Service Manual

AWG615

2.7 GS/s Arbitrary Waveform Generator

071-1516-01

This document applies to firmware version 4.0

and above.

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its suppliers and

are protected by United States copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supercedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

In North America, call 1-800-833-9200.

Worldwide, visit www.tektronix.com to find contacts in your area.

WARRANTY 2

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1) year

from the dateof shipment. If any such product proves defective during this warranty period, Tektronix, at its option,

either will repair the defectiveproduct without charge for parts and labor, or will provide a replacement in exchange

for the defective product. Parts, modules andreplacement products used by Tektronix for warranty work may be new

or reconditioned to like new performance. All replaced parts,modules and products become the property of Tektronix.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of

the warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by Tektronix, with shipping charges

prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a location within the country

in which the Tektronix service center is located. Customer shall be responsible for paying all shipping charges, duties,

taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

resulting from attempts by personnel other than Tektronix representatives to install, repair or service the product; b) to

repair damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or

malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been modified or integrated

with other products when the effect of such modification or integration increases the time or difficulty of servicing the

product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX' RESPONSIBILITY

TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY

PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS

VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

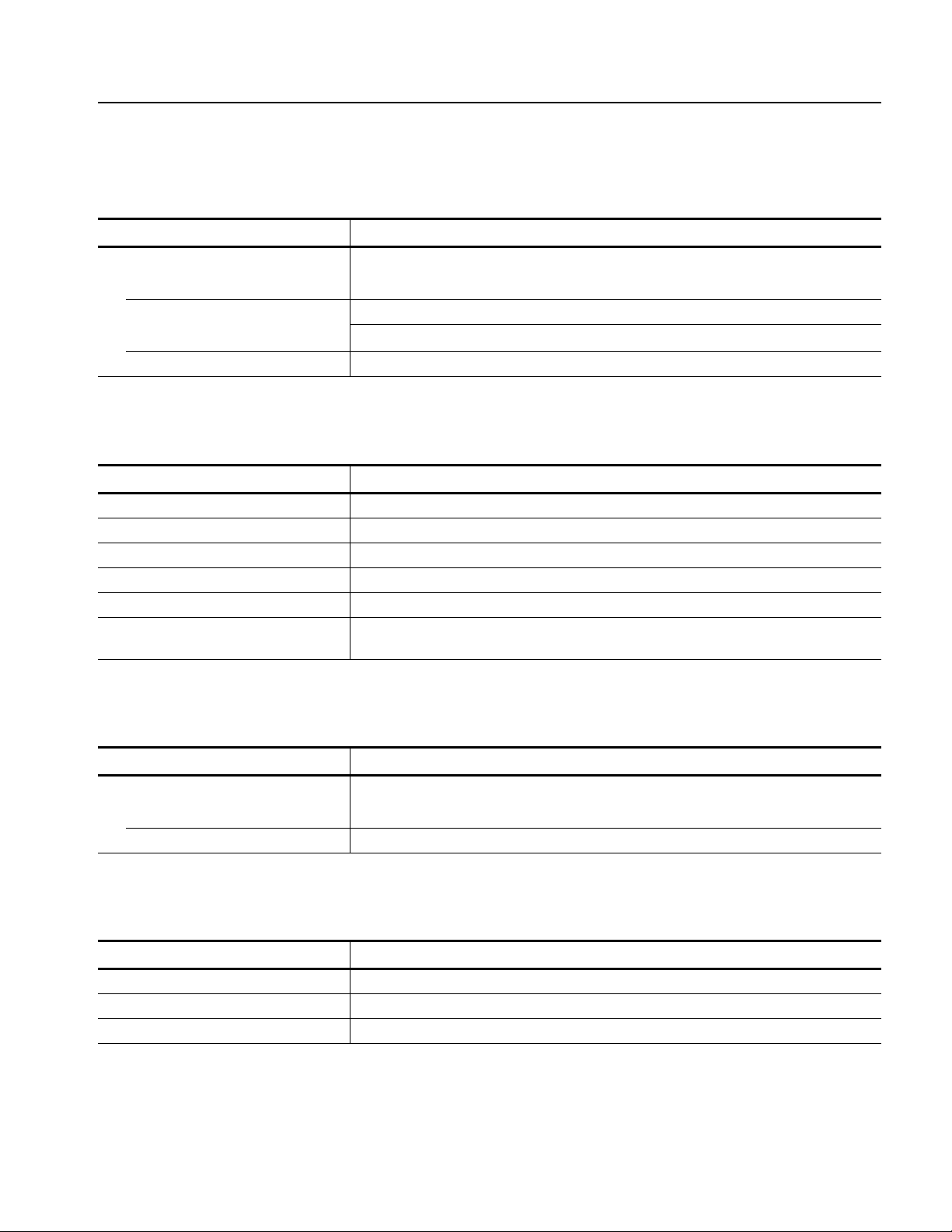

Table of Contents

Specifications

General Safety Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Service Safety Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Environmental Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Manual Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

Finding Other Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Performance Verification Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Strategy for Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Tektronix Service Offerings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Electrical Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Certification and Compliances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

Operating Information

Theory of Operation

Preparation for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Supplying Operating Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Operating Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Repackaging for Shipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Applying and Interrupting Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Operating Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Controls and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Menu Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Numeric Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Text Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Shortcut Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

File Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Double Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

Quick View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

Setup Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Signal Edit Process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

AWG615 Service Manual i

Table of Contents

Performance Verification

Performance Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Self Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Performance Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

AWG615 Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Operating Mode Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Amplitude and Offset Accuracy Tests (Normal Out), (except option 02) . . . . . . . . . 4-22

Amplitude, Offset Accuracy and Rise Time Tests (Direct DA Out),

Amplitude, Offset Accuracy and Rise Time Tests (for option 02) . . . . . . . . . . . . . . . 4-30

Pulse Response Tests (Normal Out), (except option 02). . . . . . . . . . . . . . . . . . . . . . . 4-34

Trigger Input Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Event Input and Enhanced Mode Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

External Clock Input and VCO Out Output Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-49

VCO OUT Output Frequency and 10 MHz Reference Input Tests . . . . . . . . . . . . . . 4-51

Marker Output Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-53

Synchronous Operation Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-55

(except option 02) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Adjustment Procedures

Maintenance

Adjustment Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Before Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Adjustment Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Related Maintenance Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Inspection and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Removal and Installation Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Preparation — Preparation for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Access Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Procedures for External Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

Procedures for Internal Modules(1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

Procedures for Internal Modules(2), . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-44

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-51

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-51

Messages and Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-61

Command Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-62

Execution Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-64

Device Specific Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-66

Query Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-67

Power–On Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-67

User Request Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-67

Request Control Events. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-68

Operation Complete Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-68

Device Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-69

ii AWG615 Service Manual

Options and Accessories

Options and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Power Cord Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Language Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Replaceable Electrical Parts

Electrical Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Diagrams

Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Replaceable Mechanical Parts

Replaceable Mechanical Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Parts Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Using the Replaceable Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Table of Contents

AWG615 Service Manual iii

Table of Contents

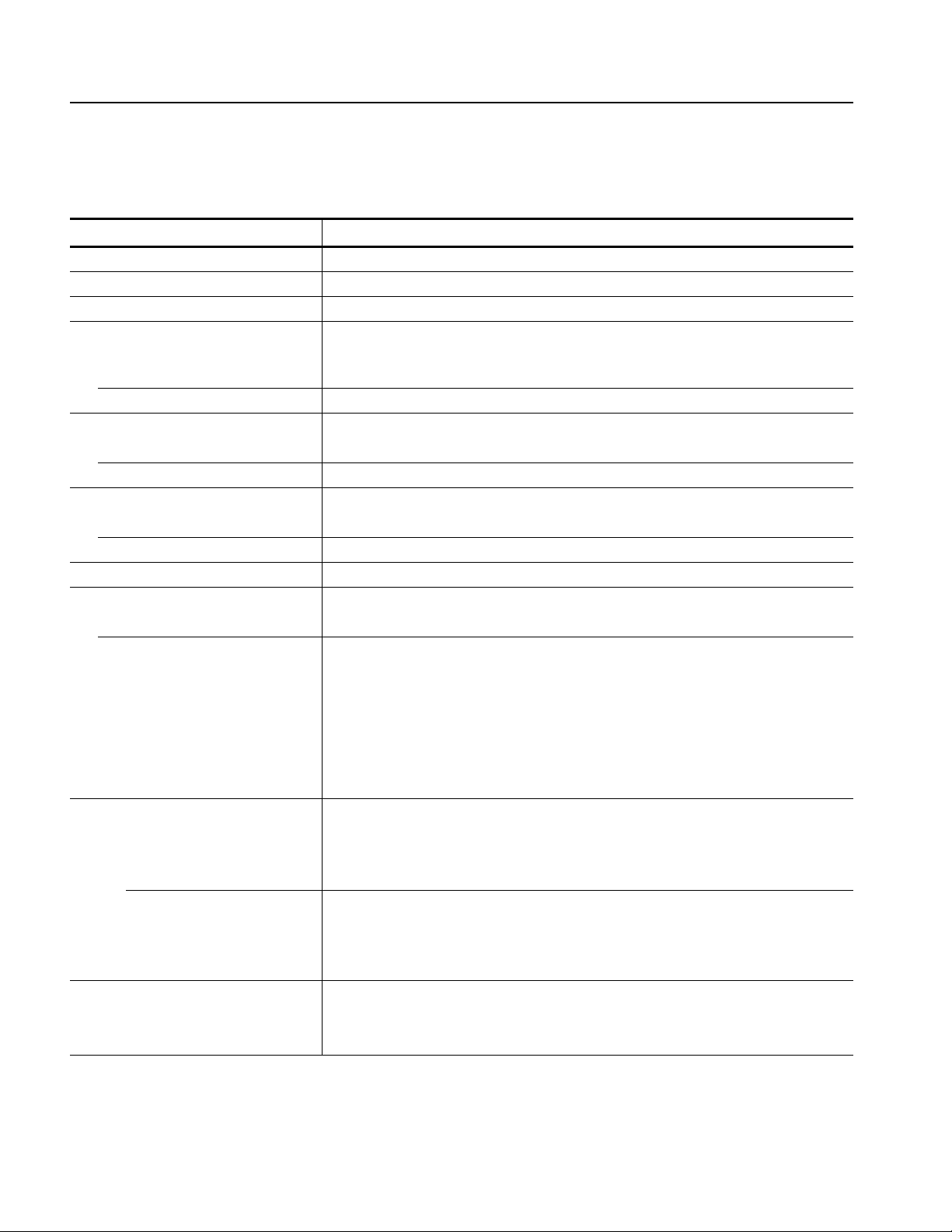

List of Figures

Figure 1-1: Signal Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Figure 1-2: Gated Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Figure 1-3: Enhanced mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Figure 1-4: Sequence 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Figure 1-5: Sequence 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Figure 1-6: Sequence 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Figure 1-7: The cable connection between units in Synchronous operation . . . 1-17

Figure 1-8: Output Voltage Window ( into 50Ω to GND ) of MARKER . . . . . . 1-18

Figure 1-9: Output part equivalent circuit of MARKE . . . . . . . . . . . . . . . . . . . . 1-19

Figure 1-10: Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

Figure 2-1: Rear panel power switch, fuse holder, and power connector . . . . . . . 2-6

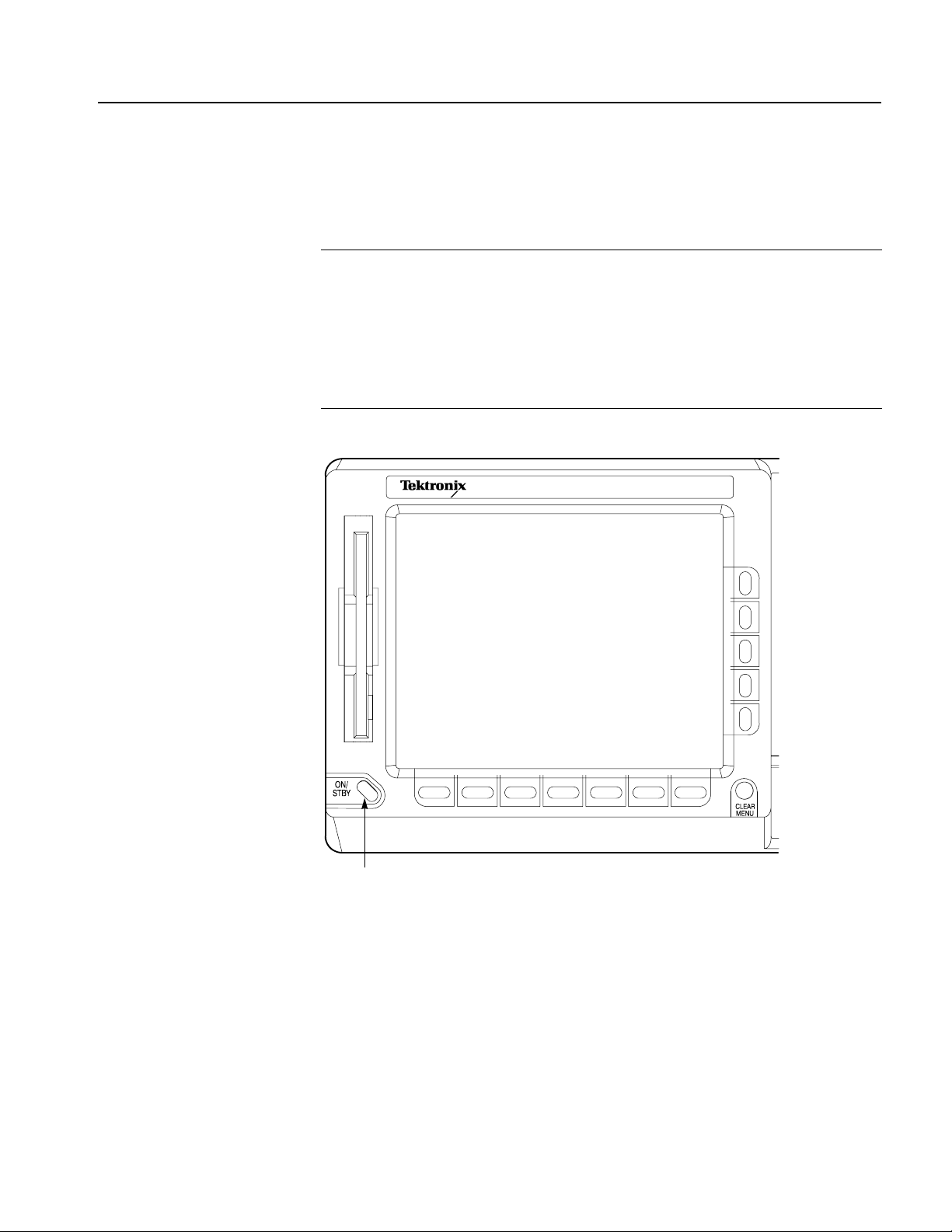

Figure 2-2: Location of the ON/STBY switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Figure 2-1: Front panel controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Figure 2-2: Front panel keypad area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Figure 2-3: Front panel trigger and output controls . . . . . . . . . . . . . . . . . . . . . . 2-14

Figure 2-4: Rear panel signal and power connectors . . . . . . . . . . . . . . . . . . . . . . 2-15

Figure 2-5: Menu buttons, bezel menu buttons,

and the CLEAR MENU button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Figure 2-6: Bottom and side menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Figure 2-7: Pop–up menu example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Figure 2-8: Dialog box example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Figure 2-9: Knob icon displayed in Status Display area . . . . . . . . . . . . . . . . . . . . 2-20

Figure 2-10: Keypad buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Figure 2-11: Three type of Input text dialog boxes . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Figure 2-12: Shortcut controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Figure 2-13: Files and directories with read only attribute . . . . . . . . . . . . . . . . . 2-29

Figure 2-14: Input Filename dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

Figure 2-15: Double windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

Figure 2-16: Overwrite confirmation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

Figure 2-17: File list window examples in which Quick View is available . . . . . 2-35

Figure 2-18: Viewing a file by Quick View function . . . . . . . . . . . . . . . . . . . . . . . 2-36

Figure 2-19: Main Setup screen (except option02) . . . . . . . . . . . . . . . . . . . . . . . . 2-37

Figure 2-20: Select File dialog on the Load menu . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

Figure 2-21: Viewing a file in the Setup screen . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

Figure 3-1: AWG615 block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Figure 3-2: Relationship between memory address control

and waveform memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Figure 4-1: Diagnostic menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Figure 4-2: Calibration result message box (except option 02) . . . . . . . . . . . . . . . 4-5

Figure 4-3: EVENT IN connector pins and signals

and ground closure connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Figure 4-4: Loading file; selecting storage drive . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Figure 4-5: Cont mode initial test hookup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Figure 4-6: Triggered mode initial test hookup . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Figure 4-7: Relationship between trigger signal and waveform output . . . . . . . 4-19

Figure 4-8: Relationship between gate signal and waveform output . . . . . . . . . 4-21

iv AWG615 Service Manual

Table of Contents

Figure 4-9: Amplitude accuracy initial test hookup . . . . . . . . . . . . . . . . . . . . . . 4-22

Figure 4-10: Direct DA output amplitude accuracy initial test hookup . . . . . . 4-26

Figure 4-11: Direct DA output pulse rise time initial test hookup . . . . . . . . . . . 4-28

Figure 4-12: Option02 output amplitude accuracy initial test hookup . . . . . . . 4-30

Figure 4-13: Optipn02 output pulse rise time initial test hookup . . . . . . . . . . . . 4-32

Figure 4-14: Pulse response initial test hookup . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

Figure 4-15: Trigger input initial test hookup . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Figure 4-16: Trigger signal and waveform output (+5 V check 1) . . . . . . . . . . . 4-38

Figure 4-17: Trigger signal and waveform output (+5 V check 2) . . . . . . . . . . . 4-38

Figure 4-18: Trigger signal and waveform output (-5 V check 1) . . . . . . . . . . . 4-39

Figure 4-19: Trigger signal and waveform output (-5 V check 2) . . . . . . . . . . . 4-39

Figure 4-20: Event input and enhanced mode initial test hookup . . . . . . . . . . . 4-40

Figure 4-21: Waveform while all ground disclosure switches are open . . . . . . . 4-42

Figure 4-22: Waveform output when the SW1 is closed . . . . . . . . . . . . . . . . . . . 4-42

Figure 4-23: Waveform output when SW2 is closed . . . . . . . . . . . . . . . . . . . . . . 4-43

Figure 4-24: Waveform output when the SW3 is closed . . . . . . . . . . . . . . . . . . . 4-43

Figure 4-25: Waveform output when SW4 is closed . . . . . . . . . . . . . . . . . . . . . . 4-44

Figure 4-26: Waveform output when SW6 is closed . . . . . . . . . . . . . . . . . . . . . . 4-45

Figure 4-27: Waveform output when SW7 is closed . . . . . . . . . . . . . . . . . . . . . . 4-45

Figure 4-28: Waveform output when SW8 is closed . . . . . . . . . . . . . . . . . . . . . . 4-46

Figure 4-29: Initial waveform output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-47

Figure 4-30: DC waveform output when the SW5 is closed . . . . . . . . . . . . . . . . 4-47

Figure 4-31: Trigger input initial test hookup . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-49

Figure 4-32: VCO OUT outputfrequency

and 10 MHz reference input initial test hookup . . . . . . . . . . . . . . . . . . . . . . . 4-51

Figure 4-33: Marker output initial test hookup . . . . . . . . . . . . . . . . . . . . . . . . . . 4-53

Figure 4-34: Synchronous operation test hookup . . . . . . . . . . . . . . . . . . . . . . . . 4-55

Figure 5-1: Accessing the service switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Figure 5-2: Hookup for the reference clock frequency adjustment . . . . . . . . . . . 5-6

Figure 5-3: Hookup for the magic frequency adjustment . . . . . . . . . . . . . . . . . . . 5-7

Figure 6-1: Instrument orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Figure 6-2: External modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Figure 6-3: Internal modules (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Figure 6-4: Internal modules(1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Figure 6-5: Internal modules(2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Figure 6-6: Knob removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

Figure 6-7: Line fuse and line cord removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

Figure 6-8: Cabinet removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Figure 6-9: Trim ring and menu buttons removal . . . . . . . . . . . . . . . . . . . . . . . 6-23

Figure 6-10: A20 Front panel assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

Figure 6-11: Disassembly of front panel assembly . . . . . . . . . . . . . . . . . . . . . . . . 6-26

Figure 6-12: Output assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

Figure 6-13: Cabinet modules removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29

Figure 6-14: Fan removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-31

Figure 6-15: Floppy disk drive removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-32

Figure 6-16: Display assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-33

Figure 6-17: Power supply module removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-35

Figure 6-18: A10 connector board removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-37

Figure 6-19: CPU unit removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-39

Figure 6-20: CPU, A40 PCI Interface, and GPIB boards removal . . . . . . . . . . 6-40

AWG615 Service Manual v

Table of Contents

Figure 6-21: Hard disk and flash disk removal . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-41

Figure 6-22: Rear chassis removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-43

Figure 6-23: Removal of the A77, A71, A60

and A50 boards (except option 02) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-45

Figure 6-24: Removal of the A72, A60 and A50 boards (for option 02) . . . . . . . 6-49

Figure 6-25: Primary troubleshooting procedure . . . . . . . . . . . . . . . . . . . . . . . . . 6-52

Figure 6-26: Troubleshooting procedure 1 — Power Supply module . . . . . . . . . 6-53

Figure 6-27: Power supply connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-54

Figure 6-28: Troubleshooting procedure 2 — CPU or front panel module . . . . 6-55

Figure 6-29: Troubleshooting procedure 3 — LCD module . . . . . . . . . . . . . . . . 6-56

Figure 6-30: A10 connector board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-57

Figure 6-31: Troubleshooting procedure 4 — Module isolation . . . . . . . . . . . . . 6-58

Figure 6-32: Troubleshooting procedure 5— Synchronous operation . . . . . . . . 6-59

Figure 9-1: Block and interconnect diagram

for the AWG615 Arbitrary Waveform Generator . . . . . . . . . . . . . . . . . . . . . . 9-2

Figure 9-2: Block and interconnect diagram for A60, A50 and Rearpanel . . . . . 9-3

Figure 10-1: Front and Display unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

Figure 10-2: Front panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-7

Figure 10-3: Front Output unit (except option 02) . . . . . . . . . . . . . . . . . . . . . . . . 10-9

Figure 10-4: Front Output unit (for option 02) . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

Figure 10-5: Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-13

Figure 10-6: CPU unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-15

Figure 10-7: Circuit boards (except option 02) . . . . . . . . . . . . . . . . . . . . . . . . . . 10-17

Figure 10-8: Circuit boards (for option 02) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-19

Figure 10-9: Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-22

Figure 10-10: Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-23

Figure 10-11: Rack mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-25

vi AWG615 Service Manual

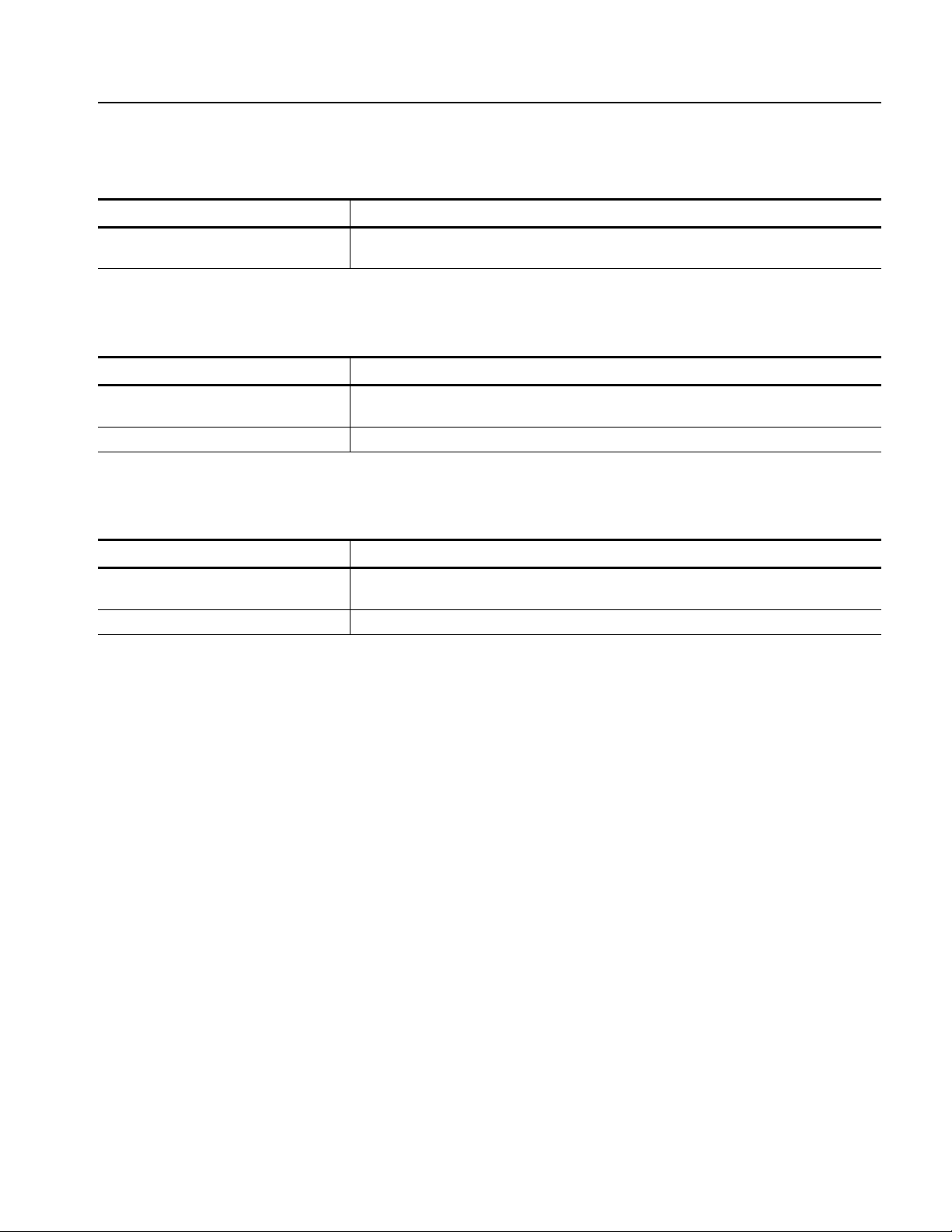

List of Tables

Table of Contents

Table 1-1: AWG615 waveform editors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Table 1-1: Run modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Table 1-2: Extended Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Table 1-3: Arbitrary waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Table 1-4: Clock generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Table 1-5: Internal trigger generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Table 1-6: Main output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Table 1-7: Filter (except option 02) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Table 1-8: Auxiliary outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Table 1-9: Marker output Period Jitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Table 1-10: Marker output Cycle to Cycle Jitter . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Table 1-11: VCO output Period Jitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Table 1-12: VCO output Cycle to Cycle Jitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Table 1-13: Auxiliary inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Table 1-14: Event Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Table 1-15: 10 MHz reference clock input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Table 1-16: External clock input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Table 1-17: C input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

Table 1-18: T input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

Table 1-19: Function Generator (FG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

Table 1-20: Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Table 1-21: AC line power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Table 1-22: Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Table 1-23: Interface connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Table 1-24: Installation requirement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Table 1-25: Maintenance requirement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Table 1-26: Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Table 1-27: Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

Table 1-28: Certifications and compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

Table 1-29: Installation category and Pollution degree Descriptions . . . . . . . . 1-27

Table 2-1: Power–cord conductor identification . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Table 2-2: Power cord identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Table 2-3: Fuse part numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Table 2-4: Fuse cap part numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Table 2-1: Side menu elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Table 2-2: Text input button functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Table 2-3: Shortcut controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Table 2-4: AWG615 Arbitrary Waveform Generator file types . . . . . . . . . . . . 2-25

Table 2-5: Drive and Directory menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Table 2-6: Waveform record length adjustment messages . . . . . . . . . . . . . . . . . 2-30

Table 2-7: File operation in double windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

Table 2-8: Confirmation selection for copy–all and move–all operations . . . . . 2-34

Table 2-9: Setup screen parameter icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

Table 2-10: Setup bottom menu buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

Table 2-11: Setup output parameter operations . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

Table 3-1: Run modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

AWG615 Service Manual vii

Table of Contents

Table 3-2: Extended operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Table 3-3: Editors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Table 4-1: Performance test items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Table 4-2: Test equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Table 4-3: Waveforms and sequences in performance check disk . . . . . . . . . . . 4-10

Table 5-1: Adjustments required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Table 5-2: Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Table 5-3: Test equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Table 5-4: File list for performance Check/adjustment disk . . . . . . . . . . . . . . . . . 5-5

Table 6-1: Relative susceptibility to static–discharge damage . . . . . . . . . . . . . . . . 6-3

Table 6-2: External Inspection Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Table 6-3: Internal inspection check list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Table 6-4: Tools required for module removal . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Table 6-5: Definition of event codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-61

Table 6-6: Command errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-62

Table 6-7: Execution errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-64

Table 6-8: Device specific errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-66

Table 6-9: Query errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-67

Table 6-10: Power–on events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-67

Table 6-11: User request events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-67

Table 6-12: Request control events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-68

Table 6-13: Operation complete events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-68

Table 6-14: Messages and codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-69

Table 7-1: Power cord options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Table 7-2: Language options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Table 7-3: Standard accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Table 7-4: Optional accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

viii AWG615 Service Manual

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to this

product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Connect and Disconnect Properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. This product is grounded through the grounding conductor of

the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings and

markings on the product. Consult the product manual for further ratings

information before making connections to the product.

The common terminal is at ground potential. Do not connect the common terminal

to elevated voltages.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components when

power is present.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

AWG615 Service Manual ix

General Safety Summary

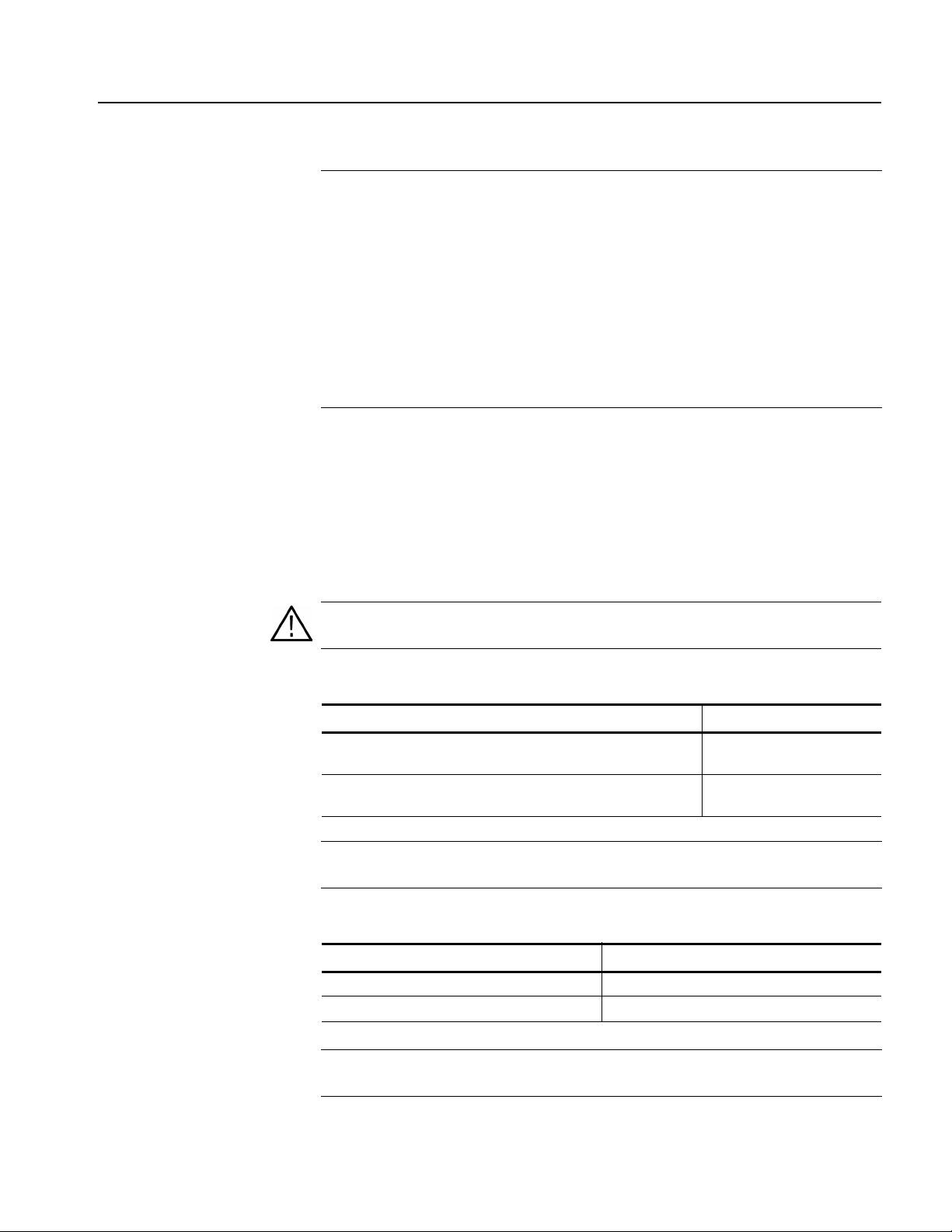

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WAR N I NG. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

WARNING

High Voltage

Protective Ground

(Earth) Terminal

CAUTION

Refer to Manual

x AWG615 Service Manual

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, disconnect the mains power by means

of the power cord or, if provided, the power switch.

Use Care When Servicing With Power On. Dangerous voltages or currents may exist

in this product. Disconnect power, remove battery (if applicable), and disconnect

test leads before removing protective panels, soldering, or replacing components.

To avoid electric shock, do not touch exposed connections.

Calendar (date and time) Backup Battery. This product contains a

Lithium:poly–carbon monofluoride battery for calendar backup purposes. This

battery is part of the CPU unit and is not replaceable.

AWG615 Service Manual xi

Service Safety Summary

xii AWG615 Service Manual

Environmental Considerations

This section provides information about the environmental impact of the product.

Product End-of-Life

Handling

Restriction of Hazardous

Substances

Observe the following guidelines when recycling an instrument or component:

Equipment Recycling. Production of this equipment required the extraction and use

of natural resources. The equipment may contain substances that could be harmful

to the environment or human health if improperly handled at the product's end of

life. In order to avoid release of such substances into the environment and to reduce

the use of natural resources, we encourage you to recycle this product in an

appropriate system that will ensure that most of the materials are reused or recycled

appropriately.

The symbol shown to the left indicates that this product complies

with the European Union's requirements according to Directive

2002/96/EC on waste electrical and electronic equipment (WEEE).

For information about recycling options, check the Support/Service

section of the Tektronix Web site (www.tektronix.com).

Mercury Notification. This product uses an LCD backlight lamp that contains

mercury. Disposal may be regulated due to environmental considerations. Please

contact your local authorities or, within the United States, the Electronics

Industries Alliance (www.eiae.org) for disposal or recycling information.

This product has been classified as Monitoring and Control equipment, and is

outside the scope of the 2002/95/EC RoHS Directive. This product is known to

contain lead, cadmium, mercury, and hexavalent chromium.

AWG615 Service Manual xiii

Environmental Considerations

xiv AWG615 Service Manual

Preface

Manual Structure

The AWG615 Arbitrary Waveform Generator service manual provides

information necessary for servicing the waveform generator to the module level.

This manual is divided into main sections that address topics such as Specifications

and Theory of Operation. Further, some sections are divided into subsections, such

as Product Description and Removal and Installation Procedures.

Sections containing procedures also contain introductions to those procedures. Be

sure to read these introductions as they provide information needed to perform the

service correctly and efficiently. The following list provides a brief description of

each manual section.

Specifications describes the waveform generator and the characteristics that

apply to it.

Operating Information includes general information and operating

instructions.

Theory of Operation explains circuit descriptions that support service to the

module level.

Performance Verification provides procedures for confirming that the

waveform generator functions properly and meets warranted limits.

Adjustment Procedures provides information and procedures to perform

waveform generator adjustments.

Maintenance contains information and procedures for performing preventive

and corrective maintenance on the waveform generator. These instructions

include cleaning, module removal and installation, and fault isolation to the

module.

Options contains information on servicing factory–installed options.

Electrical Parts List section refers you to the Mechanical Parts List section

which contains both the electrical and mechanical information on all module

parts.

Diagrams contains illustrations of modules and functional blocks in the

waveform generator.

Mechanical Parts List provides a listing of all replaceable modules, their

descriptions, and their Tektronix part numbers.

AWG615 Service Manual xv

Preface

Manual Conventions

Throughout this manual you will notice the use of certain conventions. Some

sections of the manual contain procedures for you to perform. To keep those

instructions clear and consistent, this manual uses the following conventions:

Names of front panel controls and menus appear in the same case (such as

initial capitals or all uppercase) in the manual as is used on the waveform

generator front panel and menus. Front panel names are all uppercase letters;

for example, SETUP, UTILITY, HARDCOPY.

Instruction steps are numbered unless there is only one step.

Modules

Safety

Throughout this manual, any replaceable component, assembly, or part of the

waveform generator is referred to generically as a module. A module is an

assembly (such as a circuit board), as opposed to a component (such as a resistor

or integrated circuit). Sometimes a single component is a module; for example, the

chassis of the waveform generator.

Symbols and terms related to safety appear in the Safety Summary at the front of

this manual.

Finding Other Information

Other documentation for the AWG615 Arbitrary Waveform Generator includes:

The AWG615 Arbitrary Waveform Generator user manual contains a tutorial

The AWG615 Arbitrary Waveform Generator Programmer manual explains

that describes how to operate the waveform generator. It also includes a

detailed explanation of how to best use the waveform generator features.

how to use a GPIB interface to control the waveform generator remotely.

xvi AWG615 Service Manual

Introduction

This manual provides information and procedures necessary for properly servicing

the AWG615 Arbitrary Waveform Generator, as well as general information

critical to safe and effective servicing.

To prevent personal injury or damage to the waveform generator, review the

following information before attempting service:

The procedures in this manual should be performed only by qualified service

personnel.

Read the General Safety Summary and Service Safety Summary beginning on

page ix.

Read Preparation for Use in the Operating Information subsection.

When using this manual for servicing, be sure to follow all warnings, cautions, and

notes.

Performance Verification Procedures

Strategy for Servicing

Complete the performance check described in the Performance Verification

section every 12 months. In addition, a performance check is recommended after

module replacement.

If the waveform generator does not meet performance criteria, repair is necessary.

Throughout this manual the term, module, refers to any field–replaceable

component, assembly, or part of the waveform generator.

This manual contains all the information needed for periodic maintenance of the

waveform generator. Further, it contains all information for corrective

maintenance down to the module level. To isolate a module failure, follow the

troubleshooting procedures found in the Maintenance section. To remove and

replace any failed module, follow the instructions in the Removal and Installation

Procedures subsection. After isolating a faulty module, replace it with a fully

tested module obtained from the factory. The Replaceable Mechanical Parts

subsection contains part number and ordering information for all replaceable

modules.

AWG615 Service Manual xvii

Introduction

Tektronix Service Offerings

Tektronix provides service to cover repair under warranty as well as other services

that provide a cost–effective answer to your service needs.

Whether providing warranty repair service or any of the other services listed below,

Tektronix service technicians are well trained service professionals. They have

access to the latest information on improvements to the AWG615 Arbitrary

Waveform Generator as well as new options.

Warranty Repair Service

Self Service

Tektronix warrants this product for one year from date of purchase. The warranty

appears at the front of this manual. Tektronix technicians provide warranty service

at most Tektronix service locations. The Tektronix product catalog lists all

worldwide service locations.

Tektronix supports repair to the module level by providing Module Exchange.

Module Exchange. This service reduces downtime for repair by allowing you to

exchange most modules for remanufactured ones. Each module comes with a

90–day service warranty.

For More Information. Contact your local Tektronix service center or sales engineer

for more information on any of the repair or adjustment services just described.

xviii AWG615 Service Manual

Specifications

Product Overview

Product Description

The AWG615 Arbitrary Waveform Generator is a waveform generator that can

generate simple and arbitrary waveforms, one–channel differential output arbitrary

waveforms, and function generator waveforms.

The AWG615 Arbitrary Waveform Generator allows you to create sine, triangle,

square, ramp, and complex waves, as well as direct current and noise signals. You

can also set waveform attributes such as frequency, amplitude, and offset.

This instrument contains a hard disk drive, a 3.5–inch floppy disk drive, and

Ethernet interface for storing and recalling waveform data and instrument settings.

You can control the instrument remotely by sending commands through both the

GPIB and 100/10BASE–T interfaces, as well as transfer waveform data directly

from a digital storage oscilloscope to the AWG615 Arbitrary Waveform Generator

using the GPIB interface. This enables you to use the instrument in combination

with other measurement equipment and a computer.

Main Features

The AWG615 Arbitrary Waveform Generator contains the following main

features:

2.7 GS/s sampling rate

8–bit DA converter

32.4 M–word waveform memory (64.8 M–word optional)

Two arbitrary marker outputs

Five waveform editors (see Table 1-1)

Table 1-1: AWG615 waveform editors

Editor Description

Waveform Creates analog waveform data in graphic or tabular form.

Pattern Creates analog waveform data in timing and table form.

Sequence Creates sequences of waveforms by combining the waveform files

created with the Waveform and/or Pattern Editors.

Text Edits plain ASCII format waveform files. For example, you can use

the Text editor to edit ASCII format waveform files that are read from

an external device.

Equation Creates files with equations and compiles them into waveform files.

AWG615 Service Manual 1-1

Product Overview

FG mode to generate a standard functional waveform easily.

Waveform Mixing mode to generate a mixing two-signals digitally.

Synchronous operation mode to generate 2 channel signals by two AWG615s.

Additional Features

The AWG615 Arbitrary Waveform Generator provides these additional features:

An Ethernet port for using the NFS (Network File System) and/or FTP link.

Refer to Ethernet Networking in the AWG615 Arbitrary Waveform Generator

User manual for information.

A GPIB interface that can be used for remotely controlling the AWG615

Arbitrary Waveform Generator and for transferring the waveform data from

the external oscilloscopes.

Refer to Connecting to a GPIB Network in the AWG615 Arbitrary Waveform

Generator user manual for information on setting the GPIB parameters.

Refer to the AWG615 Arbitrary Waveform Generator Programmer manual for

information on the remote control commands.

Refer to the Reference:Capturing Waveforms subsection of the AWG615

Arbitrary Waveform Generator user manual for transferring waveforms from

the external oscilloscopes to the waveform generator.

A port on the rear panel for connecting a 101– or 106– type keyboard to the

AWG615 Arbitrary Waveform Generator. You can input values or text using

the keyboard instead of the numeric keypad on the front panel. Refer to the

Reference:External Keyboards section of the AWG615 Arbitrary Waveform

Generator user manual.

An internal clock for setting up the current date and time. Refer to Internal

Clock (Date and Time) in the AWG615 Arbitrary Waveform Generator user

manual. This setup procedure is also described in Tutorial 1: Instrument Setup.

An adjustment of focused color. Focused color allows you to display the

system utility screen and set the highlight color. Refer to the Foc us ed Co l o r

subsection for further information. This setup procedure is also described in

Tutorial 1: Instrument Setup in the AWG615 Arbitrary Waveform Generator

User manual.

1-2 AWG615 Service Manual

Specifications

This section contains the AWG615 Arbitrary Waveform Generator specifications.

All specifications are guaranteed unless labeled “typical”. Typical specifications

are provided for your convenience but are not guaranteed.

Performance Conditions

Specifications that are marked with the

are checked in Appendix B: Performance Verification and the page number

referenced to the corresponding performance verification procedures can be found

in the column PV reference page.

The characteristics in the specifications are listed in tables that are divided into

categories. In these tables, the subcategories may also appear in boldface under the

column Characteristics.

The performance limits in this specification are valid with these conditions:

The AWG615 Arbitrary Waveform Generator must have been

calibrated/adjusted at an ambient temperature between +20

The AWG615 Arbitrary Waveform Generator must be in an environment with

temperature, altitude, humidity, and vibration within the operating limits

described in these specifications.

The AWG615 Arbitrary Waveform Generator must have had a warm–up

period of at least 20 minutes.

The AWG615 Arbitrary Waveform Generator must be operating at an ambient

temperature between +10

Warranted characteristics are described in terms of quantifiable performance limits

which are warranted.

° C and +40° C.

n symbol in the column Characteristics

° C and +30° C.

AWG615 Service Manual 1-3

Specifications

Electrical Specification

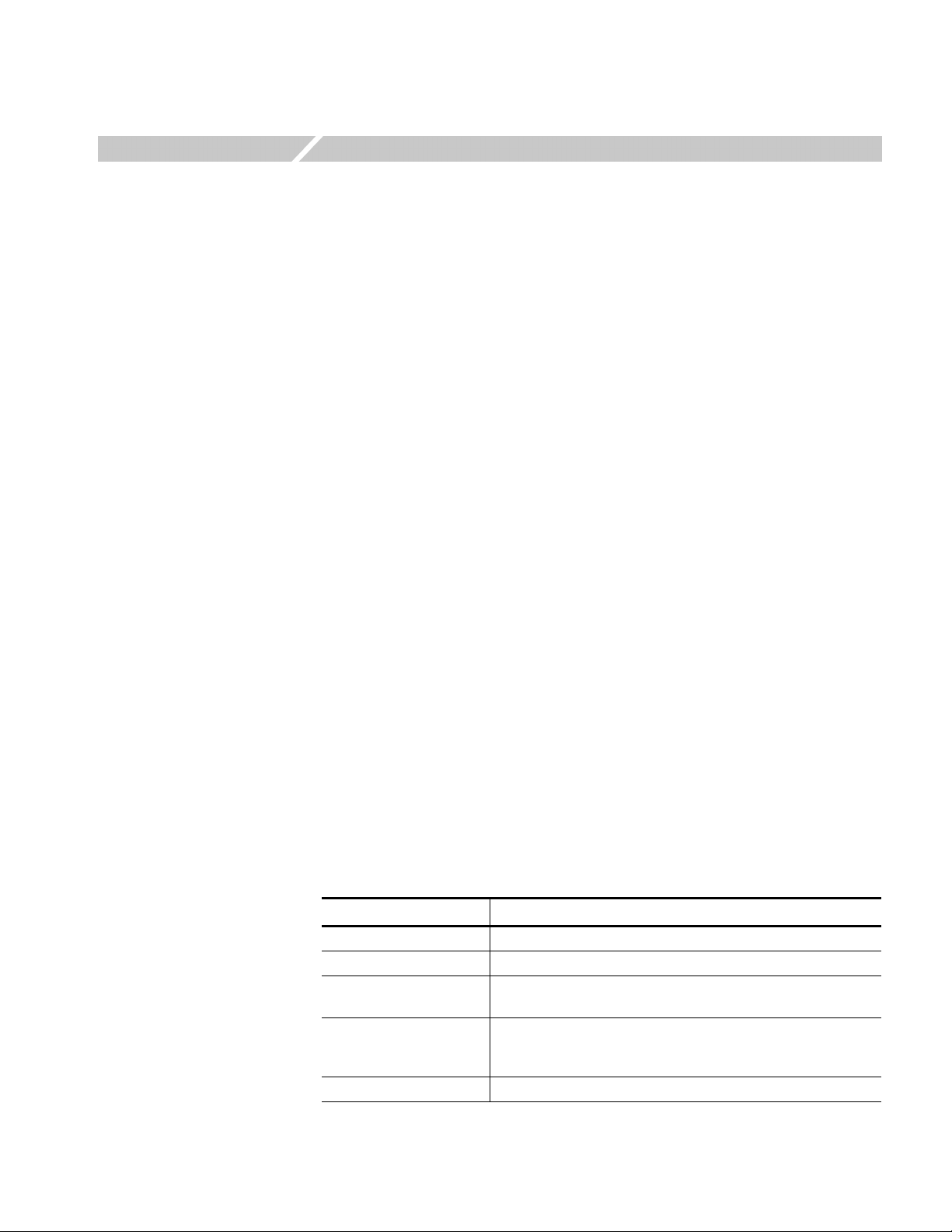

Table 1-1: Run modes

Characteristics Description

Continuous Waveform is continuously output in this mode. When a sequence is defined, waveforms are

sequentially or repeatedly output in the order defined by the sequence. The extended

sequence functions such as trigger input, event jump, and so on are neglected in this mode.

Triggered Waveform is output only once when a trigger event is created. A trigger signal is created by

the external trigger input signal, GPIB trigger command, and/or pressing the front–panel

FORCE TRIGGER button. The extended sequence functions such as trigger input, event

jump, and so on are neglected in this mode.

Gated The waveform is output in the same way as in the continuous mode only when the gate is

opened. The gate is opened by the gated signal.

Note that the output is made from the top of the first waveform for every gate period. The clock

signal continuously outputs from the connector outside the gate period.

Enhanced The waveforms are sequentially or repeatedly output according to the procedures defined in

the sequence. All extended functions such as trigger input, event jump, and so on are effective

and waveforms are controlled for output by this functions in this mode.

Event jump and Software jump are disabled in Synchronous Operation mode.

Table 1-2: Extended Operation

Characteristics Description

FG operation This mode provides user-friendliness like the conventional function generator. The output

waveforms are Sine, Triangle, Square, Ramp, Pulse and DC waveform. AWG615 is in AWG

mode when this mode is not selected.

Waveform Mixing operation This mode provides the function for mixing two-signals digitally.

Synchronous Master operation This mode provides the setup for using as a Master instrument on Synchronous Operation.

Synchronous Slave operation This mode provides the setup for using as a Slave instrument on Synchronous Operation.

Table 1-3: Arbitrary waveforms

Characteristics Description

Waveform memory Memory length: 32 400 000 words (8 bits/1 word)

Op.01 Memory length: 64 800 000 words (8 bits/1 word)

Marker memory Memory length: 32 400 000 words (2 markers × 1 bit / 1 word)

Op.01 Memory length: 64 800 000 words (2 markers × 1 bit / 1 word)

Sequence memory 1 to 8000 steps

Sequence counter 1 to 65 536 and Infinite

1-4 AWG615 Service Manual

Specifications

Table 1-3: Arbitrary waveforms

Characteristics Description

Waveform data points Multiple of 4 in the range from 960 to 32 400 000 points

Op.01 Multiple of 4 in the range from 960 to 64 800 000 points

Data storage

Hard disk ≥20 G bytes

Floppy disk 1.44 M bytes

Table 1-4: Clock generator

Characteristics Description PV reference page

Sampling frequency 50.000 000 kHz/s to 2.700 000 0 GHz/s

Resolution 8 digits

Internal clock

Phase noise at VCO output,

Ty p i c a l

1

The internal reference oscillator is used.

1

Page 4-51n Frequency accuracy ±1 ppm (10 ° C to 40 ° C), during 1 year after calibration

-58 dBc / Hz (2.7 GS/s with 10 kHz offset)

-93 dBc / Hz (2.7 GS/s with 100 kHz offset)

Table 1-5: Internal trigger generator

Characteristics Description PV reference page

Internal trigger rate

2

±0.1 %Accuracy

Range 1.0 µs to 10.0 s

Resolution 3 digits, minimum 0.1 µs

2

The internal reference oscillator is used.

Table 1-6: Main output

Characteristics

Output connector front–panel SMA connectors

Output signal Complemental; CH1 and CH1

3

Description PV reference page

AWG615 Service Manual 1-5

Specifications

Table 1-6: Main output (cont.)

Characteristics

3

Description PV reference page

DA converter

Resolution 8 bits

Differential nonlinearity Within ±1/2 LSB

Integral nonlinearity Within ±1 LSB

Output impedance 50 Ω

Normal out (except option 02)

-1.5 V to +1.5 V, into a 50 Ω loadOutput voltage

Amplitude

20 mV

p–p

to 2 V

p–p

, into a 50 Ω loadRange

Resolution 1 mV

n DC accuracy ±(2.0 % of amplitude + 2 mV), offset: 0 V Page 4-22

Offset

-0.5 V to 0.5 V, into a 50 Ω loadRange

Resolution 1 mV

nAccuracy ±1.5 % of offset ±10 mV,

(20 mV amplitude, waveform data: 0)

(Waveform data: -1 and 1, offset: 0 V, and filter: through,

Pulse response

nRise time (10 % to 90 %) ≤ 480 ps (amplitude = 1.0 V

nFall time (10 % to 90 %) ≤ 480 ps (amplitude = 1.0 V

Aberration, Typical ±10 % (amplitude + 1.0 V

Clock: 1.0 GS/s)

, calculated value ≥ 729 MHz) Page 4-34

p–p

, calculated value ≥ 729 MHz)

p–p

, using 20 GHz bandwidth oscilloscope)

p–p

Flatness, Typical ±5 % (after 20 ns from rise or fall edges)

Sinewave characteristics (Clock: 2.7 GS/s, waveform points: 32, Signal frequency: 84.375 MHz,

amplitude: 1.0 V, offset: 0 V, filter: through)

Harmonics ≤ -40 dBc (DC to 1000 MHz)

Noise ≤ -50 dBc (DC to 1000 MHz)

Page 4-22

Phase Noise, Typical ≤ -85 dBc / Hz (at 10 kHz offset)

Direct DA out (except option 02)

Amplitude

Range 20 mV

p–p

to 1 V

, into a 50 Ω load

p–p

nDC Accuracy ±(2 % of Amplitude + 2 mV) Page 4-26

Resolution 1 mV

n DC offset accuracy 0 V ± 10 mV, (20 mV amplitude, waveform data: 0) Page 4-26

1-6 AWG615 Service Manual

Table 1-6: Main output (cont.)

Specifications

Characteristics

n Pulse response (Waveform data: -1 and 1, at 0.5 V

3

Description PV reference page

) Page 4-28

p–p

Rise time (10 % to 90 %) ≤ 280 ps (calculated value ≥ 1.25 GHz)

Fall time (10 % to 90 %) ≤ 280 ps (calculated value ≥ 1.25 GHz)

Extended Bandwidth output (option 02)

Amplitude

Range 500 mV

p–p

to 1 V

, into a 50 Ω load

p–p

nDC Accuracy ±(2 % of Amplitude + 2 mV) Page 4-30

Resolution 1 mV

n DC offset accuracy 0 V ± 10 mV, (500 mV amplitude, waveform data: 0) Page 4-30

n Pulse response (Waveform data: -1 and 1, at 1 V

) Page 4-32

p–p

Rise time (10 % to 90 %) ≤ 175 ps (calculated value ≥ 2 GHz)

Fall time (10 % to 90 %) ≤ 175 ps (calculated value ≥ 2 GHz)

3

The characteristics are specified at the end of the SMA cable (174–1427–00) except for DC accuracy.

Table 1-7: Filter (except option 02)

Characteristics Description

Type Bessel low pass filter, 200 MHz,100 MHz, 50 MHz, and 20 MHz

Rise time (10 % to 90 %), Typical 20 MHz

50 MHz

100 MHz

200 MHz

Group delay, Typical 20 MHz

50 MHz

100 MHz

200 MHz

17 ns

7 ns

3.7 ns

2 ns

18 ns

8 ns

4.7 ns

3 ns

Table 1-8: Auxiliary outputs

Characteristics Description PV reference page

4

Marker

Number of markers 2 (Complementary). Marker1, Marker1, Marker2, and Marker2

Connector Front panel SMA connectors

High Level (VoH)

Range

-1.00 V to +2.45 V, into a 50 Ω load

Refer to Figure 1-8 on page 1-18

AWG615 Service Manual 1-7

Specifications

Table 1-8: Auxiliary outputs (cont.)

Characteristics Description PV reference page

Low Level (VoL)

Range

Amplitude (VoH - VoL) Range 0.05 V

Resolution 50 mV

n DC Accuracy ±0.1 V ±5 % of setting, into a 50 Ω load Page 4-53

Maximum Output Current ±80 mA

Rise and fall times (20 % to 80 %),

Ty p i c a l

Period jitter, Typical Measured by TDS6604 with TDSJIT3.

Cycle to Cycle jitter, Typical Measured by TDS6604 with TDSJIT3.

Skew, Typical <20 ps

Delay between Analog Output and

Marker Output, Typical

-2.00 V to +2.40 V, into a 50 Ω load

Refer to Figure 1-8 on page 1-18

, to 1.25 V

p–p

into a 50 Ω load

p–p

<130 ps (High: 1.0 V, Lo: 0 V, into a 50 Ω load)

Refer to Table 1-9.

Refer to Table 1-10.

Maker level: 1 V

Analog Output Amplitude: 1 V

(High: +1.0 V, Low: 0 V),

p-p

, Offset: 0 V,

p-p

Filter: Through, Refer to Figure 1-1 on page 1-11

2.4 ns (Normal Output, Offset: 0 V, Filter: Through)

-1.0 ns (Direct Output)

2.0 ns (Option 02)

VCO output

Connector Rear panel SMA connector

Amplitude 0.4V

into a 50 Ω load

p-p

0.8 V

p-p

max. open circuit

Impedance 50 Ω, AC coupling

Period jitter, Typical Measured by TDS6604 with TDSJIT3.

Refer to Table 1-11.

Cycle to Cycle jitter, Typical Measured by TDS6604 with TDSJIT3.

Refer to Table 1-12.

Connector Rear panel SMA connector

10 MHz Reference clock out

Amplitude, Typical 1.2 V

, into a 50 Ω load, Max 2.5 V

p–p

, open circuit

p–p

Impedance 50 Ω, AC coupling

Connector Rear panel BNC connector

C Out 1, C Out 2 out This signal is used for only Synchronous operation between Master and Slave unit.

Connector Rear panel SMA connector

Input Signal Type Complementary

1-8 AWG615 Service Manual

Specifications

Table 1-8: Auxiliary outputs (cont.)

Characteristics Description PV reference page

T Out 1, T Out 2 out This signal is used for only Synchronous operation between Master and Slave unit.

Connector Rear panel SMA connector

Input Signal Type Complementary

Display Monitor out

Format VGA

Connector 15 pin, D-SUB, Rear panel

Level ECL

4

The characteristics are specified at the end of the SMA cable (174–1427–00).

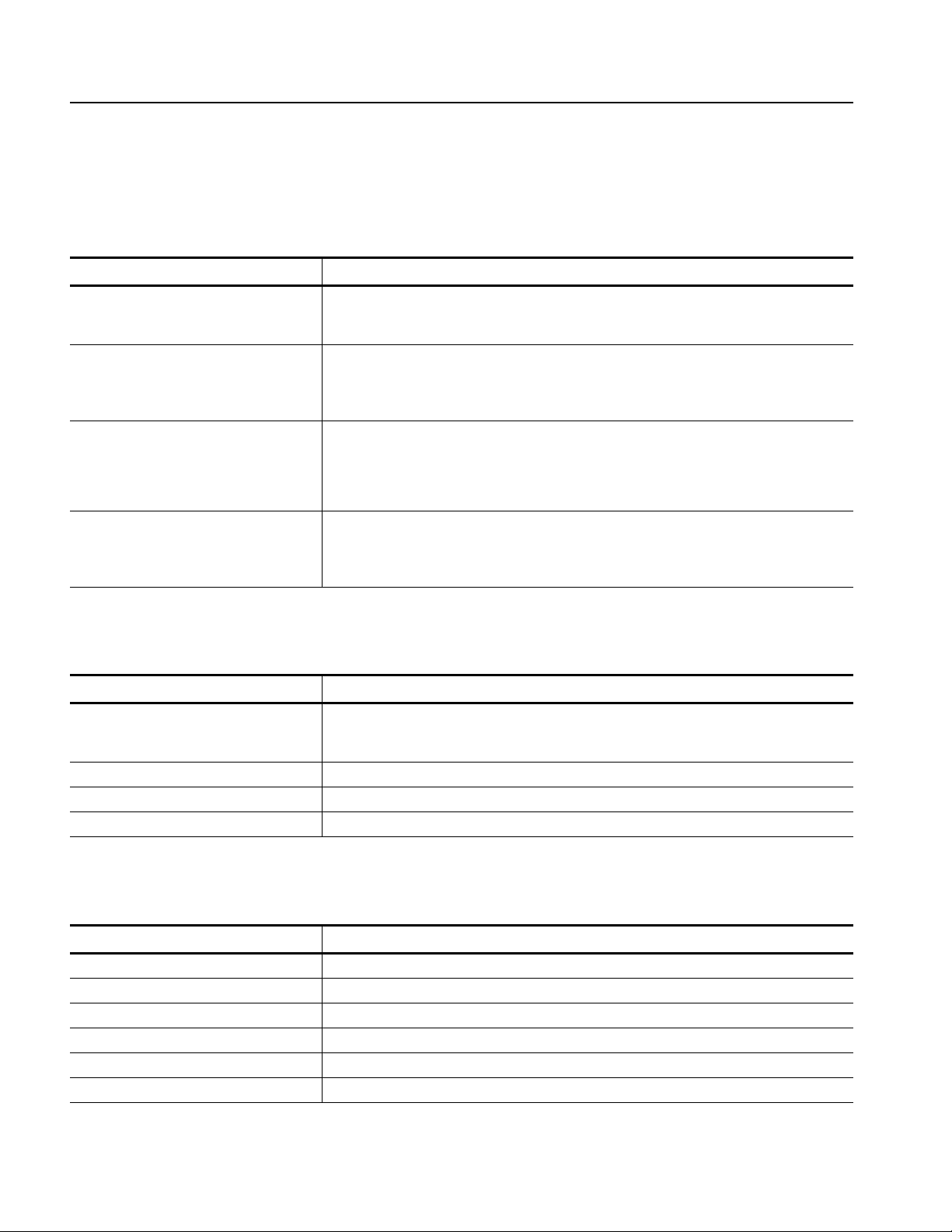

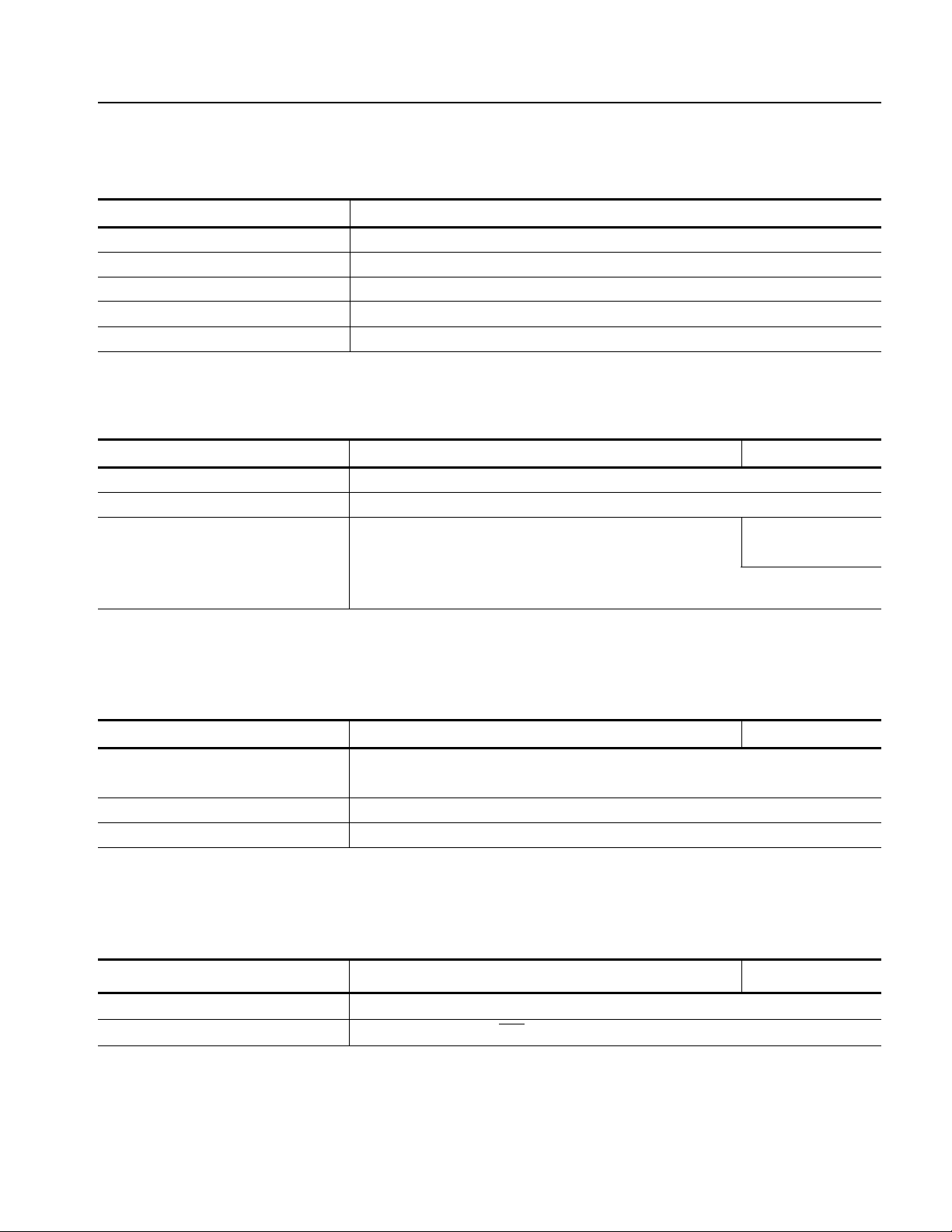

Table 1-9: Marker output Period Jitter

Clock frequency 2.7 GS/s 1.35 GS/s 675 MS/s

Measurement StdDev Pk-Pk StdDev Pk-Pk StdDev Pk-Pk

Marker output 2.1 ps 15 ps 2.1 ps 15 ps 2.0 ps 14 ps

Note.Period Jitter is measured with Clock Pattern (01010101......)

Table 1-10: Marker output Cycle to Cycle Jitter

Clock frequency 2.7 GS/s 1.35 GS/s 675 MS/s

Measurement StdDev Pk-Pk StdDev Pk-Pk StdDev Pk-Pk

Marker output 3.6 ps 26 ps 3.6 ps 26 ps 3.3 ps 23 ps

Note.Cycle to Cycle Jitter is measured with Clock Pattern (01010101......)

Table 1-11: VCO output Period Jitter

Clock frequency 2.7 GS/s 1.35 GS/s 675 MS/s

Measurement StdDev Pk-Pk StdDev Pk-Pk StdDev Pk-Pk

VCO output 1.7 ps 12 ps 1.6 ps 11 ps 1.6 ps 11 ps

AWG615 Service Manual 1-9

Specifications

Table 1-12: VCO output Cycle to Cycle Jitter

Clock frequency 2.7 GS/s 1.35 GS/s 675 MS/s

Measurement StdDev Pk-Pk StdDev Pk-Pk StdDev Pk-Pk

VCO output 3.0 ps 22 ps 2.8 ps 20 ps 2.7 ps 19 ps

Table 1-13: Auxiliary inputs

Characteristics Description PV reference page

Trigger input

Connector Rear panel BNC connector

Impedance 1 kΩ or 50 Ω

Polarity (Trigger mode)/

Slope (Gated mode)

Input voltage range -10 to +10 V, into a 1 kΩ load

Threshold

Triggered mode

Minimum pulse width 10 ns, 0.2 V amplitude ; Triggered mode

Trigger hold off time ≤ 109.5 clocks + 500 ns ; Single operation

Delay to analog out, Typical 275.5clocks + 17 ns (Output: Norm, Filter: Through)

5

POS (positive) or NEG (negative)

-5 to +5 V, into a 50 Ω load

Level -5.0 V to 5.0 V

Resolution 0.1 V

See Figure 1-1 on page 1-11

≤ 109.5 clocks + 700 ns ; Synchronous operation

Gated mode See Figure 1-2 on page 1-12

Minimum pulse width 1152 clocks + 10 ns, 0.2 V amplitude

Gate hold off time ≤ 1920 clock + 20 ns (The time interval between the last gate off point and the next gaate on

point)

Delay to analog out, Typical (1355 to 1563.5) clocks + 9 ns (Output: Norm, Filter: Through)

5

The characteristics are specified at the end of the BNC cable (012–0482–00).

1-10 AWG615 Service Manual

Specifications

External Trigger

Analog output

(Filter: Through)

The option 02 doesn’t have offset and

lowpass filter function.

Delay between Analog output and Marker output

( Norm output : 2.4 ns typical,

Direct output : -1 ns typical )

Option 02 : 2 ns typical )

Trigger Hold off (109.5 clocks + 500 ns)

Delay to analog output (275.5 clocks + 17 ns)

1 Clock

Need more 200ns in synchronous operation

Need more 3 clocks in synchronous

operation

Marker output

( Marker Skew : <20 ps typical )

Figure 1-1: Signal Timing

m0 m1 m2 m3

AWG615 Service Manual 1-11

Specifications

1. After RUN starting, Gate signal is input

1-1. The interval of Gate signal is longer than PW

RUN start point

Gate Signal

(Minimum Pulse Width) x 2

min

PW

: 1152 clocks + 10 ns

min

Analog output

1-2. The interval of Gate signal is equal to PW

Gate Signal

Analog output

2. Before RUN starting, Gate signal is input

2-1. The interval of Gate signal is longer than PW

T > PW

min

x 2

Delay to Analog output

(1355 to 1563.5) clocks + 9 ns at 2.7 GS/s

(Minimum Pulse Width) x 2

min

PW

min

Interval = PW

min

The interval of Output is equal to PW

PW

min

(Minimum Pulse Width) x 2

min

RUN start point

x 2

min

Gate Signal

PW

min

Delay to Analog output

Analog output

PW

min

The only interval of 1st Output is equal to PW

2-2. The interval of Gate signal is equal to PW

As above 1-2, the interval of Analog Output is equal to PW

(Minimum Pulse Width) x 2

min

and the others are normal.

min

.

min

Figure 1-2: Gated Mode

1-12 AWG615 Service Manual

1. Sequence 1

1-1.

Event Input

Line No. Waveform Name Wait for Trigger Jump to

n: Waveform1 Off m (Waveform3)

n+1: Waveform2 Off m+1 (Waveform4)

m: Waveform3 Off --

m+1: Waveform4 Off --

Event Input Setup time (1152 clocks)

Jump Setup time (715 clocks)

Specifications

Analog Output

1-2

Event Input

Analog Output

Wavefor m1

Event Input Setup time (1152 clocks)

Jump Setup time (715 clocks)

Wavefor m1

Wavefor m2

Minimum Output

Interval (840 to 896 clocks)

Wave form2

Minimum Output

Interval (840 to 896 clocks)

Wavefor m3

Wavefor m4

Wavefor m3

Wavefor m4

Figure 1-3: Enhanced mode

AWG615 Service Manual 1-13

Specifications

2. Sequence 2

2-1.

Line No. Waveform Name Wait for Trigger Jump to

n: Waveform1 Off m (Waveform3)

n+1: Waveform2 Off m+1 (Waveform4)

m: Waveform3 On --

m+1: Waveform4 On --

Event Input

Analog Output

Event Input

Event Input Setup time (1152 clocks)

Jump Setup time (715 clocks)

Wavefor m1

Event Input Setup time (1152 clocks)

Jump Setup time (715 clocks)

Trigger

Wavefor m2

Minimum Output Wait Trigger Trigger Delay

Interval (840 to 896 clocks)

Trigger

Wavefor m3

Analog Output

Wavefor m1

Wavefor m2

Minimum Output Wait Trigger Trigger Delay

Interval (840 to 896 clocks)

Wavefor m4

Figure 1-4: Sequence 2

1-14 AWG615 Service Manual

3. Sequence 3

3-1.

Event Input

Specifications

Line No. Waveform Name Wait for Trigger Jump to

n: Waveform1 Off m (Waveform3)

n+1: Waveform2 On m+1 (Waveform4)

m: Waveform3 Off --

m+1: Waveform4 Off --

Event Input Setup time (1152 clocks)

Jump Setup time (715 clocks)

Analog Output

Event Input

Analog Output

Wavefor m1

Event Input Setup time (1152 clocks)

Jump Setup time (715 clocks)

Wavefor m1

Wavefor m2

Minimum Output

Interval (900 to 960 clocks)

Wait Trigger Trigger Delay

Wavefor m3

Trigger

Wavefor m3

Wavefor m2

Figure 1-5: Sequence 3

AWG615 Service Manual 1-15

Specifications

4

. Sequence 4

Line No. Waveform Name Wait for Trigger Jump to

n: Waveform1 Off m (Waveform3)

n+1: Waveform2 On m+1 (Waveform4)

m: Waveform3 On --

m+1: Waveform4 On --

4-1.

Event Input

Analog Output

Event Input Setup time (1152 clocks)

Jump Setup time (715 clocks)

Wavefor m1

Event Input Setup time (1152 clocks)

Trigger

Wavefor m2

Minimum Output Wait Trigger Trigger Delay

Interval (900 to 960 clocks)

Trigger

Wavefor m3

Event Input

Jump Setup time (715 clocks)

Analog Output

Wavefor m1

Wavefor m2

Minimum Output Wait Trigger Trigger Delay

Interval (900 to 960 clocks)

Wave form4

Figure 1-6: Sequence 4

1-16 AWG615 Service Manual

Specifications

Sync Clock

AWG615

Master Unit

Master Unit

AWG710B

C Out1

C Out1

C Out2

C Out2

T Out1

T Out1

T Out2

T Out2

C In

C In

T In

T In

C In

C In

C Out1

C Out1

C Out2

C Out2

T In

T In

T Out1

T Out1

T Out2

T Out2

AWG615

AWG710B

Slave Unit

Slave Unit

Sync Clock

LAN

Local

Ethernet

Network

Figure 1-7: The cable connection between units in Synchronous operation

LAN

SMA Cable (174-1427-00)

LAN Cable

AWG615 Service Manual 1-17

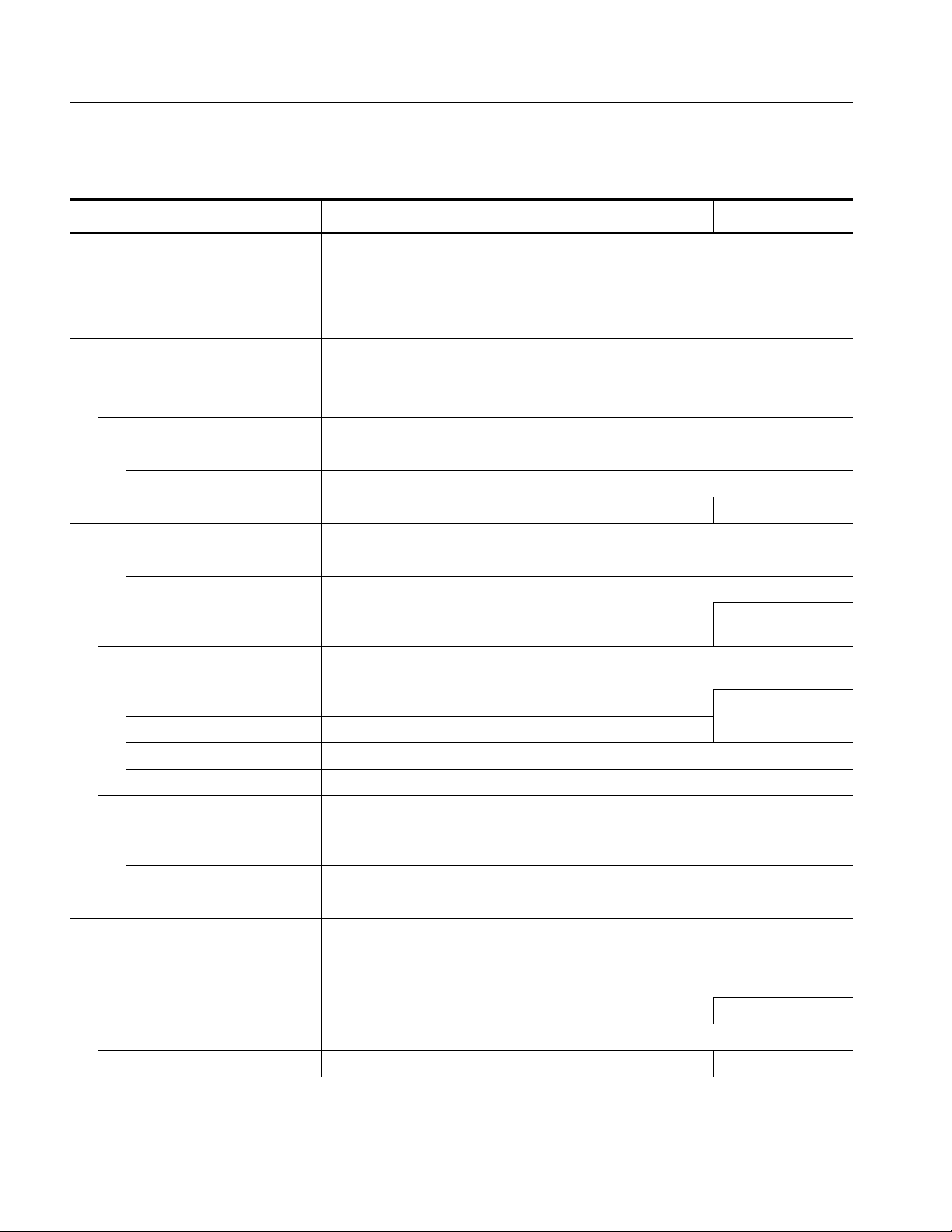

Specifications

(-1, -1.05)

VOL

4

Delay to analog output (211.5 clocks + 17 ns)

3

(2.45, 2.40)

2

1

1 Clock

(1.25, 0.0)

0

1 2 3 4 -1 -2 -3

-1

-2

VOH

(-1, -2)

-3

(-0.75, -2)

Figure 1-8: Output Voltage Window ( into 50Ω to GND ) of MARKER

1-18 AWG615 Service Manual

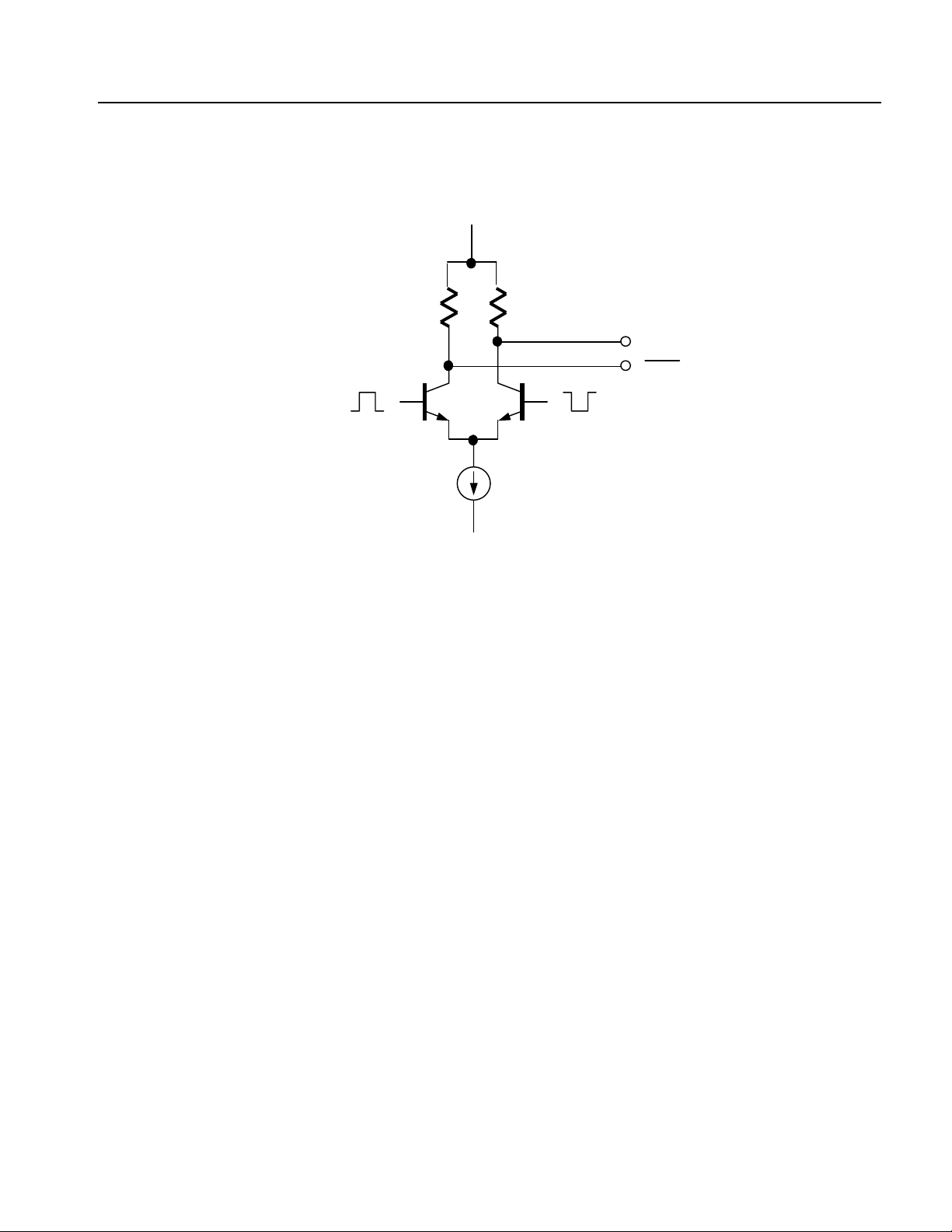

V

50

O

O

Ω

IH

50

Specifications

Ω

ut

ut

Figure 1-9: Output part equivalent circuit of MARKE

Marker output

AWG615 Service Manual 1-19

Specifications

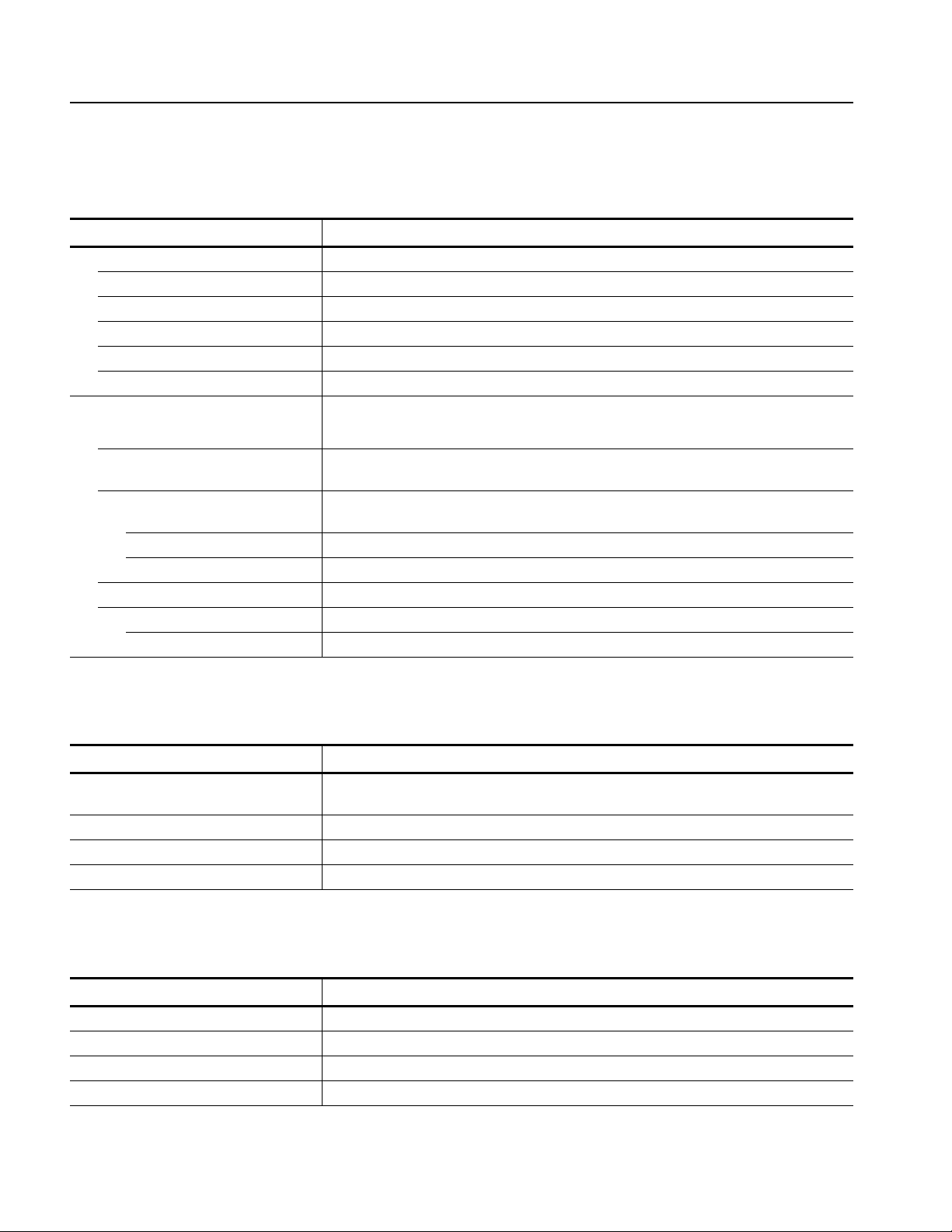

Table 1-14: Event Input

Characteristics Description

Connector 9–pin, D type on the rear panel

Number of events 7 bits

Input signal 7 event bits and Strobe

Threshold TTL level

Maximum input 0 V to + 5 V (DC + peak AC)

Impedance 1 kΩ, pull–up to +3.3 V

Enhanced mode

Minimum pulse width 320 clocks + 10 ns

Event hold off time (The time interval between the last event input point and the next acceptable event input point)

≤ 896 clocks + 20 ns

Delay to analog out, Typical

(Jump timing: ASYNC) (Output: Norm, Filter: Through)

Strobe: On 1691.5 clocks + 10 ns

Strobe: Off 1947.5 clocks + 6 ns

Event input to strobe input

Setup time 192 clocks + 10 ns

Hold time 192 clocks + 10 ns

Table 1-15: 10 MHz reference clock input

Characteristics Description

Input voltage range 0.2 V

to 3.0 V

p–p

(into a 50 Ω load, AC coupling)

p–p

Maximum ±10 V

Impedance 50 Ω, AC coupling

Frequency range 10 MHz ±0.1 MHz

Connector Rear panel BNC connector

Table 1-16: External clock input

Characteristics Description

Connector Rear panel SMA connector

Impedance 50 Ω, AC coupling

Required input voltage range swing 0.4 V

p–p

to 2 V

into a 50 Ω load

p-p

Required duty cycle 50 ±5 %

1-20 AWG615 Service Manual

Table 1-16: External clock input

Characteristics Description

Frequency range 125 MHz to 2.7 GHz

Note: Slew rate should be more than 10 mV/ns.

Table 1-17: C input

Characteristics Description

This signal is used for only Synchronous operation between Master and Slave unit.

Connector

Input signal type Complementary

Rear panel SMA connector

Table 1-18: T input

Specifications

Characteristics Description

This signal is used for only Synchronous operation between Master and Slave unit.

Connector

Input signal type Complementary

Rear panel SMA connect

AWG615 Service Manual 1-21

Specifications

Table 1-19: Function Generator (FG)

Characteristics Description

Operation Mode Continuous mode only

Waveform Shape Sine, Triangle, Square, Ramp, Pulse, DC

Frequency 1.000 Hz to 270.0 MHz

Amplitude

Range 0.020 V

( OPTION02 : 0.5 V

Resolution 1 mV

Offset (except option 02)

Range -0.500 V to +0.500 V, into a 50 Ω load

Resolution 1 mV

DC Level (except option 02) DC waveform only

Range -0.500 V to +0.500 V, into a 50 Ω load

Resolution 1 mV

Polarity Normal, Inverted

Duty

Range 0.1 % to 99.9 %

Resolution Frequency Resolution

1.000 Hz to 4.000 MHz 0.1 %

4.001 MHz to 20.00 MHz 0.5 %

20.01 MHz to 40.00 MHz 1.0 %

40.01 MHz to 80.00 MHz 2.0 %

80.01 MHz to 100.0 MHz 2.5 %

100.1 MHz to 160.0 MHz 4.0 %

160.1 MHz to 200.0 MHz 5.0 %

200.1 MHz to 270.0 MHz 10.0 %

Marker Out

Pulse Width

Mrker1 Hi : 0 % to 20 % of 1 waveform period

Lo : 20% to 100 % of 1 waveform period

Marker2 Hi : 0 % to 50 % of 1 waveform period

Lo : 50 % to 100 % of 1 waveform period

to 2.000 V

p–p

, into a 50 Ω load

p–p

to 1.0 V

p–p

, into a 50 Ω load )

p–p

Hi : 0 % to 52 % of 1 waveform period

Lo : 52 % to 100 % of 1 waveform period at frequency range is 100.1MHz to 160.0MHz

Level

Hi 1.0 V min into a 50 Ω load

Lo 0 V max into a 50 Ω load

1-22 AWG615 Service Manual

Table 1-20: Display

Characteristics Description

Display

Size 16 cm (6.4 in.) diag. LCD

Display area Horizontal: 130.6 mm (5.14 in)

Vertical: 97.0 mm (3.81 in)

Resolution 640 (H) × 480 (V) pixels

Table 1-21: AC line power

Characteristics Description

Rating voltage 100 VAC to 240 VAC, CAT II

Voltage range 90 VAC to 250 VAC

Frequency range 48 Hz to 63 Hz

Maximum consumption 240 VA

Maximum current 5 A