Page 1

Model 7153 High Voltage Low

Current Matrix Card

Instruction Manual

Contains Operating and Servicing Information

Page 2

Page 3

Model

7153

High Voltage Low

Instruction Manual

0 1990, Keithley Instruments, Inc.

Test Instrumentation Croup

All rights reserved.

Cleveland, Ohio, U.S.A.

November 1990, First Printing

Document Number: 7153.YOLRev. A

Page 4

Page 5

SAFETY PRECAUTIONS

The following safety precautions should be observed before using the

Model 7153 and the associated instruments.

This matrix card is intended for use by qualified personnel who recognize

shock hazards and are familiar with the safety precautions required to

avoid possible injury. Read over this manual carefully before using the

card.

ALWAYS remove power from the entire system (mainframe, test instruments, DUT, etc.) and discharge any capacitors before doing any of the

following:

1. Installing or removing the matrix card from the mainframe.

2. Connecting or disconnecting cables from the matrix card.

Exercise extreme caution when a shock hazard is present at the test fixture.

User-supplied lethal voltages may be present on the fixture or the connector jack. The American National Standards Institute (ANSI) states that a

shock hazard exists when voltage levels greater than 30V RMS or 42.4V

peak are present. A good safety practice is to expect that hazardous voltage is present in any unknown circuit before measuring.

Do not exceed 1300V between any two pins or between any pin and chassis ground.

Inspect the connecting cables and test leads for possible wear, cracks, or

breaks before each use.

For maximum safety, do not touch the test fixture, test cables or any instruments while power is applied to the circuit under test.

Page 6

Do not touch any object which could provide a current path to the common side of the circuit under test or power line (earth) ground.

Do not exceed the maximum signal levels of the test fixture, as defined in

the specifications and operation section of this manual.

Do not connect the matrix card (or any other instrumentation) to humans.

Do not connect the matrix card directly to unlimited power circuits. This

product is intended to be used with impedance limited sources. NEVER

connect the tmatrix card directly to AC mains.

When connecting sources, install protective devices to limit fault current

and voltage to the card.

The chassis connections must only be used as shield connections for

measuring circuits; NOT as safety earth ground connections.

The outer shields (including the triax connector shells) of the Model

7153-TRX are not connected to safety earth ground. NEVER apply more

than 30V to these shields.

To prevent voltages from being exposed or connections from shorting together, make sure cables are properly connected before applying voltage.

Do not apply power to cables that are not connected.

Page 7

Model

MATRIX CONFIGIJRATION: 4 TOWS by 5 columns.

CROSSPOINT CONFIGURATION (Signal and Guard): Z-pole Form A.

CONNECTORTYPE: Miniature coax, M-Series Receptacle.

RELAY DRWE CURRENT: 40mA (per crosspoint).

MAx,MuM SlGNAL LEVEL:

IA carry / 0.5A switched.

IOVA peak (resistive load).

Maximum Between Any 2 Pins or Chassis: 13OOV.

Max,mum Between Signal and Guard: 200”.

CONTACT LIPB:

Cold Switching: 108closures.

Maximum Signal Level: lo5 closures.

PATH RESISTANCE: <IO per contact to rated life.

ACTUATION TIME: <2ms evctusivc of mainframe.

ISOLATION:

Path to Path: >lOW and <IpF.

Differential (Signal to Guard): >lO”Q and 4OOpF.

Gammon Mode 6tgnat and Guard to Chassis): >lOQ and 4OOpP.

CROSSTALK (Adjacent Path to Path): <-50dB at IMHz, 50 n load.

INSERTION LOSS (1 MHz, 5On Source, 5On Load): 0.1 dB typical.

3dB BANDWIDTH (500 Load): 60 MHz typical.

OPPSET CURRENT (Signal to Guard): 4pA (1OfA typical)

CONTACT POTENTIAL (Signal to Guard): <5OpV typical.

ENVIRONMENT:

Isolation and Offset Current Specifications: WC, 40% R.H.

~,~~wAI;~~~~“,;~~$$ up to 35°C at 70% R.H.

7153

Specifications

c

VIMENSIONS, WEIGHT: 30mm high x 114mm wide x 288mm long

x 11.34 in.,. Net weight 0.60 kg (20.0 oz.).

)RY

ACCESSC

surrLif3.D:

Insttiction manual

(1.18 in. x

Page 8

SECTION 1

General Information

Contains information on Model 7153 features, specifications,

and accessories.

SECTION 2

Operation

Details installation of the Model 7153 High Voltage Low Current Matrix Card within theModel 705 and 706 scanners. covers

card connections, and also discusses matrix mainfrake programming and measurement considerations.

SECTION 3

Applications

Gives three typical applications for the Model 7153, including

semiconductor switching matrix, van der Pauw resistivity mearurements, and semiconductor parameter analysis using the HP

41150.

SECTION 4

Service information

Contains Matrix card cleaning and performance verification

procedures for the matrix card.

SECTION 5

Replaceable Parts

Lists replacement pans, and also includes component layout

and schematic drawing for the Model 7153

Page 9

Table of Contents

SECTION 1 - General Information

1.1

1.2

1.3 WARRANTY INFORMATION

1.4

1.5

1.6

1.7

1.7.1

1.7.2

1.7.3

1.8

1.9

INTRODUCTION ..................

FEATURES,

MANUAL ADDENDA

SAFETY SYMBOLS AND TERMS .......

SPECIFICATIONS ..................

UNPACKING AND INSPECTION ......

Inspection for Damage

Shipment Contents

Additional Instruction Manual .......

REPACKING FOR SHIPMENT .........

OPTIONAL CABLE ASSEMBLY

.......................

.........

...............

............

...............

........

SECTION 2 - Operation

2.1

2.2

2.3

2.4

2.5 CARD INSTALLATION AND REMOVAL

2.5.1

2.5.2

2.6

2.6.1

2.6.2 Recommended Cables and Adapters

2.6.3

2.6.4

2.6.5

2.7

2.8

2.8.1

INTRODUCTION

HANDLING PRECAUTIONS

ENVIRONMENTAL CONSIDERATIONS

EQUIVALENTCIRCUIT

Matrix Card Installation

Matrix Card Removal

INSTRUMENT AND DUT CONNECTIONS

Card Connectors

General Instrument Connections

Keithley Instrument Connections

Typical Test Fixture Connections

MATRIX EXPANSION

MAINFRAME CONTROL OF MATRIX CARD

Front Panel Matrix Control

............................

....................

........................

......................

.......................

...........................

...............

...............

...............

.........................

...................

...........

...........

........

............

.......

l-l

l-l

1-2

1-2

1-2

1-3

1-3

1-3

1-3

1-3

1-3

1-4

2-1

2-2

2-2

2-2

.

2-3

2-4

2-6

2-6

2-7

2-9

2.12

2-20

2-25

2-26

2-28

2.20

Page 10

2.8.2

2.9

2.9.1

2.9.2

2.9.3

2.9.4

2.9.5

2.9.6

2.9.7

Matrix Control Over IEEE-488 Bus ...........

MEASUREMENTCONSIDERATIONS ..........

Magnetic Fields .........................

Radio Frequency Interference ..............

Ground Loops ..........................

Keeping Connectors Clean ................

Noise Currents Caused by Cable Flexing

Shielding ..............................

Guarding ..............................

SECTION 3 -Applications

......

2-33

2-35

2-35

2-36

2-37

2-38

2-39

2-39

2.41

3.1

3.2

3.2.1

3.2.2

3.3

3.3.1

3.3.2

3.3.3

3.3.4

3.3.5

3.3.6

3.3.7

3.4

INTRODUCTION ...........................

SEMICONDUCTOR TEST MATRIX ..............

System Configuration

Testing Common-Source Characteristic of FETs

RESISTIVITY TESTING USING MATRIX SWITCHING

IN A SMU TEST SYSTEM ......................

System Configuration ......................

Test Configuration .........................

Resistivity Calculations

Test Connections ..........................

Measurement Considerations

Pro

ram: Resistivity Tests Using a Switching Matrix

an Source Measure Unit ...................

d:

Program Description .......................

SMU REMOTE SENSING ......................

........... ;. .........

.....................

................

...

3-1

3-1

3-2

3-3

3-4

3-4

3-4

3-7

3-7

3-8

3-9

3-10

3-13

SECTION 4 - Service Information

4.1 INTRODUCTION . . . . .

4.2

4.3 PERFORMANCE VERIFICATION

4.3.1 Environmental Conditions . . . . 4-2

4.3.2 Recommended Test Equipment . . . . 4-2

HANDLING AND CLEANING PRECAUTIONS 4-1

4-l

4-2

Page 11

4.3.3

4.3.4

4.3.5

4.3.6

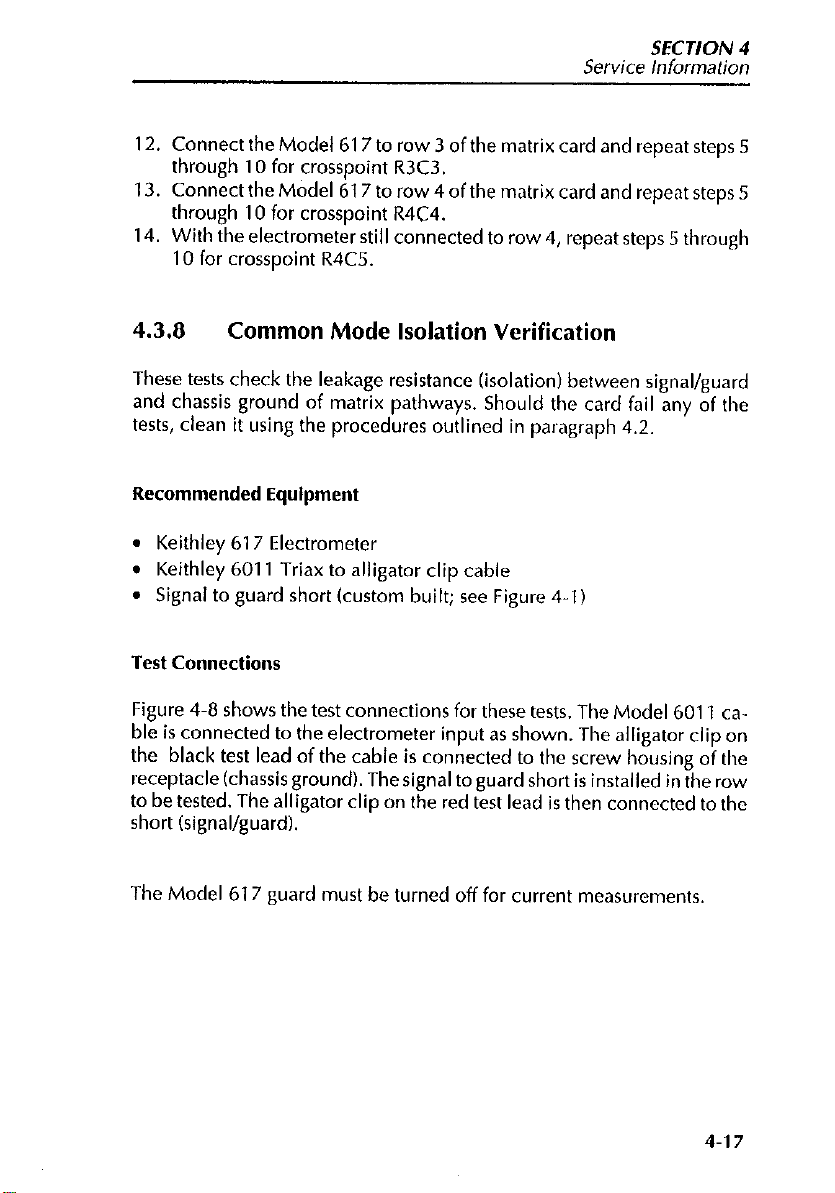

4.3.7 Differential Isolation Verification

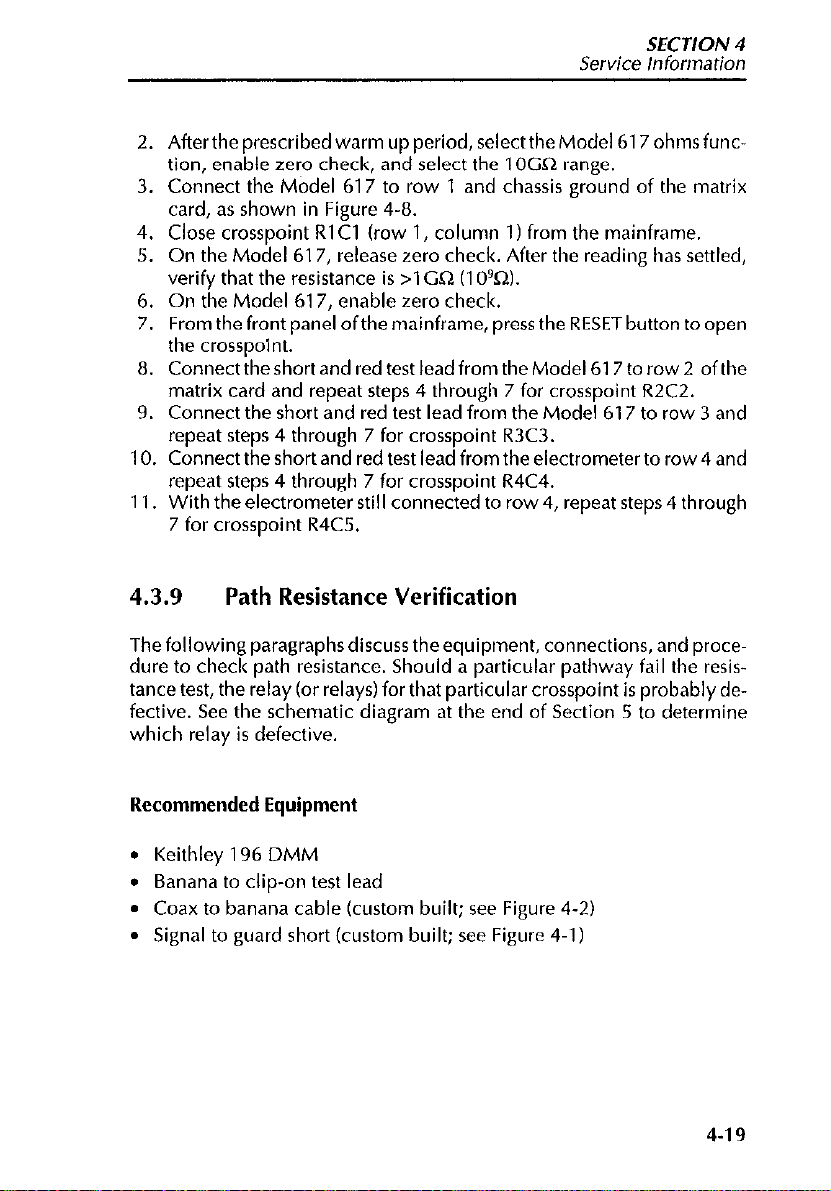

4.3.8

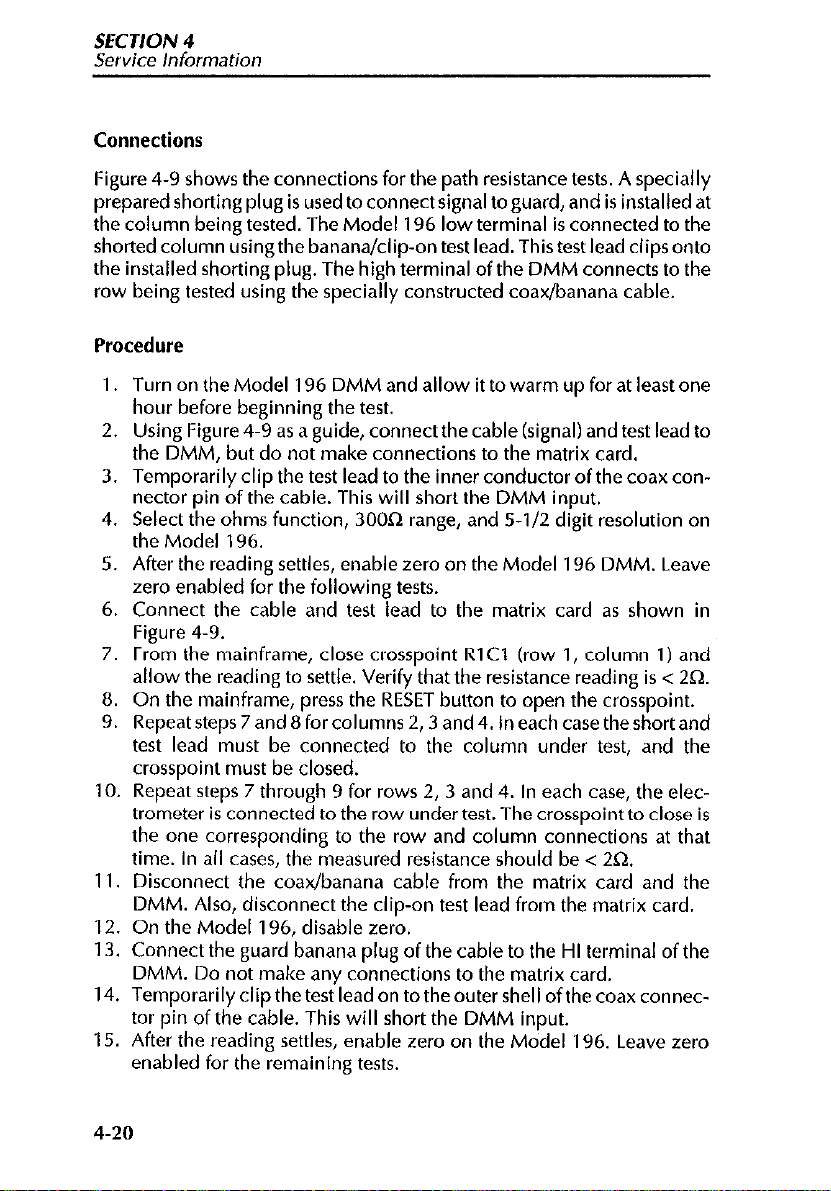

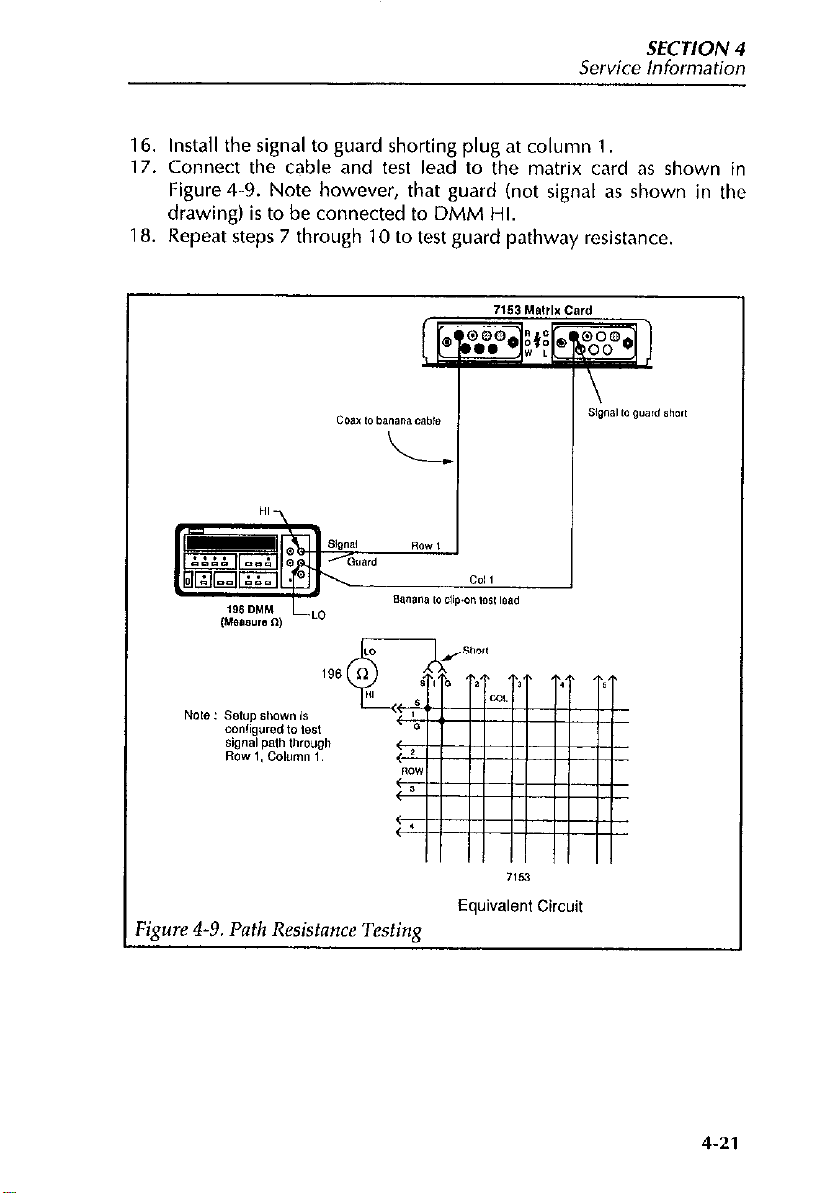

4.3.9

Special Connection Requirements

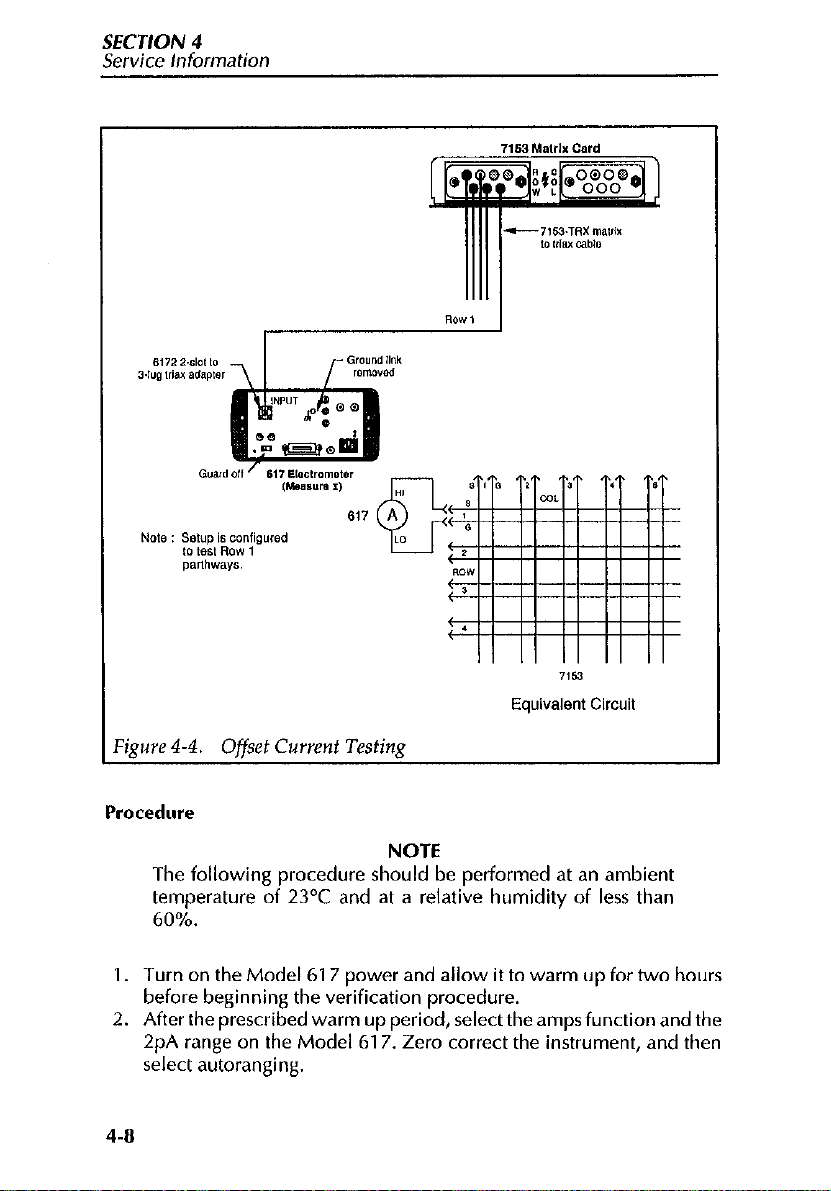

Offset Current Verification

Contact Potential Verification .

Path Isolation Verification .

Common Mode Isolation Verification

Path Resistance Verification

SECTION 5 - Replaceable Parts

4-4

4-7

4-9

4-l 1

4-14

4-17

4-19

5.1 INTRODUCTION .

5.2

5.3

5.4 FACTORY SERVICE . . . . .

5.5

PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ORDERING INFORMATION

COMPONENT LAYOUT AND SCHEMATIC DIAGRAM

3-l

3-l

3-l

3-1

3-1

Page 12

List of Illustrations

SECTION 2

Figure 2-l

Figure 2-2

Figure 2-3

Figure 2-4

Figure 2-5

Figure 2-6

Figure 2-7

Figure 2-8

Figure 2-9

Figure 2-10

Figure 2-11

Figure 2-l 2

Figure 2-13

Figure 2-14

Figure 2-l 5

Figure 2-16

Figure 2-17

Figure 2-l 8

Figure 2-l 9

Figure Z-20

Figure 2-21

- Operation

Schematic of Model 7153 ..................

Card Installation in a Model 705 .............

Card Installation in a Model 706 ............

Model 7153 Connectors ...................

Miniature Connector Configuration ...........

Model 7153-TRX Pin Identification ...........

Triax Connector Configuration (Model 7153-TRX)

General Instrument Connections .............

Electrometer Connections ..................

Model 237 Source Measure Unit .............

Model 230 Voltage Source Connections .......

Model 220 Current Source Connections .......

Typical Test Fixture Connections .............

Equivalent Circuit of Test Fixture Connections ...

Typical Row Connections for Matrix Column

Expansion ..............................

Power Line Ground Loops ..................

Eliminating Ground Loops ..................

Shielding Example ........................

Dual Shielded Test Fixture ..................

Guarded Circuit .........................

Typical Guarded Signal Connections ..........

2-3

2-5

2-6

2-8

2-8

2-l 1

2-12

2-l 5

2-21

2-22

2-23

2-24

2-25

2-26

2-27

2-37

2-38

2-40

2-41

2-42

2-43

SECTUON 3 - Applications

Figure 3-1

Figure 3-2

Figure 3-3

Figure 3-4

Multi Unit Connections to Model 7153 . .

System Configuration for Measuring Common-

Source Characteristics

System Configuration for Resistivity Tests

Resistivity Test Configuration

3-2

3-3

3-5

3-5

Page 13

Figure 3-5 Resistivity Measurement Conventions ..........

Figure 3-6 Test Connections for Resistivity Tests ...........

Figure 3-7 Program Flowchart ........................

Figure 3-8 Remote Sense and Guard Connections to Model

7153 ...................................

Figure 3-9 Remote Sensing with Guard .................

SECTION 4 - Service Information

3-6

3-8

3-l 1

3-14

3-15

Figure 4-l Signal-to-Guard Short Preparation .

Figure 4-2

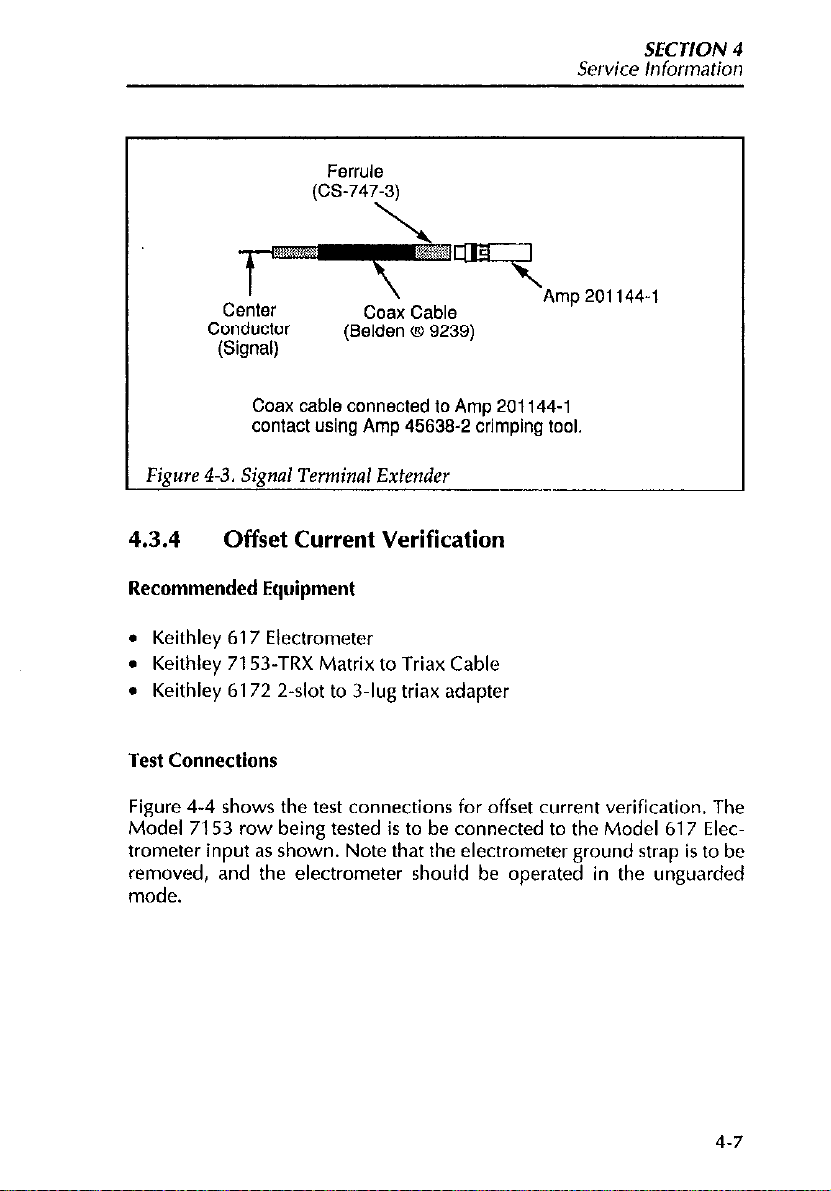

Figure 4-3 Signal Terminal Extender

Figure 4-4

Figure 4-5 Contact Potential Testing .

Figure 4-6

Figure 4-7 Differential Input Isolation Testing

Figure 4-8

Figure 4-9 Path Resistance Testing . .

Coax to Banana Cable Preparation

Offset Current Testing

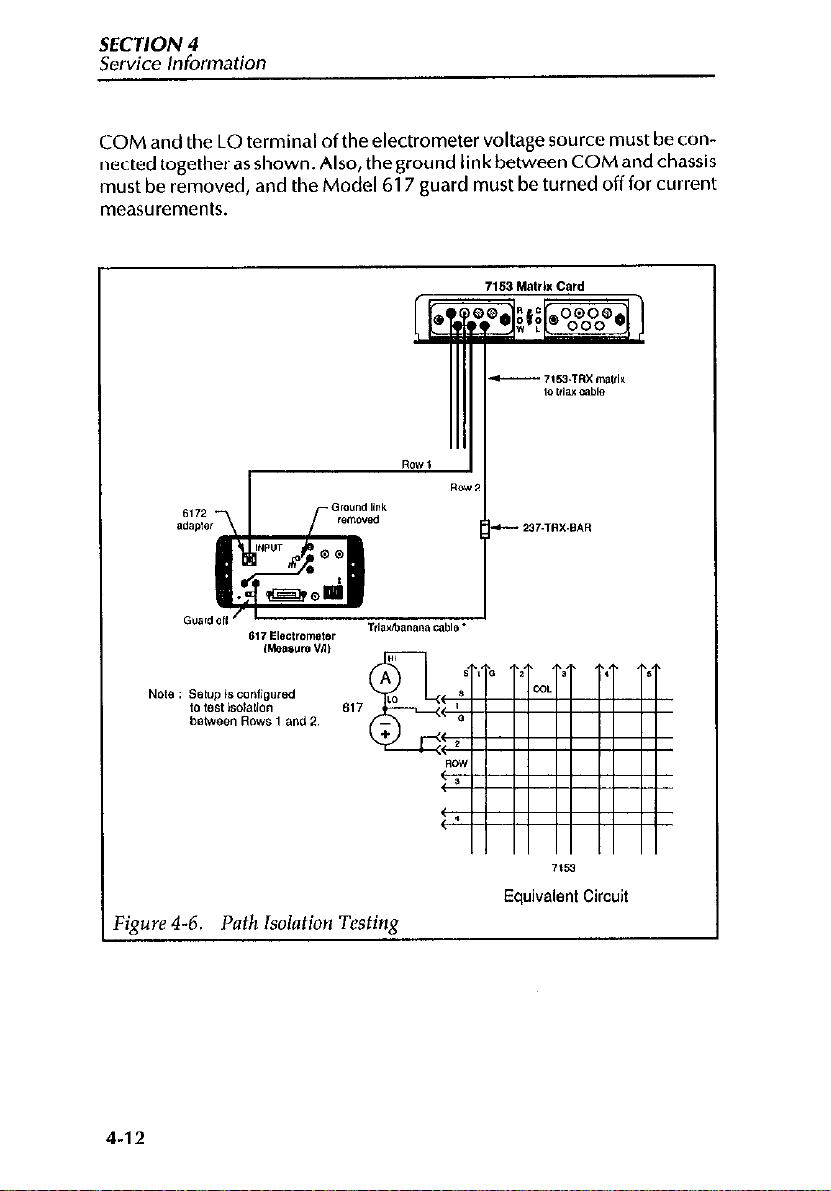

Path Isolation Testing

Common Mode Input Isolation Testing

......

......

.......

.......

.......

.......

.......

.......

4-5

4-6

4-7

4-8

4-10

4-12

4-15

4-18

4-21

Page 14

list of Tables

SECTION 2 - Operation

Table 2-l Recommended Cables and Adapters

Table 2-2

Table 2-3 Three-digit ID Numbers for Programming

Table 2-4

Two-Digit ID Numbers for Programming

Model705

Model706

Most Often Used DDCs

2.10

Z-30

2.31

2-34

SECTION 4 - Service Information

Table 4-l

Table 4-2 Special Connection Parts ......................

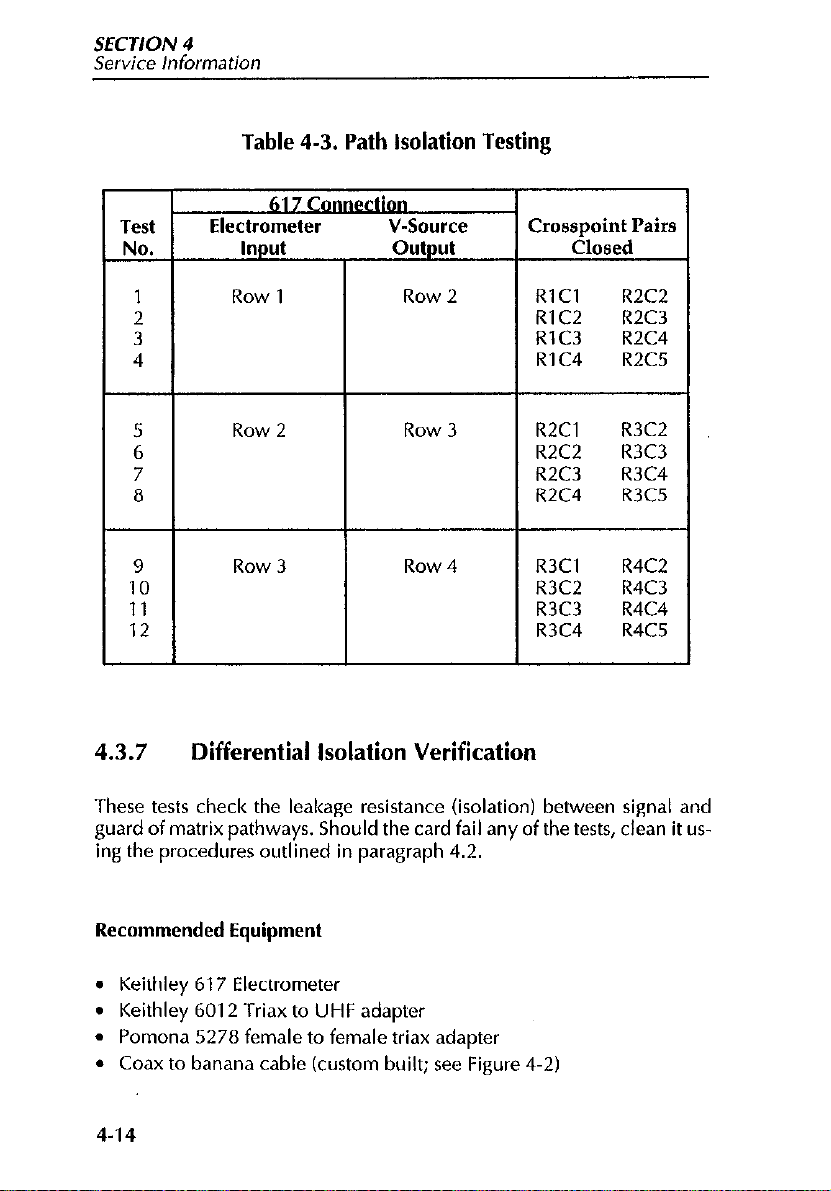

Table 4-3 Path isolation 1.esting ........................ 4-14

Recommended Test Equipment ................. 4-3

4-5

Page 15

SECTION 1 General Information

1 .l INTRODUCTION

This section contains general information about the Model 7153 High

Voltage Low Current Matrix Card and is arranged as follows:

1.2 Features

1.3 Warranty Information

1.4 Manual Addenda

1.5 Safety Symbols and Terms

1.6 Specifications

1.7 Unpacking and Inspection

1.8 Repacking for Shipment

1.9 Optional Accessories

1.2 FEATURES

Key features of the Model 7153 High Voltage Low Current Matrix Card in-

clude:

. 4 x 5 (four row by five column) switching matrix.

l

Low offset current for low-current measurements.

1-1

Page 16

SECTION 1

General

Information

1.3 WARRANTY INFORMATION

Warranty information is located on the inside front coverofthis instruction

manual. Should your Model 7153 require warranty service, contact the

Keithley representative or authorized repair facility in your area for further

information. When returning the matrix card for repair, be sure to fill out

and include the service form at the back of this manual in order to provide

the repair facility with the necessary information.

1.4 MANUAL ADDENDA

Any improvements or changes concerning the matrix card or manual will

be explained in an addendum included with the the unit. Be sure to note

these changes and incorporate them into the manual before using or serv-

icing the unit.

1.5 SAFETY SYMBOLS AND TERMS

The following symbols and terms may be found on an instrument or used

in this manual.

The A

the operating instructions located in the instruction manual.

The

sent on the terminal(s). Use standard safety precautions to avoid personal

contact with these voltages.

The WARNING heading used in this manual explains dangers that might

result in personal injury or death. Always read the associated information

carefully before performing the indicated procedure.

The CAUTION heading used in this manual explains hazards that could

damage the matrix card. Such damage may invalidate the warranty.

1-2

symbol on an instrument indicates that the user should refer to

symbol on an instrument shows that 1 kV or greater may be pre-

i

Page 17

General Information

SECTION 1

1.6 SPECIFICATIONS

Model 7153 specifications are located at the front of this manual. These

specifications are exclusive of the mainframe specifications, which are located in their respective instruction manuals.

1.7 UNPACKING AND INSPECTION

1.7.1 Inspection for Damage

Upon receiving the Model 7153, carefully unpack it from its shipping carton and inspect the card for any obvious signs of physical damage. Report

any such damage to the shipping agent immediately. Save the original

packing carton for possible future reshipment.

1.72 Shipment Contents

The following items are included with every Model 7153 order:

. Model 7153 Iiigh Voltage Low Current Matrix Card.

. Model 7153 Instruction Manual.

. Additional accessories as ordered.

1.7.3

If an additional instruction manual is required, order the manual package,

Keithley part number 7153-901-00. The manual package includes an in-

struction manual and any pertinent addenda.

Additional Instruction Manual

1.8 REPACKING FOR SHIPMENT

Should it become necessary to return the Model 7153 for repair, carefully

pack the unit in its original packing carton or the equivalent, and include

the following information:

. Advise as to the warranty status of the matrix card.

l-3

Page 18

SECTION 1

General Information

l

Write ATTENTION REPAIR DEPARTMENT on the shipping label.

. Fill out and include the service form located at the back ofthis manual.

1.9 OPTIONAL CABLE ASSEMBLY

The following cable assembly is available to make connections to the

Model 7153.

Model 7153-TRX - This 2-meter cable assembly is made up of five individual triax cables. One end of the cable assembly is terminated with a

miniature, multiple-contact plug that will mate to the matrix card receptacles. The other end of the cable assembly is terminated with five 3.slot

male triax connectors.

NOTE

Adapters that are available from Keithley are listed in Table

2-1.

l-4

Page 19

SECTION 2 Operation

2.1 INTRODUCTION

This section contains information on aspects of matrix card operation and

is arranged as follows:

2.2 Handling Precautions: Details precautions that should be observed

when handling the matrix card to ensure that its performance is not de-

graded due to contamination.

2.3 Environmental Considerations: Outlines environmental aspects of

using the Model 7153.

2.4 Equivalent Circuit: Provides the simplified matrixcard circuitforthe

Model 7153.

2.5 Card Installation and Removal: Covers the basic procedures for installing and removing the matrix card from the Model 705 or 706 main-

frame.

2.6 Connections: Discusses card connectors, cables and adapters, and

typical connections to other instrumentation and DUT test fixtures.

2.7 Matrix Expansion: Shows how to expand the matrix by connecting

two or more matrix cards together.

2.8 Mainframe Control of Matrix Card: Covers the operating aspects

specific to the Model 71 S3.

2.9 Measurement Considerations: Reviews a number of considerations

when making low-level measurements.

2-1

Page 20

SECTION 2

Operation

2.2 HANDLING PRECAUTIONS

To maintain high impedance isolation, care should be taken when handling the matrix card to avoid contamination from such foreign materials

as body oils. Such contamination can substantially lower leakage resistances, degrading performance.

To avoid possible contamination, always grasp the card by the side edges.

Do not touch the edge connectors of the card and do not touch board surfaces or components. When not installed in a mainframe, keep the card in

the bag and store in the original packing carton.

Dirt build-up over a period of time is another possible source of contamination. To avoid this problem, operatethe mainframe and matrix card only

in a clean environment.

If the card should become contaminated, it should be thoroughly cleaned

as explained in paragraph 4.2.

2.3 ENVIRONMENTAL CONSIDERATIONS

For rated performance, the card should be operated within the temperature and humidity limits given in the specifications at the front of this manual. Note that current offset and path isolation values are specified within a

lower range of limits than the general operating environment.

2.4 EQUIVALENT CIRCUIT

A simplified schematic of the Model 7153 4 x 5 matrix card is shown in

Figure 2-I. Each ofthe 20 crosspoints is made up of a two-pole switch. In

this simple configuration any row can be connected to any column by

closing the appropriate crosspoint. Mainframe control of matrix

crosspoints is covered in paragraph 2.8.

2-2

Page 21

SECTION 2

Operation

rI

I

I

I

1)

I

I

2>

’ now

3>

I

4)

I

I

I

I

I--

Figure 2-1. SchematicofModel7753

-

A diagram of the Model 7153 is provided in Appendix A. This

system configuration worksheet makes it convenient to plan a

matrix system. Additional space is provided for drawings and

notes.

__--------

Column

1 2 3 4 5

“2

97

NOTE

-1

I

I

I

I

I

I

I

I

I

I

I

I

I

- _I

2.5 CARD INSTALLATION AND REMOVAL

The following procedures explain how to install and remove the Model

7153 matrix card from the Models 705 and 706 mainframes.

WARNING

To prevent electrical shock which could result in injury or

death, turn off the mainframe power and disconnect the line

cord before installing or removing matrix cards. If there are

2-3

Page 22

SECTION 2

Ooeration

cables connected to the card, also remove power from those

circuits before proceeding.

CAUTION

Contamination will degrade the performance of the matrix

card. To avoid contamination, always grasp the card by the

side edges. Do not touch the board surfaces or components.

2.5.1

Perform the following procedure to install the Model 7153 Imatrix card in

either the Model 705 or Model 706 mainframe. Refer to Figure 2-2 to install the card in the Model 705 and refer to Figure 2-3 to install the card in

the Model 706.

1.

2.

3.

Matrix Card Installation

Slidethe card into the desired slot as shown in the appropriate illustra-

tion. Make surethe card edges ofthe bottom shield board are properly

aligned with the grooves in the receptacle.

Once the card is almost all the way in the slot, and you encounter resistance, push firmly on the edge of the card to seat it in the edge connector.

Once the card is fully seated, lock the card in place by placing the

latches in the locked position.

2-4

Page 23

SECTION 2

ODeration

Figure 2-2. Card lnstahtion in a Model 705

-

2-5

Page 24

SECTION 2

Operation

‘igure 2-3.

2.5.2

To remove the matrix card, first unlock it by pulling the latches outward,

then grasp the end of the card at the edges, and pull the card out of the

mainframe.

2.6

The information in the following paragraph explains how to connect the

matrix card to external test circuitry (instruments and DUTL

2-6

INSTRUMENT AND DUT CONNECTIONS

Card hstaallation in a Model 706

Matrix Card Removal

Page 25

SECTION 2

Operation

CAUTION

Do not connect the matrix card to unlimited power circuits.

This product is intended for use with impedance limited

sources. Do not connect directly to AC mains.

When connecting an impedance limited source, install appropriate protection (such as a fuse or a clamping circuit) to limit

potentially damaging fault currents to the matrix card.

CAUTION

Contamination will degrade the performance of the matrix

card. To avoid contamination, always grasp the card by the

side edges. Do not touch the board surfaces or components.

Card connectors, recommended cables and adapters, and typical connections to instruments and DUT are discussed in the following paragraphs.

2.6.1 Card Connectors

The card connectors are shown in Figure 2-4. There are two miniature coaxial, multiple contact receptacles. One ofthe receptacles is used for row

connections and the other is used for column connections. Row and column number designations are included in the illustration. Notice that one

contact of each receptacle is reserved for chassis ground. For each coaxial

connector, as shown in Figure 2-5, the center conductor is SIGNAL, and

the outer shell (shield Iis GUARD.

2-7

Page 26

SECTION 2

Operation

Note : Numbers indicate row and column paths.

Tzure 2-4. Model 7753 Connectors

&;a.;”

Max

Chassis Ground Connector

(1 Of 2)

IL----!

Warning : Do not exceed maximum

voltage levels shown.

t ‘igure 2-5. Miniature Connector Configuration

2-8

13oov

Max

Page 27

SECTION 2

Operation

WARNING

Do not exceed 200V behveen SIGNAL and GUARD, or 13OOV

between SIGNAL and chassis ground, or behveen GUARD

and chassis ground or between paths (see Figure 2-5). Also,

do not exceed IA carry/500mA switched, 1OVA peak (resistive load).

CAUTION

To prevent damage to the matrix card and other equipment,

do not connect equipment such that they short out on the

same row or column.

2.6.2 Recommended Cables and Adapters

Table 2-1 summarizes the cables and adapters recommended for use with

the Model 7153.

NOTE

Equivalent user-supplied items may be substituted as long as

they are of sufficient quality (low offset current, high leakage

resistance). Using substandard cables and adapters may degrade the integrity of the measurements made using the matrix

card. See paragraph 2.9 for a discussion of measurement considerations.

The following discussion provides additional information about the recommended Keithley cable; Model 7153.TRX cable.

2-9

Page 28

SECTION 2

Operation

Table 2-l. Recommended Cables and Adapters

Manufac-

tern

turer

1

Keithley

2

Keithley 6172

Keithley

Keithley 237-TRX-T

Keithley

Model or

Part No.

7153.TRX

237~BAN-3

Descriotion Applications

Matrix to triax

cable put connections

2.slot male to

3-lug female

triax adapter

3-14 female

to female triax

barrel male triax cable

3-&t male to

dual 3-lug tions for

female

3-slot triax to

male banana

plup

‘6172 is for use in low voltage kC5OOVrms) applications only.

7153 input/out-

Connect 3-slot

triax cable to

2-1~~ triax connector

Connect male

triax cable to

Dual connec-

7153.TRX

Banana plug cable

Model 7153-TRX Low Noise Matrix to Triax Cable

TheModel 7153-TRX is a 2-m&r cableassembly that is terminated with a

miniature coaxial, multiple contact plug at one end, and five 3-slot male

triax connectorsat the other end. The plug end of the cable will mate to the

ROW and COL receptacles of the matrix card. The triax connectors will

mate to standard 3-lug female triax connectors. Each triax cable is labeled

and corresponds to a ROW or COL as follows:

2-10

Page 29

SECTION 2

Operation

Triax #II = Row 1 or Column 1

Triax #t2 = Row 2 or Column 2

Triax lt3 = Row 3 or Column 3

Triax $14 = Row 4 or Column 4

Triax +#5 = Column 5

On each triax connector, as shown in Figure 2-7, the center conductor is

SIGNAL, the inner shield is GUARD, and the connector shell is connected

to the outer shield of the cable. Note that this outer shield is connected to

chassis of the Model 7153.

Pill designations

molded on plug

housing

Pill

Designation

1

F

Figure 2.6.

-

Matrix Card

ROW or Column

Model 7753.TRX Pin

Note : Pin designations 1, 2. 4. 5 and 6

iv3 coaxial co”“octor~. Pill 3 is

a s,nc$e ,,I” connector for chassis

ground.

identification

2-11

Page 30

SECTION 2

Ooeration

Signal

7153

Chassis

Ground

Warning : Do not exceed maximum

voltage levels shown.

Figure 2-7. Trim Connector Configuration (Model 71.53-TRN

2.6.3

The following paragraphs discuss connecting the Model 7153 to various

general classes of instrumentation such as DMMs, electrometers, sources,

and source/measure units. Because these configurations are generic in nature, some modification of the connecting schemes may be necessary for

your particular instrumentation. Also, special cables or adapters may be

necessary.

Figure 2-8 shows the general instrument connections for the discussions

below. Note that DUT guarding or shielding is not indicated here; see

Figure 2-18 and Figure 2-21 for shielding and guarding information. As

shown, all figures assume instruments are connected to rows, and the DUT

is connected to columns.

General Instrument Connections

WARNING

Do not use coaxial cables and adapters because hazardous

voltage from guard sources may be present on the cable

shields.

2-12

Page 31

SECTION 2

Ooeration

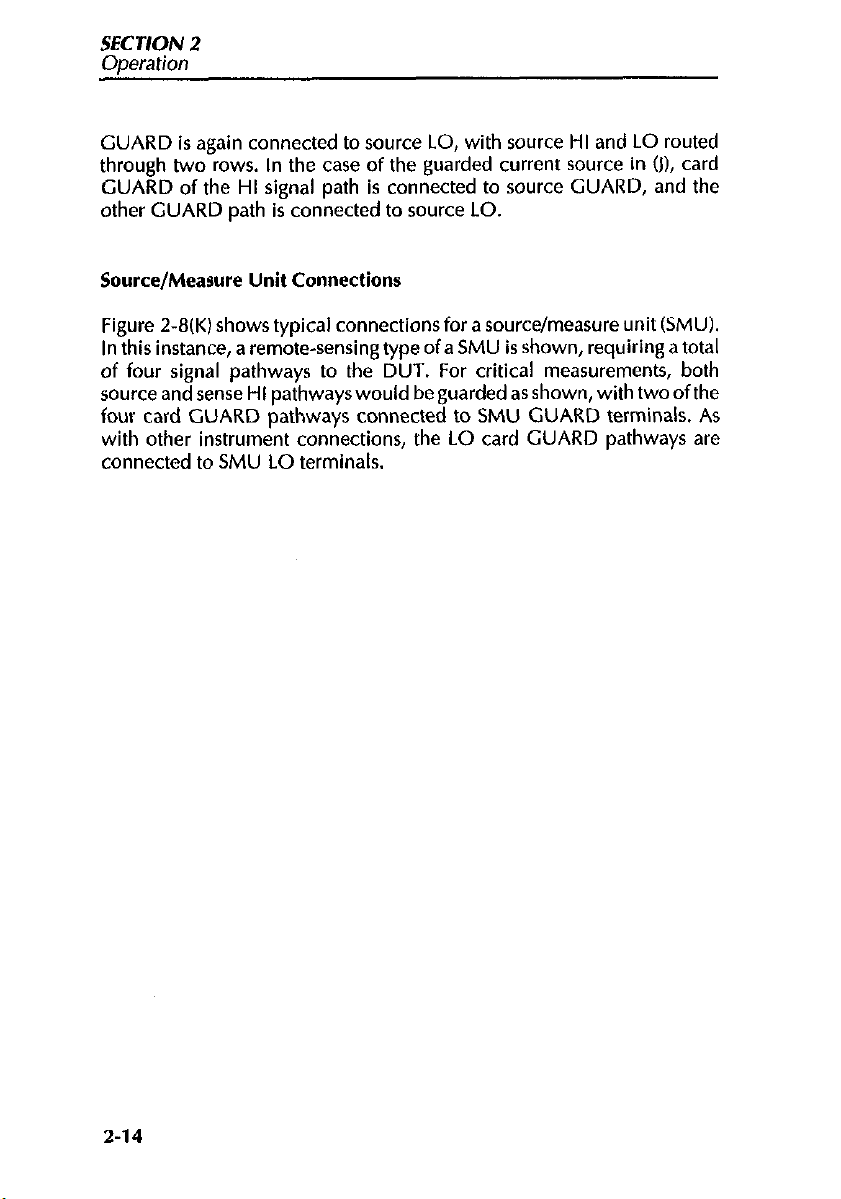

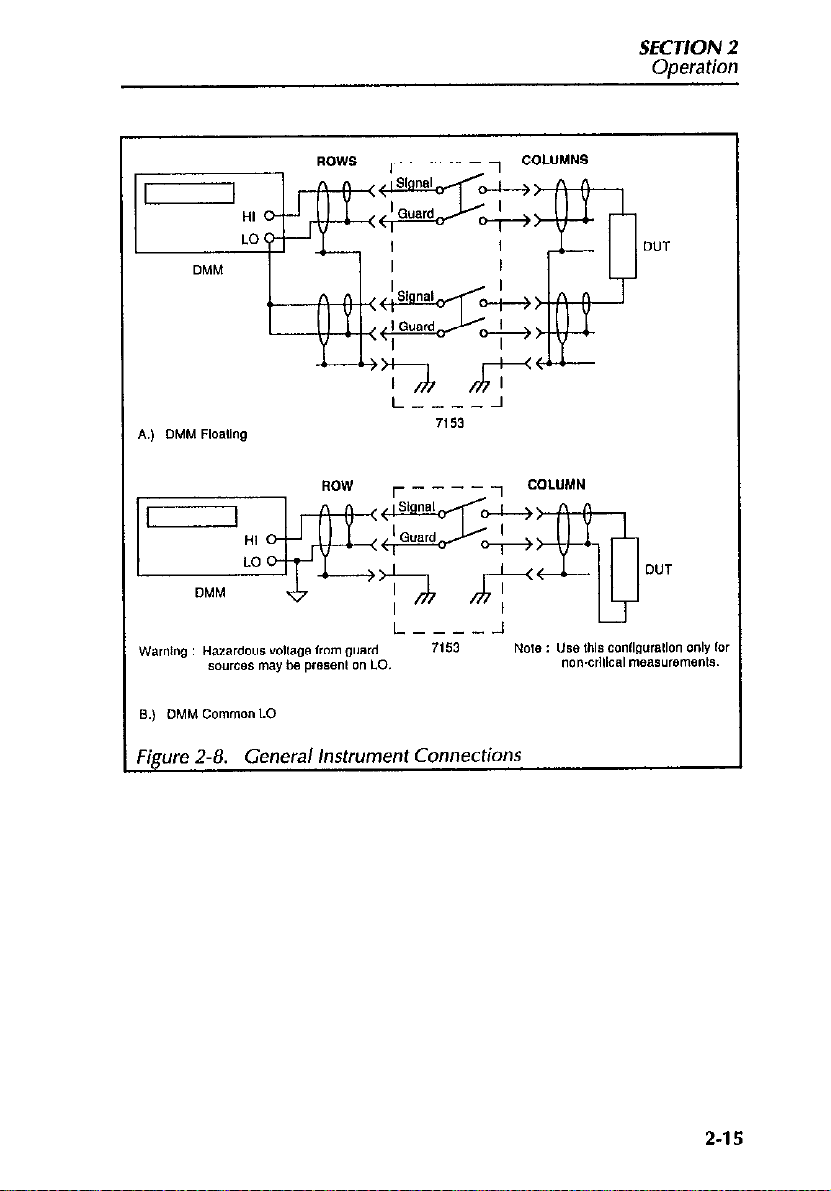

DMM Connections

General DMM connections are shown in Figure 2-13(A), @I, and (Cl. Floating connections are shown in (A), with LO and HI routed to two separate

rows on the Model 7153. The common LO connections in (5) should be

used only for non-critical applications becausethe performance (isolation)

of the GUARD pathway is not as good as a SIGNAL pathway.

WARNING

Hazardous voltage from other guard sources may be present

on LO or the DUT if other crosspoints are closed.

Four-wire DMM connections are shown in Figure 2-K). In this case, a total of four rows are required; one row for HI, one for LO, one for SENSE HI,

and one for SENSE LO.

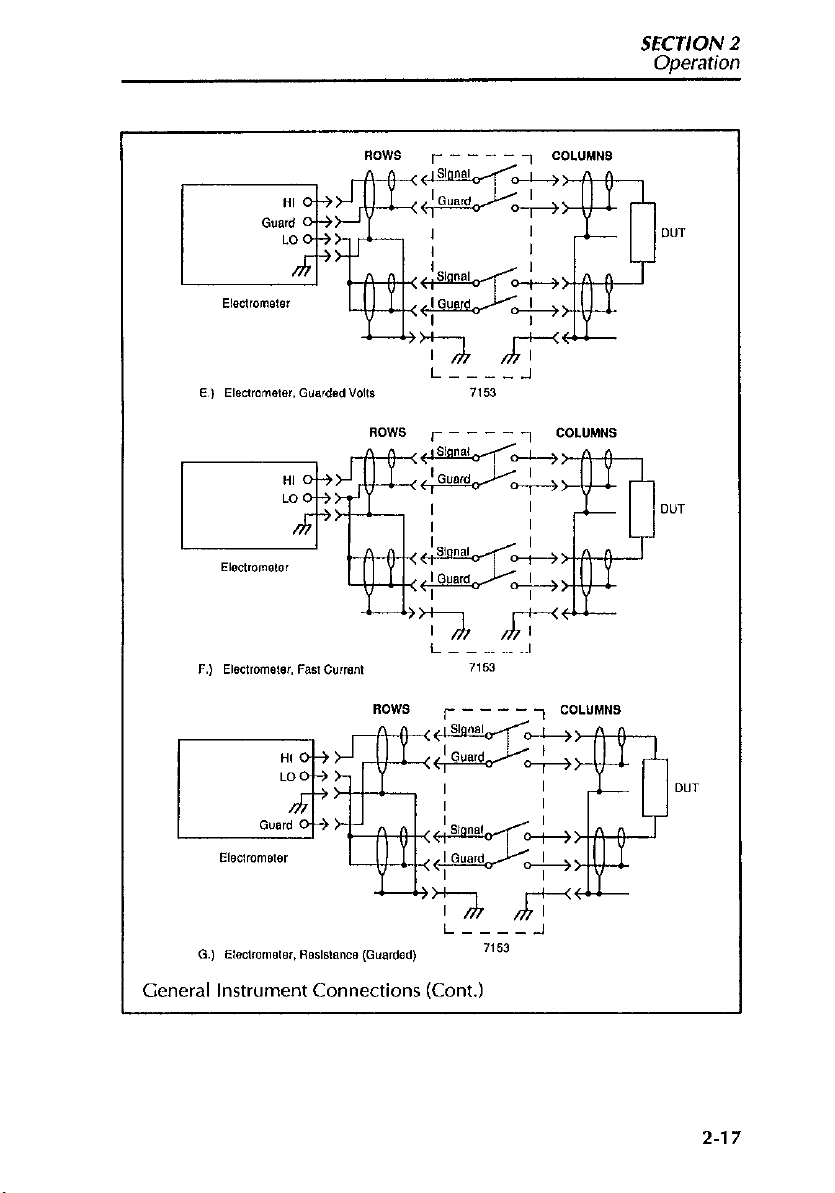

Electrometer Connections

Typical electrometer connections are shown in Figure 2-8(D) through (G).

The unguarded volts connections in (Dl show the HI signal path routed to

one row, and the LO path goes to a another row. Both GUARD pathways

are connected to electrometer LO. For guarded voltage (E), Model 7153

GUARD is connected to electrometer GUARD.

The connections for electrometer fast amps and resistance measurements

are shown in Figure 2-8(F) and (CL These configurations are essentially the

same as those discussed above. In the case of fast amps, both GUARD

paths are connected to electrometer LO, while in the case of guarded resistance, one GUARD path is connected to electrometer GUARD, and the

other GUARD path is connected to electrometer LO.

Source Connections

Voltage and current source connections are shown in Figure 2-O(H)

through (J). The HI and LO paths of the voltage source (H) are routed

through two rows, with both card GUARD pathways connected to voltage

source LO. For the unguarded current source connections (I), card

2-13

Page 32

SECTION 2

Oneration

GUARD is again connected to source LO, with source HI and LO routed

through two rows. In the case of the guarded current source in (I), card

GUARD of the HI signal path is connected to source GUARD, and the

other GUARD path is connected to source LO.

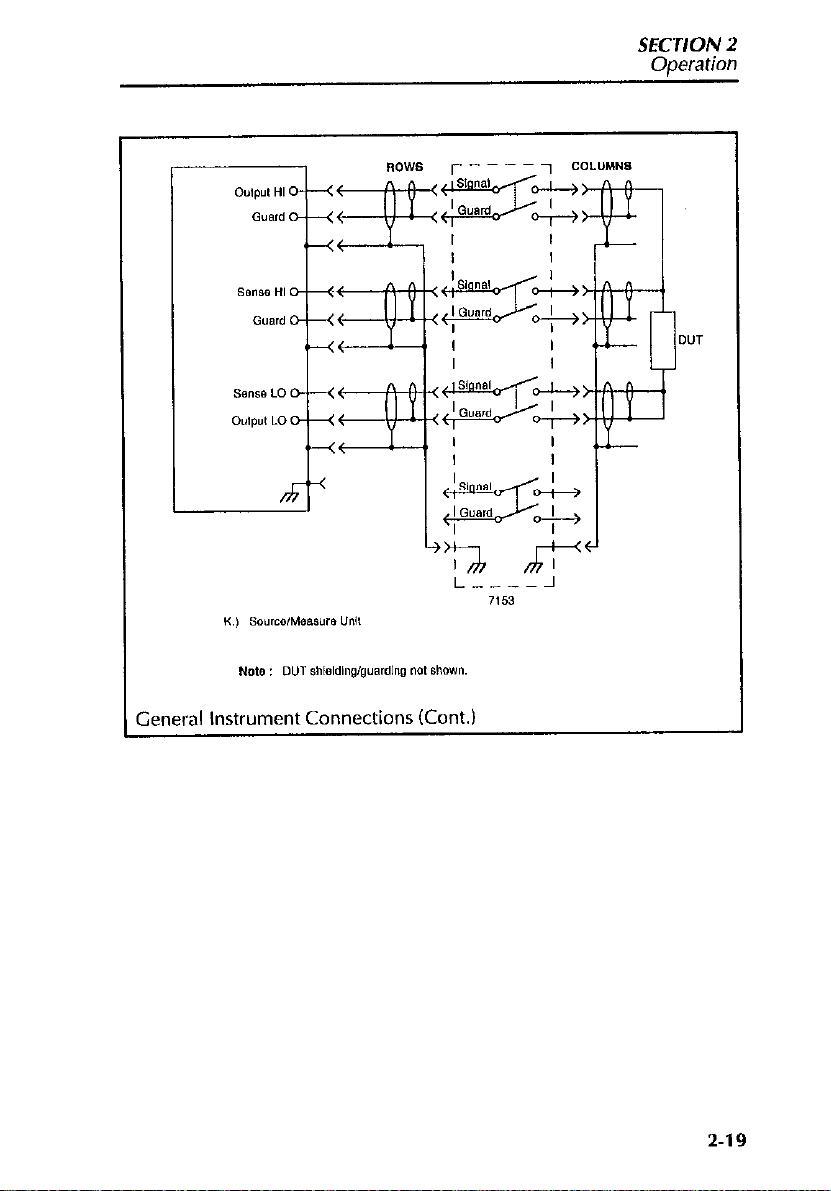

Source/Measure Unit Connections

Figure 2-8(K) shows typical connections for a source/measure unit (SMU).

In this instance, a remote-sensing type of a SMU is shown, requiring a total

of four signal pathways to the DUT. For critical measurements, both

source and sense HI pathways would be guarded as shown, with two of the

four card GUARD pathways connected to SMU GUARD terminals. As

with other instrument connections, the LO card GUARD pathways are

connected to SMU LO terminals.

2-14

Page 33

SECTION 2

Ooeration

2-15

Page 34

SECTION 2

Operation

General Instrument Connections (Cont.)

2-16

Page 35

I/h /?!I

i----J

G., Elecmnelei, ReSlslanCB (Guarded)

General Instrument Connections (Cont.)

x63

2-17

Page 36

SECTION 2

Operation

2-l 8

Page 37

SECTION 2

Operation

2-19

Page 38

SECTION 2

Operation

2.6.4 Keithley Instrument Connections

The foollowing paragraphs outline connecting typical Keithley instruments

to the Model 7153 High Voltage Low Current Matrix Card. Other similar

instruments can be connected using the same cabling as long as their input/output configurations are the same. Instrument connections covered

include:

. Model 617 Electrometer/Source

. Model 237 High Voltage Source Measure Unit

. Model 230 Programmable Voltage Source

l

Model 220 Programmable Current Source

NOTE

The following figures show instruments connected to matrix

rows. Keep in mind that they could just as well be connected to

matrix columns. Also, it doesn’t matter which rows (or columns) are used since the row/column specifications are uniform.

WARNING

To

prevent

not

apply power

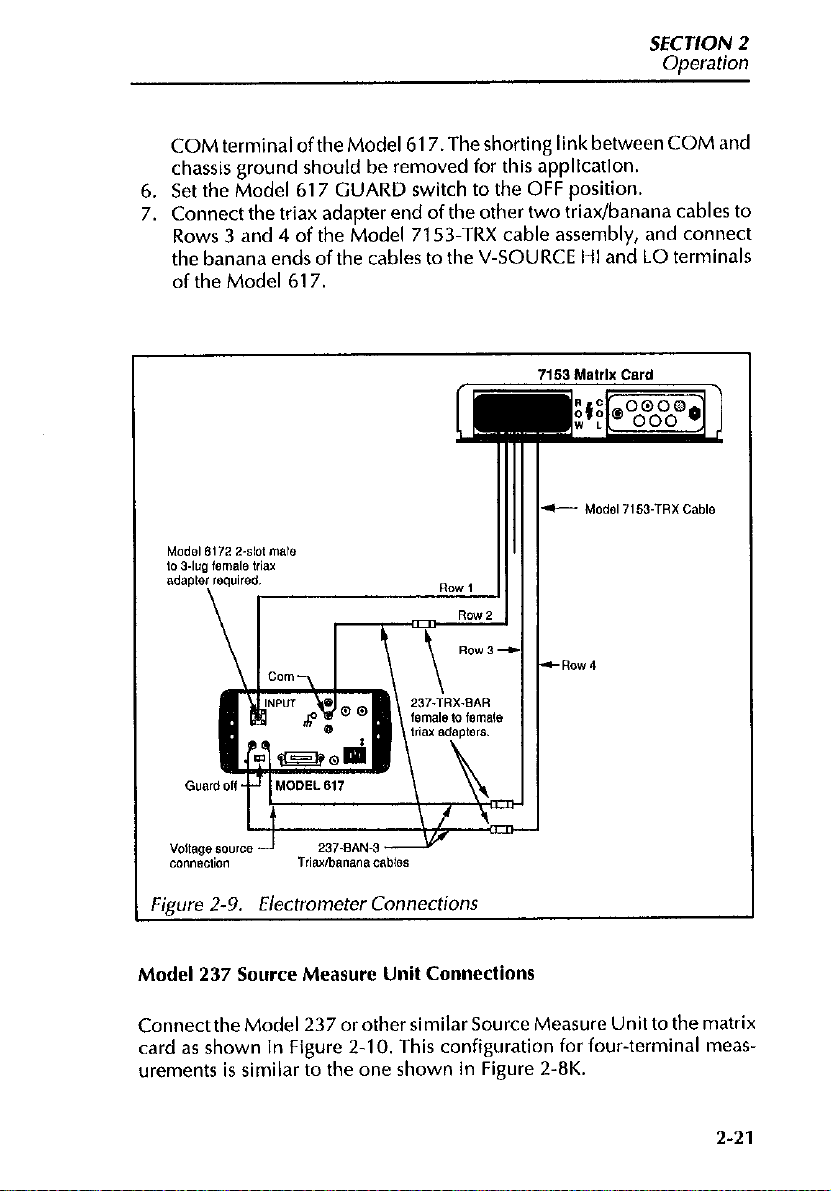

Model 617 Electrometer Connections

Connections for the Model 617 Electrometer are shown in Figure 2-9 and

are described as follows:

1, Connect the matrix end of the Model 7153-TRX cable assembly to

ROW of the Model 7153.

2. Connect the Model 6172 2-slot male to 3-lug female triaxial adapter

to the INPUT of the Model 617.

3. Connect Row 1 of the Model 7153.TRX cable assembly to the triax

adapter on the INPUT of the Model 617.

4. Connect three 3-lug female to female triax adapters (item 3 in

Table 2-l) to the three t&x/banana cables (Model 237-BAN-3)..

5. Connect the triax adapter end of a triax/banana cable to Row 2 of the

Model 7153-TRX, and connect the banana end of the cable to the

Z-20

electric shock that could cause injury or death, do

to cables that are not connected.

Page 39

SECTION 2

Oneration

COM terminal oftheModel617,Theshorting IinkbetweenCOM and

chassis ground should be removed for this application.

6. Set the Model 617 GUARD switch to the OFF position.

7. Connect the triax adapter end of the other two triaxfbanana cables to

Rows 3 and 4 of the Model 7153.TRX cable assembly, and connect

the banana ends of the cables to the V-SOURCE l-11 and LO terminals

of the Model 617

Figure 2-9. Electrometer Connections

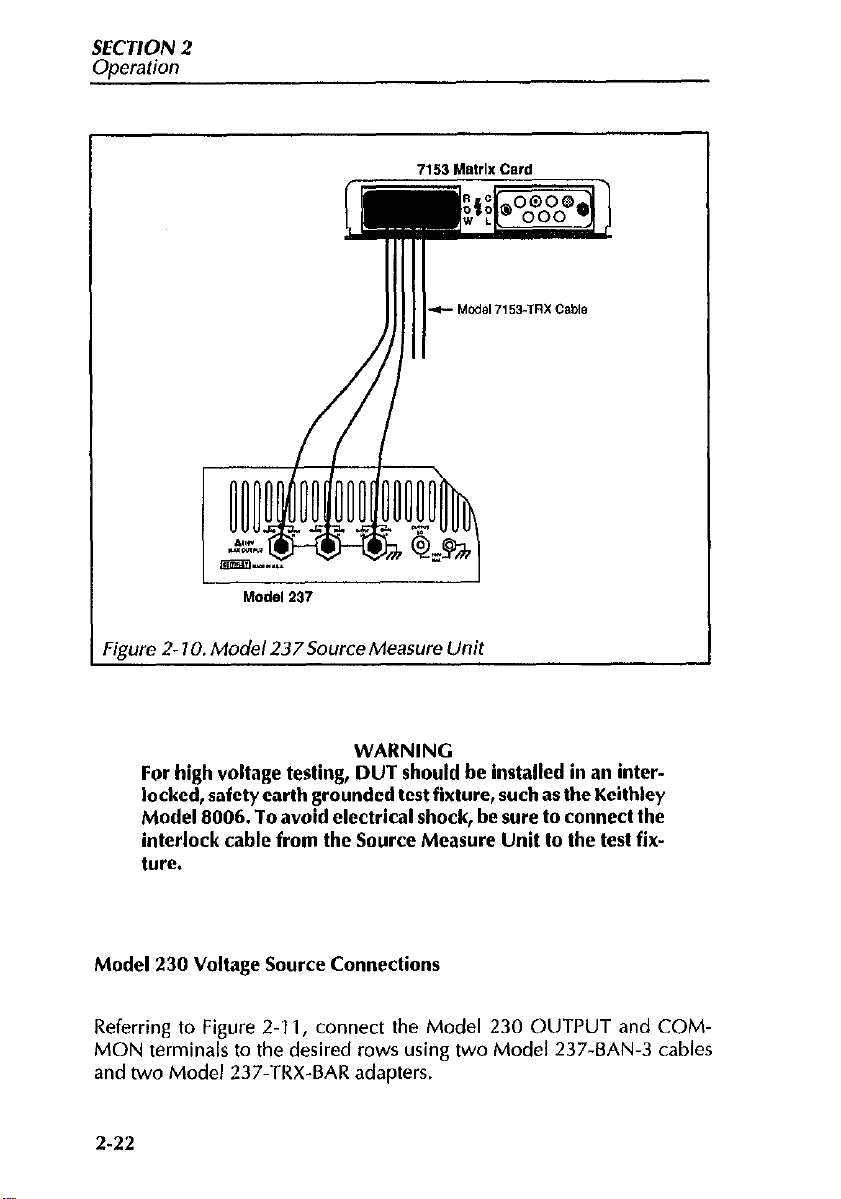

Model 237 Source Measure Unit Connections

Connectthe Model 237 orothersimilar Source Measure Unit to the matrix

card as shown in Figure 2-10. This configuration for four-terminal measurements is similar to the one shown in Figure 2-8K.

2-21

Page 40

SECTION 2

Operation

Figure 2- 10. Model 237Source Measure Unit

WARNING

For high voltage testing, DUT should be installed in an interlocked, safety earth grounded test fixture, such as the Keithley

Model 8006. To avoid electrical shock, be sure to connect the

interlock cable from the Source Measure Unit to the test fix-

ture.

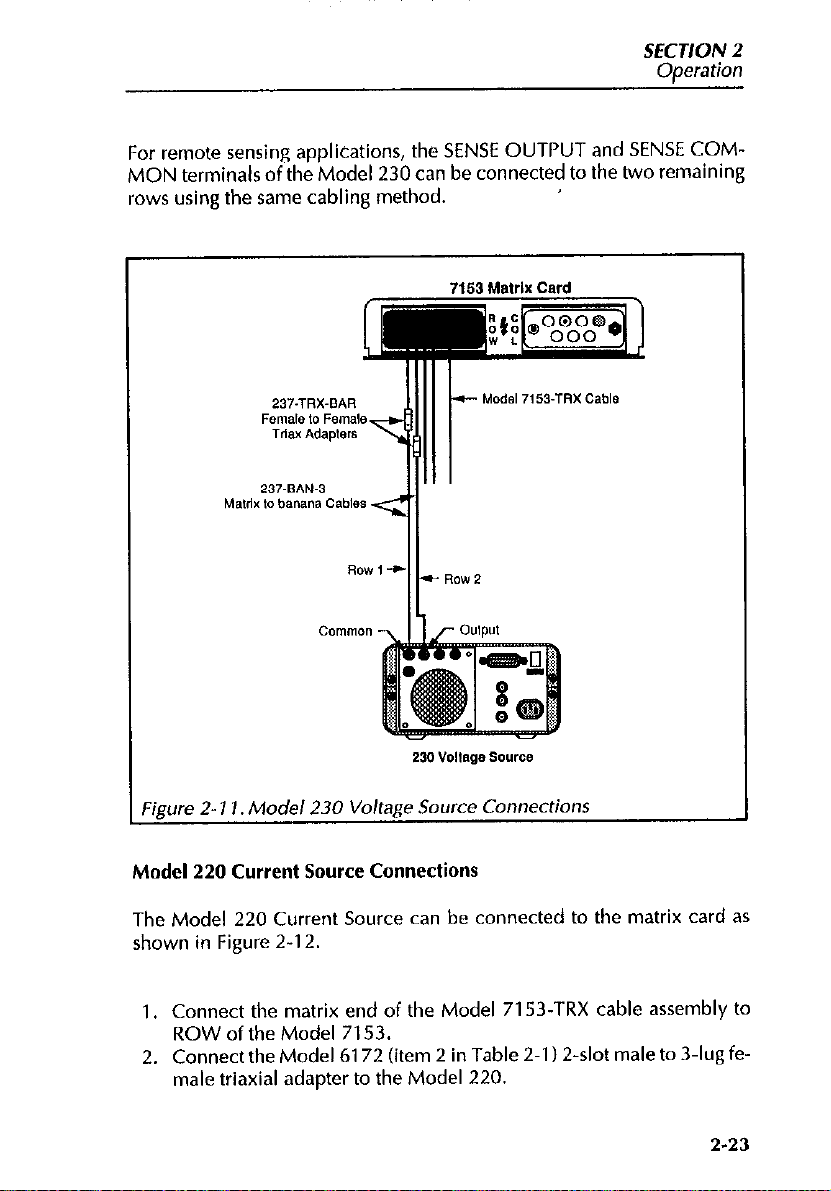

Model 230 Voltage Source Connections

Referring to Figure 2-I 1, connect the Model 230 OUTPUT and COMMON terminals to the desired rows using two Model 237-BAN-3 cables

and two Model 237.TRX-BAR adapters.

2.22

Page 41

SECTION 2

Operation

For remote sensing applications, the SENSE OUTPUT and SENSE COMMON terminals of the Model 230 can be connected to the two remaining

rows using the same cabling method.

0gure 2- 11. Model 230 Voltage Source Connections

Model 220 Current Source Connections

The Model 220 Current Source can be connected to the matrix card as

shown in Figure 2-12.

1, Connect the matrix end of the Model 7153-TRX cable assembly to

ROW of the Model 7153.

2. Connect the Model 6172 (item 2 in Table 2-l )2-slot male to 3.lug fe-

male triaxial adapter to the Model 220.

2-23

Page 42

SECTION 2

Operation

Figure 2- 12. Mode/ 220 Current Source Connections

3. Connect Row 1 of the Model 7153-TRX cable assembly to the 6172

triax adapter.

4. Connect a 3-lug female to female triax adapter to the G&banana ca-

ble.

5. Connect the triax adapter end of the triadbanana cable to Row 2 of

the Model 7153-TRX, and connect the banana end of the cable to the

OUTPUT COMMON jack of the Model 220.

NOTE

,The configuration shown allows common to be individually

switchec i (ROW 2). Thus, do not connect ROW1 Guard of the

matrix card (which is also common) to a DUT.

2-24

Page 43

SECTION 2

Ooeration

2.6.5 Typical Test Fixture Connections

Typically, a test fixture will be connected to desired columns of the Model

7153. Normally, the test fixture will be equipped with 3&g female triax

connectors to facilitate the use of the Model 7153.TRX cable assembly.

These typical test fixture connections are shown in Figure 2-13

Figure 2- 13. Typical

Do not use BNC cables and adapters because hazardous voltages from guard sources could be present on the BNC cable

shields.

Internally, the test fixture should be wired as shown in the equivalent circuit of Figure 2-14. SIGNAL isconnected totheprobeorotherdevicecon-

tact points, while GUARD is carried through as close to the device as pos-

sible. If coaxial probes are to be used, connect GUARD to the probe shield

if the probe shield is insulated from the fixture shield.

To provide protection from shock hazards, the test fixture

chassis must be properly connected to a safety earth ground.

A grounding wire (IO AWC or larger) must be attached se-

curely to the test fixture at a terminal designed for safety

rounding (the terminal should be marked with the symbol

& ). The other end of the grounding wire is then attached to a

8

Jest

Fixhire Connecrions

WARNING

WARNING

2-25

Page 44

known safety earth ground, such as a cold water pipe, or a

grounded electrical outlet box.

Figure 2-14.

Equivalent

Circuit of Test Fixture Connections

2.7 MATRIX EXPANSION

A matrix can be expanded by connecting two or more Model 7153 matrix

cards together. A single matrix card consists of 20 crosspoints. Thus, each

additional matrix card increases the matrix by 20 crosspoints. Connecting

the rows or one matrix card to the rows of another matrix card increases

thenumberofmatrixcolumns.Connectingthecolumnsofonematrixcard

to the columns of another matrix card increases the number of matrix

rows.

Matrix Expansion Connections

Model 7153.TRX cables along with the appropriate adapters can be used

for matrix expansion. Typical row connections of two matrix cards (which

will increase the available matrix columns to IO) are shown in Figure 2-l 5.

The rows of the two matrix cards are connected togehter via four Model

237-TRX-T adapters. The Model 237-TRX is a high voltage 3-&t male

triax to dual 3-lug female triax adapter. Standard 3-slot triax cables (such

as the Model 7078.TRX) from the instrumentation or DUT test fixture will

2-26

Page 45

SECTION 2

Ooeration

mate to the male end of the 9”’ adapters via four Model 237-TRX-BAR

adapters.

To connect the rows of more matrix cards, simply use additional Model

237-TRX-T adapters. Each additional matrix card will require four “T”

adapters.

Column connections, which increase matrix rows, are made in a similar

fashion. The only difference is that the Model 7153.TRX cables are instead

connected to the COL connectors on the matrix card.

Figure 2-15. Typical Row Connections for Matrix Column Expansion

2-27

Page 46

SECTION 2

Operation

2.8 MAINFRAME CONTROL OF MATRIX CARD

The information in the following paragraphs does not includeoperation of

the Model 705 or 706 mainframe. That information is provided in the respective mainframe instruction manuals. The following deals primarily

with programming information specific to controlling the Model 7153.

Whether from the front panel or over the IEEE-498 bus, matrix control is

simply a matter ofclosing and opening the appropriate matrix crosspoints.

Crosspoint assignment numbers for a Model 7153 card are determined by

its installed position (card number) in a mainframe. For daisy chain operation, the position of the mainframe in the system is also a determining factor. The following paragraphs explain how to determine crosspoint assign-

ment numbers.

2.8.1 Front Panel Matrix Control

Using the Model 7153 matrix card with an appropriate Keithley mainframe (Model 705 or 706) requires that the matrix mode be selected. To

place the mainframe in the matrix mode from the front panel, perform the

following steps:

1. Select Program 6 by pressing the PRCM key and then the number 6

key.

2. Press the 0 key and then the ENTER key.

After the ENTER key is pressed, the mainframe is placed in the matrix mode

of operation.

With the mainframe in the matrix mode, the display format is as follows:

For the Model 705:

mmnx

where: “mm n” is the crosspoint assignment number.

2-28

Page 47

SECTION 2

Operation

mm = 2-digit ID number from 01 to 50. This number identifies the mainframe and slot that the card is located in and also indicates the matrix card

column number.

n = Matrix card row from 1 to 4.

x denotes the status of the crosspoint. An 0 indicates that the crosspoint is

open, while a C indicates that the crosspoint is closed.

For the Model 706:

mmmnx

where: “mmm n” is the crosspoint assignment number

mmm = 3-digit ID number from 001 to 250. This number identifies the

mainframe and slot that the card is located in and also indicates the matrix

card column number.

n = Matrix card row from 1 to 4

x denotes the status of the crosspoint. An 0 indicates that the crosspoint is

open, while a C indicates that the crosspoint is closed.

In general, controlling the matrix from the front panel consists of display-

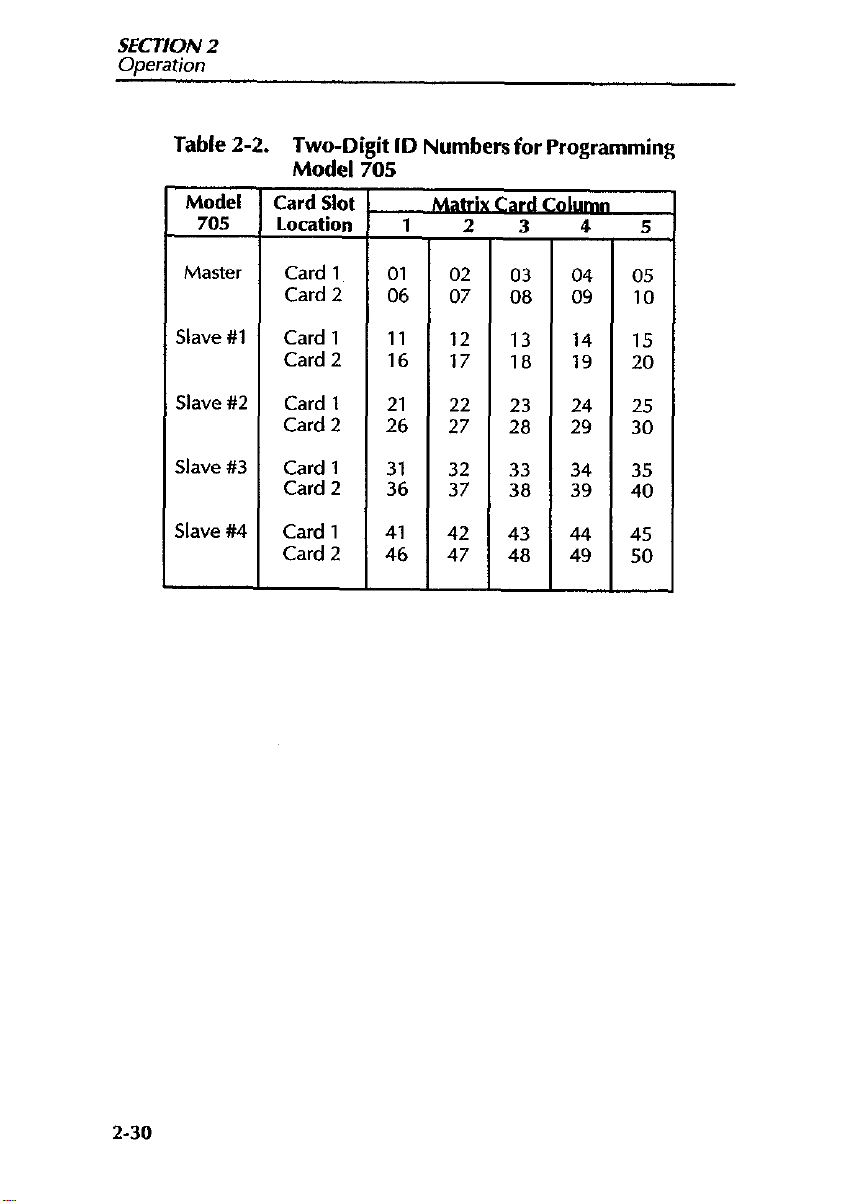

ing the desired matrix crosspointassignment number and closing (or open-

ing) the crosspoint relay. Table 2-2 and Table 2-3 provide the two-digit

(for Model 705) and three-digit (for Model 706) ID numbers that make up

the “m” portion of the crosspoint assignment number.

2-29

Page 48

SECTION 2

Operation

Table 2-2. Two-Digit ID Numbers for Programming

Model 705

Model

705

Card Slot

Location

Master

Slave #1

Slave #2

Slave #3

Slave #4

Card 1 01

Card 2 06

Card 1 11

Card 2 16

Card 1 21

Card 2 26

Card 1 31

Card 2 36

Card 1 41

Card 2 46 47

I

-

02

07

12

17

22

27

32 33

37

42

03

08 09

13

18 19

23

28

38

43

48

04

14

24

29

34

39

44

49

05

10

15

20

2s

30

35

40

45

50

2-30

Page 49

SECTION 2

Oaeration

Table 2-3. Three-dieit ID Numbers for Proeramminc!

Model 766

Model

706

Master

&we #l

;lave #2

Card Slot

location

Card 1

Card 2 006 007 008 009 010

Card 3 011 012 013 014 015

Card 4 016 017 018

Card 5

Card 6

Card 7

Card 8 036 037 038 039 040

Card 9

Card 10

Card 1 051 052

Card 2 056 057 058

Card 3

Card 4

Card 5 071 072 073

Card 6 076 077 078

Card 7 081

Card 8

card Y 091 092 093 094

Card10 096 097 098 099 100

Card 1

Card 2

Card 3

Card 4

Card 5

Card 6

Card 7

Card 8

Card 9

Card 10

Mat&&,&&Cardn

1 2 3

001 002 003 004 005

019 020

021 022 023 024 025

026

031 032 033 034 035

041

046 047 048 049 050

061 062 063 064 065

066

086 087 088 089 090

101 102

106 107

111 112

116 117

121 122

126

131 132

136 137

141 142

146 147

- -

027

042

067

082 083 084 085

127

028 029 030

043 044 045

053 054 055

059 060

068 069 070

074 075

079 080

103

108

113

118

123

128

133

138

143

148

-

104

109 110

114

119

124

129 130

134 135

139 140

144

149 150

- - L

5

095

105

115

120

125

145

2-31

Page 50

SECTION 2

Operation

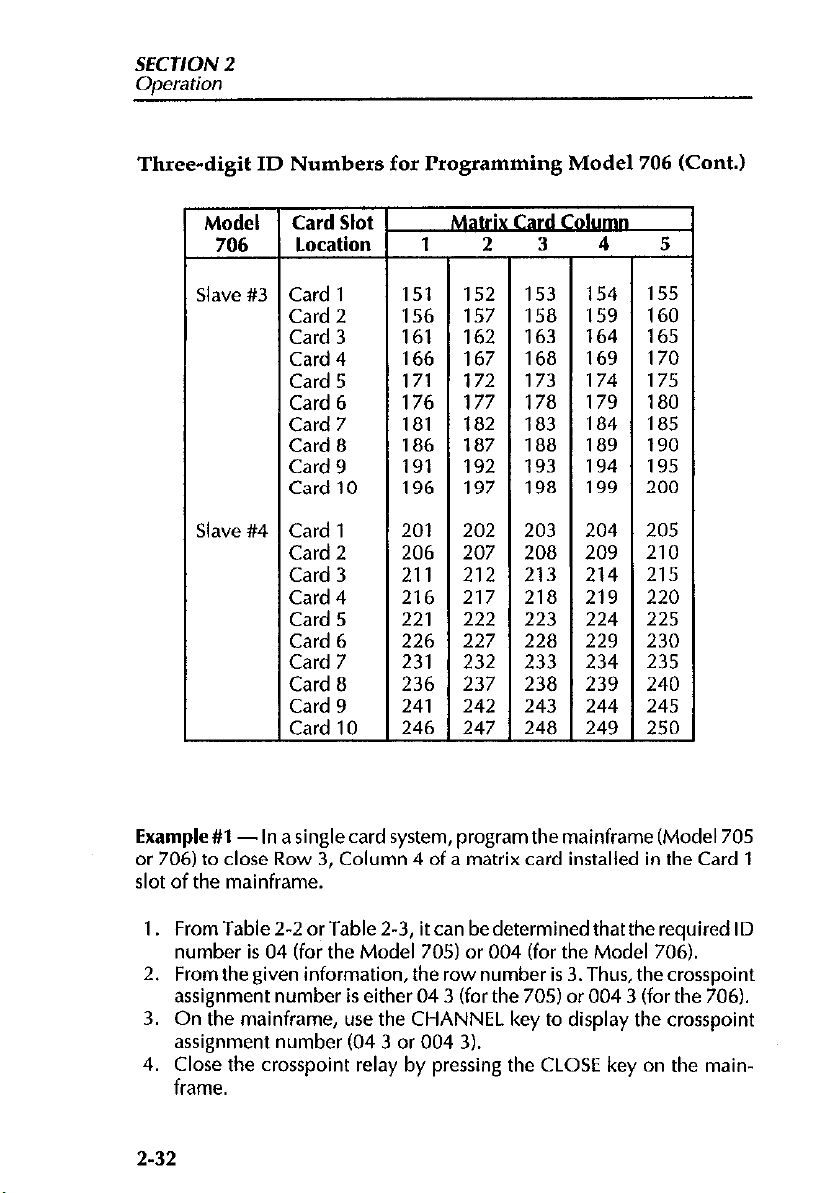

Three-digit ID Numbers for Programming Model 706 (Cont.)

Model

706

ilave #3

ilave #4

Card Slot

T

Location

Card 1

Card 2

Card 3

Card 4

Card 5

Card 6

Card 7

Card 8

Card 9

Card 10

Card 1

Card 2

Card 3

Card 4

Card 5

Card 6

Card 7

Card 8

Card 9

Card 10

151 152 153 154

156

161 162 163

166 167 168

171 172

176 177 178

181 182 183 184

186 187 188 189

191 192 193

196 197 198

201 202 203 204

206 207 208 209

211 212 213 214

216

221 222 223 224

226 227 228

231 232 233 234

236 237

241 242 243 244

246

- - - -

157 158 159

164

169

173 174

179

194

199

217 218 219

229

238

247 248 249

239

155

160

165

170

175

180

185

190

195

200

205

210

215

220

225

230

235

240

245

250

-

Example #l -In a single card system, program the mainframe (Model 705

or 706) to close Row 3, Column 4 of a matrix card installed in the Card 1

slot of the mainframe.

1. From Table 2-2 or Table 2-3, it can be determined that the required ID

number is 04 (for the Model 705) or 004 (for the Model 706).

2. From the given information, the row number is 3. Thus, thecrosspoint

assignment number is either 04 3 (for the 705) or 004 3 (for the 706).

3. On the mainframe, use the CHANNEL key to display the crosspoint

assignment number (04 3 or 004 3).

4. Close the crosspoint relay by pressing the CLOSE key on the mainframe.

2-32

Page 51

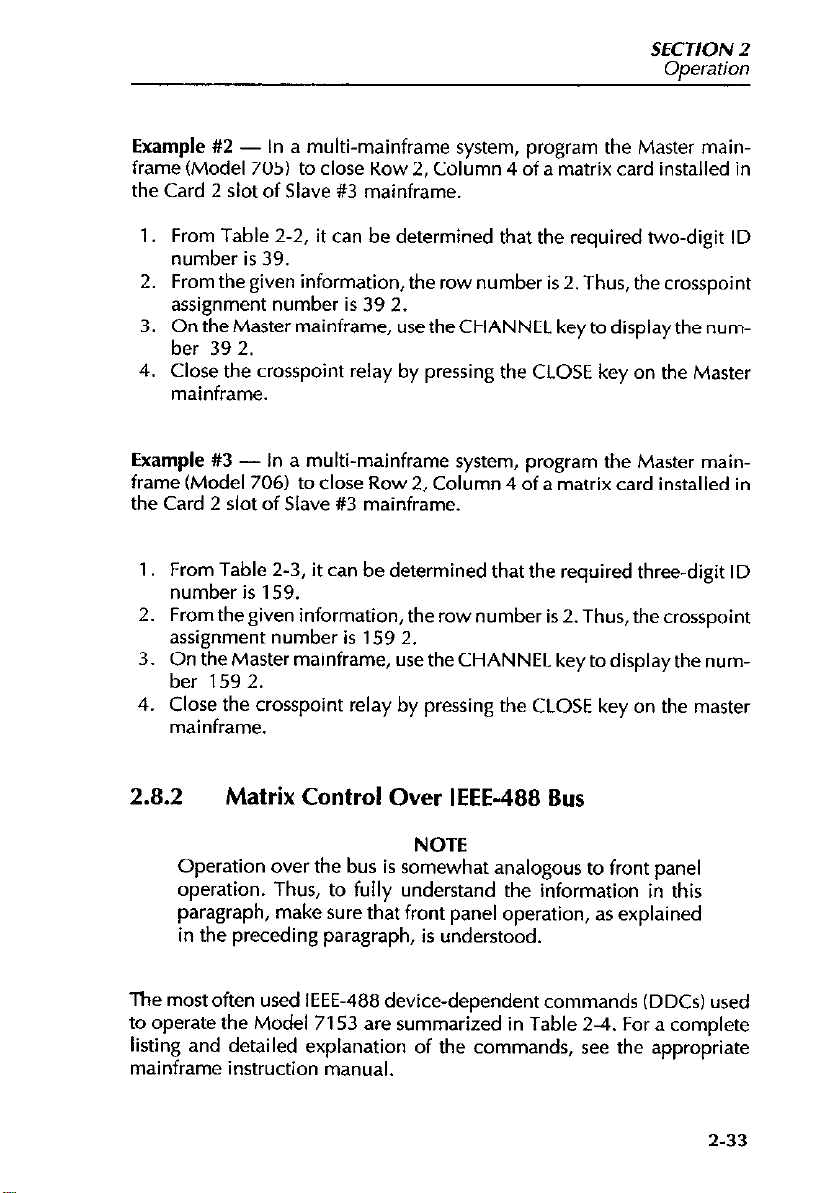

SECTION 2

Ooeration

Example #2 - In a multi-mainframe system, program the Master mainframe (Model 705) to close Row 2, Column 4 of a matrix card installed in

the Card 2 slot of Slave #3 mainframe.

1. From Table 2.2, it can be determined that the required two-digit ID

number is 39.

2. From the given information, the row number is 2. Thus, the crosspoint

assignment number is 39 2.

3. On the Master mainframe, use the CHANNEL key to display the number 39 2.

4. Close the crosspoint relay by pressing the CLOSE key on the Master

mainframe.

Example #3 - In a multi-mainframe system, program the Master mainframe (Model 706) to close Row2, Column 4 of a matrix card installed in

the Card 2 slot of Slave #3 mainframe.

1. From Table 2-3, it can be determined that the required three-digit ID

number is 159.

2. From the given information, the row number is 2. Thus, the crosspoint

assignment number is 159 2.

3. On the Master mainframe, use the CHANNEL key to display the number 159 2.

4. Close the crosspoint relay by pressing the CLOSE key on the master

mainframe.

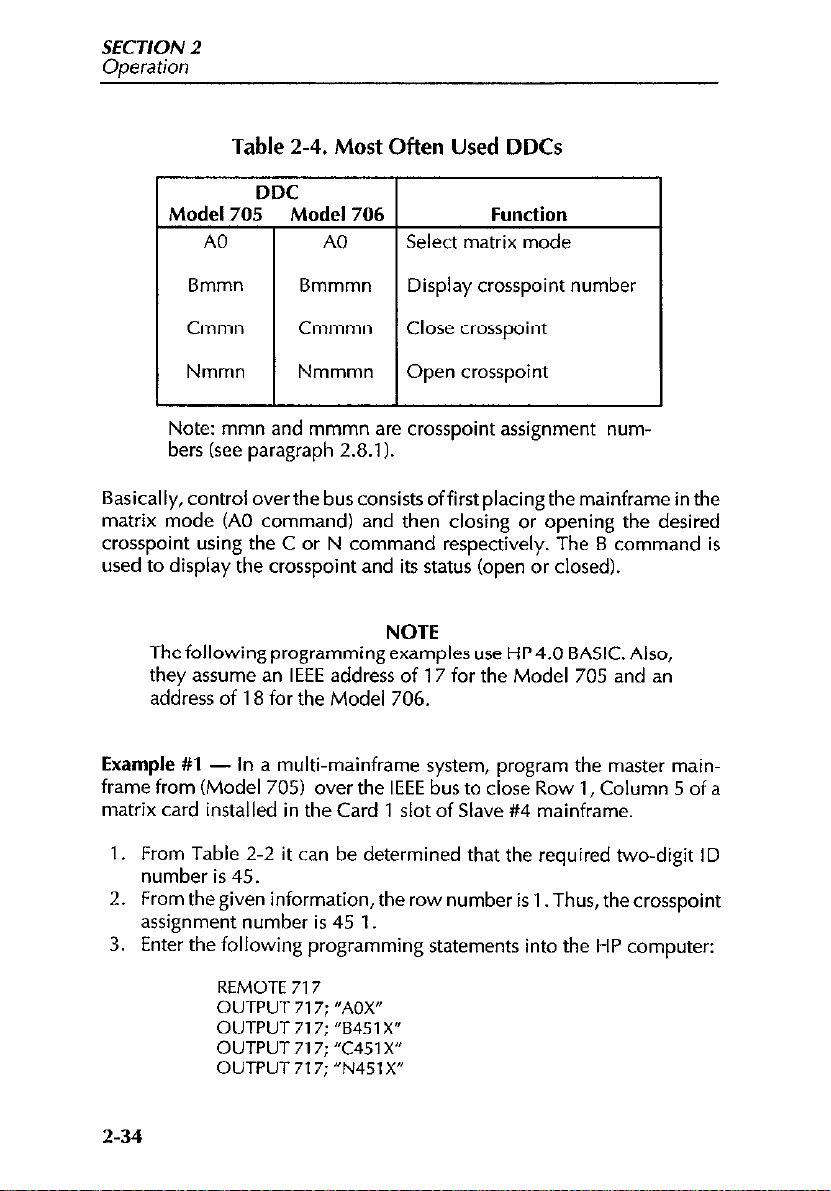

2.8.2

The most often used IEEE-488 device-dependent commands (DDCs) used

to operate the Model 7153 are summarized in Table 2-4. For a complete

listing and detailed explanation of the commands, see the appropriate

mainframe instruction manual.

Matrix Control Over IEEE-488 Bus

NOTE

Operation over the bus is somewhat analogous to front panel

operation. Thus, to fully understand the information in this

paragraph, make sure that front panel operation, as explained

in the preceding paragraph, is understood.

2-33

Page 52

SECTION 2

Ooeration

Table 2-4. Most Often Used DDCs

Function

Select matrix mode

Bmmn Bmmmn

Cmmn Cmmmn

Nmmn Nmmmn

L-L

Note: mmn and mmmn are crosspoint assignment numbers (see paragraph 2.8.1).

Basically, control over the bus consists offirst placing the mainframe in the

matrix mode (A0 command) and then closing or opening the desired

crosspoint using the C or N command respectively. The B command is

used to display the crosspoint and its status (open or closed).

Thefollowingprogrammingexamples use HP4.0 BASIC. Also, Thefollowingprogrammingexamples use HP4.0 BASIC. Also,

they assume an IEEE address of 17 for the Model 705 and an they assume an IEEE address of 17 for the Model 705 and an

address of 18 for the Model 706. address of 18 for the Model 706.

Example #l

frame from (Model 705) over the IEEE bus to close Row 1, Column 5 of a

matrix card installed in the Card 1 slot of Slave #4 mainframe.

1. From Table 2-2 it can be determined that the required two-digit ID

number is 45.

From the given information, the row number is 1. Thus, thecrosspoint

2.

assignment number is 45 1.

Enter the following programming statements into the HP computer:

3.

- In a multi-mainframe system, program the master main-

Display crosspoint number

Close crosspoint

Open crosspoint

I

NOTE NOTE

2-34

REMOTE

OUTPUT 717: “AOX”

OUTPUT

OUTPUT 717; “C451 X”

OUTPUT 717; “N45, X”

717

717: “6451 X”

Page 53

SECTION 2

Operation

The second statement places the master Model 705 in the matrix mode.

The third statement displays crosspoint 45 1 and its current status (open or

closed). The fourth statement closes crosspoint 45 1, and the last statement

opens crosspoint 45 1.

Example

frame (Model 706) from over the IEEE bus to close Row 4, Column 1 of a

matrix card installed in the Card 8 slot of Slave #4 mainframe.

1. From Table 2-3 it can be determined that the required three-digit ID

2. From the given information, the row number is4. Thus, the crosspoint

3. Enter the following programming statements into the HP computer:

The second statement places the master Model 706 in the matrix mode.

The third statement displays crosspoint 236 4 and its current status (open

or closed). The fourth statement closes crosspoint 236 4, and the last state-

ment opens crosspoint 236 4.

2.9

Many measurements made with the Model 7153 concern low-level sig-

nals. Such measurements are subject to various types of noise that can seriously affect low-level measurement accuracy. The following paragraphs

discuss possible noise sources that might affect these measurements.

#2 - In a multi-mainframe system, program the master main-

number is 236.

assignment number is 236 4.

REMOTE 718

OUTPUT 718; “AOX”

OUTPUT 718; “82364X”

OUTPUT 718; %2364X”

OUTPUT 718; “N2364X”

MEASUREMENT CONSIDERATIONS

2.9.1

When a conductor cuts through magnetic lines of force, a very small voltage is generated. This phenomenon will frequently cause unwanted sig-

nalstooccurin thetest leadsofaswitchingmatrixsystem. Iftheconductor

Magnetic Fields

2-35

Page 54

SECTION 2

Operation

has sufficient length, even weak magnetic fields like those of the earth can

create sufficient signals to affect low-level measurements.

Two ways to reduce these effects are: (1) reduce the lengths of the test

leads, and (2) minimize the exposed circuit area. In extreme cases, magnetic shielding may be required. Special metals with high permeability at

low flux densities (such as mu metal) are effective at reducing these effects.

Even when the conductor is stationary, magnetically-induced signals may

still be a problem. Fields can be produced by various signals such as the

AC power line voltage. Large inductors such as power transformers can

generate substantial magnetic fields, so care must be taken to keep the

switching and measuring circuits a good distance away from these poten-

tial noise sources.

2.9.2 Radio Frequency Interference

RFI (Radio Frequency Interference) is ageneral term used to describe electromagnetic interference over a wide range of frequencies across the spectrum. Such RFI can be particularly troublesome at low signal levels, but

can also affect measurements at high levels if the problem is of sufficient

severity.

RFI can be caused by steady-state sources such as radio or TV signals, or

some types of electronic equipment (microprocessors, high speed digital

circuits, etc.), or it can result from impulse sources, as in the case of arcing

in high-voltage environments. In either case, the effect on the measure-

ment can be considerable if enough of the unwanted signal is present. A

common problem is the rectification by semiconductor junctions of RF

picked up by leads.

RFI can be minimized in several ways. The most obvious method is to keep

the equipment and signal leads as far away from the RFI source as possible.

Shielding the matrix switching card, signal leads, sources, and measuring

instruments will often reduce RFI to an acceptable level. In extreme cases,

a specially-constructed screen room may be required to sufficiently attenuate the troublesome signal.

2-36

Page 55

SECTION 2

Ooeration

Many instruments incorporate internal filteringthat may help to reduce RFI

effects in some situations. In some cases, additional external filtering may

also be required. Keep in mind, however, that filtering may have detrimental effects on the desired signal.

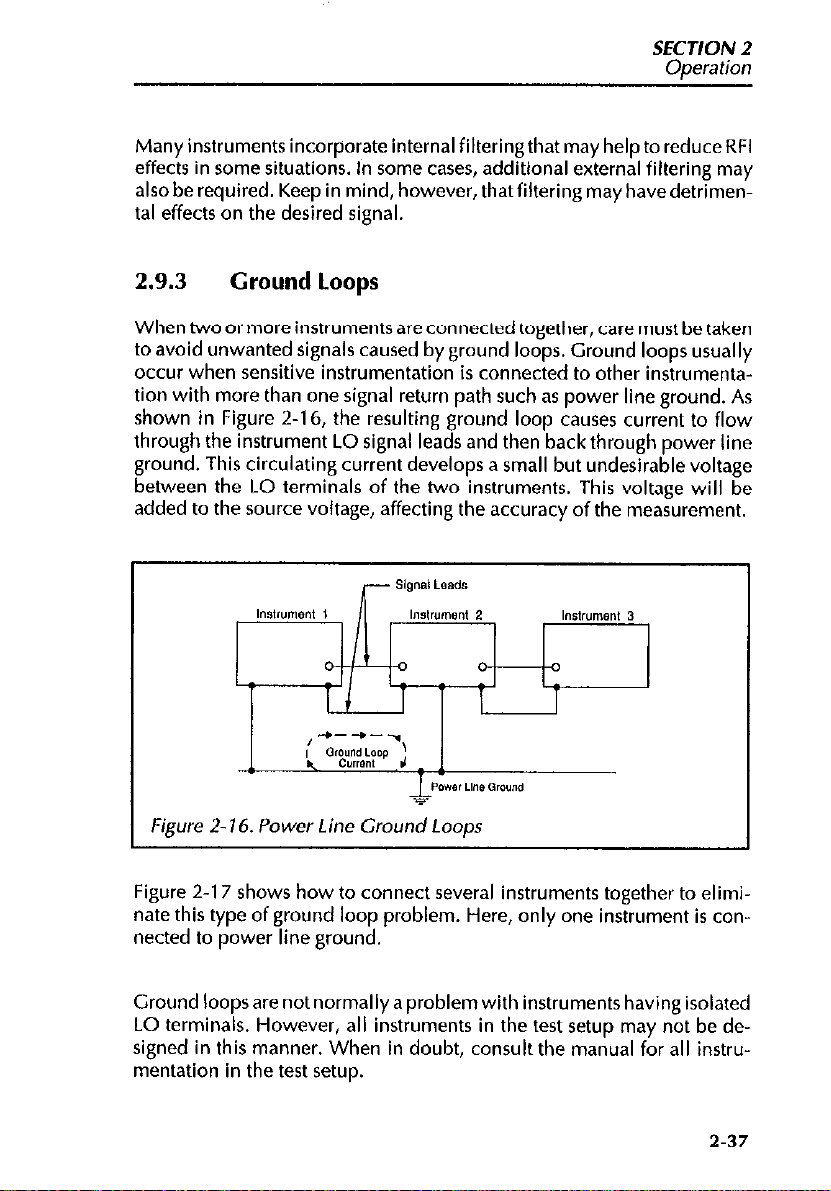

2.9.3

When two or more instruments are connected together, care must be taken

to avoid unwanted signals caused by ground loops. Ground loops usually

occur when sensitive instrumentation is connected to other instrumentation with more than one signal return path such as power line ground. As

shown in Figure 2-16, the resulting ground loop causes current to flow

through the instrument LO signal leads and then back through power line

ground. This circulating current develops a small but undesirable voltage

between the LO terminals of the two instruments. This voltage will be

added to the source voltage, affecting the accuracy of the measurement.

Ground Loops

Figure 2- 16. Power Line Ground Loops

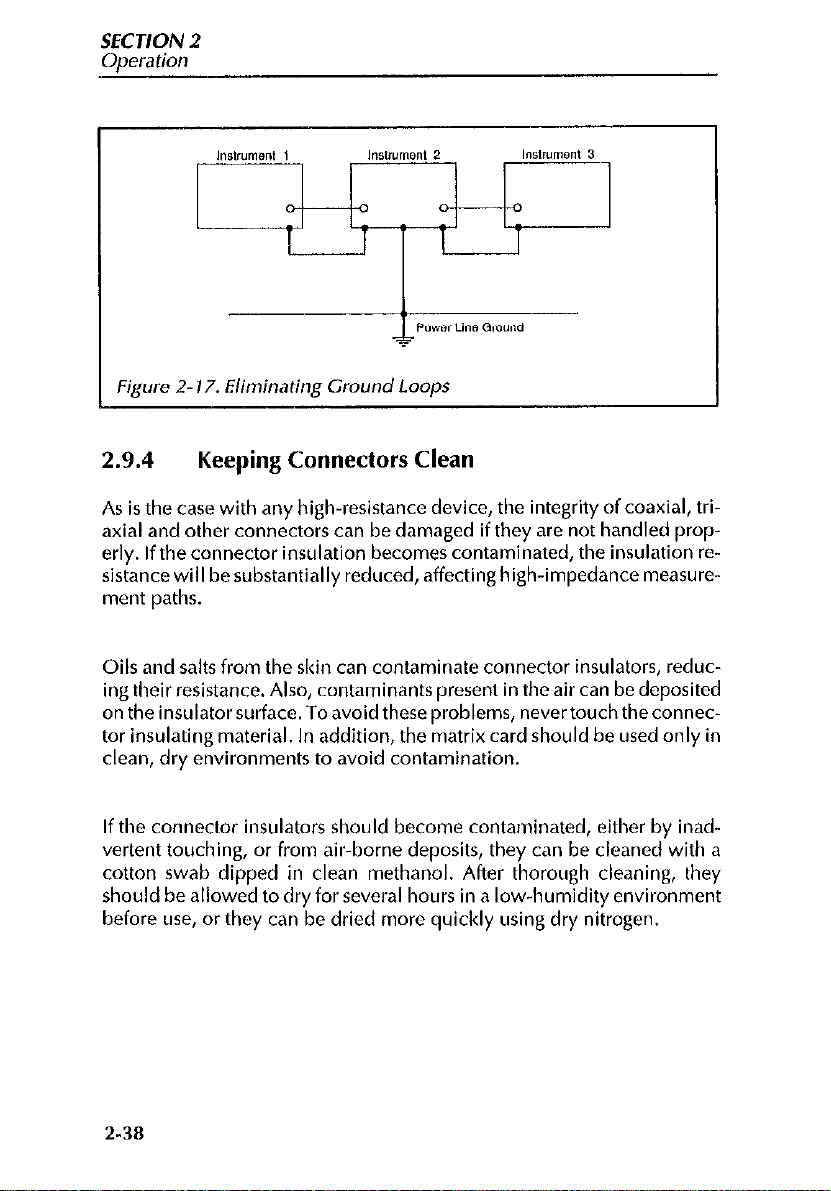

Figure 2-17 shows how to connect several instruments together to eliminate this type of ground loop problem. Here, only one instrument is connected to power line ground.

Ground loops are not normally a problem with instruments having isolated

LO terminals. However, all instruments in the test setup may not be designed in this manner. When in doubt, consult the manual for all instrumentation in the test setup.

2-37

Page 56

SECTION 2

Operation

2.9.4 Keeping Connectors Clean

As is the case with any high-resistance device, the integrity of coaxial, triaxial and other connectors can be damaged if they are not handled properly. If the connector insulation becomes contaminated, the insulation resistance will besubstantially reduced, affecting high-impedance measurement paths.

Oils and salts from the skin can contaminate connector insulators, reduc-

ing their resistance. Also, contaminants present in the air can be deposited

on the insulator surface. To avoid these problems, never touch the connector insulating material. In addition, the matrix card should be used only in

clean, dry environments to avoid contamination.

If the connector insulators should become contaminated, either by inadvertent touching, or from air-borne deposits, they can be cleaned with a

cotton swab dipped in clean methanol. After thorough cleaning, they

should be allowed todryfor several hours in a low-humidity environment

before use, or they can be dried more quickly using dry nitrogen.

2-38

Page 57

SECTION 2

ODeration

2.9.5

Noise currents can be generated by bending or flexing coaxial or triaxial

cables. Such currents, which are known as triboelectric currents, are generated by charges created between a conductor and insulator caused by

friction,

Low-noise cable can be used to minimize these effects. Such cable has a

special graphite coating under the shield to provide lubrication and to provide a conduction path to equalize charges.

Even low-noise cable generates some noise currents when flexed or subjected to vibration. To minimize these effects, keep the cables as short as

possible, and do not subject them to temperature variations that could

cause expansion or contraction. Tie down offending cables securely to

avoid movement, and isolate or remove vibration sources such as motors

or pumps.

Noise Currents Caused by Cable Flexing

2.9.6 Shielding

Proper shielding ofall unguarded signal paths and devices under test is important to minimize noise pickup in virtually any switching matrix system.

Otherwise, interference from such noise sources as line frequency and RF

fields can seriously corrupt a measurement.

In order for shielding to be effective, the shield surrounding the HI signal

path should be connected to signal LO for chassis ground for instruments

without isolated LO terminals). Since most Model 7153 matrix applica-

tions call for separately switching LO, a separate connection from LO to

the cable shield at the source or measurement end must be provided, as in

the example of Figure 2-18. Here, we are using the GUARD path of the

Model 7153 to carry the shield out to the device under test. Needless to

say, this arrangement should not be used with guarding, as GUARD and

LO should not be connected together.

2-39

Page 58

SECTION 2

Ooeration

Figure Z- 10. Shielding Example

WARNING

Hazardous voltage may be present if LO on any instrument is

floated above ground potential.

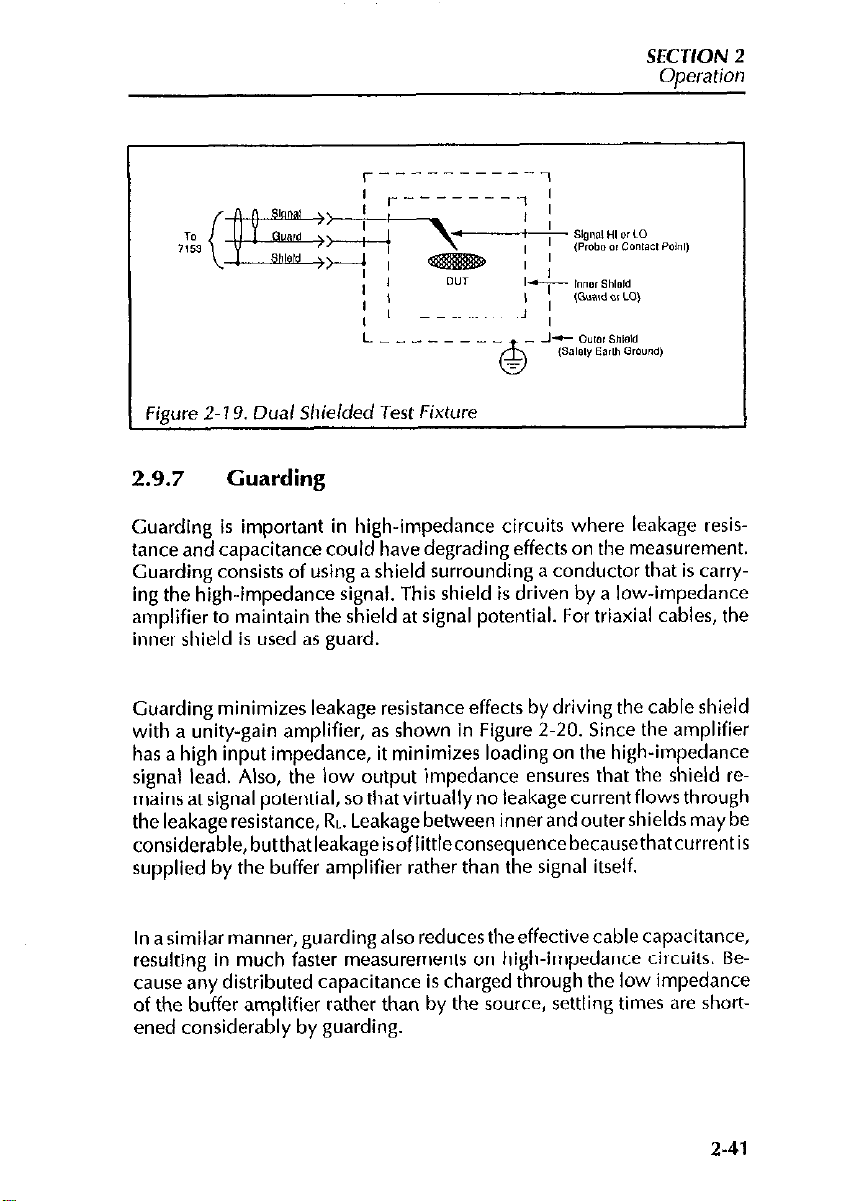

lfthe device under test is to be shielded, the shield should be connected to

the LO terminal. If you are using the GUARD connection as shield, care

should be taken to insulatethe outer ring ofthe triaxial connector mounted

on the test fixture from the test fixture itself. Otherwise, LO will be connected to earth ground, possibly resulting in a ground loop. An alternative

is to use two shields, one mounted within (and insulated from) the other. In

this case, the GUARD path would be connected to the inner shield, while

the outer shield would be earth grounded. This arrangement is shown in

Figure 2-l 9. Incidentally, this configuration is also recommended for

guarded applications, with the inner shield as guard, and the outer shield

acting as a safety shield.

2-40

Page 59

SECTION 2

Operation

Figure

2-I 9. Dual Shielded

Test

Fixture

2.9.7 Guarding

Guarding is important in high-impedance circuits where leakage resistance and capacitance could have degrading effects on the measurement.

Guarding consists of using a shield surrounding a conductor that is carry-

ing the high-impedance signal. This shield is driven by a low-impedance

amplifier to maintain the shield at signal potential. For triaxial cables, the

inner shield is used as guard.

Guarding minimizes leakage resistance effects by driving the cable shield

with a unity-gain amplifier, as shown in Figure 2.20. Since the amplifier

has a high input impedance, it minimizes loading on the high-impedance

signal lead. Also, the low output impedance ensures that the shield remains at signal potential, so that virtually no leakage current flows through

the leakage resistance, RL. Leakage between inner and outer shields may be

considerable,butthatleakageisofIittleconsequencebecausethatcurrentis

supplied by the buffer amplifier rather than the signal itself.

In a similar manner, guarding also reduces the effective cable capacitance,

resulting in much faster measurements on high-impedance circuits. Because any distributed capacitance is charged through the low impedance

of the buffer amplifier rather than by the source, settling times are shortened considerably by guarding.

2-41

Page 60

SECTION 2

Operation

2-20. Guarded

Figure

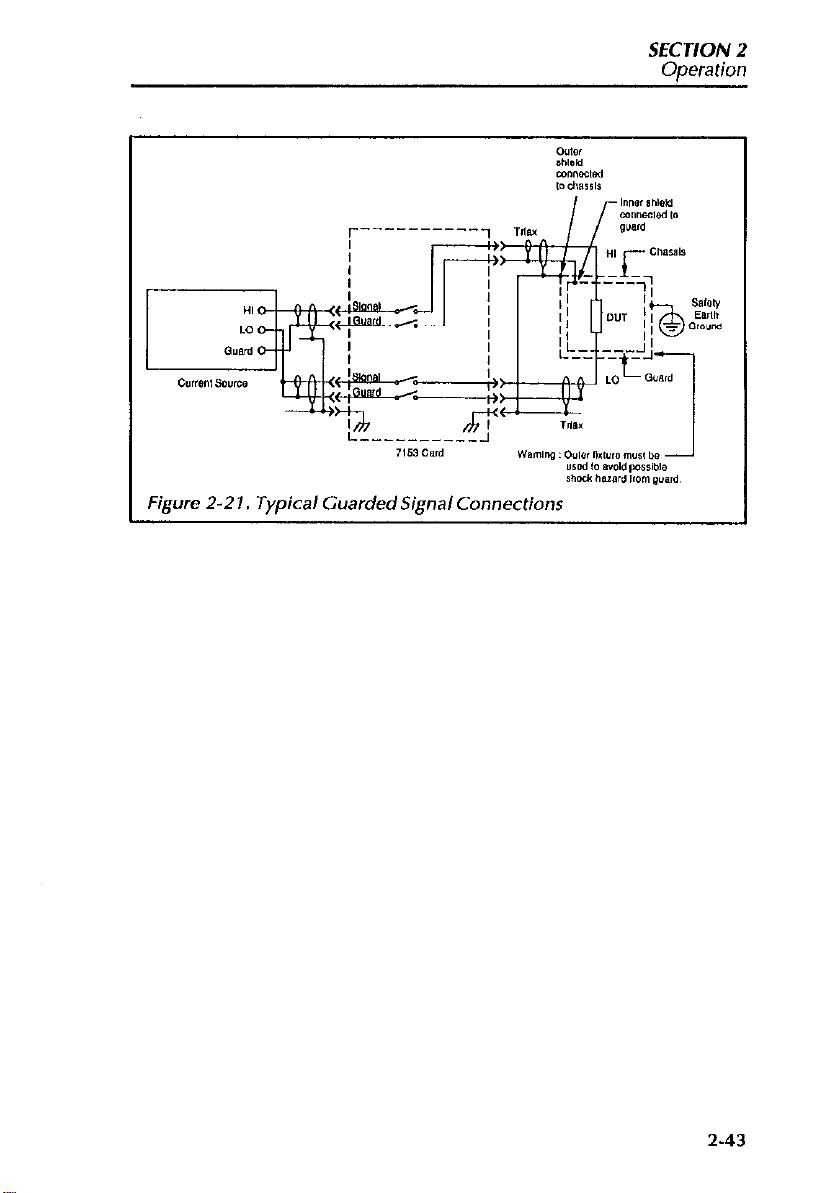

In order to use guarding effectively with the Model 7153, the GUARD path

of the matrix card should be connected to the guard output of the sourcing

or measuring instrument. Figure 2-21 shows typical connections. Guard

should be properly carried through the inner shield to the device under test

to be completely effective. The shielded, guarded test fixture arrangement

shown in Figure 2-19 is recommended for safety purposes (guard voltage

may be hazardous with some instruments). With most instruments, special

adapters or cables may be required to connect guard to the inner shield,

and at the same time route signal LO through a separate cable.

Circuit

2-42

Page 61

Figure 2-2 I, Typical Guarded Signal Connections

SEC J/ON 2

Operation

2-43

Page 62

SECTION 3

Applications

3.1 INTRODUCTION

This section covers typical applications for the Model 7153 High Voltage

Low Current Matrix card and is organized as follows:

3.2 Semiconductor Test Matrix: Details a semiconductor test matrix

that can be used to perform a variety of different tests on semiconductors

such as FETs.

3.3 Resistivity Testing Using Matrix Switching in a SMU Test System:

Covers methods to measure the resistivity of semiconductor samples using

the van der Pauw method.

WARNING

To provide protection from shock hazards, the test fixture

chassis must be properly connected to a safety earth ground.

A grounding wire (18 AWC or larger) must be attached securely to the test fixture at a terminal designed for safety

rounding (the terminal should be marked with the symbol

-h ). The other end of the grounding wire is then attached to a

b

known safety earth ground, such as a cold water pipe, or a

grounded electrical outlet box.

3.2 SEMICONDUCTOR TEST MATRIX

Two important advantages of a matrix switching system are the ability to

connect avariety of instruments to the device or devices under test, as well

3-1

Page 63

SECTION 3

Aoulications

as the ability to connect any instrument terminal to any device test node.

The following paragraphs discuss a typical semiconductor matrix test system.

3.2.1 System Configuration

Figure 3-1 shows a two Source Measure Unit test configuration. In this example, OUTPUT HI and OUTPUT LO of each Source Measure Unit are

independently switched, allowing for maximum versatility.

‘igurc 3-l. Multi Unit Connections to Mode/ 7153

This test configuration has five DUT test pins.

Source Measure Unit and test fixture connections to the matrix card are

accomplished using Model 7153-TRX cables. These cable assemblies are

3-2

Page 64

SEC JION 3

Adications

terminated with 3.slot triax connectors. On each Source Measure Unit,

notice that the banana jack is used to access OUTPUT LO rather than the

triax connector. This allows OUTPUT LO to be routed to the signal path of

the matrix. On the Source Measure Unit triax connector, OUTPUT LO is

located on the inner shell which, through normal triax connections, would

put OUTPUT LO on the guard path of the matrix card.

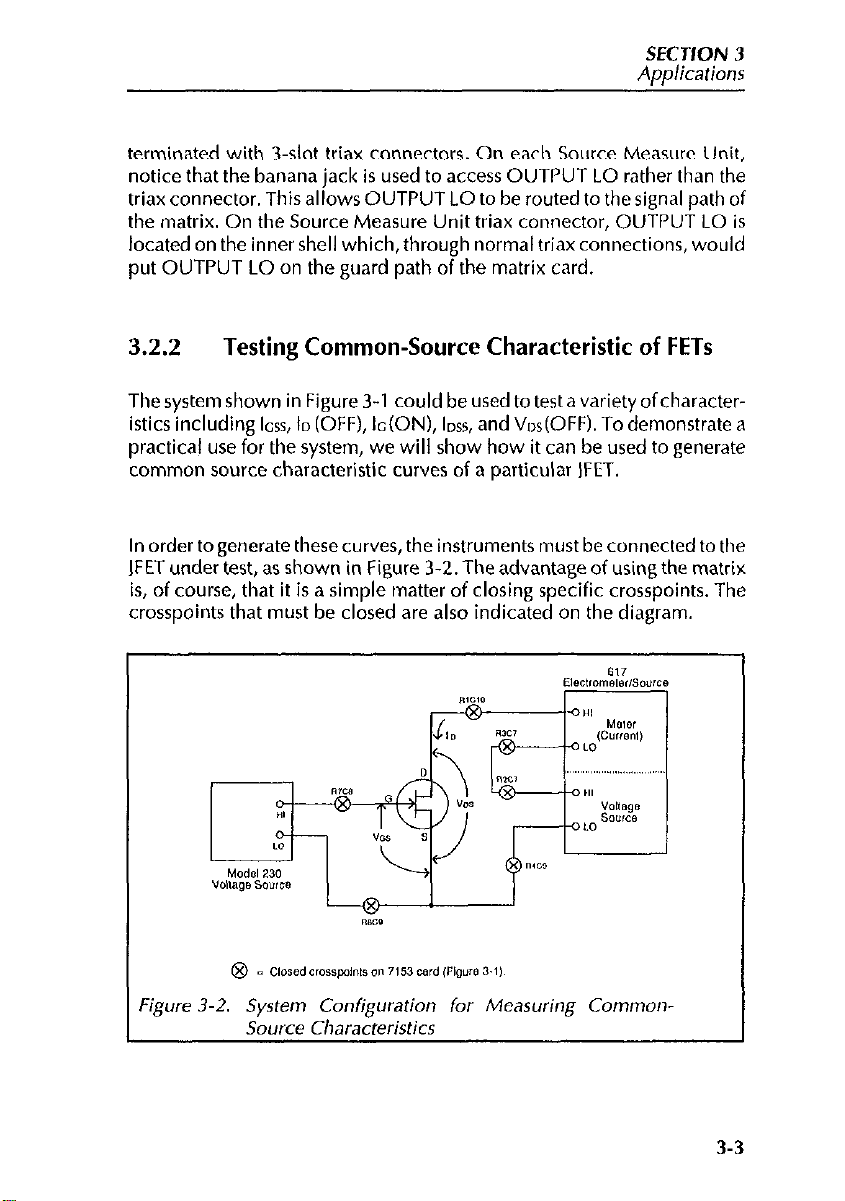

3.2.2

The system shown in Figure 3-1 could be used to test a variety ofcharacter-

istics including ICSS, ID (OFF), Ic(ON), lnss, and Vos(OFF). To demonstrate a

practical use for the system, we will show how it can be used to generate

common source characteristic curves of a particular IFET.

In order to generate these curves, the instruments tnust be connected to the

IFET under test, as shown in Figure 3-2. The advantage of using the matrix

is, of course, that it is a simple tnatter of closing specific crosspoints. The

crosspoints that must be closed are also indicated on the diagram.

Testing Common-Source Characteristic of FETs

‘igure

3-2.

System

Source Characteristics

Configuration

for Measuring Common-

3-3

Page 65

SECT/ON 3

Applications

3.3 RESISTIVITY TESTING USING MATRIX SWITCHING IN A SMU TEST SYSTEM

One example of where matrix switching is beneficial is when performing

resistivity tests on semiconductors. The following paragraphsdiscusssuch

resistivity tests using a Source Measure Unit/matrix switching system.

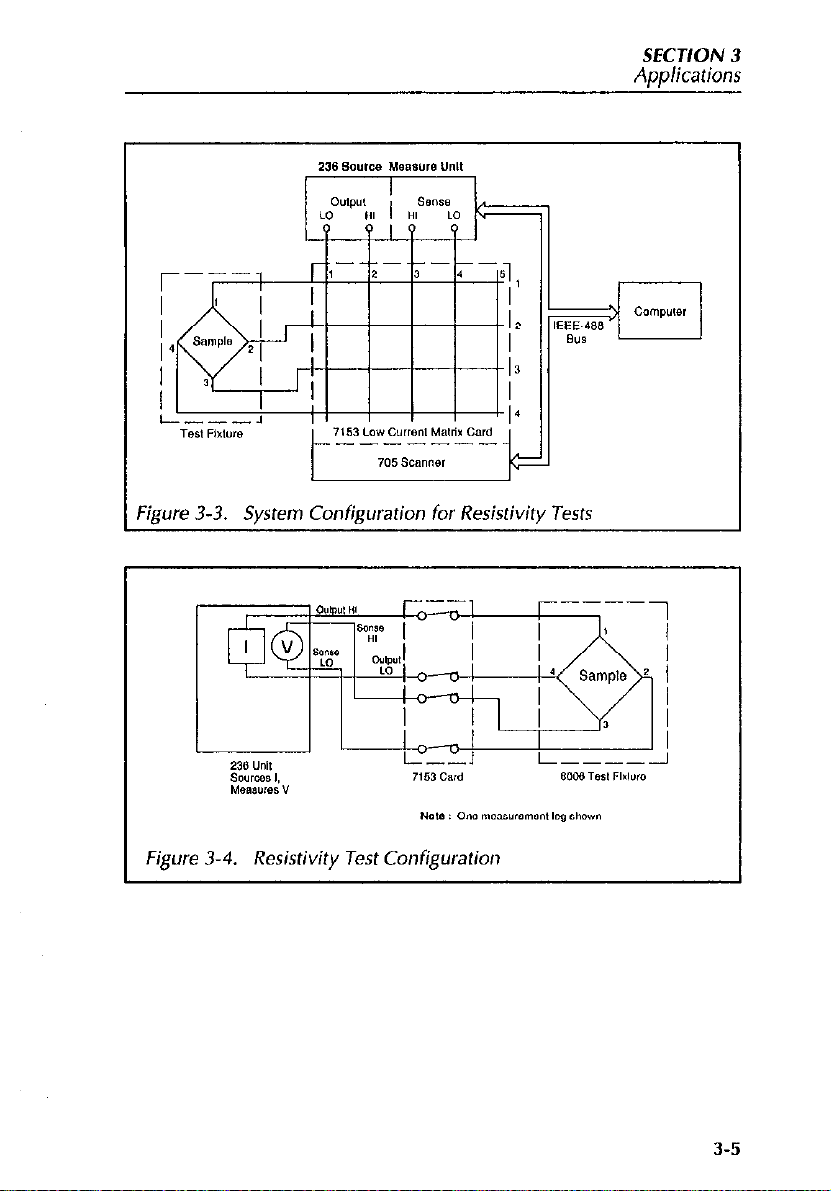

3.3.1 System Configuration

Figure 3-3 shows a typical system configuration for performing resistivity

tests using a Source Measure Unit. In addition to the Source Measure Unit,

which sources the test current and measures the resulting voltage drop

across the DUT, the system includes a Model 705 Scanner and a Model

7153 High Voltage Low Current Matrix Card for switching, as well as a

Model 8006 test fixture to house the device under test.

With the test configuration shown in Figure 3-3, onlyone4.terminal sam-

ple can be tested at any given time. However, additional Model 7153

cards can be daisy chained together to expand columns or rows, allowing

more than one sample to be tested by a single test procedure.

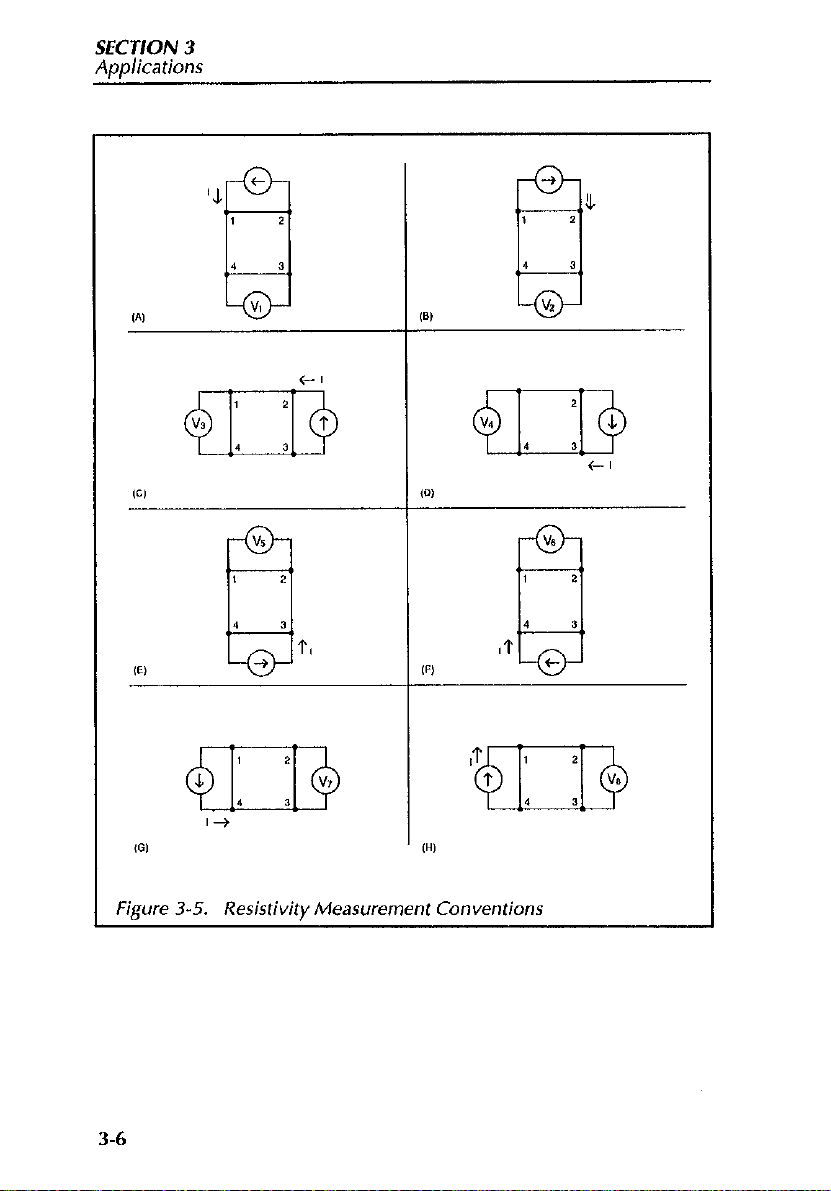

3.3.2 Test Configuration

Figure 3-4 shows a typical resistivity test configuration for a single leg

measurement of one sample. Here, the current source of the Source Measure Unit sowces a current between two terminals of the sample, while the

voltage meter section of the unit measures the voltage across two of the

opposite terminals. Generally, eight such measurements are made, as

shown in Figure 3-5.

3.4

Page 66

SECTION 3

Applications

3-5

Page 67

SEC J/ON 3

Applications

Figure 3-5. Resistivity Measurement Conventions

3-6

Page 68

SECTION 3

Aoalications

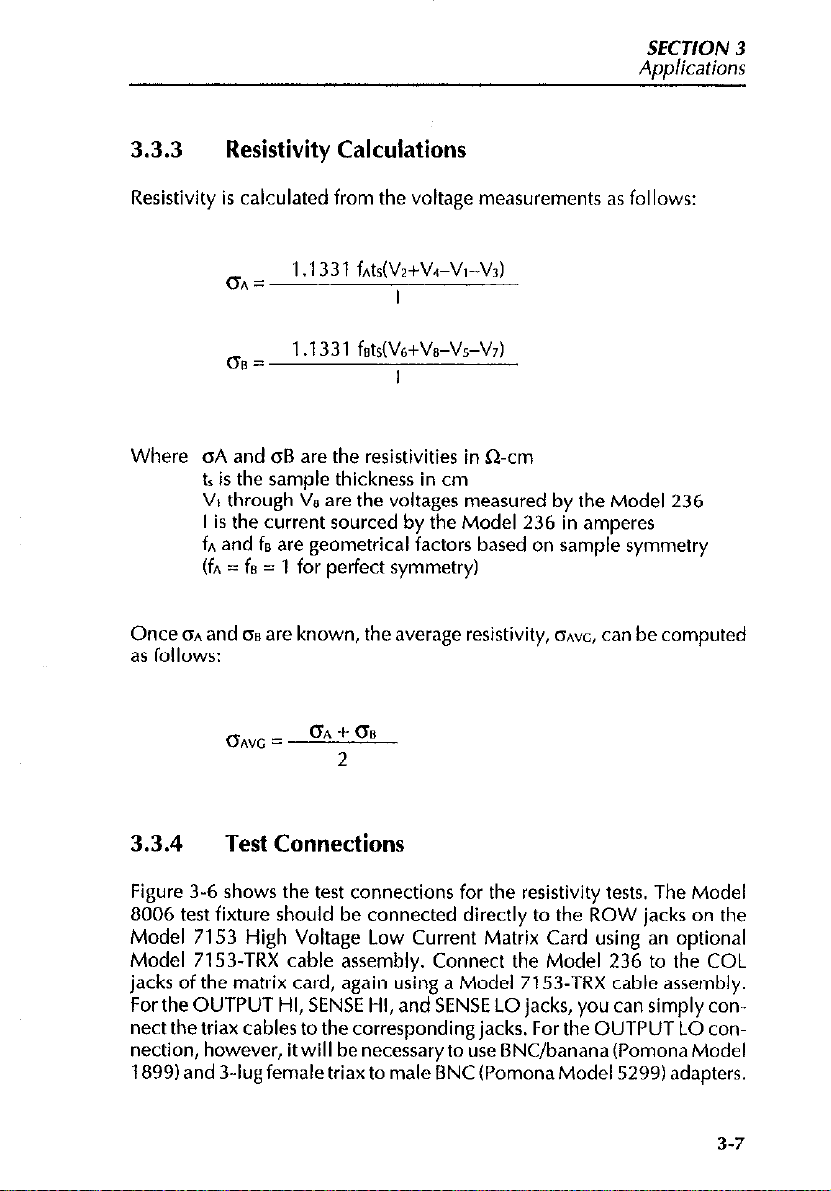

3.3.3 Resistivity Calculations

Resistivity is calculated from the voltage measurements as follows:

~~ = 1 .I 331 fntsw+V4-V,-K)

I

~” = 1 .1331 fsts(V6+Vs-Vs-V,)

I

Where oA and oB are the resistivities in &cm

tr is the sample thickness in cm

V, through Vs are the voltages measured by the Model 236

I is the current sourced by the Model 236 in amperes

fn and fe are geometrical factors based on sample symmetry

(fn = f8 = 1 for perfect symmetry)

Once ISA and 0s are known, the average resistivity, onvc, can be computed

as follows:

OAYC =

3.3.4

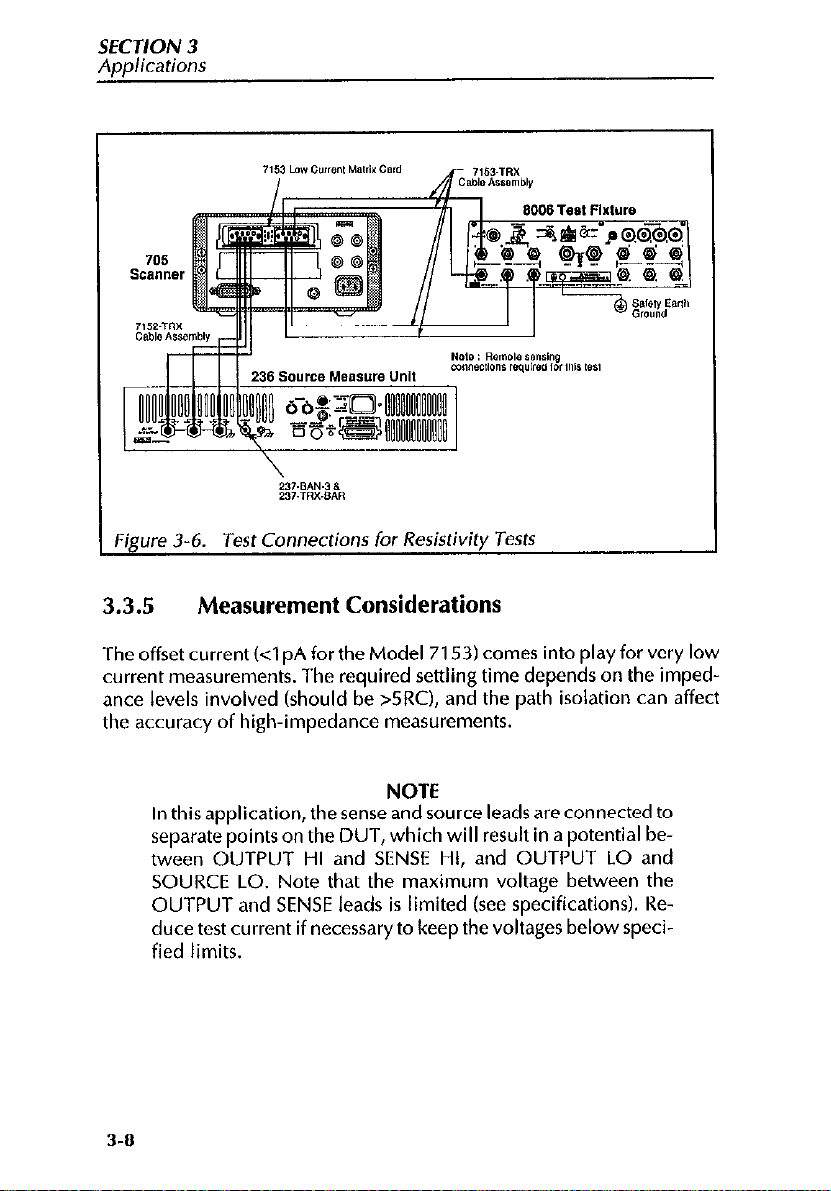

Figure 3-6 shows the test connections for the resistivity tests. The Model

8006 test fixture should be connected directly to the ROW jacks on the

Model 7153 High Voltage Low Current Matrix Card using an optional

Model 7153-TRX cable assembly. Connect the Model 236 to the COL

jacks of the matrix card, again using a Model 7153-TRX cable assembly.

For the OUTPUT HI, SENSE HI, and SENSE LO jacks, you can simply connect the triax cables to the corresponding jacks. For the OUTPUT LO connection, however, it will be necessary to use DNC/banana (Pomona Model

1899) and 3-14 female&w to male BNC (Pomona Model 5299) adapters.

Test Connections

OA + 00

2

3-7

Page 69

SFCJION 3

Applicarions

Figure 3-6.

Jest

Connections

for

Resistivity

Jests

3.3.5 Measurement Considerations

The offset current (4 pA for the Model 7153) comes into play for very low

current measurements. The required settling time depends on the impedance levels involved (should be >5RC), and the path isolation can affect

the accuracy of high-impedance measurements.

NOTE

ln this application, the sense and source leads are connected to

separate points on the DUT, which will result in a potential between OUTPUT HI and SENSE HI, and OUTPUT LO and

SOURCE LO. Note that the maximum voltage between the

OUTPUT and SENSE leads is limited (see specifications). Reduce test current if necessary to keep the voltages belowspecified limits.

3-O

Page 70

SFCJION 3

Applications

3.3.6

Program: Resistivity Tests Using a Switching

Matrix and Source Measure Unit

The following Program demonstrates programming techniques for controlling a switching matrix and Source Measure Unit to perform resistivity

tests. The basic procedure for using this program is as follows:

With power off, connect the Model 23G Source Measure Unit and the

1.

Model 705 Scanner to the IEEE-48t3 bus of the computer. Also, install

the Model 7153 Card in slot 1 of the Model 705 mainframe.

2.

Connect the test fixture and the Source Measure Unit to the matrix

card using the specified triax cables (see Figure 3-6 and the discussion

above for details on test connections).

Turn on the Model 236, and allow it to warm up for at least two hours

3.

for rated accuracy. Be sure that the primary address of the Source

Measure Unit is set to 16. Also, turn on the Model 705, and make sure

that its primary address is set to 17.

4.

Turn on the computer, then boot up BASIC.

Enter lines below into the computer.

5.

Connect the sampleto betested to the appropriate socket terminals on

6.

the test fixture, and also install the necessary test fixture jumpers. Use

the general configuration shown in Figure 3-4 as a guide to test con-

nections. Close the test fixture lid after making connections.

7.

RUN the program, and follow the prompts on the screen. You will be

prompted toenter thedesired sample current value and then the sample thickness, which should beentered in centimeters. When entering

the current, keep the approximate DUT resistance values in mind so

as not to create an over voltage compliance condition. Also, you must

not exceed the maximum voltage between output and sense lends of

the Source Measure Unit.

Oncetheparametersareentered, thetest will begin.TheprogramwiII

8.

program the Source Measure Unit, and then begin the tests by closing

crosspoints. A total of eight measurements will be taken and stored in

an array.

9.

Once the testing has been completed, the resistivityvalues will becalc&ted and displayed.

3-9

Page 71

SECTION 3

Applications

3.3.7

Program Description

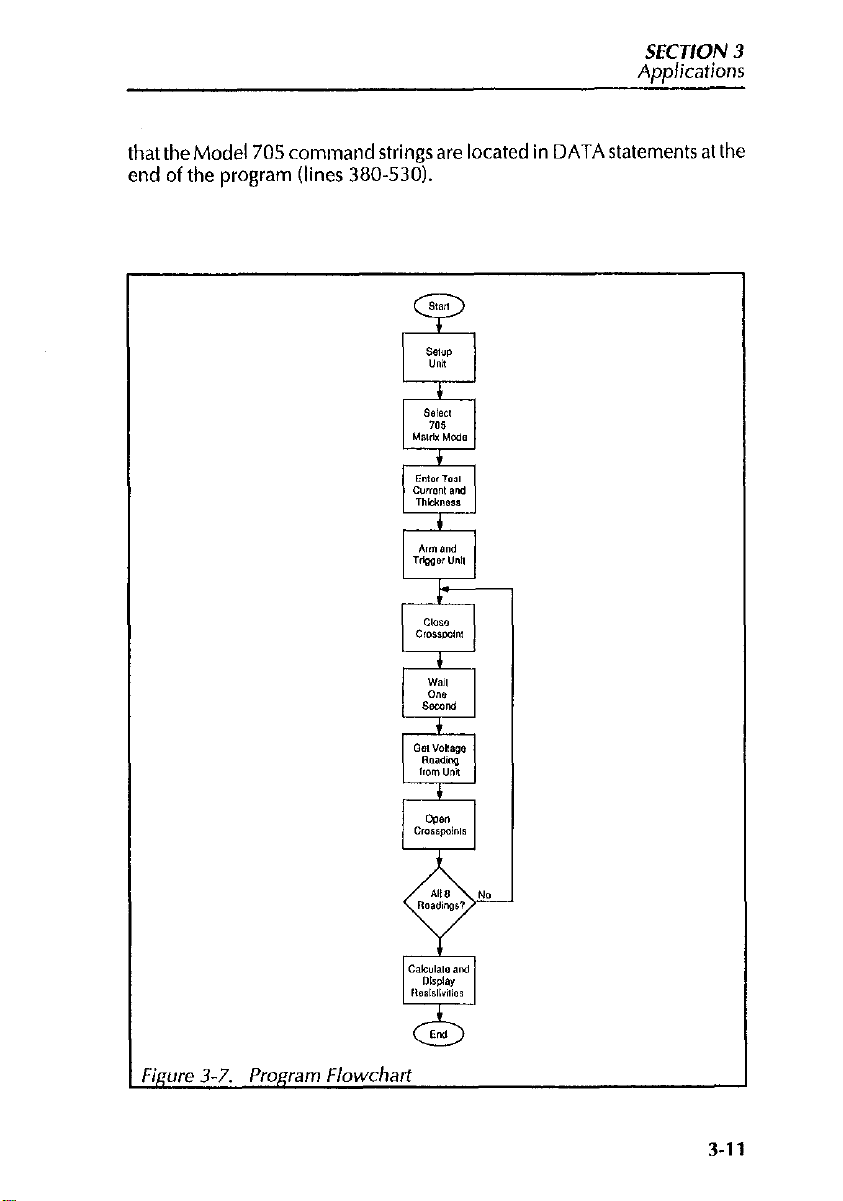

Refer to the I’rogram listing below and the flowchart shown in Figure 3-7

for the following description.

At the start of the program, both the Source Measure Unit and the scanner

are returned to default conditions (line 20), and the reading array and command string are dimensioned (line 40). Next, the Model 236, which

sources the test current and measures the sample voltage, is programmed

as follows (lines 60.120):

. Source I, DC mode

l

1 OV compliance, autorange measure

l

Remote sensing

. Measure only data format with no prefix, DC data output

l

Continuous trigger on GET

l

Line cycle integration

The Model 705 is then placed in remote (line 140), and the scanner is

placed into matrix mode (line 150). Next the operator is prompted to input

the desired test current, at which point the Source Measure Unit is programmed with the current value (lines 160 and 170). The operator is then

prompted for the sample thickness (line 180), and the program waits for

the operator’s signal to begin (lines 190 and 200).

Once the operator starts the test, the Model 236 is armed and placed into

operate (line 2101, and the unit is then triggered (line 220). The program

thenentersa loop(line230)to testthesamplewith atotalofeightreadings.

As part of each loop, the Model 705 command string is read from the

DATA statements at the end of the program (line 240), and the unit is then

programmed to close the desired crosspoints (line 250). After a two-second delay for settling (line 2601, a voltage reading is requested from the

Model 236 and placed into an array (line 270). The crosspoints are then

opened by reading the next command string (line 280) and then programming the Model 705 accordingly (line 2901, and then the program loops

back for the tnext Imeasurement (line 300)

Finally, the program computes both IX and 0~ (lines 320 and 330), and

then it calculates and displays the average resistivity, onvc (line 360). Note

3-10

Page 72

SECTION 3

Applications

that the Model 705 command strings are located in DATA statements at the

end of the program (lines 380-530).

Figure

3-7.

Program Flowchart

3-11

Page 73

SECTION 3

Appkations

3-12

Page 74

SECTION 3

Applications

3.4 SMU REMOTE SENSING

The Model 7153 matrix card can also be used by a single Source Measure

Unit for remote sensing. For remote sensing, the Source Measure Unit

could be connected to the matrix card as shown in Figure 3-8. OUTPUT

HI/GUARD, SENSE HI/GUARD, SENSE LO and OUTPUT LO are connected to separate rows for maximum switching flexibility and optimum

lowcurrentperformance. MakingtheSENSE LOconnectionalsoconnects

OUTPUT LO to the matrix card through the triax connector. However,

since it is connected to the inner shield, it is of no consequence as long as it

is not used at the test fixture. In this test configuration, OUTPUT LO is accessed at the Source Measure Unit banana jack so that it can be independently switched.

The test configuration in Figure 3-8 “uses” four matrix rows. Remote sens-

ing can be accomplished using three matrix rows by using OUTPUT LO at

the triax connector. In this configuration, SENSE LO and OUTPUT LO use

the same row. The disadvantage to this is the loss of some switching flexibility. Another option is to make OUTPUT LO a system common that is not

routed (not switched) through the card. All commons are simply

nected directly to the OUTPUT 1.0 banana jack.

con-

For high current applications where leakage current is not a consideration,

the guard paths of the matrix card can be used for 4-wire sensing as shown

in Figure 3-9. With this configuration only two matrix crosspoints are required to accomplish 4.wire connections to the DUT.

3-13

Page 75

SECTION 3

Applications

‘igure 3.0. Remote Sense and Guard Connections fo Model 7753

3-14

Page 76

r

SECTION 3

Applications

Figure 3-9.

Remote Sensing with Guard

3-15

Page 77

SECTION 3

Aodications

REFERENCES

ASTM, F76-84. “Standard Method for Measuring Hall Mobility and Hall

Coefficient in Extrinsic Semiconductor Single Crystals”. Annual Bk. ASTM

Stds., 1986: 10.05 155.

Coyle, G. et al, Switchinc! Handbook. Keithley Instruments Inc., Cleveland, Ohio (1987).