Page 1

Model 7070Universal Adapter Card

Instruction Manual

A GREATER MEASURE OF CONFIDENCE

Page 2

W ARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of 1 year

from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable

batteries, diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in Cle veland, Ohio.

You will be given prompt assistance and return instructions. Send the product, transportation prepaid, to the indicated service

facility . Repairs will be made and the product returned, transportation prepaid. Repaired or replaced products are warranted for

the balance of the original warranty period, or at least 90 days.

LIMIT A TION OF W ARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written consent, or

misuse of any product or part. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from

battery leakage, or problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY DIRECT,

INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF ITS

INSTRUMENTS AND SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN ADVANCE

OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY

PERSON, OR DAMAGE TO PROPERTY.

Keithley Instruments, Inc. • 28775 Aurora Road • Cleveland, OH 44139 • 440-248-0400 • Fax: 440-248-6168 • http://www.keithley.com

BELGIUM: Keithley Instruments B.V.

CHINA: Keithley Instruments China Y uan Chen Xin Building, Room 705 • 12 Yumin Road, Dewai, Madian • Beijing 100029 • 8610-62022886 • F ax: 8610-62022892

FRANCE: Keithley Instruments Sarl 3, allée des Garays • 91127 Palaiseau Cedex • 01-64 53 20 20 • Fax: 01-60 11 77 26

GERMANY: Keithley Instruments GmbH Landsberger Strasse 65 • 82110 Germering • 089/84 93 07-40 • Fax: 089/84 93 07-34

GREAT BRITAIN: Keithley Instruments Ltd

INDIA: Keithley Instruments GmbH Flat 2B, WILOCRISSA • 14, Rest House Crescent • Bangalore 560 001 • 91-80-509-1320/21 • Fax: 91-80-509-1322

ITALY: Keithley Instruments s.r.l. Viale S. Gimignano, 38 • 20146 Milano • 02-48 39 16 01 • Fax: 02-48 30 22 74

NETHERLANDS: Keithley Instruments B.V. Postbus 559 • 4200 AN Gorinchem • 0183-635333 • Fax: 0183-630821

SWITZERLAND: Keithley Instruments SA Kriesbachstrasse 4 • 8600 Dübendorf • 01-821 94 44 • Fax: 01-820 30 81

TAIWAN: Keithley Instruments Taiwan 1 Fl. 85 Po Ai Street • Hsinchu, Taiwan, R.O.C. • 886-3572-9077 • Fax: 886-3572-903

Bergensesteenweg 709 • B-1600 Sint-Pieters-Leeuw • 02/363 00 40 • Fax: 02/363 00 64

The Minster • 58 Portman Road • Reading, Berkshire RG30 1EA • 0118-9 57 56 66 • Fax: 0118-9 59 64 69

9/00

Page 3

Model 7070

Universal Adapter Card

Instruction Manual

©1988, Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

Second Printing, October 2000

Document Number: 7070-901-01 Rev. B

Page 4

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created for this manual. The

Revision Level letter increases alphabetically as the manual undergoes subsequent updates. Addenda, which are

released between Revisions, contain important change information that the user should incorporate immediately

into the manual. Addenda are numbered sequentially. When a new Revision is created, all Addenda associated

with the previous Revision of the manual are incorporated into the new Revision of the manual. Each new Revision includes a revised copy of this print history page.

Revision A (Document Number 7070-901-01) ............................................................ 1988

Addendum A (Document Number 7070-901-02)................................................ April 1988

Addendum A (Document Number 7070-901-03)........................................ December 1988

Revision B (Document Number 7070-901-01) ..............................................October 2000

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand and product names are trademarks or registered trademarks of their respective holders.

Page 5

Safety Precautions

The following safety precautions should be observed before using

this product and any associated instrumentation. Although some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions

may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions required to avoid possible injury. Read the operating information

carefully before using the product.

The types of product users are:

Responsible body is the individual or group responsible for the use

and maintenance of equipment, for ensuring that the equipment is

operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be

trained in electrical safety procedures and proper use of the instrument. They must be protected from electric shock and contact with

hazardous live circuits.

Maintenance personnel perform routine procedures on the product

to keep it operating, for example, setting the line voltage or replacing consumable materials. Maintenance procedures are described in

the manual. The procedures explicitly state if the operator may perform them. Otherwise, they should be performed only by service

personnel.

Service personnel are trained to work on live circuits, and perform

safe installations and repairs of products. Only properly trained service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that

are rated Installation Category I and Installation Category II, as described in the International Electrotechnical Commission (IEC)

Standard IEC 60664. Most measurement, control, and data I/O signals are Installation Category I and must not be directly connected

to mains voltage or to voltage sources with high transient over -voltages. Installation Category II connections require protection for

high transient over-voltages often associated with local AC mains

connections. The user should assume all measurement, control, and

data I/O connections are for connection to Category I sources unless otherwise marked or described in the Manual.

Exercise extreme caution when a shock hazard is present. Lethal

voltage may be present on cable connector jacks or test fixtures. The

American National Standards Institute (ANSI) states that a shock

hazard exists when voltage levels greater than 30V RMS, 42.4V

peak, or 60VDC are present.

that hazardous voltage is present in any unknown circuit before

measuring.

Users of this product must be protected from electric shock at all

times. The responsible body must ensure that users are prevented

access and/or insulated from every connection point. In some cases,

connections must be exposed to potential human contact. Product

users in these circumstances must be trained to protect themselves

from the risk of electric shock. If the circuit is capable of operating

at or above 1000 volts,

exposed.

Do not connect switching cards directly to unlimited power circuits.

They are intended to be used with impedance limited sources.

NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the connecting

cables, test leads, and jumpers for possible wear, cracks, or breaks

before each use.

When installing equipment where access to the main power cord is

restricted, such as rack mounting, a separate main input power disconnect device must be provided, in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any

other instruments while power is applied to the circuit under test.

ALWAYS remove power from the entire test system and discharge

any capacitors before: connecting or disconnecting cables or jumpers, installing or removing switching cards, or making internal

changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground. Always

make measurements with dry hands while standing on a dry , insulated

surface capable of withstanding the voltage being measured.

A good safety practice is to expect

no conductive part of the circuit may be

Page 6

The instrument and accessories must be used in accordance with its

specifications and operating instructions or the safety of the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating information, and as shown on the instrument or test fixture panels, or

switching card.

When fuses are used in a product, replace with same type and rating

for continued protection against fire hazard.

Chassis connections must only be used as shield connections for

measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use of a

lid interlock.

If a screw is present, connect it to safety earth ground using the

wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of normal

and common mode voltages. Use standard safety precautions to

avoid personal contact with these voltages.

The

WARNING heading in a manual explains dangers that might

result in personal injury or death. Alw ays read the associated infor mation very carefully before performing the indicated procedure.

The

CAUTION heading in a manual explains hazards that could

damage the instrument. Such damage may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and

all test cables.

To maintain protection from electric shock and fire, replacement

components in mains circuits, including the power transformer, test

leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable national safety approvals,

may be used if the rating and type are the same. Other components

that are not safety related may be purchased from other suppliers as

long as they are equivalent to the original component. (Note that selected parts should be purchased only through Keithley Instruments

to maintain accuracy and functionality of the product.) If you are

unsure about the applicability of a replacement component, call a

Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based

cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill

on the instrument. Products that consist of a circuit board with no

case or chassis (e.g., data acquisition board for installation into a

computer) should never require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the factory for proper

cleaning/servicing.

2/01

Page 7

SAFETY PRECAUTIONS

The following safety precautions should be observed before using the Model 7070 and the associated

instruments.

This card is intended for USC by qualified personnel who recognize shock hazards and are familiar

with the safety precautions required to avoid possible injury. Read over this manual carefully before

using the adapter card.

Exercise extreme caution when a shock hazard is present at the test circuit. User-supplied lethal voltages

may be present on the card or the card connector jacks. The American National Standards Institute

(ANSI) states that a shock hazard exists when voltage levels greater than 30V RMS or 42.4V peak are

present. A good safety practice is to expect that hazardous voltage is present in any unknown circuit

before measuring.

Do not exceed ZOOV between any two pins or any pin and earth ground

Inspect the connecting cables and test leads for possible wear, cracks, or breaks before each use.

For maximum safety, do not touch the card, test cables or any instruments while power is applied

to the circuit under test. Turn off the power and discharge any capacitors before connecting or discon-

necting cables from the adapter card.

Do not touch any object which could provide a current path to the common side of the circuit under

test or power line (earth) ground. Always make measurements with dry hands while standing on a

dry, insulated surface capable of withstanding the voltage being measured.

Do not exceed the maximum input signal levels of the adapter card, as defined in the specifications

and operation section of this manual.

Observe IEC-348 recommended voltage spacing with high-voltage circuits (>2OOV) mounted on the

unplated prototyping area (see paragraph 2.5.10).

Page 8

SPECIFICATIONS

DESCRIPTION: Backplane atender card for

707 matrix cards or breadboard card, jumper

selectable. Access to analog and digital backplanes, relay drivers, and power supplies.

MAXIM”M SIGNAL LEVEL m4CKPLANEh

2oov, IA.

SUPPLY SPECIFIC.KrIONS: 6”. 2.9A^ max-

imum; SV, 500mA maximum, digital supply.

*Assuming no other cards are installed. See

individual card specifications for their relay

drive requirements.

RELAY DRIVE LINES: 96 open collector sink

drivers, 140mA each. Coded in 8 row x 12

column format for front panel display. User

may provide external coil voltage supply up

to WI or use mainframe h” supply

BREADBOARD SPACE: Approximate,y

330mm x 228mm (13 in. x 9 in.).

RIBBON CABLE: Extends analog and digital

backplanes 10 feet for benchtop servicing

of cards.

CONNECWR TYPE: 20 quick disconnect with

3 screw termina,s. 2 strain relief clamps.

*CCESSORY SUPPLIED: instruction man”a,.

Page 9

Contains information on Model 7070 features, specifications, and accessories.

SECTION 1

General Information

Details installation of the Model 7070 Universal Adapter

Card within the Model 707 Switching Matrix, covers

card signal paths, describes use as an extender card,

and presents information for mounting relays and other

components on the breadboard portion of the Model

7070.

Gives typical applications for the Model 7070.

Contains performance verification procedures, troubleshooting information and principles of operation for

the adapter card.

Lists replacement parts, and also includes component

layout and schematic drawings for the Model 7070.

SECTION 2

Operation

SECTION 3

Applications

SECTION 4

Service Information

SECTION 5

Replaceable Parts

Page 10

Table of Contents

SECTION 1 —

1.1 INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 FEATURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.3 WARRANTY INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.4 MANUAL ADDENDA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.5 SAFETY SYMBOLS AND TERMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.6 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.7 UNPACKING AND INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.7.1 Inspect for Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.7.2 Shipment Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.7.3 Instruction Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.8 REPACKING FOR SHIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

SECTION 2 —

2.1 INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 HANDLING PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.3 CARD CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.3.1 Row/Column Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.3.2 SMB Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.3.3 Prototyping Areas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.3.4 Analog Pathway Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.3.5 Ribbon Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.3.6 CARD FUNCTION Jumper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.3.7 Relay Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.3.8 +V Relay and Digital Common Buses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.3.9 +5V and +6V Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.3.10 Chassis and GND Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.4 EXTENDER CARD OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.4.1 Selecting the Extend Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.4.2 Ribbon Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.4.3 Connecting Cards to the Extender Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.4.4 Card Installation and Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.4.5 Extender Card Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.5 PROTOTYPING CARD OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.5.1 Local Function Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.5.2 Breadboarding Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.5.3 Board Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.5.4 Power Supply Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.5.5 Internal/External Relay Powering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.5.6 Digital Common Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.5.7 Relay Coil Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.5.8 Relay Matrix Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

2.5.9 Relay Settling Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.5.10 High-Voltage Switching Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.5.11 Prototype Card Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2.5.12 Switching Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2.5.13 Internal Matrix Expansion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2.5.14 External Matrix Expansion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2.6 MEASUREMENT CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

2.6.1 Magnetic Fields. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

General Information

Operation

Page 11

2.6.2 Radio Frequency Interference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

2.6.3 Ground Loops. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

2.6.4 Keeping Connectors Clean . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

2.6.5 Shielding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

2.6.6 Guarding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

SECTION 3 —

3.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 SCANNER SWITCHING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2.1 Scanner ConÞguration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2.2 Relay Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2.3 Programming the Scanner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.2.4 A Practical Scanner Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.3 ON-CARD BUFFERING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.3.1 Buffer ConÞguration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.3.2 Buffer Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.3.3 Powering the Buffer ICs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.3.4 A Typical Buffer Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.4 SOLID-STATE RELAYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.4.1 Solid-state Relay Advantages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.4.2 Typical Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3.4.3 Solid-state Relay Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.4.4 Programming Solid-state Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

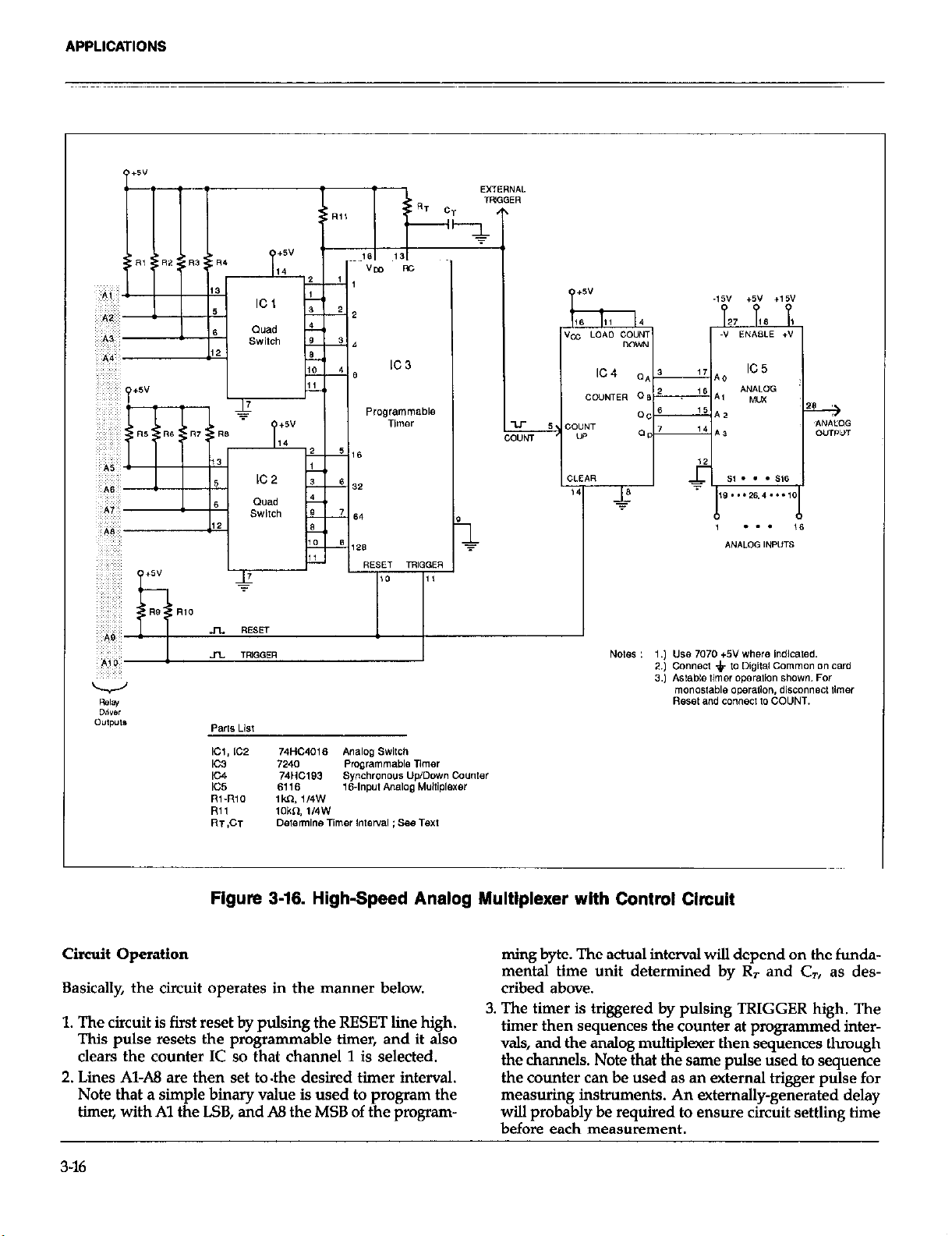

3.5 HIGH-SPEED ANALOG SWITCHING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.5.1 Analog Multiplexer ICs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.5.2 Typical Analog Switching Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3.5.3 Control Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3.6 USING THE ADAPTER CARD WITH OTHER MATRIX CARDS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.6.1 Scanner-Matrix Combination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.6.2 Signal Conditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Applications

SECTION 4 —

4.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 HANDLING AND CLEANING PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.3 SPECIAL HANDLING OF STATIC-SENSITIVE DEVICES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.3.1 Rear Shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.4 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.4.1 Recommended Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.4.2 Troubleshooting Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.5 PRINCIPLES OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.5.1 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.5.2 ID Data Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.5.3 Relay Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.5.4 Power-on Safeguard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

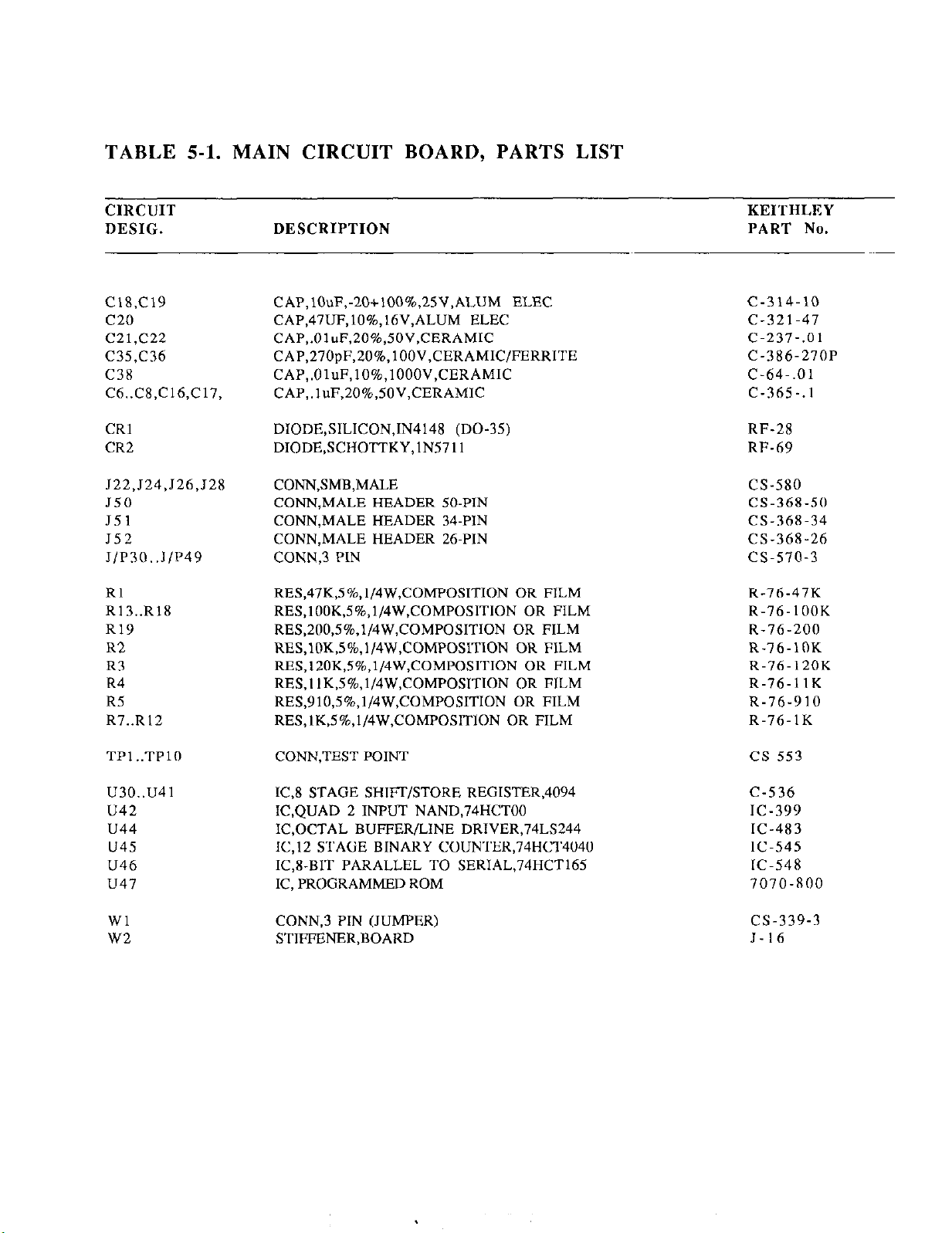

SECTION 5 —

5.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 PARTS LISTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.3 ORDERING INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.4 FACTORY SERVICE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.5 COMPONENT LAYOUT AND SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Service Information

Replaceable Parts

Page 12

List of Illustrations

SECTION 2 —

Figure 2-1 Card ConÞguration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Figure 2-2 Extend Function Jumper Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Figure 2-3 Ribbon Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Figure 2-4 Extender Board Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Figure 2-5 Model 7070 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Figure 2-6 LOCAL Function Jumper Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Figure 2-7 Jumper Installation for Internal Relay Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

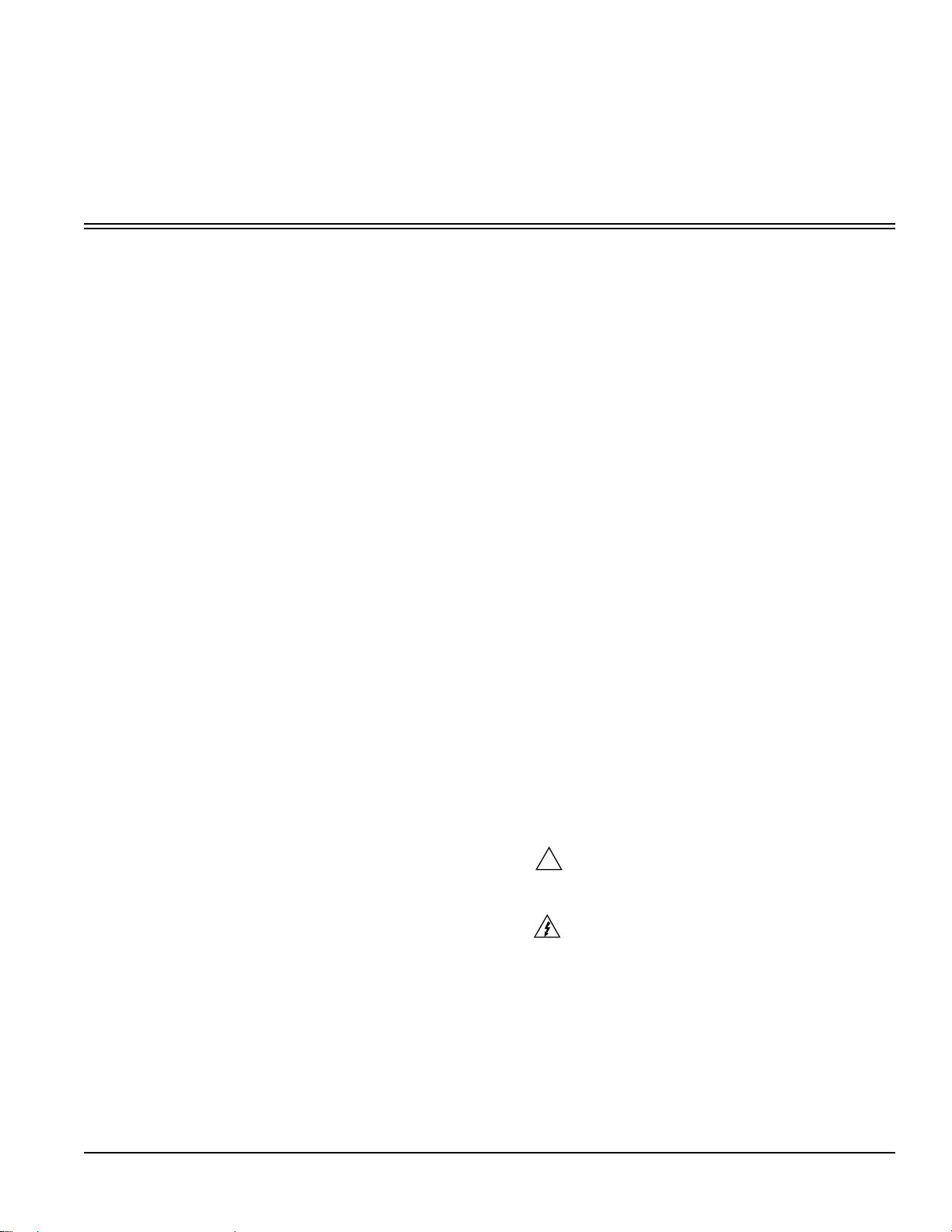

Figure 2-8 External Supply Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Figure 2-9 Typical Relay Driver Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Figure 2-10 Typical Relay Coil Connections (Row A Shown) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Figure 2-11 Relay Matrix Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Figure 2-12 Matrix Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Figure 2-13 Connecting Three Cards for 8

Figure 2-14 16

Figure 2-15 Power Line Ground Loops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Figure 2-16 Eliminating Ground Loops. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Figure 2-17 Shielding Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Figure 2-18 Guarded Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Figure 2-19 Typical Guarded Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

SECTION 3 —

Figure 3-1 A Scanner as a Rotary Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Figure 3-2 8-Input, 2-Pole Relay Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Figure 3-3 Scanner Relay Coil Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Figure 3-4 Program 1 Flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Figure 3-5 Testing Thick Film Resistor with a Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Figure 3-6 Program 2 Flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Figure 3-7 Buffer ConÞguration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Figure 3-8 DC Converter Used to Power Buffer ICs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Figure 3-9 Typical High-Resistivity Test System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Figure 3-10 Voltages Necessary to Determine Resistivity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Figure 3-11 Zero-crossing Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Figure 3-12 Typical DC Solid-state Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Figure 3-13 Typical AC Solid-state Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Figure 3-14 Typical Solid-state Relay Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Figure 3-15 Typical Multiplexer IC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Figure 3-16 High-Speed Analog Multiplexer with Control Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Figure 3-17 Program 3 Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-I7

Figure 3-18 Adding a Scanner to a Switching Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Figure 3-19 Signal Conditioning Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Operation

×

36 Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

×

36 Matrix Constructed by External Jumpering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Applications

SECTION 4 —

Figure 4-1 Removing the Rear Shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

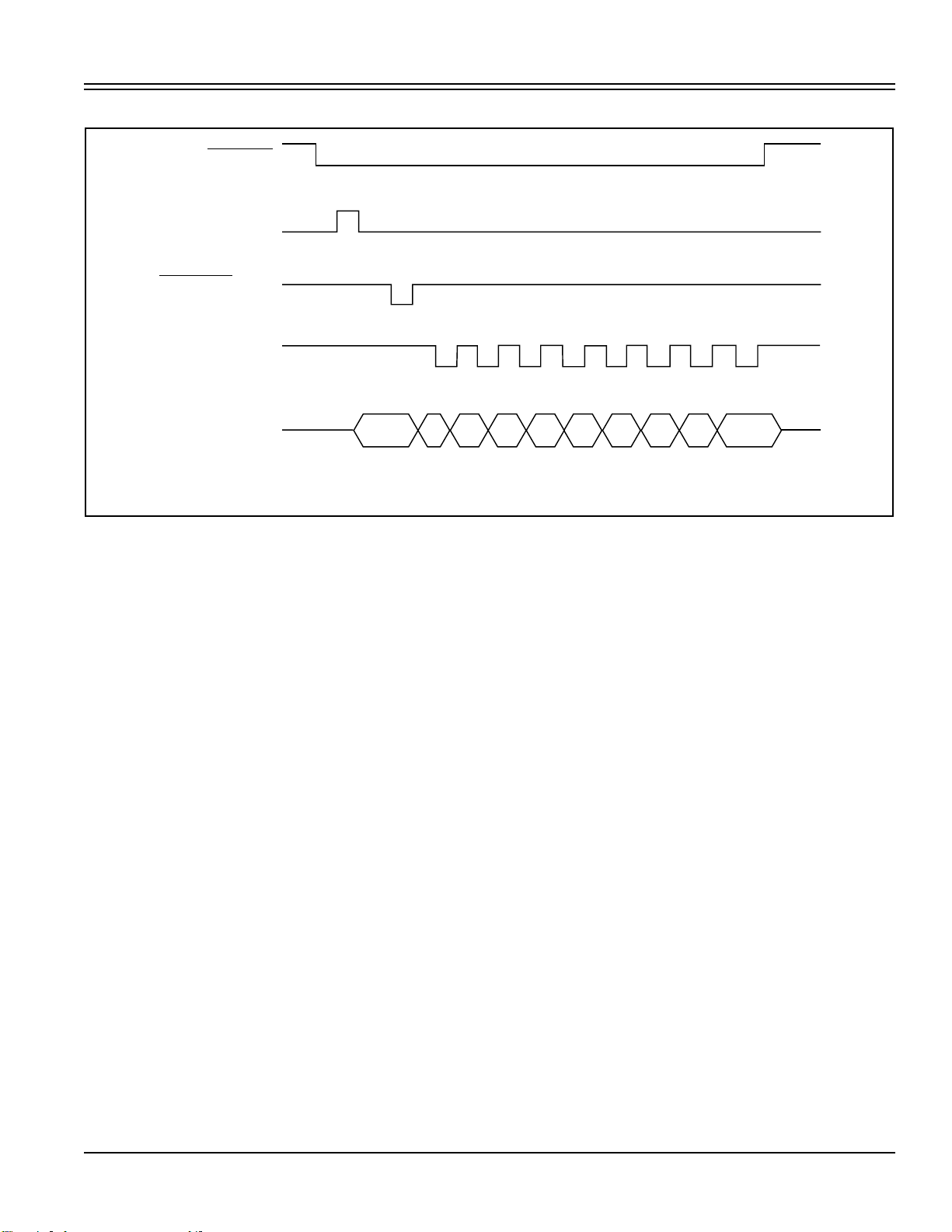

Figure 4-2 ID Data Timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Figure 4-3 Model 7070 Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Service Information

Page 13

List of Tables

SECTION 2 —

Table 2-1 Analog Pathway Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Table 2-2 Drive Current per Crosspoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Table 2-3 Partial List of Recommended Spacing for High-Voltage Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Table 2-4 Column Numbering by Slot and Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

SECTION 3 —

Table 3-1 Multiplexer IC Truth Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

SECTION 4 —

Table 4-1 Recommended Troubleshooting Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Table 4-2 Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Operation

Applications

Service Information

Page 14

SECTION 1

General Information

•

1.1 INTRODUCTION

This section contains general information about the

Model 7070.

Section 1 is arranged in the following manner:

1.2 Features

1.3 Warranty Information

1.4 Manual Addenda

1.5 Safety Symbols and Terms

1.6 SpeciÞcations

1.7 Unpacking and Inspection

1.8 Repacking for Shipment

1.2 FEA TURES

The Model 7070 Universal Adapter Card provides two functions. As an extender card, the unit is designed for backplane extension using a 10-foot ribbon cable assembly. The

second function is as prototyping or breadboarding card,

allowing for user-installed relays or other circuits for custom matrix designs.

There are now two versions of the Model 7070. The standard

Model 7070 Universal Adapter Card includes ribbon cables

for extender card operation. All sections of this manual

apply to this version of the card. The Model 7070-PCA

Prototype Circuit Assembly is intended for use only as a

prototyping card and does not include extender cables.

Those with a Model 7070-PCA should disregard all

references in this manual to extender card operation. Major

sections that do not apply to the Model 7070-PCA include:

paragraph 2.4, Table 5-2, and the extender board component

layout and schematic located at the end of Section 5.

Other key features of the Model 7070 Universal Adapter

Card include:

•

Detachable 10-foot ribbon cable assembly for extender

card operation.

•

Prototyping area consisting of a grid of holes on 0.1 in.

centers for relay and component mounting.

•

96 relay drivers, each with 140mA current sink capability.

•

On-card decoding circuity to allow mainframe front

panel and IEEE-488 control of user-installed relays and

circuits.

Plated-through holes and pads for easy access to backplane pathways and relay drivers.

•

Screw-terminal connections using quick-disconnect connectors for row and column connections.

•

8

×

12 (eight row by 12 column) matrix implementation

with user-supplied relays or circuity.

•

Guarding pathways are maintained on the card.

1.3 W ARRANTY INFORMA TION

Warranty information is located on the inside front cover of

this instruction manual. Should your Model 7070 require

warranty service, contact the Keithley representative or

authorized repair facility in your area for further

information. When returning the card for repair, be sure to

Þll out and include the service form at the back of this

manual in order to provide the repair facility with the

necessary information.

1.4 MANUAL ADDEND A

Any improvements or changes concerning the adapter card

or manual will be explained in an addendum included with

the unit. Be sure to note these changes and incorporate them

into the manual before using or servicing the unit.

1.5 SAFETY SYMBOLS AND TERMS

The following symbols and terms may be found on an

instrument or used in this manual.

!

The symbol on an instrument indicates that the user

should refer to the operating instructions located in the

instruction manual.

The symbol on an instrument shows that high voltage

may be present on the terminal(s). Use standard safety precautions to avoid personal contact with these voltages.

The

WARNING

gers that might result in personal injury or death. Always

read the associated information very carefully before performing the indicated procedure.

heading used in this manual explains dan-

1-1

Page 15

GENERAL INFORMATION

The

CAUTION

ards that could damage the adapter card. Such damage may

invalidate the warranty.

heading used in this manual explains haz-

•

Ribbon cable clips (5).

•

Model 7070 Instruction Manual.

•

Additional Accessories as ordered.

1.6 SPECIFICA TIONS

Model 7070 speciÞcations may be found at the front of this

manual. These speciÞcations are exclusive of the matrix

mainframe speciÞcations, which are located in the

Model 707 Instruction Manual.

1.7 UNP A CKING AND INSPECTION

1.7.1 Inspection for Damage

Upon receiving the Model 7070, carefully unpack it from its

shipping carton and inspect the card for any obvious signs

of physical damage. Report any such damage to the shipping agent immediately. Save the original packing carton for

possible future reshipment.

1.7.2 Shipment Contents

The following items are included with every Model 7070

order:

•

Model 7070 Universal Adapter Card.

•

Ribbon cable/extender board assembly.

1.7.3 Instruction Manual

The Model 7070 Instruction Manual is three-hole drilled so

that it can be added to the three-ring binder of the

Model 707 Switching Matrix Instruction Manual. After

removing the plastic wrapping, place the manual in the

binder after the mainframe instruction manual. Note that a

manual identiÞcation tab is included and should precede

the adapter card instruction manual.

If an additional instruction manual is required, order the

manual package, Keithley part number 7070-901-00. The

manual package includes an instruction manual and any

pertinent addenda.

1.8 REP A CKING FOR SHIPMENT

Should it become necessary to return the Model 7070 for

repair, carefully pack the unit in its original packing carton

or the equivalent, and include the following information:

•

Advise as to the warranty status of the adapter card.

•

Write ATTENTION REPAIR DEPARTMENT on the shipping label.

•

Fill out and include the service form located at the back of

this manual.

1-2

Page 16

SECTION 2

Operation

2.1 INTRODUCTION

This section contains information on card and matrix configuration, extender and prototyping functions, as well as

measurement considerations, and is arranged as follows:

2.2 Handling Precautions:

should be taken into account when handling the card

to avoid contamination that could degrade

performance.

2.3 Card Configuration: Covers the various

and pads on the card.

2.4 Extender Card Operation:

7070 as an extender card for such applications as

troubleshooting other matrix cards.

2.5 Prototype Card Operation:

relays and other circuits to construct a custom matrix

card.

2.6 Measurement Considerations: Covers some important

aspects to keep in mind when using the Model 7070.

Discusses precautions that

connectors

Details using the Model

Discusses

breadboarding

foreign materials as body oils. Such contamination can

substantially lower leakage resistances, degrading performance. To avoid any possible contamination, always grasp

the card by the handle or the card edges. Do not touch

board surfaces, edge connectors, or components after

prototyping and cleaning.

Dirt build-up over a period of time is another possible

source of contamination. To avoid this problem, operate

the mainframe and adapter card only in a clean environment.

Contamination from solder flux can also degrade performance. After soldering wires to the card, carefully clean

it using the procedure discussed in paragraph 2.6.3.

2.3 CARD CONFIGURATION

The overall configuration of the Model 7070 is shown in

Figure 2-l. The following paragraphs discuss the main

aspects of the card.

2.2 HANDLING PRECAUTIONS

To maintain isolation, care should be taken when handling the adapter card to avoid contamination from such

WARNING

User-supplied lethal voltages may be present on

the PC board or connectors.

2-112-Z

Page 17

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

01

m

m

m

m

m

Page 18

OPERATION

2.3.1 Row/Column Connectors

A 3-terminal removable connector block is available for

each row and column connection of the switching matrix.

These blocks are labelled rows A through H, and columns

1 through 12. The three terminals available are H (HI), L

(Lo), and G (guard). The connectors are equipped with

screw terminals, and they accept wires as large as #16AWG.

Plated through holes with pads adjacent to the connectors allow input/output connections to circuits and relays

mounted on the protoptyping areas.

2.3.2 SMB Connectors

The four SMB connectors are intended for expanding the

matrix of rows A, B, G, and H to a Model 7072 Semicon-

ductor Matrix Card. These jumpers are supplied with the

Model 7072, and they can be installed as discussed in the

Model 7072 Instruction Manual.

2.3.3 Prototyping Areas

There are two prototyping areas located on the card. The

larger of the two is approximately 9in. x 9in. and has

plated-through hole pairs (0.04in. in diameter) on O.lin.

centers. The unplated area is about 4.5in x 8in. and is intended for such applications as switching higher voltages

than ZOOV using suitable relays and wiring. Again, the

holes are 0.04in. in diameter and are located on O.lin.

centers.

rows A through H of the Model 7073 expansion pathways.

Note that Model 7072 expansion of rows A, B, G, and H

is available through the SMB connectors.

Table 2-1. Analog Pathway Summary

2.3.5 Ribbon Cable Connections

The three ribbon cable connectors mate with the ribbon

cable headers when the Model 7070 is being used as an

extender card. In addition to the three analog pathways,

the digital circuits are extended through the ribbon cable

so that any card connected to the extender can function

normally.

2.3.6 CARD FUNCTION Jumper

The CARD FUNCTION jumper selects the operating mode

of the adapter card. In the EXTEND position, the Model

7070 is set up for extender card operation. In the LOCAL

position, relays or circuits on the card can be controlled

by the relay drivers.

WARNING

The maximum voltage between any two

backplane connections or between any

backplane connector and chassis ground is

200V. The maximum voltage between any two

pads in the plated area is 200V. IEC-346 recommended spacing must be maintained for highvoltage circuits mounted on the unplated prototyping area. See paragraph 2.6.10 for highvoltage conslderatlons.

2.3.4 Analog Pathway Connections

Three groups of pads are intended for matrix expansion

to other cards available for the matrix system: the Model

7071 General Purpose Matrix Card, the Model 7072

Semiconductor Matrix Card, and the Model 7073 Coaxial

Matrix Card. As summarized in Table 1, ANALOG #l accesses rows C through F of the Model 7072 expansion

pathways, ANALOG #2 accesses rows A through H of the

Model 707I expansion pathways, and ANALOG #3 access

2.3.7 Relay Drivers

There are 96 relay drivers located in 12 ICs on the circuit

boards. The connecting pads for the drivers are labelled

in row-column format. The output of each driver is active

IQ with a 14OmA sink capability. Note, however, that the

maximum number of relays that can be energized is liited

by the power available; see paragraph 2.5.4 for more information.

2.3.6 +V Relay and Digital Common Buses

The +V RELAY BUS is intended for connection of the

supply voltage to the on-card relays. If using the +6V

mainframe supply, a jumper must be connected between

the +V RELAY BUS and the +6V supply pad on the card.

If an external supply is used, it should be connected to

the +V RELAY BUS, and the +6V supply must be disconnected from +V RELAY BUS.

2-5

Page 19

OPERATION

The DIGITAL COMMON BUS provides a common connection for on-card active circuits using the mainframe’s +5V

supply.

2.3.9 +5V and +6V Supplies

The +5V supply can be used to power user-installed digital

circuits mounted on the Model 7070 breadboard. Note that

the maximum +5V supply current for the card is 500mA.

The +6V supply can be used to power user-installed relays.

The maximum current available from the +6V supply 2.9A;

this value assumes that no other cards are installed in the

mainframe. See paragraph 2.5.4 for a detailed discussion of

power supply limitations.

2.3.10 Chassis and GND Connections

The two screw terminals adjacent to the input/output connectors are at chassis ground potential and can be used to

connect cable shields to chassis ground. An additional chassis ground pad is located on the lower rear corner of the

card. The GND pad located at the lower rear terminal is connected to digital common.

2.4 EXTENDER CARD OPERA TION

NOTE

If relays are mounted on the card, disconnect the

+V relay bus from the relay supply voltage before

using the Model 7070 as an extender card. Otherwise, any on-card relays will be energized when

accessing the card slot.

Card Function

Extend

Local

NOTE

This section does not apply to the Model 7070-PCA.

One of the two functions of the Model 7070 is used as an

extender card for troubleshooting or bench-top testing of

other matrix cards. The following paragraphs discuss setting up the unit as an extender card, connecting the ribbon

cables, and connecting other cards to the extender board.

2.4.1 Selecting the Extend Function

In order to use the Model 7070 as an extender card, the

CARD FUNCTION switch must be in the EXTEND position, as shown in Figure 2-2.

Figure 2-2. Extend Function Jumper Selection

2.4.2 Ribbon Cable Connections

Three 10-foot ribbon cables attached to an extender board

are supplied with the Model 7070. In order to use the

Model 7070 as an extender card, these cables must be connected to the on-card connectors, as shown in Figure 2-3.

The widest cable should be routed through the upper cable

clamp, while the two narrower cables should be routed

through the lower cable clamp (remove upper half of clamp

Þrst). After making connections, secure the ribbon cables

with the clamps. Also dress the cables with the supplied

cable clips where convenient.

2-6

Page 20

OPERATION

Connect Ribbon

Cables to Cable

Connectors

Extender

Board

Route Two -/

Narrow Cables

Through Lower

Clamp

Model 7070

Figure 2-3. Ribbon Cable Connections

2.4.3 Connecting Cards to the Extender Card

To connect other cards to the Model 7070, simply plug in

the card in question to the extender board, as shown in

Figure 2-4. Make certain the card is properly seated in the

edge connectors.

WARNING

User-supplied lethal voltages may be present on

the extender board. Place the matrix card that

has been set outslde the mainframe on a nonconductive surface. Do not place the matrix

card on a conductive surface such as a rack.

Voltages present on the card could short, caus-

ing a shock hazard or posslble damage to the

matrlx card or mainframe.

CAUTION

Do not touch any card edge connectors to avoid

contamlnatlng them; such contamination may

degrade

card performance.

2.4.4 Card Installation and Removal

After prototyping or extender card selection, the Model

7070 should be installed within the Model 707 Switching

Matrix, as summarized below. Figure 2-5 shows the installation procedure.

WARNING

Turn off the mainframe power and disconnect

the line cord before installing or removing

matrix cards.

1. Before installing the card, make sure the access door on

top of the Model 707 is fully closed and secured. The

access door contains tracks for the card slots and must

be in place to properly install the card.

2. With one hand grasping the handle, and the other

holding the back of the card, line up the card with the

tracks in the desired slot. Make certain that the component side of the card is facing the fan on the mainframe.

2-7

Page 21

OPERATION

707X Card

Extender

3

L-

gl

Seat Card

Properly in connectors

Board

To 7070

Main Board

Figure 2-4. Extender Board Connections

CAUTION

Do not touch the card surfaces or any components to avoid contamination that could

degrade card performance.

3. Slide the card into the mainframe until it is properly

seated in the edge connectors at the back of the slot.

Once the card is properly seated, secure it to the mainframe by finger tightening the spring-loaded screws.

WARNING

The mounting screws must be secured to ensure a proper chassis ground connectlon be-

tween the card and the mainframe. Failure to

properly secure this ground connection may

result in personal injury or death due to electric shock.

4. To remove a card, first turn off the power and disconnect the line cord from the mainframe. Disconnect all

external and internal cables (internal cables can be reached through the access door). Loosen the mounting

screws, then pull the card out of the mai&ame by the

handle. When the back of the card clears the mainframe,

support it by grasping the bottom edge near the rear

of the card.

2-8

Page 22

OPERATION

CARD HANDLE

Figure 2-5. Model 7070 Installation

MOUNTING SCREWS

2-9

Page 23

OPERATION

2.4.5 Extender Card Considerations

The following points should be kept in mind when using

the extender card.

1. Using the extender card may degrade the specifications

of other cards. Card specifications are not applicable

when they are used with the extender card.

2. When a matrix card is being operated outside the mainframe, it is no longer shielded from RFIEMI interference

or static discharge by the mainframe. If the card is to

be operated in such an enviroment, shield the card as

necessary.

3. Because of the long ribbon cables, the digital circuits on

the card or in the mainframe may radiate signals that

interfere with other equipment. In order to minimize

these effects, keep the ribbon cables and external card

as far away as possible from sensitive instrumentation.

l-----l

1

2.5 PROTOTYPING CARD OPERATION

A primary function of the Model 7070 is as a prototyping

card. Two large prototyping areas on the card allow the

installation of user-supplied relays or active circuits for

custom matrix applications. The following paragraphs

describe the major aspects of using the Model 7070 as a

prototyping card.

2.5.1 Local Function Selection

In order to use the Model 7070 as a prototyping card, the

CARD FUNCTION jumper must be placed in the LOCAL

position. Figure 2-6 shows the LOCAL jumper position.

Also, the ribbon cables used for the extension function

should be disconnected and removed from the card.

Figure 2-6. LOCAL Function Jumper Position

2.5.2 Breadboarding Considerations

The adapter card has two prototyping areas available for

user-installed components. The larger 9ii. x 9in. area has

plated-through hole pairs on O.lin. centers with a hole

diameter of 0.04in. The secondary (4%in. x 8in.) prototyp

ing area has unplated holes for such uses as switching

higher voltages than ZOOV. These holes are also on Olin.

centers and have a diameter of 0.04in.

The holes will accept conventional IC packages, transistors,

relays, resistors, and other similar components. In addi-

z-10

Page 24

OPERATION

tion, the holes will accept vector pins and micro klip pins

to simplify circuit connections. The plated hole pairs can

be cut with a sharp knife or razor blade, if necessary. Note

that components must be mounted on the same side of

the card as the digital components that are already

mounted on the card; soldering should be done on the

opposite side. After installing components or connecting

pins, make sure that pins or leads do not extend more than

0.25in. above the surface of the solder side. After soldering, the board should be cleaned, as discussed in

paragraph 2.5.3.

WARNING

The maximum voltage between any two plated

pad pairs, or between any plated pad and

chassis ground is ZOOV. The maximum voltage

between any two backplane connectors between any backplane connector and chassis

gmund is 2OOV. The maximum card signal level

is 2OOV, IA. IEC-346 recommended spacing

must be maintained for high-voltage clrcults

mounted on the unplated prototyping area. See

paragraph 2.5.10 for details.

CAUTION

Make certain the +5V or +6V supplies are not

shorted to chassis or common before installing

the card. Failure to

ObSeNe

this precaution may

result in card or mainframe damage.

2.5.4 Power Supply Considerations

The prototyping section has access to the mainframe’s +5V

and +6V supplies via the supply pads located on the card.

The +5V supply can be used to power digital circuits on

the card, and it has a maximum current available of

5oom.k

The +6V supply is intended for powering on-card relays,

and it has a maximum available current of 2.9A. Note,

however, that this value excludes any other cards installed in the mainframe. The available current with a given

configuration depends on how many other cards are installed in the mainframe, as well as how many crosspoints

on each card are closed at any given time.

As summarized in Table 2-2, the amount of drive current

required per crosspoint depends on the card type. To determine how much current is available for use by the Model

7070, simply multiply the maximum number of like crosspoints to be closed at any given time by the current per

crosspoint, Sum the card totals and subtract that value

from 2.9A. The result is the amount of current available

to drive prototyping relays. The total number of prototype

relays that can be closed at once can then be found by

dividing the available current by the drive current per prototyping relay. See the specifications for your relays for the

required drive current per relay.

2.5.3 Board Cleaning

Flux left on the circuit board after soldering can degrade

measurements, especially those of the high-impedance

variety. After soldering to the circuit board, the board

should be carefully cleaned as follows:

1. Carefully clean the soldered areas using Freon@ TMS or

TE, or the equivalent. Clean cotton swabs or a clean,

soft brush can be used to help remove the flux. Be

careful not to spread the flux around to other areas of

the board.

2. After cleaning with FreorP , swab the treated area with

clean methanol, then blow dry the board with dry

nitrogen gas.

3.

After cleaning the board, allow it to dry for several hours

in a 5O”C, low-humidity environment before use.

Table 2-2. Drive Current per Crosspoint

Card

7071

7072

7073

2.5.5 Internal/External Relay Powering

Card relays can be powered either from the +6V mainframe supply, or from an external supply of up to 35V, as

described below.

z-11

Page 25

OPERATION

Internal Relay Supply

To power all relays from the +6V supply, you must install

a jumper between the +6V pad and the +V RELAY BUS,

as shown in Figure 2-7. Be sure to remove this jumper if

using an external supply.

available from the +6V supply is required, an external

supply of up to +35V can be connected to the card, as

shown in Figure 2-8. Connect the positive terminal to the

+V RELAY BUS, and connect the negative terminal to the

DIGITAL COMMON BUS.

CAUTION

Do not exceed 35V for the external supply. Also,

make sure to disconnect the internal +6V supply when using an external supply, or damage

to the card or mainframe may occur.

Splitting the Relay Supply

In some cases, you may wish to split up the power supply

allotment among the relays because of different relay

voltages or other factors such as current constraints. To do

so, simply cut the +V RELAY BUS at a convenient location, and connect the two sections to the internal and external supplies, as required. Be careful to avoid a short between the two sections, or instrument damage may occur.

Power Supply Decoupling

Figure 2-7. Jumper Installation for Internal Relay

SUPPlY

External Relay Supply

In cases where more current or a higher voltage than is

Active circuits wired on the prototyping board should be

properly decoupled to ensure proper operation and

minimum EM1 radiation. For example, digital circuits

typically use a O&F capacitor between +5V and digital

common, with one capacitor per IC for MS1 and LSI

packages, and one capacitor for every three or four

packages for small scale integration ICs. Each capacitor

should be mounted as close to the IC as possible, and only low equivalent series resistance capacitors such as

ceramic film types should be used.

242

Page 26

+

External Supply

OPERATION

1

Common

Bus

Figure 2-6. External Supply Connections

2.5.6 Digital Common Connections

The DIGITAL COMMON BUS, which is located along the

bottom edge of the prototyping area, provides a common

bus for any active circuits located on the card, including

those using the +5V supply. Digital common also provides

a return path for the relay drivers located on the card.

2.5.7 Relay Coil Connections

Each relay driver has an open-collector output capable of

sinking a maximum of 140mA. A typical driver output is

shown in Figure 2-9.

To wire your relay coils, simply connect one side of each

Caution : Maximum supply voltage

is 35’ Observe polarity

and remow jumper to +W

supply ii installed.

coil to the +V RELAY BUS, and connect the other side of

the coil to the relay driver connection pad. An example

of such connections for all 12 columns of row A is shown

in Figure 2-10. Note that it is not necessary to use clamping diodes across the relay coils because they are integral

within the driver KS. Also, the +V RELAY BUS must be

connected to +6V or an external power source as prwiously described.

The specified operating voltage of each relay should, of

course, agree with the relay supply voltage. Since each

relay driver output has a specified saturation voltage of

l.lV (at lOOmA), the specified relay coil voltage should be

approximately 1V less that the supply voltage being used.

With the +6V supply voltage, for example, 5V relays

should be used. In any case, the specified relay current

must not exceed 140mA, as stated above.

2-13

Page 27

OPERATION

r----------i

I

I

I

I

I

I

I >

I

I

I

L----------A

Driver IC

I

I

+v

+35V Maximum External Supp,,,

User-installed Relay

I

I$

Figure 2-9. Typical Relay Driver Output

Digital

Common

Relay Bus (+6V or

.A,\

User-Installed

Relays

Relay Drivel

Outputs

+v Relay Bus

(+6V or +35V Maximum External Supply)

P

ii!!‘l:‘El)i’

’ { Al A2 A3 A4 A5 A6 A7 A6 A9 A10 Al 1 A12

Notes : 1.) Maximum current per relay is 140mA.

2.) Nominal driver saturation voltage is TX 1V.

Figure 2-10. Typical Relay Coil Connections (Row A Shown)

2-14

Page 28

OPERATION

2.5.6 Relay Matrix Wiring

The exact way you wire your relay contacts will, of course,

depend on your particular requirements. Typically, such

relays will be wired in a row-column matrix configuration,

as shown in Figure 2-11 (for the sake of clarity, we have

shown only a few relays on the diagram), Note that 3-pole

switching is shown, with HI, ID, and guard all switched.

If the relays are equipped with shields, guard would be

connected to the relay shields.

HI

A

B LO

LO

Guard

HI

In order to complete the matrix, the like contacts of the

relays must be connected together to complete the rowcolumn format. One end of each row and column group

would typically be connected to the input/output connectors, while the other end of each row and column group

would be connected to the pathway extension pads, if

matrix expansion to other cards in the mainframe is

required.

Guard

HI

H

LO

Guard

Figure 2-H. Relay Matrix Wiring

2-15

Page 29

2.5.9 Relay Settling Time

Any mechanical relay takes a finite length of time to make

contact and settle completely. The other cards in the Model

707 system have a hardware settling time that is dependent

on the type of relays programmed into their ROMs.

However, since there is no way to anticipate the type of

relays you will use, the Model 7070 has a hardware settling time of lmsec programmed into its ROM. For that

reason, it will be necessary for you to program a suitable

settling time into the Model 707. The required settling time

will, of courx’depend on your particular relays; see the

relay specifications for information. Settling time can be

programmed using the front panel SETTLING TIME key

(or over the bus with the S command). The allowable range

for the settling time is lmsec to 65.535~~ in lmsec

increments.

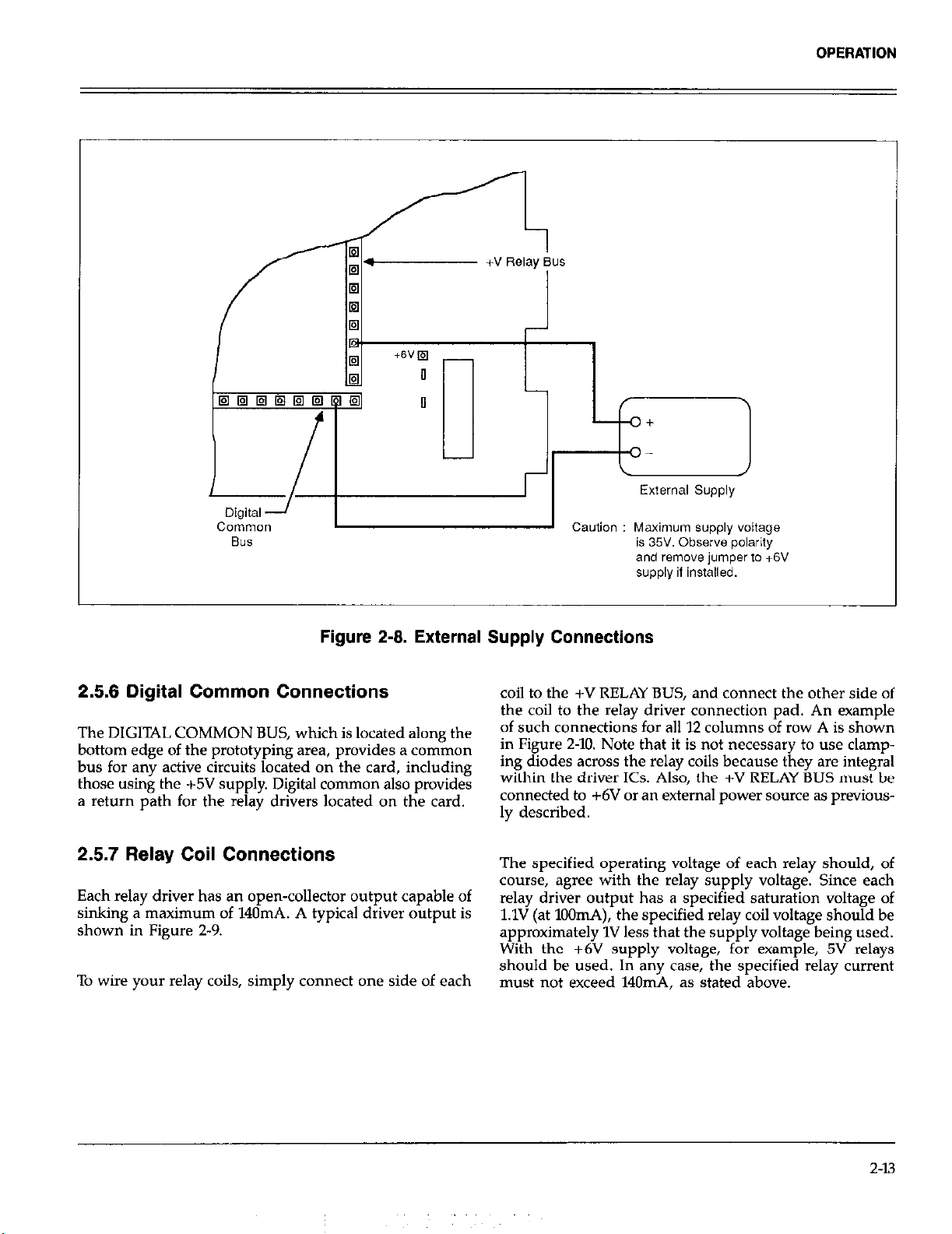

2.5.10 High-Voltage Switching Considerations

The unplated prototyping area can be populated with

suitable relays to switch voltages higher than the ZOOV

available with the plated prototyping area or other cards

in the Model 707 system. The following precautions must

be observed when prototyping high-voltage circuits on the

card.

1. Minimum terminal spacing, as recommended by the

IEC-348 standard, must be observed. A partial list of

minimum distances for various recommended voltages

is shown in Table 2-3. The clearance values are distances

in free air, whiie the creepage values are distances across

the board surfaces. For more detailed information, consult IEC (International Electrotechnical Commission)

Publication 348.

2. All wiring, relays, and connectors must have adequate

voltage rating for the expected voltage levels. Do not use

the input/output connectors supplied with the adapter

card.

3. Use shielded wire for input/output connections to

minimize EM1 radiation. Connect the shields to the card

chassis ground screws.

4. Do not connect any high-voltage circuit to pads or components on any area of the card other &an the

designated high-voltage (unplated) prototyping area.

5. If the card is to be operated outside the mainframe (for

example, with a second Model 7070 used as an extender

card), it must be properly shielded for safety and to

minimize EMI radiation. The shield must be connected

to the mainframe chassis using a heavy ground wire.

Table 2-3. Partial List of Recommended Spacing for

High-Voltage Circuits

r

DC or AC

RMS Sinusoidal

>mv, zs25w

>25w, <45Ov

>45w, <66Ov

>66Ov, ~1Ooov

etween

ctors

AC Peak

>l84v, 5355v

>354v, dl3w

>63ov, 5933v

>933v. s14oov

Minimum Spacing

T

Between C hductors

Clearance

mm (in.)

3 (0.118)

3.5 (0.138)

4 (0.157)

5.5 (0.217)

Creepage

Distance

mm (in.)

3 (O.lls)

4.5 (O.l77)

6 (0.236)

9 (0.354)

1

2-16

Page 30

OPERATION

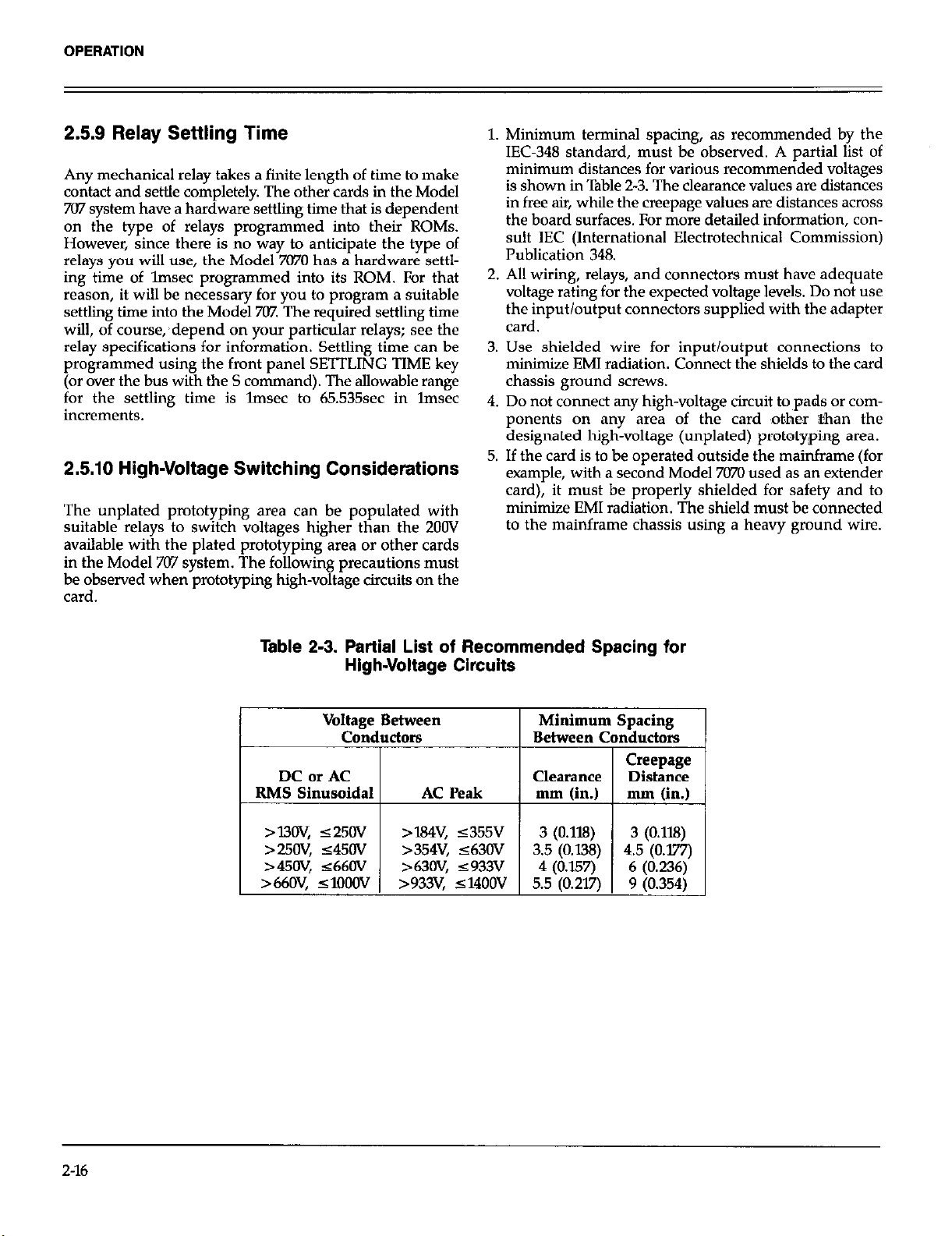

2.5.11 Prototype Card Installation

After prototyping your circuits, install the card in the

desired slot of the mainframe. The detailed installation procedure is covered in paragraph 2.4.4.

WARNING

The card mounting ecrewe must be secured to

ensure a good connection to chassis ground.

2.5.12 Switching Matrix

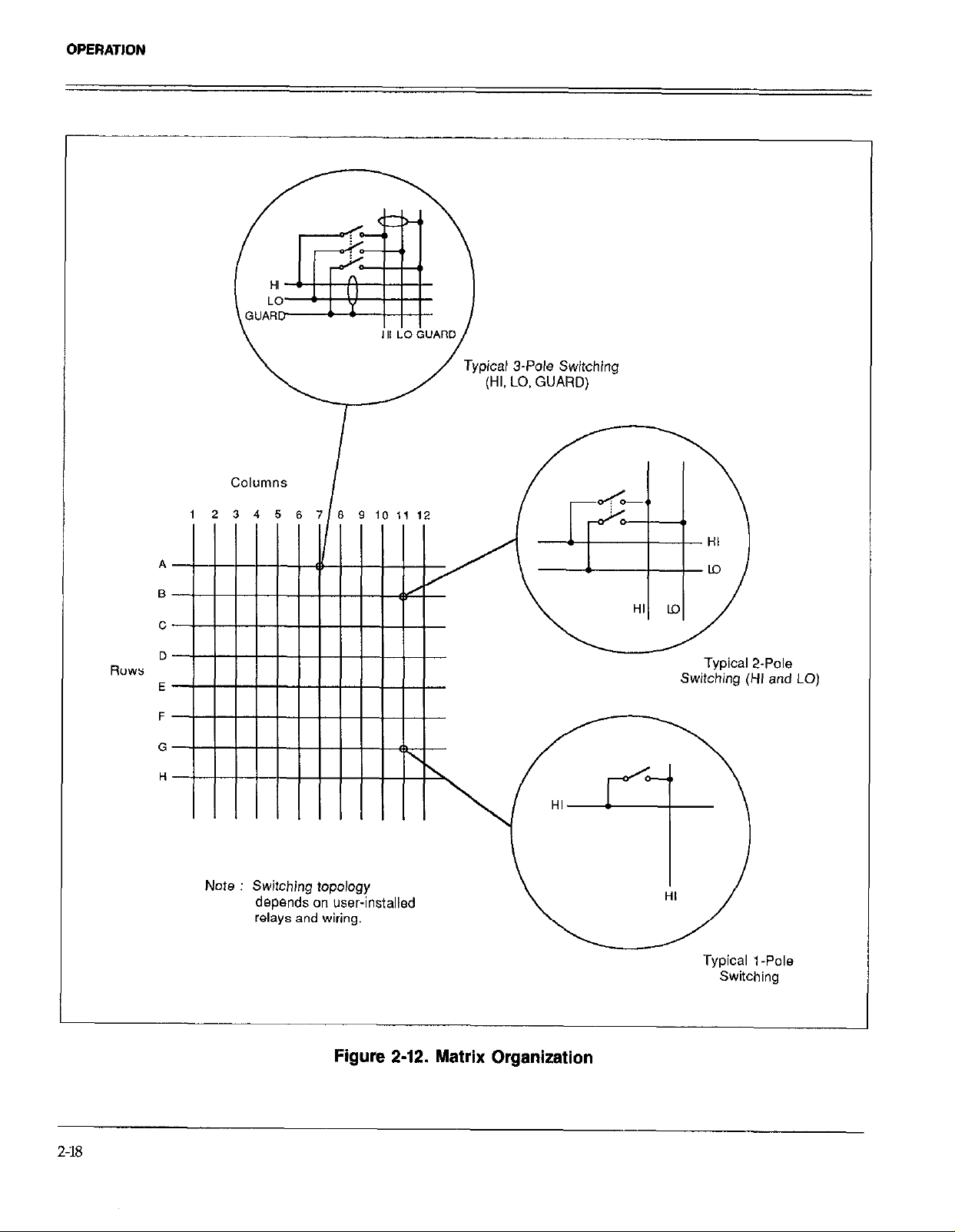

As shown in Figure 2-12, the each Model 707 matrix card

is organized as an 8 x 12 (eight row by 12 column) matrix.

The rows are labelled A through H, while the columns on

the card are numbered 1 through 12. The actual column

number to use when programming depends on the slot

and unit number, as summarized in Table 2-4. For example, card column number 2 on a card in slot 5 of unit 1

is accessed as matrix column 62.

Each intersecting point in the matrix is called a crosspoint

that can be individually closed or opened by programming

the Model 7G7 mainframe. The switching form depends on

the type of user-installed relays: one, two, or three pole

switching can be used. With single-pole switching, only

HI would be switched; with two-pole switching, both HI

and LO would be switched; and, with three-pole switching, HI, LO, and guard are switched. These three basic

switching configurations are shown on Figure 2-12.

Table 2-4. Column Numbering by Slot

Unit

1

Slot Cohnns (142)

1

2

3 25-36

4

5

6

1

2

3 97108

4 109-120

5 121-132

6 133-144

l-12

13-24

37-48

49-60

61-72

73-84

85-96

145-156

157-168

169-180

X31-192

193-204

205.216

217-228

229.240

241-252

253-264

265-276

277288

and Unit

-

289.300

301-312

313.324

325-336

337348

349-360

2-17

Page 31

OPERATION

Columns

I.0 GIJARD

HI

Typical 3-P& Switching

(HI, LO, GUARD)

i

2-18

Note : Switching topology

depends on user-installed

relays and wiring.

Typical l-Pole

Switching

Figure 2-12. Matrix Organization

Page 32

2.5.13 internal Matrix Expansion

Two to six matrix cards can be connected together within

the mainframe to yield an 8 x N matrix, where N depends

on the number of cards. Figure Z-13 shows an internally

expanded matrix with three cards, resulting in an 8 x 36

(eight row by 36 column) matrix. As summarized in Table

2-2, the actual column number used when programming

the unit is determined by the slot.

For ANALOG #2 and ANALOG #3 pathways, all rows (A

through H) are automatically connected together through

the backplane of the mainframe (you must of course make

the necessary on-card connections from your relay buses

to the appropriate pathway pads). For ANALOG #l, pathways C through F are connected through the backplane,

while rows A, 8, G, and H use the SMB connectors. As

discussed previously, ANALOG #l connects to Model 7072

cards, ANALOG #2 connects to Model 7071 cards, and

ANALOG #3 connects to Model 7U73 cards.

The mainframe can be configured for two sets of three

cards each by removing jumpers from the backplane of the

mainframe; see Section 3 of the Model 707 Instruction

Manual for details on removing the jumpers. With the row

jumpers removed, cards in slots 1 through 3 are connected,

and cards in slots 4 through 6 are connected together.

Because of more critical signal paths, rows A, B, G, and

H of ANALOG #l are not jumpered through the

backplane. Instead, you must install the coaxial jumpers

(supplied with the Model 7072) between appropriate connectors on Model 7070 and 7072 cards. Each card has one

OI two SMB coaxial connectors for each row, allowing daisy

chaining of card rows. These connectors can be reached

by lifting the access door on the top of the mainframe; it

is not necessary to remove cards to install the jumpers.

2.5.14 External Matrix Expansion

External jumper wires must be used to expand the number

of rows in the matrix, or to connect between columns of

cards installed in different mainframes. An example of

such an expanded matrix is shown in Figure 2-14. Here,

six cards are configured as a 16 x 36 matrix. Since the rows

are internally jumpered, only columns must be jumpered

externally in this configuration. Note that the backplane

jumpers must be removed to separate the cards into two

groups.

Note : Rows A-H of ANALOG #Z and ANALOG #3, and KW C-F of ANALOG #I jumpered through backplane.