Page 1

Instruction Manual

DAS 92DM923

88110 Microprocessor Support

070-8794-00

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to the Safety Summary prior to

performing service.

Please check for change information at the rear

of this manual.

First Printing: April 1993

Revised Printing: December 1993

Online Version: April 1997

Page 2

Instrument Serial Numbers

Each instrument manufactured by T ektronix has a serial number on a panel insert or tag, or stamped on the

chassis. The first letter in the serial number designates the country of manufacture. The last five digits of the

serial number are assigned sequentially and are unique to each instrument. Those manufactured in the

United States have six unique digits. The country of manufacture is identified as follows:

B010000 T ektronix, Inc., Beaverton, Oregon, USA

E200000 T ektronix United Kingdom, Ltd., London

J300000 Sony/T ektronix, Japan

H700000 T ektronix Holland, NV , Heerenveen, The Netherlands

Instruments manufactured for T ektronix by external vendors outside the United States are assigned a two digit

alpha code to identify the country of manufacture (e.g., JP for Japan, HK for Hong Kong, IL for Israel, etc.).

T ektronix, Inc., P .O . Box 500, Beaverton, OR 97077

Printed in U.S.A.

CopyrightET ektronix, Inc., 1993. All rights reserved. T ektronix products are covered by U.S. and foreign

patents, issued and pending. The following are registered trademarks: TEKTRONIX, TEK, TEKPROBE,

SCOPEĆMOBILE, DAS, PRISM, TekDB, KlipChip, and FasT rak.

Page 3

WARRANTY

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1) year from the

date of shipment. If any such product proves defective during this warranty period, Tektronix, at its option, either will repair the

defective product without charge for parts and labor, or will provide a replacement in exchange for the defective product.

In order to obtain service under this warranty,Customermustnotify Tektronixofthedefectbefore the expiration of the warranty

period and make suitable arrangements for the performance of service. Tektronix will provide such service at Customer's site

without charge during the warranty period, if the service is performed within the normal onĆsite service area. Tektronix will

provide onĆsite service outside the normal onĆsite service area only upon prior agreement and subject to payment of all travel

expenses by Customer. When or where onĆsite service is not available, Customer shall be responsible for packaging and

shipping the defective product to the service center designated by Tektronix, with shipping charges prepaid. Tektronix shall

pay for the return of the product to Customer if the shipment is to a location within the country in which the Tektronix service

center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any other charges for

products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate maintenance

and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting from attempts by

personnel other than Tektronix representatives to install, repair or service the product; b) to repair damage resulting from

improper use or connection to incompatible equipment; or c) to service a product that has been modified or integrated with

other products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THIS PRODUCT IN LIEU OF ANY OTHER

WARRANTIES, EXPRESSED OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX' RESPONSIBILITY TO REPAIR OR

REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR

BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

SOFTWARE WARRANTY

Tektronix warrants that the media on which this software product is furnished and the encoding of the programs on the media

will be free from defects in materials and workmanship for a period of three (3) months from date of shipment. If any such

medium or encoding proves defective during the warranty period, Tektronix will provide a replacement in exchange for the

defective medium. Except as to the media on which this software product is furnished, this software product is provided as is"

without warranty of any kind, either express or implied. Tektronixdoes not warrant that the functions contained in this software

product will meet Customer's requirements or that the operation of the programs will be uninterrupted or errorĆfree.

In order to obtain service under this warranty,Customermustnotify Tektronixofthedefectbefore the expiration of the warranty

period. If Tektronix is unable to provide a replacement that is free from defects in materials and workmanship within a

reasonable time thereafter, Customer may terminate the license for this software product and return this software product and

any associated materials for credit or refund.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THIS PRODUCT IN LIEU OF ANY OTHER

WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX' RESPONSIBILITY TO REPLACE

DEFECTIVE MEDIA OR REFUND CUSTOMER'S PAYMENT IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO

THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY

INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR

THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

Table of Contents

Preface:

GENERAL SAFETY SUMMARY/

MICROPROCESSOR SUPPORT -3. . . . . . . . . . . . . . . . . . . . . . . . . .

Section 1:

DAS 9200 SYSTEM SOFTWARE COMPATIBILITY 1-2. . . . . . . . . . . . .

DAS 9200 CONFIGURATION 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REQUIREMENTS AND RESTRICTIONS 1-3. . . . . . . . . . . . . . . . . . . . .

ABOUT THIS MANUAL 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Conventions 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 2:

INSTALLING SOFTWARE 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONFIGURING THE DAS 9200 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONFIGURING THE PROBE ADAPTER 2-4. . . . . . . . . . . . . . . . . . . . .

CONNECTING TO THE SYSTEM UNDER TEST 2-5. . . . . . . . . . . . . . .

Section 3:

LOADING DISASSEMBLER SOFTWARE 3-1. . . . . . . . . . . . . . . . . . . . .

CHANNEL GROUPS AND ASSIGNMENTS 3-2. . . . . . . . . . . . . . . . . . .

CHANGES THAT AFFECT DISASSEMBLY 3-2. . . . . . . . . . . . . . . . . . .

CLOCKING 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SYMBOLS 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGGERING 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 4:

ACQUIRING DATA 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VIEWING DISASSEMBLED DATA 4-1. . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Display Format 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Display Format 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Flow Display Format 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Subroutine Display Format 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly Format Definition Overlay 4-5. . . . . . . . . . . . . . . . . . . . .

Displaying the Address Group Symbolically 4-8. . . . . . . . . . . . . . . . .

Exception Vectors 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Searching Through Data 4-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PRINTING DATA 4-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REFERENCE MEMORY 4-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

92DM923 88110 Instruction Manual

Online Version

i

Page 5

Section 5:

CLOCKING 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Custom Clocking 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Internal Clocking 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

External Clocking 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGGERING 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ACQUIRING DATA 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DISPLAYING DATA 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timing Menu 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

State Menu 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SEARCHING THROUGH DATA 5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PRINTING DATA 5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A: ERROR MESSAGES AND DISASSEMBLY PROBLEMS

MODULE ERROR MESSAGES A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OTHER DISASSEMBLY PROBLEMS A-2. . . . . . . . . . . . . . . . . . . . . . . .

Appendix B: HOW DATA IS ACQUIRED

CUSTOM CLOCKING B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ALTERNATE MICROPROCESSOR CONNECTIONS B-1. . . . . . . . . . . .

Signals On the Probe Adapter B-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signals Not On the Probe Adapter B-2. . . . . . . . . . . . . . . . . . . . . . . . .

Extra 92A96 Channels B-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C: SERVICE INFORMATION

SERVICING SAFETY INFORMATION C-1. . . . . . . . . . . . . . . . . . . . . . .

PROBE ADAPTER DESCRIPTION C-1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe Adapter Circuit Description C-2. . . . . . . . . . . . . . . . . . . . . . . . .

CARE AND MAINTENANCE C-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS C-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Channel Assignments C-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DISCONNECTING PROBES C-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

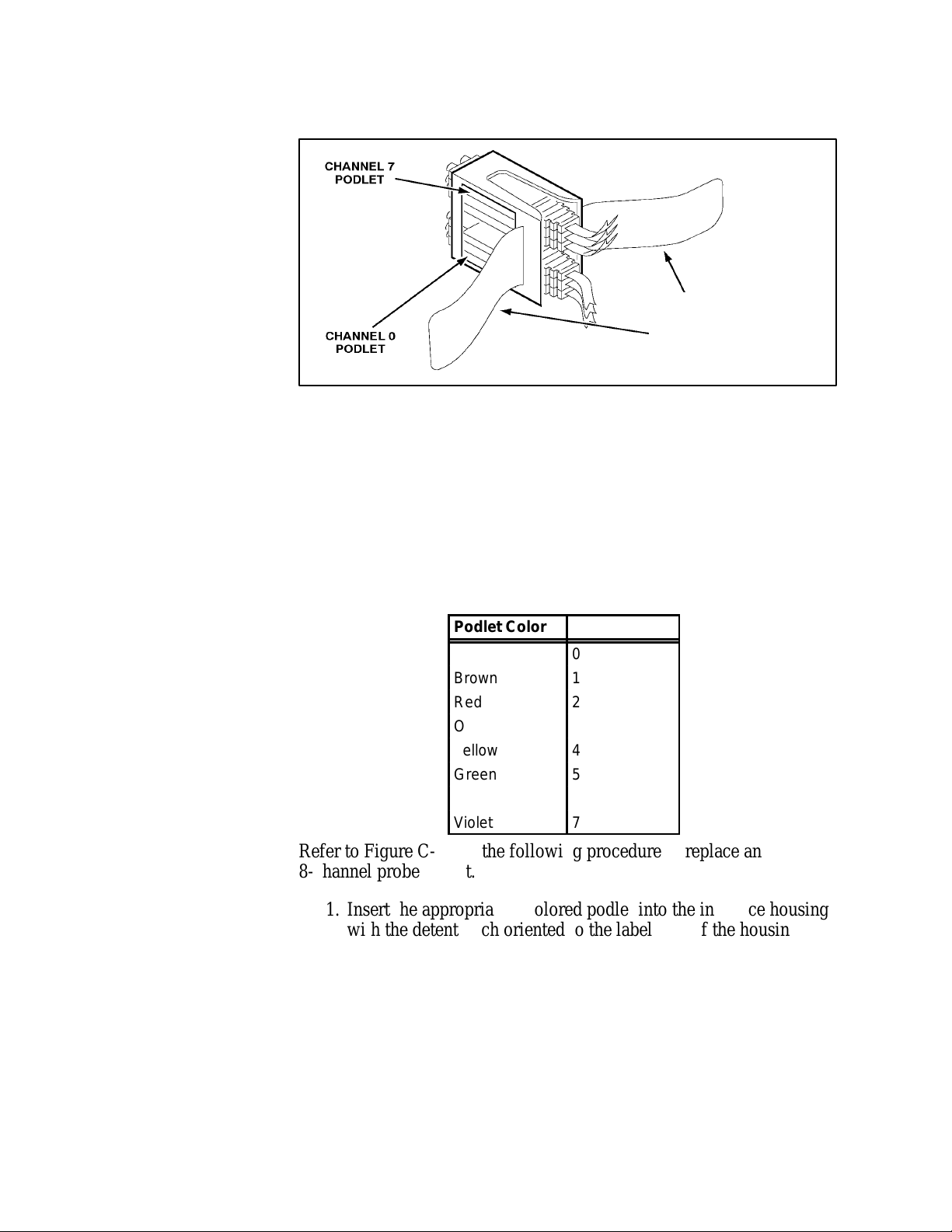

REMOVING AND REPLACING PROBE PODLETS C-16. . . . . . . . . . . . .

Removing Probe Podlets from the Interface Housing C-16. . . . . . . . . . .

Replacing a Clock Probe C-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing Probe Podlets from the Podlet Holder C-17. . . . . . . . . . . . . .

Replacing 8-Channel Probe Podlets C-18. . . . . . . . . . . . . . . . . . . . . . . .

REMOVING AND REPLACING SOCKETS C-20. . . . . . . . . . . . . . . . . . . .

Index:

ii

92DM923 88110 Instruction Manual

Online Version

Page 6

List of Figures

Figure 1-1. DAS 9200 connected to a typical probe adapter. 1-3. . . . . . . . . . . . . . . . . . . . .

Figure 2-1. Sys Config menu with a variable–width module defined. 2-3. . . . . . . . . . . . . .

Figure 2-2. Applying slot number labels. 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-3. Placing the microprocessor into a typical PGA probe adapter. 2-6. . . . . . . . . .

Figure 2-4. Connecting the podlets to a typical PGA probe adapter. 2-7. . . . . . . . . . . . . . .

Figure 2-5. Placing a typical PGA probe adapter onto the SUT. 2-8. . . . . . . . . . . . . . . . . .

Figure 4-1. Hardware display. 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-2. Disassembly Format Definition overlay. 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-3. Disassembly and State split-screen display.

Figure 5-1. Timing data using the 88110_96 Timing Format file. 5-4. . . . . . . . . . . . . . . . .

Figure 5-2. State data. 5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

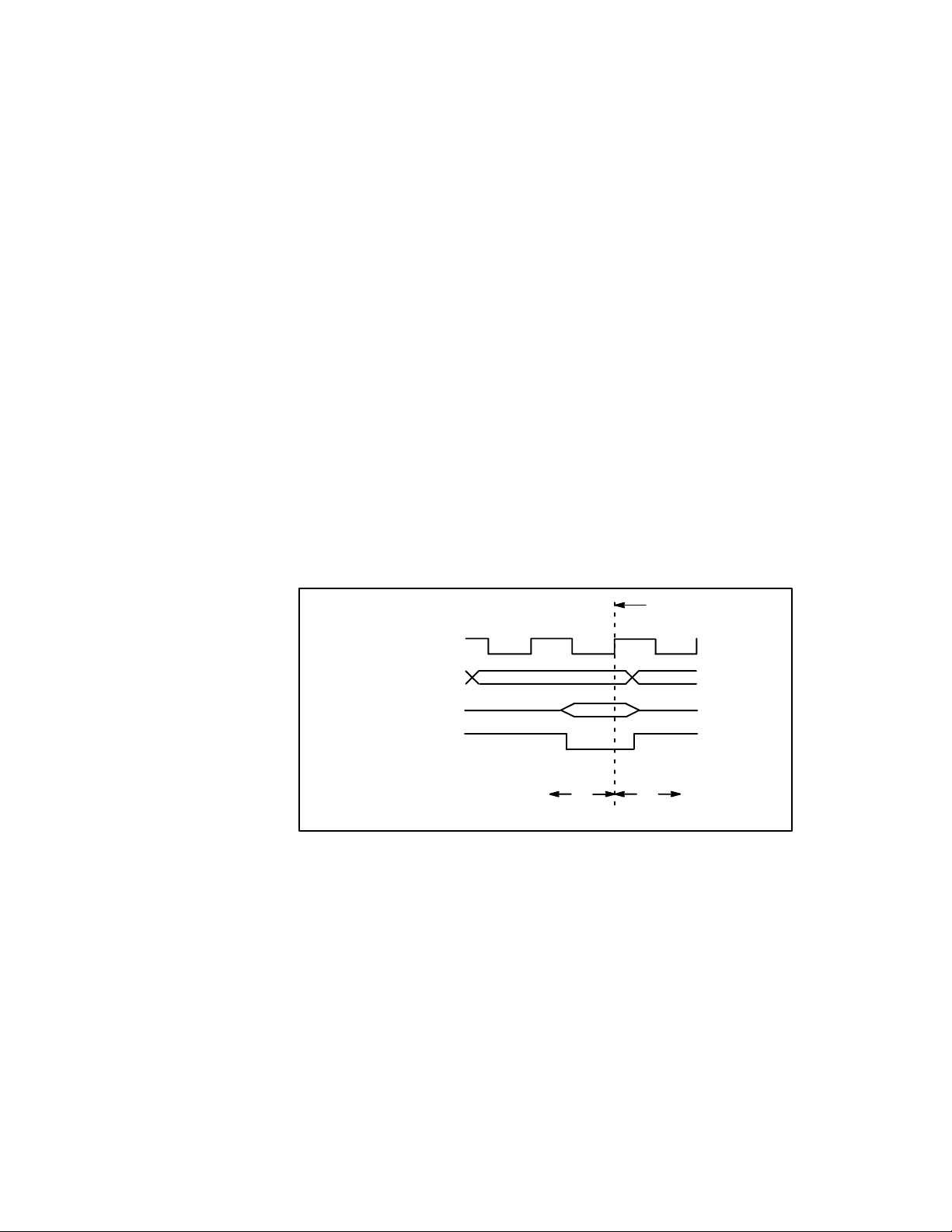

Figure B-1. 88110 bus timing. B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure C-1. Overview of the standard probe and probe adapter. C-2. . . . . . . . . . . . . . . . . . .

Figure C-2. Minimum clearance of the probe adapter. C-5. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure C-3. Disconnecting clock and 8-channel probes. C-15. . . . . . . . . . . . . . . . . . . . . . . . .

Figure C-4. Removing a clock or probe podlet from the interface housing. C-17. . . . . . . . . .

Figure C-5. Ganging together the 8-channel probe podlets. C-18. . . . . . . . . . . . . . . . . . . . . .

Figure C-6. Removing a protective socket from a typical PGA probe adapter board. C-20. .

You can use this method to perform searches. 4-11. . . . . . . . . . . . . . . . . . . . . . . . . . .

92DM923 88110 Instruction Manual

Online Version

iii

Page 7

List of Tables

T able 2-1 Choosing the Correct Floppy Disk 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 3-1 88110_TCOD Symbol Table Definitions 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 3-2 88110_RL Symbol Table Definitions 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 3-3 88110_TSIZ Symbol Table Definitions 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 4-1 Cycle Type Definitions 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 4-2 Interrupt/Exception Labels 4-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able B-1 Extra 92A96 Channels B-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

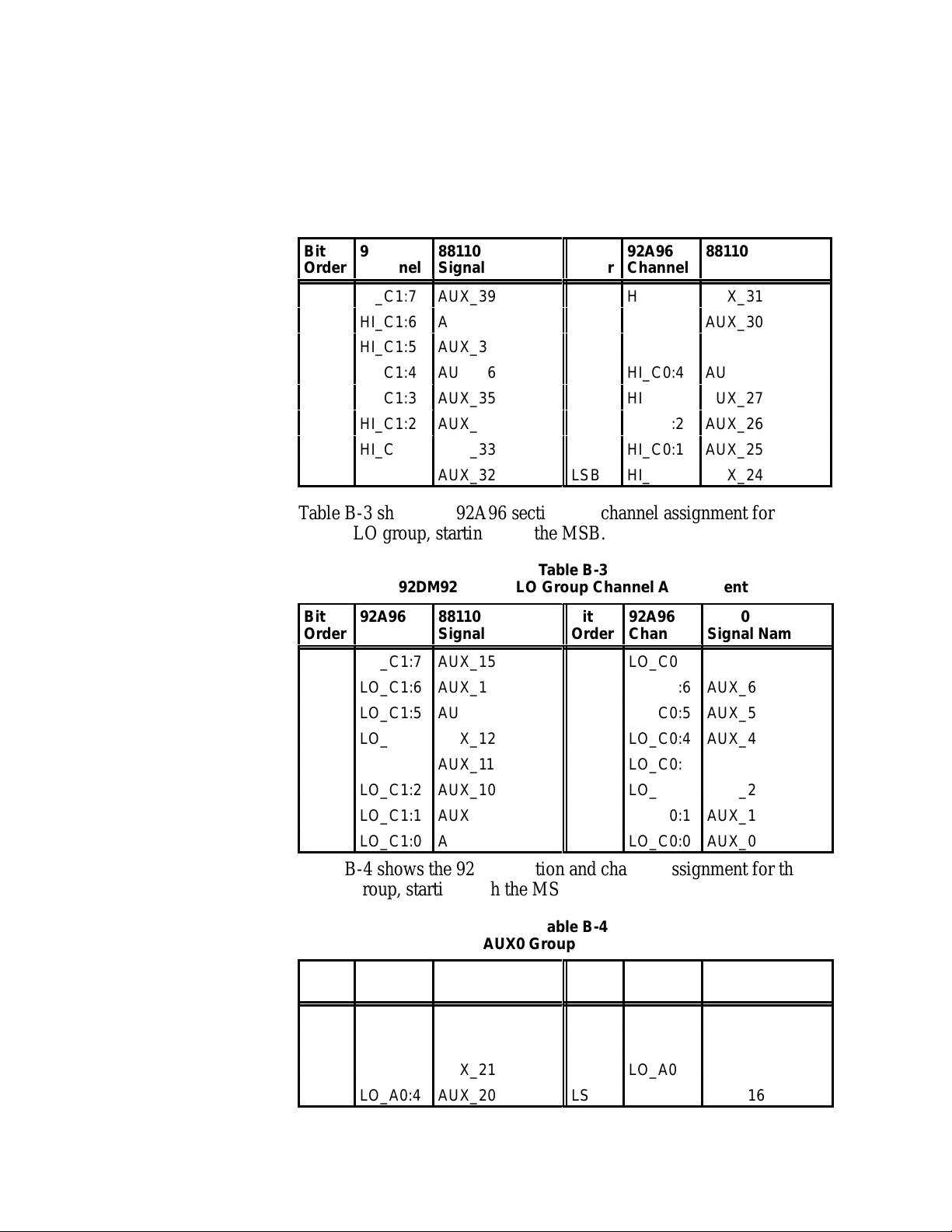

T able B-2 92DM923 AUX1 HI Group Channel Assignment B-3. . . . . . . . . . . . . . . . . . . .

T able B-3 92DM923 AUX1 LO Group Channel Assignment B-3. . . . . . . . . . . . . . . . . . . .

T able B-4 92DM923 AUX0 Group Channel Assignment B-3. . . . . . . . . . . . . . . . . . . . . . .

T able C-1 Electrical Specifications C-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able C-2 Environmental Specifications C-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

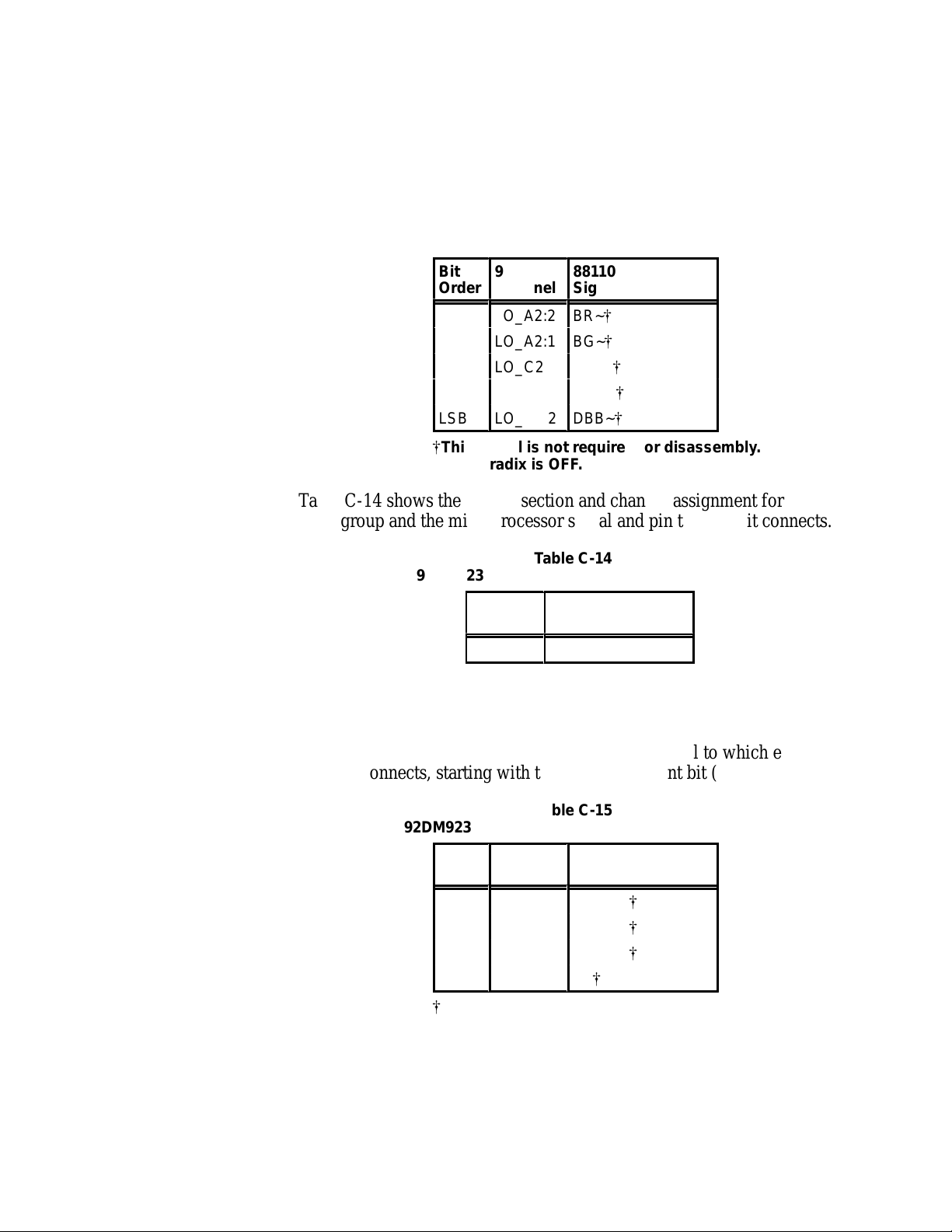

T able C-3 92DM923 Address Group Channel Assignments C-7. . . . . . . . . . . . . . . . . . . . .

T able C-4 92DM923 Hi_Data Group Channel Assignments C-8. . . . . . . . . . . . . . . . . . . . .

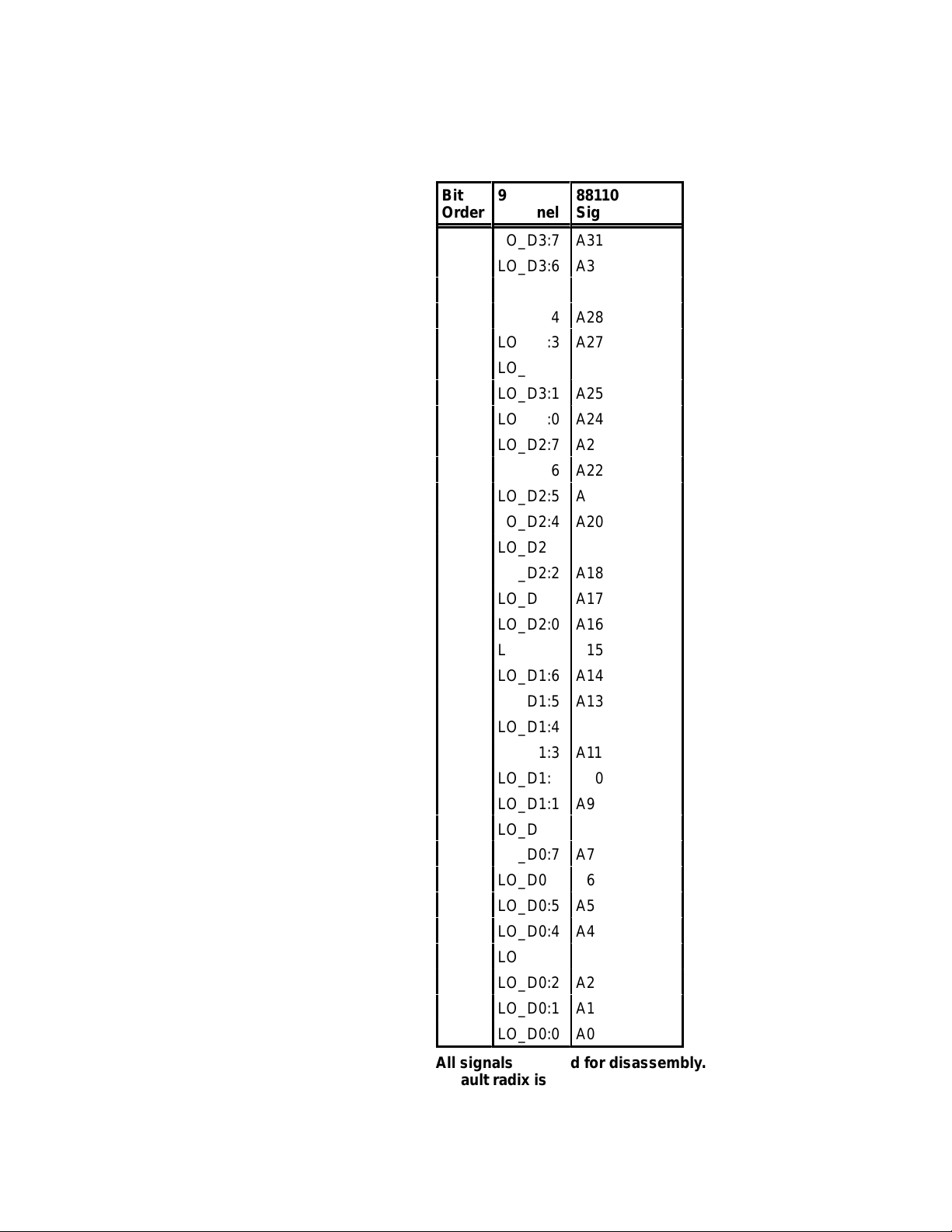

T able C-5 92DM923 Lo_Data Group Channel Assignments C-9. . . . . . . . . . . . . . . . . . . . .

T able C-6 92DM923 TSTATEA Group Channel Assignments C-10. . . . . . . . . . . . . . . . . . .

T able C-7 92DM923 TCOD Group Channel Assignments C-10. . . . . . . . . . . . . . . . . . . . . .

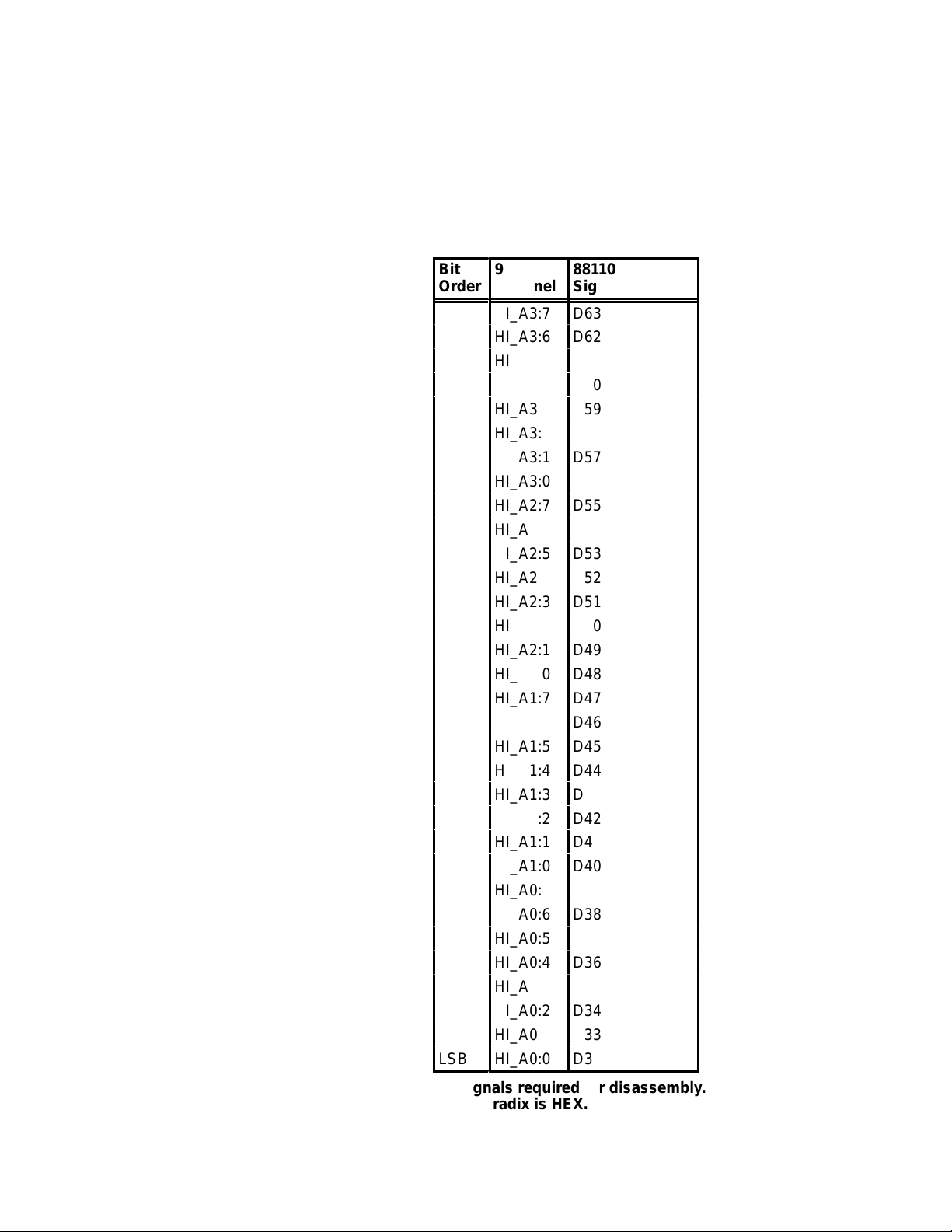

T able C-8 92DM923 DataSize Group Channel Assignments C-11. . . . . . . . . . . . . . . . . . . .

T able C-9 92DM923 RL Group Channel Assignments C-11. . . . . . . . . . . . . . . . . . . . . . . . .

T able C-10 92DM923 BP Group Channel Assignment C-11. . . . . . . . . . . . . . . . . . . . . . . . . .

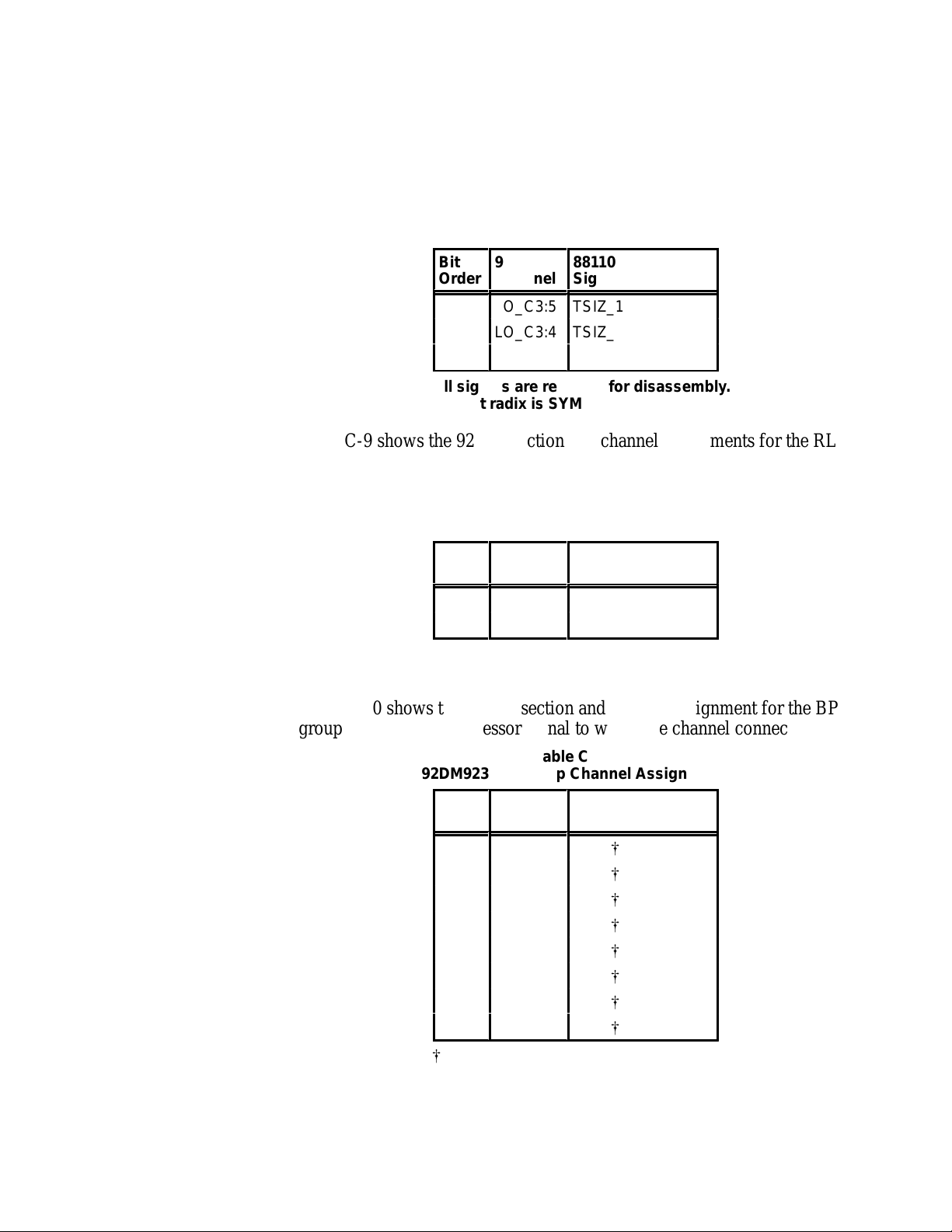

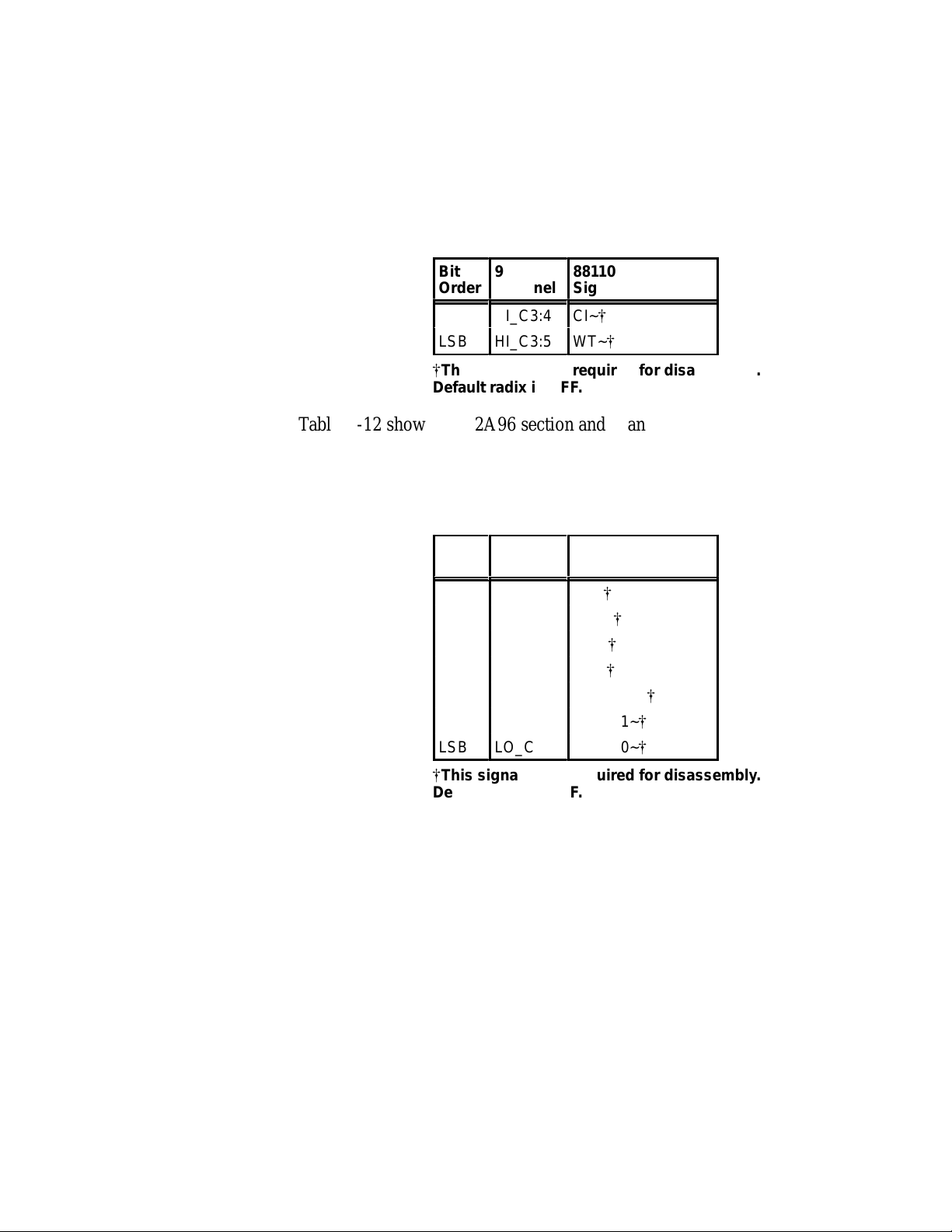

T able C-11 92DM923 CACHE Group Channel Assignments C-12. . . . . . . . . . . . . . . . . . . . .

T able C-12 92DM923 SNOOP Group Channel Assignment C-12. . . . . . . . . . . . . . . . . . . . . .

T able C-13 92DM923 ARBTR Group Channel Assignments C-13. . . . . . . . . . . . . . . . . . . . .

T able C-14 92DM923 CLK Group Channel Assignment C-13. . . . . . . . . . . . . . . . . . . . . . . .

T able C-15 92DM923 PSTAT Group Channel Assignments C-13. . . . . . . . . . . . . . . . . . . . . .

T able C-16 92DM923 INTR Group Channel Assignment C-14. . . . . . . . . . . . . . . . . . . . . . . .

T able C-17 92DM923 JTAG Group Channel Assignment C-14. . . . . . . . . . . . . . . . . . . . . . . .

T able C-18 92DM923 Clock Channel Assignments C-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able C-19 Podlet-to-Channel Color Code C-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv

92DM923 88110 Instruction Manual

Online Version

Page 8

Preface: GUIDE TO DAS 9200 DOCUMENTATION

The Digital Analysis System (DAS) 9200 documentation package

provides the information necessary to install, operate, maintain, and

service the DAS 9200. The DAS 9200 documentation consists of the

following:

S

a series of microprocessor-specific microprocessor support

instructions that describe the various microprocessor support

packages.

S

a system user manual that includes a beginning user’s orientation,

a discussion of DAS 9200 system-level operation, and reference

information such as installation procedures, specifications, error

messages, and a complete system glossary.

S

a series of module user manuals that describe each of the

DAS 9200 acquisition, pattern generation, and optional I/O modules.

S

an on-line documentation package that includes context-sensitive

technical notes.

S

a programmatic command language user manual that describes

the set of programmatic commands available for remotely

controlling the DAS 9200.

S

a series of application software user manuals that describe the

various application software packages.

S

a technician’s reference manual that helps a qualified technician

isolate DAS 9200 problems to the individual module level and

determine corrective action (including on-site removal and

replacement of modules).

S

a verification and adjustment procedures manual that allows a

qualified technician to make necessary adjustments and verify

specifications of the mainframe and modules.

S

a series of workbooks that teach concepts about the DAS 9200

acquisition modules and pattern generation modules.

92DM923 88110 Instruction Manual

Online Version

v

Page 9

GENERAL SAFETY SUMMARY/

MICROPROCESSOR SUPPORT

The general safety information in this summary is for operating and

servicing personnel. Specific warnings and cautions can be found

throughout the manual where they apply and may not appear in this

summary. While using this product you may need to access parts of the

mainframe system; if so, read the General Safety Summary in your

system user manual for warnings and cautions related to operating the

mainframe system.

TERMS IN THIS MANUAL

CAUTION statements identify conditions or practices that could result

in damage to the equipment or other property.

WARNING statements identify conditions or practices that could result

in personal injury or loss of life.

TERMS AS MARKED ON EQUIPMENT

CAUTION

CAUTION indicates a hazard to property, including the equipment

itself, and could cause minor personal injury.

WARNING

WARNING indicates solely a personal injury hazard not immediately

accessible as you read the marking.

DANGER indicates a personal injury hazard immediately accessible as

you read the marking.

SYMBOLS AS MARKED ON EQUIPMENT

DANGER

High Voltage

Protective

ground (earth)

terminal

A TTENTION

Refer to

manual

USE CARE WITH COVERS REMOVED

To avoid personal injury, remove jewelry such as rings, watches, and

other metallic objects before removing the cover. Do not touch exposed

connections and components within the product while the power cord is

connected.

vi

92DM923 881 10 Instruction Manual

Online Version

Page 10

REMOVE FROM OPERATION

If you have reason to believe that the instrument has suffered a

component failure, do not operate the instrument until the cause of the

failure has been determined and corrected.

USE THE PROPER FUSE

To avoid fire hazard, use only a fuse of the correct type, voltage rating,

and current rating.

REMOVE LOOSE OBJECTS

During disassembly or installation procedures, screws or other small

objects may fall to the bottom of the mainframe. To avoid shorting out

the power supply, do not power on the instrument until such objects

have been removed.

DO NOT OPERATE IN EXPLOSIVE ATMOSPHERES

To avoid explosion, do not operate this product in an explosive

atmosphere unless it has been specifically certified for such operation.

92DM923 88110 Instruction Manual

Online Version

vii

Page 11

Section 1: OVERVIEW

The 92DM900 series of support products are developed by third parties

to support buses, microprocessors, microcontrollers, and digital signal

processors for specific Tektronix customers. The products are currently

being successfully used by these customers. If you need assistance in

using this product, contact a Tektronix Technical Support Specialist.

This section provides basic information on the following:

S

the 92DM923 Microprocessor Support product

S

software compatibility

S

DAS 9200 configuration

S

your 88110 system requirements

S

92DM923 restrictions

S

this manual

The 92DM923 Microprocessor Support product disassembles data from

systems that are based on the Motorola 88110 microprocessor. The

92DM923 product runs on a DAS 9200 logic analyzer equipped with

two 92A96 Acquisition Modules in adjacent slots.

The 92DM923 package support the 88110 microprocessor in a 299-pin

PGA package.

This product consists of software on a floppy disk, a probe adapter, and

this manual. The software includes setup files, a demonstration

reference memory, symbol tables, and a disassembler program. A

complete list of accessories and options is provided at the end of the

mechanical parts list in Appendix D: Parts Lists.

A demonstration reference memory is provided so you can see an

example of disassembled instruction mnemonics. You can view the

reference memory without connecting the DAS 9200 to your system

under test. The reference memory is automatically installed on the

DAS 9200 when you install the disassembler software. Directions for

viewing this file are in Section 4: Acquiring and Viewing Disassembled

Data.

92DM923 88110 Instruction Manual

Online Version

REV DEC 1993

1-1

Page 12

Overview

To use this product efficiently, you need to have the following:

S

knowledge of your DAS 9200 configuration and its operation

S

knowledge of your 88110 system

S

this manual

S

the DAS 9200 System User Manual

S

the 92A96 Module User Manual, Tektronix, Inc. 1992

S

a user manual for your 88110 microprocessor

S

LA-LINK (if you want to download symbols from your high-level

development system)

DAS 9200 SYSTEM SOFTWARE COMPATIBILITY

The 92DM923 Microprocessor Support Product is compatible only with

DAS 9200 System Software Release 3, Version 1.3 or higher,

DAS 92XTerm System Software Release 3, Version 1.3 or higher, and

DAS 9202XT System Software Release 3, Version 1.3 or higher.

DAS 9200 CONFIGURATION

To use the microprocessor support product, your DAS 9200 must be

equipped with two 92A96 Modules in adjacent slots and four standard

data acquisition probes.

Figure 1-1 shows a standard probe connected to a DAS 9200.

1-2

92DM923 88110 Instruction Manual

Online Version

Page 13

Overview

PROBE

ADAPTER

Figure 1-1. DAS 9200 connected to a typical probe adapter.

REQUIREMENTS AND RESTRICTIONS

You should review all electrical, environmental, and mechanical

specifications in Appendix C as they pertain to your system under test.

The remainder of this section describes other requirements and

restrictions of the microprocessor support product.

System Clock Rate. The microprocessor support product supports the

88110 microprocessor at speeds of up to 50 MHz

Probe Adapter Clearance. Your 88110 system must have a minimum

amount of clear space surrounding the 88110 microprocessor to

accommodate the probe adapter. Figure C-2 in Appendix C: Service

Information gives these dimensions.

1

.

1

Specification at time of printing. Contact your DAS 9200 sales representative for current information on the fastest devices sup-

ported.

92DM923 88110 Instruction Manual

Online Version

1-3

Page 14

Overview

Probe Adapter Loading. Any electrical connection to your system

adds an additional ac and dc load. The probe adapter was carefully

designed to add a minimum load to your system. However, this

additional load may affect the operation of the 88110 microprocessor in

systems with extremely tight timing margins. Appendix C contains

specifications on how the probe adapter affects your system.

88110 System and Probe Adapter Cooling. You must be sure to retain

the original level of cooling for your 88110 system after you install the

probe adapter. To maintain the required operating temperature, you may

need to provide additional cooling for the probe adapter.

ABOUT THIS MANUAL

This manual is based on the assumption that you are familiar with the

operation of the DAS 9200 mainframe and the 92A96 Acquisition

Module. Therefore, details about system software and how to move

through the menu structure are not provided. An overview of those

functions is provided so that you do not need to consult another manual.

This manual provides detailed information on how to do the following:

S

connect to your system under test

S

setup disassembler software and use it

S

view acquired data

S

maintain disassembler hardware

Read Section 5: General Purpose Analysis if you are going to acquire

and view timing or state data for purposes other than disassembly.

Manual Conventions

The following conventions are used in this manual:

S

the terms disassembler and disassembler software are used

interchangeably in reference to the 92DM923 software that

disassembles bus cycles into instruction mnemonics and cycle types.

S

the term SUT (system under test) is used to refer to the

microprocessor system from which data is being acquired.

S

references to 92A96 Modules include all versions of those modules

unless otherwise noted.

1-4

S

a signal that is active low has a tilde (~) following its name.

92DM923 88110 Instruction Manual

Online Version

Page 15

Section 2: INSTALLATION AND CONNECTIONS

This section describes how to do the following:

S

install the disassembler software

S

configure the probe adapter

S

connect the DAS 9200 to the SUT (system under test)

INSTALLING SOFTWARE

Before installing the microprocessor application software, you should

be aware that there are three different versions of DAS 9200 system

software: the 9201T version, the 92XTerm version, and the 9202XT

version. The 9201T version allows you to operate the DAS 9200 from a

9201T terminal. The 92XTerm version allows you to operate the

DAS 9200 in an X window on a workstation. The 9202XT version

allows you to operate the DAS 9200 in an X window on a 9202XT

terminal.

NOTE

To use the microprocessor support package, you must

install application software that is compatible with your

DAS 9200 mainframe configuration and system software.

Two floppy disks are shipped with the 92DM923 support. To determine

which floppy disk contains compatible application software, follow

these steps:

1. Note the terminal type that will display the DAS 9200 user

interface.

2. Power on the DAS 9200 mainframe or system, and press the

Select Menu key.

3. Select the HW/SW Version menu in the Utilities menu column,

and press Return.

4. Look at the System Software line to find the version of system

software loaded. Use Table 2-1 to choose the correct floppy disk

to install. If your system software is an older version than the one

listed in the table, you should update your system software before

installing the application.

92DM923 88110 Instruction Manual

Online Version

2-1

Page 16

Installation and Connections

T erminal Type

9200T/9201T Release 3, Version 1.30[DAS 9201T Application Software - 92DM923

X window on a

workstation or

a 9202XT

*Version numbers shown are the lowest supported; higher versions within the

same release are also supported.

[

The 9201T version of this application should operate properly with DAS

9200 system software Release 2, Version 1.20. However, you should be

aware that this application was actually tested using Release 3, Version 1.3,

the currently supported version.

Table 2-1

Choosing the Correct Floppy Disk

System Software Line

Information*

Release 3, Version 1.30[DAS 92XTERM Application SW - 92DM923

Install Floppy Disk Labelled

If you have any two types of DAS 9200 system software,

(9201T, 92XTerm, 9202XT), and you switch between the two, you

must install compatible application software on each system.

If you try to install application software onto an incompatible system or

terminal using DAS 9200 System Software Release 3, V1.1 or greater,

an error message displays.

If you try to install application software onto an incompatible system or

terminal using DAS 9200 System Software Release 3, V1.0 or lower,

the system will install the software but it will not operate properly when

you try to use it.

Install the disassembler software onto the DAS 9200 as follows:

1. Power up the DAS 9200 mainframe.

2. Insert the appropriate disk into the DAS 9200’s floppy drive.

3. Press the Select Menu key, and select the Disk Services menu.

4. Select Install Application in the Operation field of the menu.

5. Press F8: EXECUTE OPERATION, and follow the on-screen

prompts.

NOTE

After each install and load operation, a message appears

on the screen informing you the operation succeeded or

failed. If the message tells you the operation failed, you

may need to remove applications or files from the hard disk

and try installing or loading again. If the operation fails

again, refer to Appendix A: Error Messages and

Disassembly Problems.

2-2

92DM923 88110 Instruction Manual

Online Version

Page 17

Installation and Connections

CONFIGURING THE DAS 9200

To acquire data from an 88110 microprocessor, two 92A96 Modules are

required. They must be configured into one variable-width module.

When using a variable-width module, both 92A96 Modules must be

positioned in adjacent DAS 9200 slots. The module in the

higher-numbered slot is referred to as the HI module; the module in the

lower-numbered slot is referred to as the LO module. You cannot use

slots 1 or 8 when creating a variable-width module. The modules do not

need to have the same memory depth.

You should check the System Configuration menu to verify that the

variable-width module is defined correctly. Figure 2-1 shows how the

Sys Config menu looks when two 92A96 Modules are combined into a

variable-width module.

Probe connections on the probe adapter board are labeled to identify

which module and which probe group connects to them. For example,

LO_A0 indicates the A0 group from the LO Module.

Figure 2-1. Sys Config menu with a variable–width module defined.

Refer to your module user manual for additional information about

variable-width modules, connecting probe cables, and positioning and

installing 92A96 Modules.

92DM923 88110 Instruction Manual

Online Version

2-3

Page 18

Installation and Connections

In a system with multiple modules, it is easier to identify which

modules are connected to the probe adapter if slot number labels are

applied to the 92A96 probe interface housings and DAS 9200

mainframe. Figure 2-2 shows how to apply slot number labels.

Apply slot number labels here.

Figure 2-2. Applying slot number labels.

CONFIGURING THE PROBE ADAPTER

You need to set a jumper on the probe adapter before connecting the

probe adapter to the SUT. This jumper can be used to disable the

microprocessor’s internal cache by pulling the DBUG pin to an active

low state.

The normal position does not pull the DBUG pin low. DBUG position

pulls the signal low. If the jumper is placed in the debug position the

DBUG pin should be disconnected from the user SUT. You can

disconnect the DBUG pin by removing the W6 pin from the sacrifice

socket.

2-4

92DM923 88110 Instruction Manual

Online Version

Page 19

Installation and Connections

CONNECTING TO THE SYSTEM UNDER TEST

Before you connect to the SUT, you must connect the standard probes

to the 92A96 Module card. Your SUT must also have a minimum

amount of clear space surrounding the microprocessor to accommodate

the probe adapter. Refer to Appendix C: Service Information for the

required clearances.

To connect the DAS 9200 to the SUT, do the following:

1. Turn off power to your SUT. It is not necessary to turn off power

to the DAS 9200.

CAUTION

Static discharge can damage the microprocessor, the probe

adapter, the podlets, or the 92A96 Module. To prevent

static damage, handle the microprocessor only in a

static-free environment.

Always wear a grounding wrist strap or similar device

while handling the microprocessor and probe adapter.

2. To discharge your stored static electricity, touch the ground jack

located on the back of the DAS 9200. Then, touch any of the

ground pins of the probe adapter to discharge stored static

electricity from the probe adapter.

3. Place the probe adapter onto the antistatic shipping foam to

support the probe as shown Figure 2-3. This prevents the circuit

board from flexing and the socket pins from bending.

4. Remove the 88110 microprocessor from your SUT.

5. Line up the pin A1 indicator on the microprocessor with the pin

A1 indicator on the probe adapter board.

CAUTION

Failure to correctly place the microprocessor into the

probe adapter may permanently damage the

microprocessor once power is applied.

6. Place the microprocessor into the probe adapter as shown in

92DM923 88110 Instruction Manual

Online Version

Figure 2-3.

2-5

Page 20

Installation and Connections

Figure 2-3. Placing the microprocessor into a typical PGA probe adapter.

7. Connect the clock and 8-channel probes to the probe adapter as

shown in Figure 2-4. Match the channel groups and numbers on

the interface housing to the corresponding pins on the probe

adapter.

2-6

92DM923 88110 Instruction Manual

Online Version

Page 21

8-CHANNEL PROBE

Hold the 8-Channel Probes

by the podlet holder when

connecting them to the

probe adapter. Do not hold

them by the cables or

necks of the podlets.

Installation and Connections

Figure 2-4. Connecting the podlets to a typical PGA probe adapter.

8. Line up the pin A1 indicator on the probe adapter board with the

pin A1 indicator on your SUT.

9. Place the probe adapter onto the SUT as shown in Figure 2-5.

NOTE

You may need to stack one or more replacement sockets

between the SUT and the probe adapter to provide

sufficient vertical clearance from adjacent components.

However, keep in mind this may increase loading, which

can reduce the electrical performance of your probe

adapter.

92DM923 88110 Instruction Manual

Online Version

2-7

Page 22

Installation and Connections

SUT SOCKET

Figure 2-5. Placing a typical PGA probe adapter onto the SUT.

2-8

92DM923 88110 Instruction Manual

Online Version

Page 23

Section 3: SETTING UP DISASSEMBLER

SOFTWARE

This section tells how to prepare the disassembler software to acquire

data and discusses the following:

S

loading support software

S

channel groups and assignments

S

changes that affect disassembly

S

clocking options

S

symbols

S

triggering

Before you acquire and disassemble data, you need to load support

software, and specify setups for clocking, triggering, and using

symbols. The disassembly software provides default values for each of

these setup controls, but you can change them as needed.

LOADING DISASSEMBLER SOFTWARE

To load the 88110 support, follow these steps:

1. Press the Menu Select key, select the appropriate 92A96 Module,

select its Configuration menu, and press Return.

2. Select 88110 in the Software Support field.

3. Press F8: EXECUTE OPERATION.

When you load the support software, the Channel, Clock, and Trigger

menus are automatically set up to acquire data from your 88110 system.

You can change the setups in the Clock and Trigger menus as needed.

Refer to Channel Groups and Assignments for information on what can

be changed in the Channel menu.

92DM923 88110 Instruction Manual

Online Version

3-1

Page 24

Setting Up Disassembler Software

CHANNEL GROUPS AND ASSIGNMENTS

The disassembler software automatically defines the channel groups for

the microprocessor. The following list describes the channel groups

defined for this microprocessor:

ADDRESS BP INTR RL TSIZ

ARBTR CACHE JTAG SNOOP TSTATEA

AUX0 CLK LO_DATA TCOD

AUX1 HI_DATA PSTAT

These groups cannot be changed; however, you can define and display

additional groups. If you want to know which signal is in which group,

refer to the channel assignment table in Appendix C: Service

Information. Channel assignments are also shown in the 92A96

Channel setup menu.

CHANGES THAT AFFECT DISASSEMBLY

You can change part of the default setups for the 92A96 Module.

However, keep in mind that if you change any of the following items,

the disassembled data will be affected:

S

threshold voltage

S

display polarity

CLOCKING

The 92DM923 software offers a customized clocking selection for the

88110 microprocessor. This clocking choice (Custom) is the default

selection.

The 92DM923 software acquires all terminated cycles. No clock

options are available. A description of how cycles are sampled by the

disassembler is found in Appendix B.

Disassembly will not be correct with the Internal or External clocking

modes. Refer to Section 5: General Purpose Analysis for a description

of using these other clock selections with this microprocessor support

package.

3-2

92DM923 88110 Instruction Manual

Online Version

Page 25

Setting Up Disassembler Software

Á

Á

Á

SYMBOLS

Symbols can be used to represent a specific channel group value or a

range of channel group values (defined by upper and lower bounds).

You can use symbol tables to display channel group information

symbolically in the State and Disassembly menus and to control

triggering. There is a symbol table file (named 88110_TCOD) supplied

by the disassembler software that replaces specific TCOD channel

group values.

Table 3-1 shows the names, bit patterns, and meaning for the symbols

in the file 88110_TCOD, the TCOD group symbol table.

Table 3-1

88110_TCOD Symbol Table Definitions

TCOD Group Value

Symbol

TC_3 TC_2 TC_1 TC_0

Meaning

USR_D_AC

ÁÁÁÁ

USR_T,F,A

D_MMU_TW

REP_CPB

SUP_D_AC

SUP_T,F,A

SN_CPB

USR_IN_AC

IN_MMU_TW

SUP_IN_AC

0001

ББББББ

0010

0011

0100

0101

0110

0111

1001

1011

1101

User data access

ББББББББББ

User touch, flush, allocate

Data MMU tablewalk

Replace copyback

Supervisor data access

Supervisor touch, flush, allocate

Snoop copyback

User instruction access

Instruction MMU tablewalk

Supervisor instruction access

Table 3-2 shows the names, bit patterns, and meaning for the symbols

in the file 88110_RL, the RL group symbol table.

Table 3-2

88110_RL Symbol Table Definitions

RL Group Value

Symbol

READ

WRITE

LK_READ

LK_WRITE

R/W LK

11

01

10

00

Meaning

Read

Write

Locked read

Locked write

92DM923 88110 Instruction Manual

Online Version

3-3

Page 26

Setting Up Disassembler Software

Á

Á

Á

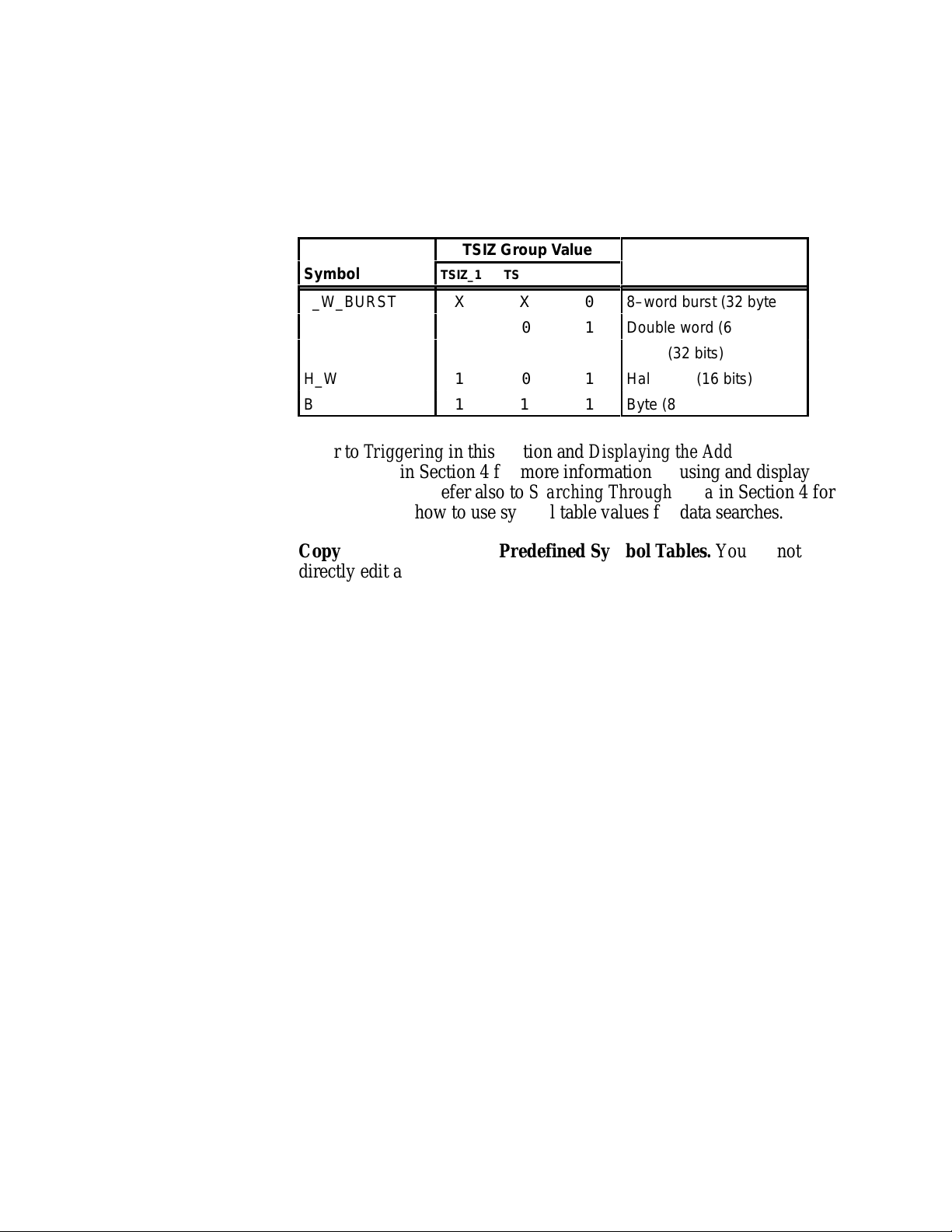

Table 3-3 shows the names, bit patterns, and meaning for the symbols

in the file 88110_TSIZ, the TSIZ group symbol table.

Symbol

Table 3-3

88110_TSIZ Symbol Table Definitions

TSIZ Group Value

TSIZ_1 TSIZ_0 TBST

Meaning

8_W_BURST

БББББ

D_W

W

H_W

B

XX0

ББББББ

001

011

101

111

8–word burst (32 bytes)

БББББББ

Double word (64 bits)

Word (32 bits)

Half word (16 bits)

Byte (8 bits)

Refer to Triggering in this section and Displaying the Address Group

Symbolically in Section 4 for more information on using and displaying

symbolic values. Refer also to Searching Through Data in Section 4 for

information on how to use symbol table values for data searches.

Copying and Editing the Predefined Symbol Tables. You cannot

directly edit any symbol tables supplied by microprocessor support.

You can make a copy of a predefined symbol table and then edit the

copy for your specific use.

To create a new symbol table, follow these steps:

1. Select the Symbol Editor menu from the Menu Selection overlay.

2. Press F2: FILE FUNCTIONS.

3. Select Open File in the Function field, and press Return.

3-4

4. Select New File in the Edit Status field, and press Return.

5. Enter a new symbol table file name in the New File Name field.

6. Select Pattern or Range in the Table Type field to match the

symbol table you are copying, and press Return.

7. Press F5: EXECUTE FUNCTION.

8. Select Merge Files in the Function field, and press Return.

9. Select the file to base your new symbol table on, such as the

88110_TCOD file.

10. Press F5: EXECUTE FUNCTION.

11. Press F8: EXIT & SAVE.

92DM923 88110 Instruction Manual

Online Version

Page 27

Setting Up Disassembler Software

12. Edit the file as desired keeping the following in mind:

S

If the new symbol has fewer don’t cares than an existing

symbol, it must be placed ahead of the existing symbol.

S

If the new symbol has more don’t cares than an existing

symbol, it must be placed after the existing symbol.

S

Do not duplicate symbol names.

Also refer to your DAS 9200 System User Manual for more

information on editing the symbol table.

13. Select the Channel menu from the Menu Selection overlay.

14. Change the file name of the symbol table for the TCOD group

(or whichever group’s symbol table you are replacing) to the one

that you specified in step 5.

TRIGGERING

All the Trigger menu selections available for use with your 92A96

Module are still valid for disassembly. Refer to your module user

manual for a list and description of these selections.

You can use the Home key to quickly clear the word recognizer field of

any channel group with a symbolic radix. To clear a word recognizer,

open the field, press the Home key, and close the field. The first entry

on the list is blank.

The DAS 9200 makes it possible to cross-trigger with other modules or

to an external instrument. You may want to consider sending or

receiving a signal to or from another module, or to the Sync Out SMB

connector on the module. You should refer to your DAS 9200 System

User Manual for an in-depth description of defining and using signals,

and to specific module user manuals for a description of using the Sync

Out SMB connector.

92DM923 88110 Instruction Manual

Online Version

3-5

Page 28

Section 4: ACQUIRING AND VIEWING

DISASSEMBLED DATA

This section describes how to acquire data and view it disassembled in

the Disassembly display. This section explains:

S

acquiring data

S

viewing disassembled data in various formats

S

functions of the Disassembly Format Definition overlay

S

displaying groups symbolically

S

restoring and viewing the demonstration reference memory

S

searching through data

S

printing data

ACQUIRING DATA

Once you load the 88110 support, choose a clocking mode, and specify

the trigger, you are ready to acquire data. Press the F1: START

acquisition key to begin the acquisition. You can press the F1: STOP

key at any time to stop acquisition.

If you have any problems acquiring data, refer to Appendix A: Error

Messages and Disassembly Problems.

VIEWING DISASSEMBLED DATA

Disassembled data is displayed in the Disassembly menu in four

different formats: Hardware, Software, Control Flow, and Subroutine.

To select a format, follow these steps:

1. Press the Select Menu key, and select the Disasm menu.

2. Press F5: DEFINE FORMAT.

3. Select the desired format in the Display Mode field.

4. Press F1: ESCAPE & CANCEL.

92DM923 88110 Instruction Manual

Online Version

4-1

Page 29

Acquiring and Viewing Disassembled Data

Hardware Display Format

The Hardware display format shows the Address, Data, and Control

channel values for each sample of acquired data in the order they

occurred. In Hardware data format, the disassembler displays certain

cycle type labels in parentheses. Table 4-1 shows these cycle type labels

and gives a definition of the cycle they represent. Reads to interrupt and

exception vectors will be labeled with the vector name.

Table 4-1

Cycle Type Definitions

Cycle Type

** RESERVED ** Reserved

(TCH/FLSH/ALLOC <CYCLESIZE>) Touch, flush, or allocate

(DATA MMU TBLWLK) Data MMU tablesearch

(RLMNT COPYBACK) Replacement copyback

(SNOOP COPYBACK) Snoop copyback

(INST MMU TBLWLK) Instruction MMU tablesearch

(FLUSH) Flush

(UNUSED PREFETCH) Unused prefetch

(TRANSFER ERROR CYCLE) Transfer error cycle

(TRANSFER RETRY CYCLE) Transfer retry cycle

(RD DA TA <CYCLESIZE>) Read data <cyclesize>

(WR DA TA <CYCLESIZE>) Write data <cyclesize>

(LWR DATA <CYCLESIZE>) Locked write data <cyclesize>

(LRD DA TA <CYCLESIZE>) Locked read data <cyclesize>

(U) = User mode.

(S) = Supervisor mode.

Definition

Figure 4-1 shows an example of the Hardware display.

4-2

92DM923 88110 Instruction Manual

Online Version

Page 30

Acquiring and Viewing Disassembled Data

3 4 5

2

1

Figure 4-1. Hardware display.

1

Cursor. Shows the DAS 9200 sequence number on which the

cursor is positioned.

2

Sequence Column. Lists DAS 9200 memory locations for the

acquired data.

3

Address Group. Lists data from channels connected to the 88110

Address bus.

4

Mnemonics Column. Lists the instructions that have been

disassembled.

5

Timestamp Column. Lists the timestamp values when a

timestamp selection is made in the Disassembly Format

Definition overlay.

Asterisks in the Mnemonics column indicate that there is insufficient

data available for complete disassembly of the instruction. The number

of asterisks shows the width of the data that is not available. Two

asterisks (**) represent a byte.

Gaps in the acquired data, caused by data qualification specified in the

Trigger menu, are indicated by a gray background behind the Address,

Hi_Data, and Lo_Data groups.

92DM923 88110 Instruction Manual

Online Version

4-3

Page 31

Acquiring and Viewing Disassembled Data

Software Display Format

The Software data format displays only the first fetch of executed

instructions. Flushed cycles and extensions are not shown, even though

they are part of the executed instruction. The display is designed to

resemble assembly language listings.

Control Flow Display Format

The Control Flow display format displays any instruction that changes

the flow of control, such as the following:

S

the first fetch of instructions that cause a branch in the address;

branches not taken are not displayed

S

conditional jumps actually taken

S

unconditional branches

S

instructions that cause traps

S

instructions that cause interrupts

S

“UNKNOWN” (“** RESERVED **”) cycles

S

exception cycles

Instructions that generate a change in the flow of control in the 88110

microprocessor are as follows:

BBO BSR RTE TCND

BB1 ILLOP TB0

BCND JMP TB1

BR JSR TBND

4-4

92DM923 88110 Instruction Manual

Online Version

Page 32

Acquiring and Viewing Disassembled Data

Subroutine Display Format

The Subroutine display format displays the first fetch of subroutine

calls and return instructions. Instructions that generate a subroutine call

or a return in the 88110 microprocessor are as follows:

BSR RTE TBND UNKNOWN OPCODE

ILLOP TBO TCND

JSR TB1 EXCEPTION CYCLES

Disassembly Format Definition Overlay

The Disassembly Format Definition overlay allows you to make

optional display selections for the Disassembly menu and tailor it for

your applications. To access this overlay, press F5: DEFINE FORMAT.

You can use this overlay to do the following:

S

choose the format (mode) in which the Disassembly menu displays

disassembled data

S

set the interval in which the data cursor will scroll through

disassembled data

S

display and define the format of the timestamp

S

highlight various types of disassembled cycles

S

change the position of any channel group in the display

S

change the radix for any channel group

S

choose which symbol tables are to be used when channel groups are

displayed symbolically

S

specify the size and starting address of the vector table

The Disassembly Format Definition overlay is shown in Figure 4-2.

92DM923 88110 Instruction Manual

Online Version

4-5

Page 33

Acquiring and Viewing Disassembled Data

1

2

3

4

5

6

9

10

11

7 8

Figure 4-2. Disassembly Format Definition overlay.

1

Display Mode. You can select either Hardware, Software,

Control Flow, or Subroutine format.

2

Timestamp. You can display the timestamp as an Absolute,

Relative, or Delta value. You can also set the timestamp display to

Off.

Timestamp values show the amount of time that has elapsed

between data samples. An Absolute timestamp shows the amount

of time elapsed between when the acquisition was started (after

pressing F1: START) and each subsequent data sample. A

Relative timestamp shows the amount of time elapsed between

successive samples. A Delta timestamp shows the amount of time

between the sample with the delta user mark and each previous or

subsequent data sample.

3

Scroll By. You can scroll by Sequence, Instruction, Control Flow,

or Subroutine.

4-6

92DM923 88110 Instruction Manual

Online Version

Page 34

Acquiring and Viewing Disassembled Data

4

Highlight. You can highlight Instructions, Control Flow, or

Subroutines. With highlighting on, only the selected type of

samples are shown as white text with a black background; all

other samples are shown as gray text with a black background.

You can also set the highlighting to Off.

5

Highlight Gaps. You can choose to highlight or not to highlight

gaps. Gaps are caused by qualifying data storage in the Trigger

menu and are indicated by a gray background behind the address

values.

6

Disasm Across Gaps. You can choose to continue or not to

continue to disassemble data across gaps. Disassembling data

across gaps causes the disassembler to disassemble data as if no

gap existed. Disassembled data will be invalid if the last sample

before the gap does not logically match the sample immediately

following the gap.

7

Vector Base Address. If your SUT has had its vector table

relocated, you must use this field to inform the disassembler of

the new base address. If the value in the Vector Base Address

field is incorrect, the disassembler will not interpret interrupts or

exceptions correctly.

8

Vector Table Size. Use this field to specify the size of the vector

table.

9

Group Name. You can specify the name of the group that

displays in the column in which the cursor is positioned. When

you move a group, the group is inserted in the new column

position and removed from its old position. The remaining

groups move either one column position to the left or one column

position to the right.

10

Group Radix. You can select the radix in which each group

displays. The radix selections for most groups are Binary, Octal,

Hexadecimal, Decimal, ASCII, Symbol, and Off. The only

selections for the Hi_Data and Lo_Data groups are Hexadecimal

or Off. The only selections for Mnemonics group are ASCII or

Off. You should only select the symbolic radix when a symbol

table is available for that group. The timestamp value always

displays in decimal.

11

Symbol Table. You can specify a symbol table to use for each

group where symbolic is the selected radix.

Function Keys

F1: ESCAPE & CANCEL. Closes the overlay and discards any

changes you have made since entering it.

92DM923 88110 Instruction Manual

Online Version

4-7

Page 35

Acquiring and Viewing Disassembled Data

F5: RESTORE FORMAT. Displays a list of saved disassembly

formats for the current module or cluster setup. Use the cursor keys to

select the desired format to restore and press the Open/Close key.

F6: SAVE FORMAT. Saves the current selections for the Disassembly

Format Definition overlay in a file on disk. You can enter a file name

up to ten characters long.

F7: DELETE FORMAT. Displays a list of saved disassembly format

files for the current module or cluster setup. Use the cursor keys to

select the desired format to delete and press the Open/Close key. You

cannot delete the Default format.

F8: EXIT & SAVE. Exits the overlay and executes or saves any

changes made.

Displaying the Address Group Symbolically

The Address group can be displayed as symbolic values in the

Disassembly menu similar to the way the TCOD group can be

displayed as symbol values in the State menu. You can use the Symbol

Editor menu to create symbol tables in which symbols are assigned to

various address ranges or patterns. You can then change the radix of the

Address group in the Disassembly menu using the Disassembly Format

Definition overlay. If an address appears in the operand field of a

mnemonic, it also will be displayed symbolically.

Exception Vectors

The 88110 microprocessor initially places the exception vector table at

address 00000000 (the default value). However, you can relocate the

table using the Processor Support submenu by entering the address in

the Vector Base Addr field. The Vector Base Addr field provides the

disassembler with the offset address; enter an eight-digit hexadecimal

value corresponding to the offset of the base address of the exception

table. The Vector Table Size field lets you specify a three-digit

hexadecimal size for the table.

Table 4-2 lists the 88110 exception vectors (exception cycle types).

Interrupt cycle types are computed cycle types and cannot be used to

control triggering. When the 88110 microprocessor processes an

exception, the disassemble software displays the type of exception, if

known.

4-8

If you defined the address of the exception table in the FORMAT

OVERLAY menu, the exception vector reads are labelled and displayed

in parentheses when disassembly is performed.

92DM923 88110 Instruction Manual

Online Version

Page 36

Acquiring and Viewing Disassembled Data

Table 4-2

Interrupt/Exception Labels

Number

0 RESET EXCEPTION

1 INTERRUPT EXCEPTION

2 INSTRUCTION ACCESS

3 DA TA ACCESS

4 MISALIGNED ACCESS

5 UNIMPLEMENTED OPCODE

6 PRIVILEGE VIOLA TION

7 BOUNDS CHK VIOLA TION

8 ILLEGAL INTEGER DIV

9 INTEGER OVERFLOW

10 ERROR EXCEPTION

11 NONMASKABLE INTERRUPT

12 DATA MMU READ MISS

13 DATA MMU WRITE MISS

14 INSTR MMU ATC MISS

15-113 RESERVED

114 SFU 1 ILLEGAL OPCODE

115 RESERVED

116 SFU 2 ILLEGAL OPCODE

117 RESERVED

118 SFU 3 ILLEGAL OPCODE

119 RESERVED

120 SFU 4 ILLEGAL OPCODE

121 RESERVED

122 SFU 5 ILLEGAL OPCODE

123 RESERVED

124 SFU 6 ILLEGAL OPCODE

125 RESERVED

126 SFU 7 ILLEGAL OPCODE

127 RESERVED

128-51 1 USER DEFINED

Exception

Searching Through Data

The disassembler does not have a Disassembly Search Definition

overlay. However, you can effectively search through disassembled data

by following these steps:

1. Press F2: SPLIT DISPLAY to use the split-screen display.

92DM923 88110 Instruction Manual

Online Version

4-9

Page 37

Acquiring and Viewing Disassembled Data

2. Press F5: SPLIT HORIZ to split the screen into two horizontal

displays.

3. Press F2: LOCK CURSOR. A list of selections appears.

4. Select lock cursors at the same sequence, and press Return.

5. Press F8: EXIT & SAVE to display the menus in a split screen.

6. If the active window is the Disassembly menu, press

F3: SWITCH WINDOWS to make the State menu active. The

cursor and Cursor field are yellow in the active window.

7. Press F6: DEFINE SEARCH to use the search function of the

State menu to search for the desired sequence.

To search on TCOD group values, change the radix to binary and refer

to Table 3-1 to find the binary equivalent values for the cycles you want

to locate.

When searching for data in a clustered module setup in the State menu,

the searches are conducted only for the master module. You can,

however, define either module to be the master module. Refer to the

description of the State Search Definition overlay in your 92A96

Module User Manual for a description of how to search through state

data. Also refer to that manual for a description of how to return to a

full screen display.

To abort a search, press the Esc (escape) key.

Figure 4-3 shows the screen split into Disassembly and State windows

with the cursors locked on the same bus cycle.

4-10

92DM923 88110 Instruction Manual

Online Version

Page 38

Acquiring and Viewing Disassembled Data

Figure 4-3. Disassembly and State split-screen display. You can use this method to

perform searches.

PRINTING DATA

To print disassembled data, use the Disassembly Print overlay. To

access this overlay, press the Shift and Print keys at the same time from

the Disassembly menu. The Disassembly Print overlay is exactly the

same as the State Table Print overlay. Refer to your 92A96 Module

User Manual for a description of this overlay.

92DM923 88110 Instruction Manual

Online Version

4-11

Page 39

Acquiring and Viewing Disassembled Data

REFERENCE MEMORY

A demonstration reference memory file is provided so you can see an

example of how your 88110 microprocessor mnemonics look when

they are disassembled. In this discussion, you will view the reference

memory. Viewing the reference memory is not a requirement for

preparing the 92A96 Module for use. You can view the reference

memory file without connecting the DAS 9200 to your SUT.

To view the 88110_Demo Refmem, follow these steps:

1. Press the Select Menu key, and select the 88110_Demo file from

the Refmem column.

2. Select the Disasm menu, and press Return.

You can affect the display of the disassembled data from the

Disassembly Format Definition overlay, which you can access through

the Disassembly menu. Displaying all disassembled instructions and

cycle types is the default format.

If there is not enough free space on the hard disk, you can delete the

88110_Demo file. It is not necessary to the operation of the

disassembler.

4-12

92DM923 88110 Instruction Manual

Online Version

Page 40

Section 5: GENERAL PURPOSE ANALYSIS

You may need to perform general purpose (timing) analysis on your

88110 system prior to, during, and after attempting to integrate your

software with the 88110 system hardware. When performing hardware

analysis, you will want to use the data acquisition module to acquire

data with a finer resolution. When more data samples are taken in a

given period of time, the resolution in the Timing display increases,

letting you see signal activity that would otherwise go undetected.

This section provides information on the following:

S

clocking

S

triggering

S

displaying data

S

supplied Timing Format Definition file

To acquire and display timing data, you need to change the clocking

selection and trigger program, acquire data, and view it in the Timing

menu. A predefined Timing Format Definition overlay file called

88110_96 can be used to view 88110 timing data. A description of this

file and how to use it can be found later in this section.

Keep in mind when you view data in the State display that it uses the

default channel grouping setup with all groups visible and will look

different than the Disassembly display.

There often is a need to view data in a split screen display with state

data in one half and timing data in the other. Do not disconnect any of

the 92A96 probe cables or interface housings if you are analyzing data

in this manner. Instead, use the extra channels available from the 92A96

Module to make other 88110 system connections.

CLOCKING

To change the data sampling rate, use the Clock menu.

When using the 92A96 Module for timing analysis, you will want to

use the Internal or External clocking modes. The Internal clock

selection can sample data up to 100 MHz, which has a 10 ns resolution

between samples. The External clock selection samples data on every

active clock edge on the 92A96 clock inputs up to 100 MHz.

92DM923 88110 Instruction Manual

Online Version

5-1

Page 41

General Purpose Analysis

The default clocking mode is Custom when microprocessor support is

used; you will need to change it to either Internal or External. Your

92A96 Module User Manual contains an in-depth description of

Internal and External clocking.

Custom Clocking

Custom clocking only stores one data sample for each bus transaction,

which can take one or more clock cycles. Custom clocking also

time-aligns certain signals that otherwise would be skewed relative to

the current bus transaction. This clocking selection is generally

unproductive for timing analysis. Refer to Appendix B for a more

in-depth description of how Custom clocking is used with the probe

adapter to acquire data.

Internal Clocking

When you select Internal as the clocking mode, the 92A96 Module

stores one data sample as often as every 10 ns (100 MHz). This

clocking selection is commonly referred to as asynchronous.

Two typical uses of Internal clocking might be to verify that all the

88110 signals are transitioning as expected or to measure timing

relationship between signal transitions.

It is possible to acquire asynchronous data at rates of 200 MHz and

400 MHz. The faster the 92A96 Module acquires data, the fewer

channels it can acquire data on. A single 92A96 Module can acquire

data on 24 channels at 400 MHz or 2.5 ns resolution. Refer to your

92A96 Module User Manual for information on sampling data at speeds

faster than 100 MHz.

External Clocking

When you select External as the clocking mode, the 92A96 Module

acquires and stores data based on the clock channel up to 100 MHz.

This clocking selection is commonly referred to as synchronous.

By selecting the rising edge of CLK: 3 on the acquisition module as the

clock channel, and turning off the remaining three clocks, the module

will sample data on every rising edge of the clock. No data is acquired

on the falling clock edge unless you select both edges.

You can also use the other three clock channels as qualifiers or clocks to

further modify the clocking in of information from your 88110 system.

5-2

92DM923 88110 Instruction Manual

Online Version

Page 42

General Purpose Analysis

TRIGGERING

All the Trigger menu selections available for use with the 92A96

Module are still valid for timing analysis. Refer to your module user

manual for a list and description of the selections.

ACQUIRING DATA

You can acquire data as described in the Acquiring Data description in

Section 4.

DISPLAYING DATA

General purpose analysis requires that you view data in either the State

or Timing menus. The following discussion describes these menus.

Timing Menu

In the Timing menu, every channel is shown as a waveform, and groups

of channels are shown as bus forms.

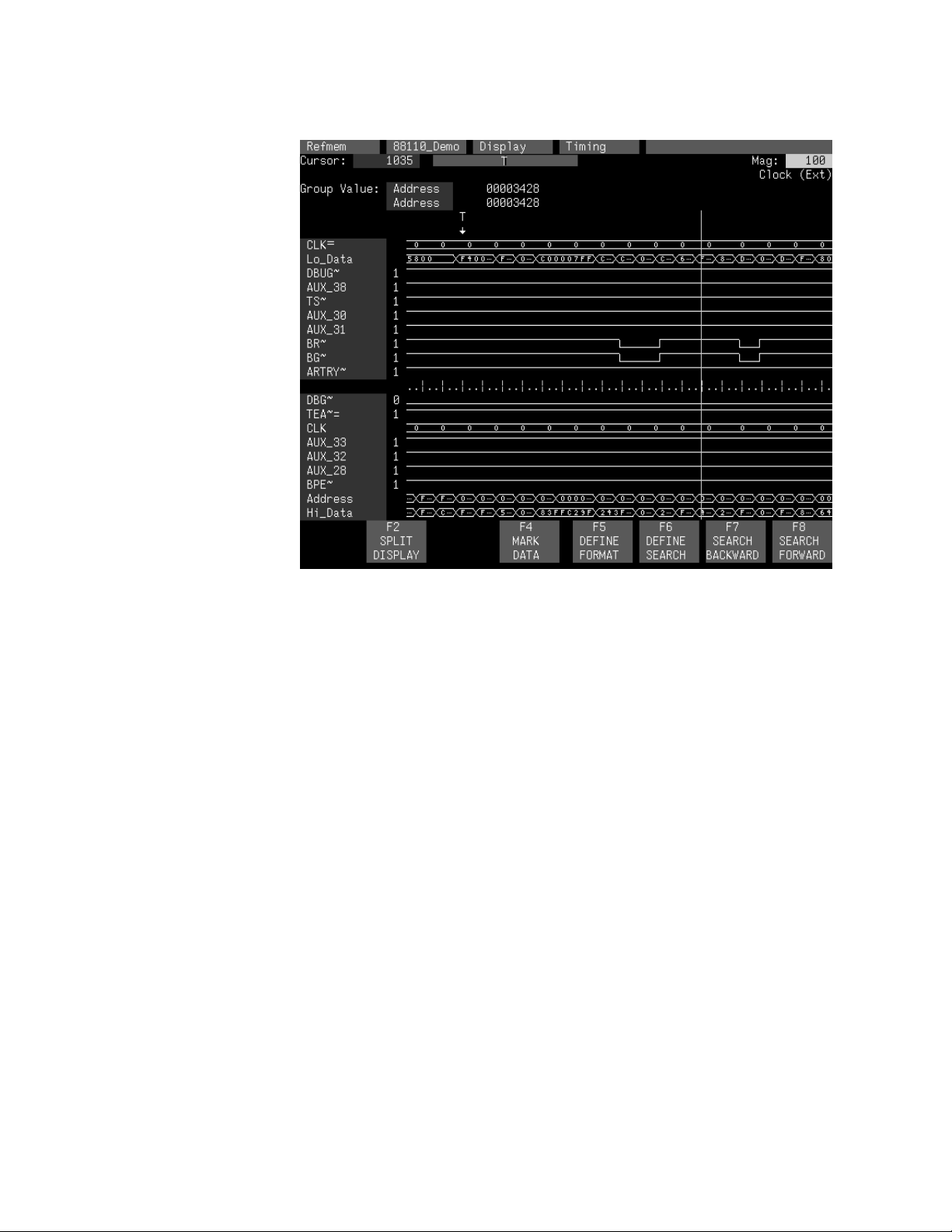

A predefined Timing Format Definition overlay file, part of the 88110

microprocessor support, is available for you to use when displaying

data in the Timing format. The 88110_96 file is installed on the

DAS 9200 with the support software.

The 88110_96 Timing Format file places the CLK= signal first

followed by the Lo_Data group displayed as bus forms containing bus

values instead of as individual timing waveforms. These groups are

followed by the 88110 system clock and other important control

signals. The Address and Hi_Data groups are also displayed as bus

forms at the bottom of the display. Figure 5-1 shows data displayed

using the 88110_96 file.

To select the supplied Timing Format Definition file, follow these steps:

1. Select the Timing menu, and press F5: DEFINE FORMAT.

2. Press F5: RESTORE FORMAT.

3. Select 88110_96, and press the Return key. A message tells you

the format file is selected.

4. Press F8: EXIT & SAVE to return to the Timing menu.

Refer to the channel assignment tables in Appendix C for the lists of

individual channels and their 88110 signal names.

92DM923 88110 Instruction Manual

Online Version

5-3

Page 43

General Purpose Analysis

Figure 5-1. Timing data using the 88110_96 Timing Format file.

State Menu

In the State menu, all channel group values are shown based on the

selected radix in the Channel menu or the State Format Definition

overlay. No disassembly occurs. Figure 5-2 shows State data.

If you want to display other channel groups, access the State Format

Definition overlay and change the radix from Off to Hex, Bin, or Oct.

This overlay also allows you to add the Timestamp group (and change

the radix) to the data display.

5-4

92DM923 88110 Instruction Manual

Online Version

Page 44

General Purpose Analysis

Figure 5-2. State data.

SEARCHING THROUGH DATA

To search through data, you can use either the Timing Search Definition

overlay or the State Search Definition overlay. You can use these

overlays and search through data as described in your 92A96 Module

User Manual.

PRINTING DATA

To print state data, you can use the State Print overlay. To access this

overlay, press the Shift and Print keys at the same time from the State

menu.

To print timing data, you can use the Timing Print overlay. To access

this overlay, press the Shift and Print keys at the same time from the

Timing menu.

For detailed information on the State Print overlay or the Timing Print

overlay, refer to your 92A96 Module User Manual.

92DM923 88110 Instruction Manual

Online Version

5-5

Page 45

Appendix A: ERROR MESSAGES AND

DISASSEMBLY PROBLEMS

This appendix describes error messages and disassembly problems that

you may encounter while acquiring data.

MODULE ERROR MESSAGES

These error messages will appear in the Module Monitor menu when

there are problems with acquiring data or satisfying the trigger

program. The error messages are listed in alphabetical order; a

description of the error message and the recommended solution follow

the error message.

Slow Clock. This message appears when the active clock channel (or

channels) is not changing, is typically changing at 1 ms or slower

intervals, or one of the clock qualifiers is held in the wrong state. Check

for the following:

1. The 88110 system is powered on and running. Be sure the system

is not halted.

2. 88110 Support is selected in the appropriate 92A96

Configuration menu.

3. Custom is selected in the Clock menu.

4. The connections between the 92A96 Module and the probe

adapter are correct.

S

The clock and 8-channel probe connections between the

interface housings and probe adapter are correct (module

name, clock, section names, and channel numbers match), are

properly oriented (GND connects to ground), and are fully

engaged.

S

The connections between the interface housings and 92A96

probe cables have matched color labels, matched slot

numbers, and are properly keyed.

S

The connections between the 92A96 probe cables and probe

connectors have matched color labels, matched slot numbers,

and are properly keyed.

5. The orientation of pin A1 on the microprocessor, the probe

adapter, and SUT are correct.

6. No pins are bent or missing on the 88110 microprocessor or on

either of the probe adapter sockets.

7. The DBUG jumper is in the Normal position.

92DM923 88110 Instruction Manual

Online Version

A-1

Page 46

Error Messages and Disassembly Problems

Waiting for Stop. This message appears when the trigger condition is

satisfied and memory is full but the Manual Stop mode is selected in

the Cluster Setup menu. The solution is to manually stop the DAS 9200

by pressing F1: STOP.

This message can also appear when other modules in the cluster have

not filled their memories. Wait for the other modules to fill their

memories. If the message does not disappear in a short time, press

F1: STOP.

Waiting for Stop-Store. This message appears when the trigger

condition is satisfied but the amount of post-fill memory specified in

the trigger position field is not yet filled. Press F1: STOP to view the

acquired data, then check for the following:

1. The trigger program in the Trigger menu is correct.

2. The storage qualification in the Trigger menu is correct.

3. The system or the module does not have an exception or fault.

The 88110 system or acquisition module might have experienced

a hardware or software exception or fault after the trigger

condition was satisfied.

Waiting for Trigger. This message appears when the trigger condition

does not occur. Check for the following:

1. The 88110 system is powered on and running. Be sure the system

is not halted.

2. The trigger conditions are not being satisfied. The Module

Monitor menu shows which state events are not occurring. Press

F1: STOP, access the Trigger menu, and redefine the conditions

for that state. Also refer to the description on Triggering in

Section 3.

OTHER DISASSEMBLY PROBLEMS

There may be problems with disassembly for which no error messages

are displayed. Some of these problems and their recommended

solutions follow.

Incorrect Data. If the data acquired is obviously incorrect, check the

following:

1. 88110 Support is selected in the 92A96 Configuration menu.

2. Custom is selected in the Clock menu.

A-2

3. The DBUG jumper is in the Normal position.

92DM923 88110 Instruction Manual

Online Version

Page 47

Error Messages and Disassembly Problems

4. The connections between the 92A96 Module and the probe

adapter are correct.

S

The clock and 8-channel probe connections between the

interface housings and probe adapter are correct (module

name, clock, section names, and channel numbers match), are

properly oriented (GND connects to ground), and are fully

engaged.

S

The connections between the interface housings and 92A96

probe cables have matched color labels, matched slot

numbers, and are properly keyed.

S

The connections between the 92A96 probe cables and probe

connectors have matched color labels, matched slot numbers,

and are properly keyed.

5. The orientation of pin A1 on the microprocessor, the probe

adapter, and SUT are correct.

6. No pins are bent or missing on the 88110 microprocessor or on

either of the probe adapter sockets.

Other Suggestions. If the previous suggestions do not fix the problem

with acquiring disassembled bus cycles or instruction mnemonics, try

the following:

1. Reload the module setup by selecting the 88110 Support in the

92A96 Configuration menu to restore the DAS 9200 to a known

state.

2. Possible ac and dc loading problems may be remedied by

removing one or both of the protective sockets from the probe

adapter. These sockets may add enough additional inductance to

your 88110 system to affect it. Refer to Appendix C for a

description to remove sockets from the probe adapter.

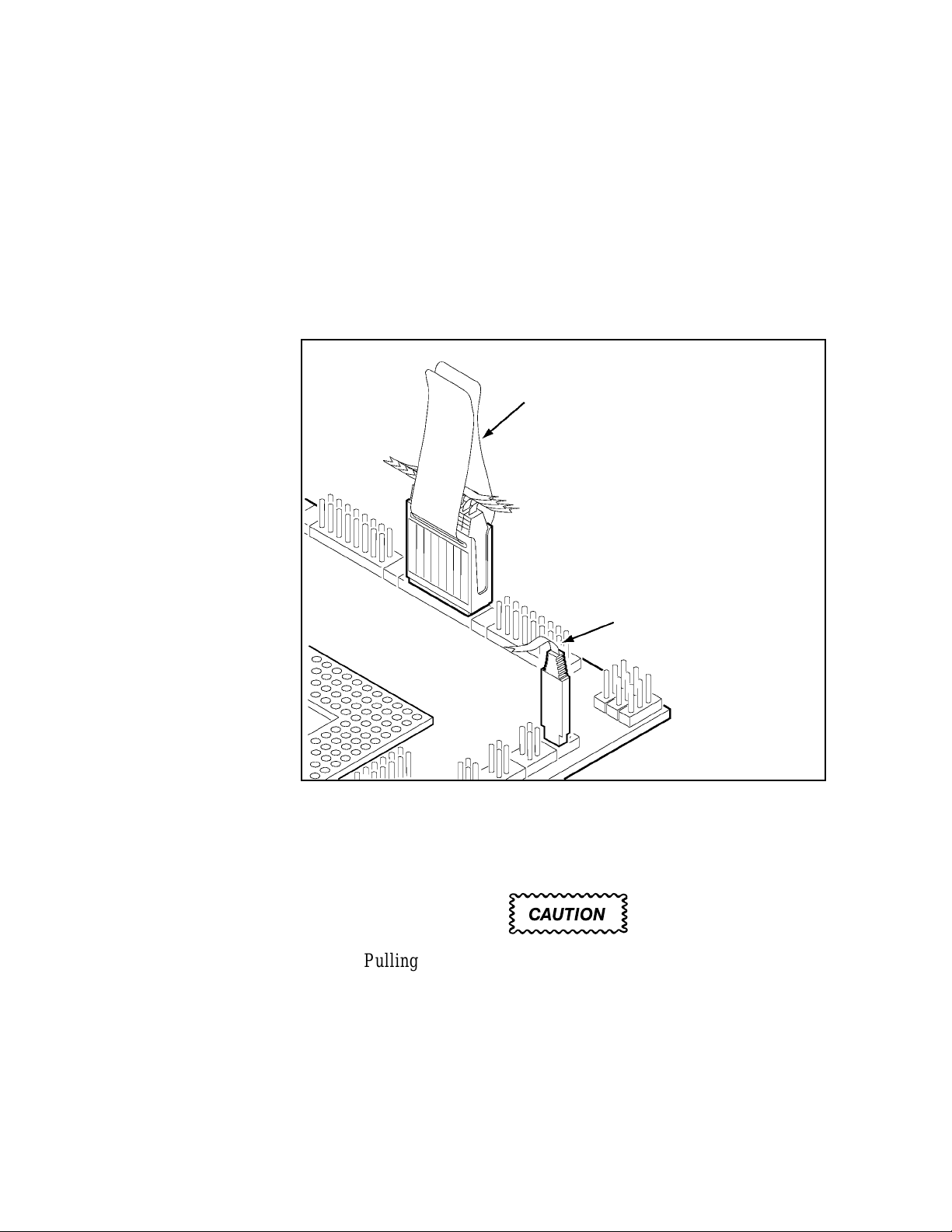

If the DAS 9200 still is not acquiring data after trying these solutions,