Page 1

Model 8006 Component Test Fixture

Instruction Manual

A GREATER MEASURE OF CONFIDENCE

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of 1 year

from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable

batteries, diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in Cleveland, Ohio.

You will be given prompt assistance and return instructions. Send the product, transportation prepaid, to the indicated service

facility. Repairs will be made and the product returned, transportation prepaid. Repaired or replaced products are warranted for

the balance of the original warranty period, or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written consent, or

misuse of any product or part. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from

battery leakage, or problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY DIRECT,

INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF ITS

INSTRUMENTS AND SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN ADVANCE

OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY

PERSON, OR DAMAGE TO PROPERTY.

Keithley Instruments, Inc. 28775 Aurora Road • Cleveland, Ohio 44139 • 440-248-0400 • Fax: 440-248-6168

1-888-KEITHLEY (534-8453) • www.keithley.com

Sales Offices:BELGIUM: Bergensesteenweg 709 • B-1600 Sint-Pieters-Leeuw • 02-363 00 40 • Fax: 02/363 00 64

CHINA: Yuan Chen Xin Building, Room 705 • 12 Yumin Road, Dewai, Madian • Beijing 100029 • 8610-6202-2886 • Fax: 8610-6202-2892

FINLAND: Tietäjäntie 2 • 02130 Espoo • Phone: 09-54 75 08 10 • Fax: 09-25 10 51 00

FRANCE: 3, allée des Garays • 91127 Palaiseau Cédex • 01-64 53 20 20 • Fax: 01-60 11 77 26

GERMANY: Landsberger Strasse 65 • 82110 Germering • 089/84 93 07-40 • Fax: 089/84 93 07-34

GREAT BRITAIN: Unit 2 Commerce Park, Brunel Road • Theale • Berkshire RG7 4AB • 0118 929 7500 • Fax: 0118 929 7519

INDIA: Flat 2B, Willocrissa • 14, Rest House Crescent • Bangalore 560 001 • 91-80-509-1320/21 • Fax: 91-80-509-1322

ITALY: Viale San Gimignano, 38 • 20146 Milano • 02-48 39 16 01 • Fax: 02-48 30 22 74

JAPAN: New Pier Takeshiba North Tower 13F • 11-1, Kaigan 1-chome • Minato-ku, Tokyo 105-0022 • 81-3-5733-7555 • Fax: 81-3-5733-7556

KOREA: 2FL., URI Building • 2-14 Yangjae-Dong • Seocho-Gu, Seoul 137-888 • 82-2-574-7778 • Fax: 82-2-574-7838

NETHERLANDS: Postbus 559 • 4200 AN Gorinchem • 0183-635333 • Fax: 0183-630821

SWEDEN: c/o Regus Business Centre • Frosundaviks Allé 15, 4tr • 169 70 Solna • 08-509 04 679 • Fax: 08-655 26 10

SWITZERLAND: Kriesbachstrasse 4 • 8600 Dübendorf • 01-821 94 44 • Fax: 01-820 30 81

TAIWAN: 1FL., 85 Po Ai Street • Hsinchu, Taiwan, R.O.C. • 886-3-572-9077• Fax: 886-3-572-9031

4/02

Page 3

Model 8006 Component Test Fixture

Instruction Manual

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand and product names are trademarks or registered trademarks of their respective holders.

©1989, Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

First Printing, June 1989

Document Number: 8006-901-01 Rev. A

Page 4

Safety Precautions

The following safety precautions should be observed before using

this product and any associated instrumentation. Although some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions

may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions required to avoid possible injury. Read and follow all installation,

operation, and maintenance information carefully before using the

product. Refer to the manual for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use

and maintenance of equipment, for ensuring that the equipment is

operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be

trained in electrical safety procedures and proper use of the instrument. They must be protected from electric shock and contact with

hazardous live circuits.

Maintenance personnel perform routine procedures on the product

to keep it operating properly, for example, setting the line voltage

or replacing consumable materials. Maintenance procedures are described in the manual. The procedures explicitly state if the operator

may perform them. Otherwise, they should be performed only by

service personnel.

Service personnel are trained to work on live circuits, and perform

safe installations and repairs of products. Only properly trained service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that

are rated Installation Category I and Installation Category II, as described in the International Electrotechnical Commission (IEC)

Standard IEC 60664. Most measurement, control, and data I/O signals are Installation Category I and must not be directly connected

to mains voltage or to voltage sources with high transient over-voltages. Installation Category II connections require protection for

high transient over-voltages often associated with local AC mains

connections. Assume all measurement, control, and data I/O connections are for connection to Category I sources unless otherwise

marked or described in the Manual.

Exercise extreme caution when a shock hazard is present. Lethal

voltage may be present on cable connector jacks or test fixtures. The

American National Standards Institute (ANSI) states that a shock

hazard exists when voltage levels greater than 30V RMS, 42.4V

peak, or 60VDC are present. A good safety practice is to expect

that hazardous voltage is present in any unknown circuit before

measuring.

Operators of this product must be protected from electric shock at

all times. The responsible body must ensure that operators are prevented access and/or insulated from every connection point. In

some cases, connections must be exposed to potential human contact. Product operators in these circumstances must be trained to

protect themselves from the risk of electric shock. If the circuit is

capable of operating at or above 1000 volts, no conductive part of

the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits.

They are intended to be used with impedance limited sources.

NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the connecting

cables, test leads, and jumpers for possible wear, cracks, or breaks

before each use.

When installing equipment where access to the main power cord is

restricted, such as rack mounting, a separate main input power disconnect device must be provided, in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any

other instruments while power is applied to the circuit under test.

ALWAYS remove power from the entire test system and discharge

any capacitors before: connecting or disconnecting cables or jumpers, installing or removing switching cards, or making internal

changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground. Always

make measurements with dry hands while standing on a dry, insulated

surface capable of withstanding the voltage being measured.

The instrument and accessories must be used in accordance with its

specifications and operating instructions or the safety of the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating information, and as shown on the instrument or test fixture panels, or

switching card.

When fuses are used in a product, replace with same type and rating

for continued protection against fire hazard.

Chassis connections must only be used as shield connections for

measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use of a

lid interlock.

2/02

Page 5

If a screw is present, connect it to safety earth ground using the

wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of normal

and common mode voltages. Use standard safety precautions to

avoid personal contact with these voltages.

The WARNING heading in a manual explains dangers that might

result in personal injury or death. Always read the associated information very carefully before performing the indicated procedure.

The CAUTION heading in a manual explains hazards that could

damage the instrument. Such damage may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and

all test cables.

To maintain protection from electric shock and fire, replacement

components in mains circuits, including the power transformer, test

leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable national safety approvals,

may be used if the rating and type are the same. Other components

that are not safety related may be purchased from other suppliers as

long as they are equivalent to the original component. (Note that selected parts should be purchased only through Keithley Instruments

to maintain accuracy and functionality of the product.) If you are

unsure about the applicability of a replacement component, call a

Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based

cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill

on the instrument. Products that consist of a circuit board with no

case or chassis (e.g., data acquisition board for installation into a

computer) should never require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the factory for proper

cleaning/servicing.

Page 6

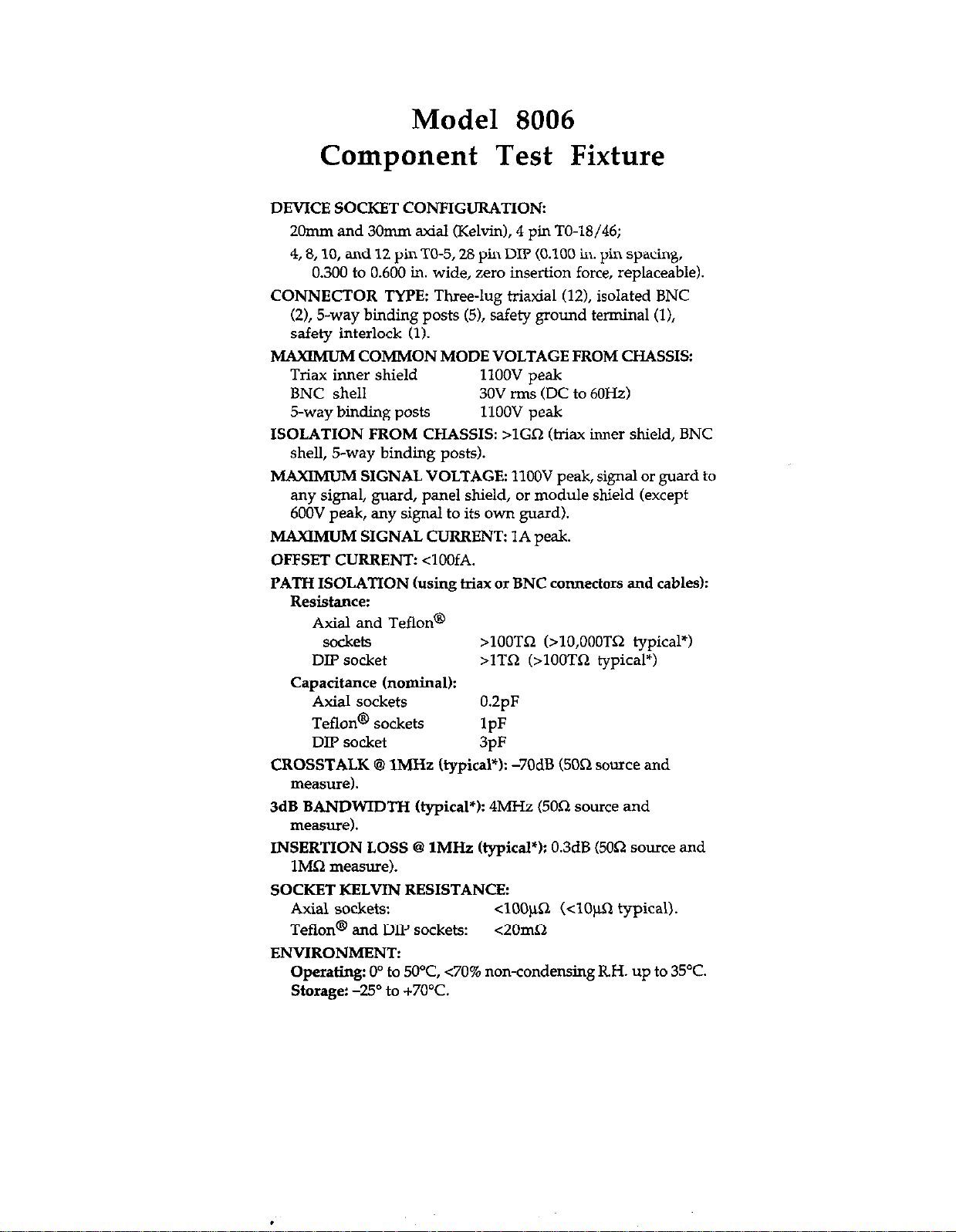

Model 8006

Component Test Fixture

DEVICE SOCKET CONFIGURATION:

‘2Omn-1 and 3Omm axial (Kelvin), 4 pin TO-W/46;

4,8,10, and 12 pinTO-5,28 pin DIP (0.100 in. pin spacing,

0.300 to 0.600 in. wide, zero insertion force, replaceable).

CONNECTOR TYPE: Three-lug triaxial (12), isolated BNC

(2), 5-way binding posts (51, safety ground terminal (l),

safety interlock (1).

MAXlMUM COMMON MODE VOLTAGE FROM CHASSIS:

Trim inner shield 1lOOV peak

BNC shell 30V rms (DC to 6OHz)

5-way binding posts

ISOLATION FROM CHASSIS: >lGO (triax inner shield, BNC

shell, 5-way binding posts).

MAXIMUM SIGNAL VOLTAGE: 1lOOV peak, signal or guard to

any signal, guard, panel shield, or module shield (except

600V peak, any signal to its own guard).

MAXIMUM SIGNAL CURRENT: 1A peak.

OFFSET CURRENT: <lOOfA.

PATH ISOLATION (using triax or BNC connectors and cables):

Resistance:

Axial and Teflon@

SO&t-S

DIP socket >lTQ (>lOOTQ typical*)

Capacitance (nominal):

Axial sockets 0.2pF

Teflon@ sockets

DIP socket

CROSSTALK @ 1MHz (typical*): -70dB (SOQ source and

measure).

3dB BANDWIDTH (typical*): 4MHz (50R source and

measure).

INSERTION LOSS @ 1MHz (typical”): 0.3dB (50R source and

1h40 measure).

SOCKET KELVIN RESISTANCE:

Axial sockets: <lOO@ (<lOpQ typical).

Teflon@ and DIP sockets: 40mO

ENVIRONMENT:

Operating: 0” to 5O”C, ~70% non-condensing RH. up to 35°C.

Storage: -25’ to +70°C.

IlOOV peak

>lOOTQ (>lO,OOOTR typical’)

IPF

3pF

Page 7

GENERAL

DIP SOCKET OPERATING LIFEz >25,000 open-close cycles.

LID INTERLOCK SWITCHING: <28VDC, 50mA.

DUIIENSIONS, WEIGHT: 14Omm high x 3OOmm wide x 3OOmm

deep (5.5 in. x 12 in. x 12 in.). Net weight 3.2kg (7 lbs. 2 oz.).

ACCESSORIES SUPPLIED:

lnstmction manual

Model 236-ILC3: Interlock Cable, 3m (10 ft.)

Model 8006-MJCz Red/Black Teflon Clip Jumpers

Model 800~MJG

Model 8006~MJS-1: Red Teflon Mini Jumper (10)

Model 8006~MJS-2:

Model 8006~MJS-3: Blue Teflon Mini Jumper (10)

Model 8007-GND-3:

ACCESSORIES AVAILABLE:

Model 7078-TRX-3: Triax Cable (3-lug), 0.9m (3 ft.)

Model 7078-TRX-10:

Model 4801: Low Noise Coax Cable, 1.2m (4 ft.)

*At room ambient conditions (18” to 28’C, ~40% R.H.).

Except where noted, specifications assume: Any socket, guarded

measurement configwation, including guarded jumpers and

lm external triax cables.

Guarded Teflon Mini Jumper (8)

Black Teflon Mini Jumper (10)

Safety Ground Wire

Triax Cable (3-lug), 3m (10 ft.)

Page 8

HOW TO USE THIS MANUAL

Contains information on Model 8006 features, specificatiom, and accessories.

Outlines test fixture connections and details how to connect

the fixture to instruments for typical device tests.

Contains performance verification and cleaning procedures for

the

test

fixture.

Lists replacement parts, and also includes component layout

and schematic drawings for the Model 8006.

SECTION 1

General Information

SECTION 2

Operation

SECTION 3

Service Information

SECTION 4

Replaceable Parts

Page 9

Table Of Contents

SECTION 1

1.1

- General Information

INTRODU’XION

1.2 FEATURES

1.3

WARRANTYINFORMATION

1.4 MANUAL ADDENDA

1.5 SAFETY SYMBOLS AND TERMS

1.6 SPECIFICATIONS

1.7 UNPACKING AND INSPECTION

1.7.1 Inspection for Damage

1.7.2 shipment contents

1.7.3

1.8

1.9

Instndion Manual

REPACKING FOR SHIPMENT

ACCESSORIES

SECTION 2 - Operation

2.1

2.2

2.2.1

2.2.2

2.2.3

2.2.4

2.2.5

2.2.6

2.2.7

2.3

2.3.1

2.3.2

2.3.3

2.3.4

2.3.5

2.3.6

2.3.7

2.4

2.4.1

2.4.2

2.4.3

2.4.4

2.4.5

2.4.6

2.4.7

2.4.8

2.4.9

INTRODUCTION ...........

PANELCONFIGURATION ...

RearPanel

..............

Signal Panel ....................

Component Test Module ...........

Installing Devices in Sockets ........

Installing Jumpers

................

Panel and Module Guarding ........

Source Measure Unit Overlays

INSTRUMENTCONNECTIONS

Source Measure Unit Connections

Current Source Connections ........

Voltage Source Connections ........

Electrometer

Connections ..........

Matrix Card Connections ..........

Dh4M Connections ...............

Miscellaneous Instrument Connections

MEASLJREMENT CONSIDERATIONS

Path Isolation ...................

Keeping Connectors and Sockets Clean

shiekiiig

Guarding

......................

...............

Cable Noise Currents ......

Magnetic Fields ...........

Radio Frequency Interference

Ground Loops ...........

Kelvin Connections ........

.............................

.............................

.............................

......

......

....

.............................

.............................

.............................

.....................

.....................

........................

........................

........................

....................

....................

....................

....................

....................

....................

....................

....................

....................

....................

....................

....................

....................

....................

.....................

l-l

l-l

l-l

l-l

1-l

l-2

l-2

l-2

l-2

l-2

l-2

l-2

.

2-l

2-l

2-l

24

24

2-5

2-5

2-7

2-7

2-7

2-8

2-12

2-14

2-16

2-17

2-19

.

2-19

2-20

2-20

2-z

2-23

2-24

2-25

2-26

2-26

2-26

2-27

Page 10

2.4.10

2.4.11

2.4.12

2.4.13

2.4.14

2.4.15

2.5

2.5.1

2.5.2

2.5.3

2.5.4

DeviceOsciIIation

Environmental Considerations

...........................

.................

Vibration .................................

Low-Current and Low-Voltage Measurements

Cumulative Power

AC Measurements

TYPICAL APPLICATIONS

DiodeTesting

Transistor Testing

..........................

..........................

......................

..............................

...........................

.....

ICTesting .................................

Semiconductor Parameter Analysis Switching System

................

................

................

................

................

................

................

2-29

2-34

2-34

2-34

2-34

2-34

2-35

2-35

2-37

240

245

SECTION

3.1

3.2

3.2.1

3.2.2

3.2.3

3.2.4

3.2.5

3.2.6

3.3

3.3.1

3.3.2

3.4

3.4.1

3.4.2

3.5

SECTION

4.1

4.2

4.3

3 - Service Information

INTRODUCTION

PERFORMANCE VERIFICATION

EnvironmentaI Conditions

Recommended Test Equipment

Performance Record

Isolation Resistance Verification

Offset Current Verification

AC Performance

HANDLING AND CLEANING PRFCAUTIONS

Component Test Module Handling and Cleaning

Connector Cleaning

DISASSEMBLY AND ASSEMBLY

Disassembly

Reassembly .............................

INTERLOCK SWITCH CALIBRATION

..........................

.............

.................

..............

......................

.............

.................

.........................

......................

..............

............................

.........

4 - Replaceable Parts

INTRODUCTION...............................

PARTSLIST . . . . . . . . . . . . . . . . . . . . .._............

ORDERTNG INFORMATION . . . . . . . . . . . . .

4.4 FACTORY SERVICE . . . . . . . . . . . . . . . .

4.5 COMPONENT LAYOUT AND SCHEMATIC DIAGRAM .

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

..............

..............

..............

..............

..............

. . . . . . . . . .

...........

...........

...........

3-l

3-l

3-l

3-1

3-2

3-2

34

3-6

3-6

3-7

3-7

3-7

3-7

3-a

3-9

4-l

41

41

4-l

4-l

Page 11

List Of Illustrations

SECTION 2

Figure 2-l

Figure 2-2

Figure 2-3

Figure 24

Figure 2-5

Figure 2-6

Figure 2-7

Figure 2-8

Figure 2-9

Figure 2-10

Figure 2-11

Figure 2-12

Figure 2-13

Figure 2-14

Figure 2-15

Figure 2-16

Figure 2-17

Figure 2-18

Figure 2-19

Figure 2-20

Figure 2-21

Figure 2-22

Figure 2-23

Figure 2-24

Figure 2-25

Figure 2-26

Figure 2-27

Figure 2-28

Figure 2-29

Figure 2-30

Figure 2-31

Figure 2-32

Figure 2-33

Figure 2-34

Figure 2-35

Figure 2-36

Figure 2-37

Figure 2-38

Figure 2-39

Figure 240

Figure 241

Figure 242

- Operation

Test Fixture Rear Panel

Connecting Interlock Circuit to Source Measure Units

Interlock Circuit Wiring

Front Panel Showing Signal Panel and Component Test Module

Jumper Installation Examples ..........................

Example of Module Guarding ..........................

Source Measure Unit Connections .......................

Unguarded Current Source Connections

Guarded Current Source Connections ....................

Unshielded Voltage Source Connections

Shielded Voltage Source Connections

Unguarded Electrometer Connections

Guarded Electrometer Connections ......................

Matrix Card Connections .............................

Unshielded DMM Connections .........................

Shielded DMM Connections

Path Isolation Equivalent Circuit

Path Isolation Resistance ..............................

Current Error Caused by Path Isolation Resistance

Shielding Example Using Triaxial Cables

Shielding Example Using Coaxial Cables

GuardedCircuit

....................................

Typical Guarded Signal Connections

PowerLineGroundLoops

EliminatingGroundLoops

Unshielded Kelvin Connections

Shielded Kelvin Connections

Kelvin Connections Equivalent Circuits

EliminatingOscillations

Test Configuration for Diode Tests

Jumper Installation for Diode Tests

EquiwlentCititforVFvs.IFTests

Equivalent Circuit for Leakage Test

Equivalent Circuit for Zener Diode Test

Test Configuration for Transistor Tests

Typical Jumper Installation for Transistor Tests

Test Configuration for Current Gain Test

Test Setup for Measuring Common-emitter Characteristics

Configuration for ICBO Test

Equipment Connections for Op Amp Tests

IC Power Supply Connections

Typical Jumper Installation for IC Test

...............................

........

..............................

..................

..................

....................

....................

...........................

........................

..........

..................

..................

.....................

............................

............................

........................

..........................

..................

..............................

......................

......................

....................

......................

..................

...................

.............

.................

....

...........................

................

..........................

...................

................

................

................

................

................

................

................

................

................

................

................

................

................

................

................

................

................

................

................

................

................

................

................

................

................

................

................

................

................

................

................

................

................

................

................

................

................

................

................

................

................

................

2-2

2-2

2-3

24

2-6

2-7

2-9

2-12

Z-13

2-14

2-15

2-16

2-17

2-18

2-19

2-20

2-21

2-22

2-22

2-23

2-24

2-24

2-25

2-26

2-27

2-27

2-27

2-28

2-31

2-35

2-36

2-36

2-37

2-37

2-38

2-39

240

241

241

242

242

243

Page 12

Figure 243 Circuit to Determine Input Bias Current

. . . . . . . . . . . .

Figure 244 Determining Input Offset Voltage Using DMM . , . . .

Figure 245 Determining Input Offset Voltage Using Nanovoltmeter

Figure 246

Figure 247

Semiconductor Parameter Analysis Switching System

Typical Test ConfIguration . . . . . . . _ . . . . .

....................

....................

....................

244

2-M

244

2-45

246

SECTION 3

Figure 3-l

Figure 3-2

Figure 3-3

Figure 34

Figure 3-5

Figure 3-6

Figure 3-7

Figure 3-8

- Service Information

Path Isolation Verification Triax Connections

Path Isolation Verification BNC Connections

Triex Conmdion+s for Offset Current Test .

BNC Connections for Offset Current Test

Connections for AC Response Test . . . .

Fixture Disassembly . . . . . . . . . . .

Hinge Alignment . . . . . . . . . . . .

Safety Interlock Switch Adjustment . .

. .

....................

....................

....................

....................

....................

....................

....................

....................

3-3

3-3

3-5

3-5

3-7

3-a

3-8

3-9

Page 13

List Of Tables

SECTION 3

Table 3-l

Table 3-2

- Service Information

Recommended Test Equipment .

PerfonnanceRecord . ..______.......____.__.,,._____......_.._.....,.....__ 3-2

3-1

Page 14

SECTION 1

General Information

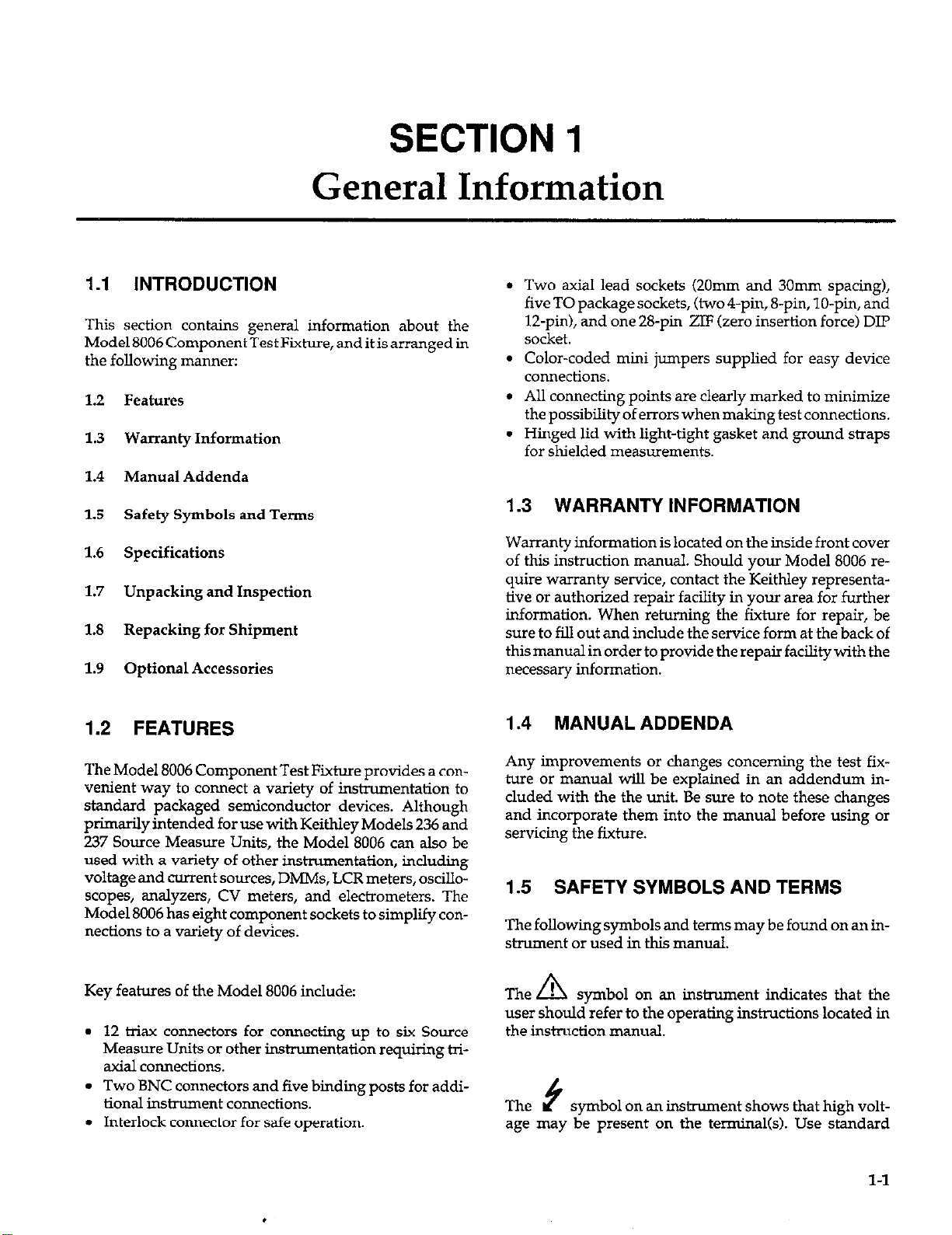

1.1 INTRODUCTION

This section contains general information about the

Model 8006 Component Test Fixture, and it is arranged in

the following manner:

1.2 Features

1.3 Warranty Information

1.4 Manual Addenda

1.5 Safety Symbols and Terms

1.6 Specifications

1.7 Unpacking and Inspection

1.8 Repacking for Shipment

1.9 Optional Accessories

1.2 FEATURES

Two axial lead sockets (2Omm and 3Omm spacing),

five TO package sockets, (two 4-pin, 8-pin, IO-pin, and

lZpin), and one 28-pin ZIF (zero insertion force) DIP

socket.

Color-coded mini jumpers supplied for easy device

connections.

All connecting points are clearly marked to minimize

the possibility of errors when making test connections.

Hinged lid with light-tight gasket and ground straps

for shielded measurements.

1.3 WARRANTY INFORMATION

Warranty information is located on the inside front cover

of this instruction manual. Should your Model 8006 require warranty service, contact the Keithley representative or authorized repair facility in your area for further

information. When returning the fixture for repair, be

sure to fill out and include the service form at the back of

this manual in order to provide the repair facility with the

necessary information.

1.4 MANUAL ADDENDA

The Model 8006 Component Test Fixture provides a convenient way to connect a variety of instrumentation to

standard packaged semiconductor devices. Although

primarily intended for use with Keithley Models 236 and

237 Source Measure Units, the Model 8006 can also be

used with a variety of other instrumentation, including

voltage and current sources, DMMs, LCR meters, oscillo-

scopes, analyzers, CV meters, and electrometers. The

Model 8006 has eight component sockets to simplify con-

nections to a variety of devices.

Key features of the Model 8006 include:

l

12 triax connectors for connecting up to six Source

Measure Units or other instrumentation requiring triaxial connections.

l

Two BNC connectors and five binding posts for additional instrument cormections.

l

Interlock connector for safe operation.

Any improvements or changes concerning the test fiuture or manual will be explained in an addendum included with the the unit. Be sure to note these changes

and incorporate them into the manual before using or

servicing the fixture.

1.5 SAFETY SYMBOLS AND TERMS

The following symbols and terms may be found on an instrument or used in this manual.

The A symbol on an instrument indicates that the

user should refer to the operating instructions located in

the instruction manual.

The

age may be present on the terminal(s). Use standard

symbol on an instrument shows that high volt-

l-1

Page 15

SECTION1

General Information

safety precautions to avoid personal contact with these

voltages.

The - screw must be connected to safety earth ground

0

using #18 AWG or larger wire.

The WARNING heading used in this manual explains

dangers that might result in personal injury or death. AIways read the associated information very carefuuy be

fore performing the indicated procedure.

The CAUTION heading used in this manual explains

hazards that could damage the unit. Such damage may

invalidate the warranty.

1.6 SPECIFICATIONS

Model 8006 specifications may be found at the front of

this manual.

1.7 UNPACKING AND INSPECTION

l

Source Measure Unit overlays to label jacks with

Model 236/237 input/output nomenclature.

l

Model 8006 Instruction Manual.

. Additional accessories as ordered.

1.7.3 Instruction Manual

If an additional instruction manual is required, order the

manual package, Keithley part number 8006-901-00. The

manual package includes an instruction manual and any

pertinent addenda.

1.8 REPACKING FOR SHIPMENT

Should it become necessary to return the Model 8006 for

repair, carefully pack the unit in its original packing carton or the equivalent, and include the following information:

. Advise as to the warranty status of the test fixture.

. Write ATTENTION REPAIR DEPARTMENT on the

shipping label.

l

Fill out and include the service form located at the back

of this manual.

1.7.1 Inspection for Damage

Upon receiving the Model 8006, carefully unpack it from

its shipping carton and inspect the fixture for any obvious signs of physical damage such as misalignment of the

lid and base. Report any such damage to the shipping

agent immediately. Save the original packing carton for

possible future reshipment.

1.7.2 Shipment Contents

The following items are included with every Model 8006

order:

Model 8006 Component Test Fixture.

30 standard color-coded Teflon@ mini jumpers, 10

each red (Model 8006-MJsl), black (Model

8006~MJSZ), and blue (Model 8006M&3).

8 guarded Teflon@ mini jumpers (Model 8CH&MJG)

for shielded or guarded connections.

Red/black pair of Teflon@ clip jumpers.

Safety Interlock Cable (Model 236-ILC-3).

Safety Grounding Cable (Model 8007-GND-3)

Component Test Module (Model 8006CTM)

1.9 ACCESSORIES

Model 236-ILC-3 Interlock Cable - The Model

236~ILC-3 Interlock Cable connects the Model 8006 to the

interlock circuit of the Model 236/237 Source Measure

Unit. The Model 236-ILC3 is 3m (loft.) in length.

Model 4801 Low-noise BNC Cable -The Model 4801 is

a low-noise coaxial cable, 1.2m (48in.1 in length, with

male BNC connectors on each end. The Model 4801 can

be used for low-noise connections to the BNC connectors

on the Model 8006.

Model 7051 BNC Cables - The Model 7051-2 is a 0.6m

(2ft) BNC to BNC RGd8C cable. The Model 7051-5 is

similar to the Model 7051-2 except that it is 1.5m (51%)

long. The Model 7051 cables can be used to connect instruments to the BNC connectors on the Model 8006. The

Model 7051 cables have a nominal 5Oa characteristic impedance.

Model 7078-TRX Triax Cables -The Model 7078-m

T&xx cables are low-noise cables terminated with male 3slot triax connectors. The Model 7078-TRX-3 is 0.9m (3 ft.)

l-2

Page 16

SECTION I

General Information

in length, and theMode 707%TRX-10 is3.Om(lO ft.) long.

The Model 707%TRX cables are recommended for making connections between the triax connectors on the

Model 8006 and external instrumentation such as the

Model 236/237 Source Measure Units.

Model 8006~CTh4 Component Test Module - The

Model 8006.CIMComponent Test Module is the module

supplied with the Model 8006 Test Fixture. The Model

8006cTM has two sets of axial lead Kelvin component

clips, five TO package sockets (two 4-pin, S-pin, IO-pin,

and 12;pin), and one 24-pin DE’ ZIF (zero insertion force

socket).

Model 8006-MJC Teflon@ Red/Black Clip Jumpers These clip jumpers can be used to make connections di-

rectly to component test leads.

Model 8006-MJG Guarded Teflon@ Mini Jumpers The Model 8006-MJG contains eight guarded mini jump-

ers like the guarded jumpers supplied with the Model

8006.

Model 8006-MJS Teflon@ Mini Jumpers -The Model

8006-MJS mini jumpers are the standard mini jumpers

supplied with the Model 8006. The jumpers are available

in three colors: black (Model 8006-MJS-I), red (Model

SC06-MJS-2), and blue (Model 8006-MJS-3). Each package

contains 10 jumpers.

Model 8007-GND-3 Safety Grounding Cable - The

Model 8007-GND-3 Safety

Groundmg

Cable is intended

for connecting fixture chassis ground to safety earth

gnxmd. One Model 8007-GND-3 is supplied with the test

fixture, and the cable is 3m (loft.) in length.

Source Measure Unit Overlays (PA-287)-The overlay

cards allow convenient identification of the rear panel

and signal panel jacks to correspond to Model 236/237

Source Measure Unit input/output nomenclature.

l-3

Page 17

SECTION 2

Operation

2.1 INTRODUCTION

This section contains information on making connections

to the Model 8006, as well as considerations when

ing measurements using

ized as follows:

Panel Configuration: Briefly discusses the connec-

2.2

tars and sockets located on the rear, instrument, and

component panels.

Instrument Connections: Shows how to connect

2.3

various types of instruments to the fixture, including

Source Measure Units, current and voltage sources, electrometers, and matrix cards.

Measurement Considerations: Outlines a number

2.4

of considerations that should be observed for optimum

performance when using the test fixture.

Typical Applications: Covers typical test fixture

2.5

appbcations such as diode, transistor, and IC tests.

The Model 8006 is intended for use by those

who are familiar with using potentially hazardous voltages. Refer to the safety precautions summarized at the front of this manual

before using the Model 8006.

the test fixture, and it is organ-

WARNING

mak-

WARNING

The maximum differential signal voltage is

1lOOV peak. The maximum signal current

for all connectors is 1A peak. Exceeding

these values may create a shock hazard.

@-.

fixture to safety earth ground.

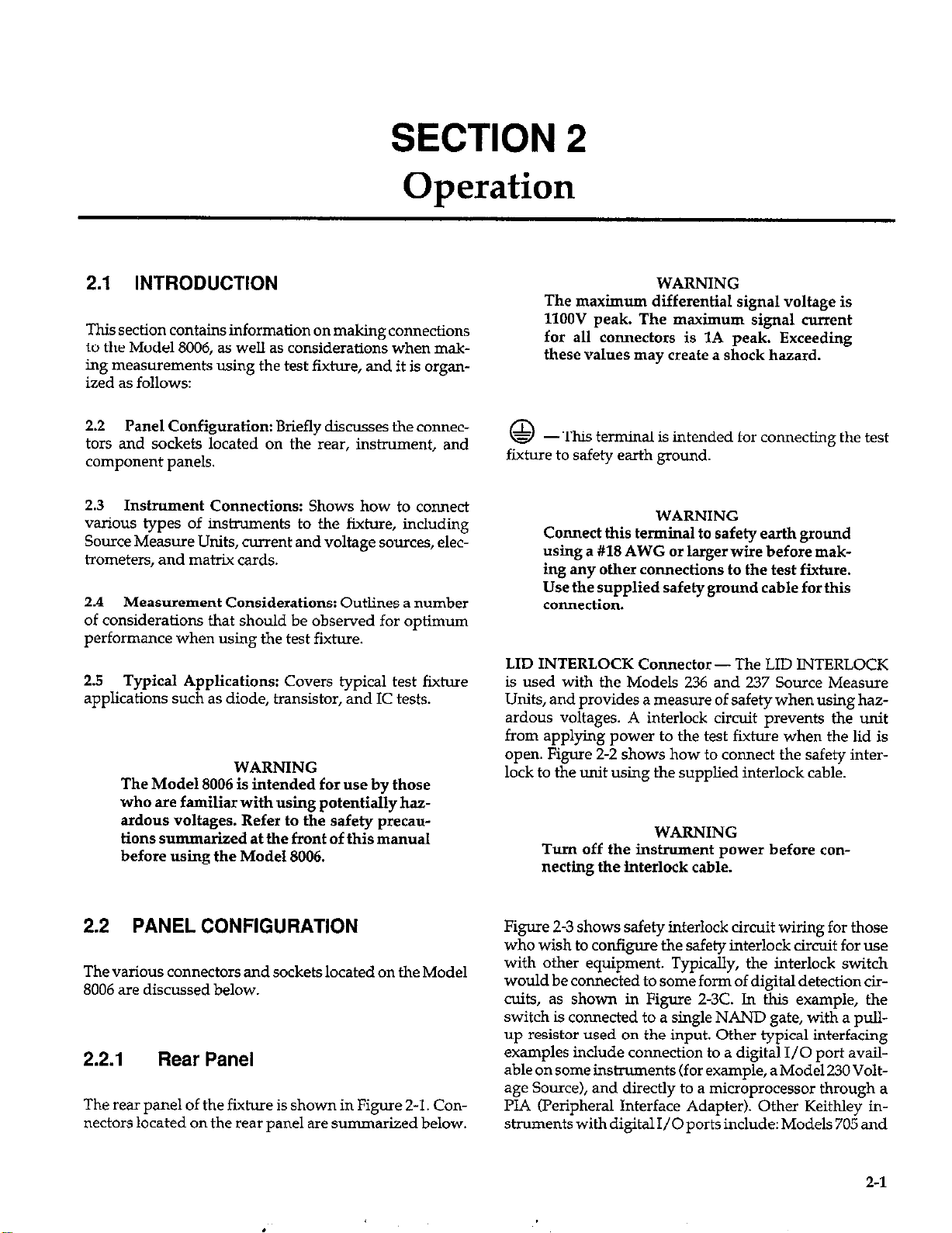

LID INTERLOCK Connector - The LID INTERLOCK

is used with the Models 236 and 237 Source Measure

Units, and provides a measure of safety when using hazardous voltages. A interlock circuit prevents the unit

from applying power to the test fixture when the lid is

open. Figure 2-2 shows how to connect the safety interlock to the unit using the supplied interlock cable.

Tlus terminal is intended for connecting the test

WARNING

Connect this terminal to safety earth ground

using a #18 AWG or largerwire before making any other connections to the test fixture.

Use the supplied safety ground cable fort&

connection.

WARNING

Turn off the instrument power before connecting the interlock cable.

2.2 PANEL CONFIGURATION

The various connectors and sockets located on the Model

8006 are discussed below.

2.2.1 Rear Panel

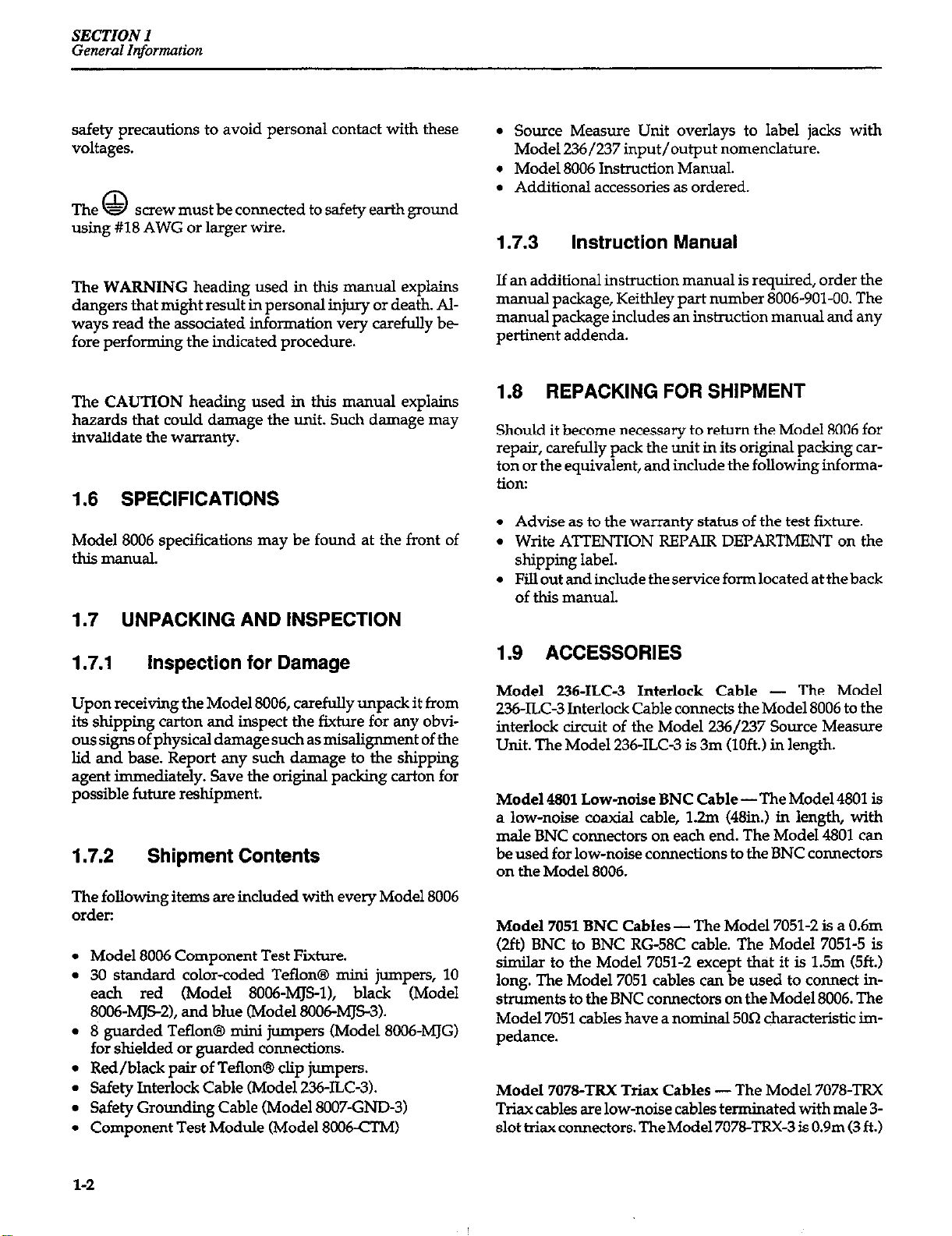

The rear panel of the fixture is shown in Figure 2-1. Connectors located on the rear panel are summarized below.

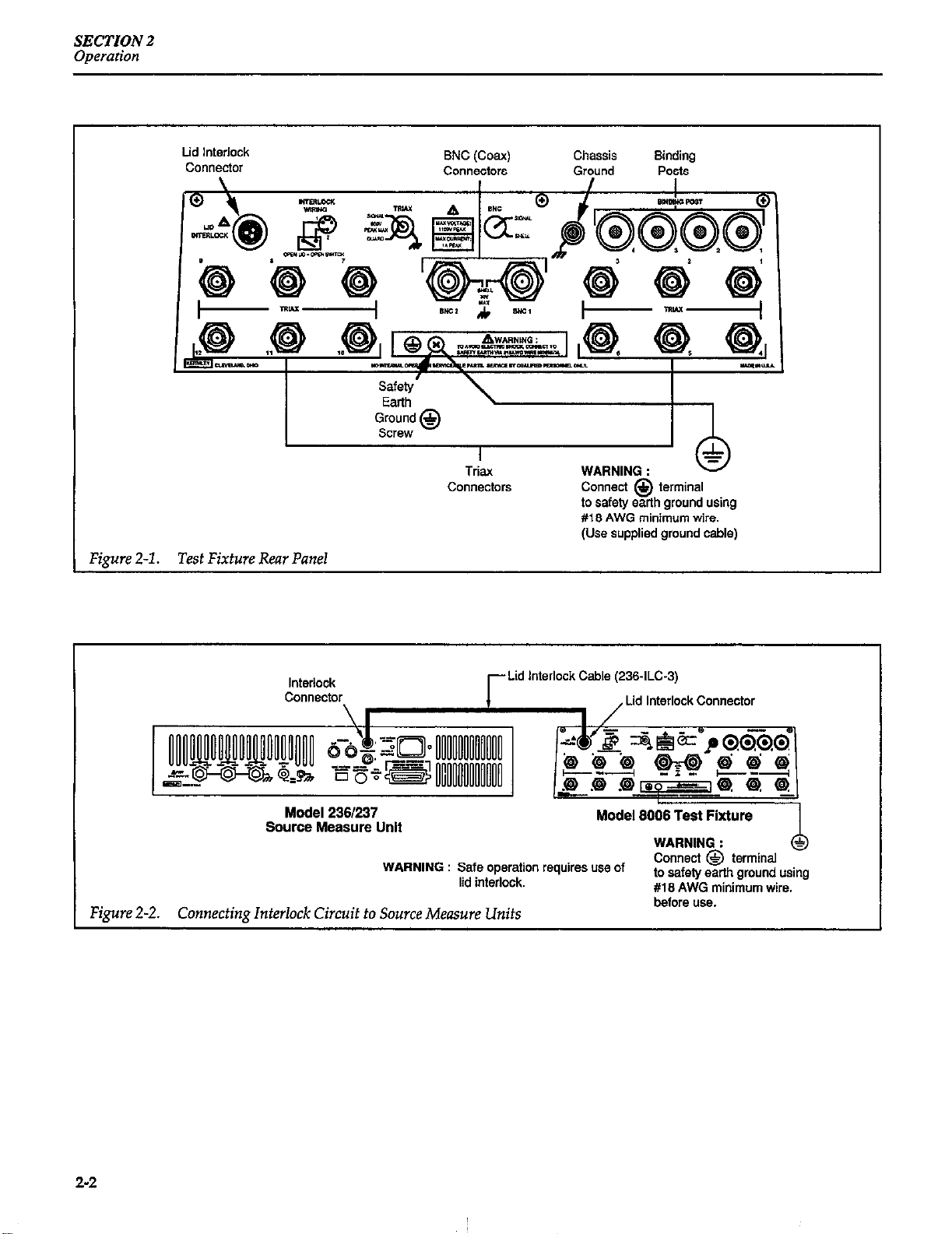

Figure 2-3 shows safety interlock circuit wiring for those

who wish to configure the safety interlock circuit for use

with other equipment. Typically, the interlock switch

would be connected to some form of digital detection circuits, as shown in Figure 2-3C. In this example, the

switch is connected to a single NAND gate, with a pullup resistor used on the input. other typical interfacing

examples include connection to a digital I/O port available on some instruments (for example, a Model 230 Voltage Source), and directly to a microprocessor through a

PL4 (Peripheral Interface Adapter). Other Keithley in-

struments

with digital I/O ports include: Models 705 and

2-l

Page 18

SECTZON 2

Operation

Lid Interlock

COllflectOr

Figure 2-1. Test Fixture Rear Panel

SNC (Coax)

COlVlFXiOlS

Chassis

Ground

Connect @ terminal

to safety earth ground using

#I 8 AWG minimum wire.

(Use supplied ground cable)

Binding

Posts

Interlock

connector

\ I

Model 2361237

Source Measure Unit

WARNING : Safe operation requires use of

lid interlock.

Lid Interlock Cable (236.ILC-3)

Figure 2-2. Connecting Interlock Circuit to Source Measure Units

, Lid Interlock Connector

WARNING :

Connect @ terminal

to safety earlh ground using

#I8 AWG minimum wire.

before use.

2-2

Page 19

SECTZON 2

Operation

Figure 2-3.

r---l

I

Internal

I ‘&$;g”

I

--------_

Interlock Circuit Wirin,q

lLlrP

A. Lid Open

I

---

I

----_

0

2 3

1

r----

I I

I I

I I

I I

-------__

r O+~V - - - -/

l**

-----__

Digital Interlock Detect

C. Typical Digital Circuit tnterfacing

Internal

Interlock

Switch

i

q

. Lid Closed

I

0

2 3

1

706 Scanners, Model 220 Current Source, and Model 707

matrix.

WARNING

User-supplied lethal voltages may be exposed when the lid is open. Safe operation

requires the use of the lid safety interlock.

CAUTION

Do not exceed the specified ratings of the interlock circuits (28V, 0.05A).

NOTE

The safety interlock cable supplied with the

Model 8006 must be used in order for the unit

to properly recognize that the test fixture lid is

open.

TRIAX Connectors-TheTRL4X connectors are laid out

in four groups of three connectors each, for a total of 12.

The center conductor of each t&.x connector is SIGNAL,

the inner ring is GUARD, and the outer ring is connected

to chassis ground. Note that the GUARD signal path can

be used either for LO or guard when guarding is required.

WARNING

Maximum trim connector common-mode

signal voltage is 1lOOV peak. Maximum voltage between signal and GUARD is 600V

pd.

BNCConnectors-TwoBNCconnectorsareincludedto

provide shielded connections. The center conductor is

SIGNAL, and the shell of each jack is SHELL (LO).

WARNING

Maximum BNC connector common mode

signal voltage is 30V RMS (dc to 60Hz).

5-Way Binding Posts-Four of the binding posts can be

used for such purposes as routing power to components

being tested. These posts are numbered 1 through 4 The

2-3

Page 20

SECTION 2

Operation

fifth binding post is chassis ground, and it is intended for

measurement grounding connections only.

WARNING

With hazardous voltages (>3OV RhCS, observe the following safety precautions when

using banana plugs.

1. Turn off all sources and discharge all capacitors before connecting them to the

banana plugs.

2. Dress all wires to ensure that no conductive surfaces are exposed after connecting

them to the binding posts.

3. Always use the lid interlock with any

scmrces connected to the banana plugs

(see the lid interlock discussion above).

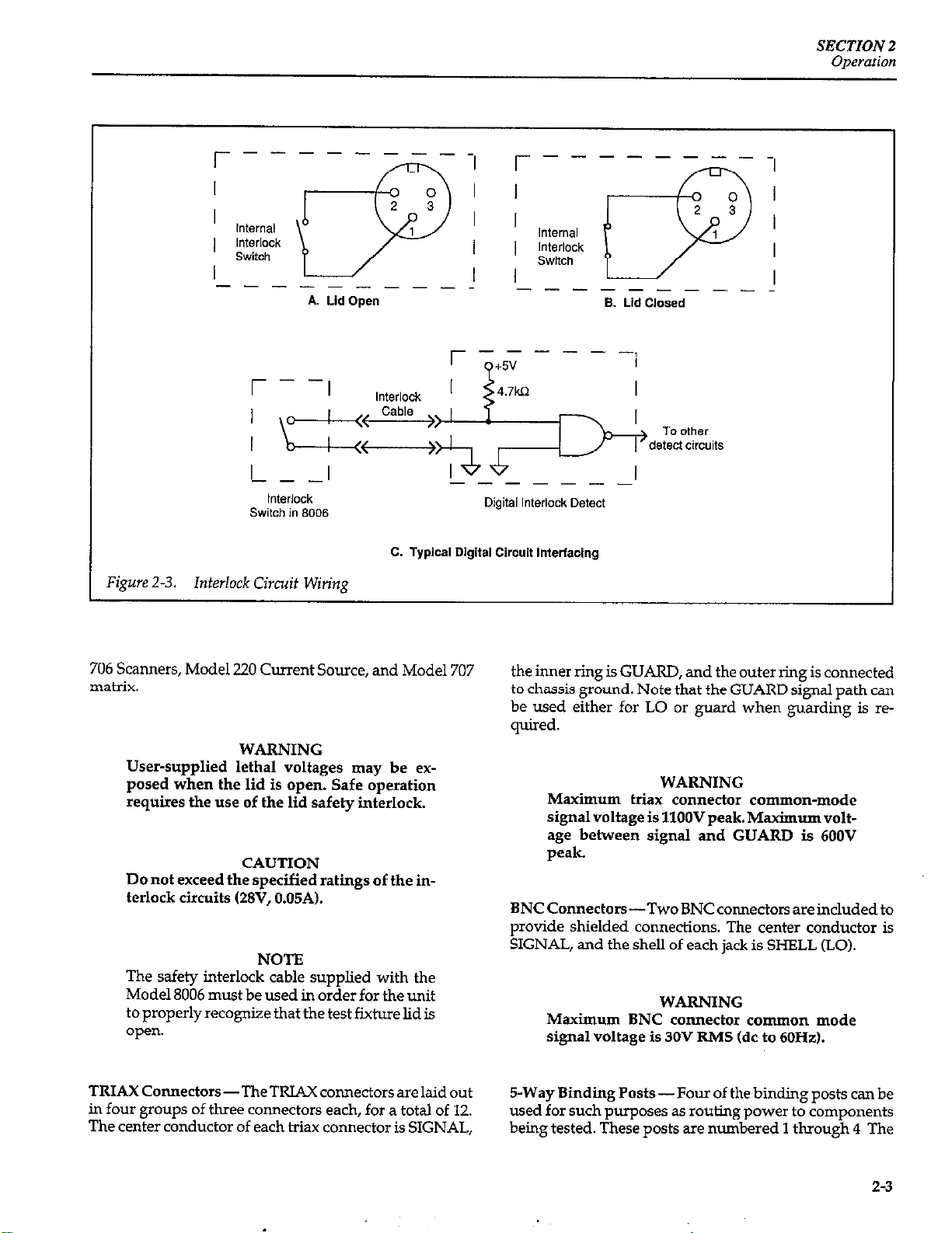

2.2.2 Signal Panel

Figure 2-4 shows the signal panel of the test fixture. The

signal panel has a number of test jacks that provide con-

necting points for the input/output pathways via the

rear panel connectors. Each test jack on the panel is

clearly marked with the corresponding rear panel connector terminal. For example, the four sets of triax terminals are individually marked as SIGNAL and GUARD to

correspond to the SIGNAL and GUARD terminals of

each rear panel TRIAX connector. The TRIAX connectors

are numbered 1 through 12 in the same manner as the

rear panel connector numbering.

The signal panel also has a test jack (PANEL SHIELD)

that is connected to the shield located immediately under

the signal panel. This jack can be connected to circuit LO

for additional shielding, or it can be guarded by connecting it an appropriate guard potential from one of the signal panel jacks.

2.2.3 Component Test Module

Figure 24 shows the component test module, which contains sockets for a variety of device packages. These sockets include:

Signal

Panel

Component Test

Module Shield

Connection

t-

Module Fasteners

‘igure 24. Front Panel Showing Signal Panel and Component T&Module

I-

+

Triax

COnIlSCtiOllS

ZIF Socket

Handle

2-4

!

Page 21

SECTION 2

Operdon

Two axial Kelvin clip pairs (2Omm and 3Omm spacing):

Used for two-terminal axial-lead devices such as diodes,

capacitors, and resistors. Each clip has a SENSE and a

SOURCE connection which provide Kelvin

to the device.

Two 4-pin TO package sockets (small pin and large pin):

Intended primarily for use with transistors.

Three multi-pin TO package sockets (S-pin, IO-pin, and

l&pin TO-5): Designed for use with multi-pin transistor

and IC packages.

28-pin dual in-line package ZIF socket: Accepts DIP

packages up to 28 pins with 0.3 to 0.6in. lead spacing. The

associated handle should be raised to open the socket,

lowered to close the socket.

Each socket terminal has an associated test jack intended

to connect that terminal to the desired input/output

pathway using the supplied mini jumpers.

connections

2.2.4

Device Handling

When handling very high impedance devices (such as

high-megohm resistors) be careful not to contaminate the

body of the device, which would lower its impedance.

Also take care when handling static-sensitive devices

such as MOSFETs so as not to damage them with static

discharge. Handle such devices only at a grounded work

station, and also ground yourself with a suitable wrist

strap. Keep static-sensitive devices in their protective

containers until ready for testing.

Axial Kelvin Clips

To install an axial component such as a resistor or diode

in one of the two sets of axial Kelvin clips, hold the device

by the test lead ends, then carefully push the device leads

down into the clips until the device is properly seated.

Installing Devices in Sockets

NOTE

With some devices, you may encounter device oscillation which could affect measurements. Refer to paragraph 2.4.10 for details on

verifying and preventing oscillation.

One of the test jacks (MODULE SHIELD) is connected to

a box shield immediately under the component test module. This jack allows the shield to be connected to circuit

LO for additional shielding, or to a guard potential if de-

sired.

Module Removal and Installation

The Model 8006~CTM Component Test Module is de-

signed for easy removal and installation. Additional

modules can be purchased, allowing several device and

circuit configurations to be easily interchanged for rapid

testing.

To remove the component test module, first disconnect

all jumpers to the signal panel, then pulJ up on the four

fasteners that secure the module to the base (see

Figure Z-4 for locations). After the fasteners are released,

pull up on the module to remove it from the base.

To install the module, install it in the base with the fasten-

ers aligned in the corresponding holes, then push down

on the four fasteners to secure the module to the base.

TO Package Sockets

For TO package installation, carefully spread the leads

apart so that they will line up with the holes in the socket,

then slide the device leads down into the holes, taking

care not to bend any of the leads. When installing these

devices, be sure to line up the tab on the package body

with the indicated tab position on the panel. Doing so

will ensure that the numbers on the panel will corre

spend to the actual device terminal numbering.

DIP Socket

Toinstall a deviceontheDIPsocket, firstraisetheleverat

the side of the socket to open the socket, then carefully install the device on the socket. Once the device is properly

seated, lower the lever to lock the device into place.

To remove a device from the DIP socket, first raise the

lever, then pull the device free of the socket.

2.2.5 Installing Jumpers

In order to complete device connections, it will be necessary for you to install the mini jumpers between the ap-

2-5

Page 22

SECTION 2

Operation

propriate socket jacks and the desired input/output

pathway jacks located on the signal panel.

Standard Mini Jumpers

For many cormections, the standard color-coded jumpers

supplied with the Model 8006 can be used. These jumpers

can be stacked to allow two or more connections to a single jack. Figure 2-5 shows an example of jumpers installed between the binding uost jacks and one mix of ax-

1

ial component sockets usi@ 4&e connections.

Guarded Jumpers

For critical measurements requiring low offset current,

low noise, or high path isolation, the guarded jumpers

should be used with the jumper shield connected to the

Standard

Jumper

appropriate GUARD or SHELL jack on the signal panel.

Doing so will shield or guard the sensitive pathway right

down to the device socket.

Figure 2-5 also shows an example of connections using a

guarded jumper. Note that the jumper shield is connected to the GUARD terminal of one of the triax connecting jacks, while the center conductor at the same end

is connected to SIGNAL.

WARNING

Make certain hazardous voltages are notpresent on any of the front panel terminals before installing jumpers. To avoid a possible

shock hazard, always use the lid safety interlock, and discharge all capacitors before installing or removing jumpers.

Guarded Jumper

(Connect shield to ward)

Page 23

SECTION 2

Owation

Jumper Cleaning

In critical applications, or in high-humidity environ-

ments, it

Freon@ or methanol before using them. Allow the jump-

ers to dry thoroughly (several hours in a low-humidity

environment) before use, and handle

clean gloves after cleaning to avoid new contamination.

All jumpers should be periodically cleaned with Freon@

or methanol to remove dirt or other contamination that

could degrade overall performance. Again, cleaned

jumpers should be allowed to dry for several hours in a

low-humidity ambient-temperature environment, or for

30 minutes to one hour in a 50°C low-humidity environ-

ment before use.

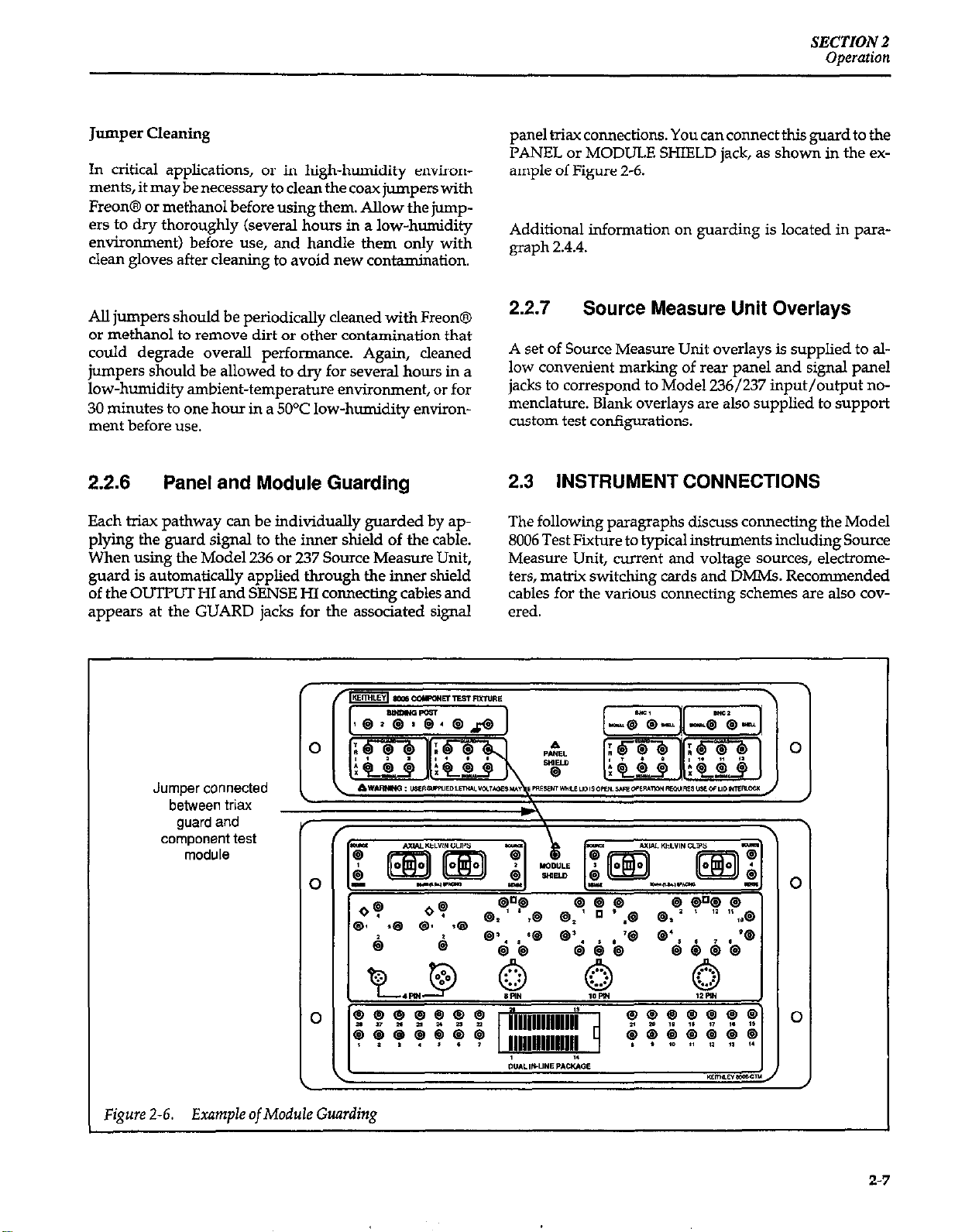

2.2.6

Each triax pathway can be individually guarded by applying the guard signal to the inner shield of the cable.

When using the Model 236 or 237 Source Measure Unit,

guard is automatically applied through the inner shield

of the OUTPUT HI and SENSE HI connectine cables and

appears at the

may

be necessary to clean the coax jumpers with

them only

Panel and Module Guarding

GUARD jacks

for the assoduted signal

with

panel triax connections. You can connect this guard to the

PANEL or MODULE SHIELD jack, as shown in the example of Figure 2-6.

Additional information on guarding is located in paragraph 2.4.4.

2.2.7

A set of Source Measure Unit overlays is supplied to allow convenient marking of rear panel and signal panel

jacks to correspond to Model 236/237 input/output nomenclature. Blank overlays are also supplied to suppoti

custom test configurations.

Source Measure Unit Overlays

2.3 INSTRUMENT CONNECTIONS

The following paragraphs discuss connecting the Model

8006 Test Fixture to typical instruments including Source

Measure Unit, current and voltage sources, electrometers, matrix switching cards and DMMs. Recommended

cables for the various connectine schemes are also covered.

”

Jumper connected

between triax a

guard and

component test

module

Figure 2-6. Example of Module Guarding

2-7

Page 24

SECTION 2

operation

WARNING

Do not exceed the maximum test fiie signal level, as defined in the specifications and

stated on the rear panel. Always bun off all

power and discharge all capacitors before

connecting or disconnecting cables. Lethal

voltages may be exposed when the lid is

open. Safe operation requires the use of the

lid safety interlock (see paragraph 2.2.1).

2.3.1 Source Measure Unit Connections

Typical connections between the Model 8006 and the

Model 236/237 Source Measure Units are shown in

Figure 2-7. Note that remote sensing, and two connecting

methods for local sensing are shown.

NOTE

With some devices, you may encounter device oscihtion that will affect your measurements. Refer to paragraph2.4.10 for details on

verifying and preventing oscillation.

both OUTPUT LO and SENSE LO via the inner shield

and center conductor respectively.

Be careful not to confuse the terminal conventions on the

Source Measure Unit and the test fixture. HI appears on

the SIGNAL jacks,and guard OUTPUT HI and SENSE HI

actnally appears on the GUARD jacks on the signal panel

of the test fixture. As with all connections, you must complete the connections to the DUT in the appropriate device socket with the mini jumpers. Use standard mini

jumpers for unshielded and unguarded pathways, and

use guarded jumpers for guarded or shielded pathways.

Local Sensing Connections (Banana Plug for LO)

Connections for local sensing require only one fxiax ca-

ble, and a single banana plug patch cord (Figure2-7C and

2-7D). Note that local sensing is recommended only for

lower current situations where voltage drops XTOSS the

test cables and connectors is not a consideration. Also,

this configuration is recommended for less-critical applications where noise is not a problem.

Remote Sensing Connections

Remote sensing connections are shown in Figure 2-7A

and 2-78. Model 7078-TRX t&x cables are recommended

for all three connections. For the OUTPUT HI and SENSE

HI cables (A and B), the center conductor is HI, the inner

shield is GUARD, and the outer shield is chassis ground.

Note that the remaining cable (connected to C) carries

Local Sensing Connections (T&IX Cable for LO)

Where noise pickup is a consideration, the local sensing

connections shown in Figure 2-m and 2-7F are recommended. Here, two Model 7078~TRX tiax cables are used

to connect the Source Measure Unit to the test fixture.

When installing jumpers, keep in mind that OUTPUT LO

appears on GUARD on the signal panel with this connection scheme.

2-8

Page 25

Model 2361237

Source Measure Unit

A. Connections (Remote sensing)

SECTION 2

Operation

Firm 2-7. Source h4easure

336/237

Source Measure Unit

Unit

Connections

6. Equivalent Circuit (Remote Sensing)

2-9

Page 26

SEC’TZON 2

Operation

Model 236/237

Source Measure Unit

C. Connections (Local sensing, banana plug for LO)

kwce

Measure Unit Connections (Cont.)

I

236i237

8ource Measure Unlt

D. Equivalent Circuit (Local sensing, banana plug for LO)

I

2-10

Page 27

Model 238/237

Source Measure Unit

E. Connections (Local sensing. triax for LO)

SECTION 2

Operation

F. Equivalent Circuit (Local sensing. Via for LO)

~urce Measure Unit Connections (Cont.)

2-11

Page 28

SECTION 2

Operation

2.3.2 Current Source Connections

Unguarded Connections

Figure 2-8 shows unguarded connections between the

test fixture and a typical current source, a Keithley Model

220. Again, a Model 7078-m triax cable is recommended for connections. A Model 617’2 Z-slot to Slug

adapter will be necessary at the current source output

jack. Note that the center conductor is HI, the inner shield

is LO, and the outer shield is chassis ground.

Guarded Connections

Guarded connections can also be made using a Model

6167 Guarded Adapter along with the current source, as

shown in Figure 2-9. In this instance, the triax cable carries HI on the center conductor and GUARD on the inner

shield. LO is routed through a separate wire connected

between current source OUTlWT COMMON and a test

fixture binding post. In some cases, it may be necessary to

shieldLOustigtriaxialorcoaxialcabletominimizenoise

pickup.

The Model 6167 Guarded Adapter normally connects

output LO to the outer shell of the output triax connector,

and it must be modified. to avoid connecting current

source LO to chassis ground at the test fixture end. To

modify the fixture, disconnect the internal wire going to

the ou$ut triax connector outer shell.

- -

Figure 2-8.

220 Current Source

A. Connections

Unguarded Current Source Connections

I

Model80~ ~~ I06 Test Fixture

WARNING: 0

connecl @ terminal

to safety emh ground using

tt8 AWG minimum wire

before use.

I

2-12

Page 29

A. Connections

SECTION 2

Operation

Figure 2-9.

220 current Commm

SWrC.3

B. Equivalent Circuit

Guarded Current Source Connections

POsf

2-13

Page 30

SECTION 2

Operation

2.3.3

Voltage Source Connections

Unshielded Connections

Shielded Connections

For low signal levels or noisy test environments, shielded

connections should be used to minimize noise

(Figure 2-11). A male BNC to dual banana plug coaxial

Unshielded voltage source connections are shown in

Figure 2-10. Here, OUTPUT HI and LO are connected to

test fixture binding posts using banana plug patch cords

(Pomona B-36-O and B-36-2).

cable (Pomona 2BC-BNC36) should be used for connec-

tions. At the voltage source, the cable shield should be

connected to OUTPU’I LO, and the center conductor

should be connected to OUTl’UT HI.

WARNING

For remote sensing, add the indicated cords and jumpers Do not float the Model 230 more than 30V

(shown with dashed lines).

RMS above earth ground.

230 Voltage Source

r-IT<

sense

OUtpA

G----D3

230 Voltage Source

6. Equivalent Circuit

Figure 2-10. Unshielded Voltage Source Connections

signal Pam

Binding

post * 2

6066 Test Fixture

Model 8006 Test Fixture

Component

Test Module

h

I

=

2-14

Page 31

A. Connections

SECTION 2

Operation

Figure 2-11.

6. Equivalent Circuit

Shielded Voltage Source Connections

2-15

Page 32

SECTION 2

Operation

2.3.4

Unguarded Connections

Typical unguarded electrometer connections are shown

in Figure 2-12. Again, a single Model 7078-TRX hiax cable can be used to make the connections. The center conductor is HI, the inner shield is LO, and the outer shield is

chassis ground. A Model 6172 2-slot to 3-lug adapter will

be necessary on the electrometer INPUT jack to adapt the

cable to the electrometer INPUT connector. Note that

V-R GUARD should be off, and the ground link between

chassis ground and COM should be removed. Typical

voltage source conneciions are also shown in Figure 2-12.

Electrometer Connections

Guarded Connections

Figure 2-13 shows guarded electrometer connections.

Again, a t&x cable/adapter combination is used between the electrometer INPUT jack and the desired hiax

connector on the test fixture. In this case, the center conductor is HI, the inner shield is GUARD, and the outer

shield is chassis ground. LO is separately routed by connecting electrometer COM to a test fixture binding post

using an ordinary patch cord. If measurement noise is a

problem, route LO through a shielded path (either coax

or hiax) using suitable cables.

For guarded measurements, the V-Q GUARD switch on

the electrometer should be in the ON position. Also, the

ground link between chassis ground and COM should

normalIy be removed. In some cases, however, low-noise

617 Electrometer

817 Electrometer

6. Equivalent Circuit

Figure Z-12. Unguarded EJectrmneter Connections

Model 6006 Test Fixture

1

8008 Test Fixture

I

“SWl”Stdbd

J”“pNS

2-16

Page 33

SECTION2

c$=$---‘~;--?~;~~

Operation

performance may be obtained with the ground link installed.

2.3.5

Typical connections to a Model 7072 Semiconductor Ma-

ti Card are shown in Figure 2-14. Direct connections

without adapters using Model 707%TRX triax cables are

used. Each cable carries SIGNAL (can be HI or LO) on the

Matrix Card Connections

center conductor, GUARD on the inner shield, and chassis ground on the outer shield.

Connections to othertypes of matrix cards can bemade in

a similar manner by using the appropriate cables. For example, connections to a Model 7073 Coaxial Matrix Card

would be similar except that coaxial cable to the BNC

connectors would be made instead of the tiax combination shown in Figure 2-14.

I

617 Electrometer

B. Equivalent Circuit

Figure 2-13. Guarded Electrometer Connections

8006

Test Fixture

2-17

Page 34

SECTION2

Operation

Figure 2-14. Matrix Card Connections

A. Connections

6. Equivalent Circuit (Two pathways shown)

before “se.

rni”irn”rn wire

2-18

Page 35

SECTION 2

Operation

2.3.6

Unshielded Connections

Figure 2-15 shows typical unshielded DMM connections.

VOLT/OHMS HI and LO are connected to the binding

posts using ordinary banana plug patch cords (Pomona

B-36-O and B-36-2). For 4-wire measurements, simply

connect two additional patch cords between OHMS

SENSE HI and LO and the remaining two binding posts,

as well as additional jumpers (shown as dashed lines).

Shielded Connections

If measurement noise is a consideration, the shielded

connections shown in Figure 2-l 6 should be used. A male

BNC to dual banana plug cable (Pomona 2BC-BNC-36) is

recommended for shielded connections. Connect

VOLTS/OHMS HI to the center conductor, and connect

VOLTS/OHMS LO to the cable shield. If shielded 4-wire

connections are required, connect a second shielded ca-

DMM Connections

ble between OHMS SENSE HI and LO and the remaining

BNC connector on the test fixture.

2.3.7

Miscellaneous Instrument Connections

Other instruments such as oscilloscopes, CV meters, LCR

meters, and network analyzers can also be connected to

the test fixture using appropriate cables. The cables used

will, of course, depend on the type of connector(s) on the

test instrument. The following general recommendations

apply when connecting these types of instruments to the

Model 8006.

50.Q BNC Connections

For instruments requiring 500 BNC connections, the

Model 7051 BNC cables are recommended. Connect the

cables to the BNC 1 or BNC 2 jacks on the test fixture. If

more

than two BNC connections are required, these BNC

cables can be connected to the test fixture TRIAX jacks us-

Figure 2-15. Unshielded DMh4 Connections

B. Equivalent Circuit

2-19

Page 36

SECTION 2

Operation

Model 196 DMM

A. Connections

B. Equivalent Circuit

Figure 2-16. Shielded Dh4h4 Connections

ing Model 7078-TRSBNX triax-to-BNC adapters. Note,

however, that the 5OQ impedance may not be maintained

through the adapters and triax jacks.

Low-Noise BNC Connections

6006 Test Fixture J.

As an alternative to the above arrangement for 2-lug

jacks, you can use Model 7024 triax cables, which are terminated with Z-slot male connectors on each end. Model

6171 3-slat to Z-lug triax adapters will be necessary to

connect these cables to the TRL4X connectors on the test

fixtwe jacks.

For low-noise BNC connections, Model 4801 low noise

coaxial cables are recommended. Connect these cables to

BNC 1 or BNC 2 on the test fixture. Again, these cables

can also be connected to the TRL4X connectors using

Model 7078-TRX-BNC adapters, if required.

Triaxial Cable Connections

Instruments equipped with triax connectors can be con-

nected to the desired test fixture TRL4X jack(s) using

Model 7078-W triax cables. Since these cables are

equipped with 3-slot male triax connectors, a Model 6172

2-&t to 3-lug triax adapter will be necessary to connect

the cables to instrument equipped with Z-lug female triax

connectors.

Z-20

2.4 MEASUREMENT CONSIDERATIONS

Many

measurements

affected by noise and leakage paths. The following para-

graphs discuss possible problems that might affect these

measurements and ways to minimize their effects.

2.4.1

Path isolation is simply the equivalent impedance be-

tween any two test paths in a measurement system. Ide-

ally, the path isolation should be infinite, but the actual

resistance and distributed capacitance of cables, connec-

Path Isolation

made with the Model 8006 can be

Page 37

SECTION 2

Operation

tars, and sockets results in less than infinite path isolation

values for these devices.

Equivalent Circuit

The equivalent path isolation circuit is shown in

Figure Z-17. The path isolation resistance, RF, and the

path isolation capacitance, CP, are assumed to be lmpsum values, and they represent the isolation from one

SIGNAL pathway to another including one-meter triax

cables and guarded jumpers to the socket connecting

jack. In this instance, tiax pathways are shown, but path

isolation to BNC and binding-post pathways is similar.

Isolation Resistance

Path isolation resistance forms a signal path that is in parallel with the equivalent resistance of the DUT, as shown

in Figure 2-18. For low-to-medium device resistance mlues, path isolation resistance is seldom a consideration;

however, it can seriously degrade measurement accuracy when testing high-impedance devices. The Current

flowing through such a device, for example, can be substantially attenuated by the current divider action of the

device source resistance and path isolation resistance, as

shown in Figure 2-19. Such leakage paths (RPATH) bleed

some of the current away from the device under test

(Row), reducing measurement accuracy.

Test Fixhue Isolation Resistance

The path isolation of the test fixture itself depends on the

connectors and sockets being used. For the triax and BNC

connectors, thelimitigfactor is thesocket,with the axial

and TO sockets having substantially higher guaranteed

path isolation values than the DIP socket. The typical isolation for the Dll? socket is much better, however; see the

specifications for complete details.

The path isolation value for the binding posts is much

lower than for the BNC and triax connectors. For that reason, the binding posts should only be used for non-critical signal paths such as power supply routing.

Path Isolation Capacitance

Any distributed capacitance between measurement

pathways affects dc measurement settling time as well as

ac measurement accuracy. Thus, it is important that such

capacitance be kept as low as possible. Although the distributed capacitance of the test fixture is generally fixed

by design, there is one area where you do have control

over the capacitance in your test system: the connecting

>

I

t-

Triax

Cables

1

Figure 2-17. Path Isolation Equivalent Circuit

1

I

Cp = Path Isolation

Capacitance

8006 Test Fixture

2-21

Page 38

SECTION 2

Operation

r-----, r-----~

I

I

I

I I I

I

I __

I -EDLIT I I

I I I

I

L-----J L-----J

R

DUT

R PATH

! I I I

I I I I

I I

DUT

I I RPATH

I I

I I

Test Fixture

R DUT

E DUT

= Source resistance of DUT

= Source voltage of DUT

= Path isolation resistance

= Input resistance of measuring instrument

RIN

I I

I I

I

I I

I I

I I

I I

r-----

I RIN

L------l

Measuring Instrument

1

I

I

I

I

I

I

Figure 2-18. Path Isolation Resistance

I DUT

R

DUT

Figure 2-19. Current Error Caused bypath Isolation Re-

sistance

cables. Use only low-capacitance cabling, and keep all cables as short as possible. Also, guarded jumpers minimize path capacitance to the test sockets.

Test Fixhw Isolation Capacitance

The test fixture isolation capacitance depends on the

socket in question. In general, the isolation capacitance is

much lower for the axial component socket than for the

TO or

DIP

package sockets.

Keep in mind that the capacitance is highest between ad-

jacent terminals

of a given socket. For that reason, it may

be advantageous to measure low capacitance values be-

tween non-adjacent terminals of a socket whenever possible.

Minimizing Path Isolation Effects

The effects of path resistance and capacitance can be

minimized by using guarded jumpers whenever possi-

ble. Paragraph 2.4.4 discusses guarding in more detail.

2.4.2 Keeping Connectors and Sockets

Clean

As is the case with any high-resistance device, the integrity of connectors and sockets can be compromised if they

are not handled properly. If the insulation becomes contaminated, the path isolation resistance will be substantially reduced, affec!ing high-impedance measurements.

Oils and salts from the skin will contaminate insulators,

reducing their resistance. Also, contaminants present in

2-22

Page 39

SECTION 2

Omration

the air can be deposited on the insulator surfaces. To

avoid these problems, never touch the connector or sock-

et insulating material. In addition, the test fixture should

be used only in clean environments to avoid contamination.

If the connector or socket insulators should become contaminated, either by inadvertent touching or from airborne deposits, they can be cleaned with a cotton swab

dipped in clean methanol. After thorough cleaning. they

should be allowed to dry for one-half to one hour in a

low-humidity environment before we, or they can be

dried more quickly using dry nitrogen gas. Do not use air

from an ordinary air compressor because oil present in

the air may result in contamination. Also, do not use air

from a tank because it can cause moisture to condense on

the socket.

2.4.3

Shielding

Proper shielding of all signal paths and devices under

test is important to minimize noise pxkup in virhlauy

any semiconductor test system. Otherwise, interference

from noise sources such as line frequency and RF fields

can st?riously corrupt a measurement.

Coaxial Cable Shielding

Coaxial cables can also be used to provide effective

shielding. Connect each coaxial cable to one of the BNC

connectors on the test fixture. The center conductor

should be connected to HI of the test instrument, and the

cable shield should be connected to LO, as in the example

of Figure Z-21. Coaxial cables can also be connected to

one of the triax connectors by using a Keithley Model

707%TRX-BNC triax to BNC adapter.

WARNING

Do not apply driven guard to coaxial cables

because hazardous voltages may be placed

on the outer cable shields, creating a possible shock hazard. Maximum common-mode

voltage for the BNC jacks (or any BNC cable)

is 30V RMS (dc to 60Hz).

Panel and Module Shielding

In many cases, it may be desirable to connect the signal

panel or component module shields to circuit LO or chassis ground. To do so, simply connect a mini jumper between each shield jack to the appropriate circuit terminal

(LO or chassis ground). As with any shielding situation,

experimentation may be necessary to determine the con-

figuration that results in the lowest noise.

Triaxial Cable Shielding

For unguarded measurements, the inner shield of thetri-

axial cable that surrounds the signal path should be connected to signal LO (or to chassis ground for instruments

without isolated LO terminals). An example of how to

maintain a shielded pathway from an instrument to the

test fixture is shown in Figure Z-20.

, , -lr

smdng 0,

mas”ring

l”Rmme”t

1. _,”

Ftgure 2 20

Shzldtng Example Using Triaxiul C.&es

Jumper Shielding

Guarded jumpers should be used in cases where the

shield must be carried through as close to the device

socket as possible. Simply connect the jumper shield to a

shield connection on the signal panel. Typically circuit

GUARD will be used as the shield connecting point, although better noise performance may obtained by con-

I

6006 Test Fixture

!

I

Z-23

Page 40

SECTION 2

Operation

I

Instrument

I

“’ \,,.a,, u

grounded on

some instruments

Figure Z-21. Shielding Example Using Coaxial Cables

netting shields to chassis ground in some cases. The same

general consideration applies to shield connection points

throughout a test system. Usually, experimentation is the

best way to determine the best shielding configuration.

In order to avoid ground loops, connect the shield to only

to one point in the drcuit.

2.4.4 Guarding

Signal Panel Te*t Module

8006 Test Fixture

Component

1

I

Guarding is especially important in high-impedance circuits where leakage resistance and capacitance could

have degrading effects on the measurement. Guarding

consists of using a shield surrounding a conductor that is

carrying the high-impedance signal. This shield is driven

by a low-impedance amplifier to maintain the shield at

signal potential. For kiaxial cables, the inner shield is

used as guard.

Guarding Principles

Guarding

minimizes leakage resistance effects by driving the inner cable shield with a unity-gain amplifier, as

shown in Figure 2-22. Since the amplifier has a high input

impedance, it

minimizes loading on the high-impedance

signal lead. Also, the low output impedance ensures that

the shield remains at signal potential, so that virtually no

leakage current flows through the leakage resistance, Rr.

Leakage between inner and outer shields may be considerable, but that leakage is of little consequence because

that cumnt is supplied by the buffer amplifier rather

than the signal itself.

In a similar manner, guarding also reduces the effective

cable capacitance, resulting in much faster measurements on high-impedance circuits. Because any distributed capacitance is charged through the low impedance

of the buffer amplifier rather than by the high-impedance

E,

= DUT source voltage

Rs = DUT source resistance

RL = Leakage resistance

‘igure 2-22. Guarded Circuit

source, settling times are shortened considerably by

guarding.

Using Guarding

In order to use individual pathway guarding effectively

with the Model 8006, the inner shield of the connecting

triaxial cable carrying the HI signal path should be connected to the guard output of the sourcing or measuring

instrument. That guard output must be at the same dc potential as the signal being guarded. Many instruments

such as the Model 236/237 Source Measure Units automatically drive. the inner shield of the HI signal pathways

2-24

Page 41

SECTION 2

opmtion

at guard potential (in the case of the Model 2% and 237,

both OLITPUT Hl and SENSE HI are separately

guarded).

Any LO signal pathways

need not be guarded. For the LO signal path, simply connect the inner shield to LO at the measuring or sourcing

instrument.

Typical Guarded Connections