Page 1

Model 8007

Semiconductor Test Fixture

Instruction Manual

Contains Operating and Servicing Information

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of I year

from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable

batteries, diskettes, and documentation.

During the warranty period, we will, at our’option, either repair or replace any product that proves to be defective,

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in Cleveland, Ohio.

You will he given prompt assistance and return instructions. Send the product, transportation prepaid, to the indicated service

facility. Repairs will be made and the product returned, transportation prepaid. Repaired or replaced products are warranted for

the balance of the original warranty period, or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written consent, or

misuse of any product or part. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from

battery leakage, or problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY DIRECT,

INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF ITS

INSTRUMENTS AND SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN ADVANCE

OFTHE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY

PERSON, OR DAMAGE TO PROPERTY.

Page 3

Model 8007

Semiconductor Test Fixture

Instruction Manual

01989, Keith@ Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

Second Printing, October 2000

Document Number: 8007-901-01 Rev. B

Page 4

Manual Print History

The print history shown hclow lists the printing dates of all Revisions and Addenda created for this manual. The

Revision Level letter increases alphabetically as the manual undergoes subsequent updates. Addenda, which are

released between Revisions, contain important change information that the user should incorporate immediately

into the manual. Addenda are numbered sequentially. When a new Revision is crcatcd, all Addenda associated

with the previous Revision of the manual arc incorporated into the new Revision of the manual. Each new Revision includes a revised copy of this print history page.

Revision A (Document Number 8007-901-01) . Janunry 1989

Addendum A (Document Number 8007-901-02) .._....,,,,,,,,,,,,,,,,,,,,,,,,,.,,,,,....,. Mnrch 1989

Revision B (Document Number X007-901-01) October2000

Page 5

SAFETY PRECAUTIONS

The following safety precautions should be observed before using the Model 8007 and the associated instruments.

This test fixture is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety

precautions required to avoid possible injury. Read over this manual carefully before using the test fixture.

Exercise extreme caution when a shock hazard is present at the test fixture. User-supplied lethal voltages may be present

on the fixture or the connector jacks. The American National Standards Institute (ANSI) states that R shock hazard exists

when voltage levels greater than 30V RMS or 42.4V peak are present. A good safety practice is to expect that hazardous

voltage is present in any unknown circuit before measuring.

Inspect the connecting cables and test leads for possible wear, cracks, or breaks before each use

For maximum safety, do not touch the test fixture, test cables or any instruments while power is applied to the circuit

under test. Turn off the power and discharge any capacitors before connecting or disconnecting cables from the test fix-

ture. Also, keep the test fixture lid closed while power is applied to the device under test. Safe operation requires the use

of the lid interlock (see paragraph 22.1).

Do not touch any object which could provide a current path to the common side of the circuit under test or power line

(earth) ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the voltage being measured.

Do not exceed the maximum signal levels of the test fixture, as defined in the specifications and operation section of this

manual.

Connect the fixture

Instrumentation and accessories should not be connected to humans.

0 = screw terminal to safety earth ground using #18 AWG or larger wire (supplied accessory).

Page 6

Page 7

Safety Precautions

The following safety precautions should be observed before using

this product and any associated instrumentation. Although some

instruments and accessories would normally be used with nonhazardous voltages, there are situations where hazardous conditions

may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions re-

quired to avoid possible injury. Read the operating infomntion

carefully before using the product.

The types of product users are:

Responsible body is the individual or group responsible for the use

and maintenance of equipment, for ensuring that the equipment is

operated within its specifications and operating limits, and for en-

suring that operators are adequately trained.

Operators use the product for its intended function. They must be

trained in electrical safety procedures and proper use of the instru-

ment. They must be protected from electric shock and contact with

hazardous live circuits.

Maintenance personnel perform routine procedures on the product

to keep it operating, for example, setting the line voltage or replac-

ing consumable materials. Maintenance procedures are described in

the manual. Tbe procedures explicitly state if the operator may perform them. Otherwise, they should be performed only by service

pW3tlllti

Service personnel arc trained to work on live circuits, and

safe installations and repairs of products. Only properly trained ser-

vice personnel may perfoorm installation and service procedures.

perform

Users of this product must be protected from electric shock at all

times. The responsible body must enwre that users are prevented

access and/or insulated from every connection point. In home cases,

connections must be exposed to potential human contact. Product

users in these circumstances most be trained to protect themselves

from the risk ofelectric shock. If the circuit is capable of operating

at or above IO00 volts, no conductive part of the circuit may be

CQXXXi.

As described in the International Electrotechnical Commission

(IEC) Standard IEC 664, digital multimeter measuring circuits

(e.g.. Keithley Models 175A, 199,2000,2001,2002, and 2010) are

Installation Category Il. All other instruments’ signal temtinals are

Installation Category I and must not be connected to mains.

Do not connect switchingcards directly tounlimited power circuits.

They are intended to be used with impedance limited sources.

NEVER connect switching cards directly to AC mains. When coonetting sources to switching cards, install protective devices to limit fault current and voltage to the card.

Before operating an instrument. make sore the line cord is connected to a properly grounded power receptacle. Inspect the connecting

cables, test leads, and jumpers for possible wear, cracks, or breaks

before each use.

For maximum safety, do not touch the product, test cables, or any

other instruments while power is applied to the circuit under test.

ALWAYS remove power from the entire test system and discharge

any capacitors before: connecting or disconnecting cables or jumpers, installing or removing switching cards, or making internal

changes, such as installing or removing jumpers.

Exercise extreme caution when a shock hazard is present. Lethal

voltage may be present on cable connector jacks or test fixtures. The

American National Standards btstitute (ANSI) states that a shock

hazard exists when voltage levels greater than 30V RMS, 42.4V

peak, or 60VDC are present. A good safety practice is to expect

that hazardous voltage is present

in

any

unknown

circuit

before

measuring.

Do not touch any object that could provide a current path to the

common side of the circuit under test or power line (earth) ground.

Always make measttrement8 with dry hands while standing on a

dry, insulated surface

measured.

capable

of withstanding the voltage being

Page 8

The instrument and accessories must be used in accordance with its

specifications and operating instructions or the safety of the equip

ment may be impaired.

The WARNING heading in a manual explains dangers that might

result in personal injury or death. Always read the associated information very carefully before performing the indicated procedure.

Do not exceed the maximum signal levels of the instruments and accessories. as defined in the specifications and operating informa-

tion, and as shown on the instrument or test fixture panels, or

switching card.

When fuses are used in a product, replace with same type and rating

for continued protection against fire hazard.

Chassis connections must only be used as shield connections for

measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is ap-

plied to the device under test. Safe operation requires the use of a

lid interlock.

,fa@

wire recommended in the user documentation.

Then

fer to the operating instructions located in the manual.

Then

sore 1000 volts or more, including the combined effect of normal

and common mode voltages. Use standard safety precautions to

avoid personal contact with these voltages.

screw is present. connect it to safety earth ground using the

symbol on an instrument indicates that the user should re-

symbol on an instrument shows that it can source or mea-

The CAUTION heading in a manual explains hazards that could

damage the instrument. Such damage may invalidate the warranty.

instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and

all test cables.

To maintain protection from electric shock and iirc, replacement

components in mains circuits, including the power transformer, test

leads, and input jacks, must be purchased from Keithley Instmmerits. Standard fuses, with applicable national safety approvals,

may be used if the rating and type are the same. Other components

that are not safety related may be purchased from other suppliers as

loog as they are equivalent to the original component. (Note that selected parts should be purchased only through Keithley Instruments

to maintain accuracy and functionality of the product.) If you are

tmsore about the applicability of a replacement component, call a

Keithley Instruments oflice for information.

To clean an instrument. use a damp cloth or mild, water based

cleaner. Clean the cxterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill

on the instrument. Products that consist of a circuit board with no

case or chassis (e.g., data acquisition board for installation into a

computer) should never require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the factory for proper

cleaning/servicing.

Rev. 10199

Page 9

Specifications

DEVICE SOCKET CONFIGURATION: 1 each, 24- and 48-pin gold contact DIP

sockets (0.100 in. pin spacing, 0.300 to 0.600 in. wide, zero insertion force, replaceable).

CONNECTOR ,TYPE: 6 mass termination connectors (12 coaxial connections each, 72

total measurement pathways).

MAXIMUM SIGNAL VOLTAGE: ZOOV peak, signal or guard to any signal, guard, sub-

chassis, or chassis.

MAXIMUM SIGNAL CURRENT: 1A peak.

OFFSET CURRENT (18’C-ZS’C, ~60% R.H.): <1 pA (0.1 pA typical @ ~40% R.H.).

PATH ISOLATION (ltl’=C -28’C, < 60% R.H.):

Resistance: >lTQ (1OTQ typical @I <40% R.H.).

Capacitance (nominal): 2pF.

CROSSTALK @ 1MHz (typical): -6OdB (5Oa scurce and measure).

3 dB BANDWIDTH (typical): 4MH.z (5On source and measure).

INSERTION LOSS @ 1MHz (typical): O.ldB (50.Q source and 1 MQ measure).

PATH RESISTANCE: <la.

ENVIRONMENT:

Operating: 0°C to 5O”C, <SO% non-condensing R.H. up to 35’C.

Storage: -25°C to t7O”C.

GENERAL:

Socket Operating Life: >25,000 open-close cycles.

Lid Interlock Switching: <28VDC, 50mA.

Dimensions, Weight: 140mm high x 305mm wide x 292mm deep (5.5 in. x 12 in. x

11.5 in.). Net weight 3.5kg (7 Ibs., 12 oz.).

ACCESSORIES SUPPLIED:

Instruction manual

Model 8007-MTC-3:

Model 8007-PTB:

Model 8007-GND-3:

Model 236~ILC-3:

ACCESSORIES AVAILABLE:

Model 8007-MTC-3:

Model 8007~PTB: Prototyping PC board

Model 236-ILC-3: Interlock cable, 3m (loft.1

3-lug triax to mass termination connector cable assembly,

3m (IO ft.), two supplied

Prototyping PC board

Safety grounding cable

Interlock cable, 3m (10 ft.)

3-1~s hiax to mass termination connector cable assemblv,

3m rloft.)

Specifications are for guarded measurement configuration, including external cables.

Prices and specifications subject to change without notice.

Page 10

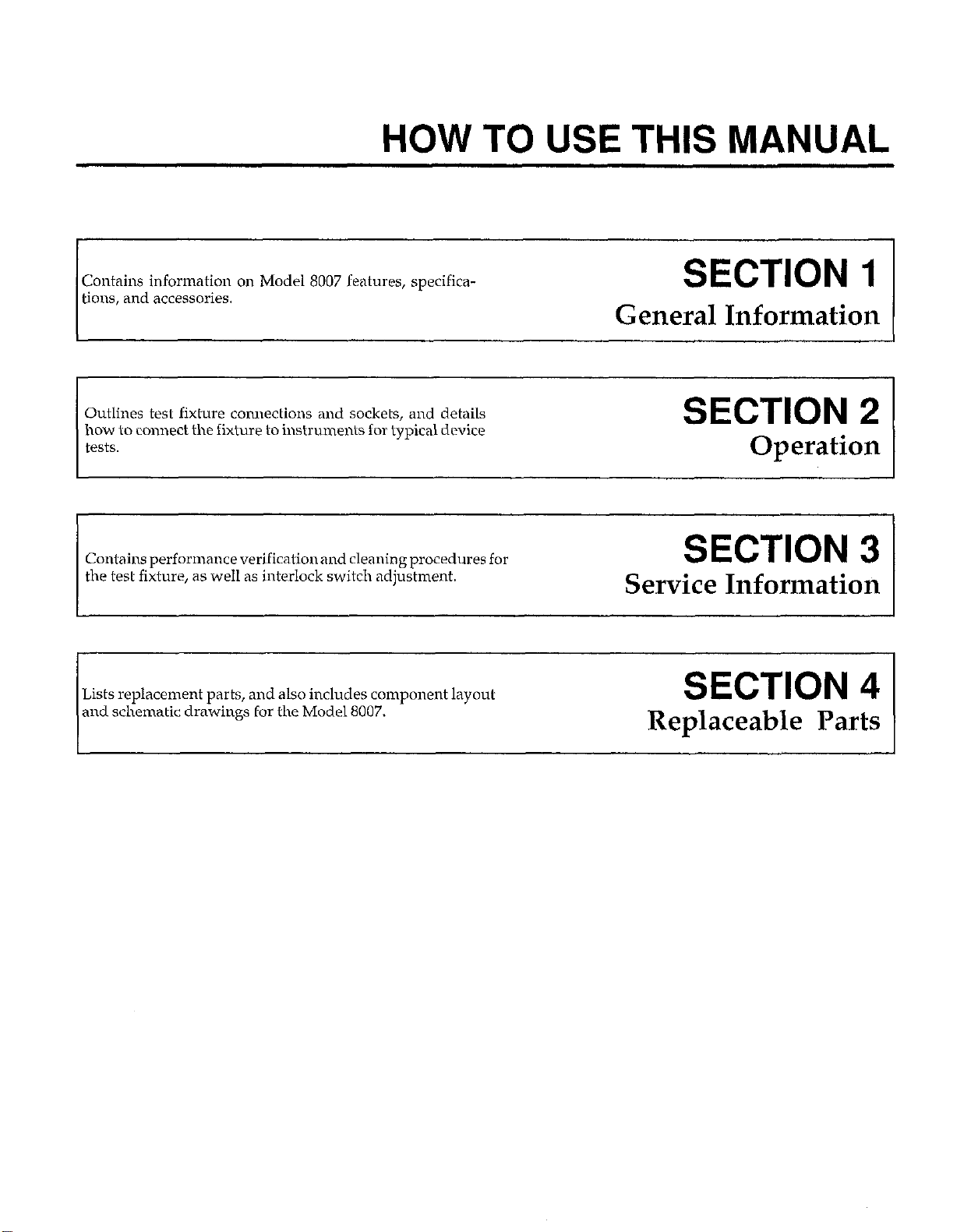

HOW TO USE THIS MANUAL

Contains information on Model 8007 features, specifications, and accessories.

Outlines test fixture connections and sockets, and details

how to connect the fixture to instruments for typical device

tests.

Contains performance verification and cleaning procedures for

the test fixture, as well as interlock switch adjustment.

Lists replacement parts, and also includes component layout

and schematic drawings for the Model 8007.

SECTION 1

General Information

SECTION 2

Operation

SECTION 3

Service Information

SECTION 4

Replaceable Parts

Page 11

Table of Contents

SECTION 1 - General Information

1.1 INTRODUCTION

1.2 FEATURES .

1.3 WARRANTY INFORMATION

1.4 MANUAL ADDENDA

1.5 SAFETY SYMBOLS AND TERMS

1.6

1.7 UNPACKING AND INSPECTION

1.7.1

1.72 Shipment Contents

1.7.3

1.8 REPACKING FOR SHIPMENT

1.9

SECTION 2 - Operation

SPECIFICATIONS

Inspection for Damage

Instruction Manual

OPTIONAL ACCESSORIES

2.1

2.2

2.2.1

2.2.2

2.2.3

2.3

2.4

2.4.1

2.4.2

2.4.3

2.4.4

2.4.5

2.5

2.5.1

2.5.2

2.5.3

2.54

2.5.5

2.5.6

2.57

2.5.8

2.5.9

2.5.10

2.5.11

2.5.12

2.5.13

2.5.14

2.5.15

INTRODUCTION

FIXTURE CONFIGURATION

RearPanel .......................

Front Panel. ......................

Sub Chassis Guarding

MATRIXCARDCONNECTIONS ......................................................

TYPICAL INSTRUMENT CONNECTIONS

Adapters

Source Measure Unit

DMM (Digital Multimeter)

Electrometer

SourceConnections

MEASUREMENT CONSIDERATIONS

Path Isolation

Keeping Connectors and Sockets Clean

Shielding

Guarding .......................................................................... 2-18

CableNoiseCurrents

MagneticFields

RadioFrequencyInterference

GroundLoops .....................................................................

Capacitance Considerations

Device Oscillation

Environmental Considerations

Vibration

Low Current and Low Voltage Measurements

Cumulative Power

AC Measurements

..........................................................................

..........................................................................

..........................................................................

..................

........

............................................................... 2-6

................................................................

...........................................................

.......................................................................

.................................................................

......................................................................

...............................................................

....................................................................

........................................................

..........................................................

..................................................................

.......................................................

..................................................................

.................................................................. 2-24

................................................. 2-l

.................................................

.................................................

.................................................

..............................................

..................................................

................................................

..........................................

2-1

2-l

2-5

2-7

2-7

2-9

2-11

2-11

2-14

2-14

2.17

2-17

2-18

2-18

2-20

2-20

2-21

2-21

2-22

2-22

2-24

2-24

2-24

2-24

Page 12

2.6

2.6.1

2.6.2

2.6.3

2.7

2.7.1

2.7.2

2.7.3

2.7.4

2.7.5

TYPICAL APPLICATIONS ...............................

CVMeasurements .....................................

FETTesting ...........................................

Semiconductor Parameter Analysis

USING THE I’ROTOTYPING BOARD

Board Wiring .........................................

Board Cleaning .......................................

Board Installation .....................................

Prototyping Board Considerations

Wiring Kelvin Connections on the Prototyping Board

SECTION 3 - Service Information

......................

.....................

.......................

......

..........

..........

.......... 2-28

..........

.......... 2-31

.......... 2-31

.......... 2-31

.......... 2-32

.......... 2-32

..........

2-25

2-25

2-29

2-32

3.1

3.2

3.2.1

3.2.2

3.2.3

3.2.4

3.2.5

3.2.6

3.2.7

3.3

3.3.1

3.3.2

3.4

3.4.1

3.4.2

3.5

3.6

3.7

3.7.1

3.7.2

3.7.3

3.7.4

INTRODUCTION ............................

PERFORMANCE VERIFICATION ..............

Environmental Conditions ...................

Recommended Test Equipment. ..............

Performance Record ........................

Isolation Resistance Verification ..............

Offset Current Verification ...................

Path Resistance Verification ..................

ACPerformance ...........................

HANDLING AND CLEANING PRECAUTIONS

Board Handling and Cleaning ................

Connector Cleaning. ........................

DISASSEMBLY ..............................

Fixture Disassembly ........................

Sub Chassis Disassembly ....................

INTERLOCK SWITCH CALIBRATION

PATHWAY MODIFICATION ..................

BINDING POST INSTALLATION ..............

Supplied Binding Posts ......................

Installation Procedure .......................

Binding Post Wiring ........................

Sub Chassis Installation .....................

.........

......

...... 3-1

......

...... 3-1

...... 3-2

...... 3-2

...... 3-4

...... 3-5

......

...... 3-7

...... 3-8

...... 3-8

......

......

...... 3-9

......

......

...... 3-11

......

...... 3-12

...... 3-12

...... 3-12

3-1

3-1

3-6

3-8

3-8

3-9

3-10

3-11

SECTION 4 - Replaceable Parts

4.1

4.2

4.3

4.4

4.5

INTRODUCTION .............................................................

PARTS LIST ..................................................................

ORDERING INFORMATION ...................................................

FACTORY SERVICE ...........................................................

COMPONENT LAYOUT AND SCHEMATIC DIAGRAM

...........................

...... 4-1

...... 4-l

......

...... 4-1

...... 4-1

4-1

Page 13

SECTION 2 - Operation

List of Illustrations

Figure 2-l

Figure 2-2

Figure 2-3

Figure 2-4

Figure 2-5

Figure 2-6

Figure 2-7

Figure 2-8

Figure 2-9

Figure 2-10

Figure 2-11

Figure 2-12

Figure 2-13

Figure 2-14

Figure 2-15

Figure 2-16

Figure 2-17

Figure 2-18

Figure 2-19

Figure 2-20

Figure 2-21

Figure 2-22

Figure 2-23

Figure 2-24

Figure 2-25

Figure 2-26

Figure 2-27

Figure 2-28 Typical Common-Source FET IV Characteristics

Figure 2-29

Figure 2-30

Figure 2-31

Figure 2-32

Figure 2-33

Figure 2-34

Model8007RearPanel ............................................................

Safety Interlock Connections

Input/OutputEquivalentCircuit ...................................................

Front Panel ......................................................................

Example of Sub Chassis Guarding

Matrix Card Connection Example

Adapters Required for Connections

Source Measure Unit Connections

DMMConnections ...............................................................

Electrometer Connections

Voltage Source Connections

Current Source Connections

Path Isolation Resistance

Voltage Attenuation by Path Isolation Resistance

ShieldingExample ................................................................

GuardedCircuit ..................................................................

Typical Guarded Signal Connections

Power Line GroundLoops .........................................................

Eliminating Ground Loops

5pe #73 Material, Impedance vs. Frequency

Type #43 Material, Impedance vs. Frequency Without Leads.

Type #43 Material, Impedance vs. Frequency With Leads.

CVTestSystem ..................................................................

Typical High Frequency CV Curve Generated by Model 590

Typical Quasistatic CV Curve Generated by Model 595

FETTestSystem ..................................................................

System Connections for JFET Test

Semiconductor Parameter Analysis Switching System

Current Gain Test Configuration

Prototyping Board ................................................................

PrototypingBoardInstallation .....................................................

KelvinConnections ...............................................................

Using Socket Jumpering to Add Kelvin Connections

.......................................................

..................................................

..................................................

................................................. 2-10

..................................................

.........................................................

........................................................

.......................................................

.......................................................... 2-17

................................................

........................................................

.........................................

...................................................

....................................................

.....................................

...........................

..............................

...........................

................................

......................................

.................................

..................................

2-2

2-3

2-5

2-6

2-7

2-8

2-12

2-13

2-14

2-15

2-16

2-18

2-19

2-19

2-20

2-21

2-21

2-23

2-23

2-23

2-25

2-26

2-27

2-28

2-29

2-29

2-30

2-31

2-32

2-33

2-33

2-33

Page 14

SECTION 3 - Service Information

Figure 3-l

Figure 3-2

Figure 33

Figure 3-4

Figure 3-5

Figure 3-6

Figure 3-7

Figure 3-8

Figure 3-9

Figure 3-10

Figure 3-11

Path Isolation Verification Connections

Offset Current Verification Connections

Path Resistance Verification Connections

Connections for AC Response Tests

Sub Chassis Removal ...................

Fixture Assembly .......................

Sub Chassis Disassembly ................

Hinge Alignment .......................

Safety Interlock Switch Adjustment

Examples of Pathway Modification

Binding Post Installation ................

.......

.......

.......

....

...

............

............

............ 3-6

............ 3-7

............ 3-8

............ 3-9

............

............ 3-10

............ 3-10

............ 3-11

............

3-4

3-5

3-9

3-12

Page 15

SECTION 2 - Operation

List of Tables

Table 2-l

Table 2-2

Input/output Numbering

Supplied Ferrite Beads.

SECTION 3 - Service Information

Table 3-1

Table 3-2

Table 3-3

Recommended Test Equipment

Performance Record

Supplied Binding Posts ......................

........................

SECTION 4 - Replaceable Parts

Table 4-l

Mass-terminated Connector Parts List

...............

2-4

2-22

......

......

...... 3-12

3-2

3-3

Page 16

Page 17

SECTION 1

General Information

1.1 INTRODUCTION

This section contains general information about the

Model 8007 Semiconductor Test Fixture, and it is arranged in the following manner:

1.2 Features

1.3 Warranty Information

1.4 Manual Addenda

1.5 Safety Symbols and Terms

1.6 Specifications

.

IHinged seamless lid for light-tight and Shielded measurements.

.

Interlocked lid for safety.

1.3 WARRANTY INFORMATION

Warranty information is located on the inside front cover

of this instruction manual. Should your Model 8007 require warranty service, contact the I<eithley representative or authorized repair facility in your area for further

information. When returning the fixture for repair, be

sure to fill out and include the service form at the back of

this manual in order to provide the repair facility with the

necessary information.

1.7 Unpacking and Inspection

1.8 Repacking for Shipment

1.9 Optional Accessories

1.2 FEATURES

The Model 8007 Semiconductor Test Fixture provides a

convenient way to connect the Model 7072 Semiconductor Matrix Card to standard packaged semiconductor devices. The Model 8007 has two ZIF (zero insertion force)

sockets to simplify connections to a variety of devices.

Key features of the Model 8007 include:

Six mass-terminated connectors located on the rear

panel for connecting the fixture to the Model 7072 matrix card or other devices.

24.pin and 48-pin ZIF sockets for ease of connections

to a variety of DIP packaged devices from 0.3” to 0.6”

lead centers.

Prototyping board, which plugs into the ZIF sockets,

can be used for custom circuit wiring.

Guarding pathways are carried through to the ZIF

socket terminals in order to maintain maximum pathway isolation.

1.4 MANUAL ADDENDA

Any improvements or changes concerning the test fixture or manual will be explained in an addendum included with the the unit. Be sure to note these changes

and incorporate them ilvto the manual before using or

servicing the fixture.

1.5 SAFETY SYMBOLS AND TERMS

The following symbols and terms may be found on an in-

strument or used in this manual.

The A

should refer to the operating instructions located in the

instruction manual.

The = symbol represents a protective grounding terminal. This terminal must be connected to a safety earth

ground via #18 AWG minimum wire before operation.

The WARNING heading used in this manual explains

dangers that might result in personal injury or death. Always read the associated information very carefully be-

fore performing the indicated procedure.

symbol on an instrument indicates that the user

0

l-1

Page 18

SECTION 1

GeneralInformation

The CAUTION heading used in this manual explains

hazards that could damage the unit. Such damage may

invalidate the warranty.

1.6 SPECIFICATIONS

Model 8007 specifications may be found at the front of

this manual.

1.7 UNPACKING AND INSPECTION

1.7.1

Upon receiving the Model 8007, carefully unpack it from

its shipping carton and inspect the fixture for any obvious signs of physical damage. Report any such damage to

the shipping agent immediately. Save the original packing carton for possible future reshipment.

1.7.2

The following items are included with every Model 8007

order:

.

Model 8007 Semiconductor Test Fixture

.

Model 8007~PTB prototyping board

.

Two Model 8007-MTC-3 mass-terminated triax cable

assemblies

.

Safety grounding cable (Model 8007-GND-3)

.

Safety interlock cable (Model 236~ILC-3)

.

Five 5-way binding posts

.

24 ferrite beads for device oscillation control (see para-

graph 2.5.10).

.

Model 8007 Instruction Manual

.

Additional accessories as ordered

1

7.3

If an additional instruction manual is required, order the

manual package, Keithley part number 8007-901-00. The

manual package includes an instruction manual and any

pertinent addenda.

Inspection for Damage

Shipment Contents

Instruction Manual

1.8 REPACKING FOR SHIPMENT

Should it become necessary to return the Model 8007 for

repair, carefully pack the unit in its original packing carton or the equivalent, and include the following information:

Advise as to the wwranty status of the test fixture.

Write ATTENTION REPAIR DEPARTMENT on the

shipping label.

Fill out and include the service form located at theback

of this manual.

1.9 OPTIONAL ACCESSORIES

Model 236ILC-3 Interlock Cable: The Model 236.ILC-3

is 3m (10 ft.) in length and is intended to connect the

Model 8007 interlock to instruments with similar inter-

lock circuits such as the Model 236 and 237 Source Meas-

ure Units.

Model 8007-MTC-3 Triax Cable Assembly: The Model

8007.MTC-3 is intended for input/output connections to

the Model 8007. The Model 8007-MTC-3 has hyelve

3.meter (lo-foot) triaxial cables that terminate to a single

mass-terminated connector on one end, and each cable is

terminated with a male triax connector on the other end.

A total of six Model 8007-MTC-3 cable assemblies are required to use all 72 input/output pathways on the test

fixture.

Model 8007-PTB Prototyping Board: The Model

8007~PTB Prototyping board is the board supplied with

the Model 8007. Additional Model 8007-FTB boards may

be ordered to allow ease of changing test circuits. The

prototyping board contains breadboarding areas with

holes on standard 0.1” centers, 0.04” in diameter for easy

mounting of standard components such as ICs, transistors, diodes, resistors, and capacitors. The Model

8007-PTB plugs into the two ZIF sockets located on the

top panel of the test fixture. The prototypingboard canbe

secured to the top panel with the captive screw, if desired, or it can be left unsecured for ease of removal.

l-2

Page 19

SECTION 2

Operation

2.1 INTRODUCTION

This section contains information on making connections

to the Model 8007, as well as considerations when making measurements using the test fixture, and it is organized as follows:

Fixture Configuration: Details the test fixture con-

2.2

nectors and sockets, and also discusses safety interlock

connections.

Matrix Card Connections: Covers test fixture con-

2.3

nections to the Model 7072 Semiconductor Matrix Card.

2.4 Typical Instrument Connections: Shows how to

connect various types of instruments to the fixture, including source measure units, current and voltage

sources, electrometers, and CV meters.

2.5 Measurement Considerations: Outlines a number

of considerations that should be observed for optimum

measurements made using the test fixture.

2.6 TypicalApplications: Summarizesapplicationsexamples for the test fixture when used with appropriate

test equipment.

@

SCP3V

The = screw provides a connecting point for safety

0

earth ground.

WARNING

To avoid electric shock, the = screw must

be connected to safety earth ground using

#I18 AWG or large wire. Use the supplied

safety

8007-GND-3).

Rear Panel Screws

The two screws that secure the rear panel to

the fixture base must be installed in order to

ensure a good ground connection between

the rear panel and the test fixture base.

Safety Interlock Connections

grounding

WARNING

0

cable (Model

2.7 Using the Prototyping Board: Summarizes use of

the prototyping board for connection of custom circuits

to the test fixture.

2.2 FIXTURE CONFIGURATION

2.2.1

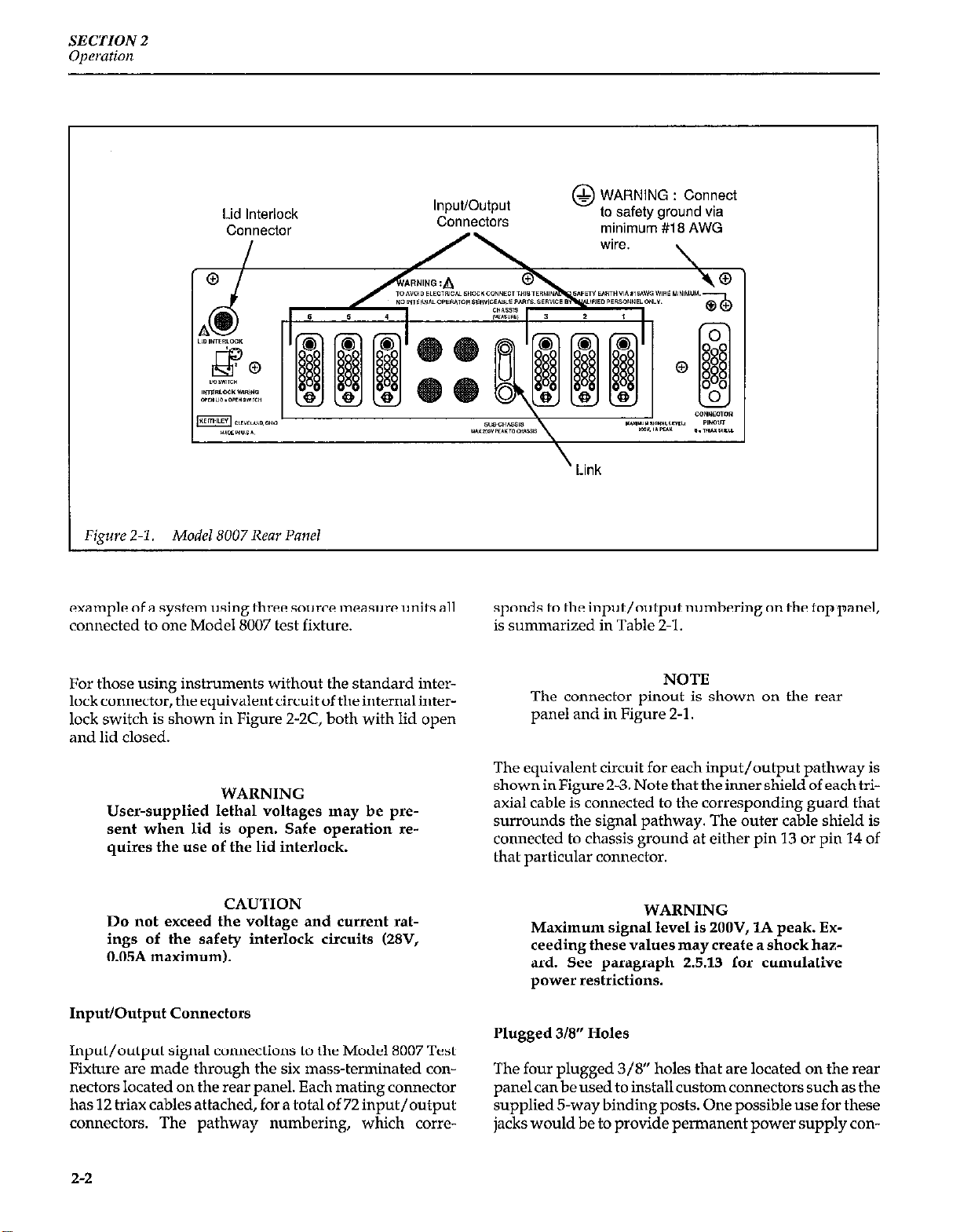

The rear panel of the Model 8007 is shown in Figure 2-1.

Keys aspects of the rear panel include the six input/output mass-terminated connectors, the safety interlock

connector, CHASSIS (MEASURE) and SUB CHASSIS

posts, the - ternmal, and the plugged 3/8” holes for 0

user expansion. Each of these items are discussed below.

Rear Panel

Thesafetyinterlockconnectorisintendedforusewithinstruments equipped tiith a matching interlock connector

to provide user safety when using hazardous voltages.

Note that you must use the Keithley safety interlock cable

(Model 236~ILC-3) with the instrument in order for the

source measure unit to properly recognize whether the

lid is open or closed.

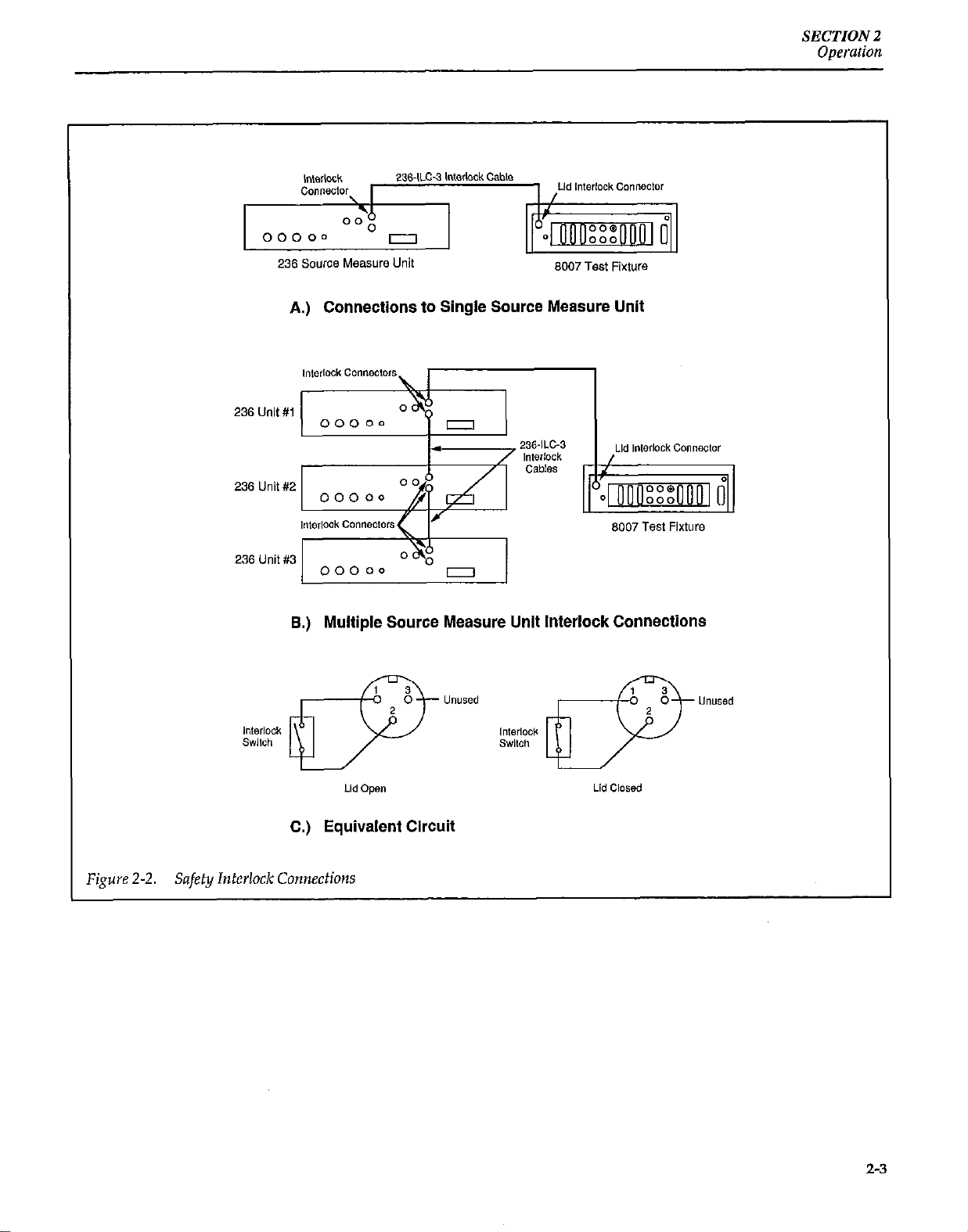

Figure 2-2A shows typical connections to a Model 236 or

237 source measure unit. Note that the Model 8007 LID

INTERLOCK connector is connected to one of the INTERLOCK connectors on the unit using the Model

236-ILC-3 interlock cable. With multiple source measure

unit systems, all source measure units should be connected to the interlock by daisy chaining the interlock

connectors of the source measure units together using

additional Model 236~ILC-3 cables. Figure 2-2B shows an

2-l

Page 20

SECTION 2

Operation

Lid Interlock

connector

Figure 2-l. Model 8007 Rear Panel

InputJOutput

Connectors

example of a system using three source measure units all

connected to one Model 8007 test fixture.

minimum #18 AWG

’ Link

sponds to the input/output numbering on the top panel,

is summarized in Table 2-l.

For those using instruments without the standard interlock connector, the equivalent circuit of the internal interlock switch is shown in Figure Z-X, both with lid open

and lid closed.

WARNING

User-supplied lethal voltages may be pmsent when lid is open. Safe operation requires the use of the lid interlock.

CAUTION

Do not exceed the voltage and current ratings of the safety interlock circuits (28V,

0.05A maximum).

Input/Output Connectors

Input/output signal connections to the Model 8007 Test

Fixture are made through the six mass-terminated connectors located on the rear panel. Each mating connector

has 12 trim cables attached, for a total of 72 input/output

connectors. The pathway numbering, which corre-

NOTE

The connector pinout is shown on the rear

panel and in Figure 2-l.

The equivalent circuit for each input/output pathway is

shown in Figure 2-3. Note that the inner shield of each triaxial cable is connected to the corresponding guard that

surrounds the signal pathway. The outer cable shield is

connected to chassis ground at either pin 13 or pin 14 of

that particular connector.

WARNING

Maximum signal level is 2OOV, 1A peak. Exceeding these values may create a shock hazard. See paragraph 2.5.13 for cumulative

power restrictions.

Plugged 3/8” Holes

The four plugged 3/8” holes that are located on the rear

panel can be used to install custom connectors such as the

supplied 5-way binding posts. One possible use for these

jacks would be to provide permanent power supply con-

2-2

Page 21

SECTION 2

Operation

236 Source Measure Unit

8007 Test Fixture

A.) Connections to Single Source Measure Unit

B.) Multiple Source Measure Unit Interlock Connections

Figure 2-2.

I

Lid open

C.) Equivalent Circuit

Safety Interlock Connections

2-3

Page 22

SECTION 2

Operation

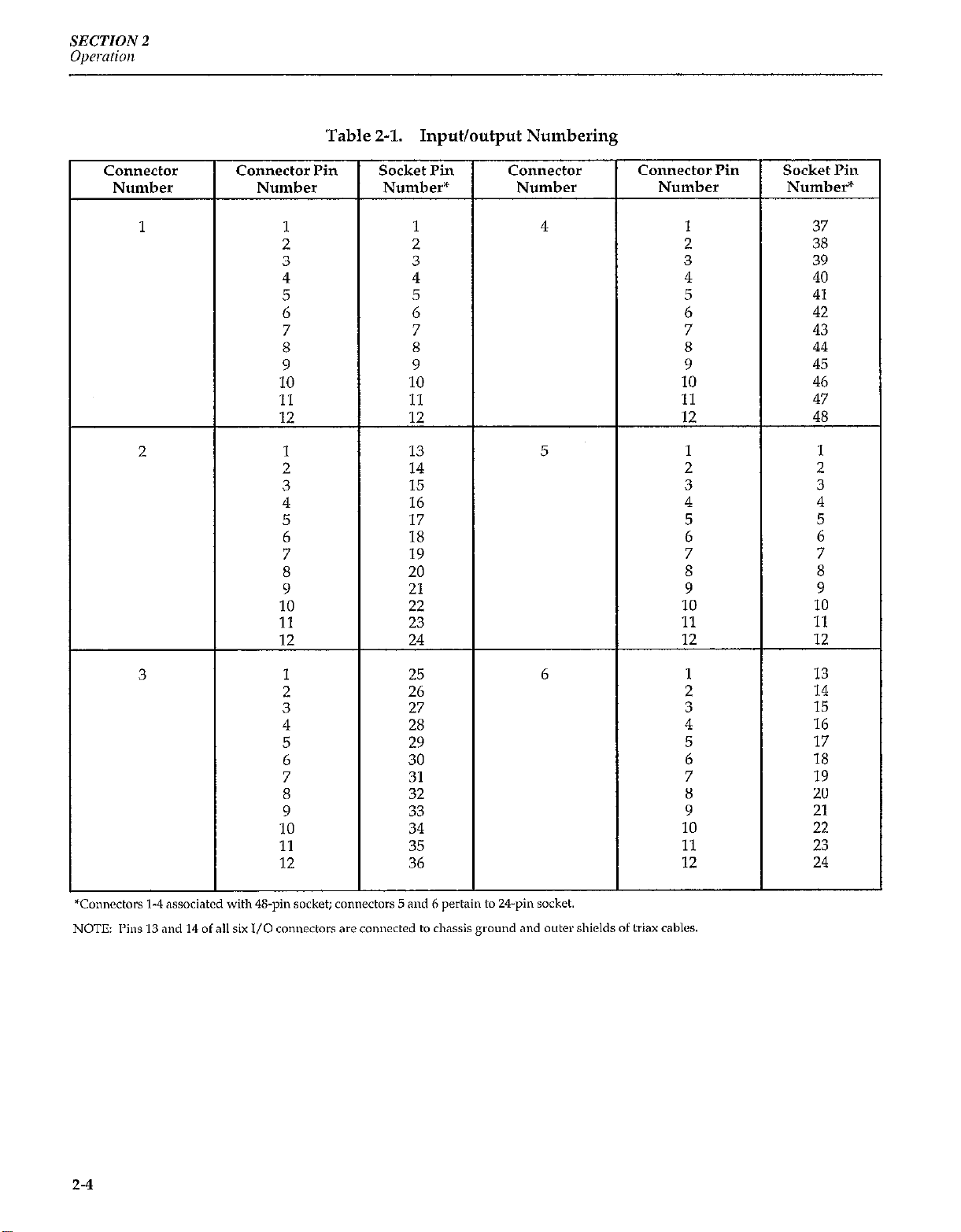

Table 2-1. Input/output Numbering

Connector Connector Pin Socket Pin Connector

Number Number Number* Number

1

1

4 1

2

3

4

5

6

7

8

9

10

11

12

2

6

7

8

9

10

11

12

13

5

14

15

16

17

6

7

8

18

19

20

9 21

10 22

11 23

24

ConnectorPin Socket Pin

Number Number*

37

2

3

4

38

39

40

41

:

7

8

9

10

11

12

42

43

44

45

46

47

48

1 1

2 2

3 3

4 4

5 5

6

7

6

7

8 8

9 9

10 10

11 11

12 12

3

25

26

27

28

29

30

7

31

8 32

9

10

11

12

33

34

35

36

6

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

2-4

Page 23

SECTION 2

Operation

Figure

Rp = Path Resistance

Cl, RI = Path Isolation (See specilications)

See paragraph 2.5 for discussion

-1

2-3.

Input/Output Equivalent Circuit

L----------------A

1

Coax Connection

,-- Guard Trace on PC Board

Chassis

Shorting

Link

I

8007 Test Fixture

nections to the two DIP sockets without having to route

power through the trim cables. Refer to paragraph 3.7 for

details on installing binding posts,

SUB CHASSIS Post

The SUB CHASSIS post is intended for applying a guard

signal from an external measuring or sourcing instmment. SUB CHASSIS is internally connected to the sub

chassis that houses the circuit board.

WARNING

Do not exceed the ZOOV peak between SUB

CHASSIS and CHASSIS. When using any

binding post with hazardous voltages (>3OV

RMS), shut off all sxnces beforeconnecting,

and dress all leads 80 that no conductive SUP

faces are exposed.

NOTE

The shorting link that connects SUB CHASSIS

to CHASSIS (MEASURE) should be discon-

nected from SUB CHASSIS when a guard signal is to be connected.

cmws (MEASURE) Post

The CHASSIS (MEASURE) binding post provides a convenient connecting point to fixture SUB CHASSIS. Normally, a shorting link is installed between this post and

the SUB CHASSIS binding post, which places the sub

chassis at chassis (earth) ground as well. If you intend to

connect a guard signal or circuit LO, the shorting link

must be removed from SUB CHASSIS.

WARNING

Do not use cmss~s (MEASURE) for safety

earth ground.

2.2.2

The front panel contains the 24-pin and 4%pin ZIF (zero

insertion force) sockets for device connections

(Figure Z-4). These two sockets can accommodate a variety of different DIP packages such as 14; 16-, and IS-pin

DIPS with 0.3 to 0.6.inch spacing. Also, the prototyping

board, which is covered in paragraph 2.7, is designed to

plug into these two sockets.

The sockets are individually numbered according to

standard DIP convention (l-24 and l-48). Table 2-1 sum-

Front Panel

2-S

Page 24

CABLE NUMBER

I

CABLE NUMBER

1 2 5

WARNING

User-supplied lethal voltages may be present while the lid is open. Safe operation requires the use of the safety interlock (paragraph 2.2.1,).

2.2.3

3

Sub Chassis Guarding

To install a device in one of the sockets, simply lift the

lever to open the socket holes, then carefully slide the

pins of tlw device down into the socket. When the device

is seated, move the socket lever down to the closed posilion to lock the d&cc into place.

2-6

NOTE

Disconnect tlw shorting link connecting SUB

CIHASSIS to CHASSIS (MEASURE) b&m

applying guard. To do so, loosen the binding

Page 25

posts, then swivel the link aside and tighten

the CHASSIS (MEASURE) binding post.

mainframe willresult in thesame 72.pin test capability as

the Model 8007 test fixture.

In order to be most effective, guard should be driven at

the same dc potential as the most critical (lowest level)

pathway to be guarded. If no guard is available, SUB

CHASSIS can be connected to circuit LO for effective

shielding of all pathways in the test fixture.

WARNING

Do not exceed the maximum recommended

SUB CHASSIS voltage (ZOOV peak).

NOTE

To avoid possible noise pickup, always cow

nect SUB CHASSIS either to guard, LO, or

CHASSIS (MEASURE).

2.3 MATRIX CARD CONNECTIONS

Model 7072 Connections

The Model 8007 is intended primarily for use with the

Model 7072 Semiconductor Matrix Card. The mass-terminated trim cable assemblies should be used to connect

the test fixture to the matrix card. Figure 2-6(A) shows an

example of how to connect the test fixture to one matrix

card. Since each Model 8007 I/O connector has connections for 12 pathways, the most logical scheme would be

to connect the test fixhm to’the columns on the Model

7072.

For additional switching pathways, additional matrix

cards must be used. SixModel 7072 cards installed in one

When making connections, keep in mind that all rows on

the Model 7072 are not the same. Rows A and B are lowcurrent rows, rows C through F are general-purpose

rows, and rows G and Hare CV rows. See the Model 7072

Instruction Manual for complete details.

Model 7152 Low-Current Matrix Card

Typical connections to a Keithley Model 7152 Low-Current Matrix Card are shown in Figure 2-6(B). Each cable

on the Model 8007-MTC-3 cable is connected to a cable on

the Model 7152-T cable using Pomona Model 5278 fe-

male-to-female trim adapters.

Model 7073 Coaxial Matrix Card

Figure 2-6(C) shows typical connections to a Model 7073

Coaxial Matrix Card. Note that each cable on the Model

8007.MTC-3 cable is connected to a BNC jack on the ma-

trix card using Pomona Model 5299 3-Q triax to BNC

adapters.

2.4 TYPICAL INSTRUMENT

CONNECTIONS

The following paragraphs show how to connect the

Model 8007 to various types of instruments through a

Model 7072 Semiconductor Matrix Card. For detailed information on cabling for matrix card-to-instrumelIt con-

nections, refer to the Model 7072 Instruction Manual, as

well as the test instrument’s instruction manual.

2-7

Page 26

SECTION 2

O/leratiorl

1

Instrument

Connections

(7078.TRX Triax)

Instrument

Connections

/----.

Mode, 8007.MTC-3 Mass-

-

7072 Semiconductor

Matrix Card

Terminated Triax Cable

A. 7072 Matrix Card Connection Example

Matrix to Triax

Cable

B. 7152 Matrix Card Example

Firwe 2-6. Matrix Cnrd Connection Exnmple

2-8

5278

Female to Female

Triax adapters

Page 27

Instrument

Connections

(7051 Coax)

SECTION 2

Opemion

7073 Coaxial

Matrix Card

C. 7073 Coaxial Matrix Card Example

Matrix Card Connection Example (Cont.)

2.4.1

In some cases, special adapters will be necessary to connect the Model 8007-MTC-3 trim cables to the instruments. Figure 2-7 shows typical connecting schemes for

Adapters

Terminated Triax Cable

trim to banana, trim cable to trim cable, 3-slot trim to

Z-lug triax, and trim to BNC connectors.

NOTE

For some connections, no commercial adapters are available. In those cases, it will be necessary to construct custom cables.

2-9

Page 28

SECTION 2

Operation

b.

BSla”a BNC/Banana

Jack

0”

ln*t,lmle”t

,,,;L; wm,..-.-D + To 8007

0 m ,,...,...,..,..... D

(Pomona 1894)

A.) TriaxiBanana

Z-Lug

Triax Adapter

,nstPunment

B.) 3-Lug Triax to Z-Lug Triax

3 Lug Triaxi BNC Triax Cable

(Pomona 5299) (8007 MTC-3)

6172

Triax

Cable

8007.MTC-3

Triax Cable

Pomona

5278

Female-to

Female Adapter

8007.MTC~3

Triax Cable

3 TO 8007

Fipre 2.7. Rdapkrs Required

C.) Triax Cable to Triax Cable

BNC Pomona

,r,,ttk,, Tg39h$ Triax Cab’e

D.) Triax to BNC

for

Connections

8007.MTC-3

Z-10

Page 29

SECTION 2

Operarion

2.4.2

Typical connections for a source measure unit are shown

in Figure 2-8. Note that the unit is connected to the rows,

while the test fixture itself is connected to the columns.

The mass-terminated triaxial cables are used to make the

connections between the test fixture and the matrix card,

while conventional trim cables should be used for connections between the unit and the matrix card.

Remote Sensing

The connections shown in Figure Z-8A are intended for

use with the source measure unit in remote sensing

mode. Remote sensing should be used when voltage

drops across the test leads and connectors are a consideration. When using remote sensing, it will be necessary

to connect two pathways to each side of the DUT. Either

but and jumper the circuit board, wire-up the prototyping board for Kelvin connections (as covered in para-

Source Measure Unit

NOTE

With some devices you may encounter device

oscillation resulting in incorrect readings. See

paragraph 2.5.10 for ways to verify the presence of oscillations and methods to minimize

them.

graph 2.7), or install short jumper wires between socket

terminals.

Local sensing

The connections shown in Figure Z-8B should be used

with the source measure unit in the local sensing mode.

Note that only two pathways are necessary through the

matrix card and test fixture to the DUT; no test fixture

modifications are necessary to use local sensing.

2.4.3

Typical connections for a DMM (for example, a Model

199) are shown in Figure 2-9. Two-wire connections are

shown in Figure 2-9(A), and 4-wire connections are

shown in Figure 2-9(B).

DMM (Digital Multimeter)

NOTE

As with source measure unit connections, the

4-wire connections will require adjacent

socket terminal jumpering or special

prototyping board wiring (paragraph 2.7) so

that two pathways are connected to each side

of the DUT.

2-11

Page 30

SECTION2

Operation

In7

I

I

! I

I !

8. Local Sensing

Page 31

SECTION 2

Opemtinn

L----J

707*

A. Z-Wire

I

L----i

Columns

8007

r----

I

1

Fipre 2-9. DMM

Connections

L----J L----.-J

7072

6. 4.Wire

8007

1

2-13

Page 32

SECTION 2

Oper&m

2.4.4

Electrometer 2.4.5 Source Connections

Two examples of electronwter connections are s11ow11 in

Figure Z-10. Guarded and unguarded volts connections

are shown in Figure 2-10(A) and Figure Z-lo(B), fast cur-

rent connections are shown in Figure Z-IO(C), and

guarded resistance connections are

shown in

Figure 2-10(D).

7072

A.) Electrometer, Unguarded Volts

Typical voltage and current source connections are

shown in Figure Z-11 and Figure 2-12 respectively. Voltage source connections are typically unguarded, while

current source connections are shown guarded, which is

the preferred configuration for low-level currents.

Coiwnns

r----

1

6.) Electrometer, Guarded Volts

7072

Columns

r----

L----J

1

0007

2-14

Page 33

r----

SECTION 2

Opemtion

C.) Electrometer, Fast Current

D.) Electrometer, Resistance (Guarded)

Electrometer Connections (Cont.)

ROW

Rows

r----7

,072

7072

COl”m”S

Columns

L----_1

r----

r----

I

8007

1

1

I

Figure 2-l 1. Voltage Source Connections

:- -) DUT

L- -.

fi

--

1

I

I

I

I

I

I

A--

l

-Socket

2-15

Page 34

SECTION 2

Operation

A,) Current Source, Unguarded

L----J

7072

Columns

Columns

r----

L----

r----

8007

1

I

I

I

I

I

I

I

6.) Current Source, Guarded

Figure Z-12. Current Source Connections

I Socket

I

I

_I

2-16

Page 35

SECTION 2

Operation

2.5 MEASUREMENT CONSIDERATIONS

Many measurements made with the Model 8007 can be

affected by noise and leakage paths. The following paragraphs discuss possible problems that might affect these

measurements and ways to minimize their effects.

2.5.1 Path Isolation

The path isolation is simply the equivalent impedance

between any two test paths in a measurement system.

Ideally, the path isolation should be infinite, but the actual resistance and distributed capacitance of cables, connectors, and sockets results in less than infinite path isolation values for these devices.

Path isolation resistance forms a signal path that is in parallel with the equivalent resistance of the DUT, as shown

in Figure Z-13. For low-to-medium device resistance values, path isolation resistance is seldom a consideration;

however, it can seriously degrade measurement accuracy when testing high-impedance devices. The voltage

measured across such a device, for example, can be substantially attenuated by the voltage divider action of the

device source resistance and path isolation resistance, as

shown in Figure 2-14. Also, leakage currents can be gen-

erated through these resistances by voltage sources in the

system.

Any distributed capacitance between measurement

pathways affects dc measurement settling time as well as

ac measurement accuracy. Thus, it is important that such

capacitance be kept as low as possible. Although the distributed capacitance of the test fixture and switching matrix card is generally fixed by design, there is one area

where you do have control over the capacitance in your

test system: the connecting cables. Use only low-capacitance cabling, and keep all cables as short as possible.

The effects of path resistance and capacitance can be

minimized by using guarding whenever possible. Paragraph 2.5.4 discusses guarding in more detail.

r-----

I

I I

I

I I

I

I __

RDUT

1

1 =E~ur

I I

I

L------l

DUT

RDUT

EDLIT

R PATH

= Source resistance of DUT

= Source voltage of DUT

= Path Isolation Resistance

= Input Resistance of Measuring Instrument

RIN

I

I

I RPATH <:

I

<

I

I

RIN <;

<

Measuring

Instrument

Figure 2-13. Path Isolation Resistance

2-17

Page 36

any semiconductor test system. Otherwise, interference

from such noise sources as line frequency and RF fields

can seriously corrupt a measurement.

-L-

- EDUT

T

2.5.2

As is the case with any hi@-resistance device, the integrity of connectors and sockets cm be compromised if they

are not handled properly. If the insulation becomes con-

taminated, the path isolation resistance will be substan-

tially reduced, nffcctillgl~igh-impedance measurements.

Oils and salts from the skin can contaminate insulators,

reducing their resistance. Also, contaminants present in

the air can be deposited on the insulator surfaces. To

avoid thcsc problems, never touch the connector or socket insulating material. In addition, the test fixture should

be used only in clean, dry environments to avoid con-

tamination.

Keeping Connectors and Sockets

Clean

For unguarded measurements, the inner shield of the triaxial cable that surrounds the signal path should be cow

netted to signal LO (or chassis ground for instruments

without isolated LO terminals). An example of how to

maintain a shielded pathway from an instrument,

through the matrix card, to the test fixture is shown in

Figure Z-15.

2.5.4

Guarding is important in high-impedance,circlLlts where

leakage resistance and capacitance coulli havedegrading

effects on the measurement. Guarding consists of using a

shield surrounding a conductor that is carrying the highimpedance signal. This shield is driven by a low-impedance amplifier to maintain the shield at signal potential.

For triaxial cables, the inner shield is used as guard. With

the Model 8007 test fixture, cach~guad p&way is carried through as close as possible to the corres~ponding device socket pin.

Guarding minimizes leakage resistance effects by driving the inner cable shield with a unity-gain amplifier, as

shown in Figure Z-16. Since the amplifier has a high input

impedance, it minimizes loading on the high-impedance

signal lead. Also, the low output impedance ensures that

the shield remains at signal potential, so that virtually no

leakage current flows through the leakage resistance, RI,.

Leakage between inner and outer shields may be consid-

erable, but that leakage is of little consequence because

that current is supplied by the buffer amplifier rather

than the signal itself.

Guarding

If the connector or socket insulators should become contaminated, either by inadvertent touching, or from air-

borne deposits, they can be cleaned wit11 a cotton swab

dipped in clean methanol. After thorough cleaning, they

should be allowed to dry for several hours in a 50°C lowhumidity environment before use, or they can be dried

more quickly using dry nitrogen gas. Do not use air from

an ordinary air compressor because oil present in the air

may result in contamination.

2.5.3

Proper shielding of all signal paths and devices under

test is important to minimize noise pickup in virtually

2-18

Shielding

In a similar manner, guarding also reduces the effective

cable capacitance, resulting in much faster measure-

ments on high-impedance circuits. Because any distrib-

uted capacitance is charged through the low impedance

of the buffer amplifier rather than by the source, settling

times are shortened considerably by guarding.

In order to use individual pathway guarding effectively

wit11 the Model 8007, the inner shield of the connecting

triaxial cable carrying the HI signal pat11 should be con-

nected to the guard output of the sourcing or measuring

instrument. That guard output should be at the same dc

potential as the signal being guarded. For the LO signal

path, simply connect the inner shield to LO at the meas-

uring or sourcing instrument.

Page 37

SE‘CTION 2

Operation

Inner

inner Shield of HI Triax

Connected to LO Connected to LO

r-----------

r-----

I

l-----------d

-----

7072 Card

Triax

1

r------i

l---- _I

8007

t

Socket

Figure 2-16.

Guarded Circuit

DUT

In

Fixture

/

Inner Shield

of Triax

r-------

Measuring

Instrument

2-19

Page 38

Figure 2-17 shows typical guarded connections, with the

guard path carried through the matrix card. Guard is carried through internally to the corresponding test socket

pin in order to provide maximum guarding benefits.

The entire sub chassis can also be guarded by connecting

a suitable guard potential to the rear panel SUB CHASSIS

jack of the test fixture. If no guard is available, connect the

SUB CHASSIS jack to circuit LO at a convenient point in

order to effectively shield internal fixture pathways.

WARNING

Maximum voltage between SUB CHASSIS

and CHASSIS (MEASURE) is 2OOV peak.

friction. l’iezoelectric charges are also generated by applying pressure to the cable.

In order to minimize cable noise currents, tie down cables

to avoid flexing, and isolate the cables from vibration

sources such as motors and pumps. Also, avoid tcmpera-

ture extremes that could lead to cable expansion and con-

traction.

2.5.6 Magnetic Fields

When a conductor loop cuts through magnetic lines of

force, a very small current ,is gener@ted. ‘This phenomenon will frequently cause unwanted signals to occur in

the test leads of a test system. If the conductor has sufficient length, even weak magnetic fields like those of the

earth can create sufficient signals to affect low-level

lneasurelnellts.

2.5.5 Cable Noise Currents

Noise currents can be generated by bending or flexing the

triaxial connecting cables. These currents, which are

known as triboelectric currents, are generated by charges

created between a conductor and insulator caused by

r-----

Two ways to reduce these effects are: (1) reduce the

lengths of the connecting cables, and (2) minimize the exposed circuit area. In extreme cases, magnetic shielding

may be required. Special metal with high permeability at

low flux densities (such as mu metal) are effective at reducing these effects.

Columns

-----

Triax

1

Triax

r------l

‘igure 2-l 7.

Z-20

L----------A

7072 Card

Socket

Typical Guarded Sigmf Connections

Page 39

Even when the conductor is stationary, magnetically-induced signals may still be a problem. Fields can be produced by various signals such as the ac power line voltage. Large inductors such as power transformers can

generate substantial magnetic fields, so care must be

taken to keep the test fixture a good distance away from

these potential noise sources.

2.5.7 Radio Frequency interference

RF1 (Radio Frequency Interference) is a general term

used to describe electromagnetic interference over a

wide range of frequencies across the spectrum. Such RF1

can be particularly troublesome at low signal levels, but it

can also affect measurements at high levels if the problem

is of sufficient severity.

RFI can be caused by steady-state sources such as radio or

TV signals, or some types of electronic equipment (mi-

croprocessors, high speed digital circuits, etc.), or it can

result from impulse sources, as in the case of arcing in

high-voltage environments. In either case, the effect on

the measurement can be considerable if enough of the

unwanted signal is present.

RF1 can be minimized in several ways. The most obvious

method is to keep the test fixture and signal leads as far

away from the RFI source as possible. Additional shielding of the test fixture, signal leads, sources, and measuring~instruments will often reduce RF1 to an acceptable

level. In extreme cases, a specially-constructed screen

room may be required to sufficiently attenuate the troublesome signal.

ment LO signal leads and then back through power line

ground. This circulating current develops a small but un-

desirable voltage between the LO terminals of the two instruments. This voltage will be added to the source voltage, affecting the accuracy of the measurement.

Fiaure Z-18. Power Line Ground LOOPS

Figure 2-19 shows how to connect several instruments

together to eliminate this type of ground loop problem.

Here, only one instrument is connected to power line

ground

Many instruments incorporate internal filtering that may

help to reduce RFI effects in some situations. In Some

cases, additional external filtering may also be required.

Keep in mind, however, that filtering may have detri-

mental effects on the desired signal.

2.5.8

When two or more instruments are connected together,

care must be taken to avoid unwanted signals caused by

ground loops. Ground loops usually occur when sensi-

tive instrumentation is connected to other instrumentation with more than one signal return path such as power

line ground. As shown in Figure Z-18, the resulting

ground loop causes current to flow through the instru-

Ground Loops

Ground loops are not normally a problem with instrulnentshavingisolated LO terminals. However, allinstruments in the test setup may not be designed in this manner. When in doubt, consult the manual for all instrumentation in the test setup.

z-21

Page 40

SECTION 2

Oat-ration

2.5.9 Capacitance Considerations

When making critical low-capacitance measurements,

keep in mind that the worst (highest) capacitance performance of the test fixture is between adjacent socket

pins. To minimize the effects of socket capacitance, measure between non-adjacent socket terminals. For example, assume you wish to measure the value of a discrete

capacitor by connecting the device between socket pins.

In this case, it would be better to connect the capacitor

across the socket rather than between adjacent socket

pins.

2.5.10 Device Oscillation

In some cases, you may encounter device oscillation

that will affect your measurements. Such oscillations are

not caused by the test fixture, but they can be present if

sufficient positive feedback is present in the test system.

This feedback can be caused by such factors as the additional capacitance of the test cables.

If present at all, oscillations will be seen more often with

multiple-instrument setups (for example, with source

measure units) when testing devices with high gainbandwidth products such as RF FETs, or with negativeresistance devices such as UJTs.

Verifying the Presence of Oscillations

With dc testing, the most obvious signs of possible oscil-

lations are:

l Unrepeatable or unstable measurements

l Inconsistent readings across ranges

l Unexpected data values

l Data changing significantly with the integration rate

of the instrument

l Changes in data with added instrument filtering.

The ac response of the pathways with ferrite beads will

be reduced, although the bulk dc resistance is very low.

Note that the beads must be installed as close to the

device package as possible to be most effective. Since

these beads typically have an inductance in the pH

range or less, this solution may be useful only for higher

oscillation frequencies (above 1OMHz or so).

Supplied Ferrite Beads

As summarized in Table 2-2, a total of 24 each of three

types of ferrite beads are supplied with the Model 8007.

These beads include leadless versions of Fair-Rite

Products Corp. types #43 and #73 ferrite material. A

version of type #43 with leads is also supplied for ease

of construction.

Table 2-2. Supplied Ferrite Beads

Qty. Description Keithley Part Number

24

Type #73, leadless CH-48

24

‘Qpe #43, leadless CH-49

24

Type #43, with leads

CH-50

Installing Ferrite Beads

If oscillation is found to be a problem, install ferrite

beads in the appropriate pathways on the prototyping

board supplied with the Model 8007 (see paragraphs

2.5.10 and 2.7 of instruction manual for information on

device oscillation and details on using the prototyping

board). In most cases, best results will be obtained by

installing beads on the gate or base leads of the DUTs.

Since the effective bead impedances at the frequency of

interest are typically less than 10051 (see below), it may

be necessary to use two or more beads, particularly in

difficult cases.

If any of these symptoms are noted, the presence of

oscillations can be verified with an oscilloscope. Note,

however, that connecting an oscilloscope may affect the

oscillation, either increasing or decreasing them, or possibly even dampening them completely.

Using Ferrite Beads

Using the supplied ferrite beads may solve the oscilla-

tion problem. These ferrite beads can be permanently

installed in all pathways going to the device under test.

2-22

Suppression Capabilities

Figure Z-20 shows how the impedance of the type #73

beads varies with frequency. Note that this material is

optimized for use below 40MHz. Figures 2-21 and 2-22

show the impedance vs. frequency curve of the type #43

material with and without leads, which is optimized for

use above 40MHz, up to a maximum of 200MHz. Note

that installation of ferrite beads may have undesirable

effects on the AC frequency characteristics of the test

circuit.

Page 41

SECTION 2

Oweration

Using Resistors

Another

solution

for oscillation - one that may also be

useful at lower frequencies-is to install series resistors

in the source or emitter of the DUT in order to reduce

overall gain. Some experimentation will be necessary to

determine the optimum value. In many cases, a small

resistance value will be all that is necessary to dampen

oscillations. In more serious cases, higher values will be

required. If you do install a series resistor, keep in mind

that it may have detrimental effects on other aspects of

the measurements. Always select as small a resistance

value as possible to minimize these effects.

LC Filters

For extreme cases, small LCT filters are available. These

filters can be mounted directly on the circuit board with

the inductive elements in series with the pathway, while

the capacitance element should be placed in parallel

with the pathway. Again, installing filters will affect the

ac performance of the test fixture.

2-23

Page 42

SECTION 2

Operation

Installing Components

In order to install series components, it will be necessary

to cut the individual circuit board traces going to the

socket terminals. For maximum benefit, devices should

be installed by soldering them to the traces as close to

the socket terminals as possible. Paragraph 3.6 discusses

circuit board modification in mcwe detail. Before modifying the test fixture, you may wish to verify that the

proposed remedy is viable by constructing a test circuit

on the prototyping board (paragraph 2.7).

CAUTION

Installing components or otherwise modifying the test fixture may degrade fixture performance specifications.

2.5.11 Environmental Considerations

Cleanliness

The test fixture should be operated only in a clean envi-

ronment. Otherwise, any dust or dirt that settles on the

fixture sockets or connectors could degrade fixture specifications. Even if front panel sockets are periodically

cleaned, long-term internal dirt build-up could also

affect specifications. If such contamination is suspected.

perform the performance verification procedures outlined in Section 3. Clean all internal parts using the procedure discussed in paragraph 3.3 if contamination is

verified.

Humidity

The test fixture should be operated within the humidity

limits given in the specifications at the front of this manual. Note that current and path isolation in particular

are affected by humidity. For best results, use the fixture

in a low-humidity environment.

Light

motors and pumps. Place the test fixture on a vibrationisolating base such as rubber if vibration swrces cannot

be completely eliminated.

2.5.13 Low Current and Low Voltage

Measurements

The effects of the fixture offset current come into play

with very low currents. To minimize these effects,

enable the instrument zero or suppression feature with

no device installed in the sockets and the lid closed to

cancel the offset current. Install the device, and make

the measurement with zero or suppress enabled. Measurements should be made as soon as possible after suppression to ensure that the offset currents are properly

suppressed.

Similarly, low-voltage measurements can be affected by

thermal EMF voltages. These voltages, which are typically generated at connector and relay contact points,

can also be suppressed by using the zero feature of the

measuring instrument. However, since these offsets are

thermally generated, temperature variations will cause

their values to drift. For that reason, the fixture should

be operated in a thermally-stable environment, especially when making critical, low-voltage measurements.

Also, it will be necessary to rezero the measuring instrument often if thermal drift is noted.

2.5.14 Cumulative Power

Each signal pathway of the test fixture is rated at ZOOV,

1A peak. Since there are 72 pathways, it is obvious that

the theoretical total power that could be dissipated by

device(s) in the fixture is extremely high. Note, however, that there is a practical limit as to how much

cumulative power can be safely dissipated within the

test fixture. To avoid fixture damage, restrict cumulative

power so that the operating temperature of the fixture

does not exceed the value stated in the specifications at

the front of this manual.

Some devices are affected by light, which is the main

reason the Model 8007 is equipped with a light-tight

gasket. In order to ensure that the light-tight environment for the device is maintained, periodically check

the gasket in the base for deterioration. Also, make certain that no obstructions such as test leads keep the lid

from seating properly.

2.5.12 Vibration

Any vibration could affect fixture performance due to

piezoelechic and triboelectric effects. To obviate these

effects, keep the fixture and cables as far away as

possible from vibration-producing sources such as

2-24

CAUTION

Exceeding the recommended operating temperature may cause fixture damage.

2.5.15 AC Measurements

The equivalent ac circuit of the test fixture is especially

important to those making ac measurements. For that

reason, typical specifications for insertion loss, crosstalk,

and 3dB bandwidth are summarized at the front of this

manual. An overview of how to go about testing these

aspects of fixture performance are summarized in paragraph 3.2.7.

Page 43

SECTION 2

Operation

2.6 TYPICAL APPLICATIONS

The following paragraphs discuss several typical applications for using the Model 8007 along with the

Model 7072 Semiconductor Matrix Card.

2.6.1 CV Measurements

CV (capacitance-voltage) measurements are often made

on semiconductor devices in order to determine

important semiconductor parameters such as doping

profile, band bending, and mobile ion concentration.

The following paragraphs discuss a typical CV system

and typical CV curves.

Typical System Configuration

Figure 2-23 shows a typical system for making CV mea-

surements on a device with several elements requiring

testing. System components perform the following

functions.

8007 Test Fixture

r-----

-------

1

Model 590 CV Analyzer: Measures CV data at 1OOkHz

and 1MHz and sends the resulting data to the computer

for further analysis.

Model 595 Quasistatic CV Meter: Measures quasistatic

CV data and sends the data to the computer.

Model 707 Switching Matrix: Controls the Semiconductor Matrix Card to close and open the desired

crosspoints at the proper time.

Model 7072 Semiconductor Matrix Card: Switches the

signal pathways to the device elements under test.

Computer: Controls the instruments in the test system

using appropriate software.

HPGL Plotter: Provides hard copy graphs for the tests.

Model 8007 Test Fixture: Holds the device package

being tested and provides the interconnection interface

between the inst&ments and the device.

707 Switching Matrix o- - ’

IEEE-488 Bus

Note: Rows C-F can be used la

this signal path.

CV Analyzer

I

HP-GL

PIOtter

‘igure Z-23.

CV Test System

2-25

Page 44

SECTION 2

Otwation

Typical CV curve8

Typical CV curves generated by the Models 590 and 595

are shown in Figure 2-24 and Figure 2-25 respectively.

The quasistatic curve is almost symmetrical, while the

high-frequency curve is asymmetrical because of the

inability of the minority carriers to follow the highfrequency test signal.