Model 7710 Multiplexer Card

User’s Guide

PA-847 Rev. B / 8-03

A GREATER MEASURE OF CONFIDENCE

.

Safety Precautions

The following safety precautions should be observed before using

this product and any associated instrumentation. Although some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions

may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions required to avoid possible injury. Read and follow all installation,

operation, and maintenance information carefully before using the

product. Refer to the manual for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product may be impaired.

The types of product users are:

Responsible body

and maintenance of equipment, for ensuring that the equipment is

operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators

trained in electrical safety procedures and proper use of the instrument. They must be protected from electric shock and contact with

hazardous live circuits.

Maintenance personnel

to keep it operating properly, for example, setting the line voltage

or replacing consumable materials. Maintenance procedures are described in the manual. The procedures explicitly state if the operator

may perform them. Otherwise, they should be performed only by

service personnel.

Service personnel

safe installations and repairs of products. Only properly trained service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that

are rated Measurement Category I and Measurement Category II, as

described in the International Electrotechnical Commission (IEC)

Standard IEC 60664. Most measurement, control, and data I/O signals are Measurement Category I and must not be directly connected to mains voltage or to voltage sources with high transient overvoltages. Measurement Category II connections require protection

for high transient over-voltages often associated with local AC

mains connections. Assume all measurement, control, and data I/O

connections are for connection to Category I sources unless otherwise marked or described in the Manual.

Exercise extreme caution when a shock hazard is present. Lethal

voltage may be present on cable connector jacks or test fixtures. The

American National Standards Institute (ANSI) states that a shock

hazard exists when voltage levels greater than 30V RMS, 42.4V

peak, or 60VDC are present.

that hazardous voltage is present in any unknown circuit before

measuring.

is the individual or group responsible for the use

use the product for its intended function. They must be

perform routine procedures on the product

are trained to work on live circuits, and perform

A good safety practice is to expect

Operators of this product must be protected from electric shock at

all times. The responsible body must ensure that operators are prevented access and/or insulated from every connection point. In

some cases, connections must be exposed to potential human contact. Product operators in these circumstances must be trained to

protect themselves from the risk of electric shock. If the circuit is

capable of operating at or above 1000 volts,

the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits.

They are intended to be used with impedance limited sources.

NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the connecting

cables, test leads, and jumpers for possible wear, cracks, or breaks

before each use.

When installing equipment where access to the main power cord is

restricted, such as rack mounting, a separate main input power disconnect device must be provided, in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any

other instruments while power is applied to the circuit under test.

ALWAYS remove power from the entire test system and discharge

any capacitors before: connecting or disconnecting cables or jumpers, installing or removing switching cards, or making internal

changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground. Always

make measurements with dry hands while standing on a dry, insulated

surface capable of withstanding the voltage being measured.

The instrument and accessories must be used in accordance with its

specifications and operating instructions or the safety of the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating information, and as shown on the instrument or test fixture panels, or

switching card.

When fuses are used in a product, replace with same type and rating

for continued protection against fire hazard.

Chassis connections must only be used as shield connections for

measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use of a

lid interlock.

no conductive part of

5/03

If a screw is present, connect it to safety earth ground using the

wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of normal

and common mode voltages. Use standard safety precautions to

avoid personal contact with these voltages.

The symbol indicates a connection terminal to the equipment

frame.

The

WARNING

result in personal injury or death. Always read the associated information very carefully before performing the indicated procedure.

The

CAUTION

damage the instrument. Such damage may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and

all test cables.

heading in a manual explains dangers that might

heading in a manual explains hazards that could

To maintain protection from electric shock and fire, replacement

components in mains circuits, including the power transformer, test

leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable national safety approvals,

may be used if the rating and type are the same. Other components

that are not safety related may be purchased from other suppliers as

long as they are equivalent to the original component. (Note that selected parts should be purchased only through Keithley Instruments

to maintain accuracy and functionality of the product.) If you are

unsure about the applicability of a replacement component, call a

Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based

cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill

on the instrument. Products that consist of a circuit board with no

case or chassis (e.g., data acquisition board for installation into a

computer) should never require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the factory for proper

cleaning/servicing.

n

Keithley Instruments, Inc.

28775 Aurora Road

Cleveland, Ohio 44139

(440) 248-0400

Fax: (440) 248-6168

www.keithley.com

Introduction

NOTE The Model 7710 will operate properly when installed in one of the following

The Model 7710 is a 20-channel differential multiplexer card with the following features:

Model 7710 Multiplexer Card

User’s Guide

Model 27xx instruments:

Model 2700 – Equipped with B05 (or later) firmware

Model 2701 – Equipped with A01 (or later) firmware

Model 2750 – Equipped with A04 (or later) firmware

• Fast actuating, long life solid state relays.

• DC and AC voltage measurement.

• 2-wire or 4-wire measurements (automatically pairs relays for four wire measurements —

+ 10).

• Temperature applications (RTD, thermistor, thermocouple).

• Built-in cold junction reference for TC temperature.

• Plug-in screw terminal connections.

WARNING Before operating the Model 27xx with an accessory card, verify that the card is

properly installed and the mounting screws are tightly fastened. If the mounting screws are not properly connected, an electrical shock hazard may be

present.

Topics

Operating instructions............................................................................................... page 2

Card configuration .................................................................................................... page 2

Fast scanning .......................................................................................................... page 4

Fast scan using 7710 module with Model 2701 mainframe ..................................... page 4

Operating considerations........................................................................................ page 10

Low-ohms measurements ...................................................................................... page 10

Voltage measurements .......................................................................................... page 11

Insertion loss .......................................................................................................... page 12

Crosstalk................................................................................................................. page 12

Additional errors for 27xx switch systems .............................................................. page 12

Heat sink temperature measurements ................................................................... page 13

Card handling precautions...................................................................................... page 13

Card connections.................................................................................................... page 14

Wiring procedure .................................................................................................... page 15

Typical connections ................................................................................................ page 17

Connection log........................................................................................................ page 19

Calibration .............................................................................................................. page 21

Specifications ...................................................................................... end of User s Guide

PA-847 Rev. B / 8-03

'

Operating instructions

CAUTION Before installing or removing a Model 77xx plug-in module, make sure the

Model 27xx power is turned off and disconnected from line power. Failure to

comply may result in incorrect operation and loss of Model 77xx EPROM data.

Switching card operation is covered in the Model 27xx User’s Manual. The Model 7710 operates

the same as the Model 7700 switching card with the following differences:

• The Model 7710 has no amps channel. The Model 7700 has two amps channels.

• The Model 7710 uses solid state opto-coupled FET relays. The Model 7700 uses latching

electromechanical relays. Solid state relays provide longer relay life and are up to six

times faster than the electromechanical types used in other switching modules.

WARNING The system’s maximum voltage, including other switch modules and front

panel terminals, is limited to 60V peak-to-peak AC or DC between any terminal

and chassis, or any two terminals when the 7710 is installed. Exceeding these

levels creates a shock hazard and could cause damage to the card. Complete

specifications are located at the end of this User’s Guide .

Topics

WARNING When a Model 7710 module is inserted into a Model 27xx, it is connected to

the front and rear inputs, as well as the other cards in the system, through the

instrument backplane. To prevent damaging the 7710 module or creating a

shock hazard, the entire test system and all of its inputs should be de-rated to

60V DC (42V rms).

Card configuration

Figure 1 shows a simplified schematic diagram of the Model 7710 module. As shown, the

Model 7710 has channels that are grouped into two banks of ten channels (twenty channels

total). Backplane isolation is provided for each bank. Each bank includes separate cold junction

reference points. The first bank contains channels 1 through 10, while the second bank contains

channels 11 through 20. Each channel of the 20-channel multiplexer card is wired with separate

inputs for HI/LO providing fully isolated inputs.

Connections to DMM functions are provided through the card backplane connector.

Channels 21, 22, and 23 are configured automatically by the Model 27xx when using system channel operation. However, by using multiple channel operation (refer to Section 2 of the Model 27xx

User’s Manual), they can be manually configured.

For example, assume a 7710 module is installed in slot 1 of the mainframe and an external source

is connected to Card Source input. To connect the source to channel 11 only, multiple channel

operation must be used:

Topics

ROUT:OPEN:ALL

ROUT:MULT:CLOS (@111,123) ' Close channels 11 and 23.

For the above command sequence, the Digital Multimeter (DMM) of the Model 27xx will be electrically

isolated from the test circuit.

2

Open all channels.

Topics

3

When using system channel operation for 4-wire measurements (including 4-wire ohms, RTD

temperature, Ratio, and Channel Average), the channels are paired as follows:

CH1 and CH11 CH6 and CH16

CH2 and CH12 CH7 and CH17

CH3 and CH13 CH8 and CH18

CH4 and CH14 CH9 and CH19

CH5 and CH15 CH10 and CH20

Figure 1

Simplified schematic of Model 7710

Card Source

Cold junction

Ref x3

Channel 1

(Channels 2-9)

Channel 10

Cold junction

Ref x3

Channel 11

HI

LO

HI

LO

HI

LO

Channel 23

2-Pole (Closed)

4-Pole (Open)

(see Notes)

HI

LO

Channel 21

(see Note)

Backplane

isolation

Channel 22

(see Note)

Backplane

isolation

HI

Input

LO

HI

Sense

LO

Topics

Topics

To Model

27xx

Backplane

(Channels 12-19)

HI

Channel 20

Card Sense

LO

HI

LO

Notes:

Channels 21, 22, and 23 in this schematic refer

to the designations used for control and not actual

available channels.

Channels 21 and 22 can be individually

controlled using multiple channel operation

(ROUT:MULT commands) if the module is not

to be connected to the internal DMM.

For more information, see Section 2 of the

Model 27xx User’s Manual.

Topics

Fast scanning

Fast scanning is achieved by using the 7710 module (which has high-speed solid state FET relays)

with the Model 2701 mainframe. With mainframe speed settings optimized for DCV or ohms measurements, the Model 2701 can scan approximately twice as fast as the Models 2700 and 2750.

To achieve the fastest scan possible, use the following Model 27xx mainframe settings for the

scan:

VOLT:AVER:STAT OFF

VOLT:DIG 4

VOLT:NPLC X

SYST:AZER:STAT OFF

SYST:LSYN OFF

TRIG:DEL 0

FORM:DATA ASCII ‘ Formats data as an ASCII string (N/A for 2701).

FORM:ELEM READ

CALC3:OUTP OFF

CALC3:LIM1:STAT OFF

DISP:ENAB OFF

When finished with the scan, the display can be turned back on with the following command:

‘ Disables filtering.

‘ Sets display resolution to 4.5 digits.

‘ Sets reading rate:

‘ where: X = 0.01 (2700 and 2750).

‘ X = 0.002 (2701)

‘ Disables auto-zero.

‘ Disables line synchronization.

‘ Sets trigger delay to 0 seconds.

‘ Returns each reading with units only.

‘ Disables limit outputs.

‘ Disables limit 1 test.

‘ Turns off display.

Topics

Topics

DISP:ENAB ON

‘ Turns on display.

Fast scan using 7710 module with Model 2701 mainframe

The following Visual Basic (VB) Version 6 program demonstrates using the Model 7710 card and

Model 2701 mainframe to achieve fast scanning. It makes use of WinSocket control to communicate

with the Model 7701 mainframe. This User’s Guide is provided as a PDF file on the product information CD-ROM. From Acrobat Reader, the program code can be copied and pasted into Visual Basic.

Topics

4

’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’

’ 7710 DCV FAST SCAN EXAMPLE FOR THE 2701 MODULE

’

’ This program is an example of configuring a simple DCV scan on the 7710 with a 2701 mainframe.

’ This program acquires readings at a rate of 500/ sec.

’

’ Note that a Winsocket control in Visual Basic is being used to communicate with the 2701.

’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’

Const ScanList = "(@101:120)"

Dim TestRunning As Boolean

Dim DataReceived As Boolean

Dim DataSent As Boolean

Dim Data As String

’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’

’ A Visual Basic function call when a Form (program window) is opened.

’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’

Private Sub Form_Load()

TestRunning = False

End Sub

Topics

Topics

’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’

’ These two functions exit the program and closes the winsocket.

’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’

Private Sub ExitButton_Click()

Unload Me

End Sub

Private Sub Form_Unload(Cancel As Integer)

Cancel = MsgBox("Exit?", 20, "Exit Verify")

If Cancel = vbYes Then

Cancel = 0

CloseWinsocket

End If

End Sub

’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’

’ This function opens the Winsocket for communication with the 2701 ethernet mainframe.

’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’

Function ConnectTo2701() As Integer

Dim Time0 As Single

Topics

5

If txtAddress.Text = "" Then

ConnectTo2701 = False

Exit Function

End If

With Winsock1

.Protocol = sckTCPProtocol

.RemoteHost = txtAddress.Text

.RemotePort = 1394

.Connect

End With

' Check for proper connection.

Time0 = Timer

While Timer - Time0 < 10! And Winsock1.State <> sckConnected: DoEvents: Wend

If Winsock1.State <> sckConnected Then

’ Could not connect to 2701.

MsgBox "Cannot connect to " + LastAddress + "!", 48, "IP Connect Error"

ConnectTo2701 = False

Exit Function

End If

’ Connection to 2701 found.

ConnectTo2701 = True

Topics

Topics

End Function

’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’

’ Event to capture data from mainframe.

’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’

Private Sub Winsock1_DataArrival(ByVal bytesTotal As Long)

Winsock1.GetData Data, vbString, 50000

’Chr$(10) Or

If (Right$(Data, 1) = Chr$(10)) Then

Data = Left$(Data, Len(Data) - 1)

DataReceived = True

End If

End Sub

’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’

’ QueryKI() retrieves data from the 2701 over the ethernet connection.

’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’

Function QueryKI() As String

’ Read Ethernet data.

Topics

6

DataReceived = False

Do

' Remain in loop until mainframe is finished sending data.

DoEvents

Loop Until DataReceived

QueryKI = Data ' Return reading

End Function

’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’

’ This event occurs when host computer is finished sending data .

’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’

Private Sub Winsock1_SendComplete()

DataSent = True

End Sub

’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’

’ SendKI() sends data to the 2701 over the ethernet connection.

’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’

Sub SendKI(Cmd As String)

’ Send command to mainframe and wait for data sent event.

DataSent = False

Winsock1.SendData Cmd + Chr$(13)

Topics

Topics

Do

DoEvents

Loop Until DataSent

End Sub

’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’

’ Close the winsocket if it is still opened.

’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’

Private Sub CloseWinsocket()

If Winsock1.State <> sckClosed Then Winsock1.Close

End Sub

’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’

’ This function is called when the run button is pressed on the Form.

’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’

Private Sub RunTestButton_Click()

'

’ If a scan is not already running, begin a new scan.

Topics

7

If Not (TestRunning) Then

Call ScanDCV

End If

End Sub

’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’

’ Data is formatted to show one reading per line in reading window.

’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’

Private Sub Format_Readings(Resp As String)

Dim Out_str As String

Dim Ch As String

Dim i As Long

i = Len(Resp)

Out_str = ""

i = 1

While (i <= Len(Resp))

Ch = Mid(Resp, i, 1)

If (Ch = ",") Then

Ch = vbCrLf

End If

Out_str = Out_str + Ch

i = i + 1

Wend

Text1.Text = Out_str

End Sub

Topics

Topics

’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’

’ This is the main function for the 7710 test program.

’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’

Private Sub ScanDCV()

Dim NumReadings As Integer

Dim Resp As String

Dim Cmd As String

If Not (ConnectTo2701) Then ' Open connection to 2701.

Exit Sub

End If

TestRunning = True

8

Topics

NumReadings = 1024 ’ Take 1024 readings.

Resp = Space$(80)

Cmd = Space$(80)

’ Configure the instrument for scanning DCV.

’

SendKI ("*RST") ' Put instrument in known state.

SendKI ("FORM:DATA ASCII") ' Format data as an ASCII string.

SendKI ("FORM:ELEM READ") ' Return the reading with units only.

SendKI ("SAMP:COUN " + CStr(NumReadings)) ' Take 1024 readings.

SendKI ("FUNC 'VOLT:DC', " + ScanList) ' Set function to DCV.

SendKI ("VOLT:RANG 100," + ScanList) ' Set Range to 100V.

SendKI ("VOLT:AVER:STAT OFF," + ScanList)

SendKI ("VOLT:DIG 4," + ScanList) ' Read to 4 significant digits.

SendKI ("VOLT:NPLC 0.002," + ScanList) ' Set NPLC to 0.002.

SendKI ("CALC3:OUTP OFF") ' Turn off limit test.

SendKI ("SYST:LSYN OFF") ' Turn off line-sync.

SendKI ("DISP:ENAB OFF") ' Turn off display.

SendKI ("SYST:AZER:STAT OFF") ' Turn off auto-zero.

SendKI ("CALC3:LIM1:STAT OFF," + ScanList) ' Turn off limits.

SendKI ("TRIG:DEL 0") ' Set trigger delay to 0 seconds.

SendKI ("TRAC:CLE") ' Clear reading buffer.

SendKI ("ROUT:SCAN " + ScanList) ' Set scan list.

SendKI ("ROUT:SCAN:LSEL INT") ' Initiate scan.

SendKI ("*OPC?") ' Determines if mainframe is ready.

Resp = QueryKI()

Topics

Topics

SendKI ("INIT") ' Initiate scan and store in buffer.

SendKI ("*OPC?")

Resp = QueryKI() ' Wait for scan to complete.

SendKI ("ROUT:SCAN:LSEL NONE;*OPC?") ' Stop scan.

Resp = QueryKI()

SendKI ("TRACE:DATA?") ' Get readings from buffer.

Resp = QueryKI()

Format_Readings (Resp)

SendKI ("DISP:ENAB ON") ' Turn display back on.

CloseWinsocket ' Disconnect connection to mainframe.

TestRunning = False

End Sub

9

Topics

Operating considerations

Low-ohms measurements

For resistances in the normal range (>100 Ω ), the 2-wire method ( Ω 2) is typically used for ohms

measurements. For low-ohms ( ≤ 100 Ω ), the signal path resistance in series with the DUT could be

high enough to adversely affect the measurement. Therefore, the 4-wire method ( Ω 4) should be

used for low-ohms measurements. The following discussion explains the limitations of the 2-wire

method, and the advantages of the 4-wire method.

2-wire method

Resistance measurements in the normal range (>100 Ω ) are generally made using the 2-wire

method ( Ω 2 function). The test current is forced through the test leads and the resistance being

measured (R

The main problem with the 2-wire method, as applied to low-resistance measurements is the test

lead resistance (R

lies in the range of 1.5 to 2.5 Ω . Therefore, it is very difficult to obtain accurate 2-wire ohms measurements below 100 Ω .

). The meter then measures the voltage across the resistance value accordingly.

S

) and the channel resistance (R

LEAD

). The sum of these resistances typically

CH

Due to this limitation, the 4-wire method should be used for resistance measurements ≤ 100 Ω .

This method is explained as follows:

4-wire method

The 4-wire (Kelvin) connection method using the Ω 4 function, as shown is Figure 2, is generally

preferred for low-ohms measurements. The 4-wire method cancels the effects of channel and test

lead resistance.

These measurements can be made using the Model 2750 Digital Multimeter. With this configuration, the test current (I

leads (R

LEAD2

and R

sured through a second set of leads (R

) is forced through the test resistance (R

TEST

), while the voltage (VM) across the Device Under Test (DUT) is mea-

LEAD3

LEAD1

and R

) called the sense leads.

LEAD4

) through one set of test

DUT

With this configuration, the resistance of the DUT is calculated as follows:

R

= VM / I

DUT

where: I

As shown in Figure 2, the measured voltage (VM) is the difference between V

equations at the bottom of Figure 2

TEST

is the sourced test current and VM is the measured voltage.

TEST

sho

w how test lead resistance and channel resistance is can-

SHI

and V

SLO

. The

celled out of the measurement process.

Maximum test lead resistance (Model 2750)

Table 1 l

i

sts the maximum test lead resistance (R

that a larger test lead resistance can be tolerated with a smaller R

), plus the resistance of the DUT (R

LEAD

DUT

, as shown in the following

). Note

DUT

example:

Example:

Topics Topics Topics

10

is 3Ω on the 10Ω range using the Ω4 (4-wire) function, then the maximum test lead resis-

If R

DUT

tance (R

) can be 4Ω.

LEAD

Table 1

Maximum test lead resistance (Model 2750)

ΩΩΩΩ2 ΩΩΩΩ4 ΩΩΩΩ4 Dry Circuit

Range

1Ω NA NA 0Ω 1.2Ω Overflow Overflow

10Ω 0Ω 2Ω 0Ω 7Ω 3Ω 12Ω

R

LEAD

R

DUT

R

LEAD

R

DUT

R

LEAD

Figure 2

Low-ohms measurements using 4-wire method

2750 DMM with 7710 card

RCH11Hi

Sense Hi

RLEAD1

Ch11 Hi

VSHI

ITEST

Ch1 Hi

RCH1Hi

Input Hi

RLEAD2

ITEST

R

DUT

V

VM

VSLO

ITEST

Ch1 Lo

RCH1Lo

RCH11Lo

Input Lo

Sense Lo

RLEAD3

RLEAD4

Ch11 Lo

Assumptions:

RDUT =

Virtually no current flows in the high-impedance sense circuit due to

the high impedance of the voltmeter (VM). Therefore, the voltage

drops across Channel 11 and test leads 1 and 4 are negligible and

can be ignored.

The voltage drops across Channel 1 Hi (R

(RLEAD2) are not measured by the voltmeter (VM).

V

ITEST

VM =

M

where: V

VSHI - VSLO

M is the voltage measured by the 2750.

ITEST is constant current sourced by the 2750 to the DUT.

CH1Hi) and test lead 2

VSHI = ITEST × (RDUT + RLEAD3 + RCH1Lo)

VSLO = ITEST × (RLEAD3 + RCH1Lo)

VSHI - VSLO = ITEST × [(RDUT + RLEAD3 + RCH1Lo) - (RLEAD3 + RCH1Lo)]

= ITEST × RDUT

= VM

RDUT

11

Voltage measurements

As previously explained, path resistance can adversely affect “Low-ohms measurements” (see

page 10). Series path resistance can also cause loading problems for DC voltage measurements

on the 100V, 10V, and 10mV ranges when the 10M Ω input divider is enabled.

High signal path resistance can also adversely affect AC voltage measurements on the 100V

range above 1kHz.

Topics Topics Topics

Insertion loss

Insertion loss is AC signal power lost between the input and the output. In general, as frequency

increases, insertion loss increases.

For the 7710 card, insertion loss is specified for a 50Ω AC signal source routed through the mod-

ule to a 50Ω load. Signal power loss occurs as the signal is routed through the signal paths of the

module to the load.

Insertion loss is expressed as dB magnitudes at specified frequencies. The specifications for insertion loss are provided in the “Specifications” at the end of this User’s Guide. (See INSERTION

LOSS in the “Specifications”.)

As an example, assume the following specifications for insertion loss:

<1dB @ 500kHz 1dB insertion loss is approximately 20% loss of signal power.

<3dB @ 2MHz 3dB insertion loss is approximately 50% loss of signal power.

As signal frequency increases, power loss increases.

NOTE The insertion loss values used in the above example may not be the actual insertion

loss specifications of the Model 7710. The actual insertion loss specifications are

provided in the “Specifications” at the end of this User’s Guide.

Crosstalk

An AC signal can be induced into adjacent channel paths on the 7710 card. In general, crosstalk

increases as frequency increases.

For the 7710 card, crosstalk is specified for an AC signal routed through the module to a 50Ω load.

Crosstalk is expressed as a dB magnitude at a specified frequency. The specification for crosstalk

is provided in the “Specifications” at the end of this User’s Guide. (See CROSSTALK in the

“Specifications”.)

As an example, assume the following specification for crosstalk:

<-40dB @ 500kHz -40dB indicates that crosstalk into adjacent channels is 0.01% of the AC

signal.

As signal frequency increases, crosstalk increases.

NOTE The crosstalk values used in the above example may not be the actual crosstalk

specification of the Model 7710. The actual crosstalk specification is provided in the

“Specifications” at the end of this User’s Guide.

Additional errors for 27xx switch systems

Additional 27xx measurement errors and typical system scanning speeds are provided after the

first page of the “Specifications” on page 23. These measurement errors are to be added on to the

specifications of the Model 27xx mainframe being used in the switch system.

• Notes 1, 2 and 3 (and tables) for “DC CHARACTERISTICS” pertain to additional errors

for high-ohms resistance measurements, voltage measurements, and temperature measurements.

• The two tables for “SYSTEM SPEEDS” provide speed data for scanning. For the various

scan functions, the tables list the fundamental reading rate setting (in PLCs) and typical

speed (in readings per second) into and out of memory.

Topics Topics Topics

12

Heat sink temperature measurements

Measuring the temperature of a heat sink is a typical test for a system that has temperature measurement capability. However, the 7710 card cannot be used if the heat sink is being floated at a

dangerous voltage level (>60V). An example of such a test is shown in Figure 3.

In Figure 3, the heat sink is floating at 120V, which is the line voltage being input to a +5V regulator. The intention is to use channel 1 to measure the temperature of the heat sink, and use channel 2 to measure the +5V output of the regulator. For optimum heat transfer, the thermocouple

(TC) is placed in direct contact with the heat sink. This inadvertently connects the floating 120V

potential to the 7710 card. The result is 115V between channel 1 and channel 2 HI, and 120V

between channel 1 and chassis. These levels exceed the 60V limit of the card creating a shock

hazard and possibly causing damage to the card.

WARNING The test in Figure 3 demonstrates how a dangerous voltage can unintention-

ally be applied to the 7710 card. Keep in mind that in any test where floating

voltages >60V are present, you must be careful not to apply the floating voltage to the card.

Figure 3

Example of an unsafe measurement practice

WARNING

Test Circuit

Heat sink floating

at 120V.

120V

DO NOT use the 7710 card to perform this type of test. It exceeds

the 60V limit creating a shock hazard and could cause damage to the

card. Excessive voltages:

The voltage differential between Ch 1 and Ch 2 HI is 115V.

The voltage differential between Ch 1 and Ch 2 LO (chassis) is 120V.

7710 Module

Ch 1

115V

Ch 2

5V

120V

IN

Thermocouple

Heat Sink

+5V

+5V

Regulator

OUT

Ch 1 configured to measure TC temperature.

Ch 2 configured to measure 5V regulator output.

Card handling precautions

The solid state relays used on the 7710 card are static sensitive devices. Therefore, they can be

damaged by electrostatic discharge (ESD).

CAUTION To prevent damage from ESD, only handle the module by the card edges. DO

NOT touch the backplane connector terminals. When working with the

quick-disconnect terminal blocks, DO NOT touch any circuit board traces or

other components. If working in a high-static environment, use a grounded

wrist strap when wiring the module.

Topics Topics Topics

13

Touching a circuit board trace may also contaminate it with body oils that may degrade the isolation

resistance between circuit paths, adversely affecting measurements. It is good practice to handle a

circuit board only by its edges.

Card connections

Screw terminals on the switching module are provided for connection to DUT and external circuitry.

The Model 7710 uses quick-disconnect terminal blocks. A terminal block can be wired outside the

module and then plugged back in. These terminal blocks are rated for 25 connect/disconnects.

WARNING The information in this section is intended for qualified service personnel. Do

not attempt to perform this procedure unless qualified to do so.

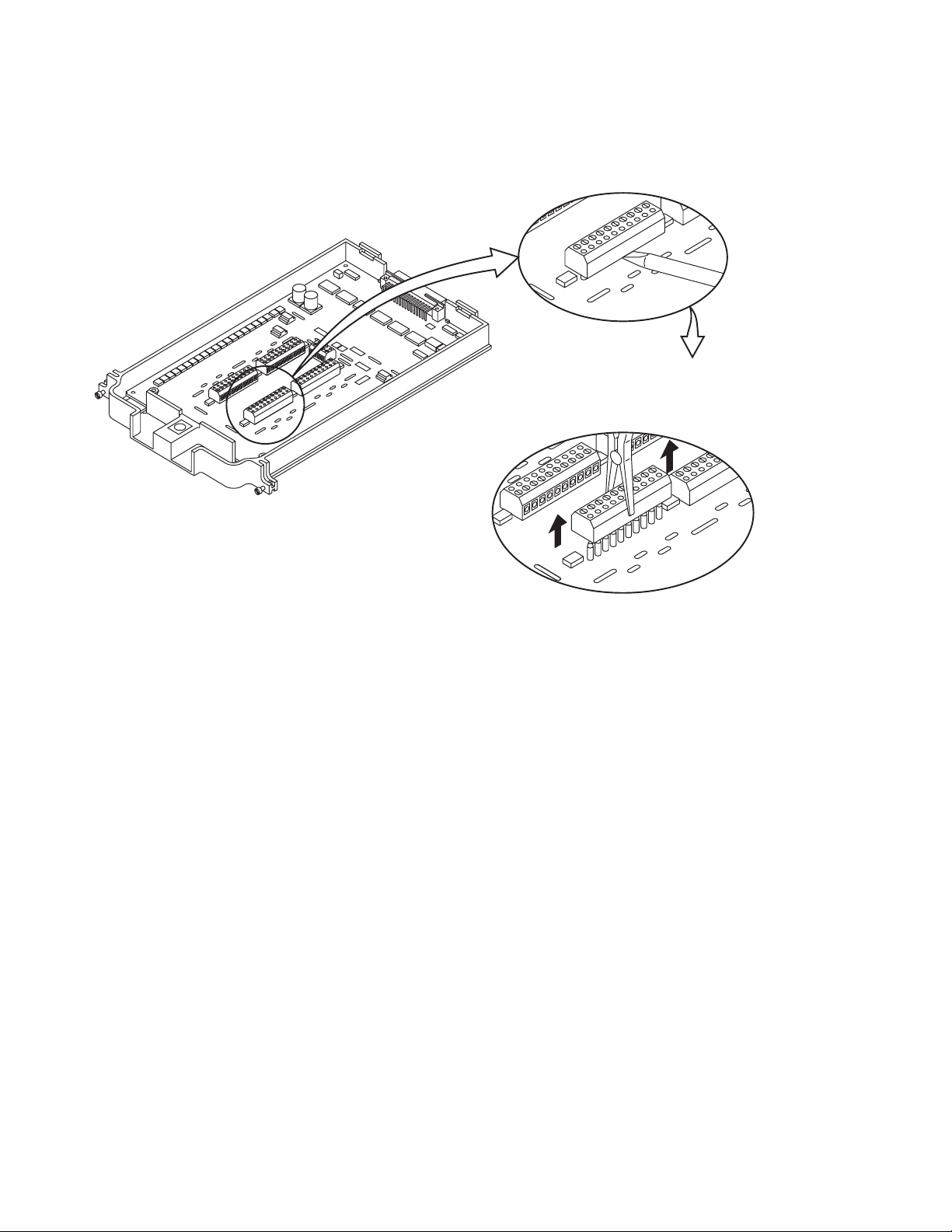

Figure 4 shows how to access the screw terminals on the Model 7710. Channel designations for

the screw terminals are contained in Figure 5.

WARNING Do not exceed the maximum specifications for the Model 7710 card. Refer to

the end of this User’s Guide for specifications.

Figure 4

Screw terminal access

LOCK

UNLOCK

Topics Topics Topics

14

Figure 5

Model 7710 screw terminal channel designations

CH1

CH2

CH3

CH4

CH5

CH6

LH

LH

LH

LH

LH

LH

CH7

LH

CH8

LH

CH9

LH

CH10

LH

LH

CH11

CH1LHCH2LHCH3LHCH4LHCH5LHCH6LHCH7LHCH8LHCH9LHCH10

LH LHLHLHLHLH

CH1LHCH2LHCH3LHCH4LHCH5

LHLH

SOURCESENSE

CH11LHCH12LHCH13LHCH14LHCH15

LHLHLHLHLH L HLHLHLHLH

CH11 CH12 CH13 CH14 CH15

LH

LH

CH12

CH13

CH6 CH7 CH8 CH9 CH10

CH16 CH17 CH18 CH19 CH20

LH LHLHLHLHLH

CH16 CH17 CH18 CH19 CH20

LH

LH

CH14

CH15

LH

LH

CH16

LH

CH17

LH

CH18

LH

CH19

LH

CH20

Wiring procedure

WARNING The information in this section is intended for qualified service personnel

only. Do not attempt to perform this procedure unless qualified to do so.

15

Use the following procedure to wire the Model 7710 card. Make all connections using the correct

wire size (up to 20 AWG). Also, make sure to add supplementary insulation around the harness for

voltages above 42V peak (see Figure 7).

1. Make sure all power is discharged from the Model 7710 card.

2. Remove the card’s top cover to gain access to the screw terminals (see Figure 4).

3. If desired, pull the appropriate quick-disconnect terminal block off the card.

4. Using a small flat-blade screwdriver, loosen terminal screws and install wires as desired (refer to

Figure 6). Figure 7 shows connections to channels 1 and 2.

Topics Topics Topics

Figure 6

Proper procedure to remove terminal blocks

Step 1. Place flat-head screwdriver

under connector and gently

push up to loosen it.

Step 2. Pull connector directly up

with needle nose pliers.

CAUTION: DO NOT rock connector

from side to side. Damage

to the pins could result.

5. Plug the terminal block back into the card.

6. Route wire along wire-path and secure with cable ties as shown.

7. Fill in a copy of the connection log (Table 2 on page 18) and affix it to the module cover.

8. Close and lock cover.

NOTE For maximum system performance, all measurement cables should be less than 3

meters.

Topics Topics Topics

16

Figure 7

Wire dressing

Typical connections

The following examples show typical wiring connections for the following types of measurements:

• Thermocouple connections, see Figure 8

• Ω 2-wire and thermistor connections, see Figure 9

•

Ω 4-wire and RTD connections, see Figure 10

• Voltage connections (DC or AC), see Figure 11

Cable Tie

Topics Topics Topics

17

Figure 8

Thermocouple connections

HI

Channel 1

LO

(Channels 2-19)

HI

Channel 20

LO

Figure 9

ΩΩΩΩ

2-wire and thermistor connections

HI

Channel 1

LO

(Channels 2-19)

HI

Channel 20

LO

Thermocouple

Resistor or

Thermistor

18

Topics Topics Topics

Figure 10

ΩΩΩΩ

4-wire and RTD connections

HI

Channel 1

LO

(Channels 2-9)

HI

Channel 10

LO

HI

Channel 11

LO

(Channels 12-19)

HI

Channel 20

LO

Resistor or

4-Wire RTD

Resistor or

4-Wire RTD

Figure 11

Voltage connections (DC or AC)

Channel 1

(Channels 2-19)

Channel 20

Connection log

Make a copy of Table 2 and the WARNING and affix them to the cover of the Model 7710. Use this

to record connection information and channel descriptions as needed.

DC Voltage AC Voltage

HI

+

LO

HI

+

LO

Topics Topics Topics

19

WARNING The system’s maximum voltage, including other switch modules and front

panel terminals, is limited to 60V peak-to-peak AC or DC between any terminal

and chassis or any two terminals when the 7710 is installed.

Table 2

Connection log Model 7710

Channel Color Description

Card Source H

L

Card Sense H

L

CH1 H

L

CH2 H

L

CH3 H

L

CH4 H

L

CH5 H

L

CH6 H

L

CH7 H

L

CH8 H

L

CH9 H

L

CH10 H

L

CH11 H

L

CH12 H

L

CH13 H

L

CH14 H

L

CH15 H

L

CH16 H

L

CH17 H

L

CH18 H

L

CH19 H

L

CH20 H

L

Topics Topics Topics

20

Calibration

The following procedures calibrate the temperature sensors on the Model 7710 plug-in cards.

WARNING The information in this section is intended only for qualified service person-

Recommended test equipment

In order to calibrate the Model 7710, you will need equipment summarized in Table 3.

Extender board connections

The Model 7710 being calibrated should be connected to the 7797 Calibration/Extender Board,

and the extender board should then be installed in scanner Slot #1. Note that the module being

calibrated will be external to the Model 27xx to avoid card heating during calibration.

nel. Do not attempt these procedures unless you are qualified to do so.

Table 3

Recommended equipment for Model 7710 calibration

Digital Thermometer:

18 to 23˚C, ±0.1˚C

Keithley 7797 Calibration/Extender Board

Model 7710 calibration

NOTE Before calibrating the Model 7710, make sure that power has been removed from

the card for at least two hours to allow card circuitry to cool down. After turning on

the power during the calibration procedure, complete the procedure as quickly as

possible to minimize card heating that could affect calibration accuracy. Allow the

Model 27xx to warm up for at least two hours.

Front panel Model 7710 calibration

1. Connect the Model 7710 to the Model 7797 Calibration/Extender Board (see “Extender board connec-

tions” above).

2. With the power off, install the Model 7710/7797 combination in Slot 1 and select the rear inputs with the

INPUTS switch. Allow three minutes for thermal equilibrium.

3. Accurately measure and record the cold temperature of the Model 7710 card surface at the center of the

card with a digital thermometer.

4. Press in and hold the Model 27xx OPEN key while turning on the power.

5. Press SHIFT then TEST, and then display TEST:CALIB with the up or down range key. Press ENTER,

select RUN, and then enter the appropriate calibration code (default: 0027xx).

6. With NEW CODE? displayed, use the up or down range key to display N, and then press ENTER.

7. Using the up or down range key, select CARD at the CAL:RUN prompt, and then press ENTER.

8. Set the display value to the cold calibration temperature (°C) you measured in Step 3, then press ENTER

to complete Model 7710 calibration.

21

Remote Model 7710 calibration

1. Connect the Model 7710 to the 7797 Calibration/Extender Board (see “Extender board connections”).

2. With the power off, install the Model 7710/7797 combination in Slot 1, and select the rear inputs with the

INPUTS switch. Allow three minutes for thermal equilibrium.

3. Accurately measure and record the cold temperature of the Model 7710 card surface at the center of the

card.

4. Press in and hold the Model 27xx OPEN key while turning on the power.

5. Enable calibration by sending the :CODE command. For example, the default command is:

CAL:PROT:CODE 'KI0027xx'

6.Initiate calibration by sending the following command:

CAL:PROT:CARD1:INIT

7. Calibrate the Model 7710 with the following command:

CAL:PROT:CARD1:STEP0 <temp>

Here <temp> is the cold calibration temperature (˚C) measured in Step 3.

8. Send the following commands to save calibration and lock out calibration:

CAL:PROT:CARD1:SAVE

CAL:PROT:CARD1:LOCK

22

7710 20-Channel High-Speed/ Long-Life Differential Multiplexer w/ Automatic CJC Specifications

CONTACT RESISTANCE: <10Ω per channel or <5Ω per

GENERAL

20 CHANNELS: 20 channels of 2-pole relay input. All channels

configurable to 4-pole.

RELAY TYPE: Solid State Opto-Coupled FET

ACTUATION TIME: <0.5mS (100mA load)

FIRMWARE: Specified for Model 2700 Rev. B05, Model 2750 Rev.

A04, and Model 2701 Rev. A01.

CAPABILITIES

CHANNELS 1-20: Multiplex one of 20 2-pole or one of 10 4-pole

signals into DMM.

INPUTS

MAXIMUM SIGNAL LEVEL: 60V DC or 42V rms between

channel (1-20) HI and channel LO or between any channel HI or LO

to any other channel HI or LO, 100mA switched, 6W, 4.2VA

maximum.

COMMON MODE VOLTAGE: 300V DC or 300V rms (425V

peak) for AC waveforms between any terminal and chassis.

SAFETY: Conforms to European Union Directive 73/23/EEC

EN61010-1, CAT I.

EMC: Conforms with European Union Directive 89/336/EEC

EN61326-1.

CONTACT LIFE: >10

level (guaranteed by design).

10

operations at cold switching or max signal

conductor. Refer to the Model 7710 User’s Guide for measurement

considerations when used in a Model 2750 on the 1Ω or 10Ω

ranges.

CONTACT POTENTIAL: <3µV per pair.

OFFSET CURRENT: <1nA @ 23°C (±5°C) for 0V, <5nA @ 23°C

(±5°C) for 60V, additional 0.13nA per 1°C above 28°C.

CONNECTOR TYPE: 3.5mm Removable Screw Terminals, #20

AWG wire size.

ISOLATION BETWEEN ANY TWO TERMINALS:

10

Ω @ 23°C, >8•109Ω @ 50°C, <100pF.

>10

ISOLATION BETWEEN ANY TERMINAL AND EARTH:

10

Ω, <100pF.

>10

CROSSTALK (CH-CH, 500kHz, 50Ω Load) : <-40dB.

INSERTION LOSS (50Ω Source, 50Ω Load): <1dB below

500kHz, <3dB below 2MHz.

ENVIRONMENTAL

OPERATING ENVIRONMENT: Specified for 0°C to 50°C.

STORAGE ENVIRONMENT: -25°C to 65°C.

WEIGHT: 0.45kg (1 lb).

ALTITUDE: <2km.

Specified for 80% R.H. at 35°C.

Cold Junction

Ref x3

Cold Junction

Ref x3

CARD SOURCE

CHANNEL 1

CHANNEL 10

CHANNEL 11

CHANNEL 20

CARD SENSE

LO

HI

LO

HI

LO

HI

LO

HI

LO

HI

LO

HI

HI

CHANNEL 21

CHANNEL 23

2-Pole (closed)

4-Pole (opened)

LO

HI

CHANNEL 22

LO

To Mainframe

Backplane

HW 11/07/02

Rev. A

Page 1 of 1

Specifications are subject to change without notice.

All Keithley trademarks and trade names are the property of Keithley Instruments, Inc. All other

trademarks and trade names are the property of their respective companies.

Keithley Instruments, Inc. 28775 Aurora Road • Cleveland, Ohio 44139 • 440-248-0400 • Fax: 440-248-6168

1-888-KEITHLEY (534-8453) • www.keithley.com

Sales Offices: BELGIUM: Bergensesteenweg 709 • B-1600 Sint-Pieters-Leeuw • 02-363 00 40 • Fax: 02-363 00 64

CHINA: Yuan Chen Xin Building, Room 705 • 12 Yumin Road, Dewai, Madian • Beijing 100029 • 8610-82251886 • Fax: 8610-82251892

FINLAND: Halsuantie 2 • 00420 Helsinki, Finland • 09-53 06 65 60 • Fax: 09-53 06 65 65

FRANCE: 3, allée des Garays • 91127 Palaiseau Cédex • 01-64 53 20 20 • Fax: 01-60 11 77 26

GERMANY: Landsberger Strasse 65 • 82110 Germering • 089-84 93 07-40 • Fax: 089-84 93 07-34

GREAT BRITAIN: Unit 2 Commerce Park, Brunel Road • Theale, Berkshire RG7 4AB • 0118 -929 75 00 • Fax: 0118- 929 75 19

INDIA: 1/5, Eagles Street • Langford Town • Bangalore 560 025 • 080 212 80-27 • Fax: 080 212 80 05

ITALY: Viale San Gimignano, 38 • 20146 Milano • 02-48 39 16 01 • Fax: 02-48 30 22 74

JAPAN: New Pier Takeshiba North Tower 13F • 11-1, Kaigan 1-chome • Minato-ku, Tokyo 105-0022 • 81-3-5733-7555 • Fax: 81-3-5733-7556

KOREA: 2FL., URI Building • 2-14 Yangjae-Dong • Seocho-Gu, Seoul 137-888 • 82-2-574-7778 • Fax: 82-2-574-7838

NETHERLANDS: Postbus 559 • 4200 AN Gorinchem • 0183-63 53 33 • Fax: 0183-63 08 21

SWEDEN: c/o Regus Business Centre • Frosundaviks Allé 15, 4tr • 16970 Solna • 08-50 90 46 00 • Fax: 08-655 26 10

TAIWAN: 13F-3, NO. 6, Lane 99, Pu-Ding Road, Hsinchu, Taiwan, ROC. • 886-3-572-9077 • Fax: 886-3-572-9031

© Copyright 2003 Keithley Instruments, Inc.

Printed in the U.S.A.

5/03

Loading...

Loading...