Page 1

www.tek.com/keithley

Model DAQ6510

Data Acquisition and Multimeter System

Calibration and Adjustment Manual

DAQ6510-905-01 Rev. D June 2022

*PDAQ6510-905-01D*

DAQ6510-905-01D

Page 2

Data Acquisition and Multimeter System

DAQ6510

Calibration and Adjustment Manual

Page 3

© 2022, Keithley Instruments, LLC

Cleveland, Ohio, U.S.A.

All rights reserved.

Any unauthorized reproduction, photocopy, or use of the information herein, in whole or in part,

without the prior written approval of Keithley Instruments, LLC, is strictly prohibited.

These are the original instructions in English.

TSPTM and TSP-LinkTM are trademarks of Keithley Instruments, LLC. All Keithley Instruments

product names are trademarks or registered trademarks of Keithley Instruments, LLC. Other brand

names are trademarks or registered trademarks of their respective holders.

The Lua 5.0 software and associated documentation files are copyright © 1994-2008, Tecgraf,

PUC-Rio. Terms of license for the Lua software and associated documentation can be accessed at

the Lua licensing site (http://www.lua.org/license.html).

Microsoft, Visual C++, Excel, and Windows are either registered trademarks or trademarks of

Microsoft Corporation in the United States and/or other countries.

Document number: DAQ6510-905-01 Rev. D June 2022

Page 4

Safety precautions

The following safety precautions should be observed before using this product and any associated instrumentation. Although

some instruments and accessories would normally be used with nonhazardous voltages, there are situations where hazardous

conditions may be present.

This product is intended for use by personnel who recognize shock hazards and are familiar with the safety precautions required

to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using the

product. Refer to the user documentation for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product warranty may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the

equipment is operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use of the

instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line

voltage or replacing consumable materials. Maintenance procedures are described in the user documentation. The procedures

explicitly state if the operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel are trained to work on live circuits, perform safe installations, and repair products. Only properly trained

service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that are measurement, control, and data I/O connections, with low

transient overvoltages, and must not be directly connected to mains voltage or to voltage sources with high transient

overvoltages. Measurement Category II (as referenced in IEC 60664) connections require protection for high transient

overvoltages often associated with local AC mains connections. Certain Keithley measuring instruments may be connected to

mains. These instruments will be marked as category II or higher.

Unless explicitly allowed in the specifications, operating manual, and instrument labels, do not connect any instrument to mains.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test

fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than

30 V RMS, 42.4 V peak, or 60 VDC are present. A good safety practice is to expect that hazardous voltage is present in any

unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators

are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential

human contact. Product operators in these circumstances must be trained to protect themselves from the risk of electric shock. If

the circuit is capable of operating at or above 1000 V, no conductive part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance-limited

sources. NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective

devices to limit fault current and voltage to the card.

Before operating an instrument, ensure that the line cord is connected to a properly-grounded power receptacle. Inspect the

connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input

power disconnect device must be provided in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under

test. ALWAYS remove power from the entire test system and discharge any capacitors before connecting or disconnecting

cables or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth)

ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the

voltage being measured.

Page 5

For safety, instruments and accessories must be used in accordance with the operating instructions. If the instruments or

accessories are used in a manner not specified in the operating instructions, the protection provided by the equipment may be

impaired.

Do not exceed the maximum signal levels of the instruments and accessories. Maximum signal levels are defined in the

specifications and operating information and shown on the instrument panels, test fixture panels, and switching cards.

When fuses are used in a product, replace with the same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as protective earth (safety ground)

connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use

of a lid interlock.

If a screw is present, connect it to protective earth (safety ground) using the wire recommended in the user documentation.

The symbol on an instrument means caution, risk of hazard. The user must refer to the operating instructions located in the

user documentation in all cases where the symbol is marked on the instrument.

The symbol on an instrument means warning, risk of electric shock. Use standard safety precautions to avoid personal

contact with these voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to prevent burns.

The symbol indicates a connection terminal to the equipment frame.

If this symbol is on a product, it indicates that mercury is present in the display lamp. Please note that the lamp must be

properly disposed of according to federal, state, and local laws.

The WARNING heading in the user documentation explains hazards that might result in personal injury or death. Always read

the associated information very carefully before performing the indicated procedure.

The CAUTION heading in the user documentation explains hazards that could damage the instrument. Such damage may

invalidate the warranty.

The CAUTION heading with the symbol in the user documentation explains hazards that could result in moderate or minor

injury or damage the instrument. Always read the associated information very carefully before performing the indicated

procedure. Damage to the instrument may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits — including the power

transformer, test leads, and input jacks — must be purchased from Keithley. Standard fuses with applicable national safety

approvals may be used if the rating and type are the same. The detachable mains power cord provided with the instrument may

only be replaced with a similarly rated power cord. Other components that are not safety-related may be purchased from other

suppliers as long as they are equivalent to the original component (note that selected parts should be purchased only through

Keithley to maintain accuracy and functionality of the product). If you are unsure about the applicability of a replacement

component, call a Keithley office for information.

Unless otherwise noted in product-specific literature, Keithley instruments are designed to operate indoors only, in the following

environment: Altitude at or below 2,000 m (6,562 ft); temperature 0 °C to 50 °C (32 °F to 122 °F); and pollution degree 1 or 2.

To clean an instrument, use a cloth dampened with deionized water or mild, water-based cleaner. Clean the exterior of the

instrument only. Do not apply cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that

consist of a circuit board with no case or chassis (e.g., a data acquisition board for installation into a computer) should never

require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board

should be returned to the factory for proper cleaning/servicing.

Safety precaution revision as of June 2018.

Page 6

Table of contents

Introduction ............................................................................................................... 1-1

Welcome .............................................................................................................................. 1-1

Introduction to this manual ................................................................................................... 1-1

Extended warranty ............................................................................................................... 1-2

Contact information .............................................................................................................. 1-2

Performance verification .......................................................................................... 2-1

Introduction .......................................................................................................................... 2-1

Verification test requirements .............................................................................................. 2-2

Environmental conditions .......................................................................................................... 2-2

Warmup period .......................................................................................................................... 2-2

Line power................................................................................................................................. 2-3

Recommended test equipment ................................................................................................. 2-3

Calibration verification limits ................................................................................................ 2-4

Example reading limit calculation .............................................................................................. 2-4

Calculating resistance reading limits ......................................................................................... 2-4

Performing the verification test procedures ......................................................................... 2-5

Test summary ........................................................................................................................... 2-5

Test considerations ................................................................................................................... 2-5

Front-panel calibration verification ....................................................................................... 2-6

DC voltage verification .............................................................................................................. 2-6

AC voltage verification .............................................................................................................. 2-9

Digitize dc voltage verification ................................................................................................. 2-14

Frequency verification ............................................................................................................. 2-17

Simulated thermocouple type J temperature verification ......................................................... 2-18

Simulated RTD temperature verification ................................................................................. 2-20

Resistance verification ............................................................................................................ 2-24

DC current verification ............................................................................................................. 2-29

Digitize current verification ...................................................................................................... 2-33

AC current verification ............................................................................................................. 2-36

Capacitance verification .......................................................................................................... 2-39

Verifying zero values using a 4-wire short ............................................................................... 2-41

Rear-panel verification ....................................................................................................... 2-43

Adjustment ................................................................................................................ 3-1

Introduction .......................................................................................................................... 3-1

Environmental conditions ..................................................................................................... 3-2

Temperature and relative humidity ............................................................................................ 3-2

Line power................................................................................................................................. 3-2

Warmup period ..................................................................................................................... 3-2

Adjustment overview ............................................................................................................ 3-3

Recommended test equipment ............................................................................................ 3-3

General adjustment considerations ..................................................................................... 3-4

Initial instrument setup ......................................................................................................... 3-5

Page 7

Table of contents

Calibration and Adjustment Manual

DAQ6510 Data Acquisition and Multimeter System

Select the correct terminals ....................................................................................................... 3-5

Select the TSP command set .................................................................................................... 3-5

Verify instrument date and time ................................................................................................. 3-6

Set up remote connections........................................................................................................ 3-6

Unlock calibration ...................................................................................................................... 3-6

Remote calibration adjustment procedures ......................................................................... 3-7

Disable temperature correction ................................................................................................. 3-7

Front-terminal adjustment with a 4-wire short ........................................................................... 3-7

Rear-terminal adjustment with a 4-wire short .......................................................................... 3-10

Front-terminal adjustment with open circuit inputs .................................................................. 3-11

Rear-terminal adjustment with open circuit inputs ................................................................... 3-13

Resistance adjustment ............................................................................................................ 3-14

DC voltage adjustment ............................................................................................................ 3-16

DC current adjustment ............................................................................................................ 3-17

AC voltage adjustment ............................................................................................................ 3-21

AC current adjustment ............................................................................................................ 3-23

Frequency adjustment ............................................................................................................. 3-25

Complete list of calibration commands .................................................................................... 3-26

Enable temperature correction ........................................................................................... 3-38

Save calibration and set the adjustment dates .................................................................. 3-39

Setting time, adjustment, and verification dates ................................................................ 3-39

Adjustment command timing and error checking ............................................................... 3-40

Handling events ................................................................................................................. 3-40

TSP command reference .......................................................................................... 4-1

TSP commands .................................................................................................................... 4-1

Introduction ............................................................................................................................... 4-1

cal.adjust.count ......................................................................................................................... 4-2

cal.adjust.date ........................................................................................................................... 4-3

cal.adjust.step.setup() ............................................................................................................... 4-4

cal.adjust.step.execute() ........................................................................................................... 4-5

cal.lock() .................................................................................................................................... 4-6

cal.password ............................................................................................................................. 4-7

cal.save()................................................................................................................................... 4-8

cal.unlock() ................................................................................................................................ 4-9

cal.verify.date .......................................................................................................................... 4-10

Page 8

Contact information ...................................................................1-2

In this section:

Welcome

The DAQ6510 is a 6½-digit data acquisition and logging multimeter system that has a touchscreen

user interface that enables faster setup time, real-time monitoring of test status, and detailed analysis

on the instrument.

Section 1

Introduction

Welcome ...................................................................................1-1

Introduction to this manual ........................................................1-1

Extended warranty ....................................................................1-2

This manual provides information on completing verification and adjustment procedures for your

DAQ6510.

Introduction to this manual

This manual provides instructions to help you calibrate and adjust your DAQ6510. In this manual,

calibration refers to the process of verifying that the accuracy of the instrument is within its one-year

accuracy specifications. Also, adjustment refers to the process of changing the calibration constants

so that the accuracy of the instrument is within its one-year accuracy specifications.

This manual presents calibration information, adjustment information, and command descriptions for

the calibration and adjustment commands.

For additional command descriptions, refer to the DAQ6510 Reference Manual available on the

Product Support and Downloads web page (tek.com/en/support/product-support

to the Release Notes for your instrument that contains relevant information on improvements,

changes, and known issues.

). Additionally, refer

Page 9

Section

Calibration and Adjustment Manual

1: Introduction DAQ6510 Data Acquisition and Multimeter System

Extended warranty

Additional years of warranty coverage are available on many products. These valuable contracts

protect you from unbudgeted service expenses and provide additional years of protection at a fraction

of the price of a repair. Extended warranties are available on new and existing products. Contact your

local Keithley Instruments office, sales partner, or distributor for details.

Contact information

If you have any questions after you review the information in this documentation, please contact your

local Keithley Instruments office, sales partner, or distributor. You can also call the Tektronix

corporate headquarters (toll-free inside the U.S. and Canada only) at 1-800-833-9200. For worldwide

contact numbers, visit tek.com/contact

.

1-2 DAQ6510-905-01 Rev. D June 2022

Page 10

Rear-panel verification ............................................................2-43

In this section:

Introduction ...............................................................................2-1

Verification test requirements ....................................................2-2

Calibration verification limits......................................................2-4

Performing the verification test procedures ...............................2-5

Front-panel calibration verification ............................................2-6

Introduction

Use the procedures in this section to verify that DAQ6510 accuracy is within the limits stated in the

instrument’s one-year accuracy specifications. Specifications and characteristics are subject to

change without notice; refer to the Product Support and Downloads web page

(tek.com/en/support/product-support) for the most recent specifications.

Section 2

Performance verification

You can use these verification procedures to:

• Make sure that the instrument was not damaged during shipment.

• Verify that the instrument meets factory specifications.

• Determine if adjustment is required.

• Verify that adjustment was done properly.

Although the following tests are based on the Model 7700 20-Channel Differential Multiplexer Module,

the same general procedures can be used for other switching modules that have similar capabilities.

Refer to the user's manual for your specific module for information on terminal connections.

The information in this section is intended for qualified service personnel only, as described

by the types of product users in the Safety precautions pages, provided at the beginning of

this document. Do not attempt these procedures unless you are qualified to do so.

Some of these procedures may expose you to hazardous voltages, that if contacted, could

ause personal injury or death. Use appropriate safety precautions when working with

c

hazardous voltages.

Page 11

Section

Calibration and Adjustment Manual

2: Performance verification DAQ6510 Data Acquisition and Multimeter System

If the instrument is still under warranty and its performance is outside specified limits, please contact

your local Keithley Instruments office, sales partner, or distributor. You can also call the Tektronix

corporate headquarters (toll-free inside the U.S. and Canada only) at 1-800-833-9200. For worldwide

contact numbers, visit tek.com/contact

.

Verification test requirements

Be sure that you perform these verification tests:

• Under the proper environmental conditions.

• After the specified warmup period.

• Using the correct line voltage.

• Using the proper test equipment.

• Using the specified output signal and reading limits.

Environmental conditions

Conduct the calibration verification procedures in a test environment with:

• An ambient temperature of 18 °C to 28 °C.

• A relative humidity of less than or equal to 80 percent, unless otherwise noted.

• No direct airflow on the input terminals.

Warmup period

Allow the DAQ6510 to warm up for at least 30 minutes before conducting the calibration verification

procedures.

If the instrument has been subjected to temperature extremes (more than 5 °C above or below T

allow additional time for the internal temperature of the instrument to stabilize. Typically, allow an

additional 30 minutes to stabilize an instrument that is 10 °C outside the specified temperature range.

Also allow the test equipment to warm up for the time recommended by the manufacturer.

CAL

),

2-2 DAQ6510-905-01 Rev. D June 2022

Page 12

DAQ6510

Performance verification

Fluke

5720A or 5730A

High-Performance

DCV, ACV, ACI, and

See following

Fluke

5725A

Amplifier

DCI and ACI

See following

note.

Multimeter

note.

Keithley

Instruments

3390

Function/Arbitrary

Waveform Generator

Frequency

See following

note.

IET Labs, Inc.

1423-A

Precision Decade

Capacitance, 1 nF to

See following

IET Labs, Inc.

HACS-Z-A-2E-1uF

Series HACS-Z High

Capacitance Box

Capacitance, 1 µF to

See following

Keithley

8610 or 8620

4-Wire DMM Shorting

DCV, digitize DCV, and

See following

Data Acquisition and Multimeter System Calibration and Adjustment Manual Section 2:

Line power

The DAQ6510 requires a line voltage of 100 V to 240 V and a line frequency of 400 Hz, 50 Hz or

60 Hz. Calibration verification tests should be performed within this range.

The instrument automatically senses the line frequency at power-up.

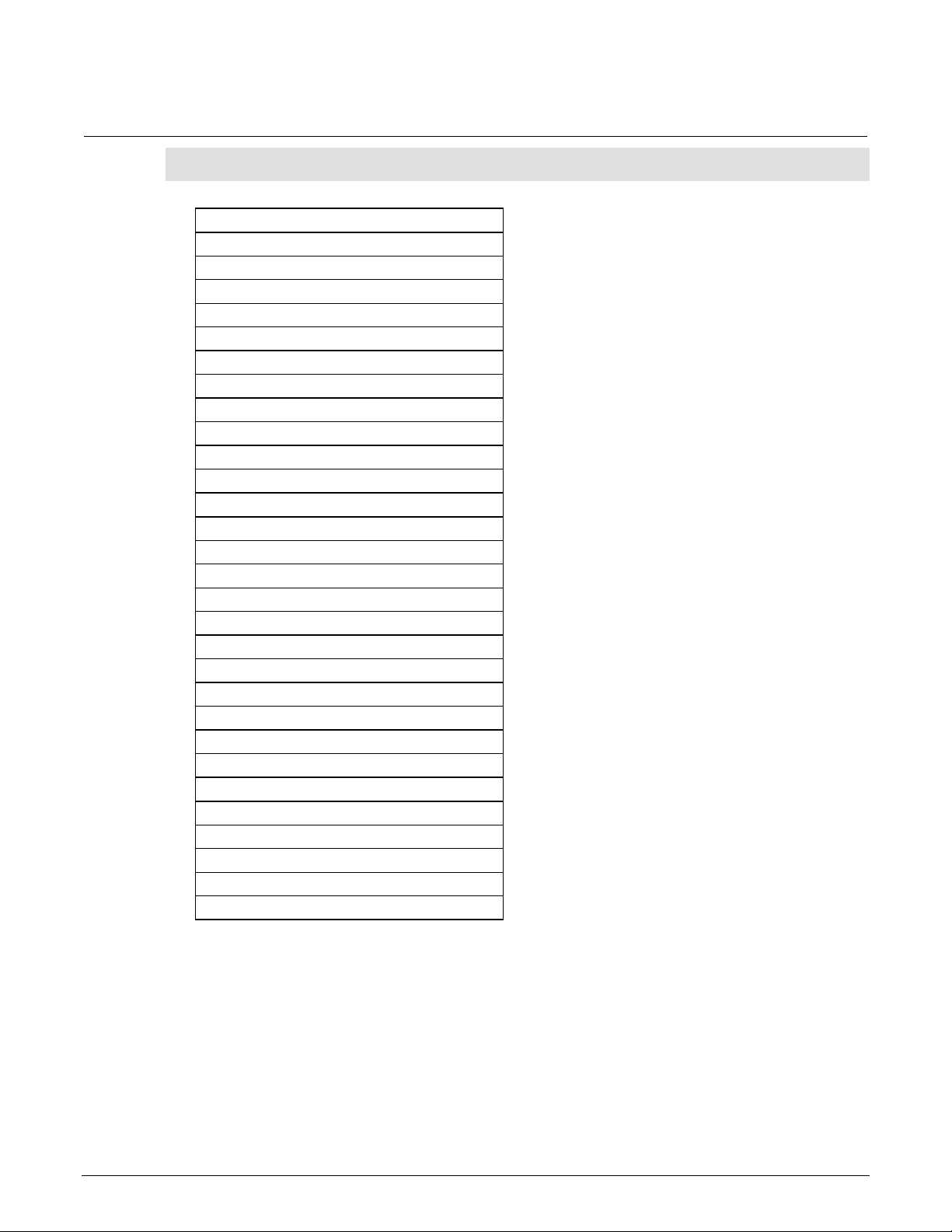

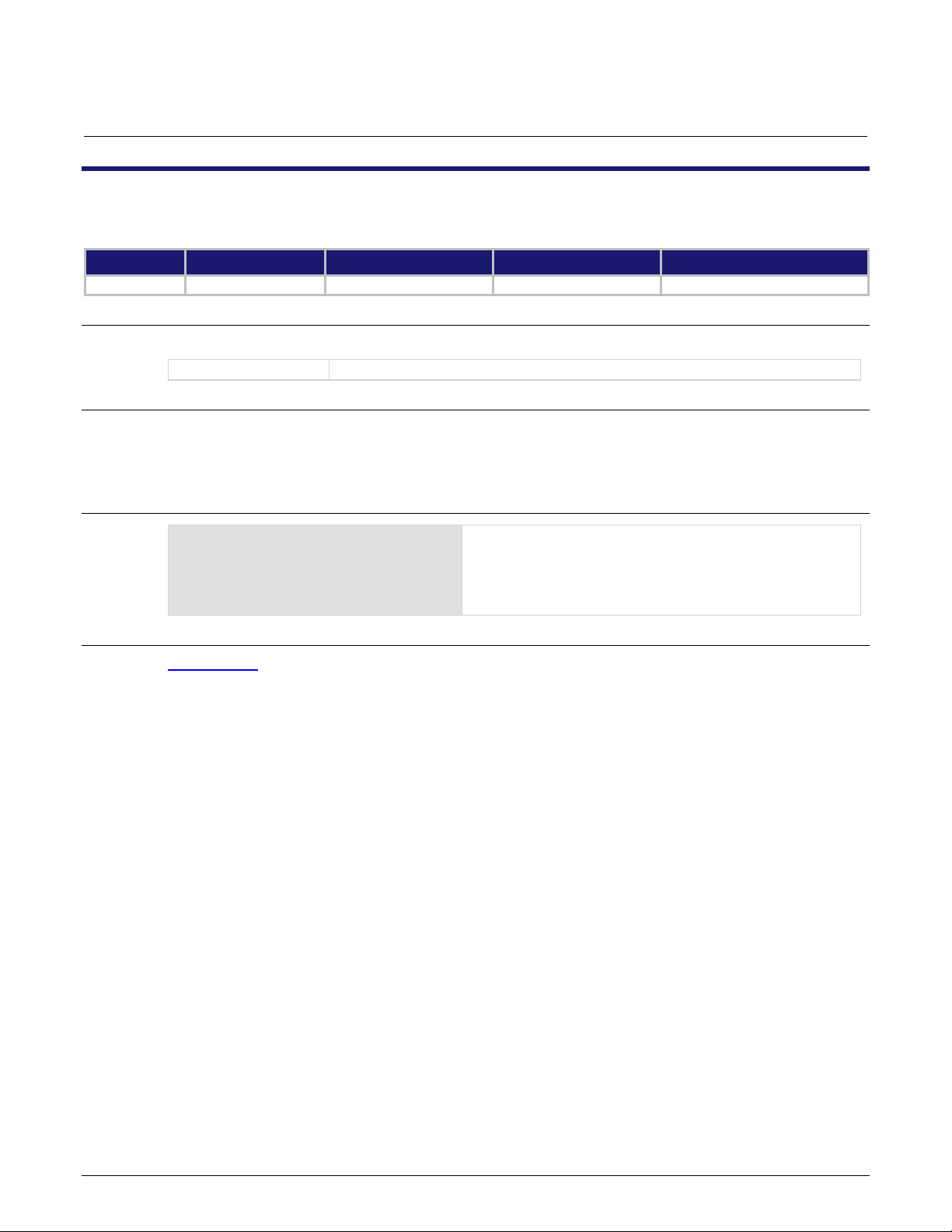

Recommended test equipment

The following table summarizes the recommended calibration verification equipment. You can use

alternate equipment if that equipment has specifications that meet or exceed those listed in the table

below. Test equipment uncertainty adds to the uncertainty of each measurement. Generally, test

equipment uncertainty should be at least four times more accurate than corresponding DAQ6510

specifications.

In this manual, the Model 8610 shorting plug is shown in the figures. However, you can use either

the Mode

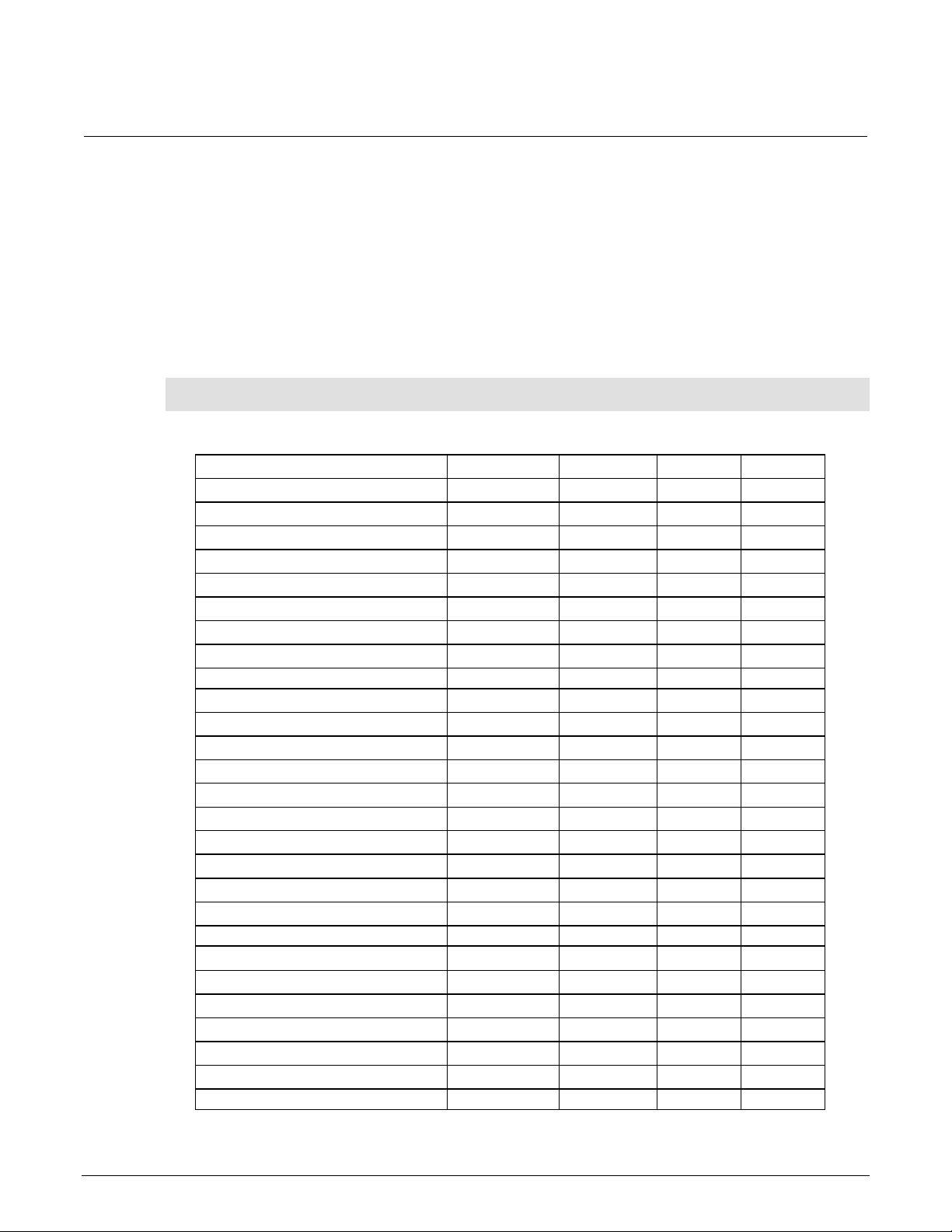

Manufacturer Model Description Used for Uncertainty

Fluke 8508A or 8588A 8.5-Digit Reference

Instruments

l 8610 or the Model 8620 shorting plug.

Multifunction Calibrator

Capacitor

Accuracy Decade

Plug

resistance

DCI See following

1 µF

100 µF

resistance

note.

note.

note.

note.

Refer to the manufacturer's specifications to calculate the uncertainty, which varies for each function

and range test point.

DAQ6510-905-01 Rev. D June 2022 2-3

Page 13

Section

Calibration and Adjustment Manual

2: Performance verification DAQ6510 Data Acquisition and Multimeter System

Calibration verification limits

The calibration verification limits stated in this section have been calculated using only the DAQ6510

one-year accuracy specifications and ambient temperature ±5 °C from T

the instrument was calibrated). They do not include test equipment uncertainty. If a particular

measurement falls outside the allowable range, recalculate new limits based on both the DAQ6510

specifications and corresponding test equipment specifications.

Specifications and characteristics are subject to change without notice; please refer to

tek.com/keithley

Example reading limit calculation

Assume you are testing the 10 V dc range using a 10 V input value. Using the DAQ6510 one-year

accuracy specification for 10 V dc of ± (25 ppm of reading + 5 ppm of range), the calculated limits are:

• Reading limits = 10 V ± [(10 V × 25 ppm) + (10 V × 5 ppm)]

for the most recent specifications.

(the temperature at which

CAL

• Reading limits = 10 V ± (0.00025 + 0.00005) V

• Reading limits = 10 V ± 0.00030 V

• Reading limits = 9.99970 V to 10.00030 V

Calculating resistance reading limits

Resistance reading limits must be recalculated based on the actual calibration resistance values

supplied by the equipment manufacturer. Calculations are performed in the same manner as shown

in the preceding example. Use the actual calibration resistance values instead of the nominal values

in the example when performing your calculations.

For example, assume that you are testing the 10 kΩ range using an actual 10.03 kΩ calibration

resistance value. Using DAQ6510 one-year 10 kΩ range accuracy of ± (75 ppm of reading + 6 ppm of

range), the calculated reading limits are:

• Reading limits = 10.03 kΩ ± [(10.03 kΩ x 75 ppm) + (10 kΩ x 6 ppm)]

• Reading limits = 10.03 kΩ ± [(0.7523) + (0.06)] Ω

• Reading limits = 10.03 kΩ ± 0.8123 Ω

• Reading limits = 10.029188 kΩ to 10.030812 kΩ

2-4 DAQ6510-905-01 Rev. D June 2022

Page 14

DAQ6510

Performance verification

Data Acquisition and Multimeter System Calibration and Adjustment Manual Section 2:

Performing the verification test procedures

The following topics provide a summary of calibration verification test procedures and items to

consider before performing any calibration verification test.

Test summary

Front-panel tests:

• DC voltage verification (on page 2-6)

• AC voltage verification (on page 2-9)

• Digitize voltage verification (on page 2-14)

• Frequency verification (on page 2-17)

• Simulated thermocouple type J temperature verification (on page 2-18)

• Simulated RTD temperature verification (on page 2-20)

• Resistance verification (on page 2-24)

• DC current verification (on page 2-29)

• Digitize current verification (on page 2-33)

• AC current verification (on page 2-36)

• Capacitance verification (on page 2-39)

• Verifying zero values using a 4-wire short (on page 2-41)

Test considerations

When performing the calibration verification procedures:

• Be sure to restore factory front-panel defaults. From the front panel, select the MENU key, select

Info/Manage, and select System Reset.

• Make sure that the test equipment is warmed up for the time recommended by the manufacturer

and is connected to the DAQ6510 input/output terminals.

• Make sure that the correct DAQ6510 terminals are selected with the TERMINALS FRONT/REAR

switch.

• Make sure the test equipment is set up for the proper function and range.

• Do not connect test equipment to the DAQ6510 through a scanner, multiplexer, or other switching

DAQ6510-905-01 Rev. D June 2022 2-5

equipment.

Page 15

Section

Calibration and Adjustment Manual

2: Performance verification DAQ6510 Data Acquisition and Multimeter System

The front and rear terminals of the instrument are rated for connection to circuits rated

Measurement Category II up to 300 V, as described in International Electrotechnical

Commission (IEC) Standard IEC 60664. This range must not be exceeded. Do not connect the

instrument terminals to CAT III or CAT IV circuits. Connection of the instrument terminals to

circuits higher than CAT II can cause damage to the equipment and severe personal injury.

Front-panel calibration verification

The following topics describe verification procedures that are done with connections attached to the

terminals on the DAQ6510 front panel.

DC voltage verification

The maximum input voltage between INPUT HI and INPUT LO is 1000 V dc and 750 V ac.

Exceeding this value may create a shock hazard.

The maximum common-mod

500 V

. Exceeding this value may cause a breakdown in insulation that can create a shock

PEAK

e voltage (the voltage between INPUT LO and chassis ground) is

hazard.

Verify dc voltage accuracy for the 100 mV to 1000 V ranges

To verify 100 mV to 1000 V dc voltage accuracies, you will:

• Apply accurate dc voltages from the calibrator to the DAQ6510 front-panel terminals.

• Verify that the displayed readings are within specified limits.

• Use the values in the tables following the steps below to verify the performance of the DAQ6510.

Actual values depend on the published specifications (see Example reading limit calculation (on

page 2-4)).

Use shielded low-ther

caused by noise or thermal effects. Connect the shield to the output LO terminal of the calibrator.

mal connections when testing the 100 mV and 1 V ranges to avoid errors

2-6 DAQ6510-905-01 Rev. D June 2022

Page 16

DAQ6510

Performance verification

Data Acquisition and Multimeter System Calibration and Adjustment Manual Section 2:

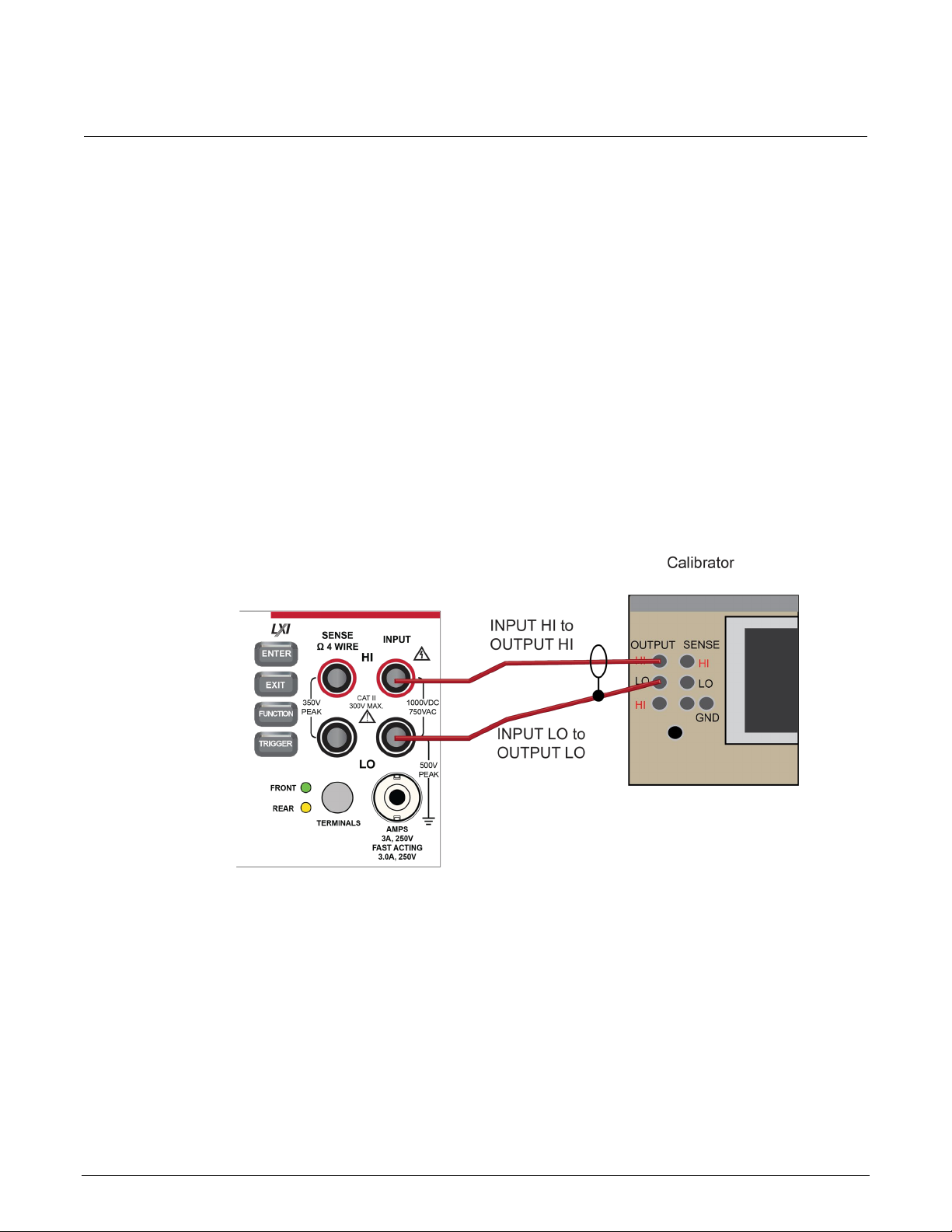

To verify dc voltage accuracy:

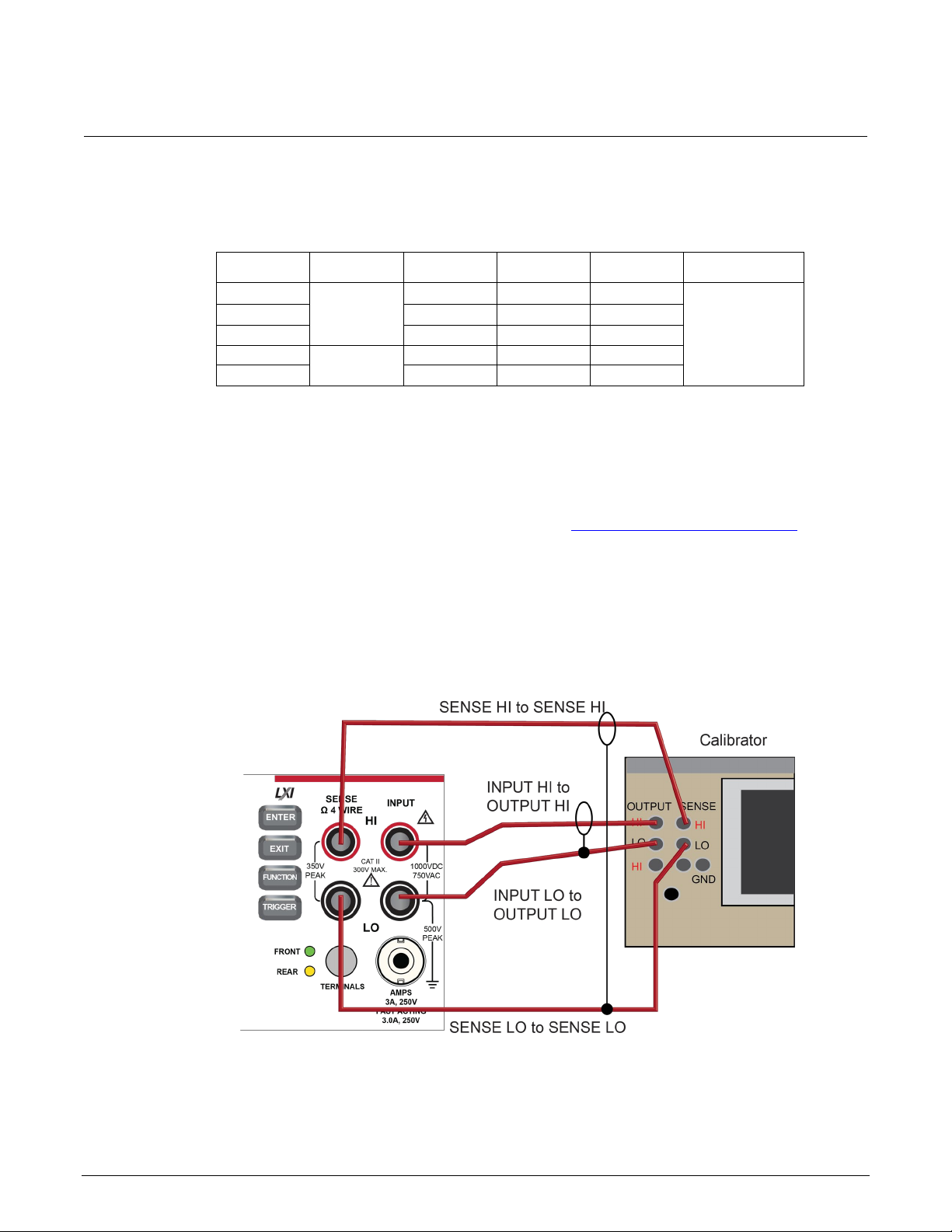

1. Use a low-thermal cable to connect the DAQ6510 HI and LO INPUT terminals to the calibrator HI

and LO terminals as shown in the following figure.

Figure 1: DC voltage 100 mV to 1000 V ranges verification connections

2. On the DAQ6510, press the FUNCTION key and select DC voltage.

3. On the home screen, select the button next to Range and select 100 mV.

4. Press the MENU key.

5. Under Measure, select Settings.

6. Set Input Impedance to Auto.

7. Set the calibrator output to 0 V.

8. Set the calibrator to OPERATE.

9. Allow 5 minutes of settling time.

10. Press the MENU key.

11. Select Calculations.

12. [Only for the 100 mV range] Select Rel Acquire.

13. Source positive and negative full-scale and half-scale voltages and allow for proper settling.

14. Select each range on the DAQ6510, allow for proper settling, and verify the ranges according to

the following tables.

DAQ6510-905-01 Rev. D June 2022 2-7

Page 17

Section

Calibration and Adjustment Manual

Perform relative

offset

0

-0.01

0.01

Full scale (+)

100

99.9935

100.0065

Half scale (–)

-50

-50.005

-49.995

Full scale (–)

-100

-100.0065

-99.9935

Full scale (+)

1

0.999969

1.000031

Half scale (+)

0.5

0.499979

0.500021

Half scale (–)

-0.5

-0.500021

-0.499979

Full scale (–)

–1

–1.000031

-0.999969

Full scale (+)

10

9.9997

10.0003

Half scale (+)

5

4.99982

5.00018

Half scale (–)

–5

–5.00018

–4.99982

Full scale (–)

–10

–10.0003

–9.9997

2: Performance verification DAQ6510 Data Acquisition and Multimeter System

Verify the dc voltage 100 mV range

Description Nominal value Lower limit Upper limit

Half scale (+) 50 49.995 50.005

Verify the dc voltage 1 V range

Description Nominal value Lower limit Upper limit

Verify the dc voltage 10 V range

Description Nominal value Lower limit Upper limit

2-8 DAQ6510-905-01 Rev. D June 2022

Page 18

DAQ6510

Performance verification

Full scale (+)

100

99.954

100.0046

Half scale (–)

-50

-50.00315

-49.99685

Full scale (–)

-100

-100.0054

-99.9946

Full scale (+)

1000

999.944

1000.056

Half scale (+)

500

499.974

500.026

Half scale (–)

-500

-500.026

-499.974

Full scale (–)

-1000

-1000.069

-999.931

Data Acquisition and Multimeter System Calibration and Adjustment Manual Section 2:

Verify the dc voltage 100 V range

The information in this section is intended for qualified service personnel only, as described

by the types of product users in the Safety precautions pages, provided at the beginning of

this document. Do not attempt these procedures unless you are qualified to do so.

Some of these procedures may expose you to hazardous voltages, that if contacted, could

c

ause personal injury or death. Use appropriate safety precautions when working with

hazardous voltages.

Description Nominal value Lower limit Upper limit

Half scale (+) 50 49.99685 50.00315

Verify the dc voltage 1000 V range

Description Nominal value Lower limit* Upper limit*

*For each additional volt over ±500 V, add 0.02 mV of uncertainty.

AC voltage verification

To verify ac voltage accuracy:

• For the 100 mV to 100 V ranges, apply accurate voltages from the calibrator to the DAQ6510

front-panel terminals.

• For the 750 V range, connect the Fluke 5725A Amplifier to the calibrator. Apply accurate voltages

from the calibrator terminals to the terminals on the front panel of the DAQ6510.

• Verify that the displayed readings are within specified limits.

Use the values in the tables following the steps below to verify the performance of the DAQ6510.

Actual values depend on the published specifications (see Example reading limit calculation (

on page

2-4)).

DAQ6510-905-01 Rev. D June 2022 2-9

Page 19

Section

Calibration and Adjustment Manual

2: Performance verification DAQ6510 Data Acquisition and Multimeter System

The maximum input voltage between INPUT HI and INPUT LO is 750 V dc. Exceeding this

value may create a shock hazard.

The maximum common-mo

500 V

. Exceeding this value may cause a breakdown in insulation that can create a shock

PEAK

de voltage (the voltage between INPUT LO and chassis ground) is

hazard.

Verify ac voltage accuracy for the 100 mV to 100 V ranges

Use shielded, low-capacitance cabling. For the 100 mV to 100 V ranges, avoid loading that exceeds

1000 pF.

Excessive capacitance may result in additional load regulation uncertainties and could cause the

cal

ibrator output to open (go into standby).

To verify ac voltage accuracy:

1. Connect the DAQ6510 HI and LO INPUT connectors to the calibrator as shown in the following

figure.

Figure 2: Connections for ac voltage verification 100 mV to 100 V ranges

2-10 DAQ6510-905-01 Rev. D June 2022

Page 20

DAQ6510

Performance verification

0.1

1 kHz

99.91

100.09

0.1

100 kHz

99.32

100.68

1

1 kHz

.9991

1.0009

1

100 kHz

.9932

1.0068

Data Acquisition and Multimeter System Calibration and Adjustment Manual Section 2:

2. On the DAQ6510, press the FUNCTION key and select AC voltage.

3. On the home screen, select the button next to Range and select 100 mV.

4. Press the MENU key.

5. Under Measure, select Settings.

6. Make sure that detector bandwidth is set to 30 Hz.

AC voltage is specified for the detector bandwidth setting of 3 Hz. Three Hz measures accurately for

input signals from 3 Hz to 300 kHz, with reading rates ≈ 2 readings/s. To improve verification

throughput to ≈ 20 readings/s, set detector bandwidth to 30 Hz for frequencies of 30 Hz to 300 kHz.

To verify frequencies 1 kHz and higher, set the detector bandwidth to 300 Hz for faster ≈ 200

readings/s throughput.

7. Source ac voltages for each of the frequencies listed in the Verify the ac voltage 100 mV range

(on page 2-11) table.

8. Repeat these steps for each range and frequency listed in the tables below. For each voltage

setting, be sure that the reading is within low and high limits.

Verify the ac voltage 100 mV range

Nominal value Frequency Lower limit Upper limit

0.1 20 Hz 99.91 100.09

0.1 50 kHz 99.83 100.17

Verify the ac voltage 1 V range

Nominal value Frequency Lower limit Upper limit

1 20 Hz .9991 1.0009

1 50 kHz .9983 1.0017

DAQ6510-905-01 Rev. D June 2022 2-11

Page 21

Section

Calibration and Adjustment Manual

10

20 Hz

9.991

10.009

10

1 kHz

9.991

10.009

10

50 kHz

9.983

10.017

10

100 kHz

9.932

10.068

100

20 Hz

99.910

100.09

100

50 kHz

99.830

100.17

100

100 kHz

99.320

100.68

2: Performance verification DAQ6510 Data Acquisition and Multimeter System

Verify the ac voltage 10 V range

Nominal value Frequency Lower limit Upper limit

Verify the ac voltage 100 V range

Nominal value Frequency Lower limit Upper limit

100 1 kHz 99.910 100.09

Verify ac voltage accuracy for the 750 V range

Use shielded low capacitance cabling. For the 750 V range, avoid cable capacitances of >150 pF.

Excessive capacitance may result in additional load regulation uncertainties and could cause the

alibrator output to open (go into standby).

c

2-12 DAQ6510-905-01 Rev. D June 2022

Page 22

DAQ6510

Performance verification

Data Acquisition and Multimeter System Calibration and Adjustment Manual Section 2:

To verify ac voltage accuracy for the 750 V range:

1. Put the calibrator in Standby.

2. Connect the DAQ6510 HI and LO INPUT connectors to the calibrator as shown in the following

figure.

3. For 750 V at 50 kHz and 100 kHz outputs, connect the calibrator to the Fluke 5725A amplifier.

Figure 3: Connections for ac voltage accuracy verification 750 V range

4. On the DAQ6510, press the FUNCTION key and select AC voltage.

5. On the home screen, select the button next to Range and select 750 V.

6. Press the MENU key.

7. Under Measure, select Settings.

8. Ensure that detector bandwidth is set to 30 Hz.

AC voltage is specified for the detector bandwidth setting of 3 Hz. Three Hz measures accurately for

input signals from 3 Hz to 300 kHz, with reading rates ≈ 2 readings/s. To improve verification

throughput to ≈ 200 readings/s, set detector bandwidth to 30 Hz for frequencies of 30 Hz to 300 kHz.

To verify frequencies 1 kHz and higher, set the detector bandwidth to 300 Hz for faster ≈ 200

readings/s throughput.

DAQ6510-905-01 Rev. D June 2022 2-13

Page 23

Section

Calibration and Adjustment Manual

740

50 Hz

739.33

740.67

740

50 kHz

738.66

741.34

740

100 kHz

734.96

745.04

2: Performance verification DAQ6510 Data Acquisition and Multimeter System

9. Set the calibrator to OPERATE.

10. Source ac voltages for each of the frequencies listed in the "Verify the ac voltage 750 V range"

table, below. Be sure that the readings are within low and high limits.

Verify the ac voltage 750 V range

Nominal value Frequency Lower limit Upper limit

740 1 kHz 739.33 740.67

Digitize dc voltage verification

To verify digitize dc voltage accuracy, you will:

• Apply accurate voltages from the calibrator to the terminals on the front panel of the DAQ6510.

• Verify that the displayed readings are within specified limits.

Use the values in the tables following the steps below to verify the performance of the DAQ6510.

Actual values depend on the published specifications (see Example reading limit calculation (on page

2-4)).

The maximum input voltage between INPUT HI and INPUT LO is 1000 V dc and 750 V ac.

Exceeding this value may create a shock hazard.

The maximum common-mo

500 V

. Exceeding this value may cause a breakdown in insulation that can create a shock

PEAK

de voltage (the voltage between INPUT LO and chassis ground) is

hazard.

Verify the digitize voltage 100 mV to 1000 V ranges

Use shielded low-thermal connections when testing the 100 mV and 1 V ranges to avoid errors

caused by noise or thermal effects. Connect the shield to the output LO terminal of the calibrator.

2-14 DAQ6510-905-01 Rev. D June 2022

Page 24

DAQ6510

Performance verification

Data Acquisition and Multimeter System Calibration and Adjustment Manual Section 2:

To verify digitize voltage accuracy:

1. Connect the DAQ6510 HI and LO INPUT connectors to the calibrator as shown in the following

figure.

Figure 4: Connections for digitize voltage verification 100 mV to 1000 V ranges

2. On the DAQ6510, press the FUNCTION key, select the Digitize Functions tab, and select

Digitize Voltage.

3. On the home screen, select the button next to Range and select 100 mV.

4. Press the MENU key.

5. Under Measure, select Settings.

6. Set the Sample Rate to 1000.

7. Set the Aperture to Auto.

8. Set the Count to 100.

9. Set the calibrator output to 0.00000 mV dc and allow the reading to settle.

10. Press the MENU key.

11. Under Measure, select Calculations.

12. Source positive and negative full-scale and half-scale voltages, as listed in the following table.

Verify the 100 mV to 100 V range settings listed in the tables below. For each voltage setting,

verify that the STATISTICS swipe screen reading for Average is within low and high limits.

The Fluke 5720A or 5730A calibrator 1000 V range 0.0 V setting is not verified.

DAQ6510-905-01 Rev. D June 2022 2-15

Page 25

Section

Calibration and Adjustment Manual

Full scale (+)

100

99.94

100.06

Half scale (+)

50

49.95

50.05

Half scale (–)

-50

-50.05

-49.95

Full scale (–)

-100

-100.06

-99.94

Full scale (+)

1

0.9996

1.0004

Half scale (–)

-0.5

-0.50025

-0.49975

Full scale (–)

-1

-1.0004

-0.9996

Full scale (+)

10

9.996

10.004

Half scale (+)

5

4.9975

5.0025

Half scale (–)

-5

-5.0025

-4.9975

Full scale (–)

-10

-10.004

-9.996

Full scale (+)

100

99.96

100.04

Half scale (+)

50

49.975

50.025

Half scale (–)

-50

-50.025

-49.975

Full scale (–)

-100

-100.04

-99.96

Full scale (+)

1000

999.6

1000.4

Half scale (+)

500

499.75

500.25

Half scale (–)

–500

-500.25

-499.75

Full scale (–)

–1000

-1000.4

-999.6

2: Performance verification DAQ6510 Data Acquisition and Multimeter System

Verify the digitize voltage 100 mV range

Description Nominal value Lower limit Upper limit

Verify the digitize voltage 1 V range

Description Nominal value Lower limit Upper limit

Half scale (+) 0.5 0.49975 0.50025

Verify the digitize voltage 10 V range

Description Nominal value Lower limit Upper limit

Verify the digitize voltage 100 V range

Description Nominal value Lower limit Upper limit

Verify the digitize voltage 1000 V range

Description Nominal value Lower limit Upper limit

2-16 DAQ6510-905-01 Rev. D June 2022

Page 26

DAQ6510

Performance verification

Data Acquisition and Multimeter System Calibration and Adjustment Manual Section 2:

Frequency verification

To verify frequency accuracy, you will:

• Apply accurate frequencies from the function generator to the terminals on the front panel of the

DAQ6510.

• Verify that the displayed readings are within specified limits.

Use the values in the table following the steps below to verify the performance of the DAQ6510.

Actual values depend on the published specifications (see Example reading limit calculation

2-4)).

1. Connect the Keithley Instruments Model 3390 function generator to the DAQ6510 INPUT HI and

LO terminals as shown in the following figure.

Figure 5: Connections for frequency verification and adjustment

(on page

2. On the DAQ6510, press the FUNCTION key, select the Measure Functions tab, and select

Frequency.

3. Select the MENU key.

4. Under Measure, select Settings.

5. Set the Aperture to 250 ms.

6. Set the Threshold Range to 10 V.

7. Press the HOME key.

8. Source the voltage and frequency values as listed in Verify the frequency (on page 2-18

). For

each setting, be sure that the reading is within low and high limits.

DAQ6510-905-01 Rev. D June 2022 2-17

Page 27

Section

Calibration and Adjustment Manual

10 Hz at 10 V

10

9.997

10.003

10 kHz at 5 V

10

9.9991

10.0009

100 kHz at 5 V

100

99.991

100.009

300 kHz at 5 V

300

299.973

300.027

2: Performance verification DAQ6510 Data Acquisition and Multimeter System

Verify the frequency

Use the following values to verify the performance of the DAQ6510. Actual values depend on

published specifications (see Example reading limit calculation (on page 2-4)).

Description Frequency (Hz) Lower limit (Hz) Upper limit (Hz)

1 kHz at 5 V 1 0.9999 1.0001

Simulated thermocouple type J temperature verification

To verify thermocouple accuracy, you will:

• Apply accurate voltages from the calibrator to the terminals on the front panel of the DAQ6510.

• Verify that the displayed readings are within specified limits.

Thermocouple accuracy is verified by using a dc voltage calibrator to output values from standard

thermocouple tables available from the National Institute of Standards and Technology (NIST) or

other sources.

In the table following the steps below, three representative values are listed from a type J

thermocouple table for temperatures –190 °C, 0 °C, and 750 °C, with their respective thermocouple

voltages listed in the “Uncompensated calibrator source value” column. The calibrator source values

are based on NIST Monograph 175, reference data 60, version 2.0.

Verify thermocouple accuracy

Because the cable connecting the calibrator to the DAQ6510 can have non-trivial thermal offset

voltages, you must first correct for these to verify the DAQ6510 specifications.

2-18 DAQ6510-905-01 Rev. D June 2022

Page 28

DAQ6510

cation

Data Acquisition and Multimeter System Calibration and Adjustment Manual Section 2: Performance verifi

To verify the simulated thermocouple type J temperature:

1. Connect the DAQ6510 HI and LO INPUT terminals to the calibrator HI and LO terminals as

shown in the following figure.

Figure 6: Connections for thermocouple verification

2. On the DAQ6510, press the FUNCTION key and select DC voltage.

3. Press the MENU key.

4. Under Measure, select Settings.

5. Set the range to 100 mV.

6. Set Input Impedance to Auto.

7. Set autozero to On.

8. Select Integration Rate. The Integration Rate dialog box opens.

9. Set the unit to NPLC.

10. Set NPLC to 1 PLC.

11. Select OK and press the HOME key to return to the Home Screen.

12. Set the calibrator to output 0 V and enable the output.

13. Allow five minutes for settling of the thermal voltage.

14. Record the measured offset voltage to 1 µV precision. If necessary, use the DAQ6510 filter

settings to reduce the noise of this measurement (for filter settings, go to MENU > Measure

Calculations).

15. Press the DAQ6510 FUNCTION key and select Temperature.

16. Press the MENU key.

17. Under Measure, select Settings.

DAQ6510-905-01 Rev. D June 2022 2-19

Page 29

Section

Calibration and Adjustment Manual

–190 °C

–7.659 mV

–190.2 °C

–189.8 °C

0 °C

0.000 mV

–0.2 °C

0.2 °C

750 °C

42.281 mV

749.8 °C

750.2 °C

2: Performance verification DAQ6510 Data Acquisition and Multimeter System

18. On the Measure Settings screen, set the following values:

Units: °C

Transducer: TC

Thermocouple: J

Temperature (simulated reference temperature): 0 °C

Integration Rate: 1 PLC

Auto Zero: On

19. Set the calibrator to the simulated thermocouple voltage you want (from the following table), first

correcting for the offset voltage measured in step 14. For example, if the measured offset voltage

was –2 µV, set the calibrator to –7.659 mV – (–0.002 mV), which equals –7.657 mV, to simulate –

190 °C.

20. Verify that the DAQ6510 reading is within lower and upper limits.

21. Repeat steps 18 and 19 for each value in the following table.

Use the following values to verify the performance of the DAQ6510. Actual values depend on

published specifications (see Example reading limit calculation (on page 2-4

)).

Simulated

temperature

Uncompensated

calibrator source

value (V)

Lower limit Upper limit

Simulated RTD temperature verification

Use the following information to verify the performance of the DAQ6510. Actual calibrator source

values will vary. RTD verification is based on the calibrator sourcing resistance and the DAQ6510

conversion of the resistance measurement to calculated temperature based on the Callendar-Van

Dusen equation.

To verify RTD temperature accuracy, you will:

• Apply accurate resistance from the calibrator to the terminals on the front panel of the DAQ6510.

• Verify that the displayed readings are within specified limits.

2-20 DAQ6510-905-01 Rev. D June 2022

Page 30

DAQ6510

Performance verification

Data Acquisition and Multimeter System Calibration and Adjustment Manual Section 2:

RTD equations

The temperature versus resistance readings listed in the RTD reference tables are calculated using

the Callendar-Van Dusen equation. There are two equations that are based on different temperature

ranges. There is an equation for the –200 °C to 0 °C range and one for the 0 °C to 850 °C range.

Equation for –200 °C to 0 °C temperature range

R

= R0 [1 + AT + BT2 + CT3(T – 100)]

RTD

where:

• R

• R

is the calculated resistance of the RTD

RTD

is the known RTD resistance at 0 °C

0

• T is the temperature in °C

• A = alpha [1 + (delta/100)]

• B = –1 (alpha)(delta)(1E-4)

• C = –1 (alpha)(beta)(1E-8)

The alpha, beta, and delta values are listed in the following table.

Equation for 0 °C to 850 °C temperature range

R

= R0 (1 + AT + BT2)

RTD

where:

• R

• R

is the calculated resistance of the RTD

RTD

is the known RTD resistance at 0 °C

0

• T is the temperature in °C

• A = alpha [1 + (delta/100)]

• B = –1 (alpha)(delta)(1E-4)

The alpha and delta values are listed in the following table.

DAQ6510-905-01 Rev. D June 2022 2-21

Page 31

Section

Calibration and Adjustment Manual

PT100

ITS-90

0.00385055

0.10863

1.49990

100.0000

D100

0.003920

0.10630

1.49710

F100

0.003900

0.11000

1.49589

PT385

IPTS-68

0.003850

0.11100

1.50700

PT3916

0.003916

0.11600

1.50594

2: Performance verification DAQ6510 Data Acquisition and Multimeter System

RTD parameters for equations

The RTD parameters for the Callendar-Van Dusen equations are listed in the following table.

DAQ6510 resistance to temperature device (RTD)

Type Standard Alpha Beta Delta R0 at 0 °C (Ω)

Verify the simulated RTD temperature

Use the values in the tables following the steps below to verify the performance of the DAQ6510.

Actual values depend on the published specifications (see Example reading limit calculation

2-4)).

(on page

To verify RTD accuracy:

1. For 4-wire accuracy, connect the DAQ6510 INPUT and SENSE terminals to the calibrator as

shown in the following figure.

Figure 7: Connections for 4-wire RTD accuracy verification

2-22 DAQ6510-905-01 Rev. D June 2022

Page 32

DAQ6510

Performance verification

Data Acquisition and Multimeter System Calibration and Adjustment Manual Section 2:

2. For 3-wire accuracy, connect the DAQ6510 INPUT and SENSE terminals to the calibrator as

shown in the following figure.

The SENSE HI wire is not required for 3-wi

re RTD measurements. For 3-wire RTD, accuracy is for

< 0.1 Ω lead resistance mismatch for input HI and LO. Add 0.25 °C per 0.1 Ω of HI-LO lead

resistance mismatch.

Figure 8: Connections for 3-wire RTD accuracy verification

3. On the DAQ6510, press the FUNCTION key and select Temperature.

4. Press the MENU key.

5. Under Measure, select Settings.

6. Select Transducer.

7. Set the Type to 4-wire RTD or 3-Wire RTD.

8. Set the RTD Type to PT100.

9. Press the HOME key.

10. On the calibrator, select 19 Ω source resistance.

11. Select the OPER and EX SNS keys.

12. Record DAQ6510 accuracies.

13. Refer to the table for PT100 accuracies.

Fluke 5720 and 5730 resistance source values vary and may require new resistance-to-temp

target accuracy values.

erature

DAQ6510-905-01 Rev. D June 2022 2-23

Page 33

Section

tment Manual

1.000000E+02

3.850550E-03

1.086300E-01

-5.775440E-07

-4.182852E-12

100

99.99707

-0.0075

0.0235

0.2932

190

189.99234

238.6775

0.0218

0.2725

2: Performance verification DAQ6510 Data Acquisition and Multimeter System Calibration and Adjus

14. Repeat for 100 Ω and 190 Ω source values.

Example PT100

R0

alpha

beta

delta

A

B

C

1.499900E+00

3.908304E-03

Nominal

calibrator

value

(Ω)

19 18.999520 -198.8900 0.0259 0.3241

Actual calibrator

value

(Ω)

Resistance verification

Use the following information to verify the performance of the DAQ6510 resistance functions.

Four-wire resistance verification

To verify the 4-wire resistance function, you will:

• Use shielded, Teflon-insulated or equivalent cables in a 4-wire configuration.

• Characterize the calibrator 1 Ω and 10 Ω nominal values with an external reference digital

multimeter (DMM); verify accuracy from the reference DMM readings.

Temperature

(°C)

4-wire RTD 3-wire RTD

±0.06 °C accuracy

(±Ω from actual

calibrator value)

±0.75 °C accuracy

(±Ω from actual

calibrator value)

• For the 100 Ω to 100 MΩ ranges, verify accuracy from actual calibrator source values.

2-24 DAQ6510-905-01 Rev. D June 2022

• Verify that the displayed readings are within specified limits.

Page 34

DAQ6510

Performance verification

Data Acquisition and Multimeter System Calibration and Adjustment Manual Section 2:

To verify 4-wire resistance accuracy:

1. Connect the DAQ6510 INPUT and SENSE terminals to the calibrator as shown in the following

figure.

Figure 9: Connections for 4-wire resistance accuracy verification

2. Set the calibrator for 4-wire resistance with external sense on.

3. On the DAQ6510, press the FUNCTION key and select 4W Res.

4. Press the MENU key.

5. Under Measure, select Settings.

6. Set Offset Compensation On.

7. Verify that Open Lead Detector is Off.

8. On the home screen, select the button next to Range and select 1 Ω.

9. Source the nominal zero and full-scale resistance values for the 1 Ω to 10 kΩ ranges. Source the

nominal zero value for the 100 kΩ range. Refer to the tables in Calculated limits (on page 2-26).

10. For the 100 kΩ range, only verify 0 Ω with Offset Compensation set to On.

11. Set Offset Compensation to Off.

12. Verify full-scale 100 kΩ on the 100 kΩ range and 0 and full-scale for the 1 MΩ and 10 MΩ ranges.

13. Verify that the readings are within calculated limits.

When Offset Compensation is set to On, ranges are limited to 1

Ω to 10 kΩ. When Offset

Compensation is set to Off, all ranges (1 Ω to 100 MΩ) are available from all interfaces.

DAQ6510-905-01 Rev. D June 2022 2-25

Page 35

Section

Calibration and Adjustment Manual

1

0 0 -0.1

0.1 1 0.999973

0.999688

1.000258

10

9.99983

9.99878

10.00088

100

0 0 -0.1

0.1

100

99.9975

99.987

100.008

1

0.99999

0.99991

1.00007

10 K

0 0 -1 1 10

9.99982

9.99901

10.00063

100 K

0 0 -10

10

2: Performance verification DAQ6510 Data Acquisition and Multimeter System

You can use either the front-panel controls or remote interface commands to set measurement

parameters for verification. For calibration, you must use remote interface commands. The example

below is an example of remote interface commands that will generate event messages.

To do the same steps over the remote interface, send the commands:

dmm.measure.func = dmm.FUNC_4W_RESISTANCE

dmm.measure.offsetcompensation.enable = dmm.OCOMP_ON

dmm.measure.range = 1e6

The following warning message is displayed:

1131, Parameter, measure range, expected value from 1 to 100000

Set dmm.measure.offsetcompensation.enable = dmm.OCOMP_OFF, and then set

dmm.measure.range = 1e6 to run without warnings.

Verify that the readings are within calculated limits.

The values and limits in the following tables are for example only. You must calculate test limits

based on the actual resistance values output by your calibrator or resistance source (see Example

reading limit calculation (on page 2-4)).

Range

(Ω)

10 0 0 -0.1 0.1

Nominal calibrator

values

(Ω)

Typical reference

DMM reading

(Ω)

Lower limit

(Ω)

Upper limit

(Ω)

Range

(Ω)

1 K 0 0 -1 1

Nominal calibrator

values

(Ω)

Actual calibrator

value

(Ω)

Lower limit

(Ω)

Upper limit

(Ω)

2-26 DAQ6510-905-01 Rev. D June 2022

Page 36

DAQ6510

Performance verification

100 K

100

100.0012

99.9928

100.0098

1 M

0 0 -1 1 1

0.999966

0.99986

1.000072

10 M

0 0 -1

1

Data Acquisition and Multimeter System Calibration and Adjustment Manual Section 2:

Four-wire resistance verification with offset compensation off

The values and limits in the following tables are for example only. You must calculate test limits

based on the actual resistance values output by your calibrator or resistance source (see Example

reading limit calculation (on page 2-4)).

For 10 MΩ verification, the Sense HI cable is optional. Measurement is with Input HI and LO and

Sense LO only.

Range

(Ω)

Nominal calibrator

values

(Ω)

10 9.99931 9.99521 10.00341

Verify 2-wire resistance accuracy

To verify the 2-wire resistance function 100 MΩ range, you will:

• Use shielded, Teflon-insulated or equivalent cables in a 2-wire configuration.

• Apply accurate resistance from the calibrator to the terminals on the front panel of the DAQ6510.

• Verify that the displayed readings are within specified limits.

Verify resistance 100 MΩ range

To verify the 100 MΩ range:

Actual calibrator

value

(Ω)

Lower limit

(Ω)

Upper limit

(Ω)

1. Connect the DAQ6510 INPUT to the calibrator as shown in the following figure.

DAQ6510-905-01 Rev. D June 2022 2-27

Page 37

Section

Calibration and Adjustment Manual

100 M

0 0 -10

10

100

100.001

99.798

100.204

2: Performance verification DAQ6510 Data Acquisition and Multimeter System

Figure 10: Connections for 100 MΩ verification

2. Set the calibrator for 2-wire resistance with external sense off.

3. On the DAQ6510, press the FUNCTION key and select 2W Res.

4. On the home screen, select the button next to Range and select 100 MΩ.

5. Source the nominal full-scale resistance values for the 100 MΩ range as shown in the following

table.

The values and limits in the following tables are for example only. You must calculate test limits

based on the actual resistance values output by your calibrator or resistance source (see

Example

reading limit calculation (on page 2-4)).

Range (Ω) Nominal calibrator

values (Ω)

Actual calibrator

(Ω)

Lower limit (Ω) Upper limit (Ω)

2-28 DAQ6510-905-01 Rev. D June 2022

Page 38

DAQ6510

mance verification

Data Acquisition and Multimeter System Calibration and Adjustment Manual Section 2: Perfor

DC current verification

The DAQ6510 dc current ranges can be verified using several methods, depending on the level of

measurement uncertainty required. This manual describes the verification procedure using a Fluke

8508A or 8588A reference digital multimeter (DMM) in series with the DAQ6510 to determine the

nominal test current value for the 10 µA to 100 mA ranges. For the 1 A to 10 A ranges, this manual

describes using direct output from a Fluke Model 5720A or 5725A calibrator.

These configurations are adequate for most purposes, but may not provide sufficient test uncertainty

io (TUR) for some users. You must evaluate the measurement uncertainties and ensure that they

rat

are adequate for your use.

DC current 10 µA to 100 mA range verification

When verifying dc current on the 10 µA to 100 mA ranges, systematic calibrator and cable offsets

must be compensated and test limits calculated based on reference digital multimeter (DMM)

readings.

In the following section, offset measurements may exceed DAQ6510 zero-current measurement

specifications due to systematic source offset current from the test setup.

To verify the DAQ6510 specifications with zero input current, disconnect all cables and calibrators

om the DAQ6510 input. This is a separate setup from that used in the procedure below for

fr

mid-scale and full-scale readings.

DAQ6510-905-01 Rev. D June 2022 2-29

Page 39

Section

Calibration and Adjustment Manual

2: Performance verification DAQ6510 Data Acquisition and Multimeter System

To prepare the DAQ6510 for dc current accuracy verification:

1. Set up the DAQ6510 for dc current and the range being tested. Make sure relative offset is

disabled.

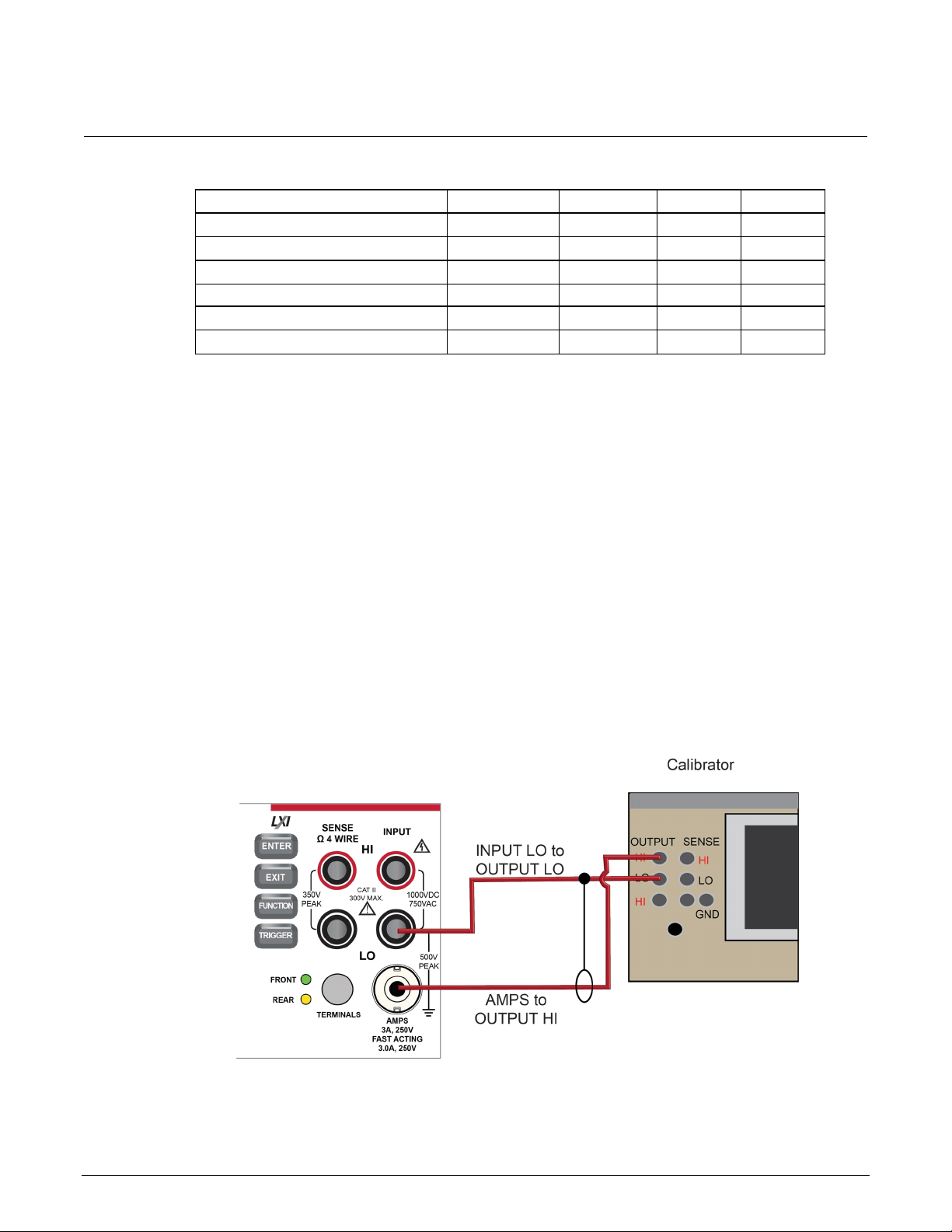

2. Connect the calibrator, DAQ6510, and reference DMM as shown in the following figure.

Figure 11: Connection for dc current

To verify DAQ6510 accuracy for each range:

1. Set the calibrator to source zero current.

2. Set the reference DMM to DC Current and select the appropriate range to be verified. Use the

Model 8508A or 8588A 200 µA range to verify the DAQ6510 10 µA and 100 µA ranges. Use the

Model 8508A or 8588A 2 mA, 20 mA, and 200 mA ranges to verify the DAQ6510 1 mA, 10 mA,

and 100 mA ranges, respectively.

3. On the calibrator, select the OPR/STBY key. Make sure that the front panel displays OPERATE.

4. On the DAQ6510, press the MENU key.

5. Select Calculations. The Calculation Settings screen is displayed.

6. On the reference DMM, zero the range for system offset.

7. Set the calibrator to source the current for the range you are verifying (listed in the 1 mA

verification table in Test limit calculation for 10 µA to 100 mA ranges).

2-30 DAQ6510-905-01 Rev. D June 2022

Page 40

DAQ6510

Performance verification

10 µA

10

0.00500

100 µA

100

0.0500

5

0.00275

50

0.0275

–5

0.00275

–50

0.0275

–10

0.00500

–100

0.0500

1 mA

1

0.000500

10 mA

10

0.00250

0.5

0.000275

5 0.00150

–0.5

0.000275

–5

0.00150

–1

0.000500

–10

0.00250

Data Acquisition and Multimeter System Calibration and Adjustment Manual Section 2:

8. Note the offset-compensated reference DMM reading, and calculate limits based on DAQ6510

specifications (use the reference DMM reading as the expected value and verify the DAQ6510

accuracy from the calculated reference DMM current).

Test limit calculation for 10 µA to 100 mA ranges

The following tables list nominal test current for 10 µA to 100 mA ranges. Test limits must be

calculated relative to actual current, as determined by the reference digital multimeter (DMM)

measurement. For example, using a specification of 60 ppm of reading + 9 ppm of range on the

10 mA range, the reference DMM measures 5.00012 mA on the nominal 5 mA test.

Specification tolerance = 5.00012 (mA) × 60 ppm + 10 (mA) × 9 ppm = 0.000390072 mA

Lower test limit = 5.00012 – 0.000390072 = 4.999729928 mA

Upper test limit = 5.00012 + 0.000390072 = 5.000510072 mA

Although the specification tolerance calculated above from the actual test current differs slightly from

the values listed in the table (based on nominal value), this difference is generally much smaller than

the measurement uncertainty and can be ignored. As a result, the test limits can be calculated from

the table specification tolerance as:

Lower test limit = 5.00012 – 0.00039 = 4.99973 mA

Upper test limit = 5.00012 + 0.00039 = 5.00051 mA

9. Repeat steps 1 through 8 for all ranges (10 µA through 100 mA).

Range Nominal

input (µA)

Specification

tolerance (µA) (based

on nominal)

Range Nominal

input (µA)

Specification

tolerance (µA)

(based on nominal)

Range Nominal

input (µA)

Specification

tolerance (µA) (based

on nominal)

Range Nominal

input (µA)

Specification

tolerance (µA)

(based on nominal)

DAQ6510-905-01 Rev. D June 2022 2-31

Page 41

Section

Calibration and Adjustment Manual

2: Performance verification DAQ6510 Data Acquisition and Multimeter System

DC current 100 mA to 3 A range verification

To verify dc current accuracy on the 100 mA to 3 A ranges, you will:

• Apply accurate current from the dc current calibrator directly to the DAQ6510 front-panel

terminals.

• Verify that the displayed readings are within specified limits.

To verify dc current accuracy:

1. Set up the DAQ6510 for dc current and the range being tested. Make sure that relative offset is

disabled.

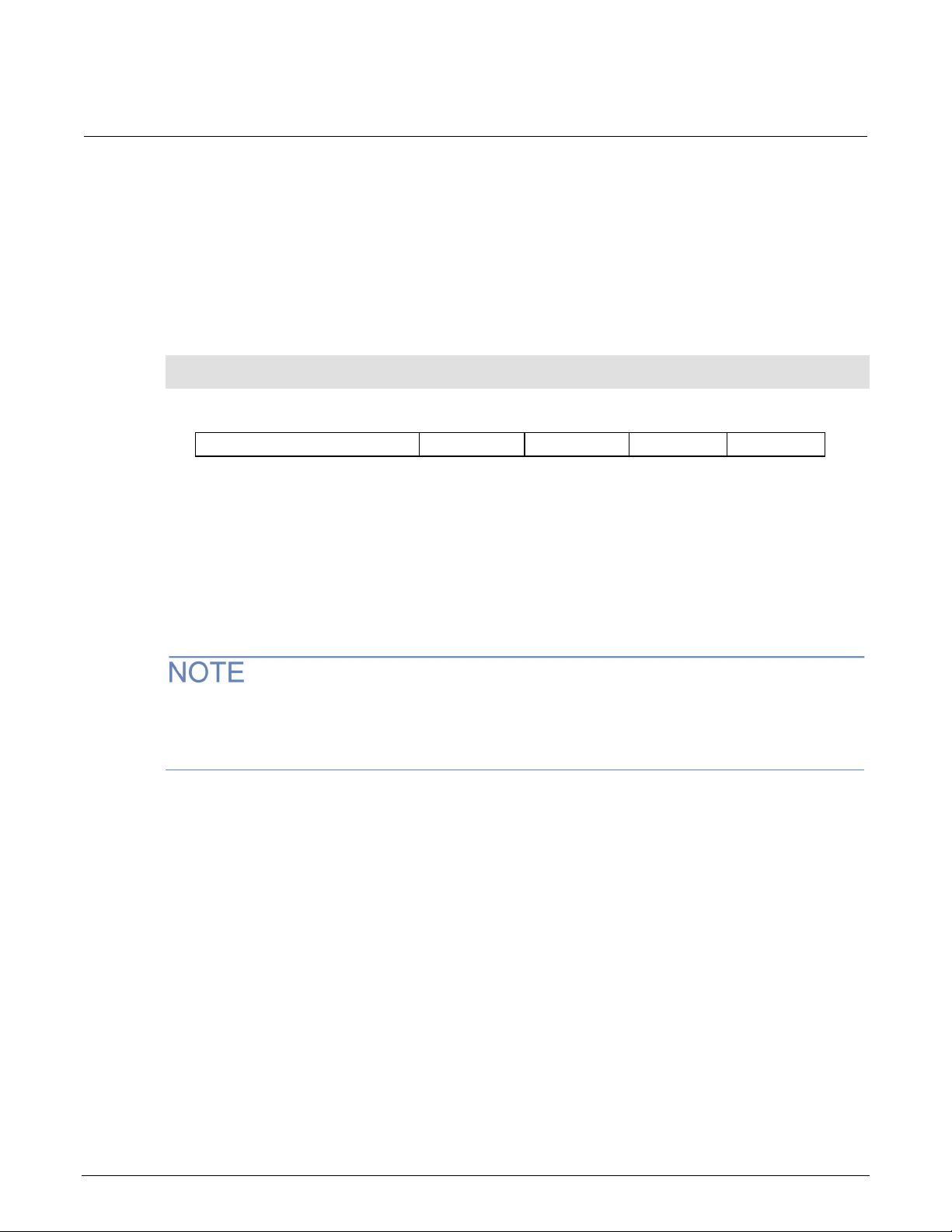

2. Connect the DAQ6510 and calibrator as shown in the following figure.

Figure 12: Connections for 100 mA to 3 A range verification

Zero verify the DAQ6510:

1. On the calibrator, select the OPR/STBY key. Make sure that the front panel displays STANDBY.

2. Set the ranges to 100 mA.

3. Verify the DAQ6510 zero reading for each range.

4. Source dc current from the following table. For each setting, be sure that the reading is within

stated limits.

5. Repeat these steps for the 1 A and 3 A ranges.

2-32 DAQ6510-905-01 Rev. D June 2022

Page 42

DAQ6510

Performance verification

Half scale (+)

50

49.985

50.015

Half scale (–)

-50

-50.015

-49.985

Full scale (–)

-100

-100.025

-99.975

Full scale (+)

1

0.99955

1.00045

Half scale (+)

0.5

0.49975

0.50025

Half scale (–)

–0.5

-0.50025

-0.49975

Full scale (–)

–1

-1.00045

-0.99955

Half scale (+)

1.5

1.49913

1.50087

Half scale (–)

–1.5

–1.50087

–1.49913

* The 3 A range full-scale test points are limited to 2 A in this table because of the accuracy

limitations of Fluke Models 57xxA and 5725A series calibrators at currents above 2.2 A.

Data Acquisition and Multimeter System Calibration and Adjustment Manual Section 2:

Verify dc current 100 mA range

Description Calibrator

Full scale (+) 100 99.975 100.025

Verify dc current 1 A range

Description Calibrator

Verify dc current 3 A range

Description Calibrator

*Full scale (+) 2 1.99888 2.00112

Lower limit Upper limit

setpoint (A)

Lower limit Upper limit

setpoint (A)

Lower limit Upper limit

setpoint (A)

*Full scale (–) –2 –2.00112 –1.99888

Digitize current verification

The following topics describe how to verify digitized dc current on the DAQ6510.

DAQ6510-905-01 Rev. D June 2022 2-33

Page 43

Section

on and Adjustment Manual

Full scale (+)

99.998

99.878

100.118

Half scale (+)

49.9991

49.9141

50.0841

Half scale (–)

-49.993

-50.0843

-49.9143

Full scale (–)

-99.9985

-100.1185

-99.8785

2: Performance verification DAQ6510 Data Acquisition and Multimeter System Calibrati

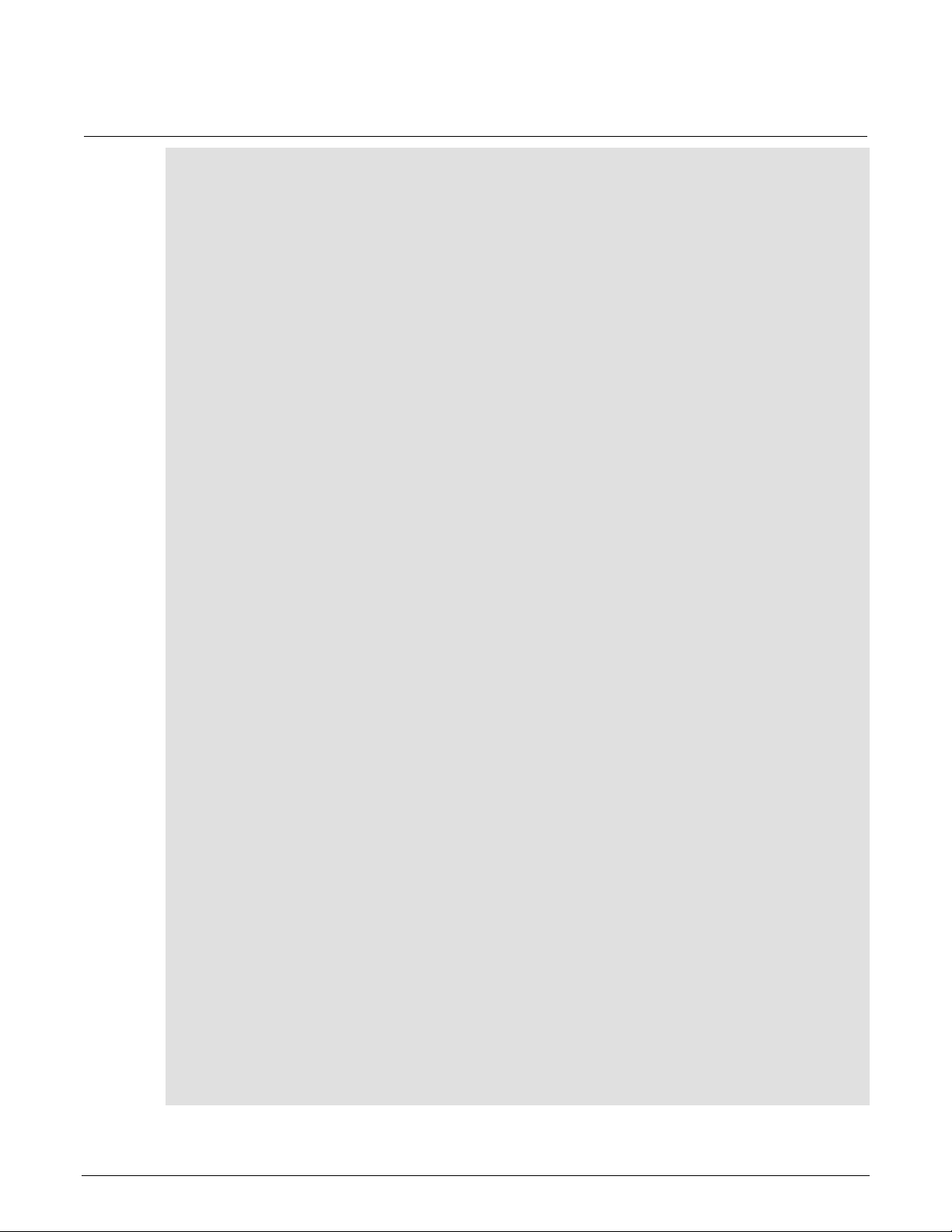

Verify digitize current 100 µA to 3 A ranges

To verify digitize dc current accuracy:

1. Connect the DAQ6510 and calibrator as shown in the following figure.

Figure 13: Connections for digitize dc current 10 µA to 3 A range verification

2. Press the FUNCTION key.

3. Select the Digitize Functions tab and select Digitize Current.

4. Press the HOME key.

5. Set the Range to 10 µA.

6. Press the MENU key.

7. Under Measure, select Settings.

8. Set the Sample Rate to 1000.

9. Set the Aperture to Auto or 1 ms.

10. Set the Count to 100.

11. Source positive and negative full-scale and half-scale currents, as listed in the following tables.

12. Repeat these steps for the 1 mA to 3 A range settings listed in the following tables.

Verify digitize current 100 µA range