Page 1

Page 2

Copyright E Sony/Tektronix Corporation. 1994. All rights reserved.

Copyright E T ektronix, Inc. 1994. All rights reserved.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Printed in Japan.

Sony/T ektronix Corporation, P.O. Box 5209, T okyo Int’l, Tokyo 100–31 Japan

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

WARRANTY

T ektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1) year

from the date of shipment. If any such product proves defective during this warranty period, T ektronix, at its option, either

will repair the defective product without charge for parts and labor, or will provide a replacement in exchange for the

defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by T ektronix, with shipping charges prepaid.

T ektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

T ektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than T ektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; or c) to service a product that has been

modified or integrated with other products when the effect of such modification or integration increases the time or

difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THIS PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESSED OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUST OMER FOR BREACH OF THIS WARRANTY. TEKTRONIX

AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

Page 5

Table of Contents

Getting Started

Operating Basics

General Safety Summary vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Description 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options And Accessories 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Source 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Fuse 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Cord 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting the Probe 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting Output Cables 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functional Check 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Turning On Power 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self-Calibration 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functional Overview 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Isolator Front Panel 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Isolator Rear Panel 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Isolator Scale Factor 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Probes 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Voltage Probe 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Common Lead Length 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A620 Current Probe 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference

A6907 & A6909 User Manual

Reference Introduction 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Adjustments 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting Offset Values 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting Gain Values 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Floating Measurements 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Common Mode Slew Rate 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Probe 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Common Lead Connections 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Common Mode Rejection Ratio (CMRR) 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GPIB Programming 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GPIB Requirements 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the GPIB Parameters 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Other Documents You Will Need 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GPIB Interface Functions 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interface Messages 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 6

Contents

Remote, Local and Lockout 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Syntax 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Command Configuration 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Header 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Arguments 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Delimiters 3–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Short Form 3–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Linking Commands 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Command Groups 3–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Channel Control 3–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration and T esting 3–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status and Events 3–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Synchronization 3–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System 3–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Commands 3–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status and Events 3–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Registers 3–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status Registers 3–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enable Registers 3–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Queues 3–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status and Event Processing Sequence 3–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Messages 3–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Synchronizing Execution 3–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications

Warranted Electrical Characteristics 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T ypical Electrical Characteristics 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Characteristics 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environmental Characteristics 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Certifications and Compliances 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Theory of Operation

Power 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signal 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control and Calibration 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification

Prerequisites 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Equipment 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Offset and Gain Check 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Low-Frequency Pulse Response (Flatness) Check 6–7. . . . . . . . . . . . . . . . . . . . . . .

Rise Time and Aberration Check 6–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bandwidth Check 6–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

A6907 & A6909 User Manual

Page 7

List of Figures

Contents

Figure 1–1: Isolator Setup 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–1: Isolator Front Panel 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–2: Isolator Rear Panel 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–3: Special Voltage Probe and Accessories 2–5. . . . . . . . . . . . . . . . . . . . . .

Figure 2–4: Waveform Distortion from Common Lead Length 2–7. . . . . . . . . . . . .

Figure 2–5: Common Lead Equivalent Circuit 2–7. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–6: A620 Current Probe 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–1: Normal and Common Mode Simplified Circuits 3–6. . . . . . . . . . . . . . .

Figure 3–2: T ypical Stacked GPIB Connectors 3–7. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–3: T ypical GPIB Network Configurations 3–8. . . . . . . . . . . . . . . . . . . . . .

Figure 3–4: The Status Byte Register (SBR) 3–33. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–5: The Standard Event Status Register (SESR) 3–34. . . . . . . . . . . . . . . . . .

Figure 3–6: The Device Event Status Enable Register (DESER) 3–36. . . . . . . . . . . .

Figure 3–7: The Event Status Enable Register (ESER) 3–36. . . . . . . . . . . . . . . . . . . .

Figure 3–8: The Service Request Enable Register (SRER) 3–36. . . . . . . . . . . . . . . . .

Figure 3–9: Status and Event Processing Sequence 3–38. . . . . . . . . . . . . . . . . . . . . . .

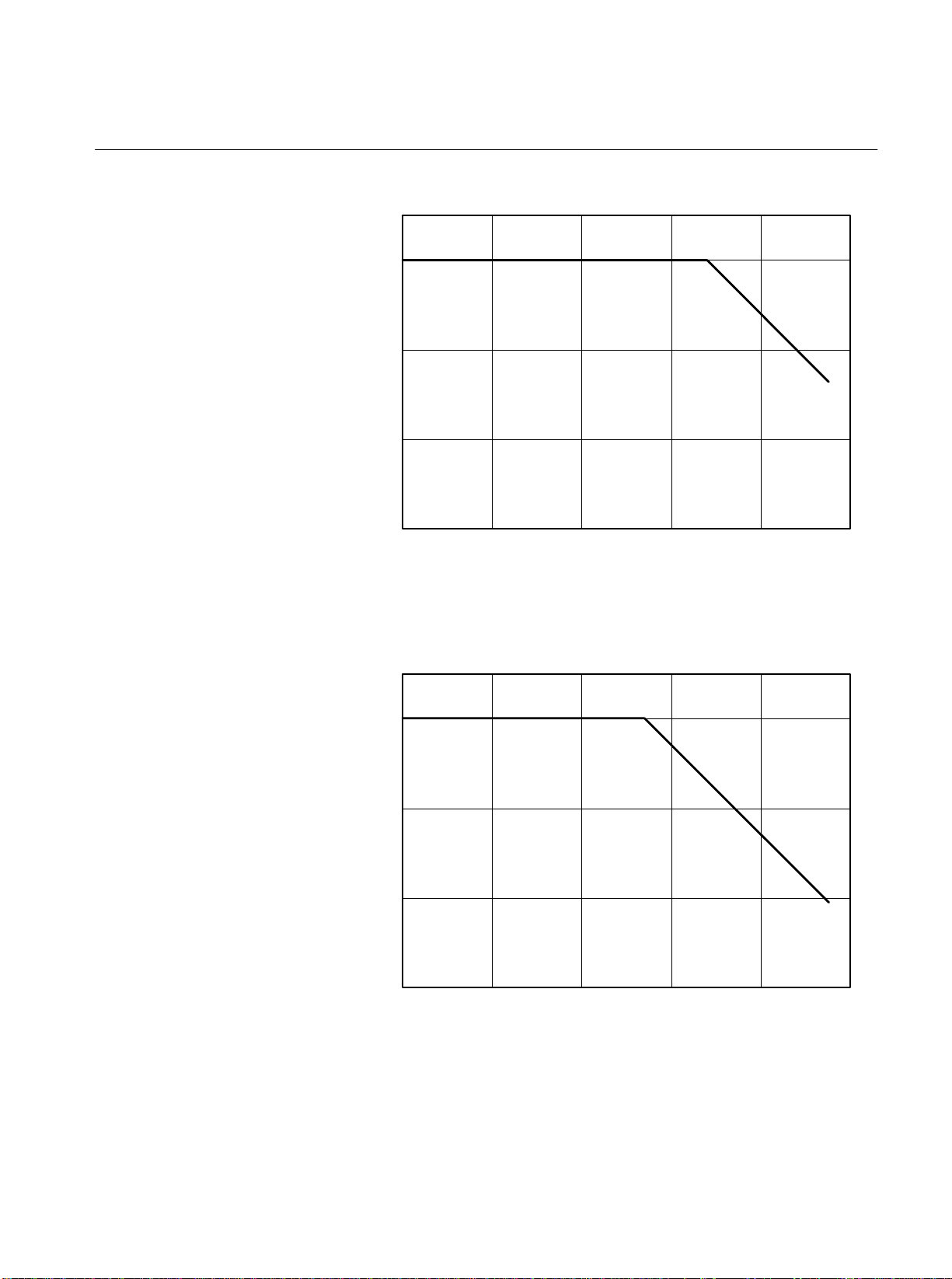

Figure 4–1: Frequency Derating for the Maximum Normal Mode Voltage 4–3. . . .

Figure 4–2: Frequency Derating for the Maximum Common Mode Voltage 4–3. . .

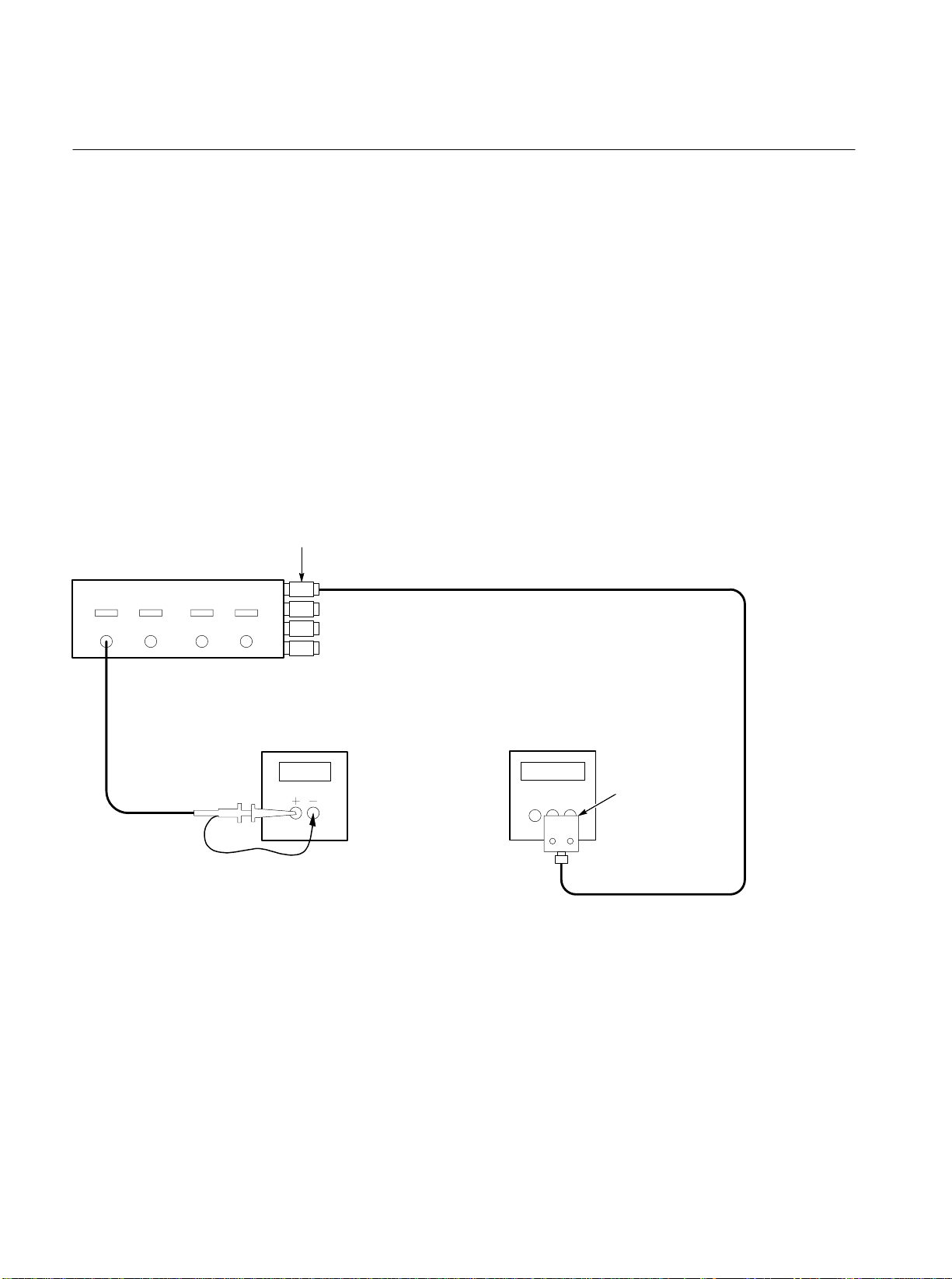

Figure 6–1: DC Offset and Gain Test Setup 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–2: Positive DC Gain T est Setup 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–3: Negative DC Gain T est Setup 6–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–4: Low-Frequency Pulse Response Check Setup 6–7. . . . . . . . . . . . . . . . .

Figure 6–5: Rise Time and Aberrations Check Setup 6–10. . . . . . . . . . . . . . . . . . . . .

Figure 6–6: Bandwidth Check Setup 6–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 7–1: Electrical-to-Optical (E/O) Isolator Adjustment Locations 7–3. . . . . . .

A6907 & A6909 User Manual

iii

Page 8

Contents

List of Tables

Table 1–1: Optional Power Cords 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 1–2: Isolator Error Codes 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 2–1: Isolator Scale Factors 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 3–1: GPIB Functions 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 3–2: BNF Symbols and Meanings 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 3–3: Header Configuration Types 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 3–4: Numeric Expressions 3–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 3–5: Channel Control 3–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 3–6: Calibration and Testing 3–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 3–7: Status and Events 3–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 3–8: Synchronization 3–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 3–9: System Commands 3–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 3–10: SRB Bit Functions 3–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 3–11: SESR Bit Functions 3–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 3–12: Normal Status 3–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 3–13: Command Errors 3–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 3–14: Execution Errors 3–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 3–15: Internal Errors 3–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 3–16: System Events 3–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 4–1: Warranted Electrical Characteristics 4–1. . . . . . . . . . . . . . . . . . . . . . . . .

T able 4–2: Typical Electrical Characteristics 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 4–3: Mechanical Characteristics 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 4–4: Environmental Characteristics 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 4–5: Certifications and Compliances 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 6–1: Required Test Equipment 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 6–2: Isolator Gain Accuracy 6–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T able 6–3: Isolator Test Qualification Record 6–15. . . . . . . . . . . . . . . . . . . . . . . . . .

iv

A6907 & A6909 User Manual

Page 9

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

Injury Precautions

Use Proper Power Cord

Avoid Electric Overload

Ground the Product

Do Not Operate in

To avoid fire hazard, use only the power cord specified for this product.

To avoid electric shock or fire hazard, do not apply a voltage to a terminal that is

outside the range specified for that terminal.

This product is grounded through the grounding conductor of the power cord. To

avoid electric shock, the grounding conductor must be connected to earth

ground. Before making connections to the input or output terminals of the

product, ensure that the product is properly grounded.

To avoid electric shock, do not operate this product in wet or damp conditions.

Wet/Damp Conditions

Do Not Operate in

Explosive Atmosphere

To avoid injury or fire hazard, do not operate this product in an explosive

atmosphere.

Product Damage Precautions

Use Proper Power Source

Do not operate this product from a power source that applies more than the

voltage specified.

Do Not Operate With

Suspected Failures

A6907 & A6909 User Manual

If you suspect there is damage to this product, have it inspected by qualified

service personnel.

v

Page 10

General Safety Summary

Safety Terms and Symbols

Terms in This Manual

Terms on the Product

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product

The following symbols may appear on the product:

DANGER

High Voltage

Certifications and Compliances

CSA Certified Power

Cords

vi

CSA Certification includes the products and power cords appropriate for use in

the North America power network. All other power cords supplied are approved

for the country of use.

Protective Ground

(Earth) Terminal

ATTENTION

Refer to

Manual

Double

Insulated

A6907 & A6909 User Manual

Page 11

Getting Started

Page 12

Page 13

Product Description

The A6907 and A6909 High Voltage Isolators connect “floating” (not referenced

to ground) signals to an oscilloscope or digitizer for measurement. Optical

couplers, insulated transformers, and plastic barriers are used for extremely high

isolation between channels and the chassis, and from channel to channel.

Signals measured between the tip and common connections of the special probes

are fully isolated from ground and other channels. The maximum rated voltage

between the probe tip and probe common (normal mode voltage) is 850 V (DC +

peak AC). The maximum rated voltage between the probe common and chassis

ground (common mode voltage) is also 850 V (DC + peak AC).

The electrical-to-optical (E/O) converter isolates the signal and converts it to an

optical analogue. The optical-to-electrical (O/E) converter demodulates the

optical signal to an electrical signal whose common mode elements have been

rejected. The E/O converter uses a unique low-contact DC to DC converter as a

power source to provide a high degree of isolation.

The A6907 and A6909 satisfy the UL1244, CSA 231, and IEC1010-1 safety

standards for floating measurements. The A6907 and A6909 have the following

special features:

H DC to 60 MHz bandwidth

H Self-calibration function for accurate measurements

H Portable configuration

H Excellent linearity and low interference

H External control through GPIB interface standard on the A6907

(option 10 on the A6909)

H 20 kV/ms slew rate

A6907 & A6909 User Manual

1-1

Page 14

Product Description

1-2

A6907 & A6909 User Manual

Page 15

Options And Accessories

Several options and accessories are available for your isolator. Please review this

listing to select the items that best suit your application.

Options

The following options are available for the A6907 and A6909:

H Option 10 includes the GPIB interface on the A6909.

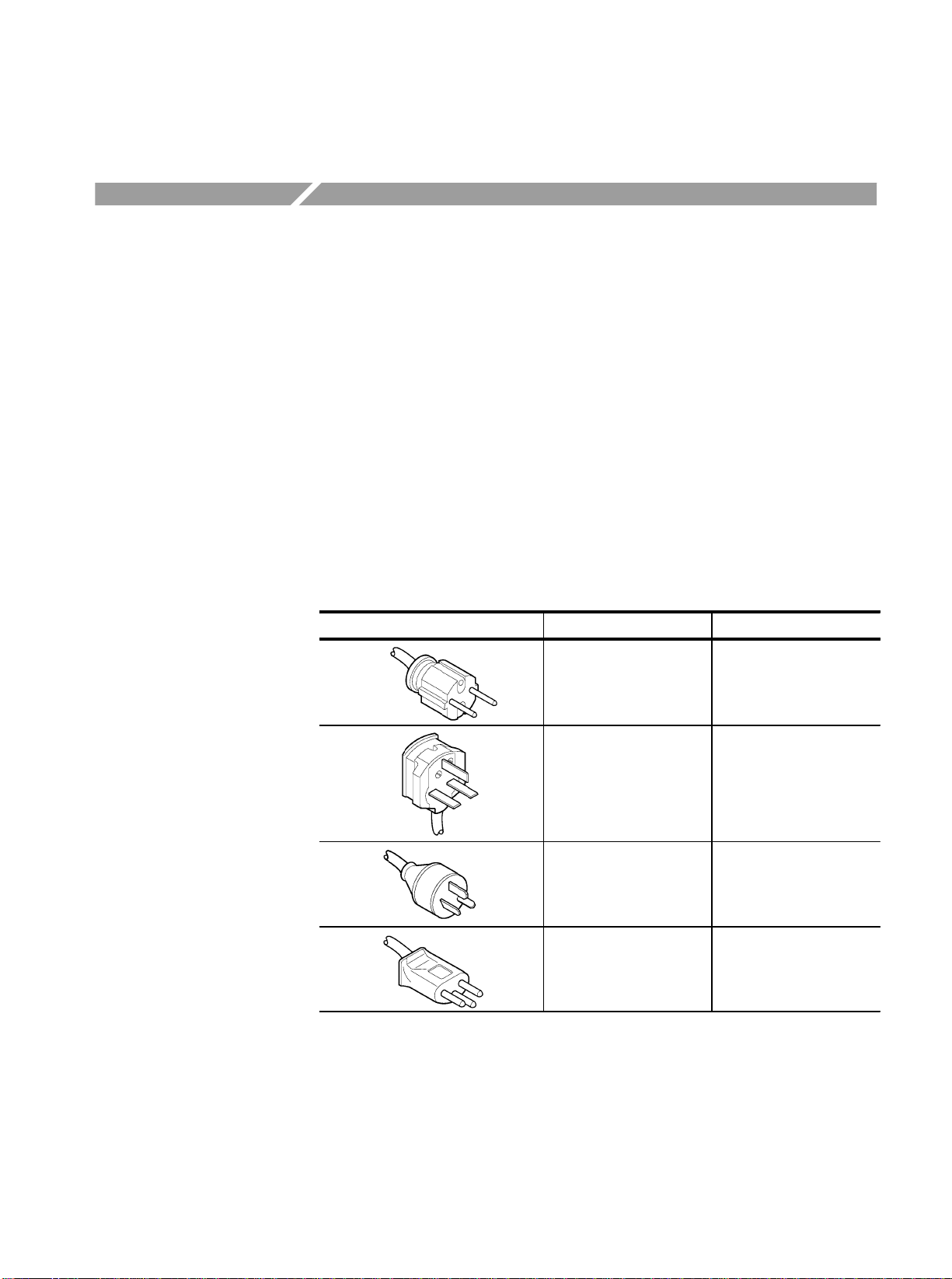

H Options A1–A3, A5. Besides the standard North American, 110 V, 60 Hz

power cord, Tektronix will ship any of four alternate power cords with the

isolator when ordered by the customer.

Table 1-1: Optional Power Cords

Plug Configuration Normal Usage Option Number

Europe

230 V

United Kingdom

230 V

Australia

230 V

Switzerland

230 V

A1

A2

A3

A5

A6907 & A6909 User Manual

1-3

Page 16

Options and Accessories

Accessories

The following standard and optional accessories are available for the A6907 and

A6909. Refer to the Replaceable Parts section for current part numbers.

Standard Accessories

Optional Accessories

The A6907 and A6909 come with the following standard accessories:

H Power cord

H Fuses (2.5 Amp, 250V, fast blow)

H 50W BNC cable set (4 cables with A6907, 2 cables with A6909)

H Special probes (4 with A6907, 2 with A6909)

H Instruction Manual

The following optional accessories are available for the A6907 and A6909:

H 50W BNC feedthrough termination

H GPIB cable

H A620 current probe

1-4

A6907 & A6909 User Manual

Page 17

Installation

Power Source

Line Fuse

The isolator must be connected to line power before you can configure it for

measurements. Please read this portion carefully to avoid equipment damage or

personal injury.

The A6907 and A6909 can be used with AC power at frequencies from 50 Hz to

60 Hz and at voltages from 100 V to 240 V.

Make sure that the proper line fuse has been installed before connecting the

isolator to the power source.

CAUTION. The isolator may be damaged if the wrong line fuse is installed.

Check the fuse holder located beneath the input power connector:

1. Disconnect all power and signal connections to the isolator.

2. Use a small straight-slot screwdriver to pry the cap out of fuse holder.

3. Verify proper fuse value:

Standard (115 V): 2.5 A, 250 V, fast-blow

Options A1, A2, A3 & A5 (230 V): 2.5 A, 250 V, slow-blow

For the correct part number of each fuse, refer to Replaceable Parts on

page **

4. Install the proper fuse and reinstall the fuse holder cap.

**.

A6907 & A6909 User Manual

1-5

Page 18

Installation

Power Cord

Connecting the Probe

WARNING. In order to prevent electrical shock, only plug the power cord into

grounded three-wire outlets. Do not defeat the ground connection on the plug.

The A6907 and A6909 power cords are three-wire grounded cords. The metal

portions on the outside of the isolator are connected to the power-source ground

by means of the ground wire in the power cord and plug.

WARNING. In order to prevent electrical shock, do not substitute any other style

of probe for the special probes provided with the isolator. The provided probes

are specially insulated for high voltage measurements.

Do not make connections to a circuit before connecting the probe to the isolator.

Firmly push the probe connector into the channel input on the front panel of the

isolator. Refer to Figure 1–1.

For information on probe accessories and probing techniques, refer to the Special

Probe section starting on page 2–5.

Connecting Output Cables

Use the 50 W BNC cables included with the instrument to connect the isolator to

an oscilloscope or digitizer. Refer to Figure 1–1.

NOTE. The input impedance of the connected oscilloscope must be 50W. If your

oscilloscope does not provide a 50W termination, attach an optional 50W

feedthrough termination between the BNC cable and the oscilloscope input

connector. Unterminated channels will report the error code E06 during

self-calibration.

1-6

A6907 & A6909 User Manual

Page 19

Test Oscilloscope

Installation

Probe

Isolator

To CH1 OUTPUT Connector

Coaxial Cable

Figure 1-1: Isolator Setup

Set the oscilloscope input attenuators to 100 mV/division.

A6907 & A6909 User Manual

1-7

Page 20

Installation

1-8

A6907 & A6909 User Manual

Page 21

Functional Check

Turning On Power

After line power is connected to the isolator, perform a functional check to test

normal system operation. To ensure proper operation of your isolator, follow

these steps:

Set the POWER switch on the rear panel to the ON position. This enables the

STBY/ON control on the front panel.

Press the STBY/ON button on the front panel. The isolator will automatically

begin the self-test procedure.

If the results of the self-test are normal, the channel display settings revert to the

values that were effective when the power was last turned off. If there is a

self-test error, an error code will appear on all of the channel indicators. See

Table 1–2.

Table 1-2: Isolator Error Codes

Error Code Description

E01 ROM checksum error

E02 RAM read/write error

E03 EEPROM checksum error

E04 EEPROM read/write error

If an error code is displayed, contact your local Tektronix Field Office for

assistance.

A6907 & A6909 User Manual

1-9

Page 22

Functional Check

SelfĆCalibration

NOTE. In order to ensure the accuracy of measurements, self-calibration should

be performed just before taking measurements.

The A6907 and A6909 are equipped with a self-calibration function that

automatically calibrates the offset and gain for each channel for maximum

accuracy. After the isolator has been warmed up for 20 minutes, use the

following procedure to perform the self-calibration:

1. Make sure that each channel output is terminated into 50 W.

2. Set the oscilloscope input attenuators to 100 mV/division.

3. Press the CAL button on the front panel. Self-calibration will begin and the

gain and offset values for each channel will be calibrated. If self-calibration

completes without error, the values shown on the indicators will return to

normal.

NOTE. If error code EO6 appears after self-calibration, it may be because a

50 W load is not connected to the channel output. If a load is properly connected but the error code is still displayed, contact your local Tektronix

Field Office.

If you need to enter custom offset or gain values, refer to the Manual Adjustments section starting on page 3–3.

1-10

A6907 & A6909 User Manual

Page 23

Operating Basics

Page 24

Page 25

Functional Overview

This section describes the controls, indicators and connectors on the A6907 and

A6909. Figures 2–1 and 2–2 show the A6907; the A6909 does not have channels

3 and 4.

Isolator Front Panel

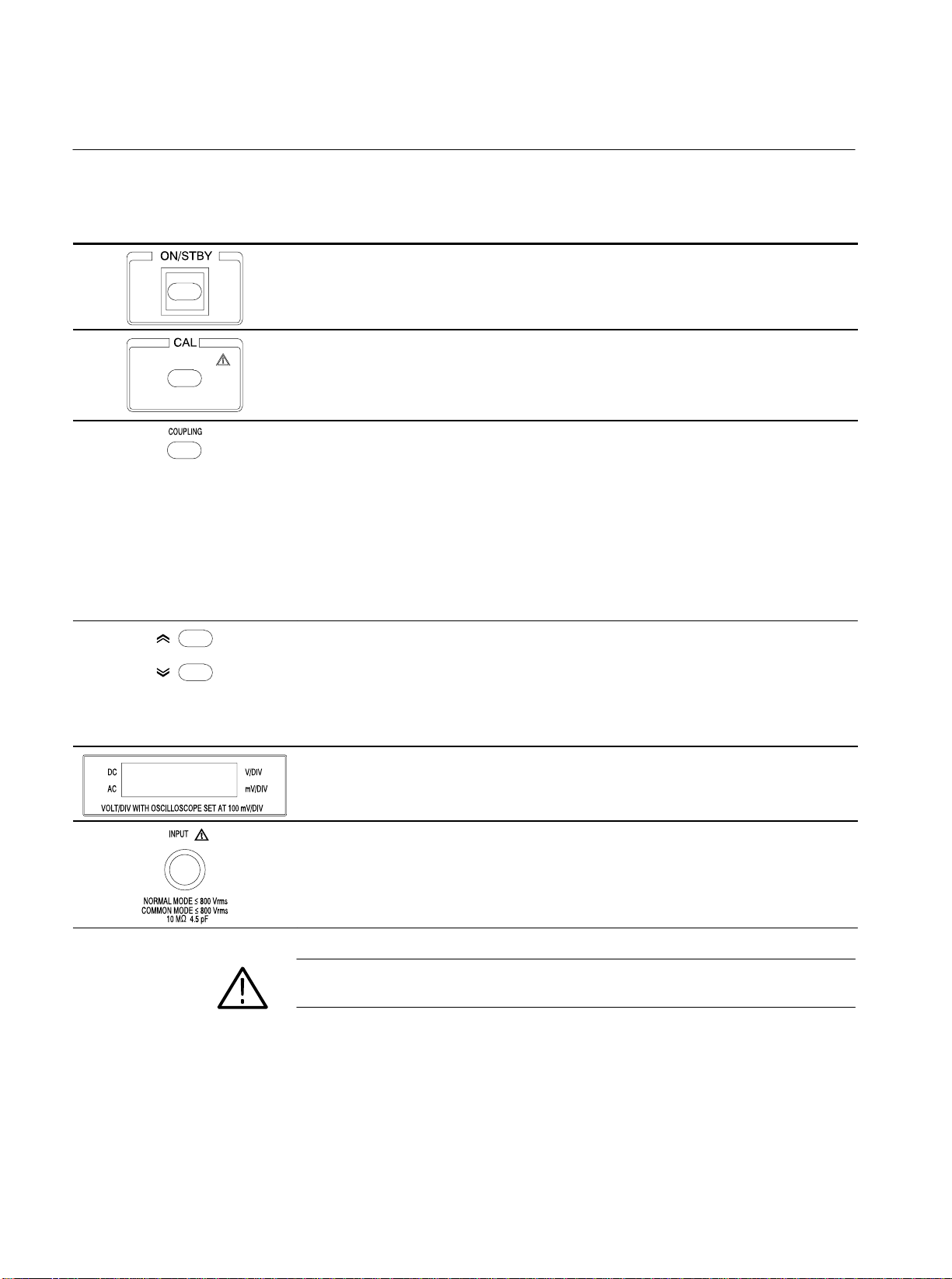

Figure 2-1: Isolator Front Panel

A6907 & A6909 User Manual

2-1

Page 26

Functional Overview

Isolator Front Panel Controls and Connections

ON/STBY. Pressing the ON/STBY button toggles the isolator between the ON and STANDBY

modes. The POWER switch on the rear panel must be in the ON position in order to enable the

ON/STBY button. See page 2-3 for more details.

CAL. Pressing the CAL button starts a selfĆcalibration process. The CAL process should be run

before making any measurements. Also, the oscilloscope input should be set to 100ĂmV/division

for the output scale factor to be accurate.

See page 1-10 for a description of the selfĆcalibration process.

COUPLING. Pressing the COUPLING button toggles the isolator between DC and AC

input coupling.

DC Coupling - All frequency components included in the input signal are passed to the

attenuator.

AC Coupling - DC signal components are blocked. The input signal first passes through a

capacitor before being coupled to the attenuator.

The coupling status is shown on the left side of the channel display. This button also provides

manual adjustment of the offset and gain values. See Manual Adjustments on page 3-3 for

more details.

SCALE. Pressing the up and down SCALE buttons adjusts the attenuator scale for each

channel on the isolator. The isolator attenuator scale can be set to any value between 100 mV

and 200 V per division in 1-2-5 increments. The value shown on the channel indicator is the

value when the oscilloscope connected to the isolator is set to 100 mV per division.

These buttons are also used during manual adjustment of the offset and gain. See Manual

Adjustments on page 3-3 for more details.

CHANNEL DISPLAY. The channel display indicates channel coupling and scale factor. The

display also shows error codes in the event of an error in the selfĆtest or selfĆcalibration

processes.

INPUT. The INPUT connection is where the probe is connected to the isolator.

Do not attempt to substitute any other style probes for the ones that are provided with the

isolator. The provided probes are specially insulated and using substitute probes may cause an

electrical safety hazard.

WARNING. To avoid the risk of electrical shock, do not connect any other probes

than those shipped with the isolator.

2-2

A6907 & A6909 User Manual

Page 27

Isolator Rear Panel

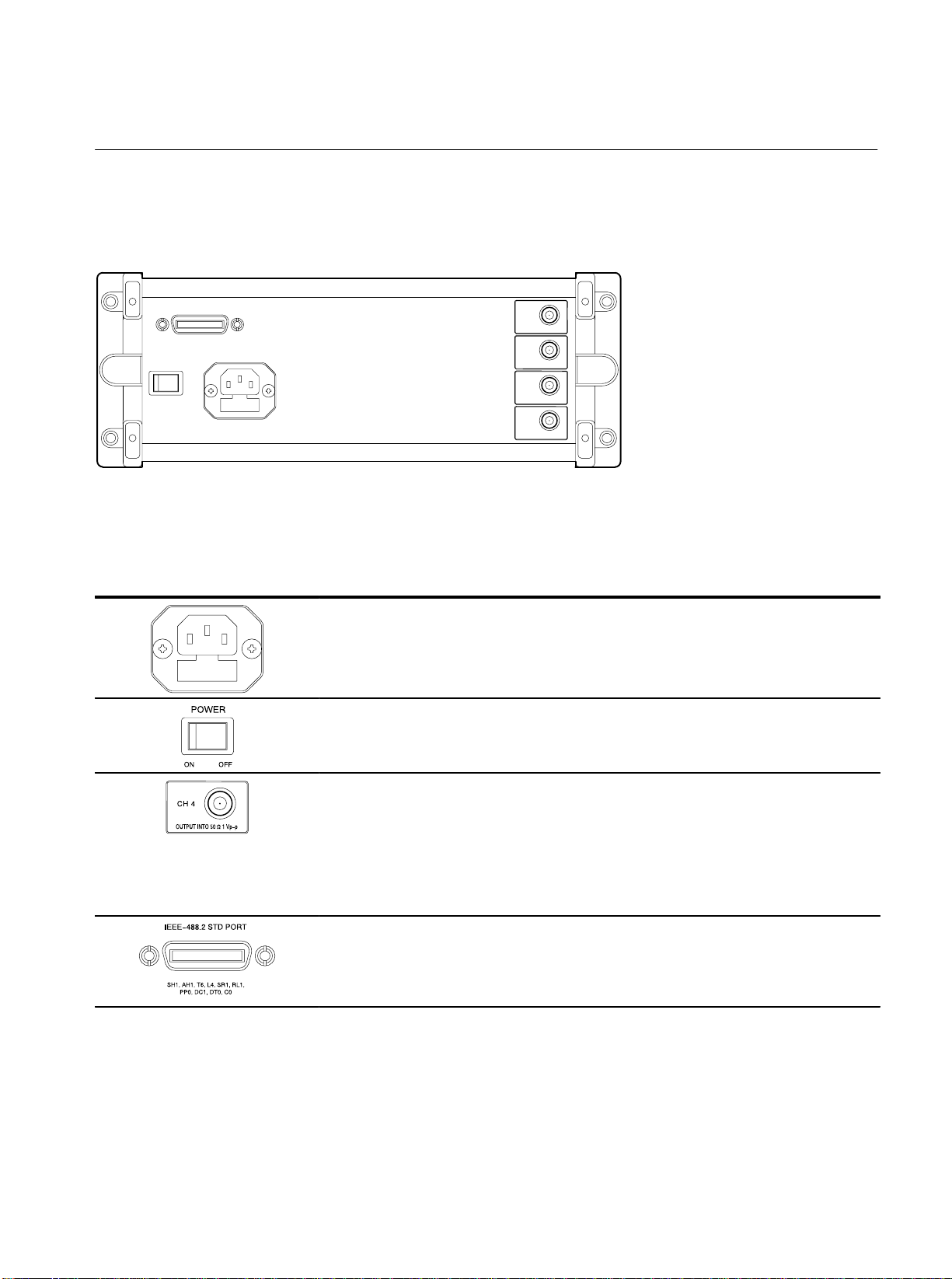

Figure 2-2: Isolator Rear Panel

Isolator Rear Panel Controls and Connections

Functional Overview

INPUT POWER. The input power connection provides a connection for the power cord and

contains the input power fuse.

For a list of the available power cords, refer to the Options section on page 1-3.

POWER ON/OFF. This is the main power switch for the instrument. It must be set to the ON

position to enable the STANDBY/ON key on the front panel.

OUTPUT. Each channel in the isolator has a 50ĂW output BNC connection. In order for the

isolator to successfully complete the selfĆcalibration, all of the channels must each be

terminated into a 50ĂW load. If the error code EO6 appears after selfĆcalibration, it may be

because the channel is not terminated into a 50ĂW load.

If your oscilloscope does not provide a 50ĂW input termination, a 50W feedthrough termination

may be ordered as an optional accessory. Also, the oscilloscope input should be set to

100ĂmV/division for the output scale factor to be accurate.

IEEEĆ488.2 STD PORT. This is a General Purpose Interface Buss (GPIB) connector. The

GPIB function is standard on the A6907 and may be ordered as option 10 with the A6909.

For more information on GPIB operation, refer to the GPIB Programming section starting on

page 3-7.

A6907 & A6909 User Manual

2-3

Page 28

Functional Overview

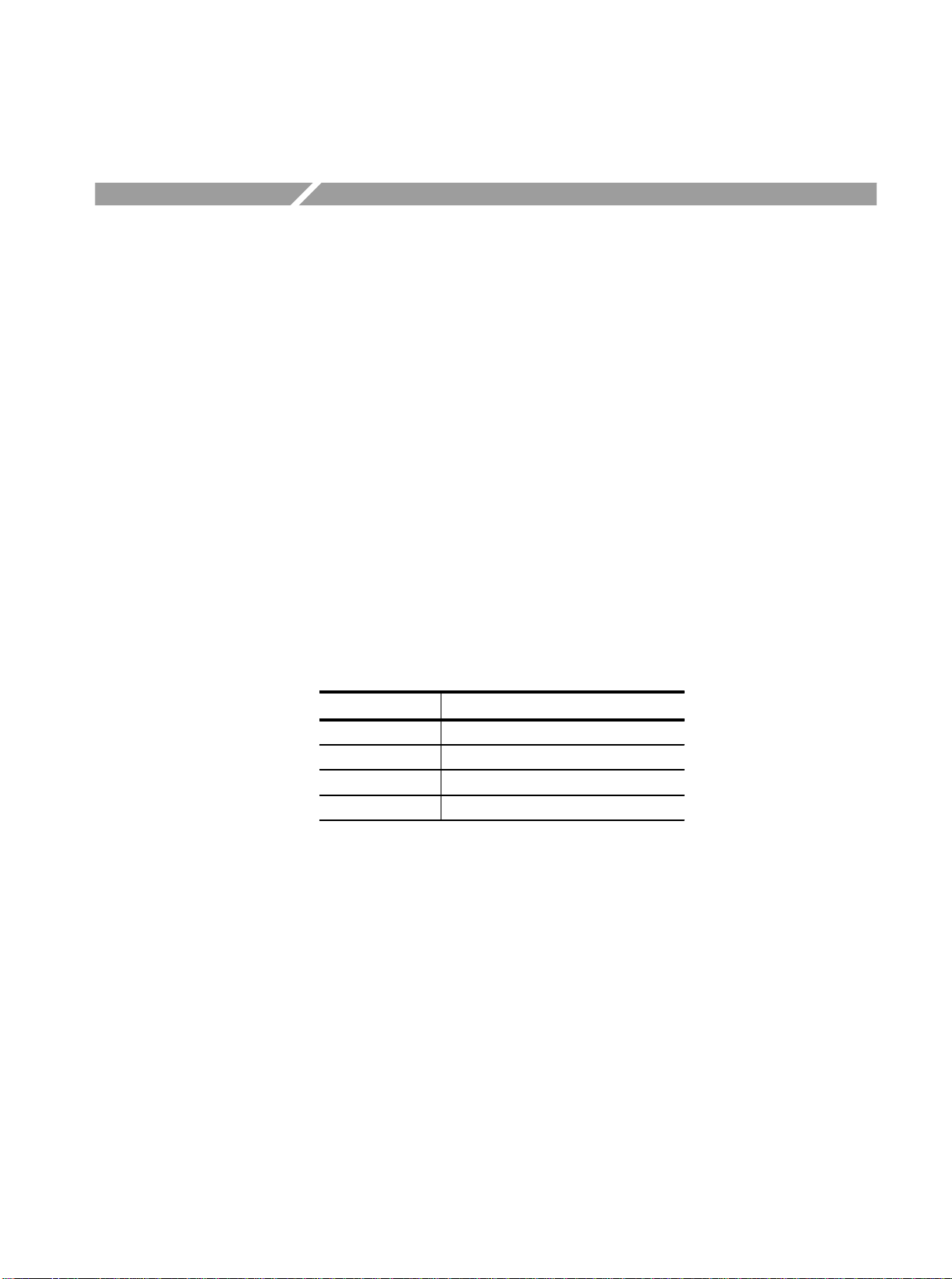

Isolator Scale Factor

The voltage scale-factor displayed on the front-panel of the isolator is valid only

when the oscilloscope is set to 100 mV/division. If you must set the oscilloscope

at other than 100 mV/division, refer to Table 2–1 to calculate the new

scale-factor.

NOTE. The performance characteristics of the isolator are not warranted if the

oscilloscope is not set to 100 mV/division.

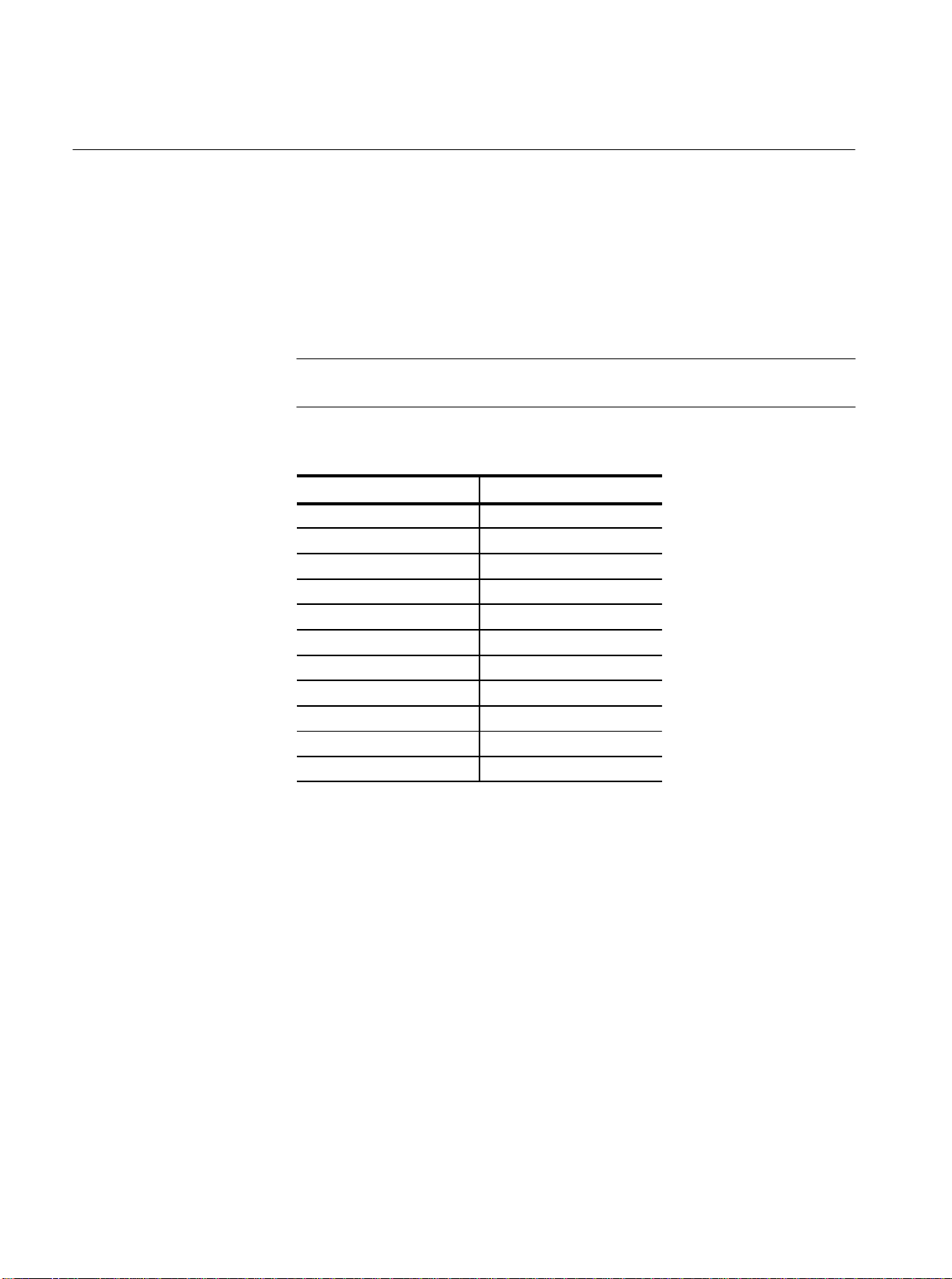

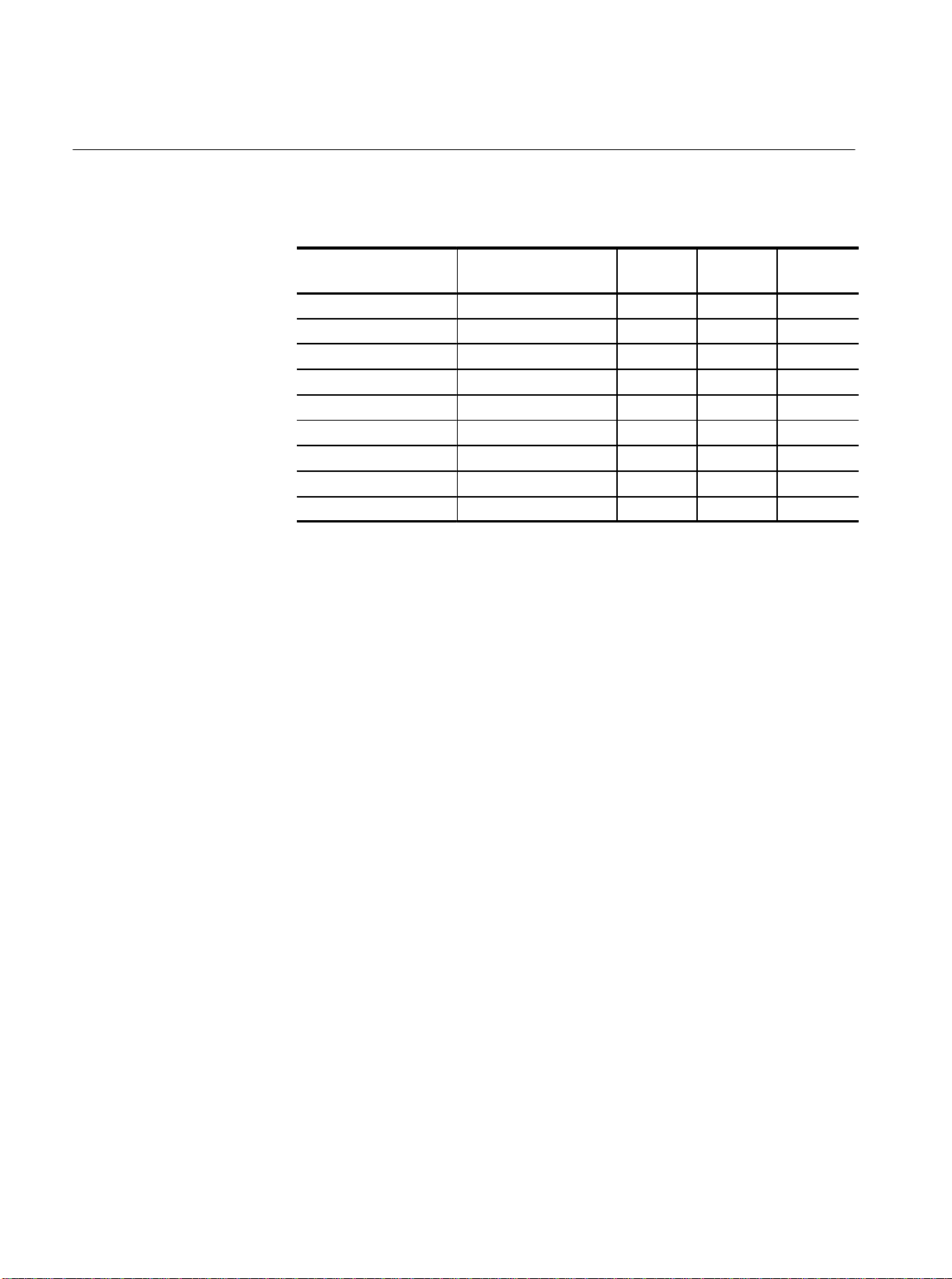

Table 2-1: Isolator Scale Factors

Oscilloscope Setting Isolator Scale Multiplier

100ĂmV 1

200ĂmV 2

500ĂmV 5

1ĂV 10

2ĂV 20

5ĂV 50

10ĂV 100

20ĂV 200

50ĂV 500

100ĂV 1000

200ĂV 2000

2-4

For example, if the isolator is set at 20 Volts/division, and the oscilloscope is set

at 1 Volt/division (scale multiplier = 10), the displayed waveform will be at 200

Volts/division (20 10 = 200).

A6907 & A6909 User Manual

Page 29

Special Probes

Voltage Probe

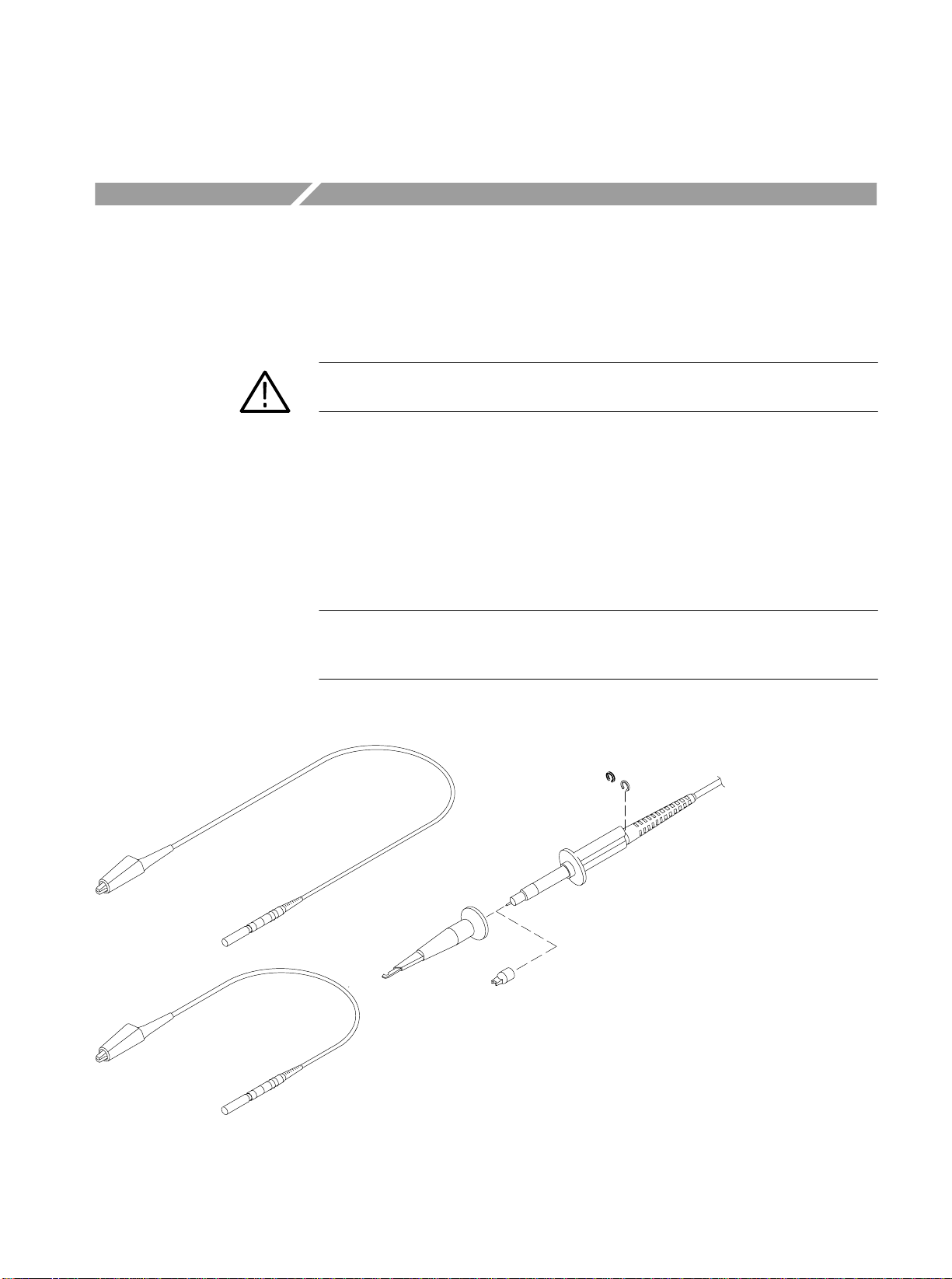

The isolator is supplied with special voltage probes for immediate use. An

optional current probe may be ordered for current measurements.

WARNING. Do not use a special probe if the probe head or leads are damaged. It

may present an electrical safety hazard resulting in injury or death.

The special voltage probe is provided with the following accessories: retractable

hook tip, IC lead protection shroud, probe common leads, and cable-marker rings

(see Figure 2–3).

NOTE. The probe included with the isolator as a standard accessory is intended

for use with the isolator only. The balun on the cable provides shielding from

dv

large

/dt fields. Do not use the special probe with other instruments.

Probe Common Leads

Retractable Hook Tip

Figure 2-3: Special Voltage Probe and Accessories

CableĆMarker

Rings

Probe Head

IC Test Tip

A6907 & A6909 User Manual

2-5

Page 30

Special Probes

Use the sharp tip of the probe to make contact with terminals covered with solder

resist or oxide. Handle the probe carefully to prevent damage to other objects or

personal injury.

Use the retractable hook tip to connect the probe to the circuit (typically a

component lead or test point connection) for “hands-free” measurements.

NOTE. When removing the hook tip from the probe, the probe may come loose

from the probe cable. If this happens, the signals will not be passed from the

probe to the isolator. When reconnecting the probe to the probe cable, make sure

that the cable is securely inserted into the probe.

When probing ICs, remove the retractable hook tip from the probe and attach the

IC test tip to the tip of the probe. The tip of the probe will stick out from the IC

test tip, but the probe tip will not come in contact with and short out an adjacent

IC lead.

Connect the common lead to the reference point in the circuit. Because of the

high capacitance of the common lead circuit, do not connect the common lead to

high-impedance sections of the circuit. The additional capacitive loading may

cause circuit damage. Connect the common lead to low-impedance sections of

the circuit.

WARNING. In order to prevent electrical shock, do not attach the standard

common lead to energized circuits above 42 V (60 VDC + peak AC). Use the

optional industrial lead set for connecting to energized circuits above 42 V.

2-6

A6907 & A6909 User Manual

Page 31

Common Lead Length

Special Probes

Always use as short a common lead as possible between the probe head and

circuit common when you are probing a circuit.

The series inductance added by the probe tip and common lead can result in a

resonant circuit; this circuit may cause parasitic “ringing” within the bandwidth

of your oscilloscope. Refer to Figure 2–4.

SixĆinch

Common

TwelveĆinch

Common

Figure 2-4: Waveform Distortion from Common Lead Length

When you touch your probe tip to a circuit element, you are introducing a new

resistance, capacitance, and inductance into the circuit. Refer to Figure 2–5.

R

source

Probe C

in

V

source

Lgl(Common Lead)

Probe R

in

Figure 2-5: Common Lead Equivalent Circuit

Ringing and rise time degradation can be masked if the frequency content of the

signal degradation is beyond the bandwidth of the oscilloscope.

A6907 & A6909 User Manual

You can determine if ground lead effects may be a problem in your application if

you know the self-inductance (L) and capacitance (C) of your probe and common

lead. Calculate the approximate resonant frequency (f

) at which this parasitic

0

circuit will resonate with the following formula:

2-7

Page 32

Special Probes

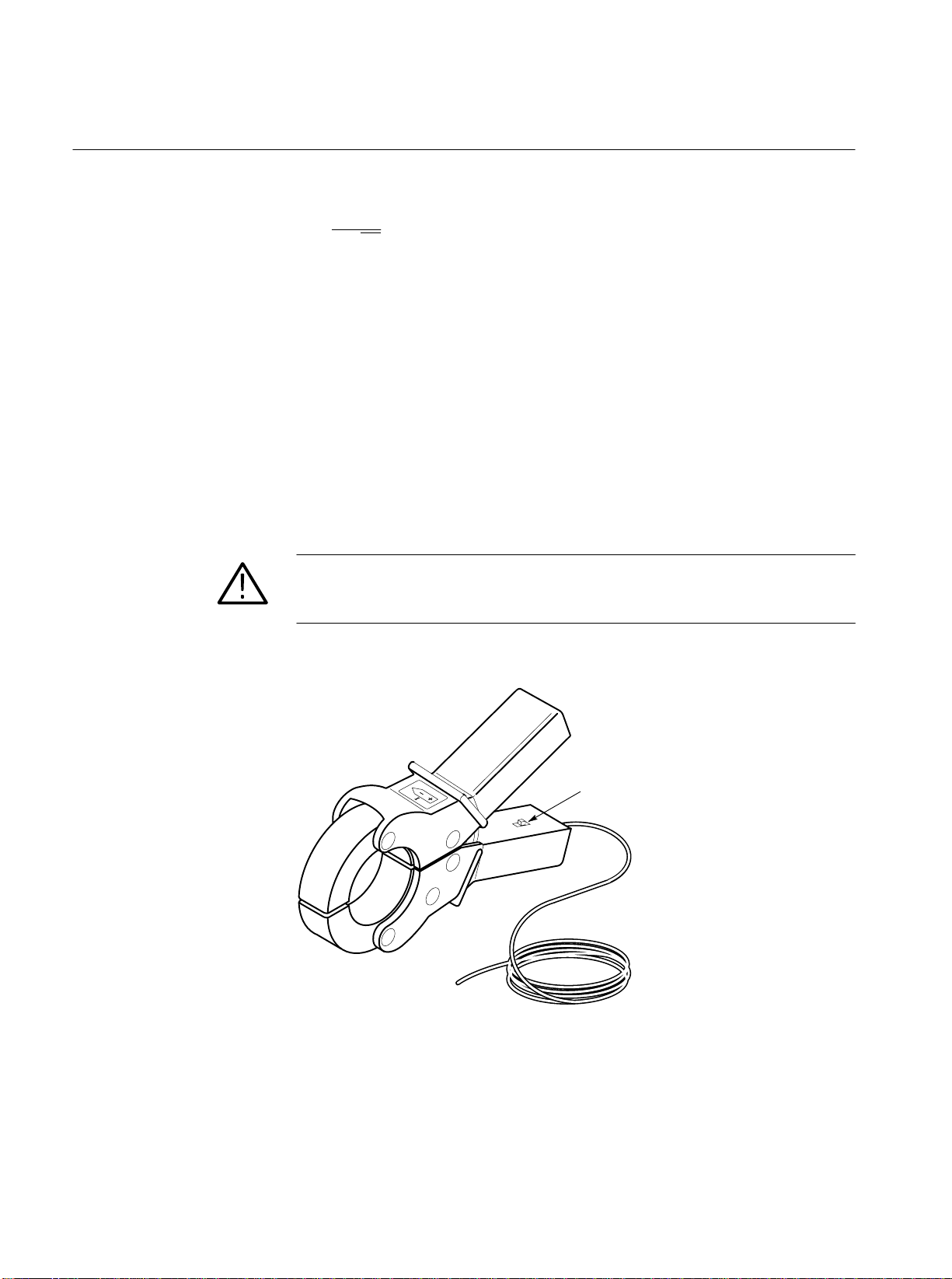

A620 Current Probe

f0+

1

Ǹ

2p LC

The preceding equation shows that reducing the common lead inductance will

raise the resonant frequency. If your measurements are affected by ringing, your

goal is to lower the inductance of your common path until the resulting resonant

frequency is well above the frequency of your measurements.

The Tektronix A620 current probe enables the display of current waveforms up

to 1000 amps when used with the isolator and an oscilloscope. The A620 is used

where the display and measurement of distorted current waveforms and

harmonics is required.

WARNING. To avoid the risk of electrical shock, do not use the A620 in circuits

operating at greater than 440 VAC (650 VDC + peak AC). Refer to the A620

Instructions for operating and safety information.

2-8

Range Switch

Figure 2-6: A620 Current Probe

A6907 & A6909 User Manual

Page 33

Special Probes

The A620 has three operating ranges, these ranges must be scaled to the

operating characteristics of the isolator using the formula below:

Current / division +

I s o l a t o r V / d i v i s i o n

A 6 2 0 R a n g e S w i t c h

NOTE. The oscilloscope vertical input must be set to 100 mv/division when using

the scale conversion formula.

For example: If the isolator is set at 10 V/div. and the probe is set to 10 mV/A,

then the displayed current per division will be 1000 A/division.

Current/division +

10 V / d i v i s i o n

10 mV/Amp

+ 1000 A/division

A6907 & A6909 User Manual

2-9

Page 34

Special Probes

2-10

A6907 & A6909 User Manual

Page 35

Reference

Page 36

Page 37

Reference Introduction

The Reference section contains information on adjusting and operating the

isolator. We have organized this section to provide basic information first, and

information for experienced users at the end. This section contains the following

information:

Manual Adjustments

After the calibration routine is completed, you may want to make adjustments to

the offset and gain factors. This section provides detailed instructions for this

process.

Floating Measurements

This section describes some of the terms and procedures used when making

measurements that are not referenced to earth ground.

GPIB Programming

Syntax

Command Groups

Commands

This section describes the set up and fundamental theory of controller operation

of the isolator.

This section describes the syntax or grammar of the commands that the

controller will pass to the isolator.

This section lists the commands in groups according to the nature of their

functions, and includes brief definitions and examples of the commands.

This section list the commands in alphabetical order and provides a detailed

description of their definitions and operation.

A6907 & A6909 User Manual

3-1

Page 38

Reference Notes

Status and Events

This section lists detailed information on the processor registers for the advanced

user or programmer.

3-2

A6907 & A6909 User Manual

Page 39

Manual Adjustments

The self-calibration process ensures a high degree of accuracy for offset and gain

values; however, the isolator also has a function for manual fine-adjustment of

offset and gain values. This function may be used to eliminate an offset included

in the input signal or to match the amplitude to that of a reference signal.

Adjusting Offset Values

Follow this procedure to change the channel offset value:

1. Press the COUPLING and down SCALE buttons simultaneously for the

channel to which you wish to apply an offset value. The mode changes to the

offset adjustment mode and an offset value (55 to 255) appears on the

indicator.

2. Use the up and down SCALE buttons to set the offset value.

3. Once again, press the COUPLING and down SCALE buttons simulta-

neously. The channel reverts to the normal operating mode.

Adjusting Gain Values

Follow this procedure to change the channel gain value:

1. Press the COUPLING and up SCALE buttons simultaneously for the

channel whose gain you wish to adjust. The mode will change to the gain

adjustment mode and a gain value (55 to 255) appears on the indicator.

2. Use the up and down SCALE buttons to set the gain value.

3. Once again, press the COUPLING and up SCALE buttons simultaneously.

The channel reverts to the normal operating mode.

NOTE. The V/DIV LED or mV/DIV LED on the indicator blinks to indicate that a

channel is not calibrated when you have adjusted the offset or gain manually. To

delete the values you have set manually, perform self-calibration again.

A6907 & A6909 User Manual

3-3

Page 40

Manual Adjustments

3-4

A6907 & A6909 User Manual

Page 41

Floating Measurements

Floating measurements are measurements where a signal is measured between

the probe tip and common, and not with respect to ground. To prevent electrical

shock, the isolator probe tip and common lead for each channel are mutually

isolated from one another as well as from the output. The E/O and O/E converters in the isolator convert the input signals into signals referenced to the chassis

after common mode elements have been rejected. As a result, the potential

between circuit elements can be measured directly regardless of the common

lead reference.

WARNING. In order to prevent electrical shock, do not attach the common lead to

energized circuits above 42 V (60 V DC + peak AC). Use the optional industrial

lead set for connecting to energized circuits above 42 V.

The isolator chassis is grounded by means of a three-line grounded cord and

three-prong plug. This ensures safety during the floating measurement process.

WARNING. In order to prevent electrical shock, check to make sure that the power

cord is firmly connected to a grounded outlet before connecting the probe of the

isolator to the circuit to be measured.

Maximum Common Mode Slew Rate

The maximum common mode slew rate indicates how fast a common mode

input the instrument can withstand. This characteristic is sometimes called the

“non-destructive

Therefore, the instrument can tolerate a common mode input signal with a slew

rate less than this value.

Special Probe

The special standard probe features extra insulation to ensure safety when

working with high voltages, and a balun to suppress the effects of large

changes in the operating area.

Touching the probe when high-frequency high voltage is applied to the common

lead will cause high-frequency current to flow by capacitive coupling to the

person holding the probe. Although this capacitive current will not cause a

A6907 & A6909 User Manual

dv

/dt.” On the A6907 and A6909, this value is 20 kV/ms.

dv

/

dt

3-5

Page 42

Floating Measurements

physical shock, it is important to know the limits of the insulation. Please refer

to figures 4–1 and 4–2 on page 4–3 for derating information.

Common Lead Connections

Although the isolator is insulated from ground, the common lead has 80 pF of

capacitance to ground. Connect the common lead to low-impedance sections of a

circuit to minimize the effects of capacitive loading

CAUTION. To prevent damage to equipment, do not connect the common lead to

high-impedance sections of a circuit. The additional capacitance may cause

circuit damage. Connect the common lead to low-impedance sections only.

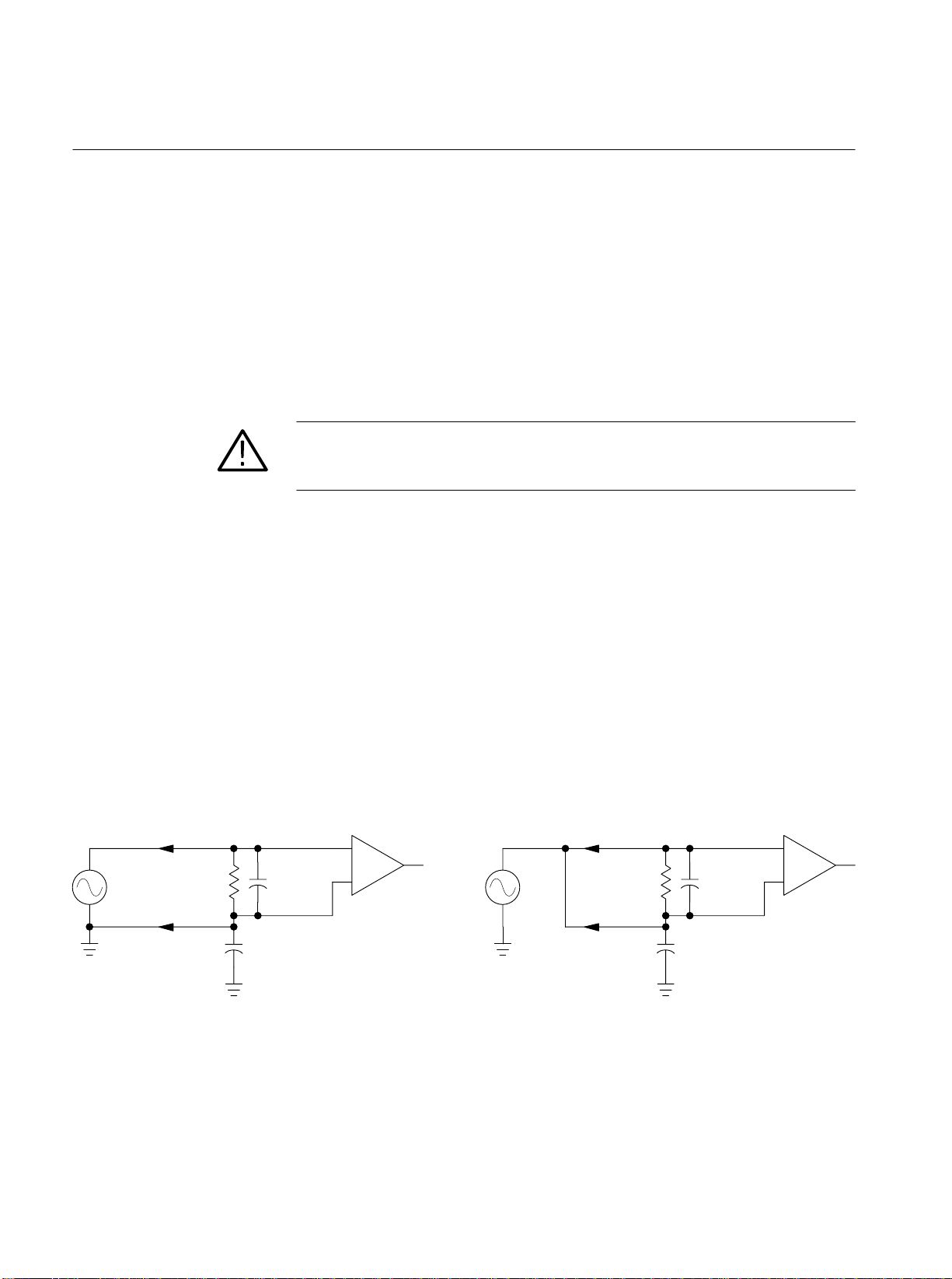

Common Mode Rejection Ratio (CMRR)

Probe

Tip

Common

Lead

The common mode rejection ratio (CMRR) indicates the quality of the floating

measurement. This characteristic is typically expressed as a value in dB or as a

ratio. The CMRR indicates the amplitude of the resulting error signal generated

by a signal that has been applied in the common mode.

On the A6907 and A6909, a CMRR value at 1 MHz is 55 dB (560:1). For

example, when a sine wave signal of 1 MHz at 100 Vp-p is applied as a common

mode input, a differential error signal of 180 mV p-p or less will be generated

(when the isolator range is set to 100 mV/div).

Probe

Tip

4.5 pF10 MW

80 pF

Normal Mode Common Mode

Common

Lead

80 pF

4.5 pF10 MW

Figure 3-1: Normal and Common Mode Simplified Circuits

3-6

A6907 & A6909 User Manual

Page 43

GPIB Programming

You can use a computer to control the A6907 isolator and make measurements.

(You can also control the A6909 with option 10 installed.) With an oscilloscope

that also can be programmed, the computer and isolator can form a complete,

automated measurement system.

Your computer, also known as the controller, must be capable of operating on a

GPIB bus that conforms to IEEE Std 488.1–1987. GPIB cards are available to

provide this capability for personal computers.

Attach an IEEE Std 488.1–1987 GPIB cable (see Optional Accessories in the

Replaceable Parts section) between the GPIB connector and your controller.

Figure 3–2 also shows how cables can be stacked together if you do not have a

multiple connection cable. You can stack a second cable on either the isolator

connector or the controller connector, to similarly connect your oscilloscope.

A6907 & A6909 User Manual

Figure 3-2: Typical Stacked GPIB Connectors

3-7

Page 44

GPIB Programming

GPIB Requirements

Observe these rules when you use your isolator with a GPIB network:

H Assign a unique device address to each device on the bus. No two devices

can share the same device address.

H Do not connect more than 15 devices to the bus.

H Connect one device for every 2 meters (6 feet) of cable used.

H Do not use more than 20 meters (65 feet) of cable for the entire bus.

H Turn on at least two-thirds of the devices on the network while using the

network.

H Connect the devices on the network in a star or linear configuration as shown

in Figure 3–3. Do not use loop or parallel configurations.

GPIB Device

Figure 3-3: Typical GPIB Network Configurations

Setting the GPIB Parameters

You must set the GPIB parameters of the isolator to match the configuration of

the bus and controller.

Setting the Bus Address

Use the following procedure to set the bus address on the isolator. The default

value for bus address set at the factory is 1.

1. Simultaneously press the CH1 COUPLING key and the CH2 down

SCALE key on the front panel. The current address setting will appear on

the CH1 indicator.

GPIB Device

GPIB Device

GPIB Device

GPIB Device

GPIB Device

GPIB Device

3-8

2. Use the CH1 up and down SCALE keys to set the value as desired.

3. Once again, press the CH1 COUPLING key and the CH2 down SCALE

key simultaneously. The value you have set will be registered as the address

and the isolator will revert to normal operation.

A6907 & A6909 User Manual

Page 45

GPIB Programming

The bus address can be set to any value between 0 and 31. Setting a value of 31

will cause the isolator to be logically separated from the GPIB interface. As a

result, it will not respond to any GPIB address and will be unable to receive or

transmit.

Message Terminators

The isolator accepts a line feed (LF) character simultaneous with the EOI as the

end of a series of received bytes. It also transmits an LF with the EOI at the end

of a series of transmitted bytes.

Other Documents You Will Need

To completely understand and implement a GPIB system, you will need the

documentation that supports your controller. If you are using a personal

computer with a GPIB card, you will need the documentation for both the PC

and the GPIB card.

GPIB Interface Functions

The GPIB interface on this instrument satisfies the IEEE 488.2-1987 standard.

Commands are compatible with Tektronix codes and format standards, making it

possible to connect with other GPIB units through the bus. Table 3–1 shows the

subsets for the GPIB interface on the isolator.

Table 3-1: GPIB Functions

A6907 & A6909 User Manual

Function Name Subset Note

Source Handshake SH1 Complete capability

Acceptor Handshake AH1 Complete capability

Talker T6 Basic Talker, Serial Poll,

Unaddress if MLA

Listener L4 Basic Listener, Unaddress if MTA

Service Request SR1 Complete capability

Remote/Local RL1 Complete capability

Parallel Poll PP0 No capability

Device Clear DC1 Complete capability

Device Trigger DT0 No capability

Controller C0 No capability

Drivers E2 ThreeĆstate

3-9

Page 46

GPIB Programming

Interface Messages

Interface messages are used by the controller to manage the talker/listener

designation and other bus control operations. This section describes the function

of the interface messages and how the isolator operates when it receives an

interface message from the controller.

My Listen Address and My

Talk Address (MLA and

MTA)

Go To Local (GTL)

Device Clear (DCL)

Selected Device Clear

(SDC)

Local Lockout (LLO)

The MLA and MTA messages are used to designate the instrument as a listener

and a talker. When the ATN line is TRUE, the instrument will become a talker

when it receives an MTA message. When the ATN line is no longer true, the

instrument will begin source handshaking and data transmission. When the ATN

line is true and the instrument receives an MLA message, it becomes a listener

and is able to receive the data sent from the talker.

When the isolator receives a GTL message, it changes to LOCAL status.

This message initializes the communication status between the instrument and

the controller. When it receives a DCL message, the instrument will clear all I/O

messages and unexecuted control settings. This will also clear all errors and all

Report Waiting events other than the Power On event. Also, when a DCL

message is received, the SRQ will be cleared if an SRQ has been sent for any

other reason than Power On.

This message is the same as the DCL message. However, only instruments

addressed as listeners will respond to an SDC message.

When the instrument receives an LLO message in REMOTE status, it will

become impossible to control the isolator using the keys on the front panel. If an

LLO message is received in LOCAL status, control using the keys on the front

panel will become ineffective when the instrument has been changed to

REMOTE status.

Serial Poll Enable and

Disable (SPE/SPD)

Unlisten and Untalk (UNL

and UNT)

Interface Clear (IFC)

3-10

The instrument addressed as the talker transmits a serial poll status byte in

response to the Serial Poll Enable (SPE) message. The Serial Poll Disable (SPD)

message returns the instrument to normal status.

The UNL message releases all instruments on the bus from their addressed

listener status. The UNT message releases all instruments on the bus from their

addressed talker status.

When an IFC message is received, the instrument status becomes the same as if

both UNL and UNT messages had been received.

A6907 & A6909 User Manual

Page 47

Remote, Local and Lockout

The instrument is normally set to one of the following three control conditions:

GPIB Programming

LOCAL

REMOTE

LOCKOUT

When the power to the instrument is turned on, it is placed in LOCAL control. In

LOCAL, the isolator is operated using the keys on the front panel. When an

MLA message is received in LOCAL, the control changes to REMOTE.

In REMOTE, the isolator can be controlled using programs from a controller.

When a command is given using the front panel controls while in REMOTE, the

instrument control will change to LOCAL.

The isolator control changes to REMOTE LOCKOUT or LOCAL LOCKOUT

status when the ATN line is true and an LLO message is received.

In LOCAL LOCKOUT control the instrument is operated using the controls on

the front panel the same as in LOCAL control. At this time, if the REN and ATN

lines are both true, the receipt of an MLA message will change control to

REMOTE LOCKOUT instead of REMOTE.

Front panel control of the isolator is not possible in REMOTE LOCKOUT

control. Also, it is not possible to use the front panel controls to change back to

LOCAL status. REMOTE LOCKOUT control will be canceled when the REN

line is no longer true.

A6907 & A6909 User Manual

3-11

Page 48

GPIB Programming

3-12

A6907 & A6909 User Manual

Page 49

Syntax

The isolator is equipped with a set of commands for remote control from an

external controller. This section describes how to use these commands to create

programs for controlling the instrument.

In explaining these commands, this manual will use the following symbols:

Table 3-2: BNF Symbols and Meanings

Symbol Meaning

<ą> Indicates a defined element

::= Indicates that the left member is defined as

shown by the right member

| Delimits Exclusive OR elements

{ą} Delimits a group of elements one of which must

be selected

[ą] Delimits an optional element (may be omitted)

.ă.Ă. Indicates that the previous element is repeated

Command Configuration

There are two types of commands: configuration commands and query commands. In this manual, we will refer to these as commands and queries.

Commands are used to set and change values on the instrument and to execute

specific operations. Queries are used to obtain information on instrument status.

Commands have the following configuration:

In several cases, the same format is used for both commands and queries. This is

done by putting a question mark (?) after the header of a command to turn it into

a query.

[:] <header> [<space><argument>]

A6907 & A6909 User Manual

3-13

Page 50

Syntax

Header

Each command requires at least a header. Headers can be divided into six types

according to their configuration:

Table 3-3: Header Configuration Types

Header Type Configuration

Simple command header A header made up of a single header mnemonic.

Example: DESE

HEADER

Simple query header A header made up of a single header mnemonic plus a

question mark (?)

Example: ALLEV?

EVENT?

Compound command header A header made up of several header mnemonics separated by

colons (:)

Arguments

Example: CH1:COUPLING

CH1:GAIN

Compound query header A header made up of several header mnemonics separated by

colons (:) with a question mark at the end (?)

Example: CH1:OFFSET?

Common command header A header made up of a header mnemonic preceded by an

asterisk (*)

Example: *RST?

NOTE: Commands that include asterisks (*) are

those defined by IEEE Std. 488.2. These commands

can be used on all instruments with GPIB systems

that support the IEEE Std 488.2.

Common query header A header made up of a header mnemonic preceded by an

asterisk (*), with a question mark at the end (?)

Example: *IDN?

Arguments are placed at the end of the header to specify the command function.

The isolator uses two types of arguments: decimal data and character string data.

3-14

Decimal Data

Three types of decimal data can be used: NR1, NR2 and NR3 as specified in

ANSI/IEEE Std 488.2-1987 (see Table 3–4). When any one of these three can be

used, it is noted as NRf.

A6907 & A6909 User Manual

Page 51

Table 3-4: Numeric Expressions

Type Format Example

NR1 Integer 1, +3, -2, +10, -20

NR2 Fixed Decimal Point 1.2, +23.5, -0.15

NR3 Floating Decimal Point 1E+2, +3.36E-2, -1.02E+3

Syntax

Character String Data

Delimiters

Character string data is also called literal or string data. Character strings are

enclosed in quotation marks.

"[<character string>]"

Example: “This is string constant.”

When the character string has quotation marks, add one more quotation mark to

each quotation mark as shown below:

Example: To make the phrase Serial Number “J310000” into a character string,

enter the following:

Serial Number J310000"""

The grammatical elements making up program message units are delimited

(differentiated) with colons, semicolons, white spaces and commas.

H Colon (:). Used to join the header mnemonics in a compound command

header.

H White Space ( ). Used to delimit the header and argument. Normally the

space character (ASCII code 32) is used as the white space, but ASCII code

characters 0 to 9 and 11 to 31 can be used as well.

Short Form

A6907 & A6909 User Manual

H Comma (,). Used to separate arguments when there is more than one

argument in a single header.

H Semicolon (;). Used to link multiple commands. See the “Linking Com-

mands” item.

In order to make it easier to create programs and reduce the time required for bus

communication, it is possible to omit some of the characters in the header and

argument. In the description of commands in this manual, characters which

3-15

Page 52

Syntax

Linking Commands

absolutely must be present are shown in CAPITAL letters; characters which may

be deleted are shown in small letters. For example, for the “VERBose?”

command any of the three versions shown may be used:

VERBOSE?

VERBOS?

VERBO?

The semicolon (;) can be used to link commands, making it possible to include

several commands in a single program message. The isolator executes linked

commands in the order in which they are received.

When linking commands, it is necessary to obey the following rules:

1. Except for the first one, headers that are completely different are separated

using semicolons and the colon that comes before the command. For

example, to link the SELFCAL command and the CH1:SCALE 100.0E-3

command, you would write the following:

SELFCAL;:CH1:SCALE 100E-3

2. When linking commands that are identical except for the mnemonic at the

end of the header, parts of the second command can be eliminated along with

the colon at the beginning. For example, to link the CH1:SCALE 1.OE-0

command with the CH1: COUPLING AC command, you would write the

following:

CH1:SCALE 1.0E-0;COUPLING AC

The same operation will be performed if the command is written out in its

entirety.

CH1:SCALE 1.0E-0;:CH1:COUPLING AC

3. Do not place a colon in front of a command that begins with an asterisk (*).

CH1:COUPLING AC;*CAL?

3-16

A6907 & A6909 User Manual

Page 53

Command Groups

This section describes the commands in general categories. Commands to the

A6907 and A6909 can be generally divided into five groups:

H Channel control

H Calibration and testing

H Status and events

H Synchronization

H System

Items followed by questions marks are queries; items without question marks are

commands. Some items in this section have a question mark in parentheses (?) in

the command header section; this indicates that the item can be both a command

and a query.

Channel Control

These items control the range, input coupling, offset and gain values for each

channel.

Table 3-5: Channel Control

Header Description

CH<x>? Range, input coupling or other query

CH<x>:CAL? Query regarding calibration status

CH<x>:COUPling (?) Input coupling setting

CH<x>:GAIn (?) Gain setting

CH<x>:OFFSet (?) Offset setting

CH<x>:SCALe (?) Range setting

A6907 & A6909 User Manual

3-17

Page 54

Command Groups

Calibration and Testing

Status and Events

These items are used to execute the instrument’s built-in self-calibration and

self-test routines.

Table 3-6: Calibration and Testing

Header Description

*CAL? Executes selfĆcalibration

SELFcal (?) Executes selfĆcalibration

*TST? Executes selfĆtest

These items set and query the status and events reporting system in order to

check the status of the instrument and control the occurrence of events. For

details on the status and event reporting system, see the Status and Events

section beginning on page 3–33.

Table 3-7: Status and Events

Header Description

ALLEv? Dequeues all events from event queue

*CLS Clears Standard Event Status Register (SESR)

DESE (?) Sets and queries DESER

*ESE (?) Sets and queries ESER

*ESR? Queries SESR setting

EVENT? Dequeues event from event queue

EVMsg? Dequeues event from event queue

EVQty? Queries the number of events in the event queue

*SRE (?) Sets SRER

*STB? Queries SBR setting

3-18

A6907 & A6909 User Manual

Page 55

Synchronization

System

Command Groups

These commands are used for synchronous control of command execution when

it is necessary to wait for all actions to finish before executing the next command. For a detailed explanation of how these commands are used, see

Synchronizing Execution on page 3–40.

Table 3-8: Synchronization

Header Description

*OPC (?) Operation finished

*WAI Waiting for command execution

These items are used to control the handling of the header in the response

message, to query ID or setting data, or to initialize the instrument.

Table 3-9: System Commands

Header Description

HEADer (?) Control header in response message

ID? Queries instrument ID data

*IDN? Queries instrument ID data

*LRN? Queries setting data

*RST Initializes instrument

SET? Queries setting data

VERBose (?) Control header in response message

A6907 & A6909 User Manual

3-19

Page 56

Command Groups

3-20

A6907 & A6909 User Manual

Page 57

Commands

ALLEv?

This section defines and discusses each command in detail.

This query retrieves the event messages corresponding to all of the event codes

in the event queue. For more information on event codes and event messages, see

Messages on page 3–39.

*CAL?

Syntax

Returns

Syntax

Returns

ALLEv?

The following is a sample response to ALLEv?

:ALLEV 100,"Command Error",200,"Execution Error"

This query executes self-calibration and returns the result.

*CAL?

<NR1>

Here <NR1> is one of the following:

0 – Self-calibration was completed without error.

100 – An error was detected in the channel 1 offset calibration.

110 – An error was detected in the channel 1 gain calibration.

200 – An error was detected in the channel 2 offset calibration.

210 – An error was detected in the channel 2 gain calibration.

300 – An error was detected in the channel 3 offset calibration.

310 – An error was detected in the channel 3 gain calibration.

400 – An error was detected in the channel 4 offset calibration.

410 – An error was detected in the channel 4 gain calibration.

A6907 & A6909 User Manual

3-21

Page 58

Commands

CH<x>?

This query returns the settings for range and coupling and the offset and gain

parameters for the designated channel.

CH<x>:CAL?

Syntax

Returns

Syntax

Returns

CH<x>? Here <x> indicates the channel of the A6907 (1, 2, 3 or 4) or the

channel of the A6909 (1 or 2).

The following is a sample response to :CH1?

:CH1:SCLE 100.0EĆ3;COUPLING DC;OFFSET 123;GAIN 117

This query returns whether or not the designated channel has been calibrated. If

it has been calibrated, a value of “1” is returned. If it has not been calibrated, a

value of “0” is returned.

CH<x>:CAL?

Here <X> indicates the channel (1, 2, 3 or 4).

The following is a sample response to :CH1:CAL?

:CH1:CAL 1

CH<x>:COUPling (?)

Syntax

Arguments

3-22

In this case, channel 1 has been calibrated.

The CH<x>:COUPling command sets the coupling value for the designated

channel. The CH<x>:COUPling? query returns the coupling status of the

designated channel.

CH<x>:COUPling {AC|DC}

CH<x>:COUPling?

Here <x> indicates the channel (1, 2, 3 or 4).

O or AC: Coupling is set to AC.

1 or DC: Coupling is set to DC.

A6907 & A6909 User Manual

Page 59

Commands

Returns

CH<x>:GAIn (?)

Syntax

Arguments

CH<x>:OFFSet (?)

The following is a sample response to the query :CH1:COUPLING?

:CH1:COUPLING DC

The CH<x>:GAIn command sets the gain value for the designated channel. The

CH<x>:GAIn? query returns the gain status of the designated channel.

CH<x>:GAIn <NR1>

CH<x>:GAIn?

Here <x> indicates the channel (1, 2, 3 or 4).

<NR1> is an integer from 55 to 255.

The CH<x>:OFFSet command sets the offset value for the designated channel.

The CH<x>:OFFSet? query returns the offset status of the designated channel.

Syntax

Arguments

CH<x>:SCALe (?)

Syntax

Arguments

CH<x>:OFFSet <NR1>

CH<x>:OFFSet?

Here <x> indicates the channel (1, 2, 3 or 4).

<NR1> is an integer from 55 to 255.

The CH<x>:SCALe command sets the range for the designated channel. The

CH<x>:SCALe? query returns the range of the designated channel.

CH<x>:SCALe <NR3>

CH<x>:SCALe?

Here <x> indicates the channel (1, 2, 3 or 4).

<NR3> indicates the range; the unit is Volt/div. On the isolator, the range can be

set to any value between 200 V/div and 100 mV/div.

A6907 & A6909 User Manual

3-23

Page 60

Commands

*CLS

DESE(?)

Examples

Syntax

In the following example, the range for channel 1 will be set to 100 mV/div.

:CH1:SCALE 100.0EĆ3

The following is a sample response to the query :CH2:SCALE?.

CH2:SCALE 5.0E+0

This command clears the Standard Event Status Register (SESR) used by the

status/event reporting system. See page 3–34 for more information on the SESR.

*CLS

The DESE command sets the bit of the Device Event Status Enable Register

(DESER) used by the status/event reporting system. The DESE? query returns

the contents of the DESER value. See page 3–35 for more information on the

DESER.

Syntax

Arguments

Examples

DESE <NR1>

DESE?

<NR1> can be set to a decimal value between 0 and 255. The corresponding

binary value is set for DESER. When the power to the instrument is turned on,

all bits in DESER are set.

In the following example, DESER will be set to 177 (10110001). In such cases,

each of the bits PON, CME, EXE and OPC will be set.

:DESE 177

The following is a sample response to the query DESE?. In this example,

DESER is set to 10110000.

:DESE 176

3-24

A6907 & A6909 User Manual

Page 61

*ESE (?)

Commands

The *ESE command sets the bit of the Event Status Enable Register (ESER)

used by the status/event reporting system. The *ESE? query returns the contents

of the ESER. For more information on the ESER, see page 3–36.

*ESR?

Syntax

Arguments

Examples

*ESE <NR1>

*ESE?

<NR1> can be set to a decimal value between 0 and 255. The corresponding

binary value is set for ESER. When the power to the instrument is turned on, all

bits in ESER are reset.

In the following example, ESER will be set to 209 (11010001). In such cases,

each of the bits PON, URQ, EXE and OPC will be set.

*ESE 209

The following is a sample response to the query *ESE?. In this example, ESER

is set to 11010000.

208

This query returns the contents of the Standard Event Status Register (SESR)

used by the status/event reporting system. See page 3–34 for more information

on the SESR.

Syntax

Examples

EVENT?

Syntax

A6907 & A6909 User Manual

*ESR?

The following is a sample response to the query *ESR?. In this example, SESR

is set to 10110101.

181

This query retrieves the code for the oldest event of the retrievable events in the

event queue. For more information on event codes, see Messages on page 3–39.

EVENT?

3-25

Page 62

Commands

EVMsg?

EVQty?

Returns

Syntax

Returns

The following is a sample response to EVENT?

:EVENT 100

This query retrieves the code for the oldest event of the retrievable events in the

event queue, as well as the message corresponding to that code. For more

information on event codes, see Messages on page 3–39.

EVMsg?

The following is a sample response to EVMsg?

:EVMSG 100,"Command Error"

This query returns the number of events in the event queue.

HEADer (?)

Syntax

Returns

Syntax

Arguments

EVQty?

The following is a sample response to EVQty?

:EVQTY 4

The HEADer command specifies whether to include or omit the header from the

response to all queries with the exception of IEEE Std 488.2 common commands. The HEADer? query returns whether or not the response message

includes a header.

HEADer {0|1|OFF|ON}

HEADer?

O or OFF – Header is omitted from response

1 or ON – Header is included in response

3-26

Examples

In this example, the header is included in the response:

A6907 & A6909 User Manual

Page 63

ID?

Commands

:HEADER ON

The following is a sample response to the HEADer? query:

:HEADER 1

In this example, the header is included in the response.

This query returns the instrument ID information.

*IDN?

*LRN?

Syntax

Returns

Examples

Syntax

Returns

Examples

ID?

ID SONY_TEK/<Model>,CF:91.1 FV:<Firmware version no.>

ID SONY_TEK/A6907,CF:91.1 FV:1.00

This query returns the instrument ID information.

*IDN?

SONY/TEK,<Model>,<Serial no.>,CF:91.1CN FV:<Firmware version no.>

SONY/TEK,A6907,0,CF:91.1CN FV:1.00

Syntax

A6907 & A6909 User Manual

This query returns the setting data for the instrument.

*LRN?

3-27

Page 64

Commands

*OPC (?)

Returns

The following is a sample response to *LRN?

:CH1:SCALE 100.0E-3;COUPLING DC;OFFSET 132;GAIN 115

:CH2:SCALE 200.0E-3;COUPLING DC;OFFSET 121;GAIN 104

:CH3:SCALE 500.0E-3;COUPLING AC;OFFSET 137;GAIN 134

:CH4:SCALE 100.0E-3;COUPLING DC;OFFSET 135;GAIN 129

:HEADER 1;:VERBOSE 1

NOTE. The *LRN? query always returns a string including the header, regardless

of the HEADer setting. When a short form response has been set using the

VERBose command, a shortened form of the header is returned.

The *OPC command sets the Standard Event Status Register (SESR) bit 0 (OPC

bit) as soon as all pending operations have been completed. The *OPC? query

returns a value of ASCII character “1” as soon as all pending operations have

been completed.

*RST

SELFcal (?)

Syntax

Examples

Syntax

Syntax

*OPC

*OPC?

The *OPC command can be used to synchronize instrument operation and

application programs. For the method used to accomplish this, see Synchronizing

Execution on page 3–40.

This command initializes the instrument.

*RST

The SELFcal command executes the self-calibration routine. The SELFcal?

query returns the results of self-calibration.

SELFcal

SELFcal?

3-28

A6907 & A6909 User Manual

Page 65

Commands

SET?

Returns

Syntax

<NR1>

Here <NR1> is one of the following:

0 – Self-calibration was completed without error.

100 – An error was detected in the channel 1 offset calibration.

110 – An error was detected in the channel 1 gain calibration.

200 – An error was detected in the channel 2 offset calibration.

210 – An error was detected in the channel 2 gain calibration.

300 – An error was detected in the channel 3 offset calibration.

310 – An error was detected in the channel 3 gain calibration.

400 – An error was detected in the channel 4 offset calibration.

410 – An error was detected in the channel 4 gain calibration.

This query returns data on instrument settings. This is the same as the operation

performed by the *LRN? query.

SET?

*SRE (?)

Returns

Syntax

Arguments

The following is a sample response to SET?

:CH1:SCALE 100.0E-3;COUPLING DC;OFFSET 132;GAIN 115

:CH2:SCALE 200.0E-3;COUPLING DC;OFFSET 121;GAIN 104

:CH3:SCALE 500.0E-3;COUPLING AC;OFFSET 137;GAIN 134

:CH4:SCALE 100.0E-3;COUPLING DC;OFFSET 135;GAIN 129

:HEADER 1;:VERBOSE 1

The *SRE command sets the bit of the Service Request Enable Register (SRER)

used by the status/event reporting system. However, SRER bit 6 is always set to

0. The *SRE? query returns the contents of the SRER. For more information on

the SRER, see page 3–36.

*SRE <NR1>

*SRE?

<NR1> can be set to a decimal value between 0 and 255. The corresponding

binary value is set for SRER. When the power to the instrument is turned on, all

bits in SRER are reset.

A6907 & A6909 User Manual

3-29

Page 66

Commands

*STB?

Examples

Syntax

Examples

In the following example, SRER will be set to 48 (00110000). In this example,

the ESB and MAV bits are set.

*SRE 48

The following is a sample response to the query *SRE?. In this example, ESER

is set to 00100000.

32

This query returns the contents of the Status Byte Register (SBR) used by the

status/event reporting system. The SBR bit 6 is interpreted as the MSS (Master

Status Summary) bit. For more information on the SBR, see page 3–33.

*STB?