Page 1

Technical Reference

CSA8000 Series Communications Signal Analyzers

TDS8000 Series Digital Sampling Oscilloscopes

Specifications and Performance Verification

071-1745-02

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Page 2

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or

suppliers, and are protected by national copyright la ws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Spec ifications and price change privileges reserved.

TEKTRONIX, TEK and TekProbe are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

H In North America, call 1-800-833-9200.

H Worldwide, visit www.tektronix.com to find contacts in your area.

Page 3

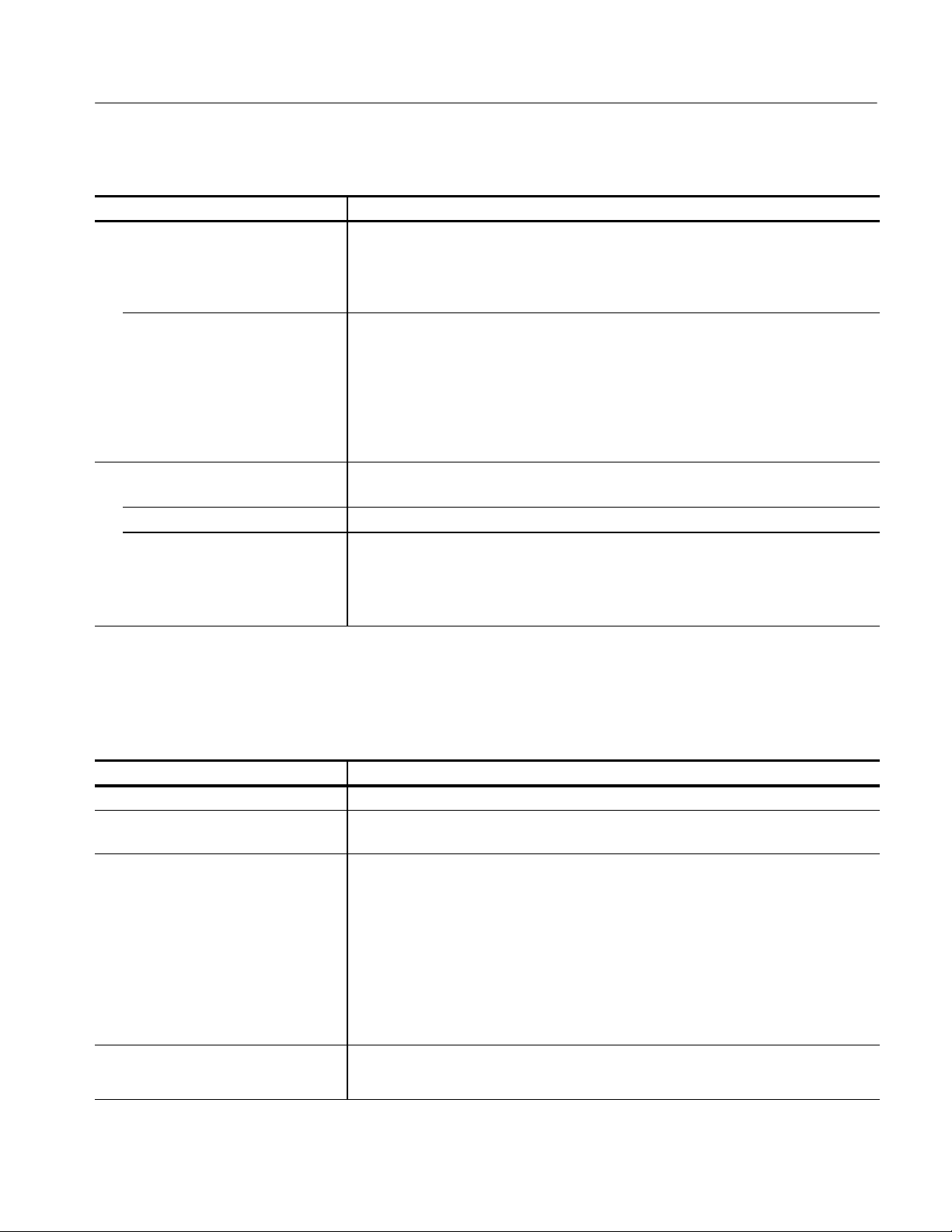

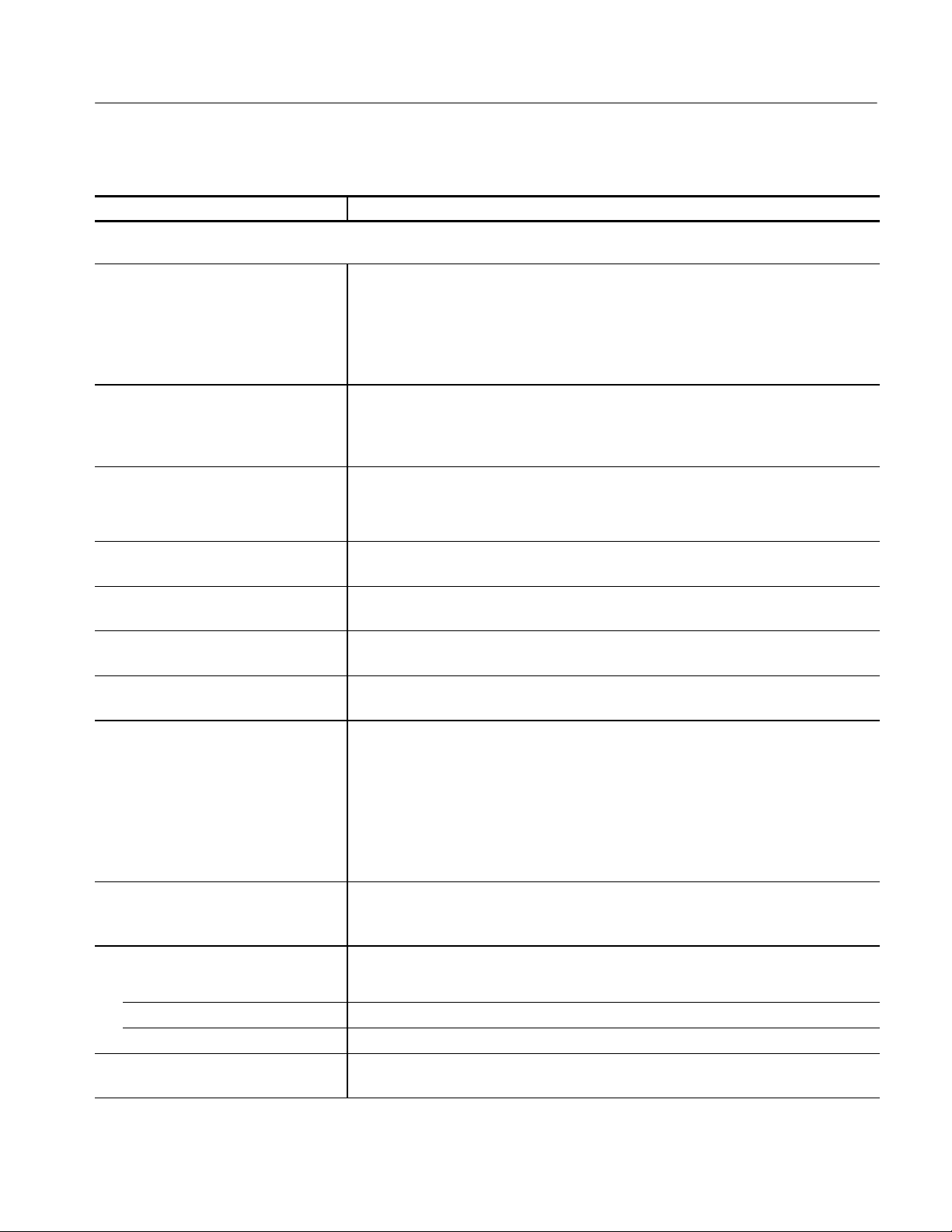

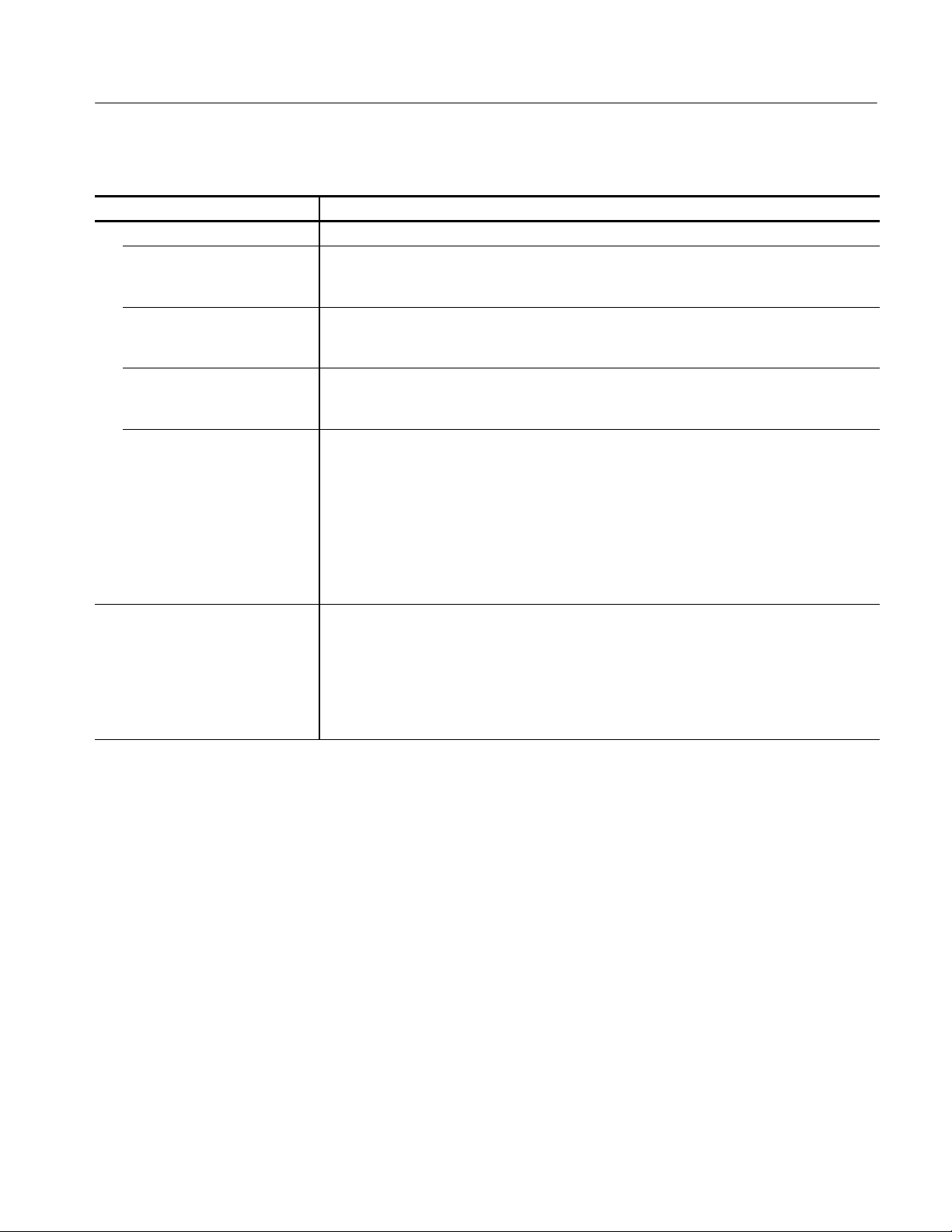

Table of Contents

Specifications

General Safety Summary vii...................................

Service Safety Summary ix....................................

Preface xi...................................................

Manual Structure xi................................................

Manual Conventions xi..............................................

Related Documentation xii...........................................

System Specifications 1--1.......................................

Certifications (CSA/TDS8000, CSA/TDS8000B) 1--16.......................

Certifications (CSA/TDS8200) 1--18.....................................

80E00 Electrical Sampling Modules Specifications 1--21..............

80C00 Optical Sampling Modules Specifications 1--31................

80A01 Trigger Prescale Preamplifier Module S pecifications 1--71......

80A02 EOS/ESD Protection Module Specifications 1--73..............

80A05 Electrical Clock Recovery Module Specifications 1--75.........

80A06 PatternSync Trigger Module Specifications 1--79..............

Performance Verification

Performance Verification Procedures 2--1.........................

Brief Procedures 2--3...........................................

Perform the Diagnostics 2--3..........................................

Perform the Compensation 2--5........................................

Perform the Functional Tests 2--7.......................................

Perform the Hardware and Operating System Tests

Performance Tests 2--27.........................................

Prerequisites 2--28....................................................

Equipment Required 2--29..............................................

CSA8000/TDS8000 Series Test Records 2--32..............................

CSA8000/TDS8000 Main-Instrument Test Record 2--33......................

CSA8000B/TDS8000B Main-Instrument Test Record 2--34...................

CSA8200/TDS8200 Main-Instrument and 82A04 Module Test Record 2--35......

80E00 Electrical Modules Test Record 2--37...............................

80C00 Optical Modules Test Record 2--45.................................

80A01 Electrical Clock Recovery Module Test Record 2--73..................

Verify Electrical Input Channels 2--7.................................

Verify Optical Input Channels 2--10...................................

Verify the Time Bases Work 2--13....................................

Perform Gated Trigger Test 2--17.....................................

Checking the Cooling Fan Operation 2--23.............................

(Microsoft Windows 98 OS Only) 2--24...............................

QA+Win32 2--24.................................................

Checking the Hardware and Operating System 2--25.....................

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

i

Page 4

Table of Contents

80A02 EOS/ESD Protection Module Test Record 2--75.......................

80A05 Electrical Clock Recovery Module Test Record 2--77..................

80A06 PatternSync Trigger Module Test Record 2--79.......................

Main Instrument 2--81..........................................

Prerequisites 2--81....................................................

Time Interval Accuracy, Short--Term Optimized and

Locked-to-Internal 10-MHz Reference Modes 2--82......................

External Direct Trigger Level Accuracy 2--85..............................

External Direct Trigger Sensitivity 2--87..................................

External Direct-Trigger Delay Jitter, Short-Term Optimized

and Locked-to-Internal 10-MHz Reference Modes 2--90..................

Trigger Delay Jitter, Free Run Phase Corrected Mode

(CSA/TDS8200 with 82A04 Module Only) 2--95........................

External Prescaled Trigger Delay Jitter, Short-Term Optimized Mode

and Locked-to-Internal 10-MHz Reference Mode 2--98...................

External Prescaled Trigger Sensitivity 2--101................................

DC Calibration Output 2--104............................................

Electrical Sampling Modules 2--107................................

Prerequisites 2--107....................................................

Input Impedance 2--109.................................................

DC Voltage Measurement Accuracy 2--111................................

Random Noise, Displayed 2--118.........................................

Analog Bandwidth to 50 GHz

(80E01, 80E06, 80E07, 80E08, 80E09, 80E10) 2--120.....................

Analog Bandwidth above 50 GHz (80E06 and 80E09) 2--129...................

TDR-System Reflected Rise Time (80E04, 80E08, 80E10) 2--142...............

TDR-System Step Response Aberrations (80E04) 2--145......................

TDR-System Step Response Aberrations (80E08 and 80E10) 2--151.............

Optical Sampling Modules 2--159..................................

Prerequisites 2--159....................................................

Dark Level and Vertical Equivalent Optical Noise 2--160......................

Minimum Optical Bandwidth and Reference Receiver Frequency Response 2--169..

Integrated Rise Time and Aberrations Check 2--192..........................

Clock Recovery Optical Sensitivity Range and

Recovered Clock Timing Jitter 2--198..................................

80A01 Trigger Prescale Limiting Preamplifier Module 2--209...........

Prerequisites 2--209....................................................

System Trigger Sensitivity 2--210.........................................

80A02 EOS/ESD Protection Module 2--213..........................

Prerequisites 2--213....................................................

Logic Control Threshold 2--213..........................................

80A05 Electrical Clock Recovery Module 2--215......................

Prerequisites 2--215....................................................

Clock Recovery Sensitivity Range and Recovered Clock Timing Jitter 2--215......

80A06 PatternSync Trigger Module 2--223..........................

Prerequisites 2--223....................................................

Supported Clock Rates, Minimum Input Sensitivity,

and Maximum Jitter Checks 2--223....................................

ii

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

Page 5

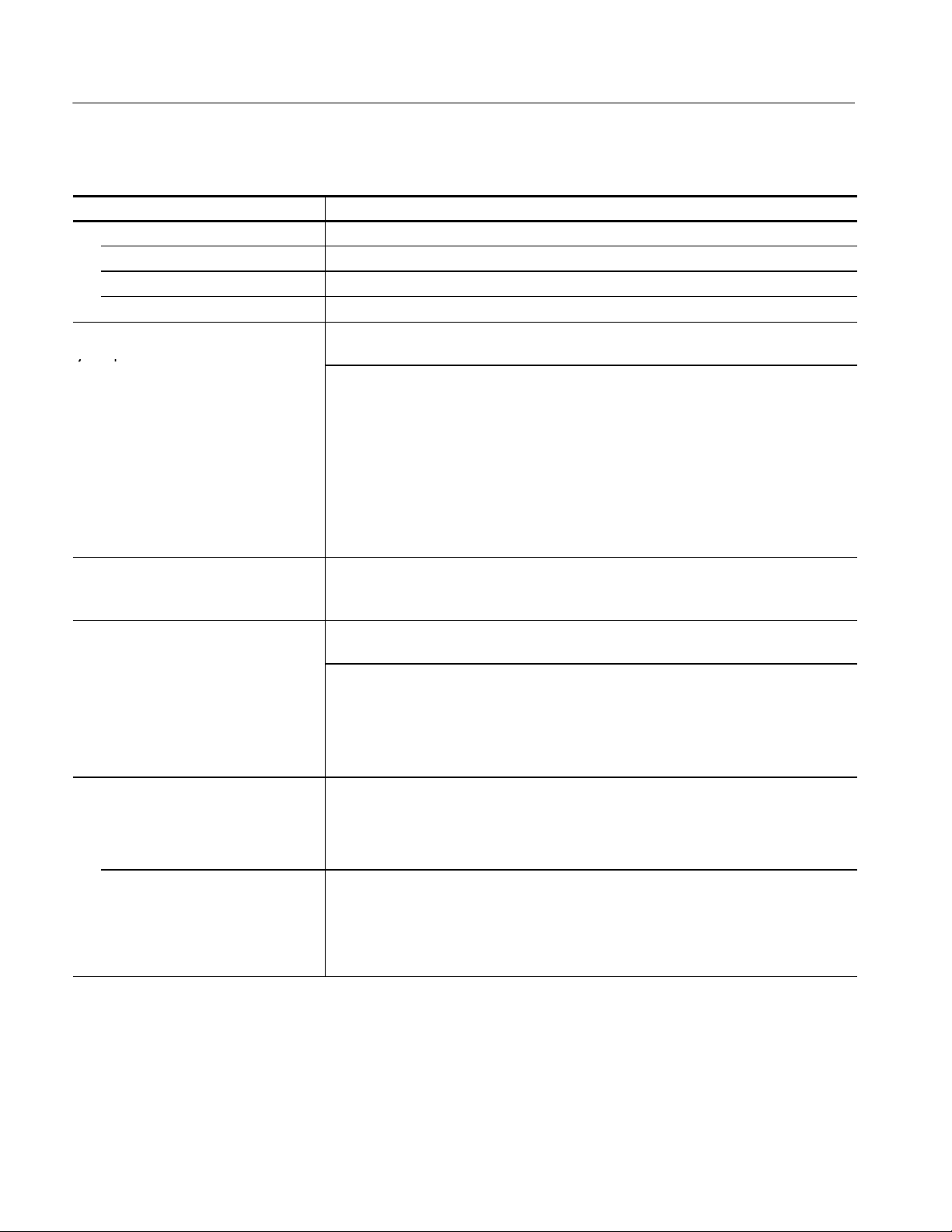

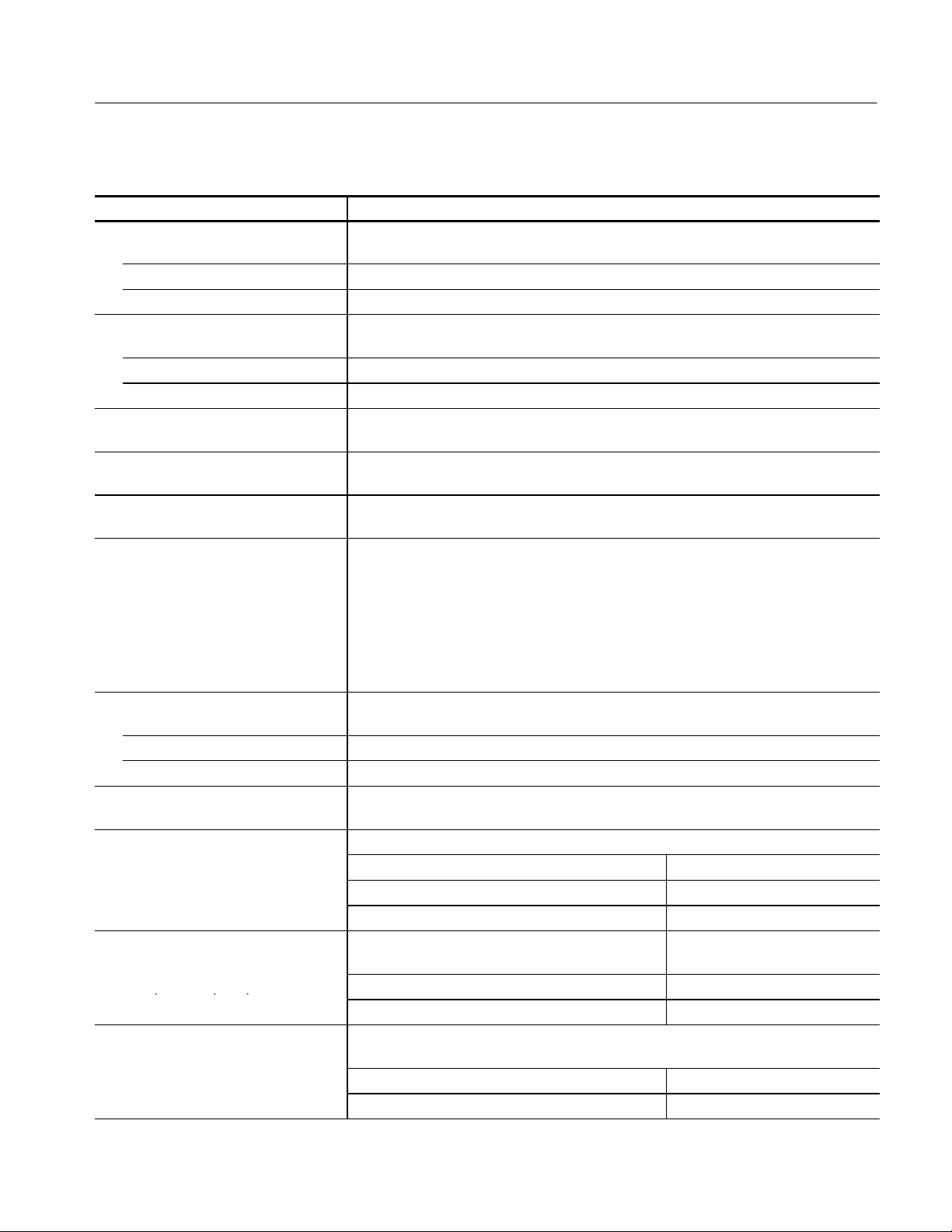

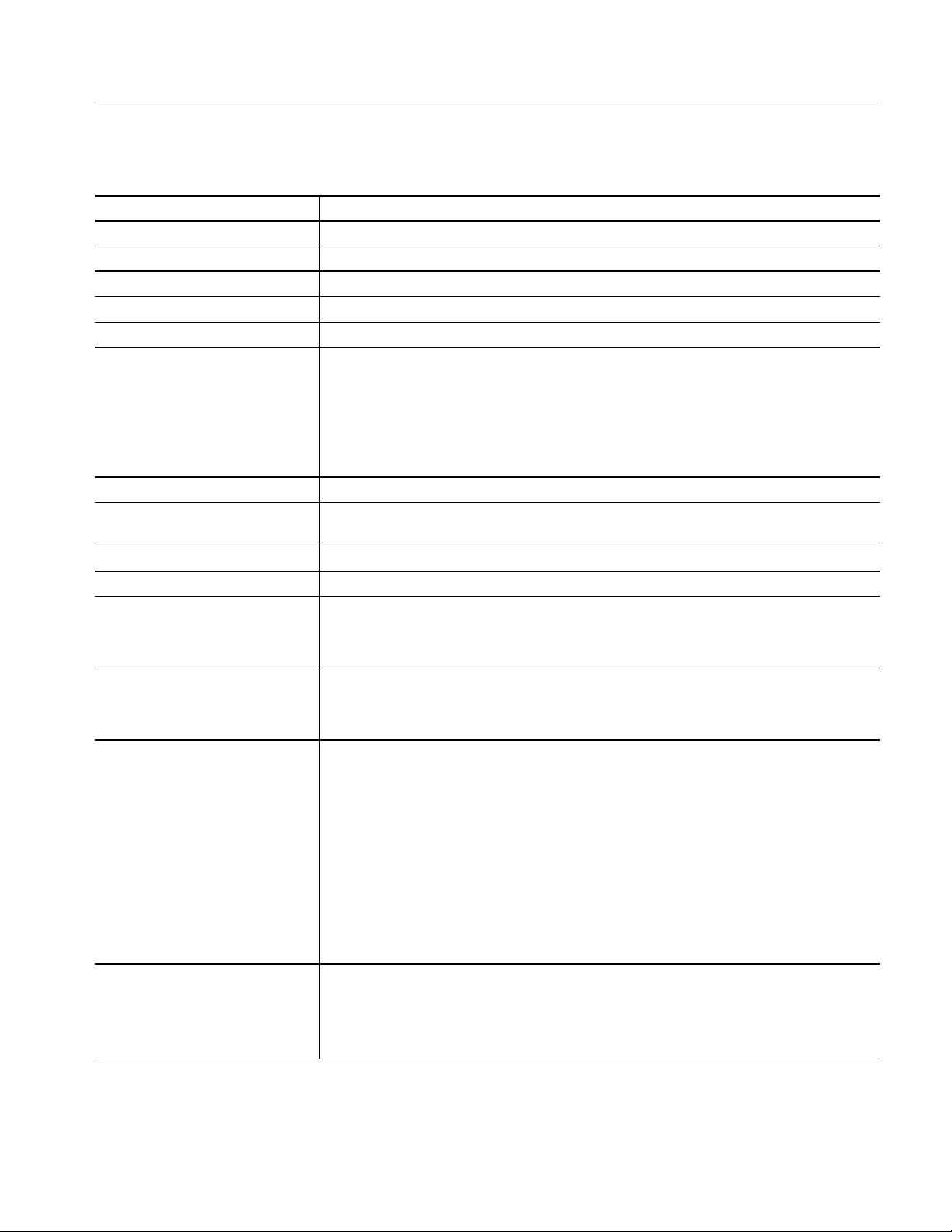

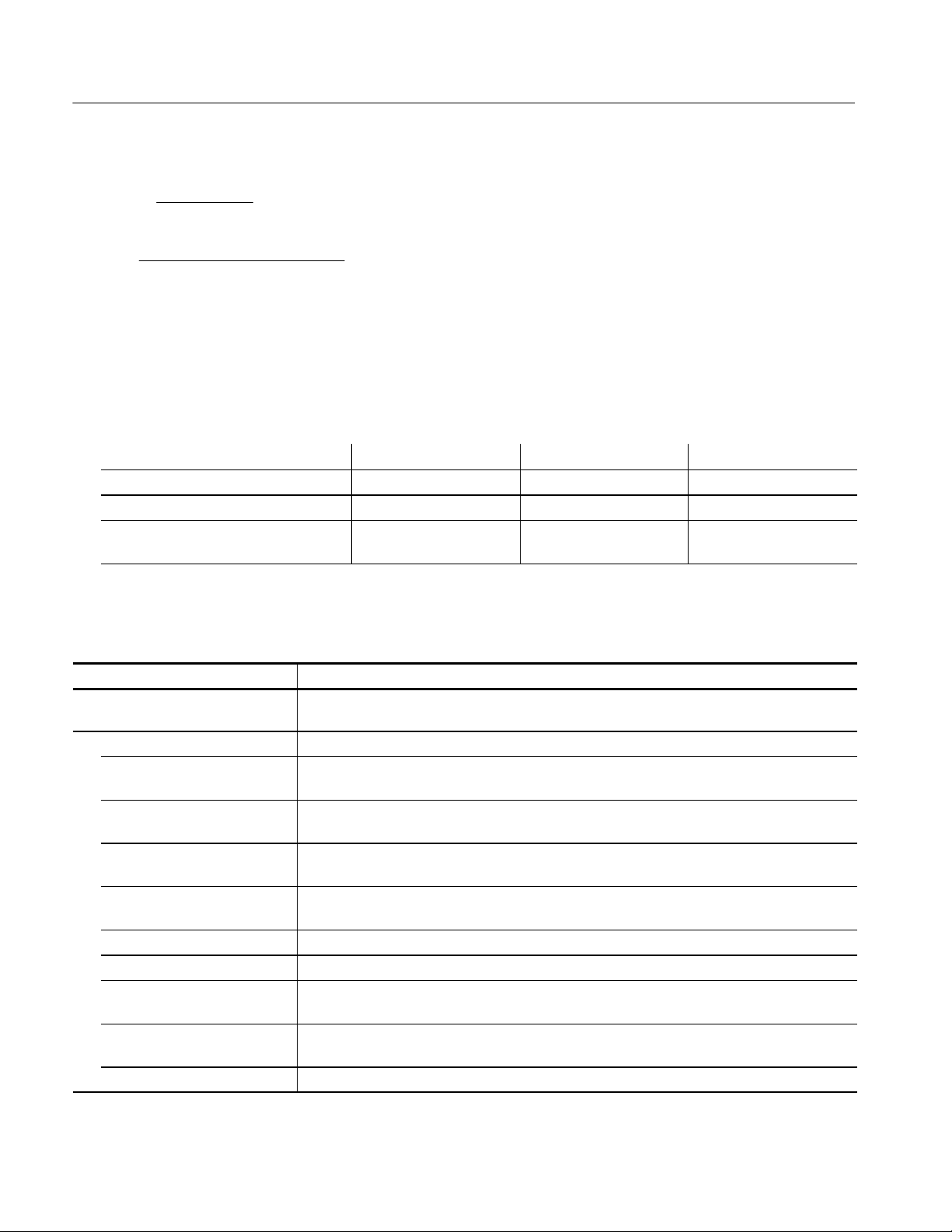

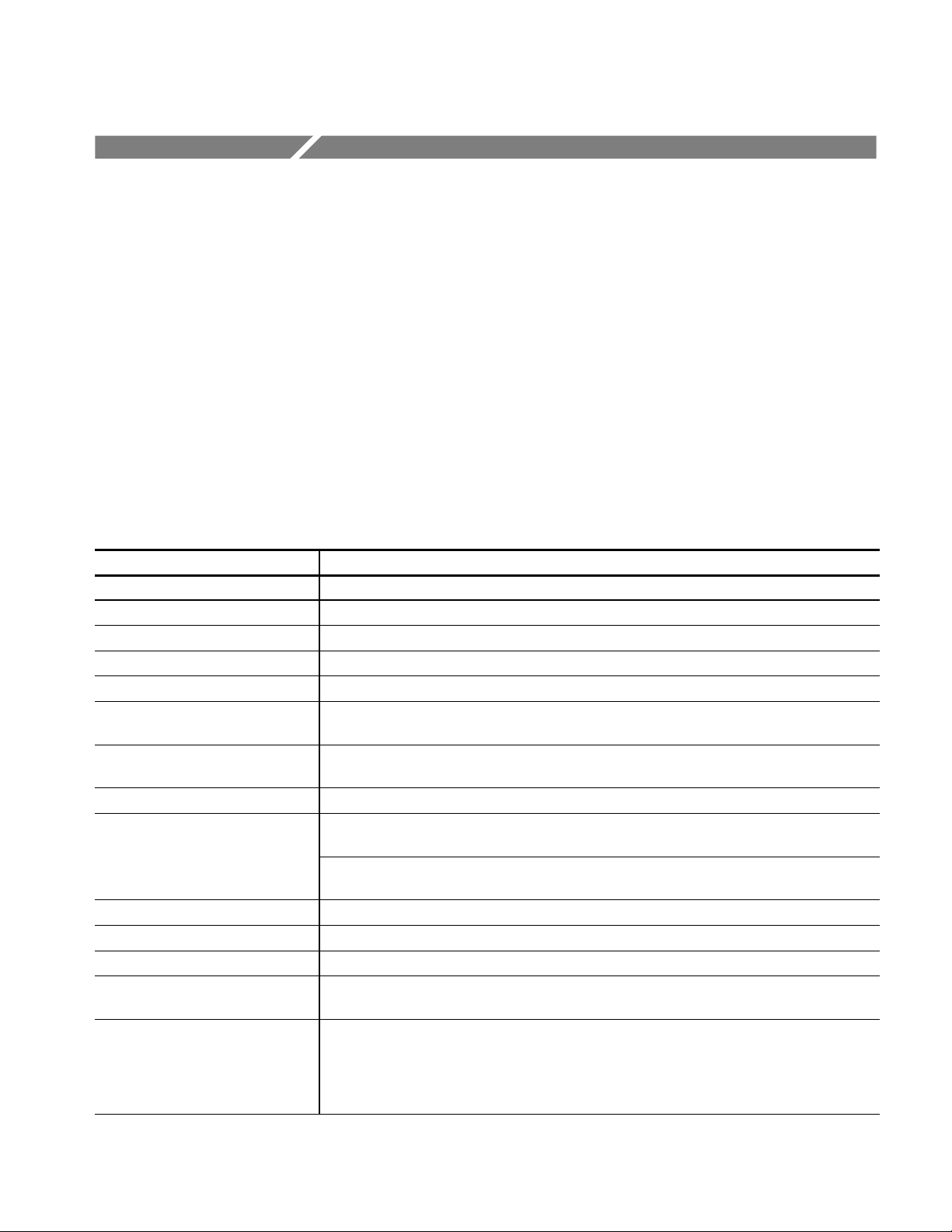

List of Figures

Table of Contents

Figure 2--1: Compensation dialog box 2--5.........................

Figure 2--2: Hookup for electrical functional tests 2--8...............

Figure 2--3: Channel button location 2--8..........................

Figure 2--4: Channel button location 2--11..........................

Figure 2--5: Optical channel verification 2--12.......................

Figure 2--6: Hookup for the time base tests 2--13.....................

Figure 2--7: Channel button location 2--14..........................

Figure 2--8: Main time base verification 2--15.......................

Figure 2--9: Mag time base verification 2--16........................

Figure 2--10: Hookup for the gated trigger tests 2--18.................

Figure 2--11: Channel button location 2--19.........................

Figure 2--12: Signal triggered 2--20................................

Figure 2--13: Signal not triggered (signal frozen) 2--21................

Figure 2--14: Signal not triggered (no waveform) 2--22................

Figure 2--15: Signal triggered 2--23................................

Figure 2--16: Time interval accuracy test hookup 2--82...............

Figure 2--17: External direct trigger test hookup 2--85................

Figure 2--18: External direct trigger sensitivity test hookup 2--88.......

Figure 2--19: External direct trigger jitter test hookup 2--90...........

Figure 2--20: Phase corrected trigger jitter test hookup 2--95..........

Figure 2--21: External prescaled test hookup 2--98...................

Figure 2--22: External prescaled trigger sensitivity test hookup 2--101....

Figure 2--23: DC calibration test hookup 2--105......................

Figure 2--24: Input impedance test hookup 2--109.....................

Figure 2--25: Vertical DC accuracy test hookup 2--112.................

Figure 2--26: Power-reference hookup 2--121.........................

Figure 2--27: Adapter characterization hookup 2--122.................

Figure 2--28: Measure reference signals 2--124........................

Figure 2--29: Reference signals hookup 2--126........................

Figure 2--30: SNA/Waveguide characterization 2--131.................

Figure 2--31: Power-reference characterization h ookup 2--133..........

Figure 2--32: Hookup to measure Power-in 2--134.....................

Figure 2--33: Adapter--loss hookup 2--136...........................

Figure 2--34: HF response hookup 2--138............................

Figure 2--35: TDR reflected rise time hookup 2--142...................

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

iii

Page 6

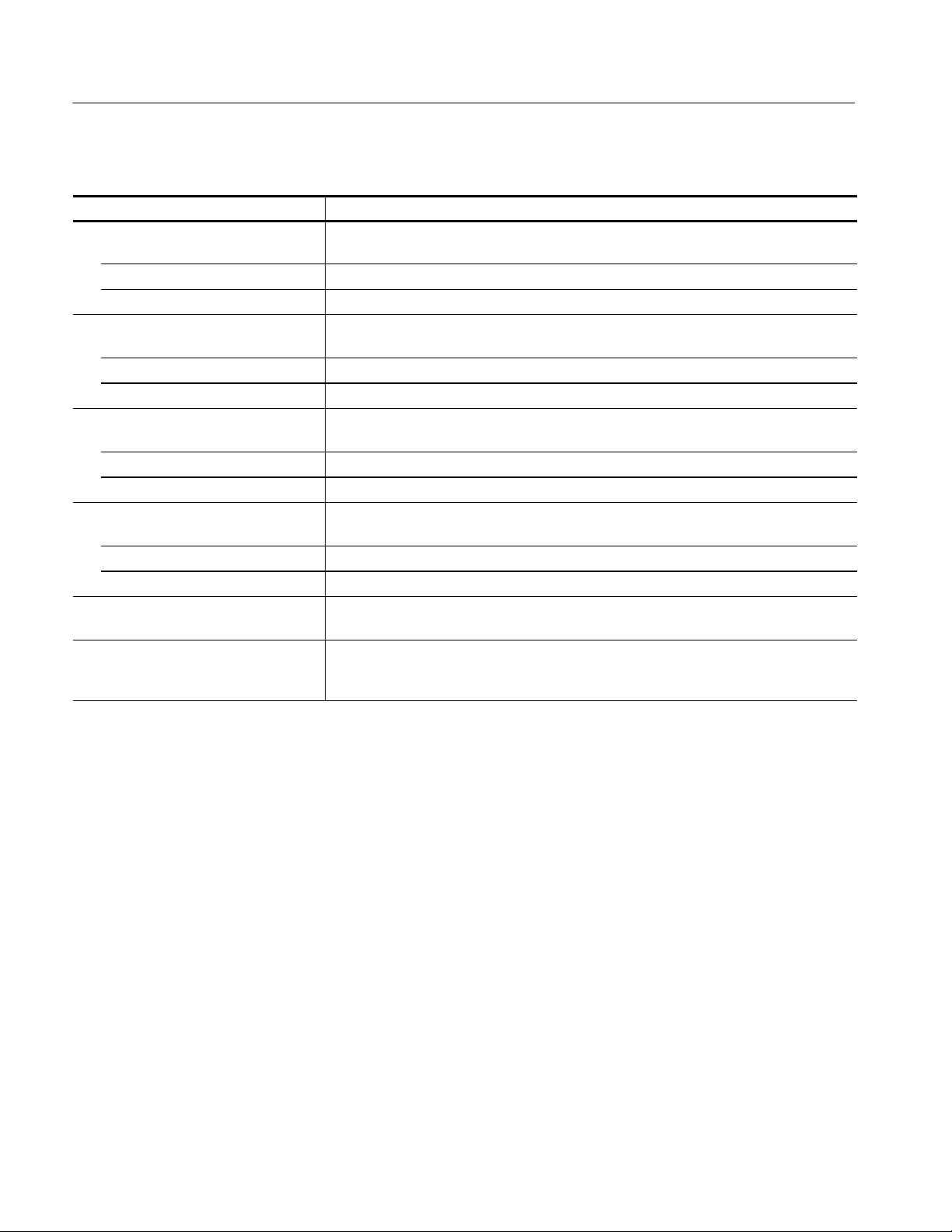

Table of Contents

Figure 2--36: TDR system step response aberrations hookup 2--145......

Figure 2--37: TDR system step response aberrations hookup 2--151......

Figure 2--38: Dark level and vertical equivalent

optical noise test hookup 2--160................................

Figure 2--39: Minimum optical bandwidth and

reference receiver frequency response hookup 2--172...............

Figure 2--40: Proper positioning of the impulse for

optimum curve download 2--176................................

Figure 2--41: Hookup for heterodyne test 2--186......................

Figure 2--42: Setup used for heterodyne sweep 2--188..................

Figure 2--43: Integrated rise time and aberrations hookup 2--193........

Figure 2--44: Clock recovery optical sensitivity range

and recovered clock timing jitter hookup 2--199...................

Figure 2--45: Display example

(clock signal not synchronized with the data rate input) 2--204......

Figure 2--46: Display example

(clock signal synchronized with the data rate input) 2--207..........

Figure 2--47: Display example (zoomed in at the crossing point) 2--208...

Figure 2--48: 80A01 test hookup 2--211..............................

Figure 2--49: 80A02 test hookup 2--214..............................

Figure 2--50: Clock recovery sensitivity range and

recovered clock timing jitter hookup 2--217.......................

Figure 2--51: Display example

(clock signal synchronized with the data rate input) 2--220..........

Figure 2--52: Display example (zoomed in at the crossing point) 2--222...

Figure 2--53: Hookup for Clock Rates, Input Sensitivity,

and Jitter Checks 2--225.......................................

Figure 2--54: Example display for Supported Clock Rates,

Minimum Input Sensitivity, and Maximum Jitter Checks 2--226.....

iv

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

Page 7

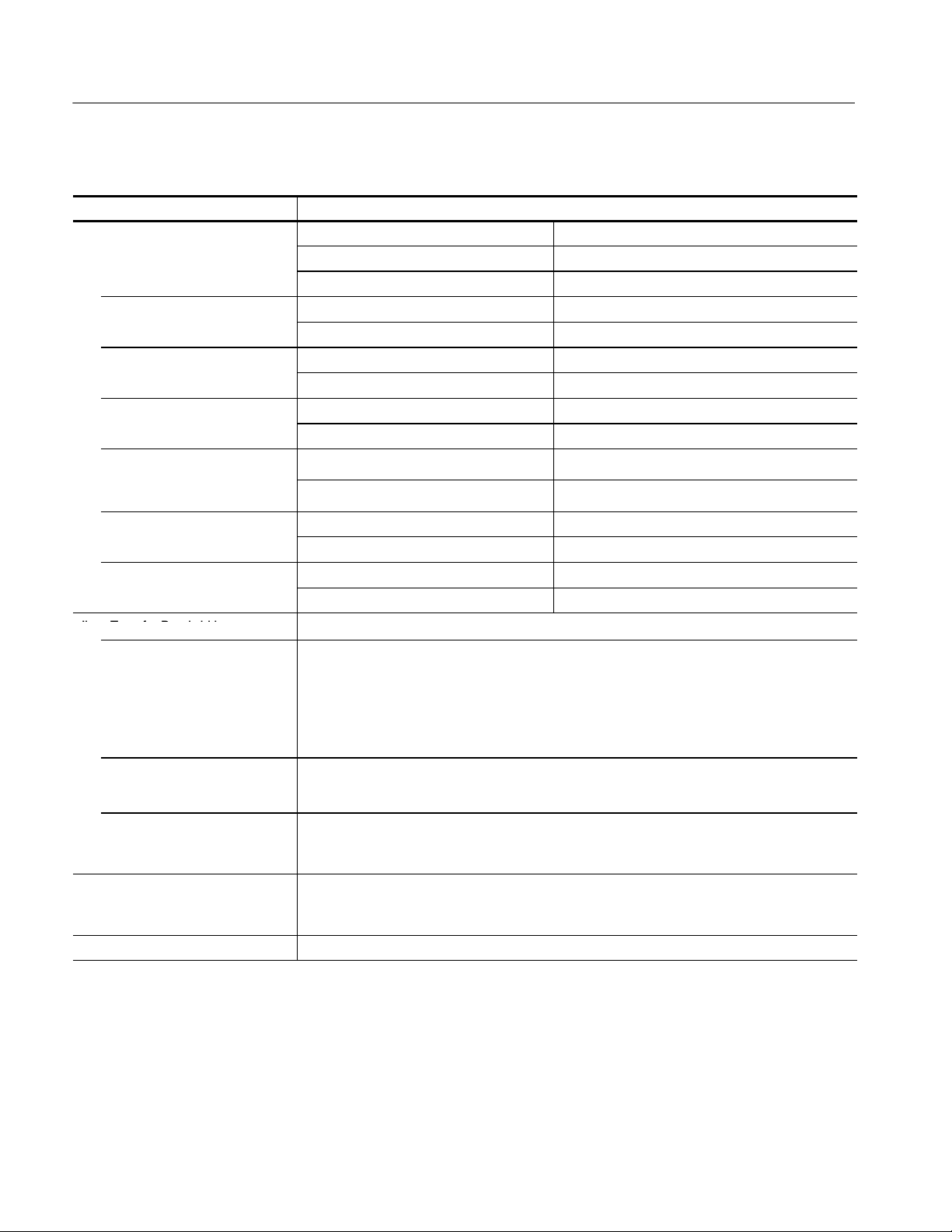

List of Tables

Table of Contents

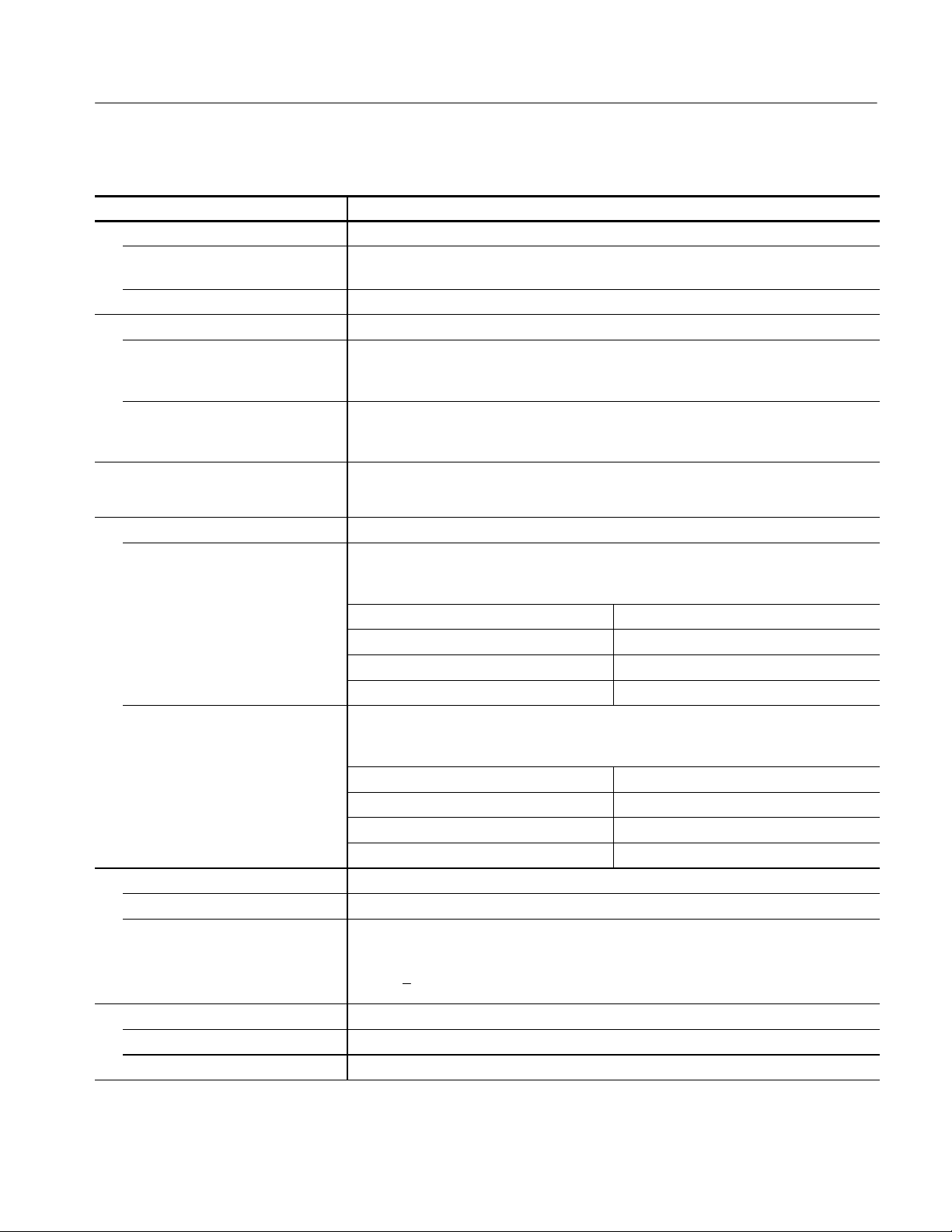

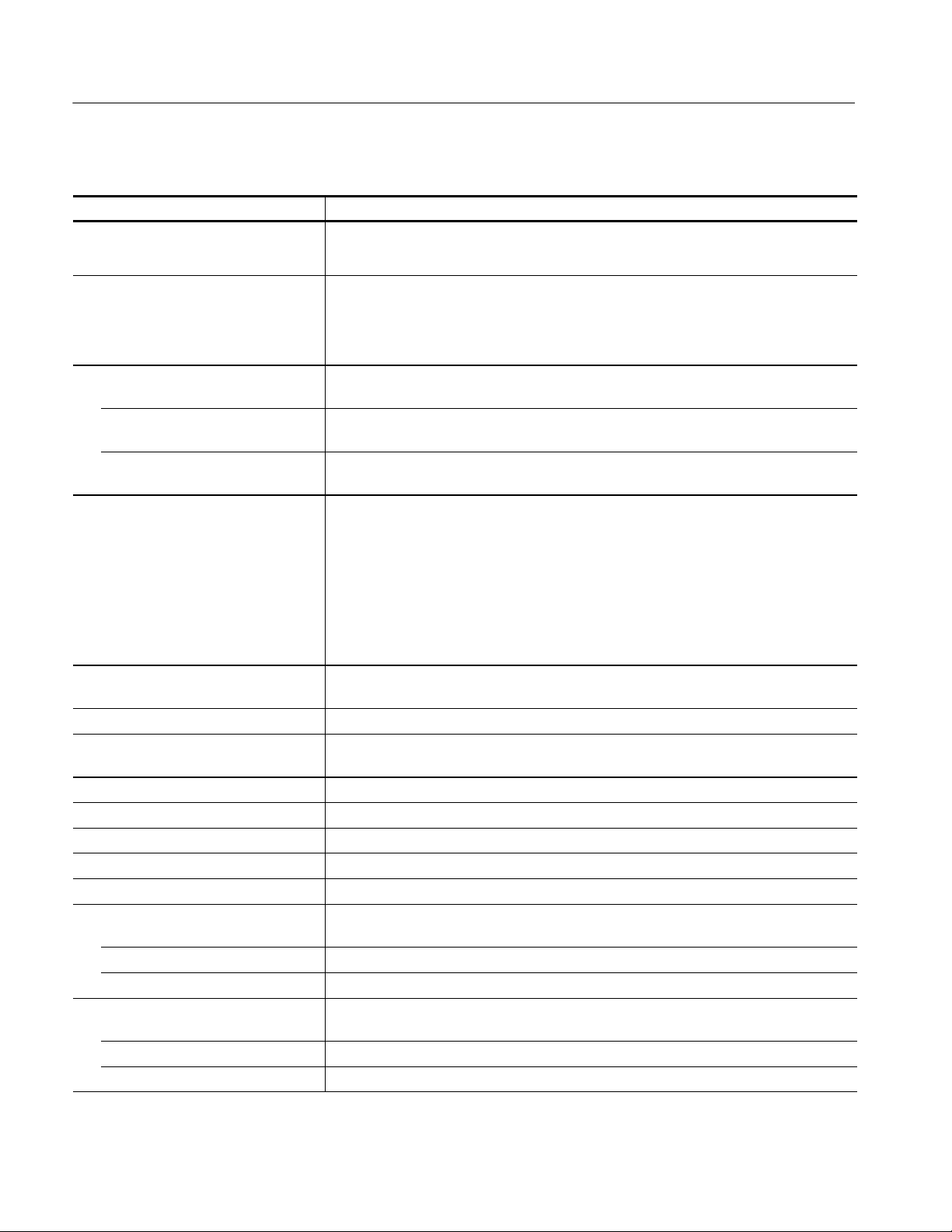

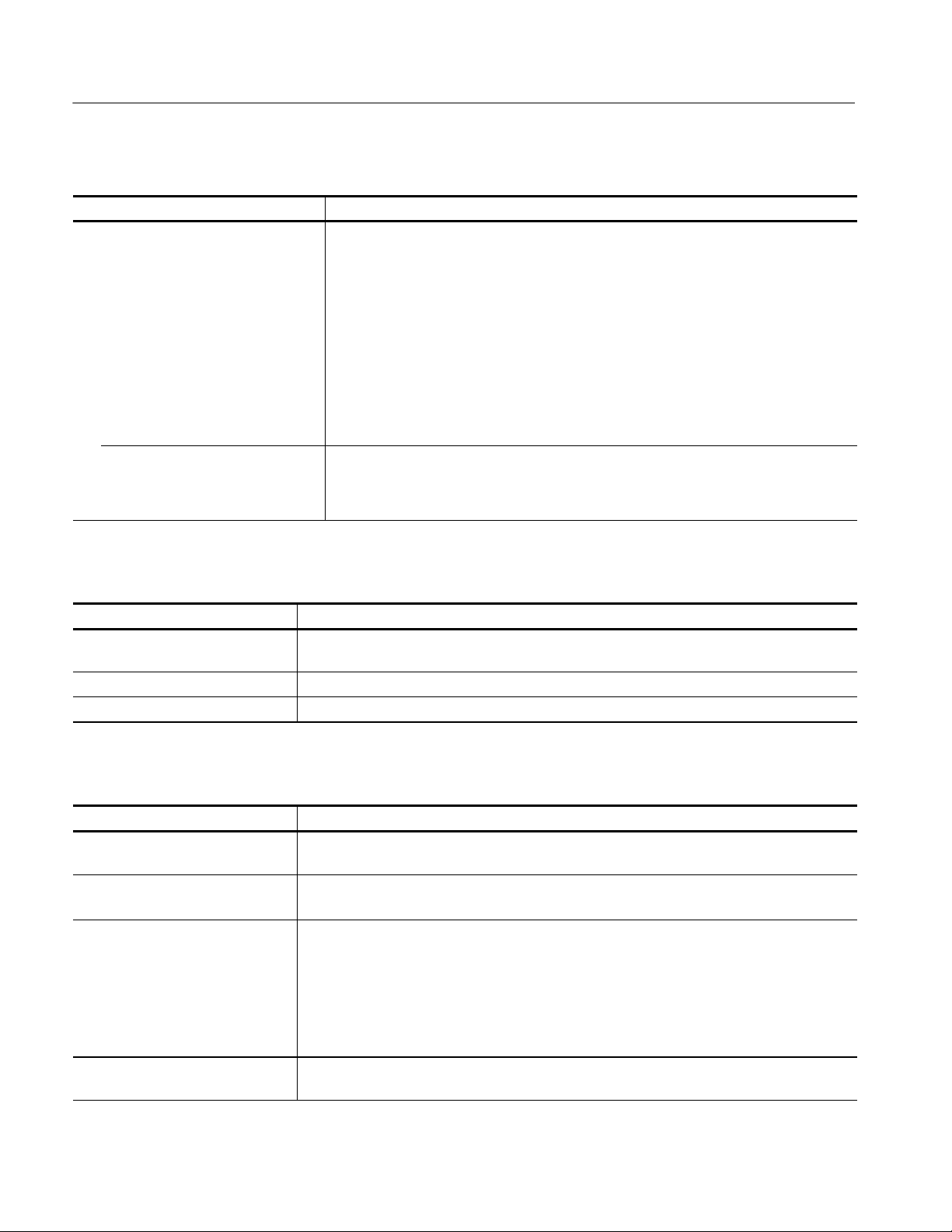

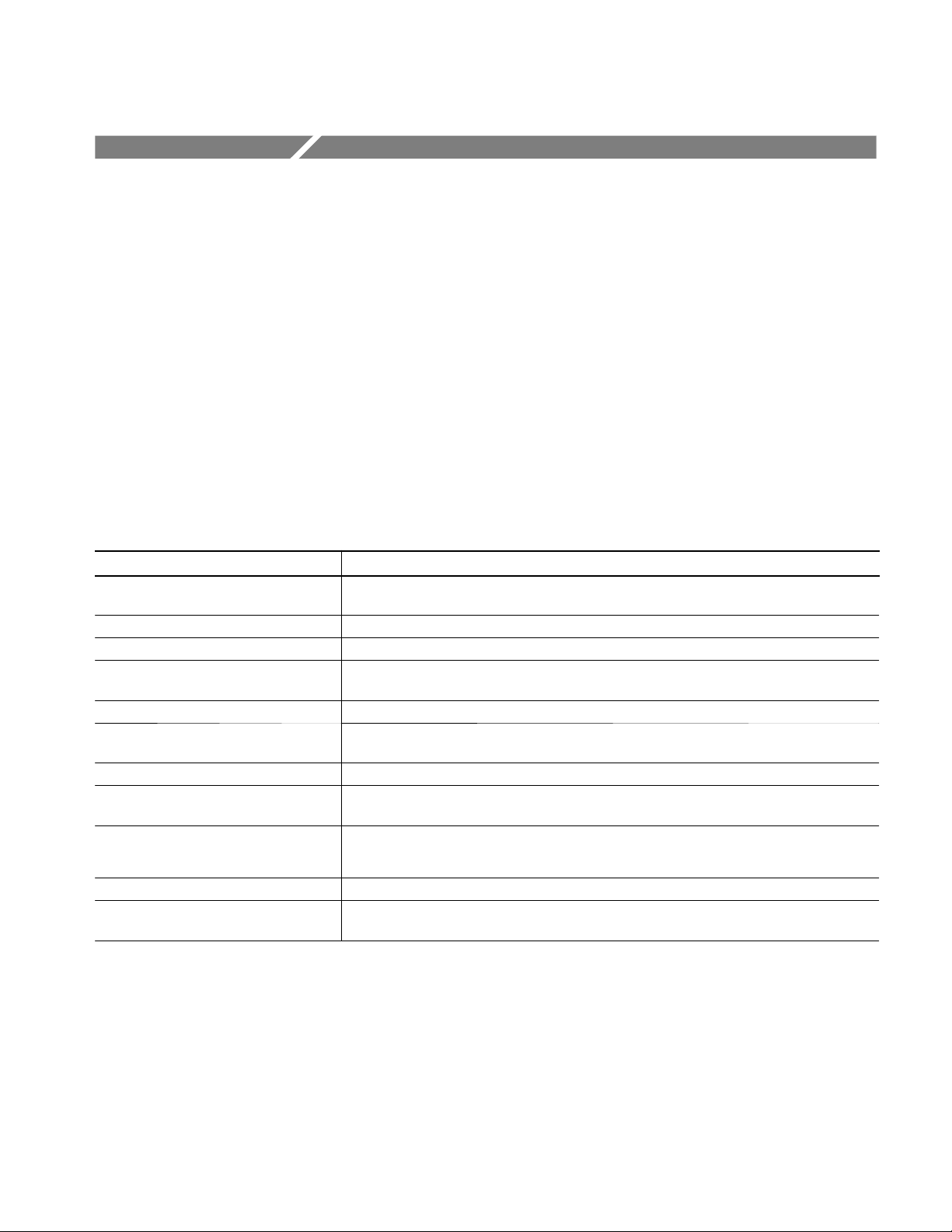

Table 1--1: System -- Signal acquisition 1--1.......................

Table 1--2: System -- Timebase 1--3..............................

T a b l e 1 -- 3 : S y s t e m -- T r i g g e r 1 -- 5................................

T able 1--4: System -- T rigger -- Phase correction modes

(CSA/TDS8200 with 82A04 Phase Reference module) 1--9........

T a b l e 1 -- 5 : D i s p l a y 1 -- 1 0........................................

T a b l e 1 -- 6 : P o r t s 1 -- 1 0..........................................

Table 1--7: Data storage 1--12....................................

Table 1--8: Power consumption, fuses, an d cooling 1--12..............

T able 1--9: Mechanical 1--14.....................................

Table 1--10: System -- Environmental 1--14.........................

T able 1--11: Mechanical -- 82A04 Phase Reference module 1--15.......

Table 1--12: Certifications and compliances 1--16....................

Table 1--13: Certifications and compliances 1--18....................

Table 1--14: Electrical sampling modules -- Signal acquisition 1--22....

Table 1--15: Electrical sampling modules (80E04, 80E08,

and 80E10 TDR Sampling Modules) -- TDR system 1--26..........

T able 1--16: Electrical sampling modules -- Timebase system 1--28.....

Table 1--17: Electrical sampling modules -- Power consumption 1--28...

T able 1--18: Electrical sampling modules -- Mechanical 1--28..........

Table 1--19: Optical modules -- Descriptions 1--32...................

Table 1--20: Optical modules -- Acquisition 1-- 35....................

T able 1--21: Optical Power Meter 1--60............................

Table 1--22: Optical modules -- Clock recovery options

(CR, CR1, CR2, CR3, and CR4) 1--60..........................

T able 1--23: Optical modules -- Mechanical 1--68....................

Table 1--24: Optical modules -- Environmental 1--69.................

T able 1--25: Module characteristics 1--71...........................

Table 1--26: Environmental specifications 1--72.....................

T able 1--27: Mechanical specifications 1--72........................

T able 1--28: Electrical 1--73......................................

Table 1--29: Environmental and mechanical 1--74...................

T able 1--30: Module characteristics 1--75...........................

Table 1--31: Environmental specifications 1--77.....................

T able 1--32: Mechanical specifications 1--77........................

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

v

Page 8

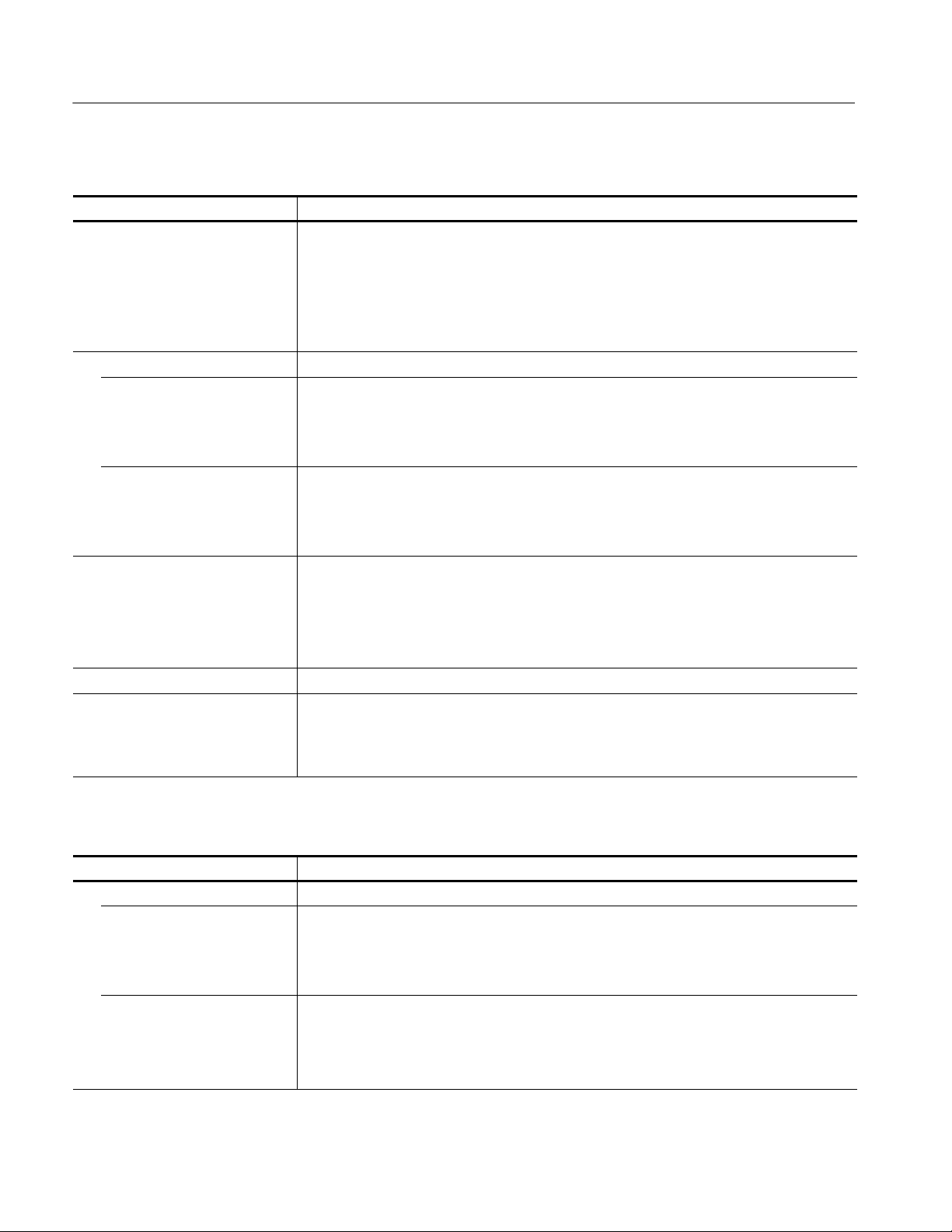

Table of Contents

Table 1--33: Product family electromagnetic compatibility

(EMC) 1--78................................................

Table 1--34: Product family dynamics 1--78.........................

Table 1--35: Product family atmospherics 1--78......................

Table 1--36: 80A06 PatternSync trigger system 1--79.................

T able 1--37: 80A06 Mechanical characteristics 1--81..................

Table 1--38: Product family electromagnetic compatibility

(EMC) 1--82................................................

Table 1--39: Product family dynamics 1--82.........................

Table 1--40: Product family atmospherics 1--82.....................

Table 2--1: Equipment required 2--29.............................

Table 2--2: Application software version required 2--108...............

Table 2--3: DC voltage measurement accuracy 2--113.................

Table 2--4: Data for calculation of gain and linearity 2--117............

Table 2--5: Random noise limits 2--119.............................

T able 2--6: Power reference 2--121.................................

Table 2--7: DUT (device under test) reference response 1 2-- 125.........

Table 2--8: Bandwidth response (55 GHz -- 65 GHz) 2--140.............

Table 2--9: Application software version required 2--159...............

Table 2--10: Dark level and vertical equivalent

optical noise limits 2--163.....................................

Table 2--11: Minimum optical bandwidth limits 2--177................

T able 2--12: Reference r eceiver frequency response limits 2--178........

T able 2--13: Reference r eceiver frequency response limits 2--191........

Table 2--14: Minimum limits 2--196................................

T able 2--15: Aberrations 2--196....................................

Table 2--16: Clock recovery settings 2--201..........................

Table 2--17: Clock recovery settings and jitter limits 2--205............

Table 2--18: Clock recovery settings 2--218..........................

Table 2--19: Clock recovery amplitude and jitter limits 2--221..........

Table 2--20: PatternSync settings and jitter limits 2-- 227...............

vi

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

Page 9

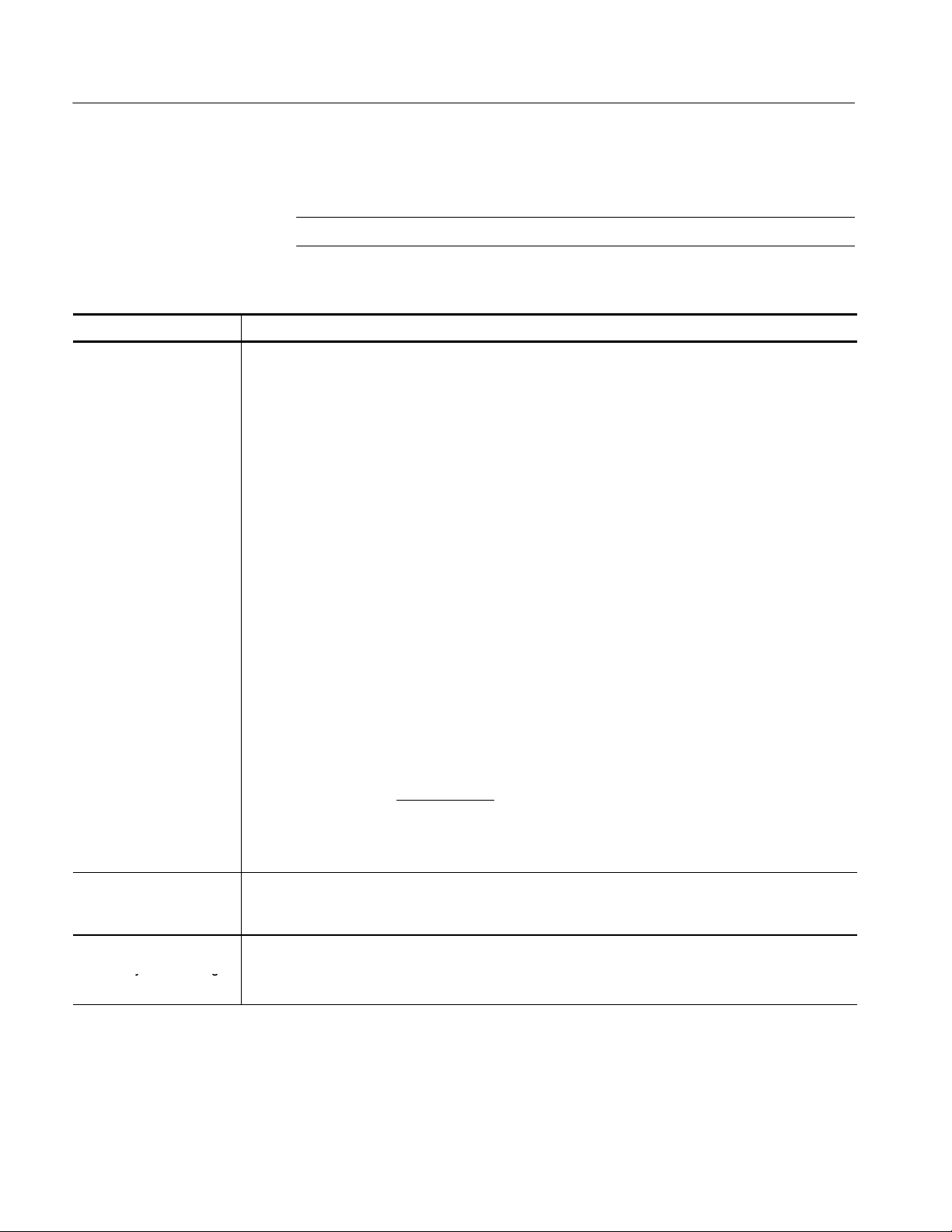

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

ToAvoidFireor

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use. Power cord needed only in the mainframe, not

modules.

Connect and Disconnect Properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. The mainframe is grounded through the grounding

conductor of the power cord. To avoid electric shock, the grounding conductor

must be connected to earth ground. Before making connections to the input or

output terminals of the product, ensure that the product is properly grounded.

Ground the Product. The modules are indirectly grounded through the grounding

conductor of the mainframe power cord. To avoid electric shock, the grounding

conductor must be connected to earth ground. Before making connections to the

input or output terminals of the product, ensure that the product is properly

grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Wear Eye Protection. Wear eye protection if exposure to high-intensity rays or

laser radiation exists.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

vii

Page 10

General Safety Summary

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

viii

CAUTION

Refer to Manual

Mains Disconnected

OFF (Power)

WARNING

High Voltage

Mains Connected

ON (Power)

Protective Ground

(Earth) Terminal

Standby

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

Page 11

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

ix

Page 12

Service Safety Summary

x

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

Page 13

Preface

Manual Structure

This manual contains the specifications and performance verification procedures

for the:

H CSA8000, CSA8000B, and CSA8200 Communications Signal Analyzers

H TDS8000, TDS8000B, and TDS8200 Digital Sampling Oscilloscopes

H Modules that install in the instruments (except the 80A03 module)

NOTE. The 80A03 instruction manual contains its own specifications and

servicing information.

Read this preface to learn how this manual is structured, what conventions it

uses, and where you can find other information related to this product.

This manual is divided into chapters, which are made up of related subordinate

topics. These topics can be cross referenced as sections.

Be sure to read the introductions to all procedures. These introductions provide

important information needed to do the service correctly, safely, and efficiently.

Manual Conventions

Modules

Safety

This manual uses certain conventions that you should become familiar with

before attempting service.

Throughout this manual, the term module appears. A module is composed of

electrical and mechanical assemblies, circuit cards, interconnecting cables, and a

user-accessible front panel. References to a module are different than references

to products such as “Sampling modules”. “Phase Reference modules”, or

“Accessory modules” which are products installed in the instrument compartments.

Symbols and terms related to safety appear in the General Safety Summary found

at the beginning of this manual.

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

xi

Page 14

Preface

Related Documentation

The following documents relate to the instruments this manual supports:

H CSA8200 and TDS8200 Quick Start User Manual. Tektronix part number

071-1482-XX. This document also contains specification changes when

using the 82A04 Phase Reference module.

H CSA8000 and TDS8000 Service Manual. Tektronix part number 071-0438-

XX.

H CSA8000 and TDS8000 Online Help. Installed with the application software

and accessed from the instrument Help menu.

H CSA8000 & TDS8000 Programmer Guide. An online document accessed

from the instrument Help menu.

H 80E01, 80E02, 80E03, 80E04, and 80E06 Electrical Sampling Modules

User Manual. Tektronix part number 071-0434-XX.

H 80E07, 80E08, 80E09, and 80E10 Electrical Sampling Remote Modules

User Manual. Tektronix part number 071-2038-XX.

H 80C00 Series Optical Sampling Modules User Manual. Tektronix part

number 071-0435-XX.

H 80A01 Trigger Prescale Limiting Preamplifier Module User Manual.

Tektronix part number 071-0873-XX.

H 80A02 EOS/ESD Protection Module Instructions. Tektronix part number

071-1317-XX

H 80A03 TekConnect Probe Interface Module Instructions. Tektronix part

number 071-1298-XX.

H 80A05 Electrical Clock Recovery Module User Manual. Tektronix part

number 071-1467-XX.

H 80A06 PatternSync Trigger Module Instructions. Tektronix part number

071-1744-XX.

H CSA8000/TDS8000 Rackmount Kit Instructions. Tektronix part number

071-0696-XX.

H TDR Z-Meas Application Online Help. Ships with this product on a separate

CD. Provides information about this TDR Impedance Measuring application

that implements the TDR calibration procedures specified by the

IPC TM-650 test method.

xii

H Fast NRZ Application Online Help. Ships with this product on a separate

CD. Provides information about this application that improves throughput

for optical eye-pattern mask testing.

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

Page 15

Specifications

Page 16

Page 17

System Specifications

NOTE. This specification is for the instrument; the specifications for the optical,

electrical, and other modules that insert in the module compartments of the

instrument front panel are included in this chapter of the manual.

This section contains the specifications for the CSA8000, CSA8000B, and

CSA8200 Communications Signal Analyzers and the TDS8000, TDS8000B, and

TDS8200 Digital Sampling Oscilloscopes.

The 82A04 Phase Reference module affects the CSA8200 and TDS8200

mainframe specifications which are documented in the mainframe specifications.

There is no separate specification section for the 82A04 module.

All specifications are guaranteed unless noted as “typical.” Typical specifications

are provided for your convenience but are not guaranteed. Specifications that are

marked with the n symbol are checked in Performance Verification chapter of

this manual.

All specifications apply to the instrument and sampling modules. unless noted

otherwise. To meet specifications, these conditions must first be met:

H The instrument must have been calibrated/adjusted at an ambient tempera-

ture between +10 _C and +40 _C.

H The instrument must have been operating continuously for 20 minutes within

the operating temperature range specified.

H The instrument must be in an environment with temperature, altitude,

humidity, and vibration with the operating limits described in these

specifications.

NOTE. “Sampling Interface” refers to both the small module compartments and

the large module compartments, unless otherwise specified.

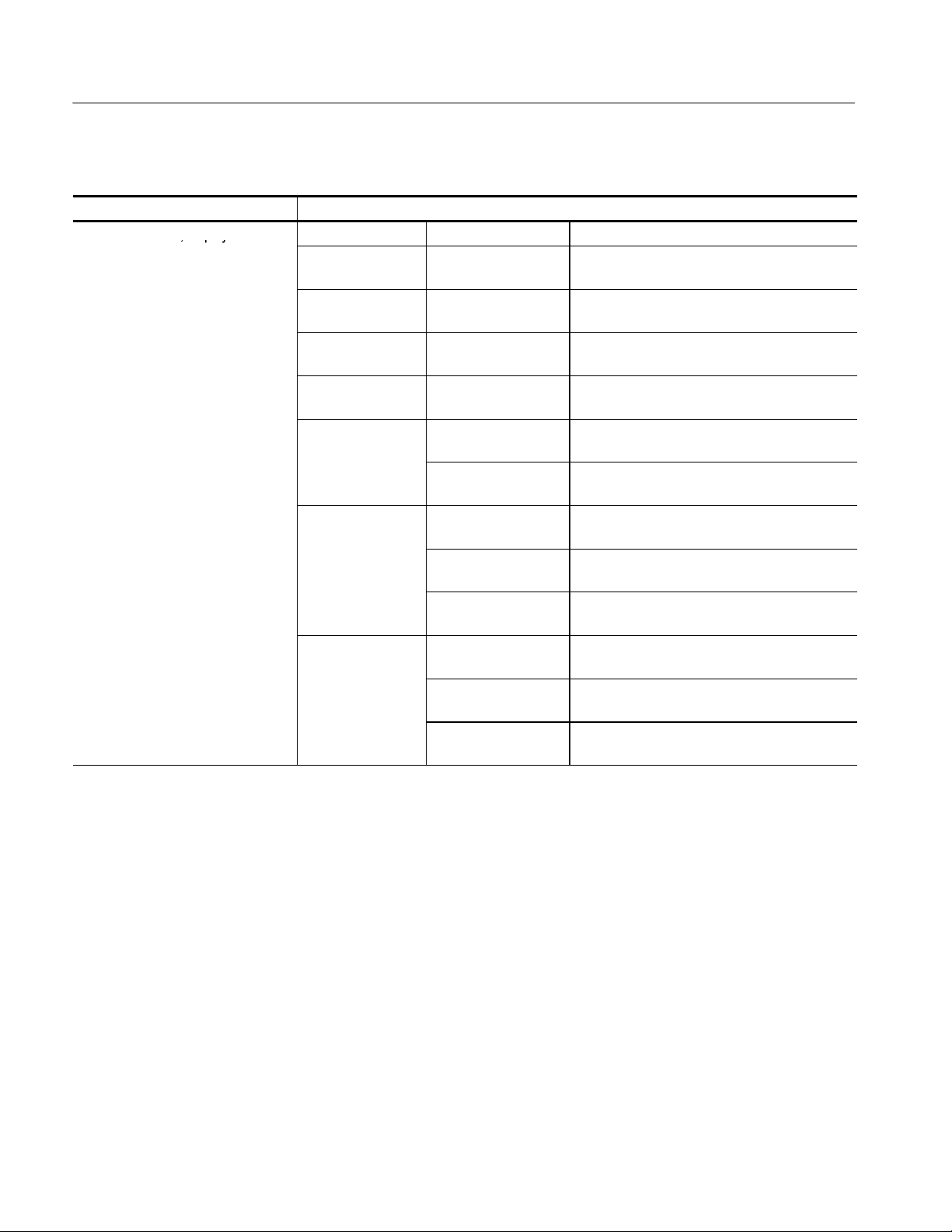

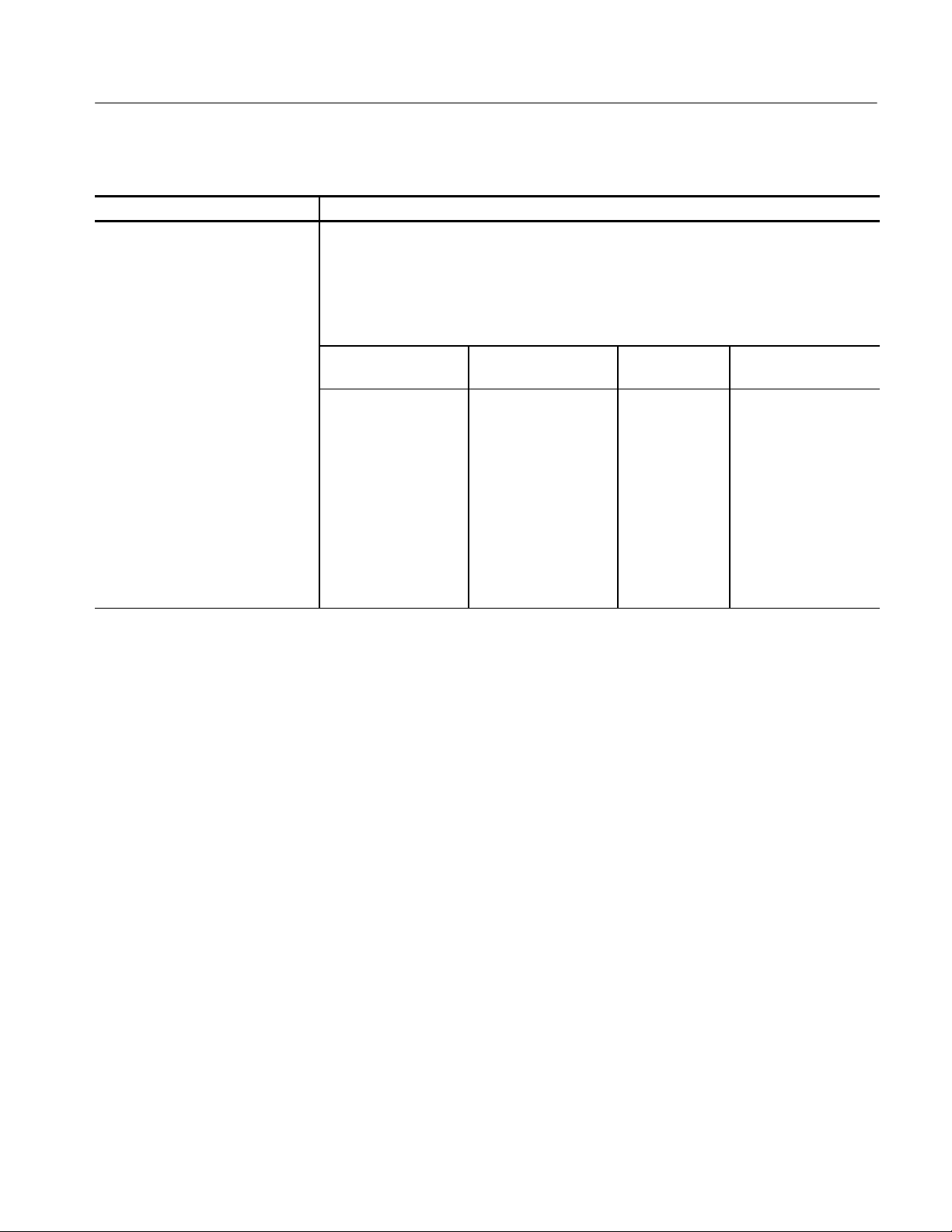

Table 1- 1: System - Signal acquisition

Description Characteristics

Number of input channels 8 acquisition channels, maximum

Number of small sampling module

compartments

4 compartments, 2 channels per compartment, for a total of 8 channels

1

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

1- 1

Page 18

System Specifications

Table 1- 1: System - Signal acquisition (cont.)

Description Characteristics

Number of large sampling module

compartments

TDS/CSA8000, TDS/CSA8000B 2 compartments, for a total of 2 channels

TDS/CSA8200 2 compartments, for a total of 4 channels

Small Sampling Module Interface Tekprobe-Sampling Level 3. Hot switching is not permitted on this interface.

Large Sampling Module Interface Tekprobe-Sampling Level 3. Hot switching is not permitted on this interface.

Compartment assignments and

conflict resolution

TDS/CSA8000, TDS/CSA8000B Population of either Ch 1 or Ch 2 large compartment with any module other than one

requiring power only, displaces functionality of the Ch 1 / Ch 2 small compartment.

TDS/CSA8200 Population of the Ch 1 / Ch 2 large compartment with any module (other than one requiring

power only) displaces functionality of the Ch 1 / Ch 2 small compartment. Population of the

Ch 3 / Ch 4 large compartment with any module (other than one requiring power only)

displaces functionality of the Ch 3 / Ch 4 small compartment.

1

1

Compartment utilization

TDS/CSA8000, TDS/CSA8000B Supports the 80xxx nomenclat ed modules.

TDS/CSA8200 Supports the 80xxx and 82xxx nomenclated modules, including Phase Reference modules.

Real time accessory interface

TDS/CSA8000, TDS/CSA8000B The small slot supports TekProbe-SMA, Levels 1 and 2. No accessory support is offered on

the large slot.

Hot switching is permitted on this real time accessory interface.

TDS/CSA8200 Small and large slots supports TekProbe-SMA, Levels 1 and 2.

Hot switching is permitted on this real time accessory interface.

Vertical sensitivity ranges 10 mV to 1 V full scale at TekProbe-Sampling interface. May be scaled according to

sampling module scaling characteristics.

Vertical operating range --1.6 V to +1. 6 V at TekProbe-Sampling interface. May be scaled according to sampling

module scaling characteristics.

Vertical number of digitized bits 14 bits at TekProbe-Sampling interface

Offset capabilities Open loop offset mode is supported at TekProbe-Sampling interface.

Offset range ±1.6 V at TekProbe-Sampling interface. May be scaled according to sampling module

offset and scaling characteristics.

Offset resolution 14 bits over ±1.8 V at TekProbe-Sampling interface.

1

Total channels ≤ 8.

1- 2

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

Page 19

System Specifications

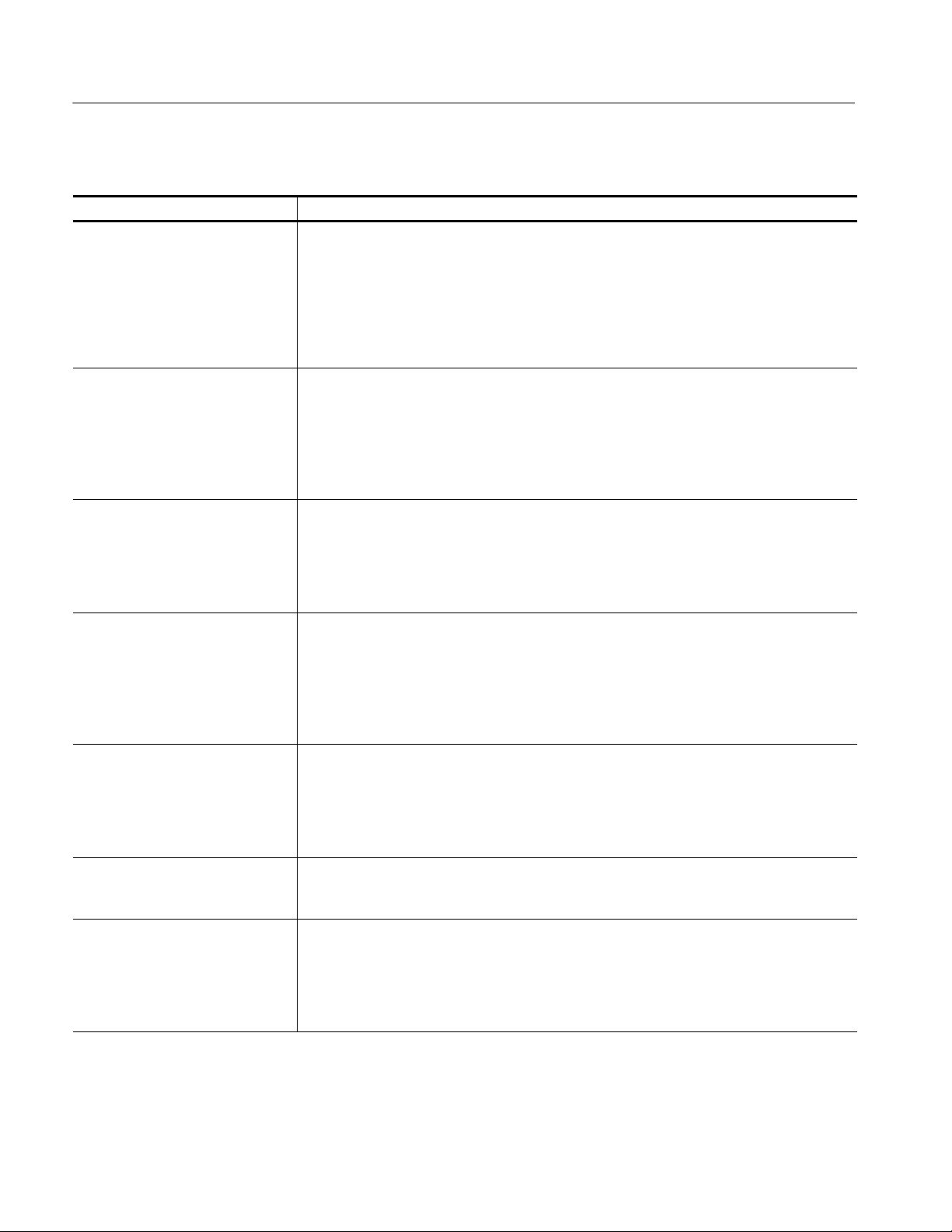

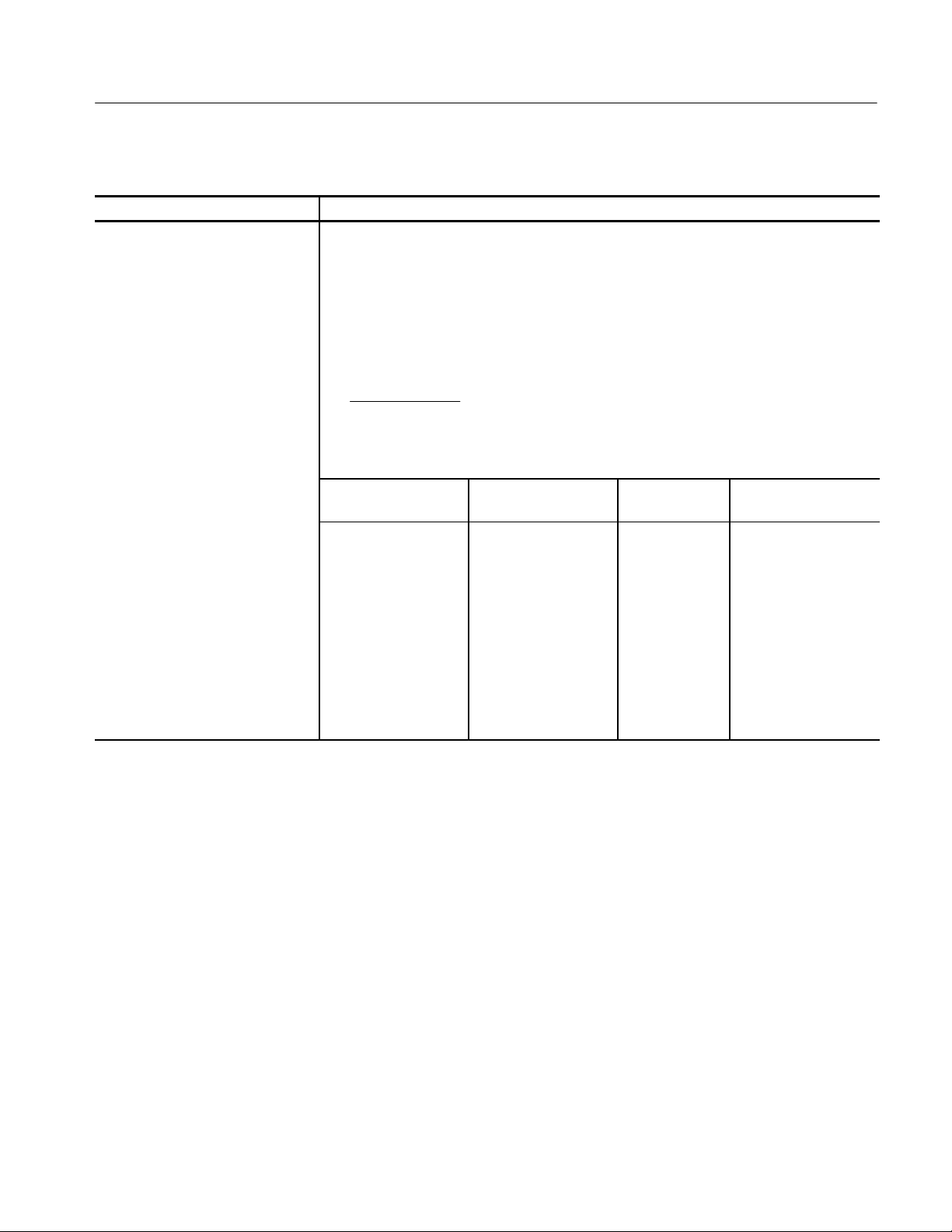

Table 1- 2: System - Timebase

Description Characteristics

Horizontal modes

All mainframes Short term jitter optimized and Locked to 10 MHz Reference are supported. The 10 MHz

reference may be internal or external.

TDS/CSA8200 with 82A04 Free Run and Triggered Modes are supported.

Sampling rate

TDS/CSA8000, TDS/CSA8000B,

and TDS/CSA8200 (regular modes)

DC -- 200 kHz maximum, dictated by trigger rate and actual holdoff setting. If trigger rate is

less than the maximum, or the requested holdoff exceeds the minimum, the trigger rate

and/or holdoff will dictate the sampling rate.

TDS/CSA8200 with 82A04 (phase

corrected modes)

DC -- 50 kHz maximum, one channel. If trigger rate is less than the maximum, or the

requested holdoff exceeds the minimum, the trigger rate and / or holdoff will dictate

sampling rate.

Record length

1

20, 50, 100, 250, 500, 1000, 2000 and 4000 samples.

Horizontal scale range

Software version 1.0 to 2.0 1 ps/div to 5 ms/div in 1, 2, 5 steps or 1 ps increments. Maximum record lengths apply at

certain ranges per table. For record lengths greater than 500, the horizontal scale is limited

as shown in the table below.

Scale set to an integer multiple of: Maximum record length

1 ps/div 1000

2 ps/div 2000

4 ps/div 4000

Software version 2.1 and above 100 fs/div to 5 ms/div in 1, 2, 5 steps or 100 fs increments are supported. Maximum record

lengths apply at certain ranges per table. For record lengths greater than 1000, the

horizontal scale is limited as shown in the table below.

Scale set to an integer multiple of: Maximum record length

100 fs/div 1000

200 fs/div 2000

400 fs/div 4000

Horizontal position range

All mainframes 50 ms maximum.

TDS/CSA8200 with 82A04 Range is det ermined by the following formula where (f) equals the frequency of the

reference clock.

1

16

× 2

f

Horizontal resolution

Software version 1.0 to 2.0 10 fs minimum

Software version 2.1 and above 1 fs minimum

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

1- 3

Page 20

System Specifications

j

p

ical)

Table 1- 2: System - Timebase (cont.)

Description Characteristics

Horizontal position setting resolution

Software version 1.0 to 1.2 1 ps minimum

Software version 1.3 to 2.0 100 fs minimum

Software version 2.1 and above 10 fs minimum

n Time interval accuracy, short term

jitter optimized mode

Strobe placement accuracy for a given horizontal interval and position on same strobe line

per table bel ow. (Contribution from 80E04 sampling module is included in speci fication.)

1 ps + 1% of interval, horizontal scale ≤ 20 ps/div, rightmost point of measurement interval

<200 ns

8 ps + 0.1% of interval, horizontal scale ≥ 21 ps/div, rightmost point of measurement

interval <200 ns (8200)

8 ps + 0.6% of interval, horizontal scale ≥ 21 ps/div, rightmost point of measurement

interval <200 ns (8000 and 8000B)

Guaranteed for all trigger rates (8200)

Guaranteed only f or ≤ 100 kHz t ri gger rate (8000 and 8000B)

Time interval accuracy, short term jitter

optimizedmode(typ

(8000 and 8000BB)

n Time interval accuracy, locked to

internal 10 MHz reference mode

Timing accuracy, free run phase

corrected mode

(Not available for TDS/ CSA8000 or

TDS/CSA8000B)

TDS/CSA8200 with 82A04 Maximum timing deviation 0.1% of phase reference signal period, typical, relative to phase

2

1 ps + 1% of interval, ≤ 20 ps/div

8 ps + 0.1% of interval, ≥ 21 ps/div for ≥ 100 kHz trigger rate

Strobe placement accuracy for a given horizontal interval and position on same strobe line

per table bel ow. Contribution from 80E04 sampling module is included in specification.

1 ps + 1% of interval, ≤ 20 ps/div

8 ps + 0.01% of interval, ≥ 21 ps/div

Guaranteed only f or ≤ 100 kHz t ri gger rate (8000 and 8000B)

Guaranteed for all trigger rates (8200)

reference signal.

Assumes that phase reference frequency has been correctly entered. Operation of phase

reference clock at frequencies requiring extended bandwidth or signal conditioning may

require an instrument option.

1- 4

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

Page 21

System Specifications

Table 1- 2: System - Timebase (cont.)

Description Characteristics

Timing accuracy, triggered phase

corrected mode

(Not available for TDS/ CSA8000 or

TDS/CSA8000B)

TDS/CSA8200 with 82A04 Maximum timing deviation relative to phase reference signal:

0.2% of phase reference signal period typical for measurements made >40 ns after

trigger event.

0.4% of phase reference signal period typical for measurements made ≤40 ns after

trigger event.

Assumes that phase reference frequency has been correctly entered.

Horizontal deskew range and

resolution

All mainframes --500 ps to +100 ns on any individual channel in 1 ps increments.

TDS/CSA8200 with 82A04 Operating in Triggered Phase Corrected modes: --500 ps to +100 ns on any individual

channel in 1 ps increments.

Operating in Free Run Phase Corrected modes: Deskew range extends over the full

clock cycle of the phase reference.

1

The total number of samples contained in a single acquired waveform record (memory length in IEEE 1057, 2.2.1).

2

80E02 sampling module is included in this specification.

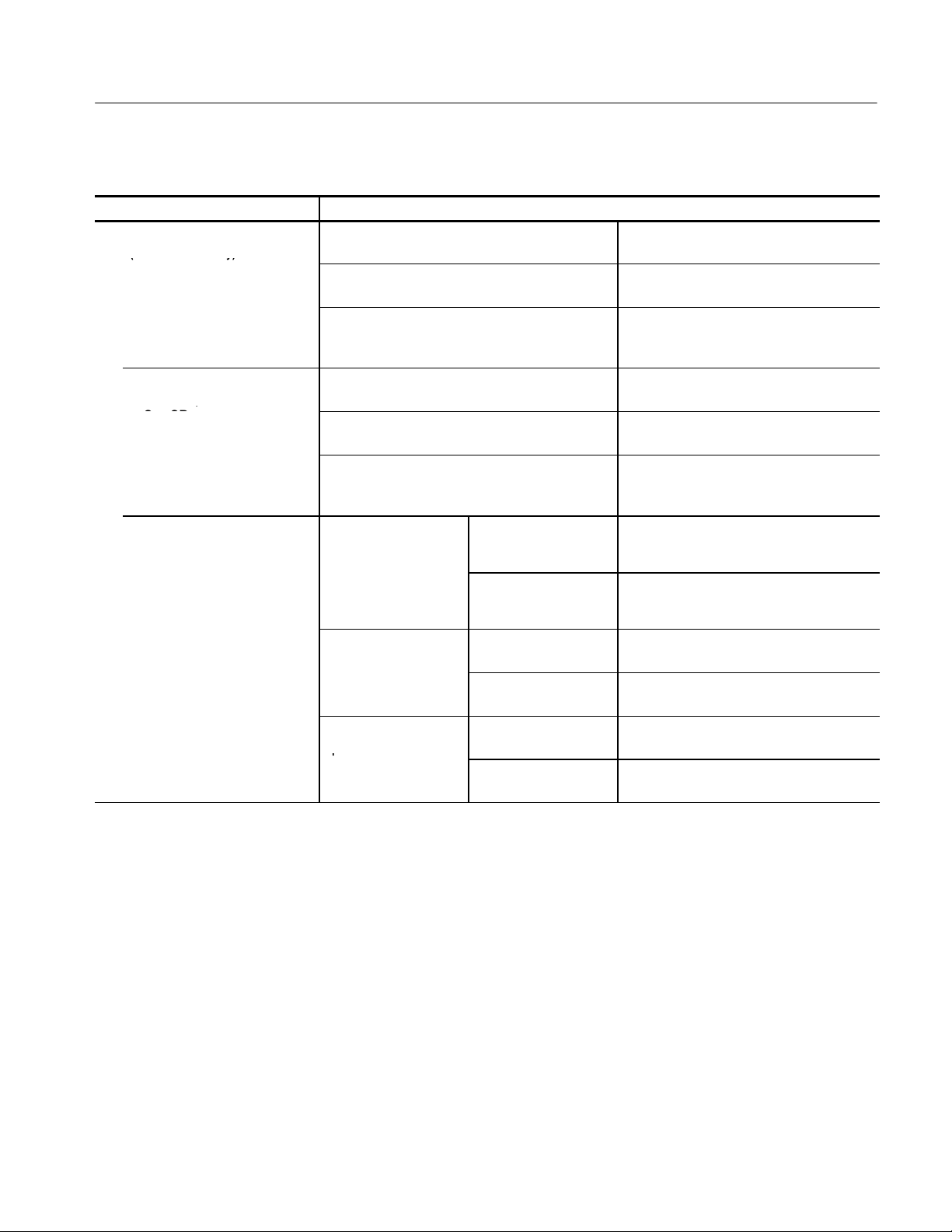

Table 1- 3: System - Trigger

Description Characteristics

Trigger sources

All mainframes External Direct Edge Trigger, External Prescaled Trigger, Internal Clock Trigger, and Clock

Recovery (with appropriately equipped optical modules)

CSA/TDS8200 with 82A04 A phase reference signal may be applied to the instrument, w hen equipped with an

82A04 Phase Reference module, to provide additional phase information for signals

being acquired in Triggered Phase Corrected modes and primary phase information

for signals being acqui red in Free Run Phase Corrected modes.

Two bandwidth options are available for the 82A04 and may be required over specific

frequency ranges of operation:

The base product has an 8 GHz -- 25 GHz range of operation.

Option 60G extends the upper frequency range of operation to 60 GHz.

Auto/normal mode Normal mode: wait for tri gger

Auto mode: Trigger automati cally generated after 100 ms time-out

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

1- 5

Page 22

System Specifications

Table 1- 3: System - Trigger (cont.)

Description Characteristics

Slope + or -- select Edge + mode: Triggers on positive-slewing edge.

Edge -- mode: Triggers on negative-slewing edge.

High frequency on/off select High Frequency ON mode: Removes trigger hysteresis and improves sensitivity. Should be

used when trigger slew rate exceeds 1 V/ns.

High Frequency OFF mode: Retains trigger hysteresis and improves noise rejection at low

slew rates.

Variable trigger hold off range and

resolution

TDS/CSA8000, TDS/CSA8000B When External Prescaled Trigger mode is used, holdoff period applies to the Prescaled

TDS/CSA8200 When External Prescaled Trigger mode is used, holdoff period applies to the Prescaled

External direct trigger capabilities and

conditions

Adjustable 5 s to 50 ms in 0.5 ns i ncrements.

input divided by 8.

input divided by 16.

Direct edge triggering on signal applied to dedicated front panel connector with Holdoff,

Level Adjust, Auto/Normal, High Frequency On/Off, and Enhanced Triggering On/Off

controls.

External direct trigger specifications apply only under the condition that no other trigger

signal is applied to respective connect ors, except 82A04 Phase Reference modules.

Short term optimized mode and locked to internal 10 MHz reference specifications only

apply under the condition that there is no external 10 MHz reference applied to the front

panel connector.

External direct trigger input characteris-

1

tics

50 Ω input resistance, DC coupled only

External direct trigger input range ±1.5 V (DC + peak AC) maximum input voltage

External direct trigger maxi mum operating

trigger signal

2

1V

p-p

External direct trigger level range Adjustable between ±1.0 V

n External direct trigger sensitivity

3

100 mV, DC -- 3 GHz

External direct trigger sensitivity 50 mV typical, DC -- 4 GHz

External direct trigger level resolution 1mV

n External direct trigger level accuracy 50 mV + 0.10 x level

External direct trigger delay jitter, short

term optimized mode (typical)

CSA/TDS8000 1.0 ps RMS + 5 ppm of horizontal position

CSA/TDS8000B, CSA/TDS8200 800 fs RM S + 5 ppm of horizontal position

n External direct trigger delay jitter, short

term optimized mode

CSA/TDS8000 1.5 ps RMS + 10 ppm of horizontal position, or better

CSA/TDS8000B, CSA/TDS8200 1.0 ps RMS + 8 ppm of horizontal position, or better

1- 6

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

Page 23

Table 1- 3: System - Trigger (cont.)

/,/

Description Characteristics

External direct delay j itter, locked to

internal 10 MHz reference mode (typical)

CSA/TDS8000 1.6 ps RMS + 0.05 ppm of horizontal position

CSA/TDS8000B, CSA/TDS8200 1.6 ps RMS + 0.01 ppm of horizontal position

n External direct delay jitter, locked to

internal 10 MHz reference mode

CSA/TDS8000 2.5 ps RMS + 0.10 ppm of horizontal position, or better

CSA/TDS8000B, CSA/TDS8200 2.5 ps RMS + 0.04 ppm of horizontal position, or better

External direct trigger mi nimum pulse

width (typical)

External direct trigger met astability

(typical)

External direct trigger real time accessory

interface

External prescaled trigger capabilities and

conditions (typical)

167 ps

Zero

Tekprobe-SMA, Levels 1 and 2. Hot switching i s permit ted on this real time accessory

interface.

Prescaled triggering on signal applied to dedicated front panel connector with Holdoff,

Auto/Normal, Metastability Reject On/Off.

System Specifications

4

External prescaled trigger specifi cations apply only under the condition that no other trigger

source is applied to respective connectors.

Short term optimized mode and locked to internal 10 MHz reference specifications only

apply under the condition that there is no external 10 MHz reference applied to the front

panel connector.

External prescaled trigger input characteristics (typical)

CSA/TDS8000, CSA/TDS8000B 50 Ω AC coupled input resistance; divide-by-eight prescaler ratio, fixed level zero volts

CSA/TDS8200 50 Ω AC coupled input resistance; divide-by-sixteen prescaler ratio, fixed level zero volts

External prescaled trigger absolute

±2.5 Vpp

maximum input (typical)

n External prescaled trigger sensitivity

CSA/TDS8000, CSA/TDS8000B Frequency range Sensitivity

2GHz--3GHz 800 mV

3 GHz -- 10 GHz 600 mV

p-p

p-p

External prescaled trigger sensitivity

(typical)

CSA/TDS8000, CSA/TDS8000B Frequency range Sensitivity

10 GHz -- 12.5 GHz 1000 mV

p-p

5

n External prescaled trigger sensitivity

and usable range

CSA/TDS8200 Frequency range Sensitivity

2GHz--12.5GHz 200 mV

to 800 mV

p-p

p-p

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

1- 7

Page 24

System Specifications

Table 1- 3: System - Trigger (cont.)

Description Characteristics

External prescaled trigger delay jitter,

short term optimized mode (typical)

CSA/TDS8000 1.0 ps

CSA/TDS8000B, CSA/TDS8200 0.9 ps

n External prescaled trigger delay jitter,

short term optimized mode

CSA/TDS8000 1.5 ps

CSA/TDS8000B, CSA/TDS8200 1.3 ps

External prescaled delay jitter, locked to

internal 10 MHz reference mode (typical)

CSA/TDS8000 1.6 ps

CSA/TDS8000B, CSA/TDS8200 1.6 ps

n External prescaled delay jitt er, locked

to internal 10 MHz reference mode

CSA/TDS8000 2.5 ps

CSA/TDS8000B, CSA/TDS8200 2.5 ps

External prescaled trigger metastability

Zero

(typical)

Internal clock trigger rates Rate selectable at 25, 50, 100, and 200 kHz internally and is provided to the trigger, to the

TDR stimulus drives in t he small sam pling module interfaces, and to the Internal Clock Out

connector on the front panel.

1

The input resistance at the external direct trigger input and the maximum input voltage.

2

Maximum signal input for maintaining calibrated time base operation.

3

Section 4.10.2 in IEEE standard number 1057. The minimum signal levels required for stable edge triggering of an

acquisition.

4

Metastability Reject is not available with product software versions 2.4 and above.

5

The 80A01 accessory is designed to allow users to enhance performance.

+ 5 ppm of horizontal position

RMS

+ 5 ppm of horizontal position

RMS

+ 10 ppm of horizontal position, or better

RMS

+ 10 ppm of horizontal position, or better

RMS

+ 0.05 ppm of horizontal position

RMS

+ 0.01 ppm of horizontal position

RMS

+ 0.1 ppm of horizontal position, or better

RMS

+ 0.04 ppm of horizontal position, or better

RMS

1- 8

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

Page 25

System Specifications

Table 1- 4: System - Trigger - Phase correction modes (CSA/TDS8200 with 82A04 Phase Reference module)

Description Characteristics

Note. The specifications in this table apply to a CSA8200 or TDS8200 mainframe equipped with an 82A04 Phase Reference module.

The CSA8000, TDS8000, CSA8000B, and TDS8000B mainframes do not support the use of the 82A04 Phase Reference module.

Phase correction capabilities and

conditions

A phase reference signal may be applied to a TDS8200 / CSA8200 equipped with the

82A04 Phase Reference module, to provide additional phase information for signals

being acquired in Triggered Phase Corrected modes and primary phase information

for signals being acqui red in Free Run Phase Corrected modes. For Phase Corrected

Triggered modes, the phase correction functionality overlays the functionality of the

basic trigger operation, al though restrictions may be imposed.

Number of phase reference module

inputs

One per 82A04 module. Up to three 82A04 modules may be inserted in the small

compartments of the TDS8200 / CSA8200 and characterized to operate with one or

more vertical sampling module(s); only one phase correction module at a time can be

used.

Phase reference input connector Precision 1.85 mm female connector (V)

A 2.4 mm m ale to 2.92 mm (K) female adapter is provided as a standard accessory to

provide connection to 3.5 mm compatible male connectors.

Phase reference module input

50 Ω AC coupled through 5 pF

characteristics (typical)

Phase reference module input

2V

(offset ±1000 mV)

p-p

dynamic range (nonclipping)

Phase reference module input

±3 V maximum

maximum nondestruct range

Phase reference module input signal

600 mV

p-p

to 1.8 V

to achieve typical specified jitter performance

p-p

level

Phase reference mode jitter (typical) Triggered and Free Run Phase Corrected Modes, 8 GHz -- 60 GHz clock,

600 mV -- 1.8 V

input: 200 fs

p-p

RMS

or better.

Triggered and Free Run Phase Corrected Modes, 2 GHz -- 8 GHz sine wave clock,

600 mV -- 1.8V

input: 280 fs

p-p

or better. The jitter increase between 8 GHz and

RMS

2 GHz is roughly inverse proportion to clock frequency.

Operation of phase reference clock at frequencies requiring extended bandwidth or

signal conditioning may require an optional filter accessory.

Phase reference module compensation temperature range (typical )

±5 _C where compensation was performed. If compartment is changed on

mainframe, or if sampling module extender is employed, or length of sampling module

extender is changed, the Phase Reference module must be recompensated.

n Phase reference module input

operating frequency

With 82A04 8 GHz to 25 GHz

With 82A04-60 G 8 GHz to 60 GHz

Phase reference module input

operating frequency (typical)

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

1- 9

Page 26

System Specifications

Table 1- 4: System - Trigger - Phase correction modes (CSA/TDS8200 with 82A04 Phase Reference module) (cont.)

Description Characteristics

With 82A04 2 GHz to 25 GHz usable range

Operation below 8 GHz requires the use of external filters, as follows:

2 GHz -- 4 GHz: requires 2.2 GHz peaked lowpass filter kit, Tektronix part

number 020-2566-00.

4 GHz -- 6 GHz: requires 4 GHz lowpass filter kit, Tektronix kit part number

020-2567-00.

6 GHz -- 10 GHz: requires 6 GHz filter lowpass filter kit, Tektronix kit part num ber

020-2568-00.

2 GHz to 25 GHz settable range.

With 82A04-60 G 2 GHz to 60 GHz usable range. Operation below 8 GHz requires the use of external

filters as noted for the standard 82A04.

2 GHz to 110 GHz settable range.

Table 1- 5: Display

Specifications Characteristics

Display type 211.2 mm (wide) x 1.58.4 mm (high), 264 mm (10.4 inch) diagonal, liquid crystal active matrix

color display (LCD).

Display resolution 640 horizontal by 480 vertical pixels.

Pixel pitch Pixels are 0.33 mm (horizontal) and 0.22 mm (vertical)

Table 1- 6: Ports

Specifications Characteristics

Video output 1 15-pin D-subminiature connector on the rear panel. Used for a second monitor. (Supports

at least the basic requirements of the PC99 specification.)

Video Output 2 15-pin D-subminiature connector on the rear panel. Used for an auxiliary duplicate primary

monitor (VGA).

Parallel port

(IEEE 1284)

25-pin D-subminature connector on the rear panel. Supports the following modes:

H Standard mode, output only

H Bi-directional, PS/2 compatible

H Bi-directional Enhanced Parallel Port (IEEE 1284 standard, Mode 1 or Mode 2, v1.7)

H Bi-directional high speed Extended Capabilities Port (ECP)

Serial port 9-pin D-submi nature serial-port connector using NS16C550 compatible UARTs supporting

transfer speeds up to 115.2 kbits/sec.

1- 10

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

Page 27

System Specifications

Table 1- 6: Ports (cont.)

Specifications Characteristics

PS/2 keyboard and mouse interface PS/2 compatible keyboard and mouse connectors.

LAN interface RJ-45 LAN connector supporting 10 base-T and 100 base-T

External audio connectors External audio jacks for MIC IN and LINE OUT

USB interface One USB connector (the second USB is disabled because of internal use)

GPIB interface Complies with IEEE 488.2

Internal clock trigger out Square wave out from 50 Ω. back termination synchronized to the TDR internal clock drive

signal. Refer to Trigger System -- Internal Clock.

Typical performance into 50 Ω termination:

--0.20 to +0.20 V low level

+0.90 to +1.10 V high level

DC calibration output DC voltage from low impedance drive, programmable to 1 mV over ±1.25 V range maximum.

DC calibration output accuracy

(typical)

n DC calibration out put accuracy 0.2 mV + 0.1% into 50 Ω.

External 10 MHz reference input 500 mV

Gated Trigger Input -- Logic Polarity

(Option GT equipped mainframes)

Gated Trigger Input -- Maximum nondestruct input levels

0.1 mV + 0.1% into 50 Ω.

p-p

to5V

AC coupled into 1 kΩ, ±5 V maximum

p-p

A TTL logic 1 enables triggers to be accepted

A TTL logic 0 disables all triggering

Input held high (enable triggers) when no control signal is present.

±5 V maximum

(Option GT equipped mainframes)

Gated Trigger Input -- Enable-to-Acquire Delay

(Option GT equipped mainframes)

3 trigger cycles, where each cycle is defined as (holdoff time + trigger latency). For example:

With holdoff set to its minimum 5 s setting, and a 2.500 GHz clock signal applied to the

External Direct Trigger input (a period of 400 ps), the Enable-to-Acquire delay is approximated

as 3 x (5 s + 0.0004 s) = 15.0012 s.

The Enable-to-Acquire delay is the amount of time after the Gated

Trigger has been enabled (the level goes from TTL LOW to HIGH) when the first valid sample is

retained by the system as the beginning of the waveform record length. When the Gated Trigger

is enabled and triggers begin to occur, the system will reject the first three samples to avoid

system recovery conditions. Once the first three points have been

discarded, then the next vali d trigger cycle will be the first point of the

record section.

Gated Trigger Input -- Maximum

Disable Time

(Option GT equipped mainframes)

The system checks the status of the gated Trigger approximately once per holdoff and re-arm

cycle. If the Gated Trigger is disabled immediately after this system check, it will allow nominally

a maximum time of (holdoff + trigger period) to elapsed before the checking for the status of the

Gated Trigger input, recognizing the disable condition, and halting any further sampling of the

signal.

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

1- 11

Page 28

System Specifications

Table 1- 7: Data storage

Specifications Characteristics

Floppy disk drive capacity 3.5 in floppy disk, 1.44 Mbyte, compatable with DOS 3.3 or later format for storing reference

waveforms, image files, and instrument setups.

Hard disk drive capacity

CSA/TDS8000 ≥ 6Gbytes

CSA/TDS8000B ≥ 20 Gbytes

CSA/TDS8200 ≥ 40 Gbytes

Table 1- 8: Power consumption, fuses, and cooling

Specifications Characteristics

Source voltage and frequency Range for the line voltage needed to power the instrument within which the instrument meets its

performance requirements.

100-240 V RMS ±10%, 50/60 Hz

115 V RMS ±10%, 400 Hz

CAT II

Fuse rating Current and voltage ratings and type of the fuse used t o fuse the source line voltage.

Twosizescanbeused:

(0.25 x 1.25 inch size): UL 198G & CSA C22.2, No. 59 Fast acting: 8 Amp, 250 V; Tektronix part

number 159-0046-00, BUSSMAN part number ABC-8, LITTLEFUSE part number 314008

(5 x 20 mm size): IEC 127, sheet 1, fast acting “F”, high breaking capacity, 6.3 Amp, 250 V;

Tektronix part number none, BUSSMAN part number GDA ±6.3, LITTLEFUSE part number

21606.3

1- 12

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

Page 29

Table 1- 8: Power consumption, fuses, and cooling (cont.)

Specifications Characteristics

Power requirements

CSA/TDS8000 Maximum: 600 Watts

Fully Loaded Typical: 275 Watts

Mainframe alone with no modules: 195 Watts

CSA/TDS8000B Maximum: 600 Watts

Fully Loaded Typical: 240 Watts

Mainframe alone with no modules: 160 Watts

CSA/TDS8200 Maximum: 600 Watts

Fully Loaded Typical: 275 Watts

Mainframe alone with no modules: 150 Watts

An example of a fully loaded mainf rame for these characteristic loads has installed optical

modules, electrical modules, and active probes comprised of:

one 80C11-CR4,

one 80A05-10G,

three 067-0387-01,

one 067-0397-00

System Specifications

There is typically a slight ±10 W deviation in the dissipation for various line conditions

ranging from 48 Hz through 400 Hz as well as operating ambient temperature.

Cooling requirements Six fans with speed regulated by internal temperature sensors.

A2I (51 mm) clearance must be maintained on the left side and right si de of the instrument,

anda0.75I (19 mm) clearance must be maintained on the bottom of the instrument for forced

air flow. It should never be operated on a bench with the feet removed, nor have any object

placed nearby where it may be drawn against the air vents.

No clearance is required on the front, back, and top.

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

1- 13

Page 30

System Specifications

Table 1- 9: Mechanical

Specifications Characteristics

Construction material Chassis: Aluminum alloy

Cosmetic covers: PC/ABS thermoplastic

Front panel: Aluminum alloy with PC/thermoplastic overlay

Module doors: Nickel plated stainless steel

Bottom cover: Vinyl clad sheet metal

Circuit boards: Glass-laminate

Cabinet: Aluminum

Weight

CSA/TDS8000 19.73 kg (43.5 lb.) (no keyboard, no mouse, no top pouch, no power cord, and no modules or

front shield installed)

22.23 kg (49.0 lb.) (keyboard, mouse, top pouch, power cord, front shield installed, and no

modules installed)

CSA/TDS8000B

CSA/TDS8200

Overall dimensions Height: 343 mm (13.5 in.)

19.5 kg (43.0 lb.) (no keyboard, no mouse, no top pouch, no power cord, and no modules or

front shield installed)

22.0 kg (48.5 lb.) (keyboard, mouse, top pouch, power cord, front shield installed, and no

modules installed)

Width: 457 mm (18.0 in.)

Depth: 419 mm (16.5 in.)

The dimensions do not include f eet, rack mount kit, or protruding connectors.

Overall mass, packaged product 35.8 kg (79 lb.)

Overall dimensions, packaged

product

Height: 613 mm (24.12 in.)

Width: 695 mm (27.37 in.)

Depth: 756 mm (29.75 in.)

Table 1- 10: System - Environmental

Description Characteristics

Dynamics

CSA/TDS8000,

CSA/TDS8000B

CSA/TDS8200 Random vibration (operating):

Random vibration (operating):

0.22 g rms, from 5 to 500 Hz, 10 minutes each axis, (3 axis, 30 minutes t otal) operating.

Random vibration (nonoperating):

2.28 g rms, from 5 to 500 Hz, 10 minutes each axis, (3 axis, 30 minutes t otal) non-operating.

0.141 g rms, from 5 to 200 Hz, 10 minutes each axis, (3 axis, 30 minutes t otal).

1- 14

Random vibration (nonoperating):

2.28 g rms, from 5 to 500 Hz, 10 minutes each axis, (3 axis, 30 minutes t otal).

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

Page 31

System Specifications

Table 1- 10: System - Environmental (cont.)

Description Characteristics

Atmospherics

Temperature: Operating:

10 °Cto+40°C

0 °Cto+35°C for 80E0X m odules on Tektronix part number 012-1569-02 meter extender

Nonoperating:

-- 2 2 °Cto+60°C

Relative humidity: Operating: 20% to 80%, with a maximum w et bul b temperat ure of 29 °C at or below

+40 °C (upper limits derates to 45% relative humidity at +40 °C, non-condensing)

Nonoperating (no floppy disk in floppy drive): 5% to 90%, with a maxi mum wet bulb

temperature of 29 °C at or below +60 °C (upper limits derates to 20% relative humidity at

+60 °C, non-condensing)

Altitude: Operating: 3,000 m (9,842 ft.)

Nonoperating: 12,190 m (40,000 ft.)

Electrostatic discharge susceptibility

1

Environmental specifications apply to all properly installed modules unless noted otherwise.

Up to 8 kV with no change to control settings, or impairment of normal operation

Up to 15 kV with no damage that prevents recovery of normal operation

Table 1- 11: Mechanical - 82A04 Phase Reference module

Specifications Characteristics

Construction material Chassis: Aluminum alloy

Front panel: Plastic laminate

Circuit boards: Glass-laminate

Cabinet sleeve and end covers: Aluminum

Weight 0.4 kg (13 oz.)

Overall Dimensions Height 25 mm (1.0 in.)

Width 79 mm (3.1 in.)

Depth 135 mm (5.3 in.)

Does not include connector, adapter, connector cover, or lock down hardware protruding

from front or rear panels.

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

1- 15

Page 32

System Specifications

Certifications (CSA/TDS8000, CSA/TDS8000B)

NOTE. Certifications apply to all properly installed modules unless noted otherwise.

Table 1- 12: Certifications and compliances

Category Standards or description

EC Declaration of Conf ormity -EMC

Meets intent of Directive 89/336/EEC for Electromagnetic Compatibility when configured with

sampling head modules designed for use with this instrument as identified in this manual.

Compliance was demonstrated to the following specifications as listed in the Official Journal of the

European Union:

EN 61326 EMC Requirements for Electrical Equipment for Measurement,

Control and Laboratory use, Annex D.

Class A Radiated and Conducted Emissions

IEC 61000-4-2

IEC 61000-4-3

IEC 61000-4-4

IEC 61000-4-5

IEC 61000-4-6

IEC 61000-4-11

1

Horizontal timing susceptibility of the optical sampling modules and their

internal clock recovery trigger signals usually increase the horizontal timing

jitter when external electromagnetic fields are applied. For fields up to 3 V/m,

the increase in the horizontal high-frequency RMS jitter is typically less than

3 ps RMS of jitter, added using the square-root-of-the-sum-of-the-squares

method. An example follo ws:

If an 80C01-CR operating in clock-recovery trigger mode exhibits 3.5 ps RMS of

edge jitter, with no EMC field applied and for an ideal jitterless input, then for

applied fields up to 3 V/m the edge jitter, degradation would typically result in a

total RMS jitter of:

1

2

Jitter ≤ 3.5ps

EN 61000-3-2 AC Power Harmonic Current Emissions

EN 61000-3-3 Voltage changes, fluctuations, and flicker

Radiated emissions may exceed the l evels specified in EN 61326 when this instrument is

connected to a test object.

Australia/New Zealand

Declaration of Conformity -EMC

General EMC To ensure compliance with EMC requirements, only high quali ty shielded cables having a reliable,

1- 16

Complies with EMC Framework per the following standard:

AS/NZS 2064.1/2 Class A Radiated and Conducted Emissions

continuous outer shield (braid & foil) with full coverage, low impedance connections to shielded

connector housings at both ends should be connected to this product.

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

Ꭹ

+ 3ps

2

= 4.61ps

Page 33

Table 1- 12: Certifications and compliances (cont.)

Category Standards or description

System Specifications

EC Declaration of Conf ormity -Low Voltage

U.S. Nationally Recognized

Testing Laboratory Listing,

mainframe

Canadian Certification,

mainframe

Installation (Overvoltage)

Category Description

Pollution Degree Descriptions A measure of the contaminates that could occur in the environment around and within a product.

Equipment Type

Safety Class Class 1 (as defined in IEC 61010-1, Annex H) -- grounded product

Overvoltage Category Overvoltage Category II (as defined in IEC 61010-1, Annex J)

Pollution Degree Pollution Degree 2 (as defined in IEC 61010-1). Note: Rated for indoor use only.

Compliance was demonstrated to the following specification as listed in the Official Journal of the

European Union:

Low Voltage Directive 73/23/EEC, amended by 93/68/EEC

EN 61010-1/A2:1995 Safety requirements for el ectrical equipment for measurement

control and laboratory use.

UL3 111-1 Standard for electrical measuring and test equipment.

CAN/CSA C22.2 No. 1010.1 Safety requirements for electrical equipment for measurement,

control, and laboratory use.

Terminals on this product may have different installation (overvoltage) category designations. The

installation categories are:

CAT III Distribution-level mains (usually permanently connected). Equipment at this level is

typically in a fixed industrial location.

CAT II Local-level mains (wall sockets). Equipment at this level includes appliances, portable

tools, and similar products. Equipment is usually cord-connected.

CAT I Secondary (signal level) or battery operated circuits of electronic equipment.

Typically the internal environment inside a product is considered to be the same as the external.

Products should be used only in the environment for which they are rated.

Pollution Degree 2 Normally onl y dry, nonconductive pollution occurs. Occasionally a

temporary conductivity that is caused by condensation must be

expected. This location is a typical office/home environment.

Temporary condensation occurs only when the product is out of

service.

Test and measuring

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

1- 17

Page 34

System Specifications

Declarati

f

Conf

y

y

g

Certifications (CSA/TDS8200)

NOTE. Certifications apply to all properly installed modules unless noted otherwise.

Table 1- 13: Certifications and compliances

Category Standards or description

EC Declaration of

Conformity -- EMC

Australia / New Zealand

on o

ormit

-- E M C

Meets intent of Directive 89/336/EEC for Electromagnetic Compatibility when configured with

sampling head modules designed for use with this instrument as identified in this manual.

Compliance was demonstrated to the following specifications as listed in the Official Journal of the

European Communities:

EN 61326 EMC requirements for Class A electrical equipment for measurement,

control and laboratory use, Annex D.

1

IEC 61000--4--2 Electrostatic discharge immunity

IEC 61000--4--3 RF electromagnetic field immunity

2

IEC 61000--4--4 Electrical fast transient / burst immunity

IEC 61000--4--5 Power line surge immunity

IEC 61000--4--6 Conducted RF immunity

IEC 61000--4--11 Voltage dips and interruptions immunity

1

Radiated emissions may exceed the levels required by this standard when this equipment is connected to

a test o bject.

2

Horizontal timing susceptibility of the optical sampling modules and their internal clock recovery trigger

signals usually increase the horizontal timing jitter when external electromagnetic fields are applied. For

fields up to 3 V/m, the increase in the horizontal high-frequency RMS jitter is typically less than 3 ps RMS

of jitter, added using the square-root-of-the-sum-of-the-squares method. An example follows:

If an 80C01-CR operating in clock-recovery trigger mode exhibits 3.5 ps RMS of edge jitter, with no EMC

field applied and fo r an ideal jitterless input, then for applied fields up to 3 V/m the ed ge jitter, degradation

would typically result in a total RMS jitter of:

Jitter ≤ 3.5 ps2+ 3 ps

Ꭹ

2

= 4.61 ps

EN 61000--3--2 AC Power Harmonic Current Emissions

EN 61000--3--3 Voltage changes, fluctuations, and flicker

Complies with EMC provision of Radiocommunications Act per the following standard(s):

AS/NZS 2064.1/2 Industrial, Scientific, and Medical Equipment: 1992

EC Declaration of

Conformity -- Low Voltage

Compliance was demonstrated to the following specification as listed in the Official Journal of the

European Communities:

Essential requirements of the Low Voltage Directive 73/23/EEC, amended by 93/68/EEC

1- 18

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

Page 35

Table 1- 13: Certifications and compliances (cont.)

gyp

Category Standards or description

System Specifications

U.S. Nationally

Recognized Testing

Laboratory Listing,

mainframe

Canadian Certification,

mainframe

Installation (Overvoltage)

Category Description

Pollution Degree

Descriptions

Equipment Type Test and measuring

Safety Class Class 1 - grounded product

Overvoltage Category Overvoltage Category II

UL61010B:2003 Standard for electrical measuring and test equipment.

CAN/CSA C22.2 No. 1010.1 Safety requirements for electrical equipment for m easurem ent,

Terminals on this product may have different installation (overvoltage) category designations. The

installation categories are:

CAT III Distribution-level mains (usually permanently connected).

CAT II Local-level mains (wall sockets). Equipment at this level includes

CAT I Secondary (signal level) or battery operated circuits of electronic

A measure of the contaminat es that could occur in the environment around and within a product.

Typically the internal environment inside a product is considered to be the same as the external.

Products should be used only in the environment for which they are rated.

Pollution Degree 2 Normally only dry, nonconductive pollution occurs. Occasionally a

control, and laboratory use.

Equipment at this level is typically in a fixed industrial location.

appliances, portable tools, and similar products. Equipment is

usually cord-connected.

equipment.

temporary conductivity that is caused by condensation must be

expected. This location is a typical office/home environment.

Temporary condensation occurs only when the product is out of

service.

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

1- 19

Page 36

System Specifications

1- 20

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

Page 37

80E00 Electrical Sampling Modules Specifications

This section contains specifications for the following electrical sampling

modules:

80E01 80E04 80E08

80E02 80E06 80E09

80E03 80E07 80E10

All specifications are guaranteed unless noted as “typical.” Typical specifications

are provided for your convenience but are not guaranteed. Specifications that are

marked with the n symbol are checked in the Performance Verification chapter.

All specifications apply to all electrical sampling models unless noted otherwise.

To meet specifications, these conditions must first be met:

H The instrument must have been calibrated/adjusted at an ambient tempera-

ture between +20 _C and +30 _C.

H The instrument must have been operating continuously for 20 minutes within

the operating temperature range specified.

H The instrument must be in an environment with temperature, altitude,

humidity, and vibration within the operating limits described in these

specifications

H A compensation must have been performed. Recompensation is required if a

module is moved to another compartment or a module extender is added or

removed.

NOTE. For Certifications, refer to the System Specifications section.

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

1- 21

Page 38

80E00 Electrical Sampling Modules Specifications

p

p

p

p

pgg

,

Verticalnondestructrang

e

y

g

g

Table 1- 14: Electrical sampling modules - Signal acquisition

Specifications Characteristics

Real time accessory interface Tekprobe--SMA interface is provided through the electrical sampling-module interface, one per

vertical channel.

Number of input channels Sampling module Channels

80E01, 80E06 1

80E02, 80E03, 80E04, 80E07, 80E08,

80E09, 80E10

Channel input connector Sampling module Input connector

80E02, 80E03, 80E04 3.5 mm female connector

80E01 2.4 mm female connector

80E06, 80E09, 80E10 1.85 mm (V) female connector

80E07, 80E08 2.92 mm (K) female SMA-compatible connector

n Input impedance Sampling module Impedance

80E01, 80E02, 80E03, 80E04, 80E06

80E07, 80E08, 80E09, 80E10

Vertical dynamic range

1Vpp(offset ±500 mV)

2

50 Ω ±0.5 Ω

50 Ω ±1 Ω

Vertical operating range1, maximum Sampling module Operating range

Vertical nondestruct range

(maximum input voltage)

80E01, 80E02, 80E03, 80E04, 80E06

80E07, 80E08, 80E09, 80E10

2

Sampling module Maximum input

80E01, 80E06, 80E07, 80E08, 80E09, 80E10

80E02, 80E03, 80E04

±1.6 V

±1.1 V

±2.0 V (DC+peak AC)

±3.0 V (DC+peak AC)

Vertical number of digitized bits 14 bi ts full scale

Vertical sensitivity range

3

The range of available full scale input settings.

Sampling module Sensitivi ty range

80E01, 80E02, 80E03, 80E04, 80E06 10 mV to 1 V full scale

80E07, 80E08, 80E09, 80E10 1 mV to 100 mV full scale

Offset range

Compensation temperature range

1

Sampling module Offset range

80E01, 80E02, 80E03, 80E04, 80E06

80E07, 80E08, 80E09, 80E10

±1.6 V

±1.1 V

±5_ C about temperature where compensation was performed.

If the module is moved to another compartment on the mainframe, a sampling module extender

is employed, or the length of the sampling module extender is changed, the channel(s) must be

recompensated.

1- 22

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

Page 39

80E00 Electrical Sampling Modules Specifications

g

g

g

,

,yp

,

Table 1- 14: Electrical sampling modules - Signal acquisition (cont.)

Specifications Characteristics

n DC voltage accuracy, single

point, within 5_C of compensated

temperature

n DC vertical voltage deviation from

linear least squares fit

n Analog bandwidth

Analog bandwidth

5

5

Analog bandwidth, reduced Sampling module Bandwidth

frequency set points, typical

Rise time4,typical Sampling module Bandwidth setting Rise time

±2 mV <system offset offset>

±0.007 * (assigned offset)

±0.02 * (vertical value -- assigned offset)

±10 mV

Sampling module Bandwidth

80E01

80E06

DC to 50 GHz, better than ±3dB

DC to 65 GHz, better than ±3dB

DC to 70 GHz, better than ±3 dB, typical

80E07, 80E08

80E09

80E10

DC to 30 GHz, better than ±3dB

DC to 60 GHz, better than ±3dB

DC to 50 GHz, better than ±3dB

Sampling module Bandwidth

80E02 12.5 GHz, typical

80E03 and 80E04 20 GHz, typical

80E07, 80E08 20 GHz

80E09, 80E10 30 GHz, 40 GHz

80E01 N/A ≤ 7ps

80E02 N/A ≤ 28 ps

80E03 and 80E04 N/A ≤ 17.5 ps

80E06 N/A ≤ 5.0 ps

80E07, 80E08 30 GHz 11.67 ps

20 GHz 17.5 ps

80E09 60 GHz 5.83 ps

40 GHz 8.75 ps

30 GHz 11.67 ps

80E10 50 GHz 7ps

40 GHz 8.75 ps

30 GHz 11.67 ps

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

1- 23

Page 40

80E00 Electrical Sampling Modules Specifications

,py

Table 1- 14: Electrical sampling modules - Signal acquisition (cont.)

Specifications Characteristics

n Random noise, displayed Sampling module Bandwidth set ting Noise

80E01 None ≤ 2.3 mV

1.8 mV

80E02 None ≤ 800 V

400 V

80E03 and 80E04 None ≤ 1.2 mV

600 V

80E06 None ≤ 2.4 mV

≤ 1.8 mV

80E07, 80E08 30 GHz < 410 V

< 300 V

20 GHz < 380 V

< 280 V

80E09 60 GHz < 600 V

< 450 V

40 GHz < 480 V

< 330 V

30 GHz < 410 V

< 300 V

80E10 50 GHz < 700 V

< 600 V

40 GHz < 480 V

< 330 V

30 GHz < 410 V

< 300 V

RMS

RMS

RMS

RMS

RMS

RMS

RMS

RMS

RMS

RMS

RMS

RMS

RMS

RMS

RMS

RMS

RMS

RMS

RMS

RMS

RMS

RMS

RMS

,typical

RMS

,typical

,typical

,typical

,typical

,typical

,typical

,typical

,typical

,typical

,typical

,typical

1- 24

CSA8000 & TDS8000 Series Instruments and Modules Technical Reference

Page 41

80E00 Electrical Sampling Modules Specifications

p

p

qyjg,yp

Table 1- 14: Electrical sampling modules - Signal acquisition (cont.)

Specifications Characteristics

Step response

aberrations7,typical

Sampling module Aberrations, step transition

80E02, 80E03, and 80E04

80E01

6

±3% or less over the zone 10 ns to 20 ps

before step transition

+10%, --5% or less for the f irst 300 ps following

step transition

±3% or less over the zone 300 ps to 5 ns

following step transition

±1% or less over the zone 5 ns to 100 ns

following step transition

±0.5% after 100 ns following step transition

±3% or less over the zone 10 ns to 20 ps

before step transition

+12%, --5% or less for the f irst 300 ps following

step transition

+5.5%, --3% or less over the zone 300 ps to

3 ns following step transition

±1% or less over the zone 3 ns to 100 ns

following step transition

±0.5% after 100 ns following step transition

80E06 + 5% or less for the first 300 ps following step

transition