit allocation

4. Setthesamplingclockfrequencyto50MHz.

--- --- ---

--- --- ---

--- --- ---

--- --- --OFF

OFF

OFF

OFF

OFF

OFF

OFF

Output Impedance Control

DG2020A Service Manual

Menu button Bottom button Popup menu Side button

Oscillator Source

(Select Int.)

Int Frequency 5, 0, MHz

PLL

(Select On.)

Front panel

button

2-19

Page 56

Operating Instructions

Setting the Signal

Generation Mode

5. Set the signal generation mode to continuous mode.

Setting the Pod Output

Level ( P3420 Only)

Menu button

Bottom button

Run Mode Repeat

Popup menu Side button

Front panel

button

There are two pod models that can be used with the DG2020A. The P3410 pod

output level is always at the TTL level. However, the P3420 pod output level is

variable. This step sets output levels for the P3420 pod.

6. Set the pod channel A-04 to A-11 output levels to 4V for the high level and

0V for the low level.

Front panel

Menu button Bottom button Popup menu Side button

Level/Delay

Select channel A-04 using the front panel up and down arrow buttons.

High Level 4, ENTER

Low Level 0, ENTER

Set the output levels for channels A-05 to A-11 in the same manner.

button

2-20

Setting the Pod

Delay Time

The delay time for channels A-08 to A-11 is variable in both the P3410 and the

P3420 pod.

7. Set the delays for the pod channels A-08 to A-11 to5ns.

Front panel

Menu button Bottom button Popup menu Side button

Level/Delay

Select channel A-08 using the front panel up and down arrow buttons.

Delay 5, ENTER

Set the delays for channels A-09 to A-11 in the same manner.

button

DG2020A Service Manual

Page 57

Operating Instructions

Output Voltage

Level Setting

Delay Time Setting

Figure 2-8: Output voltage level and delay time display for the P3420 pod

Signal Output

This step actually outputs the signals.

8. Press the START/STOP button on the front panel.

DG2020A Service Manual

2-21

Page 58

Operating Instructions

2-22

DG2020A Service Manual

Page 59

Theory of Operation