Page 1

User Manual

A6906S Fiber-Optic Isolation System

070-8900-04

Page 2

Copyright E T ektronix, Inc. 1993. All rights reserved. T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

WARRANTY

T ektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1)

year from the date of shipment. If any such product proves defective during this warranty period, T ektronix, at its

option, either will repair the defective product without charge for parts and labor, or will provide a replacement in

exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period and make suitable arrangements for the performance of service. Customer shall be

responsible for packaging and shipping the defective product to the service center designated by T ektronix, with

shipping charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a

location within the country in which the T ektronix service center is located. Customer shall be responsible for

paying all shipping charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage

resulting from attempts by personnel other than T ektronix representatives to install, repair or service the product;

b) to repair damage resulting from improper use or connection to incompatible equipment; or c) to service a

product that has been modified or integrated with other products when the effect of such modification or

integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THIS PRODUCT IN LIEU OF

ANY OTHER WARRANTIES, EXPRESSED OR IMPLIED. TEKTRONIX AND ITS VENDORS

DISCLAIM ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

P ARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO REP AIR OR REPLACE DEFECTIVE

PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR

BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY

INDIRECT, SPECIAL, INCIDENT AL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF

WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF

SUCH DAMAGES.

Page 4

Page 5

EC Declaration of Conformity

We

Tektronix Holland N.V.

Marktweg 73A

8444 AB Heerenveen

The Netherlands

declare under sole responsibility that the

A6906S Fiber Optic Isolation System

meets the intent of Directive 89/336/EEC for Electromagnetic Compatibility.

Compliance was demonstrated to the following specifications as listed in the Official

Journal of the European Communities:

EN 55011 Class A Radiated and Conducted Emissions

EN 50081-1 Emissions:

EN 60555-2 AC Power Line Harmonic Emissions

EN 50082-1 Immunity:

IEC 801-2 Electrostatic Discharge Immunity

IEC 801-3 RF Electromagnetic Field Immunity

IEC 801-4 Electrical Fast Transient/Burst Immunity

Page 6

Page 7

Table of Contents

List of Figures iii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

List of Tables iv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Safety Summary v. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Injury Precautions v. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Damage Precautions vi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Terms and Symbols vi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options viii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Accessories ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Accessories ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Customer Support x. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Getting Started 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC Power 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Charging the Battery Pack 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparing for Operation 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Basics 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power On and Calibration 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional T emperature Calibration 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning Fiber-Optic Cable Connectors 11. . . . . . . . . . . . . . . . . . . . . . . .

Programming 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Up 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GPIB Requirements 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting GPIB Parameters 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Other Documents You Will Need 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Commands 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALibration 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COUpling 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EVEnt? (Query Only) 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HELp? (Query Only) 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ID? (Query Only) 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INIt (No Query Form) 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PRObe? (Query Only) 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RANge 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RQS 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SET? (Query Only) 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STAndby 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRAns? (Query Only) 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TESt? (Query Only) 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status Bytes and Event Codes 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A6906S Fiber-Optic Isolation System User Manual

i

Page 8

Table of Contents

Appendix A: Specifications 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B: Performance Verification 27. . . . . . . . . . . . . . . . . . . . . . . . .

Prerequisites 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required T est Equipment 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Offset and Noise Check 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rise Time Check 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bandwidth Check 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gain Check 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe Check 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C: GPIB Interface Messages 37. . . . . . . . . . . . . . . . . . . . . . . . .

Appendix D: Maintenance 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing Fuses 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the Probe 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe Compensation 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the Fiber-Optic Cable 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmitter Panel Removal 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fiber-optic Cable Removal 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fiber-optic Cable Installation 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Panel Installation 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix E: Replaceable Parts List 53. . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Ordering Information 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Parts List 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

A6906S Fiber-Optic Isolation System User Manual

Page 9

List of Figures

Table of Contents

Figure i: Power-Cord Plug Options viii. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1: A69T06 Battery Removal 2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2: Battery Charging 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

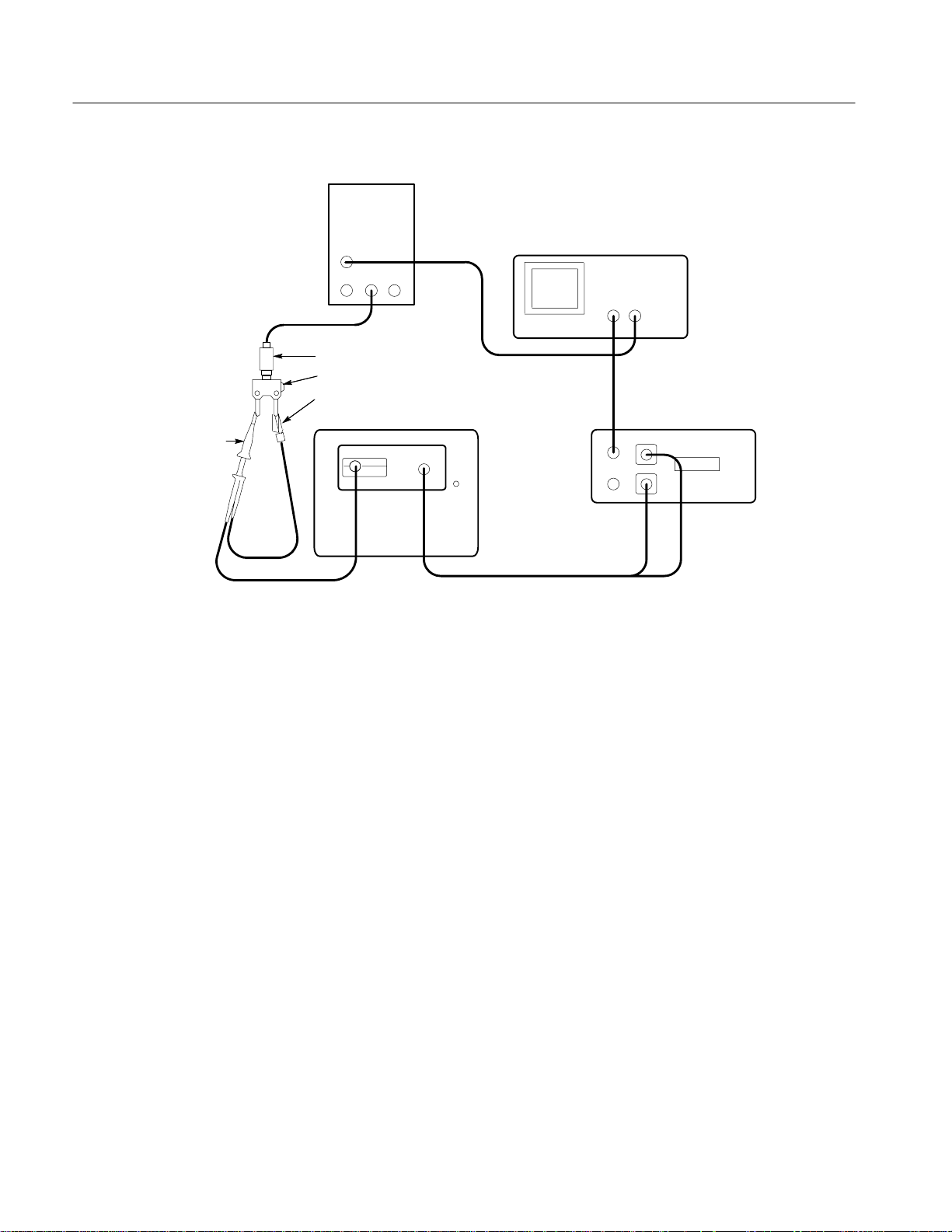

Figure 3: A6906S Connections for Use 3. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4: Connection of the Fiber-Optic Cable and Connector 4. . . . .

Figure 5: A69R06 Receiver Controls 9. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6: 6-Inch Ground Lead Clip 10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 7: Fiber-Optic Cable and Connector Cleaning 11. . . . . . . . . . . .

Figure 8: Stacked GPIB Connectors 13. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9: Typical GPIB Network Configuration 14. . . . . . . . . . . . . . . . .

Figure 10: Noise Check Setup 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 11: Rise Time Check Setup 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 12: Bandwidth Check Setup 31. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 13: Gain Check Setup 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 14: Probe Check Setup 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 15: Replacing the probe 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 16: Removing the Panel 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 17: Fiber-optic Cable Installation (for Type A) 49. . . . . . . . . . . .

Figure 18: Connection of the Fiber-optic Cable and Connector 50. . . . .

Figure 19: Fiber-optic Cable Installation (for Type B) 51. . . . . . . . . . . .

Figure 20: Replaceable Parts 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 21: Accessories 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A6906S Fiber-Optic Isolation System User Manual

iii

Page 10

Table of Contents

List of Tables

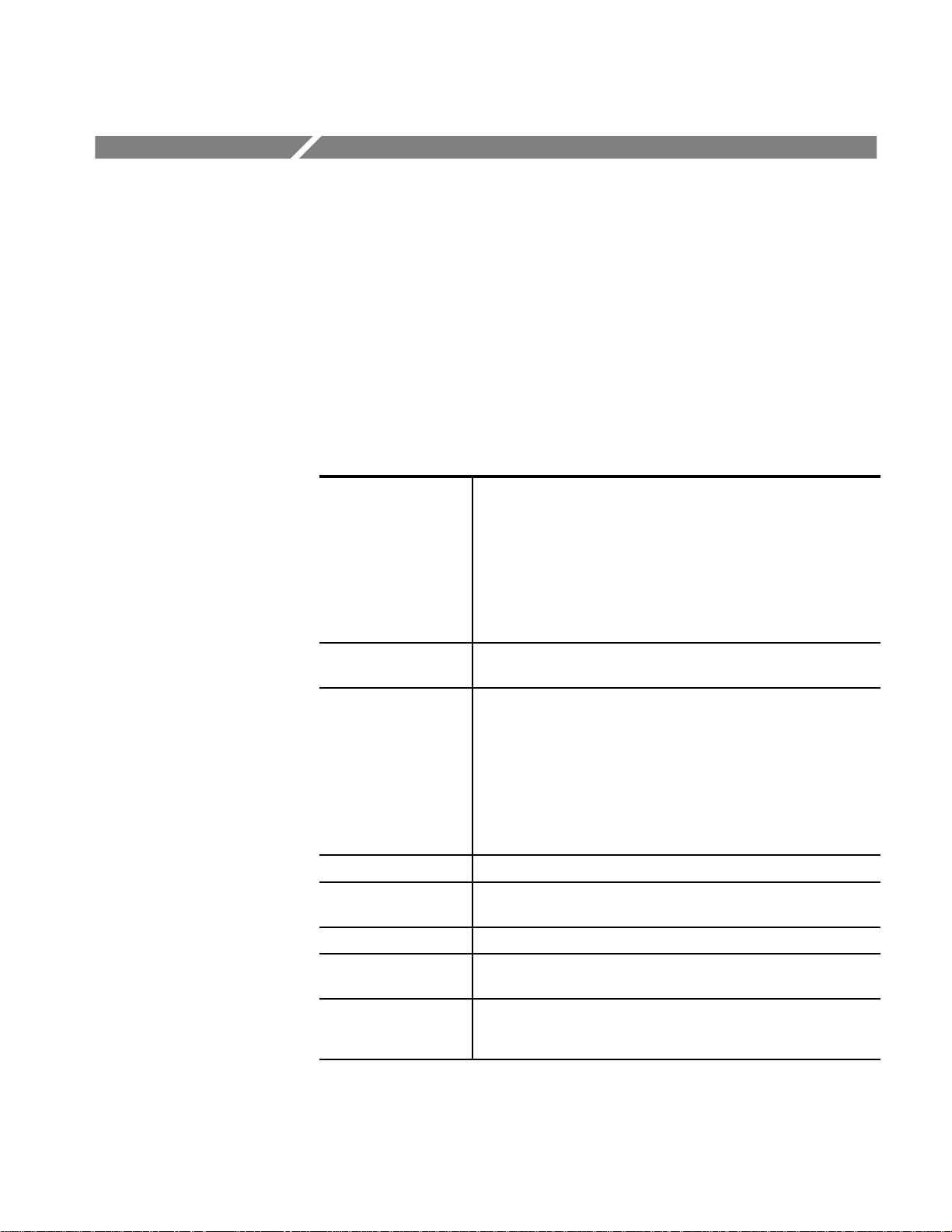

Table i: A6906S Order Options viii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1: A6906S Attenuation Factors with Probe Factor Included 9. .

Table 2: A6906S GPIB Commands 16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3: Status Bytes 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4: Event Codes 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5: Electrical Specifications 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6: Fiber-Optic Cable Characteristics 25. . . . . . . . . . . . . . . . . . . . .

Table 7: Battery Characteristics 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 8: Physical Characteristics 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 10: GPIB Interface Functions 26. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 11: Test Equipment Required for Performance Verification 28. .

Table 12: Gain Accuracy Limits 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 13: Available Fiber-Optic Cables 46. . . . . . . . . . . . . . . . . . . . . . . .

Table 14: Fiber-Optic Cable Changes Requiring Recalibration 46. . . .

iv

A6906S Fiber-Optic Isolation System User Manual

Page 11

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it.

Injury Precautions

Use Proper Power Cord

Avoid Electric Overload

Do Not Operate Without

Covers

Do Not Operate in

Wet/Damp Conditions

Ground the Product

Use Proper Fuse

Do Not Operate in

Explosive Atmospheres

To avoid fire hazard, use only the power cord specified for this product.

To avoid electric shock or fire hazard, do not apply a voltage to a probe that is

outside the range specified for that probe.

To avoid electric shock or fire hazard, do not operate this product with covers or

panels removed.

To avoid electric shock, do not operate this product in wet or damp conditions.

Portions of this product are grounded through the grounding conductors of the

power cords. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

To avoid fire hazard, use only the fuse types and ratings specified for this

product.

To avoid injury or fire hazard, do not operate this product in an explosive

atmosphere.

Wear Eye Protection

A6906S Fiber-Optic Isolation System User Manual

Wear eye protection if exposure to high-intensity rays or laser radiation exists.

v

Page 12

General Safety Summary

Product Damage Precautions

Use Proper Power Source

Do not operate this product from a power source that applies more than the

voltage specified.

Do Not Operate With

Suspected Failures

If you suspect there is damage to this product, have it inspected by qualified

service personnel.

Safety Terms and Symbols

Terms in This Manual

Terms on the Product

These terms may appear in this manual:

WARNING statements identify conditions or practices that could result in injury

or loss of life.

CAUTION statements identify conditions or practices that could result in

damage to this product or other property.

These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

Symbols in This Manual

Symbols on the Product

vi

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

This symbol may appear in the manual:

This symbol indicates where specific cautions and warnings are found.

These symbols may appear on the product:

DANGER

High Voltage

Protective ground

(earth) terminal

ATTENTION

Refer to

manual

A6906S Fiber-Optic Isolation System User Manual

Page 13

Preface

The A6906S Fiber-Optic Isolation System allows long-distance transmission of

electrical signals. Features include:

H Ability to safely use the transmitter in a floating or ungrounded environment.

H Electrical isolation between transmitter and receiver.

H Up to 200 meter fiber-optic cable length (with Option 3).

H 100 MHz bandwidth.

The A6906S Fiber-Optic Isolation System converts an input analog electrical

signal into an optical signal. This signal is then transmitted along the fiber-optic

cable, received, and converted back into an electrical signal. This transmission

scheme provides a signal transmission system that operates over long distances,

offers low distortion, transmits at high speed, and electrically insulates the

signal. The A6906S Fiber-Optic Isolation System has the following components:

H A69T06 Transmitter, with battery pack, fiber-optic cable, and probe.

H A69R06 Receiver.

H A69C06 Sealed Lead-Acid Battery Charger.

The A69T06 Transmitter is an electrical-to-optical (E/O) converter; it converts

an input electrical signal into an optical signal. System gain is controlled by an

attenuator that is set in a 1–2–5 sequence. The A69T06 is also provided with a

variable-gain amplifier for self-calibration to maintain measurement precision.

The A69T06 is powered by an internal sealed rechargeable lead-acid battery

pack.

The A69R06 Receiver is an optical-to-electrical (O/E) converter. It converts an

optical signal input, via a fiber-optic cable, into an electrical signal. This unit

functions as the controller for the A69T06 Transmitter. It can be used to control

self-calibration and transmitter attenuator switching using front-panel operations.

The A69R06 can also be controlled from an external device via the GPIB

(IEEE–488) interface.

The A69C06 Sealed Lead-Acid Battery Charger charges the battery pack while

the battery pack is removed from the A69T06.

A6906S Fiber-Optic Isolation System User Manual

vii

Page 14

Preface

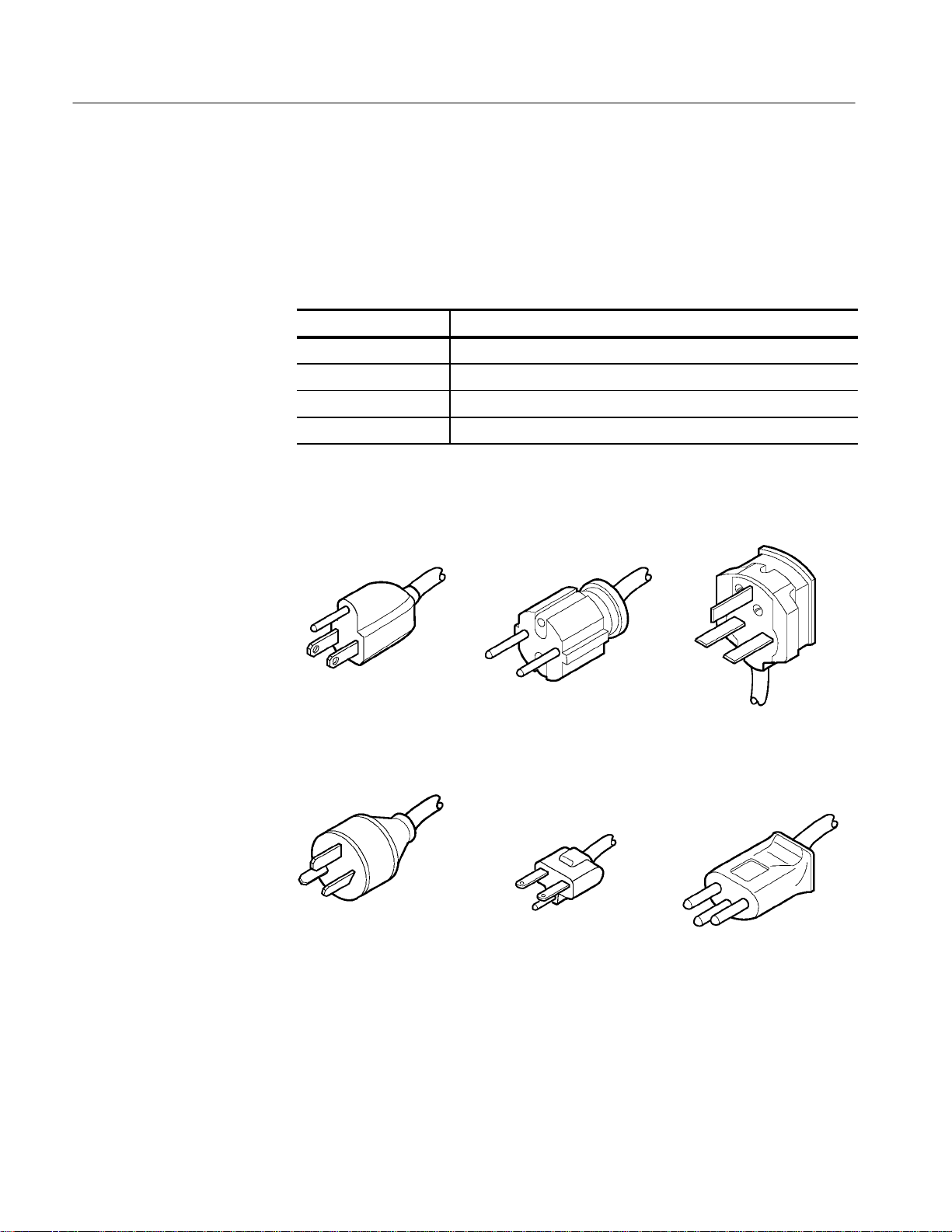

Options

You can order the A6906S Fiber-Optic Isolation System with different options,

as listed in Tables i and Figure i.

T able i: A6906S Order Options

Option Number Description

01 Replace standard 3 meter fiber-optic cable with 20meter cable.

02 Replace standard 3 meter fiber-optic cable with 100 meter cable.

03 Replace standard 3 meter fiber-optic cable with 200 meter cable.

04 Replace standard 3 meter fiber-optic cable with 10 meter cable.

Standard*

North American

115V

Option A3

Australian

230V

* Canadian Standards Association certification

includes these power plugs for use in the

North American power network

Option A1

Universal Euro

Option A4*

North American

Figure i: Power-Cord Plug Options

230V

230V

Option A2

UK

230V

Option A5

Switzerland

230V

viii

A6906S Fiber-Optic Isolation System User Manual

Page 15

Standard Accessories

Preface

The standard accessories that are included with the A6906S are listed below.

Accessories, for example spare battery packs, can be ordered separately by using

the Tektronix part numbers listed in the Replaceable Parts List on page 53.

H battery pack

H 50 W BNC Cable

H 50 W Feedthrough Termination

H Industrial lead set (for banana plug test accessories)

H Retractable Hook Probe Tip

H Spare Fuse for the A69R06

H Spare Fuse for the A69C06

H Fiber-Optic Cable Connector Cleaner (set of 5)

Optional Accessories

H A6906S Fiber-Optic Isolation System User Manual

H Two power cords

H 6-Inch Ground Lead

The optional accessories listed below can be ordered for use with your A6906S.

Tektronix part numbers for these accessories can be found in the Replaceable

Parts List on page 53.

H 75 W BNC Cable

H 75 W Feedthrough Termination

H GPIB Cable

H Index Matching Oil (for optical cable connections)

H Fiber-Optic Cable Connector Cleaner (set of 200)

A6906S Fiber-Optic Isolation System User Manual

ix

Page 16

Preface

Customer Support

To help you get the best performance from your A6906S, Tektronix offers the

sales, application, and service support:

Sales Support

Application Support

Service Support

To order optional equipment and accessories, call the Tektronix National

Marketing Center at 1-800-426-2200. Outside the United States or Canada,

contact your nearest Tektronix Service Center.

For assistance in applying the A6906S Fiber-Optic Isolation System to your

measurement needs, contact Tektronix Customer Support at 1-800-835-9433

x2400, between 6 am and 5 pm Pacific time. Outside the United States or

Canada, contact your nearest Tektronix Service Center.

To obtain exchange modules to repair your A6906S, call the Tektronix FastParts

Center at 1-800-848-5083. If you want Tektronix to perform repair or calibration

services, or should your A6906S system need repair beyond that described in

this manual, contact your nearest Tektronix Service Center.

x

A6906S Fiber-Optic Isolation System User Manual

Page 17

Getting Started

This section tells you how to set up the A6906S Fiber-Optic Isolation System for

battery charging and normal operation. Since the A69T06 Transmitter operates

using battery power, you will first need to charge the battery pack.

AC Power

The A6906S Fiber-Optic Isolation System is capable of continuous operation

with input voltages that range from 90 V to 250 V with source voltage frequencies from 47 Hz to 66 Hz.

Detachable three-wire power cords with three-contact plugs are provided with

the A69R06 Receiver and A69C06 Sealed Lead-Acid Battery Charger for

connection to both the power source and protective ground. For electrical shock

protection, insert these plugs into a power source outlet that has a properly

grounded protective ground contact.

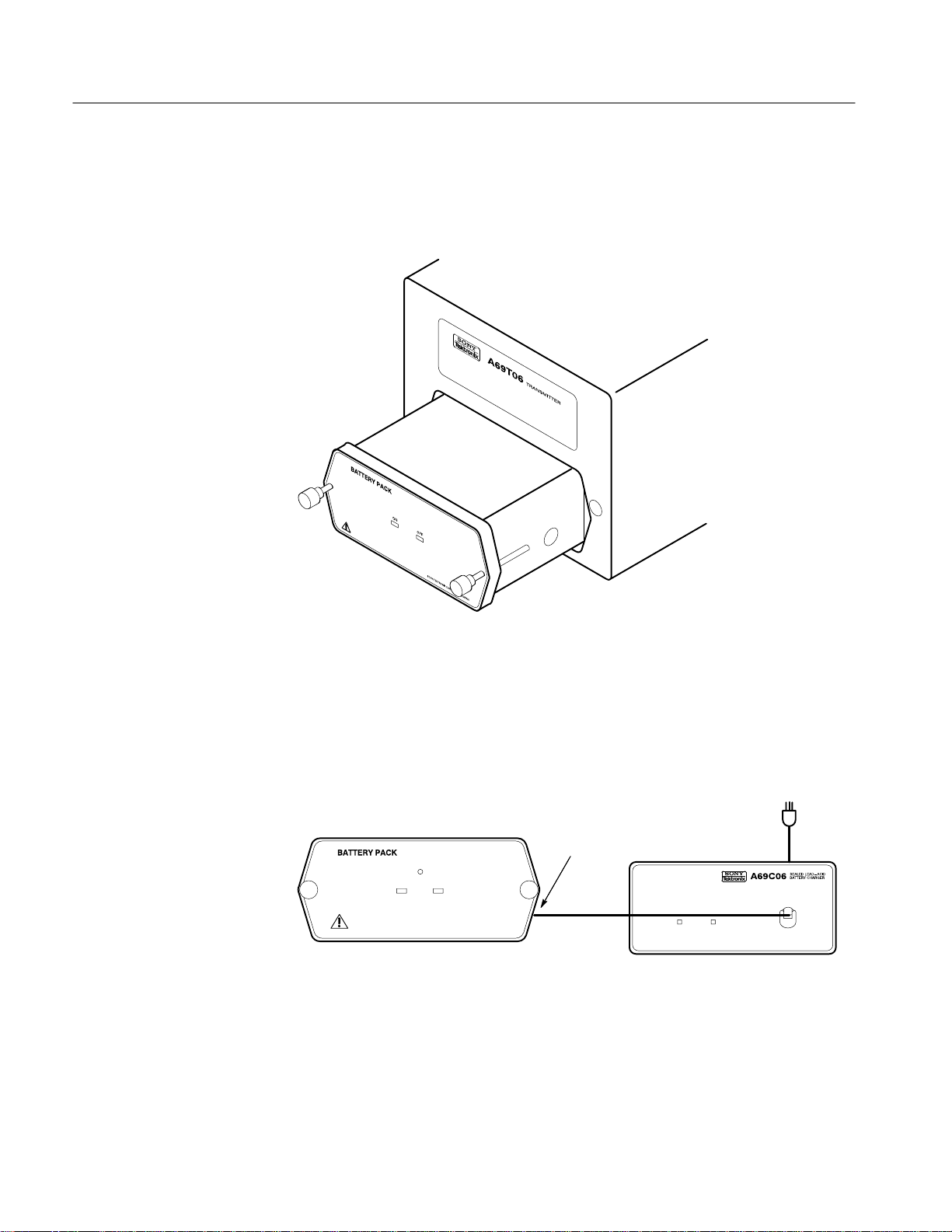

Charging the battery pack

The A69T06 Transmitter is powered from a battery pack. To charge the battery

pack, you need to remove it from the A69T06 Transmitter. It takes 12 hours to

charge a battery pack that has been fully discharged. You cannot use a battery

pack to power the A6906S while the battery pack is charging, but you can use a

second battery pack to operate the A69T06 while charging a battery pack using

the A69C06.

WARNING. Before removing the battery pack for charging, disconnect the probe

from the circuit being measured.

Do not put your hand or any foreign object into the battery pack compartment

after removing the battery pack.

Do not use the A69C06 Sealed Lead-Acid Battery Charger with any instrument

or battery other than the A6906S battery pack.

1. Connect the A69C06 Sealed Lead-Acid Battery Charger to the AC power

source through the supplied grounded power cord. Make sure that the green

POWER light is on.

2. Turn off the A69T06 by pressing the OFF button on the battery pack. The

red power light will turn off.

A6906S Fiber-Optic Isolation System User Manual

1

Page 18

Getting Started

3. Remove the battery pack from the A69T06 by unscrewing the two thumb-

screws on the front of the battery pack, as shown in Figure 1. Pull the battery

pack completely out of the A69T06.

Figure 1: A69T06 Battery Removal

4. Connect the cable from the A69C06 OUTPUT to the connector on the right

side of the battery pack, as shown in Figure 2.

To AC Power

Source

Side Connector

OUTPUT

Figure 2: Battery Charging

5. Make sure the red CHARGE light on the front of the A69C06 is on. When

the battery pack is fully charged, this light will turn off.

2

A6906S Fiber-Optic Isolation System User Manual

Page 19

Preparing for Operation

Getting Started

NOTE. battery packs are shipped fully charged. If you do not see the charge light

come on, the battery pack is still fully charged and can be used immediately.

6. When the battery pack is fully charged, disconnect it from the A69C06 and

reinstall it in the A69T06 Transmitter. Install the battery pack right-side up

in the A69T06, or the A69T06 will not operate even though the power light

turns on.

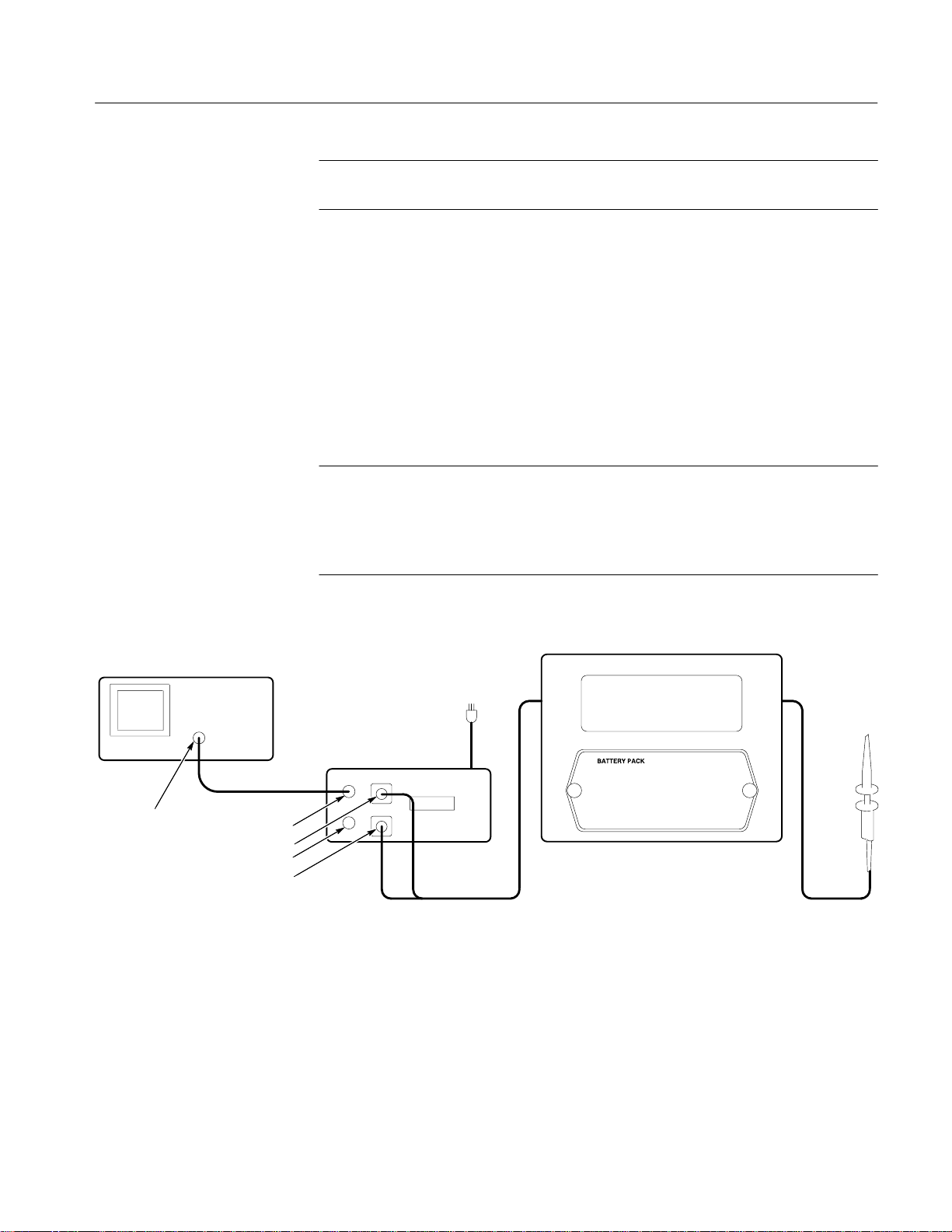

Figure 3 shows the connections necessary to use the A6906S Fiber-Optic

Isolation System.

NOTE. The A69T06 Transmitter, fiber-optic cable, and A69R06 Receiver have

been calibrated at the factory as a unit. Do not exchange modules among

A6906S Fiber-Optic Isolation Systems; Tektronix will not warrant performance

to specifications if you do so. Always use an A69T06 and A69R06 having

matching serial numbers.

Test Oscilloscope

50 W oscilloscope

input (or add 50 W

termination here if

oscilloscope has only

high-impedance input).

50 W Output

White

75 W Output

Red

Figure 3: A6906S Connections for Use

Connecting the

Fiber-Optic Cable

The fiber-optic cable connects the A69R06 Receiver to the A69T06 Transmitter.

The cable consists of two optical conductors, one for signal and one for control

commands. The two optical conductors are marked with different colored

protective caps: white marks the signal conductor and red marks the command

conductor.

A69R06

SIGNAL

COMMAND

To AC Power

Source

Fiber-Optic Cable

A69T06

Probe

A6906S Fiber-Optic Isolation System User Manual

3

Page 20

Getting Started

CAUTION. Be careful not to bend the fiber-optic cable excessively or apply

excessive force. When storing the fiber-optic cable, be sure to replace the cable

and the unit’s protective caps to protect them from soiling.

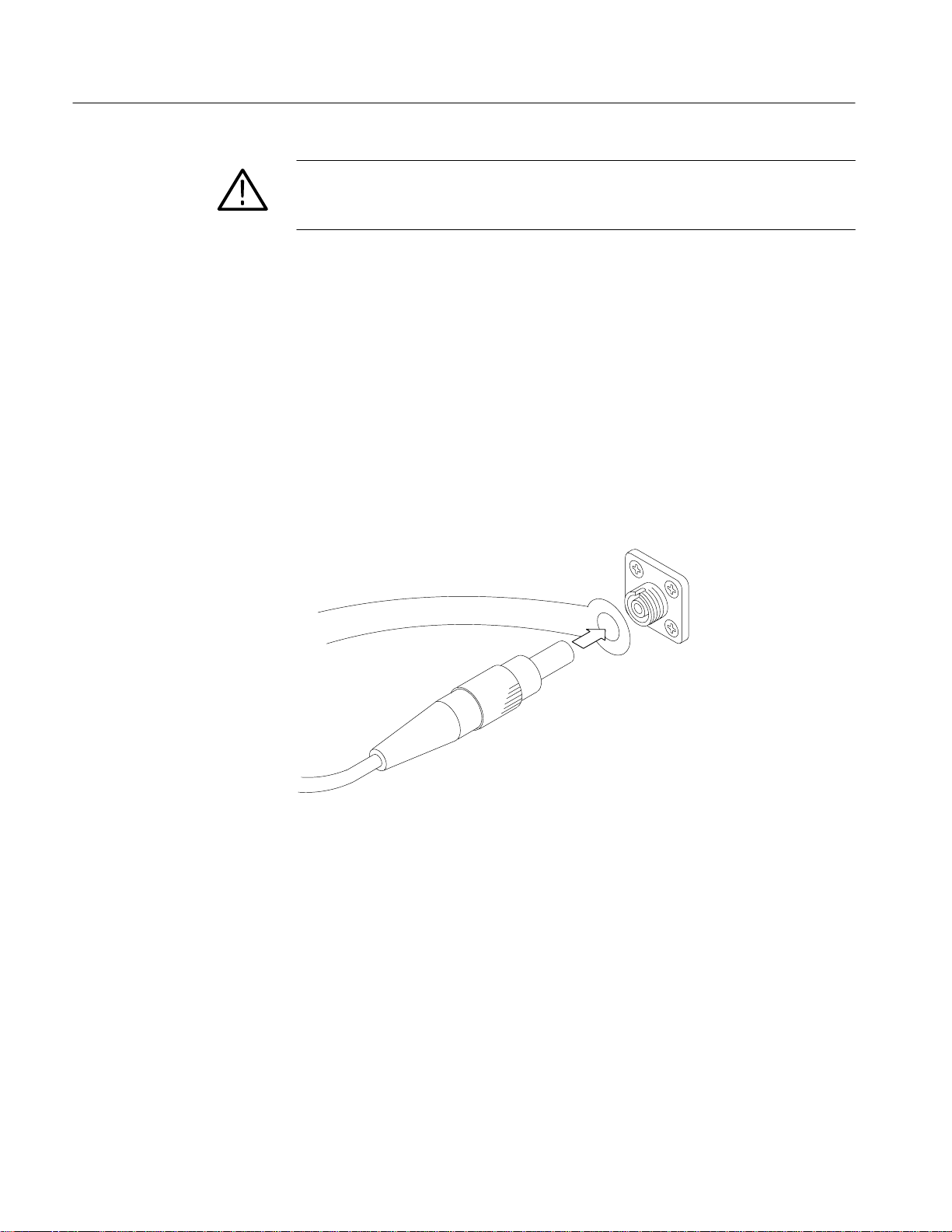

1. Remove the protective caps from the A69R06 SIGNAL and COMMAND

connectors.

2. Remove the red protective cap from the fiber-optic cable.

3. Remove the clear plastic protector from the optical surface of the fiber-optic

cable.

4. Place the cable strain relief around the A69R06 COMMAND conductor as

shown in Figure 4.

5. Insert the uncovered cable plug into the A69R06 COMMAND conductor.

Verify that the plug’s notch is completely seated in the connector’s groove

and then tighten the plug retaining ring, hand tight only.

Connecting to the

Oscilloscope

Strain relief on one connector only

Figure 4: Connection of the Fiber-Optic Cable and Connector

6. Repeat steps 2 and 5 for the white-capped fiber-optic cable, connecting it to

the A69R06 SIGNAL connector.

Use the included 50 W BNC cable to connect the A69R06 50 W OUTPUT to a

50 W oscilloscope input. If you have a 75 W system, you can use the 75 W

OUTPUT connector instead.

If your oscilloscope has only high-impedance inputs, you can install the included

50 W feedthrough termination between the oscilloscope input and the 50 W BNC

cable. Do not install the termination at the A69R06 end of the cable.

4

A6906S Fiber-Optic Isolation System User Manual

Page 21

Getting Started

NOTE. The self-calibration feature of the A6906S requires that the 50 W output of

the A69R06 be terminated into 50 W. If you are using a 75 W system, attach the

50 W feedthrough termination to the 50 W output and use the 75 W output to

connect to the system input.

AC Power

Connect the A69R06 Receiver to the AC power source through the supplied

grounded power cord.

Once you have connected the fiber-optic cable, the oscilloscope, and the power

cord, the A6906S Fiber-Optic Isolation System system is ready to power on and

use.

A6906S Fiber-Optic Isolation System User Manual

5

Page 22

Getting Started

6

A6906S Fiber-Optic Isolation System User Manual

Page 23

Operating Basics

This section tells you how to operate the A6906S Fiber-Optic Isolation System

once it is installed.

NOTE. To use this section, you must first install the A6906S as described in the

Getting Started section starting on page 1. A battery pack must be charged and

installed in the A69T06 Transmitter.

Power On and Calibration

The A6906S requires that both the A69T06 Transmitter and A69R06 Receiver be

powered on. The A69T06 takes power from its battery pack, and the A69R06

takes power from the AC line.

1. On the A69T06 battery pack, press the ON button to turn on transmitter

2. On the A69R06, turn on the power using the POWER OFF/ON switch on

power. The red light between the ON and OFF buttons will turn on.

the back panel.

If the attenuation display shows Er1, check the fiber-optic cable connections

between the transmitter and receiver. If necessary, clean the optical connectors as described in Cleaning Optical Connectors on page 11.

Allow the system to warm up for 20 minutes before proceeding. If you do

proceed to use the A6906S, perform step 3 below after 20 minutes have

passed since power on. Performance to specifications is guaranteed only after

20 minutes warm-up.

NOTE. The self-calibration feature of the A6906S requires that the 50 W output of

the A69R06 be terminated into 50 W. If you are using a 75 W system, attach the

50 W feedthrough termination to the 50 W output and use the 75 W output to

connect to the system input.

3. On the A69R06 front panel, press the CAL button to initiate the calibration

procedure. The transmitter and receiver will calibrate themselves to each

other. The calibration process takes approximately one minute the first time

after power on, subsequent calibrations take approximately 30 seconds.

When the calibration is complete, the green PASS light will turn on.

A6906S Fiber-Optic Isolation System User Manual

7

Page 24

Operating Basics

If the red FAIL light comes on instead, check the fiber-optic cable connections between the transmitter and receiver. If necessary, clean the optical

connectors as described in Cleaning Optical Connectors on page 11. If the

green PASS light still doesn’t come on, the instrument needs repair.

Once the A6906S is powered up and calibrated, it is controlled by the front panel

buttons on the front of the A69R06 Receiver. It can also be controlled by a GPIB

computer or controller connected to the A69R06, making it a part of an

automated test system.

Optional Temperature Calibration

The A69T06 monitors its internal temperature and applies internal calibration

corrections to compensate for drift in offset. Temperature does not affect the

A69R06 and so it has no temperature monitoring system.

Normally, temperature corrections are applied based on default correction values.

You can override the default values with values that are optimized to a specific

temperature; however, if the temperature changes while the override values are in

effect the A69T06 will not correct the for the offset drift induced by the changed

temperature. To set optimum override values, follow these steps:

Operation

1. Install the A6906S in the environment in which it will be used.

2. On the A69R06, press the CAL and COUPLING buttons simultaneously.

3. Press the A69R06 COUPLING button again.

4. Allow the temperature environment to stabilize. Do not continue to step 5

until the A69T06 has been in a temperature-stable environment for at least

20 minutes.

5. Press the A69R06 COUPLING button again. Until this step is completed,

the A6906S will not respond to GPIB commands.

To return to normal operation with default temperature correction values:

1. Install the A6906S in the environment in which it will be used.

2. On the A69R06, press the CAL and COUPLING buttons simultaneously.

3. Press the A69R06 CAL button again.

To use the A6906S Fiber-Optic Isolation System to take a measurement, connect

the probe to the circuit you want to test, select the ATTENUATOR and

COUPLING settings on the A69R06, and view the output on the oscilloscope.

8

A6906S Fiber-Optic Isolation System User Manual

Page 25

Operating Basics

WARNING. Do not apply the probe to voltages that exceed the maximum ratings

indicated on the rear panel of the A69T06.

"

W

"

W

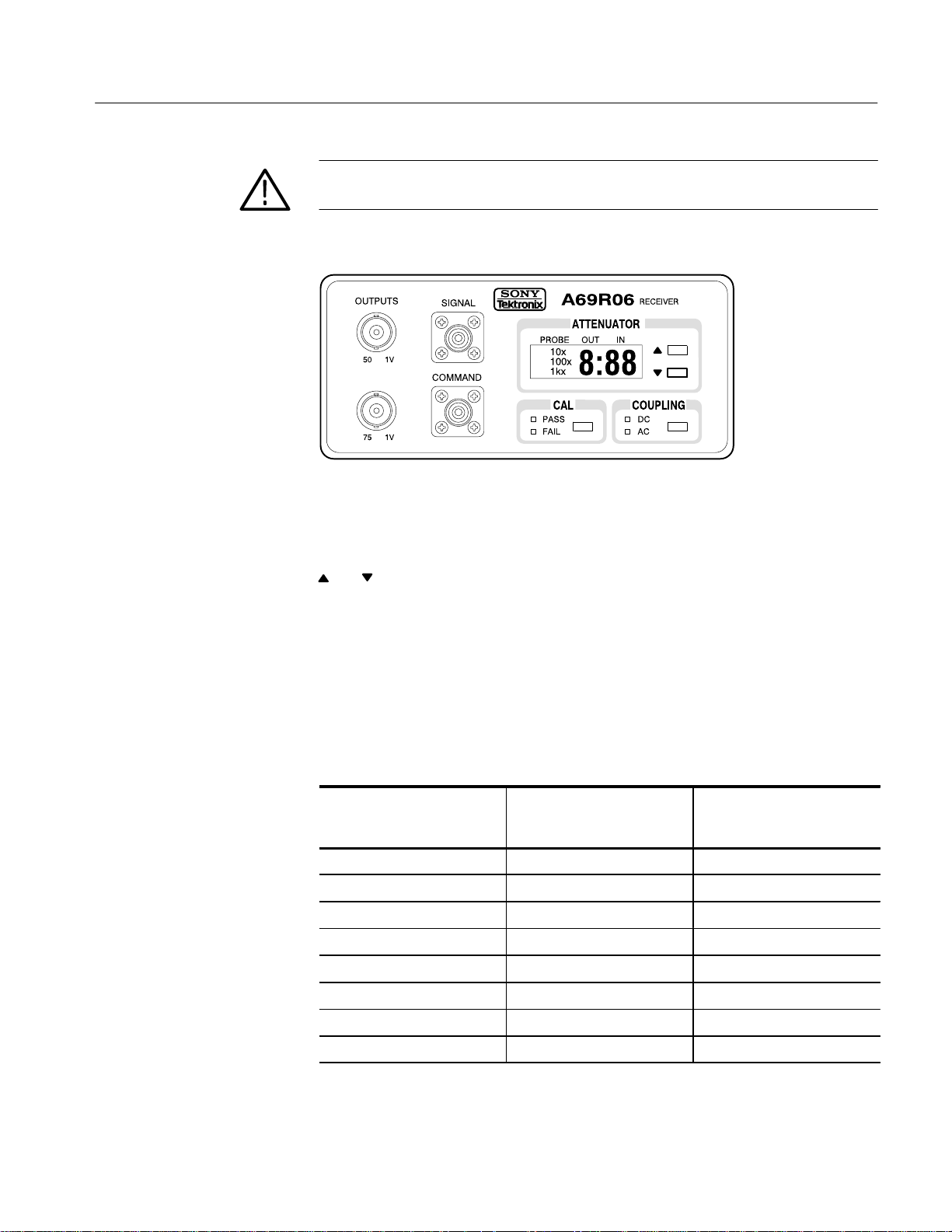

Figure 5: A69R06 Receiver Controls

Attenuator Controls

The ATTENUATOR controls consist of a digital readout and two buttons,

and . The digital readout displays the attenuation factor of the A69T06 and

A6906S, but does not include the 100× attenuation of the probe. The 100× light

in the attenuator display is always on to remind you to include this factor when

reading the displayed attenuation.

The buttons adjust the attenuation factor up or down, to increase or decrease the

displayed height of the signal on the oscilloscope display. Table 1 shows the

attenuation factors of the A69T06 including probe.

T able 1: A6906S Attenuation Factors with Probe Factor Included

Probe Tip to

Displayed Attenuation

Factor

Oscilloscope Input

Attenuation

1:50 5,000× 8mV

1:20 2,000× 20 mV

1:10 1,000× 40 mV

1:5 500× 80 mV

1:2 200× 200 mV

1:1 100× 400 mV

2:1 50× 800 mV

5:1 20× 2.0 V

Output Amplitude of a

40 V

Signal

p-p

p-p

p-p

p-p

p-p

p-p

p-p

p-p

p-p

A6906S Fiber-Optic Isolation System User Manual

9

Page 26

Operating Basics

Calibration Controls

Coupling Controls

Oscilloscope Controls

6-Inch Ground Lead

The CAL button starts the self-calibration process . This performs automatic

internal adjustments in the A69T06 and A69R06, and adjusts the transmitter and

receiver to each other. When the calibration is complete, the green PASS and red

FAIL lights tell you whether the self-calibration was successful.

If the self-calibration fails, clean the optical connectors as described in Cleaning

Fiber-Optic Cable Connectors on page 11. If the green PASS light still doesn’t

come on, the instrument needs repair.

The COUPLING button changes the A6906S system to either DC or AC

coupling. Push the button to change the setting from one to the other. The green

DC or AC lights tell you which coupling mode is selected.

The oscilloscope you use with the A6906S provides controls for triggering,

horizontal size, vertical size, and other display parameters. Use these oscilloscope controls just as you would when using a regular oscilloscope probe.

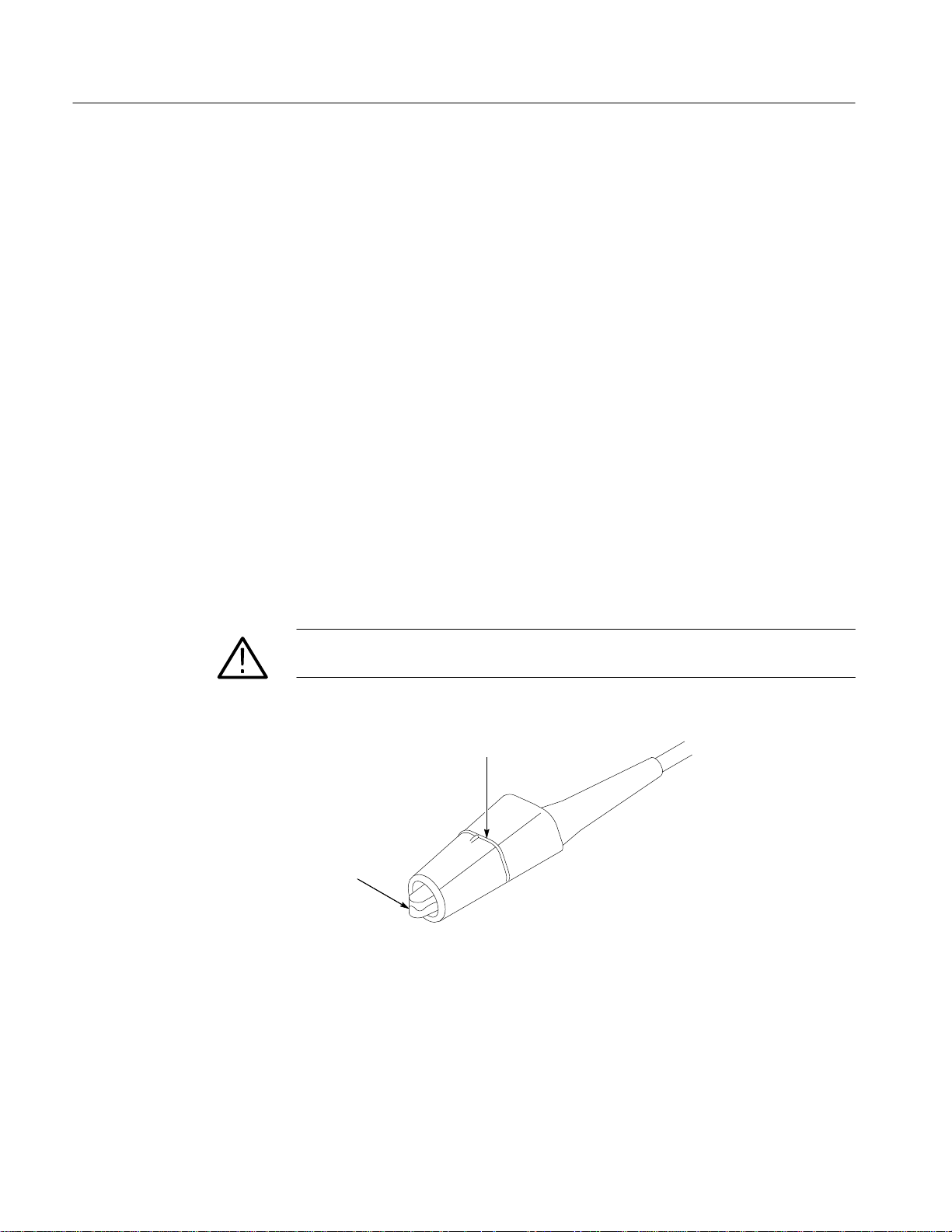

Figure 6 shows the 6-inch ground lead that is included with the A6906S as a

standard accessory. Use the 6-inch ground lead in place of the longer ground lead

for measuring fast-rising waveforms.

WARNING. To avoid electrical shock, do not touch the metal of the ground clip.

Handle the clip by the insulation above the Limit Mark as shown in Figure 6.

Limit Mark

Metal Part

Figure 6: 6-Inch Ground Lead Clip

10

A6906S Fiber-Optic Isolation System User Manual

Page 27

Cleaning Fiber-Optic Cable Connectors

If the fiber-optic cable or front panel optical connector is dirty, the system may

not perform as it should or may fail self-calibration. If the fiber-optic cable or

connector is dirty, use the fiber-optic cleaner accessory to clean it as shown in

Figure 7. Normally, a single cleaner can clean a number of fiber-optic cables or

connectors. If the connector is extremely dirty, use a small amount of alcohol and

use the cleaner only once.

Figure 7: Fiber-Optic Cable and Connector Cleaning

A6906S Fiber-Optic Isolation System User Manual

11

Page 28

Cleaning Optical Connectors

12

A6906S Fiber-Optic Isolation System User Manual

Page 29

Programming

Setting Up

You can use a computer to control the A6906S and make measurements. With an

oscilloscope that also can be programmed, the computer and A6906S can form a

complete, automated measurement system.

Your computer, also known as the controller, must be capable of operating on a

GPIB bus that conforms to IEEE Std 488.1–1987. GPIB cards are available to

provide this capability for personal computers.

The A69R06 Receiver has a 24-pin GPIB connector on its rear panel, as shown

in Figure 8. This connector has a D-type shell and conforms to IEEE Std

488.1–1987.

Attach an IEEE Std 488.1–1987 GPIB cable between this connector and your

controller. Figure 8 shows how cables can be stacked together. You can stack a

second cable on either the receiver connector or the controller connector, to

similarly connect your oscilloscope.

Figure 8: Stacked GPIB Connectors

A6906S Fiber-Optic Isolation System User Manual

13

Page 30

Programming

GPIB Requirements

Observe these rules when you use your A69R06 with a GPIB network:

H Assign a unique device address to each device on the bus. No two devices

can share the same device address.

H Do not connect more than 15 devices to the bus.

H Connect one device for every 2 meters (6 feet) of cable used.

H Do not use more than 20 meters (65 feet) of cable for the entire bus.

H Power on at least two-thirds of the devices on the network while using the

network.

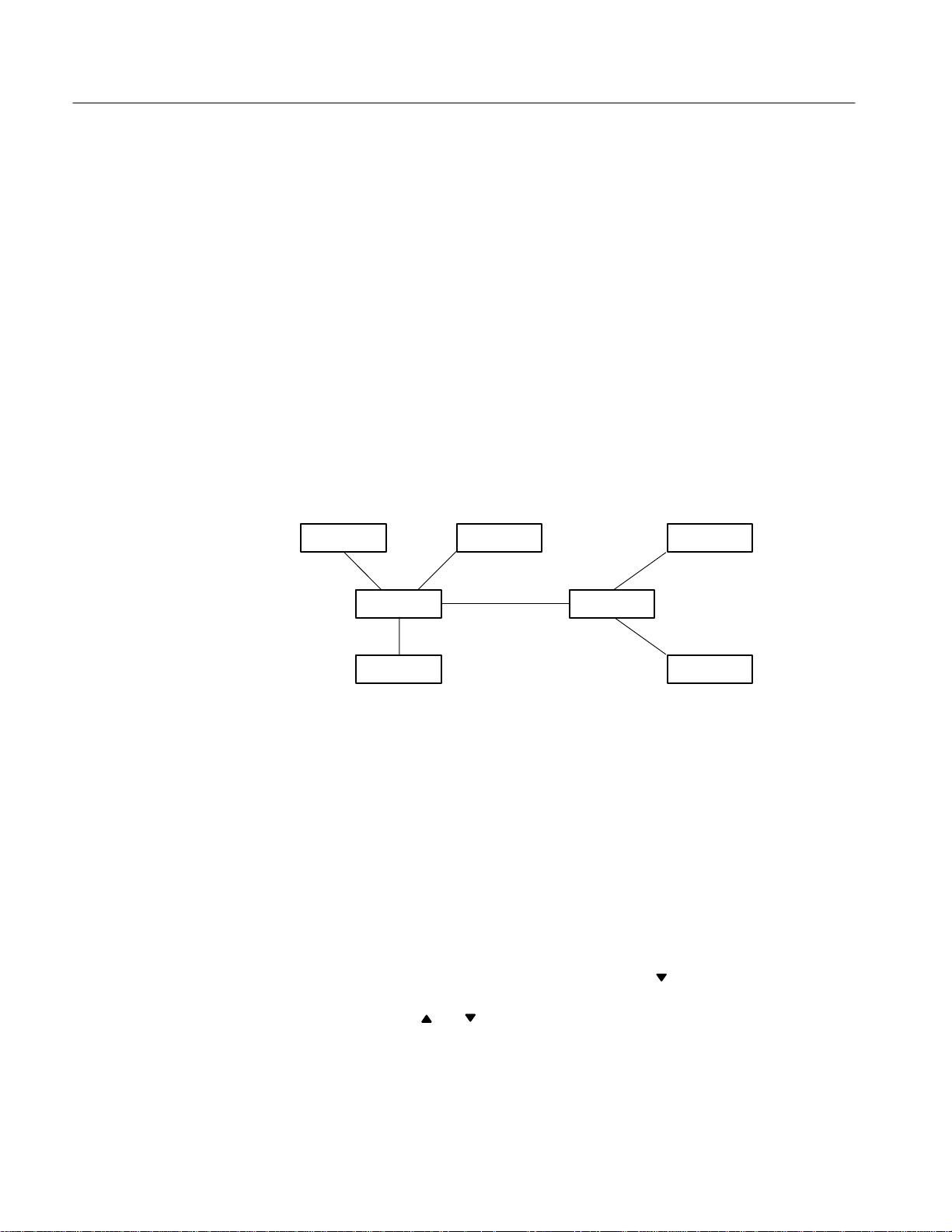

H Connect the devices on the network in a star or linear configuration as shown

in Figure 9. Do not use loop or parallel configurations.

Figure 9: Typical GPIB Network Configuration

Setting GPIB Parameters

You must set the GPIB parameters of the A69R06 to match the configuration of

the bus and controller.

GPIB Address

Set the GPIB ADDRESS using the A69R06 front panel. The GPIB controller

uses this address to send commands to the A69R06. The address of the A69R06

must be different from the addresses used by all other devices on the bus.

To set the GPIB address, press the ATTENUATOR

simultaneously and then release them. The attenuator display shows the current

address. Press the

address is set, press the COUPLING button to return to normal operation.

GPIB Device

GPIB Device

GPIB Device

GPIB Device

GPIB Device

GPIB Device

GPIB Device

and COUPLING buttons

and buttons to change the address. When the proper

14

A6906S Fiber-Optic Isolation System User Manual

Page 31

Programming

You can set the address from 0 through 30. You can also set the A69R06 to “off

line,” which disables all communications with the controller, by specifying

address 31.

GPIB Terminator

The termination mode specifies what conditions the A69R06 looks for to

determine the end of a command. The terminator may be set to “EOI” only or

“LF or EOI.” You will need to consult your controller documentation to

determine which setting is best for your configuration.

To set the GPIB terminator, press the ATTENUATOR

buttons simultaneously and then release them. The attenuator display shows the

current termination. Press the

the proper termination mode is set, press the COUPLING button to return to

normal operation.

The termination mode also specifies the termination of output messages from the

A69R06 to the controller. When the mode is “LF or EOI,” the A69R06 adds CR

and LF characters to the end of messages. In “EOI” only mode, the A69R06 adds

no characters to messages.

Other Documents You Will Need

Tektronix cannot know what type of controller you will use with your A69R06,

and so this document cannot cover the topics that are specific to your installation. To completely understand and implement a GPIB system, you will need the

documentation that supports your controller. If you are using a personal

computer with a GPIB card, you will need the documentation for both the PC

and the GPIB card.

and COUPLING

and buttons to change the termination. When

Commands

Command names show both upper- and lower-case characters. Only the

upper-case characters are required. You can abbreviate commands by omitting

lower-case characters, starting from the end. For example, you can enter the

COUpling command as COUPLING, COUPL, or COU. You can use lower-case

letters anyplace in command names or arguments: coUpLiNg, CouPl, or cou are

valid.

A6906S Fiber-Optic Isolation System User Manual

15

Page 32

Programming

T able 2: A6906S GPIB Commands

Command Name Description

CALibration Executes self-calibration, optionally returns result

COUpling Sets or queries input coupling

EVent? Returns the last pending event code

HELp? Returns a list of A6906S GPIB commands

ID? Returns instrument ID including firmware version numbers

INIt Initializes A6906S to factory default settings

PROBE? Returns the probe type

RANge Sets or queries the attenuator range

RQS Enables or disables system requests (SRQs)

SERIAL? Returns A6906S serial number

SET? Returns all A6906S settings as command string

ST Andby Sets or queries standby mode

CALibration

Syntax

Returns

Examples

TRAns? Queries status of transmitter

TESt? Performs A6906S self test query

Initiates the self-calibration of the A6906S. The query form returns the result.

PASS or FAIL, depending on the self-calibration result.

CALIBRATION

performs a self-calibration of the A6906S without a return message.

CAL?

might return CAL PASS.

16

A6906S Fiber-Optic Isolation System User Manual

Page 33

COUpling

Programming

Sets or queries the input coupling of the A6906S.

Syntax

Arguments

Examples

EVEnt? (Query Only)

Syntax

COUpling AC

COUpling DC

COUpling?

AC sets the input to AC coupling. DC sets the input to DC coupling.

COU DC

sets the A6906S input to DC coupling.

COU?

might return COUP DC, indicating that the A6906S input is set to DC coupling.

Returns the error or event code for the most recent event reported by serial poll,

or for the highest priority condition pending.

EVEnt?

Returns

Examples

HELp? (Query Only)

Syntax

Returns

The most recent error/event code.

EVE?

might return EVENT 266 as the most recent error code.

Returns a list of commands that are recognized by the A6906S.

HElp?

Will always return the string CAL, COU, EVE, HEL, ID, INI, PRO, RAN, RQS,

SET, STA, TRA, TES

A6906S Fiber-Optic Isolation System User Manual

17

Page 34

Programming

ID? (Query Only)

Returns the A6906S identification, including the Codes and Formats Version and

the firmware version.

Syntax

Returns

Examples

INIt (No Query Form)

Syntax

PRObe? (Query Only)

Syntax

ID?

The instrument identification string.

ID?

may return the string ID SONY_TEK/A69R06, V81.1, FV1.00

Initializes the A6906S (both A69R06 and A69T06) to factory default settings.

INIt

Returns the type of probe connected to the A69T06. This will always be X100.

PROBETYpe?

18

Returns

Examples

PROBETYPE X100

PROBETY?

will return PROBETYPE X100.

A6906S Fiber-Optic Isolation System User Manual

Page 35

RANge

Programming

Sets or queries the A6906S attenuator range setting.

Syntax

Arguments

Examples

RANge 1:50

RANge 1:20

RANge 1:10

RANge 1:5

RANge 1:2

RANge 1:1

RANge 2:1

RANge 5:1

RANge?

The argument tells how much the A6906S should attenuate or amplify the input

signal.

RAN 1:50

sets the A6906S to attenuate signals by a factor of 50. (Combined with the 100×

probe, the total attenuation is a factor of 5,000.)

RAN?

might return RANGE 1:1, indicating that the A6906S is set to neither amplify

nor attenuate.

RQS

Enables or disables SRQs (System Requests). When disabled, the A6906S does

not act on error conditions other than to log them, and does not signal that it is

ready to transmit data to the controller.

Syntax

Arguments

Examples

A6906S Fiber-Optic Isolation System User Manual

RQS ON

RQS OFF

RQS?

ON enables SRQ events. Off disables SRQ events.

RQS ON

enables SRQ events.

19

Page 36

Programming

SET? (Query Only)

Returns a string containing all the individual programming commands required

to return the A6906S to its present state. This string can be saved and sent at

some future time when you want to return the A6906S to all the present settings.

STAndby

Syntax

Returns

Examples

Syntax

Arguments

SET?

COU <AC | DC>;RAN <1:50 | 1:20 | 1:10 | 1:5 | 1:2 | 1:1 | 2:1 |

5:1>;RQS <ON | OFF>;STA <ON | OFF>

SET?

might return COU AC;RAN 1:2;RQS OFF;STA OFF

Enables or disables the standby mode, or queries the current standby mode

setting.

STAndby ON

STAndby OFF

STAndby?

ON turns standby mode on, OFF turns standby mode off.

20

Returns

Examples

ON or OFF

STA ON turns on standby mode.

STA?

might return STANDBY OFF, indicating standby mode is off.

A6906S Fiber-Optic Isolation System User Manual

Page 37

TRAns? (Query Only)

Programming

Queries the state of the A69T06. This is needed because the GPIB interface is a

part of the A69R06.

Syntax

Returns

Examples

TESt? (Query Only)

Syntax

Returns

NORMAL if the A69T06 has a charged battery and is responding normally,

LOW if the battery pack has a low charge level, OFF if it is powered off or not

responding, or UNKNOWN if the A69R06 cannot determine the status.

TRA?

might return TRA NORMAL, indicating that the A69T06 is operating normally

with a full battery charge.

Instructs the A6906S to perform a self-test operation and return the result.

PASS or FAIL

Examples

A6906S Fiber-Optic Isolation System User Manual

TES?

might return TEST PASS, indicating that the self-test completed successfully

with no errors.

21

Page 38

Programming

Status Bytes and Event Codes

The status and error reporting system of the A69R06 interrupts the controller by

asserting an SRQ (service request). The service request indicates that an event

has occurred that requires attention. When the controller polls the bus, the status

byte returned by the A69R06 indicates the type of event that occurred. A further

EVEnt? query will return an event code that gives more specific information

about the cause of the service request. The SRQ status byte and the event code

provide a limited amount of information about the specific cause of the service

request.

T able 3: Status Bytes

Category RQS Off RQS On RQS Off RQS On

No Status 0000 0000 0000 0000 0 0

Power On 0000 0001 0100 0001 1 65

Binary Decimal

Operation Complete 0000 0010 0100 0010 2 66

Command Error 0010 0001 0110 0001 33 97

Execution Error 0010 0010 0110 0010 34 98

Internal Error 0010 0011 01 10 0011 35 99

Execution Warning 0010 0110 0110 0110 38 102

T able 4: Event Codes

Category Code Description

Command Errors 101 Command header error

103 Command argument error

106 Missing argument

151 Command statement too long

Execution Errors 203 I/O buf fers full

204 Command received during self-calibration

Internal Errors 302 Self-calibration fail

350 Battery off

22

System Events 401 Power on

402 Self-calibration pass

Internal Warning 550 Low battery charge

A6906S Fiber-Optic Isolation System User Manual

Page 39

Appendix A: Specifications

All specifications are subject to the following conditions:

H The A6906S and probe have been warmed up for at least 20 minutes.

H The A6906S and probe have been self-calibrated at an ambient temperature

between 20_ C and 30_ C after the warm up period.

The specifications in Table 5 and Table 9 are warranted specifications unless

otherwise noted. Other specifications are typical or nominal characteristics.

T able 5: Electrical Specifications

Input-to-Output

Voltage Ratio

DC Offset Accuracy,

all ranges

Gain Accuracy,

50 W output,

at 500 mV DC

Bandwidth, –3 dB DC to 100 MHz

Flatness, passband ±5% with probe, DC to 20 MHz

User selectable: without probe (typical) with probe

1 : 50 attenuation 5,000×

1 : 20 attenuation 2,000×

1 : 10 attenuation 1,000×

1 : 5 attenuation 500×

1 : 2 attenuation 200×

1 : 1 (unity) 100×

2 : 1 gain 50×

5 : 1 gain 20×

±10 mV

without probe (typical) with probe

1 : 50 attenuation ±3.0% ±3.2%

1 : 20 attenuation ±3.0% ±3.2%

1 : 10 attenuation ±2.5% ±2.7%

1 : 5 attenuation ±2.5% ±2.7%

1 : 2 attenuation ±2.5% ±2.7%

1:1 ±2.0% ±2.3%

2 : 1 gain ±2.0% ±2.3%

5 : 1 gain ±2.0% ±2.3%

±5% without probe, DC to 30 MHz, typical

Rise Time 3.5 ns

Probe Input Impedance 10 MW, typical

Aberrations,

without probe

with probe

A6906S Fiber-Optic Isolation System User Manual

2.9 pf, typical

6%

, typical within first 20 ns

p-p

10%

, typical within first 20 ns

p-p

23

Page 40

Appendix A: Specifications

1

z

T able 5: Electrical Specifications (Cont.)

Total Harmonic

Distortion

1 kHz Sine Wave

Output Noise Level

DC to 100 MHz

Output Impedance,

at DC

Maximum Rated Normal

Mode Input Voltage

probe tip to

probe common

Maximum Rated Common Mode Input Voltage

probe common to

earth ground

Maximum Output

Voltage,

50 W Output

Common Mode

Rejection Ratio

Common Mode

Slew Rate

1.0% (at 1 V

2.0% (at 2 V

≤2.2 mV

output), typical

p-p

output), typical

p-p

RMS

50 W ±5%

75 W ±5%

848 V (DC plus peak AC)

6 kV (peak surge ≤250 ms)

848 V (DC plus peak AC)

6 kV (peak surge ≤250 ms)

2V

p-p

without probe, 1:1 range with probe, 5:1 range

120 dB at 60 Hz, typical

80 dB at 1 MHz, typical 60 dB at 1 MHz, typical

60 dB at 10 MHz, typical 40 dB at 10 MHz, typical

100 kV/ms, typical

Delay ,

50 ns, typical

3 m Fiber-Optic

Cable

Power Requirements 90 to 250 VAC, 47 to 66 Hz

10 W (A69R06), typical

25 W (A69C06), typical

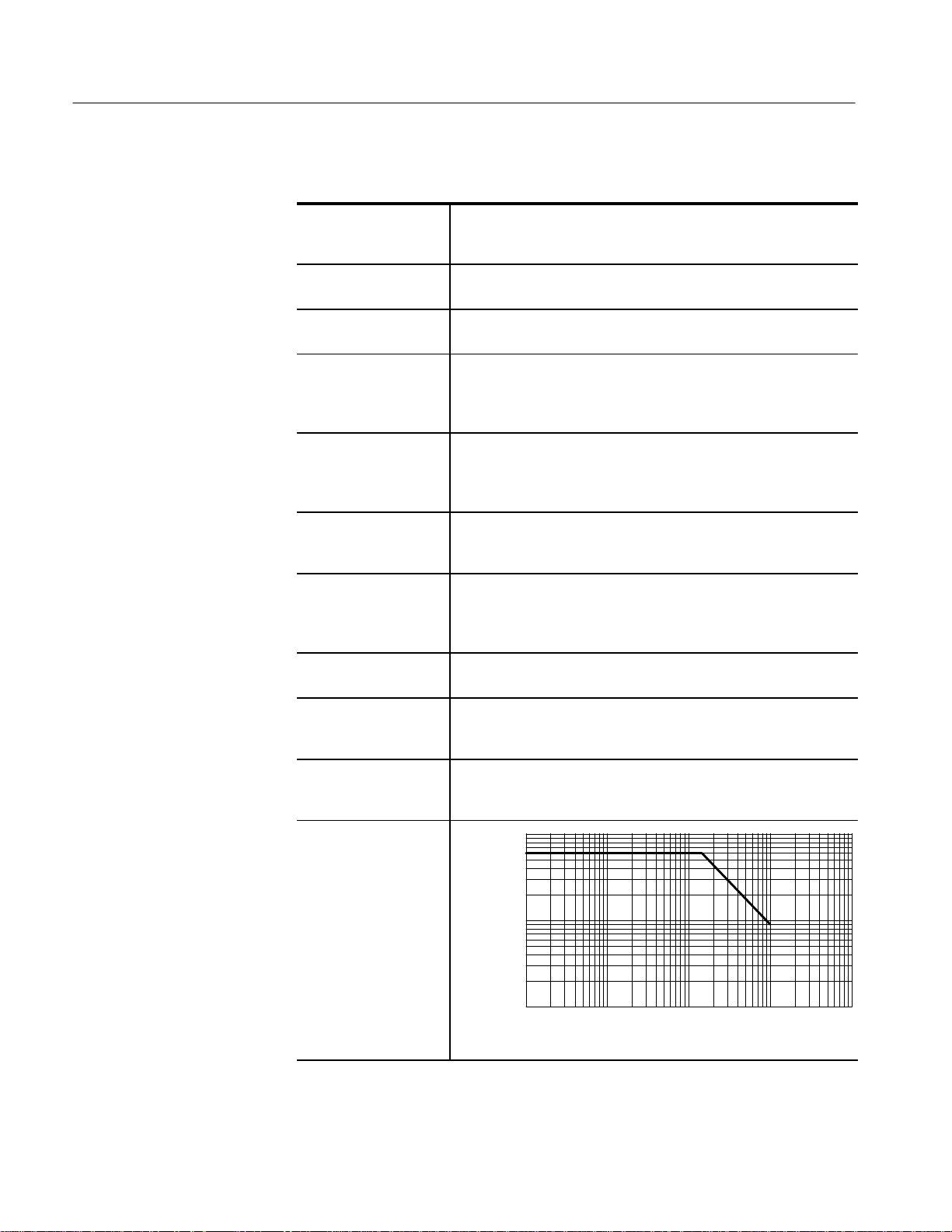

Frequency Derating with

probe, typical

kV

600 V

100 V

10 V

RMS

RMS

RMS

RMS

100

kHz

1

MHz

10

MHz

100

MHz

1

GH

24

A6906S Fiber-Optic Isolation System User Manual

Page 41

T able 6: Fiber-Optic Cable Characteristics

Optical Fiber Type Plastic clad multimode fiber

Core/Clad Size 200/230mm

Numeric Aperture 0.4

Fiber-Optic Cable

Maximum Tension,

Cable

Connector

40 kg (88 lb)

2 kg (4.4 lb)

Appendix A: Specifications

Fiber-Optic Cable

Minimum Bend Radius,

no tension

100 mm

50 mm short term

T able 7: Battery Characteristics

Battery Life,

Continuous

transmitter use

at 25_ C

Battery Rated Capacity 12 Ah

Battery Full

Charge Time

at 25_ C

DC Supply Current from

Battery to Transmitter

Maximum Battery

Charge Current

12 hours

12 hours

800 mA (normal mode)

150 mA (standby mode)

1.25 A

T able 8: Physical Characteristics

Weight A69T06: 7.8 kg (17.2 lb)

Outside Dimensions,

not including probe

or fiber-optic cable

A6906S Fiber-Optic Isolation System User Manual

A69R06: 1.7 kg (3.7 lb)

A69C06: 1.4 kg (3.1 lb)

A69T06 A69R06 and A69C06

H: 139mm (5.5 in) 56 mm (2.2in)

W: 170 mm (6.7 in) 120mm (4.7 in)

D: 475mm (18.7 in) 300 mm (11.8in)

25

Page 42

Appendix A: Specifications

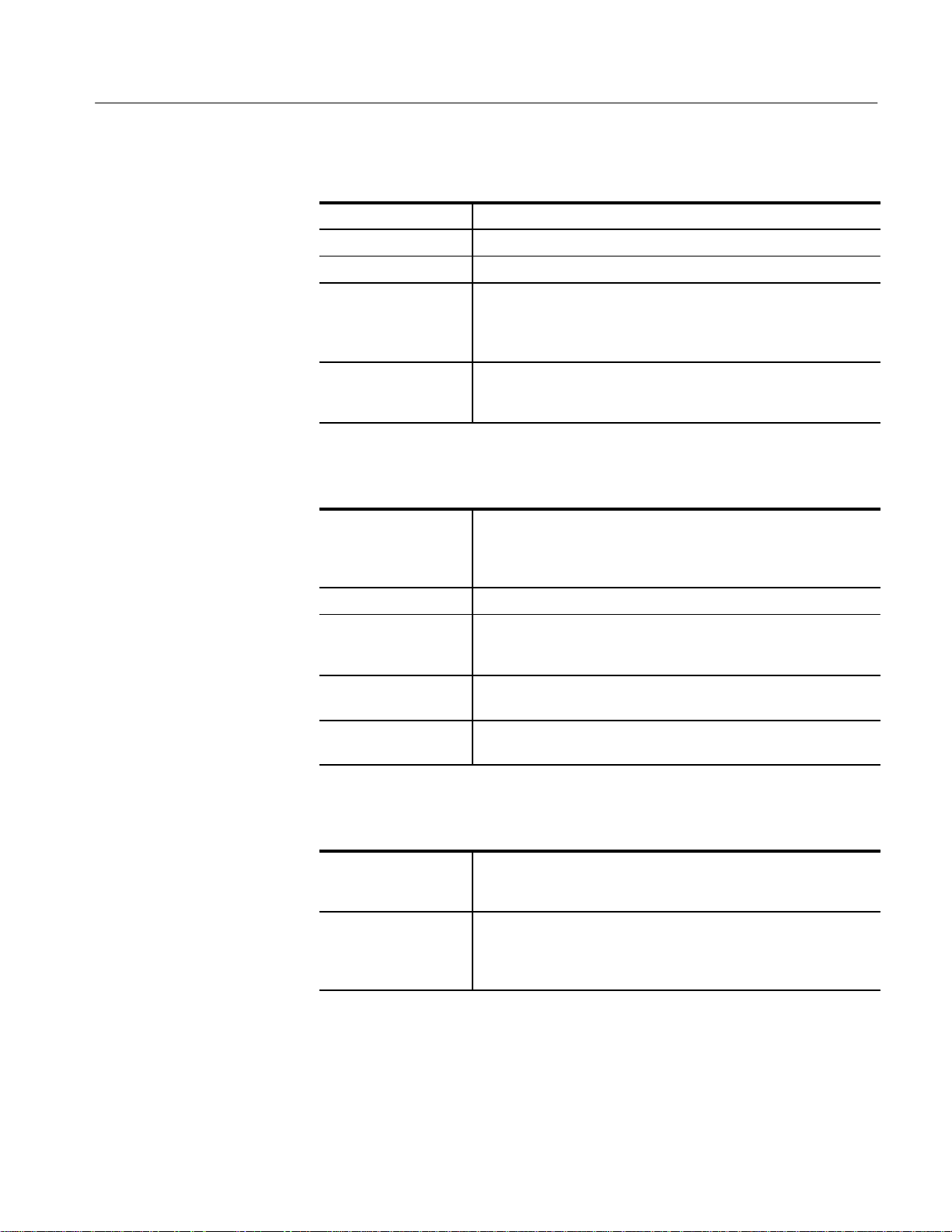

T able 9: Environmental Characteristics

Operating Temperature

A69T06, A69R06

A69C06

Humidity,

operating and

non-operating

Non-Operating

Temperature,

A69T06, A69R06

A69C06

battery pack

Electrostatic Immunity 20 kV

Safety Certifications UL1244, CSA-C22.2 #231–M89

0_ C to 50_ C

10_ C to 35_ C

95% relative humidity from 30_ C to 50_ C

MIL-E-16400F paragraphs 4.5.9 through 4.5.9.5.1, class 4.

–25_ C to 50_ C

–25_ C to 70_ C

–15_ C to 30_ C (long-term storage, >1 month)

T able 10: GPIB Interface Functions

Name Subset Notes

Source Handshake SH1 Complete capability

Acceptor Handshake AH1 Complete capability

T alker T6 Basic talker, serial poll, unaddress if MLA

Listener L4 Basic listener, unaddress if MTA

Service Request SR1 Complete capability

Remote/Local RL2 No local lockout

Parallel Poll PPO No capability

Device Clear DC1 Complete capability

Device Trigger DT0 No capability

Controller C0 No capability

26

A6906S Fiber-Optic Isolation System User Manual

Page 43

Appendix B: Performance Verification

This section contains a collection of procedures for checking that the A6906S

Fiber-Optic Isolation System performs as warranted. The procedures check all

the warranted characteristics in Appendix A: Specifications on page 23.

NOTE. A brief functional verification can be performed without test equipment.

Install the A6906S Fiber-Optic Isolation System as described in Power On and

Calibration on page 7, and perform the self-calibration. If the PASS light comes

on, the system is verified as functional.

Prerequisites

The tests in this subsection comprise an extensive, valid confirmation of

performance and functionality when the following requirements are met:

1. The battery pack must be charged as described in Charging the battery pack

on page 1. The battery pack must be installed in the A69T06.

2. The A69T06 and A69R06 must be connected with the fiber-optic cable, and

the A69R06 must be connected to an oscilloscope, as described in Preparing

for Operation on page 3.

3. All cabinets must be in place.

4. The A6906S Fiber-Optic Isolation System must have been operating for a

continuous warm-up period of at least 20 minutes within the operating

temperature specified in Appendix A: Specifications on page 23.

5. The self-calibration routine must have been performed and passed after the

warm-up period, as described in Power On and Calibration on page 7.

A6906S Fiber-Optic Isolation System User Manual

27

Page 44

Appendix B: Performance Verification

Required Test Equipment

Table 11 lists all the test equipment required to do the performance check.

T able 11: Test Equipment Required for Performance Verification

Description Minimum Requirements Example Purpose

Oscilloscope 350 MHz bandwidth,

automated measurement

capability: Mean, RMS, Rise

Time, Peak-Peak

Calibration Generator Fast-rise signal level 100 mV to

1 V, repetition rate 1MHz,

rise time ≤1 ns, flatness ±2%

Sine Wave Generator 250 kHz to 100 MHz, variable

amplitude to 1 V

50 kHz reference

Coaxial Cable, 50 W Precision

(2 required)

Feedthrough T ermination, 50W 50 W, female-to-male BNC

BNC to Dual Banana Connector Female BNC to male dual

50 W, 1 m (36 in), male-to-male

BNC connectors

connectors

banana

into 50W,

p-p

Offset and Noise Check

Perform this check with the A6906S Fiber-Optic Isolation System connected to

an oscilloscope and configured for normal use, as shown in Figure 3 on page 3.

Use the 6-inch ground lead on the probe common lead.

Tektronix TDS 460 Checking noise, rise time,

aberration and bandwidth

Tektronix PG 506A Checking rise time

Tektronix SG 503 Checking bandwidth

Tektronix part number

012-0482-00

Tektronix part number

01 1-0049-01

Tektronix part number

103-0090-00

Signal connection

Signal termination

Various tests

28

1. Short the probe tip to the probe common lead. The connections should now

be configured as shown in Figure 10.

2. On the A69R06, set the ATTENUATOR to 1 : 1 and COUPLING to AC.

3. Set the oscilloscope as follows:

Horizontal 1 ms/div. . . . . . . . . . . . . . . .

Vertical 5 mV/div. . . . . . . . . . . . . . . . . .

Coupling AC. . . . . . . . . . . . . . . . .

Impedance 50 W. . . . . . . . . . . . . . .

BW Limit On (100 MHz). . . . . . . . . . . . . . . .

Measurement RMS and Mean. . . . . . . . . . . . .

Acquisition Mode Sample (Average off). . . . . . . . . .

A6906S Fiber-Optic Isolation System User Manual

Page 45

Appendix B: Performance Verification

4. To measure noise, check that the RMS measurement readout of the

oscilloscope is less than 2.2 mV.

Oscilloscope

Probe

6-inch Ground Lead

A69T06

Fiber-Optic Cable

Coaxial Cable

A69R06

Figure 10: Noise Check Setup

5. Change the oscilloscope acquisition mode to average, and the coupling to

DC.

6. To measure offset,check that the Mean measurement readout of the

oscilloscope is <±10 mV.

7. Unclip the 6-inch ground lead from the probe tip.

Rise Time Check

Perform this check with the A6906S Fiber-Optic Isolation System connected to

an oscilloscope and configured for normal use, as shown in Figure 3 on page 3.

Use the 6-inch ground lead on the probe common lead.

1. Attach a coaxial cable to the fast rise output of the calibration generator.

Attach a 50 W feedthrough termination to the other end of the coaxial cable.

Attach a BNC to Dual Banana Connector to the 50 W feedthrough termination, and connect the A6906S probe to the banana jacks. Make sure the

probe tip is connected to the signal jack and the 6-inch ground lead is

connected to the ground jack. Attach another coaxial cable from the Trigger

Output

should now be configured as shown in Figure 11.

A6906S Fiber-Optic Isolation System User Manual

of the Cal Generator to channel 2 on the oscilloscope. The connections

29

Page 46

Appendix B: Performance Verification

Calibration Generator

Probe

Coaxial Cable

Trig Out

50 W Feedthrough Termination

BNC to Dual Banana Connector

6-inch Ground Lead

A69T06 A69R06

Fiber-Optic Cable

Figure 11: Rise Time Check Setup

2. Set up the oscilloscope as follows:

Oscilloscope

Coaxial Cable

Horizontal 10 ns/div. . . . . . . . . . . . . . . .

Measurement Rise Time. . . . . . . . . . . . .

Trigger Source Channel 2. . . . . . . . . . . .

Trigger Coupling DC. . . . . . . . . .

Channel 1 Channel 2

Vertical 2 mV/div 200 mV/div. . . . . . . . . . . . . . . . . . . . . .

Coupling DC DC. . . . . . . . . . . . . . . . . . . . . . . . . .

Impedance 50 W 50 W. . . . . . . . . . . . . . . . . . . . . . .

BW Limit Off Off. . . . . . . . . . . . . . . . . . . . . . . . .

Averaging On On. . . . . . . . . . . . . . . . . . . . . . . . . .

3. Set up the calibration generator as follows:

Amplitude Fast Rise, Positive Slope, Max Ampl.. . . . . . . . . . . . . . . .

4. On the A69R06, set the ATTENUATOR to 1 : 1 and COUPLING to AC.

5. Adjust the calibration generator pulse amplitude for five divisions of display

on the oscilloscope, and a frequency of 1 MHz. Check that the Rise Time

measurement readout of the oscilloscope is 3.5 ns or less.

30

A6906S Fiber-Optic Isolation System User Manual

Page 47

Bandwidth Check

Appendix B: Performance Verification

Perform this check with the A6906S Fiber-Optic Isolation System connected to

an oscilloscope and configured for normal use, as shown in Figure 3 on page 3.

Use the 6-inch ground lead on the probe common lead.

1. Attach a coaxial cable to the output of the sine wave generator. Attach a

50 W feedthrough termination to the other end of the coaxial cable. Attach a

BNC to Dual Banana Connector to the 50 W feedthrough termination, and

connect the A6906S probe to the banana jacks. Connect the probe tip to the

signal jack and the 6-inch ground lead to the ground jack. The connections

should now be configured as shown in Figure 12.

Sine Wave Generator

Oscilloscope

Probe

Coaxial Cable

50 W Feedthrough Termination

BNC to Dual Banana Connector

6-inch Ground Lead

A69T06

Fiber-Optic Cable

Figure 12: Bandwidth Check Setup

2. Set up the oscilloscope:

Horizontal 5 ms/div. . . . . . . . . . . . . . . .

Vertical 10 mV/div. . . . . . . . . . . . . . . . . .

Coupling DC. . . . . . . . . . . . . . . . .

Impedance 50 W. . . . . . . . . . . . . . .

BW Limit Off. . . . . . . . . . . . . . . .

Acquisition Mode Average (8). . . . . . . . . .

Trigger Source Channel 1. . . . . . . . . . . .

Trigger Coupling DC. . . . . . . . . .

Measurement Peak–Peak. . . . . . . . . . . . .

Coaxial Cable

A69R06

A6906S Fiber-Optic Isolation System User Manual

31

Page 48

Appendix B: Performance Verification

3. On the A69R06, set the ATTENUATOR to 1 : 1 and COUPLING to AC.

4. Set the output of the sine wave generator to a reference frequency of 50 kHz.

5. Adjust the sine wave generator output level so that the Peak-Peak measure-

ment readout of the oscilloscope is 50 mV.

6. Set the oscilloscope horizontal to 5 ns/div.

7. Set the sine wave generator frequency to 100 MHz.

8. Confirm that the Peak-Peak measurement readout on the oscilloscope is

≥35.4 mV.

Gain Check

Perform this check with the A6906S Fiber-Optic Isolation System connected to

an oscilloscope and configured for normal use, as shown in Figure 3 on page 3.

Use the 6-inch ground lead on the probe common lead.

Probe

Coaxial Cable

Calibration Generator

BNC to Dual Banana Connector

6-inch Ground Lead

A69T06

Figure 13: Gain Check Setup

Oscilloscope

Coaxial Cable

A69R06

Fiber-Optic Cable

32

1. Attach a coaxial cable to the standard amplitude output of the calibration

generator. Attach a BNC to Dual Banana Connector to the other end of the

A6906S Fiber-Optic Isolation System User Manual

Page 49

Appendix B: Performance Verification

coaxial cable, and connect the A6906S probe to the banana jacks. Make sure

the probe tip is connected to the signal jack and the 6-inch ground lead is

connected to the ground jack. The connections should now be configured as

shown in Figure 13.

2. Set up the oscilloscope:

Averaging On. . . . . . . . . . . . . . . .

Horizontal 500 ms/div. . . . . . . . . . . . . . . .

Vertical 100 mV/div. . . . . . . . . . . . . . . . . .

Coupling DC. . . . . . . . . . . . . . . . .

Impedance 50 W. . . . . . . . . . . . . . .

BW Limit On (20 MHz). . . . . . . . . . . . . . . .

Measurements Peak-Peak. . . . . . . . . . . . .

Acquisition Mode Hi Res. . . . . . . . . .

3. Set the output of the calibration generator to 10 V.

4. Set the A69R06 ATTENUATOR to 5 : 1 and DC coupling. Adjust the

trigger for a stable display. Use the TDS 460 SET LEVEL TO 50% button.

Check that the oscilloscope Peak-Peak measurement readout is between

488.5 mV and 511.5 mV. Repeat for each of the A69R06 ATTENUATOR

settings. Refer to Table 12 and check that the oscilloscope Peak-Peak

measurement readout is within the limits given.

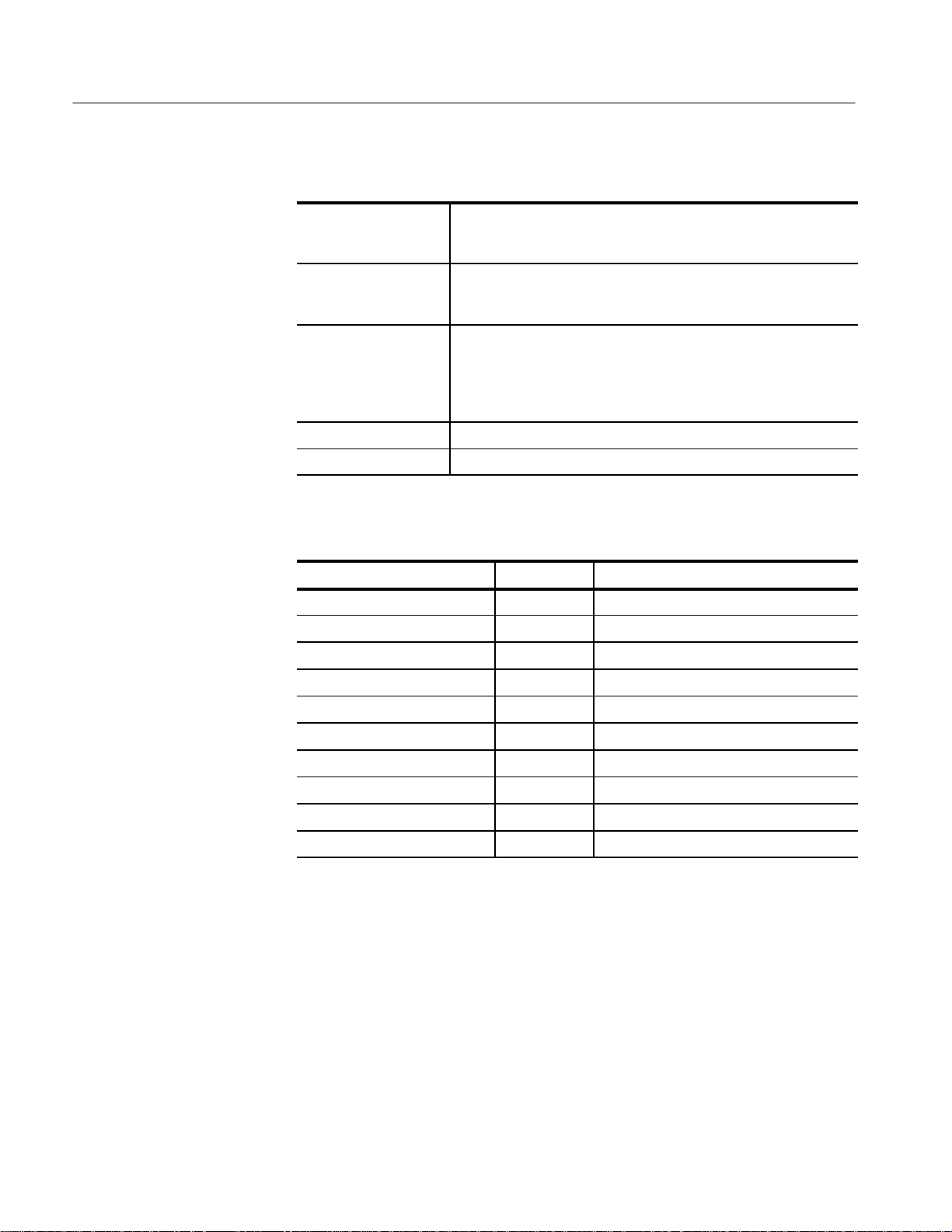

T able 12: Gain Accuracy Limits

Calibration

ATTENUATOR

Setting

5:1 10 V 100 mV/div 488.5 mV to 511.5 mV

2:1 20 V 100 mV/div 390.8 mV to 409.2mV

1:1 50 V 100 mV/div 488.5 mV to 511.5 mV

1:2 100 V 100 mV/div 486.5 mV to 513.5 mV

1:5 100 V 50 mV/div 194.6 mV to 205.4 mV

1:10 100 V 20 mV/div 97.3 mV to 102.7 mV

1:20 100 V 10 mV/div 48.4 mV to 51.6 mV

1:50 100 V 5 mV/div 19.36 mV to 20.64 mV

Generator

Voltage

Oscilloscope

Vertical Size

Oscilloscope Peak-Peak

Measurement Readout

A6906S Fiber-Optic Isolation System User Manual

33

Page 50

Appendix B: Performance Verification

Probe Check

Perform this check with the A6906S Fiber-Optic Isolation System connected to

an oscilloscope and configured for normal use, as shown in Figure 3 on page 3.

Use the 6-inch ground lead on the probe common lead.

1. Check that the probe readout on the A69R06 has the 100× light turned on.

2. Connect a coaxial cable to the HIGH AMPL (high amplitude) output of a

calibration generator. Attach a BNC to dual banana connector to the other

end of the coaxial cable. Connect the A6906S probe to the BNC to dual

banana connector by attaching the probe tip to the signal side of the BNC to

dual banana connector and attaching the reference common lead to the

ground side. Figure 14 illustrates these connections.

Calibration Generator

Oscilloscope

Probe

Coaxial Cable

50 W Feedthrough Termination

BNC to Dual Banana Connector

6-inch Ground Lead

A69T06 A69R06

Figure 14: Probe Check Setup

3. Set up the oscilloscope:

Horizontal 2 ms/div. . . . . . . . . . . . . . . .

Vertical 10 mV/div. . . . . . . . . . . . . . . . . .

Coupling DC. . . . . . . . . . . . . . . . .

Impedance 50 W. . . . . . . . . . . . . . .

BW Limit On (20 MHz or 100 MHz). . . . . . . . . . . . . . . .

Acquisition Mode Average. . . . . . . . . .

Coaxial Cable

Fiber-Optic Cable

34

A6906S Fiber-Optic Isolation System User Manual

Page 51

Appendix B: Performance Verification

4. Adjust the A69R06 ATTENUATOR to 1 : 1.

5. Set the calibration generator to produce a 10 kHz high-amplitude signal, and

the output amplitude to display a 5 division high waveform on the oscilloscope.

6. Confirm that the flatness of the upper waveform half is within 4% of total

signal amplitude.

A6906S Fiber-Optic Isolation System User Manual

35

Page 52

Appendix B: Performance Verification

36

A6906S Fiber-Optic Isolation System User Manual

Page 53

Appendix C: GPIB Interface Messages

The following explains how the A69R06 reacts to standard interface messages.

Message abbreviations used are from ANSI/IEEE Std 488–1978.

My Talk Address and

My Listen Address

(MTA and MLA)

Go to Local (GTL)

Device Clear (DCL)

Selected Device

Clear (SDC)

Serial Poll Enable and

Disable (SPE and SPD)

The A69R06’s address is established as previously explained in the GPIB

Address and Terminator information. When the A69R06 receives its own address

along with either of these messages, it responds by entering the appropriate state:

ready to talk or ready to listen.

The GTL message sets the A69R06 to local state.

The DCL message reinitializes communication between the A69R06 and the

controller. In response to DCL, the A69R06 clears any input and output

messages as well as any unexecuted control settings. Also cleared are any errors

and events waiting to be reported (except the power-on event). If the SRQ line is

asserted for any reason other than power-on, it becomes unasserted when the

DCL message is received.

The SDC message performs the same function as DCL; however, only instruments that have been listen-addressed respond to SDC.

The SPE message causes the A69R06 to transmit its serial-poll status byte when

it is talk addressed. The SPD message switches the A69R06 back to normal

operation.

Unlisten and Untalk

(UNL and UNT)

Interface Clear (IFC)

A6906S Fiber-Optic Isolation System User Manual

When the UNL message is received, the A69R06’s listen function is placed in an

idle (unaddressed) state. In the idle state, the A69R06 will not accept messages

over the bus until MLA is asserted.

The talk function is placed in an idle state when the A69R06 receives the UNT

message. In this state, the A69R06 cannot transmit via the bus until MTA is

asserted.

When IFC is asserted, both the Talk and Listen functions are placed in an idle

state. This produces the same effect as receiving both the UNT and the UNL

commands.

37

Page 54

Appendix C: GPIB Interface Messages

Remote/Local Functions

The A69R06 is always in one of the following states:

Local. The A69R06 always starts up in local mode when power is first applied.

In addition, the unit switches to local mode from remote mode when one of the

following occurs:

H A front panel operation is performed while in remote mode.

H The REN line goes false.

H The GTL message is received when addressed as a listener.

Remote. When both the ATN and REN lines are true and the A69R06 receives an

MLA message, operation changes from local status to remote status.

38

A6906S Fiber-Optic Isolation System User Manual

Page 55

Warning

The following servicing instructions are for use only by qualified personnel. To

avoid personal injury, do not perform any servicing other than that contained in

the operating instructions unless you are qualified to do so. Refer to General

Safety Summary and Service Safety Summary prior to performing any service.

Page 56

Page 57

Appendix D: Maintenance

Most of the parts of the A6906S Fiber-Optic Isolation System cannot be serviced

by the user. User repair is limited to replacing the following modules:

H The entire A69C06.

H Line fuse in the A69C06.

H The entire A69R06 (replacement requires factory recalibration of all

modules).

H Line fuse in the A69R06.

H The entire A69T06 (replacement requires factory recalibration of all

modules).

H battery pack in the A69T06.

H Probe in the A69T06.

H Fiber-Optic Cable in the A69T06 (replacement with fiber-optic cable of

different length may require factory recalibration of all modules—see

Table 14 on page 46).

NOTE. The A69T06 Transmitter, fiber-optic cable, and A69R06 Receiver are

calibrated at the factory as a matched unit. Tektronix does not warrant

performance to specifications if you exchange modules among A6906S FiberOptic Isolation Systems. Always use an A69T06 and A69R06 having matching

serial numbers.

You can replace a failed module or return it to your Tektronix Service Center for

repair. If you replace the A69T06, A69R06, or in some cases replace the

fiber-optic cable with one of a different length, you must return the entire

A6906S Fiber-Optic Isolation System to your Tektronix Service Center for

calibration or performance to specifications is not warranted.

A6906S Fiber-Optic Isolation System User Manual

41

Page 58

Appendix D: Maintenance

Replacing Fuses

Replacing the Probe

The A69R06 and A69C06 have AC line fuses. The A69T06 and the battery pack

do not have user-replaceable fuses.

CAUTION. To prevent equipment damage, do not substitute a spare fuse from one

assembly for another. The spare fuses for the A69C06 and the A69R06 are not

interchangeable.

The housing for the fuses is a part of the line cord connector in the body of the

A69R06 and A69C06 modules. To remove the fuse, unplug the AC power cord

from the A69R06 or A69C06. Using a small screwdriver, open the fuse case and

replace the fuse. Always replace the fuse with one of the same type and ratings.

You can replace the probe attached to the A69T06 by removing the panel of the

A69T06 that the probe cord passes through. You will need a small PZ1

POSIDRIV screwdriver.

WARNING. To prevent injury or death, do not use the A6906S while the transmitter is open for access to the transmitter sub-unit. Electrical isolation is not

provided and the transmitter sub-unit will be at ground potential of the system

being measured.

1. Remove the panel of the A69T06 by removing the six screws holding it in

place. Pull the panel out slowly, being careful not to put tension on the

fiber-optic cable.

CAUTION. To prevent cable or probe damage, do not pull on the fiber-optic cable

or the fiber-optic cable connectors.

If you need more free length of fiber-optic cable, carefully pull it through the

grommet holding it in the removed panel. Pull slowly and do not exert any

tension on the optical connectors inside the A69T06.

42

A6906S Fiber-Optic Isolation System User Manual

Page 59

Appendix D: Maintenance

2. Pull out the two spacers holding the transmitter sub-unit inside the A69T06.

3. Reach inside the A69T06 and pull the transmitter sub-unit out, but do not

completely remove it from the case of the A69T06. See Figure NO TAG. If

necessary, pull on the probe compensation box (part of the probe connector).

Transmitter

Sub-unit

Probe Cable

Grommet Housing

Toroid

Probe

Connector

Compensation

Box

Spacer

Panel

Figure 15: Replacing the probe

4. Remove the probe from the transmitter sub-unit ELEC INPUT connector by

rotating the probe connector counterclockwise and pulling it off.

5. Remove the probe cord grommet housing from the A69T06 panel by

removing the two screws holding it in place.

6. Remove the two screw and nut assemblies holding together the two halves of

the grommet assembly.

7. Pull the probe out through the A69T06 front panel.

A6906S Fiber-Optic Isolation System User Manual

43

Page 60

Appendix D: Maintenance

8. Remove the probe tip from the probe to allow the probe head to pass through

the toroid.

9. Unwind the probe cable from the toroid inside the probe cable grommet

housing. The toroid improves the high frequency CMRR performance of the

A6906S.