Service Manual

AWG7000 Series

Arbitrary Waveform Generators

071-1854-01

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its suppliers and

are protected by United States copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supercedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive or P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

In North America, call 1-800-833-9200.

Worldwide, visit www.tektronix.com to find contacts in your area.

Warranty 2

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1)

year from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its

option, either will repair the defective product without charge for parts and labor, or will provide a replacement in

exchange for the defective product. Parts, modules and replacement products used by Tektronix for warranty work may

be new or reconditioned to like new performance. All replaced parts, modules and products become the property of

Tektronix.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of

the warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by Tektronix, with shipping charges

prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a location within the country

in which the Tektronix service center is located. Customer shall be responsible for paying all shipping charges, duties,

taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

resulting from attempts by personnel other than Tektronix representatives to install, repair or service the product; b) to

repair damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or

malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been modified or integrated

with other products when the effect of such modification or integration increases the time or difficulty of servicing the

product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TEKTRONIX' RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Table of Contents

Operating Information

Theory of Operation

Adjustment Procedures

General Safety Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Service Safety Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Environmental Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Manual Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

General Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Module Overviews. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Adjustment Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Adjustment After Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Adjustment Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Maintenance

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Preventing ESD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Inspection and Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Removal and Installation Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Summary of Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Disconnecting and Connecting the SMP cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Procedures for External Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Procedures for Internal Modules (Upper) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Procedures for Internal Modules (Lower) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Checking Proper Connection of SMP Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

Fault Isolation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

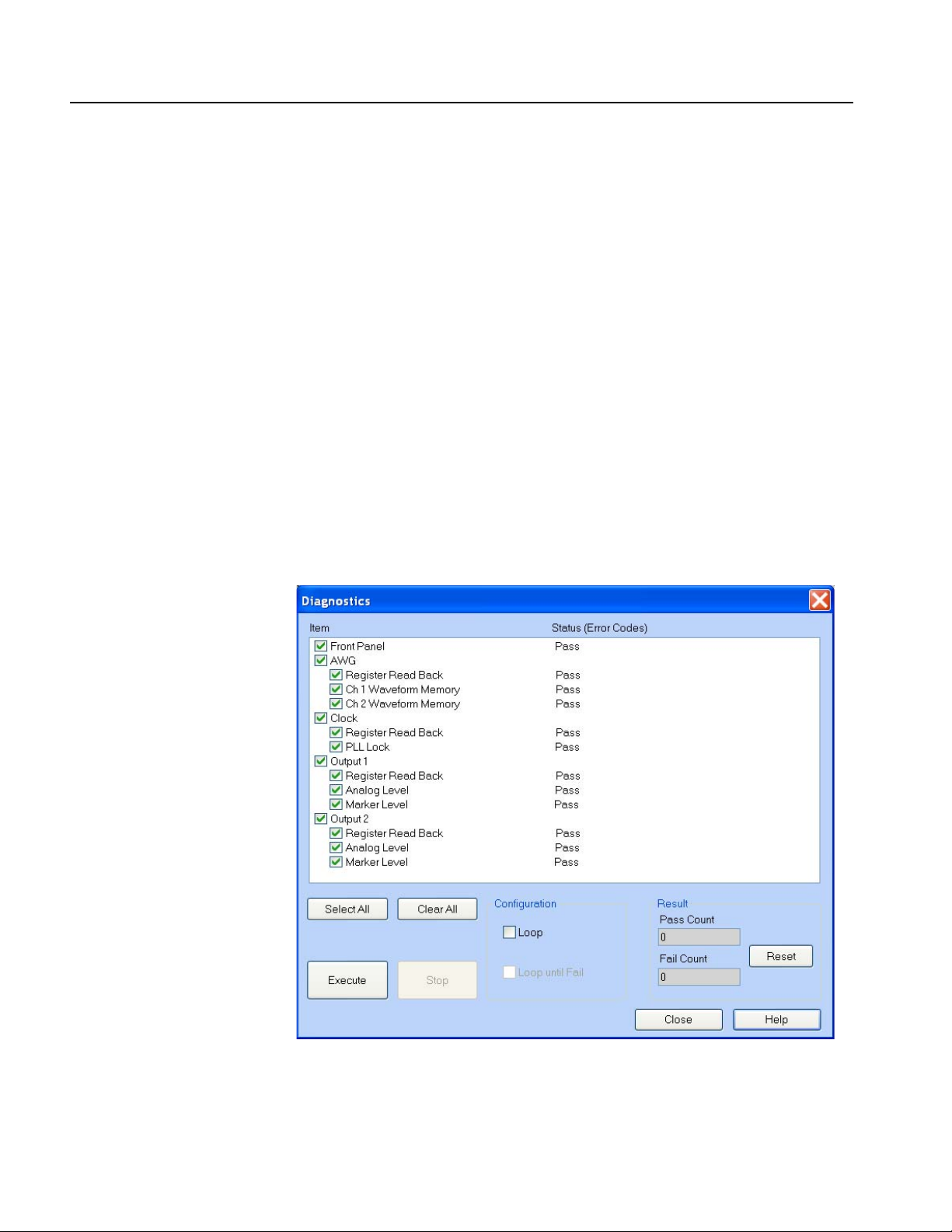

Instrument Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

Calibration Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-49

Hardware Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-53

After Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-55

Returning the Instrument for Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-56

AWG7000 Series Service Manual i

Table of Contents

Replaceable Parts

Parts Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Using the Replaceable Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

ii AWG7000 Series Service Manual

List of Figures

List of Figures

Figure 2-1: AWG7000 Series block diagram . . . . . . . . . . . . . . . . . . . . . . . 2-2

Figure 3-1: Service UI menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Figure 3-2: 10 MHz Reference calibration initial test hookup . . . . . . . . . 3-5

Figure 3-3: 10 MHz Reference Calibration setup window . . . . . . . . . . . . 3-6

Figure 3-4: Data timing calibration initial hookup . . . . . . . . . . . . . . . . . . 3-7

Figure 3-5: Data Timing Calibration setup window . . . . . . . . . . . . . . . . . 3-8

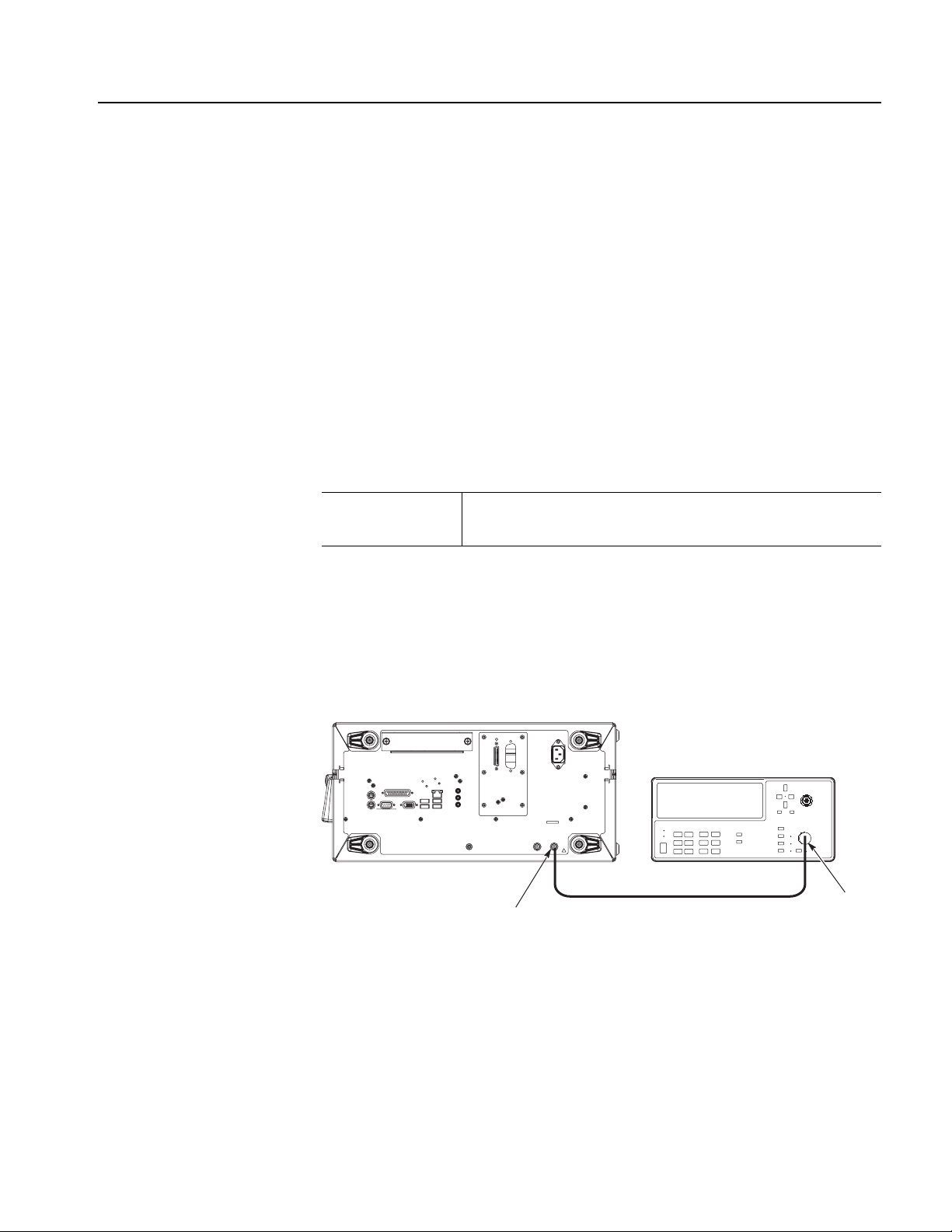

Figure 3-6: Inter-channel skew calibration initial hookup . . . . . . . . . . . 3-12

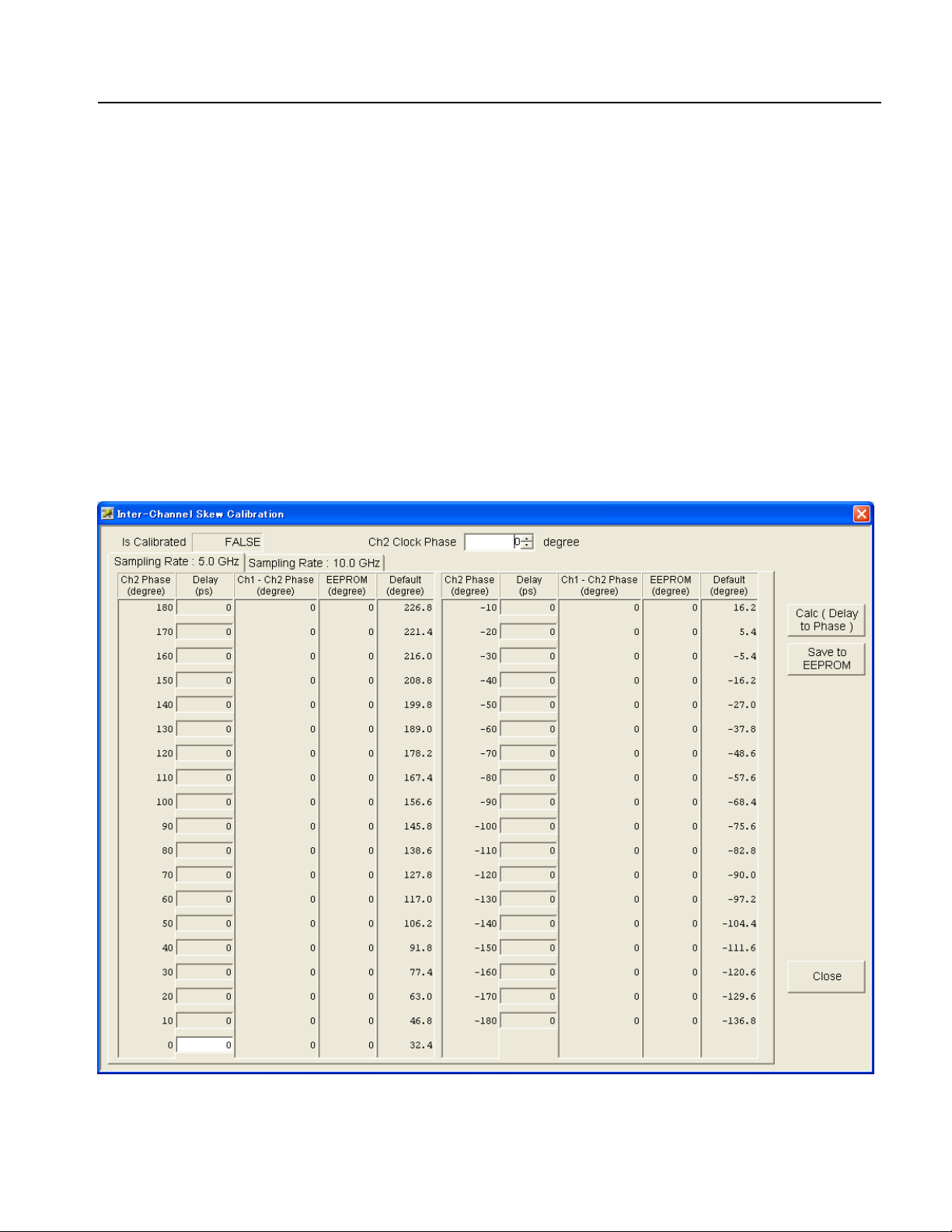

Figure 3-7: Inter-Channel Skew Calibration setup window . . . . . . . . . 3-13

Figure 3-8: Interleave calibration initial hookup . . . . . . . . . . . . . . . . . . 3-16

Figure 3-9: Interleave Calibration setup window . . . . . . . . . . . . . . . . . . 3-17

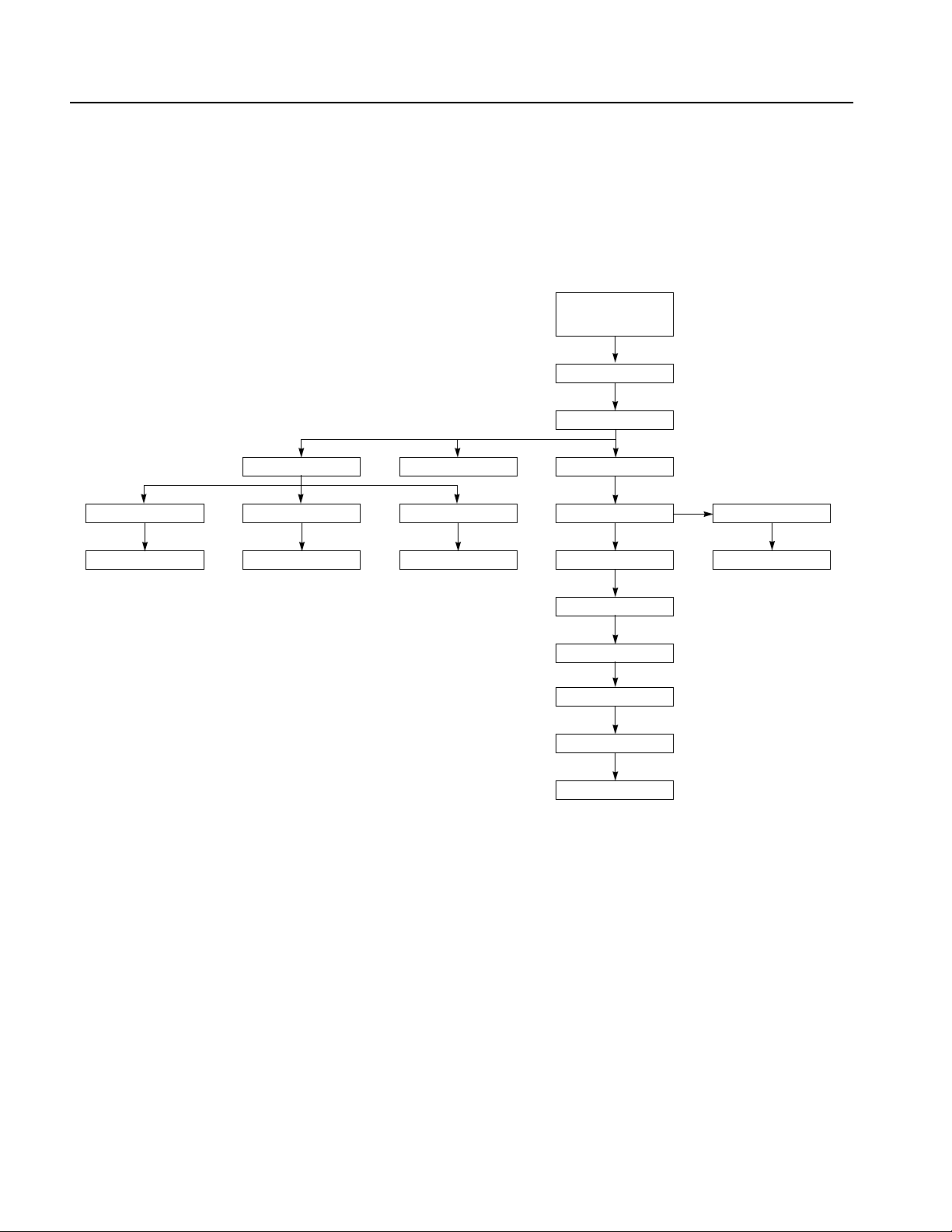

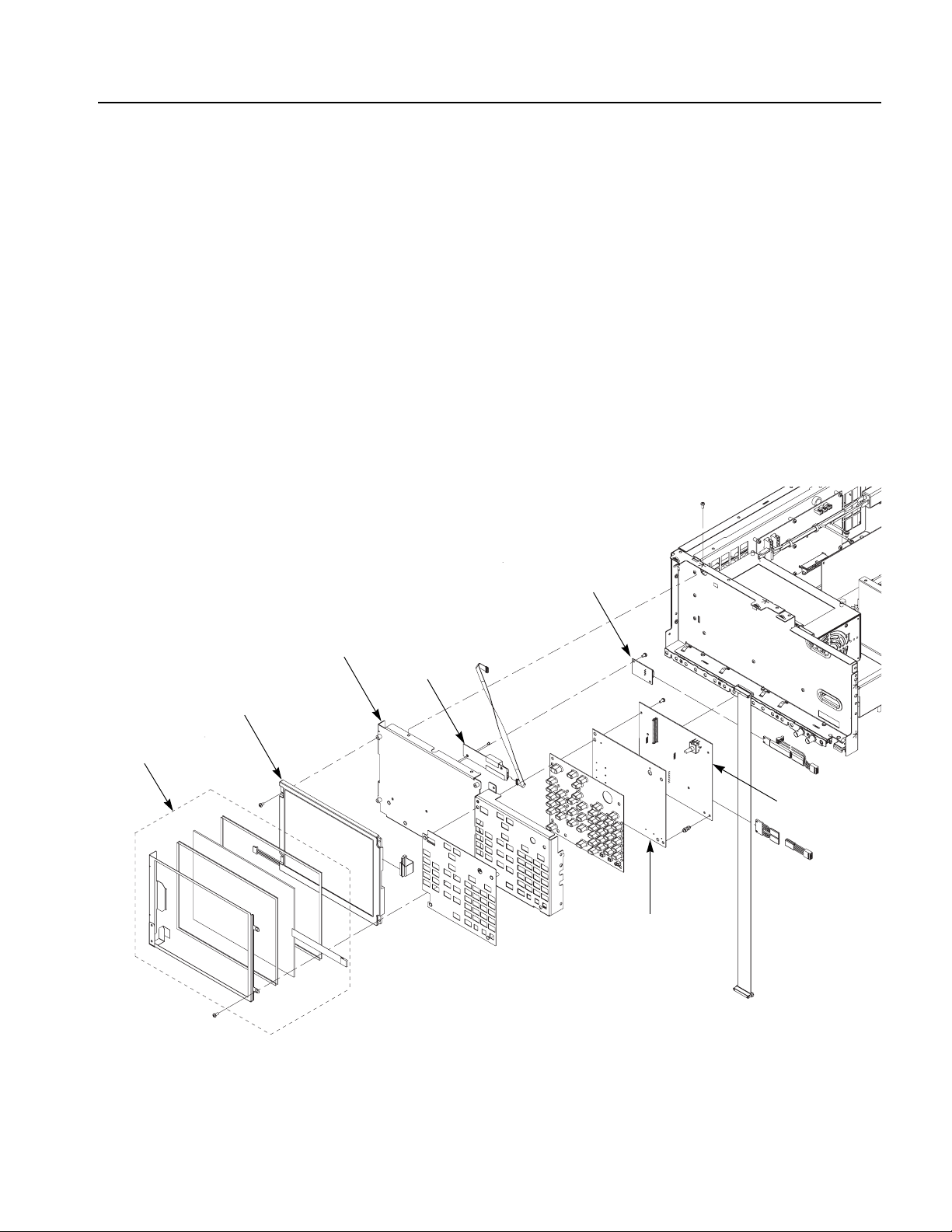

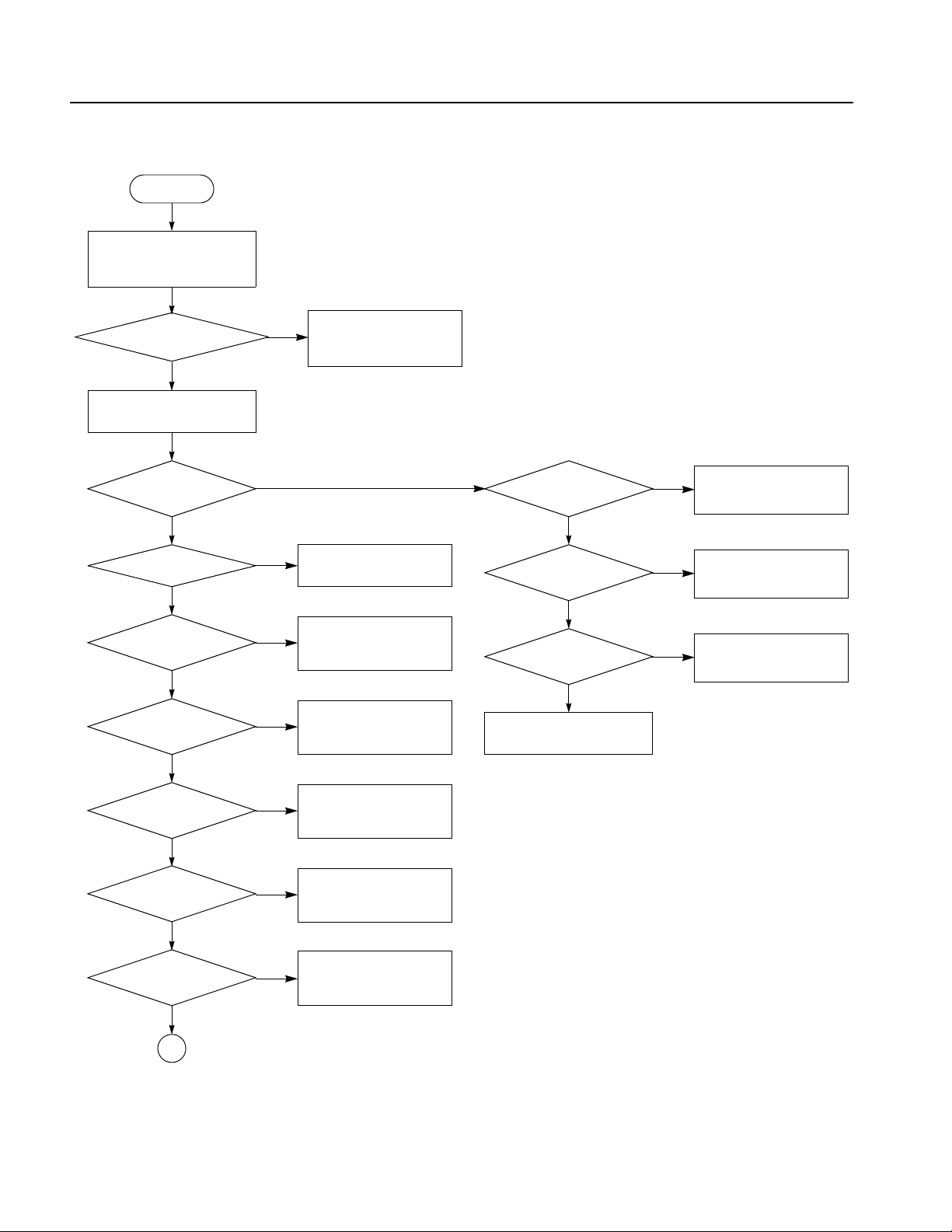

Figure 4-1: Disassembly procedures for external modules and internal

modules (top) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

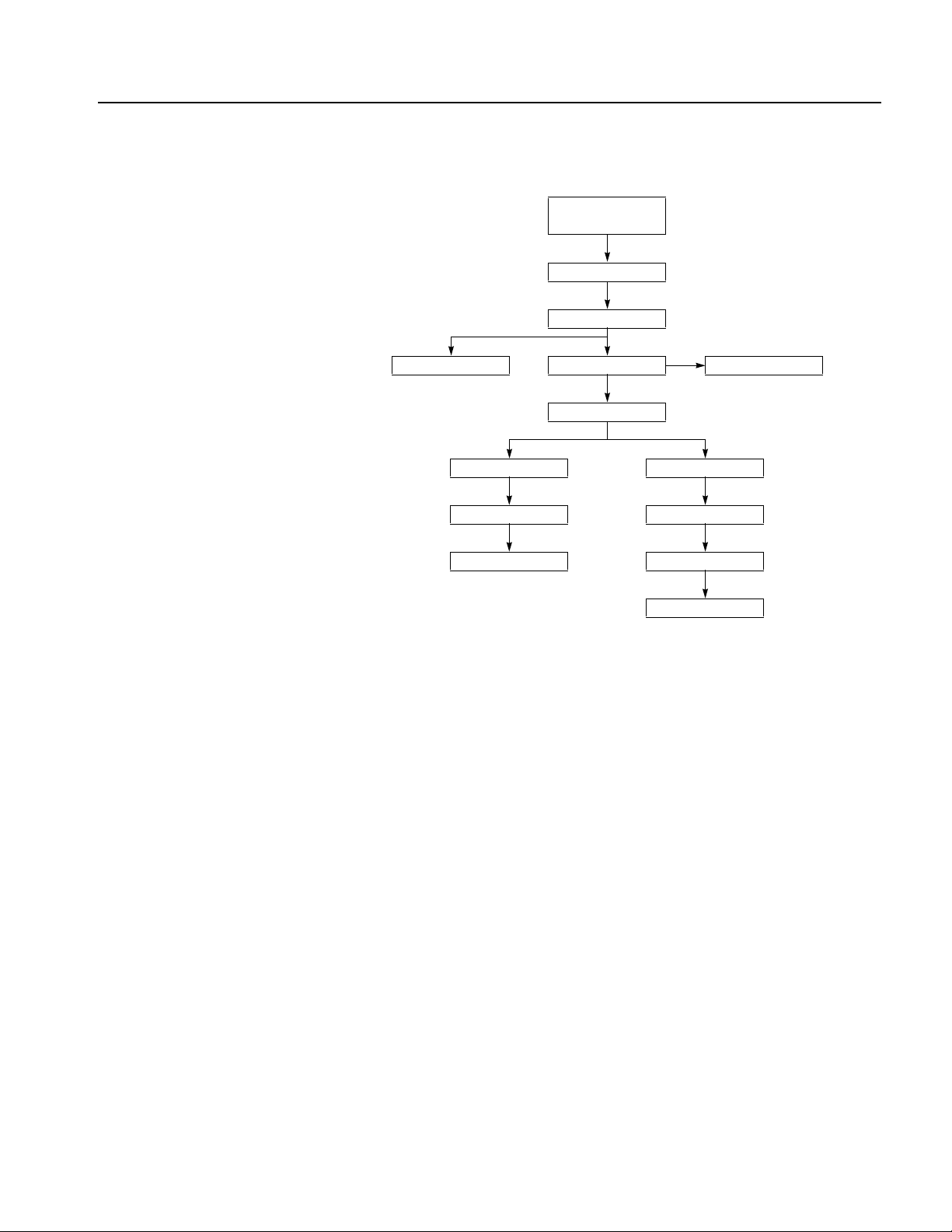

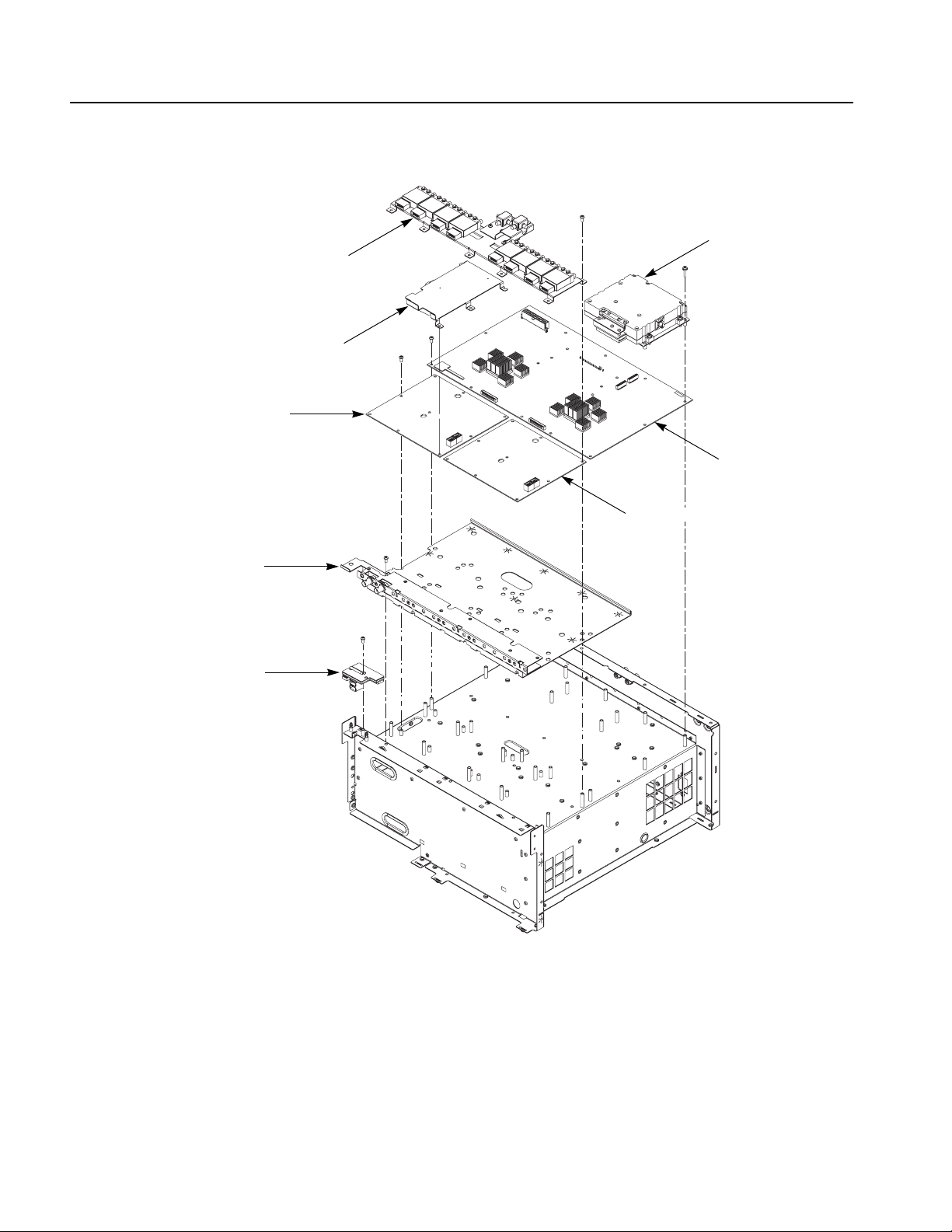

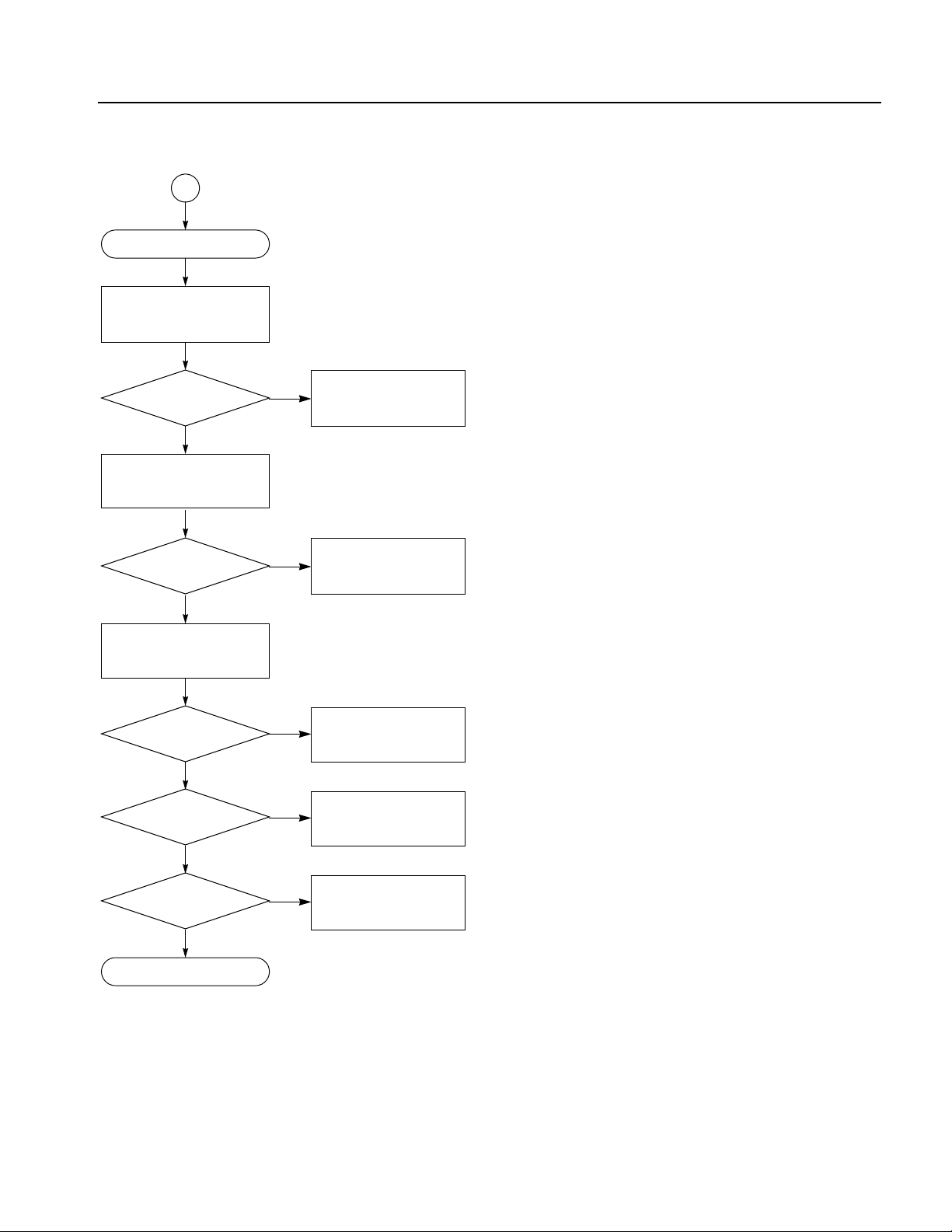

Figure 4-2: Disassembly procedures for internal modules (bottom) . . . . 4-9

Figure 4-3: Disconnecting and connecting the SMP cable . . . . . . . . . . . 4-10

Figure 4-4: Handle, snaps, cosmetic covers, and front-trim unit

removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Figure 4-5: EMI covers removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Figure 4-6: Fan tray unit removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Figure 4-7: Disassembly of front-panel assembly . . . . . . . . . . . . . . . . . . 4-17

Figure 4-8: Drive module removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Figure 4-9: Multi-Input/Output board removal . . . . . . . . . . . . . . . . . . . 4-21

Figure 4-10: Processor module removal . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Figure 4-11: Power Supply and RFI filter removal . . . . . . . . . . . . . . . . 4-25

Figure 4-12: Power board removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Figure 4-13: Front Connector board, CLK10G module, relay unit,

AWG10G board removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Figure 4-14: Disassembly of the CLK10G module . . . . . . . . . . . . . . . . . 4-30

Figure 4-15: Relay unit cable connection for option 02 . . . . . . . . . . . . . 4-31

Figure 4-16: Relay unit cable connection for option 06 . . . . . . . . . . . . . 4-32

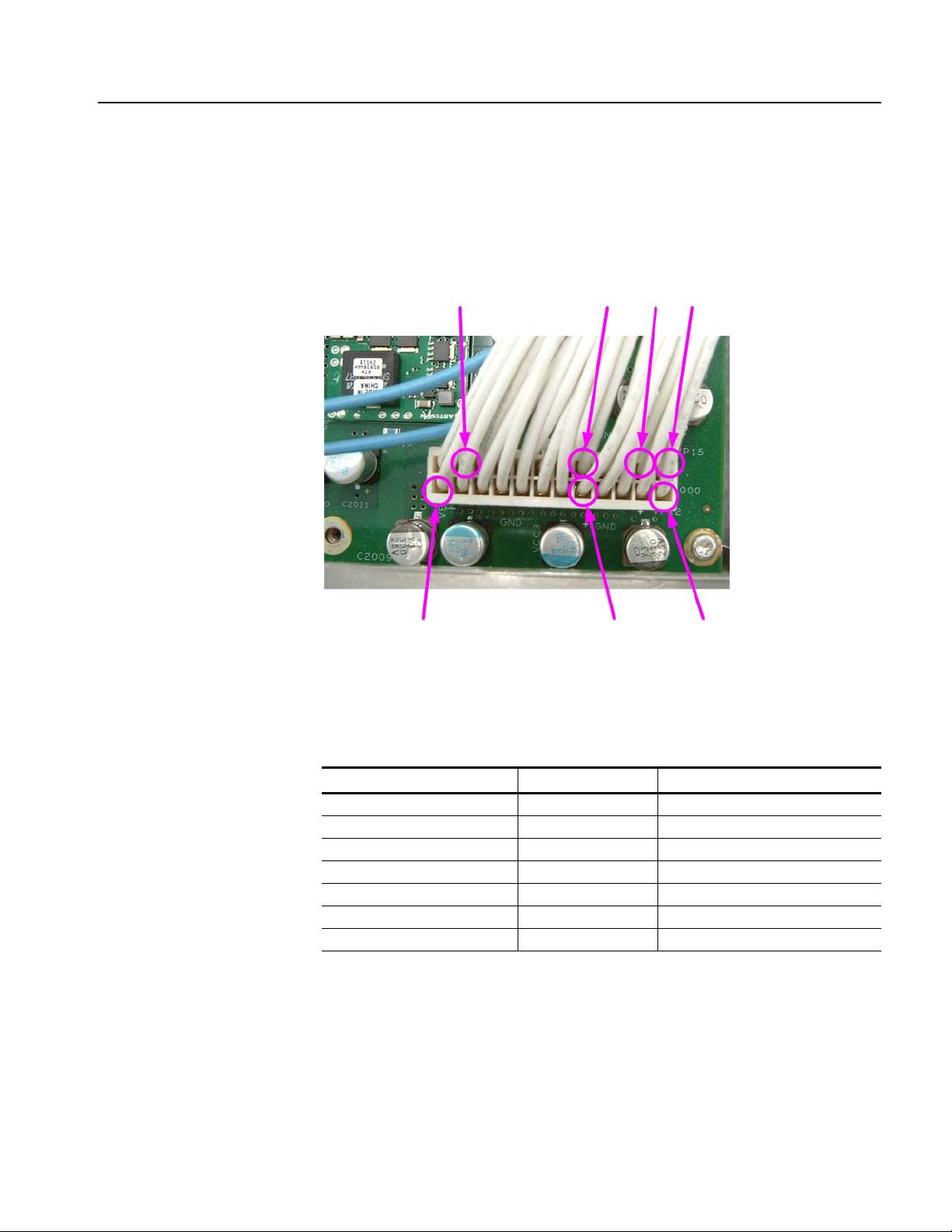

Figure 4-17: OUT10G board showing the test points . . . . . . . . . . . . . . . 4-38

Figure 4-18: Primary troubleshooting tree (1) . . . . . . . . . . . . . . . . . . . . 4-40

Figure 4-19: Primary troubleshooting tree (2) . . . . . . . . . . . . . . . . . . . . 4-41

Figure 4-20: PWR board test points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

AWG7000 Series Service Manual iii

List of Figures

Figure 4-21: AWG10G board test points . . . . . . . . . . . . . . . . . . . . . . . . . 4-43

Figure 4-22: Diagnostics dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

Figure 4-23: Calibration dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-49

Figure 5-1: Exploded diagram - Cosmetics . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Figure 5-2: Exploded diagram - EMI Covers . . . . . . . . . . . . . . . . . . . . . . . 5-6

Figure 5-3: Exploded diagram - Chassies assembly . . . . . . . . . . . . . . . . . 5-7

Figure 5-4: Exploded diagram - Front-panel assembly . . . . . . . . . . . . . . . 5-9

Figure 5-5: Exploded diagram - Drive module . . . . . . . . . . . . . . . . . . . . 5-11

Figure 5-6: Exploded diagram - Processor module . . . . . . . . . . . . . . . . . 5-13

Figure 5-7: Exploded diagram - Power supply assembly . . . . . . . . . . . . 5-15

Figure 5-8: Exploded diagram - PCI/power interface module . . . . . . . . 5-17

Figure 5-9: Exploded diagram - Fan tray assembly . . . . . . . . . . . . . . . . 5-18

Figure 5-10: Exploded diagram - USB module . . . . . . . . . . . . . . . . . . . . 5-19

Figure 5-11: Exploded diagram - AWG10G/CLK10G/OUT10G

modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Figure 5-12: Exploded diagram - CLK10G module . . . . . . . . . . . . . . . . 5-23

Figure 5-13: Exploded diagram - AWG10G module . . . . . . . . . . . . . . . . 5-25

Figure 5-14: Exploded diagram - SMA bracket . . . . . . . . . . . . . . . . . . . . 5-27

Figure 5-15: Exploded diagram - Relay unit . . . . . . . . . . . . . . . . . . . . . . 5-29

Figure 5-16: Exploded diagram - Rear connectors . . . . . . . . . . . . . . . . . 5-30

iv AWG7000 Series Service Manual

List of Tables

List of Tables

Table 1-1: General features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Table 1-2: Conbination of instrument options . . . . . . . . . . . . . . . . . . . . . . 1-2

Table 3-1: Test equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Table 4-1: External inspection checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Table 4-2: Internal inspection checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Table 4-3: Tools required for module removal and reinstall . . . . . . . . . 4-10

Table 4-4: Power supply voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

Table 4-5: PWR board voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-43

Table 4-6: Diagnostics error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-45

Table 4-7: Calibration error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-50

Table 4-8: Hardware error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-53

AWG7000 Series Service Manual v

List of Tables

vi AWG7000 Series Service Manual

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to this

product or any products connected to it.

To avoid potential hazards, use this product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or Personal

Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Connect and Disconnect Properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. This product is grounded through the grounding conductor of

the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings and

markings on the product. Consult the product manual for further ratings

information before making connections to the product.

The inputs are not rated for connection to mains or Category II, III, or IV circuits.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Power Disconnect. The power cord disconnects the product from the power source.

Do not block the power cord; it must remain accessible to the user at all times.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Avoid Exposed Circuitry. Do not touch exposed connections and components when

power is present.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

AWG7000 Series Service Manual vii

General Safety Summary

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WAR N I NG. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Cautions statements identify conditions or practices that could result in

damage to this or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

WARNING

High Voltage

Protective Ground

(Earth) Terminal

CAUTION

Refer to Manual

Double

Insulated

viii AWG7000 Series Service Manual

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

Use Care When Servicing With Power On. Dangerous voltages or currents may exist

in this product. Disconnect power, remove battery (if applicable), and disconnect

test leads before removing protective panels, soldering, or replacing components.

To avoid electric shock, do not touch exposed connections.

AWG7000 Series Service Manual ix

Service Safety Summary

x AWG7000 Series Service Manual

Environmental Considerations

This section provides information about the environmental impact of the product.

Product End-of-Life

Handling

Observe the following guidelines when recycling an instrument or component:

Equipment Recycling. Production of this equipment required the extraction and use

of natural resources. The equipment may contain substances that could be harmful

to the environment or human health if improperly handled at the product's end of

life. In order to avoid release of such substances into the environment and to reduce

the use of natural resources, we encourage you to recycle this product in an

appropriate system that will ensure that most of the materials are reused or recycled

appropriately.

The symbol shown to the left indicates that this product

complies with the European Union's requirements according to

Directive 2002/96/EC on waste electrical and electronic

equipment (WEEE). For information about recycling options,

check the Support/Service section of the Tektronix Web site

(www.tektronix.com).

Mercury Notification. This product uses an LCD backlight lamp that contains

mercury. Disposal may be regulated due to environmental considerations. Please

contact your local authorities or, within the United States, the Electronics

Industries Alliance (www.eiae.org) for disposal or recycling information.

Restriction of Hazardous

Substances

AWG7000 Series Service Manual xi

This product has been classified as Monitoring and Control equipment, and is

outside the scope of the 2002/95/EC RoHS Directive. This product is known to

contain lead, cadmium, mercury, and hexavalent ch romium.

Environmental Considerations

xii AWG7000 Series Service Manual

Preface

Manual Structure

Manual Conventions

This manual contains service information for your instrument. Read this preface to

learn how this manual is structured, the conventions it uses, and where to find

additional supplemental information related to servicing this product.

You should also read the General and Service safety summaries before servicing

the product.

This manual is divided into chapters, which are made up of related subordinate

topics. These topics can be cross referenced as sections.

Be sure to read the introductions to all procedures. These introductions provide

important information needed to do the service correctly, safely, and efficiently.

This manual uses certain conventions that you should become familiar with before

attempting service.

Modules

Replaceable Parts

Safety

Throughout this manual, any replaceable component, assembly, or part is referred

to by the term module. A module is composed of electrical and mechanical

assemblies, circuit boards, interconnecting cables, and user-accessible controls.

This manual refers to any field-replaceable assembly or mechanical part

specifically by its name or generically as a replaceable part. In general, a

replaceable part is any circuit board or assembly, such as the hard disk drive, or a

mechanical part, such as the I/O port connectors, that is listed in the replaceable

parts list of this manual.

Symbols and terms related to safety appear in the Service Safety Summary found at

the beginning of this manual.

AWG7000 Series Service Manual xiii

Preface

xiv AWG7000 Series Service Manual

Operating Information

Operating Information

For information on installing, operating, and networking the instrument, refer to

the AWG7000 Series Arbitrary Waveform Generators Quick Start User Manual.

This manual is available on the Document CD that came with your instrument, and

on the Tektronix Web site (www.tektronix.com/manuals).

General Features

The following table and bulleted list describe the general features of the AWG7000

Series Arbitrary Waveform Generators.

Table 1-1: General features

Feature AWG7101 AWG7102 AWG7051 AWG7052

Maximum Sample Rate 10 GS/s 10 GS/s (20 GS/s by

interleave)

D/A Resolution 8 bits or 10 bits (selectable)

Memory Length 32,400,000 or 64,800,000 (Option 01)

Analog Bandwidth 3.5 GHz or 5.8 GHz (Option 02, 06))

Analog Output 1212

Maximum Amplitude 2 V

Marker Output 2 4 (2/channel) 2 4 (2/channel)

p-p

5 GS/s

Windows XP Professional operation system

Up to 64,800,000 memory length (Option 01)

Extended analog output bandwidth (Option 02)

Interleave and extended analog output bandwidth (Option 06), AWG7102 only

A large 10.4 inch (264.2 mm) high resolution XGA color display

An intuitive, graphical user interface (UI), with built-in online help

80 GB removable hard drive

CD-RW/DVD

Supports USB 2.0 interface

LAN (1000/100/10 Base-T)

Touch screen user interface

AWG7000 Series Service Manual 1-1

Operating Information

Options

The following options are available for the instrument:

Option 01: Memory expansion to 64 MB

Option 02: Extended analog output bandwidth

Option 06: Interleave and extended analog output bandwidth

Table 1-2 indicates the available combinations of instrument options.

Table 1-2: Combination of instrument options

Option 01 Option 02 Option 01, 02 Option 06 Option 01, 06

AWG7102 X X X

AWG7101 X X X

AWG7052 X X X

AWG7051 X X X

Option C3: Calibration service 3 years

Option C5: Calibration service 5 years

Option D1: Calibration data report

Option D3, with Option C3: Calibration data report 3 years

Option D5, with Option C5: Calibration data report 5 years

Option R3: Repair service 3 years (including warranty)

Option R5: Repair service 5 years (including warranty)

AWG7UP Option M12: AWG7102 Field upgrade for waveform length

expansion from 32M to 64M points

AWG7UP Option M11: AWG7101 Field upgrade for waveform length

expansion from 32M to 64M points

AWG7UP Option M02: AWG7052 Field upgrade for waveform length

expansion from 32M to 64M points

AWG7UP Option M01: AWG7051 Field upgrade for waveform length

expansion from 32M to 64M points

1-2 AWG7000 Series Service Manual

Theory of Operation

Theory of Operation

This section describes the electrical operation of the AWG7000 Series Arbitrary

Waveform Generators.

Overview

The AWG7000 Series Arbitrary Waveform Generators provide four models with

different frequency and numbers of channels. Each model consists of two major

sections: the platform section and generator section. The platform section is

common to each model.

Block Diagram of the

System

The AWG7000 Series Arbitrary Waveform Generators are based on the Tektronix

DPO7000 series platform which consists of the µATX CPU board and modern

components for a PC. The instrument operates with the microsoft Window XP

operating system. Figure 2-1 on page 2-2 shows the system level block diagram of

the AWG7000 Series.

AWG7000 Series Service Manual 2-1

Theory of Operation

2QYGT5WRRN[

4GCT2CPGN

6QWEJ2CPGN

+PXGTVGT

$QCTF

.%&

(TQPV2CPGN

$QCTF

4(+

(KNVGT

1WVRWV

,

,

,

, ,

,

,

,

(CP

(CP

(CP

2QYGT$QCTF

,

,

,

,

,,,

.%&#FCRVQT

$QCTF

, ,

,

,

,*

2TQEGUUQTv#6:

$QCTF

,

,#,#

,

,

,,

,,

,,

*CTF&KUM&TKXG

,

(TQPV5YKVEJ

$QCTF

&8&41/

&TKXG

)2+$

,)

,

6GM.KPM

,

,

(TQPV%QPPGEVQT

$QCTF

176)$QCTF

(TQPV2CPGN

176)$QCTF

&GRGPFUQPVJGKPUVTWOGPVV[RG

,

,

%.-)$QCTF

, ,

#9))$QCTF

,

, ,

,

/WNVK+PRWV1WVRWV

$QCTF

,,

2%+

,

Figure 2-1: AWG7000 Series block diagram

2-2 AWG7000 Series Service Manual

Module Overviews

Theory of Operation

A Microsoft Windows processor system is the primary controller of the instrument.

The instrument features an XGA resolution flat-panel display, a transparent touch

screen, and a front panel with direct access to commonly used instrument

functions. You can also make complete use of the instrument with a mouse and a

keyboard.

Front Panel (FP) Board

LCD Adapter (LCDA) Board

Push-button switches on the Front Panel (FP) board are read by an embedded micro

controller, which sends the button and knob change information to the µATX bo ar d

via a USB path. The FP board consists of the following blocks:

USB controller (Cypress EZ-USB FX1)

FPGA (Altera Cyclone)

Key switch matrix

LED indicators (Tri-Color and Mono-Color)

The LCDA board supports interconnection between the µATX board and FP

board. Two internal USB ports come from the µATX board. One USB connects to

a touch panel controller. The other connect to a micro controller on the FP board.

Connectors related to the LCD are also included. The LCDA board consists of the

following blocks:

Touch-panel controller

Rotary encoder (signal goes to the FP board)

LCD back light controller

Connector to LCD

Multi-Input/Output (MIO)

Board

The MIO board coordinates the flow of data through the Windows PCI port from

various devices that communicate with the µATX system. The devices include the

display system, GPIB, TekLink, and data flow (PCIF) path to the waveform

generator system. An EEROM on this board is used to store the instrument setting

and calibration data. The MIO board consists of the following blocks:

PCI controller

GPIB controller

LCD display controller (ATI Mobility-MI)

PCI target adapter

PLD140 (Xilinx FPGA)

EEPROM for calibration data storage

TekLink interface

AWG7000 Series Service Manual 2-3

Theory of Operation

Front Switch (FSW) Board

Front Connector (FCON)

Board

Display Panel

Touch Panel

Processor (µATX ) B o ard

The FSW board provides interconnection between the Standby switch and µAT X

board. It includes an LED driver.

The FCON board provides front-panel connections of the USB ports and the DC

output. It includes common mode filters that suppress EMI radiation on the USB

signal.

The active-matrix LCD display is fully controlled by Windows drivers. It is

controlled by the ATI Mobility-M1 micro circuit on the MIO board. The display

has a 1024 x 768 resolution. Brightness is controlled by the intensity of the

backlight.

The touch information from the touch screen is processed by Windows drivers,

actively placing the pointer at the touched location. Actions from the mouse and

the touch panel are interchangeable, and treated alike by the user interface

software. The AccuTouch five-wire resistive touch screen uses a glass panel with

a uniform resistive coating. A thick polyester coversheet is tightly suspended over

the top of a glass substrate, separated by small, transparent insulating dots. The

coversheet has a hard, durable coating on the outer side and a conductive coating

on the inner side. The controller is located on the LCDA board.

The µATX board provides standard Windows functionality and I/O port interfaces

on the rear panel. This includes RS-232, Parallel, and Ethernet ports, as well as four

USB ports, including two USB2.0 ports located in the lower right front corner of

the instrument. The µATX board receives input from the front panel and touch

panel, and implements the appropriate changes. Video display data is transferred

to the MIO board through the PCI bus interface. The hard drive is connected to the

µATX board through the SATA interface, and the CD/DVD is connected to the

Windows system through the IDE parallel interface.

Power Supply

Fans

Power (PWR) Board

2-4 AWG7000 Series Service Manual

The power supply CVR460 is a switching AC to DC converter. It automatically

detects the line voltage over the range of 90 to 264 VAC. It supplies power to all

the circuitry in the instrument. No switch completely disconnects the line power

from the instrument. The ON/STBY switch controls the power to the instrument

through the µATX board circuitry. When in the “power off” condition, there is still

a low power standby current to allow the system to monitor the ON/STBY switch.

Three fans on the side of the instrument provide forced air cooling. The fans are

controlled by the fan speed control circuit on the PWR board and are regulated by

monitoring the temperature at the circuitry.

The PWR board provides DC power to the fans, HDD, CD Drive, µATX bo ar d ,

MIO board, and AWG10G board. All the power comes from the CVR460 module.

The fan control circuit has a thermal sensor on this board. DC voltage to the fans

is controlled relative to the sensed temperature. DC-DC converters are included for

generating different DC voltages.

Theory of Operation

CLK10G Board

AWG10G Board

The CLK10G board provides a 5 GHz to 10 GHz clock to the AWG10G board.

Two clock outputs go to the CH1 and CH2 DAC. The clock output to CH2 should

be terminated for 1 channel models. The clock input accepts 5GHz to 10 GHz clock

signals from an external signal source. The reference clock input accepts 5 MHz to

800 MHz reference clock signals from an external signal source. The 10 MHz

reference output can be used for synchronizing frequency between two or more

instruments. The CLK10G board consists of the following blocks:

YIG oscillator (5GHz to 10 GHz)

Fractional-N PLL

10.0 MHz TCXO (reference oscillator)

The AWG10G board generates arbitrary waveforms based on the waveform

memory and the sequence memory. There are two types of PLDs (Xilinx FPGA)

on the board. One is an AWG controller called PLD131 which interfaces to/from

the MIO board. The other is a memory controller called PLD130 which generates

waveform patterns. Waveform data is stored in ZBT type SRAMs. The sequence

memory is included in the memory controller PLD. The AWG10G board consists

of the following blocks:

10 GS/s DAC (HFD205 ASIC)

8 channels 8:1 MUX (TEK0015 ASIC)

PLD130 (Xilinx Virtex-2 FPGA) as a memory controller

PLD131 (Xilinx Virtex-2 FPGA) as an AWG controller

ZBT type SRAM for the waveform memory

Inter-channel phase detector

Trigger and event inputs

DC Output

DC-DC converter (1.5 V and 2.5 V power supply)

AWG7000 Series Service Manual 2-5

Theory of Operation

OUT10G1 Board for

Standard models

OUT10G2 Board for

Option 02/06

The OUT10G1 board provides analog and marker outputs to the front-panel

connector. Amplitude, filter, offset, and On/Off controls are added to the analog

outputs. High/Low voltage and On/Off controls are added to the marker outputs.

The OUT10G1 board consists of the following blocks:

Analog output amplifier

Marker output driver

Selectable low-pass filter

Selectable attenuator

Voltage monitor

Controller PLD

The OUT10G2 board uses the same raw board as the OUT10G1 board. The

difference is that the OUT10G2 board has no analog output circuitry. For Option

02 and Option 06, the analog signal path is on the relay module. The OUT10G2

board has an analog voltage monitor. The OUT10G2 board consists of the

following blocks:

Marker output driver

Voltage monitor

Relay Module (Option 02

and Option 06 only)

Coax switch driver

Controller PLD

The relay module provides switches for analog outputs. For Option 02, the relays

switch the analog outputs on and off. For Option 06, the relays switch the

interleaving and the analog outputs on and off. An RF power combiner is used for

mixing channel 1 and 2 signals. The output of the power combiner goes to the

Interleave output.

2-6 AWG7000 Series Service Manual

Adjustment Procedures

Adjustment Procedures

This section contains information about instrument adjustment. Only qualified

personnel should perform adjustment procedures. Read the Service Safety

Summary and the General Safety Summary before performing any service

procedures.

NOTE. Before performing adjustment procedures, you must warm up the arbitrary

waveform generator at least 20 minutes in an ambient temperature between 20 °C

and 30 °C. Adjustments performed before warm-up or outside this temperature

range may result in poor performance.

Adjustment Interval

If the instrument fails performance tests (refer to the AWG7000 Series Arbitrary

Waveform Generators Technical Reference Manual), then adjustment may be

required.

If periodic calibration is one of your requirements, a general rule is to verify

performance and make adjustments (only if needed) every 2000 hours of operation

or once a year if the instrument is used infrequently.

Adjustment After Repair

After removal and replacement of a module, you must perform the Performance

Verification procedure, found in the AWG7000 Series Arbitrary Waveform

Generators Technical Reference Manual. The Technical Reference PDF manual is

included in the Product Documentation CD. This manual is also available on the

Tektronix Web site (www.tektronix.com/manuals).

AWG7000 Series Service Manual 3-1

Adjustment Procedures

Required Equipment

The following equipment, or a suitable equivalent, is required to complete these

procedures.

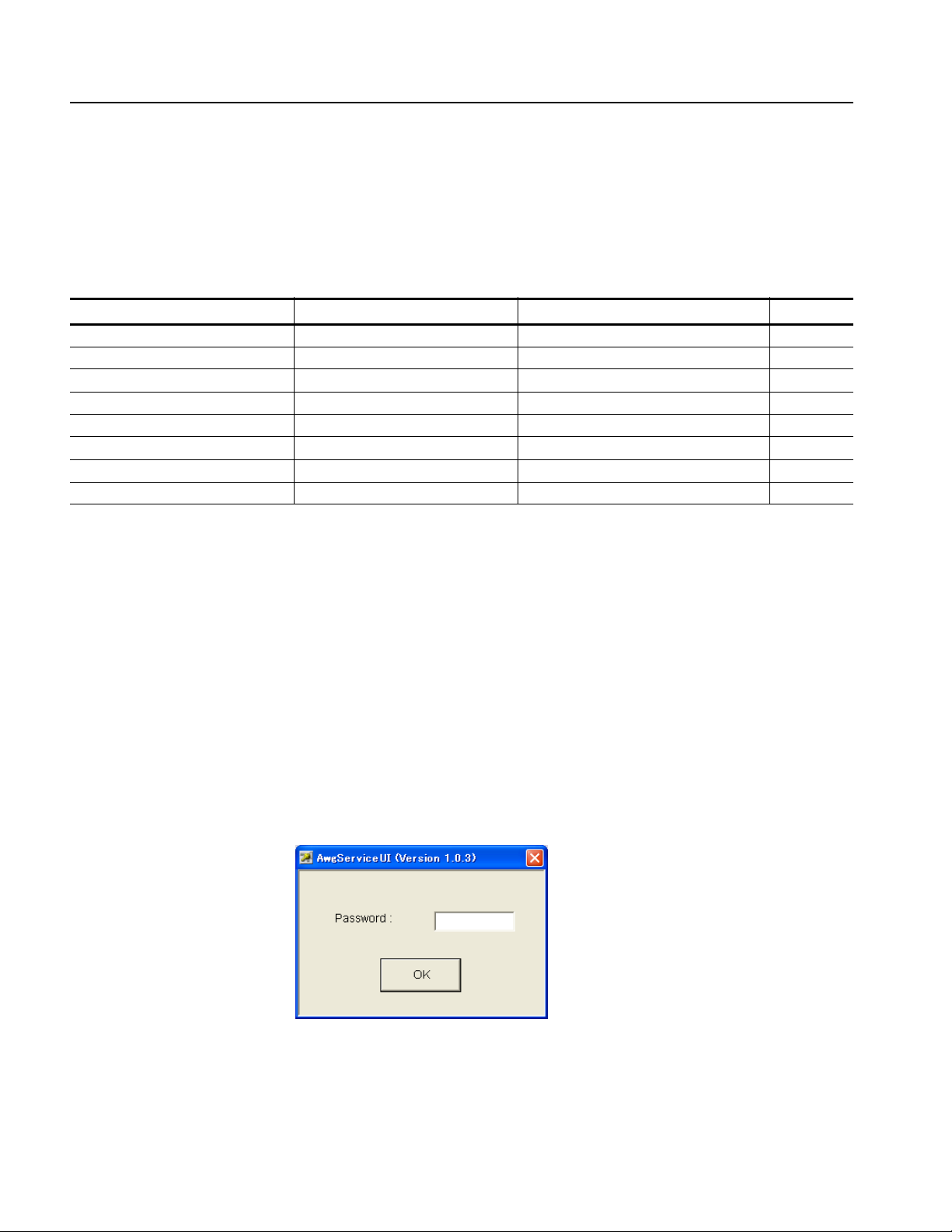

Table 3-1: Test equipment

Description Minimum requirements Examples Quantity

Sampling oscilloscope Bandwidth: 20 GHz or higher Tektronix CSA8200 with 80E03 1 ea

Oscilloscope Bandwidth: 1 GHz or higher Tektronix TDS5104B 1 ea

Frequency counter Accuracy: within ± 0.01 ppm Agilent 53181A 1 ea

50 Ω BNC cable DC to 2 GHz Tektronix 012-0482-00 1 ea

50 Ω SMA cable DC to 20 GHz Tensolite 1-3636-465-5236 2 ea

50 Ω SMA Termination DC to 18 GHz Tektronix 015-1022-01 3 ea

SMA-BNC adapter SMA male to BNC female Tektronix 015-0554-00 2 ea

50 Ω SMA Attenuator DC to 18 GHz, 12 dB Hirose AT-112 2 ea

Adjustment Overview

Enable the Service Menu

The adjustment procedure contains up to ten adjustment items, depending on the

instrument type and options. Before performing adjustment procedures, you must

warm up the arbitrary waveform generator at least 20 minutes in an ambient

temperature between 20 °C and 30 °C.

You must enable the Service menu to perform the adjustment procedure. To do

this:

1. Power on the instrument.

2. Select the System menu from the menu bar, and then select Service Mode...

3. The following dialog box is displayed. Enter the password “1185”.

3-2 AWG7000 Series Service Manual

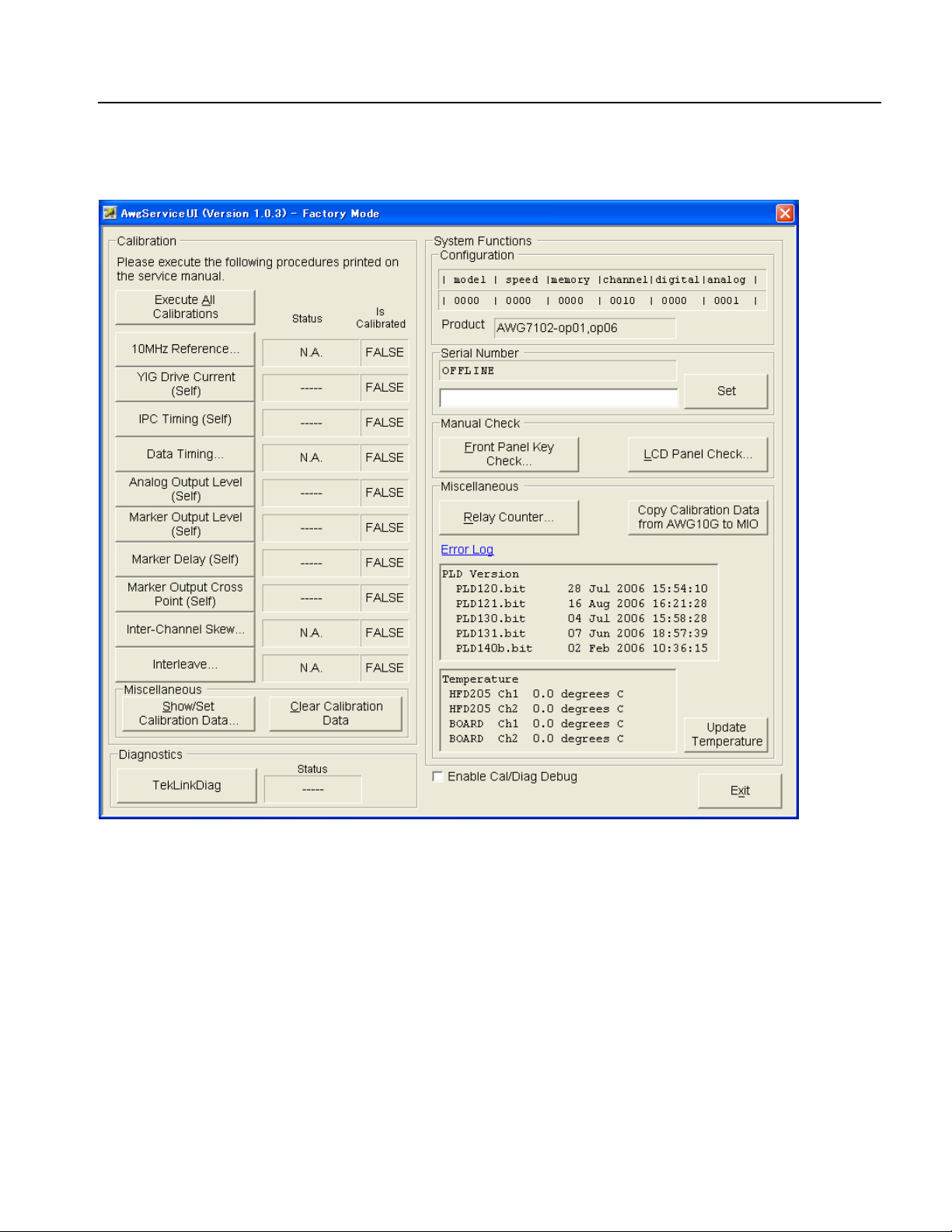

4. The following service UI menu is displayed:

Adjustment Procedures

Figure 3-1: Service UI menu

The left half of the window with the title Calibration is the calibration part of the

window. You can perform the calibrations either all in one step or individually.

However, since the calibration sequence is predefined, follow the sequence from

the top. You must finish a calibration item listed on the upper part of the screen

before performing the lower part of the items. Some items may be grayed out,

depending on your instrument option configurations.

AWG7000 Series Service Manual 3-3

Adjustment Procedures

Individual Calibrations

Execute All Calibrations

Saving the Calibration

Results to EEPROM

To perform individual calibrations, click the calibration buttons, starting with

10MHz Reference..., and the corresponding calibrations are executed.

To perform all calibrations in one step, click Execute All Calibrations and all

calibrations are executed in order starting from the top. However, since data timing

calibrations are quite time consuming, it is acceptable to perform only Step 4

(Magic Cal. -2), which depends on the instrument power supply, and skip the other

steps. Instead of performing all the steps in the data timing calibration, restore and

use the calibration constants obtained by the ATS (Auto Test System) at the factory

or during servicing. The following procedures assume that this method will be

used.

When the calibration has been performed and the results are saved to the EEPROM

(regardless of the item, all results are saved to the EEPROM on the MIO board),

the flag under Is Calibrated will be set to TRUE. If the calibration was successful,

the Status field will display PASS. If the calibration failed, FAIL will be displayed.

There are two types of calibration: Self calibration and Manual calibration.

Self calibration – The instrument performs the calibration item and ends

automatically.

Manual calibration – This calibration item requires external devices listed on

Table 3-1 and manual data input.

A warning message is displayed if you click a calibration button without waiting

for 20 minutes after the instrument powered on. Click the Cancel button and allow

at least 20 minutes for the instrument to warm up.

3-4 AWG7000 Series Service Manual

Calibration Procedure

Adjustment Procedures

Before starting the calibration procedure, you need to restore the calibration

constants that were obtained by ATS (Automatic Test System) at the factory or the

service center.

Restoring the Calibration

Constants

10 MHz Reference

Calibration

Click the Copy Calibration Data from AWG10G to MIO button in the middle

right of the Service UI window.

The calibration data saved to the EEPROM on the AWG10G board during the ATS

calibration is restored to the EEPROM on the MIO board. The calibration data on

the MIO board EEPROM is used during the following calibration procedure.

This procedure adjusts the built-in TCXO oscillator frequency for the 10 MHz

Reference Output.

Equipment required One frequency counter

One 50 Ω BNC cable

1. Install the test hookup and preset the instrument controls:

a. Connect a BNC cable from the 10 MHz Reference Output on the rear panel

of the arbitrary waveform generator to the CHANNEL 1 of the frequency

counter, as shown in Figure 3-2.

Instrument under test

Frequency counter

CHANNEL2

'ZVGTPCN

%NQEM+PRWV

ǡF$O/CZ

4GHGTGPEG

%NQEM+PRWV

ǡ8RR/CZ

/*\

4GHGTGPEG1WVRWV

LIMITS

MEASURE MASS DISPLAY

!

CHANNEL1

CHANNEL 1

10 MHz Reference Output

Figure 3-2: 10 MHz Reference calibration initial test hookup

2. Set the frequency counter CHANNEL 1 Impedance to 50

Ω..

AWG7000 Series Service Manual 3-5

Adjustment Procedures

3. Click the 10 MHz Reference... button in the Service UI menu to display the

following setup window:

Up/down button

Figure 3-3: 10 MHz Reference Calibration setup window

YIG Drive Current

Calibration

IPC Timing Calibration

Data Timing Calibration

4. Change the 10MHz Reference value using the up/down button or the

front-panel rotary knob so that the frequency counter reading is within the

range of 10 MHz ±1 Hz.

5. Click Save to EEPROM to save the data to the EEPROM.

6. Click Close to close the window.

This is a self calibration. The YIG for the internal clock source controls the

frequency by the main coil (tuning coil) and the FM coil currents. The sensitivity

differs between individual YIGs, this calibration is required to set the precise

frequency.

This is a self calibration. The instrument features high-speed communication called

IPC (Inter PLD Communication) between the internal Memory Controller and the

Awg Controller. This calibration is required to ensure the optimum timing to

enable the IPC in all frequency settings. Failing to perform this calibration may

disable access to the waveform memory and/or make the AWG board diagnostics

cause an error.

The instrument operates at extremely high speeds between the waveform memory

on the AWG board and the Memory Controller, between the Memory Controller

and TEK0015, and between TEK0015 and HFD205.

This calibration is required to ensure the optimum timing to enable waveform

outputs in all frequency settings. Failing to perform this calibration may not only

disable normal waveform outputs, but may also make the waveform memory

diagnostics cause an error.

3-6 AWG7000 Series Service Manual

Adjustment Procedures

This calibration consists of six steps from Step 0 to Step 5, but in this manual,

perform only Step 4 (Magic Cal.-2). Other calibration constants are restored by

using the data acquired by ATS at the factory or during servicing.

Basic steps are to observe output waveforms on the oscilloscope screen, and to

determine the range of abnormal outputs, which appears on the oscilloscope as a

broken waveform, by adjusting the delay in the TEK0015 Data Output.

Equipment required One oscilloscope

Two SMA-BNC adapters

Two 50 Ω SMA cables

Two 50 Ω SMA terminations

1. Install the test hookup and preset the instrument controls:

a. Hook up the oscilloscope:

Attach the SMA terminations to the Channel 1 Analog (–) and Channel 2

Analog (–) Outputs on the front panel of the arbitrary waveform generator.

Attach the SMA-BNC adapters to the CH 1 and CH 2 Input connectors of

the oscilloscope.

Connect the SMA cables from the Channel 1 Analog (+) and Channel 2

Analog (+) Outputs on the front panel of the arbitrary waveform generator

to the CH 1 and CH 2 Inputs of the oscilloscope, as shown in Figure 3-4.

Instrument under test

SMA cables

SMA terminations

Oscilloscope

SMA-BNC adapters

Figure 3-4: Data timing calibration initial hookup

AWG7000 Series Service Manual 3-7

Adjustment Procedures

b. Modify the oscilloscope settings as follows:

CH 1 and CH 2 Vertical Scale: 200 mV/div

CH 1 and CH 2 Impedance: 50 Ω.

Horizontal Scale: 20 ns/div

Trigger: Edge Trigger, CH 1/CH 2 Rising, Set Level to 50%

2. Click the Data Timing... button in the Service UI menu to display the

following setup window:

Figure 3-5: Data Timing Calibration setup window

3. Select Step 4 in the Active Step field.

4. Select Ch 1 in the Channel field.

3-8 AWG7000 Series Service Manual

Adjustment Procedures

5. Set TEK0015 Data Delay to 0 ns, and observe the oscilloscope screen. If a

sine waveform of approximately 102.4 ns period is output normally, increase

the TEK0015 Data Delay setting by 30 ps using the up/down button or the

front-panel rotary knob. You can also enter the value directly using the

keyboard.

Up/down button

6. Increase the TEK0015 Data Delay setting by 30 ps, and observe the

oscilloscope screen. If the waveform starts to break at some point, click Start

of Broken Waveform. The following shows an example of broken waveform:

7. Click End of Broken Waveform right before the next waveform is output

normally (the last position where the waveform is broken in that range).

8. Continue the measurements up to 990 ps in the TEK0015 Data Delay setting.

A set value of End of Broken Waveform is always larger than that of Start

of Broken Waveform.

You can temporarily restore the settings to re-check the waveform.

AWG7000 Series Service Manual 3-9

Adjustment Procedures

Regard the first or last settings where the waveform is broken as the end

point of broken waveform. In other words, if you have already click Start

of Broken Waveform, click End of Broken Waveform next.

If the waveform is broken with one set value only, and not across a range

of multiple settings, click both Start of Broken Waveform and End of

Broken Waveform at the same setting. Always click Start of Broken

Waveform first.

9. Select Ch 2 in the Channel field.

10. Click Set to 0. This will reset the value of TEK0015 Data Delay to 0 ps.

11. Repeat step 5 through step 8.

12. Click Update Cal Values.

13. Select Ch 1 in the Channel field.

14. Set Frequency to 10 GHz, and observe the oscilloscope screen. If a sine

waveform is not output normally, record the range as described in step 6 and

step 7.

15. Decrease Frequency in the Parameters for Step 0,4 field every 50 MHz from

10.000 GHz to 7.000 GHz using the up/down button or the front-panel rotary

knob. You can also enter the value directly using the keyboard.

16. If the waveform starts to break at some point, click Start of Broken

Waveform. Click End of Broken Waveform right before the next waveform

is output normally (the last position where the waveform is broken in that

range).

17. Continue the measurement to 7 GHz.

18. Select Ch 2 in the Channel field.

19. Reset the value of Frequency to 10 GHz.

20. Repeat step 14 through step 16.

21. Click Update Cal Values.

22. Click Save to EEPROM.

23. Click Close. The Data Timing Calibration window closes.

3-10 AWG7000 Series Service Manual

Adjustment Procedures

Analog Output Level

Calibration

Marker Output Level

Calibration

Marker Delay Calibration

Marker Output Cross Point

Calibration

This is a self calibration. This calibration is required to ensure that the analog

output levels are within the specified range.

This is a self calibration. This calibration is required to ensure that the marker

output levels are within the specified range.

This is a self calibration. This calibration is required to ensure that the marker delay

is within the specified range.

This is a self calibration. This calibration is required to ensure that the marker

output cross point is within the specified range.

AWG7000 Series Service Manual 3-11

Adjustment Procedures

Inter-Channel Skew

Calibration

(AWG7102 and AWG7052)

This calibration is required to ensure that the Ch 1 and Ch 2 output skews are set

within the specified range. This calibration is applied to both analog and marker

outputs.

Equipment required One sampling oscilloscope

Two 50 Ω SMA 12 dB attenuators

Two 50 Ω SMA cables

Three 50 Ω SMA terminations

1. Install the test hookup and preset the instrument controls:

a. Hook up the sampling oscilloscope:

Attach the SMA terminations to the Channel 1 Analog (–) Output,

Channel 2 Analog (–) Output, and Marker 1 (–) Output on the front

panel of the arbitrary waveform generator.

Connect an SMA cable from the Channel 1 Analog (+) Output on the

front panel of the arbitrary waveform generator to the CH 1 Input of

the sampling oscilloscope using the SMA attenuator, as shown in

Figure 3-6.

Connect an SMA cable from the Channel 1 Marker (+) Output on the

front panel of the arbitrary waveform generator to the TRIGGER

DIRECT INPUT of the sampling oscilloscope using the SMA

attenuator, as shown in Figure 3-6.

Sampling oscilloscope

Instrument under test

SMA attenuator

SMA termination

SMA attenuator

Figure 3-6: Inter-channel skew calibration initial hookup

3-12 AWG7000 Series Service Manual

Adjustment Procedures

b. Modify the sampling oscilloscope settings as follows:

Vertical External Attenuation: 12 dB

Vertical Scale: 200 mV/div

Horizontal Scale: 50 ps/div

Horizontal Timebase Mode: Lock to INT. 10 MHz

Trigger: External Direct Input, Level 50%

Acquisition: Average 64, Stop After Condition: Average Complete

Measurement: R1 to C1 Delay (R1/C1 Reference Level: Absolute

0.0 V)

2. Click the Inter-Channel Skew... button in the Service UI menu to display the

following setup window:

Figure 3-7: Inter-Channel Skew Calibration setup window

AWG7000 Series Service Manual 3-13

Adjustment Procedures

3. Perform the following measurements:

a. Adjust the horizontal position of sampling oscilloscope so that the rising

edge of the arbitrary waveform generator (AWG7000 series) Ch 1 Analog

(+) Output waveform is visible near the center of the oscilloscope screen,

and then select File Menu > Save Waveform... to save the waveform data

to R1.

b. Disconnect the SMA cable from the Ch 1 Analog (+) Output, and then

connect it to the Ch 2 Analog (+) Output. Do not use a different cable for

the Ch 1 and Ch 2 connectors. Always use the same SMA cable.

c. Push CLEAR DATA and then RUN/STOP on the sampling oscilloscope

front panel control.

d. Measure R1 to C1 Delay using the Measurement function of the sampling

oscilloscope with the following settings:

Sampling Rate: 5.0 GHz

Ch 2 Phase: 0 degree

e. If the delay value measured in step d is outside ±100 ps range, change the

Sampling Rate setting to 10.0 GHz and then return the setting to 5.0 GHz.

Measure R1 to C1 Delay again. Repeat this measurement until the R1 to

C1 Delay value is within the ±100 ps range.

f. Change the sampling oscilloscope settings as follows:

Sampling Rate: 5.0 GHz

Ch 2 Phase: +180 degree

g. Enter the measurement values of R1 to C1 Delay for each setting to the

first place after the decimal point while changing the Ch 2 Phase settings

from +180 degrees to –180 degrees using either the mouse or the Tab key.

Adjust the horizontal position of the sampling oscilloscope as necessary so

that the rising edge of the waveform is displayed at the center of the screen.

h. After you complete all the measurements for Sampling Rate: 5.0 GHz,

click Calc (Delay to Phase). This will display the calculated phase values

in the Ch1-Ch2 Phase (degree) field.

i. Click Sampling Rate:10.0 GHz.

j. Disconnect the SMA cable from the Ch 2 Analog (+) Output, and then

connect it to the Ch 1 Analog (+) Output.

k. Adjust the horizontal position of the sampling oscilloscope so that the

rising edge of the arbitrary waveform generator Ch 1 Analog (+) Output

waveform is visible near the center of the oscilloscope screen, and then

select File Menu > Save Waveform... to save the waveform data to R1.

l. Disconnect the SMA cable from the Ch 1 Analog (+) Output, and then

connect it to the Ch 2 Analog (+) Output.

3-14 AWG7000 Series Service Manual

Adjustment Procedures

m. Change the sampling oscilloscope settings as follows:

Sampling Rate: 10.0 GHz

Ch 2 Phase: +180 degree

n. Enter the measurement values of R1 to C1 Delay for each setting to the

first place after the decimal point while changing the Ch 2 Phase settings

in the order from +180 degrees to –180 degrees using either the mouse or

the Tab key. Adjust the horizontal position of the sampling oscilloscope as

necessary so that the rising edge of the waveform is displayed at the center

of the screen.

o. After you complete all the measurements for Sampling Rate: 10.0 GHz,

click Calc (Delay to Phase). This will display the calculated phase values

in the Ch1-Ch2 Phase (degree) field.

4. Click Save to EEPROM.

5. Click Close. The Inter-Channel Skew Calibration window closes.

Interleave Calibration

(AWG7102 Option 06 only)

This calibration consists of the following two adjustments:

Coarse adjustment – Adjust the phase difference between Ch 1 and Ch 2 to

minimize the rise time of Interleave Output.

Fine adjustment – Adjust the phase difference between Ch 1 and Ch 2 to

minimize the ripples of Interleave Output RZ.

Equipment required One sampling oscilloscope

One 50 Ω SMA 12 dB attenuator

Two 50 Ω SMA cables

Two 50 Ω SMA terminations

1. Install the test hookup and preset the instrument controls:

a. Hook up the sampling oscilloscope:

Attach the SMA terminations to the Interleave (–) Output and the

Marker 1 (–) Output on the front panel of the arbitrary waveform

generator.

Connect an SMA cable from the Interleave (+) Output on the front

panel of the arbitrary waveform generator to the CH 1 Input of the

sampling oscilloscope using the SMA attenuator.

Connect an SMA cable from the Channel 1 Marker (+) Output on the

front panel of the arbitrary waveform generator to the TRIGGER

DIRECT INPUT of the sampling oscilloscope using the SMA

attenuator, as shown in Figure 3-8.

AWG7000 Series Service Manual 3-15

Adjustment Procedures

Sampling oscilloscope

Instrument under test

SMA termination

Figure 3-8: Interleave calibration initial hookup

b. Modify the sampling oscilloscope settings as follows:

Vertical External Attenuation: 12 dB

Vertical Scale: 200 mV/div

Horizontal Scale: 50 ps/div

Horizontal Timebase Mode: Lock to INT. 10 MHz

Trigger: External Direct Input, Level 50%

Acquisition: Sample

Measurement: C1 Rise Time (C1 Reference Level: Relative

20%-80%)

SMA attenuator

SMA attenuator

3-16 AWG7000 Series Service Manual

Adjustment Procedures

2. Click the Interleave... button in the Service UI menu to display the following

setup window:

Figure 3-9: Interleave Calibration setup window

3. Click Init for Coarse Adjustment to set the mode to the Coarse Adjustment

settings.

4. Identify the minimum rise time point for the Interleave (+) Output using the

Measurement function of the sampling oscilloscope while changing the Ch2

Clock Phase settings using either the up/down button or the front-panel rotary

knob. You can also enter the value directly using the keyboard.

5. Click Set SP (Phase Offset to SP) at the minimum rise time point to calculate

and set the center point (Search Point: SP). The value will be displayed in the

SP (Search Point) field.

6. Change the vertical and horizontal scale of the sampling oscilloscope to

50 mV/div and 200 ps/div, respectively.

7. Click Init for Fine Adjustment to set the mode to the Fine Adjustment

settings.

8. Select 5.0 GHz in the Sampling Rate field.

AWG7000 Series Service Manual 3-17

Adjustment Procedures

9. Identify the minimum amplitude (ripple) point for the Ch1 waveform on the

sampling oscilloscope screen while changing the Ch2 HFD205 Phase settings

using either the up/down button or the front-panel rotary knob. You can also

enter the value directly using the keyboard.

The Skew for each sampling rate is calculated automatically using the

Inter-Channel Skew Cal. results, and the skew values are displayed in the

Skew5G through Skew10G fields.

NOTE. Ideally, the skew should not depend on the frequency, but there is a slight

dependency between skew and frequency.

10. Stop at the minimum ripple point, and select 6.0 GHz in the Sampling Rate.

11. Repeat step 9.

12. Stop at the minimum ripple point, and select 7.0 GHz in the Sampling Rate.

13. Repeat step 9.

14. Stop at the minimum ripple point, and select 8.0 GHz in the Sampling Rate.

15. Repeat step 9.

16. Stop at the minimum ripple point, and select 9.0 GHz in the Sampling Rate.

17. Repeat step 9.

18. Stop at the minimum ripple point, and select 10.0 GHz in the Sampling Rate.

19. Repeat step 9.

20. Stop at the minimum ripple point, and click Update Cal Values.

21. Click Save to EEPROM.

22. Click Close. The Interleave Calibration window closes.

23. Click Exit in the Service UI menu.

This completes the adjustment procedures. Disconnect the equipment from the

instrument.

3-18 AWG7000 Series Service Manual

Maintenance

Maintenance

This section contains information needed to do periodic and corrective

maintenance on the instrument. The following subsections are included:

Preparation — Tells you how to get ready to do arbitrary waveform generator

maintenance.

Preparation Preventing ESD — Provides general information on preventing

damage to internal modules when doing maintenance.

Inspection and Cleaning — Information and procedures for inspecting the

instrument and cleaning its external and internal modules.

Removal and Installation Procedures — Procedures for the removal of

defective modules and replacement of new or repaired modules.

Toubleshooting — Information for isolating failed modules. Included are

instructions for operating the instrument diagnostic routines and

troubleshooting trees. Most of the trees make use of the internal diagnostic

routines to speed fault isolation to a module.

Preparation

Preventing ESD

Only qualified persons should perform service procedures. Before performing any

service procedures, read the Service Safety Summary and General Safety Summary

at the front of this manual and the ESD information below. Also refer to the

Operating Information section and your arbitrary waveform generator quick start

user manual for information about using the arbitrary waveform generator.

When performing any service that requires internal access to this instrument,

adhere to the following precautions to avoid damaging internal modules and their

components due to electrostatic discharge (ESD).

CAUTION. Static discharge can damage any semiconductor component in this

instrument.

Minimize handling of static-sensitive modules.

Transport and store static-sensitive modules in their static protected containers

or on a metal rail. Label any package that contains static-sensitive modules.

AWG7000 Series Service Manual 4-1

Maintenance

Inspection and Cleaning

Discharge the static voltage from your body by wearing a grounded antistatic

wrist strap while handling these modules. Do service of static-sensitive

modules only at a static-free work station.

Do not allow anything capable of generating or holding a static charge on the

work station surface.

Handle circuit boards by the edges when possible.

Do not slide the modules over any surface.

Avoid handling modules in areas that have a floor or work-surface covering

capable of generating a static charge.

Inspection and Cleaning describes how to inspect for dirt and damage, and how to

clean the exterior and interior of the instrument. Inspection and cleaning are done

as preventive maintenance. Preventive maintenance, when done regularly, may

prevent instrument malfunction and enhance its reliability.

General Care

Preventive maintenance consists of visually inspecting and cleaning the instrument

and using general care when operating it.

How often to do maintenance depends on the severity of the environment in which

the instrument is used. A proper time to perform preventive maintenance is just

before instrument adjustment.

For optimum performance, follow these recommendations:

Protect the instrument from adverse weather conditions. The instrument is not

waterproof.

Do not store or leave the instrument where the liquid crystal display (LCD) will

be exposed to direct sunlight or high humidity for long periods of time.

The cabinet helps keep dust out of the instrument and must be in place during

normal operation.

To avoid damage to the instrument, do not expose it to any sprays, liquids, or

solvents.

4-2 AWG7000 Series Service Manual

Maintenance

Inspection and Cleaning

procedures

The collection of dirt on internal components can cause them to overheat and fail.

Dirt also provides an electrical conduction path

that could cause an instrument

failure, especially under high-humidity conditions. Inspect the instrument as often

as operating conditions require.

WAR N I NG. Before performing any of the following procedures, power down the

instrument and disconnect it from line voltage.

CAUTION. Avoid the use of chemical cleaning agents, which might damage the

plastics used in this AWG7000 Series Arbitrary Waveform Generator. Use only

deionized water when cleaning the front-panel buttons. Use an ethyl alcohol

solution as a cleaner and rinse with deionized water.

Inspection — Exterior. Inspect the outside of the instrument for damage, wear, and

missing parts, using Table 4-1 as a guide. An instrument that appears to have been

dropped or otherwise abused should be checked thoroughly to verify correct

operation and performance. Immediately repair defects that could cause personal

injury or further damage to the instrument.

Table 4-1: External inspection checklist

Item Inspect for Repair action

Cabinet, front-panel,

and cover

Front-panel knob Missing, damaged, or loose knob. Repair or replace missing or

Connectors Broken shells, cracked insulation,

Carrying handle

and cabinet feet

Accessories Missing items or parts of items,

Cracks, scratches, deformations,

damaged hardware or gaskets.

and deformed contacts. Dirt in

connectors.

Correct operation. Repair or replace defective

bent pins, broken or frayed

cables, and damaged connectors.

Repair or replace defective

module.

defective knob.

Repair or replace defective

modules. Clear or wash out dirt.

module.

Repair or replace damaged or

missing items, frayed cables, and

defective modules.

Cleaning Procedure — Exterior. Do the following steps to clean the instrument

exterior:

1. Remove loose dust on the outside of the instrument with a lint-free cloth. Use

care to avoid scratching the clear glass display shield.

AWG7000 Series Service Manual 4-3

Maintenance

2. Remove remaining dirt with a lint-free cloth dampened in a general purpose

detergent-and-water solution. Do not use abrasive cleaners.

CAUTION. To prevent getting moisture inside the instrument during external

cleaning, use only enough liquid to dampen the cloth or applicator.

To avoid damage to the surface of the instrument, do not use any abrasive or

chemical cleaning agents.

Flat Panel Display Cleaning. The display is a soft plastic display and must be treated

with care during cleaning.

CAUTION. Imported cleaning agents or methods can damage the flat panel display.

Avoid using abrasive cleaners or commercial cleaners to clean the display surface.

Avoid spraying liquids on the display surface.

Avoid scrubbing the display with excessive force.

1. Clean the flat panel display surface by gently rubbing the display with a

clean-room wipe (such as Wypall Medium Duty Wipes, #05701, available

from Kimberly-Clark Corporation).

2. If the display is very dirty, moisten the wipe with distilled water or a 75%

isopropyl alcohol solution and gently rub the display surface. Avoid using

excess force or you may damage the plastic display surface.

CAUTION. To prevent getting moisture inside the instrument during external

cleaning, use only enough liquid to dampen the cloth or applicator.

Inspection — Interior. Inspect and clean the interior if it appears that the instrument

may have been damaged or exposed to an unusually dirty environment.

To access the inside of the instrument for inspection and cleaning, refer to the

Removal and Installation Procedures in this section.

Inspect the internal portions of the instrument for damage and wear, using

Table 4-2 as a guide. Defects should be repaired immediately.

CAUTION. To prevent damage from electrical arcing, ensure that circuit boards

and components are dry before applying power to the instrument.

4-4 AWG7000 Series Service Manual

Maintenance

Table 4-2: Internal inspection checklist

Item Inspect for Repair action

Front and Rear Case Cracks or deformations. Scratched lettering

or display filter. Loose connectors or labels.

Circuit boards Loose, broken, or corroded solder

connections. Burned circuit boards. Burned,

broken, or cracked circuit-run plating.

Solder connections Cold solder or rosin joints. Resolder joint and clean

Wiring and cables Loose plugs or connectors. Burned, broken,

or frayed wiring.

Chassis Dents, deformations, and damaged

hardware.

Repair or replace defective

hardware.

Remove failed module and

replace with a new module.

with ethyl alcohol.

Firmly seat connectors.

Repair or replace modules

with defective wires or

cables.

Straighten, repair, or

replace defective hardware.

Cleaning Procedure — Interior. Do the following steps to clean the instrument

interior:

1. Blow off dust with dry, low-pressure, deionized air (approximately 9 psi).

2. Remove any remaining dust with a lint-free cloth dampened in isopropyl

alcohol (75% solution) and rinse with warm deionized water. (A cotton-tipped

applicator is useful for cleaning in narrow spaces and on circuit boards.)

NOTE. If steps 1 and 2 do not remove all the dust or dirt, please contact Tektronix.

(See Contacting Tektronix at the front of this manual.)

Lubrication. There is no periodic lubrication required for the AWG7000 Series

Arbitrary Waveform Generator.

AWG7000 Series Service Manual 4-5

Maintenance

4-6 AWG7000 Series Service Manual

Removal and Installation Procedures

This section contains procedures for removal and installation of all mechanical and

electrical modules.

Preparation

WAR N I NG. Only qualified personnel should perform service procedures.

Before performing this or any other procedure in this manual, read the General

Safety Summary and Service Safety Summary found at the beginning of this

manual.

To prevent damage to the instrument components, read Preventing ESD in this

section.

Before doing any procedure in this section, disconnect the power cord from the line

voltage source.

This section contains the following items:

This preparatory information that you need to properly do the following

procedures.

Adjustment after repair

List of Modules

List of tools required to remove and disassemble all modules.

Procedures for removal and reinstallation of the modules.

NOTE. Read Equipment Required for a list of the tools needed to remove and install

modules in this instrument. See Table 4-3, on page 4-10. Read the cleaning

procedure before disassembling the instrument for cleaning.

After the removal and replacement of a module due to electrical failure, perform

the adjustment procedures. Refer to the Adjustment Procedures section.

The Replaceable Parts section provides a list of all replaceable modules. Any

electrical or mechanical module, assembly, or part listed in the parts list is referred

to as a module.

AWG7000 Series Service Manual 4-7

Removal and Installation Procedures

Summary of Procedures

Disassembly for replacement is best achieved by removing and replacing the

modules in a specific order. Complete disassembly is best achieved by the

following procedures in the order given in Figure 4-1 and Figure 4-2.

Handle unit

Snaps

Cosmetic covers

Front trim unit

EMI Cover (top)

Front-panel assembly Fan tray unit Hard disk assembly

Front switch board LCDA Board Touchscreen assembly Drive-bay module DVD-ROM board

Inverter Front-panel board LCD display Drive-bay bracket DVD-ROM drive

MIO board

Processor module* * To remove the Processor

Power supply

RFI filter

Power board

Figure 4-1: Disassembly procedures for external modules and internal modules (top)

module, you need to

remove the AWG10G board.

4-8 AWG7000 Series Service Manual

Removal and Installation Procedures

Handle unit

Cosmetic covers

Front trim unit

EMI cover (bottom)

Front connector board CLK10G module CLK10G board

Relay unit Option 02/06 only

AWG7101/AWG7051 AWG10G 1ch board AWG10G 2ch board AWG7102/AWG7052

Shield bracket Shield brackets

CH1 OUT10G board CH1 OUT10G board

CH2 OUT10G board

Figure 4-2: Disassembly procedures for internal modules (bottom)

AWG7000 Series Service Manual 4-9

Removal and Installation Procedures

Required Equipment

Most modules in the instrument can be removed with a screwdriver handle

mounted with a size T-15, Torx screwdriver tip. All equipment required to remove

and reinstall the modules is listed in Table 4-3.

Table 4-3: Tools required for module removal and reinstall

Item # Name Description General tool #

1. Screwdriver handle Accepts Torx-driver bits 620-440

2. T-15 Torx tip Torx-driver bit for T-15 size screw

3. T-10 Torx tip Torx-driver bit for T-10 size screw

4. T-20 Torx tip Torx-driver bit for T-20 size screw

5. #1 Phillips screwdriver Screwdriver for removing #1 size

6. #2 Phillips screwdriver Screwdriver for removing #2 size

7. 3/16 inch open-end wrench Used to remove nut posts Standard tool

8. Pliers Pliers modified for use in SMP cable

9. 5/16 inch torque wrench (8.0

10. Angle-Tip Tweezers Used to remove the front-panel knob Standard tool

640-247

heads

heads

heads

Standard tool

Phillips screws

Standard tool

Phillips screws

003-1895-00

insertion/extraction

Used to remove SMA cables

in-lbs)

Disconnecting and Connecting the SMP cable

When you disconnect or connect the SMP cable, use the pliers specified in

Table 4-3 and keep the connector vertical. If excessive sideways force is applied,

the connector is damaged.

Connect and disconnect straight

Figure 4-3: Disconnecting and connecting the SMP cable

4-10 AWG7000 Series Service Manual

Do not move from side to side.

Procedures for External Modules

Removal and Installation Procedures

Handle Unit

Snaps

You need a screwdriver with a T-20 Torx tip (items 1 and 4).

Removal. To remove the handle unit, refer to Figure 4-4 on page 4-12 and follow

these steps:

1. Remove the two screws securing the handle base bracket to the cosmetic cover.

2. Grasp the bracket and handle away from the cosmetic cover.

Installation. To install, reverse this procedure.

You need a screwdriver with a T-15 Torx tip (items 1 and 2).

Removal. To remove the snaps, refer to Figure 4-4 on page 4-12 and follow these

steps:

1. Remove the four screws securing the snaps to the cosmetic cover.

2. Lift the snaps away from the cosmetic cover.

Installation. To install, reverse this procedure.

AWG7000 Series Service Manual 4-11

Removal and Installation Procedures

Cosmetic cover (top)

Front-trim unit

Snap

Cosmetic cover (bottom)

Handle base bracket

Figure 4-4: Handle, snaps, cosmetic covers, and front-trim unit removal

Cosmetic Cover (Top)

You need a screwdriver with a T-15 Torx tip (items 1 and 2).

Removal. To remove the top cosmetic cover, refer to Figure 4-4 and follow these

steps:

1. Remove the snaps.

2. Remove the two screws securing the cosmetic cover to the chassis.

3. Loosen the cover with a detaching tool, such as a flat-blade screwdriver.

4-12 AWG7000 Series Service Manual

Removal and Installation Procedures

4. Tilt the rear side of the cover up, and then pull it off the chassis.

Installation. To install, reverse this procedure.

Cosmetic Cover (Bottom)

Front-Trim Unit

You need a screwdriver with a T-15 Torx tip (items 1 and 2).

Removal. To remove the top cosmetic cover, refer to Figure 4-4 and follow these

steps:

1. Remove the handle unit.

2. Orient the instrument so its top is down on the work surface and its rear is

facing you.

3. Remove the two screws securing the cosmetic cover to the chassis.

4. Loosen the cover with a detaching tool, such as a flat-blade screwdriver.

5. Tilt the rear side of the cover up, then pull it off the chassis.

Installation. To install, reverse this procedure.

You need a screwdriver with a T-15 Torx tip, and angle-tip tweezers

(items 1, 2, and 10).

Removal. To remove the front-trim unit, refer to Figure 4-4 follow these steps:

1. Remove the handle unit, snaps, and cosmetic covers.

2. Orient the instrument so that the rear is on the work surface.

EMI Covers

3. Paste a tape to the power switch button so that it will not come off the front

trim.

4. Remove the knob by pulling it straight out from the front panel with the

angle-tip tweezers.

5. Remove the three screws at the bottom of the front trim.

6. Grasp the bottom side of the front trim, and pull off the bottom side of it by

loosening the DVD drive part.

7. The upper part of the chassis has three projections. The front trim fits in these

projections. When removing the front trim, grasp its back edge and flex it

upward before pulling it forward.

Installation. To install, reverse this procedure.

You need a screwdriver with a T-15 Torx tip (items 1 and 2).

Removal. To remove the EMI covers, refer to Figure 4-5 on page 4-14 and follow

these steps:

1. Remove the handle unit, snaps, cosmetic covers, and front-trim unit.

AWG7000 Series Service Manual 4-13

Removal and Installation Procedures

2. Remove the top cover: