Page 1

Service Manual

TDS 684A, TDS 744A, & TDS 784A

Digitizing Oscilloscope

070-8992-03

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to the Safety Summary prior to

performing service.

Please check for change information

at the rear of this manual.

Fourth Edition: January 1995

Page 2

Copyright T ektronix, Inc. 1994, 1995. All rights reserved.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

WARRANTY

T ektronix warrants that this product will be free from defects in materials and workmanship for a period of three (3) years

from the date of shipment. If any such product proves defective during this warranty period, T ektronix, at its option, either

will repair the defective product without charge for parts and labor, or will provide a replacement in exchange for the

defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by T ektronix, with shipping charges prepaid.

T ektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

T ektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than T ektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; or c) to service a product that has been

modified or integrated with other products when the effect of such modification or integration increases the time or

difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THIS PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESSED OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUST OMER FOR BREACH OF THIS WARRANTY. TEKTRONIX

AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

Page 5

Table of Contents

Specifications

General Safety Summary ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Safety Summary xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface xv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction xix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Description 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

User Interface 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signal Acquisition System 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Horizontal System 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trigger System 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Acquisition Control 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

On-Board User Assistance 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measurement Assistance 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Nominal Traits 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranted Characteristics 1–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Typical Characteristics 1–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operational Information

Installation 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supplying Operating Power 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Environment 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Applying and Interrupting Power 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repackaging Instructions 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installed Options 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Instructions 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Screen Layout 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Procedures 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Theory of Operation

Logic Conventions 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Overview 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification

Performance Verification Procedures 4–1. . . . . . . . . . . . . . . . . . . . . . . . . .

Conventions 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brief Procedures 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self Tests 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functional T ests 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TDS 684A, TDS 744A, & TDS 784A Service Manual

i

Page 6

Table of Contents

Adjustment Procedures

Maintenance

Performance Tests 4–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Prerequisites 4–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required 4–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TDS 684A T est Record 4–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TDS 7XXA T est Record 4–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signal Acquisition System Checks 4–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Time Base System Checks 4–42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trigger System Checks 4–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output Signal Checks 4–57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Option 05 Video Trigger Checks 4–65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Requirements for Performance 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Usage 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment Instructions 5–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe Adjustment for the P6139A Probe 5–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Assembly Adjustment 5–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options Electrical Parts List Diagrams Mechanical Parts LIst

Related Maintenance Procedures 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Cleaning 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Installation Procedures 6–9. . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation — Please Read 6–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Access Procedure 6–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedures for External Modules 6–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedures for Outer-Chassis Modules 6–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedures for Inner-Chassis Modules 6–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly for Cleaning 6–53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 6–57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostics 6–57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Firmware Updates 6–58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

TDS 684A, TDS 744A, & TDS 784A Service Manual

Page 7

List of Figures

Table of Contents

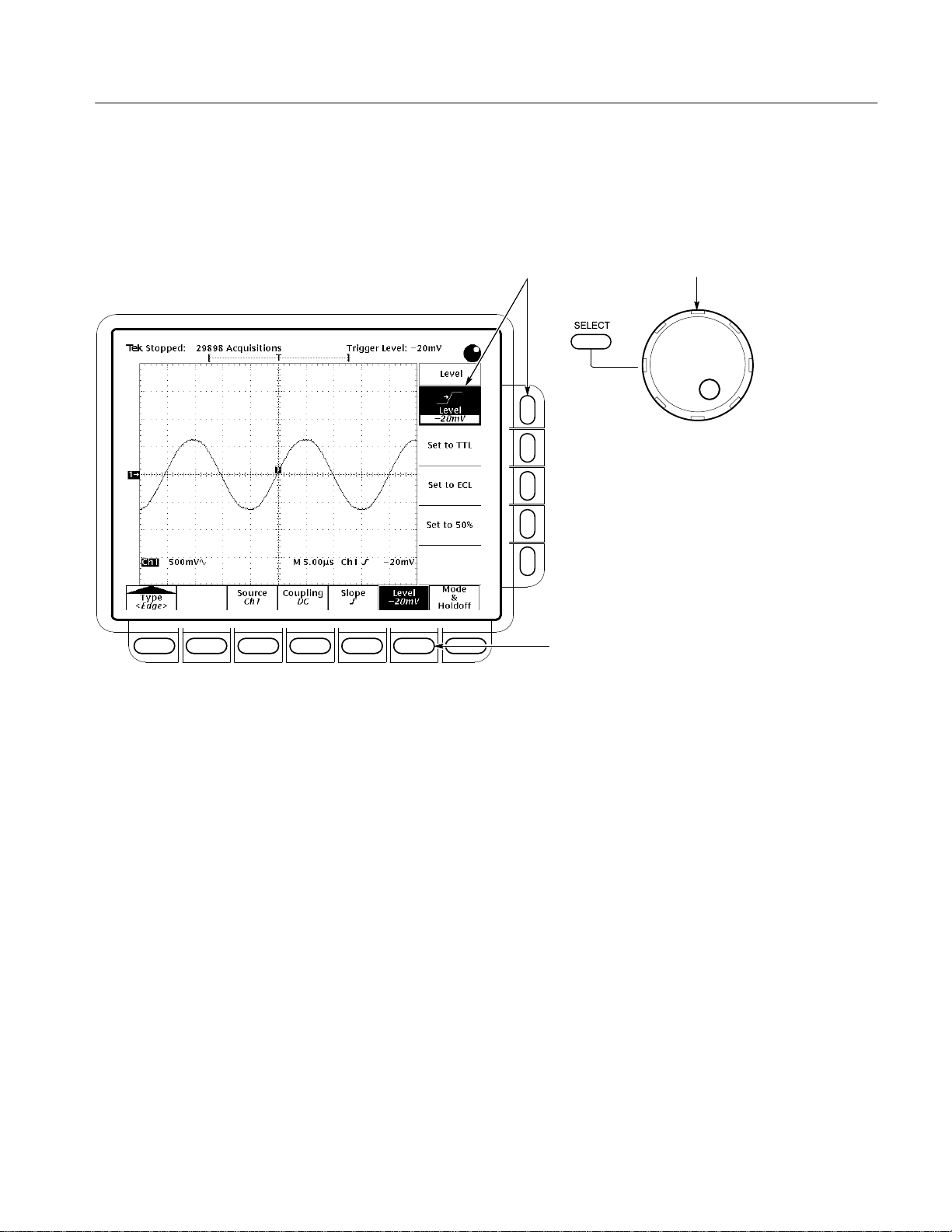

Figure 2–1: Map of Display Functions 2–8. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–1: Map of Display Functions 4–3. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–2: Verifying Adjustments and Signal-Path Compensation 4–6.

Figure 4–3: Universal Test Hookup for Functional Tests 4–8. . . . . . . . . .

Figure 4–4: Measurement of DC Offset Accuracy at Zero Setting 4–29. . .

Figure 4–5: Initial Test Hookup 4–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–6: Measurement of DC Accuracy at Maximum Offset

and Position 4–32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–7: Initial Test Hookup 4–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–8: Measurement of Analog Bandwidth 4–36. . . . . . . . . . . . . . . . .

Figure 4–9: Initial Test Hookup 4–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–10: Measurement of Channel Delay – TDS 684A Shown 4–40. .

Figure 4–11: Initial Test Hookup 4–42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–12: Measurement of Accuracy

— Long-Term and Delay Time 4–44. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–13: Initial Test Hookup 4–45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–14: Measurement of Time Accuracy for Pulse and

Glitch Triggering 4–47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–15: Initial Test Hookup 4–48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–16: Measurement of Trigger-Level Accuracy 4–50. . . . . . . . . . . .

Figure 4–17: Initial Test Hookup 4–53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–18: Measurement of Trigger Sensitivity

— 50 MHz Results Shown on a TDS 684A Screen 4–54. . . . . . . . . . . .

Figure 4–19: Initial Test Hookup 4–57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–20: Measurement of Main Trigger Out Limits 4–59. . . . . . . . . . .

Figure 4–21: Initial Test Hookup 4–61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–22: Measurement of Probe Compensator Frequency 4–62. . . . .

Figure 4–23: Subsequent Test Hookup 4–63. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–24: Measurement of Probe Compensator Amplitude 4–64. . . . .

Figure 4–25: Jitter Test Hookup 4–66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–26: Jitter Test Displayed Waveform – TDS 684A Shown 4–67. .

Figure 4–27: Jitter Test When Completed – TDS 684A Shown 4–68. . . . .

Figure 4–28: Triggered Signal Range Test – 300 mV 4–70. . . . . . . . . . . . . .

Figure 4–29: Triggered Signal Range Test – 75 mV 4–71. . . . . . . . . . . . . . .

Figure 4–30: 60 Hz Rejection Test Hookup 4–72. . . . . . . . . . . . . . . . . . . . . .

TDS 684A, TDS 744A, & TDS 784A Service Manual

iii

Page 8

Table of Contents

Figure 4–31: 60 Hz Rejection Test Setup Signal 4–72. . . . . . . . . . . . . . . . . .

Figure 4–32: Subsequent 60 Hz Rejection Test Hookup 4–73. . . . . . . . . . .

Figure 4–33: 60 Hz Rejection Test Result – TDS 684A Shown 4–74. . . . . .

Figure 4–34: Line Count Accuracy Test Hookup 4–75. . . . . . . . . . . . . . . . .

Figure 4–35: Line Count Accuracy Test Setup Waveform

– TDS 684A Shown 4–76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–36: Line Count Accuracy Correct Result Waveform 4–77. . . . . .

Figure 4–37: PG502 Setup for Sync Duty Cycle Test 4–79. . . . . . . . . . . . . .

Figure 4–38: Sync Duty Cycle Test: One-Div Neg Pulse Waveform 4–80. .

Figure 4–39: Sync Duty Cycle Test: Critically Adjusted Pulse 4–81. . . . . .

Figure 5–1: Accessing the Protection Switch 5–9. . . . . . . . . . . . . . . . . . . .

Figure 5–2: Hookup for Probe Compensation 5–11. . . . . . . . . . . . . . . . . . .

Figure 5–3: Performing Probe Compensation 5–12. . . . . . . . . . . . . . . . . . .

Figure 5–4: Proper and Improper Probe Compensation 5–12. . . . . . . . . . .

Figure 5–5: Exposing the Inner Probe Tip 5–13. . . . . . . . . . . . . . . . . . . . . .

Figure 5–6: Initial Test Hookup 5–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–7: Exposing the Probe Body 5–16. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–8: Initial Test Hookup 5–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–9: Locations of P6139A Probe Adjustments 5–19. . . . . . . . . . . . .

Figure 5–10: Adjustments versus Front-Corner Response 5–20. . . . . . . . .

Figure 5–11: Five and Ten Percent Luminance Patches 5–22. . . . . . . . . . .

Figure 6–1: External Modules 6–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–2: Outer-Chassis Modules 6–13. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–3: Inner-Chassis Modules 6–14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–4: Knob Removal 6–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–5: Line Fuse and Line Cord Removal 6–18. . . . . . . . . . . . . . . . . .

Figure 6–6: Rear Cover and Cabinet Removal 6–21. . . . . . . . . . . . . . . . . .

Figure 6–7: Front Cover, Trim Ring, Menu Buttons, and

Attenuator Panel Removal (Front Cover not Shown) 6–22. . . . . . . . .

Figure 6–8: A12 Front-Panel Assembly Removal 6–24. . . . . . . . . . . . . . . . .

Figure 6–9: Disassembly of Front-Panel Assembly 6–25. . . . . . . . . . . . . . .

Figure 6–10: Cabinet Modules Removal 6–28. . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–11: A14 D1 Bus and Analog-Power and Digital-Power

Cables Removal 6–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–12: Remove Circuit Board Assembly From Oscilloscope 6–31. .

Figure 6–13: Remove Circuit Board From Assembly 6–32. . . . . . . . . . . . .

Figure 6–14: Circuit Board Installed 6–34. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–15: Circuit Board Removal 6–35. . . . . . . . . . . . . . . . . . . . . . . . . .

iv

TDS 684A, TDS 744A, & TDS 784A Service Manual

Page 9

Table of Contents

Figure 6–16: A11 Processor/Display Removal 6–37. . . . . . . . . . . . . . . . . . .

Figure 6–17: Board Bracket Removal 6–38. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–18: A10 Acquisition Board Removal 6–41. . . . . . . . . . . . . . . . . . .

Figure 6–19: Floppy Disk Removal 6–43. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–20: Rear Chassis Removal 6–45. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–21: A16 Low Voltage Power Supply Removal 6–47. . . . . . . . . . .

Figure 6–22: Display Assembly Removal 6–49. . . . . . . . . . . . . . . . . . . . . . .

Figure 6–23: Display Driver Board Removal 6–50. . . . . . . . . . . . . . . . . . . .

Figure 6–24: Front Subpanel Removal 6–52. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–25: Accessing the Protection Switch 6–58. . . . . . . . . . . . . . . . . . .

Figure 6–26: Primary Troubleshooting Procedure 6–59. . . . . . . . . . . . . . .

Figure 6–27: Module Isolation Troubleshooting Procedure 6–61. . . . . . . .

Figure 6–28: A16 Low Voltage Power Supply Module Isolation

Troubleshooting Procedure 6–62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–29: Power Supply Voltage Measurement Locations 6–63. . . . . . .

Figure 6–30: Color Display Troubleshooting Procedure 6–64. . . . . . . . . . .

Figure 6–31: Horizontal and Vertical Sync Signals – Color Display 6–65.

Figure 6–32: A Video Signal with White, Black, and

Blanking Levels – Color Display 6–65. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–33: Processor/Acquisition Troubleshooting Procedure 6–66. . . .

Figure 6–34: Processor/Front Panel Troubleshooting Procedure 6–67. . . .

Figure 6–35: Attenuator/Acquisition Troubleshooting Procedure 6–68. . .

Figure 6–36: A11 DRAM Processor/Display Module

(View of Right Side) 6–70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–37: A11 DRAM Processor/Display Module

(View of Upper Left Corner) 6–71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–38: A11 DRAM Processor/Display Module

(View of Lower Left Corner) 6–71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–39: A10 Acquisition Module (View of Lower Right Corner) 6–72

Figure 9–1: Interconnections 9–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9–2: Block Diagram 9–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10–1: External Modules 10–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10–2: Outer-Chassis Modules 10–9. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10–3: Inner-Chassis Modules 10–10. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10–4: Cables, Bottom View 10–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10–5: Cables, Top View 10–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10–6: Floppy Disk 10–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10–7: Accessories 10–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TDS 684A, TDS 744A, & TDS 784A Service Manual

v

Page 10

Table of Contents

vi

TDS 684A, TDS 744A, & TDS 784A Service Manual

Page 11

List of Tables

Table of Contents

Table 1–1: Key Features of the TDS 684A and 7XXA Oscilloscopes 1–1

Table 1–2: Record Length vs. Divisions per Record, Samples per

Division and Sec/Div Sequence 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–3: Nominal Traits — Signal Acquisition System 1–9. . . . . . . . . .

Table 1–4: Nominal Traits — Time Base System 1–10. . . . . . . . . . . . . . . .

Table 1–5: Nominal Traits — Triggering System 1–10. . . . . . . . . . . . . . . .

Table 1–6: Nominal Traits — Display System 1–11. . . . . . . . . . . . . . . . . . .

Table 1–7: Nominal Traits — GPIB Interface, Output Ports, and

Power Fuse 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–8: Nominal Traits — Data Handling and Reliability 1–12. . . . . .

Table 1–9: Nominal Traits — Mechanical 1–13. . . . . . . . . . . . . . . . . . . . . .

Table 1–10: Warranted Characteristics

— Signal Acquisition System 1–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–11: Warranted Characteristics — Time Base System 1–17. . . . . .

Table 1–12: Warranted Characteristics — Triggering System 1–18. . . . .

Table 1–13: Warranted Characteristics — Output Ports, Probe

Compensator, and Power Requirements 1–18. . . . . . . . . . . . . . . . . . . .

Table 1–14: Warranted Characteristics — Environmental 1–19. . . . . . . .

Table 1–15: Typical Characteristics — Signal Acquisition System 1–21. .

Table 1–16: Typical Characteristics — Triggering System 1–23. . . . . . . .

Table 2–1: Power-Cord Conductor Identification 2–2. . . . . . . . . . . . . . . .

Table 2–2: Power Cord Identification 2–2. . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–3: Effects of Corrupted Data 2–4. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–1: Test Equipment 4–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–2: DC Offset Accuracy (Zero Setting) 4–28. . . . . . . . . . . . . . . . . .

Table 4–3: DC Accuracy 4–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–4: Analog Bandwidth 4–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5–1: Calibration Tests 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5–2: Adjustments Required for Module Replaced 5–4. . . . . . . . . .

Table 5–3: Adjustments and Dependencies 5–4. . . . . . . . . . . . . . . . . . . . .

Table 5–4: Test Equipment, Fixtures, and Supplies 5–5. . . . . . . . . . . . . .

Table 5–5: GPIB Board Configuration 5–7. . . . . . . . . . . . . . . . . . . . . . . . .

Table 6–1: Relative Susceptibility to Static-Discharge Damage 6–3. . . . .

TDS 684A, TDS 744A, & TDS 784A Service Manual

vii

Page 12

Table of Contents

Table 6–2: External Inspection Check List 6–5. . . . . . . . . . . . . . . . . . . . .

Table 6–3: Internal Inspection Check List 6–6. . . . . . . . . . . . . . . . . . . . . .

Table 6–4: Tools Required for Module Removal 6–11. . . . . . . . . . . . . . . . .

Table 6–5: Normal Supply Voltages (Measured on J26 and J27 on

the A11 DRAM Processor/Display Module) 6–63. . . . . . . . . . . . . . . . . .

Table 6–6: No-Load Supply Voltages (Measured on J5 and J6 on

the A17 Main LV Power Supply Module) 6–63. . . . . . . . . . . . . . . . . . . .

Table 7–1: Options 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 7–2: Standard Accessories 7–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 7–3: Optional Accessories 7–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 7–4: Accessory Software 7–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

TDS 684A, TDS 744A, & TDS 784A Service Manual

Page 13

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it.

Only qualified personnel should perform service procedures.

Injury Precautions

Use Proper Power Cord

Avoid Electric Overload

Ground the Product

Do Not Operate Without

Covers

Use Proper Fuse

Do Not Operate in

Wet/Damp Conditions

Do Not Operate in

Explosive Atmosphere

To avoid fire hazard, use only the power cord specified for this product.

To avoid electric shock or fire hazard, do not apply a voltage to a terminal that is

outside the range specified for that terminal.

This product is grounded through the grounding conductor of the power cord. To

avoid electric shock, the grounding conductor must be connected to earth

ground. Before making connections to the input or output terminals of the

product, ensure that the product is properly grounded.

To avoid electric shock or fire hazard, do not operate this product with covers or

panels removed.

To avoid fire hazard, use only the fuse type and rating specified for this product.

To avoid electric shock, do not operate this product in wet or damp conditions.

To avoid injury or fire hazard, do not operate this product in an explosive

atmosphere.

Keep Probe Surface Clean

To avoid electric shock and erroneous readings, keep probe surface clean.

Product Damage Precautions

Use Proper Power Source

TDS 684A, TDS 744A, & TDS 784A Service Manual

Do not operate this product from a power source that applies more than the

voltage specified.

ix

Page 14

General Safety Summary

Use Proper Voltage

Setting

Provide Proper Ventilation

Do Not Operate With

Suspected Failures

Do Not Immerse in Liquids

Before applying power, ensure that the line selector is in the proper position for

the power source being used.

To prevent product overheating, provide proper ventilation.

If you suspect there is damage to this product, have it inspected by qualified

service personnel.

Clean the probe using only a damp cloth. Refer to cleaning instructions.

Safety Terms and Symbols

Terms in This Manual

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

Terms on the Product

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

x

TDS 684A, TDS 744A, & TDS 784A Service Manual

Page 15

General Safety Summary

Symbols on the Product

The following symbols may appear on the product:

DANGER

High Voltage

Certifications and Compliances

CSA Certified Power

Cords

CSA Certification includes the products and power cords appropriate for use in

the North America power network. All other power cords supplied are approved

for the country of use.

Protective Ground

(Earth) T erminal

ATTENTION

Refer to

Manual

Double

Insulated

TDS 684A, TDS 744A, & TDS 784A Service Manual

xi

Page 16

General Safety Summary

xii

TDS 684A, TDS 744A, & TDS 784A Service Manual

Page 17

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone

Disconnect Power

Use Caution When

Servicing the CRT

Use Care When Servicing

With Power On

Do not perform internal service or adjustments of this product unless another

person capable of rendering first aid and resuscitation is present.

To avoid electric shock, disconnect the main power by means of the power cord

or, if provided, the power switch.

To avoid electric shock or injury, use extreme caution when handling the CRT.

Only qualified personnel familiar with CRT servicing procedures and precautions

should remove or install the CRT.

CRTs retain hazardous voltages for long periods of time after power is turned off.

Before attempting any servicing, discharge the CRT by shorting the anode to

chassis ground. When discharging the CRT, connect the discharge path to ground

and then the anode. Rough handling may cause the CRT to implode. Do not nick

or scratch the glass or subject it to undue pressure when removing or installing it.

When handling the CRT, wear safety goggles and heavy gloves for protection.

Dangerous voltages or currents may exist in this product. Disconnect power,

remove battery (if applicable), and disconnect test leads before removing

protective panels, soldering, or replacing components.

To avoid electric shock, do not touch exposed connections.

X-Radiation

TDS 684A, TDS 744A, & TDS 784A Service Manual

To avoid x-radiation exposure, do not modify or otherwise alter the high-voltage

circuitry or the CRT enclosure. X-ray emissions generated within this product

have been sufficiently shielded.

xiii

Page 18

Service Safety Summary

xiv

TDS 684A, TDS 744A, & TDS 784A Service Manual

Page 19

Preface

Manual Structure

This preface contains information needed to properly use this manual to service

the TDS 684A and 7XXA Digitizing Oscilloscopes, as well as general information critical to safe and effective servicing of this oscilloscope.

This manual is divided into sections, such as Specification and Theory of

Operation. Further, it is divided into subsections, such as Product Description

and Removal and Installation Procedures.

Sections containing procedures also contain introductions to those procedures.

Be sure to read these introductions because they provide information needed to

do the service correctly and efficiently. The following is a brief description of

each manual section.

H Specification contains a product description of the TDS 684A and

7XXA Digitizing Oscilloscopes and tables of the characteristics and

descriptions that apply to it.

H Operating Information includes general information and operating instruc-

tions at the level needed to safely power on and service this oscilloscope. A

statement of the service strategy that this manual supports, and instructions

for shipment of the Digitizing Oscilloscopes are found in this section.

H Theory of Operation contains circuit descriptions that support general service

and fault isolation down to the module level.

H Performance Verification contains a collection of procedures for confirming

that these Digitizing Oscilloscopes function properly and meet warranted

limits.

H Adjustment Procedures contains a collection of procedures for adjusting

these Digitizing Oscilloscopes to meet warranted limits.

H Maintenance contains information and procedures for doing preventive and

corrective maintenance of these Digitizing Oscilloscopes. Instructions for

cleaning, for module removal and installation, and for fault isolation to a

module are found here.

H Options contains information on servicing any of the factory-installed

options that may be present in your oscilloscope.

H Electrical Parts List contains a statement referring you to Mechanical

Replaceable Parts, where both electrical and mechanical modules are listed.

TDS 684A, TDS 744A, & TDS 784A Service Manual

xv

Page 20

Preface

Manual Conventions

H Diagrams contains a block diagram and an interconnection diagram useful

for isolating failed modules.

H Mechanical Parts List includes a table of all replaceable modules, their

descriptions, and their Tektronix part numbers.

This manual uses certain conventions which you should become familiar with

before doing service.

Modules

Safety

Symbols

Throughout this manual, any replaceable component, assembly, or part of these

Digitizing Oscilloscopes is referred to generically as a module. In general, a

module is an assembly, like a circuit board, rather than a component, like a

resistor or an integrated circuit. Sometimes a single component is a module; for

example, each chassis part of the oscilloscope is a module.

Symbols and terms related to safety appear in the Safety Summary found at the

beginning of this manual.

Besides the symbols related to safety, this manual uses the following symbols:

STOP. The stop labels information which must be read in order to correctly do

service and to avoid incorrectly using or applying service procedures.

The clock icon labels procedure steps which require a pause to wait for

the oscilloscope to complete some operation before you can continue.

Various icons such as the example icon at the left are used in procedures

to help identify certain readouts and menu functions on screen.

Related Manuals

xvi

The TDS 684A and 7XXA Digitizing Oscilloscopes come with the following

manuals:

TDS 684A, TDS 744A, & 784A User Manual (Tektronix part number

070-8991-XX) contains a tutorial to quickly show you how to operate the

TDS 684A and 7XXA Digitizing Oscilloscopes and an in depth discussion of

how to more completely use their features. Applications are also discussed.

TDS 684A, TDS 744A, & TDS 784A Reference (Tektronix part number

070-8999-XX) contains a brief overview of oscilloscope operation.

TDS 684A, TDS 744A, & TDS 784A Service Manual

Page 21

Preface

TDS Family (400, 5XXA, 6XXA, and 7XXA) Programmer Manual (Tektronix part

number 070-8709-XX) contains information for programmed operation via the

GPIB interface. Included is the complete command set, setup information, and

programming examples.

TDS 684A, TDS 744A, & 784A Technical Reference (Tektronix part number

070-8990-XX) contains performance verification procedures and specifications.

TDS 684A, TDS 744A, & TDS 784A Service Manual

xvii

Page 22

Preface

xviii

TDS 684A, TDS 744A, & TDS 784A Service Manual

Page 23

Introduction

Service Strategy

STOP. Throughout this manual, any field-replaceable component, assembly, or

part of this oscilloscope is referred to generically as a module.

This manual contains all the information needed for periodic maintenance of the

TDS 684A and 7XXA Digitizing Oscilloscopes. (Examples of such information

are procedures for checking performance and for readjustment.) Further, it

contains all information for corrective maintenance down to the module level.

This means that the procedures, diagrams, and other troubleshooting aids help

isolate failures to a specific module, rather than to components of that module.

Once a failure is isolated, replace the module with a fresh unit obtained from the

factory.

All modules are listed in Mechanical Parts List. To isolate a failure to a module,

use the fault isolation procedures found in Section 6, Maintenance Information.

To remove and replace any failed module, follow the instructions in Removal

and Installation Procedures, also found in Section 6.

Service Offerings

Warranty Repair Service

Repair or Calibration

Service

Tektronix provides service to cover repair under warranty as well as other

services that may provide a cost-effective answer to your service needs.

Whether providing warranty repair service or any of the other services listed

below, Tektronix service technicians, trained on Tektronix products, are best

equipped to service your TDS 684A and 7XXA Digitizing Oscilloscopes.

Tektronix technicians are appraised of the latest information on improvements to

the product as well as the latest new options to the product.

Tektronix warrants this product for three years from date of purchase, excluding

probes for which the warranty is one year. (The warranty appears after the title

page and copyright page in this manual.) Tektronix technicians provide warranty

service at most Tektronix service locations worldwide. Your Tektronix product

catalog lists all service locations worldwide.

The following services may be purchased to tailor repair and/or calibration of

your TDS 684A and 7XXA Digitizing Oscilloscopes to fit your requirements.

TDS 684A, TDS 744A, & TDS 784A Service Manual

xix

Page 24

Introduction

Option 9C. When you order the TDS 684A and 7XXA Digitizing Oscilloscopes

with option 9C, each one is shipped with a Certificate of Calibration and Test

Data Report. This certificate provides traceability to the National Institute of

Standards and Technology (NIST). It certifies procedures used to calibrate the

oscilloscope comply with U. S. Military Standard 45662A.

At-Depot Service. Tektronix offers several standard-priced adjustment (calibration) and repair services:

H A single repair and/or adjustment.

H Calibrations using equipment and procedures that meet the traceability

standards specific to the local area.

H Annual maintenance agreements that provide for either calibration and repair

or calibration only of the oscilloscope.

Of these services, the annual maintenance agreement offers a particularly

cost-effective approach to service for many owners of the TDS 684A and

7XXA Digitizing Oscilloscopes. Such agreements can be purchased to span

several years.

Self Service

On-Site Service. The annual maintenance agreement can be purchased with

on-site service, with repair and calibration done at your facility. This service

reduces the time your oscilloscope is out of service when calibration or repair is

required.

Tektronix supports repair to the module level by providing Module Exchange

and Module Repair and Return.

Module Exchange. This service reduces down time for repair by allowing you to

exchange most modules for remanufactured ones. Tektronix ships you an

updated and tested exchange module from the Beaverton, Oregon service center,

typically within 24 hours. Each module comes with a 90-day service warranty.

Module Repair and Return. This service returns to you within 10 days the same

module that you shipped to Tektronix. The module shipped is repaired, tested,

and returned to you from the Beaverton, Oregon service center. It is not updated

to match current modules of the same type. Again, each module comes with a

90-day service warranty.

For More Information. Contact your local Tektronix service center or sales

engineer for more information on any of the repair or adjustment services just

described.

xx

TDS 684A, TDS 744A, & TDS 784A Service Manual

Page 25

Before You Begin

Introduction

This manual is for servicing the TDS 684A and 7XXA Digitizing Oscilloscopes.

To prevent injury to yourself or damage to the oscilloscope, do the following

tasks before you attempt service:

H Be sure you are a qualified service person.

H Read the Safety Summary found at the beginning of this manual.

H Read Service Strategy in this section and Supplying Operating Power in

section 2.

When using this manual for servicing, be sure to heed all warnings, cautions, and

notes.

TDS 684A, TDS 744A, & TDS 784A Service Manual

xxi

Page 26

Introduction

xxii

TDS 684A, TDS 744A, & TDS 784A Service Manual

Page 27

Page 28

Specifications

Product Description

This section begins with a general description of the traits of the TDS 684A and

7XXA Digitizing Oscilloscopes. Three sections follow, one for each of three

classes of traits: nominal traits, warranted characteristics, and typical character-

istics.

The TDS 684A and 7XXA Digitizing Oscilloscopes are portable, four-channel

instruments suitable for use in a variety of test and measurement applications and

systems. Table 1–1 lists key features.

T able 1–1: Key Features of the TDS 684A and 7XXA Oscilloscopes

Feature TDS 684A TDS 7XXA

Digitizing rate, maximum 5 GS/s on each channel

simultaneously

Analog bandwidth 1 GHz TDS 744A: 500 MHz

TDS 744A: 2 GS/s

TDS 784A: 4 GS/s

TDS 784A: 1 GHz

Channels Four, each with 8-bit resolution

Record lengths, maximum 15,000 samples 50,000 samples

(500,000 with option 1M)

Acquisition modes Sample, envelope, and

average

Trigger modes Include: edge, logic, and pulse.

Video trigger , with option 05, modes include:

NTSC, SECAM, PAL, HDTV, and FlexFormat.

Display Color for distinguishing among waveforms, measurements, and

associated text

Storage 1.44 Mbyte, 3.5 inch, DOS 3.3-or-later floppy disk.

NVRAM storage for saving waveforms, hardcopies, and setups

I/O Full GPIB programmability.

Hardcopy output using GPIB, RS-232, or Centronics ports

Sample, envelope, average,

high-resolution, and

peak-detect

TDS 684A, TDS 744A, & TDS 784A Service Manual

1–1

Page 29

Specifications

User Interface

Use a combination of front-panel buttons, knobs, and on-screen menus to control

the many functions of the oscilloscope. The front-panel controls are grouped

according to function: vertical, horizontal, trigger, and special. Set a function you

adjust often, such as vertical positioning or the time base setting, directly by its

own front-panel knob. Set a function you change less often, such as vertical

coupling or horizontal mode, indirectly using a selected menu.

Menus

Indicators

General Purpose Knob

GUI

Pressing one (sometimes two) front-panel button(s), such as vertical menu,

displays a main menu of related functions, such as coupling and bandwidth, at

the bottom of the screen. Pressing a main-menu button, such as coupling,

displays a side menu of settings for that function, such as AC, DC, or GND

(ground) coupling, at the right side of the screen. Pressing a side-menu button

selects a setting such as DC.

On-screen readouts help you keep track of the settings for various functions,

such as vertical and horizontal scale and trigger level. Some readouts use the

cursors or the automatic parameter extraction feature (called measure) to display

the results of measurements made or the status of the instrument.

Assign the general purpose knob to adjust a selected parameter function. More

quickly change parameters by toggling the SHIFT button. Use the same method

as for selecting a function, except the final side-menu selection assigns the

general purpose knob to adjust some function, such as the position of measurement cursors on screen, or the setting for a channel fine gain.

The user interface also makes use of a GUI, or Graphical User Interface, to make

setting functions and interpreting the display more intuitive. Some menus and

status are displayed using iconic representations of function settings, such as

those shown here for full, 250 MHz and 20 MHz bandwidth. Such icons allow

you to more readily determine status or the available settings.

Signal Acquisition System

The signal acquisition system provides four, full-featured vertical channels with

calibrated vertical scale factors from 1 mV to 10 V per division. All channels can

be acquired simultaneously.

Each of the full-featured channels can be displayed, vertically positioned, and

offset, can have their bandwidth limited (250 MHz or 20 MHz) and their vertical

coupling specified. Fine gain can also be adjusted.

1–2

TDS 684A, TDS 744A, & TDS 784A Service Manual

Page 30

Horizontal System

Record Length

Specifications

Besides these channels, up to three math waveforms and four reference waveforms are available for display. (A math waveform results when you specify dual

waveform operations, such as add, on any two channels. A reference waveform

results when you save a waveform in a reference memory.)

There are three horizontal display modes: main only, main intensified, and

delayed only. You can select among various horizontal record length settings.

A feature called “Fit to Screen” allows you to view entire waveform records

within the 10 division screen area. In other words, waveforms are compressed to

fit on the screen. See Table 1–2.

T able 1–2: Record Length vs. Divisions per Record, Samples per Division and

Sec/Div Sequence

Divisions per Record

Sample/Division (Sec/Div Sequence)

Fit to Screen ON

Fit to Screen OFF

50 (1–2–5)

500 10 divs 10 divs

1000 20 divs 10 divs

2500 50 divs 10 divs

5000 100 divs 10 divs

15000 300 divs 15 divs

50000 (TDS 7XXA only) 1,000 divs 10 divs

75000 (TDS 7XXA opt. 1M only) 1,500 divs 15 divs

100000 (TDS 7XXA opt. 1M only) 2,000 divs 10 divs

130000 (TDS 7XXA opt. 1M only) 2,600 divs 13 divs

250000 (TDS 7XXA opt. 1M only,

1 or 2 channels)

500000 (TDS 7XXA opt. 1M only,

1 channel)

5,000 divs 10 divs

10,000 divs 10 divs

(Sample/Div & Sec/Div

Sequence varies)

Both the delayed only display and the intensified zone on the main intensified

display may be delayed by time with respect to the main trigger. Both can be set

to display immediately after the delay (delayed runs after main mode). The

delayed display can also be set to display at the first valid trigger after the delay

(delayed-triggerable modes).

TDS 684A, TDS 744A, & TDS 784A Service Manual

1–3

Page 31

Specifications

Trigger System

The delayed display (or the intensified zone) may also be delayed by a selected

number of events. In this case, the events source is the delayed-trigger source.

The delayed trigger can also be set to occur after a number of events plus an

amount of time.

The triggering system supports a varied set of features for triggering the

signal-acquisition system. Trigger signals recognized include:

H Edge (main- and delayed-trigger systems): This familiar type of triggering is

fully configurable for source, slope, coupling, mode (auto or normal), and

holdoff.

H Logic (main-trigger system): This type of triggering can be based on pattern

(asynchronous) or state (synchronous). In either case, logic triggering is

configurable for sources, for boolean operators to apply to those sources, for

logic pattern or state on which to trigger, for mode (auto or normal), and for

holdoff. Time qualification may be selected in pattern mode. Another class

of logic trigger, setup/hold, triggers when data in one trigger source changes

state within the setup and hold times that you specify relative to a clock in

another trigger source.

Acquisition Control

H Pulse (main-trigger system): Pulse triggering is configurable for triggering

on runt or glitch pulses, or on pulse widths or periods inside or outside limits

that you specify. It can also trigger on a pulse edge that has a slew rate faster

or slower than the rate you specify. The pulse trigger is also configurable for

source, polarity, mode, and holdoff.

H Video (with option 05: Video Trigger): Video triggering is compatible with

standard NTSC, PAL, SECAM, and HDTV formats. An additional feature

called FlexFormat

format on which to trigger.

You can choose where the trigger point is located within the acquired waveform

record by selecting the amount of pretrigger data displayed. Presets of 10%,

50%, and 90% of pretrigger data can be selected in the horizontal menu, or the

general purpose knob can be assigned to set pretrigger data to any value within

the 0% to 100% limits.

You can specify a mode and manner to acquire and process signals that matches

your measurement requirements.

TM

(flexible format) allows the user to define the video

1–4

TDS 684A, TDS 744A, & TDS 784A Service Manual

Page 32

H Select the mode for interpolation (linear or sin (x)/x). This can increase the

H Use sample, envelope, and average modes to acquire signals.

H Set the acquisition to stop after a single acquisition (or sequence of

H Select channel sources for compliance with limit tests. You can direct the

On-Board User Assistance

Help and autoset can assist you in setting up the Digitizing Oscilloscope to make

your measurements.

Specifications

apparent sample rate on the waveform when the maximum real-time rate is

exceeded.

With the TDS 7XXA, also use high-resolution and peak-detect modes.

acquisitions if acquiring in average or envelope modes) or after a limit

condition has been met.

TDS to signal you or generate hard copy output either to a printer or to a

floppy-disk file based on the results. Also, you can create templates for use

in limit tests.

Help

Autoset

Help displays operational information about any front-panel control. When help

mode is in effect, manipulating any front-panel control causes the Digitizing

Oscilloscope to display information about that control. When help is first

invoked, an introduction to help is displayed on screen.

Autoset automatically sets up the Digitizing Oscilloscope for a viewable display

based on the input signal.

Measurement Assistance

Once you have set up to make your measurements, the cursor and measure

features can help you quickly make those measurements.

Cursor

Three types of cursors are provided for making parametric measurements on the

displayed waveforms. Horizontal bar cursors (H Bar) measure vertical parameters (typically volts). Vertical bar cursors (V Bar) measure horizontal parameters

(typically time or frequency). Paired cursors measure both amplitude and time

simultaneously. These are delta measurements; that is, measurements based on

the difference between two cursors.

Both H Bar and V Bar cursors can also be used to make absolute measurements.

For the H Bars, either cursor can be selected to read out its voltage with respect

to any channel’s ground reference level. For the V Bars, the cursors measure time

TDS 684A, TDS 744A, & TDS 784A Service Manual

1–5

Page 33

Specifications

with respect to the trigger point (event) of the acquisition. The cursors can also

control the portion of the waveform on which automatic measurements are made.

For time measurements, units can be either seconds or hertz (for 1/time).

With the video trigger option installed (Option 05), you can measure the video

line number using the vertical cursors. You can measure IRE amplitude (NTSC)

using the horizontal cursors with or without the video trigger option installed.

Measure

Digital Signal Processing

(DSP)

Storage

Measure can automatically extract parameters from the signal input to the

Digitizing Oscilloscope. Any four out of the 25 parameters available can be

displayed to the screen. The waveform parameters are measured continuously

with the results updated on-screen as the Digitizing Oscilloscope continues

to acquire waveforms.

An important component of the multiprocessor architecture of this Digitizing

Oscilloscope is Tektronix’s proprietary digital signal processor, the DSP. This

dedicated processor supports advanced analysis of your waveforms when doing

such compute-intensive tasks as interpolation, waveform math, and signal

averaging. It also teams with a custom display system to deliver specialized

display modes (See Display, later in this description.)

Acquired waveforms may be saved in any of four nonvolatile REF (reference)

memories or on a 3.5 inch, DOS 3.3-or-later compatible disk. Any or all of the

saved waveforms may be displayed for comparison with the waveforms being

currently acquired.

The source and destination of waveforms to be saved may be chosen. You can

save any of the four channels to any REF memory or move a stored reference

from one REF memory to another. Reference waveforms may also be written

into a REF memory location via the GPIB interface.

I/O

1–6

The oscilloscope is fully controllable and capable of sending and receiving

waveforms over the GPIB interface (IEEE Std 488.1–1987/IEEE Std 488.2–1987

standard). This feature makes the instrument ideal for making automated

measurements in a production or research and development environment that

calls for repetitive data taking. Self-compensation and self-diagnostic features

built into the Digitizing Oscilloscope to aid in fault detection and servicing are

also accessible using commands sent from a GPIB controller.

TDS 684A, TDS 744A, & TDS 784A Service Manual

Page 34

Display

Specifications

The oscilloscope can also output copies of its display using the hardcopy feature.

This feature allows you to output waveforms and other on-screen information to

a variety of graphic printers and plotters from the TDS front panel, providing

hard copies without requiring you to put the TDS into a system-controller

environment. You can make hardcopies in a variety of popular output formats,

such as PCX, TIFF, BMP, RLE, EPS, Interleaf, and EPS mono or color. You can

also save hardcopies in a disk file in any of the formats above. The hardcopies

obtained are based on what is displayed on-screen at the time hardcopy is

invoked. The hardcopies can be stamped with date and time and spooled to a

queue for printing at a later time. You can output screen information via GPIB,

RS-232C, or Centronics interfaces.

The TDS 684A and 7XXA Digitizing Oscilloscopes offer flexible display

options. You can customize the following attributes of your display:

H Color: Waveforms, readouts, graticule, and variable persistence with color

coding

Zoom

H Intensity: waveforms, readouts, and graticule

H Style of waveform display(s): vectors or dots, intensified or nonintensified

samples, infinite persistence, and variable persistence with color coding

H Interpolation method: Sin(x)/x or Linear

H Display format: xy or yt with various graticule selections including NTSC

and PAL to be used with video trigger (option 05)

This oscilloscope also provides an easy way to focus in on those waveform

features you want to examine up close. By invoking zoom, you can magnify the

waveform using the vertical and horizontal controls to expand (or contract) and

position it for viewing.

TDS 684A, TDS 744A, & TDS 784A Service Manual

1–7

Page 35

Specifications

1–8

TDS 684A, TDS 744A, & TDS 784A Service Manual

Page 36

Nominal Traits

Ranges, Offset

Ranges, Offset

This section contains a collection of tables that list the various nominal traits

that describe the TDS 684A and 7XXA oscilloscopes. Electrical and mechanical

traits are included.

Nominal traits are described using simple statements of fact such as “Four, all

identical” for the trait “Input Channels, Number of,” rather than in terms of

limits that are performance requirements.

T able 1–3: Nominal Traits — Signal Acquisition System

Name Description

Bandwidth Selections 20 MHz, 250 MHz, and FULL

Samplers, Number of Four, simultaneous

Digitized Bits, Number of 8 bits

Input Channels, Number of Four

Input Coupling DC, AC, or GND

Input Impedance Selections

1

1 M or 50

Volts/Div Setting Offset Range

1 mV/div – 100 mV/div

±1 V

101 mV/div – 1 V/div

1.01 V/div – 10 V/div

Range, Position ±5 divisions

Range, 1 M Sensitivity 1 mV/div to 10 V/div

Range, 50 Sensitivity 1 mV/div to 1 V/div

1

Displayed vertically with 25 digitization levels (DLs) per division and 10.24 divisions dynamic range with zoom off. A DL

is the smallest voltage level change of the oscilloscope input that can be resolved by the 8-bit A-D Converter. Expressed

as a voltage, a DL is equal to 1/25 of a division times the volts/division setting.

2

The sensitivity ranges from 1 mV/div to 10 V/div (for 1 M) or to 1 V/div (for 50 ) in a 1–2–5 sequence of coarse settings

with Fit-to-Screen off. Between coarse settings, the sensitivity can be finely adjusted with a resolution equal to 1% of the

more sensitive coarse setting. For example, between 50 mV/div and 100 mV/div , the volts/division can be set with 0.5 mV

resolution.

2

1

±10 V

±100 V

TDS 684A, TDS 744A, & TDS 784A Service Manual

1–9

Page 37

Nominal Traits

T able 1–4: Nominal Traits — Time Base System

Name Description

Range, Sample-Rate

Range, Interpolated Waveform Rate

Range, Seconds/Division TDS 684A: 0.2 ns/div to 10 s/div

Record Length Selection 500 samples, 1000 samples, 2500 samples 5000 samples, 15000 samples

1,3

2,3

TDS 684A; 5 Samples/sec to 5 GSamples/sec on four channels simultaneously

TDS 744A: 5 Samples/sec to 2 GSamples/sec when acquiring 1 channel

to 1 G Sample/sec when acquiring 2 channels,

or to 500 MSamples/sec when acquiring 3 or 4 channels

TDS 784A: 5 Samples/sec to 4 GSamples/sec when acquiring 1 channel

to 2 G Sample/sec when acquiring 2 channels,

or to 1 GSamples/sec when acquiring 3 or 4 channels

TDS 684A: 10 GSamples/sec to 250 GSamples/sec

TDS 744A: 1 GSamples/sec to 100 GSamples/sec

TDS 784A: 2 GSamples/sec to 250 GSamples/sec

TDS 744A: 0.5 ns/div to 10 s/div

TDS 784A: 0.2 ns/div to 10 s/div

The TDS 7XXA also offers: 50000 samples and, with its option 1M, 75000, 100000,

130000, 250000 (1 or 2 channels), or 500000 (1 channel) samples

1

The range of real-time rates, expressed in samples/second, at which a digitizer samples signals at its inputs and stores

the samples in memory to produce a record of time-sequential samples.

2

The range of waveform rates for interpolated (or equivalent-time on the TDS 7XXA) waveform records.

3

The Waveform Rate (WR) is the equivalent sample rate of a waveform record. For a waveform record acquired by

real-time sampling of a single acquisition, the waveform rate is the same as the real-time sample rate; for a waveform

created by interpolation of real-time samples from a single acquisition or, on applicable products, the equivalent-time

sampling of multiple acquisitions, the waveform rate created is faster than the real time sample rate. For all these cases,

the waveform rate is 1/(Waveform Interval) for the waveform record, where the waveform interval (WI) is the time between

the samples in the waveform record.

T able 1–5: Nominal Traits — Triggering System

Name Description

Range, Delayed Trigger Time Delay 16 ns to 250 s

Range, Events Delay TDS 684A; 2 to 10,000,000

TDS 7XXA: 1 to 10,000,000

Range (Time) for Pulse-Glitch,

Pulse-Width, Time-Qualified Runt

Triggering, or Slew Rate Trigger, Delta

Time

1 ns to 1 s

1–10

TDS 684A, TDS 744A, & TDS 784A Service Manual

Page 38

T able 1–5: Nominal Traits — Triggering System (Cont.)

Ranges, Setup and Hold for

Ranges, Setup and Hold for

TimeSetup/Hold Violation T rigger

Ranges, Trigger Level or Threshold

Ranges, Trigger Level or Threshold

Name Description

Feature Min to max

Setup Time

Nominal Traits

–100 ns to 100 ns

Video Trigger Modes of Operation

(Option 05 Video Trigger)

Hold Time

Setup + Hold Time

For Setup Time, positive numbers mean a data transition before the clock edge and

negative means a transition after the clock edge.

For Hold Time, positive numbers mean a data transition after the clock edge and negative

means a transition before the clock edge.

Setup + Hold Time is the algebraic sum of the Setup Time and the Hold Time

programmed by the user.

Source Range

Any Channel

Auxiliary

Line

Supports the following video standards:

H NTSC (525/60) – 2 field mono or 4 field

H PAL (625/50) – 2 field mono or SECAM, 8 field

H HDTV –

(787.5/60)

(1050/60)

(1125/60)

(1250/60)

H FlexFormat

TM

(user definable standards)

–1 ns to 100 ns

2 ns

±12 divisions from center of screen

±8 V

±400 V

T able 1–6: Nominal Traits — Display System

Name Description

Video Display Color display, 7 inch diagonal, with a display area of 5.04 inches horizontally by

Video Display Resolution 640 pixels horizontally by 480 pixels vertically

Waveform Display Graticule Single Graticule: 401 × 501 pixels, 8 ×10 divisions, where divisions are 1 cm by 1 cm

Waveform Display Colors Sixteen colors in infinite-persistence or variable persistence display with color coding

TDS 684A, TDS 744A, & TDS 784A Service Manual

User can specify: field rate, number of lines, sync pulse width and polarity, line rate,

and vertical interval timing.

3.78 inches vertically

1–11

Page 39

Nominal Traits

T able 1–7: Nominal Traits — GPIB Interface, Output Ports, and Power Fuse

Name Description

Interface, GPIB GPIB interface complies with IEEE Std 488-1987

Interface, RS-232 RS-232 interface complies with EIA/TIA 574 (talk only)

Interface, Centronics Centronics interface complies with Centronics interface standard C332-44 Feb 1977,

REV A

Interface, Video VGA video output with levels that comply with EIA RS 343A standard. DB-15 connector

Logic Polarity for Main- and Delayed-

Trigger Outputs

Fuse Rating Either of two fuses1 may be used: a 0.25I × 1.25I (UL 198.6, 3AG): 6 A FAST, 250 V or

1

Each fuse type requires its own fuse cap.

Negative TRUE. High to low transition indicates the trigger occurred.

a 5 mm × 20 mm (IEC 127): 5 A (T), 250V.

T able 1–8: Nominal Traits — Data Handling and Reliability

Name Description

Time, Data-Retention, Nonvolatile

,

1

Memory

2

Floppy disk 3.5 inch, 720 K or 1.44 Mbyte, DOS 3.3-or-later compatible

1

The times that reference waveforms, stored setups, and calibration constants are retained.

2

Data is maintained by small lithium-thionyl-chloride batteries internal to the memory ICs. The amount of lithium is so

small in these ICs that they can typically be safely disposed of with ordinary garbage in a sanitary landfill.

Battery life ≥ 5 years

1–12

TDS 684A, TDS 744A, & TDS 784A Service Manual

Page 40

Nominal Traits

T able 1–9: Nominal Traits — Mechanical

Name Description

Cooling Method Forced-air circulation with no air filter. Clearance is required.

Construction Material Chassis parts constructed of aluminum alloy; front panel constructed of plastic laminate;

circuit boards constructed of glass laminate. Cabinet is aluminum and is clad in Tektronix

Blue vinyl material.

Finish Type T ektronix Blue vinyl-clad aluminum cabinet

Weight Standard Digitizing Oscilloscope

14.1 kg (31 lbs), with front cover.

24.0 kg (53 lbs), when packaged for domestic shipment

Rackmount Digitizing Oscilloscopes

14.1 kg (31 lbs) plus weight of rackmount parts, for the rackmounted Digitizing

Oscilloscopes (Option 1R).

Rackmount conversion kit

2.3 kg (5 lbs), parts only; 3.6 kg (8 lbs), parts plus package for domestic shipping

Overall Dimensions Standard Digitizing Oscilloscope

Height: 193 mm (7.6 in), with the feet installed

Width: 445 mm (17.5 in), with the handle

Depth: 434 mm (17.1 in), with the front cover installed

Rackmount Digitizing Oscilloscope

Height: 178 mm (7.0 in)

Width: 483 mm (19.0 in)

Depth: 558.8 mm (22.0 in)

TDS 684A, TDS 744A, & TDS 784A Service Manual

1–13

Page 41

Nominal Traits

1–14

TDS 684A, TDS 744A, & TDS 784A Service Manual

Page 42

W arranted Characteristics

This section lists the various warranted characteristics that describe the

TDS 684A and 7XXA Digitizing Oscilloscopes. Electrical and environmental

characteristics are included.

Warranted characteristics are described in terms of quantifiable performance

limits which are warranted.

NOTE. In these tables, those warranted characteristics that are checked in the

procedure Performance Verification appear in boldface type under the column

Name.

As stated above, this section lists only warranted characteristics. A list of typical

characteristics starts on page 1–21.

Performance Conditions

The performance limits in this specification are valid with these conditions:

H The oscilloscope must have been calibrated/adjusted at an ambient tempera-

ture between +20

H The oscilloscope must be in an environment with temperature, altitude,

humidity, and vibration within the operating limits described in these

specifications.

H The oscilloscope must have had a warm-up period of at least 20 minutes.

H The oscilloscope must have had its signal-path-compensation routine last

executed after at least a 20 minute warm-up period at an ambient temperature

within ±5

_ C of the current ambient temperature.

_ C and +30_ C.

TDS 684A, TDS 744A, & TDS 784A Service Manual

1–15

Page 43

Warranted Characteristics

Accuracy, Offset

Analog Bandwidth, DC-50 Coupled

Analog Bandwidth, DC-50 Coupled

and Bandwidth selection is FULL

Analog Bandwidth, DC-50 Coupled

selection is FULL

T able 1–10: Warranted Characteristics — Signal Acquisition System

Name Description

Accuracy, DC Gain TDS 684A: ±1.5% for all sensitivities from 2 mV/div to 10 V/div

± 2.0% at 1 mV/div sensitivity

TDS 7XXA: ±1% for all sensitivities from 1 mV/div to 10 V/div with offset from 0 V to

±100V

Volts/Div

Setting

1 mV/div –

100 mV/div

TDS 684A Offset

Accuracy

±((0.2% ×

)

| Net Offset

1

|

+ 1.5 mV +

(0.6 div x V/div))

TDS 744A Offset

Accuracy

±((0.2% ×

| Net Offset

1

|)

+ 1.5 mV +

(0.1 div x

V/div setting))

TDS 784A Offset

Accuracy

±((0.2% ×

| Net Offset

1

|)

+ 1.5 mV +

(0.1 div x

V/div setting))

with P6245 Probe and Bandwidth

selection is FULL

101 mV/div –

1 V/div

±((0.25% ×

| Net Offset

)

1

|

+ 15 mV +

1.01 V/div –

10 V/div

(0.6 div x V/div))

±((0.25% ×

| Net Offset

1 | )

+ 150 mV +

( 0.6 div x V/div))

Volts/Div 684A Bandwidth

10 mV/div –

DC – 1 GHz

1 V/div

5 mV/div –

DC – 750 MHz

9.95 mV/div

2 mV/div –

DC – 600 MHz

4.98 mV/div

1 mV/div –

DC – 500 MHz

1.99 mV/div

Volts/Div as

Read Out on

Screen

10 mV/div –

684A Bandwidth

(Not Applicable)

100 V/div

±((0.25% ×

1

| Net Offset

|)

+ 15 mV + (0.1 div x

V/div setting))

±((0.25% ×

| Net Offset

1

|)

+ 150 mV + (0.1 div x

V/div setting))

2

744A Bandwidth

2

DC – 500 MHz

DC – 500 MHz

DC – 500 MHz

DC – 450 MHz

2

744A Bandwidth

2

(Not Applicable)

±((0.25% ×

1

| Net Offset

|)

+ 15 mV + (0.1 div x

V/div setting))

±((0.25% ×

| Net Offset

1

|)

+ 150 mV + (0.1 div x

V/div setting))

784A Bandwidth

2

DC – 1 GHz

DC – 750 MHz

DC – 600 MHz

DC – 500 MHz

784A Bandwidth

2

(Not Applicable)

1–16

100 mV/div –

10 V/div

50 mV/div –

99.5 mV/div

20 mV/div –

49.8 mV/div

10 mV/div –

19.9 mV/div

DC – 1 GHz

DC – 750 MHz

DC – 600 MHz

DC – 500 MHz

TDS 684A, TDS 744A, & TDS 784A Service Manual

DC – 500 MHz

DC – 500 MHz

DC – 500 MHz

DC – 450 MHz

DC – 1 GHz

DC – 750 MHz

DC – 600 MHz

DC – 500 MHz

Page 44

T able 1–10: Warranted Characteristics — Signal Acquisition System (Cont.)

Analog Bandwidth, DC-1M Coupled

selection is FULL

Name Description

Volts/Div as

with P6139A Probe and Bandwidth

selection is FULL

Read Out on

Screen

10 mV/div –

100 V/div

684A Bandwidth

500 MHz

2

744A Bandwidth

500 MHz

Warranted Characteristics

2

784A Bandwidth

500 MHz

2

100 mV/div –

500 MHz

500 MHz

500 MHz

10 V/div

50 mV/div –

500 MHz

500 MHz

500 MHz

99.5 mV/div

20 mV/div –

500 MHz

500 MHz

500 MHz

49.8 mV/div

10 mV/div –

400 MHz

450 MHz

500 MHz

19.9 mV/div

Crosstalk (Channel Isolation) ≥100:1 at 100 MHz and ≥30:1 at the rated bandwidth for any two channels having equal

Volts/Div settings

Delay Between Channels, Full

Bandwidth

TDS 684A: ≤100 ps for any two channels with equal Volts/Div and Coupling settings

TDS 744A/784A: ≤50 ps for any two channels with equal Volts/Div and Coupling settings

Input Impedance, DC–1 M Coupled 1 M ±0.5% in parallel with 10 pF ±3 pF

Input Impedance, DC–50 Coupled

Input Voltage, Maximum, DC–1M,

50 ±1% with VSWR ≤1.3:1 from DC – 500 MHz, ≤1.5:1 from 500 MHz – 1 GHz

±400 V (DC + peak AC); derate at 20 dB/decade above 1 MHz

AC–1 M, or GND Coupled

Input Voltage, Maximum, DC-50 or

5 V

, with peaks ≤ ±30 V

RMS

AC–50 Coupled

Lower Frequency Limit, AC Coupled TDS 684A: ≤10 Hz when AC–1 M Coupled; ≤200 kHz when AC–50 Coupled

1

Net Offset = Offset – (Position × Volts/Div). Net Offset is the nominal voltage level at the oscilloscope input that

3

corresponds to the center of the A-D converter’s dynamic range. Offset Accuracy is the accuracy of this voltage level.

2

The limits given are for the ambient temperature range of 0_C to +30_C. Reduce the upper bandwidth frequencies by

5 MHz for the TDS 684A or by 2.5 MHz for the TDS 7XXA for each _C above +30_C.

3

The AC Coupled Lower Frequency Limits are reduced by a factor of 10 when 10X passive probes are used.

T able 1–11: Warranted Characteristics — Time Base System

Name Description

Accuracy, Long Term Sample Rate and

Delay Time

TDS 684A, TDS 744A, & TDS 784A Service Manual

TDS 684A: ±100 ppm over any ≥1 ms interval

TDS 7XXA: ±25 ppm over any ≥1 ms interval

1–17

Page 45

Warranted Characteristics

Sensitivity, Edge-Type T rigger, Coupling

Sensitivity, Edge-Type T rigger, Coupling

set to “DC”

1

Accuracy (Time) for Pulse-Glitch or

Accuracy (Time) for Pulse-Glitch or

Pulse-Width Triggering

Logic Levels, Main- and Delayed-Trigger

Logic Levels, Main- and Delayed-Trigger

Outputs

Output Voltage and Frequency,

Output Voltage and Frequency,

Probe Compensator

T able 1–12: Warranted Characteristics — Triggering System

Name Description

Trigger Source Sensitivity

Any Channel

Auxiliary

Time Range Accuracy

1 ns to 1 ms

TDS 684A: 0.35 division from DC to 50 MHz, increasing to

1 division at 1 GHz

TDS 7XXA: 0.35 division from DC to 50 MHz, increasing to

1 division at 500 MHz for the TDS 744A or to 1 division at 1 GHz

for the TDS 784A

TDS 684A or 784A: 250 mV from DC to 50 MHz, increasing to

500 mV at 100 Mhz

TDS 744A: 400 mV from DC to 50 MHz, increasing to 750 mV at

100 Mhz

±(20% of setting + 0.5 ns)

1.02 ms to 1 s

Input Signal Sync Amplitude for Stable

Triggering, NTSC and PAL modes

(Option 05 Video Trigger)

Jitter (Option 05 Video Trigger) 60 ns

1

The minimum sensitivity for obtaining a stable trigger. A stable trigger results in a uniform, regular display triggered on

Field selection “Odd”, “Even”, or “All”: 0.6 division to 4 divisions

Field selection “Numeric”: 1 division to 4 divisions (NTSC mode)

on NTSC or PAL signal

p-p

±(100 ns + 0.01% of Setting)

the selected slope. The trigger point must not switch between opposite slopes on the waveform, and the display must not

“roll” across the screen on successive acquisitions. The TRIG’D LED stays constantly lighted when the SEC/DIV setting

is 2 ms or faster but may flash when the SEC/DIV setting is 10 ms or slower.

T able 1–13: Warranted Characteristics — Output Ports, Probe Compensator, and Power Requirements

Name Description

Characteristic Limits

Vout (HI)

Vout (LO)

Characteristic Limits

Output Voltage

≥2.5 V open circuit; ≥1.0 V into a 50 W

load to ground

≤0.7 V into a load of ≤4 mA;

≤0.25 V into a 50 W load to ground

0.5 V (base-top) ±1% into a ≥50 W load

Output Voltage, Signal Out (CH 31) For TDS 684A: 20 mV/division ±20% into a 1 MW load;

Source Voltage 90 to 250 VAC

Source Frequency 45 Hz to 440 Hz

1–18

Frequency

1 kHz ±5%

10 mV/division ±20% into a 50 W load

For TDS 7XXA: 22 mV/division ±20% into a 1 MW load;

11 mV/division ±20% into a 50W load

, continuous range

RMS

TDS 684A, TDS 744A, & TDS 784A Service Manual

Page 46

Warranted Characteristics

T able 1–13: Warranted Characteristics — Output Ports, Probe Compensator, and Power Requirements (Cont.)

Name Description

Power Consumption ≤300 W (450 VA)

1

CH 3 signal out is present at the rear panel if CH 3 is selected as the trigger source for the main and/or delayed trigger

systems. It is not available when a channel other than CH3 is the source for the Video Trigger when Option 05 is installed.

T able 1–14: Warranted Characteristics — Environmental

Name Description

Atmospherics Temperature (no diskette in floppy drive):

TDS 684A: Operating: +4_ C to +45_ C

TDS 7XXA: Operating: +4_ C to +50_ C

Nonoperating: –22_ C to +60_ C

Relative humidity (no diskette in floppy drive):

Operating: 20% to 80%, at or below +32_ C,

upper limit derates to 30% relative humidity at +45_ C

Nonoperating: 5% to 90%, at or below +41_ C,

upper limit derates to 30% relative humidity at 60_ C

Altitude:

To 4570 m (15,000 ft.), operating

To 12190 m (40,000 ft.), nonoperating

Dynamics Random vibration (floppy diskette not installed):

0.31 g rms, from 5 to 500 Hz, 10 minutes each axis, operating

3.07 g rms, from 5 to 500 Hz, 10 minutes each axis, nonoperating

,

1

Emissions

2

Meets or exceeds the requirements of the following standards:

Vfg. 243/1991 Amended per Vfg. 46/1992

FCC Code of Federal Regulations, 47 CFR, Part 15, Subpart B, Class A

European Community Requirements

EN 55011 Class A Radiated Emissions

EN 55011 Class A Conducted Emissions

EN 50081–1

EN60555–2 Power Line Harmonic Emissions

TDS 684A, TDS 744A, & TDS 784A Service Manual

1–19

Page 47

Warranted Characteristics