Page 1

D AS-4300 Series

USER’S GUIDE

Page 2

DAS-4300 Series User’s Guide

Revision A - June 1995

Part Number: 94520

Page 3

New Contact Information

Keithley Instruments, Inc.

28775 Aurora Road

Cleveland, OH 44139

Technical Support: 1-888-KEITHLEY

Monday – Friday 8:00 a.m. to 5:00 p.m (EST)

Fax: (440) 248-6168

Visit our website at http://www.keithley.com

Page 4

The information contained in this manual is believed to be accurate and reliable. However, Keithley

Instruments, Inc., assumes no responsibility for its use or for any infringements of patents or other rights

of third parties that may result from its use. No license is granted by implication or otherwise under any

patent rights of Keithley Instruments, Inc.

KEITHLEY INSTRUMENTS, INC., SHALL NO T BE LIABLE FOR ANY SPECIAL, INCIDENT AL,

OR CONSEQUENTIAL DAMAGES RELATED TO THE USE OF THIS PRODUCT. THIS

PRODUCT IS NOT DESIGNED WITH COMPONENTS OF A LEVEL OF RELIABILITY

SUITABLE FOR USE IN LIFE SUPPORT OR CRITICAL APPLICATIONS.

Refer to your Keithley Instruments license agreement for specific warranty and liability information.

MetraByte, Visual Test Extensions, and VTX are trademarks of Keithley Instruments, Inc. All other

brand and product names are trademarks or registered trademarks of their respective companies.

© Copyright Keithley Instruments, Inc., 1995.

All rights reserved. Reproduction or adaptation of any part of this documentation beyond that permitted

by Section 117 of the 1976 United States Copyright Act without permission of the Copyright owner is

unlawful.

Keithley MetraByte Division

Keithley Instruments, Inc.

440 Myles Standish Blvd. Taunton, MA 02780

FAX: (508) 880-0179

Telephone: (508) 880-3000

●

Page 5

Preface

The DAS-4300 Series User’s Guide provides the information needed to

install and use the DAS-4301/8K high-speed analog input board.

The manual is intended for data acquisition system designers, engineers,

technicians, scientists, and other users responsible for setting up and

installing DAS-4301/8K boards. It is assumed that users are familiar with

data acquisition principles, with their computer, and with their particular

application.

The DAS-4300 Series User’s Guide is organized as follows:

●

Chapter 1 provides an overview of the features of the DAS-4301/8K

board, including a description of supported software and accessories.

●

Chapter 2 provides a technical description of the features of the

DAS-4301/8K board.

Chapter 3 describes how to unpack, set up, and install a

●

DAS-4301/8K board.

Chapter 4 describes how to use the scope and test program to test the

●

functions of the DAS-4301/8K board.

Chapter 5 provides troubleshooting information.

●

●

Appendix A lists the specifications for DAS-4301/8K boards.

●

Appendix B describes the Keithley Memory Manager.

Appendix C presents bandwidth charts for the supported input ranges.

●

An index completes this manual.

vii

Page 6

Not all features of the DAS-4301/8K board are currently supported

Note:

by all software packages. Refer to the documentation provided with your

software package to determine which features are supported.

viii

Page 7

Table of Contents

Preface

1

Overview

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Supporting Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Functional Description

2

Channels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Input Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Onboard Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Host Computer Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

I/O Address Space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Memory Address Space . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Bus Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Pacer Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Internal Pacer Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

External Pacer Clock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Triggers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Trigger Sources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Internal Trigger. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

External Analog Trigger. . . . . . . . . . . . . . . . . . . . . . . . . .2-10

External Digital Trigger. . . . . . . . . . . . . . . . . . . . . . . . . .2-11

Trigger Acquisition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Post-Trigger Acquisition . . . . . . . . . . . . . . . . . . . . . . . . .2-12

About-Trigger Acquisition . . . . . . . . . . . . . . . . . . . . . . . .2-13

Equivalent Time Sampling (ETS) . . . . . . . . . . . . . . . . . . . . . . .2-14

Random Interleave Sampling (RIS). . . . . . . . . . . . . . . . . . . . . .2-18

3

Setup and Installation

Unpacking the Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Installing the Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Installing the DAS-4300 Series Standard Software Package .3-2

iii

Page 8

Installing the ASO-4300 Software Package . . . . . . . . . . . . . .3-3

DOS Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Windows Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Configuring the Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Creating a Configuration File . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Setting Jumpers on the Board . . . . . . . . . . . . . . . . . . . . . . . .3-10

Setting the Base I/O Address . . . . . . . . . . . . . . . . . . . . . .3-12

Setting the Memory Address . . . . . . . . . . . . . . . . . . . . . .3-14

Setting the Interrupt . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

Acquiring Data from Channel B or

Calibrating the Board. . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

Selecting AC or DC Coupling . . . . . . . . . . . . . . . . . . . . .3-17

Setting the Input Impedance of Ch A Signal . . . . . . . . . .3-17

Setting the Input Impedance of the

Analog Trigger Input Signal. . . . . . . . . . . . . . . . . . . . . .3-18

Setting the 50

Ω

Termination Resistor for the

Clock Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Setting the 50

Termination Resistor for the

Ω

Trigger Input Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

Setting the 100

Ω

Pull-Up to +5 V for the

Trigger Input Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

Setting Grounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

Installing the Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

Initializing the Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Scope and Test Program

4

Control Keys for D4300.EXE . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Scope and Test Program Menus. . . . . . . . . . . . . . . . . . . . . . . . . .4-4

A/D Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Display Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Options Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

EEPROM Menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

DAS-4301/8K Board Calibration. . . . . . . . . . . . . . . . . . . . . . . .4-10

Parameter Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

Waveform Data File Format. . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

5

Troubleshooting

Identifying Symptoms and Possible Causes . . . . . . . . . . . . . . . .5-1

Testing Board and Host Computer. . . . . . . . . . . . . . . . . . . . . . . .5-3

Testing Accessory Slot and I/O Connections. . . . . . . . . . . . . . . .5-3

Technical Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

iv

Page 9

v

Specifications

A

B

Keithley Memory Manager

Installing and Setting Up the KMM. . . . . . . . . . . . . . . . . . . . . . B-2

Using KMMSETUP.EXE . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Using a Text Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Removing the KMM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

C

Bandwidth Charts for Input Voltage Ranges

Index

List of Figures

Figure 2-1. Block Diagram of the DAS-4301/8K . . . . . . . . . .2-2

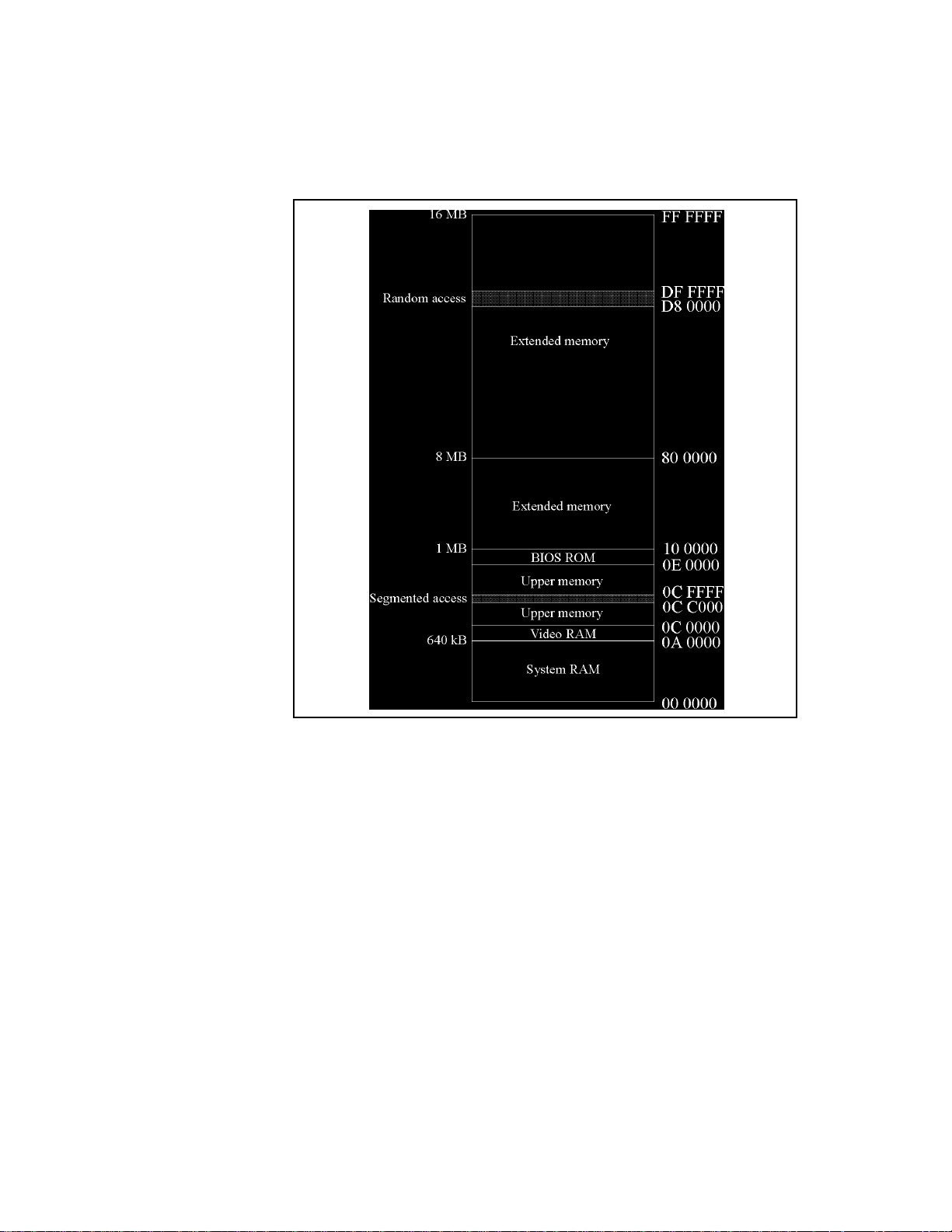

Figure 2-2. Host Computer Memory Address Space . . . . . . . .2-6

Figure 2-3. Equivalent Time Sampling (ETS) . . . . . . . . . . . .2-15

Figure 2-4. ETS Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

Figure 2-5. Random Interleave Sampling. . . . . . . . . . . . . . . .2-19

Figure 3-1. Jumper Placement on DAS-4301/8K Board . . . .3-11

Figure 3-2. Analog Input Circuitry. . . . . . . . . . . . . . . . . . . . .3-17

Figure 3-3. Clock I/O and Trigger I/O Circuitry . . . . . . . . . .3-19

Figure C-1. ±0.2 V Input Range (Gain Code 0) . . . . . . . . . . . C-1

Figure C-2. ±0.25 V Input Range (Gain Code 1) . . . . . . . . . . C-2

Figure C-3. ±0.5 V Input Range (Gain Code 2) . . . . . . . . . . . C-2

Figure C-4. ±1 V Input Range (Gain Code 3). . . . . . . . . . . . . C-3

Figure C-5. ±0.125 V Input Range (Gain Code 4) . . . . . . . . . C-3

Figure C-6. ±0.15625 V Input Range (Gain Code 5) . . . . . . . C-4

Figure C-7. ±0.3125 V Input Range (Gain Code 6) . . . . . . . . C-4

Figure C-8. ±0.625 V Input Range (Gain Code 7) . . . . . . . . . C-5

Figure C-9. ±0.1 V Input Range (Gain Code 8) . . . . . . . . . . . C-5

Figure C-10. ±0.125 V Input Range (Gain Code 9) . . . . . . . . . C-6

Figure C-11. ±0.25 V Input Range (Gain Code 10) . . . . . . . . . C-6

Figure C-12. ±0.5 V Input Range (Gain Code 11) . . . . . . . . . . C-7

Figure C-13. ±0.025 V Input Range (Gain Code 12) . . . . . . . . C-7

Figure C-14. ±0.03125 V Input Range (Gain Code 13) . . . . . . C-8

Figure C-15. ±0.0625 V Input Range (Gain Code 14) . . . . . . . C-8

Figure C-16. ±0.125 V Input Range (Gain Code 15) . . . . . . . . C-9

Page 10

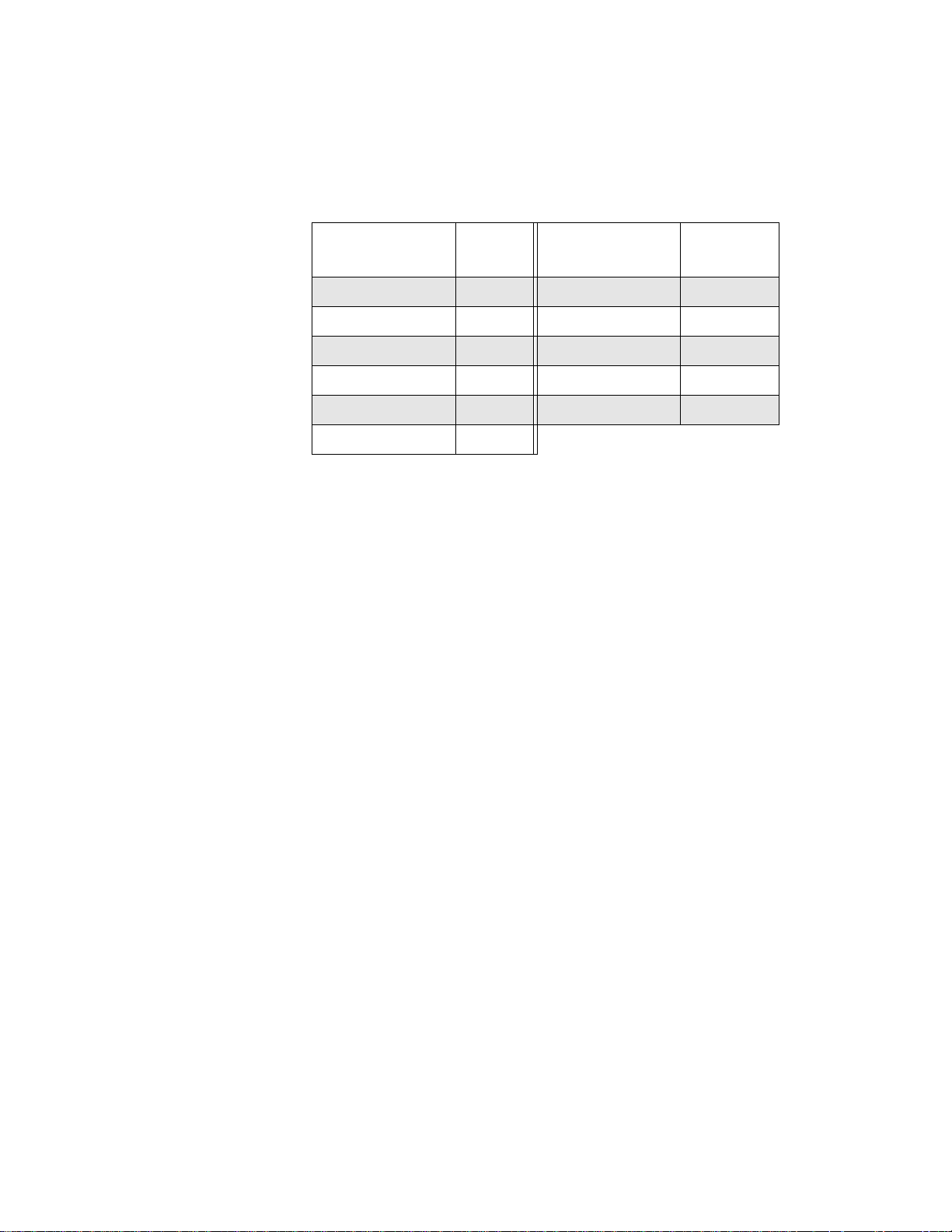

List of Tables

Table 2-1. Analog Input Ranges . . . . . . . . . . . . . . . . . . . . . . .2-4

Table 2-2. Available Conversion Rates Using Internal Clock 2-8

Table 3-1. Configuring DAS-4301/8K Boards . . . . . . . . . . . .3-6

Table 3-2. Base I/O Address . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Table 3-3. Memory Address . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Table 3-4. Interrupt Selection . . . . . . . . . . . . . . . . . . . . . . . .3-16

Table 3-5. Grounds on the DAS-4301/8K Board . . . . . . . . .3-20

Table 4-1. Control Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Table 4-2. Suffixes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Table 4-3. A/D Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Table 4-4. Display Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Table 4-5. Options Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Table 4-6. Configure EEPROM Menu . . . . . . . . . . . . . . . . . .4-9

Table 4-7. Waveform Data File Format . . . . . . . . . . . . . . . .4-11

Table 5-1. Troubleshooting Information. . . . . . . . . . . . . . . . .5-1

Table A-1. DAS-4301/8K Specifications . . . . . . . . . . . . . . . A-1

vi

Page 11

Table 2-1. Analog Input Ranges . . . . . . . . . . . . . . . . . . . . . . .2-4

Table 2-2. Available Conversion Rates Using Internal Clock 2-8

Table 3-1. Configuring DAS-4301/8K Boards . . . . . . . . . . . .3-6

Table 3-2. Base I/O Address . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Table 3-3. Memory Address . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Table 3-4. Interrupt Selection . . . . . . . . . . . . . . . . . . . . . . . .3-16

Table 3-5. Grounds on the DAS-4301/8K Board . . . . . . . . .3-20

Table 4-1. Control Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Table 4-2. Suffixes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Table 4-3. A/D Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Table 4-4. Display Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Table 4-5. Options Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Table 4-6. Configure EEPROM Menu . . . . . . . . . . . . . . . . . .4-9

Table 4-7. Waveform Data File Format . . . . . . . . . . . . . . . .4-11

Table 5-1. Troubleshooting Information. . . . . . . . . . . . . . . . .5-1

Table A-1. DAS-4301/8K Specifications . . . . . . . . . . . . . . . A-1

Page 12

Figure 2-1. Block Diagram of the DAS-4301/8K . . . . . . . . . .2-2

Figure 2-2. Host Computer Memory Address Space . . . . . . . .2-6

Figure 2-3. Equivalent Time Sampling (ETS) . . . . . . . . . . . .2-15

Figure 2-4. ETS Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

Figure 2-5. Random Interleave Sampling. . . . . . . . . . . . . . . .2-19

Figure 3-1. Jumper Placement on DAS-4301/8K Board . . . .3-11

Figure 3-2. Analog Input Circuitry. . . . . . . . . . . . . . . . . . . . .3-17

Figure 3-3. Clock I/O and Trigger I/O Circuitry . . . . . . . . . .3-19

Figure C-1. ±0.2 V Input Range (Gain Code 0) . . . . . . . . . . . C-1

Figure C-2. ±0.25 V Input Range (Gain Code 1) . . . . . . . . . . C-2

Figure C-3. ±0.5 V Input Range (Gain Code 2) . . . . . . . . . . . C-2

Figure C-4. ±1 V Input Range (Gain Code 3). . . . . . . . . . . . . C-3

Figure C-5. ±0.125 V Input Range (Gain Code 4) . . . . . . . . . C-3

Figure C-6. ±0.15625 V Input Range (Gain Code 5) . . . . . . . C-4

Figure C-7. ±0.3125 V Input Range (Gain Code 6) . . . . . . . . C-4

Figure C-8. ±0.625 V Input Range (Gain Code 7) . . . . . . . . . C-5

Figure C-9. ±0.1 V Input Range (Gain Code 8) . . . . . . . . . . . C-5

Figure C-10. ±0.125 V Input Range (Gain Code 9) . . . . . . . . . C-6

Figure C-11. ±0.25 V Input Range (Gain Code 10) . . . . . . . . . C-6

Figure C-12. ±0.5 V Input Range (Gain Code 11) . . . . . . . . . . C-7

Figure C-13. ±0.025 V Input Range (Gain Code 12) . . . . . . . . C-7

Figure C-14. ±0.03125 V Input Range (Gain Code 13) . . . . . . C-8

Figure C-15. ±0.0625 V Input Range (Gain Code 14) . . . . . . . C-8

Figure C-16. ±0.125 V Input Range (Gain Code 15) . . . . . . . . C-9

Page 13

1

Overview

Features

The DAS-4300 Series consists of the DAS-4301/8K board. The

DAS-4301/8K is an 8-bit data acquisition board available for IBM

PC A T

1 Gsamples/s. This chapter describes the features of the DAS-4301/8K

board, the software that supports it, and available accessories.

Note:

by all software packages. Refer to the documentation provided with your

software package to determine which features are supported.

The major features of the DAS-4301/8K board are as follows:

●

●

or compatible computers, with a conversion rate of up to

Not all features of the DAS-4301/8K board are currently supported

Supports high-speed data acquisition on one of two analog input

channels accessed through standard BNC connectors.

Provides an analog bandwidth at

true 1 Gsamples/s conversion rate.

3 dB of 250 MHz combined with a

−

Provides a flash converter with a resolution of 8 bits.

●

Provides 16 software-selectable input voltage ranges from

●

±0.025 V to ±1 V.

●

Provides onboard autocalibration to ensure accurate digitization.

●

Stores digitized data in an onboard 8K byte memory buffer.

Provides zero wait-state operations to transfer data off the board at up

●

to 5M byte/s via the ISA bus.

Features 1-1

Page 14

Supports jumper-selectable AC or DC signal coupling.

●

Provides jumper-selectable 50

●

●

Provides a wide variety of trigger options, including internal and

external triggering and post-trigger delay, which you can use to tailor

the operation of the board to the specific requirements of your

application.

●

Supports Equivalent Time Sampling (ETS) and Random Interleaved

Sampling (RIS) for repetitive waveforms; ETS and RIS provide

conversion rates of up to 20 Gsamples/s.

●

Provides a Synchro-Link digital signal processing (DSP) port to

transfer data from onboard memory at up to 25 Msamples/s.

Supporting Software

The following software is available for operating the DAS-4301/8K

board:

DAS-4300 Series standard software package - This package, which

●

comes with the board, is provided on 3.5-inch high-density disks. The

package includes utility programs that allow you to configure, test,

and calibrate the DAS-4301/8K board.

Ω

or 1 M

Ω

input impedance.

ASO-4300 software package - The optional Advanced Software

●

Option for DAS-4301/8K boards is provided on 3.5-inch high-density

disks. The package includes function libraries for writing application

programs using Microsoft C/C++, Borland

Visual Basic

for Windows. The package also includes support files,

®

C/C++, or Microsoft

utility programs, and language-specific example programs. Refer to

the DAS-4300 Series Function Call Driver User’s Guide for more

information.

DAS-4300 Series configuration utility - The configuration utility

●

(CFG4300.EXE), provided as part of both the DAS-4300 Series

standard software package and the ASO-4300 software package, runs

under DOS and allows you to create or modify a configuration file.

The configuration file provides information about the board; this

information is used by the DAS-4300 Series Function Call Dri ver and

other software packages to perform the board’s operations. Refer to

page 3-8 for more information.

1-2 Overview

Page 15

)

DAS-4300 Series scope and test program - The scope and test

●

program (D4300.EXE) allows you to test the hardware features of a

DAS-4301/8K board, calibrate the analog input circuitry of the board,

and perform basic oscilloscope functions on the board. This program

runs under DOS and is provided as part of both the DAS-4300 Series

standard software package and the ASO-4300 software package.

Refer to Chapter 4 for more information.

Accessories

Visual Test Extensions

●

(VTX

- These optional custom controls

for Visual Basic for W indo ws help you write application programs for

the DAS-4301/8K board. Refer to the V isual Test Extensions

User’s

Guide and the VTX online help for more information.

VisualSCOPE - This optional software package runs under Windows

●

and emulates a stand-alone oscilloscope on your host computer. Refer

to the VisualSCOPE documentation for more information.

The SDC-5600 DSP board is an accessory for the DAS-4301/8K board.

The SDC-5600 uses the optional DSP port on the DAS-4301/8K board to

transfer data at 25M byte/s for digital signal processing applications. This

accessory is available from Sonix Inc., 8700 Morrissette Drive,

Springfield, VA 22152 (703-440-0222).

Accessories 1-3

Page 16

2

Functional Description

This chapter describes the features of the DAS-4301/8K board from a

functional point of view. The intent of these descriptions is to familiarize

you with the operating options and to enable you to make the best use of

your board. Figure 2-1 shows a block diagram of the DAS-4301/8K

board.

2-1

Page 17

Channel A

Channel B

DAC

(12-bit)

Clock

Relay

DAC

(12 bit)

−10 V to +10 V

Threshold T rigger

Comparator (Ch B)

Clock

Divider

−FS to +FS

Comparator

(Ch A)

DAC (12

bit)

Offset

DC to

250 MHz

Amp

100 MHz

Oscillator

DAC

(12 bit)

In

Clock

Vernier Gain

Ref

A/D Converter

Data

8K byte

FIFO

Memory

DSP

Port

Data

Trigger

Trigger

Control

ETS

Delay

Data

ISA Bus Interface (16 bits)

RIS

Delay

Clock

Counters

Enable

Status

Data

Figure 2-1. Block Diagram of the DAS-4301/8K

2-2 Functional Description

Page 18

Channels

The DAS-4301/8K board can acquire data from one of two analog input

channels at a time: Channel A, accessed from the Ch A connector, or

Channel B, accessed from the Trg/Ch B connector.

You use software to specify Channel A. To specify Channel B, leave a

jumper installed in positions 1 and 2 of jumper block J103 (the

factory-default configuration), and use software to select Channel B.

Channel A is terminated with a 50

select an input impedance of 50

information.

The Trg/Ch B connector is also used for triggering; refer to page 2-10 for

more information on triggering using this connector and selecting the

input impedance for the signal attached to this connector.

Input Ranges

DAS-4301/8K boards support 16 bipolar, factory-calibrated analog input

ranges. Through software, you specify the input range of the analog input

channel.

T able 2-1 lists the analog input ranges supported by D AS-4301/8K boards

and their corresponding gain codes. The gain code is used in software to

determine the input voltage range. The choice of gain code affects the

bandwidth on the DAS-4301/8K board; Appendix C shows the effect of

the input ranges and gain code choices on the bandwidth of the

DAS-4301/8K board.

impedance. Using a jumper, you can

Ω

or 1 M

Ω

. Refer to page 3-17 for more

Ω

Channels 2-3

Page 19

Table 2-1. Analog Input Ranges

Memory

Analog

Input Range

±25 mV 12 ±200 mV 0

±31.25 mV 13 ±250 mV 1, 10

±62.5 mV 14 ±312.5 mV 6

±100 mV 8 ±0.5 V 2, 11

±125 mV 4, 9, 15 ±0.625 V 7

±156.25 mV 5 ±1.0 V 3

Gain

Code

Analog

Input Range

Gain

Code

The DAS-4301/8K board uses a 4096-step DC signal of fset v oltage and a

4096-step fine gain control to calibrate the voltage input ranges.

The scope and test program supports binary, twos complement, and

absolute value data coding of the digitized analog input values. The

DAS-4300 Series Function Call Driver and VTX use twos complement

data coding only.

This section describes memory on the DAS-4301/8K board and on the

host computer.

Onboard Memory

The DAS-4301/8K board contains an 8K byte (8,192 samples) memory

buffer for storing digitized data as well as a nonvolatile EEPROM

memory location for storing calibration values.

Whenever a D AS-4301/8K board is idle, the host computer can access the

data in the onboard memory buffer, download it into its own main

memory, and process it.

2-4 Functional Description

Page 20

Host Computer Memory

DAS-4301/8K boards require part of both the host computer I/O address

space and the host computer memory address space.

I/O Address Space

The DAS-4301/8K board uses a block of 16 bytes (ports) in the I/O

address space of the host computer to set up the board’s parameters.

These ports can be located anywhere below 400h, provided that they are

not used by your host computer. The default I/O address space for these

ports is 250h to 25Fh.

You select the base address for the I/O address space by setting jumpers

on the board; refer to page 3-12 for information.

Memory Address Space

The memory address space of the host computer is used for reading the

acquired data from the DAS-4301/8K onboard memory buffer. The host

computer accesses the onboard memory using the decoding logic on the

DAS-4301/8K.

The onboard 8,192 byte buffer memory is mapped into a 16K byte

window within the 1M byte address space in the host computer’s upper

memory (above the 640K byte user memory area). You select the base

address for the memory address space by setting jumpers on the board;

refer to page 3-14 for information. Figure 2-2 illustrates the memory

address space of a host computer.

The memory map must fall on a 16K byte boundary; this memory

Note:

area must not be in use by other boards or devices.

Memory 2-5

Page 21

Figure 2-2. Host Computer Memory Address Space

2-6 Functional Description

Page 22

Bus Interface

The ISA bus interface provides 16-bit data transfers and allows the host

computer to initialize all onboard parameters, read from and write to

onboard memory, and trigger the board.

As mentioned in the previous section, the bus interface uses two distinct

address spaces of the host computer: a 16 byte consecutive segment in the

I/O address space for control information and a 16K byte segment in the

memory address space for data exchange. Both the I/O base address and

memory address are jumper selectable; refer to page 3-12 and page 3-14

for more information.

The bus also provides a zero wait state, which allows data to be

transferred off the board at a rate of 5M byte/s. You enable or disable the

zero wait-state option through the configuration file; refer to page 3-8 for

more information.

An interrupt can be generated to signal the host computer at the end of a

data acquisition. You select the interrupt by setting jumpers on the board.

Refer to page 3-15 for more information.

Pacer Clock

Through software, you select either an internal or external pacer clock to

determine when each A/D conversion is initiated.

Internal Pacer Clock

The internal pacer clock circuit is composed of the onboard 100 MHz

crystal oscillator, a 2000

locked loop) circuit to generate an effective conversion rate of

1 Gsamples/s. The clock signal is fed through a driver circuit to the

Clk IO connector.

The available conversion rates and sample periods using the internal

pacer clock are shown in Table 2-2.

Ω

pull-up resistor to +5 V, and a PLL (phased

Bus Interface 2-7

Page 23

Table 2-2. Available Conversion Rates Using Internal Clock

Conversion Rate

1 Gsamples/s 1 ns 12.5 Msamples/s 80 ns

500 Msamples/s 2 ns 6.25 Msamples/s 160 ns

250 Msamples/s 4 ns 3.125 Msamples/s 320 ns

100 Msamples/s 10 ns 1.5625 Msamples/s 640 ns

50 Msamples/s 20 ns 0.78250 Msamples/s 1280 ns

25 Msamples/s 40 ns

You can also use the Clk IO connector as an output. When the board is

configured for an internal pacer clock source, a TTL-level output signal is

provided on the Clk IO connector that has the same frequency as the

crystal oscillator.

External Pacer Clock

An external pacer clock is an externally generated TTL-le v el clock signal

of at least 100 MHz, with a duty cycle of 50/50 ±20%, applied to the

Clk IO connector. When you start an analog input operation, the board is

armed. At the ne xt rising edge (and at every subsequent rising edge of the

external pacer clock), a conversion is initiated.

Sample

Period Conversion Rate

Sample

Period

A 20

The 20

74ABT series TTL input with a 2 k

appear as approximately 50

You can use a jumper-selectable 50

series protection resistor is provided on the clock input signal.

Ω

resistor combined with the output resistance of the driver IC (a

Ω

pull-up resistor) makes the output

Ω

Ω

.

Ω

termination resistor on the clock

input signal; this resistor is particularly useful when working with a signal

driving a long line or a line that is driving many devices (where the

DAS-4301/8K is at the end of the line). Refer to page 3-18 for more

information on this jumper.

2-8 Functional Description

Page 24

Notes:

−

0.7 V.

Due to excessive loading of the signal, do not use the jumper-selectable

50

Triggers

A trigger is an event that determines when a DAS-4301/8K board

responds to either an internal or an external pacer clock. Depending on

the type of acquisition and setup parameters, the trigger event can occur

before, during, or after the actual sampling of data. The trigger signal can

originate from a variety of sources.

This section describes trigger sources, types of trigger acquisition, and

trigger synchronization on DAS-4301/8K boards.

Trigger Sources

A diode on the input limits signal excursions to +5.7 V and

termination resistor when using the clock output signal.

Ω

The DAS-4301/8K board supports internal triggers, external analog

triggers, and external digital triggers.

Internal T rigger

An internal trigger (or software trigger) event occurs when a particular

instruction is executed by the host computer. When the trigger event

occurs, a signal is output on the Trg IO connector. At the end of data

acquisition, the signal on the Tr g IO connector returns to its inactive state.

Using the test and scope program, you can program the edge polarity of

the trigger output signal. Using the DAS-4300 Series Function Call

Driver or VTX, you cannot program the trigger polarity; it is always

positive.

Triggers 2-9

Page 25

External Analog Trigger

An external analog trigger (or threshold trigger) event occurs when one of

the following conditions is met by an analog input signal:

The analog input signal rises above a programmable threshold

●

(positive-edge trigger).

The analog input signal falls below a programmable threshold

●

(negative-edge trigger).

A TTL-level signal is output on the Trg IO connector when the trigger

event occurs. At the end of data acquisition, the signal on the Trg IO

connector returns to its inactive state.

Using the test and scope program, you can program the polarity of the

trigger output signal. Using the DAS-4300 Series Function Call Dri v er or

VTX, you cannot program the polarity of the trigger output signal; it is

always positive.

You can use an external analog trigger in the following ways:

You can trigger the D AS-4301/8K board using the analog input signal

●

from the Ch A connector or from the Trg/Ch B connector on the

board. When using the analog input signal as the trigger source, the

trigger channel and the data acquisition channel must be the same.

For example, if you are using the signal from the Ch A connector as

the trigger source, you must use Channel A as the data acquisition

channel. You specify the trigger channel and the data acquisition

channel in software.

Using the test and scope program, you can program the trigger

threshold in 4096 steps. Using the DAS-4300 Series Function Call

Driver or VTX, you can program the trigger threshold in 256 steps.

You can trigger the DAS-4301/8K board using the ±10 V analog

●

input trigger signal from the Trg/Ch B connector. When using the

±10 V trigger signal, you can acquire data from either Channel A or

Channel B. You specify the trigger channel and data acquisition

channel using software.

2-10 Functional Description

Page 26

Using the test and scope program, you can program the threshold in

4096 steps from

10 V to +9.995 V; the resolution is 12 bits. Using

−

the DAS-4300 Series Function Call Dri ver or VTX, you can program

the threshold in 256 steps from

−

10 V to +9.922 V; the resolution is 8

bits.

Using a jumper, you can select the input impedance (50

of the ±10 V trigger signal from the Trg/Ch B connector. Refer to

page 3-18 for more information.

External Digital Trigger

A digital trigger event occurs when an externally generated TTL-level

signal of programmable polarity (positive edge or negative edge) is

detected as an input on the Trg IO connector.

A 20

Ω

the Trg IO connector. The 20

resistance of the driver IC (a 74ABT series TTL input with a 2 k

resistor) makes the output appear as approximately 50

jumper-selectable 50

this resistor is particularly useful when working with a signal driving a

long line or a line that is driving many devices (where the DAS-4301/8K

is at the end of the line). Refer to page 3-19 for more information on this

jumper.

Notes:

0.7 V.

−

Ω

or 5600

Ω)

series protection resistor is provided on the trigger input signal of

Ω

resistor combined with the output

pull-up

Ω

. You can use a

Ω

Ω

termination resistor on the trigger input signal;

A diode on the input limits signal excursions to +5.7 V and

When you are not using the Trg IO connector for external digital

triggering, you can use the Tr g IO connector to output a TTL-le vel signal.

If you use the trigger output signal, however, do not use the

jumper-selectable 50

termination resistor due to the excessive loading

Ω

of the signal.

Triggers 2-11

Page 27

Trigger Acquisition

Depending on your application, you can sample data before and/or after a

trigger event occurs. If you want to collect data after a specific trigger

event, use post-trigger acquisition. If you want to collect data before or

before and after a specific trigger event, use about-trigger acquisition.

The maximum number of samples you can collect for each trigger event

is 8,192. The minimum number of samples you can collect for each

trigger event depends on the conversion rate as follows:

●

Conversion rate of 100 Msamples/s and slower : minimum of 1

sample in increments of 1 sample.

●

Conversion rate of 250 Msamples/s and faster : minimum of 10

samples in increments of 10 samples.

Post-Trigger Acquisition

Use post-trigger acquisition to store data samples after a trigger event

occurs. You can also use a programmable post-trigger delay. The delay is

the number of samples after the trigger and before data acquisition starts.

At a conversion rate of 100 Msamples/s or slower, the post-trigger delay

can range from 0 to 65,536 samples (in increments of 1); at a conversion

rate of 250 Msamples/s or faster, the post-trigger delay can range from 0

to 655,360 samples (in increments of 10).

Note:

VTX does not support post-trigger delay.

To start a post-trigger acquisition, perform the following steps:

1. Set up all board parameters, such as the data acquisition channel,

voltage input range, conversion rate, trigger source, trigger polarity,

the number of samples to acquire after the trigger event, and the

post-trigger delay , as appropriate. You need to set up these parameters

only once unless your application requires a change.

2. Using software, arm the board to accept the next valid trigger event.

Arming the board requires about 10

s.

µ

2-12 Functional Description

Page 28

Once the board is armed, the next valid trigger e vent starts the acquisition.

When the trigger event occurs, the post-trigger length, which includes the

post-trigger delay and the number of samples to acquire (defined by the

buffer length), is decremented until it reaches zero, at which point

acquisition stops. Using software, you can poll a status bit or use an

interrupt to determine if the acquisition is finished.

For example, assume the conversion rate is 50 Msample/s, the

post-trigger delay is 10 samples and the buffer length is 190 samples.

When a valid trigger event occurs, the first 10 samples are ignored, the

remaining 190 post-trigger samples are collected, then the acquisition

operation stops.

About-Trigger Acquisition

Use about-trigger acquisition to store data samples before a trigger event

occurs or before and after a trigger event occurs.

To start an about-trigger acquisition, perform the following steps:

1. Set up all board parameters, such as the data acquisition channel,

voltage input range, conversion rate, trigger source, trigger polarity,

and the number of samples to acquire after the trigger occurs. You

need to set up these parameters only once unless your application

requires a change.

2. Using software, arm the board to accept the next valid trigger event.

Arming the board requires about 10

s.

µ

Once armed, the board continuously acquires data and stores it in the

onboard 8K byte memory buffer. The memory buffer must fill up with

data at least once before the board can accept a trigger event. When a

valid trigger event occurs, the specified number of post-trigger samples

(defined by the buffer length) is collected.

For example, suppose you set the buffer length to 4,160 and start the

about-trigger operation. Pre-trigger data is collected and begins to fill the

8K byte buffer. Once the buffer is filled, the board can accept a trigger;

pre-trigger data continues to be collected and overwrites the data in the

buffer until the trigger event occurs. When a valid trigger event occurs,

the board collects 4,160 post-trigger samples then stops the acquisition.

The number of pre-trigger samples in the buffer is 8,192 minus 4,160 or

4,032.

Triggers 2-13

Page 29

The minimum number of pre-trigger samples is 1; the maximum number

of pre-trigger samples is 8,192.

Notes:

The term pre-trigger acquisition is often used for an about-trigger

acquisition when only the samples before the trigger event are significant.

The DAS-4300 Series Function Call Driver differentiates between

pre-trigger acquisition (where the number of post-trigger samples is zero)

and about-trigger acquisition (where you specify the number of

post-trigger samples); refer to the DAS-4300 Series Function Call Driver

User’s Guide for information. The DAS-4300 scope and test program

uses the term pre-trigger mode for both pre-trigger acquisition and

about-trigger acquisition.

You cannot specify a post-trigger delay for an about-trigger acquisition.

VTX does not support about-trigger acquisition.

Equivalent Time Sampling (ETS)

Equivalent time sampling (ETS) is an adv anced feature that allo ws you to

digitize high-frequency analog input signals and achieve f aster conv ersion

rates than 1 Gsamples/s. The advantage of ETS is that the total number of

acquisitions needed to collect a waveform is deterministic; therefore, ETS

is ideal for scanning repetitive waveforms quickly.

On the DAS-4301/8K board, ETS is implemented through a patented

circuit (U.S. Patent No. 4,595,908). The analog signal to be digitized

must be repetitive and coherent with a TTL-level trigger out signal on the

Trg IO connector of the DAS-4301/8K board.

Using ETS, the board samples a repetitive signal several times with the

pacer clock shifted relative to the input signal by a fraction of the sample

period. With N acquisitions and a pacer clock shifted by the fraction of

the sample period 1/(N * f

conversion rate is N * f

) between the acquisitions, the effective

clock

. N is called the ETS factor. The maximum

clock

ETS factor is 20, corresponding to an effective conversion rate of

20 Gsamples/second. Other supported ETS factors are as follows: 2, 4, 5,

2-14 Functional Description

Page 30

and 10 for effective conversion rates of 2, 4, 5, and 10 Gsamples/s,

respectively. Figure 2-3 illustrates an ETS factor of 2.

Input signal

Pacer clock

acquisition 1 (x)

Pacer clock

acquisition 2 (y)

y

y

x

2

3

3

x

2

y

1

x

1

x

4

x

6

y

4

y

5

x

5

y

x

x

y

7

7

6

8

y

8

x

10

x

y

9

9

y

x

x

11

12

11

y

10

y

12

Figure 2-3. Equivalent Time Sampling (ETS)

On the DAS-4301/8K board, individual samples are stored in standard

sequential format. Continuing with the previous example, the data is

stored as follows:

x

x

x

x

... x

y

y

y

y

1

2

3

4

n

1

2

... y

3

4

n

To reconstruct the correct sequence of samples, the host computer

deinterleaves the data of the individual waveforms when transferring the

data off the board. For the two waveforms (x and y) described previously,

the data is transferred as follows:

x

y

x

y

x

y

x

y

1

1

2

2

3

3

4

... xn y

4

n

The ETS process is started by an internal (software) trigger that is

generated by the DAS-4301/8K board. Note that when using ETS, the

DAS-4301/8K board waits for an internal trigger only; external analog

triggers and digital triggers cannot be used. When the trigger event

occurs, an internal trigger signal is generated synchronously to the

internal pacer clock, which performs an A/D conversion. The

synchronous trigger signal is then delayed by a programmable fraction of

Equivalent Time Sampling (ETS) 2-15

Page 31

the pacer clock and output on the Trg I/O connector; this delay is called

the ETS delay. The trigger output signal then generates the input signal,

and the entire process repeats.

The effect of ETS is that samples are digitized at progressiv ely increasing

time intervals until the entire waveform is characterized. Since the ADC

only digitizes one sample when a trigger is received, acquisition is not

limited by the conversion rate of the ADC, but eventually by the total

analog input circuitry of the board.

Figure 2-4 illustrates how ETS works. In this example, the delayed start

of the input signal causes the DAS-4301/8K board to sample the signal at

different points in the two acquisitions described previously. During

acquisition 1 with a larger ETS delay shift, the pacer clock occurs earlier

with respect to the input signal; therefore, the data from this acquisition is

sorted into the even-numbered samples of the combined data set: 0, 2, 4,

and so on. The data from acquisition 2 is sorted into the odd-numbered

samples: 1, 3, 5, and so on.

2-16 Functional Description

Page 32

Software trigger

Synchronized trigger

Pacer clock

ETS delay 1

Trigger I/O output 1

Input signal 1

ETS delay 2

Trigger I/O output 2

Input signal 2

Figure 2-4. ETS Delay

Note: The DAS-4300 Series Function Call Driver and VTX do not

support ETS.

Equivalent Time Sampling (ETS) 2-17

Page 33

Random Interleave Sampling (RIS)

In addition to ETS, the DAS-4301/8K board provides Random Interleave

Sampling (RIS). Like ETS, RIS allows the DAS-4301/8K board to

sample a repetitive signal at rates above 1 Gsamples/s. Unlike ETS,

however, the signal does not have to be coherent with the pacer clock.

This feature is particularly convenient in scope-type applications where

you may not be overly concerned about the time it takes to complete the

acquisition but you want to watch the screen filling with data.

One advantage of RIS over ETS is the ability to acquire and display

pre-trigger data at sampling rates of up to 20 Gsamples/s. RIS also offers

more trigger source options than ETS. The trigger for the signal can be

derived from the signal (external software analog trigger), external

hardware analog trigger, or e xternal digital trigger. If the trigger source is

external analog or digital, the trigger needs to be synchronized with the

signal.

RIS offers the same sampling rates as ETS: 2, 4, 5, 10, and

20 Gsamples/s. During each acquisition, an entire waveform is collected.

Ideally, at 20 Gsamples/s, 20 waveforms sampled at 1 Gsamples/s are

required to reconstruct a waveform equivalently sampled at

20 Gsamples/s. However, because the waveforms fall randomly, many

waveforms are usually required. The DAS-4300 scope and test program

updates the waveform as each is acquired.

Figure 2-5 illustrates how RIS works.

2-18 Functional Description

Page 34

1 GHz Clock

First Acquisition (x)

Measured T rigger

First Acquisition

1 GHz Clock

Second Acquisition (y)

Measured T rigger

Second Acquisition

1 GHz Clock

Third Acquisition

(z)

Measured T rigger

Third Acquisition

Threshold Level

Sampled Wav eform

z

2

y

2

x

2

z

1

y

1

x

1

x

3

y

3

z

3

x

4

y

4

z

4

z

5

y

5

x

5

z

6

y

6

x

6

Figure 2-5. Random Interleave Sampling

Note: The DAS-4300 Series Function Call Driver and VTX do not

support RIS.

Random Interleave Sampling (RIS) 2-19

Page 35

3

Setup and I

This chapter contains the information you need to set up and install your

DAS-4301/8K board.

Unpacking the Board

Caution:

damage certain electrical components on any circuit board. It is

recommended that you use wrist strap grounds when handling a board. If

wrist strap grounds are not available, make sure that you discharge static

electricity from yourself by touching a grounded conductor such as your

computer chassis (your computer must be turned OFF).

Whenever you handle a board, hold it by the edges and avoid touching

any board components. Avoid touching the gold edge connector as this

may leave fingerprints that can degrade the electrical connections.

A discharge of static electricity from your hands can seriously

nstallation

To prevent any damage to your DAS-4301/8K board, perform the

following steps when unpacking the board:

1. Remove the wrapped DAS-4301/8K board from its outer shipping

carton.

2. Carefully remove the board from its antistatic wrapping material.

(You may wish to store the wrapping material for future use.)

Note:

Do not remove the pink foam pad. Leav e the board on the pink

foam pad until you are ready to install the board in the computer.

Unpacking the Board 3-1

Page 36

3. Inspect the board for signs of damage. If any damage is apparent,

arrange to return the board to the factory; refer to page 5-4 for more

information.

4. Check the remaining contents of your package against the packing

list to ensure that your order is complete. Report any missing items

immediately.

5. Once you have determined that the board is acceptable, install the

software and configure the board. Refer to the following sections for

information.

Installing the Software

This section describes how to install the DAS-4300 Series standard

software package and how to install the ASO-4300 software package

from both DOS and W indo ws. To install other software packages, refer to

the documentation supplied with the software package.

Installing the DAS-4300 Series Standard Software Package

To install the DAS-4300 Series standard software package, perform the

following steps:

1. Make a backup copy of the supplied disks. Use the copies as your

working disks and store the originals as backup disks.

2. Insert disk #1 into the disk drive.

3. Assuming that you are using disk drive A, enter the following at the

DOS prompt:

A:install

The installation program prompts you for your installation

preferences, including the drive and directory you want to copy the

software to. It also prompts you to insert additional disks, as

necessary.

4. Continue to insert disks and respond to prompts, as appropriate.

When the installation program prompts you for a drive designation,

enter a designation of your choosing or accept the default drive C.

3-2 Setup and Installation

Page 37

When the installation program prompts you for a directory name,

enter a name of your choosing or accept the default name.

The installation program creates a directory on the specified drive and

copies all files, expanding any compressed files.

5. When the installation program notifies you that the installation is

complete, review the following files:

– FILES.TXT lists and describes all the files copied to the hard disk

by the installation program.

– README.TXT contains information that was not available when

this manual was printed.

Installing the ASO-4300 Software Package

DOS Installation

The ASO-4300 software package contains software for both the DOS and

Windows environments. This section describes how to install both the

DOS version and the Windows version of the ASO-4300 software

package.

To install the DOS version of the ASO-4300 software package, perform

the following steps:

1. Make a backup copy of the supplied disks. Use the copies as your

working disks and store the originals as backup disks.

2. Insert disk #1 into the disk drive.

3. Assuming that you are using disk drive A, enter the following at the

DOS prompt:

A:install

The installation program prompts you for your installation

preferences, including the drive and directory you want to copy the

software to. It also prompts you to insert additional disks, as

necessary.

4. Continue to insert disks and respond to prompts, as appropriate.

When the installation program prompts you for a drive designation,

enter a designation of your choosing or accept the default drive C.

Installing the Software 3-3

Page 38

When the installation program prompts you for a directory name,

enter a name of your choosing or accept the default name.

The installation program creates a directory on the specified drive and

copies all files, expanding any compressed files.

5. When the installation program notifies you that the installation is

complete, review the following files:

– FILES.TXT lists and describes all the files copied to the hard disk

– README.TXT contains information that was not available when

Windows Installation

by the installation program.

this manual was printed.

To install the Windows version of the ASO-4300 software package,

perform the following steps:

1. Make a backup copy of the ASO-W indo ws disk. Use the cop y as your

working disk and store the original as a back up.

2. Insert the ASO-Windows disk into the disk drive.

3. Start Windo ws.

4. From the Program Manager menu, select File and then select Run.

5. Assuming that you are using disk drive A, type the following at the

command line in the Run dialog box, and then choose OK:

A:SETUP

The installation program prompts you for your installation

preferences, including the drive and directory you want to copy the

software to. It also prompts you to insert additional disks, as

necessary.

6. Continue to insert disks and respond to prompts, as appropriate.

When the installation program prompts you for a drive designation,

enter a designation of your choosing or accept the default drive C.

When the installation program prompts you for a directory name,

enter a name of your choosing or accept the default name.

The installation program creates a directory on the specified drive and

copies all files, expanding any compressed files.

3-4 Setup and Installation

Page 39

The installation program also creates a DAS-4300 family group; this

group includes example Windows programs and help files.

7. When the installation program notifies you that the installation is

complete, review the following files:

– FILES.TXT lists and describes all the files copied to the hard disk

by the installation program.

– README.TXT contains information that was not available when

this manual was printed.

Configuring the Board

You configure the following items for DAS-4300 Series boards by setting

jumpers on the board and/or by specifying the configuration in a

configuration file:

●

Base I/O address

●

Memory address

●

Interrupt

Zero wait-state option

●

AC/DC couplings

●

●

Acquire data from Channel B or calibrate input ranges

●

Input impedance for signal into Ch A connector

50

●

●

●

●

termination resistor for clock input signal

Ω

50

Ω

termination resistor for trigger input signal

Ω

100

pull-up resistor to +5 V for trigger input signal

Ground connections

Table 3-1 lists the items that are configurable for DAS-4301/8K boards,

the available options, the default settings in the configuration file, and the

default jumper settings.

Configuring the Board 3-5

Page 40

Table 3-1. Configuring DAS-4301/8K Boards

Attribute Options

J

Where Option

is Set

File Board

Default

Default Jumper

Settings

1

Base I/O address

Memory address

Interrupt

AC/DC coupling AC, DC

Zero wait state

Channel B/

Calibration

1

2

&H200 to &H3FF

1

C 000 to D C00

2, 5, 7, 10, 11, 12,

15

3

Enabled, Disabled

Acquire data from

Channel B or

calibrate input

ranges

✔

✔

✔

✔

✔

✔

✔

✔

✔

&H250 J400

1: OUT

2: IN

3: IN

4: OUT

5: IN

6: OUT

C C00 J401

1: OUT

2: IN

3: IN

None J402

1 to 7: OUT

DC J106 IN

Enabled Not applicable

Acquire data from

Channel B

J103

1-2: IN

3-4: OUT

Input impedance

for Ch A signal

Input impedance

for analog trigger

signal from

Trg/Ch B

Clock input 50 Ω

termination

Trigger input 50 Ω

termination

3-6 Setup and Installation

50 Ω or 1 M Ω

50 Ω or 5600 Ω

Terminated or not

terminated

Terminated or not

terminated

✔

✔

✔

✔

50 Ω

50 Ω

Not terminated J500: OUT

Not terminated J502: OUT

105: ΙΝ

J901: IN

Page 41

Table 3-1. Configuring DAS-4301/8K Boards (cont.)

Attribute Options

Where Option

is Set

File Board

Default

Default Jumper

Settings

1

Trigger input

100 Ω pull-up to

Pulled up or not

pulled up

✔

Not pulled-up J501: OUT

+5 V

Analog-to-digital

ground to A/D

Analog-to-digital

ground to DC

Grounded or not

grounded

Grounded or not

grounded

✔

✔

Grounded J102: IN

Grounded J202: IN

converter

Bracket-to-analog

ground

DSP ground

4

Grounded or not

grounded

J302, location 19

✔

✔

Grounded J104: IN

Grounded J301:

grounded or not

DSP connector

grounded

4

DSP connector or

✔

DSP connector J302: None

2-3: IN

no connector

DSP I/O

Notes

1

jumper is inserted in the specified jumper position.

2

The setting in the configuration file must match the settings of the jumpers on the board.

3

The default setting is appropriate for most computers. If you are using an older computer, you may

want to try changing the setting.

4

These jumper settings are provided for completeness; unless you are using the SDC-5600 DSP board,

4

OUT indicates that a jumper is not inserted in the specified jumper position and IN indicates that a

None or Spare I/O

✔

Spare I/O J300: None

you do not need to change these jumper settings.

Refer to page 3-10 for information on setting the jumpers. Refer to the

next section for information on creating a configuration file.

Configuring the Board 3-7

Page 42

Creating a Configuration File

A configuration file is required by the DAS-4300 Series Function Call

Driver and other software packages to perform operations on the

DAS-4301/8K board. A def ault configuration file called DAS4300.CFG is

provided in both the DAS-4300 Series standard softw are package and the

AS0-4300 software package. The factory-default settings in

DAS4300.CFG are shown in Table 3-1.

If the default settings in the configuration file are appropriate for your

application, refer to the following section to ensure that the jumper

settings on the board match the settings in the configuration file.

If the default settings are not appropriate for your application, you must

create a new configuration file or modify an existing configuration file to

specify the correct configuration options. The CFG4300.EXE

configuration utility, shipped with both the DAS-4300 Series standard

software package and the ASO-4300 software package, is provided for

this purpose.

T o create a ne w configuration file or modify an existing configuration file,

perform the following steps:

1. Invoke the configuration utility from DOS or Windows, as follows:

– If you are running under DOS , from the directory containing the

CFG4300.EXE configuration utility, enter the following at the

DOS prompt:

CFG4300

filename

where filename is the name of the configuration file you wish to

create or modify.

– If you are running under Windows , select Run from the Program

Manager File menu, enter the following in the box, and choose

OK:

CFG4300

filename

where filename is the name of the configuration file you wish to

create or modify. Make sure that you enter the correct path to

CFG4300.EXE, or use the Browse button to find this file.

3-8 Setup and Installation

Page 43

If the utility finds a configuration file named filename , it displays the

opening menu screen with filename shown; this file contains the

configuration options found in filename . If the utility does not find a

configuration file named filename , it displays the opening menu

screen with filename shown; this file contains the default

configuration options. If you do not enter a file name, the utility

displays the opening menu screen of the default configuration file

DAS4300.CFG.

Note:

The example programs, provided with the ASO-4300 software

package, use the default configuration file DAS4300.CFG. If you

intend to use the example programs, make sure that DAS4300.CFG

exists and that the settings in DAS4300.CFG match the jumper

settings of your board.

2. On the opening menu screen, enter the number of DAS-4301/8K

boards you plan to configure (1 or 2).

The utility displays the configuration options for the first board

(board 0). The number of the board is shown in the upper-left corner

of the top menu box.

3. To modify any of the configuration options, use the arrow keys to

highlight the option you want to change, press Enter to display a list

of available settings, use the arrow keys to highlight the appropriate

setting, and press Enter . These instructions are summarized in the

Commands/Status box at the bottom of the screen.

When the configuration options for this board are correct, press N to

display the configuration options for the next board.

4. After you modify the appropriate configuration options for all boards,

press Esc. The utility asks if you want to save the new settings to the

specified configuration file.

5. Press Y to save the new settings and exit. Press N to exit without

saving the new settings.

When you finish creating or modifying the configuration file, refer to the

following section to ensure that the jumper settings on the board match

the settings in the configuration file.

Configuring the Board 3-9

Page 44

Setting Jumpers on the Board

The locations of the jumpers required for configuring DAS-4300 Series

boards are shown in Figure 3-1.

3-10 Setup and Installation

Page 45

Ch A

Trg/Ch B

Clk IO

Trg IO

Note that jumpers

J103, J104, J105,

J106, and J901 are

underneath the metal

cover; to change the

settings of these

jumpers, you first must

unscrew the metal

cover.

J104

J106

Pin 1

J105

J103

J901

J102

Pin 1

J200

J400

J402

Pin 1

J501

J502

J500

J401

Pin 1

Pin 1

J403

J404

J202

J300

J301

Pin 1

Pin 1

J302

Pin 1

Pin 1

J201

Figure 3-1. Jumper Placement on DAS-4301/8K Board

Configuring the Board 3-11

Page 46

Setting the Base I/O Address

The DAS-4301/8K board requires 16 consecuti ve bytes in the I/O address

space of the host computer. The board is shipped with a base I/O address

of 250h. If your application requires a different setting, use jumper block

J400 to set the base I/O address. Each board must have a unique base I/O

address.

Note: If you change the default base I/O address of the board and you

plan on using the DAS-4300 scope and test program, you must change the

base I/O address setting in the D4300.ADC file. See Chapter 4 for more

information.

Table 3-2 lists the settings of J400 for base I/O addresses in the range of

200h to 3FFh.

Table 3-2. Base I/O Address

Base I/O

Address

Position 1 Position 2 Position 3 Position 4 Position 5 Position 6

Jumper J400

200 to 20F OUT IN IN IN IN IN

210 to 21F OUT IN IN IN IN OUT

220 to 22F OUT IN IN IN OUT IN

230 to 23F OUT IN IN IN OUT OUT

240 to 24F OUT IN IN OUT IN IN

1

250 to 25F

260 to 26F OUT IN IN OUT OUT IN

270 to 27F OUT IN IN OUT OUT OUT

280 to 28F OUT IN OUT IN IN IN

290 to 29F OUT IN OUT IN IN OUT

2A0 to 2AF OUT IN OUT IN OUT IN

2B0 to 2BF OUT IN OUT IN OUT OUT

3-12 Setup and Installation

OUT IN IN OUT IN OUT

Page 47

Table 3-2. Base I/O Address (cont.)

Jumper J400

Base I/O

Address

2C0 to 2CF OUT IN OUT OUT IN IN

2D0 to 2DF OUT IN OUT OUT IN OUT

2E0 to 2EF OUT IN OUT OUT OUT IN

2F0 to 2FF OUT IN OUT OUT OUT OUT

300 to 30F OUT OUT IN IN IN IN

310 to 31F OUT OUT IN IN IN OUT

320 to 32F OUT OUT IN IN OUT IN

330 to 33F OUT OUT IN IN OUT OUT

340 to 34F OUT OUT IN OUT IN IN

350 to 35F OUT OUT IN OUT IN OUT

360 to 36F OUT OUT IN OUT OUT IN

370 to 37F OUT OUT IN OUT OUT OUT

Position 1 Position 2 Position 3 Position 4 Position 5 Position 6

380 to 38F OUT OUT OUT IN IN IN

390 to 39F OUT OUT OUT IN IN OUT

3A0 to 3AF OUT OUT OUT IN OUT IN

3B0 to 3BF OUT OUT OUT IN OUT OUT

3C0 to 3CF OUT OUT OUT OUT IN IN

3D0 to 3DF OUT OUT OUT OUT IN OUT

3E0 to 3EF OUT OUT OUT OUT OUT IN

3F0 to 3FF OUT OUT OUT OUT OUT OUT

Notes

1

Default base I/O address.

Configuring the Board 3-13

Page 48

Setting the Memory Address

The onboard 8K byte memory on the DAS-4301/8K board is mapped into

a 16K byte window in upper memory (above 640K bytes). The

DAS-4301/8K board is shipped with a memory address of CC00:0000. If

your application requires a different setting, use jumper block J401 to set

the memory address, as shown in Table 3-3.

Note: Note that no other boards or devices can share the selected

memory address. If you change the default memory address of the board

and you plan on using the DAS-4300 scope and test program, you must

change the memory address setting in the D4300.ADC file. See Chapter 4

for more information.

Table 3-3. Memory Address

Memory

Address

C 0000 OUT OUT OUT

C 4000 OUT OUT IN

C 8000 OUT IN OUT

C C000

D 0000 IN OUT OUT

D 4000 IN OUT IN

D 8000 IN IN OUT

D C000 IN IN IN

Notes

1

Default factory setting.

Position 1 Position 2 Position 3

1

OUT IN IN

Jumper J401

3-14 Setup and Installation

Page 49

The host computer must leave room for the onboard memory of the

DAS-4301/8K board in its memory address map. To ensure that the host

computer is configured to leave room in its memory address map, you

must exclude the memory area of 16K bytes (CC00:0000 to CFFF:000F

or your memory address setting) from the memory available for the EMS

manager of your system (for example, QEMM or EMM386).

For QEMM, your C:\CONFIG.SYS file should contain a line similar to

the following:

DEVICE = C:\QEMM\QEMM386.EXE X=CC00-CFFF

For EMM386, your C:\CONFIG.SYS file should contain a line similar to

the following:

DEVICE = C:\DOS\EMM386.EXE X=CC00-CFFF

Note that the examples assume a certain directory structure on the disk;

you may have to modify these commands.

Setting the Interrupt

If enabled in software, the DAS-4301/8K board can generate an interrupt

at the end of a data acquisition operation to notify the host computer that

the operation is completed. Selecting an interrupt connects the interrupt

line to a tristate driver on the board; this feature allows the interrupt to

remain selected while allowing other devices to use the interrupt line.

The DAS-4301/8K board is shipped with no interrupt selected. If your

application requires a different setting, select the interrupt by inserting the

jumper into one of the positions of jumper block J402. Make sure that you

insert a jumper into only one of the positions of J402; refer to Table 3-4.

Configuring the Board 3-15

Page 50

Interrupt

Table 3-4. Interrupt Selection

Jumper J402

Position1Position2Position3Position4Position5Position6Position

7

1

None

2 IN OUT OUT OUT OUT OUT OUT

5 OUT IN OUT OUT OUT OUT OUT

7 OUT OUT IN OUT OUT OUT OUT

10 OUT OUT OUT IN OUT OUT OUT

11 OUT OUT OUT OUT IN OUT OUT

12 OUT OUT OUT OUT OUT IN OUT

15 OUT OUT OUT OUT OUT OUT IN

Notes

1

Default setting.

OUT OUT OUT OUT OUT OUT OUT

Acquiring Data from Channel B or Calibrating the Board

If you want to acquire analog input data from Channel B, you must

specify Channel B in software and leave the default jumper setting of

jumper J103 in its factory-default configuration (jumper installed in

positions 1 and 2).

Positions 3 and 4 of jumper block J103 are provided for calibrating the

board. However, it is strongly recommended that you return the board to

Keithley Metrabyte if calibration is required; refer to page 5-4 for more

information on returning a board.

Jumper block J103 is underneath the metal cover on the top right of the

board. To change the jumper setting, you first must unscrew this metal

cover.

Figure 3-2 illustrates the analog input circuitry.

3-16 Setup and Installation

Page 51

CHA 5

V

rms

TRG CHB

(±10 V)

1

2

J105

1

4 5 7 8 9 1032

4 5 7 8 9 1032

R101

150

1

2

2

J100

1

6

J900

1

6

R900

150

1

2

1

R102

150

3

4

1

2

1

J103

R100

51.1

2

R938

150

2

2

1

C150

.01

R103

150

J901

1

2

1

1

1

J106

C152

.001

C153

1 µF

1

R939

150

2

2

R940

51.1

6

7

2

2

1

9

R901

4.87 k

1

2

C900

2

1

Figure 3-2. Analog Input Circuitry

Top Bracket Hole

±1.25

R902

698

1

2

MTG101

J104

Analog

Trigger In

C901

To Input

8

Buffer

4

3

CAL2-L

+5R

CAL/CHB

CAL

+5 VS

2

D900

1N4149

1

2

2

1

−5 VS

D900

1N4149

1

2

Selecting AC or DC Coupling

AC or DC coupling is determined by jumper block J106. If a jumper is

installed in jumper block J106 (the default condition), DC coupling is

selected. Removing the jumper from jumper block J106 selects AC

coupling.

Jumper block J106 is underneath the metal cover on the top right of the

board. To change the jumper setting, you first must unscrew this metal

cover.

Setting the Input Impedance of Ch A Signal

The input impedance of the signal coming into the Ch A connector is

determined by jumper block J105. If a jumper is installed in jumper block

J105 (the default condition), the input impedance is 50

jumper from jumper block J105, selects an input impedance of

approximately 1 M

Configuring the Board 3-17

Ω.

Ω. Removing the

Page 52

Jumper block J105 is underneath the metal cover on the top right of the

board. To change the jumper setting, you first must unscrew this metal

cover.

Setting the Input Impedance of the Analog Trigger Input Signal

The input impedance of the trigger input signal from the Trg/Ch B

connector is determined by jumper block J901. If a jumper is installed in

jumper block J901 (the default condition), the input impedance is 50

you remove the jumper from jumper block J901, the input impedance is

approximately 5600

Ω.

Jumper block J901 is underneath the metal cover on the top right of the

board. To change the jumper setting, you first must unscrew this metal

cover.

Setting the 50 Ω Termination Resistor for the Clock Input Signal

The clock input signal of the Clk IO connector has a jumper-selectable

50

Ω termination to ground for signals driving long lines or lines that are

driving many devices. Insert a jumper into jumper block J500 to provide

the 50

Ω termination resistor. The 50 Ω resistor is provided in the

solderless component jack, R503. By default, the jumper is removed.

Ω. If

Note: To prevent excessive loading of the signal, do not use the 50 Ω

termination resistor when the board is providing the clock output signal

on the Clk IO connector.

Figure 3-3 illustrates the clock I/O and trigger I/O circuitry.

3-18 Setup and Installation

Page 53

Clock

In/Out

(TTL)

+5 V

1

R501

2.00 k

2

J507

1

6

4 5 7 8 9 1032

1

J500

1

2

2

ENEXTCLK-L

R502

20

1

R503

49.9

D500

1N4149

2

+5 V

2

1

D501

1N4149

+5 V

U514

74ABT125

10

U514

74ABT125

8

12

9

2

1

1

14

VCC

GND

U513

100 MHz

7

Out

8

U514

74ABT125

2

1

3

Master 100

MHz Clock

Trigger

In/Out

(TTL)

13

U514

74ABT125

+5 V

1

R504

100

2

J501

J508

1

6

4 5 7 8 9 1032

2

J502

1

2

R506

2.00 k

1

2

1

+5 V

1

2

R505

20

R507

49.9

+5 V

2

1

D503

1N4149

D502

1N4149

2

1

U515

74ABT125

6

4

U515

74ABT125

6

4

3

1

5

5

U515

2

74ABT125

9

8

10

ENINTCLK-L

Trigger Out

ENTRIGOUT-L

Trigger In

Figure 3-3. Clock I/O and Trigger I/O Circuitry

Setting the 50 Ω Termination Resistor for the Trigger Input Signal

The trigger input signal of the Trg IO connector has a jumper-selectable

50

Ω termination to ground for signals driving long lines or lines that are

driving many devices. Insert a jumper into jumper block J502 to provide

the 50

Ω termination resistor. The 50 Ω resistor is provided in the

solderless component jack, R507. By default, the jumper is removed.

Note: To prevent excessive loading of the signal, do not use the 50 Ω

termination resistor when the board is providing the trigger output signal

on the Trg IO connector.

Configuring the Board 3-19

Page 54

Setting the 100 Ω Pull-Up to +5 V for the Trigger Input Signal

The trigger input signal of the Trg IO connector has a jumper-selectable

100

Ω pull-up to +5 V to float the tristate output high. Insert a jumper into

jumper block J501 to provide the 100

Ω pull-up to +5 V. The 100 Ω

pull-up to +5 V is provided in the solderless component jack, R504. By

default, the jumper is removed.

Setting Grounds

The DAS-4301/8K board provides several jumper-selectable grounds. By

default, each of these grounds is selected (a jumper is inserted in the

appropriate jumper block). Table 3-5 lists the grounds that are

jumper-selectable on the DAS-4301/8K board and their default

configurations. If you want to remove the grounds, remove the jumpers

from their respective locations.

Table 3-5. Grounds on the DAS-4301/8K Board

Ground Type Jumper

Used

Analog-to-digital ground

to A/D

Analog-to-digital ground

to DC converter

Bracket-to-analog ground J104 IN

J102 IN

J202 IN

Default

Setting

Jumper block J104 is underneath the metal cover on the top right of the

board. To change the jumper setting, you first must unscrew this metal

cover.

3-20 Setup and Installation

Page 55

Installing the Board

You can avoid many problems by providing the proper operating