Page 1

Tektvonix, Inc.

P.O. Box

Beaverton, Oregon

500

97005

INSTRUCTION MANUAL

Serial Number

972

Page 2

Page 3

TABLE

OF

CONTENTS

SECTION 1 OPERATING INSTRUCTIONS

INTRODUCTION

Description

Option

I

l

OPE RATIONAL CHECK

Controls and Connectors

Display Tests

Channels A and

INPUT CONSIDERATIONS

l

lnput Coupling

Attenuators and Maximum lnput Volts

Sensitivity and Frequency Range

Slope and LEVEL

FREQUENCY MEASUREMENTS

FREQ A

Triggering

Measurement

Measurement Rate

PERIOD MEASUREMENTS

Gating

Averaging

Low Frequencies

RATIO MEASUREMENTS

Bandwidth Limitations

Triggering

TIME INTERVAL MEASUREMENTS

Electronic

Single-Shot Using HOLD

GATE Output

MANUAL TIMING MEASUREMENTS

Starting and Stopping

Clocking Rate

I'OTALIZING

Purpose

Operation

REAR CONNECTOR

ASSIGNMENTS

Customizing the Interface

Control Lines

Signal Lines

5;PECIFlCATlONS

FUNCTIONS

DISPLAY

CH A and

OUTPUT

-Time Base

nstallation

nput Sources

StartIStop

B

B

Intervals

I10

INPUTS

Page SECTION 1 OPERATING INSTRUCTIONS (cont)

INTERNAL TlME BASE

OTHER

SECTION

SECTION

2

THEORY OF OPERATION

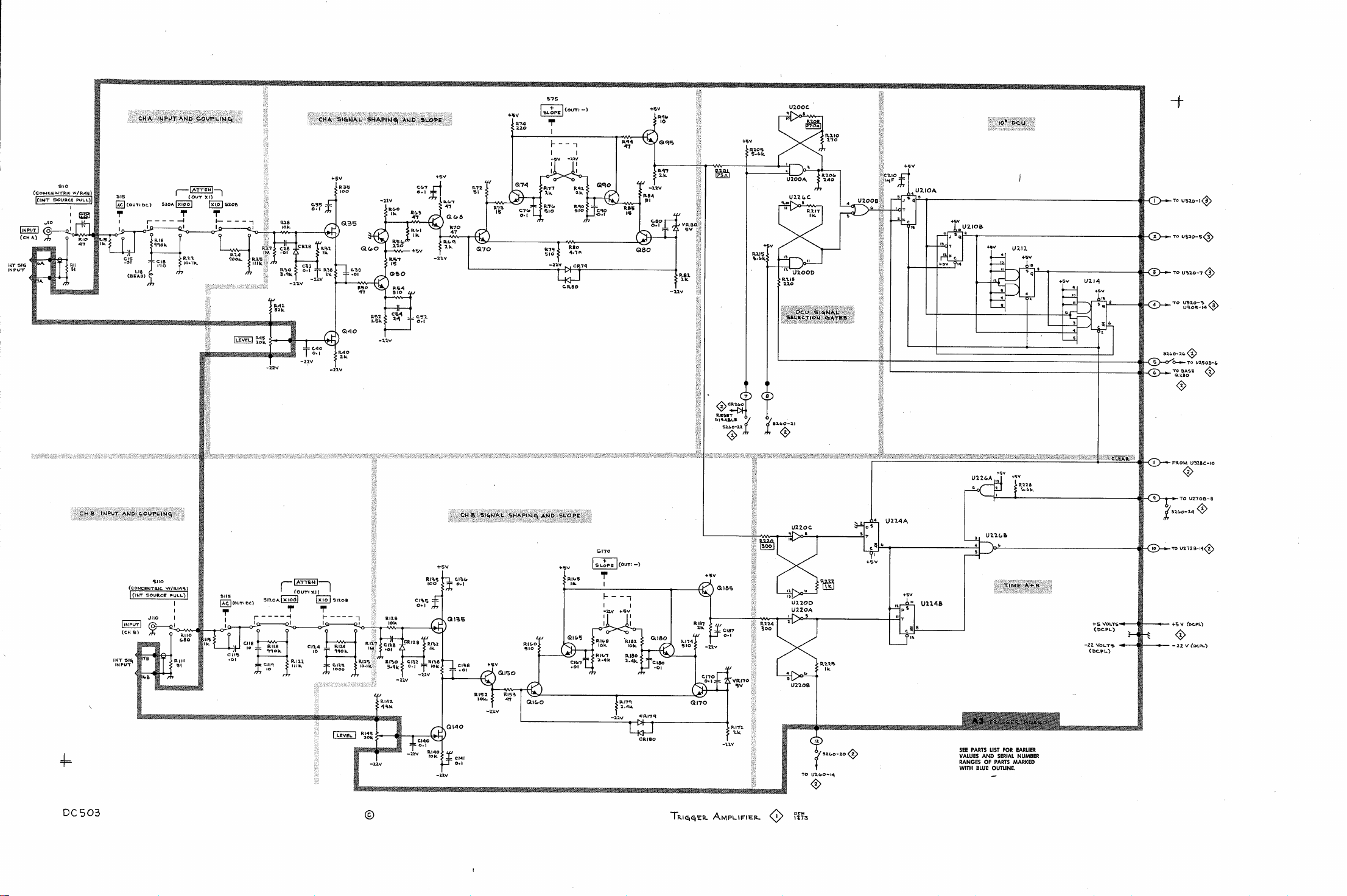

INPUT CIRCUIT

Attenuators, Channels A and

Signal Shaping and Slope Channels

A and

DCU Signal Selection Gates

Time

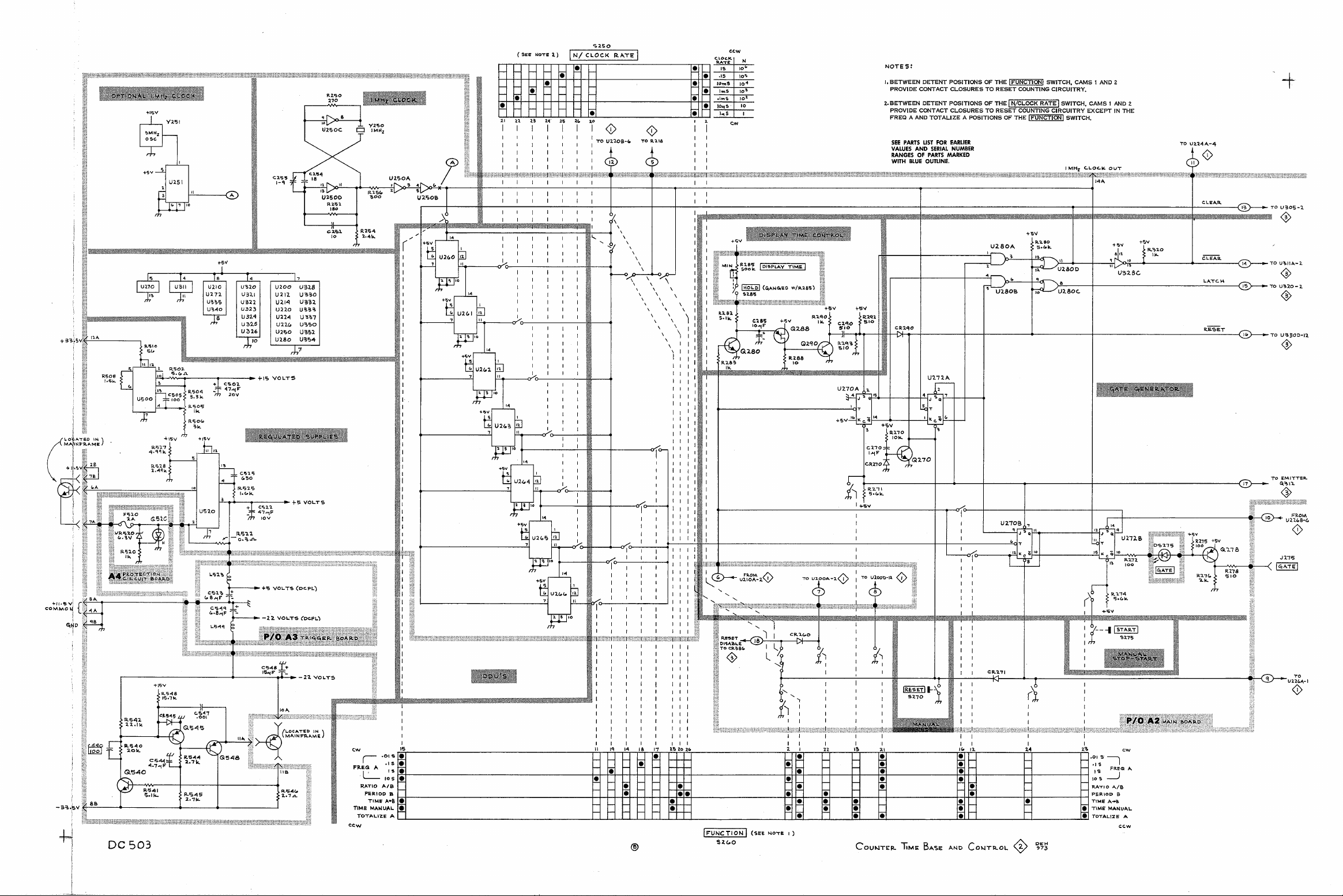

TlME BASE AND CONTROL CIRCUITS

1

Optional

Decade Divider Units

Gate Generator

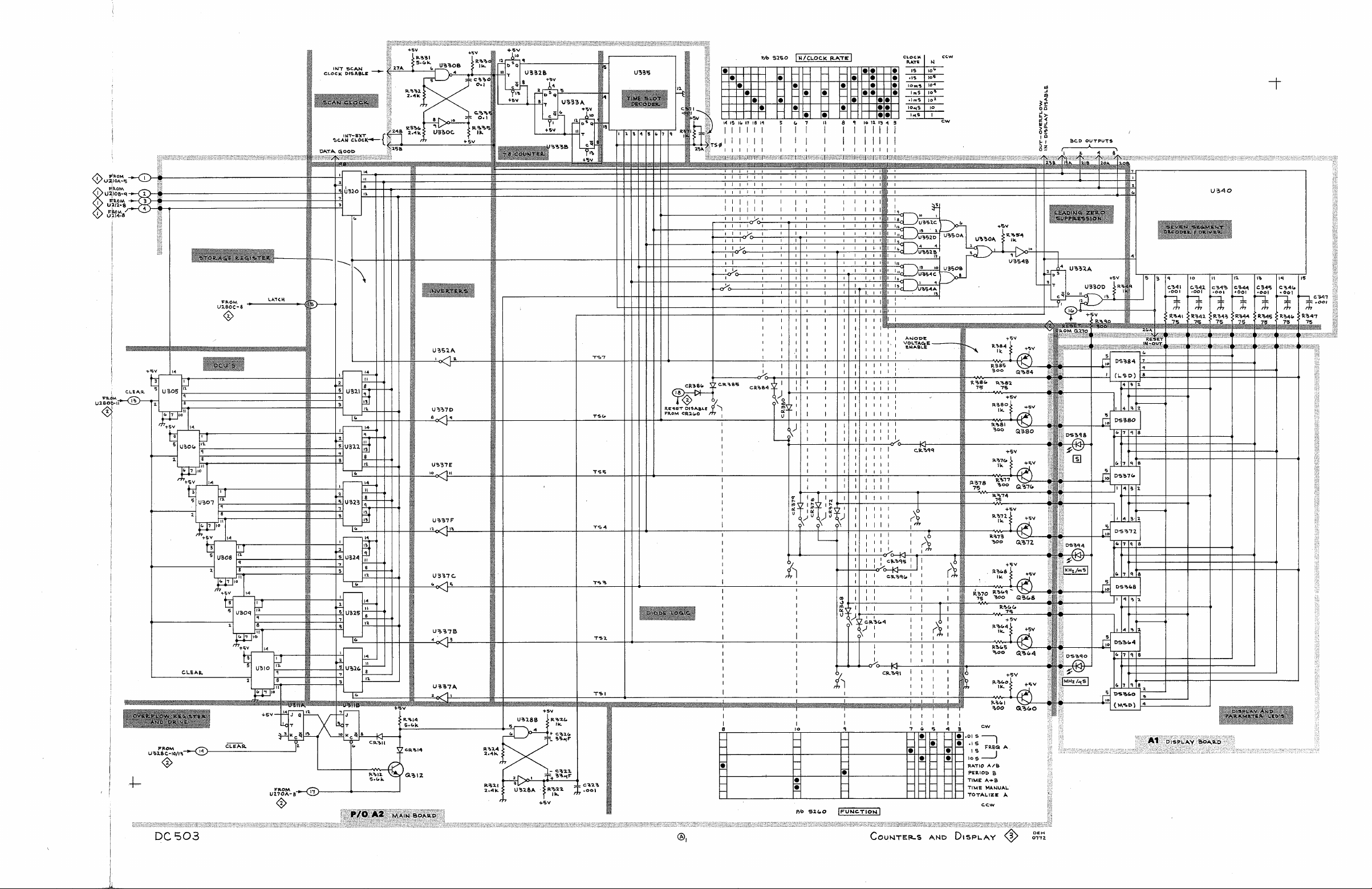

COUNTER CIRCUITS

Decade Counter Units

Storage Register

Overflow Register and Drive

DECODE AND DISPLAY MULTIPLEX

Scan Clock

+8

Seven-Segment Decoder and Driver,

Leading Zero Suppression

lnput and Output Data Lines

REGULATED POWER SUPPLIES

3

SERVICE INFORMATION

Symbols and Reference Designators

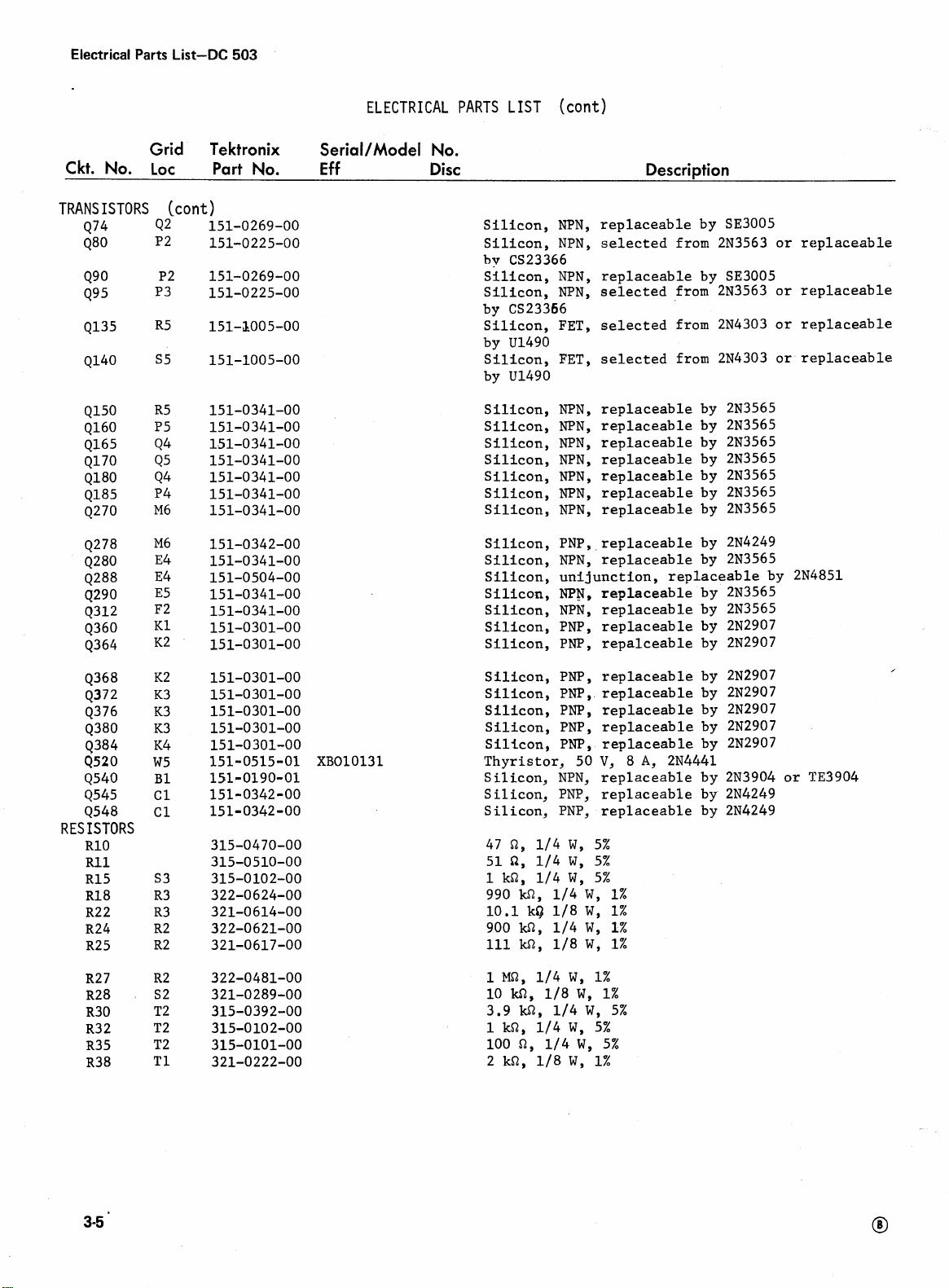

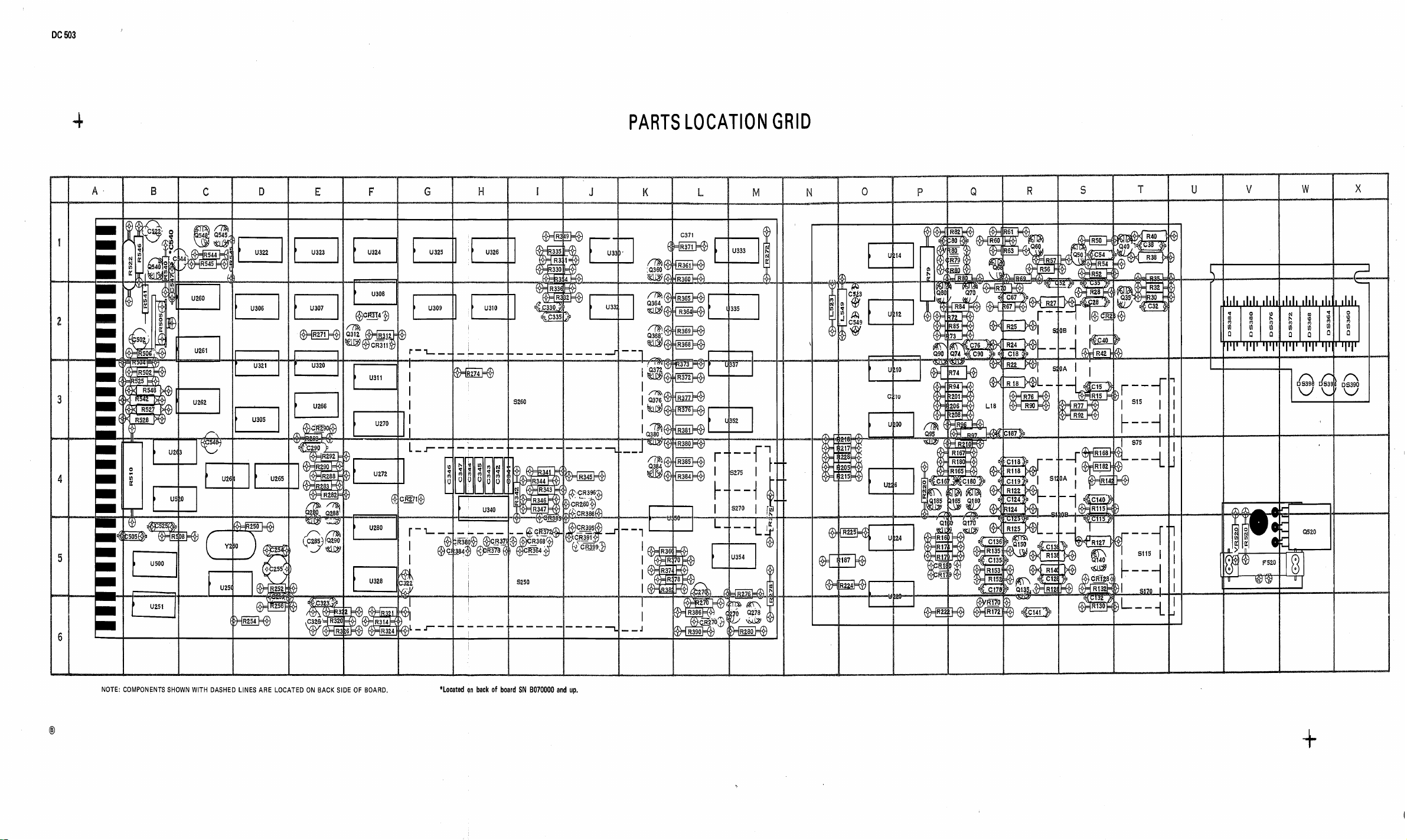

Electrical Parts List

Internal Adjustment Procedure

Controls and Connectors Illustration

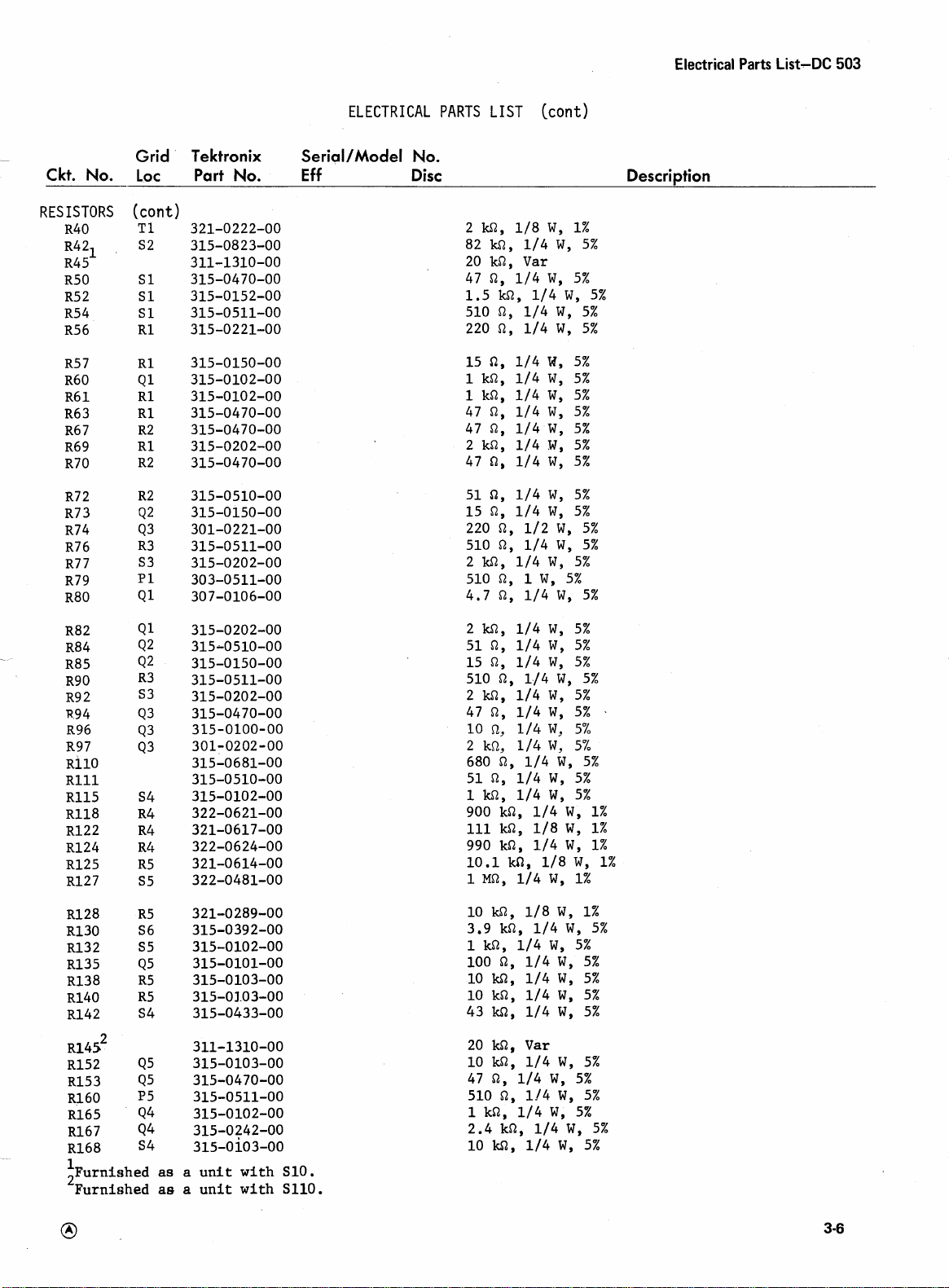

Block Diagram

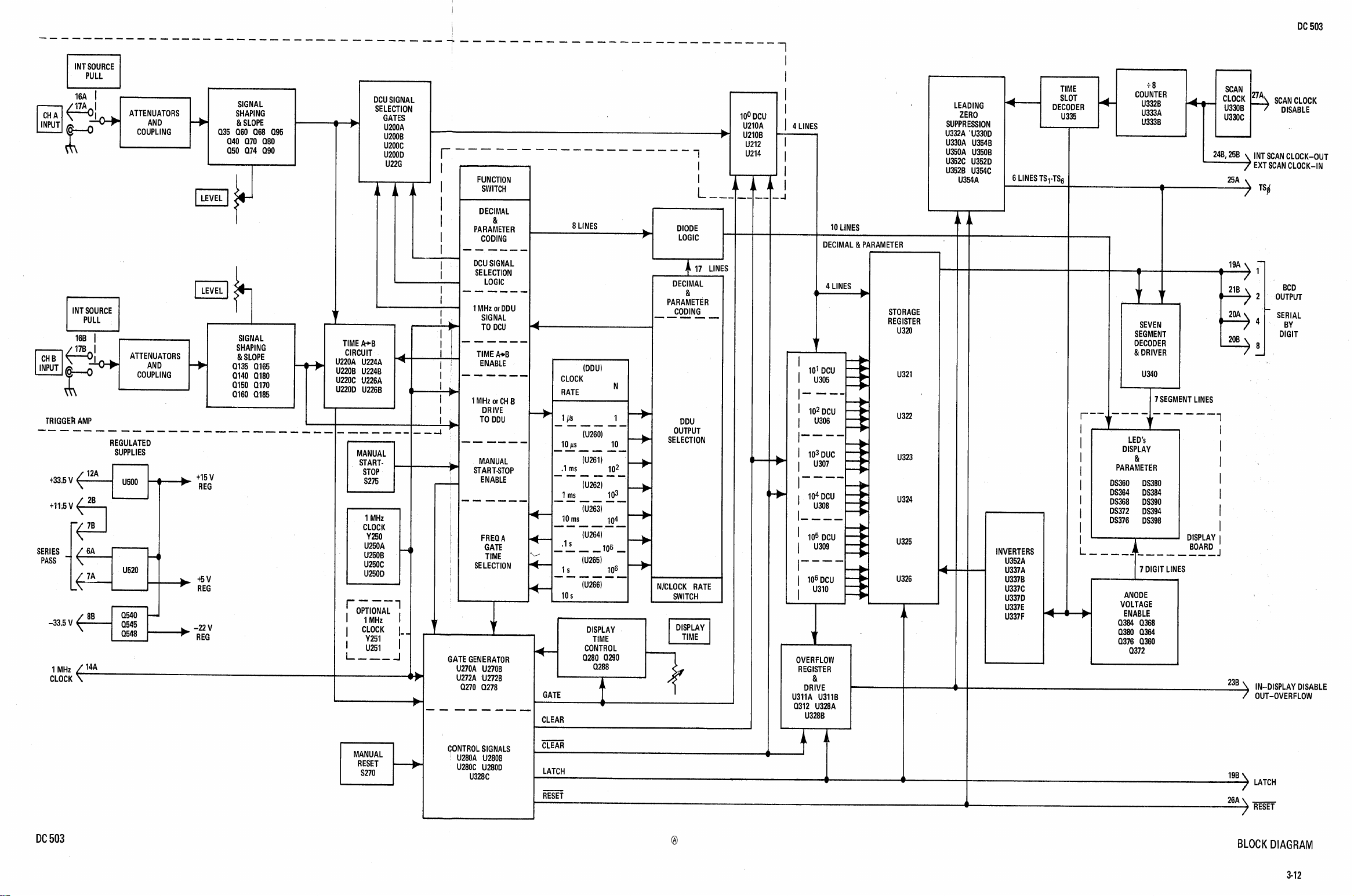

Parts Location Grid

Trigger Amplifier Diagram

Counter Time Base and Control

Counters and Display Diagram

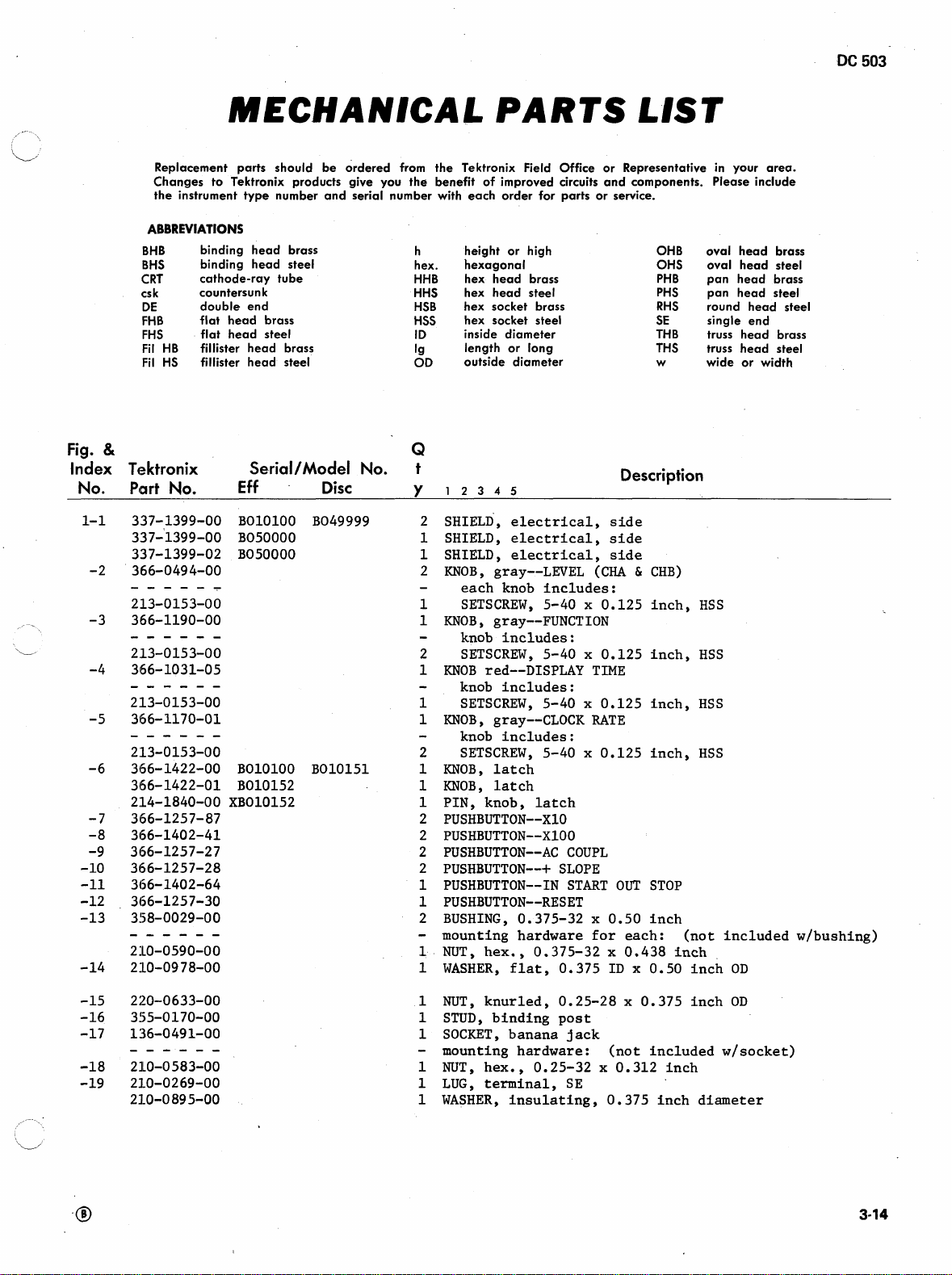

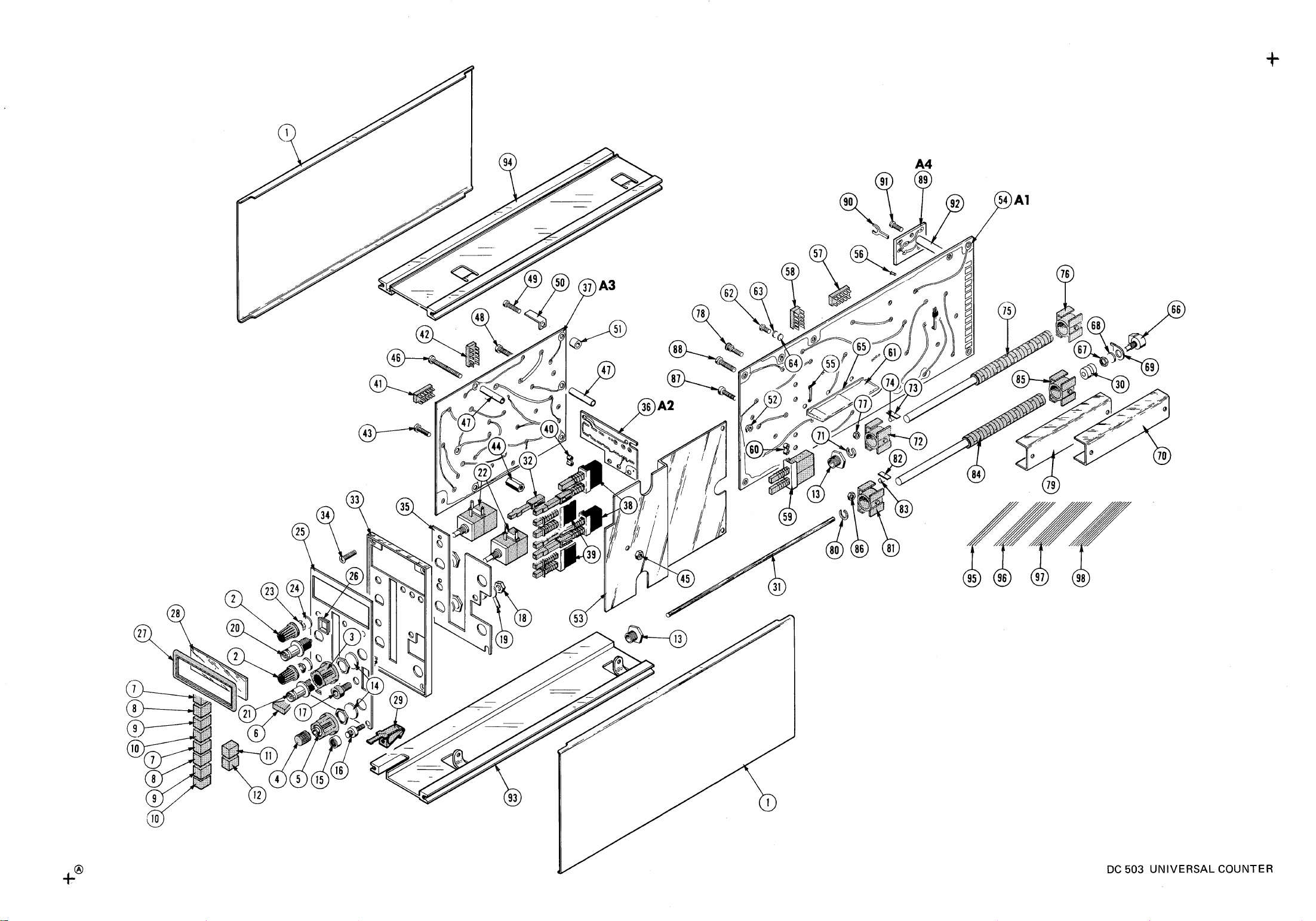

Mechanical Parts List

Fig.

Accessories and Repackaging

(B)

A

B (A Start-B Stop)

MHz Clock

1

MHz Clock

Counter and Time-Slot Decoder

and Display and Parameter

Diagram

1

Exploded View

(B)

(DDU's)

(DCU)

LED'S

.

Page

Page 4

Page 5

Section

1-DC

503

INTRODUCTION

Description

The DC 503 Universal Counter has six measurement

functions:

period timing, interval timing, manual timing, and event

counting.

The DC 503 operates in TEKTRONIX TM 500 Series

Power Modules only.

a multiple-compartment Power Module. The DC 503 is

fully compatible with other members of its digital measurement family.

The DC 503 has two channels

inputs and separate triggering level, attenuators, and

coupling mode controls. CH

CH

devices

positioned decimal point. Leading zeros to the left of the

frlequency counting, finding frequency ratios,

It

will operate in any compartment of

(A & B), each having BNC

A

has a 100 MHz capability,

B

10 MHz. Seven-segment LED numerical display

prov~ide 7-digit readout with an automatically-

SECTION

1

OPERATING

INSTRUCTIONS

most significant digit or the decimal point are blanked.

flashing display indicates register overflow.

Option

temperature-compensated, 5 MHz crystal oscillator to obtain a highly stable and precise internal time base. This

option includes

1 MHz clock.

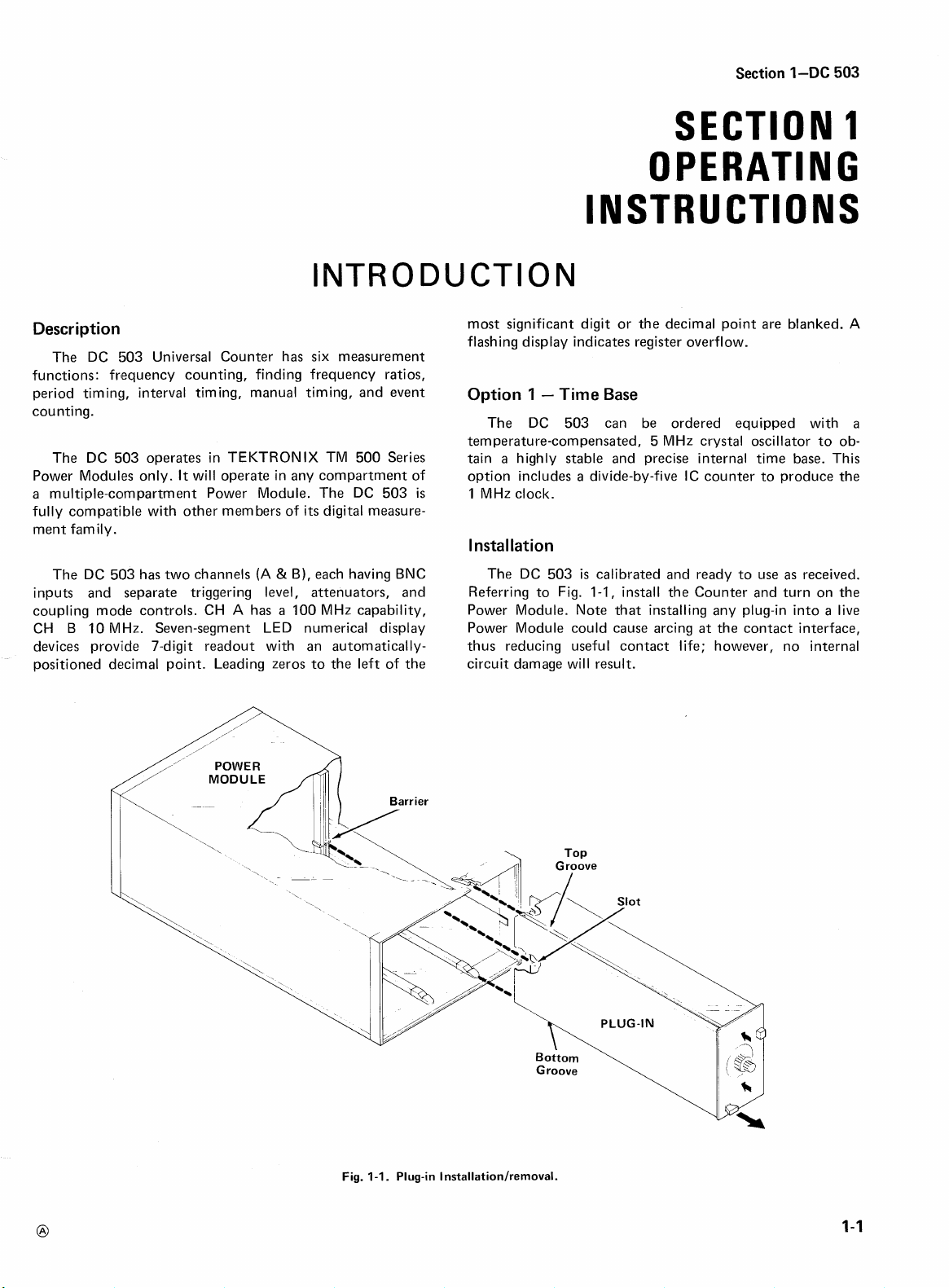

l nstallation

Referring to Fig. 1-1, install the Counter and turn on the

Power Module. Note that installing any plug-in into a live

Power Module could cause arcing

thus reducing useful contact life; however, no internal

circuit damage will result.

1

-

Time Base

The DC 503 can be ordered equipped with a

a

divide-by-five IC counter to produce the

The DC 503

is

calibrated and ready to use as received.

at

the contact interface,

A

Fig.

1-1.

Plug-in Installation/removal.

Page 6

Operating Instructions-DC

503

OPERATIONAL CHECK

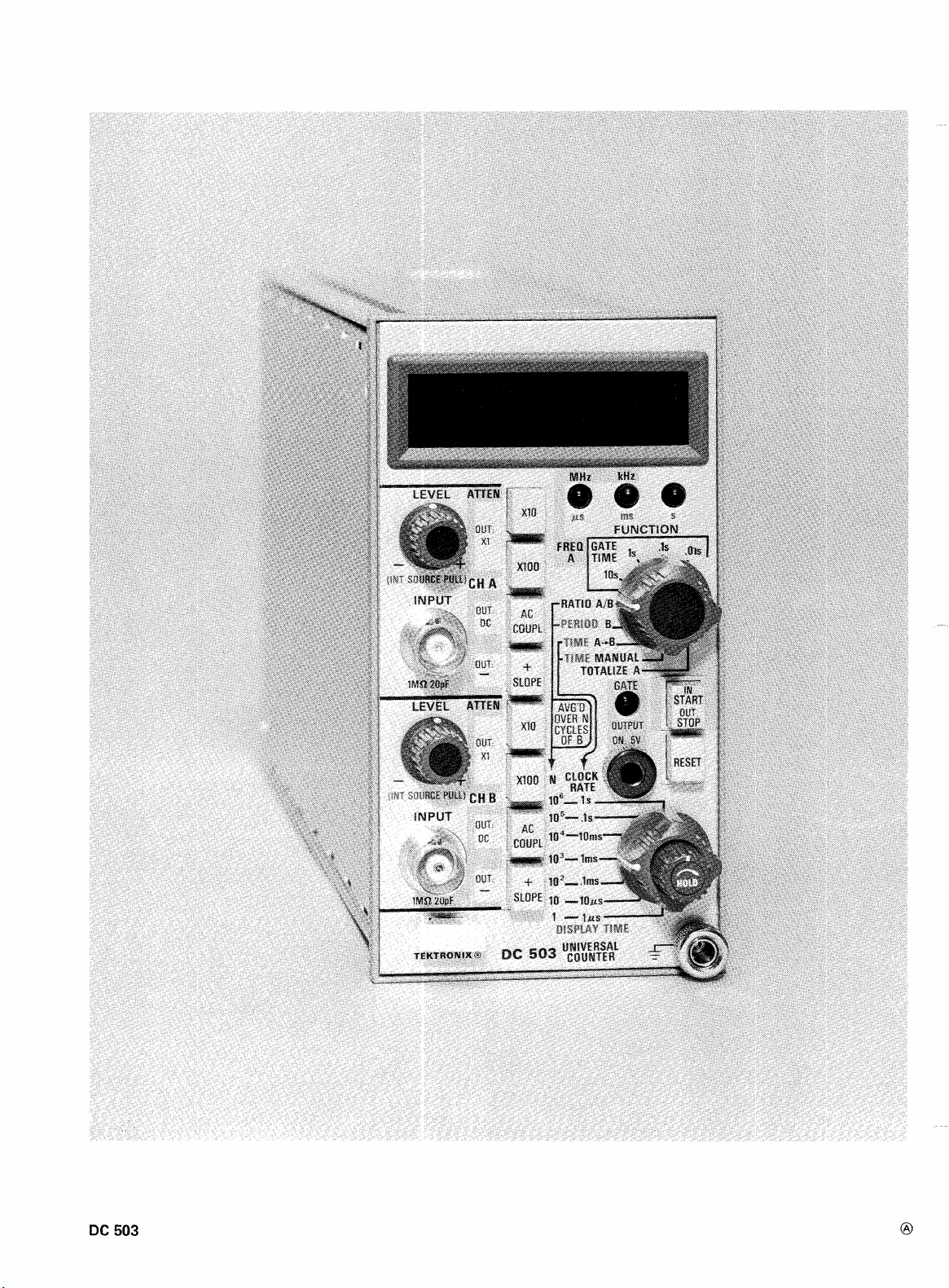

Controls and Connectors

Pull out the tab labeled "Controls, Connectors, and

Adjustments" (at the rear of the manual) to expose the

front

ane el

illustration. Review the functions of the

controls, connectors, and indicators before continuing with

the operational checks.

Display Tests

With no signal applied,

displays and switching logic. The following checks will

most of the Counter's major circuits and ensure

readiness to make measurements. If any malfunctions are

detected, first refer to the Adjustment Procedure in the

Service section of this manual, then the System Mainte-

nance section of the Power Module manual.

Readout Segment Test.

check the seven character segments of each digit. A row of

8's should be displayed. This check of the display devices

and drivers can be done at anv time.

FREQ A Displays.

FREQ A GATE TlME of

location, leading zero suppression, and units indicators

according to Table

Using the FUNCTION switch, select a

1-1.

test

the DC 503's readout

Press the RESET button to

.O1

s.

Check the decimal point

TABLE

1-1

Decimal Point

.oooo

.00000

test

its

TABLE

NICLOCK RATE Switch

106

105

1 04

I

03

The GATE and units indicators should remain off.

PERIOD B Displays.

PERIOD B and the NICLOCK RATE switch to

the readout display according to Table

TABLE

NICLOCK RATE Switch 1 Units Indicator 1 Decimal Point

1

10

1 02

I

03

I

04

I

05

1

06

TlME AtB Displays.

TlME

A+B and the NICLOCK RATE switch .to

the readout displays according to Table

1-2

I

Decimal Point

.000000

.OOOOO

.OOOO

.ooo

Set the FUNCTIOIV Switch to

1.

Check

1-3.

1-3

ms

ms

ms

PS

PS

PS

PS

Set the FUNCTION switch to

.ooo

.oooo

.00000

.ooo

.oooo

.ooooo

.000000

1

s.

Check

1-4.

-

10

s

With the DISPLAY TlME control in the full ccw

position, observe that the GATE indicator flashes rapidly

for short GATE

TIMEs. Using a short GATE TIME, rotate the DISPLAY

TlME control slowly cw. Observe that the GATE light will

stay off for a longer and longer time, until the control

clicks into the HOLD detent position, holding off the

GATE indefinitely. Return the DISPLAY TlME control to

the ccw position.

RATIO A/B Displays.

RATIO A/B and the NICLOCK RATE switch to

Check the readout display according to Table

TIMEs and more slowly for longer GATE

kHz

Set the FUNCTION switch to

.OOOO

106.

1-2.

TABLE

NICLOCK RATE Switch

I

s

TIME MANUAL Displays.

TlME MANUAL and the NICLOCK RATE switch to

Check the readout display according to Table

1-4

Units lndicators

S

Set the FUNCTION switch to

Decimal Point

1-5.

0

-

1

ps.

Page 7

Operating Instructions-DC

503

TABLE

NICLOCK

The GATE: light should turn on and an advancing count

should be diisplayed when the

pushed in. The GATE light should turn off when the count

is

stopped by releasing the STARTISTOP button. Test the

overflow display by setting NICLOCK RATE to

pressing START, letting the count advance until the last

decade (seventh digit) reaches

flash. Release the START button and observe that the

display

RESET clears the overflow condition, sets the count to

zero, and

RATE

Switch Units Indicators Decimal Point

still

flashes but the numbers do not change. Pressing

stops the flashing display.

1-5

ms

STARTISTOP button

9

and the display begins to

.ooo

I

ps,

is

TOTALIZE A

TOTALIZE A. Observe

display. The GATE light should turn on when the START

button

The units indicators should remain off.

Channels

the attenuators, can be checked in a no-signal-input

condition by generating psuedo-triggers with the LEVEL

controls.

other channel. Set FUNCTION to

CLOCK RATE to 1 ms. Rotate CH A LEVEL back and

forth through

on. Rotate CH B LEVEL back and forth through

selected slope until the GATE light turns off. The resultant

display

events.

method, consult the Service section of the manual for

troubleshooting aids.

is

pushed in, and turn off when START

A & B

The channel A & B input circuits, with the exception of

Select

+

is

If the GATE light cannot be turned on or off with this

Display. Set the FUNCTION switch to

a

zero

at

the right of the readout

is

released.

SLOPE for one channel and - SLOPE for the

TIME A-tB and NI

its

selected slope until the GATE light turns

its

the time interval between these two trigger

INPUT CONSIDERATIONS

l

nput Sourc:es

The switch] concentric with the LEVEL control of each

channel selects either the front-panel BNC connector

(external), or the rear interface connector (Internal) pins;

Channel A via pin

The External inputs present high impedances of approximately 1

input circuits; present nominal 50

typical coaxial cable signal connections.

ML2, paralleled by about 20 pF. The Internal

lnput Coupling

Front Panel pushbuttons select AC (Capacitive) or DC

(Direct) coupling for each channel's input signal. This

coupling takes place

selected

attenuators of each channel.

soulrce and before they are passed on to the

16A, and Channel B via pin 17B.

Q

impedances to match

after the signals arrive from the

Attenuators and Maximum lnput Volts

Both front-panel pushbuttons, when out, provide no

(XI

).

attenuation to the input signal

maximum safe input voltage

the frequency limit of each channel. With either the

XI 00 attenuator selected (buttons are self-cancelling), the

maximum safe input voltage

1 kHz or

less.

is

50 V (DC + peak AC), up to

is

500 V (DC + peak AC)

In this mode, the

XI0 or

Sensitivity and Frequency Range

CH A will respond to signal amplitudes of

mV, peak-to-peak, up to 100 MHz.

300

CH B will respond to signal amplitudes of at least

mV, peak-to-peak, up to 10 MHz.

300

Depending on the coupling mode selected, the low

is

frequency limit for each channel

coupled) or 10 Hz (AC-coupled).

either 0 Hz (DC-

at

least

at

Page 8

Operating Instructions-DC

503

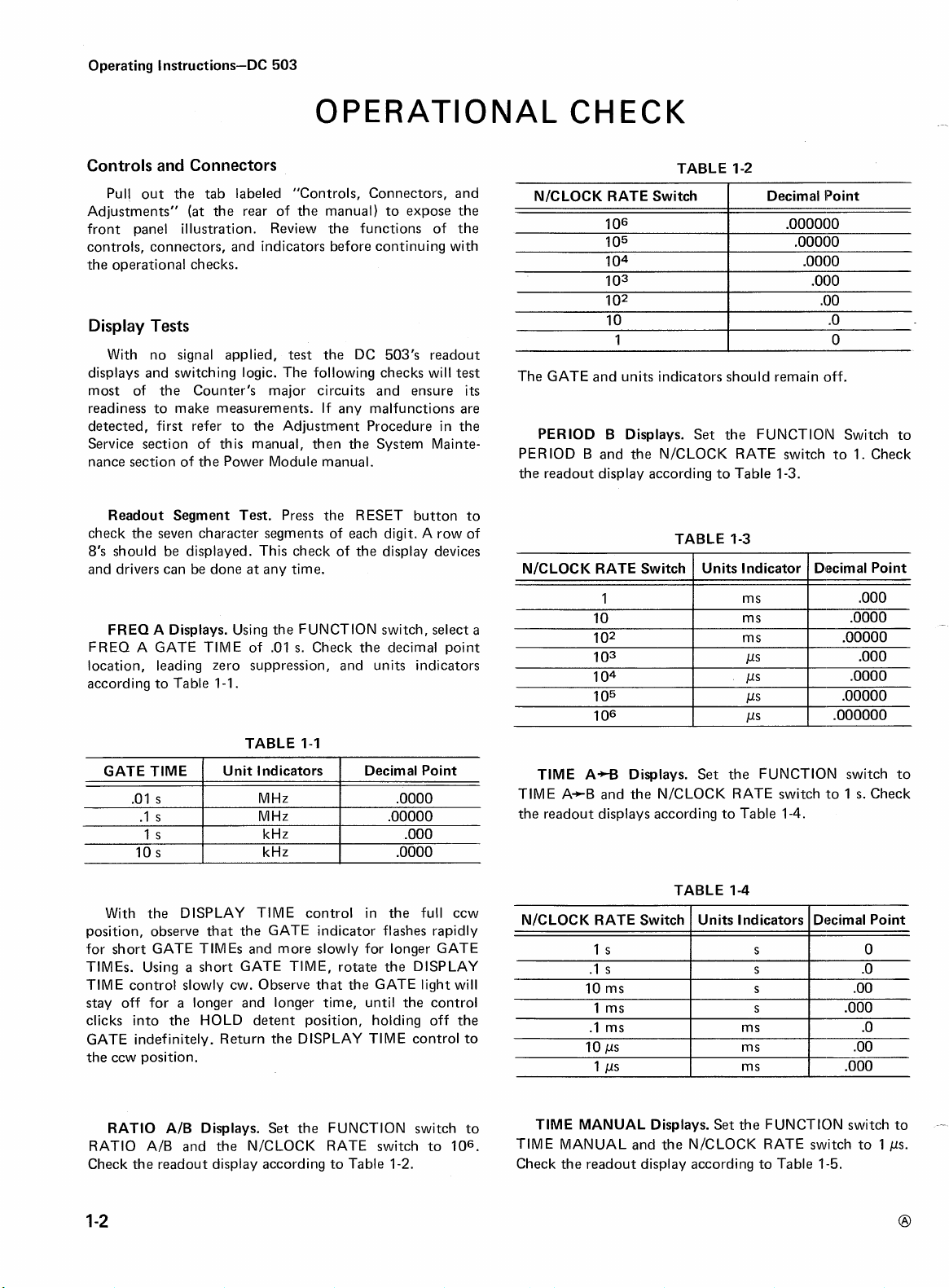

Slope and

A front-panel pushbutton for each channel determines

whether the trigger circuits will respond to either positive- stable triggering. See Fig.

or negative-going transitions of each input signal. over

(A)

LEVEL

Noise Impulses 200-millivolt

Erroneous count.

Fig.

1-2.

Triggeringcircuit responses to improper

hysteresis window

The LEVEL control for each channel allows the

operator to move the hysteresis window of the trigger

circuit to an optimum level on the input

+,I

.5

V of the input signal in the

(6)

Correct count.

(A)

and proper

(B)

LEVEL settings.

FREQUENCY MEASUREMENTS

FREO

100

GATE TIMEs

Make sure the LEVEL control

signal to the CH A INPUT. Set the DISPLAY TlME control

CCW.

Triggering

A

To measure and display the frequency of

MHz, set the FUNCTION switch to one

bracketed

under

the

heading

is

pushed in and connect the

a

signal up to

of

the shorter

of

FREO

A.

count varies from reading to reading,

jitter in the signal source. If the count changes unreasonable~

the

DC

503

is

not being triggered prc)per'yr either

because the controls are not set right or the signal

the

For frequency measurements, all CH B trigger settings

have no effect. "N" or "CLOCK RATE" settings are

irrelevant.

capabilities.

signal to assure

1-2.

The LEVEL control adjusts

XI

ATBEN position.

it

is

probably due to

is

beyond

The CH A LEVEL, Slope, Coupling, and

controls all affect the ability to make a measurement. In

general, the trigger controls are similar to oscilloscope

controls, except that the end result is not a stable waveform

graphic display, but a stable digital frequency display.

Coupling and

quency

control for changing DC levels. The repetitive nature of

frequency signals makes SLOPE selection insignificant.

5

amplitude signals, select an attenuation factor such that the

attenuated signal

peak-to-peak. The LEVEL control must be varied for a

stable reading.

amplitude and frequency are close to (or perhaps beyond)

the specified limits.

show jitter when measured with 7-digit resolution. If the

measurements

Attenuators and

V, peak-to-peak, should not be attenuated. For higher

A signal which looks stable on an oscilloscope may still

SLOPE.

falls into the range of

It

will not be touchy unless the signal

Use AC-coupling

to

avoid re-adjusting the LEVEL

LEVEL.

Signals between

ATTENuator

for

most

300

500

mV to 5 V,

fie-

mV and

Measurement Intervals

To adjust the trigger controls, choose a short GATE

TlME such as

display as to whether the Counter is being triggered or not.

If

it

is, numbers will appear in the display. (If the frequency

is below

shortest gate times. For such low frequencies, a PERIOD

measurement

Final selection of GATE TlME depends on the

quency being measured, desired resolution, and willingness

of the operator to wait for a measurement. Using short gate

times, higher frequencies may be measured, but at the

expense of the greater resolution capabilities of the longer

gate times.

Resolution.

must wait

displayed.

and accuracy for signals below

second count will display fewer than the available 7 digits.

.I

s

or

.O1

s.

This gives rapid feeldback via the

100

HZ, numbers may not appear during the

is

better

suited-)

A

10

s

GATE TlME means the operator

10

seconds for a measurement to be made and

It

is

the only way to get best possible resolution

1

MHz. Even then, a

fre-

10

-

Page 9

Operating Instructions-DC

503

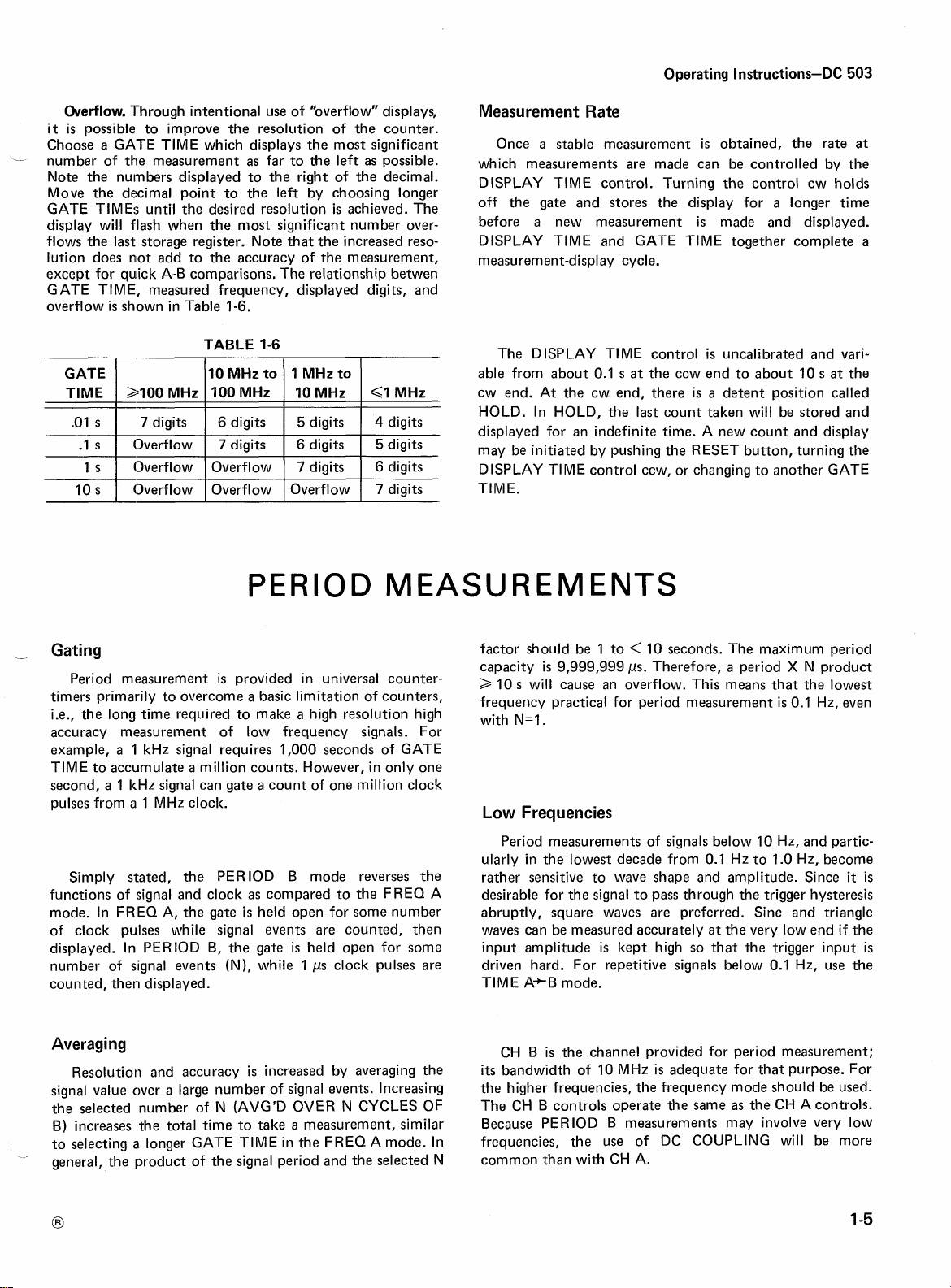

Overflow.

it

is

Choose

-

number of the measurement as far to the left

Note the

Move the decimal point to the left by choosing longer

GATE TIME!; until the desired resolution

display will flash when the most significant number over-

flows the

lution does

except for quick A-B comparisons. The relationship

GATE TIME, measured frequency, displayed digits, and

overflow

:EF

10

Through intentional use of "overflow" displays,

possible to improve the resolution of the counter.

a

GATE TlME which displays the most significant

numbers displayed to the right of the decimal.

is

achieved. The

last

storage register. Note that the increased reso-

not add to the accuracy of the measurement,

is

shown in Table 1-6.

TABLE

10

1

2100

MHz

100

;

1

7

digits

(3verflow

(3verflow Overflow

s

Overflow Overflow Overflow

1

MHz

MHz

6 digits

7

digits

1-6

1

MHz

to

,

10

MHz

1

5

digits

6

digits

7

digits 6 digits

to

as

possible.

betwen

hl

MHz

1

4

digits

5

digits

7

digits

Measurement Rate

Once a stable measurement

which measurements are made can be controlled by the

DISPLAY TlME control. Turning the control cw holds

off the gate and stores the display for

a

before

DISPLAY TlME and GATE TlME together complete

measurement-display cycle.

The D

able from about 0.1

cw end. At the cw end, there

HOLD. In HOLD, the

displayed for an indefinite time. A new count and display

may be initiated by pushing the RESET button, turning the

DISPLAY TlME control ccw, or changing to another GATE

TIME.

new measurement

ISPLAY TI ME control

s

at

the ccw end to about 10

last

is

obtained, the rate

a

longer time

is

made and displayed.

is

uncali brated and vari-

is

a

detent position called

count taken will be stored and

at

s

at

the

a

PERIOD MEASUREMENTS

-

Gating

is

Period measurement

timers primarily to overcome a basic limitation of counters,

i.e., the long time required to make a high resolution high

accuracy measurement of low frequency signals. For

example, a 1 kHz signal requires 1,000 seconds of GATE

TlME to

second, a 1 kHz signal can gate

pulses from a 1 MHz clock.

functions of signal and clock as compared to the FREQ A

mode. In FREQ A, the gate

of clock pulses while signal events are counted, then waves can be measured accurately at the very low end if the

displayed. In PERIOD B, the gate

number of signal events (N), while 1 ps clock pulses are

counted,

Averaging

signal value over

the selected number of N (AVG'D OVER N CYCLES OF

B) increases the total time to take

to selecting

general, the product of the signal period and the selected N

acc~~mulate a million counts. However, in only one

Simply stated, the PERIOD B mode reverses the rather sensitive to wave shape and amplitude. Since

then displayed.

Resolutiori and accuracy

a

large number of signal events. Increasing

a1

longer GATE TlME in the F REQ A mode. In

provided in universal counter-

a

count of one million clock

is

held open for some number abruptly, square waves are preferred. Sine and triangle

is

held open for some

is

increased by averaging the

a

measurement, similar

factor should be 1 to < 10 seconds. The maximum period

capacity

frequency

with

Low

ularly in the lowest decade from 0.1 Hz to 1.0 Hz, become

desirable for the signal to pass through the trigger hysteresis

input amplitude

driven hard. For repetitive signals below 0.1 Hz, use the

TIME A*B mode.

its

the higher frequencies, the frequency mode should be used.

The CH B controls operate the same

Because PERIOD

frequencies, the use of DC COUPLING will be more

common than with CH A.

is

9,999,999

will

cause

practical

N=~.

Frequencies

Period measurements of signals below 10 Hz, and partic-

CH

B

is

the channel provided for period measurement;

bandwidth of 10 MHz

ps.

Therefore, a period X N product

an

overflow.

for

period

is

kept high so that the trigger input

B

measurements may involve very low

This

means

that

measurement

is

adequate for that purpose. For

is

O.l

as

the CH A controls.

the

lowest

Hz,

even

it

is

is

Page 10

Operating Instructions-DC

503

RATIO MEASUREMENTS

In the RATIO A/B mode, the frequency of the signal

applied to CH A

applied to CH B, and the resultant ratio

that the normal "frequency" mode

is

divided by the frequency of the signal may be desirable to set the trigger controls independently.

is

displayed. Note This may be accomplished

is

basically a ratio

mode, in which the ratio of the unknown signal to the

internal clock

is

displayed. (Decade scaling of the internal

clock and decimal point positioning normalizes the display

relative to kHz or MHz units.)

Bandwidth Limitations

Because CH B has

feasible to make ratio measurements of two signals, both

well above

10

somewhat above

applied.

a

bandwidth of only

MHZ.

ow ever,

10

MHz if adequate signal amplitude

CH B will respond to signals

10

MHz,

it

is

not

Triggering

The operation of CH A and CH B trigger controls

same

as

for frequency and period measurement. In fact, digits will be best.

is

the

TIME INTERVAL MEASUREMENTS

since both channels must be triggered to obtain

as

follows:

1

)

Go to the FREQ A mode and adjust the CH A trigger

controls

for

a

normal

frequency

2)

Go to the PERIOD B mode and adjust the CH B

measurement.

trigger controls for a normal period measurement.

Leaving CH A and CH B trigger controls

3)

go

to

is

be

displayed.

the RATIO A/B mode. The correct ratio should

The NICLOCK RATE control may now be operated to

select maximum resolution. For most measurements, the

smallest value of "N" which produces

a

useful number of

a

display,

as

it

they

Electronic Startlstop

TlME A*B mode measures and displays the elapsed

The

time

interval

subsequent triggering of CH B. The triggering event does

not have to be the same one for both channels. Separate

events do not even have to be time related.

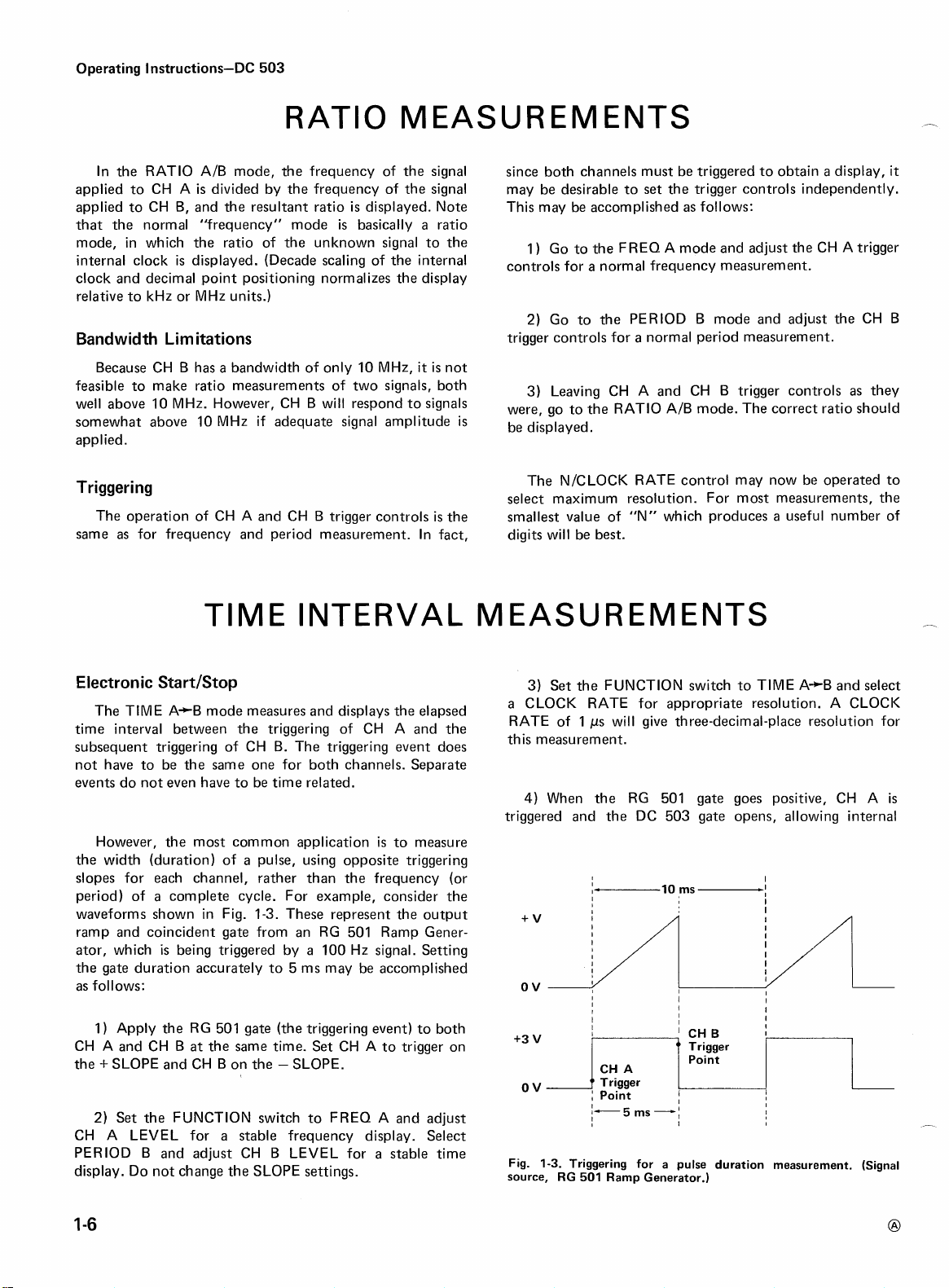

However, the most common application

the width (duration) of

slopes for each channel, rather than the frequency (or

period) of

waveforms shown in Fig.

ramp and coincident gate from an RG

ator, which

the gate duration accurately to

as

follows:

1)

Apply the RG

A

and CH B at the same time. Set CH A to trigger on

CH

the

+

SLOPE and CH B on the - SLOPE.

2)

Set the FUNCTION switch to FREQ A and adjust

CH A LEVEL for a stable frequency display. Select

PERIOD B and adjust CH B LEVEL for a stable time

display. Do not change the

between

a

complete cycle. For example, consider the

is

being triggered by

the

triggering

a

pulse, using opposite triggering

1-3.

These represent the output

5

501

gate (the triggering event) to both

SLOPE

of

CH

A

is

to measure

501

Ramp Gener-

a

100

Hz signal. Setting

ms may be accomplished

settings.

and

the

3) Set the FUNCTION switch to TIME A-+B and select

a

CLOCK RATE for appropriate resolutior~. A CLOCK

RATE of

I

ps

will give three-decimal-place resolution for

this

4)

When the RG

triggered and the DC

I

I

I

I

+3

v

CH

"

ov

Fig.

1-3.

source, RG

Trigger

I

Point

/-5ms-;

I

Triggering for a pulse duration measurement. (Signal

501

Ramp Generator.)

501

gate goes positive, CH A

503

gate opens, allovving internal

I

I

I

I

'

CHB

"

Trigger

A

Point

I

I

I

I

I

I

I

is

Page 11

Operating Instructions-DC

503

clock pulses .to be counted. When the RG 501 gate starts to

is

return to zero, CH B

and the

-

operator can adjust the RG 501 controls until the required

accuracy

accurnulated count of clock pulses

5) If the count

is

ac:h ieved.

triggered, the DC 503 gate closes,

is

displayed.

is

off the desired time interval, the

Single-Shot Using HOLD

Single-shot time intervals can be measured by putting

the

DISPLAY TlME control in HOLD. This will lock out

MANUAL TIMING MEASUREMENTS

The TlME MANUAL position

TlME

CLOCK RATE switch and

display.

A+B electronic mode. In this mode, only the

Starting antl Stopping

The TIME MANUAL mode may be thought of

"stop-watch" type of operation. With the FUNCTION

switch in the TlME MANUAL position, the display starts

counting time-base pulses when the

pressed.

lated total

last

START command

again advance), or other controls are actuated. Pushing

RESET will return the display to zero. Changing the setting

It

wnll continue to count and display the accumu-

until the STARTISTOP button

count will then be held in the display until another

is

given (in which case the count will

is

a

manual analog of the

STARTISTOP switch affect the

STARTISTOP button

is

released. The

as

both channels after CH A and CH B have been triggered,

respectively. Pushing RESET clears the display and re-arms

the trigger channels for another measurement.

GATE

front-panel GATE OUTPUT jack. Since

with the time interval measurement,

oscilloscope to graphically relate the digital measurement to

the analog signal.

of the CLOCK RATE switch will change the frequency of

the time-base pulses being counted, and return the display

to zero.

Output

The internal gate of the DC 503

it

is

available

it

may be used with an

Clocking Rate

When the CLOCK RATE switch

one-second pulses are being counted, and the display

a

accumulation advances one count per second, and so on.

On the 1

one million counts per second.

is

9,999,999, the display will flash to indicate overflow;

however, the accumulation continues at the normal rate,

except that the digits for decades above

displayed.

ys position, the count accumulates

Whenever the accumulated count

is

in the

is

at

the

is

coincident

1

s

position,

at

the rate of

greater than

107 are not

TOTALIZING

Purpose

In the TOTALIZE A mode, signal

A INPUT

displayed during the time the STARTISTOP button

pushed in. This mode

mode.

relatively infrequent and irregular events.

a~re counted and the accumulated total

is a manual analog of the frequency

It's

main application

is

Operation

Apply the signal to CH A and set the trigger controls the

same as for frequency measurement.

Starting tlie Count.

and adjust the CH A LEVEL control until

Press the STARTISTOP button in

events

applied to CH

to accumulate a count of

a

count begins to

is

is

The

advance.

numbers. Only the CH A trigger controls, the RESET

button, and the

Stopping the Count.

released and no other controls are operated, the

will continue to be displayed. No more incoming events will

be added to the total.

Restarting and Resetting.

depressed, incoming events will advance the displayed total.

Resetting the count to zero can be done at any time by

pressing the RESET button or by moving the FUNCTION

switch to some other position, then back to TOTALIZE A.

accumulated count

STARTISTOP button affect the display.

If the STARTISTOP button

is

displayed in whole

When the START

last

is

is

total

again

Page 12

Operating Instructions-DC

503

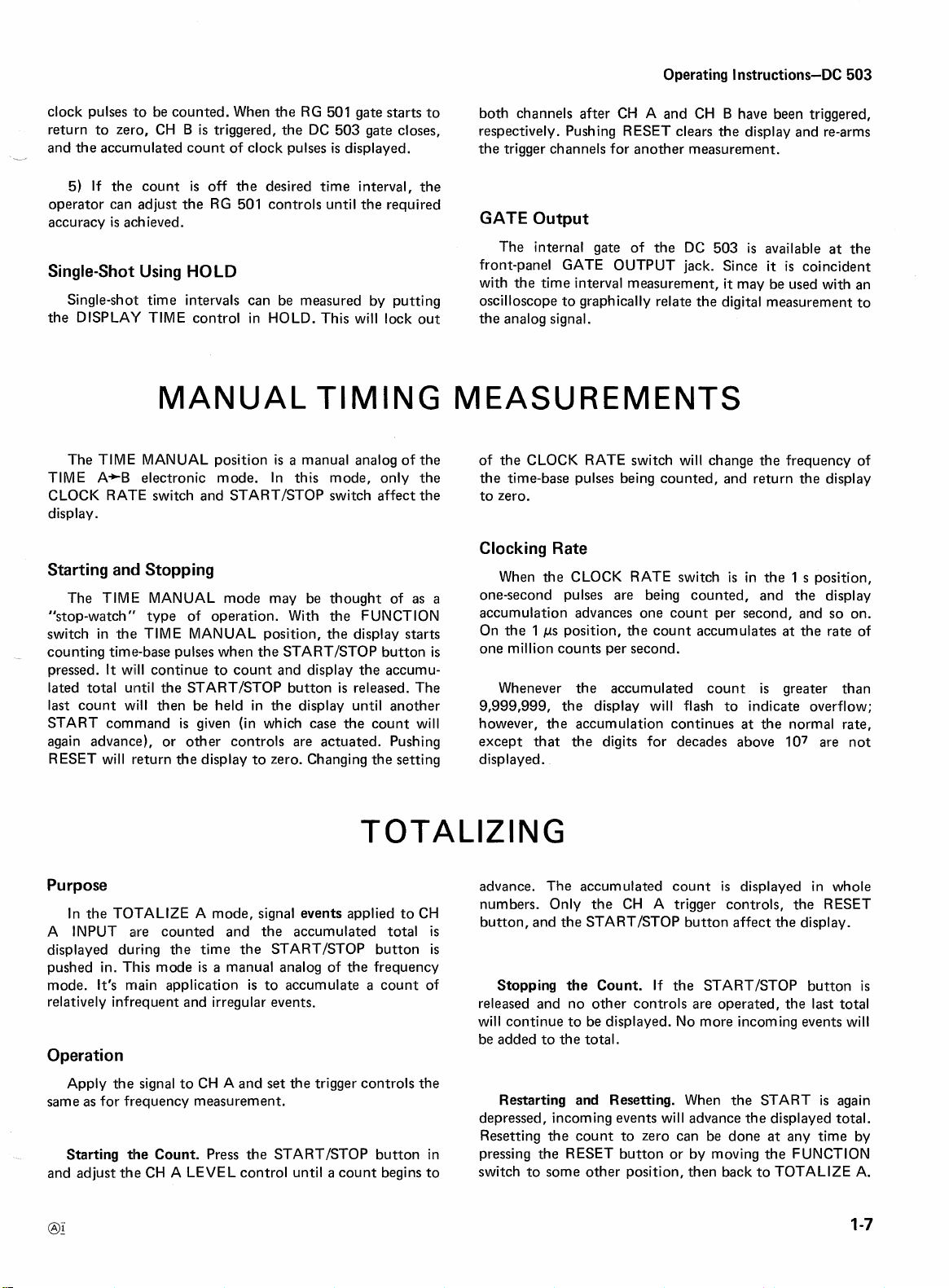

REAR

Customizing the Interface

Input and output access to the DC 503

rear of the main circuit board. Fig. 1-4 identifies the

contacts and their respective

A Power Module mainframe option (Option 2)

available which provides

to which

Also possible are intra-compartment connections with other

plug-in modules in multiple-compartment mainframes. The Reset, Time-Slot Zero

Control Lines

These lines allow the user to externally command the

DC

A Reset input line, which doubles

line, clears the Counter to zero when a low

An input line to disable the flashing overflow display also

doubles as an output signal line during overflow. The the interface for possible synchronous applications.

If0 lines can be hard-wired for external access.

503

to certain operating conditions.

CONNECTOR I/O ASSIGNMENTS

.

internal scan clock can be shut off by the Internal Scan

is

available at the

I10 assignments.

a

rear-panel, multi-pin connector

as

an output signal

is

applied to

it.

Clock Disable line, while using an external scan clock.

Signal Lines

These lines provide for signal input to each channel,

is

status and clock signal outputs, BCD data outputs, and

external scan clock inputs.

(TSO), Data Good, and

Overflow lines report the status of the DC 503. BCD data

lines report the count in an 8-4-2-1, serial-by-cligit method.

As long as the Internal Scan Clock Disable line remains

high, the Internal Scan Clock output signal

When the Disable line

Clock line becomes an input line for an External Scan

Clock signal.

The DC 503's internal

is

pulled down, the Internal Scan

1

MHz Clock signal

is

iis

available.

brought to

INTERNAL

OVERFLOW

SCAN

CLOCK

OUTIEXTERNAL

OUTIOVERFLOW

BCD

OUTPUT,

SERIAL-BY-DIGIT

CHANNEL B INPUT

FUNCTION

SCAN

DISPLAY

CHANNEL

Fig.

I

ASSIGNMENTS

CONTACT

I

I

1-

-

{

25B

24B

23

:::

19B

17B

16B

B

-1

CLOCK

IN

DISABLE

DATA

1-4.

IN

GOOD

B

INPUT

GROUND

InputIOutput contact assignments at rear connector.

4

+I

4

d

-

I

I

-

-

I

-

I

-

I

I

ASSIGNMENTS

FUNCTION

27A

26A

25A

20A

19A

17A

16A CHANNEL A INPUT

14A

INTERNAL

RESET,

TIME

SLOT

CHANNEL

1-MHz

CLOCK

SCAN

INIOUT

ZERO

BCD

OUTPUT, SERIAL-BY-DIGIT

A

INPUT

OUT

CLOCK

(TS,)

GROUNID

CllSABLE

Page 13

Operating Instructions-DC

503

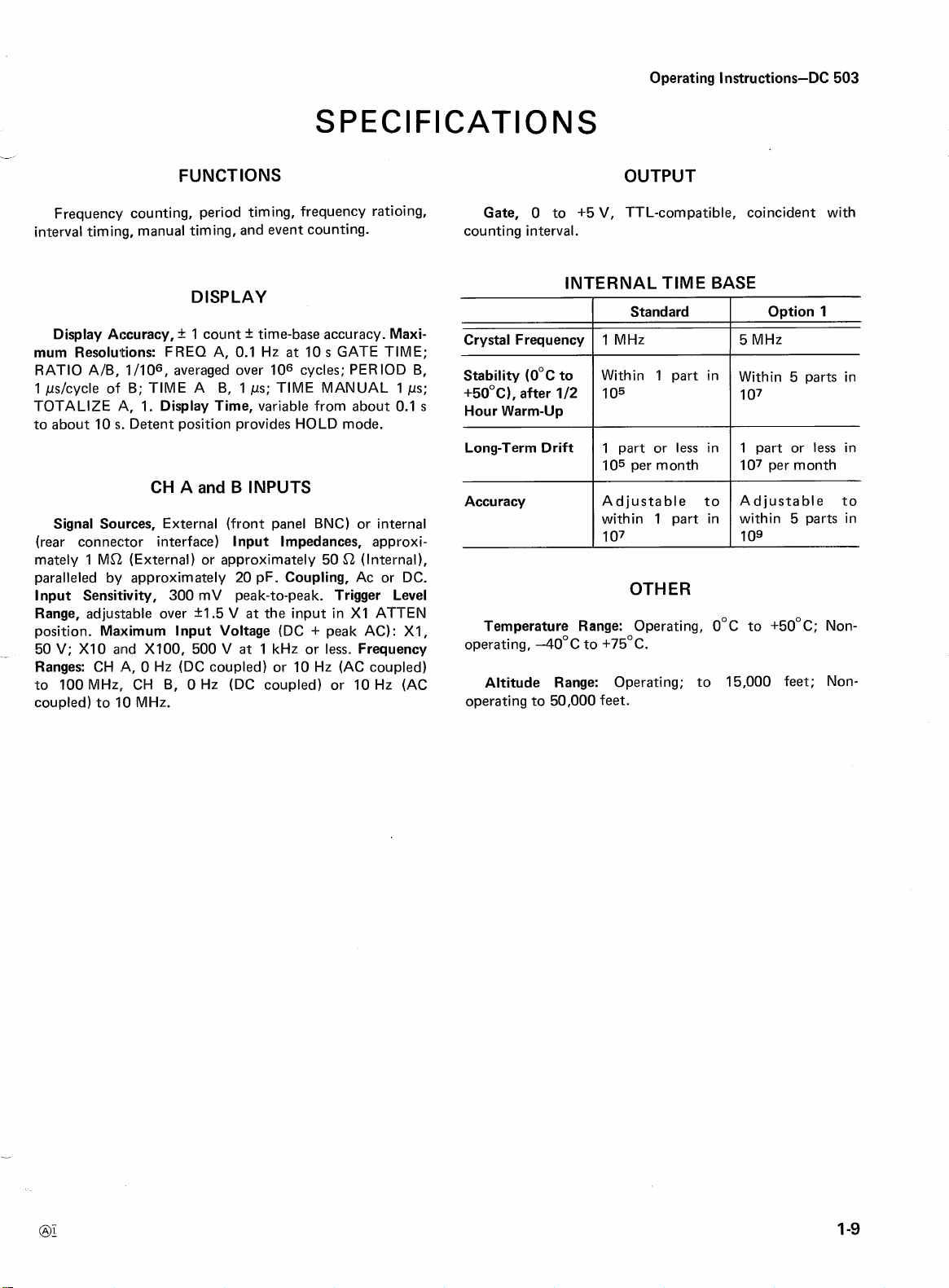

SPECIFICATIONS

+

FUNCTIONS

OUTPUT

Frequency counting, period timing, frequency ratioing,

interval timing, manual timing, and event counting.

DISPLAY

Display Accuracy,

Resolultions:

mum

RATIO

1

TOTALIZE

to about 10

(rear

mately 1

paralleled by approximately 20

l

Range,

position.

50 V; XI0 and X100, 500 V

Ranges:

to 100 MHz, CH

coupled) to 10 MHz.

A/B, 1/106, averaged over 106 cycles; PERIOD B,

ps/cycle of 6; TlME A B, I ps; TlME MANUAL I ps;

A,

s.

Signal Soi~rces,

connecitor interface)

MQ (External) or approximately 50 Q (Internal),

nput Sensit:ivity,

adjustable over

Ma:~imum Input Voltage

CH

,A,

+

1

count f time-base accuracy.

FREQ A, 0.1 Hz at 10 s GATE TIME;

1.

Display Time,

Detent position provides HOLD mode.

CH A

and

External (front panel BNC) or internal

300 mV pea k-to-pea k.

+I

0 Hz (DC coupled) or 10 Hz (AC coupled)

6, 0 Hz (DC coupled) or 10 Hz (AC

variable from about 0.1

B INPUTS

l nput Impedances,

pF.

Coupling,

.5 V

at

the input in XI ATTEN

(DC + peak AC): XI,

at

1 kHz or less.

approxi-

Ac or DC.

Trigger Level

Frequency

Maxi-

Gate,

counting interval.

Crystal Frequency

Stability

+50°c), after

s

Hour Warm-Up

Long-Term Drift

Accuracy

operating to 50,000 feet.

(O'C to

Temperature Range:

Altitude Range:

0 to +5 V, TTL-compatible, coincident with

INTERNAL TIME BASE

1 MHz

Within 1 part in

112

105

1

part or less in

1 05 per month

Adjustable to

within 1 part in

I

07

Standard

Option

5 MHz

Within 5 parts in

1 07

1

part or

107 per month

Adjustable to

within 5 parts in

I

09

1

less

in

OTHER

-400C

Operating,

+750c-

Operating; to 15,000 feet; Non-

OOC

to +50°c; Non-

Page 14

Page 15

Section

2-DC

503

INPUT

Attenuators, Channels A and (B)

Events to be counted are applied via front-panel INPUT

connector

are frequency-compensated voltage dividers consisting of

resistors R 18-R25

(C118-C125). Switches S20A (S120A) and S20B (S120B)

allow front-panel selection of XI, X10, or XI00 attenuation of

coupling.

J10 (J110) to the attenuators. The attenuators

(R 1 18-R 125) and capacitors C18

the input signal. C15 (C115) provides AC

SECTION

THEORY

OPERATION

CIRCUIT

DCU Signal Selection Gates

The two separate bistable multivibrators produce sharp

signal edges for the decade counter units

TOTALIZE A, RATIO

positions,

and

MANUAL, or TlME

bistable multivibrator for the DCU drive and

by the DDU (decade divider unit) output. In PERIOD

U200D-U226C

control signal from the 1 MHz clock.

U200A-U200C

is

switched

by the channel A input signal. In TlME

is

AIB, or one of the FREQ A

is

the active bistable multivibrator

A-tB, U200D-U226C

the active multivibrator.

OF

(DCU). In

is

the active

is

controlled

It

receives

2

B,

a

Signal Shaping and Slope, Channels A and (B)

Field effect transistor (FET) 035 (0135) presents a high

impedance

base of

between the LEVEL control R45

050 (0150). Adjustment of the LEVEL control changes

the bias on

the input signal will trigger the DC 503.

060 and 1050 in the Channel A signal shaping circuitry

comprise

in the Channel B signal shaping circuitry) acts

follower.

070-080 (0160-0170)

pair.

slope by biasing the desired slope to R74

positive slope

negative slope

follower 095

and the slope-determined output signal to the appropriate

DCU signal selection gate and the A start portion of the

Time

to1 the input signal and a low impedance to the

050 (01 50). FET 040 (0140) provides isolation

(R145) and the base of

(150 (0150) and thus selects what portion of

a

hiigh frequency, high gain amplifier. 068 (0150

as

an emitter

is

a

signal switched differential

+

SLOlPE switch S75 (S170) selects the triggering

(R165). The

is

passed through 090 (0165), while the

is

passed through 074 (0180). Emitter

(0185) couples the signal level to a TTL level

A+B ciircuit.

The output signal from the active bistable multivibrator

goes to NOR gate

toggle the decade counter units.

U200B. The output of U200B

is

used to

Time A+B (A Start-B Stop)

The two separate bistable multivibrators (U220C-U220D

and U220A-U220B) produce sharp edges to toggle U224A

and B.

In TlME

at

pin 1 of U226A, making pin 3 of NAND gate U226B

high. Pin 4 of U226B starts low when

pin 4 of U224A. Pin 5 of U226B starts high due to a low

pin 13 of U224B. An "A trigger" causes U224A to toggle,

which makes pin 4 of

pin 14 of

of event to be counted).

"armed" by the high that occurs

circuit now waits for a "B trigger" which will toggle

and put a low on pin 5 of U226B. When the B trigger

arrives,

gate generator circuit closing the gate. When the gate closes,

a CLEAR resets

A+B mode the FUNCTION switch puts a low

CLEAR

U226B high. This outputs a low to

U272B1 causing the gate to "open" (permits input

U224B simultaneously becomes

at

its

pins 12 and 13. The

U226B will output a high to pin 14 of U272B in the

U224A, which in turn resets U224B.

goes low

U224B

at

at

Page 16

Theory of Operation-DC

TIME BASE AND CONTROL CIRCUITS

503

1

MHz

Clock

A precise one-megahertz clock provides the reference for

FUNCTION switches and the DCU signal sele~ction gates to

the decade counter units.

operation of the gate-generating and time-counting circuits.

is

The output of crystal oscillator Y250

to exactly one megahertz. The four parts of U250

shaper-buffer stage to produce square-wave clock pulses and

to isolate the oscillator from the 1 MHz output line.

Optional 1 MHz

An optional 1 MHz clock

5 MHz crystal oscillator and

combination

Clock

is

available, using a very stable

a

divide-by-five counter. This

is

shown on the schematic as Y251 and U251.

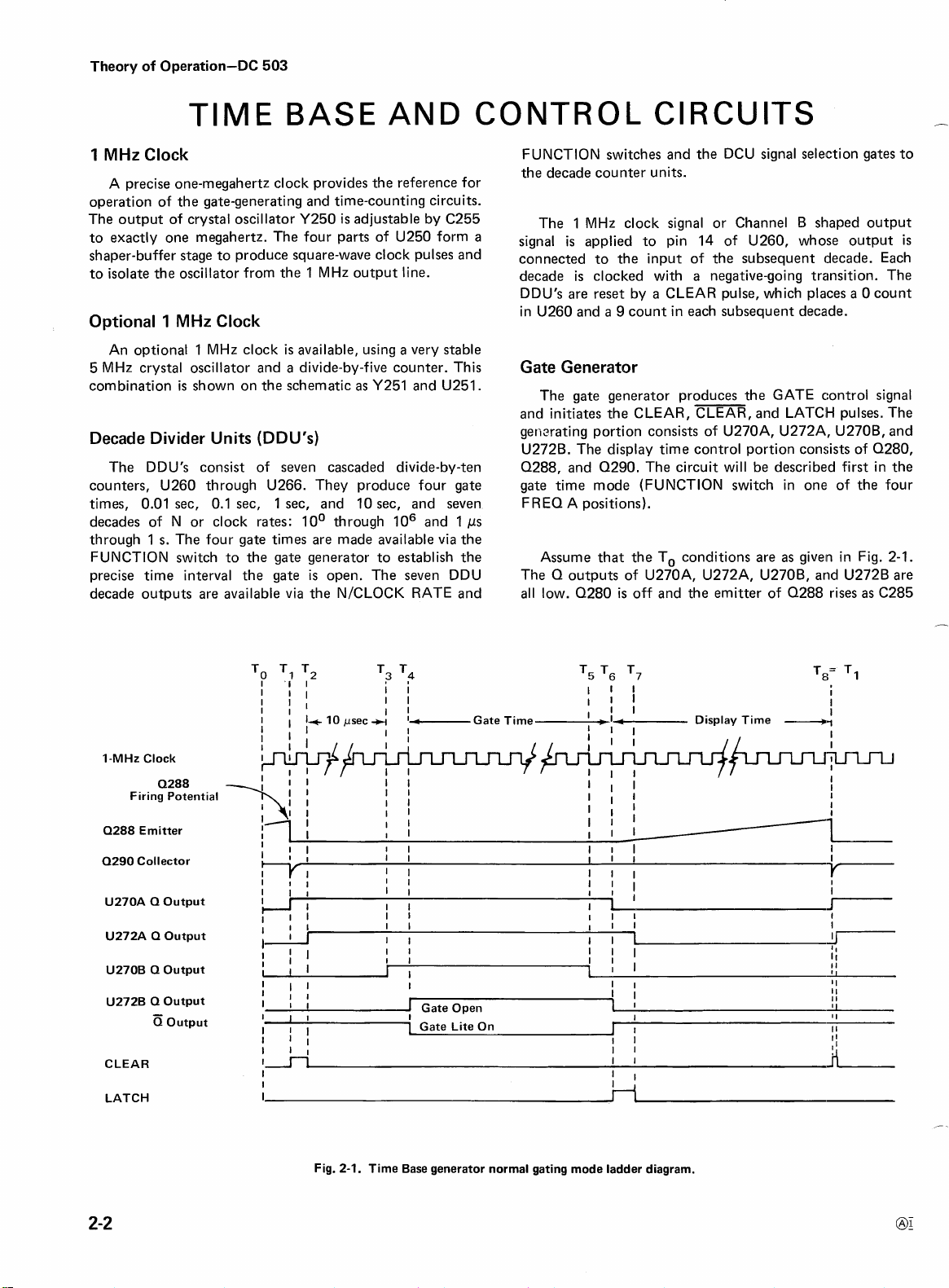

Decade Divider Units (DDU's)

adjustable by C255

form

a

Signal

is

applied

to

pin

14

of

~260, whose

connected to the input of the subsequent tjecade. Each

The 1 MHz clock signal or Channel B shaped output

is

decade

clocked with a negative-going transition. The

DDU's are reset by a CLEAR pulse, which places

in U260 and a 9 count in each subsequent decade.

Gate Generator

The gate generator produces the GATE c:ontrol signal

and initiates the CLEAR, CLEAR, and

gerwrating portion consists of U270A, U272A, U270B, and

U272B. The display time control portion consists of 0280,

LATCH pulses. The

output

a

The DDU's consist of seven cascaded divide-by-ten 0288, and 0290. The circuit will be described first in the

counters, U260 through

times,

0.01 sec, 0.1 sec, I sec, and 10 sec, and seven FREQ A positions).

decades of N or clock rates:

through 1

s.

The four gate times are made available via the

FUNCTION switch to the gate generator to establish the

precise time interval the gate

decade outputs are available via the

U266. They produce four gate gate time mode (FUNCTION switch in one of the four

lo0

through

is

open. The seven DDU The 0 outputs of U270A, U272A, U270B, arid U272B are

NICLOCK RATE and all low. 0280

lo6

and I ps

Assume that the

is

off and the emitter of 0288 rises

To conditions are as given in Fig. 2-1.

0 count

as

C285

is

1-MHz Clock

Q288

Firing Potential

0288 Emitter

0290 Collector

U270A Q Output

U272A Q Output

U270B Q Output

U272B Q Output

-

Q Output

CLEAR

LATCH

T2

I II

I

11

I

II I I

I

I

I+

f

10 psec

I' I I

~+k!f.{i

I #I

I II

Ill I

lr

j

I'

I

!I

I

11

Ill I

)

;I

T

T

B?

I

I

I I

-tl

'-Gate Time-1- Display Time

I I Ill

I

I

I

I

1

I

I I

I I

I

I

I

I

I I Ill

I I

I

I

I

I

I

I

I

I I

I

I

1

I

I I I

1

Gate openc

1

Gate Lite On

T!5

T6 T7 TE;=

;I:

I

I

II

I

I

I

I

I

I

1;

I

I!'

111

ill

Ill

111

I

I~

'11

I I

LII

.I

I

I

I

I

++lnJ

-1

TI

I

I

I

I

I

1

I

i

I

I

7

I

7

I

I

j

i

I

I

I

I,

1

I

I I

I I

I

I

I

I

I

I

I

i

2-1. Time Base generator normal gating mode ladder diagram.

Fig.

Page 17

Theory of Operation-DC

503

charges. At TI, 0288 reaches

discharges the capacitor. This results in

pulse on the direct-set input (pin 2) of U270AI forcing

-

output high and

U280A,

high,

The next high-to-low transition from the 1 MHz clock

toggles U27i!A, causing

go low. With a low applied to one of

reverts to

and CLEAR pulses. The DDU's then start counting from

their 09999919 reset condition.

DDU's to count the first digit, plus

negative transition from the DDU's via either the FUNCTION or

mode) toggles

2-1.

next negative transition from the 1 MHz clock

U272B, causing

its

GATE indicator LED,

is

preventing

(GATE)

inverter and isolation transistor

.-

selected by either the FUNCTION or

switch (depending on operating mode). At the end of this

time, which corresponds to

transition from the DDU's toggles

its

produciing the CLEAR and CLEAR control signals.

At the

N1C:LOCK RATE switch (depending on operating

U270B1s Q goes high and

a

output .to go low (supplying current to the front-panel

applied to the base of Q280, saturating the tran~stor and

is

The GATlE remains open (high) for the time duration

its

a

output low. With two high inputs on

output goes low and the output of U280D goes

its

Q output to go high and

its

original condition, terminating the CLEAR

end of a 10-microsecond delay (time for the

U270B. This event corresponds to T3 in Fig.

its

Q output to go high (GATE open) and

DS275). The U272B Q output (gate)

C:285 from charging. The U272B Q output

also supplied to a front-panel connector via

its

firing potential and

a

short-duration low

its

inputs, U280A

a

propagation delay),

output goes low. The

its

(2278.

NICLOCK RATE

T5 in Fig. 2-1, another negative

U270B. U270B1s Q

its

(T,)

its

Eto

(T4) toggles

output goes low and

negative transition from the

Q

a

U272B1 causing

Simultaneously, the Q output goes high, removing current

from the GATE indicator LED.

When the

transition toggles

U280B has two high inputs, placing a low at the output of

U280B, terminating the LATCH signal.

The display time begins when the GATE signal ends

(T6). When 0280 turns off, C285 begins to charge through

R282-R285 toward the

TIME, provides an adjustable time constant to vary the

display time form about 0.1 second to about 10 seconds.

When the DISPLAY

(HOLD detent position), S285 opens, and C285 stops

charging. When S285

ciently to bring Q288 to

display time ends and the next GATE-opening sequence

begins.

Q270 provides an automatic reset by grounding the

RESET line for

FUNCTION and NICLOCK RATE switches also provide

method of automatic reset. The two switches ground the

RESET line between switch

matic reset insures that the readout has been cleared before

the next measurement. The automatic reset can be seen by

noting that the display goes to all eights (all LED segments

lit) in between switch detent positions.

U272B Q output goes low,

a

its

output goes high. The next

1 MHz clock (T6) toggles

its

Q-output to go low, closing the gate.

U270A, switching Q low and Q high. Now

Vcc

supply. R285, DISPLAY

TlME control

is

closed and C285 charges suffi-

its

firing potential (TI

short time after instrument turn-on. The

detent positions. The auto-

is

fully clockwise

the

negative

),

the

a

COUNTER CIRCUITS

Decade Counter Units (DCU)

The 100 through 106 DCU

ten counters. The first decade counter

J-E<

individual

circuit board,, to accept the high-speed decade input (up to

100 MHz),

U210B, U21:2, and U214 comprise the first (100) decade

counter, and U305 through

DCU1s.

six

When the J and K inputs of U210A are high (GATE

open), the counter

the toggle

counted by

goes low, providing

input for the second decade counter. Each subsequent

decade divides by ten in

output lines are connected from each DCU to

storage-register latch. When the CLEAR (high) and CLEAR

flip-flops, located on the Trigger Amplifier

and each subsequent DCU

is

enabled. The input signal is applied to

input of U210A. On every tenth clock input

the first decade counter, the output of U214

a

carry signal which becomes the clock

is

seven cascaded divide-by-

is

made up of four

is a single IC. U210A,

U310 make up the remaining

a

similar manner. Four BCD

its

associated

(low) signals are activated, all of the decade counters are

reset to the zero-count

state.

Storage Register

The seven IC latches (U320 through U326) comprise

storage register which stores the corresponding decade

counter BCD output. The BCD output number

the data inputs

bits respectively). The LATCH pulse

data-strobe input

(negative transition) or when the FUNCTION switch

placed in the TOTALIZE A, or TlME MANUAL positions.

While the LATCH input

inputs are transferred to the associated BCD bit output to

be scanned by the multiplexing circuit.

at

pins 1, 5, 7, and 3 (20, 21, 22, and 23

at

pin 2 of each latch

is

high, the logic levels

at

is

applied to

is

applied to the

the end of GATE

at

the data

is

Overflow Register and Drive

When the decade counters have counted to 9,999,999,

the counters are full. At the next count the

23 output of

a

Page 18

Theory of Operation-DC

U310 goes low, providing a toggle input to U311A. When

this occurs,

U311 A. When the LATCH pulse ends (goes low), U311

toggled and the high

U311 B goes high,

high now at the input of

which causes the LED display to flash.

a

high

503

is

transferred from pin 14 to pin 12 of

B

is

transferred to pin 8. When pin 8 of

CR311 and CR314 are turned off. The

U328B starts a multivibrator

U311A goes low on the first overflow count, 0312 and

of

CR314 turn off. Since pin 8 of U311B

off) by the clear input (pin 6), this first overflow count

is

causes

overflow circuit

the display

high).

a

flashing LED display. This difference in the

is

necessary in the "manual" modes, since

is

continuously read from the DCIJrs (LATCH

is

held high (CR311

-

In the

modes, overflow indication

CR314. The emitter of 0312

closure

TIME MANUAL and TOTALIZE A counting U311A

is

achieved via 0312 and leading-zero suppression during the overflow condition, the

is

grounded by a switch display-controlling circuits are notified via U328A that the

as

is

the clear input (pin 6) of U311

B.

When pin 13 count

is

reset by the CLEAR pulse. To prevent

is

in excess of that displayed by the LED readout.

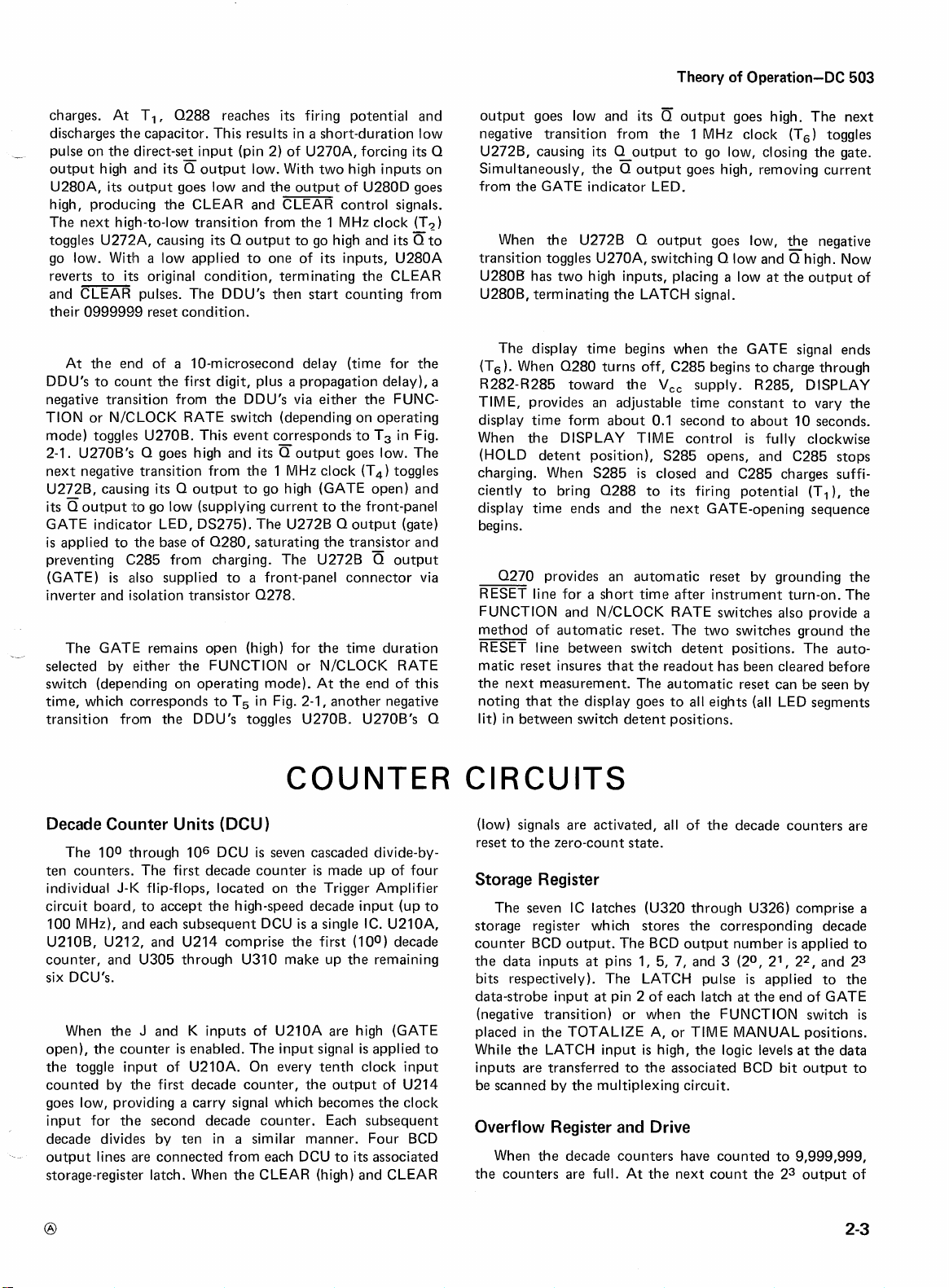

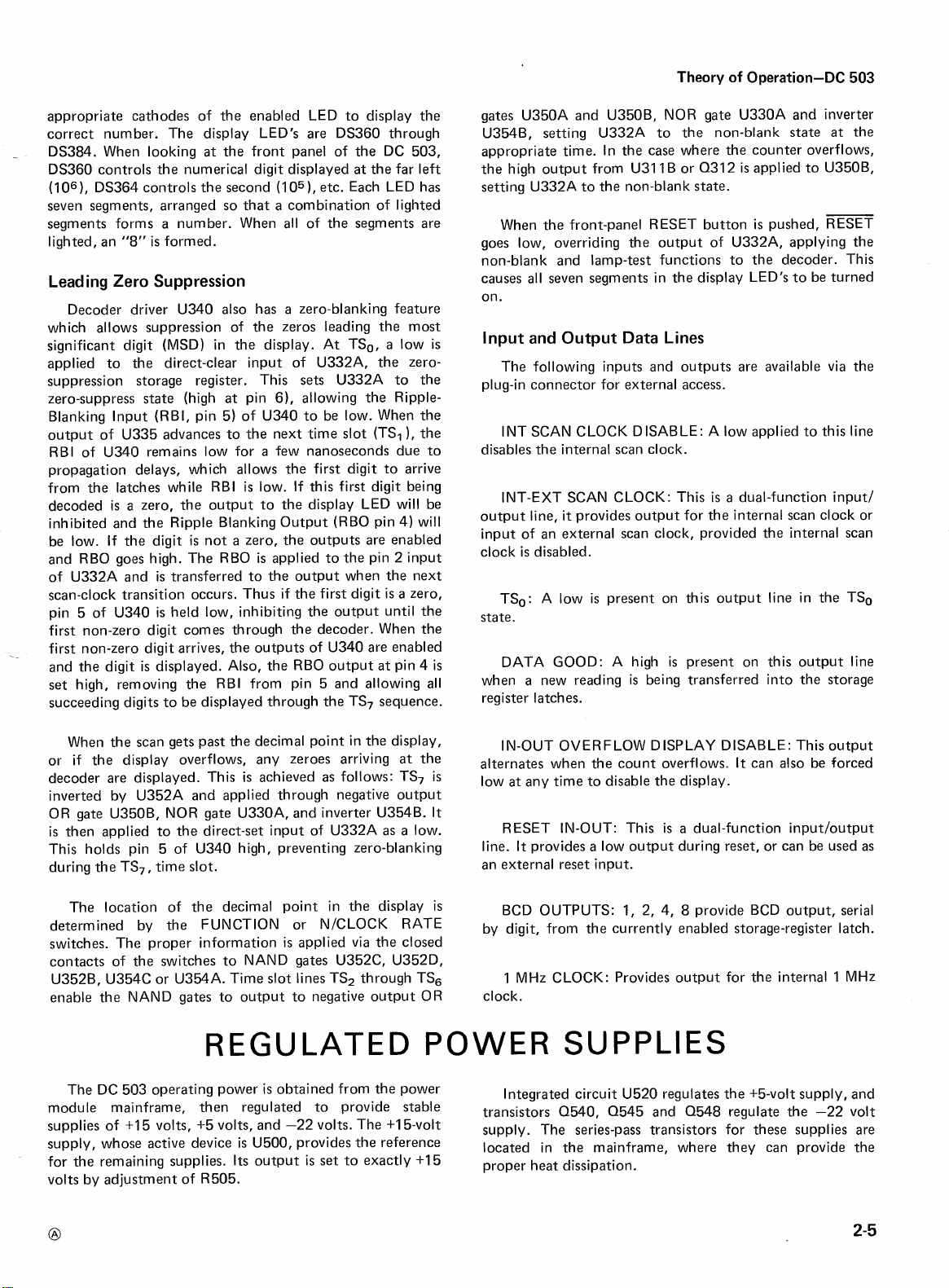

DECODE AND DISPLAY MULTIPLEX

Scan Clock

is

The scan rate of the multiplexing circuit

is

by the scan clock. The scan clock

and U330C, which operate

at an approximate 2-kilohertz rate.

provided for internal scan-clock disable, internal scan clock

output, and external scan clock input. The scan clock

output drives an eight-state counter and

for zero suppression.

+8

Counter and Time-Slot Decoder

The divide-by eight counter

U333A, and U333B. The output of this counter drives BCD output of the latches, then supplies current to the

as

composed of U330B

a

free-running multivibrator

Input/output lines are

is

made up of U332B,

determined

a

storage register

U335, a BCD-to-decimal decoder. U335 provides eight

output lines (designated TSo through TS, in the schematic,

and in Fig. 2-2) to simultaneously enable

its

each counter latch and

sequentially. For example, when the

0360

is

turned on to supply anode voltage to DS360

same time inverter

U326, enabling

allows the latches to share

U337A applies a high to pin 6 of latch

its

output. Operation in a time sequence

corresponding display LED

a

common

set

the output of

TS, line goes low,

at

the

of ou~:put lines.

Seven-Segment Decoder and Driver, and Display

and Parameter LED'S

U340

is

a

BCD-to-seven-segment decoder.

It

accepts the

-

Scan clock

TS

Q

TS

7

-

RESET Dl D2 D3 04 D5

RBI, pin

5

U340

I

Fig.

r---

I

2-2.

Multiplexing circuit ladder diagram showing timing with an all-zero display.

r----

I

-

T-"--'---'T""

I

1

1

I

I

1

L

Forced

by

-

RESET

--

Page 19

Theory of Operation-DC

503

appropriate cathodes of the enabled LED to display the

correct number. The display

DS384. When looking

DS360 controls the numerical digit displayed

(1

06), DS364 controls the second (1 05), etc. Each LED has

seven segments, arranged so that

segments forms

"8"

lighted, an

is

at

a

number. When all of the segments are

formed.

LED'S are DS360 through

the front panel of the DC 503,

at

the far left

a

combination of lighted

Leading Zero Suppression

Decoder driver U340 also has

which allows suppression of the zeros leading the most

significant digit (MSD) in the display. At

applied to the direct-clear input of U332A, the zerosuppression storage register. This

zero-suppress

Blanking Input (RBI, pin 5) of U340 to be low. When the

output of U335 advances to the next time slot

of

RBI

propagation delays, which allows the first digit to arrive

from the latches while RBI

decoded

inhibited and the ~i~~l~ ~l~~ki~~

be

low.

and RBO goes high. The RBO

of U332A and

scan-clock transition occurs. Thus if the first digit

pin 5 of U340 is held low, inhibiting the output until the

first non-zero digit comes through the decoder. When the

first non-zero digit arrives, the outputs of U340 are enabled

and the

set high, removing the RBI from pin 5 and allowing all

succeeding digits to be displayed through the

state

(high

at

U340 remains low for a few nanoseconds due to

is

a

zero, the output to the display LED will be

If the digit

digit

is

is

not a zero, the outputs are enabled

is

transferred to the output when the next

displayed. Also, the RBO output

a

zero-blanking feature

TSo, a low

sets

U332A to the plug-in

pin 6), allowing the Ripple-

(TS,

),

the

is

low. If this first digit being

output

is

applied to the pin 2 input

(RBO

pin

4) will

is

a

at

pin 4

TS7 sequence.

zero,

is

is

gates U350A and U350B, NOR gate U330A and inverter

U354B, setting U332A to the non-blank

appropriate time. In the case where the counter overflows,

031 2

the high output from U311 B or

setting U332A to the non-blank

When the front-panel RESET button

goes low, overriding the output of

non-blank and lamp-test functions to the decoder. This

causes all seven segments in the display

on.

Input

and

Output

The following inputs and outputs are available via the

connector

INT SCAN CLOCK DISABLE: A low applied to this line

disables the internal scan clock.

INT-EXT SCAN CLOCK: This

output line,

input of an external scan clock. provided the hternal scan

TSo: A low

state.

DATA GOOD: A high

when a new reading

register latches.

is

disabled.

it

Data

Lines

for

external

provides output for the internal scan clock or

is

present on this output line in the TSo

is

access.

is

present on this output line

being transferred into the storage

is

state.

U332A, applying the

is

a

dual-function input/

state

at

the

applied to U350B,

is

pushed, RESET

LED'S to be turned

When the scan gets past the decimal point in the display,

any

or

if

the

display

decoder are displayed. This is achieved

inverted by U352A and applied through negative output

OR gate

is

This holds pin 5 of U340 high, preventing zero-blanking

during the TS,, time slot.

determined

switches. The proper information

contacts of the switches to NAND gates

U352B, U354C or U354A. Time slot lines TS2 through TS6

enable the PJAND gates to output to negative output OR

U350B, NOR gate U330A, and inverter U354B. It

then applied to the direct-set input of U332A

loca,tion of the decimal point in the display

The

by

the

zeroes

is

arriving

as

follows: TS7 is

Or

NICLoCK RATE

applied via the closed

U352C, U352D1

as

at

a

low.

the

is

IN-OUT OVERFLOW DISPLAY DISABLE: This output

alternates when the count overflows. It can also be forced

low

at

any

time

to

disable the display.

RESET

line. It provides

an external reset input.

BCD OUTPUTS: 1, 2, 4, 8 provide BCD output, serial

by digit, from the currently enabled storage-register latch.

1 MHz CLOCK: Provides output for the internal 1 MHz

clock.

IN-OUT: This

a

low output during reset, or can be used

is a dual-function inputloutput

REGULATED POWER SUPPLIES

The DC 503 operating power

module mainframer then regulated to provide stable transistors Q540, 0545 and 0548 regulate the

supplies of +15 volts, 4-5 volts, and -22 volts. The +15-volt

supply, whose active device

for the remaining supplies. Its output

volts by adjustment of R505.

is

obtained from the power

is

U500, provides the reference

is

set

to exactly +I5

Integrated circuit U520 regulates the +5-volt supply, and

upp ply.

located

proper

The series-pass transistors for these supplies are

in

the

mainframe,

heat dissipation.

where they

can

as

-22

volt

provide the

Page 20

Page 21

Al'

B

BT

C

Cer

C

C

DL

D

Elect.

Ek\C

EMT

F

Ckt. No.

AS SEMBLIE3

3

A3

A3

A4

A5

CAPAC

ITORS

C10

C15

C18 R2

C28 S2

C32 T2

C35 S2

C38

C40 52

C52 S2

C54

C67

C76 '42

C80

C90

C115 s5

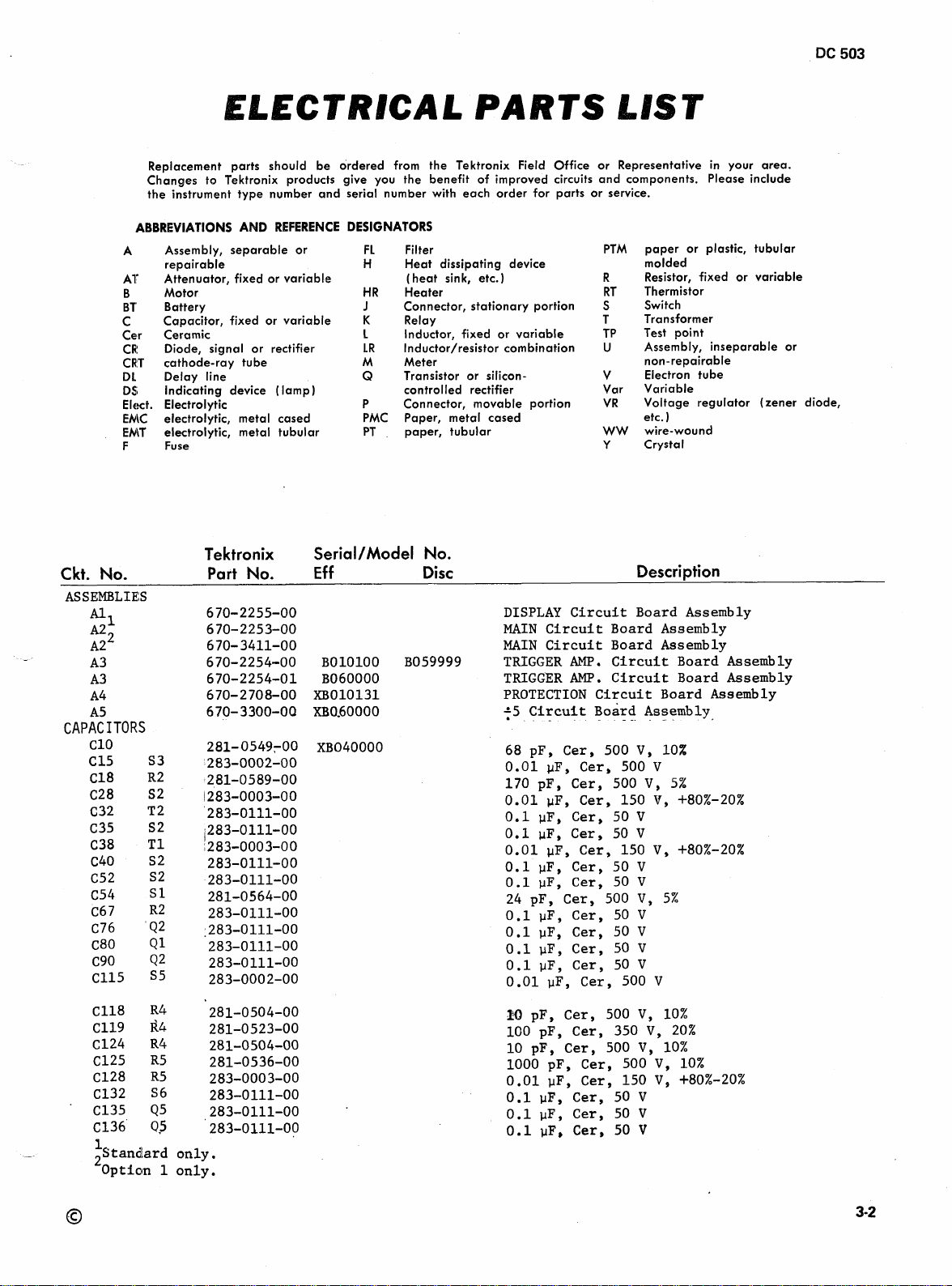

ELECTRICAL PARTS

Replacement parts should be ordered from the Tektronix Field Office or Representative in your area.

Changes to Tektronix products give you the benefit of improved circuits and components. Please include

the instrument type number and serial number with each order for parts or service.

ABBREVIATIONS AND REFERENCE DESIGNATORS

Assembly, separable or F

repairable H

Attenuator, fixed or variable

Motor HR

Battery

Capacitor, fixed or variable

Ceramic

Diode, signal or rectifier

A!

cathode-ray tube M

R!T

Delay line

Indicating device ( lamp)

5;

Electrolytic P

electrolytic, metal cased PMC

electrolytic, metal tubular PT

Fuse

Filter

L

Heat dissipating device

(

heat sink, etc.

Heater

Connector, stationary portion

J

Relay

K

Inductor, fixed or variable

L

Inductor/resistor combination

L

R

Meter

Transistor or silicon-

Q

controlled rectifier

Connector, movable portion

Paper, metal cased

paper, tubular

.

)

LIST

paper or plastic, tubular

PTM

molded

Resistor, fixed or variable

Thermistor

Switch

Transformer

Test point

Assembly, inseparable or

non-repairable

Electron tube

Variable

Voltage regulator (zener diode,

etc.

1

wire-wound

Crystal

Tektronix Serial/Model No.

Part

No.

Eff

Disc

Description

DISPLAY Circuit Board Assembly

MAIN Circuit Board Assembly

MAIN

Circuit Board Assembly

TRIGGER

TRIGGER

AMP.

Circuit Board Assembly

AMP.

Circuit Board Assembly

PROTECTION Circuit Board Assembly

S3

T1

S1

R2

Q1

42

i5 Circuit . ~oard

68 pF, Cer, 500

uF, Cer, 500

0.01

170 pF, Cer, 500

0.01 pF, Cer, 150

0.1

uF,

Cer,

0.1 pF, Cer, 50

0.01

uF,

0.1 pF, Cer, 50

0.1 pF,

Cer,

24 pF, Cer, 500

pF, Cer, 50

0.1

0.1 pF, Cer, 50

0.1 pF, Cer, 50

0.1 pF, Cer, 50

0.01 pF, Cer, 500

--

V,

50

V

V

Cer, 150

V

50

V

V,

V

V

V

V

Assembly.

.

--

10%

V

V,

5%

V,

+80%-20%

V,

+80%-20%

5%

V

'standard only.

2~ption 1 only.

20

pF, Cer, 500

100 pF, Cer, 350

10

pF, Cer, 500

1000 pF, Cer, 500

pF, Cer, 150

0.01

0.1 pF, Cer, 50

0.1 pF, Cer, 50

0.1

uF,

Cer, 50

V,

V,

V,

V,

V,

V

V

V

10%

20%

10%

10%

+80%-20%

Page 22

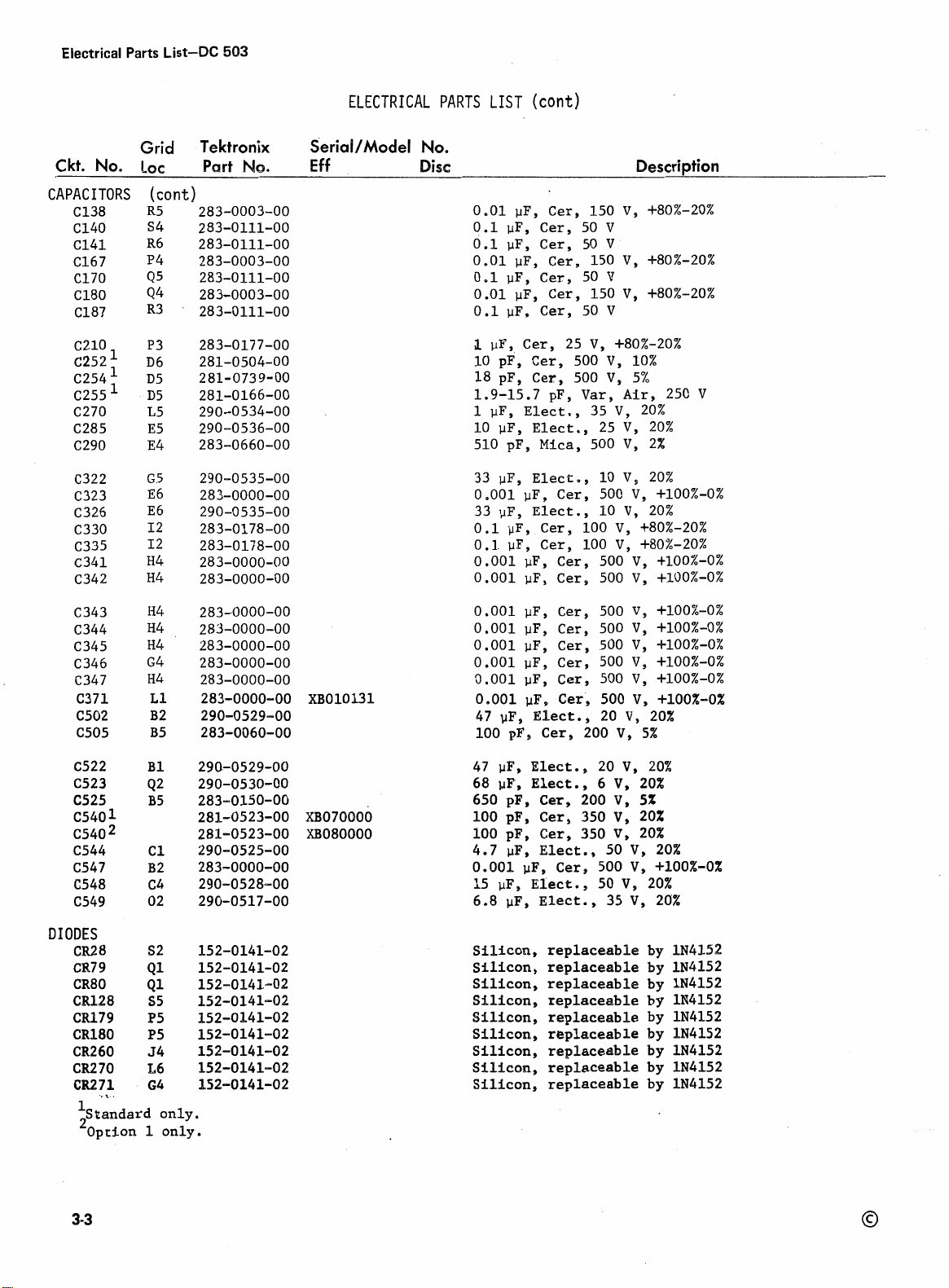

Electrical Parts

List-DC

503

@rid Tektronix

Ckt. No.

boc Part

CAPACITORS

C138

C140

C141

C167

C170

C180

C187

No.

(cont)

R5 283-0003-00

S4 283-0111-00

R6 283-0111-00

P4

Q5 283-0111-00

44 283-0003-00

R3 283-0111-00

283-0003-00

ELECTRICAL PARTS LIST

SeriaVModel

Eff

No.

Disc

(cont)

.01 pF, Cer, 150

.1

pF, Cer, 50

.1

pF, Cer, 50

.O1

pF, Cer, 150

0.1

pF, Cer, 50

0.01 pF, Cer, 150

0.1 pF,

L

pF, Cer, 25

Cer,

10 pF, Cer, 500

pF, Cer, 500

18

1.9-15.7

1

pF, Elect., 35

10

pF, Elect., 25

510

33

pF, Elect., 10

0.001

pF, Var,

pF, Mica, 500

pF, Cer, 500

33 pF, Elect., 10

pF, Cer, 100

0.1

0.1 pF, Cer, 100

0.001 pF, Cer, 500

0.001 pF, Cer, 500

50

V

V

V

V

V,

V,

V,

+80%-20%

V,

+80%-20%

V,

980%-20%

V,

+80%-20%

10%

5%

Air,

V,

20%

V,

20%

V,

2%

V,

20%

V,

V,

20%

V,

+80%-20%

V,

+80%-20%

V,

V,

250

V

+loo%-0%

+loo%-0%

+fOO%-0%

DIODES

CK28

CR7

9

CR80

CB128

CRl79

CRl80

CU60

CR270

CR271

-\.

1

'standard only.

2~pcion 1 only.

0.001 pF, Cer, 500

0.001 pF,

Cer,

0.001 pF, Cer, 500

0.001

0.001 pF,

pF, Cer, 500

Cer,

0.001 pFy Cer, 500

47 pF, Elect., 20

100

pF,

Cer,

pP, Elect., 20

47

68

pFy

Elect., 6

pF, Cer, 200

650

100 pF, Cer, 350

100 pF,

Cer,

350

200

500

500

V,

V,

V,

V,

V,

V,

V,

V,

V,

V,

V,

V,

V,

+loo%-0%

+loo%-0%

9100%-0%

+loo%-0%

+loo%-0%

+loo%-0%

20%

5%

20%

20%

5%

20%

20%

4.7 pFy Elect., 50Vy 20%

0.001

15 pF, Elect., 50

6.8

pF,

Cer,

500

pF, Elect., 35

V,

V,

V,

20%

+loo%-OX

20%

Silic~n, replaceable by IN4152

Silicon, replaceable by IN4152

Silicon, replaceable by IN4152

Silicon, replaceable by IN4152

Silicon, replaceable by IN4152

Silicon, replaceable by IN4152

Silicon, replaceable by IN4152

SI~ICQB, replaceable by IN4152

Silicon, replaceable by IN4152

Page 23

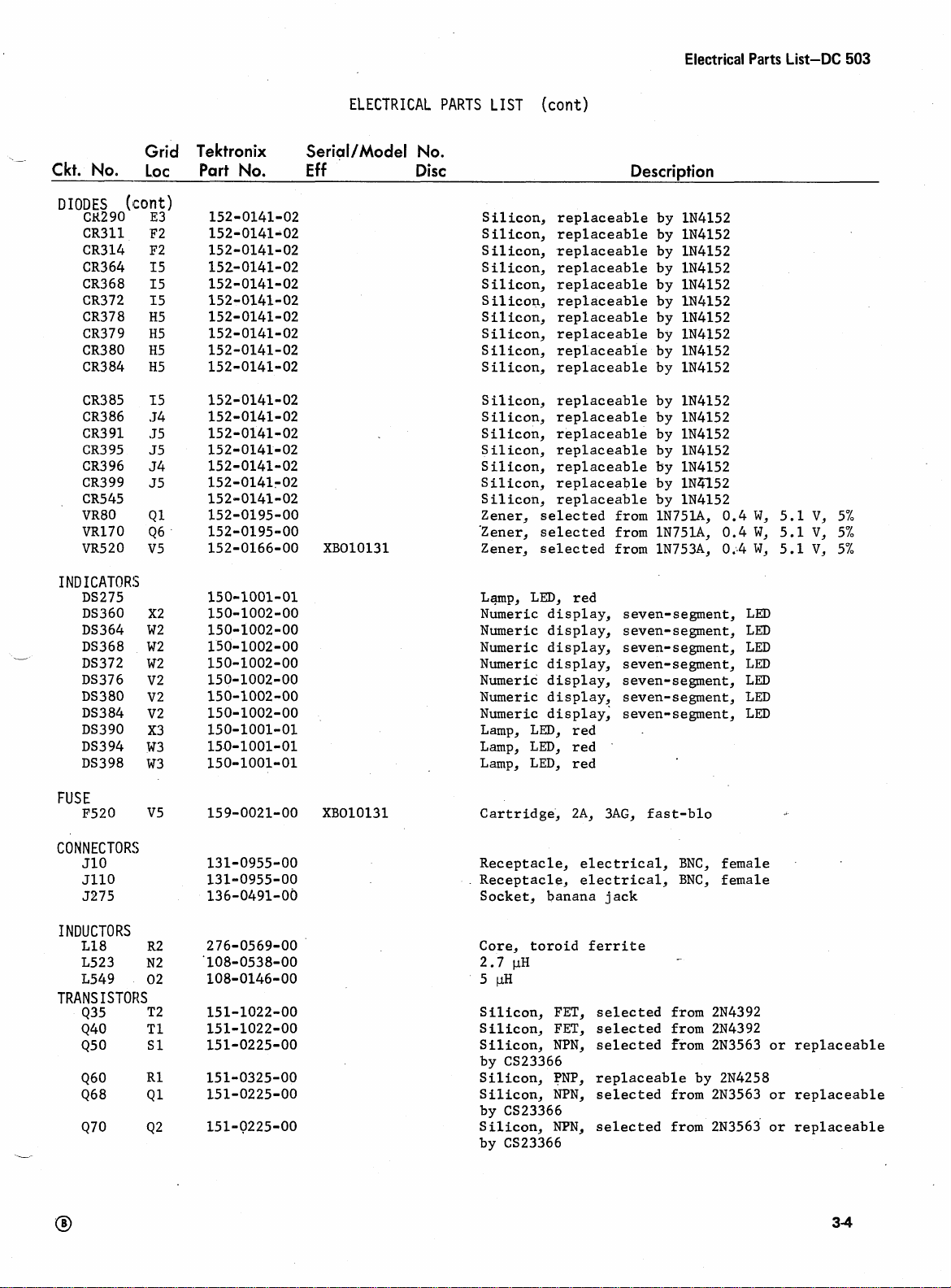

Electrical Parts List-DC

503

Ckt.

No.

DIODES

CK290

ELECTRICAL PARTS LIST

Grid Tektronix SerialIModel

Loc

(~0;:)

Part

No.

Eff

XB010131 Zener, selected from 1N753A, 0,,4

(cont)

No.

Disc Description

Silicon,

Silicon, replaceable by IN4152

S ilicon, replaceable by IN4152

Silicon, replaceable by IN4152

Silicon,

Silicon,

Silicon,

Silicon,

Silicon,

Silicon,

Silicon, replaceable by IN4152

Silicon, replaceable by IN4152

Silicon, replaceable by IN4152

Silicon, replaceable by IN4152

Silicon, replaceable by IN4152

Silicon, replaceable by IN4252

Silicon, replaceable by IN4152

Zener, selected from 1N751AY 0.4

'Zener, selected from

replaceable by

replaceable by

replaceable by

replaceable by

replaceable by

replaceable by

replaceable by

IN4152

IN4152

IN4152

IN4152

IN4152

IN4152

IN4152

1N75lAY 0.4

W,

W,

W,

5.1

5.1

5.1

V,

V,

V,

5%

5%

5%

Lamp, LED, red

Numeric display, seven-segment, LED

Numeric display, seven-segment, LED

Numeric display, seven-segment, LED

Numeric display, seven-segment, LED

Numeric display, seven-segment, LED

Numeric display, seven-segment, LED

Numeric

Lamp, LED, red

Lamp, LED, red

Lamp, LED, red

display; seven-segment, LED

.

FUSE

F520 V5 159-0021-00 XB010131 Cartridge, 2A, 3AG, fast-blo

CONNECTORS

J10 131-0955-00 Receptacle, electrical,

JllO

5275 136-0491-00 Socket, banana jack

131-0955-00 Receptacle, electrical,

INDUCTORS

L18 R2

L523 N2

L549 02

Core, toroid ferrite

pH

2.7

5

c1H

TRANS ISTORS

435 T2

Silicon, FET, selected from 2N4392

Silicon, FET, selected from 2N4392

Silicon, NPN, selected From 2N3563 or replaceable

CS23366

by

Silicon, PNP, replaceable by 2N4258

Silicon, NPN, selected from 2N3563 or replaceable

CS23366

by

Silicon, NFN, selected from 2N3563 or replaceable

CS23366

by

BNC,

BNC,

female

female

Page 24

Electrical Parts List-DC

503

Ckt. No.

TRANS IS

TORS

474

480

ELECTRICAL PARTS LIST

Grid Tektronix SerialIModel No.

Loc Part No.

Eff

Disc Description

(cont)

42 151-0269-00

P2 151-0225-00

(cont)

Silicon, NPN, replaceable by

Silicon, NPN, selected from 2N3563 or replaceable

bv

CS23366

Silicon, NPN, replaceable by SE3005

Silicon, NPN, selected from 2N3563 or replaceable

CS23366

by

Silicon, FET, selected from 2N4303 or replaceable

U1490

by

Silicon, FET, selected from 2N4303 or replaceable

U1490

by

Silicon, NPN, replaceable by 2N3565

Silicon,

Silicon, NPN, replaceable by 2N3565

Silicon, NPN, replaceable by 2N3565

Silicon, NPN, replaceable by 2N3565

Silicon, NPN, replaceable by 2N3565

Silicon, NPN, replaceable by 2N3565

Silicon, PNP, replaceable by 2N4249

Silicon, NPN, replaceable by 2N3565

Silicon, unijunction, replaceable by 2N4851

Silicon,

Silicon, NPN, replaceable by 2N3565

Silicon, PNP, replaceable by 2N2907

Silicon, PNP, repalceable by 2N2907

NPN,

replaceable by 2N3565

NPN,

replaceable by 2N3565

SE3005

4368

4372

4376

Q380

Q384

Q520

4540

4545

4548

RESISTORS

R10

R11

R15

R18

R2 2

R24

R25

Silicon, PNP, replaceable by 2N2907

Silicon, PNP, replaceable by 2~2907

Silicon, PNP, replaceable by 2N2907

Silicon, PNP, replaceable by 2N2907

Silicon, PNP, replaceable by 2N2907

Thyristor, 50

Silicon, NPN, replaceable by 2N3904 or TE3904

Silicon, PNP, replaceable by 2N4249

Silicon, PNP, replaceable by 2N4249

1

MC2,

114

10

M,

118

3.9

Wz,

1

kQ, 114

Q,

100

2

114

kQ, 118

1/4

W,

W,

W,

W,

W,

W,

V, 8 A,

1%

1%

5%

5%

5%

1%

2N4441

Page 25

Electrical Parts List-DC

503

-

Ckt. No.

RESISTORS

R40

R4

R45

R50

R52

R54

R56

z1

ELECTRICAL PARTS LIST

Grid Tektronix Serial/Model No.

Loc Part No.

(cont)

TI 321-0222-00

S2 315-0823-00

311-1310-00

S1 315-0470-00

S1 315-0152-00

S1 315-0511-00

R1 315-0221-00

Eff

Disc Description

2

W2,

82

20

47

1.5

510

220

118

W2,

114

kQ,

Var

Q,

114

kS2,

Q,

114

n,

114

(cont)

W,

W,

W,

114

W,

W,

w,

1%

5%

5%

5%

5%

5%

R82

\

R84

R85

R90

R9 2

R94

R96

R97

RllO

Rlll

R115

R118

R122

R124

R125

R127

i~urnished

Furnished

as

as

a

a

unit with

unit with

S10.

S110.

20

10

47

510

1

kQ,

2.4

10

W2,

W2,

Q,

a,

k0,

W2,

Var

114

114

1/4

114

114

114

W,

W,

W,

W,

W,

W,

5%

5%

5%

5%

5%

5%

Page 26

Electrical Parts List-DC

503

ELECTRICAL PARTS LIST (cont)

Ckt. No.

RESISTORS (cont)

R172

Q6

R174 R5

R179 P5

R180

Q4

R182 S4

R187 05

Tektronix

Bart

No.

SerialIModel No.

Eff

BOlOlOO

Disc

B049999 le5kQ,1/4W,5%

B050000 300

BOlOlOO

B050000

B049999 3.3

1

300

1

5.6

270.0, 114

180

W,

kQ,

fl,

kQ,

114

0,

114

kQ,

0,

114

114

114

114

114

W,

W,

W,

W,

W,

W,

W,

5%

5%

W,

Description

5%

5%

5%

5%

5%

5%

'standard only.

'~urnished

as

a unit with

S285.

2

kQ,

510

5.6

5.1

1

WZ,

500

10

1

kQ,

510

510

5.6

5.6

1

WT,

2.4

1

kC2,

2.4

1

m,

1

WZ,

5.6

2.4

1

kQ,

n,

kQ,

kQ,

kS1,

Q,

Q,

0,

kQ,

kQ,

kQ,

kQ,

kQ,

kC2,

114

114

1/4

114

114

Var

114

114

1/4

114

114

114

114

114

114

114

114

114

114

114

114

W,

w,

W,

W,

W,

W,

W,

W,

W,

W,

W,

W,

5%

W,

W,

5%

5%

5%

W,

W,

5%

W,

5%

W,

5%

5%

W,

W,

5%

5%

5%

5%

5%

5%

5%

5%

5%

5%

5%

5%

Page 27

Electrical Parts List-DC

503

-,

Cke. No.

Grid

LOC

Tektronix

Part No.

ELECTRICAL PARTS

SerialIModel No.

Eff

Disc

LIST

(cont)

300

n,

114

W,

5%

5.6

Q,

114

W,

5%

3.3

kS2,

114

W,

5%

1

kn,

Var

3

kS2,

114

W,

5%

1.5

kR,

114

W,

5X

56

BOlOlOO B079999 56

B080000 180

XB010131

d

'standard only.

n,

1

kS2,

0.3

1.6

4.99

2.49

20

kQ,

5.1

22.1

2.7

2.7

2.7

15.8

n, 2 W,

Q,

kn,

kS2,

kn,

kn,

kn,

kn,

W,

0,

kn,

n, 2 w,

2

W,

114

3

114

1/4

1/4

114

114

112

5x

5%

W,

W,

118

118

W,

118

W,

118

10%

5%

WW,

W,

W,

W,

5%

W,

W,

W,

W,

5%

W,

1%

5%

1%

1%

5%

1%

5%

5%

1%

'option 1 only.

Page 28

Electrical Parts List-DC

503

ELECTRICAL PARTS LIST (cont)

Ckt Grid

No.

INTEGRATED CIRCUITS

U1

U212 02

U214 01 156-0100-00

l~urnished as a unit with R45.

2~urnished as a unit with R145.

3~urnished as a unit with R285.

4

5Standard only.

Loc

Option

1

only.

Tektronix

Part No.

156-0118-00 XB060000

.

156-0100-00

Serial/Model No.

Eff

BOlOlOO

BOlOlOO

Disc

B059999X Single 40

B059999X Single 40

(INT SOURCE PULL)

Push, ATTENUATOR

AC,

Push'

Push, ATTENUATOR

Push,

Actuator assembly,

Actuator assembly, FUNCTION

Push,

HOLD, DISPLAY TIME

Dual 100

replaceable by

Quad 2-input nand gate, replaceable by SN74500N

Quad 2-input nand gate, replaceable by SN74500N

Dual 100

replaceable by

+

SLOPE (Out

AC,

DC

+

SLOPE (Out

RESET

START

(OUTcSTOP)

MHz

MHz

Coupling

J-K

J-K

MHz

replaceable by

MHz

replaceable by

Quad 2-input positive nand gate, replaceable

SN7400N

by

Dual 15

replaceable

Triple 3-input positive nand gate, replaceable

by

Quad 2-input positive nand gate, replaceable

by

Single 10

replaceable by

Single 10

replaceable by

Single 10

replaceable by

Single 10

replaceable by

Single 10

replaceable by

Single 10

replaceable by

Single 10

replaceable by

Single 10

replaceable by

MHz

SN7410N

SN7400N

D-type pos-edge-trig flip-flop

by

MHz

MHz

MHz

MHz

MHz

MHz

MHz

MHz

CHA

XlOO

CHA

x10

DC

Coupling

-)

XI0

CHB

xlOO

-)

N/CLOCK

mas ter-s lave flip-flop,

SN74S112

master-slave flip-flop,

SN74S112

J-K

edge-triggered flip-flop,

SN74H102

J-K

edge-triggered flip-flop,

SN74H102

RATE

,

SN7474N

divide-by-2-&-5 ripple counter,

SN7490N

divide-by-2-&-5 ripple counter,

SN7490N

divide-by-2-&-5 ripple counter,

SN7490N

divide-by-2-&-5 ripple counter,

SN7490N

divide-by-2-&-5 ripple counter,

SN7490N

divide-by-2-&-5 ripple counter,

SN7490N

divide-by-2-&-5 ripple counter,

SN7490N

divide-by-2-&-5 ripple counter,

SN7490N

-

Page 29

ELECTRICAL PARTS LIST (cont)

Electrical Parts List-DC

503

Ckt

No.

INTEGRATED CIRCUITS ( cont

U270 F3 156-0042-00

Grid

Tektronix

Loc Part No.

SerialIModel No.

Eff

)

BOlOlOO

B050000 Dual 15

BOlOlOO

B050000 Dual 15

Disc

Dual 15