Page 1

7313/R7313

I

OSCILLOSCOPE

MTM

OPTIDMS

OPERATORS

Page 2

Tektronix,

Inc.

P.O.

Box

500

Beaverton,

Oregon

97005

TH

OPT

IONS

OPERATORS

INSTRUCTION

MANUAL

Serial Number

First

Printing

JULY

1974

Page 3

WARRANTY

All

TEKTRONIX

instruments

are

warranted against

defective materials

and

workmanship

for

one

year.

Any

questions

with respect

to

the

warranty

should

'be

taken

up

with

your TEKTRONIX

Field

Engineer

or

representat'---

reques

..

rn

mm.

All

I

-par&

shouta

ne

alrecrea

ro

me

F

En

4

KUNIA

r~eld

Office

or

representative

in

your

area.

This

will assure

you

the

fastest

possible

service. Please include

the

instrument Type Number

or

Part Number

and Serial

Nu

ecif icatir

pyright

egon.

Pr

th

all rer

3ns and

1

quests

fc

rice

cha

by

Tek

the

Unitr

-+--*-

-4

~r

parts

lnge

privileges

reserved.

tmnix,

I

zd

State!

r..L

nc.,

Bee

;

of

Arne

ll*mb:*-.

rty11ia

reacr~ed.

COIIL~II~P

VI

11113

~UUIIC~~~IUII

IIIO~

11~1

be

reproduced

in

any

form

without

permission

of

Tektronix,

Inc.

U.S.A.

and

foreign

TEKf RONlX

products

covered

by

U.S.

and foreign

patents

and/or

patents

pending.

TEKTRON

Inc.

gistered

irk

of Tektronix,

Page 4

7313lR7313 Operators

TABLE OF CONTENTS

LlST OF ILLUSTRATIONS

LlST OF TABLES

SECTION 1 OPERATING INSTRUCTIONS

Preliminary Operation

Safety Information

Operating Voltage

Plug-In Units

Controls and Connectors

External

Internal

Familiarization Procedure

Set-Up Information

Display Controls

Vertical and Horizontal System Controls

Calibrator and Triggering Controls

Storage Controls

General Operating Information

Intensity Controls

Display Focus

Graticule

Beamfinder

Vertical Mode

Trigger Source

Readout (Deleted by Option

1)

Storage Operation

Calibrator

Signal Outputs

Remote Single Sweep Reset

(Delete with Option 7)

Display Photography

X-Y

Operation

Intensity Modulation

Raster Display

Applications

SECTION

2

SPECIFICATION

General

Standard Accessories

System Specifications

SECTION

3

RACKMOUNTING INSTRUCTIONS

lnstrument Dimensions

Rack Dimensions

Slide-Out Tracks

Mounting Procedure

Removing Or Installing The lnstrument

Slide-Out Track Lubrication

SECTION

4

INSTRUMENT OPTIONS

Option 1

Option 3

Option

5

(Rackmount lnstrument only)

Option 7

Page

I

I

iii

Page 5

7313lR7313 Operators

Figure

1-1

LIST OF ILLUSTRATIONS

Page

Frontispiece

Location of voltage selector, spare

jumper, and alternate fuse in power unit

(7313 shown).

Front-panel controls and connectors.

Rear-panel controls and connectors.

Location and function of internal

selectors.

Definition of measurement lines on the

7313lR7313 graticules.

Location of the readout on the crt

identifying the originating plug-in

compartment and channel.

Slideout track assembly.

Vertical mounting position of the left

stationary section and location of the

thumbscrew securing hole. These

dimensions also apply to the right front

rail.

Details for mounting stationary sections.

Installing and removing the instrument.

Adjusting the slide-out tracks for smooth

sliding action.

R7313 dimensional drawing.

Page 6

7313lR7313 Operators

LIST

OF

TABLES

Table

1-1 Color Coding of Cord Conductors

1-2 Regulating Range and Fuse Data

2-1 Electrical Specifications

2-2 Environmental Specifications

2-3

Physical Specifications

2-4 System Vertical Specifications

4-1 Option Information Locator

Page

1-1

1-2

2- 1

2-7

2-7

2-8

4- 1

NOTE

Refer to the

7313lR7313 Service manual for circuit

description, maintenance, calibration, diagrams, and

parts replacement information.

Page 7

7313JR7313

FEATURES

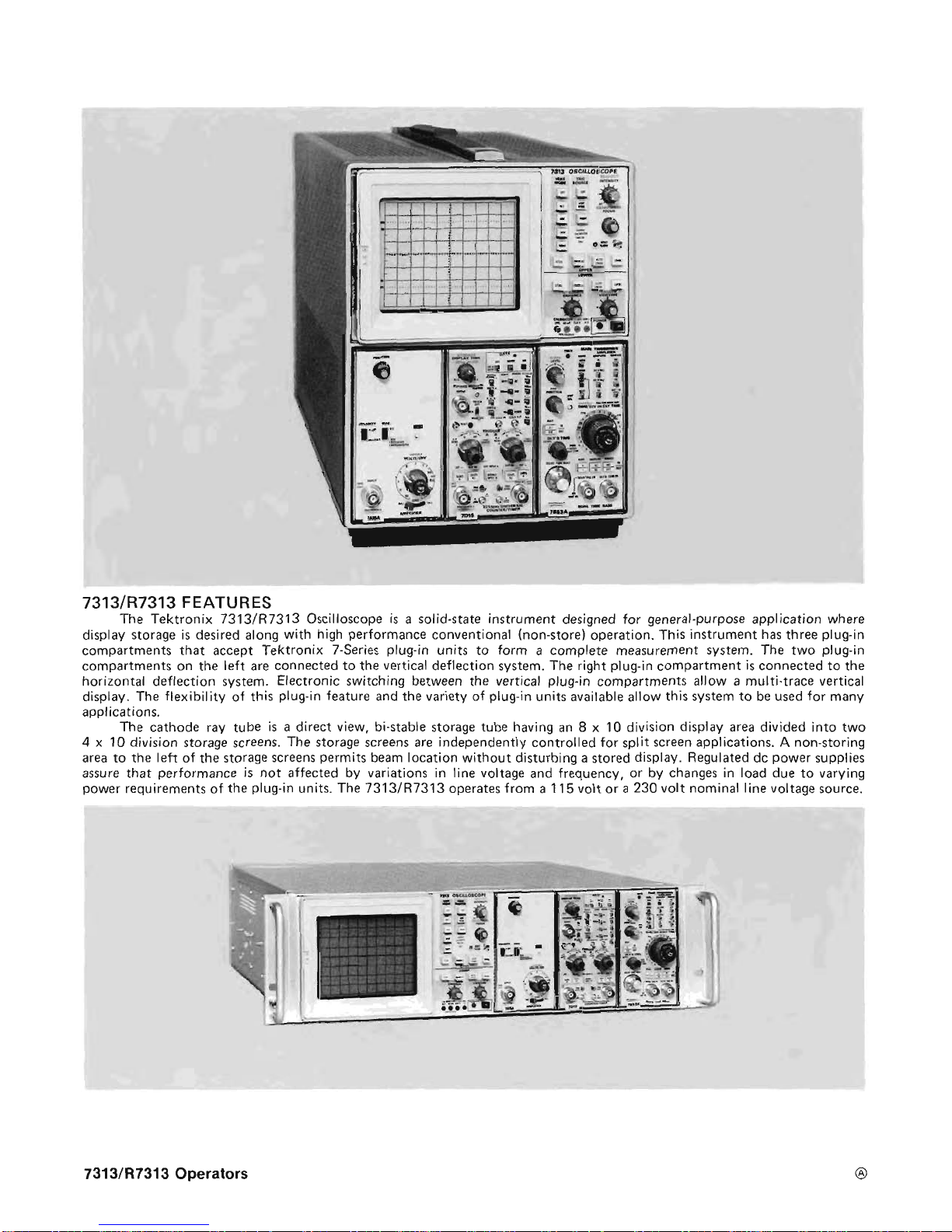

The

Tektronix

7313/RJ313

Oscilloscope

is a solid-state instrument designed for general-purpose application where

display storage is desired along

with

high performance conventional (non-store) operation.

This

instrument has three plug-in

compartments that accept Tektronix 7-Series plug-in units

to

form a complete measurement sysrem.

The

two plug-in

compartments on the left are connected

to

the vertical deflection system. The right plug-in compartment

is

connected to the

horizontal deflection system. Eleczronic switching between the vertical

plug-in

compartments

allow

a

multi-trace vertical

display. The flexibility of this plug-in feature

and

the

variety

af

plug-in units available allow this system to be

used

for many

applications.

The cathode

ray

tube is a direct view. bi-stable storage tube having an

8 x 10

division display area divided into two

4

x

10

division storage screens,

The

storage screens are independently controlled

for

split screen applfcations. A non-storing

area to the left of the storage screens permits

beam

location without disturbing a stored display. Regulated

dc

power supplies

assure that performance

is

not affected

by

variations

in

line voltage and frequency, or by changes in load due to varying

power requirements of the plug-in units.

The

7313/R7313

operates from

a

115

volt

or

a

230

volt nominal line voltage source.

7313/R7313

Operators

8

Page 8

Section 1-731 3lR7313 Operators

OPERATING INSTRUCTIONS

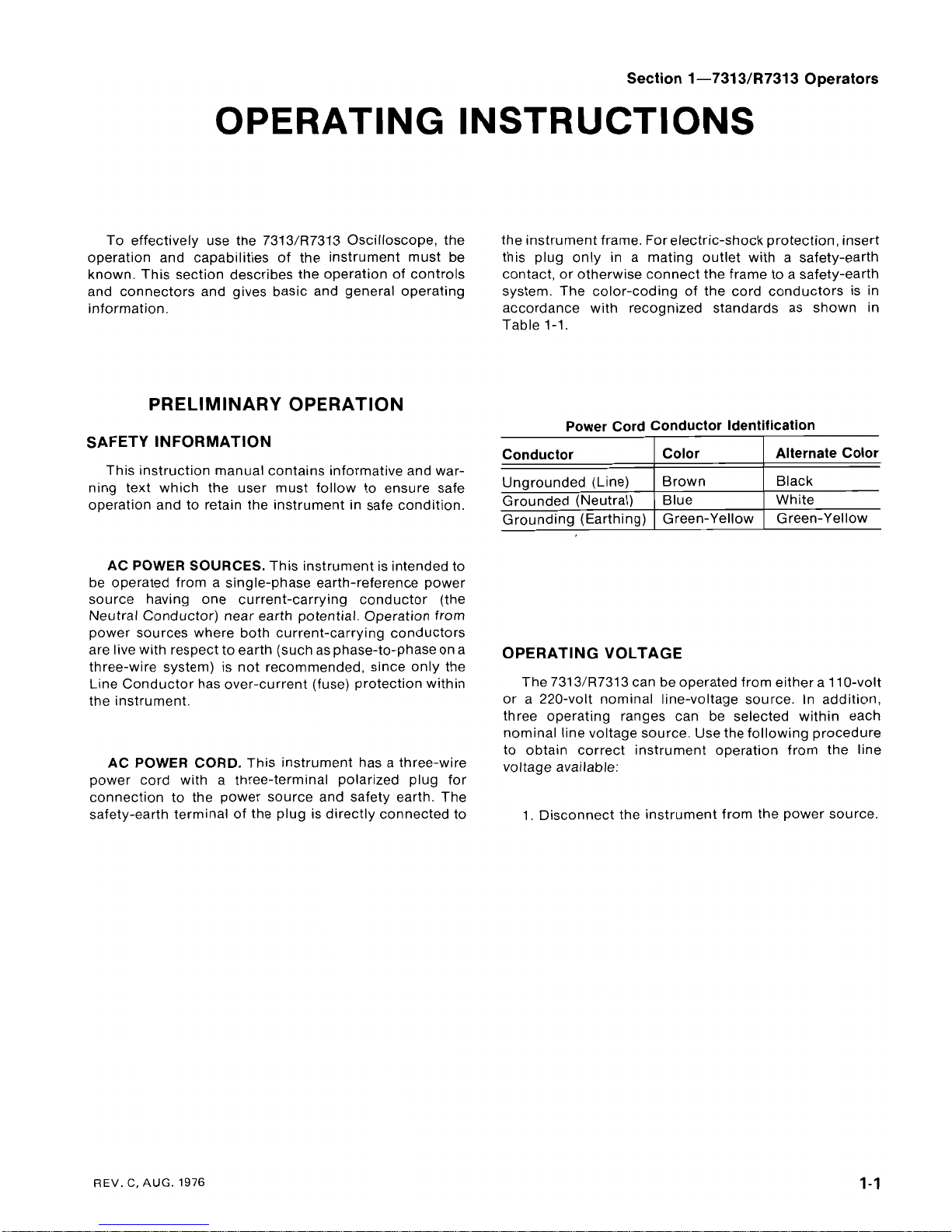

To effectively use the 7313/R7313 Oscilloscope, the the instrument frame.

for electric-shock

protection, insert

operation and capabilities of the instrument must be this plug only in a mating outlet with a safety-earth

known. This section describes the operation of controls contact, or otherwise connect the frame to a safety-earth

and connectors and gives basic and general operating system. The color-coding of the cord conductors is in

information. accordance with recognized standards as shown in

Table

1-1.

PRELIMINARY OPERATION

Power Cord Conductor Identification

SAFETY INFORMATION

Conductor Color Alternate Color

This instruction manual contains informative and war-

ning text which the user must follow to ensure safe

Ungrounded (Line)

Black

White

operation and to retain the instrument in safe condition.

Grounded (Neutral)

Grounding (Earthing) Green-Yellow Green-Yellow

AC POWER SOURCES.

This instrument is intended to

be operated from a single-phase earth-reference power

source having one current-carrying conductor (the

Neutral Conductor) near earth potential. Operation from

power sources where both current-carrying conductors

are live with respect to earth (such as phase-to-phase on a

three-wire system) is not recommended, since only the

Line Conductor has over-current (fuse) protection within

the instrument.

AC POWER CORD.

This instrument has a three-wire

power cord with a three-terminal polarized plug for

connection to the power source and safety earth. The

safety-earth terminal of the plug is directly connected to

OPERATING VOLTAGE

The 731 3/R7313 can be operated from either a 11 0-volt

or a 220-volt nominal line-voltage source. In addition,

three operating ranges can be selected within each

nominal line voltage source. Use the following procedure

to obtain correct instrument operation from the line

voltage available:

1.

Disconnect the instrument from the power source.

REV.

C,

AUG.

1976

Page 9

Operating Instructions-7313/R7313 Operators

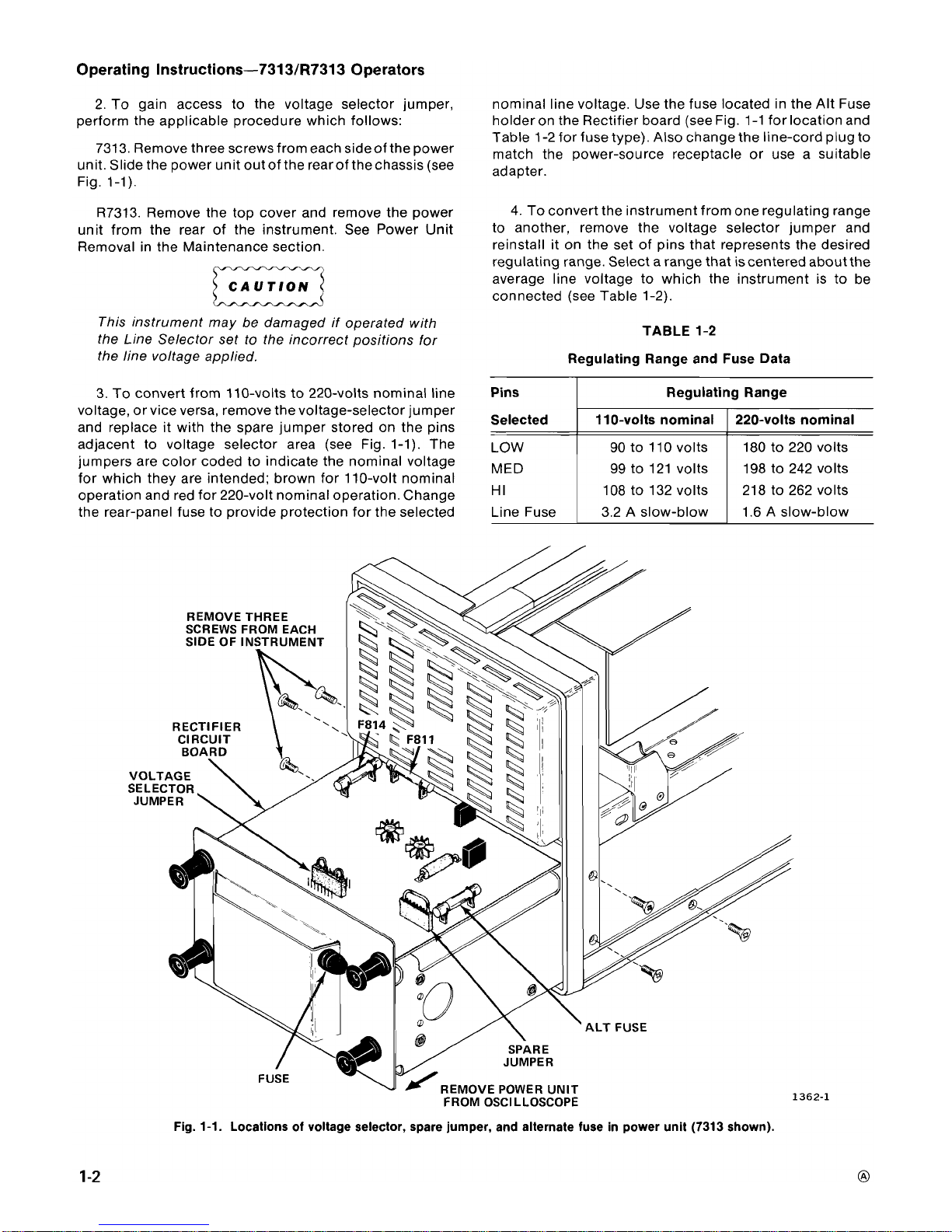

2. To gain access to the voltage selector jumper, nominal line voltage. Use the fuse located in the Alt Fuse

perform the applicable procedure which follows:

holder on the Rectifier board (see Fig. 1-1 for location and

Table 1-2 for fuse type). Also change the line-cord plug to

7313. ~emove three screws from each sideof the Power

match the power-source receptacle or use a suitable

unit. Slide the power unit out of the rearof the chassis (see

adapter,

Fig. 1-1).

R7313. Remove the top cover and remove the power

unit from the rear of the instrument. See Power Unit

Removal in the Maintenance section.

CAUTION

This instrument may be damaged if operated with

the Line Selector set to the incorrect positions for

the line voltage applied.

3. To convert from 110-volts to 220-volts nominal line

voltage, or vice versa, remove the voltage-selector jumper

and replace it with the spare jumper stored on the pins

adjacent to voltage selector area (see Fig. 1-1). The

jumpers are color coded to indicate the nominal voltage

for which they are intended; brown for 110-volt nominal

operation and red for 220-volt nominal operation. Change

the rear-panel fuse to provide protection for the selected

4. To convert the instrument from one regulating range

to another, remove the voltage selector jumper and

reinstall it on the set of pins that represents the desired

regulating range. Select a range that iscentered about the

average line voltage to which the instrument is to be

connected (see Table 1-2).

TABLE

1-2

Regulating Range and Fuse Data

REMOVE THREE

SCREWS FROM EACH

RECTIFIER

REMOVE POWER UNIT

FROM OSCILLOSCOPE

I

Pins

Selected

LOW

MED

HI

Line Fuse

Fig.

1-1.

Locations of voltage selector, spare jumper, and alternate fuse in power unit (7313 shown).

Regulating Range

110-volts nominal

90 to 110 volts

99 to 121 volts

108 to 132 volts

3.2 A slow-blow

220-volts nominal

180 to 220 volts

198 to 242 volts

218 to 262 volts

1.6 A slow-blow

Page 10

Operating Instructions-7313fR7313 Operators

PLUG-IN UNITS

The 7313lR7313 is designed to accept up to three

Tektronix 7-series plug-in units. This plug-in feature

allows a variety of display combinations and also allows

selection of polarity, sensitivity, display mode, etc. to meet

the measurement requirements. In addition, it allows the

oscilloscope system to be expaned to meet future

measurement requirements. The overall capabilities of the

resultant system are in large part determined by the

characteristics of the plug-in selected. Refer to the

Tektronix Products catalog for specifications of plug-in

units currently available.

To install a plug-in unit into one of the plug-in

compartments, align the slots in the top and bottom of the

plug-in with the associated guide rails in the plug-in

compartment. Push the plug-in unit firmly into the plug-in

compartment until it locks into place. To removea plug-in,

pull the release latch on the plug-in unit to disengage it

and pull the unit out of the plug-in compartment. Plug-in

units can be removed or installed without turning off the

instrument power.

All of the plug-in compartments do not have to be filled

to operate the instrument; the only plug-ins needed are

those required for the measurement to be made. At

environmental extremes, excess interference may be

radiated into or out of the instrument through the plug-in

compartments. To reduce such interference, or to meet

EM1 specifications on factory equipped Option 3 or field

EM1 modified instruments, all unused plug-in com-

partments must be covered with an EM1 shielded blank

plug-in panel. Order or use only Tektronix Part No. 016-

0155-00. One is required for each unused compartment.

When the 7313/R7313 is calibrated in accordance with

the calibration procedure given in the service manual, the

vertical and horizontal gains are normalized. This allows

calibrated plug-in units to be changed from one plug-in

compartment to another without recalibration. However,

the basic calibration of the individual plug-in units should

be checked when they are installed in this system to verify

their measurement accuracy. See the operating instruc-

tions section of the plug-in unit instruction manual for

verification procedure.

The plug-in versatility of the

7313/R7313 allows a

variety of display modes with many different plug-in units.

The following information is provided to aid in plug-in unit

selection.

To produce a single-trace display, install a single-

channel vertical unit (or dual-channel unit set for single-

channel operation) in either of the vertical compartments;

for dual-trace displays, either install a dual-channel

vertical unit in one of the vertical compartments or install a

single-channel vertical unit in each vertical compartment.

A combination of a single-channel and dual-channel

vertical unit allows a three-trace display; likewise, a

combination of two dual-channel vertical units allows a

four-trace display.

Non-delayed single-trace displays can be obtained

with a single-trace time-base unit.

A

dual-trace time-base

unit must be used for delayed-sweep displays.

X-Y displays can be obtained in two ways with the

7313/R7313 system. If a 7B-series time-base unit is

available that has an amplifier feature, the

X

signal can

either be routed through one of the vertical units via the

internal-trigger pickoff circuitry to the horizontal system,

or connected to the external horizontal input connector of

the time-base unit. Then, the vertical signal

(Y)

is con-

nected to the remaining vertical unit. Also, a 7A-series

amplifier plug-in can be installed in one of the horizontal

compartments for X-Y operation.

Special purpose plug-ins may have specific restrictions

regarding the plug-in compartments in which they can be

installed. This information will be given in the instruction

manuals for these plug-ins. Refer to the Tektronix

Products catalog for additional information on plug-in

unit selection.

NOTE

Later production of rackmount ocilloscopes are

provided with support posts between the individual

plug-in compartments.

A

post or posts must be

removed if a multi-width plug-in is to

be

installed. To

remove a post, unfasten the screws that secure it at

the top and bottom of the plug-in housing.

CONTROLS AND CONNECTORS

EXTERNAL

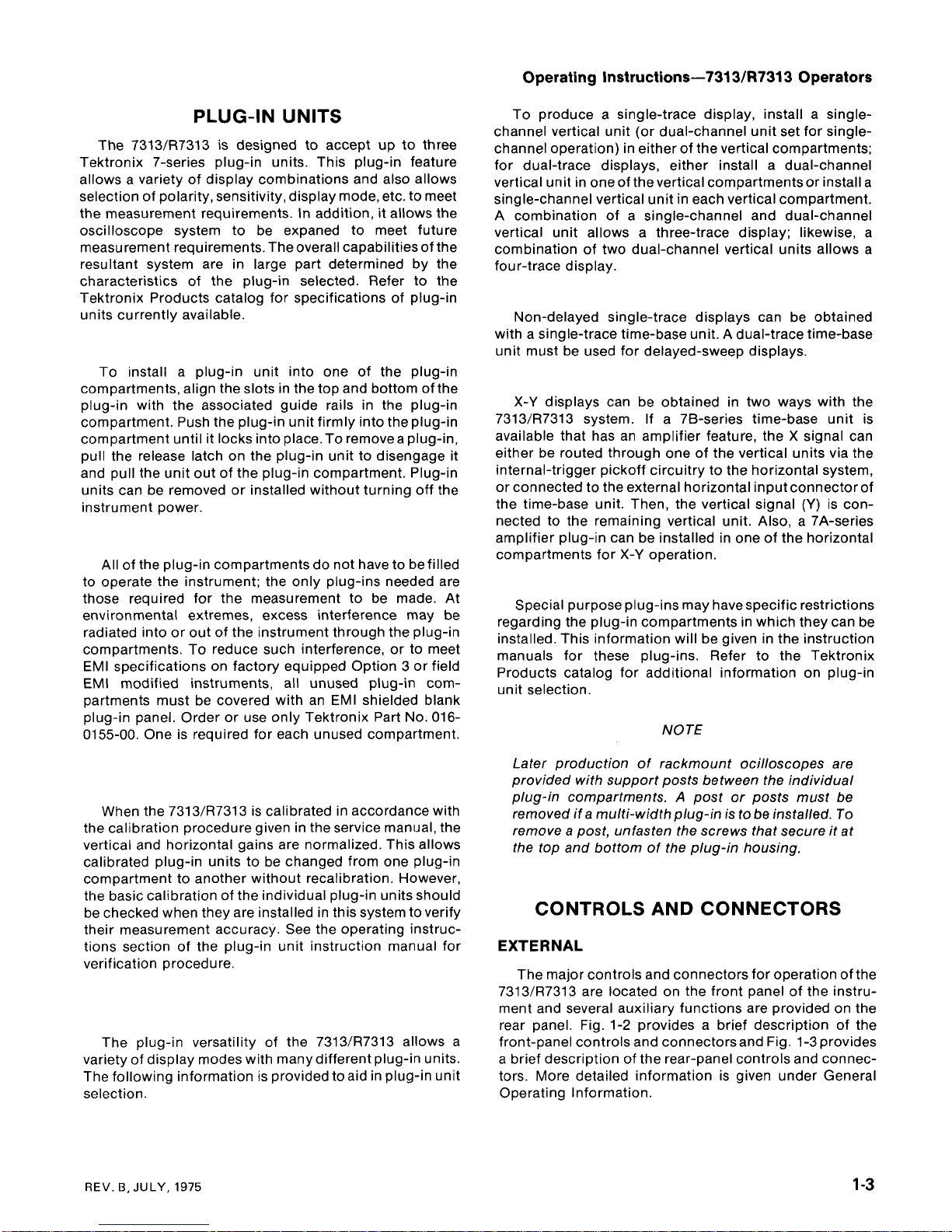

The major controls and connectors for operation of the

7313/R7313 are located on the front panel of the instru-

ment and several auxiliary functions are provided on the

rear panel. Fig. 1-2 provides a brief description of the

front-panel controls and connectorsand Fig. 1-3 provides

a brief description of the rear-panel controls and connec-

tors. More detailed information is given under General

Operating Information.

REV. B,

JULY,

1975

Page 11

Operating

Instructions-7313/R7313

Operators

a

INTENSITY.

Varies brightness of

cit

display.

@

READOUT.

Varies

brightness

of

rsadout

portion

of

cn

display.

@

FOCUS.

Provides

optimum display definition.

@

BEAMFINDER.

Returns

crt

display

by

compressing vertical

and

horizontal deflection within graticuls

area.

@

GRAT

ILLUM. Varier gratieule illumination.

@

TRIG

SOURCE.

Selects

source

of

trigger signal

for

time-bass unit.

@

VERT

MODE. Selects vertical plug-in compartment that provider vertical deflection signal.

@

STORE

(UPPER

and

LOWER).

Selects

storage

operation.

@

ENHANCE

[UPPER

and

LOWER).

Increaser writing

rate

for

storage

of

single

sweep

displays.

10

AUTO ERASE

{UPPER

and

LOWER).

Stores

the

crt

display at

the

end of each

sweep

and inhibits further

O

sweeps

for

a

time selected

by

the

VIEW

TIME

control.

@

ERASE

(UPPER

and

LOWER).

Manually

eraser

stored

diglay.

@

VIEW

TIME.

Determiner variable viewing interval

of

stored display.

@

LOCATE.

Pushbuttan switch unblankr

the

crt

to

pravids

in

indication

of

the

sweep

starting point.

@

INTEGRATE.

Permits

storage

of

very

fast

rap~titive signals.

@

ENHANCE

Level

(Level not labeled).

Provides

a

selectable increase

in

writing

speed

for

single

sweep

displays.

@

CALIRRATOR Pin

jack<

pmvirlr

rl

V,

0.4

V,

and

40

rnV

~utputs

st

a

OM

kilohertz repetition

rate.

Oc

output

can

be

selected

by

an

internal

selector.

@

POWER.

POWER

switch

controls

power

to

the instrurnenl;

POWER

light indicates

that

the

power

switch

is

on

and

the

instrument

is

connected

to

the

pawer

source.

@

Camera

Power

(not

labeled).

Provider

pawer

output

and

receives

remote

single

sweep

reset

for

compatible

camera

systems.

fig.

1-2.

Front-pmel

controls

and

connectom.

Page 12

Operating

Instructions-7313ER7313

Operators

@

FUSE. Line voltage

fuse

for instrument.

VERT

SIG

OUT

(Delete with Option

7).

Vertical

signal

selected

by

TRIG

SOURCE

and

VERT

MODE

@

switches

(Left,

Right.

Alf.

and

Add).

@

+GATE

OUT

(Delete with Option

7).

Gate rignal selected by rear-panel

gate

selector

switch

(MAIN,

AUXILIARY, and

DELAY).

@

+

SAWTOOTH

OUT

(Delete

with

Option

71.

Positive-going sawtooth

signal

from time-base unit.

@

REMOTE ERASE

IN

(Delete with

Option

7).

Provider

input

for

an

external rignal

to

erase

the

stored

display.

@

EXT

SS

RESET

IN (Delete with Option

7).

Provider

input for

an

external rignal

to

reset

the

sweep

(Time-

base

unit

operating in Single

Sweep

mode).

@

EXT

Z

AXIS

IN.

Input

for

intensity modulation

of

crt

display.

Flg.

6-3.

Rear-panel

controls

and

connectors.

Page 13

Operating Instructions-7313/R7313 Operators

INTERNAL

SET-UP

INFORMATION

Several switch functions are located on circuit boards

within the instrument. A brief description of each internal

switch is given in the following discussion.

REMOTE ERASE SELECTOR.

Internal multi-pin con-

nector (located on Storage Switch circuit board) to

determine whether the external signal, applied to the

REMOTE ERASE IN connector, erases the upper storage

screen, lower storage screen, or both storage screens. See

Fig. 1-4 for further information.

CALIBRATOR SELECTOR.

Internal multi-pin connec-

tor (located on the Calibrator circuit board) to determine

whether the CALIBRATOR output is a one-kilohertz

square-wave signal or a dc voltage level. See Fig. 1-4 for

further information.

READOUT MODE SWITCH.

Two-position switch

(located on the Readout circuit board) to determine

whether the readout display is present independent of a

sweep (free runs) or is triggered at the end of each sweep.

See Fig. 1-4 for further information.

VOLTAGE SELECTOR.

Multi-pin connector selects

Low, Medium, or High voltage regulating range. The multi-

pin connector can be exchanged to select 110-volt or 220-

volt nominal line voltage source. See Fig. 1-1 and

Preliminary Operation, in this section, for further informa-

tion.

FAMILIARIZATION PROCEDURE

The following procedure may be used for familiariza-

tion with the 7313/R7313 or as a check of basic instrument

operation. If performance of the Familiarization

Procedure reveals improper calibration or instrument

malfunction, first check the operation of the associated

plug-in units; then refer to the Calibration and

Maintenance sections of the 7313/R7313 Service Manual.

A Set-Up Status summary, preceding each major

section of the Familiarization Procedure, provides the

settings of controls and lists the signals connected at that

point in the procedure.

1. Set the front-panel controls as follows:

INTENSITY Midrange

FOCUS Midrange

READOUT OFF (counterclockwise

into switch detent)

GRAT

ILLUM (screw- Counterclockwise

driver adjustment)

VERT MODE LEFT

TRIG SOURCE VERT MODE

STORE (UPPER Off (push button out)

and LOWER)

ENHANCE (UPPER Off (push button out)

and LOWER)

AUTO ERASE (UPPER

Off (push button out)

and LOWER)

2. Connect the

7313/R7313 to a power source that

meets the voltage and frequency requirements of the

instrument. If the available linevoltage is outside the limits

of the Voltage Selector, see Operating Voltage discussion

in this section.

3. Insert Tektronix 7A-series amplifier units into both

the Left Vertical and Right Vertical compartments. lnserta

76-series dual time-base unit into the Horizontal compart-

ment.

4. Turn the POWER switch ON. Allow several minutes

warm-up so that the instrument reaches a normal

operating temperature before proceeding.

5.

Connect a BNC-to-pin-jack cable from the 4 V

CALIBRATOR output to the amplifier unit installed in the

Left Vertical compartment.

6.

Set both vertical units for a vertical deflection factor

of two volts/division and center the vertical position

controls. Set both vertical units for ac input coupling.

7. Set the time-base unit in the Horizontal compartment

for a sweep rate of one

millisecond/division. Set the

triggering for the auto mode, internal source, ac coupling,

and adjust for a stable display. Position the display as

necessary.

Page 14

Operating Instructions-7313lR7313 Operators

Fig.

1-4.

Location and function of internal selectors.

Page 15

Operating Instructions-7313lR7313 Operators

DISPLAY CONTROLS

8.

Adjust the INTENSITY control throughout its range;

then adjust so that the trace is at the desired viewing level.

9.

Adjust the FOCUS control so the top and bottom of

the displayed square wave are as thin as possible but not

elongated.

NOTE

The oscilloscope system contains circuitry to

automatically protect the crt against damage due to

excessive crt beam current. If the intensity control is

set to a point where crt phosphor damage could

occur, these circuits limit the beam current to a safe

level. The circuit action will also cause the trace to

defocus (widen), which indicates that the INTEN-

SITY should be reduced. Therefore, if the FOCUS

adjustment cannot be made satisfactorily, reduce

the INTENSITY and repeat step

9.

10. Rotate the GRAT ILLUM screwdriver control

throughout its range and notice that thegraticule Iinesare

illuminated as the control is turned clockwise. Set the

control so that the graticule lines are illuminated as

desired.

11. Set the deflection factor of the Left Vertical plug-in

unit to 0.1

volt/division. Notice that asquare-wave display

is not visible, since the deflection exceeds thescan areaof

crt.

12. Press the BEAMFINDER. Notice that the display is

returned to the viewing area in a compressed form.

Release the

BEAMFINDER switch and notice that the

display again disappears from the viewing area.

13. With the

BEAMFINDER switch pressed in, increase

the deflection factor of the Left Vertical

BE nit

until the

display is reduced to about two

divisionsvertically.Adjust

the Left Vertical unit position control to center the

compressed display about the center of the graticule.

Release the BEAMFINDER and notice that the display

remains within the viewing area.

NOTE

Readout operation steps apply only when the

7313/R7313 and the plug-in units installed in the

7313/R7313 are equipped with a Readout System.

73131R7313 Oscilloscopes with Option 1 do not

contain a Readout System.

14. Turn the READOUT control clockwise (out of

switch detent) until an alphanumeric display is visible

within the top or bottom division of the crt. Change the

deflection factor of vertical unit that is selected for display.

Notice that the readout portion of the display changes as

the deflection factor is changed. Likewise, change the

sweep rate of the time-base unit and notice that the

readout display for the time-base unit changes as the

sweep rate is changed.

15. Sequentially select all of the VERT MODE push

buttons. Notice that the readout from a particular plug-in

unit occupies a specific location on the display area. If

either of the plug-in units is a dual unit, notice that the

readout for channel

2

appears within the lower division of

the crt. Return the VERT MODE switch to LEFT.

16. Set the time-base unit for magnified operation.

Notice that the readout display changes to indicate the

correct magnified sweep rate. If a readout-encoded 10X

probe is available for use with the vertical unit, install it on

the input connector of the Right Vertical plug-in unit and

set the VERT MODE switch to RIGHT. Notice that the

deflection factor indicated by the readout is increased by

10 times when the probe is added. Return the time-base

unit to normal sweep operation and disconnect the 10X

probe.

17. Switch the vertical and horizontal unit deflection

switches (Volts/Div, Time/Div) to the uncalibrated posi-

tion. Notice the

>

symbol that precedes the readout

display. Return the vertical and horizontal unit deflection

switches to the calibrated position.

VERTICAL AND HORIZONTAL SYSTEM CON-

TROLS

Set the 7313/R7313 controls as follows:

INTENSITY

FOCUS

As desired

As desired

READOUT

As desired

GRAT ILLUM (screw- As desired

driver adjustment)

VERT MODE A LT

TRIG SOURCE VERT MODE

STORE (UPPER

Off (push button out)

and LOWER)

ENHANCE (UPPER

Off (push button out)

and LOWER)

AUTO ERASE (UPPER

Off (push button out)

and LOWER)

CALIBRATOR

4 V output connected to

the Left Vertical and

Right Vertical units

with a BNC-to-pin-jack

cable and a

BNC-to-

BNC jumper lead.

Page 16

Operating Instructions-7313/R7313 Operators

Set the associated equipment as follows:

Left Vertical unit

Deflection factor, 2 V/Div;

position, centered in

the top half of the

graticule; input

coupling ac.

Right Vertical unit

Horizontal unit

Deflection factor, 2 V/Div;

position, centered in

the bottom half of the

graticule; input

coupling, ac.

Deflection factor, 1 ms;

triggering, auto mode,

ac coupling, internal

source, level adjusted

for stable display.

18. Set the VERT MODE switch to LEFT. Rotate the

position controls of the Left and Right Vertical units and

notice that the position control of only the Left Vertical

unit has any affect on the vertical position of thedisplayed

trace.

19. Select the RIGHT VERT MODE. Notice that only the

position control of the Right Vertical unit hasany affect on

the vertical position of the displayed trace.

20. Select the ALT VERT MODE. Notice that two traces

are displayed on the crt. The upper trace is produced by

the Left Vertical unit and the lower trace is produced by the

Right Vertical unit. Change the sweep rate of the

time-

base unit to 50 millisecond/division. Notice that the

display alternates between the Left Vertical and Right

Vertical plug-in units after each sweep. Return the sweep

rate to one millisecond/division.

21. Select the CHOP VERT MODE. Notice that two

traces are displayed on the crt. Both vertical units are

displayed on each sweep on a time-sharing basis.

22. Select the ADD VERT MODE. Check for an added

display approximately four divisions iri amplitude. Notice

that the position control of either vertical unit will vertically

position the added display. Return the VERT MODE

switch to LEFT.

CALIBRATOR AND TRIGGERING CONTROLS

Set the 7313/R7313 controls as follows:

INTENSITY As desired

FOCUS

As desired

READOUT

As desired

GRAT ILLUM (screw- As desired

driver adjusment)

VERT MODE ALT

TRIG SOURCE VERT MODE

STORE (UPPER

Off (push button out)

and LOWER)

ENHANCE (UPPER

Off (push button out)

and LOWER)

AUTO ERASE (UPPER

Off (push button out)

and LOWER)

CALIBRATOR

4

V output connected to

the Left and Right

Vertical units with a

BNC-to-pin-jack

cable and a BNC-to

BNC jumper lead.

Set the associated equipment as follows:

Left Vertical unit

Deflection factor, 2

V/Div;

position, Left Vertical

unit display centered

in the top half of the

graticule; input

coupling, ac.

Right Vertical unit

Deflection factor, 2

V/Div;

position, Right Vertical

unit display centered

in the bottom half

of the graticule; input

coupling, ac.

Horizontal unit

Deflection factor, 1 ms;

triggering, auto mode,

ac coupling, internal

source, level adjusted

for a stable display.

Page 17

Operating Instructions-7313lR7313 Operators

23. Set the VERT MODE switch to LEFT. Change the

CALIBRATOR pin-jacks and notice that 4 V, 0.4 V, and

40 mV outputs can be obtained (change the amplifier unit

defection as necessary). The CALIBRATOR output must

be terminated in a one-megohm load for stated output. Set

The CALIBRATOR pin-jacks for 4 V output and set the

amplifier deflection factor to two volts/division.

24. Adjust the time-base unit triggering controls for a

stable display. Disconnect the CALIBRATOR signal froni

the Right Vertical unit. Sequentially select all VERT MODE

switch settings. Notice that a stable display is obtained in

all positions of the VERT MODE switch (as reference trace

is provided in the RIGHT VERT MODE position). Adjust

the time-base unit triggering level control as necessary.

25. Set the TRlG SOURCE switch to LEFT. Sequential-

ly select all VERT MODE switching settings. Notice that a

stable display is obtained in all positions of the VERT

MODE switch (a reference trace is provided in the RIGHT

VERT MODE position). Adjust the time-base unit trigger-

ing level control as necessary.

26. Set the TRlG SOURCE switch to RIGHT. Sequen-

tially select all VERT MODE switch settings and notice that

a stable display cannot be obtained in any

position.This is

because there is no input signal connected to the Right

Vertical unit.

27. Disconnect the 4 V CALIBRATOR signal from the

Left Vertical unit and connect it to the Right Vertical unit.

Sequentially select all VERT MODE switch settings.

Notice that a stable display is obtained in all VERT MODE

switch settings (a reference trace is provided in the LEFT

VERT MODE position). Adjust the time-base unit trigger-

ing level control as necessary.

28. Set the TRlG SOURCE switch to VERT MODE.

Sequentially select all VERT MODE switch settings.

Notice that a stable display is obtained in all VERT MODE

switch settings (a reference trace is provided in the LEFT

VERT MODE position). Adjust the time-base unit trigger-

ing level control as necessary.

29.

Set the TRlG SOURCE switch to LEFT. Sequential-

ly select all VERT MODE switch settings and notice that a

stable display cannot be obtained in any position. This is

because there is no signal connected to the Left Vertical

unit.

31. Set the VERT MODE switch to CHOP and the TRlG

SOURCE switch to LEFT and then to RIGHT. Notice that

the chopped display can be triggered from either vertical

compartment.

STORAGE CONTROLS

Set the 7313/R7313 controls as follows:

INTENSITY As desired

FOCUS

As desired

READOUT

As desired

GRAT

ILLUM (screw-

,

As desired

driver adjustment)

VERT MODE CHOP

TRIG SOURCE LEFT

STORE (UPPER

Off (push button out)

and LOWER)

ENHANCE (UPPER

Off (push button out)

and LOWER)

AUTO ERASE (UPPER

Off (push button out)

and LOWER)

CALIBRATOR

4 V output connected to

the Left and Right

Vertical units with a

BNC-to-pin-jack

cable to a

BNC-to-

BNC jumper lead.

Set the associated equipment as follows:

Left Vertical unit Deflection factor, 2 V/Div;

position, Left Vertical

unit display centered

in the top half of the

graticule; input

coupling, ac.

Right Vertical unit

Deflection factor, 2 V/Div;

position, Right Vertical

unit display centered

in the bottom half

of the graticule; input

coupling, ac.

Horizontal unit

30. Connect the 4 V CALIBRATOR signal to both

vertical units. Set the TRlG SOURCE switch to VERT

MODE and the VERT MODE switch to ALT. Check that

both traces of the alternate display are stable.

Deflection factor, 1 ms;

triggering, auto mode,

ac coupling, internal

source, level adjusted

for a stable display.

Page 18

Operating Instructions-731 3lR7313 Operators

32. Turn the INTENSITY control fully coun-

terclockwise. Press in both STORE push buttons. Notice

the normal storage mode background light level present

on the storage screens. Advance the INTENSITY control

slowly clockwise to produce awaveform display of normal

intensity; then return the INTENSITY control to minimum

intensity (fully counterclockwise). Notice a stored

waveform of moderate brightness. Press the UPPER

ERASE push button and then the LOWER ERASE push

button. Notice that each half of the crt display can be

erased or stored independently.

33. Set both STORE push buttons to their non-store

position (push buttons out). Set the

7313/R7313 and the

associated plug-in units for a stable display of normal

intensity. Set the time-base unit for single sweep opera-

tion and engage both 7313/R7313 STORE push buttons.

Apply a single sweep trace by pressing the time-base unit

reset push button. Notice a stored display on the UPPER

and LOWER storage areas. If the display is not stored,

increase the INTENSITY and repeat the demonstration.

34. Press both ERASE push buttons. Press the

LOCATE push button and notice dots slightly to the left of

the sweep starting point. The LOCATE function is useful

to locate and position the trace while the sweep is held off

(single sweep operation). Return the time-base unit to a

normal triggering mode (non-single sweep), and adjust

for a stable display.

35. Engage both AUTO ERASE push buttons. Notice

that one sweep is displayed on the crt and further sweeps

are locked out until thestored display iserased. Rotatethe

VIEW TIME control throughout its

rangeand note that this

control varies the amount of time that the display remains

stored before it is erased.

36. Rotate the VlEW TlME control fully clockwise. As

soon as the display is automatically erased and another

trace is stored, press both ERASE push buttons. Notice

that the crt is erased and other sweeps are locked out

during the period selected by the

VlEW TlME control.

Disengage both AUTO ERASE push buttons and both

STORE push buttons (push buttons out).

37. Set the time-base unit time/division switch to

0.2 microseconds/division. Adjust the INTENSITY control

fully clockwise. Position the rising portion of the waveform

within the graticule area. Adjust the INTENSITY control so

that the trace is just visible. Press both STORE push

buttons. Notice the normal storage mode background

light on the crt. Press the INTEGRATE push button

momentarily (a fraction of a second to several seconds is

reasonable). Notice a normal fully-stored display. If the

trace does not fully store on the first attempt, repeat the

integration for a longer period or with higher intensity.

Disengage both STORE push buttons and press both

ERASE push buttons. Remove the CALIBRATOR signal

from both vertical units.

38. Apply a sine-wave signal of approximatley

300 kilohertz to the Left Vertical unit. Set the

TRIG

SOURCE and VERT MODE switches to LEFT. Adjust the

amplifier unit for three divisions of display, centered on

the graticule. Adjust the oscilloscope INTENSITY for a

moderately bright trace. Set the time-base unit for single

sweep operation and engage both 7313/R7313 STORE

push buttons. Press the time-base unit reset push button

to obtain a single sweep trace. Notice that a complete

stored display cannot be obtained at any setting of the

INTENSITY control.

39. Press both ERASE push buttons; then press both

ENHANCE push buttons. Apply a single sweep trace by

pressing the reset push button. While repeatedly erasing

and applying a single-sweep signal, adjust the ENHANCE

Level control sufficiently clockwise to completely store

the display without fading the target positive (it may be

necessary to vary the oscilloscope intensity).

GENERAL OPERATING INFORMATION

INTENSITY CONTROLS

The 7313/R7313 has separate intensity controls for

display and display readout. The INTENSITY control

determines the brightness of only the signal display; the

READOUT control determines the brightness of only the

readout portion of the crt display.

The setting of the INTENSITY control may affect the

correct focus of the display. Slight re-adjustment of the

FOCUS control may be necessary when the intensity level

is changed. Do not turn the intensity control higherthan is

necessary to provide a stable display.

Be careful that the INTENSITY control is not set too

high when changing the time-base unit sweep rate from a

fast to a slow sweep rate or when changing to the X-Y

mode of operation. The oscilloscope system incorporates

protection circuitry which automatically reduces the

display intensity to a lower level when the time-base unit is

set to a slow sweep rate. This reduces the danger of

damaging the crt phosphor at slower sweep rates.

CRT light filters reduce the observed light output from

the crt. When using these filters, avoid advancing the

INTENSITY control to a setting that may burn the crt

phosphor.

Page 19

Operating Instructions-7313lR7313 Operators

DISPLAY FOCUS

LIGHT FILTER

The FOCUS control allows adjustment for best defini-

tion of the crt display. Slight re-adjustment of this control

may be necessary as the display conditions change. If a

properly focused display cannot be obtained with the

FOCUS control, the internal Astigmatism adjustment

must be re-set; see the Calibration section in the

7313/R7313 Service Manual.

The graticule of the7313/R7313 is marked on the inside

of the faceplate of the crt, providing accurate, no-parallax

measurements. The graticule is divided into eight vertical

and ten horizontal divisions. Each division is

0.975 centimeters square. In addition, each major division

is divided into five minor divisions. The vertical gain and

horizontal timing of the plug-in units are calibrated to the

graticuleso accurate measurements can be made from the

crt. The illumination of the graticule lines can be varied

with the GRAT

ILLUM screwdriver adjustment.

NOTE

Two types of crt graticules have been used in some

Tektronix oscilloscopes. One graticule has

0%

and

100%

risetime reference points that are separated by

6

vertical graticule divisions. The othergraticule has

the

0%

and

100%

risetime reference points

separated by 5 vertical divisions. In your manual,

illustrations of the crt face or risetime measurement

instructions may not correspond with the graticule

markings on your oscilloscope.

Figure 1-5 shows the graticule of the 7313/R7313 and

defines the various measurement lines. The terminology

defined here will be used in all discussions involving

graticule measurements. Notice the O0/0, 10, 90, and 100

markings on the left side of the graticule. These markings

are provided to facilitate risetime measurements.

SECOND

CENTER TENTH

VERTICAL

VERTICAL VERTICAL

LINE

LINE LINE

1

CENTER

HORIZONTAL

LlNE

1362-5

Fig. 1-5. Definition of measurement lines on the 7313lR7313

graticule.

The tinted filters provided with the 7313/R7313 reduce

light reflections from the face of the crt to improve contrast

when viewing the display under high ambient light

conditions. The light blue filter is recommended primarily

for non-storage operation and the light green filter is

recommended primarily for storage operation. These

filters should be removed for waveform photographs or

when viewing high writing-rate displays. To gain access to

the light filter, remove the plastic frame mask.

The

BEAMFINDER switch providesa means of locating

a display which overscans the viewing area eithervertical-

ly or horizontally. When the BEAMFINDER switch is

pressed, the display is compressed within the graticule

area. To locate and reposition an overscanned display,

use the following procedure:

1. Press in the BEAMFINDER switch.

2.

While the display is compressed, increase the ver-

tical and horizontal deflection factors until the vertical

deflection is reduced to about two divisions and the

horizontal deflection is

reduced to about four divisions

(the horizontal deflection needs to be reduced only when

operating in the

X-Y

mode).

3. Adjust the vertical and horizontal position controls to

center the display about the vertical and horizontal center

lines of the graticule.

4.

Release the BEAMFINDER switch; the display

should remain within the viewing area.

VERTICAL MODE

LEFT AND RIGHT MODE.

When the LEFT or RIGHT

push button of theVERT MODEswitch is pressed, only the

signal from the plug-in unit in theselected compartment is

displayed.

ALTERNATE MODE.

The ALT position of the VERT

MODE switch produces a display that alternates between

the plug-in units-in the Left Vertical and Right Vertical

compartments with each sweep of the crt. Although the

ALT mode can be used at all sweep rates, theCHOP mode

provides a more satisfactory display at sweep rates below

about 20 milliseconds/division. At these slower sweep

rates, alternate-mode switching becomes visually percep-

tible.

The TRIG SOURCE switch allows selection of the

triggering for an alternate display. When this switch is set

to the VERT MODE position, each sweep is triggered by

the signal being displayed on the crt. This provides a

stable display of two unrelated signals, but does not

indicate the time relationship between the signals. In

either the LEFT or the RIGHT positions, the two signals

are displayed showing true time relationship. However, if

the signals are not time-related, the display from the plug-

in unit which is not providing a trigger signal will appear

unstable on the crt.

REV.

B,

JULY,

1975

Page 20

Operating Instructions-7313lR7313 Operators

CHOPPED MODE.

The CHOP position of the VERT

MODE switch produces a display that is electronically

switched between channels at a one-megahertz rate. In

general, the CHOP mode provides the best display at

sweep rates lower than about

20

milliseconds/division, or

whenever dual-trace single-shot phenomena are to be

displayed. At faster sweep rates, the chopped switching

becomes apparent and may interfere with the display.

Correct internal triggering for the CHOP mode can be

obtained in any of the three positions of the TRlG

SOURCE switch. When the TRlG SOURCE switch is set to

VERT MODE, the internal trigger signals from the vertical

plug-in units are algebraically added and the time-base

unit is triggered from the resultant signal. Use of the LEFT

or RIGHT TRlG SOURCE positions triggers the time-base

unit on the internal trigger signal from theselected vertical

unit only. This allows two time-related signals to be

displayed showing true time relationship. However, if

signals are not time-related, the display from the channel

which is not providing the trigger signal will appear

unstable. The CHOP mode can be used to compare two

single-shot, transient, or random signals which occur

within the time interval determined by the time-base unit

(ten times selected sweep rate). To provide correct

triggering, the display which provides the trigger signal

must precede the second display in time. Sincethesignals

show true time relationship, time-difference

measurements can be made from the display.

The following general precautions should be observed

to provide the best display when using the ADD mode:

1. Do not exceed the input voltage ratingsof the plug-in

units.

2.

Do not apply large signals to the plug-in inputs. A

good rule to follow is not to apply a signal that exceedsan

equivalent of about eight times the vertical deflection

factors. For example, with a vertical deflection factor of

0.5

volt/division, the voltage applied to that plug-in unit

should not exceed

4

volts. Larger voltages may result in a

distorted display.

3. To ensure the greatest dynamic range in the ADD

mode, set the position controls of the plug-in units to a

setting which would result in a mid-screen display if

viewed in the LEFT or RIGHT positions of theVERT MODE

switch.

4.

For similar response from each channel, set the plug-

in units for the same input coupling.

TRIGGER SOURCE

The TRlG SOURCE switch allows selection of the

internal trigger signal for the time-base unit. For most

applications, this switch can be set to the VERT MODE

position. This position is the most convenient, since the

ALGEBRAIC ADDITION.

The ADD position of the

VERT MODE switch can be used to display the sum or

difference of two signals, for common-mode rejection to

remove an undesired signal, or for dc offset (applying adc

voltage to one channel to offset the dc component of a

signal on the other channel). The common-mode rejection

ratio between the vertical plug-in compartments of the

7313/R7313 is

100:l

from dc to

25

megahertz.

The overall deflection factor on thecrt in the ADD mode

is the resultant of the algebraic addition of thesignals from

the two vertical plug-in units. It isdifficult to determine the

voltage amplitude of the resultant display unless the

amplitude of the signal applied to one of the plug-in units

is known. This is particularly true when the vertical units

are set to different deflection factors, since it is not

obvious which portion of the display is a result of the

signal applied to either plug-in unit. Also, the polarity and

repetition rate of the applied signals enters into the

calculation.

internal trigger signal is automatically switched as the

VERT MODE switch is changed, or as the display is

electronically switched between the plug-in units in the

ALT position of the VERT MODE switch. It also provides a

usable trigger signal in the ADD or CHOP positions of the

VERT MODE switch, since the internal trigger signal in

these modes is the algebraic sum of the signals applied to

the vertical plug-in units. Therefore, the VERT MODE

position ensures that the time-base unit receives a trigger

signal regardless of the VERT MODE switch setting,

without the need to change the trigger source selection.

However, if correct triggering for the desired display is not

obtained in the VERT MODE position, the trigger source

can be changed to obtain the trigger signal from the plug-

in unit in either the Left Vertical or Right Vertical

compartment. The internal trigger signal is obtained from

the selected vertical compartment, whether the plug-in

unit in that compartment is selected for display on the crt

or not. If the internal trigger signal is obtained from

oneof

the vertical units, but the other vertical unit is selected for

display, the internal trigger signal must be time-related to

the displayed signal in order to obtain a triggered (stable)

display.

Page 21

Operating Instructions-7313lR7313 Operators

READOUT (Deleted

by

Option 1)

The Readout System of the 7313/R7313 allows

alphanumeric display of information on the crt along with

the analog waveform displays. The information displayed

by the Readout System is obtained from the plug-in units

which are installed in the plug-in compartments. The

characters of the readout display are written by the crt

beam on a time-shared basis with the signal waveforms.

The Readout Mode switch, (located on the Readout

circuit board) determines the operating mode of the

Readout System (see Fig.

1-4). When thisswitch, S2110, is

set to the Free-Run position, the Readout System random-

ly interrupts the waveform display to display readout

characters. The waveform display is interrupted for only

about 20 microseconds for each character that is dis-

played.

In theTriggered position the Readout System is locked

out so no characters are displayed during the sweep. At

the end of the sweep, the Readout System is triggered and

a complete frame of all applicable readout words is

displayed. This mode of operation can be used when the

trace interruptions necessary to display characters would

not otherwise allow a satisfactory waveform display to be

obtained. Also, when performing single-sweep photo-

graphy or during single-sweep storage operation, the

Triggered readout mode avoids blurring of the readout

characters due to continuous display. The trigger for the

Readout System in the Gate Triggered position is produc-

ed from the sweep gate selected by the rear-panel Gate

Selector switch (a time-base unit must be installed in the

Horizontal compartment.).

The readout information from each plug-in channel is

called a word. Up to six words of readout information can

be displayed on

the7313/R7313 crt (two channelsfor each

of three plug-in compartments). The location at which

each readout word is presented is fixed and is directly

related to the plug-in unit and channel from which it

originated.

Figure 1-6 shows the area of the graticule where the

readout from each plug-in unit and channel is displayed.

Notice that the readout from channel 1 of each plug-in unit

is displayed within the top division of the graticule, and the

readout from channel 2 is displayed directly below within

the bottom division of the graticule. Only the readout from

plug-in units or channels that are selected for display by

the VERT MODE switch or by the mode switches of dual

channel plug-in units, appear in the readout display. Some

special-purpose plug-in units may override the mode

switches to display readout, even though the

compartment is not selected for waveform display.

An "identify" feature is provided by the Readout

System to link the readout word with the orginating plug-

in unit and channel (amplifier units only). When the

"ldentify" button of an amplifier unit is pressed, the word

IDENTIFY appears in the readout location allocated to

that plug-in and channel. Other readout words in the

display remain unchanged. When the "identify" button is

released, the readout display from this plug-in channel is

again displayed. Circuitry may also be provided in the

amplifier unit that produces a noticeable change in the

analog waveform display to also identify the associated

trace when the "ldentify" button is pressed; see the plug-

in instruction manuals for details.

An "uncalibrated" feature is encoded into the readout

display. When the plug-in unit deflection factor switches

(Time/Div, Volts/Div) are in the uncalibrated position, the

>symbol is displayed preceding the readout display.

LEFT VERT RIGHT VERT HORlZ

CHANNEL

1

CHANNEL

1

CHANNEL

1

LEFT VERT RIGHT VERT HORlZ

CHANNEL

2

CHANNEL

2

CHANNEL

2

1362-6

Fig.

1-6.

Location of the readout on the crt identifying the origi-

nating plug-in compartment and channel.

STORAGE OPERATION

The storage feature of the 7313/R7313 increases the

versatility of this instrument. The crt display area is divided

into two

4

x

10

division storage screens that are in-

dependently controlled for split screen applications.

Separate STORE, ENHANCE, ERASE, and AUTO ERASE

switches allow independent control of these functions for

the UPPER and LOWER storage screens.

STORAGE

MODE.

The UPPER and LOWER STORE

push buttons determine the operating mode of the

associated display area. When the STORE push button is

out, the associated screen operates in the conventional

non-store manner. The remaining storage switches have

no effect on the operation of the instrument even though

they may be engaged. When the STORE push button is

pressed in, the assocated screen operates in the storage

mode and the associated storage functions are activated.

Page 22

Operating Instructions-7313lR7313 Operators

MANUAL ERASE.

When the UPPER or LOWER ERASE

push button is pressed, the associated storage screen is

erased. The ERASE switch overrides any of the other

storage switches, so the display can be manually erased in

any storage mode.

AUTOMATIC ERASE.

When the UPPER or LOWER

AUTO ERASE push button is pressed in, the stored

display is automatically erased after the viewing interval

selected by the VlEW TlME control. The VlEW TlME

control provides continuously variable viewing intervals

from less than 0.5 second (counterclockwise) to greater

than 10 seconds (clockwise). The view time begins at the

end of sweep. This is apparent at slow sweep rates.

REMOTE ERASE INPUT.

A ground closure (from a

positive level) applied to the rear-panel REMOTE ERASE

IN connector erases the stored display. The remote

actuation can be obtained from either an active system

(pulse generator, logic circuit, etc.) or a passive system

(switch or relay). Refer to the Specification section for

Remote Erase signal requirements.

A Remote Erase Selector (located on the Storage

circuit board) determines whether the external signal,

applied to the REMOTE ERASE IN connector, erases the

upper storage screen, lower stage screen or both storage

screens. See Fig. 1-4 for further information.

SINGLE SWEEP ENHANCEMENT AND LOCATION.

The ENHANCE mode (UPPER and LOWER) provides a

method of storing single-sweep or low repetition-rate

displays that exceed the normal writing speed of the

cathode-ray tube. This mode is not normally used for

repetitive sweeps.

NOTE

After sustained use

(6

hours or more) of the

7313lR7313

in the non-store mode or in the STORE

mode with nothing written, the writing speed may be

improved by leaving the crt target fully stored for five

to fifteen minutes. This procedure may be repeated

every few hours to refresh the storage target in

applications requiring maximum stored writing rate.

To use this feature, first obtain the best possible display

of the signal in the normal storage mode. Then press the

ENHANCE push buttons (UPPER or LOWER) and set the

ENHANCE Level control to about midrange. Apply a

single-sweep display. If the ENHANCE Level control is

properly set, the display will be stored with minimum

background luminance.

If the ENHANCE Level control is set too high, the

background luminance may obscure the desired display;

if the ENHANCE Level is too low, the display may not be

adequately stored. Therefore, experimentation is neces-

sary for an optimum enhanced display.

During single-sweep operation, the LOCATE push

button can be used to locate the trace or display while the

sweep is held off. Pressing the LOCATE push button

unblanks the crt and allows the display to be positioned

before storing. The start of

thesweep will be approximate-

ly 0.2 division to the right of the bright locate spot.

CARE OF STORAGE CRT.

To prolong the useful lifeof

the storage screens, the following precautions should be

observed when operating the 7313/R7313.

1. Use minimum beam intensity required to produce a

clear, well-defined display. Care must be observed in the

degree of writing-beam intensity that is used, particularly

when using slow sweep rates and sampling displays.

2.

Turn the INTENSITY control to minimum when

changing plug-in units. An undeflected spot on the crt

screen can burn the storage target.

3.

Do not increase beam intensity to store fast-

changing portions of a waveform. See instructions given

earlier in this section for storing fast-rise waveforms.

4. Avoid repeated use of the same area of the screen.

5. Do not leave a display on the crt screen (either

written or stored) when the display is not needed.

6.

Do not leave STORE switches pushed in when the

storage mode is not needed.

INTEGRATED FAST-RISE WAVEFORMS.

The

INTEGRATE push button permits storageof waveformsat

relatively fast sweep speeds with relatively low repetition

rates. Waveforms that would be difficult to see because of

the low duty cycle of the sweep, or have poor resolution

due to the required high setting of the INTENSITY control,

can often be stored, using the Integrate method, to

produce higher brightness or better resolution.

CAUTION

a

Do not attempt to store extremely fast-rising or fast-

falling portions of waveforms viewed at relatively

slow sweep rates. The high trace intensity required

(due to the intensity difference between the horizon-

tal and the vertical segments) could cause storage

target damage.

Page 23

Operating Instructions-7313lR7313 Operators

To use the INTEGRATE function, first obtain a

triggered well-defined display. Then, press the

INTEGRATE push button (a fraction of a second to several

seconds is reasonable). If all portions of the display are not

properly stored, repeat the integration for a longer period

with higher trace intensity.

Lower trace intensity and longer integration periods

produce optimum resolution of jitter-free signals. If in-

tegration is used too long, the stored image will broaden

and obscure the desired display. Use of the INTEGRATE

function in the AUTO ERASE mode is not recommended.

CALIBRATOR

The calibrator of the 7313/R7313 provides a convenient

signal source for checking basic vertical gain and for

adjusting probe compensation as described in the probe

instruction manual. In addition, the CALIBRATOR can be

used as a convenient signal source for application to

external equipment.

VOLTAGE. The CALIBRATOR provides accurate out-

put voltage of 40 millivolts, 0.4 volt, and 4 volts at the three

front-panel pin-jack connectors into high-impedance

loads. Output resistance is approximately 50 ohms at the

40 mV and 0.4 V pin jacks and approximately 450 ohms at

the 4 V pin jack.

CURRENT. A 40-milliampere, one-kilohertz output

current is provided when the optional current-loop

accessory (Tektronix Part No. 01 2-0259-00) is connected

between the 4 V pin-jack and ground. This output can be

used to check and calibrate current-measuring probe

systems.

WAVESHAPE. The CALIBRATOR output can be

switched for a dc level or one-kilohertz square-wave signal

via an internal selector

(P1066) on the Calibrator board.

See Fig. 1-4, in this section, for further information.

The square-wave output signal of the CALIBRATOR

can be used as a reference waveshape when checking or

adjusting the compensation of passive, high-resistance

probes. Since the square-wave output from the

CALIBRATOR has a flat top, any distortion in the dis-

played waveform is due to the probe compensation.

In the DC position; 40 mV, 0.4 V, and 4 V levels are

provided at the CALIBRATOR pin-jacks. When the

40 milliampere current loop is connected between the 4 V

output and GND, 40 milliamperes of dc current is provided

through the current loop.

SIGNAL OUTPUTS

NOTE

If the 7313/R7313 is ordered with Option 7, the signal

buffer assembly will not be installed in the instru-

ment. The VERT SIG OUT, +GATE OUT, +SAW-

TOOTH OUT, and the REMOTE ERASE

IN

and EXT

SS RESET

IN

rear-panel connectors are deleted.

+SAWTOOTH. The rear-panel +SAWTOOTH OUT

connector provides a positive-going sample of the saw-

tooth signal from the time-base unit in the Horizontal

compartment. The unit of time is determined by the time-

base unit time/division switch (e.g., if the time/division

switch is set to one millisecond/division, a unit of time is

one millisecond; at five milliseconds/division, a unit of

time is five milliseconds). Refer to the Specification

section for +SAWTOOTH OUT parameters.

+GATE OUT. The +GATE OUT connector provides a

positve-going rectangular output signal from the time-

base unit installed in the Horizontal compartment. The

source of the gate signal (MAINAUXILIARY, or DELAY) is

determined by the rear-panel Gate Selector switch. The

duration of the gate pulse is determined by the respective

sweep. AUXILIARY and DELAY GATE pulses can be

produced only by a compatible dual time-base unit. Refer

to the Specification section for +GATE OUT parameters.

VERTICAL SIGNAL. The VERT SIG OUT connector

provides a sample of the vertical deflection signal. The

source of this output signal is determined by the

TRIG

SOURCE switch. In the VERT MODE position of theTRIG

SOURCE switch the output signal is determined by the

setting of the VERT MODE switch. The output signal, in

the LEFT and RIGHT positionsof theVERT MODEswitch,

is obtained from the selected vertical compartment. In the

ALT position of the VERT MODE switch, the signal at the

VERT SIG OUT connector, switches between vertical

compartments along with the crt display. In the CHOPand

ADD positions of the VERT MODE switch, the output is a

composite signal. The composite signal is the resultant of

the algebraic addition of the vertical signals from the Left

Vertical and Right Vertical compartments.

The bandwidth of the VERT SIG OUT is determined by

the Amplifier plug-in unit used (see Systemsspecification

in the Specification section). Refer to the Specification

section for the parameters of the VERT SIG OUT signal.

Page 24

Operating Instructions-7313lR7313 Operators

REMOTE SINGLE SWEEP RESET (Delete with

Option 7)

An external single sweep reset signal can be applied to

the time-base unit in the Horizontal compartment through

the rear-panel EXT SS RESET IN connector. The remote

single-sweep reset actuation can by obtained from either

an active system (pulse generator, logic circuit, etc.) or a

passive system (switch or relay). Requirements for the

EXT SS RESET IN signal are given in the Specification

section.

DISPLAY PHOTOGRAHY

A permanent record of the crt display can be obtained

with an oscilloscope camera system. The instruction

manuals for the Tektronix Oscilloscope Cameras include

complete instructions for obtaining waveform

photographs. The following specific information applies

to the 7313/R7313.

The crt bezel of the 7313/R7313 provides integral

mounting for a Tektronix Oscilloscope Camera. The three

pins located on the left side of thecrt bezel connect power

to compatible camera systems. Control signals are also

received from Tektronix automatic cameras to allow

camera controlled single-shot photography (see camera

manual for further information).

When this instrument is operated in thestorage mode, a

photograph may

beeasily composed by erasing unwanted

displays as many times as necessary before the desired

display is obtained. This ability to compose a photograph

in advance prevents wasted film due to incorrect displays.

If the readout portion of the display is to be included on

waveform photographs, the following suggestions will aid

in obtaining good photographs.

1. Focus the oscilloscope display and the camera on

the center of the crt display.

2. Set the READOUT intensity control for a minimum

setting that allows the characters to be written. This

normally occurs at a slightly lower intensity level than is

necessary for complete writing of the waveform display.

Some experimentation may be necessary to establish the

correct level. Too high asetting of the READOUT intensity

control

will result in a broad, poorly defined photograph of

the readout display.

3. If single-shot photography is used, set the Readout

Mode switch to the Triggered position (see the Readout

discussion in this section for complete operating informa-

tion). Then, the readout is displayed in a single-shot

manner after the trace is complete (be sure the camera

shutter remains open at least0.5 second afterthesweep is

completed to photograph the entire readout). Also, set the

GRAT ILLUM control counterclockwise while the trace is

being photographed. Then, the graticule can be

photographed later to produce a double-exposure picture

showing complete information.

X-Y

OPERATION

In some applications, it is desirable to display one

signal versus another (X-Y) rather than against time

(internal sweep). The flexibility of the plug-in units

available for use with the 7313/R7313 provides a means of

applying an external signal to the horizontal deflection

system for this type of display. Someof the7B-series time-

base units can be operated as amplifiers in addition to

their normal use as time-base generators. This feature

allows an external signal to provide the horizontal deflec-

tion on the crt. For most of the time-base units with the

amplifier function, the X (horizontal) signal can be con-

nected either to an external input connector on the time-

base unit or it can be routed to the time-base unit through

the internal triggering system (see time-base instruction

manual for details). If the latter method is used,

theTRlG

SOURCE switch must be set so that the X (horizontal)

signal is obtained from one of the vertical units and the Y

(vertical) signal is obtained from the other vertical unit.

The advantages of using the internal trigger system to

provide the X signal are: (1) The plug-in units do not have

to be moved between compartments for X-Y operation. (2)

The attenuator switch, of the amplifier unit providing the

horizontal signal, determines the horizontal deflection

factor for full range operation.

Another method of obtaining

X-Y

display is to install

an amplifier plug-in unit in one of the horizontal plug-in

compartments (check amplifier unit gain as given in the

plug-in instruction manual to obtain calibrated horizontal

deflection factors). This method provides the best X-Y

display, particularly if two identical amplifier units are

used, since both the X and Y input systems will have the

same delay time, gain characteristics, input coupling, etc.

For further information on obtaining X-Y displays, see the

plug-in unit manuals. Also, the reference books listed

under Applications provide information on X-Y

measurements and interpreting the resultant

lissajous

displays.

Page 25

Operating Instructions-7313lR7313 Operators

INTENSITY MODULATION RASTER DISPLAY

Intensity (z-axis) modulation can be used to relate a

third item of electrical phenomena to the vertical (y-axis)

and the horizontal (x-axis) coordinates without affecting

the waveshape of the displayed signal. The z-axis

modulating signal applied to the crt circuit changes the

intensity of the displayed waveform to provide this type of

display. "Gray scale" intensity modulation can be ob-

tained by applying signals that do not completely blank

the display. Large amplitude signals of the correct polarity

will completely blank the display; the sharpest display is

provided by signals with a fast rise and fall. The voltage

amplitude required for visible trace modulation depends

upon the setting of the INTENSITY control. A two-volt

peak-to-peak signal will completely blank the display,

even at maximum intensity levels. Lower amplitude

signals can be used to only change the trace brightness,

rather than completely blank the display. Negative-going

modulating signals increase the display intensity and

positive-going modulating signals decrease the display

intensity. Useful input frequency range is dc to 10

megahertz (input voltage derating necessary above two

megahertz). The maximum input voltage should be limited

to 10 volts (dc plus peak ac). When the EXT

Z

AXlS IN is

not in use, replace the BNC cap.

Time markers applied to the EXT

Z

AXlS IN connector

provide a direct time reference on the display. With

uncalibrated horizontal sweep or external horizontal

mode operation, the time markers provide a means of

reading time directly from the display. However, if the

markers are not time-related to the display waveform, a

single-sweep display should be used (for internal sweep

only) to provide a stable display.

The following books describe oscilloscope measure-

ment techniques which can be adapted for use with this

instrument.

A

raster-typedisplay can be used to effectively increase

the apparent sweep length. For this type of display, the

trace is deflected both vertically and horizontally by

sawtooth signals. This is accomplished in the 7313/R7313

by installing a 7B-series time-base unit in one of the

vertical plug-in compartments. Normally, the time-base

unit in the vertical compartment should be set to a slower

sweep rate than the time-base unit in the horizontal

compartment; the number of horizontal traces in the raster

depends upon the ratio between the two sweep rates.

Information can be displayed on raster using several

different methods. In the ADD position of

theVERT MODE

switch, the signal from an amplifier unit can be

algebraically added to the vertical deflection. With this

method, the vertical signal amplitudeon the crt should not

exceed the distance between the horizontal lines of the

raster. Another method of displaying information on the

raster is to use the EXT

Z

AXlS IN to provide intensity

modulation of thedisplay.This typeof rasterdisplay could

be used to provide a television-type display. Complete

information on operation using the z-axis feature is given

under Intensity Modulation.

To provide a stable raster display, both time-base units

must be correctly triggered. Internal triggering is not

provided for the time-base units when they are in the

vertical compartments; external triggering must be used.

Also, blanking is not provided from the time-base units