Page 1

DAS-1800AO Series

LabVIEW

VI Driver

USER’S GUIDE

Page 2

DAS-1800AO Series

®

LabVIEW VI Driver

User’s Guide

Revision A – October 1994

Part Number: 93180

Page 3

New Contact Information

Keithley Instruments, Inc.

28775 Aurora Road

Cleveland, OH 44139

Technical Support: 1-888-KEITHLEY

Monday – Friday 8:00 a.m. to 5:00 p.m (EST)

Fax: (440) 248-6168

Visit our website at http://www.keithley.com

Page 4

The information contained in this manual is believed to be accurate and reliable. However, Keithley

Instruments, Inc., assumes no responsibility for its use or for any infringements of patents or other rights

of third parties that may result from its use. No license is granted by implication or otherwise under any

patent rights of Keithley Instruments, Inc.

KEITHLEY INSTRUMENTS, INC., SHALL NO T BE LIABLE FOR ANY SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES RELATED TO THE USE OF THIS PRODUCT. THIS

PRODUCT IS NOT DESIGNED WITH COMPONENTS OF A LEVEL OF RELIABILITY

SUITABLE FOR USE IN LIFE SUPPORT OR CRITICAL APPLICATIONS.

Refer to your Keithley Instruments license agreement for specific warranty and liability information.

MetraByte is a trademark of Keithley Instruments, Inc. All other brand and product names are

trademarks or registered trademarks of their respective companies.

© Copyright Keithley Instruments, Inc., 1994.

All rights reserved. Reproduction or adaptation of any part of this documentation beyond that permitted

by Section 117 of the 1976 United States Copyright Act without permission of the Copyright owner is

unlawful.

Keithley MetraByte Division

Keithley Instruments, Inc.

440 Myles Standish Blvd. Taunton, MA 02780

FAX: (508) 880-0179

Telephone: (508) 880-3000

●

Page 5

Preface

The DAS-1800AO Series LabVIEW

how to write LabVIEW application programs for DAS-1800AO Series

boards using the Keithley MetraByte DAS-1800 Series VI Driver.

This manual is intended for LabVIEW application programmers using a

DAS-1800AO Series board in an IBM

It is assumed that users have read the user’s guide for the board and are

familiar with the board’s features, and that they have completed the

appropriate hardware installation and configuration. It is further assumed

that users are experienced in programming in LabVIEW and are familiar

with Windows™ and with data acquisition principles.

Manual Organization

The manual is organized as follows:

●

Chapter 1 explains how to install the DAS-1800 Series VI Driver and

how to get help, if necessary.

●

Chapter 2 contains the background information needed to use the VIs

included in the DAS-1800 Series VI Driver.

VI Driver User’s Guide explains

PC AT

or compatible computer.

●

Chapter 3 provides guidelines for using the DAS-1800 Series VIs.

Chapter 4 contains detailed descriptions of the DAS-1800 Series VIs,

●

arranged in alphabetical order.

Appendix A describes the error codes returned by DAS-1800 Series

●

VIs.

Appendix B provides instructions for converting raw counts to

●

voltage and for converting voltage to raw counts.

ix

Page 6

An index completes the manual.

Conventions Used in this Manual

The following conventions are used throughout this manual:

●

References to DAS-1800A O Series boards apply to the D AS-1801AO

board and the DAS-1802AO board.

●

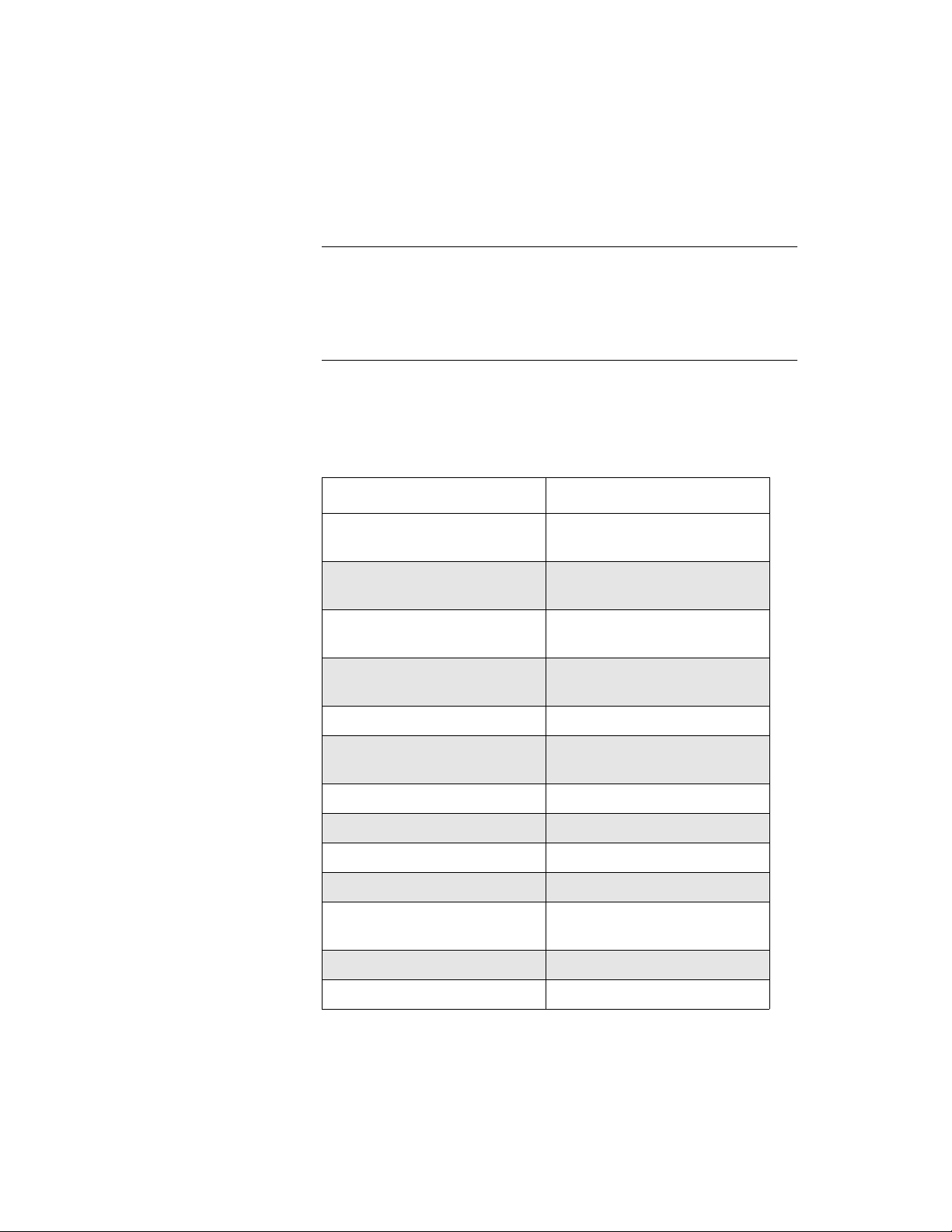

All VIs supported by the DAS-1800 Series VI Driver are illustrated

graphically, as shown in the example below. The name of the VI is

shown beneath the D AS-1800 icon; the wires connecting the inputs to

and the outputs from the DAS-1800 icon represent the data type of

the parameters.

Input Parameters

Numeric Data

Array

String

Cluster

Wiring

Output Parameters

Numeric Data

Array

String

Cluster

K_ Example VI

Name of VI

x

Page 7

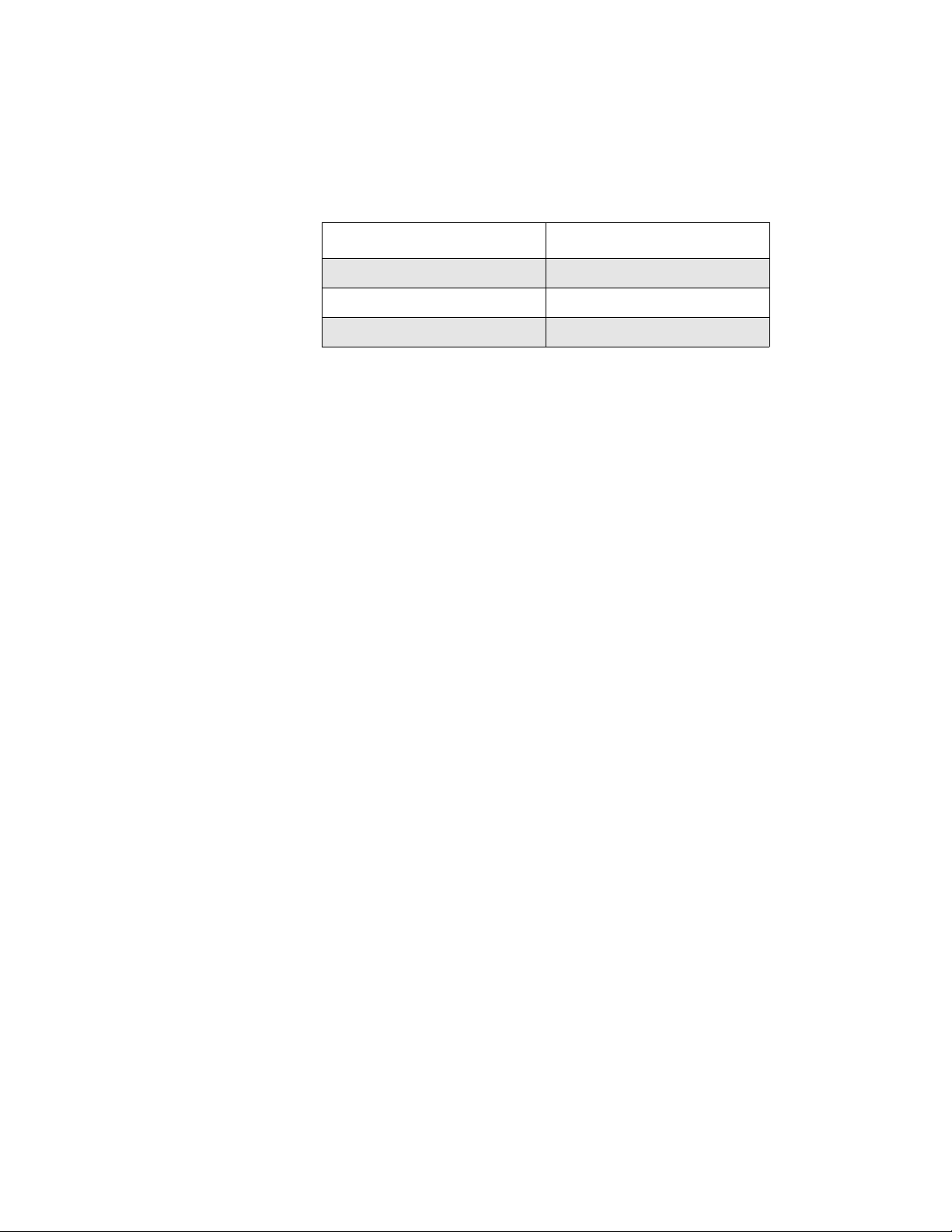

The data types of the inputs and outputs are represented as follows:

●

Inputs

I16

I32

U8

U16

U32

[ ]

I16

[ ]

U16

[ ]

U32

a b c

T F

Related Documents

For more information, refer to the following documents:

Outputs

I16

I32

U8

U16

U32

[ ]

I16

[ ]

U16

[ ]

U32

a b c

T F

Data Type

Signed 16-bit integer

Signed 32-bit integer

Unsigned 8-bit integer

Unsigned 16-bit integer

Unsigned 32-bit integer

Array of signed 16-bit integers

Array of unsigned 16-bit integers

Array of unsigned 32-bit integers

Cluster

String

Boolean

DAS-1800AO Series User’s Guide

●

LabVIEW manuals

●

xi

Page 8

Table of Contents

Preface

Manual Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

Conventions Used in this Manual . . . . . . . . . . . . . . . . . . . . . . . . . x

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

Getting Started

1

Installing the VI Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Getting Help. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

2

Available Operations

System Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Initializing the Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Initializing a Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Retrieving Revision Levels . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Handling Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Analog Input Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Operation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Memory Allocation and Management. . . . . . . . . . . . . . . . . . .2-5

Gains and Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Specifying Channels When Using EXP-1800

Expansion Boards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Acquiring Samples from a Single Channel . . . . . . . . . . .2-10

Acquiring Samples from a Group of Consecutive

Channels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

Acquiring Samples Using a Channel-Gain Array . . . . . .2-12

Conversion Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

Clock Source. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

A/D Pacer Clock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

Burst Mode Conversion Clock. . . . . . . . . . . . . . . . . . . . .2-15

Buffering Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

Trigger. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

Trigger Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

Post-Trigger Acquisition . . . . . . . . . . . . . . . . . . . . . . . . .2-20

Pre-Trigger Acquisition . . . . . . . . . . . . . . . . . . . . . . . . . .2-21

About-Trigger Acquisition . . . . . . . . . . . . . . . . . . . . . . . .2-22

iii

Page 9

Hardware Gate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

Analog Output Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-23

Operation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-23

Memory Allocation and Management. . . . . . . . . . . . . . . . . .2-25

Gains and Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-26

Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-26

Writing Values to a Single Channel . . . . . . . . . . . . . . . . .2-26

Writing Values to Both Channels Using the

Same Gain Code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-27

Writing Values to Both Channels Using

Different Gain Codes . . . . . . . . . . . . . . . . . . . . . . . . . . .2-27

Clock Source. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-28

D/A Pacer Clock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-28

External Pacer Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-29

A/D Pacer Clock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-29

Buffering Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-30

Trigger. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-30

Trigger Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-30

Retriggering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32

Hardware Gate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-33

Digital I/O Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-34

Operation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-34

Memory Allocation and Management. . . . . . . . . . . . . . . . . .2-36

Digital Input Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-36

Digital Output Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-37

Clock Source. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-38

Buffering Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-39

3

Programming with the VI Driver

How the Driver Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

General Programming Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Operation-Specific Programming Tasks. . . . . . . . . . . . . . . . . . .3-11

Analog Input Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Single Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Interrupt Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

DMA Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Analog Output Operations . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

Single Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

Interrupt Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

DMA Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Recycle Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

iv

Page 10

Digital I/O Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Single Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Interrupt Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

VI Reference

4

K_ADRead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

K_AllocChnGAry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

K_BufListAdd . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

K_BufListReset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

K_ClearFrame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

K_CloseDriver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

K_ClrAboutTrig . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

K_ClrADFreeRun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

K_ClrContRun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

K_DASDevInit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

K_DAWriteGain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

K_DIRead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

K_DMAAlloc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

K_DMAFree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

K_DMAStart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

K_DMAStatus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

K_DMAStop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-24

K_DOWrite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-25

K_FormatChnGAry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-26

K_FreeChnGAry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-27

K_FreeDevHandle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-28

K_FreeFrame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-29

K_GetADCommonMode . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-30

K_GetADConfig . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-31

K_GetADFrame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-32

K_GetADMode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-33

K_GetClkRate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

K_GetDAFrame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-35

K_GetDevHandle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-36

K_GetDIFrame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-37

K_GetDOFrame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-38

K_GetErrMsg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-39

K_GetShellVer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-40

K_GetVer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-41

K_IntAlloc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-43

K_IntFree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-44

K_IntStart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-45

v

Page 11

K_IntStatus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-46

K_IntStop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-49

K_MoveArrayToBuf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-50

K_MoveBufToArray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-51

K_OpenDriver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-52

K_SetAboutTrig . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-53

K_SetADCommonMode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-54

K_SetADConfig . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-55

K_SetADFreeRun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-56

K_SetADMode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-57

K_SetADTrig . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-58

K_SetBuf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-60

K_SetBurstTicks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-61

K_SetChn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-62

K_SetChnGAry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-63

K_SetClk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-64

K_SetClkRate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-66

K_SetContRun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-68

K_SetDITrig . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-69

K_SetDMABuf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-71

K_SetExtClkEdge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-72

K_SetG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-73

K_SetGate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-74

K_SetSSH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-75

K_SetStartStopChn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-76

K_SetStartStopG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-78

K_SetSync . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-80

K_SetTrig . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-81

K_SetTrigHyst . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-82

Error Codes

A

B

Converting Data Formats

Converting Raw Counts to Voltage . . . . . . . . . . . . . . . . . . . . . . B-1

Converting Voltage to Raw Counts . . . . . . . . . . . . . . . . . . . . . . B-3

Specifying an Analog Output Value . . . . . . . . . . . . . . . . . . . B-3

Specifying an Analog Trigger Level . . . . . . . . . . . . . . . . . . . B-3

Specifying a Hysteresis Value. . . . . . . . . . . . . . . . . . . . . . . . B-4

Index

vi

Page 12

List of Figures

Figure 2-1. Example of Logical Channel Assignments . . . . .2-10

Figure 2-2. Trigger Events for Analog Triggers. . . . . . . . . . .2-18

Figure 2-3. Using a Hysteresis Value. . . . . . . . . . . . . . . . . . .2-19

Figure 2-4. Trigger Events For Digital Triggers . . . . . . . . . .2-20

Figure 2-5. Digital Input Bits . . . . . . . . . . . . . . . . . . . . . . . . .2-36

Figure 2-6. Digital Output Bits. . . . . . . . . . . . . . . . . . . . . . . .2-37

Figure 3-1. Single-Mode Operation . . . . . . . . . . . . . . . . . . . . .3-2

Figure 3-2. Using a Frame for an Interrupt-Mode Operation. .3-3

List of Tables

Table 2-1. Supported Operations . . . . . . . . . . . . . . . . . . . . . .2-1

Table 2-2. Analog Input Ranges and Gains . . . . . . . . . . . . . .2-7

Table 2-3. Analog Output Ranges. . . . . . . . . . . . . . . . . . . . .2-26

Table 3-1. A/D Frame Elements . . . . . . . . . . . . . . . . . . . . . . .3-4

Table 3-2. D/A Frame Elements . . . . . . . . . . . . . . . . . . . . . . .3-6

Table 3-3. DI Frame Elements . . . . . . . . . . . . . . . . . . . . . . . .3-8

Table 3-4. DO Frame Elements. . . . . . . . . . . . . . . . . . . . . . . .3-9

Table 3-5. Error Cluster Elements. . . . . . . . . . . . . . . . . . . . .3-10

Table 3-6. VIs Used for Interrupt-Mode

Analog Input Operations . . . . . . . . . . . . . . . . . . .3-12

Table 3-7. VIs Used for DMA-Mode

Analog Input Operations . . . . . . . . . . . . . . . . . . .3-14

Table 3-8. VIs Used for Interrupt-Mode

Analog Output Operations. . . . . . . . . . . . . . . . . .3-17

Table 3-9. VIs Used for DMA-Mode

Analog Output Operations. . . . . . . . . . . . . . . . . .3-19

Table 3-10. VIs Used for Recycle-Mode

Analog Output Operations. . . . . . . . . . . . . . . . . .3-21

Table 3-11. VIs Used for Interrupt-Mode

Digital Input and Digital Output Operations . . . .3-23

Table 4-1. VIs by Functional Group . . . . . . . . . . . . . . . . . . . .4-2

Table A-1. Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Table B-1. Span Values For Analog Input Data

Conversion Equations . . . . . . . . . . . . . . . . . . . . . B-2

vii

Page 13

Table 2-1. Supported Operations . . . . . . . . . . . . . . . . . . . . . .2-1

Table 2-2. Analog Input Ranges and Gains . . . . . . . . . . . . . .2-7

Table 2-3. Analog Output Ranges. . . . . . . . . . . . . . . . . . . . .2-26

Table 3-1. A/D Frame Elements . . . . . . . . . . . . . . . . . . . . . . .3-4

Table 3-2. D/A Frame Elements . . . . . . . . . . . . . . . . . . . . . . .3-6

Table 3-3. DI Frame Elements . . . . . . . . . . . . . . . . . . . . . . . .3-8

Table 3-4. DO Frame Elements. . . . . . . . . . . . . . . . . . . . . . . .3-9

Table 3-5. Error Cluster Elements. . . . . . . . . . . . . . . . . . . . .3-10

Table 3-6. VIs Used for Interrupt-Mode

Analog Input Operations3-12

Table 3-7. VIs Used for DMA-Mode

Analog Input Operations3-14

Table 3-8. VIs Used for Interrupt-Mode

Analog Output Operations3-17

Table 3-9. VIs Used for DMA-Mode

Analog Output Operations3-18

Table 3-10. VIs Used for Recycle-Mode

Analog Output Operations3-20

Table 3-11. VIs Used for Interrupt-Mode

Digital Input and Digital Output Operations3-23

Table 4-1. VIs by Functional Group . . . . . . . . . . . . . . . . . . . .4-2

Table A-1. Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Table B-1. Span Values For Analog Input Data Conversion

Equations B-2

Page 14

Figure 2-1. Example of Logical Channel Assignments . . . . .2-10

Figure 2-2. Trigger Events for Analog Triggers. . . . . . . . . . .2-18

Figure 2-3. Using a Hysteresis Value. . . . . . . . . . . . . . . . . . .2-19

Figure 2-4. Trigger Events For Digital Triggers . . . . . . . . . .2-20

Figure 2-5. Digital Input Bits . . . . . . . . . . . . . . . . . . . . . . . . .2-35

Figure 2-6. Digital Output Bits. . . . . . . . . . . . . . . . . . . . . . . .2-36

Figure 3-1. Single-Mode Operation . . . . . . . . . . . . . . . . . . . . .3-2

Figure 3-2. Using a Frame for an Interrupt-Mode Operation. .3-3

Page 15

1

Getting Started

The DAS-1800 Series VI Driver is a library of data acquisition and

control VIs (Virtual Instruments) used to write application programs for

DAS-1800AO Series data acquisition boards.

This chapter describes how to install the DAS-1800 Series VI Driver and

how to get help, if required.

Installing the VI Driver

To install the DAS-1800 Series VI Driver, perform the following

procedure:

1. Insert the VI Driver disk into the appropriate disk drive of your

computer.

2. Enter Windo ws.

3. From the Program Manager File menu, select Run.

4. Assuming you are using drive A, type the following command line in

the Run dialog box:

A:SETUP

5. Select OK.

6. Respond to the installation prompts as appropriate.

The program creates a Program Manager setup group called KEITHLEY

DAS-1800 VI Driver. This group contains files for the VI driver, utilities,

and example programs using the DAS-1800 Series VIs.

1-1

Page 16

Once you have installed the DAS-1800 Series VI Driver, install your

DAS-1800AO Series board and its software, run the Keithley Memory

Manager utility, and run the configuration program. Refer to the user’s

guide for your board for the information required to perform these steps.

The above steps must be completed in order to open the VI Driver

example programs. You can open LabVIEW from the Program Manager

group by opening a VI Driver example program.

After installation, you may want to review the following files:

Readme.Txt - An ASCII file containing information available after

●

the publication of this manual.

Files.Txt - An ASCII file that describes all of the files available.

●

Getting Help

If you need help installing or using the DAS-1800 Series VI Driver, call

your local sales office or the Keithley Metrabyte Applications

Engineering Department at:

(508) 880-3000

Monday - Friday, 8:00

A.M.

- 6:00

, Eastern Time

P.M.

An applications engineer will help you diagnose and resolve your

problem over the telephone.

1-2 Getting Started

Page 17

Please make sure that you have the follo wing information av ailable before

you call:

Board Configuration Model

Serial #

Revision code

Base address setting

Interrupt level setting

Number of channels

Input (S.E. or Diff.)

Mode (uni. or bip.)

DMA chan(s)

Number of SSH-8s

Number of EXPs

Computer

Operating System

LabVIEW Package

Manufacturer

CPU type

Clock speed (MHz)

KB of RAM

Video system

BIOS type

Windows version

Windows mode

Version ____________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________

___________________

___________________

___________________

___________________

___________________

___________________

______

___________________

___________________

__

Accessories

Type

Type

Type

Type

Type

Type

Type

Type

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

________

1-3

Page 18

2

Available Operations

This chapter contains the background information you need to use the VIs

to perform operations on DAS-1800AO Series boards. The supported

operations are listed in Table 2-1.

Table 2-1. Supported Operations

Operation Page Reference

System page 2-1

Analog input page 2-4

Analog output page 2-23

Digital input and output (I/O) page 2-34

System Operations

This section describes the miscellaneous operations and general

maintenance operations that apply to DAS-1800AO Series boards and to

the DAS-1800 Series VI Driver. It includes information on initializing a

driver, initializing a board, retrieving revision levels, and handling errors.

2-1

Page 19

Initializing the Driver

You must initialize the DAS-1800 Series VI Driv er and any other Keithle y

DAS VI Drivers you are using in your application program. To initialize

the drivers, use K_OpenDriver . You specify the configuration file that

defines this particular use of the driver. The driver returns a unique

identifier for the particular use of the driver; this identifier is called the

driver handle. A maximum of 30 driver handles can be specified for all

the Keithley MetraByte boards accessed from your application program.

If a particular use of a driver is no longer required and you want to free

some memory or if all 30 driver handles have been used, you can use

K_CloseDriver to free a driver handle and close the associated use of the

driver. If the driver handle you free is the last driver handle specified for a

VI Driver, the driver is shut down.

Initializing a Board

The DAS-1800 Series VI Driver supports up to three boards. You must

use K_GetDevHandle to specify the boards you want to use. The driver

returns a unique identifier for each board; this identifier is called the board

handle. Board handles allow you to communicate with more than one

board. In subsequent VIs related to the board, you use the board handle

returned by K_GetDevHandle . A maximum of 30 board handles can be

specified for all the Keithley DAS boards accessed from your application

program.

If a board is no longer being used and you want to free some memory or if

all 30 board handles have been used, you can use K_FreeDevHandle to

free a board handle.

To reinitialize a board during an operation, use K_DASDevInit , which

performs the following tasks:

Aborts all operations currently in progress that are associated with the

●

board identified by the board handle.

●

Verifies that the board identified by the board handle is the board

specified in the configuration file.

2-2 Available Operations

Page 20

Retrieving Revision Levels

If you are having problems with your application program, you may want

to verify which versions of the VI Driver, Keithley DAS Driver

Specification, and Keithley DAS Shell are installed on your board.

K_GetVer allows you to get both the revision number of the DAS-1800

Series VI Driver and the revision number of the Keithley DAS Driver

Specification to which the driver conforms. K_GetShellVer allows you to

get the revision number of the Keithley DAS Shell (the Keithley DAS

Shell is a group of VIs that are shared by all DAS boards).

Handling Errors

Error information is passed from one VI to the next in your application

program. You must first create an error cluster, which consists of three

variables:

A Boolean error status (True/False: True = error)

●

A numeric error code for the number of the error, if an error occurred

●

(0 = no error, nonzero = error occurred)

●

A string for the name of the VI (error source) that returned the error,

if an error occurred

You then wire the cluster to each VI in your program, normally starting

with K_OpenDriver. When the program begins, the first VI checks the

error status; if the status is False (no error), the VI runs. When it has

finished, the VI sets the error status. If an error occurred during the

execution of the VI, the error status is set to True, the error code is set to a

nonzero value identifying the error , and the error source is set to the name

of the VI that caused the error. The next VI in the program reads the error

status; if it finds that the error status is True, the VI does not execute. All

VIs remaining in the program do likewise.

You can read the error information by placing an Unbundle by Name

function after a VI (normally the last VI in your program,

K_CloseDriver ). You create a variable for each element in the error

cluster; once the variables are wired to the Unbundle by Name cluster , the

error information is displayed there.

Appendix A contains a complete list of error codes and their descriptions.

2-3

Page 21

Analog Input Operations

This section describes the following:

●

Analog input operation modes available.

How to allocate and manage memory for analog input operations.

●

●

How to specify the following for an analog input operation: channels

and gains, conversion mode, clock source, buffering mode, trigger

source, and hardware gate.

Operation Mode

The operation mode determines which attributes you can specify for an

analog input operation and how data is transferred from the board to the

computer. You can perform analog input operations in one of the

following modes:

Single mode - In single mode, the board acquires a single sample

●

from an analog input channel. The driver initiates conversions; you

cannot perform any other operation until the single-mode operation is

complete.

Use K_ADRead to start an analog input operation in single mode.

You specify the board you want to use, the analog input channel, and

the gain code for the gain at which you want to read the signal.

●

Interrupt mode - In interrupt mode, the board acquires a single

sample or multiple samples from one or more analog input channels.

A hardware clock initiates conversions. Once the analog input

operation begins, control returns to your application program. The

hardware temporarily stores the acquired data in the onboard A/D

FIFO (first-in, first-out data buffer) and then transfers the data to a

user-defined buf fer in the computer using an interrupt service routine.

Use K_IntStart to start an analog input operation in interrupt mode.

You can specify either single-cycle or continuous buffering mode for

interrupt-mode operations. Refer to page 2-16 for more information

on buffering modes. Use K_IntStop to stop an interrupt-mode

operation. Use K_IntStatus to determine the current status of an

interrupt operation.

2-4 Available Operations

Page 22

DMA mode - In DMA mode, the board acquires a single sample or

●

multiple samples from one or more analog input channels. A

hardware clock initiates conv ersions. Once the analog input operation

begins, control returns to your application program. The hardware

temporarily stores the acquired data in the onboard A/D FIFO and

then transfers the data to a user-defined DMA buffer in the computer.

Note:

You can perform an analog input operation in single-DMA

mode or dual-DMA mode, depending on whether you specified one

or two DMA channels in your configuration file. Refer to your

DAS-1800AO Series User’s Guide for more information.

Use K_DMAStart to start an analog input operation in DMA mode.

You can specify either single-cycle or continuous buffering mode for

DMA-mode operations. Refer to page 2-16 for more information on

buffering modes. Use K_DMAStop to stop a continuous-mode DMA

operation. Use K_DMAStatus to determine the current status of a

DMA operation.

The converted data is stored as ra w counts. For information on converting

raw counts to voltage, refer to Appendix B.

Memory Allocation and Management

Interrupt-mode and DMA-mode analog input operations require memory

buffers in which to store the acquired data. You can reserve a single

buffer, or you can reserve multiple buffers (up to a maximum of 150) to

increase the number of samples you can acquire. Buffers must be

dynamically allocated outside of your application program’s memory

area.

Use K_IntAlloc to allocate memory dynamically for interrupt-mode

operations; use K_DMAAlloc to allocate memory dynamically for

DMA-mode operations. You specify the operation requiring the buffer

and the number of samples to store in the buffer (up to 65,536). The driv er

returns the starting address of the buffer and a unique identifier for the

buffer; this identifier is called the buffer handle.

2-5

Page 23

T o assign the starting address of a b uffer and the number of samples in the

buffer, use K_SetBuf for interrupt operations or K_SetDMABuf for

DMA operations. If you are using multiple buffers, use K_BufListAdd to

add each buffer to the list of multiple buffers associated with each

operation. To move the contents of an allocated buffer to a LabVIEW

array, use K_MoveBufToArray .

The following example shows how to allocate multiple buffers using

K_DMAAlloc and K_BufListAdd . For each K_DMAAlloc VI used, you

use the K_BufListAdd VI to add the allocated b uffer to the list of b uf fers.

The example is illustrated in DMA mode; interrupt mode is identical

except that you use the appropriate interrupt-mode VIs. Refer to the

examples on disk for more information.

Frame Handle

Error In

Number of Samples

U32

Buffer Address

K_DMAAlloc

U32

Note:

U16

K_BufListAdd

Buffer Handle

K_DMAAlloc

If you are using multiple buffers, it is recommended that you use

U16

K_BufListAdd

To K_DMAFree

Buffer Handle

• • •

To K_DMAFree

the Keithley Memory Manager before you begin programming to ensure

that you can allocate enough buffers and large enough buffers. Refer to

your DAS-1800 Series board user’s guide for more information about the

Keithley Memory Manager.

When a buffer is no longer required, you can free its memory for another

use by specifying the buffer handle in K_IntFree for interrupt-mode

operations or in K_DMAFree for DMA-mode operations.

2-6 Available Operations

Page 24

Gains and Ranges

Each analog input channel on a DAS-1800AO Series board can measure

signals in one of four software-selectable unipolar or bipolar analog input

ranges. The input range type (unipolar or bipolar) is initially set according

to your configuration file; use K_SetADMode to reset the input range

type. Refer to your DAS-1800AO Series User’s Guide for more

information about analog input ranges.

Table 2-2 lists the analog input ranges supported by DAS-1800AO Series

boards and the gain and gain code associated with each range. (The gain

code is used by the VIs to represent the gain.)

Table 2-2. Analog Input Ranges and Gains

Analog Input Range

Boards

Bipolar Unipolar

DAS-1801AO ±5 V 0 to 5 V 1 0

±1 V 0 to 1 V 5 1

±100 mV 0 to 100 mV 50 2

±20 mV 0 to 20 mV 250 3

DAS-1802AO ±10 V 0 to 10 V 1 0

±5 V 0 to 5 V 2 1

±2.5 V 0 to 2.5 V 4 2

±1.25 V 0 to 1.25 V 8 3

DAS-1801AO with

EXP-1800 attached

±100 mV 0 to 100 mV 50 4

±20 mV 0 to 20 mV 250 5

±2 mV 0 to 2 mV 2500 6

±0.4 mV 0 to 0.4 mV 12.5k 7

Gain

Gain

Code

2-7

Page 25

Table 2-2. Analog Input Ranges and Gains (cont.)

N

Boards

DAS-1802AO with

EXP-1800 attached

Channels

Analog Input Range

Gain

Bipolar Unipolar

±200 mV 0 to 200 mV 50 4

±100 mV 0 to 100 mV 100 5

±50 mV 0 to 50 mV 200 6

±25 mV 0 to 25 mV 400 7

Gain

Code

DAS-1800AO Series boards are configured with either 16 onboard

single-ended or eight onboard differential analog input channels. You can

increase the number of channels to 256 single-ended channels using

EXP-1800 expansion boards, described in the next section.

The input channel configuration (differential or single-ended) is initially

set according to the configuration file; use K_SetADConfig to reset the

input channel configuration. Use K_SetADCommonMode to set the

common-mode ground reference for boards configured for single-ended

input.

You can perform an analog input operation on a single channel or on a

group of multiple channels. The following subsections describe how to

specify the channels you are using.

Specifying Channels When Using EXP-1800 Expansion Boards

To increase the number of analog input channels, you can attach up to 16

EXP-1800 expansion boards to the DAS-1800AO Series board. Each

EXP-1800 board has 16 analog input channels. If you are using

EXP-1800 boards, you must attach them to DAS-1800AO channels 0 to

N-1 . Refer to the user’s guide for information on connecting EXP-1800

boards to DAS-1800AO Series boards.

2-8 Available Operations

Page 26

The analog input channel connections on a DAS-1800AO Series board or

EXP-1800 board are designated with numbers from 0 to 15. These

numbers are the physical channel numbers . If a system includes a

DAS-1800AO Series board and one or more EXP-1800s, then that system

contains duplicate physical channel numbers. To uniquely identify a

physical channel, the VI Driver uses a scheme of logical channel

numbers. The channel# argument for any VI must be specified as a logical

channel number.

The logical channel number corresponding to a particular physical

channel number is given by one of the following equations:

If the physical channel is on a DAS-1800AO Series board:

LogicalChan# PhysicalChan#15NumEXPs×()+=

If the physical channel is on an EXP-1800:

LogicalChan# PhysicalChan#16EXP#×()+=

where

NumEXPs is an integer from 0 to 16 that identifies the number of

EXP-1800s connected to the DAS-1800AO Series board, and

EXP# is an integer from 0 to 15 that indicates on which EXP-1800

the physical channel is located (0 indicates the first EXP-1800).

2-9

Page 27

For example, consider the system illustrated in Figure 2-1, in which three

EXP-1800s are connected to a DAS-1801AO.

0 1 2 ... 15

EXP #0

0 1 2 ... 15

EXP #1

0 1 2 ... 15

EXP #2

Logical Channel 48

Logical Channel 60

DAS-1801AO

0

1

2

3

15

Figure 2-1. Example of Logical Channel Assignments

The logical channel that identifies channel 3 on the DAS-1801A O is gi ven

by:

LogicalChan# 3 15 3×()+ 3 45 48=+==

The logical channel that identifies channel 15 on the third EXP-1800 is

given by:

Logical Channels 0 to 15

Logical Channels 16 to 31

Logical Channels 32 to 47

LogicalChan#15 162×()15 32+47==+=

Acquiring Samples from a Single Channel

You can acquire a single sample or multiple samples from a single analog

input channel.

For single-mode analog input operations, you can acquire a single sample

from a single analog input channel. Use K_ADRead to specify the

channel and the gain code.

2-10 Available Operations

Page 28

For interrupt-mode and DMA-mode analog input operations, you can

acquire a single sample or multiple samples from a single analog input

channel. Use K_SetChn to specify the channel and K_SetG to specify

the gain code.

Acquiring Samples from a Group of Consecutive Channels

For interrupt-mode and DMA-mode analog input operations, you can

acquire samples from a group of consecutive channels. Use

K_SetStartStopChn to specify the first and last channels in the group.

The channels are sampled in order from first to last; the channels are then

sampled again until the required number of samples are read.

For example, assume that the start channel is 14, the stop channel is 17,

and you want to acquire five samples. Your program reads data first from

channel 14, then from channels 15, 16, and 17, and finally from

channel 14 again.

You can specify a start channel that is higher than the stop channel. For

example, assume that you are using a single-ended input configuration

with no expansion boards, the start channel is 15, the stop channel is 2,

and you want to acquire five samples. Your program reads data first from

channel 15, then from channels 0, 1, and 2, and finally from channel 15

again.

Use K_SetG to specify the gain code for all channels in the group. (All

channels must use the same gain code.) Use K_SetStartStopG to specify

the gain code, the start channel, and the stop channel in a single VI.

Refer to Table 2-2 on page 2-7 for a list of the analog input ranges

supported by DAS-1800 Series boards and the gain code associated with

each range.

2-11

Page 29

Acquiring Samples Using a Channel-Gain Array

For interrupt-mode and DMA-mode analog input operations, you can

acquire samples from channels in a hardware channel-gain queue. You

create an array and specify the channels you want to sample, the order in

which you want to sample them, and a gain code for each channel. You

can set the channels in the channel-gain array in consecutive order or in

nonconsecutive order. You can also specify the same channel more than

once. The channel gain array can contain up to 256 entries.

The channels are sampled in order from the first channel specified in the

array to the last channel specified in the array; the channels in the array

are then sampled again until the specified number of samples is read.

For example, assume you want to sample channels 0, 5, and 3. Channel 0

uses a gain code of 1, channel 5 uses a gain code of 2 and channel 3 uses

a gain code of 3. Your array would look like this:

# of

Entries Chan

3 015233

Gain

Code Chan

Gain

Code Chan

Gain

Code

where the first element is the number of entries and the remaining pairs of

elements represent the channel to read and its associated gain code.

After you create the channel-gain array, you allocate space for the

channel-gain array in your program using K_AllocChnGAry; you

initialize the channel-gain array using K_FormatChnGAry; you set the

frame element for the channel-gain array using K_SetChnGAry. When

the operation is finished with the channel-gain array, you can free its

space using K_FreeChnGAry.

Refer to Table 2-2 on page 2-7 for a list of the analog input ranges

supported by DAS-1800AO Series boards and the gain code associated

with each range.

2-12 Available Operations

Page 30

Conversion Mode

The conversion mode determines how the board regulates the timing of

conversions when you are acquiring multiple samples from a single

channel or from a group of multiple channels (known as a scan). For

interrupt-mode and DMA-mode analog input operations, you can specify

one of the following conversion modes:

● Paced mode - Use paced mode if you want to accurately control the

period between conversions of individual channels in a scan. Paced

mode is the default conversion mode.

● Burst mode - Use burst mode if you want to accurately control both

the period between conversions of individual channels in a scan and

the period between conversions of the entire scan. Use

K_SetADFreeRun to specify burst mode.

Use burst mode with SSH (sample-and-hold) if you want to

simultaneously sample all channels in a scan using the SSH-8

accessory board. Use K_SetSSH to specify burst mode with SSH.

Note: If you use an SSH-8 accessory board, you must use burst mode

with SSH. One extra tick of the burst mode conversion clock is

required to allow the SSH-8 board to sample and hold the values.

Refer to the SSH-8 board documentation for more information.

Clock Source

Refer to your DAS-1800AO Series User’s Guide for more information

about conversion modes.

DAS-1800AO Series boards provide two clock sources for analog input

operations: an A/D pacer clock and a burst mode conversion clock. Each

clock has a dedicated use. When performing interrupt-mode and

DMA-mode analog input operations in paced mode, you use only the A/D

pacer clock; when performing interrupt-mode and DMA-mode analog

input operations in burst mode and burst mode with SSH, you use both

the A/D pacer clock and the burst mode conversion clock. These clock

sources are described in the following subsections.

2-13

Page 31

A/D Pacer Clock

In paced mode, the A/D pacer clock determines the period between the

conversion of one channel and the con v ersion of the next channel. In b urst

mode and burst mode with SSH, the A/D pacer clock determines the

period between the conversions of one scan and the conversions of the

next scan. Use K_SetClk to specify an internal or an external A/D pacer

clock source. The internal A/D pacer clock is the default pacer clock.

The internal and external A/D pacer clocks are described as follows:

● Internal A/D pacer clock - The internal A/D pacer clock uses two

cascaded counters of the onboard counter/timer circuitry. The

counters are normally in an idle state. When you start the analog input

operation (using K_IntStart or K_DMAStart), a conversion is

initiated. Note that a slight time delay occurs between the time the

operation is started and the time conversions begin.

After the first conversion is initiated, the counters are loaded with a

count value and begin counting do wn. When the counters count do wn

to 0, another conversion is initiated and the process repeats.

Because the counters use a 5 MHz time base, each count represents

0.2

µs. Use K_SetClkRate to specify the number of counts (clock

ticks) between conversions. F or example, if you specify a count of 30,

the period between conversions is 6

µs (166.67 ksamples/s).

You can specify a count between 15 and 4,294,967,295. The period

between conversions ranges from 3

µs to 14.3 minutes.

When using the internal A/D pacer clock, use the following formula

to determine the number of counts to specify:

counts

5 MHz time base

---------------------------------------- -=

conversion rate

For example, if you want a conversion rate of 10 ksamples/s, specify

a count of 500, as shown in the following equation:

5 000 000,,

-------------------------- -500=

10 000,

2-14 Available Operations

Page 32

External A/D pacer clock - You connect an external pacer clock to

●

the XPCLK pin (pin 44) on the board’s main I/O connector. When

you start an analog input operation (using K_IntStart or

K_DMAStart ), conversions are armed. At the next active edge of the

external pacer clock (and at every subsequent active edge of the

external pacer clock), a conversion is initiated. Use

K_SetExtClkEdge to specify the active edge (rising or falling) of the

external pacer clock. A falling edge is the default active edge for the

external pacer clock.

The rate at which the computer can reliably read data from the

Note:

board depends on a number of factors, including your computer, the

operating system/environment, the gains of the channels, and other

issues. If you are using an external pacer clock for analog input

operations, make sure that the clock initiates conv ersions at a rate that

the ADC can handle.

Refer to your DAS-1800AO Series User’s Guide for more information

about the pacer clock.

Burst Mode Conversion Clock

In burst mode and burst mode with SSH, the burst mode conversion clock

determines the period between the conversion of one channel in a scan

and the conversion of the next channel in the scan.

Because the burst mode conversion clock uses a 1 MHz time base, each

clock tick represents 1

µ

s. Use K_SetBurstTicks to specify the number

of clock ticks between conversions. For example, if you specify 30 clock

ticks, the period between conversions is 30

s (33.33 ksamples/s).

µ

You can specify between 3 and 63 clock ticks. The period between

conversions ranges from 3

µ

s to 63

µ

s.

When using the burst mode conversion clock, use the following formula

to determine the number of clock ticks to specify:

clock ticks

1 MHz time base

---------------------------------------------------------------- -=

burst mode conversion rate

2-15

Page 33

For example, if you want a burst mode conversion rate of 20 ksamples/s,

specify 50 clock ticks, as shown in the following equation:

Refer to your DAS-1800AO Series User’s Guide for more information

about the burst mode conversion clock.

Buffering Mode

The buffering mode determines how the driver stores the converted data

in the buffer. For interrupt-mode and DMA-mode analog input

operations, you can specify one of the following buffering modes:

●

●

1 000 000,,

-------------------------- -50=

20 000,

Single-cycle mode - In single-cycle mode, after the board converts

the specified number of samples and stores them in the buffer, the

operation stops automatically. Single-cycle mode is the default

buffering mode.

Continuous mode - In continuous mode, the board continuously

converts samples and stores them in the buffer until the process is

stopped; any values already stored in the buffer are overwritten. Use

K_SetContRun to specify continuous buffering mode.

Trigger

A trigger is an event that starts or stops an interrupt-mode or DMA-mode

analog input operation. An operation can use either one or two triggers.

Every operation must have a start trigger that marks the beginning of the

operation. You can use an optional second trigger, the about trigger , to

define when the operation stops. If you specify an about trigger, the

operation stops when a specified number of samples has been acquired

after the occurrence of the about-trigger event.

A post-trigger acquisition refers to an operation that uses only a start

trigger. The about trigger provides the capability to define operations that

acquire data before a trigger event (pre-trigger acquisition) and operations

that acquire data about (before and after) a trigger event (about-trigger

acquisition). The supported trigger sources and post-trigger, pre-trigger,

and about-trigger acquisitions are described in the following subsections.

2-16 Available Operations

Page 34

Trigger Source

The VI Driver supports two trigger sources: internal and external. For

interrupt-mode and DMA-mode analog input operations, use K_SetTrig

to specify the trigger source. External triggers can be analog triggers or

digital triggers.

The trigger event is not significant until the operation the trigger governs

has been started (using K_DMAStart or K_IntStart ). The point at which

conversions be gin depends on the pacer clock; refer to page 2-13 for more

information.

The internal trigger, external analog trigger, and external digital trigger

are described as follows:

Internal trigger - An internal trigger is a softw are trigger . The trigger

●

event occurs immediately after you start the operation. Consequently,

K_DMAStart or K_IntStart is considered the trigger event for an

internal trigger. The internal trigger is the default trigger source.

External analog trigger - Y ou can use the signal on any analog input

●

channel as the trigger signal for an analog trigger. Trigger events for

analog triggers (illustrated in Figure 2-2) are described as follows:

– Positive trigger - The trigger signal changes from a voltage that

is less than the trigger level to a voltage that is greater than the

trigger level.

– Negative trigger - The trigger signal changes from a voltage that

is greater than the trigger level to a voltage that is less than the

trigger level.

Analog triggering is a feature of the VI Driver and is not

Note:

implemented at the hardware level. Consequently, there is a delay

between the time the trigger event occurs and the time the driver

recognizes that the trigger event occurred.

2-17

Page 35

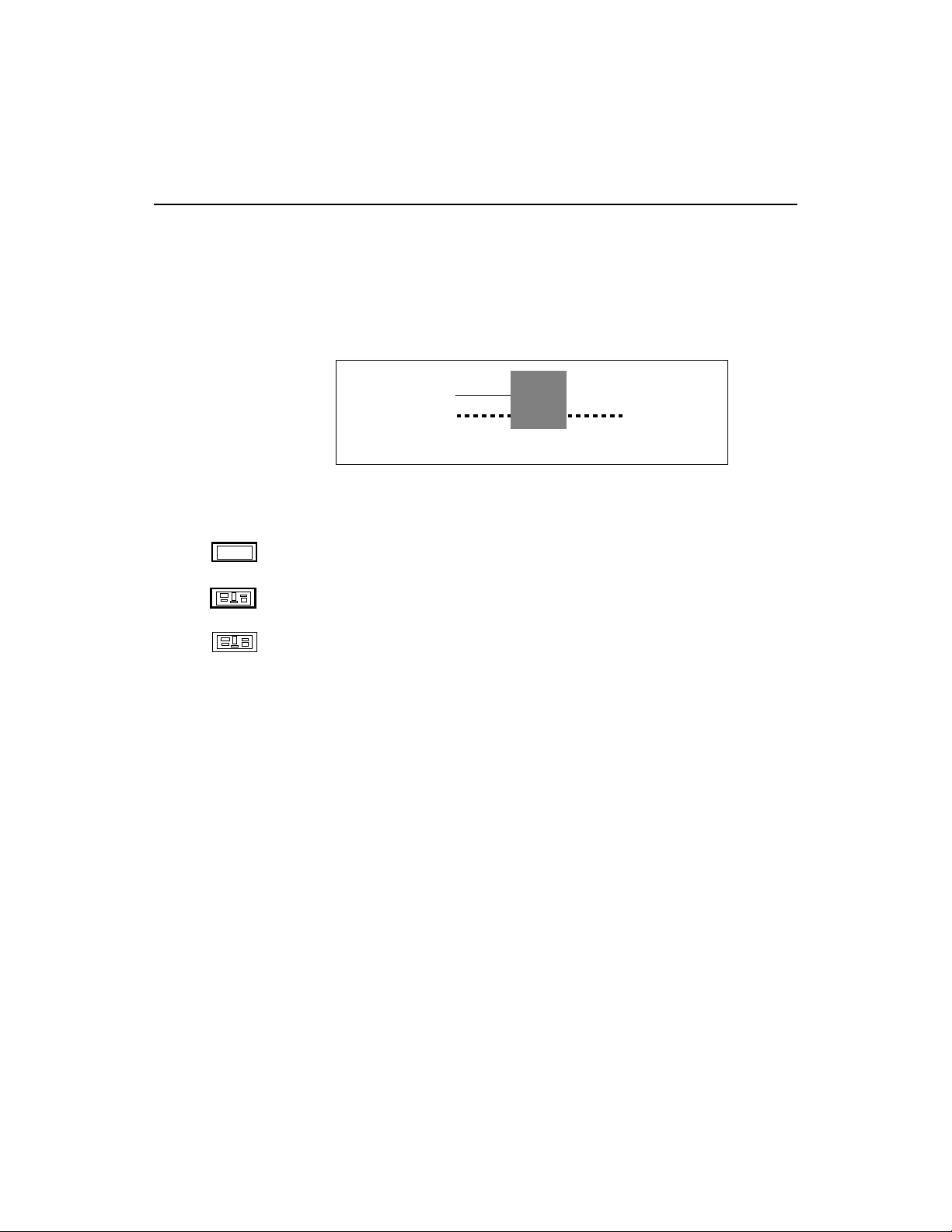

Positive trigger

Trigger level

Trigger signal

Trigger event

Negative trigger

Trigger level

Trigger signal

Figure 2-2. Trigger Events for Analog Triggers

Trigger event

Use K_SetADTrig to specify the analog input channel to use as the

trigger channel, the trigger level, and the trigger polarity (positive or

negative).

You specify the trigger level as a raw count value. Refer to

Appendix B for information on how to convert a voltage value to a

raw count value.

You can specify a hysteresis value to prevent noise from triggering an

operation. Use K_SetTrigHyst to specify the hysteresis value. For a

positive trigger, the analog signal must be below the specified trigger

level by at least the amount of the hysteresis v alue and then rise above

the trigger level before the trigger occurs; for a negative trigger, the

analog signal must be above the specified trigger level by at least the

amount of the hysteresis value and then fall below the trigger level

before the trigger occurs.

The hysteresis value is an absolute number, which you specify as a

raw count value between 0 and 4095. When you add the hysteresis

value to the trigger level (for a negative trigger) or subtract the

hysteresis value from the trigger level (for a positive trigger), the

resulting value must also be between 0 and 4095.

2-18 Available Operations

Page 36

Level +4 V

+3.9 V

For example, assume that you are using a negative trigger on a

channel of a board configured for an analog input range of ±5 V. If the

trigger level is +4.8 V (4014 counts), you can specify a hysteresis

value of 0.1 V (41 counts) because 4014 + 41 is less than 4095, but

you cannot specify a hysteresis value of 0.3 V (123 counts) because

4014 + 123 is greater than 4095. Refer to Appendix B for information

on how to convert a voltage value to a raw count value.

In Figure 2-3, the specified trigger level is +4 V and the hysteresis

value is 0.1 V. The analog signal must be below +3.9 V and then rise

above +4 V before a positi ve trigger occurs; the analog signal must be

above +4.1 V and then fall below +4 V before a negative trigger

occurs.

Positive trigger

occurs

Hysteresis = 0.1 V

Analog input operation

start VI is executed

+4.1 V

Level +4 V

Hysteresis = 0.1 V

Negative trigger

occurs

Analog input operation

start VI is executed

Figure 2-3. Using a Hysteresis Value

2-19

Page 37

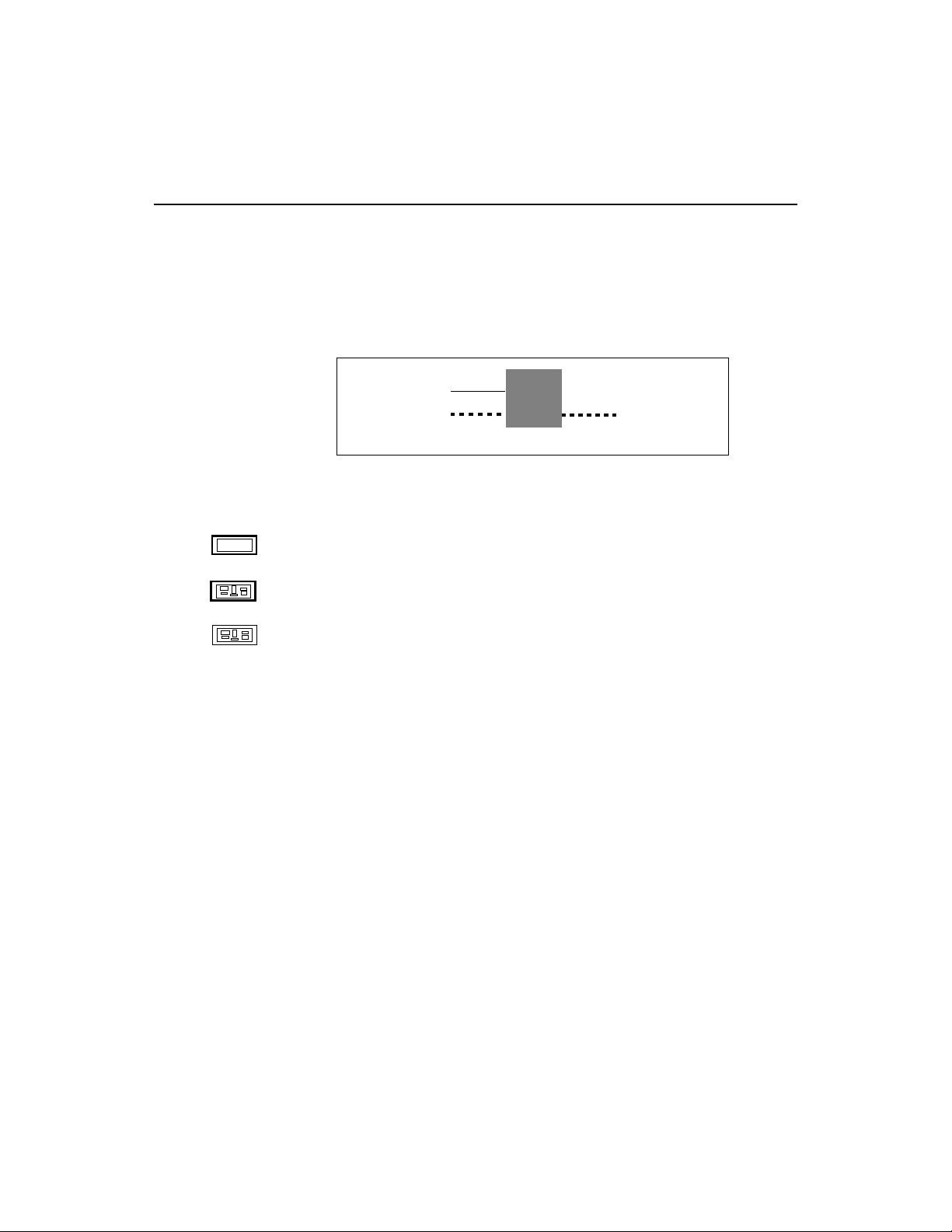

● External digital trigger - The digital trigger signal is a vailable on the

TGIN pin (pin 46) on the board’s main I/O connector. Use

K_SetDITrig to specify whether you want the trigger event to occur

on a rising edge (positive polarity) or a falling edge (negative

polarity). These trigger events are illustrated in Figure 2-4.

Trigger

Positive polarity

Trigger signal

Negative polarity

Trigger signal

event

Trigger event

Figure 2-4. Trigger Events For Digital Triggers

Post-Trigger Acquisition

Use post-trigger acquisition in applications where you want to collect

data after a specific event. Acquisition starts on an internal, analog, or

digital trigger event and continues until a specified number of samples has

been acquired or until the operation is stopped by K_DMAStop or

K_IntStop.

To specify post-trigger acquisition, use the following VIs:

1. If you want acquisition to continue until you stop it with

K_DMAStop or K_IntStop, use K_SetContRun to set the buffering

mode to continuous.

2-20 Available Operations

Page 38

2. If you want acquisition to stop after a specified number of samples

has been acquired, use K_ClrContRun to set the buffering mode to

single-cycle (in this buffering mode, the operation stops as soon as

the board has acquired the number of samples specified by

K_SetBuf, K_SetDMABuf, or K_BufListAdd).

3. Use K_SetTrig to specify the trigger source that will start the

operation (internal for an internal trigger, external for an analog or

digital trigger).

4. If you are using an analog trigger, use K_SetADTrig to define the

trigger conditions; if you are using a digital trigger, use K_SetDIT rig

to define the trigger conditions.

5. Use K_ClrAboutTrig to disable the about trigger.

Pre-Trigger Acquisition

Use pre-trigger acquisition in applications where you want to collect data

before a specific digital trigger event (this is the about trigger event).

Acquisition starts on an internal, analog, or digital trigger event and

continues until the about-trigger event. Pre-trigger acquisition is av ailable

with DMA-mode operations only.

To specify pre-trigger acquisition, use the following VIs:

1. Use K_SetTrig to specify the trigger source that will start the

operation (internal for an internal trigger, external for an analog or

digital trigger).

2. If you are using an analog start trigger, use K_SetADTrig to define

the trigger conditions; if you are using a digital start trigger, use

K_SetDITrig to define the trigger conditions.

3. Use K_SetAboutTrig to enable the about trigger and to set the

number of post-trigger samples to 1.

4. If the start trigger is not digital, use K_SetDITrig to specify the

active edge for the about trigger. (If the start trigger is digital, then its

active edge is also used for the about trigger).

2-21

Page 39

About-Trigger Acquisition

Use about-trigger acquisition in applications where you want to collect

data both before and after a specific digital trigger event (this is the

about-trigger event). Acquisition starts on an internal, analog, or digital

trigger event and continues until a specified number of samples has been

acquired after the about-trigger event. About-trigger acquisition is

available with DMA-mode operations only.

To specify about-trigger acquisition, use the following VIs:

1. Specify the trigger that will start the operation. Use K_SetTrig to

specify the trigger source (internal for an internal trigger, external for

an analog or digital trigger).

2. If you are using an analog start trigger, use K_SetADTrig to define

the trigger conditions; if you are using a digital start trigger, use

K_SetDITrig to define the trigger conditions.

3. Use K_SetAboutTrig to enable the about trigger and to specify the

desired number of post-trigger samples.

4. If the start trigger is not digital, use K_SetDITrig to specify the

active edge for the about trigger. (If the start trigger is digital, then its

active edge is also used for the about trigger).

Hardware Gate

A hardware gate is an externally applied digital signal that determines

whether conversions occur. You connect the gate signal to the TGIN pin

(pin 46) on the board’s main I/O connector. If you have started an

interrupt-mode or DMA-mode analog input operation (using K_IntStart

or K_DMAStart) and the hardware gate is enabled, the state of the gate

signal determines whether conversions occur.

If the board is configured with a positive gate, conversions occur only if

the gate signal to TGIN is high; if the gate signal to TGIN is low,

conversions are inhibited. If the board is configured with a negative gate,

conversions occur only if the gate signal to TGIN is lo w; if the gate signal

to TGIN is high, conv ersions are inhibited. Use K_SetGate to enable and

disable the hardware gate and to specify the gate polarity (positive or

negative). The default state of the hardware gate is disabled.

2-22 Available Operations

Page 40

You can use the hardware gate with an external analog trigger. The

software waits until the analog trigger conditions are met, and then the

hardware checks the state of the gate signal.

If you are not using an analog trigger, the gate signal itself can act as a

trigger. If the gate signal is in the inactive state when you start the analog

input operation, the hardware waits until the gate signal is in the active

state before conversions begin.

Note: You cannot use the hardware gate with an external digital trigger. If

you use a digital trigger at one point in your application program and later

want to use a hardware gate, you must first disable the digital trigger. Y ou

disable the digital trigger by specifying an internal trigger in K_SetTrig

or by setting up an analog trigger (using K_SetADTrig).

Analog Output Operations

This section describes the following:

● Analog output operation modes available.

● How to allocate and manage memory for analog output operations.

● How to specify the following for an analog output operation:

Operation Mode

The operation mode determines which attributes you can specify for an

analog output operation. Y ou can perform analog output operations in one

of the following modes:

● Single mode - In single mode, the driver writes a single value to one

channels and gains, clock source, buffering mode, trigger source, and

hardware gate.

analog output channel; you cannot perform any other operation until

the single-mode operation is complete.

Use K_DAWriteGain to start an analog output operation in single

mode. You specify the board you want to use, the analog output

channel, the gain code, and the value you want to write.

2-23

Page 41

● Interrupt mode - In interrupt mode, the driver writes a single value

or multiple values to one or both analog output channels. A hardware

clock paces the updating of the analog output channels. Once the

analog output operation begins, control returns to your application

program. You store the values you want to write in a user-defined

buffer in the computer. The hardware temporarily stores the output

data in the onboard D/A FIFO and then writes the data using an

interrupt service routine. Use K_IntStart to start an analog output

operation in interrupt mode.

You can specify either single-cycle or continuous buffering mode for

interrupt-mode operations. Refer to page 2-30 for more information

on buffering modes. Use K_IntStop to stop an interrupt operation.

Use K_IntStatus to determine the current status of an interrupt

operation.

● DMA mode - In DMA mode, the driver writes a single sample or

multiple samples to one or both analog output channels. A hardware

clock paces the updating of the analog output channels. Once the

analog output operation begins, control returns to your application

program. You store the values you want to write in a user-defined

DMA buffer in the computer. The hardware temporarily stores the

output data in the onboard D/A FIFO and then writes the data. Use

K_DMAStart to start an analog output operation in DMA mode.

You can specify either single-cycle or continuous buffering mode for

DMA-mode operations. Refer to page 2-30 for more information on

buffering modes. Use K_DMAStop to stop a DMA operation. Use

K_DMAStatus to determine the current status of a DMA operation.

● Recycle mode - In recycle mode, the driver writes a single sample or

up to a total of 2048 samples to one or both analog output channels. A

hardware clock paces the updating of the analog output channels.

Once the analog output operation begins, control returns to your

application program. You store the values you want to write in a

user-defined buffer in the computer. The hardware temporarily stores

the output data in the onboard D/A FIFO and then writes the data.

The data in the D/A FIFO is continuously recycled until the operation

is stopped. Use K_DMAStart or K_IntStart to start an analog

output operation in recycle mode.

If you are performing a recycle mode analog output operation, the

board automatically uses the onboard D/A FIFO; the PC’s interrupt or

DMA resources are not used. In this case, the board attains its highest

transfer rate (up to 500 ksamples/s).

2-24 Available Operations

Page 42

You must specify continuous buffering mode for recycle-mode

operations. Refer to page 2-30 for more information on buffering

modes. Use K_DMAStop or K_IntStop to stop a recycle-mode

operation. Use K_DMAStatus or K_IntStatus to determine the

current status of a recycle-mode operation.

For an analog output operation, the values are written as raw counts. For

information on converting voltage to raw counts, refer to Appendix B.

Memory Allocation and Management

Interrupt-mode and DMA-mode analog output operations require

memory buffers in which to store the data to be written to the analog

output channels. You can reserve a single buffer, or you can reserve

multiple buffers (up to a maximum of 150) to increase the number of

samples. Recycle-mode analog output operations require a single memory

buffer of no more than 2048 samples. Buffers must be dynamically

allocated outside of your application program’s memory area.

Use K_IntAlloc to allocate memory dynamically for interrupt-mode or

recycle-mode operations; use K_DMAAlloc to allocate memory

dynamically for DMA-mode or recycle-mode operations. You specify the

operation requiring the buffer and the number of samples to store in the

buffer (up to 65,536). The driver returns the starting address of the buffer

and a unique identifier for the buffer; this identifier is called the buffer

handle.

T o assign the starting address of a b uffer and the number of samples in the

buffer, use K_SetBuf for buffers allocated with K_IntAlloc or

K_SetDMABuf for buffers allocated with K_DMAAlloc. If you are

using multiple buffers, use K_BufListAdd to add each buf fer to the list of

multiple buffers associated with each operation. Refer to page 2-5 for an

example of using multiple buffers. To move the contents of a LabVIEW

buffer to an allocated buffer, use K_MoveArrayToBuf.

When a buffer is no longer required, you can free it for another use by

specifying the buffer handle in K_IntFree for buffers allocated with

K_IntAlloc or in K_DMAFree for buffers allocated with K_DMAAlloc.

2-25

Page 43

Note: If you are using multiple buffers, it is recommended that you use

the Keithley Memory Manager before you begin programming to ensure

that you can allocate enough buffers and large enough buffers. Refer to

the DAS-1800AO Series User’s Guide for more information about the

Keithley Memory Manager.

Gains and Ranges

Each analog output channel on a DAS-1800AO Series board can write an

analog output signal in one of two software-selectable ranges. Table 2-3

lists the analog output ranges supported by DAS-1800AO Series boards

and the gain code associated with each range.

Table 2-3. Analog Output Ranges

Analog Output Range Gain Code

±5 V 0

±10 V 1

Channels

DAS-1800AO Series boards contain two digital-to-analog converters

(DACs), each of which is associated with an analog output channel. You

can perform an analog output operation on a single channel or on both

channels. The following subsections explain how to specify the channels.

Writing Values to a Single Channel

For single-mode operations, you can write a single value to a single

analog output channel. Use K_DAWriteGain to specify the channel and

the gain code.

For interrupt-mode, DMA-mode, and recycle-mode operations, you can

write a single value or multiple values to a single analog channel. Use

K_SetChn to specify the channel and K_SetG to specify the gain code.

2-26 Available Operations

Page 44

Writing Values to Both Channels Using the Same Gain Code

For interrupt-mode, DMA-mode, and recycle-mode analog output

operations, you can write a single value or multiple values to both analog

output channels simultaneously when both channels use the same gain

code. Use K_SetStartStopChn to specify channel 0 as the start channel

and channel 1 as the stop channel; use K_SetG to specify the gain code

for both channels. Y ou can also use K_SetStartStopG to specify the start

channel, the stop channel, and the gain code in a single VI.

At each pacer clock pulse, two values in the buffer are written

simultaneously. The first value is written to channel 0 and the second

value is written to channel 1. After all the values in the buffer are written

once, the values are written again until the required number of values are

written.

Writing Values to Both Channels Using Different Gain Codes

For interrupt-mode, DMA-mode, and recycle-mode analog output

operations, you can write a single value or multiple values to both analog

output channels simultaneously when each channel uses a different gain

code. Both channels are updated simultaneously until the specified

number of values is written.

To specify one gain code for channel 0 and another gain code for channel

1, create a two-entry channel-gain array with channel 0 and its gain code

as the first channel-gain pair and channel 1 and its gain code as the second

channel-gain pair. For example, assume you want channel 0 configured

for a ±5 V range (gain code of 0) and channel 1 configured for a ±10 V

range (gain code of 1). Your channel-gain array would look like the

following example:

# of

Entries Chan

2 0011

Gain

Code Chan

Gain

Code

where the first element is the number of entries in the channel-gain array.

2-27

Page 45

Clock Source

D/A Pacer Clock

After you create the channel-gain array, you allocate space for the

channel-gain array in your program using K_AllocChnGAry; you

initialize the channel-gain array using K_FormatChnGAry; you set the

channel-gain array element using K_SetChnGAry. When the operation

is finished with the channel-gain array, you can free its space using

K_FreeChnGAry.

Refer to Table 2-3 for the analog output ranges supported by

DAS-1800AO Series boards and the gain code associated with each

range.

When performing interrupt-mode, DMA-mode, or recycle-mode analog

output operations, you can use one of three pacer clocks to determine the

period between the updating of a single analog output channel or between

each simultaneous updating of both analog output channels: the D/A

pacer clock, an external pacer clock, or the A/D pacer clock. These clock

sources are described in the following subsections.

To specify the internal D/A pacer clock source, use K_SetClk to set the

clock source to internal.

Since the D/A pacer clock uses a 5 MHz time base, each count represents

0.2

µs. The driver automatically enables the divide-by-10 prescaler. Use

K_SetClkRate to specify the number of counts (clock ticks) between

updates. For example, if you specify a count of 30, the period between

updates is 6

updated simultaneously at the rate of the pacer clock.

You can specify a count between 10 and 655,350. The period between

updates ranges from 2

When using the D/A pacer clock, use the following formula to determine

the number of counts to specify:

2-28 Available Operations

µs (166.67 ksamples/s). If two channels are selected, they are

µs to 131 ms.

counts

5 MHz time base

---------------------------------------- -=

update rate

Page 46

For example, if you want an update rate of 10 ksamples/s, specify a count

of 500, as shown in the following equation:

External Pacer Clock

To specify an external pacer clock, use K_SetClk to set the clock source

to external.

You connect an external pacer clock to the XPCLK pin (pin 44) on the

board’s main I/O connector. When you start an analog output operation

(using K_IntStart or K_DMAStart ), the driver starts monitoring the

state of the external pacer clock. At the next active edge of the external

pacer clock (and at every subsequent active edge of the external pacer

clock), the analog output channels are updated. Use K_SetExtClkEdge

to specify the active edge (rising or falling) of the e xternal pacer clock. A

falling edge is the default active edge for the external pacer clock.

Note:

depends on a number of factors, including your computer, the operating

system/environment, the range of the channels, and other issues. If you

are using an external pacer clock for analog output operations, make sure

that the clock initiates conversions at a rate that the DACs can handle.

5 000 000,,

-------------------------- -500=

10 000,

The rate at which the computer can reliably write data to the board

A/D Pacer Clock

Refer to your DAS-1800AO Series User’s Guide for more information

about the external pacer clock.

A DAS-1800AO Series board can synchronize digital-to-analog (D/A)

conversions with analog-to-digital (A/D) conversions. Use K_SetClk to

set the clock source to internal, and then use K_SetSync to specify that

the analog output operation will be synchronized with the analog input

operation.