Page 1

TM 11-6625-2749-14&P

OPERATOR’S, ORGANIZATIONAL, DIRECT SUPPORT, AND GENERAL SUPPORT

MAINTENANCE MANUAL

(INCLUDING REPAIR PARTS AND SPECIAL TOOLS LISTS)

FOR

DIFFERENTIAL AMPLIFIER AM-6786/U

(TEKTRONIX TYPE 7A22, VERTICAL PLUG-IN UNIT)

(NSN 6625-00-478-0597)

HEADQUARTERS,

DEPARTMENT OF THE ARMY

OCTOBER 1979

Page 2

CLEANING THE INTERIOR

Use an eye-shield when cleaning with pressurized air. Hardened dirt can be

removed with a paint brush, cotton tipped swab or cloth dampened with a

water and mild detergent solution. Avoid the use of chemical cleaning agents

that might damage the plastic parts.

SPECIFIC COMPONENT REPLACEMENT INFORMATION

Disconnect the instrument from the power source before removing or replacing components.

The pushbutton switches are not repairable and should be replaced if defective. Components which are mounted on the circuit board associated with the

pushbutton switch can be replaced using the normal replacement procedure.

See the information under Light-Bulb Replacement for bulb replacement.

Page 3

TM 11-6625-2749-14&P

This manual contains copyright material reproduced by permission of Tektronix, Incorporated.

TECHNICAL Manual

HEADQUARTERS

DEPARTMENT OF THE ARMY

No. 11-6625-2749-14&P

OPERATOR’S, ORGANIZATIONAL, DIRECT

MAINTENANCE

SUPPORT,

MANUAL

Washington, DC,

AND GENERAL SUPPORT

10 October

1979

(INCLUDING REPAIR PARTS AND SPECIAL TOOLS LISTS)

FOR

DIFFERENTIAL AMPLIFIER AM-6786/U

(TEKTRONIX TYPE 7A22, VERTICAL PLUG-IN UNIT)

NSN 6625-00-478-0597)

Current as of 20 March 1979

REPORTING OF ERRORS

You can improve this manual by recommending improvements using DA Form 2028-2 located in

the back of the manual. Simply tear out the self-addressed form, fill it out as shown on the sample, fold

it where shown, and drop it in the mail.

If there are no blank DA Forms 2028-2 in the back of your manual, use the standard DA Form

2028 (Recommended Changes to Publications and Blank Forms) and forward to the Commander, US

Army Communications and Electronics Materiel Readiness Command, ATTN: DRSEL-ME -MQ, Fort

Monmouth, NJ 07703.

In either case, a reply will be furnished direct to you.

This manual is an authentication of the manufacturer’s commercial literature which, through usage,

has been found to cover the data required to operate and maintain this equipment. Since the manual

was not prepared in accordance with military specifications, the format has not been structured to

consider levels of maintenance.

i-0.1

Page 4

Page 5

TM 11-6625-2749-14&P

TABLE OF

SECTION O

Introduction . . . . . . . . . . . . . . . . . . .

SECTION 1 SPECIFICATION

Introduction . . . . . . . . . . . . . . . . . . . .

Electrical Characteristics . . . . . . . . . . .

Deflection Factor . . . . . . . . . . . . . . .

Gain . . . . . . . . . . . . . . . . . . . . . . . .

Differential Dynamic Range . . . . . .

DC Offset . . . . . . . . . . . . . . . . . . . .

Frequency Response . . . . . . . . . . . .

Bandwidth limit . . . . . . . . . . . . . . .

Recovery Time . . . . . . . . . . . . . . . .

Common-Mode Signal Range . . . .

Common-mode Rejection Ratio . . . .

Maximum input Voltage . . . . . . . .

Input Rand C . . . . . . . . . . . . . . . . .

Maximum Input Gate Current . . . .

Variable Balance . . . . . . . . . . . . . .

Step Attenuator DC Balance . . . . . .

Displayed Noise

(Tangentially Measured) . . . . . . .

DC Drift . . . . . . . . . . . . . . . . . . . . .

Isolation between + and — Inputs

Environmental Characteristics . . . . . . .

Altitude . . . . . . . . . . . . . . . . . . . . .

Transportation . . . . . . . . . . . . . . . .

Physical Characteristics . . . . . . . . . . . .

Finish . . . . . . . . . . . . . . . . . . . . . . .

Dimensions . . . . . . . . . . . . . . . . . . .

Weight . . . . . . . . . . . . . . . . . . . . . .

SECTION 2 OPERATING INSTRUC-

TIONS

Introduction . . . . . . . . . . . . . . . . . . . . 2-1

Front Panel Controls and Connectors . 2-1

Operating Instructions . . . . . . . . . . . . . 2-2

First Time Operation . . . . . . . . . . . 2-2

General Operating Information . . . . . 2-4

Trace Drift . . . . . . . . . . . . . . . . . . . .

Page

0-1

1-1

1-1

1-1

1-1

1-1

1-1

1-1

1-1

1-1

1-1

1-1

1-3

1-3

1-3

1-3

1-3

1-3

1-3

1-3

1-3

1-3

1-3

1-3

1-3

1-3

1-3

2-4

CONTENTS

Input Gate Current . . . . . . . . . . . . .

Voltage Measurement . . . . . . . . . . .

Signal Input Connectors . . . . . . . . .

High Input Impedance . . . . . . . . . . .

Display Polarity . . . . . . . . . . . . . . .

Deflection Factor . . . . . . . . . . . . . .

Bandwidth Selection . . . . . . . . . . . .

Voltage Comparison Measurements 2-10

Differential Operation . . . . . . . . . . 2-10

DC Offset Operation . . . . . . . . . . . . 2-11

Input Overdrive Indicator . . . . . . . . 2-12

Readout . . . . . . . . . . . . . . . . . . ...2-12

Trace Identify . . . . . . . . . . . . . . . 2-13

SECTION 3 CIRCUIT DESCRIPTION

Introduction . . . . . . . . . . . . . . . . . . . . 3-1

Block Diagram Description . . . . . . . . . 3-1

Input Coupling . .

Input Attenuators

Preamp . . . . . . . .

L F -3 dB Point .

Output Amplifier

H F -3 dB Point

General Information

Feedback Amplifiers . . . . . . . . . . . . 3-2

Differential Configuration . . . . . . . 3-3

Detailed Circuit Description . . . . . . . . 3-3

Input Coupling . . . . . . . . . . . . . . . . 3-3

Input Attenuators . . . . . . . . . . . . . . 3-4

Gate Current Compensation . . . . . . 3-4

Input Amplifier . . . . . . . . . . . . . . . . 3-4

X15 Preamp . . . . . . . . . . . . . . . . . 3-4

DC Balance . . . . . . . . . . . . . . . .

Floating Power Supply . . . . . . . . 3-5

Common-Mode Rejection . . . . . . 3-5

Cross Neutralization . . . . . . . . . . 3-6

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . 3-2

. . . . . . . . . . . . . .

‘age

2-4

2-4

2-4

2-5

2-5

2-5

2-5

3-1

3-1

3-1

3-1

3-2

3-2

3-4

i

Page 6

TM 11-6625-2749-14&P

TABLE OF

Input Overdrive Protection . . . . . 3-7

DC Off set . . . . . . . . . . . .

Offset Generator . . . . . .

Input Overdrive Indicator

LF

-3 dB Point Selector

Output Amplifier . . . . . . . .

Gain Switching Amplifier

Variable Output Stage . . .

Signal Output Amplifier .

Trigger Output Amplifier .

Indicator Oscilloscope Readout . . . . 3-11

Probe Sensing . . . . . . . . . . . . . . . 3-11

Trace Identify . . . . . . . . . . . . . .

SECTION 4 MAINTENANCE

Introduction . . . . . . . . . . . . . . . . . . . .

Preventive Maintenance . . . . . . . . . . .

General . . . . . . . . . . . . . . . . . . . . .

Cleaning Front Panel . . . . . . . . . . . .

Cleaning Interior . . . . . . . . . . . . . . .

Visual Inspection . . . . . . . . . . . . . .

Transistor Checks . . . . . . . . . . . . . .

Calibration . . . . . . . . . . . . . . . . . . .

Corrective Maintenance . . . . . . . . . . . .

General . . . . . . . . . . . . . . . . . . . . .

Obtaining Replacement Parts . . . . .

Special Parts . . . . . . . . . . . . . . . . . .

Soldering Techniques . . . . . . . . . . .

Component Replacement Information

Troubleshooting . . . . . . . . . . . . . . . . .

Introduction . . . . . . . . . . . . . . . . . .

Indicator Oscilloscope . . . . . . . . . . .

Operating Procedure and

Control Settings . . . . . . . . . . . . .

Trouble Symptoms

Visual Inspection .

Calibration Check

. . . . . . . . . . . . . . 4-4

. . . . . . . . . . . . . . 4-4

. . . . . . . . . . . . . .

. . . . . . 3-7

. . . . . . 3-7

. . . . . . 3-8

. . . . . . 3-9

. . . . . .

. . . . . . 3-9

. . . . . .

. . . . . .

. . . . . . 3-11

Page

3-9

3-11

3-11

3-11

4-1

4-1

4-1

4-1

4-1

4-1

4-1

4-1

4-1

4-1

4-2

4-2

4-2

4-3

4-3

4-3

4-4

4-4

4-4

CONTENTS

Detailed Troubleshooting . . . . . . . . . . 4-4

General . . . . . . . . . . . . . . . . . 4-4

Test Equipment Recommended . . . . 4-4

DC Balance Check . . . . . . . . . . . . .

Troubleshooting by Direct

Replacement . . . . . . . . . . . . . . . . 4-5

Component Checks . . . . . . . . . . . . . 4-6

Transistors . . . . . . . . . . . . . . . . .

Diodes . . . . . . . . . . . . . . . . . . . . 4-6

Resistors . . . . . . . . . . . . . . . . . . . 4-6

Capacitors . . . . . . . . . . . . . . . . . 4-7

SECTION 5 PERFORMANCE CHECK/

CALIBRATION PROCEDURE

Introduction . . . . . . . . . . . . . . . . .

Test Equipment Required . . . . . . . .

General . . . . . . . . . . . . . . . . . .

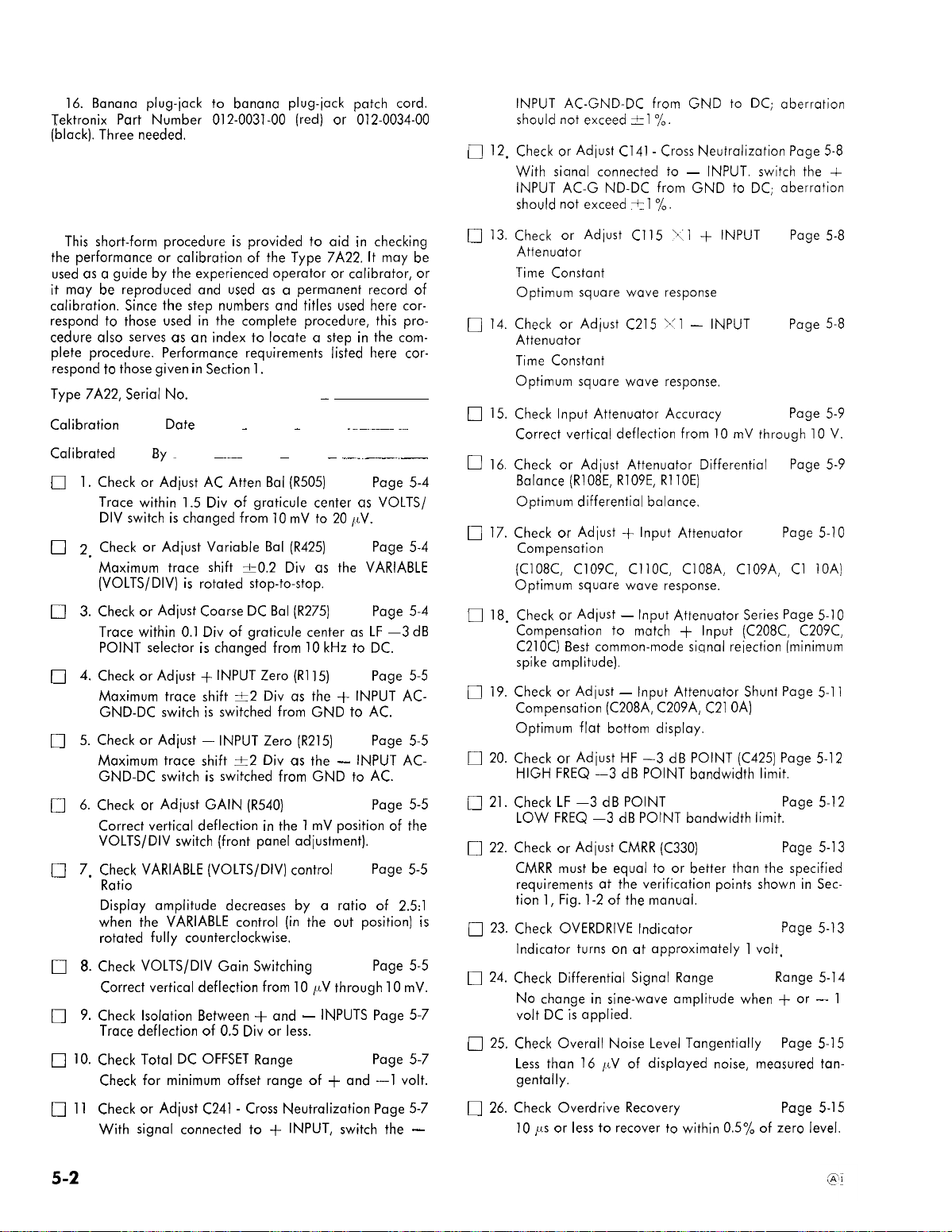

Short Form Procedure . . . . . . . . . .

Performance Check/Calibration

Procedure . . . . . . . . . . . . . . . . .

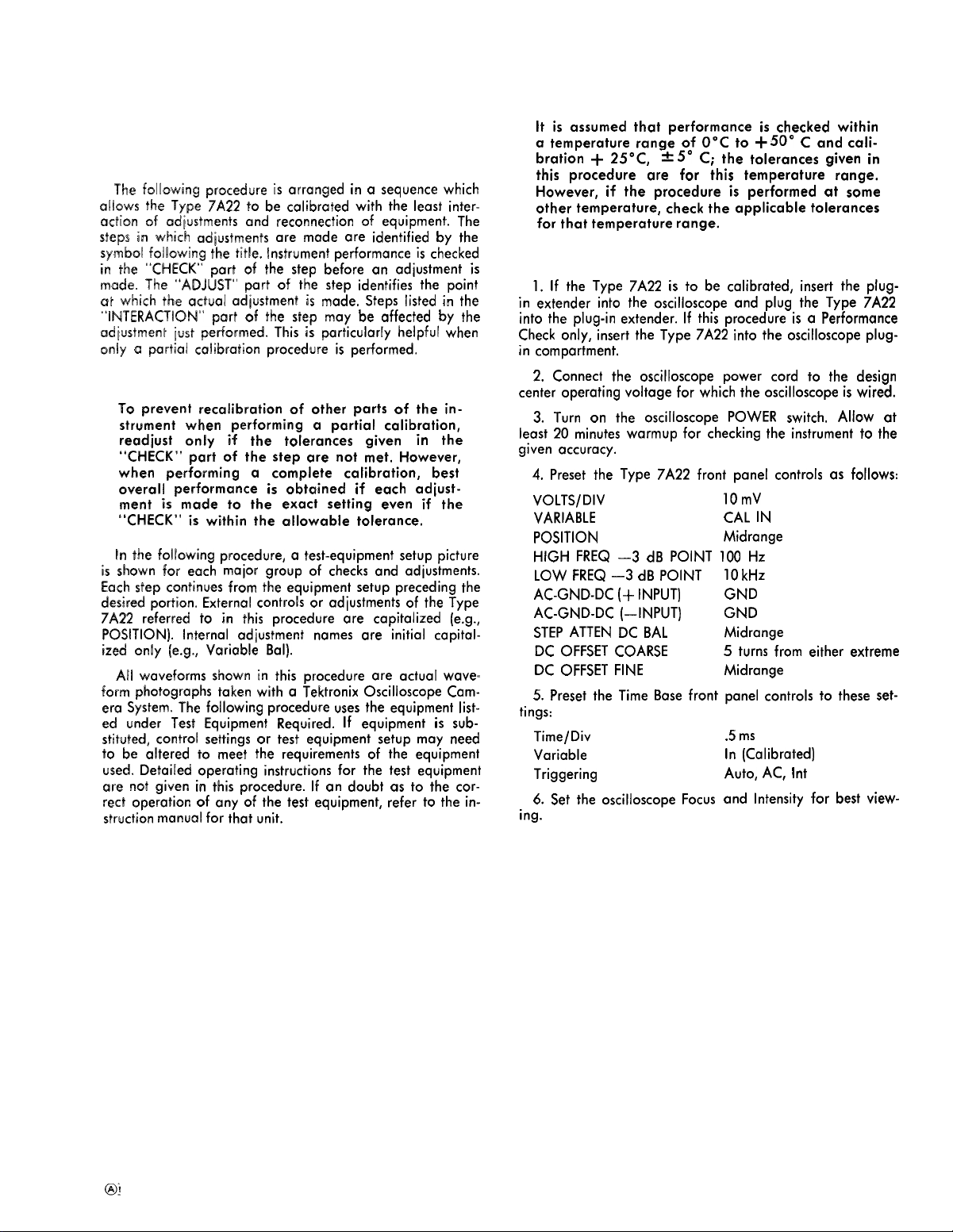

General . . . . . . . . . . . . . . . . . .

Preliminary . . . . . . . . . . . . . . . .

Check or Adjust . . . . . . . . . . . .

AC Atten Balance . . . . . . . . .

Variable Balance . . . . . . . . .

Coarse DC Balance. . . . . . .

+ Gate Current Zero . . . . .

- Gate Current Zero . . . .

GAIN . . . . . . . . . . . . . . . . . .

VARIABLE Control Ratio . .

VOLTS/DIV Gain Switching .

Isolation between + and -

Inputs . . . . . . . . . . . . . . . .

Total DC Offset Range . . . . .

C241 + Cross Neutralization

C141 - Cross Neutralization

Cl 15 Xl +Input Atten Time

Constant . . . . . . . . . . . . . .

. . . 5-1

. . . 5-1

. . .

. . . 5-2

,..

. . . 5-3

. . . 5-3

. . . 5-4

. . . 5-4

. . . 5-4

. . . 5-4

. . .

. . . 5-5

. . . 5-5

. . . 5-5

. . . 5-5

. . . 5-7

. . . 5-7

. . . 5-7

. . . 5-8

. . . 5-8

Page

4-4

4-6

5-1

5-3

5-5

ii

Page 7

TABLE OF CONTENTS

TM 11-6625-2749-14&P

Page

C215 x1

Constant . . . . . . . . . . . . . . . . . 5-8

Input Atten Accuracy . . . . . . . . . 5-9

Input Atten Differential Balance . 5-9

+ Input Atten

- Input Atten Time

Series

Compensation . . . . . . . . . . . . . 5-10

- Input

-input

Atten Compensation . . . 5-10

Atten Shunt

Compensation . . . . . . . . . . . . . 5-11

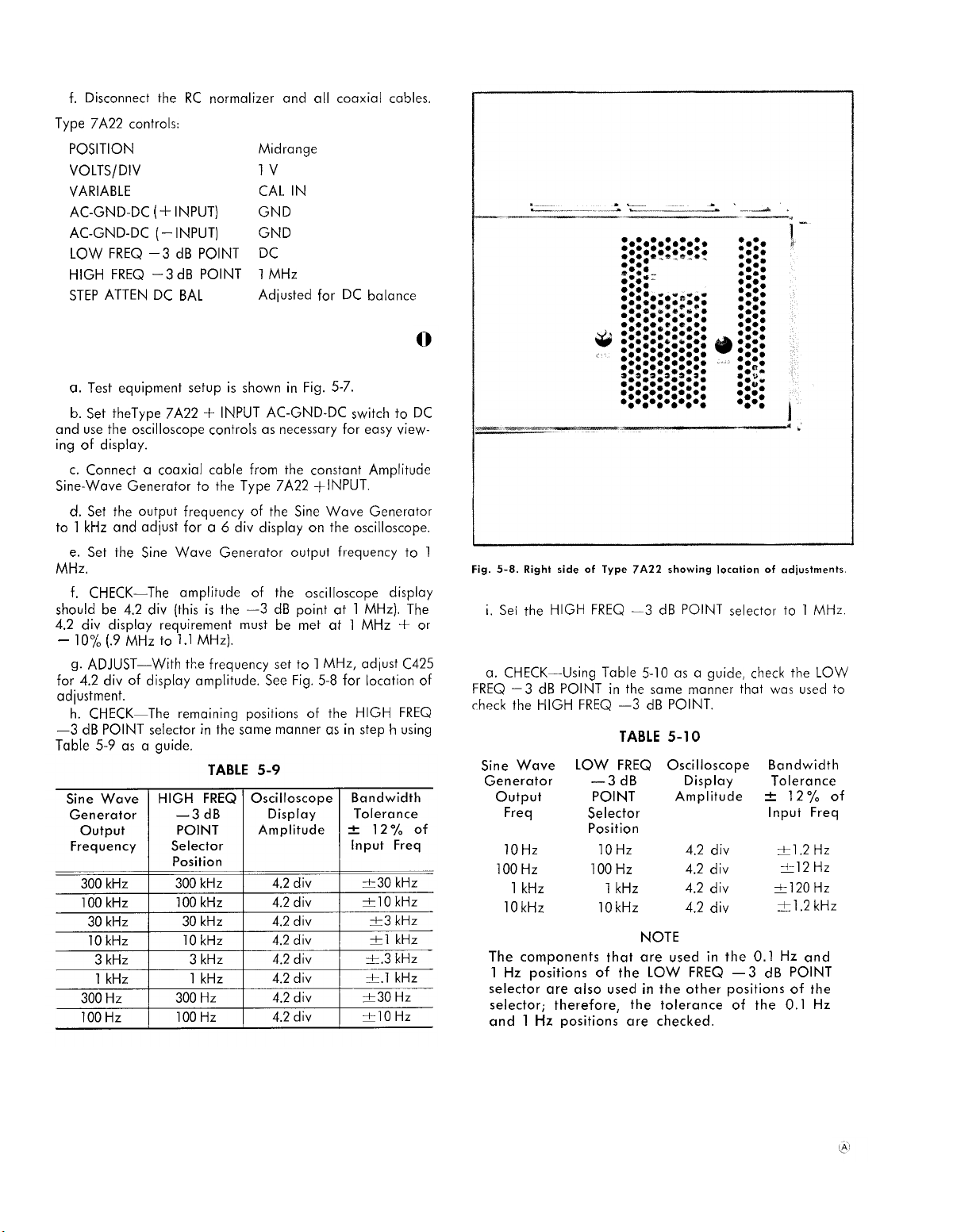

HF -3dB Point . . . . . . . . . . . . 5-12

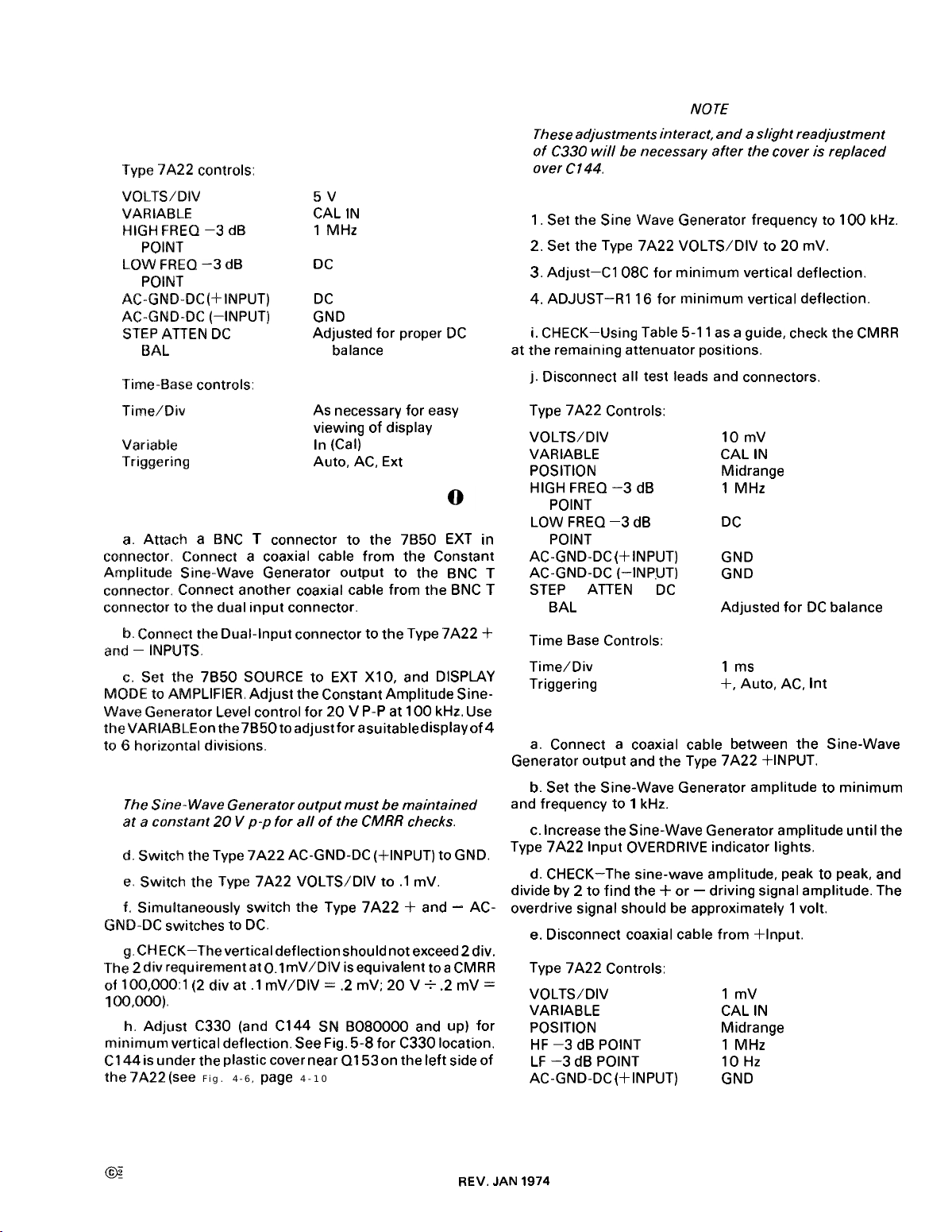

LF

-3dB Point . . . . . . . . . . . . . . . . . . . . . . .5- 12

CMRR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . .5-13

Input Overdrive Indicator . . . . . . 5-13

Differential Dynamic Range . . . . 5-14

Overall Noise Level

(Measured Tangentially) . . . . . 5-15

Overdrive Recovery Time . . . . . . 5-15

SECTION 10 CALIBRATION TEST

EQUIPMENT REPLACEMENT

APPENDIX A. REFERENCES

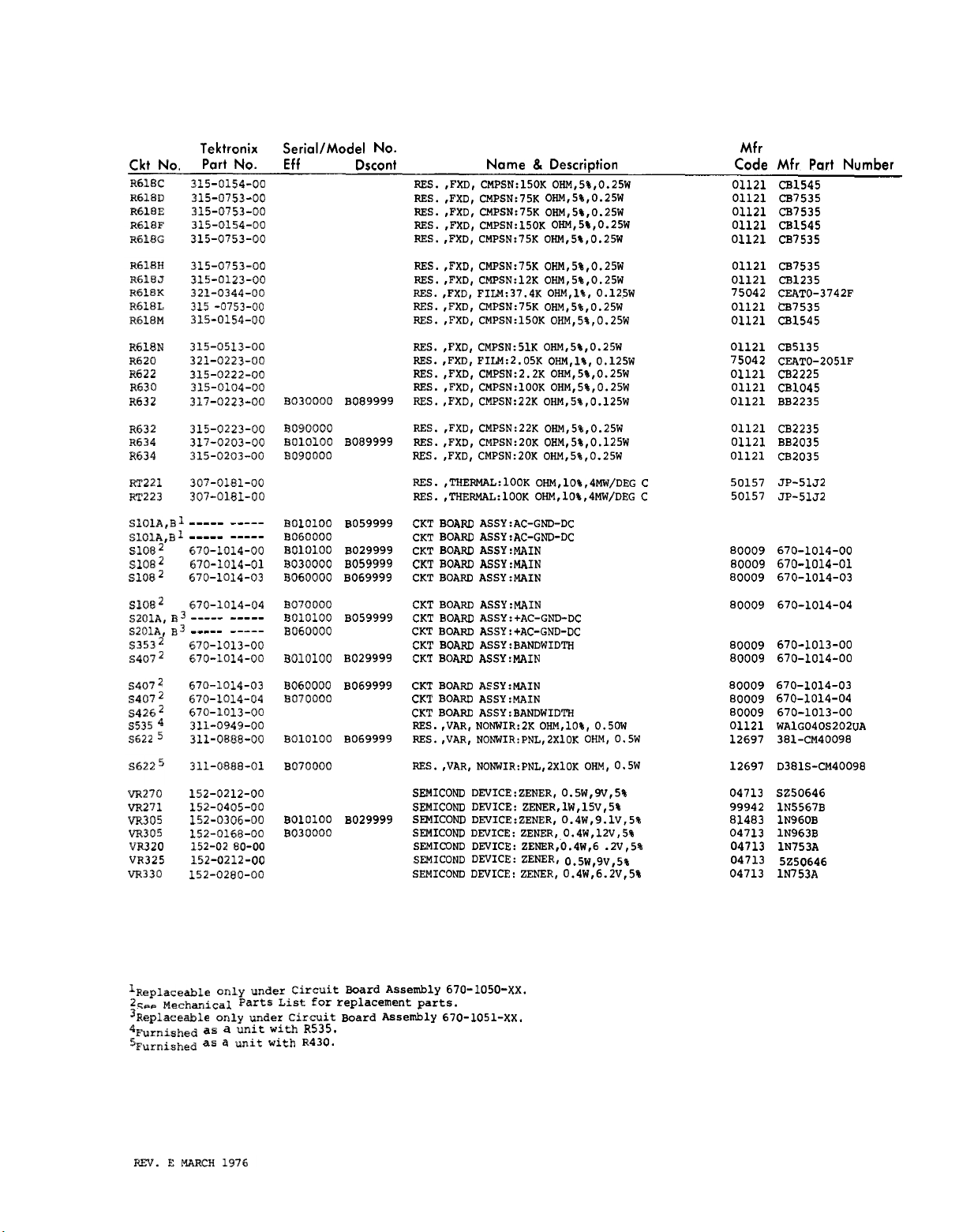

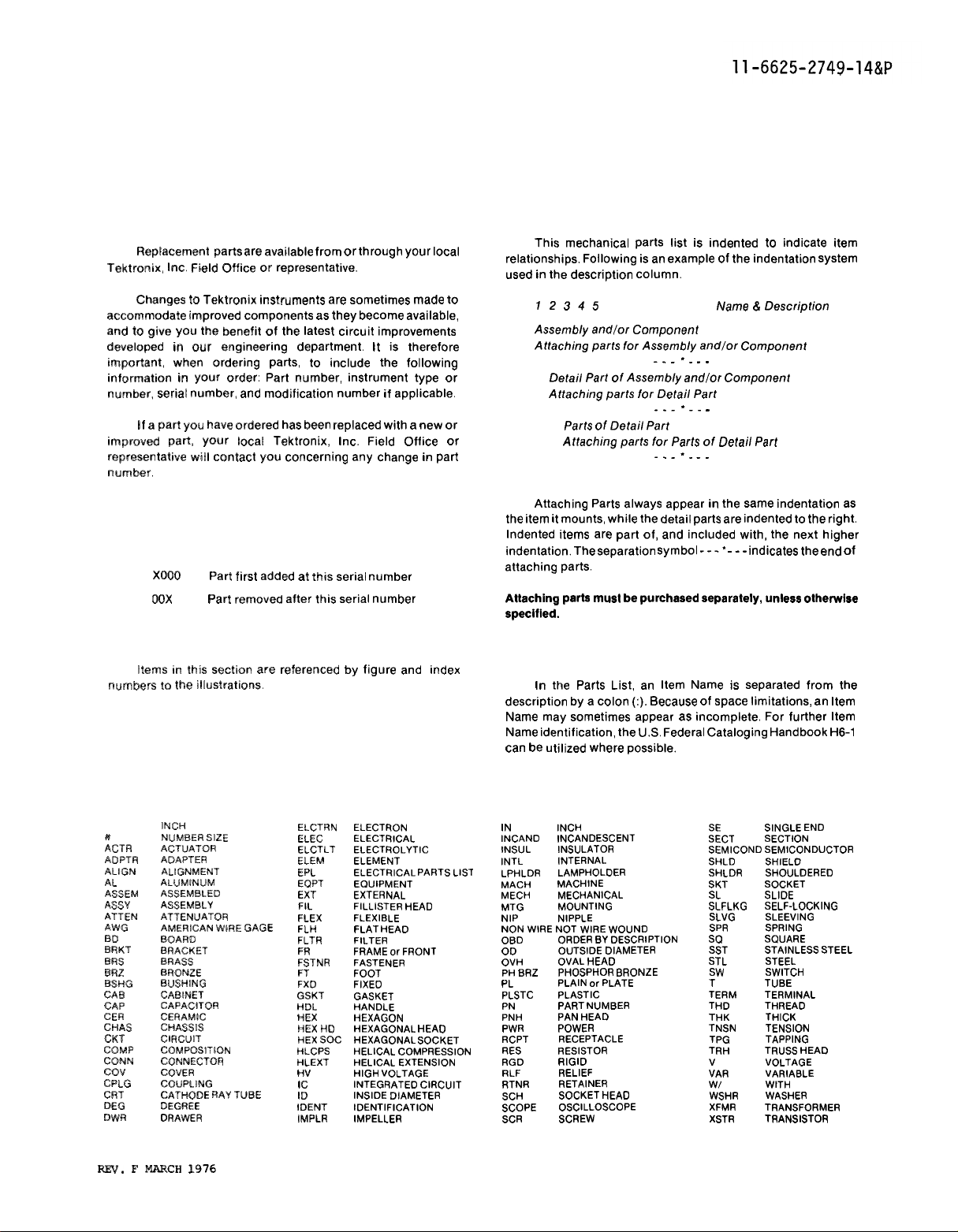

SECTION 6 ELECTRICAL PARTS LIST

Abbreviations and Symbols

Parts Ordering Information

Index of Electrical Parts List

Electrical Parts List

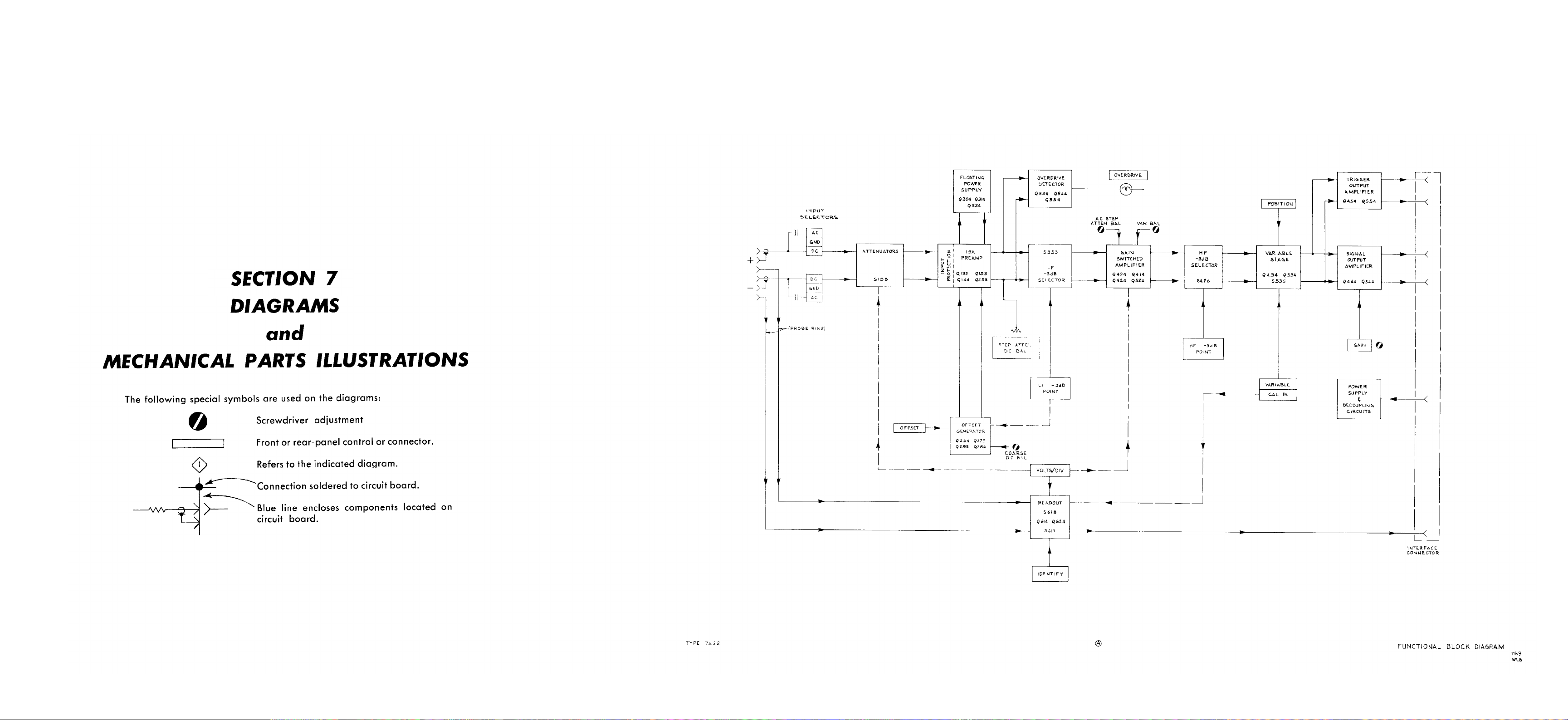

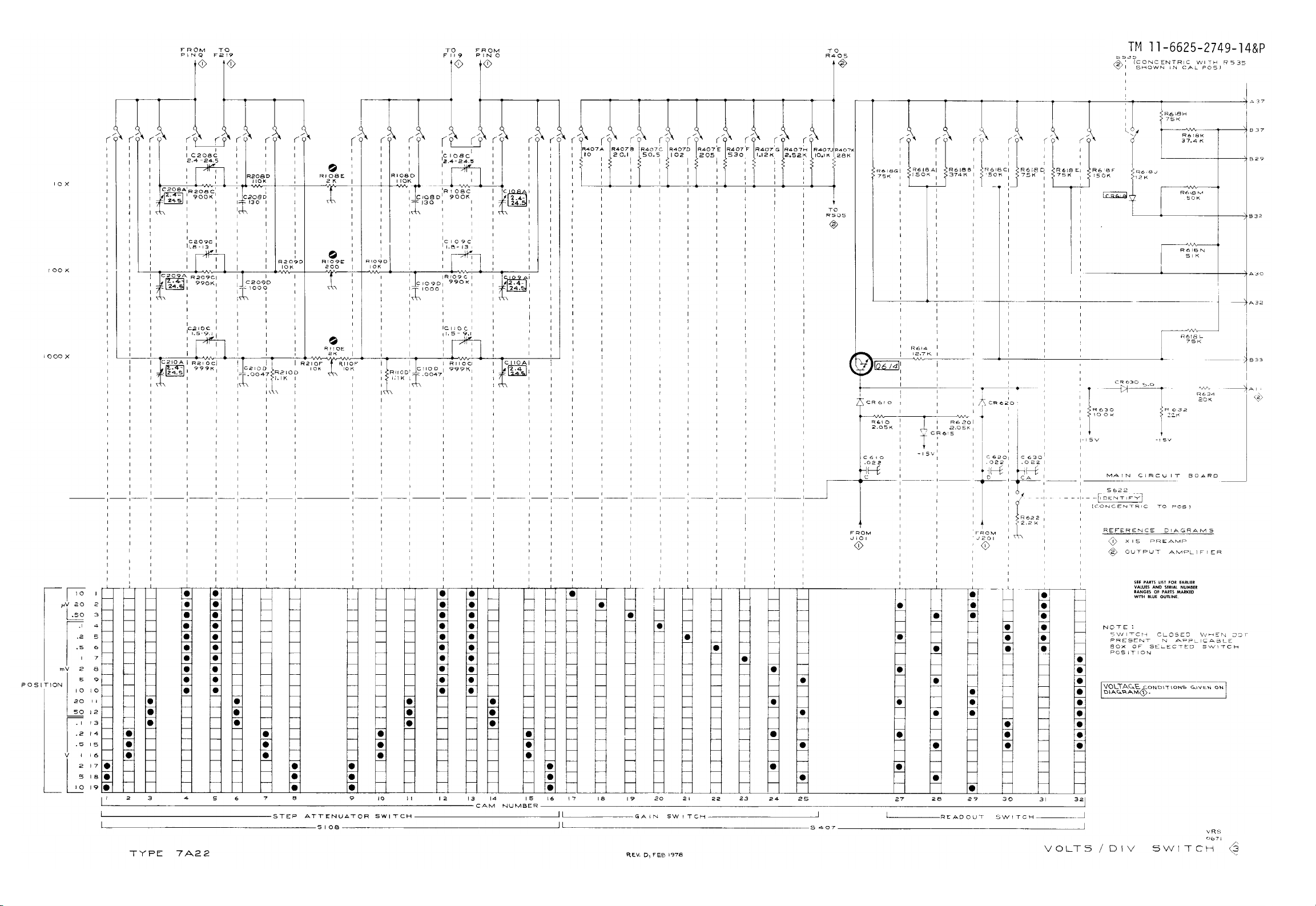

SECTION 7 DIAGRAMS AND ME-

CHANICAL PARTS ILLUSTRATIONS

Diagrams

Mechanical Parts Illustrations

SECTION 8 MECHANICAL PARTS

LIST

Mechanical Parts list Information

Index of Mechanical Parts Illustrations

Mechanical Parts List

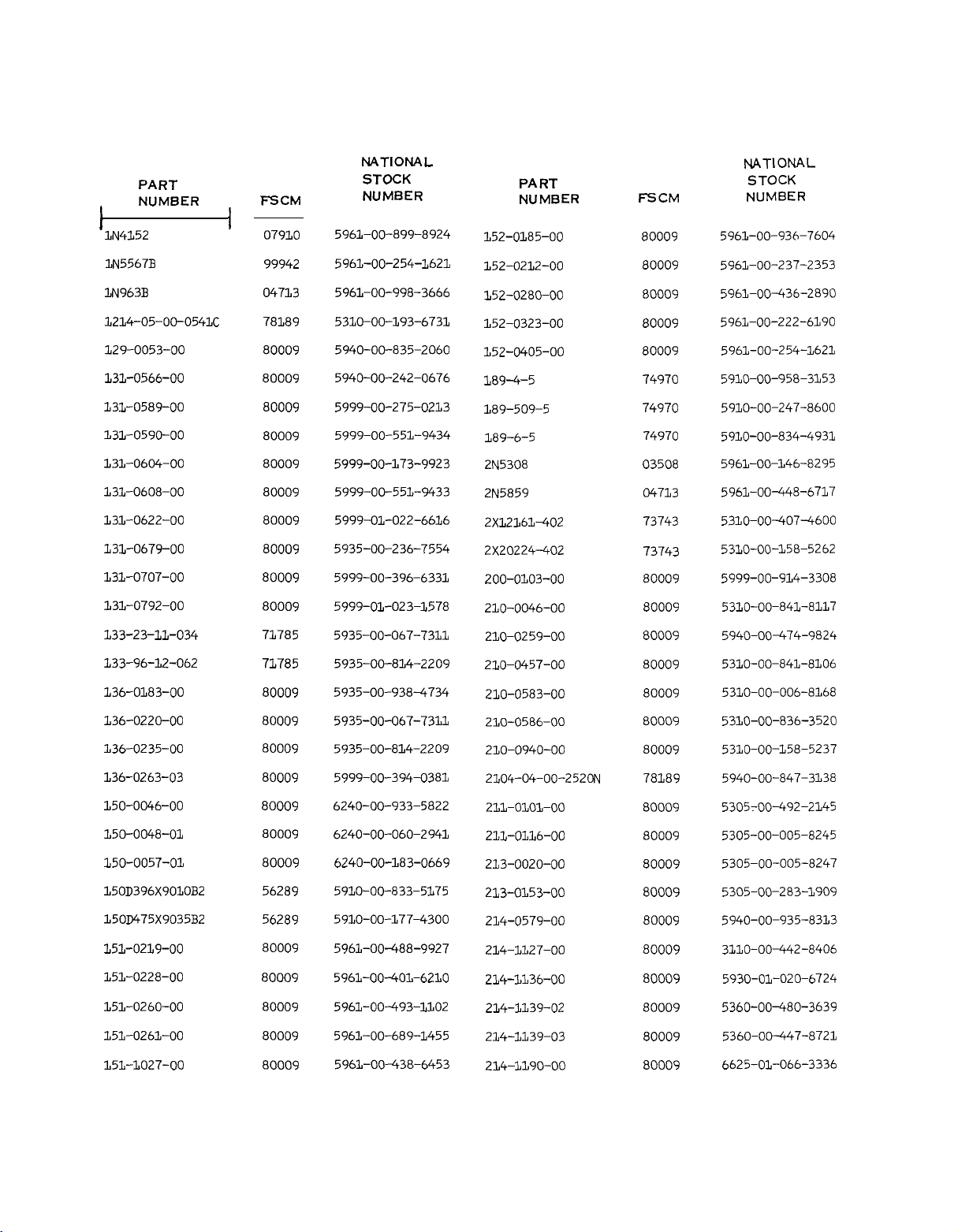

SECTION 9 PART NUMBER-NATIONAL STOCK

NUMBER CROSS REFERENCE

INDEX.

A - 1

COMPONENTS

B.

C. ADDITIONAL AUTHORIZATION LIST (Not Applicable)

D. MAINTENANCE ALLOCATION

Section I. General

Maintenance Allocation Chart for Differential Amplifier

II.

AM-6786/U

III.

Tool and Test Equipment Requirements for Differential

Amplifier AM-6786/U

APPENDIX E.

EXPENDABLE SUPPLIES AND MATERIALS LIST (Not Applicable)

OF END ITEM LIST (Not Applicable)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D-1

D-4

D-5

iii

Page 8

TM 11-6625-2749-14&P

LIST OF ILLUSTRATIONS

Figure

1-1

1-2

2-1

2-2

2-3

2-4A

2-4B

2-5

Page

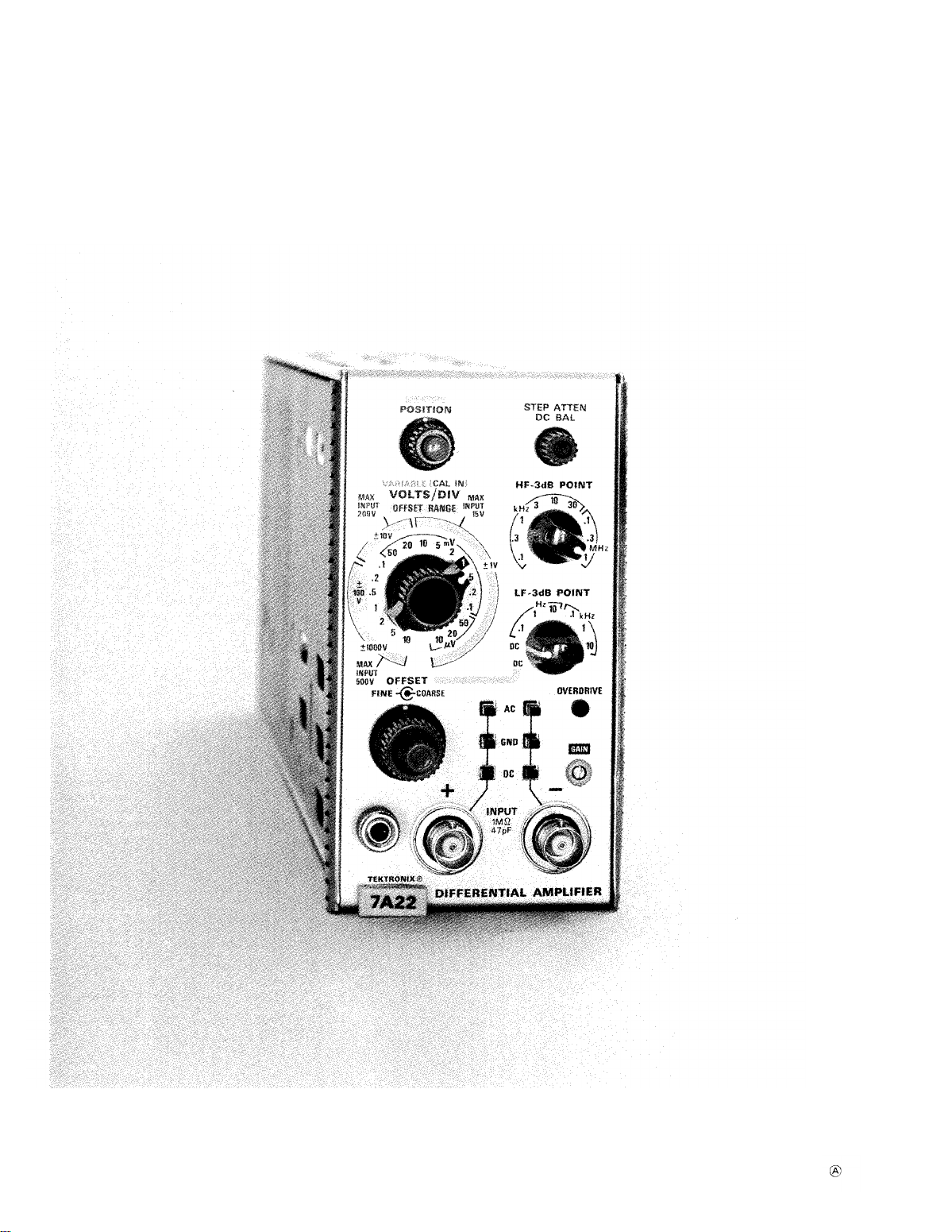

Type 7A22 Differential Amplifier. . . . . . . . . . . . . . . . .

A

CMRR vs Frequency for signal not exceeding Common Mode

Signal Range . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2

Signals applied to the + INPUT Connector Produce an

Upright Display, while signals applied to the - INPUT

are inverted . . . . . . . . . . . . . . . . . . . . . . . . . .

Location of AC ATTEN BAL Control . . . . . . . . . . . . . . . .

2-1

2-3

Location of wire strap between input line and internal

gate . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5

7A22 CMRR at 10 uV/Div to 10 mV/Div. Inputs DC Coupled.

Worst-case degradation due to source resistance . . . . . . . .

2-6

7A22 Bandwidth and VOLTS/DIV Error as functions of Source

Resistance . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7

7A22 FREQUENCY RESPONSE as a function of LF -3 dB POINT

SETTING (HF-3 dB POINT at l MHz) . . . . . . . . . . . . .

2-8

2-6

2-7

2-8

2-9

3-1

3-2

3-3

3-4

3-5

3-6

3-7

7A22 FREQUENCY RESPONSE as a function of HF -3 dB POINT

settings (LF -3 dB POINT of DC).

. . . . . . . . . . . . . . . . . . . . . . .

Improving signal-to-noise ratio by setting bandwidth . . . . .

2-9

2-10

Waveforms showing differential rejection of a common-mode

signal

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting a differential amplifier across a circuit . . . . .

2-11

2-12

Generalized feedback system showing the relation between

input and output . . . . . . . . . . . . . . . . . . . . . .

Feedback amplifier (Single-ended version).

. . . . . . . . . . . . . . .

Feedback amplifier (Differential configuration). . . . . . . . . .

Gate Current Compensation . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Common-mode Rejection using floating power supply . . . . . . . .

Input cross neutralization

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Effects of high impedance to ground in the - INPUT . . . . . . .

3-2

3-2

3-3

3-4

3-5

3-6

3-7

iv

Page 9

TM 11-6625-2749-14&P

Figure

3-8

3-9

3-10

3-11

4-1

4-2

4-3

4-4

4-5

4-6

Page

(A) Overdrive Protection System showing current paths.

(B, C) Sequence of events leading to excessive

overdrive

Offset system showing (A) Conditions with zero offset, (B)

0.25V DC offset

Functional arrangement of the offset generator

Partial Low Frequency -3 dB Point selector for + Input

amplifier

Removing or replacing component on circuit board

Transistor junction-voltage measurements

Transistor base pin and socket arrangement

Diode polarity and color code

Color code for resistors and ceramic capacitors

Plain circuit board (components)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . .

. . . . . . . . . . .

. . . . . . . . .

. . . . . . . . . .

3-8

3-9

3-10

3-11

4-2

4-6

4-7

4-8

4-8

4-10

4-7

4-8

5-1

5-2

5-3

5-4

5-5

5-6

5-7

5-8

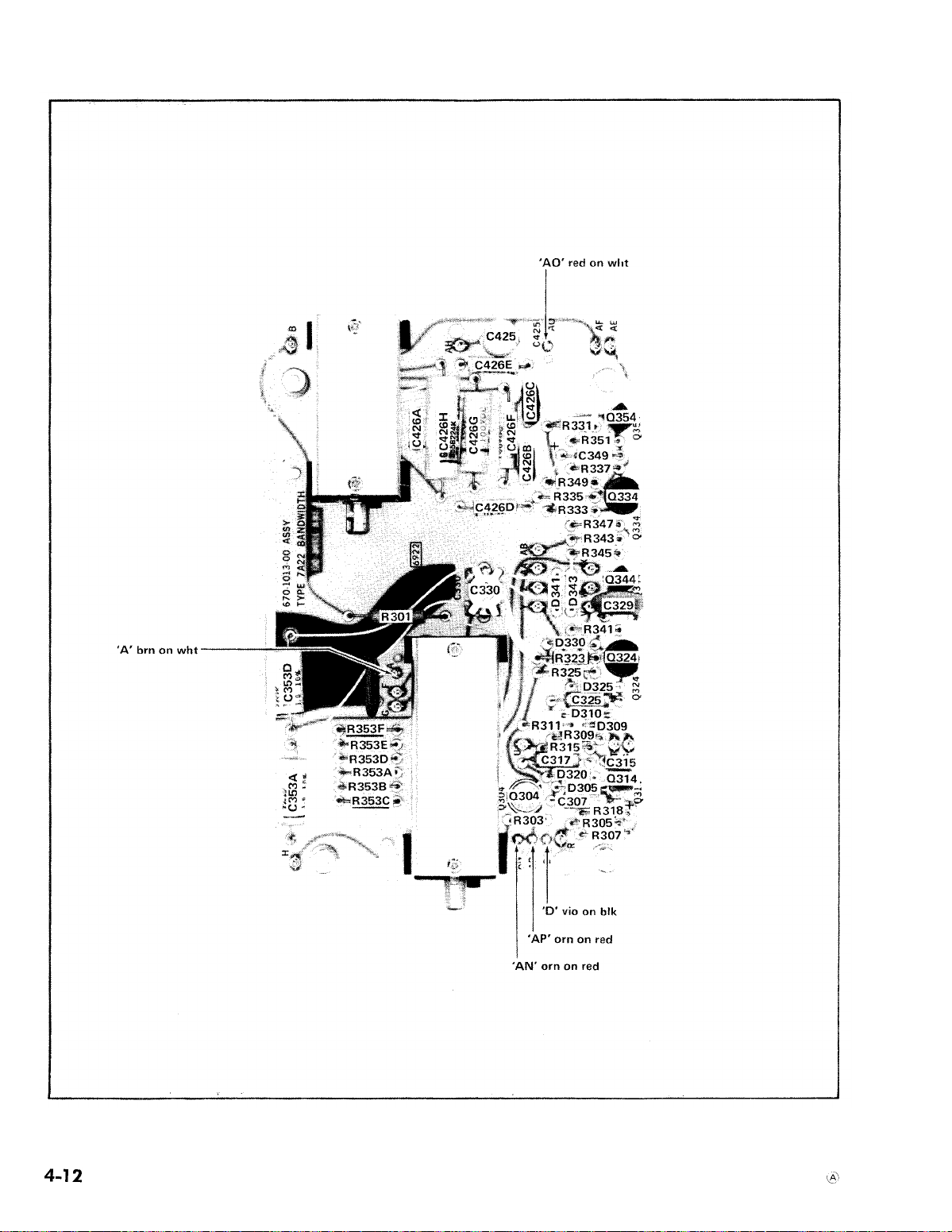

Main circuit board (wire color code)

Bandwidth circuit board (components and wire color code) .

Left side of the 7A22 showing adjustment locations

Equipment required for steps 6 through 19

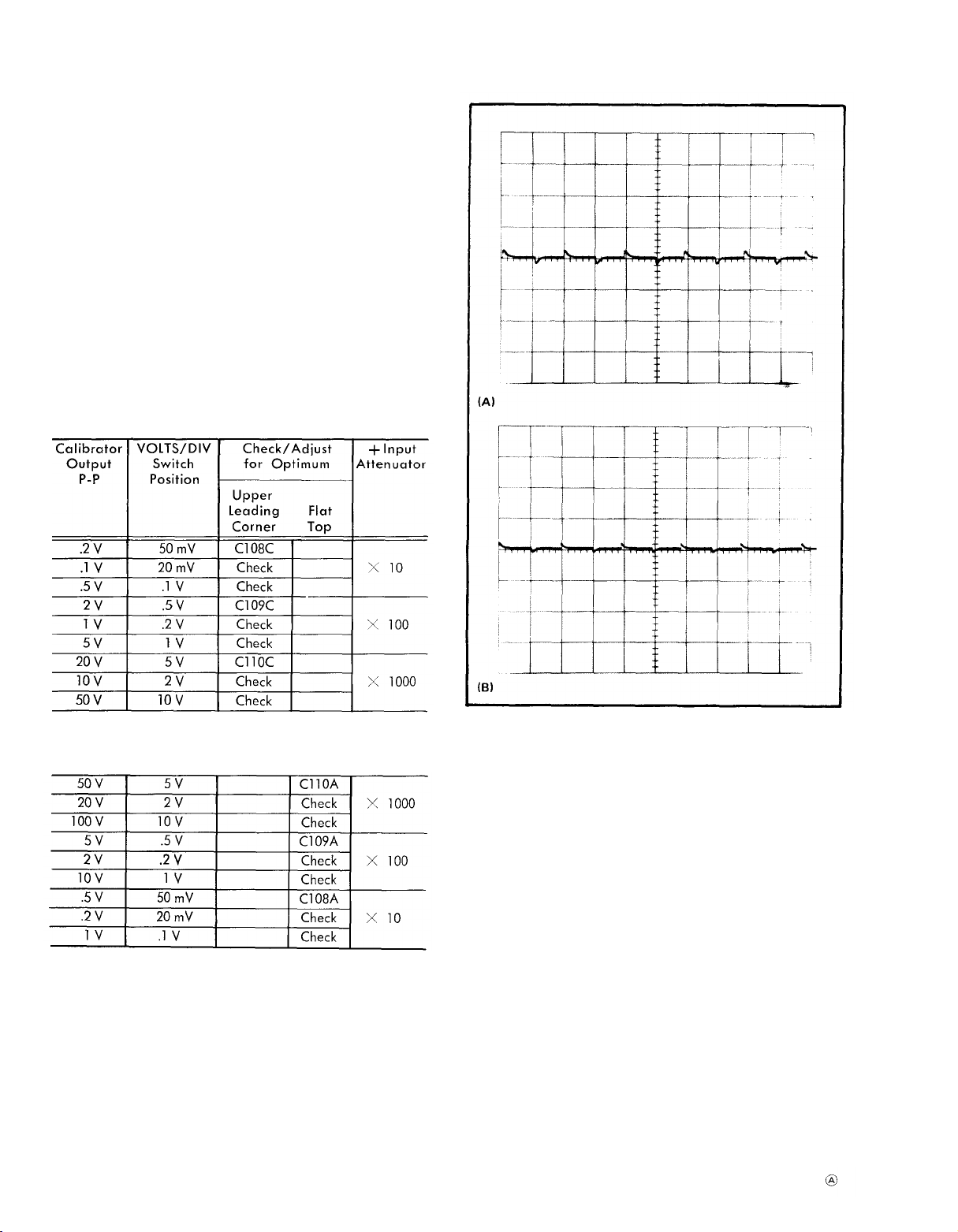

Typical waveform showing (A) Cross neutralization properly

adjusted, (B) incorrectly adjusted

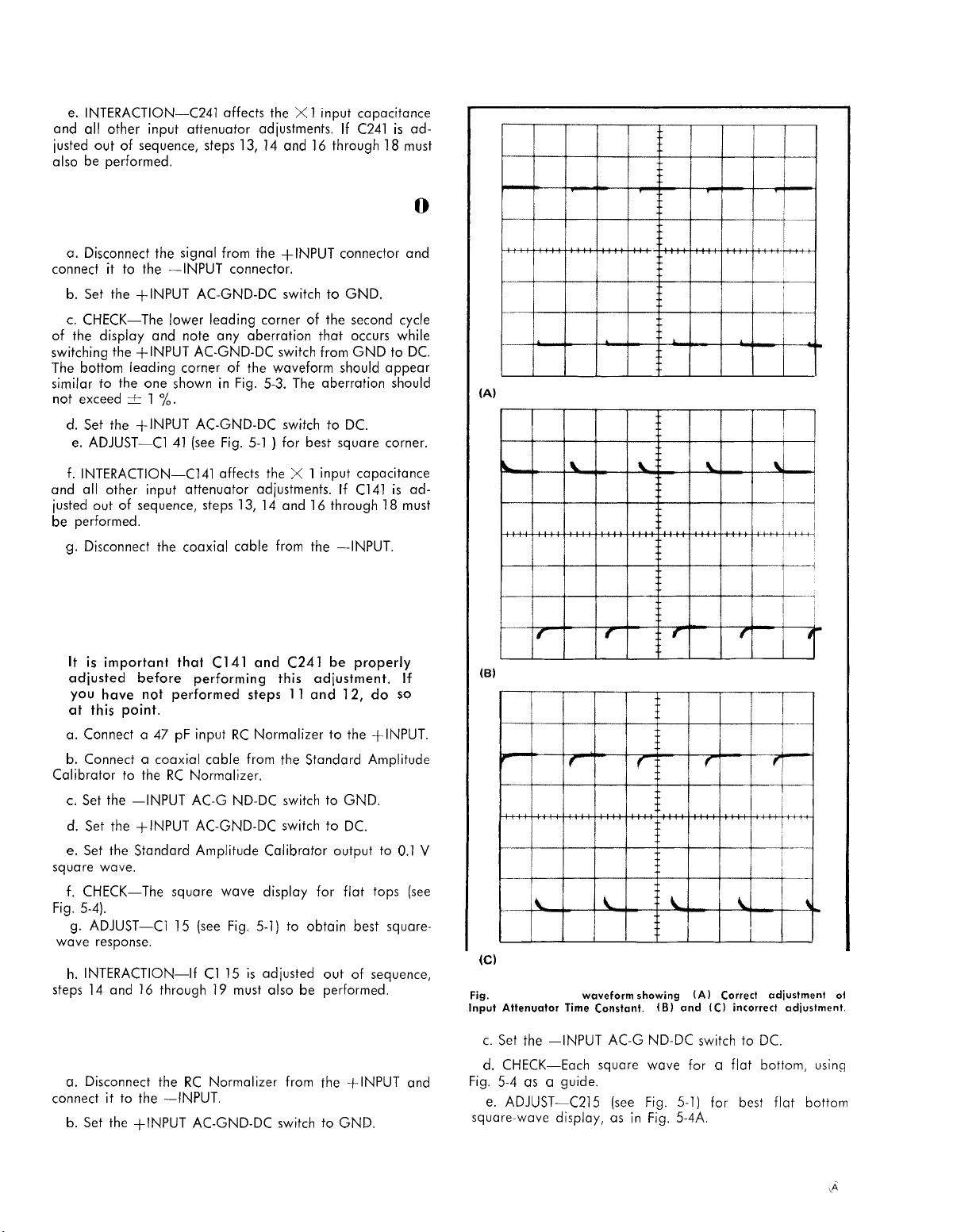

Typical waveform showing (A) Correct adjustment of Input

Attenuator Time Constant. (B) and (C) incorrect

adjustment

Typical display obtained when Input Attenuators are

adjusted for optimum differential balance

Typical display obtained with - Input attenuator adjusted

for optimum Common-Mode signal rejection. (A) C208C

adjusted properly (B) C209C adjusted properly

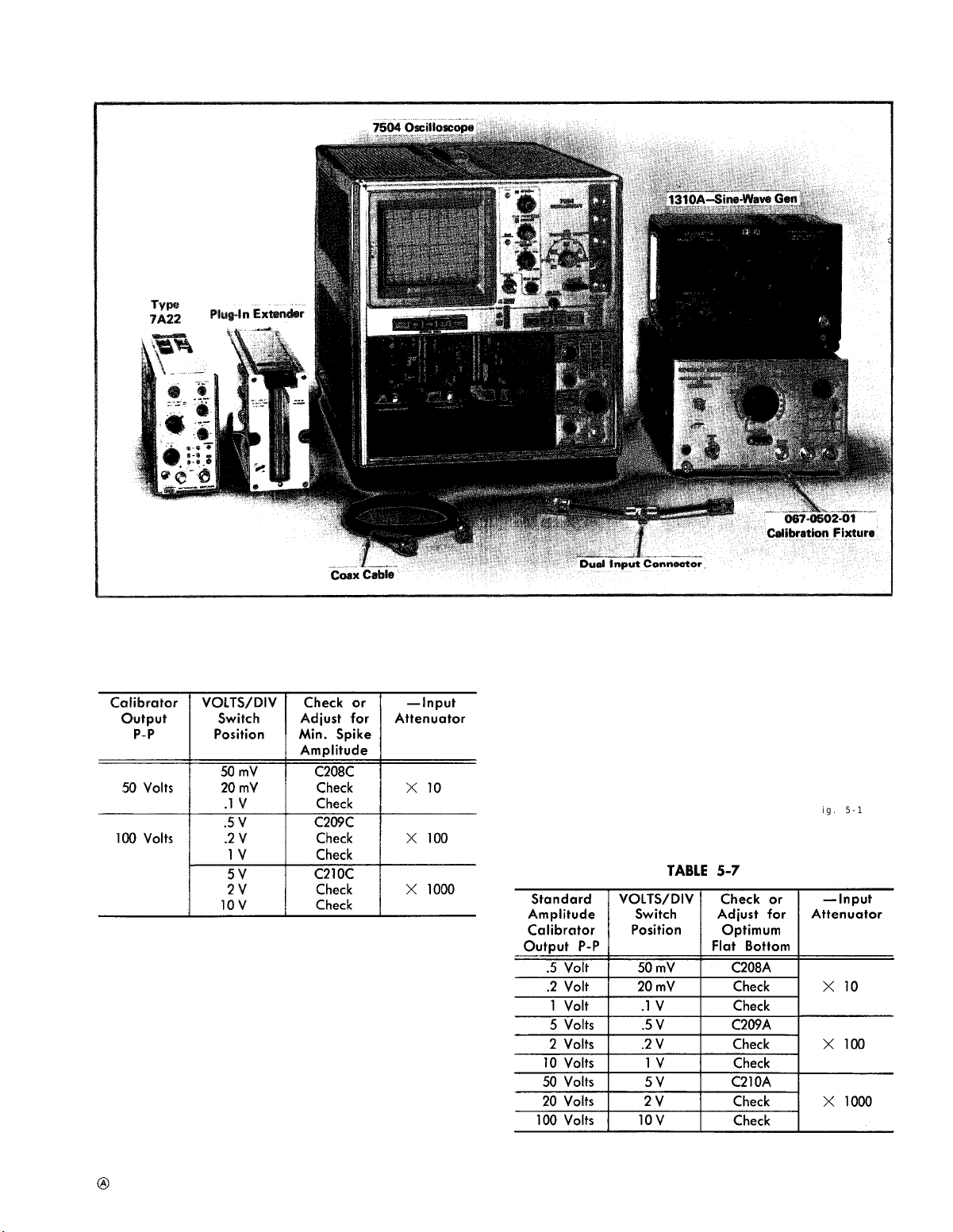

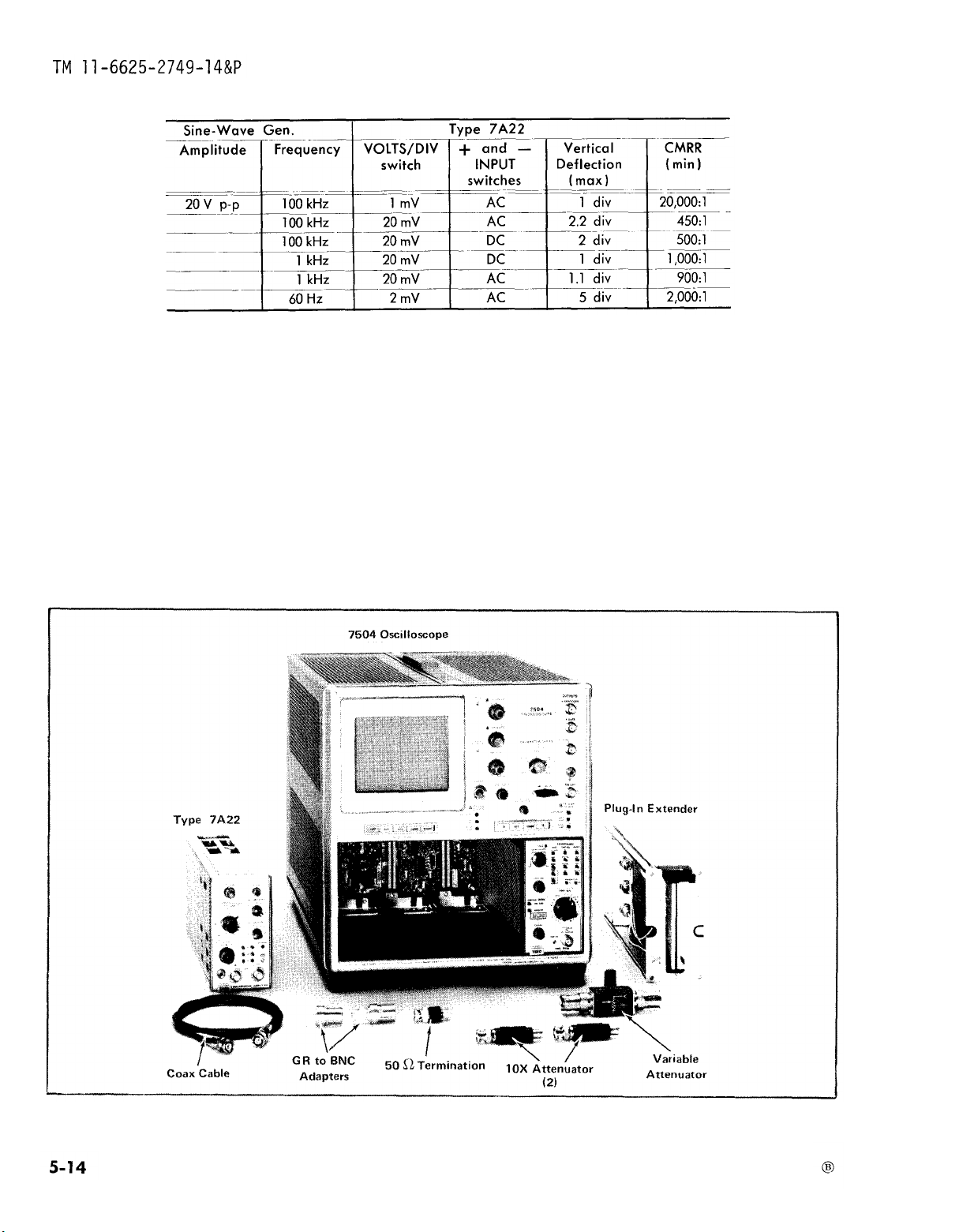

Equipment required for steps 20 through 24

Right side of Type 7A22 showing location of adjustments . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . . . .

4-11

4-12

5-4

5-6

5-7

5-8

5-9

5-10

5-11

5-12

v

Page 10

TM 11-6625-2749-14&P

Figure

5-9

5-10

5-11

5-12

Page

Equipment required for step 25

. . . . . . . . . . . . . . . . . . . . . . . . . . .

5-14

Typical display showing (A) two noise bands and (B) merging

noise bands . . . . . .

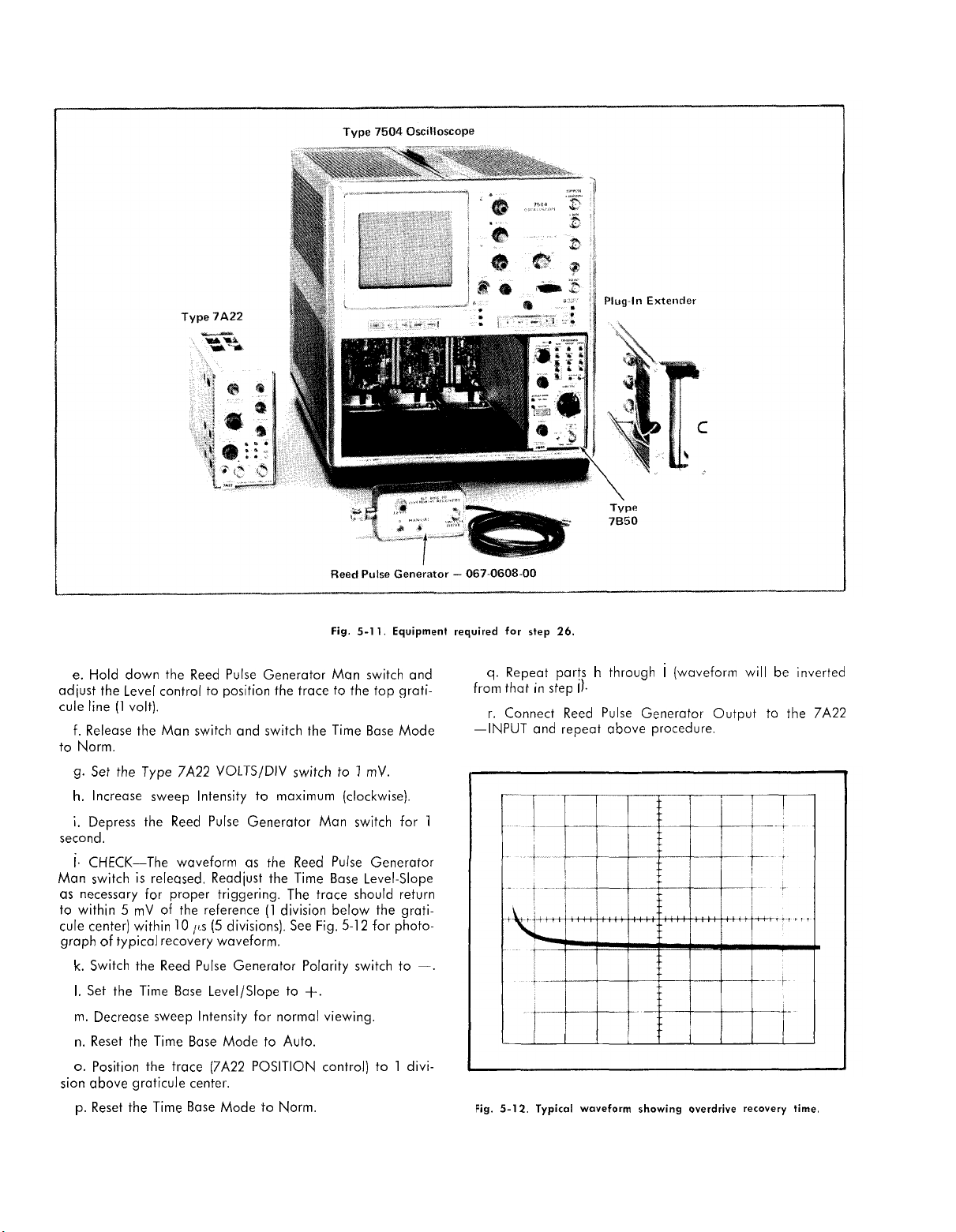

Equipment required for step 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Typical waveform showing overdrive recovery time . . . . .

5-15

5-16

5-16

vi

Page 11

Page 12

TM 11-6625-2749-14&P

Type 7A22

Fig. 1-1. Type 7A22 Differential Amplifier.

Page 13

SECTION 0

INTRODUCTION

TM 11-6625-2749-14&P

0-1.

6786/U and provides instructions for operation and maintenance. Throughout

this manual, the AM-6786/U is referred to as Tektronix Type 7A22 Differential

Amplifier.

included is a repair parts list.

0-2.

whether there are new editions, changes, or additional publications pertaining

to the equipment.

modification work orders (MWO’S) pertaining to the equipment.

0-3.

forms, records, and reports which are to be used by maintenance personnel

at all maintenance levels are listed in and prescribed by TM 38-750.

DD Form 6 (Packaging Improvement Report) as prescribed in AR 700-58/NAVSUPINST

4030.29/AFR 71-13/MCO P4030.29A and DLAR 4145.8.

SCOPE

This manual describes Vertical Plug-In Unit, Differential Amplifier AM-

The maintenance allocation chart appears in appendix D. Also,

INDEXES OF PUBLICATIONS

DA Pam 310-4.

a.

b.

DA Pam 310-7.

FORMS AND RECORDS

Reports of Maintenance and Unsatisfactory Equipment. Maintenance

b.

Report of Packaging and Handling Deficiencies. Fill out and forward

Refer to the latest issue of DA Pam 310-4 to determine

Refer to DA Pam 310-7 to determine whether there are

Discrepancy in Shipment Report (DISREP) (SF 361). Fill out and for-

ward Discrepancy in Shipment Report (DISREP) (SF 361) as prescribed in AR

55-38/NAVSUPINST 4610.33B/AFR 75-18/MCO P461O.19C and DLAR 4500.15.

0-4.

tions for preparing EIR’s are provided in TM 38-750, The Army Maintenance

Management System. EIR’s should be mailed direct to Commander, US Army

Communications and Electronics Materiel Readiness Command; ATTN: DRSEL-ME-MQ,

Fort Monmouth, NJ 07703.

0-5.

shall be in accordance with TM 750-244-2.

0-6.

in accordance with TM 750-244-2.

REPORTING EQUIPMENT IMPROVEMENT RECOMMENDATIONS (EIR)

EIR’s will be prepared using DA Form 2407, Maintenance Request. Instruc-

A reply will be furnished directly to you.

ADMINISTRATIVE STORAGE

Administrative storage of equipment issued to and used by Army activities

DESTRUCTION OF ARMY ELECTRONICS MATERIEL

Destruction of Army electronics materiel to prevent enemy use shall be

0-1

Page 14

Page 15

TM 11-6625-2749-14&P

SECTION

SPECIFICATION

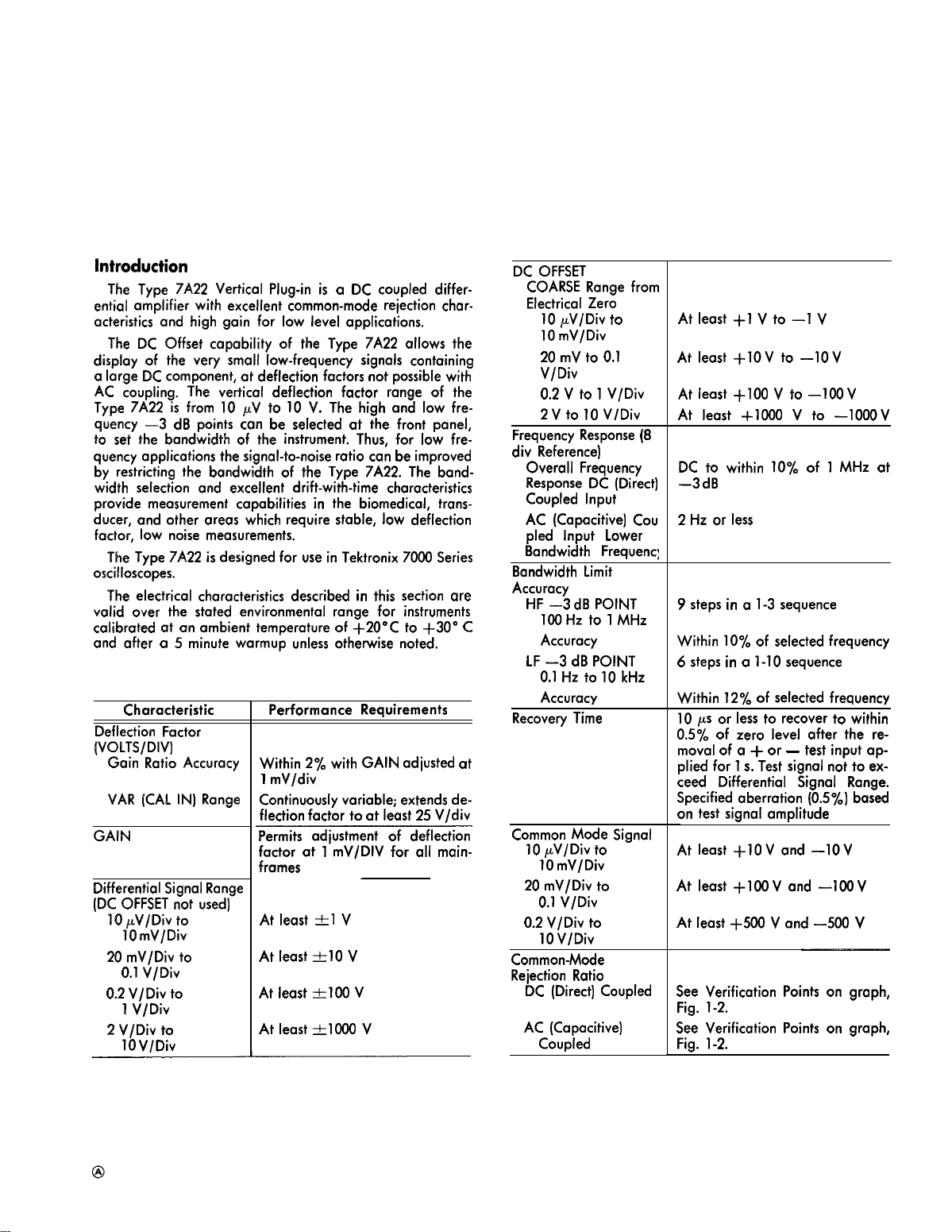

Introduction

h Type 7A22 Vertical Plug-in is

enticd

amplifier with excellent common-mode reiection char-

acteristics and high gain for low level applications.

The DC Offset capability of the Type 7A22 allows the

display of the very small low-frequency signals containing

a

large DC component, at deflection factors not possible with

AC coupling. The vertical deflection factor range of the

Type 7A22 is from 10 pV to 10 V. The high and low frequency —3 dB points

to set the bandwidth of the instrument. Thus, for low fre-

quency applications the signal-to-noise ratio can be improved

by restricting the bandwidth of the Type 7A22. The bandwidths selection and excellent drift-with-time

provide measurement capabilities in the biomedical, trans-

ducer, and other areas which require stable, low deflection

factor, low noise measurements.

The Type 7A22 is designed for use in Tektronix 7000 Series

oscilloscopes.

The electrical characteristics described in this section are

volid over the stated environmental range for instruments

ccdibrated at an ambient temperature of +20”C to +30”

and after

a 5

can be

minute warmup unless otherwise noted.

ELECTRICAL CHARACTERISTICS

Characteristic

Deflection Factor

~VOLTS/DIV]

Gain Ratio Accuracy

VAR (CAL IN) Range

GAIN

Differential Signal Range

[DC OFFSET not used)

10 pV/Div to

TO

mV/Div

20 mV/Div to

0.1 V/Div

0.2 V/Div to

1 V/Div

2 V/Div to

10 V/Div

Performance

Within 2% with GAIN ad@sted at

1 mV/div

Continuously variable; extends deflection factor to at least 25 V/div

Permits ad@stment of deflection

factor at 1 mV/DIV for all mainframes

At least AI V

At least *1O V

At least A1OO V

At least A1OOO V

a DC

selected at the front panel,

coupled differ-

characteristics

Requirements

C

1

DC OFFSET

COARSE Range from

Electrical Zero

10 pV/Div to

10mV/Div

20 mV to 0.1

V/Div

0.2 V to 1 V/Div

2V to 10 V/Div

Frequency Response (8

div Reference)

Overall Frequency

Response DC (Direct)

Coupled Input

AC (Capacitive) Cou

pled Input Lower

Bandwidth Frequencj

Bandwidth Limit

Accuracy

HF –3dB POINT

100Hz to 1 MHz

Accuracy

LF –3 dB POINT

0.1 Hz to 10 kHz

Accuracy

Recovery Time

Common Mode Signal

10 pV/Div to

10 mV/Div

20 mV/Div to

0.1 V/Div

0.2 V/Div to

10 V/Div

Common-Mode

Reiection Ratio

DC (Direct) Coupled

AC (Capacitive)

Coupled

At least +1 V to –1 V

At least +1OV to –1OV

At least +100 V to –1OOV

At least +1000 V to –1OOOV

DC to within 10~o of 1 MHz at

–3 dB

2 Hz or less

9 steps in

Within 10~o of selected frequency

6 steps in

Within 12% of selected frecluency

10 ps or less to recover to within

0.5% of zero level after the removal of

plied for 1 s. Test signal not to exceed

Specified aberration (0.5%) based

on test signal amplitude

At least +1OV and –1OV

At least +1OOV and –1OOV

At least +500 V and –500 V

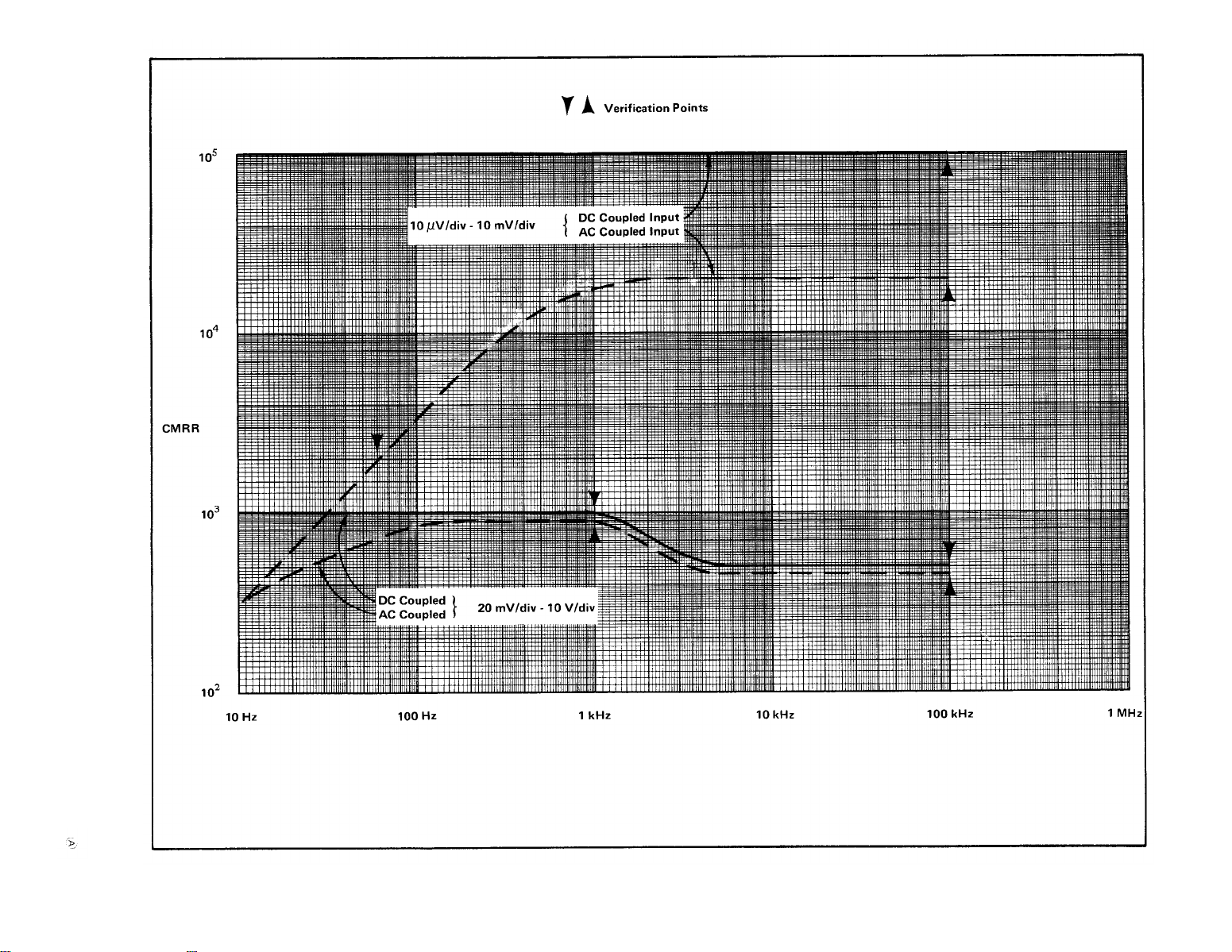

See Verification Points on graph,

Fig. 1-2.

See Verification Points on graph,

Fig. 1-2.

a

1-3 sequence

a

1-10 sequence

a + or —

Differential Signal Range.

test input ap-

1-1

Page 16

1-2

Fig. 1-2. CMRR vs. Frequency for signals not exceeding Common Mode Signal Range.

TM 11-6625-2749-14&P

Page 17

ELECTRICAL CHARACTERISTICS (cont)

Characteristic

Maximum Input Voltage

krch insxst}

Input R and C

Maximum Input Gate

Current

Varicrkde Balance

Displayed Noise (Tangentially Measured)

,-.

,

DC (Direct) Coupled,

EK + Peak AC, AC

Component 1 Mt-lz or

less

10pV/Div

mV/Div

20 mV/Div to 0.1

V/Div

.2 V/Div to 10 V/

Div

AC (Capcrcitive)

Coupled

Input DC Voltage

AC (Capacitive]

Coupled

Input DC Reiection

Resistcmce

Capacitance

F! & C Product

10 ~V/Div to 10 mV/

Div

20 mV/Div to IOV

Div

Display Shift at 10 pV

jDiv (AC Coupled]

tO

Performance

1

10

M least 4 X

lMa & l~o

Approximate

Within 3=1 Y. between all deflection factors

+25°

C

+-20 pA *1OO pA each input

+40 pA *200 pA Differentially

&lOpA

&20pA

A4 div &20 div

).2 div or less shift with VARIABLE

:ontrol turned from fully cw to

UIIY ccw position

6 pV or 0.1 Div (whichever is

~reater), 1 MHz HF –3 dB POINT,

ource resistance

Requirements

05:1

47.0 pF

25 Q or

-4-50°c

less

TM 11-6625-2749-14&P

DC Drift

Drift with Time (Ambient Temperature and

Line Voltage Constant)

Short Term

Long Term

Drift with Ambient

Temperature (Line

Voltage Constant)

Isolation between + and

– Inputs (+ INPUT to

an Open — INPUT, —

INPUT to on Open

INPUT)

5 pV (P-P) or 0.1 div (whichever

is greater) in any minute after 1

hour warmup

10 pV (P-P) or 0.1 div (whichever

is greater) in any hour after 1

hour warmup

50 pV/ “C or less

-f-

At least 200:1, DC to 1 MHz

ENVIRONMENTAL

PLUG-IN TESTED OUT OF INDICATOR

ITEM

Altitude

Non-operating

Transportation

CHARACTERISTIC

To 50,000 feet and —55° C

Qualified under National Safe

Tronsit Committee test procedure

1A, Category

PHYSICAL

ITEM CHARACTERISTIC

Finish

Dimensions

Weight

Front panel is anodized aluminum

s

145/8

478 inch H

=

25/8

Ibs

II

inch L X

OSCILLOSCOPE

2S/8

inch W X

1-3

Page 18

Page 19

TM 11-6625-2749-14&P

SECTION 2

OPERATING INSTRUCTIONS

Introduction

This section opens with a brief functional description of

the front-panel controls, input overdrive lamp, and input

connectors. Following the front-panel description is a familiarization procedure and finally a general discussion of the

operation of the Type 7A22.

CONTROLS AND CONNECTORS

INPUT Input overdrive indicator lamp turns on

OVERDRIVE

VOLTS/DIV Volts per displayed division. Nineteen

VARIABLE

(CAL IN]

GAIN

POSITION

IDENTIFY

HIGH

FREQUENCY

-3 dB POINT

to indicate excessive differential drive

to the input amplifier stage. Lights when

the differential dynamic range between

input connectors is exceeded.

position switch used to select the calibrated deflection factors.

Two-position switch activated by the

VARIABLE knob to select calibrated or

uncalibrated deflection factors. At the

IN position, the VARIABLE control is inoperative and the deflection factor is

calibrated. When pressed and released,

the knob moves outward to activate the

VARIABLE control for uncalibrated de-

flection factors. The uncalibrated posi-

tion provides continuously variable uncalibrated attenuation between the calibrated deflection factors and extends

the deflection factor to at Ieost 25

VOLTS/DIV.

Screwdriver adjust control to set the CRT

display scale factor to agree with the

VOLTS/DIV switch indication. Adjusted

for proper deflection with the VOLTS/

DIV switch set to the 1 mV position.

The control that vertically positions the

trace or display.

Momentary contact, push-button switch,

concentric with POSITION. Will cause

the trace, representing the output of the

Type 7A22, to move a small amount

when pressed. Aids in identifying the

Type 7A22 trace when multiple traces

are displayed.

Nine position switch to select the approximate high frequency -3 dB point.

The switch positions are: 100 Hz, 300 Hz,

1 kHz, 3 kHz, 10 kHz, 30 kHz, 100 kHz,

300 kHz, and 1 MHz.

LOW

FREQUENCY

-3 dB POINT

+INPUT

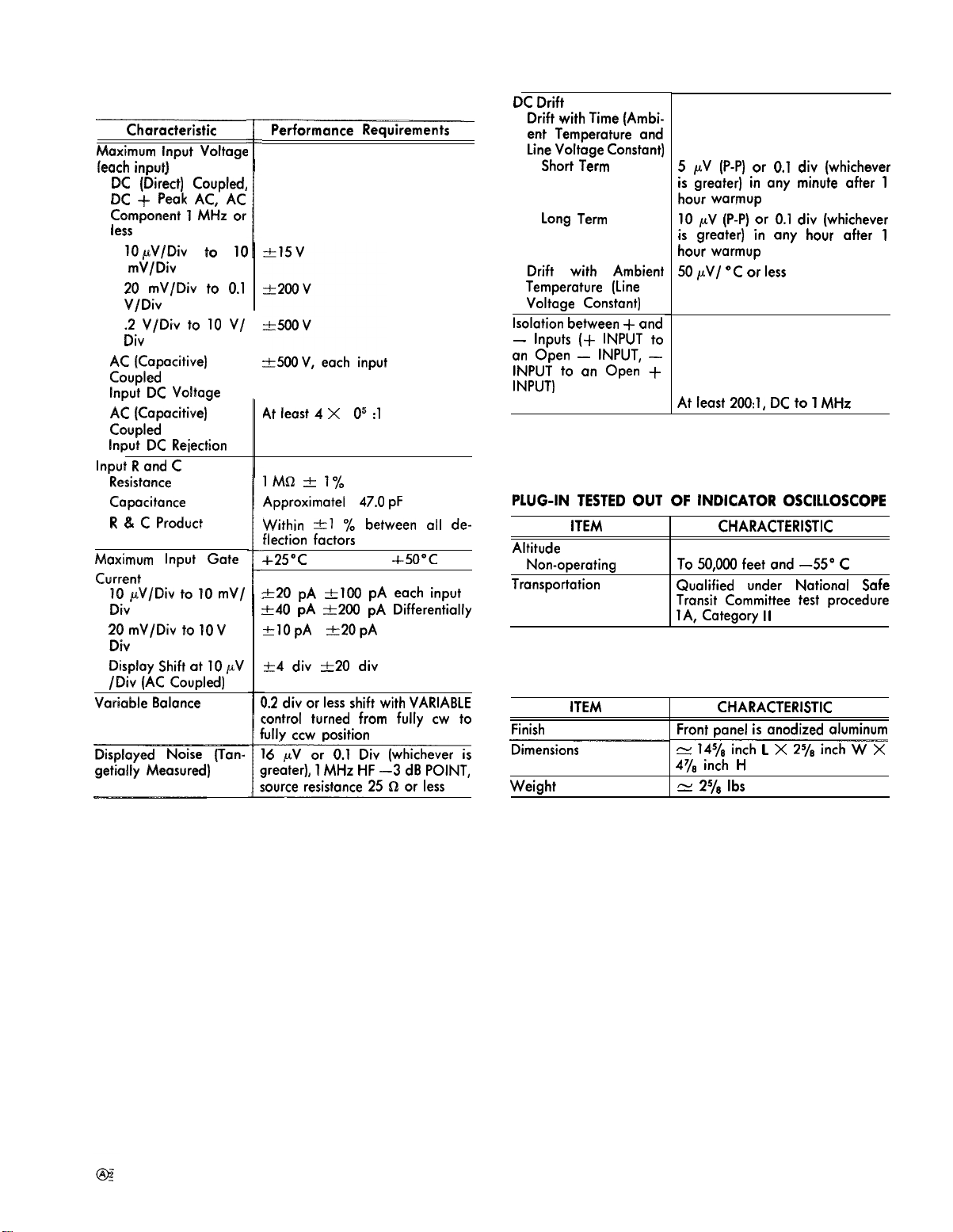

Fig. 2-1. Signals applied to the + INPUT connector produces an

upright display, while signals applied to the — INPUT are inverted.

+ AC-GND-DC

Eight position switch to select DC coupling or the approximate low frequency

-3 dB points. The switch positions are:

DC OFFSET, DC, .1 Hz, 1 Hz, 10 Hz,

100 Hz, 1 kHz, and 10 kHz.

Signal input connector. Positive input

produces deflection upward (see Fig.

2-l).

Signal input connector. Positive input

produces deflection downward (see Fig.

Fig. 2-1

A miniature illuminated push-button type

switch. The buttons are interlocked so

that only one button may be depressed

at one time. When the ‘AC’ button is

depressed the signal is coupled through

0.1 µF to the Input Amplifier and only

the varying component of the input sig-

nal is amplified.

When the ‘DC’ button is depressed the

signal is coupled directly to the Input

Amplifier and the entire input signal,

both AC and DC, is amplified. When

the ‘GND’ button (or none of the buttons) is depressed, the signal is coupled

Mfl

through 0.1 µF and through 1

ground. The Amplifier Input is grounded

in this condition.

to

2-1

Page 20

TM 11-6625-2749-14&P

aEoch push-button is illuminated from

behind when the button is depressed.

– AC-GND-DC

The following

when the LOW

is set to DC

STEP ATTEN

DC BAL (DC MODE the amplifier input stage. With

ONLY)

DC OFFSET

(DC OFFSET

mode only)

RELEASE LATCH Gray rectangular knob near the bottom

Same function as the + AC-GND-DC

switch but applied to the — INPUT.

IMPORTANT

two controls ore operative only

FREQUENCY

or

DC OFFSET.

Front panel cantrol for DC balancing

nals applied ta the input connectors,

the control is adlusted for

shift as the VOLTS/DIV switch is moved

from the 10 mV pasition to the 10

position.

Coarse and fine controls to provide

internal offset bias while maintaining

the differential

range of the offset bias depends upon

the settings of the VOLTS/DIV

and is indicated by shaded gray bands

(OFFSET RANGE) around the VOLTS/

DIV switch.

left of the front panel. Pull out to remove Plug-In fram Plug-In compartment.

—3 dB

POINT switch

capability. Available

no

no

switch,

sig-

trace

~LV

OPERATING INSTRUCTIONS

First-Time Operation

Steps

to help place the trace

the unit for immediate use. Steps 6 through 8 are used to

check

remaining are intended to demonstrate some of the basic

functions of the Type 7A22.

ment.

clockwise and turn the oscilloscope Power ON. Preset the

time-base and triggering controls

and automatic triggering.

oscilloscope to warm up.

1 through 5 in the following procedure are intended

the GAIN adjustment. These steps slang with those

1.

Insert the unit inta the ascilloscape plug-in compart-

2. Set the Type 7A22 front-panel controls as follaws:

VOLTS/DIV

VARIABLE

POSITION

HIGH FREQUENCY

–3dB POINT

LOW FREQ –3 dB

AC-GND-DC

AC-GND-DC

STEP ATTEN DC BAL

3. Turn the oscilloscope Intensity control fully counter-

4. Wait about five minutes for the Type 7A22 and the

(+

(–

INPUT)

INPUT)

on

the screen quickly and prepare

1 mV

IN (CAL)

Midrange

1 MHz

POINT

DC

GND

GND

Midrange

for a .5

ms sweep rate

NOTE

About five minutes is sufficient time for warmup

when using the Type 7A22 for short-term DC measurements. For long-term DC measurements

the lower deflection factors, allow at least one

hour.

5, Adlust the Intensity control for normal viewing of

the trace. The trace shauld appear near the graticule center.

6. Using the POSITION control, position the trace 2 divi-

sions below graticule center.

CAUTION

If the maximum input voltage rating in the 10 /IV

to 10 mV range of the VOLTS/DIV

ceeded, the inputs are diode-clamped

voltages of approximately

—16.5 volts and damage to the signal source is

possible. If the signal source can supply more than

1/1 6 A of current, the input protective fuse (s)

will open. An apen input fuse is indicated by the

lighting of the INPUT OVERDRIVE indicator with the

input coupling switches set to GND.

7. Apply

a

coaxial cable to the + INPUT connector

7A22.

8. For DC coupled, single-ended operation, set the +

INPUT AC-GND-DC

should

bottom of the disploy at the reference established in step 6.

9. For AC coupled, single-ended operation, reposition the

display with the Type 7A22 POSITION control to place the

bottom of the display at the graticule center line.

10. Set the + INPUT AC-GND-DC coupling switch to AC

and note that the display shifts downward about 2 divisions

to its average Ieve!,

11. Disconnect the coaxial cable from

nector. Connect

and — INPUT connectors. Connect the coaxial cable from

the Calibrator

12. For AC coupled differential

—INPUT AC-GND-DC

brator signal is now coupled to both inputs as

mode signal. A straight line display should

since the common-mode is being relected.

Operational Adjustments

Most of the following checks and adjustments may

be made after

to the DC drift of the amplifier during

warmup,

adjusted for each check or adjustment,

warmup of at least one hour should be allowed

before

in conjunction with the Type 7A22 is correctly cali-

brated (refer to the oscilloscope manual) and that

the calibrated output voltage is correct.

a 4 mV

be

square waves 4 divisions in amplitude with the

the

a

BAL is attempted. Insure that the oscilloscope used

peak-to-peak calibrator signal through

coupling switch to DC. The display

a

dual input connector

to

the dual input connector.

a 5

STEP ATTEN DC

final adjustment of the STEP ATTEN DC

+

coupling switch

NOTE

minute warmup; however due

16.5 volts and/or

the +

to

operation, set the

to

BAL shauld be re-

using

switch is ex-

to

fixed

on

the Type

INPUT con-

the + INPUT

AC. The cali-

a

common-

be

observed,

subsequent

and

a

2-2

Page 21

TM 11-6625-2749-14&P

1. AC ATTEN BAL

LOW FREQ —3 dB POINT switch is used to limit the low

frequency response of the Type 7A22, the unit employs

AC stabilization. This means that when the switch is set

to

crny

position except DC or DC OFFSET, the STEP ATTEN

DC BAL and DC OFFSET controls become inoperative.

VOLTS/DIV

BALI ;; inkm-ml cdiushent

Fig.

When trcsnsferring the Type 7A22 from ane oscilloscope

to another, it may

ad~ustment of this control, due to normal power supply varicstions between oscilloscopes.

Ixslance is then controlled with the AC ATTEN

2-2. location

of AC ATTEN BAL

be

(internal adiustmerst) . When the

(see

Fig. 2-2].

control.

necessary to perform

a

minor re-

NOTE

An unbalance of up to 30 pV is normal and cannot be reduced by adiusting the AC ATTEN BAL

control.

a.

With the Type 7A22 inserted into the oscilloscope, re-

move the left side panel of the oscilloscope and set the

Type 7A22 controls as follows:

VOLTS/DIV

AC-GND-DC (+ INPUT)

AC-GND-DC (–INPUT)

LOW FREQ —3 dB POINT 10 Hz

HIGH FREQ –3 dB POINT 100 Hz

b.

Using the POSITION

graticule center.

c. Set the VOLTS/D[V

d.

Adiust the AC ATTEN BAL control, R505, to position

the trace to within 1.5 divisions of graicu[e center. (See

note in step

INTERACTION:

1).

quence, steps 2 and 3 must also

If

this adjustment is made out of se-

1 mV

GND

GND

control, position the trace to

switch to 20 pV.

be

performed.

2.

VAR BAL R425.

a.

Set the Type 7A22 controls as in step 1 -a.

b.

Position the trace to graticule center with the POSl-

TION control.

c.

With the VAR (CAL IN) in the out position, rotate the

VARIABLE control from stop to stop. Check for no move-

ment of trace.

d.

Adiust R425 for no movement of trace as the VARlABLE control is rotated from stop to stop. (See Fig. 2-2 for

location of adjustment.)

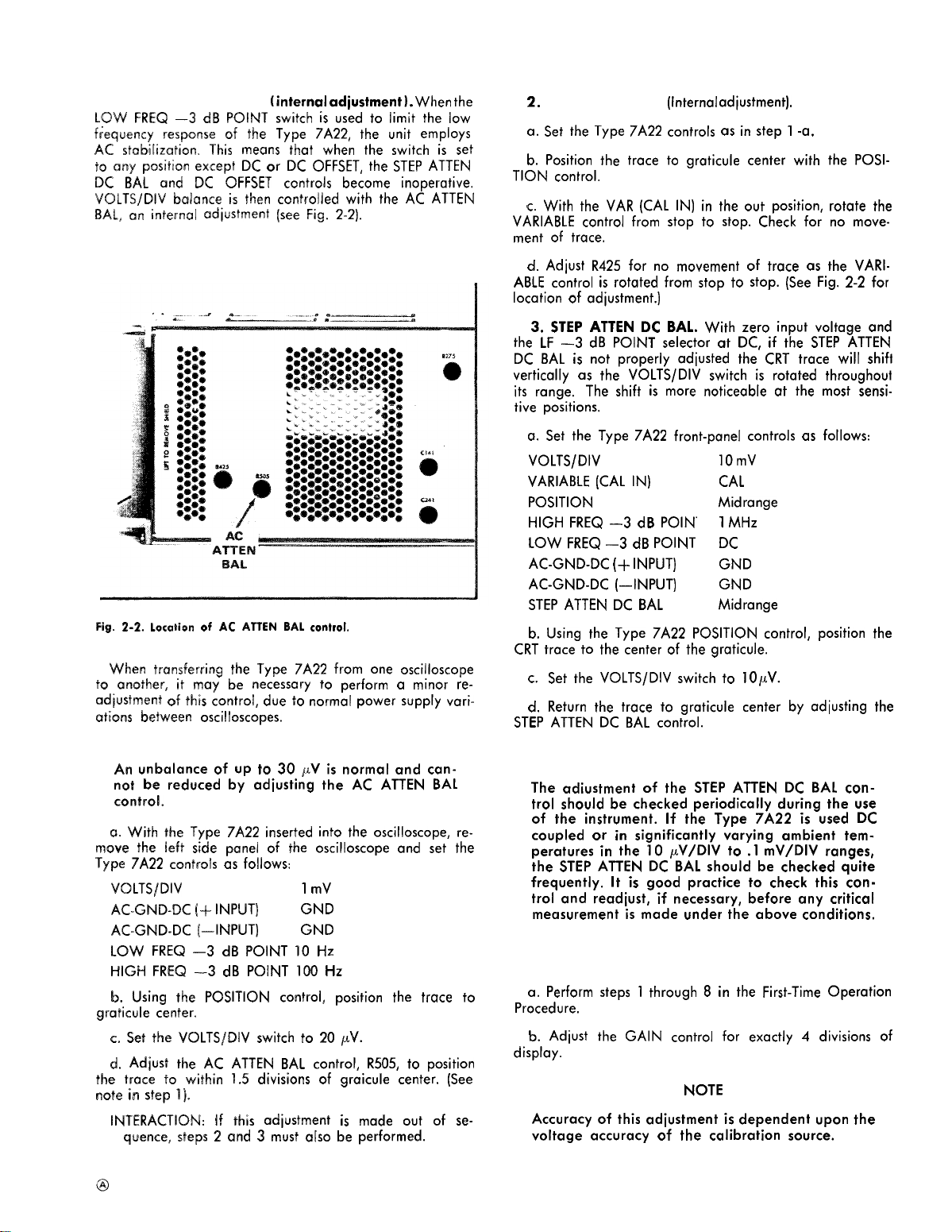

3. STEP ATTEN DC BAL. With zero input voltage and

the LF –3 dB POINT selector at DC, if the STEP ATTEN

DC BAL is not properly adiusted the CRT trace will shift

vertically as the VOLTS/DIV

its range.

tive positions.

a.

VOLTS/DIV

VARIABLE [CAL IN)

POSITION

HIGH FREQ –3 dB POIN’

LOW FREQ –3 dB POINT

AC-GND-DC (+ INPUT)

AC-GND-DC (–INPUT)

STEP ATTEN DC BAL

b.

CRT trace to the center of the graticule.

c.

d.

STEP

The shift is more noticeable at the most sensi-

Set the Type 7A22 front-panel centrals as follows:

Using the Type 7A22 POSITION control, position the

Set the VOLTS/DIV

Return the trace to graticule

ATTEN DC BAL cantrol.

(Internal adjustment].

switch is rotated throughout

10mV

CAL

Midrange

1 MHz

DC

GND

GND

Midrange

switch to

I o pv.

center by adiusting the

NOTE

The adjustment of the STEP ATTEN DC BAL con-

trol should be checked periodically

of the instrument. If the Type 7A22 is used DC

coupled or in significantly

peratures in the 10 KV/DIV to

the STEP ATTEN DC BAL should be checked quite

frequently.

trol and readiust, if necessary, before any critical

measurement is made under the above conditions.

It is

good practice to check this con-

during the use

varying ambient tem-

.1

mV/DIV ranges,

4. GAIN

a.

Perform steps 1 through 8 in the First-Time Operation

Procedure.

b.

Adiust the GAIN control for exactly 4 divisions of

display.

NOTE

Accuracy of this adjustment is dependent upon the

voltage accuracy of the calibration source.

2-3

Page 22

TM 11-6625-2749-14&P

GENERAL OPERATING INFORMATION

Trace Drift

The environment in which the Type 7A22 is operated and

the inherent characteristics of the Type 7A22 influence trace

drift. Therefore, to determine trace drift for

vironment refer to the Specification Section. In environment

in which the ambient temperature does not vary

as an air-conditioned building) the trace drift generally will

not exceed 10 ~LV in one hour.

Input Gate Current

When using the .1 mV/DIV to 10 ILV/DIV ranges for measurement with

where the source impedance is high

input gate current should

adlusted to zero. This is particularly desired at high temperatures (abave 40”

Check/Calibration

procedures for setting the gate current to zero.

Voltage Measurement

To obtain accurate DC measurements at maximum sensitivity, it is necessary

the amplifier lust before making the measurement. This is

accomplished by adiusting the STEP ATTEN DC BAL as

described under operational adjustment number 3.

When measuring DC voltages, use the largest deflection

factor (10 V/DIV) when first connecting the Type 7A22 to

an unknown voltage source.

small to make the measurement, switch to

tion factor. If the input stage is overdriven,

of current might flow into the input. See CAUTION after

item 6 of First Time Operation.

Where only the AC component of

AC and DC components is to

GND-DC switches to take advantage of the pre-charging

circuit incorporated in the unit. The pre-charging circuit

permits the coupling capacitor to charge to the DC source

voltage when the AC-GND-DC switch is set to GND. Procedure for using this circuit is as follows:

a.

Before connecting the Type 7A22 to

ing

a DC

switch to GND. Then connect the input to the circuit under

test.

b.

Allow about one second for the coupling capacitor to

charge.

b.

Set the input coupling switch to AC. The display will

remain

ured in the usual manner.

d. On

DC switch to GND and short the input connector to ground.

The above procedure should

other signal with

If the Type 7A22 is connected to

age source

sion,

an AC

companent, set the AC-GND-DC

on

the screen and

completion of the measurement, set the AC-GND-

the peak charging current (into 0.1 ILF

coupled input, for DC measurements

be

C).

Steps 7 and 8 in the Performance

Procedure describe the

to

ground the input and DC balance

the AC

a

different DC level is connected.

CAUTION

without using the pre-charge provi-

(in

checked and allowed for, or

Then, if the deflection is too

a

be

measured, use the AC-

component

be

followed whenever an-

a

specific

much (such

excess of 1 Mo) the

check

signal having both

a

a

large DC volt-

and adiust

a

lower deflec-

a

large amount

signal containinput coupling

can be

en-

meas-

capacitor)

source, and this source may be damaged or de-

stroyed.

When

7A22 with the input AC coupled, the input coupling capacitor acquires

as

a

very slowly decaying output voltage. This

sequent AC coupled measurements at other DC voltages

and drive the trace off-screen. A period of at least 10 min-

utes, with input set to GND, should

reasonable recovery from polarization, and a longer period

may

be

connectors are shorted to ground the depolarization process will require less time.

Signal Input Connectors

When connecting signals to the +INPUT and –INPUT

connectors

pling that will

sometimes

source, particularly when

is monitored at

of these factors are missing, it becomes increasingly important to use shielded signal cables. In all cases, the signaltransparting leads should

When making single-ended input measurements,

to establish

test and the Type 7A22. The shield of

normally used for this purpose.

In some cases differential measurements require

mon ground’,

ference by ground loop currents. Some problems with

stray magnetic coupling into the signal transporting leads

can

also

single-ended measurement.

cussed later in this section under Differential Operation.

It is always important to consider the signal-source loading and resulting change in the source operating characteristics due to the signal-transporting

circuit of the Type 7A22. The circuit at the input connectors

can

normally

ground paralled by 47 pF. A few feet of shielded cable

may increase the parallel capacitance

In many cases, the effects of these resistive and capacitive

loads may

them through the use of

Attenuator probes not only decrease the resistive and

capacitive loading of

measurement range of the Type 7A22 to include substantially higher voltages. Passive attenuator probes having attenuation factors of 10X, 100X, and lOOOX, as well as other

special-purpose types are available through your Tektronix

Field Engineer or Field Office.

Some measurement situations require

put to the Type 7A22 with very littIe source loading or sig-

‘The DC plus

to the chassis

the levels listed in Section 1 under

Voltage

reiection ratio

will be limited only by the signal

a

large DC voltage has been applied

a

low voltage, high impedance voltage source with

characteristics.

charge due

necessary for critical measurements. If the input

on

the Type 7A22, consider the method of

be

be

used to connect the Type 7A22 to

a

a

common ground between the device under

and therefore are less susceptible to inter-

be

minimized by using

be

represented by

be

too great and it may

peak

AC

potential

and

exceed the input

to

dielectric polarization and acts

be

used. Ordinary unshielded test leads

a

high level, low-frequency signal

low impedance point, However when any

be

kept as short as practical.

a

These considerations

an

attenuator probe.

a

signal source, but also extend the

voltages

of the Type

Higher

on the test points with respect

levels will

differential rather than

leads and

a 1

megohm resistance ta

to

be

desirable to minimize

a

7A22

Maximum

degrade

voltage rating

to

the Type

can

offset sub-

allowed to assure

cau

a

be

a

coaxial cable is

no

are dis-

the

100 pF or more.

high-resistance in-

should be limited to

Common-mode Input

the common-mode

of the unit.

a

can

signal

sure

com-

input

-

2-4

Page 23

TM 11-6625-2749-14&P

not attenuation. In such

probe cannot

by using an

vision of the Type 7A22.

High Input Impedance

TIM

coupled signals which permit the use of 10mV through 10

pV”psitions

no input attenuator is used at these switch positions, the

internal gate return resistor olone establishes the 1 megohm

input resistance.

The high input impedance is obtained by unsoldering the

wire strap

nal gate return resistance. The signal source must then provide

a DC

be

csetive

high input impedance provision applies only to DC

of

the VO”LTS/DIV switch, (DC coupled). ‘Since

(see

Fig. 2-3] between the input line and the inter-

path for the FET gate current.

a

situcstion

used. However, this problem may

probe or the high input impedance pro-

a

passive attenuator

be

solved

Display Polarity

Single-ended signals

or —INPUT connector. If the + INPUT is chosen, positivegoing changes in the input signal will cause the trace to be

deflected upward, and negative-going changes will cause

the trace to

chosen, input-to-display polarity relationship will

as shown previously in Fig. 2-1.

Deflection

The amount of trace deflection produced by

determined by the signal amplitude, the attenuation factor

of the probe, the setting of the VOLTS/DIV switch and the

setting of the VARIABLE control. The calibrated deflection

factors indicated by the VOLTS/DIV switch apply only when

the VARIABLE control is pushed “in” to the CAL IN position.

The range of the VARIABLE control is at least 2.5:1. It provides uncalibrated deflection factors covering the full range

between the fixed settings of the VOLTS/DIV switch. The control can be set to extend the deflection factor to at least 25

volts/div.

Noise

be

Factor

Can be

deflected downward. If the —INPUT is

applied to either the +INPUT

be

reversed

a

signal is

Fig.

2-3. location of wire

return resistor.

The uncompensated gate current is typically less than 100

picoamperes,

upon the operating temperature. The signal-source imped-

ance is therefore can important factor since gate current will

produce

current through 10 megohms produces

may resu[t in

concern.

Men the wire straps are removed, R111 and R211

are disconnected. The deflection factor in the 20 m V/

DI V to 10 V/Dl V range will be incorrect.

The high-frequency response will

but may

a DC

a

signcsl-source impedance,

between the source

input capacitance, must charge and discharge through that

impedance [see Fig. 2-4).

strap between input

be

several times higher depending

offset. For example,

significant error where small voltages are of

NOTE

since various shunt capacitances

cmd

the 7A22 input as well as the 47 pF

line and internal gate

a

100 picoampere gate

a 1 mV

also depend upon the

offset; this

To reduce noise and obtain

the VOLTS/DIV switch is operated in the 10 wV, 20 wV, and

50 pV positions or when the signal source is “noisy, it is suggested that the HIGH FREQ —3 dB POINT selector

to use the lowest bandwidth setting which does not appreciably distort the desired features of the signal under observation. Refer to Fig. 2-6 for the high frequency rolloff for each

setting of the HIGH FREQ —3 dB POINT selector.

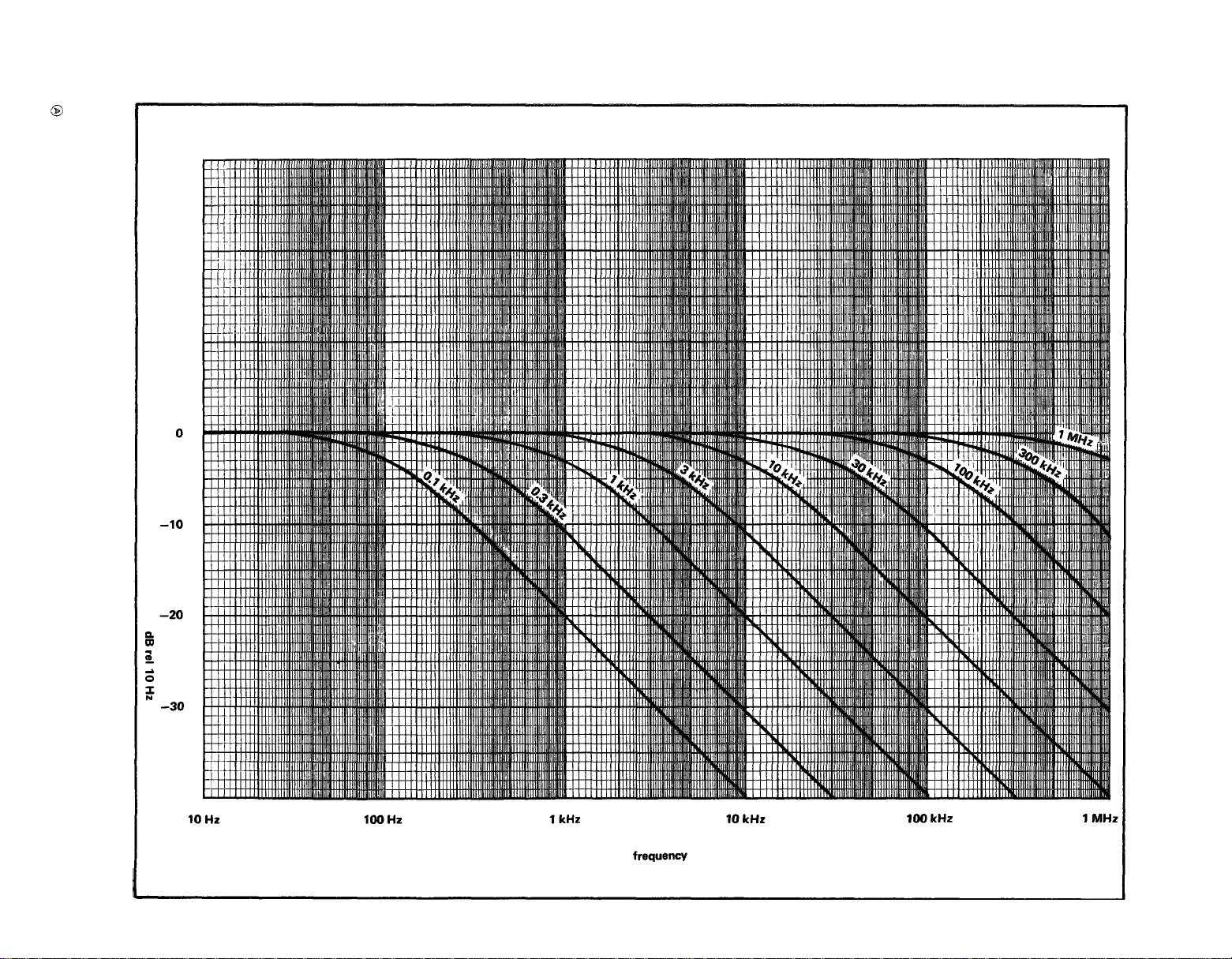

Bandwidth

In addition to the differential reiection of unwanted signals,

many times an undesired signal

the bandwidth of the unit. The LOW FREQ –3 dB POINT

and HIGH FREQ —3 dB POINT selectors on the front panel

of the 7A22 control the low-frequency and high-frequency

–3 dB points of the amplifier. The LOW FREQ –3 dB POINT

selector provides low-frequency response to DC or to ap-

proximate —3 dB points at .1 Hz, 1 Hz, 10 Hz, 100 Hz, 1 kHz,

and 10 kHz. Refer to Fig. 2-5. The HIGH FREQ —3 dB POINT

selector controls the high-frequency rolloff from 1 MHz to

100 Hz in

frequency response falls off at

to Fig. 2-6.

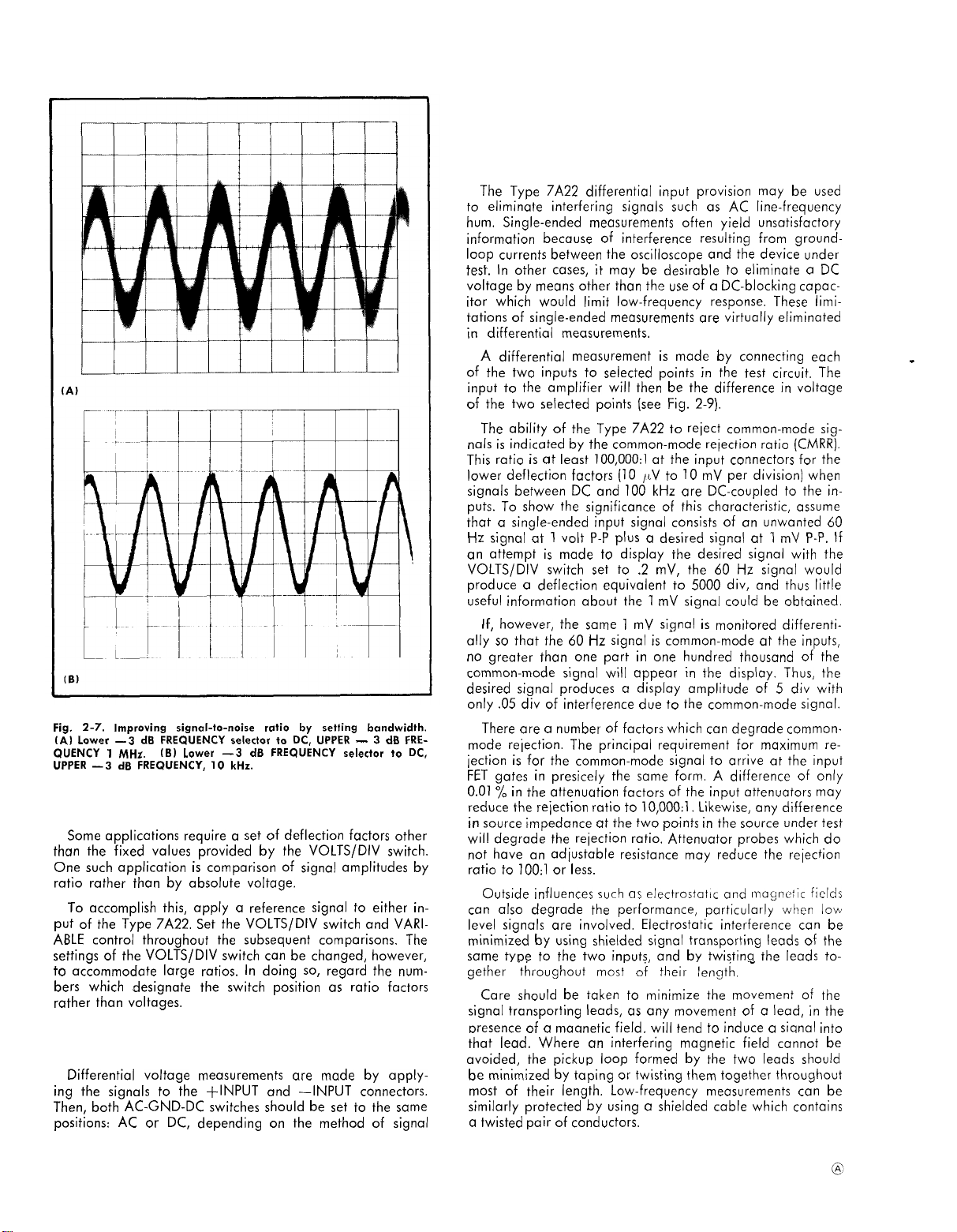

Varying the bandwidth of the Type 7A22 is useful, for example, when displaying

the high-frequency response the noise can, in many cases, be

considerably reduced without distorting the desired signal

(see Fig. 2-7). Likewise, undesired line-frequency signals can

be

filtered out by restricting the low-frequency response of

the unit. When using the LOW FREQ —3 dB POINT and

HIGH FREQ —3 dB POINT selectors, care must be taken not

to distort non-sinusoidal waveforms by overly restricting the

amplifier bandwidth.

Selection

a

1-3-10 sequence. Beyond the –3 dB points the

a

more usable display when

can be

a 6 dB

a

low-frequency signal. By reducing

attenuated by varying

per octave rate. Refer

be

set

REV. B, FEB. 1975

2-5

Page 24

2-6

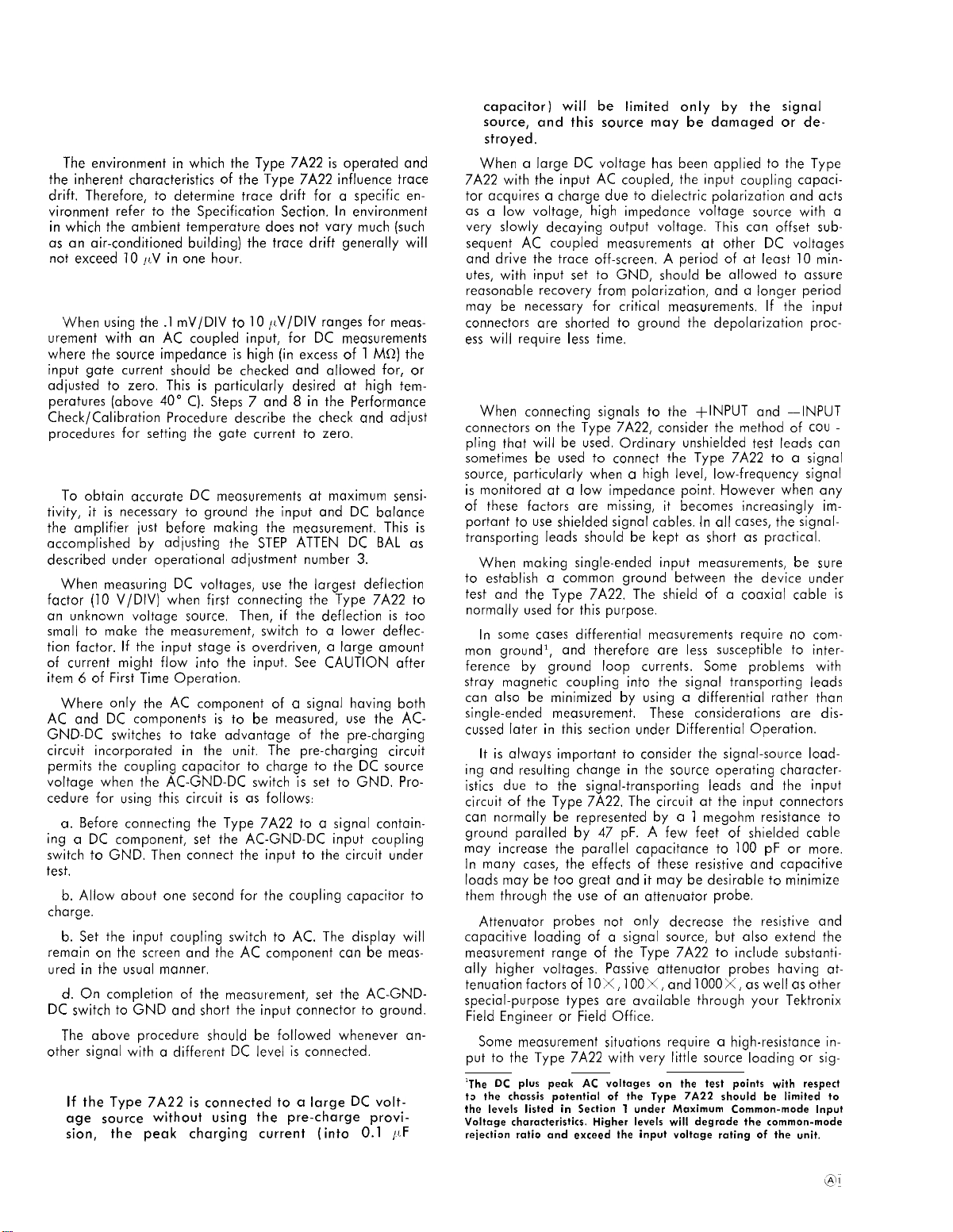

Fig. 2-4A. 7A22 CMRR at 10 µV/Div to 10 mV/Div. Inputs DC Coupled. Worst-case degradation due to source resistance.

TM 11-6625-2749-14&P

Page 25

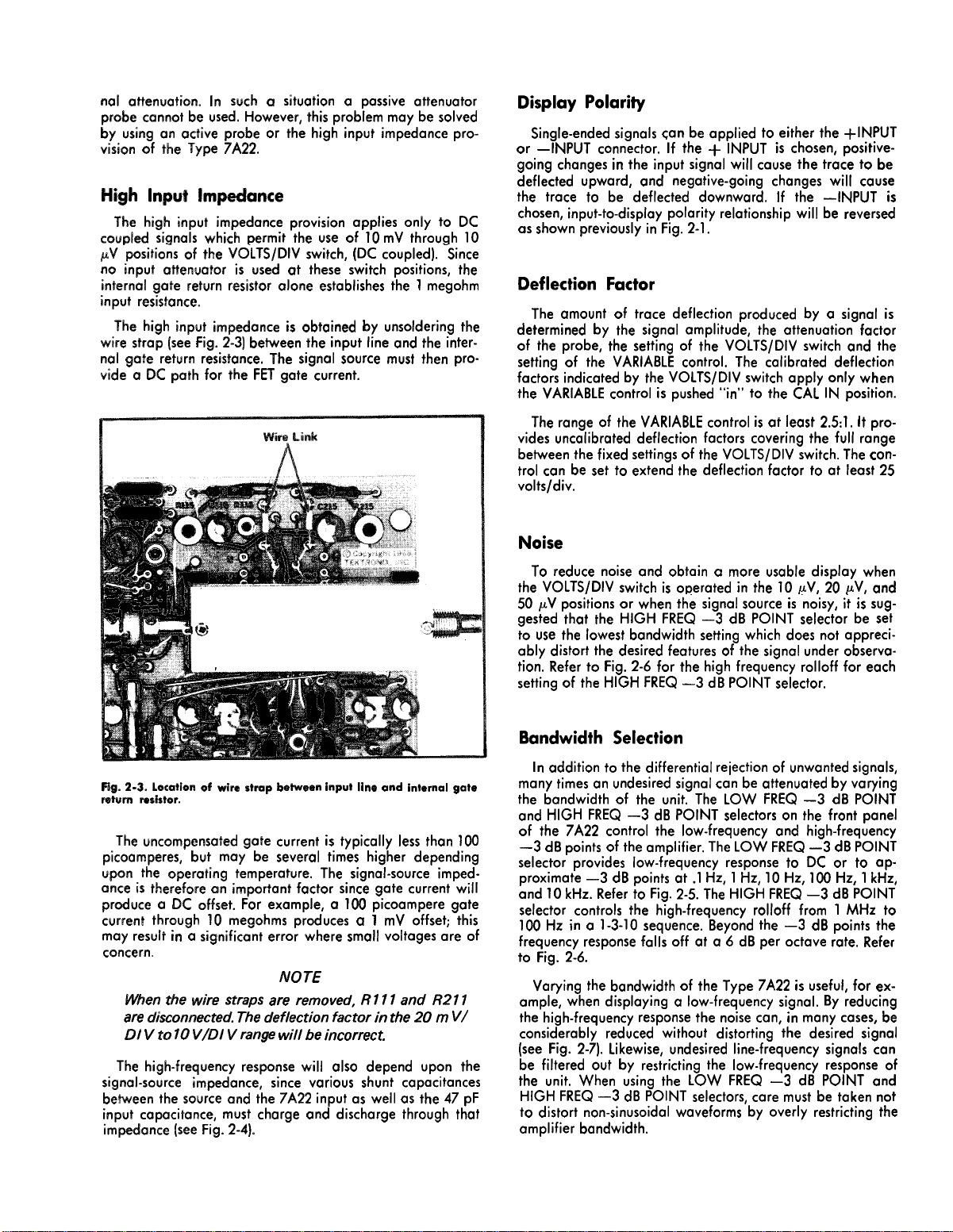

Fig. 2-4B. 7A22 Bandwidth and VOLTS/DIV Error as functions of Source Resistance.

TM 11-6625-2749-14&P

2-7

Page 26

2-8

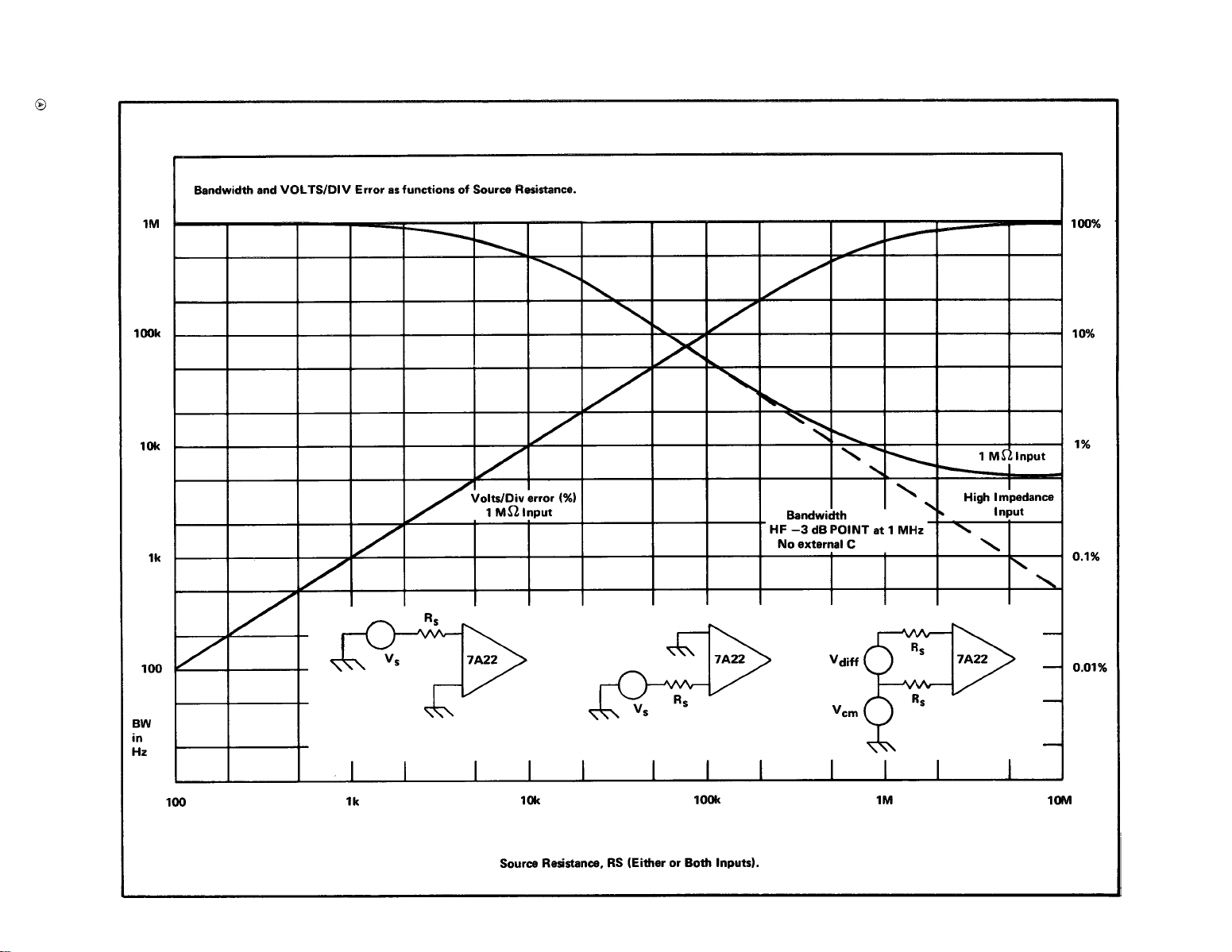

Fig. 2-5. 7A22 FREQUENCY RESPONSE as a function of LF -3 dB POINT SETTING (HF -3 dB POINT at 1 MHz)

TM 11-6625-2749-14&P

Page 27

Fig. 2-6. 7A22 FREQUENCY RESPONSE as a function of HF - 3 dB POINT settings ( LF —3 dB POINT of DC).

2-9

TM 11-6625-2749-14&P

Page 28

TM 11-6625-2749-14&P

2-7.

Fig.

QUENCY 1 MHz.

UPPER —3 dB FREQUENCY, 10 kHz.

Improving

(Al

Lower —3 dB FREQUENCY selector to DC, UPPER — 3 dB FRE-

signal-to-noise

[B) Lower —3 dB FREQUENCY selector to DC,

ratio by setfing

bandwidth.

Voltage Comparison Measurements

Some applications require

than the fixed values provided by the VOLTS/DIV

One such application is comparison of signal amplitudes by

ratio rather than by absolute voltage.

To accomplish this, apply

put of

the

ABLE control throughout the subsequent comparisons. The

settings of the VOLTS/DIV switch

to accommodate large ratios. In doing so, regard the num-

bers which designate the switch position as ratio factors

rather than voltages.

Type 7A22. Set the VOLTS/DIV switch and VARl-

a

set of deflection factors other

a

reference signal to either in-

can be

changed, however,

switch.

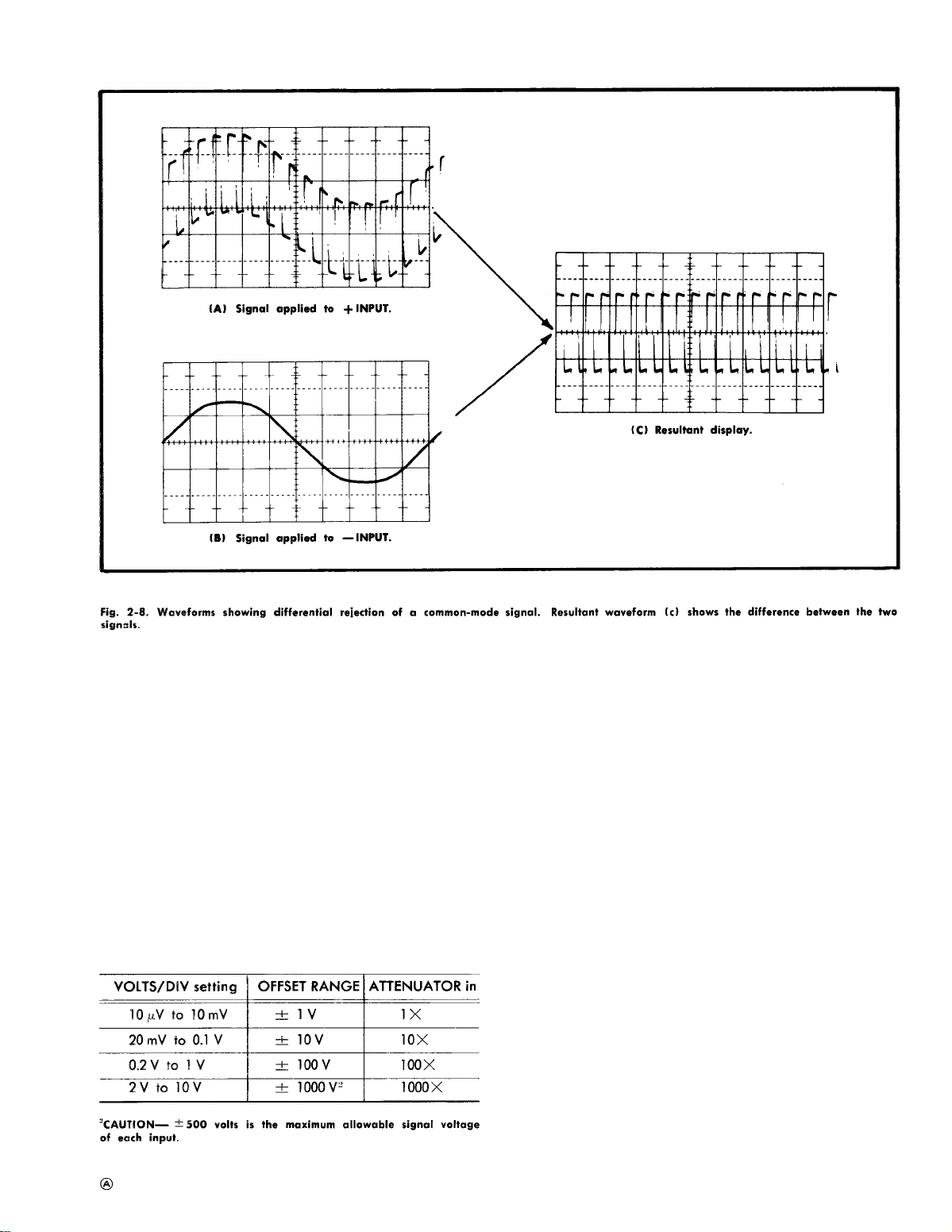

Differential Operation

Differential voltage measurements are made by applying the signals to the +INPUT

Then, both AC-GND-DC switches should

positions: AC or DC, depending

and —INPUT connectors.

be

set to the same

on

the method of signal

The Type 7A22 differential input provision may

to eliminate interfering signals such as AC line-frequency

hum. Single-ended measurements often yield unsatisfactory

information because of interference resulting from groundIoop currents between the oscilloscope and the device under

test. In other cases, it may

voltage by means other than the use of

itor which would limit low-frequency response. These limitations af single-ended measurements are virtually eliminated

in differential measurements.

A differential measurement is made by connecting

of the two inputs to selected points in the test circuit. The

input to the amplifier will then

of the two selected points

The ability of the Type 7A22 to relect common-mode sig-

nals is indicafed by the common-mode relection ratio (CMRR).

This ratio is at least 100,000:1 at the input connectors for the

lower deflection factors (10

signals between DC and 100 kHz are DC-coupled to the in-

puts. To show the significance of this characteristic, assume

that

a

single-ended input signal consists of

Hz signal at 1 volt P-P plus

an attempt is made to display the desired signal with the

VOLTS/DIV

produce

useful information about the 1 mV signal could

If, however, the same 1 mV signol is monitored differentially so that the 60 Hz signal is ;ommon-mode at the inputs,

no

common-mode signal will appear in the display. Thus, the

desired signal produces

only .05 div of interference due to the common-mode signal.

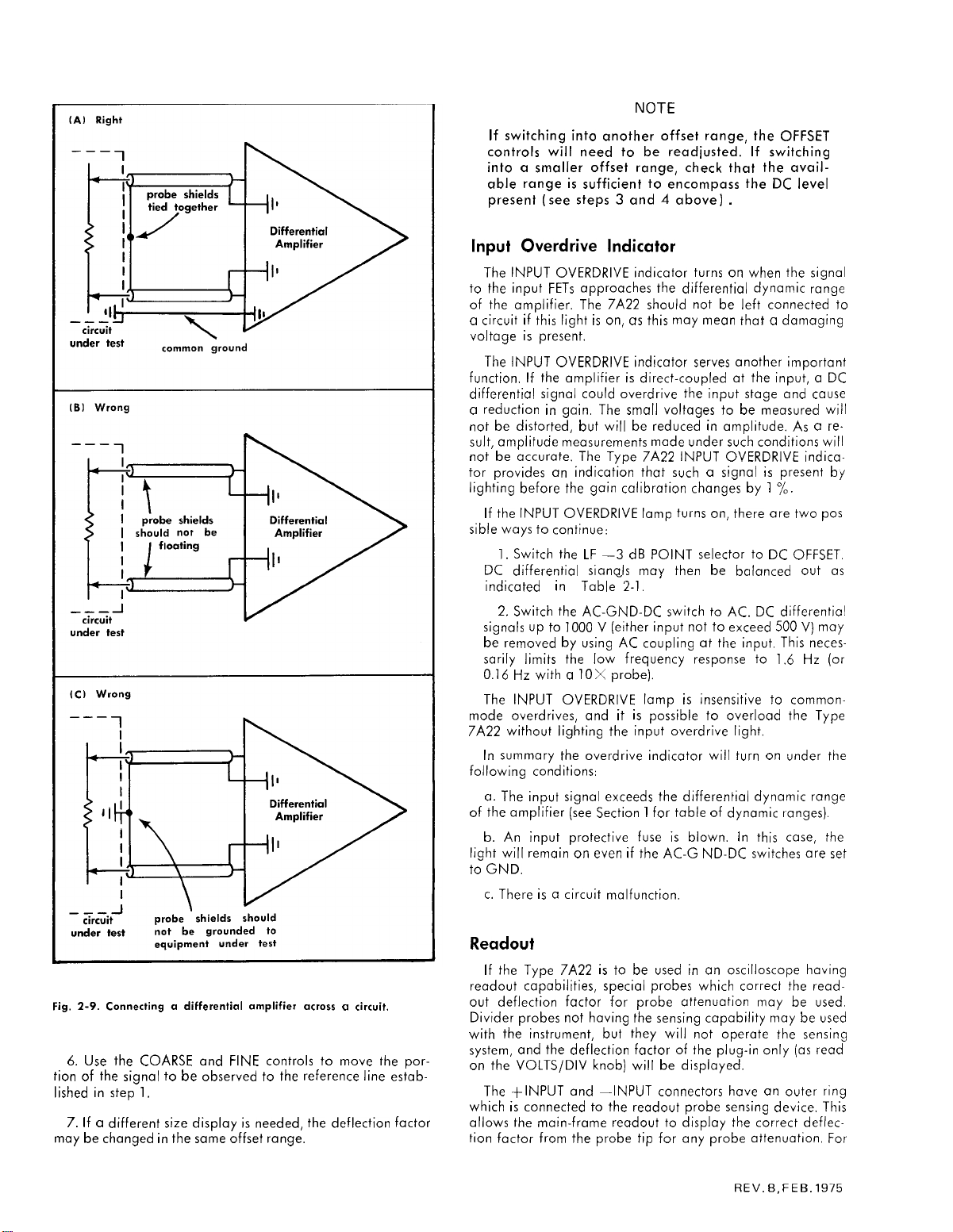

There are

mode rejection. The principal requirement for maximum reiection is for the common-mode signal to arrive at the input

FET gotes in presicely the same form. A difference of only

0.01 ~o in the attenuation factors of the input attenuators may

reduce the rejection ratio to 10,000:1. Likewise, any difference

in source impedance at the two points in the source under test

will degrade the relecfion ratio. Attenuator probes which do

not have an adjustable resistance may reduce the rejection

ratio to 100:1 or less.

Outside influences such as electrostatic and Imagnefic fields

can

level signals are involved. Electrostatic interference

minimized by using shielded signal transporting leads of the

same ty~e to the two inputs, and by twisting the leads to-

gether ‘throughout most of their length. -

Care should

signal transporting leads, as any movement of

txesence of

that lead. Where

avoided, the pickup loop formed by

be

minir’nized by taping or twisting them together throughout

most of their length. Low-frequency measurements

similarly protected by using

a

twisted pair of conductors.

switch set to .2 mV, the 60 Hz signal would

a

deflection equivalent to 5000 div, and thus little

greater than one part

a

number of factors which

also degrade

the

be

taken to minimize the movement of

a

maanetic field, will tend to induce

an

be

desirable to eliminate

a

DC-blocking copac-

be

the difference in voltage

(see

Fig. 2-9).

/LV to 10 mV

a

desired signal at 1 mV P-P. If

in

one hundred thousand of

a

disploy amplitude af 5 div with

performance, particularly when low

interfering magnetic field cannot

a

shielded cable which contains

per division) when

an

can

degrade common-

the

two leads should

be

a

each

unwanted 60

be

obtained.

can be

a

lead, in the

a

sianal into

can be

used

DC

the

the

be

.

2-10

Page 29

Fig. 2-8

TM 11-6625-2749-14&P

DC Offset Operation

By using the DC OFFSET controls, it is possible to use the

Type 7A22 differentially in a slide-back mode, to observe

small signal whose DC potential difference may be considerable. The offset is continuously adjustable from +1 V to

–1 V when the VOLTS/DIV switch is in the 10µV to 10mV

positions. In the 20mV, 50mV and .1 V positions of the

VOLTS/DIV switch, the 1 V offset is effectively multiplied by

the input attenuator to a range of ±10 V. Table 2-1 sum-

marizes the effective DC offset voltages internally available

for all the VOLTS/DIV switch positions. The table also lists

the input attenuator that is switched into the amplifier circuit

for the various VOLTS/DIV switch positions.

TABLE 2-1

Using the DC OFFSET functions:

Set the Type 7A22 controls as follows:

VOLTS/DIV

VARIABLE (CAL IN) CAL

POSITION Midrange

AC-GND-DC GND

(+ and – INPUT)

HF -3 dB POINT 1 MHz

LF -3 dB POINT DC

STEP ATTEN DC BAL Adjusted for DC balance

1. Position the trace to graticule center (or some other

convenient reference line) using the POSITION control.

2. Connect a coaxial cable from the signal source to the

+INPUT.

3. Set the + INPUT AC-G ND-DC switch to DC and meas-

ure the DC level to be offset.

4. Set the VOLTS/DIV to the largest deflection factor in an

offset range which will encompass the DC level measured in

step 3. See Table 2-1 and front panel color bands.

5. Set the LF -3 dB POINT selector to DC OFFSET,

10V

2-11

Page 30

TM 11-6625-2749-14&P

NOTE

If switching into another offset range, the OFFSET

controls will need to be readjusted. If switching

into

a

smaller offset range, check that the avail-

able range

present (see steps 3 and 4 above) .

is

sufficient to encompass the DC level

Input Overdrive

The INPUT OVERDRIVE indicator turns

to

the input FETs approaches the differential dynamic range

of the amplifier. The 7A22 should not

a

circuit if this light is on, as this may mean that

voltage is present.

The INPUT OVERDRIVE indicator serves another important

function. If the amplifier is direct-coupled at the input, a DC

differential signal could overdrive the input stage ond cause

a

reduction in gain, The small voltages to

not

be

distorted, but will

sult, amplitude measurements made under such conditions will

not

be

accurate. The Type 7A22 INPUT OVERDRIVE indicator provides

lighting before the gain calibration changes by 1

If

the

sible ways to continue:

DC differential sicinals may then

indicated in Table-2-l.

signals up to 1000 V (either input not to exceed 500

be

sarily limits the low frequency response to 1,6 Hz (or

0.16 Hz with

The INPUT OVERDRIVE lamp is insensitive

mode overdrives, and it is possible to overload the Type

7A22 without lighting the input overdrive light.

In summary

following conditions:

a.

of the amplifier

b. An

light will remain on even if

to

GND.

c. There is

an

INPUT OVERDRIVE lamp turns on, there are two pos

1.

Switch the LF —3 dB POINT selector

2. Switch the AC-GND-DC switch to AC. DC differential

removed by using AC coupling at the input. This

The input signal exceeds the differential dynamic range

input protective fuse is blown. In this case,

a

Indicator

be

be

reduced in amplitude. As

indication that such

a

10X probe).

the

overdrive indicator will turn

(see

Section 1 for table of dynamic ranges).

the

circuit malfunction.

a

be

‘

AC-G ND-DC switches are set

on

when the signol

left connected

a

be

measured will

signal is present by

~o.

to DC

balanced out as

to

on

damaging

a

OFFSET.

V)

may

neces-

common-

under the

the

to

re-

Fig,

2-9. Connecting

6. Use the COARSE and FINE controls to move

tion of the signal to

lished instep

7. If

a

may

2-12

different size display isneeded, the deflection factor

be

changed in the same offset range.

1.

a

differential amplifier

be

observed to the reference line estab-

across a

circuit.

the

por-

Readout

If

the

Type 7A22 is

readout capabilities, special probes which correct

out deflection factor for probe attenuation may

Divider probes not having

with the instrument, but they will not operate the sensing

system, and the deflection factor of

on the VOLTS/DIV knob) will

The +INPUT and —INPUT connectors have

which is connected

allows

the

tion factor from the probe tip for any probe attenuation, For

main-frame readout

to be

to

used

in an

the

sensing capability may

be

the readout probe sensing device. This

to

oscilloscope having

the

plug-in only (as reed

displayed.

display

the

REV.

an

correct deflec-

B, FE B.

the

read-

be

used.

be

outer ring

1975

used

Page 31

TM 11-6625-2749-14&P

example: if a 10X probe is used it will increase the deflec-

tion factor, in the readout display, by a factor of 10. Then the

actual deflection factor at the probe tip is displayed (see

Table 2-2).

NOTE

If only one divider probe (or two probes with

equal divider ratios) is connected, the deflection

factor at the probe tip will displayed; if probes

with different divider ratios are connected (e.g.,

IOX and 100X), the readout will display the de-

flection factor at the tip of the probe with the

larger division ratio (100X).

TABLE 2-2

TYPE 7A22

Plug In

VOITS/DIV Probe Atten Probe Atten Probe Atten

Setting

.5 mV

50 mV

Trace Identify. With the oscilloscope turned on and a

sweep displayed on the CRT, check for approximately 0.2 div

of vertical movement of the trace when the IDENTIFY

pushbutton is depressed. The vertical scale factor readout

associated with the 7A22 will change to the ward IDENTIFY.

An incorrect CRT readout will occur in the 10V/div

position when using the 100X Readout coded probe

(P6009, Tektronix Part No. 010-0264-01). When used in

10 V/div setting, reading will show IV instead of 1KV.

Main-Frame Displayed Readout

used 1 X used 10X

500

µV

50 mV

NOTE

5 mV

500 mV

used 100X

50 mV

5V

REV. B, AUG. 1974

2-13

Page 32

Page 33

TM 11-6625-2749-14&P

SECTION 3

CIRCUIT DESCRIPTION

introduction

A

Mock diagram description covering the general con-

figuration of

this section. Following the block diagram description is

detailed description of each circuit and the functions of spe-

cific components.

Simplified drawings ore provided where necessary for easier circuit understcsnding. Complete schematic diagrams are

included in the Diagrams section. These should be referred

to throughout the detailed circuit description.

The values of resistors on the schematics are in ohms unless otherwise specified. Capacitor values are indicated in

the following manner unless otherwise specified: whole numbers indicate that the value is. in pF, decimal numbers indiccste that the

pF.

each

circuit in the Type 7A22 is included in

vcdue is in

pF. For example, 33 pF and 0.1

BLOCK DIAGRAM DESCRIPTION

(see Block Diagram Pullout

preceding schematics)

Input coupling

A signal applied to the + or —Input connector passes

through the input coupling selector switch to the input attenuator circuit. The signals

pled or disconnected internally. (See Schematic Diagram

Number

1].

can be AC

coupled, DC cou-

a

Preamp

From the input attenuators, the signal is coupled to the

preamp. The preamp consists of two identical feedback amplifiers connected in

all differential gain is approximately 15.

The supply voltages for the two amplifiers are obtained

from

a

input to improve the common-mode reiection ratio of the

preamp.

cuit consiting of fuses and clamping diades. For deflection

factors from 10 pV/DIV through 10 mV/DIV the fuse will

open if the current exceeds

at the input), preventing damage to the input circuitry.

common power supply which is bootstrapped to the

Each input is equipped with an overdrive protection cir-

a

differential configuration. The over-

‘/IA A

(approximately

CAUTION

16.5 volts

Input Attenuators

The input attenuators for the -f- and —inputs are iden-

ticcsl

and are conventional RC type attenuators. Common

resistive elements are adjustable to facilitate matching the

—

and +- attenuators to obtain optimum DC common-mode

signcrl re~ection.

The attenuators (Schematic Diagram number

quency-compensated

stant attenuation at all frequencies within the passband of

the instrument, while maintaining

voltage dividers which pravide con-

a

constant input time con-

3)

are fre-

Low Frequency

The push-pull output of the preamp is coupled through

LOW FREQ —3 dB POINT selector. The selector switches the

components of the coupling network in each half of the pre-

amp to select the low frequency —3 dB points (.1 Hz, 1 Hz,

10 Hz, 100 Hz, 1 kHz and 10 kHz). The DC position of the

selector bypasses the low frequency selection circuitry and

direct-couples the preamp to the Output Amplifier.

— 3 dB

Point

3-1

a

Page 34

TM 11-6625-2749-14&P

Output Amplifier

The signal from the LF -3dB POINT selector is coupled

to the gain-switching section of the Output Amplifier. This

section of the Output Amplifier is a pair of feedback am-

plifiers similar to ‘that of the prearnp. The VOLTS/DIV

switch changes the amplifier gain.

Fig, 3-1. Generalized feedback system showing the relation between

input and output.

High Frequency -3 dB Point

The HF -3dB POINT selector switches capacitance across

the output of the Gain Switching Amplifier to set the high

frequency -3 dB point at any of 9 frequencies; 100 Hz, 300

Hz,’ 1 kHz, 3 kHz, 10 kHz, 30 kHz, 100 kHz, 300 kHz, and

1 MHz. The capacitance used in the 1 MHz position is adjustable to set the bandwidth to normal value.

Positioning of the trace, and VARIABLE VOLTS/DIV, are

provided in the stage following the HF -3 dB POINT se-

lector.

Overall amplifier gain is adjusted in the signal output

stage of the Output Amplifier by adjusting the common emitter resistance.

GENERAL INFORMATION

Feedback Amplifiers

Since the Type 7A22 utilizes several multi-stage feedback

amplifiers, a brief review of feedback systems in general

is given.

Fig. 3-1 represents a generalized feedback system in which

it is desired to produce an output signal accurately and stably

related to the input. The arrangement of Fig. 3-1 causes the

modified output to be nearly equal to the input. Any difference between these is detected by the comparator, which

produces an error signal equal to the difference, and applies

this error to the amplifier, which amplifies the error and

feeds back a correction to’ reduce the ‘original error

3-2

Fig. 3-2. Feedback amplifier (Single-ended version)

Page 35

TM ll-6625-2749-14&P

The input to the modifier (the system output) is

curately related to the system input, provided the

is constructed of stable components.

Another way of looking at the system is to start at the

output and work backward. Specifically, assume an amplifier gain of 10,000 and

divider. Assume

volt, and the error signal (output-gain)

input is 1.001 valts. In this case, the errar between the desired output [1 OX input) of 10.01 volts and the actual output

of 10.00 volts is only 10 mV, or 1 part in 1,000.

[n

practice the comparator and error amplifier are often

combined in

of the basic configuration used in the Type 7A22 is illustrated in Fig. 3-2, with the basic blocks of Fig. 3-1 identified.

The comparator is FET Q,. Any change in the gate-to-source

bias voltage [dictated by the standing current established

by R, and the supply voltages) will cause

current, the change being applied as an error signal to the

input of the error amplifier.

The error amplifier consists of grounded emitter stage Q,

driving emitter fol[ower Q,. The internal output appears at

the emitter of

modifier [voltage divider) Rz,

tem output, V.,,

a

Qa

can be

a

feedback modifier which isa 10X

a 10

volt output. The modifier output is 1

differential amplifier. A single-ended version

and is fed back ta the comparator input via

R1.

determined by:

is 1

mV, so that the

a

change in drain

For this amplifier, the sys-

also ac-

modifier

Since

Vom is

then

the

R,

1?,

“

The useful output of the amplifier is the Q, collector signal

current

small error current from QJ. VOm = ioRl and since

approximately equal to Vi, and i. is approximately equal to

iO’ then i. is approximately equal to —

cur-rent vs. the input voltage depends primarily on the gainsetiing resistor,

An output voltage

through t-he load resistor,

v.

—,which

vi

cspproximcrtely equal to the input voltage Vi,

system gain, ~,

io’,

which flows through RI (in addition to the relatively

R1.

can

is

approximately equci[ to—

is approximately equal to 1 +

0s

Vi

Thus the output

RI “

also be obtained by passing i.

R~.

The overall voltage gain is then

R,

R,

“

Vo~

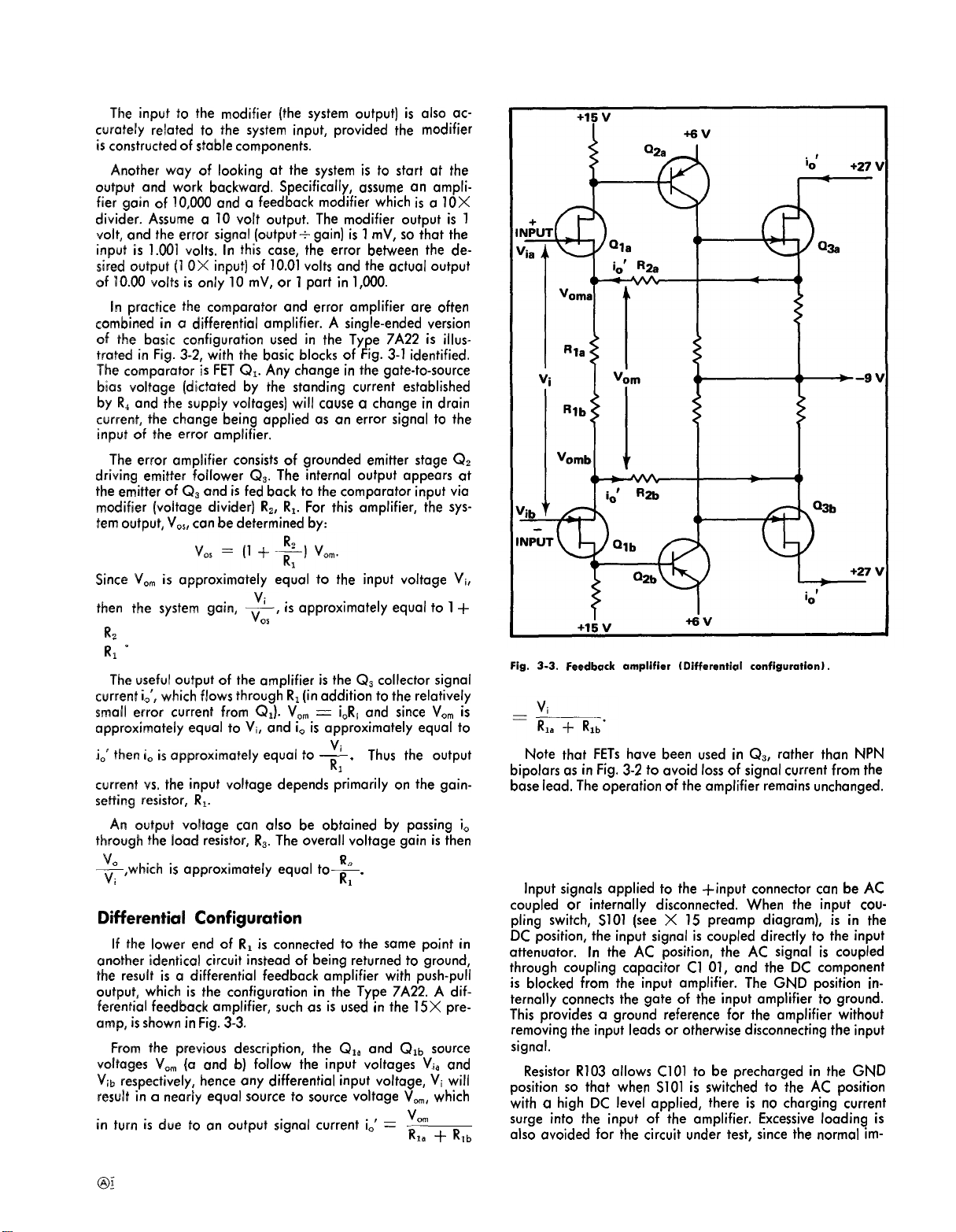

Differential Configuration

If the lower end of R, is connected to the same point in

another identical circuit instead of being returned to ground,

the result is

output, which is the configuration in the Type 7A22. A dif-

ferential feedback amplifier, such as is used in the 15X pre-

amp, is shown in Fig. 3-3.

From the previous description, the Ql, and Qlb source

voltages VO.

Vi~ respectively,

result in

in turn is due to an output signal current

a

differential feedback amplifier with push-pull

(a

and

b)

follow the input voltages Vi. and

hence

any differential input voltage, Vi will

a

nearly equal source to source voltage VO., which

i~’

=

v

R; +

R1~

Fig.

3-3.

Feedback

amplifier (Differential configuration).

is

Note that FETs have been used in Q,, rather than NPN

bipolars as in Fig. 3-2 to avoid loss of signal current from the

base lead. The operation of the amplifier remains unchanged.

DETAILED CIRCUIT DESCRIPTION

Input Coupling (See Schematic 1)

Input signals applied to the +input connector

coupled or internally disconnected. When the input cou-

pling switch, S101

DC position, the input signal is coupled directly to the input

attenuator.

through coupling capacitor Cl 01, and the DC component

is blocked from the input amplifier. The GND position internally connects the gate of the input amplifier to ground.

This provides

removing the input leads or otherwise disconnecting the input

signal.

Resistor R103 allows C101 to

position so that when S101 is switched to the AC position

with

a

surge into the input of the amplifier. Excessive loading is

also avoided for the circuit under test, since the normal im-

high DC level applied, there is no charging current

(see X 15

In the AC position, the AC signal is coupled

a

ground reference for the amplifier without

preamp diagram), is in the

be

precharged in the GND

can be

AC

3-3

Page 36

TM 11-6625-2749-14&P

pedance of 1 MQ-47 pF is still seen by the signal source.

—input switch, S201, functions in the same manner as

+input.

The

the

Input Attenuators

To produce the vertical deflection factor indicated on the

front panel by the VOLTS/DIV switch, the gain of the

feedback amplifier in the gain switched amplifier circuit is

changed by switching the source resistor (R407) of Q404

A and B (See Schematic 2 ) for switch positions 10 µV to

10 mV. For switch positions above 10 mV, input attenuators

are switched by S108 into the input circuit of the Type 7A22,

in conjunction with the gain switching resistors, R407, to

produce the selected deflection factors.

These attenuators are frequency-compensated voltage

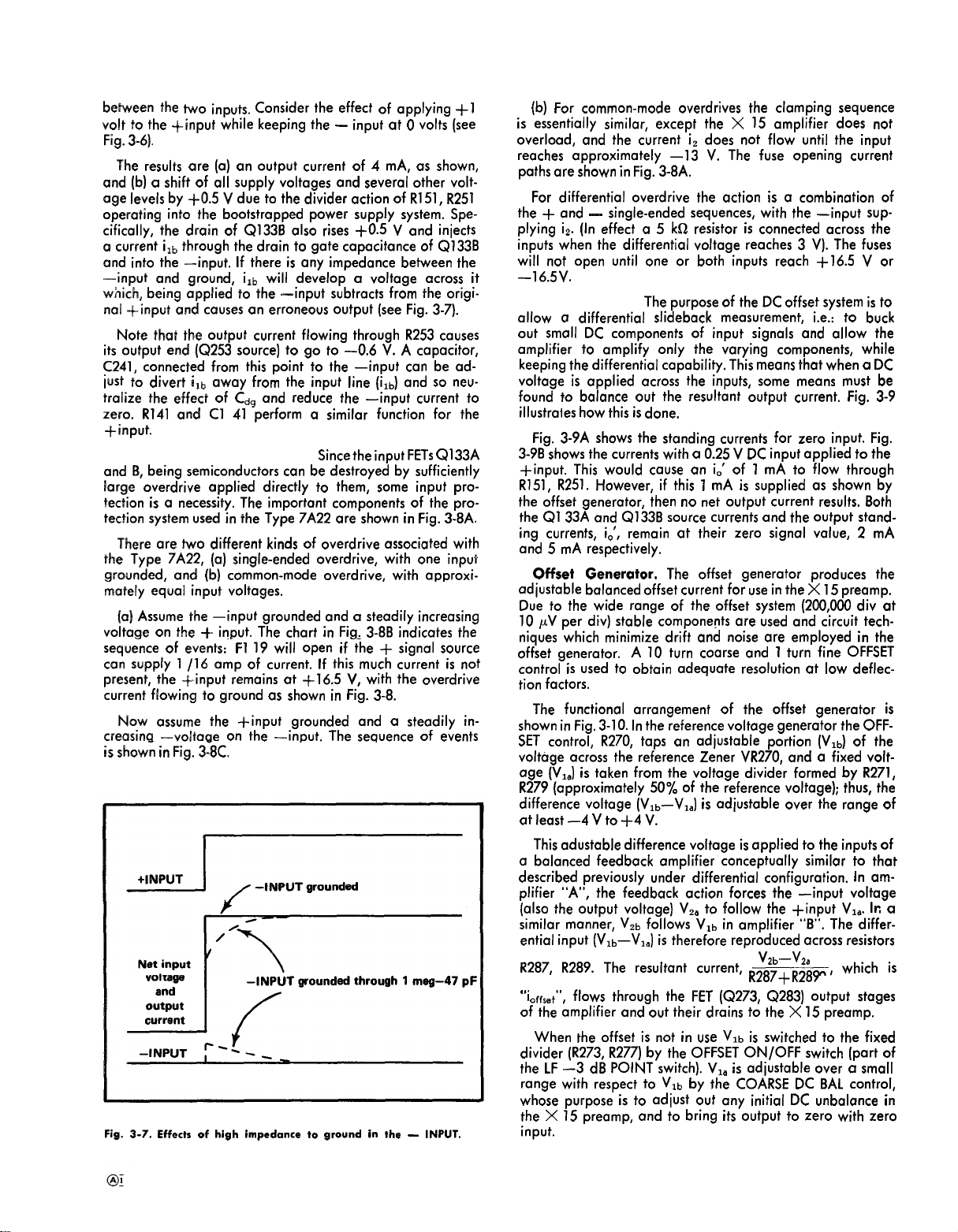

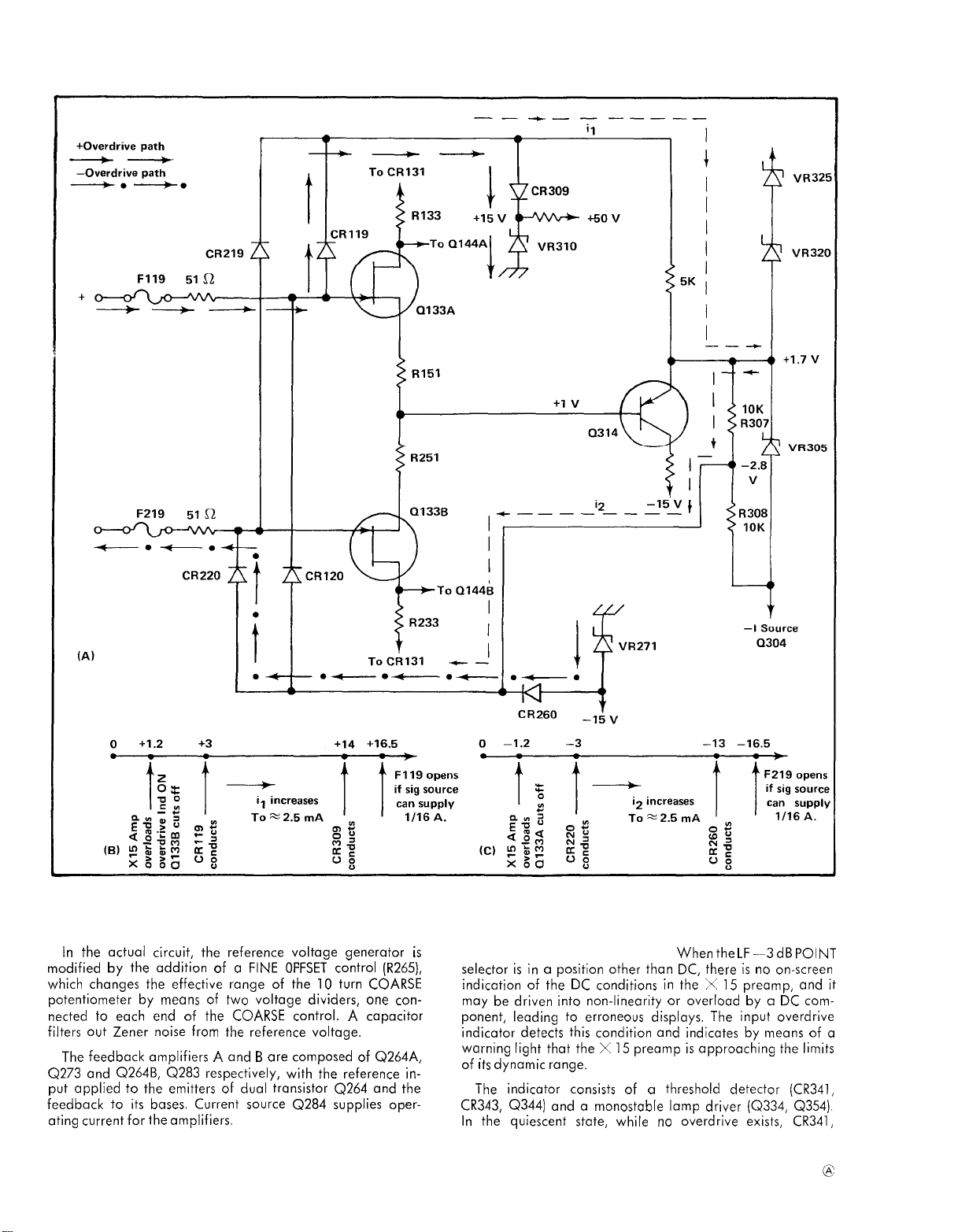

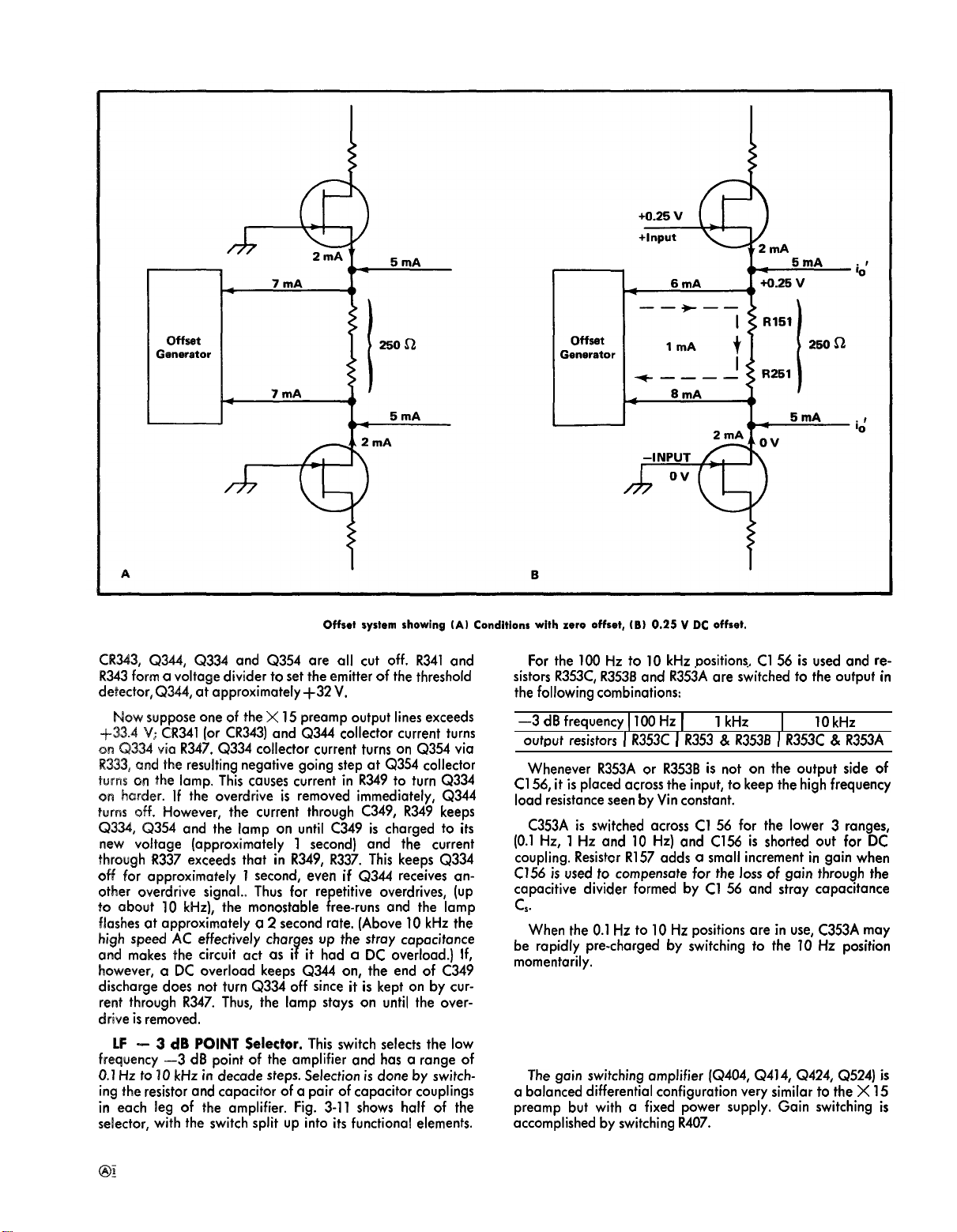

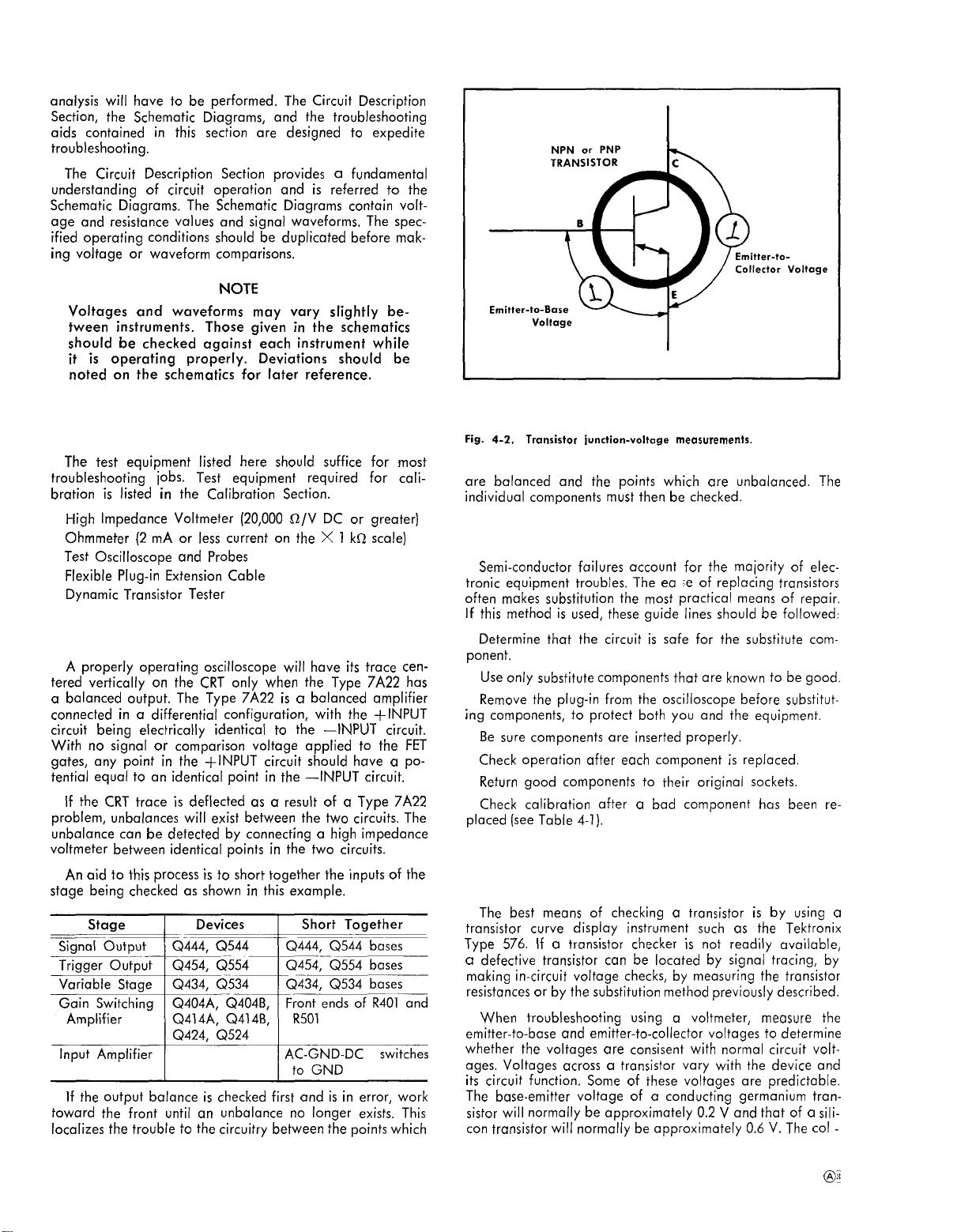

dividers. For DC and low frequency signals, they are pri-