Service Manual

CSA8000 Series

Communications Signal Analyzers,

TDS8000 Series

Digital Sampling Oscilloscopes,

and Modules

071-0438-07

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or

suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and pri ce change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

H In North America, call 1-800-833-9200.

H Worldwide, visit www.tektronix.com to find contacts in your area.

Warranty 2

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1) year

from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its option, either

will repair the defective product without charge for parts and labor, or will provide a replacement in exchange for the

defective product. Parts, modules and replacement products used by Tektronix for warranty work may be new or

reconditioned to like new performance. All replaced parts, modules and products become the property of Tektronix.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by Tektronix, with shipping charges prepaid.

Tektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

Tektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than Tektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or malfunction

caused by the use of non-Tektronix supplies; or d) to service a product that has been modified or integrated with other

products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY OTHER

WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PAR TICULAR PURPOSE. TEKTRONIX’

RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY

PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY . TEKTRONIX AND ITS VENDORS WILL

NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES

IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS ADV ANCE NOTICE OF THE POSSIBILITY

OF SUCH DAMAGES.

Table of Contents

Operating Information

General Safety Summary ix...................................

Service Safety Summary xi....................................

Preface xiii...................................................

Manual Structure xiii................................................

Manual Conventions xiii..............................................

Related Documentation xiv...........................................

Installation 1--1...............................................

Check the Environmental Requirements 1--1..............................

Site Considerations 1--1...........................................

Operating Requirements 1--1.......................................

Rackmount Requirements 1--2......................................

Install the Sampling Modules 1--2.......................................

Check Your Sampling Module Manual(s) 1--2..........................

Maximum Configuration 1--3.......................................

Connect the Peripherals 1--3...........................................

Power On the Instrument 1--5..........................................

Powering Off the Instrument 1--6.......................................

Software Installation 1--7..............................................

Description 1--7.................................................

Software Release Notes 1--7........................................

Operating System Reinstallation 1--7.................................

System Hard Drive Rebuild 1--8....................................

System Diagnostics 1-- 8...........................................

Windows Safe Mode 1--8..........................................

Theory of Operation

Theory of Operation 2--1.......................................

Logic Conventions 2--1...............................................

Mainframe Overview 2--1.............................................

Input Signal Path 2--1.............................................

Display Panel 2--2................................................

Front Panel 2--2..................................................

Rear Panel 2--2..................................................

Low Voltage Power Supply 2--2.....................................

Fans 2--3.......................................................

Electrical Sampling Modules Overview 2--3..............................

80E01, 80E02, 80E03, 80E06, 80E07, and 80E09 Sampling Modules 2--3...

80E04, 80E08, and 80E10 TDR/Sampling Modules 2--4.................

CSA8000 & TDS8000 Series Instruments and Modules

i

Table of Contents

Optical Sampling Modules Overview 2--5................................

80C01 Optical Sampling Module 2--7................................

80C02 Optical Sampling Module 2--7................................

80C03 Optical Sampling Module 2--8................................

80C04 Optical Sampling Module 2--8................................

80C05 Optical Sampling Module 2--9................................

80C06 Optical Sampling Module 2--9................................

80C07 Optical Sampling Module 2--9................................

80C07B Optical Sampling Module 2--10...............................

80C08 Optical Sampling Module 2--10................................

80C08B Optical Sampling Module 2--10...............................

80C08C Optical Sampling Module 2--11...............................

80C09 Optical Sampling Module 2--11................................

80C10 Optical Sampling Module 2--11................................

80C11 Optical Sampling Module 2--12................................

80C12 Optical Sampling Module 2--12................................

80A01 Trigger Prescale Preamplifier Module 2--12..........................

80A02 EOS/ESD Protection Module 2--13.................................

80A05 Electrical Clock Recovery Module 2--13............................

80A06 PatternSync Trigger Module 2--14.................................

82A04 Phase Reference Module 2--14....................................

Adjustment Procedures

Maintenance

Adjustment Interval 3--1..............................................

Adjustment Environment 3--1..........................................

Adjustment After Repair 3--1..........................................

Required Equipment 3--2..............................................

Instrumentation Setup 3--2.............................................

Main Instrument Adjustments 3--3......................................

DC Calibrator Adjust 3--3..........................................

DC Calibrator Adjust Verification 3--4...............................

Internal 10 MHz Adjust 3--5........................................

Preventing ESD 4--1.................................................

Inspection and Cleaning 4--2...........................................

General Care 4--2................................................

Flat Panel Display Cleaning 4--2....................................

Exterior 4--3....................................................

Interior 4--4.....................................................

Removal and Installation Procedures 4--7.........................

Preparation 4--7.....................................................

Procedures for External Modules 4--9....................................

Front-Panel Knobs 4--9............................................

Trim and Carrying Handle 4--10.....................................

Bottom Cover 4--11...............................................

Covers 4--13.....................................................

Line Fuses and AC power cord connector 4--16.........................

ii

CSA8000 & TDS8000 Series Instruments and Modules

Table of Contents

Procedures for Modules 4--21...........................................

Front Panel Assembly 4--21.........................................

Front Panel Board 4--23............................................

Front Panel Keypad 4--24...........................................

Display Assembly 4-- 25............................................

Display Adapter Board 4--27........................................

Standby/On Switch Flex Circuit Removal 4--29.........................

Floppy Disk Drive 4--31............................................

Hard Disk Drive 4--32.............................................

CD Drive 4--34...................................................

Fan Assembly Removal 4--35........................................

Front and Rear Power Distribution Boards 4--37.........................

Low-Voltage Power Supply 4--38.....................................

NLX Board 4--40.................................................

Microprocessor 4--43..............................................

PC Processor Board 4--45...........................................

Acquisition Assembly 4--47.........................................

Large Module Interface Circuit Board 4--53............................

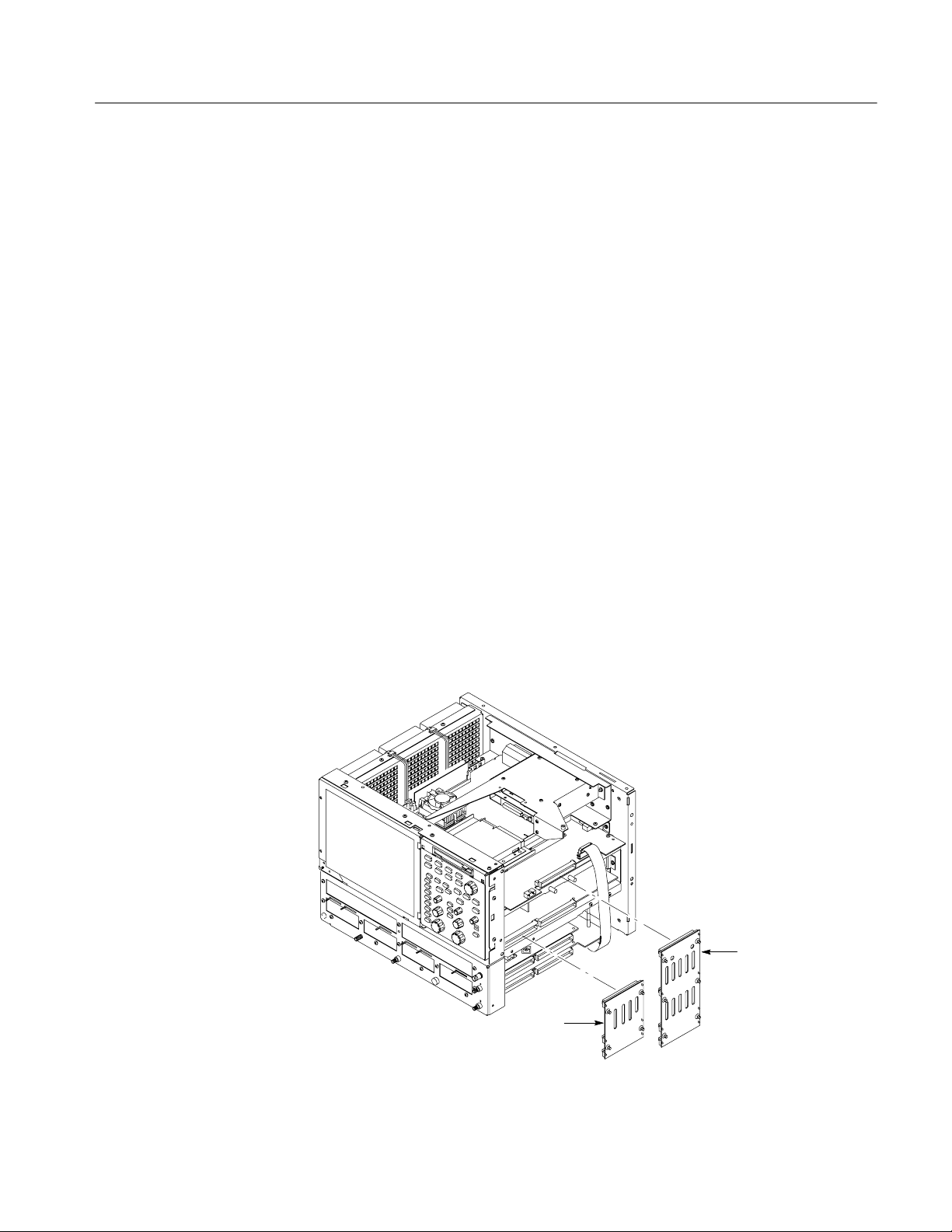

Module Slot Doors 4 --55...........................................

Electrical Modules 4--64............................................

Exchanging the Electrical Sampling Module 4--65..........................

Replacing the sampling module chassis 4--65...........................

Reinstalling exchange module serial number 4--65.......................

Optical Modules 4--66.............................................

80A00 and 82A00 Series Modules 4--67...............................

Troubleshooting 4--69...........................................

Check for Common Problems 4--69......................................

Equipment Required 4 --72..............................................

Isolating Failures between the 80E0X/80C0X Modules or the Mainframe 4--72...

Isolating to a Board if Power Will Not Come Up 4--73....................

Checking the Power Supply Voltages 4--74...............................

If the instrument Will Not Boot 4--75.................................

Booting Into Windows 4--76.........................................

PPC and NLX PC Diagnostics 4--76......................................

Power-On Diagnostics 4--76.........................................

QAPlus/Win 4--76.................................................

Diagnostics 4--77.................................................

Firmware Updates 4--77................................................

After Repair 4--78....................................................

Installing the Instrument Model and Serial Number 4--78.....................

Update/Restore the NLX Board CMOS 4--79...............................

Repackaging Instructions 4--81...................................

Packaging 4--81......................................................

Shipping to the Service Center 4--81......................................

Diagrams

Symbols 5--1.......................................................

CSA8000 and TDS8000 Series Block Diagram 5--2.........................

Electrical Sampling Modules Block Diagram 5--3..........................

Optical Sampling Modules Block Diagrams 5--4...........................

80A01 Block Diagram 5--26............................................

CSA8000 & TDS8000 Series Instruments and Modules

iii

Table of Contents

Replaceable Parts

80A02 Block Diagram 5--27............................................

80A05 Block Diagram 5--28............................................

80A06 Block Diagram 5--29............................................

82A04 Block Diagram 5--30............................................

Replaceable Parts List 6-- 1......................................

Parts Ordering Information 6--1.........................................

Module Servicing 6--1............................................

Using the Replaceable Parts List 6--2....................................

iv

CSA8000 & TDS8000 Series Instruments and Modules

List of Figures

Table of Contents

Figure 1--1: Compartments for sampling modules 1--2...............

Figure 1--2: Locations of peripheral connectors on rear panel 1--4.....

Figure 1--3: Line fuse and power cord connector locations,

rear panel 1-- 5.............................................

Figure 1-- 4: On/Standby switch location 1--6.......................

Figure 3-- 1: Adjustment setup using the DMM 3-- 3..................

Figure 3-- 2: Adjustment setup using the signal generator 3-- 5.........

Figure 4--1: Knob removal 4--9..................................

Figure 4--2: Trim removal 4--11...................................

Figure 4--3: Bottom cover removal 4--12............................

Figure 4--4: Cover removal 4--14..................................

Figure 4--5: Cover removal 4--15..................................

Figure 4--6: Line fuses and line cord removal 4--17...................

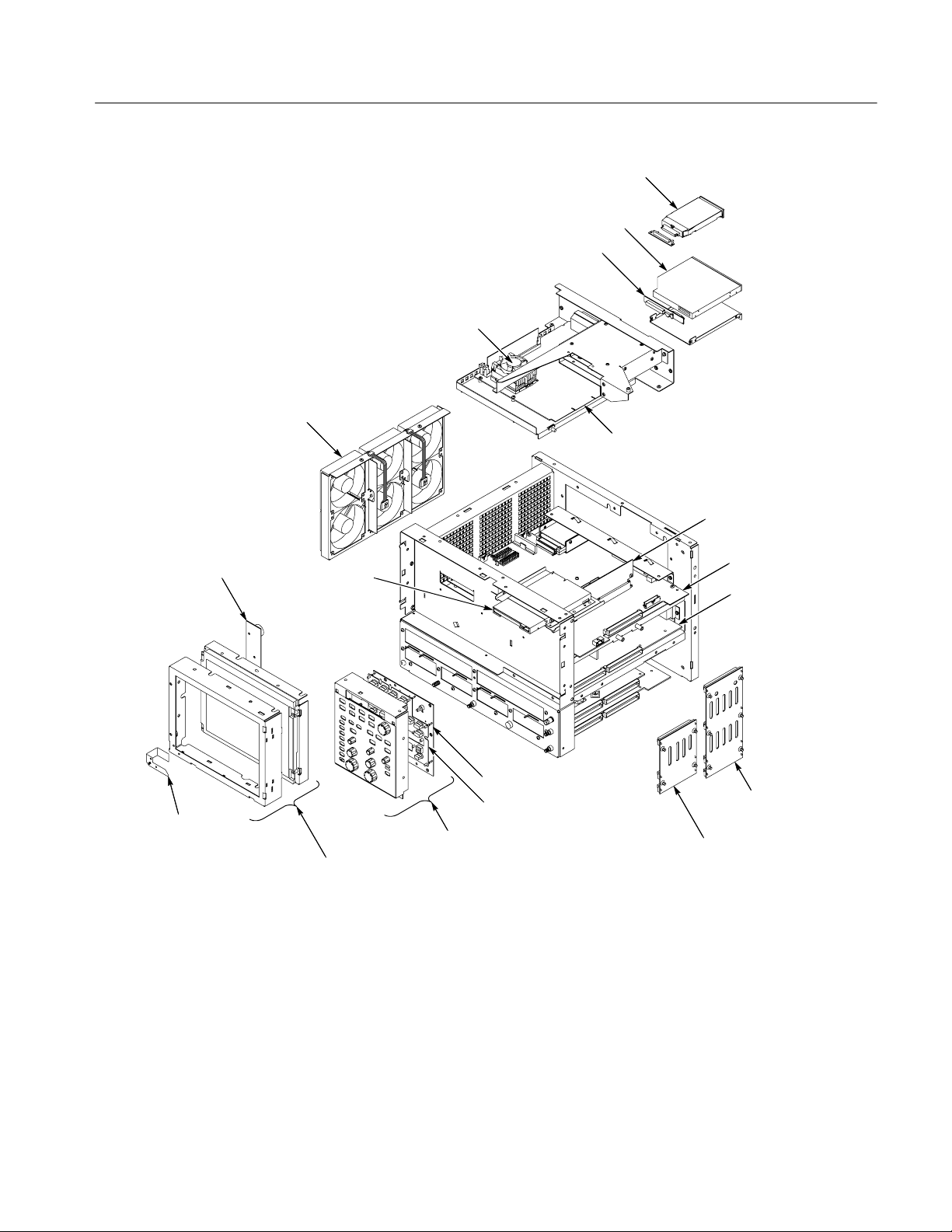

Figure 4--7: External modules 4--18................................

Figure 4-- 8: Internal modules 4-- 19................................

Figure 4-- 9: Acquisition modules 4-- 20.............................

Figure 4--10: Front panel assembly removal 4--22....................

Figure 4--11: J1 flex cable connector removal 4--23...................

Figure 4--12: Front panel board and keyboard removal 4--24..........

Figure 4--13: Display removal 4--26................................

Figure 4--14: Touch panel and LCD assembly removal 4--27...........

Figure 4--15: Display adaptor board removal 4--28...................

Figure 4--16: Connector clip assembly 4--28.........................

Figure 4-- 17: Standby/On switch flex circuit removal 4--30............

Figure 4--18: Floppy disk drive removal 4--31.......................

Figure 4--19: Hard drive disk removal 4--33.........................

Figure 4--20: Removing the hard disk drive from the cartridge 4--33....

Figure 4--21: CD drive and bracket removal 4--35....................

Figure 4--22: Fan assembly removal 4--36...........................

Figure 4--23: Front and rear power distribution board removal 4--37...

Figure 4-- 24: Low-voltage power supply removal 4--39................

Figure 4--25: NLX assembly removal 4--41..........................

Figure 4--26: Riser adapter and NLX board removal 4--42............

Figure 4--27: Microprocessor removal 4--44.........................

CSA8000 & TDS8000 Series Instruments and Modules

v

Table of Contents

Figure 4--28: Processor board removal 4--46........................

Figure 4--29: T-10 screws and threaded posts 4--48...................

Figure 4--30: Thermal cover removal (8200 only) 4--49................

Figure 4--31: Acquisition circuit board assembly removal (8000) 4--50...

Figure 4--32: Acquisition circuit board assembly removal (8000B) 4--51.

Figure 4--33: Acquisition circuit board assembly removal (8200) 4--52...

Figure 4--34: Large module interface circuit board removal

(8000 and 8000B) 4--54.......................................

Figure 4--35: Large module interface circuit board removal (8200) 4--55.

Figure 4--36: Small and Large module chassis removal 4--57...........

Figure 4--37: Module door spring removal 4--59.....................

Figure 4--38: Module slot door removal 4--60........................

Figure 4--39: Module ejector handles removal 4--62..................

Figure 4--40: Spring arm position 4--63............................

Figure 4--41: Electrical module hardware removal 4--64..............

Figure 4--42: Optical module cover removal 4--66....................

Figure 4--43: 80A00 and 82A00 series parts removal

(80A01 shown) 4--67.........................................

Figure 4--44: Location of power-on and over current LEDs 4--73.......

Figure 4--45: Location of debug pins 4--74..........................

Figure 4--46: Connectors J1 and J2 4--75...........................

Figure 5--1: Block diagram for CSA8000 and TDS8000

Series Instruments 5--2......................................

Figure 5--2: Block diagram for the 80E00 Series Electrical

Sampling Modules 5-- 3......................................

Figure 5--3: 80C01 Optical sampling block diagram 5--4.............

Figure 5--4: 80C01 Optical sampling with clock recovery block

diagram 5--5..............................................

Figure 5--5: 80C02 Optical sampling block diagram 5--6.............

Figure 5--6: 80C02 Optical sampling with clock recovery block

diagram 5--7..............................................

Figure 5--7: 80C03 Optical sampling block diagram 5--8.............

Figure 5--8: 80C03 Optical sampling with clock recovery block

diagram 5--9..............................................

Figure 5--9: 80C04 Optical sampling block diagram 5--10.............

Figure 5--10: 80C04 Optical sampling block diagram with clock

recovery 5--1 1..............................................

Figure 5--11: 80C05 Optical sampling block diagram 5--12............

Figure 5--12: 80C06 Optical sampling block diagram 5--13............

vi

CSA8000 & TDS8000 Series Instruments and Modules

Table of Contents

Figure 5--13: 80C07 and 80C07B Optical sampling block diagram 5--14.

Figure 5--14: 80C07 and 80C07B Optical sampling with CR1 clock

recovery block diagram 5--15.................................

Figure 5--15: 80C08/80C08B/80C08C Optical sampling block

diagram 5--16..............................................

Figure 5--16: 80C08/80C08B/80C08C Optical sampling with CR1,

CR2, & CR4 clock recovery block diagram 5--17.................

Figure 5--17: 80C09 Optical sampling block diagram 5--18............

Figure 5--18: 80C09 Optical sampling with CR1 clock recovery

block diagram 5--19.........................................

Figure 5--19: 80C10 Optical sampling block diagram 5--20............

Figure 5--20: 80C11 Optical sampling block diagram 5--21............

Figure 5--21: 80C11 Optical sampling with CR1 clock recovery

option block diagram 5--22...................................

Figure 5--22: 80C11 Optical sampling with CR2 and CR3 clock

recovery option block diagram 5--23...........................

Figure 5--23: 80C11 Optical sampling with CR4 clock recovery

option block diagram 5--24...................................

Figure 5--24: 80C12 Optical sampling block diagram 5--25............

Figure 5--25: 80A01 block diagram 5--26...........................

Figure 5--26: 80A02 block diagram 5--27...........................

Figure 5--27: 80A05 block diagram 5--28...........................

Figure 5--28: 80A06 block diagram 5--29...........................

Figure 5--29: 82A04 block diagram 5--30...........................

Figure 6--1: External parts 6--4..................................

Figure 6-- 2: Front panel and drives 6-- 7...........................

Figure 6-- 3: Power supply 6-- 10...................................

Figure 6--4: Acquisition 6--12.....................................

Figure 6--5: 8000 and 8000B coaxial cables 6--14.....................

Figure 6--6: 8200 coaxial cables 6--16..............................

Figure 6--7: 80E01, 80E02, 80E03, and 80E04 modules 6--18...........

Figure 6--8: 80E05 module (Option 10G shown) 6--19................

Figure 6--9: 80E06 module 6--20..................................

Figure 6--10: 80E07, 80E08, 80E09, and 80E10 modules 6--21..........

Figure 6--11: Optical modules 6--22................................

Figure 6--12: 80A01 module 6--23.................................

Figure 6--13: 82A04 module 6--24.................................

Figure 6--14: 80A06 module 6--26.................................

CSA8000 & TDS8000 Series Instruments and Modules

vii

Table of Contents

List of Tables

Table 1--1: Additional accessory connection information 1--3.........

Table 1--2: Line fuses 1--5......................................

T able 2--1: Module optical/electrical split 2--6......................

Table 3--1: Adjustments required for module replaced 3--1...........

Table 3--2: Required equipment and materials 3--2.................

T able 4--1: External inspection check list 4--3......................

T able 4--2: Internal inspection check list 4--4......................

Table 4--3: Tools required for module removal 4--8.................

Table 4--4: Failure symptoms and possible causes 4--69...............

Table 4--5: Power supply voltages 4--75............................

Table 4--6: Action required for module replaced 4--78................

viii

CSA8000 & TDS8000 Series Instruments and Modules

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

ToAvoidFireor

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use. Power cord needed only in the mainframe, not

modules.

Connect and Disconnect Properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. The mainframe is grounded through the grounding

conductor of the power cord. To avoid electric shock, the grounding conductor

must be connected to earth ground. Before making connections to the input or

output terminals of the product, ensure that the product is properly grounded.

Ground the Product. The modules are indirectly grounded through the grounding

conductor of the mainframe power cord. To avoid electric shock, the grounding

conductor must be connected to earth ground. Before making connections to the

input or output terminals of the product, ensure that the product is properly

grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Wear Eye Protection. Wear eye protection if exposure to high-intensity rays or

laser radiation exists.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

CSA8000 & TDS8000 Series Instruments and Modules

ix

General Safety Summary

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

CAUTION

Refer to Manual

Mains Disconnected

OFF (Power)

WARNING

High Voltage

Mains Connected

ON (Power)

x

Protective Ground

(Earth) Terminal

Standby

CSA8000 & TDS8000 Series Instruments and Modules

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

CSA8000 & TDS8000 Series Instruments and Modules

xi

Service Safety Summary

xii

CSA8000 & TDS8000 Series Instruments and Modules

Preface

Manual Structure

This is the service manual for the:

H CSA8000, CSA8000B, and CSA8200 Communications Signal Analyzers

H TDS8000, TDS8000B, and TDS8200 Digital Sampling Oscilloscopes

H modules that install in the instruments (except the 80A03 module)

NOTE. The 80A03 instruction manual contains its own specifications and

servicing information.

Read this preface to learn how this manual is structured, what conventions it

uses, and where you can find other information related to servicing this product.

Read the Introduction following this preface for safety and other important

background information needed before servicing this product.

This manual is divided into chapters, which are made up of related subordinate

topics. These topics can be cross referenced as sections.

Manual Conventions

Modules

Replaceable Parts

Safety

Be sure to read the introductions to all procedures. These introductions provide

important information needed to do the service correctly, safely, and efficiently.

This manual uses certain conventions that you should become familiar with

before attempting service.

Throughout this manual, the term module appears. A module is composed of

electrical and mechanical assemblies, circuit cards, interconnecting cables, and a

user-accessible front panel. References to a module are different than references

to products such as “Sampling modules”. “Phase Reference modules”, or

“Accessory modules” which are products installed in the instrument compartments.

This manual refers to any field-replaceable assembly or mechanical part by its

name or generically as a replaceable part. In general, a replaceable part is any

circuit board or assembly, such as a hard disk drive, or a mechanical part, such as

I/O port connectors, that is listed in the replaceable parts list of Chapter 8.

Symbols and terms related to safety appear in the General Safety Summary found

at the beginning of this manual.

CSA8000 & TDS8000 Series Instruments and Modules

xiii

Preface

Related Documentation

The following documents relate to the instruments this service manual supports:

H CSA8200 and TDS8200 Quick Start User manual. Tektronix part number

071-1482-XX. This document also contains specification changes when

using the 82A04 Phase Reference module.

H CSA8000 and TDS8000 Specifications and Performance Verification

manual. Tektronix part number 071-xxxx-XX.

H CSA8000 and TDS8000 Online Help. Installed with the application software

and accessed from the instrument Help menu.

H CSA8000 & TDS8000 Programmer Guide. An online document accessed

from the instrument Help menu.

H 80E01, 80E02, 80E03, 80E04, and 80E06 Electrical Sampling Modules

User manual. Tektronix part number 071-0434-XX.

H 80E07, 80E08, 80E09, and 80E10 Electrical Sampling Remote Modules

User manual. Tektronix part number 071-2038--XX.

H 80C00 Series Optical Sampling Modules User manual. Tektronix part

number 071-0435-XX.

H 80A01 Trigger Prescale Limiting Preamplifier Module User manual.

Tektronix part number 071-0873-XX.

H 80A02 EOS/ESD Protection Module Instructions. Tektronix part number

071-1317-XX

H 80A03 TekConnect Probe Interface Module Instructions. Tektronix part

number 071-1298-XX.

H 80A05 Electrical Clock Recovery Module User manual. Tektronix part

number 071-1467-XX.

H 80A06 PatternSync Trigger Module Instructions. Tektronix part number

071-xxx-XX.

H CSA8000/TDS8000 Rackmount Kit Instructions. Tektronix part number

071-0696-XX.

H TDR Z-Meas Application Online Help. Ships with this product on a separate

CD. Provides information about this TDR Impedance Measuring application

that implements the TDR calibration procedures specified by the

IPC TM-650 test method.

xiv

H Fast NRZ Application Online Help. Ships with this product on a separate

CD. Provides information about this application that improves throughput

for optical eye-pattern mask testing.

CSA8000 & TDS8000 Series Instruments and Modules

Operating Information

Installation

This section covers installation of the instrument, addressing the following

topics:

H Check the Environment Requirements on page 1--1

H Install the Sampling Modules on page 1--2

H Connect the Peripherals on page 1--3

H Power On the Instrument on page 1--5

H Powering Off the Instrument on page 1--6

The basic operating software is already installed on the hard disk. If reinstallation of software becomes needed, see the following topic:

H Software Installation on page 1--7

Check the Environmental Requirements

Site Considerations

Operating Requirements

Read this section before attempting any installation procedures. This section

describes site considerations, power requirements, and ground connections for

your instrument.

The instrument is designed to operate on a bench or on a cart in the normal

position (on the bottom feet). For proper cooling, at least two inches (5.1 cm) of

clearance is recommended on the sides of the instrument.

You can also operate the instrument while it rests on its rear feet. Make sure that

you properly route any cables coming out of the rear of the instrument to avoid

damaging them.

CAUTION. Keep the bottom of the instrument clear of obstructions to ensure

proper cooling.

Specifications in chapter 1 list the operating requirements for the instrument.

Power source and temperature, humidity, and altitude are listed.

CSA8000 & TDS8000 Series Instruments and Modules

1- 1

Installation

Rackmount Requirements

If this instrument is rackmounted, see the TDS8000 & CSA8000 Rackmount

Instructions for additional site considerations or operating requirements. This

document ships with the Option 1R (rackmount kit).

Install the Sampling Modules

CAUTION. Do not install or remove any sampling modules while the instrument is

powered on.

Always power the instrument down before attempting to remove or insert any

sampling module.

WARNING. Sampling modules are inherently vulnerable to static damage. Always

observe static-safe procedures and cautions as outlined in your sampling module

user manual.

Check Your Sampling

Module Manual(s)

Read the sampling-module user manual for instructions on how to install your

sampling modules.

Large-module compartments (2)

Small-module compartments (4)

Connect ESD wrist strap here

NOTE. After first installing a sampling module(s) or after moving a sampling

module from one compartment to another, you should run compensation from the

Utilities menu to ensure the instrument meets its accuracy specifications. You

must run a compensation (accessed from the Utilities menu) whenever the

extender configuration is changed from that present at the last compensation. In

short, if you install or remove an 80E00 extender, run a compensation. If you

exchange a extender for one of a different length, run a compensation.

Figure 1--1 shows compartments for both large and small sampling modules,

along with the plug-in connector for the ESD wrist strap that you must use to

install and remove these modules.

Figure 1- 1: Compartments for sampling modules

1- 2

CSA8000 & TDS8000 Series Instruments and Modules

Installation

Maximum Configuration

You can install up to two large sampling modules and four small modules for a

maximum of 10 inputs (CSA and TDS 8000 and 8000B) or 12 inputs (CSA and

TDS 8200). Of these inputs, only eight inputs can be active at one time. Also,

note that installing a large module may disable a small-module compartment.

Refer to the user manual for compartment interaction for the various CSA and

TDS 8000 Series mainframes.

Install probes, cables, and other connection accessories to your sampling

modules as appropriate for your application and sampling module. Again,

consult your sampling-module and connection-accessory manuals. Continue with

the next section after installing the sampling modules.

Connect the Peripherals

The peripheral connections are mostly the same as those you would make on a

personal computer. The connection points are shown in Figure 1--2. See

Table 1--1 on page 1--3 for additional connection information.

WARNING. Before installing peripheral accessories to connectors (mouse, keyboard,

etc.), power down the instrument. See Powering Off the Instrument on page 1--6.

Table 1- 1: Additional accessory connection information

Item Description

Monitor If you use a non-standard monitor, you may need to change the the

Windows display settings to achieve the proper resolution for your monitor.

Printer Connect the printer to the EPP (enhanced parallel port) connector directly. If

your printer has a DB-25 connector, use the adapter cable that came with

your printer to connect to the EPP connector.

Rackmount Refer to the CSA8000 & TDS8000 Rackmount Installation Instructions for

information on installing the rackmount kit.

Other Refer to the Appli cation release notes (readme.txt) in the C:\Program

Files\TDSCSA8000\System directory of the instrument for possible

additional accessory installation information not covered in this manual.

CSA8000 & TDS8000 Series Instruments and Modules

1- 3

Installation

Description..........................Icon/Label Locations

Monitor.............

Printer......................

RS-232.................

Network.............................

PS2 mouse

PS2 keyboard

1,2

......................

1,2

..............

USB................................

Audio line out.......................

Audio line in........................

Removable hard drive.....................

CD drive.........................

GPIB...........

Monitor....................

3

Card slot

...........

Gated trigger...........

1

Product ships with a USB keyboard, that plugs into the USB port, and a USB mouse that plugs into the back of the keyboard

2

Some instruments ship with the keyboard and mouse ports reversed.

3

Card slot not available on CSA/TDS8000B or CSA/TDS8200 instruments. The card slot is disabled in instruments running Microsoft Windows 2000.

Figure 1- 2: Locations of peripheral connectors on rear panel

1- 4

CSA8000 & TDS8000 Series Instruments and Modules

Power On the Instrument

Follow these steps to power on the instrument for the first time.

1. Check that the line fuses are correct for your application. Both fuses must be

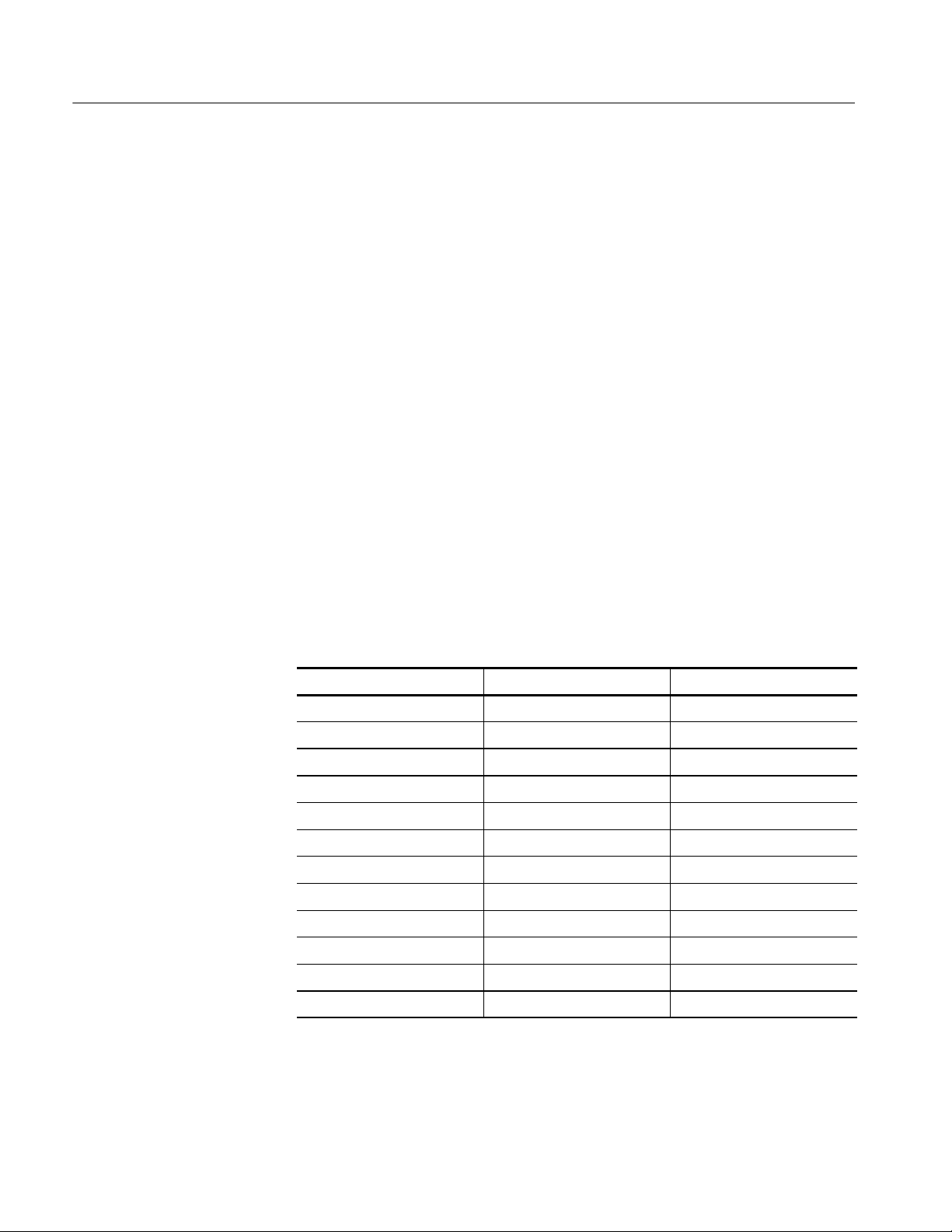

Table 1- 2: Line fuses

Fuse type Rating Fuse part number

0.25 x 1.250 inch 8 A, fast blow, 250 V 159-0046-00 200-2264-00

5x20mm 6.3 A, fast blow, 250 V 159-0381-00 200-2265-00

Installation

the same rating and type. Fuse types require a unique cap and fuseholder. See

Table 1--2 and Figure 1--3.

Cap & fuseholder

part number

Fuses AC powerPower switch

Figure 1- 3: Line fuse and power cord connector locations, rear panel

CAUTION. Connect accessories (such as a PS2 keyboard and mouse, and other

accessories) before applying power to the product. Some accessories can be

damaged if connecting or disconnecting with the instrument power on.

USB devices can be plugged or unplugged without first turning power off.

2. Connect the keyboard and mouse, observing the caution above.

NOTE. Connection of the keyboard and mouse is optional. You can operate most

features without them, using the front-panel controls and the touchscreen.

3. Connect the power cord.

4. Turn the Power switch on at the rear panel. (See Figure 1--3 on page 1--5 for

switch location.)

5. Push the On/Standby switch to power on the instrument (see Figure 1--4 for

the switch location).

CSA8000 & TDS8000 Series Instruments and Modules

1- 5

Installation

Switch

Figure 1- 4: On/Standby switch location

6. Wait for the boot routine and low-level self test to complete.

7. Follow any instructions on the screen.

The internal setup software will automatically configure your instrument and

install all required devices, depending on the installed accessories.

Powering Off the Instrument

The instrument has a built-in soft power-down function that safely powers down

the instrument when you push the On/Standby button. You do not need to close

the UI application or Windows before using the On/Standby button.

To completely remove power to the instrument, first soft power-down the

instrument using the On/Standby button, and then set the power switch on the

rear panel to off.

You can restore the UI application to the screen by clicking its button in the

Windows Task bar.

1- 6

CSA8000 & TDS8000 Series Instruments and Modules

Software Installation

Installation

This section describes how to install the system software found on the 8000

Series OS Restore CDs that accompany this product. The instrument ships with

the product software installed, so only perform these procedures if reinstallation

becomes necessary.

Description

Software Release Notes

The product software comprises two parts:

H Microsoft Windows. The Microsoft Windows operating system comes

preinstalled on the instrument. Microsoft Windows is the operating system

on which the user-interface application of this product runs. The CD-

ROM(s) included with your instrument contain the Windows operating

system which can be used to rebuild the instrument hard drive.

If you need to reinstall Windows, you may be able to do so without

rebuilding the instrument hard drive. See Operating System Reinstallation on

page 1--7 for more information.

H User Interface (UI) Application. The UI application complements the

hardware controls of the front panel, allowing complete set up of all

instrument features. The CD-ROM(s) included with your instrument contain

the UI application for reinstallation if rebuilding the hard drive.

Tektronix provides updates to the user interface application on a regular

basis. Updates can be obtained by visiting the Tektronix Web site at

www.tektronix.com.

Read the software release notes in the Release Notes file (or Readme file for

earlier versions), if present, on the CD-ROM containing the user interface

application before performing any installation procedures. This file contains

additional installation and operation information that supercedes other product

documentation.

After installation, you can also read the copy from a directory on the product:

C:\Programs Files\TDSCSA8000\System

Operating System

Reinstallation

CSA8000 & TDS8000 Series Instruments and Modules

If reinstalling Microsoft Windows becomes necessary, use the Windows

Operating System restore CD(s) that came with your instrument. Follow the

installation procedures provided with the CD(s). The procedures vary between

instruments and the version of Microsoft Windows being installed.

NOTE. Only do the reinstall if the Microsoft Windows operating system is

missing or corrupted.

1- 7

Installation

System Hard Drive

Rebuild

System Diagnostics

Windows Safe Mode

If you cannot reboot from the instrument hard drive, you must rebuild the

instrument hard drive. This process will return the hard disk to the its original

condition present when the instrument shipped.

Data and programs you may have installed will be lost when rebuilding the hard

drive.

If you must rebuild the system hard drive, use the System Rebuild CD(s) that

shipped with the instrument. Follow the instructions in the booklet found in the

CD case.

In case of instrument problems, you may wish to run the system diagnostics. If

needed, you can see the procedure in the Performance Verification and Specifica-

tions manual.

If the instrument is turned off before the operating system boots, or if you’ve

installed a third-party product with a driver incompatible with instrument start

up, Windows will open in Safe mode. The touchscreen will be inoperable;

therefore, you must install the standard-accessory mouse and keyboard to operate

the instrument.

When you have finished investigating and removed any barrier to Windows

start-up, you can reboot. If the instrument no longer boots to Safe mode, you can

remove the keyboard and mouse if desired.

1- 8

CSA8000 & TDS8000 Series Instruments and Modules

Theory of Operation

Theory of Operation

This chapter describes the electrical operation of the instrument and sampling

modules. The diagrams in Chapter 9 show the interconnections of the major

circuit blocks.

Logic Conventions

The instrument contains many digital logic circuits. This manual refers to these

circuits with standard logic symbols and terms. Unless otherwise stated, all logic

functions are described using the positive-logic convention: the more positive of

the two logic levels is the high (1) state, and the more negative level is the low

(0) state. Signal states may also be described as “true” meaning their active state

or “false” meaning their nonactive state. The specific voltages that constitute a

high or low state vary among the electronic devices.

Mainframe Overview

This mainframe overview describes the basic operation of each functional circuit

block as shown in Figure 5--1 on page 5--2.

General

Input Signal Path

The instrument control system is a dual Wintel/PowerPC based processor board.

The platform features VGA resolution flat-panel display, transparent touch

screen and user front-panel with direct access to commonly used scope functions.

The instrument is also equipped with a mouse pointing device to facilitate access

to more advanced scope functions

A signal enters the instrument through a direct coaxial connection to the input

connector on a sampling module, or a real time probe connected to the sampling

module channel.

Acquisition System. The acquisition system conditions the input signals, samples

them, converts them to digital signals, and controls the acquisition process under

direction of the processor system. The acquisition system includes the multisource trigger, acquisition timebase, and acquisition mode generation and control

circuitry. The acquisition board is located in the bottom compartment of the

instrument and can accommodate four small slot sampling plug-ins, two large

slot plug-ins and a trigger/holdoff subsystem. Up to 8 vertical channels are

accommodated simultaneously . Channels 1 and 2 (CSA and TDS8000 and

8000B) or channels 1, 2, 3, and 4 (CSA and TDS8200) can be either large or

small slots. The presence of a module in one or both large slots displaces the

CSA8000 & TDS8000 Series Instruments and Modules

2- 1

Theory of Operation

small slot functionality in the corresponding small slots. The external trigger and

all small slot channels feature a Tekprobe Level 2 probe power connector for

additional front end signal conditioning functions like high input-impedance

real-time probes, if equipped on the sampling module.

Processor System. The processor system contains a dual Wintel/PowerPC. The

basic instrument configuration supports up to eight channels labeled Ch1 through

Ch 8, provides two external trigger inputs for direct and prescaled triggering

through built--in prescaler and is able to support two optional internal trigger

sources associated with the large slot channels.

Display Panel

Front Panel

Rear Panel

Color LCD display Active-matrix touch panel.

Display System. The display system sends the text and waveform information to

the display panel.

Touch Panel. The Display board sends information to the processor. Any changes

in their settings are reported to the processor system.

The front panel board reads the front-panel switches and knob sensors. Any

changes in their settings are reported to the processor system. The front panel

board also turns the LEDs on and off and generates the bell signal.

Front-panel menu switches are also read by the PPC processor board. The

processor sends any changes in menu selections to the processor system. The

ON/STBY switch is one of the menu switches. However, it is not read by the

front panel board, but passes through the front panel board to the low voltage

power supply.

The hard drive and CD Rom provides access to stored waveform data and to load

software to customized your instrument with your measurement needs. The

GPIB allows for external control of the instrument.

Low Voltage Power Supply

2- 2

You can make hardcopies on the GPIB and RS-232 ports. Other ports from the

front panel board: PC cardbus x 2 and cal adjust lock.

Outputs from the NLX board: SVGA, USB (1), sound, serial, parallel, Ethernet,

mouse, keyboard.

The low voltage power supply is a switching power converter with active power

factor control. It supplies power to all of the circuitry in the instrument.

The principal POWER switch, located on the rear panel, controls all power to the

instrument including the Low Voltage Power Supply. The ON/STBY switch,

CSA8000 & TDS8000 Series Instruments and Modules

Theory of Operation

located on the front panel, also controls all of the power to the instrument except

for part of the circuitry in the Low Voltage Power Supply.

The power supply sends a power fail (~PF) warning to the processor system if

the power is going down.

Fans

The fan assembly provides forced air cooling for the instrument. The fans are

controlled by the PPC processor.

Electrical Sampling Modules Overview

80E01, 80E02, 80E03,

80E06, 80E07, and 80E09

Sampling Modules

Table 2- 1: Electrical sampling module features

Feature 80E01 80E02 80E03 80E06 80E07 80E09

Number of independent channels 1 2 2 1 2 2

Bandwidth 50 GHz 12.5 GHz 20 GHz 70 GHz 30 GHz 60 GHz

Selectable bandwidths N.A. N.A. N.A. N.A. 20 GHz,

Signal connectors 2.4 mm

Remote sampler N.A. N.A. N.A. N.A. 2 meter cable 2 meter cable

The electrical sampling modules (non-TDR capable) are one- and two-channel

sampling modules. Their basic features are listed in the following table. (The

TDR capable sampling modules are describe later.)

40 GHz,

female

3.5 mm

female

3.5 mm

female

1.85 mm (V)

female

30 GHz

2.92 mm (K)

female

30 GHz,

60 GHz

1.85 mm (V)

female

For the two-channel modules, a single strobe delivered from the instrument

mainframe to both acquisition channels controls the timing of the strobe

assertion to both channels. If channel-to-channel deskew is zero and the channel

delays (if equipped) are matched, the sampling coincidence between channels is

very close. Acquisition deskew function is carried out either by making separate

acquisitions over individual acquisition windows or by adjusting Channel Delay

(if equipped).

For the one-channel modules, an individual strobe delivered from the instrument

mainframe to the acquisition channel controls the timing of the strobe assertion

to the channel. Acquisition deskew function is carried out by moving the strobe

timing for the channel to a unique acquisition window or by adjusting Channel

Delay (if equipped).

CSA8000 & TDS8000 Series Instruments and Modules

2- 3

Theory of Operation

Most electrical channels feature a Tekprobe Level 2 probe power connector for

attachment of a real time probe. The control of this probe is a mainframe

function.

All module calibration signals are derived from a 2.5 V precision voltage

reference internal to the sampling module. Settings derived from this reference

are stored in a non-volatile EEPROM in the sampling module, although the

responsibility for the execution of these settings is with the mainframe.

For major functional circuit blocks refer to Figure 5--2 on page 5 --3.

80E04, 80E08, and 80E10

TDR/Sampling Modules

The TDR/Sampling modules are low noise samplers, with each channel capable

of generating its own Time Domain Reflectometry (TDR) step. The basic

features of these modules are listed in the following table.

Table 2- 2: TDR sampling module features

Feature 80E04 80E08 80E10

Number of independent channels 2 2 2

Number of TDR channels 2 2 2

Bandwidth 20 GHz 30 GHz 50 GHz

Selectable bandwidths N.A. 20 GHz, 30 GHz 40 GHz, 30 GHz, 50 GHz

Signal connectors 3.5 mm female 2.92 mm (K) female 1.85 mm (V) female

Remote sampler N.A. 2 meter cable 2 meter cable

For these modules, a single strobe delivered from the instrument mainframe to

both acquisition channels controls the timing of the strobe assertion to both

channels. If channel-to-channel deskew is zero and the channel delays (if

equipped) are matched, the sampling coincidence between channels is very close.

Acquisition deskew function is carried out by making separate acquisitions over

acquisition windows or by adjusting Channel Delay (if equipped).

2- 4

Each electrical channel features a Tekprobe Level 2 probe power connector for

attachment of a real time probe. The control of this probe is a mainframe

function.

All module calibration signals are derived from a 2.5 V precision voltage

reference internal to the sampling module. Settings derived from this reference

are stored in a non-volatile EEPROM in the sampling module, although the

responsibility for the execution of these settings is with the mainframe.

When used in the acquisition mode (that is, with the TDR step generator turned

off) each channel functions as a normal sampling input. In the TDR mode, a fast

rise time step is generated internally for each channel and applied to the input

signal path for that channel. The acquisition portion of the TDR/sampling

CSA8000 & TDS8000 Series Instruments and Modules

module remains functional for monitoring the primary step and its reflected

components. The sampling module provides two self- contained TDR channels.

The polarity of the output step can be selected independently for each channel.

This allows differential or common mode testing of two coupled lines as well as

independent testing of isolated lines.

For major functional circuit blocks refer to Figure 5--2 on page 5 --3.

Optical Sampling Modules Overview

80C0X and 80C0X-CR optical modules share the same mechanical package and

are built with a common circuit board. Different functionality within the modules

(current and future modules) is achieved by installing different O/E modules,

filters and clock recovery boards along with setting the sampler bandwidth as

demanded. The key features supported in the module are:

H A one channel, low noise, adjustable bandwidth sampler allowing multiple

bandwidth settings for optimizing noise versus bandwidth demands.

Theory of Operation

H An amplified or non-amplified O/E converter.

H Support for internal RF switches in the signal path with a straight-through

path and two hardware-filtered reference receiver paths between the O/E

converter and the sampler.

H An average optical power meter.

H Integral clock recovery option with internal coaxial connection to the

mainframe trigger, front panel clock and data output (not all have data).

H Communication with the mainframe for identification, control and calibra-

tion/compensation storage.

The “system response” depends on all of the components in the signal path from

the front panel to the sampler. Bandwidth and reference receiver responses are

calibrated at the factory with a sub-picosecond optical impulse applied to the

front panel connector or with an optical heterodyne system. This insures that all

components are included, but also means that components can not be replaced

without performing calibration.

Compensation performs a DC transfer curve characterization for each bandwidth/

reference receiver setting. The curve data is stored in the module’s EEPROM and

used to generate a look-up table in the mainframe. This data corrects for

linearity, gain and offset errors in the sampler.

Reference receivers can be created in any of the following ways:

H A hardware filter inserted between the O/E and the sampler and dominates

the response.

CSA8000 & TDS8000 Series Instruments and Modules

2- 5

Theory of Operation

H No filter is used, but the sampler’s bandwidth is adjusted.

H The O/E bandwidth is adjusted and dominates the response.

Information about the available bandwidth and reference receiver selections, and

the method used to set the bandwidth for the optical modules starts on

page 2--7.

The power monitor is a second measure of the photodiode current that is

independent of the sampler signal path. Analog circuitry continuously senses the

current flowing into the bias side of the photodiode. The signal is amplified by a

programmable gain amplifier and input to an 8 bit AD converter. The AD

converter and amplifier are controlled through the I

2

C interface. Compensation

performs two functions in the power meter: First, two offset inputs are adjusted

in the amplifier so that the signal stays in range for all of the gain settings. Next,

offset is measured for all gain settings and stored so it can be subtracted from the

raw measured current. Because the measurements are made through independent

paths the power monitor is useful in debugging module/mainframe problems.

The main board of the module only provides power and control bits to the clock

recovery board. A small fraction of the input signal is split off and applied to the

clock recovery components. The type of splitter for each module is shown in

Table 2--3.

Table 2- 3: Module optical/electrical split

Module Optical Split Electrical Split

C01 n

C02 n

C03 n

C04 n

C07 n

C07B n

C08 n

C08B n

C08C n

C09 n

C11 n

C12 n

The recovered clock is routed in coaxial cable through the rear connector of the

module to the Optical Front End board in the mainframe. The Optical Front End

2- 6

CSA8000 & TDS8000 Series Instruments and Modules

Theory of Operation

board has a switch that selects which modules clock will be applied to the

trigger. The control signal for that switch comes from the optical module.

80C01 Optical Sampling

Module

The 80C01 module supports conformance testing of long wavelength

(1100-1650 nm) signals at 622, 2488, and 9953 Mb/s as well as general purpose

testing up to 20 GHz optical bandwidth. Bandwidth and reference receiver

calibration is performed with a sub-picosecond optical impulse and a fourier

transform method.

H OC12: The electrical sampler is adjusted to approximately 7.5 GHz (--3 dB)

bandwidth and signal is routed through a hardware filter designed to result in

the combined system having an OC12 (STM-4) Reference Receiver

response.

H OC48: The electrical sampler is adjusted to 7.5 GHz (--3 dB) bandwidth and

signal is routed through a hardware filter designed to result in the combined

system having an OC48 (STM-16) Reference Receiver response. These

adjustments must be made at the factory.

H OC192: The electrical sampler is adjusted to give the desired response, and

signal is not routed through any filter (signal is sent through the straightthrough path). The sampler bandwidth and response is optimized during the

calibration such that the combined system will have an OC192 (STM-64)

Reference Receiver response.

H 12.5 GHz: The sampler bandwidth and response is set during the calibration

such that the combined system will have an Optical Bandwidth (--6 dB)

>12.5 GHz.

H 20 GHz: The sampler bandwidth and response is set during the calibration

such that the combined system will have an Optical Bandwidth (--6 dB)

>20 GHz.

For major functional circuit blocks refer to Figures 5--3 and 5--4 beginning on

page 5--4.

80C02 Optical Sampling

Module

CSA8000 & TDS8000 Series Instruments and Modules

The 80C02 module is optimized for testing of long-wavelength (1100-1650 nm)

signals at (9.953 Gb/s) SONET OC-192 / SDH STM-64 standards. With its high

optical bandwidth (>30 GHz) it is also well suited to general purpose high-performance optical component testing.

H OC192: The electrical sampler is adjusted to give the desired response, and

signal is not routed through any filter (signal is sent through the straightthrough path). The sampler bandwidth and response is optimized during the

calibration such that the combined system will have an OC192 (STM-64)

Reference Receiver response.

2- 7

Theory of Operation

H 12.5 GHz: The sampler bandwidth and response is set during the calibration

such that the combined system will have an Optical Bandwidth (--6 dB)

>12.5 GHz.

H 20 GHz: The sampler bandwidth and response is set during the calibration

such that the combined system will have an Optical Bandwidth (--6 dB)

>20 GHz.

H 30 GHz: The sampler bandwidth and response is set during the calibration

such that the combined system will have an Optical Bandwidth (--6 dB)

>30 GHz.

For major functional circuit blocks refer to Figures 5--5 and 5--6 beginning on

page 5--6.

80C03 Optical Sampling

Module

The 80C03 module supports conformance testing of both short and long

bandwidth (700-1650 nm) signals at 1.063, 1.250, and 2.488 Mb/s as well as

general purpose testing with >2.3 GHz optical bandwidth. Its amplified optical to

electrical converter design enables the user to examine very low-level optical

signals.

H OC48: The electrical sampler is adjusted to approximately 12.5 GHz (--3 dB)

bandwidth and signal is not routed through any filter (signal is sent through

the straight-through path). The O/E converter is designed by the vendor to

match the OC48 reference receiver response curve. The span adjustment

provides limited adjustment of the frequency response. It is adjusted at the

factory so that the combined system will have an OC48 (STM-64) R eference

Receiver response. This mode is synonymous with the 2.3 GHz maximum

bandwidth setting.

H FC1063: The electrical sampler is adjusted and O/E converter span voltage

are the same values as in the OC48 mode. The signal is routed through a

hardware filter designed to result in the combined system having an FC1063

(1.0625 Gb/s Fibre Channel) Reference Receiver response.

H GBE: The electrical sampler is adjusted and O/E converter span voltage are

the same values as in the OC48 mode. The signal is routed through a

hardware filter designed to result in the combined system having an GBE

(1.25 Gb/s Gigabit Ethernet) Reference Receiver response.

80C04 Optical Sampling

Module

2- 8

The 80C03 module can be configured with clock recovery that supports Fibre

Channel 1063 (1.063 Gb/s) and OC-48 / STM-16 (2.488 Gb/s) standards.

For major functional circuit blocks refer to Figure 5--7 and 5--8 beginning on

page 5--8.

The 80C04 module is optimized for testing of long wavelength (1100--1650 nm)

signals at either 9.953 Gb/s or 10.664 Gb/s. With its high optical bandwidth

CSA8000 & TDS8000 Series Instruments and Modules

Theory of Operation

>28 GHz, it is also well suited to general-purpose, high-performance optical

component testing.

H OC192 or 10.664 Gb/s: The electrical sampler is adjusted to give the desired

response, and signal is not routed through any filter (signal is sent through

the straight-through path). The sampler bandwidth and response is optimized

during the calibration such that the combined system will have an OC192

(STM-64) or 10.66 Gb Reference Receiver response.

H 20 GHz: The sampler bandwidth and response is set during the calibration

such that the combined system will have an Optical Bandwidth (--6 dB)

>20 GHz.

H 30 GHz: The sampler bandwidth and response is set during the calibration

such that the combined system will have an Optical Bandwidth (--6 dB)

>28 GHz.

The 80C04 can be optionally configured with clock recovery (Opt. CR-1) that

supports 9.953 Gb/s telecom standards.

80C05 Optical Sampling

Module

80C06 Optical Sampling

Module

For major functional circuit blocks refer to Figures 5--9 and 5--10 beginning on

page 5--10.

The 80C05 module is designed to test long wavelength (1520--1580 nm) signals.

This module is intended to be used as a test and measurement tool for high

bandwidth telecommunications with its high optical bandwidth >40 GHz.

H OC192: There is one Reference Receiver setup selectable for 9.95328 Gb/s

SONET/SDH standard.

H There is no clock recovery option available.

For major functional circuit blocks refer to Figure 5--11 on page 5--12.

The 80C06 module is designed to test long wavelength (1520--1580 nm) signals.

This module is intended to be used as a test and measurement tool for high

bandwidth telecommunications with its high optical bandwidth >55 GHz.

H 55 GHz: There is only a single bandwidth selection available, no Reference

Receiver setups selectable.

H There is no clock recovery option available.

For major functional circuit blocks refer to Figure 5--12 on page 5 --13.

80C07 Optical Sampling

Module

CSA8000 & TDS8000 Series Instruments and Modules

The 80C07 module is designed to test both long and short wavelength

(700--1650 nm) signals. This module is intended to be used as a test and

2- 9

Theory of Operation

measurement tool for high bandwidth telecommunications with its high optical

bandwidth >2.3 GHz.

H Filtered rates are OC-3, OC-12; unfiltered rate is OC-48.

H There is clock recovery option available (155/622/2488 Multi-rate)

For major functional circuit blocks refer to Figures 5--13 and 5--14 on page 5-- 14.

80C07B Optical Sampling

Module

80C08 Optical Sampling

Module

The 80C07B module is designed to test both long and short wavelength

(700--1650 nm) signals. This module is intended to be used as a test and

measurement tool for high bandwidth telecommunications with its high optical

bandwidth >2.3 GHz.

H Supported standards or data filtering rates include OC--3, OC--12, OC-48,

ENET2500/2GBE, GBE, FC1063, FC2125, and Infiniband.

H Clock recovery options are available

(155/622/1063/1250/2125/2488/2500/2666)

For major functional circuit blocks refer to Figures 5--13 and 5--14 on page 5-- 14.

The 80C08 module is designed to test both long and short wavelength

(700--1650 nm) signals. This module is intended to be used as a test and

measurement tool for high bandwidth telecommunications with its high optical

bandwidth >9.0 GHz.

H 10.0 GHz: No filter is used and the sampler bandwidth is adjusted; the O/E

bandwidth is adjusted and dominates the response (9.953/10.3125 Gb/s

Multi--rate).

H There is clock recovery option available (9.953/10.3125 Gb/s Multi-rate).

80C08B Optical Sampling

Module

2- 10

For major functional circuit blocks refer to Figures 5--15 and 5--16 beginning on

page 5--16.

The 80C08B module is designed to test both long and short wavelength

(700--1650 nm) signals. This module is intended to be used as a test and

measurement tool for high bandwidth telecommunications with its high optical

bandwidth >9.5 GHz.

H 10.0 GHz: No filter is used and the sampler bandwidth is adjusted; the O/E

bandwidth is adjusted and dominates the response (9.953/10.3125 Gb/s

Multi-rate).

H Clock recovery options are available (9.953/10.3125/10.51875 Gb/s

Multi-rate).

CSA8000 & TDS8000 Series Instruments and Modules

Theory of Operation

For major functional circuit blocks refer to Figures 5--15 and 5--16 beginning on

page 5--16.

80C08C Optical Sampling

Module

80C09 Optical Sampling

Module

The 80C08C module is designed to test both long and short wavelength

(700--1650 nm) signals. This module is intended to be used as a test and

measurement tool for high bandwidth telecommunications with its high optical

bandwidth >10 GHz.

H 10.0 GHz: No filter is used and the sampler bandwidth is adjusted; the O/E

bandwidth is adjusted and dominates the response

(9.953/10.3125/10.518/10.66/10.709/11.1 Gb/s).

H Clock recovery options are available (9.953/10.3125/10.518 Gb/s and

Continuous-rate from 9.8 Gb/s to 12.6 Gb/s).

For major functional circuit blocks refer to Figures 5--15 and 5--16 beginning on

page 5--16.

The 80C09 module is designed to test long wavelength (1100--1650 nm) signals.

This module is intended to be used as a test and measurement tool for high

bandwidth telecommunications with its high optical bandwidth >30 GHz.

H Supported standards or data filtering rates include OC-192 and FEC10.709.

H Clock recovery options are available (OC-192 and FEC10.709)

For major functional circuit blocks refer to Figures 5--17 and 5--18 beginning on

page 5--18.

80C10 Optical Sampling

Module

CSA8000 & TDS8000 Series Instruments and Modules

The 80C10 module is designed to test long wavelength (1310 and 1550 nm)

signals. This module is intended to be used as a test and measurement tool for

high bandwidth telecommunications with its high optical bandwidth >65 GHz.

H Supported standards or data filtering rates include OC-768 and FEC43.02

(G.709).

H 30 GHz: The sampler bandwidth and response is set during the calibration

such that the combined system will have an Optical Bandwidth (--6 dB)

>30 GHz.

H 65 GHz: The sampler bandwidth and response is set during the calibration

such that the combined system will have an Optical Bandwidth (--6 dB)

>65 GHz.

H There is no clock recovery option available.

For major functional circuit blocks refer to Figure 5--19 on page 5 --20.

2- 11

Theory of Operation

80C11 Optical Sampling

Module

80C12 Optical Sampling

Module

The 80C11 module is designed to test long wavelength (1100--1650 nm) signals.

This module is intended to be used as a test and measurement tool for high

bandwidth telecommunications with its high optical bandwidth >20 GHz.

H Supported standards or data filtering rates include

9.953/10.31/10.518/10.66/10.71/11.1 Gb/s.

H Clock recovery options are available (9.953/10.66/10.71 Gb/s and Continu-

ous-rate from 9.8 Gb/s to 12.6 Gb/s)

For major functional circuit blocks refer to Figures 5--20, 5--21, 5--22, and 5--23

beginning on page 5--21.

The 80C12 module is designed to test both long and short wavelength

(700--1650 nm) signals. This module is intended to be used as a test and

measurement tool for high bandwidth telecommunications with its high optical

bandwidth >10 GHz.

H There are three Reference Receiver filters selectable that are customer

specified from the following list of five rates: 1FC (FC1063) for 1.0625Gb/s

FibreChannel, 2FC (FC2125) for 2.125Gb/s FibreChannel, 10GBase-X4 for

3.125Gb/s, VSR-5 for 3.31776 Gb/s, and 4FC (FC4250) for 4.25 Gb/s Fibre

Channel. A filterless, full-bandwidth setting (9 GHz) is also available.

H In addition, this module offers the option to support 10 Gb/s optical

standards as well. This option is mutually exclusive with the sub--10Gb/s

filter options. The standard reference receiver filter rates offered with the

Option 10G are SONET/SDH OC-192/STM-64, 10GBase-W, 10 Gb

Ethernet (9.95338 Gb/s), 10GBase-R (10.3125 Gb/s), 10G Fibre Channel

(10.51875 Gb/s), G.975 FEC (10.66 Gb/s), G.709 FEC (10.71 Gb/s), 10GBE

FEC (11.0957 Gb/s). These filter settings require no hardware filters.

H An electrical clock recovery output signal is provided that can be routed to

the Tektronix 80A05 Electrical Clock Recovery module for clock recovery.

For major functional circuit blocks refer to Figure 5--24 on page 5 --25.

80A01 Trigger Prescale Preamplifier Module

The 80A01 module is designed to increase the sensitivity of the prescale trigger

input of the CSA8000/TDS8000 instruments to ≤200 mV

The major function block of the module is a high sensitivity, high gain RF

amplifier. The input and output to this amplifier are routed to two identical

SMA, female connectors, labelled Input and Output at the module front panel.

pk-pk

.

2- 12

CSA8000 & TDS8000 Series Instruments and Modules

The module receives power from the main instrument through a single connector

at the rear of the module. The power LED indicates the module is receiving

power through the interface connector.

For major functional circuit blocks refer to Figure 5--25 on page 5 --26.

80A02 EOS/ESD Protection Module

The 80A02 EOS/ESD (Electrical Over Stress/Electro-Static Discharge)

protection module provides static electricity damage protection to vulnerable

sampling head input stages and/or other sensitive elements.

The 80A02 works with any CSA/TDS8000 series instruments or with 11K series

sampling instruments (11800 or CSA803 series instruments).

The 80A02 EOS/ESD module has a 26 GHz bandwidth, making it possible to

provide static protection to a sensitive single input channel of a sampling

oscilloscope with very minimal speed degradation.

Theory of Operation

The 80A02 EOS/ESD module is designed to work with either the Tektronix

P8018 probe for manual test station static protection as well as automated test

stations.

For major functional circuit blocks refer to Figure 5--26 on page 5 --27.

80A05 Electrical Clock Recovery Module

The electrical clock recovery module is capable of performing clock recovery on

the input signal (signal input must meet data rate and format requirements), and

provides this signal as a trigger source to the CSA/TDS8000 series instruments.

Front panel connectors provide a replica of the recovered clock signal.

The module uses one of two separate clock recovery circuits dependant on the

specified data rate. The single-ended or complementary input signals are split

with a 1:2 divider and routed to the two circuits.

The low bandwidth circuit recovers clock and data from input data in the

50 Mb/s to 2.7 Gb/s range. The recovered clock from this circuit is routed

directly to the front panel and internal trigger.

The high bandwidth circuit recovers clock and data from input data in the

2.7 Gb/s to 12.6 Gb/s range. The recovered clock to the front panel and internal

trigger signals are always clock/16.

With option 10G, the 10G recovered clock is also routed to the front panel.

CSA8000 & TDS8000 Series Instruments and Modules

2- 13

Theory of Operation

There is one front panel indicator LED -- Clock Recovery Enable. It indicates the

clock recovery circuitry is on and programmed to the requested bit rate.

For major functional circuit blocks refer to Figure 5--27 on page 5 --28.

80A06 PatternSync Trigger Module

The 80A06 PatternSync Trigger Module is designed to provide a frame trigger

for the CSA8000 and TDS8000 series instruments. The instrument must be using

the Windows 2000 Operating System and product software version 2.4 or

greater.

The frame trigger is derived by counting a programmed amount of user supplied

clock cycles and generating a pulse at the completion of the count. This pulse is

then routed externally to the main instrument’s external trigger direct input.

An additional buffered copy of the input clock is output to the front panel for