Page 1

Instructions

AM 503B, AM 5030 & A6300 Series

067-0271-00 Verification and Adjustment Kit

070-9352-01

This document applies to firmware version 3.0

and above.

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

Page 2

Copyright T ektronix, Inc. All rights reserved.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

Table of Contents

General Safety Summary iii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Safety Summary vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Kit Description 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Kit Parts List 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AM 503B and AM 5030 Performance Verification 3. . . . . . . . . . . . . . .

T est Procedure Conditions 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Gain Accuracy 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Balance 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RMS Noise 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bandwidth 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Degauss 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GPIB Installation 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assemble GPIB Test Fixture 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remove Side Covers 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install GPIB T est Fixture 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AM 503B and AM 5030 Adjustments 19. . . . . . . . . . . . . . . . . . . . . . . . . .

Amplifier Setup 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calculate and Load New Calibration Constants 20. . . . . . . . . . . . . . . . . . . . . . . . .

GPIB Removal (AM 503B Only) 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification Setup for Current Probes 23. . . . . . . . . . . . . .

T est Procedure Conditions 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Preparation 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

W arranted Specifications 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A6312 Performance Verification 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Test Equipment 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bandwidth 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rise Time 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Gain Accuracy 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A6302 and A6302XL Performance Verification 35. . . . . . . . . . . . . . . . . .

Required Test Equipment 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bandwidth 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rise Time 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Gain Accuracy 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A6303 and A6303XL Performance Verification 45. . . . . . . . . . . . . . . . . .

Required Test Equipment 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bandwidth 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rise Time 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Gain Accuracy 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A6304XL Performance Verification 55. . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Test Equipment 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rise Time 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bandwidth 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Gain Accuracy 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

i

Page 4

Table of Contents

Adjustment Procedures for Current Probes 63. . . . . . . . . . . . . . . . . . . . .

A6312, A6302 and A6302XL Adjustment 65. . . . . . . . . . . . . . . . . . . . . . .

Required Test Equipment 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A6312, A6302 and A6302XL DC Offset Adjustment 65. . . . . . . . . . . . . . . . . . . . .

A6303 and A6303XL Adjustments 69. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Test Equipment 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A6303 and A6303XL DC Offset Adjustment 70. . . . . . . . . . . . . . . . . . . . . . . . . . .

A6303 and A6303XL Transient Response and Gain Adjustment 72. . . . . . . . . . . .

A6304XL Adjustments 75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Test Equipment 75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A6304XL DC Offset Adjustment 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Gain Adjustment 78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A6304XL Transient Response Adjustment 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

Page 5

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

Injury Precautions

Ground the Product

Do Not Operate Without

Covers

Do Not Operate in

Wet/Damp Conditions

Do Not Operate in

Explosive Atmosphere

Avoid Exposed Circuitry

This product is grounded through the grounding conductor of the power cord. To

avoid electric shock, the grounding conductor must be connected to earth

ground. Before making connections to the input or output terminals of the

product, ensure that the product is properly grounded.

To avoid electric shock or fire hazard, do not operate this product with covers or

panels removed.

To avoid electric shock, do not operate this product in wet or damp conditions.

To avoid injury or fire hazard, do not operate this product in an explosive

atmosphere.

To avoid injury, remove jewelry such as rings, watches, and other metallic

objects. Do not touch exposed connections and components when power is

present.

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

iii

Page 6

General Safety Summary

Product Damage Precautions

Use Proper Power Source

Use Proper Voltage

Setting

Provide Proper Ventilation

Do Not Operate With

Suspected Failures

Do not operate this product from a power source that applies more than the

voltage specified.

Before applying power, ensure that the line selector is in the proper position for

the power source being used.

To prevent product overheating, provide proper ventilation.

If you suspect there is damage to this product, have it inspected by qualified

service personnel.

Safety Terms and Symbols

Terms in This Manual

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

Terms on the Product

iv

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

Page 7

General Safety Summary

Symbols on the Product

The following symbols may appear on the product:

DANGER

High Voltage

Certifications and Compliances

CSA Certified Power

Cords

Safety Certification of

Plug-in Modules

CSA Certification includes the products and power cords appropriate for use in

the North America power network. All other power cords supplied are approved

for the country of use.

For plug-in modules that are safety certified by Underwriters Laboratories, UL

Listing applies only when the module is installed in a UL Listed product. CSA

Certification applies only when the module is installed in a CSA Certified

product.

Protective Ground

(Earth) T erminal

ATTENTION

Refer to Manual

Double

Insulated

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

v

Page 8

General Safety Summary

vi

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

Page 9

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone

Disconnect Power

Use Care When Servicing

With Power On

Do not perform internal service or adjustments of this product unless another

person capable of rendering first aid and resuscitation is present.

To avoid electric shock, disconnect the main power by means of the power cord

or, if provided, the power switch.

Dangerous voltages or currents may exist in this product. Disconnect power,

remove battery (if applicable), and disconnect test leads before removing

protective panels, soldering, or replacing components.

To avoid electric shock, do not touch exposed connections.

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

vii

Page 10

Service Safety Summary

viii

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

Page 11

Kit Description

Kit Parts List

This kit includes parts and instructions for verifying and adjusting the AM 503B

and AM 5030 Current Probe Amplifiers. The recommended calibration interval

is one year.

These instructions assume a certain familiarity with the AM 503B and AM 5030

amplifiers. For servicing information, refer to the AM 503B & AM 5030

Instruction Manual (070-8766-XX).

Before you begin the AM 503B or AM 5030 amplifiers, assemble the test

equipment required and determine if a full calibration is necessary. None of the

components contained in this kit require calibration.

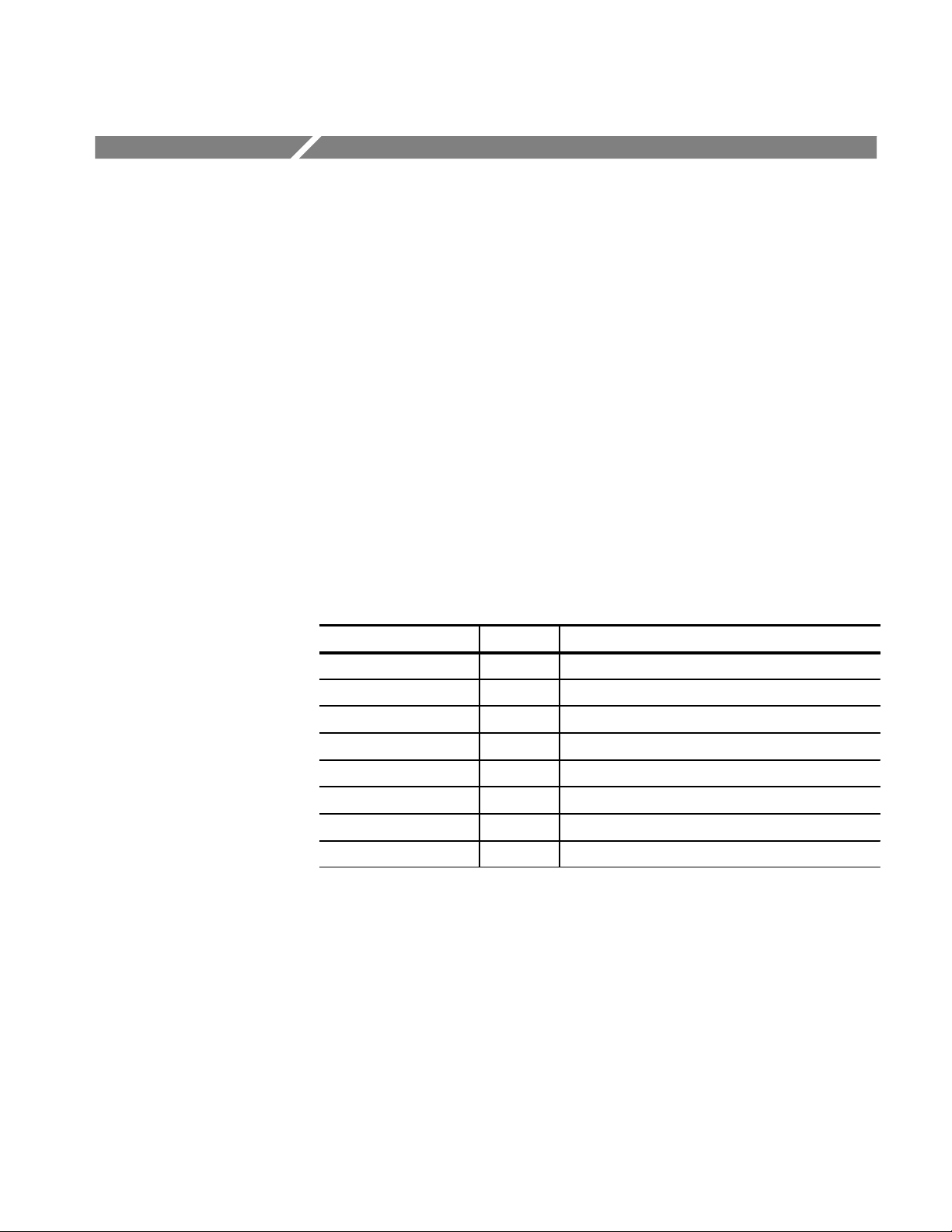

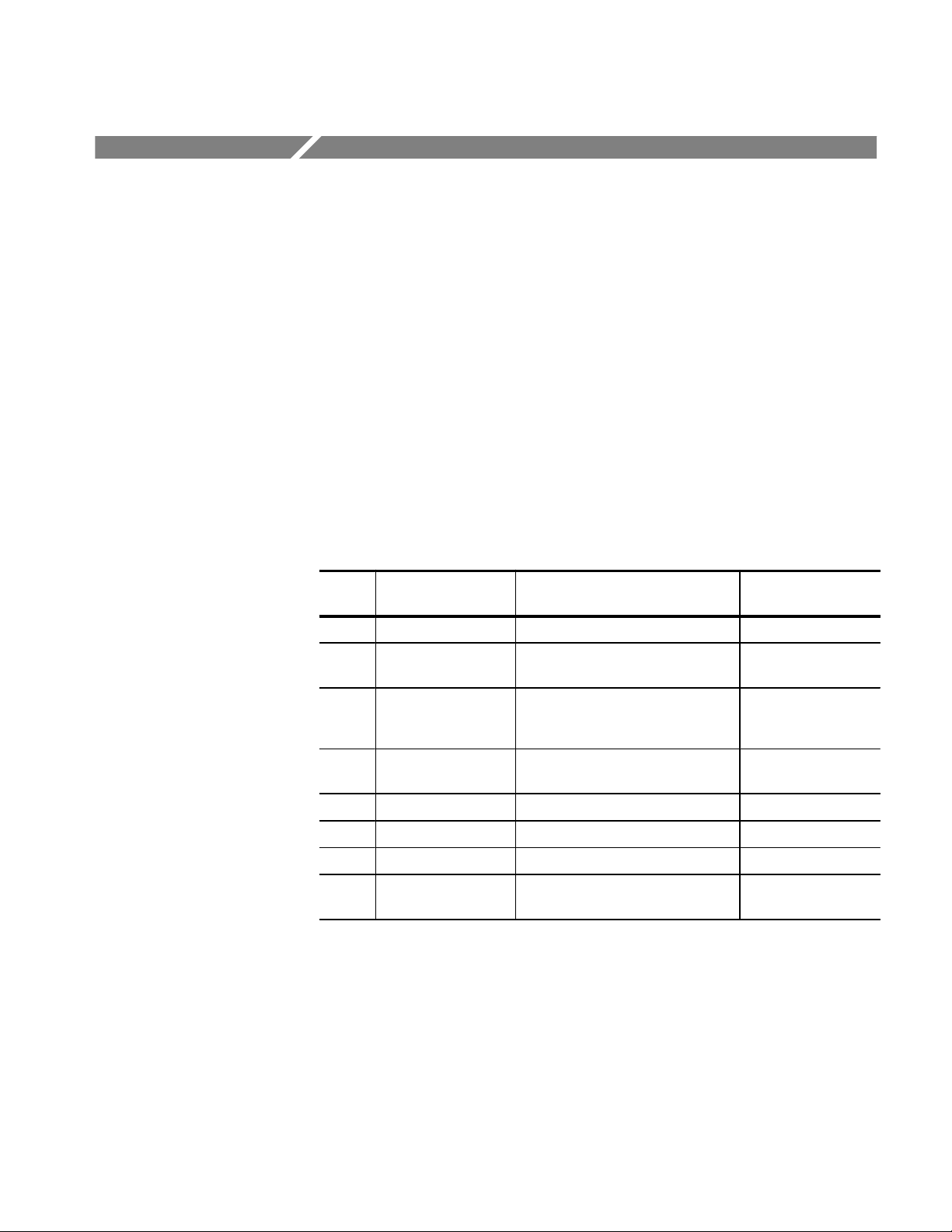

This kit includes the parts listed in Table 1.

T able 1: Kit Parts List

Tektronix Part Number Quantity Description

015-0598-00 1 Voltage adapter

Equipment Required

015-0670-00 1 Feed-thru adapter

129-0425-00 2 Spacer, post: 0.9 L, 4-40 thru, 0.25 hex

174-2314-00 1 Ribbon cable

21 1-0408-00 6 Screw, assem wshr: 4-40 X 0.250, T-10 Torx

220-0729-00 1 Nut block: 4-40 X 0.188

679-2836-02 1 GPIB board

070-9352-XX 1 Calibration Kit Manual

The installation procedure requires a T-10 Torx screwdriver and a flat-blade

screwdriver.

The performance verification and adjustment procedures require the test

equipment listed in Table 2. The test equipment must meet or exceed the

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

1

Page 12

Kit Description

specifications listed. You may need to modify the test procedures if you do not

use the recommended equipment.

T able 2: Required Test Equipment

Recommended

Qty Item Description

1 Oscilloscope 500 MHz bandwidth TDS 520B

Equipment

1 Leveled Sine Wave

Generator

1 Digital Multimeter 0.20%, 31/2 digit resolution, range

1 Current Source 0.1%, 0 to ±1 A Fluke 5700A or

1 Calibration Fixture 50 , BNC Connector 015-0601-50

1 Termination 50 ±0.1%, 0.5 W 01 1-0129-00

2 BNC Cables 50 , 1.05m (42in) long 012-0057-01

2 BNC to Dual

Banana Adapters

1 Feed-thru Fixture supplied with kit 015-0670-00

1 Voltage Adapter supplied with kit 015-0598-00

1 Current Probe

1

Required for functional test only.

1

3 MHz to 100 MHz Wavetek 9100 with

Option 250 or SG 503

equivalent.

DM2510/G or

±50 mV

Fluke 850x/884x

Wavetek 9100 with

Option 250

103-0090-00

A6302

2

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

Page 13

AM 503B and AM 5030 Performance Verification

Refer to the list of equipment required in Table 2 on page 2. Set up the AM 503B

or AM 5030 amplifiers as follows:

1. Plug the AM 503B or AM 5030 amplifier into the TM 5000 mainframe.

2. Power the amplifier on and let it warm up at least 20 minutes.

The procedures in this section verify that the AM 503B or AM 5030 amplifier

meets the warranted specifications listed in Table 3.

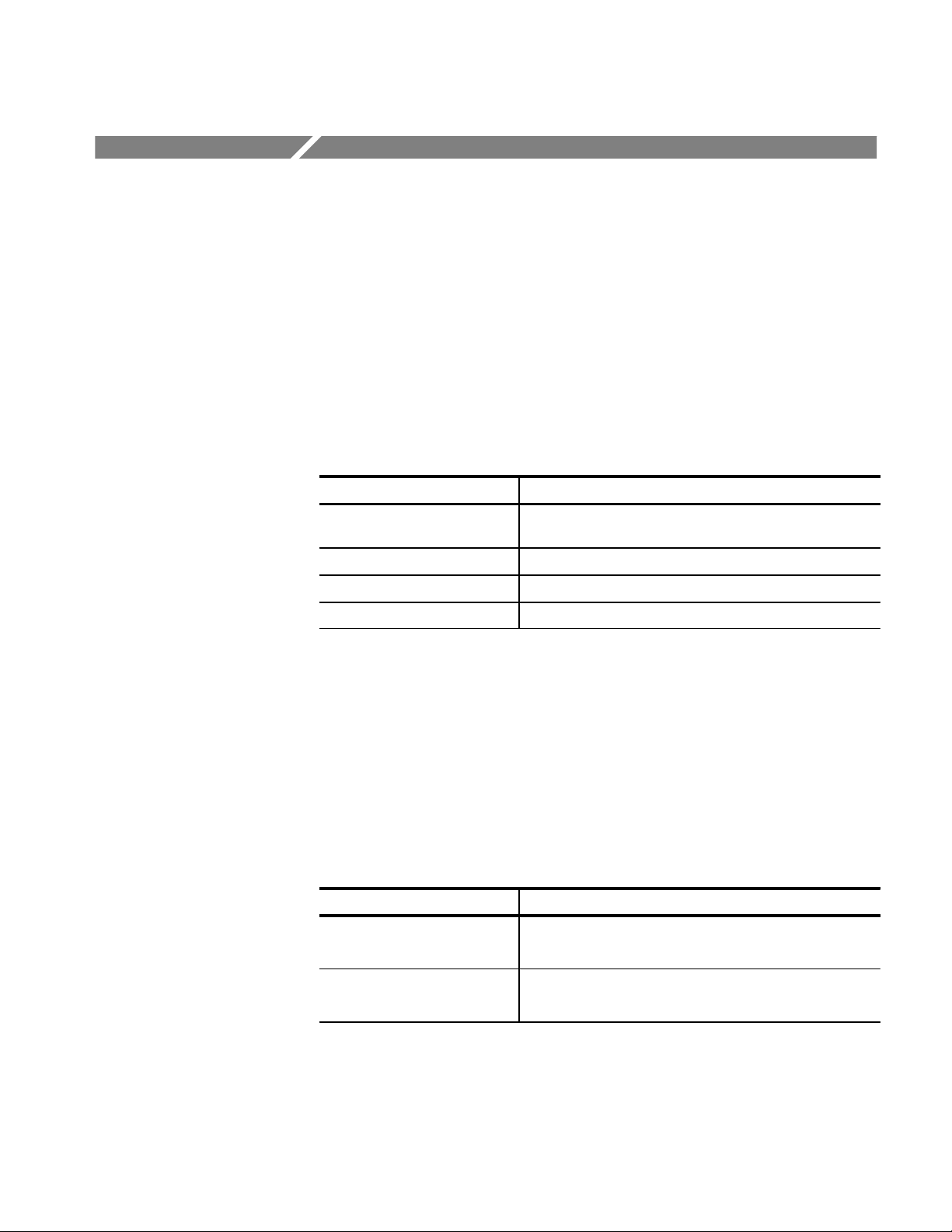

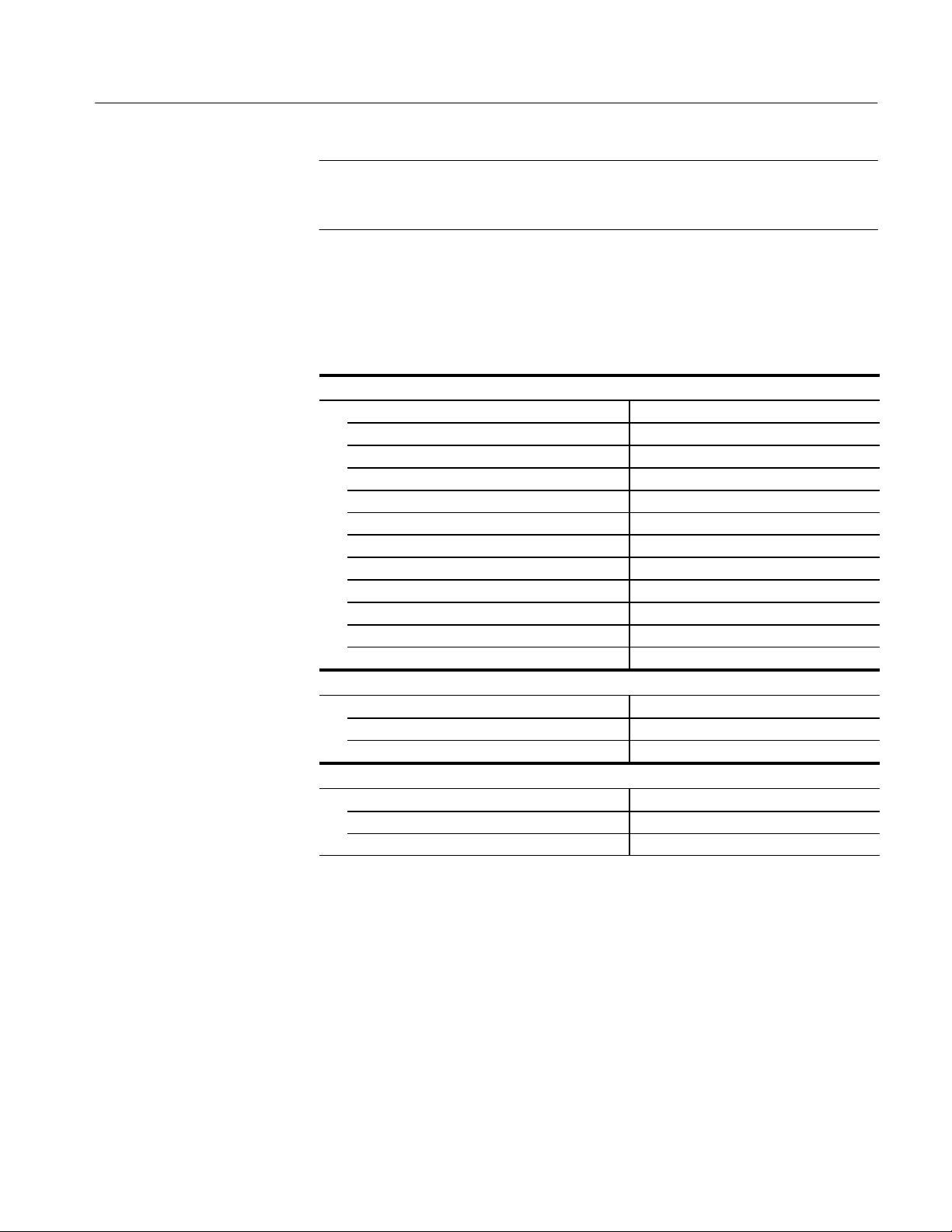

T able 3: AM 503B and AM 5030 Warranted Specifications

Parameter Characteristic

DC Gain Accuracy ≤ 1.5% after DC accuracy measurement and cal constant

loading.

DC Balance ± 2 mV

RMS Noise ≤ 250 A (2.5 mV)

Bandwidth ≥ 100 MHz

Test Procedure Conditions

These procedures are valid only under the following conditions:

H The system has been calibrated at an ambient temperature of 23_ ±5_ C.

H The system is operating in an environment whose limits are described in

T able 4: AM 503B and AM 5030 Environmental Characteristics

Parameter Characteristic

Ambient Temperature

Humidity

H The system, including probe, has had a warm-up period of at least

Table 4.

Operating 0_ C to +50_ C

Operating 50_ C, to 95% R.H.

20 minutes.

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

3

Page 14

AM 503B and AM 5030 Performance Verification

DC Gain Accuracy

Use the following procedure to verify the DC gain accuracy of the amplifier.

Test Equipment Setup

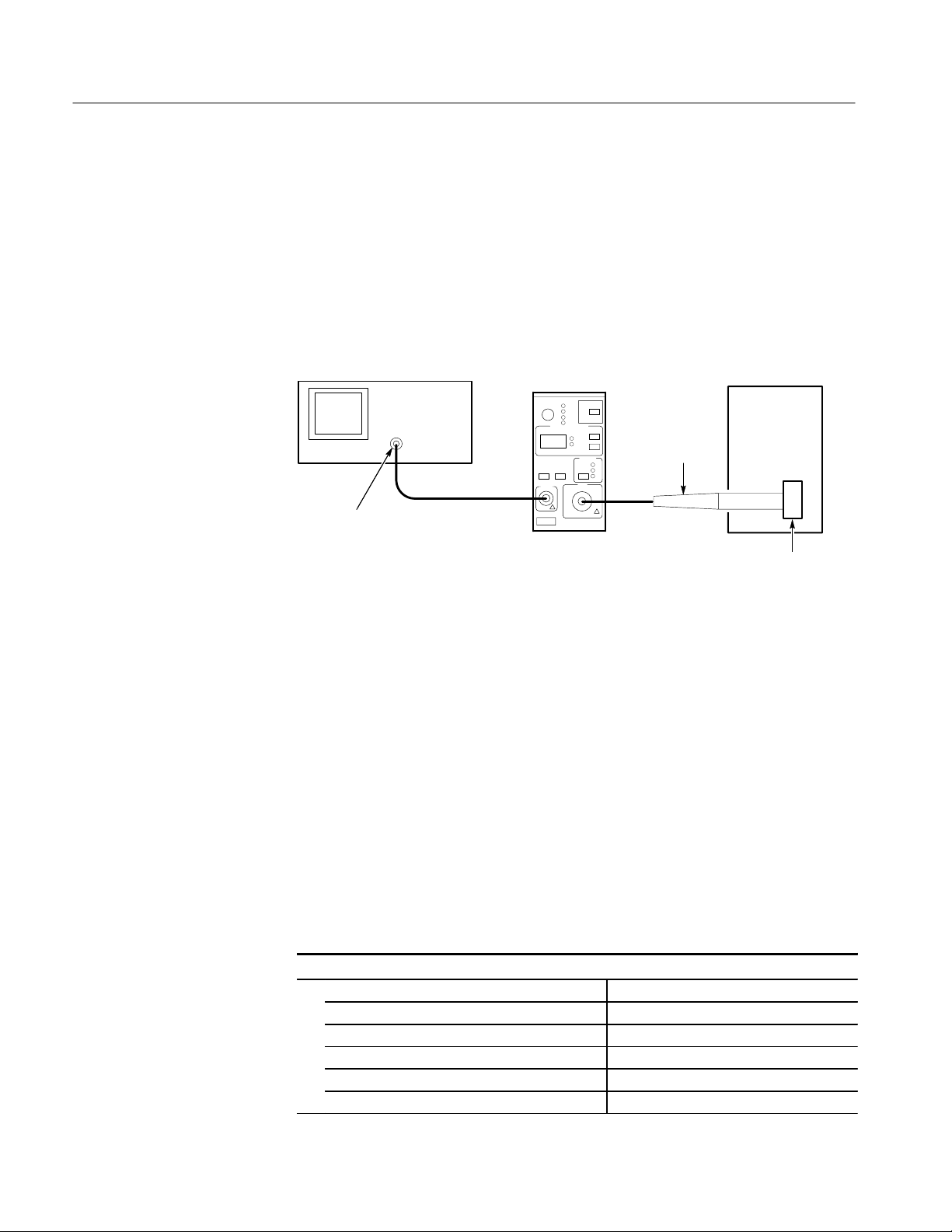

Refer to Figure 1 and set up the test equipment as follows:

1. Connect the output of the amplifier to the DMM.

a. Connect a BNC Cable from the AM 503B/AM 5030 OUTPUT to the

50 feedthrough termination.

b. Attach the termination to a BNC-to-dual banana adapter.

c. Observe polarity and insert the dual banana adapter into the digital

multimeter DC voltage input.

2. Connect the input to current source.

a. Connect the other BNC cable from the Voltage Adapter to a BNC-to-

dual banana adapter.

b. Observe polarity and insert the dual banana adapter into the current

source DC output. Do not connect the voltage adapter to the amplifier at

this time.

Amplifier in TM

Series Power

Module

DMM

Current

Source

+–

BNC to Dual

Banana Adapter

50 T ermination

50 Coaxial

Cable

+–

Feed-Thru Fixture

Voltage Adapter

BNC to Dual

Banana Adapter

Figure 1: Test Equipment Setup

4

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

Page 15

AM 503B and AM 5030 Performance Verification

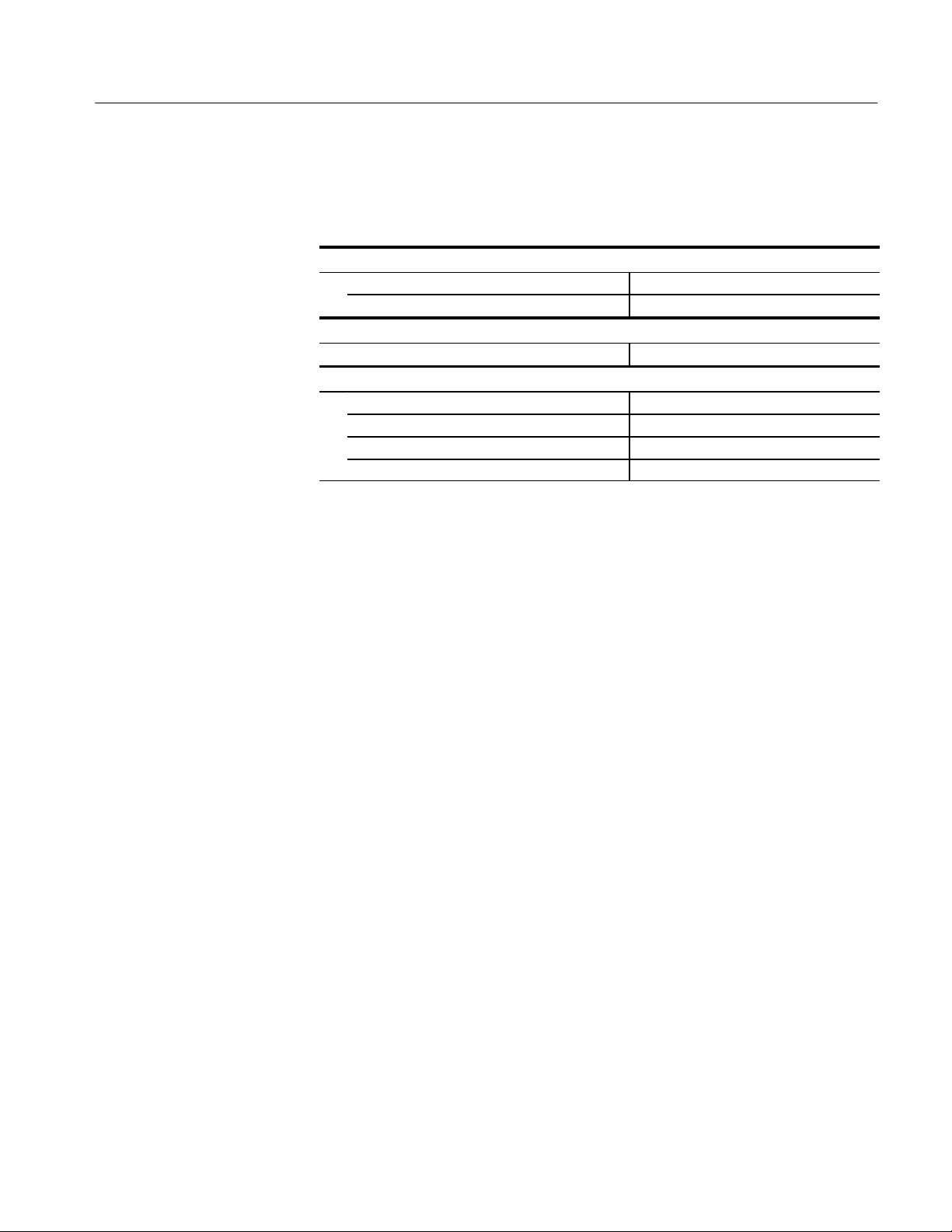

3. Make or verify the equipment settings in Table 5:

T able 5: Equipment Settings

Digital Multimeter

Measurement Type DC volts

Range Autoranging

Current Source

Output Off

AM 503B and AM 5030 Amplifier

Coupling DC

BW Limit On (20MHz)

Current/division 10 mA/division

Probe Trim 000

Procedure

After the equipment is set up, proceed as follows:

1. Connect the feed-thru fixture (015-0670-00) to the INPUT of the AM 503B/

AM 5030 amplifier and press the PROBE DEGAUSS AUTOBALANCE

button. Wait for the degauss/autobalance routine to complete before

proceeding. The routine is complete when the indicator light turns off.

2. Remove the feed-thru fixture from the INPUT of the amplifier and connect

the Voltage Adapter (015-0598-00) to the INPUT of the amplifier. Do not

press the PROBE DEGAUSS AUTOBALANCE button again even though

the indicator is flashing.

3. For each of the current/division settings in Table 6, perform the following

steps. Remember that any errors that develop here will affect the final DC

gain accuracy calculations at the end.

a. Set the Amplifier to the desired current/division setting from Table 6.

b. Set the current source to the correct positive test current using Table 6.

c. Turn on the current source.

d. Record the exact measurement of the digital multimeter as M

. (You can

1

copy Table 7 on page 8 to record the results of your measurements.)

e. Set the current source for the correct negative test current using Table 6.

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

5

Page 16

AM 503B and AM 5030 Performance Verification

T able 6: DC Gain Accuracy Calibration Test for the AM503X

AM 503B and AM 5030

Current/Division

1 m A ±100 A 10 mA

2 m A ±200 A 20 mA

5 m A ±500 A 50 mA

10 m A ±1mA 100 mA

20 m A ±2mA 200 mA

50 m A ±5mA 500 mA

100 m A ±10mA 1 A

200 m A ±20mA 2 A

500 m A ±50mA 5 A

1 A ±100 mA 10 A

2 A ±100 mA 10 A

Current Source Output Test Current (It)

5 A ±100 mA 10 A

f. Record the digital multimeter reading as M2.

g. Calculate the measured current (I

I

m

M1–M

2

(currentdivision)

0.01

) using the following formula:

m

For example, you might have obtained values of 51.0 mV for M1 and

–53.0 mV for M

sion, you can compute I

(51.0x10

I

m

. If you are using an Amplifier setting of 10 mA/divi-

2

as:

m

–3

) – (–53.0x10–3)

0.01

(10x10–3) 104 mA

6

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

Page 17

AM 503B and AM 5030 Performance Verification

h. Calculate the %Error between the measured current (I

current (I

%Error +

) %Error as follows:

t

I

* I

m

t

100

I

t

) and the test

m

For example, using a test current It of 100 mA and a measured current I

of 104 mA, the %Error would be:

%Error +

104 – 100

100

100 +)4%

NOTE. It is important that the correct polarity be used in order to calculate the

% error

4. Copy the work sheet in Table 7 and fill it in with required data. Calculate the

values for each New Rin Cal Constant only if adjustment is required.

m

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

7

Page 18

AM 503B and AM 5030 Performance Verification

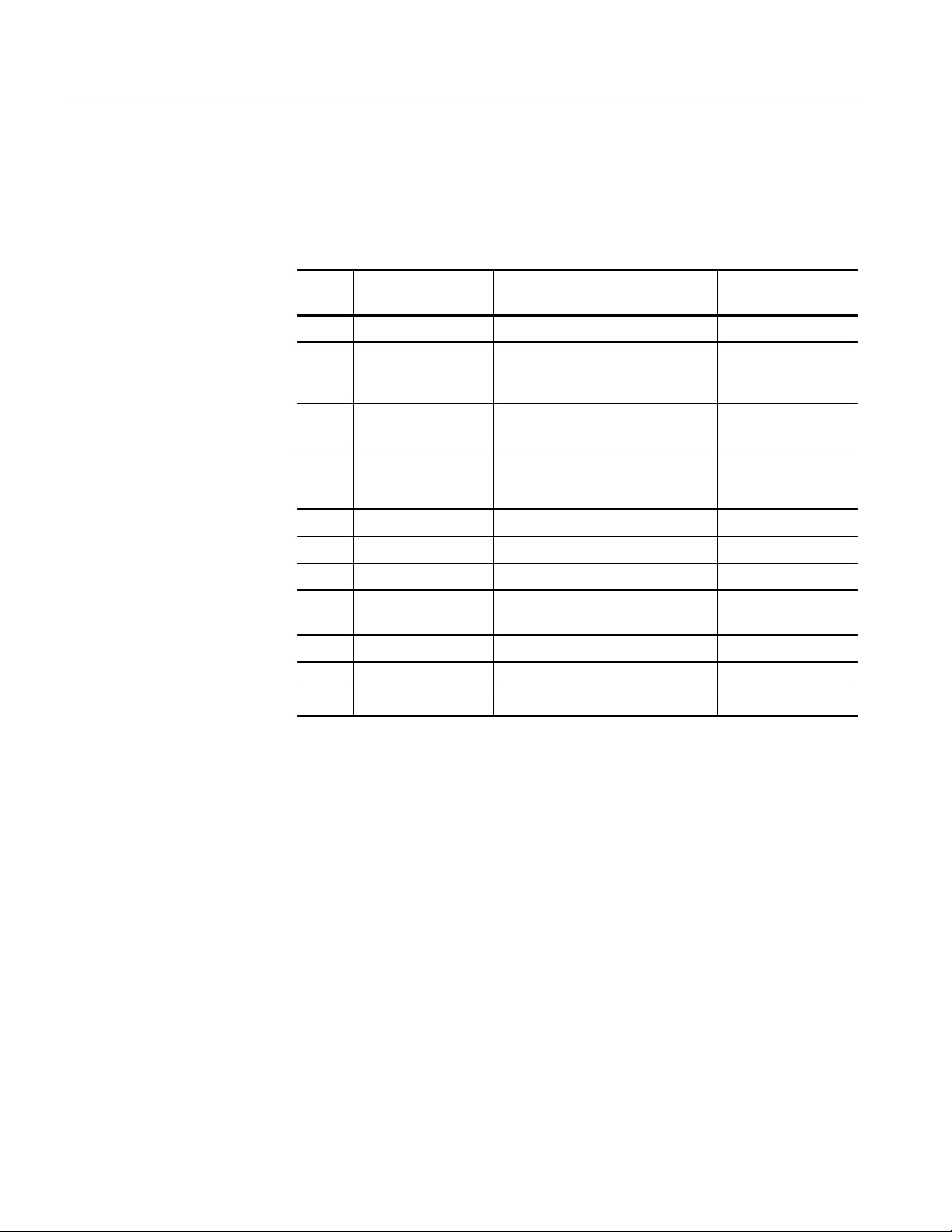

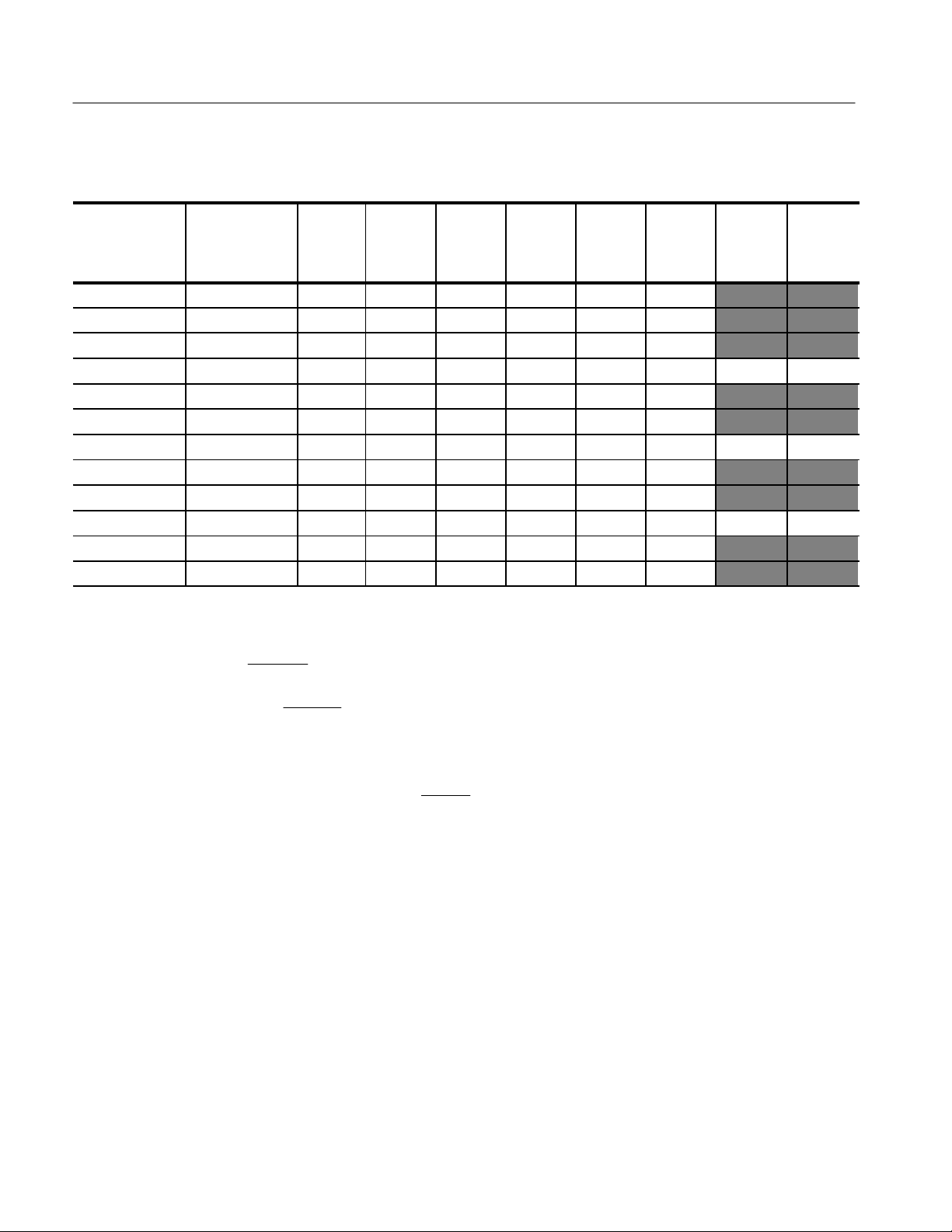

T able 7: Work Sheet for DC Gain Accuracy Calibration

AM 503B and

AM 5030

Current/

Division

Current/Voltage

Source Output

Test

Current

I

t

I

m

M

1

M

2

(Note A)

%Error

(Note B)

Rin

Name

1mA ±100 A 10 mA

2mA ±200 A 20 mA

5mA ±500 A 50 mA

10 mA ±1mA 100 mA Rin1X

20 mA ±2mA 200 mA

50 mA ±5mA 500 mA

100 mA ±10 mA 1 A Rin10X

200 mA ±20 mA 2 A

500 mA ±50 mA 5 A

1 A ±100 mA 10 A Rin100X

2 A ±100 mA 10 A

5 A ±100 mA 10 A

Note A

Note B

M2* M

+

I

m

0.01

%Error +

1

(currentńdivision)

* I

I

m

t

100

I

t

Note C Query amplifier for existing Rin1X, Rin10X, and Rin100X Cal Constants

(CALC? 00, CALC? 01, and CALC? 02 respectively).

Note D

New Rin Cal Constant + (1 )

%Error

100

) Existing Rin Cal c onstant

(Calculate this value only if adjustment is required.)

Existing

Cal

Constant

(Note C)

New

Cal

Constant

(Note D)

8

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

Page 19

DC Balance

AM 503B and AM 5030 Performance Verification

5. Verify that the measured DC gain accuracy is within ±1.5% at all settings.

NOTE. If the % Error on any of the settings is greater than ±1.5%, you must

perform the Cal Constant loading sequence. Refer to the adjustment procedure

that begins on page 19.

This procedure checks the DC Balance Test of the AM 503B and AM 5030.

1. Connect a BNC cable from the AM 503B/AM 5030 amplifier OUTPUT to

the 50 feedthrough termination. Attach the termination to a BNC-to-dual

banana adapter.

2. Taking care to observe and maintain polarity, insert the dual banana adapter

into the digital multimeter DC voltage input. Refer to Figure 2.

Amplifier in TM

Series Power

Module

DMM

+–

BNC to Dual

Banana Adapter

50 Termination

50 Coaxial

Cable

Voltage Adapter

Figure 2: Setup for DC Balance

3. Connect the Voltage Adapter (015-0598-00) to the INPUT of the amplifier

and disconnect the other end of the Voltage Adapter from ALL other sources.

In other words, the BNC end of the Voltage adapter should not be connected

up to any thing.

4. Make or verify the equipment settings in Table 8.

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

9

Page 20

AM 503B and AM 5030 Performance Verification

T able 8: Equipment Settings for DC Balance

Digital Multimeter

Measurement Type DC volts

Range Autoranging

AM 503B and AM 5030 Amplifier

Coupling REF

BW Limit On (20MHz)

Current/division 1 mA/division

5. Press the PROBE DEGAUSS AUTOBALANCE button. Wait for the

degauss/autobalance routine to complete before proceeding. The routine is

complete when the indicator light turns off.

6. For each of the Amplifier settings (AC, DC, 1 mA, 2 mA, 5 mA, 10 mA,

20 mA, 50 mA, 100 mA, 200 mA, 500 mA, 1 A, 2 A, 5 A), perform the

following steps.

RMS Noise

a. Set the amplifier to the desired setting from above.

b. Measure the exact DC voltage with the digital multimeter.

c. Verify that the measured DC voltage is less than ±2mV (0.2 divs).

This procedure tests the RMS noise level of the AM 503B and AM 5030 Current

Probe Amplifier. In this test you measure the RMS voltage of the amplifier

output when the amplifier is set to the most sensitive setting and BW LIMIT is

off. Refer to Figure 4 when making equipment connections.

Amplifier in TM

Test Oscilloscope

Series Power

Module

Voltage Adapter

10

50 oscilloscope input (or add 50

termination here if oscilloscope has

only high-impedance input).

Figure 3: RMS Noise Test Setup for stand alone AM 503B/AM 5030

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

Page 21

AM 503B and AM 5030 Performance Verification

1. Using a 50 W BNC cable, connect the Amplifier OUTPUT to a 50 W

oscilloscope input. If the input impedance of your oscilloscope is 1 MW,

connect a 50 W feedthrough termination at the oscilloscope input. Do not

connect the termination at the Amplifier output.

2. Connect the Voltage Adapter to the Amplifier INPUT.. The other end of the

Voltage Adapter should not be connected to anything.

3. Make or verify the equipment settings in Table 9.

T able 9: Equipment Settings for RMS Noise Check

Oscilloscope

Vertical input impedance 50

Vertical gain 10 mV/division

Time base 2 us/division

Record length 500

Coupling DC

Offset 0 V (mid-scale)

Trigger type Edge

Trigger mode Auto

Trigger position 50%

Acquisition mode Sample

Bandwidth 100 MHz

Measurement type RMS

AM 503B and AM 5030

Coupling DC

BW Limit Off (full bandwidth)

Current/division 1 mA/division

4. Press the Amplifier PROBE DEGAUSS AUTOBALANCE button. Wait

for the degauss/autobalance routine to complete before proceeding. The

routine is complete when the indicator light turns off.

5. Set the Oscilloscope couping to AC.

6. Using the RMS measurement capability of the oscilloscope, measure the

RMS reading, and verify that it is less than 250 mA (2.5 mV).

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

11

Page 22

AM 503B and AM 5030 Performance Verification

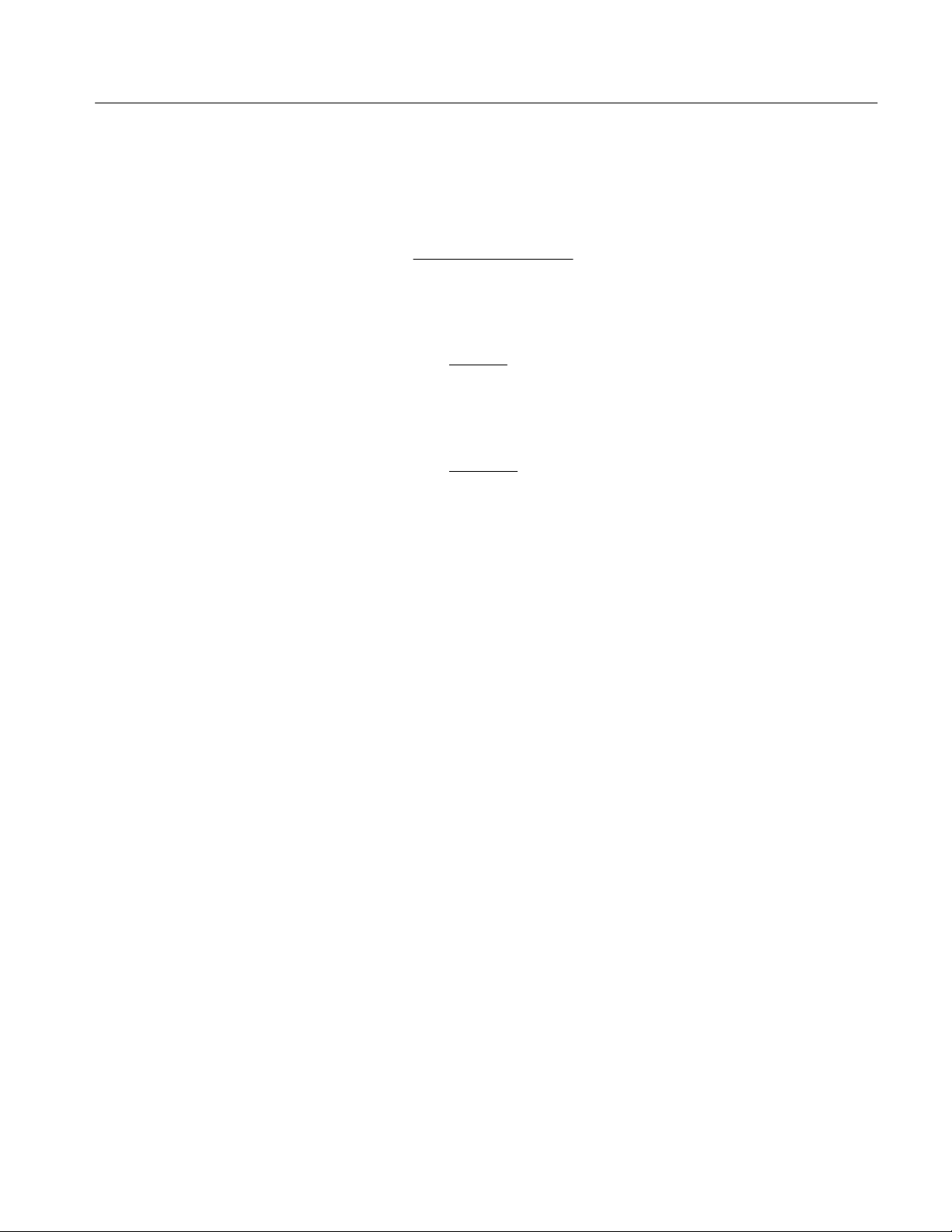

Bandwidth

This procedure tests the bandwidth of the AM 503B and AM 5030. In this test

you measure a signal at a relatively low frequency and again at the upper test

frequency. The two measurements are compared to verify that the signal

amplitude does not fall below a certain limit. Refer to Figure 4 when making

equipment connections.

Leveled

Sine Wave

Generator

Output

Test Oscilloscope

50 oscilloscope input (or add 50

termination here if oscilloscope has

only high-impedance input).

Amplifier in TM

Series Power

Module

Voltage Adapter

Figure 4: Bandwidth Test Setup

1. Using a 50 W BNC cable, connect the Amplifier OUTPUT to a 50 W

oscilloscope input. If the input impedance of your oscilloscope is 1 MW,

connect a 50 W feedthrough termination at the oscilloscope input. Do not

connect the termination at the Amplifier output.

2. Connect the Voltage Adapter to the Amplifier INPUT.

3. Make or verify the equipment settings in Table 10:

12

T able 10: Equipment Settings for Bandwidth Check

Oscilloscope

Vertical input impedance 50

Vertical gain 10 mV/division

Time base 100 ns/division

Record length 500

Coupling DC

Offset 0 V (mid-scale)

Trigger type Edge

Trigger mode Auto

Trigger position 50%

Acquisition mode Average

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

Page 23

AM 503B and AM 5030 Performance Verification

T able 10: Equipment Settings for Bandwidth Check (Cont.)

Oscilloscope

Number of waveforms to average 16

Measurement type Peak-to-Peak

Leveled Sine Wave Generator

Frequency 3MHz

Amplitude 3.0 V

AM 503B and AM 5030

Coupling DC

BW Limit Off (full bandwidth)

Current/division 500 mA/division

p-p

4. Press the Amplifier PROBE DEGAUSS AUTOBALANCE button. Wait

for the degauss/autobalance routine to complete before proceeding. The

routine is complete when the indicator light turns off.

5. Connect the BNC cable from the output of the leveled sine wave generator to

the BNC end of the Voltage Adapter.

6. Adjust the signal generator output so that the Amplifier output is approximately 60 mV

, or six graticule divisions on the oscilloscope.

p-p

7. Using the peak-peak measurement capability of the oscilloscope, measure

and record the peak-peak reading as M

.

1

8. Set the oscilloscope time base to 5 ns/division. Increase the signal generator

frequency to 100 MHz, the upper test frequency.

9. Using the peak-peak measurement capability of the oscilloscope, measure

and record the peak-peak reading as M

.

2

10. The system meets the bandwidth specification if the ratio of the signal

amplitude at the warranted bandwidth is at least 70% of the signal amplitude

at 3 MHz. Using the following calculation, verify system bandwidth:

M

2

ǒ

Ǔ

u 0.707

M

1

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

13

Page 24

AM 503B and AM 5030 Performance Verification

Degauss

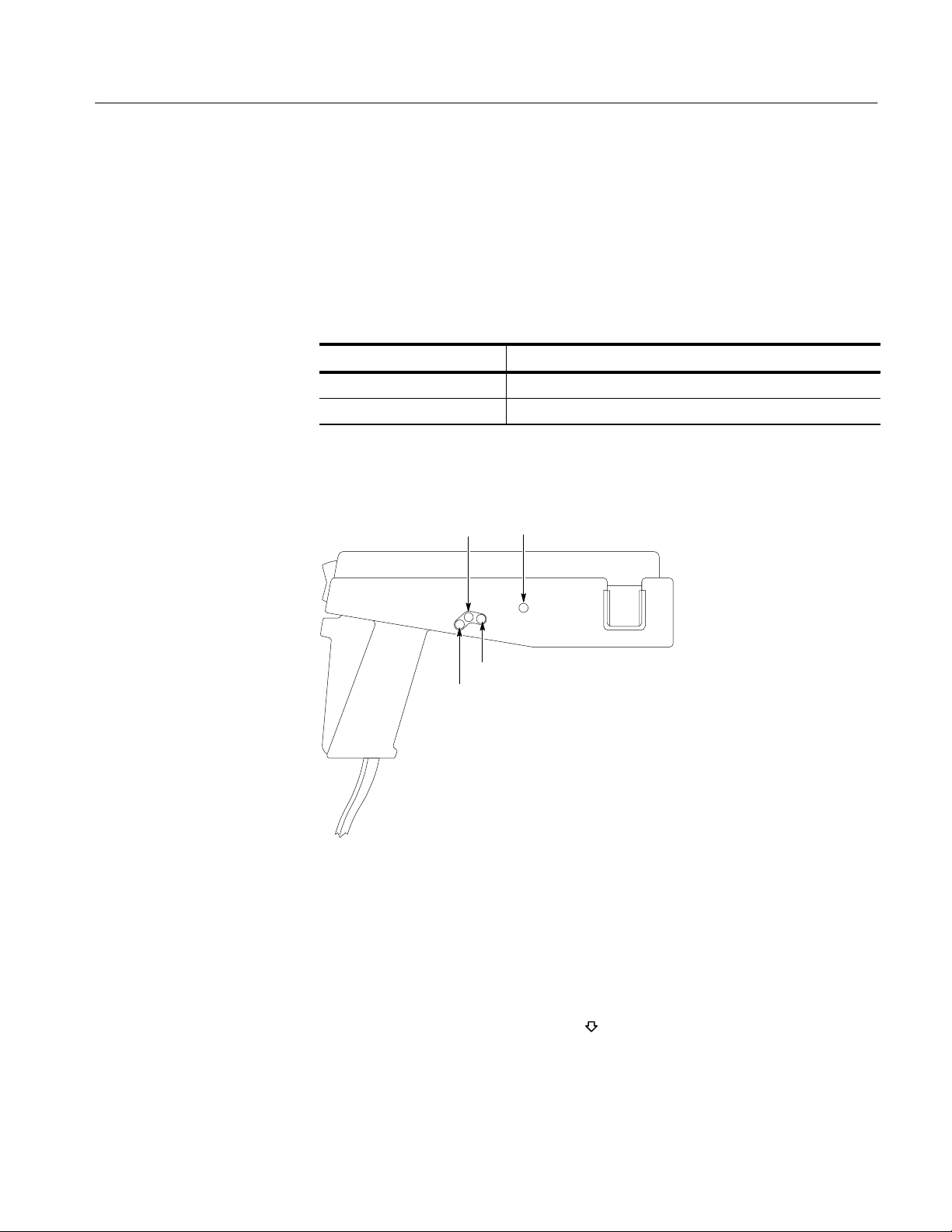

This is only a functional test of the degauss operation. Refer to Figure 5.

1. Connect a current probe to the output of the AM 503B or AM 5030.

2. Press the Amplifier PROBE DEGAUSS AUTOBALANCE button. Wait

for the indicator light to turn off.

3. Verify that there are no error codes.

Test Oscilloscope

Amplifier in TM

Series Power

Module

Current Probe

50 Input

Figure 5: Setup for Degaussing the Current Probe

This completes the performance verification.

If the AM 503B or AM 5030 amplifier fails any of the verification tests, refer to

the AM 503B and AM 5030 Instruction Manual for servicing information.

14

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

Page 25

GPIB Installation

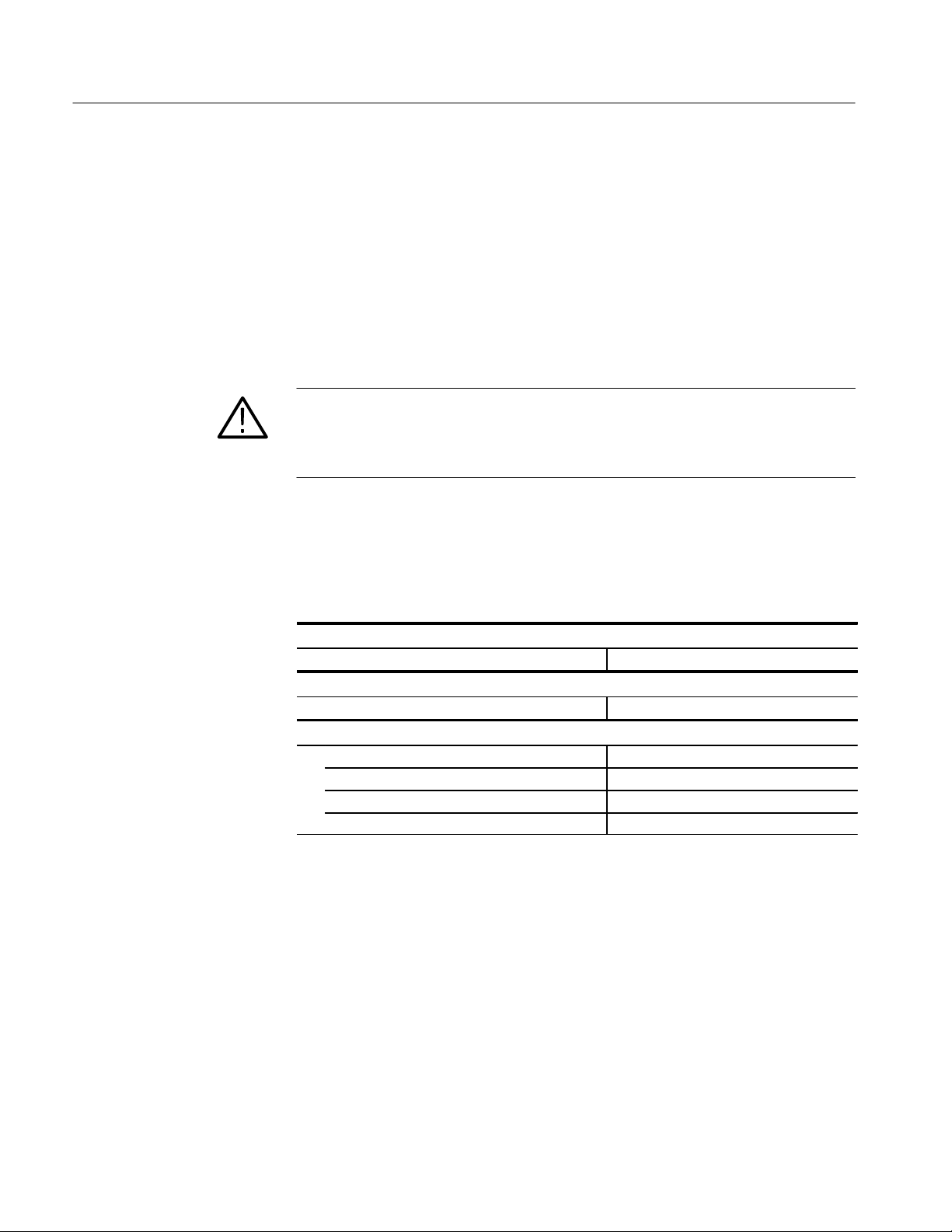

WARNING. Instrument disassembly should only be performed by qualified service

personnel.

This section details how to assemble the GPIB test fixture and install it in the

AM 503B Current Probe Amplifier prior to performing the adjustment procedure. The AM 503B amplifier requires the GPIB test fixture in order to set the

internal calibration constants. After the adjustment procedure is complete, you

must remove the test fixture.

The AM 5030 amplifier already contains a GPIB board. If you are calibrating an

AM 5030 amplifier, disregard this section and proceed with the adjustment

procedure on page 19.

CAUTION. GPIB installation should only be performed by qualified service

personnel.

Assemble GPIB Test Fixture

Use the following procedure to assemble the GPIB test fixture. Once you

assemble the fixture, you can use it to calibrate any number of AM 503B

amplifiers.

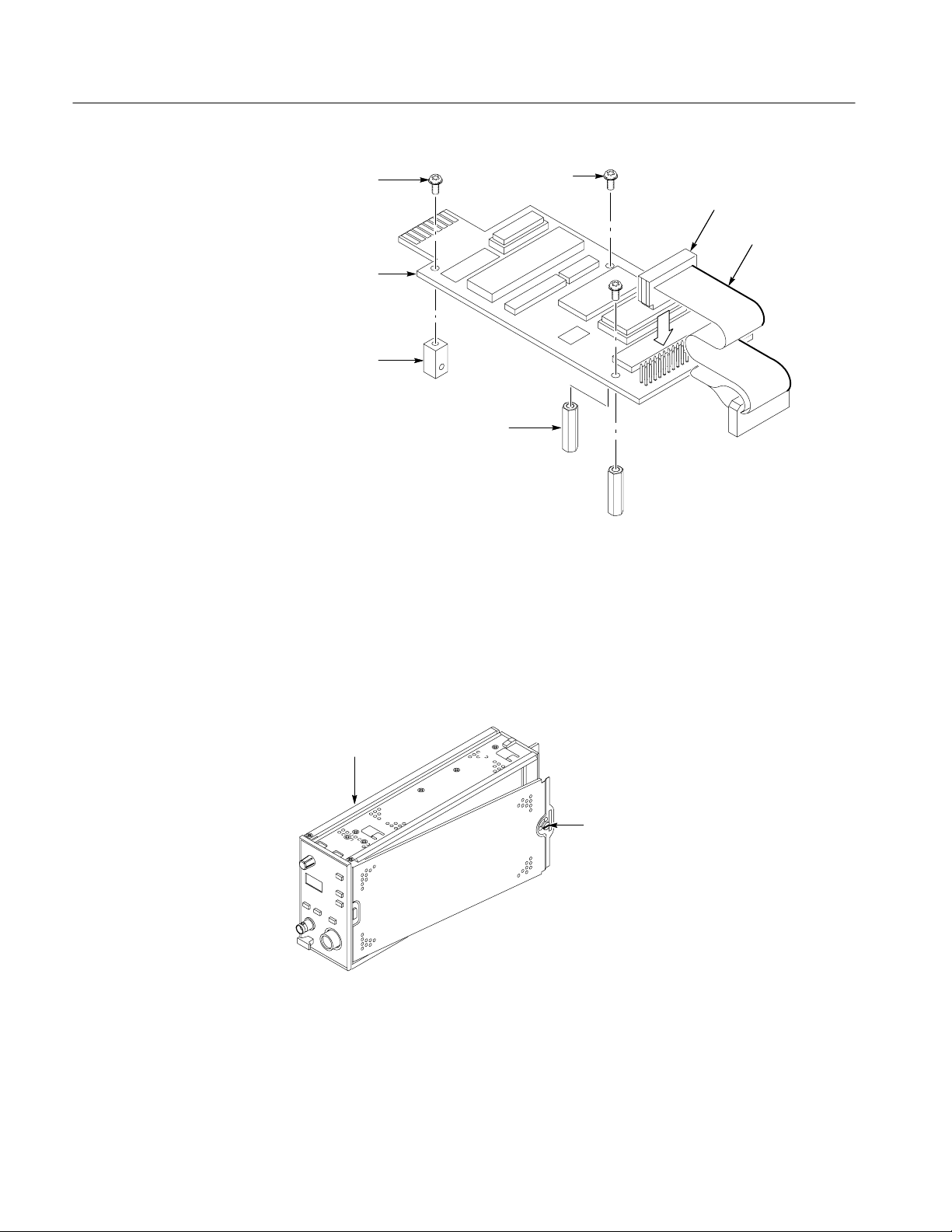

1. Refer to Figure 6. Install the spacers (129-0425-00) onto the GPIB board

with two screws (210-0408-00).

2. Install the ribbon cable (174-2314-00) onto the GPIB with the RED edge

oriented as shown. (The tabbed end of the connector connects to the main

board of the AM 503B amplifier.)

3. Install nut block (220-0729-00) onto the GPIB board with one screw

(210-0408-00).

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

15

Page 26

GPIB Installation

Screw

GPIB Board

Nut Block

Spacers (2)

Screws (2)

Figure 6: Assembling the GPIB Test Fixture

Ribbon Cable

Red Edge

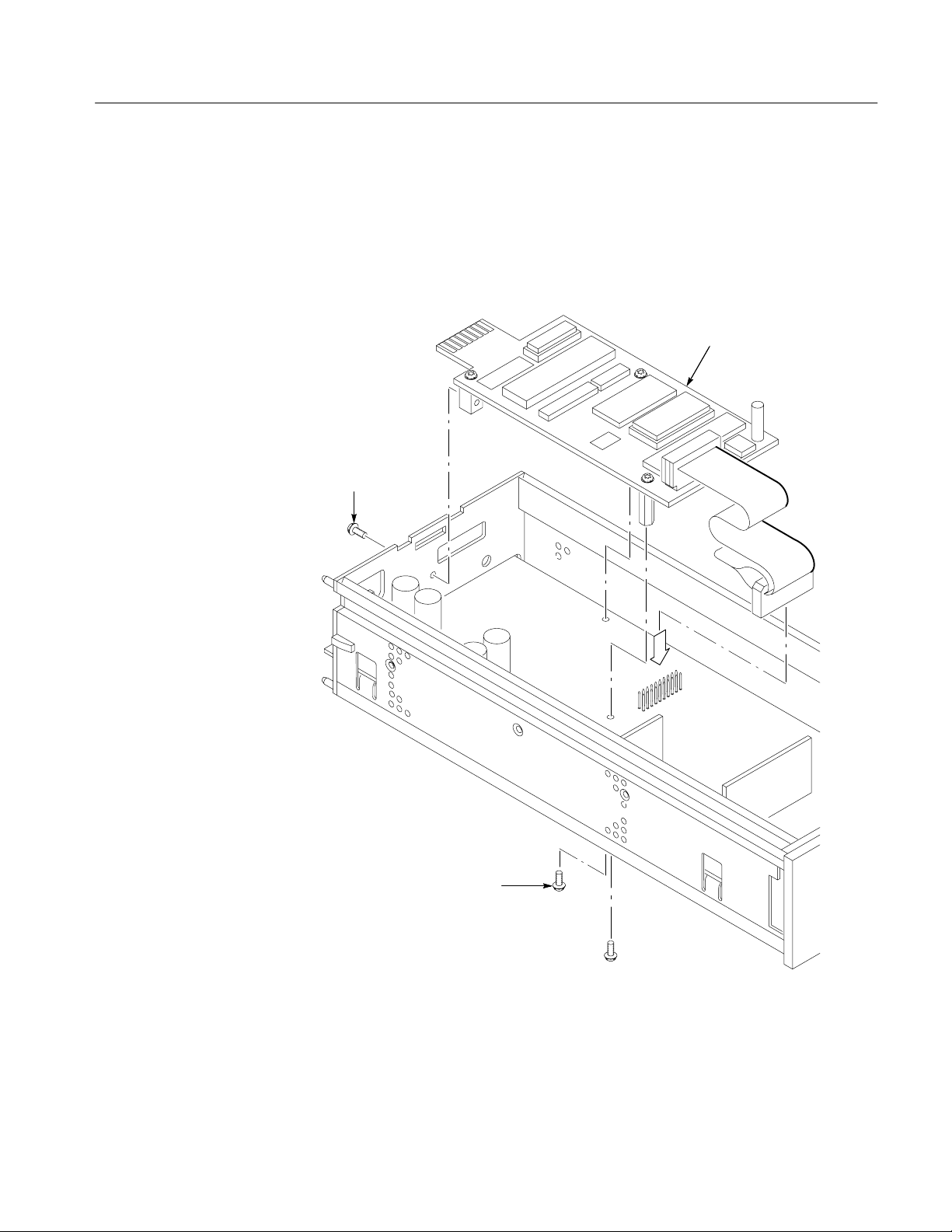

Remove Side Covers

Refer to Figure 7 and unlatch the securing screws with a flat-blade screwdriver.

Remove both covers from the AM 503B and set them to one side.

Amplifier

Securing Screw

Figure 7: Removing the AM 503B Side Covers

16

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

Page 27

Install GPIB Test Fixture

GPIB Installation

Refer to Figure 8 and install the GPIB test fixture on the AM 503B main board.

1. Install the tabbed end of the ribbon cable (174-2314-00) onto the main board

keeping the RED edge towards rail.

GPIB Board

Screw

Screws (2)

Figure 8: Installing the GPIB Test Fixture

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

17

Page 28

GPIB Installation

CAUTION. To avoid damaging the circuits, make sure the connectors are properly

aligned with the pins. Check to be sure all pins are connected.

2. Dress the excess ribbon cable back under the GPIB board and insert the end

of the board with the gold contacts into the slot of the rear frame.

3. Align the spacers of the test fixture over the holes on the main circuit board.

a. Install two screws (210-0408-00) through the main board to both

spacers.

b. Install one screw (210-0408-00) through the rear frame to the nut block

on the GPIB board.

This completes the GPIB installation. Remove the GPIB test fixture and reinstall

the side covers after the adjustment procedure is complete.

18

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

Page 29

AM 503B and AM 5030 Adjustments

The adjustment procedure consists of a series of steps to determine and set the

proper calibration constants of the AM 503B and AM 5030 Current Probe

Amplifiers.

NOTE. To set the internal calibration constants of the AM 503B amplifier, you

must install the GPIB test fixture. Refer to the procedure that begins on page 15.

Amplifier Setup

Set up the AM 503B or AM 5030 amplifiers as follows:

1. Plug the AM 503B or AM 5030 into the TM 5000 mainframe.

2. Power the amplifier on and let it warm up at least 20 minutes. The amplifier

must be calibrated at an ambient temperature between 25 ±5_ C.

3. Enable the Cal Mode of the amplifier by sending the following command

over the GPIB interface:

NOTE. You must send the command in order to load the calibration

constants.

4. On the AM 5030 amplifier only, send the query and verify that the

serial number is correct.

If the serial number of the AM 5030 amplifier is not correct, perform the

following steps:

a. Send the following command over the GPIB interface:

!

Be sure to hit the space bar twice before entering the serial number

(i.e. ).

b. Send the query again to verify that the serial number of the

AM 5030 is now correct.

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

19

Page 30

AM503B and AM5030 Adjustments

Calculate and Load New Calibration Constants

Use the following procedure to calculate and load new calibration (cal) constants

for Rin1X, Rin10X and Rin100X.

NOTE. Perform this procedure only if the amplifier fails the DC Gain Accuracy

test on page 4.

1. Query amplifier for existing Rin1X, Rin10X, and Rin100X Cal Constants

(, , and respectively). Enter these values in

Table 7 on page 8.

2. For each Existing Rin Cal Constant entered in Table 7 on page 8, calculate

the New Rin Cal Constants using the following formulas:

New Rin Cal Constant + (1 )

%Error

100

) Existing Rin Cal Constant

For example, having a %Error of +4.0% at 10 mA and an Existing

Rin1X Cal Constant of 25500 would translate into a New Rin Cal

Constant as follows:

New Rin Cal Constant + (1 )

) 4.0

) 25500 + 26520

100

NOTE. The Rin Cal Constants must be five digit numbers.

3. Enter the New Cal Constant for each of the three settings, Rin1X, Rin10X,

and Rin100X in Table 7 on page 8.

4. Over the GPIB interface load the New Rin Cal Constants:

a. Send the command:

The parameter, , is the Cal Constant for Rin 1X

from Table 7.

For example, using the New Rin1X calculated above of 26520, the GPIB

command sent to the amplifier would be as follows:

20

This will load the Rin1X with the new calibration constant to fine tune

the DC gain accuracy of the amplifier.

b. Send the command:

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

Page 31

AM503B and AM5030 Adjustments

The parameter, , is the New Cal Constant for

Rin 10X from Table 7.

c. Over the GPIB interface send the following command to the amplifier:

The parameter, is the New Cal Constant for

Rin 100X from Table 7.

d. Verify the Cal Constants by sending the following commands:

e. Connect a feed-thru adapter to the input of the amplifier and send the

command:

NOTE. It is important to use the feed-thru adapter and the DEGAuss 1 command;

otherwise the gain check will not work

5. Repeat the DC Gain Accuracy check on page 4.

GPIB Removal (AM 503B Only)

Remove the GPIB test fixture from the AM503B amplifier only. The GPIB

board of the AM 5030 remains with the amplifier. Refer to Figure 8 on page 17

and use the following procedure:

1. Power the amplifier off and remove amplifier from the TM 5000 mainframe.

2. Remove the screw from the rear frame.

3. Remove the two screws from the bottom of the main board that connect to

the spacers of the test fixture.

4. Remove the GPIB Test Fixture Board

5. Disconnect the tabbed end of the ribbon cable (174-2314-00) from the main

board. Leave the cable attached to the GPIB board.

6. Reinstall the side covers on the amplifier.

7. Store the test fixture with standoffs and cable intact.

This completes the adjustment procedure.

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

21

Page 32

AM503B and AM5030 Adjustments

22

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

Page 33

Performance Verification Setup for Current Probes

The Performance Verification tests allow you to demonstrate that the A6300

Series Current Probe meets its specified levels of performance. The recommended calibration interval is one year.

An AM 503B or AM 5030 Current Probe Amplifier that meets the tolerances of

the AM 503B and AM 5030 Performance Verification Procedure (page 3) can be

used as a standard for calibrating the current probes. Since the amplifier and

probe are designed as a system with known performance characteristics, it is not

necessary for the amplifier to meet the 4:1 uncertainty ratio that is normally

recommended for calibrations. To calibrate probes using an AM 503B or

AM 5030 as a standard, follow the performance verification procedures in these

instructions or in the AM 503B and AM 5030 Instruction Manual.

No probe or Amplifier adjustments are required during these test procedures.

Should any test fail, refer to the troubleshooting section in the AM 503B and

AM 5030 Instruction Manual for recommendations.

Tolerances that are specified in these procedures apply to the Amplifier and

current probe and do not include test equipment error.

Test Procedure Conditions

These procedures are valid only under the following conditions:

H The system has been calibrated at an ambient temperature of 25_±5_ C.

H The system is operating in an environment whose limits are described in

H The system, including probe, has had a warm-up period of at least

H The probe degauss/autobalance routine has been performed after the

Equipment Preparation

Before performing the verification tests, install all plug-in units into the power

module and turn the power on. Turn any remaining equipment on and allow the

entire system, including the attached probe, to warm up for a minimum of 20

minutes.

Table 4 on page 3.

20 minutes.

20-minute warm-up period.

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

23

Page 34

Performance Verification Setup for Current Probes

arameter

NOTE. Before performing any verification procedure, properly degauss the

probe. Remove the probe from any current-carrying conductor, lock the probe,

and press the Amplifier PROBE DEGAUSS AUTOBALANCE button. The

degauss/autobalance routine is complete when the indicator light turns off.

The Amplifier front panel will display an error code 266 during the degauss/

autobalance routine if the Amplifier is not properly terminated into 50 . Verify

that the oscilloscope input is 50 and set to DC coupling. Use a 50

feedthrough termination, attached at the oscilloscope input, if necessary.

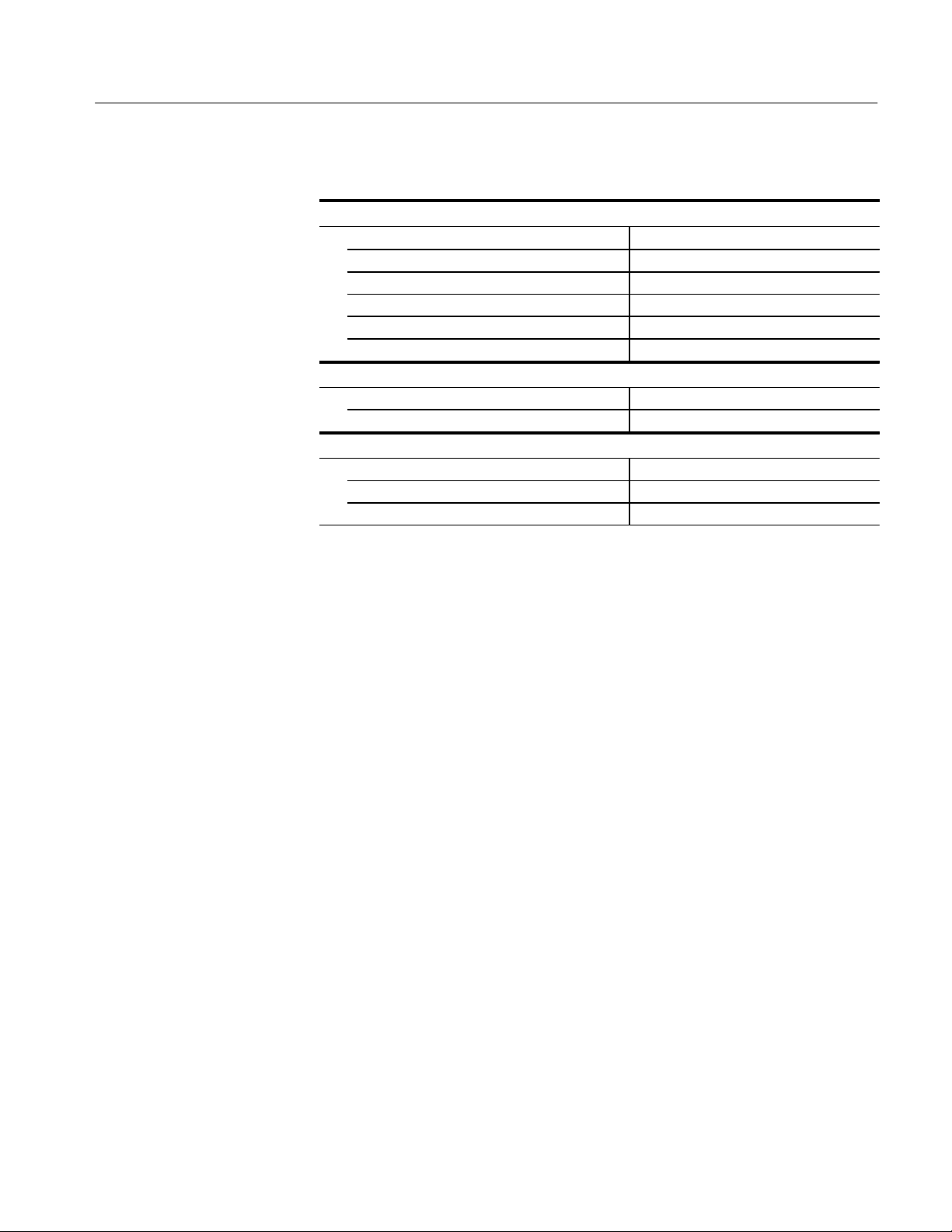

Warranted Specifications

Warranted specifications, Table 11, are guaranteed performance specifications

unless specifically designated as typical or nominal.

T able 11: Warranted AM 503B and AM 5030 Specifications

Installed Probe

P

Bandwidth DC to 100 MHz,

Rise Time, 10% to 90% 3.5 ns 7 ns 23 ns 20 ns 35 ns 175 ns

DC Gain Accuracy 3% 3% 3% 3% 3% 3%

A6312 A6302 A6303 A6302XL A6303XL A6304XL

–3 dB

DC to 50 MHz,

–3 dB

DC to 15 MHz,

–3 dB

DC to 17 MHz,

–3 dB

DC to 10 MHz,

–3 dB

DC to 2 MHz,

–3 dB

24

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

Page 35

A6312 Performance Verification

The test procedures in this section verify proper performance of the A6312

current probe.

Read page 23 before starting these procedures. Also, read each procedure

through completely before starting to ensure proper completion.

Required Test Equipment

To perform the acceptance tests in this section, you will need the test equipment

listed in Table 12. The test equipment must meet or exceed the specifications

listed. The test procedures may need to be modified if the recommended

equipment is not used.

T able 12: Required Test Equipment

Qty Item Description

1 Oscilloscope 500 MHz bandwidth TDS 520B

Recommended

Equipment

1 Current Probe

Amplifier

1 Leveled Sine Wave

Generator

1 Calibration Generator 1 MHz square wave, rise time <1 ns,

1 Digital Multimeter 0.25% 31/2 digit resolution

1 Current Source 0.3% accuracy, 0 to ±2 A Fluke 5700A or

1 Calibration Fixture 50 , BNC Connector 015-0601-50

1 Current Loop 20 turns 27 AWG coated wire Refer to page 40.

1 Termination 50 ±0.1%, 0.5 W 01 1-0129-00

1 BNC Cable 50 , 1.05m (42in) long 012-0057-01

1 BNC to Dual

Banana Adapter

3 MHz to 100 MHz Wavetek 9100 with

1V

into 50

p-p

at ± 50 mV

AM503B or AM5030

Option 250 or

SG 503 equivalent.

Wavetek 9100 with

Option 250 or

PG 506A equivalent

DM2510/G or

Fluke 850x/884x

Wavetek 9100 with

Option 250

103-0090-00

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

25

Page 36

A6312 Performance Verification

Bandwidth

This procedure tests the bandwidth of the A6312 Current Probe. In this test you

measure a signal at a relatively low frequency and again at the rated bandwidth

of the probe. The two measurements are compared to verify that the signal

amplitude does not fall below –3 dB at the probe bandwidth. Refer to Figure 9

when making equipment connections.

Equipment Connections

Leveled

Sine Wave

Generator

Output

Calibration

Fixture

Test Oscilloscope

50 oscilloscope input (or add 50

termination here if oscilloscope has

only high-impedance input).

Amplifier in TM

Series Power

Module

Current Probe

Figure 9: Bandwidth Test Setup for A6312

1. Using a 50 W BNC cable, connect the Amplifier OUTPUT to a 50 W

oscilloscope input. If the input impedance of your oscilloscope is 1 MW,

connect a 50 W feedthrough termination at the oscilloscope input. Do not

connect the termination at the Amplifier output.

2. Connect the current probe to the Amplifier INPUT.

26

Equipment Settings

3. Connect the current loop calibration fixture to the output of the leveled sine

wave generator.

Make or verify the equipment settings in Table 13.

T able 13: Equipment Settings for Bandwidth

Oscilloscope

Vertical input impedance 50

Vertical gain 10 mV/division

Time base 200 ns/division

Record length 500

Coupling DC

Offset 0 V (mid-scale)

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

Page 37

A6312 Performance Verification

T able 13: Equipment Settings for Bandwidth (Cont.)

Oscilloscope

Trigger type Edge

Trigger mode Auto

Trigger position 50%

Acquisition mode Average

Number of waveforms to average 8

Measurement type Peak-to-Peak

Leveled Sine Wave Generator

Frequency 3MHz

Amplitude 3V

AM 503B and AM 5030

Coupling DC

BW Limit Off (full bandwidth)

Current/division 10 mA/division

p-p

Procedure

1. Do not clamp the current probe around any conductor, but make sure the

jaws are locked shut.

2. Press the Amplifier PROBE DEGAUSS AUTOBALANCE button. Wait

for the degauss/autobalance routine to complete before proceeding. The

routine is complete when the indicator light turns off.

3. Clamp the current probe around the calibration fixture.

4. Adjust the signal generator output so that the Amplifier output is approxi-

mately 60 mV

, or six graticule divisions on the oscilloscope.

p-p

5. Using the peak-peak measurement capability of the oscilloscope, measure

and record the peak-peak reading as M

.

1

6. Set the oscilloscope time base to 5 ns/division. Increase the signal generator

frequency to the warranted bandwidth. Refer to Table 11 on page 24.

7. Using the peak-peak measurement capability of the oscilloscope, measure

and record the peak-peak reading as M

.

2

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

27

Page 38

A6312 Performance Verification

8. The probe meets the bandwidth specification if the ratio of the signal

amplitude at the warranted bandwidth is at least 70.7% of the signal

amplitude at 3 MHz. Using the following calculation, verify probe bandwidth:

M

2

ǒ

Ǔ

u 0.707

M

1

NOTE. The impedance of the calibration fixture used in this test changes between

3 MHz and 100 MHz. Typically the impedance changes from 50 at 3 MHz to

59 at 100 MHz. Thus you can substitute the following equation to make this

test more accurate:

M

2

ǒ

(

1.18

Ǔ

)

u 0.707

M

1

Rise Time

This procedure measures the rise time of the A6312. In this test you directly

measure the rise time of a step input. Refer to Figure 10 when making equipment

connections.

Test Oscilloscope

50 Input

Amplifier in TM

Series Power

Module

Current Probe

Calibration

Generator

Fast Rise

Output

Calibration

Fixture

Figure 10: Rise Time Test Setup for A6312

Equipment Connections

28

1. Using a 50 BNC cable, connect the Amplifier OUTPUT to a 50

oscilloscope input. If the input impedance of your oscilloscope is 1 M,

connect a 50 feedthrough termination at the oscilloscope input. Do not

connect the termination at the Amplifier output.

2. Connect the current probe to the Amplifier INPUT.

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

Page 39

A6312 Performance Verification

3. Connect the current loop calibration fixture to the calibration generator 50

fast rise output.

NOTE. If your oscilloscope cannot trigger on the pulse, use another BNC cable

to connect the trigger output of the pulse generator to the trigger input of the

oscilloscope. Configure the oscilloscope for an external trigger.

Equipment Settings

Make or verify the equipment settings in Table 14:

T able 14: Equipment Settings for Rise Time

Oscilloscope

Vertical input impedance 50 W

Vertical gain 10 mV/division

Time base 2 ns/division

Record length 500

Coupling DC

Offset 0 V (mid-scale)

Trigger type Edge

Trigger mode Auto

Trigger position 50%

Acquisition mode Average

Number of waveforms to average 32

Measurement type Rise Time

Calibration Generator

Period 1 ms

Output Fast rise

Amplitude Maximum

AM 503B and AM 5030

Coupling DC

BW Limit Off (full bandwidth)

Current/division 5 mA/division

Procedure

1. Do not clamp the current probe around any conductor, but make sure the

jaws are locked shut.

2. Press the Amplifier PROBE DEGAUSS AUTOBALANCE button. Wait

for the degauss/autobalance routine to complete before proceeding. The

routine is complete when the indicator light turns off.

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

29

Page 40

A6312 Performance Verification

3. Clamp the current probe around the calibration fixture. Verify that the

arrow-shaped indicator on the probe points away from the pulse source.

4. Using the measurement capability of the oscilloscope, measure the rise time

of the displayed pulse from 10% to 90% amplitude.

DC Gain Accuracy

Current Loop for DC Gain

Accuracy Check

5. Calculate the rise time of the probe (t

trprobe + trmeasured2* trsystem

Ǹ

probe) using the formula below:

r

2

The measured rise time (tr measured) is the value calculated in step 4.

The system rise time (t

system) is the rise time of the displayed signal when

r

output of the pulse generator is connected directly to the oscilloscope input.

(The current probe and amplifier are excluded.)

6. Verify that the probe rise time is less than the warranted specification. Refer

to Table 11 on page 24.

This procedure tests the DC gain accuracy of the A6312 Current Probes. In this

test you compare the voltage output of the Amplifier to a reference input.

You will need to construct a simple current loop in order to complete the DC

gain accuracy tests.

WARNING. Magnetic fields are produced that may cause a malfunction in heart

pacemakers, or damage to sensitive equipment.

Equipment Connections

30

Construct the loop using a cylindrical form approximately 3 inches in diameter,

wind exactly 20 turns of #27 coated wire.

NOTE. Ensure that the current loop has exactly 20 turns. A significant error will

result for each turn variance from 20 turns.

1. Using a BNC cable, connect the Amplifier OUTPUT to the 50 feed-

through termination. Attach the termination to a BNC-to-dual banana

adapter. Taking care to observe and maintain polarity, insert the dual banana

adapter into the digital multimeter DC voltage input.

2. Connect the current loop to the current source as shown in Figure 11.

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

Page 41

DMM

Amplifier in TM

Series Power

Module

A6312 Performance Verification

Current

Source

Equipment Settings

+–

20 Turns

BNC to Dual

Banana Adapter

50 Termination

50 Coaxial

Cable

Probe

Figure 11: DC Gain Accuracy Test Setup for A6312

Make or verify the equipment settings in Table 15:

T able 15: Equipment Settings for DC Gain Accuracy

Digital Multimeter

Measurement Type DC volts

Range Autoranging

Current Source

Output Off

AM 503B and AM 5030

Coupling DC

BW Limit On (20MHz)

Current/division 1 mA/division

Probe Trim 000

Output

Current Flow

+–

Procedure

1. Do not clamp the current probe around any conductor, but make sure the

jaws are locked shut.

2. Press the Amplifier PROBE DEGAUSS AUTOBALANCE button. Wait

for the degauss/autobalance routine to complete before proceeding. The

routine is complete when the indicator light turns off.

3. Clamp the current probe around the 20 turn current loop, as shown in Figure

14 on page 41. Verify that the arrow-shaped indicator on the probe points

away from the current source.

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

31

Page 42

A6312 Performance Verification

4. For each of the Amplifier current/division settings in Table 16, perform the

following steps:

a. Set the Amplifier to the desired current/division setting from Table 16.

b. Set the current source to the correct positive test current using Table 16.

c. Turn on the current source.

d. Record the exact measurement of the digital multimeter as M

. (You can

1

copy Table 17 on page 34 to record the results of your measurements.)

e. Set the current source for the correct negative test current using Table 16.

T able 16: DC Gain Accuracy Test for A6312

Turns of Current

Loop Passing

Through Probe

20 1mA ±250 A 10 mA

20 2mA ±500 A 20 mA

20 5mA ±1.25 mA 50 mA

20 10 mA ±2.5 mA 100 mA

20 20 mA ±5mA 200 mA

20 50 mA ±12.5 mA 500mA

20 100 mA ±25 mA 1 A

20 200 mA ±50 mA 2A

20 500 mA ±125 mA 5A

20 1A ±250 mA 10 A

AM 503B and

AM 5030

Current/Division

Current Source

Output

Test Current

I

t

32

20 2A ±500 mA 20 A

20 5A ±1 A 40A

f. Record the digital multimeter reading as M2.

g. Calculate the measured current (I

I

m

M1–M

2

(currentdivision)

0.01

) using the following formula:

m

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

Page 43

A6312 Performance Verification

For example, you might have obtained values of 50 mV for M

48 mV for M

you can compute I

(50.0x10

I

+

m

. If you are using an Amplifier setting of 10 mA/division,

2

as:

m

–3

) – (–48x10–3)

0.01

(10x10–3) + 98 mA

and

1

h. Verify that the measured current (Im) is within ±3% of the test current (It)

by computing %Error as follows:

I

* I

%Error +

m

For example, using a test current It of 100 mA and a measured current I

t

100

I

t

m

of 98 mA, the %Error would be:

%Error +

98 – 100

100

100 + –2%

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

33

Page 44

A6312 Performance Verification

T able 17: DC Gain Accuracy Test Worksheet for A6312

Turns of Current

Loop Passing

Through Probe

AM 503B and

AM 5030

Current/Division

Current Source

Output

Test Current

I

t

20 1mA ±250 A 10 mA

20 2mA ±500 A 20 mA

20 5mA ±1.25 mA 50 mA

20 10 mA ±2.5mA 100 mA

20 20 mA ±5mA 200mA

20 50 mA ±12.5mA 500mA

20 100 mA ±25 mA 1A

20 200 mA ±50 mA 2A

20 500 mA ±125 mA 5A

20 1A ±250 mA 10 A

20 2A ±500 mA 20 A

20 5A ±1 A 40 A

Note A

Note B

M1–M

+

I

m

0.01

%Error +

2

(currentńdivision)

I

* I

m

t

100

I

t

I

m

M

1

M

2

(Note A)

%Error

(Note B)

34

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

Page 45

A6302 and A6302XL Performance Verification

The test procedures in this section verify proper performance of the A6302 and

A6302XL current probes.

Read page 23 before starting these procedures. Also, read each procedure

through completely before starting to ensure proper completion.

Required Test Equipment

To perform the acceptance tests in this section, you will need the test equipment

listed in Table 18. The test equipment must meet or exceed the specifications

listed. The test procedures may need to be modified if the recommended

equipment is not used.

T able 18: Required Test Equipment

Qty Item Description

1 Oscilloscope 350 MHz bandwidth TDS 520B

Recommended

Equipment

1 Current Probe

Amplifier

1 Leveled Sine Wave

Generator

1 Calibration Generator 1 MHz square wave, rise time <1 ns,

1 Digital Multimeter 0.25% 31/2 digit resolution

1 Current Source 0.3% accuracy, 0 to ±2 A Fluke 5700A or

1 Calibration Fixture 50 , BNC Connector 015-0601-50

1 Current Loop 20 turns 27 AWG coated wire Refer to page 40.

1 Termination 50 ±0.1%, 0.5 W 01 1-0129-00

1 BNC Cable 50 , 1.05m (42in) long 012-0057-01

1 BNC to Dual

Banana Adapter

3 MHz to 50 MHz Wavetek 9100 with

1V

into 50

p-p

at ± 50 mV

AM503B or AM5030

Option 250 or

SG 503 equivalent

Wavetek 9100 with

Option 250 or

PG 506A equivalent

DM2510/G or

Fluke 850x/884x

Wavetek 9100 with

Option 250

103-0090-00

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

35

Page 46

A6302 and A6302XL Performance Verification

Bandwidth

This procedure tests the bandwidth of the A6302 and A6302XL Current Probes.

In this test you measure a signal at a relatively low frequency and again at the

rated bandwidth of the probe. The two measurements are compared to verify that

the signal amplitude does not fall below –3 dB at the probe bandwidth. Refer to

Figure 12 when making equipment connections.

Equipment Connections

Leveled

Sine Wave

Generator

Output

Calibration

Fixture

Test Oscilloscope

50 oscilloscope input (or add 50

termination here if oscilloscope has

only high-impedance input).

Amplifier in TM

Series Power

Module

Current Probe

Figure 12: Bandwidth Test Setup for A6302

1. Using a 50 W BNC cable, connect the Amplifier OUTPUT to a 50 W

oscilloscope input. If the input impedance of your oscilloscope is 1 MW,

connect a 50 W feedthrough termination at the oscilloscope input. Do not

connect the termination at the Amplifier output.

2. Connect the current probe to the Amplifier INPUT.

36

Equipment Settings

3. Connect the current loop calibration fixture to the output of the leveled sine

wave generator.

Make or verify the equipment settings in Table 19.

T able 19: Equipment Settings for Bandwidth

Oscilloscope

Vertical input impedance 50

Vertical gain 10 mV/division

Time base 200 ns/division

Record length 500

Coupling DC

Offset 0 V (mid-scale)

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

Page 47

A6302 and A6302XL Performance Verification

T able 19: Equipment Settings for Bandwidth (Cont.)

Oscilloscope

Trigger type Edge

Trigger mode Auto

Trigger position 50%

Acquisition mode Average

Number of waveforms to average 8

Measurement type Peak-to-Peak

Leveled Sine Wave Generator

Frequency 3MHz

Amplitude 3V

AM 503B and AM 5030

Coupling DC

BW Limit Off (full bandwidth)

Current/division 10 mA/division

p-p

Procedure

1. Do not clamp the current probe around any conductor, but make sure the

jaws are locked shut.

2. Press the Amplifier PROBE DEGAUSS AUTOBALANCE button. Wait

for the degauss/autobalance routine to complete before proceeding. The

routine is complete when the indicator light turns off.

3. Clamp the current probe around the calibration fixture.

4. Adjust the signal generator output so that the Amplifier output is approxi-

mately 60 mV

, or six graticule divisions on the oscilloscope.

p-p

5. Using the peak-peak measurement capability of the oscilloscope, measure

and record the peak-peak reading as M

.

1

6. Set the oscilloscope time base to 10 ns/division. Increase the signal generator

frequency to the warranted bandwidth. Refer to Table 11 on page 24.

7. Using the peak-peak measurement capability of the oscilloscope, measure

and record the peak-peak reading as M

.

2

8. The probe meets the bandwidth specification if the ratio of the signal

amplitude at the warranted bandwidth is at least 70.7% of the signal

amplitude at 3 MHz. Using the following calculation, verify probe bandwidth:

M

2

ǒ

Ǔ

u 0.707

M

1

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

37

Page 48

A6302 and A6302XL Performance Verification

NOTE. The impedance of the calibration fixture used in this test changes slightly

between 3 MHz and 50 MHz. Typically the impedance changes from 50 at

3 MHz to 53 at 50 MHz. Thus you can substitute the following equation to

make this test more accurate:

M

2

ǒ

(

1.06

Ǔ

)

u 0.707

M

1

Rise Time

This procedure measures the rise time of the A6302 and A6302XL. In this test

you directly measure the rise time of a step input. Refer to Figure 13 when

making equipment connections.

Equipment Connections

Test Oscilloscope

50 Input

Amplifier in TM

Series Power

Module

Current Probe

Calibration

Generator

Fast Rise

Output

Calibration

Fixture

Figure 13: Rise Time Test Setup for A6302/A6302XL

1. Using a 50 BNC cable, connect the Amplifier OUTPUT to a 50

oscilloscope input. If the input impedance of your oscilloscope is 1 M,

connect a 50 feedthrough termination at the oscilloscope input. Do not

connect the termination at the Amplifier output.

2. Connect the current probe to the Amplifier INPUT.

38

3. Connect the current loop calibration fixture to the calibration generator 50

fast rise output.

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

Page 49

A6302 and A6302XL Performance Verification

NOTE. If your oscilloscope cannot trigger on the pulse, use another BNC cable

to connect the trigger output of the pulse generator to the trigger input of the

oscilloscope. Configure the oscilloscope for an external trigger.

Equipment Settings

Make or verify the equipment settings in Table 20:

T able 20: Equipment Settings for Rise Time

Oscilloscope

Vertical input impedance 50 W

Vertical gain 10 mV/division

Time base 2 ns/division

Record length 500

Coupling DC

Offset 0 V (mid-scale)

Trigger type Edge

Trigger mode Auto

Trigger position 50%

Acquisition mode Average

Number of waveforms to average 8

Measurement type Rise Time

Calibration Generator

Period 1 ms

Output Fast rise

Amplitude Maximum

AM 503B and AM 5030

Coupling DC

BW Limit Off (full bandwidth)

Current/division 5 mA/division

Procedure

1. Do not clamp the current probe around any conductor, but make sure the

jaws are locked shut.

2. Press the Amplifier PROBE DEGAUSS AUTOBALANCE button. Wait

for the degauss/autobalance routine to complete before proceeding. The

routine is complete when the indicator light turns off.

3. Clamp the current probe around the calibration fixture. Verify that the

arrow-shaped indicator on the probe points away from the pulse source.

4. Using the measurement capability of the oscilloscope, measure the rise time

of the displayed pulse from 10% to 90% amplitude.

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

39

Page 50

A6302 and A6302XL Performance Verification

5. Verify that the rise time is less than the warranted specification. Refer to

Table 11 on page 24.

DC Gain Accuracy

This procedure tests the DC gain accuracy of the A6302 and A6302XL Current

Probes. In this test you compare the voltage output of the Amplifier to a

reference input.

Current Loop for DC Gain

Accuracy Check

Equipment Connections

You will need to construct a simple current loop in order to complete the DC

gain accuracy tests.

WARNING. Magnetic fields are produced that may cause a malfunction in heart

pacemakers, or damage to sensitive equipment.

Construct the loop using a cylindrical form approximately 3 inches in diameter,

wind exactly 20 turns of #27 coated wire.

NOTE. Ensure that the current loop has exactly 20 turns. A significant error will

result for each turn variance from 20 turns.

1. Using a BNC cable, connect the Amplifier OUTPUT to the 50 feed-

through termination. Attach the termination to a BNC-to-dual banana

adapter. Taking care to observe and maintain polarity, insert the dual banana

adapter into the digital multimeter DC voltage input.

2. Connect the current loop to the current source as shown in Figure 14.

40

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

Page 51

DMM

A6302 and A6302XL Performance Verification

Amplifier in TM

Series Power

Module

Current

Source

Equipment Settings

+–

20 Turns

BNC to Dual

Banana Adapter

50 Termination

50 Coaxial

Cable

Probe

Figure 14: DC Gain Accuracy Test Setup for A6302/A6302XL

Make or verify the equipment settings in Table 21:

T able 21: Equipment Settings for DC Gain Accuracy

Digital Multimeter

Measurement Type DC volts

Range Autoranging

Current Source

Output Off

AM 503B and AM 5030

Coupling DC

BW Limit On (20MHz)

Current/division 1 mA/division

Probe trim 000

Output

Current Flow

+–

Procedure

1. Do not clamp the current probe around any conductor, but make sure the

jaws are locked shut.

2. Press the Amplifier PROBE DEGAUSS AUTOBALANCE button. Wait

for the degauss/autobalance routine to complete before proceeding. The

routine is complete when the indicator light turns off.

3. Clamp the current probe around the 20 turn current loop, as shown in Figure

14 on page 41. Verify that the arrow-shaped indicator on the probe points

away from the current source.

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

41

Page 52

A6302 and A6302XL Performance Verification

4. For each of the Amplifier current/division settings in Table 22 on page 42,

perform the following steps:

a. Set the Amplifier to the desired current/division setting from Table 22.

b. Set the current source to the correct positive test current using Table 22.

c. Turn on the current source.

d. Record the exact measurement of the digital multimeter as M

. (You can

1

copy Table 23 on page 44 to record the results of your measurements.)

e. Set the current source for the correct negative test current using Table 22.

T able 22: DC Gain Accuracy Test for A6302

Turns of Current

Loop Passing

Through Probe

20 1mA ±250 A 10 mA

20 2mA ±500 A 20 mA

20 5mA ±1.25 mA 50 mA

20 10 mA ±2.5 mA 100 mA

20 20 mA ±5mA 200 mA

20 50 mA ±12.5 mA 500mA

20 100 mA ±25 mA 1 A

20 200 mA ±50 mA 2A

20 500 mA ±125 mA 5A

20 1A ±250 mA 10 A

AM 503B and

AM 5030

Current/Division

/A6302XL

Current Source

Output

Test Current

I

t

42

20 2A ±500 mA 20 A

20 5A ±1 A 40A

f. Record the digital multimeter reading as M2.

g. Calculate the measured current (I

I

m

M1–M

2

(currentdivision)

0.01

) using the following formula:

m

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

Page 53

A6302 and A6302XL Performance Verification

For example, you might have obtained values of 50 mV for M

48 mV for M

you can compute I

(50.0x10

I

+

m

. If you are using an Amplifier setting of 10 mA/division,

2

as:

m

–3

) – (–48x10–3)

0.01

(10x10–3) + 98 mA

and

1

h. Verify that the measured current (Im) is within ±3% of the test current (It)

by computing %Error as follows:

I

* I

%Error +

m

For example, using a test current It of 100 mA and a measured current I

t

100

I

t

m

of 98 mA, the %Error would be:

%Error +

98 – 100

100

100 + –2%

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

43

Page 54

A6302 and A6302XL Performance Verification

T able 23: DC Gain Accuracy Test Worksheet for A6302/A6302XL

Turns of Current

Loop Passing

Through Probe

AM 503B and

AM 5030

Current/Division

Current Source

Output

Test Current

I

t

20 1mA ±250 A 10 mA

20 2mA ±500 A 20 mA

20 5mA ±1.25 mA 50 mA

20 10 mA ±2.5mA 100 mA

20 20 mA ±5mA 200mA

20 50 mA ±12.5mA 500mA

20 100 mA ±25 mA 1A

20 200 mA ±50 mA 2A

20 500 mA ±125 mA 5A

20 1A ±250 mA 10 A

20 2A ±500 mA 20 A

20 5A ±1 A 40 A

Note A

Note B

M1–M

+

I

m

0.01

%Error +

2

(currentńdivision)

I

* I

m

t

100

I

t

I

m

M

1

M

2

(Note A)

%Error

(Note B)

44

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

Page 55

A6303 and A6303XL Performance Verification

The test procedures in this section check for proper performance of the A6303

and A6303XL current probes.

Read page 23 before starting these procedures. Also, read each procedure

through completely before starting to ensure proper completion.

Required Test Equipment

To perform the acceptance tests in this section, you will need the test equipment

listed in Table 24. The test equipment must meet or exceed the specifications

listed. The test procedures may need to be modified if the recommended

equipment is not used.

T able 24: Required Test Equipment

Qty Item Description

1 Oscilloscope 350 MHz bandwidth TDS 520B

Recommended

Equipment

1 Current Probe

Amplifier

1 Leveled Sine Wave

Generator

1 Calibration Generator 1 MHz square wave, rise time <1 ns,

1 Digital Multimeter 0.25% 31/2 digit resolution

1 Current Source 0.3% accuracy, 0 to ±2 A Fluke 5700A or

1 Calibration Fixture 50 , BNC Connector 015-0601-50

1 Current Loop 50 turns 21 AWG coated wire Refer to page 50.

1 Termination 50 ±0.1%, 0.5 W 01 1-0129-00

1 BNC Cable 50 , 1.05m (42in) long 012-0057-01

1 BNC to Dual

Banana Adapter

3 MHz to 15 MHz Wavetek 9100 with

1V

into 50

p-p

at ± 50 mV

AM503B or AM5030

Option 250 or

SG 503 equivalent

Wavetek 9100 with

Option 250 or

PG 506A equivalent

DM2510/G

Wavetek 9100

103-0090-00

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

45

Page 56

A6303 and A6303XL Performance Verification

Bandwidth

This procedure tests the bandwidth of the A6303 and A6303XL Current Probes.

In this test you measure a signal at a relatively low frequency and again at the

rated bandwidth of the probe. The two measurements are compared to check that

the signal amplitude does not fall below –3 dB at the probe bandwidth. Refer to

Figure 15 when making equipment connections.

Equipment Connections

Leveled

Sine Wave

Generator

Fast Rise

Calibration

Test Oscilloscope

50 oscilloscope input (or

add 50 termination here

if oscilloscope has only

high-impedance input).

Amplifier in TM

Series Power

Module

Current

Probe

Figure 15: Bandwidth Test Setup for an A6303 or A6303XL

1. Using a 50 W BNC cable, connect the Amplifier OUTPUT to a 50 W

oscilloscope input. If the input impedance of your oscilloscope is 1 MW,

connect a 50 W feedthrough termination at the oscilloscope input. Do not

connect the termination at the Amplifier output.

2. Connect the current probe to the Amplifier INPUT.

Output

Fixture

46

Equipment Settings

3. Connect the current loop calibration fixture to the output of the leveled sine

wave generator.

Make or check the equipment settings in Table 25:

T able 25: Equipment Settings for Bandwidth

Oscilloscope

Vertical input impedance 50

Vertical gain 10 mV/division

Time base 200 ns/division

Record length 500

Coupling DC

Offset 0 V (mid-scale)

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

Page 57

A6303 and A6303XL Performance Verification

T able 25: Equipment Settings for Bandwidth (Cont.)

Oscilloscope

Trigger type Edge

Trigger mode Auto

Trigger position 50%

Acquisition mode Average

Number of waveforms to average 8

Measurement type Peak-to-Peak

Leveled Sine Wave Generator

Frequency 3MHz

Amplitude 3V

AM 503B and AM 5030

Coupling DC

BW Limit Off

Current/division 10 mA/division

p-p

Procedure

1. Do not clamp the current probe around any conductor, but make sure the

jaws are locked shut.

2. Press the Amplifier PROBE DEGAUSS AUTOBALANCE button. Wait

for the degauss/autobalance routine to complete before proceeding. The

routine is complete when the indicator light turns off.

3. Clamp the current probe around the current loop calibration fixture.

4. Adjust the signal generator output so that the Amplifier output is

≈60 mV

, or six graticule divisions on the oscilloscope.

p-p

5. Using the peak-peak measurement capability of the oscilloscope, measure

and record the peak-peak reading as M

.

1

6. Set the oscilloscope time base to 50 ns/division. Increase the signal generator

frequency to the warranted bandwidth. Refer to Table 11 on page 24.

7. Using the peak-peak measurement capability of the oscilloscope, measure

and record the peak-peak reading as M

.

2

AM 503B, AM 5030, and A6300 Series Verification and Adjustment

47

Page 58

A6303 and A6303XL Performance Verification

8. The probe meets the bandwidth specification if the ratio of the signal

amplitude at the warranted bandwidth is at least 0.707 of the signal

amplitude at 3 MHz. Use the following formula to check probe bandwidth:

M

2

ǒ

Ǔ

u 0.707

M

1

Rise Time

This procedure measures the rise time of the A6303 and A6303XL. In this test

you directly measure the rise time of a step input. Refer to Figure 16 when

making equipment connections.

Equipment Connections

Test Oscilloscope

50 Input

Amplifier in TM

Series Power

Module

Current

Probe

Calibration

Generator

Fast Rise

Output

Calibration

Fixture

Figure 16: Rise Time Test Setup for A6303 or A6303XL

1. Using a BNC cable, connect the Amplifier OUTPUT to a 50 oscilloscope