Tektronix Counter/Timer Programming Guide for Keithley DriverLINX (from DOCS-850A13) User manual

Page 1

DriverLINX

Page 2

Information in this document is subject to change without notice. The software

described is this document is furnished under a license agreement. The software may

be used or copied only in accordance with the terms of the agreement.

SCIENTIFIC SOFTWARE TOOLS, INC. SHALL NOT BE LIABLE FOR ANY

SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES RELATED TO

THE USE OF THIS PRODUCT. THIS PRODUCT IS NOT DESIGNED WITH

COMPONENTS OF A LEVEL OF RELIABILITY SUITABLE FOR USE IN LIFE

SUPPORT OR CRITICAL APPLICATIONS.

This document may not, in whole or in part, be copied, photocopied, reproduced,

translated or reduced to any electronic medium or machine readable form without

prior written consent from Scientific Software Tools, Inc.

DriverLINX Counter/Timer Programming Guide

Copyright 1997-2001, Scientific Software Tools, Inc.

All rights reserved.

SST 08-0101-1

LabOBJX, DriverLINX, and SSTNET are registered trademarks and

DriverLINX/VB is a trademark of Scientific Software Tools, Inc.

Microsoft and Windows are registered trademarks and Visual C++ and Visual Basic

are trademarks of Microsoft Corporation.

Borland is a registered trademark and Borland C++ is a trademark of Borland

International, Inc.

All Keithley product names are trademarks or registered trademarks of Keithley

Instruments, Inc.

All other brand and product names are trademarks or registered trademarks of their

respective companies.

Page 3

Contents

Preface 7

Software License and Software Disclaimer of Warranty...........................................................7

About DriverLINX.....................................................................................................................9

About This Programming Guide................................................................................................9

Conventions Used in This Manual...........................................................................................11

Why Use a Counter/Timer Device Driver 13

Using Direct Hardware I/O......................................................................................................13

Advantages of Device Drivers.................................................................................................13

Introducing DriverLINX 15

About DriverLINX...................................................................................................................15

DriverLINX Hardware Model..................................................................................................15

DriverLINX Programming Model...........................................................................................16

Summary.................................................................................................................................. 18

DriverLINX Driver....................................................................................................15

Logical Devices.........................................................................................................15

Logical Subsystems...................................................................................................16

Logical Channels.......................................................................................................16

Logical Device Descriptors .......................................................................................17

Service Requests ........................................................................................................17

C/C++ Interface.........................................................................................................18

Control Interface........................................................................................................18

Counter/Timers and DriverLINX 19

Counter/Timer Hardware Description......................................................................................19

Intel 8254...................................................................................................................19

KPCI-3140 Counter/Timer Chip ...............................................................................20

Am9513.....................................................................................................................20

DriverLINX Counter/Timer Model..........................................................................................21

DriverLINX Task Model .........................................................................................................26

Hardware Sharing......................................................................................................26

Creating Tasks...........................................................................................................26

Monitoring and Stopping Tasks.................................................................................27

DriverLINX Events ...................................................................................................27

DriverLINX Operations.............................................................................................28

DriverLINX Modes ...................................................................................................29

Individual and Group Tasks.......................................................................................29

Mapping Logical Channels to Counter/Timer Hardware Channels.........................................29

Digital I/O Hardware ...............................................................................................................30

Mapping Logical Channels to Digital Hardware Channels......................................................31

Properties of Logical Channels..................................................................................31

Combining or Splitting Logical Channels .................................................................31

DriverLINX Counter/Timer User’s Guide Contents • 3

Page 4

Implementation Notes................................................................................................33

Programming Counter/Timers with DriverLINX 35

DriverLINX Counter/Timer Operations...................................................................................35

DriverLINX Tasks for All Subsystems......................................................................36

DriverLINX Tasks for Counter/Timer Subsystem.....................................................36

Foreground Tasks ......................................................................................................37

Background Tasks......................................................................................................37

Group Tasks...............................................................................................................38

DriverLINX Tasks for Digital Subsystems................................................................38

Using DriverLINX’s Service Requests....................................................................................39

Properties Common to All Service Requests.............................................................39

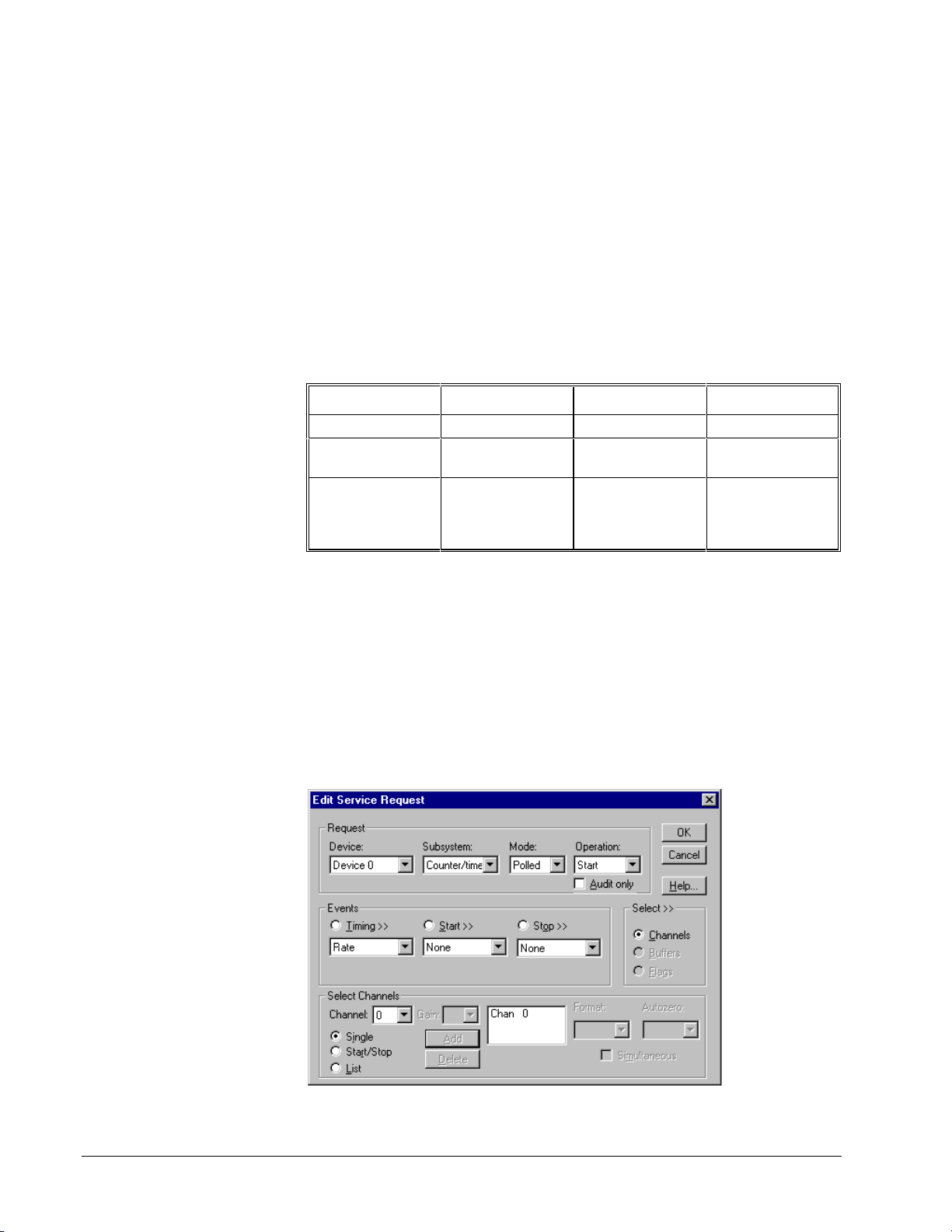

Modes and Operations for Counter/Timers................................................................40

Using Events to Control Service Requests ................................................................41

Events for the Counter/Timer....................................................................................41

Specifying Counter/Timer Channels in a Service Request........................................42

Specifying Data Buffers in a Service Request...........................................................43

Interfacing to DriverLINX.......................................................................................................43

Opening and Closing a DriverLINX Device Driver.................................................................44

Selecting a DriverLINX Device Driver....................................................................................46

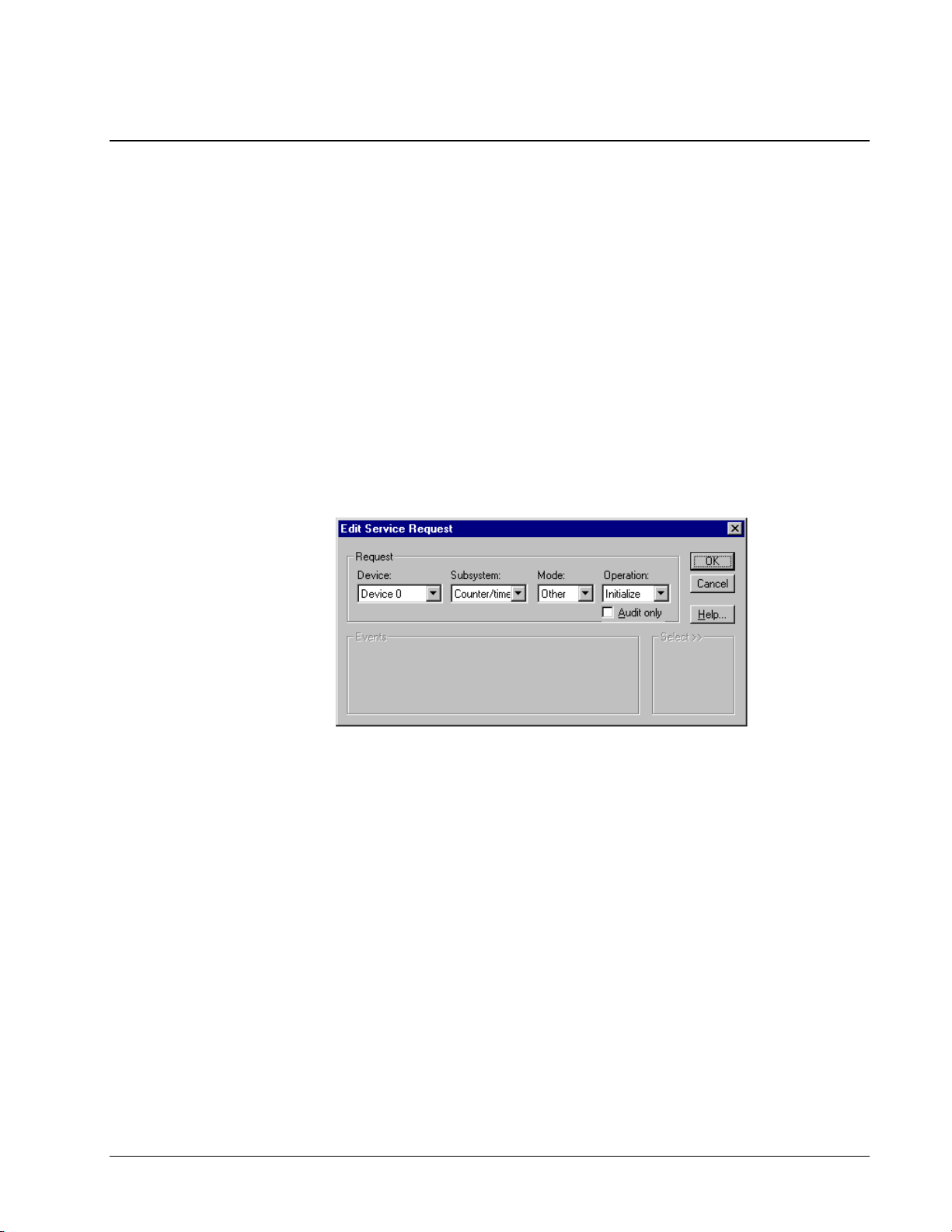

Displaying the Edit Service Request Dialog............................................................................47

Reporting a DriverLINX Error.................................................................................................48

Stopping A DriverLINX Task..................................................................................................49

Initializing the Device..............................................................................................................50

Initializing a Counter/Timer Subsystem...................................................................................51

Using Messages and Events.....................................................................................................52

Events for Foreground Tasks.....................................................................................53

Events for Background Tasks....................................................................................53

Counter Output.........................................................................................................................55

Status Polling a Counter/Timer................................................................................................56

Configuring a Counter/Timer Channel.....................................................................................57

Converting Between Counts and Time....................................................................................58

Using Background Tasks.........................................................................................................60

Using a Counter/Timer to Generate Clock Messages................................................60

Storing the Counter/Timer Value at Each Interrupt ...................................................61

Controlling Group Tasks..........................................................................................................63

Select Channels..........................................................................................................64

Polled Mode Groups..................................................................................................65

Interrupt Mode Groups ..............................................................................................67

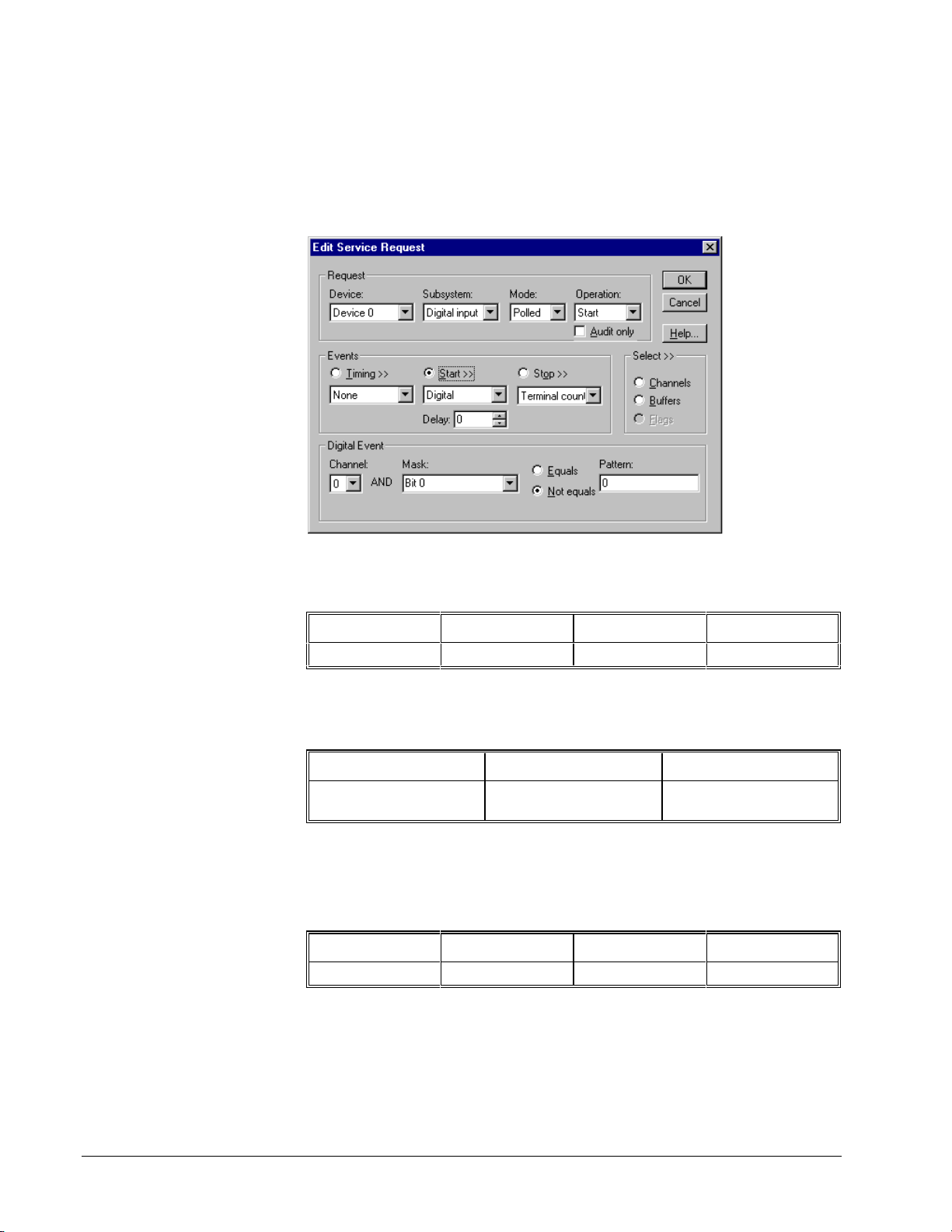

Using Digital I/O Tasks ...........................................................................................................68

Reading or Writing a Single Digital Value................................................................68

Reading or Writing Specific Digital Bits...................................................................72

Rapidly Transferring a Block of Digital Data............................................................75

Using Task-Oriented Functions 79

DriverLINX’s Task-Oriented Functions..................................................................................79

Event Counting ................................................................................................................. ....... 79

Starting an Event Counter ..........................................................................................79

Specifying the Rate Event for Event Counting..........................................................80

Hardware Setup for Event Counting..........................................................................84

Event Counting Using C/C++ .................................................................................... 84

Event Counting Using Visual Basic...........................................................................85

Frequency Measurement..........................................................................................................85

Starting a Frequency Counter ....................................................................................86

4 • Contents DriverLINX Counter/Timer User’s Guide

Page 5

Specifying the Rate Event for Frequency Measurements..........................................87

Hardware Setup for Frequency Measurement ...........................................................89

Frequency Measurement Using C/C++ .....................................................................90

Frequency Measurement Using Visual Basic............................................................91

Interval Measurement ........................................................................................................... ...92

Starting an Interval Counter.......................................................................................92

Specifying the Rate Event for Interval Measurements ..............................................93

Hardware Setup for Interval Measurements..............................................................94

Interval Measurement Using C/C++..........................................................................94

Interval Measurement Using Visual Basic ................................................................95

Period and Pulse Width Measurement.....................................................................................96

Starting an Period or Pulse Width Measurement.......................................................96

Specifying the Rate Event for Period and Pulse Width Measurements.....................97

Hardware Setup for Period and Pulse Width Measurements.....................................98

Period or Pulse Width Measurements Using C/C++.................................................99

Period or Pulse Width Measurement Using Visual Basic........................................100

Pulse and Strobe Generation..................................................................................................101

Starting Pulse and Strobe Generation......................................................................101

Specifying the Rate Event for Pulses and Strobes...................................................102

Hardware Setup for Pulses and Strobes...................................................................104

Pulse and Strobe Generation Using C/C++ .............................................................105

Pulse and Strobe Generation Using Visual Basic....................................................106

Frequency Generation............................................................................................................107

Starting Frequency Generation................................................................................107

Specifying the Rate Event for Frequency Generation..............................................107

Hardware Setup for Frequency Generation .............................................................110

Frequency Generation Using C/C++ .......................................................................111

Frequency Generation Using Visual Basic..............................................................112

Hardware Reference 113

8254 Operating Modes...........................................................................................................113

Operating Mode Descriptions..................................................................................114

KPCI-3140 Operating Modes................................................................................................116

Operating Mode Descriptions..................................................................................116

Am9513 Operating Modes.....................................................................................................117

Operating Mode Descriptions..................................................................................118

Glossary of Terms 127

Index 129

DriverLINX Counter/Timer User’s Guide Contents • 5

Page 6

Page 7

Preface

Software License and Software Disclaimer of Warranty

This is a legal document which is an agreement between you, the Licensee, and Scientific S oftware Tools, Inc. By opening this

sealed diskette package, Licensee agrees to become bound by the terms of this Agreement, which include the Software License and

Software Disclaimer of Warranty.

This Agreement constitutes the complete Agreem ent between Licensee and Scientific Software Tools, Inc. If Licensee does not

agree to the terms of this Agreement, do not open the diskette pack age. Promptly return the unopened disk ette package and the other

items (including written materials , binders or other containers, and hardware, if any) t hat are part of this product to Scientific Software

Tools, Inc. for a full refund. No refunds will be given for products that have opened disk packages or missing components.

Licensing Agreement

Copyright. The software and documentation is owned by Scient ific Software Tools, Inc. and is prot ected by both United States

copyright laws and international treaty provisions. Scientific Software Tools, Inc. authorizes the original purchas er only (Licensee) to

either (a) make one copy of the software solely for backup or archival purposes, or (b) transfer the software to a single hard disk only.

The written materials accompanying the software may not be duplicated or copied for any reason.

Trade Secret. Licensee understands and agrees that the software is the proprietary and confidential property of Scientif ic Software

Tools, Inc. and a valuable trade sec ret. Licensee agrees t o use the software only for the intended use under t his License, and shall not

disclose the software or its contents to any third party.

Copy Restrictions. The Licensee may not modify or translate the program or relat ed documentation without the prior written

consent of Scientific Software Tools, Inc. All modifications, adaptations, and merged porti ons of the software constitute the s oftware

licensed to the Licensee, and the terms and conditions of this agreement apply t o same. Licensee may not distribute copies, i ncluding

electronic transfer of copies, of the modified, adapted or merged software or accompanying written materials to others. Licens ee agrees

not to reverse engineer, decompile or disassemble any part of the software.

Unauthorized copying of the software, including software that has been modif ied, merged, or included with other software, or of the

written materials is expressly forbidden. Licensee may not rent, transf er or lease the software to any third parties. Licensee agrees to

take all reasonable steps to protect Scientific Software Tools’ software from theft, disclosure or use contrary to the terms of the License.

License. Scientific Software Tools, Inc. grants the Licensee only a non-exclusive right t o use the serialized copy of the software on a

single terminal connected to a single computer. The Licensee may not network the software or use it on more than one computer or

computer terminal at the same time.

Term. This License is effective until terminated. This License will terminate automatically without notice from Scientific Software

Tools, Inc. if Licensee fails t o comply with any term or condition of this Lic ense. The Licensee agrees upon suc h terminat ion to return or

destroy the written materials and all copies of the software. The Licensee may terminat e the agreement by returning or destroying the

program and documentation and all copies thereof.

DriverLINX Counter/Timer User’s Guide Preface • 7

Page 8

Limited Warranty

Scientific Software Tools, Inc. warrants that the software will perform substantially in accordance with the written materials and that

the program disk, instructional manuals and reference materials are free from defects in materials and workmanship under normal use for

90 days from the date of receipt. All express or implied warranties of the software and related materials are limited to 90 days.

Except as specifically set forth herein, t he software and accompanying writt en materials (including i nstructions for use) are provided

“as is” without warranty of any kind. Furt her, Scientific Software Tools, Inc. does not warrant, guarantee, or make any represent atio ns

regarding the use, or the results of the use, of the software or written materi als in terms of correctness, accuracy , reliability, c urrent ness,

or otherwise. The entire risk as to the results and performance of the software is assumed by Licensee and not by Scientific Software

Tools, Inc. or its distributors, agents or employees.

EXCEPT AS SET FORTH HEREIN, THERE ARE NO OT HER WARRANTIES, EITHE R EXPRESS OR IMPL IED, I NCLUDING BUT

NOT LIMITED TO IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, WITH

RESPECT TO THE SOFTWARE, THE ACCOMPANYING WRITTEN M AT ERIALS, AND ANY ACCOMPANYING HARDWARE.

Remedy. Scientific Software Tools’ entire liability and the Lic ensee’s exclusive remedy shall be, at Scientific Software Tools’ opt ion,

either (a) return of the price paid or (b) repair or replacement of the software or ac companying materials. In the event of a defect in

material or workmanship, the item may be returned withi n the warranty period to Scientific Software Tools for a replacement without

charge, provided the licensee previously sent in the limited warranty registration card to Sc ientific Software Tools, Inc., or can furnish

proof of the purchase of the program. This remedy is void if failure has resulted from accident, abus e, or mis appl ication. Any replacement

will be warranted for the remainder of the original warranty period.

NEITHER SCIENTIFIC SOFTWARE TOOLS, INC. NOR ANYONE ELSE WHO HAS BEEN INVOLVED IN THE CREATION,

PRODUCTION, SALE OR DELIVERY OF THIS PRODUCT SHALL BE LIABLE FOR ANY DIRECT, INDIRECT, CONSEQUENTI AL,

OR INCIDENTAL DAMAGES (INCLUDING DAMAGE S FOR LOSS OF BUSINESS PROFITS, BUSINESS I NTERRUPTION, L OSS OF

BUSINESS INFORMATION AND THE L I KE) ARI SING OUT OF THE USE OF OR THE INABILITY TO USE SUCH PRODUCT EVEN IF

SCIENTIFIC SOFTWARE TOOLS HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. BECAUSE SOME

JURISDICTIONS DO NOT ALLOW THE EXCLUSION OR LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL

DAMAGES, OR LIMITATIONS ON DURATION OF AN IMPLIED WARRANTY , THE ABOVE LIMITATIONS MAY NOT APPLY TO

LICENSEE.

This agreement is governed by the laws of the Commonwealth of Pennsylvania.

8 • Preface DriverLINX Counter/Timer User’s Guide

Page 9

About DriverLINX

Welcome to DriverLINX for Microsoft Windows, the high-performance real-

time data-acquisition device drivers for Windo ws application development.

DriverLINX is a language- and hardware-independent application-programming

interface designed to support hardware manufacturers’ high-speed analog, digital,

and counter/timer data-acquisition boards in Windows. DriverLINX is a multi-user

and multitasking data-acquisition resource manager providing more than 100

services for foreground and background data acquisition tasks.

Included with your DriverLINX package are the following items:

• The DriverLINX DLLs and drivers supporting your data-acquisition

hardware

• Learn DriverLINX, an interactive learning and demonstration program

for DriverLINX that includes a Digital Storage Oscilloscope

• Source code for the sample programs

• The DriverLINX Application Programming Interface files for your

compiler

• DriverLINX On-line Help System

• DriverLINX 4.0 Installation and Configuration Guide

• DriverLINX Technical Reference Manual

• Supplemental Documentation on DriverLINX and your data acquisition

hardware

About This Programming Guide

The purpose of this manual is to help you quickly learn to program DriverLINX for

counter/ti mer operat i ons with your hardware.

• For help installing and configuring your hardware and DriverLINX,

please see the hardware manuals that accompanied your board and the

DriverLINX 4.0 Installation and Configuration Guide for your version

of Windows.

• For more information on the DriverLINX API, please see the on-line

DriverLINX Technical Reference Manual.

• For additional help programming your board, please exa mine the

source code examples on the Distribution Disks.

This manual is divided into the following chapters:

Why Use a Counter/Timer Device Driver

Brief discussion of why modern operating systems require device drivers.

Introducing DriverLINX

Presents a quick overview of DriverLINX’s hardware and programming model.

Counter/Timers and DriverLINX

Describes how DriverLINX’s hardware model supports counter/timer boards.

DriverLINX Counter/Timer User’s Guide Preface • 9

Page 10

Programming Counter/Timers with DriverLINX

Explains how to program counter/timer tasks.

Using Task-Oriented Functions

Describes counter/timer functions that DriverLINX defines with a task orientation

rather than a hardware orientation.

Hardware Reference

Describes Intel 8254, KPCI-3140 and Am9513 operating modes and how they map

onto the DriverLINX programming model.

10 • Preface DriverLINX Counter/Timer User’s Guide

Page 11

Conventions Used in This Manual

The following notational conventions are used in this manual:

• A round bullet identifies itemized lists (•).

• Numbered lists indicate a step-by-step procedure.

• DriverLINX Application Programming Interface and Windows macro

and function names are set in bold when mentioned in the text.

• DriverLINX indicates the exported function name of the device driver

DLL while DriverLINX indicates the product as a whole.

• DriverLINX Application Programming Interface identifiers, menu

items, and Dialog Box names are italicized when mentioned in the text.

• Italics are used for emphasis.

• Source code and data structure examples are displayed in Courier

typeface and bounded by a box with a single line.

Code

• A box with a double line bound tables of information.

Tables

Concept

• Important concepts and notes are printed in the left margin.

DriverLINX Counter/Timer User’s Guide Preface • 11

Page 12

Page 13

Why Use a Counter/Timer Device

Driver

Using Direct Hardware I/O

Most counter/timer devices are simple devices to program. For years most

application developers wrote directly to the I/O hardware using the CPU’s I/O

instructions (inp and outp) or using Peek and Poke statements in Basic. This was

simple, fast, and efficient and required a minimal learning curve.

Under Windows 3.x, C/C++ developers could use these same techniques for most

ports despite Microsoft’s strong recommendation against doing so. Visual Basic

programmers, however, found that Microsoft had removed all direct I/O statements

from the language, but they quickly discovered they could replace the missing

statements with calls to simple DLLs.

With the arrival of Windows NT, direct hardware I/O in user applicatio ns is not

physically possible. Hardware I/O in DOS and Win16 apps may appear to execute,

but the CPU never actually executes the I/O instructions. In Win32 apps hardware

I/O instructions generate a “privileged instruction exception” and terminate the

offending app.

To perform user-level I/O in Windows NT and future versions of Windows 95, the

operating system requires that applications communicate with the hardware using a

device driver. Modern device drivers are effectively trusted operating system

extensions that have more privileges than ordinary user-mode applications, DLLs,

and services.

Advantages of Device Drivers

Using device drivers to control hardware offers an application in a modern

multitasking, multithreaded operating system several advantages and one major

disadvantage. The application advantages of the device driver model are

• hardware-independent access to boards belonging to a class of devices,

• resource sharing of a single physical device among multiple

applications and/or threads,

DriverLINX Counter/Timer User’s Guide Why Use a Counter/Timer Device Driver • 13

Page 14

• resource arbitration when multiple device users contend for the same

hardware resources, and

• system security either at the logical level of authorized device users or

at the physical level of preventing misuse of a device.

The main disadvantage of the device driver model is the extra overhead the system

requires to communicate device requests between the application, the device driver,

and the hardware. For device requests, such as acquiring a million data samples

in one request, the overhead is negligible, but for acquiring one sample using a

million separate requests, the time penalty is significant. For this reason,

developers must often redesign the protocols and algorithms that worked well in a

single-tasking OS, such as DOS, for use in a multitasking system, such as Windows

NT.

14 • Why Use a Counter/Timer Device Driver DriverLINX Counter/Timer User’s Guide

Page 15

Introducing DriverLINX

About DriverLINX

The DriverLINX Distribution

Disks contain many sample

programs for a variety of

hardware devices. Many

samples will not work with

counter/timer devices.

Welcome to DriverLINX for Microsoft Windows. DriverLINX is a language and

hardware-independent, high-performance, real-time, data-acquisition device driver

for 16 and 32-bit Windows 3.x, Windows 95 and Windows NT. DriverLINX

supports an abstract hardware model for generalized data-acquisition hardware that

includes analog and digital I/O as well as counter/timer functions.

This chapter briefly surveys the DriverLINX hardware and programming model. The

on-line DriverLINX Technical Reference Manual included with the DriverLINX

package is the complete, board-independent specification for the abstract

DriverLINX hardware model. Whether or not you are familiar with DriverLINX

programming, this guide will ease your learning curve by focusing on just the

counter/timer subsystem programming model.

DriverLINX Hardware Model

DriverLINX Driver

Each DriverLINX driver supports one or more models of a device series in a

manufacturer’s product line. You can control multiple products from different series

by opening several DriverLINX drivers. You can program each product using

different “Service Requests” for each overlapping data-acquisition task.

Logical Devices

A single DriverLINX driver can support multiple boards from its list of supported

models. During configuration, you assign each physical device a Logical Device

number that you use to identify a particular board to DriverLINX. At run time,

applications can determine the manufacturer, model name, I/O address, and hardware

resources of a Logical Device by consulting DriverLINX’s Logical Device

Descriptor.

DriverLINX Counter/Timer User’s Guide Introducing DriverLINX • 15

Page 16

Logical Subsystems

DriverLINX treats all data-acquisition devices uniformly as abstract hardware

consisting of seven possibl e subsystems.

• DEVICE—the physical hardware considered as a whole.

• AI (Analog Input)—the A/D converters, multiplexers, and associated

hardware.

• AO (Analog Output)—the D/A converters and associated hardware.

• DI (Digital Input)—the digital input ports and associated hardware.

• DO (Digital Output)—the digital output ports and associated hardware.

• CT (Counter/Timer)—the counter/timer channels and associated

hardware.

DriverLINX’s Logical Device Descriptor contains properties specifying which

Logical Subsystems are available for a particular device. Counter/timer boards

always support the DEVICE and CT subsystems, and some boards support

additional subsystems, such as DI and DO.

Logical Channels

The subsystems, except DEVICE, consist of one or more data channels known as

Logical Channels. Usually a Logical Channel corresponds to one hardware channel,

but, for some boards, DriverLINX may use multiple Logical Cha nnel numbers to

access a group of hardware channels using different data widths. DriverLINX

records the number of Logical Channels and their capabilities in the Logical Device

Descriptor.

DriverLINX Programming Model

Programming DriverLINX for data-acquisition tasks differs from the approach you

may have used previously. Most vendors’ data-acquisition packages consist of thick

documents describing hundreds of hardware-specific calls to configure and program

a data-acquisition board. DriverLINX, in contrast, uses a board-independent list of

properties to specify the parameters for a data-acquisition t a sk.

All data-acquisition tasks in DriverLINX use the same, simple three-step protocol:

1. Decide how you want to acquire data.

2. Specify your task by setting the properties of an object or data structure

known as the Service Request.

3. Pass the Service Request to DriverLINX, which sets up the hardware

and acquires the data for you.

The power of the Service Request approach is that you use the same structure for all

data-acquisition tasks on any supported hardware. Once you understand how to

program one type of device, you can use that knowledge to program any other

supported device.

To notify an application of the progress or error conditions detected during a dataacquisition task, DriverLINX sends the application a series of messages just as

Windows sends messages to an application’s message loop. This feature allows an

16 • Introducing DriverLINX DriverLINX Counter/Timer User’s Guide

Page 17

application to overlap data processing with data acquisition and easil y synchronize

the two activities.

Most data-acquisition drivers manage a hardware board exclusively for one

application. DriverLINX, however, manages the subsystems of a hardware board as

a shared resource that multiple applications or threads can share. If your hardware

board has the necessary features, DriverLINX supports running multiple,

independent tasks concurrently on one board.

Logical Device Descriptors

DriverLINX does not require

that applications reference or

use the LDD to program

data-acquisition tasks.

The on-line DriverLINX

Technical Reference Manual

defines the DriverLINX

Specification for all dataacquisition boards.

Using DriverLINX for a

specific board requires

learning just the supported

properties for the board.

For writing hardware-independe nt applications, you may need to know the hardware

specifications of the board your program is controlling. DriverLINX ma kes this

information available to your program with another device-independent data

structure known as the Logical Device Descriptor (LDD). The LDD contains

information about number and types of data channels on the board, the allowed

operating modes and commands, and many other details. For more information, see

the on-line DriverLINX Technical Reference Manual.

Service Requests

The most important DriverLINX concept to understand is the Service Request. This

is the object, data structure, or form that you use to specify all data-acquisition tasks.

As much as is possible, DriverLINX treats all data-acquisition tasks as similar

using the same concepts and properties to define each possible task.

The key to learning how to specify a Service Request is first learning the major

groups of a Service Request, and then learning the properties for each group.

A Service Request consists of four major property groups:

• Request Group—specifies the target Logical Device and Logical

Subsystem of a task and the data-acquisition mode and operation to

perform.

• Events Group—specifies how DriverLINX should time or pace data

acquisition, when DriverLINX should start acquisition, and when it

should end.

• Select Group—specifies the Logical Channels to acquire and the

number and length of data buffers to acquire.

• Results Group—DriverLINX uses these properties to return result

codes and single data values.

You can fill out Service Requests either interactively using the Edit Service Request

Property page in DriverLINX or programmatically by assigning values to the

required properties in each group.

DriverLINX Counter/Timer User’s Guide Introducing DriverLINX • 17

Page 18

Summary

C/C++ Interface

If you are using C/C++, the Service Request is a C data struc ture type definition.

Create an instance of the data structure, set all fields to zero, and then assign the

proper values to each needed property in the groups. After setting up the Service

Request, pass the address of the Service Request to DriverLINX for execution.

DriverLINX will report information about the task back to t he app lication using

Windows messa ges.

Control Interface

If you are using the Visual Basic custom control (VBX) or ActiveX (OLE or OCX)

version of DriverLINX, the Service Request is an instance of the control o bject on

your form or dialog. Assign the proper values to the needed properties for your task.

Then tell DriverLINX to execute the Service Request by calling the Refresh method

for the control. DriverLINX will report information about the task back to the

application using control events.

DriverLINX provides a hardware-independent, abstract model of data-acquisition

hardware co nsisting of seven possible Logical Subsystems. Each Logica l Subsystem

treats data-acquisition tasks as conceptually similar. Develo pers program dataacquisition tasks by setting up the proper ties in the Request, Event, and Select

Groups of a Service Request.

The on-line DriverLINX Technical Reference Manual def ines the DriverLINX

Specification for all data-acquisition boards. Using DriverLINX for a particular

board requires learning the supported properties for the hardware.

18 • Introducing DriverLINX DriverLINX Counter/Timer User’s Guide

Page 19

Counter/Timers and DriverLINX

Counter/Timer Hardware Description

Most counter/timer boards use either the Intel 8254 Programmable Interval Timer or

the AMD Am9513 System Timing Controller. The Intel 8254 is a much simpler

device than the Am9513 chip, and the 8254 has limited capabilities without external

circuitry and connections. Most vendors use the 8254 for clock generation on dataacquisition devices, but, for stand-alone counter/timer devices, the y usually use the

more complex Am9513 chip or proprietary chips as in the Keithley KPCI-3140 (and

the compatible KPCI-3100 Series).

The DriverLINX Counter/Timer programming model supports diverse hardware

using a common programming model. Although the programming model is common,

developers should understand the inherent hardware differences among counter/timer

chips if they need to write applications to support different counter/timers. The

following sections present an overview of hardware features of these chips.

Intel 8254

The Intel 8254 provides three 16-bit timing channels per chip that support six pulse

and frequency generation modes. The Intel 8254 is capable of simple event counting,

rate and square wave generation, one-shot, and strobe applications.

The following table describes the six operation modes and variations of the Intel

8254 counter/timer chip. For a detailed description of these modes, see “8254

Operating Modes” on page 113.

Mode Description

0 Event counting

1 Hardware retriggerable one-shot

2 Rate generator

3 Square wave generator

4 Software triggered strobe

5 Retriggerable hardware triggered strobe

Table 1 Designations for 8254 Counter/Timer Modes

DriverLINX Counter/Timer User’s Guide Counter/Timers and DriverLINX • 19

Page 20

Without external circuitry, however, the Intel 8254 does not support selectable clock

sources, gating control, or output polarity. The effect of the gate input on counting is

a function of the selected mode. The 8254 has no built-in frequency prescaler and

only counts in binary.

For more information, see the Intel 8254 Programmable Interval Timer data sheet

and your counter/timer hardware User’s Guide.

KPCI-3140 Counter/Timer Chip

The counter/timer chip in the Keithley KPCI-3140 and KPCI-3100 Series provides

four 16-bit timing channels per chip that support 3 pulse and frequency generation

modes. In addition, the chip has two 24-bit counters but the onl y counter/ti mer

function they can perform is to pace interrupt mode tasks.

The following table describes the three operation modes of the KPCI-3140

counter/timer chip. For a detailed description of these modes, see “KPCI-3140

Operating Modes” on page 116.

Mode Description

0 Non-retriggerable One-shot

1 Retriggerable One-shot

2 Continuous Increment

Table 2 Designations for KPCI-3140 Counter/Timer Modes

Am9513

The Am9513 provides five 16-bit timing channels per chip that support 19 pulse and

frequency generation modes. In addition, the Am9513 supports a variety of software

options to electronically interconnect counter channels and to program outputs. The

Am9513 allows software to select 16 counting sources and 5 output modes

independent of the chip’s operating mode. This chip has five built-in frequency

prescalers and can count in either binary or binary coded decimal (BCD) modes.

When using the prescalers in binary mode, each counter channel has an effective

dynamic range of 32-bits.

The following table describes the 19 operation modes of the Am9513 and AMD’s

letter designation for each mode. For a detailed description of these modes, see

“Am9513 Operating Modes” on page 117.

Mode Description

A Software triggered Strobe with no hardware gating

B Software triggered Stro b e with level gating

C Hardware triggered Stro b e

D Rate Generator with no hardware gating

E Rate Generator with level gating

F Non-retriggerable One-Shot

G Software triggered delayed Pulse one-shot

H Software triggered delayed Pulse one-shot with hardware gating

20 • Counter/Timers and DriverLINX DriverLINX Counter/Timer User’s Guide

Page 21

Mode Description

I Hardware triggered delayed Pulse strobe

J Variable Duty Cycle rate generator with no hardware gating

K Variable Duty Cycle rate generator with level gating

L Hardware triggered delayed Pulse one-shot

N Software triggered Strobe with level gating and hardware retriggering

O Software triggered Strobe with edge gating and hardware retriggering

Q Rate Generator with synchronization

R Retriggerable One-Shot

S Delayed Pulse one-shot with level-selected reloading

V

X Rate Generator with edge gating

Table 3 Letter Designations for Am9513 Counter/Timer Modes

Frequency -Shift Keying

Each Am9513 chip occupies 2 consecutive I/O addresses. The first location

addresses a control port and the second a data port.

The Am9513 can be a complex chip to learn, program, and use because of its rich

feature set. For detailed hardware information, consult Advanced Micro Devices’

Am9513A/Am9513 System Timing Controller Technical Manual and your

counter/timer hardware user’s guide.

DriverLINX Counter/Timer Model

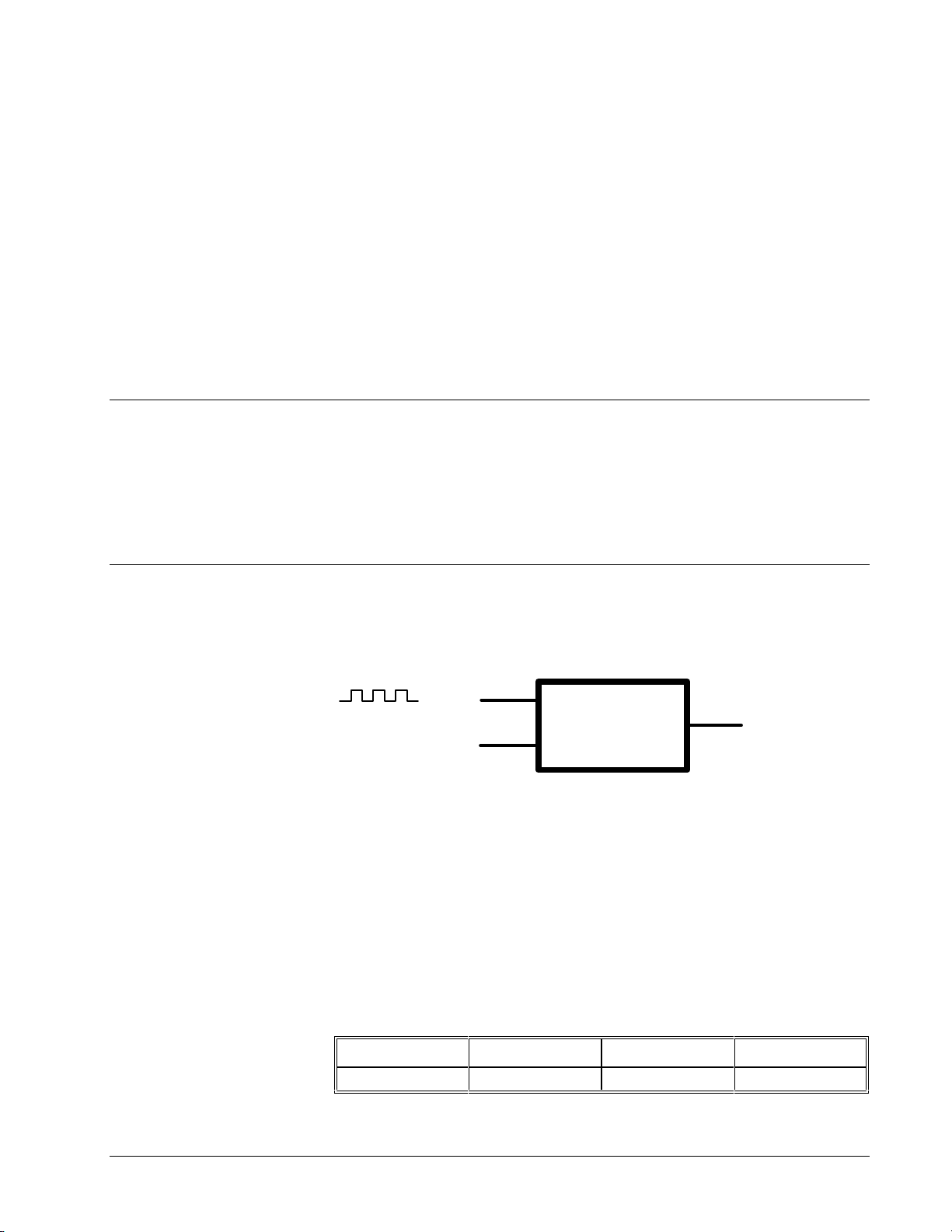

Figure 1 DriverLINX Counter/Timer Model

DriverLINX abstracts all counter/timer hardware chips as an array of three terminal

devices. The terminals of an individual counter/timer are

• Clock—the source input for dividing down to a lower frequency or for

counting external events.

• Gate—the control input for triggerin g, re-triggeri ng, or gating the

counter/timer operation.

• Output—the counter/timer output frequency, pulse, or stro be.

DriverLINX associates with each counter/timer channel four operating properties.

The properties are

• Mode—defines the operational task for the counter/timer channel.

• Period—defines the cycle period or divisor for the counter/timer

channel.

DriverLINX Counter/Timer User’s Guide Counter/Timers and DriverLINX • 21

Page 22

• OnCount—defines high duration of the period for asymmetrical output

trains or pulses.

• Pulses—defines the number of periods to generate.

22 • Counter/Timers and DriverLINX DriverLINX Counter/Timer User’s Guide

Page 23

Capabilities of DriverLINX’s

f

counter/timer subsystem

depend on the hardware

eatures of your board.

By selecting values for these seven properties and, where necessary, making the

appropriate connections between counters, applications can program DriverLINX to

execute one of the counter/timer’s basic operating modes or the following

counter/timer operations and tasks:

• Event counting—16-, 32-, and 64-bit counters for signals at the Clock

input.

• Frequency measurement—16- and 32-bit frequency measurement.

• Interval measurement—Measure time between two consecutive

pulses at a single input or two pulses at separate inputs.

• Period and pulse width measurement—Measure duration of each

cycle or half cycle.

• Pulse generation—Generate a variety of one-shot pulses and strobes.

• Frequency generation—Generate periodic pulse trains, variable duty

cycle waveforms, square waves, or input-modulated waveforms.

Applications may program and operate counter/timers independently, or they may

configure the operating mode for several counter/timers and start or stop them

synchronously. For hardware boards that support interrupts, applications may

program a list of timers whose current value DriverLINX will read into a buffer on

each interrupt.

The following tables show the legal values for the Clock, Gate, Output, and Mode

fields of a DriverLINX logical counter channel. Note that the capabilities of the Intel

8254 are a subset of the Am9513’s capabilities.

Clocks

The Clock property specifies the source input for the abstract counter/timer of a

Logical Channel.

Clock Description Intel 8254 KPCI-3140 Am9513

Internal1..

Internal5

Source1..

Source5

Gate1..

Gate5

External External clock frequency

ExternalPE External clock frequency

ExternalNE Ext ernal clock frequency

TCNm1 Use channel N-1 terminal

Table 4 Allowed Values for Rate Event Clock Property

Internal clock frequency

prescaled at 1 of 5 taps

Use channel 1..5 source

(clock) input

Use channel 1..5 gate input no no yes

(usually positive edge)

(positive edge clocking)

(negative edge clocking)

count output

yes

(Internal1

only)

no no yes

yes yes yes

yes yes yes

no yes yes

no yes yes

yes (Internal1

only)

yes

DriverLINX Counter/Timer User’s Guide Counter/Timers and DriverLINX • 23

Page 24

• For the Am9513-based counter/timers, you may also request that the

clock input use the negative-going edge of the clock input rather than

the positive edge.

• Internal1 always designates the onboard hardware clock.

Internal2..Internal5 designate lower frequency taps of the master clock

if the hardware supports this capability.

• If the application uses an Internal1 clock with a Period value greater

than the hardware counter/timer supports, DriverLINX will

automatically select available hardware prescalers to obtain the closest

value to the requested Period.

Gates

The Gate property selects how the abstract counter/timer uses the gate input of a

Logical Channel. Generally, this input gates the counting or measuring process or

triggers the counter/timer operation.

Gate Description Intel 8254 KPCI-3140 Am9513

Enabled Enable gate yes yes yes

Disabled Enable gate no* yes yes

NoConnect No connection modes 0,2-4 yes yes

LoLevel

GateN

LoEdge

GateN

HiLevel

GateN

HiLevel

GateNp1

HiLevel

GateNm1

HiTcNm1 Positive edge at terminal

HiEdge

GateN

Logic low level at gate input N no mode 2 yes

Negative edge at gate input N no modes 0,1 yes

Logic high level at gate

input N

Logic high level at gate

input N+1

Logic high level at gate

input N-1

count output N-1

Positive edge at gate input N modes 1,5 modes 0,1 yes

modes 0,2-4 mode 2 yes

no no yes

no no yes

no no yes

Table 5Allowed Values for Rate Event Gate Property

*Some boards provide off-chip hardware that can disable the 8254’s gate.

24 • Counter/Timers and DriverLINX DriverLINX Counter/Timer User’s Guide

Page 25

Outputs

The Output property programs the polarity and duty cycle of the abstract

counter/timer’s output port.

Output Description Intel 8254 KPCI-3140 Am9513

Default Depends on operation (see

“Counter Output” on page

55)

LoToggled Start low; toggle at TC yes yes yes

LoActive Active low pulse at TC yes yes yes

LoZ Inactive low impedance

output

Toggled Toggle at TC yes no yes

HiToggled S tart high; toggle at TC yes yes yes

HiActive Active high pulse at TC no yes yes

HiZ Inactive high impedance

output

Table 6 Allowed Values for Rate Event Output Property

DriverLINX automatically selects an output type if the application requests Default.

Depending on hardware capabilities, DriverLINX chooses the output option based on

the requested Mode. The Intel 8254 allows only one output mode, which depends on

the operation.

yes yes yes

no no yes

no no yes

Modes

The Mode property selects the type of rate generator or task the abstract

counter/timer will perform. Mode values fall into two gener a l gro ups—pulse and

wavefor m generators and measurement tasks. Note that the generator modes (e.g.,

RateGen, SqWave, etc.) program a single Logical Channel of an abstract

counter/timer while the measurement modes (e.g., Frequency, Interval, etc.) may

program multiple Logical Channels.

Generator Description Intel 8254 KPCI-3140 Am9513

RateGen Periodic rate generator yes yes yes

SqWave Square wave generator yes yes yes

VDCGen Variable duty cycle rate

generator

BurstGen Burst rate generator no no no

Divider Frequency divider no yes yes

Freq Frequency counter yes yes yes

Interval Interval timer yes no yes

Count Event counter yes yes yes

PulseWd Pulse width measurement yes yes yes

SplitClk Split frequency rate

generator

yes yes yes

no no no

DriverLINX Counter/Timer User’s Guide Counter/Timers and DriverLINX • 25

Page 26

Generator Description Intel 8254 KPCI-3140 Am9513

FskGen Frequency-shift keying no no yes

PulseGen Pulse generator no yes yes

Retrig

RateGen

Retrig

SqWave

Count32 32-bit event counter no yes yes

Count64 64-bit event counter no yes yes

Freq32 32-bit frequency counter no yes yes

FreqRatio Frequency ratio counter no no no

OneShot One-shot pulse or strobe yes yes yes

Retrig

OneShot

Table 7 Allowed Values for Rate Event Mode Property

Retriggerable rate generator no no yes

Retriggerable square wave

generator

Retriggerable one-shot pulse

or strobe

no no yes

yes no yes

• Some of the above mode field options, e.g., BurstGen, specify features

that require external connections, which some vendors have prewired

into their products.

• Other options, such as frequency measurement modes, require external

user connections between counter/timer terminals.

DriverLINX Task Model

To manage a user application’s data-acquisition requests, DriverLINX creates tasks.

A DriverLINX task consists of the set of hardware and system resources and the

board-specific protocols required to execute the data-acquisition request.

Applications can start tasks, monitor tasks, and stop tasks by submitting Service

Requests to DriverLINX.

Hardware Sharing

DriverLINX allows multiple applications to share a data-acquisition device or allows

multiple tasks to run on a device if the hardware can support concurrent operations.

To support hardware sharing and concurrency, DriverLINX assigns resources to each

task and then compares the resource requirements of a new task with the in-use

resources of all current tasks. If the new requirements do not conflict with the current

in-use resources, DriverLINX updates the in-use resources and starts the task.

Otherwise, DriverLINX rejects the newly requested task.

Creating Tasks

User applications create data-acquisition tasks by setting the properties of a Service

Request to values that specify the task. Then the application submits the Service

Request to DriverLINX, which transforms each Service Request into a procedure for

performing the task on the requested hardware subsystem. To execute a new task,

DriverLINX performs the following steps for each Service Request:

26 • Counter/Timers and DriverLINX DriverLINX Counter/Timer User’s Guide

Page 27

A Start operation fills in the

Applications may also check the status of a task or terminate a task by modifying the

taskId property. DriverLINX

uses the taskId to determine

to which task a Status or Stop

operation applies.

1. Audit the Service Request fields to determine if the hardware can

perform the task.

2. Request necessary hardware and system resources to perform task.

3. Con vert the Service Request into the hardware parameters and

protocols to perform the task.

4. Execute the task on the hardware.

5. Notify application of any requested task events as they occur.

6. Wait for the task to complete.

7. Release requested hardware and system resource used by the task.

If DriverLINX detects any errors in the Service Request or in the hardware during

the task, it aborts the task and returns an error code to the application. If the

application requests hardware resources that are already in use by another thread or

process, DriverLINX also stops the task and notifies the application.

Monitoring and Stopping Tasks

operation property of the Service Request used to create the task and resubmitting it

to DriverLINX. To check status, change the operation property to “status”. To

terminate a task, change the operation property to “stop”.

DriverLINX Events

Applications can request that DriverLINX notify the application of significant events

during execution of a task. By designing a data-acquisition task to use events, an

application can overlap data processing with data collection. Events allow the

application to coordinate these two activities without t he overhead associated with

polling for the status of the data collection task and without the scheduling pr oblem

of coordinating data processing with partial data collection.

DriverLINX posts events to an application through t he Windows messaging

mechanism. DriverLINX supports the following messages:

Message Description Posted

ServiceStart Task is starting Default. Can disable.

ServiceDone Task is complete Default. Can disable.

BufferFilled Buffer processing complete Can enable.

DataLost Data over/underrun Always reported.

TimerTic Timer interrupt occurred Non-buffered CT task.

StartEvent Start event detected Can enable.

StopEvent Stop event detected Can enable.

CriticalError Hardware error Always reported.

Table 8 DriverLINX Messages

DriverLINX Counter/Timer User’s Guide Counter/Timers and DriverLINX • 27

Page 28

The most useful events for applications are ServiceDone, BufferFilled, and DataLost.

• The ServiceDone event notifies the application that DriverLINX

terminated the task. Tasks may end because the application stopped it,

the stop event condition in a Service Request was satisfied, or

DriverLINX detected a run-time error and stopped the task.

• The BufferFilled event notifies the application that DriverLINX has

read or written the current buffer. Applications can use this message

with multiple data buffers to eliminate polling the driver for the status

of the task and to overlap data processing with data acquisition.

• The DataLost event notifies the application that DriverLINX detected

that the hardware was filling or emptying buffers faster than the

application or driver could process the buffers.

The other DriverLINX events are useful for special cases.

• The ServiceStart event notifies the application that DriverLINX is

starting the task. An application might use this event to provid e visual

feedback to the user interface that the task is starting.

• The TimerTic event notifies the application that DriverLINX has

processed a clock interrupt. DriverLINX only reports this event for the

counter/timer subsystem when the task is not using data buffers.

• The StartEvent notifies the application that DriverLINX detected that

the logical condition the application specified in the Service Request’ s

Start Event is true. DriverLINX can only report this event if the

hardware generates an interrupt associated with the Start Event.

• The StopEvent notifies the application that DriverLINX detected that

the logical condition the application specified in the Service Request’ s

Stop Event is true. DriverLINX can only report this event if the

hardware generates an interrupt associated with the Stop Event.

• The CriticalError event notifies the application that DriverLINX

detected an unexpected critical error other than DataLost. This usually

indicates either the hardware or software is malfunctioning and needs

repair or re-configuration.

DriverLINX Operations

For most counter/timer hardware, applications can select one of five operations for a

task. The basic counter/timer task operations are

• Initialize—resets the counter/timer subsystem software and/or

hardware.

• Configure—set up a counter/timer for a task, but do not start the task.

• Start—set up and arm a counter/timer for a task. The Gate, Clock, and

Mode properties determine when the hardware starts counting.

• Status—return the current counter/timer count value and status to the

application.

• Stop—disarm the counter/timer task and make the task resources

available for new tasks.

The Initialize, Configure, and Start operations all create a DriverLINX task. The task

that DriverLINX creates for the first two operations exists only briefly during the

28 • Counter/Timers and DriverLINX DriverLINX Counter/Timer User’s Guide

Page 29

application’s function call to DriverLINX. For a Start operation, however,

operation to read the current count value of a counter/timer. The counter/timer

DriverLINX creates a task that may exist indefinitely until the application explicitly

ends the task with a Stop operation or DriverLINX ends the task because the Stop

Event has become true.

DriverLINX Modes

For most counter/timer hardware, DriverLINX supports three task modes, OTHER,

POLLED and INTERRUPT.

• When an application uses OTHER mode, DriverLINX initializes the

subsystem or configures a Logical Channel without starting the

counter.

• When an application uses POLLED mode, DriverLINX starts the

counter/timer hardware running, but it does not automatically report

any status information about the task to the application.

• When an application uses INTERRUPT mode, DriverLINX starts the

counter/timer hardware running with a hard wa re interrupt enabled. At

each interrupt, DriverLINX either sends a TimerTic event to the

application or saves the current count of the requested counter/timers

into a data buffer.

For other subsystems, polled

mode tasks start and stop

before DriverLINX returns

control to the application.

When using polled mode counter/timer operations, DriverLINX return s control to

the application after starting the counter/timer hardware. Applications must use the

Status

task will run until the application ends it with a Stop operation.

When using interrupt mode counter/timer operations, DriverLINX also returns

control to the application after starting the counter/timer hardware. However, if the

application specified data buffers in the Service Request, DriverLINX will

automatically read and store the current counter value(s) into the buffer. The

application may request that DriverLINX read the next Logical Cha nnel in the

Channel list at each interrupt or that DriverLINX read all Logical Channels at each

interrupt. If the application is not using buffers, then DriverLINX sends a TimerTic

event to the application at each interrupt.

Individual and Group Tasks

Applications can control individual counter/timer channels as separate task s or they

can synchronize the starting and stopping of multiple channels. To collect multiple

channels into a group, the application first performs Configure operations on each

channel in the group to set up the hardware. Then the application can start the

channels in the group by executing a Service Request with a Start operation that lists

the group’s channels in the Service Request’s channel list. By using a Stop operation

instead, the application can simultaneously stop all channels in the group. For more

information, see “Group Tasks” on page 38.

Mapping Logical Channels to Counter/Timer Hardware

Channels

DriverLINX maps the hardware’s counter/timer channels to consecutive Logical

Channels. The following table shows the correspondence between the hardware

channels and Logical Channels. Note that DriverLINX always uses zero-based

DriverLINX Counter/Timer User’s Guide Counter/Timers and DriverLINX • 29

Page 30

numbering for Logical Channels while vendors often use one-based channel

numbering.

Logical

Channel

CTM-05 1 2 3 4 5

CTM-05A 1 2 3 4 5

CTM-10 1A 2A 3A 4A 5A 1B 2B 3B 4B 5B

Table 9 Map of Logical Channels to Counter/Timer Hardware Channels

For other models, see the appropriate Using DriverLINX with your Hardware

manual.

Digital I/O Hardware

0 1 2 3 4 5 6 7 8 9

Software cannot read or

control the strobe lines for

digital inputs without external

connections.

The MetraByte counter/timer boards support one or more digital I/O ports. The

CTM-05/A board has one 8-bit digital input port with latch and one 8-bit digital

output port with latch. The CTM-10 board has two 8-bit digital input ports with

latches and two 8-bit digital output ports with latc hes. A strobe line input at each

input port controls whether the input data passes through the latch or is held by the

latch. There is no software control over this strobe line. For more infor mation, see

the CTM-10 and CTM-05/A User’s Guide.

These digital ports are physically independent of the counter/timers and do not have

any internal connections to the counter/timers. Also, the digital I/O ports do not

generate any hardware interrupts. Applications can read or write the digital ports

independently of the counter/timers. DriverLINX does support reading a digital input

port at each counter/timer interrupt to start or stop a counter/timer task.

The CTM Ser ies boards also have a digital input line that generates a hardware

interrupt. DriverLINX models this line as a special-purpose, 1-bit digital input

channel. Associated with the interrupt input line is another external input line t hat

enables or disables the interrupt input line. DriverLINX has no direct hardware

control over this gating line.

For other models, see the appropriate Using DriverLINX with your Hardware

manual for details on digital I/O features.

30 • Counter/Timers and DriverLINX DriverLINX Counter/Timer User’s Guide

Page 31

Mapping Logical Channels to Digital Hardware Channels

DriverLINX maps the hardware’s digital channels to consecutive Logical Channels.

The following table shows the correspondence between the hardware chan nels and

Logical Channels. Note that DriverLINX always uses zero-based numbering for

Logical Cha nnels while vendors often use one-ba sed channel numbering.

Logical

Channel

CTM-05 Port A I/O external interrupt

CTM-05A Port A I/O external interrupt

CTM-10 Port A I/O Port B I/O external interrupt

Table 10 Map of Logical Channels to Digital Hardware Channels

To support writing hardware-independent applications, DriverLINX assigns special

fixed Logical Channel numbers as aliases for the Logical Channel of an external

interrupt line.

For other models, see the appropriate Using DriverLINX with your Hardware

manual for details on digital I/O features.

Properties of Logical Channels

0 1 2

DriverLINX also supports bitlevel I/O using masks. See

“Reading or Writing Specific

Digital Bits” on page 72.

The hardware design of the digital channels on the CTM Series does not support

reading back the last value written to a digital output port. Writing Logical Channel 0

outputs data to a physically different latch than when an application reads Logical

Channel 0. If needed, applications must maintain their own shadow copies of the

values written to a digital output port.

Applications that want to shar e an output port with another thread or process can do

so without knowing the current output value of the port. Use either bit-level I/O (see

“Reading or Writing Specific Digital Bits” on page 72) or extended Logical Channel

addressing (see “Combining or Splitting Logical Channels” on page 31).

Combining or Splitting Logical Channels

DriverLINX supports a software extens ion to Logical Channel addressing that

allows applications to combine adjacent Logical Channels into a single channel or

split a Logical Channel into smaller addressable parts. For instance, applications can

address individual bits on the digital I/O board o r read and write multiple channels

with a single operation.

To use the Logical Channel addressing extensions, form a 16-bit Logical Channel

address by combining the channel number of an addressable unit with a size field as

follows:

DriverLINX Counter/Timer User’s Guide Counter/Timers and DriverLINX • 31

Page 32

Always 0 Size Channel

Bits

Range

Table 11 Field Layout of an Extended Logical Channel Address

15 14..12 11..0

0..1 0..7 0..4095

The following table specifies the 3-bit size codes:

Size Code Unit Bits

0 native varies with hardware

1 bit 1

2 half nibble 2

3 nibble 4

4 byte 8

5* word 16

6* dword 32

7* qword 64

Table 12 Size Codes for Extended Logical Channel Address

* Neither the CTM-05/A nor CTM-10 support 32- or 64-bit digital I/O, and the

CTM-05/A does not support 16-bit digital I/O.

“Native” units refer to the hardware-defined digital channel size. For most boards,

this is the same as an 8-bit byte. When using extended Logical Channel addressing,

DriverLINX groups digital bits in units defined by the size code and then assigns

consecutive channel numbers starting from zero. For instance, a CTM-10 with two 8bit ports would have the following channel addresses for each size code:

Unit Channels Address (dec) Address (hex)

native 0..1 0..1 0..1

bit 0..15 4096..4111 1000..100F

half nibble 0..3 8192..8195 2000..2003

nibble 0..2 12288..12290 3000..3002

byte 0..1 16384..16385 4000..4001

word 0 20480 5000

32 • Counter/Timers and DriverLINX DriverLINX Counter/Timer User’s Guide

Page 33

Implementation Notes

• For extended Logical Channel addressing of unit sizes less than the

native size, DriverLINX only supports single-value transfers.

• For block I/O transfers, DriverLINX only allows Logical Channel

addressing at unit sizes equal or larger than the native size. Note that

extended Logical Channels may not map to consecutive physical

channels. Because DriverLINX uses the CPU’s block I/O instructions

for polled, block I/O transfers, some bytes will not represent I/O ports.

• When using size codes larger than the native addressing unit, you may

not be able to address all hardware ports if the number of available

digital I/O lines is not an integral multiple of the size unit.

DriverLINX Counter/Timer User’s Guide Counter/Timers and DriverLINX • 33

Page 34

Page 35

Programming Counter/Timers

with DriverLINX

DriverLINX Counter/Timer Operations

The DriverLINX API is

available as a C/C++, VBX,

or ActiveX interface. See

“Interfacing to DriverLINX”

on page 43.

This chapter describes how to control your counter/timer b oard using the

DriverLINX API for the most common tasks. Each section presents background

information and concepts for performing a particular task and then presents

DriverLINX procedures in C/C++ and Visual Basic for a task. Users of other

programming languages should use the ActiveX control interface for DriverLINX

and look at the Visual Basic examples for how to program tasks.

The DriverLINX counter/timer model provides over 12,000 potential configurations

for each counter/timer channel. If you allow for interconnecting counter/timer

channels, the number of potential combinations is staggering. Naturally, real

hardware only supports a subset of possible configurations. To keep things

manageable, follow these simple steps:

1. Decide the basic task category you need—event counting, frequency

measurement, interval measurement, period and pulse width

measureme nt , pulse and st robe generation, frequency generation.

2. Go to the section of t his guide that describes using a counter/timer for

your task.

3. Decide if you need a repe titive or non-repetitive measurement or

waveform generation.

4. Decide if you need trig gering (ris ing or falling edge) or ga ting (active

high or low levels).

5. Look at the Rate Event Properties tables for your task to determine if

DriverLINX supports your require ments.

6. Look at “Counter Output” on page 55 to set up the counter/timer

output.

If the Rate Event Properties tables do not show an entry for your requirements, then

you may need additional external hardware and/or multiple counter/timer chan nels to

support your task. Look at “Hardware Reference” on page 113 Operating Modes to

see if any of the basic hardware modes, alone or in combination, will meet your

requirements. If so, look for the corresponding mode in one of the Rate Event

Properties tables and configure each counter/timer channel as shown. If you do not

DriverLINX Counter/Timer User’s Guide Programming Counter/Timers with DriverLINX • 35

Page 36

find what you are seeking, then you will need to design some external hardware for

your application.

DriverLINX Tasks for All Subsystems

The following DriverLINX tasks are common for all subsystems and all supported

hardware boards:

• Connecting to a driver—DriverLINX requires applications to open,

select, and close drivers for specific boards. See “Opening and Closing

a DriverLINX Device Driver” on page 44.

• Selecting a driver—DriverLINX allows your application to co ntrol

multiple different types of hardware boards. See “Selecting a

DriverLINX Device Driver” on page 46.

• Edit a Service Request—DriverLINX allows your application to

display the Edit Service Request property page to quickly test or modify

Service Requests during application development. See “Displaying the

Edit Service Request Dialog” on page 47.

• Error reporting—Applications can use DriverLINX to display

DriverLINX errors in message boxes. See “Reporting a DriverLINX

Error” on page 48.

• Stopping a task—Applications can use a Service Request to stop a

DriverLINX task. See “Stopping A DriverLINX Task” on page 49.

• Device initialization—DriverLINX requires your application to

initialize all subsystems on a board before performing any other tasks.

See “Initializing the Device” on page 50.

• Subsystem initialization—Applications can initialize a single,

specified subsystem. See “Initializing a Counter/Timer Subsystem” on

page 51.

• Using DriverLINX messages a nd events—DriverLINX reports task

information to your application using the Windows messages or events.

See “Using Messages and Events” on page 52.

DriverLINX Tasks for Counter/Timer Subsystem

The following DriverLINX tasks are specific to the counter/timer subsystem:

• Counter output—DriverLINX defines defaul t output signals for

counter/timer channels as well as application-defined output s. See

“Counter Output” on page 55.

• Status polling—Applications can use a Service Request to monitor the

current value and status of a counter/timer. See “Status Polling a

Counter/Timer” on page 56.

• Configuring a counter/timer—Applications can configure and arm a

counter/timer without actually starting the counter. See “Configuring a

Counter/Timer Channel” on page 57.

• Converting between counts and time—DriverLINX supp orts

methods to convert between counter tics and time. See “Converting

Between Counts and Time” on page 58.

36 • Programming Counter/Timers with DriverLINX DriverLINX Counter/Timer User’s Guide

Page 37

The following task-oriented functions, although specific to the counter /timer

subsystem, are defined to be portable across data-acquisition boards:

• Event counting—DriverLINX supports counting external events using

16-, 32-, or 64-bit counters. See “Using Task-Oriented Functions” on

page 79.

• Frequency measurement—DriverLINX supports counting events for

a known time period. See “Frequenc y Measurement” on page 85.

• Interval measurement—DriverLINX can measure the interval

between two pulses on a single input line or on two separate input lines.

See “Interval Measurement” on page 92.

• Period and pulse width measurement—Driver LINX can measure the

duration or period of a single cycle of an input or the duration of the

positive or negative half cycle of an input. See “Period and Pulse Width

Measurement” on page 96.

• Pulse and strobe generation—DriverLINX can generate a variety of

single, delayed pulses and strobes. See “Pulse and Strobe Generation”

on page 101.

• Frequency generation—DriverLINX can generate a variety of pulse

trains, variable duty cycle wavefo rms, square waves, and frequencyshift keyed waveforms. See “Frequency Generation” on page 107.

Foreground Tasks

The simplest technique for your application to control counter/timers with

DriverLINX is to use a foreground task. Your application starts a counter/timer using

a DriverLINX Service Request with the Mode property set to “Polled” and the

Operation property set to “Start”. DriverLINX will configure, arm, and start a

counter/timer task.

If your application needs to monitor the current count of the counter/timer, it should

poll the counter/timer’s status. See “Status Polling a Counter/Timer” on page 56.

DriverLINX will return to your application the current count value with each Service

Request. See “Converting Between Counts and Time” on page 58 for how to convert

a count to seconds.