x

Tektronix BERTScope

Bit Error Rate Analyzers

BSA85C, BSA125C, BSA175C, BSA260C, BSA286C

ZZZ

Quick Start User Manual

*P071286903*

071-2869-03

xx

Tektronix BERTScope

Bit Error Rate Analyzers

BSA85C, BSA125C, BSA175C, BSA260C, BSA286C

ZZZ

Quick Start User Manual

www.tektronix.com

071-2869-03

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or suppliers, and are

protected by na

tional copyright laws and international treaty provisions.

Tektronix pro

previously published material. Specifications and price c hange privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

ducts are covered by U.S. and foreign patents, issued and pending. Information in this publication supersedes that in all

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

In North America, call 1-800-833-9200.

Worldwide, visit www.tektronix.com to find contacts in your area.

Warranty

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1) year from the date of

shipment. If any such product proves defective during this warranty period, Tektronix, at its option, either will repair the defective

product without charge for parts and labor, or will provide a replacement in exchange for the defective product. Parts, modules and

replacement products used by Tektronix for warranty work may be new or reconditioned to like new performance. All replaced

parts, modules and products become the property of Tektronix.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the warranty period

and make suitable arrangements for the performance of service. Customer shall be responsible for packaging and shipping the

defective product to the service center designated by Tektronix, with shipping charges prepaid. Tektronix shall pay for the return of the

product to Customer if the shipment is to a location within the country in which the Tektronix service center is located. Customer shall

be responsible for paying all shipping charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate m aintenance and

care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting from attempts by personnel

other than Tektronix representatives to install, repair or service the product; b) to repair damage resulting from improper use or

connection to incompatible equipment; c) to repair any damage or malfunction caused by the use of non-Tektronix supplies; or

d) to service a product that has been modified or integrated with other products when the effect of such modification or integration

increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY OTHER WARRANTIES,

EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX' RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS

IS THE SOLE AND E XCLU S IVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX

AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES

IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

[W2 – 15AUG04]

Table of Contents

General safety summary ..... . . . . . ..... . . . . . ....... . . . . ..... . . . . . ....... . . . . ..... . . . . . ...... . . . . . ...... . . . . ...... . . . . . ..... . . . . . ...... iii

Compliance information ............................................................................................................... v

EMC compliance................................................................................................................. v

Safety compliance................................................................................................................vi

Environmentalconsiderations ................................................................................................. viii

Preface................................................................................................................................. ix

Features and benefits............................................................................................................ ix

Documentation...................................................................................................................x

Conventions used in this manual..... . . . . ...... . . . . . ....... . . . . ....... . . . . . ....... . . . . ...... . . . . . ..... . . . . . . ....... . . . . ...... . . . x

Introduction .... . . . . . ..... . . . . . ...... . . . . . ..... . . . . . ...... . . . . . ...... . . . . ...... . . . . . ..... . . . . . ...... . . . . . ..... . . . . . ....... . . . . . ......... xi

Product description .. . . . ...... . . . . . ....... . . . . ....... . . . . ...... . . . . . ..... . . . . . ........ . . . . ..... . . . . . ....... . . . . ...... . . . . . ...... ....... xi

Key specifications............................................................................................................... xii

Options .......................................................................................................................... xii

Installation.............................................................................................................................. 1

Standard accessories . . . ...... . . . . . ...... . . . . . ....... . . . . ....... . . . . ....... . . . . ....... . . . . . ....... . . . . ....... . . . . ....... . . . . ..... 1

Optional accessories... . . . . ...... . . . . . . ...... . . . . . ...... . . . . . ....... . . . . ....... . . . . ....... . . . . ....... . . . . ........ . . . . ....... . . . . .1

Site considerations............................................................................................................... 2

Preventing ESD .................................................................................................................. 2

Power onthe instrument......................................................................................................... 3

Power off the instrument......................................................................................................... 4

Operation............................................................................................................................... 5

Front panel controls and connectors . . . . . ...... . . . . ....... . . . . ..... . . . . . ..... . . . . . ..... . . . . . ....... . . . . ..... . . . . . ..... . . . . . ..... 5

Rear panel connectors.... . . . . ...... . . . . . ..... . . . . . ...... . . . . . ..... . . . . . ...... . . . . . ..... . . . . . ...... . . . . . ..... . . . . . ...... . . . . . .... 8

Menu overview .................................................................................................................. 10

Access system information ..................................................................................................... 12

Applications ........................................................................................................................... 13

Example 1: Configure the Pattern Generator . . ....... . . . . ..... . . . . . ....... . . . . ..... . . . . . ..... . . . . . ..... . . . . . ....... . . . . ..... . . . . . .. 13

Example 2: Set up the Error Detector ............................................................................................... 16

Identify Pattern Generator and Error Detector synchronization problems. . . . . . . ...... . . . . ...... . . . . . ..... . . . . . ....... . . . . ... 18

Example 3: Reset the BER and Resyncs to zero

rence............................................................................................................................. 20

Refe

Operating system restore....................................................................................................... 20

User service........................................................................................................................... 21

Service offerings ................................................................................................................21

General care.....................................................................................................................21

Preventive maintenance .. . . . . . ....... . . . . ...... . . . . . ....... . . . . ....... . . . . ...... . . . . . ..... . . . . . . ....... . . . . ..... . . . . . ....... . . . 21

Connector replacement . . . ..... . . . . . ..... . . . . . ....... . . . . ..... . . . . . ..... . . . . . ..... . . . . . ..... . . . . . ....... . . . . ...... . . . . ....... . . . 23

Fuse replacement ............................................................................................................... 23

Instrument calibration ...........................................................................................................23

Repack the instrumentfor shipment............................................................................................ 23

Specifications .........................................................................................................................24

Index

Table of Content

................................................................................... 19

s

Tektronix BERTScope Bit Error Rate Analyzers Quick Start User Manual i

Table of Content

s

ii Tektronix BERTScope Bit Error Rate Analyzers Quick Start User Manual

General safety s

ummary

General safet

Review the following safety precautions to avoid injury and prevent damage to this product or any products connected to it.

To avoid potential hazards, use this product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of a larger system. Read the safety sections of the other

component manuals for warnings and cautions related to operating the system.

To avoid fire or personal injury

Use proper power cord. Use only the power cord specified for this product and certified for the country of use.

Connect and disconnect properly. Do not connect or disconnect probes or test leads while they are connected

to a voltag

Ground th

shock, the grounding conductor must be connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe all terminal ratings. To avoid fire or shock hazard, observe all ratings and markings on the product. Consult the

product

Power di

must remain accessible to the user at all times.

e source.

e product.

manual for further ratings information before making connections to the product.

sconnect.

y summary

This product is grounded through the grounding conductor of the power cord. To avoid electric

The power cord disconnects the product from the power source. Do not block the power cord; it

Do not operate without covers. Do not operate this product with covers or panels removed.

Do not operate with suspected failures. If you suspect that there is damage to this product, have it inspected by

qualified service personnel.

Avoid exposed circuitry. Do not touch exposed connections and components when power is present.

Use proper fuse. Use only the fuse type and rating specified for this product.

Wear eye protection. Wear eye protection if exposure to high-intensity rays or laser radiation exists.

Do not operate in wet/damp conditions.

Do not operate in an explosive atmosphere.

Keep product surfaces clean and dry.

Provide proper ventilation.

per ventilation.

pro

Refer to the manual's installation instructions for details on installing the product s o it has

Tektronix BERTScope Bit Error Rate Analyzers Quick Start User Manual iii

General safety s

Termsinthismanual

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in damage to this product or other property.

Symbols and terms on the product

These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the marking.

WARNING indicates an injury hazard not immediately accessible as you read the marking.

CAUTION indicates a hazard to property including the product.

The following symbol(s) may appear on the product:

ummary

iv Tektronix BERTScope Bit Error Rate Analyzers Quick Start User Manual

Compliance info

rmation

Compliance in

This section lists the EMC (electromagnetic compliance), safety, and environmental standards with which the instrument

complies.

EMC compliance

EC Declarati

Meets intent of Directive 2004/108/EC for Electromagnetic Compatibility. Compliance was demonstrated to the following

specifications as listed in the Official Journal of the European Communities:

EN 61326-1 2006. EMC requirements for electrical equipment for measurement, control, and laboratory use.

CISPR 11:2003. Radiated and conducted emissions, Group 1, Class A

IEC 61000-4-2:2001. Electrostatic discharge immunity

IEC 61000-4-3:2002. RF electromagnetic field immunity

IEC 61000-4-4:2004. Electrical fast transient / burst immunity

IEC 61000-4-5:2001. Power line surge immunity

IEC 61000-4-6:2003. Conducted RF immunity

on of Conformity – EMC

formation

123

IEC 61000-4-11:2004. Voltage dips and interruptions immunity

EN 61000-3-2:2006. AC power line harmonic emissions

EN 61000-3-3:1995. Voltage changes, fluctuations, and flicker

European contact.

Tektronix UK, Ltd.

Western Peninsula

Western Road

Bracknell, RG12 1RF

United Kingdom

1

This product is intended for use in nonresidential areas only. Use in residential areas may cause electromagnetic interference.

2

Emissions which exceed the levels required by this standard may occur when this equipment is connected to a test object.

3

For compliance with the EMC standards listed here, high quality shielded interface cables should be used.

Tektronix BERTScope Bit Error Rate Analyzers Quick Start User Manual v

Compliance info

Australia / New Zealand Dec laration of Conformity – EMC

Complies with the EMC provision of the Radiocommunications Act per the following standard, in accordance with ACMA:

CISPR 11:2003. Radiated and Conducted Emissions, Group 1, Class A, in accordance with EN 61326-1:2006.

rmation

Australia / Ne

Baker & McKen

Level 27, AMP Centre

50 Bridge Street

Sydney NSW 2

w Zealand contact.

000, Australia

Safety compliance

EC Declaration of Conformity – Low Voltage

Compliance was demonstrated to the following specification as listed in the Official Journal of the European Communities:

Low Voltage Directive 2006/95/EC.

EN 61010-1: 2001. Safety requirements for electrical equipment for measurement control and laboratory use.

U.S. Nationally Recognized Testing Laboratory Listing

UL 61010-1:2004, 2ndEdition. Standard for electrical measuring and test equipment.

Canadian Certification

CAN/CSA-C22.2 No. 61010-1:2004. Safety requirements for electrical equipment for measurement, control, and

atory use. Part 1.

labor

zie

Additional Compliances

IEC 61010-1: 2001. Safety requirements for electrical equipment for measurement, control, and laboratory use.

Equipment Type

Test and measuring equipment.

Safety Class

Class 1 – grounded product.

vi Tektronix BERTScope Bit Error Rate Analyzers Quick Start User Manual

Compliance info

rmation

Pollution Degree Description

A measure of the contaminants that could occur in the environment around and within a product. Typically the internal

environment inside a product is considered to be the same as the external. Products should be used only in the environment

for which they are rated.

Pollution Degree 1. No pollution or only dry, nonconductive pollution occurs. Products in this category are generally

encapsulated, hermetically sealed, or located in c lean rooms.

Pollution Degree 2. Normally only dry, nonconductive pollution occurs. Occasionally a temporary conductivity that is

caused by condensation must be expected. This location is a typical office/home environment. Temporary condensation

occurs only when the product is out of service.

Pollution Degree 3. Conductive pollution, or dry, nonconductive pollution that becomes conductive due to condensation.

These are sheltered locations where neither temperature nor humidity is controlled. The area is protected from direct

sunshine, rain, or direct wind.

Pollution Degree 4. Pollution that generates persistent conductivity through conductive dust, rain, or snow. Typical

outdoor locations.

Pollution Degree

Pollution Degree 2 (as defined in IEC 61010-1). Note: Rated for indoor use only.

Installation (Overvoltage) Category Descriptions

Terminals on this product may have different installation (overvoltage) category designations. The installation categories are:

Measurement Category IV. For measurements performed at the source of low-voltage installation.

Measurement Category III. For measurements performed in the building installation.

Measurement Category II. For measurements performed on circuits directly connected to the low-voltage installation.

Measurement Category I. For measurements performed on circuits not directly connected to MAINS.

Overvoltage Category

Overvoltage Category II (as defined in IEC 61010-1)

Tektronix BERTScope Bit Error Rate Analyzers Quick Start User Manual vii

Compliance info

rmation

Environmental considerations

This section provides information about the environmental impact of the product.

Product end-of-life handling

Observe the following guidelines when recycling an instrument or component:

Equipment recycling. Production of this equipment required the extraction and use of natural resources. The equipment

may contain substances that could be harmful to the environment or human health if improperly handled at the product’s

end of life. To avoid release of such substances into the environment and to reduce the use of natural resources, we

encourage you to recycle this product in an appropriate syste m that will ensure that most of the materials are reused

or recycled appropriately.

This symbol indicates that this product complies with the applicable European Union requirements according

to Directives 2002/96/EC and 2006/66/EC on waste electrical and electronic equipment (WEEE) and

batteries. For information about recycling options, check the Support/Service section of the Tektronix Web

site (www.tektronix.com).

Mercury notification. This product uses an LCD backlight lamp that contains mercury. Disposal may be regulated due to

environm

Web page (www.eiae.org) for disposal or recycling information.

ental considerations. Please contact your local authorities or, within the United States, refer to the E-cycling Central

Perchlorate materials. This product contains one or more type CR lithium batteries. According to the state

of California, CR lithium batteries are classified as perchlorate materials and require special handling. See

www.dtsc.ca.gov/hazardouswaste/perchlorate for additional information.

Restriction of hazardous substances

This product is classified as an industrial monitoring and control instrument, and is not required to comply with the substance

ictions of the recast RoHS Directive 2011/65/EU until July 22, 2017

restr

viii Tektronix BERTScope Bit Error Rate Analyzers Quick Start User Manual

Preface

This document provides high-level information on theTektronix BERTScope Bit Error Rate Analyzers. It helps you install

and use the instruments.

Features and benefits

The BERTScope series of instruments provide the following features and benefits:

Pattern Generation and Error Analysis, High-speed BER Measurements up to 28.6 Gb/s

Integrated, Calibrated Stress Generation to Address the Stressed Receiver Sensitivity and Clock Recovery Jitter

Tolerance T

est Requirements for a Wide Range of Standards

Preface

Electrica

Jitter

Fast In

Physi

with Standard or User-defined Libraries of Jitter Tolerance Templates

Integrated Eye Diagram Analysis with BER Correlation

Optional Jitter Map Comprehensive Jitter Decomposition – with Long Pattern (PRBS-31) Jitter Triangulation to Extend

BER-based Jitter Decomposition Beyond the Limitations of Dual Dirac TJ, DJ, and RJ for a Comprehensive Breakdown

of Ji

l Stressed Eye Testing for the following:

PCI Expres

10/40/100

SFP+/SFI

XFP/XFI

OIF/CEI

Fibre Ch

SATA

USB 3.0

InfiniB

Tolerance Compliance Template Testing with Margin Testing

put Rise Time / High Input Bandwidth Error Detector for Accurate Signal Integrity Analysis

cal Layer Test Suite with Mask Testing, Jitter Peak, BER Contour, and Q-factor Analysis for Comprehensive Testing

tter Subcomponents

s

Gb Ethernet

annel (FC8, FC16, FC32)

and (SDR, QDR, FDR, EDR)

nted Error Location Analysis enables Rapid Understanding of your BER Performance Limitations and Assess

Pate

Deterministic versus Random Errors, Perform Detailed Pattern-dependent Error Analysis, Perform Error Burst Analysis,

or Error-free Interval Analysis

Tektronix BERTScope Bit Error Rate Analyzers Quick Start User Manual ix

Preface

Documentation

In addition to Quick Start user manual, the following documentation is available on the instrument:

Online help, including remote control commands

Online remote control guide (PDF)

Online help is available for most controls and instrument features. Touch a control on the screen and the select the “Help on

...” listing for help on that control or feature.

Check the Tektronix Web Site for additional product documentation at www.Tektronix.com.

Conventions used in this manual

conventions

The following icons are used throughout this manual.

Sequence

Step

The terms “touch” and “click” are used interchangeably in this document. The instrument has a touchscreen interface to

the instrument by touching buttons or controls on the screen or by using a mouse.

control

The term

NOTE. A notice statement identifies conditions under which may result in unintended operating modes, incorrect

measurement results, or require resetting the instrument or personal computers operating software interacting with it.

s “view” and “menu” are used interchangeably in this document. A view is defined as the current on-screen menu.

Front panel

power

Connect

power

Network

PS2 SVGA USB

x Tektronix BERTScope B it Error Rate Analyzers Quick Start User Manual

Introduction

The Tektronix BERTScope BSA85C, BSA125C, BSA175C, BSA260C, BSA286C Bit Error Rate Analyzers support serial data

interfaces from 1 Gb Ethernet to future 16x Fibre Channel and 4x 25.78 Gb/s 100 Gb Ethernet. BE RTScope Bit Error Rate

Analyzers reduce your time to market by providing the most advanced and comprehensive combination of signal integrity

analysis and test tools available in a single instrument.

The BERTScope analyzer has the comprehensive set of tools you need to perform receiver compliance testing, transmitter

debug, and advanced analysis to 28.6 Gb/s. Featuring easy and flexible stress testing, physical layer analysis such as BER

Contour and Jitter measurements, and a Compliance Contour view for Mask Test, it represents a breakthrough in insight and

saved development time. Compliance Contour is a bridge between BER and mask testing, needed to meet the requirements

of standards such as OIF CEI, 40/100G Ethernet XLAUI/CAUI, and XFP/XFI.

NOTE. Optical transmitter compliance tests such as those required for optical 8x and 16x Fibre Channel, 10 GBASE-SR, LR,

and 40 and 100 GBASE-SR-4, LR-4, SR-10, and ER-4 are best addressed by the Tektronix DSA8300 sampling oscilloscope

with the appropriate reference receiver module.

Use the BERTScope analyzer together with the Tektronix BERTScope Clock Recovery instruments and the Digital

pre-emphasis processors to provide a complete testing solution.

Product descrip

tion

Product description

This document supports the following Tektronix BERTScope Bit Error Rate Analyzers:

BSA85C, Single Channel, BERTScope 8.5 Gb/s Bit Error R ate Analyzer

BSA125C, BERTScope 12.5 Gb/s Bit Error R ate Analyzer

BSA175C, BERTScope 17.5 Gb/s Bit Error R ate Analyzer

BSA260C, BERTScope 26.0 Gb/s Bit Error R ate Analyzer

BSA286C, BERTScope 28.6 Gb/s Bit Error R ate Analyzer

The Tektronix BERTScope Bit Error Rate Analyzers provide methods of measuring the signal integrity of serial data systems.

They provide quick, accurate, and thorough bit error ratio detection by bridging eye diagram analysis with BER pattern

ration. These instruments help isolate problematic bit and pattern sequences and analyze seven types of advanced

gene

error analysis with statistical measurement depth.

The instruments have a software-based graphical user interface from a series of View menus. Detailed information on the

operation of the control interface can be accessed at any time through the Help menus available in the separate View menus.

Tektronix BERTScope Bit Error Rate Analyzers Quick Start User Manual xi

Product descrip

tion

Key specifications

The following key specifications are common to all BSA instruments:

Stressed Eye – SJ, RJ, BUJ, SI:

Option STR

Output Rise Time & Jitter

25 ps, 23 ps typical, rise time (10-90%)

Options

The following table lists the options available for all BERTScope analyzers:

Table i: BERTScope analyzer options

Item Description

ECC

F2

J-MAP

JTOL

LDA

MAP

PCISTR Add PCIe Extended Stress Generation

PL

PV

SF

SLD Add Stressed Live Data option SW

STR Stressed Signal Generation (Includes options ECC, MAP, PL, XSSC, JTOL, SF)

XSSC

1

<10 ps

typical jitter (20-80%)

p-p

Output Voltage Range

250 mV to 2 V

Input Sensitivity

100 mV

50 mV

1

1

1

1

single ended (typical)

p-p

differential (typical)

p-p

U

1

1

Included in Option STR

Add Error Correction Coding Emulation Software

F/2 Jitter Generation at 8G/10.3125G (requires Option STR)

Add Jitter Decomposition Software

Add Jitter Tolerance Templates Software

Add Live Data Analysis Software

Add Error Mapping Analysis Software

Add Physical Layer Test Suite Software

Add PatternVu Equalization Processing Software

Add Symbol Filtering option Software

Extended Spread Spectrum Clocking (SSC)

xii Tektronix BERTScope Bit Error Rate Analyzers Quick Start User Manual

Installation

Standard accessories

This Quick Start user manual

USB keyboard

USB mouse

Power cord

Short low-loss SMA cables

DVI adapter

Optional accessories

Table 1: BERTScope analyzer accessories

Accessory Description

CR125ACBL High performance Delay Matched Cable Set (required for BERTScope analyzer and

100PSRTFILTER 100 ps rise time filter

BSA12500ISI Differential ISI board

PMCABLE1M

SMAPOWERDIV SMA power dividers

BSARACK BSA-rackmount kits

BSAUSB3 USB3 Instrument Switch with cables and automation software

Installation

Clock Recovery instrument in SSC applications)

Precision phase matched cable pair, 1 m

Tektronix BERTScope Bit Error Rate Analyzers Quick Start User Manual 1

Installation

Site considerations

Read this section before installing the instrument. This section describes environmental considerations, operating

requirements, and power considerations.

Table 2: Environmental considerations

Characteristic Description

Warm-up time 20 minutes

Operating temperature 10 °C to 35 °C ( 50 °F to 95 °F)

Operating Humidity Noncondensing at 35 °C, 15% to 65%

Place the instrument on a cart or bench. The instrument should rest on its bottom or rear feet. An optional rack mounting kit

is available. Observe the following clearance requirements:

Table 3: Clearance requirements

Feature Description

Top

Left and right sides 76 mm (3.0 in)

Bottom

Rear

0mm(0in)

0 mm (0 in) standing on feet, flip stands down

0 mm (0 in) on rear feet

Table 4: Instrument power requirements

Feature Description

Power 460 W Maximum

Voltage & frequency 100 to 240 VAC, 50/60 Hz

Fuse

Preventing ESD

CAUTION. A direct electrostatic discharge can damage the instrument input. To learn how to avoid this damage, read

the following information.

Electrostatic discharge (ESD) is a concern when handling any electronic equipment. The instrument is designed with

robust ESD protection; however it is still possible that large discharges of static electricity directly into the signal input

may damage the instrument. To avoid damage to the instrument, use the following techniques to prevent electrostatic

discharge to the instrument.

1. Discharge the static voltage from your body by wearing a grounded antistatic wrist strap while connecting and

disconnecting cables and adapters. The instrument provides a front panel connection for this purpose.

2. A cable that is left unconnected on a bench can develop a large static charge. Discharge the static voltage from all

cables before connecting them to the instrument or device under test by momentarily grounding the center conductor of

the cable, or by connecting a 50 Ω termination to one end, before attaching the cable to the instrument.

5A, 250 V, 5 mm x 20 mm, fast blow

2 Tektronix BERTScope Bit Error Rate Analyzers Quick Start User Manual

Power on the instrument

The following sections assumes that you have properly connected the input and output cables to the instrument before you

power on the instrument.

1. Connect the power cord to the rear of the

instrument and to a properly grounded

power source.

2. Push the front panel power button to turn

the instrument on.

The green power indicator on the button

will turn on and the instrument will begin

the startup process.

The instrument performs a self-test at

start-up. If any tests fail, the tests are listed

in the Self Test dialog box. Contact Technical

Support for information on any failed tests

and for recommended action.

Installation

After the instrument completes the start-up

sequence, the Home view displays.

From the Home view, access other menus of

the instrument by touching the View button.

The contents of the list under the View menu

depend on the options and configuration of

your instrument.

Tektronix BERTScope Bit Error Rate Analyzers Quick Start User Manual 3

Installation

Power off the instrument

Use the Shutdown button to exit the BERTScope application before powering off the instrument. Do not turn the instrument

off by holding down the front panel power button or by disconnecting the power cord.

1. Touch Shutdown on the lower-right side

of the screen.

2. Do one of the following:

Select Power down to close the

BERTScope application and power

off the instrument.

Select Exit Application to close the

BERTScope application and access

the computer desktop.

3. To power off the instrument from the

computer

applications and then push the front

panel power button.

The gree

will turn off and the instrument will begin

the shut down process.

desktop, close any active

n power indicator on the button

4. Disconnect the power cord from the rear

of the instrument to completely remove

power from the instrument after it shuts

down.

4 Tektronix BERTScope Bit Error Rate Analyzers Quick Start User Manual

Operation

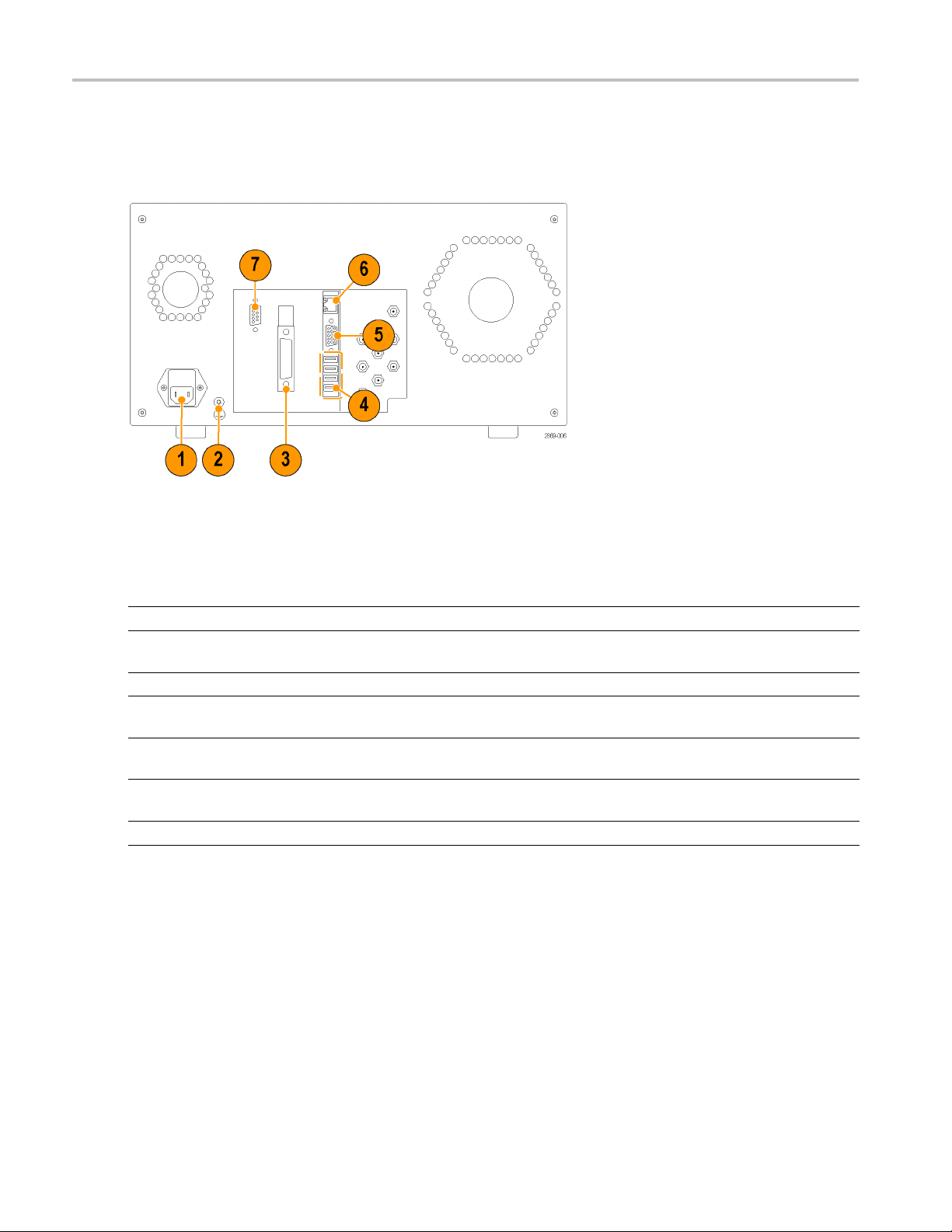

Front panel controls and connectors

The following figure and table describe common front panel controls and connectors.

Operation

Figure 1: BSA front panel

Table 5: C ommon front panel controls and connectors

ctor

Conne

1 Display

2 Power switch Activates the power supply to provide power to the primary circuits in the instrument. The

3

4

5

trol knob

Con

USB Use the USB connectors for connecting USB devices such as a mouse, keyboard, or USB

Ground

nnector

co

iption

Descr

uchscreen display to set up, control, and view information in the menus.

TFT to

ch has a green light when power is turned on.

swit

The primary power control circuitry is always live whenever the power cord is connected to

the instrument. To completely disconnect power from the instrument, disconnect the power

at the rear of the instrument.

cord

the multifunction knob to control items in the display such as moving the cursor, scaling

Use

inputs, and zooming data.

flash drive. Four additional USB connectors are located on the back of the instrument.

Use this connector to connect a common ground to other instruments.

Tektronix BERTScope Bit Error Rate Analyzers Quick Start User Manual 5

Operation

The following figure and table describe the Pattern Generator front panel connectors (outlined in blue).

Figure 2: Pattern Generator front panel connectors

Table 6:

Pattern Generator front panel connectors

Connector Description

1

2DATA

3

4

CLOCK

OUTPUT

OUTPUT

OCK

EXT CL

HF JITTER

Clock Output connectors. Use the differential connectors to output a clock signal from the

Pattern Generator. (Amplitude range: 250 mV to 2 V

Data Output connectors. Use the differential connectors to output data from the Pattern

ator. (Amplitude range: 250 mV to 2 V

Gener

External clock input connector. Use this input to connect an external clock source to the

Scope analzyer; (maximum input amplitude of +10 dBm or 2 V

BERT

-frequency jitter insertion input connector. Use this c onnector to add external

High

high-frequency jitter (DC to 1 GHz) to the instrument with up to 0.5% UI. Apply signals

up to 16 dBm (4 V

s connector is available on the rear panel of BSA286C instruments.

Thi

RATE

SUB

CLOCK–

286C only, Pattern Generator Subrate c lock–. Use this connector to provide the –

BSA

side of a differential clock.

The signal available at this output connector depend on the settings in the Generator view.

lect SUBRATE to produce a Pattern Generator clock or a submultiple of the clock without

Se

any added jitter (useful for measuring any jitter that was added to the Pattern Generator

output). Select STRESS to produce a version of the Pattern Generator clock including

y added jitter.

an

5

UBRATE

S

CLOCK

attern Generator Subrate clock output connector. (See the description above.) For the

P

BSA286C instruments, this is the + output of the differential signal. For other BSA versions,

this is a single-ended output.

6

TRIGGER Pattern Generator trigger output connector. Use this connector to s ynchronize external

equipment, such as an oscilloscope to the BERTScope analyzer.

) if needed.

p-p

).

p-p

).

p-p

).

p-p

6 Tektronix BERTScope Bit Error Rate Analyzers Quick Start User Manual

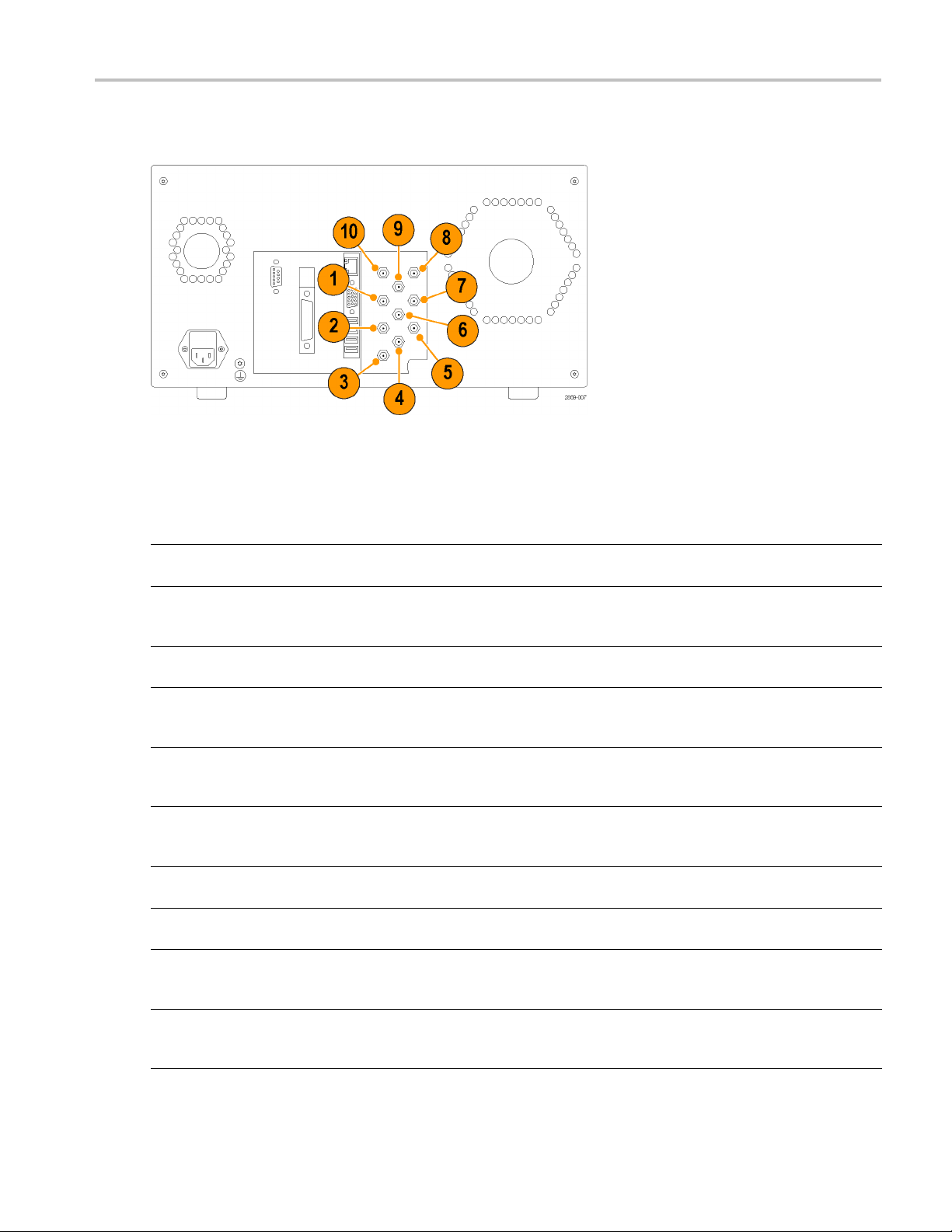

The following figure and table describe the Error Detector front panel connectors (outlined in green).

Figure 3: Error Detector front panel connectors

Operation

Table 7: Error Detector front panel connectors

Connector Description

1

2 DATA INTPUT Error Detector data input connectors. Use the Data+ and Data– connectors to input

3 MARKER Detector Marker input connector. Use this connector to accept a TTL-level Marker signal.

4 BLANK Error Blank input connector. Use this connector to accept a TTL-level signal to cause the

5

6

CLOCK

INPUT

ERROR

TRIGGER

Error Detector clock input connector. Use this connector to provide a single-ended clock

input to the Error Detector. The input frequency range depends on the instrument model.

(Amplitude range: –2 V to +3 V, 50 Ω, AC-coupled)

differential data signals to the Error Detector. (Amplitude range: –2 V to +3 V, 50 Ω,

AC-coupled)

The signal can be used to synchronize error analysis with low-speed reference signals, such

as mechanical frequencies, packet boundaries, or loop markers. The minimum pulse width is

128 clock periods with a maximum repetition rate of 512 serial clock periods.

Error Detector to ignore errors. The Error Detector will ignore errors while this signal is active.

Error output connector. Use this connector to provide a 1000 mV pulse when an error is

detected. The m inimum pulse width is 128 serial clock periods.

Trigger output connector. Use this connector to synchronize external equipment, such as an

oscilloscope to the BERTScope analyzer.

Tektronix BERTScope Bit Error Rate Analyzers Quick Start User Manual 7

Operation

Rear panel connectors

The following figure and table describe the rear panel power and communication connectors. The location and type of

connectors may vary depending on the instrument model.

Figure 4: Rear panel connectors

Table 8:

Connector Description

1

2

3 IEEE4888

4

5

6 LAN

7

Rear panel power and communications connectors

AC power Connect a suitable power cord to match the local power outlet type.

Chassis

ground screw

USB Four USB connectors (two additional connectors are located on the front of the instrument).

EO

VID

DPP SI LINK Miniature type D connector for standard RS232 communication.

Connect a common ground to other instruments.

GPIB connector.

ect USB devices such as keyboard, mouse, or USB flash drive.

Conn

itor/display connector. Connect an external display device. Earlier models have VGA

Mon

connectors, newer versions have DVI connectors (DVI adapters are available).

Connect the instrument to a network for remote control operation, file sharing, and other

network operations.

8 Tektronix BERTScope Bit Error Rate Analyzers Quick Start User Manual

The following figure and table describe the rear panel BNC connectors. Pattern Generator connectors are on a blue

background; Er

ror Detector connectors are on a green background.

Figure 5: Rear panel BNC connectors

Table 9: Rear panel BNC connectors

Operation

Connector Description

1

PAT START Pattern Start input. Use this input connector to simultaneously synchronize the patterns of

multiple data streams from multiple instruments.

2

PAGE SEL Page Select. If a User Pattern file with two pages is loaded into the Generator, this signal

selects which page is being transmitted, based on the TTL level of the input signal. A logic 0

(low) selects Page A; a logic 1 (high) selects Page B.

3

DET START Detector Start Input. Use this input to synchronize the Error Detector with external

equipment. (LVTTL logic level, >1 kΩ into 0 V)

4

SI OUT Sine Interference Out. Use this connector to output a voltage waveform when the Sine

Interference mode is set to External. The voltage range is from 0 mv to 3.0 V. For e xample,

use this signal with external equipment to apply sinusoidal interference to an optical signal.

5

REF- OUT Reference Output (–). Use this connector with the (+) connector to provide a differential

reference frequency for other instruments (typically 100 MHz). For single-ended

applications, use the (+) connector.

6

LF SIN-OUT Low-Frequency Sine Jitter Out. Use this connector to track the internal sine jitter modulation

frequency. It can be used to ensure that two BERTScope analyzers are both in-phase or

out-of-phase.

7

REF+ OUT Reference Output (+). Use this connector with the (–) connector to provide a differential

reference frequency for other instruments (typically 100 MHz).

8REFIN

Reference Input. Use this connector to provide an input reference signal (amplitude:

–6 dBm to +6 dBm; frequencies: 10, 100, 106.25, 133.33, 165.25, 166.67, and 200 MHz).

9LFJIT-IN

Low Frequency Jitter In. Use this connector to add external low frequency jitter (DC

to 80 MHz) to the instrument. The maximum signal level for this connector for normal

operation is +10 dBm (2 V

10 HF JIT-IN

BSA286C only. High-frequency jitter insertion input connector. Use this connector to add

external high-frequency jitter (DC to 1 GHz) to the instrument with up to 0.5% UI. Apply

signals up to 16 dBm (4 V

).

p-p

) if needed.

p-p

Tektronix BERTScope Bit Error Rate Analyzers Quick Start User Manual 9

Operation

Menu overview

The BERTScope analyzer is controlled by a graphical user interface and on-screen controls. The on-screen controls can be

accessed with the touch screen or with a mouse and keyboard.

The Home view displays when you first turn on the instrument. The Home view introduces the instrument and provides

high-level on-screen information to help you get started using the instrument. It also provides useful links to help you set up

the instrument, such as connecting to the Internet, connecting to a printer, or accessing the Tektronix BERTScope Web site.

Figure 6: Home view

The Control console is common to all views. It consists of three major areas to help you control and navigate the different

views:

Title bar. The Title bar contains the name of your instrument and a history of recent views or views within a group.

Touch any of the listed views to quickly return to that view.

Control buttons. Use the buttons on the right side of the display to control the overall instrument operation. The following

table provides a high-level overview of each button.

Table 10: Control console button overview

Item Description

Touch View to access a variety of views available on the BERTScope analyzer.

The contents of the pop-up list depend on the features and options available with

your instrument.

Touch Back or Forward to quickly scroll through the history of displayed views. The

buttons become active after selecting different views.

Touch Run to start the Pattern Generator, Error Detector, or other data analysis

application in the current view. The button lights up while the applications are

running. Touch the button a second time to stop the applications.

10 Tektronix BERTScope B it Error Rate Analyzers Quick Start User Manual

Table 10: Control console button overview (cont.)

Item Description

Touch the Print button to print the current view to a designated printer or to a file.

Printer settings are made in the System view, on the Tools tab, under the Setup

column. (Touch View and select System to access the System view).

Touch the Config button to access configuration files, which store the setups of

your instrument.

Touch the Help button for easy access to the online help on the current view.

Touch the Shutdown button to quit the BERTScope application or to turn off the

instrument.

Status bar. The Status bar provides information about the current operating status. It is made up of the following

different areas:

Pattern Generator (Gen) and Error Detector (Det). These areas display the data pattern, measured clock frequency,

and sync

hronization status. The areas will be yellow and display error messages if the system is not in sync.

Operation

Measure

small image to the right animates when an analysis is running.

Local/remote control. This area indicates how the instrument is being controlled, locally or by remote control.

NOTE. The Gen or Det areas are shortcuts; touch one of these areas to take you directly to that view.

d BER, Error Count, Bit Count. Touch this area to display the measured BER, error count, or bit count. The

Tektronix BERTScope Bit Error Rate Analyzers Quick Start User Manual 11

Operation

Access system information

The System view includes access to setup, test, and registry settings and information. You might need access to this

information when you first set up your instrument.

Touch View and then select System.

The System view opens showing separate

tabbed pages to access system information.

Under the

buttons to access setup information, view the

desktop, use the Microsoft tools, or access

the Inte

Touch other tabs in the System view for additional information:

Tools tab, touch any of the

rnet.

The Registry tab displays the current paths in the Windows file system for assets, such as user patterns or configurations.

The Settings tab displays a list of user-definable settings. It also allows you to set preferences, such as whether dialog

boxes appear to recommend calibration as appropriate. It also display product options installed in the instrument.

The About tab provides information about your instrument, such as product name, serial number, and software versions.

The Log tab allows you to view or clear the Error Log file. It also displays the path to the log file on your instrument.

The Self-Test tab allows you to run the self test routine. The results of the self test are displayed on the screen and

saved to the Error Log file.

12 Tektronix BERTScope B it Error Rate Analyzers Quick Start User Manual

Applications

The following examples provide simple exercises to help you get familiar with the BERTScope analyzer and to navigate

the instrument views.

Example 1: Configure the Pattern Generator

Example 1: Config

ure the Pattern Generator

This example

using differential CMI voltage levels.

provides examples of how to set up the Pattern Generator to output PRBS-7 data at a specified data rate

Connect the front panel cables

When connecting cables to the front panel use high quality coaxial cables with APC3.5 or SMA connectors.

Connect three SMA cables on the front panel as described below:

1. Connect an SMA cable from the Pattern Generator + Clock Output connector to the Error Detector Clock Input connector.

Terminate the Pattern Generator – Clock Output with a 50 Ω terminator.

2. Connect two SMA cables from the Pattern Generator +/– Data Output connectors to the Error Detector +/– Data Input

connectors.

3. Power on the instrument.

Set up the Pattern Generator

te the following steps to configure the Pattern Generator.

Comple

1. Touch V

iew on the control console and

then select Generator to display the

Generator view.

Tektronix BERTScope Bit Error Rate Analyzers Quick Start User Manual 13

Example 1: Config

2. Touch the SYNTHESIZER input icon on

the Generator view to open the Internal

Clock Input se

Use Keypad.

3. Enter 1.0 GHz and then touch OK.

The dialog box closes and the

SYNTHESIZER input icon displays the

new clock frequency.

ure the Pattern Generator

ttings box and then select

4. Touch t

5. Select Pattern from the first level list and

he GENERATOR icon button in

the center of the Generator view to open

the Generator settings box.

elect PRBS-7 from the list.

then s

14 Tektronix BERTScope B it Error Rate Analyzers Quick Start User Manual

6. Touch the CLOCK + icon button and

verify that Link Clock +/- Signals is

selected.

This setting links the Clock + and Clock –

outputs together.

7. Select Logic Family in the list and then

select CML f

rom the pop-up list.

Example 1: Config

ure the Pattern Generator

8. Repeat the

outputs for the Data + output icons.

9. Touch the Outputs On/Off button at the

top of the Generator view to enable the

Clock an

When the Generator outputs are turned

on, the clock and data information

displa

buttons.

previous two steps to set the

d Data outputs.

ys under the Clock and Data

attern Generator is now transmitting PRBS-7 data at 1 Gb/s on the clock and differential D ata outputs set to the

The P

industry standard CML levels.

Tektronix BERTScope Bit Error Rate Analyzers Quick Start User Manual 15

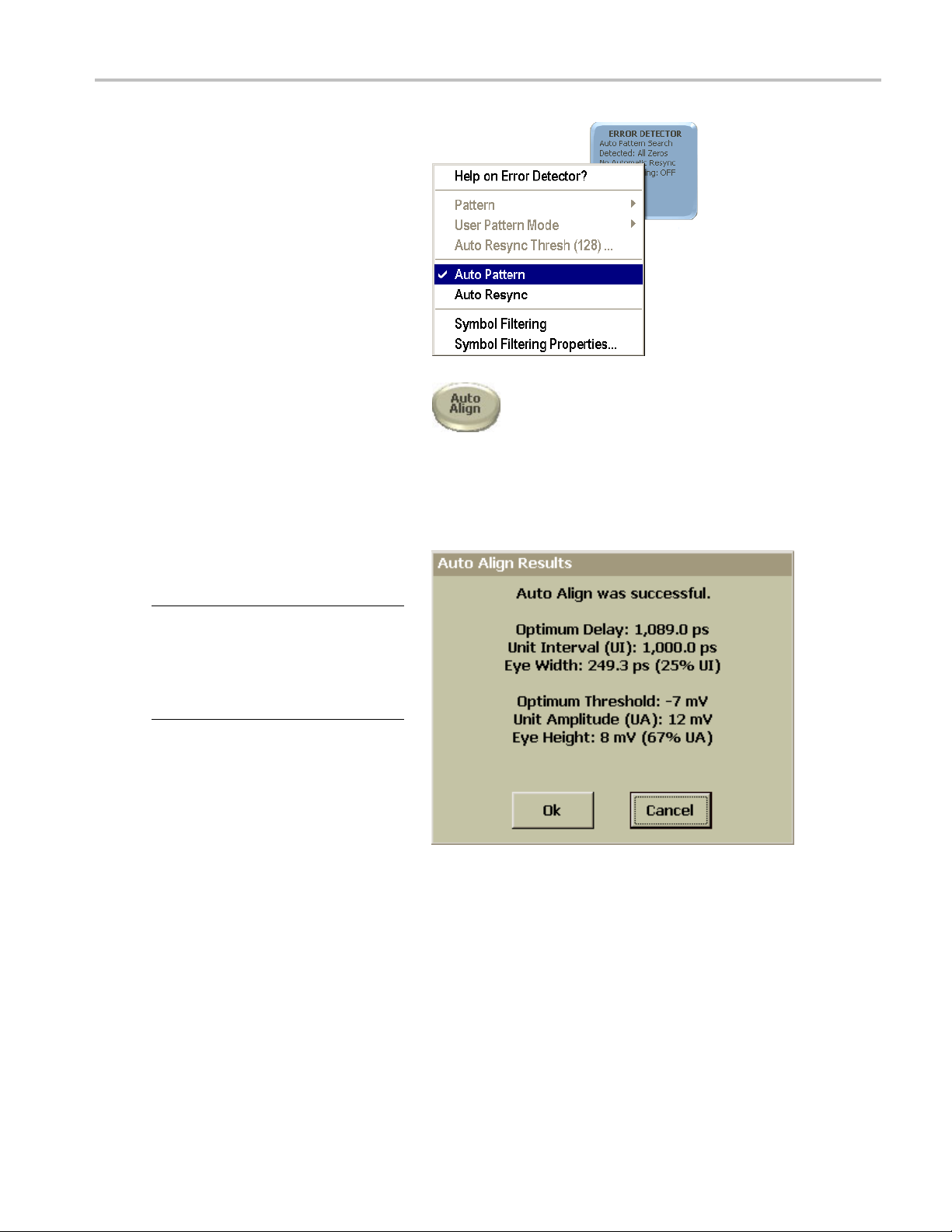

Example 2: Set up

the Error Detector

Example 2: Set

This example uses the same setups as Example 1. It provides information on how to set up the Error Detector to accept

differential CML signals and to make a bit error rate measurement.

NOTE. Before continuing, make sure that you have the high-quality coaxial cables as describe in Example 1. (See page 13,

Connect the front panel cables.)

1. Touch View on the control console and

then select Detector to display the

Detector view.

up the E rror Detector

2. Touch the Data button, select Interface

Mode, and then select Differential.

3. Touch the Data button again, select

Logic Family, and then select

DIFF-CML/SCFL.

16 Tektronix BERTScope B it Error Rate Analyzers Quick Start User Manual

Example 2: Set up

the Error Detector

4. Touch t he Error

Auto Pattern from the list.

This enables the Error Detector to compare

all known PRBS

acquiring synchronization.

5. Clear the Auto Resync selection if it is

selected.

6. Touch the A uto Align button at the top

of the Detector view.

The Auto Al

measurement point with the incoming

data signal. This moves the delay timing

and volta

sampling point in the received eye for

making BER measurements.

The Auto Align Results dialog box displays

if the Auto Align process is successful and

nization is achieved.

synchro

Detector icon and select

data patterns when

ign optimizes the data

ge threshold to find the best

NOTE. You might be asked to recalibrate

the delay element when you touch the

ign button. The instrument monitors

Auto Al

changes in data frequency and temperature;

it can automatically recalibrate the built-in

le delay element within a few seconds.

variab

7. Click Ok to close the dialog box.

Tektronix BERTScope Bit Error Rate Analyzers Quick Start User Manual 17

Example 2: Set up

8. Verify that the data pattern type and

the data rate are the same for the

Pattern Gener

(as displayed on the Status Bar at the

bottom of the screen).

the Error Detector

ator and Error Detector

NOTE. In addi

between the views by touching or clicking the Pattern Generator or Error Detector areas of the Status Bar at the bottom

of the screen.

Identify P

If the Pattern Generator and the Error Detector are not synchronized, you must address the problem before continuing. Use

the following steps to help identify the source of the synchronization problems:

1. Verify that you are using the correct, high-quality coaxial cables with APC3.5 or SMA connectors.

2. Carefully check the cable connections to the instrument and the polarity of the connections; make any corrections

as needed.

3. Check that the Pattern Generator has its clock outputs switched on (touch Outputs On/Off).

4. If the status information on the bottom of the Error Detector says Unstable Clock, check for the following:

5. Verify that the Status Bar at the bottom of the Generator and Detector views s how the same data type and data rate.

If synchronization is not achieved, the Statu s Bar will be a bright yellow c olor and displays No Sync. If this happens,

check for the following:

tion to using the View menus to navigate between the Generator and Detector views, you can easily navigate

attern Generator and Error Detector synchronization problems.

Check that the Pattern Generator clock has the internal clock source selected, rather than external.

Check that the Clock Input termination is set to the same termination as the Generator clock output.

Check that the Error Detector Data Input termination is set to the same termination as the Generator output setting.

Check that the Error Detector Data Input is set to Differential input.

6. Verify that the data type is PRBS-7. If not, check for the following:

Check that the Data Type setting on the Generator view is set to PRBS-7. If necessary reset it to PRBS-7.

Check that the Data Type setting on the Detector view is set to PRBS-7. If necessary reset it to PRBS-7.

7. Verify that the X1/X2 settings in the Detector view are correct for your application.

8. Verify that the Generator Clock rate is set to 1 GHz. If necessary, reset it to 1.0 GHz.

9. Verify that the Error Detector settings are the same as the Generator Clock and Data settings. This includes the Interface

Mode and Logic F amily settings. Change them as necessary.

10. Try to resynchronize again by touching the Auto Align button.

18 Tektronix BERTScope B it Error Rate Analyzers Quick Start User Manual

Example 3: Reset

Example 3: Reset the BER and R esyncs to zero

This example assumes that you have completed steps in this Examples 1 and 2 and that the instrument has achieved

synchronization.

1. Touch the Run on the Control console

two times to start and stop the detector.

The button changes color when the

instrument is running.

2. Touch t he Reset Results button at

the top of the screen to reset the

measurement results.

3. Check the Detector view for the following:

The clock rate (1,000.00 Mbit/s)

matches th

transmitted by the Generator.

The data type is set to PBRS-7.

e 1 GHz rate being

the BER and Resyncs to zero

The Detector Results box indicates

zero BER and zero resyncs.

Tektronix BERTScope Bit Error Rate Analyzers Quick Start User Manual 19

Reference

Reference

Operating system restore

The BERTScope analyzer contains an operating system restore file in a separate partition of the hard drive. Use this file

to restore the instrument operating system.

CAUTION. Using the restore process reformats the hard drive and reinstalls the operating system. All saved data is lost. If

possible, save important files to external media before performing a system restore.

1. Restart the instrument. During the boot-up process you will see the following message at the top of the screen:

Acronis Loader

Press F5 to start the Acronis Startup Recovery Manager.

2. Repeatedly press the F5 key until the Acronis True Image Tool opens. There is a 15-second delay after the message

appears until the instrument proceeds with normal instrument startup. If the instrument does not open the Acronis

application, power off the instrument, then power on the instrument and try again.

3. Touch Restore.

4. In the Confirmation dialog box, touch Yes to restore the instrument operating system, or No to exit the restore process.

The restore process takes approximately 30 minutes; the actual time depends on the instrument configuration.

5. If you have not already done so, go to the Tektronix Web site to download the application software

(www.tektronix.com/software) and follow the instructions to install the software for your instrument.

20 Tektronix BERTScope B it Error Rate Analyzers Quick Start User Manual

User service

This section describes high-level service information and procedures for your instrument.

Service offerings

Tektronix provides service to cover repair under warranty and other services that are designed to meet your specificservice

needs.

her providing warranty repair service or any of the other services listed below, Tektronix service technicians are well

Whet

equipped to service the logic analyzers. Services are provided at Tektronix Service Centers and on-site at your facility,

depending on your location.

ranty repair service

War

Tektronix warrants this product as described in the warranty statements at the front of this manual. Tektronix technicians

provide warranty service at most Tektronix service locations worldwide. The Tektronix product catalog lists all service

locations worldwide.

User service

Calibration and repair service

In addition to warranty repair, Tektronix Service offers calibration and other services that provide cost-effective solutions to

your service needs and quality standards compliance requirements. Tektronix instruments are supported worldwide by the

leading-edge design, manufacturing, and service resources of Tektronix to provide the best possible service.

General care

Protect the instrument from adverse weather conditions. The instrument is not waterproof. Do not store or leave the

instrument where the display will be exposed to direct sunlight for long periods of time.

CAUTION. To avoid damage to the instrument, do not expose it to sprays, liquids, or solvents.

Preventive maintenance

Preventive maintenance mainly consists of periodic cleaning. Periodic cleaning reduces instrument breakdown and

increases reliability. Clean the instrument as needed, based on the operating environment. Dirty conditions may require

more frequent cleaning than computer room conditions.

Clean the flat panel display

The flat panel display is a soft plastic display and must be treated with care during cleaning.

CAUTION. Improper cleaning agents or methods can damage the flat panel display.

Tektronix BERTScope Bit Error Rate Analyzers Quick Start User Manual 21

User service

Do not use abrasive cleaners or commercial glass cleaners to clean the display surface.

Do not spray liquids directly on the display surface.

Do not scrub the display with excessive force.

Avoid getting moisture inside the instrument while cleaning the display; use only enough solution to dampen the wipe.

Clean the flat panel display surface by gently rubbing the display with a cleanroom wipe (such as Wypall Medium Duty

Wipes, #0570

1, available from Kimberly-Clark Corporation).

If the displa

display surface. Avoid using excess force or you may damage the plastic display surface.

y is very dirty, moisten the wipe with distilled water or a 75% isopropyl alcohol solution and gently rub the

Clean the exterior surfaces

Clean the exterior surfaces with a dry, lint-free cloth or a soft-bristle brush. If dirt remains, use a cloth or swab dampened with

a 75% isopropyl alcohol solution. A swab is useful for cleaning in narrow spaces around the controls and connectors. Do not

use abrasive compounds on any part of the instrument.

To avoid damaging the instrument follow these precautions:

Avoid getting moisture inside the instrument during external cleaning and use only enough solution to dampen the

cloth or swab.

Do not wash the front-panel power switch. Cover the switch while washing the instrument.

Use only deionized water when cleaning. Use a 75% isopropyl a lcohol solution as a cleanser and rinse with deionized

water.

Do not use chemical cleaning agents; they may damage the instrument. Avoid chemicals that contain benzene, toluene,

xylene, acetone, or similar solvents.

Battery information

The coin cell battery on the instrument computer motherboard is not a user replaceable part. The coin cell battery is not

rechargeable. Under no circumstances attempt to recharge the battery.

22 Tektronix BERTScope B it Error Rate Analyzers Quick Start User Manual

Connector replacement

The Pattern Generator CLOCK OUTPUT and CLOCK INPUT connectors and the Error Detector DATA O UTPUT and DATA

INPUT connectors use 3.5 mm to PAC Planar Crown® adapters. These facilitate user replacement of the adapter, should it

become damaged. Replacement adapters can be ordered from Tektronix.

Replace the front panel connectors

1. Remove a damaged connector by grasping the knurled outer part of the ring with your fingers and turning

counterclockwise.

Do not allow foreign material to enter the connector body when replacing the adapter.

2. Position the two locating tabs in the corresponding slots of the instrument-mounted part of the connector and seat

the replac

ement adapter.

User service

3. Align the r

Tightene

to tighten it.

etaining ring and tighten by rotating clockwise

d the connector finger-tight. To avoid over-tightening and possibly damaging the connector, do not use a tool

Fuse replacement

The instrument is protected by a fuse placed in series with the power line input. The fuse is conservatively rated and should

never open through the life of the instrument. A blown fuse would generally indicate a problem with the instrument which

requires factory service. It is recommended that you arrange to have the instrument serviced if you experience a blown fuse.

Instrument calibration

The instrument uses digital calibration of the output buffers. To maintain the accuracy of the output amplitude and offset,

annual calibration is recommended. Contact Tektronix to schedule instrument calibration.

Repac

k the instrument for shipment

If the instrument is to be shipped to a Tektronix service center for repair, attach a tag showing the following information:

Name of the product owner

Address of the owner

Instrument serial number

A description of the problems encountered and/or service required

When packing an instrument for shipment, use the original packaging. If it is unavailable or not fit for use, contact your

Tektronix representative to obtain new packaging.

Tektronix BERTScope Bit Error Rate Analyzers Quick Start User Manual 23

Specifications

Specification

Table 11: PC-related specifications

Characteristic Description

Display

Touch sensor Analog resistive

Processor

Hard disk drive

DRAM

Operating system Microsoft s® XP Professional

Remote control

Network connection 100 base T Ethernet LAN

Supported interfaces USB 2.0 (6 total, 2 front, 4 rear)

Table 12: Physical specifications

Characteristic Description

Weight

Dimensions

Height

Width

Depth

s

TFT Touch screen, 640 x 480 VGA

Pentium® P4; 1.5 GHz or greater

160 GB or greater

2GB

IEEE-488 (GPIB) or TCP/IP

DVI/VGA external display

25 kg (55 lbs), instrument only

34.5 kg (76 lbs), shipping

22 cm (8.75 in)

39.4 cm (15.5 in)

52 cm (20.375 in)

Table 13: Environmental specifications

Characteristic Description

Temperature

Operating +10 °C to +35 °C (50 °F to 95 °F), with 15 °C (59 °F)/hour maximum gradient, non

condensing, derated 1 °C (34 °F) per 300 m (984 ft) above 1500 m (4921 ft) altitude

Nonoperating

Humidity

Operating 5% to 95% relative humidity at up to 30 °C (86 °F)

Nonoperating

Altitude

Operating To 3000 m (9843 ft.)

Nonoperating

–20 °C to +60 °C (–4 °F to 140 °F), with 30 °C (86 °F)/hour maximum gradient

5% to 65% relative humidity above 30 °C (86 °F) up to 35 °C (95 °F), non

condensing, limited by maximum w et-bulb temperature of 29 °C (84 °F), derates

relative humidity to 65% at +35 °C (95 °F)

5% to 95% relative humidity at up to 30 °C (86 °F)

5% to 65% relative humidity above 30 °C (86 °F) up to 60 °C (140 °F), non

condensing, limited by maximum w et-bulb temperature of 29 °C (84 °F), derates

relative humidity to 12% at +60 °C (140 °F)

To 12,000 m (39,370 ft.)

24 Tektronix BERTScope B it Error Rate Analyzers Quick Start User Manual

Index

Index

A

About tab, 12

accessories

optional, 1

standard, 1

application software, 20

B

battery information, 22

C

on, 23

calibrati

cleaning

exterior, 22

flat panel

clearance requirements, 2

clock input

Error De

clock output

Pattern Generator, 6

complia

EMC, v

environmental, viii

optica

safety, vi

compliance information, v

connec

connectors

Error Detector, 7

front

Pattern Generator, 6

rear panel, 8, 9

ol buttons, 10

contr

Control console, 10

conventions, x

display, 21

tector, 7

nce

l transmitter, xi

tor replacement, 23

panel, 5, 6, 7

D

a input

dat

Error Detector, 7

data output

tern Generator, 6

Pat

detector start input

Error Detector, 9

cumentation, x

do

DVI connector, 8

E

electrostati

environmental

error blank input

Error Detec

error output

ESD, 2

external clock input

c discharge, 2

considerations, 2

specificatio

Error Detector, 7

clock input, 7

data input, 7

detector s

error blank input, 7

error output, 7

front pane

marker input, 7

set up, 16

synchron

trigger output, 7

Error Det

Pattern

ns, 24

tor

tart input, 9

l connectors, 7

ization problems, 18

ector, 7

Generator, 6

F

features and benefits, i x

flat panel display

ng, 21

cleani

front panel

connectors, 5, 6, 7

panel connectors

front

Error Detector, 7

Pattern Generator, 6

fuse

replacement, 23

specifications, 2

H

h-frequency jitter input

hig

Pattern Generator, 6, 9

Home view, 3, 10

K

y features, ix

ke

key specifications, xii

L

Log tab, 12

low-frequen

low-frequency sine jitter out

cy sine jitter in

Pattern Generator, 9

Pattern Gene

rator, 9

M

maintenance

cleaning, 21, 22

preventiv

manual

conventions, x

marker inp

Error Detector, 7

e, 21

ut

O

on-screen controls, 10

elp, x

online h

operating requirements, 2

operating system restore, 20

al accessories, 1

option

options, xii

P

packaging, 23

elect

page s

Pattern Generator, 9

Pattern Generator

output, 6

clock

data output, 6

external clock input, 6

t panel connectors, 6

fron

high-frequency jitter input, 6, 9

low-frequency sine jitter in, 9

frequency sine jitter out, 9

lowpage select, 9

pattern start input, 9

erence in, 9

ref

reference out, 9

set up, 13

e interference out, 9

sin

subrate clock, 6

subrate clock output, 6

nchronization problems, 18

sy

trigger output, 6

Tektronix BERTScope Bit Error Rate Analyzers Quick Start User Manual 25

Index

pattern start input

Pattern Genera

power off procedure, 4

power on procedure, 3

power require

preventive maintenance, 21

product options, xii

product over

tor, 9

ments, 2

view, xi

R

rear panel

connectors, 8, 9

reference i

reference out

Registry tab, 12

repackaging, 23

repair ser

requirements

n

Pattern Generator, 9

Pattern Ge

clearance, 2

operatin

power, 2

voltage, 2

nerator, 9

vice, 21

g, 2

S

Safety S

self test, 3, 12

service offerings, 21

ummary, iii

Settings tab, 12

shut down proce

sine interference out

Pattern Generator, 9

site consider

specifications

altitude, 24

environment

fuse, 2

humidity, 24

key, xii

PC-related, 24

physical, 24

temperatur

standard accessories, 1

static precautions, 2

Status bar

subrate clock

Pattern Generator, 6

subrate cl

Pattern Generator, 6

supported instruments, xi

synchron

System view, 12

About tab, 12

Log tab,

Registry tab, 12

Self test tab, 12

Setting

Tools tab, 12

dure, 4

ations, 2

al, 24

e, 24

,11

ock output

ization problems, 18

12

s tab, 12

T

Tools tab, 12

touch

defined, x

trigger output

Error Detector, 7

Pattern Gene

troubleshooting

operating system restore, 20

synchroniza

rator, 6

tion problems, 18

V

VGA connector, 8

view

defined, x

voltage

requirements, 2

W

warranty

service, 21

26 Tektronix BERTScope B it Error Rate Analyzers Quick Start User Manual

Loading...

Loading...