Page 1

cover.frm Black I

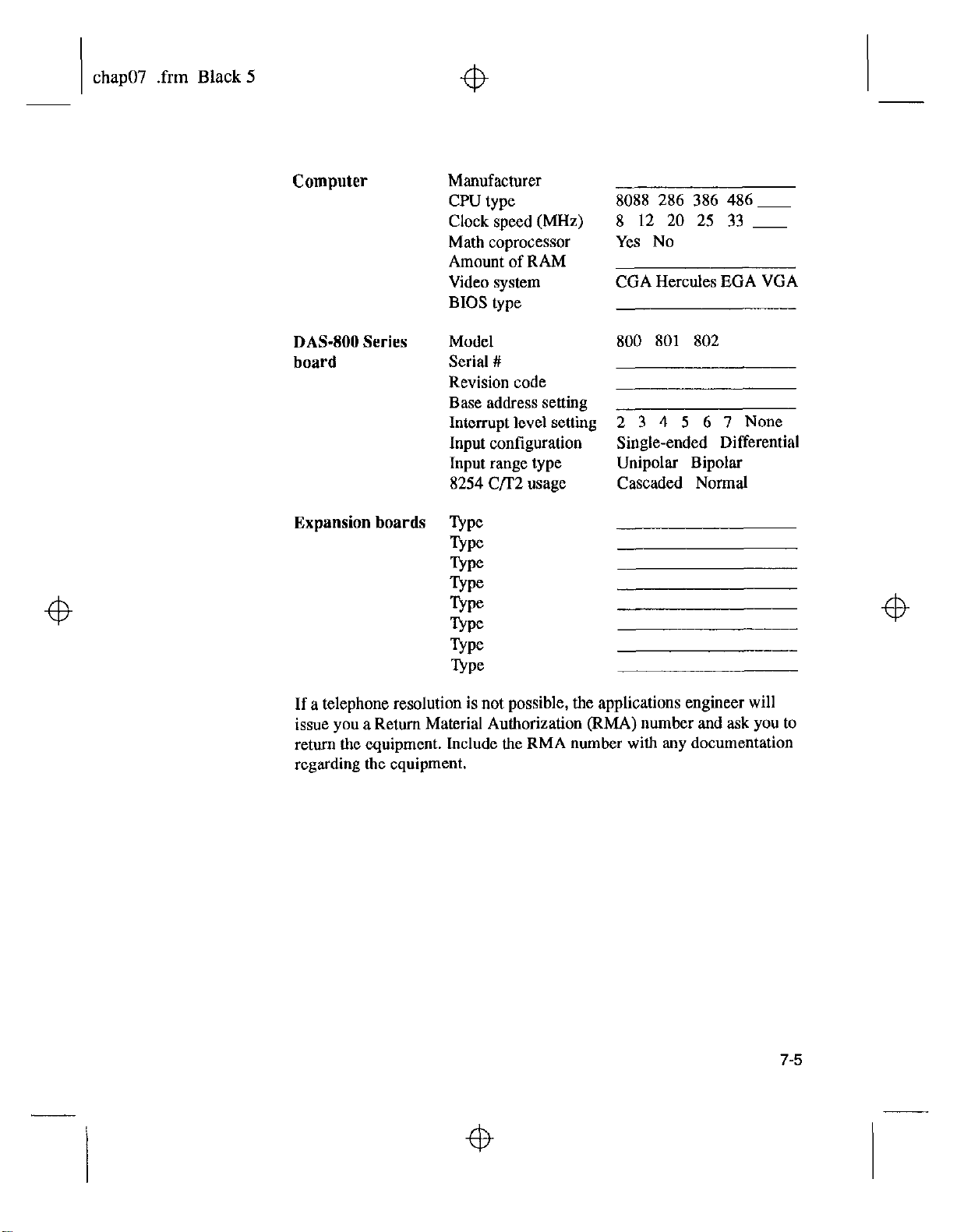

DAS-800 Series

User’s Guide

Page 2

titlepgfrm Black 1

DAS-800 Series

User’s Guide

Revision A - December 1993

Part Number: 85790

Page 3

noticep.frm Black I

The information contained in this manual is believed to be accurate and reliable. However, the

manufacturer assumes no responsibility for its use; nor for any infringements or patents or other rights

of third parties that may result from its use. No license is granted by implication or otherwise under any

patent rights of the manufacturer.

THE MANUFACTURER SHALL NOT BE LIABLE FOR ANY SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES RELATED TO THE USE OF THIS PRODUCT. THIS PRODUCT

IS NOT DESIGNED WITH COMPONENTS OF A LEVEL OF RELIABILITY THAT IS SUITED

FOR USE IN LIFE SUPPORT OR CRITICAL APPLICATIONS.

All brand and product names are trademarks or registered trademarks of their respective companies,

0 Copyright Keithley Instruments, Inc., 1993.

All rights reserved. Reproduction or adaptation of any part of this documentation beyond that permitted

by Section 117 of the 1976 United States Copyright Act without permission of the Copyright owner is

unlawful.

+b

Page 4

800ug.toc Black iii

+b

Table of Contents

Preface

1 Overview

Supporting Software . . . . . . . . . . . . .

Accessories

2 Functional Description

Analog Input Features ..............

Channel Configuration ...........

Input Configuration ...........

Gains and Ranges. ............

Channel Selection ............

Channel Expansion ...........

Conversion Clock Sources ........

Triggers. ......................

Gates .........................

Data Transfer. ..................

Digital I/O Features ................

8254 Counternimer Circuity ........

Interrupts ........................

Power ...........................

........

........

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

. . . . l-2

. . . . 1-4

. ...2-2

. ...2-3

. ...2-3

. . . .2-4

. ...2-5

. ...2-6

. ...2-8

. ..2-12

. ..2-14

. ..2-16

. ..2-17

. ..2-17

. ..2-25

. ..2-26

3 Setup and Installation

Installing the Software. ...............................

Installing the DAS-800 Series Standard Software Package . .3-5

Installing the ASO- Software Package

DOS Installation. ...............................

Windows Installation ............................

Unpacking the Board. ................................

Configuring the Board. ...............................

Creating a Configuration File.

Setting the Base Address ...........................

Setting the Input Contiguration ......................

Setting the Interrupt Level .........................

Installing the Board .................................

.3-4

.............. .3-6

.3-6

.3-7

.3-8

.3-8

....................... .3-9

.3-13

.3-16

.3-17

.3-19

iii

Page 5

800ug.toc Black iv

4

Cabling and Wiring

Attaching Accessory and Expansion Boards.

Attaching an STC-37 Screw Terminal Connector

Attaching an STA-08 / STA-OSPGA Screw Terminal

Accessory. .....................................

Attaching an EXP-16 or EXP-16/A Expansion Board.

Attaching an EXP-GP Expansion Board

Attaching an MB Series Backplane ...................

Connecting Multiple Expansion Boards.

Connecting Signals ..................................

Connecting an Analog Input Signal to a Single-Ended Input. 4-9

Connecting an Analog Input Signal to a Differential Input .4-10

Connecting Digital Signals, ........................

Connecting Counter/Timer I/O Signals

Synchronizing Conversions on Multiple Boards

5

The Control Panel

..............

........ .4-3

...............

...............

...............

........ .4-13

.4-l

.4-4

.... .4-5

.4-6

.4-7

.4-7

.4-9

.4-12

.4-12

6 Calibration

Equipment Required

Potentiometers

Calibration Utility

7

Troubleshooting

Problem Isolation

Troubleshooting Table.

Technical Support

A

Specifications

B

Connector Pin Assignments

............................

.................................

..............................

...............................

..........................

..............................

c DAS-800 Series External Driver

Running the DAS-800 Series External Driver. . . . . . .

Accessing the DAS-800 Series External Driver

Special Characteristics.. . . . . . . . . . . . .

Pseudo-Digital Output: Extended Functions. . . . .

Analog Triggers

Data Formats . . . . . . . . . . . . .

Using Expansion

Board

Gains . . . .

.,6-l

.6-2

.6-4

.,7-l

. . l-2

. l-4

.c-2

.c-2

.c-3

. .c-3

.C-6

.c-9

.c-11

iv

Page 6

800ug.toc Black v

Software Interrupt Vectors ......................

Counter/Iimer Functions .......................

Error Messages. .................................

II

Keithley Memory Manager

Installing and Setting Up the KMM.

Using

KMMSETUP.EXE

Using a Text Editor.

.......................

...........................

.................

Removing the KMM .............................

Index

List of Figures

Figure 2-l. DAS-800 Series Functional Block Diagram

Figure 2-2. Channel Expansion

...................

Figure 2-3. Initiating Conversions .................

Figure 2-4. Initiating Conversions with a Hardware

Trigger

Figure 2-5. Hardware Gate.

.............................

......................

Figure 2-6. Pulse on Terminal Count Mode. .........

Figure 2-7. Programmable One-Shot Mode. .........

Figure 2-8. Rate Generator Mode.

.................

Figure 2-9. Square-Wave Generator Mode ..........

Figure 2- 10. Software-Triggered Strobe Mode ........

Figure 2-l 1

Figure 3-l.

Figure 3-2.

Figure 3-3.

Figure 3-4.

Figure 3-5.

Figure 4-l.

Figure 4-2.

Hardware-Triggered Strobe Mode. .......... .2-24

DAS-800 Board. ......................... .3-2

DAS-Sol/802 Board ...................... .3-3

Setting the Base Address. ................. .3-14

Setting the Input Configuration. ............ .3-17

Setting the Interrupt Level. ................ ,3-18

Main I/O Connector on a DAS-800 Board ..... .4-2

Main I/O Connector on a DAS-801 or

DAS-802 Board. ......................... .4-3

Figure 4-3.

Attaching an STC-37 Screw Terminal

Connector. .............................. .4-4

Figure 4-4.

Attaching an STA-08 / STA-OSPGA Screw

Terminal Accessory. ...................... .4-5

Figure 4-5.

Attaching an EXP-16 or EXP-16/A Expansion

Board .................................. .4-6

Figure 4-6.

Figure 4-7.

Attaching an EXP-GP Expansion Board. ...... .4-7

Connecting Multiple Expansion Boards ....... .4-8

.c-12

.c-12

.c-13

. D-2

D-2

. D-3

D-4

. .2-2

. .2-l

.2-10

.2-13

.2-15

,2-19

.2-20

.2-21

.2-22

.2-23

Page 7

800ug.toc Black vi

Figure 4-8.

Figure 4-9.

Single-Ended Input , . . . . . . . . . . . . .4-10

Differential Input. . . . . . . . . . . .4-l 1

Figure 4-10. Synchronizing Conversions on Multiple

Boards . . . . . . , . . . . . . . . . . . . .4-13

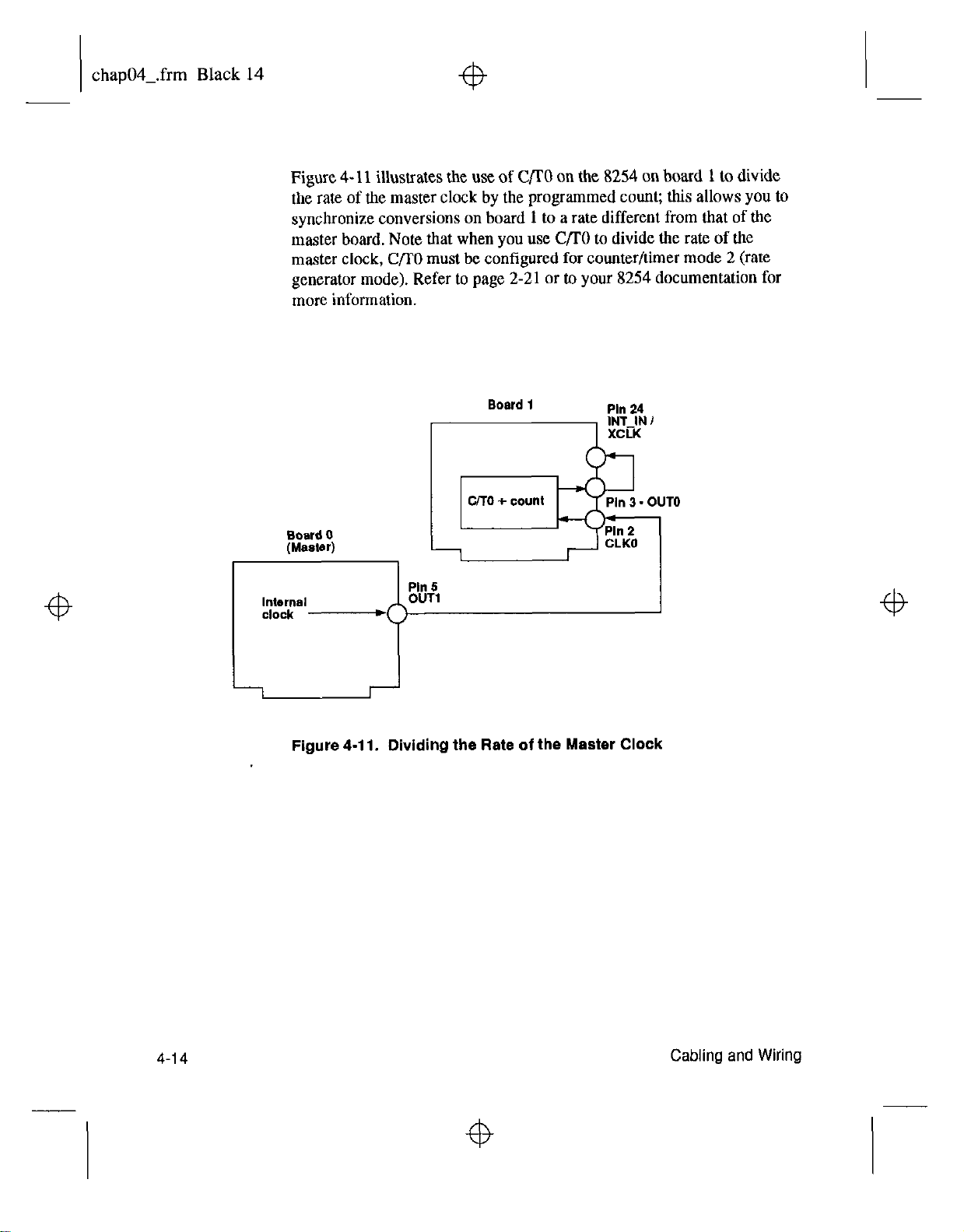

Figure 4-l 1.

Figure 6-l.

Figure 6-2.

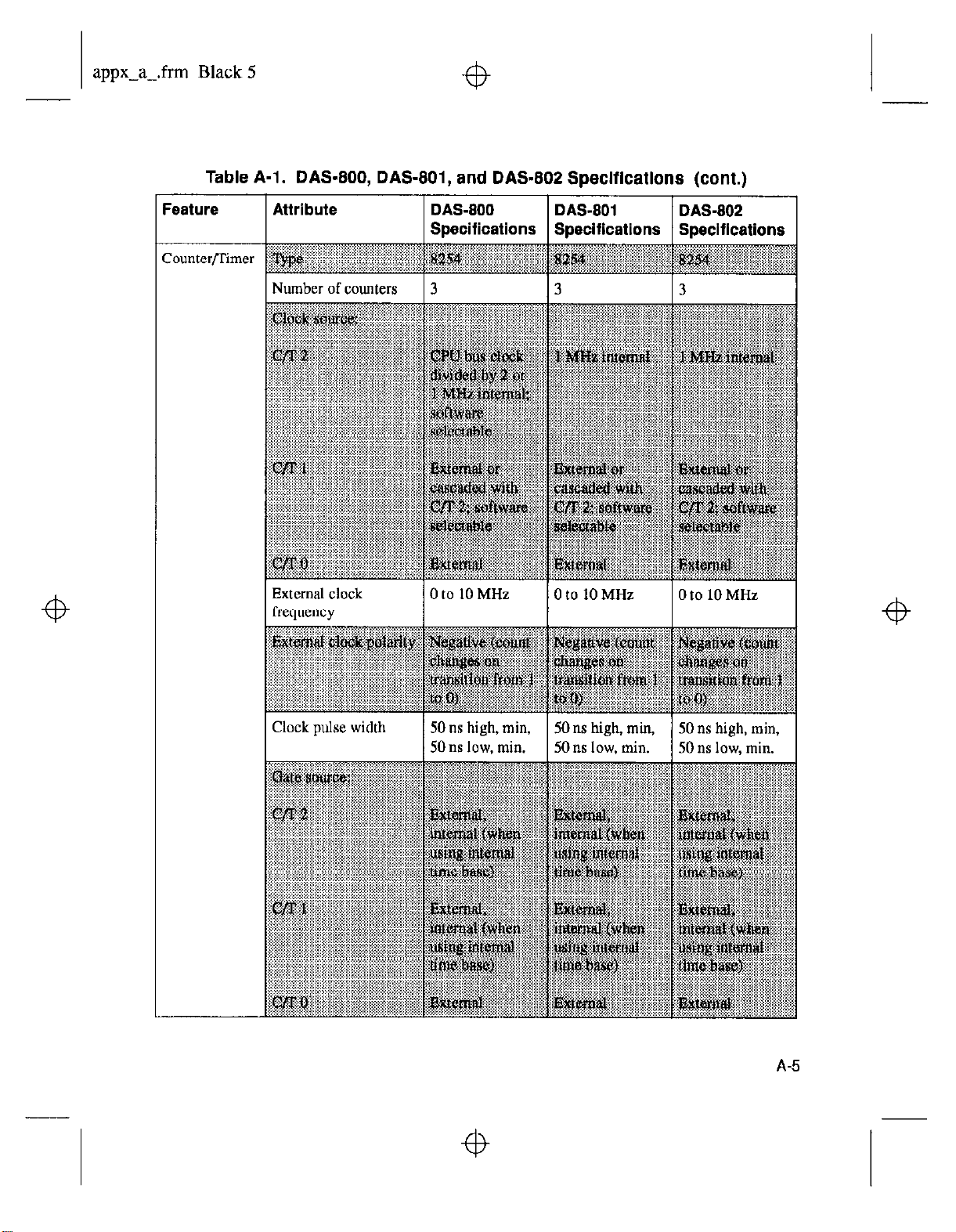

Figure B-l.

Figure B-2.

Figure C-l.

Figure C-2.

Figure C-3.

List of Tables

Table 2-1.

Table 2-2.

Table 2-3.

Dividing the Rate of the Master Clock .4-14

Potentiometers (DAS-800) . . . . . . . . . .6-3

Potentiometers (DAS-801 / DAS-802) . .6-3

Main I/O Connector (DAS-800) . . . . .B-2

Main I/O Connector @AS-801 / DAS-802) . . .B-5

Analog Trigger Conditions . . .C-7

Using a Hysteresis Value. . , . . . . . .C-8

Initiating Conversions with an Analog Trigger. . .C-9

Supported Gains .........................

Sources for 8254 Documentation

...........

Expansion Board / Backplane Power

Limitations .............................

Table 3-1.

Table 3-2.

Table 3-3.

Table 7-1.

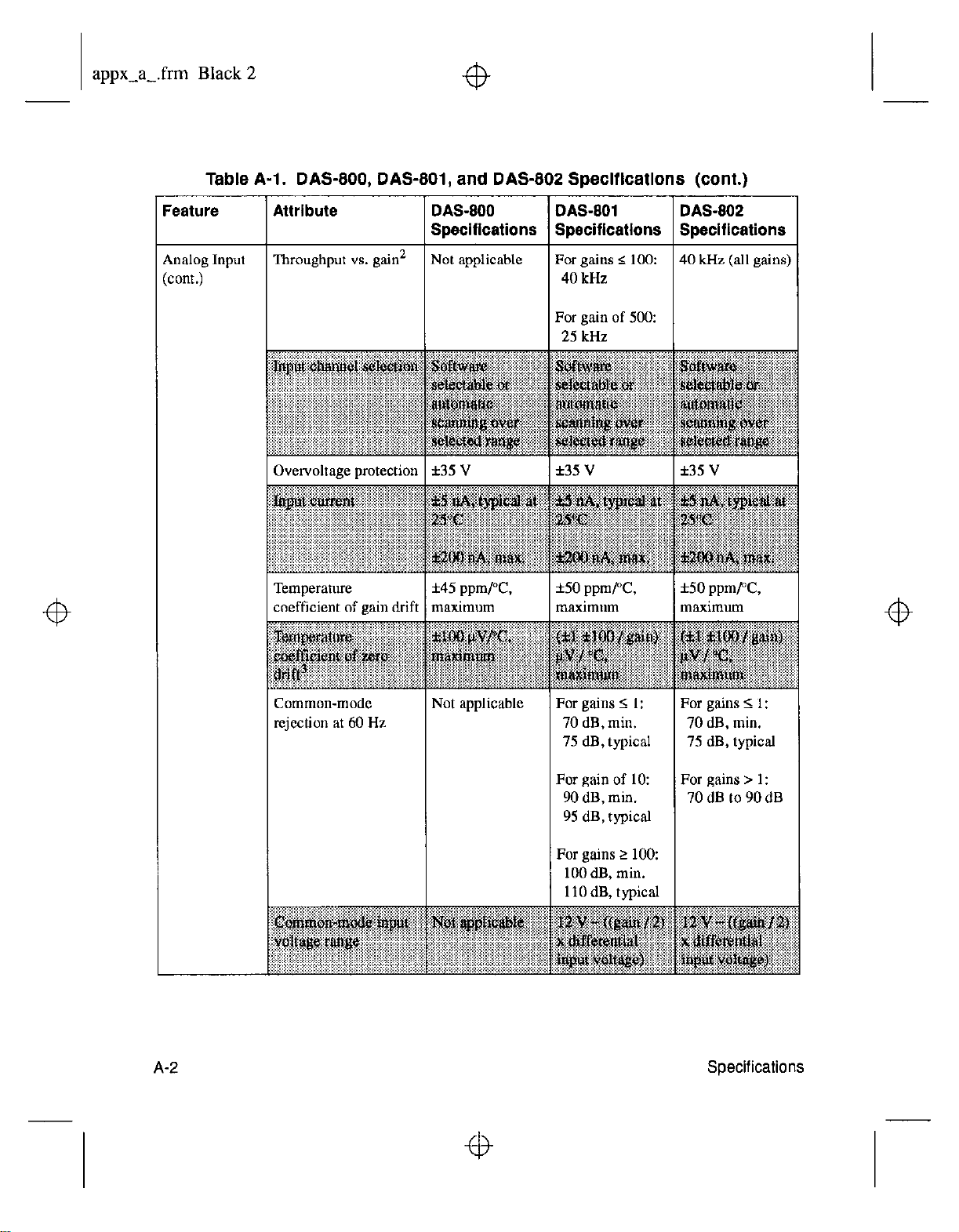

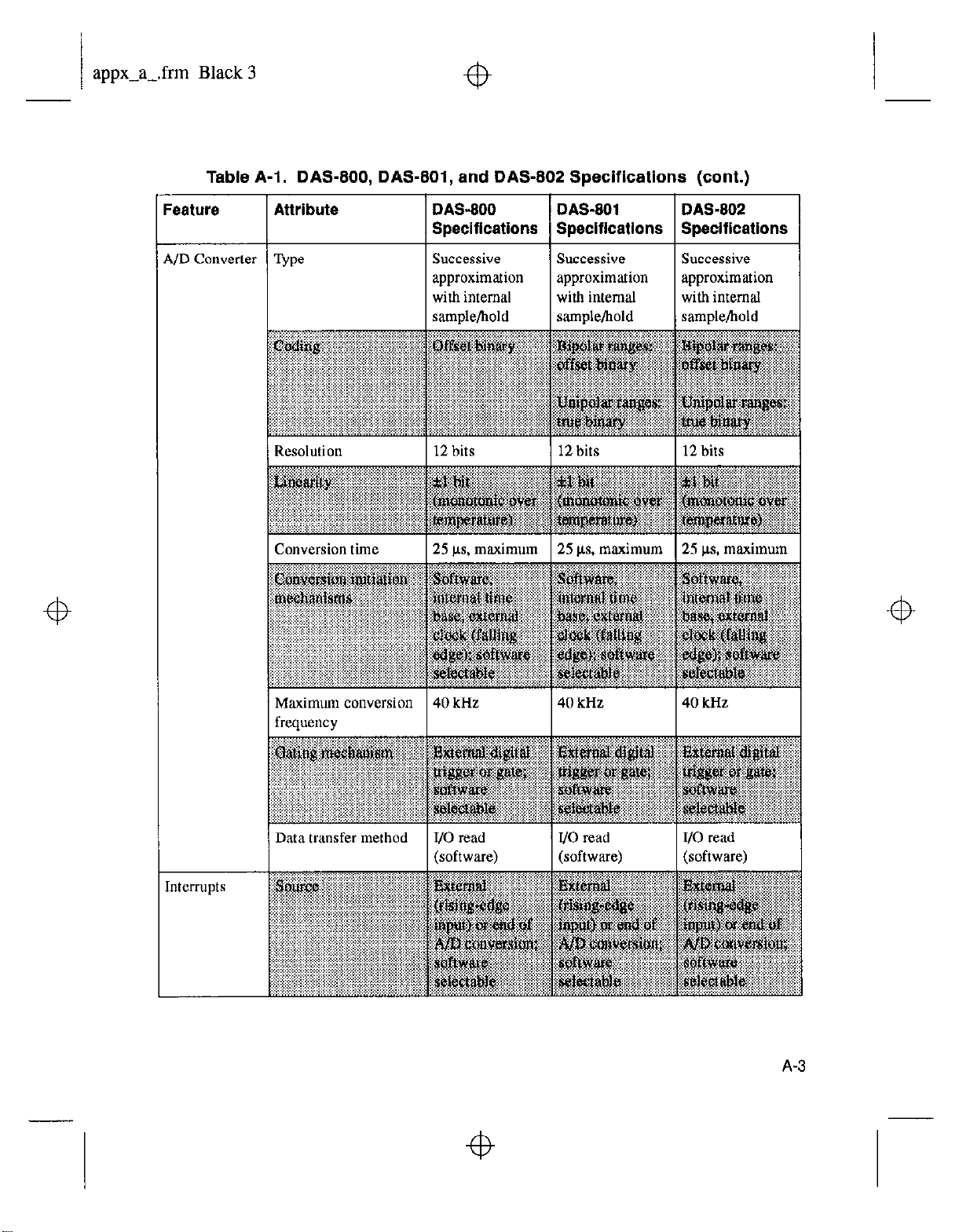

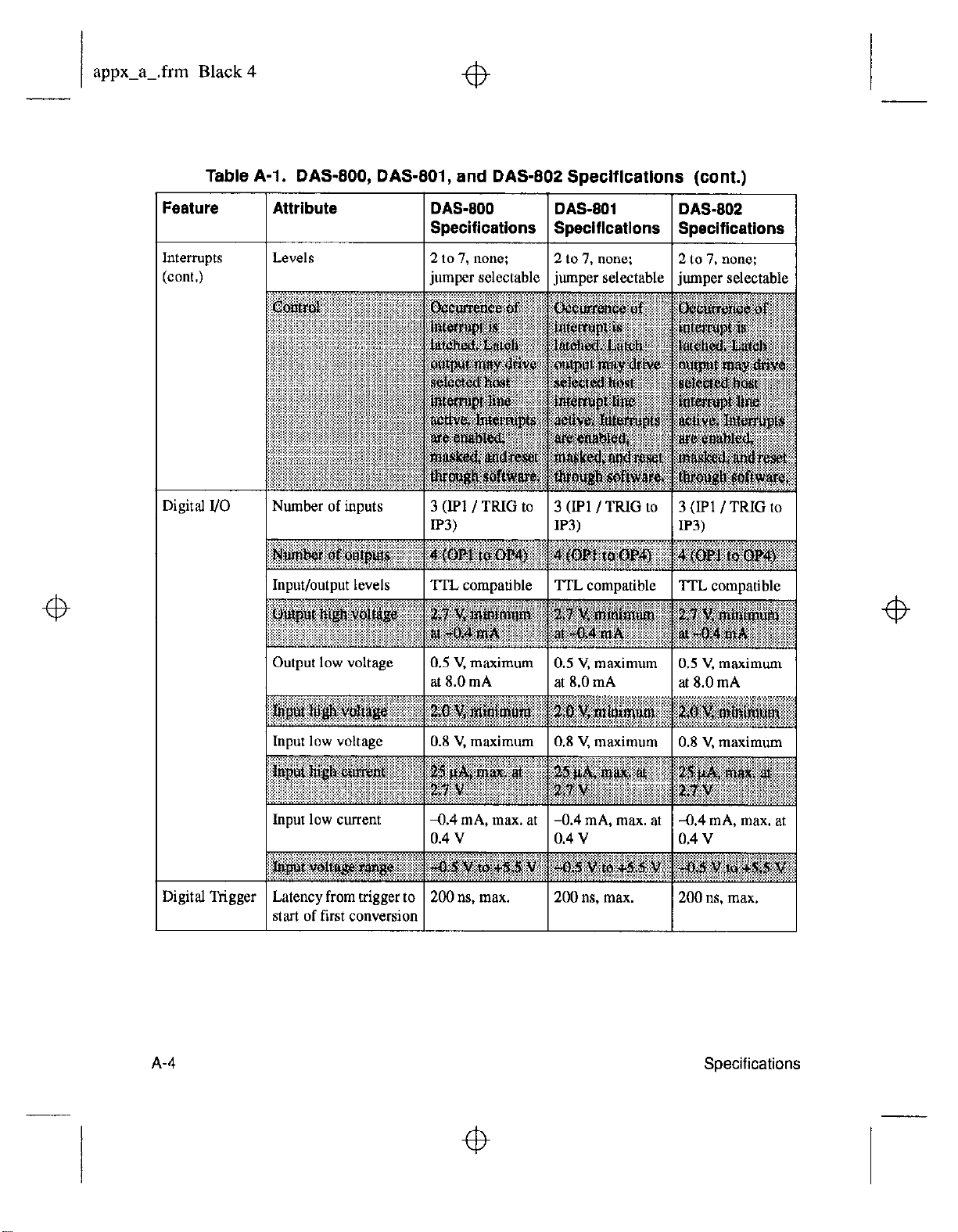

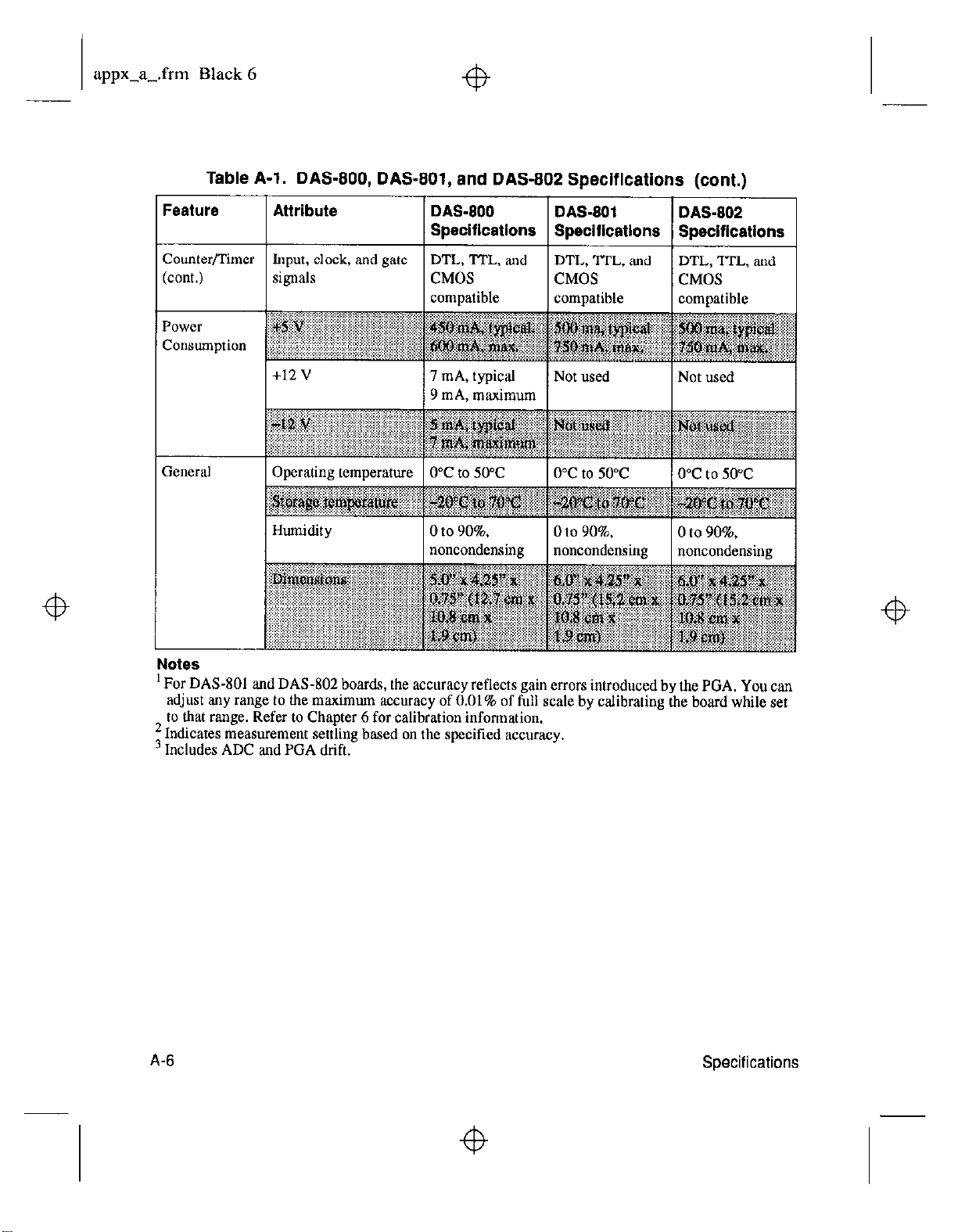

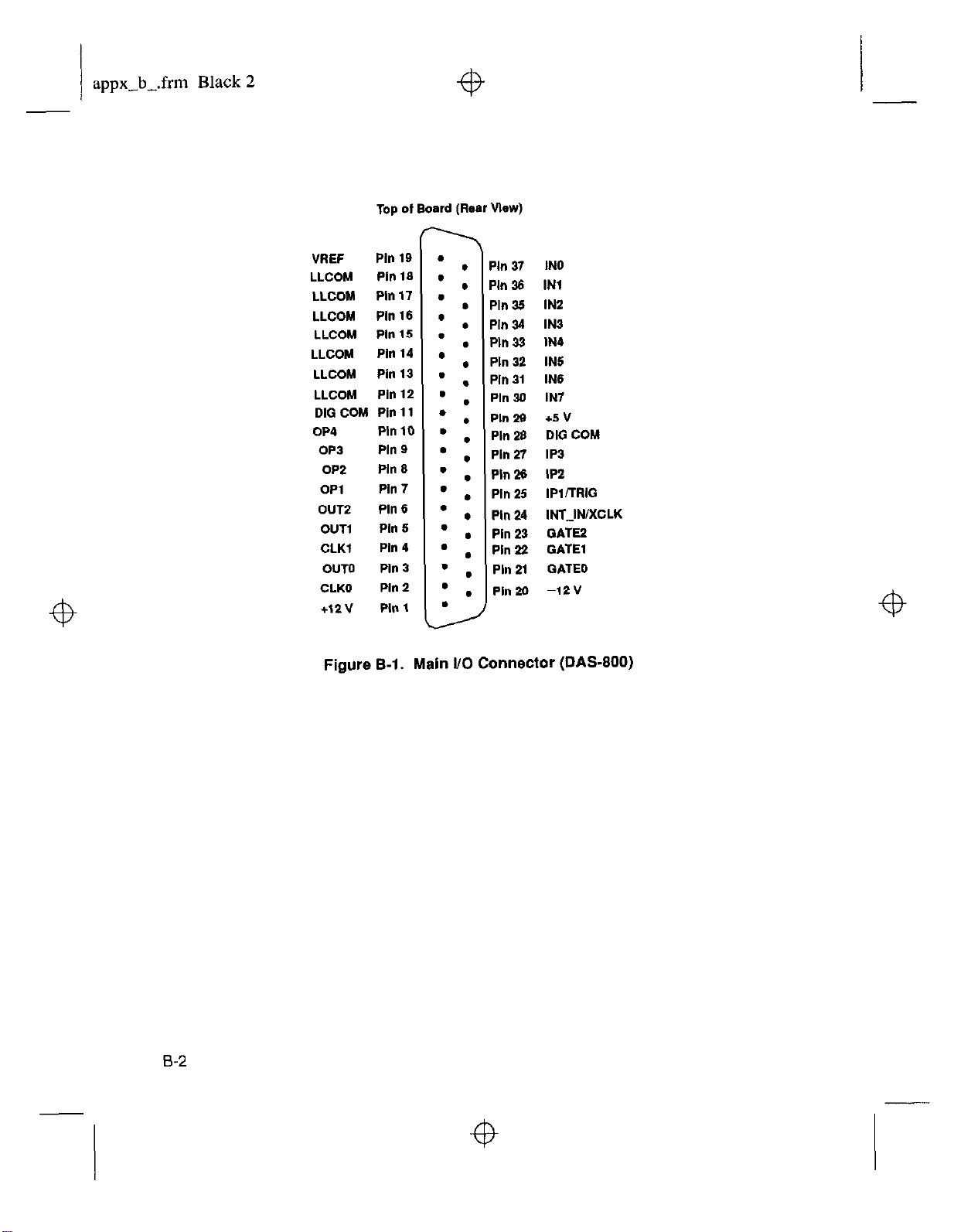

Table A- 1.

Default Configuration

I/O Address Map (OOOH to 3FFH)

....................

..........

Interrupt Levels .........................

Troubleshooting Information.

...............

DAS-800, DAS-801, and DA.%802

Specifications. ...........................

Table B-l.

Main I/O Connector Pm Assignments for the

DAS-SOO................................B- 3

Table B-2.

Table C- 1.

Table C-2.

Table C-3.

Main I/O Connector Pin Assignments for the

DAS-801 /DAS-802

Pseudo-Digital Output Channels

......................

.............

Interrupt Vectors ........................

Error/Status Codes

.......................

.2-4

.2-25

.2-27

.3-10

.3-14

.3-18

.7-2

A- 1

.B-6

.C-4

.C-12

.C-13

vi

Page 8

preface.frm Black vii

f@

Preface

The DAM00 Series User’s Guide provides the information needed to set

up, install, and use DAS-800 Series boards.

The manual is intended for data acquisition system designers, engineers,

technicians, scientists, and other users responsible for setting up, cabling,

and wiring signals to DA,%800 Series boards. It is assumed that users are

familiar with

application.

data

acquisition principles and with their particular

The

DAS-BOO Series

Chapter 1 provides an overview of the features of DA%800 Series

boards, including a description of supported software and accessories.

Chapter 2 provides a more detailed description of the analog input,

digital I/O, and counter/timer I/O features of DAS-800 Series boards.

Chapter 3 describes how to unpack, configure, and install DAS-800

Series boards.

Chapter 4 describes how to attach accessory and expansion boards

and how to wire signals to DAS-800 Series boards.

Chapter 5 describes how to use the Control Panel to test the functions

of DAS-800 Series boards.

Chapter 6 describes how to calibrate DAS-800 Series boards.

Chapter 7 provides troubleshooting information.

Appendix A lists the specifications for DAS-800 Series boards.

User’s Guide is organized as follows:

vii

Page 9

preface.frm Black viii

. Appendix B lists the connector pin assignments.

. Appendix C describes how to use the DAS-800 Series External

Driver. The DAS-800 Series External Driver allows you to use

DAS-800 Series boards with certain data acquisition and analysis

software packages.

. Appendix D describes the Keithley Memory Manager. The Keithley

Memory Manager allows you to allocate sufficient memory when

running under Windowsm.

An index completes this manual.

Throughout the manual, keep the following in mind:

. References to DAS-800 Series boards apply to the DAS-800,

DAS-801, and DAS-802 boards. When a feature applies to a

particular board, that board’s name is used.

. References to Microsoft@ QuickBasic” apply to both Microsoft

QuickBASIC (Version 4.0) and Microsoft QuickBasic (Version 4.5).

Page 10

chapOl_.frm Black 1

Overview

The DAS-800 Series is a family of analog input and digital input and

output (I/O) boards for an IBM@ PC/XTTM, AT’ or compatible computer.

The DAS-80 Series includes the DAS-800, DAS-801, and DAS-802

boards, The major features of DAS-800 Series boards are as follows:

Eight analog input channels (single-ended on the DAS-800;

single-ended or differential on the DAS-801 and DAS-802).

Fixed f5 V analog input range for the DAS-800; nine unipolar and

bipolar, software-selectable analog input ranges for the DAS-801 and

DAS-802.

On-board 8254 counter/timer circuitry, which you can use as a

hardware internal clock source and/or for general-purpose

counter/timer I/O operations.

Software-selectable conversion clock source.

Digital trigger.

Hardware gate.

Four-word FIFO to store converted data: overrun detection logic to

detect lost dam points.

Software-selectable interrupt source.

Three bits of digital input.

. Four bits of digital output.

l-1

Page 11

chapOl_.frm Black 2

Note:

DAS-800 boards are enhancements of DAS-8 boards; DAS-801

boards are enhancements of DAS-8 PGA boards; DAS-802 boards are

enhancements of DAS-8 PGA/G2 boards. You can use application

programs written to support the DAS-8 with the DAS-800, application

programs written to support the DAS-8 PGA with the DAS-801, and

application programs written to support the DAS-8 PGA/GZ with the

DAS-802.

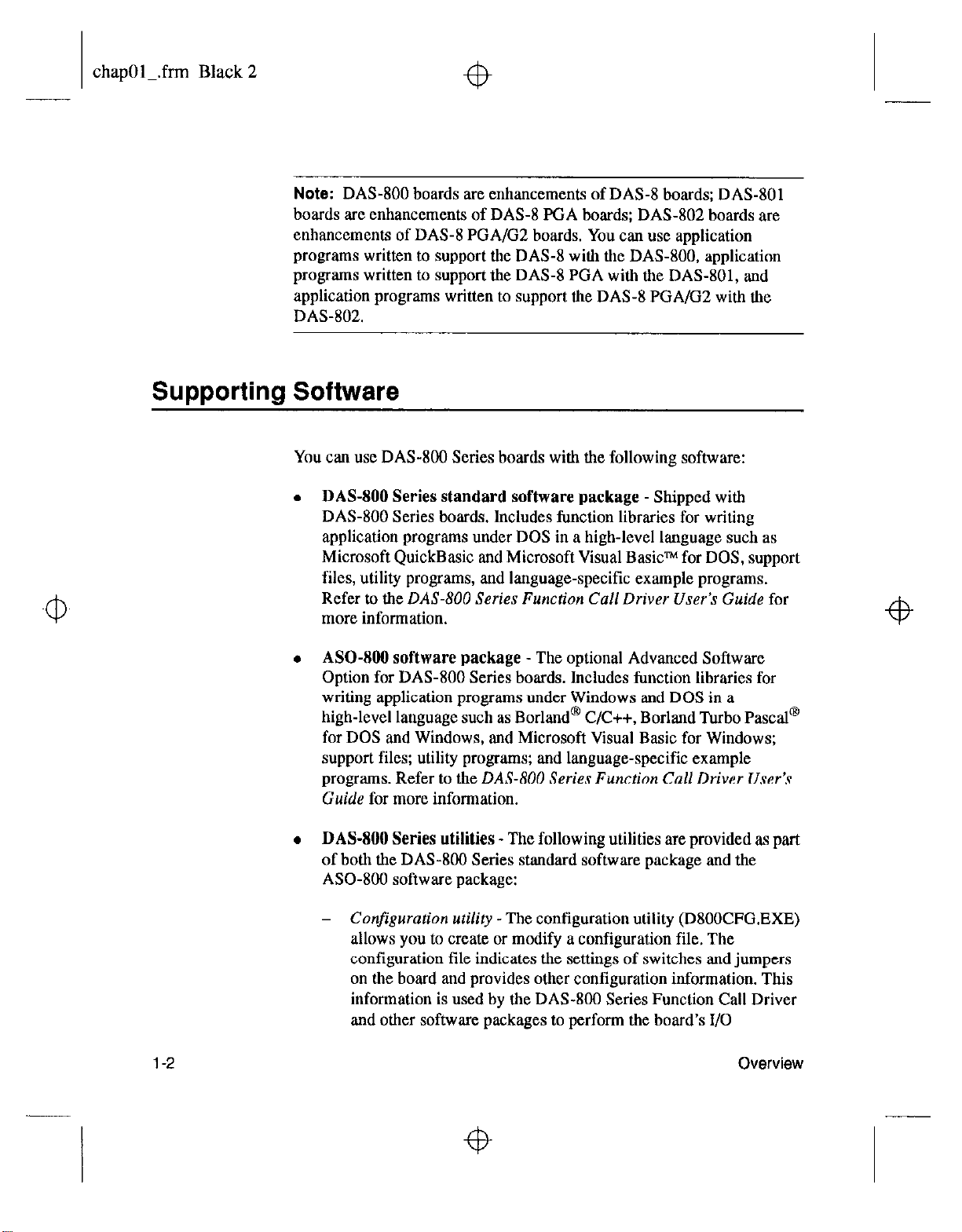

Supporting Software

You can use DAS-800 Series boards with the following software:

DASJOO Series standard software package

DAS-800 Series boards. Includes function libraries for writing

application programs under DOS in a high-level

Microsoft QuickBasic and Microsoft Visual BasicTM for DOS, support

files, utility programs, and language-specific example programs.

Refer to

more information.

the DAM00 Series Function Call Driver User’s Guide

- Shipped with

language

such as

for

l-2

ASO-

software package - The optional Advanced Software

Option for DAS-800 Series boards. Includes function libraries for

writing application programs under Windows and DOS in a

high-level language such as Borland@ C/C++, Borland Turbo Pascal@

for DOS and Windows, and Microsoft Visual Basic for Windows;

support files; utility programs; and language-specific example

programs. Refer to the

Guide

for more information.

DA&800 Series utilities

DA&BOO Series Function Cull Driver User’s

- The following utilities are provided as part

of both the DAS-800 Series standard software package and the

ASO- software package:

-

Confgurarion urilify

-The configuration utility (D800CFG.EXE)

allows you to create or modify a configuration tile. The

configuration tile indicates the settings of switches and jumpers

on the board and provides other configuration information. This

information is used by the DAS-800 Series Function Call Driver

and other software packages to perform the board’s I/O

Overview

Page 12

chapOl_.frm Black 3

operations. Refer to page 3-9 for more information about the

configuration utility.

-

Control Panel

-The Control Panel allows you to perform

operations on DAS-800 Series boards, without programming. It

provides a quick way to test your board and monitor

your I/O

operation. Two versions of the Control Panel are available:

CTL800.EXE (for DOS) and CTLBOOW.EXE (for Windows).

Refer to Chapter 5 for more information about the Control Panel.

-

Calibrafion uriliry

- The calibration utility (CALSOO.EXE) allows

you to calibrate the analog input circuitry of DAS-800 Series

boards. Refer to Chapter 6 for more information about the

calibration utility.

. DAM300 Series custom controls

programs in Visual Basic for Windows. Refer to the

Custom

. Data acquisition and analysis application software -

Controls User’s Guide

- Help you to write application

VisualDAS

for more information.

Many

menu-driven, integrated software packages are available for

DAS-800 Series boards, including VIEWDAC?, EASYEST LXa’,

and EASYEST AGW. In addition, programming tools, such as the

ASYST@ scientific and engineering programming

language, are

available to help you customize your own application program.

Note:

If you use VIBWDAC!, EASYEST LX / AG, or ASYST to

program your DAS-800 Series board, you must use the DA&800

Series External Driver, which is shipped as part of the DAS-800

Series standard software package. Refer to Appendix C for

information on using the DAS-800 Series External Driver.

. DAS-800 Series register I/O map - If you cannot satisfy your

application’s requirements with the available software packages and

you are an experienced programmer, you may be able to program

your DAS-800 Series

board

through direct register I/O instructions.

Contact the factory for more information.

I-3

Page 13

chapOl_.frm

Accessories

Black 4

The following accessories are available for use with DAS-800 Series

boards:

. STC-37 screw terminal connector - For

all DAS-800 Series boards,

provides 37 screw terminals that allow you to access the functions of

the board; connects directly to the DAS-800 Series board without a

cable.

l

STA-08 screw terminal accessory - For the DAS-800 board

provides screw terminals that allow you to access the functions of the

board; provides a breadboard area with power and additional screw

terminals to access the user-designed circuitry.

. STA-08PGA screw terminal accessory

- For the DAS-801 and

DAS-802 boards only, provides screw terminals that allow you to

access the functions of the

board;

provides a breadboard area with

power and additional screw terminals to access the user-designed

circuitry.

. EXP-16 and EXP-16/A expansion boards

- Sixteen-channel

multiplexer and signal-conditioning expansion boards; provide cold

junction compensation (CJC) for thermocouples and

switch-selectable gains ranging from 0.5 to 2000.

. EXP-GP expansion board

- An 8-channel signal-conditioning

expansion board; connects to RTDs, thermistors, strain gages, and

other variable resistance sensors; provides CJC for thermocouples

and switch-selectable gains of 1, 10, 100, and 1000 or 2.5.25.250,

and 2500.

only,

1-4

. MB Series modules and backplanes

- MB Series modules are

high-performance, signal-conditioning modules that measure

thermocouple, RTD, strain gage, voltage, and current inputs and are

installed in MB Series backplanes. MB Series backplanes provide

screw terminals for connecting the high-level analog I/O signals.

Overview

Page 14

chapOl_.frm Black 5

. STA-SCM8

screw terminal accessory - Allows you to

connect a

DAS-800 Series board to up to four MB-02 backplanes; provides

screw terminals that allow you to access the functions of the board;

provides a breadboard area with power for the user-designed circuitry.

. C-1800 cable

-Unshielded, la-inch cable with a 37-pin connector on

each end: allows you to connect a DAS-800 Series board to an

STA-08, STA-08PGA, EXP-16, EXP-16/A, or EXP-GP.

. S-1800 cable - Shielded, la-inch cable with a 37-pin connector on

each end; allows you to connect a DAS-800 Series board to an

STA-08, STA-OBPGA, EXP-16, EXP-16/A, or EXP-GP.

. CB-MB1

cable

- Cable with a 37-pin connector on one end and a

26-pin-connector on the other end; allows you to connect a DAS-800

Series board to an MB-01 or MB-02 backplane.

. C-2600 cable

- An la-inch cable with a26-pin connector at each end;

allows you to connect an STA-SCM8 screw terminal accessory to an

MB-02 backplane.

l-5

Page 15

chapOl_.frm Black 6

Page 16

chap02Lfrm Black 1

4

2

Functional Description

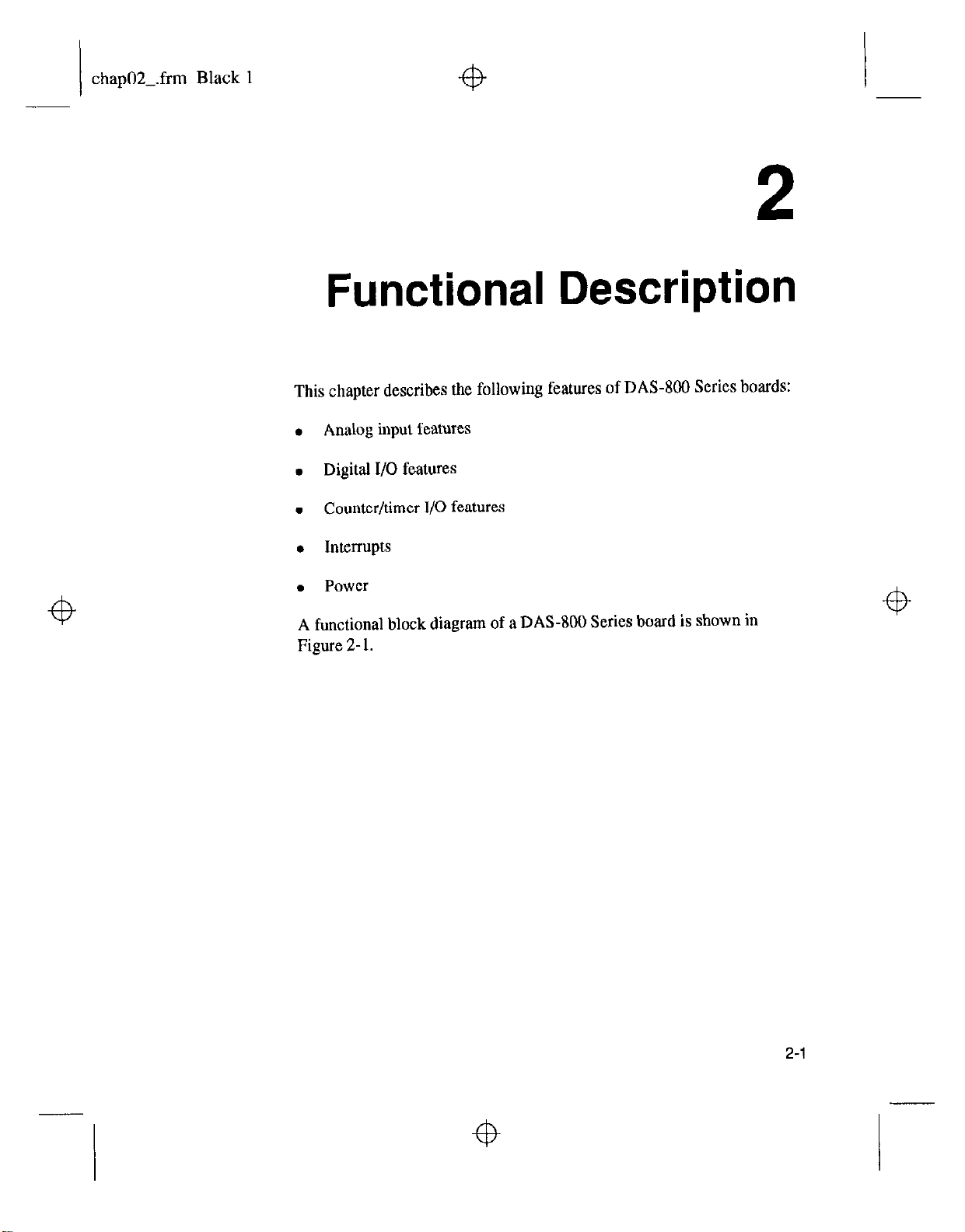

This chapter describes the following features of DAS-800 Series boards:

. Analog input features

. Digital I/O features

. Counter/timer I/O features

4

l

Interrupts

. Power

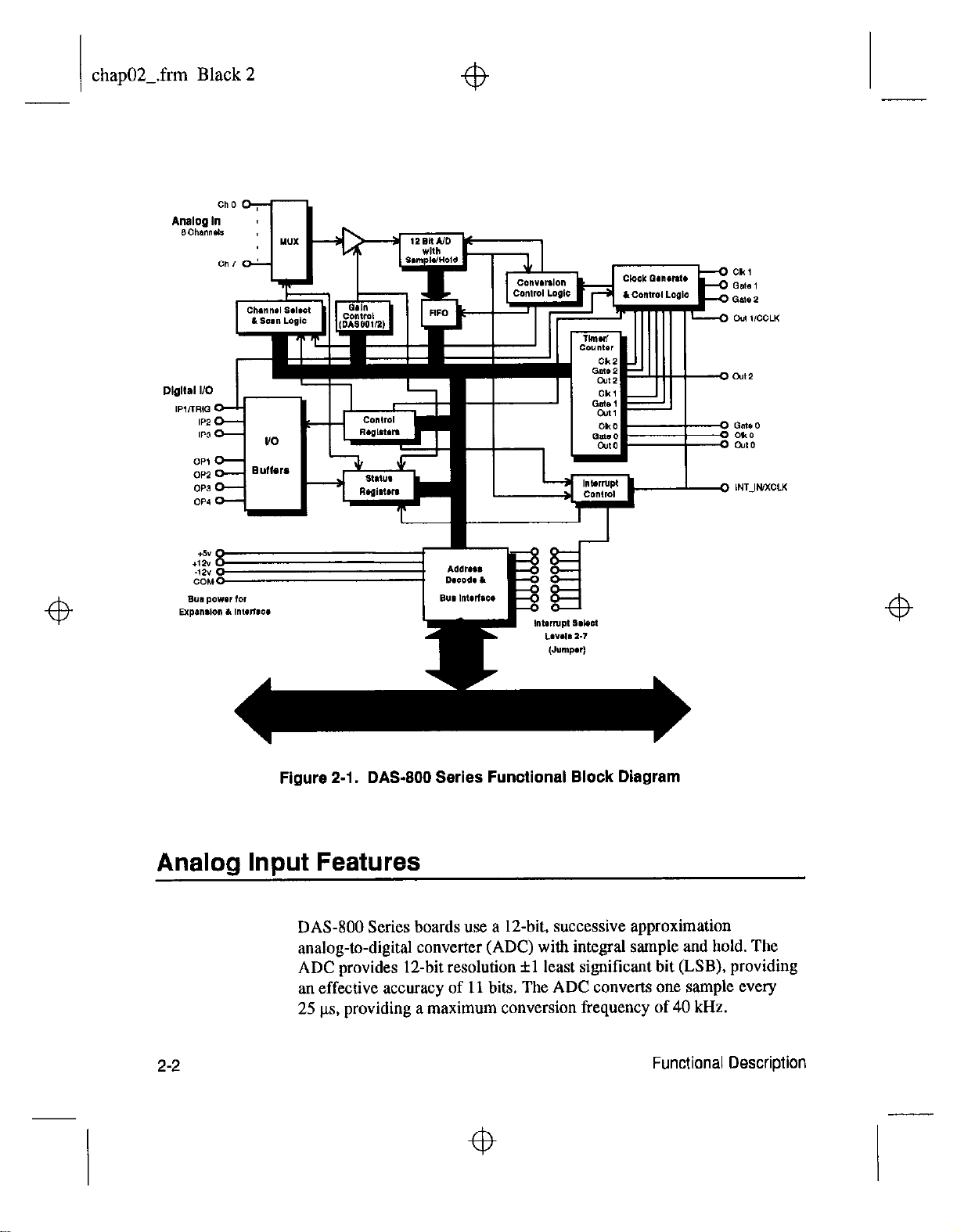

A functional block diagram of a DAS-800 Series board is shown in

Figure 2- 1.

4

2-l

Page 17

chap02-.frm Black 2

4

4

Figure 2-1. DAS-800 Series Functional Block Diagram

Analog Input Features

DAS-800 Series boards use a 12-bit, successive approximation

analog-to-digital converter (ADC) with integral sample and hold. The

ADC provides 1Zbit resolution fl least significant bit (LSB), providing

an effective accuracy of 11 bits. The ADC converts one sample every

25 ks, providing a maximum conversion frequency of 40 kHz.

2-2

4

Functional Description

4

Page 18

chap02-.frm Black 3

Channel Configuration

DAS-800 Series boards contain eight on-board analog input channels.

The following subsections describe the input configurations supported for

each channel, the gains

the methods of specifying a channel or channels for an analog input

operation.

On the DA%801 and DAS-802, you can configure each channel as either

single-ended or differential. The differences between a single-ended and a

differential input configuration are described as follows:

and

input ranges supported for each channel, and

4

. Single-ended

you are measuring relatively high-level signals (greater than 1 V), if

the source of the input signal is close to the board (less than two feet),

or if all input signals are referred to a common ground. This

configuration does not provide common-mode noise rejection.

. Differential

are measuring low-level signals, if high source resistances (greater

than 100 D) exist, or if common-mode voltages exist between the

voltage source and the host’s chassis ground. In a differential

configuration, a separate positive and negative terminal is provided

for each channel. Any common-mode noise that is picked up equally

on both inputs is rejected because the difference is zero.

You specify the input configuration by setting switches on the board. The

switches connect or disconnect the inverting side of the input signal to

low-level ground. Refer to page 3-16 for information on setting the

switches.

Notes: On the DAS-800, the

single-ended; ah signals are referred to a single low-level ground.

- A single-ended input configuration is appropriate if

- A differential input configuration is appropriate if you

channels are always configured as

4

If you are using BXP-16, EXP-16/A, or EXP-GP expansion

MB-02 backplanes, you must configure the on-board analog input

channels associated with the expansion boards or backplanes as

single-ended.

boards or

4

2-3

Page 19

chap02Lfrm Black 4

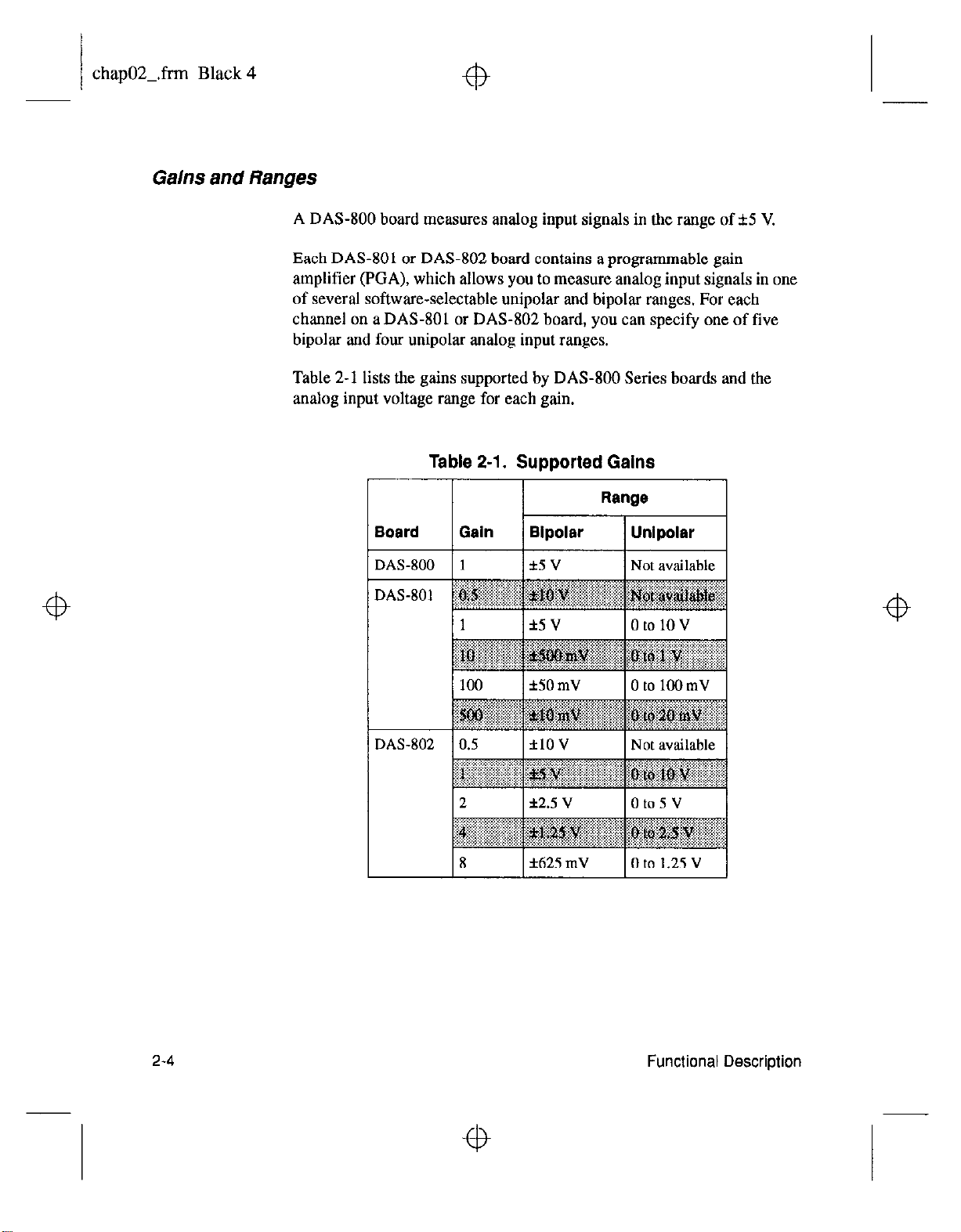

Gains and Ranges

4

A DAS-800 board measures analog input signals in the range of f5 V.

Each DAS-801 or DAS-802 board contains a programmable gain

amplifier (EGA), which allows you to measure analog input signals in one

of several software-selectable unipolar and bipolar ranges. For each

channel on a DAS-801 or DAS-802 board, you can specify one of five

bipolar and four unipolar analog input ranges.

Table 2-1 lists the gains supported by DAS-800 Series boards and the

analog input voltage range for each gain.

Table 2-l. Supported Gains

2-4

4

Functional Description

4

Page 20

chap02-.frm Black 5

4

4

Note:

with protection against signals outside the specified analog input range.

All DAS-800 Series boards can tolerate voltages up to f35 V and

transients of several hundred volts without damaging the board.

When measuring signals at differential inputs, DAS-801 and DAS-802

boards can tolerate common-mode voltages up to f35 V and transients of

several hundred volts without damaging the board; however, for normal

operation of the board, make sure that the common-mode voltage is no

more than 12 V - ((C / 2) x

differential input voltage.

Channel Selection

You can use DAS-800 Series boards to acquire data from a single analog

input channel or from a range of contiguous, on-board analog input

channels using automatic channel scanning. These two methods of

channel selection are described as follows:

.

Analog input channels on DAS-800 Series boards are provided

V,),

Single

initiate a conversion.

channel - You use software to specify a single channel and

where G is tbe gain and

V,

is the

4

. Automatic channel scanning

and last channels in a range of contiguous, on-board channels (0 to 7).

The channels are sampled in order from first to last; the hardware

automatically increments the analog input multiplexer address shortly

after the start of each conversion. When the last address is reached,

the multiplexer returns to the start address and the channels are

sampled again. For example, assume that the start channel is 4, the

stop channel is 7, and you want to acquire five samples. Your

program reads data first from channel 4, then from channels 5, 6, and

7, and finally from channel 4 again.

The start channel can be higher than the stop channel. For example,

assume that the start channel is 7, the stop channel is 2, and you want

to acquire five samples. Your program reads data first from channel 7,

then from channels 0, 1, and 2, and finally from channel 7 again.

When using automatic channel scanning, all contiguous, on-board

channels must have the same gain (analog input range).

- You use software to specify the first

2-5

4

Page 21

chap02Lfrm Black 6

fb

Note:

that includes channels on expansion boards or MB Series backplanes,

you can create a group of consecutive channels through software. tn

addition, if your application requires non-consecutive channels or

different gains for each channel, you can create a channel-gain list

through software. The DAS-800 Series Function Call Driver provides

functions for creating a group of consecutive channels or

channel-gain list; refer to the

User’s

you to set up a group of consecutive channels or channel-gain list;

refer to Chapter 5 for more information. You can also set up a group

of consecutive channels or channel-gain list using DAS-800 Series

custom controls; refer to

Guide

Automatic channel scanning is a hardware feature. The functions

used to create a group of consecutive channels or a channel-gain list

emulate automatic channel scanning through software. Therefore, the

maximum attainable conversion frequency is reduced when using a

group of consecutive channels or a channel-gain list.

Channel Expansion

If you want to acquire

Guide

for more information. The Control Panel also allows

the VisualDAS Custom Controls User’s

for more information.

data

from a range of multiple channels

DAM00 Series Function Call Driver

Z-6

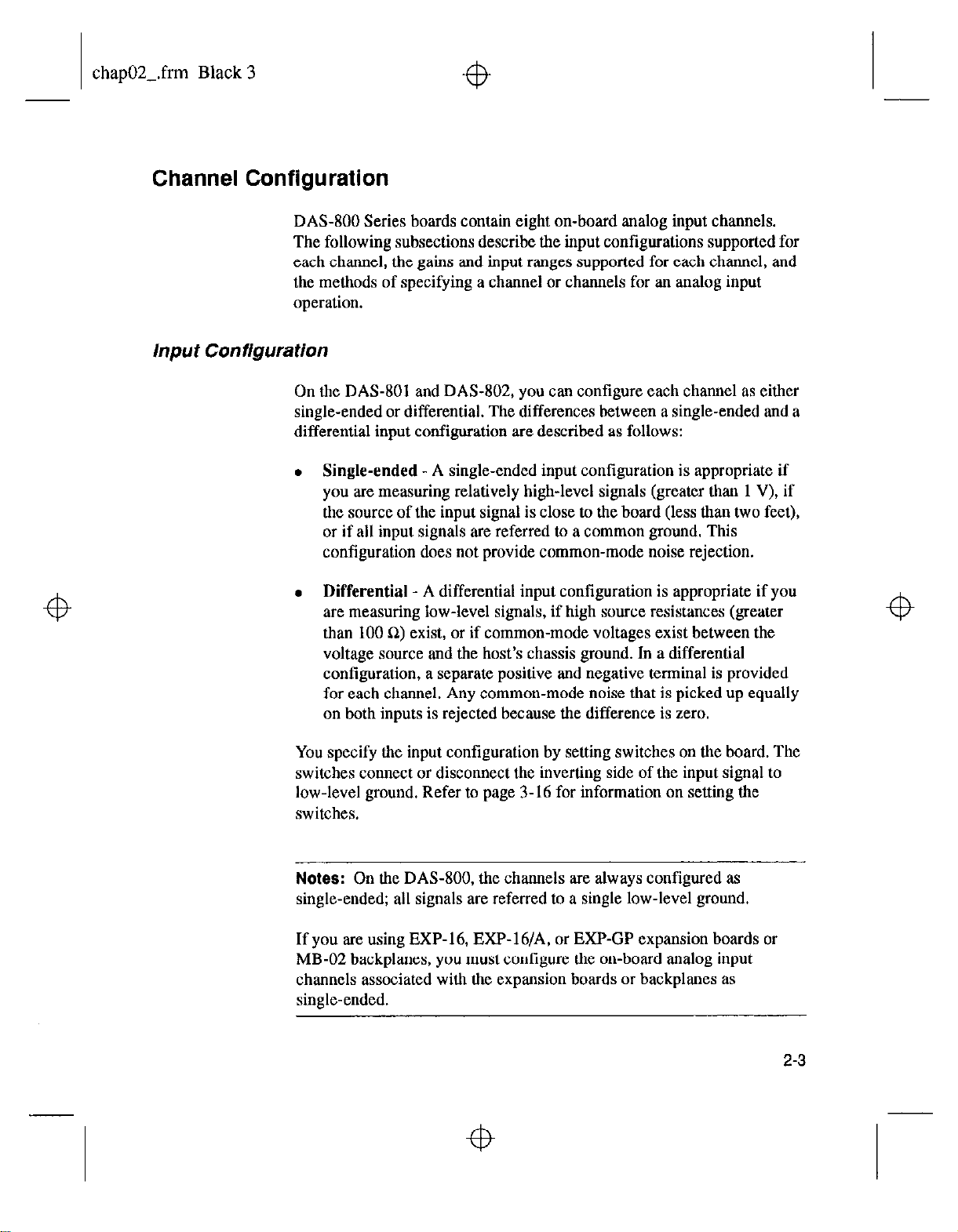

If you require additional analog input channels or signal conditioning for

transducer inputs, you can use any combination of up to eight 16-channel

EXP-16 expansion boards, eight 16-channel EXP-16/A expansion boards,

and/or eight X-channel EXP-GP expansion boards to increase the number

of available channels to 128. You can also use up to four MB-02

backplanes to increase the number of available channels to 68.

For the EXP-16, EXP-16/A. and EXP-GP, you attach the expansion

boards in a daisy-chain configuration using the S-1800 or C-1800 cable.

The first expansion board in the daisy chain is associated with on-board

channel 0, the next expansion board is associated with

1, and so on. You specify the associated on-board channel by setting a

jumper on each expansion board. You can access any unused on-board

channels by attaching an STA-08 or STA-OBPGA screw terminal

accessory to the last expansion board in the daisy-chain configuration.

on-board

Functional Description

channel

Page 22

chapOZ.frm Black 7

fb

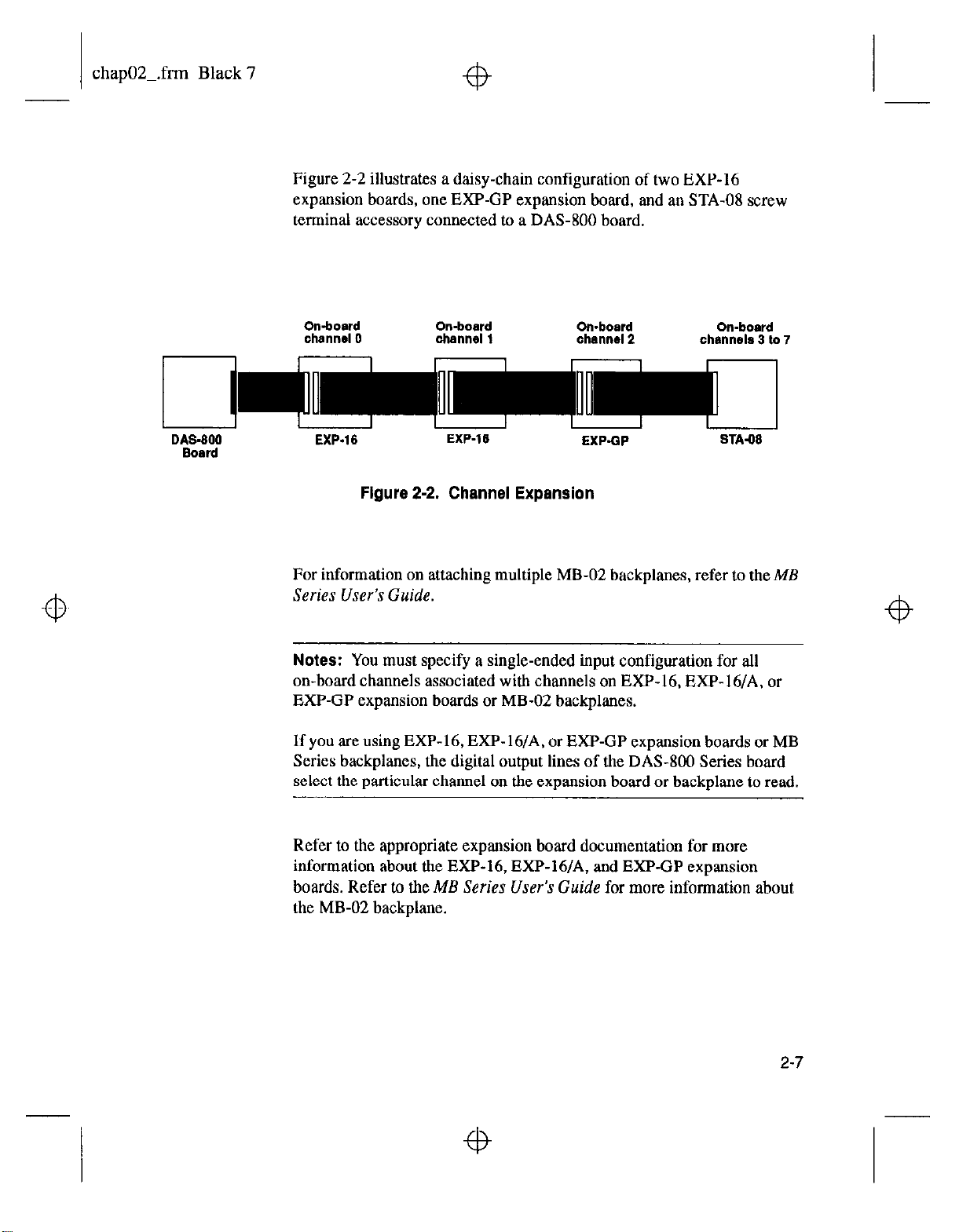

Figure 2-2 illustrates a daisy-chain configuration of two EXP-16

expansion boards, one EXP-GP expansion board, and an STA-08 screw

terminal accessory connected to a DAS-800 board.

Omboard

channel 0

I I I I r I I I

D&3-600

Board

EXP.16

Figure 2-2. Channel Expansion

On-board On-board

channel 1

EXP-16

channal2 chsnnsls 3 to 7

EXPQP

For information on attaching multiple MB-02 backplanes, refer to the ME

Series User’s Guide.

Notes:

You must specify a single-ended input configuration for all

on-board channels associated with channels on EXP-16, EXP-16/A. or

EXP-GP expansion boards or MB-02 backplanes.

If you are using EXP-16, EXP- 16/A, or EXP-GP expansion boards or MB

Series backplanes, the digital output lines of the DAS-800 Series board

select the particular channel on the expansion board or backplane to read.

On-board

STA.08

Refer to the appropriate expansion board documentation for more

information about the EXP-16, EXP-16/A, and EXP-GP expansion

boards. Refer

to the ME Series User’s Guide

for more information about

the MB-02 backplane.

2-7

Page 23

chap02-.frm Black 8

Conversion Clock Sources

4

The conversion clock source determines when each analog-to-digital

(A/D) conversion is initiated. DAS-800 Series boards provide the

following software-selectable conversion clock sources:

. Software -When using a software conversion clock, the host

computer issues a command to initiate a conversion. The host polls

the board to determine if the conversion is complete. When the

conversion is complete, the host reads the data from the ADC and

returns the value. If the host reads data before the conversion is

complete, the data will be invalid.

Software-initiated conversions are suitable for measuring DC

voltages; however, in applications where you must accurately control

the sampling rate (as when measuring time-varying signals), it is

recommended that you use either an internal or an external hardware

conversion clock source.

4

At power-up or system reset, the board assumes that conversions will

be initiated through software.

. Hardware (internal clock source) -The internal clock source uses

the on-board 8254 counter/timer circuitry and a crystal-controlled

I MHz time base. The 8254 counter/timer circuitry is normally in an

idle state. When you start an analog input operation, a conversion is

initiated immediately. The 8254 is loaded with its initial count value

and begins counting down. When the 8254 counts down to 0, another

conversion is initiated and the process repeats.

Because the 8254 counter/timer uses a 1 MHz time base, each count

represents 1 ps. For example, if you load a count of 25, the time

interval between conversions is 25 ps: if you load a count of 65536,

the time interval between conversions is 65.536 ms.

4

2-6

Functional Description

4

Page 24

chap02Lfrm Black 9

+b

The 8254 contains three counter/timers: C/TO, Cnl, and C/r2. If you

are using a hardware internal clock source, the time base logic uses

C/T1 and C/r2 in either normal or cascaded mode, as follows:

- Normal

of the 8254 counter/timer circuitry. Each time C/r2 reaches

terminal count, a conversion is initiated. The time interval

between conversions ranges from 25 FLS to 65.536 ms.

Cascaded Mode

C/r2 and C/r1 of the 8254 counter/timer circuitry. When CK2

counts down to 0, CR1 decrements by 1. Cn2 is reloaded with

its count value and begins counting down again. Each time C/r2

counts down to 0, Cm1 decrements by 1. Each time both C/r2

and CR1 reach terminal count, a conversion is initiated. The time

interval between conversions ranges from 25 ps to 1.2 hours.

Note:

system reset, the DA%800 board connects the clock input of C/r2 to

the CPU bus clock divided by two. If you specify a hardware internal

clock source through software, the DAS-800 board connects the clock

inputs of C/T1 and CD2 to the 1 MHz time base. The DAS-801 and

DAS-802 boards always connect the clock input of C/f2 to the

1 MHz time base.

Refer to page 2-17 for more information about the 8254 counter/timer

circuitry.

Mode

- A software-selectable count is loaded into C/r2

- A software-selectable count is divided between

For compatibility with the DAS-8 board, on power-up or

. Hardware (external clock source) - An external clock source is

useful if you want to sample at rates not available with the 8254

counter/timer circuitry, if you want to sample at uneven intervals, or if

you want to sample on the basis of an external event. An external

clock also allows you to synchronize conversions on multiple boards

to a common timing source.

2-9

Page 25

chap02-.frm Black 10

fb

The external clock source is an externally applied TTL-compatible

signal, which you attach to the INT-IN / XCLK pin (pin 24) of the

main I/O connector. When you start an analog input operation,

conversions are

soume (and at every subsequent falling edge of the external clock

source), a conversion is initiated.

armed.

At the next falling edge of the external clock

Note:

use the INT-IN / XCLK pin (pin 24) to generate interrupts.

Figure 2-3 illustrates how conversions are initiated when using an internal

and an external clock source. (Note that Figure 2-3 assumes that you are

not using a hardware trigger; refer to Figure 2-4 for an illustration of

conversions when using a hardware trigger.)

If you are using a hardware external clock source, you cannot

2-l 0

Figure 2-3. Initiating Conversions

Functional Description

Page 26

chap02Lfrm Black 11

Notes: The ADC acquires data at a maximum of 40 kHz (one sample

every 25 ns). If you are using a hardware external clock, make sure that

the clock does not initiate conversions at a faster rate than the ADC can

handle.

To achieve full measurement accuracy when using a gain of 500, you

should limit me conversion frequency to a maximum of 25 kHz (one

sample every 40 its).

If you are acquiring samples from multiple channels. the maximum

sampling rate for each channel is equal to 40 kHz divided by the number

of channels.

The rate at which the computer can reliably read data from the board

depends on a number of factors, including your computer, the operating

system/environment, whether you are using expansion boards, the gains

of the channels, and software issues.

You can synchronize conversions on multiple DAS-800 Series boards to a

common, externally applied conversion clock. In addition, you can use a

DAS-801 or DAS-802 board as a timing master; the output of the OUT1

pin (pin 5) on the main I/O connector of the master board acts as an

external hardware conversion clock to any additional boards. You can use

external circuitry, such as CEO on the 8254, to divide the rate of the

master clock; this allows you to synchronize conversions on the

additional hoards to a rate different from that of the master board. Refer to

page 4-13 for more information on synchronizing conversions on multiple

boards.

2-11

Page 27

chap02_.frm Black 12

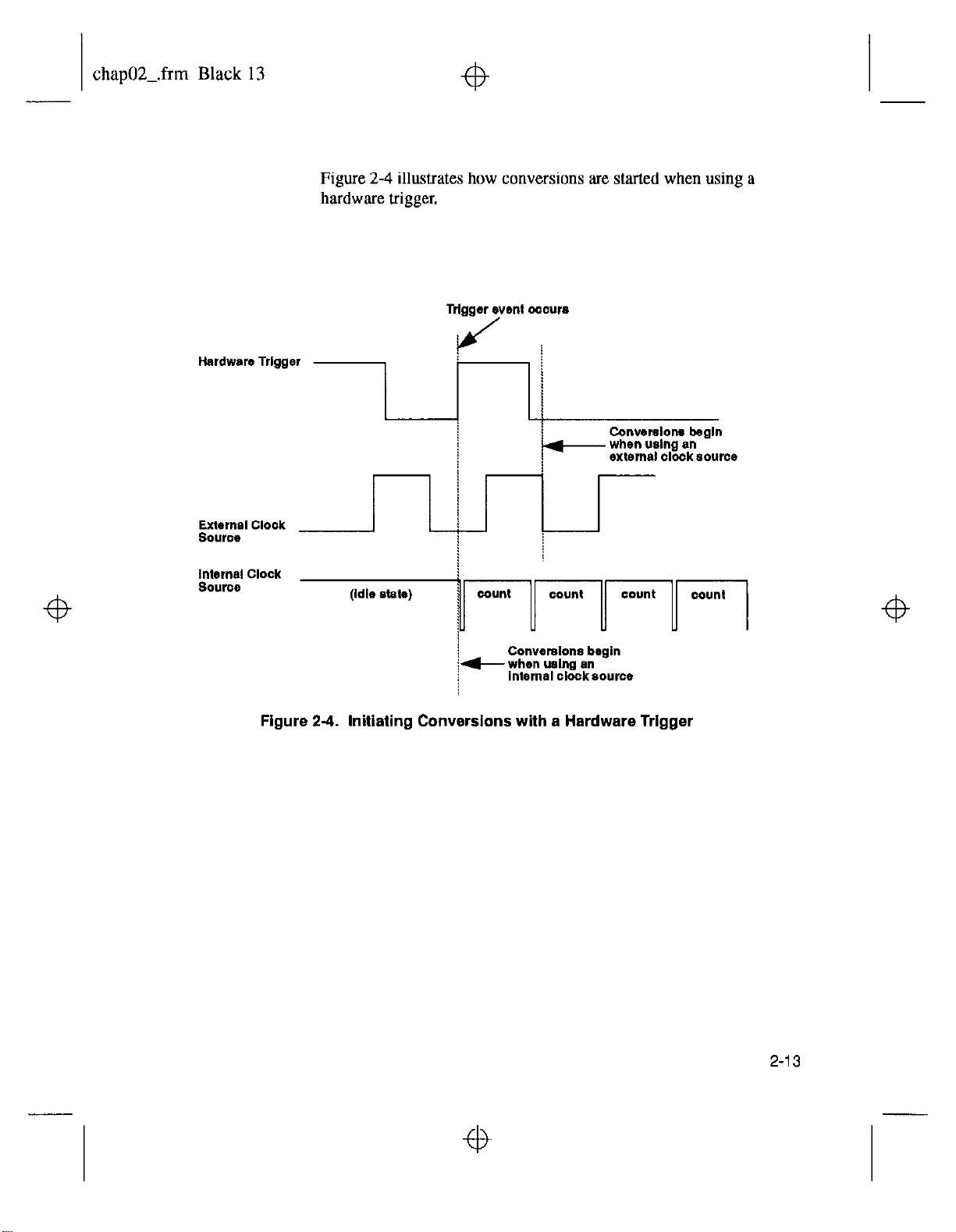

Triggers

A trigger is an event that must occur before a DAS-800 Series board starts

an analog input operation. You can use one of the following trigger

sources to trigger aa analog input operation:

. Software - When you start the analog input operation, conversions

begin

immediately.

. Hardware - You connect a digital trigger signal to the digital input

IP 1 /TRIG pin (pin 25) of the main I/O connector. The trigger event

occurs when the board detects a rising edge on IP1 /TRIG.

The actual point at which conversions begin depends on whether you

are using an internal or external clock soorce. These considerations

are described as follows:

-

Internal clock

source - The 8254 counter/timer circuitry remains

idle until the trigger event occurs. When the trigger event occurs,

the

board

initiates the first conversion immediately.

- Enrernal

clock

source - Conversions are armed when the trigger

event occurs. At the next falling edge of the external clock

source, the board initiates the first conversion.

2-12

Functional Description

Page 28

chap02-.frm Black 13

Figure 2-4 illustrates how conversions are started when using a

hardware trigger.

External Clock

source

Figure 24. Initiating Conversions

!

!

with

a Hardware Trigger

2-13

Page 29

chap02-.frm Black 14

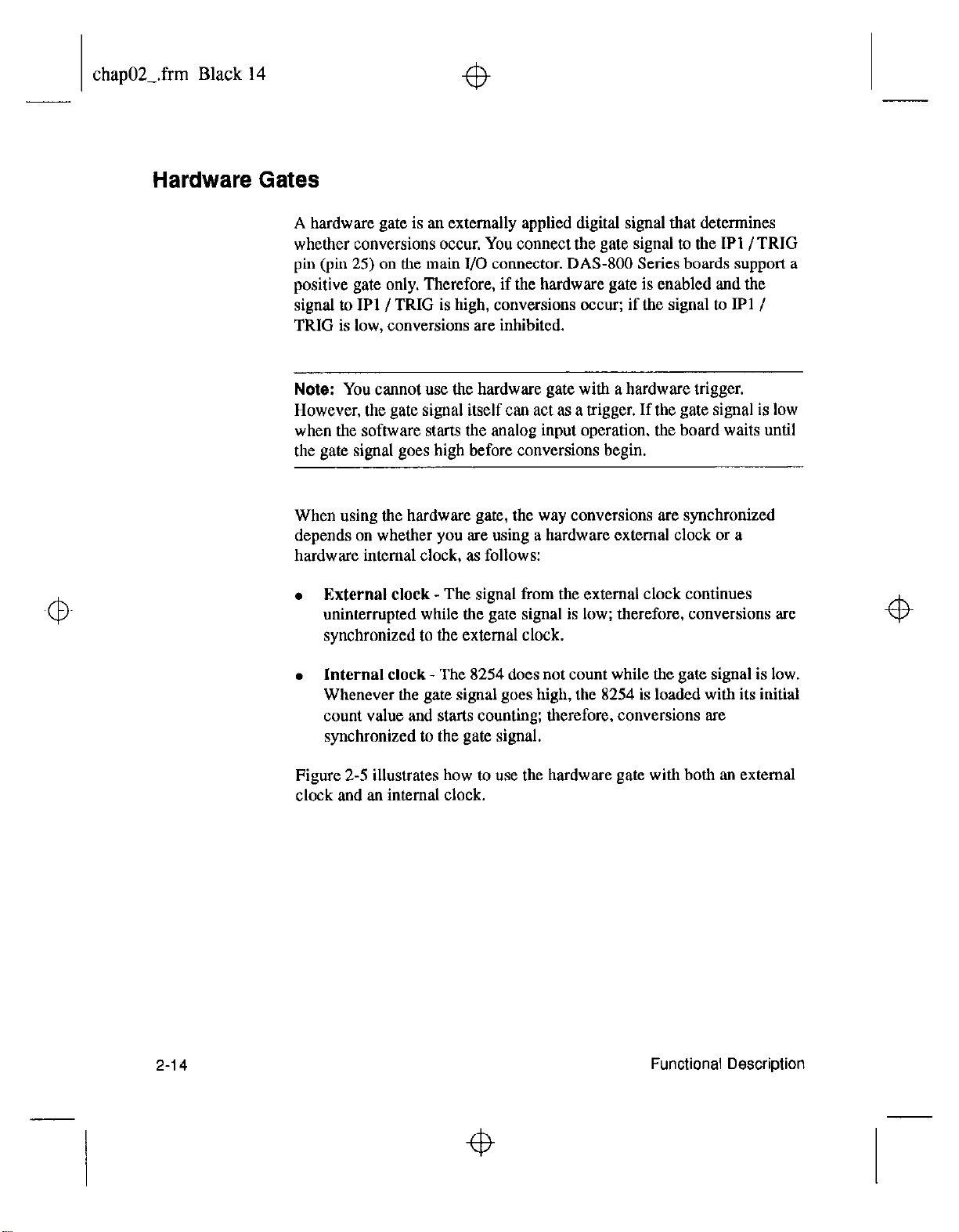

Hardware Gates

A hardware gate is an externally applied digital signal that determines

whether conversions occur. You connect the gate signal to the IPl /TRIG

pin (pin 25) on the main I/O connector. DAS-800 Series boards support a

positive gate only. Therefore, if the hardware gate is enabled and the

signal to IPl /TRIG is high, conversions occur; if the signal to IPl /

TRIG is low. conversions are inhibited.

Note:

You cannot use the hardware gate with a hardware trigger.

However, the gate signal itself can act as a trigger. If the gate signal is low

when the software starts the analog input operation, the board waits until

the gate signal goes high before conversions begin.

When using the hardware gate, the way conversions are synchronized

depends on whether you are using a hardware external clock or a

hardware internal clock, as follows:

. External

clock

- The signal from the external clock continues

uninterrupted while the gate signal is low; therefore, conversions are

synchronized to the external clock.

. Internal clock - The 8254 does not count while the gate signal is low.

Whenever the gate signal goes high, the 8254 is loaded with its initial

count value and starts counting; therefore, conversions are

synchronized to the gate signal.

Figure 2-5 illustrates how to use the hardware gate with both an external

clock and an internal clock.

2-14

Functional Description

Page 30

chap02-.frtn Black 15

sonware starts

ths

operation -b

3rd convmsion

2nd conversion

/ /

p-r . . . . . . * . . . . .

at wnverslon ,

(Intcmsl clock)

Note:

analog trigger, you can program an analog trigger through software, using

one of the analog input channels as the trigger channel. The DAS-800

Series Function Call Driver provides functions for an analog trigger; refer

to

the DAS-800 Series Funciion Call Driver User’s Guide

information. The Control Panel also allows you to set up an analog

trigger; refer to Chapter 5 for more information. You can also set up an

analog trigger using DAS-800 Series custom controls; refer to the

VisualDAS

2nd mnvwston

(Inkmel clock)

Figure 2-5. Hardware Gate

t

3rd l2dverslon

(Internal clock)

4th converslbn

(Internalclock)

A-

Although DAS-800 Series boards do not provide a hardware-based

for more

Custom

Controls Lrser’x Guide

for more information.

2-I 5

Page 31

chapOZ.frm Black 16

Data Transfer

fb

Because DAS-800 Series boards do not support DMA (Direct Memory

Access), data is always transferred from a DAS-800 Series board to the

host computer’s memory through an output port. Data can be transferred

as either a foreground process or a background process. If data is

transferred in the background, the end-of-conversion interrupt must be

enabled so that the board can notify the host computer when new data is

available; refer to page 2-25 for more information about interrupts. If data

is transferred in the foreground, interrupts are not required.

DA%800 Series boards contain a four-word, first-in, first-out memory

location (FIFO). When you initiate conversions under hardware control,

using an internal or external clock source, the result of each conversion is

automatically stored in the FIFO.

Note:

logic is automatically disabled and the FIFO is emptied.

The FIFO increases the maximum attainable conversion frequency by

increasing the maximum software interrupt latency allowed by a factor of

four (up to the maximum conversion frequency of 40 kHz).

If the conversion frequency is too fast or if the time required to service the

interrupt is too long, the hardware may perform more than four

conversions before the converted data is read. The hardware can detect

this condition and generate an error to indicate that unread data in the

FIFO was overwritten and samples were lost.

Panel, or Custom Controls, the operation of the FIFO is transparent. The

Function Call Driver, Control Panel, or Custom Controls software

When you use software to initiate conversions, the FIFO control

Note:

performs the data transfer.

When using the DAS-800 Series Function Call Driver, Control

2-I 6

Functional Description

Page 32

chap02-.frm Black 17

Digital l/O Features

DAS-800 Series boards contain three digital input lines and four digital

output lines. The digital input lines are associated with the IPI /TRIG,

IP2, and IP3 pins on the main I/O connector; the digital output lines are

associated with the OPI. OP2. OP3. and OP4 pins on the main I/O

connector. Logic 1 at a pin indicates that the input/output is high (greater

than 2.0 V); logic 0 at a pin indicates that the input/output is low (less

than 0.8 V).

The digital input lines are compatible with TTL-level signals. If no signal

is connected to a digital input line, the input appears high (logic 1).

You can use the digital input and output lines for any general-purpose

task, with the following exceptions:

. If you are using an expansion board for an analog input operation, the

four digital output lines control the multiplexem on the expansion

boards to determine the expansion board channel that is acquiring

data; in this case, you cannot use the digital output lines for

general-purpose digital output operations.

. If you are using an external digital trigger or hardware gate, you must

use the IPI /TRIG pm to attach the trigger/gate signal: in this case,

you cannot use IPl /TRIG for general-purpose digital input

operations.

8254 Counter/Timer Circuitrv

Each DAS-800 Series board contains 8254 counter/timer circuitry; the

8254 contains three counter/timers: C/IO, Cnl, and W2.

C/IO is always available for general-purpose tasks. If you are using a

hardware internal clock source for an analog input operation, both C/T1

and C/T2 of the 8254 counter/timer circuitry are dedicated to internal

functions and cannot be used for general-purpose tasks. If you are using a

hardware external clock source, ClrO, C/Tl, and C/I’2 are always

available for general-purpose tasks.

2-17

Page 33

chap02-.frm Black 18

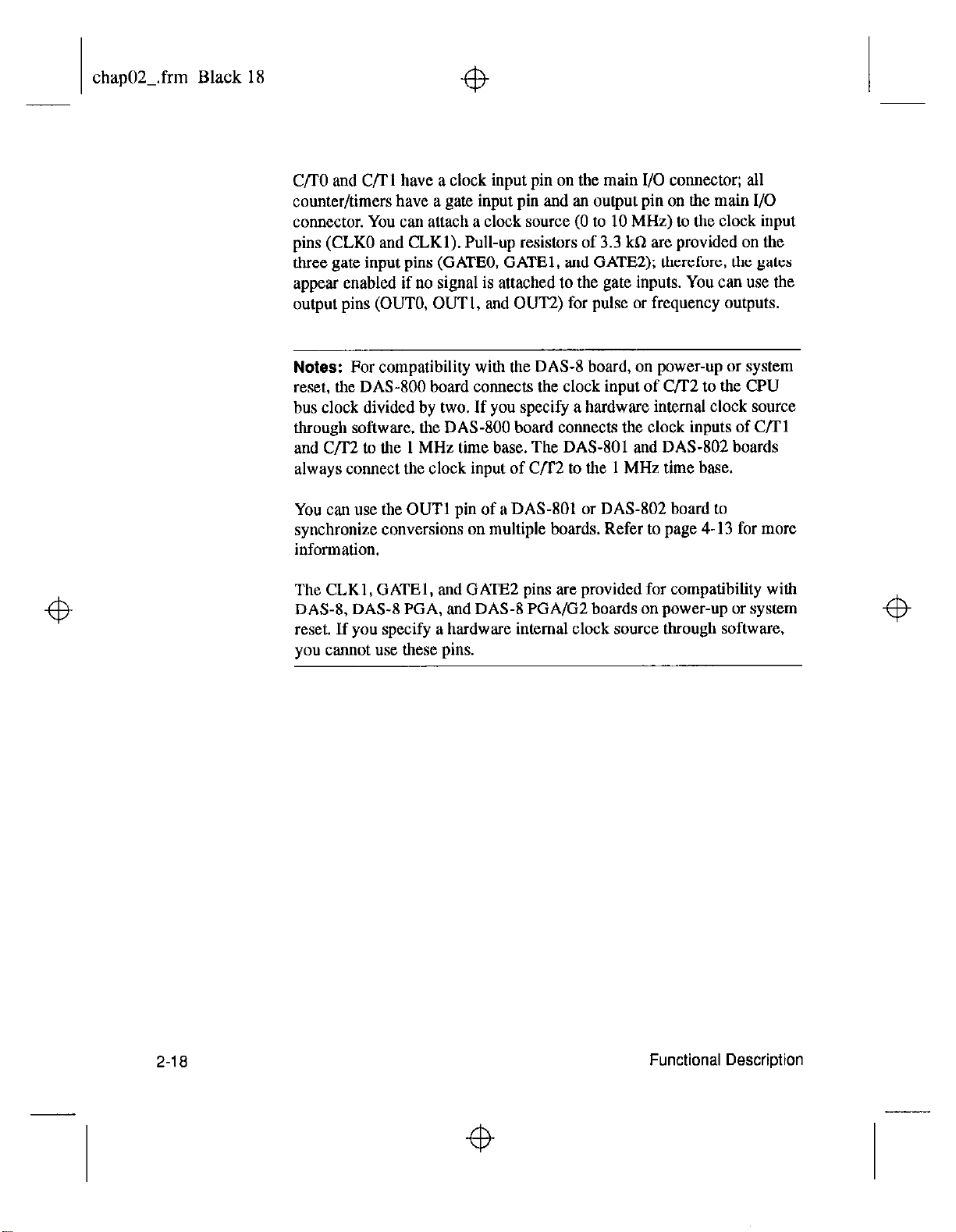

C/TO and C/T1 have a clock input pin on the main I/O connector; all

counter/timers have a gate input pin and an output pin on the main I/O

connector. You can attach a clock source (0 to 10 MHz) to the clock input

pins (CLKO and CLKl). Pull-up resistors of 3.3 ka are provided on the

three gate input pins (GATEO, GATEl, and GATE2); therefore, the gates

appear enabled if no signal is attached to the gate inputs. You can use the

output pins (OUTO, OUTl, and OUT2) for pulse or frequency outputs.

Notes: For compatibility with the DAS-8 board, on power-up or system

reset, the DAS-800 board connects the clock input of CF2 to the CPU

bus clock divided by two. If you specify a hardware internal clock source

through software, the DA%800 board connects the clock inputs of C/T1

and C/r2 to the 1 MHz time base. The DAS-801 and DAS-802 boards

always comect the clock input of Cn2 to the 1 MHz time base.

You can use the OUT1 pin of a DAS-801 or DAS-802 board to

synchronize conversions on multiple boards. Refer to page 4- 13 for more

information.

The CLKl, GATEl, and GATE2 pins are provided for compatibility with

DAS-8, DAS-8 PGA, and DAS-8 PGA/G2 boards on power-up or system

reset. If you specify a hardware internal clock source through software,

you cannot use these pins.

2-i 6

Functional Description

Page 34

chap02Lfrm Black 19

fb

You can program the 8254 counter/timer circuitry to operate in one of the

following counter/timer modes:

. Pulse on terminal count (Mode 0) - This mode is useful for event

counting or for programming a time delay. The software forces the

output low. On the next clock pulse after the software writes the

initial count value, the counter is loaded. When the counter reaches

zero, the output goes high and remains high until the software writes a

new count value. Note that the output does not go high until n + 1

clock pulses after the initial count is written, where n indicates the

loaded count.

A high gate input enables counting; a low gate input disables

counting. The gate input has no effect on the output. Note that an

initial count value written while the gate input is low is still loaded on

the next clock pulse.

Figure 2-6 illustrates pulse on terminal count mode.

clock pulse

softwar* tomes

output low --)

output

I

Figure 2-6. Pulse on Terminal Count Mode

3

2

1

2-19

Page 35

chapO2Lfrm Black 20

+b

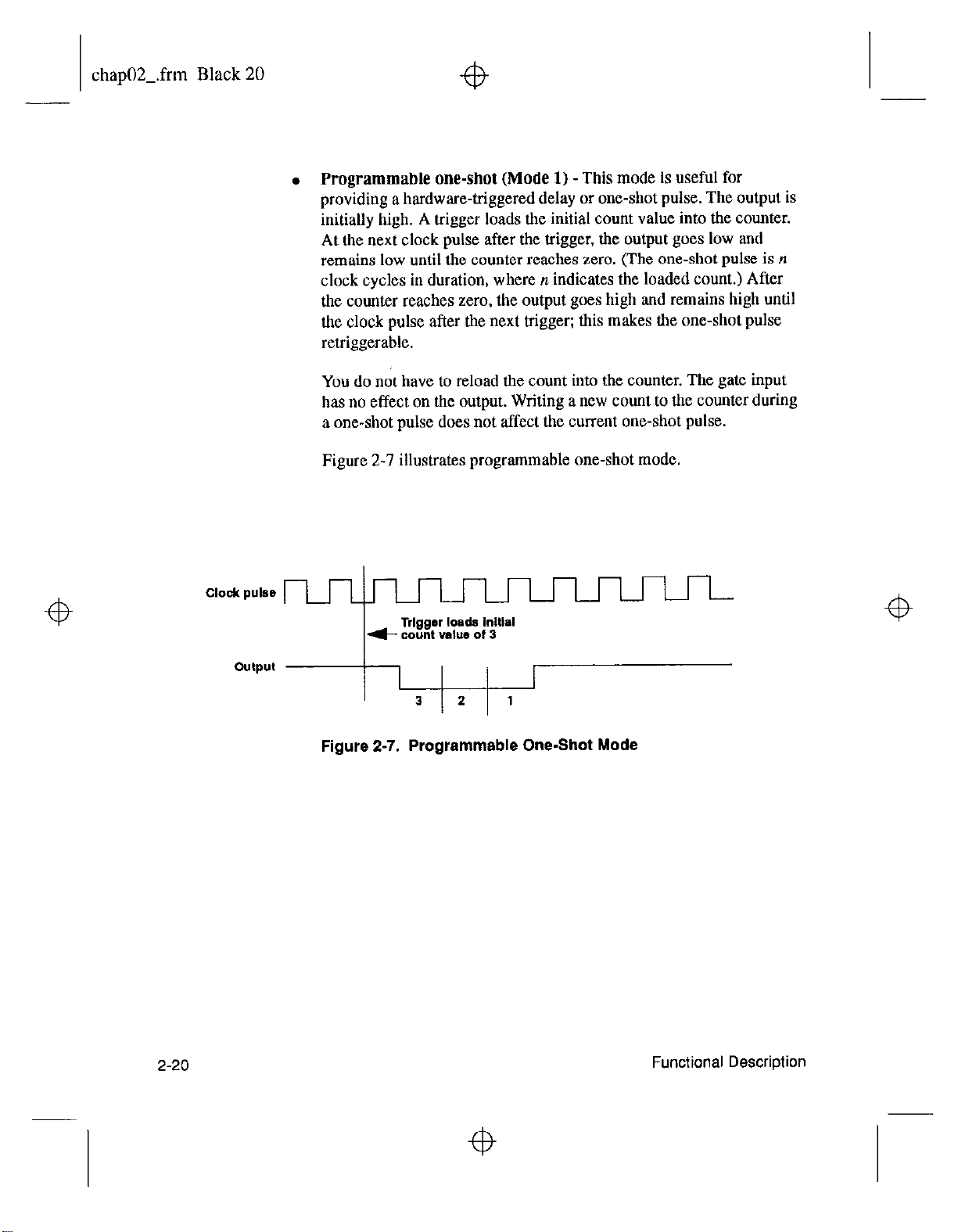

. Programmable one-shot (Mode 1) -This

mode is useful for

providing a hardware-triggered delay or one-shot pulse. The output is

initially high. A trigger loads the initial count value into the counter.

At the next clock pulse after the trigger, the output goes low and

remains low until the counter reaches zero. (The one-shot pulse is n

clock cycles in duration, where n indicates the loaded count.) After

the counter reaches zero, the output goes high and remains high until

the clock pulse after the next trigger; this makes the one-shot pulse

retriggerable.

You do not have to reload the count into the counter. The gate input

has no effect on the output. Writing a new count to the counter during

a one-shot pulse does not affect the current one-shot

pulse.

Figure 2-7 illustrates programmable one-shot mode.

Z-20

output

I

3 2 1

Figure 2-7. Programmable One-Shot Mode

Page 36

chap02Lfrm Black 21

l

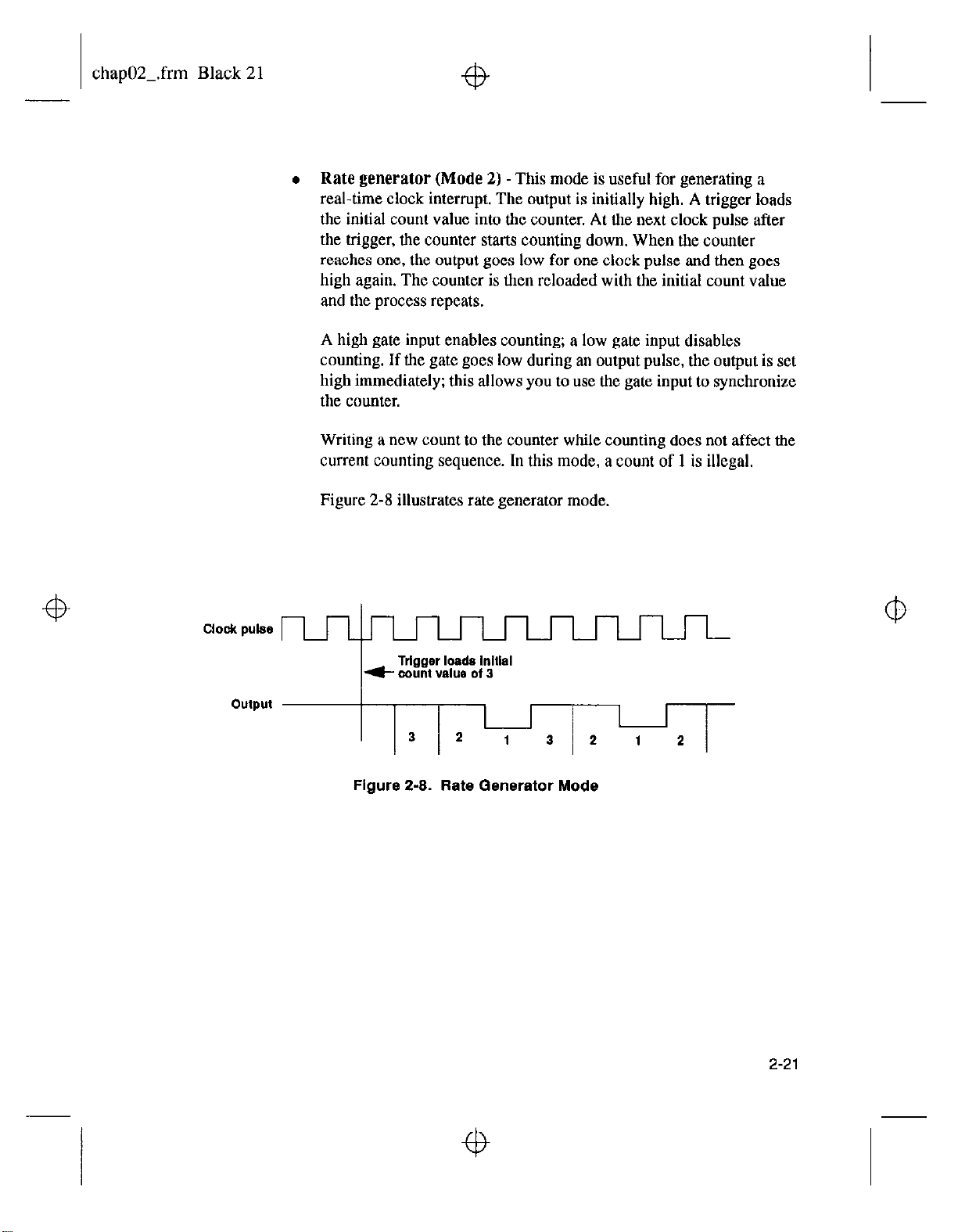

Rate generator

(Mode 2) -This mode is useful for generating a

real-time clock interrupt. The output is initially high. A trigger loads

the initial count value into the counter. At the next clock pulse after

the trigger, the counter starts counting down. When the counter

reaches one, the output goes low for one clock pulse and then goes

high again. The counter is then reloaded with the initial count value

and the process repeats.

A high gate input enables counting; a low gate input disables

counting. If the gate goes low during an output pulse, the output is set

high immediately; this allows you to use the gate input to synchronize

the counter.

Writing a new count to the counter while counting does not affect the

current counting sequence. In this mode, a count of 1 is illegal.

Figure 2-8 illustrates rate generator mode.

ClOdI pulse

Figure 2-8. Rate Generator Mode

2-21

Page 37

chap02-.frm Black 22

+b

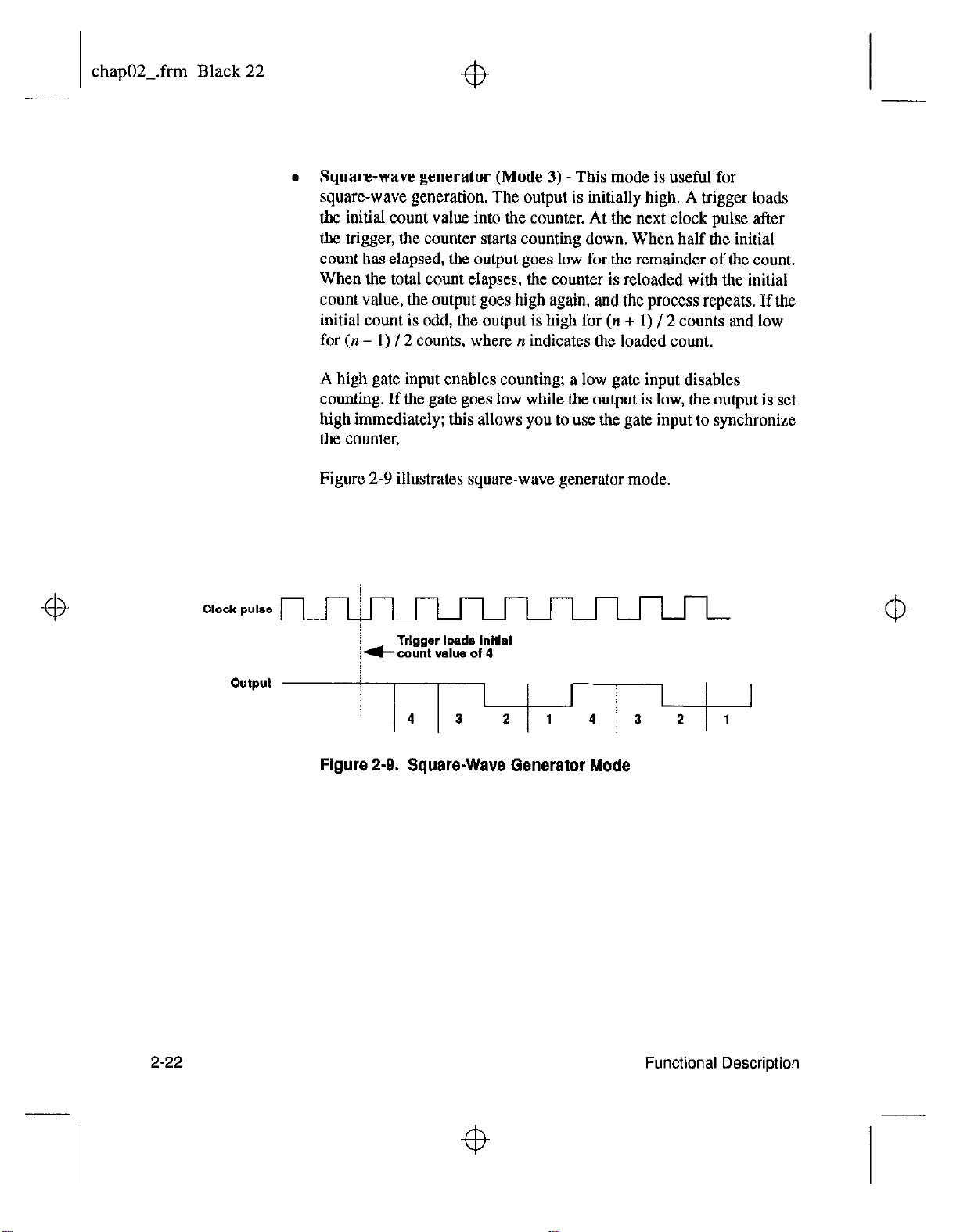

. Square-wave generator (Mode 3) -This mode is useful for

square-wave generation. The output is initially high. A trigger loads

the initial count value into the counter. At the next clock pulse after

the trigger, the counter starts counting down. When half the initial

count has elapsed, the output goes low for the remainder of the count.

When the total count elapses, the counter is reloaded with the initial

count value, the output goes high again, and the process repeats. If the

initial count is odd, the output is high for (n + 1) / 2 counts and low

for (n - 1) / 2 counts, where n indicates the loaded count.

A high gate input enables counting; a low gate input disables

counting. If the gate goes low while the output is low, the output is set

high immediately: this allows you to use the gate input to synchronize

the counter.

Figure 2-9 illustrates square-wave generator mode.

2-22

output

1 I I

14 3

2

Figure 2-9. Square-Wave Generator Mode

2 1

Functional Description

Page 38

chap02-.frm Black 23

Clock

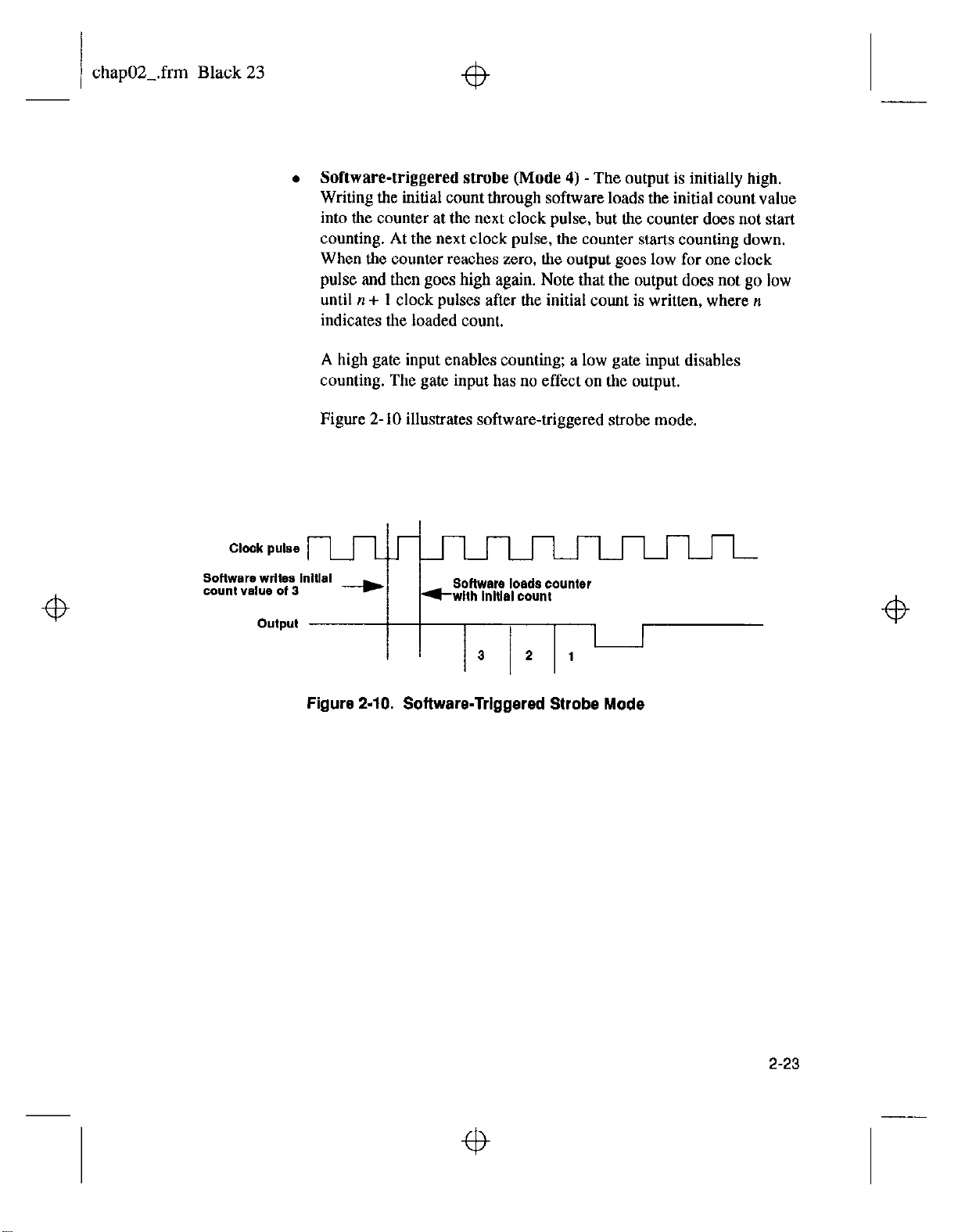

. Software-triggered strobe

Writing the initial count through software loads the initial count value

into the counter at the next clock pulse, but the counter does not start

counting. At the next clock pulse, the counter starts counting down.

When the counter reaches zero, the output goes low for one clock

pulse and then goes high again. Note that the output does not go low

until n + 1 clock pulses after the initial count is written, where n

indicates the loaded count.

A high gate input enables counting: a low gate input disables

counting. The gate input has no effect on the output.

Figure 2- 10 illustrates software-triggered strobe mode.

pulse

I

output

I

(Mode 4) -The output is initially high.

Figure 2-10. Software-Triggered Strobe Mode

2-23

Page 39

chap02-.frm Black 24

fb

l

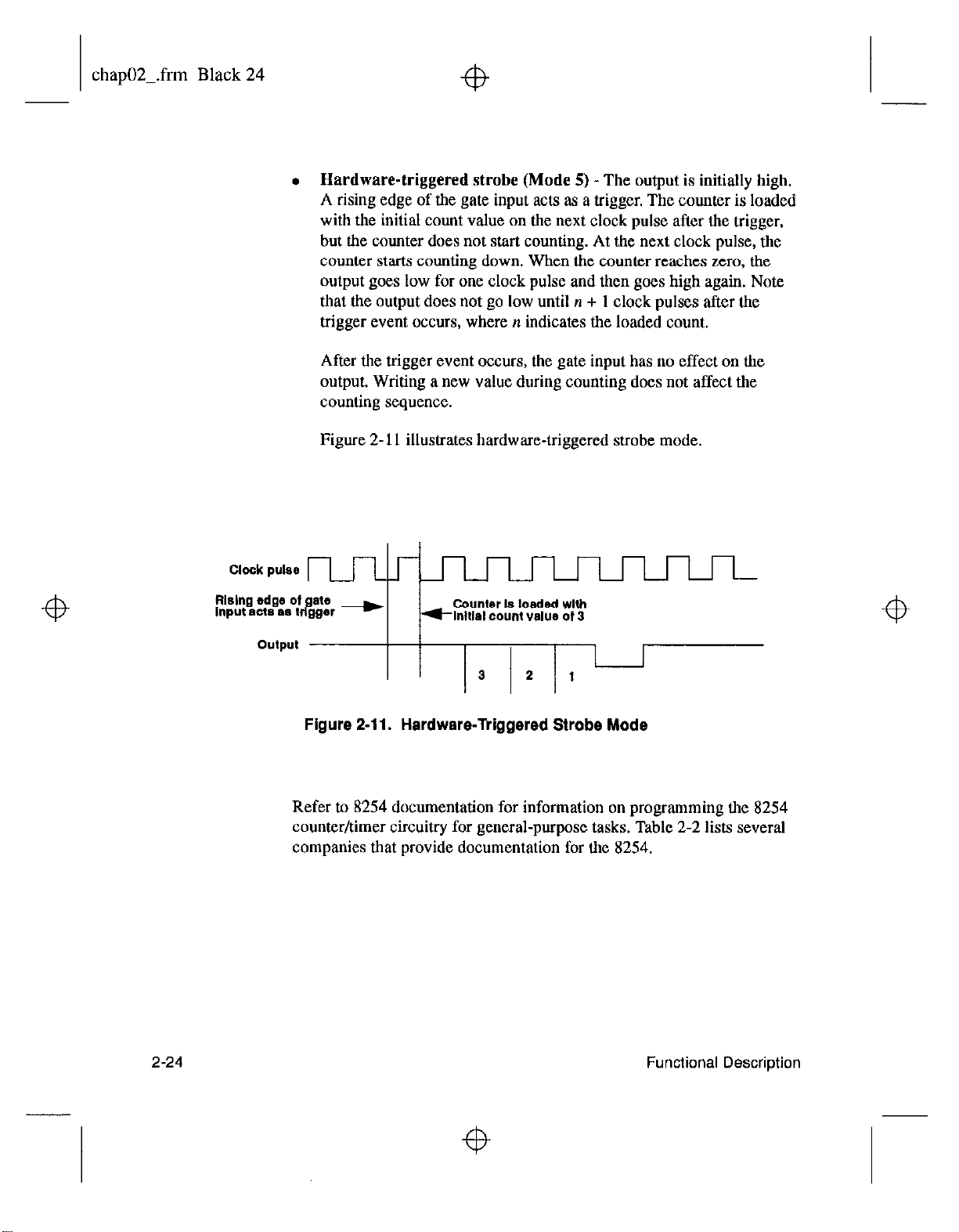

Hardware-triggered strobe (Mode

A rising edge of the gate input acts as a trigger. The counter is loaded

with the initial count value on the next clock pulse after the trigger,

but the counter does not start counting. At the next clock pulse, the

counter starts counting down. When the counter reaches zero, the

output goes low for one clock pulse and then goes high again. Note

that the output does not go low until n + 1 clock pulses after the

trigger event occurs, where n indicates the loaded count.

After the trigger event occurs, the gate input has no effect on the

output. Writing a new value during counting does not affect the

counting sequence.

Figure 2- 11 illustrates hardware-triggered strobe mode,

5) - The output is initially high.

Clock

pulse

flislng edge of ate

input act* as I rf gger -

output

Figure 2-11. Hardware-Triggered Strobe Mode

Refer to 8254 documentation for information on programming the 8254

counter/timer circuitry for general-purpose tasks. Table 2-2 lists several

companies that provide documentation for the 8254.

Counter Is loaded wllh

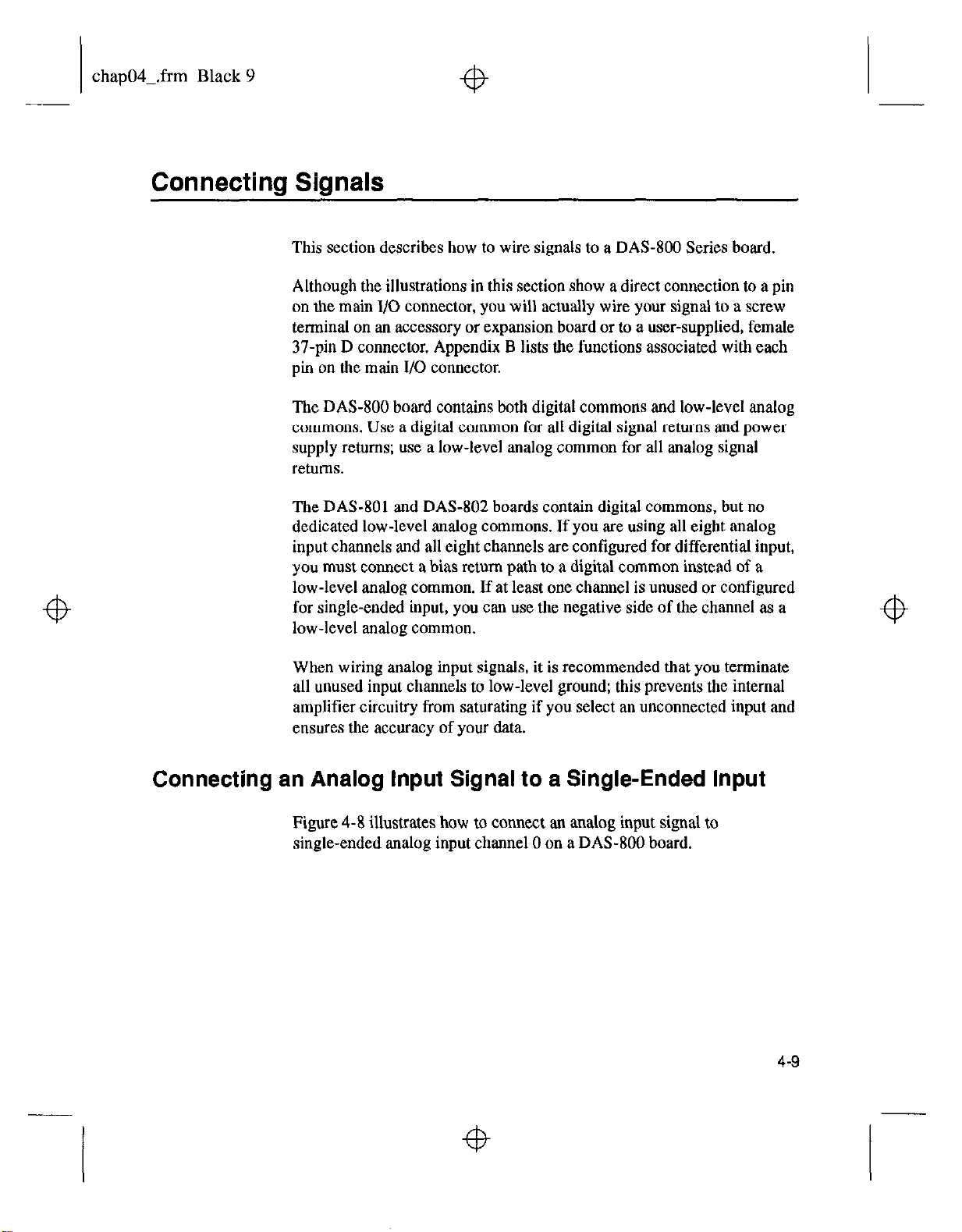

flnldal CO”“t value of 3

2-24

Functional Description

Page 40

chap02-.frm Black 25

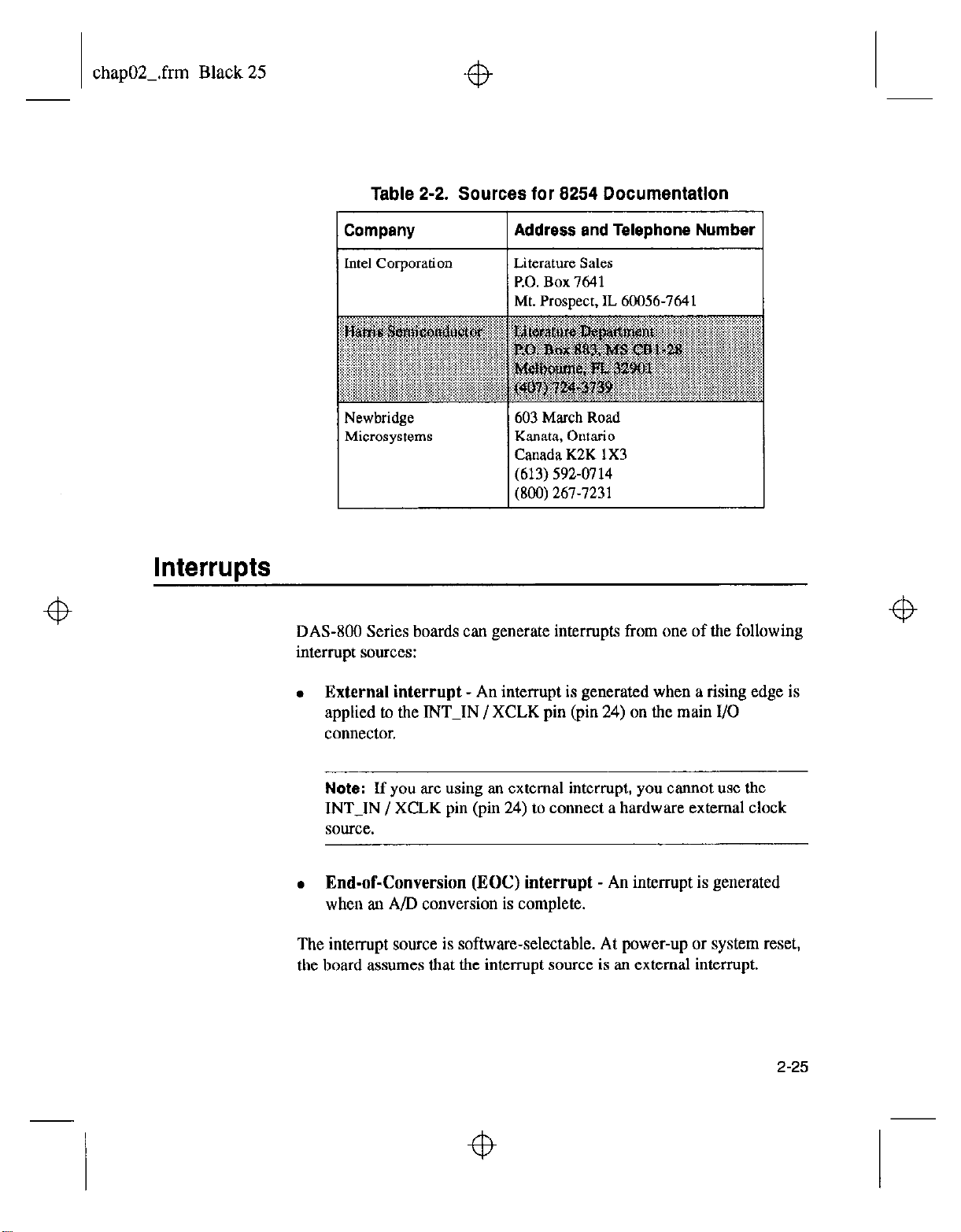

Table 2-2. Sources for 8254 Documentation

Company 1 Address and Telephone Number 1

lntel Corporation Literature Sales

P.O. Box 7641

Mt. Prospect, IL 60056-7641

Interrupts

Newbridge

Microsystems

603 March Road

Kanata, Ontario

Canada K2K 1X3

(613) 592-0714

(800) 267-7231

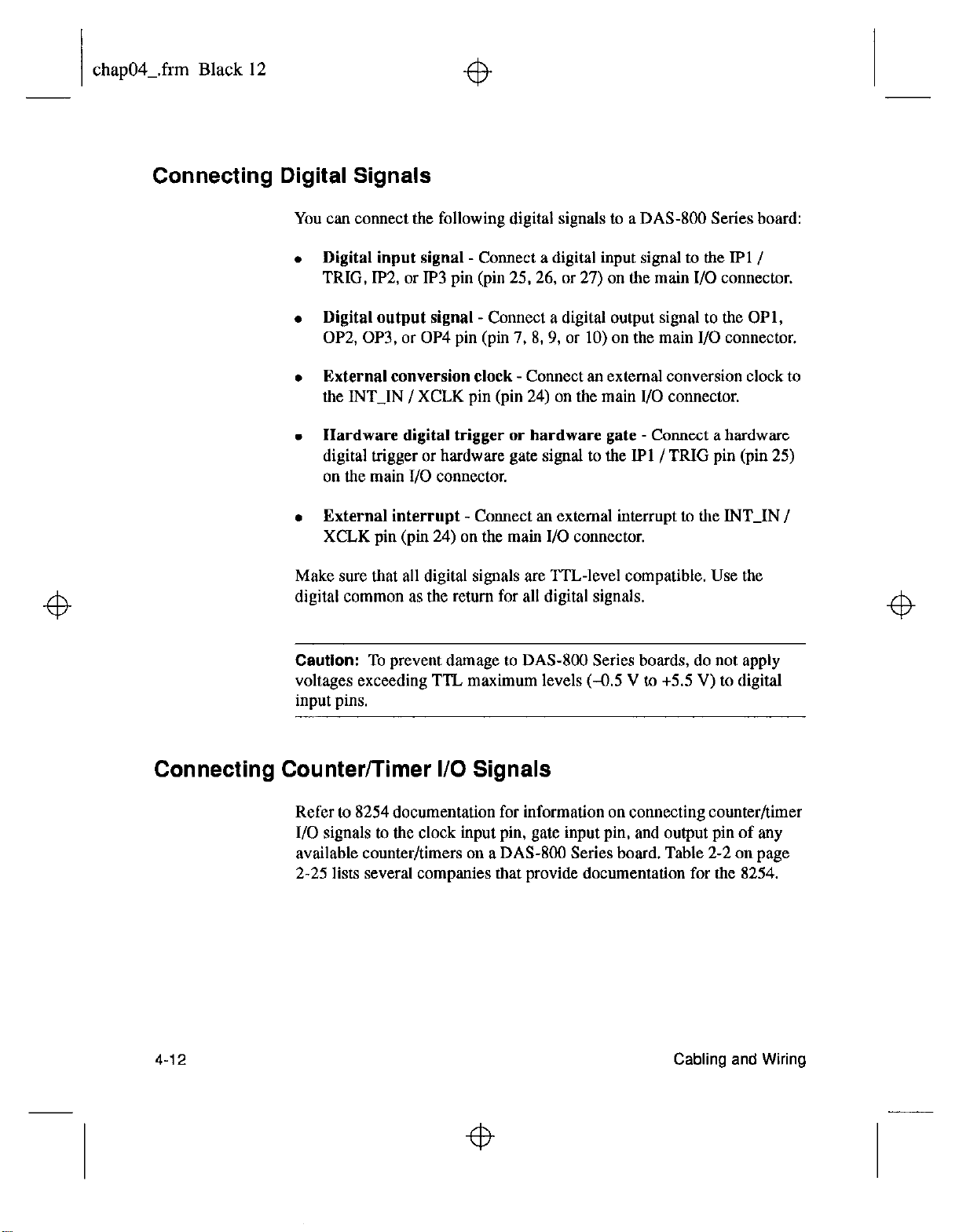

DAS-800 Series boards can generate interrupts from one of the following

interrupt sources:

. External interrupt

- An interrupt is generated when a rising edge is

applied to the INT-IN / XCLK pin (pin 24) on the main I/O

connector.

Note: If you are using an external interrupt, you cannot use the

INT-IN

/ XCLK pin (pin 24) to connect a hardware external clock

source.

. End-of-Conversion (EOC) interrupt

- An interrupt is generated

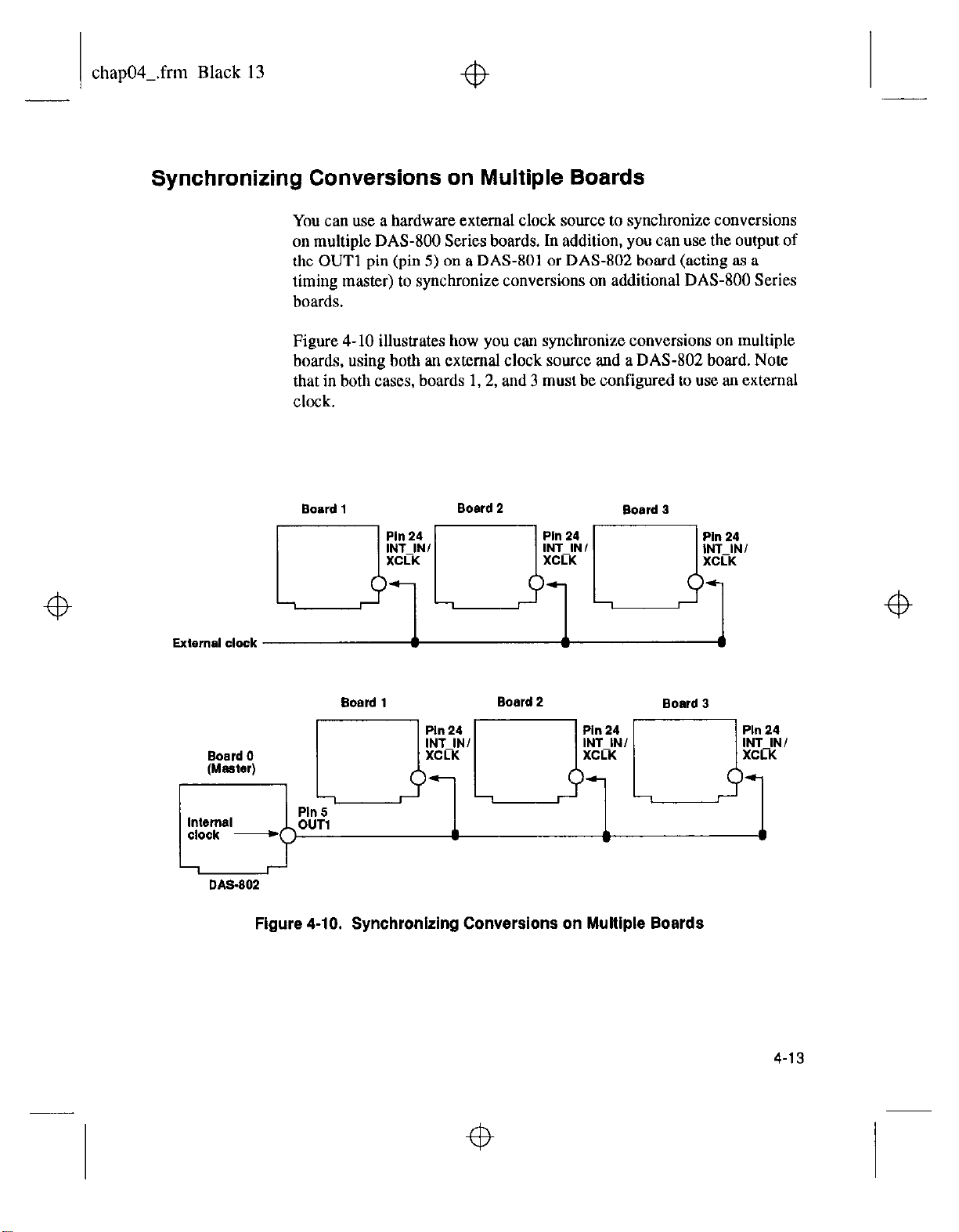

when an A/D conversion is complete.

The interrupt source is software-selectable. At power-up or system reset,

the board assumes that the interrupt source is an external interrupt.

2-25

Page 41

chapOZ_.frm Black 26

f9

You can select only one interrupt at a time. If you are using an interrupt,

you must select the interrupt level (2, 3,4,5,6, or 7) using a jumper on

the board. If you are not using an interrupt, you can disable interrupts

using a jumper on the board. Refer to page 3-17 for more information.

Power

Note:

enabled and the interrupt source must be an EOC interrunt.

If an interrupt condition is satisfied, an on-board flip-flop is set. If

interrupts are enabled (through both hardware and software), the board

generates an interrupt to the host, driving the selected host interrupt line

to an active state.

The analog circuitry on the DAS-800 board is powered by the f12 V of

the host computer. The DAS-801 and DAS-802 boards contain a DC/DC

converter to provide power to the analog circuitry.

Note:

computers do not have a -12 V power supply. If your computer does not

have a -12 V power supply, you cannot use a DA%800 board.

If you are acquiring data in the background, interrupts must be

Many laptop computers and other types of battery-operated

2-26

The host computer can provide power for EXP-16, EXP- 16/A, and

EXP-GP expansion boards and MB Series backplanes: however, certain

power limitations exist. Table 2-3 lists the maximum number of

expansion boards

and

backplanes that the host can power.

Functional Description

Page 42

chap02-.frm Black 27

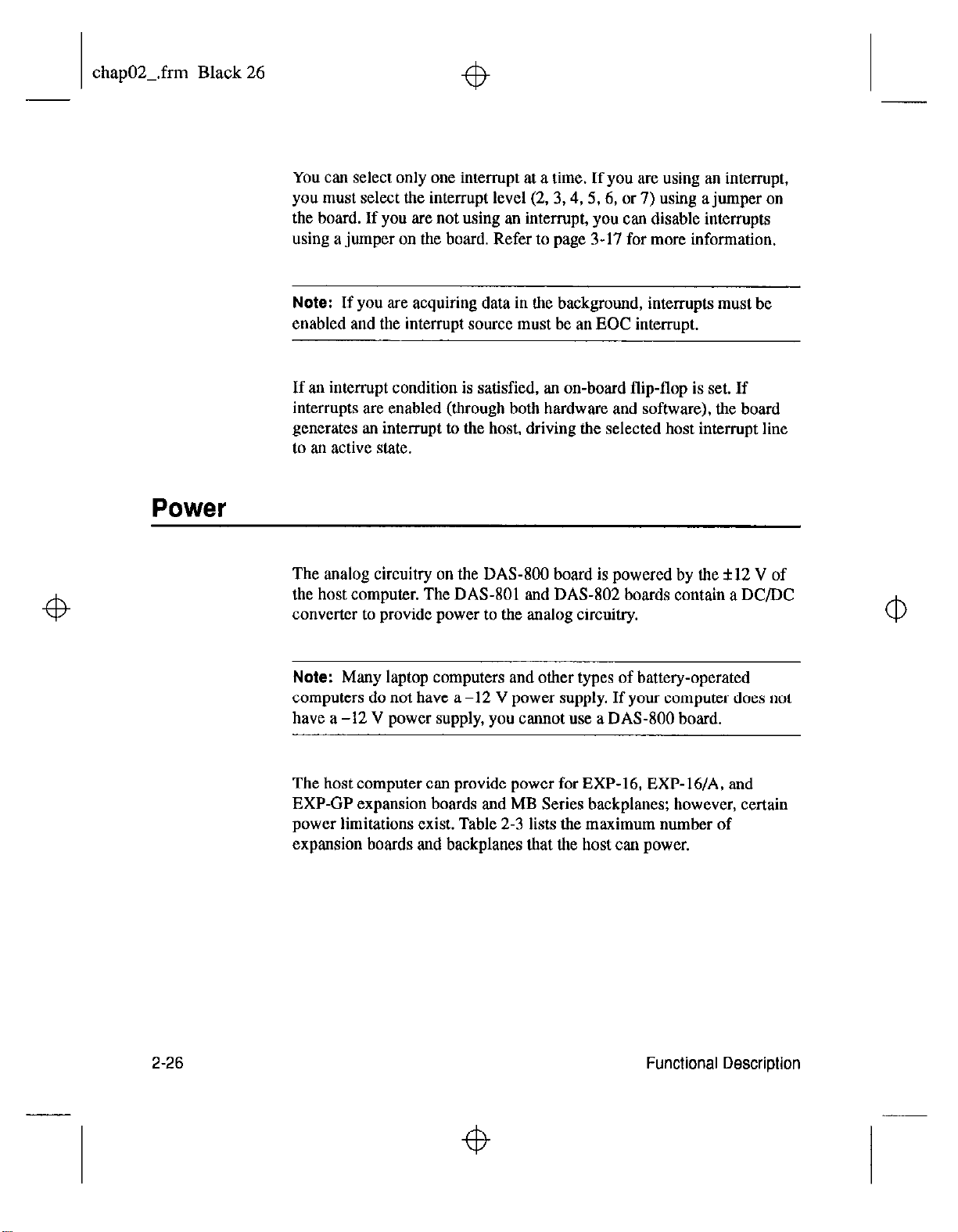

Table 2-3. Expansion Board / Backplane Power Limitations

Expansion Board / Maximum Number

Backplane Powered by Host

I

If you want to use more expansion boards or backplanes than indicated in

Table 2-3, you must connect an external power supply to the additional

expansion boards or backplanes. Refer to the appropriate expansion board

documentation for information on providing external power to EXP- 16.

EXP-16/A, and EXP-GP expansion boards. Refer to theME

Guide

for information on providing external power to MB Series

Series User’s

backplanes.

2-27

Page 43

chap02-.frm Black 28

4

Page 44

chap03-.frm Black 1

4

3

Setup and Installation

This chapter describes how to install the software in your computer,

unpack and inspect the board, configure the board, and install the board in

your computer.

If you are familiar with switches and jumpers and with the items that are

configurable on DAS-800 Series boards, you can use Figure 3-1 as a

quick reference for configuring a DA%800 board and Figure 3-2 as a

quick reference for configuring a DAS-801 or DAS-802 board. If you

need additional information, refer to Configuring the Board on page 3-8.

3-1

4

Page 45

chap03-.frm Black 2

BASE ADDRESS

::I

Ai

C

-

J2

Jl

ilOWW q 300H

I”ierrup\ level

(X E disabled)

Figure 3-1. DAS-300 Board

3-2

Setup and Installation

Page 46

chap03-.frm Black 3

BASE ADDRESS

3

’ 2 3 4 5 6 ’

~~~fjfl~~[

A

Base dddnss

b”,“&&:“,,=d

OWWOl = WBH

OWWIO z OlOH

ilOWW = 300H

1111111 s3FBH

SWlwl fhckS2

OOOOI

t

0

1

2

3

4

5

6

7

Input ConfiguratIon

(On rslngleemdsd,

Switch 1 I Channel

Swllch 2 E Channel

Stitch 3 = Channel

Swllch 4 = Channel

Switch 5 z Channel

Switch 6 q Channel

Switch 7 z Channel

Swllch 8 = Channel

Jl

I

I

Interrupt Ioval

(X q disabled)

Off L dlfferenUsl)

Figure 3-2. DAS-8011802 Board

3-3

Page 47

chap03-.frm Black 4

Installing the Software

This section describes how to install the DA%800 Series standard

software package and how to install the ASO- software package from

both DOS and Windows. The contents of these software packages are

described as follows:

. DAS-800 Series standard software package

-This is tbe software

package that is shipped with DAS-800 Series boards; it includes the

following:

- The Control Panel, running under DOS, which allows you to test

all features of DAS-800 Series boards before programming.

-

Libraries of functions for Microsoft QuickBasic, Microsoft

Professional Basic, and Microsoft Visual Basic for DOS.

- Support files, containing such program elements as function

prototypes and definitions of variable types, which are required

by the functions.

-

Utility programs, running under DOS, that allow you to configure

and calibrate DAS-800 Series

-

Language-specific example programs.

-

The External Driver, which is required for programming with

boards.

VIEWDAC, EASYEST LX 1 AG, and ASYST.

l

ASO- software package

- This is the optional Advanced

Software Option for DAS-800 Series boards. You purchase the

ASO- software package separately from the board; it includes the

following:

3-4

-

The Control Panel, running under DOS and Windows, which

allows you to test all features of DAS-800 Series boards before

programming.

-

Libraries of functions for Microsoft C/C++, Borland C/C++, and

Borland Turbo Pascal.

Setup and Installation

Page 48

chap03-.frm Black 5

-

Dynamic Link Libraries (TILLS) of functions for Microsoft Visual

Basic for Windows, Microsoft QuickC for Windows, Microsoft

Visual C++, and Borland Turbo Pascal for Windows.

-

Support files, containing program elements, such as function

prototypes and definitions of variable types, that are required by

the functions.

-

Utility programs, running under DOS and Windows, that allow

you to configure and calibrate DAS-800 Series boards.

-

Language-specific example programs.

Note: To install other software packages, refer to the documentation

supplied with the software package.

Installing the DAS-800 Series Standard Software Package

To install the DAS-800 Series standard software package, perform the

following steps:

1. Make a back-up copy of the supplied disks.

2. Insert disk #1 into the disk drive.

3. Assuming that you are using disk drive A, enter the following at the

DOS prompt:

A:install

The installation program prompts you for your installation

preferences, including the name of the directory you want to copy the

software to. It also prompts you to insert additional disks, as

necessary.

4. Continue to insert disks and respond to prompts, as appropriate.

The installation program expands any files that are stored in a

compressed format and copies all files to the directory you specified

(DAS800 directory on hard disk C if you do not specify otherwise).

3-5

Page 49

chap03-.frm Black 6

Installing the ASO- Software Package

DOS Installation

fb

5. Review the following files:

-

FILESTXT lists and describes all the files copied to the hard disk

by the installation program.

-

README.TXT contains information that was not available when

this manual was printed.

This section describes how to install the ASO- software package from

both DOS and Windows.

To install the ASO- software package from DOS, perform the

following steps:

1. Make a back-up copy of the supplied disks.

2. Insert disk #l into the disk drive.

3. Assuming that you are using disk drive A, enter the following at the

DOS prompt:

A:install

The installation program prompts you for your installation

preferences, including the name of the directory you want to copy the

software to. It also prompts you to insert additional disks, as

necessary.

4. Continue to insert disks and respond to prompts, as appropriate.

The installation program expands any files that are

compressed format and copies all files to the directory you specified

(AS0800 directory on hard drive C if you do not specify otherwise).

5. Review the following files:

-

FIL,ES.TXT lists and describes all the tiles copied to the hard disk

by the installation program.

stored in a

3-6

Setup and Installation

Page 50

chap03-.frm Black 7

Windows installation

- README.TXT contains information that was not available when

this manual was printed.

To install the ASO- software package from Windows, perform the

following steps:

1. Make a back-up copy of the ASO-Windows disk.

2. Insert the ASO-Windows disk into the disk drive.

3. Start Windows.

4. From the Program Manager menu, choose File and then choose Run.

5. Assuming that you are using disk drive A, type the following at the

command line in the Run dialog box, and then select OK:

A:SETUP

The installation program prompts you for your installation

preferences, including the name of the directory you want to copy the

software to.

6. Type the path name and select Continue.

The installation program expands any files that are stored in a

compressed format and copies all files to the directory you specified

(ASOSOthWINDOWS directory on hard drive C if you do not specify

otherwise).

The installation program also creates a DAS-800 Series family group:

this group includes example Windows programs and help tiles.

7. Review the following files:

-

FILES.TXT lists and describes all the files copied to the hard disk

by the installation program.

-

README.TXT contains information that was not available when

this manual was printed.

3-7

Page 51

chap03-.frm Black 8

Umackina the Board

To prevent any damage to your DAS-800 Series board, perform the

following steps when unpacking the board:

1. Remove the wrapped DAS-800 Series board from its outer shipping

carton.

2. Making sure that your computer is turned OFF but grounded, hold the

wrapped board in one hand while placing your other hand firmly on a

metal portion of the computer chassis: this discharges any static

electricity.

3. Carefully remove the board from its anti-static wrapping material.

(You may wish to store the wrapping material for future use.)

4. Inspect the board for signs of damage. If any damage is apparent,

arrange to return the board to the factory; refer to Chapter 7 for more

information.

5. Check the remaining contents of your package against the packing list

to ensure that your order is complete. Report any missing items to the

factory immediately.

6. Once you have determined that the

configure the board. Refer to the next section for configuration

options.

Configuring the Board

You can configure the following items on DAS-800 Series boards:

. Board type @AS-800, DAS-801, or DAS-802).

. Base address (required by the DA%800 Series Function Call Driver

and other software packages to perform DAS-800 Series board

operations).

. Use of C/T2 on the 8254 (cascaded or normal).

board is

acceptable, you can

3-8

Setup and Installation

Page 52

chap03-.frm Black 9

4

Input range type (unipolar or bipolar) for a DAS-801 or DAS-802

board.

Input configuration (single-ended or differential) for each channel on

a DAS-801 or DAS-802 board.

Interrupt level.

Expansion boards used (information includes the number of

expansion boards, the gains used by channels on the expansion

boards, and the channel used as the CJC sensor).

4

Note:

must also set switches on the expansion boards to specify the gains

used by channels on the expansion boards. Refer to the appropriate

expansion board documentation for information about setting the

switches.

You must specify the base address and input configuration by setting

switches on the board and the interrupt level by setting a jumper on the

board. In addition, if you intend to use your DAS-800 Series board with

the DAS-800 Series Function Call Driver, Control Panel, custom controls,

or External Driver or with any application program that requires a

configuration file, you must indicate all your configuration options in a

configuration file.

The following sections describe how to create a configuration file and

how to set the base address, input configuration, and intermpt level.

For EXP-16, EXP-16/A, and EXP-GP expansion boards, you

Creating a Configuration File

A default configuration tile called DASSOO.CFG is provided in both the

DAS-800 Series standard software package and the ASO- software

package. The factory-default settings inDAS8OGCFG are shown in Table

3-1.

4

3-9

Page 53

chap03-.frm Black 10

Table 3-I. Default Configuration

4

Attribute

Board type

8254 Clr2 usage

~~~~~~~~~~~.~~~~~~~~ ~~~~~~~~~~~~~~~~

.:.:; .,.....,.,........./....,./.......... . .._ I ..j..........j.jj....j..... :.:../,.< ,...,.,.....,...,.,,....,.... :<.:.:. :.:.:.:.:.:,.,:.:.::.‘.~ :...:.:,..: .,... I:.

Channel 0 input configuration Single-ended

Default Configuration

1 DAS-800

Cascaded

I

4

3-10

Gain of EXP-GPs

Notes

’ The setting in the configuration file must match the settings of

the switches and jumper on the board.

‘The default base address for board 0 is 300H. If you are using

multiple DAS-800 Series boards, the default base address for

board 1 is 308H, the default base address for board 2 is 310H.

and the default base address for board 3 is 318H.

3 For the purposes of the configuration file, an MB-02 backplane

is the same as anEXP-16 expansion board. Therefore, if you are

using MB-02 backplanes instead of EXP-16 or EXP-16/A

expansion boards, specify the number of MB-02 backplanes

here.

1 [N/Al

Setup and Installation

4

I

Page 54

chap03-.frm Black 11

+b

4 If you are using MB-02 backplanes instead of EXP-16 or

EXP-16/A

channels are set to 1.

If the default settings are appropriate for your application and match the

settings of the switches and jumper on the board, you can skip the rest of

this section and proceed directly with installing the board. Refer to page

3-19 for information on installing the board.

If the default settings are not appropriate for your application, you must

create a new configuration file or modify an existing configuration file to

specify the correct configuration options. The DSOOCFG.EXE

configuration utility, shipped with both the DAS-800 Series standard

software package and the ASO- software package, is provided for this

purpose.

To create or modify a configuration file, perform the following steps:

1. Invoke the configuration utility from DOS or Windows, as follows:

expansion boards, make sure that the gains of all

- If you are running under

DEOOCFG.EXB configuration utility, enter the following at the

DOS prompt:

DBOOCFG

wherefilename is the name of the configuration file you wish to

create or modify.

-

If you are running under Windows,

Manager File menu. Enter the following in the box and select

OK:

D800CFG

wherefilename is the name of the configuration tile you wish to

create or modify.

Make sure that you enter the correct path to DSOOCFG.EXE, or

use the Browse button to find this file.

If the utility finds a configuration file namedfilename, it displays the

opening menu screen with the name of the existing configuration file

shown. If the utility does not fmd a configuration file named

filename

filename

DOS,

from the directory containing the

choose Run from the Program

3-11

Page 55

chap03-.frm Black 12

+B

filename, it displays the opening menu screen withfilename shown;

this file contains the default configuration options. If you do not enter

a tile name, the utility assumes that you want to modify the default

configuration file DASSOO.CFG.

Note:

Series standard software package and the ASO- software package,

use the default configuration file DASSOO.CFG. If you intend to use

the example programs, make sure that DASSOb.CFG exists and that

the settings in DASSOO.CFG match the settings of your

2. On the opening menu screen, enter the number of DAS-800 Series

boards you plan to configure (1 to 4).

The utility displays the configuration options for the first board

(board 0). The number of the board is shown in the upper-left corner

of the menu box.

3. To modify any of the configuration options, use the arrow keys to

highlight the option you want to change, press [Enter] to display a list

of available settings, use the arrow keys to highlight the appropriate

setting, and press @nter]. These instructions are summarized in the

Commands/Status box at the bottom of the screen.

When the configuration options for this board are correct, press [N] to

display the configuration options for the next board.

The example programs, provided with both the DAS-800

board.

3-12

4. If you modify the base address, input configuration, or interrupt level,

you can press [S] to display the corresponding switch or jumper

settings. You can use this display as a reference when setting the

switches and jumper.

Note:

provided in the following sections. Refer to page 3-13 for information

on setting the base address; refer to page 3-16 for information on

setting the input configuration; refer to page 3-17 for information on

setting the interrupt level.

Information on setting the switches and jumper is also

Setup and Installation

Page 56

chap03-.frm Black 13

Setting the Base Address

5. After you modify the appropriate configuration options for all boards,

press [Esc]. The utility asks if you want to save the new settings.

6. Press [Y] to save the settings to the configuration file you specified.

DAS-800 Series boards are shipped with a base address of 300H. If any of

the address locations between 300H and 307H are being used by another

resource in your system (including another DAS-800 Series board), you

must reconfigure the base address using the base address switch block

(labeled Sl on the DAS-800 board: labeled S2 on DAS-801 and DAS-802

boards).

Note: The default base address settings in the configuration file are 300H

for board 0,308H for board 1,310H for board 2, and 318H for board 3.

Make sore that the switch settings for each board match the settings in the

configuration tile for each board.

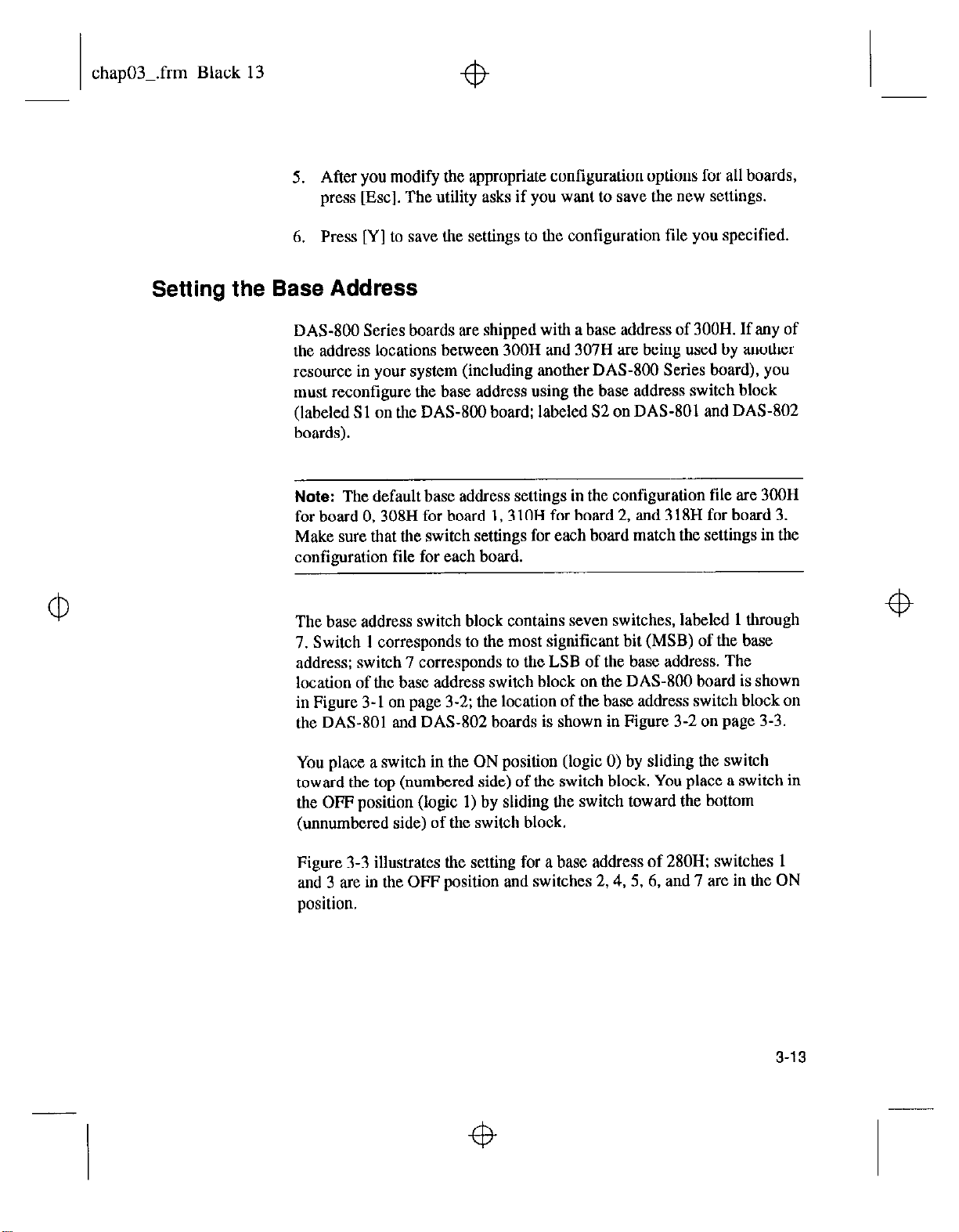

The base address switch block contains seven switches, labeled 1 through

7. Switch 1 corresponds to the most significant bit (MSB) of the base

address; switch 7 corresponds to the LSB of the base address. The

location of the base address switch block on the DAS-800 board is shown

in Figure 3-l on page 3-2, the location of the base address switch block on

the DAS-801 and DAS-802 boards is shown in Figure 3-2 on page 3-3.

You place a switch in the ON position (logic 0) by sliding the switch

toward the top (numbered side) of the switch block. You place a switch in

the OFF position (logic 1) by sliding the switch toward the bottom

(unnumbered side) of the switch block.

Figure 3-3 illustrates the setting for a base address of 280H; switches 1

and 3 are in the OFF position and switches 2,4, 5, 6, and 7 are in the ON

position.

3-13

Page 57

chap03-.frm Black 14

Figure 3-3. Setting the Base Address

Table 3-2 lists I/O addresses commonly used by IBM PC/XT, AT, and

compatible computers. Determine an even boundary of eight I/O

addresses within the range of OOOH to 3FSH that is not being used by

another resource in your system (including another DA%800 Series

board), and set the switches to the appropriate

base address.

Table 3-2. I/O Address Map (OOOH to 3FFH)

1 Address Range 1 Use

OOOH to OOFH

OAOH to OAFH

8237 DMA #I

NM1 mask register (XT)

200H to 2FFH Game /control

I

I

I

3-14

Setup and Installation

Page 58

chap03_.frm Black 15

Table 3-2. l/O Address Map (OOOH to 3FFH) (cont.)

Address Range U-Se

238Hto

23BH Busmouse

3-15

I

Page 59

chap03-.frm Black 16

f@

Notes:

The DBOOCFG.EXE configuration utility allows you to set base

addresses between 200H and 3FSH‘ only. Therefore. if you are using your

DAS-800 Series board with software that requires a configuration file,

you must specify an even boundary of eight I/O addresses within the

range of 200H to 3F8H.

If you press [S] after you specify the base address in the configuration

file, the configuration utility illustrates the appropriate switch settings for

you; refer to page 3-9 for more information about the configuration utility.

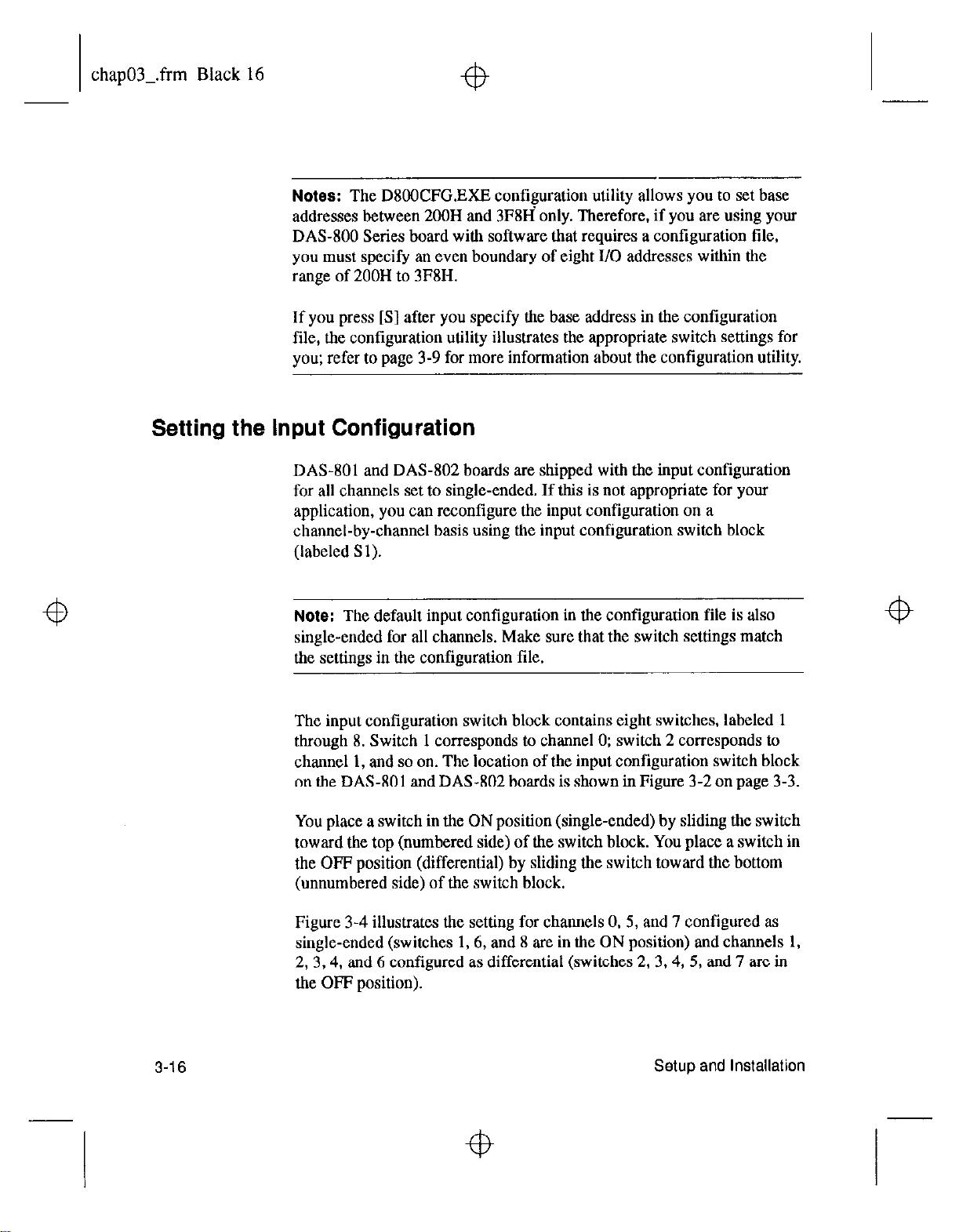

Setting the Input Configuration

DAS-801 and DAS-802 boards are shipped with the input configuration

for all channels set to single-ended. If this is not appropriate for your

application, you can reconfigure the input configuration on a

channel-by-channel basis using the input configuration switch block

(labeled Sl).

Note:

single-ended for all channels. Make sure that the switch settings match

the settines in the confieuration file.

The default input configuration in the configuration file is also

3-16

The input configuration switch block contains eight switches, labeled 1

through 8. Switch 1 corresponds to channel 0: switch 2 corresponds to

channel 1, and so on. The location of the input configuration switch block

on the DAS-80 1 and DAS-802 boards is shown in Figure 3-2 on page 3-3.

You place a switch in the ON position (single-ended) by sliding the switch

toward the top (numbered side) of the switch block. You place a switch in

the OFP position (differential) by sliding the switch toward the bottom

(unnumbered side) of the switch block.

Figure 3-4 illustrates the setting for channels 0. 5, and 7 configured as

single-ended (switches 1, 6, and 8 are in the ON position) and channels 1,

2, 3.4, and 6 configured as differential (switches 2,3,4, 5, and 7 are in

the OFF position).

Setup and Installation

Page 60

chap03-.frm Black 17

+b

Figure 3-4. Setting the Input Conflguration

Notes: Since

configuration, they do not contain an input configuration switch block.

If you press [S] after you specify the input configuration in the

configuration file, the configuration utility illustrates the appropriate

switch settings for you; refer to page 3-9 for more information about the

configuration utility.

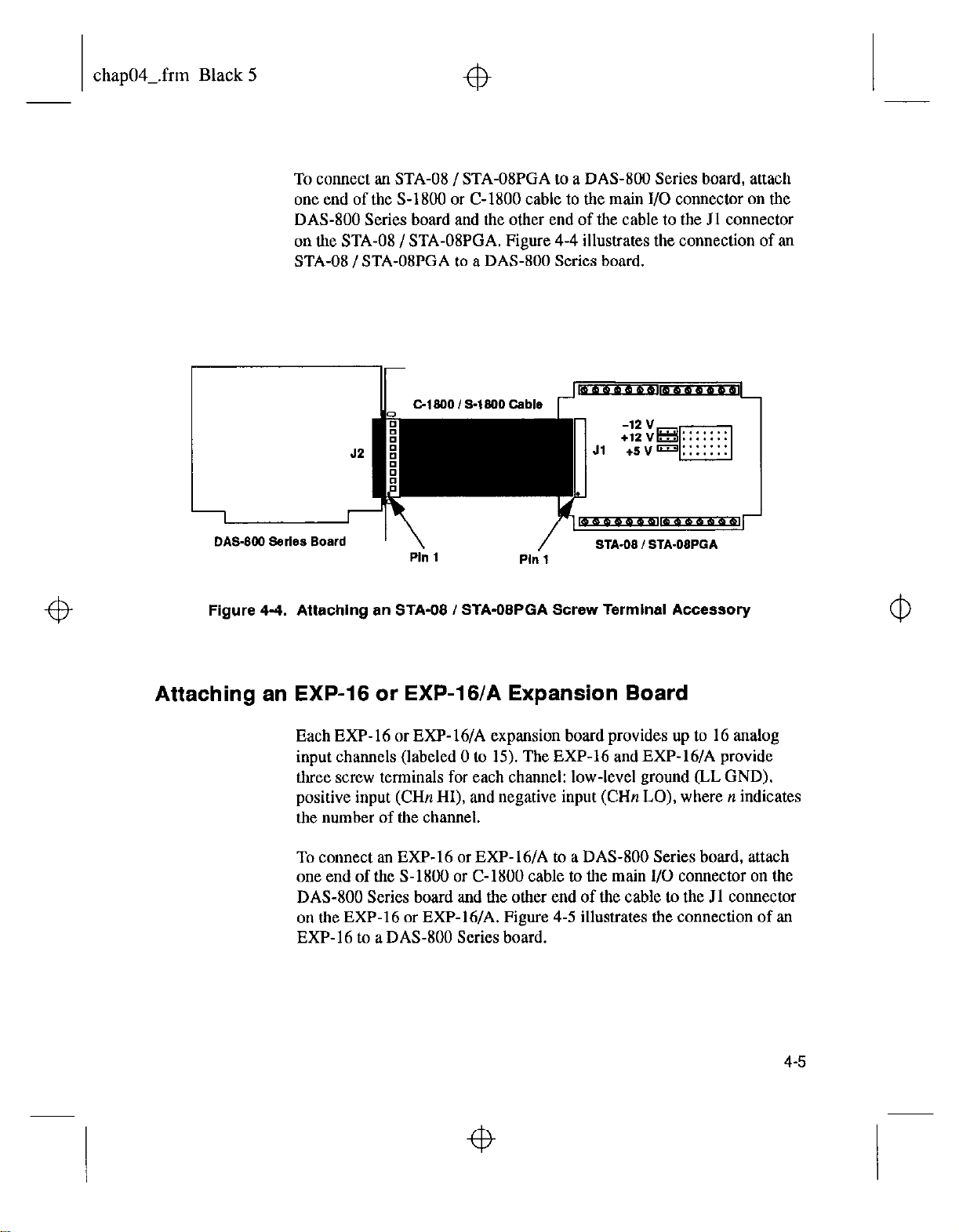

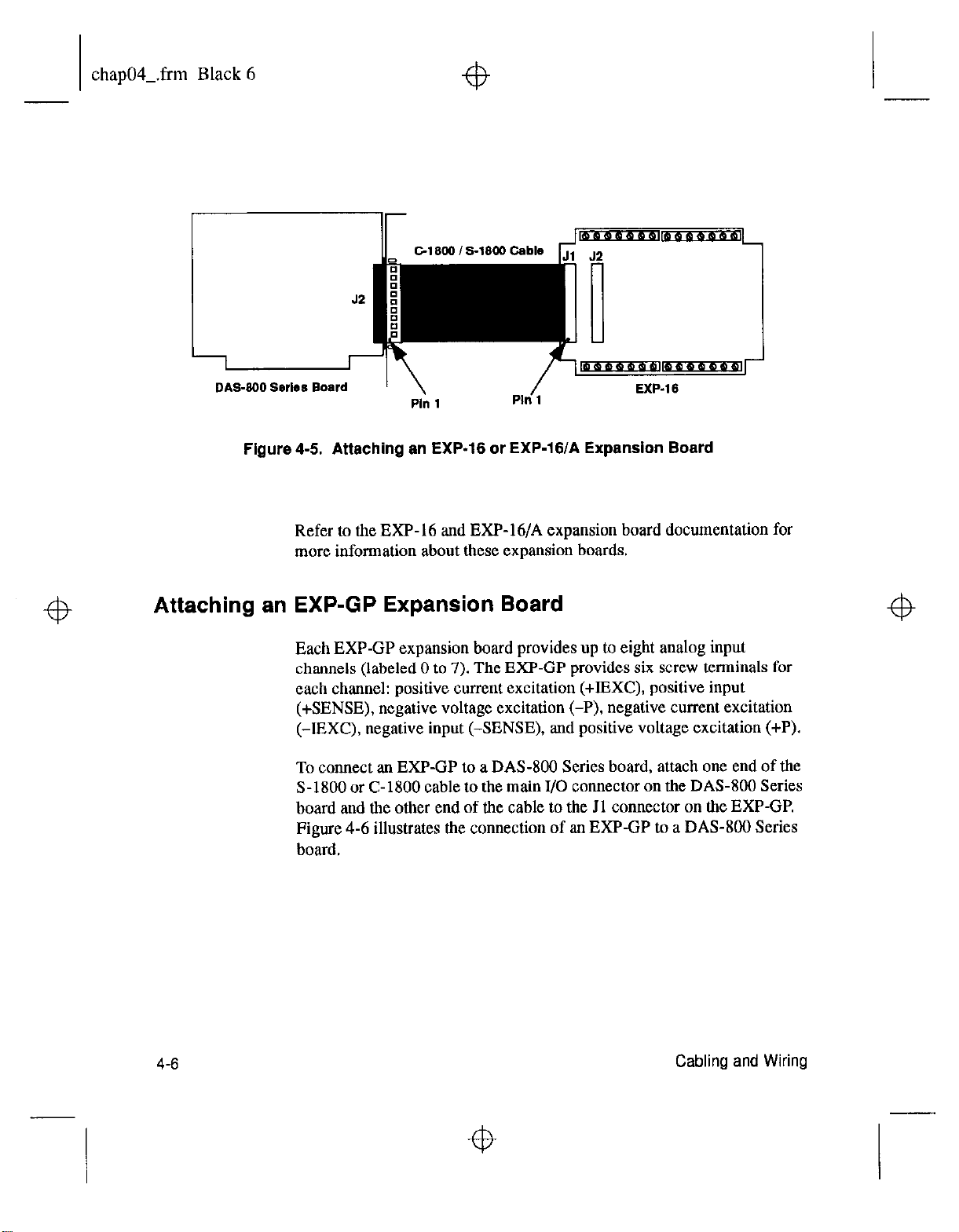

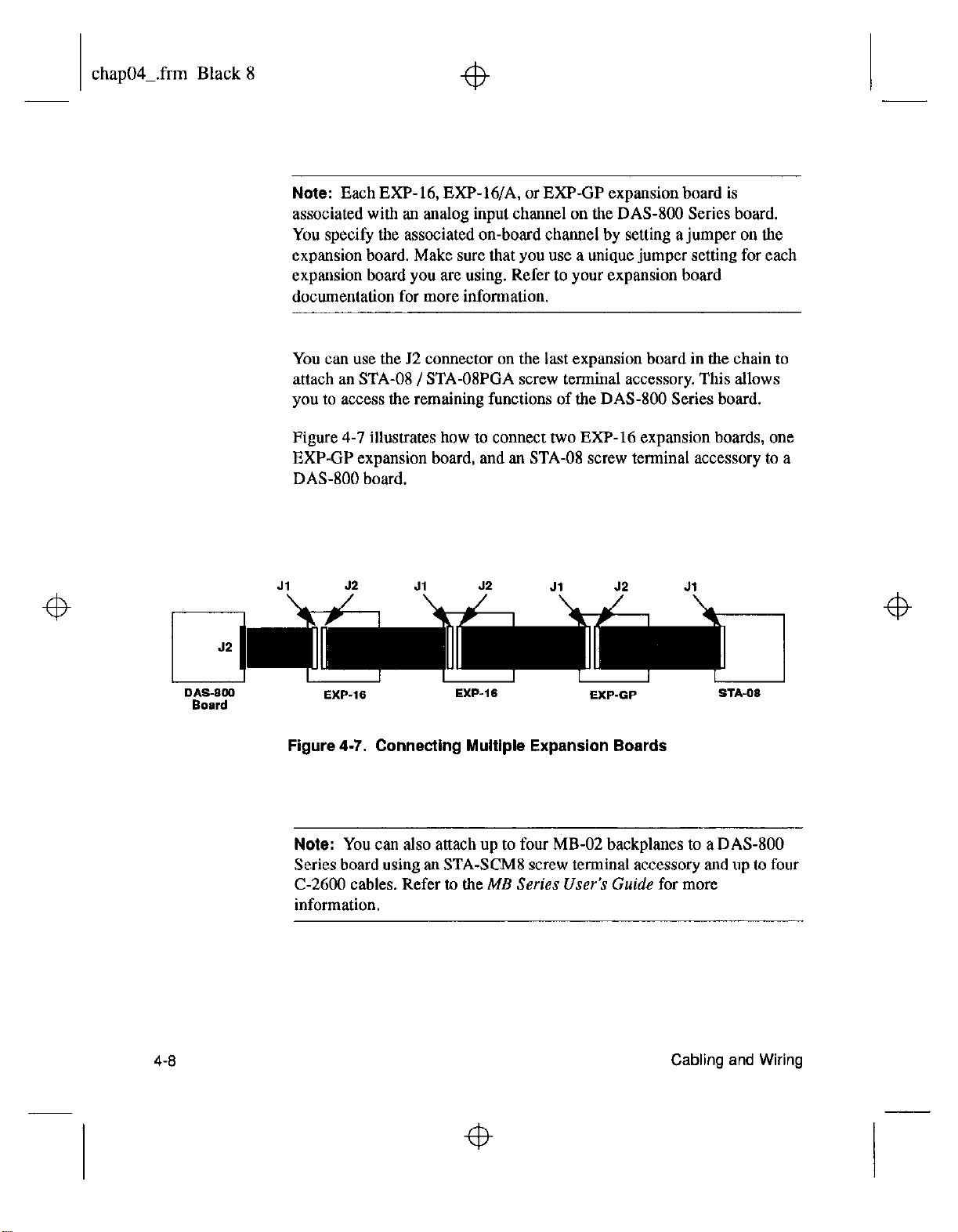

DAM00 boards always use a single-ended input