Instruction Manual

Model 775A

Programmable Counter / Timer

©1987, Keithley Instruments, Inc.

All rights reserved.

Any unauthorized reproduction, photocopy, or use the information herein, in whole or in part, without the prior written approval

of Keithley Instruments, Inc. is strictly prohibited.

All Keithley Instruments product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand names are trademarks or registered trademarks of their respective holders.

Cleveland, Ohio, U.S.A.

Document Number: 775-901-01 Rev. B / February 1987

WARRANTY

Keithley instruments, Inc. warrants this product to be free from defects

in material and workmenship for a period of 1 year from date of shipment. During the warranty period, we will, at our option, either repair

or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley represent-

ative, or contact Keithley headquarters in Cleveland, Ohio. You will be

given prompt assistance and return instructions. Send the instrument,

transportation prepaid, to the indicated service:facility. Repairs will be

made and the instrument returned, transportation prepaid. Repaired

products are warranted for the balance of the original warranty period,

or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from unauthorized

modification or misuse of any product or part. This warranty also does

not apply to fuses, batteries, or damage from battery leakage.

This warranty is in lieu of all other warranties, expressed or implied, in-

cluding any implied warranty of merchantability or fitness for a par-

ticular use. Keithley Instruments, Inc. shall not be liable for any indirect,

special or consequential damages.

STATEMENT OF CALIBRATION

This instrument has been inspected and tested in accordance with

specifications published by Keithley Instruments, Inc.

The accuracy and calibration of this instrument are traceable to the

National Bureau of Standards through equipment which is calibrated at

planned intervals by comparison to certified standards maintained in

the Laboratories of Keithley Instruments, Inc.

KEITHLEY INSTRUMENTS, INC.

INSTRUMENT DIVISION I 29775 Aurora Road / Cleveland. Ohio 44139 / U.S.A. / 1216) 246-0400 / Telex: 99.5469

WEST QERMANY:

aREA BRITAIN: Keithlay Instruments, Ltd. / 1, Boulton Road / Reading, Berkshire RG 2 ONL / 10734) 66-l 2.67/66 / Telex: 94.7047

FRANCE Keithlsy Instruments SARL / 2, Bis Rue L&n Blum / 9.P. 60 / 91121 P$laiseau Cedex / 16101 l-51 -55 /Telex: 600-933

NETHERLAND%

SWITZERLAND:

AUSTRI*:

ITALY:

Keith@ lnatruments Ges.m.b.H. / Doblinger Haupstr. 32 / 1190 Wien / 314 299 / Telex: 13-4500

Kelthley Instruments, SRL / Viale S. Gimignano 4/A / 20100 Milano, Italy / 4120360

Keithley Instruments GmbH / Heiglhofstr. 5 / 6000 Munchen 70 / 10691 710020 / Telex: 52.12160

Kelthley Instruments BV / Arkelsedijk 4 / Postbus 559 / 4200 AN Gorinchem / 101 1930.25577 / Telex: 24-664

Kelthley Instruments SA / Kriesbachstr. 4 / 9600 Oibendorf / 01/821-94-44 / Telex: 57-536

SPECIFICATIONS

INPUT CHARACTERISTICS

Channel A, B; each channel

RANGE:

SENSITIVITY (d):

DYNAMIC RANGE (xl): 50mV to 5V pk-pk, <ZOMHz.

COUPLING: ac or dc, switchable.

IMPEDANCE: lMR nominal, shunted by <60pF.

ATTENUATOR: xl or xl0 nominal, switchable.

LOW PASS FILTER: -1OdB

SIGNAL OPERATING RANGE (xl): -2.55V dc to t2.55V dc.

TRIGGER LEVEL: -2.55V dc to +2.55V dc, xl.

TRIGGER LEVEL RESOLUTION: lGmV, xl.

TRIGGER LEVEL SElTING ACCURACY:

TRIGGER LEVEL SETTING OUTPUT: via rear panel BNC,

SLOPE: + or - slope, switchable.

DAMAGE LEVEL:

0 to l20MHz, dc coupled.

30Hz to IZOMHz, ac coupled.

25mV rms, <lOMHz.

50mV rms, > 1OMHz.

14OmV to 2.5V pk-pk, >20MHz.

at

1OOkHz nominal, switchable.

:25.5V dc to +25.5V dc, x10.

Mo”v, xx?

*(35mV + 2% of setting), xl.

*(35OmV + 2% of setting), x10

not adjusted for attenuators.

xl: dc-2kHz 250V dc + peak ac

2kHz-100kHz 5 x 1OsV rms*Hz/frequency

> 1OOkHz

x10: dcZOkHz 250V dc + peak ac

20kHz.100kHz 5 x 10%’ rms.Hz/frequency

> 1OOkHz

5v rms

5oV rms

PERIOD A

RANGE:

LSD DISPLAYED: 1Ons to O.lms.

ACCURACY:

Mns to 10” seconds.

*l LSD *(Time Base Error x Period) f Trigger Error.

PERIOD AVERAGE A

RANGE: 1Ons to 10sec.

LSD

DISPLAYED: (10ns x l’eriod)/Gate Time.

RESOLUTION:

fl LSD f

ACCURACY:

NUMBER OF PERIODS AVERAGED: Gate Time/Period

(1.4 x Trigger Error + Zns) x Period

Gate Time

f Resolution *(Time Base Error x Period)

TIME INTERVAL A-B

RANGE: 1011s to

LSD DISPLAYED: 1Ons to O.lms.

ACCURACY: fl LSD *(Time Base Error x Time Interval)

f Trigger Error * Trigger Timing Error -t2ns.

lo4 seconds.

PULSE WIDTH A (Positive or Negative)

RANGE: Mns to lo4 seconds.

LSD DISPLAYED: lOns to O.lms.

ACCURACY: fl LSD *(Time Base Error x Pulse Width)

f Trigger Error f Trigger Timing Error f2ns.

mALIZE A

Channel C (with Model 7751 option)

RANGE: 5OMHz to 1.3GHz.

SENSITIVITY: l5mV, 50MHz to l.OCHz;

25mV, l.OGHz to 1.2GHz;

75mV, 1.2GHz to 1.3GHz

DYNAMIC RANGE: 25mV rms to 1V rms.

COUPLING: ac.

IMPEDANCE: 500.

DAMAGE LEVEL:

dc-100kHz

>.lOOkHz

l5V dc + peak ac

5v rms

FREQUENCY A, B

RANGE: O.lHz to l20MHz.

LSD DISPLAYED: (101~s x Frequency)/Cate Time

RESOLUTION:

*l ,.SD -t (1.4 x Trigger Error + 2ns)x Frequency

Gate Time

ACCL RACY:

*Resolution *(Time Base Error x Frequency)

DIGITS DISPLAYED: 8 per second of Gate Time, minimum.

MODES: Cumulative or A gated by B

RANGE: 0 to lo”-1

REPETITION RATE: lZ0MHz “ax.

LSD DISPLAYED: 1 count up to lOLo-1, then 9 most signifi-

cant digits.

ACCURACY: kl LSD

GATE/DELAY

INTERNAL GATE TIME: Variable from loops to IOsec in 45

increments, or one period of the input, whichever is longer.

May be used in Frequency and Period Average

measurements.

EXTERNAL GATE TIME: Continuously variable from loops

to Klsec, or one period of the input, whichever is longer.

EXTERNAL GATE DELW: 10~s + one period of the

input signal, maximum.

INTERNAL DELAY TIME: Variable from lOO@ to 10s~ in 45

increments. May be used in Period, Time Interval and Pulse

Width measurements.

EXTERNAL DELAY TIME: Continuously variable from loops

to >l hour.

EXTERNAL GATE/DELAY INPUT: Positive TTL signal via

rear panel BNC.

TIME BASE

GENERAL

FREQUENCY: 1OMH.z.

AGING RATE: 55 x lo-‘/month.

TEMPERATURE: f5 x lo-! 0’ to 40°C, ref 25’C.

TCXO (with Model 7752 option)

FREQUENOI: l!&II-Iz

AGING RATE: <l x IO-‘/month.

TEMPERATURE: *I x 10-q 0 to 4O’C, ref 25’C.

LINB VOITAGE: < 1 x lO-’ for 10% change.

IEEE-488 INTERFACE

MULTILINE COMMANDS: DCL, LLO, SDC, Gm, GTL,

UNT, UNL, SPE, SPD.

UNILINE COMMANDS: IFC, RBN, EOI, SRQ, NN.

INTERFACE FUNCTIONS: SHl, AHl, T6, TEO, IA, LEO, SRl,

PPO, DCl, DTI, CO, El.

PROGRAMMABLE PARAMETERS: AI1 front panel controls

(except POWER) plus Reading Rate, Data Format, Trigger,

EOI, Terminator, Service Request, Self Test, Display, Stahu.

READING RATES: one shot, normal (3/second), fast

(ZYsecond), or dump (14O/second).

DISPLAY:

BENCH READING RATES: One shot, or normal (3/second).

ARMING nRIGGER): Each channel is armed by it’s own

signal; or RESET button 01 EXT ARMING input when in one

shot (HOLD) mode.

ARMING DELAY: 30~ in Frequency and Period Average;

lOas in Period, Tie Interval and Pulse Width.

EXTERNAL ARMING INPUT: positive edge ‘IX signal via

rear panel BNC.

EXTERNAL TIME BASE INPUT: lOMHz ‘ITL signal via rear

panel BNC

TIME BASE,OUT: 2V minimum @ MMHz, 1OOD output resis-

tance, via rear panel BNC.

GATE: LED ,indicator lights when gate is open.

WARMUP: 2 hours to rated accuracy and stability

OPERATING TEMPERATURE: 0” to 4O”C, 0% to 80% relative

humidity

STORAGE TEMPERATURE: -25” to 65°C.

POWER: lO?-l25V or 2lO-250V (rear panel switch selected),

50-6OHz. 35VA max. 90-1lOV available.

DIMENSIONS, WEIGHT: l27mm high x 2l5mm wide x

359mm deep (5”~ 8’X’x 14r).

Net weight 3.5kg (8 lbs).

Nine

LED digits with decimal point and exponent.

Specifications subject to change without notice.

TABLE OF CONTENTS

SECTION l-GENERAL INFORMATION

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

INTRODUCTION.

MODEL775 FEATURES

WARRANTY INFORMATION

MANUAL ADDENDA

SAFETY SYMBOLS AND TERMS

INSPECTION

USING THE MODEL 775 MANUAL

ACCESSORIES

...........................................................................

......................................................................

................................................................. l-l

.......................................................................

.............................................................

...............................................................................

..........................................................

..............................................................................

SECTION Z-BASIC COUNTER/TIMER OPERATION

2.1

2.2

2.2.1

2.2.2

2.2.3

2.2.4

2.3

2.3.1

2.3.2

2.3.3

2.3.4

2.4

2.5

2.5.1

2.6

2.6.1

2.6.2

2.6.3

2.6.4

2.6.5

2.6.6

2.6.7

2.6.8

2.6.9

2.7

2.7.1

2.7.2

2.7.3

2.7.4

2.8

INTRODUCTION

FRONTI’ANEL FAMILIARIZATICJI’J

Controls

Terminals .................................................................................

Display and Indicators

TiltBail

REAR PANELFAMILIARIZATION

Connectors and Terminals

Line Voltage Selector Switch ................................................................

IEEE-488 Address Switches .................................................................

Line Fuse

POWER-UP PROCEDURE ....................................................................

DISPLAYMESSAGES ........................................................................

No Option Message

CONTROL SELECTION

Function

Selecting GateTime .......................................................................

User Gate Function ........................................................................

Using Delay ...............................................................................

User Delay Function ......................................................................

Selecting Measurement Rate

Selecting the Number of Displayed Digits.

Input Condition Controls Setting.,

Setting Trigger Levels

ARMING..

Continuous Arming....................~ ..................................................

Front Panel Arming

External Arming ..........................................................................

Alarm Conditions

APPLICATIONS

..................................................................................

................................................................................... 2-6

.................................................................................

..................................................................................

...........................................................................

..........................................................

..................................................................... 2-6

............................................................ 2-6

.................................................................. 2-6

......................................................................

.....................................................................

............................................................... 2-10

.................................................. 2-10

......................................................... 2-11

.....................................................................

................................................................................

.......................................................................

.........................................................................

............................................................................

l-l

l-1

l-1

l-1

l-2

l-2

1-2

2-l

2-4

2-4

2-5

2-6

2-6

2-6

2-6

2-7

...2- 7

2-8

2-8

2-8

2-9

2-9

2-10

2-11

2-12

2.12

2-12

2-13

2-13

2-U

SECTION 3-IEEE-488 OPERATION

3.1

3.2

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .._..._.................................. 3-l

BUS DESCRIPTION . . . . . . . . . . . . . . . . . . .._...............................................,,... 3-l

TABLE OF CONTENTS

3.3

3.3.1

3.3.2

3.3.3

3.4

3.4.1

3.4.2

3.4.3

3.4.4

3.4.5

3.5

3.6

3.6.1

3.6.2

3.6.3

3.7

3.7.1

3.7.2

3.7.3

3.8

3.8.1

3.8.2

3.8.3

3.0.4

3.9

3.9.1

3.9.2

3.9.3

3.9.4

3.9.5

3.9.6

3.9.7

3.9.8

3.10

3.10.1

3.102

3.10.3

3.10.4

3.10.5

3.10.6

3.10.7

3.108

3.10.9

3.10.10

3.10.11

3.10.12

3.1o.u

3.10.14

3.10.15

3.10.16

3.10.17

3.11

3.11.1

3.11.2

3.11.3

3.u.4

3.: A

IEEE-488 BUS LINES . .

Bus Management Lines.. ..................................................................

HandshakeLines ..........................................................................

Data Lines

................................................................................

BUS COMMANDS ..........................................................................

Uniline Commands

........................................................................

UniversalCommands ......................................................................

Addressed Commands .....................................................................

Unaddressed Commands

..................................................................

Device-Dependent Commands .............................................................. 3-5

COMMAND CODES

COMMAND SEQUENCE. ..............................................

........................................................................

.< ................... 3-6

Addressed Command Sequence ............................................................

Universal Command Sequence .............................................................

Device-Dependent Command Sequence

.....................................................

HARDWARE CONSIDERATIONS ............................................................

Typical Controlled Systems. ................................................................

BusConnections.. ........................................................................

Primary Address Programming ............................................................

:

SOFTWARE CONSIDERATIONS I .............................

...............................

Controlled Interface Routines ..............................................................

HP-8 BASIC Statements ....................................................................

Interface Function Codes . . .

Model 775 Interface Commandr

GENER,

AL BUS COMMAND PROGRAMMING

;

............................................................

..............................................

REN (Remot e Enable) .....................................................................

IFC (Interface Clear)

LLO‘(Local Lockoui)

GTL (Go To Local)

DCL(Device Clear)

SDC (Selective Device Clear)

GET (Group Execute Trigger)

Serial Polling (SPE,

..,,,...,,,,.......................................................... 3-14

...................................... 3-14

..............................

.:

........................................................................

.......................................................................

..............................................................

..............................................................

SPD)

..................................................................

DEVICE-DEPENDENT COMMAND PROGRAMMING ........................................

Execute (X). ..............................................................................

Function(F) ..............................................................................

Channels A, d Coupling (AC, BC) .........................................................

Channels A, B Attenuator (AA, BA) .......................................................

Channels A, B Filter (AF, BF)

Channels A, B Slope (AS, BS).

Channels A, B Trigger Level (AL,

.............................................................

............................................................

BL)

......................................................

Rate(S) .................................................................................

Gate Time(G) ...........................................................................

Delay Time(W) ..........................................................................

Delay(I) .................................................................................

Displayed Digits(N)

Triggering (T)

......................................................................

............................................................................

EOI(K) .................................................................................

SRQ Mode (M) and Serial Poll Status Byte Format

Displayed Modes (D)

Self-Test

(J) ...............................................................................

READING FROM THE MODEL 775

Data Control Commands (B)

Status Word

Terminator (Y)

Prefix(P)

(U)

...........................................................................

................................................................................

Dump Mode (53 Rate Mode)

.....................................................................

.........................................................

..............................................................

..........................................................................

..............................................................

..........................................

3-2

3-2

3-2

3-3

3-3

3-4

3-4

3-5

3-5

3-5

3-6

3-6

3-6

3-6

3-6 1~

3-8

3-10

3-10. ...

3-10

3-11

3-L?

3-13

3-13

3-13

3-14

3-15

,3-15

3-15

3-16

3-16

3-19

3-19

3-19’ ’

3-20

3-20

3-20

3-20

3-21

3-22

3-22

3-23 I

3-23

3-23

3-23

3-24

3-26

3-27

3-27

3-28

3-29

3-30

3-31

3-31

TABLEOFCONTENTS

.

a 4.5.7

. +,4.5.8

3.12

3.x2.1

FRONT PANEL PROGRAhJ.MING

IDDCError .........................................................................................

3.12.2 IDDCO Error

.......................................................................................

...................................................................... 3-34

SECTION G-PERFORMANCE VERIFICATION

...........................................................................

...........................................................

...........................................................

...

......................................................

............................................................

.....................................................

............................................................

..................................................

ii

413

‘~ 4.4

4.5

4.5.1

4.52

‘4.5.3

.,- 4.5.4

4.5.5

4.5.6

4.5.9

INTRODUCTION

ENVIRONMENTAL CONDITIONS

RECOMMENDED TEST EOUIFMENT

INITIAL CONDITIONS VERIFICATION PROCEDURES

Channels A, B and C Inputs Sensitivity.

Period Measurement Accuracy Check ...............................................

Period Averaged Measurement Accuracy Check

Tie Interval A-B Measurement Operation Check.,

Pulse A Measurement Operation Check.. ...........................................

Delay Operation Check

External Gate Operation Check

Arming Operation Check

Model7752TCXO Accuracy Check

SECTION 5-THEORY OF OPERATION

5.1

5.2

5.3

5.3.1

5.3.2

5.3.3

5.3.4

5.3.5

5.3.6

5.3.7

* 5.4

5.4.1

5.4.2

5.4.3

54.4

5.4.5

INTRODUCTION

OVERALL FUNCTIONAL DESCRIPTION

ANALOG CIRCIJITP.Y.

Input Circuits A and B ....................................................................

Input C~cuitC

1OMHz Standard Reference Oscillator

1OMHz ICXO Reference Oscillator

100MHzMultiplier

Measurement Section ......................................................................

Power Supply .............................................................................

DIGITAL CIRCUITRY

Microcomputer Block Diagram

Memory Mapping ........................................................................

Address Decoding

Keyboard/Display Interface

IEEE Interface

...........................................................................

....................................................................... 5-3

............................................................................

..........................................................

........................................................................

.......................................................................

.............................................................

........................................................................ 5-13

................................................................ 5-14

............................................................................

3-34

3-34

4-l

4-l

........................................................ 4-l

.............................................

......................................

.................................

5-l

......................................................

5-l

5-3

5-3

.......................................................

5-3

5-3

5-3

5-4

5-4

5-D

5-13

5-13

5-14

SECTION 6-MAINTENANCE

6.1

6.2

243

6.5

6.6

6.7

6.7.1

6.7.2

6.7.3

6.7.4

6.7.5

INTRODUCTION

LINE VOLIAGE SELECTION

FUSE REPLACEMENT

USING AN EXTERNAL TIME BASE,,

MODEL 7751 CHANNEL C OPTION INSTALLATION

MODEL 7752 TCXO OPTION INSTALLATION

CALIBRATION

Environmental Conditions.

Warm-Up Period

Recommended Test Equipment

Calibration Procedure

Multiplier Adjustment

..................................................................

.......................................................................

.............................................................................

..........................................................................

......................................................................

........................................................

........................................................

.........................................

................................................

.................................................................

.............................................................

.....................................................................

6-l

6-l

6-l

6-2

6-3

6-4

6-5

6-5

6-5

6-5

6-5

6-7

iii

TABLE OF CONTENTS

6.7.6

6.7.7

6.7.8

6.7.9

6.7.10

6.8

6.9

6.10

6.10.1

6.10.2

6.10.3

6.10.4

6.10.5

6.10.6

6.10.7

6.10.8

6.10.9

Trigger Level Adjustment

Channels A and B Sensitivity Adjustment

Inputs A and B Attenuator Compensation

Tune Base Adjustment (Standard 5 PPM Tune Base)

Time Base Adjustment (Optional 1 PPM Tie Base)

SPECIAL HANDLING OF SEATIC SENSITIVE DEVICES

DISASSEMBLY INSTRUCI’IONS. .............................................................

TROUBLESHOOnNG ......................................................................

Recommended Test Equipment. ............................................................

Power-Up Self Diagnostics .................................................................

Power Supply Checks

Reference Oscillator and Clock Checks

Digital Circuitry and Display Checks

Signal Conditioning and Input Circuit Checks.

Multiplier Circuit Checks ..................................................................

Trigger Level Checks ......................................................................

Measurement Section Checks.. ............................................................

...................................................................

.....................................................................

SECTION 7-REPLACEABLE PARTS

Zl

7.2

7.3

7.4

7.5

INTRODUCTION ............................................................................

PARTS LIST..

ORDERING INFORMATION .................................................................

FACTORY SERVICE

SCHEMATIC DIAGRAM AND COMPONENT LOCATION DRAWINGS

...............................................................................

..........................................................................

6-7

...................................................

...................................................

..........................................

..........................................

.......................................

......................................................

....................................................... 6-11

..............................................

..........................

6-7

6-7

6-7

6-7

6-8

6-8

6-10

6-10

6-10

6-10

6-11

6-11

6-11

6-11

6-11

7-1

7-l

7-l

7-1

7-l

A

I

APPENDIX..

INDEX

......................................................................................

...............................................................................

A-l

I-l

iV

LIST OF ILLUSTRATIONS

2-l

2-2

2-3

2-4

2-5

3-l

3-2

3-3

3-4

3-5

3-6

3-7

3-8

3-9

3-10

5-l

5-2

5-3

5-4

5-5

5-6

5-7

5-8

6-l

6-2

6-3

6-4

6-5

Model775

Model775RearPanel ........................................................................

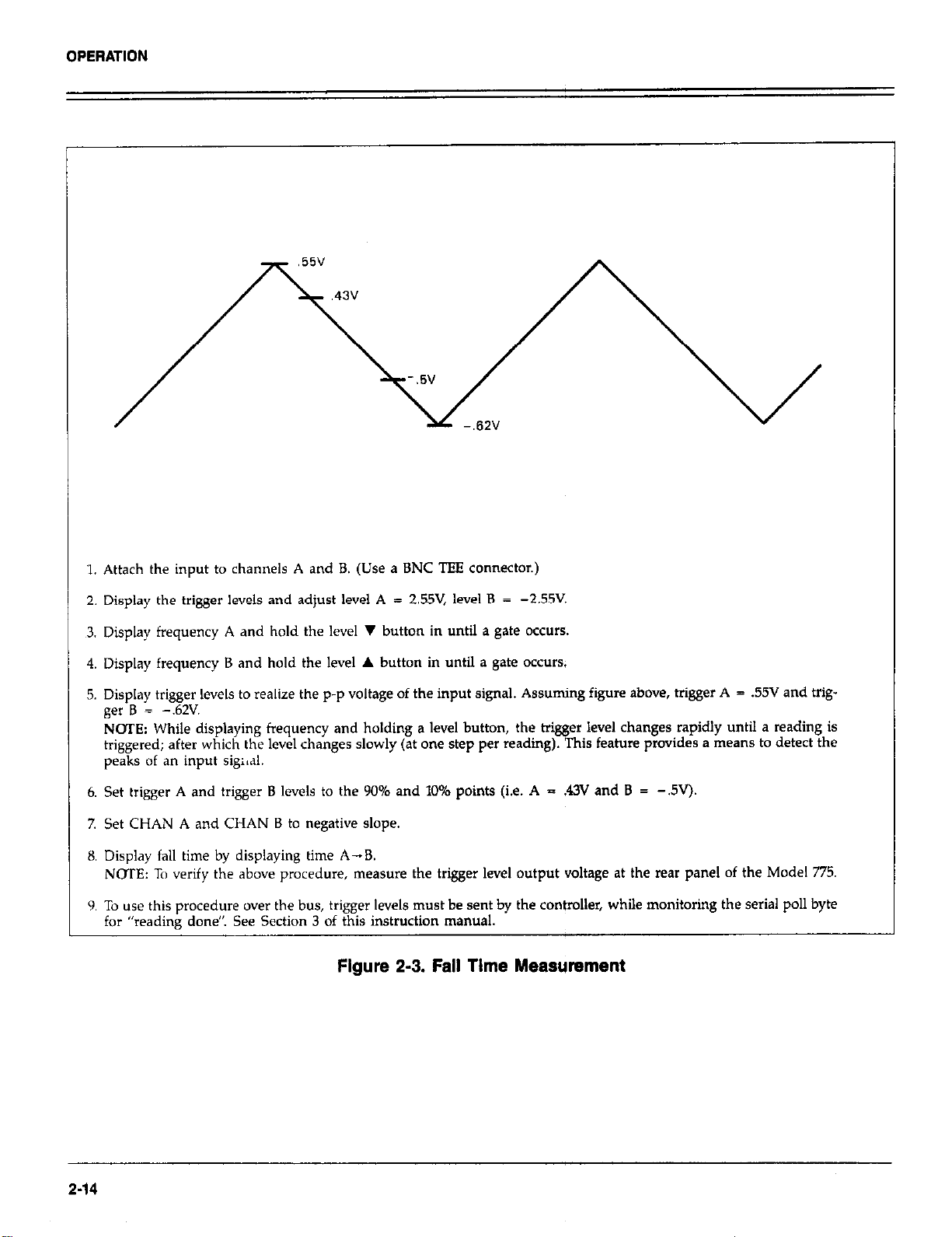

FallTime Measurement

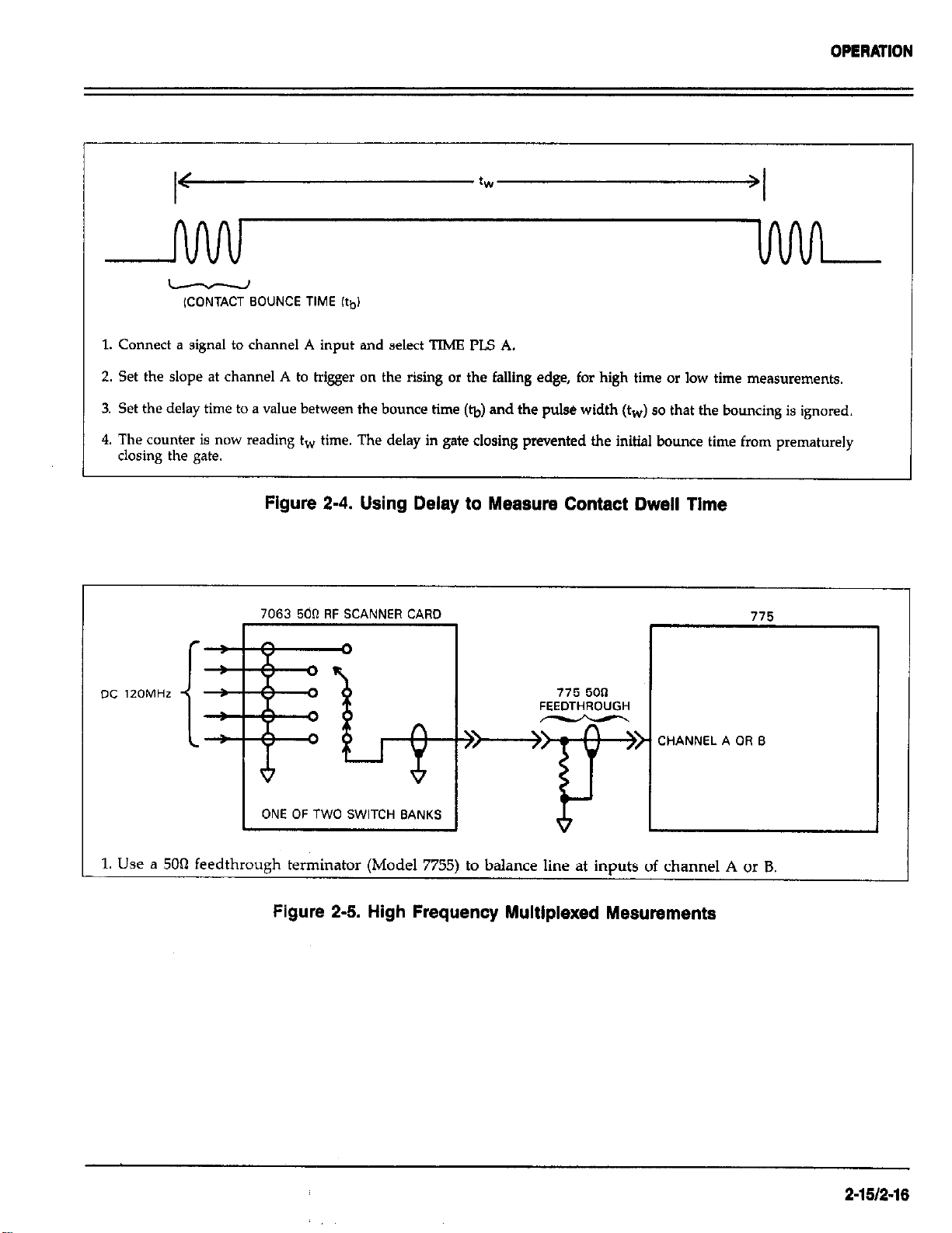

Using Delay to Measure Contact Dwell Time

High Frequency Multiplexed Measurements

IEEE Bus Configuration

IEEE Handshake Sequence

Command Codes

System Types ............................................ 3-8

IEEE-468 Connector ......................................

IEEE-488 Connections., ...................................

Rear Panel of Model 775 Showing IEEE connector

Contact Assignments ..................................... 3-9

Typical IEEE-488 Bus Driver (One of 16)

IEEE-488 Display Error Messages ..........................

Model775 Simplified BlockDiagram

Frequency A Measurement Block Diagram.

Frequency B Measurement Block Diagram

Frequency C Measurement Block Diagram

Period A Measurement Block Diagram

Time Interval A-B Measurement Block Diagram

Pulse Width Measurement Block Diagram.

Microcomputer Block Diagram

Model 775 Standard 5ppm Timebase

Model 7751 Installation

Model 7752 Installation

Model 775 Calibration Adjustments

Model 775 Exploded View ................................

Front Panel

....................................................................... 2-2

2-3

..................................................................... 2-14

.................................................. Z-15

................................................... 2-15

................................... 3-2

................................ 3-3

........................................ 3-7

3-8

................... 3-10

.......................................................... 5-2

.................................................... 5-6

..................................................... 5-7

..................................................... 5-8

........................................................

.................................................... 5-11

............................................................... 5-12

.......................

...................................

...................................

........................

..,...

...........

.............................................. 5-10

.,..,.

.,....

3-9

3-9

3-35

5-9

6-2

b-3

b-4

6-6

6-9

7-l

7-2

7-3

7-4

7-5

7-b

7-7

7-8

7-9

7-10

Mother Board, Component Location Drawing

Mother Board, Schematic Diagram

Display Board, Component Location Drawing

Display Board, Schematic Diagram

Model 7751, Component Location Drawing

Model 7751, Schematic Diagram ....................................................

Model 7752, Component Location Drawing

Model 7752, Schematic Diagram

5 ppm Oscillator, Component Location Drawing.

5 ppm Oscillator, Schematic Location Diagram

.................................................

..................................................

....................................................

.......................................

........................................

..........................................

..........................................

.....................................

.......................................

7-11

7-13

7-26

7-27

7-29

7-30

7-31

7-32

7-33

7-34

LIST OF TABLES

2-l

2-2

3-l

3-2

3-3

3-4

3-5

3-6

3-7

3-8

3-9

3-10

3-11

3-12

3-D

3-14

3-15

3-16

3-17

3-18

3-19

3-20

3-21

4-l

Gate/Delay Determination.

Alarm Condition

IEEE-488BusCommand Summary

Hexadecimal and Decimal Command Codes

Typical Addressed Command Sequence

Typical Device-Dependent Command Sequence

IEEE Contact Designations

HP-85 IEEE-488 BASIC Statements

Model 775 Interface Function Codes,,

IEEE Command Groups .....................................................................

General Bus Commands

Default Conditions (Status Upon Power Up or After SDC or

Device-Dependent Command Summary

Rate Commands ............................................................................

Gate/Delay Time Predetermined Value.,

SRQ

Mask Commands

SRQ Mask Legal Commands..

Status Byte Interpretation

Data

String Format

Prefixes.

Status Word Format

DumpMode Specifications........................................................:

Dump Ouput Mode Result Calculation

Recommended Test Equipment for Performance Verification

.............................................................................

.........................................................................

...............................................

...................................................................

............................................................

.......................

.......................................................

................................................

...................................................................

...........................................................

........................................................

...........................................................

DCL)

......................................................

...................................................... 3-23

......................................................................

..............................................................

...............................

....................................

... ..............

...................................

,

.

...................................

, ...................................

..................................... 4-l

..............................

.................................

...........................

........ 3-13

3-24

3-25

3-26

3-28

..........

3-34

2-8

Z-13

3-4

3-h

3-b

3-6

3-9

3-11

3-12

3-13

3-15

3-17

3-21

3-2’)

3-30

3-33

5-l

6-l

6-2

6-3

6-4

6-5

6-6

6-7

6-8

6-9

6-10

6.11

6-12

7-l

7-2

7-3

Model775 Memory Mapping ................................................................

Line Fuse Selection

Recommended Test Equipment for Calibration

Static Sensitive Device

Recommended Minimum Test Equipment for Troubleshooting

Power Supply Checks

Reference Oscillator and Clock Checks

Digital Circuitry and Display Checks

Signal Conditioning Checks

Input Circuit Checks

Multiplier Circuit Checks

Trigger Level Circuit Checks..

Measuring Section Circuit Checks

Mother Board, Parts List

Display Board, Parts List

Model 775 Mechanical Parts List

........................................................................... b-l

............

.......................................................................

.......................................................................

..............

.. .............

..............

........................................................................

....................................................................

...............................................................

..........

.....................................................................

....................................................................

......

..................................................

................................................. 6-14

.................................................

.

....................................

.................................. 6-K)

........................................ b-12

........................................

5-13

6-5

6-8

b-11

6-12

b-13

6-U

6-13

b-14

7-2

7-25

7-35

vi

GLOSSARY OF TERMS

Time Base Uror4ime base error is the maximum frac-

tional frequency change in the time base frequency due

to all errors (e.g. aging, temperature, line voltage).

ligger Ermr-

q ei2 + en2

Input Slew Rate at Trigger Point

Where:

ei is the RMS noise voltage of the counter’s input channel

(25OhV typical).

en is the RMS noise of the input signal for lZ0MHz

bandwidth.

LSD-Unit value ot%eleast significant digit. Calculations

should ba rounded as follows: 1 to 1.3Hz becomes IHz,

l.hwec to liinsec becomes IOnsec, etc.

lklgger Timing Error-

35mV 35mV

+

Input Slew Rate at Start Input Slew Rate at Stop

Trigger Point Trigger Point

External Arming (Wgger) Delay-External arming delay

is the time from the positive going slope of the arming

signal to the internal gate open signal.

External Gate Delay-External gate delay is the time from

the positive going slope of the gating signal to the internal gate open signal.

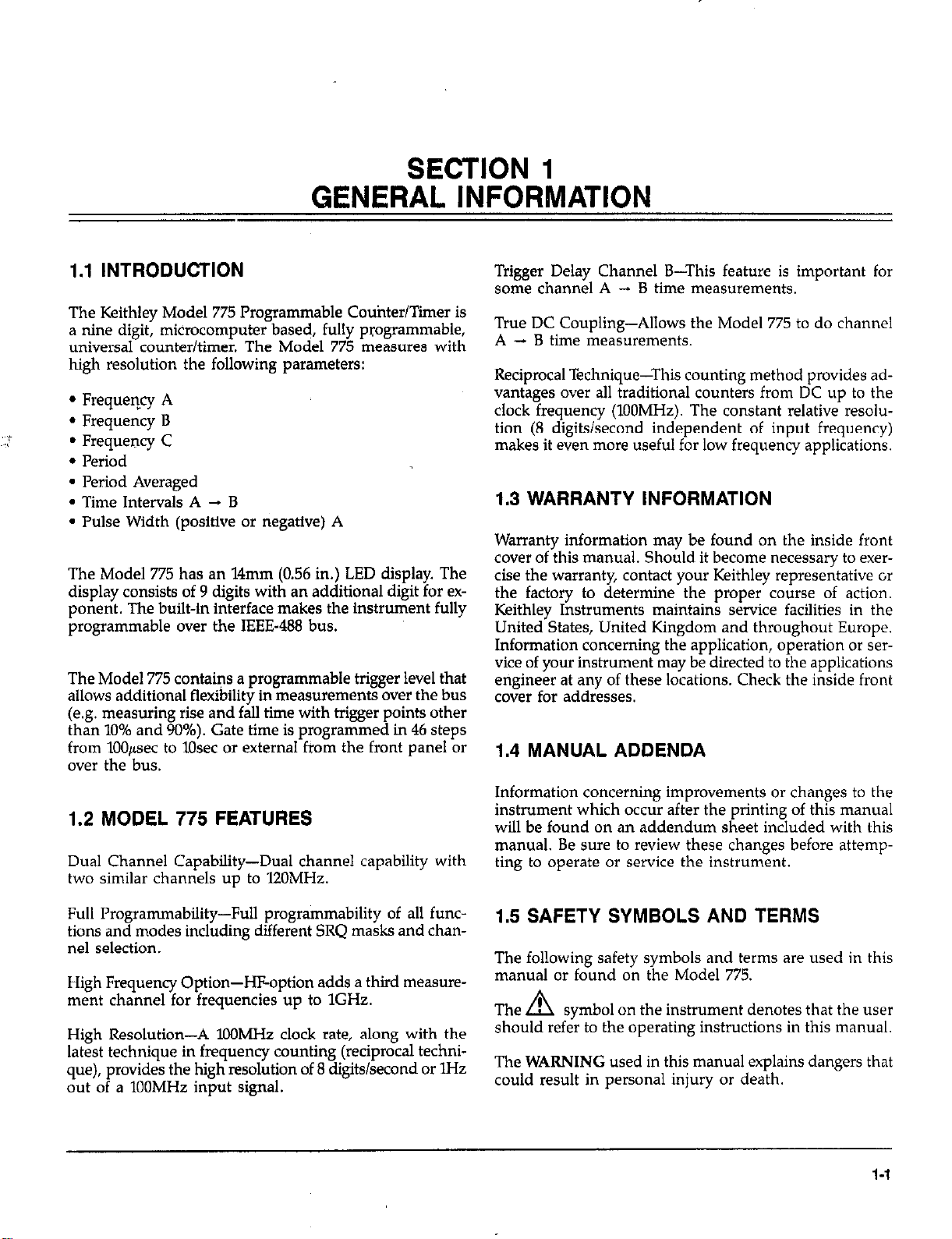

SECTION 1

GENERAL INFORMATION

1.1 INTRODUCTION

The Keithley Model 775 Programmable CouirterlTimer is

a nine digit, microcomputer based, fully programmable,

universal counter/timer. The Model 775 measures with

high resolution the following parameters:

l

Frequency A

l

Frequency B

l

Frequency C

l

Period

. Period Averaged

l

Time Intervals A - B

l

Pulse Width (positive or negative) A

The Model 775 has an 14mm (0.56 in.) LED display. The

display consists of 9 digits with an additional digit for exponent. The built-in interface makes the instrument fully

programmable over the IEEE-488 bus.

The Model 775 contains a programmable trigger level that

allows additional flexibility in measurements over the bus

(e.g. measuring rise and fall time with trigger points other

than 10% and 90%). Gate time is programmed in 46 steps

from 100psec to 1Osec or external from the front panel or

over the bus.

Trigger Delay Channel B-This feature is important for

some channel A - B time measurements.

True DC Coupling-Allows the Model 775 to do channel

A - B time measurements.

Reciprocal Technique-This counting method provides advantages over all traditional counters from DC up to the

clock frequency (100MHz). The constant relative resolution (8 digits/second independent of input frequency)

makes it even more useful for low frequency applications.

1.3 WARRANTY INFORMATION

Warranty information may be found on the inside front

cover of this manual. Should it become necessary to exercise the warranty, contact your Keithley representative cur

the factory to determine the proper course of action.

Keithley Instruments maintains service facilities in the

United States, United Kingdom and throughout Europe.

Information concerning the application, operation or service of your instrument may be directed to the applications

engineer at any of these locations. Check the inside front

cover for addresses.

1.4 MANUAL ADDENDA

1.2 MODEL 775 FEATURES

Dual Channel Capability-Dual channel capability with

two similar channels up to ‘IZOMHz.

Full Programmability-Full programmability of all functions and modes including different SRQ masks and channel selection.

High Frequency Option-H&option adds a third measurement channel for frequencies up to 1GHz.

High Resolution-A 1OOMHz clock rate, along with the

latest technique in frequency counting (reciprocal technique), provides the high resolution of 8 digits/second or VIZ

out of a 1OOMHz input signal.

Information concerning improvements or changes to the

instrument which occur after the printing of this manual

will be found on an addendum sheet included with this

manual. Be sure to review these changes before attempting to operate or service the instrument.

1.5 SAFETY SYMBOLS AND TERMS

The following safety symbols and terms are used in this

manual or found on the Model 775.

Then

should refer to the operating instructions in this manual.

The WARNING used in this manual explains dangers that

could result in personal injury or death.

symbol on the instrument denotes that the user

l-l

The CAUTION used in this manual explains hazards that

could damage the instrument.

1.6 INSPECTION

The Model 775 was inspected both mechanically and electrically before shipment. After unpacking all the items from

the shipping carton, check for any obvious signs of

physical damage that may have occurred during transit.

Report any damage to the shipping agent. Retain and use

the original packing materials in case reshipment is

necessary. The following items are shipped with every

Model 775.

Model 775 Programmable Counter/Timer

Model 775 Instruction Manual

Additional accessories as ordered.

If an additional Instruction Manual is required, order the

manual package (Keithley part number 775-901-00). The

manual package includes an instruction manual and any

applicable addenda.

1.7 USING THE MODEL 775 MANUAL

l

Section 1 contains general information about the

instrument.

l

Section 2 contains detailed operating information on using the front panel controls and rear panel terminals.

l

Section 3 contains information necessary to operate the

Model 775 over the IEEE-488 bus.

l

Section 4 contains performance verification procedures

for the instrument. This information is helpful if you

wish to verify that the instrument is operating in compliance with stated specifications.

l

Section 5 contains a description of operating theory.

l

Section 6 contains information for servicing the instrument. This section includes information on line voltage

selection, fuse replacement, adjustments and

troubleshooting.

l

Section 7 contains replacement parts information.

Model 1019s Slide Rack Mount-The Model 10195 is a

sliding rack mount kit that allows the Model 775 to be rack

mounted with the added feature of sliding the instrument

forward for easy access to the rear panel and top cover.

Model 7007 IEEE-488 Shielded Cables-The Model 7007

connects the Model 775 to the IEEE-488 bus using shielded cables to reduce electromagnetic interference (EMI). The

Model 7007-1 is one meter in length and has an EM1 shielded IEEE-488 connector at each end. The Model 7007-2 is

identical to the Model 7007-1, but is two meters in length.

Model 7008 IEEE-486 Cables-The Model 7008 connects the

Model 775 to the IEEE-488 bus. The Model 7008-3 is 0.9m

(3 ft.) in length and has a standard IEEE-488 connector at

each end. The Model 7008-6 cable is identical to the Model

7008-3, but is 1.8m (6 ft.) in length.

Model 7051 BNC to BNC Cable--The Model 7051 is 1.5m

(5 ft.) in length and is terminated on each end with a BNC

Ph%

Model 7751 1GHz Channel C Option-The Model 7751 is

a factory-installed option which provides a third channel

(C) for measuring frequencies between 50MHz and IGHz.

Model 7752 TCXO-High Stability Crystal Oscillator

Option-The Model 7752 is a factory-installed TCXO-high

stability crystal oscillator that offers improvement over the

standard time base, relative to aging and temperature.

Model 7754-3 BNC to Alligator Cable-The Model 7754-3

is 0.9m (3 ft.) in length and is terminated on one end with

a BNC plug and on the other with two alligator clips.

Model 7755 5012 Feedthrough Termination-Ihe Model 7755

is a BNC tb BNC adapter for terminating RG 58 cable in

its characteristic impedance. VSWR <l.l, DC -250MHz.

SNC

PLUG

BNC

JACK

1.8 ACCESSORIES

The following optional accessories are available to enhance

the Model 775 capabilities.

Model 1019A Fixed Rack Mount-The Model 1019A is a stationary rack mount kit that allows the Model 775 to be

mounted in a standard 19 inch rack.

l-2

SECTION 2

BASIC COUNTER/TIMER OPERATION

2.1 INTRODUCTION

Model 775 operation is divided into the two general

categories: basic bench operation, and IEEE-488 operation.

Basic bench operation which is covered in this section, consists of using the Model 775 to perform basic frequency

and time measurements. IEEE-488 programming can also

be used. These aspects are covered in detail in Sections

3 and 4. A layout of the front and rear panels of the Model

775 are shown in Figures 2-l and 2-2 respectively, includ-

ed is a brief description of each control, terminal and

indicator.

NOTE

Any front panel button push or IEEE devicedependent command (see Section 3) will cause the

measurement to restart, which will affect, for example, a measurement of the time from channels

A to B.

2-1

OPERATION

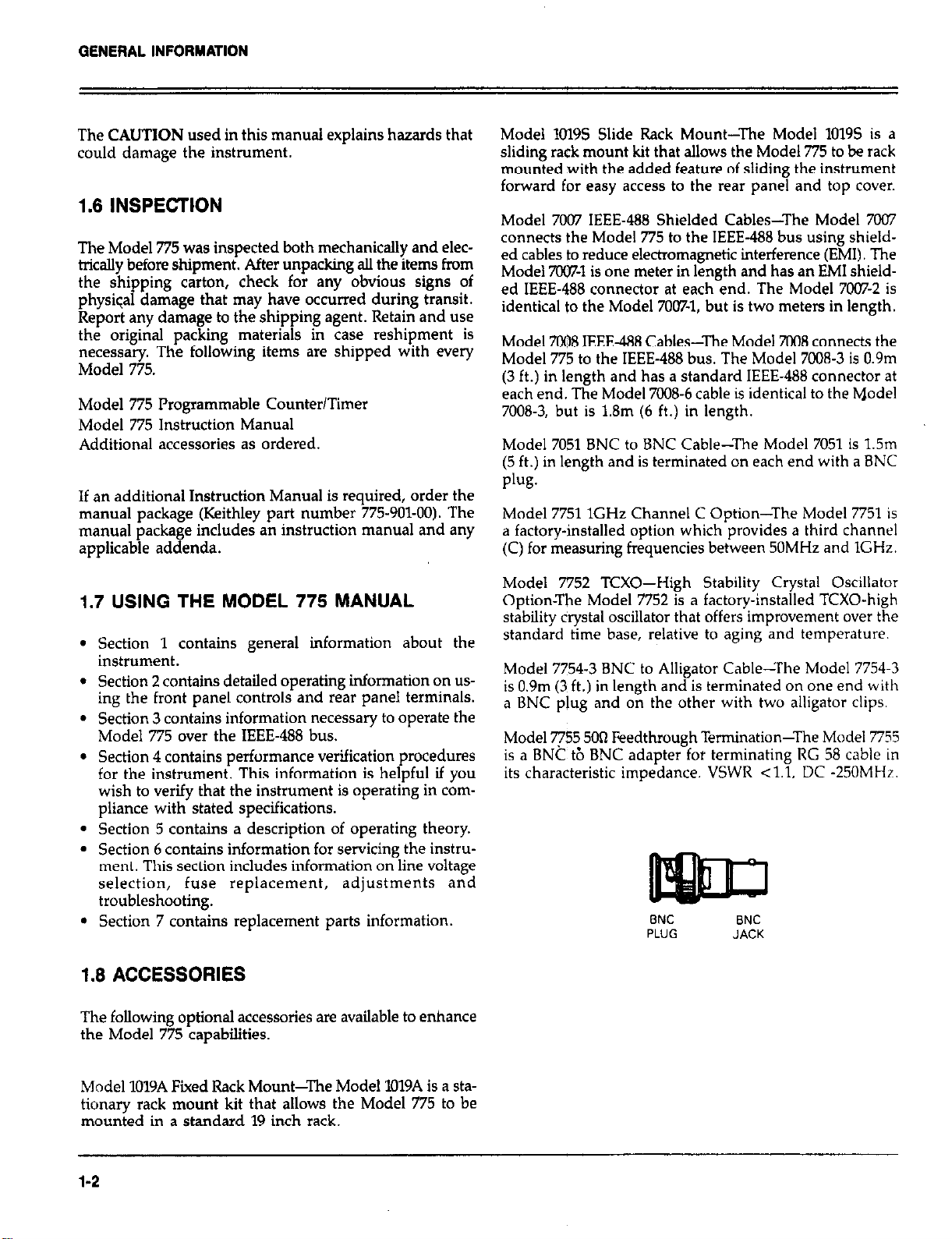

q

POWER ON/OFF-Turns the unit on or off.

q

FUNCIXON GROUP-

l

FREQ button toggles measurement between frequency

at channel A and frequency at channel 8.

l

PERIOD button toggles measurement b&./em the

period A and period average A.

l

TIME button toggles measurement between the time

interval A-B and pulse width of A.

l

MODE button places instrument in either the hold,

delay, both hold and delay, or normal mode.

El CHAN C-Measures frequencies from 50MHz to 1GHz

through channel C.

El

INPUT SEITING GROUP-

l

DC/AC button toggles instrument between AC and DC

coupling of the input signal.

* SLOPE button toggles instrument between the positive

or negative edge trigger.

l

A’lTEN button tot&sinstmment between the xl and

x10 input attenuZon.

l

FUR button toggles filter between on and off.

* LEVEL buttons select the threshold point on a signal

that the instrument will trigger.

El

DISPLAY MODIFY GROIJP. GATE/DELAY button modifies display horn normal fre-

quency (or time reading) to gate time or delay time.

l

TRIGGER LEVEL button modifies the display to show

trigger level of both channels A and B.

El GATE/DELAY TIME CROUP-

. GATE/DELAY TIME buttons control: time gate is

open, delay of gate closure and number of digits

displayed.

l

These buttons increment or decrement the displayed

value by one step.

El

LOCAL-Enables front panel operation.

q

RESET-Resets display to initiate new measurement cy.

cle during normal or hold mode operation.

El TERMINALS-

l

CHAN A used when making frequency and time

measurements.

* WAN B used when making frequency and time A-B

measurmlents.

. CHAN C used when making high frequency measure-

ments up to 1GHz with a 500 input impedance (7751

option). The shell is connected to chassis ground as

indicated by the I symbol.

El DISPW AND INDICATORS-

l

Display consists of a nine digit mantissa and a single

digit exponent.

l

Ran

e indicator consist of Hz, SEC, V. Hz is on dur-

ing

qwncy measurement. SEC is on during time

te

and ,period measurements. V is on when TRIGGER

LEVEL button is pressed.

l

GATE indicator blinks at a rate proportional to gate

time.

l

IEEE status indicators select either remote. talk or listen

when programming over IEEE-488 bus.

2-2

Figure 2-1. Model 775 Front #Panel

OPERATION

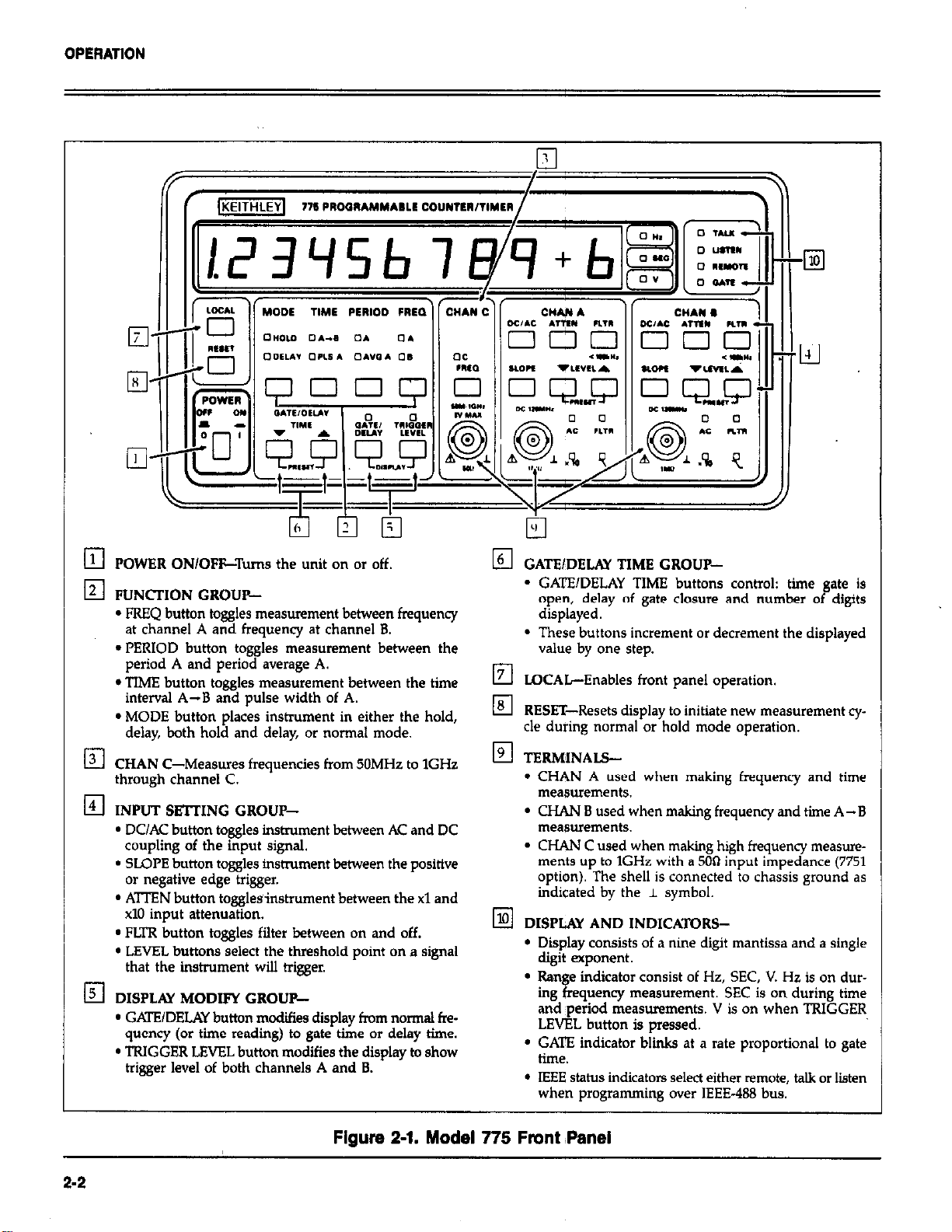

CONNECrORS AND TRRMINALS-

El

l

AC receptacle connects to a three wire line cord

which provides connection to the line voltage.

l

IEEE-483 connector is used to connect the instrument

to the IEEE-488 bus. IEEE interface functions are

marked above the connector.

l

TRIGGER LEVEL OLPTPLJT connections are used to

connect the DC voltage level from the trigger circuits

to an external Dh4M or osciIloscope. DC output range

is marked above the connector.

l

CLOCK connactor is used to output the internal clock

as a reference to another instrument or to use an axternal clock as the Model 775’s time base.

. EXT ARMING & GATE DELAY connector is used to

receive one of three signals: arming pulse, external

gate signal or external delay pulse.

Figure 2-2. Model 775 Rear Panel

LINE VOLTAGE SELEOR switch selects the line

El

voltage that the unit will operate on.

IEEE-488 address switches set the primary address for

El

IEEE-488 bus operation.

LINE FUSE provides protection on the AC power line

El

input.

2-3

OPERATION

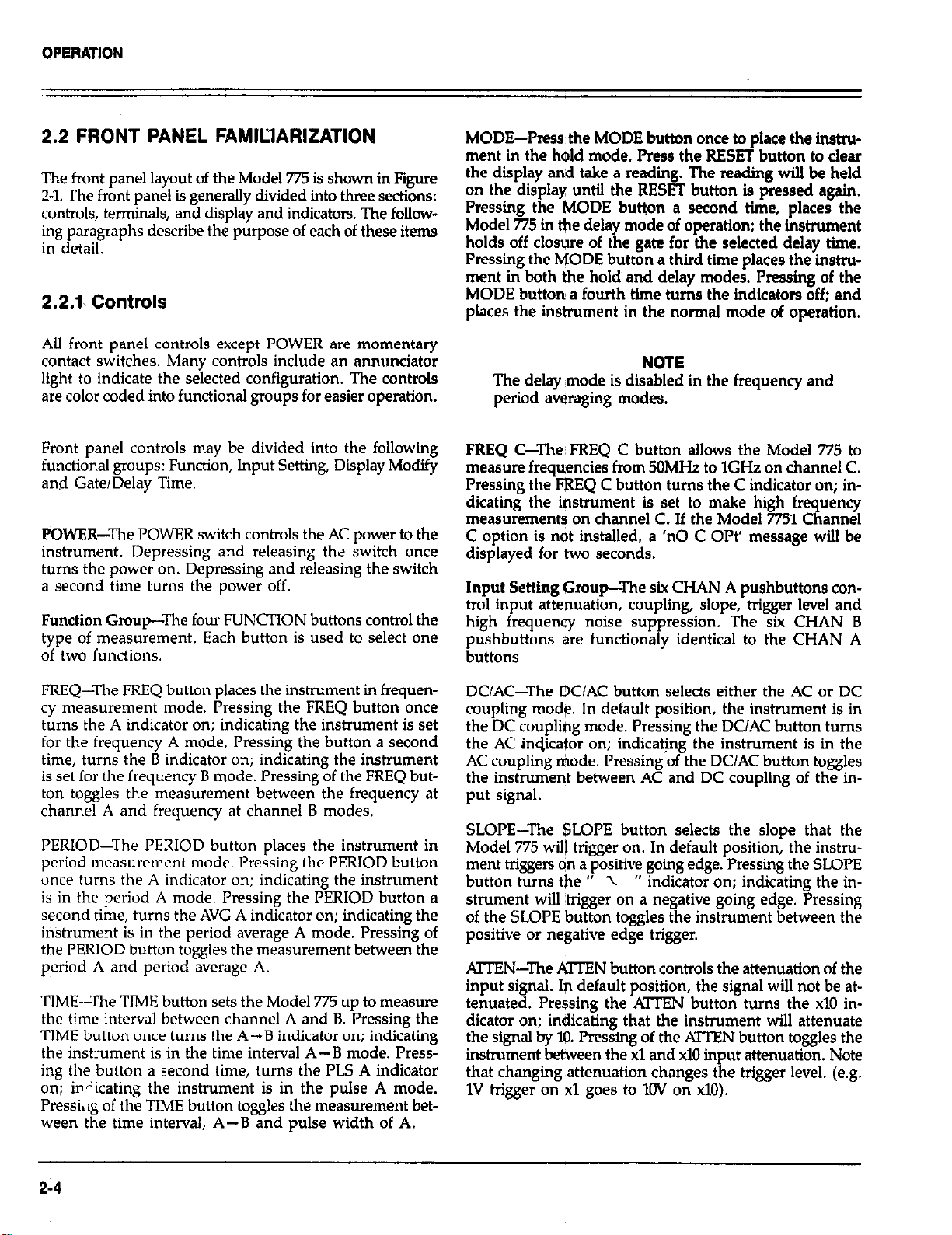

2.2 FRONT PANEL FAMIC1ARIZATION

The front panel layout of the Model 775 is shown in Figure

2-1. The front panel is generally divided into three sections:

controls, terminals, and display and indicators. The following paragraphs describe the purpose of each of these items

in detail.

2.2.1~ Controls

All front panel controls except POWER are momentary

contact switches. Many controls include an annunciator

light to indicate the selected configuration. The controls

are color coded into functional groups for easier operation.

Front panel controls may be divided into the following

functional groups: Function, Input Setting, Display Modify

and Gate/Delay Time.

POWER-The POWER switch controls the AC power to the

instrument. Depressing and releasing the switch once

turns the power on. Depressing and releasing the switch

a second time turns the power off.

Function GrouP4he four FUNCTlON buttons control the

type of measurement, Each button is used to select one

of two functions.

MODE-Press the MODE button once to place the lnstrument in the hold mode. Press the RESET button to clear

the display and take a reading. The reading will be held

on the display until the RESET button is pressed again.

Pressing the MODE butt.on a second time, places the

Model 775 in the delay mode of operation; the instrument

holds off closure of the gate for the selected delay time.

Pressing the MODE button a third time places the instrument in both the hold and delay modes. Pressing of the

MODE button a fourth time turns the indicators off: and

places the instrument in the normal mode of operation.

NOTE

The delay ,mode is disabled in the frequency and

period averaging modes.

FREQ C--The: FREQ C button allows the Model 775 to

measure frequencies from 50MHz to lGHz on channel C.

Pressing the FREQ C button turns the C indicator on; lndicating the instrument is set to make high frequency

measurements on channel C. If the Model 7751 Channel

C option is not installed, a ‘no C OPY message will be

displayed for two seconds.

Input Setting Group-The six WAN A pushbuttons control input attenuation, coupling, slope, trigger level and

high frequency noise suppression. The six CHAN B

pushbuttons are functionaly identical to the CHAN A

buttons.

FREQ-The FREQ button places the instrument in frequency measurement mode. Pressing the FREQ button once

turns the A indicator on; indicating the instrument is set

for the frequency A mode. Pressing the button a second

time, turns the B indicator on; indicating the instrument

is set for the frequency B mode. Pressing of the FREQ button toggles the measurement between the frequency at

channel A and frequency at channel B modes.

PERIOD-The PERIOD button places the instrument in

period measurement mode. Pressing the PERIOD button

once turns the A indicator on; indicating the instrument

is in the period A mode. Pressing the PERIOD button a

second time, turns the AVG A indicator on; indicating the

inetrument is in the period average A mode. Pressing of

the PERIOD button toggles the measurement between the

period A and period average A.

TIME-The TIME button sets the Model 775 up to measure

the time interval between channel A and 8. Pressing the

TIME button once turns the A-B indicator on; indicating

the instrument is in the time interval A-B mode. Pressing the button a second time, turns the PLS A indicator

on; indicating the instrument is in the pulse A mode.

l’ressi,ig of the TIME button toggles the measurement between the time interval, A-B and pulse width of A.

DC/AC-The DC/AC button selects either the AC or DC

coupling mode. In default position, the instrument is in

the DC coupling mode. Pressing the DC/AC button turns

the AC indicator on; indicating the instrument is in the

AC coupling mode. Pressing of the DC/AC button toggles

the instrument between AC and DC coupling of the input signal.

SLOPE-The $LQPE button selects the slope that the

Model 775 will trigger on. In default position, the instrument triggers on a positive going edge. Pressing the SLQPE

button turns the ” 1

strument will trigger on a negative going edge. Pressing

of the SLOPE button toggles the instrument between the

positive or negative edge trigger.

ATTEN-The ATTEN button controls the attenuation of the

input signal. In default position, the signal will not be attenuated. Pressing the ATTEN button turns the x10 indicator on; indicating that the instrument will attenuate

the signal by Ill. Pressing of the ATTEN button toggles the

instrument between the xl and xl0 input attenuation. Note

that changing attenuation changes the trigger level. (e.g.

1V trigger on xl goes to lOV on x10).

” indicator on; indicating the in-

OPERATION

FLTR-The FLTR button limits high frequency noise to

about 1OOkHz through a low-pass filter installed at the input terminal. In default position, the low-pass filter is off.

Pressing the FLTR button turns the FLTR indicator on; indicating that the low-pass filter is on. Pressing of the FLTR

button toggles the filter between on and off.

LEVEL-The LEVEL buttons select the signal voltage level

that will trigger the instrument (e.g. start and/or stop the

measurement interval). Pressing the ‘I button decrements

the level by one step. Pressing the A button increments

the level by one step. Each step is 1OmV on the xl attenuator

setting or 1OOmV on the x10 attenuator setting. Holding the

LEVEL A or v button in for more than one second, causes

the trigger level to continuously move up or down respectively. Holding the LEVEL A and v buttons in at the same

time, causes the instrument to jump to the preset position O.OOV (or OO.OV).

Display Modify Group-The two pushbuttons in the

display modify group modify the display from normal frequency (or time reading) to another reading such as trigger level, gate time, delay time or displayed number of

digits.

GATE/DELAY-The GATE/DELAY pushbutton has two

functions: When instrument is in the frequency or period

averaged functions, this button modifies the display to

display the time that the gate remains open to complete

one cycle. When instrument is in the time interval, period

A or pulse A function, this button modifies the display

to show the time that the closure of the gate is delayed

after its opening. Press GATE/DELAY to exit.

TRIGGER LEVEL-The TRIGGER LEVEL button may be

used to modify the display to show the trigger level of both

channels A and B. Pressing !he TRIGGER LEVEL button

turns the indicator above the button on, indicating that

the instrument is in the trigger level display mode. The

display will contain two sets of readings (three digits for

each channel). The three digits to the left on the display

concern channel A, while the three digits to the right on

the display concern channel B. Use CHAN A or CHAN

B Level buttons to modify the values. Press TRIGGER

LEVEL to exit.

Display Function-The display function allows the user to

select the maximum number of most significant digits

which are to be displayed. In the normal operating mode,

the instrument will display a maximum of nine digits. The

minimum number of digits displayed is three. To access

the display function press simultaneously the

GATE/DELAY and TRIGGER LEVEL buttons. Select the

number of digits to be displayed by pressing the

GATE/DELAY TIME A or v button to increment or decre-

ment the display. To resume normal operation, simply

press any other button on the front panel. The instrument

will display its measurements with the preselected number

of digits.

GATE/DELAY TIME-The two GATE/DELAY TIME buttons

control: the time that the gate is open from 100~s~ to 1Osec

in 46 steps; the delay of the gate closure from 100psec to

1Osec in 46 increments; and the number of digits to be

displayed in increments of seven.

GATE/DELAY A, V-Each time the A button is pressed,

the gate or delay increments one step. Each time the v

button is pressed, the gate or delay decrements one step.

If A or v button is held in for more than one second, the

instrument will continuously increment or decrement. If

the A and v buttons are held in at the same time, the

instrument will jump to a preset position of laec delay time

or nine digits displayed numbers.

User Gate/Delay Function-Information on accessing this

function will be given later in this chapter.

LOCAL--Pressing the LOCAL button when the instrument is in remote operation (but not in remote (local)

lockout condition), will place the instrument in local operation. Pressing this button when the instrument is already

in local operation will have no effect on the instrument.

RESET-Pressing the RESET button during normal operation will reset the display and initiate a new measurement

cycle. When the instrument is in the hold mode of operation, pressing the RESET button clears the display and

arms the instrument for the next measurement.

2.2.2 Terminals

The terminals are used to connect the Model 775 to the

signal to be measured.

Channel A-The CHAN A terminal is used when making

frequency and time measurements.

Channel B-The CHAN B terminal is used when making

frequency and time A-B measurements.

Channel C-The CHAN C terminal is used for high fre-

quency measurements up to 1GHz with a 5Ofl input impedance Although this terminal is always installed, the

internal circuitry needed to operate this function is optional

and may not be installed. BNC shell is connected to chassis

ground as indicated by the I symbol.

2-5

OPERATION

2.2.3 Display and indicators

The function of the display and indicators is described

below.

Display-The display consists of a nine digit mantissa and

a single digit exponent. The exponent uses a leading minus

to indicate negative values. The sign on the exponent

changes to + for zero or positive values. The dimension

is determined by the exponent and the Hz, SEC or V

indicdtors.

Units Indicators-The units are shown by three indicators.

The Hz indicator is on during frequency measurements

and the SEC indicator is on during time and period

measurements. When TRIGGER LEVEL button is pressed,

the V (volts) indicator turns on.

GATE Indicator-When the instrument takes a measurement, the GATE indicator blinks at a rate which is proportional to the gate time.

IEEE Status Indicators-The REMOTE, TALK and LISTEN

indicators are used when programming the instrument

over the IEEE-488 bus. Refer to Section 3 for complete IEEE

programming information. These status indicators are not

operational during front panel instrument operation.

2.2.4 Tilt Bail

IEEE-488 Connector--This connector is used to connect the

instrument to the IEEE-488 bus. IEEE interface functions

are marked above the connector.

TRIGGER LEVEL OUTPUT Connector-These two BNC

connectors are used to connect the DC voltage level from

the trigger circuits to an external Dh4M or oscilloscope. DC

output range is marked above the connectors.

CLOCK Connector-This BNC connector is used to output the internal clock as a reference to another instrument.

The same ihput may be connected to an external clock

reference. lb use an external clock reference, the internal

time base must be set for external operation. Refer to Section 6 for this procedure and proper signal levels to apply.

EXT ARMING & GATE/DELAY Connector-A BNdconnectar which may receive one of three signals: arming

pulse, external gate signal or external delay pulse. This input is useful when gate or delay times other than the internal times are required or to take one reading with the

Model 775 in synchronized with other equipment.

2.3.2 LINE VOLTAGE SELECTOR Switch

The LINE VOLTAGE SELECTOR switch selects the line

voltage that, the Model 775 will operate on. For information on voltage selection refer to Section 6.

The tilt bail, which is located on the bottom cover of the

instrument, is useful for elevating the front of the instrument to a convenient viewing height. To extend the bail,

first rotate it 90” away from the bottom cover and push up

on the leg to lock it into pIdie. To retract the bail, pull the

legs away from the bottom cover and then rotate the bail

until it is flush with the bottom cover.

2.3 REAR PANEL FAMILIARIZATION

Figure 2-2 shows the rear panel lavout of the Model 775.

2.3.1 Connectors and Terminals

AC Receptacle-Power is applied through the supplied

power cord to the 3-terminal AC receptacle. Note that the

selected power supply voltage is marked on the rear panel

above the line voltage selector switch.

2.3.3 IEEE-488 Address Switches

The IEEE-488 address switches are used to program the

primary.a@ress for IEEE-488 interface operation. The address may be set from 0 to 30.

2.3.4 Line Fuse

The LINE FUSE provides protection for the AC power line

input. For information on replacing this fuse, refer to Section 6.

2.4 POWER-UP PROCEDURE

The basic procedure of powering up the Model 775 is

described below.

1. Connect the female end of the power cord to the AC

receptacle on the rear panel. Connect the other end of

the pow& cord to a grounded AC outlet.

2-6

CAUTION

Be sure the power line voltage agrees with the

indicated value on the rear panel of the instrument. Failure to heed this warning may result

in instrument damage. If necessary, the power

line voltage may be changed by siidlng the

recessed LINE VOLTAGE SELECTOR switch to

the required voltage positlon. Refer to Section

6 for details

WARNING

The Model 775 is equipped with a 3.wire power

cord desianed to be used with arounded

outlets. When the proper connections are

made, instrument chassis Is connected to

power line ground. Failure to use a properly

grounded outlet may result in personal injury

or death because of electric shock.

Turn on the power by depressing and releasing the

POWER switch on the front panel.

The instrument will then begin operation by performing a display and indicator test for about one second.

All mode and IEEE indicators will turn on and the

display will appear as follows:

8.8.8.8.8.8.8.8.8*8

To verify that all display segments are operating, compare the instrument’s display during the test with the

above figure.

Once the test is completed, the instrument will perform

ROM and RAM tests. If all these tests are passed, the

display will show the software revision level for about

one second similar to the example below:

SoFt A.1

Following the software revision level, the instrument

will display the default IEEE primary address which is

set by the IEEE address switch on the rear panel. For

example, with the rear panel switch set to address 23,

the display will show:

IE Adr 23

Following these display messages, the instrument will

go into the normal operating mode and is ready to take

readings, The instrument will be in the following

configuration:

OPERATION

l

Freq A

l

Gate/Delay Time = 1Sec

l

Trigger Levels = O.OOV

l

Filters: Off

l

Attenuators: Off

. DC/AC: DC

l

Slope: Positive

l

Mode: Normal

l

IEEE Status: Local

l

Displayed digits: 9

7. If any of the power tests fail, the instrument will lock

up and display an error message as follows:

FAtAL Err 1

It is recommended that the power-up procedure be

repeated several times to verify that a consistent error

occurs; if so, a problem exists in the instrument. See Section 6 for troubleshooting information,

2.5 DISPLAY MESSAGES

The Model 775 has two display messages associated with

basic front panel operation. One message indicates that

Model 7751 option is not installed, the other that gate time

or delay time are user selectable. Note that the instrument

has a number of additional display messages associated

with IEEE-488 programming.

2.5.1 No Option Message

The Model 7751 option must be installed in the instrument

before it can measure frequencies through the channel C

input terminal. If the FREQ C button is depressed and the

Model 7751 option is not installed, the following message

will be displayed:

no c oPt

NOTE

There are no additional software modifications required after the Model 7751 option is installed.

After the Model 7751 option is installed, the no

option message will no longer be displayed.

2-7

OPERATION

2.6 CONTROL SELECTION

Selecting the various front panel operating modes is simply

a matter of depressing, once or twice, the appropriate button as described in the following paragraphs.

2.6.1 Function

The Model 775 must be set up for the proper measuring

function with one of the four function buttons.

1. To measure frequency through the channel A input ter-

minal, depress the FREQ button.

2. To measure frequency through the channel B input ter-

minal, depress the FREQ button a second time.

3. To measure the period of a signal through the channel

A input terminal, depress the PERIOD button.

4. To measure the period averaged of a signal through the

channel A input terminal, depress the PERIOD button

a second time.

5. To measure time intervals from events in channel .4 to

events in channel B, depress the TIME button.

6. To measure the pulse width of a pulse at channel A in-

put terminal, depress the TIME button a second time.

Use the slope button(s) to select the desired portion of

the input signal.

7. To measure frequency through the channel C input ter-

minal, depress the FREQ C button.

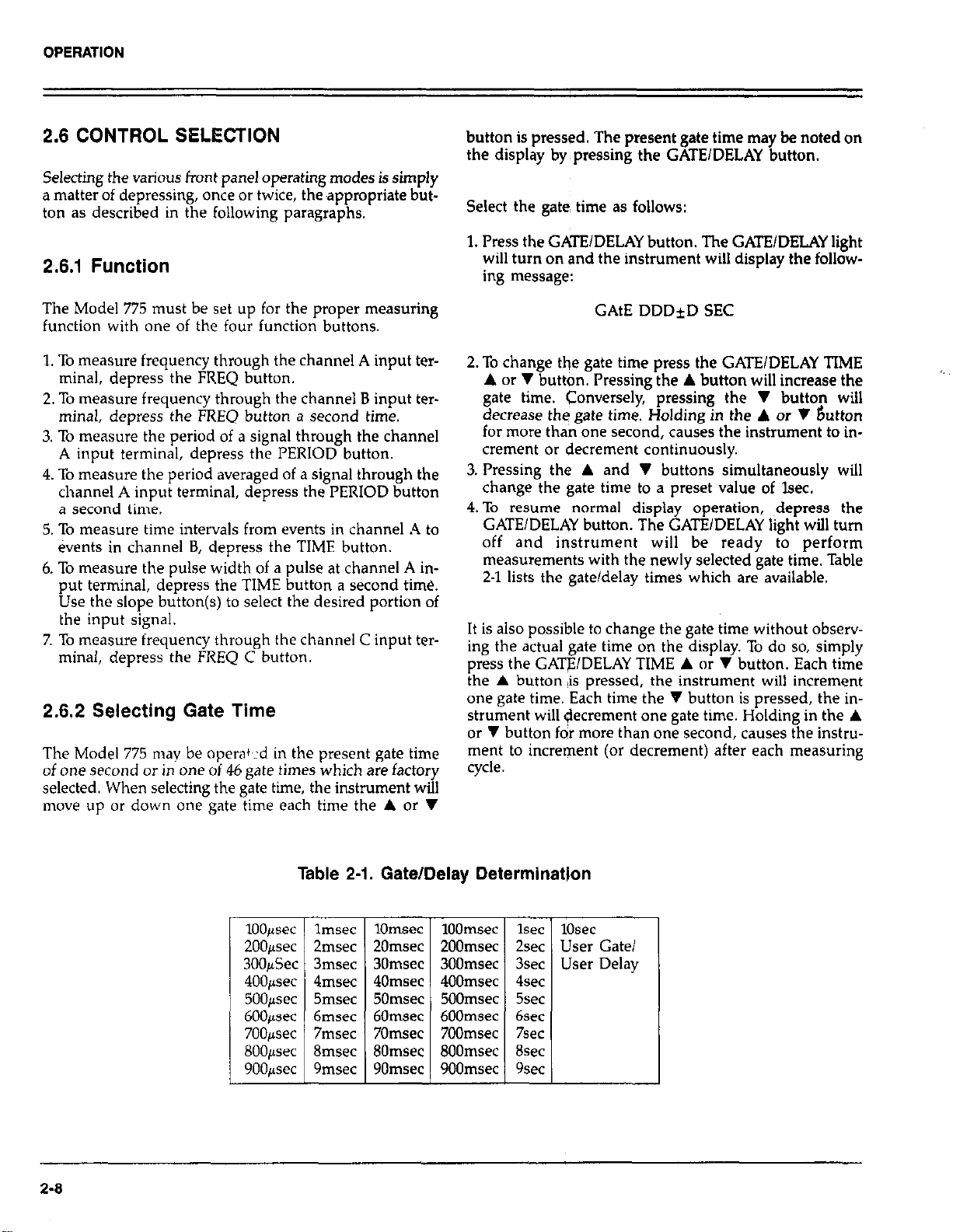

2.6.2 Selecting Gate Time

The Model 775 may be operak:d in the present gate time

of one second or in one of 46 gate times which are factory

selected. When selecting the gate time, the instrument will

move up or down one gate time each time the A or V

button is pressed. The present gate time may be noted on

the display by pressing the GATE/DELAY button.

Select the gate: time as follows:

1. Press the GATE/DELAY button. The GATE/DELAY light

will turn on and the instrument will display the following message:

GAtE DDD*D SEC

2. To change the gate time press the GATE/DELAY TIME

A or V button. Pressing the A button will increase the

gate time. Conversely, pressing the V button will

decrease the gate time. Holding in the A or V button

for more than one second, causes the instrument to increment or decrement continuously.

3. Pressing the A and V buttons simultaneously will

change the gate time to a preset value of lsec.

4. To resume normal display operation, ~depress the

GATE/DELAY button. The GATE/DELAY light will turn

off and instrument will be ready to perform

measurements with the newly selected gate time. Table

2-1 lists the gate/delay times which are available.

It is also possible to change the gate time without observing the actual gate time on the display. To do so, simply

press the GATE/DELAY TIME A or V button. Each time

the A button #is pressed, the instrument will increment

one gate time. Each time the V button is pressed, the in-

strument will decrement one gate time. Holding in the A

or V button for more than one second, causes the instrument to increment (or decrement) after each measuring

cycle.

2.0

Table 2-1. Gate/Delay Determination

OPERATION

NOTE

To prevent operator error, there is an internal

alarm that beeps whenever a limit is reached,

(e.g. 1OOjwsc low limit or 1Osec high limit). With

the GATE/DELAY light on, the alarm will sound

when the users gate is displayed and the A button is pressed. Refer to Table 2-2 alarm conditions.

2.6.3 User Gate Function

The user gate function is useful when a gate time other

than the predetermined gate times listed in Table 2-l is required. The limits which must be observed are the

minimum limit of lO@sec and the maximum limit of 10sec.

The user gate function is accessible in the FREQ A, B and

C and Period Averaged functions. To operate the instrument in the user gate mode proceed as follows:

1. Press the GATE/DELAY button and observe that the light

turns on and the instrument displays the’ following

message:

GAtE DDD+D SEC

2.6.4 Using Delay

The Model 775 has a delay function which disables the

closure of the opened gate for the predetermined periods

listed in Table 2-1. This function is very useful in burst

measurements, relay open/close time measurements where

bounce time should be eliminated or in measurements

done on a train of pulses.

NOTE

The delay mode is accessible only when PERIOD

A, TIME A-B or PLS A functions are on. The

selection of any other function, when the DELAY

light is on, will cause the instrument to exit from

delay mode

The delay time may be selected as follows:

1.

Press

the GATE/DELAY button. The GATE/DELAY light

will turn on and the instrument will display the following message:

dELAY DDDiD SEC

This display shows the actual gate time that the instru-

ment is set to operate. DDDiD SEC may be any time

from lOOE-6 to 10EcO.

2. Press and hold in the GATE/DELAY TIME A button and

observe that the display increments. After the 10s~ gate

time the instrument will enter the user gate mode and

the instrument will display the following:

USEr GATE SEC

Pressing the A button after the gate is displayed will

sound an alarm.

3. Press the GATE/DELAY button. The light will turn off

and the instrument will be ready for measurements with

an external gate time.

4. Apply a ‘ITL pulse to the rear panel EXT ARMING &

GATE/DELAY BNC terminal. The high level of the TTL

pulse width determines the length of the gate time.

NOTE

The user gate function may be accessed only

when the GATE/DELAY light is on. To exit the

user gate function press the GATE/DELAY TIME

V button, or both the A and V buttons to preset

the gate tiine to kc.

2. To change the delay time, press the GATE/DELAY TIME

A or V button. When the A or V button is depressed

for more than one second, the instrument will increment

or decrement continuously.

3. Pressing the A and y buttons simultaneously will

change the delay time to a preset value of lsec.

4.To resume normal display operation, press the

GATE/DELAY button. The GATE/DELAY light will turn

off and instrument will be ready to perform measurement with the newly selected delay time. Table 2-1 lists

the gate/delay times which are available as preselected

values.

It is also possible to change the delay time without obser-

ving the actual delay time on the display. To do so, simpl;,

press the GATE/DELAY TIME A or V button. Exh timk

the A button is pressed, the instrument will increment

one delay time. Each time the V button is pressed, the

instrument will decrement one delay time. When A or V

button is held in for more than one second, the instru-

ment will increment (or decrement) after each measuring

cycle.

2-9

OPERATION

NOTE

To prevent operator error, there is an internal

alarm that beeus whenever a limit is reached.

(e.g. 100ssec 10; limit or 1Osec high limit). When

the GATE/DELAY light is on, the alarm will

sound when the user’s delay is displayed and the

A button is pressed. Refer to Table 2-2.

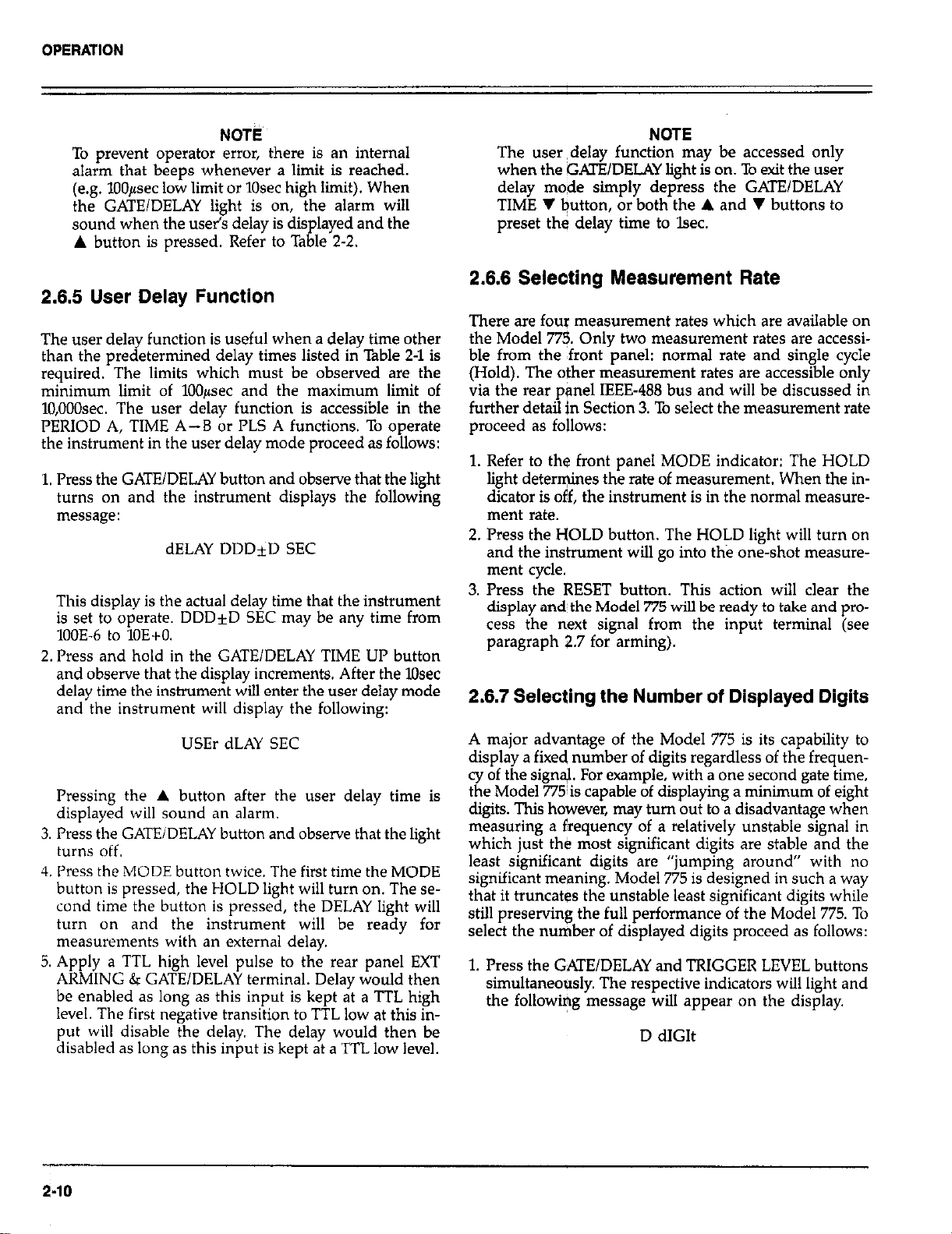

2.6.5 User Delay Function

The user delay function is useful when a delay time other

than the predetermined delay times listed in Table 2-l is

required. The limits which must be observed are the

minimum limit of 100ssec and the maximum limit of

10,OOOsec. The user delay function is accessible in the

PERIOD A, TIME A-B or PLS A functions. To operate

the instrument in the user delay mode proceed as follows:

1. Press the GATE/DELAY button and observe that the light

turns on and the instrument displays the following

message:

dELAY DDD*D SEC

This display is the actual delay time that the instrument

is set to operate. DDDiD SEC may be any time from

lOOE-6 to lOE+O.

2. Press and hold in the GATE/DELAY TIME UP button

and observe that the display increments. After the 1Osec

delay time the instrument will enter the user delay mode

and the instrument will display the following:

NOTE

The user,delay function may be accessed only

when the GATE/DELAY light is on. To exit the user

delay mode simply depress the GATE/DELAY

TIME v button, or both the A and v buttons to

preset the delay time to lsec.

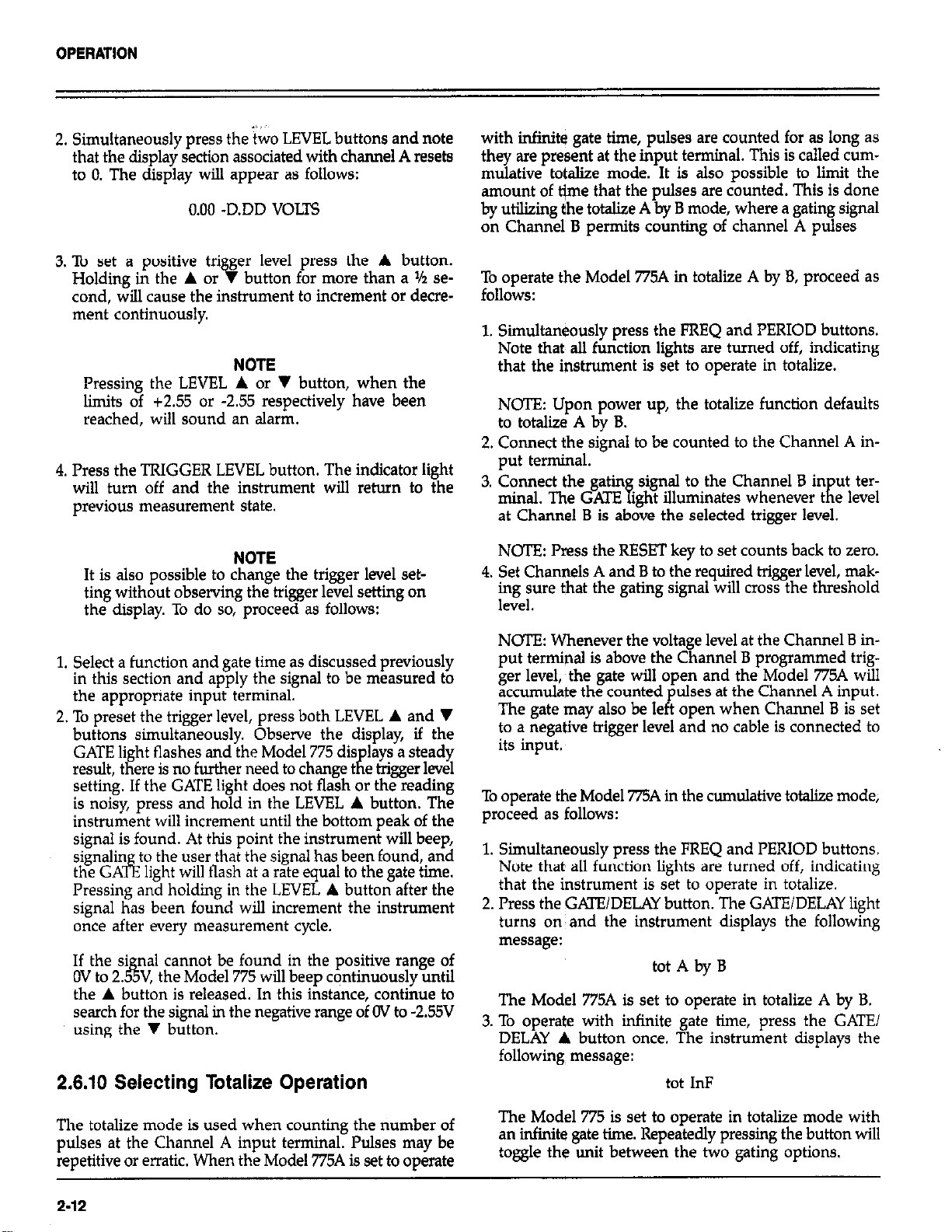

2.6.6 Selecting Measurement Rate

There are four measurement rates which are available on

the Model 775. Only two measurement rates are accessible from the front panel: normal rate and single cycle

(Hold). The other measurement rates are accessible only

via the rear panel IEEE-488 bus and will be discussed in

further detail in Section 3. To select the measurement rate

proceed as follows:

1. Refer to the front panel MODE indicator: The HOLD

light determines the rate of measurement. When the indicator is off, the instrument is in the normal measurement rate.

2. Press the HOLD button. The HOLD light will turn on

and the instrument will go into the one-shot measurement cycle.

3. Press the RESET button. This action will clear the