cover.frm Black 1

DAS-800 Series

Function Call Driver

User’s Guide

1 titlepgfrm Black 1

DAS-800 Series

Function Call Driver

User’s Guide

Revision A - December 1993

Part Number: 66770

noticep.frm Black 1

The information contained in this manual is believed to be accurate and reliable. However. the

manufacturer assumes no responsibility for its use; nor for any infringements or patents or other rights

of third parties that may result from its use. No license is granted by implication or otherwise under any

patent rights of the manufacturer.

THE MANUFACTURER SHALL NOT BE LIABLE FOR ANY SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES RELATED TO THE USE OF THIS PRODUCT. THIS PRODUCT

IS NOT DESIGNED WITH COMPONENTS OF A LEVEL OF RELIABILITY THAT IS SUITED

FOR USE IN LIFE SUPPORT OR CRITICAL APPLICATIONS.

All brand and product names are trademarks or registered trademarks of their respective companies.

0 Copyright Keithley Instruments, Inc., 1993.

All rights reserved. Reproduction or adaptation of any part of this documentation beyond that permitted

by Section I I7 of the 1976 United States Copyright Act without permission of the Copyright owner is

unlawful.

+b

800fcd.toc Black iii

Table of Contents

Preface

1

Getting Started

Installing the Software.. 1-2

Installing the DAS-800 Series Standard Software Package 1-2

Installing the ASO- Software Package 1-3

DOS Installation.. 1-3

Windows Installation 1-4

Setting Up the Boards . . . . l-5

Getting Help.. . . l-6

2 Avallable Operations

Analog Input Operations

Operation Modes.

Memory Allocation and Management

Input Range Qpe

.......................................

Gains

Channels

....................................

Single Channel,

Multiple Channels Using a Group of Consecutive

Channels

................................

Multiple Channels Using a Channel-Gain List

Conversion Clocks

Buffering Mode.

Triggers

.....................................

Analog Triggers

Digital Triggers

Hardware Gates.

Digital I/O Operations

Counternimer I/O Operations.

System Operations.

Initializing the Driver.

Initializing a Board

Retrieving the Revision Level.

Handling Errors.

..........................

.............................

.............

.............................

............................

....

............................

..............................

............................

............................

..............................

............................

.....................

..............................

.........................

............................

...................

..............................

,.,2-l

2-2

.2-3

2-5

2-5

.2-6

.,.2-x

.2-9

.2-9

.2-13

.2-16

.2-16

.2-17

.2-20

.2-22

,2-24

: :

2-26

2-27

.2-28

.2-29

: : 2-30 2-30

8OOfcd.toc Black iv

Programming with the Function Call Driver

3

How the Driver Works ................................ ,3-l

Programming Overview ............................... .3-5

Preliminary Tasks. ................................... .3-6

Operation-Specific Programming Tasks ,3-6

Analog Input Operations. .3-6

Single Mode, .................................. .3-7

Synchronous Mode ............................. .3-7

Interrupt Mode. ................................ .3-9

Digital I/O Operations ............................. .3-12

Language-Specific Programming Information ............ (3-12

Microsoft C/C++. ................................ .3-13

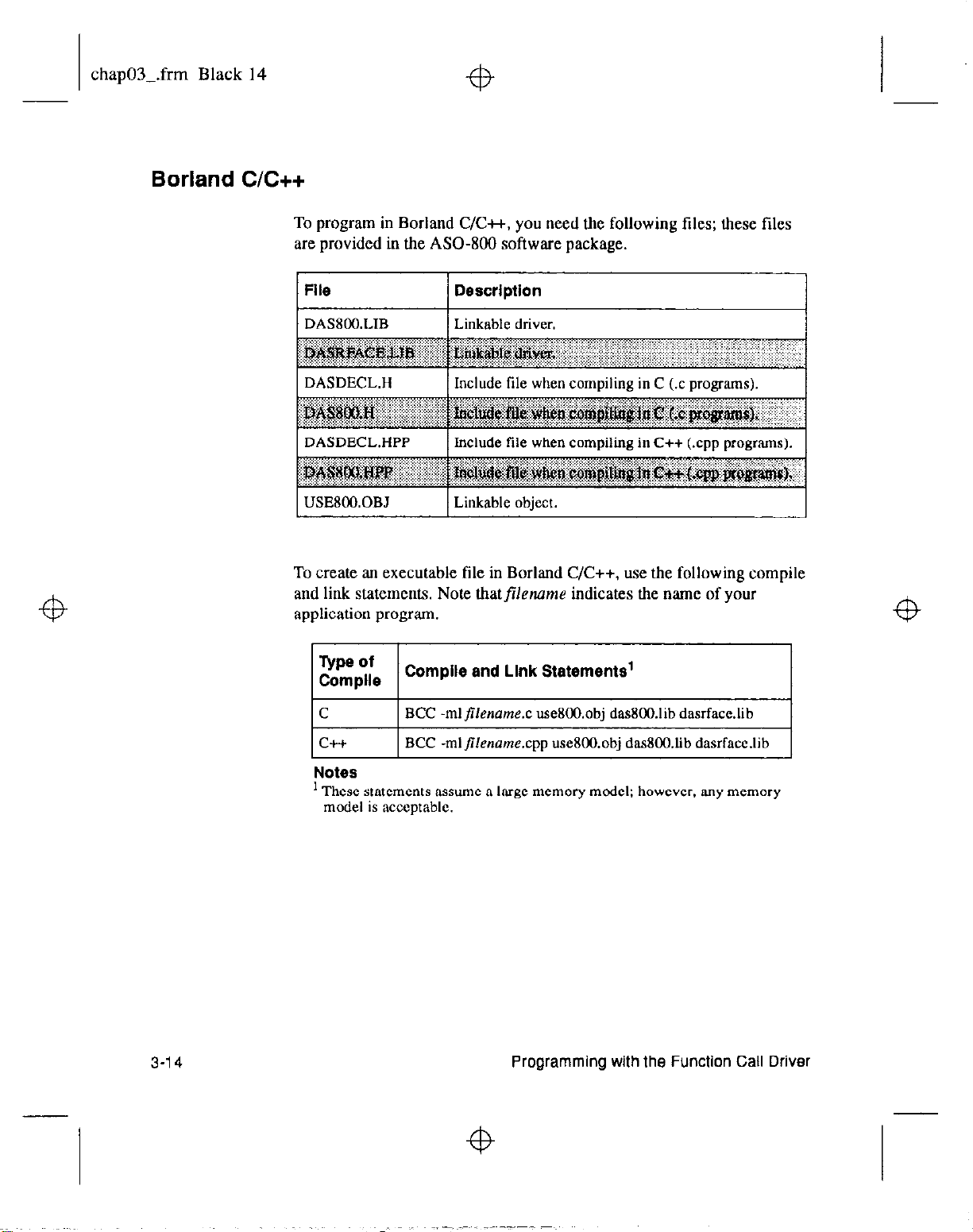

Borland C/C++ .................................. .3-14

Microsoft QuickC for Windows ..................... .3-I5

Microsoft Visual C++ ............................. .3-16

Borland Turbo Pascal ............................. .3-16

Borland Turbo Pascal for Windows .................. .3-17

Specifying the Buffer Address (Pascal) ............... .3-1X

Specifying the Channel-Gain List Starting

Address (Pascal). ............................... .3-19

Microsoft QuickBASIC (Version 4.0) ................ .3-20

Microsoft QuickBasic (Version 4.5). ................. .3-21

Microsoft Professional Basic (Version 7.0) ............ .3-22

Microsoft Visual Basic for DOS

...................... 3-23

Microsoft Visual Basic for Windows .................. 3-24

Specifying the Buffer Address (All BASIC Languages) .. .3-25

iv

Function Reference

4

DASXOO-DevOpen ........

DAS800-GetADGainMode.

DAS800-GetDevHandle . ...

DAS800-Get8254 : ........

DAS800&SetADGainMode .

DAS800-Set8254 .........

K-ADRead. ..............

K-BufListAdd ............

K-BufListReset ...........

K-ClearFrame ............

K-CloseDriver

K-ClrConiRun

............

............

K-DASDevInit ...........

K-DIRead ...............

........

........

........

........

........

........

........

........

........

........

........

........

........

........

.4-6

.4-9

.4-II

.4-13

.4-15

.4-17

.4-19

.4-22

.4-24

,4-26

,4-28

.4-30

4-32

.4-33

800fcd.toc Black v

K-DOWrite ..............

K-FormatChanGAry

K-FreeDevHandle

K-FreeFrame

.........

.............

K-GetADFrame. ..........

KGetADTrig ............

K-GetBuf. ...............

K-GetChn ...............

K-GetChnGAry

K-GetClk

................

K-GetClkRate ............

K-GetContRun ...........

K-GetDevHandIe. .........

K-GetDITrig .............

K-GetErrMsg. ............

K-GetG .................

K-GetGate

K-GetStartStopChn

KGetStartStopG

...............

........

..........

K-GetTrig ...............

K-GetTrigHyst. ...........

K-GetVer

................

K-InitFrame. .............

K-IntAlloc

K-IntFree

...............

................

K-IntStart. ...............

K-IntStatus ..............

KJntStop. ...............

K-MoveBuffoArray .......

K-OpenDriver

K-RestoreChanGAry

............

.......

K-SetADTrig. ............

K_SetBuf ................

K-SetBufI ...............

K-SetChn. ...............

K-SetChnGAry ...........

K-SetClk ................

K-SetClkRate ............

K-SetContRun. ...........

K-SetDITrig. .............

K-SetG. .................

K-SetGate ...............

.4-35

.4-37

.4-3x

.4-39

.4-40

.4-42

.4-44

,446

. ..4-48

.4-50

.4-52

.4-54

.4-56

. ..4-58

.4-60

.4-61

.4-63

.4-65

,4-67

.4-70

.4-72

,4-14

.4-76

.4-7x

,4-80

.4-81

.4-x3

.4-X6

4-88

.4-x9

.4-92

.4-93

.4-95

.4-97

.4-99

,4-101

.4-103

.4-I05

.4-107

.4-109

..4-111

.4-113

SOOfcd.toc Black vi

K-SetStartStopChn ............................

K-SetStartStopG ..............................

K-SetTrig .................................... .4-120

K-SetTrigHyst

................................ 4-122

K-SyncStart ..................................

A Error/Status Codes

B

Data Formats

Converting Raw Counts to Voltage

Converting Voltage to Raw Counts

Specifying an Analog Trigger Level.

Specifying a Hysteresis Value.

Index

List of Figures

Figure 2-l.

Analog Input Channels

Figure 2-2. Channel-Gain List (C or Pascal)

Figure 2-3. Sample Channel-Gain List (C or Pascal).

Figure 2-4. Channel-Gain List (BASIC)

Figure 2-5. Sample Channel-Gain List (BASIC).

Figure 2-6. Initiating Conversions

Figure 2-7. Analog Trigger Conditions

Figure 2-8. Using a Hysteresis Value. . .

Figure 2-Y. Initiating Conversions with an External

Analog Trigger

Figure 2-10. Initiating Conversions with an External

Digital Trigger. . 2-21

Figure 2-l I. Hardware Gate. : : 2-23

Figure 2-12. Digital Input Bits. .2-24

Figure 2-13. Digital Output Bits. .2-25

.4-115

.4-l I7

4-124

B-2

.B-3

.B-3

.B-5

.2-x

.2-IO

.2-I1

.2-I2

.2-12

.2-I5

.2-I7

2-19

.2-20

vi

SOOfcd.toc Black vii

List of Tables

Table 2-l.

Supported Operations .2-l

Table 2-2. Analog Input Ranges., .2-6

Table 2-3.

Table 3-l.

Table 3-2.

Channels in Maximum Configuration. .2-7

A/D Frame Elements. .3-3

Setup Functions for Synchronous-Mode

Operations.. . . . . . . . . . . . .3-7

Table 3-3.

Table 4-1.

Table 4-2.

Setup Functions for Interrupt-Mode Operations .3-IO

FCD Functions. . .4-2

Default Configuration .4-7

Table A- I. Error/Status Codes. A-l

vii

800fcd.toc Black viii

preface.frm Black ix

+b

Preface

The

DAS-BOO Series Function Call Driver User’s Guide

write application programs for DAS-800 Series boards using the

DA.%800 Series Function Call Driver. The DAS-X00 Series Function Call

Driver supports the following DOS-based languages:

. Microsoft@ QuickBASIC (Version 4.0)

l

Microsoft QuickBasicm (Version 4.5 and higher)

describes how to

. Microsoft Professional Basic (Version 7.0 and higher)

. Microsoft Visual BasicTM for DOS (Version 1.0)

. Microsoft C/C++ (Version 4.0 and higher)

. Borland@ C/C++ (Version I.0 and higher)

l

Borland Turbo Pascal@ for DOS (Version 6.0 and higher)

The DAS-800 Series Function Call Driver also supports the following

WindowsTM-based languages:

l

Microsoft Visual Basic for Windows (Version 2.0 and higher)

. Microsoft QuickC@ for Windows (Version 1.0)

l

Microsoft Visual C++TM (Version I .O)

. Borland Turbo Pascal for Windows (Version 1.0 and higher)

preface.frm Black x

f@

The manual is intended for application programmers using a DAS-800,

DAS-801, or DAS-802 board in an IBM’ PC/XY, ATa or compatible

computer, It is assumed that users have read the

Guide

to familiarize themselves with the boards’ functions, and that they

DAS-800 Series User’s

have completed the appropriate hardware installation and configuration. It

is also assumed that users are experienced in programming in their

selected language and that they are familiar with data acquisition

principles.

The

DAS-800

Series

Function Call Driver

User’s

Guide

is organized as

follows:

Chapter I contains the information needed to install the DAS-800

Series Function Call Driver and to set up DAS-800 Series boards.

Chapter 2 contains the background information needed to use the

functions included in the DAS-800 Series Function Call Driver.

Chapter 3 contains programming guidelines and language-specific

information related to using the DA.5800 Series Function Call

Driver.

Chapter 4 contains detailed descriptions of the DAS-XtlO Series

Function Call Driver functions, arranged in alphabetical order.

Appendix A contains a list of the error codes returned by DAS-800

Series Function Call Driver functions.

Appendix B contains instructions for converting raw counts to

voltage and for converting voltage to raw counts.

An index completes this manual.

prefacefrm Black xi

Keep the following conventions in mind as you use this manual:

. References to DAS-800 Series boards apply to the DAS-800,

DAS-801, and DAS-802 boards. When a feature applies to a

particular board, that board’s name is used.

. References to BASIC apply to all DOS-based BASIC languages

(Microsoft QuickBASIC (Version 4.0). Microsoft QuickBasic

(Version 4.5), Microsoft Professional Basic, and Microsoft Visual

Basic for DOS). When a feature applies to a specific language, the

complete language name is used. References to Visual Basic for

Windows apply to Microsoft Visual Basic for Windows.

. Keyboard keys are enclosed in square brackets ([ 1).

4

xi

4

preface.frm Black xii

4

4

chapOl_.frm Black 1

fb

Getting Started

The DAS-800 Series Function Call Driver is a library of data acquisition

and control functions (referred to as the Function Call Driver or FCD

functions). It is part of the following two software packages:

4

. DAS-X00

package that is shipped with DAS-800 Series boards; it includes the

following:

-

- Support files, containing such program elements as function

-

-

.

ASOSoftware Option for DAS-800 Series boards. You purchase the

ASO- software package separately from the board; it includes the

following:

Series

Libraries of FCD functions for Microsoft QuickBASIC

(Version 4.0) Microsoft QuickBasic (Version 4.5), Microsoft

Professional Basic, and Microsoft Visual Basic for DOS.

prototypes and definitions of variable types, which are required

by the FCD functions.

Utility programs, running under DOS, that allow you IO

configure, calibrate, and test the functions of DAS-800 Series

boards.

Language-specific example programs,

software package

Libraries of FCD functions for Microsoft C/C++, Borland

C/C++, and Borland Turbo Pascal.

standard

software package -This

- This is the optional Advanced

is the software

4

4

l-l

chapOl_.frm Black 2

+D

- Dynamic Link Libraries (DLLs) of FCD functions for Microsoft

Visual Basic for Windows, Microsoft QuickC for Windows,

Microsoft Visual C++. and Borland Turbo Pascal for Windows.

- Support files. containing program elements, such as function

prototypes and definitions of variable types. that are required by

the FCD functions.

- Utility programs, running under DOS and Windows, that allow

you to configure, calibrate, and test the functions of DAS-800

Series boards.

- Language-specific example programs.

This chapter contains the information needed to install the DAS-800

Series Function Call Driver in your computer and set up your DAS-800

Series boards. It also contains information on where to get help if you

have problems installing or using the Function Call Driver.

Installing the Software

Before you can use the Function Call Driver, you must install the

appropriate software package, either the DAS-800 Series standard

software package or the ASO- software package.

The following sections describe how to install the DAS-800 Series

standard software package and how to install the AS0400 software

package from both DOS and Windows.

Installing the DAS-800 Series Standard Software Package

To install the DAS-800 Series standard software package, perform the

following steps:

1. Make a back-up copy of the supplied disks.

2. Insert disk #l into the disk drive.

l-2

Getting Started

chapOl_.frm Black 3

3. Assuming that you are using disk drive A, enter the following at the

DOS prompt:

A:install

The installation program prompts you for your installation

preferences, including the name of the directory you want to copy the

software to. It also prompts you to insert additional disks, as

necessary.

4. Continue to insert disks and respond to prompts, as appropriate.

The installation program expands any files that are stored in a

compressed format and copies them into the directory you specified

(DAS800 directory on hard disk C if you do not specify otherwise).

5. Review the following tiles:

- FILES.TXT lists and describes all the files copied to the hard disk

by the installation program.

-

README.TXT contains information that was not available when

this manual was printed.

installing the ASO- Software Package

This section describes how to install the ASO- software package from

both DOS and Windows.

DOS Installation

To install the ASO- software package from DOS, perform the

following steps:

1. Make a back-up copy of the supplied disks.

2. Insert disk #1 into the disk drive.

3. Assuming that you are using disk drive A. enter the following at the

DOS prompt:

A:install

1-3

chapOl_.frm Black 4

The installation program prompts you for your installation

preferences, including the name of the directory you want to copy the

software to. It also prompts you to insert additional disks, as

necessary.

4. Continue to insert disks and respond to prompts, as appropriate.

The installation program expands any files that are stored in a

compressed format and copies them into the directory you specified

(AS0800 directory on hard drive C if you do not specify otherwise).

5. Review the following files:

- FILES.TXT lists and describes all the files copied to the hard disk

by the installation program.

-

README.TXT contains information that was not available when

this manual was printed.

Windows Installation

To install the ASO- software package from Windows, perform the

following steps:

I. Make a back-up copy of the ASO-Windows disk

2. Insert the ASO-Windows disk into the disk drive.

3. Start Windows,

4. From the Program Manager menu, choose File and then choose Run.

5. Assuming that you are using disk drive A, type the following at the

command line in the Run dialog box, and then select OK:

The installation program prompts you for your installation

preferences, including the name of the directory you want to copy the

software to.

6. Type the path name and select Continue.

A: SETUP

1-4

Getting Started

chapOl_.frm Black 5

Setting Up the Boards

fb

The installation program expands any tiles that are stored in a

compressed format and copies them into the directory you specified

(ASOBOWWINDOWS directory on hard drive C if you do not specify

otherwise).

The installation program also creates a DAS-800 family group; this

group includes example Windows programs and help files.

7. Review the following files:

-

FILES.TXT lists and describes all the tiles copied to the hard disk

by the installation program.

- README.TXT contains information that was not available when

this manual was printed.

Before you use the Function Call Driver. make sure that you have

performed the following steps:

1. Installed the software.

If not, install the appropriate software package (either the DAS-800

Series standard software package or the ASO- software package)

on your IBM PC/XT, AT or compatible computer. Refer to page 1-2

for information on installing the DAS-800 Series standard software

package; refer to page 1-3 for information on installing the ASO-8OU

software package.

2. Created a configuration file.

If not, use the DXOOCFG.EXE utility to create a configuration file for

the DAS-800 Series boards you are using. For each board, make sure

that you specify the board model, the base address, the use of

counter/timer 2 (C/IY2) on the 8254 counter/timer circuitry, the input

range type (unipolar or bipolar), the input configuration (single-ended

or differential) for each channel on each DAS-801 and DAS-802

board, the interrupt level, and the expansion boards used. Refer to the

DAS-800 Series

(/ser’s

Guide

for more information.

l-5

chapOl_.frm Black 6

3. Configured the hardware.

If not, use switches on the boards to set the base address of each

DA.%800 Series board and the input contiguration (single-ended or

differential) for each channel on each DAS-801 and DAS-802 board.

Use the jumper on the boards to set the interrupt level of each

DAS-800 Series board. Refer to the instructions in the

DXOOCFG.EXE utility and the

DAS-800 Series User’s Guide

for more

information.

4. Installed the board(s).

If not, with the computer powered down, install the DAS-800 Series

boards in your computer. The DAS-800 requires a single, short slot;

the DAS-801 and DAS-802 require a single, l/2-slot. Refer to the

documentation provided with your computer for more information on

installing boards.

5. Tested the board(s), if desired.

Getting Help

If you need help installing or using the DA.%800 Series Function Call

Driver, contact the factory.

Note: The DAS-800 Series Function Call Driver supports a

maximum of four DAS-800 Series boards.

If you want to test the functions of the boards before writing your

application program, use the CTLXOO.EXE utility (for DOS) or the

CTLXOOW.EXE utility (for Windows). Refer to the

User’s

Guide

for more information.

DA.5800 Series

l-6

-

chapOl_.frm Black 7

An applications engineer will help you diagnose and resolve your

problem over the telephone. Please make sure that you have the following

information available before you call:

Software package Version

Invoice/order #

4

Compiler

Operating system

Computer

DAS-800 board

Language

Manufacturer

Version

DOS

version

Windows version 3.0 3.1

mode Standard Enhanced

Manufacturer

CPU type

Clock speed (MHz)

Math coprocessor

Amount of RAM

Video system

BIOS type

Model

Serial I#

Base address setting

Interrupt level setting

Input configuration

Input range type

8254 C/l? usage

8088 286 386 4868 12 20 25 33 _

Yes No

CGA Hercules EGA VGA

800 801 802

2 3 4 5 6 7 None

Single-ended Differential

Unipolar Bipolar

Cascaded Normal

4

Expansion boards ‘I)pe

;;:

;;:

5Pe

4

l-7

chapOl_.frm Black 8

chap02-.frm Black 1

2

Available Operations

This chapter contains the background information you need to use the

FCD functions to perform operations on DAS-800 Series

supported operations are listed in Table 2- 1.

Table 2-1. Supported Operations

Operation Page Reference

boards.

The

Analog

Counter/timer l/O

input

Analog Input Operations

This section describes the following:

. Analog input operation modes available.

. How to allocate and manage memory.

. How to modify the input range type.

. How to specify channels and gains, a conversion clock source. a

buffering mode, and a trigger source for an analog input operation.

page 2-I

page 2-26

2-l

chap02-.frm Black 2

Operation Modes

The operation mode determines which attributes you can specify for an

analog input operation and whether the operation is performed in the

foreground or in the background. You can perform analog input

operations in one of the following modes:

. Single

mode

- In single mode, the board acquires a single sample

from an analog input channel. The driver initiates the conversion and

the board acquires the data in the foreground: you cannot perform any

other operation until the single-mode operation is complete.

You use the K-ADHead function to start an analog input operation in

single mode. You specify the board you want to use, the analog input

channel, the gain at which you want to read the signal, and the

variable in which to store the converted data.

. Synchronous mode - In synchronous

mode, the board acquires a

single sample or multiple samples from one or more analog input

channels. A hardware conversion clock initiates conversions while

the board acquires data in the foreground: you cannot perform any

other operation until the synchronous-mode operation is complete.

After the driver transfers the specified number of samples to the host.

it returns control to the application program, which reads the data.

Synchronous mode provides the fastest acquisition of multiple

samples.

You use the K-SyncStart

function to start an analog input operation

in synchronous mode. You specify the channel(s). gain(s). conversion

clock source, buffer address, and trigger source.

2-2

. Interrupt mode

- In interrupt mode, the board acquires a single

sample or multiple samples from one or more analog input channels.

A hardware conversion clock initiates conversions while the board

acquires data in the background; system resources can be used by

other programs. The driver transfers data to the host in the

background using an interrupt service routine.

You use

the

K-In&art

function to start an analog input operation in

interrupt mode. You specify the channel(s), gain(s), conversion clock

source, buffering mode, buffer address, and trigger source.

Available Operations

chap02-.frm Black 3

+b

You can specify either single-cycle or continuous buffering mode for

interrupt-mode operations. Refer to page 2-16 for more information

on buffering modes.

continuous-mode interrupt operation.

You

can

use the K-IntStatus

of an interrupt operation. In addition,

function to determine the status of all interrupt operations on a

particular board.

For single mode, synchronous mode, and interrupt mode, the converted

data is stored as raw counts. For information on converting raw counts to

voltage, refer to Appendix B.

Note: In applications where you must accurately control the sampling

rate, it is recommended that you perform the analog input operation in

either synchronous mode or interrupt mode so that you can specify a

conversion clock source.

You

can

use the K-IntStop

function to determine the current status

you can use the K-InitFrame

function 10 stop a

Memory Allocation and Management

Synchronous-mode and interrupt-mode analog input operations require a

memory buffer in which to store the acquired data. You can provide the

required memory buffer in one of the following ways:

. Within your application program’s memory area

memory buffer is always available to your program; however. your

application program may require a large amount of memory. You can

dimension a local memory buffer for any supported language. Since

the DAS-800 Series Function Call Driver stores data in l6-bit

integers, you must dimension all local memory buffers as integers.

. Outside of your application program’s memory area - You

allocate memory as needed. For all C languages, all Pascal languages,

and Visual Basic for Windows,

to allocate memory dynamically, outside of your program’s memory

area. You specify the operation requiring the buffer, the number of

samples to store in the buffer, the starting address of the buffer, and

the name you want to use to identify the buffer (this name is called the

memory handle). When the buffer is no longer required. you can free

- The local

you can use the K-IntAlloc

function

2-3

chap02Lfrm Black 4

the buffer for another use by specifying this memory handle in the

K-IntFree

function.

Note:

You cannot allocate memory dynamically in BASIC; in

BASIC, you must dimension the memory buffer locally.

You can use multiple buffers to increase the number of samples you can

acquire. Each synchronous-mode or interrupt-mode analog input

operation has a buffer list associated with it. You can use the

K-BufListAdd

You can use the K-BufListReset

function to add a buffer to the list of multiple buffers.

function to clear the list of multiple

buffers.

Note:

If you are using a Windows-based language in Enhanced mode,

you may be limited in the amount of memory you can allocate. If you are

allocating memory dynamically or if you are using multiple buffers. it is

recommended that you use the Keithley Memory Manager before you

begin programming to ensure that you can allocate a large enough buffer

or buffers. Refer to the

DAS-800 Series User’s Guide

for more

information about the Keithley Memory Manager.

After you allocate or dimension your buffer(s). you must specify the

starting address of the buffer(s) and the number of samples to store in the

buffer(s), as follows:

2-4

l

For BASIC

- You use the

K SetBufI

function to specify the starting

address of a single, locally dimensioned memory buffer. When using

multiple buffers, you

use the K-BufListAdd

function both IO add

buffers to the multiple-buffer list and to specify the starting address of

each buffer.

. For Visual Basic for Windows - You use the K SetBufl

function to

specify the starting address of a single, locally dimensioned integer

memory buffer; you use the

address of a single buffer allocated dynamically using

When using multiple buffers, you use the

K-SetBuf function

K-BufListAdd

to specify the starting

K-IntAlloc.

function

both to add buffers to the multiple-buffer list and to specify the

starting address of each buffer.

Available Operations

chap02-.frm Black 5

Input Range Type

Note: If you allocated your buffer dynamically using K~lntAlloc,

you

must use the

K-MoveBufIbArray

function to transfer the

acquired data from the dynamically allocated buffer to a local buffer

that your Visual Basic for Windows program can we. Refer to page

3-25 for more information.

l

For C and Pascal - You use the K-SetBuf function to specify the

starting address of a single buffer, whether the buffer was

dimensioned locally or allocated dynamically using

When using multiple buffers, you use the

K-BuIListAdd

K-IntAlloc.

function

both to add buffers to the multiple-buffer list and to specify the

starting address of each buffer.

Normally, the driver determines the input range type for a DAS-801 or

DAS-802 board (bipolar or unipolar) by reading the configuration tile.

You can change the input range type without modifying the configuration

file by using the

DAS800-SetADGainMode function.

Gains

Note: The input range type of the DAS-800 board is always bipolar.

Use the

range type. If

DAS800 GetADGainMode

contigu&on file; if you have used

DAS800-GetADGainMode

DAS800-GetADGainMode

you never used DASSOO SetADGainMode,

function to get the current input

reads the%put range type from the

DASSOO-SetADGainMode.

reads the last input range type you

programmed through software.

DAS-800 boards measure analog input signals in the range of f5 V.

DA%801 and DAS-802 boards measure analog input signals in one of

several software-selectable unipolat and bipolar ranges. For each channel

on aDAS- or DAS-802 board, you can select one of five bipolar and

four unipolar analog input ranges.

Z-5

chap02-.frm Black 6

Table 2-2 lists the analog input ranges supported by DAS-800 Series

boards and the gain and gain code associated with each range. (The gain

code is used by the FCD functions to represent the gain.)

Table 2-2. Analog Input Ranges

4

Channels

Board

I DAS-800 1 fS V

The analog input channels are the analog input connections from which

you acquire data. DAS-800 Series boards contain eight on-board analog

input channels, numbered 0 through 7. If you require additional channels,

you can use any combination of up to eight I&channel EXP-16 or

EXP-16/A expansion boards and/or 8-channel EXP-GP expansion boards

to increase the number of available channels to 128. You can also use up

to four MB-02 backplanes to increase the number of available channels to

68.

isi Gal”

1 Not available

1

Gain Code

lo I

2-6

4

Available

Operations

chap02-.fnn Black 7

Expansion boards are assigned to consecutive on-board analog input

channels, beginning with on-board channel 0. To ensure that the DA.%X00

Series Function Call Driver reads the channel numbers correctly. you

must attach all EXP- I6 and EXP-16/A expansion boards first, followed

by all EXP-GP expansion boards. You can also use the remaining

on-board channels. Refer to the

appropriate expansion board documentation for more information.

The maximum supported configuration is eight EXP-16 or EXP- 16/A

expansion boards, eight EXP-GP expansion boards, or four MB-02

backplanes. Table 2-3 lis!s the software channels associated with each

expansion board.

Table 2-3. Channels In Maximum Configuration

DAS-800 Series User’s Guide

Software Channels

or the

4

4

Figure 2- 1 illustrates the use of one EXP- 16 expansion board, two

EXP-GP expansion boards, and the five remaining on-board channels.

The channels on the EXP-16 attached to analog input channel 0 are

referred to in software as channels 0 to 15; the channels on the EXP-GP

attached to analog input channel 1 are referred to in software as channels

16 to 23; the channels on the EXP-GP attached to analog input channel 2

are referred to in software as channels 24 to 3 1; the remaining five

2-7

chap02-.frm Black 8

on-board analog input channels (3,4,5.6. and 7) are referred to in

software as channels 32,33,34, 35, and 36.

EXP-16

channels

0.16

rl

I

I

Single Channel

o-

DA8400

sorts. Board

Figure 2-1. Analog input Channels

l-

:

:

;

You can perform an analog input operation on a single channel or on

multiple channels. The following subsections describe how to specify the

channel(s) you are using.

You can acquire a single sample or multiple samples from a single analog

input channel.

For single-mode analog input operations, you can acquire a single sample

from a single analog input channel. You

use the K-ADRead

function to

specify the channel and the gain code.

2-8

For synchronous-mode and interrupt-mode analog input operations. you

can acquire a single sample or multiple samples from a single analog

input channel. You

the

K-SetG

use the K SetChn

function to specify the channel and

function to specify the gain code.

Available Operations

chap02-.frm Black 9

Multiple Channels Using a Group of Consecotlve Channels

For synchronous-mode and intemrpt-mode analog input operations, you

can acquire samples from a group of consecutive channels. You use the

K-SetStartStopChn

group. The channels are sampled in order from first to last; the channels

are then sampled again until the required number of samples are read.

For example, assume that you have an EXP-16/A expansion board

attached to on-board channel 0. You specify the start channel as 14, the

stop channel as 17. and you want to acquire five samples. Your program

reads data first from channels 14 and 15 (on the EXP-16/A), then from

channels 16 and 17 (on-board channels 1 and 2). and fmally from channel

14 again.

If you are not using any expansion boards, you can specify a start channel

that is higher than the stop channel. For example, assume that the start

channel is 7, the stop channel is 2. and you want to acquire five samples.

Your program reads data first from channel 7. then from channels 0. 1,

and 2. and finally from channel 7 again.

function to specify the first and last channels in the

You can use the K-SetC function to specify the gain code for ah channels

in the group. (All channels in a group of consecutive channels must use

the same gain code.) You can

specify the gain code, the start channel, and the stop channel in a single

function call.

Refer to Table 2-2 on page 2-6 for a list of the analog input ranges

supported by DAM00 Series boards and the gain code associated with

each range.

also

use the K-SetStartStopG function to

Multiple Channels Using a Channel-Gain List

For synchronous-mode and interrupt-mode analog input operations. you

can acquire samples from channels in a channel-gain list. In the

channel-gain list, you specify the channels you want to sample, the order

in which you want to sample them, and the gain code for each channel.

2-9

chap02-.frm Black 10

The channels in a channel-gain list are not necessarily in consecutive

order, and you can specify the same channel more than once (up to a total

of 256 channels in the list). For the DAS-801 and DAS-802 boards, you

can use a different gain code for each channel in a channel-gain list; for

the DAS-800 board, every channel must use a gain code of 0 (gain of I).

The channels are sampled in order from the first channel in the list to the

last channel in the list; the channels in the list are then sampled again until

the required number of samples are read.

Refer to Table 2-2 on page 2-6 for a list of the analog input ranges

supported by DAS-X00 Series boards and the gain code associated with

each range.

Note:

The maximum attainable conversion frequency when using a

channel-gain list is less than the maximum attainable conversion

frequency when using a group of consecutive channels.

You specify the channels and gains in one of the following ways:

. For C and Pascal

- You use two adjacent g-bit bytes to specify a

channel and its gain code (the channel number is specilied in the first

byte; the gain code is specified in the second byte). The first two

bytes in the channel-gain list specify the number of channels

(subsequent pairs of bytes) in the list. Figure 2-2 illustrates the format

of a channel-gain list for C or Pascal, where n is the number of

channels (pairs) in the list.

syte 0 1

Value "

#Of pairs

2 3 4

than jeahl than /g&l

pair 1

pair 2

6 ~..~.~. 2n

..- cbn ~ @"

2" + 1

pair n

Z-10

Figure 2-2. Channel-Gain List (C or Pascal)

Available Operations

chap02-.frm Black 11

Figure 2-3 illustrates a channel-gain list of four channels on a

DAS-801 board: channel 5 is sampled at a gain of 0.5 (gain code = 1).

channel 2 is sampled at a gain of 10 (gain code = 2) channel 4 is

sampled at a gain of 100 (gain code = 3), and channel 2 is sampled at

a gain of 500 (gain code = 4).

"a,"e 0 4 6 1 2 2 4 3 2 4

Figure 2-3. Sample Channel-Galn List (C or Pascal)

After you create the channel-gain list in C or Pascal, use the

K-SetChnCAry function to specify the starting address of the list.

For Pascal only, you must define a record type for the channel-gain

list before you specify the starting address. Refer to page 3- I9 for

more information.

. For BASIC

and

Visual

Basic for Windows

- You use two adjacent

l6-bit words to specify a channel and its gain code (the channel

number is specified in the first word; the gain code is specified in the

second word). The first word in the channel-gain list specifies the

number of channels (subsequent pairs of words) in the list. Figure 2-4

illustrates the format of a channel-gain list for BASIC and Visual

Basic for Windows, where n is the number of channels (pairs) in the

list.

Z-11

chap02-.frm Black 12

Word

V&NJ

0 1

n

cflan

2

b-in

w Of pairs pair 1

Figure 24. Channel-Gain List (BASIC)

Figure 2-5 illustrates a channel-gain list of three channels on a

DAS-80 1 board: channel 5 is sampled at a gain of 0.5 (gain code = 1).

channel 2 is sampled at a gain of 10 (gain code = 2), and channel 4 is

sampled at a gain of 100 (gain code = 3).

Word

I IO 11121314151~1

ValUe 3 5 1 2 2

3

p&s pdr

1 pal, 2

2n.1

Ohm

pair n

4 3

pair 3

2n

win

2-12

Figure 2-5. Sample Channel-Gain List (BASIC)

After you create your channel-gain list in BASIC or Vwal Basic for

Windows,

you

must

use the K FormatChanCAry

function to

convert the 16-bit values to X-bit values that the DAS-800 Series

Function Call Driver can use. After

convert your

list,

use the K-SetChnCAry

you use K-FormatChanCAry

function to specify the

starting address of the list.

Your program cannot read

K-FormatChanCAry

K RestoreChanCAry

the

channel-gain list

converted

by the

function; you must use the

function 10 restore the converted list to its

original format.

Available Operations

to

chap02-.frm Black 13

Conversion Clocks

The conversion clock determines the time interval between conversions.

For synchronous-mode and interrupt-mode analog input operations, you

can use the K-SetClk function to specify an internal or an external

conversion clock source. These conversion clock sources are described as

follows:

. Internal clock source

- The internal clock source is tbc on-board

8254 counter/timer circuitry. The 8254 counter/timer circuitry is

normally in an idle state. When you start the analog input operation

(using

K-In&art or K-SyncStart),

a conversion is initiated

immediately. The 8254 is loaded with a count value and begins

counting down. When the 8254 counts down to 0, another conversion

is initiated and the process repeats.

Because the 8254 counter/timer uses a I MHz time base, each count

represents I

KS.

Use the

K-SetClkRate

to specify the number of

counts (clock ticks) between conversions. For example, if you specify

a count of 25, the time interval between conversions is 25 ps; if you

specify a count of 65535, the time interval between conversions is

65.535 ms.

The 8254 contains three counter/timers: CEO, CR I, and C/IT. If you

are using an internal clock source. the 8254 uses both CM and CK I.

The driver uses C/T2 and CKl in either normal or cascaded mode, as

follows:

-

Normal

mode

- The driver loads the count you specify into Cn2

of the 8254 counter/timer circuitry. Each time C/f2 reaches

terminal count, a conversion is initiated. The time interval

between conversions ranges from 25 bs to 65.535 ms.

-

Cascaded mode

- The driver divides the count you specify

between Cn2 and Clrl of the 8254 counter/timer circuiuy.

When C/r2 counts down to 0, CR1 decrements by I. Cfl2 is

reloaded with its count value and begins counting down again.

Each time C/T2 counts down to 0. Cfll decrements by I. Each

time both C/l’2 and C/l’1 reach terminal count. a conversion is

initiated, The time interval between conversions ranges from

25

us to 1.2 hours.

2-l 3

chap02-.frm Black I4

Note: You configure the 8254 counter/timer circuitry for normal

mode or cascaded mode using the DBOOCFG.EXE configuration

utility. Refer to the

DAS-800 Series User’s Guide

for more

information.

When using an internal clock source, use the following formula to

determine the number of counts to specify:

counts =

conversion frequency

I MHz

For example, if you want a conversion frequency of 10 kHz. specify a

count of 100.

. External clock source - Use an external clock sonrce if you want to

sample at rates not available with the 8254 counter/timer circuitry. if

you want to sample at uneven intervals. or if you want to sample on

the basis of an external event.

You attach an external clock sonrce to the INT-IN / XCLK pin

(pin 24). When you start the analog input operation (using

K-IntStart

or

K-Sync&art),

conversions are armed. At the next

falling edge of the external clock source (and at every subsequent

falling edge of the external clock source), a conversion is initiated.

Figure 2-6 illustrates the initiation of conversions when using an internal

and an external clock source. (Note that Figure 2-6 assumes that you are

not using an external trigger; refer to Figure 2-10 on page 2-21 for an

illustration of conversions when using an external trigger.)

2-14

Available Operations

chap02-.frm Black 15

+b

Figure 2-6. Initiating Conversions

Notes:

maximum of 40 kHz (one sample every 25 us). If you arc using an

external clock, make sure that the clock does not initiate conversions at a

faster rate Tao the ADC can handle.

To achieve full measurement accuracy when using a gain of 500, you

should limit the conversion frequency to a maximum of 25 kHz (one

sample every 40 ps).

If you are acquiring samples from multiple channels, the maximum

sampling rate for each channel is equal to 40 kHz divided by the number

of channels.

The rate at which the computer can reliably read data from the

depends on a number of factors, including your computer, the operating

system/environment, whether you are using expansion

of the channels, and other software issues.

For single-mode analog input operations, the software initiates each

conversion with a call to the K-ADRead function.

The analog-to-digital converter (ADC) acquires samples at a

board

boards, the gains

2-15

chap02-.frm Black 16

Buffering Mode

The buffering mode determines how the driver stores the converted data

in the buffer. For interrupt-mode analog input operations. you can specify

one of the following buffering modes:

. Continuous mode - In continuous mode, the board continuously

converts samples and stores them in the buffer until it receives a stop

function; any values already stored in the buffer are overwritten. You

use the K-SetContRun function to specify continuous buffering

mode.

. Single-cycle mode - In single-cycle mode, after the board converts

the specified number of samples and stores them in the buffer. the

operation stops automatically. You use the K-ClrContRun function

to specify single-cycle buffering mode. (Note that single-cycle mode

is the default buffering mode.)

Triggers

A trigger is a set of conditions that must occur before a DAS-800 Series

board starts an analog input operation. For synchronous-mode and

interrupt-mode analog input operations, you can use the K-Setltig

function to specify one of the following trigger sources:

l

Internal trigger - An internal trigger is a software trigger; when you

start the analog input operation (using K-IntStart or K-SyncStart).

conversions begin immediately.

. External trigger - An external trigger is either an analog trigger or a

digital trigger; when you start the analog input operation (using

K-IntStart or K-SyncStart), the application program waits until a

trigger event occurs and then begins conversions.

Analog and digital triggers are described in the following subsections.

2-16

Available Operations

chap02-.frm Black 17

Analog Triggers

An analog trigger event occurs when one of the following conditions is

met by the analog input signal on a specified analog trigger channel:

. The analog input signal rises above a specified voltage level

(positive-edge trigger).

. The analog input signal falls below a specified voltage level

(negative-edge trigger).

Figure 2-7 illustrates these analog trigger conditions, where the specitied

voltage level is +5 V.

Flgure 2-7. Analog Trlgger Conditions

You use the K-SetADTrig function to specify the analog input channel to

use as the trigger channel, the voltage level. the trigger polarity, and the

trigger sense.

2-17

chap02-.frm Black 18

fb

Note: You specify the voltage level as a raw count value between 0 and

4095. Refer to Appendix B for information on how to convert a voltage

value to a raw count value.

You can use the K-Set’lXgHyst function to specify a hysteresis value to

prevent noise from triggering an operation. For a positive-edge trigger,

the analog signal must fall below the specified voltage level by at least the

amount of the hysteresis value before the trigger event can occur; for a

negative-edge trigger, the analog signal must rise above the spccifted

voltage level by at least the amount of the hysteresis value before the

trigger event can occur.

The hysteresis value is an absolute number, which you specify as a raw

count value between 0 and 4095. When you add the hysteresis value to

the voltage level (for a negative-edge trigger) or subtract the hysteresis

value from the voltage level (for a positive-edge trigger). the resulting

value must also be between 0 and 4095. For example, assume that you are

using a negative-edge trigger on a channel configured for a bipolar input

range type. If the voltage level is +4.8 V (4014 counts), you can specify a

hysteresis value of 0.1 V (41 counts), but you cannot specify a hysteresis

value of 0.3 V (123 counts). Refer to Appendix B for information on how

to convert a voltage value to a raw count value.

2-10

In Figure 2-8. the specified voltage level is +5 V and the hysteresis value

is 0. I V. The analog signal must fall below i4.9 V and then rise above

+5 V before a positive-edge trigger event occurs; the analog signal must

rise above +5. I V and then fall below +5 V before a negative-edge trigger

event occurs.

Available

Operations

chap02Lfrm Black 19

Poalthnadge

trigger event OOO”,~

start fumtlon b mewled

Figure 2-8. Uslng s Hysteresis Value

When using an analog trigger, the driver samples the specified analog

trigger channel to determine whether the trigger condition has been met.

Therefore, a slight time delay may occur between the time the trigger

condition is actually met and the time the driver realizes that the trigger

condition has been met and begins conversions. In addition, the actual

point at which conversions begin depends on whether you are using an

internal or external clock source These considerations are described as

follows:

c Internal

clock source

- The 8254 counter/timer circuitry remains idle

until the driver detects the trigger event. When the driver detects the

trigger event, the hoard begins conversions immediately.

. External clock souree

- Conversions are armed when the driver

detects the trigger event. At the next falling edge of the external clock

source, the board begins conversions.

2-19

chapOZ.frm Black 20

External Analog /

Tdggsr

Figure 2-9 illustrates how conversions arc started when using an external

analog trigger.

Internal Clock

source

Figure 2-Q. lnltiating Conversions with an External Analog Trigger

Digital Triggers

CclUnt

1

A digital trigger event occurs when the board detects a rising edge on the

digital trigger signal connected to the IPl /TRIG pin (pin 25). You we the

K-SetDITrig function to specify an external digital trigger.

2-20

chap02-.frm Black 21

When using a digital trigger, the actual point at which conversions begin

depends on whether you are using an internal or external clock source.

These considerations are described as follows:

. Internal clock

. External clock

Figure 2-10 illustrates how conversions are started when using an external

digital trigger.

External DIgItal

Trigger

source -The 8254 counter/timer circuitry remains idle

until the trigger event occurs. When the trigger event occurs. the

board begins conversions immediately.

source - Conversions are armed wheo the trigger

event occurs. At the next falling edge of the external clock source. the

board begins conversions.

Internal Clock

source

Convenlons begIn

Figure 2-10. Initiating Conversions with an External Digital Trigger

2-21

chap02-.frm Black 22

Hardware Gates

A hardware gate is an externally applied digital signal that determines

whether conversions occur. You connect the gate signal to the IP 1 /TRIG

pin (pin 25) on the main I/O connector. If you have started an analog input

operation (using

K-IntStart

or

K-SyncStart)

and the hardware gate is

enabled, the state of the gate signal determines whether conversions

occur.

DAS-800 Series boards support a positive gate only. Therefore, if the

signal to IPl /TRIG is high, conversions occur; if the signal to IPI /

TRIG is low, conversions are inhibited. You use the

K-SetGate

function

to enable and disable the hardware gate.

You can use the hardware gate with an external analog trigger. The

software waits until the analog trigger event occurs and then checks the

state of the gate signal. If the gate signal is high, conversions begin; if the

gate signal is low, the software waits until the gate signal goes high before

conversions begin.

If you are not using an analog trigger, the gate signal itself can act as a

trigger. If the gate signal is low when you start the analog input operation.

the software waits until the gate signal goes high before conversions

begin.

Note: You cannot use the hardware gate with an external digital trigger. If

you use a digital trigger at one point in your application program and later

want to use a hardware gate, you must first disable the digital trigger. You

disable the digital trigger by specifying an internal trigger in

or by setting up

an

analog trigger (using

the K-SetAD’kig

K-SetTrig

function).

When the hardware gate is enabled, the way conversions are synchronized

depends on whether you are using an external or an internal clock source.

These considerations are described as follows:

. Internal clock source

-The 8254 stops counting when the gate signal

goes low. When the gate signal goes high again, the 8254 is reloaded

with its initial count value and starts counting again; therefore, when

using an internal clock, conversions are synchronized to the rising

edge of the gate signal.

2-22

Available Operations

chap02-.frm Black 23

+b

. External clock source

Figure 2-l 1 illustrates the use of the hardware gate with both an external

clock and an internal clock.

Gale Signal -

-The signal from the external clock continues

uninterrupted while the gate signal is low. When the gate signal goes

high again, the software waits for the next falling edge of the external

clock before initiating another conversion; therefore, when using an

external clock, conversions are synchronized to the falling edge of the

external clock.

Gate b high;

convemlons OCcur

Gstm Is low;

oo”“.,.lo”. InhlMted

3rd conv:nlon

(exlamal dock)

181 mnverdon

(Internal clock)

Figure 2-11. Hardware Gate

. . . . . .

4th mnvenlon

(Internalclock)

II’

2-23

chap02Lfrm Black 24

Digital I/O Operations

DAS-800 Series boards contain three digital input lines and four digital

output lines. The digital input lines are associated with the IPl /TRIG,

IP2. and IP3 pins on the main I/O connector; the digital output lines are

associated with the OPI, OP2, OP3. and OP4 pins on the main l/O

connector. If the digital I/O lines are not used for an internal operation,

you can use them for general-purpose digital I/O. as follows:

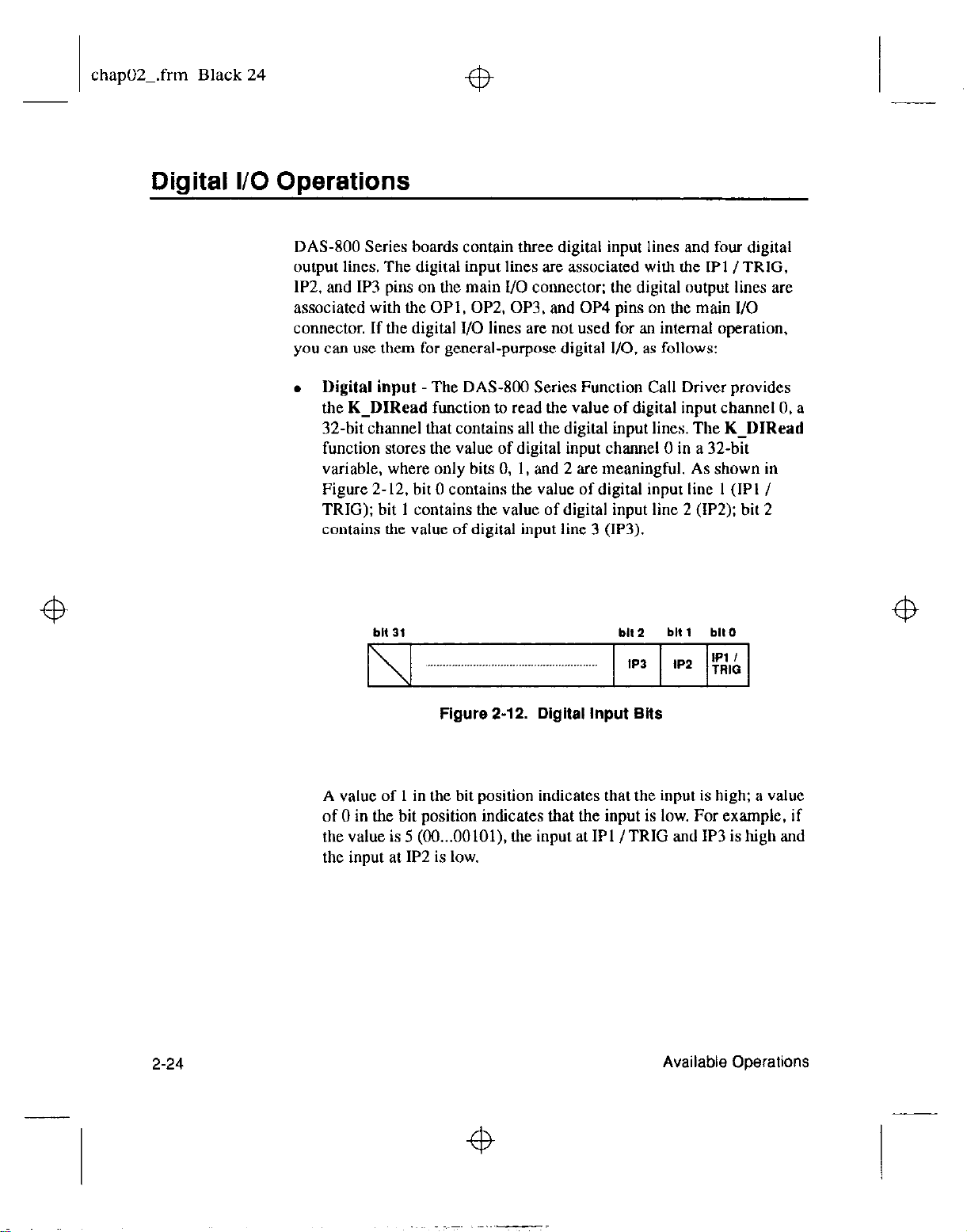

. Digital input

the

K-DIRead

32-bit channel that contains all the digital input lines.

function stores the value of digital input channel 0 in a 32-bit

variable, where only bits 0, 1. and 2 are meaningful. As shown in

Figure 2-12. bit 0 contains the value of digital input line I (IPI /

TRIG); bit 1 contains the value of digital input line 2 (IP2); bit 2

contains the value of digital input line 3 (IP3).

A value of I in the bit position indicates that the input is high; a value

of 0 in the bit position indicates that the input is low. For example, if

the value is 5 (OO...OOlOl), the input at IPI /TRIG and IP3 is high and

the input at IP2 is low.

-The DAS-800 Series Function Call Driver provides

function to read the value of digital input channel 0. a

The K-DIRead

Figure 2-12. Digital Input Bits

2-24

Available Operations

chap02-.frm Black 25

Notes: If you are using an external digital trigger, you cannot use the

IPl /TRIG pin (pin 25) for general-purpose digital input operations.

If no signal is connected to a digital input line, the input appears high

(value is 1).

l

Digital output - The DAS-800 Series Function Call Driver provides

the K DOWrite function to write a value to digital output channel 0.

a 32-l% channel that contains all the digital output lines. The

K-DOWrite function writes the value to digital output channel 0 as a

32-bit variable, where only bits 0, 1, 2, and 3 are meaningful. As

shown in Figure 2-13, bit 0 contains the value written to digital output

line 1 (OPl); bit I contains the value written to digital output line 2

(OP2); bit 2 contains the value written to digital output line 3 (OP3);

bit 3 contains the value written to digital output line 4 (OP4).

bit 31 bit 3 bit 2

. .

OP4 OP3 oP2 OPl

bll 1 bit0

Figure 2-13. DlgItaI Output Bits

A value of 1 in the bit position indicates that the output is high: a

value of 0 in the bit position indicates that the output is low. For

example, if the value written is 12 (OO...OlIOO), the output at OPl and

OP2 is forced low and the output at OP3 and OP4 is forced high.

2-25

chap02-.frm Black 26

Notes:

function for reading the current state of the digital output lines. To

determine the last value written to the digital output lines, check your

application program.

If you are using an expansion board for an analog input operation, the

driver uses all four digital output lines to specify the expansion hoard

channel that is acquiring data; in this case, you cannot use the digital

output lines for general-purpose digital output operations.

The DAS-800 Series Function Call Driver does not provide a

Counter/Timer I/O Operations

DAS-800 Series boards contain 8254 counter/timer circuitry; the 8254

contains three counter/timers: ClrO, C/II, and C/T2. If these

counter/timers are not being used for an internal operation, you can use

them for another task, such as frequency measurement.

Note:

using an internal clock source for an analog input operation, C/r2 and

C/T1 are not available for general-purpose tasks. If you are using an

external clock source, CfTO, C/Tl, and C/T2 are always available for

general-purpose tasks. Refer to page 2-13 for more information about the

use of the 8254 as an internal clock source.

C/TO is always available for general-purpose tasks. If you are

2-26

Available Operations

chap02-.frm Black 27

To configure a counter/timer on the 8254, you can use the

DASIIOO-Set8254 function. You specify both an initial count value to

load into the counter/timer and a counter/timer mode. The initial count

value can range from 2 to 65535. The following counter/timer modes arc

supported:

c Pulse on terminal count

c Programmable one-shot

c Rate generator

c Square-wave generator

c Software-triggered strobe

c Hardware-triggered strobe

Refer to the

counter/timer modes and on how to program the 8254 counter/timer

circuitry.

Use the DASSOO-Get8254 function to obtain the counter/timer mode and

the current count value of a counter/timer on the 8254 counter/timer

circuitry.

System Operations

This section describes the miscellaneous operations and general

maintenance operations that apply to DAS-800 Series boards and to the

DAS-800 Series Function Call Driver. It includes information on

initializing the driver, initializing a board, retrieving the revision level,

and handling errors.

DAS-800

Series User’s

Guide

for more information on the

2-27

chap02-.frm Black 28

Initializing the Driver

Before you can use any of the functions included in the DAS-800 Series

Function Call Driver, you must initialize the driver using one of the

following driver initialization functions:

. Board-specific driver initialization function - You can use the

board-specific driver initialization function

DASEOO-DevOpen

to

initialize the DAS-800 Series Function Call Driver only. You specify

a configuration file;

according to the configuration file you specify. Refer to the

Series

User’s

Guide

DASIlOO-DevOpen

initializes the driver

DAS-800

for information on creating and modifying

configuration files.

. Generic driver initialization function

- If you want to initialize

several different DAS Function Call Drivers from the same

application program, you can use the generic driver initialization

function

and a configuration file;

according to the configuration file you specify. Refer to the

Series User’s Guide

K-OpenDriver.

for information on creating and modifying

You specify the DAS board you are using

K OpenDriver

initializes the driver

DAS-800

configuration files.

You also specify the name you want to use to identify this particular

use of the driver; this name is called the driver handle. You can

specify a maximum of 30 driver handles for all the DAS boards

accessed from your application program.

If a particular use of a driver is no longer required and you want to

free some memory or if you have used all 30 driver handles. you can

use the K-CloseDriver

associated use of

function to free a driver handle and close the

the driver. K-CloseDriver also frees any system

resources associated with the driver handle.

If the driver handle you free is the last driver handle specified for a

Function Call Driver, the driver is shut down. (For Windows-based

languages only, the DLLs associated with the Function Call Driver

are shut down and unloaded from memory.)

2-28

Available Operations

chap02-.frm Black 29

Initializing a Board

fb

The DAS-800 Series Function Call Driver supports up to four boards.

You must use a board initialization function to specify the board you want

to use and the name you want to use to identify the board: this name is

called the board handle. Board handles allow you to communicate with

more than one board. You use the board handle you specify in the board

initialization function in all subsequent function calls related to the board.

The DAS-800 Series Function Call Driver provides the following board

initialization functions:

. Board-specific board initialization function - You can use the

board-specific board initialization function

to initialize a DAS-800 Series board only.

DAS8OO~GetDevHandle

. Generic driver initialization function

several different DAS boards from the same application program, you

can use the generic board initialization function

You can specify a maximum of 30 board handles for all the DAS

boards accessed from your application program.

If a board is no longer being used and you want to free some memory

or if you have used all 30 board handles, you can use the

K-FreeDevHandle

K-FreeDevHandle

the board handle.

To reinitialize a board during an operation, you can use the

K-DASDevInit

and K-DASDevInit perform the following tasks:

. Abort all analog input operations currently in progress that are

associated with the board identified by the board handle.

. Verify that the board identified by the board handle is the board

specified in the configuration tile.

function.

Retrieving the Revision Level

- If you want to initialize

K-GetDevHandle.

function to free a board handle.

also frees any system resources associated with

DAS8OO_GetDevHandle, K-GetDevHandle.

If you are using functions from different DAS Function Call Drivers in

the same application program, you may want to verify which versions of

2-29

chap02-.frm Black 30

Handling Errors

+b

the Function Call Drivers are installed on your board to determine if a

particular function is available to you. The K-GetVer function allows

you to get both the revision number of the DAS-800 Series Function Call

Driver and the revision number of the Keithley DAS Driver Specitication

to which the driver conforms.

Each FCD function returns a code indicating the status of the function. To

ensure that your application program runs successfully. it is recommended

that you check the returned code after the execution of each function. If

the status code equals 0. the function executed successfully and your

program can proceed. If the status code does not equal 0, an error

occurred; ensure that your application program takes the appropriate

action. Refer to Appendix A for a complete list of error codes.

For C-language application programs only, the DAS-800 Series Function

Call Driver provides the K-GetErrMsg function, which gets the address

of the string corresponding to an error code.

2-30

Available ODerations

chap03-.frm Black 1

3

Programming with the

Function Call Driver

This chapter contains an overview of the structure of the DAS-800 Series

Function Call Driver, as well as programming guidelines and

language-specific information to assist you when writing application

programs with the DAS-800 Series Function Call Driver.

How the Driver Works

The Function Call Drivers for all DAS boards allow you to perform I/O

operations in various operation modes. For single mode, the 110 operation

is performed with a single call to a function; the attributes of the I/O

operation are specified as arguments to the function and a single value is

obtained. For other operation modes, such as synchronous mode and

interrupt mode, the driver uses frames to perform the I/O operation. A

frame is a data structure whose elements define the particular I/O

operation.

Frames help you create structured application programs. You set up the

attributes of the I/O operation in advance, using a separate function call

for each attribute, and then start the operation at an appropriate point in

your program. Frames are useful for operations that have many defining

attributes, since providing a separate argument for each attribute could

make a function’s argument list unmanageably long. In addition, some

attributes, such as conversion clock source and trigger source. are only

available for I/O operations that use frames.

3-1

chap03-.frm Black 2

You indicate that you want to perform an I/O operation by getting an

available frame for the driver and specifying the name you want to use to

identify the frame; this name is called the frame handle. You then specify

the attributes of the I/O operation by using setup functions to define the

elements of the frame associated with the operation. For example, to

specify the channel on which to perform an I/O operation, you might use

the K-SetChn setup function.

For each setup function, the Function Call Driver provides a readback

function, which reads the current definition of a particular element. For

example, the K-GetChn readback function reads the channel used for the

I/O operation.

You use the frame handle you specified when accessing the frame in all

setup functions, readback functions, and other functions related to the I/O

operation. This ensures that you are defining the same I/O operation.

When you are ready to perform the I/O operation you have set up, you can

start the operation in the appropriate operation mode. referencing the

appropriate frame handle.

Different I/O operations require different types of frames. For example, to

perform a digital input operation, you use a digital input frame; to

perform an analog output operation, you use an analog output frame.

For DAS-800 Series boards, the only operations that use frames are

synchronous-mode and interrupt-mode analog input operations. The

DAM00 Series Function Call Driver provides eight identical analog

input frames, called A/D (analog-to-digital) frames. You use the

K-GetADFrame function to access an available A/D frame and specify a

frame handle.

Note: Drivers for other DAS boards may provide additional functions for

accessing analog output, digital input, or digital output frames.

If you want to perform a synchronous-mode or interrupt-mode analog

input operation and all eight frames have been accessed, you can use the

K-FreeFrame function to free a frame that is no longer in use. You can

then redefine the elements of the frame for the next operation.

3-2

Programming with the Function Call Driver

chap03-.frm Black 3

Table 3-1 lists the elements of a DAS-800.4/D frame, the default value of

each element, the setup function(s) used to define each element, and the

readback function(s) used to read the current definition of the element.

Table 3-1. A/D Frame Elements

Element

Buffering Mode

Default Value Setup Function

Readback Function

Single-cycle K-ClrContRun K-GetContRun

KSetContRun

Number of Samples 0 K-SetBuf K-GetBuf

KSetBufl I

Stop Channel

0 KSetStartStopChn K-GetStartSmpChn

K-SetStartStopG K-GetStartStopG

Trigger ‘&pe

1 Digital I KSetADTrig

1 K-GctAD’IYig

I

3-3

chap03-.frm Black 4

fb

Table 3-l. A/D Frame Elements (cont.)

Element Default Value

Trigger Polarity Positive (for analog K-SetADTrig

@%w)

Positive (for digital Not applicable2 Not applicable2

Trigger Pattern Not used3 Not applicable2 Not applicable2

Notes

’ This element must be set.

‘The default value of this element cannot be changed.

3 This element is not currently used: it is included for future compatibility.

When you access an A/D frame with K-GetADFrame, the elements me

set to their default values.

to return all the. elements of a frame to their default values.

Setup Function Readback Function

K-GetADTrig

You can also use the K-ClearFrame

function

3-4

Note:

functions that are not related to controlling frames, defining the elements

of frames, or reading the values of frame elements. These functions

include single-mode operation functions. initialization functions, memory

management functions. and other miscellaneous functions.

For information about using the FCD functions in your application

program, refer to the following sections of this chapter. For detailed

information about the syntax of FCD functions, refer to Chapter 4.

The DAS-800 Series Function Call Driver provides many other

Programming with the Function Call Driver

chap03-.frm Black 5

Programming Overview

To write an application program using the DAS-800 Series Function Call

Driver, perform the following steps:

1. Define the application’s requirements. Refer to Chapter 2 for a

description of the board operations supported by the Function Call

Driver and the functions that you can use to define each operation,

2. Write your application program. Refer to the following for additional

information:

- Preliminary Tasks, the next section, describes the programming

tasks that are common to all application programs.

- Operation-Specific Programming Tasks, on page 3-6. describes

operation-specific programming tasks and the sequence in which

these tasks must be performed.

- Chapter 4 contains detailed descriptions of the FCD functions.

- The DAS-800 Series standard software package and the

ASO- software package contain several example programs.

The FILES.TXT file in the installation directory lists and

describes the example programs.

3. Compile and link the program. Refer to Language-Specific

Programming Information, starting on page 3-12, for compile and

link statements and other language-specific considerations for each

supported language.

3-5

chap03-.frm Black 6

Preliminary Tasks

fb

For every Function Call Driver application program, you

the following preliminary tasks:

1. Include the function and variable type definition file for your

language. Depending on the specific language you are using, this iile

is included in the DAS-800 Series standard software package or the

ASO-ROO software package.

2. Declare and initialize program variables.

3. Use a driver initialization function

K-OpenDriver)

4. Use a board initialization function

K GetDevHandle)

initialize the board. If you are using more than one hoard, u.se the

board initialization function once for each hoard you are using.

to initialize the driver.

to specify the hoard you want to use and to

(DASSOO-DevOpen or

(DAS800-GetDevHandle or

Operation-Specific Programming Tasks

After you perform the preliminary tasks, perform the appropriate

operation-specific programming tasks. The operation-specific tasks for

analog input and digital I/O operations are described in the following

sections.

must perform

Note: Any FCD functions that are not mentioned in the

operation-specific programming tasks can be used at any point in your

application program.

Analog Input Operations

The following subsections describe the operation-specific programming

tasks required to perform single-mode, synchronous-mode, and

interrupt-mode analog input operations.

3-6

Programming with

the

Function Call

Driver

chap03-.frm Black 7

Single Mode

Synchronous Mode

To perform a single-mode analog input operation. perform the following

tasks:

1. Declare the buffer or variable that will hold the single value IO be

read.

2. Use the K-ADRead function to read the single analog input value;

specify the attributes of the operation as arguments to the function.

To perform a synchronous-mode analog input operation, perform the

following tasks:

I. Use the K-GetADFrame function to access an A/D frame.