Technical Reference

Bench Test Instruments and

Handheld Oscilloscopes

Basic Service

061-4124-02

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Copyright © Tektronix, Inc. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or

suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publi cation supercedes

that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sal es, service, and technical support:

H In North America, call 1-800-833-9200.

H Worldwide, visit www.tektronix.com to find contacts in your area.

Service Reference

This manual contains the Performance Verification and Adjustment procedures

for many benchtop products. Table i lists the products supported by this manual.

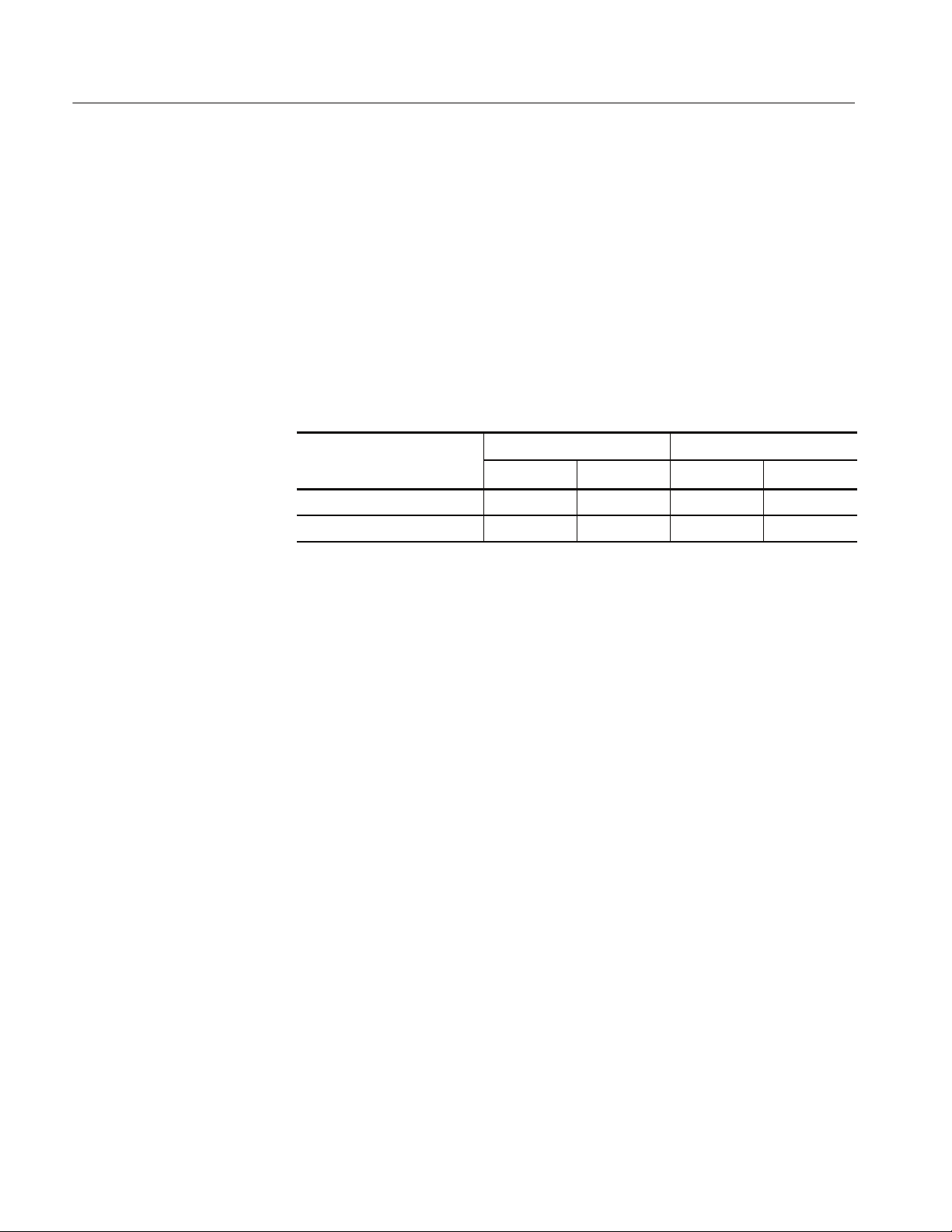

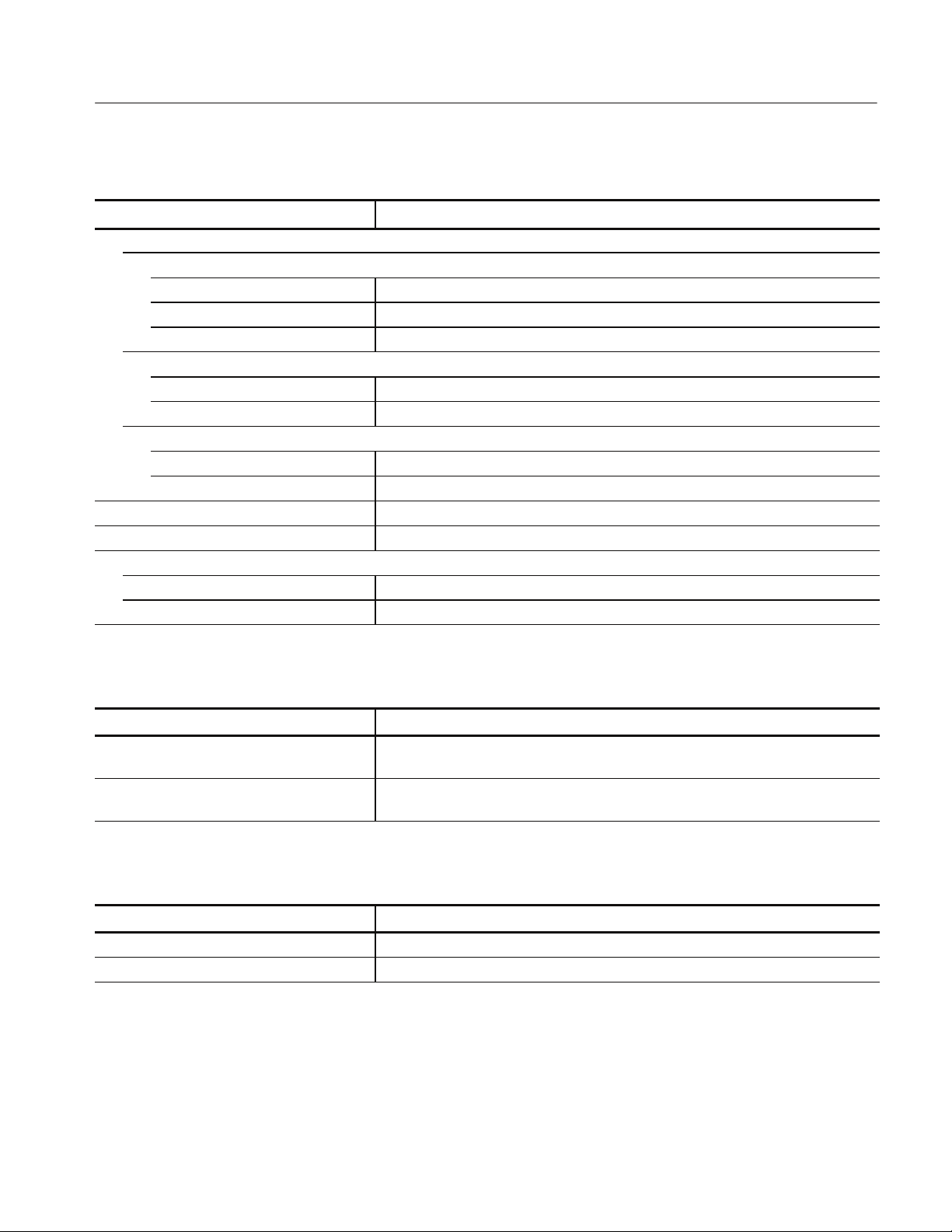

Table i: Benchtop and handheld products supported by this manual

Products

PS280 and PS283 Power Supplies

PS2520, PS2520G, PS2521, and PS2521G Power Supplies

TAS 210 and TAS 220 Digital Oscilloscopes

TMM420 Digital Multimeter

THM500 Series Multimeter/Scope

Service information of products not provided in this manual may be available

under separate cover. Table ii provides a list of many handheld and benchtop

instruments and their service documentation.

Table ii: Handheld and benchtop instruments service manuals

Product Tektronix part number

212 Oscilloscope 070-5053-00

214 Oscilloscope 070-5055-00

214 Storage Oscilloscope 070-1483-00

221 Oscilloscope 070-1573-01

222 Digital Storage Oscilloscope 070-7459-00

222A DSO:

B010100 thru B039999

B040000 and above

222PS Power Scout 070-8098-02

224 Digital Storage Oscilloscope 070-8405-02

305 DMM Oscilloscope 070-2423-01

314 Storage Oscilloscope 070-1824-00

335 Oscilloscope 070-1943-01

336 Digital Storage Oscilloscope 070-4421-00

2201 Portable Oscilloscope 070-7189-00

2205 Oscilloscope 070-6716-00

070-8330-00

070-8330-02

Bench Test Instruments and Handheld Oscilloscopes Basic Service

i

Service Reference

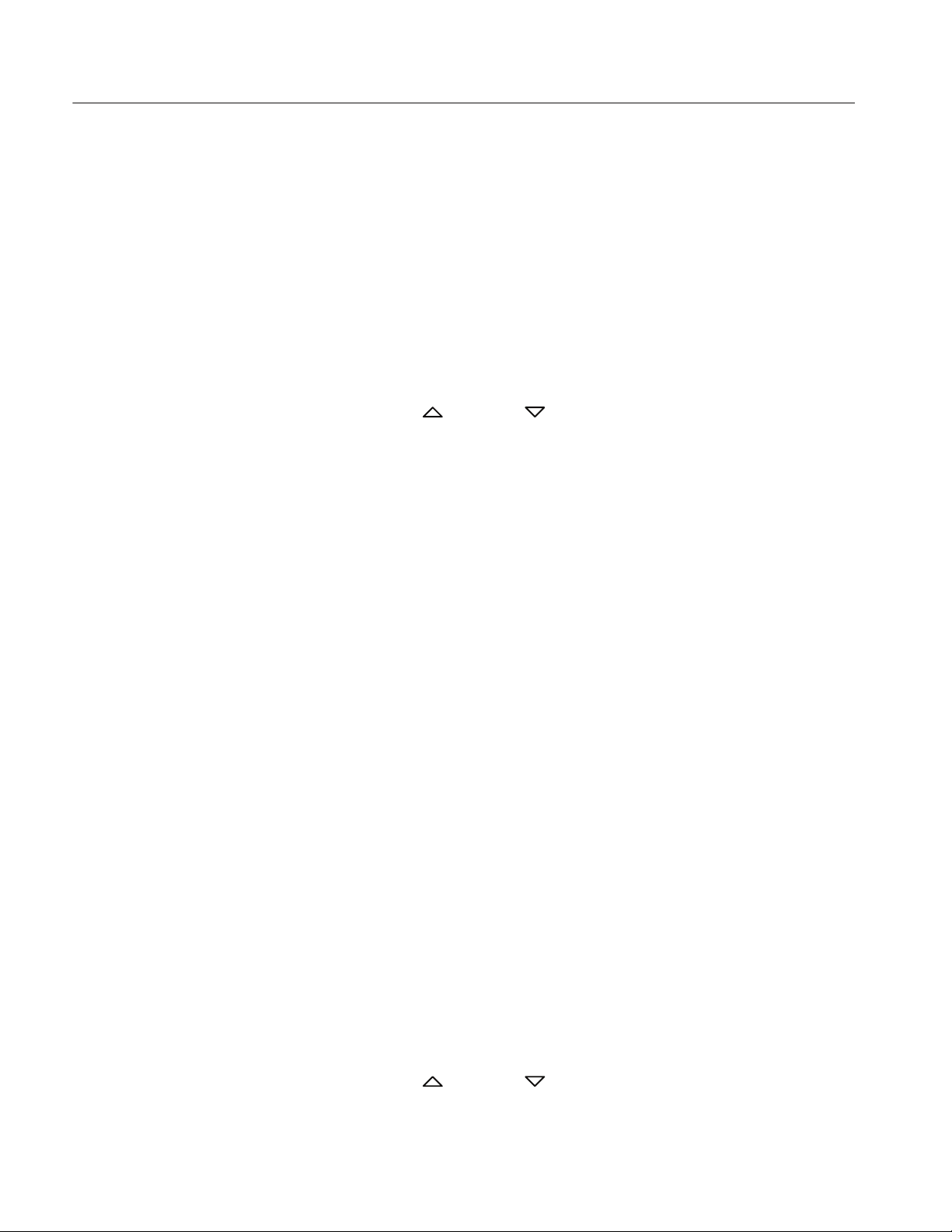

Table ii: Handheld and benchtop instruments service manuals (cont.)

Product Tektronix part number

2211 Oscilloscope 070-7234-00

2214 Digital Storage Oscilloscope 070-7783-00

2220 Digital Storage Oscilloscope 070-5302-00

2221A Oscilloscope:

B010100 to B019999

B020000 and above

2225 Oscilloscope 070-6299-00

2230 Digital Storage Oscilloscope 070-4999-00

2232 Digital Storage Oscilloscope:

B010100 to B029999

B030000 and above

2235 AN/USM-488 Oscilloscope 070-4977-00

2245 Portable Oscilloscope 070-6276-00

070-8157-01

070-8549-00

070-7067-01

070-8548-00

2245A Portable Oscilloscope:

B010100 to B015999

B016000 and above

2246A Portable Oscilloscope 070-6555-00

2246/1Y/2R/2246 Mod A 070-7062-00

2247A Portable Oscilloscope 070-6367-00

2252 Portable Oscilloscope 070-7838-01

2335 Oscilloscope 070-4116-00

2336 Oscilloscope 070-4118-00

2336YA Oscilloscope 070-5011-00

2337 Oscilloscope 070-4120-00

TAS 455/465 Oscilloscope 070-8524-02

TAS 465 Oscilloscope 070-9403-00

TAS 475/485 Oscilloscope:

B010100 to B020099

B020100 and above

TDS 210/220 Oscilloscope 070-9693-01

TDS 310/320/350 Oscilloscope 070-8570-05

TDS 340/340A/360/380 Oscilloscope 070-9435-02

070-6557-00

070-7672-00

070-8878-01

070-9404-00

THS 710/720/730 Oscilloscope 070-9246-03

ii

Bench Test Instruments and Handheld Oscilloscopes Basic Service

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

the products in this manual or any products connected to them. To avoid

potential hazards, use these products only as specified.

Only qualified personnel should perform service procedures.

While using these products, you may need to access other parts of the system.

Read the General Safety Summary in other system manuals for warnings and

cautions related to operating the system.

ToAvoidFireor

Personal Injury

Use Proper Power Cord. To avoid fire hazard, use only the power cord specified

for the product you are using.

Use Proper Voltage Setting. B efore applying power, ensure that the line selector is

in the proper position for the power source being used.

Connect and Disconnect Properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. Some of these products are grounded through the grounding

conductor or the power cord. To avoid electric shock, the grounding conductor

must be connected to earth ground. Before making connections to the input or

output terminals of the product you are using, ensure that the product is properly

grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product you are using. Consult the product manual for

further ratings information before making connections to the product.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Replace Batteries Properly. Replace batteries only with the proper type and rating

specified.

Recharge Batteries Proper ly. Recharge batteries for the recommended charge

cycle only .

Use Proper AC Adapter. Use only the AC adapter specified for the product you

are using.

Bench Test Instruments and Handheld Oscilloscopes Basic Service

iii

General Safety Summary

Do Not Operate Without Covers. Do not operate these products with covers or

panels removed.

Use Proper Fuse. Use only the fuse type and rating specified for the product you

are using.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate in Wet/Damp Conditions. To avoid electric shock, do not operate

these products in wet or damp conditions.

Do Not Operate in Explosive Conditions. To avoid injury or fire hazard, do not

operate these products in an explosive atmosphere.

Keep Product Surfaces Clean and Dry. To avoid electric shock and erroneous

readings, keep probe surfaces clean and dry.

Symbols and Terms

Provide Proper Ventilation. Refer to the product installation instructions for details

on installing the product so it has proper ventilation.

Terms in this Manual. These terms may appear in this manual.

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Products. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

iv

Bench Test Instruments and Handheld Oscilloscopes Basic Service

General Safety Summary

Symbols on the Product. The following symbols may appear on the product:

DANGER

High Voltage

Protective Ground

(Earth) Terminal

ATTENTION

Refer to Manual

Double

Insulated

Bench Test Instruments and Handheld Oscilloscopes Basic Service

v

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, disconnect the main power by means

of the power cord or, if provided, the power switch.

Use Caution When Servicing the CRT. To avoid electric shock or injury, use

extreme caution when handling the CRT. Only qualified personnel familiar with

CRT servicing procedures and precautions should remove or install the CRT.

CRTs retain hazardous voltages for long periods of time after power is turned off.

Before attempting any servicing, discharge the CRT by shorting the anode to

chassis ground. When discharging the CRT, connect the discharge path to ground

and then the anode. Rough handling may cause the CRT to implode. Do not nick

or scratch the glass or subject it to undue pressure when removing or installing it.

When handling the CRT, wear safety goggles and heavy gloves for protection.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

X-Radiation. To avoid x-radiation exposure, do not modify or otherwise alter the

high-voltage circuitry or the CRT enclosure. X-ray emissions generated within

this product have been sufficiently shielded.

vi

Bench Test Instruments and Handheld Oscilloscopes Basic Service

Preventing Electrostatic Discharge

CAUTION. Static discharge can damage internal semiconductor components.

Follow the guidelines listed below to avoid product damage.

When performing service that requires internal access to an instrument, adhere to

the following precautions to avoid damaging internal modules or their components:

H Avoid handling modules or components in areas that have floors or work

surfaces capable of generating a static charge.

H Spray carpeted work areas with a solution of equal parts of water and fabric

softener.

H Wear clothing made from materials that do not accumulate static charges.

Avoid Wool (and some artificial fibers) which build up static charges readily;

wear cotton which conducts electricity and resists static accumulation.

H Minimize the handling of static-sensitive devices.

H Transport and store static-sensitive devices in their protected containers or on

a metal rail. Label any package that contains static-sensitive parts.

H Service instruments and modules at grounded, static-free work stations.

H Do not allow devices capable of generating a static charge on a work station

surface.

H Wear a grounding strap while working with static-sensitive devices.

H Handle circuit boards by their edges, if possible.

H Do not slide static-sensitive components over any surface.

H Do not use high-velocity compressed air to clean or dry components or

modules.

Bench Test Instruments and Handheld Oscilloscopes Basic Service

vii

Preventing Electrostatic Discharge

viii

Bench Test Instruments and Handheld Oscilloscopes Basic Service

Preface

This manual contains service information for a wide range of handheld and

benchtop products. Each section covers a product or related series of products

and includes the following information:

H A product description that details instrument functions, capabilities, and

recommended uses

H A front panel illustration

H A set of electrical, mechanical, environmental, and physical specifications

H A performance verification procedure to ensure the instrument meets

specifications

H An adjustment procedure to return the instrument to factory calibration (not

included for all instruments)

The information contained in this manual is current at the date of publication and

is typical or suggested, not guaranteed. Since manual updates occur at approximately six month intervals, information may be incomplete or missing in some

versions.

Some instruments have optional service information available under separate

cover. This manual does not duplicate information from optional service

manuals. Refer to the optional accessories list in your user manual for Tektronix

part numbers of optional service manuals. A list of Handheld and Benchtop

instruments manuals can also be found in Table ii on Page i.

NOTE. This manual provides the necessary service information to verify that

your instrument is working properly. Should you have service-related questions

not covered in either this manual or in an optional service manual, please

contact your Tektronix Service Center for additional information.

For product warranty information, refer to the user manual supplied with your

instrument.

Bench Test Instruments and Handheld Oscilloscopes Basic Service

ix

Preface

x

Bench Test Instruments and Handheld Oscilloscopes Basic Service

Instructions Manual

PS280 and PS283

Power Supplies

070-9894-01

www.tektronix.com

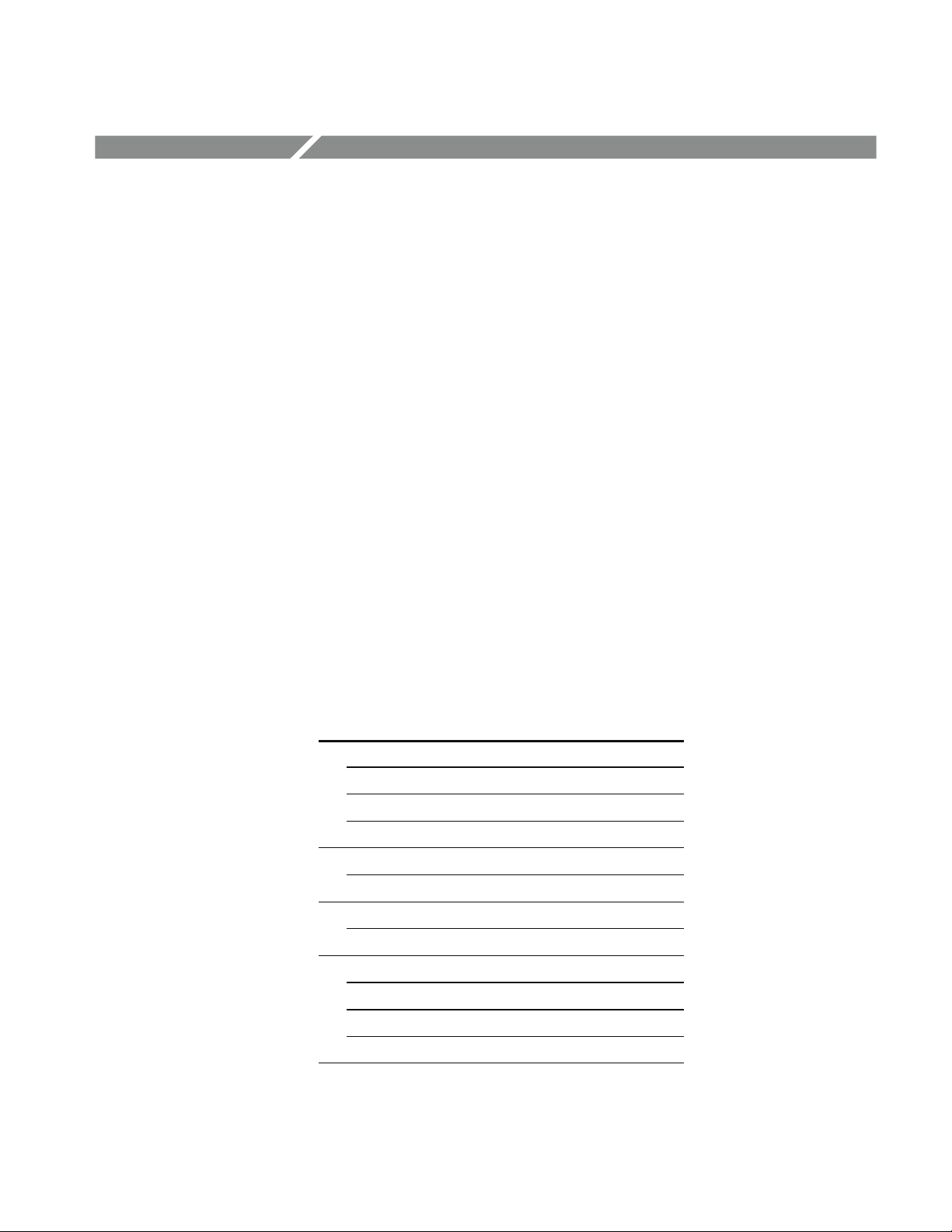

Table of Contents

PS280 and PS283 Specifications 3..............................

PS280 and PS283 Performance Verification 7....................

Test Equipment 8..................................................

Constant Current Load Regulation Check 9.............................

Constant Current Ripple and Noise Check 11............................

Constant Voltage Regulation Check 13..................................

PS280 and PS283 Adjustment Procedures 15.....................

List of Adjustments 15..............................................

Test Equipment 16..................................................

Preparation for Adjustment 16........................................

Independent Mode Adjustments 19.....................................

Series Tracking Mode Adjustments 21..................................

Parallel Tracking Mode Adjustments 22.................................

5 V Fixed Output Adjustments 23......................................

Bench Test Instruments and Handheld Oscilloscopes Basic Service

i

Table of Contents

ii

Bench Test Instruments and Handheld Oscilloscopes Basic Service

PS280 and PS283 Power Supplies

The Tektronix PS280 and PS283 Laboratory DC Power Supplies are multifunction benchtop or portable instruments. These regulated triple output power

supplies provide one fixed 5 V, 3 A output suitable for powering logic circuits

and two variable 0 to 30 V outputs useful in a wide variety of test and experimental uses.

The current output of the PS280 varies from 0 to 2 A. The current output of the

PS283 varies from 0 to 1 A. In all other respects, the instruments are identical.

Unless otherwise noted, descriptions and procedures in this manual apply to both

instruments.

The front panel switches provide three modes of operation for the PS280 and

PS283 power supplies:

H Independent mode: the output voltage and current of each supply is

controlled independently.

H Series mode: the variable outputs are connected in series and the controls of

the MASTER power supply adjust the voltages or currents of both supplies.

Series mode allows the supplies to vary from 0 to 60 V at 0 to 2 A for the

PS280 and 0 to 60 V at 0 to 1 A for the PS283.

H Parallel mode: the variable outputs are connected in parallel and the controls

of the MASTER power supply adjust the voltages or currents of both

supplies. Parallel mode allows the supplies to vary from 0 to 4 A at 0 to

30 V for the PS280 and 0 to 2 A at 0 to 30 V for the P S283.

Figure 1: PS280 DC Power Supply

Bench Test Instruments and Handheld Oscilloscopes Basic Service

1

PS280 and PS 283 Power Supplies

2

Bench Test Instruments and Handheld Oscilloscopes Basic Service

PS280 and PS283 Specifications

The characteristics listed in this section apply under the following conditions:

H The instrument operates in a 0_ to 40_ C(32_ to 104_ F) ambient environ-

ment, unless otherwise noted.

H The instrument warms up for at least twenty minutes.

NOTE. All characteristics are warranted unless marked “typical”. Typical

characteristics are not guaranteed but are provided for the convenience of the

user.

Table 1: Operational characteristics

Characteristic Description

Outputs Onefixed5VDC,twovariable0to30VDC

Voltage (5 V Fixed Supply) 5.0 VDC ±0.25 VDC at 3.0 A maximum, foldback current limited

Voltage (0 to 30 V Supplies) PS280: 0 to 30 VDC constant at 2.0 A constant, maximum

PS283: 0 to 30 VDC constant at 1.0 A constant, maximum

Line regulation

5V <5mV

CV PS280: ≤0.01% + 3 mV

PS283: ≤0.01% + 5 mV

CC ≤0.2% + 3 mA

Load regulation

5V ≤0.2%

CV ≤0.01% + 3 mV (rating current ≤3A)

≤0.01% + 5 mV (rating current >3 A PS280)

≤300 mV (0 to 60 VDC single series tracking supply)

CC ≤0.2% + 3 mA

Bench Test Instruments and Handheld Oscilloscopes Basic Service

3

PS280 and PS283 Specifications

Table 1: Operational characteristics (cont.)

Characteristic Description

Ripple and Noise

5V ≤2mV

CV 5Hzto1MHz:≤1mV

CC ≤3mA

RMS

RMS

RMS

Temperature coefficient (CV) ≤300 ppm/ _C

Recovery time (CV) ≤100 s (time to recover after a 50% load change with 0.5 A

minimum)

Tracking error (SLAVE) ≤0.5% + 10 mV of the MASTER supply

Indicator Two 3½ digit, 0.5 inch LED panel displays

Meter indicators 0to30VDC±(0.5% of RDG + 2 digits)

0to2A±(0.5% of RDG + 2 digits)

Insulation

Chassis to terminals ≥20 MΩ at 500 VDC

Chassis to AC cord ≥30 MΩ at 500 VDC

Table 2: Electrical characteristics

Characteristic Description

Line Voltage 90 to 110, 108 to 132, 198 to 242, and 216 to 250 VAC

Line Frequency 50 to 60 Hz

Power Consumption PS280: 348 VA, 250 W maximum

PS282: 254 VA, 172 W maximum

Table 3: Environmental characteristics

Characteristic Description

Operating Temperature 0° to 40° C(32° to 104° F), ≤70% relative humidity

Nonoperating Temperature -- 1 0 ° to +70° C(14° to 158° F), ≤80% relative humidity

4

Bench Test Instruments and Handheld Oscilloscopes Basic Service

Table 4: Physical characteristics

Characteristic Description

Width 255 mm (10.04 inch)

Height 145 mm (5.71 inch)

Depth 335 mm (13.19 inch)

Weight PS280: 11.5 kg (25.3 lb)

PS283: 9.0 kg (19.8 lb)

PS280 and PS283 Specifications

Bench Test Instruments and Handheld Oscilloscopes Basic Service

5

PS280 and PS283 Specifications

6

Bench Test Instruments and Handheld Oscilloscopes Basic Service

PS280 and PS283 Performance Verification

This section contains procedures to verify that PS280 or PS283 power supplies

perform as warranted. Implement the performance verification procedures

whenever the accuracy or function of your instrument is in question.

The performance verification procedures provide a valid confirmation of

instrument electrical characteristics and function under the following conditions:

H The instrument operates in a 20_ to 30_ C(68_ to 104_ F) ambient

environment.

H The instrument warms up for at least 20 minutes before the verification

begins.

H The cabinet remains installed on the instrument.

The PS280 and PS283 performance verification consists of the checks listed in

Table 5.

Table 5: Performance verification checks

Constant Current Load Regulation Check

MASTER Current Regulation (INDEP mode)

SLAVE Current Regulation (INDEP m ode)

MASTER Current Regulation (PARALLEL mode)

Constant Current Ripple and Noise Check

MASTER Current Ripple

SLAVE Current Ripple

Constant Voltage Regulation Check

MASTER Voltage Regulation

SLAVE Voltage Regulation

5 V Fixed Voltage Regulation

The performance verification procedure should be performed annually or after

every 2000 hours of operation if used infrequently.

Bench Test Instruments and Handheld Oscilloscopes Basic Service

7

PS280 and PS283 Performance Verification

Test Equipment

The performance verification procedures use external traceable test equipment to

directly check warranted characteristics.

Alternative test equipment must meet or exceed the intended minimum

requirements. If you substitute equipment, you may need to modify the

performance verification procedures.

NOTE. Before beginning the performance verification procedures, warm up the

test equipment according to the manufacturer’s recommendations.

Table 6: Performance verification and adjustment test equipment

Description Minimum requirements Example product

Oscilloscope 50 MHz, 3% vertical deflection accuracy Tektronix TDS300 Series Oscilloscope

Digital Multimeter 35 V, 4 A, ±0.1% Accuracy Tektronix DMM914 Digital Multimeter

Fixed Resistive Loads 20 Ω 30 W

10 Ω 30 W

2 Ω 5W

1 Ω 30 W

7 Ω 140 W

0.5 Ω 5W

15 Ω 70 W

30 Ω 140 W

7.5 Ω 140 W

30 Ω 40 W

60 Ω 70 W

Variable Resistive Load 0to2Ω 30 W

Shorting Strap with Alligator Clips Insulated

8

Bench Test Instruments and Handheld Oscilloscopes Basic Service

Constant Current Load Regulation Check

To check the constant current load regulation of your power supply, perform the

following tests.

PS280 and PS283 Performance Verification

MASTER Current

Regulation (INDEP mode)

RL2

DMM

Shorting strap

RL1

Power supply

-- +

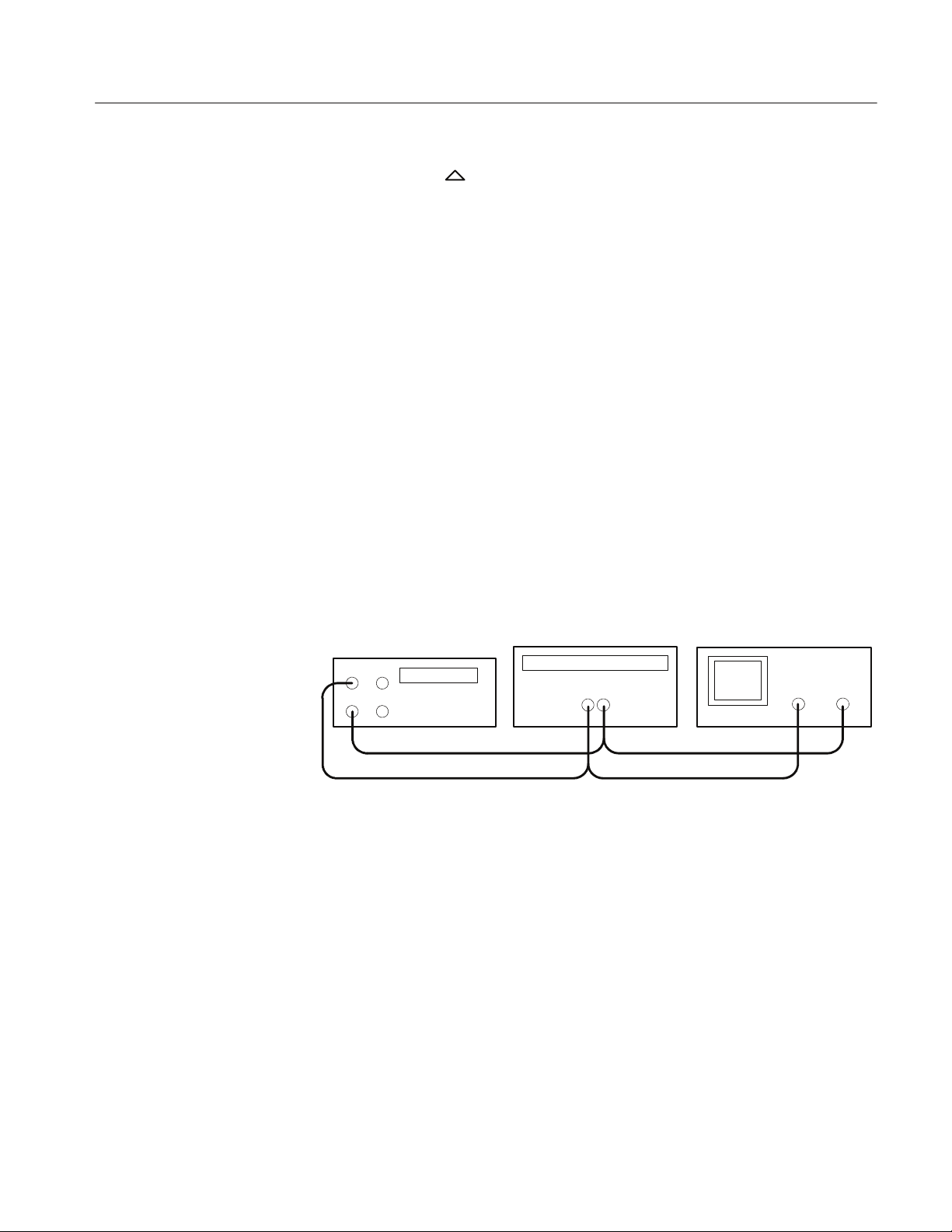

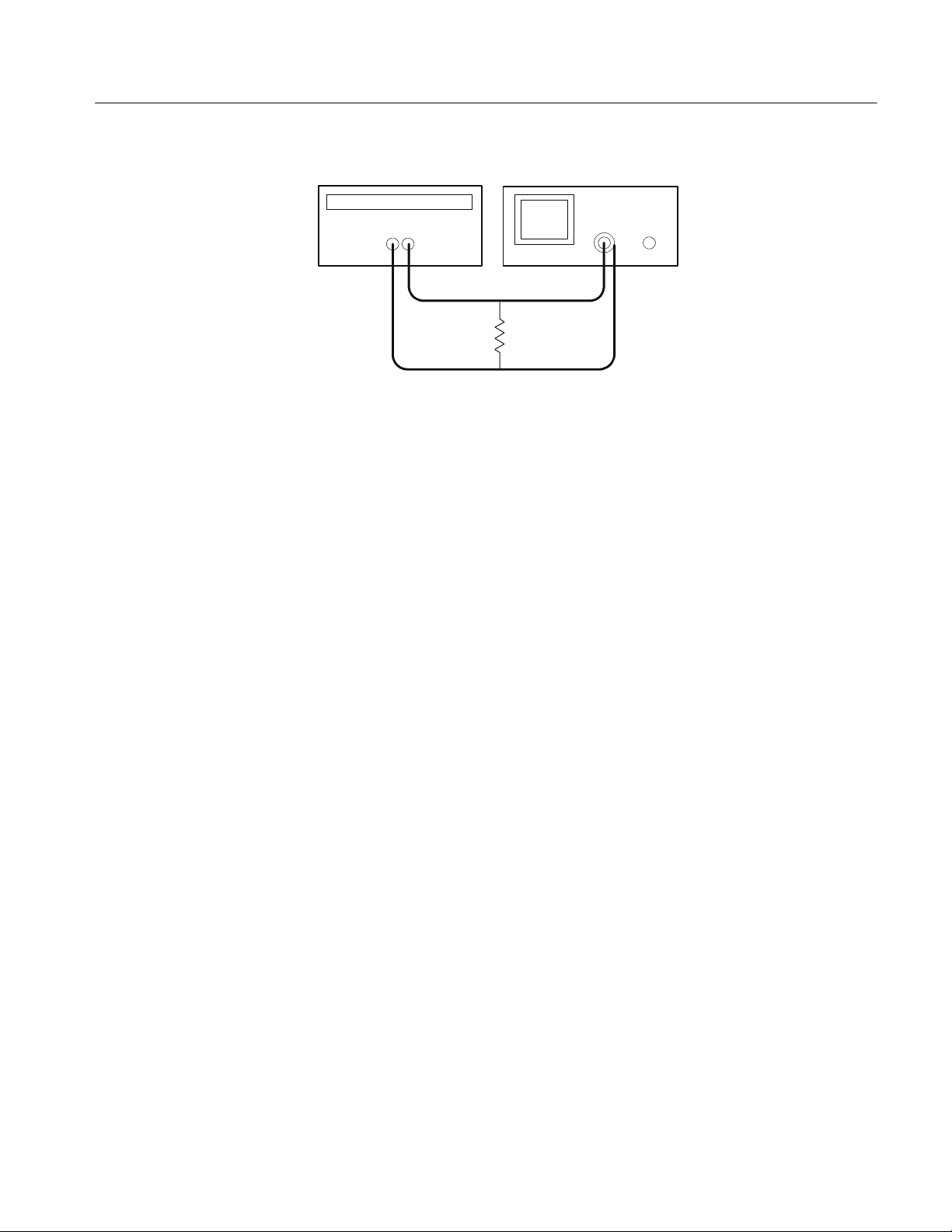

Figure 2: Constant current test setup

The following check verifies the INDEP mode MASTER current regulation

performance.

1. Set the power supply to the INDEP operating mode by disengaging both

TRACKING mode switches (both switches out).

2. Set the power supply MASTER AMPS/VOLTS selection switch to AMPS.

3. Set up the digital multimeter to measure 25 VDC.

4. Connect the digital multimeter to the + and -- terminals of the power supply

MASTER output.

5. Adjust the power supply MASTER VOLTAGE control until the multimeter

reads 25 VDC.

6. Disconnect the digital multimeter from the power supply.

7. Set the digital multimeter to measure a DC current of at least 1 A (PS280) or

0.5 A (PS283).

8. Connect the digital multimeter and load resistors to the + and -- terminals of

the power supply MASTER output as shown in Figure 2. See Table 7 for the

appropriate load resistor values.

9. Verify that the power supply output current varies less than 0.2%

while shunting load resistor RL1 with the shorting strap. See Figure 2 above.

Bench Test Instruments and Handheld Oscilloscopes Basic Service

±3mA

9

PS280 and PS283 Performance Verification

Table 7: Load resistor values for current checks

PS280 PS283

SLAVE Current Regulation

(INDEP Mode)

Mode

INDEP 20 Ω,30W 2 Ω,5W 20 Ω,30W 2 Ω,5W

PARALLEL 10 Ω,30W 1 Ω,30W 10 Ω,30W 1 Ω,30W

RL1

RL2 RL1 RL2

The following check verifies the INDEP mode SLAVE current regulation

performance.

1. Set the power supply SLAVE AMPS/VOLTS meter selection switch to

AMPS.

2. Set up the digital multimeter to measure 25 VDC.

3. Connect the digital multimeter to the + and -- terminals of the power supply

SLAVE output.

4. Adjust the power supply SLAVE VOLTAGE control until the multimeter

reads 25 VDC.

5. Disconnect the digital multimeter from the power supply.

6. Set the digital multimeter to measure a DC current of at least 1 A (PS280) or

0.5 A (PS283).

MASTER Current

Regulation

(PARALLEL Mode)

7. Connect the digital multimeter and load resistors to the + and -- terminals of

the power supply SLAVE output as shown in Figure 2. See Table 7 for the

appropriate load resistor values.

8. Verify that the power supply output current varies less than 0.2%

±3mA

while shunting load resistor RL1 with the shorting strap. See Figure 2 above.

The following check verifies the PARALLEL mode MASTER current regulation

performance.

1. Set the power supply to the PARALLEL operating mode by engaging both

TRACKING mode switches (both switches in).

2. Set up the digital multimeter to measure 25 VDC.

3. Connect the digital multimeter to the + and -- terminals of the power supply

MASTER output.

4. Adjust the power supply MASTER VOLTAGE control until the digital

multimeter reads 25 VDC .

5. Disconnect the digital multimeter from the power supply.

10

Bench Test Instruments and Handheld Oscilloscopes Basic Service

6. Set the digital multimeter to measure a DC current of at least 1 A (PS280) or

0.5 A (PS283).

7. Connect the digital multimeter and load resistors to the + and -- terminals of

the power supply MASTER output as shown in Figure 2. See Table 7 for the

appropriate load resistor values.

8. Verify that the power supply output current varies less than 0.2% ±5mA

while shunting load resistor RL1 with the shorting strap. See Figure 2 above.

Constant Current Ripple and Noise Check

To check the constant current ripple and noise performance of your power

supply, perform the following tests.

PS280 and PS283 Performance Verification

MASTER Current Ripple

Power supply

-- +

R

S

R

L

Test oscilloscope

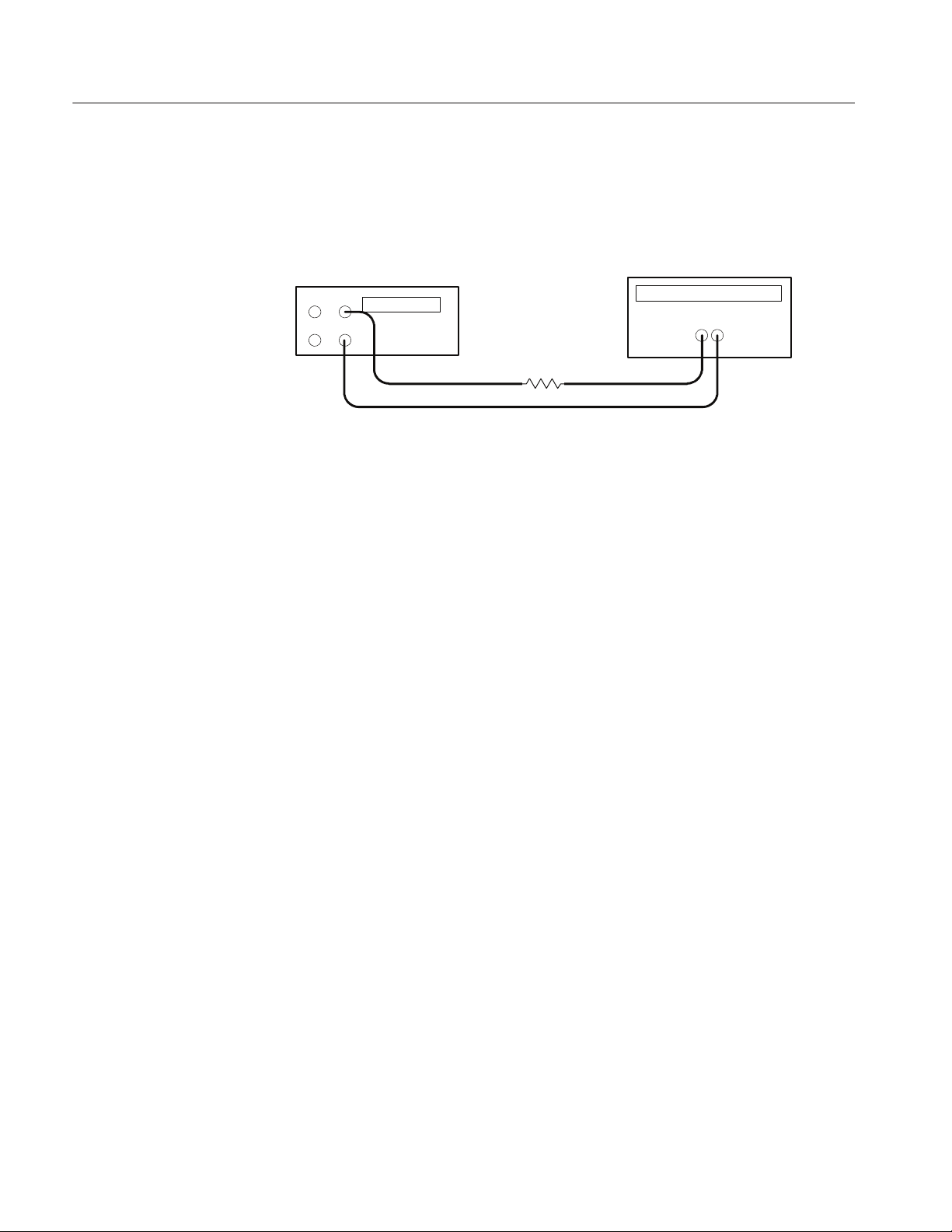

Figure 3: Constant current ripple and noise test setup

The following check verifies the MASTER current ripple.

1. Set the power supply to the INDEP operating mode by disengaging both

TRACKING switches (both switches out).

2. Set the power supply MASTER AMPS/VOLTS meter selection switch to

VOLTS.

3. Set the power supply to 25 VDC using the digital display.

4. Connect the test oscilloscope and load resistors to the + and -- terminals of

the MASTER output as shown in Figure 3. See Table 8 for the appropriate

load resistor values.

5. Verify that the peak-to-peak ripple viewed on the oscilloscope is less than

3mV.

Bench Test Instruments and Handheld Oscilloscopes Basic Service

11

PS280 and PS283 Performance Verification

6. Set the power supply to the PARALLEL operating mode by engaging both

TRACKING mode switches (both switches in).

7. Verify that the peak-to-peak ripple viewed on the oscilloscope is less than

2.5 mV.

8. Set the power supply to the SERIES operating mode by disengaging the

right TRACKING mode switch (switch out).

9. Verify that the peak-to-peak ripple viewed on the oscilloscope is less than

5mV.

Table 8: Load resistor values for ripple checks

PS280 PS283

SLAVE Current Ripple

Mode

INDEP 15 Ω,70W 0.5 Ω,5W 30 Ω,40W 0.5 Ω,5W

PARALLEL 7 Ω, 140 W 10 Ω,30W 15 Ω,70W 0.5 Ω,5W

R

L

R

S

R

L

R

S

The following check verifies the SLAVE current ripple.

1. Set the power supply to INDEP operating mode by disengaging both

TRACKING switches (both switches out).

2. Set the power supply SLAVE AMPS/VOLTS meter switch to VOLTS.

3. Set the power supply to 25 VDC using the digital display.

4. Connect the test oscilloscope and load resistors to the + and -- terminals of

the SLAVE output as shown in Figure 3. See Table 8 for the appropriate load

resistor values.

5. Verify that the peak-to-peak ripple viewed on the oscilloscope is less than

3mV.

12

Bench Test Instruments and Handheld Oscilloscopes Basic Service

Constant Voltage Regulation Check

To check the constant voltage regulation of your power supply, perform the

following tests.

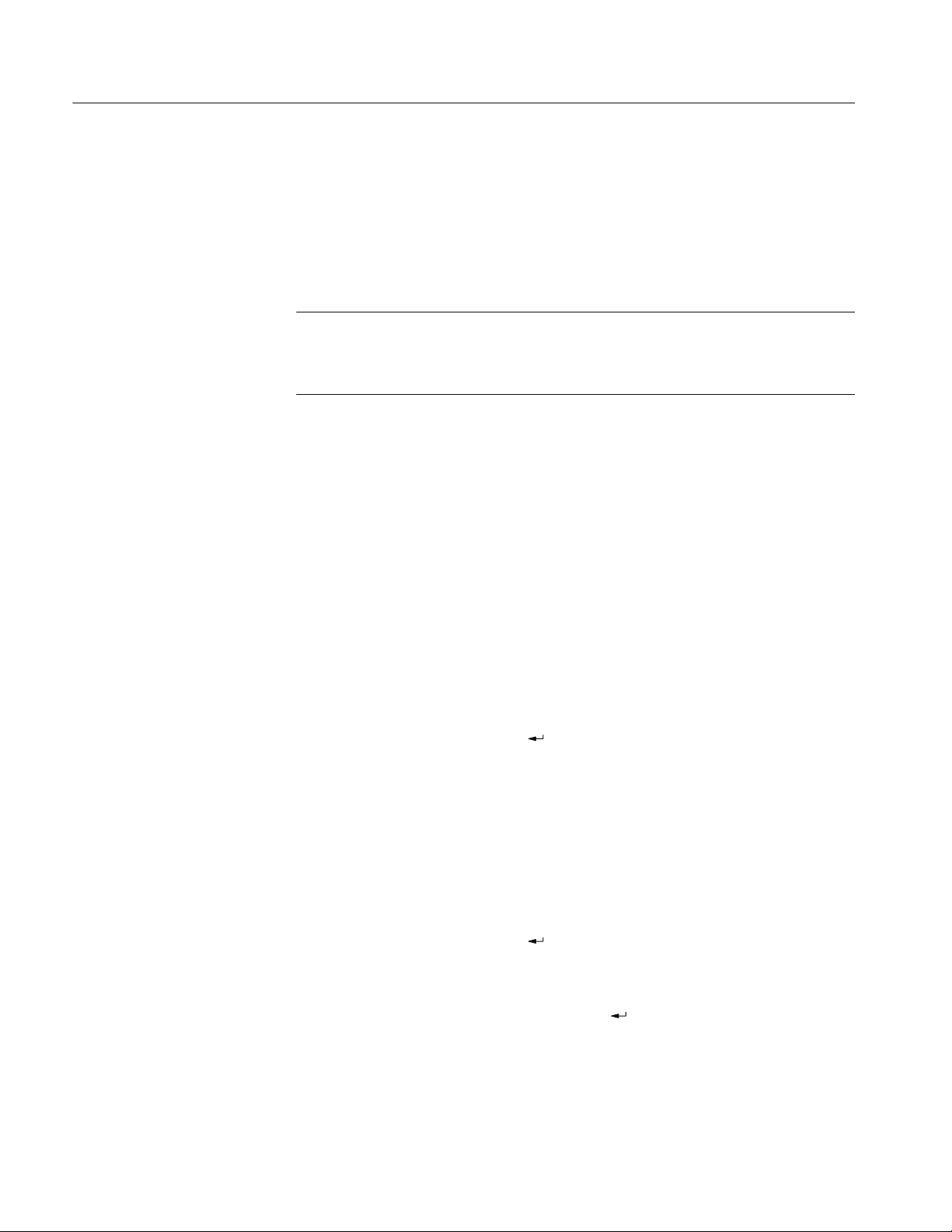

Power supply DMM

Figure 4: Constant voltage test setup

-- +

PS280 and PS283 Performance Verification

R

L

MASTER Voltage

Regulation

The following check verifies the MASTER voltage regulation performance.

1. Set the power supply to the INDEP operating mode by disengaging both

TRACKING mode switches (both switches out).

2. Set up the digital multimeter to measure 60 VDC.

3. Connect the digital multimeter and load resistors to the + and -- terminals of

the power supply MASTER output as shown in Figure 4. See Table 9 for the

appropriate load resistor values.

4. Verify that you can adjust the power supply from 0 to 30 V.

5. Set the power supply to the SERIES operating mode by engaging the left

TRACKING mode switch (switch in) and disengaging the right TRACKING

mode switch (switch out).

6. Verify that you can adjust the power supply from 0 to 60 V.

7. Set the power supply to the PARALLEL operating mode by engaging both

TRACKING mode switches (both switches in).

8. Verify that you can adjust the power supply from 0 to 30 V.

Bench Test Instruments and Handheld Oscilloscopes Basic Service

13

PS280 and PS283 Performance Verification

Table 9: Load resistor values for voltage checks

PS280 PS283

SLAVE Voltage Regulation

5 V Fixed Voltage

Regulation

Mode

INDEP 15 Ω,70W 30 Ω,40W

SERIES 30 Ω, 140 W 60 Ω,70W

PARALLEL 7.5 Ω, 140 W 15 Ω,70W

5V FIXED 1.7 Ω,20W 1.7 Ω,20W

R

L

R

L

The following check verifies the SLAVE voltage regulation performance.

1. Set the power supply to the INDEP operating mode by disengaging both

TRACKING mode switches (both switches out).

2. Set up the digital multimeter to measure 30 VDC.

3. Connect the digital multimeter and load resistors to the + and -- terminals of

the SLAVE output as shown in Figure 4. See Table 9 for the appropriate load

resistor values.

4. Verify that you can adjust the power supply from 0 to 30 V.

The following check verifies the 5 V fixed voltage regulation performance.

1. Set up the digital multimeter to measure 5 VDC.

14

2. Connect the digital multimeter and load resistors to the 5V FIXED 3A

terminals. Use the test setup illustrated in Figure 4. See Table 9 for the

appropriate load resistor values.

3. Verify that the power supply maintains an output of 5 V,

±0.25 V.

Bench Test Instruments and Handheld Oscilloscopes Basic Service

PS280 and PS283 Adjustment Procedures

This section contains procedures to adjust PS280 and PS283 power supplies. If

your instrument fails a performance requirement, use these procedures to return

it to factory specifications.

In this section you will find the following information:

H A list of adjustments

H A list of test equipment needed to make the adjustments

H Instructions on how to prepare instruments for adjustment

H Step-by-step adjustment procedures

The procedures in this section do not verify performance. To confirm that your

power supply meets factory specifications, implement the procedures in the

Performance Verification section.

List of Adjustments

Use the adjustments listed in Table 10 to return PS280 and PS283 power

supplies to factory calibration.

Table 10: PS280 and PS283 adjustments

Independent Mode Adjustments

MASTER Voltage Output

SLAVE Voltage Output

MASTER Current Output

SERIES Tracking Mode Adjustments

Series Tracking

PARALLEL Tracking Mode Adjustments

Parallel Tracking

5 V Fixed Output Adjustments

5 V Output

Current Limit

Overload Indicator

Bench Test Instruments and Handheld Oscilloscopes Basic Service

15

PS280 and PS 283 Adjustment Procedures

Test Equipment

To ensure accurate adjustments, use the recommended or equivalent test

equipment specified in Table 6 on page 8. If you substitute equipment, always

choose instruments that meet or exceed the minimum requirements.

NOTE. Before making any adjustment, warm up the test equipment according to

the manufacturer’s recommendations.

Preparation for Adjustment

The following guidelines apply to all PS280 and PS283 power supply adjustments:

Remove Instrument Cover

H Perform the adjustments in a 20_ to 30_ C(68_ to 104

environment with a relative humidity of 75% or less.

H Before making any adjustment, warm up the instrument for at least 20

minutes.

H Read the Safety Summary at the beginning of this manual.

H Do not alter any setting without reading the entire adjustment procedure first.

H Do not alter any setting unless a performance characteristic cannot be met at

the current setting.

You must remove the instrument cover to make internal adjustments.

WARNING. To avoid electrical shock, disconnect the power cord from its source

while removing the instrument cover. Following the adjustment procedure,

replace the instrument cover before using the power supply.

To remove the instrument cover, refer to Figure 5 while performing the following

steps.

1. Remove the two handle mounting screws and remove the handle.

_ F) ambient

16

2. Remove the three screws on the left side and the three screws on the right

side of the instrument.

3. Slide the cover toward the rear of the instrument and lift.

To reinstall the cover, perform steps 1 through 3 above in reverse order.

Bench Test Instruments and Handheld Oscilloscopes Basic Service

PS280 and PS 283 Adjustment Procedures

Figure 5: PS280/PS283 instrument cover removal

Bench Test Instruments and Handheld Oscilloscopes Basic Service

17

PS280 and PS 283 Adjustment Procedures

Circuit Board Locations

Refer to Figure 6 to locate PS280/PS283 internal circuit boards.

Front Panel controls circuit board

Display Assembly circuit board

Master/Slave circuit board

5 V circuit board

18

Figure 6: PS280/PS283 internal circuit board locations

Bench Test Instruments and Handheld Oscilloscopes Basic Service

Independent Mode Adjustments

Refer to Figures 6, 7, and 8 for the circuit board and adjustment locations used in

this procedure.

PS280 and PS 283 Adjustment Procedures

MASTER Vo ltage Output

To adjust the MASTER voltage output, perform the following steps.

1. Disengage both TRACKING mode switches (both switches out) so that the

power supply is in the INDEPendent operating mode.

2. Set the MASTER AMPS/VOLTS meter selection switch to VOLTS.

3. Set the digital multimeter to measure a DC voltage of

±16 mV.

4. Set the PS280/PS283 MASTER VOLTAGE control to minimum (fully

counterclockwise).

5. Connect the digital multimeter to the + and -- terminals of the MASTER

output.

6. Adjust VR102 (Master/Slave circuit board) for a reading of --15 mV, within

±15 mV on the multimeter.

7. Set the digital multimeter to measure a DC voltage of

±35 V.

8. Set the MASTER VOLTAGE control to maximum (fully clockwise).

9. Adjust VR101 (Master/Slave circuit board) for a reading of 31.5 V on the

multimeter.

10. Adjust VR201 (Display Assembly circuit board) until the PS280/PS283

front panel display reads 31.5 V.

11. Disconnect the digital multimeter from the power supply.

VR502

Figure 7: Master/Slave circuit board adjustments

Bench Test Instruments and Handheld Oscilloscopes Basic Service

VR303

VR102

VR103

VR301

VR306

VR302

VR101

19

PS280 and PS 283 Adjustment Procedures

SLAVE Voltage Output

To adjust the SLAVE voltage output, perform the following steps.

1. Disengage both TRACKING mode switches (both switches out) so that the

power supply is in the INDEPendent operating mode.

2. Set the SLAVE AMPS/VOLTS meter selection switch to VOLTS.

3. Set the digital multimeter to measure a DC voltage of

±16 mV.

4. Set the power supply SLAVE VOLTAGE control to minimum (fully

counterclockwise).

5. Connect the digital multimeter to the + and -- terminals of the SLAVE

output.

6. Adjust VR302 (Master/Slave circuit board) for a reading of --15 mV, within

±15 mV on the multimeter.

7. Set the digital multimeter to measure a DC voltage of

±35 V.

8. Set the SLAVE VOLTAGE control to maximum (fully clockwise).

9. Adjust VR301 (Master/Slave circuit board) for a reading of 31.5 V on the

multimeter.

10. Adjust VR601 (Display Assembly circuit board) until the PS280/PS283

front panel display reads 31.5 V.

MASTER Current Output

11. Disconnect the digital multimeter from the power supply.

J1044

VR601

VR602

VR201

VR202

Figure 8: Display Assembly circuit board adjustments

To adjust the MASTER current output, perform the following steps.

1. Disengage both TRACKING mode switches (both switches out) so the

power supply is in the INDEPendent operating mode.

2. Set the MASTER AMPS/VOLTS meter selection switch to AMPS.

3. Set the digital multimeter to measure a DC current of 2 A.

4. Connect the digital multimeter to the + and -- terminals of the MASTER

output.

5. Set the MASTER CURRENT control to maximum (fully clockwise).

20

Bench Test Instruments and Handheld Oscilloscopes Basic Service

PS280 and PS 283 Adjustment Procedures

6. Adjust VR103 (Master/Slave circuit board) for a reading of 1.05 A (PS283)

or 2.1 A (PS280) on the multimeter.

7. Adjust VR202 (Display Assembly circuit board) until the PS280/PS283

front panel display reads 1.05 A (PS283) or 2.1 A (PS280).

8. Disengage both TRACKING mode switches (both switches out) so that the

power supply is in the INDEPendent operating mode.

9. Set the SLAVE AMPS/VOLTS meter selection switch to AMPS.

10. Set the digital multimeter to measure a DC current of 2 A.

11. Connect the digital multimeter to the + and -- terminals of the SLAVE

output.

12. Set the SLAVE CURRENT control to maximum (fully clockwise).

13. Disconnect the digital multimeter from the power supply.

Series Tracking Mode Adjustments

Refer to Figures 6, 7, and 9 for the circuit board and adjustment locations used in

this procedure.

SERIES Tracking

To adjust the series tracking mode, perform the following steps.

1. Engage the left TRACKING mode switch (switch in) and disengage the right

TRACKING mode switch (switch out) so that the power supply is in the

SERIES operating mode.

2. Set the SLAVE CURRENT control to midrange.

3. Set the MASTER VOLTAGE control to near minimum (counterclockwise).

4. Set the digital multimeter to measure a low DC voltage.

5. Connect the digital multimeter to the + and -- terminals of the MASTER

output and adjust the MASTER VOLTAGE control until the digital

multimeter reads 500 mV.

6. Connect the digital multimeter to the + and -- terminals of the SLAVE

output.

7. Adjust VR306 (Master/Slave circuit board) until the voltage output of the

SLAVE output matches the reading obtained from the MASTER output.

8. Set the MASTER VOLTAGE control to maximum (fully clockwise).

9. Set the digital multimeter to measure a DC voltage of

Bench Test Instruments and Handheld Oscilloscopes Basic Service

±35 V.

21

PS280 and PS 283 Adjustment Procedures

10. Connect the digital multimeter to the + and -- terminals of the MASTER

output and note the reading obtained.

11. Connect the digital multimeter to the + and -- terminals of the SLAVE

output.

12. Adjust VR501 (Front Panel Controls circuit board) until the voltage of the

SLAVE output matches the reading obtained from the MASTER output in

step 10 above.

13. Recheck the value of the MASTER output compared to the value of the

SLAVE output. Readjust VR501 if the outputs do not match.

14. Disconnect the test setup.

J3082

VR501

Figure 9: Front Panel Controls circuit board adjustm ents

Parallel Tracking Mode Adjustments

Refer to Figures 6 and 7 for the circuit board and adjustment locations used in

this procedure.

PARALLEL Tracking

To adjust the PARALLEL tracking Mode, perform the following steps.

1. Disengage both TRACKING mode switches (both switches out) so that the

power supply is in the INDEPendent operating mode.

2. Set the MASTER VOLTAGE and CURRENT controls to minimum (fully

counterclockwise).

3. Set the digital multimeter to measure a DC current of 4 A.

4. Connect the digital multimeter to the + and -- terminals of the MASTER

output.

5. Set the MASTER VOLTAGE control to midrange and adjust the MASTER

CURRENT control until a reading of 1 A (PS283) or 2 A (PS280) is

displayed on the multimeter.

22

Bench Test Instruments and Handheld Oscilloscopes Basic Service

NOTE. Do not readjust the CURRENT control setting through the remainder of

this procedure.

6. Engage both TRACKING switches (both switches in) so that the power

supply is in the PARALLEL operating mode.

7. Set the SLAVE CURRENT control to maximum (fully clockwise) and set

the SLAVE VOLTAGE control to midrange.

8. Adjust VR502 (Master/Slave circuit board) until a reading of 2 A (PS283) or

4 A (PS280) is displayed on the multimeter.

9. Disconnect the test setup.

5 V Fixed Output Adjustments

Refer to Figures 6 and 10 for the circuit board and adjustment locations used in

this procedure.

PS280 and PS 283 Adjustment Procedures

5 V Output

To adjust the 5 V fixed output, perform the following steps.

1. Set the digital multimeter to measure a DC voltage of +5.25 V.

2. Connect the digital multimeter to the terminals of the 5 V FIXED 3A output.

3. Adjust VR401 (5 V circuit board) until the multimeter displays 5.00 V

±0.25 V.

4. Disconnect the multimeter from the power supply.

VR401

VR403

VR402

Figure 10: 5 V circuit board adjustments

Bench Test Instruments and Handheld Oscilloscopes Basic Service

23

PS280 and PS 283 Adjustment Procedures

Current Limit

Overload Indicator

To adjust the current limit, perform the following steps.

1. Set the digital multimeter to measure a DC current of 3.25 A.

2. Adjust VR403 (5 V circuit board) fully counterclockwise.

3. Connect a variable load and the multimeter in series to the terminals of the

5 V FIXED 3A output.

4. Adjust the variable load until the multimeter displays 3.25 A.

5. Disconnect the multimeter from the power supply and reconnect the variable

load (without changing the setting) to the terminals of the 5 V FIXED 3A

output.

6. Set the digital multimeter to measure a DC voltage of +5.25 V.

7. Connect the digital multimeter to the terminals of the 5 V FIXED 3A output.

8. Slowly adjust VR403 (5 V circuit board) clockwise until the multimeter

display shows a voltage drop of 5 to 6 mV.

9. Disconnect the test setup.

To adjust the current limit overload indicator, perform the following steps.

1. Set the digital multimeter to measure a DC current of 3.25 A.

2. Connect a variable load and the multimeter in series to the terminals of the

5 V FIXED 3A output.

3. Adjust the variable load until the multimeter displays 3.10 A.

4. Adjust VR402 (5 V circuit board) until the OVERLOAD 5V3A indicator

starts to light on the power supply.

5. Disconnect the test setup.

24

Bench Test Instruments and Handheld Oscilloscopes Basic Service

Instructions Manual

PS2520 and PS2521 Series

Power Supplies

070-9854-03

www.tektronix.com

Table of Contents

PS2520 and PS2521 Series Power Supplies 1.....................

PS2520 and PS2521 Series Specifications 3......................

PS2520 and PS2521 Series Performance Verification 7............

Test Equipment 8..................................................

Set Up 8.........................................................

PS2520 and PS2520G Checks 9......................................

PS2521 and PS2521G Checks 32......................................

PS2520 and PS2521 Series Adjustment Procedures 55..............

List of Adjustments 55..............................................

Test Equipment 56..................................................

Preparation for Adjustment 56........................................

Adjustment Procedure 58............................................

Bench Test Instruments and Handheld Oscilloscopes Basic Service

i

Table of Contents

ii

Bench Test Instruments and Handheld Oscilloscopes Basic Service

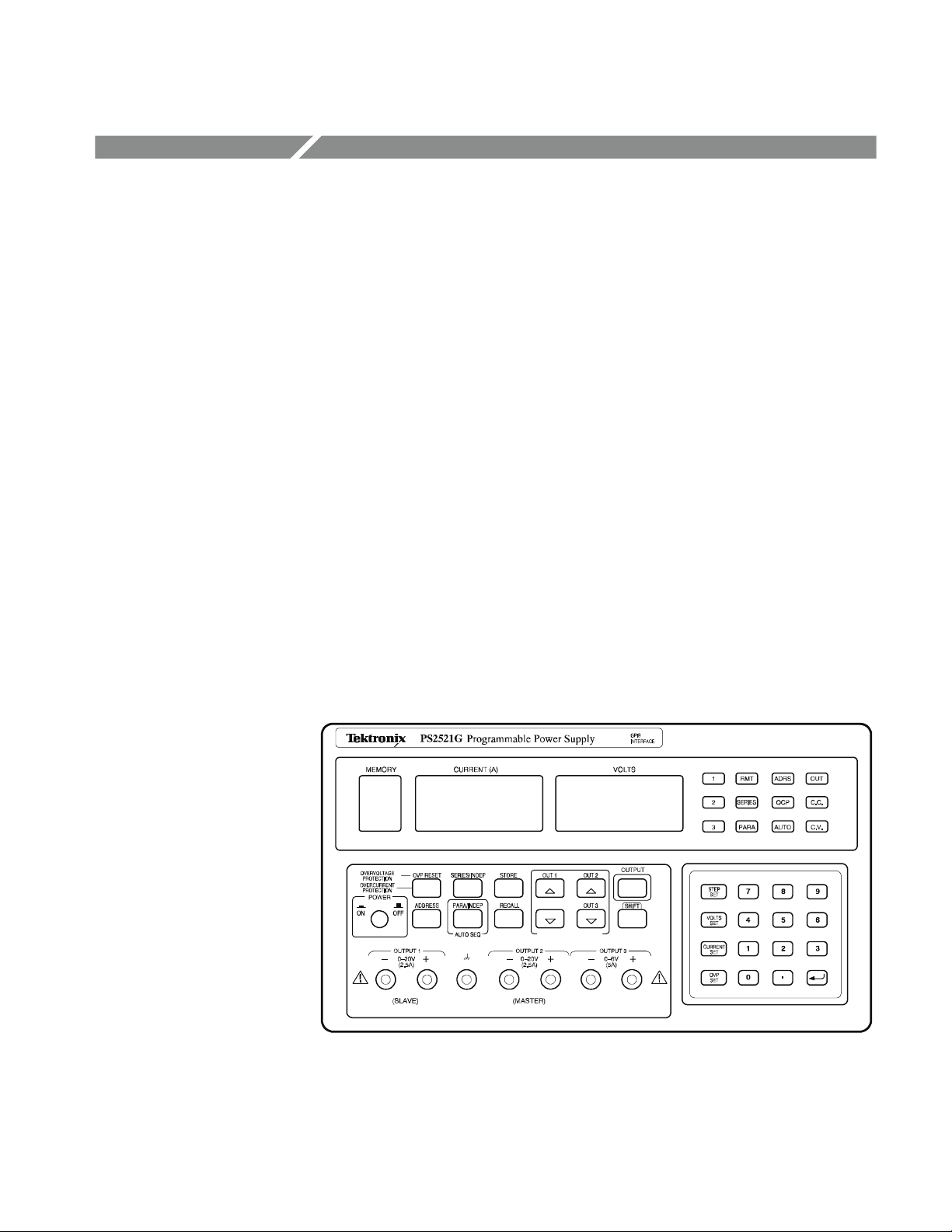

PS2520 and PS2521 Series Power Supplies

The Tektronix PS2520, PS2520G, PS2521, and PS2521G power supplies are

multifunction benchtop or portable instruments. All PS2520 series power

supplies include the following standard features:

H Three high stability low drift outputs (outputs may be configured for

independent, series, or parallel operation)

H Automatic series or parallel tracking

H Push-button controls

H Keypad and up-down key data entry

H Four-digit display of voltage and current

H High resolution digital-to-analog converter

H Memory storage and recall

H Display readout of output, memory, and error codes

H Automatic sequencing with timer

H Self-test diagnostic at power up

H Overvoltage protection (OVP) and overcurrent protection (OCP)

Figure 1: PS2521G power supply

Bench Test Instruments and Handheld Oscilloscopes Basic Service

1

PS2520 and PS 2521 Series Power Supplies

The descriptions and procedures in the following sections apply to all PS2520

series power supplies (unless specifically noted), with the following exceptions:

H The PS2520 and PS2520G power supplies have two variable outputs

providing 0 to 36 V at 0 to 1.5 A and one variable output providing 0 to 6 V

at0to3A.

H The PS2521 and PS2521G power supplies have two variable outputs

providing 0 to 20 V at 0 to 2.5 A and one variable output providing 0 to 6 V

at0to5A.

H The PS2520G and PS2521G include General Purpose Interface Bus (GPIB)

operation.

2

Bench Test Instruments and Handheld Oscilloscopes Basic Service

PS2520 and PS2521 Series Specifications

The characteristics listed in this section apply under the following conditions:

H The power supply operates in a 20_ to 30_ C(68_ to 86_ F) ambient

environment, unless otherwise noted.

H The instrument warms up for at least 20 minutes.

NOTE. All specifications are warranted unless marked “typical.” Typical

characteristics are not guaranteed but are provided for the convenience of the

user.

Table 1: Operational characteristics

Characteristic Description

Independent Output Ratings

PS2520 and PS2520G Twooutputs: 0to36Vat0to1.5A

One output: 0 to 6 V at 3 A

PS2521 and PS2521G Twooutputs: 0to20Vat0to2.5A

Oneoutput: 0to6Vat0to5A

Series Tracking Output Rating

PS2520 and PS2520G 0to72Vat0to1.5A

PS2521 and PS2521G 0to40Vat0to2.5A

Parallel Tracking Output Rating

PS2520 and PS2520G 0to36Vat0to3A

PS2521 and PS2521G 0to20Vat0to5A

Maximum Overvoltage Protection

PS2520 and PS2520G 36 V outputs: 38.5 V

6 V output: 7.0 V

PS2521 and PS2521G 20 V outputs: 22.5 V

6 V output: 7.0 V

Load Effect

Voltage Rear output: ≤3mV

Front output:≤6mV

Current ≤3mA(≤6 mA if rating current > 3.5 A)

Source Effect

Voltage ≤3mV

Current ≤3mA

Bench Test Instruments and Handheld Oscilloscopes Basic Service

3

PS2520 and PS 2521 Series Specifications

Table 1: Operational characteristics (cont.)

Characteristic Description

Resolution

Voltage 10 mV (20 mV if rating voltage > 36 V)

Current 1mA(2mAifratingcurrent>3.5A)

Overvoltage Protection 10 mV (20 mV if rating voltage > 36 V)

Program Accuracy

Voltage ≤0.05% + 25 mV (50 mV if rating voltage > 36 V)

Current ≤0.2% + 10 mA

Overvoltage Protection ≤2% + 0.6 V

RippleandNoise20Hzto20MHz

Voltage Ripple 1mV

Voltage Noise 2mV

Current ≤3mA

Temperature Coefficient 0_ to 40_ C(32_ to 104_ F)

Voltage ≤100 ppm + 3mV

Current ≤150 ppm + 3mA

Readback Resolution

Voltage 10 mV (20 mV if rating voltage > 36 V)

Current 1mA(2mAifratingcurrent>3.5A)

Readback Accuracy

Voltage ≤0.05% + 25 mV (50 mV if rating voltage > 36 V)

Current ≤0.2% + 10 mA

Response Time

10 to 90% (up) ≤100 ms

90 to10% (down) ≤100 ms (≥10% rating load)

Readback Temperature Coefficient

Voltage ≤100 ppm + 10 mV (20 mV if rating voltage > 36 V)

Current ≤150 ppm + 10 mA

1

Drift

Voltage ≤0.03% + 6 mV

Current ≤0.1% + 6 mA

Series Tracking

Tracking Error Voltage ≤0.1% + 50 mV

Load Effect Voltage ≤50 mV

Source Effect Voltage ≤3mV

1

Change in output over an 8 hour interval with a constant line voltage, load, and ambient temperature. Requires a 30

minute warm-up.

RMS

RMS

RMS

(3 mV

(30 mV

(≤5mA

)

p-p

)

p-p

if rating current > 3.5 A)

RMS

4

Bench Test Instruments and Handheld Oscilloscopes Basic Service

PS2520 and PS 2521 Series Specifications

Table 1: Operational characteristics (cont.)

Characteristic Description

Parallel Tracking

Program Accuracy

Voltage ≤0.05% + 25 mV (50 mV if rating voltage > 36 V)

Current ≤0.2% + 20 mA

Overvoltage Protection ≤2% + 0.6 V

Load Effect

Voltage ≤3 mV rear output (≤6 mV front output)

Current ≤6mA(≤12 mA if rating current > 3.5 A)

Source Effect

Voltage ≤3mV

Current ≤6mA

GPIB Capability (Optional IEEE-488.2) SH1, AH1, T6, L4, SR1, RL1, PP0, DC1, DT0, C0, E1

Memory Locations (Store and Recall) 00 to 49 (50 locations)

Timer

Setting Time 1 to 65535 seconds

Resolution 1 second

Table 2: Electrical characteristics

Characteristic Description

Power Source 100, 120, and 220 VAC ±10% at 50 to 60 Hz

240 VAC --10%, +4.2%, at 50 to 60 Hz

Safety ETL list ed to UL 1244

Certified to CSA-C22.2 No 231-M89

Table 3: Environmental characteristics

Characteristic Description

Operating Temperature 0_ to 40_ C(32_ to 104_ F)

Nonoperating Temperature -- 1 0 _ to +70_ C(14_ to 158_ F)

Bench Test Instruments and Handheld Oscilloscopes Basic Service

5

PS2520 and PS 2521 Series Specifications

Table 4: Physical characteristics

Characteristic Description

Width 255 mm (10.04 inch)

Height 145 mm (5.71 inch)

Depth 346 mm (13.62 inch)

Weight 10 kg (22 lbs)

6

Bench Test Instruments and Handheld Oscilloscopes Basic Service

PS2520 and PS2521 Series Performance Verification

This section contains procedures to verify that PS2520, PS2520G, PS2521, or

PS2521G power supplies perform as warranted. Implement the performance

verification procedures whenever the accuracy or function of your power supply

is in question.

The performance verification procedures provide a valid confirmation of

instrument electrical characteristics and function under the following conditions:

H The instrument operates in a 20° to 30° C(68° to 86° F) ambient environ-

ment.

H The instrument warms up for at least 20 minutes.

H The cabinet remains installed on the instrument.

The performance verification procedure should be performed annually or after

every 2000 hours of operation if used infrequently.

The PS2520 series performance verification consists of the checks listed in

Table 5.

Table 5: Performance verification checks

Basic Function

Voltage Set Accuracy

Current Set Accuracy

Overvoltage Protection (OVP) Accuracy

Constant Voltage Load Accuracy

Constant Voltage Source Accuracy

Constant Voltage Ripple and Noi se Accuracy

Constant Current Load and Overcurrent Protection (OCP)

Accuracy

Constant Current Source Accuracy

There are two separate performance verification procedures for the

PS2520/2520G and PS 2521/2521G series instruments. The PS2520/2520G

procedures begin on page 9; the PS2521/2521G procedures begin on page 32.

Use the procedure appropriate to your instrument.

You will find the recommended test equipment and initial settings for all

verification procedures listed on page 8.

Bench Test Instruments and Handheld Oscilloscopes Basic Service

7

PS2520 and PS2521 Series Performance Verification

Test Equipment

The performance verification procedures use external traceable test equipment to

directly check warranted characteristics.

Alternative test equipment must meet or exceed the intended minimum

requirements. If you substitute equipment, you may need to modify the

procedures.

NOTE. Before beginning the performance verification procedures, warm up the

test equipment according to the manufacturer’s recommendations.

Table 6: Performance verification test equipment

Description Minimum requirements Example product

Digital Volt Meter (DVM) 100 V DC, accuracy within ±0.01% Agilent 34401A

Digital Current Meter 5A DC, accuracy within ±0.02% Fluke 45

Oscilloscope 20 MHz, 3% vertical deflection accuracy Tektronix TDS300 Series

Electronic Load 40 V, 8 A CR mode

Vari a c 0to250V,2A

Resistors 2.2 Ω 50 W, 27 Ω 100 W

Set Up

Following a 20 minute warm-up period, preset your power supply to the settings

listed in Table 7.

Table 7: Power supply initial settings

Control Setting

(SHIFT) RECALL Enter 00 on keypad

AUTO SEQ OFF

(SHIFT) OUT 1

OCP OFF

(SHIFT) SERIES/INDEP INDEP

(SHIFT) PARA/INDEP INDEP

OUTPUT OFF

STEP SET (volts) 1

STEP SET (current) 0.1

8

Bench Test Instruments and Handheld Oscilloscopes Basic Service

PS2520 and PS2520G Checks

To verify the function and performance of the PS2520 and PS2520G power

supplies, implement the following checks in sequential order. To verify the

function and performance of the PS2521 and PS2521G power supplies, see

page 32.

NOTE. To clear a memory location, enter “0” as the VOLTS SET and CURRENT

SET values; then save the “0” values to the desired memory location.

For a list of error code descriptions, see your User manual.

PS2520 and PS2521 Series Performance Verification

Basic Function

Complete the following procedures to verify basic instrument function.

Outputs 1, 2, and 3. Use the following steps to verify OUTPUT 1, OUTPUT 2,

and OUTPUT 3 basic function.

1. Press SHIFT

2. Set up the power supply as follows:

VOLTS SET 10 V

CURRENT SET 1 A

OVP SET 38 V

DELAY 3 s

3. Press SHIFT

location. Verify that the MEMORY, CURRENT (A), and VOLTS readouts

display the values listed in step 2 for memory location 01.

4. Reset the power supply as follows:

VOLTS SET 11 V

CURRENT SET 1.1 A

OVP SET 38 V

DELAY 3 s

→ OUT 1; verify that the “1” indicator lights up on the display.

→ STORE → 1 to store the above values in the memory 01

5. Press SHIFT

location. Verify that the MEMORY, CURRENT (A), and VOLTS readouts

display the values listed in step 4 for memory location 02.

6. Press SHIFT

7. Press RECALL LAST; verify that the readouts display the data stored in the

memory 02 location.

Bench Test Instruments and Handheld Oscilloscopes Basic Service

→ STORE → 2 to store the above values in the memory 02

→ RECALL; then enter 1.2 .

9

PS2520 and PS2521 Series Performance Verification

8. Press RECALL LAST again; verify that the readouts now display the data

stored in the memory 01 location.

9. Press RECALL NEXT; verify that the readouts display the data stored in the

memory 02 location.

10. Press OUTPUT ON/OFF. Verify that the “OUT” indicator lights up on the

display.

11. Press AUTO SEQ ON/OFF and verify that the “AUTO” indicator lights up

on the display. Verify that the front panel readouts alternately display the

memory 01 and memory 02 setups from steps 2 and 4 above, every three

seconds.

12. Press AUTO SEQ ON/OFF and OUTPUT ON/OFF. Verify that the “AUTO”

and “OUT” indicators turn off.

13. Press STEP SET. Set the VOLTS SET to 1.00 V.

14. Press VOLTS

and verify that as you attempt to decrease the voltage

below 0.00 V, “Err - 018” appears on the CURRENT (A) and VOLTS

readouts. The voltage should decrease in 1 volt steps on the VOLTS readout.

15. Press VOLTS

and verify that as you attempt to increase the voltage past

37.00 V, “Err - 016” appears on the readouts. The voltage should increase in

1 volt steps on the VOLTS readout.

16. Press STEP SET. Set the CURRENT SET to .1 A.

17. Press CURRENT

and verify that as you attempt to decrease the current

below 0.000 A, “Err - 019” appears on the readouts and the “C.C.” indicator

lights. The current should decrease in .1 ampere steps on the CURRENT (A)

readout.

18. Press CURRENT and verify that as you attempt to increase the current

past 1.550 A, “Err - 017” appears on the readouts. The current should

increase in .1 ampere steps on the CURRENT (A) readout.

To check the function of OUTPUT 2, press SHIFT

→ OUT 2. Verify that the “2”

indicator lights up on the display; then repeat steps 2 through 18 above.

To check the function of OUTPUT 3, press SHIFT

→ OUT 3. Verify that the “3”

indicator lights up on the display; then continue with the steps below.

10

19. Set up the power supply as follows:

VOLTS SET 5 V

CURRENT SET 2 A

OVP SET 7 V

DELAY 3 s

Bench Test Instruments and Handheld Oscilloscopes Basic Service

PS2520 and PS2521 Series Performance Verification

20. Press SHIFT

→ STORE → 1 to store the above values in the memory 01

location. Verify that the MEMORY, CURRENT (A), and VOLTS readouts

display the values listed in step 19 for memory location 01.

21. Reset the power supply as follows:

VOLTS SET 6 V

CURRENT SET 3 A

DELAY 3 s

22. Press SHIFT

→ STORE → 2 to store the above values in the memory 02

location. Verify that the MEMORY, CURRENT (A), and VOLTS readouts

display the values set in step 21 for memory location 02.

23. Repeat steps 6 through 12 above.

24. Press STEP SET. Set the VOLTS SET to 1 V.

25. Press VOLTS

and verify that as you attempt to decrease the voltage

below 0.00 V, “Err - 018” appears on the CURRENT (A) and VOLTS

readouts. The voltage should decrease in 1 volt steps on the VOLTS readout.

26. Press VOLTS

and verify that as you attempt to increase the voltage past

6.50 V, “Err - 016” appears on readouts. The voltage should increase in

1 volt steps on the VOLTS readout.

27. Press STEP SET. Set the CURRENT SET to .1 A.

28. Press CURRENT

and verify that as you attempt to decrease the current

below 0.000 A, “Err - 019” appears on the readouts and the “C.C.” indicator

lights. The current should decrease in .1 ampere steps on the CURRENT (A)

readout.

29. Press CURRENT

and verify that as you attempt to increase the current

past 3.100 A, “Err - 017” appears on the readouts. The current should

increase in .1 ampere steps on the CURRENT (A) readout.

OCP, Series, and Parallel Mode Indicators. Use the following steps to verify OCP,

series, and parallel output indicator function.

1. On the power supply front panel, press OCP ON/OF F to enable the OCP.

Verify that the “OCP” indicator lights up on the display.

2. Press OCP ON/OFF. Verify that the “OCP” indicator turns off.

3. Press SHIFT

→ SERIES/INDEP to configure the power supply outputs for

series operation. Verify that the “SERIES” indicator lights up on the display.

4. Press SHIFT

→ PARA/INDEP to configure the power supply outputs for

parallel operation. Verify that the “PARA” indicator lights up on the display.

Bench Test Instruments and Handheld Oscilloscopes Basic Service

11

PS2520 and PS2521 Series Performance Verification

Voltage Set A ccuracy

5. Press SHIFT

→ PARA/INDEP again to reconfigure the outputs for indepen-

dent operation. Verify that the “PARA” and “SERIES” indicators turn off.

Set GPIB. Use the following steps to check the GPIB address.

1. Press LOCAL.

2. Enter a GPIB address <0 to 30> and press

.

3. Press SHIFT → ADDRESS. Verify that the address entered in step 2 above

appears on the readout for about one second.

Complete the following procedures to verify voltage setting and readout

accuracy.

Outputs 1 and 2. Use the following steps to check the OUTPUT 1 and

OUTPUT 2 accuracy.

1. Press SHIFT

→ OUT 1; verify that the “1” indicator lights up on the display.

2. Set up the power supply as follows:

VOLTS SET 36 V

OVP SET 37 V

3. Press STEP SET. Set the VOLTS SET to 0.05 V.

4. Ensure that the power supply output is disabled. Configure the DVM to

measure 40 VDC across the front panel OUTPUT 1 (2) terminals.

5. Press OUTPUT ON/OFF. Verify that the “OUT” indicator lights up on the

display.

6. Verify that the DVM reads between 35.950 and 36.050 VDC.

7. Press VOLTS

or VOLTS to adjust the power supply output voltage

until the DVM reads 36.00 VDC.

8. Verify that the power supply VOLTS readout indicates between 35.950 and

36.050 V.

9. Press VOLTS SET. Set the power supply output voltage to 0.1 V.

10. Set the DVM to measure 1 VDC across the power supply OUTPUT 1 (2)

terminals.

11. Verify that the DVM reads between 0.0749 and 0.1250 VDC.

12. Press OUTPUT ON/OFF. Verify that the “OUT” indicator turns off.

12

Bench Test Instruments and Handheld Oscilloscopes Basic Service

PS2520 and PS2521 Series Performance Verification

13. Press SHIFT

→ OUT 2; verify that the “2” indicator lights up on the display.

14. Repeat steps 2 through 12 above to measure the OUTPUT 2 voltage setting

and readout accuracy .

Output 3. Use the following steps to check the OUTPUT 3 accuracy.

1. Press SHIFT

→ OUT 3; verify that the “3” indicator lights up on the display.

2. Set up the power supply as follows:

VOLTS SET 6 V

OVP SET 7 V

3. Press STEP SET. Set the VOLTS SET to 0.05 V.

4. Ensure that the power supply output is disabled. Configure the DVM to

measure 10 VDC across the power supply front panel OUTPUT 3 terminals.

5. Press OUTPUT ON/OFF. Verify that the “OUT” indicator lights up on the

display.

6. Verify that the DVM reads between 5.972 and 6.028 VDC.

7. Press VOLTS

or VOLTS to adjust the power supply output voltage

until the DVM reads 6.00 VDC.

8. Verify that the power supply VOLTS readout indicates between 5.950 and

6.050 V.

9. Press VOLTS SET. Set the power supply output voltage to 0.1 V.

10. Set the DVM to measure 1 VDC across the power supply OUTPUT 3

terminals.

11. Verify that the DVM reads between 0.0749 and 0.1250 VDC.

12. Press OUTPUT ON/OFF. Verify that the “OUT” indicator turns off.

Series Operation. Use the following steps to check the series mode accuracy.

1. Press SHIFT

→ OUT 2; verify that the “2” indicator lights up on the display.

2. Set up the power supply as follows:

VOLTS SET 36 V

OVP SET 37 V

3. Press STEP SET. Set the VOLTS SET to 0.05 V.

Bench Test Instruments and Handheld Oscilloscopes Basic Service

13

PS2520 and PS2521 Series Performance Verification

4. Ensure that the power supply output is disabled. Configure the DVM to

measure 100 VDC across the front panel OUTPUT 2 (+) and OUTPUT

1 (--) terminals.

5. Press SHIFT

→ SERIES/INDEP to configure OUTPUT 1 and OUTPUT 2

for series operation. Verify that the “SERIES” indicator lights up on the

display.

6. Press OUTPUT ON/OFF. Verify that the “OUT” indicator lights up on the

display.

7. Verify that the DVM reads between 71.900 and 72.100 VDC.

8. Press VOLTS

or VOLTS to adjust the power supply output voltage

until the DVM reads 72.000 VDC.

9. Verify that the power supply VOLTS readout indicates between 35.950 and

36.050 V.

10. Press VOLTS SET. Set the power supply output voltage to 0.1 V.

11. Set the DVM to measure 1 VDC across the power supply OUTPUT 2 (+)

and OUTPUT 1 (--) terminals.

12. Verify that the DVM reads between 0.1498 and 0.2500 VDC.

13. Press OUTPUT ON/OFF. Verify that the “OUT” indicator turns off.

Parallel Operation. Use the following steps to check the parallel mode accuracy.

14

1. Press SHIFT

→ OUT 2; verify that the “2” indicator lights up on the display.

2. Set up the power supply as follows:

VOLTS SET 36 V

OVP SET 37 V

3. Press STEP SET. Set the VOLTS SET to 0.05 V.

4. Ensure that the power supply output is disabled. Configure the DVM to

measure 40 VDC across the power supply front panel OUTPUT 2 terminals.

5. Press SHIFT

→ PARA/INDEP to configure OUTPUT 1 and OUTPUT 2 for

parallel operation. Verify that the “PARA” indicator lights up on the display.

6. Press OUTPUT ON/OFF. Verify that the “OUT” indicator lights up on the

display.

7. Verify that the DVM reads between 35.950 and 36.050 VDC.

8. Press VOLTS

or VOLTS to adjust the power supply output voltage

until the DVM reads 36.00 VDC.

Bench Test Instruments and Handheld Oscilloscopes Basic Service

PS2520 and PS2521 Series Performance Verification

9. Verify that the power supply VOLTS readout indicates between 35.950 and

36.050 V.

10. Press VOLTS SET. Set the power supply output voltage to 0.1 V.

11. Set the DVM to measure 1 VDC across the power supply OUTPUT 2

terminals.

12. Verify that the DVM reads between 0.0749 and 0.1250 VDC.

13. Press OUTPUT ON/OFF. Verify that the “OUT” indicator turns off.

Current Set Accuracy

14. Press SHIFT

→ PARA/INDEP to reconfigure the outputs for independent

operation. Verify that the “PARA” indicator turns off.

Complete the following procedures to verify current setting and readout

accuracy.

Outputs 1 and 2. Use the following steps to check the OUTPUT 1 and

OUTPUT 2 accuracy.

1. Press SHIFT

→ OUT 1; verify that the “1” indicator lights up on the display.

2. Set up the power supply as follows:

VOLTS SET 10 V

CURRENT SET 1.5 A

OVP SET 11 V

3. Press STEP SET. Set the CURRENT SET to 0.002 A.

4. Ensure that the power supply output is disabled. Configure the Current

Meter to measure 2 amperes DC across the front panel OUTPUT 1 (2)

terminals.

5. Press OUTPUT ON/OFF. Verify that the “OUT” indicator lights up on the

display.

6. Verify that the Current Meter reads between 1.487 and 1.513 A.

7. Press CURRENT

or CURRENT to adjust the power supply output

current until the Current Meter reads 1.500 A.

8. Verify that the power supply CURR ENT (A) readout indicates between

1.487 and 1.513 A.

9. Press CURRENT S ET. Set the power supply output current to 0.1 A.

10. Verify that the Current Meter reads between 0.089 and 0.111 A.

11. Press OUTPUT ON/OFF. Verify that the “OUT” indicator turns off.

Bench Test Instruments and Handheld Oscilloscopes Basic Service

15

PS2520 and PS2521 Series Performance Verification

12. Press SHIFT

→ OUT 2; verify that the “2” indicator lights up on the display.

13. Repeat steps 2 through 11 above to measure the OUTPUT 2 current setting

and readout accuracy .

Output 3. Use the following steps to check the OUTPUT 3 accuracy.

1. Press SHIFT

→ OUT 3; verify that the “3” indicator lights up on the display.

2. Set up the power supply as follows:

VOLTS SET 6 V

CURRENT SET 3 A

OVP SET 7 V

3. Press STEP SET. Set the CURRENT SET to 0.002 A.

4. Ensure that the power supply output is disabled. Configure the Current

Meter to measure 10 amperes DC across the front panel OUTPUT 3

terminals.

5. Press OUTPUT ON/OFF. Verify that the “OUT” indicator lights up on the

display.

6. Verify that the Current Meter reads between 2.984 and 3.016 A.

7. Press CURRENT

or CURRENT to adjust the power supply output

current until the Current Meter reads 3.000 A.

8. Verify that the power supply CURRENT (A) readout indicates between

2.984 and 3.016 A.

9. Press CURRENT S ET. Set the power supply output current to 0.1 A

10. Verify that the Current Meter reads between 0.089 and 0.111 A.

11. Press OUTPUT ON/OFF. Verify that the “OUT” indicator turns off.

Parallel Operation. Use the following steps to the check parallel mode accuracy.

1. Press SHIFT

→ OUT 2; verify that the “2” indicator lights up on the display.

2. Set up the power supply as follows:

VOLTS SET 10 V

CURRENT SET 1.5 A

OVP SET 11 V

3. Press STEP SET. Set the CURRENT SET to 0.002 A.

16

Bench Test Instruments and Handheld Oscilloscopes Basic Service

PS2520 and PS2521 Series Performance Verification

4. Ensure that the power supply output is disabled. Configure the Current

Meter to measure 10 amperes DC across the power supply front panel

OUTPUT 2 terminals.

5. Press SHIFT

→ PARA/INDEP to configure OUTPUT 1 and OUTPUT 2 for

parallel operation. Verify that the “PARA” indicator lights up on the display.

6. Press OUTPUT ON/OFF. Verify that the “OUT” indicator lights up on the

display.

7. Verify that the Current Meter reads between 2.974 and 3.026 A.

8. Press CURRENT

or CURRENT to adjust the power supply output

current until the Current Meter reads 3.000 A.

9. Verify that the power supply CURR ENT (A) readout indicates between

2.974 and 3.026 A.

10. Press CURRENT SET. Set the power supply output current to 0.1 A.

11. Verify that the Current Meter reads between 0.089 and 0.11 1 A.

12. Press OUTPUT ON/OFF. Verify that the “OUT” indicator turns off.

13. Press SHIFT

→ PARA/INDEP to reconfigure the outputs for independent

operation. Verify that the “PARA” indicator turns off.

14. Disconnect the Current Meter from the power supply output terminals.

Overvoltage

Protection Accuracy

Complete the following procedures to verify OVP (overvoltage protection)

accuracy.

Outputs 1 and 2. Use the following steps to check the OUTPUT 1 and

OUTPUT 2 accuracy.

1. Press SHIFT

→ OUT 1; verify that the “1” indicator lights up on the display.

2. Press OVP SET; set the OVP to 38.6 V. Verify that the power supply

readouts display the error message “Err - 065”.

3. Press OVP SET again; set the OVP to 38.5 V. Verify that the power supply

readouts display no error message.

4. Set up the power supply as follows:

VOLTS SET 34.5 V

CURRENT SET .1 A

OVP SET 36 V

5. Press STEP SET. Set the VOLTS SET to 0.02 V.

Bench Test Instruments and Handheld Oscilloscopes Basic Service

17

PS2520 and PS2521 Series Performance Verification

6. Press OUTPUT ON/OFF. Verify that the “OUT” indicator lights up on the

display.

7. Press VOLTS to increase the power supply output voltage until the error

message “Err - 013” appears on the readouts. Verify that this event occurs

between 34.68 and 37.32 V.

8. Press SHIFT

→ OVP RESET.

9. Reset the output voltage to 34.5 V.

10. Repeat steps 6 through 9 above as necessary to determine the exact voltage.

11. Press OUTPUT ON/OFF. Verify that the “OUT” indicator turns off.

12. Press SHIFT

→ OUT 2; verify that the “2” indicator lights up on the display.

13. Repeat steps 2 through 11 above.

Parallel Operation. Use the following steps to check the parallel mode output

accuracy.

1. With the power supply still set to OUT 2, press SHIFT

→ PARA/INDEP to

configure OUTPUT 1 and OUTPUT 2 for parallel operation. Verify that the

“PARA” indicator lights up on the display.

2. Repeat steps 2 through 11 of the Outputs 1 and 2 procedure above.

3. Press SHIFT

→ PARA/INDEP to reconfigure the outputs for independent

operation. Verify that the “PARA” indicator turns off.

18

Output 3. Use the following steps to check the OUTPUT 3 accuracy.

1. Press SHIFT

→ OUT 3; verify that the “3” indicator lights up on the display.

2. Press OVP SET; set the OVP to 7.1 V. Verify that the power supply readouts

display the error message “Err - 065”.

3. Press OVP SET again; set the OVP to 7 V. Verify that power supply readouts

display no error message.

4. Set up the power supply as follows:

VOLTS SET 4 V

CURRENT SET .1 A

OVP SET 5 V

5. Press STEP SET. Set the VOLTS SET to 0.02 V.

6. Press OUTPUT ON/OFF. Verify that the “OUT” indicator lights up on the

display.

Bench Test Instruments and Handheld Oscilloscopes Basic Service

PS2520 and PS2521 Series Performance Verification

Constant Voltage

Load Accuracy

7. Press VOLTS

to increase the power supply output voltage until the error

message “Err - 013” appears on the readouts. Verify that the readouts

indicate between 4.3 and 5.7 V prior to error message activation.

8. Press SHIFT

→ OVP RESET.

9. Reset the output voltage to 4 V.

10. Repeat steps 6 through 9 above as necessary to determine the exact voltage.

11. Press OUTPUT ON/OFF. Verify that the “OUT” indicator turns off.

Complete the following procedures to verify constant voltage load accuracy.

Outputs 1 and 2. Use the following steps to check the OUTPUT 1 and

OUTPUT 2 accuracy.

1. Press SHIFT

→ OUT 1; verify that the “1” indicator lights up on the display.

2. Ensure that the power supply output is disabled. Connect the DVM and

electronic load to the front panel OUTPUT 1 terminals. See Figure 2 for

details.

Digital multimeter

--

COM

+

10 A

Power supply

+

--

Electronic load

+--

Figure 2: Constant voltage load test setup

3. Set the DVM to measure 40 VDC.

4. Set up the power supply as follows:

VOLTS SET 36 V

CURRENT SET 1.55 A

OVP SET 38.5 V

5. Press OUTPUT ON/OFF. Verify that the “OUT” indicator lights up on the

display.

6. Enable the electronic load. Adjust the load until the power supply

CURRENT (A) readout indicates 1.500 A.

Bench Test Instruments and Handheld Oscilloscopes Basic Service

19

PS2520 and PS2521 Series Performance Verification

7. Record the DVM voltage (V1).

8. Turn off the electronic load and record the DVM voltage again (V2).

9. Verify that the difference between V1 and V2 is ≤6mV.

10. Press OUTPUT ON/OFF. Verify that the “OUT” indicator turns off.

11. Ensure that the power supply output is disabled. Remove the leads from the

front panel OUTPUT 1 terminals and connect them to the OUTPUT 1

terminals on the rear of the instrument. Maintain the equipment configuration and polarities shown in Figure 2.

12. Repeat steps 5 through 8 above and verify that the difference between V1

andV2is≤3mV.

13. Press OUTPUT ON/OFF. Verify that the “OUT” indicator turns off.

14. Press SHIFT