Page 1

Model 82-WIN Simultaneous C-V Measurement

User’s Manual

A GREATER MEASURE OF CONFIDENCE

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a

period of 1 year from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables,

rechargeable batteries, diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in

Cleveland, Ohio. You will be given prompt assistance and return instructions. Send the product, transportation

prepaid, to the indicated service facility. Repairs will be made and the product returned, transportation prepaid.

Repaired or replaced products are warranted for the balance of the original warranty period, or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written

consent, or misuse of any product or part. This warranty also does not apply to fuses, software, non-rechargeable

batteries, damage from battery leakage, or problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE.

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR

ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF

THE USE OF ITS INSTRUMENTS AND SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS

BEEN ADVISED IN ADVANCE OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL AND INSTALLATION,

LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY PERSON, OR DAMAGE TO PROPERTY.

Keithley Instruments, Inc.

Sales Offices: BELGIUM: Bergensesteenweg 709 • B-1600 Sint-Pieters-Leeuw • 02-363 00 40 • Fax: 02/363 00 64

CHINA: Yuan Chen Xin Building, Room 705 • 12 Yumin Road, Dewai, Madian • Beijing 100029 • 8610-8225-1886 • Fax: 8610-8225-1892

FINLAND: Tietäjäntie 2 • 02130 Espoo • Phone: 09-54 75 08 10 • Fax: 09-25 10 51 00

FRANCE: 3, allée des Garays • 91127 Palaiseau Cédex • 01-64 53 20 20 • Fax: 01-60 11 77 26

GERMANY: Landsberger Strasse 65 • 82110 Germering • 089/84 93 07-40 • Fax: 089/84 93 07-34

GREAT BRITAIN: Unit 2 Commerce Park, Brunel Road • Theale • Berkshire RG7 4AB • 0118 929 7500 • Fax: 0118 929 7519

INDIA: 1/5 Eagles Street • Langford Town • Bangalore 560 025 • 080 212 8027 • Fax: 080 212 8005

ITALY: Viale San Gimignano, 38 • 20146 Milano • 02-48 39 16 01 • Fax: 02-48 30 22 74

JAPAN: New Pier Takeshiba North Tower 13F • 11-1, Kaigan 1-chome • Minato-ku, Tokyo 105-0022 • 81-3-5733-7555 • Fax: 81-3-5733-7556

KOREA: 2FL., URI Building • 2-14 Yangjae-Dong • Seocho-Gu, Seoul 137-888 • 82-2-574-7778 • Fax: 82-2-574-7838

NETHERLANDS: Postbus 559 • 4200 AN Gorinchem • 0183-635333 • Fax: 0183-630821

SWEDEN: c/o Regus Business Centre • Frosundaviks Allé 15, 4tr • 169 70 Solna • 08-509 04 600 • Fax: 08-655 26 10

TAIWAN: 13F-3, No. 6, Lane 99, Pu-Ding Road • Hsinchu, Taiwan, R.O.C. • 886-3-572-9077 • Fax: 886-3-572-9031

28775 Aurora Road • Cleveland, Ohio 44139 • 440-248-0400 • Fax: 440-248-6168

1-888-KEITHLEY (534-8453) • www.keithley.com

2/03

Page 3

Model 82-WIN Simultaneous C-V Measurement

User’s Manual

©1997, Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

Second Printing, October 1999

Document Number: 82WIN-900-01 Rev. B

Page 4

Manual Print History

The print history shown below lists the printing dates of all Re visions and Addenda created

for this manual. The Revision Le vel letter increases alphabetically as the manual undergoes

subsequent updates. Addenda, which are released between Revisions, contain important

change information that the user should incorporate immediately into the manual. Addenda

are numbered sequentially . When a ne w Revision is created, all Addenda associated with the

previous Revision of the manual are incorporated into the ne w Re vision of the manual. Each

new Revision includes a revised copy of this print history page.

Revision A (Document Number 82WIN-900-01)...............................................................April 1997

Revision B (Document Number 82WIN-900-01).................................................................October 1999

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand names are trademarks or registered trademarks of their respective holders.

Page 5

S

afety Precautions

The following safety precautions should be observed before using this product and any associated instrumentation. Although

some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous

conditions may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions

required to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using the product. Refer to the manual for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product may be impaired.

The types of product users are:

Responsible body

ment is operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators

instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel

voltage or replacing consumable materials. Maintenance procedures are described in the manual. The procedures explicitly state

if the operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel

trained service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that are rated Installation Category I and Installation Category II,

as described in the International Electrotechnical Commission (IEC) Standard IEC 60664. Most measurement, control, and data

I/O signals are Installation Category I and must not be directly connected to mains voltage or to voltage sources with high transient over-voltages. Installation Category II connections require protection for high transient over-voltages often associated with

local AC mains connections. Assume all measurement, control, and data I/O connections are for connection to Category I sources unless otherwise marked or described in the Manual.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test fixtures.

The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than 30V RMS,

42.4V peak, or 60VDC are present.

circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators

are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential

human contact. Product operators in these circumstances must be trained to protect themselves from the risk of electric shock.

If the circuit is capable of operating at or above 1000 volts,

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance limited sources. NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input power disconnect device must be provided, in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under

test. ALWAYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting ca-

is the individual or group responsible for the use and maintenance of equipment, for ensuring that the equip-

use the product for its intended function. They must be trained in electrical safety procedures and proper use of the

perform routine procedures on the product to keep it operating properly, for example, setting the line

are trained to work on live circuits, and perform safe installations and repairs of products. Only properly

A good safety practice is to expect that hazardous voltage is present in any unknown

no conductive part of the circuit may be exposed.

5/02

Page 6

bles or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the voltage being measured.

The instrument and accessories must be used in accordance with its specifications and operating instructions or the safety of the

equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating information, and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use

of a lid interlock.

If or is present, connect it to safety earth ground using the wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of

normal and common mode voltages. Use standard safety precautions to avoid personal contact with these voltages.

The

WARNING

information very carefully before performing the indicated procedure.

The

CAUTION

ranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits, including the power transformer,

test leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable national safety approvals, may be used if the rating and type are the same. Other components that are not safety related may be purchased from

other suppliers as long as they are equivalent to the original component. (Note that selected parts should be purchased only

through Keithley Instruments to maintain accuracy and functionality of the product.) If you are unsure about the applicability

of a replacement component, call a Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist of a circuit board with

no case or chassis (e.g., data acquisition board for installation into a computer) should never require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the factory for

proper cleaning/servicing.

heading in a manual explains dangers that might result in personal injury or death. Always read the associated

heading in a manual explains hazards that could damage the instrument. Such damage may invalidate the war-

Page 7

User’s Guide

Model 82~WIN

Simultaneous C-V

Measurement

Keithley instruments, Inc.

Release Date: April 1997

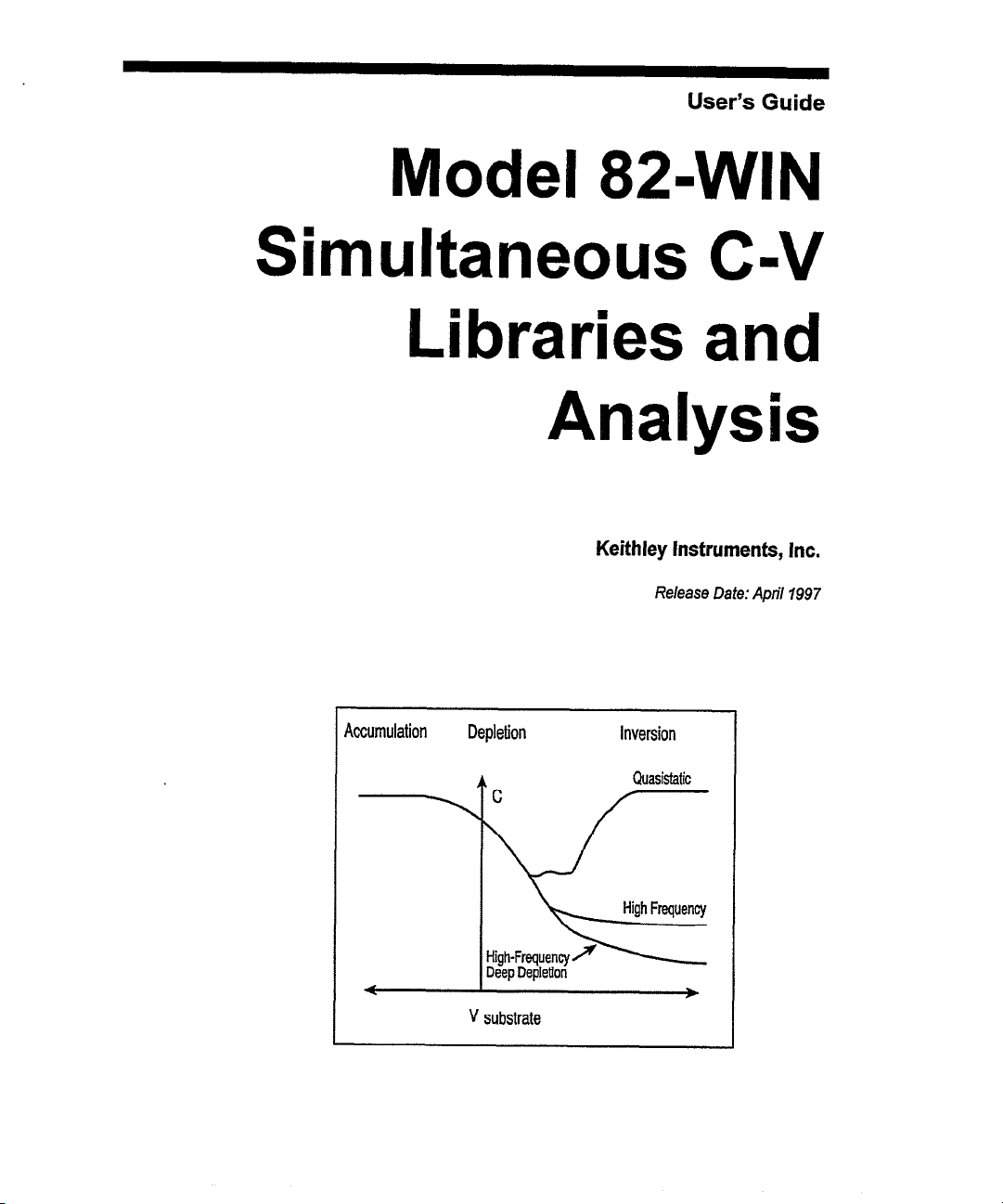

Accumulation

I-

Depletion

if-

\

ligh-Frequenqd .

he0 Deoletion

. .

V substrate

Inversion

Quasistatic

High Frequency

l

Page 8

Contents

C-V Measurement

Introduction

Typical Measurement Sequence

First Time System Testing and

Measurement Procedures

Choose the Right Parameters .................................................................................................. .18

Additional C-V Measurement Features

Measurement Considerations

................................................................................................................................

Leakage Test

Cable Correction

GPIB Configuration

Instrument Selection

Instrument Setup

Making C-V Measurements

Analyzing Data

Optimal C-V Measurement Parameters

Determining the Optimal Delay Tie

Squarewave

Staircase

Capacitance vs. Delay Tie

Time Options

Potential Error Sources

...........................................................................................

1

1

.................................................................................................

Cable Correction

.....................................................................

................................................................................................................

Correcting for Excess Leakage Current

Correcting for Stray Capacitance

......................................................................

..............................................................................

..........................................................................................................

Performing Cable Correction

.....................................................................................

.........................................................................................................

...................................................................................................

.................................................................................................

........................................................................................................

.......................................................................................

..........................................................................................................

.....................................................................

Start, Stop, and Step Voltages..

Sweep Direction

Delay Time

.......................................................................................................

...............................................................................................................

...............................................................................

.......................................................................

Measurement Results

Determining Delay Tie with

Testing Slow Devices..

...............................................................................................

Leaky Devices .........................................................

............................................................................................

....................................................................................

................................................................................................................

.....................................................................................................................

......................................................................................

.............................................................................................................

...................................................................................................

.............................................................................................

Stray Capacitances

Leakage Resistances

High-frequency Effects

....................................................................................................

.................................................................................................

...........................................................................................

3

.5

5

6

-6

7

8

10

10

.l 1

11

13

15

18

.18

19

20

21

.23

24

.25

26

26

26

26

26

28

.28

28

31

.32

User’s Guide Model 82WN Simultaneous C-V

C-V Measurement l i

Page 9

Avoiding

Capacitance

Cabling Considerations ...........................................................................................

Device Connections

Test Fixture

Correcting Residual

Offsets .....................................................................................................................

Errors..

Shielding .............................................................................................

Errors .......................................................................................

Gain and Nonlinearity

Voltage-dependent

Curve Misalignment.. .......................................

Noise .......................................................................................................................

Interpreting C-V Curves

Maintaining

Analyzing

Initial Equilibrium

Dynamic

Range Considerations.. ..............................................................................

Curves for

Equilibrium..

Equilibrium.. ..........................................................................

Series and Parallel Model

Example.. .................................................................................................................

Device Considerations

Series Resistance

Device

Test

Structure .......................................................................................................

Device Integrity..

Equipment Considerations

Light Leaks.. ............................................................................................................

Thermal Errors

...............................................................................................

.........................................................................................................

..................................................................................

..................................................................................................

.34

.34

35

.36

.36

.36

Errors

..................................................................................

Offset..

......................................................................................

.

......................................................

...........................................................................................

........................................................................................

.37

.37

.37

,38

.3 8

38

.40

....................................................................................................

41

.42

Equivalent Circuits.. ........................................................

......................................................................................................

.....................................................................................................

................................................................................

.42

.45

46

46

.46

.47

.47

.47

47

ii 0 C-V Measurement

User’s Guide Model 82-WIN Simultaneous C-V

Page 10

C-V Measurement

Introduction

This chapter provides detailed information on using Metrics ICS

software with Keithley Model 82-WIN to set up C-V

measurements and acquire C-V data. A quicker and easier

approach is to use Keithley libraries, which contain typical

measurement setup parameters and analysis algorithms to

extract many parameters from basic C-V measurements. The

next chapter provides detailed information on how to use

Keithley libraries.

This chapter is organized as the following:

Typical Measurement Sequence: Outlines the basic

measurement sequence that should be followed to ensure

accurate measurements and analysis.

First Time System Testing and Cable Correction: Describes

the procedure to test the complete system for the presence of

unwanted characteristics such as leakage resistance, leakage

current, and stray capacitance. It also details the cable correction

procedure that must be performed in order to ensure accuracy of

high-frequency C-V measurement.

Measurement Procedures: Describes basic procedures for

making C-V measurement. A simultaneous C-V measurement

example is included to illustrate the procedures.

User’s Guide Model 82-WIN Simultaneous C-V

C-V Measurement l 1

Page 11

Choosing the Right Parameters: Briefly discusses the

considerations in choosing right measurement parameters to

achieve accurate

C-V

measurements. It also describes a

procedure to determine the correct delay time to optimize C-V

measurements.

Additional C-V Measurement Features: Includes a

description of squarewave, single staircase, double staircase,

and capacitance vs. delay time measurements.

Measurement Considerations: Outlines numerous factors that

should be taken into account in order to maximize measurement

accuracy and minimize errors.

2 0 C-V Measurement User’s Guide Model 824MN Simultaneous C-V

Page 12

Typical Measurement Sequence

Measurements should be carried out in the proper sequence in

order to ensure that the system is optimized and error terms are

minimized. The basic sequence is outlined below. If your

system is properly set up, tested, and calibrated, you may skip

Steps 1 and 2. Otherwise you must perform the testing and

calibration procedures.

Step 1: Test and

Correct for System Leakage and Strays

Initially, you should test and determine if any problems, such as

excessive leakage or unwanted stray capacitance, are present.

You should correct these problems before making C-V a

measurement. Refer to your system manuals for proper

installation and testing procedures. After initial testing, the

system need be tested only when you have changed some

aspects of its configuration, such as connecting cables or test

futures.

Probe-up suppression should be performed before each

measurement to ensure accuracy. This procedure is discussed in

the measurement section in detail.

Step 2: Correct for Cabling Effects

Cable correction is necessary to compensate for transmission

line effects through the connecting cables and remote input

coupler. Transmission line effects are more significant at higher

frequencies and with longer cables, or with switches in the

system. Failure to perform cable correction will result in

substantially reduced accuracy of high-f?equency C-V

measurement. In order to perform correction, you must connect

the Model 5909 calibration capacitors to the system, and

perform the correction procedure under Metrics ICS. Cable

correction must be performed the first time you use your

User’s Guide Model 82-WIN Simultaneous C-V

C-V Measurement * 3

Page 13

system. After that, it needs to be performed only if the system

configuration

is

changed in

some

manner, or if the ambient

temperature changes by more than 5’C.

Step 3: Configure Your System with Metrics ICS

If you are not using the Keithley library setup to make C-V

measurement, it will be necessary for you to properly configure

your system under Metrics ICS, including GPIB, instrument,

switching matrices, measurement parameters, etc. You should

refer to the Metrics ICS and Keithley C-V Driver manuals for

detailed information regarding configuration of your system.

Step 4: Make a C-V Measurement

Before you can actually make measurements, you must select

measurement parameters such as sweep mode, range, frequency,

and voltage values. As the sweep is performed, measured values

are stored in data arrays for analysis and later retrieval.

Step 5: Analyze C-V Data

4. C-V Measurement

Besides Metrics ICS and Keithley C-V drivers, the Keithley

C-V system includes libraries for setup and data analysis.

Depending on the options you choose, you will be able to

extract a large amount of useful information from your C-V

measurement data. Available analysis features include doping

profile, flatband capacitance and voltage, interface trap density,

and mobile ion density, etc.

User’s Guide Model 82-WIN Simultaneous C-V

Page 14

First Time System Testing and Cable Correction

Leakage Test

Before using the system, it is necessary to check system

leakage. Zero suppress in Metrics ICS is intended to correct for

small system leakage current and stray capacitance. Any

excessive leakage problem must be solved before attempting a

measurement. Procedures are outlined below.

You should run a probe-up test sweep to determine if there is

excessive system or voltage-dependent leakage and stray

capacitance. You may also load the Keithley standard system

leakage check library. Refer to the C-V Libraries and Analysis

chapter for information on using the leakage check library. Note

that setup parameters should be same as those used for your

measurement.

Once leakage check setup is loaded and properly configured,

click on Single on the Meas button. After the sweep, you may

view the capacitance and Q/t vs. voltage plots. There are two

key items to note when performing this procedure. For a typical

system, capacitance and Q/t values should be as small as

possible. Ideally, the stray capacitance should be less than 1%

of the expected capacitance values for optimal accuracy, and

leakage current should be very small as well. Typically, leakage

current should be less than 0.5 pA on the 200pF range, while on

the 2nP range, leakage current should be less than 2pA. In

addition, stray capacitance or leakage current should not display

any voltage-dependent features.

User’s Guide Model 824MN Simultaneous C-V C-V Measurement l 5

Page 15

Make sure proper cables are installed in the correct

1.

places. Be certain you have not interchanged Model

4801 (low noise) cables with the Model 705 1 (50R)

cables or other regular cables.

Make sure all connecting jacks and connectors are f?ee

2.

of contamination. Clean any dirty connectors with

methanol, and allow them to dry thoroughly before

use.

Be certain that you are making a probe-up

3.

measurement.

Check to see that no leakage paths are present in the

4.

test future.

If necessary, tie down cables to avoid noise currents

5.

caused by cable flexing. Also avoid vibration during

testing.

6 l C-V Measurement

Verify that all cables are of the proper type and not of

1.

excessive length.

Verify the integrity of all cable shields, and that the

2.

shield connections are carried through to the

connectors.

Again, make sure the procedure is being performed in

3.

the probe-up configuration.

User’s Guide Model 824VlN Simultaneous C-V

Page 16

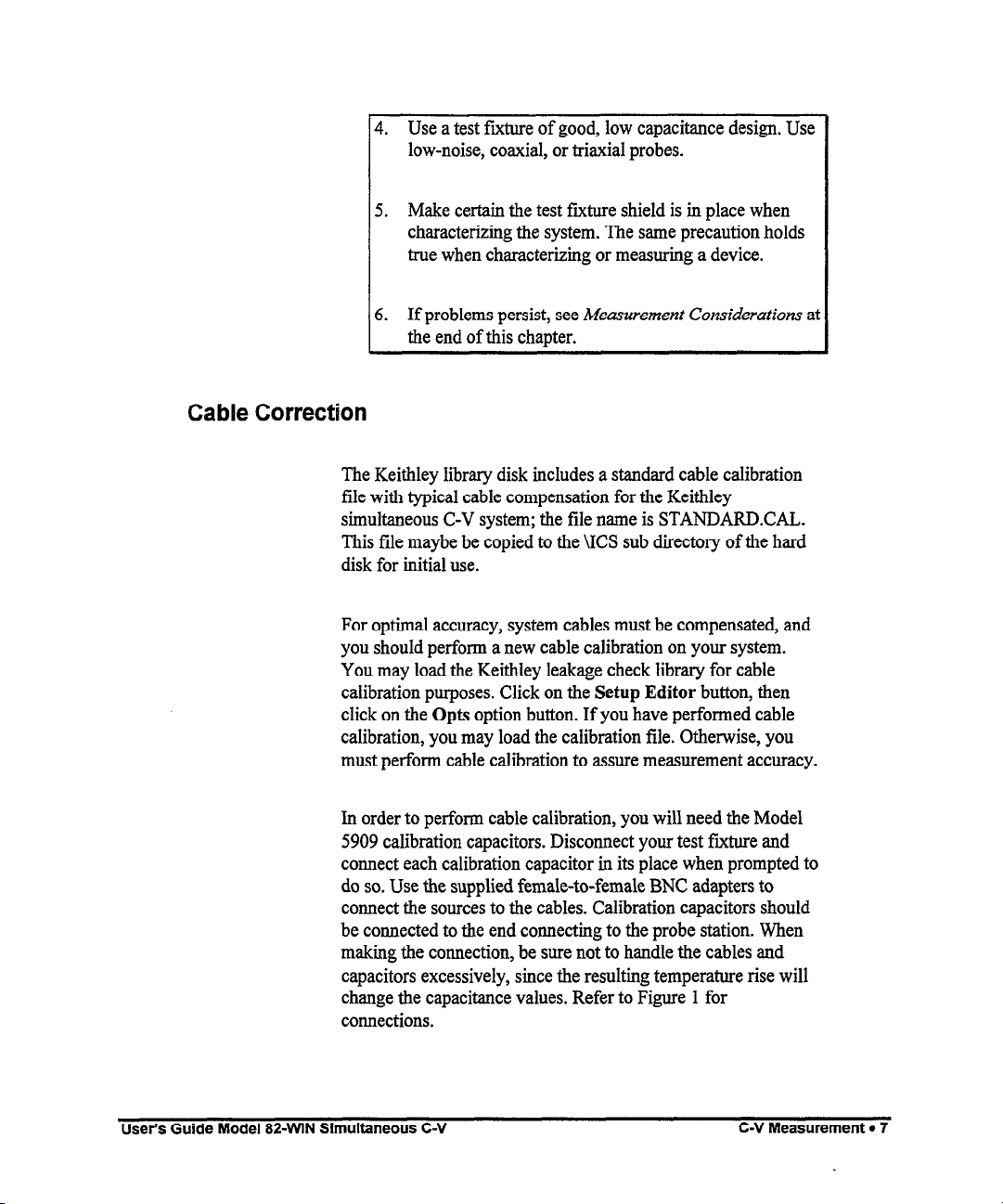

Cable Correction

The Keithley library disk includes a standard cable calibration

file with typical cable compensation for the Keithley

simultaneous C-V system; the tile name is STANDARDCAL.

This file maybe be copied to the UCS sub directory of the hard

disk for initial use.

For optimal accuracy, system cables must be compensated, and

you should perform a new cable calibration on your system.

You may load the Keithley leakage check library for cable

calibration purposes. Click on the Setup Editor button, then

click on the Opts option button. If you have performed cable

calibration, you may load the calibration file. Otherwise, you

must perform cable calibration to assure measurement accuracy.

4. Use a test fixture of good, low capacitance design. Use

low-noise, coaxial, or triaxial probes.

5. Make certain the test fucture shield is in place when

characterizing the system. The same precaution holds

true when characterizing or measuring a device.

6. If problems persist, see Measurement Considerations at

the end of this chapter.

In order to perform cable calibration, you will need the Model

5909 calibration capacitors. Disconnect your test future and

connect each calibration capacitor in its place when prompted to

do so. Use the supplied female-to-female BNC adapters to

connect the sources to the cables. Calibration capacitors should

be connected to the end connecting to the probe station. When

making the connection, be sure not to handle the cables and

capacitors excessively, since the resulting temperature rise will

change the capacitance values. Refer to Figure 1 for

connections.

User’s Guide Model 82WlN Simultaneous C-V

C-V Measurement l 7

Page 17

5951

Remote Input Coupler

to sa%rssmElNFvrauRER

Figure 1

Cable Correction Capacitor Connecfions

Performing Cable Correction

1.

Click on the Calibration button, and the cable

calibration window shown in Figure 2 will be

displayed.

2.

Select the frequency and range you want to calibrate,

then follow the prompts to connect the calibration

capacitors to the cable.

3.

Once calibration is finished, the screen should appear

as shown in Figure 3.

8 l C-V Measurement

User’s Guide Model 82-WIN Simultaneous C-V

Page 18

4. Save this file as CABLE.CAL or the name you prefer.

Note that the file extension must be .CAL.

5. Now load the calibration file, then exit the Opts

window. You should now be in the Setup editor.

6. Click the Done button to exit SetuD.

Current calibration filename

Calibration file

Low CAP @f) :

High CAP

KO, Real

KO,

Kl, Real :

Kl, lmag :

hag

(~9 :

:

:

595 Display

Figure 2

1.

1 kHr -: rjl oakliz

fas1.933 I 1461.97 I 1462.4 1

Options Setup window

”

;,.,, I <..i^ ‘.:

I

,nlMht

Figure 3

User’s Guide Model 82-WIN Simultaneous C-V

System Cable Calibration window

C-V Measurement l 9

Page 19

Measurement Procedures

Detailed information about properly configuring your system

can be found in Metrics ICS and Keithley Instruments C-V

driver manuals. Here, only a brief summary related to Keithley

C-V system is provided. An example of making a simultaneous

C-V measurement is outlined.

GPIB Configuration

Once the GPIE3 board is properly installed and tested, click on

the GPIB button on the menu strip. You should select the GPIB

card installed in your computer (see Figure 4). Note that the

GPIB Timeout option must be set to at least two times the

expected maximum sweep delay time, or a GPIB timeout error

may occur.

WPE

.

:

-“‘I

IO. C-V Measurement

Sub-Type

IKI KMCX38.2

Oj#i 0 ns:

Timeout

30 sect

Delay

No Delay

Figure 4

q

Iail

@!I

ED &ddr

]

I

Cl Show Messages

q

Show bog

Communicafions Setup Window

User’s Guide Model 824VlN Simultaneous C-V

Page 20

Instrument Selection

You may have installed several Keithley instrument drivers with

your Metrics core. You can make a selection here, such as a

K182 Simultaneous C-V system. Alternatively, you can select

KI23x I-V, KU90 High Frequency C-V, and KI595 Quasistatic

C-V instruments.

Instrument Setup

1.

Click the Connect button to select the K182 driver.

GPIB bus address menu appears when you click the

Configuration button.

2.

Type in the corresponding primary address for each

instrument.

3.

Click the Verify button to test if instruments are

correctly configured. If they are not correctly

configured, an error message will appear. Otherwise,

the following message will be displayed: “The system

is correctly configured.”

4.

Once the system is correctly configured, ICS will

automatically store the configuration. After this

procedure, the configuration step need not be run again

unless the instrument configuration changes.

1. Click on the Setup button; the instrument setup editor

window will appear. (See Figure 5.)

The

2. Click on New, and the program will prompt you to

type in the Setup name.

User’s Guide Model 824MN Simultaneous C-V

C-V Measurement l 11

Page 21

You may

select many different devices. For this

example, select the MOSFET icon.

Click on Source Unit, then click on K182 IN to select

the input.

Click on the G (gate) on the MOSFET symbol to

connect the input to the gate.

Similarly, click on KI82.OUT to select the output,

then click on the B (substrate) symbol of the MOSFET

to connect the output to the substrate.

Click on the W82 OUT icon; the measurement

parameter setup window will appear. (See Figure 6.)

You may now select the proper measurement

parameters. The parameter window should appear like

the one shown in the Figure 6. Refer to the Metrics ICS

and Keithley C-V driver manuals for full details on all

setup parameters.

12 * C-V Measurement

Before you make a measurement, be sure to load the

cable correction and calibration file. To do so, click on

the Opts. button in the Setup Editor, then click on

Load option to select the calibration file for your test

fucture.

Exit from the Opts. window and the Setup Editor

window.

User’s Guide Model 824VlN Simuttandous C-V

Page 22

Figure 5 instrument Setup Editor Window

Stimulus

Bulkhbstrate voltage

Mode: -1

Start (V) :

stop [v] :

Step (VI :

No. Points

Delay (s) :

Time measurement bias

Bias voltage : 14

User’s Guide Model 82-WIN Simultaneous C-V

a

12

10.5 1

Figure 6

Measure

q cs:

q GorR:)G~

•I Vsub :

-

q t?/t:

i?iT:

Range

590: p-i@/

595: 12°F

1

lvsuB

r--l

I

Measurement Setup Parameter Window

Options

Model

@Parallel 0 Series

I

m

C-V Measurement l 13

Page 23

Making C-V Measurements

. The zero cancel procedure described below will correct

system leakage and stray capacitance. Note that large

leakage current or stray capacitance should not be

suppressed. Determine the source of the problems, and

correct them before using your system.

!. Click on the Meas. button, and note there are several

options from which to choose. (See Figure 7.)

;. Before you make measurements, you should do a

probe-up zero suppress by clicking on the Zero Cancel

button and following the instructions.

C. After the zero cancel procedure, the message “Please

lower your probe” will be displayed on the screen.

During this period, the Model 590 C-V meter is in its

active reading mode, and you may lower your probe to

contact the DUT while at same time observing the

Model 590 display reading. Doing so ensures proper

electrical contact between the probe and DUT.

14 0 C-V Measurement

i. You are now ready to make a C-V measurement. For

this example, click on the Single button to make a

single-sweep measurement. You may observe that

when instrument finishes data taking, the data screen

will flicker a few times. This situation is normal while

ICS is updating the data. If the analysis package has

been loaded, it make take some time to perform the

calculations and display the data, depending on the

amount of data and the speed of your computer.

User’s Guide Model 824VlN Simultaneous C-V

Page 24

Analyzing Data

Before you attempt to analyze data, you should plot raw dam

and determine if there are any obvious measurement problems.

Keep in mind that no analysis will compensate for substandard

system-related problems and select better measurement

parameters. If a large amotmt of noise is present, analysis results

will not be dependable and may even be meaningless. Repeat

the measurement procedure to determine the root cause of the

problems, and correct them before proceeding.

Figure 7

Measurement Selection Window

data caused by measurement problems. At this time, you may

find it necessary to make a few adjustments to compensate for

The first step is to transfer the analysis constants to

Metrics. Click on the Transform Editor button, then

the name, value, unit, and comments into the fields.

User’s Guide Model 82WlN Simultaneous C-V

C-V Measurement 0 15

Page 25

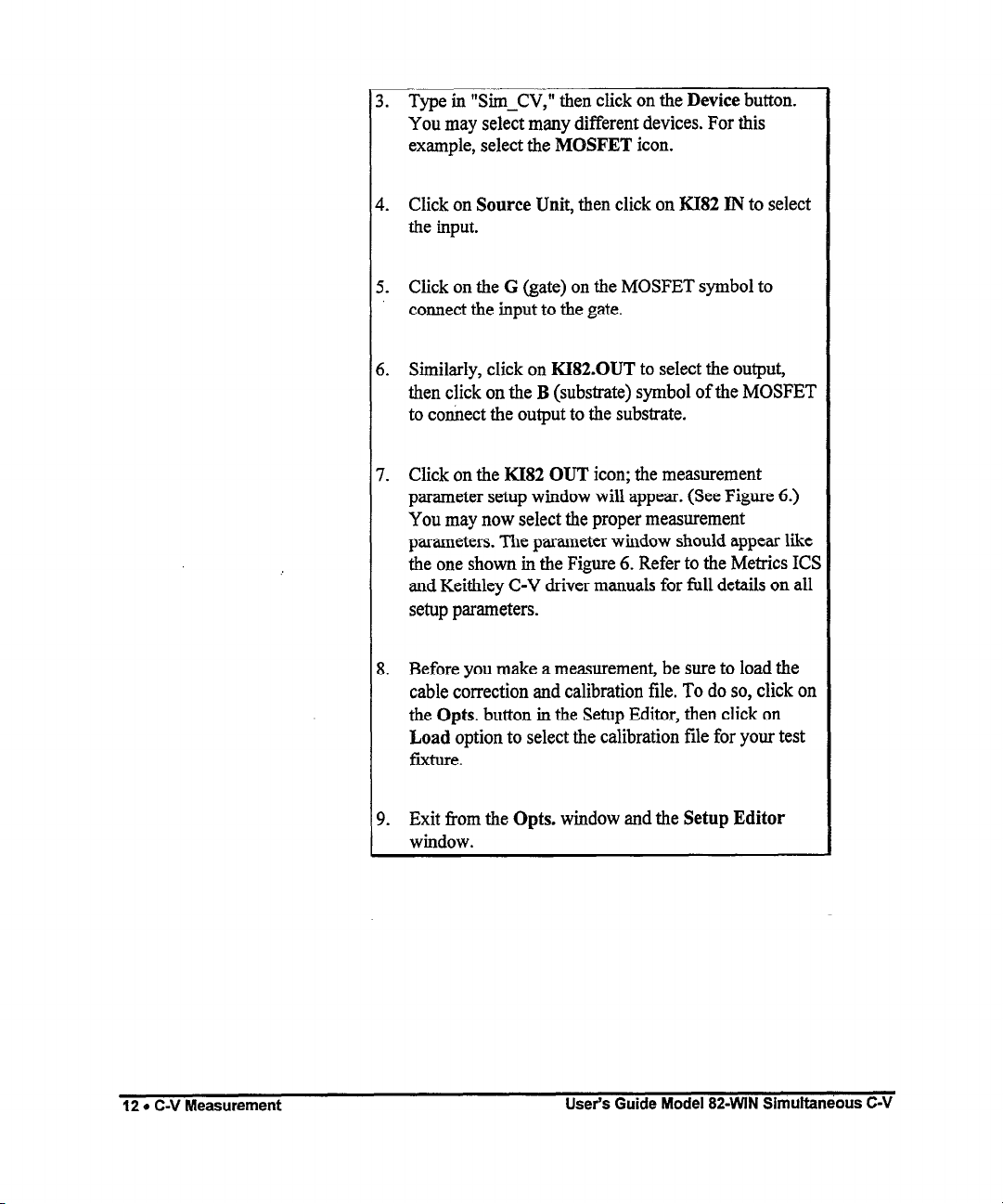

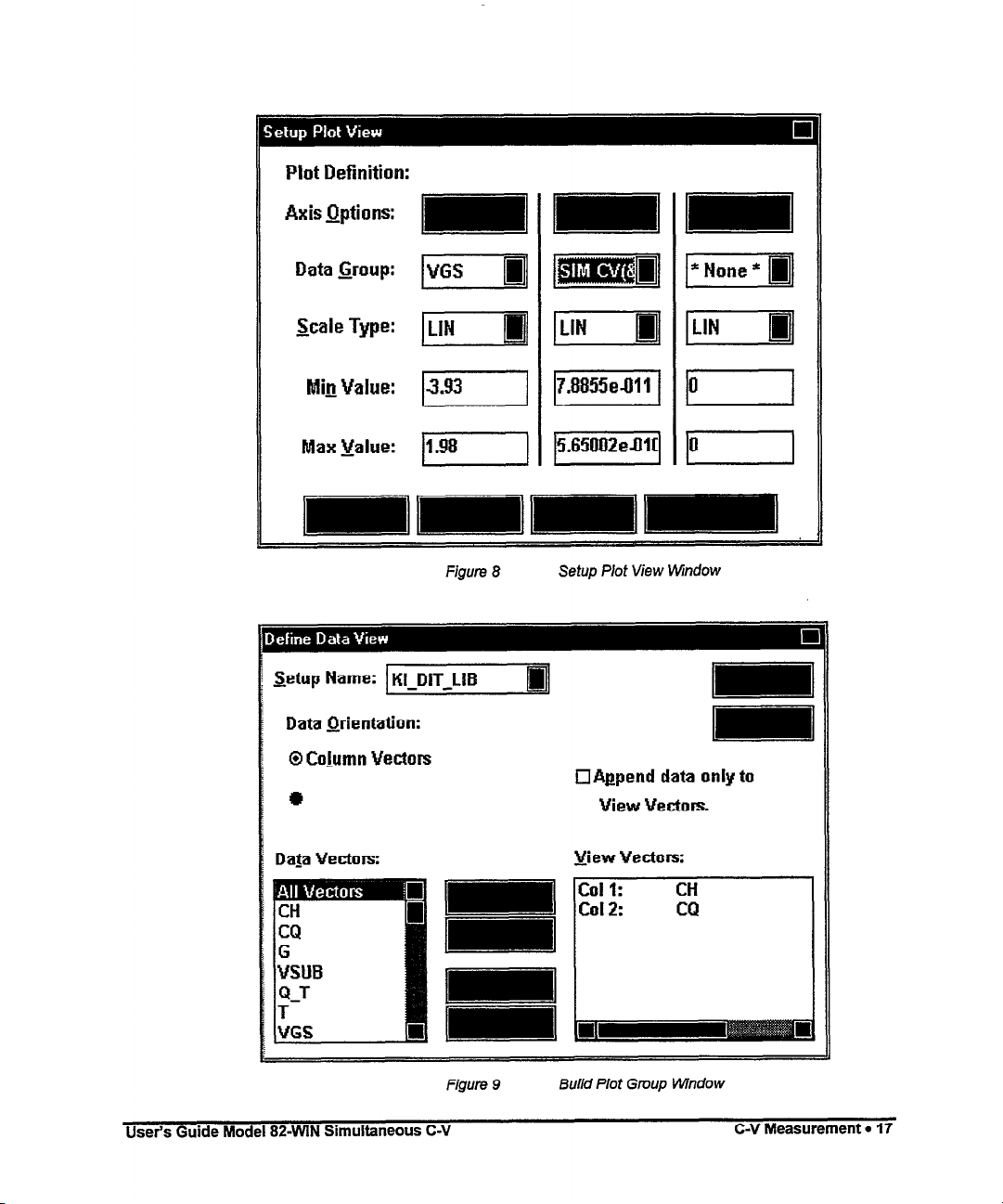

2.

Click on the New Plot button to draw a new graph.

The Setup Plot window will pop up. (See Figure 8.)

3.

Select the data option you wish to plot. For our

example, select Vsm as the X-Axis data parameter. Fo:

a simultaneous C-V measurement, plot both Cn and Cc

on the y-axis.

t.

You may select one data set to plot on the y axis.

Select the data you wish to plot on the Y l-Axis

column. If you wish to plot another data set on a

different scale but on the same graph, select that data

set for the Y2-Axis column.

j.

If you wish to plot two sets of dam on the same scale

you may use the Build Group feature. Click on the

Build Group button, and add both Cu and Co to the

group, for example Sim-CV. (See Figure 9.) After you

close this window, you will notice a Sim-CV group is

available under the y-axis sub-menu selection. Choose

Sim-CV for the y-axis.

18

l C-V

Measurement

i.

Click on Apply and then Done. You should see both

Co and C, curves plotted on the graph. By using the

Build Group feature of Metrics ICS, you can put many

curves on the same graph. Also notice that you can set

up a second y-axis with different scale and different

data set.

User’s Guide Model 82WlN Simultaneous C-V

Page 26

Plot Definition:

Axis Options:

Data Group:

Scale Type:

Min Value:

Max Value: 11.981

Setup Name: -1

Data Orientation:

Q Column Vectors

*

m-o]

-1

piz--l

Figure 8

Setup PIof View Mlindow

q

lAEpend data only to

View Vectors.

Data Vectors:

User’s Guide Model 82-WIN Simultaneous C-V

Figure 9

View Vectors:

Col 1: CH

Co12 CQ

Build Plot Group window

C-V Measurement. 17

Page 27

Choose the Right Parameters

Optimal C-V Measurement Parameters

Simultaneous C-V measurement is a complicated matter.

Besides system considerations, you should carefully choose the

measurement parameters. Refer to the following discussion for

considerations when selecting these parameters.

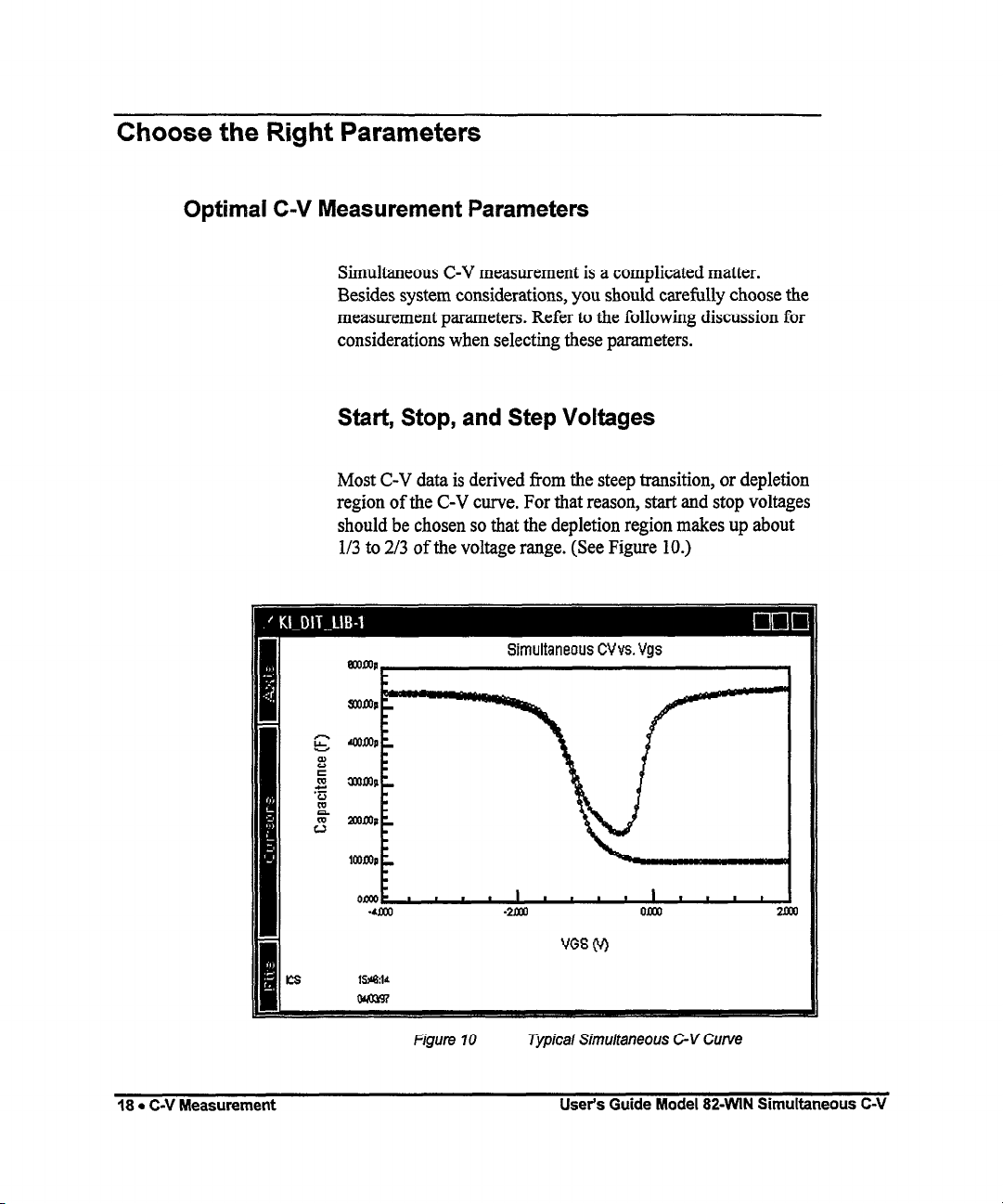

Start, Stop, and Step Voltages

Most C-V data is derived from the steep transition, or depletion

region of the C-V curve. For that reason, start and stop voltages

should be chosen so that the depletion region makes up about

113 to 213 of the voltage range. (See Figure 10.)

Simultaneous CVvs. Vgs

18 l C-V Measurement

VGS (‘4)

Figure 10 Typical Simultaneous C-V Curve

User’s Guide Model 824MN Simultaneous C-V

Page 28

The upper flat, or accumulation region of the high frequency

C-V curve defines the oxide capacitance, Cox. Since most

analysis relies on the ratio C/Cox, it is important that you

choose a start or stop voltage (depending on the sweep

direction) to bias the device into strong accumulation at the start

or the end of the sweep.

You should carefully consider the size of the step voltage. Start,

stop, and step size determine the total number of data points in

the sweep. Some compromise is necessary between having too

few data points in one situation, or too many data points in the

other.

For example, the complete doping profile is derived from data

taken in the depletion region of the curve by using a derivative

calculation. As the data point spacing decreases, the vertical

point scaling is increasingly caused by noise rather than changes

in the desired signal. Consequently, choosing too many points

in the sweep will result in increased noise rather than an

increased resolution in C-V measurement. It also takes more

time to perform a C-V sweep.

Many calculations depend on good measurements in the

depletion region, and too few dam points in this region will give

poor results. A good compromise results from choosing

parameters that will yield a capacitance change of

approximately ten times the percentage error in the signal.

Sweep Direction

For C-V sweeps, you can sweep either from accumulation to

inversion, or from inversion to accumulation. Sweeping from

accumulation to inversion will allow you to achieve deep

depletion-profiling deeper into the semiconductor than you

otherwise would obtain by maintaining equilibrium. When

sweeping from inversion to accumulation, you should use a

light pulse to achieve equilibrium more rapidly before the

sweep begins.

User’s Guide Model 82-WIN Simultaneous C-V

C-V Measurement l 19

Page 29

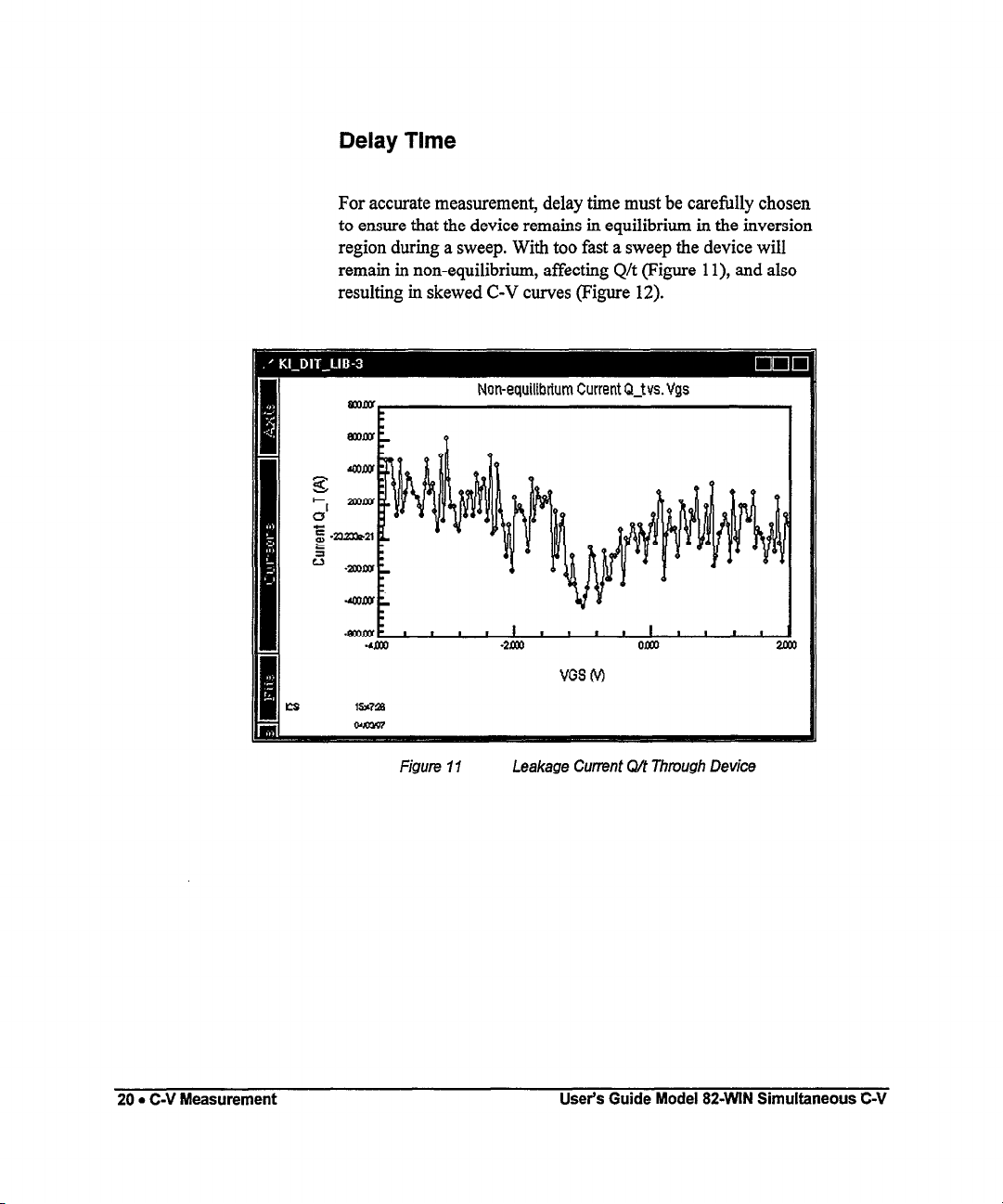

Delay Time

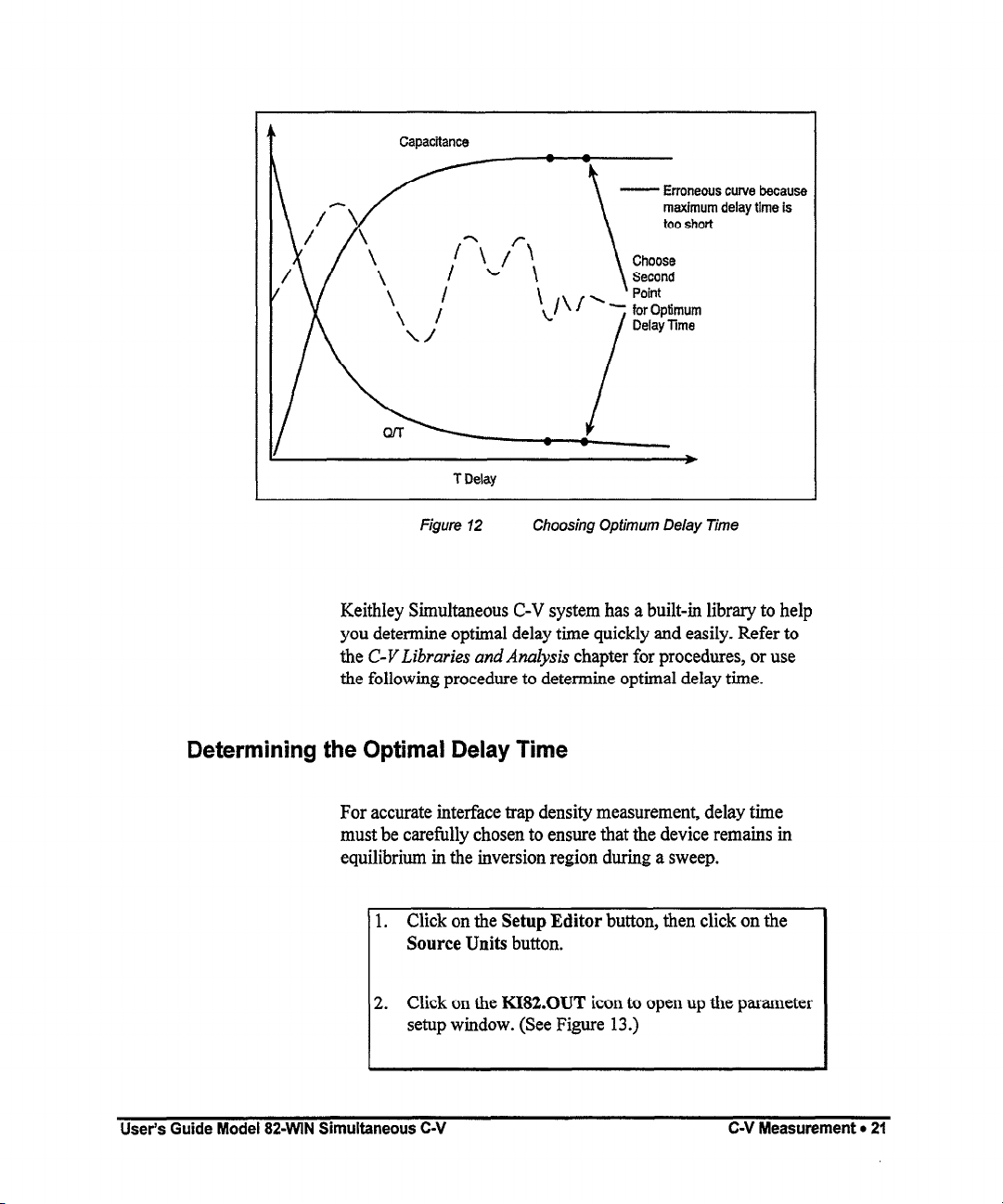

For accurate measurement, delay time must be carefully chosen

to ensure that the device remains in equilibrium in the inversion

region during a sweep. With too fast a sweep the device will

remain in non-equilibrium, affecting Q/t (Figure 1 l), and also

resulting in skewed C-V curves (Figure 12).

Non-equilihrium Current Q-tvs.Vgs

20. C-V Measurement

Figure 11

Leakage Current Q/t 77mugh Device

User’s Guide Model 82WN Simultaneous C-V

Page 30

Capacitance

T Delay T Delay

- Erroneous curve because - Erroneous curve because

maximum maximum delay time is delay time is

Figure 12 Figure 12

Choosing Optimum Delay Time Choosing Optimum Delay Time

Keithley Simultaneous C-V system has a built-in library to help

you determine optimal delay time quickly and easily. Refer to

the C-V Libraries and Analysis chapter for procedures, or use

the following procedure to determine optimal delay time.

Determining the Optimal Delay Time

For accurate interface trap density measurement, delay time

must be carefully chosen to ensure that the device remains in

equilibrium in the inversion region during a sweep.

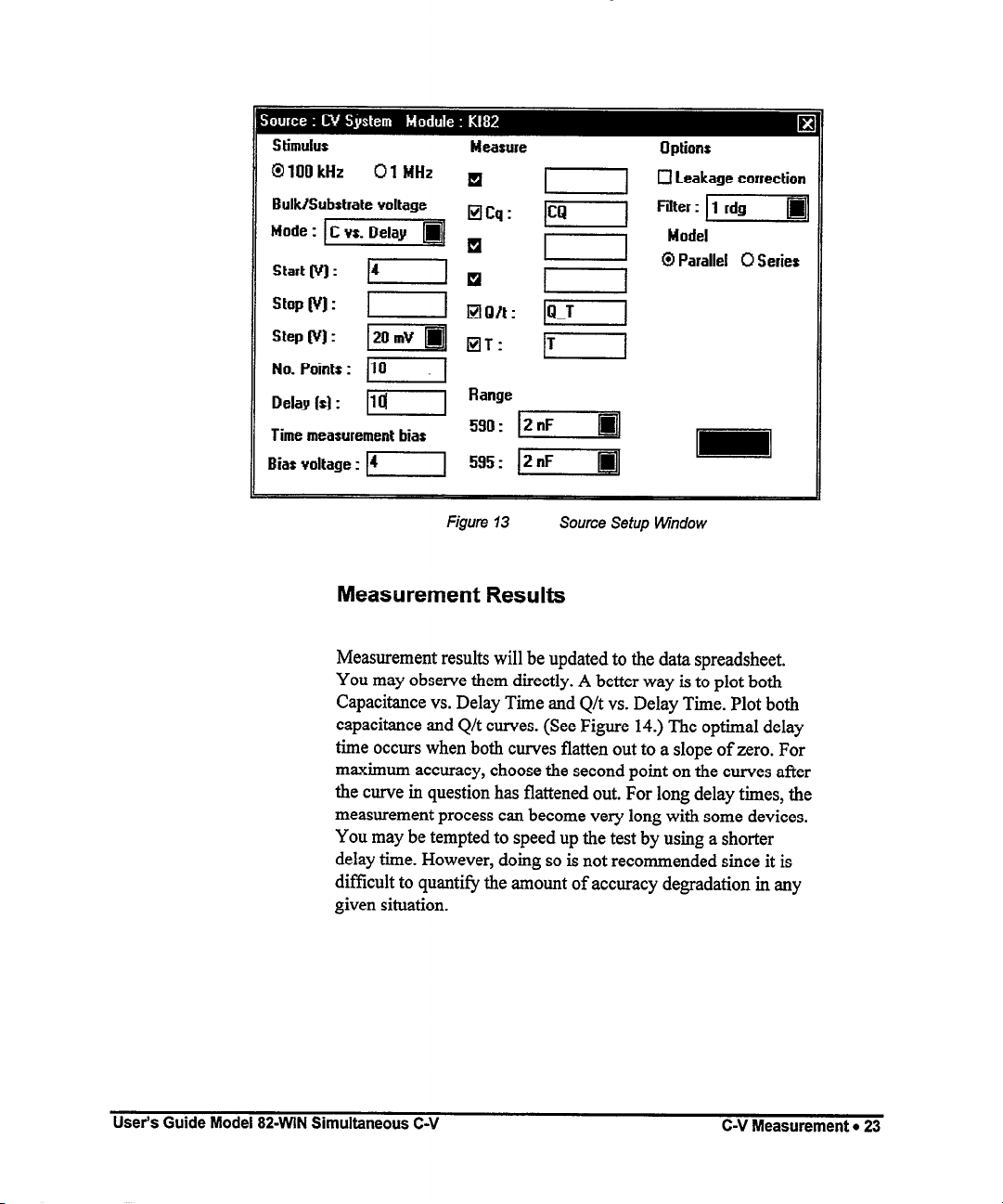

1. Click on the Setup Editor button, then click on the

Source Units button.

2. Click on the IU82.OUT icon to open up the parameter

setup window. (See Figure 13.)

User’s Guide Model 82JMN Simultaneous C-V

C-V Measurement l 21

Page 31

3.

In the Mode section, select the C vs. Delay t

measurement.

4.

Type in the Start voltage to specify the bias voltage on

the DUT during this measurement. Remember that the

DUT should be biased in the inversion region for this

measurement.

Type in the maximum delay times in the Delay (s) box.

5.

Note that the total measurement period will be several

times longer than the maximum delay time you select.

Other parameters should be selected according to your

6.

device under test as in the simultaneous C-V

measurement example.

Click on the OK button to exit from this window, then

7.

Click on the Done button to exit from the Setup

Editor.

Click on the Meas button, then click on the Single

8.

button to start the measurement.

22 0 C-V Measurement

User’s Guide Model 824MN Simultaneous C-V

Page 32

Stimulus

@I 100 kHz

BulklSubstrate voltage

Mode:

Start (V] :

stop (V] :

Step (V] :

No. Points : j-iii-q

Delay (s] :

Time measurement bias

Bias voltage I 14 1

01 MHz

JCvf.Delay

L--l

llol

Measure

R

Hcq:

R

R

q

Q/t: m

MT:

Range

Options

0 Leakage correction

PI

Figurn 13

Source Setup Window

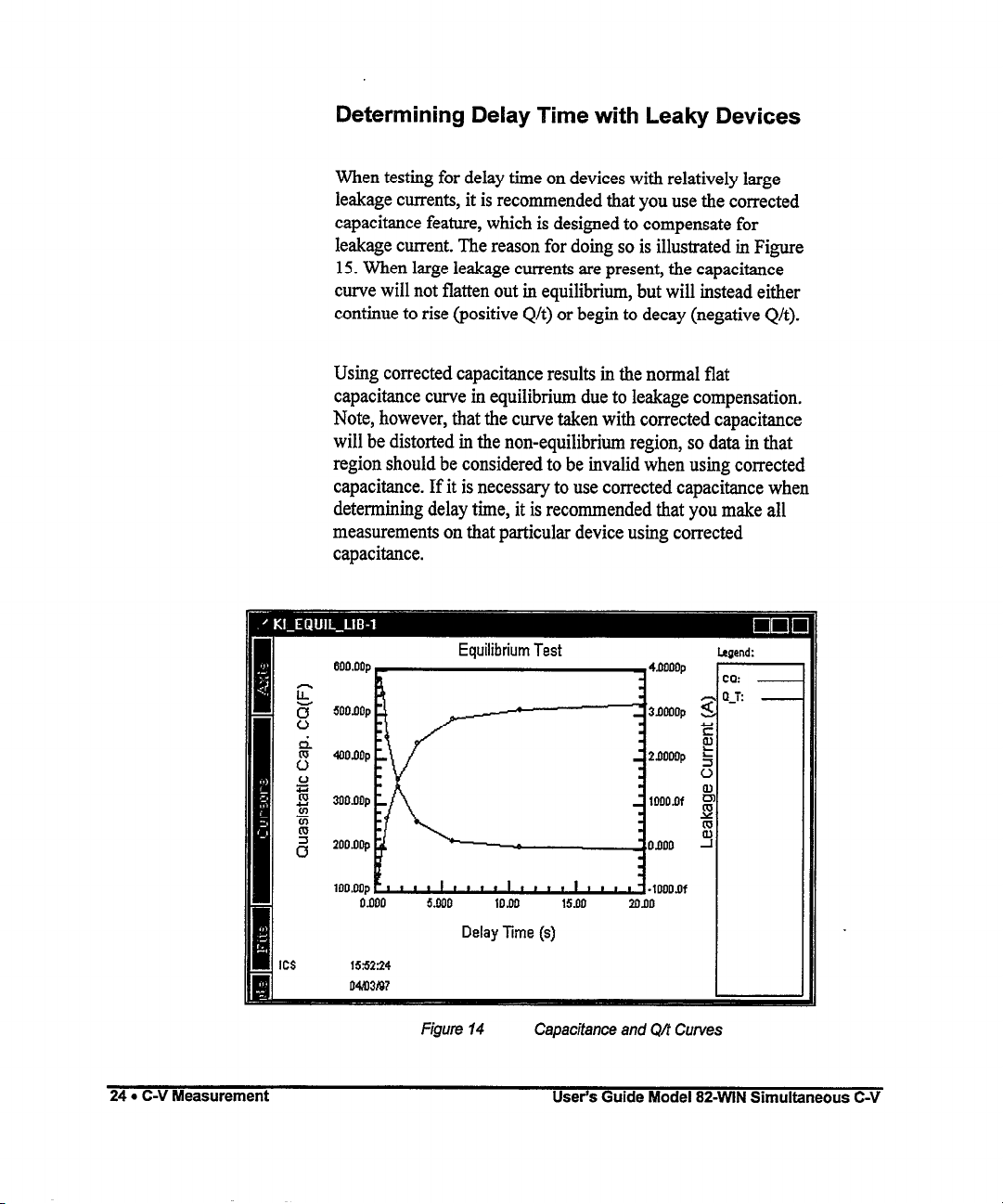

Measurement Results

Measurement results will be updated to the data spreadsheet.

You may observe them directly. A better way is to plot both

Capacitance vs. Delay Time and Q/t vs. Delay Time. Plot both

capacitance and Q/t curves. (See Figure 14.) The optimal delay

time occurs when both curves flatten out to a slope of zero. For

maximum accuracy, choose the second point on the curves after

the curve in question has flattened out. For long delay times, the

measurement process can become very long with some devices.

You may be tempted to speed up the test by using a shorter

delay time. However, doing so is not recommended since it is

difficult to quantify the amount of accuracy degradation in any

given situation.

User’s Guide Model 824MN Simultaneous C-V

C-V Measurement l 23

Page 33

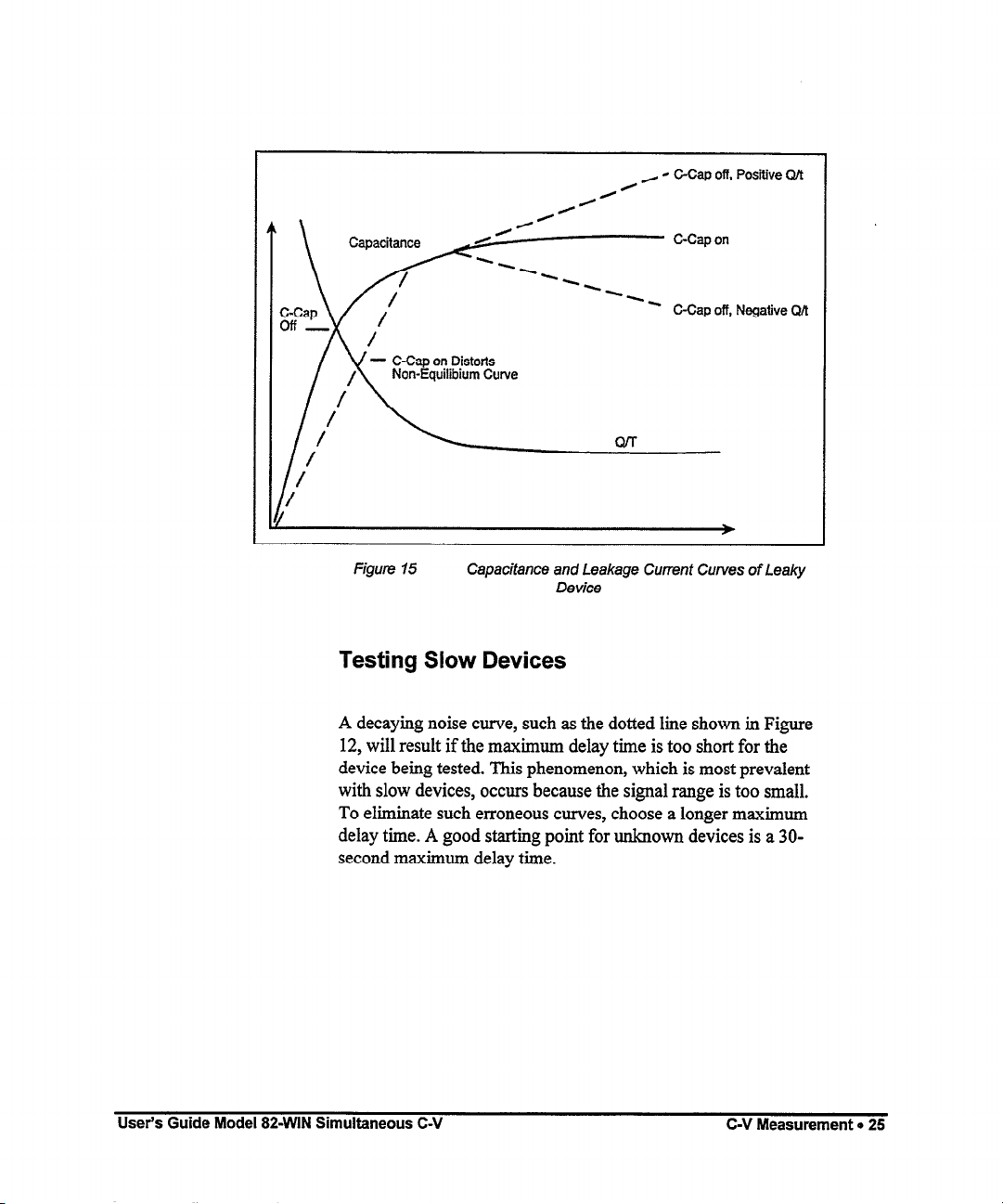

Determining Delay Time with Leaky Devices

When testing for delay time on devices with relatively large

leakage currents, it is recommended that you use the corrected

capacitance feature, which is designed to compensate for

leakage current. The reason for doing so is illustrated in Figure

15. When large leakage currents are present, the capacitance

curve will not flatten out in equilibrium, but will instead either

continue to rise (positive Q/t) or begin to decay (negative Q/t).

Using corrected capacitance results in the normal flat

capacitance curve in equilibrium due to leakage compensation.

Note, however, that the curve taken with corrected capacitance

will be distorted in the non-equilibrium region, so data in that

region should be considered to be invalid when using corrected

capacitance. If it is necessary to use corrected capacitance when

determining delay time, it is recommended that you make all

measurements on that particular device using corrected

capacitance.

24 l C-V Measurement

zj; fi-q-zq[;;

155224

04&3197

Figure 14

Equilibrium Test

5.Mtl ID.00

Delay Time (s)

Capacitance and Q/f Curves

Legend:

15.M 20.00

User’s Guide Model 82WlN Simultaneous C-V

Page 34

A’

A - C-Cap 137, Positive Q/t

.’

- c-capon

Negative Q/t

Figure 15

Capacifance and Leakage Current Curves of Leaky

Device

Testing Slow Devices

A decaying noise curve, such as the dotted line shown in Figure

12, will result if the maximum delay time is too short for the

device being tested. This phenomenon, which is most prevalent

with slow devices, occurs because the signal range is too small.

To eliminate such erroneous curves, choose a longer maximum

delay time. A good starting point for unknown devices is a 30second maximum delay time.

User’s Guide Model 82WlN Simultaneous C-V

C-V Measurement * 25

Page 35

Additional C-V Measurement Features

Besides making basic simultaneous C-V measurements, there

are other features available in the C-V system, including

squarewave, single staircase, double staircase, and Capacitance

vs. delay time.

Squarewave

The squarewave option lets you select a constant output bias

voltage. A squarewave will be output to make the measurement.

This feature may be useful for monitoring device change during

some time period. Under this option, you may select bias

voltage, squarewave step size, and time period.

Staircase

Single Staircase will let you sweep bias voltage in either

direction. The Double Staircase option will let you sweep in one

direction and then return to the original starting voltage. The

sweep step will be the same in both directions. Ideally, if the

DUT is in equilibrium during measurement, C-V curves should

not exhibit any hysteresis. Hence this option provides you with

another means of monitoring the device under test.

Capacitance vs. Delay Time

26 l C-V Measurement

The Capacitance vs. Delay Time option is very useful to help

determine the proper delay time. Detailed procedures are

provided in a previous section.

User’s Guide Model 824MN Simultaneous C-V

Page 36

Time Options

There are many different timing options for you to choose. For

details, refer to the section on Setup Editor and Measurement in

ICS and Keithley C-V driver manuals.

User’s Guide Model 82WlN Simultaneous C-V

C-V Measurement o 27

Page 37

Measurement Considerations

The importance of making careful C-V curve measurements is

often underestimated. However, errors in the C-V data will

propagate through calculations, resulting in errors in device

parameters derived t?om the curves. These errors can be

amplified during calculations by a factor of 10 or more.

With careful attention, the effects of many common error

sources can be miniiized. In the following paragraphs, we will

discuss some common error sources and provide suggested

methods for avoiding them.

Potential Error Sources

Theoretically, a capacitance measurement using one of the

common techniques would require only that two leads be used

to connect the measuring instrument to the device under test

(DUT)-the input and output. In practice, however, various

parasitic or stray components complicate the measuring circuit.

28. C-V Measurement

Stray Capacitances

Regardless of the measurement frequency, stray capacitances

present in the circuit are important to consider. Stray

capacitances can cause offsets when they are in parallel with the

device, can act as a shunt load on the input or output, or can

cause coupling between the device and nearby AC signal

sources.

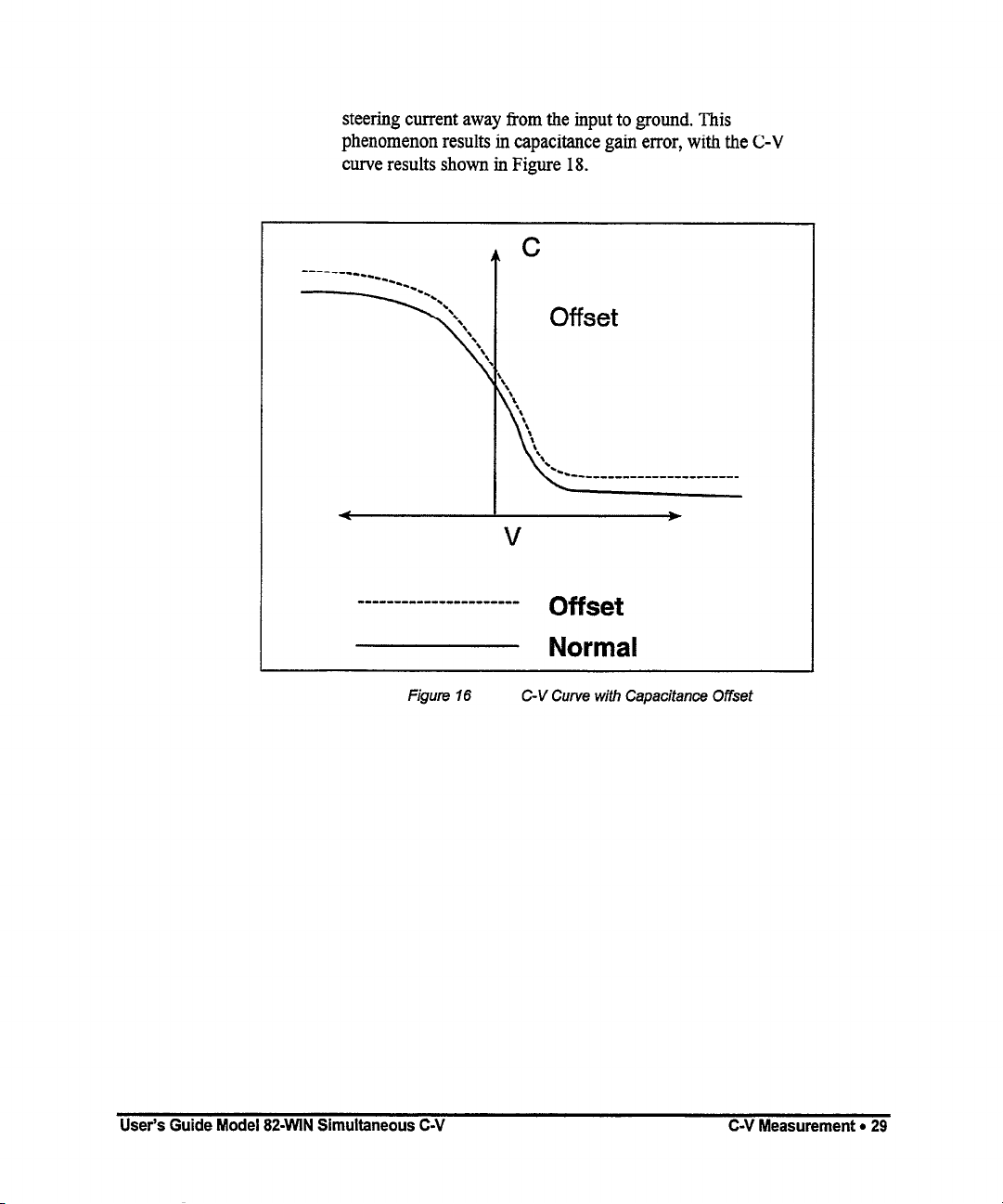

When stray capacitance is in parallel with the DUT, it causes a

capacitance offset, adding to the capacitance of the device under

test (CD,), as shown in Figure 16. Shunt capacitance, on the

other hand, often increases the noise gain of the instrumentation

amplifiers, increasing capacitance reading noise (Figure 17).

Shunt capacitance also forms a capacitive divider with Cuur,

User’s Guide Model 82-WIN Simultaneous C-V

Page 38

steering current away from the input to ground. This

phenomenon results in capacitance gain error, with the C-V

curve results shown in Figure 18.

-------------_-_---_-- offset

Normal

Figure 16 GV Curve with Capacitance Offset

User’s Guide Model 82-WIN Simultaneous C-V

C-V Measurement l 29

Page 39

Figure 17 C-V Curve wifh Added Noise

30 * C-V Measurement

4

I

V

___---_-----___----_--- With Gain Error

Normal

Figure ‘f8

GV Curve Resulting from Gain Ermr

User’s Guide Model 82-WIN Simultaneous C-V

*

Page 40

Stray capacitance may also couple charge current from nearby

AC signal sources into the input of the measuring instrument.

This noise current adds to the device current and results in noisy

or unrepeatable measurements. For quasistatic measurements,

power line frequency and electrostatic coupling are particularly

troublesome, while digital and RF signals are the primary cause

of noise induced in high-frequency measurements.

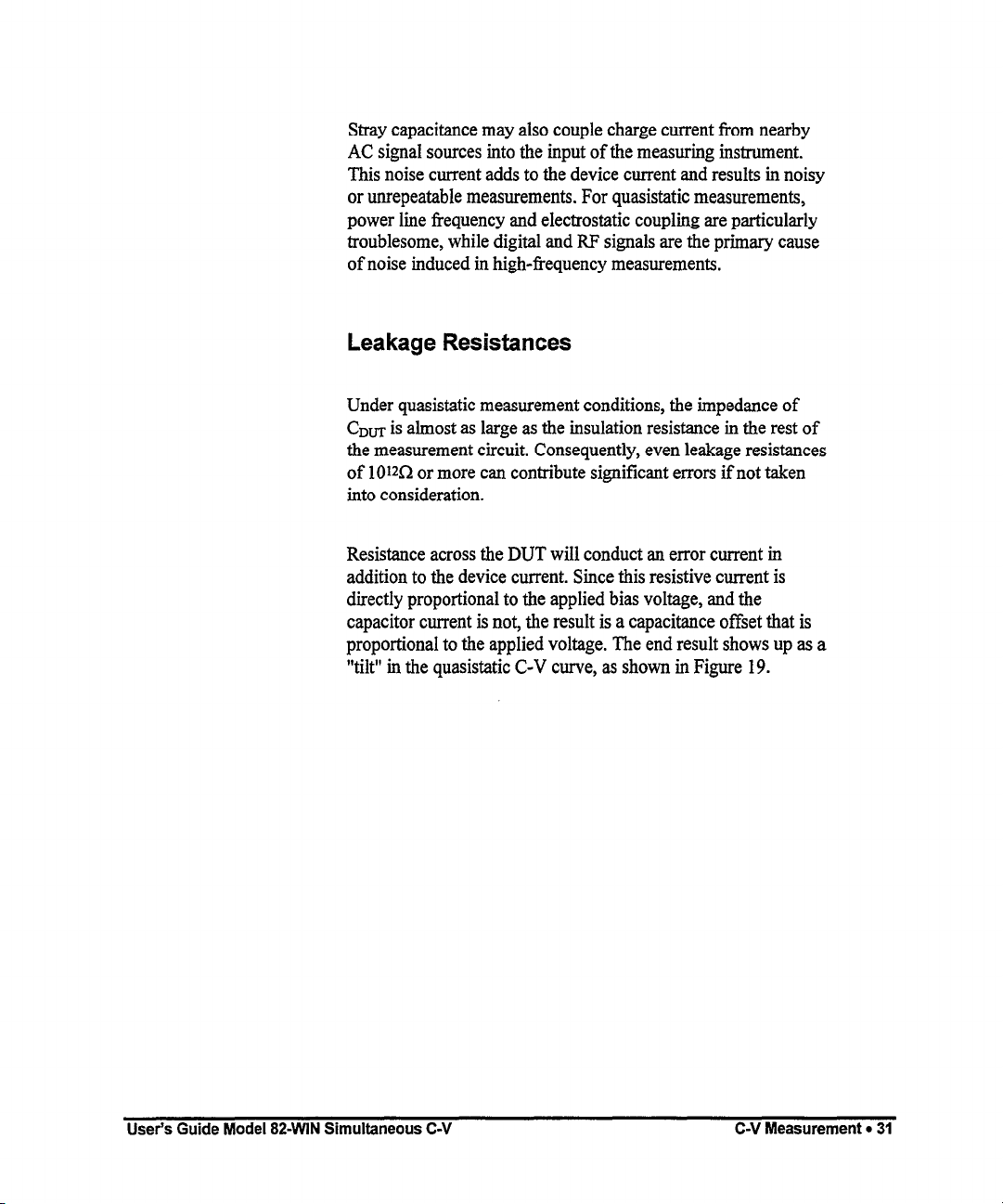

Leakage Resistances

Under quasistatic measurement conditions, the impedance of

CDm is almost as large as the insulation resistance in the rest of

the measurement circuit. Consequently, even leakage resistances

of 101X2 or more can contribute significant errors if not taken

into consideration.

Resistance across the DUT will conduct an error current in

addition to the device current. Since this resistive current is

directly proportional to the applied bias voltage, and the

capacitor current is not, the result is a capacitance offset that is

proportional to the applied voltage. The end result shows up as a

“tilt” in the quasistatic C-V curve, as shown in Figure 19.

User’s Guide Model 82-WIN Simultaneous C-V C-V Measurement l 31

Page 41

-------------- Titled Curve Caused by

Leakage

Normal

Figure 19

Curve 77/f Caused by Voltage-Dependent Leakage

Stray resistance to nearby fixed voltage sources results in a

constant (rather than a bias voltage-dependent) leakage current.

Other sources of constant leakage currents include instrument

input bias currents, and electrochemical currents caused by

device or future contamination. Such constant leakage currents

t cause a voltage-independent capacitance offset.

Keep in mind that insulation resistance is reduced, and leakage

current is increased by high humidity as well as by

contaminants. In order to minimize these effects, always keep

devices and test fuctures in clean, dry conditions.

High-frequency Effects

At measurement frequencies of approximately 1OOkHz and

higher, the impedance of Cour may be so small that any series

impedance in the rest of the circuit may cause errors, Whether

such series impedance is caused by inductance (such as from

32 l C-V Measurement

User’s Guide Model 82WlN Simultaneous C-V

Page 42

leads or probes), or from resistance (as with a high-resistivity

substrate), this series impedance causes non-linearity in the

measured capacitance. The resulting C-V curve is, of course,

affected by such non-linearity, as shown in Figure 20.

-------------- With Nonlinearity

Normal

Figure 20 GV Curve Caused by Nonlinearity

Another high-frequency effect is caused by the AC network

formed by the instrumentation, cables, switching circuits, and

the test fuctures. Referred to as transmission line error sources,

the network essentially transforms the impedance of Cum when

it is referred to the input of the instrument, altering the

measured value. Transmission line effects alter the gain and

produce non-linearities.

User’s Guide Model 82JMN Simultaneous C-V

C-V Measurement l 33

Page 43

Avoiding Capacitance Errors

Many possible error sources that can affect C-V measurements

may seem overwhelming at times, but careful attention to a few

key details will reduce errors to an acceptable level. Once most

of the error sources have been minimized, any residual errors

can be further reduced by using the probe-up suppression and

corrected capacitance features.

Key details that require attention include use of proper cabling

and effective shielding. These important aspects are discussed

below.

Cabling Considerations

Cables must be used to connect the instruments to the device

under test. Ideally, these cables should supply the test voltage to

the device unaltered in any way. The test voltage is converted

into a current or charge in the DUT, and should be carried back

to the instruments undisturbed. Along the way, potential error

sources must be minimized.

34 l C-V Measurement

Coaxial cable is usually used in order to eliminate stray

capacitance between the measurement leads. The cable shield is

connected to a low-impedance point (guard) that follows the

meter input. This technique, known as the three-terminal

capacitance measurement, is almost universally used in

commercial instrumentation. The shield shunts current away

f?om the input to the guard.

Coaxial cables also serve as smooth transmission lines to carry

high-frequency signals with minimal attenuation. For this

reason, the cable‘s characteristic impedance should closely

match that of the instrument input and output, which is usually

50R. Standard RG-58 cable is adequate for frequencies in the

range of &Hz to more than 1 OMHz. High-quality BNC

User’s Guide Model 824MN Simultaneous C-V

Page 44

connectors with gold-plated center conductors reduce errors

from high series contact resistance.

Quasistatic C-V measurements are susceptible to shunt

resistance and leakage currents as well as to stray capacitances.

Although coaxial cables are still appropriate for these

measurements, the cables should be checked to ensure that the

insulation resistance is sufficiently high (>lOK2 ). Also, when

such cables are flexed, the shield rubs against the insulation,

generating small currents due to triboelectric effects. These

currents can be minimized by using low-noise cable (such as the

Model 480 1) that is lubricated with graphite to reduce friction

and to dissipate generated charges.

Flex-producing vibration should be eliminated at the source

whenever possible. If vibration cannot be entirely eliminated,

cables should be securely fastened to prevent flexing.

One final point regarding cable precautions is in order: Cables

can only degrade the measurement, not improve it. Thus, cable

lengths should be miniiized where possible, without straining

cables or connections.

Device Connections

Care in properly protecting the signal path should not stop at the

cable ends where the connection is made to the DUT future. In

fact, the device connection is an extremely important aspect of

the measurement. For the same reasons given for coaxial cables,

it is best to continue the coaxial path as close to the DUT as

possible by using coaxial probes. Also, it is important to

minimize stray capacitance and maximum insulation resistance

in the pathway from the end of the coaxial cable to the DUT.

Most devices have one terminal that is well insulated from other

conductors, as in the gate of an MOS test dot. The input should

be connected to the gate because it is more susceptible to stray

signals than is the output. The output can better tolerate being

connected to a terminal with high shunt capacitance, noise, or

User’s Guide Model 82WlN Simultaneous C-V

C-V Measurement l 35

Page 45

poor insulation resistance, although these characteristics should

still be optimized for best results.

Test Fixture Shielding

At the point where the coaxial cable shielding ends, the

sensitive input node is exposed, inviting error sources to

interfere. Proper device shielding need not end with the cables

or probes, however, if a shielded test fixture is used.

A shielded furture, sometimes known as a Faraday cage,

consists of a metal enclosure that completely surrounds the

DUT and leads. In order to be effective, the shield must be

electrically connected to the coaxial shield. Typically, bulkhead

connectors are mounted to the side of the cage to bring in the

signals. Coaxial cables should be continued inside, if possible,

or individual input and output leads should be widely spaced in

order to maintain input/output isolation.

Correcting Residual Errors

36 l C-V Measurement

Controlling errors at the source is the best way to optimize C-V

measurements, but doing so is not always possible. Remaining

residual errors include offset, gain, noise, and voltagedependent errors. Ways to deal with these error sources are

discussed in the following paragraphs.

Offsets

Offset capacitance and conductance caused by the test apparatus

can be eliminated by performing a suppression with the probes

in the up position. These offsets will then be nulled out when

the measurement is made. Whenever the system configuration is

changed, the suppression procedure should be repeated. For

maximum accuracy, it is recommended that you perform a

probes-up suppression or at least verify prior to every

measurement.

User’s Guide Model 82-WIN Simultaneous C-V

Page 46

Gain and Nonlinearity Errors

Gain errors are difficult to quantify. For that reason, gain

correction is applied to every measurement. Gain constants are

determined by measuring accurate calibration sources during

the cable correction process.

Nonlinearity is normally more difficult to correct for than are

gain or offset errors. The cable correction utility, however,

provides nonlinearity compensation for high-frequency

measurements, even for non-ideal configurations such as

switching matrices.

Voltage-dependent Offset

Voltage-dependent offset (curve tilt) is the most difficult to

correct error associated with quasistatic C-V measurements. It

can be eliminated by using the corrected capacitance function of

the software. In this technique, the current flowing in the device

is measured as the capacitance value is measured. The current is

known as Q/t because its value is derived from the slope of the

charge integrator waveform. Q/t is used to correct capacitance

readings for offsets caused by shunt resistance and leakage

currents.

Care must be taken when using the corrected capacitance

feature, however. When the device is in non-equilibrium, device

current adds to any leakage current, with the result that the

curve is distorted in the non-equilibrium region. The solution is

i0 keep ‘the uevice m equumrmm mrougnout me sweep by

carefully choosing the delay time.

>--.I-- :- _ -.-llll...I.-... II. .~~ -1~ --a Ll

Curve Misalignment

User’s Guide Model 824MN Simultaneous C-V

C-V Measurement l 37

Page 47

At times, quasistatic and high frequency curves may be slightly

misaligned due to gain errors or external factors. In such cases,

curve gain and offset factors can be applied to the curves to

properly align them..

Noise

Residual noise on the C-V curve can be minimized by using

filtering when taking your data. However, the filter will reduce

the sharpness of the curvature in the transition region of the

quasistatic curve depending on the number of dam points in the

region. This change in the curve can cause

resulting in erroneous Dn calculations. If this situation occurs,

turn off the filter or add more dam points.

Interpreting C-V Curves

Even when all the precautions outlined here are followed, there

are still some possible obstacles to successfully using C-V

curves to analyze semiconductor devices.

CQ

to dip below Cu

38. C-V Measurement

Semiconductor capacitances are far from ideal, so care must be

taken to understand how the device operates. Also, the curves

must be generated under well-controlled test conditions that

ensure repeatable, analyzable results.

Maintaining Equilibrium

The condition of the device when all internal capacitances are

fully charged is referred to as equilibrium. Most quasistatic and

high-frequency C-V curve analysis is based on the simplified

assumption that the device is measured in equilibrium. Internal

RC time constants limit the rate at which the device bias may be

swept while maintaining equilibrium. They also determine the

hold time required for device settling after setting the bias

voltage to a new value before measuring C&r.

User’s Guide Model 82JMN Simultaneous C-V

Page 48

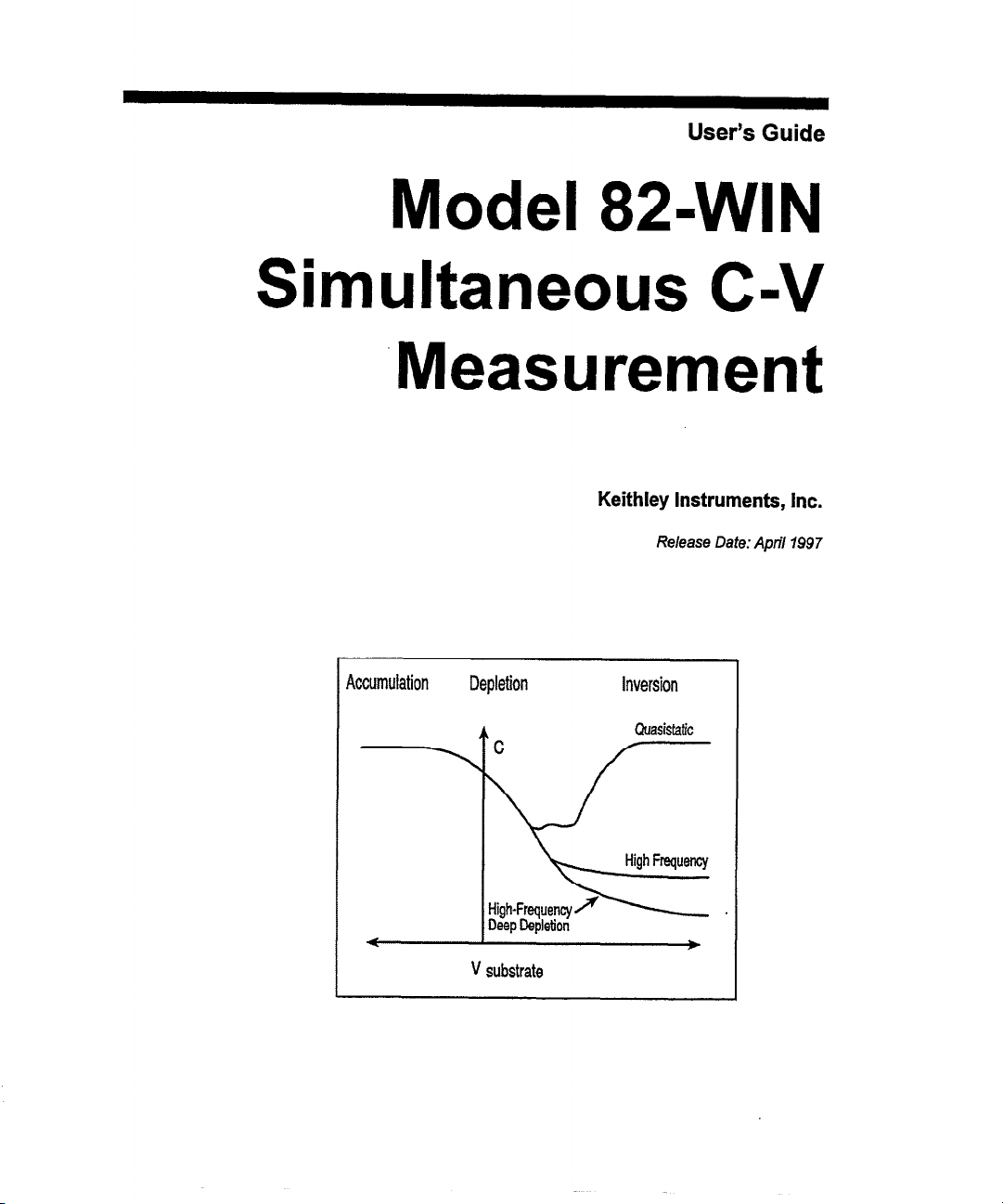

The two main measurement parameters that affect equilibrium,

then, are the bias sweep rate and the hold time. When these

parameters are set properly, the normal C-V curves shown in

Figure 2 1 result. Once the proper sweep rate and hold time have

been determined, it is important that all curves compared with

one another be measured under the same test conditions;

otherwise, it

may

be the parameters, not the devices themselves,

that cause the compared curves to differ.

Accumulation

Deep Depletion

V substrate

/=igm 21

Inversion

Quasistatic

High Frequency

Normal C-V Curves

User’s Guide Model 82JMN Simultaneous C-V

C-V Measurement l 39

Page 49

Analyzing Curves for Equilibrium

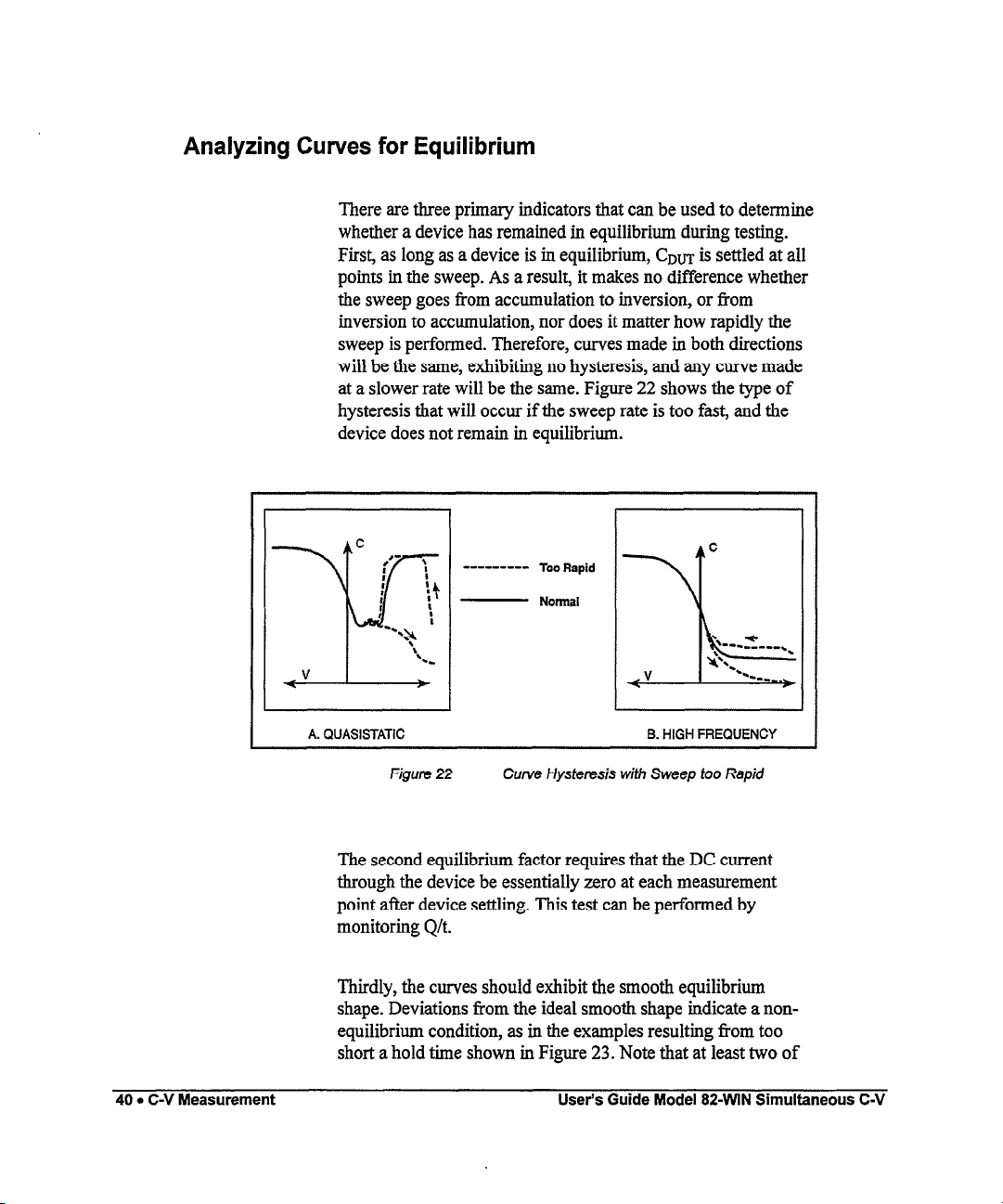

There are three primary indicators that can be used to determine

whether a device has remained in equilibrium during testing.

First, as long as a device is in equilibrium, CD~JT is settled at all

points in the sweep. As a result, it makes no difference whether

the sweep goes tiom accumulation to inversion, or from

inversion to accumulation, nor does it matter how rapidly the

sweep is performed. Therefore, curves made in both directions

will be the same, exhibiting no hysteresis, and any curve made

at a slower rate will be the same. Figure 22 shows the type of

hysteresis that will occur if the sweep rate is too fast, and the

device does not remain in equilibrium.

c

Normal

‘L-2 ---.

+

foo

%.

Rapid

V

L

A. QUASISTATIC B. HIGH FREQUENCY

Figure 22

Curve Hysteresis with Sweep

.

---

The second equilibrium factor requires that the DC current

through the device be essentially zero at each measurement

point after device settling. This test can be performed by

monitoring Q/t.

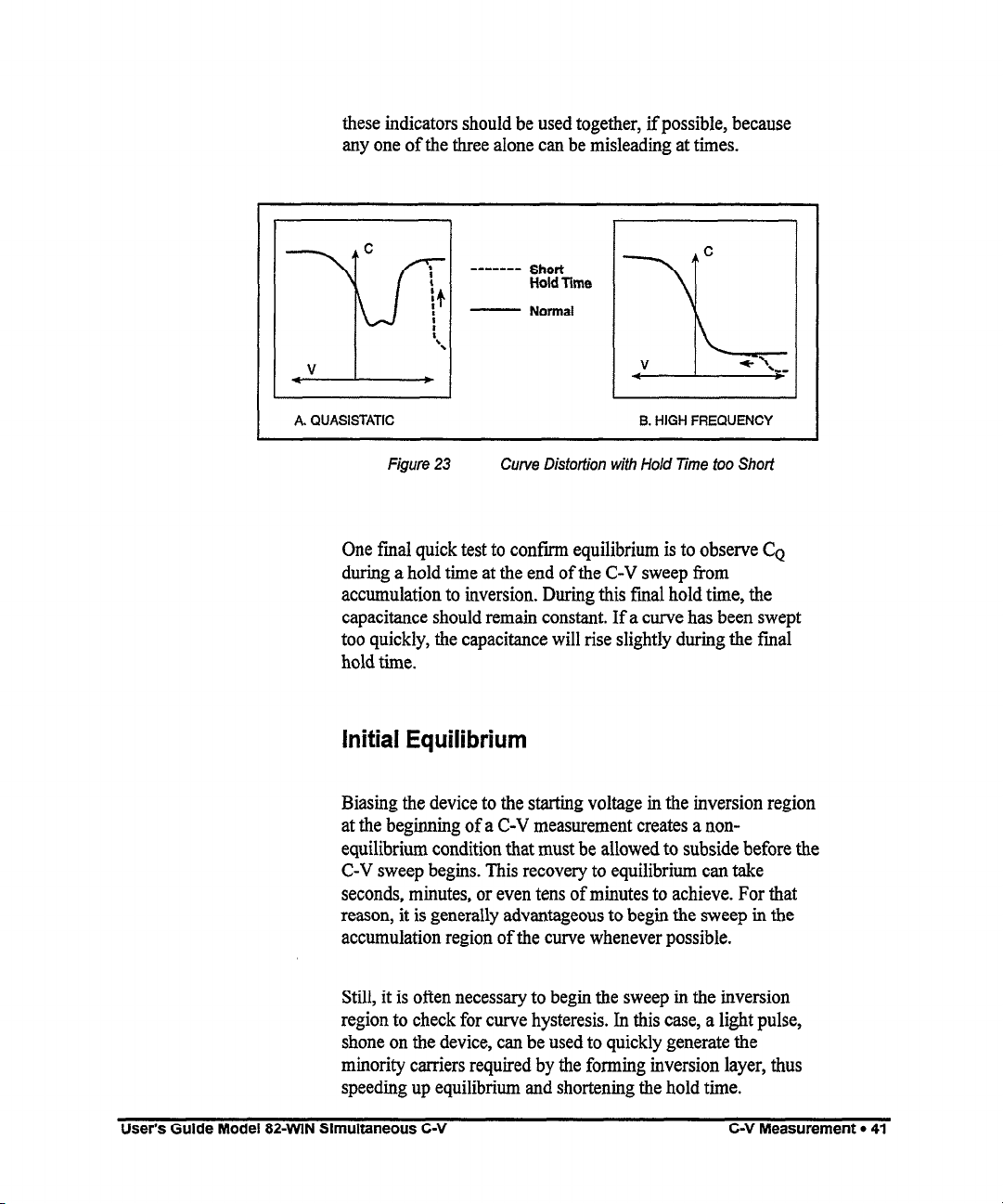

Thirdly, the curves should exhibit the smooth equilibrium

shape. Deviations from the ideal smooth shape indicate a non-

equilibrium condition, as in the examples resulting from too

short a hold time shown in Figure 23. Note that at least two of

40. C-V Measurement User’s Guide Model 82-WIN Simultaneous C-V

Page 50

these indicators should be used together, if possible, because

any one of the three alone can be misleading at times.

I 1

C

- Normal

V

I

A. QUASISTATIC

Figure 23

One final quick test to confvm equilibrium is to observe

during a hold time at the end of the C-V sweep from

accumulation to inversion. During this fmal hold time, the

capacitance should remain constant. If a curve has been swept

too quickly, the capacitance will rise slightly during the final

hold time.

Curve Disfortion wifh Hold Time too Short

Initial Equilibrium

Y!z

0. HIGH FREQUENCY

f- ‘8,

CQ

Biasing the device to the starting voltage in the inversion region

at the beginning of a C-V measurement creates a nonequilibrium condition that must be allowed to subside before the

C-V sweep begins. This recovery to equilibrium can take

seconds, minutes, or even tens of minutes to achieve. For that

reason, it

accumulation region of the curve whenever possible.

Still, it is often necessary to begin the sweep in the inversion

region to check for curve hysteresis. In this case, a light pulse,

shone on the device, can be used to quickly generate the

minority carriers required by the forming inversion layer, thus

speeding up equilibrium and shortening the hold time.

User’s Guide Model 82WlN Simultaneous C-V C-V Measurement l 41

is

generally advantageous to begin the sweep in the

Page 51

The best way to ensure equilibrium is initially achieved is to

monitor the DC current in the device and wait for it to decay to

the DC leakage level of the system. A second indication that

equilibrium is reached is that the capacitance level at the initial

bias voltage decays to its equilibrium level.

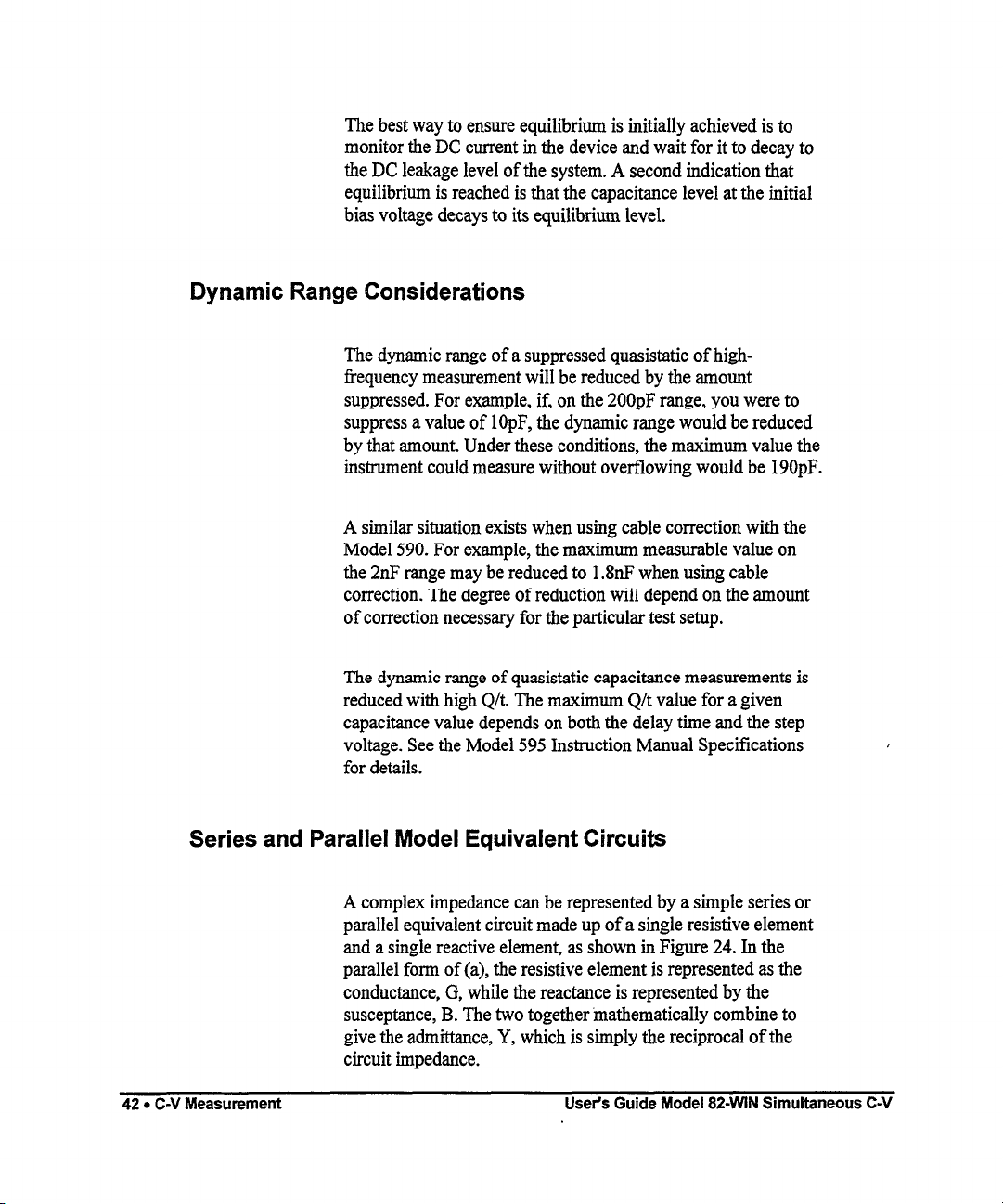

Dynamic Range Considerations

The dynamic range of a suppressed quasistatic of highfrequency measurement will be reduced by the amount

suppressed. For example, if, on the 200pF range, you were to

suppress a value of lOpF, the dynamic range would be reduced

by that amount. Under these conditions, the maximum value the

instrument could measure without overflowing would be 190pF.

A similar situation exists when using cable correction with the

Model 590. For example, the maximum measurable value on

the 2nF range may be reduced to 1.8nF when using cable

correction. The degree of reduction will depend on the amount

of correction necessary for the particular test setup.

Series and Parallel Model Equivalent Circuits

42. C-V Measurement

The dynamic range of quasistatic capacitance measurements is

reduced with high Q/t. The maximum Q/t value for a given

capacitance value depends on both the delay time and the step

voltage. See the Model 595 Instruction Manual Specifications

for details.

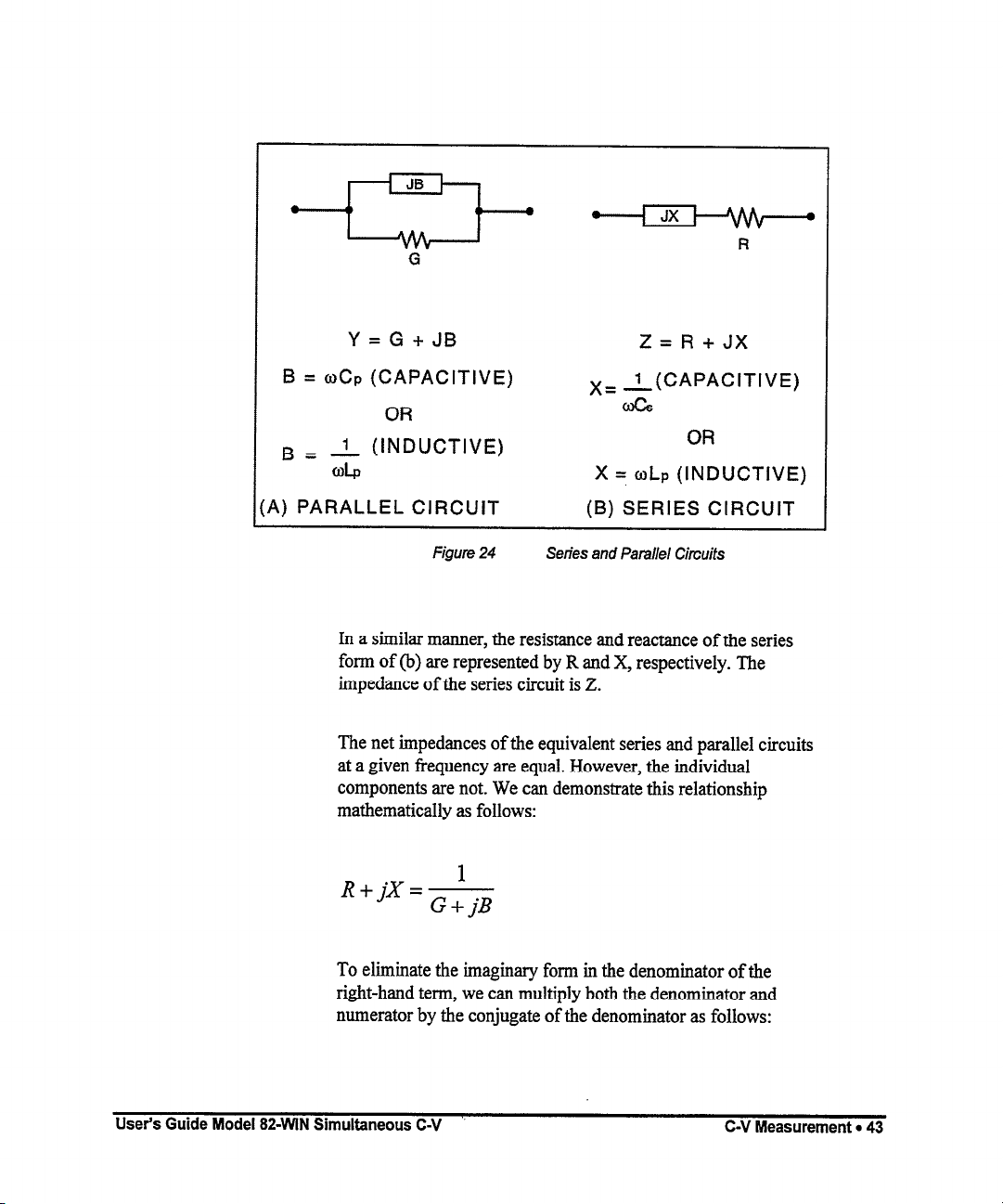

A complex impedance can be represented by a simple series or

parallel equivalent circuit made up of a single resistive element

and a single reactive element, as shown in Figure 24. In the

parallel form of (a), the resistive element is represented as the

conductance, G, while the reactance is represented by the

susceptance, B. The two together mathematically combine to

give the admittance, Y, which is simply the reciprocal of the

circuit impedance.

User’s Guide Model 82WlN Simultaneous C-V

Page 52

Y=G+JB

Z=R+JX

B = mCp (CAPACITIVE)

OR

1 (INDUCTIVE)

B=

OLp

(A) PARALLEL CIRCUIT

Figure 24

In a similar manner, the resistance and reactance of the series

form of(b) are represented by R and X, respectively. The

impedance of the series circuit is Z.

The net impedances of the equivalent series and parallel circuits

at a given frequency are equal. However, the individual

components are not. We can demonstrate this relationship

mathematically as follows:

1

R+jX

=

G+jB

x= L(CAPACITIVE)

OIG

OR

X = wLp (INDUCTIVE)

(B) SERIES CIRCUIT

Series and Parallel Circuits

To eliminate the imaginary form in the denominator of the

right-hand term, we can multiply both the denominator and

numerator by the conjugate of the denominator as follows:

User’s Guide Model 82-WIN Simultaneous C-V

C-V Measurement l 43

Page 53

R+jX=-x-

1

G-jB

G+jB G-jB

Performing the multiplication and combining terms, we have:

G-jB

R+jX= G2 +B2

If we assume the reactance is capacitive, we can use -1 /wCs for

the reactance and oCp for the susceptance (Cs is the equivalent

series capacitance, and Cp is the equivalent parallel

capacitance). The above equation then becomes:

R-jX

QG

In a lossless circuit (R and G both 0), Cp and Cs would be equal.

A practical circuit, however, does have loss be cause of the

finite values of R or G. Thus, Cs and Cp are not equal -the

greater the circuit loss, the larger the disparity between these

two values.

Series and parallel capacitance values can be converted to their

equivalent forms by taking into account a dissipation factor, D,

which is simply the reciprocal of the Q of the circuit. For a

parallel circuit, the dissipation factor is:

---

G- jo.C,

= G2 +co’C;

1 G

D=Q-wC,

For the series circuit, the dissipation factor is defined as:

44 l C-V Measurement

User’s Guide Model 82-WIN Simultaneous C-V

Page 54

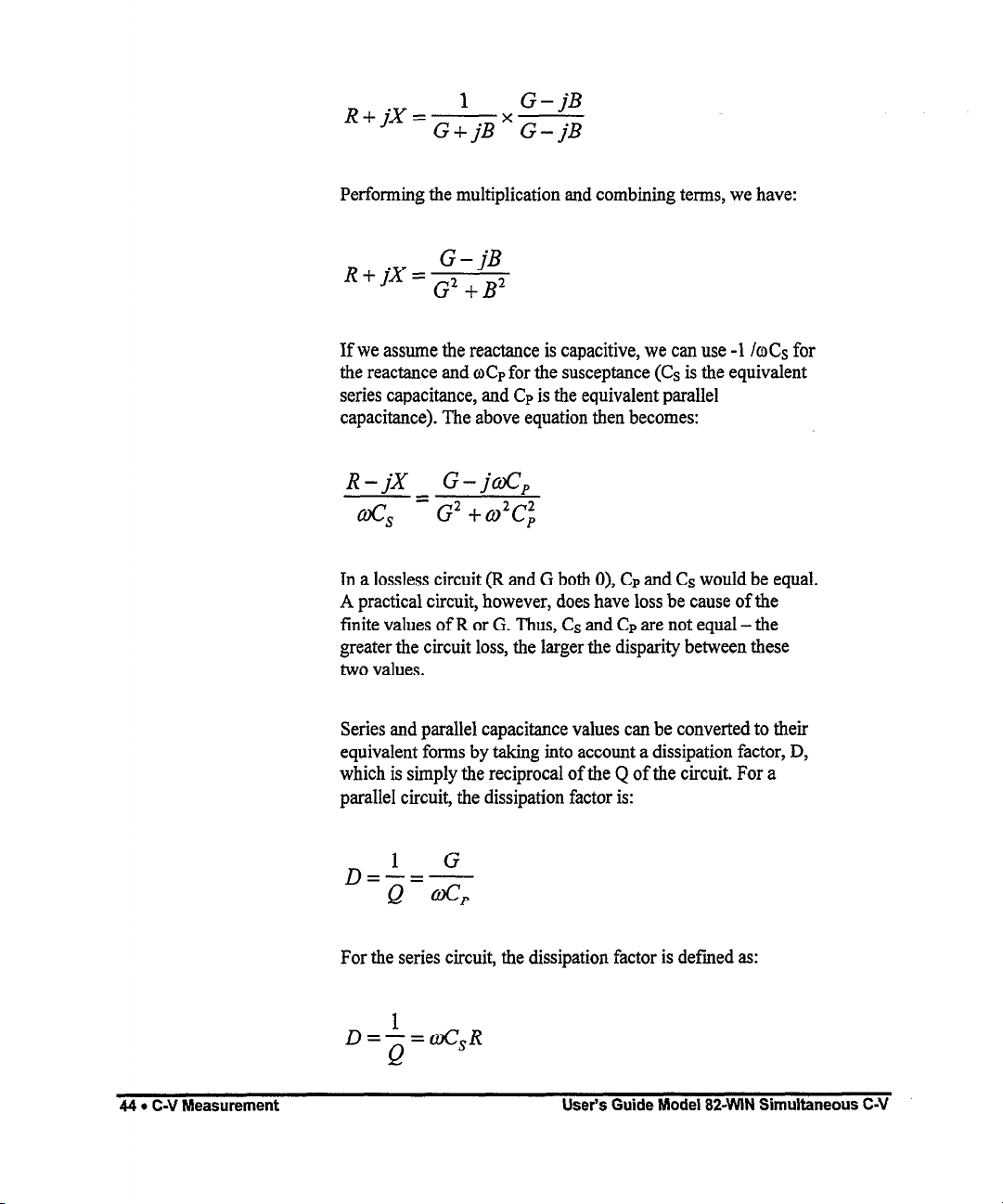

By using the dissipation factor along with the formulas

summarized in Table 1, you can convert from one form to

another. Note that Cs and Cp are virtually identical for very

small values of D. For example, if D is 0.01 Cs and Cp are

within 0.0 1% of one another.

Table I Converting series-parallel equivalent circuits

Model

Parallel Cr, G

Series C,, R

Dissipation factor Capacitance Resistance or

conductance

1 G

D=s=wc,

Cs =(l+

D2)Cp

‘=(l+;‘)G

1

=oC,R Cp=&

D=e

G = (,+;‘)R

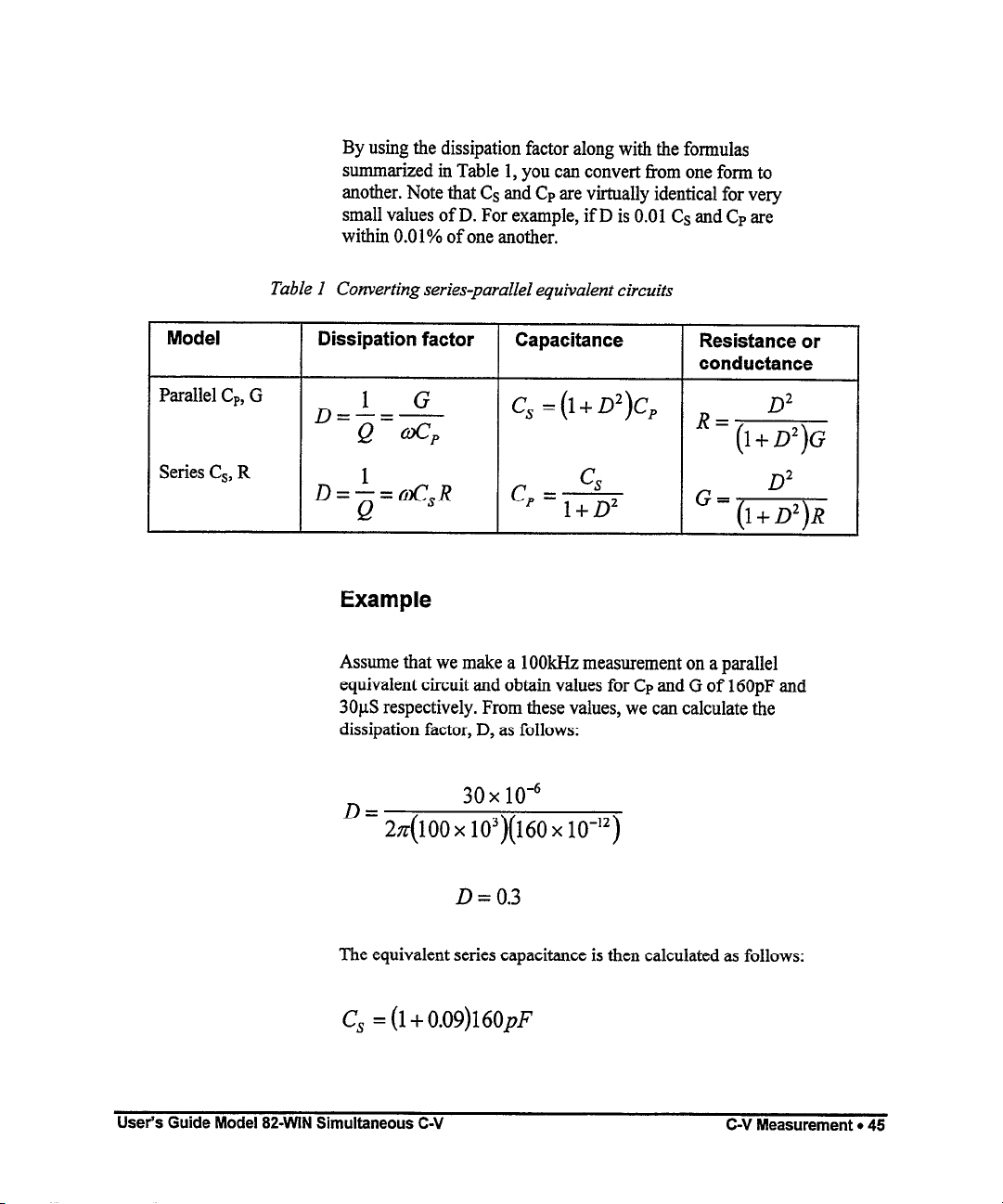

Example

Assume that we make a 1 OOkHz measurement on a parallel

equivalent circuit and obtain values for Cp and G of 160pF and

30~s respectively. From these values, we can calculate the

dissipation factor, D, as follows:

30

x lOA

D = 24100 x 103)(160x 10-l’)

The equivalent series capacitance is then calculated as follows:

Cs = (1 + O.O9)16OpF

User’s Guide Model 82-WIN Simultaneous C-V

D = 0.3

C-V Measurement l 45

Page 55

Cs = 174.4pF

Device Considerations

Series Resistance

Devices with high series resistance

analysis errors unless steps are taken to compensate for this

error term. The high dissipation factor caused by series

resistance can cause errors in Cox measurement, resulting in

errors in analysis functions (such as doping concentration) that

use Cox for calculations.

The software uses a three-element model to compensate for

series resistance. The series resistance, Rsm is an analysis

constant that can be determined using the procedure covered

previously.

The software determines the displayed value of Rsa by

converting parallel model data from the Model 590 into series

model data. The resistance value corresponding to the

maximum high-frequency capacitance in accumulation is

defined as h.

Device Structure

The standard analysis assumes a conventional MOS structure

made up of silicon substrate, silicon dioxide insulator, and

aluminum gate material. You can change the program for use

with other types of materials by modifying the material

constants using the Transform editor. For compound materials,

a weighted average of pertinent material constants is often used.

Typical compound materials include silicon nitride and silicon

dioxide in a two- or three-layer sandwich.

can

cause

measurement

and

46 l C-V Measurement

User’s Guide Model 82JMN Simultaneous C-V

Page 56

Device Integrity

In order for analysis to be valid, device integrity should be

checked before measurement. Excessive leakage current

through the oxide can bleed off the inversion layer, causing the

device to remain in non-equilibrium indefinitely. In this

situation, the inversion layer would never form completely, and

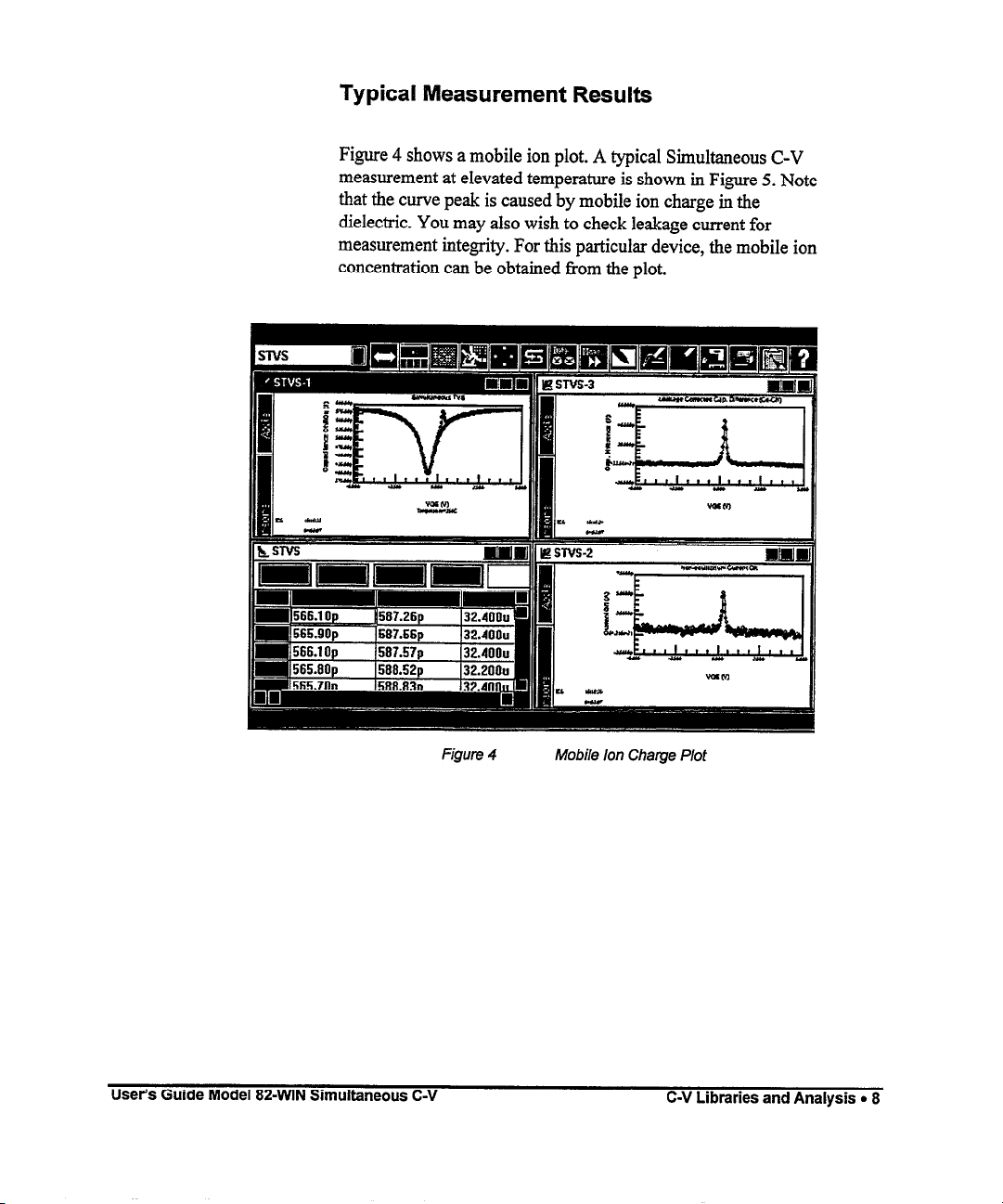

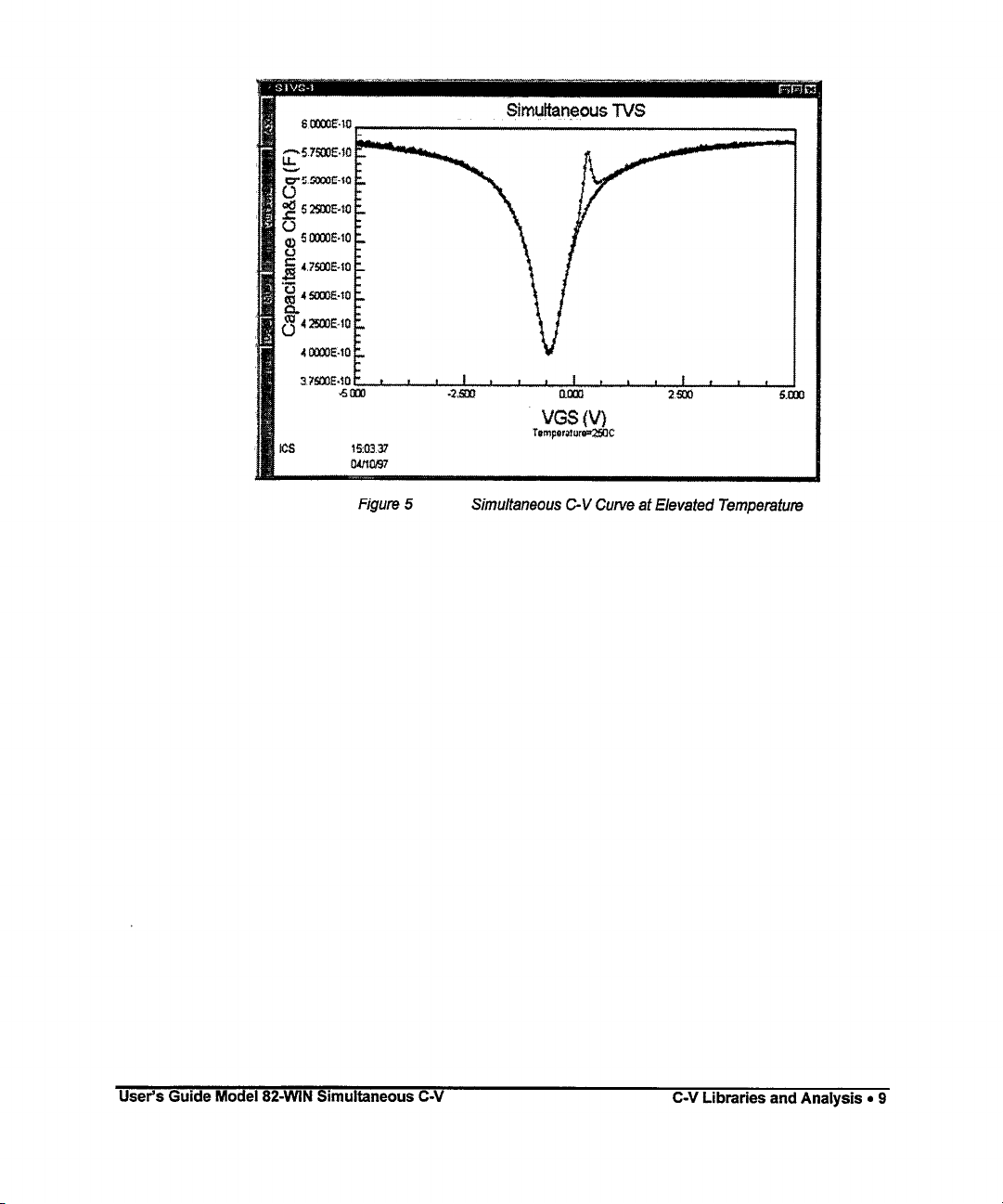

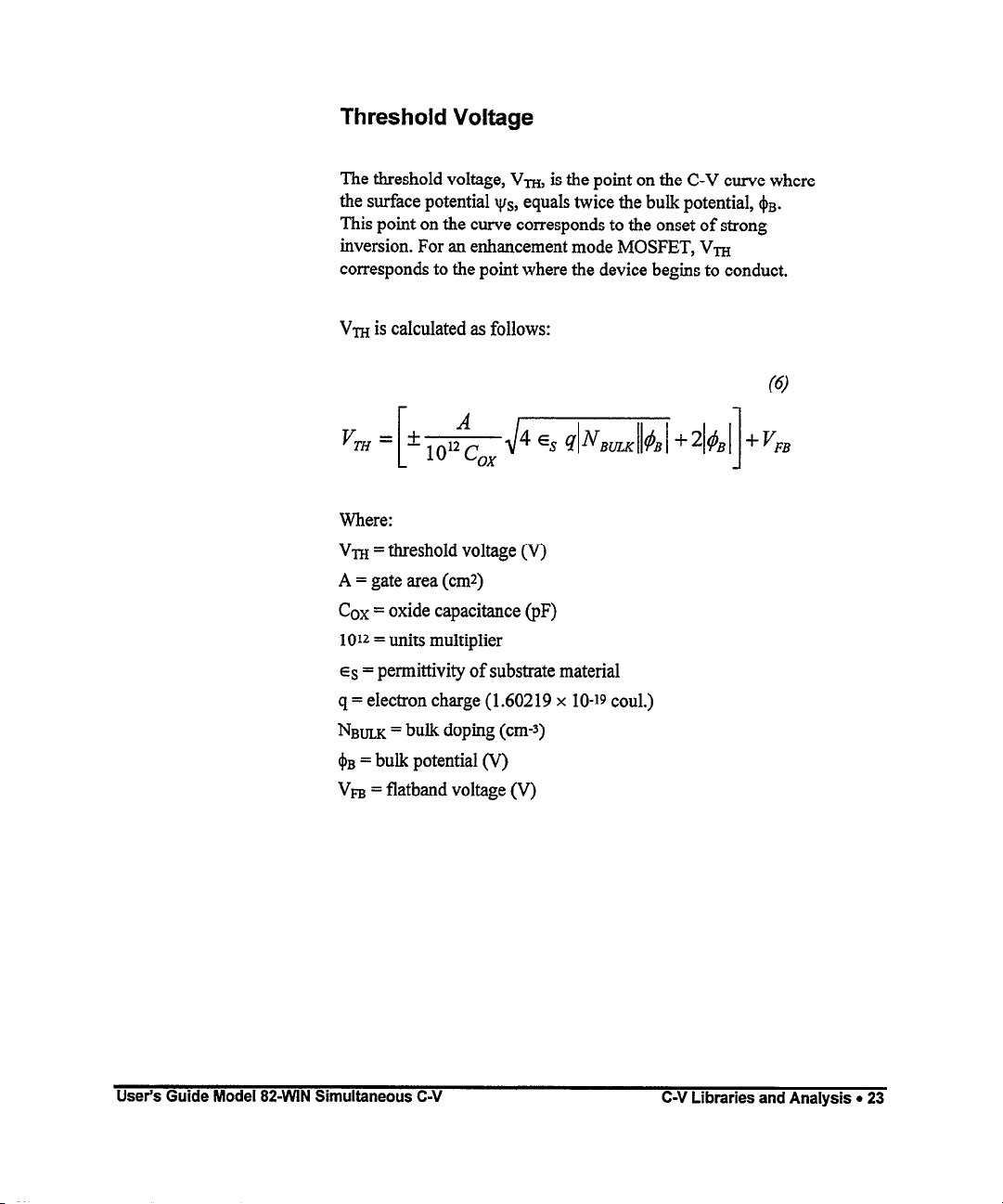

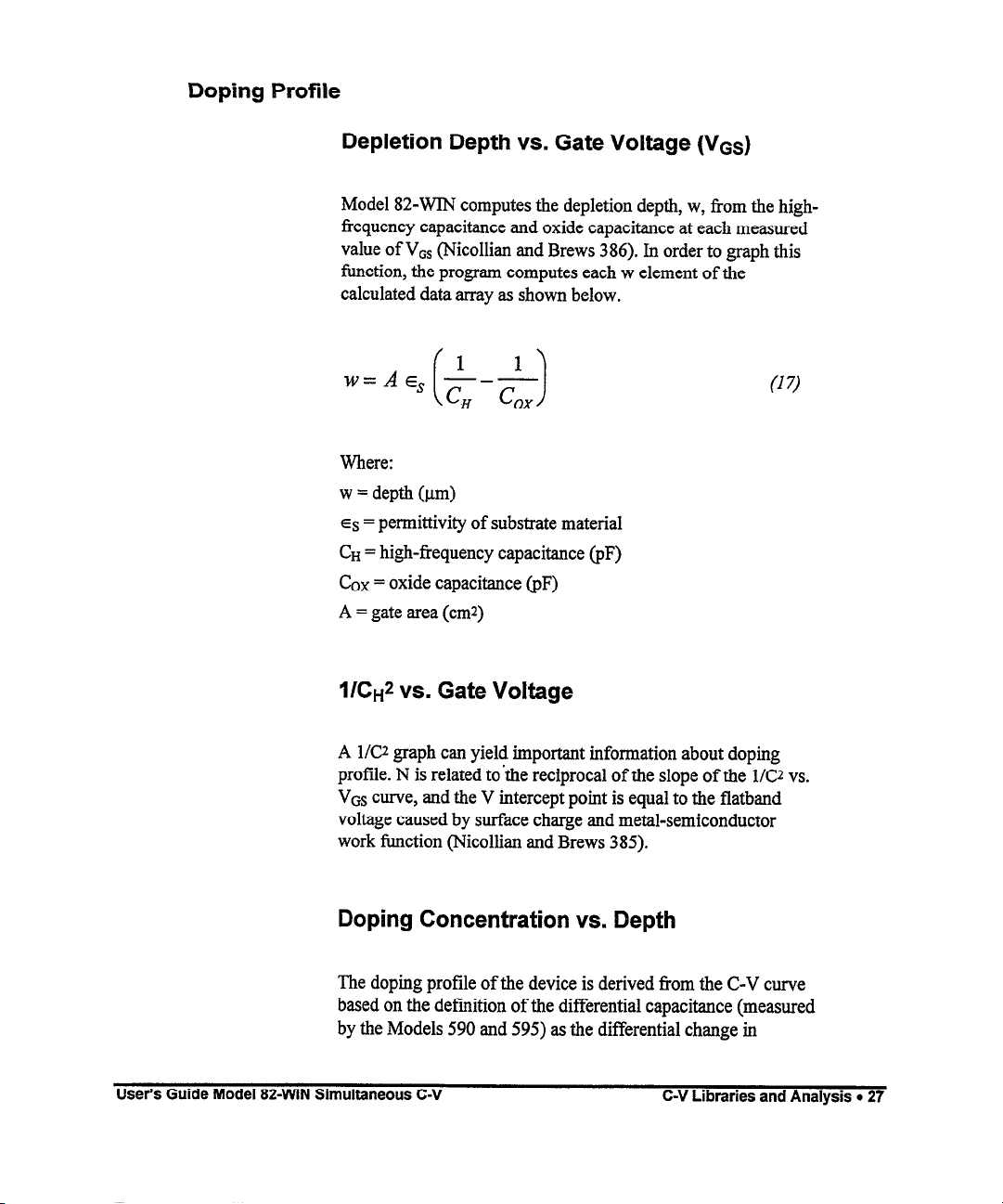

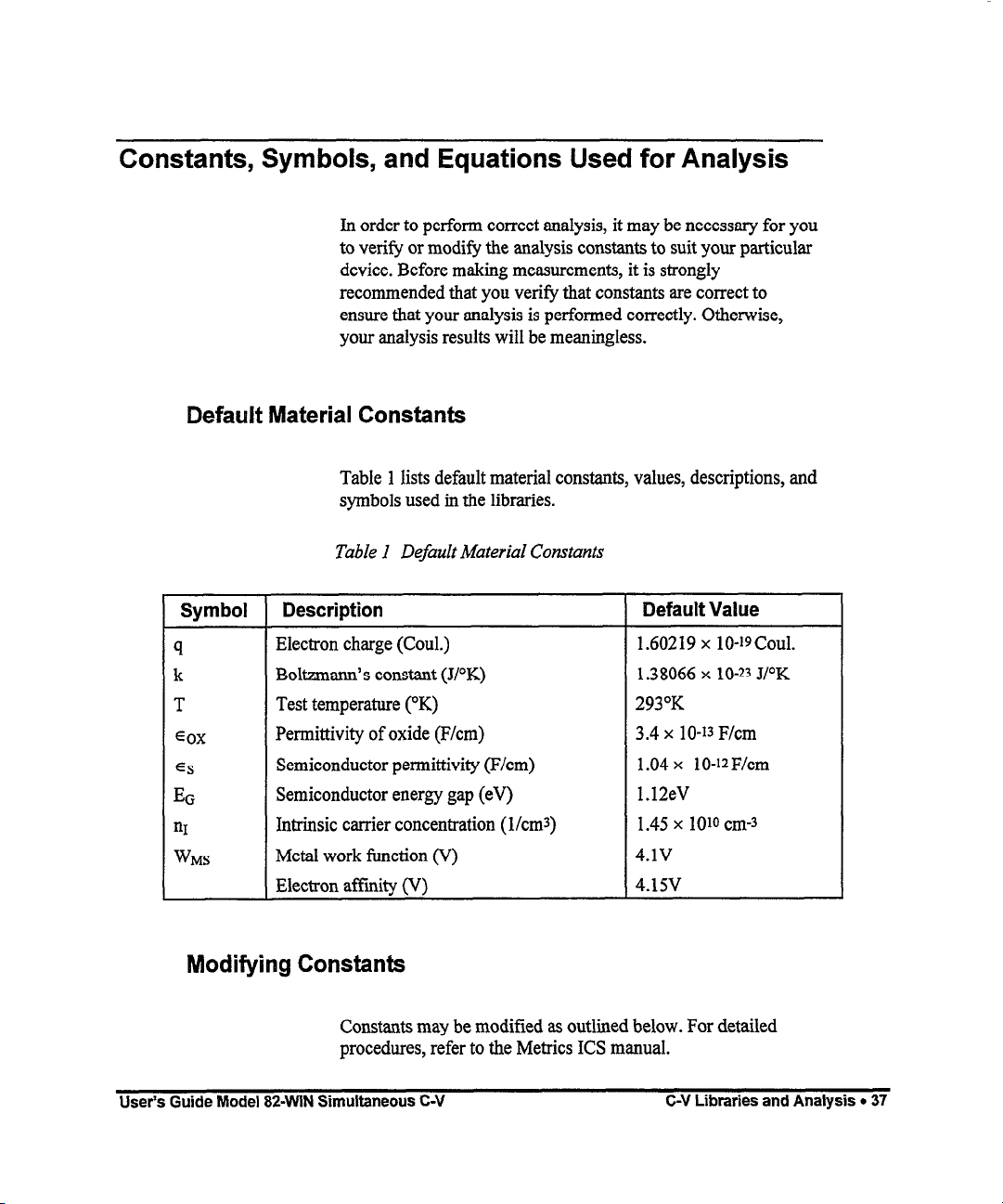

CM, measurements would be inaccurate.