Page 1

User Manual

CSA8000B Communications Signal Analyzer

TDS8000B Digital Sampling Oscilloscope

071-1099-03

This document applies to firmware version 2.0

and above.

www.tektronix.com

Page 2

Copyright © Tektronix, Inc. All rights reserved. Licensed software products are owned by Tektronix or its suppliers and

are protected by United States copyright laws and international treaty provisions.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (c)(1)(ii) of the

Rights in Technical Data and Computer Software clause at DFARS 252.227-7013, or subparagraphs (c)(1) and (2) of the

Commercial Computer Software -- Restricted Rights clause at FAR 52.227-19, as applicable.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Tektronix, Inc., P.O. Box 500, Beaverton, OR 97077

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

FrameScan is a registered trademark of Tektronix, Inc.

Page 3

WARRANTY

Tektronix warrants that the products that it manufactures and sells will be free from defects in materials and

workmanship for a period of one (1) year from the date of shipment. If this product proves defective during its

warranty period, Tektronix, at its option, will either repair the defective product without charge for parts and labor,

or provide a replacement in exchange for the defective product.

This warranty applies only to products returned to the designated Tektronix depot or the Tektronix authorized

representative from which the product was originally purchased. For products returned to other locations,

Customer will be assessed an applicable service charge. The preceding limitation shall not apply within the

European Economic Area, where products may be returned for warranty service to the nearest designated service

depot regardless of the place of purchase.

In order to obtain service under this warranty, Customer must provide the applicable office of Tektronix or its

authorized representative with notice of the defect before the expiration of t he warranty period and make suitable

arrangements for the performance of service. Customer shall be responsible for packaging and shipping the

defective product to the service center designated by Tektronix or its representative, with shipping charges

prepaid. Tektronix or its representative shall pay for the return of the product to Customer. Customer shall be

responsible for paying any associated taxes or duties.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty:

a) to repair damage resulting from attempts by personnel other than Tektronix representatives to install, repair or

service the product;

b) to repair damage resulting from improper use or connection to incompatible equipment;

c) to repair any damage or malfunction caused by the use of non-Tektronix supplies or consumables;

d) to repair a product that has been modified or integrated with other products when the effect of such

modification or integration increases the time or difficulty of servicing the product; or

e) to repair damage or malfunction resulting from failure to perform user maintenance and cleaning at the

frequency and as prescribed in the user manual (if applicable).

THE ABOVE WARRANTIES ARE GIVEN BY TEKTRONIX WITH RESPECT TO THIS PRODUCT IN LIEU OF

ANY OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’

RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE

REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS

VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE

POSSIBILITY OF SUCH DAMAGES.

Page 4

Page 5

Table of Contents

Getting Started

General Safety Summary ix...................................

Preface xi...................................................

About This Manual xi...............................................

Related Manuals and Online Documents xii..............................

Conventions xii....................................................

Contacting Tektronix xiii............................................

Product Description 1--1........................................

Models 1--1........................................................

Key Features 1-- 1....................................................

Product Software 1--3................................................

Firmware Upgrade 1--4...............................................

Sampling Modules Supported 1--4......................................

Check the Package Contents 1--7.................................

Installation 1--9...............................................

Check the Environmental Requirements 1--9..............................

Install the Sampling Modules 1--10.......................................

Connect the Peripherals 1--12...........................................

Power On the Instrument 1--13..........................................

Powering Off the Instrument 1--15.......................................

Brightness and Contrast Adjustment (Gamma) 1--15.........................

Back Up User Files 1--15...............................................

Software Installation 1--15..............................................

Description 1--16.................................................

Software Release Notes 1--16........................................

Operating System Reinstallation 1-- 16.................................

System Diagnostics 1--16...........................................

Windows Safe Mode 1--16..........................................

Incoming Inspection 1--17.......................................

Assemble Equipment 1--17.............................................

Perform the Diagnostics 1--18...........................................

Perform the Compensation 1--20.........................................

Perform the Functional Tests 1--21.......................................

Perform the Hardware and Operating System Tests (Windows 98 Only) 1--38.....

Accessories and Options 1--41....................................

Accessories 1--41.....................................................

Standard 1--41....................................................

Optional 1--42....................................................

Options 1--43........................................................

CSA8000B & TDS8000B User Manual

i

Page 6

Table of Contents

Operating Basics

Reference

Operational Maps 2--1.........................................

Documentation Map 2--2.......................................

System Overview Maps 2--4.....................................

Functional Model Map 2--4............................................

Process Overview Map 2-- 6............................................

User Interface Map -- Complete Control and Display 2--7............

Front Panel Map -- Quick Access to Most Often Used Features 2--8....

Display Map -- Single Graticule View 2--9.........................

Display Map -- Multiple Views 2--10...............................

Front Panel I/O Map 2--11.......................................

Rear Panel I/O Map 2--12.......................................

Overview 3--1.................................................

Acquiring Waveforms 3--3......................................

Signal Connection and Scaling 3--4.....................................

Why Use? 3-- 4..................................................

What’s Special? 3 --5..............................................

What’s Excluded? 3--5............................................

Keys to Using 3--5...............................................

To Set Up the Signal Input 3--8.....................................

To Autoset the Instrument 3--11......................................

To Reset the Instrument 3--13........................................

Signal Conditioning Background 3--13................................

Setting Acquisition Controls 3--21.......................................

Why Use? 3-- 21..................................................

What’s Special? 3-- 21..............................................

What’s Excluded? 3--22............................................

Keys to Using 3--22...............................................

To Set Acquisition Modes 3-- 24......................................

To Start and Stop Acquisition 3-- 26...................................

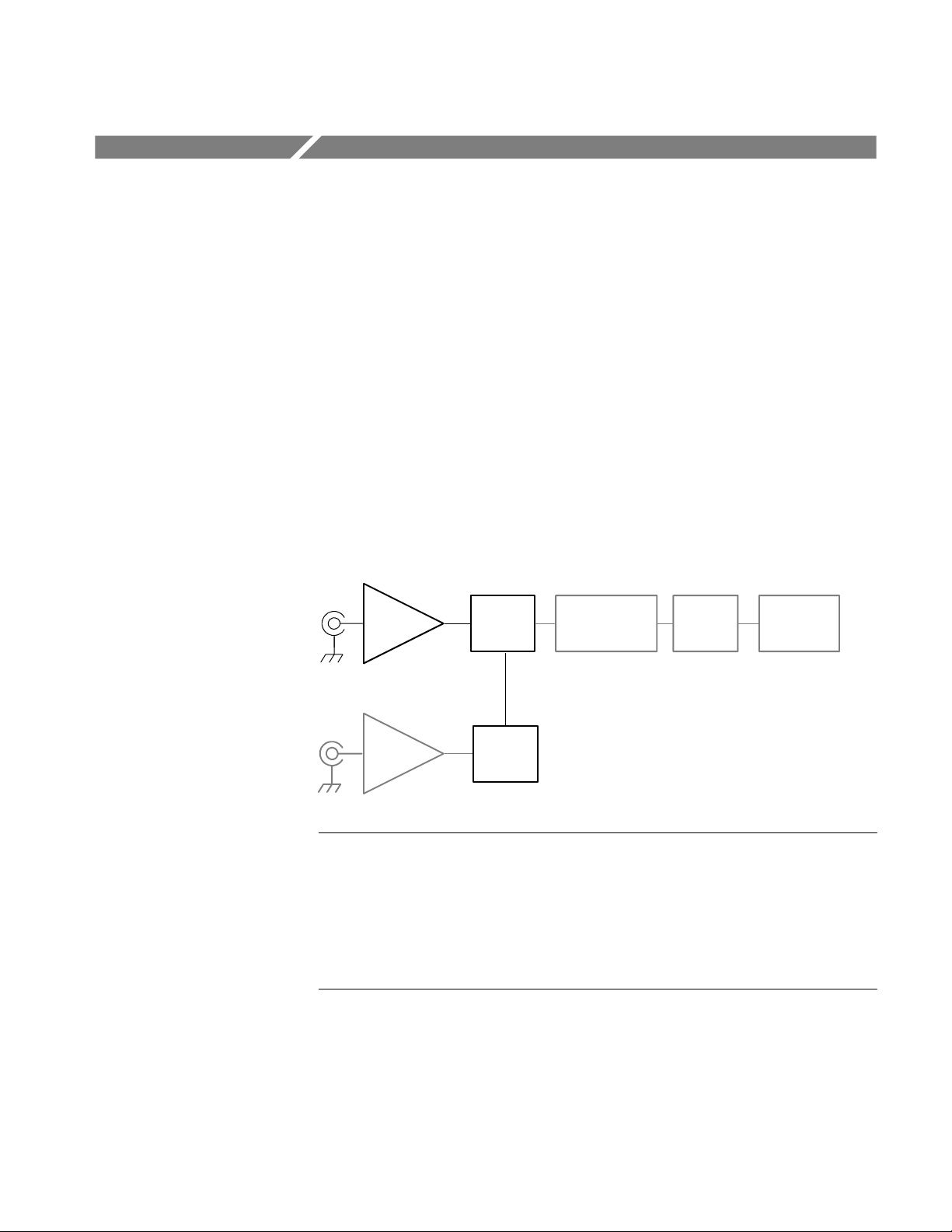

Acquisition Control Background 3--27....................................

Acquisition Hardware 3--27.........................................

Sampling Process 3--27.............................................

Sampling Modes 3--28.............................................

Waveform Record 3--28............................................

Acquisition Cycle 3 --29............................................

FrameScan Acquisitions 3-- 30...........................................

Why Use? 3-- 30..................................................

What’s Special? 3-- 30..............................................

What’s Excluded? 3--31............................................

Keys to Using 3--31...............................................

To Acquire in FrameScan Mode 3--33.................................

To Catch a Bit Error 3--36..........................................

ii

CSA8000B & TDS8000B User Manual

Page 7

Table of Contents

Triggering 3--39................................................

Edge Triggering 3--39.................................................

Why Use? 3-- 39..................................................

What’s Special? 3--39..............................................

Keys to Using 3--40...............................................

To Trigger 3--48..................................................

To Use Gated Trigger 3--50.........................................

Displaying Waveforms 3--53......................................

Using the Waveform Display 3--53.......................................

Why Use? 3-- 55..................................................

What’s Special? 3--55..............................................

What’s Excluded? 3--55............................................

Keys to Using 3--56...............................................

To Display Waveforms in the Main Time Base View 3-- 62................

To Display Waveforms in a Mag View 3-- 64............................

Customizing the Display 3--66..........................................

Why Use? 3-- 66..................................................

What’s Special? 3--66..............................................

Keys to Using 3--66...............................................

To Set Display Styles 3--68.........................................

To Customize the Graticule and Waveforms 3--69.......................

Measuring Waveforms 3--73.....................................

Taking Automatic Measurements 3-- 74....................................

Why Use? 3-- 74..................................................

What’s Measured? 3--74............................................

What’s Special? 3--74..............................................

What’s Excluded? 3--76............................................

Keys to Using 3--76...............................................

To Take Automatic Measurements 3-- 80...............................

To Localize a Measurement 3-- 83....................................

Taking Cursor Measurements 3--85.......................................

Why Use? 3-- 85..................................................

What’s Measured? 3--85............................................

What Sources Can I Measure? 3-- 86..................................

Keys to Using Cursors 3--86.........................................

To Take a Cursor Measurement 3--89.................................

To Set the Cursor Sources 3--90......................................

Optimizing Measurement Accuracy 3--92..................................

Why Use? 3-- 92..................................................

Compensation 3-- 92...............................................

To Compensate the Instrument and Modules 3--92.......................

To Perform Dark-Level and User Wavelength Gain Compensations 3--98.....

Creating Math Waveforms 3--101..................................

Defining Math Waveforms 3--101.........................................

Why Use? 3--102..................................................

What’s Special? 3--102..............................................

What’s Excluded? 3--102............................................

Keys to Using 3--103...............................................

To Define a Math Waveform 3--105....................................

CSA8000B & TDS8000B User Manual

iii

Page 8

Table of Contents

Operations on Math Waveforms 3--107.....................................

Why Use? 3--107..................................................

What’s Excluded? 3--107............................................

Keys to Using 3--108...............................................

To Use Math Waveforms 3--109.......................................

Data Input and Output 3--113.....................................

Saving and Recalling Setups 3-- 113.......................................

Why Use? 3--113..................................................

What’s Special? 3--114..............................................

What’s Excluded? 3--114............................................

Keys to Using 3--114...............................................

To Save Your Setup 3--115...........................................

To Recall Your Setup 3-- 118..........................................

Saving and Recalling Waveforms 3--120...................................

Why Use? 3--120..................................................

What’s Special? 3--120..............................................

What’s Excluded? 3--120............................................

To Save Your Waveform 3--121.......................................

To Recall Your Waveform 3--124......................................

To Clear References 3--127..........................................

Exporting Waveforms and Histograms 3--128...............................

Why Use? 3--128..................................................

Keys to Using 3--128...............................................

To Export Your Waveform 3--128.....................................

To Export Your Histogram 3--129.....................................

To Use an Exported Waveform (or Histogram) 3--129.....................

Printing Waveforms 3--132..............................................

Remote Communication 3-- 139...........................................

Using Masks, Histograms, and Waveform Databases 3--141............

Mask Testing Waveforms 3--141..........................................

Why Use? 3--141..................................................

What’s Special? 3--141..............................................

What’s Excluded? 3--142............................................

Keys to Using 3--142...............................................

To Mask Test a Waveform 3--145......................................

To Edit a Mask 3--149..............................................

Counting Masks 3--151..............................................

To Create a New Mask 3--152........................................

Taking Histograms 3--154...............................................

Why Use? 3--154..................................................

What’s Special? 3--154..............................................

What’s Excluded? 3--155............................................

Keys to Using Histograms 3--155......................................

To Take a Histogram 3--156..........................................

Histogram Statistics 3--158...........................................

iv

CSA8000B & TDS8000B User Manual

Page 9

Appendices

Table of Contents

Using Waveform Databases 3--159........................................

Why Use? 3--159..................................................

What’s Special? 3--159..............................................

What’s Excluded? 3--159............................................

Keys to Using 3--160...............................................

To Set Up a Waveform Database 3--162................................

To Customize the Database Display 3--164..............................

Accessing Online Help 3--167......................................

What’s Available? 3--167...............................................

Why Use? 3--167..................................................

Keys to Using 3--167...............................................

How to Use Online Help 3--168..........................................

Cleaning the Instrument 3-- 175....................................

Exterior Cleaning 3--175................................................

Flat Panel Display Cleaning 3--176........................................

Optical Connector Cleaning 3--176........................................

Appendix A: Specifications A--1..................................

Certifications A--11...................................................

Appendix B: Automatic Measurements Reference B--1..............

Pulse Measurements -- Amplitude B--2...................................

Pulse Measurements -- Timing B--8......................................

Pulse Measurement -- Area B-- 14.........................................

Return-to-Zero (RZ) Measurements -- Amplitude B--15.......................

Return-to-Zero (RZ) Measurements -- Timing B-- 29..........................

Return-to-Zero (RZ) Measurements -- Area B--36............................

Non-Return-to-Zero (NRZ) Measurements -- Amplitude B--37.................

Non-Return-to-Zero (NRZ) Measurements -- Timing B-- 50....................

Non-Return-to-Zero (NRZ) Measurements -- Area B-- 55......................

Measurement Reference Parameters and Methods B--56..............

All Sources B--56.....................................................

Pulse Sources B--57...................................................

RZ Sources B--60.....................................................

NRZ Sources B--62....................................................

Tracking Methods B--68................................................

Mid-reference Level B--69.............................................

To Optimize the Vertical Resolution B--69.................................

Use a Waveform Database B--70.........................................

Glossary

Index

CSA8000B & TDS8000B User Manual

v

Page 10

Table of Contents

List of Figures

Figure 1--1: Compartments for sampling modules 1--11...............

Figure 1 --2: Maximum inputs in three configurations 1--11............

Figure 1--3: Locations of peripheral connectors on rear panel 1--12.....

Figure 1--4: Line fuse and power cord connector locations,

rear panel 1--13.............................................

Figure 1 --5: On/Standby switch location 1--14.......................

Figure 1--6: Compensation dialog box 1--20.........................

Figure 1--7: Hookup for electrical functional tests 1--23...............

Figure 1--8: Channel button location 1--23..........................

Figure 1--9: Channel button location 1--26..........................

Figure 1--10: Optical channel verification 1--27......................

Figure 1--11: Hookup for the time base tests 1--28....................

Figure 1--12: Channel button location 1--29.........................

Figure 1--13: Main time base verification 1--30......................

Figure 1--14: Mag time base verification 1--31.......................

Figure 1--15: Channel button location 1--32.........................

Figure 1--16: Hookup for the gated trigger tests 1--33.................

Figure 1--17: Signal triggered 1--34................................

Figure 1--18: Signal not triggered (signal frozen) 1--35................

Figure 1--19: Signal not triggered (no signal) 1--36...................

Figure 1--20: Signal triggered 1--37................................

Figure 3--1: Acquisition and display controls 3--4...................

Figure 3 --2: Setting vertical scale and position of input channels 3--15...

Figure 3--3: Varying offset positions vertical acquisition

window on waveform amplitude 3--17..........................

Figure 3--4: Horizontal acquisition window definition 3--18...........

Figure 3--5: Common trigger, record length, and acquisition

rate for all channels 3--20.....................................

Figure 3-- 6: Aliasing 3-- 23........................................

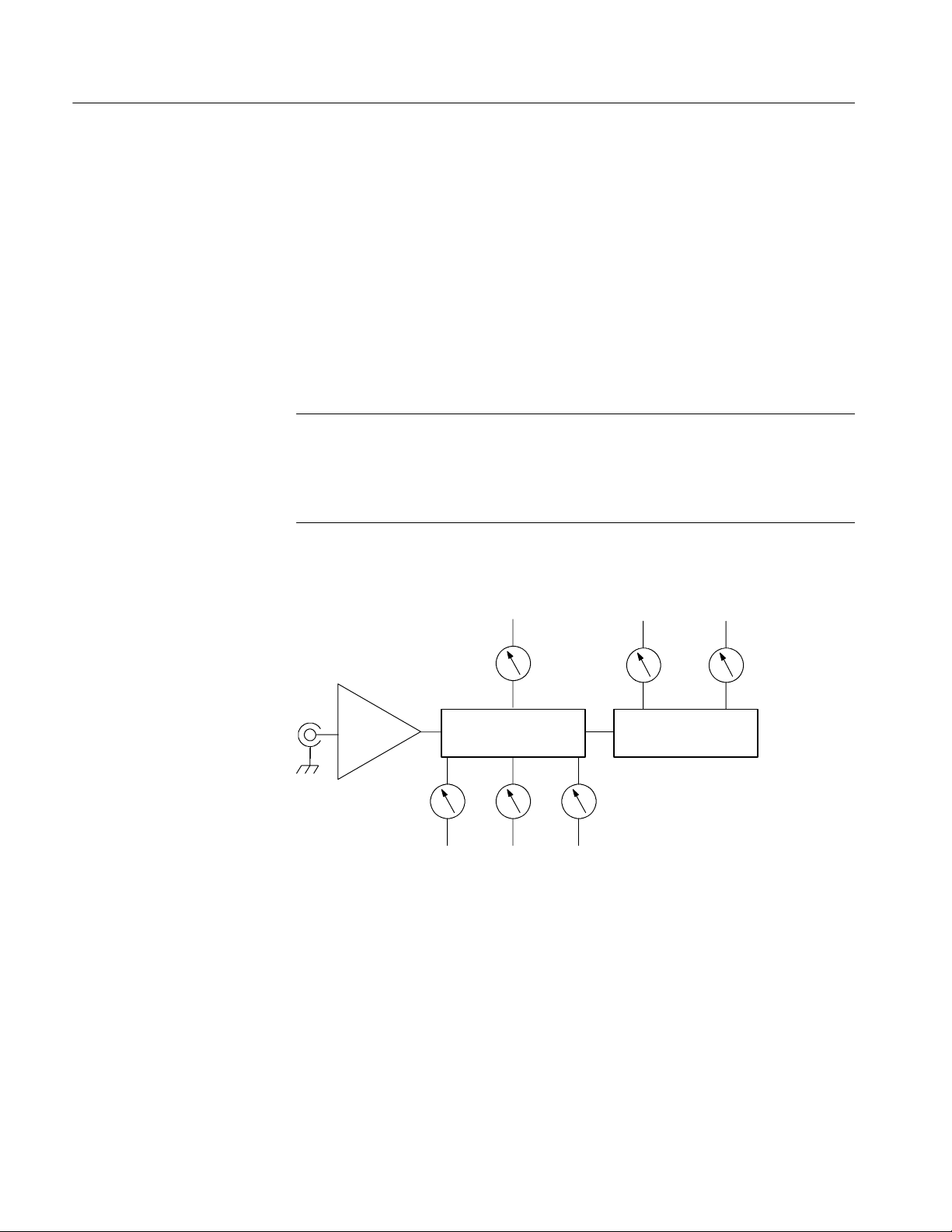

Figure 3--7: Channel configuration 3--27...........................

Figure 3--8: Digital acquisition — sampling and digitizing 3--28........

Figure 3--9: The waveform record and its defining parameters 3--29....

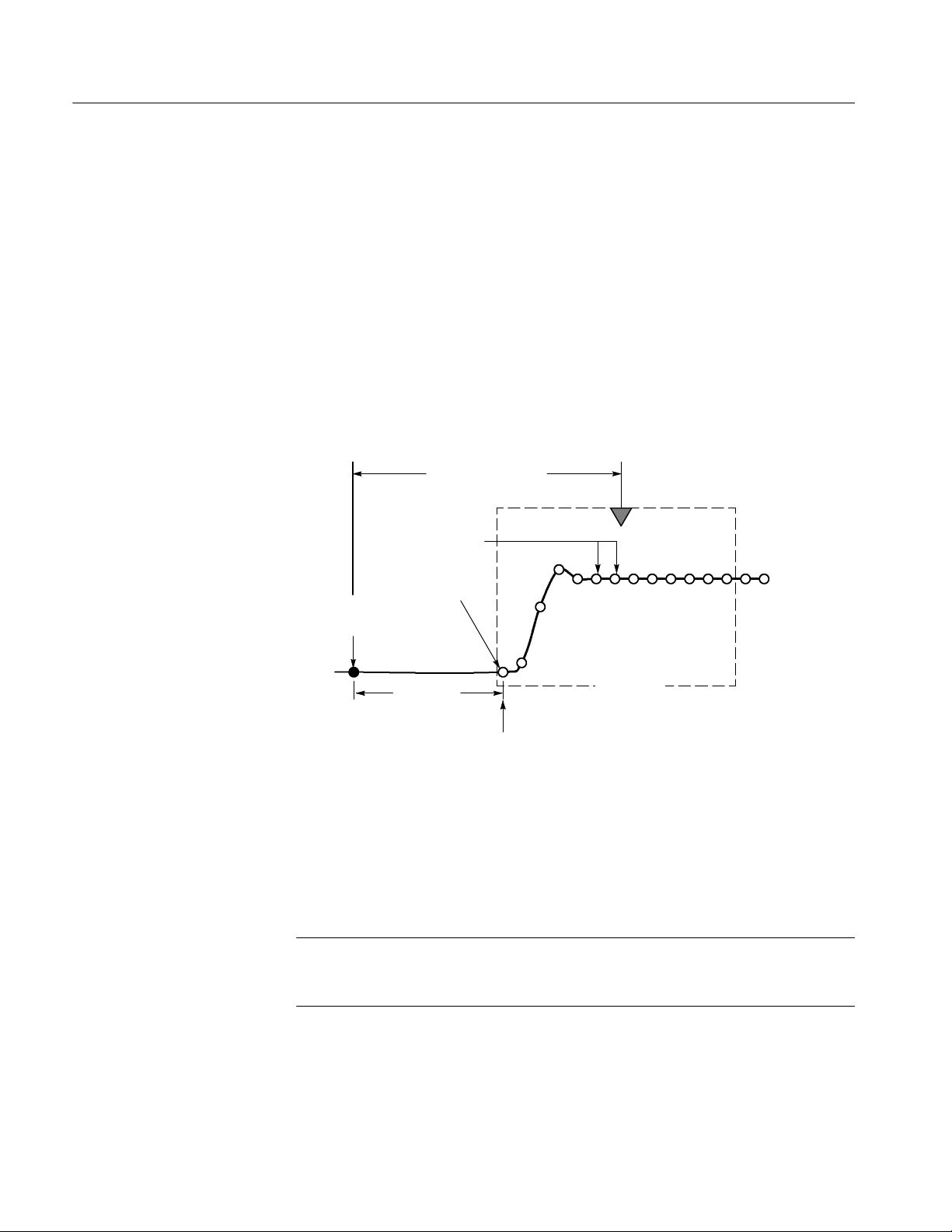

Figure 3--10: How FrameScan acquisition works (scanning on

a 127-bit PRBS shown) 3--32..................................

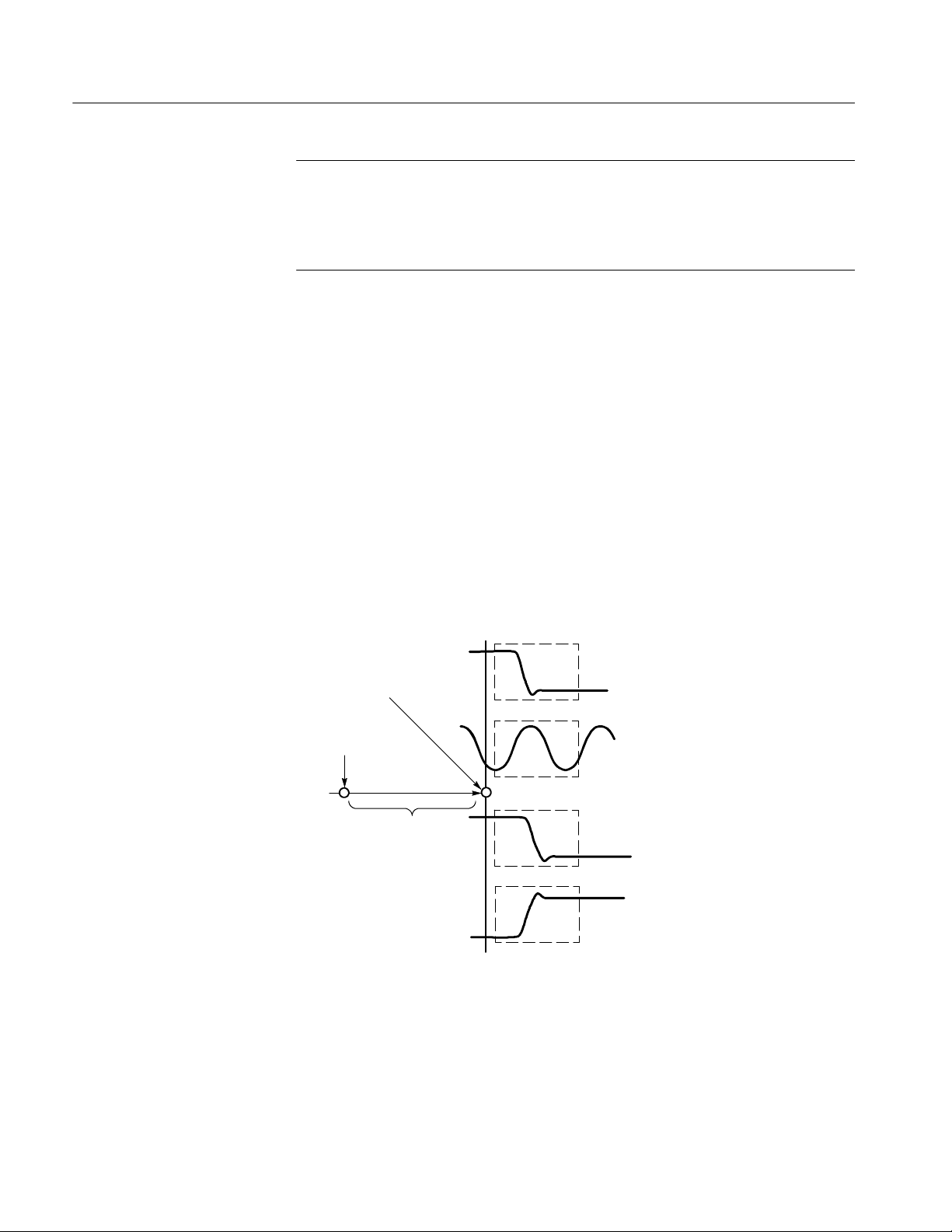

Figure 3--11: Slope and level define the trigger event 3--41.............

vi

CSA8000B & TDS8000B User Manual

Page 11

Table of Contents

Figure 3--12: Triggered versus untriggered displays 3--41.............

Figure 3 --13: Trigger inputs 3--42.................................

Figure 3--14: Holdoff adjustment can prevent false triggers 3--46.......

Figure 3--15: Trigger to End Of Record Time (EORT) 3--47...........

Figure 3--16: Display elements 3--54...............................

Figure 3--17: Horizontal position includes time to Horizontal

Reference 3--59.............................................

Figure 3--18: Graticule, cursor and automatic measurements 3--73.....

Figure 3--19: Measurement annotations on a waveform 3--75..........

Figure 3--20: High/Low tracking methods 3--78......................

Figure 3--21: Reference-level calculation methods 3--79...............

Figure 3--22: Horizontal cursors measure amplitudes 3--86............

Figure 3 --23: Components determining Time cursor readout

values 3--88................................................

Figure 3--24: Functional transformation of an acquired

waveform 3--101.............................................

Figure 3--25: Export dialog box 3--129..............................

Figure 3--26: Creating a user mask 3--144...........................

Figure 3--27: Adding a new vertex 3--144............................

Figure 3--28: Vertical histogram view and statistics on data 3--154.......

Figure 3--29: Normal vector view of a waveform 3--163................

Figure 3--30: Waveform database view of a waveform 3--163............

Figure B--1: Reference-level calculation methods B--56................

Figure B--2: Pulse-reference levels B--57............................

Figure B--3: Pulse crossings and mid-reference level B--58.............

Figure B--4: AOP pulse crossings and mid-reference level B--59........

Figure B--5: Overshoot levels B--59................................

Figure B --6: RZ measurement reference levels B-- 60..................

Figure B --7: RZ crossings B-- 61...................................

Figure B--8: RZ eye--aperture parameters B--62......................

Figure B--9: NRZ measurement reference levels B--63.................

Figure B--10: NRZ crossings B--64.................................

Figure B--1 1: NRZ eye-aperture parameters B--65....................

Figure B--12: NRZ overshoot levels B--66...........................

Figure B--13: NRZ Crossings (OMA) B--67..........................

CSA8000B & TDS8000B User Manual

vii

Page 12

Table of Contents

List of Tables

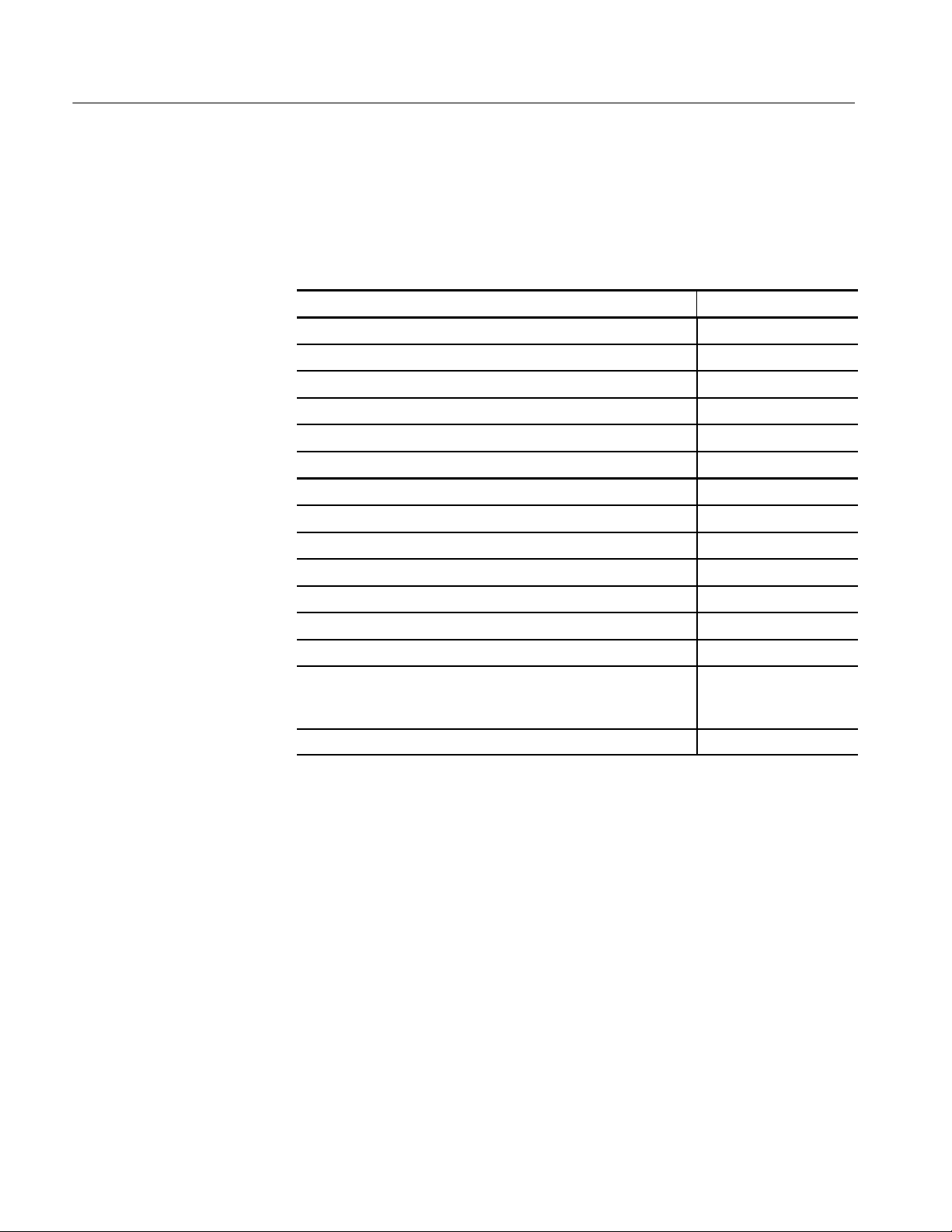

Table 1--1: Additional accessory connection information 1--13.........

Table 1-- 2: Line fuses 1--13......................................

T able 1--3: Standard accessories 1--41.............................

Table 1--4: Optional accessories 1--42..............................

Table 3-- 1: Application-based triggering 3--43......................

Table 3--2: Defining and displaying waveforms 3--56.................

T able 3--3: Operations performed based on the selected

waveform 3--57............................................

Table 3--4: Equivalent mouse and touchscreen operations 3--61........

Table 3--5: Customizable display attributes 3--66....................

Table 3-- 6: Cursor functions (types) 3--85..........................

Table 3-- 7: Cursor units 3-- 88....................................

Table 3--8: Math expressions and the math waveforms produced 3--103..

Table 3-- 9: Standard masks 3--142.................................

Table 3--10: Histogram statistics 3--158.............................

Table A--1: System -- Signal acquisition A--1.......................

Table A-- 2: System -- Timebase A--2..............................

T a b l e A -- 3 : S y s t e m -- T r i g g e r A -- 3................................

Table A-- 4: System -- Environmental A--6..........................

Table A--5: Power consumption and cooling A--7...................

T a b l e A -- 6 : D i s p l a y A -- 7........................................

T a b l e A -- 7 : P o r t s A -- 8..........................................

Table A--8: Data storage A--9....................................

T able A--9: Mechanical A--10.....................................

Table A--10: Certifications and compliances A--11...................

Table B--1: Pulse Measurements — Amplitude B--2.................

Table B--2: Pulse Measurements -- Timing B--8.....................

Table B--3: Pulse Measurements -- Area B--14.......................

Table B--4: RZ Measurements -- Amplitude B-- 15....................

Table B--5: RZ Measurements -- Timing B--29.......................

Table B--6: RZ Measurements -- Area B--36.........................

Table B--7: NRZ Measurements -- Amplitude B--37..................

Table B--8: NRZ Measurements -- Timing B-- 50.....................

Table B--9: NRZ Measurements -- Area B--55.......................

viii

CSA8000B & TDS8000B User Manual

Page 13

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

ToAvoidFireor

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Connect and Disconnect Properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Wear Eye Protection. Wear eye protection if exposure to high-intensity rays or

laser radiation exists.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

CSA8000B & TDS8000B User Manual

ix

Page 14

General Safety Summary

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

CAUTION

Refer to Manual

Mains Disconnected

OFF (Power)

WARNING

High Voltage

Mains Connected

ON (Power)

Protective Ground

(Earth) Terminal

Standby

x

CSA8000B & TDS8000B User Manual

Page 15

Preface

About This Manual

This is the user manual for the CSA8000B Communications Signal Analyzer and

TDS8000B Digital Sampling Oscilloscope. It covers the following information:

H Describes the capabilities of the instrument: how to install it and reinstall its

software

H Explains how to operate the instrument: how to control acquisition of,

processing of, and input/output of information

H Lists the specifications and accessories of the instrument

This manual is composed of the following chapters:

H Getting Started shows you how to configure and install your instrument and

provides an incoming inspection procedure.

H Operating Basics uses maps to describe the various interfaces for controlling

the instrument, including the front panel and the software user interface.

These maps provide overviews of the product and its functions from several

viewpoints.

H Reference comprises an encyclopedia of topics (see Overview on page 3--1)

that describe the instrument interface and features, and that give background

and basic information on how to use them. (The online help onboard the

instrument application describes the interface, features, and their usage in

more detail; detailed descriptions of all programming commands are found

in the online CSA8000 & TDS8000 Programmer Guide manual.)

H Appendices provides additional information including the specifications and

automatic measurement definitions.

CSA8000B & TDS8000B User Manual

xi

Page 16

Preface

Related Manuals and Online Documents

This manual is part of a document set of standard-accessory manuals and online

documentation; this manual mainly focuses on installation and background

needed to use the product features. See the following list for other documents

supporting instrument operation and service. (Manual part numbers are listed in

Table 1--3 on page 1--41.)

Manual name Description

CSA8000 & TDS8000 Online Help An online help system, integrated with the User Interface application that ships with this

product.

CSA8000B & TDS8000B References A quick reference to major features of the instrument and how they operate.

CSA8000 & TDS8000 Programmer Guide Part of the online help system this guide comprises an alphabetical listing of the

programming commands and other information related to controlling the instrument over

the GPIB. This is an online document.

Electrical Sampling Modules User Manual The user manual for the electrical sampling modules. Included as a PDF file on the

product software CD or the PDF file can be downloaded from the Tektronix website.

80C00 Series Optical Sampling Modules

User Manual

80A01 Trigger Prescale Limiting Preamplifier Module User Manual

80A02 EOS/ESD Protection Module

Instructions

CSA8000 & TDS8000 Service Manual Describes how to service the instrument to the module level. This optional manual must

The user manual for the optical sampling modules. Included as a PDF file on the product

software CD or the PDF file can be downloaded from the Tektronix website.

The user manual for the 80A01 Trigger Prescale Limiting Preamplifier Module. Included

as a standard accessory if you ordered this module with this instrum ent. Shipped in the

module package, not the main instrument package.

The instructions for the 80A02 EOS/ESD Protection Module. Included as a standard

accessory if you ordered this module with this instrument. Shipped i n the module

package, not the main instrument package.

be ordered separately.

Conventions

xii

For more information on how the product documentation relates to the

instrument operating interfaces and features, see Documentation Map on

page 2--2.

This manual uses the terms vertical acquisition window and horizontal acquisi-

tion window throughout this section and elsewhere. These terms refer to the

vertical and horizontal range of the acquisition window, which defines the

segment of the input signal that the acquisition system acquires.

The terms do not refer to any operating system windows that you might display

on screen.

CSA8000B & TDS8000B User Manual

Page 17

Contacting Tektronix

Preface

Phone 1-800-833-9200*

Address Tektronix, Inc.

Department or name (if known)

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

Web site www.tektronix.com

Sales support 1-800-833-9200, select option 1*

Service support 1-800-833-9200, select option 2*

Technical support Email: techsupport@tektronix.com

1-800-833-9200, select option 3*

6:00 a.m. -- 5:00 p.m. Pacific time

* This phone number is toll free in North America. After office hours, please leave a

voice mail message.

Outside North America, contact a Tektronix sales office or distributor; see the

Tektronix web site for a list of offices.

CSA8000B & TDS8000B User Manual

xiii

Page 18

Preface

xiv

CSA8000B & TDS8000B User Manual

Page 19

Product Description

This chapter describes your instrument, which is either the CSA8000B Communications Signal Analyzer or the TDS8000B Digital Sampling Oscilloscope, and

its options. Following this description are four sections:

H Check the Package Contents, on page 1--7, shows you how to verify that you

have received all of the parts of your instrument.

H Installation, on page 1--9, shows you how to configure and install the

instrument, as well as how to reinstall the system software included with the

product.

H Incoming Inspection, on page 1--17, provides a procedure for verifying basic

operation and functionality.

H Accessories and Options, on page 1--41, lists the instrument options

available and the standard and optional accessories for this product.

Models

This manual supports two very similar instruments:

Key Features

H The CSA8000B Communications Signal Analyzer.

H The TDS8000B Digital Sampling Oscilloscope.

Differences between the two instruments will be called out when necessary;

otherwise, the material applies to both instruments. The word “instrument” refers

to either product.

The instrument is a high-speed, precision sampling system that finds use in

validation and conformance testing and impedance verification for:

H high-performance semiconductor/computer applications, such as semicon-

ductor testing, TDR characterization of circuit boards, IC packages and

cables, and high-speed serial digital data communications.

H high-performance communications applications, such as design evaluation

and manufacturing test of datacom and telecom components, transceiver

subassemblies, and transmission systems.

The instrument includes a user interface that runs on the Microsoft Windows

operating system as a windowed application. You operate the instrument using

CSA8000B & TDS8000B User Manual

1- 1

Page 20

Product Description

front-panel controls with the mouse and keyboard or with the touch screen. The

installed Windows operating system (MS Windows 98 or MS Windows 2000) is

dependent on the purchase date or product upgrade status.

Key features include:

H industry-leading waveform acquisition and measurement rate, with Sample,

Envelope, and Average acquisition modes.

H support for up to six sampling modules (two large and four small modules)

for a maximum configuration of ten inputs. (Up to eight inputs can be active

at a time. See Maximum Configuration on page 1--11).

H supports integrated optical signal pick-off and clock recovery enabling

accurate triggering on optical communication-signals.

H support for optical modules with several integrated, selectable reference

receivers, which eliminates the need for a multitude of add-on reference

receivers.

H full programmability, with an extensive GPIB-command set and a message-

based interface.

H true differential TDR, with fast step (35 psec reflected risetime) when used

with a TDR-capable sampling module.

H industry-leading trigger bandwidth (12+ GHz) when using the built-in-

prescaler.

H support of both telecom (SONET and SDH) and datacom (Fibre Channel,

Infiniband, and Gigabit Ethernet) optical communication standards.

H powerful built-in measurement capability, including histograms, mask

testing, and automatic measurements.

H automatic measurements operate on Pulses, RZ eye patterns, and NRZ eye

patterns.

H DC to 65 GHz optical bandwidth; DC to 65 GHz electrical bandwidth, with

up to 12.5 GHz triggering.

NOTE. Bandwidth is determined by the specific modules that are installed.

H FrameScan acquisition for isolating data-dependent failures during confor-

mance/performance testing and for examining very low-level repetitive

signals.

1- 2

H support for optical conformance testing of SONET/SDH signals (including

the various forward error correction rates for these telecom rates) from

155 Mbps to 43 Gb/s, 1 and 10 Gb/s FibreChannel signals, 10. 52 Gb/s

CSA8000B & TDS8000B User Manual

Page 21

Product Description

FibreChannel signals, and 1, 2, and 10 Gigabit FibreChannel signals as well

as 2.5 Gb/s Infiniband signals.

NOTE. Support for conformance testing rates is determined by the specific

modules that are installed.

H high precision time base with two modes of operation, locked and short-term

jitter-optimized

H negligible long-term jitter degradation (<0.1 ppm), which substantially

improves the ability to view signals that are delayed far from the trigger

point without distortion.

H improved short-term and long-term trigger jitter.

H a gated trigger option (Option GT) that lets you disable or enable (gate)

triggering based on a TTL signal you connect to the instrument rear panel.

H the GT feature also allows you to use recirculating buffers as part of your test

setup to simulate the effects of very long optical links that are typical of

undersea cables and other long terrestrial links.

Product Software

H analysis and connectivity tools enable the instrument to be controlled from a

variety of local and remote environments and to share data with other

commercially available analysis programs.

H pre-defined, built-in masks in addition to the user-defined masks.

H a large 10-inch color display that supports color grading of waveform data to

show sample density.

H an intuitive UI (User Interface), with built-in online help displayable on

screen.

The instrument includes the following software:

H MS Windows comes preinstalled on the instrument. MS Windows is the

operating system on which the user-interface application of this instrument

runs. The OS Rebuild CDs include the software needed to rebuild the

instrument operating system if that becomes necessary.

H The User Interface (UI) Application (product software) comes preinstalled on

the instrument. This UI application complements the hardware controls of

the front panel, allowing complete set up of all instrument features. The

Product Software CD includes the UI Application for use if reinstalling the

CSA8000B & TDS8000B User Manual

1- 3

Page 22

Product Description

product software becomes necessary. See Software Installation on

page 1--15.

New versions of the software may become available at our web site. See

Contacting Tektronix on page xiii in Preface.

Firmware Upgrade

Tektronix may offer firmware upgrade kits for the instrument. Contact your

Tektronix service representative for more information (see Contacting Tektronix

on page xiii).

Sampling Modules Supported

This product can use the following optical and electrical sampling modules listed

below. These modules, which plug into the instrument, are more fully described

in their respective user manuals. These manuals were shipped with those

sampling modules that were ordered with this product.

The sampling modules listed here were available at the time this manual was

published; see your Tektronix product catalog for current offerings.

Optical Sampling Modules.

H 80C01 -- 622/2488/9953 Mb/s, 12.5/20 GHz optical module.

Clock Recovery (622/2488 Mb/s) added with option CR.

H 80C02 -- 9.953 Gb/s, 20/30 GHz optical module.

Clock Recovery (9.953 Gb/s) added with option CR.

H 80C03 -- 1.063/1.250/2.488/2.500 Gb/s amplified optical module.

Clock Recovery for all rates added with option CR.

This module has been superseded by the 80C07B.

H 80C04 -- 9.953/10.3125 Gb/s, 20/30 GHz optical module.

Clock Recovery (9.953 Gb/s) added with option CR1.

Clock Recovery (9.953 Gb/s and 10.66 Gb/s) added with option CR2.

This module has been superseded by the 80C11.

H 80C05 -- 9.953 Gb/s, 20/30/40 GHz optical module for 10/40 Gb/s NRZ.

This module has been superseded by the 80C10.

1- 4

H 80C06 -- 55 GHz optical module for 40 Gb/s RZ and NRZ telecom.

This module has been superseded by the 80C10.

CSA8000B & TDS8000B User Manual

Page 23

Product Description

H 80C07 -- 155/622/2488 Mb/s amplified optical module.

Clock Recovery for all rates added with option CR1.

This module has been superseded by the 80C07B.

H 80C07B -- 155/622/1063/1250/2125/2488/2500 Mb/s amplified optical

module. (The module is limited to five receivers configured at the time of

order.)

Clock Recovery for all rates (plus 2666 Mb/s) added with option CR1.

H 80C08 -- 9.953/10.31 Gb/s Multi-rate amplified optical module.

Clock Recovery (9.953 and 10.3125 Gb/s) added with option CR1.

This module has been superseded by the 80C08C.

H 80C08B -- 9.953/10.31/10.52 Gb/s Multi-rate amplified optical module.

Clock Recovery (9.953 and 10.3125 Gb/s) added with option CR1.

FibreChannel Clock Recovery (10.3125 and 10.51875 Gb/s) added with

option CR2.

This module has been superseded by the 80C08C.

H 80C08C -- 9.953/10.31/10.52/11.10 Gb/s Multi-rate amplified optical

module.

Clock Recovery (9.953 and 10.3125 Gb/s) added with option CR1. Clock

Recovery (10.3125 and 10.51875 Gb/s) added with option CR2.

Continuous-rate clock recovery added with CR4.

H 80C09 -- 9.953/10.71 Gb/s Multi-rate optical module.

Clock Recovery (9.953 and 10.709 Gb/s) added with option CR1.

This module has been superseded by the 80C11.

H 80C10 -- 65 GHz optical module for 40 Gb/s RZ and NRZ telecom.

H 80C11 -- 9.953/10.31/10.52/10.66/10.71//11.10 Gb/s Multi-rate amplified

optical module.

Clock Recovery (9.953 Gb/s) added with option CR1.

Clock Recovery (9.953 and 10.66 Gb/s) added with option CR2.

Clock Recovery (9.953 and 10.71 Gb/s) added with option CR3.

Continuous-rate clock recovery added with CR4.

Electrical Sampling Modules.

H 80E01 -- A single-channel, 50 GHz sampling module

H 80E02 -- A dual-channel, 12.5 GHz, 50 Ω, sampling module with low noise

H 80E03 -- A dual-channel, 20 GHz sampling module. This model provides the

same features as 80E04, but without the TDR step generators.

CSA8000B & TDS8000B User Manual

1- 5

Page 24

Product Description

H 80E04 -- A dual-channel, 20 GHz TDR sampling module. The TDR step

generator provides 35 ps reflected step risetime. Voltage polarity can be

reversed on either step to provide true differential TDR.

H 80E06 -- A single-channel, 70+ GHz sampling module. This model provides

very high performance bandwidth for general-purpose characterization of

high speed devices and circuits.

Other Modules.

H 80A01 Trigger Prescale Limiting Preamplifier Module -- A single-channel

module providing 8-14 GHz AC coupled 50 Ω limiting preamplification. It

increases the sensitivity of the prescale trigger input of the 8000 Series

instruments to ≤200 mV

pk-pk

.

H 80A02 EOS/ESD Protection Module -- A module that protects the sensitive

input stage of instruments (such as the sampling bridge of Tektronix

electrical TDR sampling modules) from damage due to electro-overstress

(EOS) and electro static discharge (ESD) from the device under test (DUT).

1- 6

CSA8000B & TDS8000B User Manual

Page 25

Check the Package Contents

Verify that you have received all of the parts of your instrument. You should

verify that you have:

H the main instrument.

H all the standard accessories for the main instrument. Standard accessories are

listed in Table 1--3 on page 1--41.

H the correct power cords for your geographical area.

H the OS Rebuild CDs and Product Software CD that include an installation

copy of the software installed on the instrument and all files needed to

rebuild your instrument operating system if necessary. Store the CDs in a

safe location where you can easily retrieve them for maintenance purposes.

NOTE. Keep the certificate of authenticity that accompanies the product-software

CD.

H the 8000 Series Demo Applications Software CD that includes an installa-

tion copy of the software. This CD, which is a separate CD from the

Oscilloscope software, includes the TDR Impedance Measuring application,

which implements the TDR calibration procedures specified by the

IPC-TM-650 test methodology, and the Fast NRZ application, which allows

you to improve throughput for when eye-pattern mask testing.

NOTE. New versions of the product and/or demo application software may

become available at our web sit. See Contacting Tektronix on page xiii.

Remember to fill out and send in the customer registration card. The registration

card is packaged in an envelope in the shipping package.

CSA8000B & TDS8000B User Manual

1- 7

Page 26

Check the Package Contents

1- 8

CSA8000B & TDS8000B User Manual

Page 27

Installation

This section covers installation of the instrument, addressing the following

topics:

H Check the Environment Requirements on page 1--9

H Install the Sampling Modules on page 1--10

H Connect the Peripherals on page 1--12

H Power On the Instrument on page 1--13

H Powering Off the Instrument on page 1--15

H Brightness and Contrast Adjustment (Gamma) on page 1--15

H Back Up User Files on page 1--15

The basic operating software is already installed on the hard disk. If reinstallation of software becomes necessary, see the following topic:

H Software Installation on page 1--15

Check the Environmental Requirements

Read this section before attempting any installation procedures. This section

describes site considerations, power requirements, and ground connections for

your instrument.

Site Considerations

The instrument is designed to operate on a bench or on a cart in the normal

position (on the bottom feet). For proper cooling, at least two inches (5.1 cm) of

clearance is recommended on the rear and sides of the instrument.

You can also operate the instrument while it rests upright on its rear feet. If you

operate the instrument while it is resting on the rear feet, make sure that you

properly route any cables coming out of the rear of the instrument to avoid

damaging them.

CAUTION. Keep the bottom of the instrument clear of obstructions to ensure

proper cooling.

CSA8000B & TDS8000B User Manual

1- 9

Page 28

Installation

Operating Requirements

Rackmount Requirements

Specifications in Appendix A list the operating requirements for the instrument.

Power source and temperature, humidity, and altitude are listed.

If this instrument is rackmounted, see the TDS8000 & CSA8000 Rackmount

Instructions for additional site considerations or operating requirements. This

document ships with the Option 1R (rackmount kit).

Install the Sampling Modules

CAUTION. Do not install or remove any sampling modules while the instrument is

powered on.

Always power the instrument down before attempting to remove or insert any

sampling module.

CAUTION. Sampling modules are inherently vulnerable to static damage. Always

observe static-safe procedures and cautions as outlined in your sampling module

user manual.

Check Your Sampling

Module Manual(s)

Read the appropriate sampling module user manual for instructions on how to

install your sampling modules, and then install them as outlined. (Sampling

modules do not ship preinstalled.)

NOTE. After first installing a sampling module(s) or after moving a sampling

module from one compartment to another, you should run compensation from the

Utilities menu to ensure the instrument meets it specifications. You must run a

compensation (accessed from the Utilities menu) whenever the extender

configuration is changed from that present at the last compensation. In short, if

you install or remove an 80E00 extender, run a compensation. If you exchange a

extender for one of a different length, run a compensation. For instructions on

running a compensation, see Optimizing Measurement Accuracy on page 3--92.

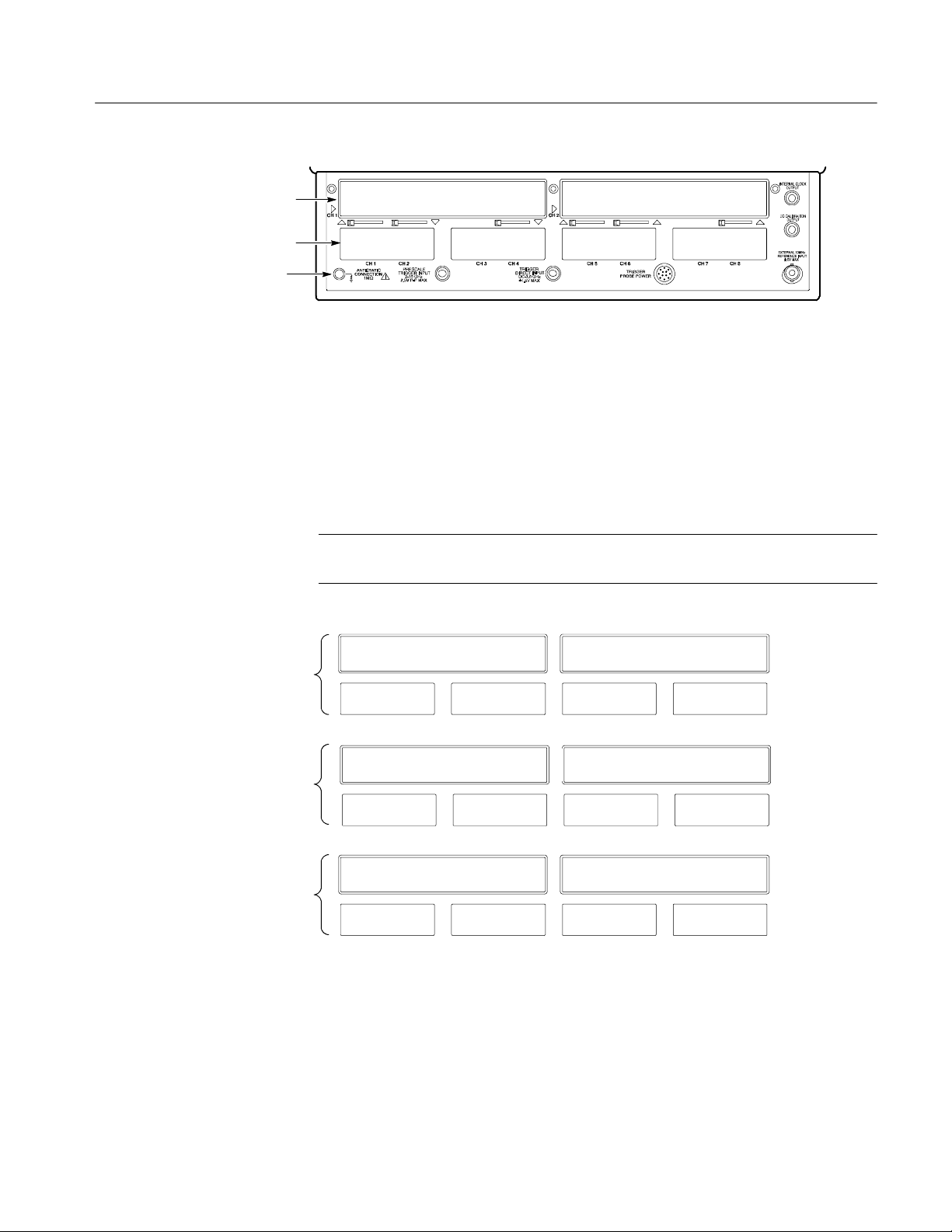

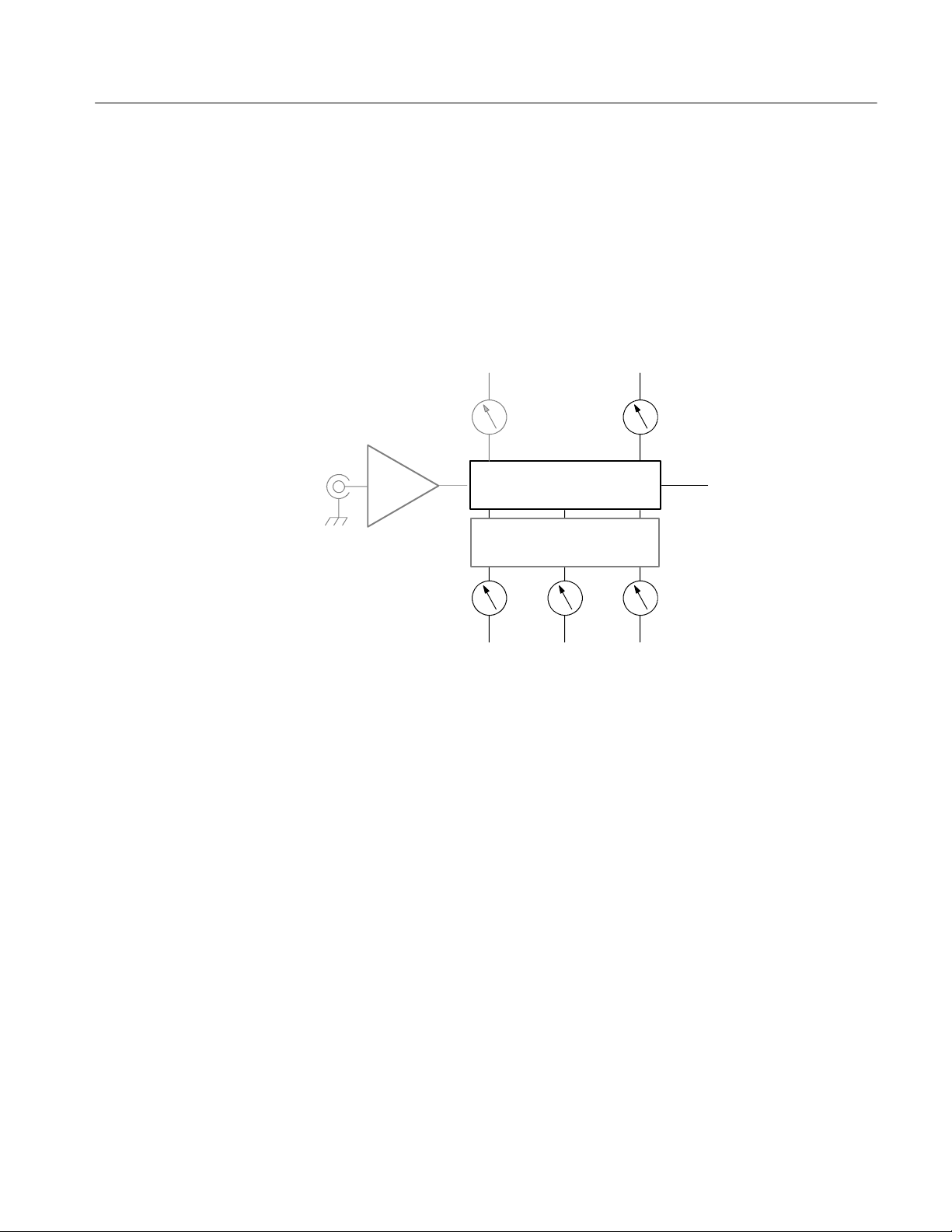

Figure 1--1 shows compartments for both large and small sampling modules,

along with the plug-in connector for the ESD wrist strap that you must use while

installing or removing these modules.

1- 10

CSA8000B & TDS8000B User Manual

Page 29

Large-module compartments (2)

Small-module compartments (4)

Connect ESD wrist strap here

Installation

Figure 1- 1: Compartments for sampling modules

Maximum Configuration

Eight channels: Two large modules and

three small modules

Eight channels: No large and four

small modules

You can install up to two large sampling modules and four small modules for a

total of 10 inputs. Of these 10 inputs, only eight inputs can be active at one time

(see Figure 1--2, top two configurations). Also, note that installing a single large

module in either compartment disables the first small-module compartment (see

note). This configuration (see Figure 1--2, bottom configuration) limits the input

count to seven—one from the large, six from the small compartments.

NOTE. Power is still provided to this small slot, which does allow an 80A01 to

be functional in this slot even when a large module is installed.

CH 1 CH 2

1

N.A.

N.A.

CH 1 CH 2 CH 6CH 3 CH 8CH 5 CH 7

CH 4

CH 6CH 3 CH 8CH 5 CH 7N.A. CH 4

N.A.

Seven channels: One large module,

installed in either compartment, and

three small modules

N.A. CH 6CH 3 CH 5 CH 7N.A. CH 4

1

Not Available

Figure 1- 2: Maximum inputs in three configurations

Install probes, cables, and other connection accessories to your sampling

modules as appropriate for your application and sampling module. Again,

consult your sampling-module and connection-accessory manuals. Continue with

the next section after installing the sampling modules.

CSA8000B & TDS8000B User Manual

CH 1/N.A.

CH 2/N.A.

CH 8

1- 11

Page 30

Installation

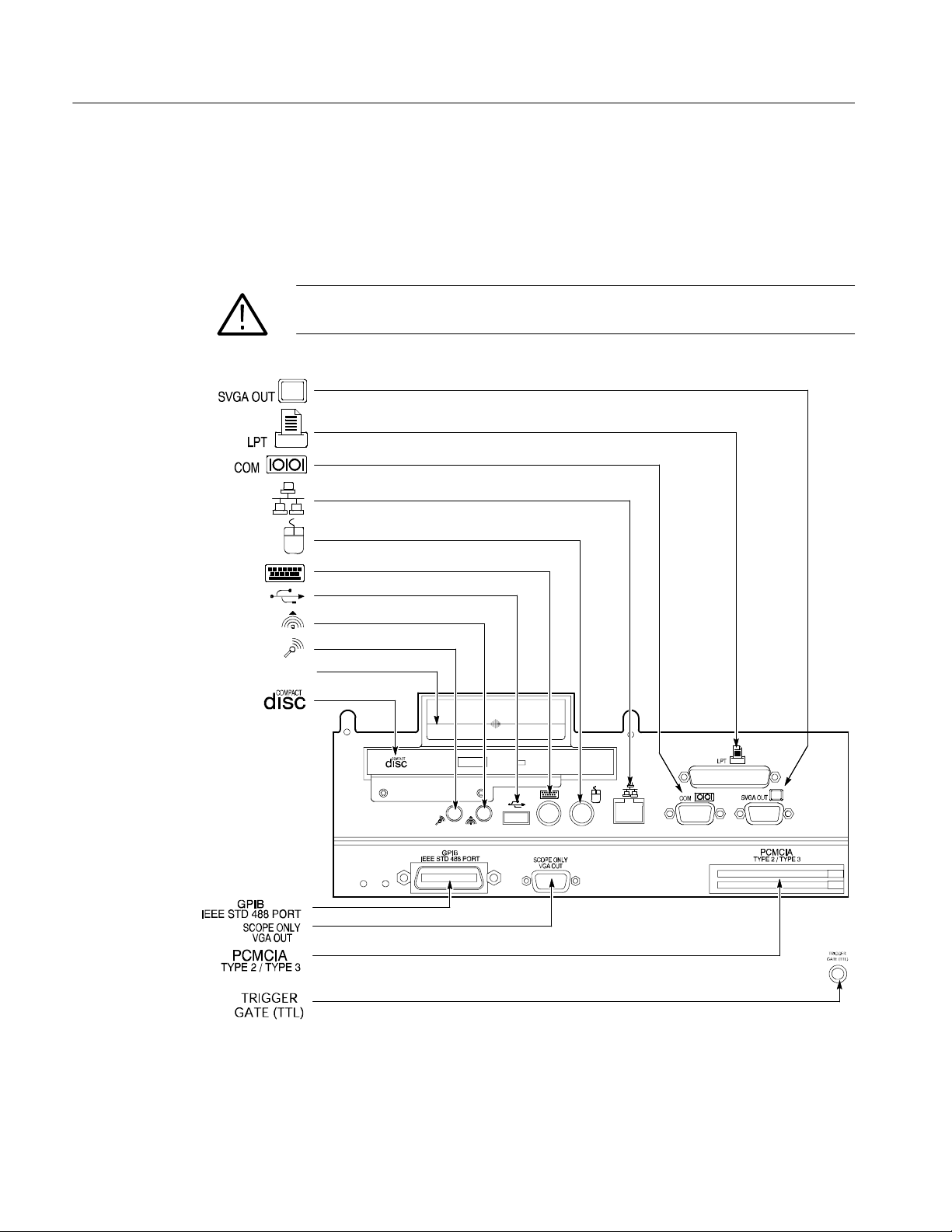

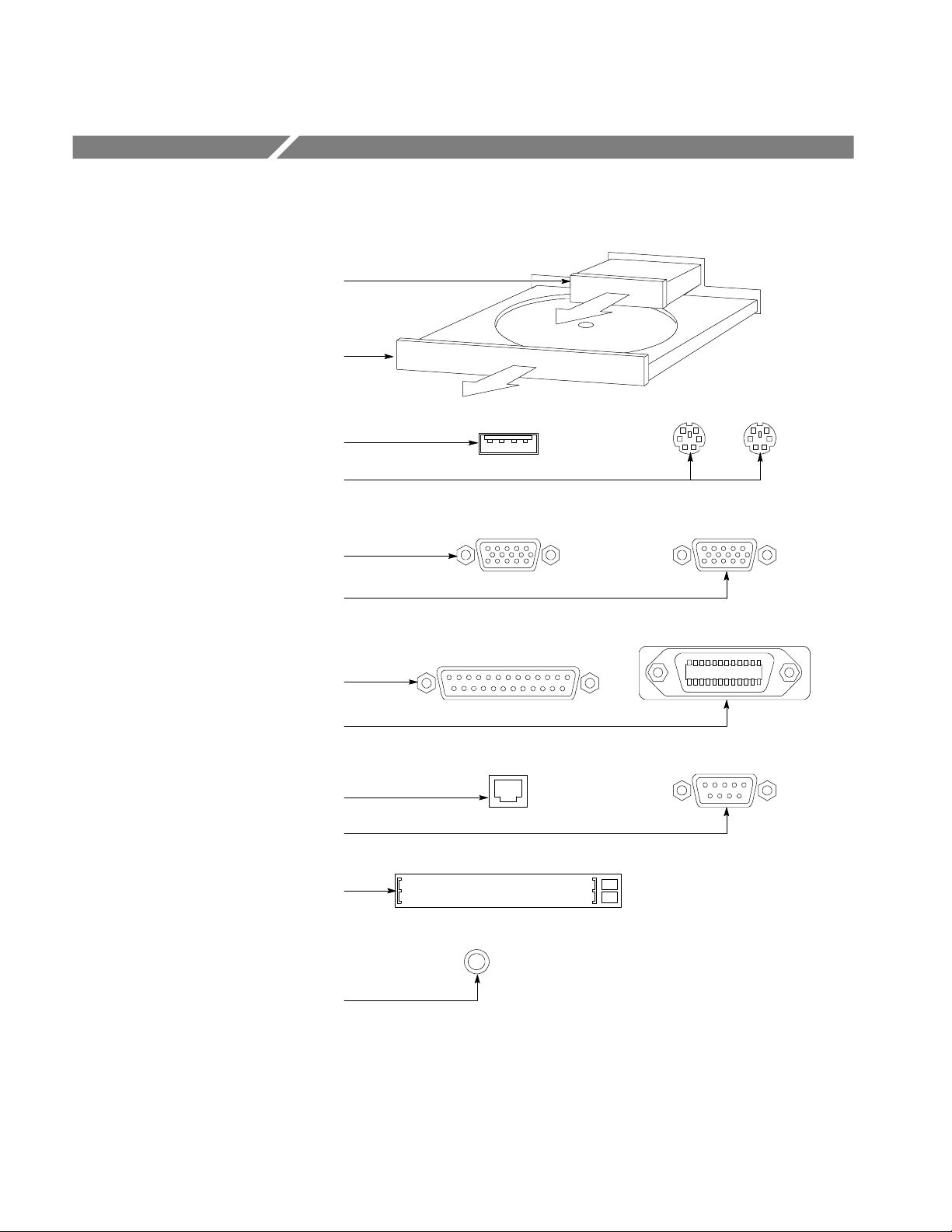

Connect the Peripherals

The peripheral connections are mostly the same as those you would make on a

personal computer. The connection points are shown in Figure 1--3. See

Table 1--1 on page 1--13 for additional connection information.

WARNING. Before installing peripheral acc e ssories to connectors (mouse, keyboard,

etc.), power down the instrument. See Powering Off the Instrument on page 1--15.

Monitor.............

Printer......................

RS-232.................

Network.............................

PS2 mouse

PS2 keyboard

USB................................

Audio line out.......................

Audio line in........................

Removable hard drive.....................

CD drive.........................

GPIB...........

Monitor....................

Card slot

Gated trigger...........

1

.......................

1

2

...........

................

(only available with Option GT)

1

Product ships with a USB keyboard that plugs into the USB port and a USB mouse that plugs into the back of the keyboard

2

PCMCIA card readers are not available on the following products: CSA8000B SN B020338 and above, TDS8000B SN B020346 and above.

Product software version 2.0 (or greater) does not support PCMCIA readers.

Figure 1- 3: Locations of peripheral connectors on rear panel

1- 12

CSA8000B & TDS8000B User Manual

Page 31

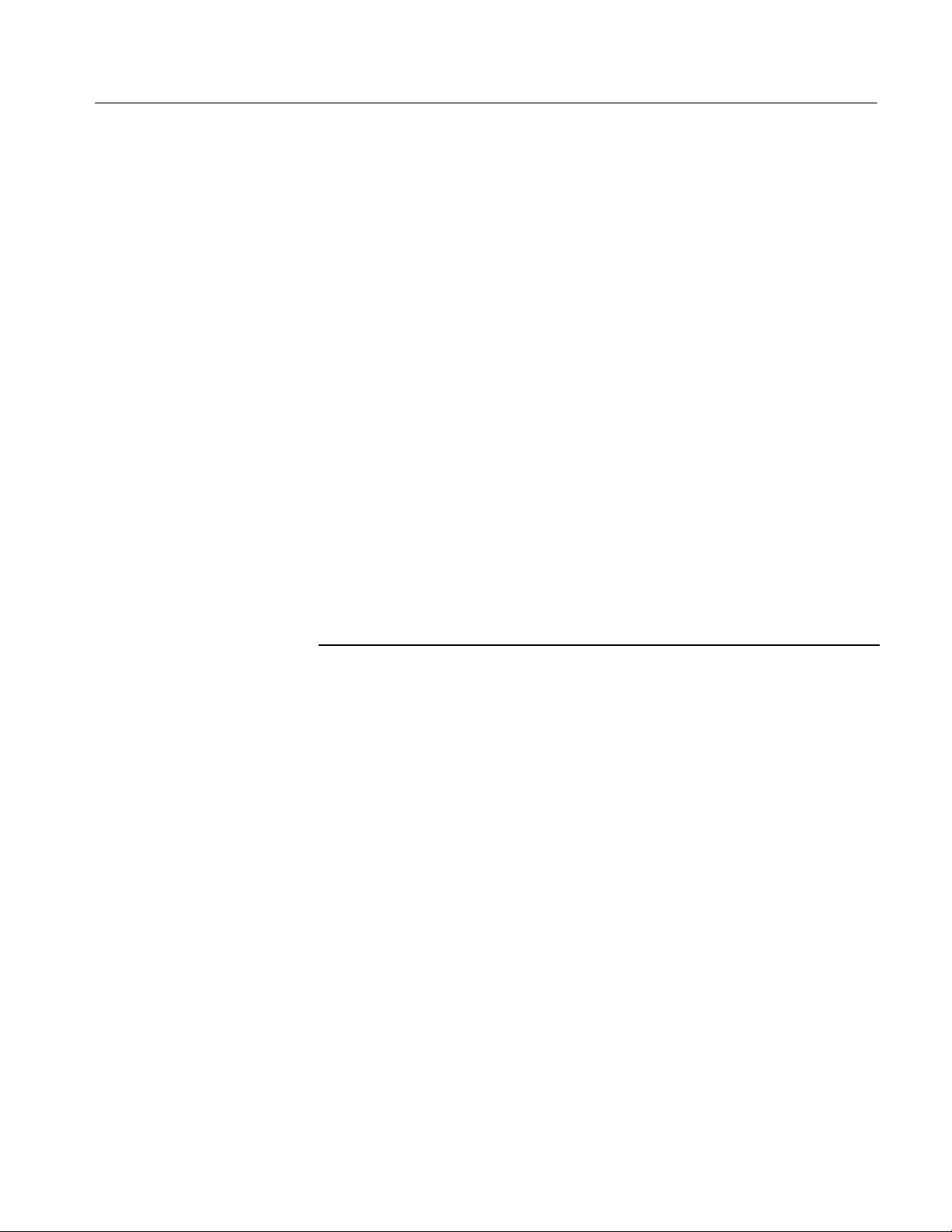

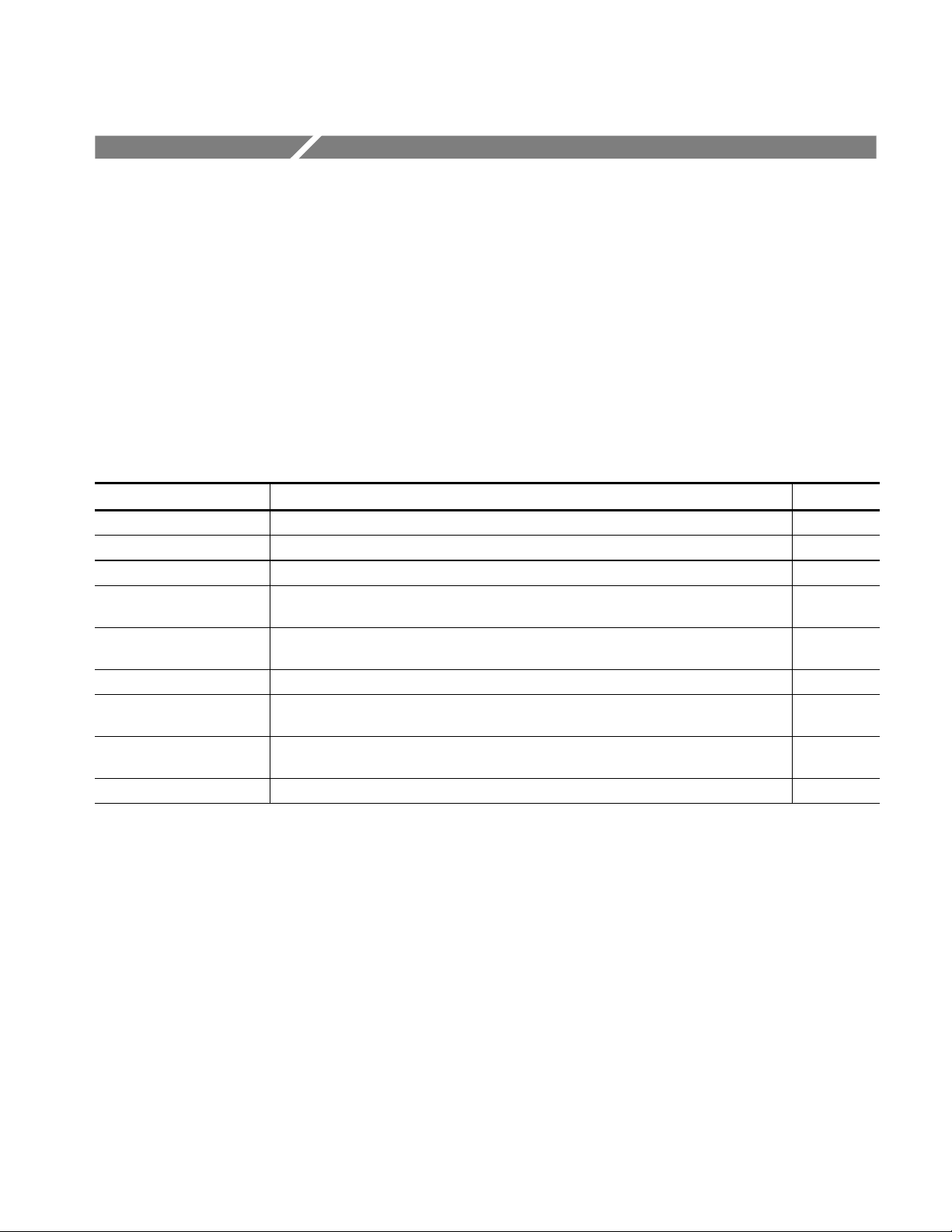

Table 1- 1: Additional accessory connection information

Item Description

Monitor If you use a non-standard monitor, you may need to change the

Printer Connect the printer to the EPP (enhanced parallel port)

Other Refer to the Application release notes on your System Rebuild

Power On the Instrument

Installation

the Windows display settings to achieve the proper resolution

for your monitor.

connector directly. If your printer has a DB-25 connector, use

the adapter cable that came with your printer to connect to the

EPP connector. For information on printer usage, see Printing

Waveforms on page 3-126.

CD for possible additional accessory installation information

not covered in this manual.

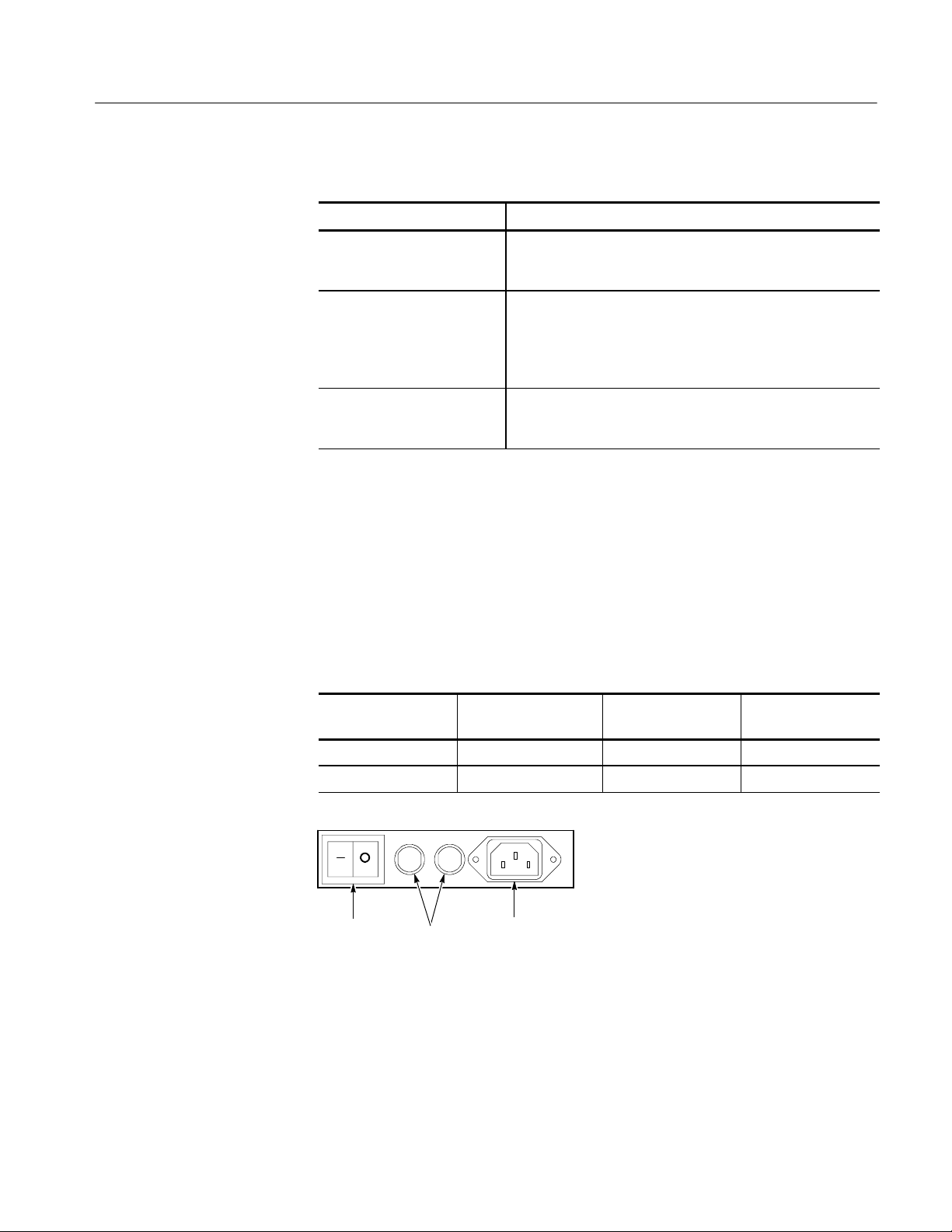

Follow these steps to power on the instrument for the first time.

1. Check that the line fuses are correct for your application. Both fuses must be

the same rating and type. Fuse types require a unique cap and fuseholder. See

Table 1--2 and Figure 1--4.

Table 1- 2: Line fuses

Cap & fuseholder

Fuse type Rating Fuse part number

0.25 x 1.250 inch 8 A, fast blow, 250 V 159-0046-00 200-2264-00

5x20mm 6.3 A, fast blow, 250 V 159-0381-00 200-2265-00

Fuses

AC powerPower switch

part number

Figure 1- 4: Line fuse and power cord connector locations, rear panel

CSA8000B & TDS8000B User Manual

1- 13

Page 32

Installation

CAUTION. Connect the keyboard, mouse, and other accessories before applying

power to the product. Connecting the accessories after powering on the

instrument can damage the accessories. T wo exceptions are the USB keyboard

and mouse that ships with the instrument. Both can be plugged or unplugged

without first turning power off.

2. Connect the keyboard and mouse, observing the caution above. Note that the

instrument ships with a USB keyboard, which plugs into the USB port (see

Figure 1--3 on page 1--12 for location) and a USB mouse, which plugs into

the back of the USB keyboard.

NOTE. Connection of the keyboard and mouse is optional. You can operate most

features without them, using the front-panel controls and the touchscreen.

3. Connect the power cord.

4. If you have an external monitor, connect the power cord and power on the

monitor.

Switch

5. Turn the Power switch on at the rear panel. (See Figure 1--4 on page 1--13 for

switch location.)

6. Push the On/Standby switch to power on the instrument (see Figure 1--5 for

the switch location).

Figure 1- 5: On/Standby switch location

7. Wait for the boot routine and low-level self test to complete.

1- 14

8. Follow any instructions on the screen.

The internal setup software will automatically configure your instrument and

install all required devices, depending on the installed accessories.

CSA8000B & TDS8000B User Manual

Page 33

Powering Off the Instrument

The instrument has a built-in soft power-down function that safely powers down

the instrument when you push the On/Standby button. You do not need to close

the UI application or Windows before using the On/Standby button.

To completely remove power to the instrument, first soft power-down the

instrument using the On/Standby button, and then set the power switch on the

rear panel to off.

Brightness and Contrast Adjustment (Gamma)

Although this instrument is set for optimal Gamma display before shipping, you

can adjust it to suit your preferences. If you wish to do so, use the Display

settings located in the Windows Control Panel.

Back Up User Files

Installation

Software Installation

You should back up your user files on a regular basis. Use the Windows Back Up

tool to back up files stored on the hard disk. The Back Up tool is located in the

System Tools folder in the Accessories folder.

1. Minimize the UI application by clicking the minimize (--) button in the

upper-right corner on screen.

2. Click Start in the Task bar to pop up the Start menu.

3. Select Programs > Accessories > System Tools > Backup in the Start menu.

4. Use the backup tool that displays to select your back-up media and to select

the files and folders that you want to back up. Use the Windows online help

for information on using the Backup tool. You can back up to the floppy

drive or to a networked storage device over the ethernet port (rear panel).

5. You can restore the UI application to the screen by clicking its button in the

Windows Task bar.

This section describes how to install the software found on the CSA8000 &

TDS8000 OS Restore and Product Software CDs that accompany this product.

The instrument ships with the product software installed, so only perform these

procedures if reinstallation becomes necessary.

CSA8000B & TDS8000B User Manual

1- 15

Page 34

Installation

Description

Software Release Notes

There are two sets of CDs that ship with this instrument:

H OS Rebuild CD. This 2-disk set contains the operating system for the

instrument. This CD set, which can be used to rebuild the instrument hard

drive, includes the Windows operating system installation.

H Product Software CD. The product software, or UI application, complements

the hardware controls of the front panel, allowing complete set up of all

instrument features. The Product Software CD includes software allowing

you to reinstall the product software without having to rebuild the entire

operating system.

Read the software release notes README.TXT ASCII file if present on the

Product Software CD before performing any installation procedures. This file

contains additional installation and operation information that supercedes other

product documentation.

To view the README.TXT file, open the Notepad Windows accessory and open

the file on the CD. After installation, you can also read the copy from a directory

on the product:

C:\Programs Files\TDSCSA8000\System

Operating System

Reinstallation

System Diagnostics

Windows Safe Mode

If it becomes necessary to reinstall the Windows operating system, use the CDs

and instructions provided with your Windows Operating System Rebuild kit

(shipped with your instrument).

This process will return the hard disk to the its original condition present when

the instrument shipped.

NOTE. All data and programs you may have installed will be lost when reinstalling the Windows Operating System.

In case of instrument problems, you may wish to run the system diagnostics. If

so, see the procedure Perform the Diagnostics, on page 1--18.

If the instrument is turned off before the operating system boots, or if you’ve

installed a third-party product with a driver incompatible with instrument start

up, Windows will open in Safe mode. The touchscreen will be inoperable;

therefore, you must install the standard-accessory mouse and keyboard to operate

the instrument.

When you have finished investigating and removed any barrier to Windows

start-up, you can reboot. If the instrument no longer boots to Safe mode, you can

remove the keyboard and mouse if desired.

1- 16

CSA8000B & TDS8000B User Manual

Page 35

Incoming Inspection

This section contains instructions for performing an incoming inspection of this

instrument. Performance of an incoming inspection is not required to put the

instrument in service.

These instructions verify that the instrument is operating correctly after

shipment, but do not check product specifications. An incoming inspection

includes the following parts:

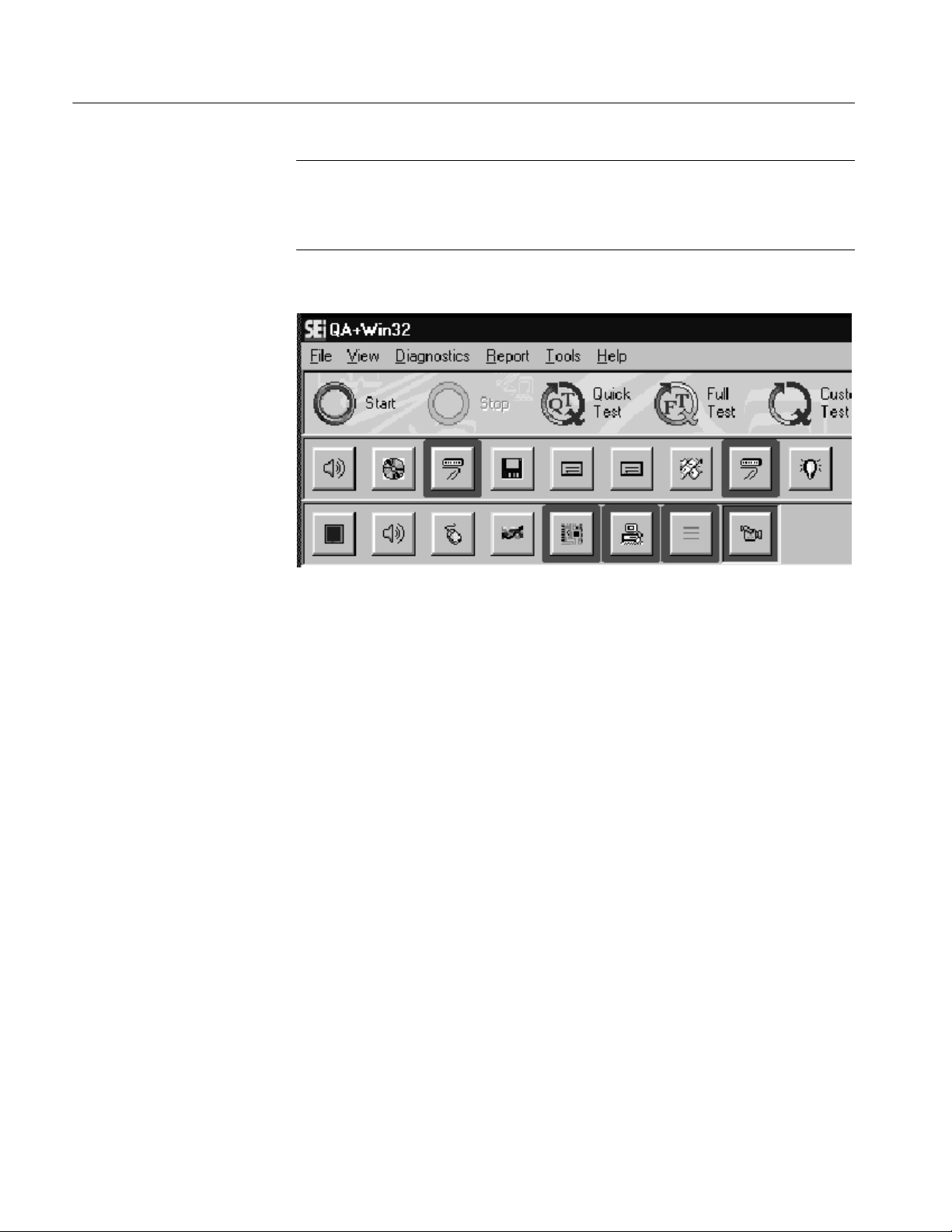

H Perform the Diagnostics on page 1--18 runs the internal diagnostics.

H Perform a Compensation on page 1--20 runs the self compensation routine.

H Perform the Functional Tests on page 1-- 21 uses the DC CALIBRATION

OUTPUT and the INTERNAL CLOCK OUTPUT connectors to verify that

the instrument is functioning.

H Perform the Hardware and Operating System Tests (Windows 98 only) on

page 1--38 uses a software program called QAPlus/Win to verify instrument

hardware and the MS Windows 98 operating system is functioning.

QAPlus/Win is only available on instruments using the MS Windows 98

operating system. Instruments using the MS Windows 2000 operating

system do not include QAPlus/Win software.

Assemble Equipment

NOTE. The procedures that follow contain instructions based on the menus and

controls supported by the version 1.5 release and later of the instrument

firmware. The procedures will work for earlier versions of software, but the

control and menu names may vary slightly.

If the instrument fails any test within this section, it may need service. To contact

Tektronix for service, see Contacting Tektronix on page xiii of Preface.

Make sure you have put the instrument into service as detailed in Installation

starting on page 1--9. Then assemble the following test equipment and proceed

with the procedures that follow.

To complete the incoming inspections procedures requires the following test

equipment:

H One SMA cable, such as Tektronix part number 174-1427-00.

H One 50 Ω BNC cable, such as Tektronix part number 174-1341-00.

CSA8000B & TDS8000B User Manual

1- 17

Page 36

Incoming Inspection

H One SMA 10X attenuator, such as Tektronix part number 015-1003-00.

H One or more (quantity to match number of electrical channels to compen-

H One 50 Ω terminator cap, such as Tektronix part number 011-0049-02

H One 80E00-series electrical sampling modules installed as outlined in its

H One 80C00-series optical sampling module installed as outlined in its User

H Mouse

H Keyboard

Perform the Diagnostics

The instrument Diagnostics use internal routines to confirm basic functionality

and proper adjustment.

sate) 50 Ω terminators, such as Tektronix part number 015-1022-01

User manual.

manual (optional; test only if purchased with/for your instrument).

Equipment required

Prerequisites First, all sampling modules to be diagnosed must be installed as

None

outlined in their user manuals.

Second, power on the instrument and allow a 20 minute warm-up

before doing this procedure.

1. Set up the instrument: From the application menu bar, select Utilities, and

then select Diagnostics. The Diagnostics dialog box displays. See below.

1- 18

CSA8000B & TDS8000B User Manual

Page 37

2. Select a diagnostics suite:

Incoming Inspection

a. In the dialog box, click the Subsystem Level tab.

b. Select the all the entries by clicking the first entry Control Proc and

dragging down to select the rest. All entries should be highlighted as

shown above.

c. In the Run box, leave Loop and Halt on Failure unchecked.

3. Verify that the diagnostic suite passes:

a. Click the Run button to execute the diagnostics.

b. The diagnostics may take several minutes to complete. Verify that Pass

appears as Status in the dialog box when the diagnostics complete.

c. If instead an error number appears as Status, rerun the diagnostics. If

Fail status continues after rerunning diagnostics and you have allowed

warm up to occur, the module or main instrument may need service.

4. Close the diagnostic dialog box.

End of Procedure

CSA8000B & TDS8000B User Manual

1- 19

Page 38

Incoming Inspection

Perform the Compensation

This procedure uses internal routines to verify that the instrument compensates

properly.

Equipment required

Prerequisites First, all sampling modules to be compensated must be installed as

For sampling modules:

H 50 Ω terminations on all electrical module channels (Tektronix

part number 015-1022-xx).

H Dust covers on all optical module channels.

The sampling modules ship from Tektronix with the proper terminations and dust covers installed.

outlined in their user manuals.

Second, power on the instrument and allow a 20 minute warm-up

before doing this procedure.

1. Run the compensation routines:

a. From the application menu bar, select Utilities, and then select Com-

pensation.

In the Compensation dialog box, the main instrument (mainframe) and

sampling modules are listed. The temperature change from the last

compensation is also listed. See Figure 1--6.

1- 20

Click to select compensate

Choose all as targets

Click to start compensation

Figure 1- 6: Compensation dialog box

CSA8000B & TDS8000B User Manual

Page 39

Incoming Inspection

b. Wait until the Status for all items you wish to compensate changes from

Warm Up to Pass, Fail,orComp Req’d.

c. Under Select Action, click the Compensate option button.

d. From the top pulldown list, choose All (default selection) to select the

main instrument and all its modules as targets to compensate.

e. Click the Execute button to begin the compensation.

f. Follow the instructions to disconnect inputs and install terminations that

will appear on screen; be sure to follow static precautions (see the user

manual for your sampling module) when following these instructions.

NOTE. Failing to install the 50 Ω terminations on electrical inputs can yield

erroneous compensation failures or results.

2. Verify that the compensation routines pass:

a. The compensation may take several minutes to complete. Verify that

b. If instead Fail appears as Status, rerun the compensation. If Fail status

c. If you want to save the compensation constants generated by this

3. Close the compensation dialog box.

End of Procedure

Perform the Functional Tests

These procedures use the DC CALIBRATION OUTPUT and the INTERNAL

CLOCK OUTPUT connectors to further verify that the instrument functions

properly. An SMA cable and a 10x attenuator are required to do these test

procedures.

Pass appears as Status for the main instrument and for all sampling

modules listed in the Compensation dialog box when compensation

completes.

continues after rerunning compensation and you have allowed warm up

to occur, the module or main instrument may need service.

compensation, click the Save option button under Select Action. Click

the Execute button to save the compensation.

The purpose of these procedures is to confirm that the instrument functions

properly. The equipment required is intentionally kept to a minimum.

CSA8000B & TDS8000B User Manual

1- 21

Page 40

Incoming Inspection

STOP. These procedures verify functions; that is, they verify that the instrument

features operate. They do not verify that they operate within limits; therefore, do

not interpret any quantities cited (such as “about five horizontal divisions”) as

limits.

STOP. DO NOT make changes to the front-panel settings that are not called out

in the procedures. Each verification procedure will require you to set the

instrument to default settings before verifying functions. If you make changes to

these settings, other than those called out in the procedure, you may obtain

invalid results. In this case, go back to step 1 and repeat the procedure.

Verify Electrical Input

Channels

Install the test hookup and preset the instrument controls:

Equipment

required

Prerequisites At least one electrical (80E00 series) sampling module must be

One SMA cable, such as Tektronix part number 174-1427-00.

installed as outlined in its user manual.

1. Initialize the instrument: Push the front-panel DEFAULT SETUP button,

and click Yes in the confirmation dialog box.

2. Set the Trigger System: In the UI application toolbar, select Internal Clock

from the Trig list box as shown below.

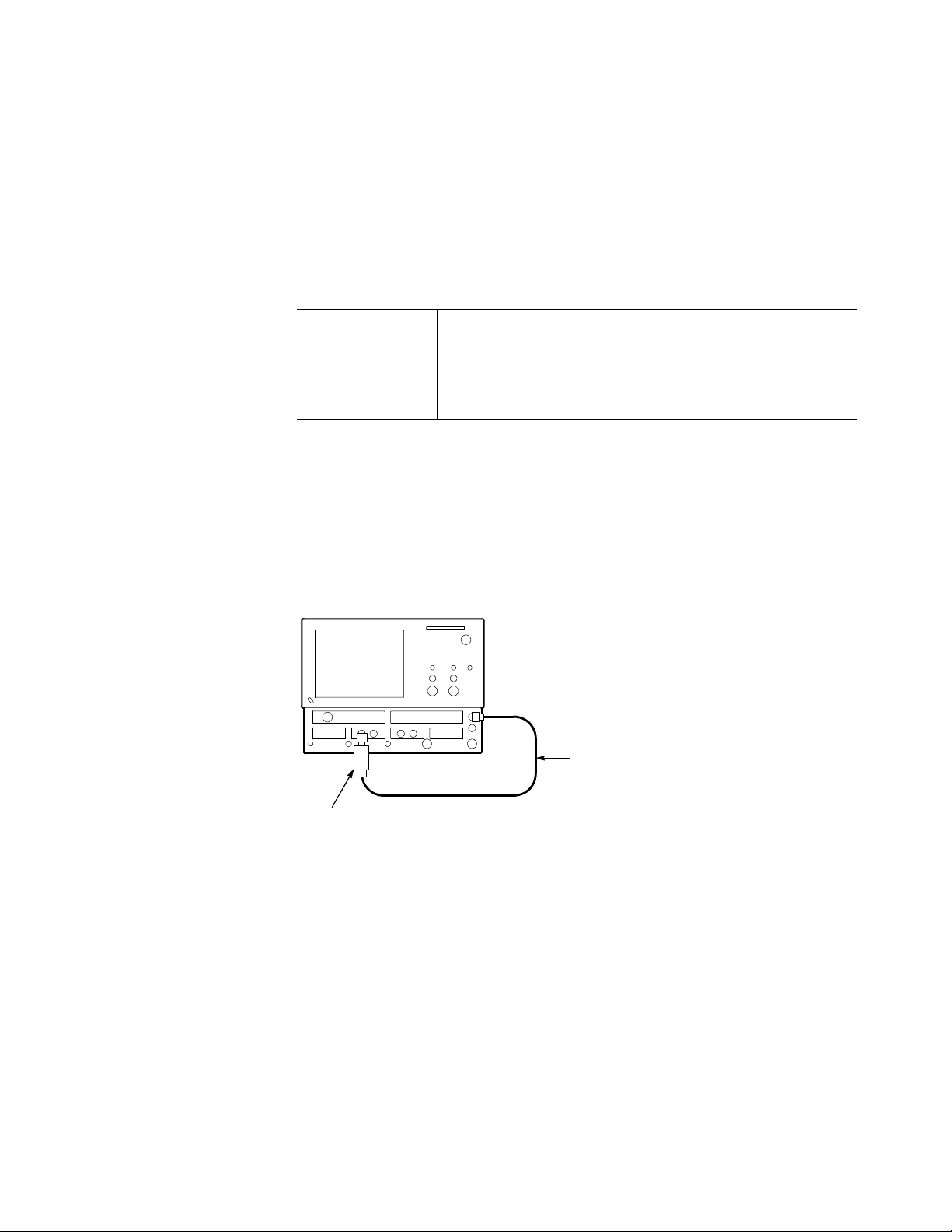

3. Hook up the signal source: Connect the SMA cable from the DC CALIBRA-

TION output to the channel input that you want to test as shown in

Figure 1--7.

1- 22

CSA8000B & TDS8000B User Manual

Page 41

Incoming Inspection

CSA8000/TDS8000

SMA cable from DC calibration

output to 80E00 C3 input

Figure 1- 7: Hookup for electrical functional tests

4. Set the DC CALIBRATOR OUTPUT:

a. Push the Vertical MENU front-panel button. This displays the Vert

Setup dialog box.

NOTE. When an optical module is installed, the optical setup dialog box displays

by default. Click the Basic button to display the basic dialog box.

b. Enter a level of 200 mV in the DC CAL box.

c. Push the Vertical MENU front-panel button again to dismiss the Vert

Setup dialog box.

5. Select the channel to test: Push the channel button for the channel you want

to test. The button lights and the channel display comes on. See Figure 1--8.

Channel

buttons

Figure 1- 8: Channel button location

CSA8000B & TDS8000B User Manual

1- 23

Page 42

Incoming Inspection

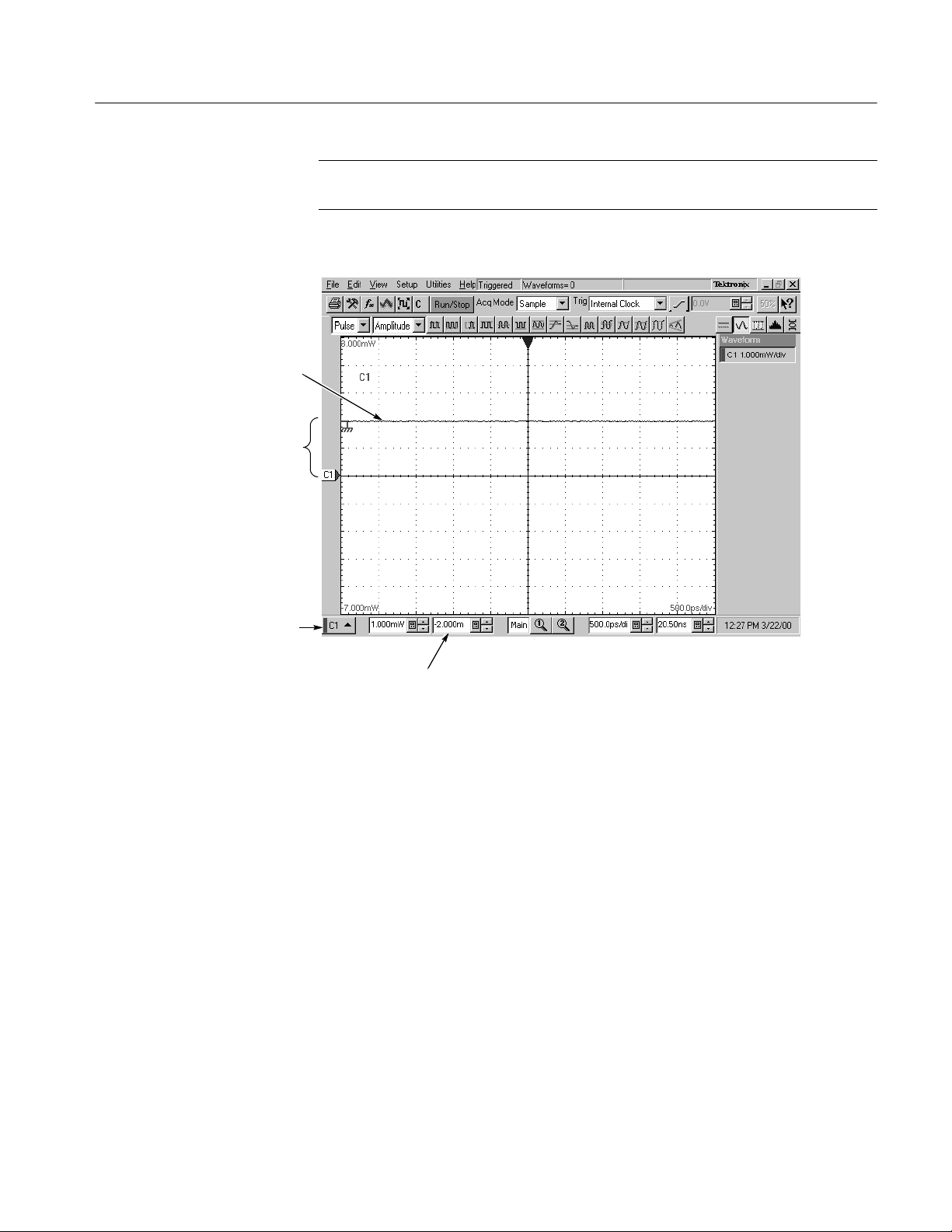

6. Verify that the channel is operational: Confirm that the following statements

are true:

H The vertical scale readout for the channel under test shows a setting of

100 mV, and a DC level is at about 2 divisions above center screen.

H The front-panel vertical POSITION knob (for the channel you are

testing) moves the DC level up and down the screen when rotated.

Return the DC level to 2 divisions above center screen before continuing.

H Turning the vertical SCALE knob to 50 mV changes the amplitude of

the DC level to about 4 divisions above center screen, and returning the

knob to 100 mV returns the amplitude to about 2 divisions above center

screen.

7. Verify that the channel acquires in all acquisition modes: Push the

front-panel Acquisition MENU button to display the Acq setup dialog box.

Click each of the three acquisition modes, and confirm that the following

statements are true:

H Sample mode displays an actively acquiring waveform on-screen. (Note

that there is a small amount of noise present on the DC level).

H Average mode displays an actively acquiring waveform on-screen with

the noise reduced.

H Envelope mode displays an actively acquiring waveform on-screen with

the upper and lower extremes of the noise displayed.

8. Close Acquisition setup dialog box: Push the Acquisition MENU button to

close the Acq setup dialog box.

9. Verify the DC accuracy compensation: Do the following substeps:

a. Select Measurement from the Setup menu. In the Meas Setup dialog box

that displays:

H Select as Source the channel under test. For example, select Main C3

for channel 3.

H Select Meas1.

H Set the Select Meas menu to Pulse > Amplitude > Mean.

b. Push the Vertical MENU front-panel button to switch to the Vert Setup

dialog box.

1- 24

CSA8000B & TDS8000B User Manual

Page 43

Incoming Inspection

c. Set the Vertical Scale, Vertical Offset, and DC Calibration Output to the

levels shown in the first row of the table that follows.

d. In Measurement readout on screen, verify that the Mean measurement

for the channel under test falls within the limits given in the table.

e. Repeat steps c and d for each row in the table.

Vertical Scale Vertical Offset DC CAL Output Limits

(mV/div) (mV) (mV) Minimum (mV) Maximum (mV)

100

100 0.0 --450 --461.0 --439.0

100 0.0 0 -- 2 . 0 2.0

100 0.0 450 439.0 461.0

100 1000.0 1000.0 991.0 1009.0

--1000.0 --1000.0 --1009.0 --991.0

Verify Optical Input

Channels

10. Test all channels: Repeat steps 3 through 9 until all electrical input channels

are verified.

11. Remove the test hookup: Disconnect the SMA cable from the channel input

and the DC CALIBRATION output.

After verifying the electrical channels and if you have an 80C00 Series Sampling

Module installed, you can now verify its optical channels. This verification is

done without an input signal.

Equipment

required

Prerequisites At least one optical (80C00 series) sampling module must be installed

None.

as outlined in its user manual.

1. Initialize the instrument: Push the front-panel DEFAULT SETUP button,

and click Yes in the confirmation dialog box.