Page 1

Keithley Instruments

28775 Aurora Road

Cleveland, Ohio 44139

1-800-935-5595

tek.com/keithley

Model 7709 6 × 8 Matrix Module

1

Instructions for use with DAQ6510

Introduction

The 7709 switching module is a two-pole, 6 × 8 matrix switching module. It can connect any combination of six

differential channels of instrumentation to any combination of eight differential device-under-test channels. The

instrumentation can be AC and DC sources, such as internal or external meters or oscilloscopes. This matrix

configuration allows wide flexibility for complex test systems.

Figure 1: Model 7709

Item shipped may vary from model pictured here.

The Model 7709 is a 2-pole, 6 × 8 matrix card with the following features:

▪ Automatic 2-wire or 4-wire connection to DMM

▪ 6 row × 8 column matrix

▪ Expandable to larger switch configurations by daisy-chaining or cascading multiple modules

▪ Two female D-sub connectors are standard for secure hook-up and quick teardown

▪ 300 V, 1 A capacity

▪ Relay closures stored in onboard memory

If you are using this switching module with the 2700, 2701, or 2750, please see Model 7709

Multiplexer Card User's Guide, Keithley Instruments PA-771.

077147500 / June 2018

*P077147500*

Page 2

Model 7709 6 × 8 Matrix Module Instructions for use with DAQ6510

2

Schematic information

Connection and wiring procedures in this document are intended for use by qualified

personnel only, as described by the types of product users in the Safety precautions (on

page 19). Do not perform these procedures unless qualified to do so. Failure to recognize and

observe normal safety precautions could result in personal injury or death.

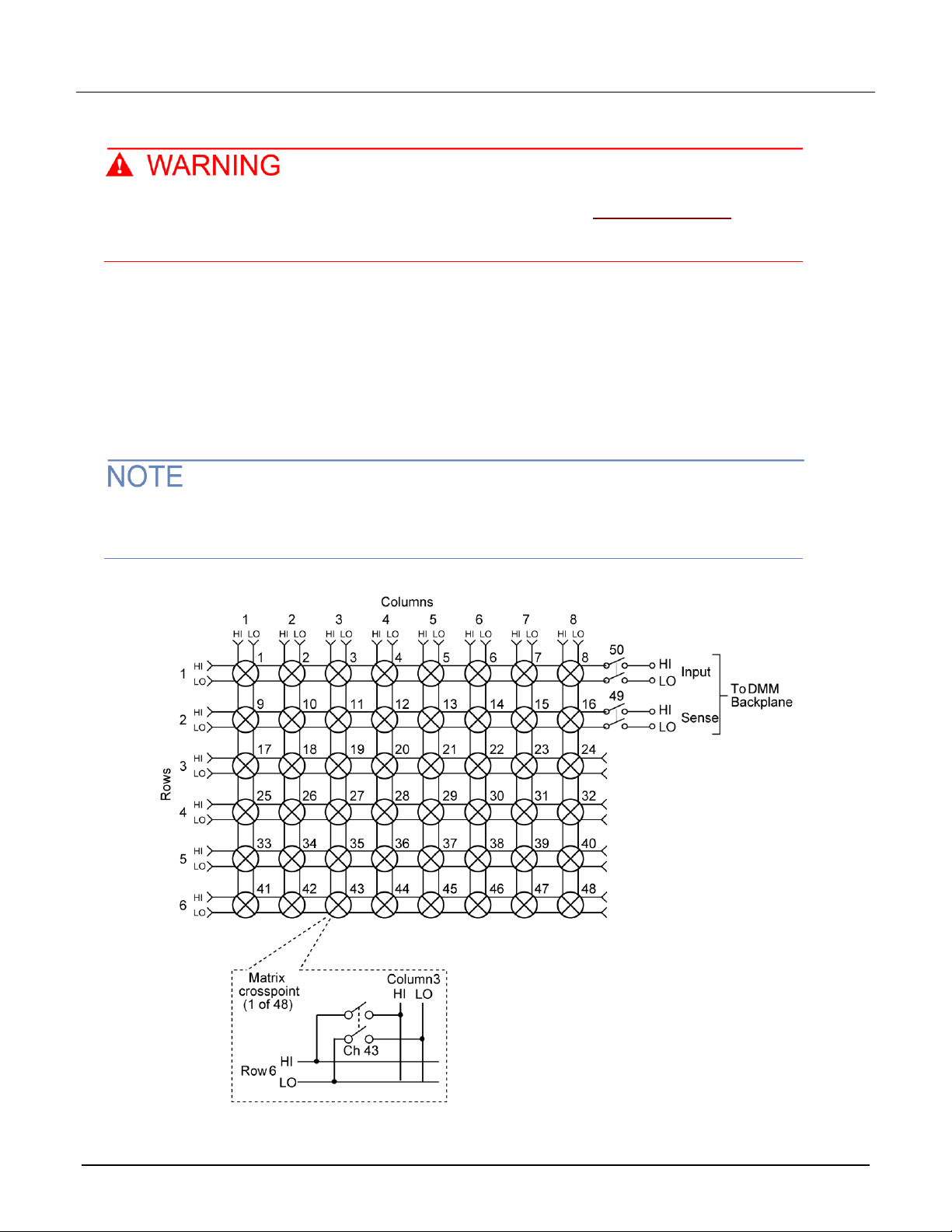

The following figure shows a simplified diagram of the 7709 switching module. The matrix consists of 48

crosspoints. Each crosspoint channel is a 2-pole switch that, when closed, connects a row to a column. For

example, closing channel 43 connects row 6 to column 3.

Two switches (channels 49 and 50) are used to connect rows 1 and 2 to the backplane of the DAQ6510. When

channel 50 is closed, row 1 is connected to the INPUT of the DMM. When channel 49 is closed, row 2 is

connected to SENSE of the DMM.

Devices under test (DUT) are to be connected to the matrix columns. Using 2-wire connections, up to eight

DUTs can be tested. For 4-wire connections, up to four DUTs can be tested. Rows 3 to 6 can be used to add

one or more external sources to the test system.

Although the 7709 relays are the latching type (relays hold their state even after power has been

removed), all relay states are set to open a few seconds after either a power cycle or a *RST or

reset () command is issued.

Figure 2: Simplified schematic for Model 7709

077147500 / June 2018

Page 3

Model 7709 6 × 8 Matrix Module Instructions for use with DAQ6510

3

Matrix expansion

Basic matrix column expansion

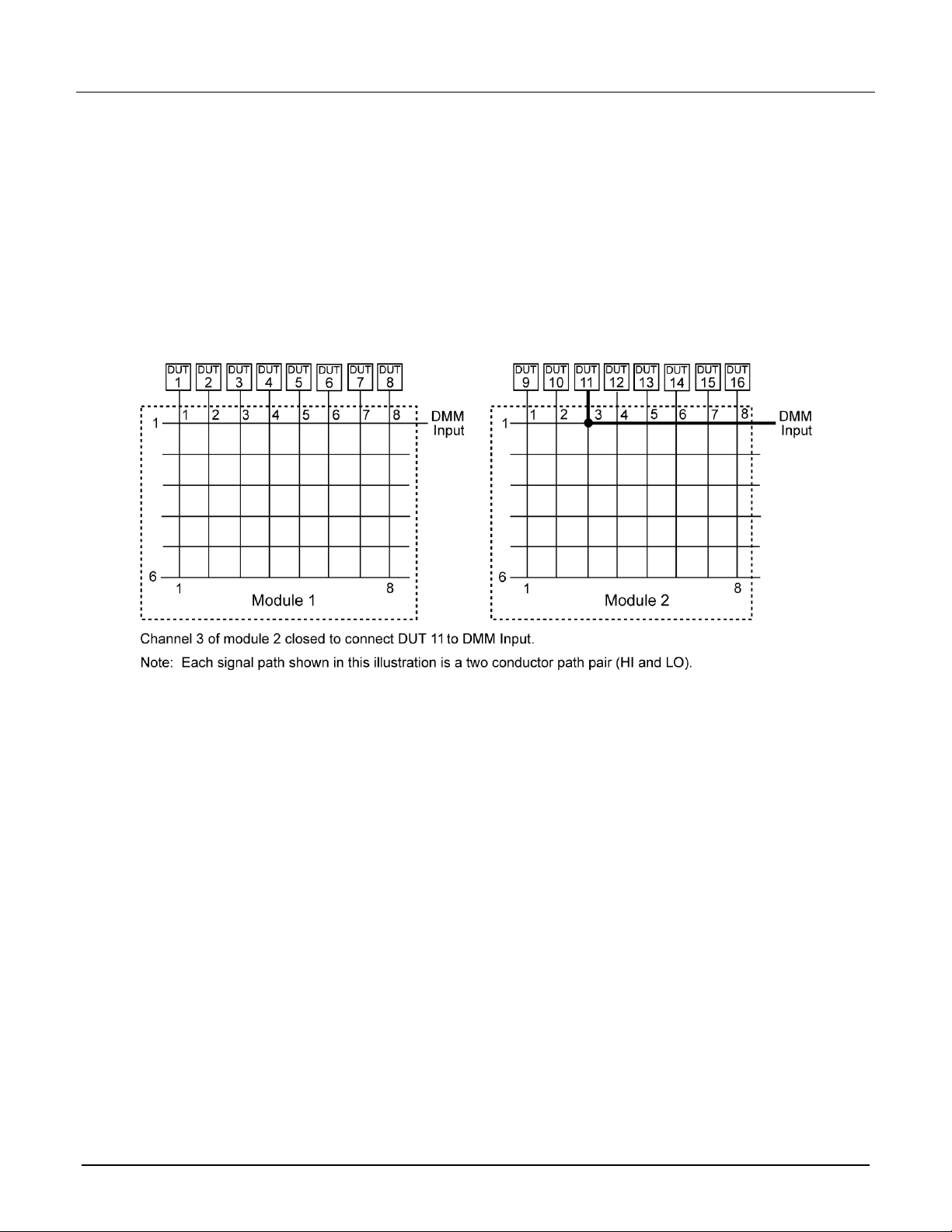

The number of columns in a matrix test system can be increased by installing another 7709 in the DAQ6510.

Adding a second 7709 increases the total number of columns to 16.

The following figure shows a two matrix module system to test 16 DUTs. It is similar to a 2-wire DUT

measurement except that the second card allows eight more DUTs to be tested. As shown, channel 3 of the

second module is closed to connect DUT 11 to the DMM Input.

Figure 3: Two matrix module test system

The following figure shows a two matrix module system that uses an external source. It is similar to the one in

the previous figure except that it allows more DUTs to be tested. The first matrix module is used to route the

external source to the DUT, while the second module is used to measure the DUT.

As shown in the following figure, DUT 1 is tested by closing multiple channel 25 and channel 1 of the two

respective modules.

The other DUT is tested in a similar manner. DUT 2 is tested with channels 26 and 2 closed, DUT 3 is tested

with channels 27 and 3 closed, and so on.

077147500 / June 2018

Page 4

Model 7709 6 × 8 Matrix Module Instructions for use with DAQ6510

4

Figure 4: Two matrix module test system with an external source

Daisy-chaining matrix rows

To route one or more external sources to other matrix modules, the rows of the modules must be

daisy-chained. External cabling is used to connect the rows of the matrix modules together.

The following figure shows examples of row daisy-chained matrix systems. For the 6 × 16 matrix,

daisy-chaining the two matrix modules allows the external source to be routed to the second module.

The matrix in this illustration is simplified to show external source connections to other matrix

modules. Connections to the DMM are not shown. Each signal path shown in this illustration is a two

conductor path pair (HI and LO).

Figure 5: Daisy-chained matrix modules

077147500 / June 2018

Page 5

Model 7709 6 × 8 Matrix Module Instructions for use with DAQ6510

5

Installation

Before operating an instrument with a switching module, verify that the switching module is

properly installed and the mounting screws are tightly fastened. If the mounting screws are

not properly connected, an electrical shock hazard may be present.

If you are installing two switching modules, it is easier to install one switching module into slot 2 first, then install

the second switching module into slot 1.

If you have a Keithley Instruments Model 2700, 2701, or 2750 instrument, you can use your existing

switching module in the DAQ6510. Follow the instructions in your original equipment documentation

to remove the module from the instrument, then use the following instructions to install it in the

DAQ6510. You do not need to remove wiring to the module.

For inexperienced users, it is recommended that you do not connect a device under test (DUT) and

external circuitry to the switching module. This allows you to exercise close and open operations

without the dangers associated with live test circuits. You can also set up pseudocards to experiment

with switching. Refer to "Pseudocards" in the Model DAQ6510 Data Acquisition and Multimeter

System Reference Manual for information on setting up pseudocards.

To prevent electric shock that could result in injury or death, never handle a switching

module that has power applied to it. Before installing or removing a switching module, make

sure the DAQ6510 is turned off and disconnected from line power. If the switching module is

connected to a DUT, make sure power is removed from all external circuitry.

If a card slot is unused, you must install slot covers to prevent personal contact with high

voltage circuits. Failure to install slot covers could result in personal exposure to hazardous

voltages, which could cause personal injury or death if contacted.

Before installing or removing a switching module, make sure the DAQ6510 power is turned

off and disconnected from line power. Failure to comply may result in incorrect operation and

loss of data in the memory.

Required equipment:

▪ Medium flat-blade screwdriver

▪ Medium Phillips screwdriver

077147500 / June 2018

Page 6

Model 7709 6 × 8 Matrix Module Instructions for use with DAQ6510

6

To install a switching module into the DAQ6510:

1. Turn off the DAQ6510.

2. Disconnect the power cord from the power source.

3. Disconnect the power cord and any other cables that are connected to the rear panel.

4. Position the DAQ6510 so you are facing the rear panel.

5. Use the screwdriver to remove the slot cover screws and the cover plate. Retain the plate and screws for

future use.

6. With the top cover of the switching module facing up, slide the switching module into the slot.

7. Press the switching module in firmly to make sure the switching module connector is connected to the

DAQ6510 connector.

8. Use the screwdriver to tighten the two mounting screws to secure the switching module to the mainframe.

Do not overtighten.

9. Reconnect the power cord and any other cables.

Remove a switching module

Before you remove a switching module or begin any testing, make sure that all the relays are open.

Since some relays may be latched closed, you must open all the relays before removing the

switching module to make connections. Additionally, if you drop your switching module, it is possible

for some relays to latch closed.

To open all channel relays, go to the CHANNEL swipe screen. Select Open All.

To prevent electric shock that could result in injury or death, never handle a switching

module that has power applied to it. Before installing or removing a switching module, make

sure the DAQ6510 is turned off and disconnected from line power. If the switching module is

connected to a DUT, make sure power is removed from all external circuitry.

If a card slot is unused, you must install slot covers to prevent personal contact with high

voltage circuits. Failure to install slot covers could result in personal exposure to hazardous

voltages, which could cause personal injury or death if contacted.

Before installing or removing a switching module, make sure the DAQ6510 power is turned

off and disconnected from line power. Failure to comply may result in incorrect operation and

loss of data in the memory.

Required equipment:

▪ Medium flat-blade screwdriver

▪ Medium Phillips screwdriver

077147500 / June 2018

Page 7

Model 7709 6 × 8 Matrix Module Instructions for use with DAQ6510

7

To remove a switching module from the DAQ6510:

1. Turn off the DAQ6510.

2. Disconnect the power cord from the power source.

3. Disconnect the power cord and any other cables that are connected to the rear panel.

4. Position the DAQ6510 so you are facing the rear panel.

5. Use the screwdriver to loosen the mounting screws that secure the switching module to the instrument.

6. Carefully remove the switching module.

7. Install a slot plate or another switching module in the empty slot.

8. Reconnect the power cord and any other cables.

Wiring

The 7709 is supplied with one 50-pin male IDC ribbon cable connector, and one 25-pin male IDC ribbon cable

connector. These ribbon cable connectors mate to the D-shell connectors of the switching module.

When using IDC ribbon cable connections, do not exceed 42 V anywhere in the test system or

at the front-panel inputs. For higher voltage applications, use larger wire (up to #20 AWG) and

solder cup D-shell connectors.

The 7709 is shipped with plastic connector covers installed on the D-shell connectors. Each cover is

secured to the connector by two screws. After removing a connector cover, retain it and the screws

for future use. Any unused D-shell connector must have the connector cover installed.

There are two connector kits that have connectors that can be used with the 7709:

▪ Model 7790 ribbon cable adapter kit: Contains one female DB-50, one male DB-50, and one male DB-25

IDC ribbon cable connectors. The two male IDC connectors mate to the female connectors on the 7709.

▪ Model 7789 50/25-pin solder cup connector kit: Contains one male DB-50 and one male DB-25 solder cup

connectors. These connectors mate to the female connectors on the 7709.

D-shell connectors

The following figure shows the pin numbers for the 7709 rear-panel connectors. The 50-pin D-shell is used for

DUT and external source connections. The 25-pin D-shell is used to daisy-chain the matrix rows of two 7709

switching modules. Terminal identification for the female connector pins are in the following table.

Figure 6: Model 7709 D-shell pinouts

077147500 / June 2018

Page 8

Model 7709 6 × 8 Matrix Module Instructions for use with DAQ6510

8

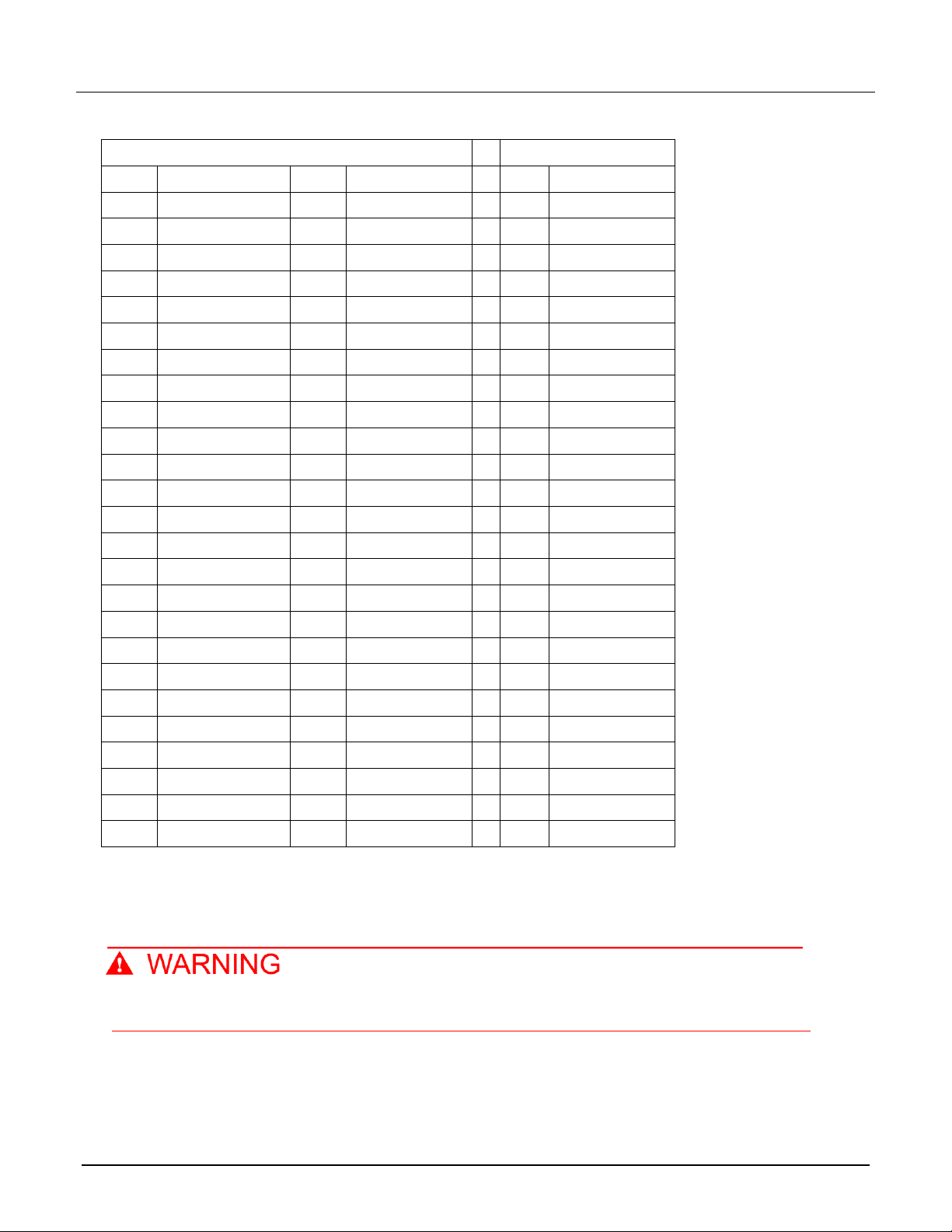

50-pin D-shell (DB-50)

25-pin D-shell (DB-25)

Pin

Matrix terminal

Pin

Matrix terminal

Pin

Matrix terminal

1

Row 1 HI

26

Col 3 Hi

1

Row 1 HI

2

Row 2 Lo

27

Col 4 Lo

2

Row 2 HI

3

——

28

Col 5 Hi

3

Row 3 HI

4

Row 4 Lo

29

Col 6 Lo

4

——

5

——

30

Col 7 Hi

5

Row 4 HI

6

Row 6 Lo

31

Col 8 Lo

6

Row 5 HI

7

——

32

——

7

——

8

Col 1 Lo

33

——

8

Row 6 HI

9

——

34

Row 1 Lo

9

——

10

Col 3 Lo

35

Row 3 HI

10

——

11

——

36

——

11

——

12

Col 5 Lo

37

Row 5 HI

12

——

13

——

38

——

13

——

14

Col 7 Lo

39

——

14

Row 1 Lo

15

——

40

——

15

Row 2 Lo

16

——

41

Col 2 Hi

16

Row 3 Lo

17

——

42

——

17

——

18

Row 2 HI

43

Col 4 Hi

18

Row 4 Lo

19

Row 3 Lo

44

——

19

Row 5 Lo

20

Row 4 HI

45

Col 6 Hi

20

——

21

Row 5 Lo

46

——

21

Row 6 Lo

22

Row 6 HI

47

Col 8 Hi

22

——

23

——

48

——

23

——

24

Col 1 Hi

49

——

24

——

25

Col 2 Lo

50

——

25

——

DUT and external source connections

DUT and external sources are to be wired to a 50-pin male D-shell connector. An IDC D-shell ribbon cable

connector or a D-shell solder cup connector can be used.

When using IDC ribbon cable connections, do not exceed 42 V anywhere in the test system or

to the front-panel inputs.

077147500 / June 2018

Page 9

Model 7709 6 × 8 Matrix Module Instructions for use with DAQ6510

9

Ribbon Cable*

Matrix

DB-50

Ribbon Cable

Matrix

DB-50

Conductor

Color

Terminal

Pin #

Conductor

Color

Terminal

Pin #

1

Brown

Row 1 Hi

1

26

Blue

——

——

2

Red

Row 1 Lo

34

27

Violet

Col 3 Hi

26 3 Orange

Row 2 Hi

18

28

Gray

Col 3 Lo

10 4 Yellow

Row 2 Lo

2

29

White

Col 4 Hi

43 5 Green

Row 3 Hi

35

30

Black

Col 4 Lo

27

6

Blue

Row 3 Lo

19

31

Brown

——

——

7

Violet

——

——

32

Red

——

——

8

Gray

——

——

33

Orange

Col 5 Hi

28 9 White

Row 4 Hi

20

34

Yellow

Col 5 Lo

12

10

Black

Row 4 Lo

4

35

Green

Col 6 Hi

45

11

Brown

Row 5 Hi

37

36

Blue

Col 6 Lo

29

12

Red

Row 6 Lo

21

37

Violet

——

——

13

Orange

——

——

38

Gray

——

——

14

Yellow

——

——

39

White

Col 7 Hi

30

15

Green

Row 6 Hi

22

40

Black

Col 7 Lo

14

16

Blue

Row 6 Lo

6

41

Brown

Col 8 Hi

47

17

Violet

——

——

42

Red

Col 8 Lo

31

18

Gray

——

——

43

Orange

——

——

19

White

——

——

44

Yellow

——

——

20

Black

——

——

45

Green

——

——

21

Brown

Col 1 Hi

24

46

Blue

——

——

22

Red

Col 1 Lo

8

47

Violet

——

——

23

Orange

Col 2 Hi

41

48

Gray

——

——

24

Yellow

Col 2 Lo

25

49

White

——

——

25

Green

——

——

50

Black

——

——

The connector cover for the 25-pin D-shell connector on the Model 7709 must be installed if

the connector is not going to be used. If the connector is left open, an electrical shock hazard

may be present.

IDC ribbon cable connections

Connect an appropriate length of 50-conductor IDC ribbon cable to a 50-pin male D-shell IDC connector. The

following table provides terminal identification for the 50-pin ribbon cable connections.

077147500 / June 2018

*50-conductor IDC ribbon cable is available from Keithley Instruments.

Page 10

Model 7709 6 × 8 Matrix Module Instructions for use with DAQ6510

10

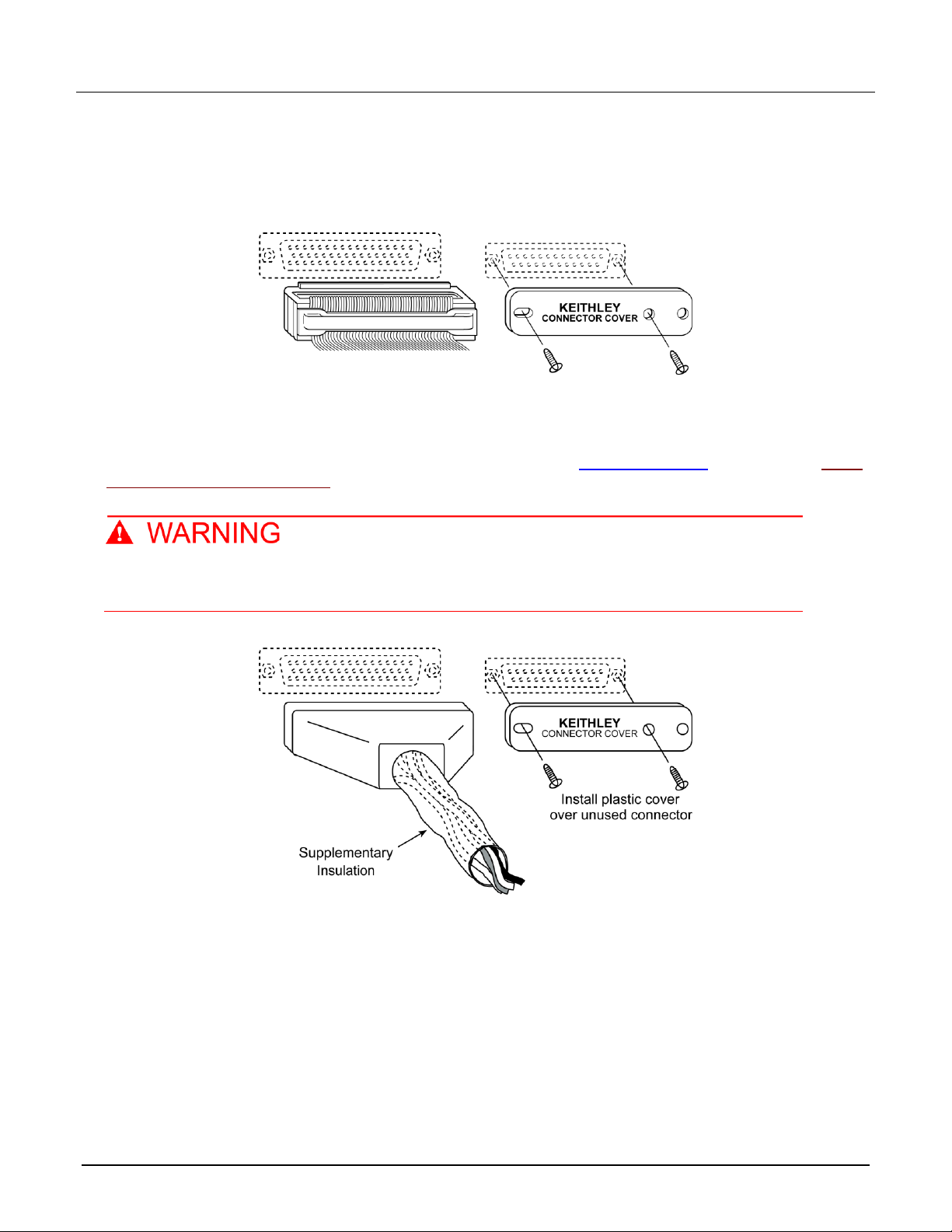

Connecting ribbon cable assembly

The following figure shows the connector of the prepared ribbon cable assembly mates to the 50-pin D-shell

connector of the Model 7790. Make sure the connector cover for the 25-pin D-shell connector is installed if it is

not going to be used.

Figure 7: Connecting ribbon cable assembly

Solder cup cable connections

Make all connections to a 50-pin D-shell male solder cup connector using the correct wire size up to 20 AWG.

Terminal identification for the 50-pin D-shell connector is provided in D-shell connectors (on page 7) and DUT

and external source connections (on page 8). Make sure to add supplementary insulation around the harness

for voltages above 42 V

PEAK

.

All solder cup wiring must be rated for the maximum voltage in the system. For example, if

1000 V is applied to the front terminals of the DMM, all matrix module wiring must be rated for

1000 V.

Figure 8: Solder cup cable connections

077147500 / June 2018

Page 11

Model 7709 6 × 8 Matrix Module Instructions for use with DAQ6510

11

Row daisy-chain connections

Row daisy-chain ribbon cable assembly

A convenient method to daisy-chain the two 7709s is to use a 25-conductor ribbon cable assembly with IDC

ribbon cable connectors attached to it. For the DAQ6510, a two-connector ribbon cable assembly will

daisy-chain two matrix modules.

To build a row of daisy-chain cable:

1. Start with an appropriate length of 25-conductor IDC ribbon cable. A 3½” length of cable is needed, as

shown in the following figure.

Figure 9: Row daisy-chain ribbon cable assembly

2. Route the cable over the back side of the connector and install the strain relief for the connector. Make sure

the cable is firmly clamped to the connector body. The following figure shows how the cable is routed

through the strain reliefs of the connectors.

Figure 10: Daisy-chain ribbon cable routing side view

The following figure shows the row of daisy-chain ribbon cables connected to the 25-pin D-shell connectors of

the 7709s. Matrix terminal identification for the 25-conductor ribbon cable is provided in the following table.

Figure 11: Connecting row daisy-chain cables

077147500 / June 2018

Page 12

Model 7709 6 × 8 Matrix Module Instructions for use with DAQ6510

12

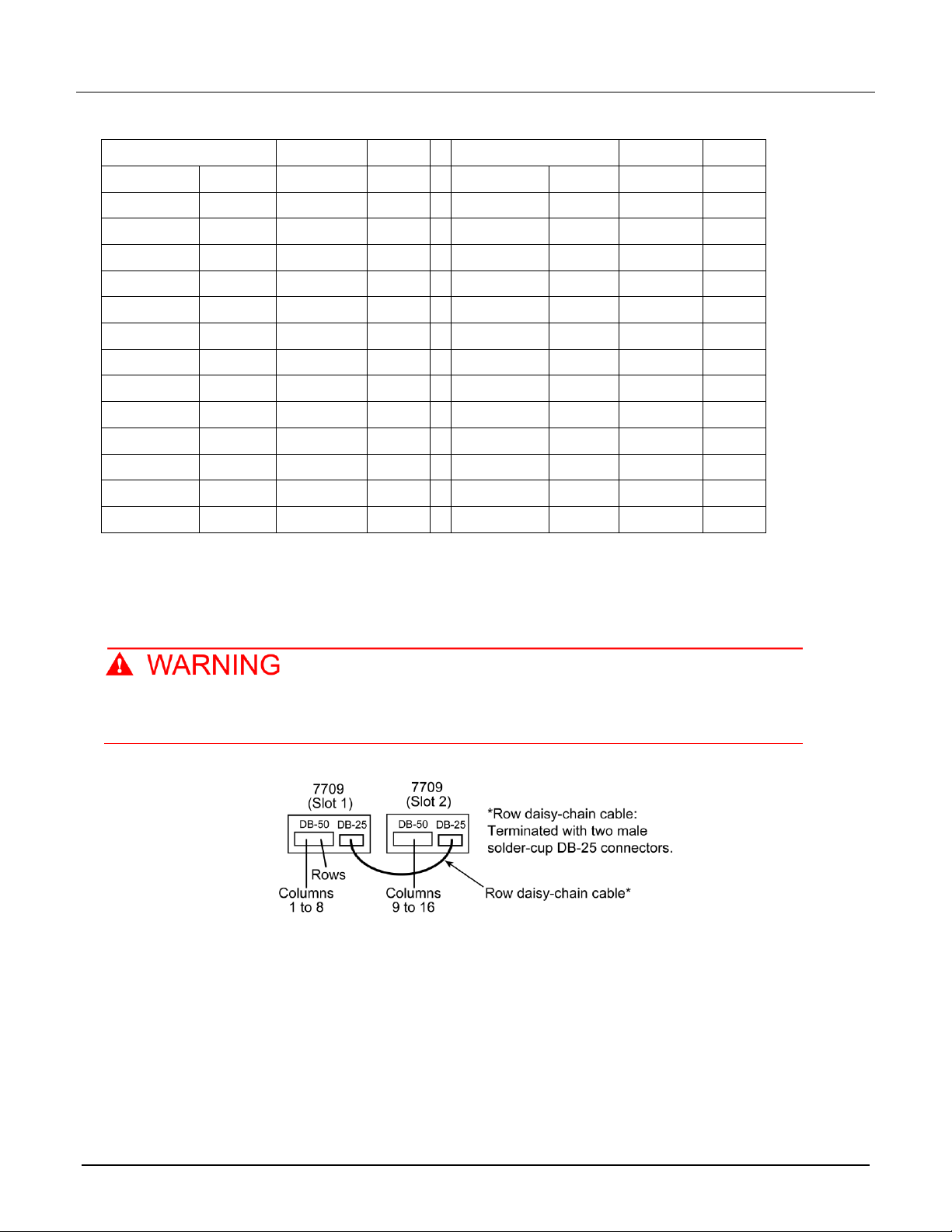

Ribbon Cable*

Matrix

DB-25

Ribbon Cable*

Matrix

DB-25

Conductor

Color

Terminal

Pin #

Conductor

Color

Terminal

Pin #

1

Brown

Row 1 Hi

1

14

Yellow

——

——

2

Red

Row 1 Lo

14

15

Green

Row 6 Hi

8 3 Orange

Row 2 Hi

2

16

Blue

Row 6 Lo

21 4 Yellow

Row 2 Lo

15

17

Violet

——

——

5

Green

Row 3 Hi

3

18

Gray

——

——

6

Blue

Row 3 Lo

16

19

White

——

——

7

Violet

——

——

20

Black

——

——

8

Gray

——

——

21

Brown

——

——

9

White

Row 4 Hi

5

22

Red

——

——

10

Black

Row 4 Lo

18

23

Orange

——

——

11

Brown

Row 5 Hi

6

24

Yellow

——

——

12

Red

Row 5 Lo

19

25

Green

——

——

13

Orange

——

——

*25-conductor IDC ribbon cable is available from Keithley Instruments, part number15025.

Row daisy-chaining using solder cup connectors

The following figure shows how to daisy-chain rows using solder cup connectors.

All solder cup wiring must be rated for the maximum voltage in the system. For example, if

1000 V is applied to the front terminals of the DMM, all matrix module wiring must be rated for

1000 V.

Figure 12: Row daisy-chaining using solder cup connectors

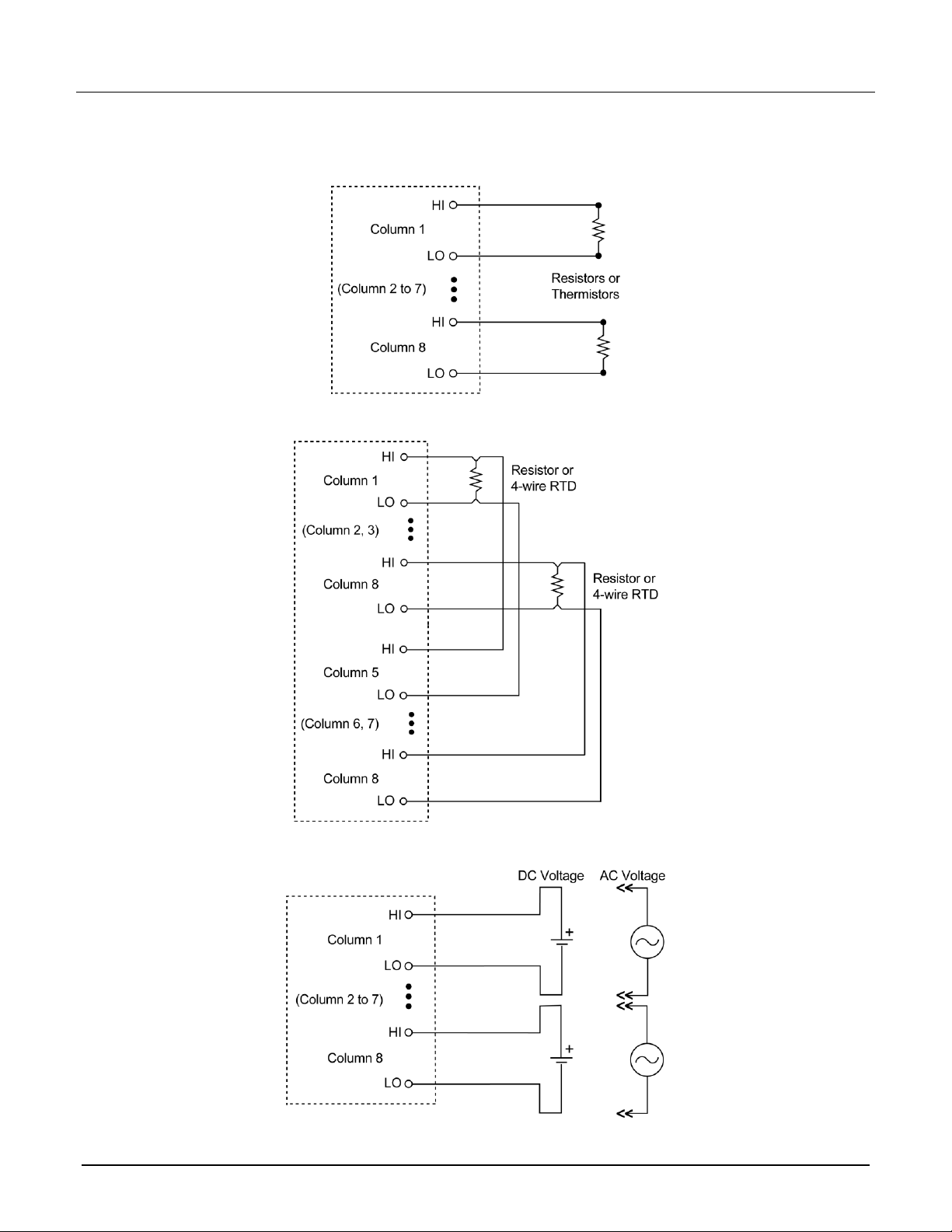

Typical connections

The following examples show typical wiring connections for the following types of measurements:

▪ Two-wire resistance and thermistor

▪ Four-wire resistance and RTD

▪ DC or AC voltage

077147500 / June 2018

Page 13

Model 7709 6 × 8 Matrix Module Instructions for use with DAQ6510

13

Figure 13: Two-wire resistor or thermistor connections

Figure 14: Four-wire resistance or RTD connections

077147500 / June 2018

Figure 15: AC or DC voltage connections

Page 14

Model 7709 6 × 8 Matrix Module Instructions for use with DAQ6510

14

Column/Row

Color

Description

Col 1

H

L

Col 2

H

L

Col 3

H

L

Col 4

H

L

Col 5

H

L

Col 6

H

L

Col 7

H

L

Col 8

H

L

Row 1

H

L

Row 2

H

L

Row 3

H

L

Row 4

H

L

Row 5

H

L

Row 6

H

L

Connection log

You can use the following table to record connection information and channel descriptions as needed.

077147500 / June 2018

Page 15

Model 7709 6 × 8 Matrix Module Instructions for use with DAQ6510

15

Operation

The following summarizes basic operation and provides operating information specific to the 7709.

Channel operation

Channel operation is used to connect matrix columns to the DAQ6510. With a 2-wire function selected,

channels 1 to 8 can be closed. When one of these channels is closed, channel 50 automatically closes to

connect row 1 to the DAQ6510. The following figure shows channel 3 closed to connect column 3 to the

DAQ6510.

With a 2-wire function selected, channels 9 through 48 cannot be closed using normal channel

operation.

With a 4-wire function selected, channels 1 to 4 can be closed. When one of these channels is closed, its

paired channel also closes, and the backplane relays for sense and input (channels 49 and 50) also close.

For a 4-wire function, channels are paired as follows:

▪ CH1 and CH13

▪ CH2 and CH14

▪ CH3 and CH15

▪ CH4 and CH16

The following figure shows channel 3 closed to connect the DUT to the DAQ6510 Input and Sense.

Figure 16: Four-wire DUT measurements

With a 4-wire function selected, channels 5 to 12 and channels 17 to 48 cannot be closed using

normal channel operation.

Additional information on controlling channels is available in the Model DAQ6510 Data Acquisition and

Multimeter System Reference Manual.

077147500 / June 2018

Page 16

Model 7709 6 × 8 Matrix Module Instructions for use with DAQ6510

16

Rows 1 and 2

Normal DAQ6510 operation is used to close rows 1 and 2 channels to connect a DUT to the DMM. With a

2-wire function selected, such as DC voltage, channels 1 to 8 can be closed. When one of these channels is

closed, channel 50 automatically closes to connect row 1 to the DMM Input. The following figure shows a DUT

connected to column 3 of the matrix. Closing channel 3 connects the DUT to the DMM.

Figure 17: Two-wire DUT measurements

With a 4-wire function selected, such as 4-wire resistance, channels 1 to 4 can be closed. These four channels

are paired to channels 13 to 16 (channel 1 paired to channel 13, channel 2 paired to channel 14, and so on).

When one of these channels is closed, its paired channel, and channels 49 and 50 also close to connect the

DUT to the DMM. As shown in the following figure, closing channel 3 also closes channels 15, 49, and 50 to

connect the DUT to the DMM.

Figure 18: Four-wire DUT measurements

077147500 / June 2018

Page 17

Model 7709 6 × 8 Matrix Module Instructions for use with DAQ6510

17

Rows 3 to 6

As shown in figure 1, channels 17 to 48 are the channels for rows 3 to 6. These channels can only be closed

using multiple channel operation (SCPI :ROUTe:MULTiple:CLOSe or TSP channel.multiple.close).

When you close multiple channels, only the specified channels close. Other channels are not affected. Using

normal channel operation, the channels for rows 3 to 6 cannot be closed.

Careless multiple channel operation could create an electric shock hazard that could result in

severe injury or death. Improper operation can also cause damage to the switching modules

and external circuitry. Operating channels independently should be restricted to experienced

test engineers who recognize the dangers associated with multiple independent channel

closures. Do not attempt to perform this procedure unless you are qualified, as described by

the types of product users in the Safety precautions (on page 19). Do not perform these

procedures unless qualified to do so. Failure to recognize and observe normal safety

precautions could result in personal injury or death.

When closing multiple channels, it is possible to connect incompatible test equipment and

DUTs causing high currents to flow. This can cause serious damage to test equipment and

DUTs.

For more information, refer to "Multiple channel operation" in the Model DAQ6510 Data Acquisition and

Multimeter System Reference Manual.

Rows 3 to 6 are used to connect one or more external sources to the test system. An external source is

typically used to power a DUT. To prevent overloading of the external source, each DUT can be powered

separately.

As shown in the following figure, DUT 1 is tested by closing channel 3 and channel 17. The external source is

connected to row 3 and the power cables for the two DUTs are connected to columns 1 and 2.

077147500 / June 2018

Page 18

Model 7709 6 × 8 Matrix Module Instructions for use with DAQ6510

18

To test DUT 2, use the following sequence:

1. Open multiple channel 17 to remove power from DUT 1.

2. Close channel 4 to connect DUT 2 to the DMM (channel 3 opens automatically).

3. Close multiple channel 18 to apply power to DUT 2.

Figure 19: Adding external source to the test system

Current measurements

This switching module does not support current measurements. If the instrument has the TERMINALS switch

set to REAR and you are working with the slot that contains this switching module, the AC, DC, and digitize

current functions are not available. You can measure current using the front panel or using another slot that

contains a switching module that supports the AC, DC, and digitize current measurements.

If you use remote commands to attempt to measure current when configuring a channel, an error is returned.

Factory service

To return the switching module to Keithley Instruments for repair:

▪ Call the Repair Department at 1-800-833-9200 or send an email to RMAREQUEST@tektronix.com for a

Return Material Authorization (RMA) number.

▪ Carefully pack the instrument in the original packing carton.

▪ Write ATTENTION REPAIR DEPARTMENT and the RMA number on the shipping label.

077147500 / June 2018

Page 19

19

Safety precautions

The following safety precautions should be observed before using this product and any associated instrumentation. Although

some instruments and accessories would normally be used with nonhazardous voltages, there are situations where hazardous

conditions may be present.

This product is intended for use by personnel who recognize shock hazards and are familiar with the safety precautions required

to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using the

product. Refer to the user documentation for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product warranty may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the

equipment is operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use of the

instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line

voltage or replacing consumable materials. Maintenance procedures are described in the user documentation. The procedures

explicitly state if the operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel are trained to work on live circuits, perform safe installations, and repair products. Only properly trained

service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that are measurement, control, and data I/O connections, with low

transient overvoltages, and must not be directly connected to mains voltage or to voltage sources with high transient

overvoltages. Measurement Category II (as referenced in IEC 60664) connections require protection for high transient

overvoltages often associated with local AC mains connections. Certain Keithley measuring instruments may be connected to

mains. These instruments will be marked as category II or higher.

Unless explicitly allowed in the specifications, operating manual, and instrument labels, do not connect any instrument to mains.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test

fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than

30 V RMS, 42.4 V peak, or 60 VDC are present. A good safety practice is to expect that hazardous voltage is present in any

unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators

are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential

human contact. Product operators in these circumstances must be trained to protect themselves from the risk of electric shock. If

the circuit is capable of operating at or above 1000 V, no conductive part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance-limited

sources. NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective

devices to limit fault current and voltage to the card.

Before operating an instrument, ensure that the line cord is connected to a properly-grounded power receptacle. Inspect the

connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input

power disconnect device must be provided in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under

test. ALWAYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting

cables or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth)

ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the

voltage being measured.

077147500 / June 2018

Page 20

20

For safety, instruments and accessories must be used in accordance with the operating instructions. If the instruments or

accessories are used in a manner not specified in the operating instructions, the protection provided by the equipment may be

impaired.

Do not exceed the maximum signal levels of the instruments and accessories. Maximum signal levels are defined in the

specifications and operating information and shown on the instrument panels, test fixture panels, and switching cards.

When fuses are used in a product, replace with the same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as protective earth (safety ground)

connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use

of a lid interlock.

If a screw is present, connect it to protective earth (safety ground) using the wire recommended in the user documentation.

The symbol on an instrument means caution, risk of hazard. The user must refer to the operating instructions located in the

user documentation in all cases where the symbol is marked on the instrument.

The symbol on an instrument means warning, risk of electric shock. Use standard safety precautions to avoid personal

contact with these voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to prevent burns.

The symbol indicates a connection terminal to the equipment frame.

If this symbol is on a product, it indicates that mercury is present in the display lamp. Please note that the lamp must be

properly disposed of according to federal, state, and local laws.

The WARNING heading in the user documentation explains hazards that might result in personal injury or death. Always read

the associated information very carefully before performing the indicated procedure.

The CAUTION heading in the user documentation explains hazards that could damage the instrument. Such damage may

invalidate the warranty.

The CAUTION heading with the symbol in the user documentation explains hazards that could result in moderate or minor

injury or damage the instrument. Always read the associated information very carefully before performing the indicated

procedure. Damage to the instrument may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits — including the power

transformer, test leads, and input jacks — must be purchased from Keithley. Standard fuses with applicable national safety

approvals may be used if the rating and type are the same. The detachable mains power cord provided with the instrument may

only be replaced with a similarly rated power cord. Other components that are not safety-related may be purchased from other

suppliers as long as they are equivalent to the original component (note that selected parts should be purchased only through

Keithley to maintain accuracy and functionality of the product). If you are unsure about the applicability of a replacement

component, call a Keithley office for information.

Unless otherwise noted in product-specific literature, Keithley instruments are designed to operate indoors only, in the following

environment: Altitude at or below 2,000 m (6,562 ft); temperature 0 °C to 50 °C (32 °F to 122 °F); and pollution degree 1 or 2.

To clean an instrument, use a cloth dampened with deionized water or mild, water-based cleaner. Clean the exterior of the

instrument only. Do not apply cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that

consist of a circuit board with no case or chassis (e.g., a data acquisition board for installation into a computer) should never

require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board

should be returned to the factory for proper cleaning/servicing.

Safety precaution revision as of June 2017.

077147500 / June 2018

Loading...

Loading...