Page 1

COMMITTED

TO

EXCELLENCE

Tektronix, Inc.

P.O. Box

Beaverton, Oregon

070-2958-00

Product Group 75

500

97077

PLEASE CHECK FOR CHANGE INFORMATION

AT THE REAR OF

INSTRUCTICIN

THIS MANUAL.

MANUAL

Serial

Number

First Printing AUG 1980

Revised

NOV

1981

Scans

by

ARTEK

MEDIA

=>

Page 2

Scans

Arfek

1042

Plummer

Rochester,

Media

Cir.

MN

55902

SW

"High

If

your

looking

our

ma~ilals@arlekmedia.com

manuals

If

still

would

reasonably

Typically the

If

ArtekMedia)

"friend"

"share

appreciated

reproduce,

this

mailed

WEB

you

don't

be

able

like

I)

Typed

2)

Photo

3)

Schematic

dpi unless

some

you

purchased

ware".

manual.

to

site

we

have

see

to

scanned

in consideration

scans

text

pages

70's

thank

for

free

in

book,

Donations

us

the

resolution

for

a

quality

at

www.artekmedia.com

available.

the

manual

point

you

please

in

our

pages

diagram

the

vintage

we

By

that

are

are

typically

original

this

manual

you

very

would appreciate

we

recognition

link

etc.),

via

address

to

manuals

pages

TeMronix

of

above.

scans

scanned

and

we

will

you

need

other

sources.

write

for

adding

are

typically

scanned

are

manual

manuals).

from

much.

mean

the

energy

PayPal

a

time

and

of

obsolete

technical

be

happy

on

the

If

for

details,

your manual

done

as

scanned

in

gray

typiwlly

had

colored

us

(typically

If

you

received

your

treating

donation

(a

manual

qualrty

go

rnanuals~~i~l~corn

to:

-.

technical

manual

or

drop

to

email

tist

drop

you

have

This

to

follows;

in

black

scale

scanned

high

through

of

at

least

can

take

of

effort

-

-

manuals"

in

PDF

you

us

a

an

can

often

our

library.

and

white

mode

in

b

tack and

lighting

this

from

this

much

$5-10

as

that

7-

format

us

a

current

tine

existing manual

at

600

(as

our

much

went

-

please visit

an

email

list

of

anyway

be

at

is

Ebay

a

like

per

as

into preserving

we

done

300

dpi.

dpi

white

the

at

case

name

well-meaning

you

would

manual

40

hours

or

can

at

the

may

you

very

600

for

of

is

to

be

T

anks

Dave 8 Lynn

Artek

Media

Henderson

Page 3

Copyright @ 1980

Contents of this publication may not be reproduced in any

form without the written permission of Tektronix, Inc.

Products of Tektronix. Inc. and

by U.S. and foreign patents and/or pending patents.

TEKTRONIX. TEK. SCOPE-MOBILE, and

istered trademarks of Tektronix. Inc.

Printed in U.S.A. Specification and price change privileges

are reserved.

Tektronix. Inc. All rights reserved.

itssubsidiariesarecovered

@

are reg-

O

1980

Copyright

halten. Der lnnalt dieser Publikation darf ohne Genehmlgung

von Tektronix, Inc. nicht weitergegeben werden.

Produkte von Tektronix, Inc. und seinen Tochtergesellschaften

sind durch US- und Auslandspatente

Patente abgedeckt.

TEKTRONIX, TEK. SCOPE-MOBILE und

Warenzeichen von Tektronix, Inc.

Gedruckt in U.S.A. Spezifikations- und

bleiben vorbehalten.

durch Tektronix, Inc. Alle Rechte vorbe-

undloder schwebende

@

sind geschlltzte

PreisBnderungen

Copyright

Le contenu de ce manuel ne peut etre reproduit sous quelque tor-

me

Tous les produits TEKTRONlX sont brevetes

les logotypes TEKTRONI X, TEK SCOPE MOBILE.

dews&.

lmprimb aux USA. TEKTRONIX se reserve le droit de modif~er

caracteristiques et prlx dans le cadre de developpements technologiques.

O

1980

TEKTRONIX INC. Tous droits reserves.

que ce soit sans I'accord de Tektron~x Inc.

US

et Etranger et

'@

01980

R12-79

:

$Kkt8ifi?7-7-

TEKTRONIX, TEK, SCOPE-MOBILE.

t-

~=9i+iaffti%~~f.

%m

11

~p~lj,

eh.8,

'I

3

7-

9

t-

f*+$~

~rdfita,~

q

=

9

x+I,,

T~W,

7~

(

~~76

3%

Scans

by

ARTEK

MEDLA

=>

Page 4

TABLE OF CONTENTS

Page

LlST OF ILLUSTRATIONS

LIST OF TABLES v

OPERATOR'S SAFETY SUMMARY vi

SERVICE SAFETY SUMMARY vii

Section

Section

I

SPECIFICATION

Instrument Description

Performance Conditions 1-1

Electrical Characteristics

Environmental Characteristics 1-7

Physical Characteristics 1-8

English Version

2

OPERATING INSTRUCTIONS

Preparation for Use 2-1

Repackaging Information 2-1

Controls. Connectors. and Indicators 2-2

Instrument Connections

Level Measurements

Distortion Measurements

Distortion Measurement Procedure

IM Distortion Measurements

(Option 01)

IM Distortion Measurement Procedure

(Option 01) 2-1 1

Filters

Displays

Monitoring

..................

..................

......................

....................

...................

..........

.........

.........

..........

..............

............

........

.........

............

........

.

1-1

1-2

2-4

2-5

2-6

2-7

2-9

2-11

2-12

2-13

Page

i

v

CHAPITRE 2 INSTRUCTIONS D'UTILISATION

Kapitel2 BEDIENUNGSANLEITUNG 2.1

French Version

Instructions de reemballage pour

expedition

Cornmandes. connecteurs

lumineux

Connexions de I'appareil

Mesures de distorsion

MBthode de rnesure de distorsion

Mesures de distorsion d'intermodula-

tion (option

MBthode de rnesure de la distorsion

par interrnodulation (option

Filtres

Affichages

ContrBle

German Version

................

et

temoins

................

........

..........

01)

............

01)

....................

..................

..................

2-1

2-2

2-4

2-6

.

.

2-8

2-9

.

.

2-1

2-11

2-13

2-13

...........

lnbetriebnahme 2-1

Verpackung des Gerates

Bedienungselernente. Anschliisse

und Anzeigen

Anschlusse an das Instrument

Pegelmessungen

Verzerrungsmessungen

Durchfuhrung der

Verzerrungsmessung 2-7

......................

.............

........................

.......

.....................

..............

................

2-1

2-2

2-4

2-5

2-6

1

lnterrnodulationsverzerrungs-

Messung (Option 01) 2-9

Messung von Interrnodulations-

verzerrungen (Durchfijhrung) 2-11

.................................

Filter 2-11

Darstellungen 2-12

~berwachung 2-13

........................

........................

................

........

REV

NOV

1981

Scans

by

ARTEK

MEDLQ

=>

Page 5

TABLE

Japanese Version Page

OF

CONTENTS

Section

4

CALIBRATION

(cont)

Page

THE FOLLOWING SERVICING INSTRUCTIONS ARE

.

FOR USE BY QUALIFIED PERSONNEL ONLY

PERSONAL INJURY.

VICING OTHER THAN THAT CONTAINED IN

OPERATING INSTRUCTIONS UNLESS YOU ARE

QUALIFIED TO DO SO

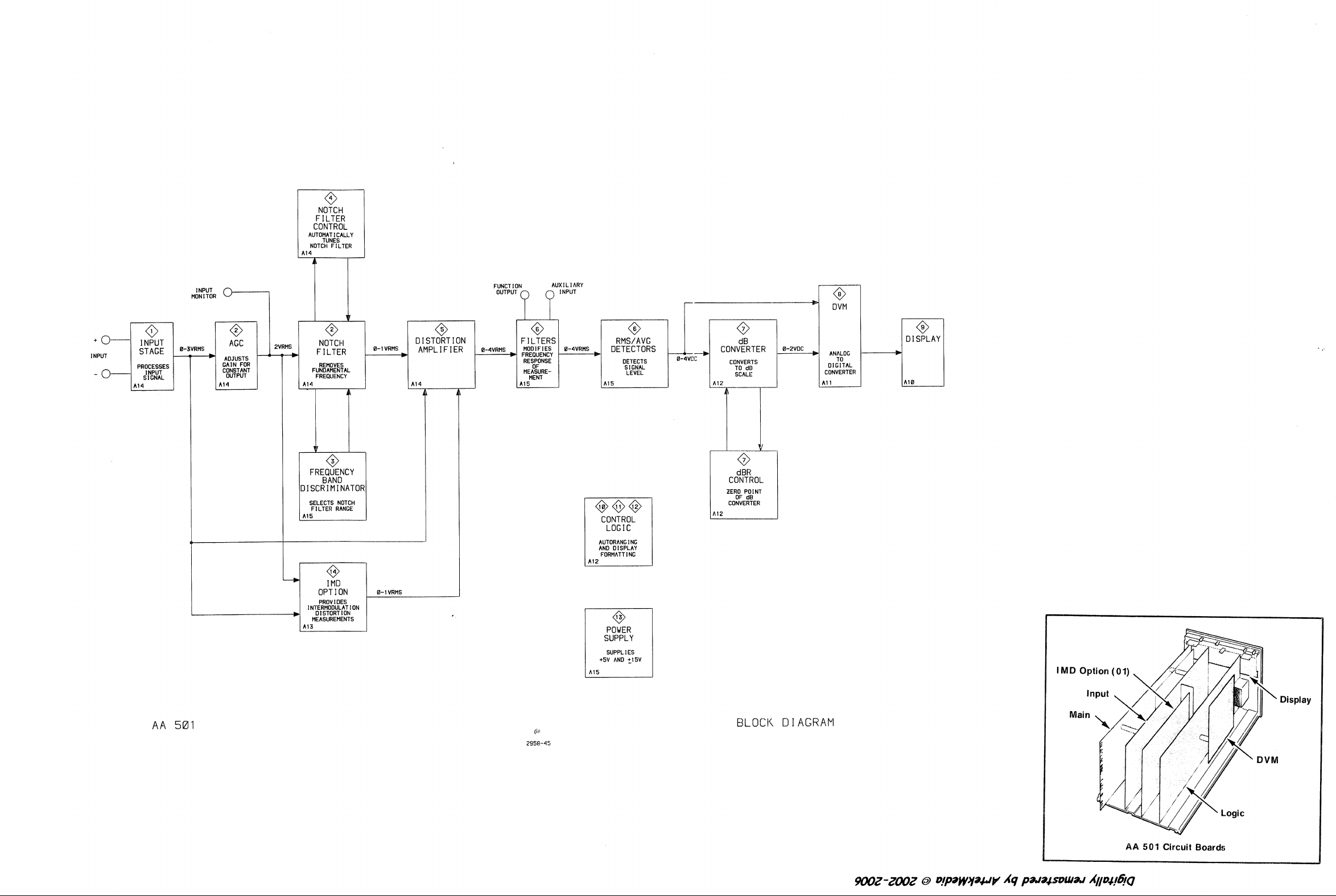

Section 3 THEORY OF OPERATION

Introduction

Input Amplifier

Automatic Gain Control

Notch Filter

Frequency Band Discriminator

Notch Filter Control

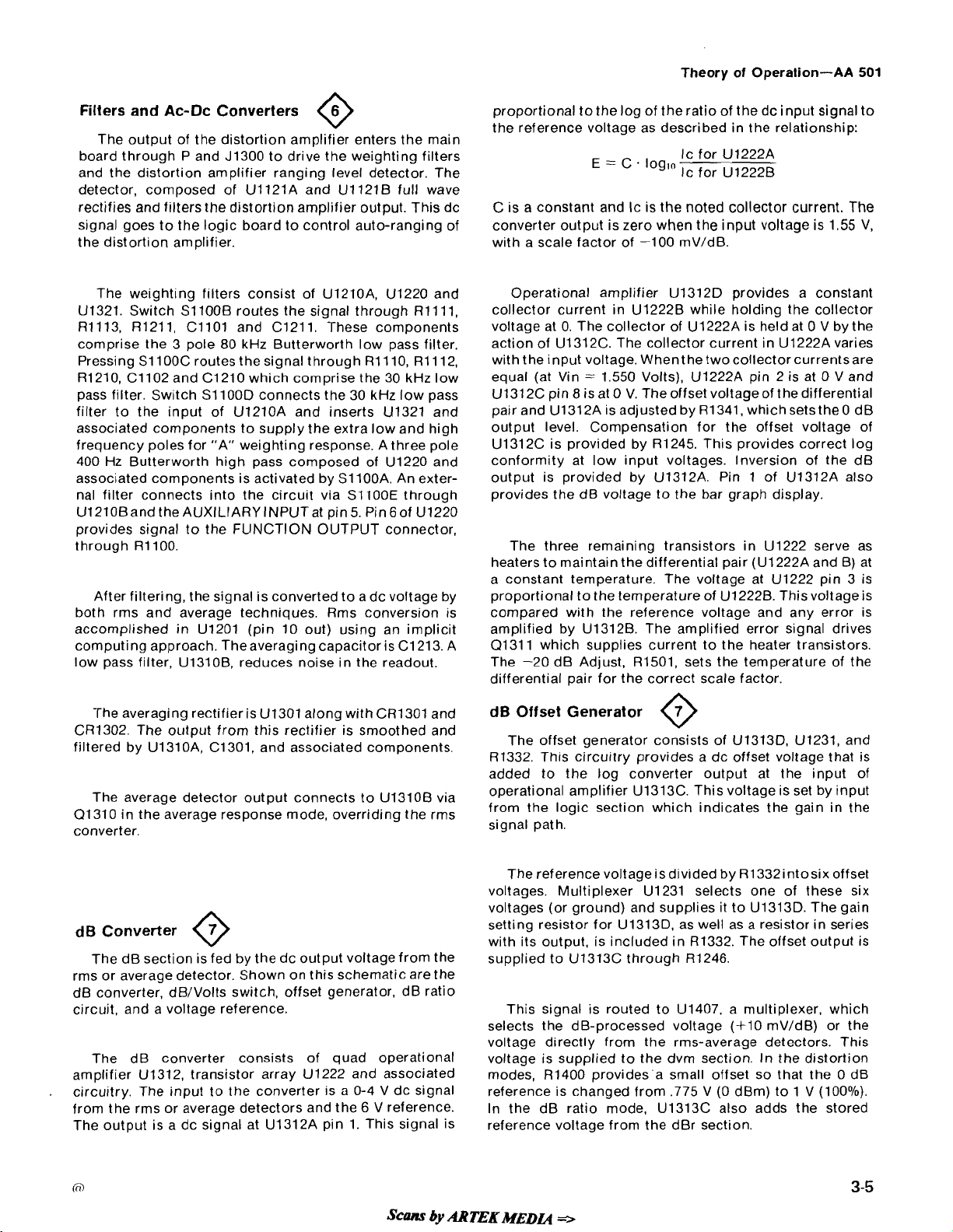

Distortion Amplifier

Filters and AC-DC Converters

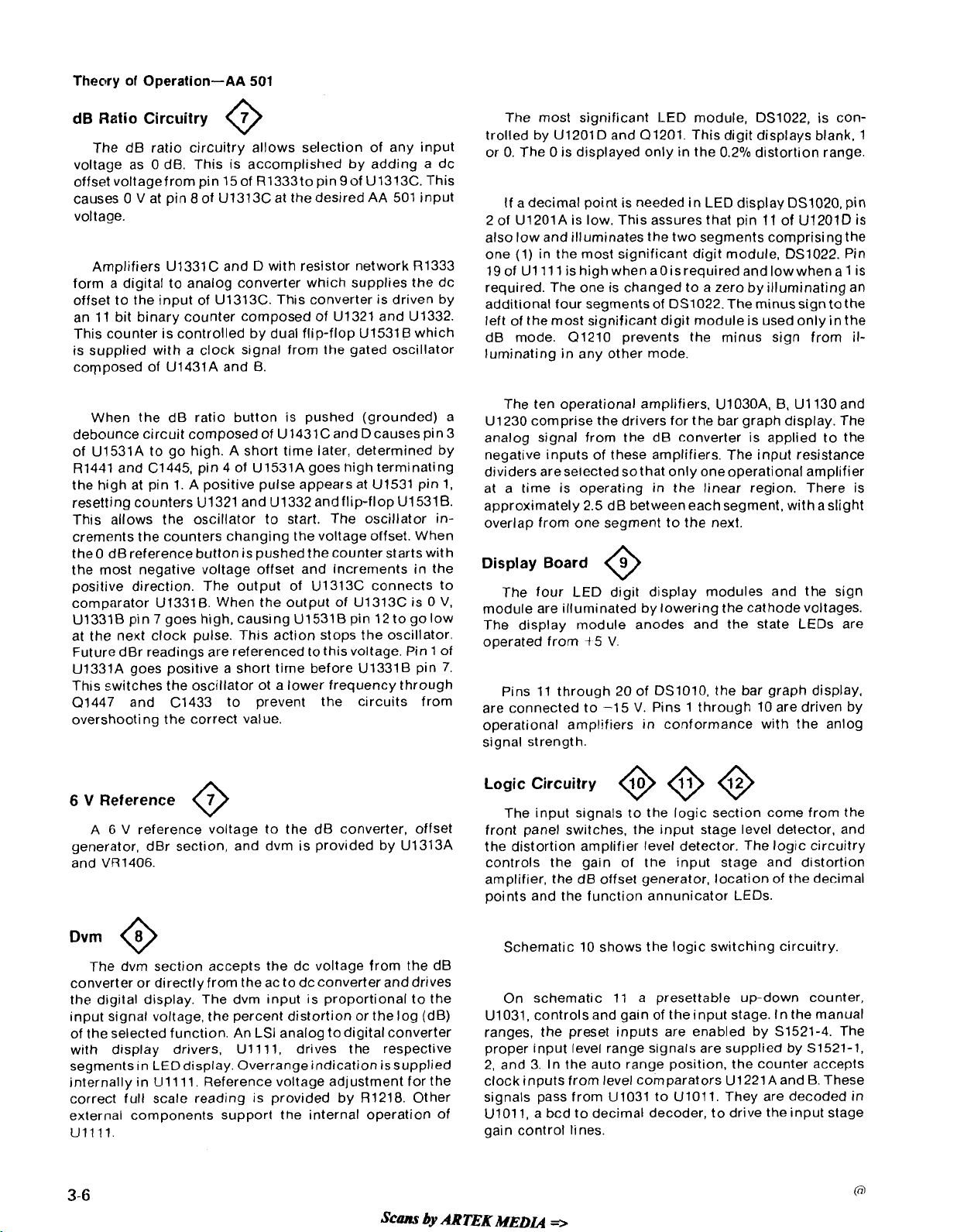

dB

Converter

dB Offset Generator

dB Ratio Circuitry

6

V

Reference

Dvm

Display Board

Logic Circuitry

Power Supplies

..

15 V Supply

IM

option

@

DO

NOT PERFORM ANY SER-

.

..................

0

a

.............

v

$$

6

@

@

...........

...

@

............

.........

...............

.............

TOAVOID

......

....

:

:

:

...

@

........

......

........

:

3-1

3-1

3-2

3-2

Performance Check Procedure

Introduction

Test Equipment Required

List of Check and Adjustment Steps

Performance Check Summary

Sheet 4-4

Internal Adjustment Procedure

Introduction

Services Available

Test Equipment Required

Adjustment Access

Section 5 MAINTENANCE

General Maintenance Information

Static-Sensitive Components

Cleaning

Obtaining Replacement Parts

Soldering Techniques

Semiconductors

Interconnecting Pins

Coaxial Cables

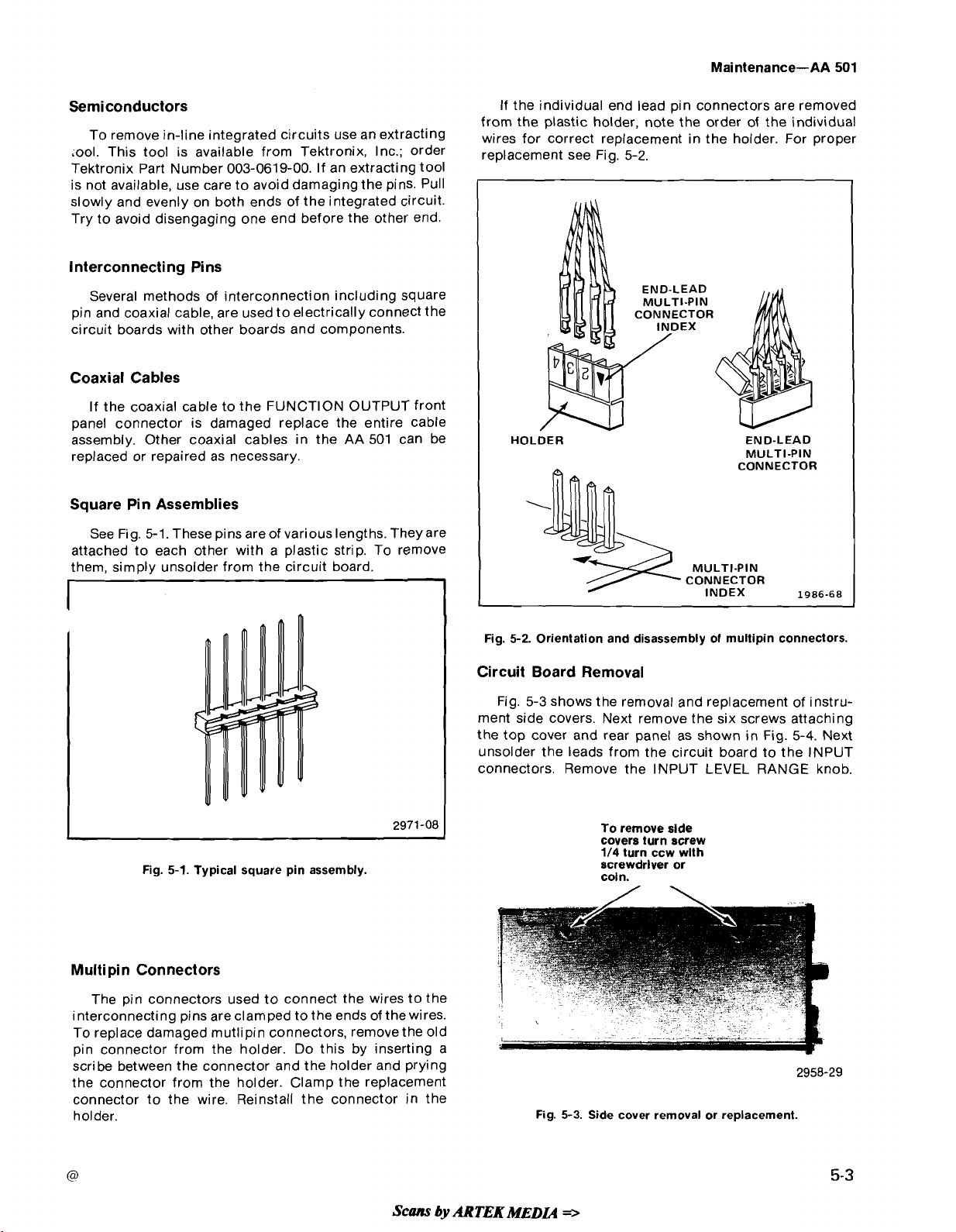

Square Pin Assemblies

Multipin Connectors

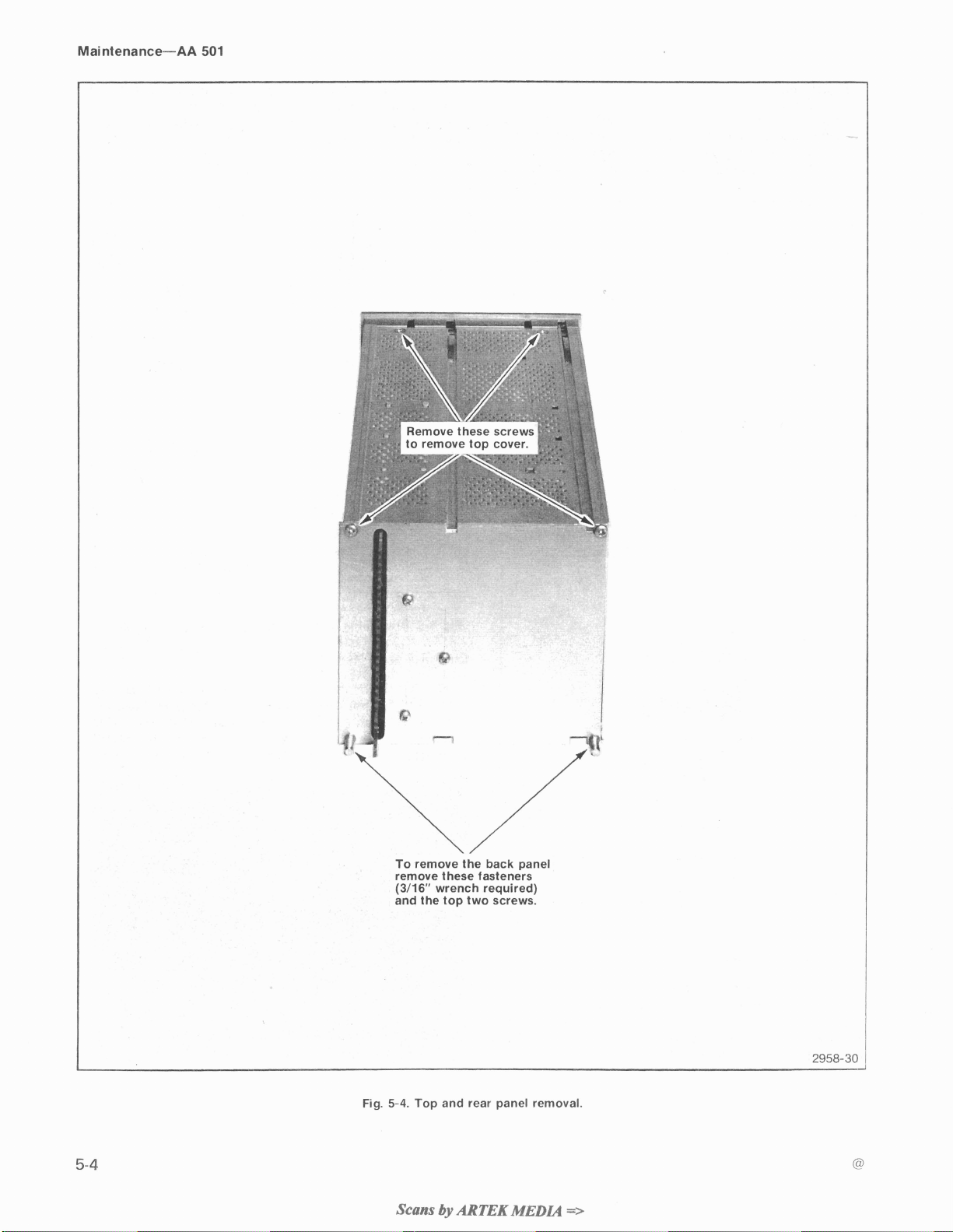

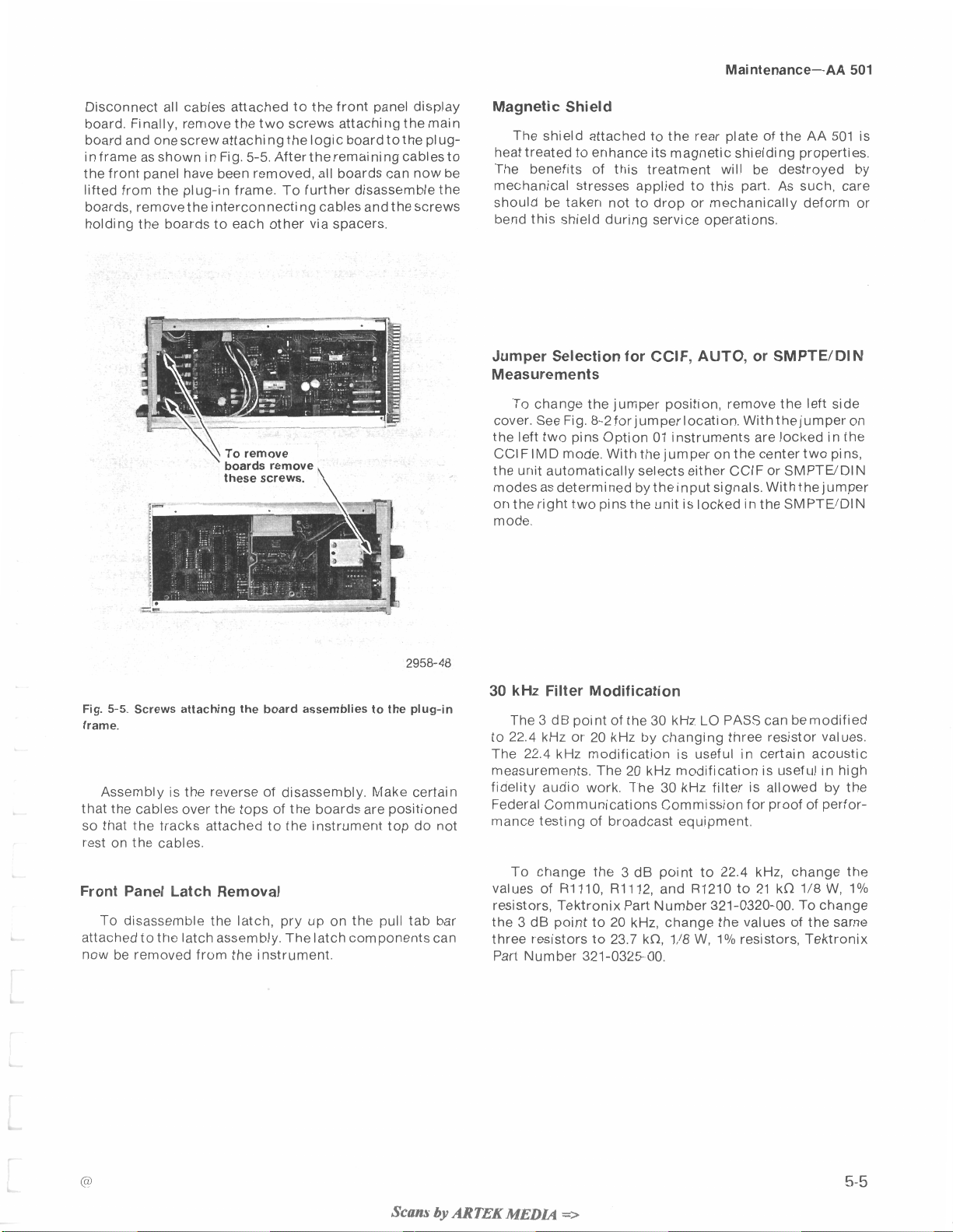

Circuit Board Removal

Front Panel Latch Removal

Magnetic Shield

Jumper Selection for CCIF. AUTO.

or

30 kHz Filter Modification

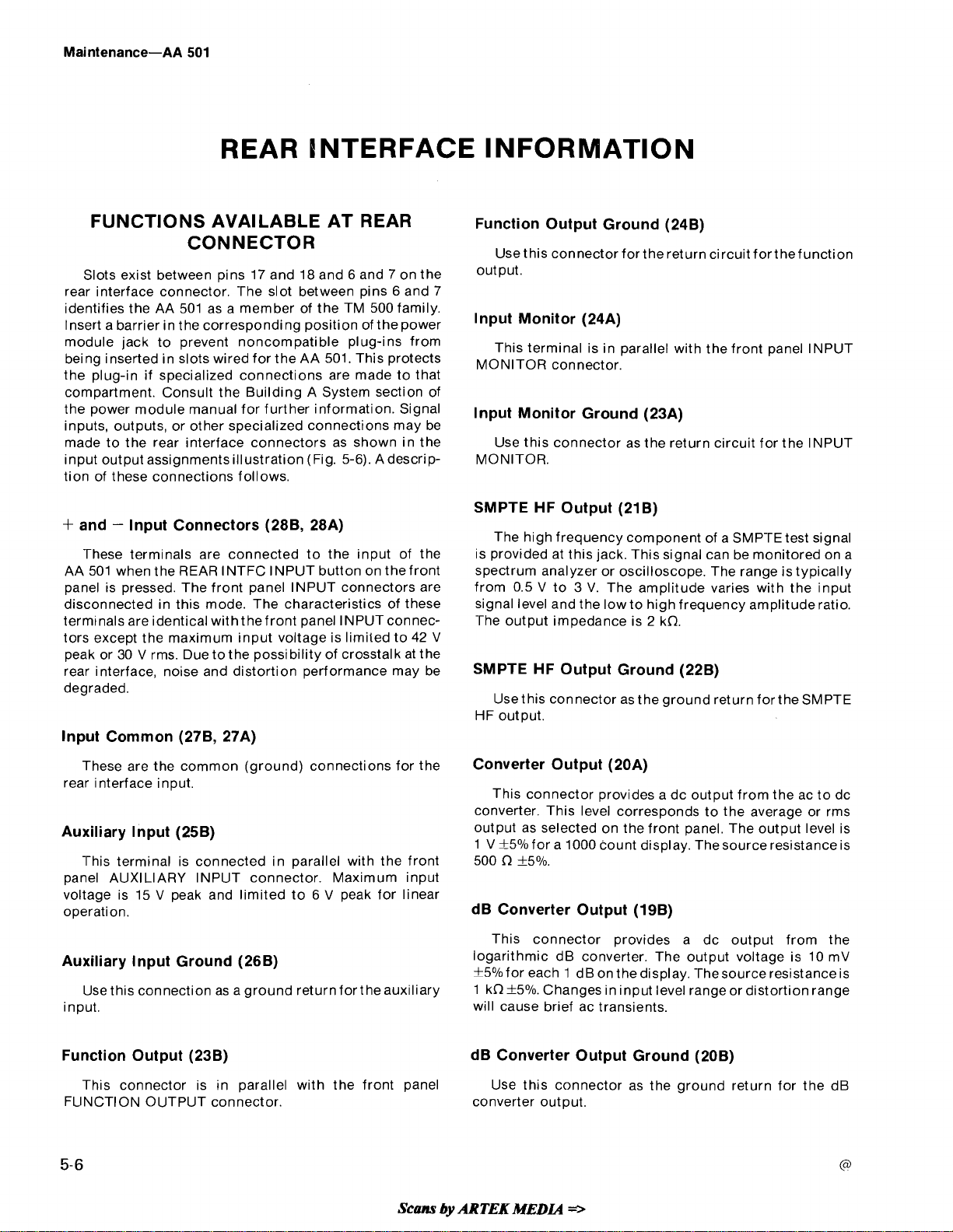

Rear Interface Information

Functions Available at Rear

Connector

Section 6 OPTIONS

7

Section

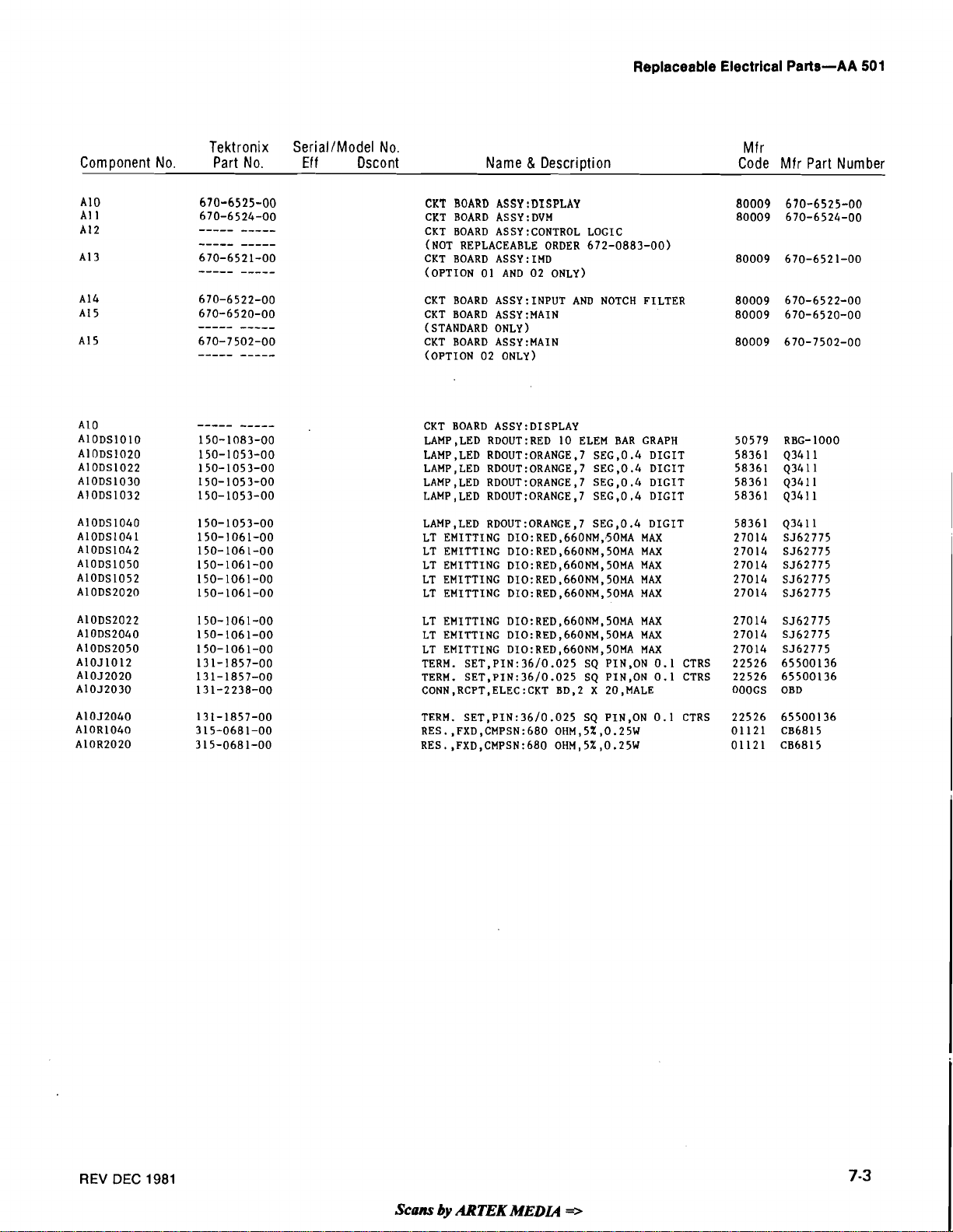

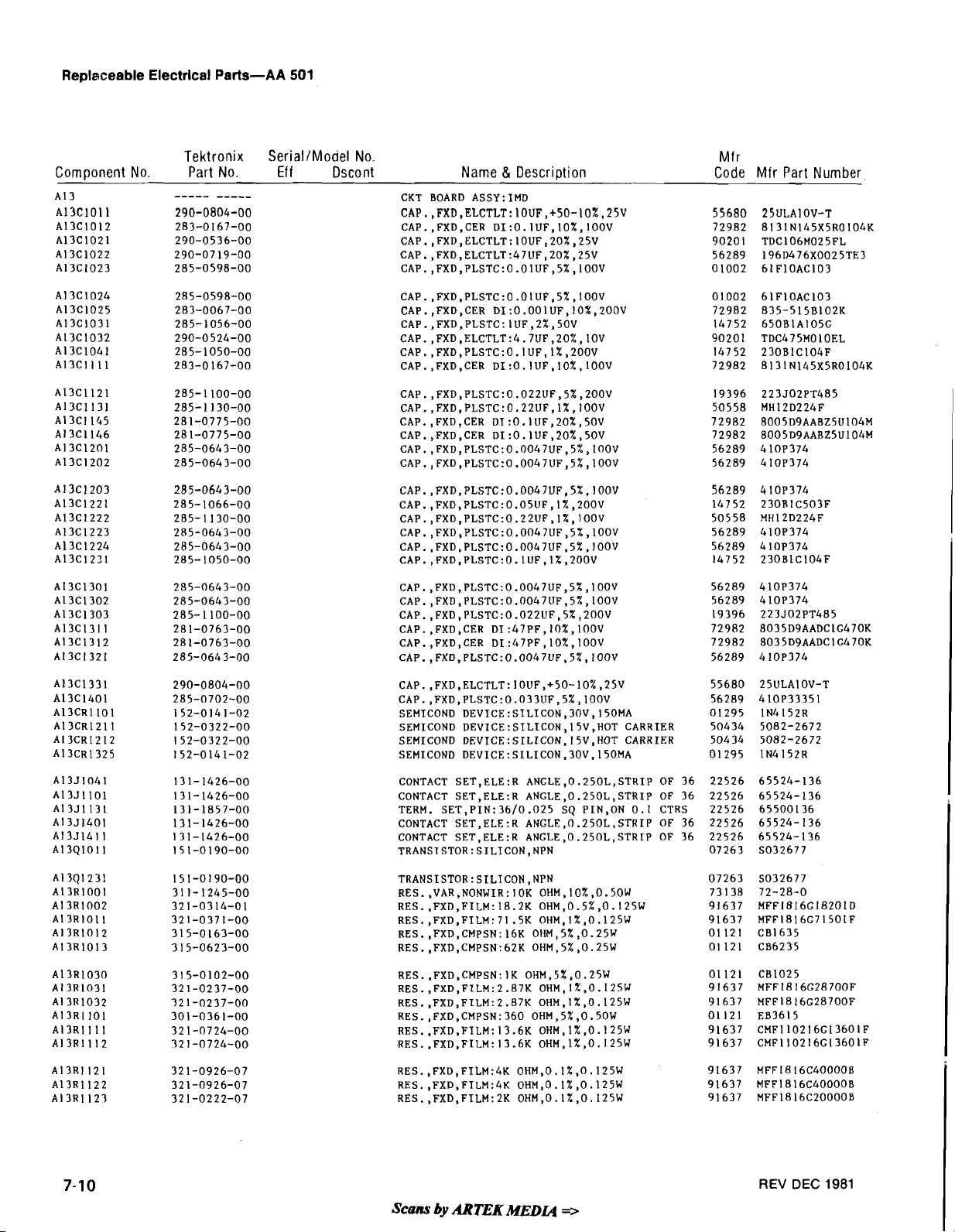

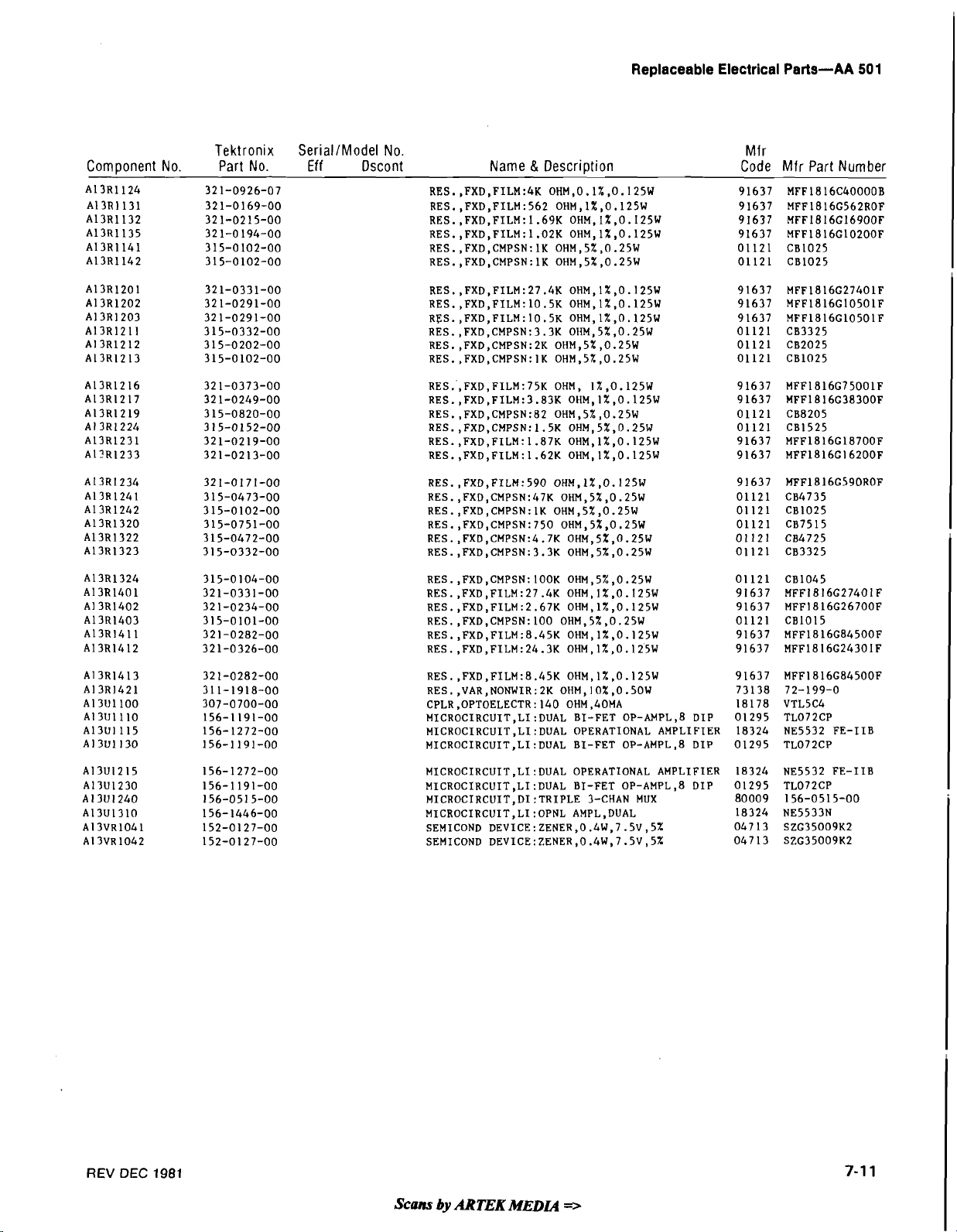

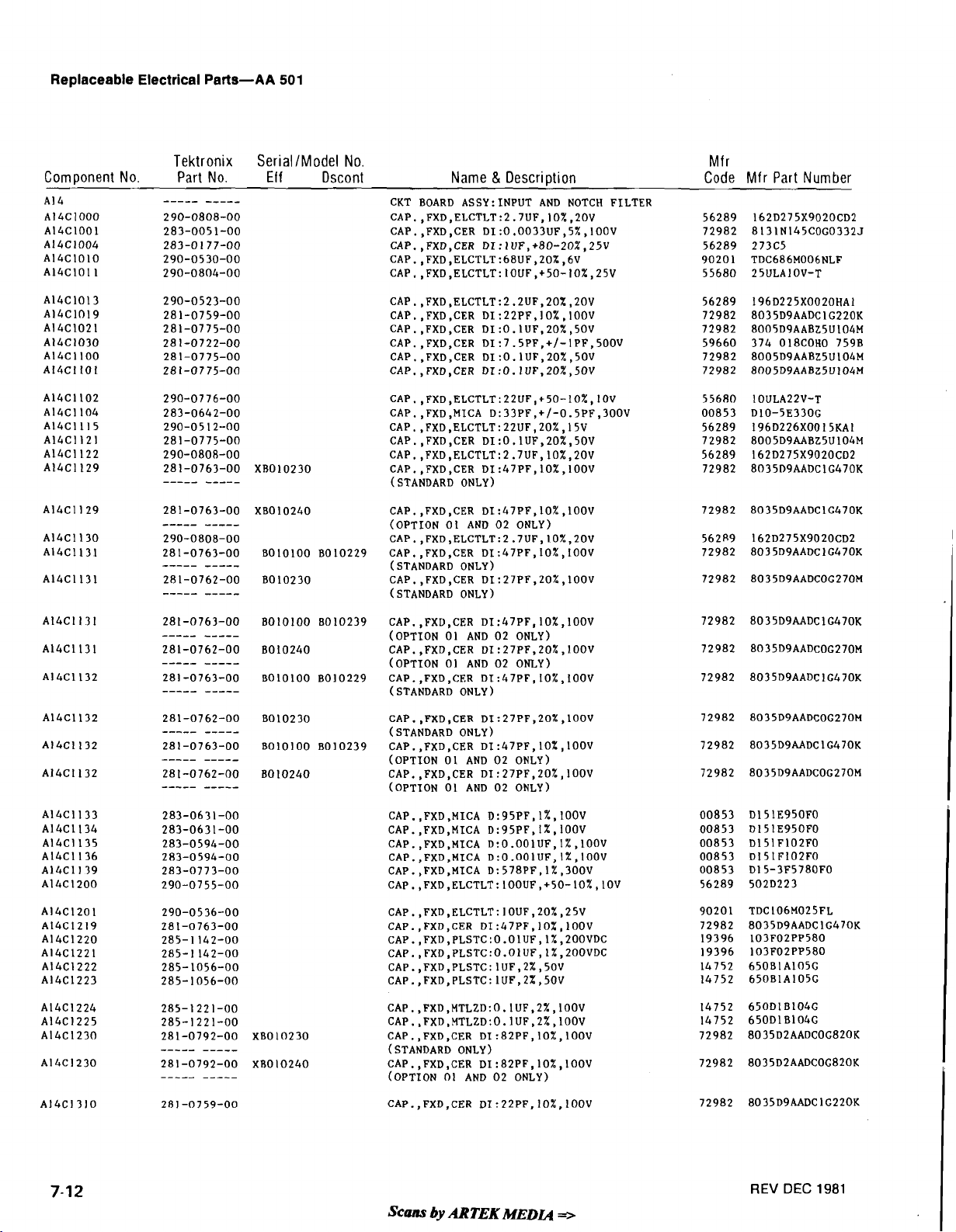

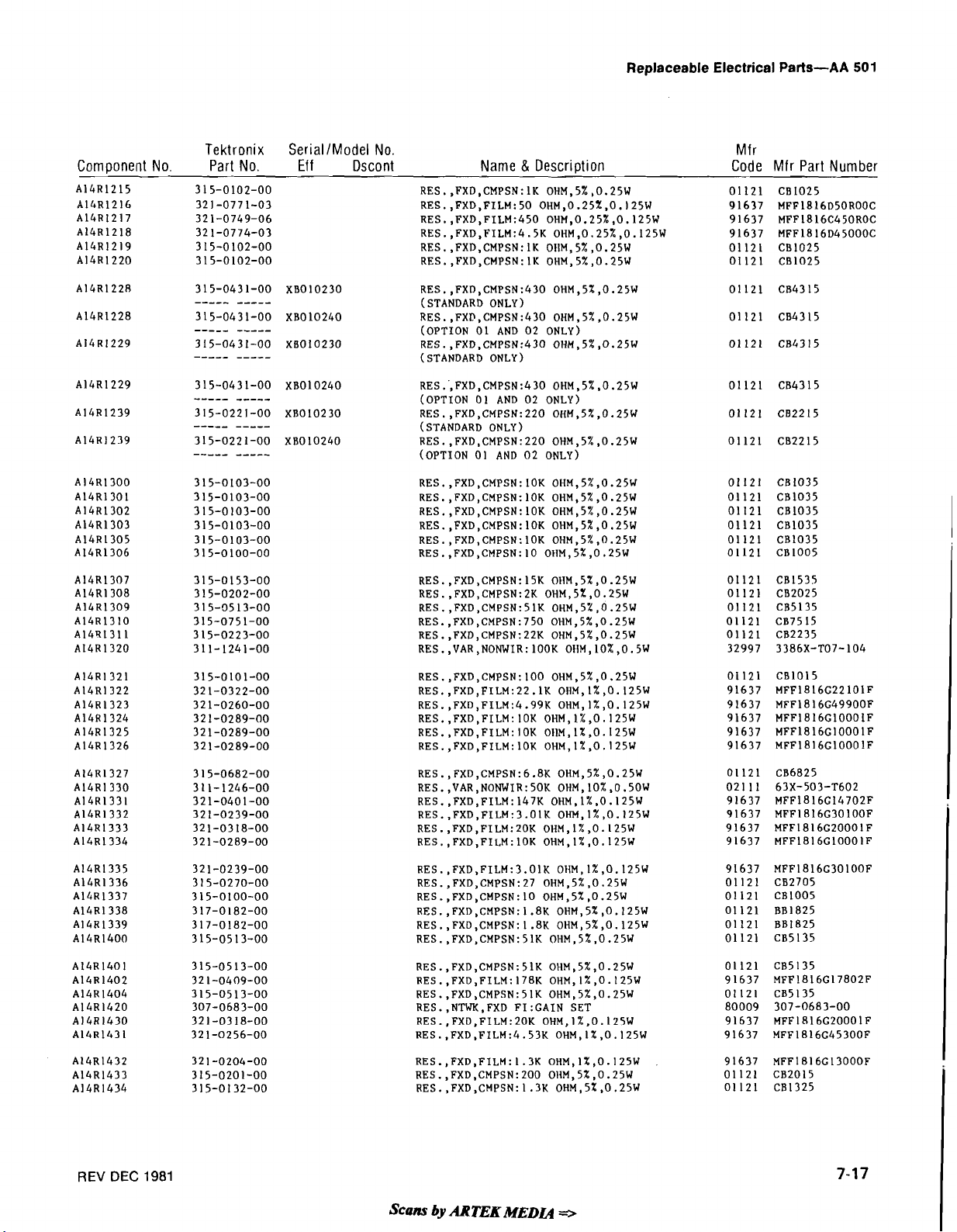

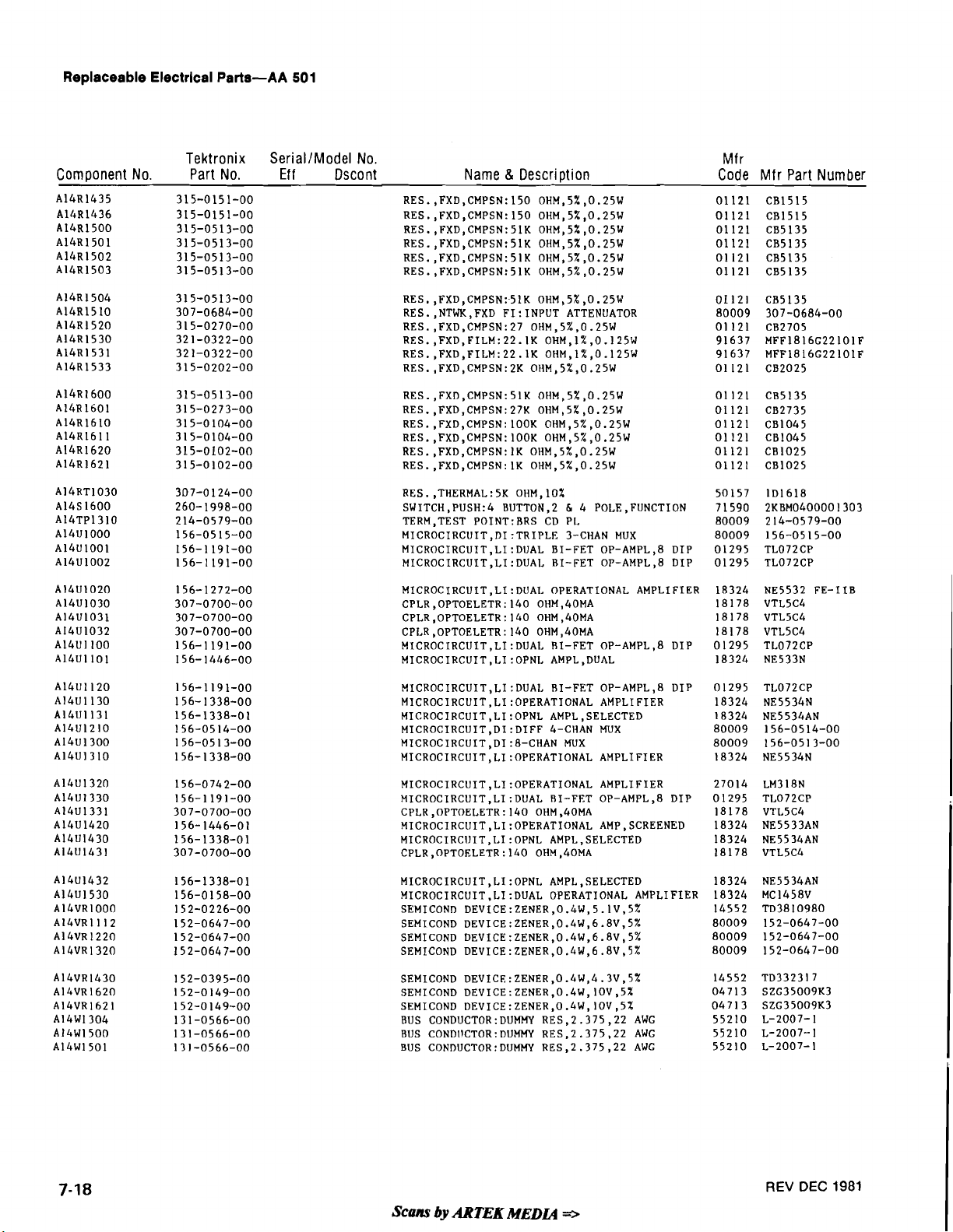

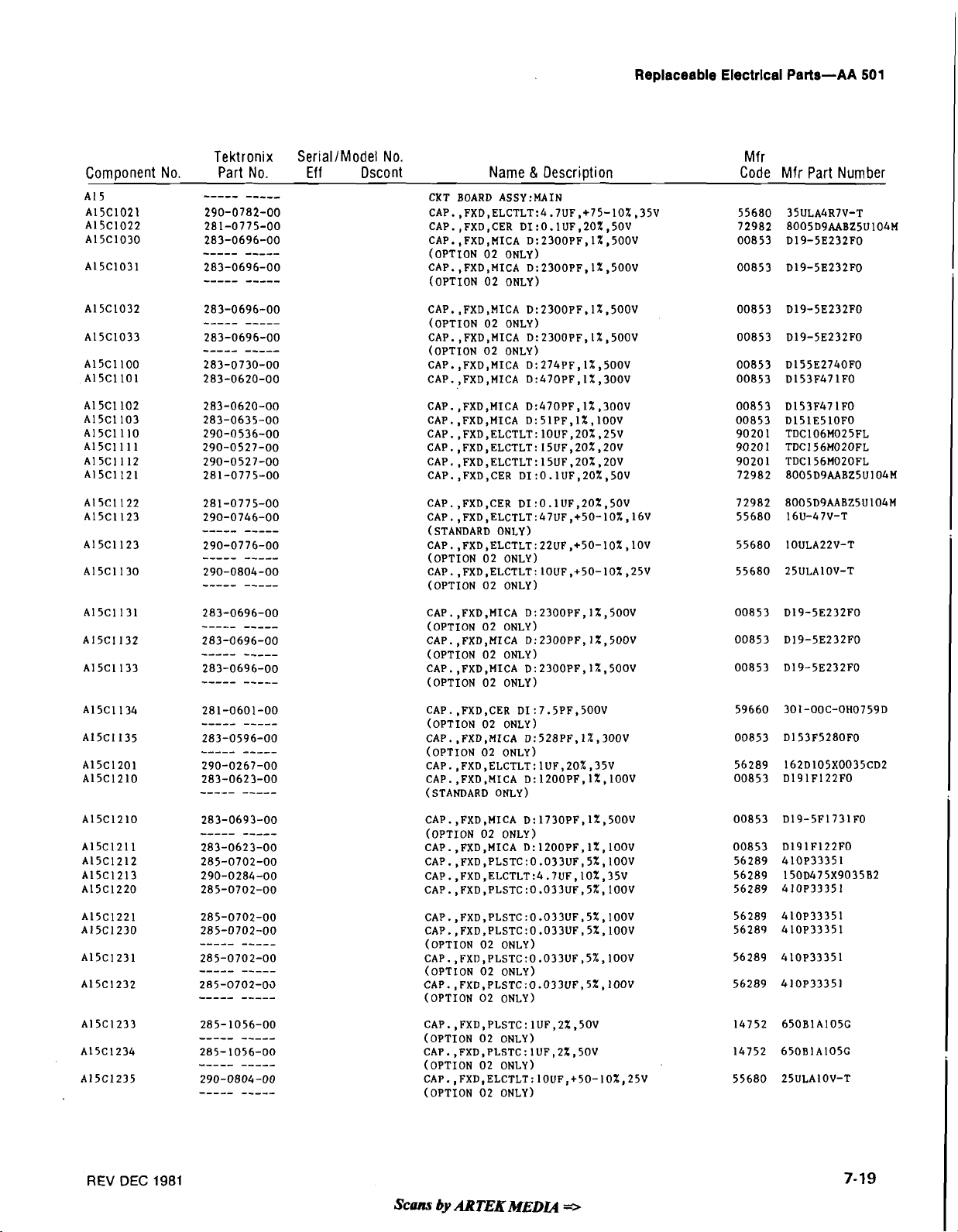

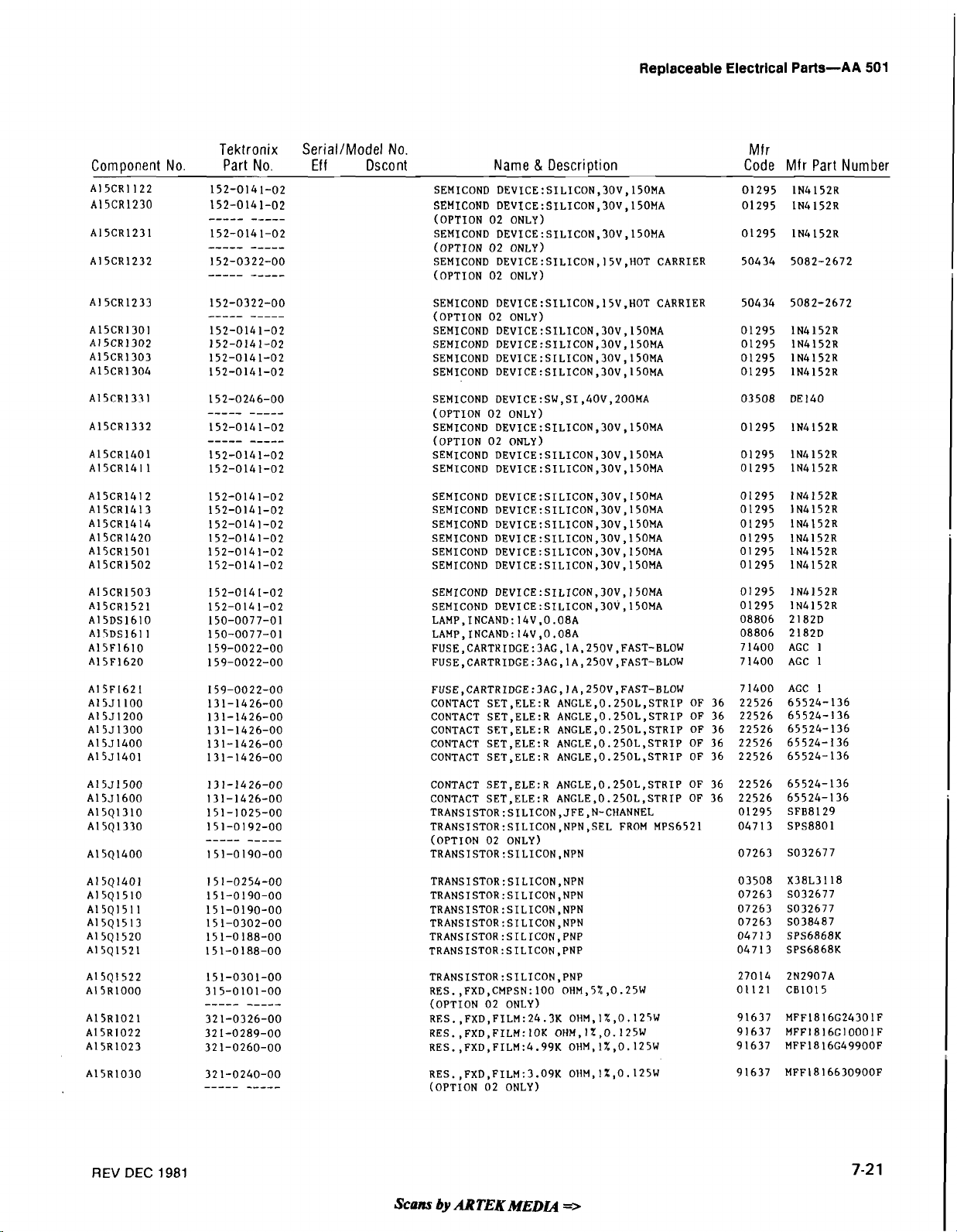

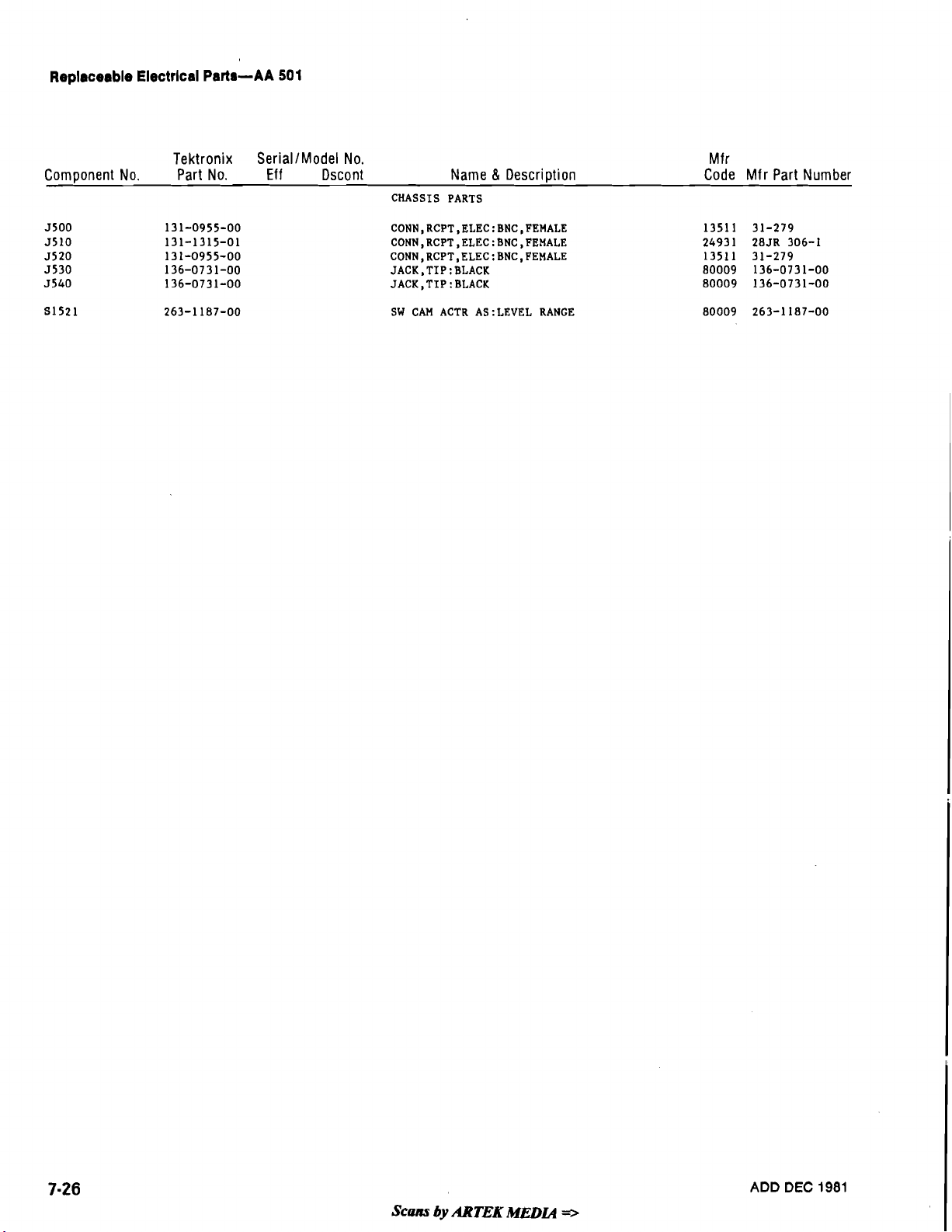

REPLACEABLE ELECTRICAL PARTS

....................

..................

SMPTWDIN Measurements

....

................

......

....

................

...........

......

...........

. .

....

...

.........

.............

..........

..............

........

..........

........

.....

.............

...

......

.......

.................

4-1

4-1

4-1

4-3

4-18

4-18

4-18

4-18

4-18

Scam

by

ARTEK

MEm

+

REV

JUL

1981

Page 6

TABLE

OF CONTENTS

(cont)

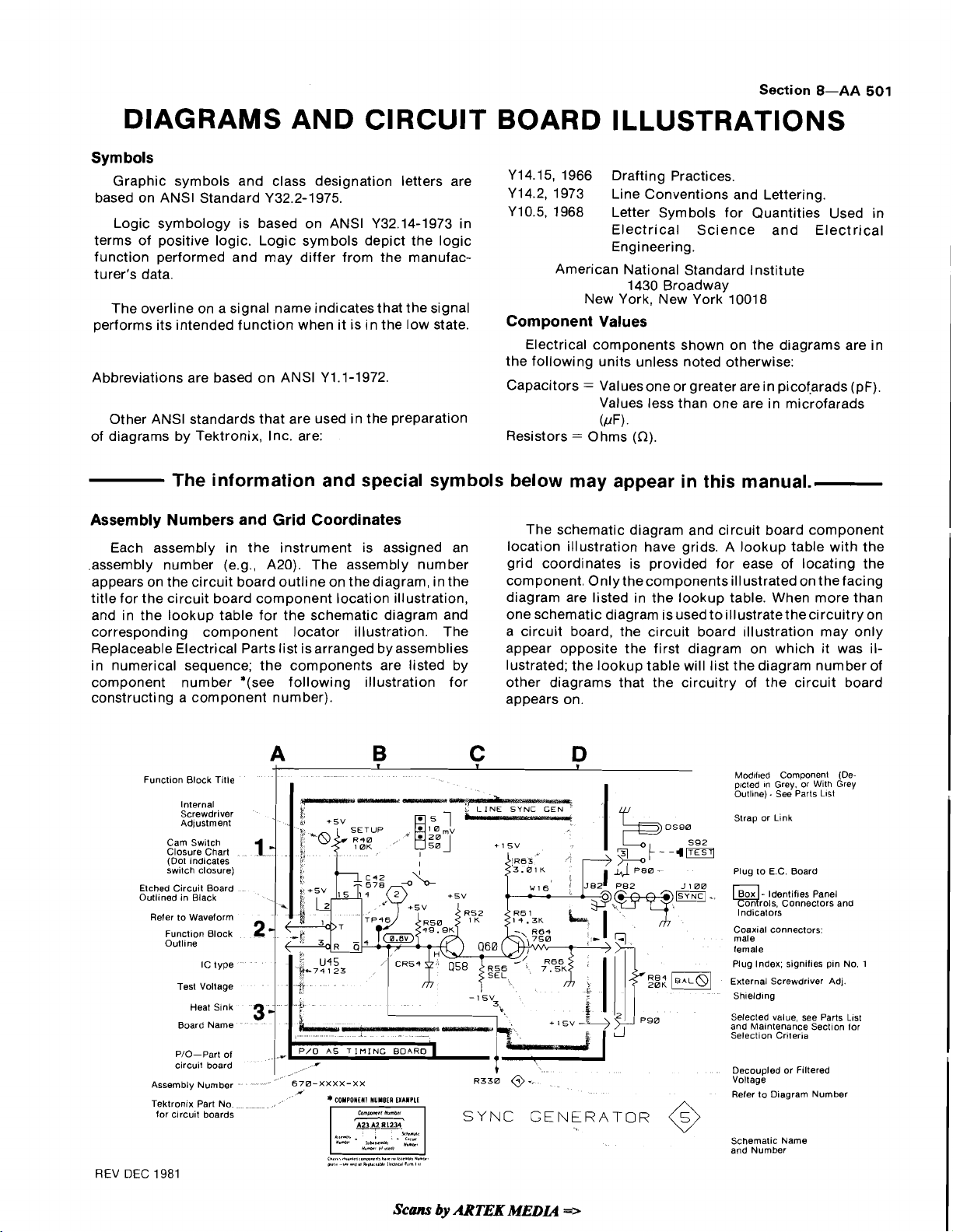

Section 8 DIAGRAMS AND CIRCUIT BOARD

ILLUSTRATIONS

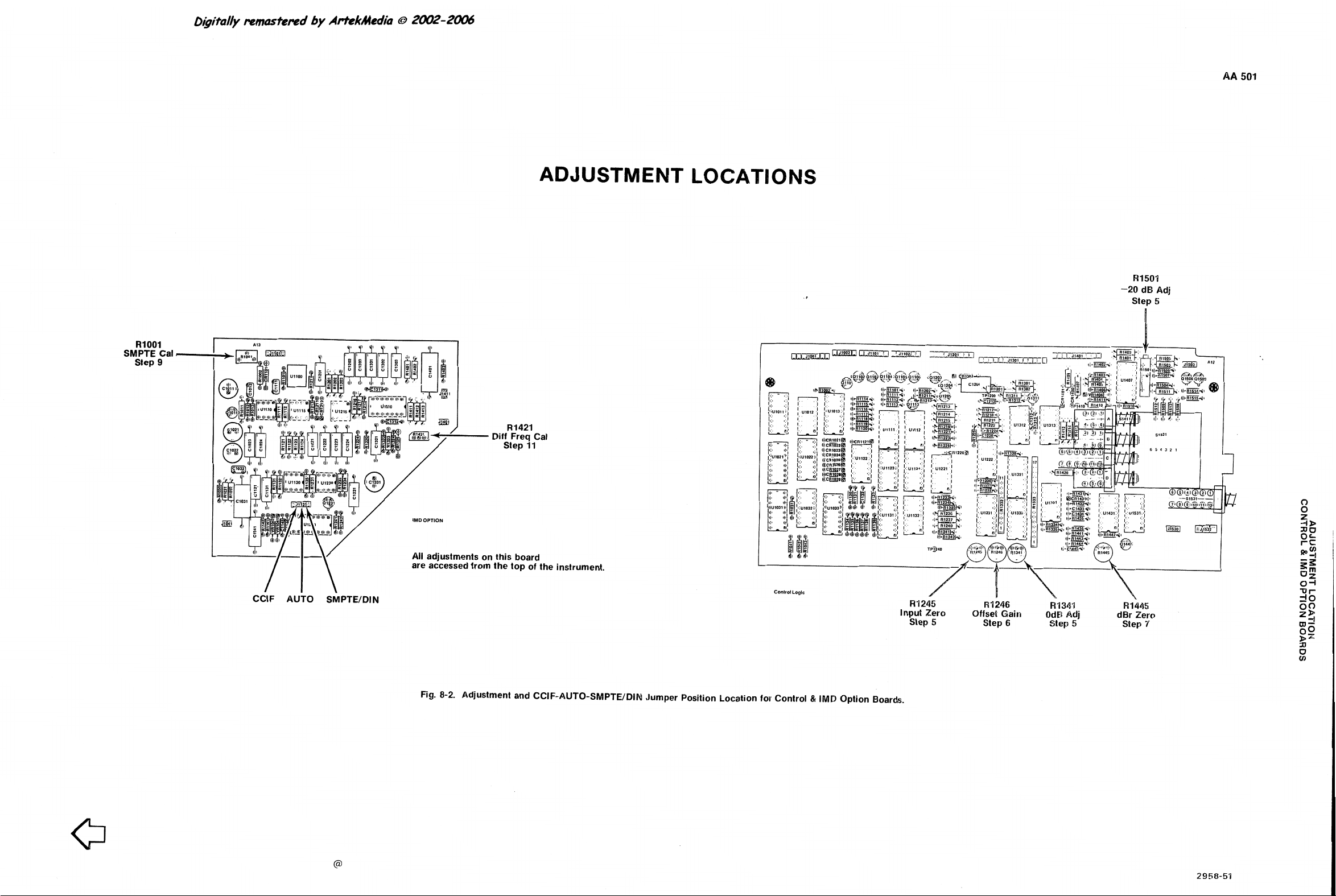

Adjustment Locations

Component Reference Charts

Schematic Diagrams

Section 9 REPLACEABLE MECHANICAL

PARTS

Fig. 1 Exploded View

Accessories

CHANGE INFORMATION

iii

Page 7

LIST

OF

ILLUSTRATIONS

Fig.

No.

AA

501 Distortion Analyzer

2-1 Installation and removal

2-2

Front panel controls and connectors

2-3 Typical connections for distortion

measurements. See text

2-4 Block diagram of a basic harmonicdistortion

analyzer

2-5 Transfer characteristics of an audio device

THD test of transfer characteristics

2-6

2-7 Block diagram of a basic IM analyzer

IM test of transfer characteristics in time and

2-8

frequency domain.

Response curves for AA 501 filters

2-9

2- 10 Oscilloscope display of deviation from

linearity

Simplified notch filter and control loop

3-1

3-2 Typical frequency discriminator waveforms

at about 800 Hz

3-3 lntermodulation distortion option block

diagram

4-1 Check step 1. Input impedance

4-2 Check step

4-3 Check step

4-4 Check step 4. Bandwidth

4-5 Check step

4-6 Check steps 6,9,10,11 and adjustment steps

9,

CClF distortion and CClF residual

distortion

Check step

4-7

.........................

.................

......................

...................

.........................

2.

Common mode rejection

3.

Level function accuracy

5.

Residual noise

10, and 11. Total harmonic, SMPTE and

........................

7.

Residual THD

...........

.............

....

.............

.....

....

......

.

........

. .

...

.............

..........

IM

tN

........

Page Fig.

N

0.

i

x

2- 1 residual intermodulation distortion

2-3 4-9 Check step

2-5

2-7 4-12 Check step 14. Function output

2- 7 4-13 Check step 15. Auxiliary input

2-8 4-14 Adjustment test setup for steps 1 and 2

2-9 4-15 Adjustment test setup for steps 3, 4.5,6. and

2-10 5-1 Typical square pin assembly

Check step

4-8

Alternate CClF IM distortion accuracy

4-10 Check step 12. Filter accuracy

4-11 Check step 13. lnput monitor.

..............................

7

Orientation and disassembly of multipin

connectors

Side cover removal or replacement

Top and rear panel removal

Screws attaching the board assemblies tothe

plug-in frame

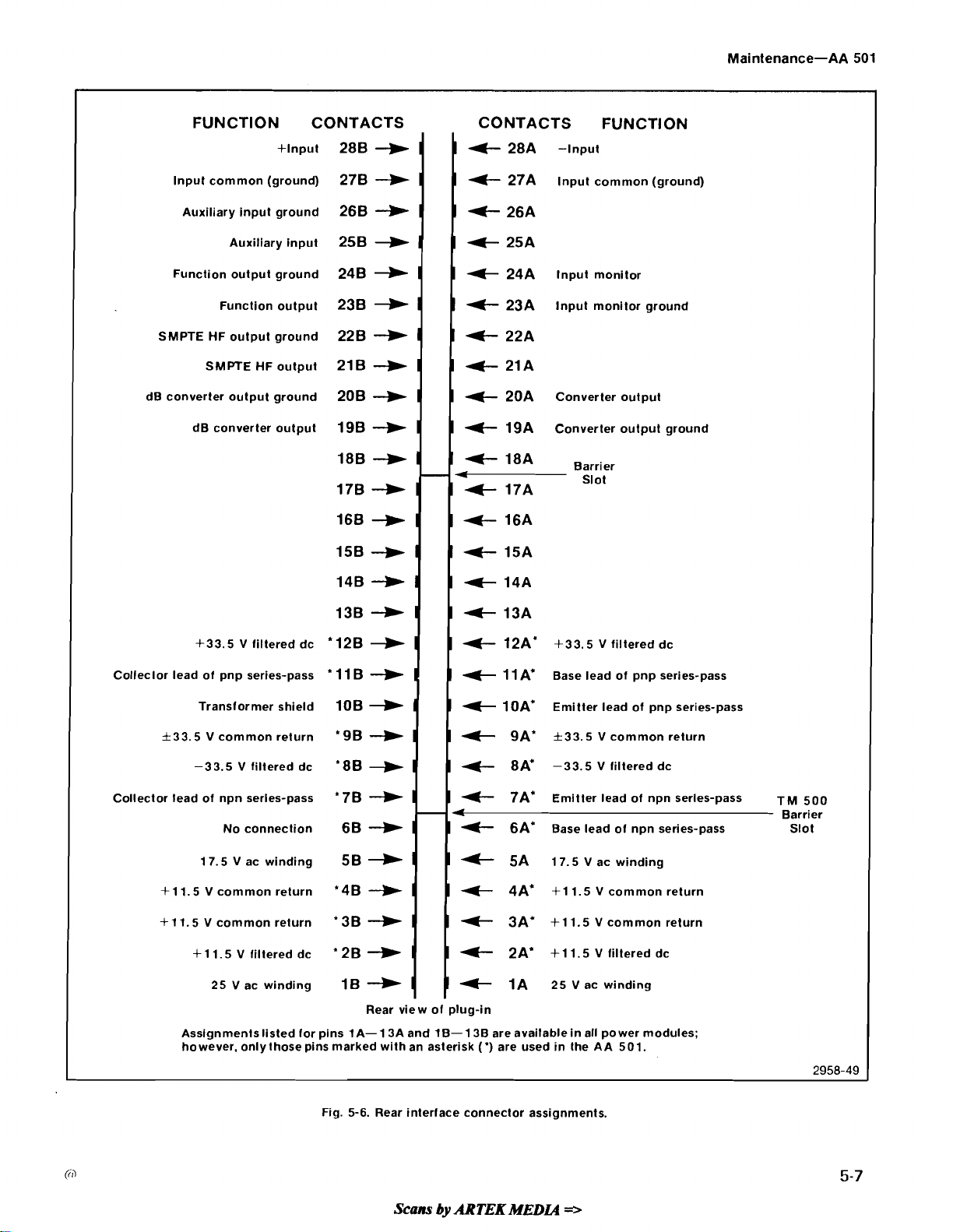

Rear interface connector assignments

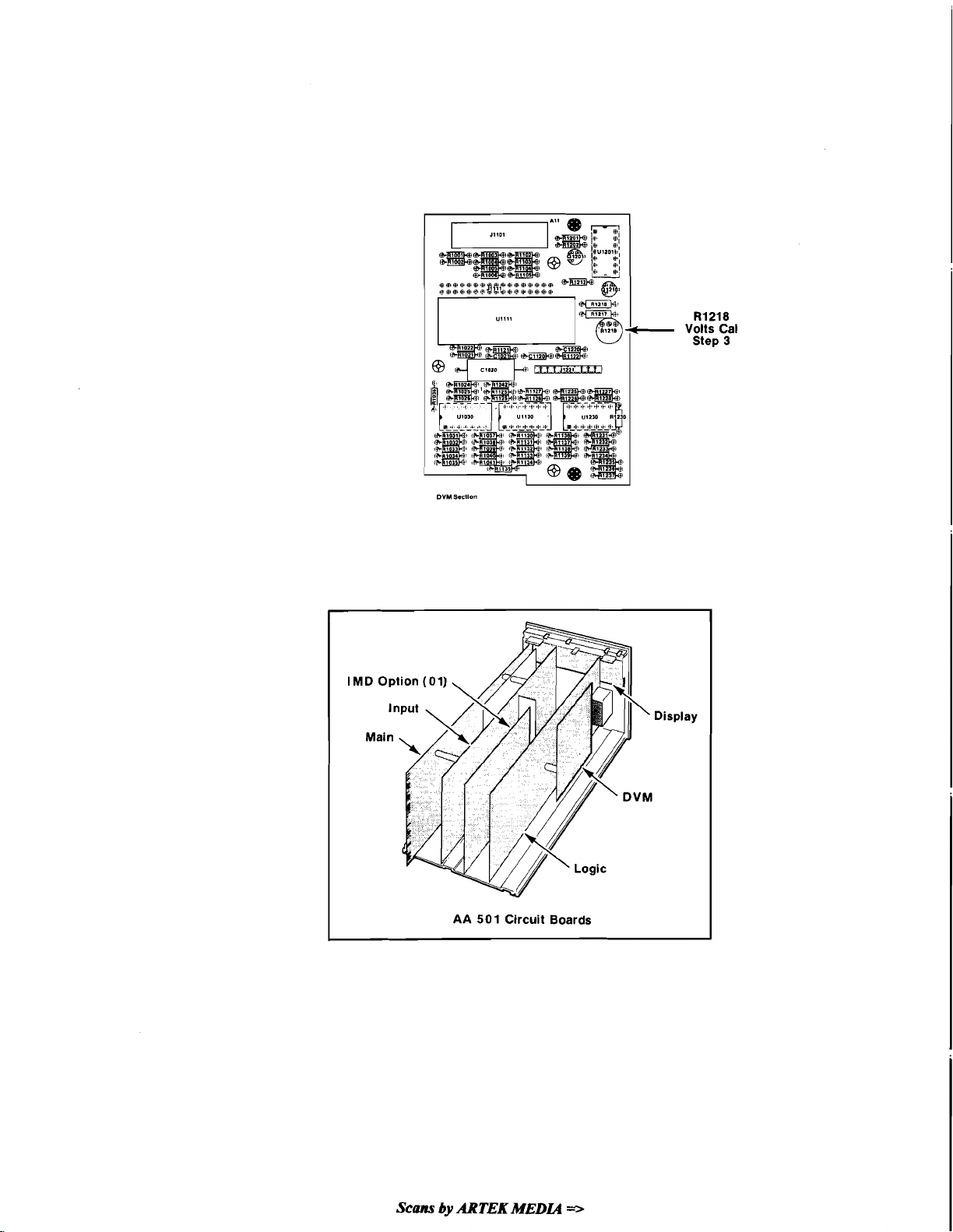

Adjustment location illustration for Main,

lnput and Notch dvm boards.

Adjustment location illustration for Control

and IMD Option boards.

lnput board

Main board

Logic board

Dvm board

Display board

IMD option board

8

and adjustment step

8.

SMPTE

......

11A and adjustment step 11A.

.........

.........

........

.........

..........

.......................

.....

...........

.....................

(A14) parts location grid.

(A15) parts location grid.

(A12) parts location grid.

(A1 1) parts location grid.

(A10) parts location grid.

(A13) parts location grid.

...

.

.

...

Page

Scam

by

ARTEK

MEN

=r

Page 8

LIST

OF

TABLES

Table

No.

Electrical Characteristics

Environmental Characteristics

Physical Characteristics

Gains from INPUT terminals to FUNCTION

OUTPUT connector for various settings of

the INPUT LEVEL RANGE control

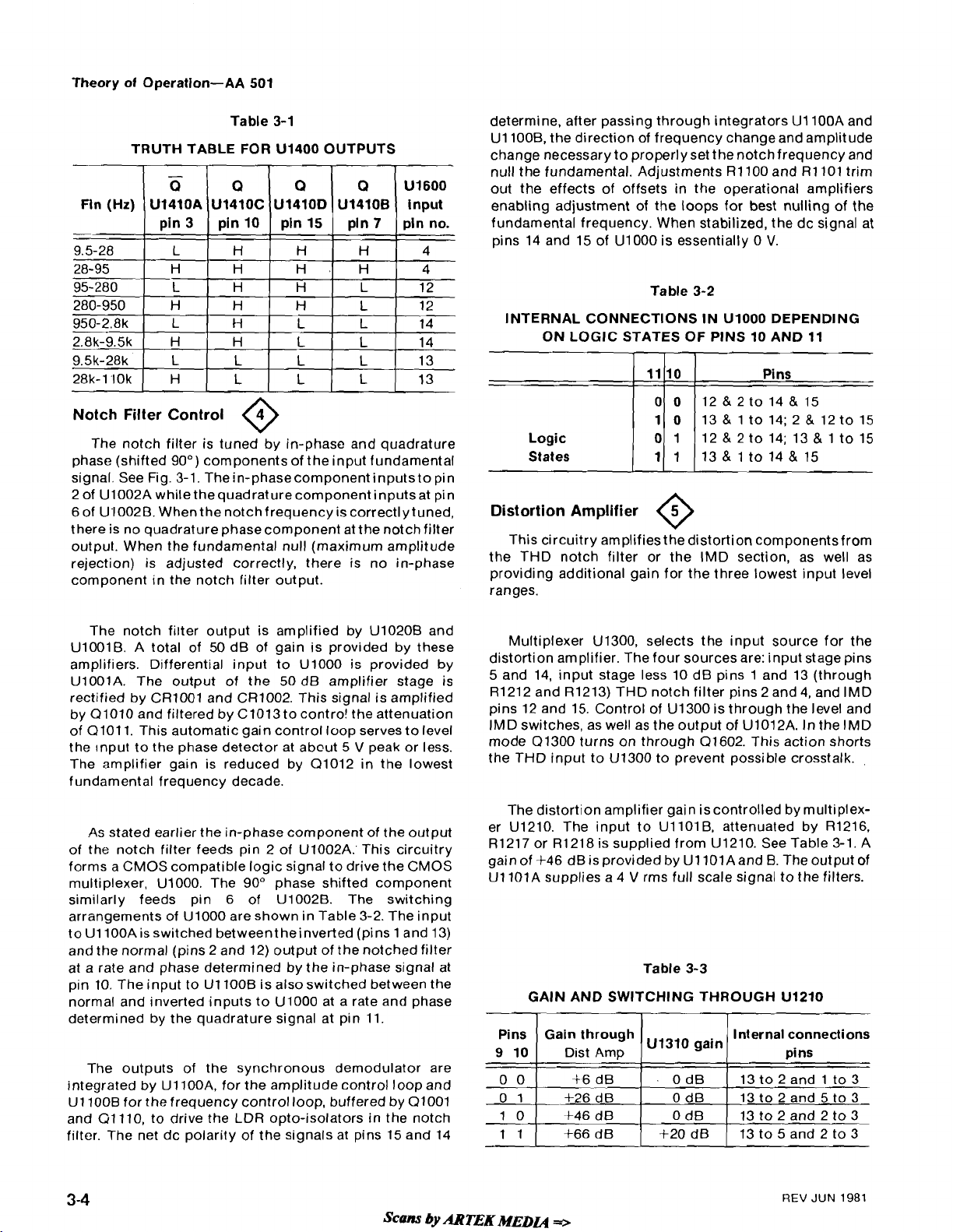

Truth Table for U1400 Outputs 3-4

Internal Connections in

Logic States of pins 10 and 11

GainandSwitchingthroughU1210

Suggested Test Equipment

Common Mode Rejection Check

Level Function Accuracy

Relative Susceptibility to Static Discharge

Damage..

The following lables are located in the diagrams

foldout section at the rear of this manual.

lnput Board (A14) Component Reference

8-1

Chart.

8-2 lnput Board (A14) Component Reference

Chart.

8-3 Main Board (A15) Component Reference

Chart.

8-4 lnput Board (A14) Component Reference

Chart.

.......................

NOTE

.............

.........

.............

......

........

U1000 Depending on

.........

.....

..........

.......

.............

Page Table

N 0.

1-2

1-6

1-7

2-13

3-4

3-4

4-1

4-6

4-6

5-1

8-5

8-6 Main Board

8-7

8-8 Dvm Board (All) Component Reference

8-9 Display Board

8-10 Logic Board

8-11 Logic Board

8-12 Logic Board

8-13 Main Board (A1 5) Component Reference

8-14 IMD Option Board

lnput Board

Chart.

Chart.

Logic Board

Chart.

Chart.

Chart.

Chart.

lnput Board

Chart.

Main Board

Chart.

Chart.

Chart.

Chart.

Reference Chart.

(A14) Component Reference

(A15) Component Reference

(A12) Component Reference

(A12) Component Reference

(A14) Component Reference

(A15) Component Reference

(A12) Component Reference

(A12) Component Reference

Page

(A10) Component Reference

(A13) Component

Page 9

OPERATORS SAFETY SUMMARY

The general safety information in this part of thesummary

is for both operating and servicing personnel. Specific

warnings

manual where

s~lmmarv.

-

-

.

. . .

. . -.

,

and

cautions

they apply, but may not appear

.

will

be

found

throughout

in

the

this

TERMS

In This Manual

CAUTION Statements identify

could result in damagetotheequipment or other property,

WARNING

that could result in personal injury or loss of life.

As Marked on Equipment

CAUTION indicates a personal injury hazard not immediately

hazard to property including the equipment itself.

DANGER indicates a personal injury hazard immediately

accessible as one reads the marking.

accessible as one reads the marking, or a

conditionsor practicesthat

identify conditions

or

practices

Power Source

This product is intended to operate from a power module

connected to a Power source that will not apply morethan

250

volts rms between the supply conductors or between

either supply conductor and ground. A protective ground

connection by way of the grounding conductor in the

power cord is essential for safe operation.

Grounding the Product

This product is grounded through the grounding conduc-

tor of the power module power cord. To avoid electrical

Shock, plug the Power cord into a properly wired recep-

tacle

before

terminals. A protective ground connection by way of the

grounding conductor in the power module power cord is

essential for safe operation.

'Onnecting

the

product input

Or

Output

Danger Arising From Loss of Ground

Upon loss of the protective-ground ~~nnection, all

accessible conductive parts (including knobs and controls that may appear to be insulating) can render an

electric

SYMBOLS

In This Manual

symbol indicates where applicable

This

cautionary or other information is to be

found.

As Marked on Equipment

9

DANGER - High voltage.

@

Protective ground (earth) terminal.

ATTENTION

-

refer to manual.

Use the Proper Fuse

To avoid fire hazard, use only the fuse of correct type,

voltage rating and current rating as specified in the parts

list for your product.

Refer fuse replacement to qualified service personnel.

DO

NO^

Operate in Explosive Atmospheres

To avoid explosion, do not operate this product in an

explosive atmosphere unless it has been specifically

certified for such operation.

Do Not Operate Without Covers

To avoid personal injury, do not operate this product

without covers or panels installed. Do not apply power to

the plug-in via a

plug-in.extender.

Scans

by

ARTEK

MEDLQ

=>

Page 10

SERVICE SAFETY SUMMARY

FOR QUALIFIED SERVICE PERSONNEL ONLY

Refer also to the preceding Operators Safety Summary.

Do Not Service Alone

Do not perform internal service or adjustment of this

product unless another person capable of rendering first

aid and resuscitation is present.

Use Care When Servicing With Power On

Dangerous voltages may exist at several points in this either supply conductor and ground.

product. To avoid personal injury, do not touch exposed connection by way of the grounding conductor in the

connections and components while power is on. power cord is essential for safe operation.

Disconnect power before removing protective panels,

soldering, or replacing components.

Power Source

This product is intended to operate in a power module

connected to a power source that will not apply more than

250

volts rms between the supply conductors or between

A

protective ground

Scans

by

AR

TEK

MEDL4

vii

=>

Page 11

~lrkvpr

MAX

+

AA501

Distortion

Analyzer

r

-RMs

L

AVC

1

rn

"1

f:~~R

r

viii

Scans

by

ARTEK

MEDIA

=>

Page 12

SPECIFICATION

Instrument Description

The AA 501 is a fully automatic distortion analyzer,

packaged as a two-wide

distortion is measured with the standard instrument. Option

01 instruments also measure

distortion and

tion. Option 02 instruments permit noise measurements in

45405.

Distortion set level, frequency tuning and nulling are

fully automatic, requiring no operator adjustment. Input

level range and distortion measurement range selections

are fully automatic or may be manually selected. Distortion readout is provided in percent or dB.

The

audio frequency voltmeter. Readings may be in volts,

dBm, or dB relative to any arbitrary reference.

Filters are included which allow measurement of noise to

IHF and FCC specifications. Option 02 instruments provide

a quasi-peak detector for noise measurements in accordance with

provided as are provisions for external filters.

All readings are displayed on a

uncalibrated analog readout is also provided to aid in nulling

and peaking applications.

Ac to dc conversion is either average or true rms re-

sponding, allowing conformance with most standards.

CClF two-tone difference frequency distor-

with

CC'R

AA

501 is also a high sensitivity, autoranging,

CClR or DIN standards. A hum rejection filter is

TM

500 plug-in. Total harmonic

SMPTEIDIN intermodulation

468-2

3

112 digit readout. An

Or

Op-

tion 02 instruments provide quasi-peak or true rms

detection. This feature

obtained

the

on

other

Ac input and output connections are available on both

front

respondingtothedisplayed

therearinterface.

with other instruments such as filters, chart recorders,

spectrum analyzers, oscilloscopes, etc.

'permits comparison with readings

instruments.

and

the

rear

interface.

reading,

Thisallowsflexibilityininterconnection

Dc

signals,

areavailablethrough

tor-

Performance Conditions

The electrical characteristics in this specification are

AA

valid only if the

temperature between

must be in a noncondensing environment

described under the

minutes warm-up time for operation to specified ac-

curacy; sixty minutes after exposure to or storagein a high

humidity (condensing) environment. Any conditions that

are unique to

stated as part of that characteristic.

The electrical and environmental performance limits,

together with their related validation procedures, com-

prise a complete statement of the electrical and en-

vironmental performance of a calibrated instrument.

Items listed in the Performance Requirements column

of the Electrical Characteristics are verified by completing

the Performance Check in the Calibration section of this

manual. ltems listed in the Supplemental Information

column are not verified in this manual.

501 has been adjusted at an ambient

+20° C and +30° C. The instrument

whoselimits are

environmental part. Allow twenty

a

particular characteristic are expressly

REV

NOV

1981

SCMS

by

ARTEK

MEDLQ

=>

Page 13

-

--

-

-

--

-

--

-

Characteristics

.-

-

-

- - -- - -

INPUT (all functions)

Impedance

----

-

.

-

-

Maximum Input voltage

-

Common mode rejection

(inputs shorted)

-

-

--

- -

LEVEL FUNCTION

Table

1-1

7-

--

-.

-

-

--

Performance Requirements

.

--

ELECTRICAL CHARACTERISTICS

-

--

-

r

Supplemental Information

-

-

--

--

--

-

-

-

-.

,

100

kR,

+

2%, each side to ground

200

pV to 200 V in 10 steps (2-6 se-

quence from 200

-

--

-

--

250 dB at 50 or 60

mV to 200 V)

~

---

~-

--

Hz

--

for common

mode signals up to one-half of selected

input range or 50

mV, whichever is

greater.

Full differential. Each side ac coupled

through

1

pF

and shunted to ground by

100 pF. Dual banana jack connectors at

0.750 inch spacing with ground connector

additionally provided.

--

-

-.

-

Range selection is manual or automatic.

Auto-ranging time is typically

(1

second.

Separate increase range and decrease

range indicators illuminate whenever input

level does not fall within optimum window

for selected range. For specified instrument performance both indicators must

be extinguished.

-

-

- - --

. . -.

300 V peak, 200 V rms either input to

ground or differentially. Will recover without damage from continuous overloads of

120

V

rms or 200 V rms for 30 minutes on

all ranges. For linear response peak input

voltage must not exceed 3 times INPUT

LEVEL RANGE setting.

~~

~~

~

Typically 240 dB to 300

kHz.

=

Modes

-

--

Accuracy (V,, a 100 pV

with level ranging indicators

extinguished)

20

Hz

-

to 20

kHz

-

---

Volts

Within

+

2%

I

I

1

(

Volts, dBm (600

0).

or dB ratio with push

to set 0 dB reference. lnput range determines display range. Single effective

range in dB modes with 0.1 dB resolution.

Stored

subsequent changes in mode or function.

-

0 dB reference is unaffected by

-.

On the 200 pV range accurcy above

50

kHz

is +4%, -6% (+0.5 dB,

-0.7 dB). Accuracy with quasi-peak re-

sponse (Option 02 only) is valid from

20

Hz

to 50

kHz

only).

REV

NOV

1981

Page 14

1-1

Table

-

(cont)

Performance Requirements

- - -

--

- - -

-

-

At least 300 kHz with no filters

selected.

-

-

-

--

Supplemental Information

--

Residual noise

(Source resistance

-

G

1 kS1)

TOTAL HARMONIC DISTORTION

PLUS NOISE FUNCTION

Fundamental frequency

range

Minimum input level

Distortion ranges

--

Accuracy (THD ~30%

and readings 34% of

selected distortion range)

~3.0 rV

(-

108 dBm) with 80 kHz,

400 Hz filters and rms response

~1.5pV (-114dBm) with A

weighting filter and rms response

(standard and Option 01 instruments

only)

~5.0 wV

(-

104 dBm) with CClR

weighting filter and quasi-peak response (Option 02 only)

-

--

- - -

-.

10 Hz to 100 kHz

Fully automatic tuning and nulling. For

proper tuning

THD+ N <1O0/0. After initial

tunlng THD+ N can degrade to 30% without loss of lock for

nulling

time is less than 5 s above 20 Hz.

-

SINAD testing. Typical

--

-

-

Autorange, 20°/0, 2%, 0.2%, and dB. dB is

internally autoranging with single effective

display range. Autorange allows measurements above 20%.

+

Accuracy is limited by residual THD

N

and filter selection. Not applicable with

quasi-peak response (Option

02 only).

20 Hz to 20 kHz

10 Hz to 100 kHz

-

---

Residual

THD+N (V,,, a250 mV,

source resistance G 1 kS1)

20 Hz to 20 kHz with

80 kHz noise limiting filter

<+40°C

and T

10Hz to50kHz

50 kHz to 100 kHz

Typical fundamental

rejection

REV

NOV

1981

Within

Within

--

for harmonics

- - -

<

100 kHz.

+

10%

(k

1 dB) for harmonics

+lO%, -30%

~300 kHz.

- - -

- - -

(+ 1 dB,

--

-3

dB)

-

-

-.

-

- - -

SG

Measured with

505 oscillator. All dis:ortion, noise, and nulling error sources

:ombined.

~0.0025~/0 (-92 dB) average

response

~0.0032% (-90 dB) rms response

=z0.0071

=zO.OIOO/~

O/O

(-83 dB), rms response

(-

80 dB), rms response

it

least 10 dB below specified residual

rHD

+

N

or the actual signal THD, which-

!ver is greater.

~cMs

by

ARTEK

MEDL4

=,

Page 15

--

.-

Characteristics

- - -

-

-.

-

-

-

INTERMODULATION DISTORTION

FUNCTION

Table

1-1

(cont)

-

Performance Requirements

-

---

-

--

-

-

--

-

--

-

-

Supplemental lnformatlon

-

--

--

--

Operation

SMPTE and DIN tests

Lower frequency range

Upper frequency range

Level ratio range

Residual IMD

(V, 2250 mV,

source resistance 61 kil,

~40°C)

.-

~

CClF difference tone test

(IM components

G

Frequency range

Difference frequency range

Residual IMD

(Vn a250 mV,

source resistance 6 1 kR,

<+40°C)

Minimum input level

-

-~

~~

-

-

~

Accuracy (IMD ~30% and

readings

distortion range)

---.

~.~

>4% of selected

-~

FILTERS

1 kHz)

Fully automatic SMPTE, DIN, or CClF difference tone tests depending upon actual

input signal whenever respective IMD

620%. Distortion ranges are same as

THD

t

N function.

-.

- - -

50 Hz to 250 Hz

3

kHz to 100 kHz

:

1

to 5: 1 (lower : upper)

1

~0.0025% (-92 dB) for 60 Hz-7 kHz

or 250 Hz-8 kHz, 4: 1 signals,

-

response

rms

4 kHz to 100 kHz

80 Hz to 1 kHz

~0.0018% (-95 dB) with 14 kHz and

15 kHz,

Within

rms

k

10%

response

(i

1 dB)

-

-

.

-

Accuracy is limited by residual IMD and

filter selection. Not applicable with quasi-

~

peak response (Option 02 only)

400 Hz high pass

~~~

80 kHz low pass

~

.

30 kHz low pass

(standard and Option 01

only)

~

-

-~

-

22.4 Hz-22.4 kHz

{Option 02 only)

-~

-

~~~-.~ ~ -~.~ - .~

A weighting (standard and

Option 01 only)

~ ~

~

~

CClR WTG (Option 02 only)

-3 dB at 400 Hz,

+

5%; at least

-40 dB rejection at 60 Hz

-3 dB at 80 kHz,

-3

dB at 30 kHz, k 5%

-3

dB at 22.4 Hz, + 5% and

22.4 kHz,

+-

Scans

5%

by

_+

5%

ARTEK

MEDL4

=>

3

pole Butterworth response

-.

- - --

3

pole Butterworth response

3

pole Butterworth response

--

.-

Nithin specifications of CClR Recommenjation 468-2 and DIN 45405 for

~nweighted measurement response.

Nithin specifications for type 1 sound lev?I

meters listed in ANSI S 1.4 1971 (re-

lised 1976) and IEC Recommendation

179.

-

-

Nithin specifications of CClR Recommeniation 468-2 and DIN 45405 for noise

neasurements. Functional only with quaii-peak detector (response).

-

-

-

-

.

- - -

-

--

REV

NOV

1981

Page 16

Table

1-1

(cont)

Performance

--

-

--

Requirements

-

-- . - - -

-

-

-

---

-

Supplemental Information

-

.

--

-

--

- - -

-

-

---

-

Auxiliary

-

--

-

-

-

.-

FRONT PANEL SIGNALS

MONITOR OUTPUT

lmpedance

FUNCTION OUTPUT

Signal

Sensitivity

Maximum

Input Voltage

Selects front panel AUXILIARY INPUT alowing connect~on of external filter be-

-

--

-

-

-

1 V rms, k 10%

ween lt and FUNCTION OUTPUT.

-

-

-

- - -

-

-

Constant amplitude (average response)

version of differential input signal. THD is

typically

20

Hz

~O.OOIOO/~

to 20 kHz.

(-

100 dB) from

Approximately 20 times input signal.

1

V,

+-

3%,

for 1000 count volts or

display.

+-

3%, for 1000 count volts or

1 V,

display.

Selected and filtered ac signal actually be-

O/O

ing measured.

Loop-through accuracy from FUNCTION

O/O

IS

t

OUTPUT

3%.

15 V peak, 6 V peak for linear response.

lmpedance

DETECTORS AND DISPLAYS

Detectors (Response)

RMS

AVG (standard and

Option

Q-PK

01)

-

- - - - -

(Opt~on 02 only)

- - - - -

Ac coupled.

True rms detection.

- - - - -

-

- - -

-

-

Average detection, rms calibrated for

sinewaves. Typically reads 1 to 2 dB lower than true rms detection for noise,

THO+

N,

-.

-.

--

and IMD measurements.

~

~

Quasi-peak detection, rms calibrated for

sinewaves. Within specifications of

CClR

Recommendation 468-2 and DIN 45405.

Due to the peak hold nature of its response readings considerably higher than

rms response will occur with large crest

factor signals such as noise. The input

range indicators should be ignored and

auto-ranging avoided with these types of

signals.

REV

NOV

1981

Scans

by

ARTEK

MEDU

=,

Page 17

--

~

Displays

Digital

~

Characteristics

~

--

~

--

--

I

Table

1-1

--

(cont)

-

.

--

--

3

112 digit, 2000 count

LED.

Overrange in-

--

Performance Requirements Supplemental Information

dication is 1, blank, blank, blank.

--

Analog bar graph

MISCELLANEOUS

Power consumption

Internal poker supplies

+5

-.

-

-

Fuse Data

Recommended adjustment

interval

Warm-up time

10 segment LED intensity modulated bar

graph display of digital readout. Seg-

ments are logarithmically activated with

approximately 2.5

--

-.

-

I

224

-

-

.

watts

Nominally + 15.1

Nominally - 15.1

--

-

Nominally +5.0

3

AG,

1

A,

3

AG,

1

A,

3

AG,

1

A,

-

-

-- --

-.

250

250

250

dBIsegment.

-

-

- - - . - - -

V,

k

3%

V,

k

5%

V,

+

-.

V,

fast blow

V,

fast blow

V,

fast blow

--

5%

- - --

- - -

-

-

-

-.

--

1000 hours or 6 months whichever occurs

first

20 minutes (60 minutes after storage in

high humidity environment)

-

-

-

cons

by

ARTEK

MEDIA

=.>

REV

NOV

1981

Page 18

Table

1-2

ENVIRONMENTAL CHARACTERISTICSa

..~

Characteristics

-

--

-

.

.

--

. .

Temperature Meets MIL-T-28800B, class 5.

.

i

ppppp.-----

Description

Operating

Humidity

--

Altitude

Operating

Non-operating

-

- - - . -

-

Vibration

- --

-

95% RH,

45% RH, to t-50°C

0°C to +40°C

-

4.6 km (1 5,000 feet)

15 km (50,000 feet)

.

Exceeds

----

-

Exceeds MIL-T-28800B, class 5.

p-

- . --

Exceeds MIL-T-28800B, class 5, when

MIL-T-28800B, class 5

~~

installed in qualified power modulesb.

0.38 mm

(0.015") peak-to-peak, 5 Hz

to 55 Hz, 75 minutes.

MIL-T-028800B, class 5, when

Shock

Meets

installed in qualified power modulesb.

30 g's

(112 sine) 11 ms duration, 3

shocks in each direction along 3 major

axes. 18 total shocks.

-

Bench handlingC

-.

~-

~

~~

.. - .

EMC

Electrical discharge

----

-

-

.With power module.

b~efer to

TM

500

power module specifications.

=Without power module.

Meets

MIL-T-28800B, class 5.

12 drops from

45@. 4" or equilibrium,

whichever occurs first.

Qualified under National Safe Transit Association Preshipment Test Procedure

B-1 and 1A-B-2.

Within limits of MIL-461A.

20 kV maximum charge applied to instrument case.

I

.. . . - . . .

.

-

..

-

-

.

.

1A-

REV

NOV

1981

Scans

by

ARTEK

MEDL4

=>

Page 19

Characteristics

.

-~

-~-.

~

-.~~- . --

-

-

~-

Maximum Overall Dimensions

1-3

Table

PHYSICAL CHARACTERISTICS

p--.---p-----.---.-

-..

-

Description

.. - . - -.

~-

-

.

---

---

-~

~

Height

Width

Length

-

Net Weight

-

--

Finish

Front Panel

- - --

--

126.0 mm (4.96 inches)

131.2 mm (5.1 6 inches)

(1

-.

285.5 mm

~1.7

1.24 inches)

kg (3.75 Ibs.)

Plastic-aluminum laminate

Anodized aluminum

Scam

by

ARTEK

MEDL4

-->

@

NOV

1981

Page 20

OPERATING INSTRUCTIONS

Section

2-AA

501

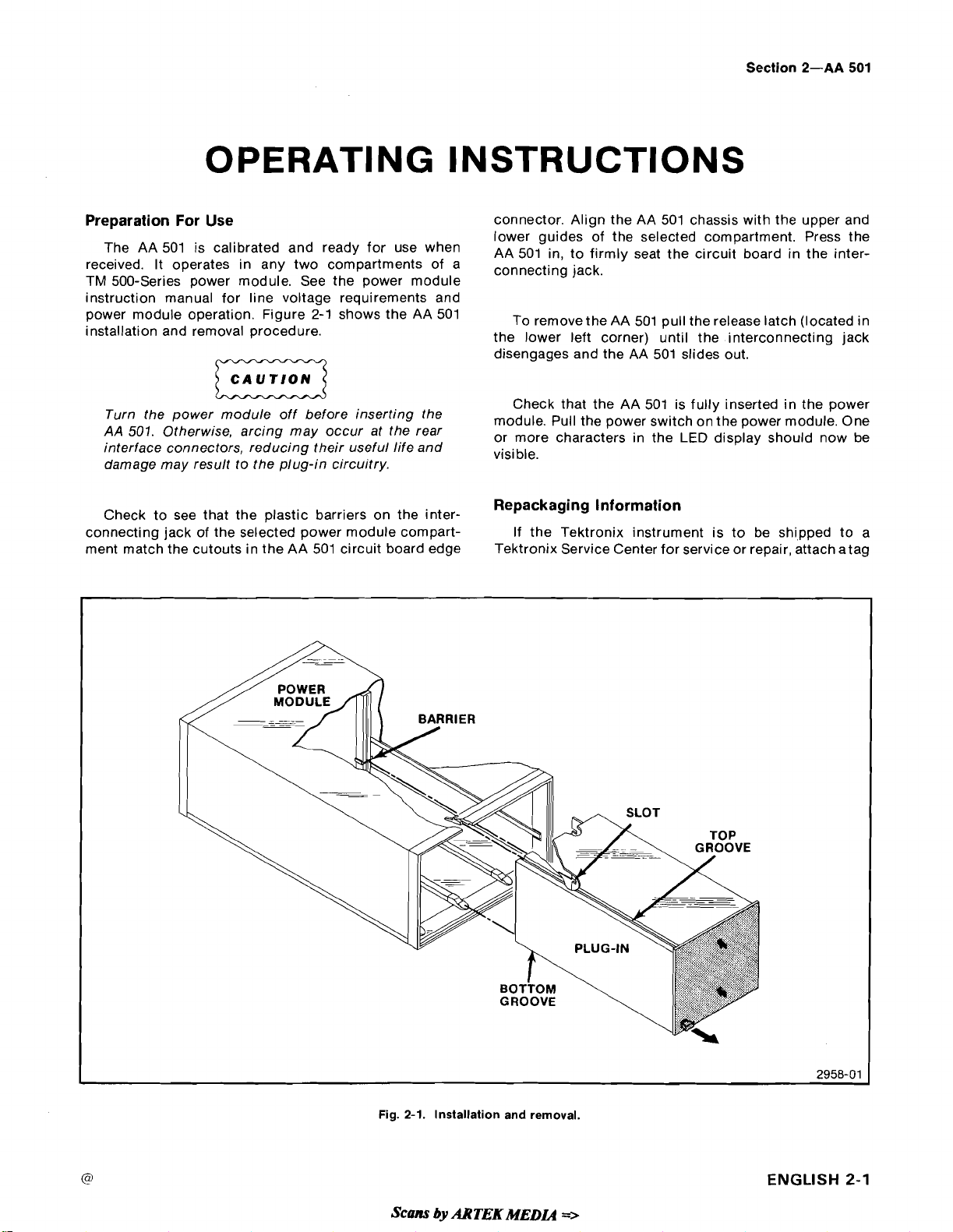

Preparation For Use

The AA is calibrated and

received. It operates in any two compartments of a

TM 500-Series power module. See the power module

instruction manual for line voltage requirements and

power module operation. Figure

installation and removal procedure.

Turn the power module off before inserting the

AA

501.

Otherwise, arcing may occur at the rear

interface connectors, reducing their useful life and

damage may result to the plug-in circuitry.

Check to see that the plastic barriers on the

connecting jack of the selected power module compartment match the cutouts in the AA 501 circuit board edge

2-1

shows the AA 501

use

when

inter-

connector. Align the AA 501 chassis with the upper and

lower guides of the selected compartment. Press the

AA 501 in, to firmly seat the circuit board in the inter-

connecting

To remove the AA 501 pull the release latch (located in

the lower left corner) until the interconnecting jack

disengages and the AA 501 slides out.

Check that the AA 501 is fully inserted in the power

module. Pull the power switch on the power module. One

or more characters in the

visible.

jack.

LED

display should now be

Repackaging Information

If the Tektronix instrument is to be shipped to a

Tektronix Service Center for service or repair, attach atag

Fig.

Scans

2-1.

Installation and removal.

by

AR

TEK

MEDL4

=>

ENGLISH

2-1

Page 21

Operating Instructions-AA 501

showing the owner (with address) and the name of an

individual at your firm that can be contacted. Include the

complete instrument serial number and a description of

the service required.

Save and reuse the package in which your instrument

was shipped. If the original packaging is unfit for use or

not available, repackage the instrument as follows:

Surround the instrument with polyethylene sheeting to

protect the finish of the instrument. Obtain a carton of

corrugated cardboard of the correct carton strength

and having inside dimensions of no Iessthan six inches

more than the instrument dimensions. Cushion the

instrument by tightly packing three inches of dunnage

or urethane foam between carton and instrument on all

sides. Seal the carton with shipping tape or an in-

dustrial stapler.

The carton test strength for this instrument is 200

pounds per square inch.

Controls, Connectors, and Indicators

All controls, connectors and indicators (except for the

rear interface connector) required for operation of the

AA 501 are located on the front panel. Figure2-2 provides

a brief description of all front panel controls, connectors,

and indicators.

@

@

@

@

@

Release Latch

LEVEL

Button in selects input level measuring function.

VOLTS

Button in selects voltage units for level function.

Button in selects

n)

600

dB

Button in selects dB ratio, with respect to preset

level, as units for level function.

PUSH TO SET 0

Push button to set display to 0 with input signal

applied to INPUT terminals in LEVEL function.

dB RATIO and LEVEL pushbuttons must be in for

this feature to operate.

units for level function.

RATIO

dBm (reference is 1 mW into

dB

REF

@

@

@

@

@

INPUT LEVEL RANGE

Selects input voltage range or AUTORANGE.

The three most sensitive ranges operate in the

LEVEL FUNCTION only.

DECREASE RANGE

When this light is illuminated, reduce the INPUT

LEVEL RANGE until the light goes out.

INCREASE RANGE

When this light is illuminated, increasethe INPUT

LEVEL RANGE until the light goes out.

INPUT

Differential input terminal. Positive going input

signal provides positive going output signal at

INPUT MONITOR.

INPUT

Differential input terminal. Negative going input

signal provides positive going output at INPUT

MONITOR.

@

REAR INTFC-INPUT

Button in selects rear interface input; button out

selects front panel input.

@

RESPONSE

Button in gives RMS detection (responds to the

rms value of the input waveform). Button out

gives average detection (rms calibrated for

si newaves).

Button in selects total harmonic distortion

FUNC-I-ION.

@

IMD (Option 01 instruments only)

Button in selects intermodulation distortion func-

tion.

@

AUTO RANGE

Button in selects automatic distortion range

selection (0.2% to 100% full scale).

Scans

by

ARTEK

MEDL4

=>

Page 22

Operating Instructions-AA

501

REV

NOV

1981

Fig. 2-2. Front panel controls and connectors.

Scans

by

AR

TEK

MEDIA

=>

2958-1

ENGLISH

3A

2-3

Page 23

Operating Instructions-AA 501

@

20% AUXILIARY INPUT

Button in selects full scale distortion readout of Provides input to the detector circuit when the

20% with 0.01% resolution.

Button in selects full scale distortion readout of

2% with 0.001% resolution.

Button in selects full scale distortion readout of digital display for nulling and peaking. Each

0.2% with 0.0001% resolution.

@

dB

Selects single equivalent 0 dB to -100 dB distor-

tion display range with 0.1 dB resolution.

@

400 Hz HI PASS

Button in connects filter before detector circuit in

all functions.

EXT FILTER button is pressed.

@

Ground

Provides front panel chassis ground connection.

LED Bar Graph

Provides approximate analog display of the

segment represents about 2.5 dB.

@

Digital Display

3

1/2 digits. Overrange indication is a blanked

display with the numeral 1 in the most significant

digit position.

@

VOLTS

llluminated when display units are volts.

@

@

80 kHz LO PASS

Button in connects filter before detector circuit in

all functions.

@

30 kHz LO PASS

Button in connectsfilter beforedetector circuit in

all functions.

@

'A'

WEIGHTING

Button in connects filter before detector circuit in

all functions.

@

EXT FILTER

Button in allows connection of external filter

between FUNCTION OUTPUT and AUXILIARY

INPUT in all functions.

Instrument Connections

INPUT MONITOR

Provides a sample of the input signal.

@

FUNCTION OUTPUT

Provides a sample of the selected FUNCTION the rear interface signal input press the INPUT pushbut-

signal. ton.

Connections can be made to the rear interface connector.

However, due to possible crosstalk, low level or distortion

measurements made through the rear interface may be

degraded. To measure signals connected to the front

panel make certain the INPUT pushbutton is out.

mVOLTS

llluminated when display units are millivolts.

@

pVOLTS

llluminated when display units are microvolts.

llluminated when display units are percent.

@)

dBm

Illuminated when display units are

@

dB

Illuminated when display units are dB.

To make connections to the AA 501, refer to Fig. 2-3.

dBm.

Toselect

Scans

by

ARlEK

MEDIA

=>

Page 24

SG

505

Oscillator

AA501

Dlstortlon Analyzer Oscilloscope

Operatlng

Shielded twlsted pair

Instructions-AA

501

Fig.

2-3.

Typlcal connectlons for distortlon measurements. See text.

300

V

Maximum front panel input voltage is

200

V

rrns either input to ground or differentially.

42

V

Maximum rear interface input is

rms.

AA

The

cidental overloading. This circuitry will recover without

damage from continuous 120 V rms (30 minutes at 200 V

rms) overloads in any INPUT LEVEL RANGE setting.

In most cases, for maximum hum rejection, follow the

cabling and grounding as shown in the figure. Shielded,

twisted pair offers maximum hum and radio frequency

interference rejection. Cable shielding, if used, should be

grounded only at the AA 501 front panel ground post. Use

shielded cable to connect the output of an oscillator,

external to the device under test, to the input of the device.

Generally, if the device under test has one side of the input

grounded, float the output of the external oscillator to

avoid possible ground loops. If the input to the device

under test is floating (not chassis grounded) then select

the grounded mode for the output of the oscillator.

Terminate the output of the device under test in its

501 input circuitry is protected against ac-

peak and

peak,

30

V

2958-02

recommended load impedance, or the load impedance

specified in the appropriate standard.

The illustration shows an optional oscilloscope for

visual monitoring. If connected as shown in the illustration. channel 1 displays a sample of the input signal and

channel 2 displays the distortion components when in the

IM or THD+N function.

Level Measurements

In the LEVEL function the AA 501 operates as a wide

band ac voltmeter. The Specification section of this

manual contains operating parameters for this meter. The

meter is rms calibrated and either rrns or average responding, depending on the position of the RESPONSE

pushbutton.

Press the FUNCTION LEVEL pushbutton. The top

three buttons to the left of the FUNCTION pushbuttons

dBm

600

n,

select readout units as VOLTS,

An LED to the right of the display indicates the display

units. To measurevoltage press the VOLTS pushbutton. If

the INCREASE RANGE LED is illuminated, adjust the

INPUT LEVEL RANGE control to higher ranges until the

or dB RATIO.

ENGLISH

2-5

Page 25

Operatlng Instructions-AA

501

LED goes out. If the DECREASE RANGE LED is illuminated, turn the INPUT LEVEL RANGE control

counterclockwise to a lower range until the DECREASE

RANGE LED goes out. For specified instrument accuracy

adjust the INPUT LEVEL RANGE as just described.

However, readings are usable as long as the display is not

overranged. Overrange is indicated by a blank display with

the numeral 1 in the most significant digit slot. If the

INPUT LEVEL RANGE switch is placed in the AUTO

RANGE position, the input level adjustment is ac-

complished automatically. The

or pVOLTS) automatically illuminate showing the proper

display units. Notice that the three most sensitive ranges

on the INPUT LEVEL RANGE control operate in the

LEVEL FUNCTION only.

When the

opposite

The reference level for this measurement,

dissipated in 600

developed across a 600

RANGEswitch operates in thesamemanner as previously

described.

The dB RATIO mode permits direct ratio meas-

urements of two input signal amplitudes. When the dB

RATIO pushbutton is pressed, the LED opposite the dB

nomenclature on the display is illuminated. To use this

feature, press the dB RATIO pushbutton. To establish the

input signal as

0 dB REF pushbutton and notice that the display reads all

zeros. As the amplitude of the input signal is changed, the

display will read the dB ratio of the input signal to the

reference signal amplitudes.

There are many useful applications for the dB RATIO

mode in measurements of gain-loss, frequency response,

S/N ratio, etc. For example, the corner frequency of a filter

may be quickly checked. Set the test frequency to some

midband value and set the zero dB reference. Adjust the

test frequency until the display reads -3.0 dB; this is the

corner frequency of the

Gain measurements may be similarly simplified by

using this feature. Set the device to be tested as desired

and connect the AA 501 input to the input of the device

under test. Press the PUSH TO SET

Connect the input of the AA

read the gain or loss directly from thedisplay. When using

the SG 505 oscillator and the TM 500 rear interface

feature, changing of external connections to establish the

0 dB input level reference is not necessary. Interconnect

the Buffered Main Output of the SG 505 and the rear

interface input of the AA 501. Pressing the REAR

pushbutton will conveniently allow direct measurement of

the signal level going to the input of the device under test.

dBm 600

dBm on the display indicates the display units.

0 dB reference, push the PUSH TO SET

f2

f2.

This is equivalent to 0.7746 V rms

fllter.

LED'S (VOLTS, mVOLTS

pushbutton is pressed, the LED

0 dBm, is 1 mW

C2

resistor. The INPUT LEVEL

0 dB REF pushbutton.

501

to the device output and

INTFC

When measuring signal to noise ratio or making noise

level measurements, it is often desired to employ a

frequency dependent weighting network. The AA 501

provides several internal filters as well as facilities for

connecting external filters. For information on their

operation and use, see the text under Filtersin thissection

of the manual.

Dlstortlon Measurements

Distortion is a measure of signal impurity. It is usually

expressed as a percentage or dB ratio of the undesired

components to the desired components of a signal.

Harmonic distortion

ly related or integral multiples of

the fundamental, and can be expressed for each particular

harmonic. Total harmonic distortion, or THD, expresses

the ratio of the total power in all significant harmonics to

that in the fundamental.

A distortion analyzer removes the fundamental of the

signal to be investigated and measures the remainder. See

Fig.

2-4. Because of the notch filter response, any signal

other than the fundamental will influence the measure-

A

ment.

inevitably include effects from noise or hum. The term

THD+N has been recommended' todistinguish distortion

measurements made with a distortion analyzer from those

made with a spectrum analyzer. A spectrum analyzer

allows direct measurement of each harmonic. However, it

is relatively complex, time consuming, and requires

interpretation of a graphic display.

All distortion analyzers are limited ultimately by their

internal distortion and noise. Traditionally, distortion

analyzer residual noise and distortion have been specified

separately. However, because an actual measurement

always includes both effects, both residuals must be

combined to determine the minimum valid reading. For

example, an analyzer rated at 0.002% residual distortion

and 0.002% noise may exhibit a

0.0028% and still be within specification. Also, average

responding analyzers may read up to

rms responding analyzers. The AA 501 specifies the

combined residual effect with rms response and offers

selection of rms or average response.

Distortion analyzers can quantify the nonlinearity of a

device or system. The transfer (input vs output)

characteristic of a typical device is shown in Fig. 2-5.

Ideally this is a straight line. A change in the input

produces a proportional change in the output. Since the

actual transfer characteristic is nonlinear, a distorted

'

IHF-A-202 1978. Standard Methods of Measurement for Audio

Ampllflers. The Institute of High Fidelity, Inc., 489 Fifth Avenue.

New York, N.Y. 10017

total harmonic distortion measurement will

issimply the presence of harmonical-

a

single pure tone called

THD+N reading of

25% lower than true

ENGLISH

2-6

Page 26

-

Fig.

2-4.

Block dlagram of a baslc harmonlc dlstortlon analyzer.

version of the input waveshape appears at the output. The

output waveform is the projection of the input sine wave

on the device transfer characteristic as shown in Fig.

2-6.

The output waveform is no longer sinusoidal, due to the

nonlinearity of the transfer characteristic. Using Fourier

series it can be shown that the output waveform consists

of the original input sine wave, plus sine waves at integer

multiples of the input frequency. These harmonics represent nonlinearity in the device under test. Their

amplitudes are related to the degree of nonlinearity.

Distortion Measurement Procedure

All of the controls found on a traditional distortion

analyzer areautomated on the

to set the INPUT LEVEL RANGE and distortion range

switches to AUTO RANGE, press

for a reading. Minimum input signal amplitude for distortion measurements is 60

the instrument may be manually operated as described in

the following paragraphs.

AA

mV. To

501.

It isonly necessary

THD+N and wait briefly

providegreaterflexibility

-

-

A

Output

Fig. 2-5. Transfer characterlstlcs of an audio device.

4

0

2958-04

REV

NOV

1981

Scum

by

ARTEK

MEDU

ENGLISH

2-7

Page 27

Operating

Instructions-AA

501

A

Actual

transfer

characterlstlc

/

Actual Ideal

Output output output

/

/

1

/

/

/

/

Fig.

2-6.

Input

THD

test of transfer characterlstlcs.

lnput

'.be/

/

2958-05

-

Adjustment of the input level range control is the same

as for level measurements. Manually setting the INPUT

LEVEL RANGE control to the correct scale ensures that

10

to

12

the input is within the

derangeof theinternalauto

set-level circuitry. The range lights must be extinguished

200

to make readings to specified accuracy. The

and

20

mV ranges do not operate in the distortion

pV, 2 mV

function.

To manually select a distortion range, press the

THD

tN button and the desired range button. Selection of

AUTO RANGE causes the instrument to autorange the

distortion readout. The remaining range pushbuttons

cause the instrument to stay in these ranges without

autoranging. This can reduce the measurement time

slightly if the approximate reading is already known. This

is useful in production line testing or in the testing of low

distortion equipment.

ENGLISH

2-8

ThedB display iseffectively asingle

range; however, internal instrument operation is identical

to AUTO RANGE.

When making distortion measurements, the

RESPONSE button should normally be in the RMS

position. Current distortion measurement standards re-

quire the use of rms reading instruments by specifying

power summation of each of the components. The AVG

mode may be used when making comparisons with

readings taken with traditional distortion analyzers.

However, it may read up to

25% (2

dB) lower than rms

response.

For frequencies below

measurement may be improved by activating the

LO PASS filter.

If

'20

kHz the residual noisein the

80

kHz

hum (line related components) are

interfering with the measurement, they may be removed

Page 28

Operating Instructions-AA

501

with the 400 Hz HI PASS filter. This filter should not be

employed at frequencies below 1 kHz as erroneous

readings will result. For more information see text under

Filters in this section of this manual.

A distortion analyzer must tune out the fundamental

frequency. In the AA 501 all tuning of frequency is done

automatically. For input signals with greater than about

20% noise and distortion, care must be taken to ensure

proper locking of thiscircuitry. Inmost applications which

require higher distortion measurements (for example,

SINAD' testing) the circuitry remains locked after it is

initially given a clean signal. To perform a

receiver under test is first given a high level input. The

AA 501 will lock onto the audio signal at theoutput. Therf

level feeding the receiver is then reduced until a 712 dB

distortion reading is obtained on the AA 501.

'

Defined in Electronic Industries Association Standard No.

RS

204A, July 1972, Electronic Industries Association,

Engineering Department, 2001 Eye St. N.W., Washington, D.C.

20006.

SlNAD test, the

IM Distortion Measurements (Option

Another measurement of distortion is the interaction of

two or more signals. Many tests have been devised to

measure this interaction. Three standards are

DIN4, and CCIF'. The Option 01 AA 501 is capable of

automatically selecting and performing all three tests.

To measure intermodulation distortion (IM), according

to SMPTE and DIN standards, the device under test is

excited with a low frequency and high frequency signal

simultaneously (Fig. 2-7). The output signal is high-pass

filtered to remove the low frequency component. The high

frequency tone is then demodulated, as an AM radio

signal. The demodulator output is low-pass filtered to

Society of Motion Picture and Television Engineers, Standard

No. TH 22.51, 862 Scarsdale Avenue, Scarsdale, N.Y. 10583.

Deutsches lnstitut fur Normung e V, No. 45403 Blatt 3 and 4,

January 1975, Beuth Verlag GmbH, Berlin 30 and Koln 1.

'

International Telephone Consultative Committee.

01)

SMPTE~,

High Frequency

Oscillator

-

Fig. 2-7. Block diagram of basic IM analyzer.

Scans

by

ARTEK

MEDU

=>

Meter

2958-06

ENGLISH

2-9

Page 29

Operating Instructions-AA

remove the residual carrier (high frequency) components.

The amplitude of the low frequency modulation is displayed as a percentage of the high frequency level.

As shown in Fig. 2-8, when this composite signal is

applied to the device, the output waveform isdistorted. As

the high frequency tone is moved along the transfer

characteristic, by the low frequency tone, its amplitude

changes. This results in low frequency

tion of the high frequency tone. This modulation is

apparent in the frequency domain as sidebands around

the high frequency tone. The power in these sidebands

represents nonlinearity in the device under test.

The amplitude ratio of low to high frequencies should

be between

ly adjusts calibration to compensate for the selected test

signal ratio. Some additional range is provided in this

circuitry to enable measurement of devices with nonflat

frequency response.

4.1 and 1.1. The AA 501 circuitry automatical-

501

amplitudemodula-

7

SMPTE standard test frequencies are 60 Hz and

The DIN standard is virtually identical to the SMPTE

standard except for the two frequencies used. They may

be any pair of octave band center frequencies, with the

upper at least eight times as high as

8 kHz are common). The AA 501 can accept a wide range

of test frequencies as shown in the Specification section.

CCIF difference frequency distortion is measured with

two high frequency sine waves driving the device under

test. Both are of equal level and closely spaced in

frequency. Nonlinearities in the device under test cause

the sine wavesto cross modulate. This creates new signals

at various sum

For example, the commonly used 14 kHz and 15

frequencies produce 1 kHz, 13 kHz, 14 kHz, 15 kHz,

16 kHz, 28 kHz, etc. Ideally, one would measureeach new

component with a tunable filter such as a spectrum

analyzer. However, this is usually limited to an 80 dB

dynamic range and is very tedious, Agood measureof this

anddifferencefrequenciesfrom

thelower (250 Hzand

kHz.

theinputs.

kHztest

-

Transfer (input-output)

characteristics of

test device

I

ENGLISH

2-10

Fig.

2-8.

IM

test of transfer characteristics in time and frequency domain.

Scam

by

ARTEK

MEDLd

=>

2958-07

Page 30

Operating Instructions-AA

501

distortion may be obtained by measuring only the

difference frequency (in this example 1 kHz). If only the

low frequency component is measured, it is called a CClF

second order difference frequency distortion test.

To measure two tone difference frequency distortion

the device is excited with two input signals as described

above. The output of the device is low-pass filtered to

extract the difference frequency. The level of this compo-

nent is expressed as a percentage of the high frequency

signals and is another measure of nonlinearity.

The AA 501 CCIF difference frequency mode will

accept any pair of input frequencies which are within

limitsas listed in

of the two signals should be equal.

IM

Distortion Measurement Procedure (Option

Intermodulation and THD testing aresimilar, using the

AA 501 (Option

signal source to the device under test, set the INPUT

LEVEL RANGE as described in the THD section. Press the

IMD FUNCTION button and select a distortion range.

Selecting AUTO RANGE or dB provides automatic ranging. The AA 501 accepts either a SMPTE,

difference frequency test signal. Selection between the

necessary analyzing circuits is accomplished

automatically.

There is a moveable jumper inside the AA 501 to allow

selection of SMPTE-DIN, CClF or automatic selection

between the two modes. Defeating the automatic test

selection circuitry is recommended if making

modulation distortion measurements greater than 20%.

Refer any jumper changes to qualified service personnel.

The

LO

will have little effect. The 400 Hz HI PASS and the 'A'

WEIGHTING filters will cause erroneous readings

because the

tests fall between 50 Hz and

activated in the

components being measured.

thespecification section. Theamplitudes

01)

01 only). After

PASS filters may beselected inthe IM mode but

IM components of interest generated by the

IM mode attenuate someof the frequency

connectingtheappropriate

DIN, or a CCIF

inter-

1

kHz. These filters, when

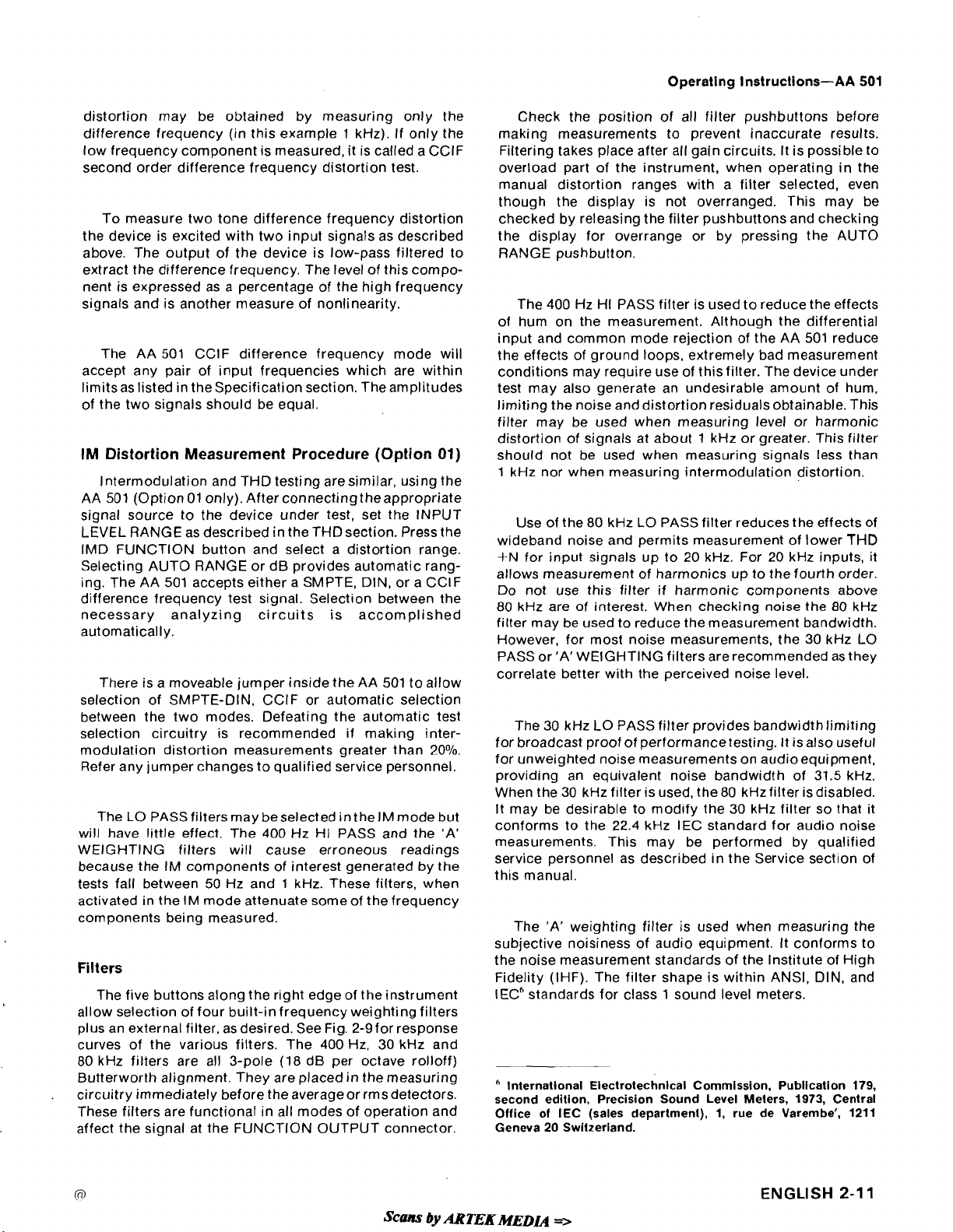

Filters

The five buttons along the right edge of the instrument

allow selection of four built-in frequency weighting filters

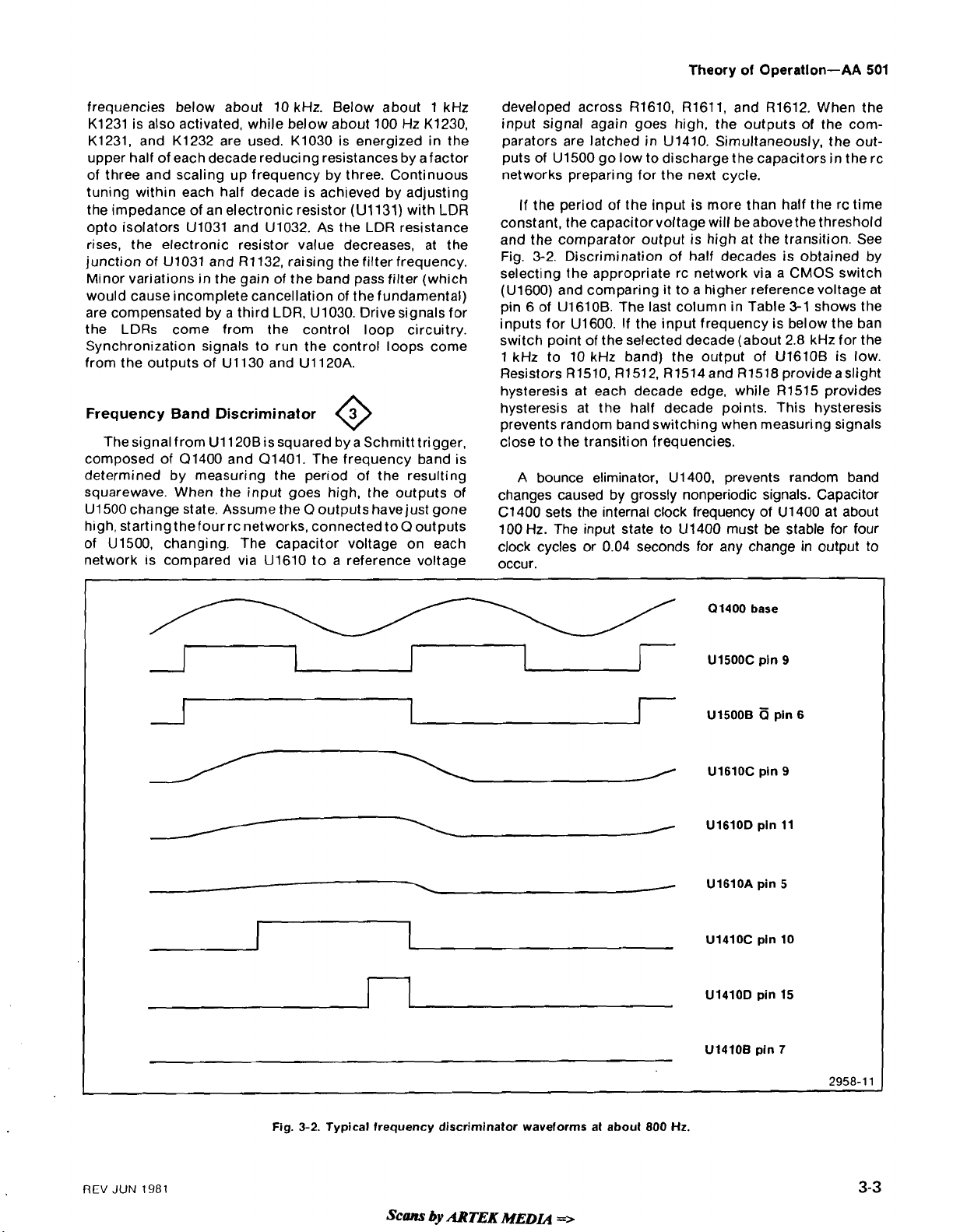

plus an external filter, as desired. See Fig.

curves of the various filters. The 400 Hz, 30 kHz and

80 kHz filters are all 3-pole (18 dB per octave

Butterworth alignment. They are placed in the measuring

circuitry immediately before the average or rms detectors.

These filters are functional in all modes of operation and

affect the signal at the FUNCTION OUTPUT connector.

2-9for response

rolloff)

Check the position of all filter pushbuttons before

making measurements to prevent inaccurate results.

Filtering takes place after all gain circuits. It is possible to

overload part of the instrument, when operating in the

manual distortion ranges with a filter selected, even

though the display is not overranged. This may be

checked by releasing the filter pushbuttons and checking

the display for overrange or by pressing the AUTO

RANGE pushbutton.

The 400 Hz HI PASS filter is used to reduce the effects

of hum on the measurement. Although the differential

input and common mode rejection of the AA 501 reduce

the effects of ground loops, extremely bad measurement

conditions may require use of this filter. The device under

test may also generate an undesirable amount of hum.

limiting the noise and distortion residuals obtainable. This

filter may be used when measuring level or harmonic

distortion of signals at about 1 kHz or greater. This filter

should not be used when measuring signals less than

1

kHz nor when measuring intermodulation distortion.

Use of the 80 kHz LO PASS filter reduces the effects of

wideband noise and permits measurement of lower

+N for input signals up to 20 kHz. For 20 kHz inputs, it

allows measurement of harmonics up to the fourth order.

Do not use this filter if harmonic components above

80 kHz are of interest. When checking noise the 80 kHz

filter may be used to reduce the measurement bandwidth.

However, for most noise measurements, the 30 kHz LO

PASS or 'A' WEIGHTING filters are recommended as they

correlate better with the perceived noise level.

The 30 kHz LO PASS filter provides bandwidth limiting

for broadcast proof of performancetesting. It is also useful

for unweighted noise measurements on audioequipment.

providing an equivalent noise bandwidth of 31.5 kHz.

When the 30 kHz filter is used, the 80

It may be desirable to modify the 30 kHz filter so that it

conforms to the 22.4 kHz IEC standard for audio noise

measurements. This may be performed by qualified

service personnel as described in the Service section of

this manual.

The 'A' weighting filter is used when measuring the

subjective noisiness of audio equipment. It conforms to

the noise measurement standards of the Institute of High

Fidelity (IHF). The filter shape is within ANSI, DIN, and

IECQtandards for class 1 sound level meters.

International Electrotechnlcal Commlssion. Publlcatlon

second edition, Precision Sound Level Meters,

Office of IEC (sales

Geneva

20

Switzerland.

department),

kHzfilter is disabled.

1,

rue de Varembe',

1973,

THD

179,

Central

1211

ENGLISH

2-11

Page 31

Operstlng

Instructions-AA

501

10

Hz

20 30 50 100

Hz

200 300 500

Flg. 2-9. Response curves for AA

Connections for an external filter are also provided.

Press the EXT FILTER pushbutton. Connect the external

filter between the FUNCTION OUTPUT and the AUXILIARY INPUT. One application for the external filter is

selective measurement of individual harmonics or components of an input signal. This may be accomplished

using a TEKTRONIX AF 501

filter. Adjust the AF 501 to the desired

cy; set the mode switch to NARROW and the gain to

bandpass filter as an external

harmonicfrequen-

1.

Another application, using the external filter, is the

measurement of noise according to the

CCIR/ARM~

method. A C~1R"ilter is inserted as an external filter with

the response button in the AVG position.

Dolby et al, CCIR/ARM: A Practical Nolse-Measurement

Method, Journal of the

March 1979, p. 149.

lnternatlonal Radio

Audio Englneerlng Soclety,

Consultative

Committee.

Vol.

27,

No.

3,

1

kHz 2

501

filters.

5

10 kHz 20 30 50 100 kHz

2958-08A

When the AA 501 is used as a sound level meter, an

octave or one-third octave filter set may be used to

measure sound spectra.

Therear interface outputs may be

used to drive a storage oscilloscope or chart recorder for

plots, as desired.

Displays

The AA 501 provides two forms of display for

measurements. The digital readout displays the selected

function with units. Overrange indication blanks all digits

and displays a 1 in the most significant digit slot.

For rapid nulling or peaking applications, the digital

display is supplemented by an uncalibrated LED bar graph

for an analog meter-like display. The bar graph responds

logarithmically, with each segment representing ap-

2.5

proximately a

Additionally, the intensity of the segments is modulated

between steps permitting resolution of changes as small

as 0.5 dB. The range of the bar graph is determined

dB change in the selected function.

by

the

ENGLISH

2-12

Scans

by

ARTEK

MEDL4

=>

REV

NOV

1981

Page 32

Operating Instructions-AA

501

measurement range in use. When using this featureit may

be desirable to select a manual range to prevent confusing

displays caused by autoranging.

Monitoring

The interface capabilities of the AA 501 may aid

considerably in the interpretation of measurements.

The INPUT MONITOR connector provides a fixed

(-1

amplitude version

signals of 50

input signal on an oscilloscope, without constantly read-

justing the oscilloscope sensitivity. At input levels below

about 50

ly 26 dB (A =20) above the input signal level.

The FUNCTION OUTPUT is taken after the distortion

measurement and high gain amplifier circuitry. It can be

used for monitoring the signal read on the display. The

signal at the FUNCTION OUTPUT connector is

full scale reading on the display. In the level function this

connector becomes an amplified version of the input

signal. The gain from the input to this output is dependent

on the LEVEL RANGE switch, and is given in Table

When the AA 501 is used as a constant gain differential

amplifier the INPUT LEVEL RANGE switch must be set to

a fixed range. In the distortion function this output can be

displayed

components. This output may also be used to drive a

spectrum analyzer or selective voltmeter for examining

the individual harmonics or modulation products. When

an oscilloscope is used, the triggering signal is best taken

from the sync

possible (for example in tape recorder or Telco link

testing) it should be obtained from the INPUT MONITOR

connector on the AA 501.

mV or greater. This allows display of the

mVthe INPUT MONITOR signal isapproximate-

in an oscilloscope to view the distortion

V rms) of the input signal for input

2

V for a

2-1.

output on the oscillator. If this is not

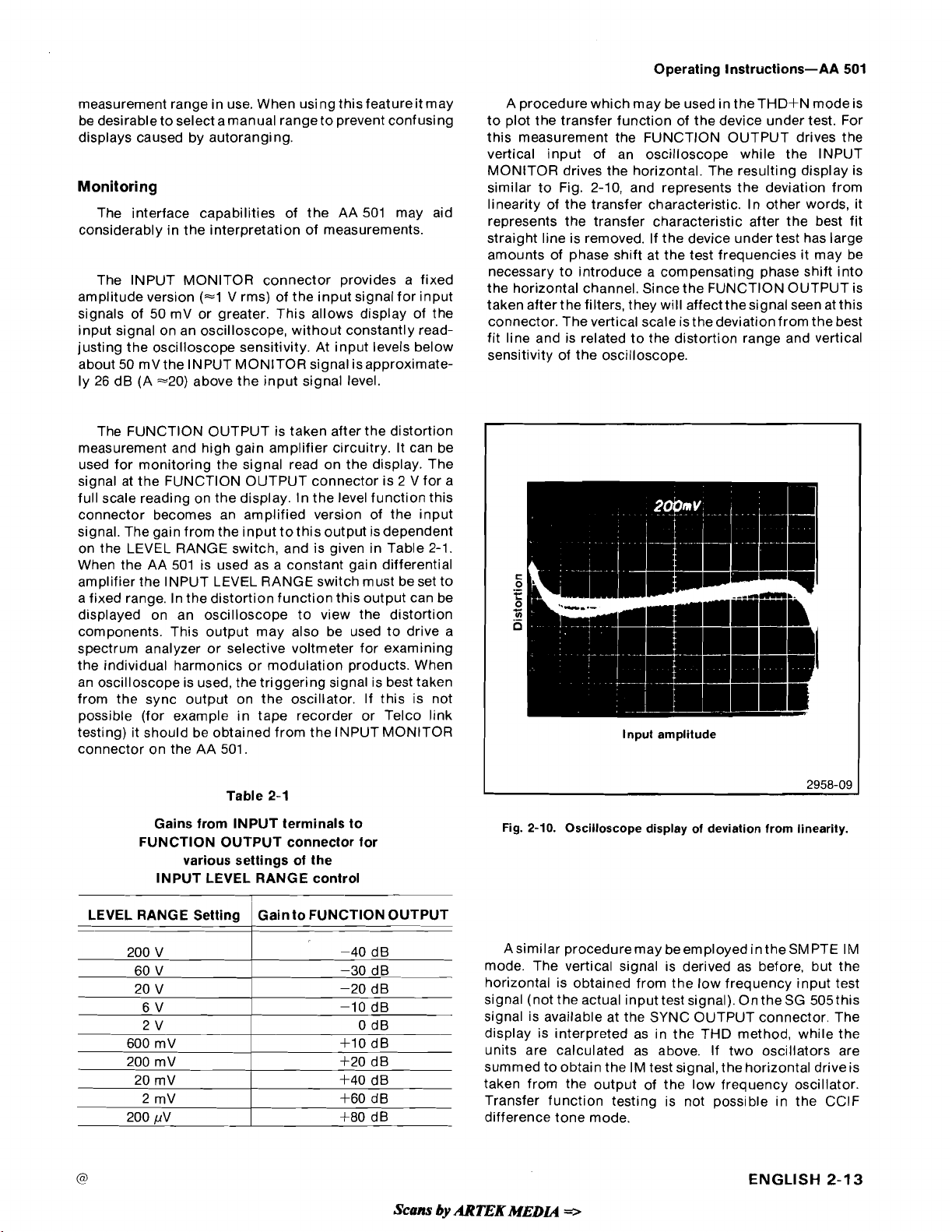

A procedure which may be used in

to plot the transfer function of the device under test. For

this measurement the FUNCTION OUTPUT drives the

vertical input of an oscilloscope while the INPUT

MONITOR drives the horizontal. The resulting display is

similar to Fig. 2-10, and represents the deviation from

linearity of the transfer characteristic. In other words, it

represents the transfer characteristic after the best fit

straight line is removed. If the device under test has large

amounts of phase shift at the test frequencies it may be

necessary to introduce a compensating phase shift into

the horizontal channel. Since the FUNCTION OUTPUT is

taken after the filters, they

connector. The vertical scale is the deviation from the best

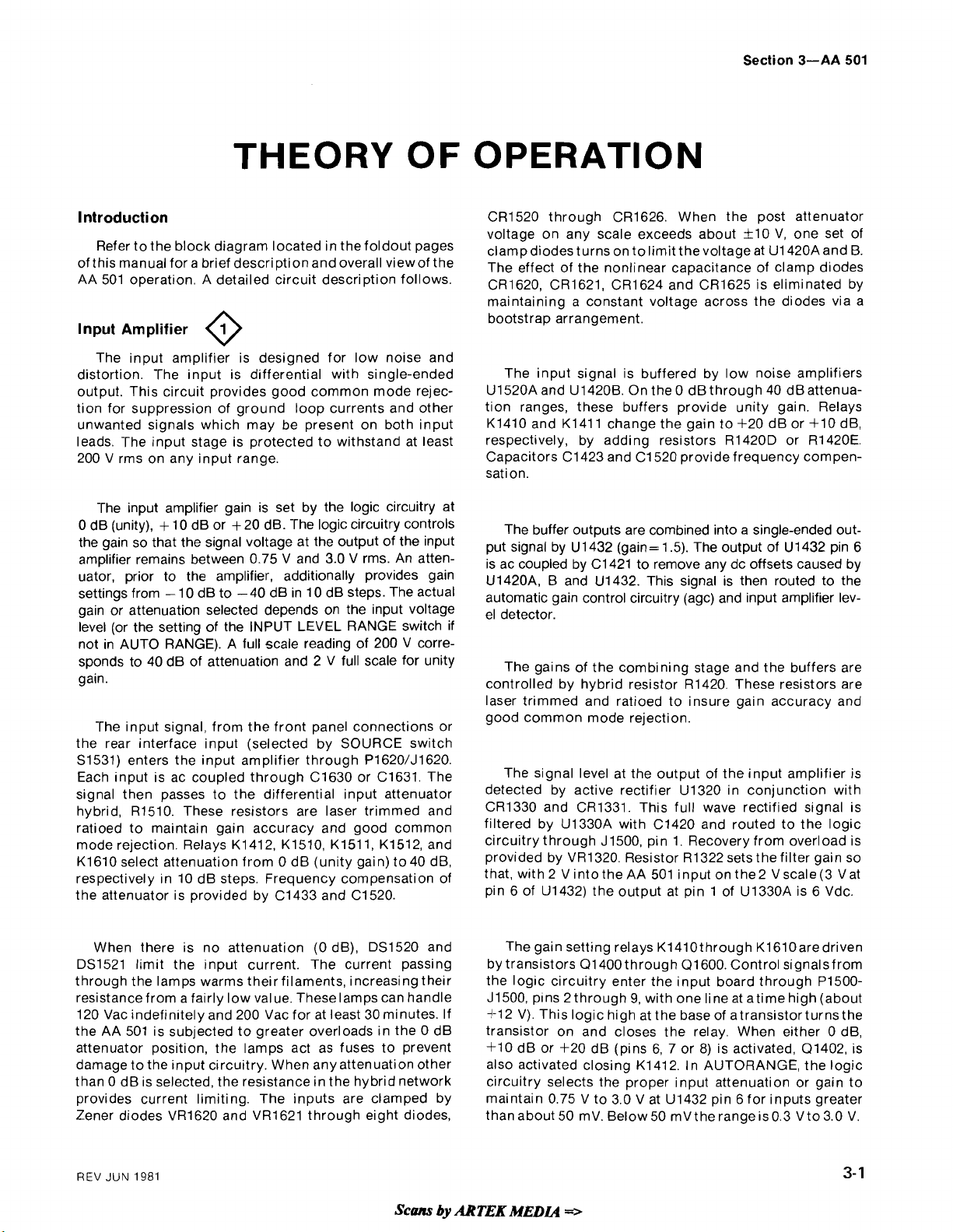

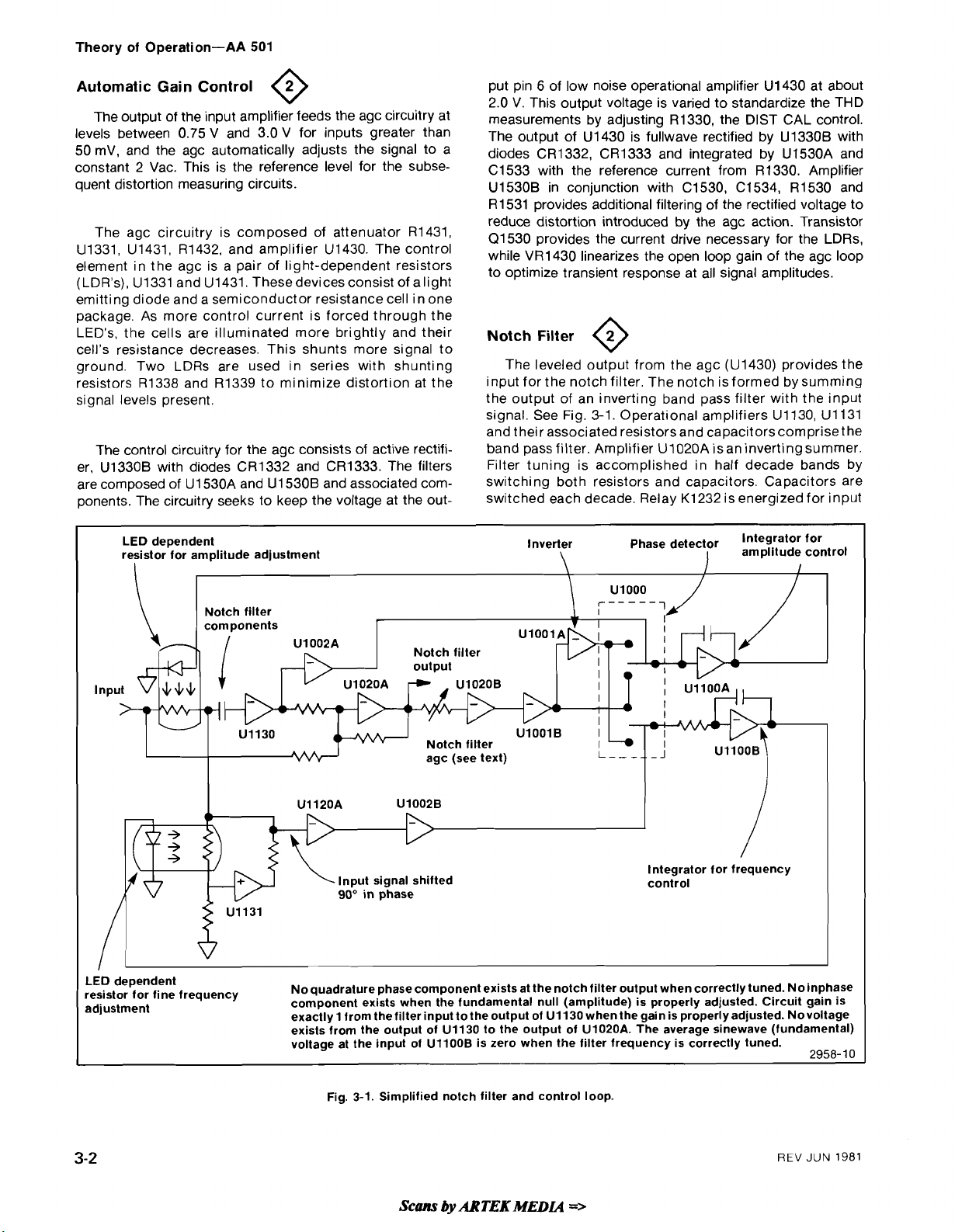

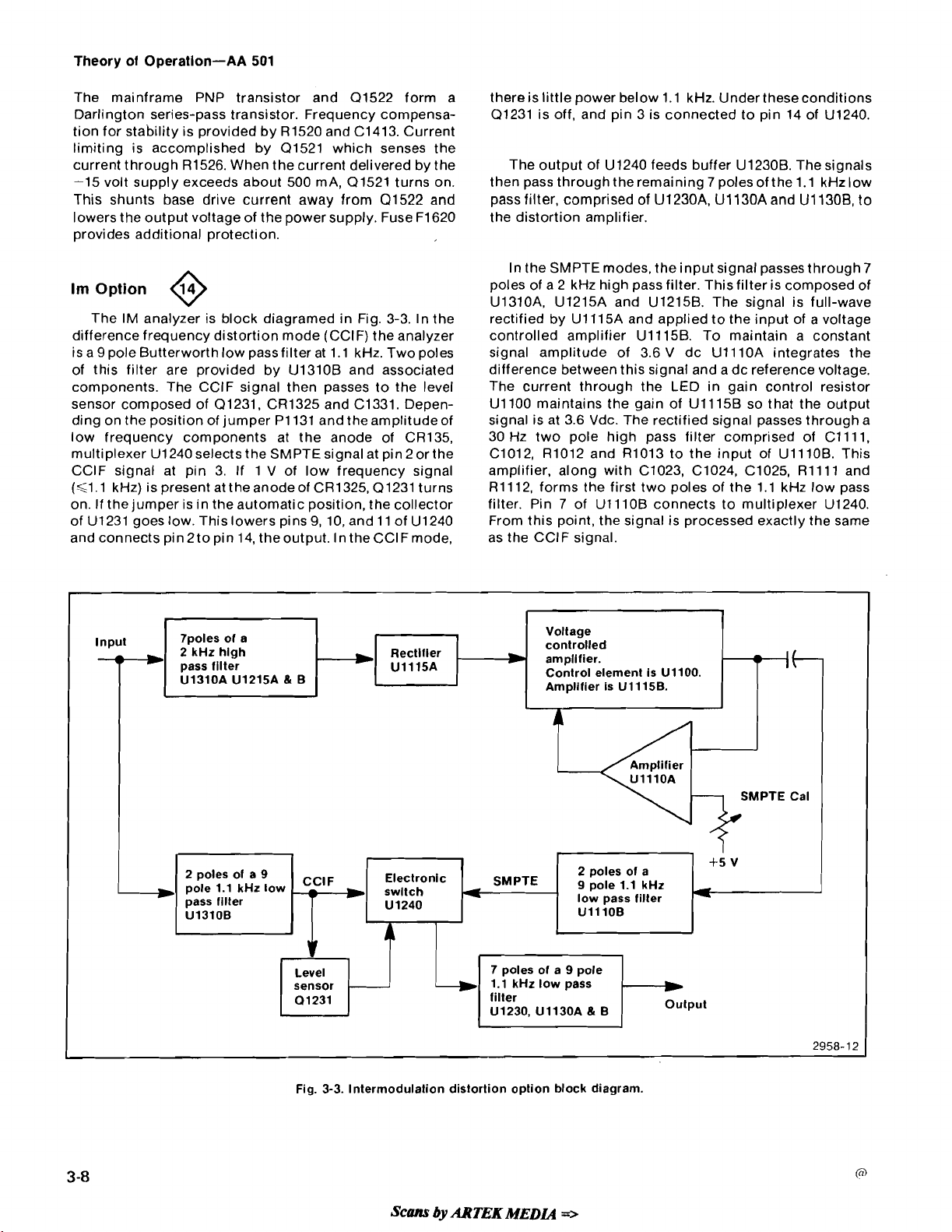

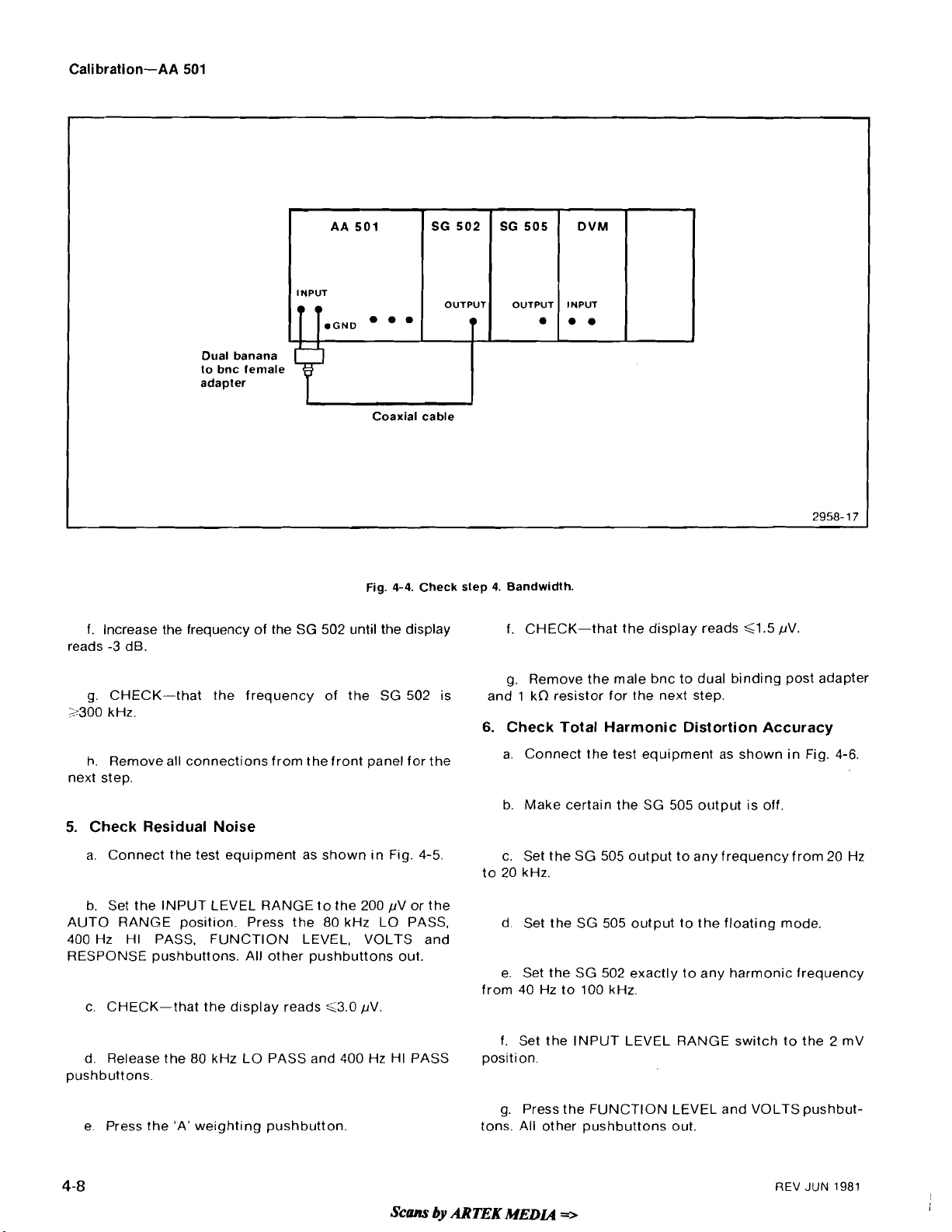

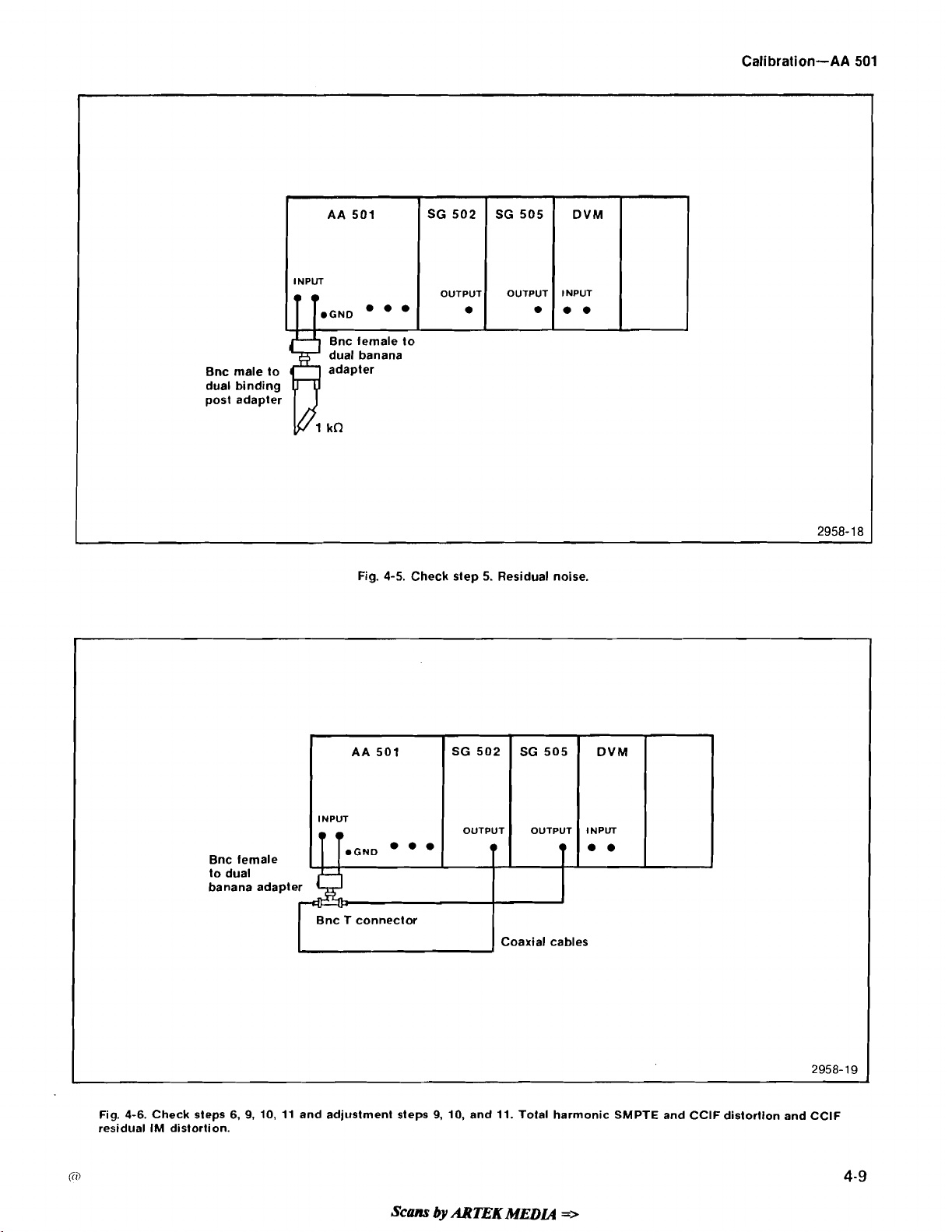

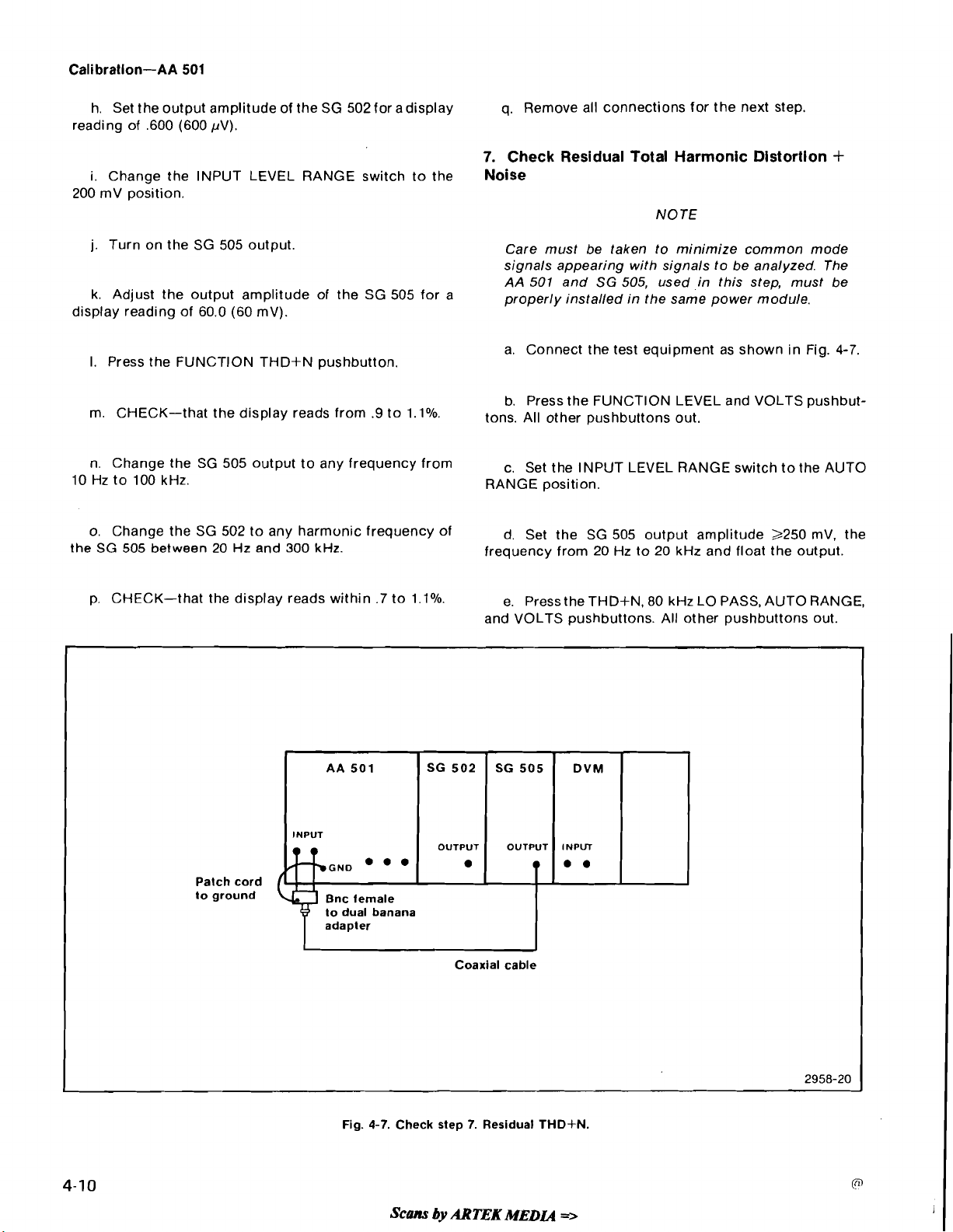

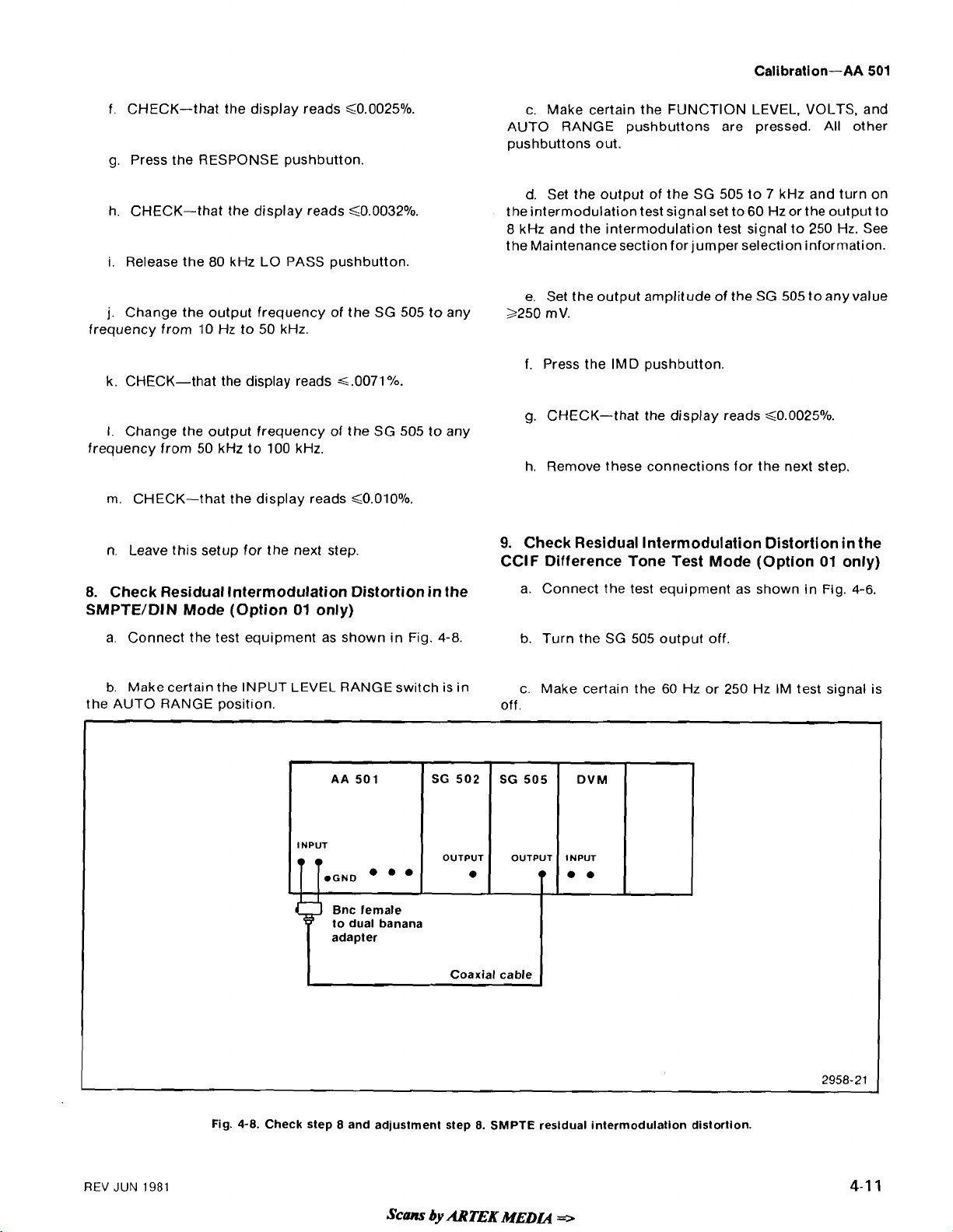

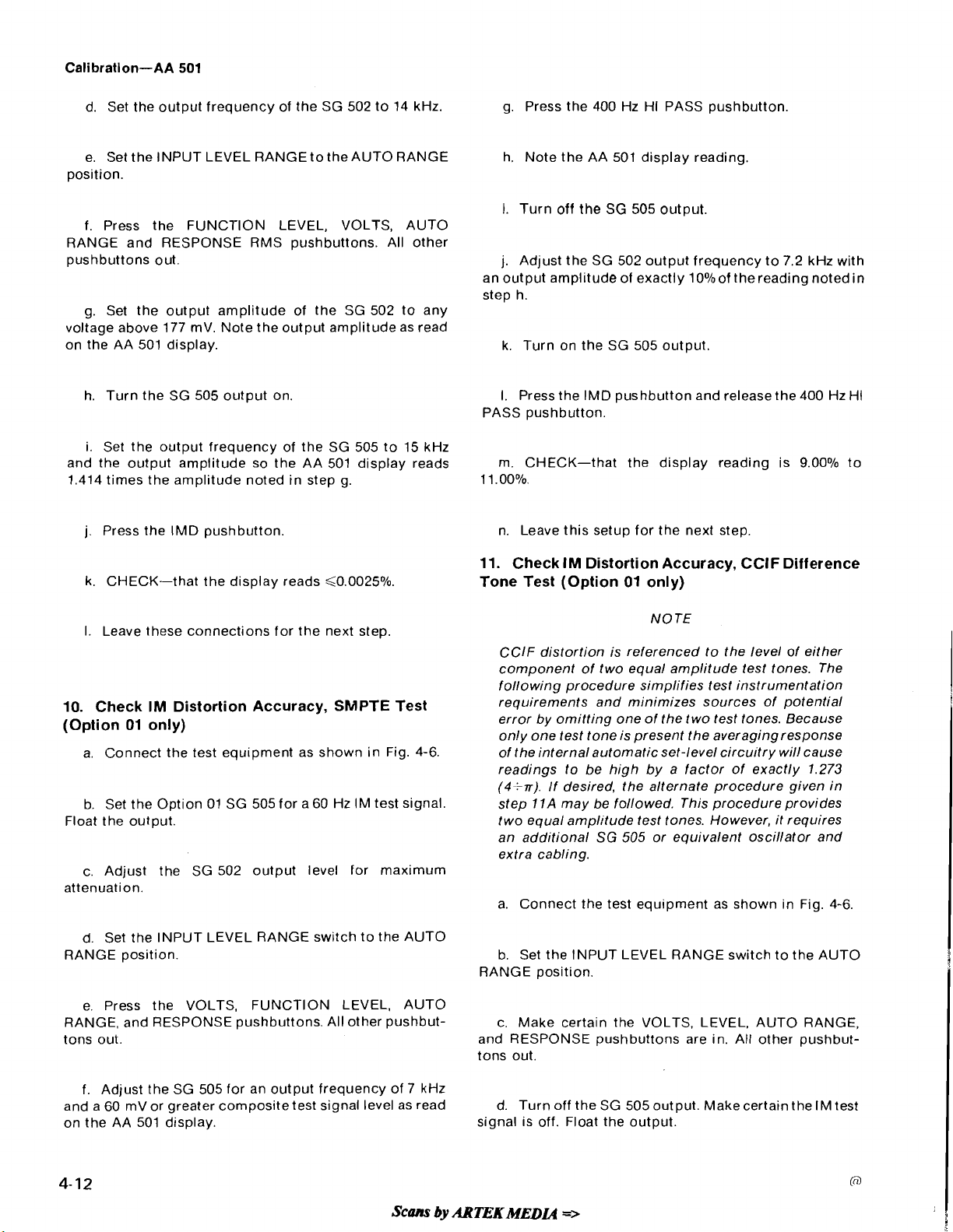

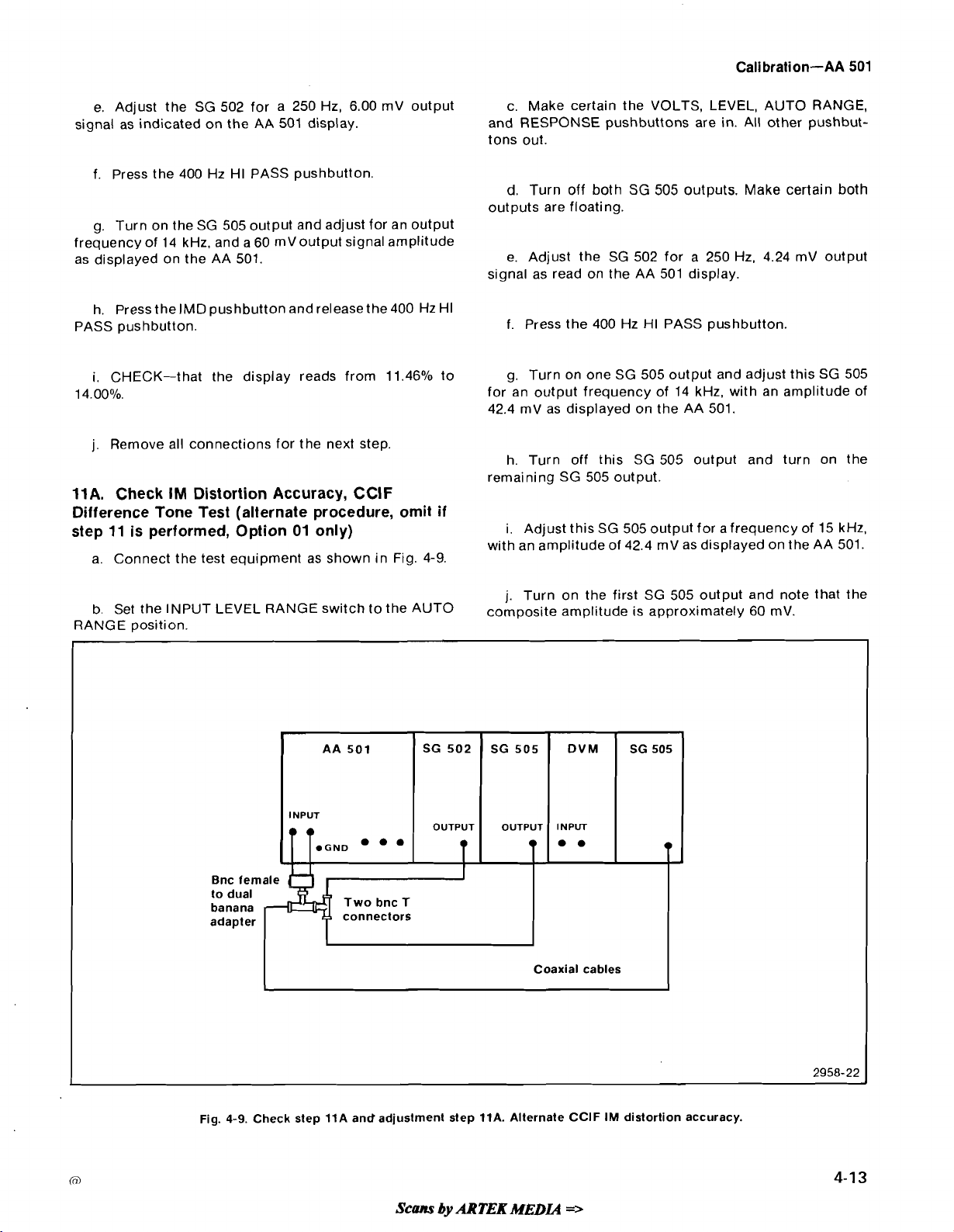

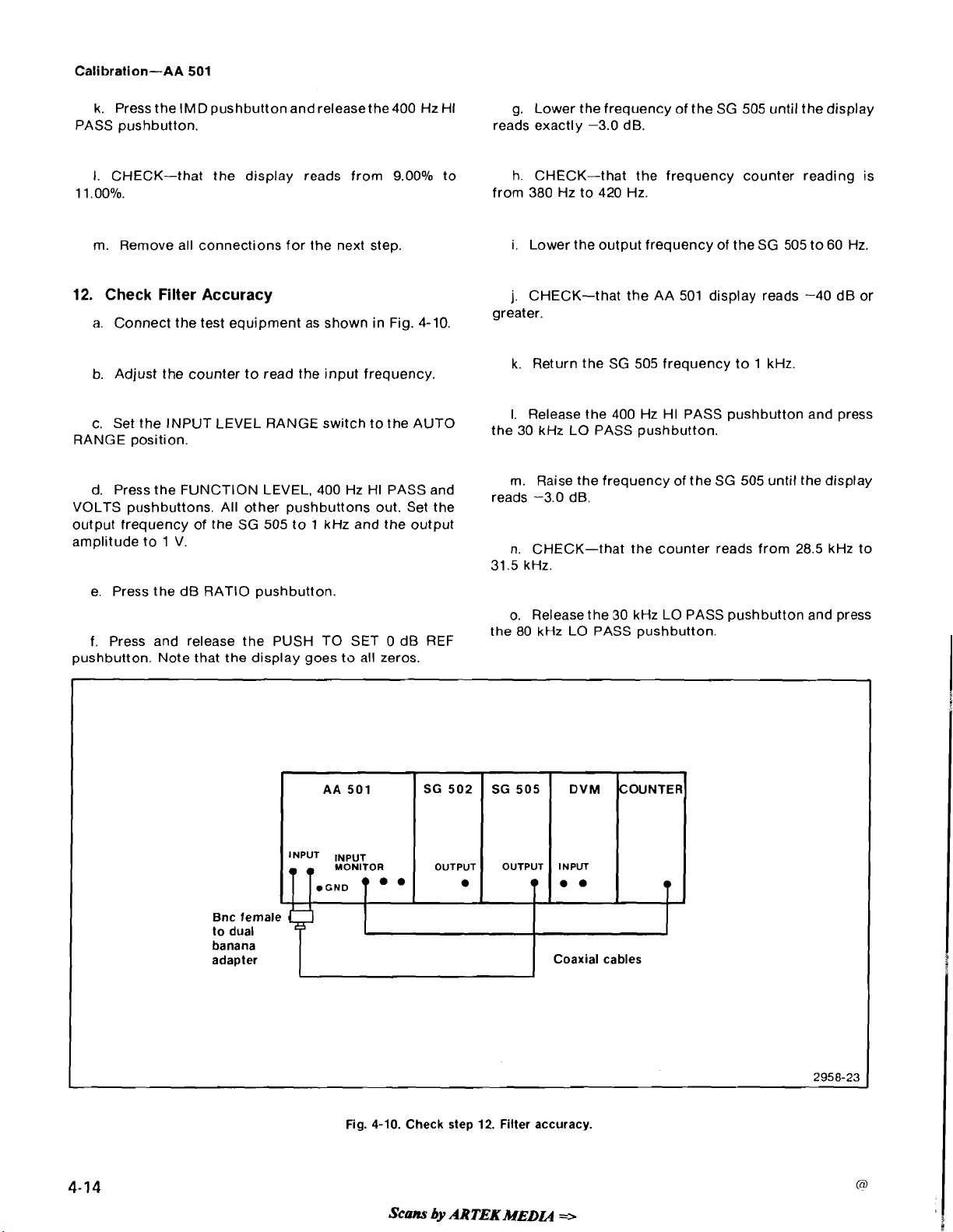

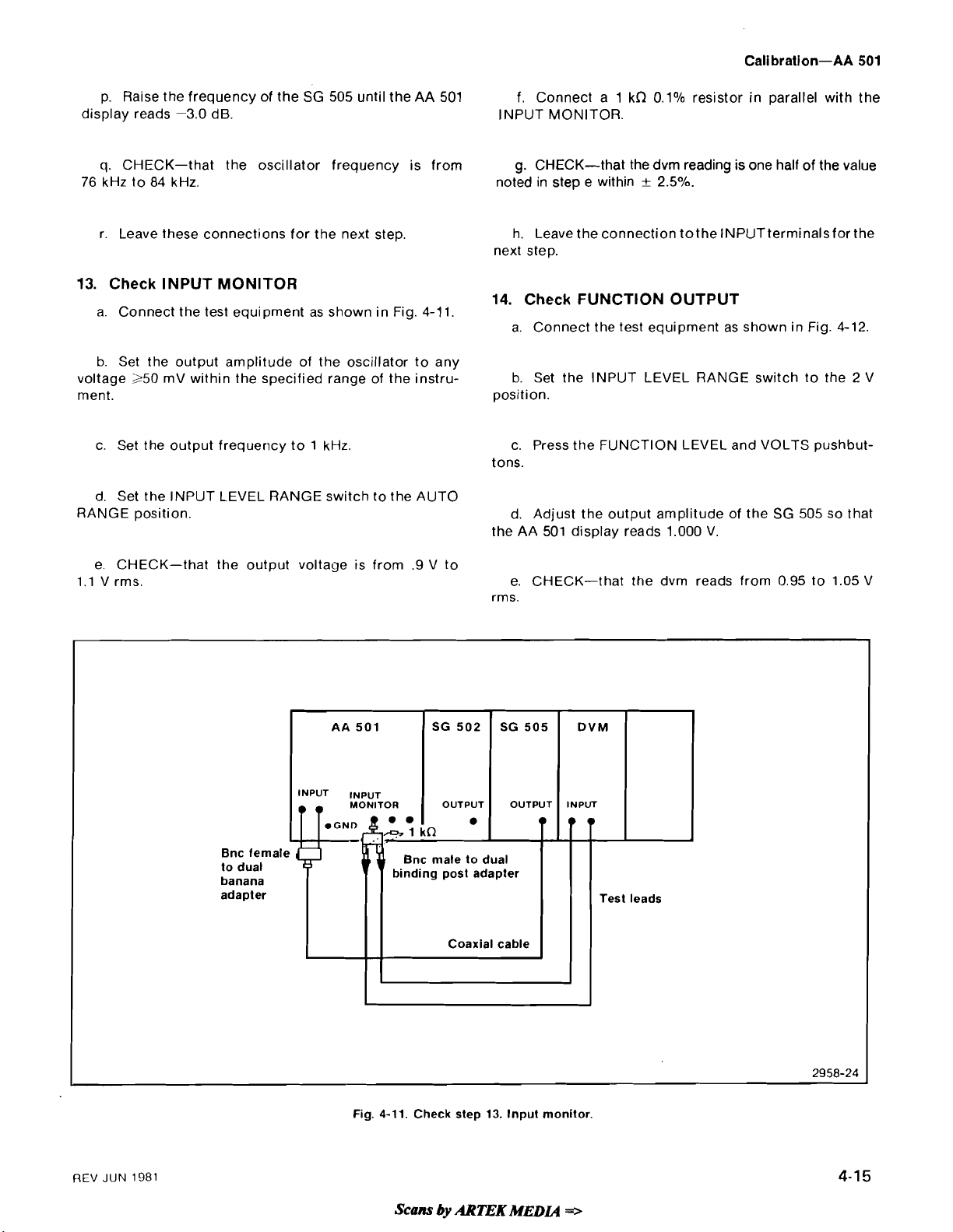

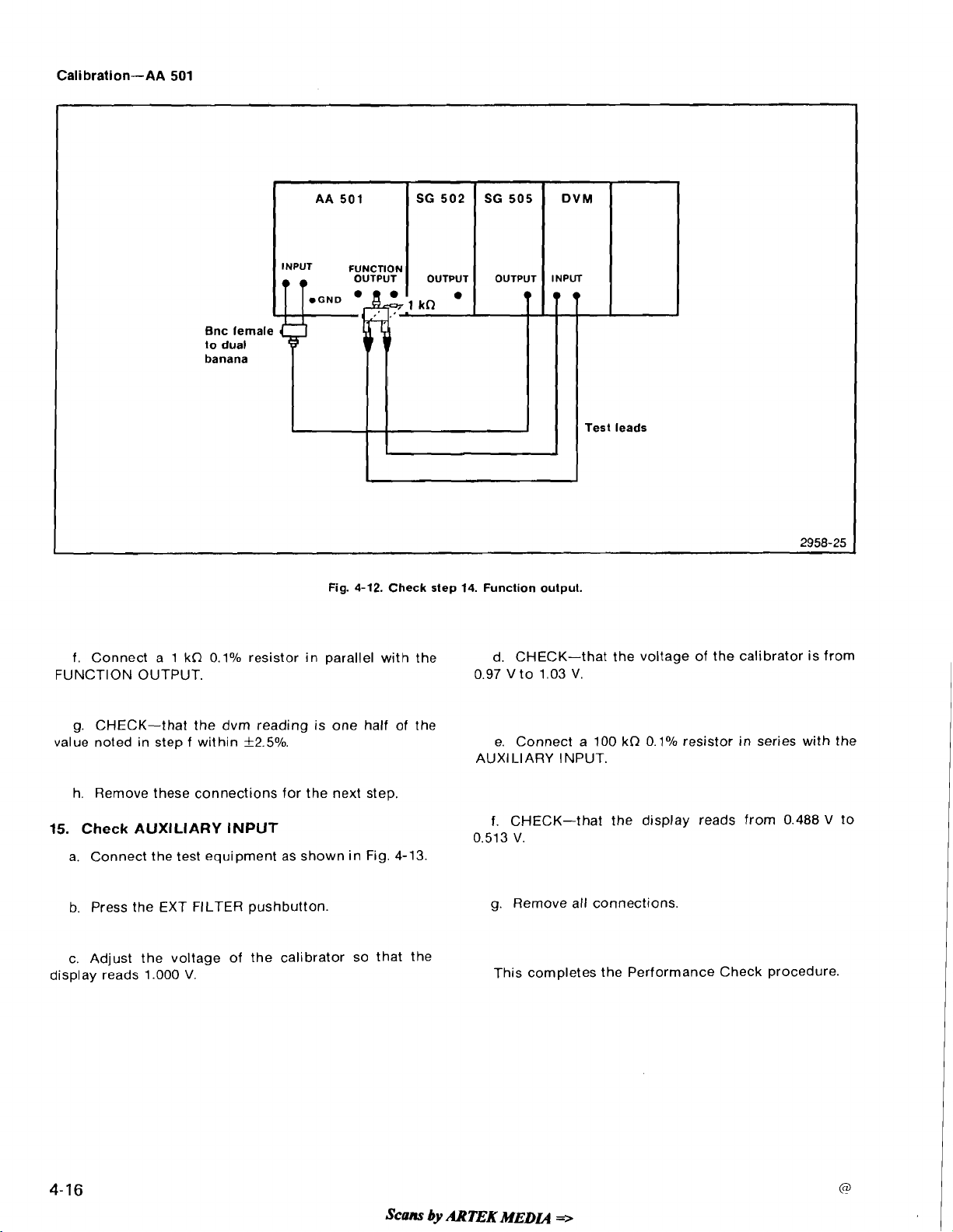

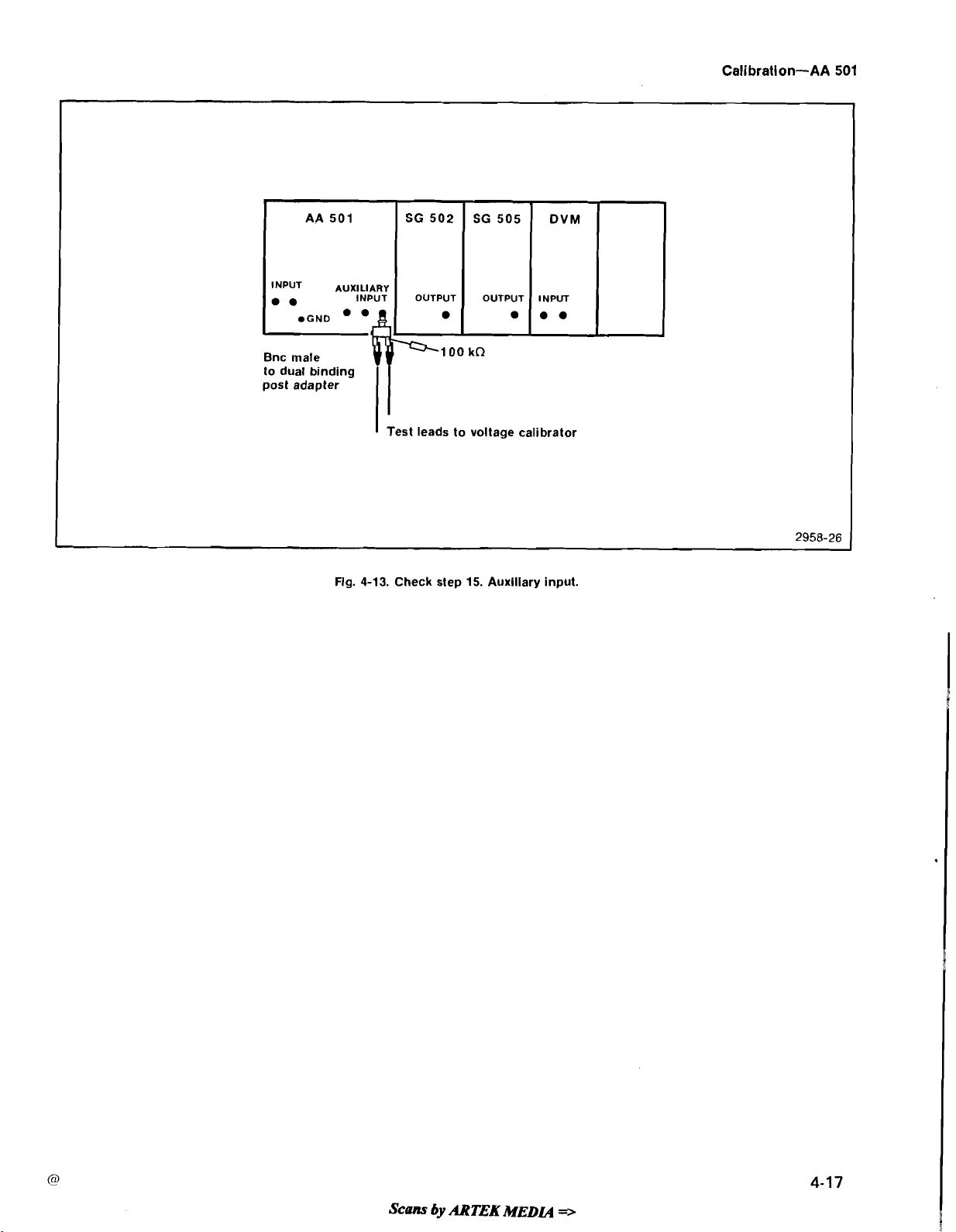

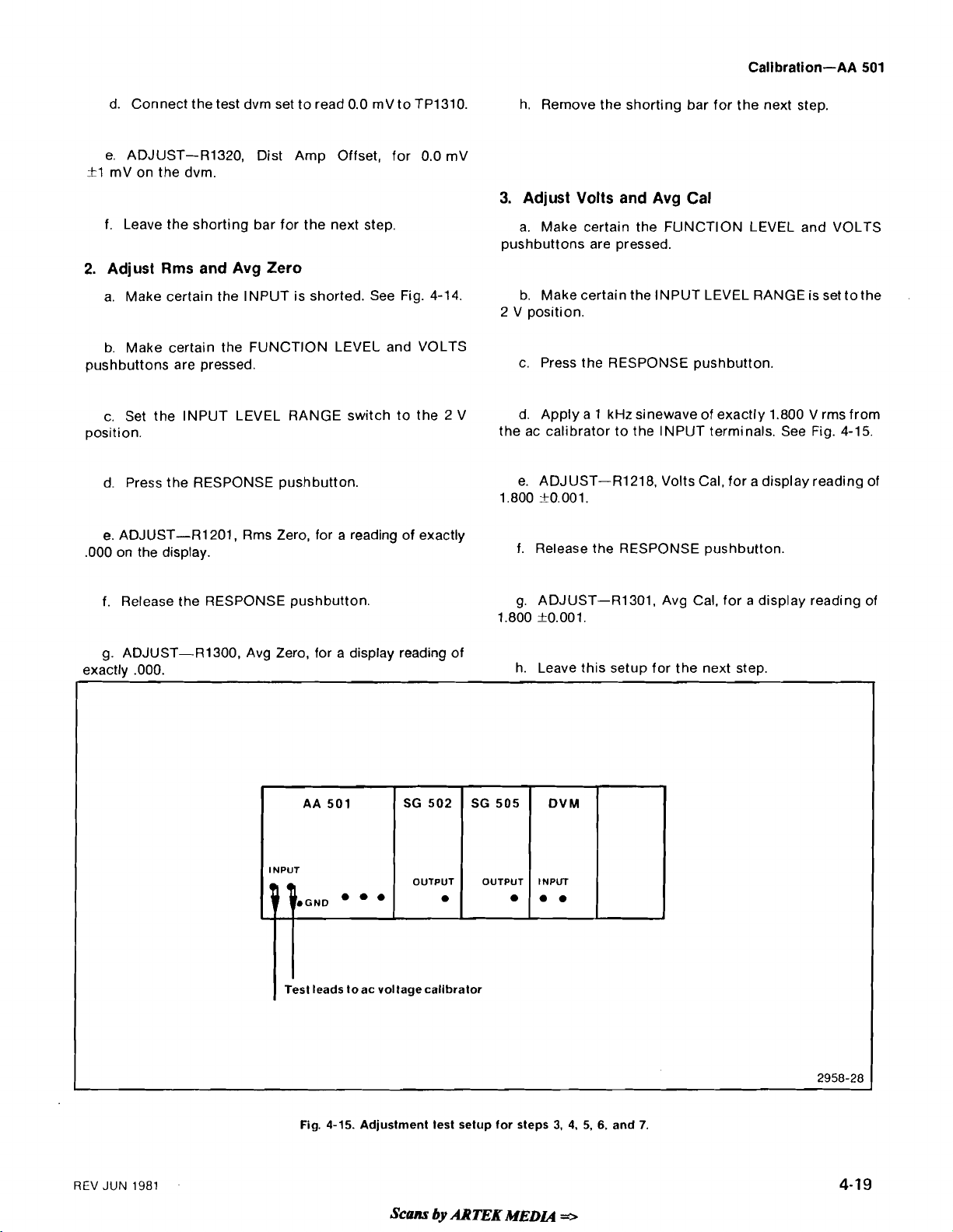

fit line and is related to the distortion range and vertical