Page 1

Instruction Manual

R

DAS

/TLA LADM934

MBus Bus Support

070-9366-00

Page 2

Copyright E Tektronix, Inc. 1995. All rights reserved. Licensed software products are owned by Tektronix or its

suppliers and are protected by United States copyright laws and international treaty provisions.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (c)(1)(ii) of the

Rights in T echnical Data and Computer Software clause at DFARS 252.227-7013, or subparagraphs (c)(1) and (2) of the

Commercial Computer Software – Restricted Rights clause at F AR 52.227-19, as applicable.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supercedes that in all previously published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

R

DAS

TEKTRONIX, TEK, and DAS are registered trademarks of T ektronix, Inc.

NT and DASR XP are trademarks of

Tektronix, Inc.

Page 3

HARDWARE WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects in materials and

workmanship for a period of one (1) year from the date of shipment. If a product proves defective during this

warranty period, T ektronix, at its option, either will repair the defective product without charge for parts and labor,

or will provide a replacement in exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period and make suitable arrangements for the performance of service. Customer shall be

responsible for packaging and shipping the defective product to the service center designated by T ektronix, with

shipping charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a

location within the country in which the T ektronix service center is located. Customer shall be responsible for

paying all shipping charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage

resulting from attempts by personnel other than T ektronix representatives to install, repair or service the product;

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any

damage or malfunction caused by the use of non-T ektronix supplies; or d) to service a product that has been

modified or integrated with other products when the effect of such modification or integration increases the time

or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS

OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’

RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUST OMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT , SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR

THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

SOFTWARE WARRANTY

T ektronix warrants that the media on which this software product is furnished and the encoding of the programs on

the media will be free from defects in materials and workmanship for a period of three (3) months from the date of

shipment. If a medium or encoding proves defective during the warranty period, T ektronix will provide a

replacement in exchange for the defective medium. Except as to the media on which this software product is

furnished, this software product is provided “as is” without warranty of any kind, either express or implied.

T ektronix does not warrant that the functions contained in this software product will meet Customer’s

requirements or that the operation of the programs will be uninterrupted or error-free.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period. If T ektronix is unable to provide a replacement that is free from defects in materials and

workmanship within a reasonable time thereafter, Customer may terminate the license for this software product

and return this software product and any associated materials for credit or refund.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS

OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’

RESPONSIBILITY TO REPLACE DEFECTIVE MEDIA OR REFUND CUSTOMER’S PAYMENT IS

THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS

WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT,

SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER

TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 5

Table of Contents

Getting Started

Operating Basics

General Safety Summary v. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Safety Summary vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface: A Guide to DAS/TLA Documentation ix. . . . . . . . . . . . . . . . . . . . . . . . .

Product Description 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Analyzer System Software Compatibility 1–2. . . . . . . . . . . . . . . . . . . . . . . . .

Logic Analyzer Configuration 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Requirements and Restrictions 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the DAS 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Variable-Width Module 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing and Loading the Application 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Application 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loading the Application 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Probe Adapter 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting to the System Under T est 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Up Disassembler Software 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Channel Groups and Assignments 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changes that Affect Disassembly 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Custom Clocking 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Symbols 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Acquiring and Displaying Disassembled Data 2–6. . . . . . . . . . . . . . . . . . . . . . . . . .

Acquiring Data 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Viewing Disassembled Data 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly Format Definition Overlay 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . .

Displaying Channel Groups Symbolically 2–12. . . . . . . . . . . . . . . . . . . . . . . . . .

Searching Through Disassembled Data 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printing Disassembled Data 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference Memory 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Purpose Analysis 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clocking 2–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Searching Through State and Timing Data 2–16. . . . . . . . . . . . . . . . . . . . . . . . . .

Printing State and Timing Data 2–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timing Display 2–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

State Display 2–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LADM934 MBus Bus Support Instruction Manual

Online version

i

Page 6

Contents

Specifications

Maintenance

Replaceable Parts

Probe Adapter Description 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Channel Assignments 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MBus-2 Support Setup 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MBus_Tmg_96 Module Setup 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How Data is Acquired 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alternate Connections 3–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signals Not On the Probe Adapter 3–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Extra Channels 3–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Care and Maintenance 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing And Replacing Signal Leads 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Ordering Information 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Parts List 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix

Index

Appendix A: Error Messages and Disassembly A–1. . . . . . . . . . . . . . . . . . . . . . . . . .

Module Error Messages A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Slow Clock A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Waiting for Stop A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Waiting for Stop-Store A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Waiting for Trigger A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly Problems A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Incorrect Data A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Other Suggestions A–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

LADM934 MBus Bus Support Instruction Manual

Online version

Page 7

List of Figures

Contents

Figure 1–1: DAS connected to a typical probe adapter 1–3. . . . . . . . . . . .

Figure 1–2: Applying slot number labels 1–5. . . . . . . . . . . . . . . . . . . . . . .

Figure 1–3: Jumper location 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–4: Connecting podlets to the MBus probe adapter 1–8. . . . . . .

Figure 1–5: Placing the MBus probe adapter onto the SUT 1–9. . . . . . . .

Figure 2–1: Disassembled data in the Hardware display format 2–9. . . .

Figure 3–1: Minimum clearance of the probe adapter 3–2. . . . . . . . . . . .

Figure 3–2: MBus bus timing 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–3: An example of jumper connections for dedicated

MBus signals 3–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LADM934 MBus Bus Support Instruction Manual

Online version

iii

Page 8

Contents

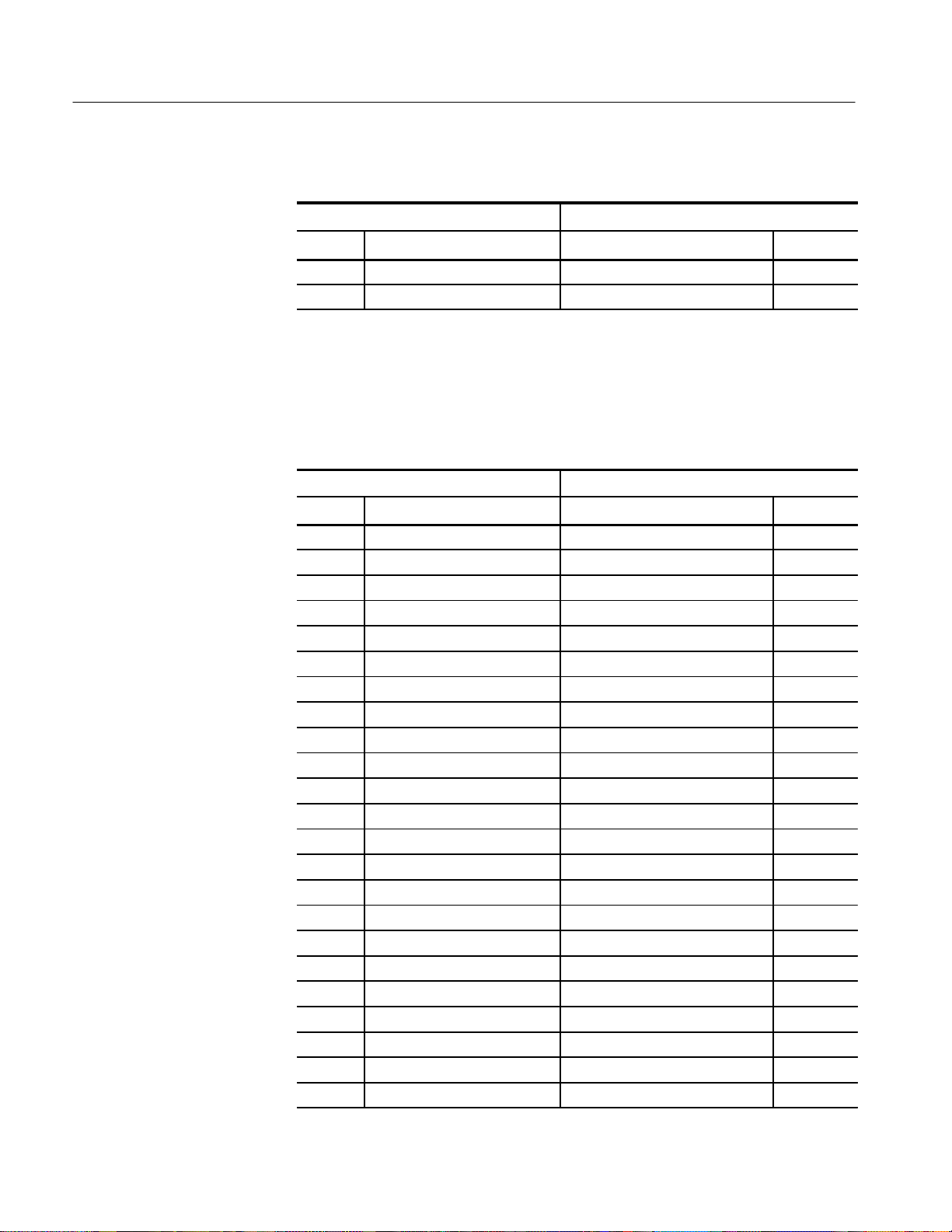

List of Tables

Table 2–1: Control group symbol table definitions 2–3. . . . . . . . . . . . . . .

Table 2–2: Size group symbol table definitions 2–4. . . . . . . . . . . . . . . . . .

Table 2–3: lrl_0 and lrl_1 group symbol table definition 2–4. . . . . . . . . .

Table 2–4: Cycle type definitions 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–1: MBus–2: V_Addr group channel assignments 3–3. . . . . . . . .

Table 3–2: MBus–2: Hi group channel assignments 3–3. . . . . . . . . . . . . .

Table 3–3: MBus–2: P_Addr_L group channel assignments 3–4. . . . . . .

Table 3–4: MBus–2: Data_H group channel assignments 3–5. . . . . . . . .

Table 3–5: MBus–2: Data_L group channel assignments 3–6. . . . . . . . . .

Table 3–6: MBus–2: Control group channel assignments 3–7. . . . . . . . .

Table 3–7: MBus–2: Size group channel assignments 3–8. . . . . . . . . . . . .

Table 3–8: MBus–2: lrl_0 group channel assignments 3–8. . . . . . . . . . . .

Table 3–9: MBus–2: lrl_1 group channel assignments 3–8. . . . . . . . . . . .

Table 3–10: MBus–2: JTAG group channel assignments 3–9. . . . . . . . . .

Table 3–11: MBus–2: Misc group channel assignments 3–9. . . . . . . . . . .

Table 3–12: MBus–2: Clock channel assignments 3–10. . . . . . . . . . . . . . . .

Table 3–13: MBus_Tmg_96: MAD_H group channel assignments 3–11. .

Table 3–14: MBus_Tmg_96: MAD_L group channel assignments 3–12. .

Table 3–15: MBus_Tmg_96: Control group channel assignments 3–13. .

Table 3–16: MBus_Tmg_96: lntr_0 group channel assignments 3–13. . . .

Table 3–17: MBus_Tmg_96: lntr_1 group channel assignments 3–14. . . .

Table 3–18: MBus_Tmg_96: JTAG group channel assignments 3–14. . . .

Table 3–19: MBus_Tmg_96: MISC group channel assignments 3–14. . . .

Table 3–20: MBus_Tmg_96: Clock channel assignments 3–15. . . . . . . . . .

Table 3–21: Extra 92C96 groups and channels 3–18. . . . . . . . . . . . . . . . . .

iv

LADM934 MBus Bus Support Instruction Manual

Online version

Page 9

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

Injury Precautions

Do Not Operate in an

Explosive Atmosphere

Avoid Exposed Circuitry

To avoid injury or fire hazard, do not operate this product in an explosive

atmosphere.

To avoid injury, remove jewelry such as rings, watches, and other metallic

objects. Do not touch exposed connections and components when power is

present.

Product Damage Precautions

Provide Proper Ventilation

Do Not Operate With

Suspected Failures

To prevent product overheating, provide proper ventilation.

If you suspect there is damage to this product, have it inspected by qualified

service personnel.

Safety Terms and Symbols

Terms in This Manual

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

LADM934 MBus Bus Support Instruction Manual

Online version

v

Page 10

General Safety Summary

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product

These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product

The following symbols may appear on the product:

DANGER

High Voltage

Certifications and Compliances

EMC Compliance

This product has demonstrated compliance to the Electromagnetic Compatibility

(EMC) specifications when attached to the instrument identified in the product

specifications. If this probe is attached to an instrument other than the one

identified in the product specifications, the EMC performance may exceed the

EMC specifications published with the instrument.

Protective Ground

(Earth) T erminal

ATTENTION

Refer to Manual

Double

Insulated

vi

LADM934 MBus Bus Support Instruction Manual

Online version

Page 11

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone

Disconnect Power

Use Care When Servicing

With Power On

Do not perform internal service or adjustments of this product unless another

person capable of rendering first aid and resuscitation is present.

To avoid electric shock, disconnect the main power by means of the power cord

or, if provided, the power switch.

Dangerous voltages or currents may exist in this product. Disconnect power,

remove battery (if applicable), and disconnect test leads before removing

protective panels, soldering, or replacing components.

To avoid electric shock, do not touch exposed connections.

LADM934 MBus Bus Support Instruction Manual

Online version

vii

Page 12

Preface: A Guide to DAS/TLA Documentation

The Digital Analysis System (DAS) documentation package provides the

information necessary to install, operate, maintain, and service the DAS/NT,

DAS/XP, and 92XTerm system and modules, and TLA 510 and TLA 520 system

units. The DAS/TLA documentation consists of the following:

H

The DAS System User Manual or TLA 500 Series Logic Analyzer User

Manual, the main reference manuals for the DAS/TLA systems, that

provides an overview of the operating system, basic installation information,

a tutorial for new users, and information for system-level menus.

H

The DAS 92A96 & 92C96 Acquisition Module User Manual that provides

detailed information on the 92A96 and 92C96 Data Acquisition Modules

and application; consult this manual for information on the 92A96 and

92C96 Setup and Display menus, and for information on how to connect

acquisition probes to the system under test.

H

A series of other module user manuals that provide detailed information on

the data acquisition and pattern generation modules available for use with the

DAS/TLA systems; consult the individual manuals for information on the

Setup and Display menus for each module and for information on how to

connect the probes to the system under test.

H

An LA-OffLine User Manual that describes how to transfer, display, and

analyze data (acquired on a DAS/TLA system) from a personal computer or

a workstation.

H

A series of bus, microprocessor, microcontroller, data communications, and

digital signal processor support product instruction manuals that describe the

various support products available with the DAS/TLA systems.

H

A technician’s reference manual that provides service information for

qualified service technician to isolate problems to the module level.

H

A series of software user manuals that accompany the various software

support products.

LADM934 MBus Bus Support Instruction Manual

Online version

ix

Page 13

Preface

About This Manual

This manual is based on the assumption that you are familiar with how to

operate the system software for the DAS, TLA 510 and TLA 520 logic analyzers, and the 92A96 acquisition module application. Therefore, details about the

system software and the acquisition application, and how to move through the

menu structures are not provided. An overview of some of those functions is

provided so that you do not need to consult another manual.

This manual provides detailed information for the MBus support product on how

to do the following:

H

Install and load application software

H

Connect to your system under test

H

Setup the disassembler software and use it

H

View acquired data

The following conventions are used in this manual:

H

The terms disassembler and disassembler software are used interchangeably

in reference to the MBus support software that disassembles bus cycles into

instruction mnemonics and cycle types.

H

The term SUT (system under test) is used to refer to the MBus from which

data is being acquired.

H

References to DAS include TLA 510 and TLA 520 system units unless

otherwise noted; these Tektronix Logic Analyzer (TLA) products operate

identically to the DAS.

H

References to 92C96 Modules include all versions of this modules unless

otherwise noted.

H

A signal that is active low has a tilde (~) following its name.

x

LADM934 MBus Bus Support Instruction Manual

Online version

Page 14

Getting Started

The DAS 92DM900 series of support products are developed by third parties to

support buses, microprocessors, microcontrollers, and digital signal processors

for specific Tektronix customers. These support products are currently being

successfully used by these customers. If you need assistance in using this

product, contact your local Tektronix Technical Support Specialist.

This section provides information on the following:

H

The MBus Support product

H

Logic analyzer system software (DAS) compatibility

H

Logic analyzer configuration (DAS)

H

Your MBus system requirements

H

MBus support restrictions

H

How to install and load software

H

How to configure the probe adapter

Product Description

H

How to connect the DAS to the system under test

The MBus Bus Support product disassembles data from systems based on Texas

Instruments SuperSPARC microprocessors using MBus protocol. The instruction

mnemonics are based on the SPARC Version 8 and SuperSPARC instruction set.

The MBus support product runs on a DAS logic analyzer equipped with at least

two 92C96 Acquisition Modules.

These products consist of an application on a floppy disk, a probe adapter, and

this manual. The application includes setup files, one demonstration reference

memory, and a disassembler program. A complete list of all accessories and

options is provided at the end of the mechanical parts list in the Replaceable

Mechanical Parts section.

A demonstration reference memory is provided so you can see an example of

disassembled instruction mnemonics. You can view the reference memory

without connecting the DAS to your SUT. The reference memory is automatically installed on the logic analyzer when you install the disassembler software.

Directions for viewing this file can be found in the Operating Basics section.

LADM934 MBus Bus Support Instruction Manual

Online version

1–1

Page 15

Getting Started

To use this product efficiently, you need to have the following:

H

Knowledge of your specific DAS configuration and its operation

H

Knowledge of your MBus and SuperSPARC system

H

This manual

H

The DAS System User Manual, Tektronix, Inc.

H

The 92C96 Module User Manual, Tektronix, Inc.

H

The SPARC MBus Interface Specification, SPARC International, Inc. 1991

Logic Analyzer System Software Compatibility

The LADM934 MBus Support Product is compatible with any DAS System

Software Release 3, Version 1.5 or higher. You can operate the software in an X

window on a workstation (X terminal) or an X11/R4-compatible display.

Logic Analyzer Configuration

To use the bus support product, your DAS must be equipped with two 92C96

Modules. The modules must be combined to form a variable–width (192–channel wide) module in a single DAS mainframe.

Figure 1–1 shows an overview of a DAS connected to a typical probe adapter.

1–2

LADM934 MBus Bus Support Instruction Manual

Online version

Page 16

DAS

92A96 Probe

cables

Getting Started

To 92A96 Cards

Probe adapter

Figure 1–1: DAS connected to a typical probe adapter

Requirements and Restrictions

This section describes requirements and restrictions of the bus support product.

MBus System and Probe Adapter Cooling. You must retain the original level of

cooling for your system after you install the probe adapter. To maintain the

required operating temperature, you may need to provide additional cooling for

the probe adapter.

92A96 Interface

housing

Clock probe

8-Channel probe

LADM934 MBus Bus Support Instruction Manual

Online version

1–3

Page 17

Getting Started

Disabling the Instruction and Data Caches. To disassemble acquired data, you

must disable the internal instruction and data caches on the SuperSPARC

microprocessor. Disabling the cache makes all instruction prefetches visible on

the MBus bus so they can be acquired and disassembled.

Configuring the DAS

When there are two or three 92C96 Modules in adjacent slots, they are automatically formed into a variable-width module by the system software at power up. If

you need to to use one 92C96 Module from a variable-width module, you must

reconfigure the DAS prior to selecting software support in the 92C96 Configuration menu. Refer to the discussion of the System Configuration menu in the DAS

System User Manual for details on how to reconfigure variable-width modules.

Configuring the Variable-Width Module

To acquire data from a system using MBus protocol, two 92C96 Modules are

required; they must be configured into one variable–width module (192–channels wide).

When using a variable–width module, both modules must be positioned in

adjacent DAS slots in a single mainframe. You cannot use slots 1 or 8 when

creating a variable–width module. The modules do not need to have the same

memory depth.

Check the System Configuration menu to see if the module is defined correctly.

The Module in the higher–numbered slot is referred to as the HI module; the

module in the lower–numbered slot is referred to as the LO module. Probe

connections on the probe adapter board are labeled to identify which module and

which probe group connects to them. For example, HI_A0 indicates the A0

probe group from the HI module.

Clock pins on the probe adapter do not have the HI/LO designation; they are just

labeled CK0, CK1, CK2, and CK3. Each pair of clock pins connect to the same

signal on the probe adapter. The clock probes from both modules must connect

to the appropriate clock pins for custom clocking to function properly.

Refer to your module user manual for information about variable–width

modules, and for additional information about connecting probe cables, and

positioning and installing modules.

In a system with many modules, it is easier to identify which modules are

connected to the probe adapter if slot number labels are applied to the 92C96

probe interface housings and DAS mainframe. Figure 1–2 shows where to apply

slot number labels.

1–4

LADM934 MBus Bus Support Instruction Manual

Online version

Page 18

Apply slot number labels here.

Figure 1–2: Applying slot number labels

Getting Started

Installing and Loading the Application

When you install the bus support software on the DAS system, you copy the

files from the floppy disk to the mainframe’s hard disk. When you load the

application, the software from the mainframe’s hard disk is loaded into the DAS

system RAM.

If you have the 9201T version of the DAS system, you must change the system

to the 92XTerm or 9202XT version.

Installing the Application

One floppy disk is shipped with the LADM934 support product for installing the

application on a DAS system. The amount of disk free space required after

installation is shown on the label of the floppy disk. During installation, you will

need approximately twice that amount of disk space.

To install the application onto the DAS, follow these steps:

1. Power on the DAS mainframe.

2. Insert the disk labeled LADM934 Bus Support into the DAS’s floppy drive.

3. Press the Select Menu key, and select the Disk Services menu.

4. Select Install Application in the Operation field of the menu.

5. Press F8: EXECUTE OPERATION, and follow the on-screen prompts.

LADM934 MBus Bus Support Instruction Manual

Online version

1–5

Page 19

Getting Started

NOTE. After each install and load operation, a message appears on the screen

informing you the operation succeeded or failed. If the message tells you the

operation failed, you may need to remove applications or files from the hard disk

and try installing or loading again. If the operation fails again, refer to

Appendix A: Error Messages and Disassembly Problems.

If there is inadequate disk free space available on the hard disk, you must use the

Remove Application or Delete File function of the Disk Services menu to free up

enough disk space to install the application.

For information on installing the LA-OffLine bus support application on your

workstation, refer to the LA-OffLine User Manual.

Loading the Application

To load the MBus disassembler, follow these steps:

1. Press the Menu Select key, select the appropriate 92C96 module, and select

its Configuration menu.

2. Select MBus–2 Support in the Software Support field.

When you load the disassembler, the Channel, Clock, and Trigger menus are

automatically set up to acquire data from your MBus system. You can change the

setups in the Clock and Trigger menus as needed. Refer to Channel Groups and

Assignments in the next section for information on what can be changed in the

Channel menu.

If you want to perform general purpose analysis, such as timing using Internal or

External clocking, you need to restore the MBus_Tmg_96 Module Setup file. To

do this, follow these steps:

1. Press the Menu Select key and select the Save/Restore utility menu.

2. Select Restore Setup in the Operation field of the Save/Restore menu.

3. Select MBus_Tmg_96 in the File field.

4. Press F8: EXECUTE OPERATION.

When you restore the MBus_Tmg_96 setup file, the Channel menu is automatically set up to acquire multiplexed address and data from your MBus system.

Configuring the Probe Adapter

You can use the MCLK jumper, J150, to set the source of the clock signal on the

probe adapter for proper clocking. The jumper position must match the MCLK

signal used in the your MBus system: MCLK0, MCLK1, MCLK2, or MCLK3.

Figure 1–3 shows the location of the MCLK jumper.

1–6

LADM934 MBus Bus Support Instruction Manual

Online version

Page 20

J150

Figure 1–3: Jumper location

Getting Started

Connecting to the System Under Test

Before you connect to the SUT, you must connect the standard probes to the

92C96 module card. Your SUT must also have a minimum amount of clear space

surrounding the MBus connector to accommodate the probe adapter.

To connect the DAS to the SUT, follow these steps:

1. Turn off power to your SUT. It is not necessary to turn off power to the DAS

CAUTION. Static discharge can damage the microprocessor, the probe adapter,

the podlets, or the 92C96 Module. To prevent static damage, handle all of the

above only in a static–free environment.

Always wear a grounding wrist strap or similar device while handling the probe

adapter.

2. To discharge your stored static electricity, touch the ground jack located on

the back of the DAS. Then, touch any of the ground pins of the probe

adapter to discharge stored static electricity from the probe adapter.

3. Connect the 92C96 clock and 8–channel probes to the probe adapter as

shown in Figures 1–4. Match the channel groups and numbers on the probe

interface housing to the corresponding pins on the probe adapter. Match the

ground pins on the probes to the corresponding pins on the probe adapter.

LADM934 MBus Bus Support Instruction Manual

Online version

1–7

Page 21

Getting Started

Hold the 8-Channel probes by the podlet

holder when connecting them to the

probes adapter. Do not hold them by the

cables or necks of the podlets.

8-Channel probes

Clock probes

Probe adapter

Figure 1–4: Connecting podlets to the MBus probe adapter

4. Align pin 1 on the probe adapter connector with pin 1 on the connector in

your SUT and connect the two together as shown in Figure 1–4.

1–8

LADM934 MBus Bus Support Instruction Manual

Online version

Page 22

Getting Started

Pin 1

SUT socket

Figure 1–5: Placing the MBus probe adapter onto the SUT

LADM934 MBus Bus Support Instruction Manual

Online version

1–9

Page 23

Operating Basics

This section provides information on preparing the disassembler for acquiring

data, and on acquiring and displaying data. Information on general purpose

analysis is also provided.

Setting Up Disassembler Software

This part of the section discusses the following:

H

Channel groups and assignments

H

Changes that affect disassembly

H

Clocking options

H

Symbols

Before you acquire and disassemble data, you need to load disassembler software

and specify setups for clocking, triggering, and using symbols. The disassembly

software provides default values for each of these setup controls, but you can

change them as needed.

Channel Groups and

Assignments

Changes that Affect

Disassembly

Custom Clocking

The disassembler software automatically defines the channel groups for the

MBus. The channel groups for the MBus are found in the channel assignment

tables in the Specifications section.

Channel groups cannot be changed nor can the channels be reused in another

group, but you can define and display additional groups. Channel assignments

are also shown in the 92C96 Channel Setup menu.

You can change part of the default setups for the 92C96 Module. If you change

the threshold voltage or display polarity, the disassembled data will be affected.

You can use the 92C96 Clock menu to set clocking choices to control data

sampling. The MBus application offers a specific clocking mode for MBus

protocol. This clocking mode (Custom) is the default choice whenever you select

MBus-2 Support in the Configuration menu.

The MBus application acquires all MBus cycles. No clocking options are

available. A description of how cycles are sampled by the disassembler, probe

adapter and 92C96 module is found in the Specifications section.

LADM934 MBus Bus Support Instruction Manual

Online version

2–1

Page 24

Operating Basics

To select the clocking mode, follow these steps:

1. Press the Select Menu key.

2. Select the Clock menu for the module you want to use.

Disassembly will not be correct with the Internal or External clocking modes.

Descriptions of using the other clock selections with the MBus support product

can be found later in this section.

Symbols

Symbols can be used to represent data as a specific value (pattern symbols)

or as a range of channel group values (range symbols are defined by upper and

lower bounds.

A table of pattern symbols for the Control channel group is supplied by the

disassembler and is automatically loaded with the disassembler software. You

can use symbol tables to display channel group information symbolically in the

State and Disassembly menus and to control triggering.

Table 2–1 shows the name, bit pattern, and meaning for the symbols in the

Control group symbol table. The Control group symbol table file name is

MBus-2_Ctrl.

2–2

LADM934 MBus Bus Support Instruction Manual

Online version

Page 25

T able 2–1: Control group symbol table definitions

Control group value

Symbol

CRI

WRDY~ MAD39

MERR~ MSI_L MAD39

101100101

WRDY~ MAD38

MSH_L MAD37

Operating Basics

Meaning

Coherent Read and Invalidate

CRI_O_DATA

CWI

CR_Sh_Data

CR_O_Data_LLM

CR_O_Data_FM

CI

RD

WR

IDLE

R&R

Valid_Data

Bus_Error

Timeout

Uncorrectable

101100101

101XX0100

101010011

101000011

101110011

101XX0010

101XX0001

101XX0000

111XXXXXX

110XXXXXX

101XXXXXX

011XXXXXX

010XXXXXX

001XXXXXX

Coherent Read and Invalidate

(of owned data)

Coherent Write and Invalidate

Coherent Read and Invalidate

(of Shared Data)

Coherent Read of Owned data

(long-latency memory)

Coherent Read of Owned data

(fast memory)

Coherent Invalidate

Any memory or I/O read

Any memory or I/O write

Idle Cycles

Relinquish and Retry

Valid Data Transfer

Bus Error

Timeout

Uncorrectable

Retry*

Undefine

* Symbols used only for triggering with the Internal or External clock mode; they do

not appear in the Disassembly or State displays.

Table 2–2 shows the name, bit pattern, and meaning for the symbols in the Size

group symbol table. The Size group symbol table file name is MBus-2_Size.

LADM934 MBus Bus Support Instruction Manual

Online version

000XXXXXX

XXXXXXXXX

Retry

Reserved for future use or undefined

2–3

Page 26

Operating Basics

T able 2–2: Size group symbol table definitions

Size group value

MAD39

Symbol

MAD37

MAD39

Meaning

Byte

Half-word

Word

Double-word

16-byte-Burst

32-byte-Burst

64-byte-Burst

128-byte-Burst

000

001

010

011

100

101

110

111

Byte access (8 bits)

Half word access (16 bits)

Word access (32 bits)

Double word access (64bits)

Burst 16 bytes

Burst 32 bytes

Burst 64 bytes

Burst 128 byte

Table 2–3 shows the name, bit pattern, and meaning for the symbols in the Irl_0

and Irl_1 group symbol table. The Irl_0 and Irl_1 group symbol table file name

is MBus-2_Intr.

T able 2–3: lrl_0 and lrl_1 group symbol table definition

Irl_0 and Irl_1 group value

IRL[3]

IRL[2]

Symbol

INT 15

IRL[1]

IRL[0]

1111

Meaning

Interrupt Request Level 15

2–4

INT 14

INT 13

INT 12

INT 11

INT 10

INT 9

INT 8

INT 7

INT 6

INT 5

INT 4

1110

1101

1100

1011

1010

1001

1000

0111

0110

0101

0100

Interrupt Request Level 14

Interrupt Request Level 13

Interrupt Request Level 12

Interrupt Request Level 11

Interrupt Request Level 10

Interrupt Request Level 9

Interrupt Request Level 8

Interrupt Request Level 7

Interrupt Request Level 6

Interrupt Request Level 5

Interrupt Request Level 4

LADM934 MBus Bus Support Instruction Manual

Online version

Page 27

T able 2–3: lrl_0 and lrl_1 group symbol table definition (Cont.)

Irl_0 and Irl_1 group value

IRL[3]

IRL[2]

Symbol Meaning

INT 3

IRL[1]

IRL[0]

0011

Interrupt Request Level 3

Operating Basics

INT 2

INT 1

–

0010

0001

0000

Interrupt Request Level 2

Interrupt Request Level 1

No Interrupt

Refer to Displaying Channel Groups Symbolically in this section for more

information on displaying symbolic values. Refer also to Searching Through

Disassembled Data in this section for information on how to use symbol table

values for 92C96 data searches.

Copying and Editing the Predefined Symbol Tables. You cannot directly edit any

symbol tables supplied by bus support. But you can make a copy of a predefined

symbol table and then edit the copy for your specific use.

To create a new symbol table, follow these steps:

1. Select the Symbol Editor menu from the Menu Selection overlay.

2. Press F2: FILE FUNCTIONS.

3. Select Open File in the Function field, and press Return.

4. Select New File in the Edit Status field, and press Return.

5. Enter a new symbol table file name in the New File Name field.

6. Select Pattern or Range in the Table Type field to match the symbol table

you are copying, and press Return.

7. Press F5: EXECUTE FUNCTION.

8. Select Merge Files in the Function field, and press Return.

9. Select the file to base your new symbol table on, such as the MBus-2_Ctrl

file.

10. Press F5: EXECUTE FUNCTION.

11. Press F8: EXIT & SAVE.

12. Edit the file as desired keeping the following in mind:

LADM934 MBus Bus Support Instruction Manual

Online version

2–5

Page 28

Operating Basics

H

If the new symbol has fewer don’t cares than an existing symbol, it must

be placed ahead of the existing symbol.

H

If the new symbol has more don’t cares than an existing symbol, it must

be placed after the existing symbol.

H

Do not duplicate symbol names.

Also refer to your system user manual for more information on editing the

symbol table.

13. Select the Channel menu from the Menu Selection overlay.

14. Change the file name of the symbol table for the Control group (or the

group’s symbol table you are replacing) to the one that you specified in

step 5.

Acquiring and Displaying Disassembled Data

Acquiring Data

This part of this section describes how to acquire data and view it disassembled

in the Disassembly menu of the DAS. These descriptions include:

H

Acquiring data

H

Viewing disassembled data in various formats

H

Functions of the Disassembly Format Definition overlay

H

Displaying groups symbolically

H

Searching through data

H

Printing data

H

Viewing the demonstration reference memory

Once you load the MBus-2 Support, choose a clocking mode, and specify the

trigger, you are ready to acquire and disassemble data.

On the DAS, press the F1: START acquisition key to begin the acquisition. You

can press the F1: STOP key at any time to stop acquisition.

If you have any problems acquiring data, refer to Appendix A: Error Messages

and Disassembly Problems.

2–6

LADM934 MBus Bus Support Instruction Manual

Online version

Page 29

Operating Basics

Viewing Disassembled

Data

Disassembled data is displayed in the Disassembly menu of the DAS in four

different formats: Hardware, Software, Control Flow, and Subroutine (State

display is also a selection you can choose, but you will not see disassembled

data.)

To select a format in the Disassembly menu of the DAS, follow these steps:

1. Press the Select Menu key and select the Disasm menu.

2. Press F5: DEFINE FORMAT.

3. Select the desired format in the Display Mode field.

4. Press F8: EXIT & SAVE.

You can select the display format and tailor it for your application using the

Disassembly Format Definition overlay. Figure 2–1 shows an example of MBus

data.

NOTE. Selections in the Disassembly Format Definition overlay must be set

correctly in order for your acquired data to be disassembled correctly. Refer to

Disassembly Format Definition Overlay later in this section.

Hardware Display Format. The Hardware display format shows the Hi,

P_Addr_L, Data_H, and Data_L channels for each sample of acquired data. In

Hardware data format, all bus cycles are shown in the order that they occurred.

Instruction Mnemonics are displayed on assumed instruction Fetch cycles and

cycle-type information is displayed for all other cycles. The disassembler cannot

detect flushes following a branch instruction. Non-instruction bus cycles are

displayed as either 32-bit or 64-bit wide data transfers.

The Hi group column in the Disassembly display shows the high-order 4 bits of

the address. If your MBus system is restricted to a 32-bit physical address, you

can make this group invisible in the Disassembly Format Definition overlay.

However, making this group invisible will not stop the disassembler from

displaying the appropriate value in the operand.

The P_Addr_L group column in the Disassembly display shows value for the

low-order 32 bits of the address at each sequence. The module latches the value

during the address part of the MAD bus as P_Addr_L, and, based on that value,

the disassembler synthesizes the addresses for the data cycles.

For block reads and writes, the calculated address follows the rules of Sub-block

Ordering. For each double-word cycles, the address calculated for the first line

will be modulo-8 and the address calculated for the second line will be modulo-8

plus 4.

LADM934 MBus Bus Support Instruction Manual

Online version

2–7

Page 30

Operating Basics

The Data_H and Data_L in the Disassembly shows value for the data part of the

MAD bus. Valid data bytes of the data will be shown during data transfers. All

invalid bytes will be dashed (– –) out.

Due to superscaler architecture, the SuperSPARC microprocessor reads two

instructions simultaneously. If the microprocessor cannot execute two instructions simultaneously, it reads the same instructions again. Since the bus does not

indicate which instruction was executed or not, instruction mnemonics are

displayed on all assumed instruction fetch cycles.

Table 2–4 shows cycle type labels and gives a definition of the cycle they

represent.

T able 2–4: Cycle type definitions

Cycle type Definition

( IDLE )

Idle cycles

( Relinquish & Retry )

( ERROR 1: Bus Error )

( ERROR 2: Bus Timeout )

( ERROR 3: Bus Uncorrectable )

( CRI )

( CRI Owned Data )

( CWI )

( CR Shared Data )

( CR Owned Data LLM )

( CR Owned Data FM )

(CI)

(RD)

(WR)

( Undefine )

Relinquish and retry

Bus error

Timeout

Uncorrectable

Coherent read and invalidate

Coherent read and invalidate of owned data

Coherent write and invalidate

Coherent read and invalidate of shared data

Coherent read of owned data (long-latency

memory)

Coherent read of owned data (fast memory)

Coherent invalidate

Any memory or I/O read

Any memory or I/O write

Undefined

Figure 2–1 shows an example of disassembled MBus data in the Hardware

display format.

2–8

LADM934 MBus Bus Support Instruction Manual

Online version

Page 31

Operating Basics

Sequence Hi P_Addr_L Data_H Data_L Mnemonic

------------------------------------------------------------------- 9 F F00109A0 01000000 10800010 NOP

F F00109A4 01000000 10800010 BA F:F00109E4

10 F F00109A8 01000000 A8102700 NOP

F F00109AC 01000000 A8102700 OR %g0, 0700, %l4

11 F F00109E0 EAA00080 27380004 STA %l5, [%g0 + %g0] 04

F F00109E4 EAA00080 27380004 SETHI 380004, %l3

12 F F00109E8 A614E008 EC84C5E0 OR %l3, 0008, %l3

F F00109EC A614E008 EC84C5E0 LDA [%l3 + %g0] 2F, %l6

13 F F00109F0 AC2DA00E EA800080 ANDN %l6, 000E, %l6

F F00109F4 AC2DA00E EA800080 LDA [%g0 + %g0] 04, %l5

14 F E0001008 00000003 -------- ( RD )

15 F F00109F8 A935601C 80A52000 SRL %l5, 001C, %l4

F F00109FC A935601C 80A52000 SUBcc %l4, 0000, %g0

16 F F00109F8 A935601C 80A52000 SRL %l5, 001C, %l4

F F00109FC A935601C 80A52000 SUBcc %l4, 0000, %g0

17 F F0010A00 22800005 A8102008 BE, a F:F0010A14

F F0010A04 22800005 A8102008 OR %g0, 0008, %l4

18 F F0010A08 A935600F 1080000A SRL %l5, 000F, %l4

F F0010A0C A935600F 1080000A BA F:F0010A34

19 F F0010A10 A80D200F 808D6800 AND %l4, 000F, %l4

F F0010A14 A80D200F 808D6800 ANDcc %l5, 0800, %g0

Figure 2–1: Disassembled data in the Hardware display format

Software display Format. The Software display format displays all assumed

instruction fetches. Labels that indicate the beginning of exception handler

routines are displayed. All other cycle types are suppressed. The disassembler

cannot detect flushes following branch instruction. The display is designed to

resemble assembly language listings.

Control Flow Display Format. The Control Flow display format shows instructions

that change the flow of control. Some instructions that do not actually change the

control flow are displayed, such as a conditional branch that is not taken.

Exception handler entry labels and the instruction at that location will be

displayed for control flow instructions. The label is always displayed regardless

of the type of instruction.

Subroutine Display Format. The Subroutine display format shows the first fetch of

subroutine calls and return instructions. Subroutine call are assumed to be branch

and jump instructions that perform a link. Because the disassembler cannot

detect when a flush occurs, conditional branches are always displayed.

LADM934 MBus Bus Support Instruction Manual

Online version

2–9

Page 32

Operating Basics

Disassembly Format

Definition Overlay

The Disassembly Format Definition overlay allows you to make optional display

selections for the Disassembly menu and tailor it for your applications.

You can use this overlay to do the following:

H

Choose the format (mode) in which the Disassembly menu displays

disassembled data

H

Set the interval in which the data cursor will scroll through disassembled

data

H

Display and define the format of the timestamp

H

Highlight various types of disassembled cycles

H

Choose to disassemble across gaps

H

Specify the starting address of the trap area

H

Specify the total number of traps

H

Specify the starting address of program code area

H

Specify the size of program code area

H

Change the position of any channel group in the display

H

Change the radix for any channel group

H

Choose which symbol tables are to be used when channel groups are

displayed symbolically

Press F5: DEFINE FORMAT from the Disassembly menu to see the overlay.

The following paragraphs describe the fields and selections available in the

Disassembly Format Definition overlay.

Display Mode. You can select Hardware, Software, Control Flow, or Subroutine

format.

Timestamp. You can display the timestamp as an Absolute, Relative, or Delta

value. You can also set the timestamp display to Off.

Timestamp values show the amount of time that has elapsed between data

samples. An Absolute timestamp shows the amount of time elapsed between

when the acquisition was started (after pressing F1: START) and each subsequent data sample. A Relative timestamp shows the amount of time elapsed

between successive samples. A Delta timestamp shows the amount of time

elapsed between the sample with the delta user mark and each previous or

subsequent data sample.

2–10

LADM934 MBus Bus Support Instruction Manual

Online version

Page 33

Operating Basics

Scroll By. You can scroll by Sequence, Instruction, Control Flow, or Subroutine.

Highlight. You can highlight Instructions, Control Flow, or Subroutines. With

highlighting on, only the selected type of samples are shown as white text with a

black background; all other samples are shown as gray text with a black

background. You can also set the highlighting to Off.

Highlight Gaps. You can choose to highlight or not to highlight gaps. Gaps are

caused by qualifying data storage in the Trigger menu and are indicated by a gray

background behind the address values.

Disasm Across Gaps. You can choose to continue or not to continue to disassemble data across gaps. Disassembling data across gaps causes the disassembler

to disassemble data as if no gap existed. Disassembled data will be invalid if the

last sample before the gap does not logically match the sample immediately

following the gap.

Trap Base Address. You must enter the base address for the trap area. The default

trap area base value is 0.

T otal Number of Traps. You must enter the total number of hardware and software

traps. The default number of traps is 100.

Program Area Begin [35-32]. Since the MBus does not indicate whether a read is

filling the instruction cache or the data cache, you must enter the upper four bits

of the beginning address and size of the program code area. The default value

is F.

The disassembler assumes that read cycles are instructions within the address

range specified in the Program Area Begin fields and the Program Area Size

field.

Program Area Begin [31-0]. Since the MBus does not indicate whether a read is

filling the instruction cache or the data cache, you must enter the lower 32 bits of

address and size of the program code area. The default value is F0000000.

Program Area Size. You can enter the size of the program code area. The default

value is 100000.

LADM934 MBus Bus Support Instruction Manual

Online version

2–11

Page 34

Operating Basics

Group Name. You can specify the name of the group that displays in the column

in which the cursor is positioned. When you move a group, the group is inserted

in the new column position and removed from its old position. Remaining

groups will move one column position to the left or right as appropriate.

Group Radix. You can select the radix in which each group displays. The radix

selections for most groups are Binary, Octal, Hexadecimal, Symbol, and Off.

The only selections for the Data group are Hexadecimal or Off. The only

selections for Mnemonics group are ASCII or Off. You should only select the

symbolic radix when a symbol table is available for that group. The timestamp

value always displays in decimal.

Symbol Table. You can specify a symbol table to use for each group where

symbolic is the selected radix.

F1: ESCAPE & CANCEL. Closes the overlay and discards any changes you

have made since entering it.

Displaying Channel

Groups Symbolically

F5: RESTORE FORMAT. Displays a list of saved disassembly formats for the

current module or cluster setup. Use the cursor keys to select the desired format

to restore, and press the Open/Close key.

F6: SAVE FORMAT. Saves the current selections for the Disassembly Format

Definition overlay in a file on disk. You can enter a file name up to ten characters

long.

F7: DELETE FORMAT. Displays a list of saved disassembly format files for

the current module or cluster setup. Use the cursor keys to select the desired

format to delete, and press the Open/Close key. You cannot delete the Default

format.

F8: EXIT & SAVE. Exits the overlay and executes or saves any changes made.

Any channel group can be displayed as symbolic values in the Disassembly

menu similar to the way the Control group can be displayed as symbolic values.

If you create a range symbol table for the Address group, the address will also

be displayed symbolically when it appears in the operand field of a mnemonic.

You can use the Symbol Editor menu to create symbol tables in which symbols

are assigned to various channel group values (ranges or patterns). You can then

change the radix of the channel group in the Disassembly menu using the

Disassembly Format Definition overlay, and select the symbol table you created

to use for display, triggering, or data search purposes.

2–12

LADM934 MBus Bus Support Instruction Manual

Online version

Page 35

Operating Basics

Searching Through

Disassembled Data

The MBus application does not have a Disassembly Search Definition overlay.

However, you can effectively search through disassembled data by following

these steps:

1. Press F2: SPLIT DISPLAY to use the split-screen display.

2. Press F5: SPLIT HORIZ to split the screen into two horizontal displays.

3. Press F2: LOCK CURSOR. A list of selections appears.

4. Select lock cursors at the same sequence, and press Return.

5. Press F8: EXIT & SAVE to display the menus in a split screen.

6. If the active window is the Disassembly menu, press F3: SWITCH

WINDOWS to make the State menu active. The cursor and Cursor field are

yellow in the active window.

7. Press F6: DEFINE SEARCH to use the search function of the State menu

to search for the desired sequence.

To search on Control group values, change the radix to binary and refer to

Table 2–1 in this section to find the binary equivalent values for the cycles you

want to locate. You can also use this method to search on binary equivalent

values for other channel groups with symbol tables.

Printing Disassembled

Data

Reference Memory

When searching for data in a clustered module setup in the State menu, the

searches are conducted only for the master module. You can, however, define

either module to be the master module. Refer to the description of the State

Search Definition overlay in your 92C96 Module User Manual for a description

of how to search through state data. Also refer to that manual for a description of

how to return to a full screen display.

To abort a search, press the Esc (escape) key.

To print disassembled data, use the Disassembly Print overlay. To access this

overlay, press the Print Screen key from the Disassembly menu. The Disassembly Print overlay is exactly the same as the State Print overlay. Refer to your

module user manual for a description of this overlay.

A demonstration reference memory file is provided so you can see an example of

how data from your system based on a SuperSPARC microprocessor using

MBus protocol looks when it is displayed. Viewing the reference memory is not

a requirement for preparing the 92C96 module for use. You can view the

reference memory file without connecting the DAS to your SUT.

LADM934 MBus Bus Support Instruction Manual

Online version

2–13

Page 36

Operating Basics

To view the MBus_Demo Refmem, follow these steps:

1. Press the Select Menu key and select the MBus_Demo file from the

2. Select the Disasm menu from the Display column and press Return.

You can change the display of disassembled data from the Disassembly Format

Definition overlay, which you can access through the Disassembly menu.

If there is not enough free space on the hard disk, you can delete the

MBus_Demo reference memory file. They are not necessary to the operation of

the application.

General Purpose Analysis

You may need to perform general purpose (timing) analysis on your MBus

system prior to, during, and after attempting to integrate your software with the

MBus system hardware. When performing hardware analysis, you will want to

use the data acquisition module to acquire data with a finer resolution. When

more data samples are taken in a given period of time, the resolution in the

Timing display increases, letting you see signal activity that would otherwise go

undetected.

Refmem column.

This part of this section provides information on the following:

H

Timing analysis

H

State analysis

H

Displaying data

H

Supplied Timing Format Definition file

Keep in mind when you view state data in the State menu (92C96) that it uses

the default channel grouping setup with all groups visible and that disassembly

does not occur. All channel groups will display in the default order and and will

look different than disassembled data.

Refer to the channel assignment tables in the Specifications section to see which

channels are not required for disassembly. You can disconnect these channels to

make other MBus system connections.

2–14

LADM934 MBus Bus Support Instruction Manual

Online version

Page 37

Operating Basics

Clocking

To change the data sampling rate, use the 92C96 Clock menu.

When using the 92C96 Module for timing analysis, you will want to use the

Internal or External clocking modes. The Internal clock selection can sample

data up to 100 MHz, which has a 10 ns resolution between samples. The

External clock selection samples data on every active clock edge on the 92C96

clock inputs up to 100 MHz.

The default clocking mode is Custom when MBus-2 Support is selected in the

Configuration menu; you will need to change it to either Internal or External.

Your module user manual contains an in-depth description of Internal and

External clocking.

Custom Clocking. Custom clocking only stores one data sample for each bus

transaction, which can take one or more clock cycles. Custom clocking also time

aligns certain signals that otherwise would be skewed relative to the current bus

transaction. This clocking selection is generally unproductive for timing

analysis. Refer to the Specifications section for a more in depth description of

how Custom clocking is used with the probe adapter to acquire data.

Internal Clocking. Because the Data_H and Data_L groups are demultiplexed

from the MAD bus by Custom Clocking, in Internal Clocking, this data cannot

be acquired and displayed. You should use MBus_Tmg_96 Module Setup for

timing analysis. Information on how to restore this setup is under Loading the

Application in the Getting Started section.

When you select Internal as the clocking mode, the 92C96 Module stores one

data sample as often as every 10 ns (100 MHz). This clocking selection is

commonly referred to as asynchronous.

Two typical uses of Internal clocking might be to verify that all the MBus signals

are transitioning as expected or to measure timing relationship between signal

transitions.

It is possible to acquire asynchronous data at rates of 200 MHz and 400 MHz.

The faster the 92C96 Module acquires data, the fewer channels it can acquire

data on. A single 92C96 Module can acquire data on 24 channels at 400 MHz or

2.5 ns resolution. Refer to your 92C96 Module User Manual for information on

sampling data at speeds faster than 100 MHz.

External Clocking. Because the Data_H and Data_L groups are demultiplexed

from the MAD bus by Custom Clocking, in External Clocking, this data cannot

be acquired and displayed. You should use MBus_Tmg_96 Module Setup for

timing analysis. Information on how to restore this setup is under Loading the

Application in the Getting Started section.

LADM934 MBus Bus Support Instruction Manual

Online version

2–15

Page 38

Operating Basics

When you select External as the clocking mode, the 92C96 Module acquires and

stores data based on the clock channel up to 100 MHz. This clocking selection

is commonly referred to as synchronous.

Searching Through State

and Timing Data

Printing State and Timing

Data

Timing Display

To search through 92C96 data, you can use either the Timing Search Definition

overlay or the State Search Definition overlay. You can use these overlays and

search through data as described in your 92C96 Module User Manual.

Before performing a search in the Timing menu, be sure to check the State

Format Definition overlay and make sure the channels on which you want to

conduct the search will be displayed (radix is not Off). Channels in the TIming

menu cannot be searched on unless they can also be displayed in the State menu.

To print 92C96 state data, you can use the State Table Print overlay. To access

this overlay, press the Shift and Print keys at the same time from the State menu.

To print timing data, you can use the Timing Print overlay. To access this

overlay, press the Shift and Print keys at the same time from the Timing menu.

For detailed information on the State Table Print overlay or the Timing Print

overlay, refer to your 92C96 Module User Manual.

General purpose analysis requires that you view data in either the State or

Timing display menus (or both). In the Timing display, every channel is shown

as a waveform, and groups of channels (such as the P_Addr_L group) are shown

as bus forms.

2–16

Two predefined Timing Format Definition overlay files, part of the MBus

support product, are available for you to use when viewing data in the Timing

display. The MBus-2_96 and MBus_Tmg_96 files are installed on the DAS

when you install the application.

The MBus-2_96 Timing Format Definition file places the Hi, P_Addr_L,

Data_H, and Data_L groups first and displays them as bus forms containing bus

values instead of as individual timing waveforms. These groups are followed by

other important control signals.

The MBus_Tmg_96 Timing Format Definition file places the MAD_H and

MAD_L groups first and displays them as bus forms containing bus values

instead of as individual timing waveforms. These groups are followed by other

important control signals.

To select a supplied Timing Format Definition file, follow these steps:

1. Press the Select Menu key, select the Timing menu and press F5: DEFINE

FORMAT.

2. Press F5: RESTORE FORMAT.

LADM934 MBus Bus Support Instruction Manual

Online version

Page 39

Operating Basics

3. Select MBus_96 if you are using the MBus-2 Support setup, or select

MBus_Tmg_96 if you are using the MBus_Tmg_96 Module setup and press

the Return key.

4. Press F8: EXIT & SAVE to return to the Timing menu.

Refer to the channel assignment tables in the Specifications section for the lists

of individual channels and their MBus signal names.

State Display

In the State menu, all channel group values are shown based on the selected

radix in the Channel menu or the State Format Definition overlay. Disassembly

does not occur.

If you want to display other channel groups (such as Misc), access the State

Format Definition overlay and change the radix for the group from Off to Hex,

Bin, or Oct. This overlay also allows you to add the Timestamp group (and

change the radix) to the data display.

LADM934 MBus Bus Support Instruction Manual

Online version

2–17

Page 40

Specifications

This section contains the following information:

H

H

H

H

Probe Adapter Description

The probe adapter is a nonintrusive piece of hardware that allows the 92C96 to

acquire data from an MBus in its own operating environment with little affect, if

any, on that system. Refer to the DAS overview figure in the Getting Started

section while reading the next paragraph.

The probe adapter consists of a circuit board and a socket for the MBus. The

probe adapter connects to the bus in the SUT (system under test). Signals from

the MBus system flow from the probe adapter to the probes (podlet groups). The

signals flow through the probe signal leads to either the 92C96 Acquisition

Module.

Brief description of the probe adapter

Channel assignment tables

Description of how the 92C96 Module acquires MBus signals

List of accessible MBus signals and extra 92C96 channels

All circuitry on the probe adapter is powered from the SUT.

The probe adapter accommodates the MBus signals in a 100-pin connector.

There is one jumper, J150, used to set the MCLK signal source on the probe

adapter for proper clocking. The jumper position must match the MCLK signal

used in the SUT: MCLK1, MCLK1, MCLK2, or MCLK3. A description of

configuring the probe adapter is located in the Operating Basics section.

Figure 3–1 shows the dimensions of the probe adapter.

LADM934 MBus Bus Support Instruction Manual

Online version

3–1

Page 41

Specifications

84 mm

(3.30 in)

146 mm

(5.75 in)

Channel Assignments

43 mm

(1.70 in)

17 mm

(6.50 in)

Figure 3–1: Minimum clearance of the probe adapter

Channel assignments shown in Table 3–1 through Table 3–20 use the following

conventions:

H

All signals are required for disassembly (MBus-2 Support with Custom

clocking) or general purpose analysis (MBus_Tmg_96 Module Setup with

External or Internal clocking) unless indicated otherwise

H

Channels are shown starting with the most significant bit (MSB) descending

to the least significant bit (LSB)

3–2

H

A tilde sign (~) following a signal name indicates an active low signal

H

An equals sign (=) following a signal name indicates that the signal is double

probed

LADM934 MBus Bus Support Instruction Manual

Online version

Page 42

Specifications

H

The module in the higher-numbered slot is referred to as the HI module; the

module in the lower-numbered slot is referred to as the LO module

MBus-2 Support Setup

Tables 3–1 through 3–12 show the channel assignments for the MBus-2 Support

setup used to disassemble data with Custom clocking.

Table 3–1 shows the 92C96 section and channel assignments for the V_Addr

group, and the MBus signal and pin number to which each channel connects.

The default display radix is OFF.

T able 3–1: MBus-2: V_Addr group channel assignments

Acq. module bit order and channel MBus

Bit no. 92C96 Signal name Pin no.

7 HI_A2:5 MAD53 80

6 HI_A2:4 MAD52 79

5 HI_A2:3 MAD51 78

4 HI_A2:2 MAD50 77

3 HI_A2:1 MAD49 76

2 HI_A2:0 MAD48 75

1 LO_A3:7 MAD47 74

0 LO_A3:6 MAD46 73

Table 3–2 shows the 92C96 section and channel assignments for the Hi group,

and the MBus signal and pin number to which each channel connects. The

default display radix is Hex.

T able 3–2: MBus-2: Hi group channel assignments

Acq. module bit order and channel MBus

Bit no. 92C96 Signal name Pin no.

3 LO_A2:3 MAD35 62

2 LO_A2:2 MAD34 61

1 LO_A2:1 MAD33 60

0 LO_A2:0 MAD32 59

Table 3–3 shows the 92C96 section and channel assignments for the P_Addr_L

group, and the MBus signal and pin number to which each channel connects.

The default display radix is Hex.

LADM934 MBus Bus Support Instruction Manual

Online version

3–3

Page 43

Specifications

T able 3–3: MBus-2: P_Addr_L group channel assignments

Acq. module bit order and channel MBus

Bit no. 92C96 Signal name Pin no.

31 HI_A1:7 MAD31 42

30 HI_A1:6 MAD30 41

29 HI_A1:5 MAD29 40

28 HI_A1:4 MAD28 39

27 HI_A1:3 MAD27 38

26 HI_A1:2 MAD26 37

25 HI_A1:1 MAD25 36

24 HI_A1:0 MAD24 35

23 HI_A0:7 MAD23 34

22 HI_A0:6 MAD22 33

21 HI_A0:5 MAD21 32

20 HI_A0:4 MAD20 31

19 HI_A0:3 MAD19 30

18 HI_A0:2 MAD18 29

17 HI_A0:1 MAD17 28

16 HI_A0:0 MAD16 27

15 LO_A1:7 MAD15 26

14 LO_A1:6 MAD14 25

13 LO_A1:5 MAD13 24

12 LO_A1:4 MAD12 23

11 LO_A1:3 MAD11 22

10 LO_A1:2 MAD10 21

9 LO_A1:1 MAD9 20

8 LO_A1:0 MAD8 19

7 LO_A0:7 MAD7 18

6 LO_A0:6 MAD6 17

5 LO_A0:5 MAD5 16

4 LO_A0:4 MAD4 15

3 LO_A0:3 MAD3 14

2 LO_A0:2 MAD2 13

1 LO_A0:1 MAD1 12

0 LO_A0:0 MAD0 11

3–4

LADM934 MBus Bus Support Instruction Manual

Online version

Page 44

Specifications

Table 3–4 shows the 92C96 section and channel assignments for the Data_H

group, and the MBus signal and pin number to which each channel connects.

The default display radix is HEX.

T able 3–4: MBus-2: Data_H group channel assignments

Acq. module bit order and channel MBus

Bit no. 92C96 Signal name Pin no.

31 HI_A3:7 MAD63 90

30 HI_A3:6 MAD62 89

29 HI_A3:5 MAD61 88

28 HI_A3:4 MAD60 87

27 HI_A3:3 MAD59 86

26 HI_A3:2 MAD58 85

25 HI_A3:1 MAD57 84

24 HI_A3:0 MAD56 83

23 HI_A2:7 MAD55 82

22 HI_D2:6 MAD54 81

21 HI_D2:5 MAD53 80

20 HI_D2:4 MAD52 79

19 HI_D2:3 MAD51 78

18 HI_D2:2 MAD50 77

17 HI_D2:1 MAD49 76

16 HI_D2:0 MAD48 75

15 LO_D3:7 MAD47 74

14 LO_D3:6 MAD46 73

13 LO_D3:5 MAD45 72

12 LO_D3:4 MAD44 71

11 LO_D3:3 MAD43 70

10 LO_D3:2 MAD42 69

9 LO_D3:1 MAD41 68

8 LO_D3:0 MAD40 67

7 LO_D2:7 MAD39 66

6 LO_D2:6 MAD38 65

5 LO_D2:5 MAD37 64

4 LO_D2:4 MAD36 63

3 LO_D2:3 MAD35 62

2 LO_D2:2 MAD34 61

LADM934 MBus Bus Support Instruction Manual

Online version

3–5

Page 45

Specifications

T able 3–4: MBus-2: Data_H group channel assignments (Cont.)

Acq. module bit order and channel MBus

Bit no. Pin no.Signal name92C96

1 LO_D2:1 MAD33 60

0 LO_D2:0 MAD32 59

Table 3–5 shows the 92C96 section and channel assignments for the Data_L

group, and the MBus signal and pin number to which each channel connects.

The default display radix is HEX.

T able 3–5: MBus-2: Data_L group channel assignments

Acq. module bit order and channel MBus

Bit no. 92C96 Signal name Pin no.

31 HI_D1:7 MAD31 42

30 HI_D1:6 MAD30 41

29 HI_D1:5 MAD29 40

28 HI_D1:4 MAD28 39

27 HI_D1:3 MAD27 38

26 HI_D1:2 MAD26 37

25 HI_D1:1 MAD25 36

24 HI_D1:0 MAD24 35

23 HI_D0:7 MAD23 34

22 HI_D0:6 MAD22 33

21 HI_D0:5 MAD21 32

20 HI_D0:4 MAD20 31

19 HI_D0:3 MAD19 30

18 HI_D0:2 MAD18 29

17 HI_D0:1 MAD17 28

16 HI_D0:0 MAD16 27

15 LO_D1:7 MAD15 26

14 LO_D1:6 MAD14 25

13 LO_D1:5 MAD13 24

12 LO_D1:4 MAD12 23

11 LO_D1:3 MAD11 22

10 LO_D1:2 MAD10 21

9 LO_D1:1 MAD9 20

3–6

LADM934 MBus Bus Support Instruction Manual

Online version

Page 46

Specifications

T able 3–5: MBus-2: Data_L group channel assignments (Cont.)

Acq. module bit order and channel MBus

Bit no. Pin no.Signal name92C96

8 LO_D1:0 MAD8 19

7 LO_D0:7 MAD7 18

6 LO_D0:6 MAD6 17

5 LO_D0:5 MAD5 16

4 LO_D0:4 MAD4 15

3 LO_D0:3 MAD3 14

2 LO_D0:2 MAD2 13

1 LO_D0:1 MAD1 12

0 LO_D0:0 MAD0 11

Table 3–6 shows the 92C96 section and channel assignments for the Control

group, and the MBus signal and pin number to which each channel connects.

The default display radix is SYM for MBus Support.

T able 3–6: MBus-2: Control group channel assignments

Acq. module bit order and channel MBus

Bit no. 92C96 Signal name Pin no.

8 HI_ & LO_C2:2 MERR~ 52