AM

503

CURRENT

PROBE

AMPLIFIER

7

e

I

d

ronbc

INSTRUCTION

MANUAL

Tektronix,

Inc

.

P.O.

Box

500

Beaverton,

Oregon

97077

Serial

Number

COMMITTED

TO

EXCELLENCE

PLEASE

CHECK

FOR

CHANGE

INFORMATION

AT

THE

REAR

OF

THIS

MANUAL

.

AM

503

CURRENT

PROBE

AMPLIFIER

070-2052-01

First

Printing

SEP

1976

Product

Group

75

Revised

DEC

1985

Copyright

`'

1976,

1979

Tektronix,

Inc

.

All

rights

reserved

.

Contents

of this

publication

may

not

be

reproducedinany

form

without

the

written

permission

of

Tektronix,

Inc

.

Products

of

Tektronix,

Inc.and

its

subsidiaries are

covered

byU.S.and

foreign

patents

and/or

pending patents

.

TEKTRONIX,

TEK,

SCOPE-MOBILE,

and

ilk

are

registered

trademarksofTektronix,

Inc.TELEQUIPMENT

isaregistered

trademarkofTektronixU.K

.

Limited

.

PrintedinU

.S .A

.

Specification

and

price

change

privileges

are

reserved

.

INSTRUMENT

SERIAL

NUMBERS

Each

instrument

has

a

serial

number

on a

panel

insert,

tag,

or

stamped

on

the

chassis.The

first

number

or

letter

designates

the

countryofmanufacture.The

last

five

digits

of

the

serial

number

are

assigned

sequentially

and

are

unique

to

each

instrument.Those

manufactured

in

the

United

States

have

six

unique

digits

.

The

country

of

manufacture

is

identifiedasfollows

:

B000000

Tektronix,

Inc.,Beaverton,

Oregon,

USA

100000

Tektronix

Guernsey,

Ltd.,Channel

Islands

200000

Tektronix

United

Kingdom,

Ltd

.,

London

300000

Sony/Tektronix,

Japan

700000

Tektronix

Holland,

NV,

Heerenveen,

The

Netherlands

TABLE

OF

CONTENTS

Page

OPERATOR'S

SAFETY

SUMMARY

. . . . .

. . . . . . . . . . . . . . ...

. . . .

. . . . . . . . . . . . . .

SERVICE

SAFETY

SUMMARY

. . .

. . . . . .

. . . . . . . . . . . . . ... .

. . . .

. . . . . . . . . . . . . .

V

SECTION

1

OPERATING

INSTRUCTIONS

. . . . . . . . .

. . . . . .

. . . . . .

. . . . . . . . . .

1-1

SECTION

2

SPECIFICATION

AND

PERFORMANCE

CHECK

. ... . . . . . . . . . .

. . . .2-1

WARNING

The

remaining

portionofthis

TableofContents

lists

servicing

instructions

that

expose

personneltohazardous

voltages.These

instructions

are

for

qualified

service

personnel

only

.

SECTION

3

ADJUSTMENT

. . . . . .

. . . . . . . . . . . . . . .

. . . . .

. . . . . . . . . . . . . . . .3-1

SECTION

4

MAINTENANCE

. . ...

. . . . . . . . . . . . . . . .

. . . . .

. . . . . . . . . . . . . . .

4-1

SECTION

5

CIRCUIT

DESCRIPTION

. . . . . . . . . . . . . .

. . . . .

. . . . . . . . . . . . . . . .

5-1

SECTION

6

REPLACEABLE

ELECTRICAL

PARTS

. . . ...

. . . .

. . . . . . . . . . . . . . .6-1

SECTION

7

DIAGRAM

AND

CIRCUIT

BOARD

ILLUSTRATION

.

.

. . . . . . . . . .

. . . .7-1

SECTION

8

REPLACEABLE

MECHANICAL

PARTS

AND

EXPLODED

VIEW

. . . . . . .8-1

CHANGE

INFORMATION

AM

503

LIST

OF

ILLUSTRATIONS

Fig

.

No

.

Page

No

.

1-1

Plug-in

installation

and

removal

. . .

. . . . . . . . . . . . . .

. . . . . . .

. . . . . . . . . . . . . .

1-1

1-2

AM

503

controls

and

connectors.. .

. . . . . . . . . . . . . .

.

. . . . .

. . . . . . . . . . . . . .

1-3

2-1

Test

setup

forACDynamic

Range

check..

. . . . . . . . . . .

. . . . .

. . . . . . . . . . . . .

2-7

2-2

Displayoftangentially

measured

noise

. . . .

. . . . . . . . . . . . .

. . . . . . . .

. . . . . . . .2-

8

3-1

Construction

details

for

Special

Adapter

. . . . . .

. . . . . . . . . . . .

.

. . . . ... . . . .

. .

3-3

3-2

Power

supply

test

point

and

adjustment

locations.. .

. . . . . . . . .

. . . . . . . . . .

. . .

3-3

3-3

Gain

and

compensation

adjustment

locations

. . . . . . .

. . . . . . . . . . . . . .

. . . . . . .

3-5

3-4

Exampleofcorrect

compensation

.

. . . . . . . .

. . . . . . . .

. . . . . . . . . . . . . ... .

. .

3-5

4-1

Lubrication

procedure

foratypical

cam

switch

. .

. . . . . . . . .

. . . . . . . . . . . . . . . .

4-2

42

Semiconductor

lead

configurations

. . . . . . . . . . .

. .

. . . . . .

. . . . . . . . . . . . . . . .

4-4

43

Installation

of

lead-end

connectors

. . . . . . . .

. . . . . .

. . . . . . .

. . . . . . . . . . . . . .

47

44

Circuit

board

pin

and

ferrule

assembly

. . . . . . . . . . . . . .

. . . . . .

. .

. . . . . . ... . . .

47

5-1

AM

503and

probe

waveforms

. . . . . . . .

. . . .

. . . . . . . . . .

. . . . . . . . .

. . . . . . . .

5-1

OPERATOR'S

SAFETY

SUMMARY

The

followingtext

containsa

two-part

summary

of

general

safety

precautions

that

must

be

observed

during

all

phasesofoperation,

service,

and

repair of

this

instrument

.

OPERATORS

SAFETY

SUMMARY

The

general

safety

informationinthis

part of

the

summary

is

for

both

operating

and

servicing

personnel.Specific

warnings

and

cautions

will

be

found

throughout

the

manualwhere

they

apply,

but

may

not

appear

in

this

summary

.

In

This

Manual

TERMS

CAUTION

statements

identify

conditionsorpractices

that

could

resultin

damage

to

the

equipment

or

other

property

.

WARNING

statements

identify

conditions

or

practices

that

could

resultinpersonal

injuryorlossoflife

.

As

Marked

on

Equipment

CAUTION

indicatesapersonal

injury

hazard

not im-

mediately

accessible

as

one

reads

the

marking,

or

a

hazardtoproperty

including

the

equipment

itself

.

DANGER

indicates

a

personal

injury

hazard

immediately

accessibleasone

reads

the

marking

.

In

This

Manual

SYMBOLS

A

This

symbol

indicates

where

applicable

cautionary

or

other

information

istobe

found

.

As

Marked

on

Equipment

DANGER

-

High

voltage

.

REVANOV

1979

Power

Source

Protective

ground

(earth)

terminal

.

ATTENTION

-

refertomanual

.

This

productisintendedtooperate

fromapower

source

that

will

not

apply

more

than

250

volts

rms

between

the

supply

conductors

or

between

either

supply

conductor

and

ground.A

protective

ground

connection

bywayofthe

groundingconductor

in

the

power

cordisessential

for

safe

operation

.

Grounding

the

Product

This

productisgrounded

through

the

grounding

conduc-

torofthe

power

cord.To

avoid

electrical

shock,

plug

the

power

cord

intoaproperly

wired

receptacle

before

connecting

to

the

product

inputoroutput

terminals.A

protective

ground

connection

by

way

of

the

grounding

conductor

in

the

power

cordisessential

for

safe

opera-

tion

.

Danger

Arising

From

Loss

of

Ground

Upon

loss of the

protective-ground

connection,

all

accessible

conductive

parts

(including

knobs

and

con-

trols

that

may

appear

to

be

insulating)

can

renderan

electric

shock

.

Use

the

Proper

Power

Cord

Use

only

a power

cord

thatisin

good

condition

.

Use

the

Proper

Fuse

Use

only

the

power

cord

and

connector

specified

for

your

product

.

Refer

cord

and

connector

changes

to qualified

service

personnel

.

To

avoid

fire

hazard,

use

only

the

fuseofcorrect

type,

voltage

rating

and

current

ratingasspecifiedinthe

parts

list

for

your

product

.

Refer

fuse

replacement

to qualified

service

personnel

.

AM

503

Do

Not

Operate

in

Explosive

Atmospheres

To

avoid

explosion,donot operate

this

productinan

explosive

atmosphere

unlessithas

been

specifically

certified

for

such

operation

.

Do

Not

Remove

Covers

or

Panels

To

avoid

personal

injury,donot

remove

the

product

iv

covers

or

panels.Do

not

operate

the

product

without

the

covers

and

panels

properly

installed

.

Do

Not

Operate

Without

Covers

(for

TM

500

plug-

ins

only)

To

avoid

personal

injury,donot

operate

this

product

without covers

or panels

installed

.

Do

not

apply

power

to

the

plug-in

viaaplug-in

extender

.

REVA

NOV

1979

Do

Not

Service

Alone

REVA

NOV

197

9

SERVICING

SAFETY

SUMMARY

FOR

QUALIFIED

SERVICE

PERSONNEL

ONLY

Do

not

perform

internal

service

or

adjustmentofthis

product

unless

another

person

capableofrendering

first

aid

and

resuscitation

is

present

.

Use

Care

When

Servicing

With

Power

On

Dangerous

voltages

existatseveral

pointsinthis

product

.

To

avoid

personal

injury,donot

touch

exposed

connec-

tions

and

components

while

power

is

on

.

Refer

also to

the

preceding

Operators

Safety

Summary

.

AM

503

Disconnect

power

before

removing

protective

panels,

soldering,

or

replacing

components

.

Power

Source

This

product

is

intendedtooperate

fromapower

source

that

will

not

apply

more

than

250

volts

rms

between

the

supply

conductors

or

between

either

supply

conductor

and

ground.A

protective

ground

connectionbywayofthe

grounding conductor

in

the

power

cordisessential

for

safe

operation

.

v

AM

503

2052-9

REV

A

NOV

197

9

All

references

to

the

P6302

probe

also

apply

to the

A6302

probe

.

All

referencestothe

P6303

probe

also

apply

to the

A6303

probe

.

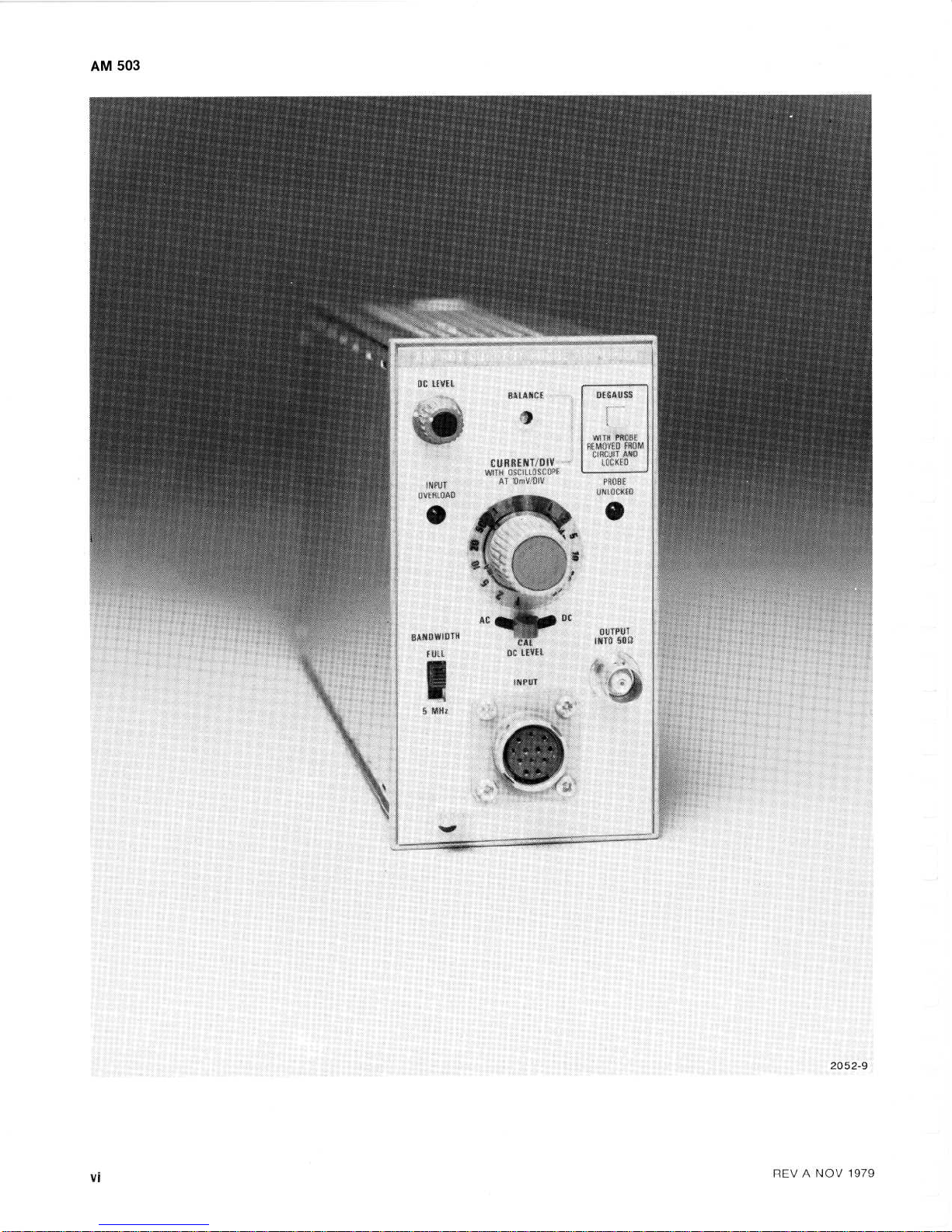

Description

OPERATING

INSTRUCTIONS

NOTE

The

AM

503

Current

Probe

Amplifierisdesigned

for

use

with

any

of

the

compatible

current

probes

(see

Mechanical

Parts

list

for

accessories).The

input

attenuator

is

calibratedina

1, 2,5sequence,

and

the

attenuator

knob-skirt

illumination

provides

direct

indica-

tionofcurrent/division.An

auto-scale

switch

changes

the

knob-skirt

illumination

automatically

to

match

the

sen-

sitivityofthe

probe

used

.

Bandwidth

is

selectable

for

either

FULL

(limited

by

current

probeinuse) or5MHz.Input

couplingisselec-

table

(acordc);ac provides

a

meansofmeasuring

low

amplitude

ac

signalsona high

leveldocurrent

.

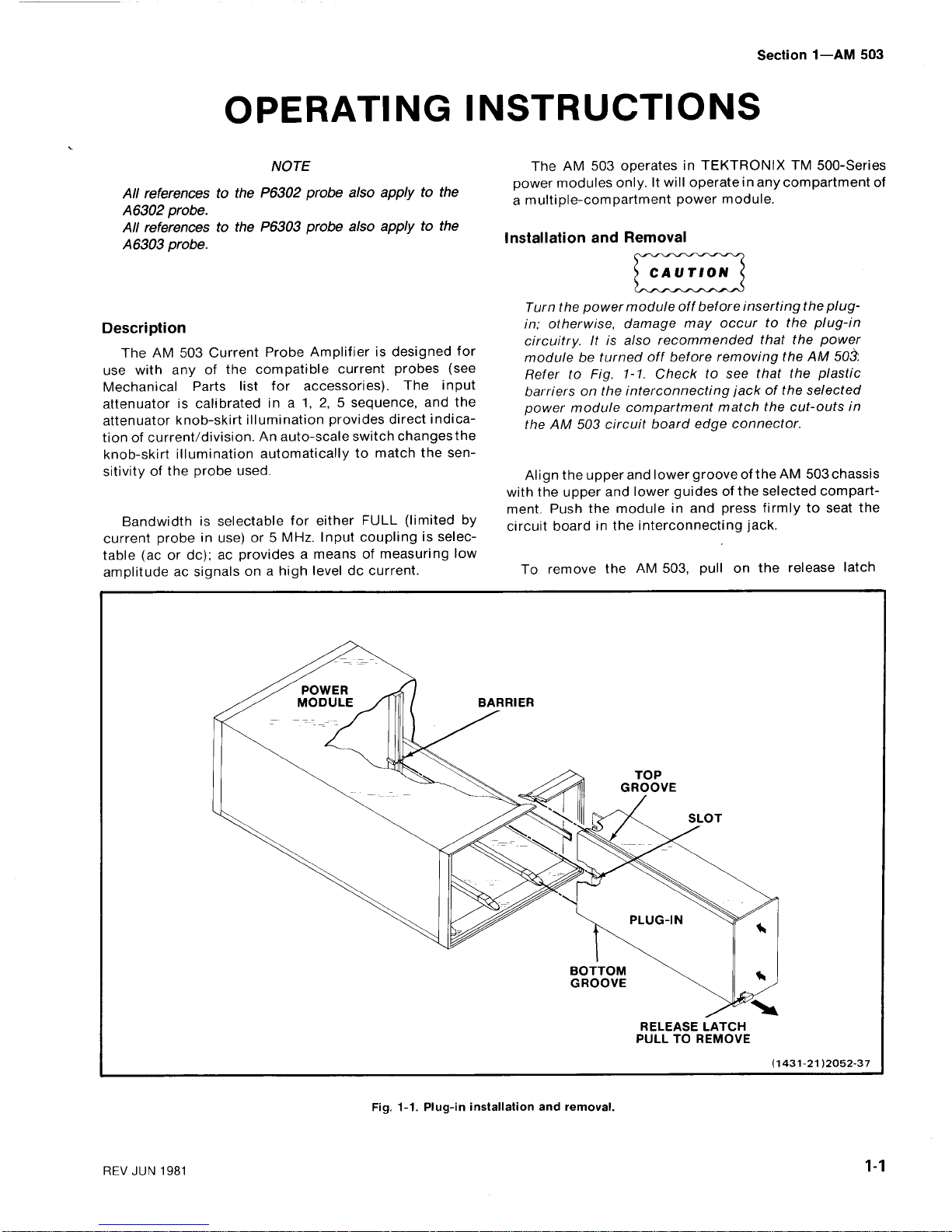

Installation

and

Removal

RELEASE

LATCH

PULL

TO

REMOVE

(1431-21)2052-37

REVJUN

198

1

Fig.1-1.Plug-in

installation

and

removal

.

Section

1-AM

503

The

AM

503

operates

in

TEKTRONIX

TM

500-Series

power

modules

only.It

will

operatein

any

compartment

of

a

multiple-compartment

power

module

.

Turn

the

power

module

off

before

inserting

the

plug-

in;otherwise,

damage

may

occur

to the

plug-in

circuitry.Itisalso

recommended

that

the

power

modulebeturned

off

before

removing

the

AM

50,'~

RefertoFig

.

1-1.Check

to

see

that

the

plastic

barriers

on

the

interconnecting

jackofthe

selected

power

module

compartment

match

the

cut-outs

in

theAM503

circuit

board

edge

connector

.

Alignthe

upper

and

lower

grooveoftheAM503

chassis

with

the

upper

and

lower

guidesofthe

selected

compart-

ment.Push

the

module

in

and

press

firmlytoseat

the

circuit

boardinthe

interconnecting

jack

.

To

remove

the

AM

503,

pullonthe

release

latch

Operating

Instructions-AM

503

(locatedinthe lower

left

corner)

until

the

interconnecting

jack

disengages

and

the

AM

503

will

slide

out

.

OPERATING

CONSIDERATIONS

Introduction

The

remainder

of this

section

contains

the

operating

information

required

to

obtain

the

most

effective

perfor-

mance

from

the instrument

.

This

includes

the

function

and

actionsofthe

controls

and

connectors,

input

connec-

tions,

andageneral

descriptionofthe operating

modes

and

procedures

for

making

basic

measurements

.

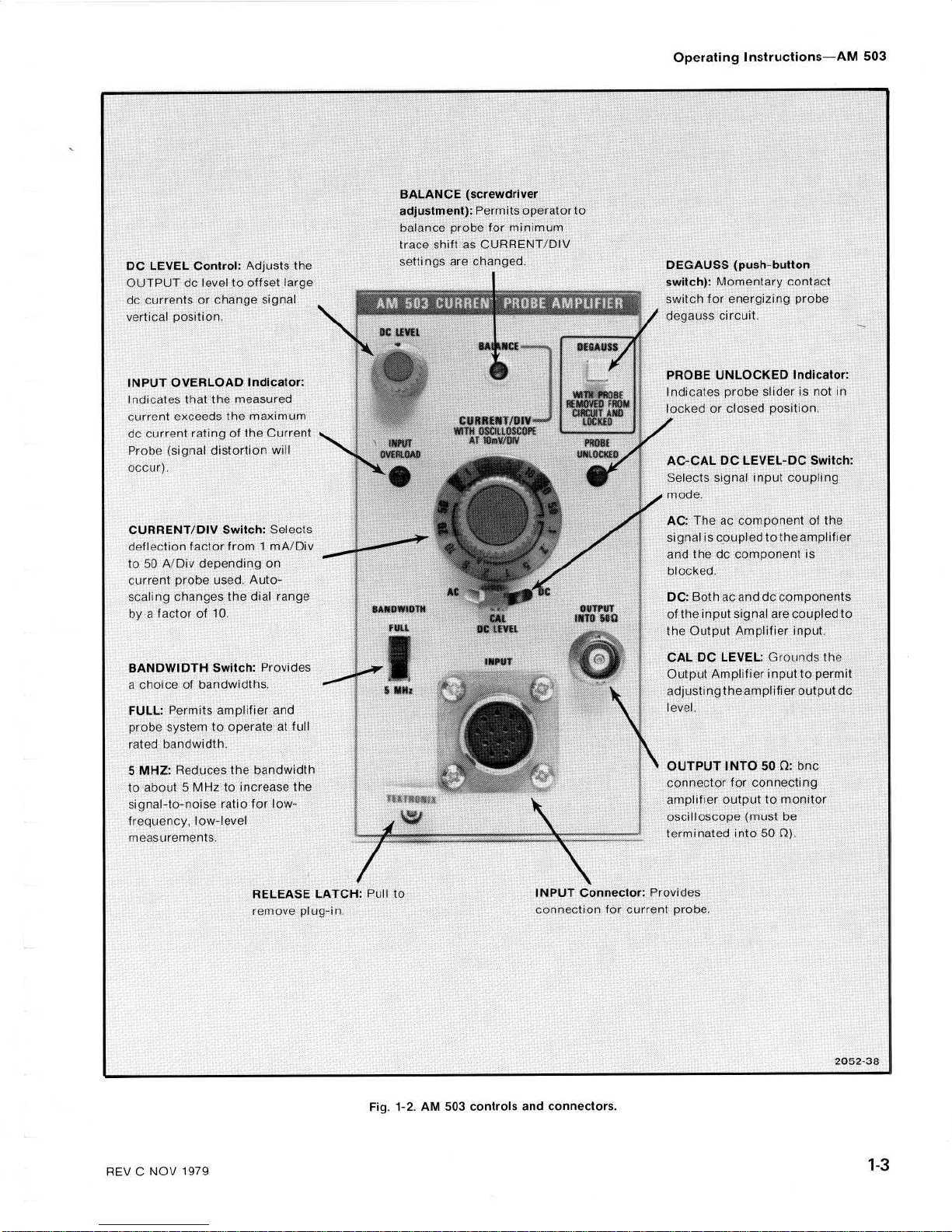

Controls

and

Connectors

Allofthe

major

controls

and

connectors

for

operation

of

the

AM

503

are

located

on

the

front

panel

of

the

unit.A

brief

functional

descriptionofeach

control

and

connector

is

included

in

Fig.1-2

.

Monitor

Oscilloscope

The

bandwidth

requiredofthe

oscilloscope

used

with

the

AM

503

depends

upon

the

frequencyofthe

signal

being

measured.Oscilloscope

vertical

bandwidth

should

be

at

least

twice

the

frequency

of

the

signal

being

measured

.

Deflection

.

Conventional

current flowing

in

the

direc-

tionofthe

arrow

on

the

current-probe

slider

produces

a

positive

deflectionofthe

oscilloscope

display

.

Ground-clip

Leads

Ground-clip

leads

are furnished

with

some

current

probes

to

ground

the cable

shieldatthe

probe

end

.

The

ground

leadisused

to

reduce

high-frequency

elec-

trostatic

voltages

that

could

couple

into

the

probe

and

cause

errorsinmeasuring

.Aground

lead

is

normally not

usedinthe

lower

(1,

2, 5,

and

10

mA)

sensitivity

positions

of

the

attenuator

switch

becauseofundesirable

chassis

currents

that

may

appear

in

these

more

sensitive

positions

.

When

observing

high-frequency

signals,

use

the

shortest

practical

ground-clip

lead

available

.

Output

Connection

output

connection

can

be

accomplished

through

the

OUTPUT

INTO

50

f2

connectororthe

rear

interconnec-

ting

jackatpin

28A.Pin

28Aatthe

rear

interconnecting

jackisterminated

in50S2.Connector

J480,

located

onthe

right

side

upper-rearofthe

instrument,iswhere

the

output

cable

connects

for

rear

interface

output

.

With

the

output

cable

connected

for

rear

interface

output,

atermination

is

not

required

because

of

the

internal

(factory

wired)

termination.The

monitor

oscilloscope

input

impedance

should not be 50Oif

the

rear

interface

connection

is

used

.

It

will

cause

an

impedance

mis-match

and

possible

loading

of

the

AM

503

.

Changing

output

to rear

interface.Remove

the

right

side

snap-in

cover

from

the

AM

503.Unplug

the

coaxial

cable

from

the

rear of

the

OUTPUT

INTO

50Oconnector

.

Carefully

align

the

coaxial

cableatthe

upper-rear

coaxial

connector;pressing

firmly,

insert

the

cable

.

The

coaxial

cable

connector

center

piniseasily

bent

and

alignment

is

critical

when

making

the

connec-

tion

for

rear

interface

output

.

With the output

cable

(internal)

connectedtothe

rear

interconnecting

jack

output,

the

front-panel

OUTPUT

INTO

50

O

connector

will

not

have

an output

signal

available

.

Connecting

the

AM

503

Install

the

AM

503

into

the

TM

500-Series

power

module

.

Ensure

that

the

power

module

into

which

the

AM

503

willbeinstalled

is

suitably

adapted

to

the

line

voltagetobe

applied

.

Connect

a 500cable

with

bnc

connectors

(and

if

necessary,

a 50

O

termi

nation for

impedance

matching)

to

the

monitor

oscilloscope

vertical

input

.

Set

the

monitor

oscilloscope

vertical

sensitivity

for

10

mV/Div

.

The

horizontal

sweep

speed

should be

consis-

tent

with

the

signal

frequencytobe

examined

.

Connectacurrent

probetothe

AM

5031NPUTconnec-

tor

.

Turn

all

equipment

on

and

allow 20

minutes

for

the

equipmenttowarm

up

and

stabilize

.

REVBNOV

197

9

DC

LEVEL

Control:Adjusts

the

OUTPUT

do

leveltooffset

largo

do

currentsorchange

signal

vi

:rti-l

p-tior

INPUT

OVERLOAD

Indicator

:

Indicates

that

the

measured

current

exceeds

the

maximum

do

current

rating of

the

Current

Probe

(signal

distortion

will

occur)

.

CURRENT/DIV

Switch

:

Selects

deflection

factor

from1mA/Div

to

50 A/Div

depending

on

current

probe

used.Auto-

scaling

changes

the

dial

range

by

a

factorof10

.

BANDWIDTH

Switch

:

Provides

a

choiceofbandwidths

.

FULL:Permits

amplifier

and

probe

systemtooperateatfull

rated

bandwidth

.

5

MHZ:Reduces

the

bandwidth

to

about5MHztoincrease

the

signal-to-noise

ratio

for

low-

frequency,

low-level

measurements

.

REV

C

NOV

197

9

F'.;:,tL

,

Y4'tD1H

RELEASE

LATCH

:

Pull

to

t,:dove

plug-in

.

BALANCE

(screwdriver

adjustment):Permits

operritorto

!-Iaiice

probe

for

minimum

tr,p,shiftasCURRENT

DIV

- .tt

;,w,

are

changed

.

Fig.1-2.AM

503

controls

and

connectors

.

INPUT

Connector:Provides

c

m),~,

tion

for

current

probe

.

Operating

Instructions-AM

503

DEGAUSS

(push-button

switch):Momentary

contact

switch

for

energizing

probe

degauss

circuit

.

PROBE

UNLOCKED

Indicator

:

Indicates

probe

sliderisnot

in

locked

or

closed

position

AC-CAL

DC

LEVEL-DC

Switch

:

Selects

signal

input

coupling

mode

.

AC:TheaccomponentoftI

signaliscoupled

tothe

amplifier

and

thedocomponent

is

blocked

.

DC:Both ac

anddocomponents

of

the

input

signal

are

coupled

to

the

Output

Amplifier

input

.

CAL

DC

LEVEL:Grounds

th

Output

Amplifier

inputtopermit

adjusting

the

amplifier

output

do

level

.

OUTPUT

INTO50O

:

bnc

connector

for

connecting

amplifier

outputtomonitor

oscilloscope

(must be

terminated

into50S2)

.

2052-38

Operating

Instructions-AM

503

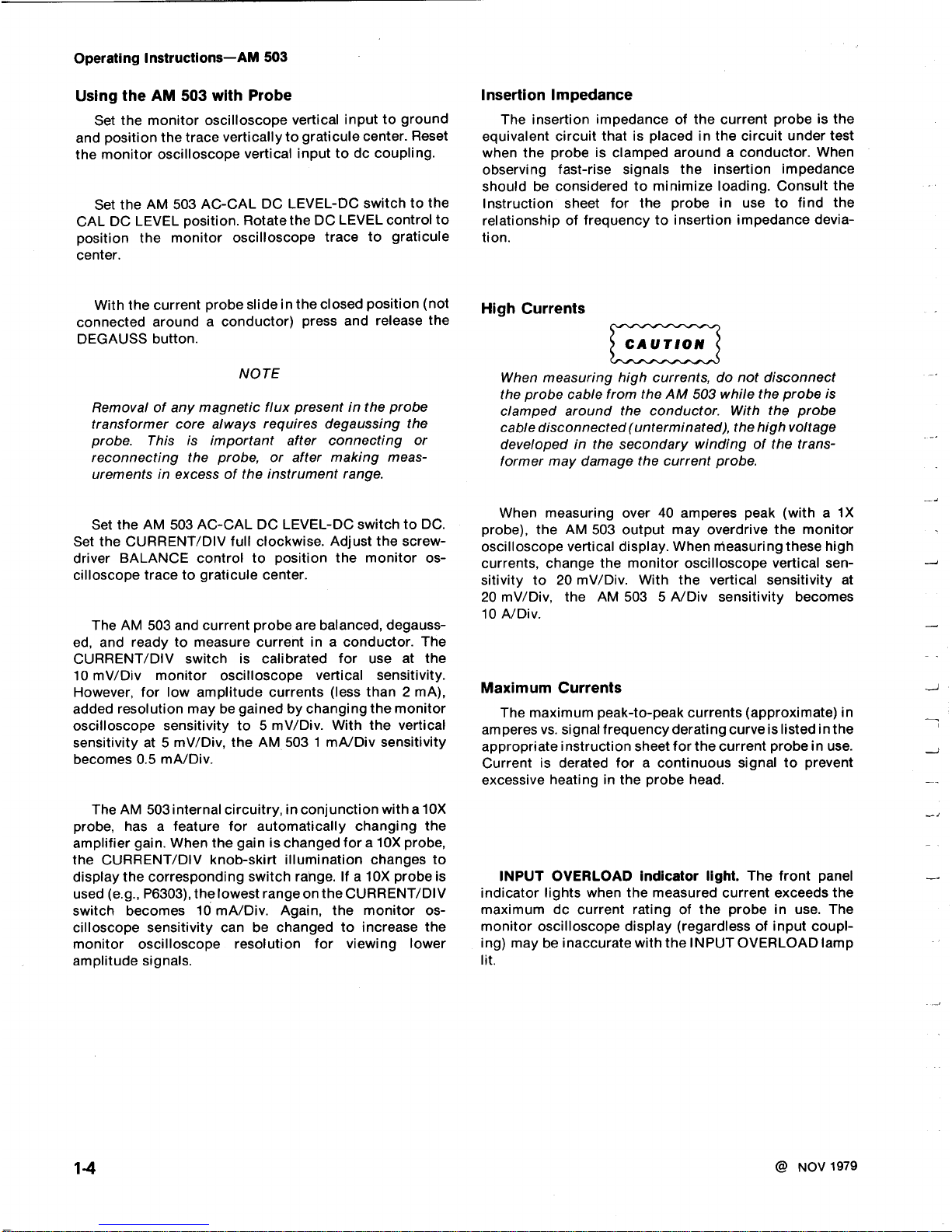

Using

the

AM

503

with

Probe

Set

the

monitor

oscilloscope

vertical

inputtoground

and

position

the

trace

verticallytograticule

center.Reset

the

monitor

oscilloscope

vertical

inputtodo

coupling

.

Set

the

AM

503

AC-CAL

DC

LEVEL-DC

switchtothe

CAL

DC

LEVEL

position.Rotate theDCLEVEL

control

to

position

the

monitor

oscilloscope

trace

to

graticule

center

.

With the

current

probe

slideinthe closed

position

(not

connected aroundaconductor)

press

and

release

the

DEGAUSS

button

.

NOTE

Removalofany

magnetic

flux

presentinthe

probe

transformer core

always

requires

degaussing

the

probe.This

is

important

after

connecting

or

reconnecting

the

probe,

or

after

making

meas-

urementsinexcessofthe instrument

range

.

Set

the

AM

503

AC-CAL

DC

LEVEL-DC

switchtoDC

.

Set

the

CURRENT/DIV

full

clockwise.Adjust

the screw-

driver

BALANCE

controltoposition

the

monitor

os-

cilloscope

tracetograticule

center

.

The

AM

503

and

current

probe

are

balanced,

degauss-

ed,

and

readytomeasure

currentina

conductor.The

CURRENT/DIV

switch

is

calibrated

for

use

at

the

10

mV/Div

monitor

oscilloscope

vertical

sensitivity

.

However,

for

low

amplitude

currents

(less

than

2

mA),

added

resolution

maybegainedbychanging

the

monitor

oscilloscope

sensitivityto5

mV/Div.With

the

vertical

sensitivityat5

mV/Div,

the

AM

5031mA/Div

sensitivity

becomes0.5

mA/Div

.

The

AM

503

internal

circuitry,inconjunction

witha10X

probe,

hasafeature

for

automatically

changing

the

amplifier

gain.When

the

gainischanged

fora10X

probe,

the

CURRENT/DIV

knob-skirt

illumination

changes

to

display

the

corresponding

switch

range.Ifa10X

probe

is

used

(e.g.,

P6303),

the

lowest

rangeonthe

CURRENT/DIV

switch

becomes

10

mA/Div.Again,

the

monitor

os-

cilloscope

sensitivity

can

be

changed

to

increase

the

monitor

oscilloscope

resolution

for

viewing lower

amplitude

signals

.

Insertion

Impedance

The

insertion

impedance

of

the

current

probeisthe

equivalent

circuit

thatisplacedinthe

circuit

under

test

when

the

probeisclamped

aroundaconductor.When

observing

fast-rise

signals

the

insertion

impedance

should

be

consideredtominimize

loading.Consult

the

Instruction

sheet

for

the

probe

in

use

to find

the

relationshipoffrequencytoinsertion

impedance

devia-

tion

.

High

Currents

When

measuring

high

currents,donot

disconnect

the

probe

cable

from

theAM503

while

the

probe

is

clamped

around

the

conductor.With

the

probe

cable

disconnected

(unterminated),

thehigh

voltage

developedinthe

secondary

winding

of the

trans-

former

may

damage

the

current

probe

.

When

measuring

over

40

amperes

peak

(with

a 1X

probe),

the

AM

503

output

may

overdrive

the

monitor

oscilloscope

vertical

display.When

measuring

these

high

currents,

change

the

monitor

oscilloscope

vertical

sen-

sitivityto20

mV/Div.With

the

vertical

sensitivity

at

20

mV/Div,

the

AM

5035A/Div

sensitivity

becomes

10

A/Div

.

Maximum

Currents

The

maximum

peak-to-peak

currents

(approximate)

in

amperesvs.

signal

frequency

derating

curveislistedinthe

appropriate

instruction

sheet

for

the

current

probeinuse

.

Currentisderated

foracontinuous

signal to

prevent

excessive

heatinginthe

probe

head

.

INPUT

OVERLOAD

indicator

light.The

front

panel

indicator

lights

when

the

measured

current

exceeds

the

maximum

do

current

ratingofthe

probe

in

use.The

monitor

oscilloscope

display

(regardless

of

input

coupl-

ing)

may

be

inaccurate

with

the

INPUT

OVERLOAD

lamp

lit

.

@

NOV

1979

SPECIFICATION

AND

PERFORMANCE

CHECK

Performance

Conditions

The

electrical

characteristics

are

valid

onlyifthe

AM

503 has

been

calibratedatan

ambienttemperature

between

+20°Cand

+30'C

and

is

operatingatan

ambient

temperature

between

0°C

and

+50°C,

unless

otherwise

stated

.

REV

SEP

1984

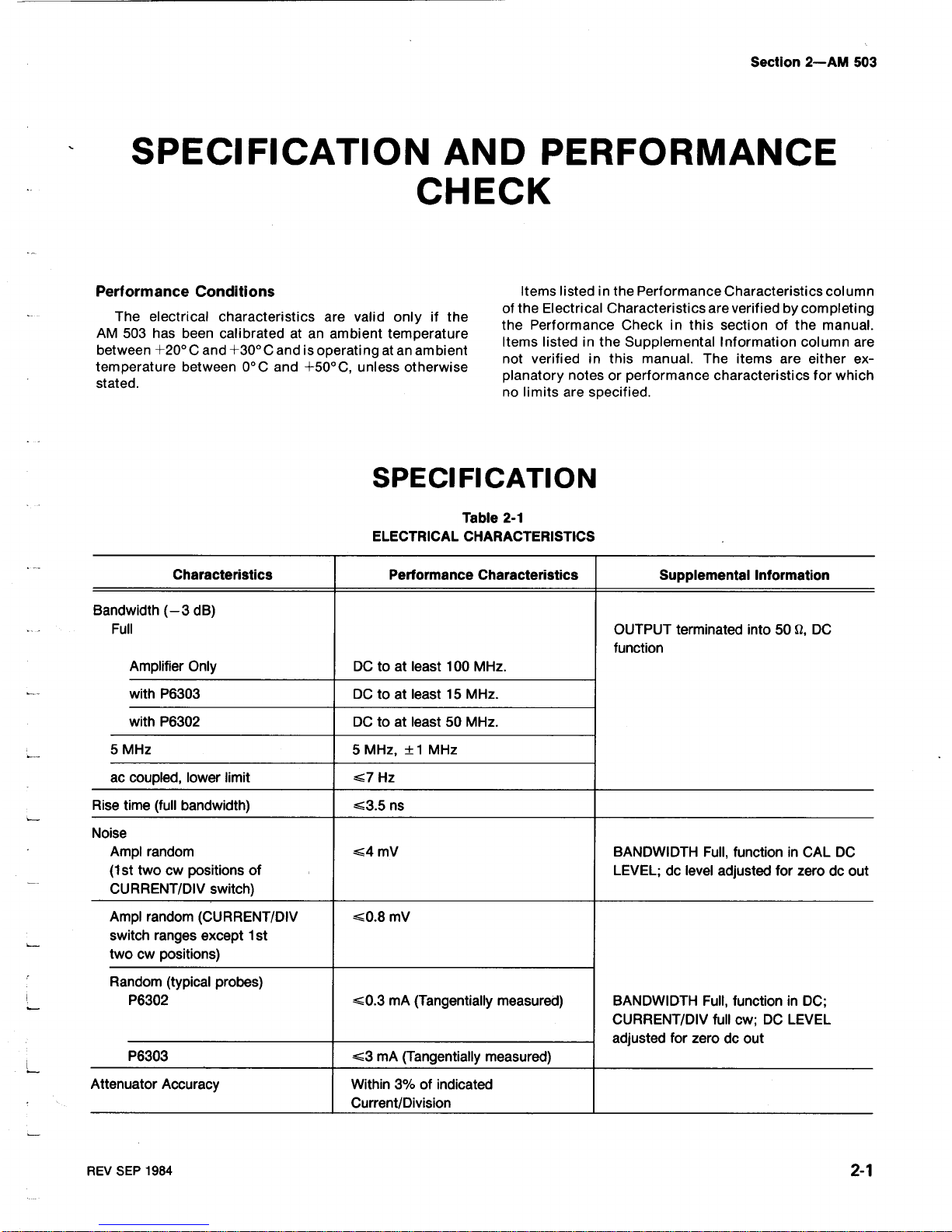

SPECIFICATION

Table

2-1

ELECTRICAL

CHARACTERISTICS

Section

2-AM

503

Items

listedinthe

Performance

Characteristics

column

of

the

Electrical

Characteristics

are

verifiedbycompleting

the

Performance

Check

in

this

sectionofthe

manual

.

Items

listedinthe

Supplemental

Information

column

are

not

verifiedinthis

manual.The

items

are

either

ex-

planatory

notesorperformance

characteristics

for

which

no

limits

are

specified

.

Characteristics

Performance

Characteristics

Supplemental

Information

Bandwidth

(-3

dB)

Full

OUTPUT

terminated

into

5012,

DC

function

Amplifier

Only

DC

to at

least

100

MHz

.

with

P6303

DC

to at

least15MHz

.

with

P6302

DC

to at

least50MHz

.

5

MHz

5

MHz,

±1

MHz

ac

coupled,

lower

limit

-7

Hz

Rise time

(full

bandwidth)

_3.5ns

Noise

Ampl

random

_-4

mV

BANDWIDTH

Full,

functioninCAL

DC

(1

st

twocwpositions

of

LEVEL;do

level

adjusted

for

zerodoout

CURRENT/DIV

switch)

Amplrandom

(CURRENT/DIV

_-0

.8

mV

switch

ranges except

1st

two

cw

positions)

Random

(typical

probes)

P6302

_-0.3mA

(Tangentially

measured)

BANDWIDTH

Full,

functioninDC

;

CURRENT/DIV

fullcw;DCLEVEL

adjusted

for

zerodoout

P6303

<3

mA

(Tangentially

measured)

Attenuator

Accuracy

Within3%of

indicated

Current/Division

Specification

and

Performance

Check-AM

503

2-2

Standard

Instrument

Table

2-1

(cont)

ELECTRICAL

CHARACTERISTICS

POWER

CONSUMPTION

L

Table

2-2

ENVIRONMENTAL

CHARACTERISTICS

--17

W

REVBNOV

1979

Characteristics

Performance

Characteristics

Supplemental

Information

Deflection

Factor

(typical

probes)

P6302

1mAto

5 A/divina

1,

2,

5

sequence

P6303

10

mAto50

A/divina

1, 2,

5

sequence

Thermal

Drift

Amplifier

Only

In

first

two

cw

positions

;

2

mV/°C

or less at

OUTPUT

(from

+15°C

to

+35°C

ambient)

In

all

but

first

two

cw

positions

;

0.4mV/°C

at

OUTPUT

(from

+15

0Cto

+350C

ambient)

OUTPUT

dynamic

range

+80

mV

and

-80

mV

with

less

CURRENT/DIV

setto5

mA/Div

.

than

5%

compression

(into50i2)

Monitor

oscilloscope

set

for

20

mV/div

Characteristics

Information

Temperature

Testtoprocedures

of

MIL-STD-810CMethods

502.1and

501.1using

Procedure

IasspecifiedinMIL-T-2880013

paragraph4.5 .5.1.3

and4.5

.5 .1 .4

.

Operating

0°Cto

+50°C.

Non-operating

-55°Cto

+75°C.

Humidity

Operating

+50°C

to

95%

relative

humidity

.

Non-operating

+60°C

to

95%

relative

humidity

.

TesttoMIL-STD-810C

Method

507.1Procedure

IV,

modified

as

specified

in

MIL-T-2880013

paragraph

4.5.5.1.1.2.

Altitude

TesttoMIL-STD-810C

Method

500.1Procedure

Iasspecified

in

MIL-T-2880013

paragraph

4

.5 .5 .2

.

Operating

To

15,000

feet

.

Non-operating

To

50,000

feet

.

Introduction

This

procedure

checksthe

electrical

characteristics

of

theAM503

that

appearinthe

Specification

sectionofthis

manual.If

the

instrument

failstomeet

the

requirements

given

in this

performance

check, the

adjustment

procedure

shouldbeperformed.This

procedurecan

also

be

used

by an

incoming

inspection

facilitytodetermine

acceptabilityofperformance

.

The

electrical

characteristicsinSection 2arevalid

only

if

the

AM

503iscalibratedatan

ambienttemperature

of

+20'C

to

+30°Cand

operatedatan

ambient

temperature

of

0°Cto

+50'C

.

REVB

NOV

1979

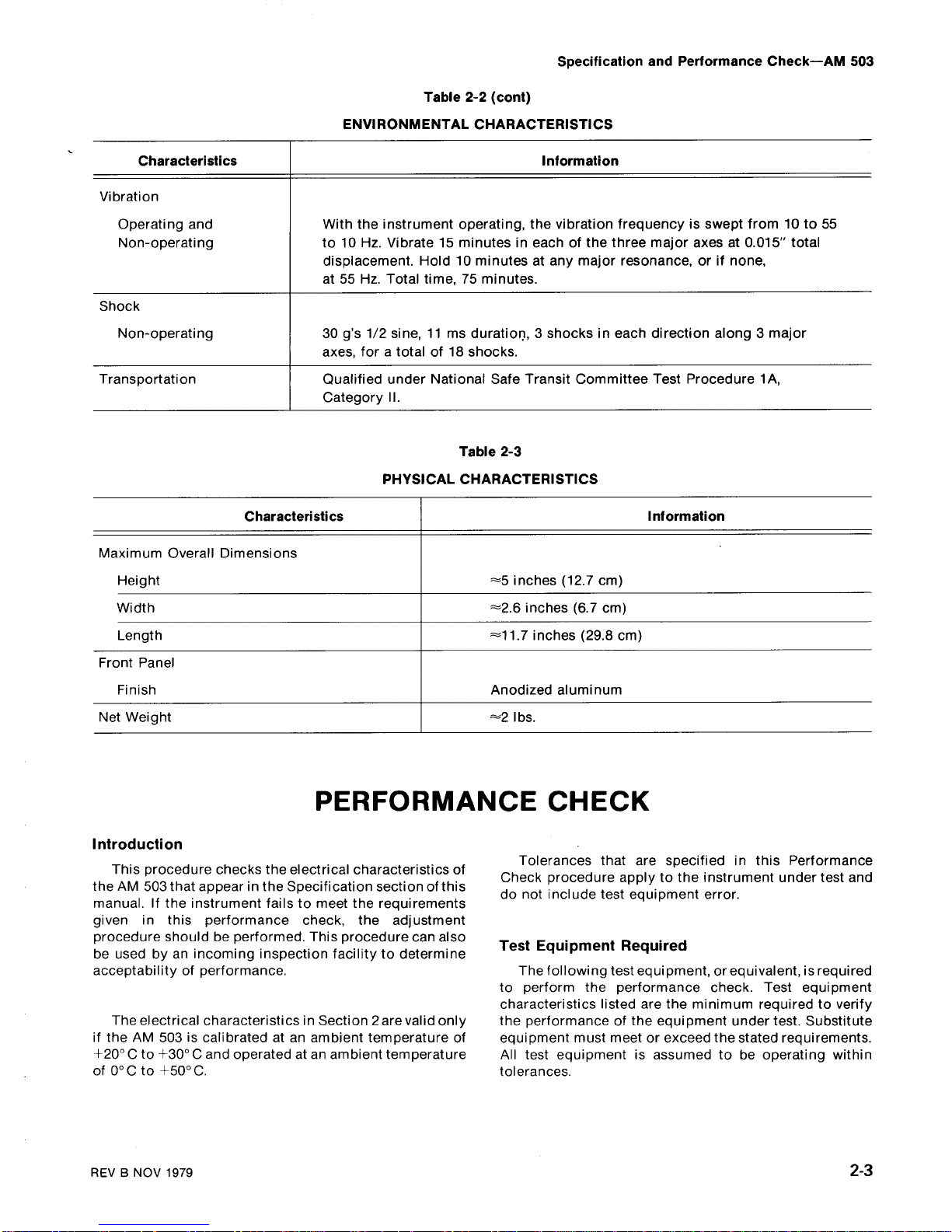

Table

2-2

(cont)

ENVIRONMENTAL

CHARACTERISTICS

Table

2-3

PHYSICAL

CHARACTERISTICS

PERFORMANCE

CHECK

Specification

and

Performance

Check-AM

503

Tolerances

that

are specifiedinthis

Performance

Check

procedure

applytothe instrument

under

test

and

do

not

include

test

equipment

error

.

Test

Equipment

Required

The

following

test

equi

pment,orequivalent,isrequired

to

perform

the

performance

check.Test

equipment

characteristics

listed

are

the

minimum

requiredtoverify

the

performanceofthe

equipment

under

test.Substitute

equipment

mustmeetorexceed

the

stated

requirements

.

All

test

equipment

is

assumed

to

be operating

within

tolerances

.

2-

3

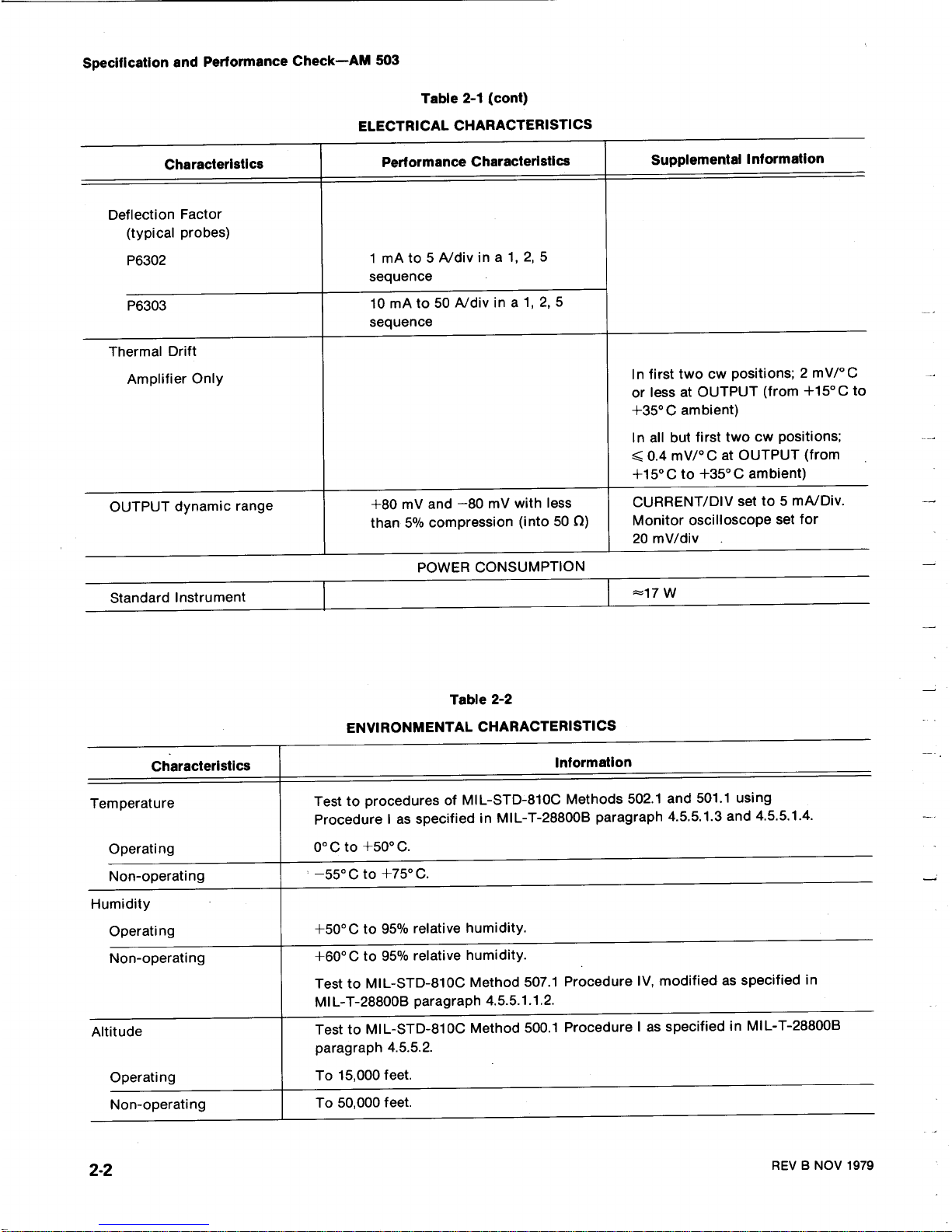

Characteristics

Information

Vibration

Operating

and

With

the instrument

operating,

the

vibration

frequencyisswept

from10to

55

Non-operating

to10Hz.Vibrate15minutesineachofthe

three

major

axesat0

.015"

total

displacement.Hold10minutesatany

major

resonance,orif

none,

at

55 Hz.Total time,75minutes

.

Shock

Non-operating

30

g's

1/2

sine,11ms

duration,3shocksineach

direction

along3major

axes,

foratotalof18

shocks

.

Transportation

Qualified

under

National

Safe

Transit

Committee

Test

Procedure

1A,

CategoryII.

Characteristics

Information

Maximum

Overall

Dimensions

Height

-5

inches

(12.7cm)

Width

=2.6inches

(6 .7

cm)

Length

-11.7inches

(29.8cm)

Front Panel

Finish

Anodized

aluminum

NetWeight

-=2

lbs

.

Specification

and

Performance

Check-AM

503

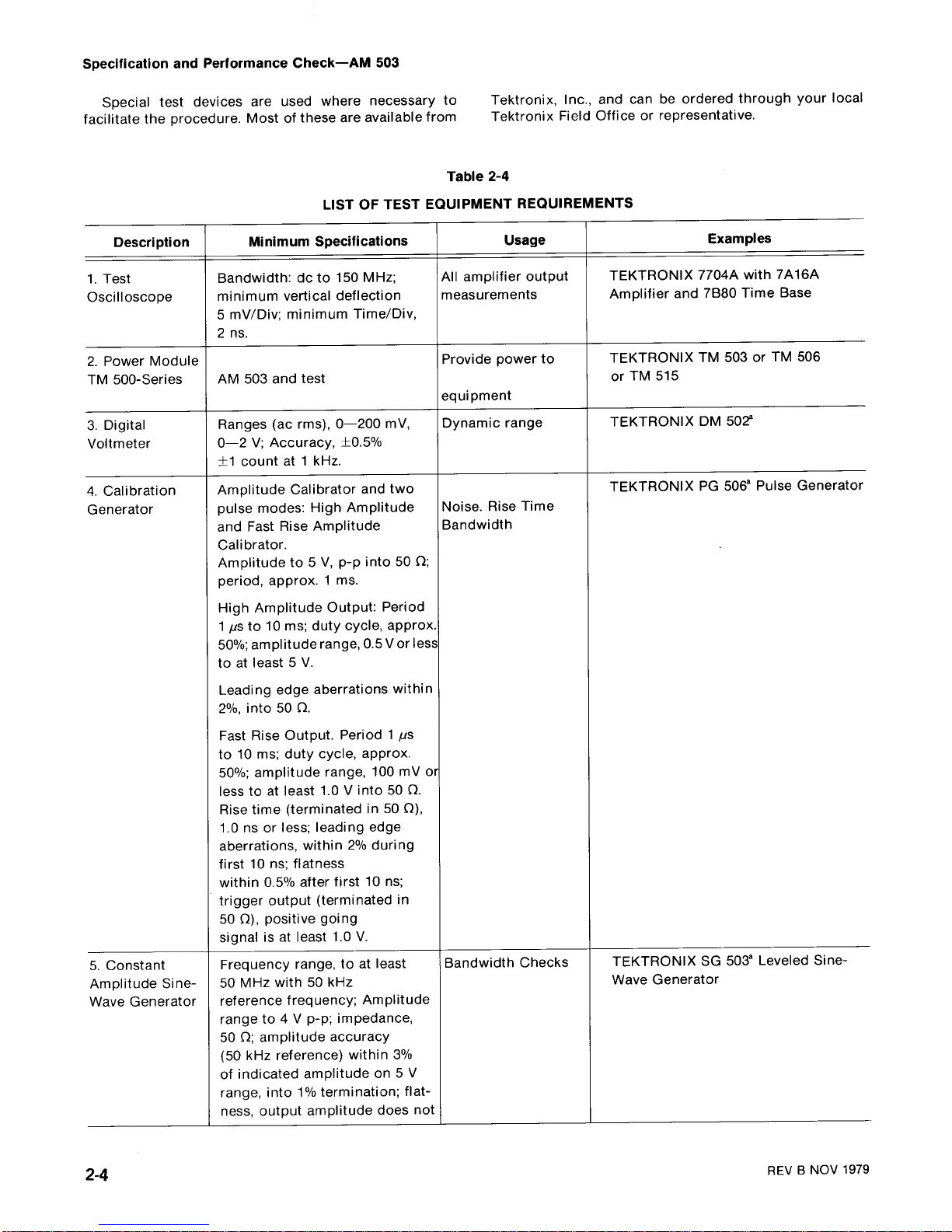

Special

test

devices are used

where

necessary

to

Tektronix,

Inc.,and

canbeorderedthrough

your

local

facilitate

the

procedure.Most

of

these

are available

from

Tektronix

Field

Officeorrepresentative

.

Table

2-4

LIST

OFTEST

EQUIPMENT

REQUIREMENTS

2-

4

REV

B

NOV

1979

Description

Minimum

Specifications

Usage

Examples

1.Test

Bandwidth

:doto

150

MHz

;

All

amplifier

output

TEKTRONIX

7704A

with

7A16A

Oscilloscope

minimum

vertical

deflection

measurements

Amplifier

and

71380

Time

Base

5

mV/Div;minimum

Time/Div,

2ns.

2.Power

Module

Provide

power

to

TEKTRONIX

TM

503

or

TM

506

TM

500-Series

AM

503

and

test

or

TM

515

equipment

3.Digital

Ranges

(ac

rms),

0-200

mV,

Dynamic

range

TEKTRONIX

DM

502'

Voltmeter

0-2

V;Accuracy,±0.5%

±1

countat1

kHz

.

4

.

Calibration

Amplitude

Calibrator

andtwo

TEKTRONIX

PG

506'

Pulse

Generator

Generator

pulse

modes

:

High

Amplitude

Noise

.

Rise

Time

and

Fast

Rise

Amplitude

Bandwidth

Calibrator

.

Amplitude

to

5V,p-p

into50C2

;

period,

approx.1ms.

High

AmplitudeOutput:Period

1

/is

to

10ms;

duty

cycle,

approx

.

50%

;

amplitude

range,0.5Vor less

toatleast5V

.

Leading

edge

aberrations

within

2%,

into50Q

.

Fast

Rise

Output.Period1/is

to10ms;duty

cycle,

approx

.

50%;amplitude

range,

100

mV

or

lesstoat

least

1.0V

into50Q

.

Rise

time

(terminatedin50

S2),

1.0ns

or less;leading

edge

aberrations,

within

2%

during

first

10 ns

;

flatness

within0.5%

after

first10ns

;

trigger

output

(terminated

in

50

O),

positive

going

signal

is

at

least1.0V.

5.Constant

Frequency

range,toat

least

Bandwidth

Checks

TEKTRONIX

SG

503'

Leveled Sine-

Amplitude

Sine- 50

MHz

with

50

kHz

Wave

Generator

Wave

Generator

reference

frequency;Amplitude

rangeto4Vp-p;impedance,

500;

amplitude

accuracy

(50

kHz

reference)

within

3%

of

indicated

amplitudeon5

V

range,

into1%termination;flat-

ness,

output

amplitudedoes

not

8

RequiresTM500-Series

Power

Module

.

Table

2-4

(cont)

LIST

OF

TEST

EQUIPMENTREQUIREMENTS

Specification

and

Performance

Check-AM

503

Preliminary

Procedure

1.Check

Current/Division

Accuracy

1.Ensure

that

all

power

switches

are

off

.

Set the

following

controlsasindicated

:

2.Ensurethat

all

test

equipment

and

the

power

module

into

which

the

AM

503

under

test

willbeinstalled

are

suitably

adaptedtothe

line

voltagetobe

applied

.

3.Install

the

AM

503

into

the

power

module,

and

if

applicable,

install

all

otherTM500-Series

test

equipment

into

the

power

module

.

4.Connect

the

power

module(s)

and

test

equipment

to

a

suitable

line

voltage

source.Turn

all

equipment

on

and

allowatleast20minutes

for

the

equipmenttowarmupand

stabilize

.

REVBDEC

1980

AM

503

CURRENT/DIV

5

A

Coupling

DC

BANDWIDTH

FULL

Calibration

Generator

Amplitude

lo

v

Mode

std

ampl

Monitor

Oscilloscope

Volts/Div

5

mV

Time/Div

50

/is

Input

Coupling

do

Triggering

ext

2-5

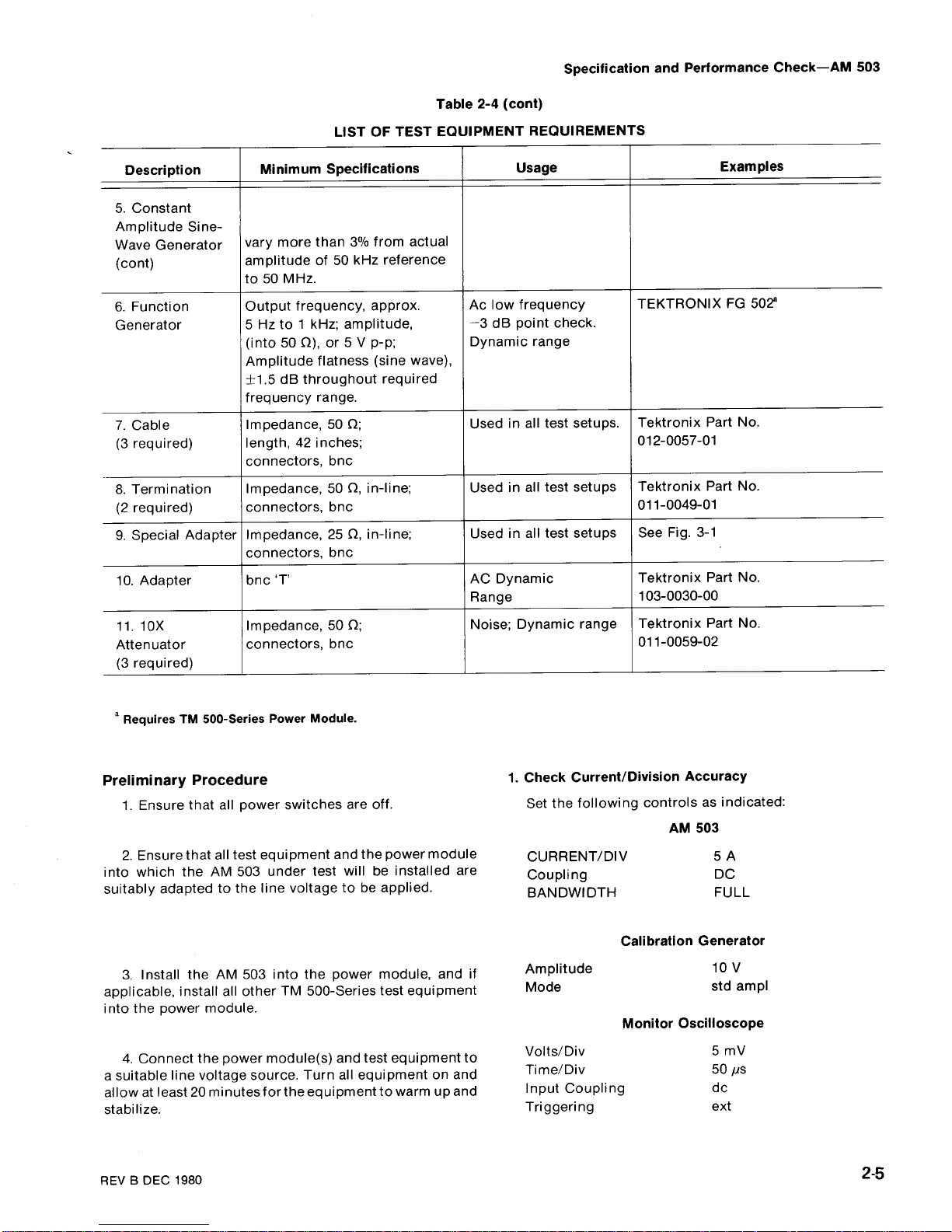

Description

Minimum

Specifications

Usage

Examples

5.Constant

Amplitude

Sine-

Wave

Generator

vary

more

than3%from

actual

(cont)

amplitudeof50

kHz

reference

to50MHz

.

6.Function

Output

frequency,

approx

.

Ac

low

frequency

TEKTRONIX

FG

502

8

Generator

5

Hzto1

kHz;amplitude,

-3

dB

point

check

.

(into50S2),or5Vp-p

;

Dynamic

range

Amplitude

flatness

(sine

wave),

+1.5dB

throughout

required

frequency

range

.

7.Cable

Impedance,

50

f2

;

Usedinall

test

setups

.

Tektronix

PartNo.

(3

required)

length,

42 inches

;

012-0057-01

connectors,

bnc

8.Termination

Impedance,

50

S2,

in-line

;

Usedinall

test

setups Tektronix

PartNo.

(2

required)

connectors,

bnc

011-0049-01

9.Special

Adapter Impedance,

25

S2,

in-line

;

Usedinall

test

setups

See

Fig.3-1

connectors,

bnc

10.Adapter

bnc

`T'

AC

Dynamic

Tektronix

PartNo.

Range

103-0030-00

11.10X

Impedance,

50

O

;

Noise

;

Dynamic

range

Tektronix

PartNo.

Attenuator connectors,

bnc

011-0059-02

(3

required)

Specification

and

Performance

Check-AM

503

a.Connect

the

OUTPUT

of

the

AM

503tothe

input

of

the

monitor

oscilloscope

using a 500cable

and

a 50

O

terminator

.

b

.

Connect

the

Ampl

Output

of

the

calibration

generatortothe

AM

503

INPUT

using

the

special

adapter

(see

Fig.3-1)

anda500cable

.

c.Using

theAM503DCLEVEL

control

andthe

monitor

oscilloscope

vertical

position

control,

center

the

display

.

e.Set

the

AM

503,

calibration

generator,

and

monitor

oscilloscopeasindicatedinTable

2-2

.

f.Check-that

the

signal

amplitudeineach

step

isfive

divisions±0.15

division

.

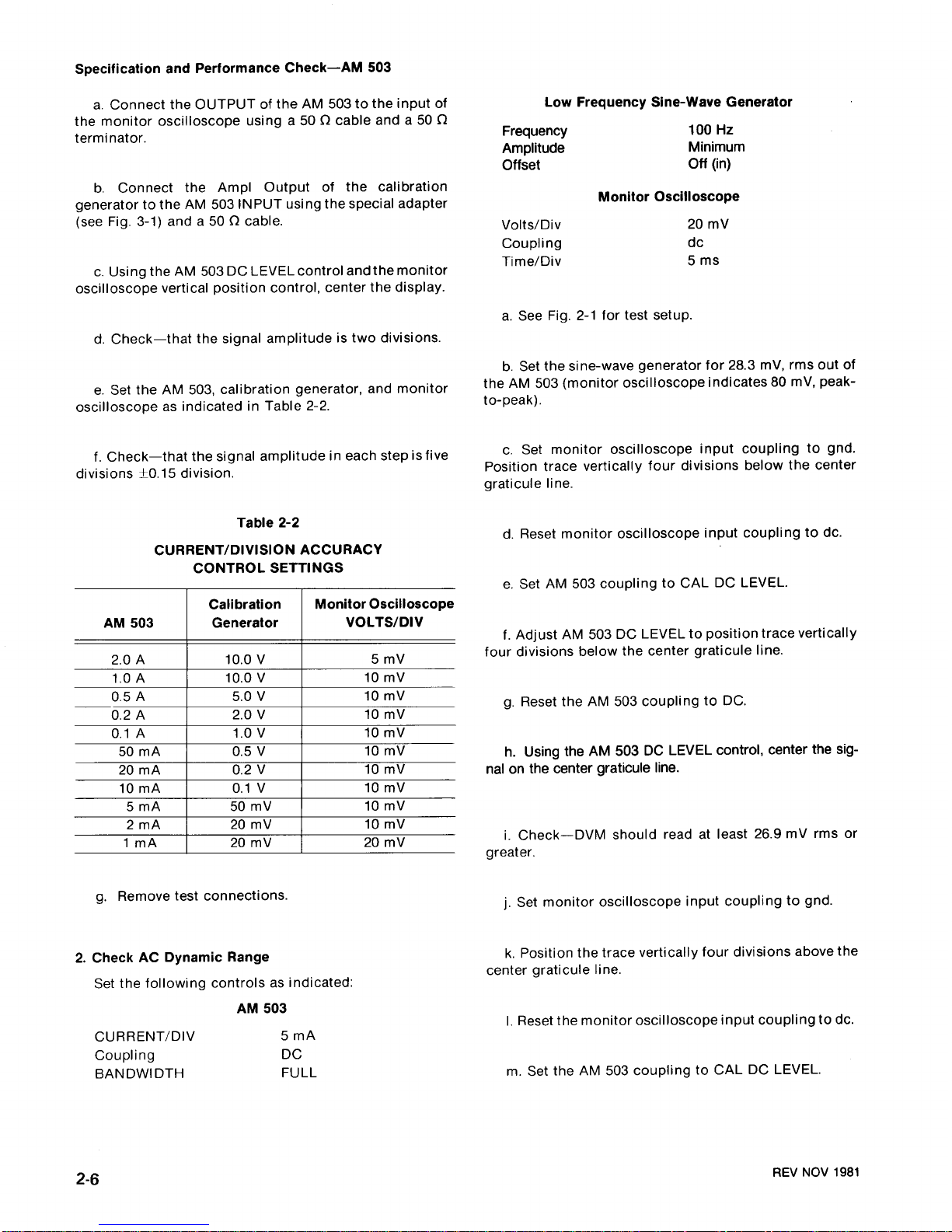

2.Check

AC

Dynamic

Range

2-6

d.Check-that

the

signal

amplitudeistwo

divisions

.

Table

2-2

CURRENT/DIVISION

ACCURACY

CONTROL

SETTINGS

g

.Remove

test

connections

.

Set the

following

controls

as

indicated

:

AM

503

CURRENT/DIV

5

mA

Coupling

DC

BANDWIDTH

FULL

Low

FrequencySine-Wave

Generator

Frequency

100

Hz

Amplitude

Minimum

Offset

Off

(in)

Monitor

Oscilloscope

Volts/Div

20

mV

Coupling

do

Time/Div

5

ms

a.See

Fig.2-1

for

test

setup

.

b.Set

the

sine-wavegenerator

for

28.3mV,rms

out

of

theAM503

(monitor

oscilloscope

indicates80mV,

peak-

to-peak)

.

c.Set

monitor

oscilloscope

input

couplingtognd

.

Position

trace

vertically

four

divisions

below

the

center

graticule

line

.

d.Reset

monitor

oscilloscope

input

coupling todc.

e.Set

AM

503

couplingtoCAL

DC

LEVEL

.

f.Adjust

AM

503

DC

LEVELtoposition

trace

vertically

four

divisions

below

the

center

graticule

line

.

g.Reset the

AM

503

coupling toDC.

h.Using

theAM503

DC

LEVEL

control,

center the

sig-

nalonthe center

graticule

line

.

i .

Check-DVM

should

readatleast26.9mVrms

or

greater

.

j .

Set

monitor

oscilloscope

input

couplingtognd

.

k.Position

the

trace

vertically

four

divisions

above

the

center

graticule

line

.

I.Reset the

monitor

oscilloscope

input

couplingtodc

.

m

.

Set

the

AM

503 couplingtoCAL

DC

LEVEL

.

REV

NOV

1981

AM

503

Calibration

Generator

Monitor

Oscilloscope

VOLTS/DIV

2

.0A

10

.0V

5

mV

1

.0A

10

.0V

10

mV

0

.5A

5

.0V

10

mV

0

.2A

2

.0V

10

mV

0

.1A

1

.0V

10

mV

50mA 0.5V

10

mV

20mA

0

.2V

10

mV

10

mA

0.1V

10

mV

5

mA

50

mV

10

mV

2

mA

20

mV

10

mV

1

mA

20

mV

20

mV

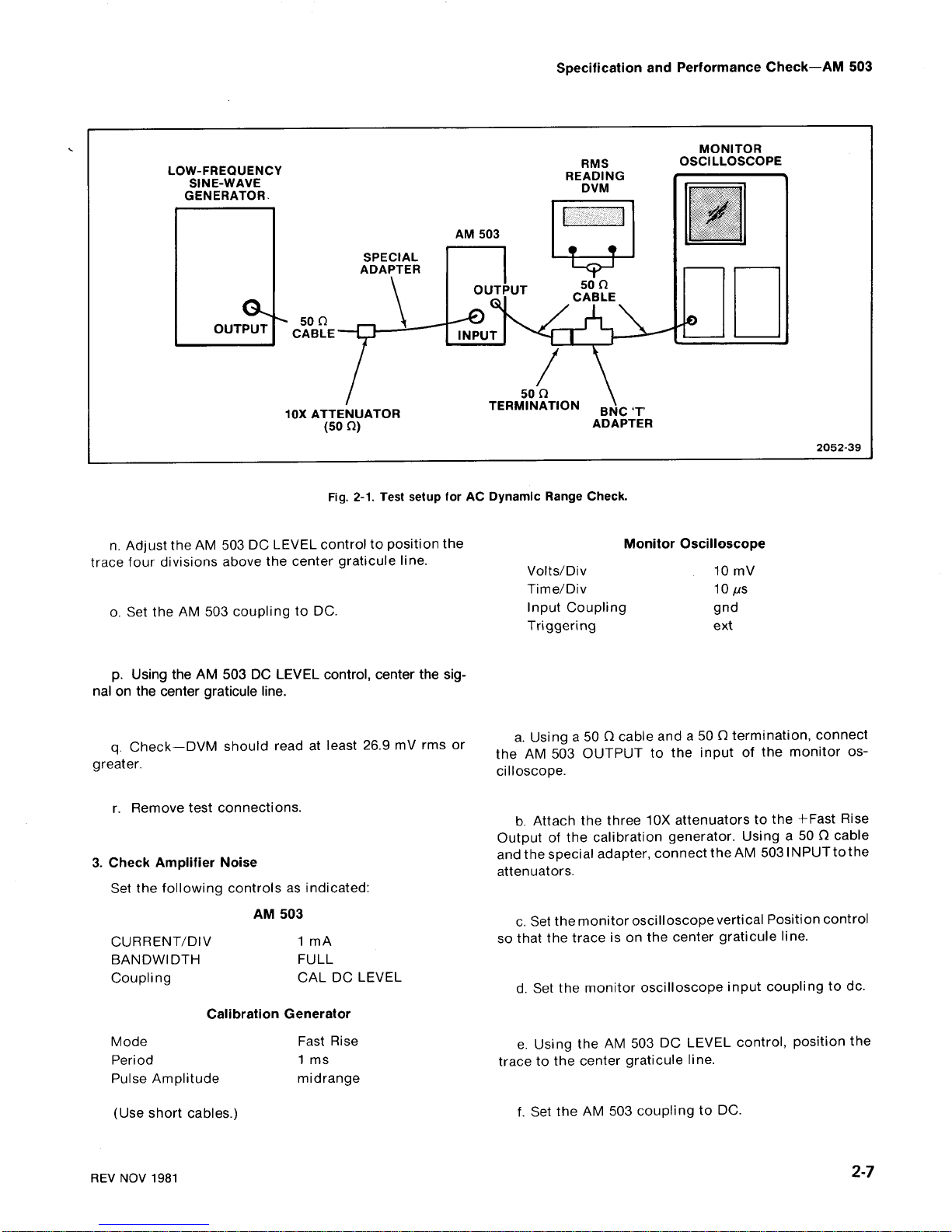

LOW-FREQUENCY

SINE-WAVE

GENERATOR

.

50

f2

CABLE

SPECIAL

ADAPTER

AM

503

50

D

10X

ATTENUATOR

TERMINATION

BNC

'T'

(50

S2)

ADAPTER

MONITOR

RMS

OSCILLOSCOPE

READING

DVM

2052-39

n.Adjust

the

AM

503

DC

LEVEL

controltoposition

the

Monitor

Oscilloscope

trace

four

divisions

above

the

center

graticule

line

.

Volts/Div

10

mV

Time/Div

10

us

o.Set the

AM

503

couplingtoDC

.

Input

Coupling

gnd

Triggering

ext

p.Using

theAM503

DC

LEVEL

control,

center

the

sig-

nal

on

the center

graticule

line

.

q.Check-DVM

should

read

at

least26.9mVrms

or

greater

.

r.Remove

test

connections

.

3.Check

Amplifier

Noise

Set the

following

controlsasindicated

:

c

.

Setthe

monitor

oscilloscope

vertical

Positioncontrol

CURRENT/DIV

1

mA

so

that

the

traceison

the

center

graticule

line

.

BANDWIDTH

FULL

Coupling

CAL

DC

LEVEL

d

.

Set

the

monitor

oscilloscope

input

couplingtodc

.

Mode

Fast

Rise

Period

1

ms

Pulse

Amplitude

midrange

(Use

short

cables

.)

REV

NOV

198

1

AM

503

Calibration

Generator

Fig.2-1.Test

setup

forACDynamic

Range

Check

.

Specification

and

Performance

Check-AM

503

a.Using

a 500cable

and

a 50Otermination,

connect

the

AM

503

OUTPUT

to

the

inputofthe

monitor

os-

cilloscope

.

b.Attach

the

three

10X

attenuatorstothe

+Fast

Rise

Output

of

the

calibration

generator.Using

a

500cable

andthespecialadapter,

connecttheAM

5031NPUTtothe

attenuators

.

e

.

Using

the

AM

503

DC

LEVEL

control,

position

the

tracetothe

center

graticule

line

.

f.Set the

AM

503

couplingtoDC

.

2-7

Specification

and

Performance

Check-AM

503

g.Decrease

the

calibration

generator

output

amplitude

until

the

two

traces

just

merge

(no

darkarea

between

the

traces,

see

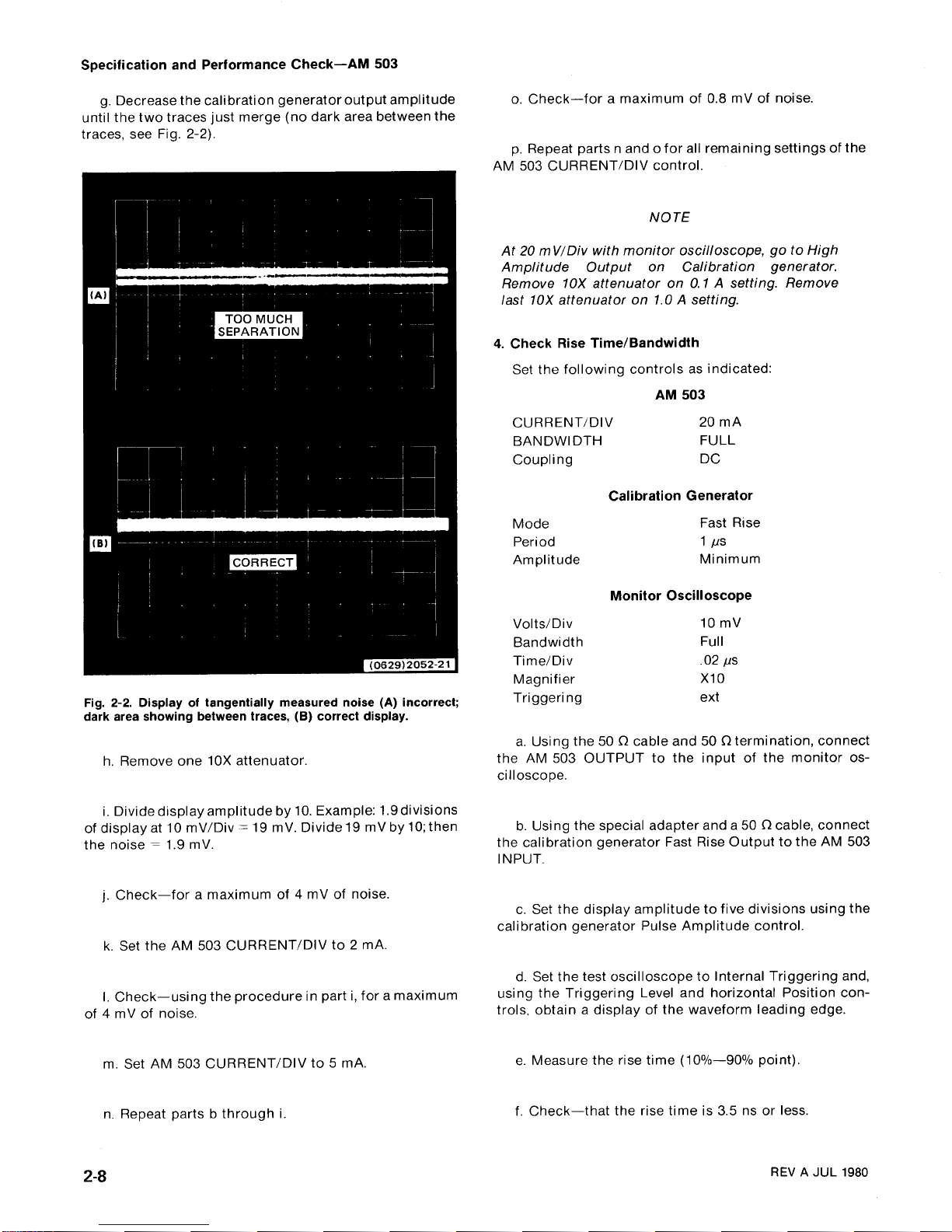

Fig.2-2)

.

Fig.2-2.Display

of

tangentially

measured

noise

(A) incorrect

;

dark area

showingbetween

traces,

(B)

correct display

.

h.Remove

one10X

attenuator

.

i .

Divide

display

amplitude

by10.Example:1.9divisions

of

displayat10

mV/Div=19mV.

Divide19mVby10;then

the

noise=1.9mV

.

j

.

Check-for

a

maximum

of4mV

of

noise

.

k.Set

the

AM

503

CURRENT/DIV

to 2

mA

.

I.Check-using

the

procedure

in

parti,foramaximum

of4mV

of

noise

.

m.Set

AM

503

CURRENT/DIV

to

5mA.

n.Repeat

parts b

throughi.

o.Check-for

a

maximum

of

0.8mV

of

noise

.

p.Repeat

parts n

and

o

for

all

remaining

settings of

the

AM

503

CURRENT/DIV

control

.

NOTE

At20

mV/Div

with

monitor

oscilloscope,goto

High

Amplitude

Output

on

Calibration

generator

.

Remove

1OX

attenuator

on0.1Asetting.Remove

last

1OX

attenuator

on1.0Asetting

.

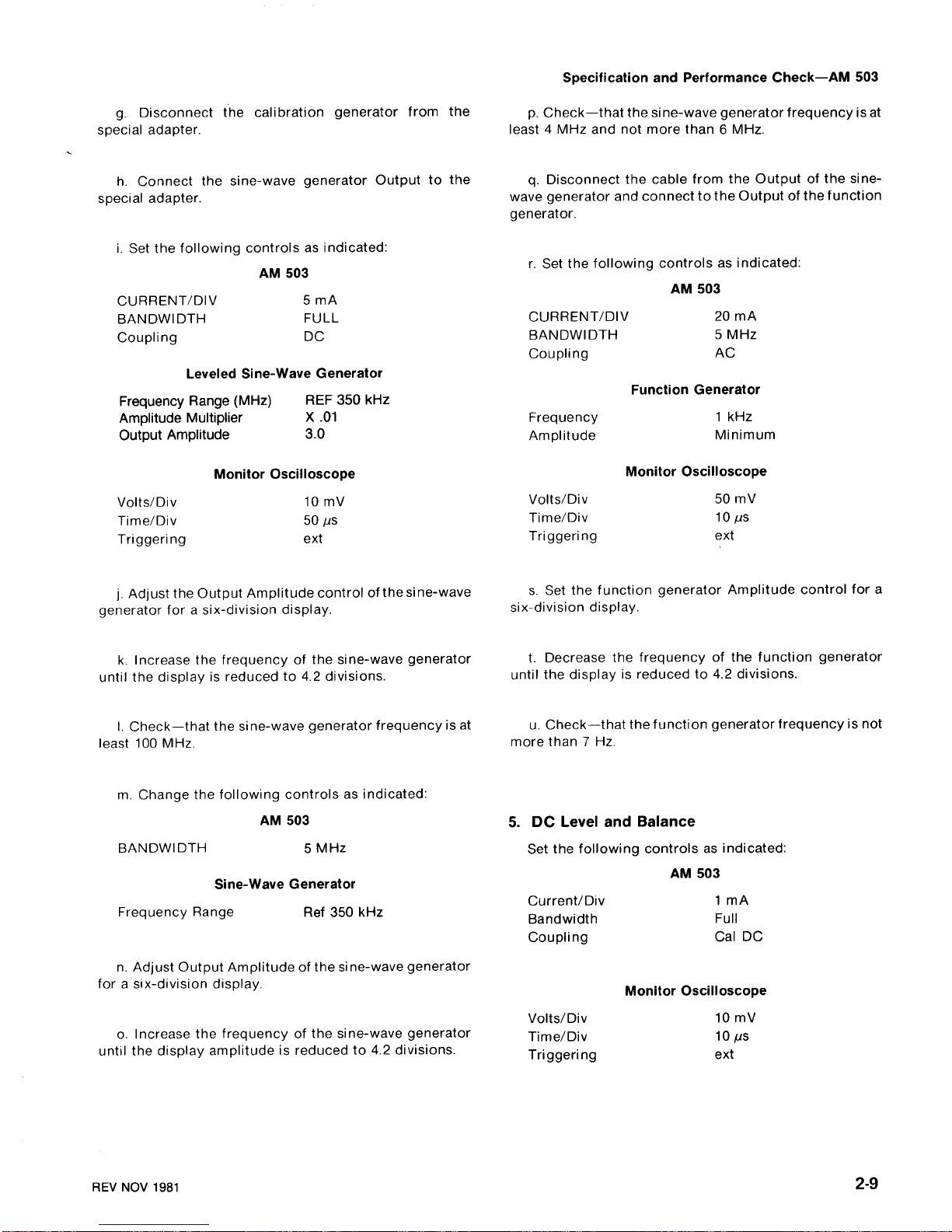

4.Check

Rise

Time/Bandwidth

Set

the following

controlsasindicated

:

AM

503

CURRENT/DIV

20

mA

BANDWIDTH

FULL

Coupling

DC

Calibration

Generator

Mode

Fast Rise

Period

1

ps

Amplitude

Minimum

Monitor

Oscilloscope

Volts/Div

10

mV

Bandwidth

Full

Time/Div

.02

ps

Magnifier

X10

Triggering

ext

a.Using

the

50S2cable

and

50

S2

termination,

connect

the

AM

503

OUTPUT

to

the

input

of

the

monitor

os-

cilloscope

.

b.Using

the

special

adapter

anda50S2cable,

connect

the

calibration

generator

Fast

Rise

Outputtothe

AM

503

INPUT

.

c.Set

the

display

amplitudetofive

divisions

using

the

calibration

generator

Pulse

Amplitude

control

.

d.Set the

test

oscilloscopetoInternal

Triggering

and,

using

the

Triggering

Level

and

horizontal

Position

con-

trols,

obtainadisplayofthe

waveform

leading

edge

.

e.Measure

the

rise

time

(10%-90%

point)

.

f.Check-that

the

rise

timeis3.5nsorless

.

REV

A JUL

1980

g.Disconnect

the

calibration

generator

from

the

special

adapter

.

least4MHz

and

not

more

than6MHz

.

h.Connect

the

sine-wave

generator

Output

to

the

q.Disconnect

the

cable

from

the

Output

of

the

sine

special

adapter

.

wave

generator

and

connecttothe

Outputofthe

function

generator

.

i .

Set

the following

controlsasindicated

:

AM

503

j

.

Adjust

the

Output

Amplitude

controlofthesine-wave

s.Set the

function

generator

Amplitude

control

for

a

generator

forasix-division

display

.

six-division

display

.

k.Increase

the

frequency

of

the

sine-wave

generator

t.Decrease

the

frequency

of

the

function

generator

until

the

displayisreduced

to 4.2divisions

.

until

the

displayisreduced

to4.2

divisions

.

I .

Check-that

the

sine-wave

generator

frequencyisat

u.Check-that

the

function

generator

frequencyisnot

least

100

MHz

.

more

than7Hz

.

REV

NOV

198

1

Specification

and

Performance

Check-AM

503

p.Check-that

the

sine-wavegenerator

frequencyisat

r.Set

the following

controlsasindicated

:

2-9

m.Change

the

following

controlsasindicated

:

AM

503

BANDWIDTH

5

MHz

Sine-Wave

Generator

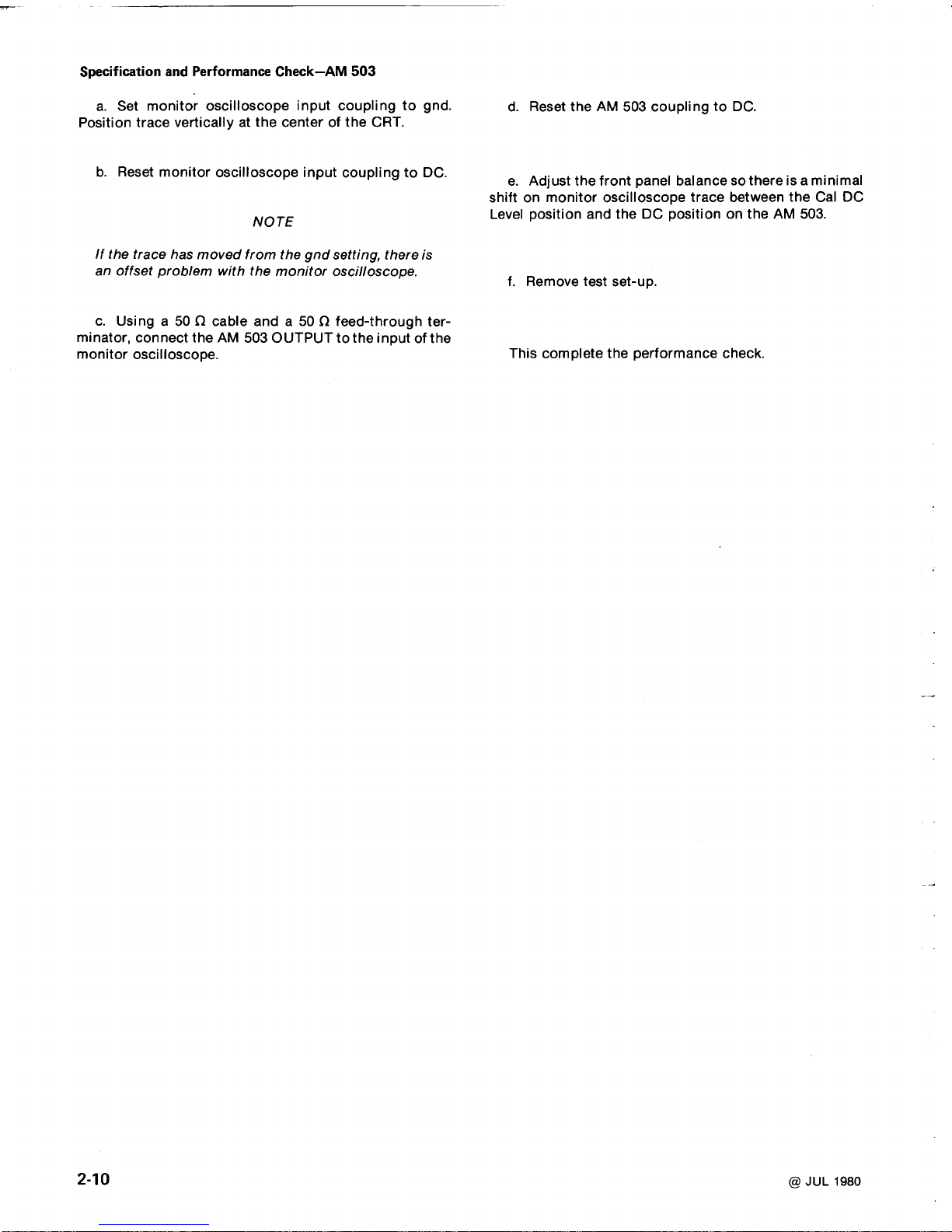

5.DC

Level

Set the

following

and

Balance

controls

as

indicated

:

AM

503

Current/Div

1

mA

Frequency

Range

Ref

350

kHz

Bandwidth

Full

Coupling

Cal

DC

n.Adjust

Output

Amplitude

of

the

sine-wave

generator

forasix-division

display

.

Monitor

Oscilloscope

Volts/Div

10

mV

o.Increase

the

frequency

of

the

sine-wave

generator

Time/Div

10us

until

the

display

amplitude

is

reduced

to 4.2divisions

.

Triggering

ext

CURRENT/DIV

5

mA

AM

503

BANDWIDTH

FULL

CURRENT/DIV

20

mA

Coupling

DC

BANDWIDTH

Coupling

5

MHz

AC

Leveled

Sine-Wave

Generator

Function

Generator

Frequency

Range

(MHz)

REF

350kHz

Amplitude

Multiplier

X

.01

Frequency

1

kHz

Output

Amplitude

3

.0

Amplitude

Minimum

Monitor

Oscilloscope

MonitorOscilloscope

Volts/Div

10

mV

Volts/Div

50

mV

Time/Div

50"s

Time/Div

lops

Triggering

ext

Triggering

ext

Specification

and

Performance

Check-AM

503

a.Set

monitor

oscilloscope

input

couplingtognd

.

Position

trace

verticallyatthe

centerofthe

CRT

.

2-10

b.Reset

monitor

oscilloscope

input

coupling toDC.

NOTE

If

the

trace

has

moved

from

the

gnd

setting,

there

is

an

offset

problem

with

the

monitor

oscilloscope

.

c.Usinga50Ocable

and

a50f2

feed-through

ter-

minator,

connect

the

AM

503

OUTPUT

to

the

inputofthe

monitor

oscilloscope

.

d.Reset

the

AM

503

couplingtoDC

.

e.Adjust

the

front

panel

balance

sothereisa

minimal

shiftonmonitor

oscilloscope

trace

between

the

Cal

DC

Level

position

and

the

DC

position

on

the

AM

503

.

f.Remove

test

set-up

.

This

complete

the

performance

check

.

@

JUL

198

0

WARNING

THE

FOLLOWING

SERVICING

INSTRUCTIONS

ARE FOR

USE

BY

QUALIFIED

PERSONNEL

ONLY

.

TOAVOID

PERSONAL

INJURY,

DO

NOT

PERFORM

ANY

SERVICING

OTHER

THAN

THAT

CONTAINED

IN

OPERATING

INSTRUCTIONS

UNLESS

YOUARE

QUALIFIED

TO

DO SO

.

REFER

TO

OPERATORS

SAFETY

SUMMARY

AND

SERVICE

SAFETY

SUMMARY

PRIOR

TO

PERFORMING

ANY

SERVICE

.

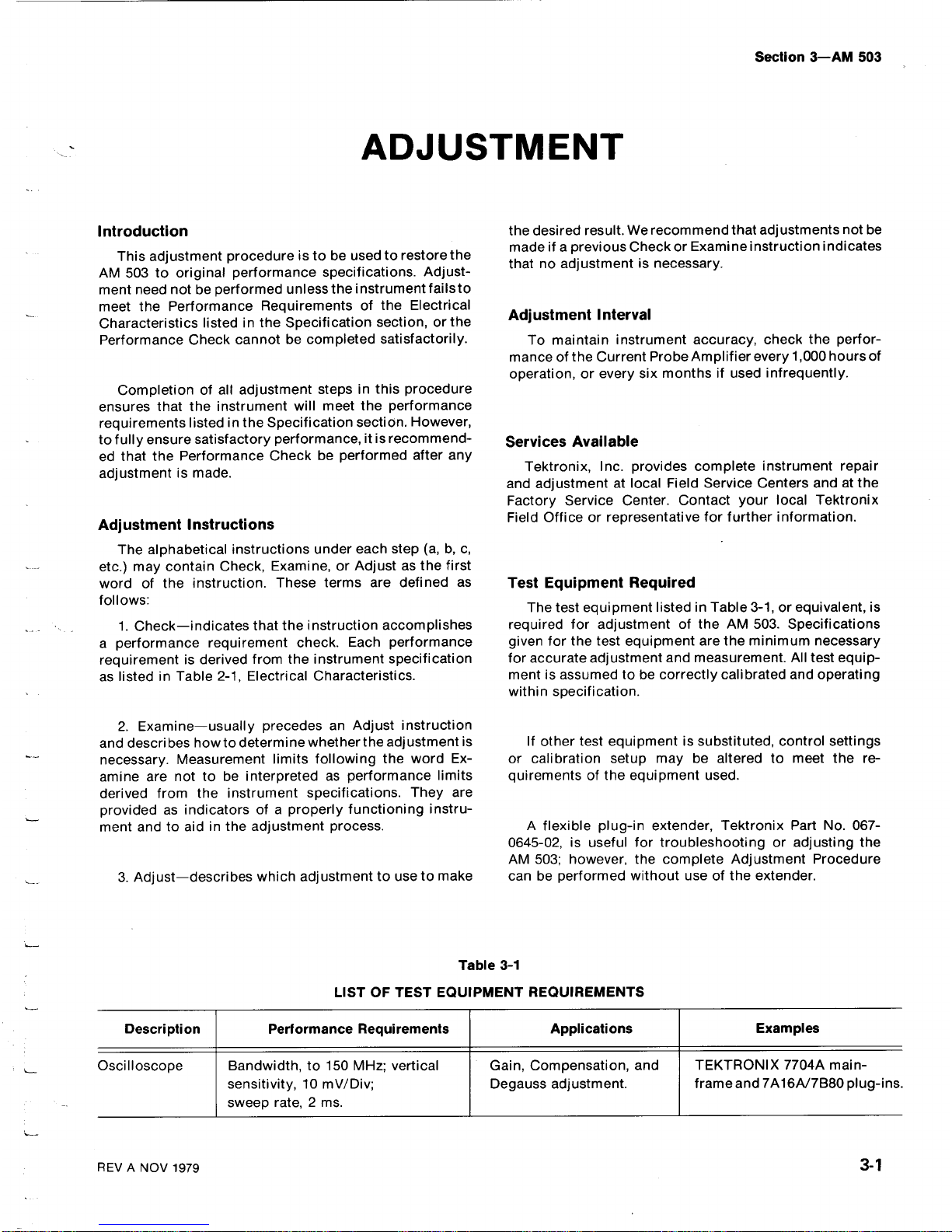

Introduction

This

adjustment

procedureistobeusedtorestore

the

AM

503tooriginal

performance

specifications.Adjust-

ment

need

notbeperformed

unlessthe

instrument

failsto

meet

the

Performance

Requirements

of

the

Electrical

Characteristics

listedinthe

Specification

section,

or the

Performance

Check

cannotbecompleted

satisfactorily

.

Completion

of

all

adjustment

steps

in

this

procedure

ensures

that

the

instrument

will

meet

the

performance

requirements

listedinthe

Specification

section.However,

to

fully

ensure

satisfactory

performance,itis

recommend-

ed

that

the

Performance

Check

be

performed

after

any

adjustment

is

made

.

Adjustment

Instructions

The

alphabetical

instructions

under

each

step

(a,

b, c,

etc.)may

contain

Check,

Examine,orAdjust

as the

first

word

of

the

instruction.These

terms

are

defined

as

follows

:

1.Check-indicates

that

the

instruction

accomplishes

a

performance

requirement

check.Each

performance

requirementisderived

from

the

instrument

specification

as

listed

in

Table

2-1,

Electrical

Characteristics

.

2

.

Examine-usually

precedes

an

Adjust

instruction

and

describes

howtodetermine

whethertheadjustment

is

necessary.Measurement

limits

following

the

word

Ex-

amine

are nottobe

interpreted

as

performance

limits

derived

from

the instrument

specifications.They

are

provided

as

indicatorsofa

properly functioning

instru-

ment

andtoaidinthe

adjustment

process

.

3.Adjust-describes

which

adjustmenttousetomake

REV

A

NOV

197

9

ADJUSTMENT

Table

3-1

Adjustment

Interval

Services

Available

Test

Equipment

Required

LIST

OF

TEST

EQUIPMENTREQUIREMENTS

Section

3-AM

503

the

desired

result.We

recommend

that

adjustments

not

be

madeifa

previous

CheckorExamine

instruction

indicates

thatnoadjustmentisnecessary

.

To

maintain instrument accuracy,

check

the

perfor-

manceofthe Current

Probe

Amplifier

every

1,000

hours

of

operation,orevery

six

monthsifused

infrequently

.

Tektronix,

Inc.provides

complete

instrument

repair

and

adjustmentatlocal Field

Service

Centers

andatthe

Factory Service

Center.Contact

your

local

Tektronix

Field

Officeorrepresentative

for

further

information

.

The

test

equipment

listedinTable

3-1,orequivalent,

is

required

for

adjustment

of

the

AM

503.Specifications

given

for

the

test

equipment

arethe

minimum

necessary

for

accurate

adjustment

and

measurement.All

test

equip-

mentisassumedtobe

correctly

calibrated

and

operating

within

specification

.

If

other

test

equipmentissubstituted,

control

settings

or

calibration

setup

may

be

alteredtomeet

the

re-

quirementsofthe

equipment

used

.

A

flexible

plug-in

extender,

Tektronix

Part

No

.

067-

0645-02,isuseful

for

troubleshootingoradjusting

the

AM

503;however,

the

complete

Adjustment

Procedure

canbeperformed

without

useofthe extender

.

Description

Performance

Requirements

Applications

Examples

Oscilloscope

Bandwidth,to150

MHz;vertical

Gain,

Compensation,

and

TEKTRONIX

7704A

main-

sensitivity,10mV/Div

;

Degauss

adjustment

.

frame

and7A16A/7B80plug-ins

.

sweep

rate,2ms

.

Adjustment-AM

503

Preparation

3-

2

a

RequiresTM500-Series

Power

Module

.

a.Construct

Special

AdapterasshowninFig.3-1

.

b.Remove

the

left

side

cover

of

the

AM

503

to

gain

access

to

the

adjustments.Pull

the

rear

endofthe

side

cover

outward

from

the

sideofthe instrument

(the

cover

snaps

into

place)

.

c.Be

sure

that

the

power

switchisoff.Set the

power

module

for

the

line

voltagetobe

applied

and

connectitto

the

line

voltage

source

.

d.Install

the

otherTM500-Series

equipment

into

the

power

module

.

Table

3-1 (cont)

LIST

OFTEST

EQUIPMENTREQUIREMENTS

e.Turnon

all

test

equipment

and

allow 20

minutes

for

warm

up

and

stabilization

.

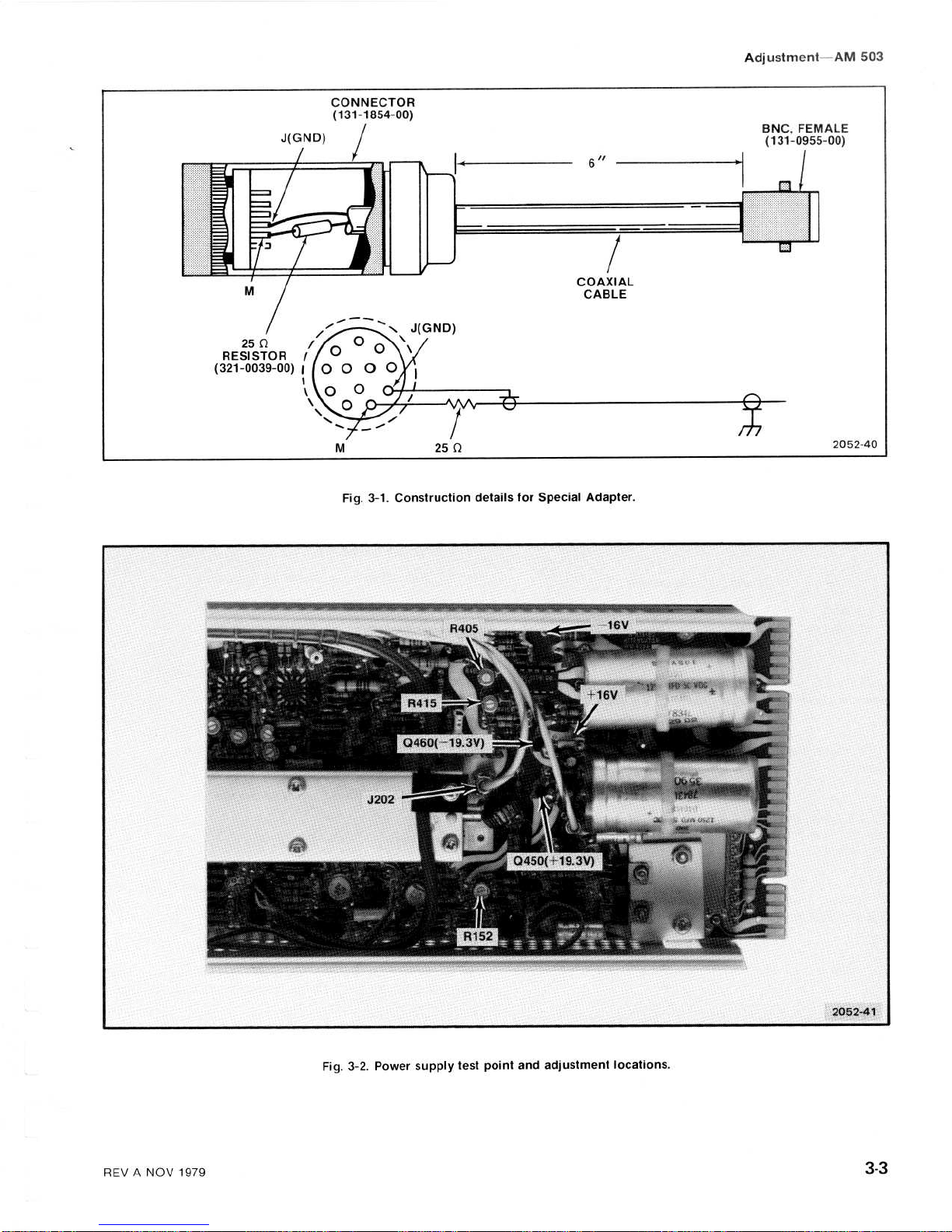

1.Adjust

Power

Supply

Voltages

a.Connect

the

DVM

between

each

voltage

test

point

and

ground

forthesupplies

listedinTable3-2.See

Fig.3-2

for

test

point

and

adjustment

locations

.

b

.

Examine-each

supply voltagetodetermine

ifitis

within

the

range

given

.

c

.

Adjust-each

supply

voltage

with

the

indicated

adjustment

.

REVANOV

1979

Description

Performance

Requirements

Applications

Examples

Calibration

Pulse

Output:period1us

to

10ms;

Gain

and

Compensation

TEKTRONIX

PG

506'

Generator

duty

cycle,

~50%

;

amplitude

adjustment

.

Pulse

Generator

.

range,0.5Vor less to

at

least5V

.

Leading

edge

aberrations

<2%,

into500

.

Rise time

(terminated

into

50 0)

<10ns.

Digital

Range,

0 to 20V;

accuracy

Power

supply

voltage

TEKTRONIX

DM

5029

Voltmeter

within0.2%

.

check

.

Digital

Multimeter

.

Probe

1X

Gain

adjustment

.

TEKTRONIX

P6101

.

Termination

Impedance,

500;

connector,

bnc

.

All

measurements

.

Tektronix

PartNo.

011-0049-01

.

Cable(2required)

Impedance,

50S2;

length,

All

measurements

.

Tektronix

PartNo.

42 inches;connectors,

bnc

.

012-0057-01

.

Resistor

Fixed

wire-wound,3S2,

Degauss

adjustment

.

Tektronix

PartNo.

3W,5%

.

308-0441-00

.

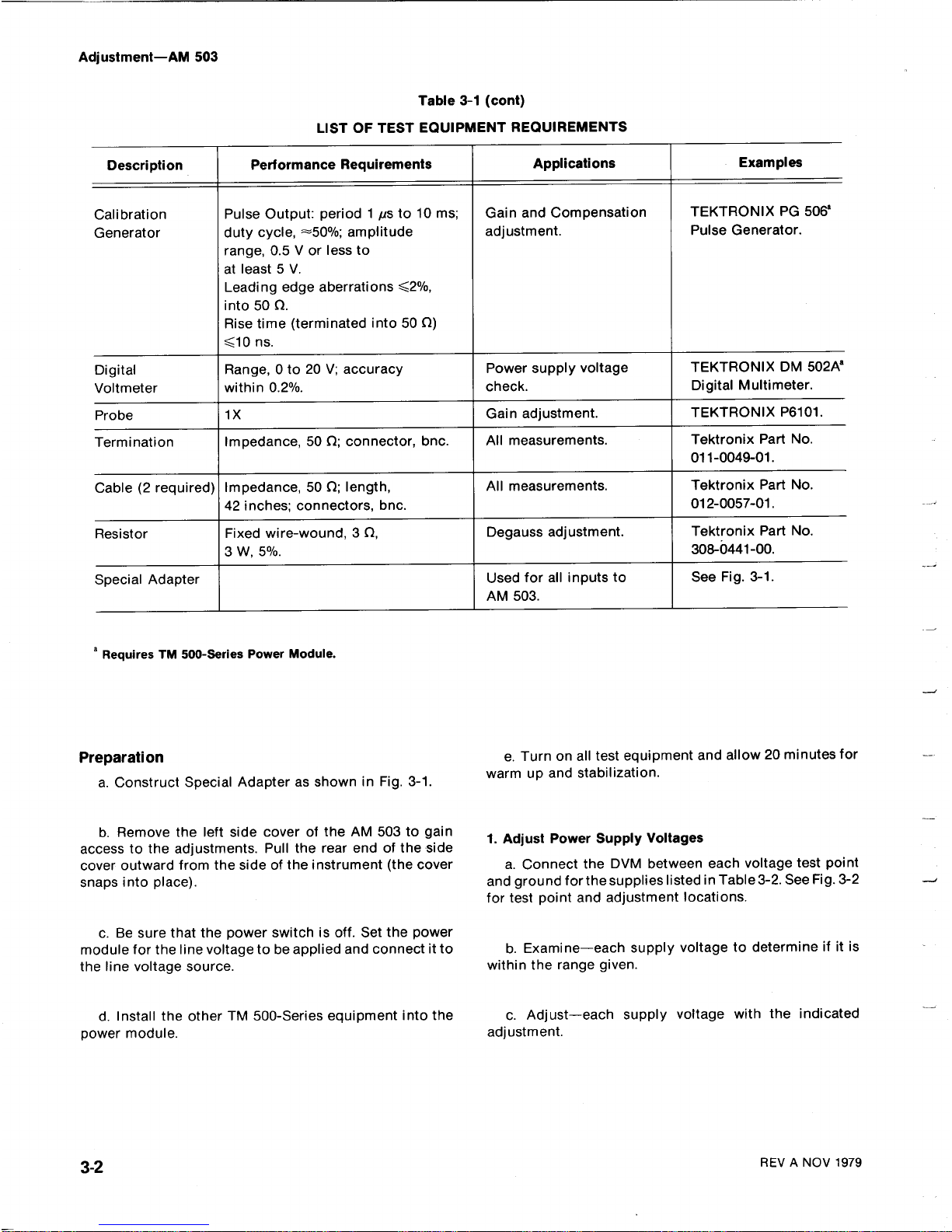

Special

Adapter

Used

for

all

inputs

to

See

Fig.3-1

.

AM

503

.

J(GND)

250

RESISTOR

/

(321-0039-00)

f

I

w

CONNECTOR

(131-1854-00)

COAXIAL

CABLE

BNC,

FEMALE

(131-0955-00)

2052-40

Fig.3-1.Construction

details

for

Special

Adapter

.

Fig.3-2.Power

supply

test

point

and

adjustment

locations

.

Adjustment-AM

503

REVANOV

1979

3-3

Loading...

Loading...