Page 1

Technical Reference

DAS 9200

Technician’s Reference

070-5959-09

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

Page 2

Copyright T ektronix, Inc. All rights reserved. Licensed software products are owned by Tektronix or its suppliers and

are protected by United States copyright laws and international treaty provisions.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (c)(1)(ii) of the

Rights in T echnical Data and Computer Software clause at DFARS 252.227-7013, or subparagraphs (c)(1) and (2) of the

Commercial Computer Software – Restricted Rights clause at F AR 52.227-19, as applicable.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

DASNT and DASXP are trademarks of T ektronix, Inc.

Page 3

WARRANTY

T ektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1) year

from the date of shipment. If any such product proves defective during this warranty period, T ektronix, at its option, either

will repair the defective product without charge for parts and labor, or will provide a replacement in exchange for the

defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. T ektronix will provide such service at

Customer’s site without charge during the warranty period, if the service is performed within the normal on-site service

area. T ektronix will provide on-site service outside the normal on-site service area only upon prior agreement and subject

to payment of all travel expenses by Customer. When or where on-site service is not available, Customer shall be

responsible for packaging and shipping the defective product to the service center designated by T ektronix, with shipping

charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a location within the

country in which the T ektronix service center is located. Customer shall be responsible for paying all shipping charges,

duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than T ektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; or c) to service a product that has been

modified or integrated with other products when the effect of such modification or integration increases the time or

difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THIS PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESSED OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUST OMER FOR BREACH OF THIS WARRANTY. TEKTRONIX

AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

Page 5

Table of Contents

General Safety Summary xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Safety Summary xv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface xvii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction to DAS Hardware

Introduction to DAS Hardware 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mainframes and Terminals 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T erminals 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mainframe Hardware 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mainframe Power Requirements 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAS with Option 04 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAS 92E9 Expansion Mainframe 1–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Acquisition and Pattern Generation Modules 1–16. . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance

Maintenance 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preventive Maintenance 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Static Precautions 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning Guidelines 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mainframe 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T erminal and Keyboard 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAS Modules 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

92HS8/8E Cabinet 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Corrective Maintenance 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Obtaining Replacements 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting the Line Voltage and Replacing the Line Fuse 2–6. . . . . . . . . . . . . . .

Replacing the Battery on the DAS 9219/9220 Controller Board 2–14. . . . . . . . .

Disposing the Lithium Battery 2–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly/Reassembly Procedures

Disassembly/Reassembly Procedures 3–1. . . . . . . . . . . . . . . . . . . . . . . . . .

General Precautions 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T ools Required 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly/Reassembly of the Mainframes 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

DAS 9200 Technician’s Reference

i

Page 6

Table of Contents

Procedure 1:Removing the Mainframe Top Cover 3–3. . . . . . . . . . . . . . . . . . . .

Procedure 2:Removing a Module From the Card Cage 3–5. . . . . . . . . . . . . . . .

Procedure 2a:Removing the 92LANSE Module 3–6. . . . . . . . . . . . . . . . . . . . .

Procedure 3:Removing the Front Panel 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure 4:Removing the Fan 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure 5:Removing the Media Frame 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure 6:Removing the Disk Drives From the Media Frame 3–9. . . . . . . . .

Procedure 7:Removing the Power Supply 3–15. . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure 8:Removing the Card Cage 3–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure 9:Removing the Controller Board 3–20. . . . . . . . . . . . . . . . . . . . . . . .

Procedure 10:Removing and Disassembling the Expansion Cable

(DAS 92E9 only) 3–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure 11:Removing the Expansion Slave Board (DAS 92E9 only) 3–21. . .

Procedure 12: Removing the Backplane 3–22. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly/Reassembly of the 92HS8 Cabinet 3–22. . . . . . . . . . . . . . . . . . . . . . . . .

Procedure 1:Removing the 92HS8 Cabinet Covers 3–23. . . . . . . . . . . . . . . . . . .

Procedure 2:Elevating the 92HS8 Memory Board 3–23. . . . . . . . . . . . . . . . . . . .

Procedure 3:Removing the 92HS8 Power Supply 3–24. . . . . . . . . . . . . . . . . . . .

Procedure 4:Removing the 92HS8 Cooling Fans 3–24. . . . . . . . . . . . . . . . . . . . .

Procedure 5:Replacing 92HS8 Probes 3–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly/Reassembly of Probes 3–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P6461/E Data Acquisition Probe 3–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P6460 Data Acquisition Probe 3–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P6464 Pattern Generator Probe 3–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P6465 Pattern Generator Probe 3–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P6463/A Pattern Generator Probe 3–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

92A60/90 Buffer Probe 3–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T erminals 3–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting

Troubleshooting 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mainframe Troubleshooting Overview 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Troubleshooting Overview 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power-On Diagnostics 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9200T T erminal Diagnostics 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9201T T erminal Diagnostics 4–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9202XT and 9203XT T erminal Diagnostics 4–10. . . . . . . . . . . . . . . . . . . . . . . .

9204XT, 9205XT, and 9206XT Terminal Diagnostics 4–13. . . . . . . . . . . . . . . .

DAS Mainframe Diagnostics 4–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

92LAN Diagnostics 4–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error Codes 4–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

92LAN Boot-Up Status 4–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Extended 92LAN Diagnostics 4–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Construction 4–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

DAS 9200 Technician’s Reference

Page 7

Table of Contents

Mainframe Troubleshooting 4–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply Check 4–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Control Signals 4–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIP Switches on the Controller Board 4–45. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS-232 Ports 4–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hard and Floppy Disk Drive Power Connector 4–47. . . . . . . . . . . . . . . . . . . . . .

Hard Disk Drive Switch and Jumper Positions 4–47. . . . . . . . . . . . . . . . . . . . . . .

Floppy Disk Drive Jumper Positions 4–56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Floppy Disk Drive Strapping on the Controller Board 4–67. . . . . . . . . . . . . . . . .

Other Controller Board Jumpers 4–67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loading System Software 4–69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hard Disk Format Utility 4–70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAS 9221 SCSI Hard Disk Format Utility Menus 4–71. . . . . . . . . . . . . . . . . . . .

DAS 9219/9220 ST506 Hard Disk Format Utility Menus 4–76. . . . . . . . . . . . . .

File System Make Utility 4–83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

File System Install Utility 4–91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration Utility 4–96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional System Software 4–108. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Application Software 4–109. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operator’s Checkout Procedure 4–110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9200T or 9201T T erminal Power-Up Diagnostics 4–110. . . . . . . . . . . . . . . . . . . .

Power-Up Self-Test 4–110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X T erminal Power-Up Diagnostics 4–11 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mainframe Power-Up Diagnostics 4–111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting the DAS Modules 4–112. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

92A16/16E Troubleshooting 4–112. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

92A60/90 Troubleshooting 4–114. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

92A96 and 92C96 Troubleshooting 4–114. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

92HS8 Troubleshooting 4–119. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

92S16/32 Troubleshooting 4–121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

92SX109/118 Troubleshooting 4–121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

92C01/02 Troubleshooting 4–121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAS LAN Troubleshooting 4–122. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X T erminal Traits 4–122. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAS Stand-Alone LAN Troubleshooting 4–123. . . . . . . . . . . . . . . . . . . . . . . . . . .

LAN Network Troubleshooting 4–126. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LAN Communications 4–130. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Snoopy Mode for ARP and TCP/IP 4–132. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Circuit Functions

General Circuit Functions 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAS Mainframe 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAS 92E9 Expansion Mainframe 5–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Expansion Slave Board 5–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAS 9200 Technician’s Reference

Backplane Board 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controller Board 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memory Board (DAS 9219/9220 Only) 5–11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hard and Floppy Disk Drives 5–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply 5–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iii

Page 8

Table of Contents

92A16/16E Data Acquisition Module 5–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P6461/E Data Acquisition Probe 5–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P6460 Data Acquisition Probe 5–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

92A60/90 Data Acquisition Module 5–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

92A60/90 Controller Board 5–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

92A60/90 Memory Board 5–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

92A60/90 Buffer Probe 5–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

92A96 and 92C96 Data Acquisition Modules 5–20. . . . . . . . . . . . . . . . . . . . . . . . . . .

92HS8/8E High-Speed Data Acquisition Module 5–21. . . . . . . . . . . . . . . . . . . . . . . .

92S16 Pattern Generation Module 5–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

92S32 Pattern Generation Module 5–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P6464 and P6465 Pattern Generation Probes 5–25. . . . . . . . . . . . . . . . . . . . . . . .

P6463A Pattern Generation Probe 5–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

92SX109/118 Pattern Generation Module 5–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

92C01/02/03 GPIB and Expansion Modules 5–27. . . . . . . . . . . . . . . . . . . . . . . . . . . .

92LAN Module 5–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

92LANSE Module 5–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Electrical Parts

Replaceable Electrical Parts 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Ordering Information 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Electrical Parts List 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Mechanical Parts

Replaceable Mechanical Parts 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Ordering Information 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Mechanical Parts List 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagrams

Diagrams 7–81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv

DAS 9200 Technician’s Reference

Page 9

List of Figures

Table of Contents

Figure 1–1: DAS Basic Configurations 1–1. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–2: Master Mainframe Internal Components (Memory Board in

Slot 1 for DAS 9219/9220) 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–3: DAS Master Mainframe Connected with One Expansion

Mainframe 1–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–4: Twenty-Eight Slots Available with One Master and Three

Expansion Mainframes 1–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–1: Location of Power Supply Frame Screws 2–7. . . . . . . . . . . . .

Figure 2–2: Location of Line Voltage Selection Jacks 2–8. . . . . . . . . . . . .

Figure 2–3: Position of Line Voltage Selection Jacks for 115 V or 230 V

Operation 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–4: Location of DAS 9221 Back Panel Fuse and Line Voltage

Indicator Knob (DAS 9219/9220 Look Similar) 2–9. . . . . . . . . . . . . . .

Figure 2–5: Location of AC Voltage Selector Switches on the 9200T 2–10

Figure 2–6: Location of the Line Voltage Selector and Line Fuse

Behind the 92HS8/8E Side Panel 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–7: Back Panel Location of the 92HS8 Line Voltage

Indicator Screw 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–8: Location of C921 on Mainframe Controller Board 2–15. . . . .

Figure 3–1: DAS Mainframe Internal Components (Memory Board in

Figure 3–2: Removing the Mainframe Top Cover 3–4. . . . . . . . . . . . . . . .

Figure 3–3: Ejector Tools and Location of Card-Cage

Figure 3–4: Location of Latches for Removing the Front Panel 3–7. . . .

Figure 3–5: Location of Screws for Removing the Media Frame 3–9. . . .

Figure 3–6: Typical Cable Connections for Fixed-Mount Hard and Floppy

Figure 3–7: Typical Cable Connections for Fixed-Mount Hard and Floppy

Figure 3–8: Folding the Ribbon Cables 3–13. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–9: Removable 20 Mbyte Drive in DAS 9219/9220

Figure 3–10: Removable Hard Disk Drive in a Media Frame 3–15. . . . . .

Figure 3–11: Location of Screws for Removing the Mainframe

DAS 9200 Technician’s Reference

Slot 1 for DAS 9219/9220) 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Door Fasteners 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disk Drives for DAS 9219 and DAS 9220 Mainframes 3–11. . . . . . . . .

Disk Drives For DAS 9221 Mainframes 3–12. . . . . . . . . . . . . . . . . . . . .

Media Frame 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

v

Page 10

Table of Contents

Figure 3–12: Back Panel Screw Locations for Removing the

Card Cage 3–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–13: Bottom-front Screw Locations for Removing the

Card Cage 3–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–14: Location of Screws for Elevating the 92HS8

Memory Board 3–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–15: Location of Screws for Removing the 92HS8

Power Supply 3–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–1: Location of SELF TEST and RESET Buttons on the 9200T

Rear Panel 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–2: Location of S TEST and RESET Buttons on the 9201T

Front Panel 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–3: Extended Self Test Main Menu 4–10. . . . . . . . . . . . . . . . . . . . .

Figure 4–4: Extended Self Test Main Menu with Peripheral Tests 4–12. .

Figure 4–5: Peripheral Tests Menu 4–12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–6: Local Self Test Menu 4–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–7: Extended Self Test Main Menu 4–14. . . . . . . . . . . . . . . . . . . . .

Figure 4–8: Floppy and Hard Disk Drive Power Connector. 4–47. . . . . . .

Figure 4–9: Switch Locations on the 10 Mbyte Hard Disk Drive Circuit-

Board (Factory Settings Shown) 4–48. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–10: Jumper Locations on the 20 Mbyte Fixed Hard Disk Drive

(Factory Settings Shown) 4–49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–11: Jumper Locations on the 20 Mbyte Removable Hard Disk

Drive (Factory Settings Shown) 4–50. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–12: Jumper Locations on the 5.25-Inch 40 Mbyte Hard Disk

Drive (Factory Settings Shown) 4–51. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–13: Jumper Locations on the 3.5-Inch 40 Mbyte Hard Disk

Drive (Factory Settings Shown) 4–52. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–14: Jumper Locations on the 3.5-Inch 80 Mbyte Hard Disk

Drive (Factory Settings Shown) 4–53. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–15: Jumper Locations on the 100 Mbyte Hard Disk Drive

(Factory Settings Shown) 4–54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–16: Jumper Locations on the 127, 170, and 270 Mbyte Hard

Disk Drives (Factory Settings Shown) 4–55. . . . . . . . . . . . . . . . . . . . . .

Figure 4–17: Jumper Locations on the 1.2 Gbyte Hard Disk Drive

(Factory Settings Shown) 4–56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–18: Jumper Locations on the 3.5-inch 1.44 Mbyte Teac

Model FD-235HF-2301 Floppy Disk Drive

(Factory Settings Shown) 4–57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

DAS 9200 Technician’s Reference

Page 11

Table of Contents

Figure 4–19: Jumper Locations on the 3.5-inch 1.44 Mbyte Teac

Model FD-235HF-6529 Floppy Disk Drive

(Factory Settings Shown) 4–58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–20: Jumper Locations on the 3.5-inch 1.44 Mbyte Teac

Model FD-235HF-7529 Floppy Disk Drive

(Factory Settings Shown) 4–59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–21: Jumper Locations on the Model JU455-5 400 Kbyte

Floppy Disk Drive (Factory Settings Shown) 4–60. . . . . . . . . . . . . . . . .

Figure 4–22: Jumper Locations on the Model JU455-7 400 Kbyte

Floppy Disk Drive (Factory Settings Shown) 4–61. . . . . . . . . . . . . . . . .

Figure 4–23: Jumper Locations on the Model SA455 400 Kbyte

Floppy Disk Drive (Factory Settings Shown) 4–62. . . . . . . . . . . . . . . . .

Figure 4–24: Jumper Locations on the Model JU475-2 1.2 Mbyte

Floppy Disk Drive (Factory Settings Shown) 4–63. . . . . . . . . . . . . . . . .

Figure 4–25: Jumper Locations on the Model JU475-3 1.2 Mbyte

Floppy Disk Drive (Factory Settings Shown) 4–64. . . . . . . . . . . . . . . . .

Figure 4–26: Jumper Locations on the Model JU475-4 1.2 Mbyte

Floppy Disk Drive (Factory Settings Shown) 4–65. . . . . . . . . . . . . . . . .

Figure 4–27: Jumper Locations on the Model JU475-5 1.2 Mbyte

Floppy Disk Drive (Factory Settings Shown) 4–66. . . . . . . . . . . . . . . . .

Figure 4–28: Location of 0 W Resistors W381 and W575 on the

Controller Board 4–67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–29: Location of Jumpers J8700, J8710, and J9700 on the

Controller Board 4–68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–30: SCSI Hard Disk Format Utility Main Menu 4–72. . . . . . . . .

Figure 4–31: Configuration Utility Main Menu. 4–98. . . . . . . . . . . . . . . . .

Figure 4–32: Hardware Configuration and Diagnostic

Results Display 4–99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–33: Factory Default Network Configuration Display 4–101. . . . .

Figure 4–34: Pod Connector of the P6461/E Probe 4–113. . . . . . . . . . . . . . .

Figure 4–35: Coaxial Probe Cable Header Pin Orientation 4–116. . . . . . . .

Figure 4–36: Removing a Coaxial Conductor (Wire) 4–118. . . . . . . . . . . . .

Figure 4–37: Snoopy Mode Example Request ARP Message 4–134. . . . . . .

Figure 4–38: Snoopy Mode Example Response ARP Message TCP/IP

Message 4–135. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–39: Snoopy Mode Example Response TCP/IP Message 4–136. . .

Figure 4–40: 92LAN Snoopy Mode ICMP Example Message 4–137. . . . . .

Figure 5–1: DAS 9219/9220 Mainframe Cable Diagram 5–2. . . . . . . . . . .

Figure 5–2: DAS 9221 Mainframe Cable Diagram 5–3. . . . . . . . . . . . . . .

Figure 5–3: DAS System Bus Diagram 5–4. . . . . . . . . . . . . . . . . . . . . . . . .

DAS 9200 Technician’s Reference

vii

Page 12

Table of Contents

Figure 5–4: DAS 9221 Controller Board Block Diagram 5–6. . . . . . . . . .

Figure 5–5: DAS 9219/9220 Controller Board Block Diagram 5–9. . . . . .

Figure 5–6: DAS 9219/9220 Memory Board Block Diagram 5–11. . . . . . .

Figure 5–7: DAS 92E9 Expansion Mainframe Cable Diagram 5–14. . . . .

Figure 5–8: 92A96 and 92C96 Module Functional Block Diagram 5–21. .

viii

DAS 9200 Technician’s Reference

Page 13

List of Tables

Table of Contents

Table 1–1: Power for Master Mainframes 1–9. . . . . . . . . . . . . . . . . . . . . .

Table 1–2: Power for Expansion Mainframes 1–9. . . . . . . . . . . . . . . . . . .

Table 1–3: Power for DAS Cards (with Probes) 1–10. . . . . . . . . . . . . . . . .

Table 1–4: DAS Series Acquisition and Pattern Generation

Modules 1–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–1: Power-supply Connections 3–17. . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–1: DAS 9221 Level 0 Diagnostics Messages 4–17. . . . . . . . . . . . . .

Table 4–2: DAS 9219/92200 Level 0 Diagnostics Messages 4–18. . . . . . . .

Table 4–3: Error Messages for DAS Mainframes 4–19. . . . . . . . . . . . . . . .

Table 4–4: LED Diagnostic Errors for DAS 9221 4–21. . . . . . . . . . . . . . . .

Table 4–5: DAS 9219/9220 Controller Board LED

Diagnostic Errors 4–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–6: DAS 9219/9220 Memory Board

Diagnostic Errors 4–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–7: Previous Shutdown Field Messages 4–25. . . . . . . . . . . . . . . . . .

Table 4–8: DAS 9219/9220 Controller Board Diagnostic

Error Codes 4–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–9: DAS 9219/9220 8 Mbyte Memory Diagnostic

Error Codes 4–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–10: DAS 9221 Controller Board Diagnostic

Error Codes 4–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–11: 92A60/90/60D/90D Controller Diagnostic

Error Codes 4–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–12: 92A60/90/60D/90D Memory Diagnostic

Error Codes 4–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–13: 92A96 and 92C96 Diagnostic Error Codes 4–30. . . . . . . . . . .

Table 4–14: 92HS8/8E Diagnostic Error Codes 4–32. . . . . . . . . . . . . . . . . .

Table 4–15: 92S16/92SX109 Diagnostic Error Codes 4–33. . . . . . . . . . . . .

Table 4–16: 92S32/92SX118 Diagnostic Error Codes 4–34. . . . . . . . . . . . .

Table 4–17: 92A16/16E Diagnostic Error Codes 4–35. . . . . . . . . . . . . . . . .

Table 4–18: 92C01/02/03 Diagnostic Error Codes 4–36. . . . . . . . . . . . . . . .

Table 4–19: Diagnostic Bar Codes 4–38. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–20: Power-On LAN Controller Tests 4–39. . . . . . . . . . . . . . . . . . .

Table 4–21: Shared-Memory Tests 4–39. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–22: LAN Diagnostic Word 4–40. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAS 9200 Technician’s Reference

ix

Page 14

Table of Contents

Table 4–23: 92LAN DTP Commands 4–41. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–24: DTP Cable Wiring 4–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–25: Power-Supply Voltages 4–44. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–26: Test-Pad Signal Descriptions 4–44. . . . . . . . . . . . . . . . . . . . . .

Table 4–27: Baud Rate Dip Switches 4–46. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–28: Hard Disk Byte vs. Sector 4–78. . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–29: Default Swap Partition Size 4–82. . . . . . . . . . . . . . . . . . . . . . .

Table 4–30: Phase 1 File System Check Error Messages 4–86. . . . . . . . . .

Table 4–31: Phase 2 File System Check Error Messages 4–87. . . . . . . . . .

Table 4–32: Phase 3 File System Check Error Messages 4–88. . . . . . . . . .

Table 4–33: Phase 4 File System Check Error Messages 4–88. . . . . . . . . .

Table 4–34: Phase 5 File System Check Error Messages 4–90. . . . . . . . . .

Table 4–35: System Software vs Operating Modes 4–102. . . . . . . . . . . . . . .

Table 4–36: Probe-Cable Pin to Display-Channel Mapping 4–116. . . . . . .

Table 4–37: Terminal Factory Default Boot Parameters 4–124. . . . . . . . . .

Table 4–38: 92LAN Module Diagnostics 4–131. . . . . . . . . . . . . . . . . . . . . . .

x

DAS 9200 Technician’s Reference

Page 15

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it.

Only qualified personnel should perform service procedures.

Injury Precautions

Use Proper Power Cord

Ground the Product

Do Not Operate Without

Covers

Use Proper Fuse

Do Not Operate in

Wet/Damp Conditions

Do Not Operate in

Explosive Atmosphere

Avoid Exposed Circuitry

To avoid fire hazard, use only the power cord specified for this product.

This product is grounded through the grounding conductor of the power cord. To

avoid electric shock, the grounding conductor must be connected to earth

ground. Before making connections to the input or output terminals of the

product, ensure that the product is properly grounded.

To avoid electric shock or fire hazard, do not operate this product with covers or

panels removed.

To avoid fire hazard, use only the fuse type and rating specified for this product.

To avoid electric shock, do not operate this product in wet or damp conditions.

To avoid injury or fire hazard, do not operate this product in an explosive

atmosphere.

To avoid injury, remove jewelry such as rings, watches, and other metallic

objects. Do not touch exposed connections and components when power is

present.

Product Damage Precautions

Use Proper Power Source

DAS 9200 Technician’s Reference

Do not operate this product from a power source that applies more than the

voltage specified.

xi

Page 16

General Safety Summary

Use Proper Voltage

Setting

Provide Proper Ventilation

Do Not Operate With

Suspected Failures

Before applying power, ensure that the line selector is in the proper position for

the power source being used.

To prevent product overheating, provide proper ventilation.

If you suspect there is damage to this product, have it inspected by qualified

service personnel.

Safety Terms and Symbols

Terms in This Manual

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product

Symbols on the Product

These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

The following symbols may appear on the product:

DANGER

High Voltage

Protective Ground

(Earth) T erminal

ATTENTION

Refer to

Manual

Double

Insulated

xii

DAS 9200 Technician’s Reference

Page 17

Certifications and Compliances

General Safety Summary

CSA Certified Power

Cords

Compliances

CSA Certification includes the products and power cords appropriate for use in

the North America power network. All other power cords supplied are approved

for the country of use.

Consult the product specifications for IEC Installation Category, Pollution

Degree, and Safety Class.

DAS 9200 Technician’s Reference

xiii

Page 18

General Safety Summary

xiv

DAS 9200 Technician’s Reference

Page 19

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone

Disconnect Power

Use Caution When

Servicing the CRT

Use Care When Servicing

With Power On

Do not perform internal service or adjustments of this product unless another

person capable of rendering first aid and resuscitation is present.

To avoid electric shock, disconnect the main power by means of the power cord

or, if provided, the power switch.

To avoid electric shock or injury, use extreme caution when handling the CRT.

Only qualified personnel familiar with CRT servicing procedures and precautions

should remove or install the CRT.

CRTs retain hazardous voltages for long periods of time after power is turned off.

Before attempting any servicing, discharge the CRT by shorting the anode to

chassis ground. When discharging the CRT, connect the discharge path to ground

and then the anode. Rough handling may cause the CRT to implode. Do not nick

or scratch the glass or subject it to undue pressure when removing or installing it.

When handling the CRT, wear safety goggles and heavy gloves for protection.

Dangerous voltages or currents may exist in this product. Disconnect power,

remove battery (if applicable), and disconnect test leads before removing

protective panels, soldering, or replacing components.

To avoid electric shock, do not touch exposed connections.

X-Radiation

DAS 9200 Technician’s Reference

To avoid x-radiation exposure, do not modify or otherwise alter the high-voltage

circuitry or the CRT enclosure. X-ray emissions generated within this product

have been sufficiently shielded.

xv

Page 20

Service Safety Summary

xvi

DAS 9200 Technician’s Reference

Page 21

Preface

The Digital Analysis System (DAS) 9200 documentation package provides the

information necessary to install, operate, maintain, and service the DAS. DAS

documentation consists of:

H This technician’s reference manual, which helps you isolate DAS problems

to the module level, replace that module, and recheck the status of the system

H A verification and adjustment procedures manual, that allows a qualified

technician to verify specifications of the mainframe and modules

H A system user manual, which includes a beginning user orientation, a

discussion of DAS system-level operation, and reference information such as

installation procedures, specifications, error messages, and a complete

glossary of terms

H A series of module user manuals that cover each of the DAS acquisition,

pattern generation, and optional I/O modules

H An on-line documentation package that includes a location-dependent

system of technical notes

H A programmatic command language user manual that describes the set of

programmatic commands available for remotely controlling the DAS

H A series of application software user manuals that describe the various

application software packages

H A series of microprocessor-specific microprocessor support instructions

(designed to accompany the 92A60/90 Module User Manual and 92A96 &

92C96 Module User Manual) that describe the various microprocessor

support packages

H A series of workbooks that teach concepts about DAS acquisition modules

and pattern generation modules

The DAS Technician’s Reference Manual is designed for use by qualified service

personnel. It contains information necessary to check, troubleshoot, and maintain

the DAS mainframe and all associated modules. Troubleshooting is primarily

based on internal power-up diagnostics. These diagnostics isolate problems to

the board (or module) level. Once the faulty board is identified, use the

instructions provided in this manual to remove and replace it. Replacing the

faulty board allows a minimum of downtime for the user. The board is later

repaired at the factory.

DAS 9200 Technician’s Reference

xvii

Page 22

Preface

This manual contains the following sections:

H Introduction to DAS Hardware. Provides a basic description of the DAS

system.

H Maintenance. Provides information on how to keep the mainframe and

modules in good working condition. Line-voltage selection and lithium

battery replacement procedures are also given.

H Disassembly/Reassembly Procedures. Gives instructions for disassembling

and reassembling the mainframe and probes.

H Troubleshooting. Provides information on diagnostics and troubleshooting

practices.

H General Circuit Functions. Gives an overview of circuit functions on

mainframe boards and instrument modules; bus descriptions are also given.

H Replaceable Electrical Parts. Contains a list (including Tektronix part

numbers) of replaceable electrical parts for the DAS mainframe and

associated modules; some parts are only replaceable to the module/board

level.

H Replaceable Mechanical Parts. Contains a list (including Tektronix part

numbers) of replaceable mechanical parts for the DAS mainframe and

associated modules.

xviii

DAS 9200 Technician’s Reference

Page 23

Page 24

Page 25

Introduction to DAS Hardware

The Digital Analysis System (DAS) 9200 is a highly modular set of state-of-theart digital analysis tools. It includes the following items:

H A mainframe

H A color terminal

H Acquisition and pattern-generation modules

H Application software packages

H Probes

By selecting and configuring these tools, you can customize your digital analysis

system for your applications.

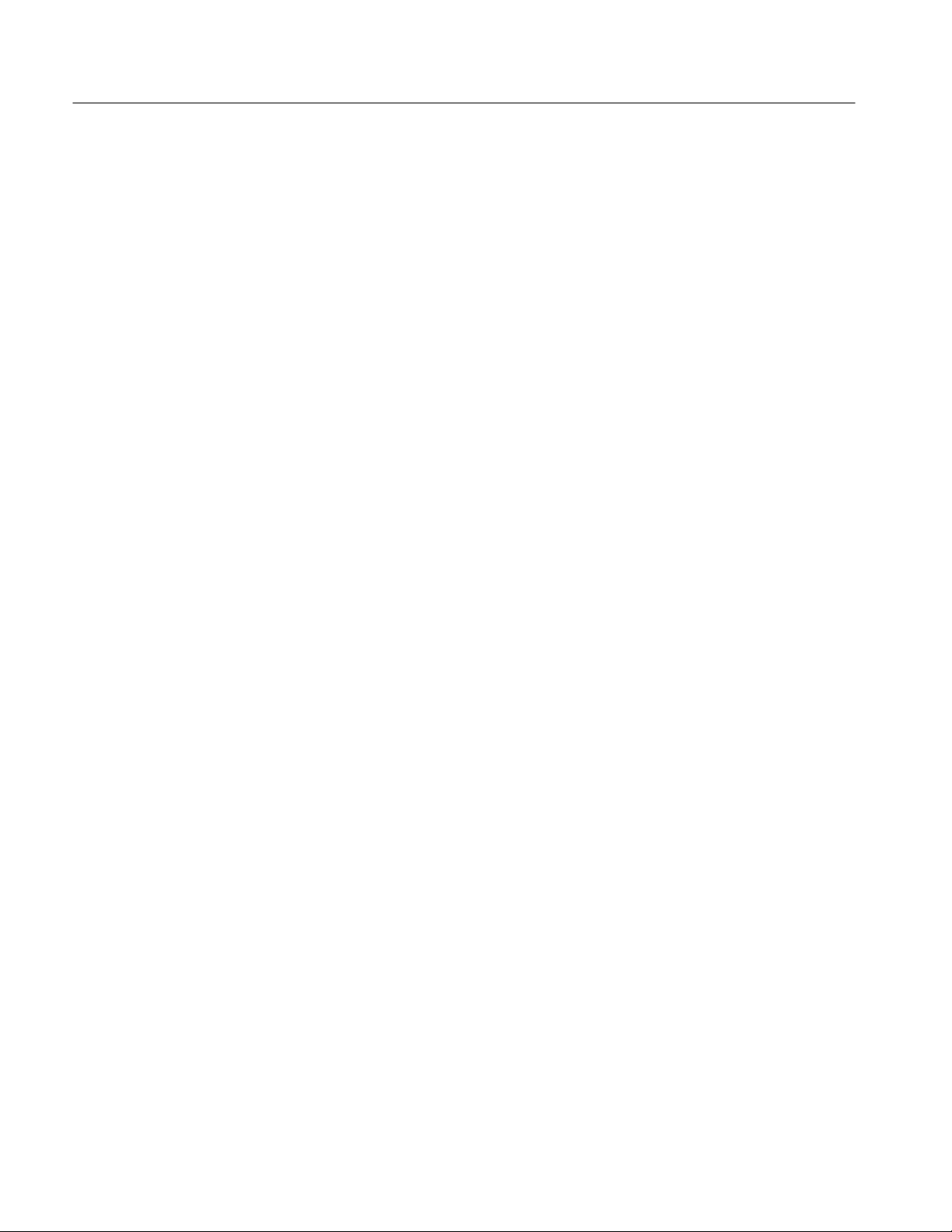

The DAS can be used either as a stand-alone digital analysis system or as an

intelligent peripheral device connected to a host computer or controller.

Figure 1–1 shows two example configurations. On the left, a DAS stand-alone

system (DASXP) is connected to a terminal; on the right, a DAS sends data to a

controlling host computer (DASNT).

Optional Host

Computer

Connection

DAS 9200 Mainframe

Pattern Generation

Data Probe

System

Under Test

Figure 1–1: DAS Basic Configurations

Terminal

Acquisition Data

Probe

Optional Host

Computer

Connection

DAS 9200 Mainframe

Pattern Generation

Data Probe

Host Computer

Acquisition Data

Probe

System

Under Test

DAS 9200 Technician’s Reference

1–1

Page 26

Introduction to DAS Hardware

As a stand-alone system, the DAS can be connected to a Tektronix color

terminal, host computer, printer, or copier. The color terminal displays the

interactive menus. The host computer can be used to transfer acquisition,

stimulation, and instrument setup data to or from the DAS. Various types of

parallel and serial printers are supported to generate non-color (monochrome)

reproductions of display screens and acquisition and pattern-generation data.

Using the optional 92XTerm software (also known as DASNT systems), you can

operate the DAS from a window on a workstation. The interactive menus appear

in the workstation window and are controlled with the mouse and keyboard.

Communication between the DAS and the workstation is over a local area

network (LAN).

As a peripheral device remotely controlled by a host computer, the DAS supports

a Programmatic Command Language (PCL) that is an alternative to the keyboard

and menu interface. PCL commands let you start and stop acquisitions, manage

files, and report status and error information. Data can be processed either by the

DAS or the host computer; when the host computer processes data, the DAS is

the source of raw or partially processed data.

Mainframes and Terminals

The mainframes provide computing power, input and output features, and mass

storage for your modules. The mainframe provides enhanced computing power

due to its larger memory and faster CPU. The mainframes exist in the following

versions:

H DAS 9221 with 16 Mbyte RAM on the Controller board, 100 Mbyte (or

H DAS 9220 with 8 Mbyte RAM on the Memory board, 40 Mbyte hard disk

H DAS 9219 with 2 Mbyte RAM on the Memory board, 20 Mbyte hard disk

The DAS 92E9 is an Expansion mainframe with extra slots for additional modules.

greater) hard disk drive, and 1.4 Mbyte floppy disk drive

drive, and 1.2 Mbyte floppy disk drive

drive, and 400 Kbyte floppy disk drive (the DAS 9219 is no longer

available)

1–2

DAS 9200 Technician’s Reference

Page 27

Introduction to DAS Hardware

Terminals

The standard display device is a Tektronix color terminal with a detachable

keyboard. Earlier versions of the DAS used a 9200T or a 9201T monitor; newer

versions use an X terminal with a detachable keyboard and mouse. Interactive

menus, which are manipulated from the keyboard or mouse, allow you to define the

contents of the system, enter parameters and data, and control the outputs of the

instrument. These menus use color-coded command fields to show the available

selections.

You can power on and power off your mainframe and terminal from a 9200T or

9201T using the terminal power button. This feature is built into DAS 9221

mainframes; for DAS 9219/9220 mainframes, you must install an optional

one-button power-switch adapter.

The 9201T is a direct replacement for the 9200T, so references in this manual to

the 9201T also apply to the 9200T. However, references to the 4205 Service

Manual apply only to the 9201T; if you use a 9200T, refer instead to the 4105

Service Manual.

The X terminal requires a 92LANSE LAN (local area network) module installed

in the mainframe. You can use the X terminal only with the DAS/SE, DASXP, or

DASNT mainframes. For service information, refer to the TekXpress X Terminal

Service Manual.

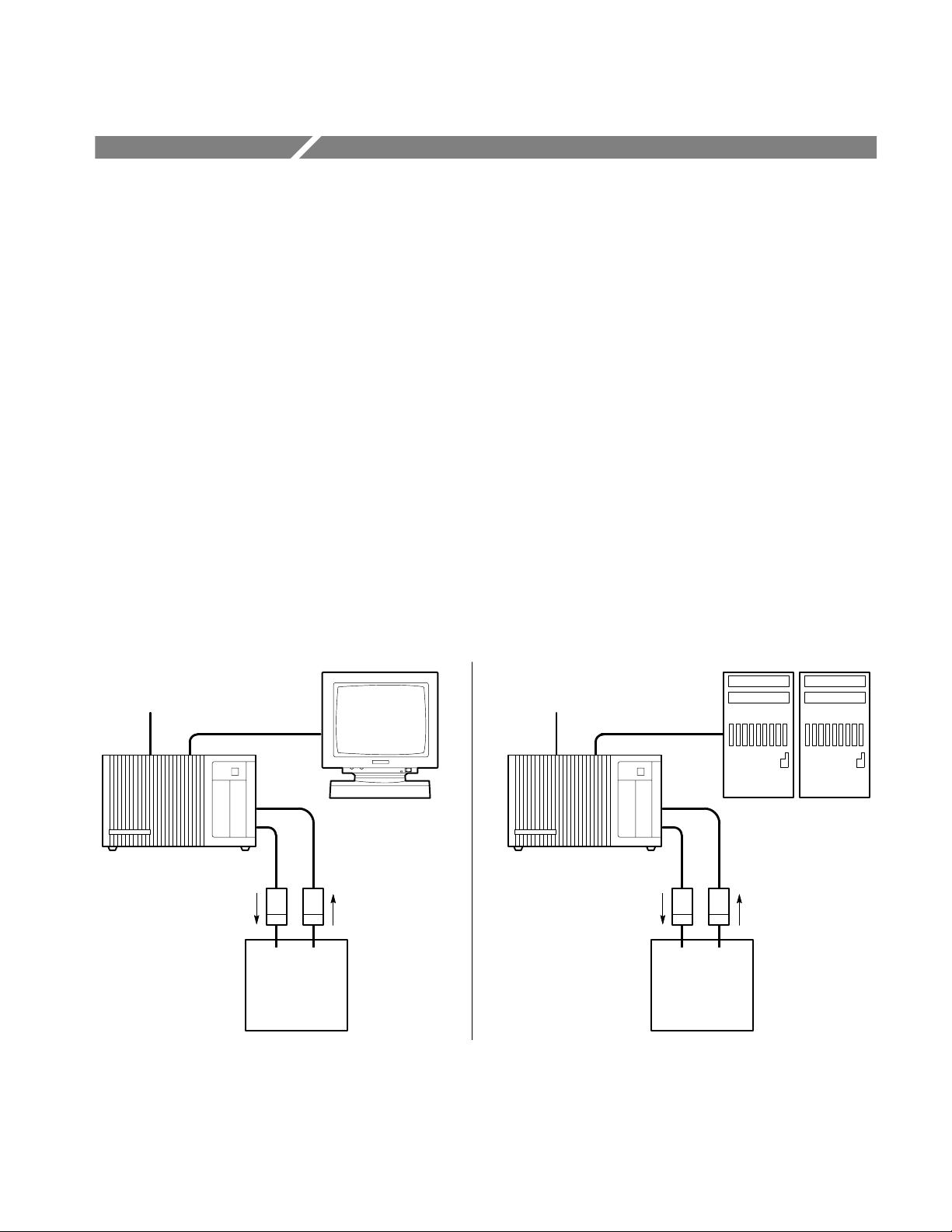

Mainframe Hardware

The mainframe shown in Figure 1–2 consists of the following major internal components:

H Mechanical chassis

H Controller board (with 16 Mbyte RAM for the DAS 9221)

H Memory board with either 2 Mbyte or 8 Mbyte RAM (DAS 9219/9220)

H Backplane board with 8 module slots

H Hard disk drive

H 3.5 inch or 5.25 inch floppy disk drive

H Three RS-232 ports

H Power supply with a maximum output of 700 watts

DAS 9200 Technician’s Reference

1–3

Page 28

Introduction to DAS Hardware

Card Cage

Fan

RS-232 Ports

(back of Mainframe)

Controller

Board (slot 0)

Power

Supply

Backplane

Board

Hard and

Floppy Disk

Drives

Figure 1–2: Master Mainframe Internal Components (Memory Board in Slot 1 for

DAS 9219/9220)

Mechanical Chassis. The chassis provides the mechanical connection and cooling

for all mainframe components and options. DAS modules reside in the card cage;

probes connect to the modules through openings in the rear of the chassis.

NOTE. To install, remove, or reposition any DAS module, you must remove the

mainframe top cover and card-cage door.

To disassemble major chassis components, refer to Disassembly/Reassembly

Procedures beginning on page 3–3.

Controller Board. The Controller board resides in slot 0 of the Master mainframe;

Expansion mainframes use an Expansion Slave board instead of a Controller

board. The Controller board provides the following resources:

H DAS 9221 mainframes use a 68EC030 microprocessor with address

decoding for an asynchronous bus structure (32-bit address, 32-bit data).

DAS 9219/9220 mainframes use a 68010 microprocessor (24-bit address,

16-bit data).

1–4

DAS 9200 Technician’s Reference

Page 29

Introduction to DAS Hardware

H Nonvolatile RAM for storing interrupt routine addresses, previous shutdown

conditions, and pointers to other processes

H 64 Kbytes of boot ROM in DAS 9221 (32 Kbytes in DAS 9219/9220) for

power-up sequences and diagnostics

H 16 Mbytes of dynamic RAM (DAS 9221 only) with refresh circuitry

H A communication interface between circuit boards, the hard disk drive, and

the floppy disk drive

H Asynchronous time bases and other circuitry supporting the expansion of up

to four time-aligned mainframes

H A clock/calendar with battery backup

H Power-supply control for mainframe shutdown

Memory Board (DAS 9219 and DAS 9220). There are two different Memory boards:

the 2 Mbyte dynamic RAM board is standard with the DAS 9219, and the

8 Mbyte dynamic RAM board is standard with the DAS 9220. The 8 Mbyte

board is also available as a performance upgrade for the DAS 9219. Only one

Memory board can be installed in the Master mainframe, and it must reside in

slot 1; Expansion mainframes do not use a Memory board. (The DAS 9221 has

Memory-board functions resident on the Controller board.) The Memory board

provides the following resources:

H 2 Mbytes of dynamic RAM (standard with the DAS 9219) with refresh

circuitry for supporting system software, post-processing of acquired data,

and other calculations.

H 8 Mbytes of dynamic RAM (standard with the DAS 9220) with refresh

circuitry. The lower part of RAM supports system software and post-proces-

sing of acquired data. The upper part of RAM temporarily stores configura-

tion and data files to improve the system response time.

H Circuitry supporting the Memory Management Unit (MMU), for multiple

process control.

H An interface to the Controller board, allowing access to the system RAM and

to the terminal, host, and auxiliary communication ports.

Backplane Board. This board provides the mechanical and electrical connections

between the Controller board, the Memory board (DAS 9219 and DAS 9220),

and the eight slots used for the acquisition and pattern generation modules.

Signals are carried on bus structures, some of which extend outside the Master

mainframe to Expansion mainframes.

DAS 9200 Technician’s Reference

1–5

Page 30

Introduction to DAS Hardware

Hard and Floppy Disk Drives. The operating system software is installed on the

hard disk, along with other files (such as user-generated setups and reference

memories).

The DAS 9221 mainframes have been available with 100 Mbyte, 127 Mbyte,

170 Mbyte, and 270 Mbyte SCSI hard disk drives. The DAS 9220 mainframes

used 40 Mbyte and 80 Mbyte hard disk drives (ST506 interface), while the

DAS 9219 mainframes had 10 Mbyte and 20 Mbyte hard disk drives. To

determine the size of hard disk in your mainframe, refer to the Diagnostic menu.

An optional 80 Mbyte hard disk drive is available for DAS 9219/9220 mainframes. If data security or portability is a concern, you can order your mainframe

with a removable hard disk drive, so that setup and data files can be secured

overnight or easily transported to another DAS. An 80 Mbyte removable drive is

available for the DAS 9219/9220; a 127 Mbyte, 170 Mbyte, or 270 Mbyte

removable drive is available for the DAS 9221. (Other versions of the removable

hard disk drive were available for earlier versions of the mainframe.)

WARNING. The removable drive for the DAS 9221 (SCSI drive) is not interchangeable with the removable drives for the DAS 9219/9220 (ST506 interface

drives). If you install the wrong type of drive into your mainframe, you can

damage the drive.

Do not disconnect or remove the removable hard disk drive while the mainframe

is powered. Doing so will damage the hard disk or corrupt the file system.

The floppy disk drives are used for loading application software from floppy disk,

copying files for use on other mainframes, and making and restoring backup files.

Backup procedures with on-screen instructions are available. A light on the front of

the floppy disk drive indicates when a floppy disk is being accessed.

A 3.5 inch, 1.4 Mbyte floppy disk drive is standard in DAS 9221 mainframes

with System Software Release 3, Version 1.40 and higher. The floppy disk drive

is also available as an upgrade kit for older systems.

A 5.25 inch, 1.2 Mbyte floppy disk drive was available in earlier versions of the

DAS 9220 and DAS 9221 mainframes. This disk drive is available as an option

for the DAS 9219 mainframe. This drive reads floppy disks written in

360 Kbyte/400 Kbyte format; however, it cannot write to disks of this type. For

write operations, use only 96 TPI (tracks per inch), double-sided, high-density

floppy disks with this drive.

A 5.25 inch, 400 Kbyte floppy disk drive was standard in the DAS 9219

mainframe. This drive can read or write to floppy disks in 360 Kbyte/400 Kbyte

format only. Use only 48 TPI, double-sided, double-density floppy disks with

this drive; do not use 96 TPI high-density disks.

1–6

DAS 9200 Technician’s Reference

Page 31

Introduction to DAS Hardware

RS-232 Ports. The DAS 9219/9220 mainframes have three 25-pin DCE RS-232

ports and the DAS 9221 mainframe has three 9-pin DCE RS-232 ports. Other

devices access these ports through openings on the rear panel. The three ports

have the following functions:

H The terminal port connects the mainframe to a display device. Baud rates are

38400 (default), 19200, 9600, 4800, 2400, 1200, 600, 300, and 110.

H The host port connects the mainframe to a host computer system with a

null-modem cable. Baud rates are 38400, 19200, 9600 (default), 4800, 2400,

1200, 600, 300, and 110.

H The auxiliary port connects the mainframe to other RS-232-compatible

devices (for example, a printer). Baud rates are 38400, 19200,

9600 (default), 4800, 2400, 1200, 600, 300, and 110.

The host and auxiliary ports transmit eight data bits, no parity, and one stop bit. You

can configure the terminal and host port protocol using the Communications menu.

Optional Expansion and I/O Ports. The 92C01, 92C02, and 92C03 GPIB/Expansion modules are optional interface boards for the DAS. These modules function

as follows:

H The 92C01 module provides a GPIB port for the mainframe. (It was

available for earlier versions of the mainframe.)

H The 92C02 module provides a GPIB port and an interface to the DAS 92E9

Expansion mainframe.

H The 92C03 module provides an interface only to the DAS 92E9 Expan-

sion mainframe.

Master mainframes have direct memory access (DMA) capability; this feature is

not available in Expansion mainframes. Therefore, 92C01/02/03 modules must

be installed in slot 8 of the Master mainframe. The GPIB portion of the 92C01

and 92C02 modules does not work in the DAS 92E9 Expansion mainframe;

however, the 92C03 module and the expansion portion of the 92C02 module are

fully functional when installed in slot 8 of the Expansion mainframe. Therefore,

you should use the 92C03 module in Expansion mainframes.

LAN Interfaces. The 92LANSE and 92LAN Modules provide a LAN (local area

network) interface for the DAS mainframe. The 92LANSE module is standard in

a DAS 9221 mainframe used with the X terminals. These modules were optional

in other mainframes. The 92LANSE Module connects directly to the DAS 9221

Controller board and can only be used with DAS 9221 mainframes.

The 92LAN Module is no longer available. For information on the 92LAN

module, refer to the 92LAN User/Installation Manual.

DAS 9200 Technician’s Reference

1–7

Page 32

Introduction to DAS Hardware

Power Supply . The power supply module consists of two boards that supply

power to all mainframe components. This supply can deliver up to 650 watts

from either a 115 V or 230 V AC power source (see Table 1–1 for Master

mainframes and Table 1–2 for Expansion mainframes).

WARNING. To change the line-voltage input of the power supply (between 115 V

and 230 V), refer to Maintenance beginning on page 2–1.

Mainframe Power

Requirements

The DAS mainframes support different numbers of acquisition and pattern-generation modules based on the type of power cord and power supply used with

each mainframe. The standard 12 A power cord should be used for Master

mainframes drawing less than 400 watts (12 A/115 V) and for Expansion

mainframes drawing less than 475 watts. When the module configuration in the

mainframe requires more power, a higher-current power-cord/power-supply

combination must be used (refer to Tables 1–1 and 1–2). If the module configuration in the Master mainframe requires more than 575 watts (650 watts in

Expansion mainframes), the DAS will automatically shut off.

NOTE. If you install the 15 A power cord (Option 1A), put the label supplied with

the power cord on the DAS back panel over the existing description that reads:

1900 VA MAX., FREQ. 48-63 Hz.

The power source must be capable of supplying the maximum line current

required for your system. A mainframe connected to a 115 V power source draws

a maximum continuous current of 15 A; the one-cycle surge current is 25 A

nominal. Therefore, a Master mainframe with three Expansion mainframes may

require a total line current of 60 A. (A mainframe connected to a 230 V power

source draws a maximum continuous current of 10 A, so a Master mainframe

with three Expansion mainframes may require a total line current of 40 A.)

1–8

When the DAS is connected to a 230 V power source, you must use a 230 V

power cord. The DAS draws no more than 10 A when operating at 230 V, but

when the DAS is connected to a 3-phase power source, the mainframe draws no

more than 8 A on any phase. The three-phase power cord is permanently attached

to the power supply. To upgrade your mainframe’s power supply with the

three-phase option, contact your Tektronix field service center.

DAS 9200 Technician’s Reference

Page 33

Introduction to DAS Hardware

Á

Á

Á

Á

Á

Á

Á

Á

T able 1–1: Power for Master Mainframes

Watts Voltage Cord Option Source

400 W

500 W

575 W

БББББ

2

700 W

1

Operation at a low line of 90 V is possible if the card-cage load is reduced to

105 V – 127 V

105 V – 127 V

200 V – 250 V

БББББ

1

200 V – 250 V

(phase-to-phase)

Std.

Opt. 1A

A1 – A5

ÁÁÁÁ

Opt. 1B

(3-phase)

3

115 V, 12 A

115 V, 15 A

230 V, 10 A

БББББ

120/208 V, 8 A

425 watts or less.

2

The 700 W 3-phase power supply option was discontinued as of serial number

B061162.

3

The three-phase load is Y-connected. A maximum of 15 A at three times the

frequency may flow into the neutral conductor. A switch or circuit breaker at the

installation site is required by some international standards.

T able 1–2: Power for Expansion Mainframes

Watts Voltage Cord Option Source

475 W

575 W

650 W

2

750 W

БББББ

1

Operation at a low line of 90 V is possible if the card-cage load is reduced to

425 watts or less.

2

The 750 W 3-phase power supply option was discontinued as of serial number

B061162.

3

The three-phase load is Y-connected. A maximum of 15 A at three times the

frequency may flow into the neutral conductor. A switch or circuit breaker at the

installation site is required by some international standards.

105 V – 127 V

105 V – 127 V

1

200 V – 250 V

200 V – 250 V

(phase-to-phase)

БББББ

Std.

Opt. 1A

A1 – A5

Opt. 1B

(3-phase)

3

ÁÁÁÁ

115 V, 12 A

115 V, 15 A

220 V, 10 A

120/208 V, 8 A

БББББ

Refer to Selecting the Line Voltage and Replacing the Line Fuse beginning on

page 2–6 for instructions on how to change the line voltage.

Module Power Requirements. Each combination of boards requires a different

amount of power from the mainframes. Therefore, you must select a power cord,

power supply, and power source that meets your system line-current demands.

DAS 9200 Technician’s Reference

1–9

Page 34

Introduction to DAS Hardware

Á

Á

To determine the power cord and power source you need, check the message

displayed during power-on that shows the total wattage for the boards installed

in each mainframe. (The power-up message is erased when the system menus

display.) Calculate the total wattage required (from Table 1–3) and compare it

with the available power (from Tables 1–1 and 1–2). If the installed boards

require more power than is available from your current power cord and power

source, then you must upgrade your mainframe to meet those requirements.

NOTE. If you reconfigured the boards in your mainframe since the last powerdown or added boards to your system, check the power values in Tables 1–1,

1–2, and 1–3 to ensure that the total wattage required by the new configuration

can be supplied by your current mainframe power cord and power source.

Table 1–3 lists the power consumed for each board. Use this table to calculate

the power required for your mainframe’s configuration. For example, if your

mainframe contains the following boards: one 92A16, two 92A16Es, one 92S16,

and one 92S32, then the total power required equals: 107 W (A16) + 166 W

(A16Es) + 78 W (S16) + 79 W (S32), or 430 W. Next, compare this value with

the power-cord options in Tables 1–1 and 1–2. Since the standard 12 A power

cord delivers a maximum of 400 watts, the Option 1A power cord must be used

to supply up to 500 watts to the card cage.

T able 1–3: Power for DAS Cards (with Probes)

Card Type Power (watts)

92A16 Master Interface

92A16E Expander Interface

92A96/SD/UD

92A96D/XD

92C96/D/XD/SD

92A60 Controller

92A60/D Memory

92A90 Controller

92A90/D Memory

92S16

92S32

ББББББББ

92SX109

92SX1 18

92C01

92C02

92C03

107

83

1

150

140

1

150

80

50

80

50

78

79

БББББ

78

79

25

30

25

1–10

DAS 9200 Technician’s Reference

Page 35

T able 1–3: Power for DAS Cards (with Probes) (Cont.)

Á

Á

Card Type Power (watts)

Introduction to DAS Hardware

92HS8 Master Interface

92HS8E Standard Interface

92LAN

92V64PM Pattern Master

92V64PE Pattern Expander

92V64E Error Memory

ББББББББ

1

Acquisition Module power requirements reduced to

20

12

25

64

64

64

БББББ

140 W max. effective SN B061162 and above

The DAS software checks your configuration at power on and warns you to use

the correct power source and power cord. The power supply and module cards

can be damaged if you try to operate the DAS in an illegal configuration. The

DAS 9221 Controller board contains a set of jumpers that identify the type of

power cord and power supply in the mainframe. If you change the power cord or

power supply, then you should relocate these jumpers to reflect the new configuration (refer to Jumper J8700 in Figure 4–29 on page 4–68). If the power requirements exceed safe limits, the system shuts down. For example, if you have five

92A96 Modules in one mainframe (700 W, which exceeds the power requirements), the DAS displays a warning message at power-up and then shuts down.

Power Cords. The mainframe has no main AC power switch, so the power cord

serves as the main-power disconnect. The power-cord connection for the Master

mainframe and Expansion mainframe is on the rear panel. The standard power

cord for the mainframe is rated at 12 A; optional power cords are available for

mainframe configurations requiring more power.

The mainframe uses a three-wire power cord with a three-contact plug for

connection to the power source and protective ground. The plug’s protectiveground connects to accessible metal parts of the mainframe.

WARNING. To protect against electrical shock, insert the power-cord plug into a

grounded power source receptacle.

External Event Connections. The optional 92C02 and 92C03 modules provide a

set of pins that support external event I/O signals. For more information, refer to

Using the External Event I/O Pins in the DAS System User Manual.

DAS 9200 Technician’s Reference

1–11

Page 36

Introduction to DAS Hardware

The External Event In pin accepts a TTL-level signal from an external source.

The received event can be monitored by (or can control) other modules. You can

set this up in the Signal Definition overlay (Cluster Setup menu).

The External Event Out pin passes a TTL-level event signal from a DAS to an

external component to use as an arming or triggering signal. For example, the

event-out signal can trigger an oscilloscope or stop, start, or trigger a separate

DAS system.

Discrete I/O Port (DAS 9221 Mainframes with 92LANSE Modules). The optional

92PORT software product allows you to monitor and send signals to a systemunder-test using the 37-pin D-connector on the rear of the Master mainframe.

DAS with Option 04

An option to the DAS mainframe, Option 04, allows the mainframe to satisfy the

German electromagnetic interference (EMI) requirements. Refer to Replaceable

Mechanical Parts serial number history of Option 04 on page 7–24.

DAS Systems Prior to January 1, 1996. DAS mainframes equipped with Option 04

that were sold prior to January 1, 1996 satisfied the German electromagnetic

interference (EMI) requirements VDE 0871, Class B. This VDE option applied

to mainframes set for 230 V operation only; operation at 115 V exceeds

component ratings. A mainframe with Option 04 includes the following items:

H Conductive elastic between the front panel and media mount

H Rear-panel probe shields

H EMI gasket material on the edges of the baseplate

H Clip for holding the power supply tightly against the inside of the rear panel

H Probe clamps for holding probes to the rear panel

H Six grounding clamps for RS-232 connectors (DAS 9219/9220 only)

H Conductive paint on the inside of the top cover and baseplate to make a

connection to the EMI gasket material along the edges of the baseplate

1–12

H Screen material on the front panel and top cover

H EMI gasket material on the inside-rear edge of the top cover

DAS 9200 Technician’s Reference

Page 37

Introduction to DAS Hardware

Follow these precautionary guidelines when using an Option 04-equipped

mainframe:

H Avoid scratching any surface coated with conductive paint.

H Avoid bending or tearing gasket material along the edges of the baseplate

and snagging clothing on gasket material.

H Avoid bending or snagging the EMI gasket material when installing or

removing boards from mainframe slots.

Remove only shields that correspond to probes or cables being attached, because

unnecessary removal of the shields increases EMI radiation. Remove a rear-panel

probe shield as follows:

1. Remove the two top screws.

2. Remove the two screws that attach the adjacent shield.

3. Remove the rear-panel probe shield.

4. Replace the screws attaching the adjacent shield.

To connect to the host port of a DAS 9219/9220 mainframe, you must remove

the corresponding port connector shield.

DAS Systems After January 1, 1996. Newer DAS mainframes with Option 04 meet

Directive 89/336/EEC for electromagnetic compatibility. Option 04 applies to

mainframes set for 230 V operation only; operation at 115 V exceeds component

ratings. A mainframe with Option 04 includes a 230 V line filter to eliminate or

reduce electromagnetic interference.

DAS 9200 Technician’s Reference

1–13

Page 38

Introduction to DAS Hardware

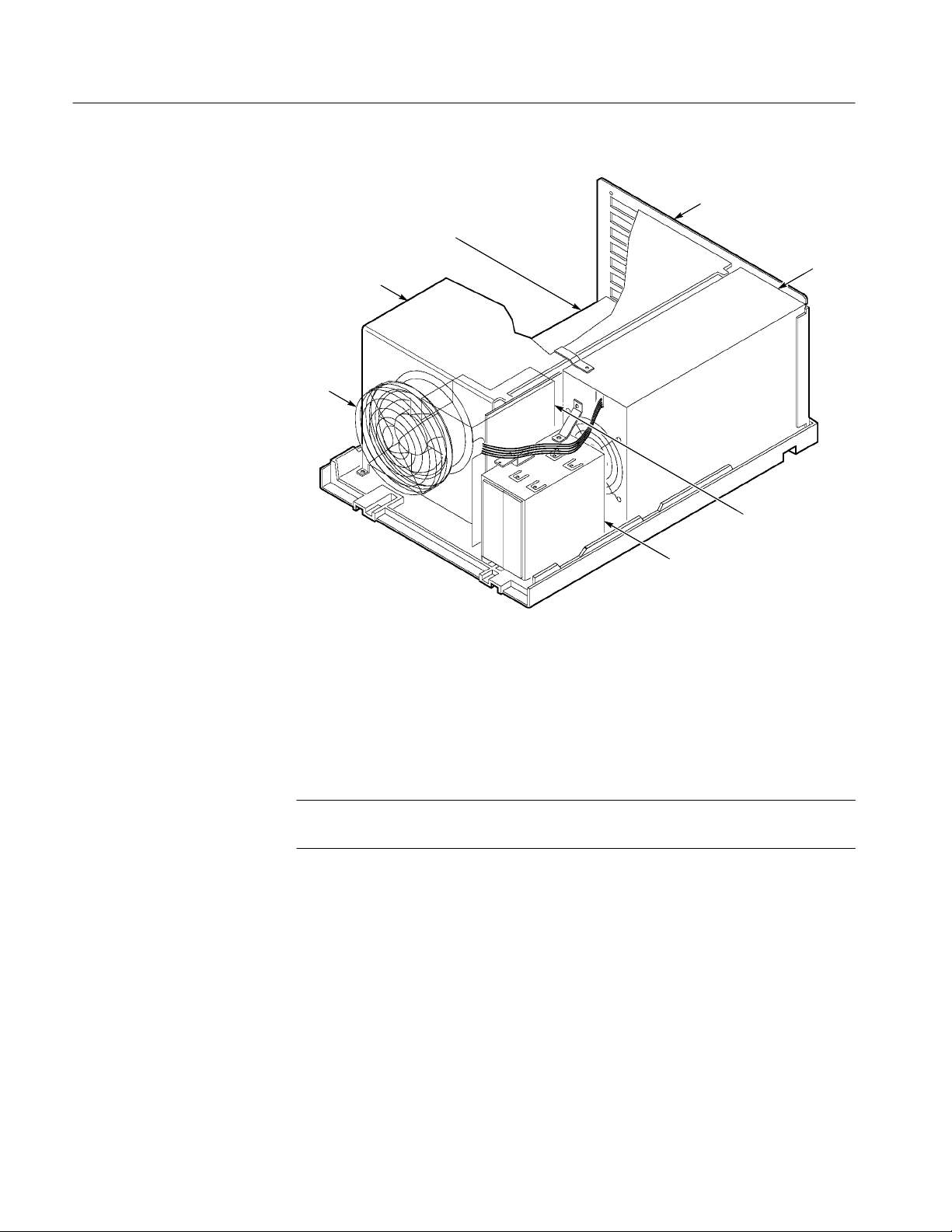

DAS 92E9 Expansion

Mainframe

The DAS 92E9 Expansion mainframe provides additional slot space for

acquisition and pattern generation modules. Up to three Expansion mainframes

can be added to the Master mainframe. A fully-expanded system (Master

mainframe with three Expansion mainframes) provides a total of 28 usable slots.

Expansion and Master mainframes use the same mechanical chassis, backplane,

and power supply. However, the Expansion mainframe does not contain a

Memory board, power switch, or disk drives. In an Expansion mainframe, an

Expansion Slave board replaces the Master mainframe’s Controller board.

If you have one Expansion mainframe with the Master mainframe, you can place

it on top of the Master mainframe, as in Figure 1–3; the Master mainframe can

support the weight of only one Expansion mainframe. When using two or three

Expansion mainframes, all mainframes must be vertically rackmounted; the

Master mainframe must be positioned as the lowest mainframe in the rack. For

complete details on rackmounting, refer to the Option 05: Rackmount Installa-

tion Instructions document.

Acquisition Data Probe

Expansion

Mainframe

Master

Mainframe

Pattern Generation

Data Probe

System Under Test

Figure 1–3: DAS Master Mainframe Connected with One Expansion Mainframe

In a fully-expanded system (see Figure 1–4), the Master mainframe and

Expansion mainframes 1 and 2 require an Expansion board in slot 8 of each

mainframe. The Master mainframe uses either a 92C02 GPIB/Expansion module

or a 92C03 Expansion module to make the connection to the Expansion Slave

board installed in the next mainframe. Expansion mainframes 1 and 2 use a

92C03 module. Refer to Disassembly/Reassembly of the Mainframes beginning

on page 3–3 for module installation and removal instructions.

1–14

DAS 9200 Technician’s Reference

Page 39

Introduction to DAS Hardware

NOTE. The system software numbers the DAS 92E9 Expansion Mainframe slots

from 9-35. You can use these slots, except the Expansion Slave board slot, for

modules.

Expansion Mainframe 3

Slot 35

8 slots for Acquisition and/or

Pattern Generation Modules

Slot 27

Slot 26

Slot 18

Slot 17

Slot 9

Slot 8

Expansion Slave Board

Expansion Cable

Expansion Mainframe 2

Expansion Board

7 slots for Acquisition and/or

Pattern Generation Modules

Expansion Slave Board

Expansion Cable

Expansion Mainframe 1

Expansion Board

7 slots for Acquisition and/or

Pattern Generation Modules

Expansion Slave Board

Expansion Cable

Master Mainframe

Expansion or Exp/GPIB

Figure 1–4: T wenty-Eight Slots Available with One Master and Three Expansion

Mainframes

DAS 9200 Technician’s Reference

Slot 0

6 slots for Acquisition and/or

Pattern Generation Modules

Controller Board

1–15

Page 40

Introduction to DAS Hardware

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Acquisition and Pattern Generation Modules

Data acquisition and pattern generation modules, consisting of one or more

printed-circuit boards, are the building blocks of the DAS system. These boards

are installed in mainframe bus slots according to configuration guidelines in the

user manual for each module. Refer to Table 1–4 for a list of available modules.

Brief descriptions of these modules are included in General Circuit Functions.

For detailed information on individual modules, including specifications and

menu and field descriptions, refer to the appropriate user manual.

T able 1–4: DAS Series Acquisition and Pattern Generation Modules

Module Purpose Channels Depth Speed

92A16

acquisition

16

4K

200 MHz

92A16E

1

92A60

1

92A60D

1

92A90

1

92A90D

ÁÁÁ

2

92A96

2

92A96D

92A96XD

92A96SD

92A96UD

2

92C96D

92C96XD

92C96SD

ÁÁÁ

3

92HS8

92HS8E

3

92S16

92S32

acq. expander

acquisition

acquisition

acquisition

acquisition

acquisition

acquisition

2

acquisition

2

acquisition

2

acquisition

acquisition

2

acquisition

2

acquisition

acquisition

acq. expander

pattern generation

pattern generation

ББББББ

ББББББ

16

60

60

90

90

ÁÁÁ

96

96

96

96

96

96

96

96

ÁÁÁ

8

8

16

32

4K

32K

128K

32K

128K

ÁÁÁ

8K

32K

128K

512K

2M

32K

128K

512K

ÁÁÁ

8K

8K

1K

8K

200 MHz

20 MHz

20 MHz

20 MHz

20 MHz

ÁÁÁ

100 MHz

100 MHz

100 MHz

100 MHz

100 MHz

100 MHz

100 MHz

100 MHz

ÁÁÁ

2 GHz

2 GHz

50 MHz

50 MHz

1–16

92SX109

92SX1 18

1

The 92A60/D and 92A90/D are both two-board sets; other modules consist of a single

pattern generation

pattern generation

18

9

2K

16K

100 MHz

100 MHz

board.

2

The 92A96 High-Speed timing offers asynchronous support of 48 channels at

200 MHz and 24 channels at 400 MHz.

3

The 92HS8 has a mainframe cabinet that connects to the DAS through an interface

board.

DAS 9200 Technician’s Reference

Page 41

Introduction to DAS Hardware

You can combine modules functionally in menus. Combining acquisition

modules adds data-channel width (for example, combining 92A16 and 92A16E

boards). Combining pattern generation modules increases pattern memory depth

(for example, combining 92S16 and 92S32 boards). You can also group modules

to operate as an independently functioning unit (called a cluster); several clusters

can run simultaneously. For more information on grouping modules and clusters,

refer to the DAS System User Manual.

DAS 9200 Technician’s Reference

1–17

Page 42

Introduction to DAS Hardware

1–18

DAS 9200 Technician’s Reference

Page 43

Page 44

Page 45

Maintenance

This chapter explains how to keep your DAS mainframe, associated modules, and

terminal in good working condition. It also contains procedures on how to change

the line-voltage selection (between sources of 115 V and 230 V) and replace the