Instruction Manual

AM 503B & AM 5030

AC/DC Current Probe Amplifiers

070-8766-05

This document applies for firmware version 3.0

and above.

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to the Safety Summary prior to

performing service.

Copyright T ektronix, Inc. 1994. All rights reserved. Licensed software products are owned by Tektronix or its suppliers

and are protected by United States copyright laws and international treaty provisions.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (c)(1)(ii) of the

Rights in T echnical Data and Computer Software clause at DFARS 252.227-7013, or subparagraphs (c)(1) and (2) of the

Commercial Computer Software – Restricted Rights clause at F AR 52.227-19, as applicable.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

WARRANTY

T ektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1) year

from the date of shipment. If any such product proves defective during this warranty period, T ektronix, at its option, either

will repair the defective product without charge for parts and labor, or will provide a replacement in exchange for the

defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by T ektronix, with shipping charges prepaid.

T ektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

T ektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than T ektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; or c) to service a product that has been

modified or integrated with other products when the effect of such modification or integration increases the time or

difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THIS PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESSED OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUST OMER FOR BREACH OF THIS WARRANTY. TEKTRONIX

AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

EC Declaration of Conformity

We

Tektronix Holland N.V.

Marktweg 73A

8444 AB Heerenveen

The Netherlands

declare under sole responsibility that the

AM503B Current Probe Amplifier

meet the intent of Directive 89/336/EEC for Electromagnetic Compatibility.

Compliance was demonstrated to the following specifications as listed in the Official

Journal of the European Communities:

EN 50081-1 Emissions:

EN 55022 Class B Radiated and Conducted Emissions

EN 60555-2 AC Power Line Harmonic Emissions

EN 50082-1 Immunity:

IEC 801-2 Electrostatic Discharge Immunity

IEC 801-3 RF Electromagnetic Field Immunity

IEC 801-4 Electrical Fast Transient/Burst Immunity

IEC 801-5 Power Line Surge Immunity

This product complies when installed into the following Tektronix instrument

enclosure:

TM502A Power Supply

EC Declaration of Conformity

We

Tektronix Holland N.V.

Marktweg 73A

8444 AB Heerenveen

The Netherlands

declare under sole responsibility that the

AM5030 and AM5030S Current Probe Amplifiers

meet the intent of Directive 89/336/EEC for Electromagnetic Compatibility.

Compliance was demonstrated to the following specifications as listed in the Official

Journal of the European Communities:

EN 55011 Class B Radiated and Conducted Emissions

EN 50081-1 Emissions:

EN 60555-2 AC Power Line Harmonic Emissions

EN 50082-1 Immunity:

IEC 801-2 Electrostatic Discharge Immunity

IEC 801-3 RF Electromagnetic Field Immunity

IEC 801-4 Electrical Fast Transient/Burst Immunity

Table of Contents

Getting Started

Operating Basics

General Safety Summary ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Safety Summary xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface xv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Getting Started 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Customer Support 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AM 503B and AM 5030 System Configuration 1–2. . . . . . . . . . . . . . . . . . . . . . . . .

Standard Accessories 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Accessories 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the TM Series Power Module 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the AM 503B or AM 5030 Into the Power Module 1–5. . . . . . . . . . . . . . .

Connecting the Amplifier to an Oscilloscope 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting a Current Probe to the Amplifier 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Measurements 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating the Current Probe Slide 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Degaussing and Autobalancing the Current Probe 2–2. . . . . . . . . . . . . . . . . . . . . . .

DC Measurements 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC Measurements 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Summary 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AM 503B and AM 5030 Controls 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AM 5030 GPIB Controls 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GPIB Operation 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GPIB Requirements 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the GPIB Parameters 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Other Documents You Will Need 2–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functional Command Groups 2–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Commands 2–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GPIB Status Commands 2–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Amplifier Status Commands 2–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe Status Commands 2–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Commands 2–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ALLEve? (Query Only) 2–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AMPS 2–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BWLIMit 2–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COUpling 2–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DCLEVel 2–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DEGAuss (No Query Form) 2–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ERRor? (Query Only) 2–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EVent? (Query Only) 2–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EXit 2–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FPLock 2–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AM 503B & AM 5030 Amplifier Instruction Manual

i

Contents

Reference

HELp? (Query Only) 2–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ID? (Query Only) 2–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INIT (No Query Form) 2–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OVerload? (Query Only) 2–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PATH 2–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PROBEOPen? (Query Only) 2–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PROBETRim 2–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PROBETYpe? (Query Only) 2–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RQS 2–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERIAL? (Query Only) 2–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SET? (Query Only) 2–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TEST (No Query Form) 2–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIts? (Query Only) 2–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error Messages & Codes 2–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference Notes 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Degaussing a Probe with an Unpowered Conductor in the Jaws 3–1. . . . . . . . . . . . .

Bandwidth Limiting 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

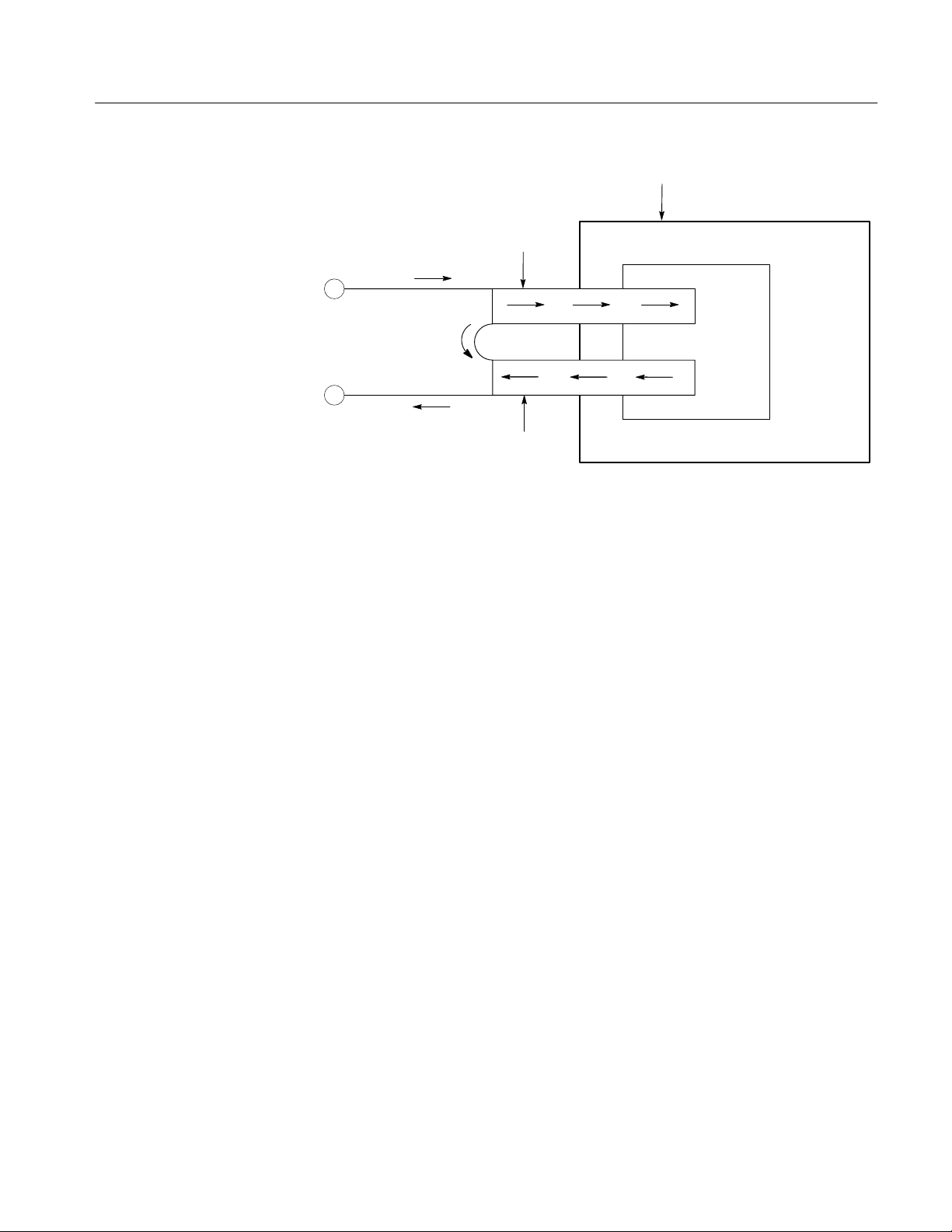

Measuring Differential Current 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC and DC Coupling 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Current Limits 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Extending Current Range 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Increasing Sensitivity 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Application Notes 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

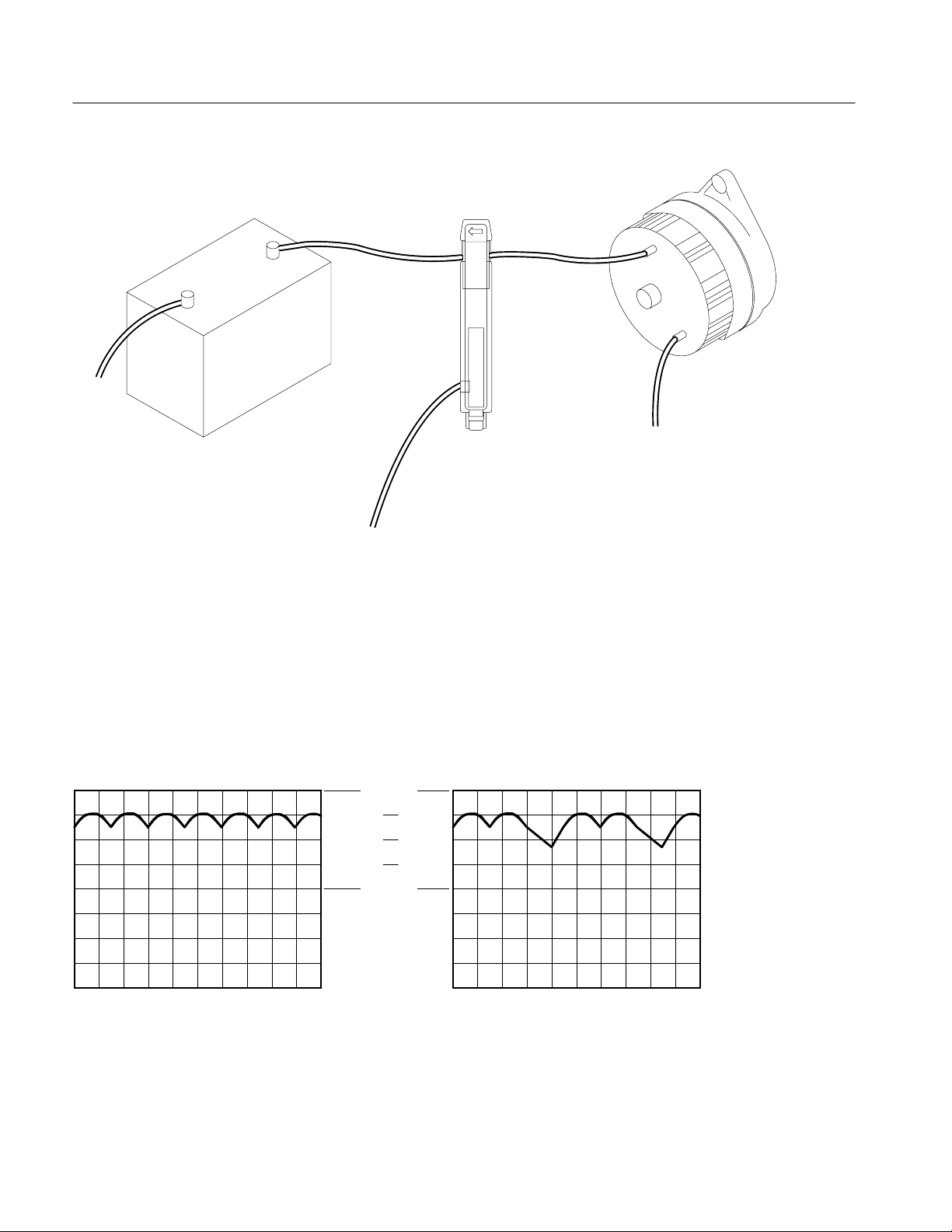

Automobile Charging Systems 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

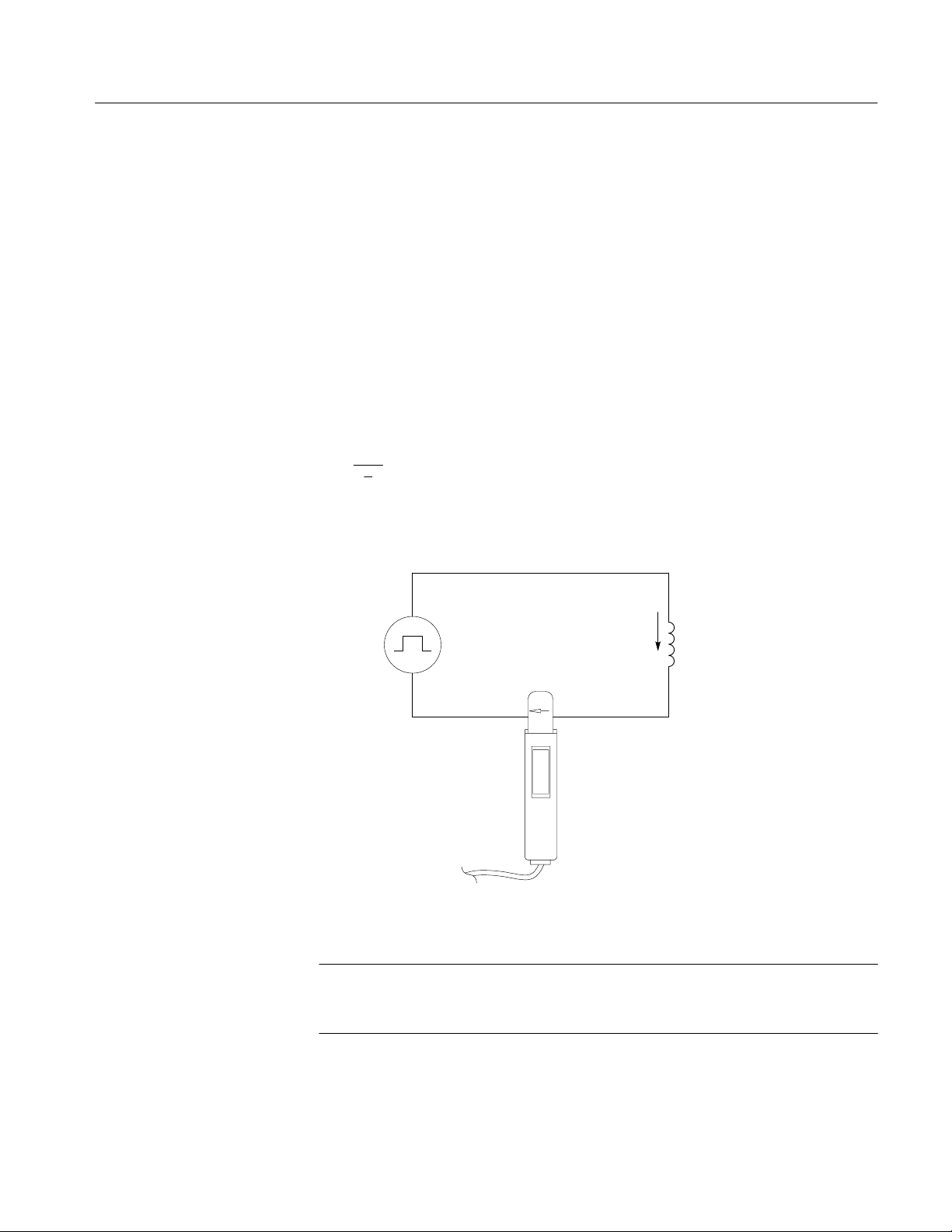

Inductance Measurements 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuity T est of Multiple-Conductor Cable 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . .

Measuring Inductor Turns Count 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error Codes 3–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 3–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications

Specifications 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranted Specifications 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Nominal and T ypical Characteristics 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environmental Characteristics 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification

Performance Verification Setup 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T est Procedure Conditions 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Preparation 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

W arranted Specifications 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification with an A6312 5–3. . . . . . . . . . . . . . . . . . . . . . .

Required Test Equipment 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bandwidth 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rise Time 5–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Gain Accuracy 5–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

AM 503B & AM 5030 Amplifier Instruction Manual

Adjustment Procedures

Contents

Performance Verification with an A6302 or A6302XL 5–15. . . . . . . . . . . .

Required Test Equipment 5–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bandwidth 5–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rise Time 5–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Gain Accuracy 5–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification with an A6303 or A6303XL 5–27. . . . . . . . . . . .

Required Test Equipment 5–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bandwidth 5–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rise Time 5–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Gain Accuracy 5–32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification with an A6304XL 5–37. . . . . . . . . . . . . . . . . . . .

Required Test Equipment 5–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rise Time 5–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bandwidth 5–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Gain Accuracy 5–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment Procedures for Current Probes 6–1. . . . . . . . . . . . . . . . . . . . .

A6312, A6302 and A6302XL Adjustment 6–3. . . . . . . . . . . . . . . . . . . . . . .

Required Test Equipment 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A6312, A6302 and A6302XL DC Offset Adjustment 6–3. . . . . . . . . . . . . . . . . . . . .

A6303 and A6303XL Adjustments 6–7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Test Equipment 6–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A6303 and A6303XL DC Offset Adjustment 6–8. . . . . . . . . . . . . . . . . . . . . . . . . . .

A6303 and A6303XL Transient Response and Gain Adjustment 6–10. . . . . . . . . . . .

A6304XL Adjustments 6–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Test Equipment 6–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A6304XL DC Offset Adjustment 6–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Gain Adjustment 6–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A6304XL Transient Response Adjustment 6–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance

Customer Maintenance 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Strategy 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preventive Maintenance 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 7–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Static Device Precautions 7–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Knobs 7–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Side Covers 7–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel and Release Lever Assembly 7–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Disassembly 7–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Rear Interface Output Connector 7–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Replacement 7–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Mechanical Parts

Replaceable Parts 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Ordering Information 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Parts List 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AM 503B & AM 5030 Amplifier Instruction Manual

iii

Contents

Glossary and Index

iv

AM 503B & AM 5030 Amplifier Instruction Manual

List of Figures

Contents

Figure 1–1: Configuring the AM 503B and AM 5030 Current

Measurement System 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–2: TM Series Power Module Voltage Selector 1–4. . . . . . . . . . .

Figure 1–3: Changing the TM 502A Operating Voltage 1–5. . . . . . . . . . .

Figure 1–4: Installing the AM 503B and AM 5030 into the

Power Module 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–5: Connecting a Current Probe to the Amplifier 1–8. . . . . . . . .

Figure 2–1: A6312, A6302, and A6302XL Slide Operation 2–1. . . . . . . . .

Figure 2–2: A6303, A6303XL, and A6304XL Slide Operation 2–2. . . . . .

Figure 2–3: Current Probe Polarity 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–4: The AM 503B and AM 5030 Front Panel 2–7. . . . . . . . . . . . .

Figure 2–5: Stacked GPIB Connectors 2–13. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–6: Typical GPIB Network Configurations 2–14. . . . . . . . . . . . . .

Figure 3–1: Measuring Differential Current and Nulls 3–2. . . . . . . . . . . .

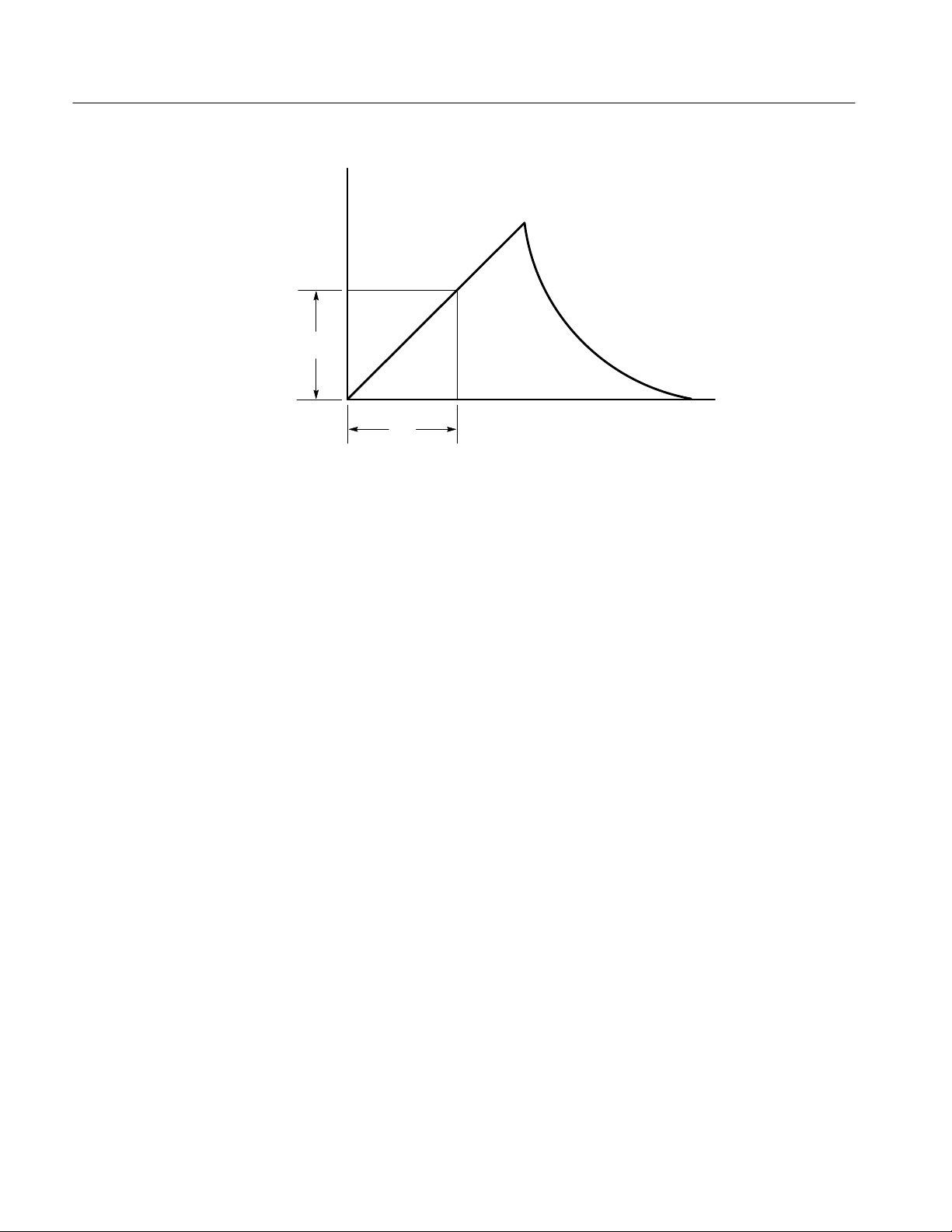

Figure 3–2: Effect of AC or DC Coupling on Low-Frequency Signals 3–3

Figure 3–3: Applying the Amp-Second Product Rule 3–5. . . . . . . . . . . . .

Figure 3–4: Increasing the DC Measurement Range 3–6. . . . . . . . . . . . . .

Figure 3–5: Increasing Probe Sensitivity 3–7. . . . . . . . . . . . . . . . . . . . . . . .

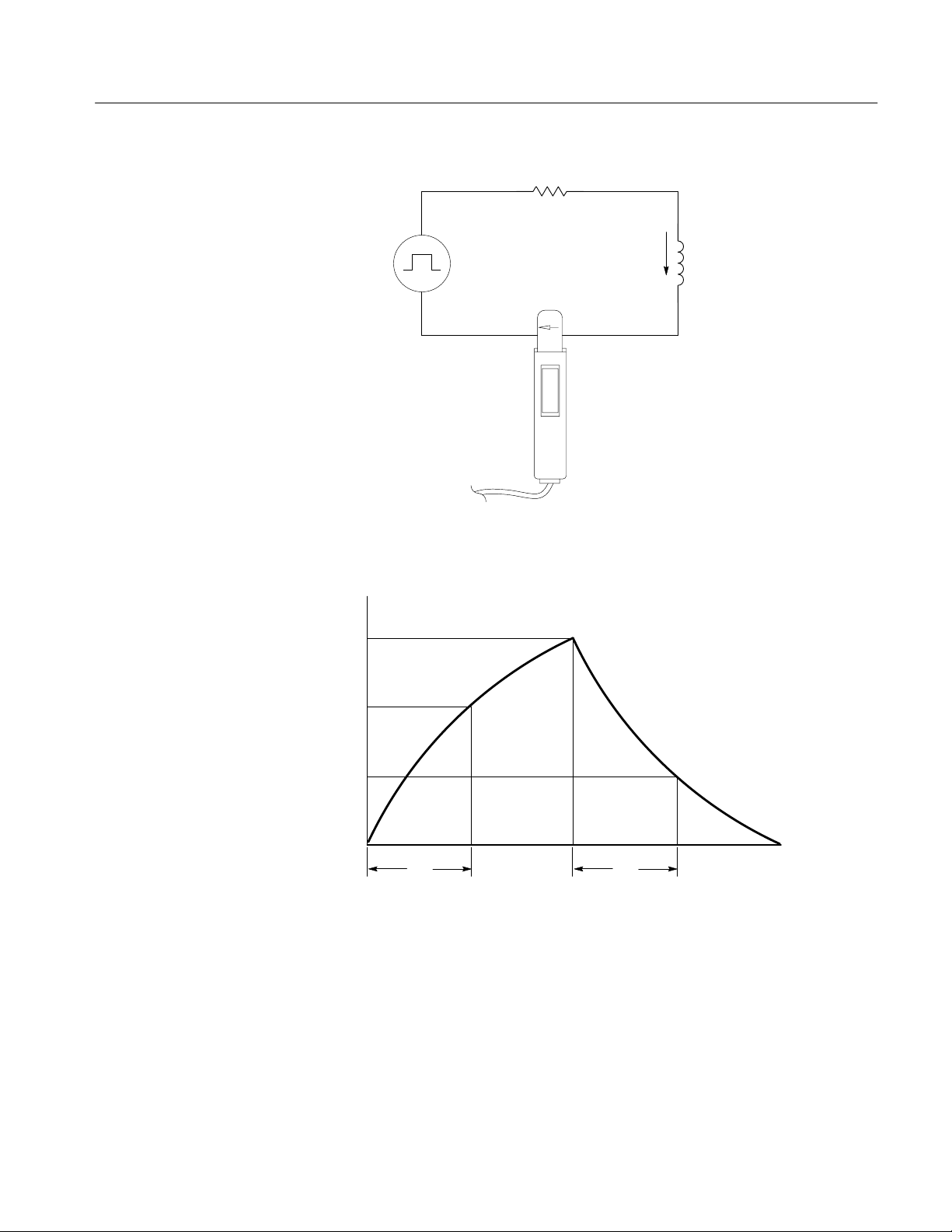

Figure 3–6: Setup for Measuring Charging Current 3–10. . . . . . . . . . . . . .

Figure 3–7: Charge Current Waveforms 3–10. . . . . . . . . . . . . . . . . . . . . . .

Figure 3–8: Measuring Inductance with a Low-Impedance Source 3–11. .

Figure 3–9: Linear Current vs. Time Ramp 3–12. . . . . . . . . . . . . . . . . . . . .

Figure 3–10: Measuring Inductance with a High-Impedance Source 3–13

Figure 3–11: High-Impedance Source Current Ramp 3–13. . . . . . . . . . . . .

Figure 3–12: Measuring the Number of Turns in a Coil 3–14. . . . . . . . . . .

Figure 3–13: Turns Measurement Using Reference Coil 3–15. . . . . . . . . . .

Figure 5–1: Bandwidth Test Setup for A6312 5–5. . . . . . . . . . . . . . . . . . . .

Figure 5–2: Rise Time Test Setup for A6312 5–7. . . . . . . . . . . . . . . . . . . .

Figure 5–3: DC Gain Accuracy Test Setup for A6312 5–10. . . . . . . . . . . . .

Figure 5–4: Bandwidth Test Setup for A6302/A6302XL 5–17. . . . . . . . . . .

Figure 5–5: Rise Time Test Setup for A6302/A6302XL 5–19. . . . . . . . . . . .

Figure 5–6: DC Gain Accuracy Test Setup for A6302/A6302XL 5–22. . . .

Figure 5–7: Bandwidth Test Setup for an A6303/A6303XL 5–28. . . . . . . .

AM 503B & AM 5030 Amplifier Instruction Manual

v

Contents

Figure 5–8: Rise Time Test Setup for A6303/A6303XL 5–30. . . . . . . . . . . .

Figure 5–9: DC Gain Accuracy Test Setup for A6303/A6303XL 5–33. . . .

Figure 5–10: Rise Time Test Setup for the A6304XL 5–38. . . . . . . . . . . . . .

Figure 5–11: DC Gain Accuracy Test Setup for the A6304XL 5–41. . . . . .

Figure 6–1: A6312, A6302 and A6302XL DC Offset Adjustment

Location 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–2: A6303 and A6303XL Adjustment Locations 6–8. . . . . . . . . .

Figure 6–3: A6303 and A6303XL Adjustment Setup 6–11. . . . . . . . . . . . . .

Figure 6–4: A6304XL Adjustment Locations 6–15. . . . . . . . . . . . . . . . . . . .

Figure 6–5: DC Gain Accuracy Adjustment Setup 6–17. . . . . . . . . . . . . . .

Figure 6–6: A6304XL Adjustment Setup 6–18. . . . . . . . . . . . . . . . . . . . . . .

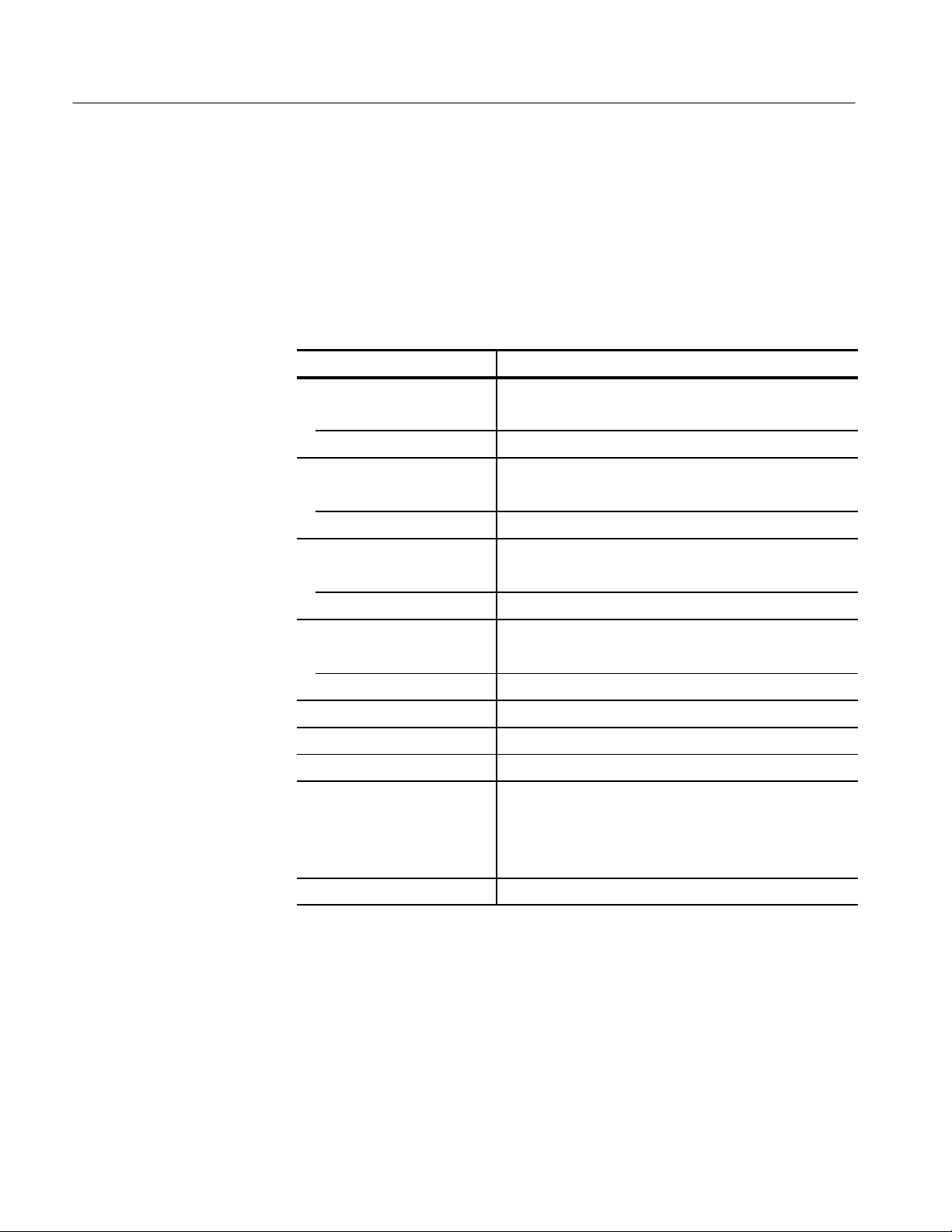

Figure 7–1: Removing the AM 503B and AM 5030 Side Covers 7–4. . . .

Figure 7–2: Removing the Amplifier Release Lever 7–5. . . . . . . . . . . . . .

Figure 7–3: Location of Amplifier Interface Cables 7–5. . . . . . . . . . . . . .

Figure 7–4: Location of Front Panel Screws 7–6. . . . . . . . . . . . . . . . . . . . .

Figure 7–5: Removing the Latch Bar Assembly 7–6. . . . . . . . . . . . . . . . . .

Figure 7–6: Removing the Amplifier Output Connector 7–7. . . . . . . . . . .

Figure 7–7: Removing the Amplifier Front Panel Board 7–8. . . . . . . . . .

Figure 7–8: Using the Rear Interface Output Connector 7–9. . . . . . . . . .

Figure 7–9: Prying Battery Terminal to Remove Battery 7–10. . . . . . . . . .

Figure 7–10: Removing the Backup Battery 7–10. . . . . . . . . . . . . . . . . . . . .

Figure 7–11: Replacing the Backup Battery 7–11. . . . . . . . . . . . . . . . . . . . .

Figure 8–1: AM 503B & AM 5030 Replaceable Parts 8–3. . . . . . . . . . . . .

Figure 8–2: AM 503B & AM 5030 Standard Accessories 8–6. . . . . . . . . .

vi

AM 503B & AM 5030 Amplifier Instruction Manual

List of Tables

Contents

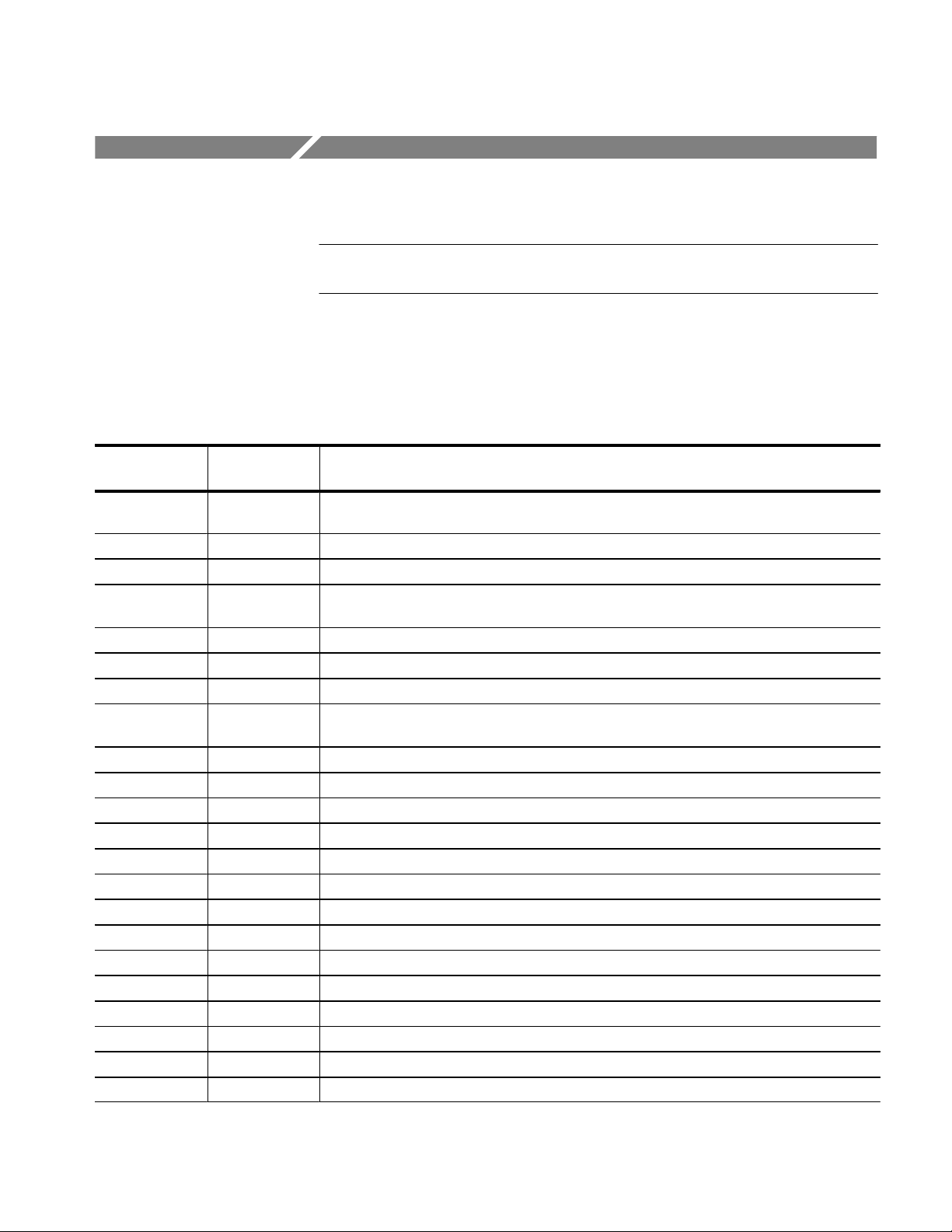

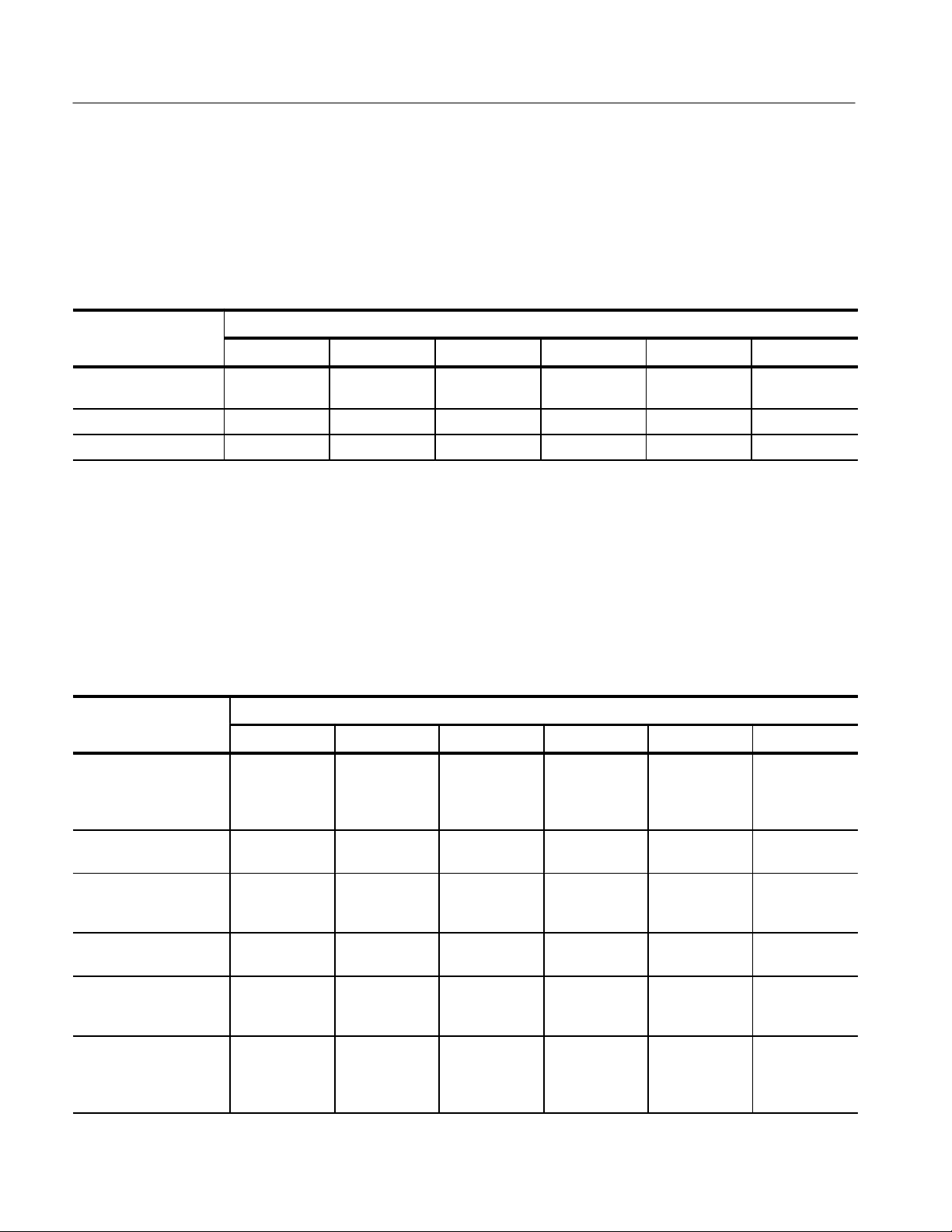

Table 2–1: Front Panel Commands 2–17. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–2: GPIB Status Commands 2–18. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–3: Amplifier Status Commands 2–18. . . . . . . . . . . . . . . . . . . . . . .

Table 2–4: Probe Status Commands 2–19. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–5: AM 5030 Event Codes 2–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–1: Unpowered Circuit Degauss Limits 3–1. . . . . . . . . . . . . . . . . .

Table 3–2: Automobile Charging Systems Test Setup 3–9. . . . . . . . . . . . .

Table 3–3: AM 503B and AM 5030 Front-Panel Error Codes 3–18. . . . . .

Table 3–4: Troubleshooting 3–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

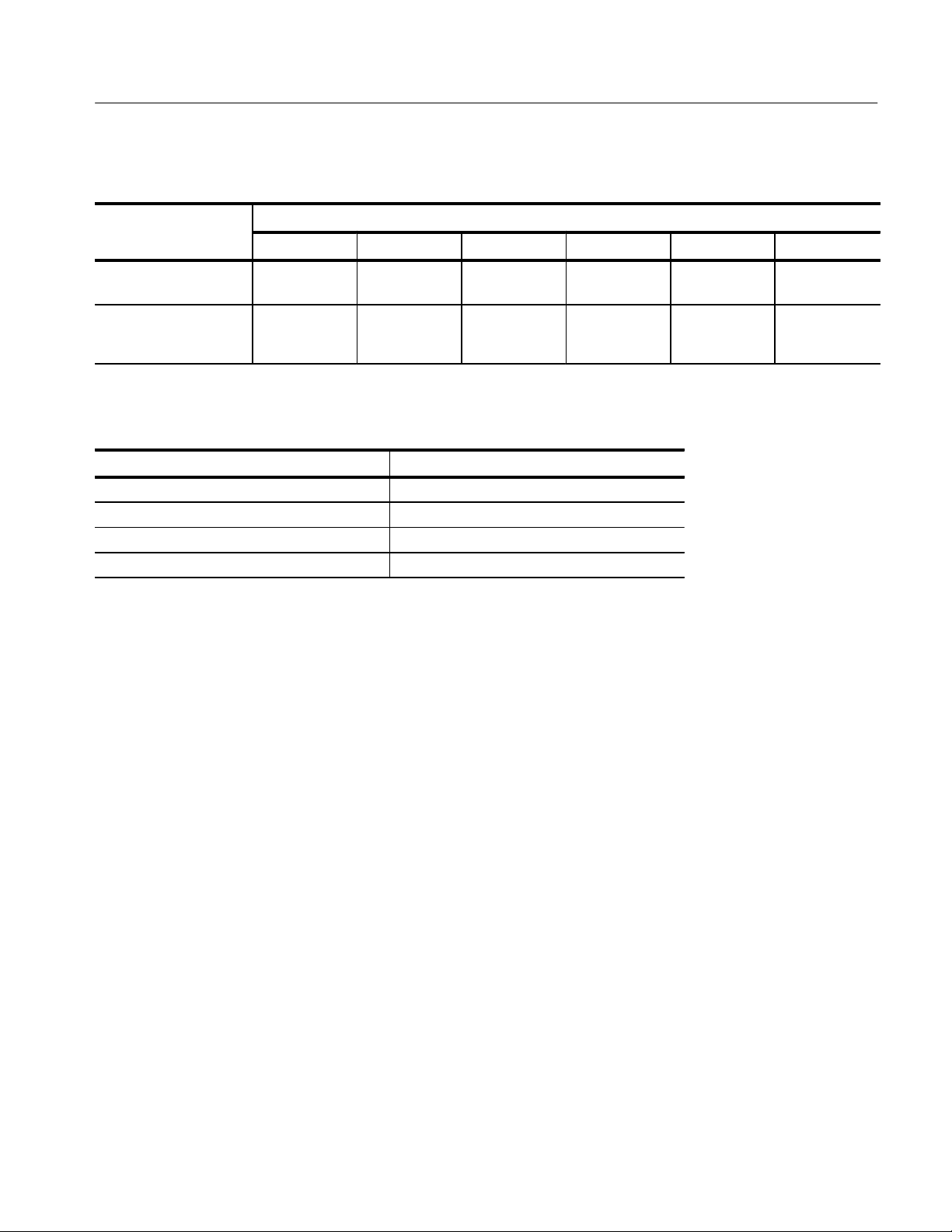

Table 4–1: Warranted AM 503B and AM 5030 Specifications 4–2. . . . .

Table 4–2: Nominal and Typical AM 503B and AM 5030

Characteristics 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–3: AM 503B and AM 5030 Mechanical Characteristics 4–3. . . .

Table 4–4: AM 503B and AM 5030 Environmental Characteristics 4–4.

Table 5–1: Required Test Equipment 5–4. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5–2: Equipment Settings for Bandwidth 5–5. . . . . . . . . . . . . . . . . .

Table 5–3: Equipment Settings for Rise Time 5–8. . . . . . . . . . . . . . . . . . .

Table 5–4: Equipment Settings for DC Gain Accuracy 5–10. . . . . . . . . . .

Table 5–5: DC Gain Accuracy Test for A6312 5–11. . . . . . . . . . . . . . . . . . .

Table 5–6: DC Gain Accuracy Test Worksheet for A6312 5–13. . . . . . . . .

Table 5–7: Required Test Equipment 5–16. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5–8: Equipment Settings for Bandwidth 5–17. . . . . . . . . . . . . . . . . .

Table 5–9: Equipment Settings for Rise Time 5–20. . . . . . . . . . . . . . . . . . .

Table 5–10: Equipment Settings for DC Gain Accuracy 5–22. . . . . . . . . .

Table 5–11: DC Gain Accuracy Test for A6302/A6302XL 5–23. . . . . . . . .

Table 5–12: DC Gain Accuracy Test Worksheet for A6302/A6302XL 5–25

Table 5–13: Required Test Equipment 5–27. . . . . . . . . . . . . . . . . . . . . . . . .

Table 5–14: Equipment Settings for Bandwidth 5–29. . . . . . . . . . . . . . . . .

Table 5–15: Equipment Settings for Rise Time 5–31. . . . . . . . . . . . . . . . . .

Table 5–16: Equipment Settings for DC Gain Accuracy 5–32. . . . . . . . . .

Table 5–17: DC Gain Accuracy Test for A6303/A6303XL 5–34. . . . . . . . .

Table 5–18: DC Gain Accuracy Test Work Sheet for

A6303/A6303XL 5–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5–19: Required Test Equipment 5–37. . . . . . . . . . . . . . . . . . . . . . . . .

Table 5–20: Equipment Settings for Rise Time 5–39. . . . . . . . . . . . . . . . . .

AM 503B & AM 5030 Amplifier Instruction Manual

vii

Contents

Table 5–21: Equipment Settings for DC Gain Accuracy 5–41. . . . . . . . . .

Table 5–22: DC Gain Accuracy Test for the A6304XL 5–43. . . . . . . . . . . .

Table 5–23: DC Gain Accuracy Test Work Sheet for the A6304XL 5–44.

Table 6–1: Required Test Equipment 6–3. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6–2: Settings for DC Offset Adjustment 6–4. . . . . . . . . . . . . . . . . .

Table 6–3: Error Codes Requiring DC Offset Adjustment 6–5. . . . . . . .

Table 6–4: Required Test Equipment 6–7. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6–5: Settings for DC Offset Adjustment 6–9. . . . . . . . . . . . . . . . . .

Table 6–6: Error Codes Requiring DC Offset Adjustment 6–9. . . . . . . .

Table 6–7: Settings for Transient Response and Gain Adjustments 6–11.

Table 6–8: Required Test Equipment 6–13. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6–9: Settings for DC Offset Adjustment 6–14. . . . . . . . . . . . . . . . . .

Table 6–10: Error Codes Requiring DC Offset Adjustment 6–15. . . . . . .

Table 6–11: Equipment Settings for DC Gain Accuracy 6–16. . . . . . . . . .

Table 6–12: Equipment Settings for Transient Response 6–18. . . . . . . . . .

viii

AM 503B & AM 5030 Amplifier Instruction Manual

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

Injury Precautions

Ground the Product

Do Not Operate Without

Covers

Do Not Operate in

Wet/Damp Conditions

Do Not Operate in

Explosive Atmosphere

Avoid Exposed Circuitry

This product is grounded through the grounding conductor of the power cord. To

avoid electric shock, the grounding conductor must be connected to earth

ground. Before making connections to the input or output terminals of the

product, ensure that the product is properly grounded.

To avoid electric shock or fire hazard, do not operate this product with covers or

panels removed.

To avoid electric shock, do not operate this product in wet or damp conditions.

To avoid injury or fire hazard, do not operate this product in an explosive

atmosphere.

To avoid injury, remove jewelry such as rings, watches, and other metallic

objects. Do not touch exposed connections and components when power is

present.

AM 503B & AM 5030 Amplifier Instruction Manual

ix

General Safety Summary

Product Damage Precautions

Use Proper Power Source

Use Proper Voltage

Setting

Provide Proper Ventilation

Do Not Operate With

Suspected Failures

Do not operate this product from a power source that applies more than the

voltage specified.

Before applying power, ensure that the line selector is in the proper position for

the power source being used.

To prevent product overheating, provide proper ventilation.

If you suspect there is damage to this product, have it inspected by qualified

service personnel.

Safety Terms and Symbols

Terms in This Manual

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

Terms on the Product

x

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

AM 503B & AM 5030 Amplifier Instruction Manual

General Safety Summary

Symbols on the Product

The following symbols may appear on the product:

DANGER

High Voltage

Certifications and Compliances

CSA Certified Power

Cords

Safety Certification of

Plug-in Modules

CSA Certification includes the products and power cords appropriate for use in

the North America power network. All other power cords supplied are approved

for the country of use.

For plug-in modules that are safety certified by Underwriters Laboratories, UL

Listing applies only when the module is installed in a UL Listed product. CSA

Certification applies only when the module is installed in a CSA Certified

product.

Protective Ground

(Earth) T erminal

ATTENTION

Refer to Manual

Double

Insulated

AM 503B & AM 5030 Amplifier Instruction Manual

xi

General Safety Summary

xii

AM 503B & AM 5030 Amplifier Instruction Manual

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone

Disconnect Power

Use Care When Servicing

With Power On

Do not perform internal service or adjustments of this product unless another

person capable of rendering first aid and resuscitation is present.

To avoid electric shock, disconnect the main power by means of the power cord

or, if provided, the power switch.

Dangerous voltages or currents may exist in this product. Disconnect power,

remove battery (if applicable), and disconnect test leads before removing

protective panels, soldering, or replacing components.

To avoid electric shock, do not touch exposed connections.

AM 503B & AM 5030 Amplifier Instruction Manual

xiii

Service Safety Summary

xiv

AM 503B & AM 5030 Amplifier Instruction Manual

Preface

This Instruction Manual supports the operation and basic maintenance of the

AM 503B and AM 5030 Current Probe Amplifiers.

If you are not familiar with this product, please refer to the Getting Started and

Operating Basics chapters of this manual for basic operating information.

If you are an advanced user, the Reference section contains information on

advanced applications as well as user diagnostic and troubleshooting information.

The Performance Verification and Adjustment Procedure sections support the

qualification and calibration of the probes when used with either amplifier.

NOTE. Except for the A6303, once a probe has been calibrated, it can be used

with any other AM 503B or AM 5030 without readjustment.

The Maintenance section supports the routine maintenance and repair of

mechanical parts associated with the amplifiers.

Related Manuals

Manual Conventions

The Glossary and Index are provided as quick reference locators for important

information.

You can find the documentation supporting the maintenance and repair of the

current probes in the following manuals:

H A6312 Instructions

H A6302 & A6302XL Instructions

H A6303 & A6303XL Instructions

H A6304XL Instructions

The term “Amplifier” is used to refer to either the AM 503B or AM 5030 when

referring to common attributes. If a subject is unique to either amplifier, the

amplifier will be referred to directly by model.

AM 503B & AM 5030 Amplifier Instruction Manual

xv

Preface

xvi

AM 503B & AM 5030 Amplifier Instruction Manual

Getting Started

Getting Started

The AM 503B and AM 5030 current probe amplifiers let you use one probe to

simultaneously measure AC and DC current. The Amplifier converts the sensed

current into a proportional voltage signal that you can measure directly with an

oscilloscope.

The AM 503B and AM 5030 provide better linearity than other current

measurement systems because of a current feedback process used with the probe.

DC measurement capability and high bandwidth allow the Amplifier to

accurately represent square waves and fast-rise signals.

The AM 503B and AM 5030 provide these features:

H Simultaneous DC and AC current measurements.

H High sensitivity.

H One-button autobalancing and probe degaussing.

H No adjustments needed to match a current probe to an individual amplifier

(except for the A6303 current probe).

Customer Support

Operational Support

Service Support

H Probe trim adjust allows fine tuning of gain for increased accuracy.

The AM 5030 provides an additional feature:

H Programmable control from a GPIB controller.

To help you get the best performance from your Amplifier, Tektronix offers the

following customer support services.

If you need assistance operating your amplifier system, please call our Customer

Support Center at 1-800-TEK-WIDE

are outside the United States or Canada, please contact your nearest Tektronix

Service Center.

Should your Amplifier system need repair beyond that described in this manual,

please contact your nearest Tektronix Service Center.

(1-800-835-9433), extension 2400. If you

AM 503B & AM 5030 Amplifier Instruction Manual 1–1

Getting Started

Sales Support

To order optional equipment and accessories, call the Tektronix National

Marketing Center at 1-800-426-2200. If you are outside the United States or

Canada, please contact your nearest Tektronix Service Center.

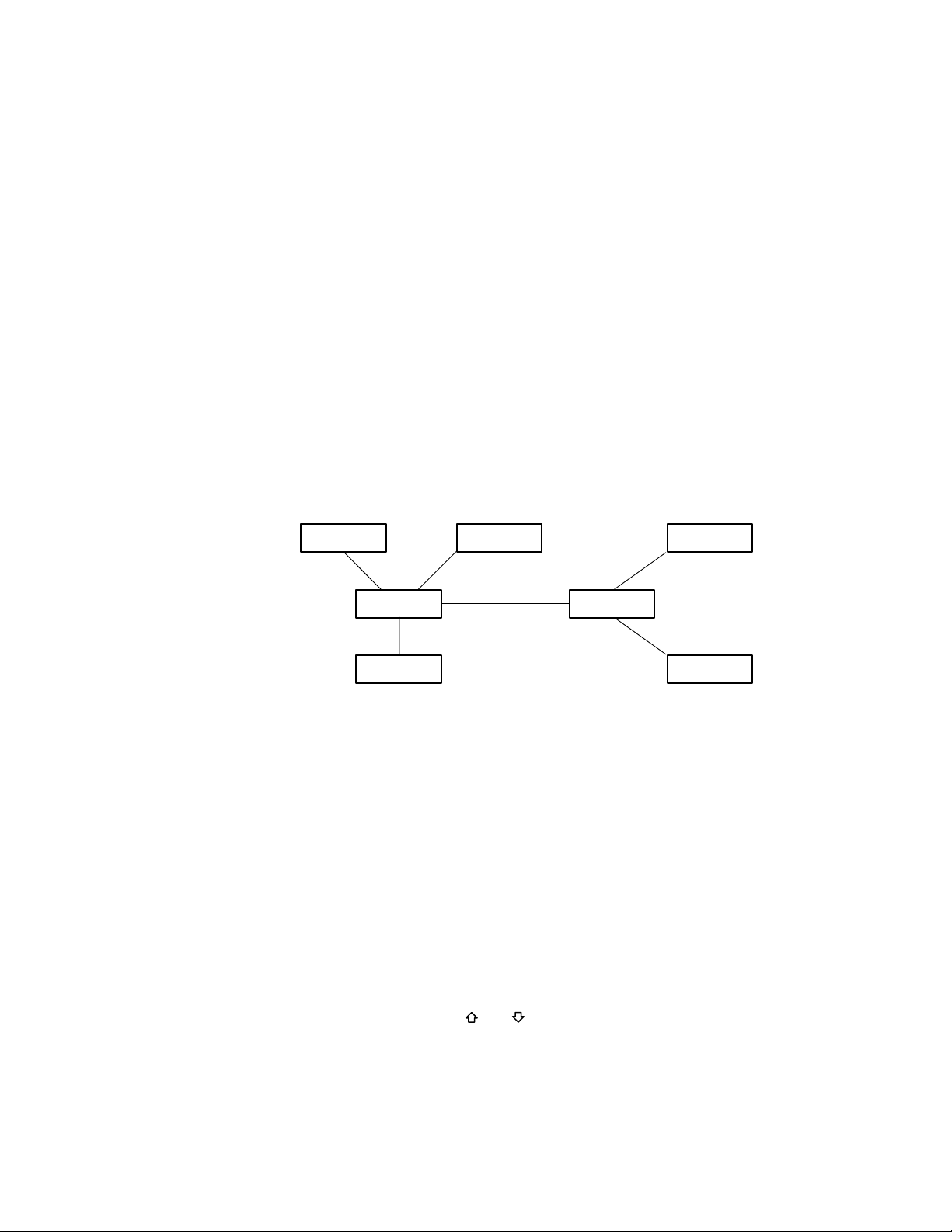

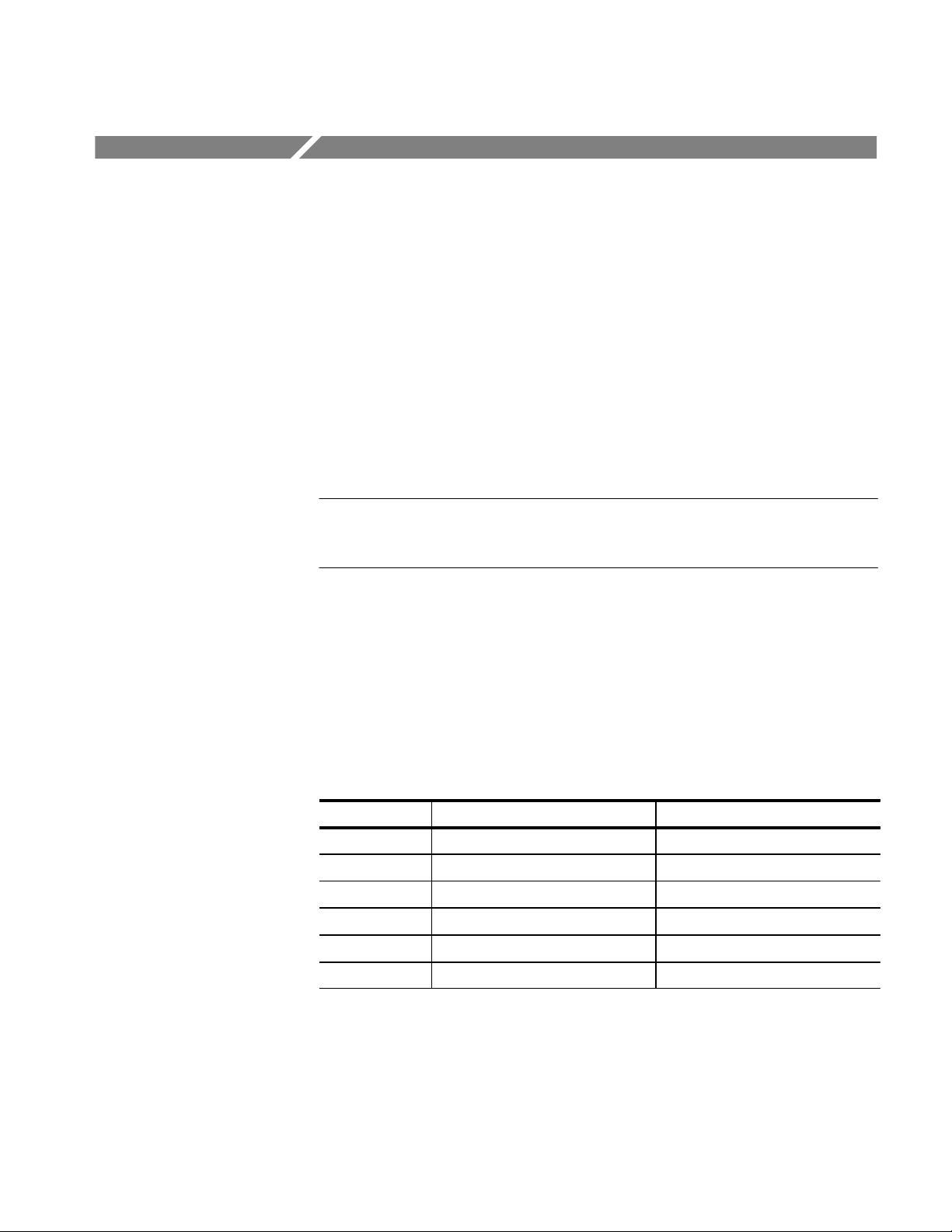

AM 503B and AM 5030 System Configuration

A complete AM 503B or AM 5030 current measurement system consists of a

current probe amplifier, a compatible current probe, a TM 500 or TM 5000 series

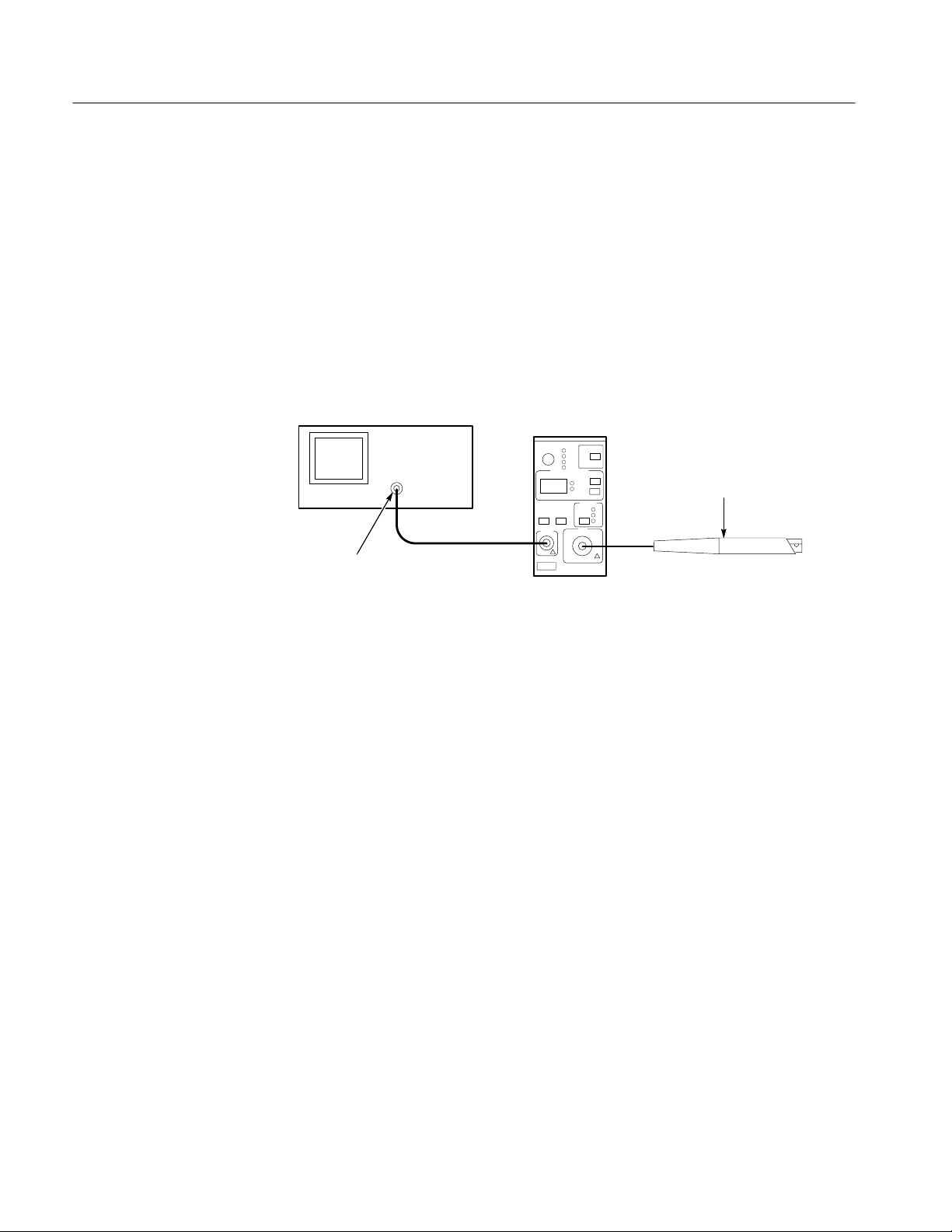

power module, and an appropriate oscilloscope. Refer to Figure 1–1.

Test Oscilloscope

Output

50 oscilloscope input (or add 50

termination here if oscilloscope has

only high-impedance input).

Amplifier in TM Series

Power Module

Current Probe

Input

AM 503B & AM 5030

Current Probe Amplifier

Current Probes

Figure 1–1: Configuring the AM 503B and AM5030 Current Measurement System

The AM 503B is a single-width instrument that plugs into any Tektronix

TM 500 or TM 5000 series power module. The AM 5030 is a single-width

instrument that plugs into any Tektronix TM 5000 series power module. The

Amplifier amplifies the current sensed by the probe and converts the current to a

proportional voltage that is displayed on an oscilloscope or other similar

measuring device.

The AM 503B and AM 5030 systems may be used with the following Tektronix

probes:

H A6312 (20 amps)

H A6302 and A6302XL (20 amps)

H A6303 and A6303XL (100 amps)

H A6304XL (500 amps)

You can also use the CT-4 High-Current Transformer with the A6312, A6302,

and A6302XL current probes to extend their AC current measurement range to

20,000 peak amps.

1–2 AM 503B & AM 5030 Amplifier Instruction Manual

Getting Started

TM 500 Series Power

Modules

TM 5000 Series Power

Module

Oscilloscope

Standard Accessories

The AM 503B operates in a Tektronix TM 500 or TM 5000 series power module

that powers one or more TM 500 series instruments. The Power Module operates

on either 110 or 220 VAC, 50 or 60 Hz.

The AM 5030 operates in a Tektronix TM 5000 series power module that powers

one or more TM 5000 series instruments while providing GPIB support. The

Power Module operates on either 110 or 220 VAC, 50 or 60 Hz.

An oscilloscope displays the output from the current measuring system. A 50

cable is included to connect the Amplifier to the oscilloscope input channel.

If the oscilloscope does not have an input that can be set to 50 impedance, you

need a feedthrough 50 termination. This termination is included as a standard

accessory with your AM 503B and AM 5030 Current Probe Amplifier.

These accessories are shipped with either the AM 503B or AM 5030:

H 50 coaxial cable

Optional Accessories

H 50 feedthrough termination

H Instruction Manual

H Reference card

If you ordered an AM 503S system, you will have received these items:

H AM 503B

H Current Probe (specific probe type depends on option ordered with the

Amplifier)

H TM 502A Power Module

H Toolbox

H AC Power cord

You can order the following optional accessories for the AM 503B and

AM 5030 Current Probe Amplifiers. Refer to the Replaceable Parts List on page

8–6 for Tektronix part numbers to use in ordering these accessories.

AM 503B & AM 5030 Amplifier Instruction Manual 1–3

Getting Started

H One-turn 50 current loop. The current loop is used in the performance

verification procedure for checking the performance of the AM 503B and

AM 5030.

H If you need to measure high-amplitude AC currents, consider using a

Tektronix CT-4 High-Current Transformer with the A6312, A6302, or

A6302XL probes. The CT-4 provides step-down ratios of 20:1 or 1000:1.

For more information about the CT-4, consult your Tektronix sales representative.

Installing the TM Series Power Module

If you ordered your current probe amplifier as a part of a system, a power

module will have been provided. Follow these instructions for the proper setup

and installation of the power module.

The TM Series Power Module can operate from one of four AC line voltages.

The operating voltage is determined by the voltage selector, located on the rear

panel of the TM Series Power Module, as shown in Figure 1–2.

WARNING. To avoid personal injury or equipment damage, do not connect the

power module to the AC line receptacle or turn the power module on until you

have verified that the proper operating voltage is selected.

Voltage Selector

Selector Window

Latch

TM Series

Power Module

Figure 1–2: TM Series Power Module Voltage Selector

1–4 AM 503B & AM 5030 Amplifier Instruction Manual

Getting Started

The value displayed in the voltage selector window should match the value of

your line voltage. If the two values don’t match, perform these steps to select the

correct value:

1. Push up on the latch and pull the voltage selector assembly out.

2. Disassemble the voltage selector as shown in Figure 1–3.

3. Rotate the fuse block until the proper voltage appears in the window.

4. Reassemble the voltage selector and push it back into the power module

until it snaps into place.

5. Using the correct power cord, connect the power module to the AC line

receptacle.

Rotate fuse block so that

the correct voltage

appears in the window

Fuse Block

Selector Window

Figure 1–3: Changing the TM 502A Operating Voltage

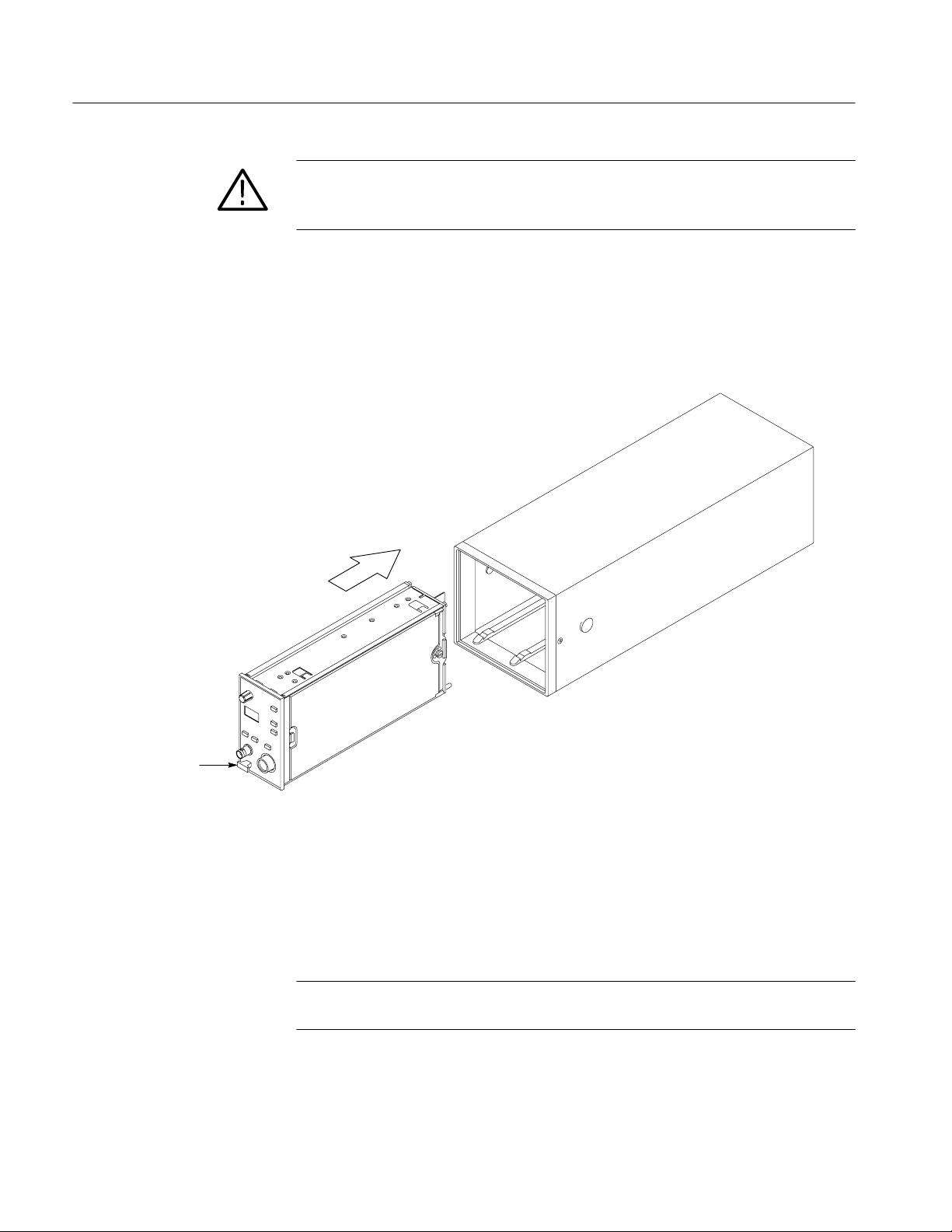

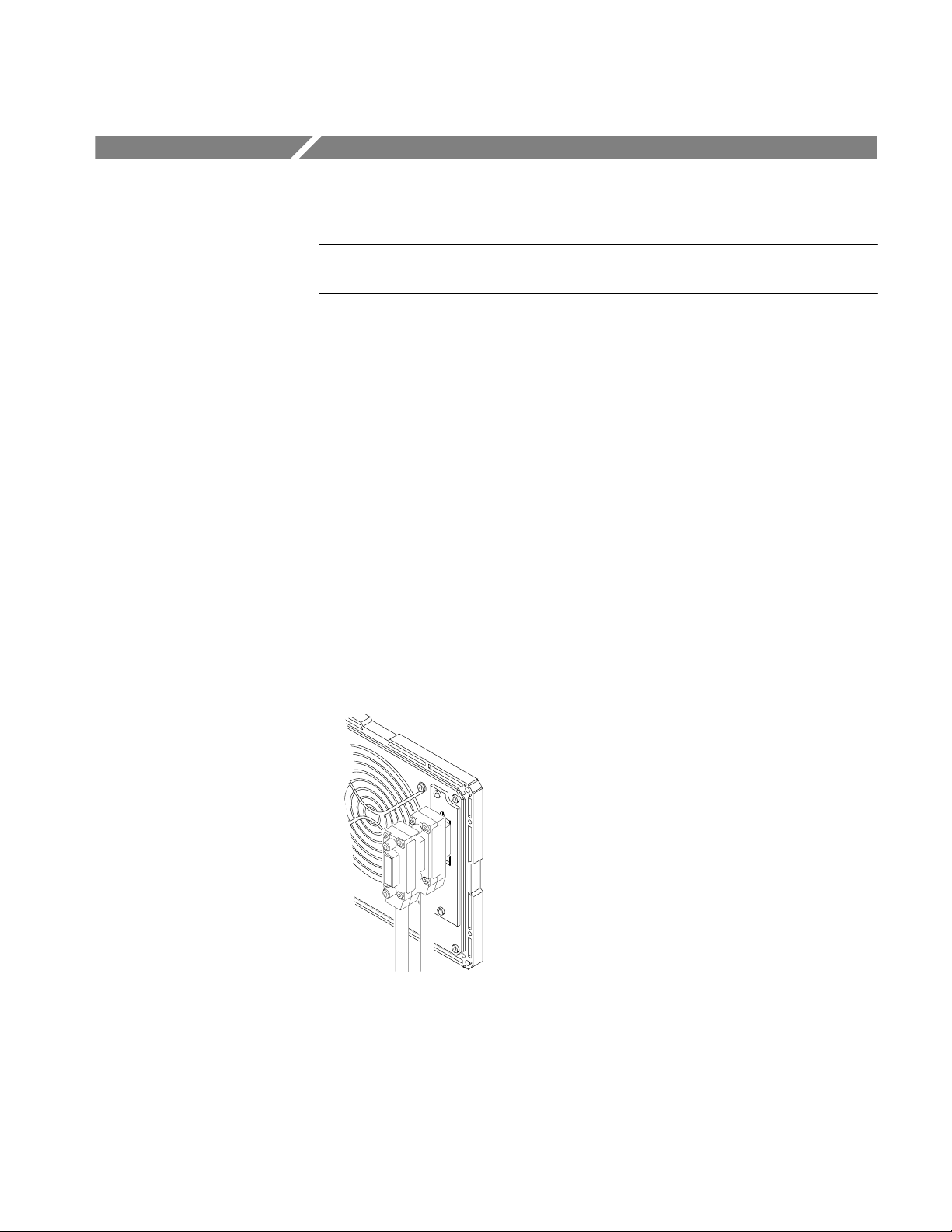

Installing the AM 503B or AM 5030 Into the Power Module

CAUTION. Make sure the power switch of the power module is turned off before

installing the Amplifier. If you install or remove a plug-in instrument while the

power module is on, you could damage the power module, the Amplifier, or the

current probe.

Fuse

AM 503B & AM 5030 Amplifier Instruction Manual 1–5

Getting Started

CAUTION. Do not attempt to install an AM 5030 amplifier into a TM 500 series

power module. The backplane connector scheme is different, and damage to the

amplifier will result.

To install the Amplifier into the power module, align the grooves of the

Amplifier with the rails of the power module and push the Amplifier into the

power module until the instrument snaps into place (see Figure 1–4). To remove

the Amplifier, grasp the release lever at the lower left corner of the Amplifier

front panel and pull the Amplifier out of the power module.

Slide instrument into

power module

Release Lever

Figure 1–4: Installing the AM 503B and AM5030 into the Power Module

After you have installed the Amplifier and all other desired plug-in instruments

into the power module, you may turn the power module on. A digital readout

should appear on the Amplifier front panel and a coupling light should come on.

See Figure 2–4 on page 2–7 for the location of the coupling lights.

NOTE. When the AM 5030 is not connected to a GPIB controller, the SRQ light is

normally on.

1–6 AM 503B & AM 5030 Amplifier Instruction Manual

Connecting the Amplifier to an Oscilloscope

You will need an oscilloscope to display the AM 503B and AM 5030 measurement output. The oscilloscope must be capable of displaying a vertical scale

factor of 10 mV/div.

Use the supplied 50 BNC cable to connect the Amplifier OUTPUT connector

to your oscilloscope (see Figure 1–1 on page 1–2).

The input impedance of the oscilloscope channel must be 50 , otherwise you

will encounter slowed pulse response, increased aberrations, or incorrect DC

measurement amplitudes. If your oscilloscope provides only 1 M inputs, you

need to attach a 50 feed-through termination between the oscilloscope input

and the BNC cable. Do not install this termination at the Amplifier end of the

BNC cable.

To utilize the full bandwidth capability of the AM 503B and AM 5030 and

attached current probe, the oscilloscope bandwidth should be approximately five

times that of the current probe. For example, when using an A6312 Current

Probe, the oscilloscope bandwidth should be at least 500 MHz. When using an

A6302 Current Probe, the oscilloscope bandwidth should be at least 250 MHz.

Getting Started

After you have connected the Amplifier to the oscilloscope, make the following

adjustments to the oscilloscope channel you are using. Perform these adjustments only after all equipment has warmed up to a stable temperature; usually

20 minutes are required.

1. Make sure the oscilloscope input impedance is 50 . If your oscilloscope

provides only 1 M inputs, you need to attach a 50 feedthrough

termination between the oscilloscope input and the BNC cable. Do not

install this termination at the AM 503B and AM 5030 end of the BNC cable.

2. Set the vertical gain of the oscilloscope to 10 mV/div.

3. Set the oscilloscope ground reference so the trace appears at the center

graticule line or at the desired zero-current reference.

4. Set the input coupling of the oscilloscope to DC.

5. Turn off any oscilloscope bandwidth filters.

Once you have set up the oscilloscope, you do not need to further adjust the

oscilloscope vertical controls while you are using the AM 503B and AM 5030.

Use the oscilloscope controls to adjust the time base or trigger settings only.

NOTE. To maintain accurate readings while using the AM 503B and AM 5030,

the vertical gain of the oscilloscope channel must always remain at 10 mV/Div

and the coupling must remain at DC.

AM 503B & AM 5030 Amplifier Instruction Manual 1–7

Getting Started

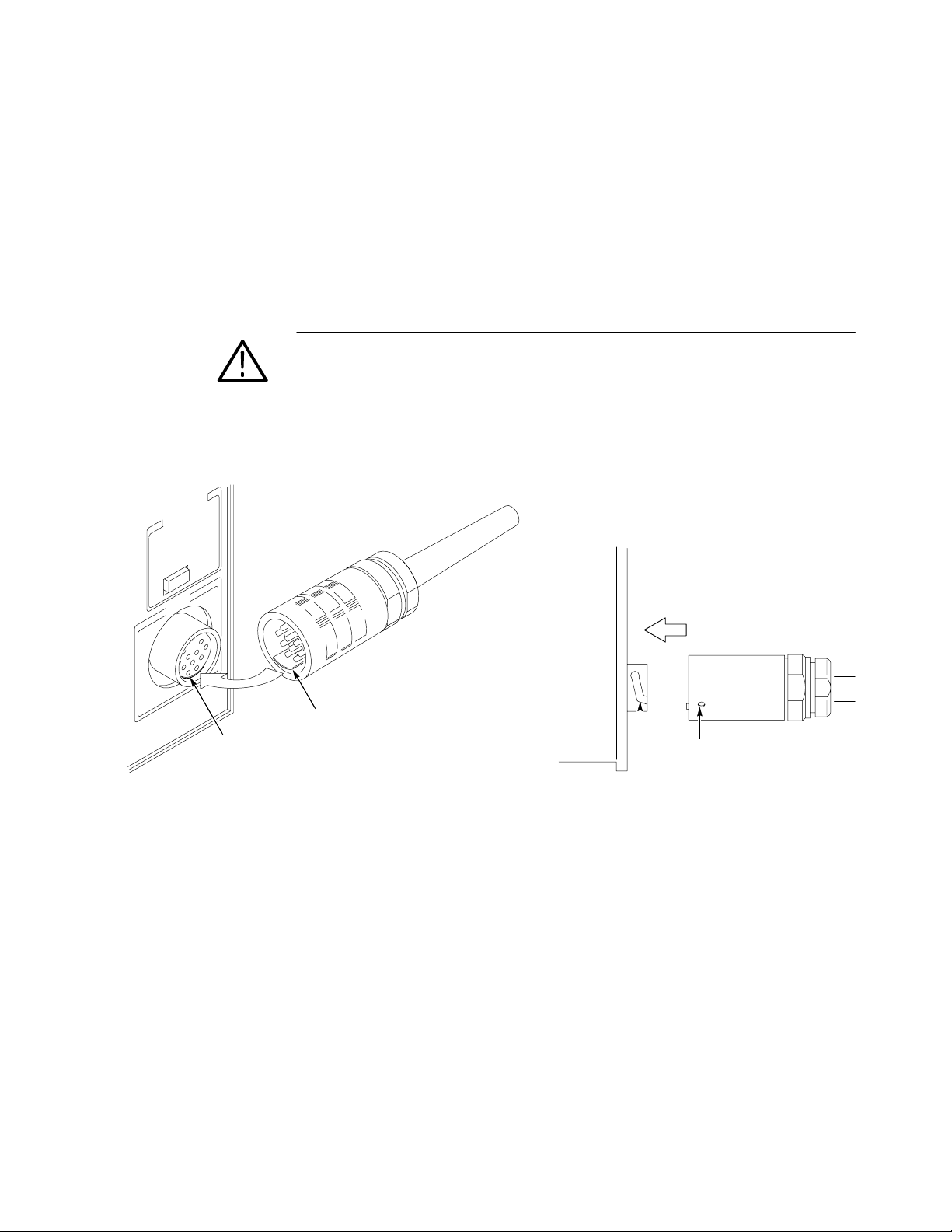

Connecting a Current Probe to the Amplifier

To connect a current probe to the Amplifier input connector, align the tab of the

probe connector with the slot in the Amplifier INPUT connector as shown in

Figure 1–5(a). Align the dot on the probe connector with the groove opening of

the input connector as shown in Figure 1–5(b). Push the probe connector in

while twisting the barrel clockwise to lock the connector.

CAUTION. Handle current probes with care. Do not drop a probe or subject it to

impact, or the core may crack. Do not connect or disconnect a current probe

while the probe is clamped around a live conductor, or while the AM 503B and

AM 5030 is powered on, or the probe may suffer electrical damage.

Amplifier

Current Probe Connector

Tab

Slot

(a) Align the Tab With the Connector Slot

Figure 1–5: Connecting a Current Probe to the Amplifier

Each current probe is calibrated before it is shipped, and should not require

further adjustment. If a probe requires adjustment, refer to the Adjustment

Procedure on page 6–1 or contact your nearest Tektronix Service Center. The

adjustment procedure should be performed only by qualified service personnel.

Push connector in

and twist to lock

Current Probe

Connector

Amplifier

(b) Insert the Connector Into the Amplifier

Groove

Alignment Dot

1–8 AM 503B & AM 5030 Amplifier Instruction Manual

Operating Basics

Measurements

This section provides operating techniques and measurement procedures for

using the AM 503B and AM 5030-compatible current probes.

Operating the Current Probe Slide

The current probes each have a slide mechanism that opens and closes the probe

jaw. This allows you to clamp the probe around a conductor under test. The slide

must be locked closed to accurately measure current or to degauss the probe. If a

probe is unlocked, the PROBE OPEN indicator on the Amplifier will light.

WARNING. When the probe slides are open, the exposed ferrite core pieces are

not insulated. To avoid injury or equipment damage, remove power from an

uninsulated wire before clamping the current probe around it.

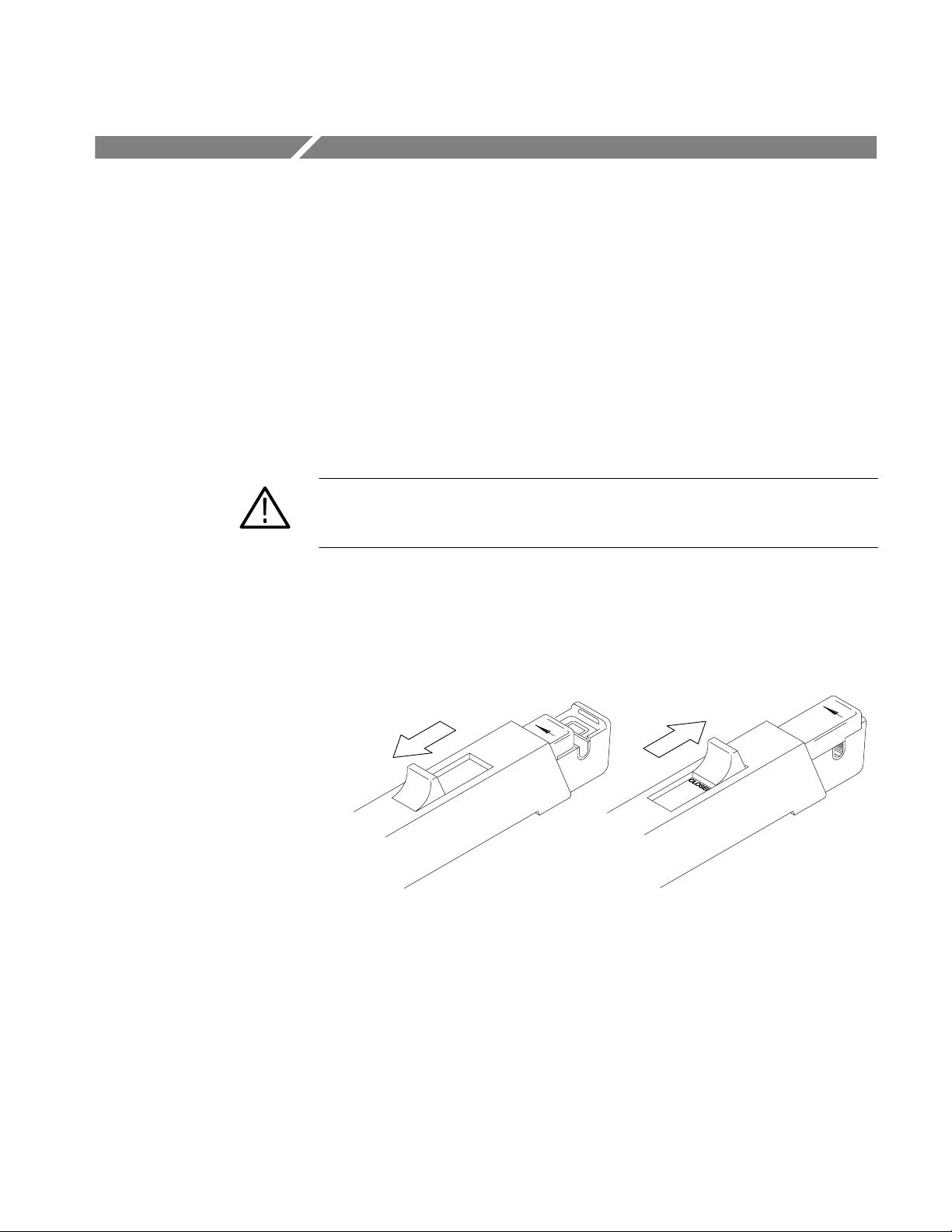

Figure 2–1 illustrates the slide operation of the A6312, A6302, and A6302XL

current probes. To open the probe, pull the slide back until the jaw is open. To

lock the probe, push the slide forward until the detent snaps into place.

Probe Open Probe Locked

Figure 2–1: A6312, A6302, and A6302XL Slide Operation

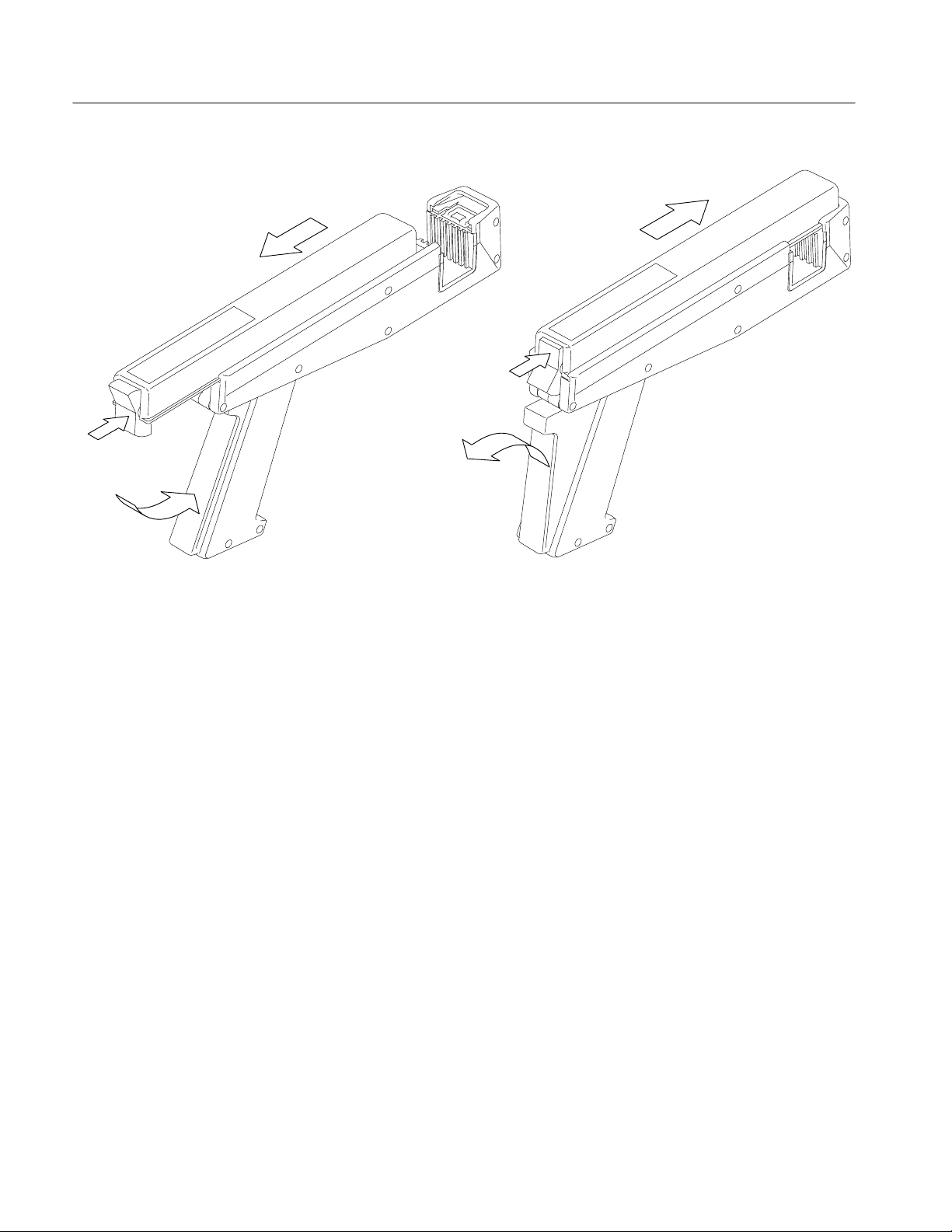

Figure 2–2 illustrates the slide operation of the A6303, A6303XL, and A6304XL

current probes. To open the probe, press the bottom of the lock button and

squeeze the handle until the core is open. To lock the probe, release the squeeze

handle and press the top of the lock button.

AM 503B & AM 5030 Amplifier Instruction Manual 2–1

Measurements

(1) Unlock the probe

(2) Squeeze

the handle

(a) Opening the Probe

(2) Lock the probe

(1) Release the handle

(b) Closing and Locking the Probe

Figure 2–2: A6303, A6303XL, and A6304XL Slide Operation

Degaussing and Autobalancing the Current Probe

Degaussing the probe removes any residual magnetization from the probe core.

Such residual magnetization can induce measurement error. Autobalancing

removes unwanted DC offsets in the amplifier circuitry.

Failure to degauss the probe is a leading cause of measurement errors. To

maintain measurement accuracy, degauss your probe in each of these cases:

H After turning on the Amplifier and allowing a 20-minute warm-up period.

H Before connecting the probe to a conductor or changing conductors under

test.

H Whenever an overload condition occurs.

H Whenever the probe is subjected to a strong external magnetic field.

H Periodically during normal use.

2–2 AM 503B & AM 5030 Amplifier Instruction Manual

Measurements

To degauss and autobalance a current probe, perform these steps:

1. Verify that the current probe is connected to the Amplifier.

2. Remove the current probe from the conductor under test.

3. Lock the probe slide closed (see Figures 2–1 and 2–2).

4. Press the Amplifier PROBE DEGAUSS AUTOBALANCE button.

NOTE. The degauss procedure will fail if the Amplifier is not properly connected

to an oscilloscope having 50 input impedance. If this occurs, an error code of

266 will be displayed on the Amplifier front panel.

After you have completed the oscilloscope adjustments and the Amplifier

degauss/autobalance procedure, your system is ready to measure current.

DC Measurements

To measure DC current, perform these steps:

1. Verify that the vertical gain of the oscilloscope is 10 mV/div, the input

coupling is DC, and the input impedance is set to 50 .

2. Adjust the ground reference of the oscilloscope to move the trace to the

desired graticule line.

NOTE. Once the first two steps have been completed, no further adjustments are

required on the oscilloscope vertical amplifier during the measurement session.

Use the Amplifier controls for everything except time base and trigger adjustment. See Figure 2–4.

3. Lock the probe closed without a conductor passing through it. Press the

Amplifier COUPLING button repeatedly until the REF light comes on, and

then press the Amplifier PROBE DEGAUSS AUTOBALANCE button.

4. After the degauss/autobalance routine completes, adjust the ground reference

(if necessary) using the Amplifier OUTPUT DC LEVEL control.

5. Open the probe slide, place the probe around the conductor under test, and

then lock the slide. For correct measurement polarity, make sure the probe

arrow is pointing in the direction of conventional (positive to negative)

current flow. Reversing the flow will display the current waveform upside-

down on the oscilloscope.

AM 503B & AM 5030 Amplifier Instruction Manual 2–3

Measurements

6. Press the Amplifier COUPLING button repeatedly until the DC light comes

on. Set the Amplifier CURRENT/DIVISION to the desired setting using

the

and buttons.

7. If necessary, vertically position the resulting waveform using the OUTPUT

DC LEVEL knob of the Amplifier.

8. Adjust the oscilloscope time base and trigger as needed.

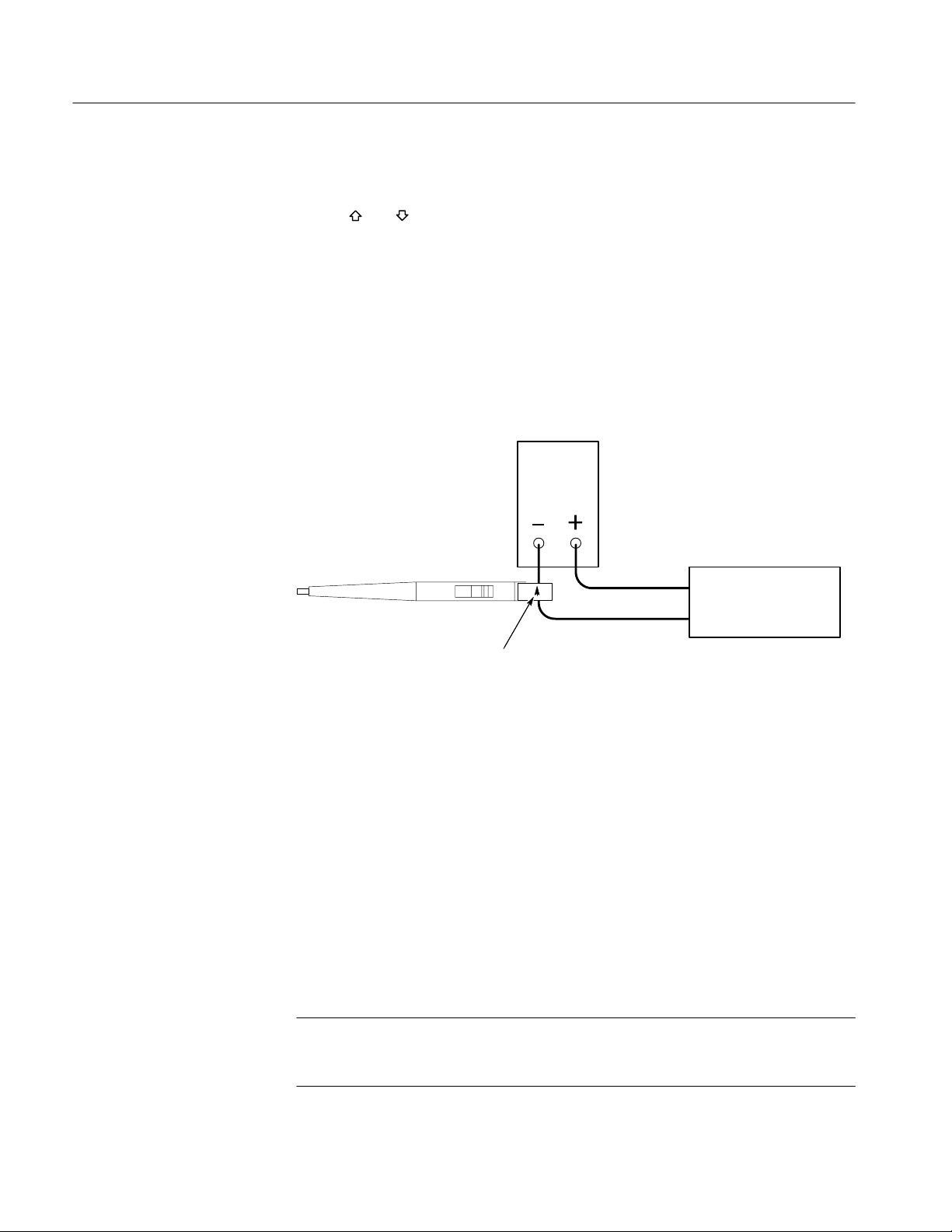

Figure 2–3 shows a current probe connected to a power supply line. Notice that

the probe arrow points toward the negative terminal of the power supply to

conform to the conventional current flow of positive (+) to negative (–).

Power Supply

AC Measurements

Current Probe

Load

Conventional Current Arrow

Figure 2–3: Current Probe Polarity

To measure AC current only, and remove the DC component of the current being

measured, follow the instructions below. These are identical to the instructions

for DC current measurements except that the Amplifier coupling in step 6 is set

to AC.

1. Verify that the vertical gain of the oscilloscope is 10 mV/div, the input

coupling is DC, and the input impedance is set to 50 .

2. Adjust the ground reference of the oscilloscope to move the trace to the

desired graticule line.

NOTE. Once the first two steps have been completed, no further adjustments are

required on the oscilloscope vertical amplifier during the measurement session.

Use the Amplifier controls for everything but time base and trigger adjustment.

2–4 AM 503B & AM 5030 Amplifier Instruction Manual

Measurements

3. Lock the probe closed without a conductor passing through it. Press the

Amplifier COUPLING button repeatedly until the REF light comes on, and

then press the Amplifier PROBE DEGAUSS AUTOBALANCE button.

4. After the degauss/autobalance routine completes, adjust the ground reference

(if necessary) using the Amplifier OUTPUT DC LEVEL control.

5. Open the probe slide, place the probe around the conductor under test, and

then lock the slide. For correct measurement polarity, make sure the probe

arrow is pointing in the direction of conventional (positive to negative)

current flow. Reversing the flow will invert the displayed current waveform

on the oscilloscope.

6. Press the Amplifier COUPLING button repeatedly until the AC light comes

on. Set the Amplifier CURRENT/DIVISION to the desired setting using

the

and buttons.

NOTE. Even when making AC current measurements, leave the oscilloscope

coupling on DC. Change only the Amplifier coupling to AC. Using the oscilloscope AC coupling may cause the Amplifier to exceed its output dynamic range.

7. If necessary, vertically position the resulting waveform using the OUTPUT

DC LEVEL knob of the Amplifier.

8. Adjust the oscilloscope time base and trigger as needed.

AM 503B & AM 5030 Amplifier Instruction Manual 2–5

Measurements

2–6 AM 503B & AM 5030 Amplifier Instruction Manual

Control Summary

This section describes the function of each AM 503B and AM 5030 front panel

control and connector. The overview in Figure 2–4 is followed by a detailed

description.

Some seldom-used functions do not appear in Figure 2–4. These functions are

completely discussed in the detailed descriptions that follow Figure 2–4.

The OUTPUT DC LEVEL knob

vertically positions the signal on the

oscilloscope screen.

The CURRENT/DIVISION display shows the

current AM 503B and AM 5030 scale factor in

either mA/division or A/division. Error codes

and output DC level also appear here.

The 20 MHz BW LIMIT button alternately

selects or deselects the 20 MHz bandwidth

limit for noise filtering.

Hold down the GPIB ADDRESS button while

adjusting the CURRENT/DIVISION buttons to

change the GPIB address. (AM 5030 only.)

The AM 503B and AM 5030 output appears at

the OUTPUT connector. Connect this to a 50

input of your oscilloscope.

Pull the release lever to remove the AM 503B and

AM 5030 from the power module.

Figure 2–4: The AM 503B and AM 5030 Front Panel

The two indicator lights: PROBE OPEN and

OVERLOAD give you local status information.

The two indicator lights: SRQ and REMOTE

give you remote status information. (AM 5030

only.)

The PROBE DEGAUSS AUTOBALANCE button

removes residual magnetism from the attached

current probe. The probe must be removed from

the test circuit and locked.

The CURRENT/DIVISION buttons change the

AM 503B and AM 5030 scale factor.

The COUPLING button selects AC or DC probe

coupling or a zero-current reference, as

indicated by the lights.

The current probes connect to the AM 503B and

AM 5030 at the INPUT connector.

AM 503B & AM 5030 Amplifier Instruction Manual 2–7

Control Summary

AM 503B and AM 5030 Controls

These front panel controls and indicators are common to both the AM 503B and

AM 5030 current probe amplifiers.

OUTPUT DC LEVEL

Control

PROBE OPEN Indicator

The OUTPUT DC LEVEL knob adjusts the DC offset that appears at the

Amplifier OUTPUT connector. The OUTPUT DC LEVEL knob adjusts the

displayed waveform relative to ground. After setting a zero-current reference, do

not use the oscilloscope vertical position to move the waveform up and down on

the display; use the Amplifier OUTPUT DC LEVEL knob instead.

As you adjust the OUTPUT DC LEVEL knob, the display shows you the output

level in divisions. When you stop moving the OUTPUT DC LEVEL knob, the

display reverts to show current per division.

The PROBE DEGAUSS AUTOBALANCE button will change the output DC

level setting if the Amplifier coupling is set to REF. In this case only, the output

DC level setting will be reset to ground; otherwise, the DC level setting will

remain at its previous setting.

NOTE. To maintain measurement accuracy, position the signal with the AM 503B

and AM 5030

!

When lit, this indicator informs you that the current probe is unlocked. You must

have the probe slide locked in order to degauss the probe or to accurately

measure current.

OVERLOAD Indicator

PROBE DEGAUSS

AUTOBALANCE Button

2–8 AM 503B & AM 5030 Amplifier Instruction Manual

When lit, this indicator informs you that the measurement you are taking exceeds

the continuous amplitude limit of the AM 503B and AM 5030. The detection

circuits only detect low frequency (≈10 kHz) and DC overloads. Since overloads

can magnetize the probe, you should always degauss the probe after an overload.

WARNING. To avoid personal injury or equipment damage, do not exceed the

specified electrical limits of the AM 503B and AM 5030 or any applicable

accessories.

When pressed, this button performs two functions that maximize measurement

accuracy. First, the Amplifier generates a degauss signal to remove any residual

magnetism from the attached current probe. Second, the Amplifier initiates an

operation to remove any undesired DC offsets from its circuitry. During the

degauss process, the Amplifier is busy and cannot be used to measure current.

Control Summary

The indicator light in the PROBE DEGAUSS AUTOBALANCE button will

blink whenever the Amplifier detects that the current probe needs degaussing or

DC balancing. The Amplifier cannot detect all circumstances that require probe

degaussing, so you may need to degauss the probe at times when the PROBE

DEGAUSS AUTOBALANCE light is not blinking. The blinking light serves as

a reminder to degauss the current probe when one of the following conditions

occurs:

H The Amplifier has just been turned on with a current probe connected.

H The current probe has been changed.

H The internal temperature of the Amplifier changed by more than 10° C.

H An overload has occurred.

The indicator stays on steady during the time the Amplifier is busy performing

the probe degauss functions. When the degauss and autobalance procedure is

complete, the indicator light turns off.

To perform the probe degauss/autobalance function, remove the probe from

around all conductors (or ensure that the conductor under test has no power),

make sure the probe is locked closed, and then press the PROBE DEGAUSS

AUTOBALANCE button.

The probe degauss/autobalance routine will not work if the current probe is

unlocked or disconnected from the Amplifier input. To properly degauss the

current probe, remove it from the conductor under test and lock the probe.

If the PROBE DEGAUSS AUTOBALANCE button is pressed while the

coupling is set to REF, the Output DC level is reset to ground. If either AC or

DC coupling is selected when the PROBE DEGAUSS AUTOBALANCE button

is pressed, the DC level is not changed from its previous setting.

NOTE. The Amplifier displays error code 266 when the Amplifier output is not

properly terminated into a 50 load. Make sure your Amplifier OUTPUT is

connected to an oscilloscope input using a 50 BNC cable, and that the

oscilloscope input is set to 50 impedance. See Figure 1–1 on page 1–2 for

proper cabling.

If your oscilloscope does not have 50 impedance settings for inputs, you can

place a 50 feed-through termination on the oscilloscope input and connect the

Amplifier output cable to the termination. Do not place the feed-through

termination at the Amplifier end of the BNC connecting cable.

AM 503B & AM 5030 Amplifier Instruction Manual 2–9

Control Summary

CURRENT/DIVISION

Buttons

COUPLING Button

The CURRENT/DIVISION

the AM 503B and AM 5030 in a 1–2–5 sequence. The setting of this control is

displayed on the digital readout and the units indicator. The CURRENT/DIVISION display indicates the Amplifier scale factor only; it is not a current

measurement readout. The measurement output is displayed on the oscilloscope.

NOTE. To maintain accurate measurements, the vertical gain of the oscilloscope

must remain at 10 mV/div.

The COUPLING button determines the coupling between the current probe and

the AM 503B and AM 5030. Press the COUPLING button repeatedly until the

desired indicator lights up. To couple the current probe for DC plus AC

measurements, use DC coupling. For AC measurements only, use AC coupling.

To establish a zero-current reference, use REF coupling. While using REF

coupling, you cannot measure current or view current waveforms.

NOTE. Even when making AC current measurements, leave the oscilloscope

coupling on DC. Change only the Amplifier coupling to AC. Using the oscilloscope AC coupling may cause the Amplifier to exceed its output dynamic range.

and buttons set the scale factor (sensitivity) of

20 MHz BW LIMIT Button

Probe Trim Adjust

The 20 MHz BW LIMIT button lets you limit the current probe amplifier

bandwidth to 20 MHz. This can be useful to remove high-frequency noise. Press

the button again to return to full bandwidth. When the button lights, the

bandwidth limit is on. System bandwidth depends on the type of current probe

you are using. Refer to the specifications table on page 4–3 for the bandwidth

limit frequency for your current probe.

After the PROBE DEGAUSS AUTOBALANCE routine has been run, the probe

and amplifier system will meet all published specifications; however, if you want

to improve the tolerance of the system accuracy, or to intentionally offset the

accuracy to make up for total system errors, the probe trim adjust routine may be

performed.

Probe trim adjust is a multiplicative factor that you can use to adjust the gain of

the current amplifier system. You can set this multiplier in increments of 0.001

from 0.750 through 1.250. Probe trim adjust is used for an optional calibration of

some current probes. If you are not performing such an adjustment, leave probe

trim adjust to the factory-default of unity gain (1.000).

To set probe trim adjust, press and hold the 20MHz BW LIMIT button while

pressing and releasing the COUPLING button. Use the

and buttons to

2–10 AM 503B & AM 5030 Amplifier Instruction Manual

Control Summary

adjust the setting that is displayed in the CURRENT/DIVISION display. When

finished, press either the 20MHz BW LIMIT or COUPLING button to restore

normal operation.

The display shows the last three significant digits of the display adjust setting;

the leading 0. or 1. are omitted. If the first digit displayed is 7, 8, or 9, then the

leading digit must be 0. If the first digit displayed is 0, 1, or 2, then the leading

digit must be 1.

OUTPUT Connector

INPUT Connector

The Amplifier current measurement output is accessed at the OUTPUT

connector, which should be connected to the oscilloscope input. Attach one end

of a 50 BNC cable to this connector and the other end to a 50 vertical input

of your oscilloscope. The output impedance of the Amplifier is 50 .

NOTE. To obtain accurate measurements, the input impedance of your oscilloscope must be 50 . Make sure your Amplifier OUTPUT is connected to an

oscilloscope input using a 50 BNC cable, and that the oscilloscope input is set

to 50 impedance. See Figure 1–1 on page 1–2 for proper cabling.

If your oscilloscope does not have 50 impedance settings for inputs, you can

place a 50 feedthrough termination on the oscilloscope input and connect the

Amplifier output cable to the termination. Do not place the feedthrough

termination at the Amplifier end of the BNC connecting cable.

All current probes compatible with the AM 503B and AM 5030 attach at the

INPUT connector, which is a 12-pin female connector. For information about

connecting a probe, see Connecting a Current Probe to the AM 503B and

AM 5030 on page 1–8.

CAUTION. To avoid equipment damage, turn the TM Series Power Module off

before removing or installing a current probe.

Release Lever

AM 503B & AM 5030 Amplifier Instruction Manual 2–11

The release lever has the Tektronix name printed on it. Pull the release lever to

remove the Amplifier from the power module.

CAUTION. To avoid equipment damage, turn the TM Series Power Module off

before removing or installing any plug-in unit.

Control Summary

AM 5030 GPIB Controls

These indicators and controls are unique to the AM 5030 and do not appear on

the AM 503B front panel.

SRQ Indicator

REMOTE Indicator

GPIB ADDRESS Indicator

GPIB ADDRESS Button

When lit, this indicator informs you that the AM 5030 has requested service

from the controller.

When lit, this indicator informs you that the front panel of the AM 5030 is

temporarily locked out because the Amplifier is responding to a GPIB command

from the controller.

The GPIB ADDRESS button has a light in it. When lit, this indicator informs

you that the AM 5030 has been addressed by the controller and that communication is taking place.

The GPIB ADDRESS button lets you set the AM 5030 device address. The

GPIB controller must use this address to send commands to the Amplifier. To set

the GPIB address, press and hold the GPIB ADDRESS button and, while

holding it down, use the

in the CURRENT/DIVISION display.

You can set the address from 0 (A00) through 30 (A30). You can also set the

Amplifier off line, which disables all communications with the controller. The

off line setting is A––.

and buttons to adjust the address that is displayed

GPIB Terminator

2–12 AM 503B & AM 5030 Amplifier Instruction Manual

The GPIB ADDRESS and 20MHz BW LIMIT buttons together let you define

the AM 5030 GPIB terminator. The terminator may be set to EOI only or EOI

followed by LF. To set the GPIB terminator, press and hold the GPIB ADDRESS button, and also press and hold the 20 MHz BW LIMIT button. While

holding them down, use the

displayed in the CURRENT/DIVISION display. The display shows EOI if the

terminator is EOI only and LF if the terminator is EOI followed by LF.

and buttons to adjust the setting that is

GPIB Operation

NOTE. This material applies only to the AM 5030 Programmable Amplifier. The

AM 503B does not support a GPIB interface.

You can use a computer to control the AM 5030 and make measurements. With

an oscilloscope that also can be programmed, the computer and AM 5030 can

form a complete, automated measurement system.

Your computer, also known as the controller, must be capable of operating on a

GPIB bus that conforms to IEEE Std 488.1–1987. GPIB cards are available to

provide this capability for personal computers.

The TM 5000 Series Power Module has a 24-pin GPIB connector on its rear

panel, as shown in Figure 2–5. This connector has a D-type shell and conforms

to IEEE Std 488.1–1987.

Attach an IEEE Std 488.1–1987 GPIB cable (see Optional Accessories in the

Replaceable Mechanical Parts section) between this connector and your

controller. Figure 2–5 also shows how cables can be stacked together. You can

stack a second cable on either the TM 5000 Series Power Module connector or

the controller connector, to similarly connect your oscilloscope.

Figure 2–5: Stacked GPIB Connectors

AM 503B & AM 5030 Amplifier Instruction Manual 2–13

GPIB Operation

GPIB Requirements

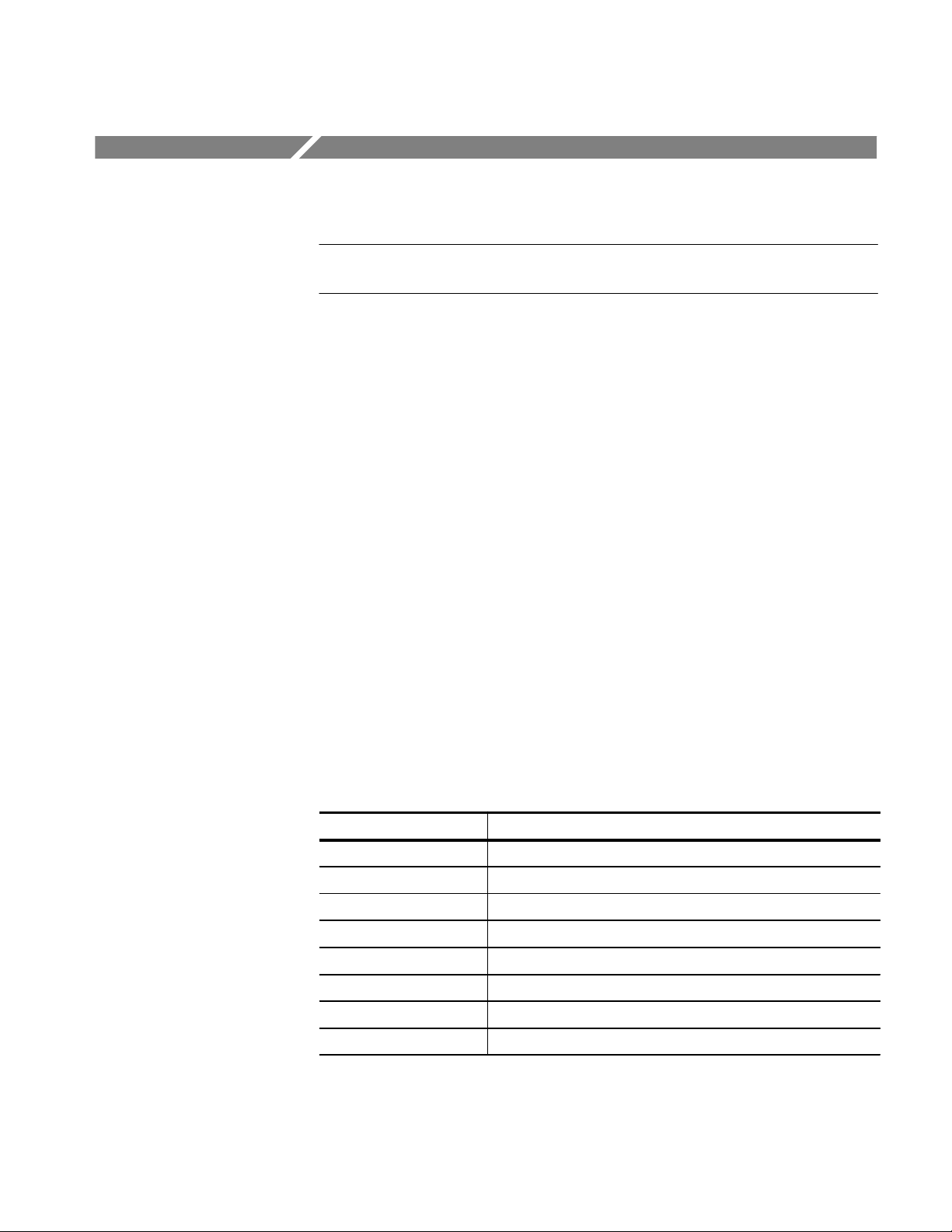

Observe these rules when you use your AM 5030 with a GPIB network:

H Assign a unique device address to each device on the bus. No two devices

can share the same device address.

H Do not connect more than 15 devices to the bus.

H Connect one device for every 2 meters (6 feet) of cable used.

H Do not use more than 20 meters (65 feet) of cable for the entire bus.

H Turn on at least two-thirds of the devices on the network while using the

network.

H Connect the devices on the network in a star or linear configuration as shown

in Figure 2–6. Do not use loop or parallel configurations.

GPIB Device

Figure 2–6: T ypical GPIB Network Configurations

Setting the GPIB Parameters

You must set the GPIB parameters of the AM 5030 to match the configuration of

the bus and controller.

GPIB Address

The GPIB ADDRESS button lets you set the AM 5030 device address. The

GPIB controller must use this address to send commands to the AM 5030. The

address of the AM 5030 must be different from the addresses used by all other

devices on the bus.

GPIB Device

GPIB Device

GPIB Device

GPIB Device

GPIB Device

GPIB Device

To set the GPIB address, press and hold the GPIB ADDRESS button and, while

holding it down, use the

and buttons to adjust the address that is displayed

in the digits. You can set the address from 0 (A00) through 30 (A30). You can

also set the AM 5030 off line, which disables all communications with the

controller. The off line setting is A––.

2–14 AM 503B & AM 5030 Amplifier Instruction Manual

GPIB Operation

GPIB Terminator

Pressing both the GPIB ADDRESS and 20MHz BW LIMIT buttons at the same

time lets you set the AM 5030 GPIB terminator. The terminator may be set to

EOI only or EOI followed by LF. You will need to consult your controller

documentation to determine which setting is best for your configuration.

To set the GPIB terminator, press and hold both the GPIB ADDRESS and

20MHz BW LIMIT buttons and, while holding them down, use the

buttons to adjust the setting that is displayed in the digits. The display shows

EOI when the terminator is EOI only and LF when the terminator is EOI

followed by LF.

Other Documents You Will Need

We cannot know what type of controller you will use with your AM 5030. This

document cannot cover the topics that are specific to your installation. To

completely understand and implement a GPIB system, you will need the

documentation that supports your controller. If you are using a personal

computer with a GPIB card, you will need the documentation for both the PC

and the GPIB card.

and

AM 503B & AM 5030 Amplifier Instruction Manual 2–15

GPIB Operation

2–16 AM 503B & AM 5030 Amplifier Instruction Manual

Functional Command Groups

NOTE. This material applies only to the AM 5030 Programmable Amplifier. The

AM 503B does not support a GPIB interface.

The AM 5030 GPIB interface commands fall into four groups:

H Front panel commands

H GPIB Status commands

H Amplifier Status commands

H Probe Status commands

Command names show both upper- and lower-case characters. Only the

upper-case characters are required. You can abbreviate commands by omitting

lower-case characters, starting from the end. For example, you can enter the

ALLEve command as ALLEVE, ALLEV, or ALLE.

The AM 5030 is not case-sensitive. You can use lower-case letters anyplace in

command names or arguments: alLeVe, AllEv, or alle are valid.

Front Panel Commands

The commands listed in Table 2–1 are used to control or duplicate the front panel

controls and indicators of the AM 5030.

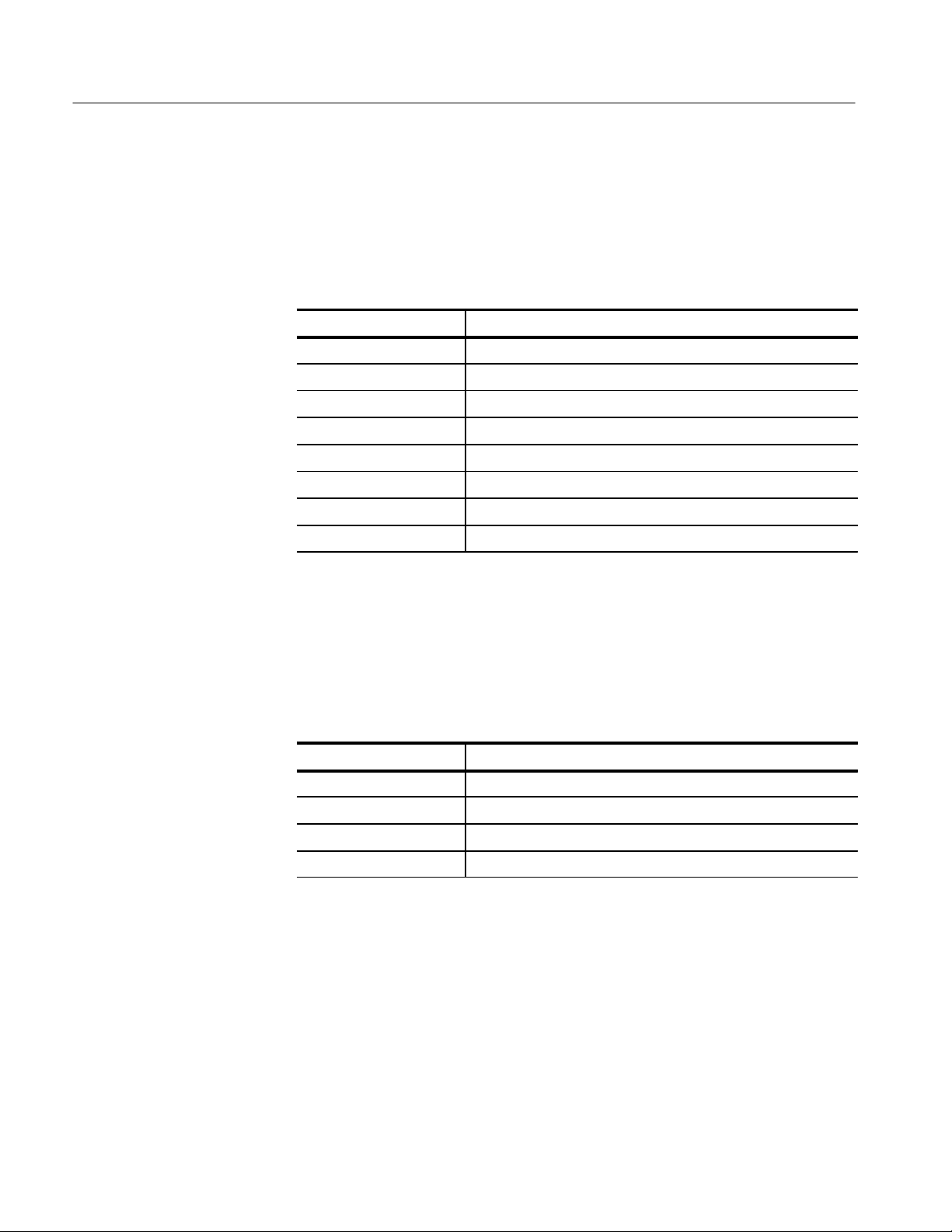

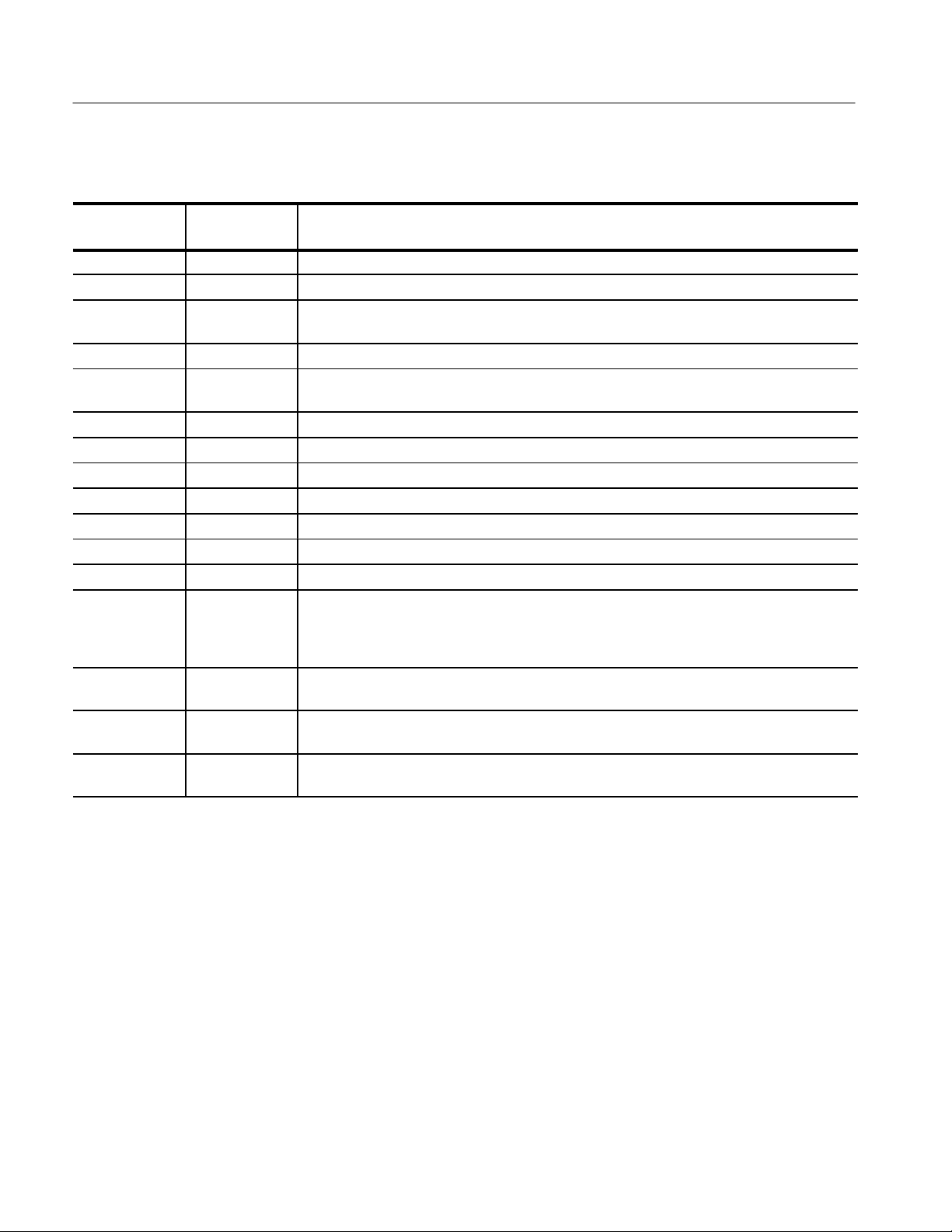

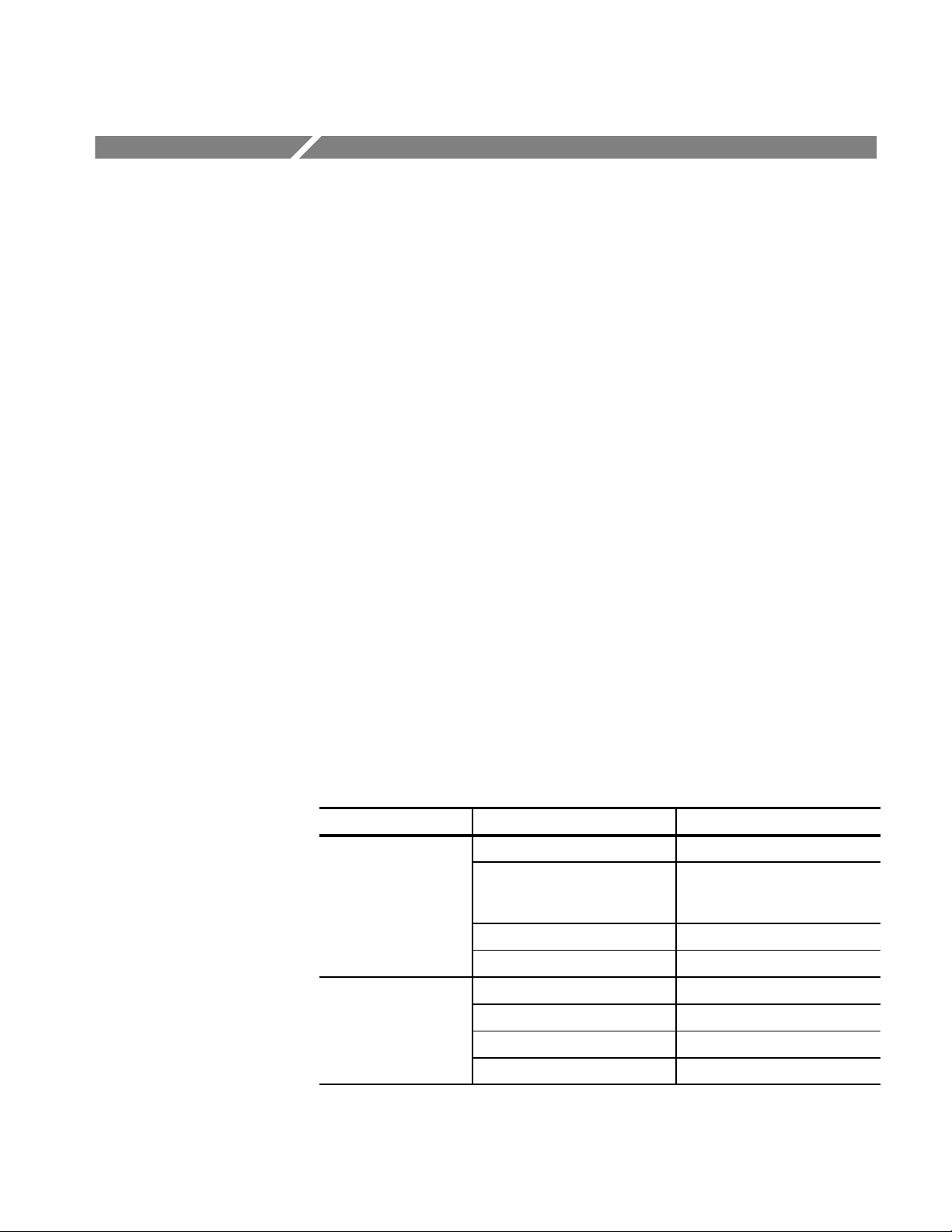

T able 2–1: Front Panel Commands

Command Name Description

AMPS Sets output resolution

BWLIMit Sets or resets bandwidth limiting

COUpling Sets input coupling

DCLEVel Adjusts output DC offset (reference) level

DEGAuss Starts the degauss/autobalance sequence

FPLock Disables and enables front-panel controls

OVerload? Returns the state of the overload indicator

UNIts? Returns units of AM 5030 output

AM 503B & AM 5030 Amplifier Instruction Manual 2–17

Functional Command Groups

GPIB Status Commands

The commands listed in Table 2–2 are used to provide event information and

configure the GPIB interface.

T able 2–2: GPIB Status Commands

Command Name Description

ALLEve? Returns all pending event codes

ERRor? Returns the last pending event code

EVent? Returns the last pending event code

EXit Recovers from an error condition

HELp? Returns a list of AM 5030 GPIB commands

PATH Sets whether queries return command names

RQS Enables or disables system requests (SRQs)

SET? Returns all AM 5030 settings as command string

Amplifier Status Commands

The commands listed in Table 2–3 are used to identify, configure, and test the

AM 5030 amplifier.

T able 2–3: Amplifier Status Commands

Command Name Description

ID? Returns instrument ID including firmware version numbers

INIT Initializes AM 5030 to factory default settings

SERIAL? Returns AM 5030 serial number

TEST Performs AM 5030 self test

2–18 AM 503B & AM 5030 Amplifier Instruction Manual

Probe Status Commands

The commands listed in Table 2–4 are used to adjust and provide information

about the probe currently in use.

T able 2–4: Probe Status Commands

Command Name Description

PROBEOPen? Returns the state of the probe open indicator

PROBETRim Sets probe gain adjustment factor

PROBETY pe? Returns model of current probe being used

NOTE. The PROBETYpe? query returns PROBETYPE A6302 for both A6302 and

A6312 current probes.

Functional Command Groups

AM 503B & AM 5030 Amplifier Instruction Manual 2–19

Functional Command Groups

2–20 AM 503B & AM 5030 Amplifier Instruction Manual

Commands

ALLEve? (Query Only)

This section supports the GPIB commands with command definitions, syntax,

return messages, and examples.

Returns a comma-delimited list of up to 41 pending event codes. If no event is

pending, it returns the code for “no events to report.”

AMPS

Syntax

Returns

Examples

Syntax

ALLEve? only produces meaningful results when RQS is off. When RQS is on,

ALLEve? operates the same as EVent?, except that the returned header is

ALLEVE instead of EVENT.

ALLE?