Page 1

xx

AWG5200 Series

Arbitrary Waveform Generators

ZZZ

Specifications and Performance Verification

Technical Reference

Rev A

Warning

The servicing instructions are for use by qualified personnel

only. To avoid personal injury, do not perform any servicing

unless you are qualified to do so. Refer to all safety summaries

before performing service.

www.tek.com

077-1335-01

Page 2

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are c overed by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O . B ox 50 0

Beaverto

USA

For product information, sales, service, and technical support:

n, OR 97077

In North America, call 1-800-833-9200.

Worldwide, visit www.tek.com to find contacts in your area.

Page 3

Table of Contents

General safety summary ........................ ................................ ................................ ... v

Service safety summary.......................................................................................... vii

Preface.............................................................................................................. ix

Related doc

Specifications .......... ................................ ................................ ............................. 1

Performance conditions ........................ ................................ ............................... 1

Electrical specifications ............................ ................................ ........................... 2

Mechanical characteristics ......................... ................................ .......................... 21

Environmental characteristics ......... ................................ ................................ ...... 23

Perform

Brief procedures ................................................................................................... 27

Perf

ance verification procedures ............................................................................ 25

Input and output options ..................................................................................... 26

Diagnostics .................................................................................................... 27

Calibration ......................... ................................ .................................. .......... 28

Functional test................................................................................................. 30

ormance tests........ ................................ .................................. ........................ 42

Prerequisites ............................... ................................ .................................. .. 42

Required equipment .......... .................................. ................................ .............. 42

Termination resistance measurement ........................... .................................. .......... 44

Analog amplitude accuracy . ... . . . ... . ... . .... . . ... . ... . .... .. ... . ... . .... . . ... . ... . .... .. ... . ... . .... . . ... . . 45

Analog offset accuracy (DC output paths) ................................................................. 51

alog DC Bias accuracy (AC output paths).............................................................. 54

An

Marker high and low level accuracy........................................................................ 58

10 MHz reference frequency accuracy ..................................................................... 63

Test record ..................................................................................................... 64

uments...................................... ................................ ...................... ix

AWG5200 Series Technical Reference i

Page 4

Table of Contents

List of Figure

Figure 1: Peripheral connections ................ .................................. .............................. 26

Figure 2: 1 G

Figure 3: Equipment connection to measure terminator resistance ...................... .................... 44

Hz output waveform....................................... ................................ ........ 38

s

ii AWG5200 Series Technical Reference

Page 5

List of Tables

Table 1: Run mode .......................... ................................ ................................ ....... 2

Table 2: Arbitrary waveform ......................... ................................ ............................. 2

Table 3: Real time digital signal processing..................................................................... 3

Table 4: Sequencer ........................ ................................ ................................ ......... 3

Table 5: Sample clock generator........................... ................................ ....................... 4

Table 6: Analog output skew..................... ................................ ................................. 4

Table 7: Signal output characteristics ............... ................................ ............................. 5

Table 8: Harmonic distortion (DC High

Table 9: Harmonic distortion (AC Direct output path)........................................................ 12

Table 10: Harmonic distortion (AC Amplified output path) ................................ .................. 12

Table 11: SFDR operating at 2.5 GS/s ................ ................................ .......................... 12

Table 12: SFDR operating at 5 GS/s ...................... .................................. .................... 13

Table 13: SFDR operating at 10 GS/s ................................. ................................ .......... 13

Table 14: Phase noise operating at 2.5 GS/s.... .................................. .............................. 14

Table 15: Phase noise operating at 5.0 GS/s or 10 GS/s with DDR enabled................................ 14

Table 16: Marker outputs ................. ................................ .................................. ...... 14

Table 17: 10 MHz Ref Out (reference output) ................................................................. 15

Table 18: Ref In (reference input) ............................................................................... 15

Table 19: Clock Out............................................................................................... 15

Table 20: Clock In..................... ................................ ................................ ............ 16

Table 21: Sync In........................ ................................ .................................. ........ 16

Table 22: Sync Out ................................................................................................ 16

Table 23: Sync Clock Out ........................ ................................ ................................ 17

Table 24: Trigger Inputs .......................................................................................... 17

Table 25: Pattern Jump In connector ................ ................................ ............................ 19

Table 26: Auxiliary Outputs (Flags). ... . ... . .... . . ... . ... . ... . ... . ... . .... .... . . ... . ... . ... . ... . ... . .... .... .. .. 20

Table 27: Computer

Table 28: Display.................................................................................................. 20

Table 29: Power supply... .................................. ................................ ...................... 20

Table 30: Mechanical characteristics............................................................................ 21

Table 31: Environmental characteristics ........................................................................ 23

Table 32: Required equipment for the functional test ......................... ................................ 30

Table 33: Required equipment for performance tests ..................... .................................. .. 42

Table 34: Analog amplitude accuracy (DC High BW output path). ... . ... . .... .. ... . ... . ... . . . ... . ... . ... . . 46

Table 35: Analog amplitude accuracy (DC High Volt output path). .. ... . ... . ... . .... .. ... . ... . ... . .... .. ... 50

Table 36: Offset accuracy ........ ................................ ................................ ................ 53

Table 37: Analog DC bias accuracy............................................................................. 56

Table 38: Marker high level accuracy..................... ................................ ...................... 60

Table of Contents

BW output path).................................................... 11

system .................. .................................. ................................ .. 20

AWG5200 Series Technical Reference iii

Page 6

Table of Contents

Table 39: Marke

r low level accuracy.............................................. .............................. 61

iv AWG5200 Series Technical Reference

Page 7

General safety summary

General safet

To avoid fir

e or personal

injury

y summary

Review the fo

this product or any products connected to it.

To avoid pot

Only qualified personnel should perform service procedures.

Use proper

certified for the country of use.

Ground th

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe all terminal ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

llowing safety precautions to avoid injury and prevent damage to

ential hazards, use this product only as specified.

power cord. Use only the power cord specified for this product and

e product. This product is grounded through the grounding conductor

Power disconnect. The power cord disconnects the product from the power source.

Do not block the power cord; it must remain accessible to the user at all times.

Do not operate without covers. Do not operate this product with covers or panels

removed.

Do not operate with suspected failures. If you suspect that there is damage to this

product, have it inspected by qualified service personnel.

Avoid exposed circuitry. Do not touch exposed connections and components when

power is present.

Do not operate in wet/damp conditions.

Do not operate in an explosive atmosphere.

Keep product surfaces clean and dry.

Provide proper ventilation. Refer to the manual's installation instructions for details

on installing the product so it has proper ventilation.

AWG5200 Series Technical Reference v

Page 8

General safety summary

Termsinthismanual

Symbols and terms on the

product

These terms may

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

These terms may a ppear on the product:

DANGER in

the marking.

WAR NI NG

read the marking.

CAUTIO

The following symbol(s) may appear on the product:

appear in this manual:

dicates an injury hazard immediate l y accessible as you read

indicates an injury hazard not immediately accessible as you

N indicates a hazard to property including the product.

vi AWG5200 Series Technical Reference

Page 9

Service safety summary

Service safet

ysummary

Only qualifie

safety summary and the General safety summary before performing any service

procedures.

Do not service alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

Use care when servicing with power on. Dangerous voltages or currents may exist

in this p

test leads before removing protective panels, soldering, or replacing components.

To avoi

d personnel should perform service procedures. Read this Service

roduct. Disconnect power, remove battery (if applicable), and disconnect

d electric shock, do not touch exposed connections.

AWG5200 Series Technical Reference vii

Page 10

Service s afety summary

viii AWG5200 Series Technical Reference

Page 11

Preface

Related documents

This manual contains specifications and performance verification procedures for

the AWG5200 Series Arbitrary Waveform Generators.

The following documents are also available for this product and can be

downloade

AWG5200 Series Installation and Safety Manual. This document provides

safety in

071-3529-xx.

d from the Tektronix website www.tek.com/manual/downloads.

formation and how to install the generator. Tektronix part number:

AWG5200 S

programming commands to remotely control the generator. Tektronix part

number: 077-1337-xx.

AWG5200 User Manual. This document is a printable version of the

AWG5200 help system. Tektronix part number: 077-1334-xx.

eries Programmer Manual. This document provides the

AWG5200 Series Technical Reference ix

Page 12

Preface

x AWG5200 Series Technical Reference

Page 13

Specifications

Performance conditions

This section contains the specifications for the AWG5200 series Arbitrary

Waveform Generators.

All specifications are typical unless noted as warranted. Warranted specifications

that are marked with the

To meet speci fications, the following conditions must be met:

The instrument must have been calibrated/adjusted at an ambient temperature

between +20 °C and +30 °C.

The instrument must be operating within the environmental limits. (See

Table 31 on page 23.)

The instrument must be powered from a sourc e that meets the specifications.

(See Table 29 on page 20.)

The instrument must have been operating continuously for at least 20 minutes

within the specified operating temperature range.

symbol are checked in this manual.

AWG5200 Series Technical Reference 1

Page 14

Specifications

Electrical sp

ecifications

Table 1: Run mode

Characteris

Continuous m

Triggered mode

Triggered

tics

ode

continuous mode

Description

An arbitrary

An arbitrar

is output, the instrument waits for the next trigger signal.

An arbitrary waveform is output continuously after a trigger signal is applied.

waveform is output continuously.

y waveform is output only once when a trigger signal is applied. After the waveform

Table 2: Arbitrary waveform

Characteristics Description

Waveform memory Real Waveforms: 2 Gs/channel

Complex waveforms: 1 Gs/channel

Minimum waveform size

Continuous run mode

Triggered run modes or sequence

Waveform granularity

Continuous run mode

Triggered run modes 1 sample

IQ (Complex) waveform support IQ waveforms, referred to as “Complex waveforms”, are supported for use with real time

1 sample

Real waveform: 2400 samples

Complex waveform: 1200 samples

Real waveforms are waveforms that have a single input value for each sample point. IQ

waveforms, referred to as “Complex waveforms”, use 2 values for each sample point.

1 sample

digital up-conversion and play out. The carrier signal is generated independently of the

waveform with an NCO (Numerically Controlled Oscillator).

The w aveform requires 2 values for each sample point. In the IQ waveform, I and Q

samples alternate in pairs or groups depending on the interpolation selection. The

format depends on the interpolation rate selected (2x or 4x)

2 AWG5200 Series Technical Reference

Page 15

Specifications

Table 3: Real ti

Characteristics Description

Double Data Rate Interpolation (DDR

Mode)

Digital Up-conversion (DIGUP license

required)

Waveform interpolation Real time interpolation of IQ (complex) waveforms is supported independently on each

Inverse SINC filter Real time correction of the sinx/x frequency roll off can be enabled or disabled

me digital signal processing

Enabling DDR mode increases the output sample rate to 5 to 10 GS/s (2*fclk) and

interpolates the input sample data by 2X to match the output rate. 2X interpolation is

required for

With DDR enabled, the output image moves from ( fclk - fout) to (2*fclk - fout). Because

the input data rate does not increase, the output bandwidth remains (fclk/2).

DDR is most u

to specify the output center frequency up to the DDR Nyquist frequency. When the

waveform is a traditional, real valued, waveform (not IQ), enabling DDR applies a low

pass filter a

(fclk/2) and (2*fclk - fclk/2).

The DAC system in each channel includes a digital IQ modulator and numerically

controlled oscillator (NCO ) that provides digital up-conversion to a specified carrier

frequenc

Digital up-conversion requires an IQ input waveform. In the IQ waveform I and Q

samples alternate in pairs or groups depending on the interpolation selection.

Digital u

interpolation w hen a lower waveform sample rate is needed.

channel during play out.

Suppor

Only IQ (complex) waveforms can be interpolated. The interpolation factor refers to the

sample rate of the complex pair of points relative to the global instrument sample rate

set by t

factor is 2, then the waveform sample rate of both I and Q samples is 2.5 GS/s. DDR

interpolation offers an additional doubling o f the sample rate.

indep

sample rates above 5.0 GS/s.

seful when combined with digital up-conversion which allows the user

t a frequency just below (fclk/2) so that no signal is generate between

y

p-conversion can only be used with sample rates between 2.5 and 5 GS/s. Use

ted interpolation rates are 2x and 4x.

he clock. For example if the sample rate is set to 5 GS/s and the interpolation

endently on each channel.

Table 4: Sequencer

Characteristics Description

Number of steps

Maximum repeat count

16,384

14 address bits. Numbers are zero-0 based in HW (0 to -16383).

1048576 (2

20

)

AWG5200 Series Technical Reference 3

Page 16

Specifications

Table 5: Sample

Characteristics Description

Sample rate The sample clock frequency is a global parameter that applies to all channels. DDR can be

DDR enabled:

DDR disabled

Sample rate resolution

Jitter Reduction Mode (PLL

integer mode)

Without Jitter Reduction (PLL

FracN mode)

Sample rate frequency

accuracy

10 MHz reference accuracy

clock generator

enabled on a per channel basis allowing the sam ple rate to be doubled on selected channels.

The sample cl

lower than 2.5 GS/s, the system replicates points. The number of replicated points increases

by powers of 2, therefore the clock frequency is SR×2

a frequency

When using complex waveforms digital up conversion, the sample rate is limited to 2.5 GS/s to

5 GS/s. To achieve lower sample rates, use waveform interpolation.

Real waveforms: 596 S/s to 10 GS/s

Complex (I

Real wave

Complex (IQ) waveforms: 2.5 GS/s to 5 GS/s

3 digits with jitter reduction (50 MHz sample clock frequency steps from 2.5 GHz to 5 GHz).

With DDR enabled, the resolution is 100 MHz Sample rates below the clock range are a power

of 2 div

the 50 MHz stepped frequencies.

8digit

Sample Rate * 10 MHz Ref Accuracy/10 MHz

Examp

10 MHz ± 20 Hz

perature between 0 to 50 °C; includes aging within 1 y ear of calibration.)

(Tem

ock frequency is always between 2.5 GHz and 5 GHz. To achieve sample rates

n

,. where n is an integer that results in

between 2.5 GHz and 5 GHz.

Q)waveforms: 5GS/sto10GS/s

forms: 298 S/s to 5 GS/s

ision of the clock frequency so Low Jitter sample rates are a power of 2 divisions of

s

le:5GS/s*(±20Hz)/10MHz=10kHz

Table 6: Analog output skew

Characteristics Description

Skew between (+) and (–) outputs

Skew between channels

(DC high BW mode only)

Delay change from DC High BW

output path to other output paths

DC High Volt

(Option HV)

AC Direct

AC Amplified

(Option AC)

Skew adjustment range

±15 ps

±25 ps

Skew is calibrated using the (+) outputs of the DC High BW output path for each channel.

Channel delay will change when a different path is selected or when various DAC features are

enabled.

1.2 ns

340 ps

740 ps

±2 ns

Used to adjust skew between channels in a single instrument.

4 AWG5200 Series Technical Reference

Page 17

Specifications

Table 6: Analog output skew (cont.)

Characteristics Description

Skew adjustment resolution 250 fs

Skew stability between channels

Sync out to channel < ±0.5 ps/ °C

Channel to channel < ±0.5 ps/ °C (±0.18 ps/ ° C @ 1 GHz)

Phase adjustment Used to adjust skew between all channels in an instrument relative to another instrument.

Range

Resolution

-8,640° to +8,640° of the DAC clock.

1° of the DAC clock.

Table 7

Characteristics Description

Connector type 2 SMA connectors per channel.

Number of outputs AWG5202: 2.

DAC

Type of outputs

ON/OFF control Independent control for each analog output channel.

Output impedance 50 Ω

: Signal output characteristics

AWG5204: 4.

208: 8.

AWG5

resolution

Output path

DC High BW (+) and (–) complementary (differential).

DC High Volt

(Option HV)

AC Direct Single ended output from the (+) connector.

AC Amplified

(Option AC)

16, 15, 14, 13 or 12 bits.

bling markers degrades resolution.

Ena

16-bit mode: 0 markers available.

15-bit mode: 1 marker, M1.

bit mode: 2 markers, M1, M2.

14-

13-bit mode: 3 markers, M1, M2, M3.

12-bit mode: 4 markers, M1, M2, M3, M4.

Includes a variable gain, high bandwidth, DC coupled amplifier in the signal path.

(+) and (–) complementary (differential).

An additional amplifier adds high amplitude with reduced bandwidth.

A direct connection to the DAC output including a balun to reduce common mode distortion.

The AC Direct path offers the lowest noise and distortion performance.

Single ended output from the (+) connector.

Includes an amplified path and a passive variable attenuator path to provide a large output

amplitude range.

AWG5200 Series Technical Reference 5

Page 18

Specifications

Table 7: Signal output characteristics (cont.)

Characteristics Description

VSWR/return loss

Output path

DC High BW

(Includes option DC)

AC Direct 10 MHz to 1 GHz < 1.6:1.

AC Amplified

(Option AC)

Output Modes

NRZ

RZ

MIX Mode

Sin(x)/x Bandwidth 4.44 GHz * fsample ÷ 10 GS/s (DDR Mode).

Amplitude control

Amplitude range

Output path

DC High B W 25 mV

DC High BW

(Option DC)

DC High Volt

(Option HV)

DC to 1 GHz < 1.4:1.

1 GHz to 3 GHz < 1.6:1.

3 GHz to 4 GHz < 2.0:1.

1 GHz to 4 GHz < 2.0:1.

10 MHz to 1 GHz < 1.4:1.

2 GHz to 4 GHz < 1.5:1.

In NRZ mode, each sample is held for the entire sam ple period (1/sample rate). This results

in the familiar sin(x)/x frequency response. With DDR mode enabled, the sin(x)/x bandwidth

doubles.

In RZ mode, each sample is held for half of the sample period. This doubles the sin(x)/x

bandwidth, but reduces the amplitude by half. This may be useful when playing a real

waveform with the signal in the second Nyquist zone. For real waveforms, DDR mode filters

the signal in the 2nd and 3rd Nyquist zones and is not useful in this case.

In Mix mode, each sample is inverted for the second half of the sample period. This is

effectively like mixing the output waveform with the sample clock. This boosts the signal in

the s econd Nyquist zone, but zeros the DC component of the waveform and reduces low

frequency components. This may be useful when playing a real waveform with the signal in

the second Nyquist zone. For real waveforms, DDR mode filters the signal in the 2nd and 3rd

Nyquist zones and is not useful in this case.

fsample = sample rate.

The sin(x)/x bandwidth can be solved by using the following equation:

20 * log (sin(x)/x) = –3.

x=π * fout ÷ fsample.

fsample = sample rate.

fout = sin(x)/x bandwidth.

Independent amplitude control for all channels.

Units of dBm or V can be selected.

50 mV

25 mV

50 mV

10 mV

20 mV

to 750 mV

p-p

to 1.5 V

p-p

to 1.5 V

p-p

to 3.0 V

p-p

to 5 V

p-p

to 10.0 V

p-p

into 50 Ω single-ended.

p-p

into 100 Ω differential.

p-p

into 50 Ω single-ended.

p-p

into 100 Ω differential.

p-p

into 50 Ω single-ended.

p-p

into 100 Ω differential.

p-p

6 AWG5200 Series Technical Reference

Page 19

Table 7: Signal output characteristics (cont.)

Characteristics Description

AC Direct

AC Amplified

(Option AC)

Amplitude adjustment resolution

Output paths

DC High BW

DC High Volt

(Option HV)

AC Direct

AC Amplified

(Option AC)

DC amplitude accuracy

Output path

DC High BW Amplitude < 100 mV: ±(5% of amplitude).

igh Volt

DC H

(Option HV)

AC amplitude accuracy

Output path

AC Direct 0.5 dB at 100 MHz (0 °C to 45 °C)

AC Amplified

(Option AC)

DC Offset range

Output path

DC High BW ± 2 V into 50 Ω to ground.

DC High Volt

(Option HV)

DC Offset resolution

Output path

DC High BW

DC High Volt

(Option HV)

–17 dBm to –5 dBm.

10 MHz to 3.5 GHz.

–85 dBm to 10 dBm (10 MHz to 3.5 GHz.)

–50 dBm to 10 dB m (3.5 GHz to 5 GHz.)

Amplitude accuracy and flatness degrades at frequencies beyond 3.5 GHz and below –50 dBm

output amplitude. It is not recommended to operate in this region.

1.1 mV or 0.1 dB.

1.1 mV or 0.1 dB.

0.1 dB

0.1 dB

Within ±5 °C of internal self calibration temperature.

Amplitude 100 mV to 750 mV: ±(2% of amplitude).

litude 100 mV to 1.5 V (Option DC): ±(2% of amplitude).

Amp

litude < 160 mV: ±(5% of amplitude).

Amp

Amplitude 160 mV to 5 V: ±(2% of amplitude).

1 dB at 100 MHz (45 °C to 50 °C)

0.5dBat100MHz(0°Cto45°C)

1 dB at 100 MHz (45 °C to 50 °C)

± 4 V into high resistance or m atching voltage termination.

±2Vinto50Ω to ground.

± 4 V into high resistance or m atching voltage termination.

1mV

1mV

Specifications

AWG5200 Series Technical Reference 7

Page 20

Specifications

Table 7: Signal output characteristics (cont.)

Characteristics Description

DC Offset accuracy Differential offset is sensitive to output amplitude setting.

Within ±5 °C of internal self calibration temperature.

Common mode = ((OutP + OutN)/2).

Differential Mode = (OutP - OutN).

Output path

DC High BW

Common mo

(Warranted)

Differential mode ±25 mV; into 100 Ω differential.

DC High Volt

(Option HV)

Common mode

(warranted)

Differential mode ± 88 mV; Into 100 Ω differential.

AC output DC bias range

Output path

AC Direct

AC Amplified

(Option AC)

AC DC bias resistance

Output path

AC Direct 1 Ω

AC Amplified

(Option AC)

AC DC bias accuracy

(warranted)

Output path

AC Direct ±(2% of bias + 20 mV); into an open circuit (zero load current).

AC Amplified

(Option AC)

de

±(2% of |offset| + 10 mV); into 50 Ω to G nd.

±(2% of |offset| + 1% of amplitude + 20 mV).

± 5 V at 150 mA.

± 5 V at 150 mA.

1 Ω

±(2% of bias + 20 mV); into an open circuit (zero load current).

8 AWG5200 Series Technical Reference

Page 21

Table 7: Signal output characteristics (cont.)

Characteristics Description

Analog bandwidth

Output path

DC High BW

DC High BW

(Option DC)

DC High Volt

(Option HV)

AC Direct 10 MHz - 2 GHz (–3 dB bandwidth).

AC Amplified

(Option AC)

Rise/fall time Rise and fall times only apply to DC output paths.

Output path

DC High BW

DC High BW

(Option DC)

DC High Volt

(Option HV)

Step response aberrations Step response aberrations only apply to DC output paths.

Output path

DC High BW < 16%

DC High BW

(Option DC)

DC High Volt

(Option HV)

Analog bandwidth is measured with the ideal sin(x)/x response curve of the DAC

mathematically removed from the measured data.

At 750 mV

single ended:

pp

DC - 2 GHz (–3 dB bandwidth).

DC - 4 GHz (–6 dB bandwidth).

At 1.5 V

single ended:

pp

DC - 1.3 GHz (–3 dB bandwidth).

The analog bandwidth degrades as the amplitude is increased beyond 750 mV.

At 2 V

single-ended:

pp

DC – 370 MHz (–3 dB bandwidth).

At 4 V

single-ended:

pp

DC – 200 MHz (–3 dB bandwidth).

10 MHz - 4 GHz (–6 dB bandwidth).

10 MHz - 2 GHz (–3 dB bandwidth).

10 MHz - 4 GHz (–6 dB bandwidth).

< 110 ps at 750 mV

< 180 ps at 1.5 V

<1.3ns,at5V

<1.1ns,at4V

<0.8ns,at3V

<0.6ns,at2V

, at 750 mVppsingle ended.

pp

< 16%

,at1.5Vppsingle ended.

pp

single ended.

pp

single ended.

pp

single-ended.

pp

single-ended.

pp

single-ended.

pp

single-ended.

pp

< 10%pp,at5Vppsingle ended.

Specifications

AWG5200 Series Technical Reference 9

Page 22

Specifications

Table 7: Signal output characteristics (cont.)

Characteristics Description

Harmonic distortion

Output path

DC High BW (See Table 8 on page 11.)

AC Direct (See Table 9 on page 12.)

AC Amplified

(Option AC)

ENOB

(See Table 10 on page 12.)

SFDR SFDR is the difference in dB between a CW carrier signal and the largest spur, excluding

harmonics, within a defined frequency range around the carrier. Measured with a balun and

h output amplitude set to 500 mV.

wit

erating at 2.5 GS/s

Op

erating at 5 GS/s

Op

perating at 10 GS/s

O

Phase noise

Operating at 2.5 GS/s (See Table 14 on page 14.)

Operating at 5 GS/s or

10 GS/s with DDR enabled

ee Table 11 on page 12.)

(S

ee Table 12 on page 13.)

(S

See Table 13 on page 13.)

(

(See Table 15 on page 14.)

10 AWG5200 Series Technical Reference

Page 23

Specifications

Table 8: Harmon

ic distortion (DC High BW output path)

DC High BW output path

At 500 mV

pp

2nd harmonic

(Differenti

al or with a balun)

10MHzto1GH

1GHzto1.5G

1.5 GHz to 4

GHz

2nd harmonic

(Single e

nded)

10 MHz to 500 MHz < –55 dBc

500 MHz to 1 GHz

1GHzto4GHz

3rd harmonic

o 750 MHz

to 1.2 GHz

zto2GHz

At 1.5 V

10 MHz t

750 MHz

1.2 GH

pp

2nd harmonic

(Differential or with a balun)

10 MHz to 500 MHz < –55 dBc

500 MHz to 1 GHz

1GHzto4GHz

d harmonic

2n

(Single ended)

MHz to 500 MHz

10

00MHzto1GHz

5

GHzto4GHz

1

3rd harmonic

10 MHz to 500 MHz < –33 dBc

500 MHz to 1 GHz

1GHzto4GHz

Hz

z

< –65 dBc

< –60 dBc

< –50 dBc

< –48 dBc

< –30 dBc

< –65 dB

c

< –50 dBc

< –40 dBc

5 dBc

<–4

5 dBc

<–3

38 dBc

<–

< –25 dBc

< –20 dBc

< –25 dBc

< –20 dBc

AWG5200 Series Technical Reference 11

Page 24

Specifications

Table 9: Harmon

AC Direct output path

At –5 dBm

2nd harmonic

10MHzto4GHz

3rd harmonic

10 MHz to 500

500 MHz to 4

ic distortion (AC Direct output path)

< –65 dBc

MHz

GHz

< –75 dBc

< –65 dBc

Table 10: Harmonic distortion (AC Amplified output path)

AC Amplified output path

At –5 dBm

2nd harmonic

10MHzto4GHz

10MHzto4GHz

10MHzto4GHz

3rd harmonic

10 MHz to 500 MHz < –75 dBc at Pout = –15 dBm

500 MHz to 4 GHz

10MHzto4GHz

10MHzto4GHz

< –65 dBc at Pout = –15 dBm

< –50 dBc at Pout = 0 dBm

< –26 dBc at Pout = 10 dBm

< –65 dBc at Pout = –15 dBm

< –48 dBc at Pout = 0 dBm

< –28 dBc at Pout = 10 dBm

le 11: SFDR operating at 2.5 GS/s

Tab

Output paths

DC High BW

High Voltage

DC

AC Direct

AC Amplified

In band performance Out of band performance

Output frequency

100 MHz 10 – 500 MHz –80 dBc

10 – 625 MHz 10 – 625 MHz –70 dBc

0.01–1.0GHz 0.01–1GHz

1.0 – 1.25 GHz 1 – 1.25 GHz

Measured across

Specification

–60 dBc

–60 dBc

Measured across

0.01 – 1.25 GHz

0.01 – 1.25 GHz

0.01 – 1.25 GHz

0.01 – 1.25 GHz

Specification

–72 dBc

–62 dBc

–58 dBc

–54 dBc

12 AWG5200 Series Technical Reference

Page 25

Specifications

Table 12: SFDR o

Output paths

DC High BW

DC High Voltage

AC Direct

AC Amplified

Output frequency

100 MHz

0.01 – 1.25 GHz 0.01 – 1.25 GHz

0.01–2.0GHz 0.01–2.0GHz

2.0 – 2.5

1

Measured with a balun, excluding harmonics.

Table 1

3: SFDR operating at 10 GS/s

Output path

AC Dire

Output frequency

perating at 5 GS/s

GHz

ct

In band performance Out of band performance

Measured ac

0.01 – 1.0 G

2.0 – 2.5

In band performance Out of band performance

Measu

ross

Hz

GHz

red across

Specification

–80 dBc

–70 dBc

–60 dBc

–60 dBc

Specification

Measured ac

0.01 – 1.25

0.01 – 1.25 GHz

0.01 – 1.25 GHz

0.01 – 1.

Measu

ross

GHz

25 GHz

red across

Specification

–72 dBc

–62 dBc

–58 dBc

–54 dBc

Specification

100 MHz

0.01 – 1.25 GHz 0.01 – 1.25 GHz

0.01–2.0GHz 0.01–2.0GHz

0–3.5GHz

2.

3.5 – 4.0 GHz 3.5 – 4.0 GHz

Output path

AC Amplified

2.0 – 3.5 GHz 2.0 – 3.5 GHz

3.5 – 4.0 GHz 3.5 – 4.0 GHz

Output path

DC High BW

2.0 – 3.5 GHz 2.0 – 3.5 GHz

3.5 – 4.0 GHz 3.5 – 4.0 GHz

2.0 – 3.5 GHz 2.0 – 3.5 GHz

3.5 – 4.0 GHz 3.5 – 4.0 GHz

0.01

0–3.5GHz

2.

0 dBm amplitude

1

500 mV amplitude, measured single ended

1.5 V amplitude, measured single ended

–1.0GHz

–80 dBc

–70 dBc

dBc

–60

–60 dBc

–56 dBc

50 dBc

–

–46 dBc

–60 dBc

–56 dBc

–60 dBc

–56 dBc

–5GHz

0.01

0.01 – 5 GHz

0.01 – 5 GHz

01 – 5 GHz

0.

0.01 – 5 GHz

0.01 – 5.0 GHz

0.01 – 5.0 GHz

0.01 – 5.0 GHz

0.01 – 5.0 GHz

0.01 – 5.0 GHz

0.01 – 5.0 GHz

–72 dBc

–62 dBc

dBc

–58

–54 dBc

–50 dBc

44 dBc

–

–44 dBc

–54 dBc

–50 dBc

–54 dBc

–50 dBc

AWG5200 Series Technical Reference 13

Page 26

Specifications

Table 14: Phase

noise operating at 2.5 GS/s

Analog output frequency

Offset frequency 100 MHz 1 GHz

100 Hz

1kHz

10 kHz

100 kHz

1MHz

10 MHz

–112 dBc/Hz –92 dBc/Hz

–132 dBc/Hz –110 dBc/Hz

–136 dBc/Hz –117 dBc/Hz

–134 dBc/Hz –114 dBc/Hz

–144 dBc/Hz –124 dBc/Hz

–160 dBc/Hz –150 dBc/Hz

Table 15: Phase noise operating at 5.0 GS/s or 10 GS/s with DDR enabled

Analog output frequency

Offset 100 MHz 1 GHz 2 GHz 4 GHz

100 Hz

1kHz

10 kHz

100 kHz

1MHz

10 MHz

–112 dBc/Hz –92 dBc/Hz –86 dBc/Hz –80 dBc/Hz

–132 dBc/Hz –110 dBc/Hz –105 dBc/Hz –99 dBc/Hz

–138 dBc/Hz –118 dBc/Hz –112 dBc/Hz –106 dBc/Hz

–138 dBc/Hz –118 dBc/Hz –112 dBc/Hz –106 dBc/Hz

–148 dBc/Hz –128 dBc/Hz –122 dBc/Hz –116 dBc/Hz

–160 dBc/Hz –150 dBc/Hz –140 dBc/Hz –140 dBc/Hz

Table 16: Marker outputs

Characteristics Description

Connector type SMA on rear panel.

Number of outputs

Type of output Single ended.

ON/OFF Control Independent control for each marker.

Output impedance 50 Ω

Output voltage Independent control for each m arker.

Amplitude range

Window

Resolution 0.1 mV

External termination voltage –1.0 V to +3.5 V.

Maximum output current 60 mA

DC accuracy (warranted)

Rise/fall time < 150 ps (20% to 80% of swing when High = 0.4 V, Low = –0.4 V).

Aberrations

Random jitter

4 per channel.

Output voltage into RLOAD [Ω] to GND is approximately (2 * RLOAD / (50 + RLOAD) ) times of

voltage setting.

0.2 V

to 1.75 V

p-p

into 50 Ω.

p-p

–0.5 V to 1.7 V into 50 Ω.

±(10% of |output high or low setting| + 25 mV) into 50 Ω.

< 20%

for the first 1 ns following the step transition w ith 100% reference at 10 ns.

p-p

5ps

14 AWG5200 Series Technical Reference

Page 27

Table 16: Marker outputs (cont.)

Characteristics Description

Sample rate 2.5 GS/s to 5 GS/s.

Minimum pulse width 400 ps

2 Samples at 5 GS/s.

Maximum data rate

Skew between markers

(From the same channel)

Variable delay control

Range ±2 ns

Resolution 1 ps

Accuracy

2.5 Gb/s.

Minimum pulse width does not support data output at maximum sample rate.

±25 ps

Independent control for each marker.

±25 ps from delay value.

Table 17: 10 MHz Ref Out (reference output)

Characteristics Description

Connector type SMA on rear panel.

Output impedance 50 Ω (AC coupled).

Amplitude

Frequency (warranted)

+4 dBm, ±2 dBm. Sine wave output.

Within ±(1 ppm + Aging), Aging: ±1 ppm per year.

(Temperature between 0 °C to 50 °C.)

Specifications

Table 18: Ref In (reference input)

Characteristics Description

Connector type SMA on rear panel.

Input impedance

Input amplitude –5 dBm to +5 dBm.

Fixed frequency range

Variable frequency range

50 Ω (AC coupled).

10 MHz, ±40 Hz.

35 MHz to 240 MHz.

Acceptable frequency drift while the instrument is operating is ± 0.1%.

Table 19: Clock Out

Characteristics Description

The external clock output is a copy of an internal clock generator that is used to create the

DAC sample clock. This clock always operates in the

multiplied and divided to create the effective DAC sampling rate.

Connector type SMA on rear panel.

Output impedance 50 Ω AC coupled.

Output amplitude

+3 dBm to +10 dBm.

octave range specified below. It is

AWG5200 Series Technical Reference 15

Page 28

Specifications

Table 19: Clock Out (cont.)

Characteristics Description

Frequency range

2.5GHzto5GHz.

For sample rates lower than 2.5 GS/s the output frequency is: Fout = SR * 2n ; where n is an

integer that gives Fout between 2.5 GHz and 5 GHz.

Frequency resolution

Internal and fixed reference

clock operation

External variable reference

clock operation

With jitter reduction: 50 MHz.

Without jitter reduction: 100 MHz ÷ 2

With jitter reduction: Fref ÷ R.

Without jitter reduction: Fref ÷ R ÷ 2

Fref = reference clock frequency

R = 4 when 140 MHz < Fref ≤ 240 MHz

R = 2 when 70 MHz < Fref ≤ 140 MHz

R = 1 when 35 MHz ≤ Fref ≤ 70 MHz

Table 20: Clock In

20

.

20

Characteristics Description

The external clock input can be used to create the DAC

operate in the octave range specified below. It is multiplied and divided to create the actual

DAC sample clock.

Connector type SMA on rear panel.

Input impedance

50 Ω (AC coupled).

Input amplitude 0 dBm to +10 dBm.

Frequency range

2.5GHzto5GHz.

Acceptable frequency drift while the instrument is operating is ±0.1%.

Table 21: Sync In

Characteristics Description

Connector type SMA on rear panel.

Input impedance

Input amplitude 2.5 V

Frequency

500 Ω (AC coupled)

Max

p-p

Clock output ÷ 32.

Table 22: Sync Out

Characteristics Description

Connector type SMA on rear panel.

Output impedance 50 Ω (AC coupled).

Output amplitude 1 V

Frequency

, ±20% into 50 Ω.

p-p

Clock output ÷ 32.

sample clock. This clock must always

16 AWG5200 Series Technical Reference

Page 29

Specifications

Table 23: Sync C

lock Out

Characteristics Description

Connector type SMA on rear panel.

Output impedance 50 Ω (AC coupled).

Output amplitude 0.85 V to 1.25 V

Frequency

Clock output ÷ 32.

p-p

Table 24: Trigger Inputs

Characteristics Description

Number of inputs 2 (A and B)

On 2 and 4 channel instruments, only one trigger is usable for asynchronous triggering. On 8

channel instruments, both triggers can be used.

Connector SMA on rear panel.

Trigger modes

Input impedance

Slope / Polarity

Input voltage range

1kΩ selected

50 Ω selected

Input voltage minimum amplitude 0.5 V

Threshold control

Range –5.0 V to 5.0 V.

Resolution 0.1 V

Accuracy

Minimum pulse width 20 ns

Synchronous and Asynchronous, selectable.

When asynchronous trigger mode is selected, playback starts on the next qualified sample

clock edge. If the trigger pulse has no fixed timing relationship with the sample clock, then

delay jitter w ill vary by 1 clock cycle.

When synchronous mode is selected, playback starts on the next qualified Sync Clock edge

(Clock ÷ 32). If the trigger pulse is made synchronous with the Sync Out clock, then very low

delay jitter is possible. Using the Sync Out clock provides a larger setup time for the trigger

pulse so that stable triggering can be achieved.

1kΩ or 50 Ω selectable, DC coupled.

Positive or negative, selectable

–10Vto10V.

<5V

RMS

p-p

± 5% of setting + 0.1 V.

into 50 Ω.

AWG5200 Series Technical Reference 17

Page 30

Specifications

Table 24: Trigger Inputs (cont.)

Characteristics Description

Delay to analog output

Asynchronous trigger mode

Synchronous trigger mode 8275 / fclk + 30 ns ±20 ns

Hold off

Jitter, asynchronous mode

1kΩ selected 440 ps

50 Ω selected 420 ps

Jitter, synchronous mode

Trigger synchronized to

Internal or Ext Clock

Trigger synchronized to

Variable Reference

Trigger synchronized to Fixed

10 MHz Reference

The DAC sampling clock frequency is displayed on the clock settings tab when the external

clock output is enabled.

8760/ fclk +68 ns ± 20 ns.

(1.820 μsat5GS/s)

(3.572 μsat5GS/s)

fclk is the frequency of the DAC sampling clock. The DAC sampling clock frequency is

displayed on the clock settings tab when the external clock output is enabled.

(1.685 μs at 5 GS/s.)

(3.340 μs at 2.5 GS/s.)

fclk is the frequency of the DAC sampling clock. The DAC sampling clock frequency is

displayed on the clock settings tab when the external clock output is enabled.

>2 μs

Trigger hold off is the amount of delay required at the end of a waveform before another trigger

pulse can be processed.

The asynchronous jitter performance is directly proportional the frequency of the DAC sampling

clock. The DAC sampling clock frequency is displayed on the clock settings tab when the

external clock output is enabled.

for 2.5 GHz DAC sampling clock.

p-p

240 ps

220 ps

300 fs

400 fs

1.7 ps

for 5 GHz DAC sampling clock.

p-p

,24ps

p-p

,14ps

p-p

rms

rms

rms

for 2.5 GHz DAC sampling clock.

rms

for 5 GH z DAC sampling clock.

rms

18 AWG5200 Series Technical Reference

Page 31

Specifications

Table 25: Patte

Characteristics Description

Connector type 15-pin D-sub female connector on rear panel.

Input signal

put levels

In

Input impedance

Number of jump destinations

Strobe

Polarity Data is clocked in on negative edge.

Minimum pulse width 64 ns

Setup and hold Setup: 5 ns.

Holdoff time

rn Jump In connector

pin assignment

Pin assignm

1

2 Data bit 0, input

3 Data bit 1, input

4Databit2

5

6

7

8

9

10 Data bit 4, input

11 Da ta b

12 Data bit 6, input

13 Data bit 7, input

14

15

3.3 V LVCMOS.

5VTTLcompliant.

1kΩ resistor pull down to GND.

256

Hold: 5 ns.

>18 μs

Strobe hold off is the amount of delay required at the end of a waveform before another strobe

pulse can be processed.

ents

GND

, input

Data bit 3, input

GND

Strobe, input

GND

GND

it 5, input

GND

GND

AWG5200 Series Technical Reference 19

Page 32

Specifications

Table 26: Auxil

Characteristics Description

Connector type SMB on rear panel.

Number of outputs AWG5202 and AWG5204: 4

Output impedance 50 Ω

Output Amplitude High: 2.0 V into 50 Ω.

Maximum to

iary Outputs (Flags)

ggle frequency

AWG5208: 8

Low: 0.7 V w

<11 MHz

It will tr

hen sinking 10 mA.

ack the sequencer step rate.

Table 27: Computer system

Characteristics Description

CPU Intel core I7-4700EQ, 4 core, 2.4 GHz, 6M cache.

Memory

Hard disk drive

Video output

ESATA 1 port on rear panel, 1.5 Gb/s.

USB 4 ports, USB 3.0, rear panel, type A connector.

GPIB An optional GPIB to USB Adapter enables GPIB control through a USB B port

Video output

LAN

16 GB (2 x 8 GB), DDR3-1600 or faster SODIMM.

Solid state, ≥1 TB, removable.

1 VGA port on rear panel.

Instrument must be powered down to make connection.

2 ports, USB 2.0, front panel, type A connector.

The control interface is incorporated into the instrument user interface.

1 VGA port on rear-panel.

RJ-45 LAN connector supporting 10/100/1000 Ethernet on rear panel.

Table 28: Display

Characteristics Description

Display area

Resolution 1024 X 768 pixels

Touch s creen Built-in touch screen

132 mm X 99 mm (5.2 in X 3.9 in, 6.5 in diagonal)

Table 29: Power supply

Characteristics Description

Source voltage and frequency

Rating voltage 100 VACto 240 VAC.

Frequency range 50 Hz to 60 Hz.

Power consumption 750 W maximum.

WARNING. To reduce the risk of fire and shock, ensure that the mains supply voltage

fluctuations do not exceed 10% of the operating voltage range.

20 AWG5200 Series Technical Reference

Page 33

Mechanical characteristics

Table 30: Mechanical characteristics

Characteristics Description

Net weight

AWG5202 AWG5204 AWG5208

Without pac

With packag

Dimensions, with feet and handles

Height

Width

Length

Cooling method Forced-air circulation with no air filter.

Cooling clearance

Top 0 in

Bottom 0 in

Left side 50 mm (2 in)

Right side

Rear 0 in

kage

e

44 lb (19.96 kg) 45.45 lb (20.62 kg), 50.7 lb (23 kg),

46.35 lb (21.02 kg) 47.75 lb (21.66 kg) 53 lb (24.04 kg)

153.6 mm (6.05 in)

460.5 mm (18.13 in)

603 mm (23.76 in)

50 mm (2 in)

Specifications

AWG5200 Series Technical Reference 21

Page 34

Specifications

22 AWG5200 Series Technical Reference

Page 35

Environmental characteristics

Table 31: Environmental characteristics

Characteristics Description

Temperature

Operating 0 °C to +50 °C (+32 °F to 122 °F)

Nonoperati

Relative humidity

Operating 5% to 90% relative humidity at up to +30 °C (+86 °F).

Nonoperating

Altitude

Operating Up to 3,000 m (approximately 10,000 feet).

Nonope

ng

rating

–20 °C to +60 °C (-4 °F to 140 °F) w ith 30 °C/hour (86 °F/hour) maximum gradient, with

no media installed in disc drives.

5% to 45% relative humidity above +30 °C (+ 86 °F) up to +50 °C (122 °F) noncondensing.

5% to 90% relative humidity at up to 30 °C.

5% to 45% r

Maximu

(4921 ft).

Up to 12,000 m (approximately 40,000 feet).

elative humidity above +30 °C (+86 °F) up to +60 °C (140 °F) noncondensing.

m operating temperature decreases 1 °C (34 °F) each 300 m (984 ft) above 1.5 km

Specifications

AWG5200 Series Technical Reference 23

Page 36

Specifications

24 AWG5200 Series Technical Reference

Page 37

Performance verification procedures

Two types of performance verification procedures can be performed on the

instrument: Brief Procedures and Perform ance Tests. You may not need to

perform all o

To rapidly confirm that the instrument functions and was adjusted properly,

perform Dia

Advantages: These procedures are quick to do and require no external equipment

or signal s

testing to provide high confidence that the instrument will perform properly.

f these procedures, depending on what you want to accomplish.

gnostics and Calibration.

ources. These procedures perform extensive functional and accuracy

To furthe

and then perform Functional Test.

Advanta

requires minimal equipment. The procedure can be used when the instrument is

first received.

If more extensive confirmation of performance is desired, complete the self

tests and functional test, and then do the Performance Tests.

Advantages: These procedures add d irect checking of warranted specifications.

These procedures require specific test equipment. (See page 42, Required

equipment.)

If you are not familiar with operating this instrument, refer to the online help or

the user information supplied with the instrument.

r check functionality, first perform Diagnostics and Calibration,

ges: The procedure requires minimal additional time to perform, and

AWG5200 Series Technical Reference 25

Page 38

Performance verification procedures

Input and output options

The instrument has two USB ports on the front panel, and four USB ports on the

rear panel. (See Figure 1.) These ports can be used for an external mouse and/or

keyboard. Additionally, an external video display can be connected to the VGA

display port on the rear panel.

Figure 1

: Peripheral connections

26 AWG5200 Series Technical Reference

Page 39

Brief procedures

Brief procedu

Diagnostics

res

There are thr

basic functionality and proper adjustment:

Diagnostics

Calibration

Functional test

The following steps run the internal routines that confirm basic functionality

and proper adjustment.

Equipment Prerequisites

None None

1. Disconnect all the cables from the output channels.

2. From the Utilities tab, select Diag & Cal.

3. Click the Diagnostics & Calibration button and then select Diagnostics.

ee procedures in this section that provide a quick way to confirm

4. In the Diagnostics dialog box, confirm that all the check boxes are selected. If

they are not all selected, click the Select all tests button.

AWG5200 Series Technical Reference 27

Page 40

Brief procedures

Calibration

5. Click the Start

The internal diagnostics perform an exhaustive verification of proper

instrument fu

verification is completed, the resulting status will appear in the dialog box.

6. Verify that

complete.

7. Click the Cl

Equipment Prerequisites

None Power on the instrument and allow a

1. From the Utilities tab, select System.

2. From the Utilities tab, select Diag & Cal.

Click the Diagnostics & Calibration button and then select Calibration.

button to execute the diagnostics.

nction. This verification may take several minutes. When the

Pass appears as Status in the dialog box when the diagnostics

ose button.

20 minute warm-up before doing this

procedure.

3. Click the Start button to start the routine.

28 AWG5200 Series Technical Reference

Page 41

Brief procedures

4. Verify that Pas

calibration completes.

5. Click the Clos

s appears in the Summary column for all items when the

e button.

AWG5200 Series Technical Reference 29

Page 42

Brief procedures

Functional test

The purpose of the procedure is to confirm that the instrument functions properly.

The procedures use “AWG” when referring to the AWG5200 series instruments.

The required

equipment is listed below.

Table 32: Required equipment for the functional test

Item Qty. Minimum requirements Recommended equipment

Oscilloscope

Function generator 1 ea. 1 kHz, square wave, 5 V

Signal analyzer

Adapter 4 ea

50 Ω SMA cable

50 Ω SMA terminator

50 Ω BNC cable

SMA-BNC adapter

Planar Crown RF Input

Connector – 7005A-1 SMA

Female

1 ea.

1 ea.

4 ea.

3 ea.

1 ea. Male connectors both ends Tektronix part number 012-0057-01

3 ea.

1 ea.

Bandwidth: 4 GHz or higher

4 channels

output

p-p

Bandwidth: 14 GHz or higher Tektronix RSA5126B

TekConnect oscilloscope input to SMA input Tektronix TCA-SMA

DC to 20 GHz

DC to 18 GHz

SMA female to BNC male connector

Planar Crown RF Input Connector – Type N

to SMA Female

For use with Tektronix RSA5126B signal

analyzer

Tektronix DPO70404C

Tektronix AFG3021C

Tensolite 1-3636-465-5236

Tektronix part number 136-7162-xx

(supplied with AWG).

Tektronix part number 015-0572-00

Tektronix part number 131-8689-00

Functional check

requisites

pre

1. Click the Reset to Default Setup button in the toolbar .

2. Load the test waveform PV_Square.wfmx into the Waveform List.

Test waveforms are located at C:\Program

Files\Tektronix\AWG5200\Samples\PV.

30 AWG5200 Series Technical Reference

Page 43

Brief procedures

Checking the a

channel outputs

nalog

Required equipment Prerequisites

Oscilloscope

One TCA-SMA adapter

One 50 Ω SMA cable

One 50 Ω SMA terminator

None

1. Set the test oscilloscope as follows:

a. Vertical scale: 200 mV/div (CH 1 and CH 2)

b. Horizontal scale: 100 ns/div

c. Input coupling: DC (CH 1 and CH 2)

d. Input impedance: 50 Ω (CH 1 and CH 2)

e. Position: +2 div (CH 1 and CH 2, if necessary)

f. Trigge

r source: CH 1

g. Trigger level: 0 mV

h. Trigger slope: Positive

i. Trigger mode: Auto

2. Press the AWG front panel All Outputs Off button (or click All Outputs Off

on the Home screen) to disable the outputs (front panel light on).

3. Connect CH 1 (+) of the AWG to channel 1 of the test oscilloscope using a

50 Ω SMA cable and a TCA-SMA adapter.

4. Connect CH 1 (–) of the AWG to channel 2 of the test oscilloscope using a

50 Ω SMA cable and a TCA-SMA adapter.

5. Click the Home tabonthedisplay.

AWG5200 Series Technical Reference 31

Page 44

Brief procedures

6. From the Wavefo

to Channel 1.

7. Click the Setu

8. Press the AWG front panel All Outputs Off button (or click All Outputs Off

on the Home

9. Click the Play button on-screen or press the button on the front panel of the

AWG.

10. Check that the channel’s waveform is properly displayed on the test

scope screen.

oscillo

rm List window, assign the waveform PV_Square.wfmx

p -> Channel tab and enable Channel 1.

screen) to enable the outputs (front panel light off).

11. Press AWG the front panel All Outputs Off button (or click All Outputs Off

he Home screen) to disable the outputs (front panel light on).

on t

12. Repeat steps 3 through 11 until all channels are checked, modifying the

structions with the channel number under test.

in

13. Disconnect the test setup.

32 AWG5200 Series Technical Reference

Page 45

Brief procedures

Checking the m

outputs

arker

Required equipment Prerequisites

Oscilloscope

Four TCA-SMA adapters

Four 50 Ω SMA cables

None

1. Set the test oscilloscope as follows:

a. Vertical scale: 1 V/div (CH 1 through CH 4)

b. Horizontal scale: 100 ns/div

c. Input coupling: DC

d. Input impedance: 50 Ω

e. CH 1 through CH 4 position: adjust as necessary to display all four traces

f. Trigger

source: CH1

g. Trigger level: 0 mV

h. Trigger slope: Positive

i. Trigger mode: Auto

2. If needed, press the AWG front panel All Outputs Off button (or click All

Outputs Off on the Home screen) to disable the outputs (front panel light on).

3. Connect the AWG’s Channel 1 markers to the test oscilloscope using a

50 Ω SMA cable and a TCA-SMA adapter.

Connect marker CH1:1 to channel 1 of the test oscilloscope.

Connect marker CH1:2 to channel 2 of the test oscilloscope.

nnect marker CH1:3 to channel 3 of the test oscilloscope.

Co

Connect marker CH1:4 to channel 4 of the test oscilloscope.

OTE. If a channel’s marker is not connected to the test oscilloscope, it must

N

be terminated with a 50 Ω SMA terminator.

AWG5200 Series Technical Reference 33

Page 46

Brief procedures

4. Click the Home tabonthedisplay.

5. From the W

to Channel 1.

6. Click th

7. In the Setup -> Channel tab, select Output Settings and set the Channel 1

Resol

8. Click the Play button on-screen or on the front panel.

9. Press the AWG front panel All Outputs Off button (or click All Outputs Off

on the Home screen) to enable the outputs (front panel light off).

10. Check that the CH1:1 through CH1:4 waveforms are properly displayed on

the test oscilloscope screen.

aveform List window, assign the waveform PV_Square.wfmx

e Setup -> Channel tab and enable the select Channel 1 output.

ution to 12+4 Mkrs.

34 AWG5200 Series Technical Reference

Page 47

Brief procedures

11. Press th

on the Home screen) to disable the outputs (front panel light on).

12. Repeat s

instructions with the channel number under test.

Discon

e AWG front panel All Outputs Off button (or click All Outputs Off

teps 3 through 11 until all channels are checked, modifying the

nect the test setup.

AWG5200 Series Technical Reference 35

Page 48

Brief procedures

Checking the A

Coutput

Required equipment Prerequisites

Signal analyzer

One 50 Ω SMA cable

Planar Crown RF Input Connector – Type N

to SMA Female

Two 50 Ω SMA terminators

None

1. If needed, press the AWG front panel All Outputs Off button (or click All

Outputs Off on the Home screen) to disable the outputs (front panel light on).

2. Create a 1 GHz test waveform from the AWG using the Basic Waveform

plug-in.

a. Click the Waveform Plug-in tabonthedisplay.

b. Select Basic Waveform from the Waveform Plug-ins drop down list.

c. Click the Reset Plug-in button.

d. Set the Function to Sine.

e. Set the Frequency to 1 GHz.

NOTE. Leave all other settings at their default settings.

f. Click the Compile Settings icon to open the compile settings dialog screen.

g. In the Name field, change the name to Waveform_1 GHz.

36 AWG5200 Series Technical Reference

Page 49

Brief procedures

h. Close the compi

i. Click Compile.

3. Set the spectrum analyzer as follows:

a. Press the Preset button to set the analyzer to its default settings.

b. Display the Spectrum measurement.

c. Set Center Frequency to 1 GHz.

4. Use a 50 Ω SM

the RF input of the signal analyzer.

le settings dialog screen.

A cable to connect the CH 1 AC connector (+) on the AWG to

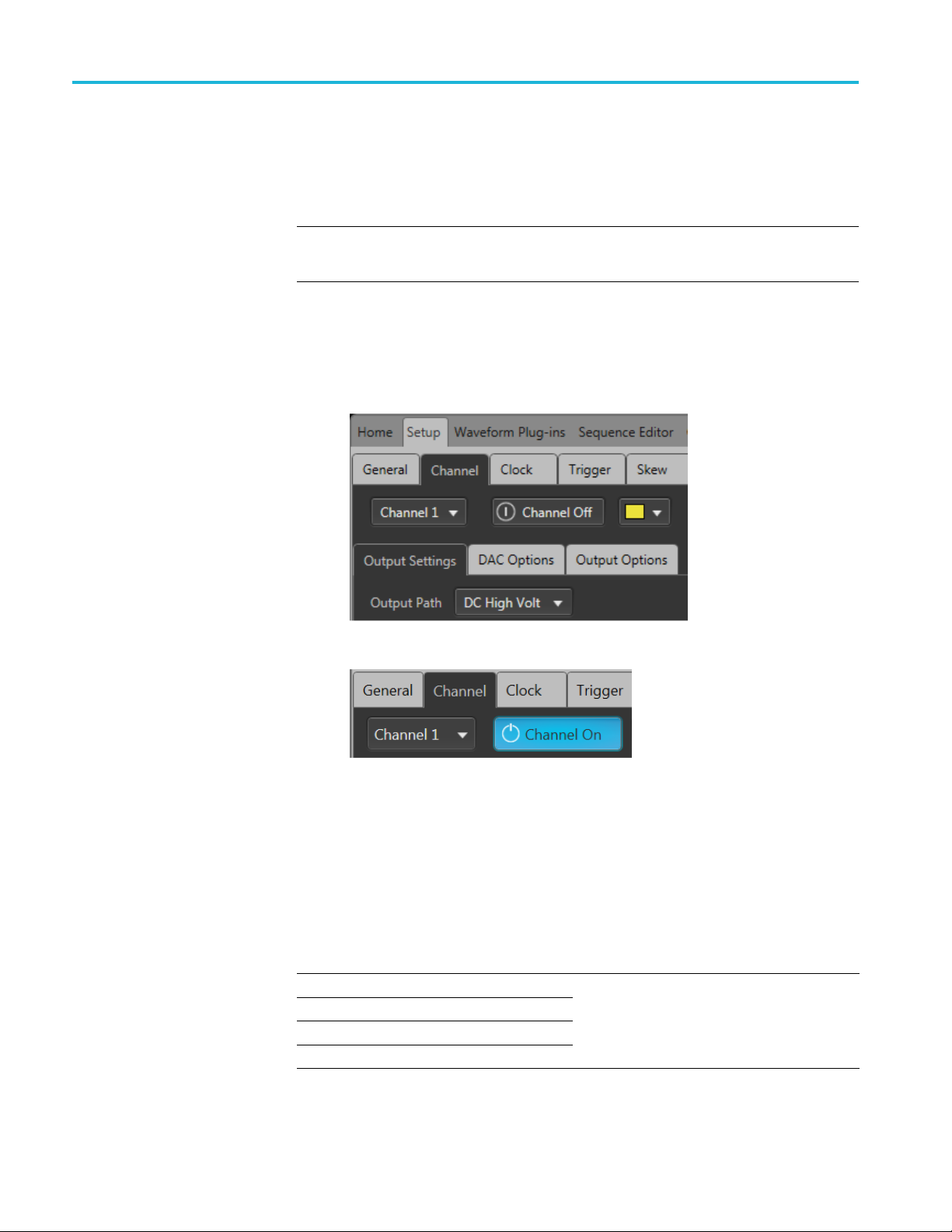

5. Click the Setup -> Channel tab and click the Output Settings tab.

a. Select Channel 1.

b. Set the Output Path to AC Direct.

c. Enable the Channel 1 output.

AWG5200 Series Technical Reference 37

Page 50

Brief procedures

6. Click the Home tabonthedisplay.

7. In the Waveform List window, assign the Waveform_1 GHz waveform to

the Channel 1.

8. Press the Play button, or click Play on the display.

9. Press the A

on the Home screen) to enable the outputs (front panel light off).

10. Check tha

WG front panel All Outputs Off button (or click All Outputs Off

t the waveform is properly displayed on the signal analyzer screen.

Figure 2: 1 GHz output waveform

11. Press the AWG front panel All Outputs Off button (or click All Outputs Off

on the Home screen) to disable the outputs (front panel light on).

12. Repeat steps 4 through 11 until all channels are checked, modifying the

instructions with the channel number under test.

Disconnect the test setup.

38 AWG5200 Series Technical Reference

Page 51

Brief procedures

Checking the t

riggered

outputs

Required equipment Prerequisites

Oscilloscope

Function Generator (AFG3021C or

equivalent)

One TCA-SMA adapter

Two 50 Ω SMA cables

One SMA female to BNC male adapter

None

1. Set the oscilloscope as follows:

a. Vertical scale: 200 mV/div (CH 1)

b. Horizontal scale: 20 ns/div

c. Trigger source: CH 1

d. Trigger level: 100 mV

2. Press the AWG front panel All Outputs Off button (or click All Outputs Off

on the Home screen) to disable the outputs (front panel light on).

3. Connect a BNC to SMA adapter to the output of the function generator.

4. Connect an SMA cable between the output of the function generator and the

Trigger A input on the rear panel of the AWG.

5. Connect CH 1 (+) of the AWG to channel 1 of the test oscilloscope using a

50 Ω SMA cable and a TCA-SMA adapter.

7. Click the Home tabonthedisplay.

AWG5200 Series Technical Reference 39

Page 52

Brief procedures

8. Click the Reset to Default Setup button in the toolbar .

9. Set the Function Generator to output a 1 kHz square wave at 5 V

p-p

.

10. Turn on the output of the Function Generator.

11. Load the test waveform PV_Square.wfmx into the Waveform List.

Test waveforms are located at C:\Program

Files\Tektronix\AWG5200\Samples\PV.

12. From the Waveform List window, assign the waveform PV_Square.wfmx

to Channel 1.

13. Click the Home tab and set the AWG’s Channel 1 as follows:

Run Mode to Trig g e re d

Trigger Input to A

Enable the Channel

14. In the Setup -> Trigger tab, set the External Trigger Level to 1.0 V (A and

B). Leave all other settings to their default settings.

40 AWG5200 Series Technical Reference

Page 53

Brief procedures

15. Click the Play b

16. Click the Home tab and verify that the squarewave output is displayed on

the AWG.

17. Verify that the squarewave output is displayed on the test oscilloscope.

utton on-screen or on the front panel of the AWG.

18. Move the cable from the Trigger A input to the Trigger B input.

19. Click the Home tab and set the trigger input to B.

20. Verify that the output is displayed on the test oscilloscope (as in step 17).

21. Press the AWG front panel All Outputs Off button (or click All Outputs Off

on the Home screen) to disable the outputs (front panel light on).

22. Disconnect the test setup.

AWG5200 Series Technical Reference 41

Page 54

Performance tests

Performance t

Prerequisites

ests

This section

listed below.

10 MHz reference frequency acc uracy

Analog amplitude accuracy

Marker high and low level accuracy

The tests in this section provide confirmation of performance and functionality

The following requirements and conditions must be met:

The cabinet must be installed.

The AWG must have been last adjusted at an ambient temperature between

+20 °C and +30 °C, must have been operating for a warm-up period of at

least 20 minutes, and must be operating at an ambient temperatures between

+10 °C and +40 °C.

You must have performed and passed the procedure Diagnostics and

Calibration, and the procedure Functional Tests.

contains performance verification procedures for the specifications

Required equipment

The following table lists the test equipment required to perform the performance

verification procedures. The table identifies examples of recommended equipment

and lists the required precision where applicable. If you substitute other test

equipment for the listed examples, the equipment must meet or exceed the listed

tolerances.

Table 33: Required equipment for performance tests

Item Qty. Minimum requirements Recommended equipment

Frequency counter 1 ea. Frequency accuracy: within ± 0.01 ppm

Digital multimeter 1 ea.

Adapter 3 ea.

50 Ω SMA cable

50 Ω SMA terminator

50 Ω BNC feed-through

terminator

1 ea.

3 ea.

1 ea.

DC accuracy: within ± 0.01%

TekConnect oscilloscope input to SMA input Tektronix TCA-SMA

DC to 20 GHz

DC to 18 GHz

DC to 1 GHz, feedthrough

Tektronix MCA 3040

Keithley 2000 DMM or

Tektronix DMM4040/4050

Tensolite 1-3636-465-5236

Tektronix part number 136-7162-xx

(supplied with AWG).

Tektronix part number 011-0049-02

42 AWG5200 Series Technical Reference

Page 55

Performance tests

Table 33: Required equipment for performance tests (cont.)

Item Qty. Minimum requirements Recommended equipment

SMA-BNC adapter

SMA-BNC adapter

BNC-dual banana adapter

3 ea.

1 ea.

1 ea.

SMA female to BNC male connector

SMA male to BNC female connector

BNC to dual banana plugs

Tektronix part number 015-0572-00

Tektronix part number 015-0554-00

Tektronix part number 103-0090-00

Test record

Photocopy the test records and use them to record the performance test results.

(See pag

e64,Test record.)

AWG5200 Series Technical Reference 43

Page 56

Performance tests

Te rmination resistance measurement

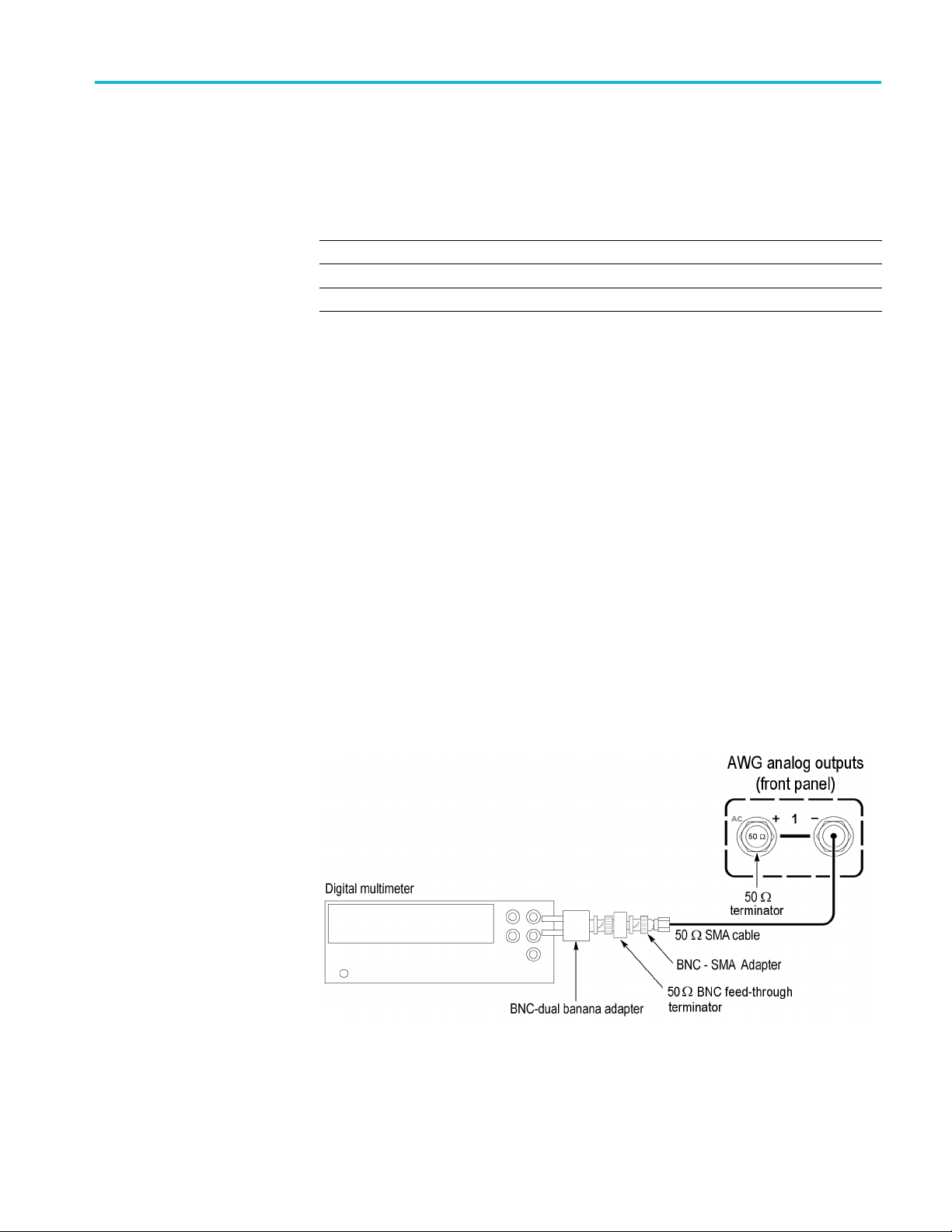

Many of the performance tests use a BNC-dual banana adapter and 50 Ω BNC

feed-through terminator connected to a DMM.

For accuracy, the termination resistance of this connection is used in the

calculations.

Use this procedure and note the measured value for use in these procedures.

1. Connect the BNC-dual banana adapter and 50 Ω BNC feed-through terminator

to the HI and LO inputs of the digital multimeter.

Figure 3: Equipment connection to measure terminator resistance

2. Set the digital multimeter to the Ω 2wiresmode.

3. Measure the resistance and note the value as Term_R.

Keep this value available for use in several performance chec k calculations.

4. Set t

NOTE. Lead resistance is not included in the measurement results when using

four wire ohms. The accuracy is higher especially for small resistances. Use a

four wire method if necessary.

he digital multimeter to the DCV mode.

44 AWG5200 Series Technical Reference

Page 57

Analog amplitude accuracy

Required equipment Prerequisites

Digital multimeter

BNC-dual banana adapter

50 Ω BNC feed-through terminator

SMA female-B NC male adapter

50 Ω SMA terminator

Before starting this procedure, ensure you have the “Term R” value used in the

calculations. (See page 44, Termination resistance measurement.)

Performance tests

AWG preparation and load test waveforms

(See page 42.)

Termination resistance measurement

procedure (Term R) (See page 44.)

DC High BW output path

1. Click the Reset to Default Setup button in the toolbar .

2. Press the AWG front panel All Outputs Off button (or click All Outputs Off

on the Home screen) to disable the outputs (front panel light on).

3. Load the test waveforms PV_DC_Plus.wfmx and PV_DC_Minus.wfmx

into the Waveform List.

NOTE. Test waveforms are located at

ogram Files\Tektronix\AWG5200\Samples\PV.

C:\Pr

4. From the Waveform List window, assign the test waveform

C_Plus.wfmx to Channel 1.

PV_D

5. Connect the CH 1 (+) c onnector from the AWG to the HI and LO inputs of

digital multimeter.

the

Use a 50 Ω SMA cable, a BNC-SMA adapter, a 50 Ω BNC feed-through

rminator, and a BNC dual banana adapter.

te

6. Terminate the CH 1 (–) connector on the AWG with a 50 Ω SMA terminator.

AWG5200 Series Technical Reference 45

Page 58

Performance tests

7. Press the AWG front panel All Outputs Off button (or click All Outputs Off

on the Home screen) to enable the outputs (front panel light off).

8. Click the Setup -> Channel tab and click the Output Settings tab.

a. Select Channel 1.

b. Set the Output Path to DC High BW.

c. Enable the Channel 1 output.

9. Set the Amplitude of the AWG as shown in the following table. (See

Table 34.)

Table 34: Analog amplitude accuracy (DC High BW output path)

Amplitude settings Accuracy lim its

25 mV

100 mV

p-p

p-p

23.75 mV to 26.25 mV

98 mV to 102 mV

46 AWG5200 Series Technical Reference

Page 59

Performance tests

Table 34: Analog amplitude accuracy (DC High BW output path) (cont.)

Amplitude settings Accuracy lim its

200 mV

p-p

500 mV

p-p

750 mV

p-p

1V

p-p

(Requires option DC)

1.5 V

p-p

(Requires option DC)

196 mV to 204 mV

490 mV to 510 mV

735 mV to 765 mV

980 mV to 1.02 V

1.47Vto1.53V

10. Press the Play button, or click Play on the display.

11. Measure the output voltage on the digital multimeter and note the value as

Measured_voltage_1.

12. Use the following formula to compensate the voltage for the 50 Ω BNC

feed-through terminator:

V_high = [(Term_R + 50) / (2 Term_R)] Measured_voltage_1

Where Term_R is the resistance of the 50 Ω BNC feed-through terminator.

(See page 44, Termination resistance measurement.) procedure.

13. From the Waveform List window, assign the waveform PV_DC_Minus.wfmx

to Channel 1.

14. Measure the output voltage on the digital multimeter and note the value as

Measured_voltage_2.

15. Use the following formula to compensate the voltage for the 50 Ω BNC

feed-through terminator:

V_low = [(Term_R + 50) / (2 Term_R)] Measured_voltage_2

Where Term_R is the resistance of the 50 Ω BNC feed-through terminator.

(See page 44, Termination resistance measurement.) procedure.

16. Verify that the voltage difference |(V_high – V_low)| falls within the limits

given in the table. (See Table 34 on page 46.)

17. Repeat steps 9 through 16 for each Amplitude setting in the table. (See

Table 34 on page 46.)

18. Press the AWG front panel All Outputs Off button (or click All Outputs Off

on the Home screen) to disable the outputs (front panel light on).

19. Move the SMA cable from the CH 1 (+) connector to the CH 1 (–) connector

and move the 50 Ω SMA terminator from the CH 1 (–) connector to the CH

1(+)connector.

AWG5200 Series Technical Reference 47

Page 60

Performance tests

DC High Volt output path

20. Press the A

on the Home screen) to enable the outputs (front panel light off).

21. Repeat st

22. Repeat steps 4 through 21 until all channels are checked, modifying the

instruc

23. Press the AWG front panel All Outputs Off button (or click All Outputs Off

on the H

24. Disconnect the test setup.

NOTE. This is the start of testing the optional DC High Volt output path

(Option HV).

If option HV is not licensed, skip this procedure.

1. Click the Reset to Default Setup button in the toolbar .

2. Load the te

into the Waveform List.

WG front panel All Outputs Off button (or click All Outputs Off

eps 9 through 17 for the CH1 (–) connector.

tions for the channel under test.

ome screen) to disable the outputs (front panel light on).

st waveforms PV_DC_Plus.wfmx and PV_DC_Minus.wfmx

NOTE. Test waveforms are located at

C:\Program Files\Tektronix\AWG5200\Samples\PV.

3. From the Waveform List window, assign the waveform PV_DC_Plus.wfmx

to Channel 1.

4. Press the AWG front panel All Outputs Off button (or click All Outputs Off

on the Home screen) to disable the outputs (front panel light on).

48 AWG5200 Series Technical Reference

Page 61

Performance tests

5. Connect the CH 1

the digital multimeter.

Use a 50 Ω SMA ca

terminator, and a BNC dual banana adapter.

6. Terminat e t

7. Press the AWG front panel All Outputs Off button (or click All Outputs Off

on the Home screen) to enable the outputs (front panel light off).

he CH 1 (–) connector on the AWG with a 50 Ω SMA terminator.

(+) connector from the AWG to the HI and LO inputs of

ble, a BNC-SMA adapter, a 50 Ω BNC feed-through

8. Click the Setup -> Channel tab and click the Output Settings tab.

a. Select Channel 1.

b. Set th

c. Enable the Channel 1 output.

e Output Path to DC High Volt.

AWG5200 Series Technical Reference 49

Page 62

Performance tests

9. Set the Amplitu