Page 1

AIM3A

Analog Input Module

Introduction

The AIM3A analog input module accepts input signals of

flOOmV full scale through klOV full scale, and outputs a

signal of flOV full scale to the A/D converter module in

slot1 ofthedataacquisitionsystem.TheAIM3Acanaccept

32 single-ended (common ground) inputs, or 16 differential (floating) inputs, or a mixture of both. All AEvl3A

functions,includinggainofxl,x10,andx100,areprogrammable, permitting single-ended and differential inputs to

be intermixed with a different gain setting for each channel. Full 16-bit precision results from the AIM3A’s lownoise instrumentation amplifier, linearity of 0.005%, and

attention to design, signal routing, and shielding. When

used with an AMMlA (AMMZ) A/D module, the AIM3A

will support 5OkHz (62.51d-12) measurements at any gain

and channel mix.

The AIM3A can be configured to accept current inputs by

installing appropriate current sensing resistors in the op.

tionalresistorlocationsprovidedon themodule.Theinput

signals are connected to removable screw terminal ships.

Alternately, a user-installed mass termination connector is

available for single-ended channels0-7 and 16-32, or differential channels O-7. The mass termination connector uses

the pin out format of the Analog Devices 3B mainframe

ribbon cable connector to permit direct connection of the

AlM3A to a 3B signal conditioning subsystem.

Hardware Compatibility

The AIM3A can be used in slots 2 through 10 of the 500A

and 5OOP. Up to 9 AJM3A modules can be used in these

systemsforamaximumof3@4analoginputchannels(32SE

channels per AIM3A plus 16 SE channels on the AMMx in

slot 1). For best performance, analog modules should be

mounted in the lowest-numbered available slots. The

Alh43A can also be used in the option slot of the Model 575

or576forupto48analoginputchannels(32SEchannelson

the AlM3A plus 16 SE channels on the AMMx).

Document Number: 501-918-01 Rev. C / 3-92

Copyright 0 1989 Keithley Instruments, Inc., Cleveland, OH 44139 (216)248-0400 AIM3A-1

Page 2

SH 0

0 0

I I

1

2

I 0 I

3

0 SH

0 o0

0

0 l-

o 2-

0 3-

qo 4-

0 5-

0 6-

0 7-

0 NC

LJ

Page 3

AlM3A

Analog Input Module

Software Compatibility

Full control of the AIM3A requires software specifically

designed for this module. Keithley’s KDAC500 software

fully supports the AlM3A. If you are using third-party

software, be certain that the software fully supports the

AIM3A.

AIM3A Specifications

(Specifications apply for 18” to 28”C, 1 year)

Input channels: 16 differential or 32 single-ended, software

selectable

Input characteristics:

Input Protection: lt3OV max (powered), i-15V max

(unpowered)

Input Resistance: IOOMR

Input Bias Current: 5OnA

Software selectable gains:

Input range (+V):

Gain accuracy (% rdg): 0.05 0.01

Gain Nonlinearity (%): 0.005 0.005 0.005

Gain Tempco (%/“C): 0.002 0.002 0.002

Input offset @IV): 250 25 25

Offset Tempco QV/“C): 50 6

Input noise

@V RMS, 1OOKHz BW):

Settling time to .Ol%:

CMRR (DC to 60Hz): 70db 90db 100db

Power up conditions: gain = Xl, input channels = differential, channel selected = channel 0.

xl

10 1

24 2.7 1.3

15ps 15ps 15la

X10

xl00

0.1

0.01

2

Standard Connections

terminal block, first strip 3/16 of insulation from the end of

the wire which you want to attach. Loosen the desired

terminal screw on the block and insert the bare end of the

wire into the corresponding hole. Tighten the screw securely to compress the tab against the wire.

After you have attached all the desired signal wires to a

terminal block, replace the terminal block by lining it up

with the mating pins on the AIM3A and pressing it back

into place.

Alternate connections are available through the optional

cable mass termination connector Jll. Note that Jll connects only to channels 0 through 7 and 16 through 23 in

single-ended mode, or 0 through 7 in differential mode.

This connector is available from Scotch/3M as Part Number 3429, and can be easily field-installed if it is needed.

Installation

All features and operating modes of the AlM3A module

are programmable with the exception of jumpers Wl and

W2 and resistor sockets J5 JlO. Jumpers Wl and W2

connect input low to module ground, and are normally left

in place. They may be removed for measurements where

remote ground sensing is needed. A jumper may be plain

wire, or may resemble a resistor.

Sockets J5 JlO are used for current sensing resistors, or for

ground reference resistors for some types of differential

measurements. These are special situations which are

covered under the “Applications” topic later in this manual.

The input connections to the AIM3A are made through

quick-disconnect terminal blocks Jl, J2, J3, and J4,or through

mass termination Jll.

A quick-disconnect terminal block can be removed from

the AlM3A to facilitate making connections. Pull the block

straight off the board with a firm, even pressure. Do not pry

the terminals with a screwdriver or sharp object, or you

may damage the circuit board.

Note that each individual terminal on a terminal block

consists of a small metal block with a hole and metal

compression tab within the hole. To make connections to a

CAUTION

Turn off power to the data acquisition system

before you insert or remove any module. To

minimize the possibility of EM1 radiation,

always operate the data acquisition system

with the cover in place and properly secured.

CAUTION

Make sure you have discharged any static

charges on your body before handling the

AIM3A. You can do this most easily by simply

touching the chassis of a computer or data

acquisition mainframe which is plugged into

AIM3A-3

Page 4

AIM3A

Analog Input Module

a grounded, 3-wire outlet. Avoid touching

components or the card edge connector of the

module.

NOTE

Analog input modules should be placed in the

lowest-numbered availableslots. Thispositioning will provide the shortest distance to the

Analog Master Measurement module in slot 1,

and will also minimize any possibility of noise

pick-up from the power supply or other mod-

l&S.

For a compatible multi-slot data acquisition system (e.g.

Model 5OOA or 5OOP), remove the top cover of the system

by loosening the cover retaining screws located in the

upper corners of the rear panel. Slide the cover back about

one inch and then lift it off. Insert the AIM3A module in the

desired slot with the component side facing the system

power supply. Replace the system cover.

In a single-slot system such as the Model 575 or 576, first

attach the supplied right-angle bracket to the AIM3A (see

Figure 2). Install the AIM3A in the option slot, with the

component side of the board facing upward. Secure the

bracket to the rear panel of the system. Close and secure the

cover.

The AIM3A has a single, differential instrumentation amplifier that amplifies all input signals, whether singleended or differential. A differential amplifier responds

only to the difference in voltage between two signals

connected to its non-inverting (+) and inverting (-) inputs.

The common mode voltage is the average of the two input

voltages. The actual voltage at each input is not important

as long as the common voltage is within the common mode

range of the amplifier. The common mode range of thi

AIM3Awillnotbeexceededaslongasallinputsarewithin

the range -lOV to +lOV referenced to module ground.

For example, if the input to the (+) input is 9 Volts and the

input to the (-) input is 8 Volts, the amplifier will amplify

the +1 Volt difference signal and reject (ignore) the 8.5 volt

common mode signal at both inputs. The ability to reject

the8.5Volt commonsignal isreferred toasCommonMode

Rejection.

When the AIM3A amplifies a differential input signal, the

(+) input of the amplifier is connected to the selected (+)

channel on terminal block Jl or J3, and the (-) input of the

amplifier is connected to the corresponding (-) channel

terminal on J2 or J4. For example, if channel 2 and differential mode are selected, the (+) input of the amplifier is

connected to pin 7 of Jl, and the (-1 input of the amplifier is

connected to pin 4 of JZ. As long as the voltage at either pin

is within +lO to -10 volts as measured to the module

ground (pin 10 of Jl and J3, or pin 1 of J2 and J4), the

amplifier will amplify the difference between the inputs.

End View Top View

I

-e

screws

Threaded Hole

screw

Bracket

‘@we 2. Model 575 Mounting Bracket

Applications

The following brief description of the AIM3A’s amplifier

circuitry will help you make the most effective use of the

module.

AIM3A-4

When the AIM3A amplifies a single-ended input signal,

the (+) input is connected to the selected channel on terminalblockJ1, J2, J3,or J4,and the (-1 inputisconnected toone

of common input low connections available on Jl, JZ, J3, or

14.

The jumpers Wl and W2 provide a user-removable connection between the input low connections and module

ground,andshouldnormallybeleftlnposition.TheAIM3A

amplifier will now amplify the voltage difference between

the selected (+) input terminal and module ground.

As an example, if channel 30 and single-ended mode are

selected, the (+) input of the amplifier is connected to pin

8 of J4, and the (-) input of the amplifier is connected to pin

10 of J4 (or pin 1 of J3, since these two pins are internally

connected). Pin 10 of J4 and pin 1 of J3 are jumpered to

module ground by WZ. The amplifier will amplify the

difference between pin 8 of J4 and pin 10 of J4.

Page 5

AlM3A

Analog Input Module

There are two groups of 16 single-ended input channels,

and each group has its own (-) input connection. Singleended channels 0 through 7 and 16 through 23 form one

group, with their (-) input connection brought to pin 1 of Jl

and pin 10 of J2. Jumper Wl connects this (-) input connection to the module ground as supplied from the factory.

Single-ended channels 8 through 15 and 24 through 31

form the second group, with their (-) input connection

brought to pin 1 of J3 and pin 10 of J4. Jumper WZ connects

this (-1 input connection to the module ground as supplied

from the factory.

CAUTION

To minimize the possibility of EMI radiation,

use shielded cable for input signals. Connect

the shield to module ground, but do not connect the shield at the opposite cable end to

anything.Themaximuminputvoltageallowed

with module power on is i30 Volts, or 225

Volts with module power off. If any input

exceeds f10 Volts, all inputs will be lnoperative.

There are several choices for the method of connecting

inputs to the AIM3A. You must decide which method will

yield the best results for a given application. To achieve 16bit performance, care must be taken to minimize error

sources caused by ground loops and shielding problems.

The guidelines for choosing connection methods are as

follows:

Single-ended Input, Local Ground Sensing. Using

Terminal Blocks

For input sources which can be grounded, but are not

connected to a ground of their own, the connections shown

in Figure 3 will give good results. The AIM3A provides the

ground connection for the input sources. Two possible

connectionsareshown.SourcesVOandVl haveindividual

cables going to each source. Up to 32 sources can be

connected to a single AIh43A in this way. Four input

common terminals are provided, one on each connector.

Connectall thewiresfromasingleinputsource to thesame

connector, asshownfor Jl inFigure3. SourcesV16andV17

show a cable with a single input common wire. This

connection method can be used for up to 16 sources in a

group where all the sources have one wire in common. The

sources in a single group must be connected to channels

which all use the same input common connection. There

are two input common connections, one for channels 0

through 7 and 16 through 23, and a second input common

connection for channels 8 through 15 and 24 through 31.

Single-ended Input, Remote Ground Sensing, Using

Terminal Blocks

Figure 4 shows four single-ended inputs connected to the

AIM3A using a remote ground sense line. All 16 singleended inputs on Jl and J2 use a single ground sense line.

This method is useful when up to 16 voltage sources to be

measured are all located at a single remote location, with

one side of each signal source connected to ground at the

remote location. There may be a voltage difference be-

tween the ground at the remote location and the ground on

theAlM3A. This will cause an error in the voltage readings

if the connection in Figure 3 is used.

In Figure 4, the ground connection on theAIM3A is disconnected by removing jumper Wl. The ground at the remote

location is carried to the AlM3A by the remote ground

sense wire. The AIM3A will measure the difference between the remote signal, and the remote ground, and

eliminate the error caused by the difference in ground

voltage between it and the remote location. Two groups of

16 single-ended inputs can be wired this way, with the first

group using Jl, J2, and Wl, and the second group using J3,

J4, and W2 Refer also to Figures 10 and 11 later in this

manual.

Differential Inputs, Using Terminal Blocks

When there are multiple inputs with different ground

points, or the actual ground points are not known, the

differential input wiring can be used to prevent ground

loop errors and reject common mode noise. Figure 5 shows

two inputs connected as differential input channels 2 and

3. Either the (+) or the (-) input on any differential input

maybeconnected toground,orbothmay bediiferent from

ground. A restriction does exist, however. No input terminal on the AIM3A can be connected to a voltage beyond

+lOVor-10Vwithrespecttothe.4IM3Agroundreference.

If this happens, reading errors may occur on the channel

which is greater than 10 volts. At about +15 or -15 volts,

other channels will begin to read in error, and above +3OV

or -3OV, the AIM3A will be damaged.

When the AtM3A is used to measure a floating source, the

readings may appear noisy, or may fluctuate or rise until

they reach the maximum input permitted by the programmed gains. This problem results where the floating

sourcehasnolow-impedancecurrentretumpathtoground.

Over a period of seconds to minutes, the input of the

AIM3A charges off the input signal until the common

mode voltage present at the input exceeds the allowable

level, and the module no longer functions properly. The

AIM3A-5

Page 6

AIM3A

Analon Inaut Module

solution is to install a resistor for the affected channel from

inputlow toground.Thevalueof theresistormaybein the

range of 5k-lOOk, depending on the signal characteristics,

and should be determined empirically. These resistors can

be mounted on headers which are plugged into the avail-

able resistor sockets on the AEvf3A.

Notes:

1. Jumpers Wl and W2 must be in position. Wl connects input common for signals connected to Jl

and J2 to module ground. W2 connects input common of J3 and J4 to module ground.

2. All shields for singleended signals connected to Jl are attached to pin 10 of Jl, The shield input

on any connector is the right-most pin (Le. closest to the strain relief block of the AIM3A).

3. All input common lines for single-ended signals connected to Jl are attached to pin 1 of Jl, The

input common on any connector is the left-most pin (i.e. furthest from the strain relief block of the

AIM3A).

‘igure 3. Single-ended, Local Ground Sense, Using Terminal Blocks

AIM3A-6

Page 7

AIM3A

Analog Input Module

Notes:

Wl Removed for remote

Ground sense with Jl & J2

I---

A+

Remote Ground

Sense

1. Jumpers Wi and or W2 must be removed for this mode of operation: Remove Wl if connections

Ji and J2 are used, or W2 if J3 or J4 are used.

2. The input common on any connector is the left-most pin (Le. furfhest from the strain relief block

of the AIM3A.

3. The shield input on any connector is the right-most pin (i.e. closest to the strain relief block of

the AIM3A.

‘igure 4. Single-ended, Remote Ground Sense, Using Terminals

AIM3A-7

Page 8

AIM3A

Analog Input Module

Notes:

1. Jumpers Wl and or W2 may be in or out for this setup.

2. Input Common terminals have no effect for differential measurements.

3. The input common on any connector is the left-most pin (i.e. furthest from the strain relief

block of the AIM3A.

4. The shield input on any connector is the right-most pin (i.e. closest to the strain relief block of

the AIM3A.

igure 5. Differential Inputs, Using Terminal Blocks

Single-ended Inputs, Using Mass-termination

A location is provided near the strain relief block of the

AIh43A module for an optional mass termination connec-

tor Jl 1. Connector Jl 1 has its pins wired in parallel with the

connections on Jl and JZ, and provides a method for

quickly connecting up to 16 single-ended or 8 differential

signals to the AIM3A. The pin out of Jll is identical to that

of the Analog Devices 38 subsystem connector. When Jll

is used, the remaining input terminals on J3 and J4 of the

AIh43A may still be used in the usual fashion.

The pin out of Jll when used for single-ended inputs is

shown in Figure 6. The pin out of Jll when used with

differential inputs is shown in Figure 7. AU the input signal

connections previously described in Figures 3,4, and 5 can

be implemented with Jll. When Jll is used with the

AnalogDevices3B subsystem, the single-ended input with

remote ground sensing configuration is used, and Wl

must be removed.

AIh43A-8

Page 9

AlM3A

Analog Input Module

Remove Wl if remote ground is used

To Input 6

To Input Common

Pinout of user-installed connector

( ~$$?$zd

Typical Input Wiring :

Remote ground,

if used

Notes:

1. Connector is user-installable. ScotchWM Part Number 3429.

2. Connectors J3 and J4 can be wired for other operating modes.

3. Jumper Wl connects input common to module ground. Remove Wl if remote ground sensing is

used

‘igure 6. Single-ended Hook-up, Using Mass Termination

AIM3A-9

Page 10

AIM3A

Analog Input Module

Wl and W2 have no effect on

differential measurements

Pinout of user-installed connector

/

Typical Input Wiring :

To Input 5+

To Input 5-

To Shield

Notes:

I, Connector is user-installable, Scotchl3M Part Number 3429.

2. Connectors J3 and J4 can be wired for other operating modes.

3. Jumpers Wl and W2 have no effect on differential measurements.

‘igure 7. Differential Hook-up, Using Mass Termination

Current Measurement Using Terminal Blocks

TheAIM3A can measure currents by using current sensing

resistors to convert the current to a voltage. The voltage

drop across the current sensing resistor may then be measured and converted to a current. DIP sockets and DIP

headers are provided on the AIM3A to mount the current

sensing resistors. If all the currents being measured have a

common rehzrn path, the connection method shown in

Figure 8 can be used. If the currents being measured have

different return paths, the connection method shown in

Figure 9 must be used. In both connection methods, the

common mode voltage limitation applies as described

before; that is, no input terminal can be more than 10 volts

positive or negative with respect to the module ground.

The example in Figure 8 shows two 4-20 ma current loop

sensors being connected to single-ended channels 0 and 1.

An external power supply is needed to power the sensors.

Up to 16 current loop sensors can be connected to Jl and J2

and use the common current return path as shown. 16

additional current loop sensors can be wired to J3 and J4,

and use the second common current return path. When the

AIM3A-10

Page 11

Remove Wl for single-ended

current loop senscrs

connected to Jl & J2

AIM3A

Analog Input Module

I, \

I+

4 20mA

current

senscrs

External

voltage source

to power senscm

Sensc<cu3nt

return path for

channels 0 - 7

and16-23

1. Up to 16 senscrs can be connected to Jl and J2

2. Precision 250 ohm 0.01% O.iW resistors are available from Keithley DAC as part number 500.

RES-250. These resistors can be soldered to the DIP header plugs which are supplied in J5-JlO.

3. Remove jumper Wl if connectors Ji and/or J2 are used. Remove W2 if J3 and/or J4 are used

4. The same configuration can be repeated for J3 and J4.

‘igure 8. Measuring Currents Using Single-ended Inputs

common current retcrn is used as shown for single-ended

current inputs, single-ended voltage inputs in that group

of 16cannot beused. Figure9showsasingle4-ZOmasensor

connected up for current sensing in the differential mode.

In this connection method, either input terminal on the

AIM3A may be connected to ground either at the external

power supply or at the sensor.

The resistor value used for current measurements should

be chosen such that the resulting voltage drop does not

exceed the voltage input range for the channel being used.

Thus, if a maximum cuTTent of 20 mA is expected, and if the

input range is HOV, the resistor cannot be any larger than

5OOn or the resulting input voltage will be greater than

1OV. Ohm’s Law can be used to calculate the value as

fellows:

Voltagedrop = maximumexpectedcurrentxresistorvalue

Generally, you may choose any resistor value which gives

a suitable voltage drop. To avoid heating which may affect

measurement accuracy, make sure the maximum power

dissipated in the resistor is well within the power rating of

the resistor. Calculate this dissipation with another Ohm’s

law equation,

I’d2 x R

AlM3A-11

Page 12

AIM3A

Analog Input Module

WI and W2 have no affect

on differential current

measurements

.Eb m

nnnlti

’ I--

Each sensor

has its own

return current

path

1

+ External

v

4

+7

4 - 20mA

sensor

voltage supply

to power sensor

1. Up to 8 sensors can be connected to Jl and J2

2. Precision 250 ohm 0.01% 0.1 W resistors are available from Kelthley DAC as part number 500.

RES-250. These resistors can be soldered to the DIP header plugs which are supplied in J5-JlO.

3. Jumpers Wl and W2 have no effect on differential current measurements.

4. The same configuration can be repeated for J3 and J4.

‘igure 9. Measuring Currents Using Differential Inputs

There is one case where you most install a specific value

resistor. Keithley’s software includes an engineering units

flag which facilitates measurement of 4-2OmA current

loops. This EUF rehnns a reading of current in inilliamps.

It equates 4mA as 1V measured across the resistor, and

2OmA as 5V. Ohm’s law requires a resistor value of 250

ohms for this relationship to hold. Single-ended or differentialmcdecanbeused. Resistorswith avalueof250ohms

@ 0.01% are available from DALE resistors; part number

RN55E25008, or from Kaithley in packs of eight resistors as

500~RES-250.

Grounding

Care must be taken in wiring test circuits to minimize

errors due to the resistance of connection wire, especially

where the wire must carry an appreciable current. Figure

10 shows a circuit which has an inherent problem resulting

in a measurement error of 26%. The 1.28 ohm and 50 ohm

resistors are not actually discrete resistors in the circuitry,

but instead represent the equivalent resistances of wire or

other components. Figure 11 shows how the jumper Wl

may be removed to overcome this measurement problem.

AIM3A-12

Page 13

Amplifies 0.626V

AIM3A

Analog Input Module

Voltage drop

E=IR=0.10~1.26=0.126~

Error in measured voltage =

0.126VIO.5V n 26%

in ground wire =

‘igure 10. Errors Due to Ground Loop

(0.626V - 0.126V) - 0.5V

50 ft. of

#24 awg

50R = 1 OOmA load

(Sensor amp circuit

power, for example)

Using remote ground sensing

subtracts the ermr due to

ground wire resistance

‘igure 11. Avoiding Ground Loop Errors with Remote Ground Sensing

50 ft. of #24 awg

50R - 1 OOmA load

(Sensor amp circuit

power. for example)

Page 14

AIM3A

Analog Input Module

Selecting gains

The AIM3A module must be used with a data acquisition

system containing an AMMlA, AMM2, or other A/D

module. AllKeithleymasteranalogandA/Dmodulesalso

include a programmable gain (“global”) amplifier which

can be used to amplify any analog signal before it is

digitizedbytheA/Dconverter.TheAIM3Aalsohasanonboard (“local”) instnxmentation amplifier which amplifies

only those signals connected to the AIM3A. Thus, total

gains of xl, x2, x5, x10, x20, x50, x100, x500, and xlOW can

be applied to signals connected to the AIM3A. The following guidelines should be used in selecting gains:

Where possible, the amplifier on the AlM3A should be

used. The AIM3A amplifier processes the signal before

it passes through the remaining multiplexer and amplifier circuits, so the amount of noise which is amplified

along with the signal will be minimized.

The maximum signal presented to the A/D converter

as a result of all the applied gains cannot exceed the

A/D converter range.

Input filtering

Some types of measurements may be susceptible to noise

from the environment. Examples include measurement of

high-impedancesignals,ormeasurementsperformednear

motors, SCR controllers, etc. You should routinely take

care to minimize noise in your measurement setups. Typical steps include:

1.

Use short cable runs and shielded connecting cables.

2.

Properly use shielding. Only one differential signal

should be carried in a shielded cable. The shield should

be terminated only on one end of the cable; generally to

a shield terminal on the AIM3A.

3.

Minimize external sources of noise, re-orient equipment, or use a power outlet for the data acquisition

system which is not shared by any other equipment.

4.

Take several readings and average them. If the noise is

random, it will be filtered out mathematically through

averaging.

5.

Use any filtration available in the data acquisition system. The AMM2 module includes a programmable

filter with pass bands of 1OOkHz or ZkHz. The reading

rate available with the 1 OOkHz filter is 50kHz, while the

reading rate available with the 2kHz filter is 1kHz.

6.

Consider external conditioning or filtration. In some

casesyoumaywant toimplementafilterdirectlyatone

or more inputs of the AIM3A. A single-pole input filter

may be easily constructed using one resistor and one

capacitor (see Figure 12). The relative RC values will

depend on a variety of factors, including the frequency

of the noise, the required attenuation, and the necessary response time. The RC values can be computed

from the formula:

f&m =&

Where f is in Hz, C is farads, and R is ohms. The resulting

system response time within 0.01% is then equal to 9.2xRC.

As an example, assume that 10 counts of 60Hz noise is

present in the signal. To reduce the noise to one count (i.e.

to reduce the noise voltage by a factor of lo), an attenuator

factor of 10 (20dB) will be necessary at 60Hz. A single-pole

filter will roll off at a rate of 20dB per decade. Thus, a 3dB

point of 6Hz would be chosen to attenuate to 6OHz noise by

20dB. Rearranging the above equation to solve for R we

have:

R=

Picking a nominal value of 0.5pF for C, the necessary resis-

tance is:

R=

2rr x (0.5 x 10-6) x 6

R = 53,OOOohms

The resulting response time (Tr) is:

Tr = 9.2xRC

Tr = 9.2 x 53000 x 0.5

Tr = 0.24~~

Note that there are a number of RC values that can be used

in a given application. To minimize the effects of the series

resistance, however, keep the value of R as low as possible.

1

2n x c x f(s*)

1

AIM3A-14

Page 15

AIM3A

Analog Input Module

Where signals of low to moderate impedance are mixed on

one AIM3A, sufficient settling time or other measures

must be taken to assure accurate measurements. When the

AIM3A multiplexer selects any channel, a small charge

flows into or out of the AIM3A. If the next channel selected

by the multiplexer is a low impedance source, the AIM3A

and source will rapidly settle for the next measurement. If

the multiplexer instead switches to a high impedance

signal source, more time will be required for the AlM3A

input to settle at the new voltage.

igure 12. Single-pole Input Filter

High-Impedance Measurements

In measuring an analog signal, the measurement instrument places a small load on the signal and absorbs a small

amount of current from the signal source. Ideally, this load

should be zero, but will actually be some finite value. The

input impedance of the AIM3A is 100 Megohms, which is

comparable to a high-quality digital multimeter. Under

most measurement situations, the AIM3A will present a

negligible load to the signal source. However, measurement of signals from very high-impedance transducers

such as pH meter electrodes requires input impedance

several orders of magnitude higher.

Table 1. User-configured Components on the AIM3A Module

Application

Where high and low impedance signals are mixed on one

AIM3A, it is thus important that sufficient settling time be

provided per channel. It may also be helpful to short one

AIM3A channel to ground, and to scan that channel between the actual signal channels. Alternately, an external

buffer amplifier may be inserted between a high impedance signal and the AIM3A input. Such an amplifier presents a low impedance to the AIM3A, and may also be

designed with some gain as well. A buffer amplifier can be

built using an SET-input op amp and a few components.

See an analog IC applications guide for more information.

User-Configured Components

The user-configurable components on the AIh43A are J5,

J6, J7, J8, J9, JlO, Jll, Wl and W2.

Used for current sense resistors for single-ended inputs 0 through 7, or for ground reference resistors for

differential (+) input channels 0 through 7.

Used for current sense resistors for single-ended inputs 8 through 15, or for ground reference resistors

for differential (+) input channels 8 through 15.

Used for current sense resistors for single-ended inputs 16 through 23, or for ground reference resistors

for differential (-) input channels 0 through 7.

Used for current sense resistors for single-ended inputs 24 through 31, or for ground reference resistors

for differential f-1 input channels 8 through 15.

Used for current sense resistors for differential inputs 0 through 7.

Used for current sense resistors for differential inputs 8 through 15.

Jumper which connects the input common of single-ended input channels 0 through 7 and 16 through

23 to module ground.

Jumper which connects the input common of single-ended input channels 8 through 15 and 24 through

31 to module ground.

AIM3A-15

Page 16

AlM3A

Amlo,q Input Module

Table 2. Pin Outs for Single-ended Input Current Sense Resistors

Single-ended

Connector Channel

;z 0 1

; 3 2

J5 4

;z 5 6

J5 7

J6 8

fi 10 9

:z 11 12

; 14 13

J6 15

;: 17 16

J7 18

:: 20 19

Differential

Channel

co +I 8 7 10 9

+3 +2 6 5 12 11

+4 4 13

c5 +6 3 2 14 15

+7 1 16

+8 8 9

+I0 +9 7 6 10 11

+12 +11 5 4 12 13

+13 +I4 3 2 14 15

+15 1 16

-0 -1 10 9 8 7

-2 11 6

-3 -4 12 13 4 5

Input Input

TWIlliII~l Common

:; 21 22

J7 23

:: 24 25

; 26 27

:: 29 28

30

31

-6 -5 14 15 3 2

-7 16 1

-8 -9 10 9 8 7

-11 -10 11 12 6 5

-12 -13 13 14 4 3

-14 15 2

-15 16 1

AIh43A-16

Page 17

Table 3. Pin Outs for Differential Current Sense Resistors

1 Differential

connector Channel

I

0

1

11

;i

;

:;

2 3

4 5

6 7

12 5

13 4

14

15

16 1

I

6

3

2

AIM3A

Analog Input Module

Jl’J

JlO

JlO

JlO

JlO

JlO

Jl’J

Jl’J

8

9

10

11

12

13

14

15

Theory of Operation

The AlM3A circuitry is divided into three sections. The

input multiplexer consists of Ul, U2, U3, U4, and U5. The

instrumentation amplifier consists of U6, U7, U8, and the

associated resistors. ThedigitalcontrollogicconsistsofU9,

UlO, Ull, U12, U13, and U14.

The programmable gain instrumentation amplifier is constructed using an AD625JN amplifier (U7). The inputs of

U7 are connected to the input multiplexer through protection resistors R25 and R26. The output of Ui’ at pin 10 is

connected to J12 pin 3. The ANA-COM signal at pins 2 and

43ofJ12isthesystemzerovoltagereferencepoint,grounded

at the A/D converter input on the Ah4MlA or Ah@E. U8

buffers this ground reference, and feeds the U7 ground

reference input at pin 7.

U6 and resistors Ii11 through R24 form the programmable

gain control for amplifier U7. Pins 5 and 12 of U7 drive the

ends of a balanced voltage divider, and U6 selects two taps

on the divider based on the gain setting programmed. The

selected voltage divider taps are connected to U7 pins 2

and 15.

9

10 7

11

12 5

13 4

14 3

15

16 1

The input multiplexer allows either single-ended or differential signals to be selected as inputs to the instnunentation amplifier. When a differential input is selected, the (+)

input of the selected channel is connected to the noninverting input of the instrumentation amplifier by Ul (for

channels 0 through 7) or U3 (for channels 8 through 15).

The (-1 input of the selected channel is routed through U2

(Ch O-7) or U4 (Ch 8-15) to pin 14 of U5B. U5B is enabled,

connecting the (-) input of the selected channel to the

inverting input of the instrumentation amplifier. The 1K

resistor networks Rl, R2, R3, R4 combine with clamping

diodes inside Ul, U2, U3, U4 to provide input over voltage

protection. The diodes are arranged to conduct whenever

the input voltages either go above the +15 volt supply, or

go below the -15 volt supply.

Whenasingle-endedinputisselected,oneofthefourinput

multiplexers,Ul,U2,U3,orU4,connects theselectedinput

to its output. U5A is enabled, so that the outputs of all four

input multiplexers are connected to the non-inverting

input of theinsmunentationamplifier. If the selected input

is on either Jl or J2, then U5C is enabled, connecting the

inverting input of the instrumentation amplifier to input

low reference connections on Jl and J2. If the selected input

is on J3 or J4, then U5D is enabled, connectig the inverting

I 8

6

2

AlM3A-17

Page 18

AIM3A

Analog Input Module

input of the instrumentation amplifier to input low refer-

ence connections on J3 and J4.

ThedigitalcontrollogicrespondsonlytoawritetoCMDA.

A write to CMDA occurs when CMDA and R/W are both

pulsed low, causing U9D to pulse high. U14E inverts the

output of U9D, and will cause U12 to latch the data on DO

through D4 at the trailing edge of the pulse. The input

channel selection is controlled by these latched data bits,

which are further decoded by U9A, U9B, U9C, UlOA,

UlOB, UlOC, U14A, and U14B. When a write pulse occurs,

data is not latched by Ull if data bits D6 and D7 are both

low at the time of the write pulse. This is accomplished by

AND gate UlOD, which combines the write pulse from

U9D with the output of U13A. U13A is high if either D6 or

D7 or both are high. When a write is allowed to Ull, it

latches data bits D5, D6, and D7. Latched data bit D5 selects

single-ended or differential input mode by altering the

decoding of the channel selection data bits D3 and D4 in

Table 4. AIM3A Command Locations and Functions

portionsofU9andUlO.LatcheddatabitsD6andD7switch

the gain of the instrumentation amplifier by controlling

U6.

AIM3A Commands and Command Loca-

tions

The AlM3A is controlled by writing to the Command A

(CMDA) address for the slot in which the module is

mounted. Programmable parameters include selection of

channel, single-ended or differential mode, and gain.

Command B is not implemented on the AlM3A, and there

are also no READ modes for the AIM3A.

Keithley’s KDAC500 software offers complete programmability of the AIM3A.

Read Functions:

COMMAND FUNCTION

CMDA

CMDB NOW2

Write Functions:

COMMAND

CMDA Select channel, gain, and single-ended or differential input.

CMDB

NOIW

FUNCTION

NOIVZ

AlM3A-18

Page 19

16 Diff

32%

Inputs

AIM3A

Analog Input Module

Table 4. AIM3A Command Locations and Functions (Cont.)

TO

AMMlA

At%2

Multiplexer

Multiplexer

Channel select

(CMDA write)

Programmable gain

(CMDA write)

D7 D6 D5 D4 D3 D2 Dl DO

T -II- s!g$y;:

lo-x10Gain

11 - x100 Gain

* A simultaneous write of 000 or 001 to bits D7. D6, and D5 will have no effect on the last write to

D5, D6, or D7.

AIh43A-19

Page 20

AlM3A

Analog Input Module

Calibration Procedure

There are four adjustments on the AIM3A: Xl0 gain, Xl00

gain,andfwooffsetvoltageadjustments.Theoffsetadjustments can be made with equipment of average accuracy,

whereas the gain adjustments require equipment meeting

or exceeding the performance of the equipment specified

for the procedures. The gain calibrations will degrade by a

maximum of 0.01% per year. If the gains require readjust-

ment,bestresultswillbeobtainedifthemoduleisrehuned

for factory calibration.

Offset Adjustment

Equipment Required:

Keithley Model 196 DMM or equivalent

Keithley Model 500,5OOA, or 575 Data Acquisition System

Procedure:

1.

Install the AIM3A module to be calibrated in slot 3 of

the Data Acquisition System. Install either an AMMIA

or an AMMZ into slot 1 of the Data Acquisition System,

then tom on the system power. Provide 15 minutes for

the equipment to warm up.

2.

Short single-ended channel 0 to ground by installing a

jumper wire between pin9 and pin 1 of input connector

Jl. If jumper Wl has been disconnected, it will also be

necessary to also install a jumper wire between pin 1

and pin 10 of input connector Jl for this test.

3.

Attach the (-) lead of the DMM to TPl (labeled ANA

COM) on the AIM3A. Attach the (+) lead of the DMM

to TP2 (labeled ANA OUT) on the AIM3A. Select the

most sensitive DC voltage range.

4.

If U7, R27, or R28 have been replaced, preset R27 and

R28 to near the center of their adjustment range by first

rotating the adjustment screws counterclockwise at

least 25 turns (or until a clicking sound is heard as the

screw is rotated), and then rotating the adjustment

screws clockwise 13 turns. R27 and R28 should not be

presetiftheboardwasfunctioningnormallybefore this

calibration was begun, since R27 and R28 are probably

close to the proper adjustment.

5.

Invoke BASICA on the computer controlling the data

acquisition system. Using the BASICA direct mode,

execute the following statement:

DEF SEG = &HCFF&?

If the IBIN card in your system is set to an address other

than CAFE, use that address instead of CFFB in the DEF

SEG statement.

Using the BASICA immediate mode, execute the fol-

6.

lowing statement:

POKE 4,96

This will select the Xl gain and single-ended channel 0.

7.

Adjust R28 for a DMM Indication of 0 volts, within 50

microvolts.

8.

Using the BASICA immediate mode, execute the following statement:

POKE 4,224

ThisstatementselectsXlOOgainandsingle-endedchannel0.

9.

Adjust R27 for a DMM indication of 0 volts, within 500

microvolts.

10. Repeat steps 6, 7, 8, and 9 in order until no further

improvement is obtained.

Gain Adjustment

Equipment Required:

Fluke Model 5101 Voltage Calibrator or equivalent

Keithley Model 196 DMM or equivalent

Keithley Model 500,5OOA, or 575 Data Acquisition system

Procedure:

Install the AIM3A module to be calibrated in slot 3 of

the Data Acquisition System. Install either an AMMlA

or an AMMZ into slot 1 of the Data Acquisition System,

then hum on the system power. Provide 15 minutes for

the equipment to warm up.

Connect the (-) lead of the voltage calibrator output to

Jl pin 1 and the (+) lead of the voltage calibrator output

to Jl pin 9. If jumper Wl has been disconnected, it is

necessary to also install a jumper wire between pin 1

and pin 10 of input connector Jl for this test.

Attach the (-) lead of the DMM to TPl (labeled ANA

COM) on the AIM3A, and the (+) lead of the DMM to

TI?? (labeled ANA OUT) on theAIM3A. Select the most

sensitive DC voltage range that can display a 10 volt

reading.

Invoke BASICA on the computer controlling the data

acqtisitionsystem.UslngtheBASICAimmediatemode,

AIM3A-20

Page 21

AIM3A

Analog Input Module

execute the following statement:

DEF SEG = &HCFJF8

If the IBIN card in your system is.& to an address other

than CFF8, use that address instead of CFFB in the DEF

SEG statement.

5. Using the BASICA direct mode, execute the following

statement:

POKE 4,160

This will select the X10 gain and single-ended channel

0.

6. With the voltage calibrator set to produce 0 volts output, note the offset voltage reading on the Dh4M.

7. Set the voltage calibrator to produce 1.0000 volts.

8. AdjustR21foraDMMreadingequaltolOvoltsplusthe

offset voltage reading noted in step 6. When adding the

offset reading, be sure to use the correct polarity.

9. Using the BASICA direct mode, execute the following

statement:

Faulty software or applications programs - If you have

completed a new program which does not work as anticipated, review the program design and be certain that it

actually functions as you assume. If a program which had

been running properly begins to behave erratically, either

the supporting software package or the application program may have been corrupted. This may occur through

disk media failures, power supply problems, hardware

failures, or operator error.

Compare your software package to a back-up copy or the

original diskettes. If the software is questionable, you

should reinstall the software t&m the original diskettes or

known-good copies. Likewise, your applications program

should be restored from backups if a problem develops.

Note that it is crucial to back up important software and

programs. Ideally, you should make at least two copies,

and store one in a location away from your work site.

Application programs should be backed up regularly as

they are being developed. Printouts of program listings

may also be desirable.

POKE 4,224

This will select the Xl00 gain and single-ended channel

0.

10. With the voltage calibrator set to produce 0 volts output, note the offset voltage reading on the DMM.

11. Set the voltage calibrator to produce 100.00 millivolts.

12. AdjustR17foraDMMreadingequaltolOvoltsplusthe

offset voltage reading noted in step 6. When adding the

offset reading, be sure to use the correct polarity.

Troubleshooting

Any observed or suspected problem with a system or

module may be the result of malfunctions in any part of the

system. A hierarchy of possible problem areas is listed

below. The list should help you apply an organized approach to troubleshooting, starting with software and

working toward a specific module. It assumes that your

system and software have both worked properly in the

past. If you have spares, you can most quickly verify a

system component through simple substitution. Check

your data acquisition system manual or computer documentation - they may contain additional instructions on

troubleshooting.

Faulty computer system -A malfunctioning computer or

peripheral can affect the data acquisition software and

hardware, ranging from minor problems to total failure.

These problems may be continuous or intermittent. If you

suspect your computer, remove the data acquisition interface and run any diagnostics which came with the system

to verify its performance. Also try running other software

with which you are familiar. Pay close attention for any

erratic behavior of the software which points to hardware

problems.

Defective interface - A malfunctioning data acquisition

interface can prevent the computer from booting up and

operatingproperly,oritcanaffect only thedataacquisition

system. Some graphics, mouse, and networking adapters

have been observed to conflict with data acquisition interfaces as a result of both using the same addresses or

interrupts. The system operates properly with only one of

the cards in place, but diagnostic error messages or other

problems result with both cards plugged into the system.

You can usually determine incompatibility by trying each

suspected card individually, and then together in the system. Such incompatibility can often be overcome through

switch settings, configuration changes, or minor modifications to the hardware.

AIh43A-21

Page 22

AIM3A

An&g Input Module

Defective data acquisition interface cable-The cable car-

ries essential power, control, or data signals. Open conduc-

tors in a cable will disrupt the process. Cable shorts,

especially in lines carrying system power supply voltages,

may cause a total shutdown of the computer or data

acquisition mainframe. If these problems exist, try discon-

necting the interface cable from the computer and data

acquisition system.

There is amaximum permissible length specified forinterface cables. Exceeding the length will also introduce problems. You may note erratic operation of the computer,

corrupt data, or a failure of the indicator lamps on the data

acquisition system to light.

Defective data acquisition mainframe-A mainframe de-

fect can affect any and all data acquisition functions. Main

areas of include the mother board logic and connectors, the

expansion slots, and the power supply. In the case of a

completely dead system, always check any fuses and cabling which camy power.

An individual slot may also be bad. A known good module

can be tried in various slots to determine the condition of

individual mainframe slots.

power control modules. The PIM modules use an external

board and solid state relays. These should also be considered in situations where PIM modules are suspected of

being faulty.

In troubleshooting modules, use a software package with

which you are familiar to write a few simple test programs

for the suspected module. Elaborate programs should

generally not be used. They may contain their own errors

which mask problems with hardware.

If a suspected module does not respond as expected, you

may assume that the module requires calibration or is

defective. If a module has no calibratable components, a

problem at this point will normally indicate a failure

within the module.

Defective AIMSAmodule -An AIM3A can be checked by

running a few simple programs which test individual

features of the module. If you suspect a noise problem, try

shorting both inputs for a given channel to ground. The

CMDA and CMDB registers can also be exercised to determine correct operation of the module. See information

elsewhere in this manual.

Defective module(s) in general - Failures in a module’s

address, data, or control circuitry can affect other modules

if they ultimately reach the data acquisition mother board

orpowersupply.Youmaybeable tolocateafaultymodule

byremotigmodulesindividuallyuntil theproblemclears.

The master A/D module in slot 1 is a special case because

it processes data from all analog input channels. Any

analog input involves its global multiplexer, programmable gain amplifier, and A/D converter. If only the

analog input functions are faulty, you should also consider

themasterA/Dmodule. Useaknown-good A/Dmodule,

or first verify your A/D module for proper operation

before troubleshooting another analog module.

Analog output normally relies only on circuitry within an

analogoutputmoduleunlessdocumentationforthemodule

staates otherwise.

Digital input and output are also performed wholly on a

single module, with the exception of the PIMI and PIM2

Askilled technicianwhohasaccesstoelectronictestequipment may be able to troubleshoot individual circuits on a

module to isolate the faulty parts. A full parts list and

diagram set are included with each module to aid the

technician.

If a defective component is found, replacement parts may

be obtained from Keithley. If factory service is desired, the

module may be returned for repair. All Keithley-manufachued systems and modules are warranted against defects

in material and workmanship for a period of one year. For

information on replacement parts or factory service, see

the Parts List section of the appropriate manual.

NOTE

If a calibratable module which had been working accurately suddenly becomes inaccurate by

more than a few percent, the problem is more

likely a malfunction and not a calibration problem. If you cannot calibrate the hardware after

two attempts, you should return it to Keithley

for repair or calibration at the factory.

AIM3A-22

Page 23

AIM.3A

Analog Input Module

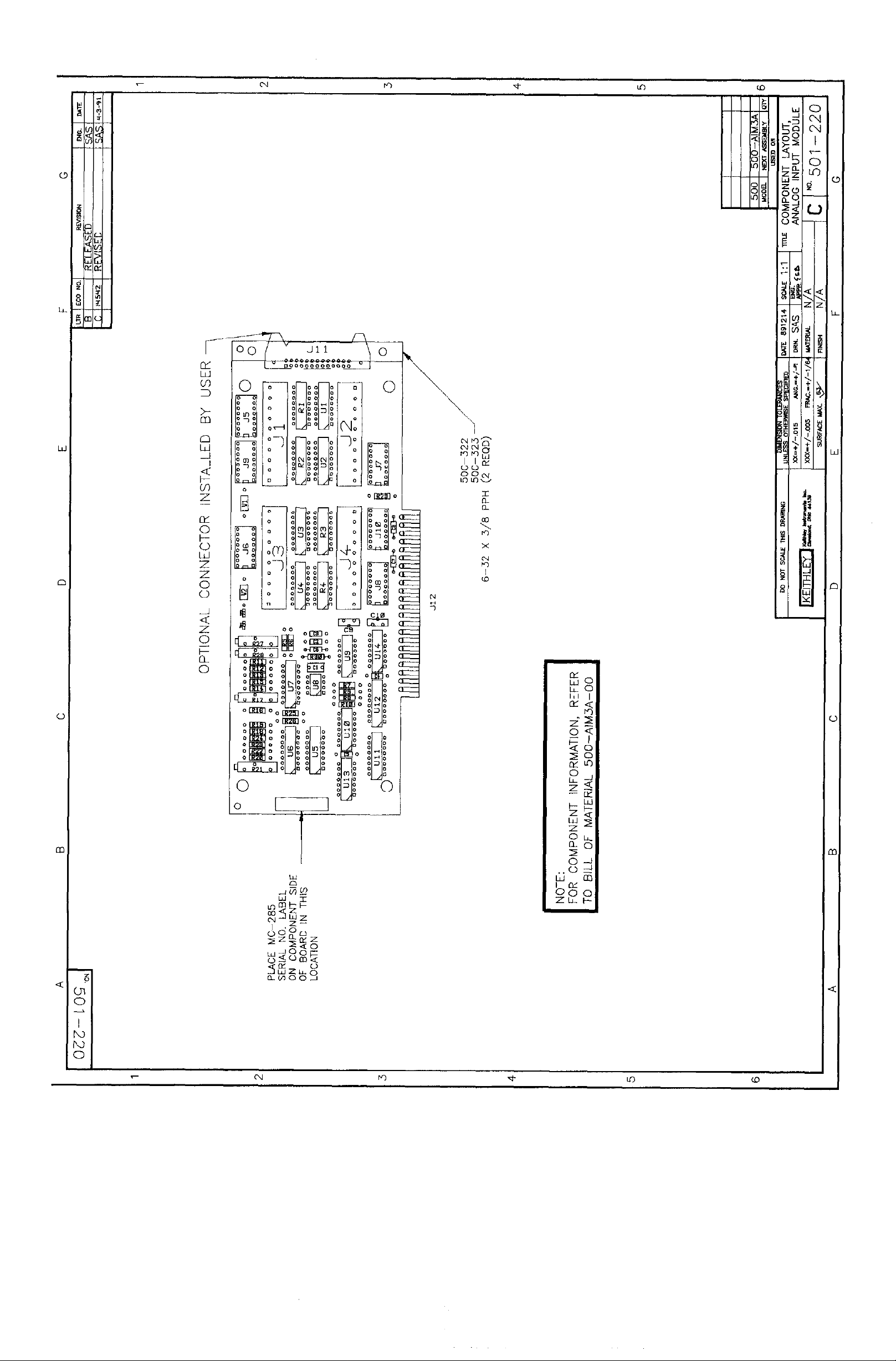

Parts List

This section contains replacement parts information,

component location drawings and schematic diagrams for

the AIM3A module. Parts are listed alphanumerically in

order of their circuit designations. You may obtain spares

from Keithley Instruments, Inc., 28775 Aurora Road,

Cleveland, OH 44139.

To place a parts order, or obtain information concerning

replacement parts, first contact the Keithley customer

service department at (216) 248-0400 X7.725. When ordering parts, include the following information:

1, Model Number

2. Serial Number

3. Part Description

4. Circuit Designation (if applicable)

5. Keithley Part Number

If an additional instruction manual is required, order the

manual package, Keithley Part Number 501-918-00. The

manual package contains an instruction manual and any

applicable addenda.

To place orders for additional AIM3A’s or for any catalog

part #, contact Sales Order Entry at 508-880-3000.

AIM3A-23

Page 24

AlM3A

Analog Input Module

Table 5. Parts List - Model SOO-AIM3A Analog Input Module

Part No.

C-365-.1 4 Cap, .luF, 20%, 5OV, Ceramic c2, c3, c4, c5

C-64IOOP

CS-521-2

CS-553 2

IC-163

xc-179 1 IC, Quad 2 Input NOR, 74LSO2 u9

IC-156

IC-203

lC-215 1

IC-267

IC-320

IC-366 1

IC-473

IC-679 1

IC-680

J-3

R-176-1.09K

R-263-1.52K 2

R-263-15.2K 2

R-263-402

R-76-1K 2

R-76-4.7K

R-76-6.8M

R-55-l .5K 2

R-55-10

R-55-152

R-55-20K 2 RES, ZOK, l%, l/BW, Metal Film Rll, R24

R-55-61.9K 1 RES, 61.9K, l%, l/SW, Metal Film R19

R-5549.5K

&ant@

1 Cap, lOOpF, lo%, lOOOV, Ceramic Cl

4 corm, strip, 10 Pin

1 IC, Quad 2 Input NAND, 74LSO0 u13

1 IC, Hex Inverter, 74LSO4 u14

1 IC, 15V OP-AMP, 305AW US

4 IC, 5 Ch CMOS Analog Multiplexer, 6108

1 IC, SPST CMOS Analog Switch, DG211 u5

1 IC, 4 Chan Diff CMOS Analog Multi, 6208

1 IC, HEX/Quad D Type Flip Flop, 74LS175

2

1 RES, l.O9K, .l%, l/SW, Metal Film

1 RES, 402, .l%, l/lOW, Metal Film

4 RES, 4.7K, 5%, 1/4W, Composition or Film

1 RES, 6.5M, 5%, 1/4W, Composition or Film

1 RES, 10.5K, l%, l/SW, Metal Film

1 RES, 152,1%, 1/5W, Metal Film

1 RES, 69.5K, l%, 1 /SW, Metal Film

Title

Corm, Test Point TPI,Ti?.

IC, Quad 2 Input Pas AND, 74LSO5 UlO

IC, 4 Bit Bistable Latch, 74LS75

IC, Programmable Gain Inst Amp, AD625JN

Jumper, Circuit

RBS, 1.82K, .l%, l/lOW, MetalFilm

RBS, 15.2K, .l%, l/lOW, Metal Film

RES, lK, 5%, 1/4W, Composition or Fiirn

RES, 1.5K, l%, 1/5W, Metal Film

Designation

Jl, J2, J3,J4

Ul, u2, u3, u4

Ull

U6

u7

u12

WI, w2

R29

R13, R18

R12, R22

R14

=J,u

R7, RS, R9, RlO

R23

R25, R26

R16

R20

R15

RI-89-10K

RP-89-200

SO-65

TF-177-l

500-323

500-321

500-322

500-322

6-32X1 /ZPI’H

501-915-00

AIM3A-24

2 POT, lOK, lo%, .75W, Non-Wirewound R27, R28

2 POT, 200,10%, .75W, Non-Wirewound R17, R21

6 16-Pin Socket

RES Network, lK, 2%, 2.25W

Cable Clamp Assy

Cable Clamp

Strip Rubber

Strip Rubber

Screw

Manual Package

JS...JlO

Rl, R2, R3, R4

Page 25

Page 26

4.7K UlOA

R13

1.82K

R25

1.5K

TP1

TP2

J2

R12

18.2K

Rll

20K

R26

J12

R29

i

r~ - !

1090

u13c

,-?&A

U9D

U14D

,olD*

- - MO.

EC0 REV

C AIM3A 501-226 lllSL(2 C

Page 27

Page 28

Loading...

Loading...