Page 1

Model 7 116~MWS

Microwave Switch System

Instruction

Manual

Contains Operating and Servicing Information

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product lo he free from deCects in material and workmanship for a period of I year from date of

shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable batteries,

diskettes, and documentation.

During the Wmnty period, we will, at our option, cithcr repair or rcplacc any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Kcithlcy headquwtcrs in Cleveland, Ohio. You will

be given prompt assistance and return instructions. Send the product, transportation prepaid, to the indicated service facility. Repairs

will be made and the product returned, transportation prepaid. Repaired or replaced products arc warranted Coor the balance of the original warranty period, or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modilication without Keithley’s express written consent, or misuse of

any product or part. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from battery leakage, or

problems arising from normal wew or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES PROVIDED HEREIN ARE

BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUeNTIAL DAMAGES ARISING OUT OF THE USE OF ITS INSTRUMENTS AND

SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN ADVANCE OF THE POSSIBILITY OF

SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL

AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY PERSON, OR DAMAGE TO PROPERTY,

Keithley Instruments, Inc. * 28775 Aurora Road - Cleveland, OH 44139 * 440-248-0400 *Fax: 440-248-6168 * http://www.keithley.com

Page 3

Model 7116-MWS 16-Channel Microwave Switch System

Instruction Manual

01996, Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

Third Printing, July 1998

Document Number: 7116MWS-901-01 Rev. C

Page 4

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created toor this manual. The Revision

Level letter increases alphabetically as the manual undergoes subsequent updates. Addenda, which are released between Revisions, contain important change inkmnation that the user should incorporate immcdiatcly into the manual. Addenda are numbered sequentially. When a new Revision is crcatcd, all Addenda associated with the previous Revision of the manual we

incorporated into the new Revision of the manual. Each new Revision includes a revised copy oi this print history page.

Page 5

Safety Precautions

The following safety precautions should bc observed before using

this product and any associated instrumentation. Although some instruments and acccssorics would normally be used with non-hazardous voltages, there are situations where hazardous conditions

may bc prcscnt.

This product is intended for USC by qualified personnel who recognize shock hazards and arc familiar with the safety precautions required to avoid possible injury. Read tbc operating infoarmation

carefully beforc using the product.

The types of product users are:

Responsible body is the individual OT group responsible for the use

and maintenance of equipment. and for ensuring that operators are

adequately uained.

Operators use the product for its intended function. They must be

trained in electrical safety procedures and proper use of the instrument. They must he prolected from electric shock and contact with

hazardous live circuits.

Maintenance personnel perform routine procedures on the product

to keep it operating, for example, setting the line voltage or replacing consumable materials. Maintenance procedures are described in

the manual. The procedures explicitly state if the operator may perform them. Otherwise, they should he performed only by service

perS”““el.

Service

personnel

safe instatIations and repairs of products. Only properly trained service personnel may perform installation and service procedures.

Exercise extreme caution when a shock hazard is present. Lethal

voltage may he present on cable connector jacks or test fixtures. The

American National Standards Institute (ANSI) states that a shock

hazard exists when voltage levels greater than 30V RMS, 42.4V

peak,

or 60VDC are present. A good safety practice is to expect

are trained to work on live circuits, and perform

that hazardous voltage is present in any unknown circuit before

measuring.

Users of this product most he protected from electric shock at all

Limes. The responsihlc body nest ensue thal users are prevented

access and/or insulated from every connectloo point. In some cases,

connections must bc exposed to potential human contact. Product

UXTS in these circumstances most be trained to prolect themselves

from the risk of electric shock. If the circuit is capable of operating

at or above 1000 volts, no conductive part of the circuit may he

exposed.

As described in the International Electrotechnical Commission

(IEC!) Standard IEC 664, digital multimeter measuring circuits

(e.g., Keitbley Models 175A. 199,2000,2OUl, 2002, and 2010) arc

Installation Category II. All other instruments’ signal terminals are

Installation Category I and must not be connected to mains.

Do not connect switching cards directly to unlimited power circuits.

They are intended to he used with impedance limited sources.

NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit fault torrent and voltage to the card.

Before operating an instrument, make sore the line cord is connect-

ed to a properly grounded power receptacle. Inspect the connecting

cables, test leads, and jumpers for possible wear, cracks, or breaks

before each use.

For maximum safety, do not touch the product, test cables, 01 any

other instroments while power is applied to the circuit under test.

ALWAYS remove power from the entire test system and discharge

any capacitors before: connecting or disconnecting cables or jumpers, installing or removing switching cards, or making internal

changes, such as installing or removing jumpers.

Do not touch any object that could provide a torrent path to the

common side of the circuit under lest or power line (earth) ground.

Always make measurements with dry hands while standing on a

dry, insulated surface capable of withstanding the voltage being

measured.

Page 6

Do not exceed the maximum signal levels of the instruments and accessories, as dcfincd in the specilications and upcrating information, and as shown on tbc instrument or test fixture panels, or

switching card.

When fuses are used in a product, replace with same type and rating

for continued protection against fire hazard.

Chassis connections must only be used as shield connections for

measuring circuits, NOT as safety earth ground connections.

If you arc using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires tbc USC of a

lid interlock.

Ifa@ screw is prcscnt, connect it to safety earth ground using the

wire recommended in the user documentation.

The A symbol on an instrument indicates that the user should rcfer to the operating instructions located in the manual.

Then

sure 1000 volts or more, including tbc combined effect of normal

and common mode voltages. USC standard safety precautions to

avoid personal contact with these voltages.

The WARNING heading in a manual explains dangers that might

result in personal injury or death. Always read the associated information very carefully before performing the indicated procedure.

symbol on an instrument shows that it can sowcc or mea-

lnslrumcntation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and

all test cables.

‘To maintain protection from electric shock and fix, rcplacemcnt

components in mains circuits, including the power transformer, test

leads, and input jacks, must be purchased from Kcithley Instrw

merits. Standard fuses, with applicable national saCety approvals,

may be used if the rating and type are the same. Other components

that are not safety related may be purchased from other suppliers as

long as they are equivalent to the original component. (Note that selected parts should be purchased only through Keithley Instruments

to maintain accuracy and functionality of the product.) If you are

unsure about the applicability of a replacement component, call

technical support for information.

To clean the instrument, use a damp cloth or mild, water based

cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill

on the instrument.

The CAUTION heading in a manual explains hazards that could

damage the instrument. Such damage may invalidate the warranty.

Page 7

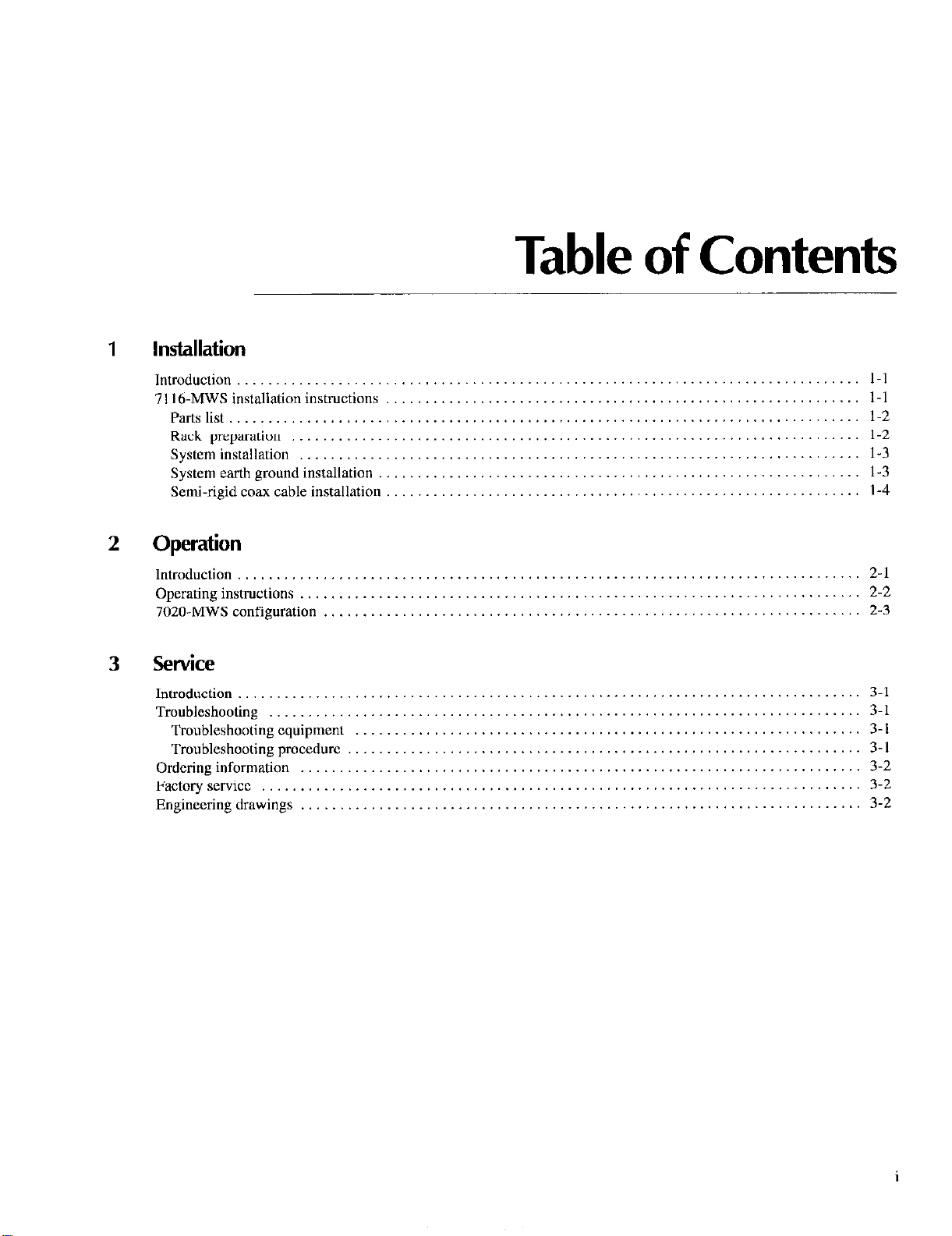

1 Installation

Table of Contents

Introduction

7116.MWS installation instructions

Parts list

Rack preparation

System installation

System earth ground installation

Semi-rigid coax cable installation

2

Operation

Introduction ...................

Operating instructions ...........

7020-MWS configuration ........

3 Service

Introduction .._....._....

Troubleshooting

Troubleshooting equipment

Troubleshooting procedure

Ordering information

Factory service

Engineering drawings

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

......

......

......

......

......

......

......

..........

..........

..........

..........

..........

..........

..........

......

......

......

......

......

......

......

......

......

......

......

......

......

......

I-I

1-I

1-2

1-2

l-3

1-3

1-4

2-1

2-2

2-3

3-l

3-l

3-i

3-l

3-2

3-2

3-2

Page 8

List of Illustrations

1

Figure I-1

Figure l-2

Figure 1-3

2

Figure 2-I

1

Installation

Fastener installation

Mounting kit installation

Cable installation

.....................................................................

.......................................................................

.................................................................. l-3

l-2

1-4

Operation

Tree switching network 2-l

List of Tables

Installation

Table l-l

2

Table 2-l

3

Table 2-1

ii

Model 7116.MWS rack assembly parts l-2

Operation

Model 7001 outputs, memory locations, and commands 2-2

Service

Troubleshooting procedure ,_.,_.__,,,.,,,,..........._.....................,.........._... 3-2

Page 9

Introduction

The Model 7116-MWS 16-Channel Microwave Switch System provides an integrated solution for multiplexed signal routing

of microwave signals at frequencies up to 18GH.z. The Model 71 I6-MWS switch system can be used to test wireless telecom-

munication devices and systems such as cellular phones, cordless phones, pagers, antenna systems, base stations, and other

wireless transmission productions.

It consists of:

- Five 1x4 microwave RF multiplexer switch modules

* A Model 7020.MWS switching card

* A Model 7001 switching mainframe

* An off-line power supply

. Semi-rigid cables

7116-MWS installation instructions

WARNING

The information on the following pages is intended for qualified service personnel only. Do not attempt

these procedures unless you are qualified to do so.

CAUTION

To prevent flexing of the connections and possible damage, ensure that the Model 7020~MWS card is

secured with its thumbscrew to the Model 7001 rear panel, and that the cable assembly is secured with

its two screws to the 7020-MWS card.

l-l

Page 10

Table I-l

Model 7116MWS rack assembly parts

Quantity

Description

Keithley

part number

Function

2 Bracket, rear support

4 I O-32 Kept””

4 IO-32 x % Phillips pan head screw

8 Fastener, captive nut

8 IO-32 x % Phillips pa” head screw

I IO-32 x % Phillips pa” head sems screw 10-32.x3/8 PPHSEM

2 Semi-rigid cable

2 Semi-rigid cable

BR-21 Attaches chassis rear to rear rack rails.

I O-32 KEPNUT Attaches rear support brackets to chassis.

10-32x3/8 PPM

FA-148 Attachcs rear support brackets and front

10-32x5/8 PPH

panel to rails.

Connect ground cable to earth ground.

7116-307-I

7116-307-2

Parts list

Table l-l lists the parts supplied with the Model 71 I6-MWS 16.Channel Microwave Switch System.

Rack preparation

I. Select a location in the rack. The assembly will take up to 5% inches of vertical space

2. Hold up the system at the selected location in the rack. The four slotted mounting holes in the front panel dictate the location

of the captive ““t fasteners on the front rack rails. Mark where the fasteners are to be installed.

3. Referring to Figure I- I, install four fasteners so the captive nuts are located behind the appropriate holes on the front rack rails.

.J

Figure 1-I

Fastener installation

Front Rack

Rail

1-2

Page 11

System installation

Refer to Figure l-2 to install the chassis and support brackets in the rack,

24”

10-32x 318 PP

&

#IO-32 KEynut

Figure Z-2

Mounting kit

installation

I, Loosely attach lhe rear support brackets to the chassis with kepnuts and lo-32 x % screws.

2. Position the chassis assembly in the rack to adjust the support brackets, and note the location for the captive nul fasteners

on the rear rack rails.

3. Install four fasteners so the captive nuts arc located behind the appropriate holes on the rear rack rails.

4. Loosely attach the chassis assembly to the front and rear rack rails with 10-32x % saews. Secure the rear support brackets

to the chassis.

5. Tighten all screws.

Power SuppI

WARNING

The Model 7116~MWS must be separately connected to a safety earth ground to maintain protection

against possible shock hazard. Failure to connect the unit to a safety earth ground may result in personal injury or death due to an electric shock.

System earth ground installation

1, Remove all power from the system.

2. Connect the loose end of the six foot green/yellow ground cable to a quality ground located within your facility using the

#I 0 screw provided.

1-3

Page 12

Semi-rigid coax cable installation

WARNING

Contact with exposed conductors carrying RF power may cause burns. Place protective caps on all un-

used switch inputs. All cables and connectors should be properly mated and shielded.

I. Remove all power from the system.

2 Remove the plastic protective caps from the switch inputs shown in Figure l-3. Leave Lhc olher caps on. Saw Lhc removed

caps for l’ulurc USC. Conneci the cables to the switches as shown in Figure l-3 and tightcn using a VIS inch wrench, to 7. IO

in.-lb.

Figure Z-3

Cable installation

1-4

Page 13

2

Operation

Introduction

The Model 7116-MWS system is a 16.input microwave mulliplexer. Sixteen inputs are achieved by connecting five single-pole,

four-throw switches together forming a tree switching network as shown in Figure 2-l.

Figure 2-z

Tree switching network

2-l

Page 14

Operation

Operating instructions

To selecl an input channel, the Model 7001 must close tw” switches at the same time. Table 2-l lists which Model 7020.MWS

digital outputs must be activated to select each respective RF input. The table also shows 7001 channels used to sclcct the inputs.

Table 2-Z

Model 7001 channels und memory locutionsfor lx16 multiplexer

7020-MWS Digital Outputs

7116-MW!

Input

Ch. 1

Ch. 2

Ch. 3

Ch. 4

Bank A Bank B

OUT 1

OUT 2

OUT 3

OUT 4

Bank C Bank D

OUT 21 1!1,1!21

OUT 21 I !2,1!21

OUT 21 1!3,1!21

OUT 21 1!4,1!21

T

Channels

7001

7001

Memory

Location

Ml

M2

M3

M4

--

7116-MM

7s

Relays

Kl.K5

Ch. 5

Ch. 6

Ch. 7

Ch. 8

Ch. 9

Ch. 10

Ch. 11

Ch. 12

Ch. 13

Ch. 14

Ch. 15

Ch. 16

Outpul patterns for each input are stored in the Model 7001 memory al the factory. The user can call up memory locations to

select each input. For example, calling up memory location 1 selects input 1. Some programming examples are listed below.

In either configuration of the Model 7116.MWS, as one I x I6 multiplexer ol; with the semi-rigidjumper cables

removed, as Jive I x 4 multiplexers, ensure that only one channel

relays are energized simultaneously per bank.

OUT 5

OUT 6

OUT 7

OUT 8

OUT 9

OUT 10

OUT11

OUT 12

OUT 13

OUT 14

OUT 15

OUT 16

OUT 22 1!5,1!22 MS

OUT 22 1!6,1!22

OUT 22 1!7,1!22

OUT 22 I !8,1 !22 MX

OUT 23 1!9,1!23

OUT 23

OUT 23 1!11,1!23

OUT 23 1!12,1!23 Ml2

OUT 24 1!13,1!24

OUT 24

OUT 24 1!15,1!24

OUT 24

NOTE

is

1!10,1!23 Ml0

1!14,1!24 Ml4

1!16,1!24 Ml6

closedper relay, and that no more than two

M6

M7

M9

Ml1

Ml3

Ml5

K2, K5

K3, K5

K4, KS

2-2

For further information on operation and programming, refer to the Models 7001 and 7020 Instrwtion Manuals

Page 15

Operation

Power Limits

The Model 7020-MWS card is a modified version of the Model 7020 Digital I/O Interfacc Card. Among other changes, the output

protection network has hecn removed for greater sink current capacity.

CAUTION

This card is not intended for use in applications other than the Model 7116-MWS system. The 7020.

MWS and 7020 cards are not interchangeable. Damage or unintended operation may result if a Model

7020 is substituted for a 7020-MWS.

NOTE

A hank refer,~ to the

(banks) to accomodate the 40 output channels. The outputs are grouped

Bank A = OUT 1 through OUT 8

Bank B = OUT 9 through OUT 16

Bank C = OUT 17 through OUT 24

Bank D = OUT 25 through OUT 32

Bank E = OUT 33 through OUT 40

internal

IC that is used to drive eight output channels. The card uses five driver ICs

asfollowsfor

each bank:

2-3

Page 16

Operation

2-4

Page 17

3

Service

Introduction

The following paragraphs contain troubleshooting and replacement parts information. Schematic diagrams, and component layout drawings for the Model 7116.MWS chassis arc also included. Refer to Model 7001 and 7020 manuals for further information about these components.

Troubleshooting

WARNING

The information in this section is intended for qualified service personnel only.

may expose you to hazardous voltages that could result in personal injury or death. Do not attempt to

perform these procedures unless you are qualified to do so.

Troubleshooting equipment

The Model 2000 Digital Multimeter is recommended for troubleshooting

Troubleshooting procedure

Table 3-l summarizes the procedure Coor verifying operation of the Model 7116.MWS. Refer to the system schematic and the

chassis wiring diagram (drawing number 7116.051) for component locations.

Some of the procedures

3-1

Page 18

Table 3-I

Troubleshooting procedure

step

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

IX

YrE: see

Item/component

Chassis

I

Kl-KS, pin COM

KI pin I, K5 pin I

KI pin 2, K5 pin 1

Kl pin 3, K5 pin I

KI pin 4, K5 pin I

K2pinl,K5pin2

K2 pin 2, K5 pin 2

K2 pin 3, K5 pin 2

K2 pin 4, K5 pin 2

K3pinl,K5pin3

K3 pin 2, K5 pin 3

K3 pin 3, K5 pin 3

K3 pin 4, K5 pin 3

K4pin l,K5pin4

K4 pin 2, K5 pin 4

K4 pin 3, K5 pin 4

K4 pin 4, K5 pin 4

ble 2-1 for information on clos

T

Required condition

4

< 29VDC

< I .5v

< 1.5v

< 1.5v

< I .5v

< 1.5v

< 1.5v

< 1.5v

< 1.5v

< 1.5v

< 1.5v

< 1.5v

< 1.5v

< 1.5v

< 1.5v

< l.SV

< 1.w

channels.

Comment

I

All voltages rcfcrenccd to chassis

Relay coil voltage

Close channel I

Close channel 2

Close channel 3

ClOSC channel 4

Close channel 5

Close channel 6

Close channel 7

Close channel 8

Close channel 9

Close channel 10

Close channel 11

Close channel 12

Close channel 13

Close channel 14

Close channel 15

Close channel 16

Ordering information

To place an order or to obtain information concerning replacement parts, contact your Keithlcy representative or the factory.

When ordering parts, be sure to include the following information:

. Model numbers 7116-MWS, 7020.MWS, and 7001

- Serial number OC the chassis, card, or mainframe

- Part description

* Circuit designation (if applicable)

* Keithley part number

Factory service

If the Model 7116.MWS system must be returned to Keithley for repair, perform the following:

1. Call the Repair department at 1-800-552-I 115 for a Return Material Authorization (RMA) number.

2. Complete the service form at the back of this manual and include it with the card.

3. Carefully pack the card in the original packing carton.

4. Write ATTENTION REPAIR DEPT and the RMA number on the shipping label.

Engineering drawings

The Model 7116.MWS schematic (7116.MWS-406). chassis assembly (7116.050), and chassis wiring (7116.051) drawings

are included on the following pages.

3-2

Page 19

Page 20

Page 21

Page 22

Service Form

Model No.

Serial No.

Date

Name and Telephone No.

Company

List all control settings, dcscribc problem and check boxes that apply to problem.

0 Intermittent

u IEEE failure

m Front panel operational

Display or output (check one)

Ll Drifts

0 Unstable

0 Overload

a Calibration only

0 Data required

(attach any additional sheets as necessary)

Show a block diagram of your measurement system including all instruments connected (whether power is hzned on or not).

Also, describe signal source.

0 Analog output follows display

0 Obvious problem on power-up

m All ranges or functions are bad

n Unable to zero

0 Will not read applied input

u Certificate of calibration required

a Particular range or function bad; specify

0 Batteries and fuses are OK

a Checked all cables

Where is the measurement being performed? (factory, controlled laboratory, out-of-doors, etc.)

What power line voltage is used?

Relative humidity?

Any additional information. (If special modifications have been made by the user, please describe.)

Cther?

Ambient temperature?

“F

Page 23

Keithley Instruments, Inc.

28775 Aurora Road

Cleveland, Ohio 44 I39

Loading...

Loading...