Page 1

PLEASE

7B53A

AT

THE

CHECK

REAR

OF

Fi3R

THlS

CHANGE

MANUAL,

"P853AI7B53AN

fNFOT"IMA"I"ION

Tektranlx,

F'-0.

Box

50Q

Beavertan,

070-1

342-02

Product

Group

tnc.

Oregon

42

970n

DUAL

TIME

INSTRUCTION

BASE

MANUAL

First

Printing

Revised

MAY

SEP

f

988

1980

Page 2

Copyright

7B53A

Contents of this

form without the written permission

"41972,

1980

Tektronix, fne.

publication may not be reproduced

All

rights reserved.

of

Tektronix, Inc.

in

any

Products

by

TEKTRONiX,

registered trademarks

is

a

Printed

are

Each instrument

or

designates the country

of

unique to each instrument.

United States have

manufacture

of

Tektrcmix, tnc.

US,

and foreign patents and/or pending patents.

TEK,

registered trademark of Tektronix

in

t1.5,A.

Spcification

and

its

subsidiaries are cgvered

SCOPE-MOBILE, and

of

Tekrronix. Inc

U.K.

and

price change priviteges

resewed.

INSTRUMENT

has

starnm on the chassis, The

the, serial nurnbr are assigned sequentially

is

identified as follows:

SERIAL

a serial number

of

manufacture.

Those manufaciur& in the

six

unique digits. Tha

NUMBERS

on a panel

first

"i"hs

IELE%MLNI

Limited,

inseft, tag,

numwr or letter

last

five

digits

and

are

country

of

BOOQOOO

100000

ZOOOOQ

300000

7OOQOQ

Tektronix,

Tektronix Guernsey, Ltd,, Channel isrands

"Taktronix Unit& Kingdom, ttd., Landon

Sonynektronix,

Tektranix

The Netherlands

Inc., Beave~on,

Japan

Holland,

NV,

Heerenvwn,

Orwon,

USA

Page 3

TABLE

7B53A

OF CONTENTS

Page Page

LIST OF ILLUSTRATIONS

LIST OF SABLES

OPERATORS SAFETY SUMMARY

SERVICE SAFETY SUMMARY

Section

Section

7Be remaining portion of this Table of Contents lists the

servicing instructions

use by qualified personnel only

do not perform any

operating instructions unless qualified to do so

Section

1

2

3

...........................

SPECIFICATION

OPERATING INSTRUCTIONS

Controls and Connectors

Operating Checkout

General Operating Instructions

Applications 2-1 3

Repackaging for Shipment

sewicing other than that called out in the

THEORY OF OPERATION..

Simplified Block Diagram

Circuit Operation 3-3

Main Trigger Preamp

Main Trigger Generator (SN

&

Up 7B53A Only) 3-4

Main Trigger Generator (SN 8209999

&

Below)

Main Sweep Generator

Delayed

(SN B210000 & Up 7B53A Only)

....................

.............

.................

..................

........

...........

2-1

2-1

...............

.......

......................

..........

.

These servicing instructions are for

.

To avoid electrical shock.

.

...........

............

..................

...............

B210000

.................

.........................

.............

Trigger Generator

.....

2-3

2-6

2-20

3-1

3-1

3-4

3-7

3-9

3-12

iii

iv

vii

Section 3 'THEORY OF OPERATION

Section

Section 5 MAINTENANCE

Section

Section 7 REPLACEABLE ELECTRICAL PARTS

Section

Section

(cont'd)

Delayed Trigger Generator

(SN 8209999 & Below)

Delayed Sweep Generator

Horizontal Preamp

Readout Switching 3-18

4

CALIBRATION

Test Equipment Required

PART 1 PERFORMANCE CHECK

Trigger System Check

Horizontal System Check

PART 2 ADJUSTMENT

Trigger System Adjustment

Horizontal System Adjustment

....................

.............

.........

.................

................

...........

..............

...........

............

..........

.......

..................

Preventive Maintenance

Troubleshooting

Corrective Maintenance

6

OPTIONS

8

DIAGRAMS AND CIRCUIT BOARD

DESCRIPTIONS

9

REPLACEABLE MECHANICAL PARTS

...................

........................

............

............

....

3-17

4-21

4-24

5-1

5-1

5-2

5-4

6-1

REV

DEC

1982

Page 4

Fig.

7B53A

No.

Page

Fig.

No.

Page

7B53N7B53AN Dual Time Base

Location of release latch.

Front-panel controls and connectors.

Frequency range of each COUPLING

switch position.

Effect of LEVEL control and SLOPE switch

on CRT display.

Composite

Area of graticule used for accurate time

measurements.

Operation of Sweep Magnifier.

(A) Intensified Sweep display; (B) Delayed

Sweep display.

Typical Mixed Sweepdisplay (DELAY TIME

MULT dial set to 3.55).

DELAY

3.55.

Measuring the time duration between

points on a waveform.

Measuring risetime.

Measuring time difference using delayed

sweep

Using delayed sweep for magnification.

Displaying a complex signal using delayed

sweep

Measuring pulse jitter.

7B53A/7B53AN Simplified Block Diagram. 3-2

Trigger Preamp and Input Switching Block

Diagram.

Main Trigger Generator Block Diagram

(SN

Main Trigger Generator Block Diagram

(SN

Main Sweep Generator Block Diagram.

Delayed Trigger Generator Block Diagram

(SN B210000 and up 7B53A only).

Delayed Trigger Generator Block Diagram

(SN

Delayed Sweep Generator Block Diagram. 3-15

Horizontal Preamp Block Diagram.

Location of Delayed Gate Out and Variable

Selector multi-pin connectors.

"TIME MULT dial. Reading shown

..........................

..........................

..........................

.......................

B210000 and up 7B53A only).

B209999 and below).

B209999and below).

..................

..................

T'ime/Division switch.

...................

...................

.............

..............

...............

.............

.......

...........

......

.......

.....

...........

.....

...........

........

...

.

.

....

.viii

2-1

2-2

2-7

2-9

2-10

2-1 1

2-71

2-12

2-12

2-12

2-15

2-16

2-17

2-18

2-19

2-20

3-5

3-6

3-8

3-10

3-13

3-14

3-17

4-2

4-2 Typical delay time error measurement.

4-3 Typical Delay Time Error Figures.

4-4 Allowable Delay Time Error. 4-17

4-5 Typical CRT display when checking sweep

length..

4-6

5-1 Location of pins on interface connector.

5-2 Cam Switch Removal.

The illustrations in Section 8 are located near their

associated diagrams on the foldout page.

8-1 Electrode configuration for

8-2

8-3 Partial Al--.Interface circuit board

8-4 Partial

8-5 A2-Source Switch circuit board

8-6 A3-.-Coupling Switch circuit board

8-7 Partial

8-8 Partial

8-9 Partial

8-10 Partial

8-1 1 AS-Mode Switch circuit board.

8-12 Partial

8-13

8-14 Partial

Typical

Sweep Start and Dly'd Sweep Stop.

semiconductors in the instrument.

Location of circuit boards in the

7B53A/7B54AN.

component locator (SN

component locator (SN 8089999 and

below).

component locator.

component locator.

component locator

(SN

component locator (SN 8209999 and

below).

component locator (SN

component locator (SN

below).

component locator

(SN

A7--Delayed Trigger Switch circuit board

component locator.

component locator (SN 8209999 and

below).

........................

CRTdisplayfor adjustment of DIy'd

Al--Interface circuit board

A4----Trigger circuit board

7B53A only

B210000 and up).

A4-Trigger circuit board

A6-.-Sweep circuit board

A6---Sweep circuit board

A4.--Trigger circuit board

7B53A only

B210000 and up).

A4---Trigger circuit board

.........

..............

B090000 and up).

B090000 and up).

8089999 and

..

.....

....

.

4-16

4-17

4-25

4-26

5-3

5-7

@?

JUN

1980

Page 5

Fig.

7B53A

No.

Fig.

No.

Partial A6--Sweep circuit board

component locator (SN 8090000 and up).

Partial

component locator (SN 3089999 and

below).

on1 y) component locator.

A8---Readout circuit board

component locator.

A6-Sweep circuit board

Partial

Al--Interface circuit board (7653A

A1 --Interface circuit board

Partial

(7653AN only) component locator.

(7853A only)

Partial

component locator (SN 8090000 and up).

A6--Sweep circuit board

LIST

Table

No.

OF

8-21 Partial A6---Sweep circuit board

component locator (SN 8089999 and

below).

8-22

8-23

8-24

8-25

Partial AG.--Sweep circuit board

component locator

Location of adjustments in the

7653A/7853AN (SN 6209999 and below).

Location of adjustments in the

(SN 8210000 and up).

Location of adjustments in the

7853A/7 B53AN.

(SN

8090000 and up).

TABLES

Page

7853A

Electrical

Environmental

Physical

Deflection Factor of the X Signal

Risetime Measurements

Test Equipment 4-3

Main Sweep Timing

Delayed Sweep Timing

Main Sweep Magnifier Accuracy

Delayed Sweep Magnifier Accuracy

Relative Susceptibility to Static Discharge

Damage

.......................

...................

.......................

......

............

..................

...............

.............

......

....

........................

1-1

1-6

1-6

2-13

2-16

4-13

4-14

4-15

4-15

5-2

@?

JUN

1980

Page 6

OPERATORS

7B53A

The general safety information in this part of the summary is for both operating and servicing personnel. Specific

warnlngs and cautions will be found throughout the manual where they apply, but may not appear in this summary.

IN THlS MANUAL

CAUTION statements identify conditions or practices that could result in damage to the equipment or other property.

WARNING statements identify conditions or practices that could result in personal injury or loss of life

AS MARKED ON EQUIPMENT

CAUTION indicates a personal injury hazard not immediately accessible as one reads the marking, or a hazard to

property including the equipment itself.

DANGER indicates a personal injury hazard immediately accessible as one reads the marking.

SAFETY

SUMMARY

SYMBOLS

IN THlS MANUAL

@

Static-Sensitive Devices.

This symbol indicates where applicable cautionary or other information is to be found

AS MARKED ON EQUIPMENT

DANGER-H~gh voltage.

@

Protective ground (earth) terminal.

A

ATTENTION----refer to manual.

WARNINGS

POWER SOURCE

This product is intended to operate in a mainframe connected to a power source that will not apply more than

rms between the supply conductors or between either supply conductor and ground.

way of the

GROUNDING THE PRODUCT

'This product is grounded throirgh the grounding conductor of the mainframe power cord. To avoid electrical shock, plug

the

mainframe power cord into a properly w~red receptacle before connecting to the product input or output term~nals. A

protective ground connection by way of the grounding conductor in the mainframe power cord is essential for safe

operation.

ground~ng conductor in the mainframe power cord is essential for safe operation.

A

protective ground connection by

250

volts

REV

JAN

1985

Page 7

DANGER ARISING FROM

7B53A

Upon loss of the protectwe-ground connection, all access~bie condijctrve parts (~ncludrng knobs and controls that may

appear to be

rnsulat~ng), can render an electr~c shock

LOSS

OF

GROUND

DO NOT OPERATE IN EXPLOSIVE ATMOSPHERES

To avoid explosion, do not operate this product in an atmosphere of explosive gases unless it has been specifically

certified for such operation.

DO NOT OPERATE PLUG-IN UNIT

To avoid personal injury, do not operate this product without covers or panels installed.

unlt via a plug-in extender.

WITHOUT

COVERS

Do

not apply power to the plug-~n

@

JUN

1980

Page 8

SERVICING

7B53A

SAFETY

SUMMARY

FOR

QUALIFIED

SERVICE

PERSONNEL

ONLY

Refer also to the preceding Operators Safety Summary

DO NOT SERVICE ALONE

Do not perform internal service or adjustment of this product unless another person capable of rendering first aid and

resuscitation is present.

USE CARE WHEN SERVICING WITH POWER ON

Dangerous voltages exist at several points in this product. To avoid personal injury, do not touch exposed connections

and components while power is on.

Disconnect power before

POWER SOURCE

This product is intended to operate in a mainframe connected to a power source that will not apply more than

rms between the supply conductors or between either supply conductor and ground.

way of the grounding conductor in the mainframe power cord is essential for safe operation.

removlng protective panels, soldering, or replacing components.

A

protective ground

250

connection

volts

by

@

JUN

1980

Page 9

7B53A

Page 10

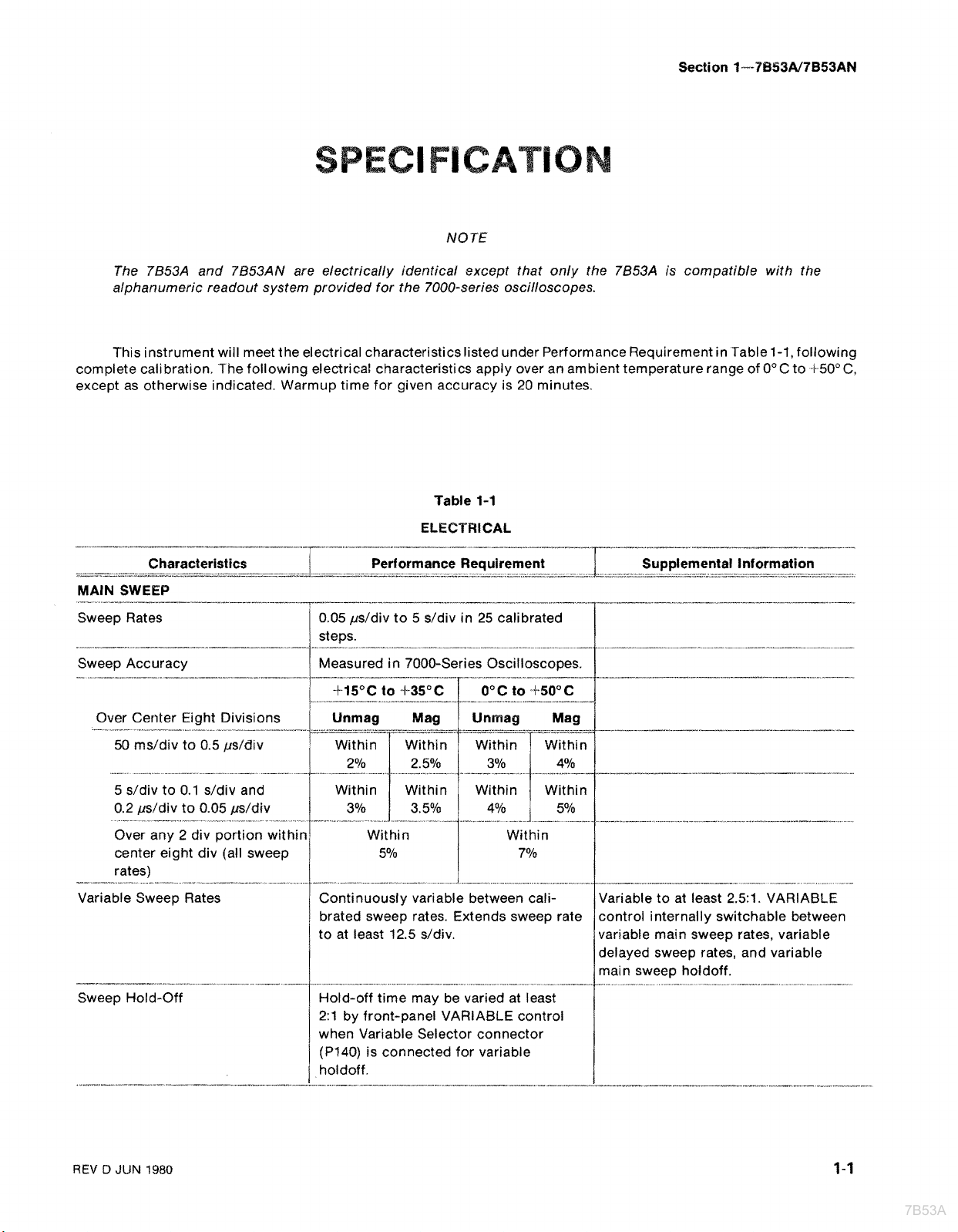

The

7B53A

7B53A

alphanumeric readout system provided for the 7000-series oscilloscopes.

and

7B53AN

are electrically identical except that only the

785314

Section 1-.--7B53A/7B53AN

is compatible with the

This instrument will meet the electrical characteristics listed under Performance Requirement in Table

The

complete calibration.

except as otherwise indicated. Warmup time for given accuracy is 20 minutes.

-

-.--.

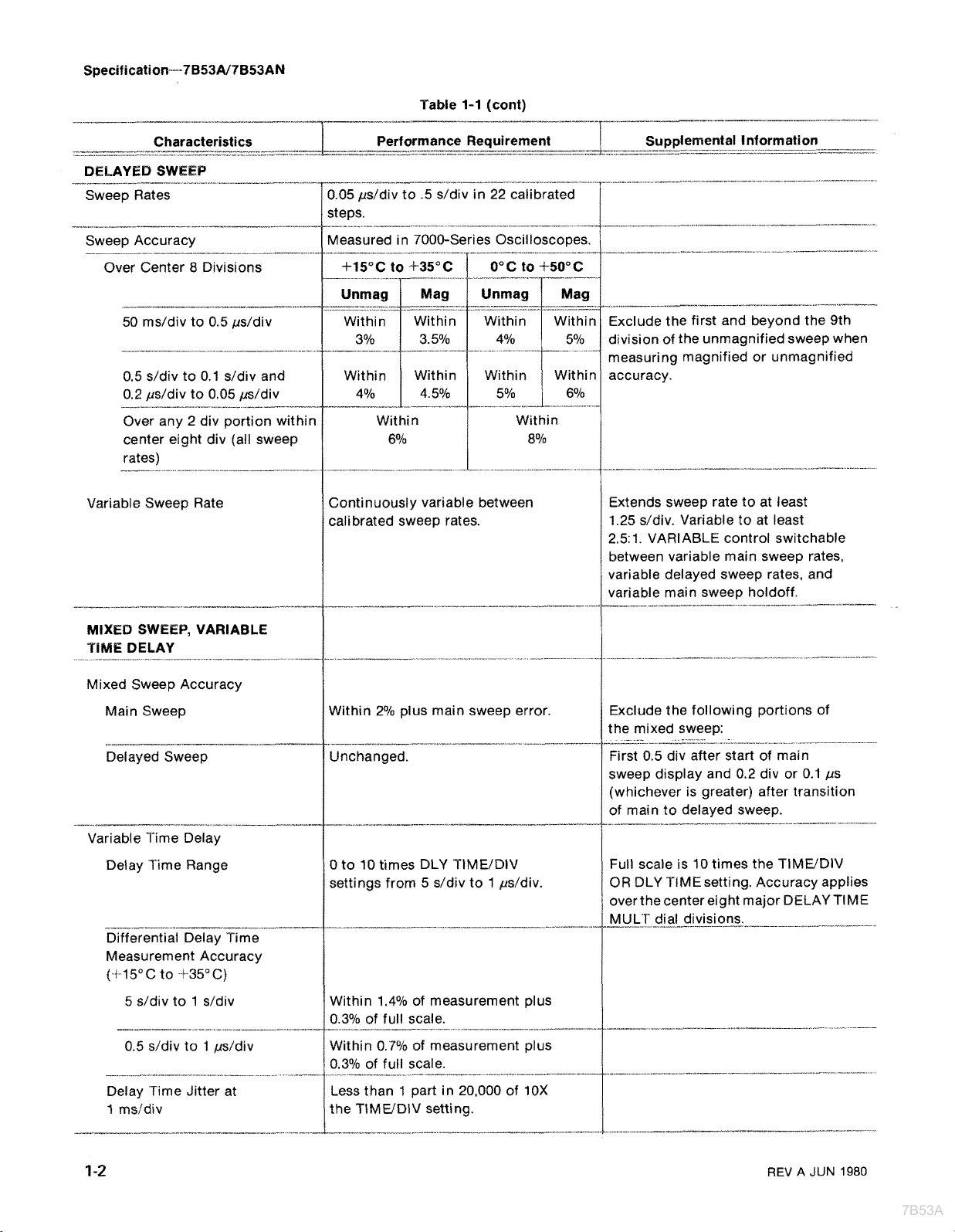

MAIN SWEEP

Sweep Rates 0.05 ys/div to 5 s/div in 25 calibrated

Sweep Accuracy

-

."

Over Center Eight Divisions

-

- - -

Variable Sweep Rates

Characteristics Performance Requirement Supplemental information

-

.

50 ms/div to 0.5 ysldiv

.-~

5 s/div to 0.1 s/div and

0.2

ys/div to 0.05 psldiv

Over any 2 div portion within

center eight div (all sweep

rates)

-

- - -

-

-

--

following electrical characteristics apply over an ambient temperature range of 0°C to +-50°C,

Table 1-1

to

-C35OC

[

:in

". .

1

3.5%

--

5%

---

- - -

ELECTRICAL

".

.

.

--

--

.

O°C to +50°C

------"

1

w;;n

Within

-

4%

T-".-'-."

-

..

.,

..

1..

I

1

w!;i

.

~

I

Within

5%

Within

7%

)variable to at least 2.5:l. VARIABLE

".'."

-

delayed sweep rates, and variable

main sweep

holdoff.

~

-,--

r.-,.-.---.--.-.w-

"

~

-

--

-

-

--

-

J

..4.--"

-A=-"

steps.

Measured in 7000-Series Oscilloscopes.

-115OC

I

Unmag Unmag Mag

--.m----....-..-."

1

w;itn

..

.".

~

Within W~th~n

3%

---

-

With~n

-

.

- - -

-

/

Continuously variable between cali-

/

brated sweep rates. Extends sweep rate /control internally switchable between

I

to at least 12.5 s/div. variable main sweep rates, variable

--

1-1,

^-"

.

following

Sweep Hold-Off Hold-off time may be varied at least

2:l

by front-panel VARIABLE control

when Variable Selector connector

(P140) is connected for variable

holdoff.

REV

D

JUN

1980

Page 11

Table

7B53A

1-1

(cont)

..

DELAYED

Sweep Rates

Over Center

Variable Sweep Rate

Characteristics Performance Requirement Supplemental l nformation

.

SWEEP

50

ms/div to 0.5 psldiv

0.5 s/div to 0.1 sldiv and

Over any 2 div portion within

center eight div (all sweep

rates)

"

8

Divisions

__

-l.__."

_

-.,---

"^

-l_-....l...lI

.l-ll___.

.05

ps/div to .5 s/div in 22 calibrated

easured in 7000-Series Oscilloscopes.

Continuously variable between

calibrated sweep rates.

_l__-..--------"

"."

---.----,-.

1

-l_l._l_.l

division of the unmagnified sweep when

5%

--

-.

-~

....

"

measuring

Extends sweep rate to at least

1.25

2.51. VARIABLE control switchable

between variable main sweep rates,

variable delayed sweep rates, and

variable main sweep

-.--_

_-_

magnified

sldiv. Variable to at least

or

unmagnified

holdoff.

"--

MIXED

PIME

Mixed Sweep Accuracy

Variable Time Delay

SWEEP, VARIABLE

DELAY

. .- .

- - - - -

Main Sweep

Delayed Sweep

Delay Time Range

Differential Delay Time

Measurement Accuracy

(-+-15OC

Delay Time Jitter at

1

to +35'C)

5 s/div to 1 s/div

msfdiv

- -

-

-

I

Within

0 to 10 times DLY TIME/DIV

I

Within

I

1

the TlMVDlV setting.

2%

plus main sweep error.

settings from 5 s/div to 1 ps/div.

Within 1.4% of measurement plus

0.3% of full scale.

0.7%

0.3% of full scale.

Less than 1 part in 20,000 of 1 OX

...

"

of measurement plus

.....-..l._-.

""

_..__..._-,._l."__

--

I

Exclude the following portions of

the mixed sweep:

First 0.5 div after start of main

sweep display and 0.2 div or 0.1

(whichever is greater) after transition

of main to delayed sweep.

Full scale is 10 times the TlMWDlV

OR DLY TlMEsetting. Accuracy applies

over the center eight major DELAY TIME

MULT dial divisions.

""

I

I

I

.

. . .

.- . -.

-

ps

--

----

-

-

"

-

1-2

REV

A

JUN

1980

Page 12

-"

7B53A

~

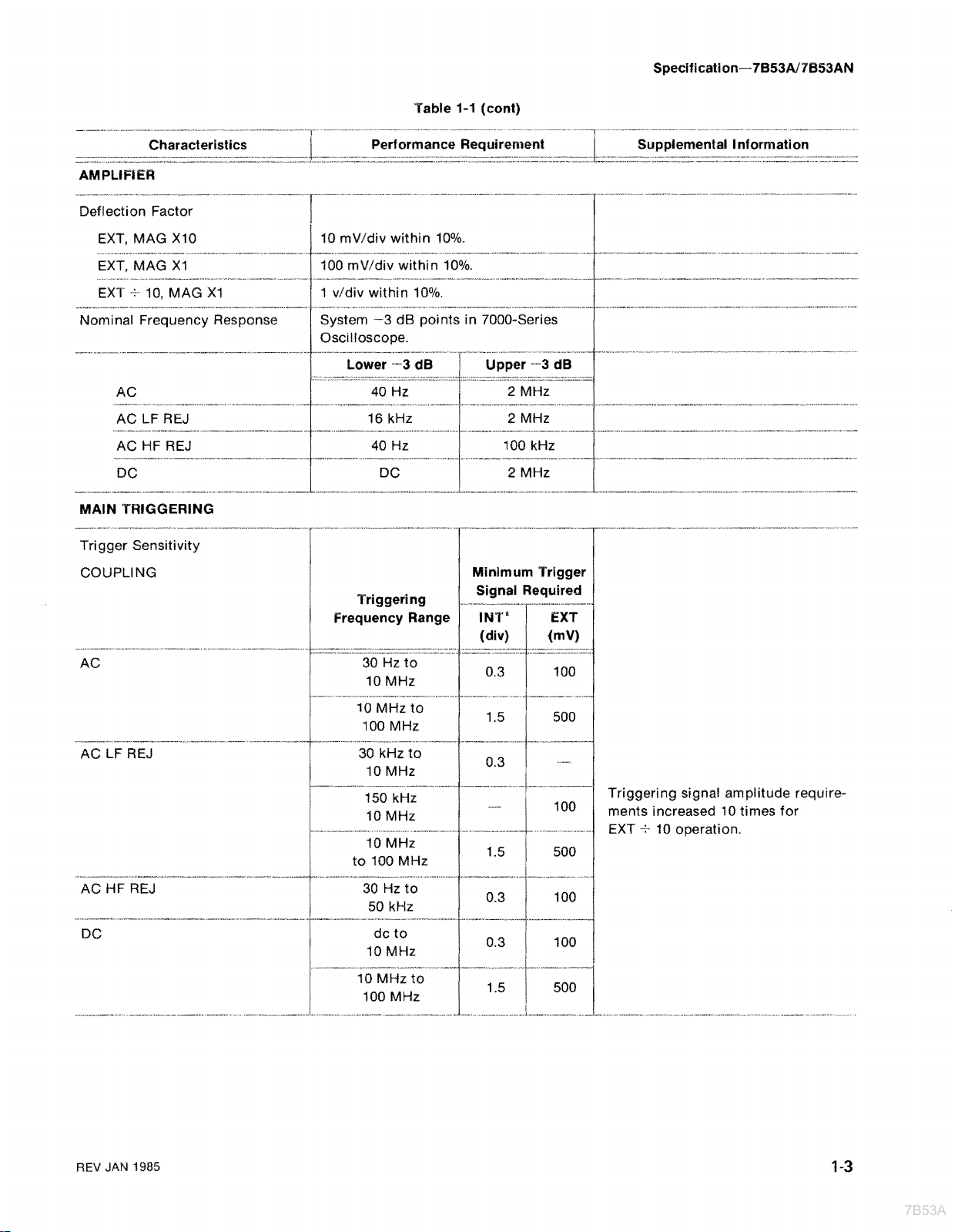

,

AMPLIFIER

Deflection Factor

EXT, MAG

EXT, MAG Xl

.

.

EXT

Nominal Frequency Response

Characteristics Performance Requirement Supplemental Information

.. - .

.-

.-i

10, MAG XI

AC

AC

LF REJ

Xi0

"..

......-----A-

""

"

"".

""

"*.."

i

1

10 mV/div within 10%.

100

"~.

mVfdiv within 10%.

1

v/div within 10%.

"

System

Oscilloscope.

.--3

Table

1-1

(cont)

~."

dB

points in 7000-Series

".

.

.

..

...

".

-.

"-

--

"

~

.-..

".

.-

."

-.

.-

.

--

-

.....

"

,.-"

"""

"."

.

-----

""

-

..

--

..

AC HF REJ 100 kHz

DC

MAIN TRIGGERING

Trigger Sensitivity

COUPLING

AC LF REJ 30 kHz to

"

~re~uentq Range

"

Hz

""

DC

Triggering

30

Hz

to

10 MHz

10 MHz

150 kHz

10 MHz

Minimum Trigger

I

.-

"-

/

I

10 MHz

to 100 MHz

AC HF REJ 30 Hz

1

50 kHz

to

1

1

~

""

2

MHz

Signal Required

--

---

0.3

1.5

0.3 100

EXT

1

100

/

500

---

I

1

Triggering signal

~ncreased 10 times for

ments

EXT

+

10 ooeration.

1

1

amplitude

requtre-

DC

-

-"

REV

JAN

---

1385

dc to

10 MHz

-

-

--

-

-

-

--

--

---

10 MHz to

100 MHz

--

0 3

-"-

-

--

1.5

d

-

--

100

,-

--

--

500

--

-

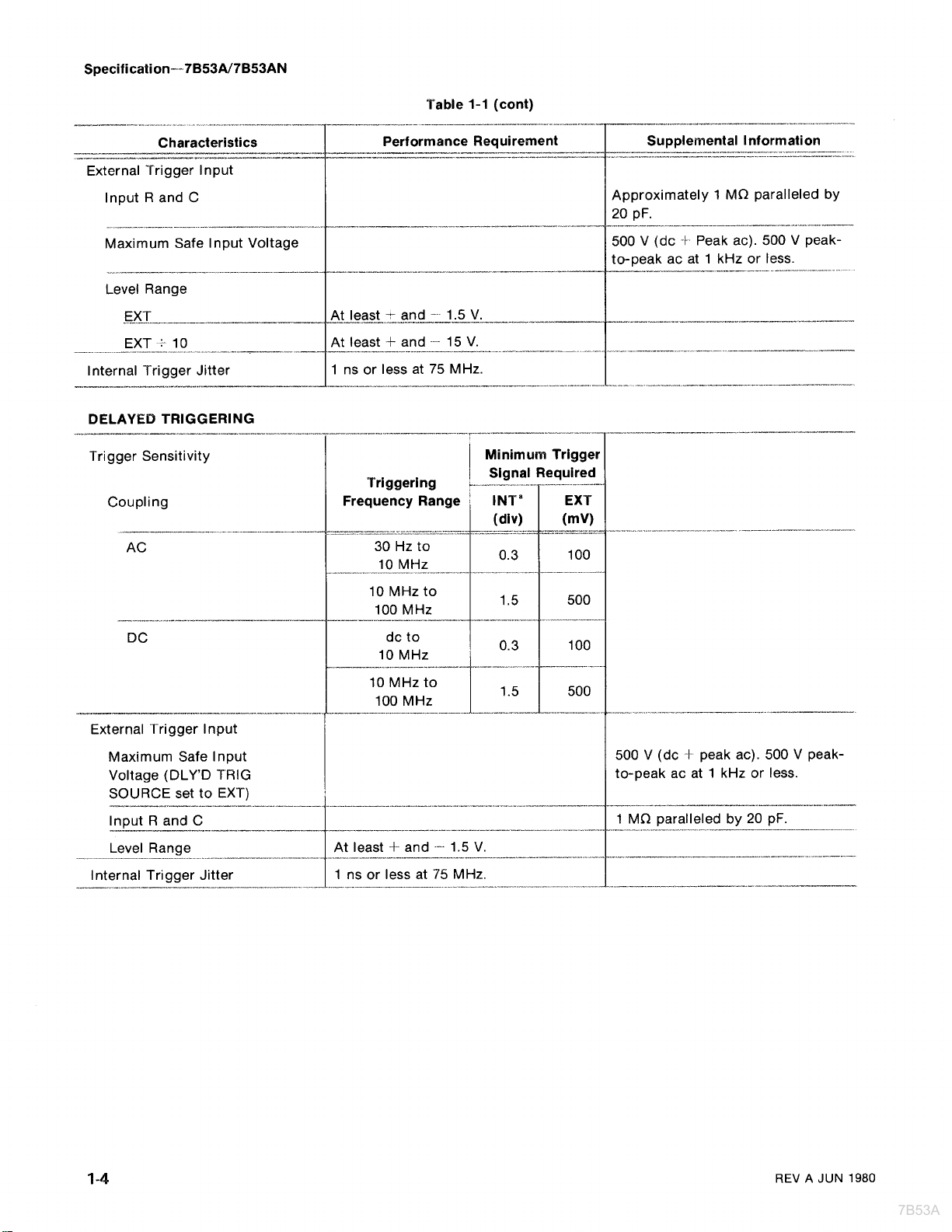

Page 13

Table

7B53A

1-1

(cont)

---------".-

External Trigger Input

lnput

Maximum Safe Input Voltage

Level Range

Internal Trigger Jitter

DELAYED TRIGGERING

Trigger Sensitivity

Coupling

Characteristics Performance Requirement Supplemental Information

-

R and C

EXT

EXT

-,"---.----

-:-

10 At least + and 15 V.

--,.-,"

I

I

least + and - 1.5 V.

1 ns or less at 75 MHz.

Triggering

Frequency Range

--

30 Hz to

-

10 MHz

.

.-

10 MHz to

100 MHz

---

--.

Minimum Trigger

Signal Required

.-

- - -

-

Approximately 1 Mf2 paralleled by

20

pF.

500 V (dc

to-peak ac at 1 kHz or less.

-1

Peak ac). 500 V peak-

."..

-

-.

.

I

---.

-.

.-

----

. .

-

External 'Trigger lnput

Maximum Safe lnput

Voltage

SOURCE set to EXT)

--

Input R and C

Level Ranae

Internal Trigger Jitter

(DLY'D

TRIG

- - - - --

dc to

10 MHz

I

At least + and - 1.5 V.

-

1 ns or less at

1.

--_---p-....."

75

MHz.

500 V (dc

to-peak ac at 1 kHz or less.

11 Mf2 paralleled by 20 pF.

-1-

peak ac). 500 V peak-

I

1

l..lll...lll..-..-.----ll

--

---

..

-

REV A JUN

1980

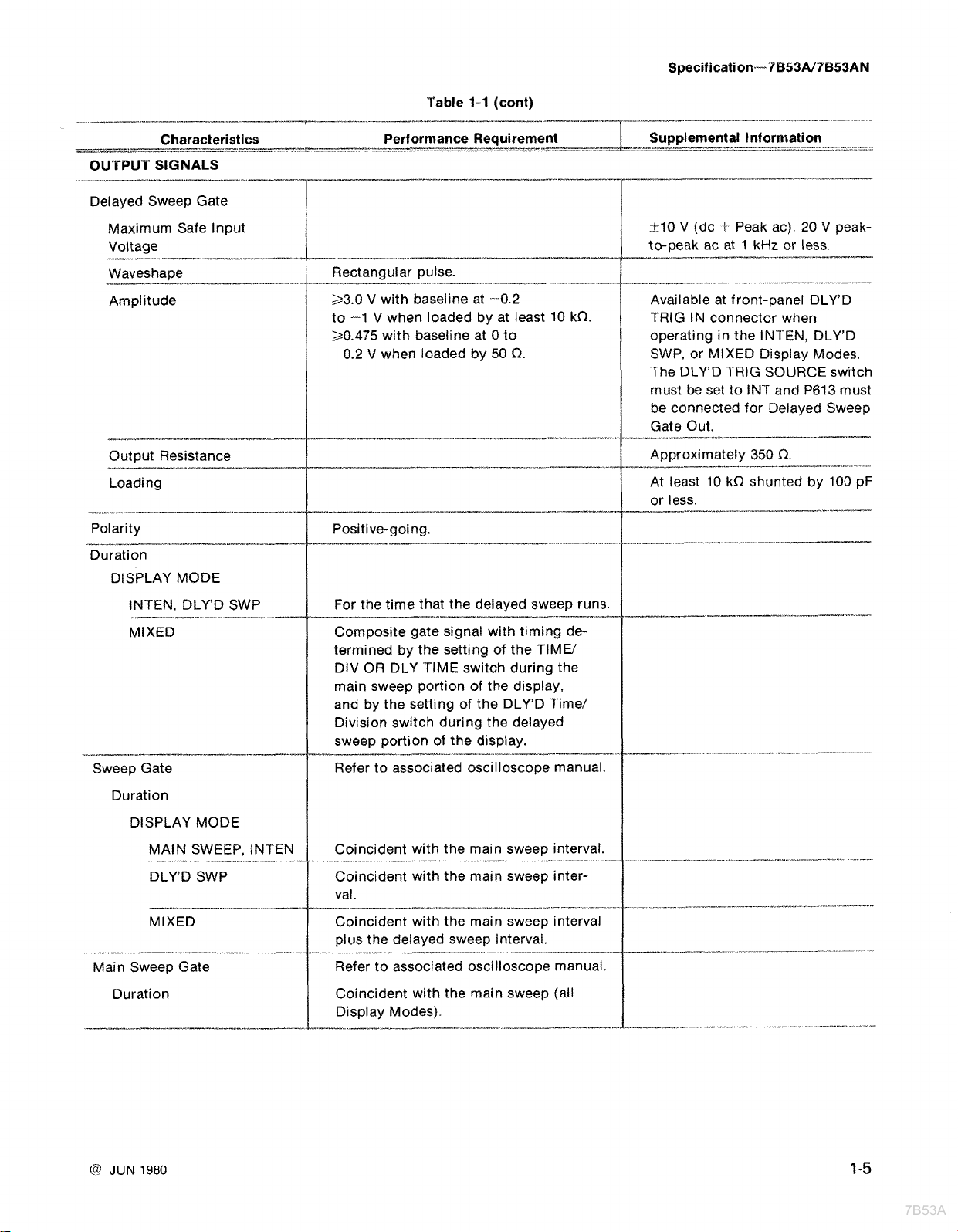

Page 14

OUTPUT

7B53A

Table

1-1

(cont)

Characteristics Performance Requirement Supplemental Information

SIGNALS

Delayed Sweep Gate

Maximum Safe Input

Voltage

--.".-..-

Amplitude

Output Resistance

Loading

Polarity

Duration

DISPLAY MODE

INTEN, DLY'D SWP

----.-----.---.--

MIXED

..".-,"---".~-

I

--

-....""~~.v",~-~~~-

Rectangular pulse.

23.0

V with baseline at

to

--I

V when loaded by at least

20.475

--0.2

Positive-goi ng.

ll--l~_l_____----.---~-~-.~-"--~--

For the time that the delayed sweep runs.

-----.--.-

--

Composite gate signal with timing de-

termined by the setting of the

DIV OR DLY TIME switch during the

main sweep portion of the display,

and by the setting of the DLY'D

Division switch during the delayed

sweep portion of the display.

with baseline at 0 to

V

when loaded by

--,~-...-----.---"

.

---0.2

50

0.

10

kfl.

----.-----

TIMV

lime/

rtlO

V

(dc i Peak ac).

to-peak ac at

Available at front-panel DLY'D

TRIG IN connector when

operating in the

SWP, or MIXED Display Modes.

The DLY'D

must be set to

be connected for Delayed Sweep

Gate Out.

Approximately

At least

or less.

-,--,."-----.....-....----

1

kHz

or less.

INTEN, DLY'D

TRIG SOURCE switch

IN-i and P613 must

350

---

10

kfl shunted

n.

-

t

I

20

V peak-

by

----

100

--

pF

Sweep Gate

Duration

DISPLAY MODE

MAIN SWEEP, INTEN

DLY'D SWP

MIXED

l_l-~l-..l"

Main Sweep Gate

Duration

@

JUN

1980

----.-.-._lll.-..---

Refer to associated oscilloscope manual.

I

1

Coincident with the main sweep interval.

""-

Coincident with the main sweep interval.

"_

-l.ll_,ll)....

Coincident with the main sweep interval

plus the delayed sweep interval.

.--_____-lll.-.,l_-l

Refer to associated oscilloscope manual.

i

Coincident with the main sweep (all

Display Modes).

""

-

__III^.._,.l

_

I

1

^..

"..

".-

"--.

"

-.-----.l"....X-..-.

X.

-

---

-----

--

.-

---

--

I

Page 15

Table

7B53A

1-1

(cont)

"

Sawtooth

Waveshape

-

.-

Duration

a

For Internal Triggering only, the specified

when the number in the table is greater than the

Characteristics Performance Requirement Supplemental Information

-----

.-.....-~wp-.--"

"--

Refer to associated oscilloscope manual.

"

1

I

DISPLAY MODE

MAIN SWP, INTEN

DLY'D SWP

MIXED

I I

Sawtooth signal with slope determined

by setting of the

TIME switch.

Sawtooth signal with slope determined

by the setting of the DLY'D

Division switch.

Composite sawtooth signal with slope

determined by the setting of the

TlMWDlV OR DLY TIME switch during

the main sweep portion of display, and

by

Division switch during the delayed

sweep portion of display.

Coincident with the time that each

sweep is displayed.

-

I

TlMWDlV

the setting of the DLY'D Time/

--3

dB frequency of the vertical system replaces any frequencies in the above table

--3

dB frequency of the vertical system.

OR

---.-

Time/

DLY

--

--

__.."l-___-_.l_l_._

Characteristics

Size

Weight

Table

1-2

ENVIRONMENTAL

Refer to the Specification for the associated oscilloscope.

Table

1-3

Ibs

(1.5

PHYSICAL

kg).

-.."

Fits all 7000-series plug-in compartments.

3.3

@

JUN

1980

Page 16

Section

7B53A

2-7B53N7B53AN

OPERAT

7B53N7B53AN

The 7B53A and 7B53AN Dual Time Base units provide

Main, Intensified, Delayed, and Mixed sweep operation for

'EKTRRONIX 7000-Series Oscilloscopes. Calibrated

sweep rates from 5

magnification) and triggering to 100 MHz are provided.

7B53A and 7B53AN are electrically identical except

The

that only the

readout system provided for 7000-Series Oscilloscopes.

Other features include

delay,

variable main and delayed sweeprates, and variable

main sweep holdoff. Separate triggering controls are

provided for main and delayed sweep triggering, and

when operating in the AUTO MAIN TRIGGERING MODE,

a bright base line is displayed in the absence of a trigger

signal. The

amplifier for

Features

s/div to 50 ns/div

7B53A is compatible with the alphanumeric

0 to 10 times continuous sweep

7B53N7B53AN can also be used as an

X-Y

operation.

NG

(5

ns with XI0

INSTRUCTIONS

To install the

ment, push it in until it fits firmly into the

The front panel of the 7653N7653AN should beftush with

the front panel of the indicator oscilloscope. Even though

the gain of the indicator oscilloscope is standardized to

minimize adjustment when inserting plug-in units, the

sweep calibration of the

ed when installed. The procedure for checking the unit is

given under Sweep Calibration in

procedure in this section.

To remove the

(see ~i~,

oscilloscope and pull it out of the plug-in compartment.

2-11

7B53N7B53AN in a plug-in compart-

compaitment.

7B53A17B53AN should becheck-

theoperating Checkout

7853N7B53AN, pull the release latch

to disengage the unit

from

the indicator

General

The 7B53A17B53AN operates with a TEKTHONIX 7000Series Oscilloscope and a 7A-Series Amplifier unit to form

a complete oscilloscope system. To

7B53A/7B53AN, its operation and capabilities should be

known. 'This section explains the operation of the

panel controls and connectors, provides an Operating

Checkout procedure, gives general operating information, and describes basic applications for this

effective1 y use the

front-

instrurnent.

Installation

The 7853A17853AN is designed to operate in the

horizontal compartment of the indicator oscilloscope.

Thisinstrument can also beinstalled

compartment to provideasweepthat runsvertically on the

crt. However, when used in this manner, there are no

retrace blanking or internal triggering provisions, and the

unit may not meet the specifications given in Section

The instructions in this manual are written for use of the

7B53N7B53AN in the horizontal plug-in compartment,

Before proceeding with installation it is necessary to

check the internal connections of the Variable Selector

connector and the Delayed Sweep Gate Out connector.

These connections should be checked against those

4-1

shown in Fig.

by qualified service personnel.

inthevertical plug-in

1.

Fig.

2-1.

Location

of

release latch.

CONTROLS AND CONNECTORS

General

All controls required for the operation of the

7B53N?B53AN, except the Variable Selector and the

Dly'd Sweep Gate Out connector are located on the front

panel of the instrument.

capabilities of this instrument, the operator should be

familiar with the function and use of each control. A brief

description of the front-panel controls and connectors is

given here. More detailed information is given under

'To make full use of the

REV 6 JUN

1980

2-

1

Page 17

Operating

7B53A

Instructions.---9853A17B53AN

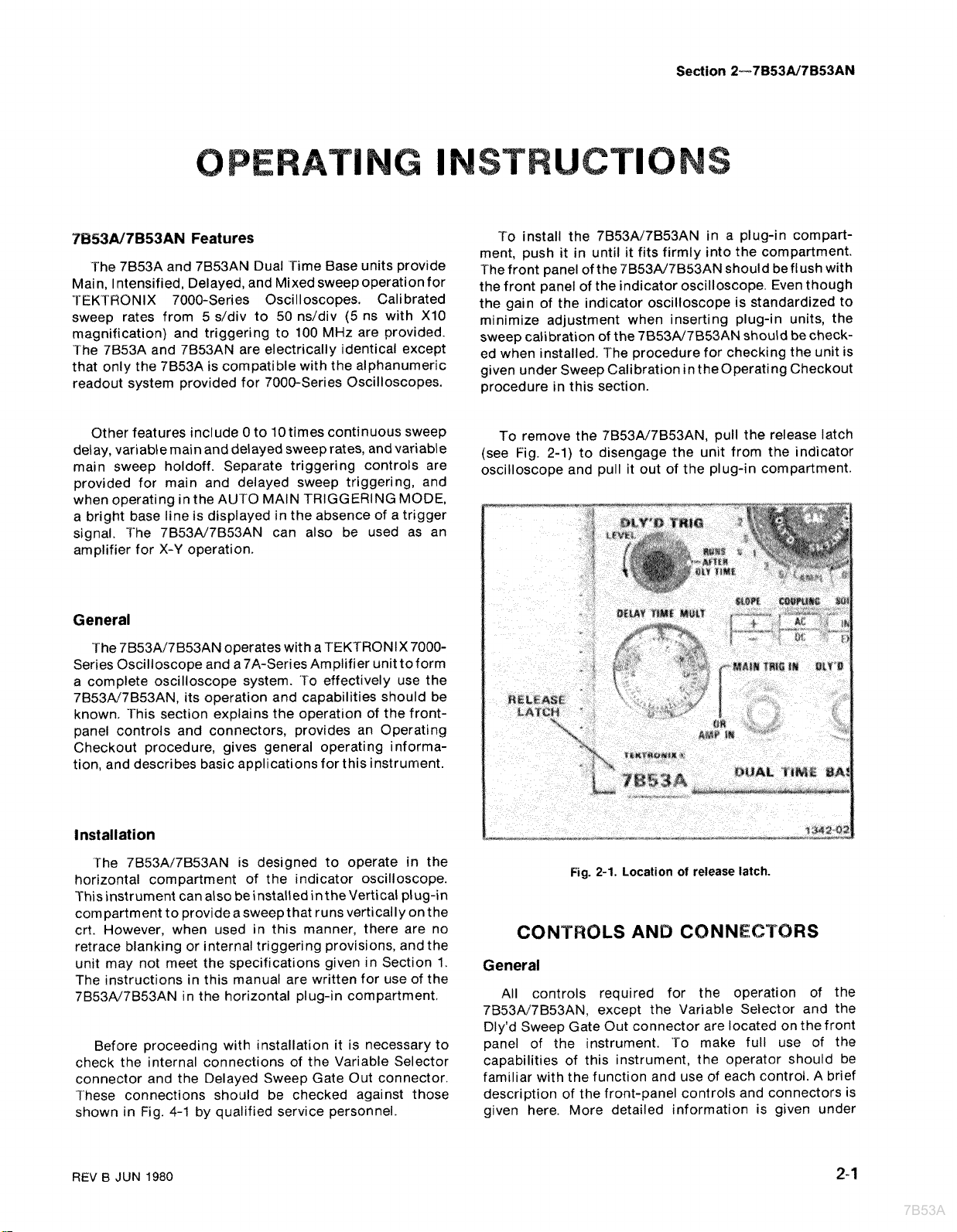

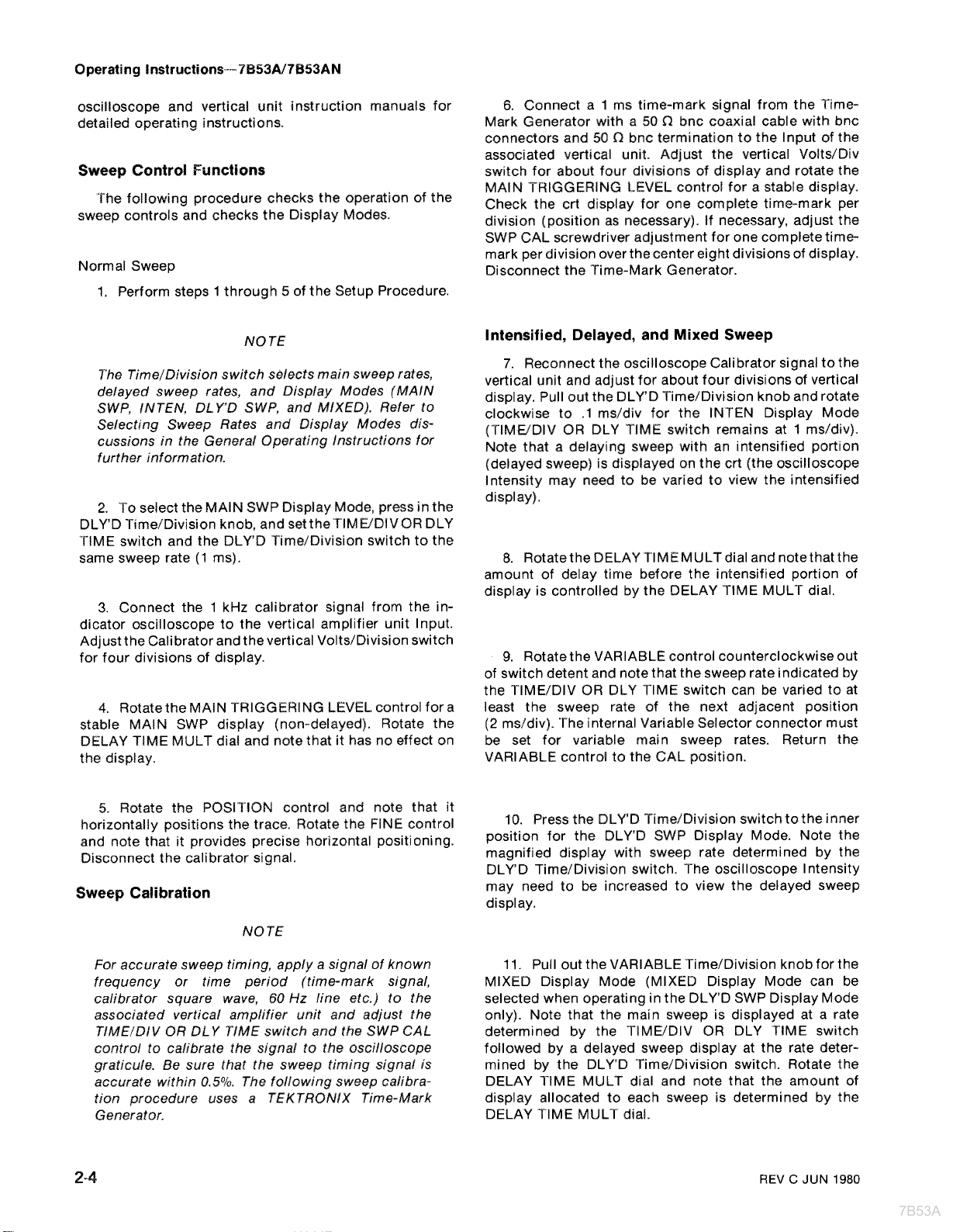

General Operating Information. Fig.

2-2

shows the front

panel and external controls and connectors of the

7

B53A/7 B53AN.

1.

Main Triggering Controls

LEVEL. Selects the amplitude point on the trigger

signal where sweep triggering occurs.

SLOPE. Two-position switch permits triggering on the

positive-going or negative-going portion of the main

triggering signal.

TRIG'D. Light indicates that the main sweep is

triggered and will produce a display.

MODE. Pushbutton switches select the operating mode

for the main triggering circuits.

COUPLING. Pushbutton switches select the method of

coupling the triggering signal to the main triggering

circuits.

SOURCE. Pushbutton switches select thesource of the

main triggering signal.

2. Sweep

Controls

TIMEIDIV OR DLY TIME. Selects the sweep rate of the

main sweep generator (see Fig.

2-5).

DLY'D Time/Division. Selects the sweep rate of the

MAIN

delayed sweep generator and selects the

INT'EN, and

DLY'D

SWP Display Modes (see Fig. 2-5).

SWP,

VARIABLE. Provides continuously variable main

sweep rates, continuously variable delayed sweep rates,

Fig.

2-2.

Front-panel controls

and

connectors.

REV

C

JUN

1980

Page 18

Operating

7B53A

Instructions-7B53A17B53AN

or variable main sweep holdoff; depending on the setting

of the Variable Selector multi-pin connector

VARIABLE control also selects the MIXED Display Mode

(see Fig. 2-5).

SWP CAL. Screwdriver adjustment to match the gain of

7653A/7B53AN to the indicator oscilloscope for

the

calibrated sweep rates.

POSITION. Controls horizontal position of display.

FINE. Provides precise control of horizontal position

adjustment,

MAG. Pushbutton switch selects

magnification.

3.

Delay Time Control

DELAY l IME MULT. Provides variable sweep delay

between 0.00 and 10.0 times the delay time indicated by

TIMUDIV OR DLY rlME switch.

the

4.

Delayed Triggering Controls

XI or XI0 horizontal

(P140). The

OPERATING

CHECKOUT

Introduction

The following procedure checks the basic operation of

the

7B53A/7653AN. It may also be usedfor familiarization

with this instrument or as an incoming inspection. This

procedure is divided into two parts, Sweep Control

Functions, and Main and Delayed Triggering Functions. A

complete operating check of the

functions can be made by performing both parts, or each

part may be performed separately.

NOTE

For optimum performance, the

should

similar frequency and sweep rate capabilities.

be

instalied

in

an oscilfoscope system

7853N7853AN control

7853Ai7B53AN

with

Setup Procedure

1.

Install the 7B53A/7B53AN in the right horizontal

compartment of the indicator oscilloscope.

2.

Install a Vertical Amplifier unit in the left vertical

compartment.

LEVEL. Selects the RUNS AFTER DLY TIME or

Triggerable After Dly Time Modes, and the amplitude

point at which the delayed sweep is triggered.

SLOPE. Two-position switch permits triggering on the

positivegoing or negative-going portion of the delayed

triggering signal.

COUPLING. Two-position switch selects the method of

coupling the triggering signal to the delayed triggering

circuits.

SOURCE. Two-position switch to select the source of

the delayed triggering signal.

5.

InputlOutput Connectors

MAlN TRIG IN OR AMP IN. Front-panel bnc connector

serving as an external trigger input for the maintriggering

circuit or as an external horizontal input, depending upon

the setting of the

MAlN TRIGGERING SOURCE switch.

TRlG IN. Front-panel bnc connector serving as

DLY'D

an external trigger input forthedelayed triggering circuits

or as a delayed sweep gate output; depending upon the

DLY'D TRlG SOURCE switch, the position of

the DISPLAY MODE.

TIMVDIV OR DLY TlMEswitch and the

P613, and

3.

Turn on the indicator oscilioscopeand allow at least

20 minutes

4.

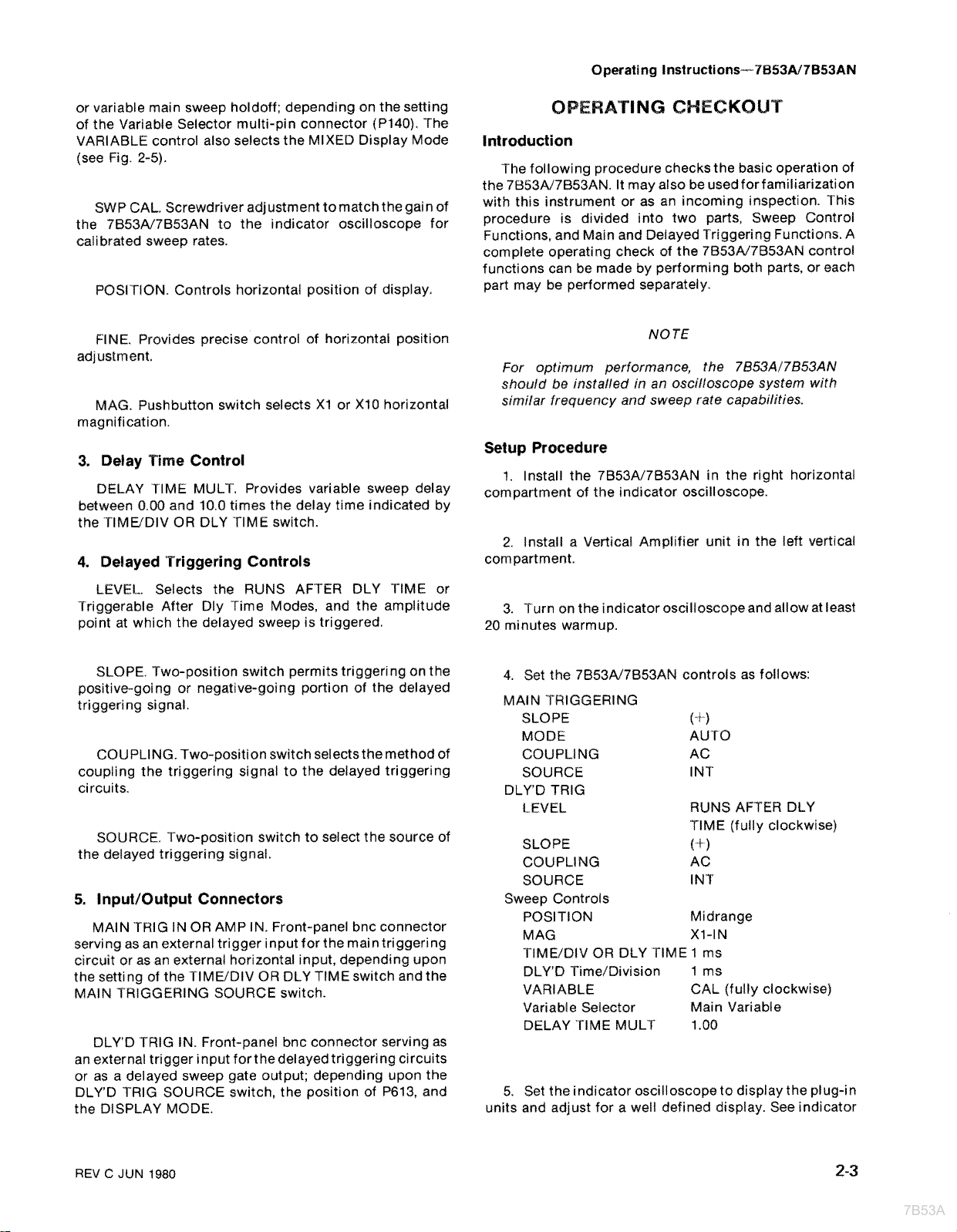

MAlN TRIGGERING

DLY'D TRlG

Sweep Controls

5. Set the indicator oscilloscope to display the plug-in

units and adjust for

warmup.

Set the 7B53N7653AN controls as follows:

SLOPE

MODE AUTO

COUPLING AC

SOURCE INT

I.

EVEL RUNS AFTER DLY

SLOPE

COUPLING AC

SOURCE

POSITION Midrange

MAG

TlMElDlV OR DLY FlME 1 ms

DLY'D TrmefDivision

VARIABLE CAL (fully clockwise)

Variable Selector Main Variable

DELAY[-IMEMULT 1.00

a

well defined display. See indicator

(-f

)

TIME (fully clockwise)

(f)

INT

X1-IN

1

ms

REV

C

JUN

1980

2-3

Page 19

Operating

7B53A

oscilloscope and vertical unit instruction manuals for

detailed operating instructions.

Sweep

'The following procedure checks the operation of the

sweep controls and checks the Display Modes.

Normal Sweep

1.

Instructions~--7B53A/7B53AN

Control

Perform steps 1 through 5 of the Setup Procedure.

Functions

6.

Connect a 1 ms time-mark signal from the TimeMark Generator with a

connectors and 50

associated vertical unit. Adjust the vertical

switch for about four divisions of display and rotate the

MAIN TRIGGERING

Check the crt display for one complete time-mark per

division (position as necessary). If necessary, adjust the

SWP CAL screwdriver adjustment for one complete

mark per division over the center eight divisions of display.

Disconnect the "Time-Mark Generator.

50

Z;1

bnc coaxial cable with bnc

62

bnc termination to the Input of the

VoltdDiv

1-EVEL controt for a stable display.

time

NOTE

The TimeIDivision switch selects main sweep rates,

delayed sweep rates, and Display Modes (MAIN

SWP, INTEN. DL Y'D

Seiectrng Sweep Rates and Display Modes dis-

in

cussions

further information.

2.

To select the MAlN SWP Display Mode, press in the

Time/Division knob, and set the TIMVDIV OR DLY

DLY'D

TIME switch and the DLY'D TimelDivision switch to the

same sweep rate

3.

Connect the 1 kHz calibrator signal from the in-

dicator oscilloscope to the vertical amplifier unit Input.

Adjust the Calibrator and thevertical

for four divisions of display.

4.

Rotatethe MAlN TRIGGERING LEVEL control for a

stable MAIN

DELAY TIME MULT dial and note that it has no effect on

the display.

the General Operating

(1

SWP

SWP,

and MIXEL?). Refer lo

instructions

ms).

Volts/Division switch

display (non-delayed). Rotate the

for

Intensified, Delayed, and Mixed Sweep

7.

Reconnect the osciIloscope Calibrator signal to the

vertical unit and adjust for about four divisions of vertical

display. Pull out the DLY'D

clockwise to

(TIMVDIV OR DLY TlME switch remains at 1 msldiv).

Note that a delaying sweep with an intensified portion

(delayed sweep) is displayed on the crt (the oscilloscope

Intensity may need to be varied to view the intensified

display).

8.

Rotatethe DELAY'T'IMEMULTdial andnotethatthe

amount of delay

display is controlled by the DELAY TlME MULT dial.

9.

Rotate the VARIABLE control counterclockwise out

of switch detent and note that the sweep rate indicated by

TIME/DIV OR DLY TIME switch can be varied to at

the

least the sweep rate

(2

msl'divj. 'The internal Variable Selector connector must

be

set for variable main sweep rates. Return the

VARIABLE control to the GAL position.

.1 msi'div for the INTEN Display Mode

time before the intensified portion of

TimelDivision knob and rotate

of the next adjacent position

5.

Rotate the POSITlON control and note that

horizontally positions the trace, Rotate the FINE control

and note that it provides precise horizontal positioning. position

Disconnect the calibrator signal.

Sweep Calibration

NOTE

For accurate sweep timing, apply a signal of known

frequency or time period (time-mark signal,

60

Hz

calibrator square wave,

associated vertical amplifier unit and adjust the

TIMEIDIV OR DLY nME switch and the

control to calibrate the signal

graticule. Be sure that the sweep timing signa! is

0.5%.

accurate within

tion procedure uses

Generator.

The following sweep caiibra-

a

TEKTRONIX

line etc.) to the

SWP

to

the oscilloscope

Time-Mark

CAF

it

10. Press the DLY'D

magnified display with sweep rate determined by the

DLY'D

may need to be increased to view the delayed sweep

display.

11.

MIXED Display Mode (MIXED Display Mode can be

selected when operating in the DLY'D SWP Display Mode

only). Note that the main sweep is displayed at a rate

determined by the

followed by a delayed sweep display at the rate determined by the DLY'D

DELAY TlME MULT dial

display allocated to each sweep is determined by the

DELAY TlME

2-4

Time/Division switch to the inner

for DLY'D SWP

Time/Division switch. The oscilloscope Intensity

Pull out the VARIABLE "l"ime/Division knob for the

'TIMEIDIV OR DLY TlME switch

Time/Division switch. Rotate the

and note that the amount of

MULT

dial.

REV

C

JUN

the

1980

Page 20

Main and Delayed Sweep Triggering Functions

7B53A

The following procedure checks the operation of the

main and delayed triggering controls:

Partial Procedure. To begin the Operating Checkout

1

with triggering, perform steps

Procedure provided at the beginning of the Operating

Checkout. Connect the

indicator

osciIioscope to the vertical unit Input and adjust

1

for about four divisions of vertical display.

12.

Set the TIME/DIV OR DLY TlME switch and the

DLY'D

DLY'D

Time/Division switch to 1 ms and press in the

TimeiDivision switch and the Variable control.

CHECK---that a stable display can be obtained with the

COUPLING switch for MAlN

HF REJ, and DC for both the positive and negative

positions of the SLOPE switch (MAIN TRIGGERING

LEVEL control may be adjusted as necessary to obtain a

stable main sweep display). Remove all connections from

the oscilloscope system.

13.

Connect a 60

n

cable or voltage probe to the vertical unit Input and

50

adjust the

VoltsIDiv switch for about four divisions of

Hz

signal (iine voltage, etc.) with a

display. Set the MAlN TRIGGERING COUPLING switch

to AC LF REJ and set the

10

ms. Rotate the MAIN TRIGGERING LEVEL control

to

"r^lMVDlV OR DLY TIME switch

throughout its range and check that a stable display

cannot be obtained (TRIG'D light off).

14.

Change the MAlN 'TRIGGERING SOURCEswitch

to LINE and the COUPLING switch to AC. Check that a

stable main sweep display can be obtained with the MAIN

TRIGGERING COUPLING switch set to AC, AC HF REJ,

and DC (MAlN TRIGGERING LEVEL control may be

adjusted as necessary). Remove all connections from the

oscilloscope system.

15.

Connect the indicator oscilloscope Calibrator

signal to the verticai unit Input connector and

TRIG IN connector. Set the Calibrator for a 0.4 V,

signal and adjust the vertical unit

about four divisions of display. Set

TIME switch and the DLY'D

Set the MAlN TRIGGERING SOURCE switch to EXT and

check that a stable display can be obtained with the

COUPLING switch for MAIN TRIGGERING set to AC, AC

HF REJ, and DC, for both the positive and negative

positions of the SLOPE switch (MAIN TRIGGERING

LEVEL control may be adjusted as necessary for a stable

display).

16.

Change the MAlN TRIGGERING SOURCE switch

-:--

to EXT

1

kHz and adjust the vertical unit VoltsiDiv switch for

10. Set the oscilloscope Calibrator for 4 V at

through 5 of the Setup

kHz calibrator signal from the

'T'RIGGERING set to AC, AC

tothe MAIN

1

kHz

Volts/Div switch for

the'TIMWDIV OR DLY

TimelDivision switch to 1 ms.

about

Operating

4

divisions of display. Check that a stable display

Instructions--~7B53A/7B53AN

can be obtained with the COUPLING switch for MAIN

TRIGGERING set to AC, AC HF REJ, and DC, for

boththe

positive and negative positions of the SLOPE switch

(MAIN TRIGGERING LEVEL control may be adjusted as

necessary to obtain a stable delaying sweep display).

Remove the Calibrator signal from the MAlN TRIG IN

connector.

17.

Set the MAlN "TRIGGERING COUPLING switch to

AC and the SOURCE switch to

INT. Adjust the MAlN

TRIGGERING LEVEL control for a stable display. Set the

MODE switch to NORM and check for a stable display.

Change the

MODEswitch to AUTO and adjust the LEVEL

control for a free-running display. Change the MODE

switch to NORM and check for no display.

18.

Adjust the MAlN TRIGGERING LEVEL control for

a stable display. Change the MAlN TRIGGERING MODE

switch to SINGLE SWP. Press the

check for one sweep. Remove the

RESET button and

1

kHz signal from the

vertical unit and press the RESET button. CHECK for no

1

display and that the READY light is on. Connect the

kHz

signal to the vertical unit and check for one sweep as the

signal is applied.

19.

Set the MAIN TRIGGERING MODE switch to

AUTO. With the

pull out the DLY'D

.2

ms (Intensified Display Mode). Rotate the MAlN

TIMWDIV OR DLY TIME switch

Time/Division switch and rotate to

at

1

ms,

TRIGGERING LEVEL control for a stable display

(oscilloscope Intensity may need to be varied to view the

intensified display). Rotate the

Df LAY TlME MULT dial

and note that the intensified portion of display is con-

tinuously variable.

20.

Rotate the DLY'D TRlG LEVEL control counterclockwise out of switch detent for a triggered delayed

sweep. With the DLY'D

SOURCE switches set to

TRIG SLOPE, COUPLING, and

(-f

),

AC, and INT; rotate the

DLY'D TRIG LEVEL control for astable intensified portion

of display. Rotate the DELAY

TIME MULT dial and note

that the intensified portion of display does not start at the

completion

of the

of the delay time (determined by the settings

TIMEIDIV OR DLY TIME switch and the DELAY

TIME MULT dial), but waits for the next trigger pulse.

21.

Press the DLY'D Time/Division switch in for the

DLY'D SWP Display Mode. Rotate the DLY'DTWIG LEVEL

control for a stable delayed sweep display (oscilfoscope

Intensity may need to be varied). Check that a stable

delayed sweep display can be obtained with the DLY'D

TRIG COUPLING switch set to AC and

-

positions of the SLOPE switch (DLY'D TRIG LEVEL

DCfor both

.I-

and

control may be adjusted as necessary for a stable delayed

sweep display).

REV

A

JUN

1980

2-5

Page 21

Operating

7B53A

Instructions-.-7B53Ai1B53AN

22.

Change the DLY'D TRIG SOURCE switch to EXT.

Connect the indicator oscilloscope Calibrator signal to

the DLY'D

Calibrator for

Volts/Division switch for about 4 divisions of display.

Check that a stable delayed sweep display can be

obtained with the DLY'D TRlG COUPLING switch set to

AC and DC for both the

switch (DLY'D TRlG LEVEL control may be adjusted as

necessary for a stable delayed sweep display).

TRlG IN connector. Set the oscilloscope

0.4

V at 1 kHz

-t-

and adjust the vertical

and positions of the SLOPE

GENERAL OPERATING INSTRUCTIONS

Pushbutton Switch Logic

The MODE, COUPLING, and SOURCE pushbuttons of

the MAlN TRIGGERING switches are arranged in

sequence that places the most-often used position at the

top of each series of pushbuttons. With this arrangement,

a stable display can usually be obtained by pressing the

top pushbuttons: AUTO, AC, and INT. When an adequate

trigger signal is applied, the unit is triggered as indicated

by the illuminated

of the LEVEL control and SLOPE switch. If the

light is not on, the LEVEL control isat asetting outsidethe

range of the trigger signal applied to this unit from the

vertical unit, the trigger signal is inadequate, or its

frequency is below the lower frequency limit of the AC

COUPLING switch position. If the desired display is not

obtained with these buttons pushed in, other selections

must be made. Refer to the following discussions or the

intruction manuals for the associated oscilloscope and

vertical unit for more information.

Triggered Light

'IRIG'D light, with the correct settings

TRIG'D

switch are correctly set. The TRIG'D light indicates when

the display is triggered.

When the trigger repetition rate is below about

outside the frequency range selected by the COUPLING

switch, or when thetrigger signal is inadequate,

free-runs at the sweep rate indicated by the -TIMVDlV OR

DLY TIME switch (TRIG'D light off). When an adequate

trigger signal is again applied,

ends and a triggered display is presented. The sweep also

free-runs when the LEVEL control is at a setting outside

the amplitude range of the trigger signal.

running display can be useful when it is desired to

measure only the maximum peak-to-peak amplitude of a

signal without observing the waveshape (such as in

bandwidth measurements). When the display is of amuch

a

greater amplitude than can be displayed on the crt, the

sweep will be triggered in all positions of the LEVEL

control and will not free-run.

NORM.

triggered display is presented with the correct setting of

the LEVEL control and SLOPE switch whenever an

adequate trigger signal is applied.

indicates when the display is triggered.

The NORM trigger mode must be used to produce

triggered displays with trigger repetition rates below

about

outside the amplitude range of thetrigger signal,

trigger repetition rate is outside the frequency range

selected by the COUPLING switch, or when the trigger

signal is inadequate,

When the NORM pushbutton is pressed, a

30

Hz.

When the LEVEL control is at a setting

thereis no trace (TRIG'D light isoff).

the free-running

Thistype of free-

"The TRIG'D light

30

Hz,

thesweep

condition

whenthe

The TRIG'D light conveniently indicates the condition

of the triggering circuits. If the MAlN TRIGGERING

controls are correctly set and an adequate trigger signal is

applied, the TRIG'D light is on. Under certain conditions,

the TRIG'D light may be off, indicating that the sweep is

not triggered. The cause could be a misadjusted LEVEL

control, incorrectly set COUPLING or SOURCE switches,

low trigger signal amplitude, or a triggering signal repetition rate outside the acceptable frequency range. This

light can be used as a general indication of correct

triggering. It is particularly useful when setting up the

trigger circuits when a triggering signal is available

without a display on the crt.

Main Trigger Mode

The pushbuttons located under the MODE title select

the mode in which the main sweep is triggered.

AUTO.

triggered display is presented whenever an adequate

trigger signal is applied and the

When the AU'TO pushbutton is pressed, a

LEVELcontrol and SLOPE

2-6

SINGLE

be displayed is not repetitve or varies in amplitude,

waveshape, or repetition rate, a conventional repetitive

type display may produce an unstable presentation. A

stable display can often be obtained under these circumstances by using the SINGLE

The SINGLE SWP MODE is also useful

non-repetitive or unstable displays.

To obtain a single-sweep display of a repetitive signal,

first obtain the best possible display in the NORM MODE.

Then without changing the other MAlN TRIGGERING

switches, press the SINGLE SWEEP pushbutton. When

ready to view thesingle-sweep display, press the

READY pushbutton. A single trace is presented each time

the RESET-READY pushbutton is pressed

repetitive signal remains connected to the system and

MAlN TRIGGERING switches are correctly set); further

sweeps cannot be presented until the RESET-READY

pushbutton is pressed again. If the display signal is a

complex waveform composed of varying amplitude,

successive single-sweep displays may not start at the

SWEEP,

RESET-READY.

SWPfeature of this unit.

When the signal to

to

photograph

RESET-

(as long as the

REV

B

JUN

1980

Page 22

7B53A

Page 23

Operating

7B53A

Instructions---7B53A/7B53AN

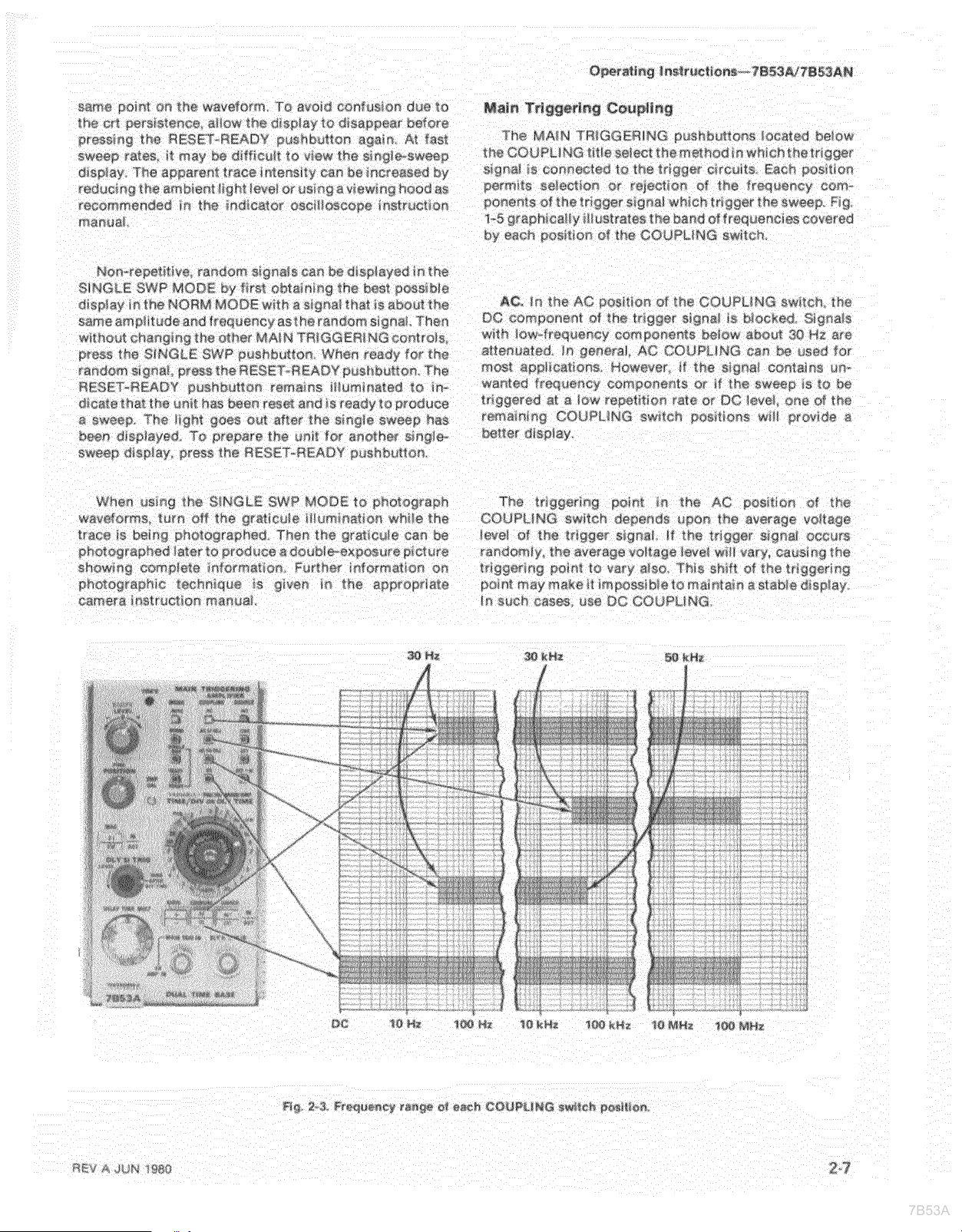

AC

LF

REJ.

In the AC LF REJ position of the

COUPLING switch, dc is rejected and low-frequency

kHz

trigger signals below about 30

Therefore, the sweep is triggered only by the

are attenuated.

higher-

frequency components of the trigger signal. This position

is particularly useful for providing stable triggering if the

trigger signal contains line-frequency components. Also,

the AC LF REJ position provides the best alternate vertical

displays at fast sweep rates when comparing two or more

unrelated signals.

AC

HF

REJ.

The AC

HF

REJ position of theCOUPLlNG

switch passes all low-frequency signals between about

Hz

and 50 kHz. Dc is rejected and signals outside the

30

above rage are attenuated. When triggeringfrom complex

waveforms, this position is useful to provide a stable

display of the low-frequency components.

DC.

The DC position of the COUPLING switch can be

used to provide stable triggering with low-frequency

signals which would be attenuated in the other modes, or

with low-repetition rate signals. It can also be used to

trigger the sweep when the trigger signal reaches a dc

level selected by the setting of the LEVEL control. When

using internal triggering, the setting of the vertical unit

position control affects the dc triggering point.

Main Triggering Source

'TheMAIN TRIGGERING pushbutton located belowthe

SOURCEtitle select the source of the trigger signal which

is connected to the main triggering circuits.

INT.

In the IN% position of the SOURCE switch, the

trigger signal is derived from the associated vertical unit.

Further selection of the internal trigger signal may be

provided by the associated vertical unit or indicator

oscilloscope; see the instruction manuals for these instruments for information. For most applications, the

position of the SOURCE switch can be used. However,

some applications requirespecial triggering which cannot

be obtained in the

such cases the

INT position of the SOURCEswitch. In

LlNE or EXT positions of the SOURCE

switch must be used.

INT

be time-related to the displayed waveform for a stable

display. An external trigger signal can provide a triggered

display when the internal signal is too

low in amplitude for

correct triggering, or contains signal components on

which it is not desired to trigger. It is also useful when

signal tracing in amplifiers, phase shift networks,

waveshaping circuits, etc.

the circuit undertest can beconnected

Thesignal from a single point in

tothe EXTqI"'RIG IN

connector with a probe or cable. The sweep is then

triggered by the same signal at all times and allows

amplitude, time relationship, or waveshape changes of

signals at various points in the circuit to be examined

without resetting the MAIN TRIGGERING controls.

-i-

10.

EXT

Operation in the EXT t 10 position of the

SOURCE switch is the same as described for EXT except

that the external signal is attenuated

lotimes. Attenuation

of high-amplitude external trigger signals is desirable to

broaden the range of the LEVEL control.

Trigger Slope

The MAIN TRIGGERING SLOPE switch (concentric

with the MAIN TRIGGERING LEVEL control) determines

whether the trigger circuit responds on the positive-going

or negative-going portion of the trigger signal. When the

SLOPE switch is in the

-I-

position, the display startsonthe

positive-going portion of the waveform; in the position,

the display starts with the negative-going portion of the

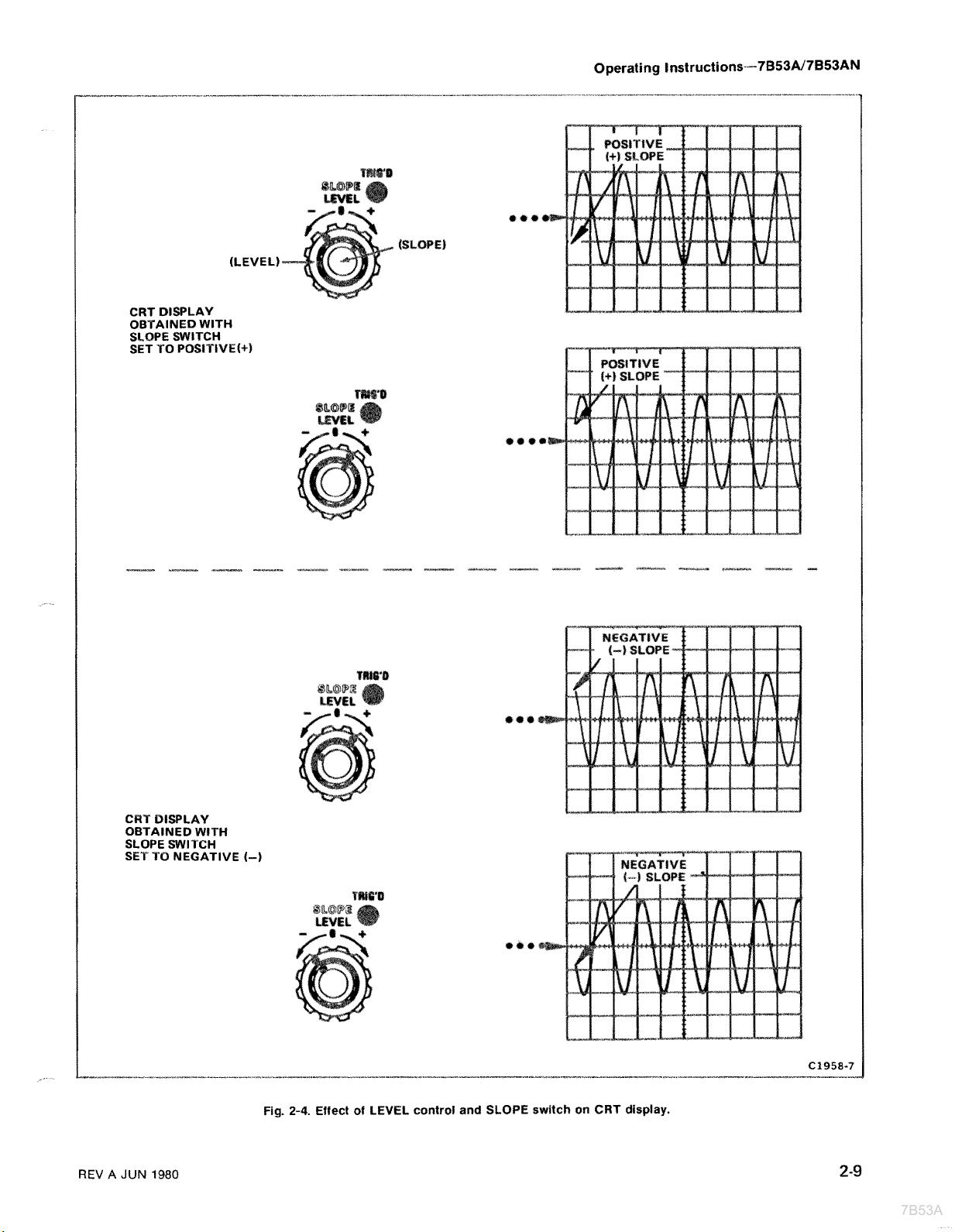

2-4).

waveform (see Fig.

When several cycles of a signal

appear in a display, the setting of the SLOPE switch is

often unimportant. However, if only a certain portion of a

cycle is to be displayed, correct setting of the SLOPE

switch is important to provideadisplay which starts on the

desired slope of the input signal.

Trigger Level

"The MAlN TRIGGER LEVEL control determines the

voltage level on the trigger signal at which the sweep is

4-

triggered. When the LEVEL control is set in the

the trigger circuit responds at a more positive point on the

trigger signal. When the LEVEL. control is set in the

region, the trigger circuit responds at a more negative

2-4

point on the trigger signal. Fig.

illustrates this effect

with different settings of the SLOPE switch.

region,

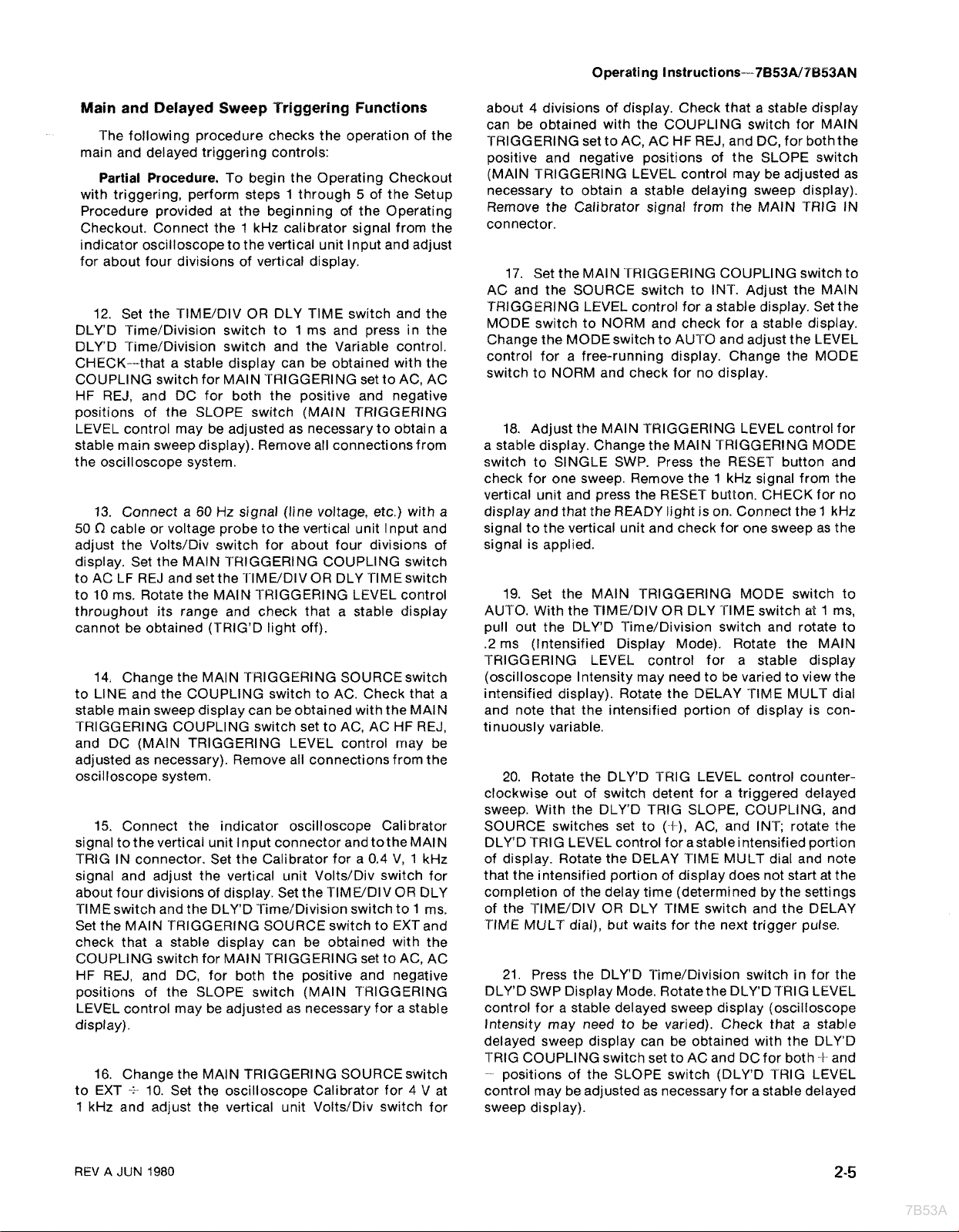

-

LINE.

The LlNE ~osition of the SOURCE switch

connects a sample of the power-line voltage from the

indicator oscilloscope to the trigger circuit. Line

trigger-

ing is useful whentheinput signal istime-related (multiple

or submultiple) to the line frequency. It is also useful for

providing a stable display of a line-frequency component

in a complex waveform.

EX$.

An external signal connected to the MAIN TRIG The TIME/DIV OR DLY TIME switch selects calibrated

IN connector can be used to trigger the sweep in the EXT

position of the SOURCE switch.

The external signal must

2-8

Before setting the MAIN TRIGGERING LEVEL, set the

desired

the

clockwise

SLOPE,

LEVEL

MODE, COUPLING,

control

until

the

fully

display

and

counterclockwise

starts

at

the

desired

SOURCE,

and then

point,

Set

rotate

Selecting Sweep Rates

sweep rates for the main sweep generator and the DLY'D

I'imeiDivision switch selects calibrated sweep rates for

REV A JUN

1980

Page 24

(LEVEL)

7B53A

Operating

Instructions--7B53A/7B53AN

CRT DISPLAY

OBTAINED

SLOPE SWITCH

SET

WITH

TO

POSITIVE(+)

REV

A

car

DISPLAY

OBTAINED

SLOPE SWITCH

SET

JUN

W1TH

TO NEGATIVE

1980

(-)

Fig.

2-4.

Effect of LEVEL control and SLOPE

switch

on CRT display.

Page 25

Operating

7B53A

Instructions--7BS3A/7B53AN

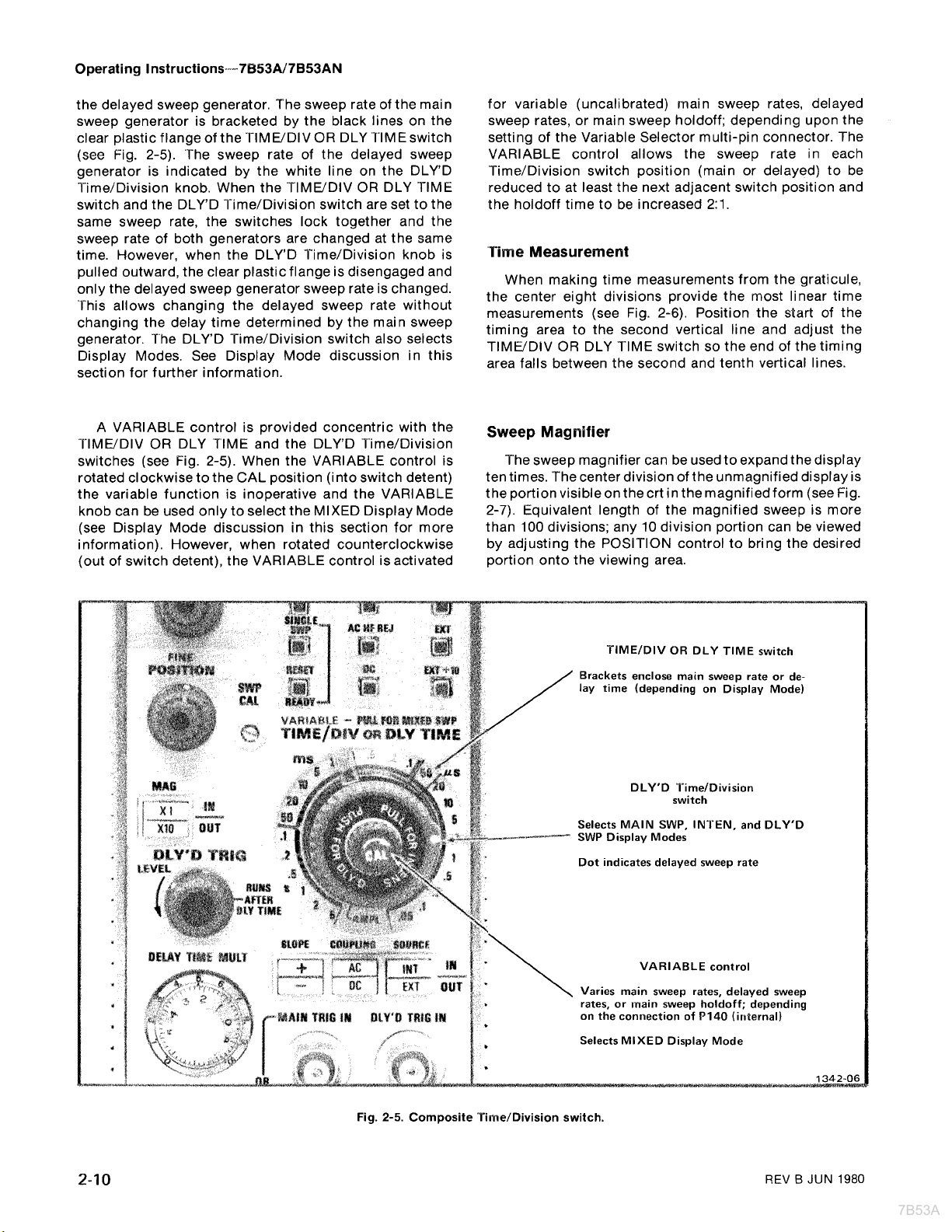

the delayed sweep generator. The sweep rate of the main

sweep generator is bracketed by the black lines on the

clear plastic flange of the TIMVDIV OR DLY TIME switch

(see Fig. 2-5). The sweep rate of the delayed sweep

generator is indicated by the white line on the DLY'D

Time/Division knob. When the T'IMVDIV OR DLY TlME

switch and the DLY'D Time/Division switch are set to the

same sweep rate, the switches lock together and the

sweep rate of both generators are changed at the same

time. However, when the DLY'D

pulled outward, the clear plastic flange is disengaged and

the

all0ws changing

changing

generator. The DLY'D Time/Division switch also seiects

section for further information.

A VARIABLE control is provided concentric with the

T'IMVDIV OR DLY

switches (see Fig. 2-5). When the VARIABLE control is

rotated clockwise to the CAL position (into switch detent)

the variable function is inoperative and the VARIABLE

knob can be used only to select the MIXED Display Mode

(see Display Mode discussion in this section for more

information). However, when rotated counterclockwise

(out of switch detent), the VARIABLE control is activated

the

Modes.

sweep generator sweep

the

time

determined

See

TlME and the DLY'D Time/Division

Time/Division knob is

rate

is

changed'

sweep

Mode

rate

the

main

discussion

without

sweep

in

this

for variable (uncalibrated)

sweep rates, or main sweep

setting of the Variable Selector multi-pin connector. The

VARIABLE control allows the sweep rate in each

Time/Division switch position (main or delayed) to be

reduced to at least the next adjacent switch position and

holdoff time to be increased

the

main sweep rates, delayed

holdoff; depending upon the

2:l.

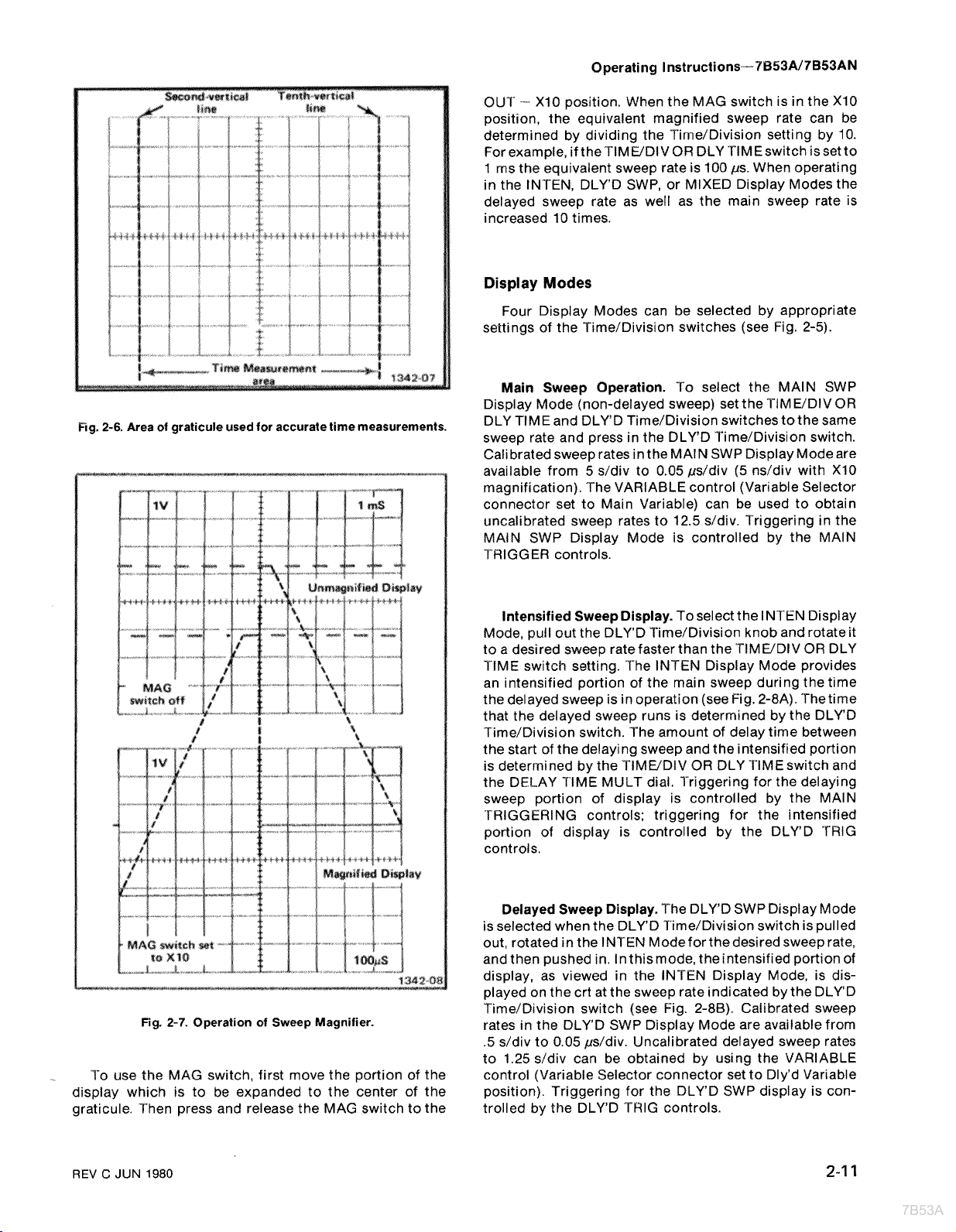

"Time Measurement

When making time measurements from the graticule,

the center eight divisions provide the most linear time

measurements (see Fig, 2-6).

timing

TIMUD,,,

area falls between the second and tenth vertical lines,

area

to the second vertical line and adjust the

OR

DLY

Position the start

switch

so

the

end

of

the

of

the

timing

Sweep Magnifier

The sweep magnifier can be used to expand the display

ten times. The center division of the unmagnified display is

the portionvisibleon thecrt in themagnifiedform (see Fig.

2-7).

Equivalent length of the magnified sweep is more

100

than

by adjusting the POSITION control to bring the desired

portion onto the viewing area.

divisions; any

10

division portion can be viewed

Fig.

2-5.

Composite Time/Division switch.

REV 6 JUN

1980

Page 26

Operating

7B53A

Instructions---7B53A/7B53AN

Fig.

2-6.

Area of graticule used for accurate time measurements.

OUT

position, the equivalent magnified sweep rate can be

determined by dividing the

Forexample,

1

in the

delayed sweep rate as well as the main sweep rate is

increased 10 times.

Display

settings of the

DisIJlav Mode (non-delayed sweep) set the TIMVDIV OR

DLY

sweep rate and press in the DLY'D

Calibrated sweep rates in the MAIN SWP Display Mode are

available from 5

magnification). The VARIABLE control (Variable Selector

connector set to Main Variable) can be used to obtain

uncalibrated sweep rates to 12.5

MAlN SWP Display Mode is controlled by the MAlN

TRIGGER controls.

XI0 position. When the MAG switch is in the XI0

Time/Division setting by 10.

iftheTlMVDlVOR DLY TlMEswitch issetto

ms the equivalent sweep rate is 100 ps. When operating

INTEN, DLY'D SWP, or MIXED Display Modes the

Modes

Four Display Modes can be selected by appropriate

Time/Division switches (see Fig. 2-5).

Main Sweep Operation.

TIME

~~~'DLYD

~ime/~ivisibk switches to the same

s/div to 0.05 ps/div (5 ns/div with X10

To select the MAlN SWP

Time/Division switch.

sldiv. Triggering in the

Fig.

2-7.

Operation of Sweep Magnifier.

TO use the MAG switch, first move the portion of the

display which is to be expanded to the center of the

graticule. Then press and release the MAG switch to the

Intensified SweepDisplay.

Mode, pull out the DLY'D

to a desired sweep rate faster than the TIMVDIV OR DLY

TIME switch setting. The INTEN Display Mode provides

an intensified portion of the main sweep during the time

the delayed sweep is in operation (see Fig. 2-8A). The time

that the delayed sweep runs is determined by the DLY'D

Time/Division switch. The amount of delay time between

the start of the delaying sweep and the intensified portion

is determined by the

the DELAY

sweep portion of display is controlled by the MAlN

"TRIGGERING controls; triggering for the intensified

portion of display is controlled by the DLY'D TRIG

controls.

Delayed Sweep Display.

is selected when the DLY'D

out, rotated in the

and then pushed in, In this mode, the intensified portion of

display, as viewed in the

played on the crt at the sweep rate indicated by the DLY'D

Time/Division switch (see Fig. 2-88}. Calibrated sweep

rates in the DLY'D SWP Display Mode are available from

.5 s/div to 0.05 psldiv. Uncalibrated delayed sweep rates

to 1.25

control (Variable Selector connector set to Dly'd Variable

position). Triggering for the DLY'D SWP display is controlled by

TIME MULT dial, Triggering for the delaying

s/div can be obtained by using the VARIABLE

the DLY'D TRIG controls.

TiMEIDIV OR DLY 'TIMEswitch and

INTEN Modeforthedesiredsweeprate,

To select the INTEN Display

Time/Division knob and rotateit

The DLY'D SWP Display Mode

Time/Division switch is pulled

INTEN Display Mode, is dis-

REV

C

JUN

1980

2-1

1

Page 27

Operating

7B53A

Instructions--78fi3Al7B53AN

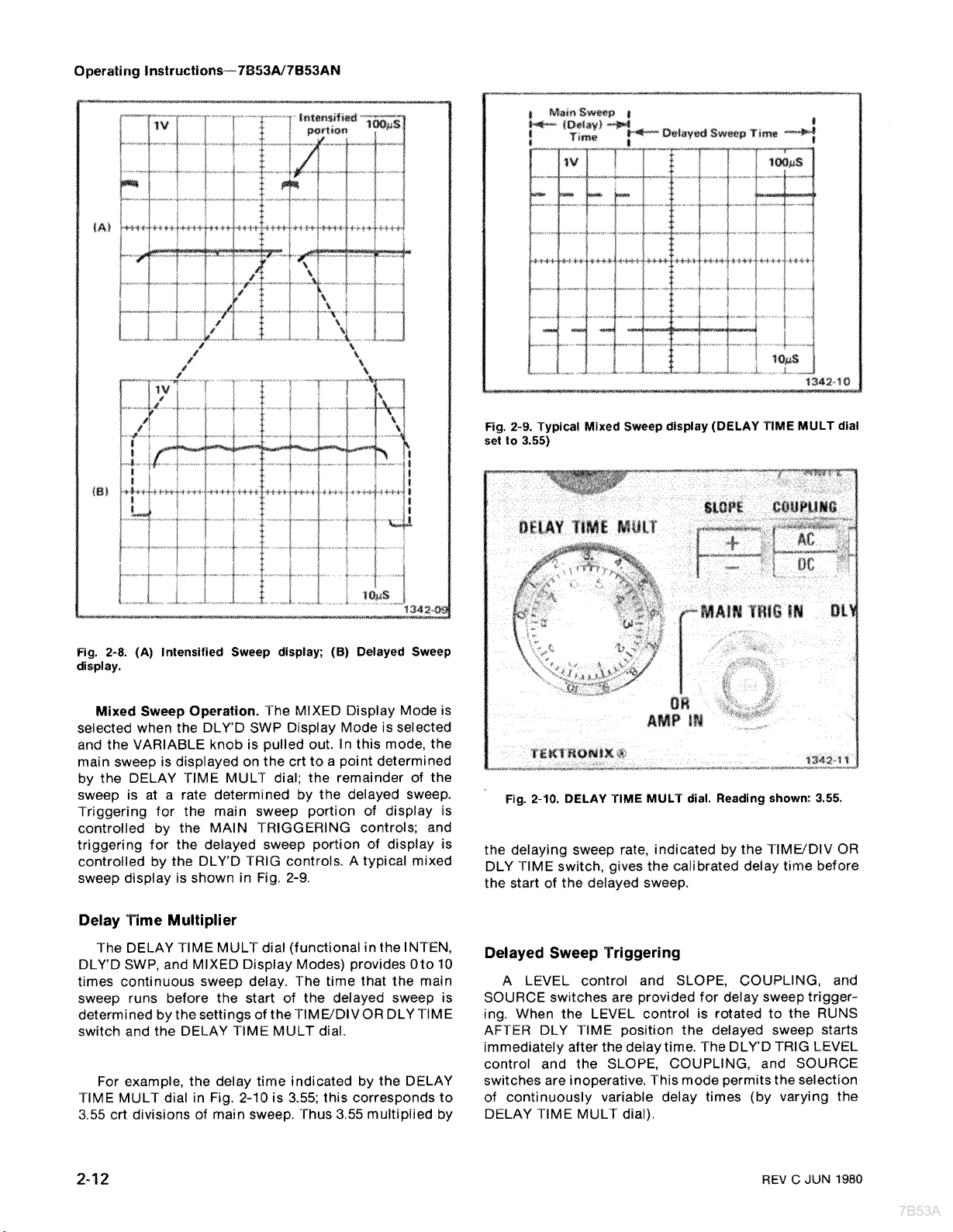

Fig.

set to

2-9.

Typical Mixed Sweep display (DELAY TIME MULT dial

3.55)

Rg.

2-8.

display.

(A) Intensified Sweep display;

Mixed Sweep Operation.

The MIXED Display Mode is

(B)

Delayed Sweep

selected when the DLY'D SWP Display Mode is selected

and the VARIABLE knob is pulled out. In this mode, the

main sweep is displayed on the crt to a point determined

by the DELAY 'TIME MULT dial; the remainder of the

sweep is at a rate determined by the delayed sweep.

Triggering for the main sweep portion of display is

controlled by the MAIN TRIGGERING controls; and

triggering for the delayed sweep portion of display is

TRlG

controlled by the DLY'D

controls. A typical mixed

sweep display is shown in Fig. 2-9.

Delay Time Multiplier

'The DELAY TIME MULT dial (functional in the INTEN,

DLY'D SWP, and MIXED Display Modes) provides Oto 10

times continuous sweep delay. The time that the main

sweep runs before the start of the delayed sweep is

determined by the settings of the

switch and the DELAY TlME MULT dial.

For example, the delay time indicated by the DELAY

"TIME MULT dial in Fig.

3.55

crt divisions of main sweep. Thus 3.55 multiplied by

2-10

TlMVDlVOR DLY TIME

is 3.55; this corresponds to

Fig.

2-10.

DELAY TlME MULT dial. Reading shown: 3.55.

the delaying sweep rate, indicated by the 'TIMVDIV OR

DLY TlME switch, gives the calibrated delay time before

the start of the delayed sweep.

Delayed Sweep Triggering

A LEVEL control and SLOPE, COUPLING, and

SOURCE switches are provided for delay sweep triggering. When the LEVEL control is rotated to the RUNS

AFTER DLY TIME position the delayed sweep starts

immediately after the delay time. The DLY'D

control and the SLOPE, COUPLING, and SOURCE

switches are inoperative. This mode permits the selection

of continuously variable delay times (by varying the

DELAY TlME MULT dial).

TRlG LEVEL

2-12

REV C JUN

1980

Page 28

Operating

7B53A

Instructions--7B53A/7B53AN

When the DLY'D TRlG LEVEL control is rotated

counterclockwise (out of switch detent), the delayed

sweep is triggerable. The delayed sweep does not start at

completion of the delay time but, waits until a trigger

the

pulse is received by the delayed sweep triggering circuit.

I'he delay time in this mode is dependent not only on the

settings of the delay-time controls, but on the delayed

sweep triggering controls and the occurrence of the

delayed sweep triggering signal. 'The primary purpose of

this mode is to eliminate jitter from the display delayed

sweep waveform. Since the delayed sweep is triggered by

the input waveform, jitter is eliminated from the delayed

sweep display even though it may be inherent in the input

waveform.

When the delayed sweep is triggerable, the LEVEL

control can be rotated to select the amplitude point on the

trigger signal at which the delayed sweep is triggered. The

DLY'D PRIG SLOPE, COUPLING, and SOURCE switches

are activated and their functions are the same for delayed

triggering as functions with the same title are for MAIN

'TRIGGERING (see Main Triggering Level, Slope, Coupling, and Source discussions in this section).

InputIOutput Connectors

Two dual-function bnc connectors are provided on the

instrument front-panel.

MAlN TRIG IN OR AMP IN.

external trigger input for the main triggering circuit when

the MAIN TRIGGERING SOURCE switch is set to EXT or

+

10 and the TIMVDIV OR DLY IIMEswitch is set to

EXT

any position except AMPL. When the

TIME switch is set to AMPL and the MAlN TRIGGERING

SOURCE switch is set to EXTor EXT

serves as an external horizontal input (see X-Y Operation).

'This connector is an

TlMWDlV OR DLY

1.-

10,

this connector

To apply an external signal (X-signal) to the horizontal

system, set the

7B53A/7B53AN TIM WDIV OR DLY TIME

switch to AMPL and the MAlN TRIGGERING SOURCE

EXT.

switch to

The MAlN TRIGGERING COUPLING

selected affects the frequency response of the X-signal.

Apply the external signal to the MAIN TRIG IN OR AMP IN

connector. Deflection factor of the X-signal is provided in

2-1.

multiples of 10 as shown in Table

The Y-signal can be

applied to the plug-in unit installed in the vertical compartment.

Table

2-7

DEFLECTION FACTOR OF

THE

X

SIGNAL

Main Deflection

Triggering

-,.-"--"

.------- "-

EXT 10 mV/div

EX7 700 mV/div

". .-

EXT + 10

.--.-.-.-

,"

----."

.-------.-.

""

--,-

"

1

---.

Vldiv

""

-.----.--

"-----

'To apply the X-signal internally via the triggering

system set the

S'IME/DIV OR DLY TlME switch to AMPL

and the MAlN TRIGGERING SOURCE switch to INT.

Apply the external signal to the Amplifier unit installed in

the vertical compartment. "The attenuator switch of the

Amplifier unit determines the horizontal deflection factor.

For information on X-Y applications see the oscilloscope manual. Also, the reference books listed under

Applications provide information on X-Y measurements

and interpreting the resultant

lissajous displays.

Mainframe Operating Modes

-

DLY'D TRIG IN.

This connector is an external input for

the delayed triggering circuit when the DLY'D TRlG

EXT.

SOURCE switch is set to

When the DLY'D T'RIG

SOUHCE switch is set to INT and P613 is properly

connected,

the DLY'D TRlG IN connector serves as a

Delayed Sweep Gate Out connector (not labeled). The

Delayed Sweep Gatesignal is arectangular positive-going

pulse with approximately 3.0 V amplitude and pulse width

coincident with the delayed sweep.

X-Y

Operation

Some applications required one signal displayed versus another rather than against time (internal sweep). The

amplifier function of the

7B53A/7B53AN allows an external signal to be appliedtothe horizontal deflection system

either externally via the MAIN TRlG IN OR AMP IN

connector or internally by way of the triggering system.

REV

A

JUN

1980

The 7B53A17B53AN can be operated in a 7000-Series

OsciIIsocope which has four plug-in compartments, either

independently, in the Alternate or Chopped Horizontal

Modes, or as a delayed sweep unit. However, when the

7B53N7B53AN is operated as a delayed sweep unit, it

must be triggered for a crt display.

It cannot delay another

time base unit but it can delay its own internal delayed

sweep. Refer to the appropriate oscilloscope manual for

additional mainframe horizontal operating information.

General

The following information describes the procedureand

techniques for making basic measurements with a

7B53N7B53AN installed in a 7000-Series Oscilloscope.

These applications are not described in detail, since each

application must be adapted to the requirements of the

2-13

Page 29

Operating

7B53A

Instructions--7B53A/7B53AN

individual measurement. This instrument can also be used

for many applications not described in this manual.

Contact your local Tektronix

Fieldofficeor representative

for assistance in making specific measurements. The

following books describe oscilloscope measurement

techniques which can be adapted for use with this

instrument. horizontal

4. Divide the period of the reference signal (seconds)

by the product of the horizontal deflection established in

2

(division) and the setting of the TIMWDIV OR DLY

step

TIME switch. This is the horizontal conversion factor:

Horizontal

Conversion

Factor

reference signal period (seconds)

-

deflection

TIM WDlV OR

X

DLY TlME

(divisions) switch setting

J. Czech, "Oscilloscope Measuring Techniques",

Phillips Technical Library, Springer-Verlag, New York,

1965. 5. To measure the period of an unknown signal

disconnect the reference signal and connect the unknown

signal tothevertical unit. Set the TIMWDIVOR

DLY'TIME

switch to a setting that provides sufficient horizontal

John

D.

Lenkl

andbo book

and Applications", Prentice-Hall, Inc. Englewood

of Oscillosco~e

deflection to make an accurate measurement. Do not

the

VARIABLE

control,

Cliffs, N.J., 1968.

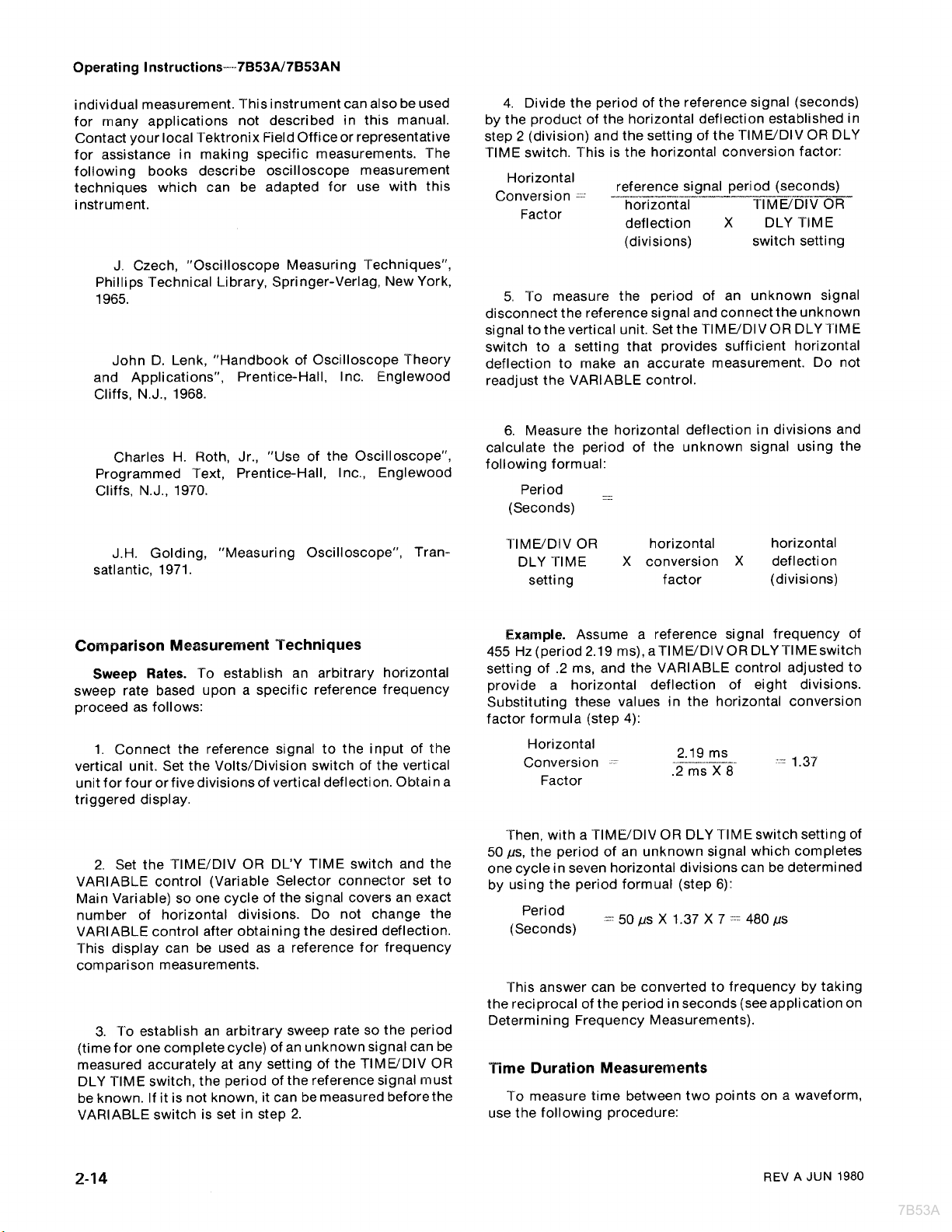

6. Measure the horizontal deflection in divisions and

Charles

H.

Roth, Jr., "Use of the Oscilloscope",

Programmed Text, Prentice-Hall, Inc., Englewood

cliffs, N.J., 1970.

J.H. Golding, "Measuring Oscilloscope", Tran-

satlantic, 1971.

calculate the period of the unknown signal using the

following formual:

Period

(Seconds)

-

--

7-IMVDIV OR horizontal horizontal

X

DLY TIME

setting

conversion

factor (divisions)

X

deflection

Comparison Measurement Techniques

Sweep Rates. To establish an arbitrary horizontal

Example. Assume a reference signal frequency of

455 Hz(period2.19

setting of

.2